Al-Fe-Os-RE aluminium alloy, preparation method thereof and power cable

An al-fe-os-re, power cable technology, applied in the field of alloys, can solve problems such as poor comprehensive performance, quality problems, and potential safety hazards of aluminum alloy power cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The present invention also provides a method for preparing an Al-Fe-Os-RE aluminum alloy, comprising the following steps:

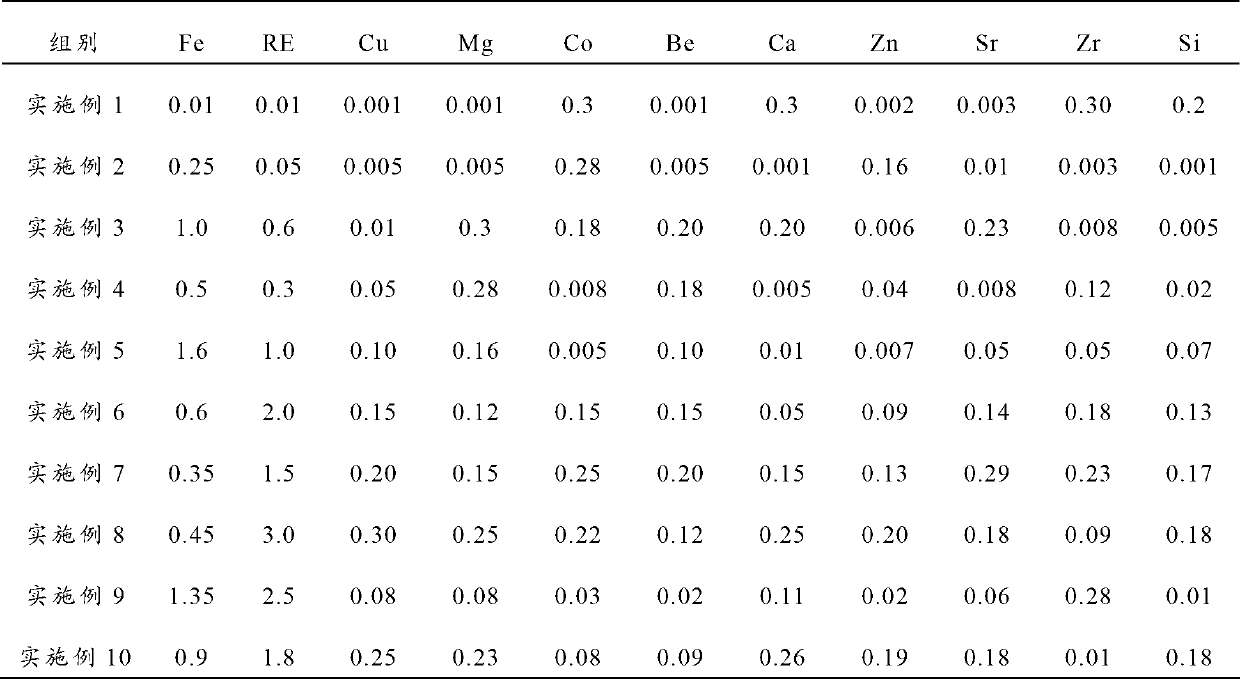

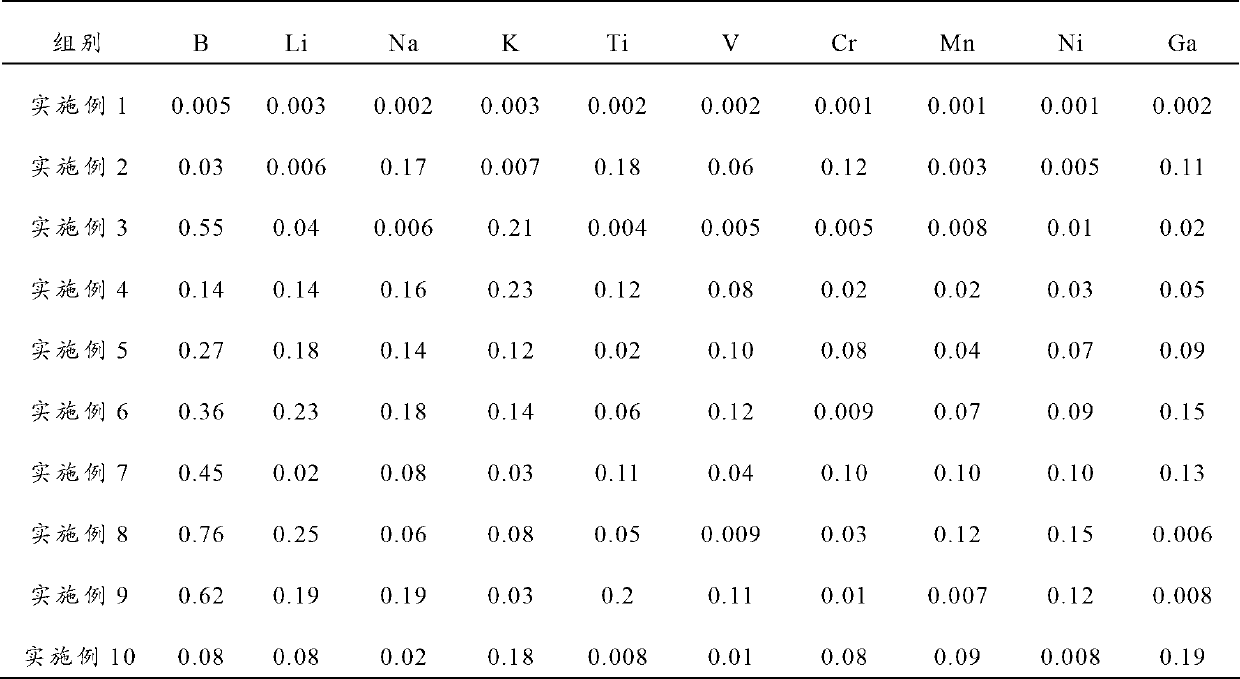

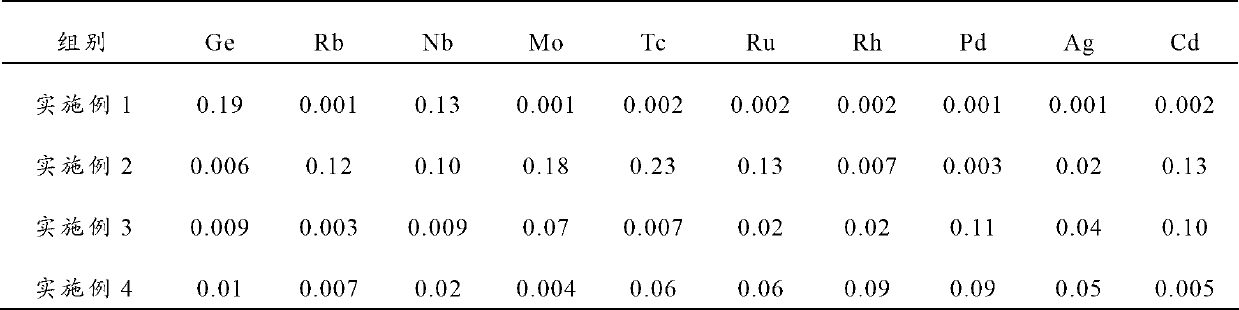

[0072] a) Casting raw materials with the following composition to obtain an aluminum alloy ingot: 0.01~1.6wt% Fe, 0.001~0.3wt% Cu, 0.001~0.3wt% Mg, 0.001~0.3wt% Co, 0.001~0.2 wt% Be, 0.001~0.3wt% Ca, 0.001~0.2wt% Zn, 0.001~0.3wt% Sr, 0.001~0.3wt% Zr, 0.002~0.25wt% Li, 0.001~0.2wt% Na, 0.002~0.25wt% K, 0.001~0.2wt% Ti, 0.001~0.15wt% V, 0.001~0.12wt% Cr, 0.001~0.12wt% Mn, 0.001~0.15wt% Ni , 0.001~0.2wt% of Ga, 0.003~0.2wt% of Ge, 0.001~0.2wt% of Rb, 0.001~0.15wt% of Nb, 0.001~0.2wt% of Mo, 0.001~0.25wt% of Tc, 0.001 ~0.15wt% Ru, 0.002~0.1wt% Rh, 0.001~0.12wt% Pd, 0.001~0.1wt% Ag, 0.002~0.13wt% Cd, 0.003~0.18wt% In, 0.001~0.08 wt% Sn, 0.001~0.3wt% Sb, 0.001~0.2wt% Cs, 0.001~0.08wt% Ba, 0.001~0.22wt% Hf, 0.002~0.16wt% Ta, 0.001~0.08wt% W, 0.002~0.18wt% of Re, 0.002~0.08wt% of Os, 0.01~3.0wt% of RE, greater than zero and less than or equal to 0.2wt% ...

Embodiment 1

[0085] (1) Put the aluminum ingot into the furnace, heat it to melt and keep it warm at 720°C. The melting process is completed in a sealed environment; first add Al-Fe, Al-Cu, Al-Mg, Al-Co, Al-Be , Al-Ca, Al-Zn, Zn-Sr, Al-Zr, Al-Si, Al-B, Al-Li, Al-Na, Al-K, Al-Ti, Al-V, Al-Cr, Al -Mn, Al-Ni, Al-Ga, Al-Ge, Al-Rb, Al-Nb, Al-Mo, Al-Tc, Al-Ru, Al-Rh, Al-Pd, Al-Ag, Al-Cd , Al-In, Al-Sn, Al-Sb, Al-Cs, Al-Ba, Al-Hf, Al-Ta, Al-W, Al-Re and Al-Os master alloys, stir well and then add rare earth RE Stir for 20 minutes until it is fully stirred evenly, then keep it warm for 30 minutes; then refine the above alloy melt in the furnace; add refining agent to the alloy melt, stir evenly, then keep it for 30 minutes, and melt refining is operated in a sealed environment After refining, slag removal, standing still, and temperature adjustment to 650 ° C, the alloy liquid was poured out of the furnace, and after degassing and slag removal, it was cast in a casting machine to obtain an alumin...

Embodiment 2

[0091] (1) Put the aluminum ingot into the furnace, heat it to melt and keep it warm at 740°C. The melting process is completed in a sealed environment; first add Al-Fe, Al-Cu, Al-Mg, Al-Co, Al-Be , Al-Ca, Al-Zn, Zn-Sr, Al-Zr, Al-Si, Al-B, Al-Li, Al-Na, Al-K, Al-Ti, Al-V, Al-Cr, Al -Mn, Al-Ni, Al-Ga, Al-Ge, Al-Rb, Al-Nb, Al-Mo, Al-Tc, Al-Ru, Al-Rh, Al-Pd, Al-Ag, Al-Cd , Al-In, Al-Sn, Al-Sb, Al-Cs, Al-Ba, Al-Hf, Al-Ta, Al-W, Al-Re and Al-Os master alloys, stir well and then add rare earth RE Stir for 20 minutes until it is fully stirred evenly, then keep it warm for 30 minutes; then refine the above alloy melt in the furnace; add refining agent to the alloy melt, stir evenly, then keep it for 30 minutes, and melt refining is operated in a sealed environment After refining, slag removal, standing still, and temperature adjustment to 720 ° C, the alloy liquid is poured out of the furnace, and after degassing and slag removal, it enters the casting machine for casting to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com