Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3642results about "Electrophoretic coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrophoretic medium and process for the production thereof

Owner:E INK CORPORATION

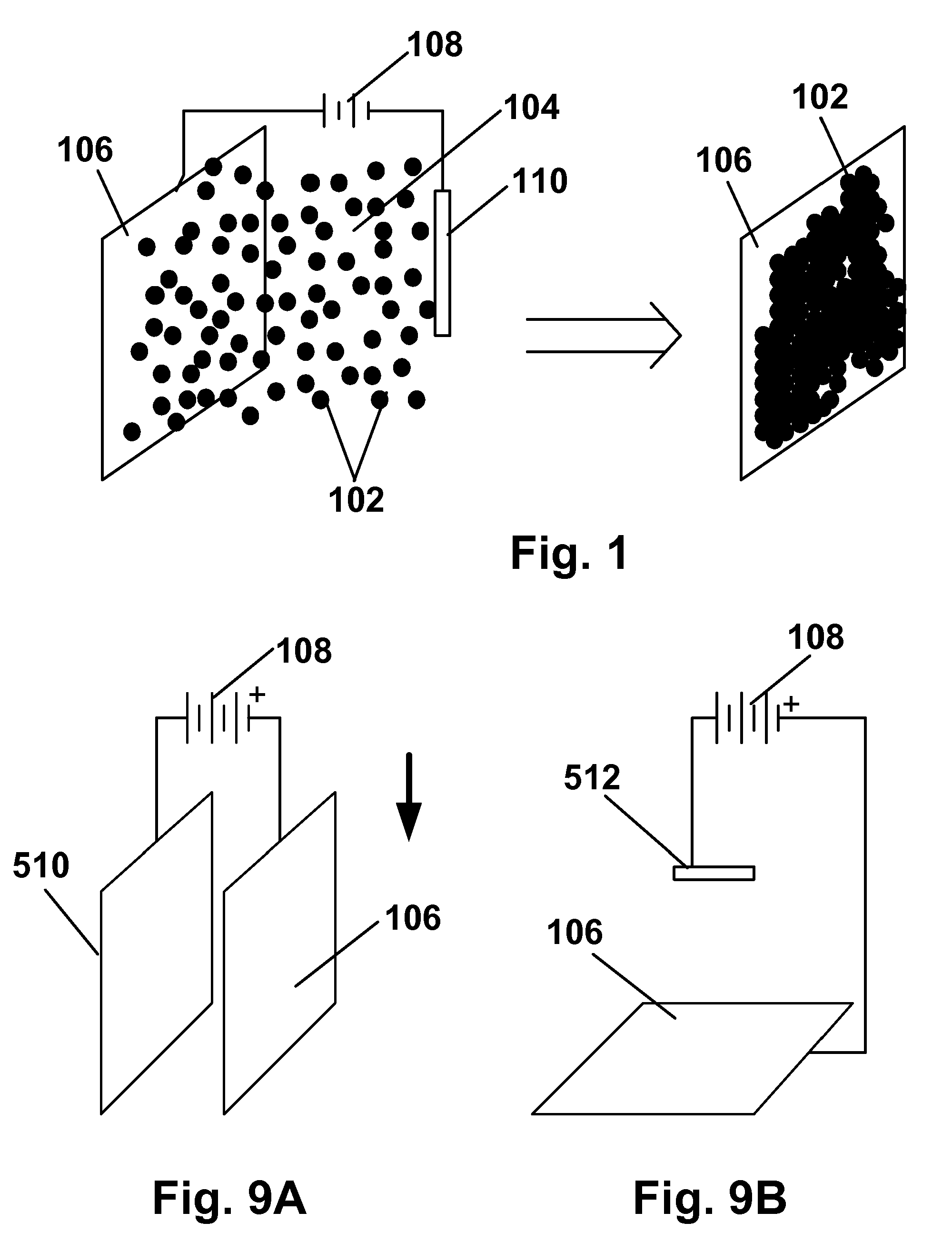

Processes for the production of electrophoretic displays

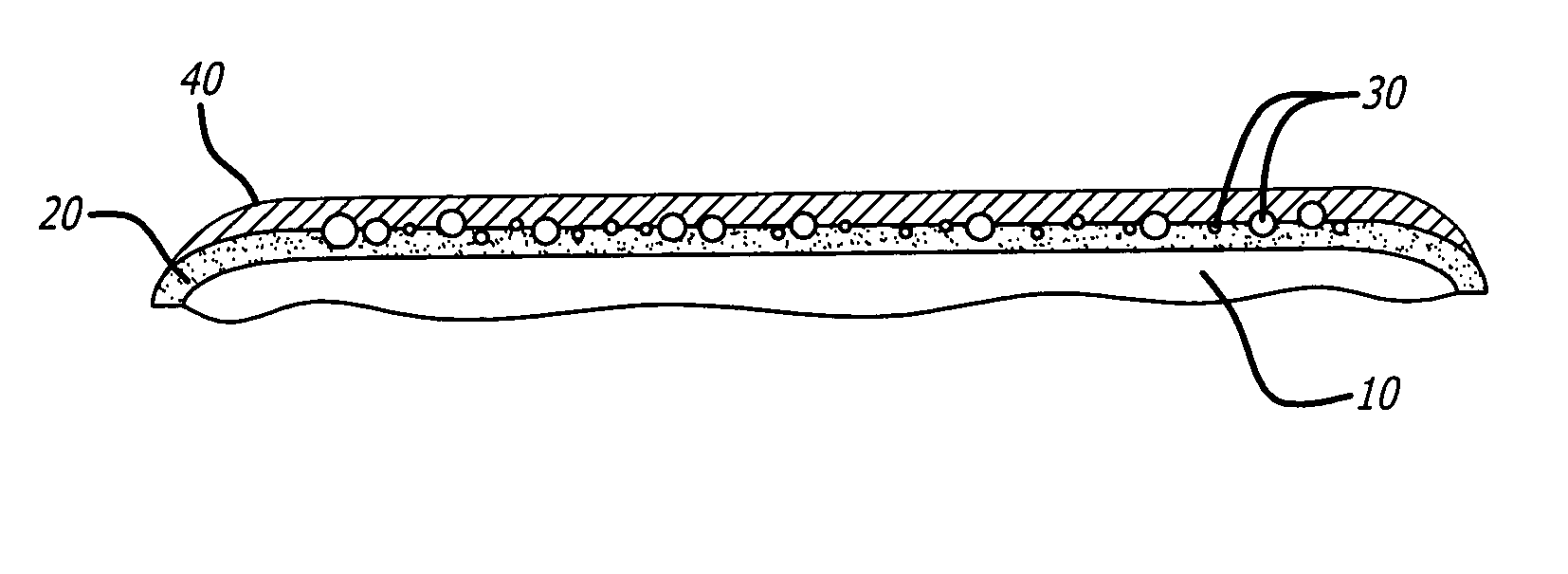

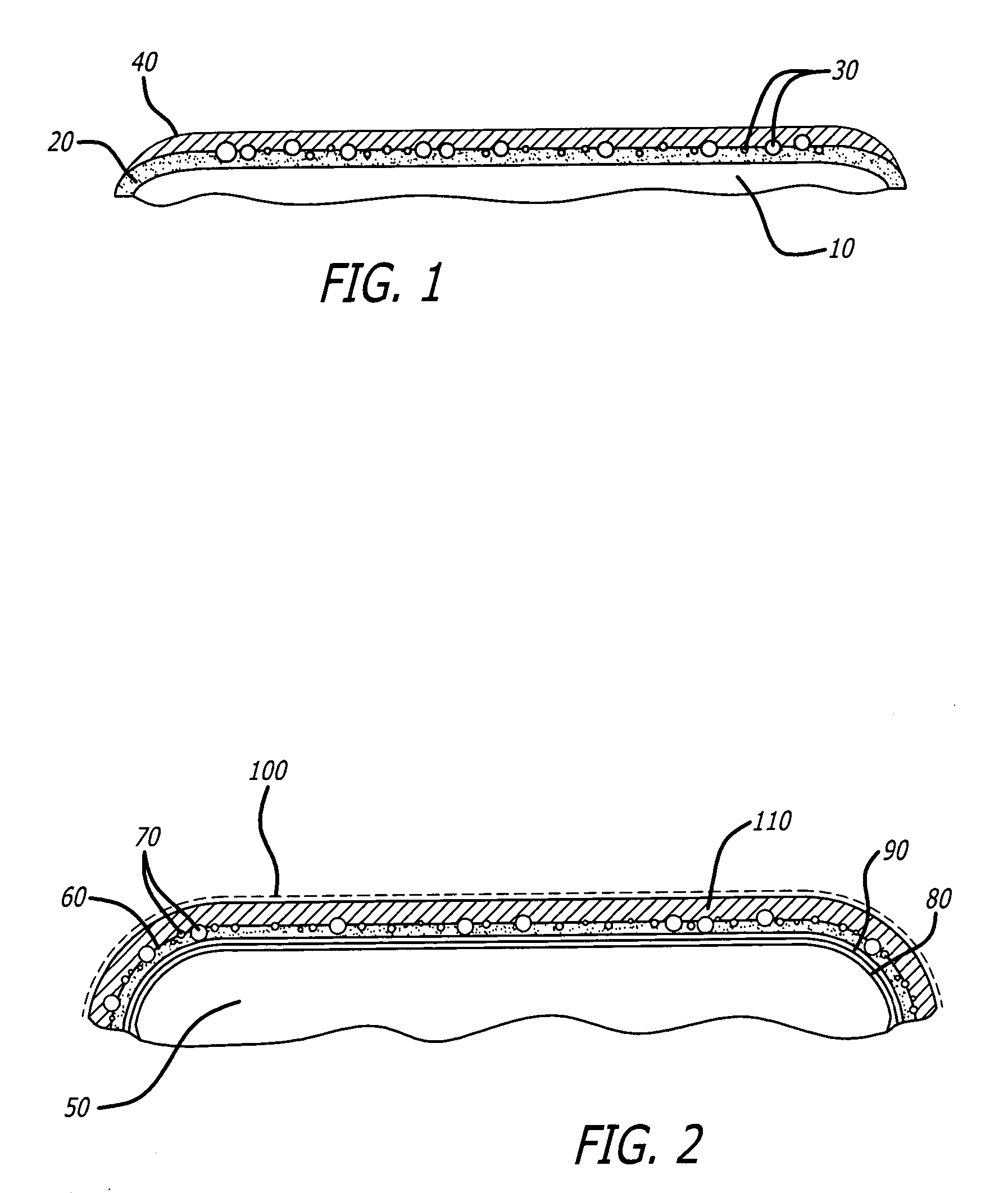

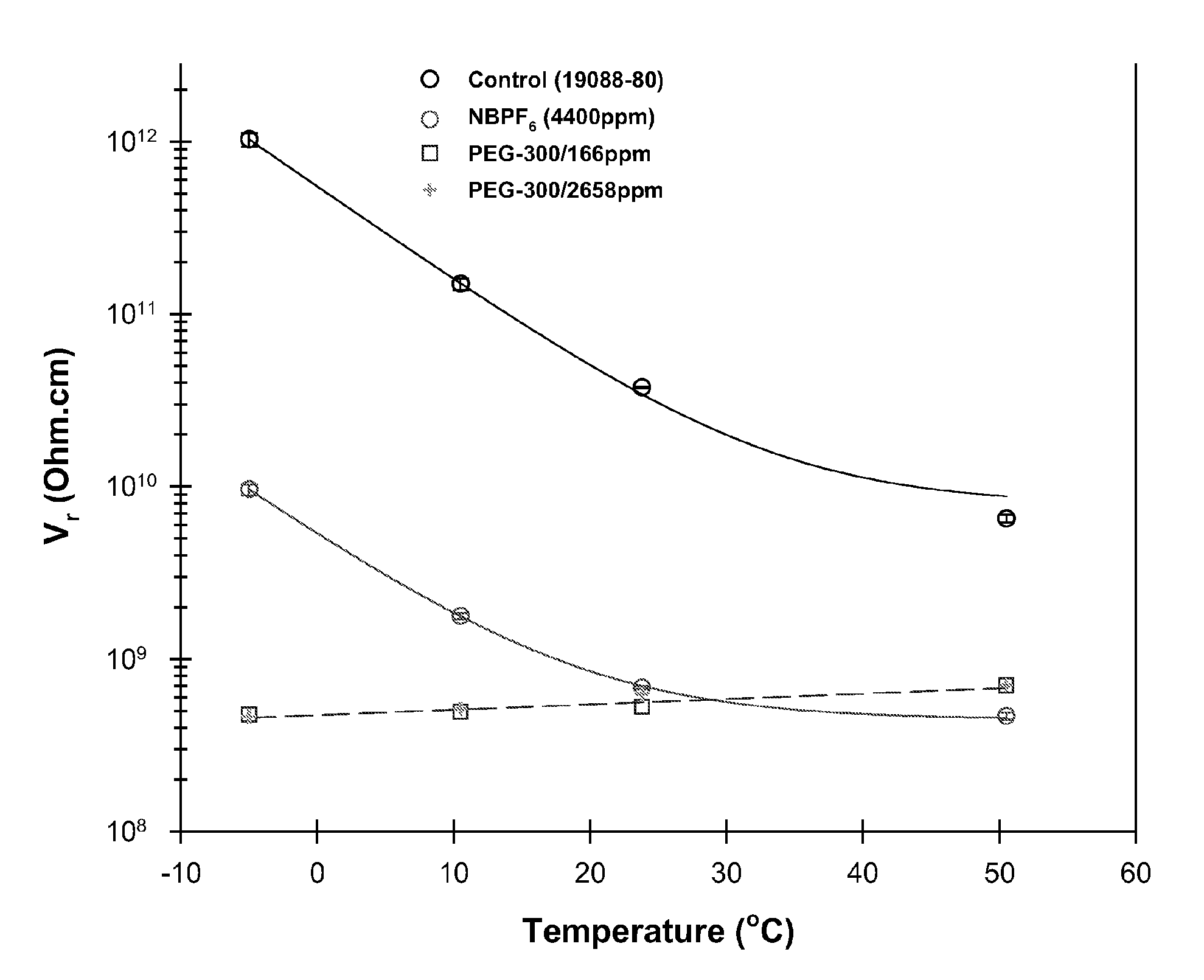

ActiveUS7339715B2Electric shock equipmentsElectrophoretic coatingsElectrophoresisPotential difference

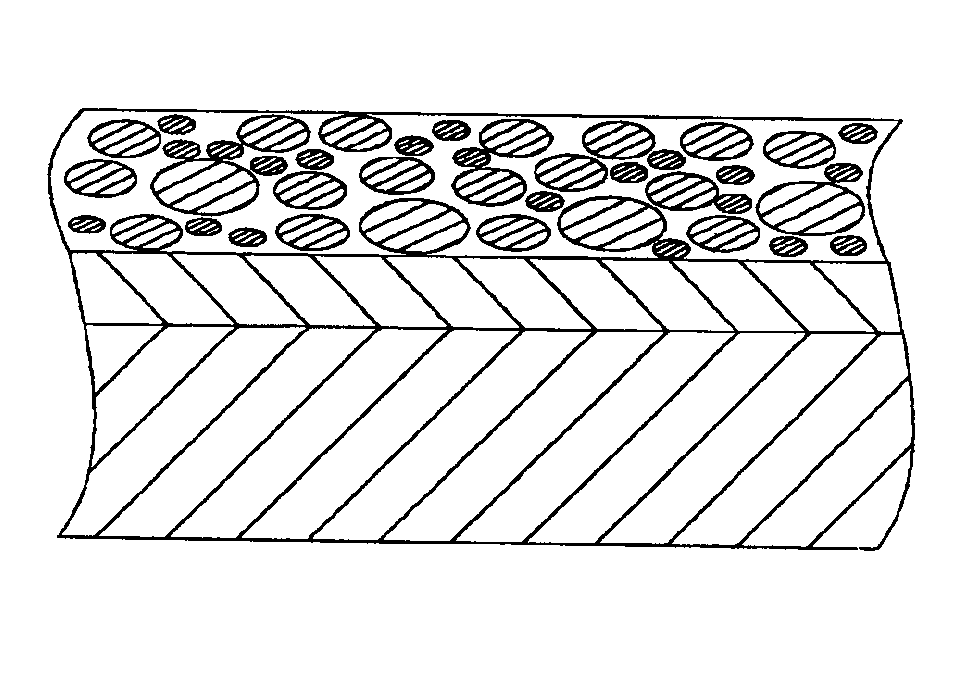

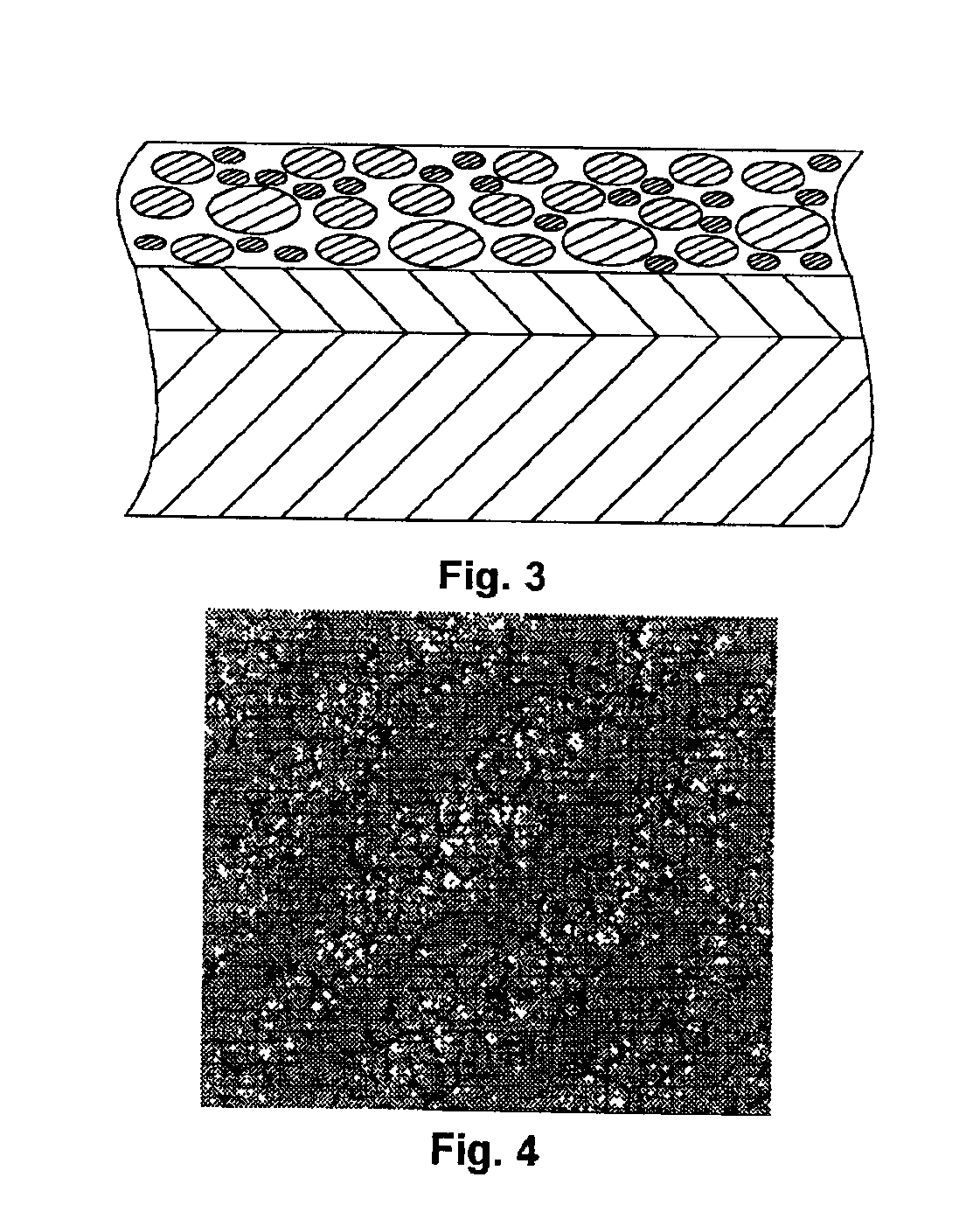

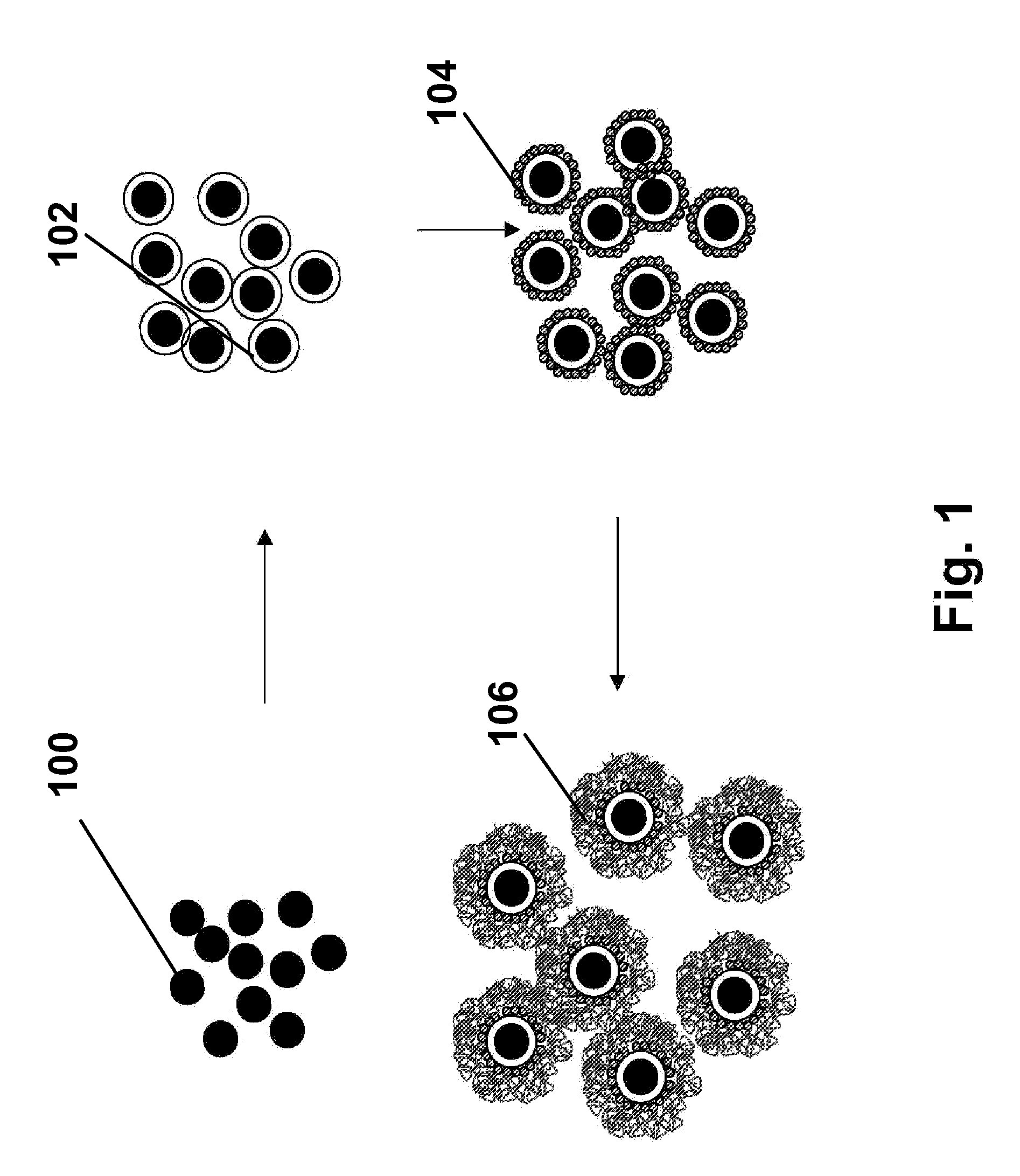

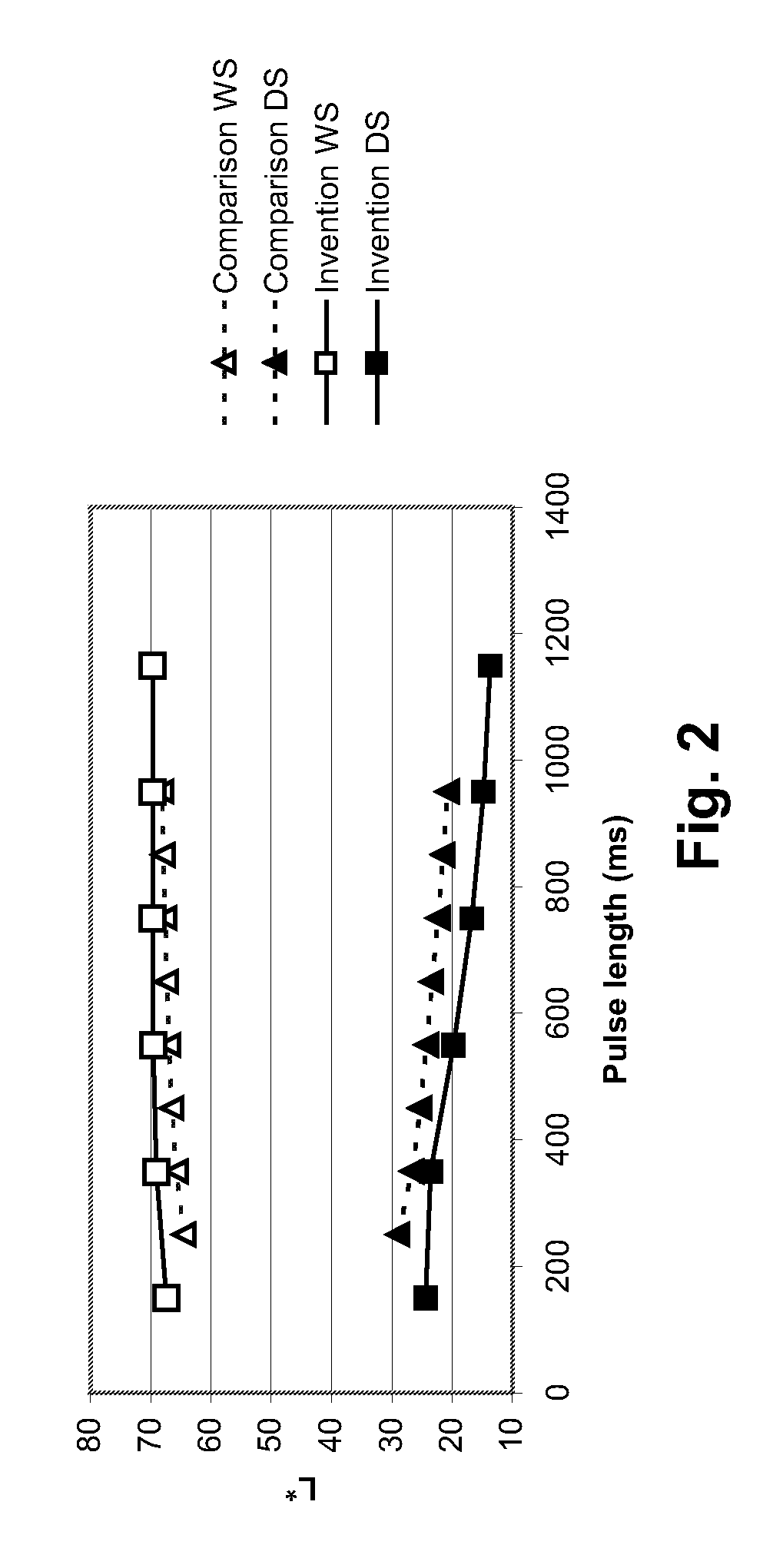

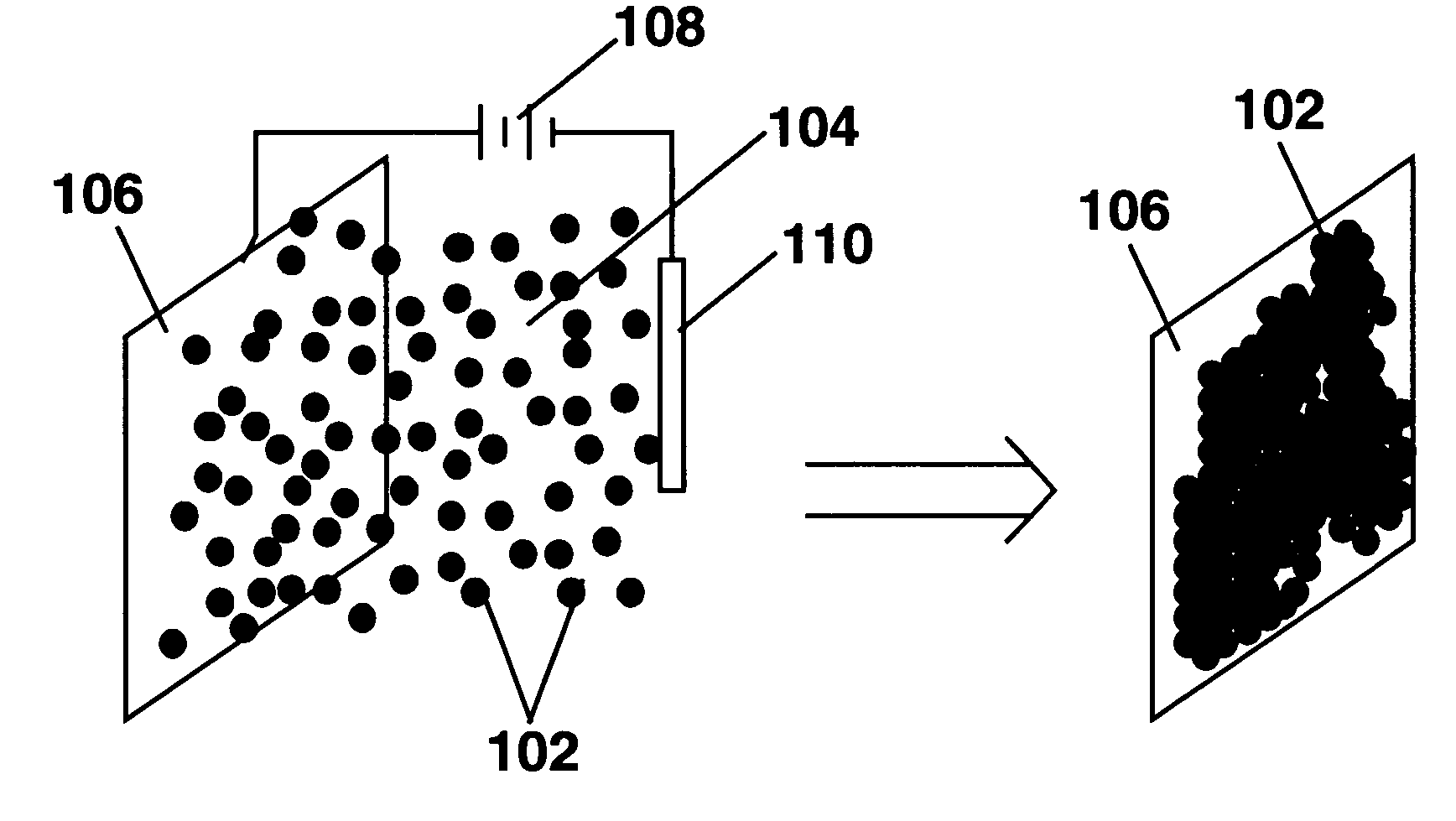

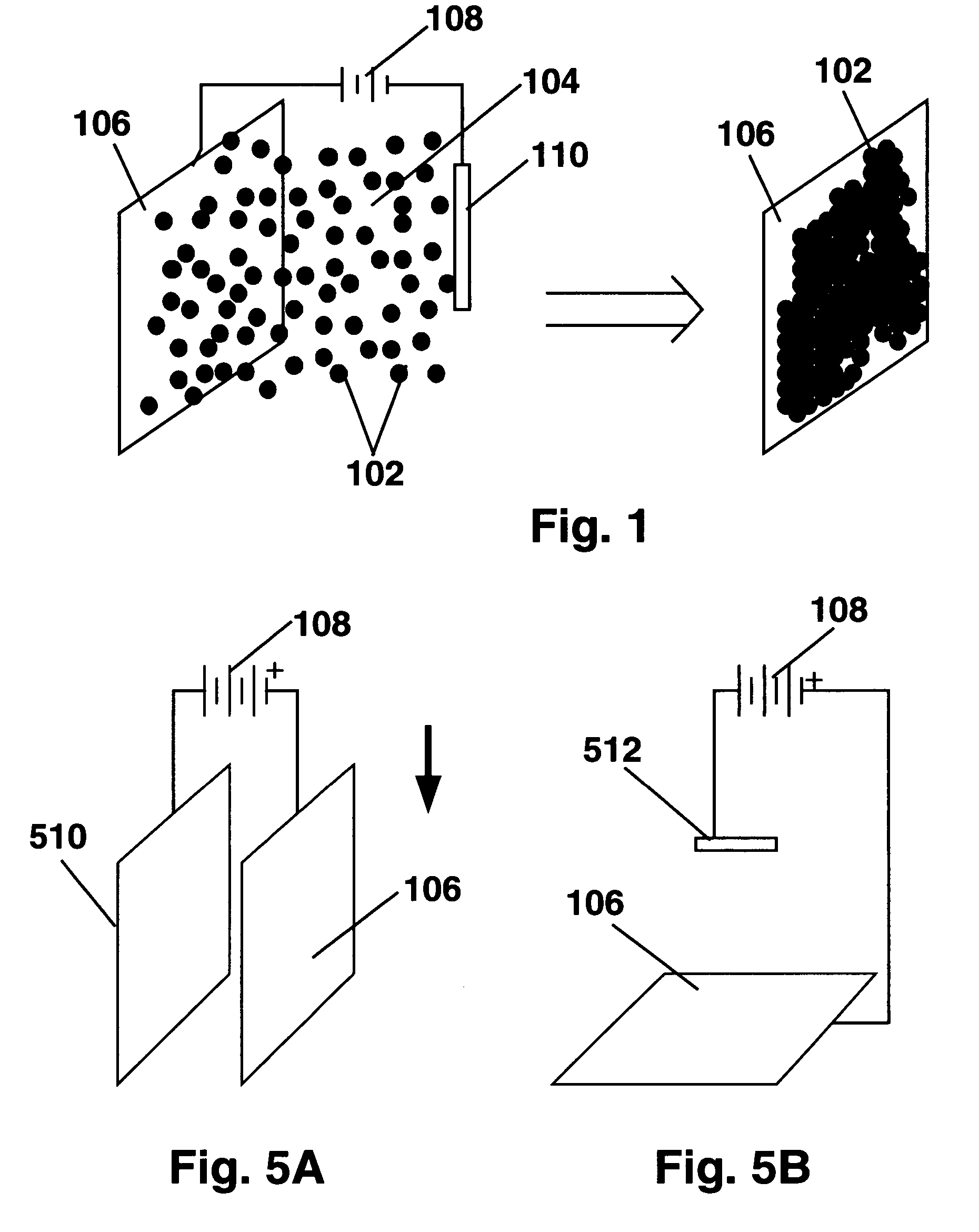

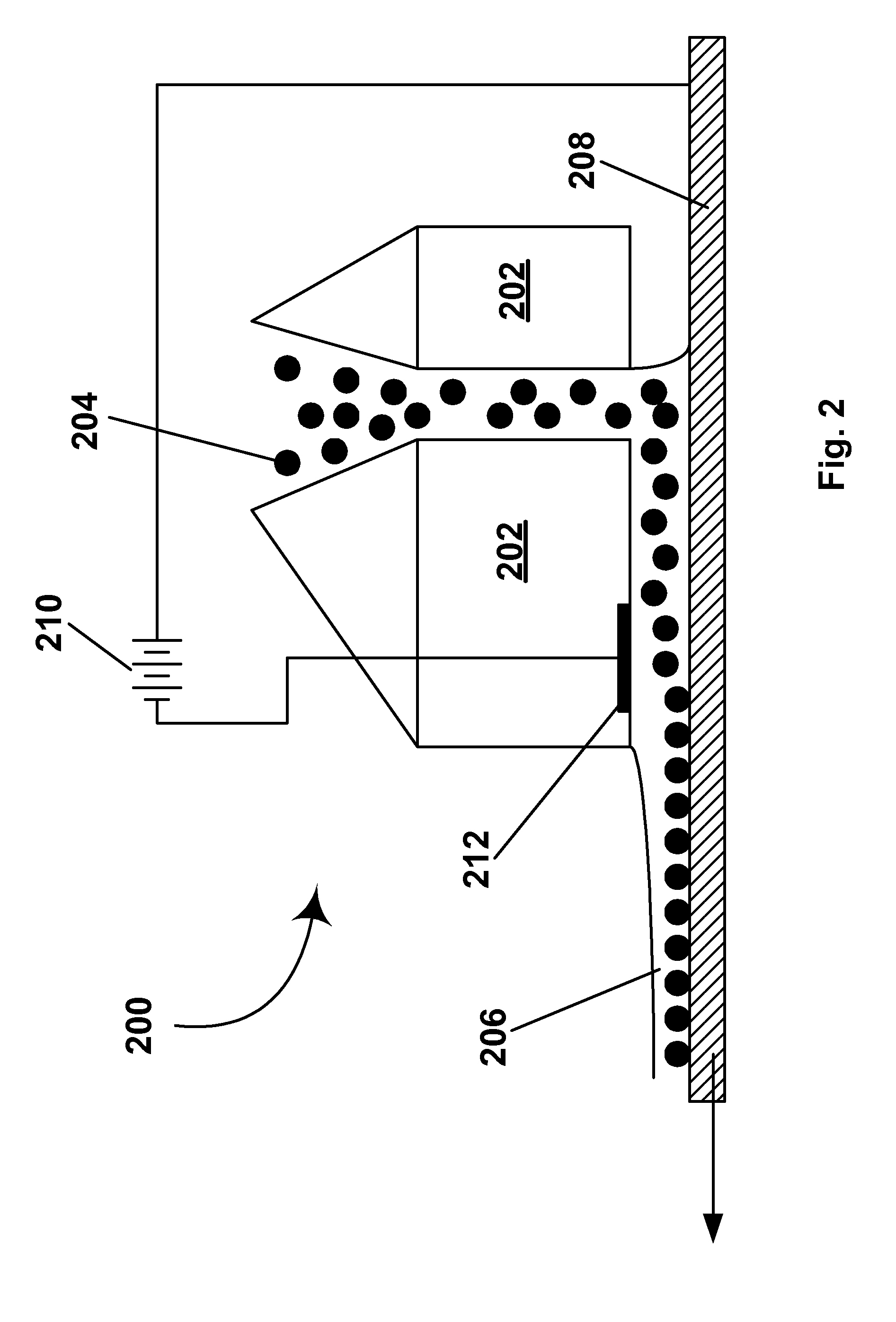

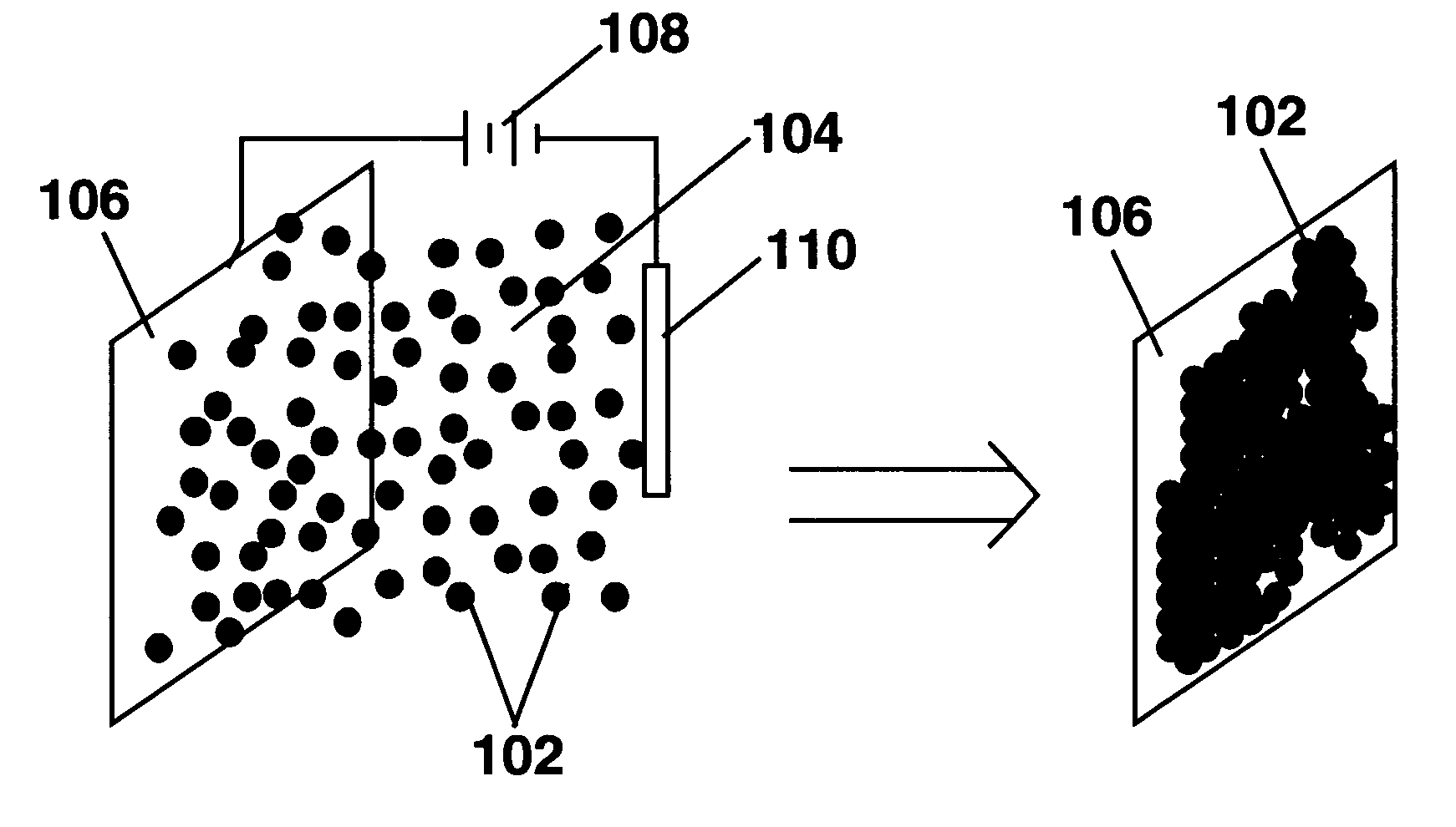

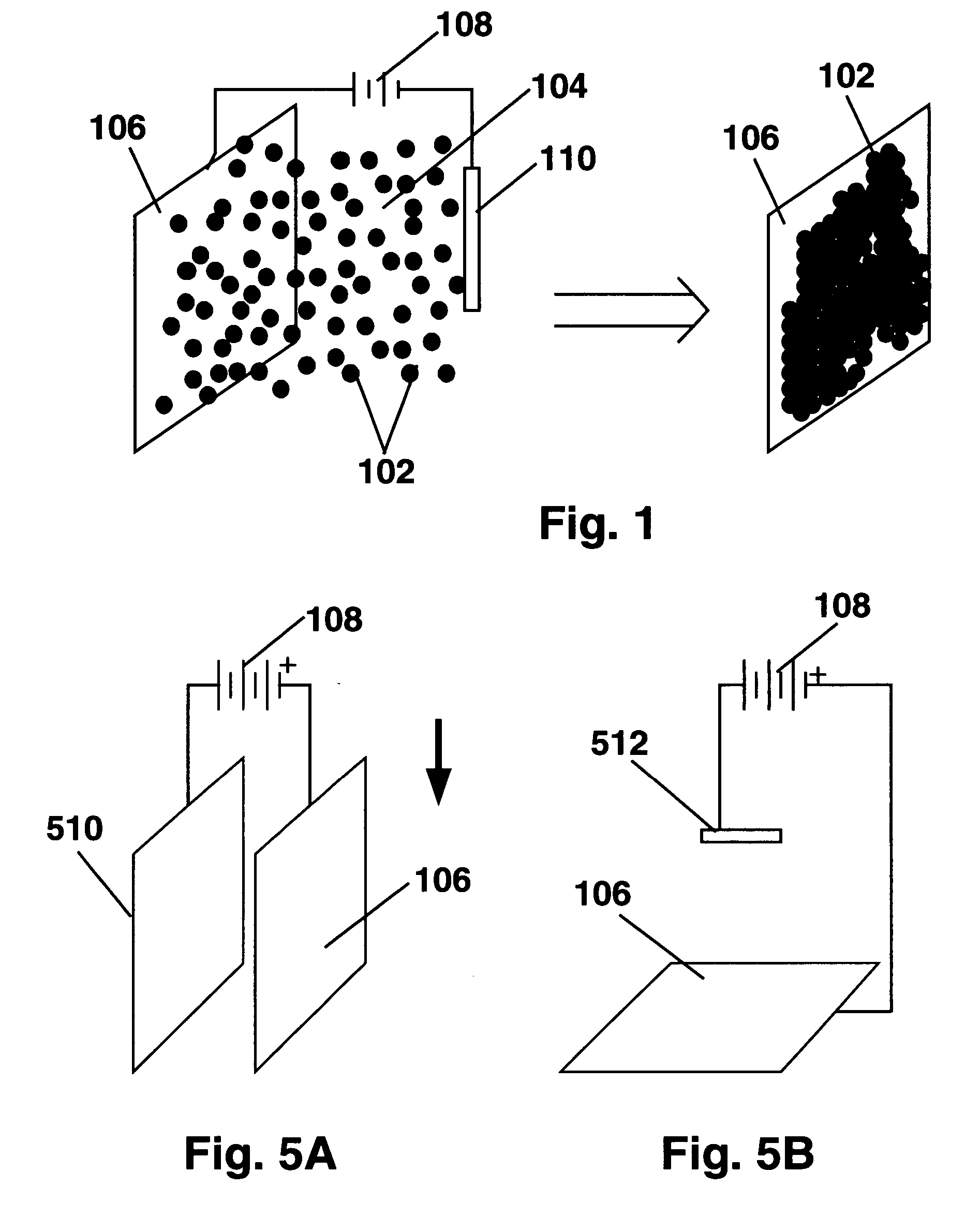

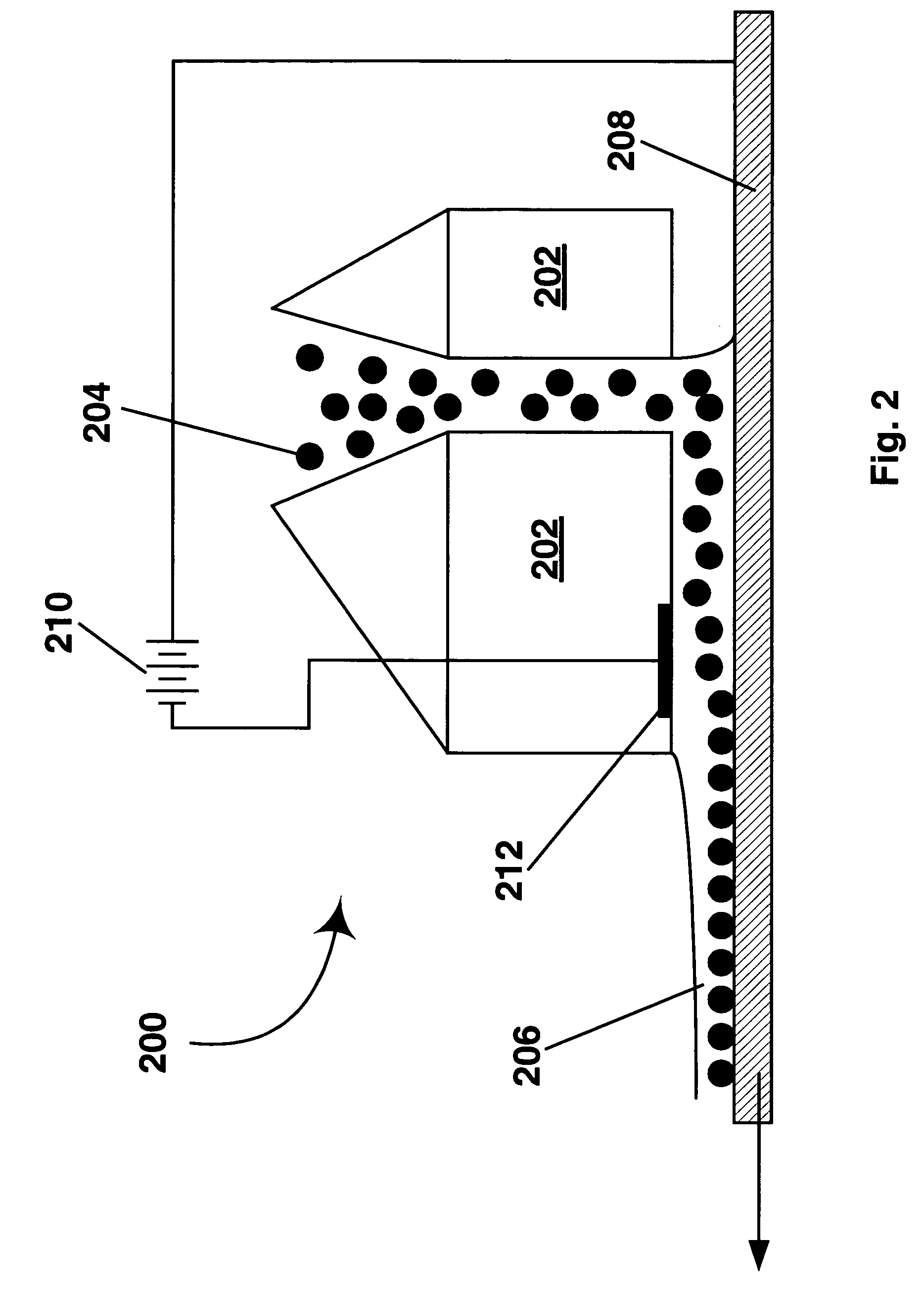

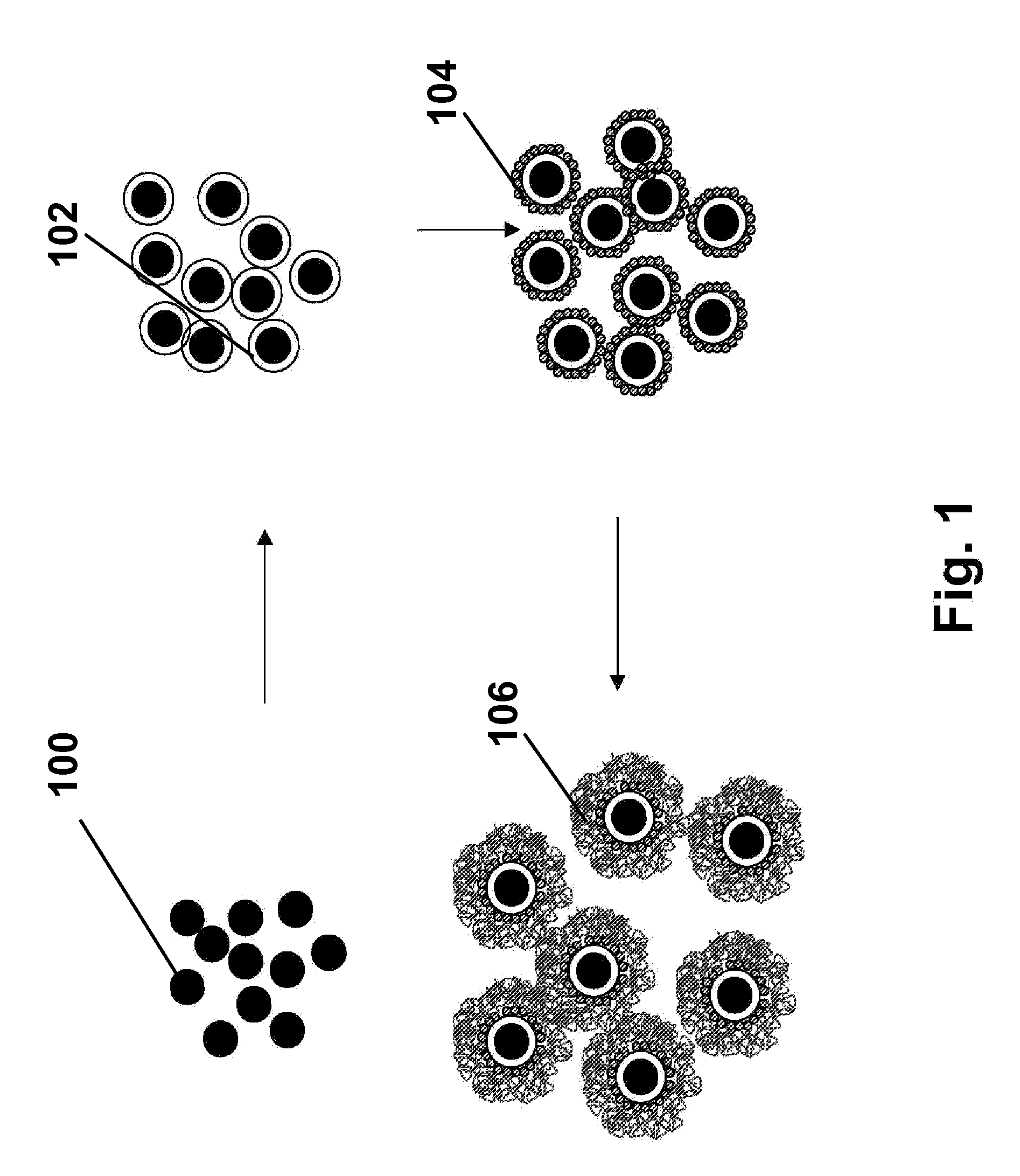

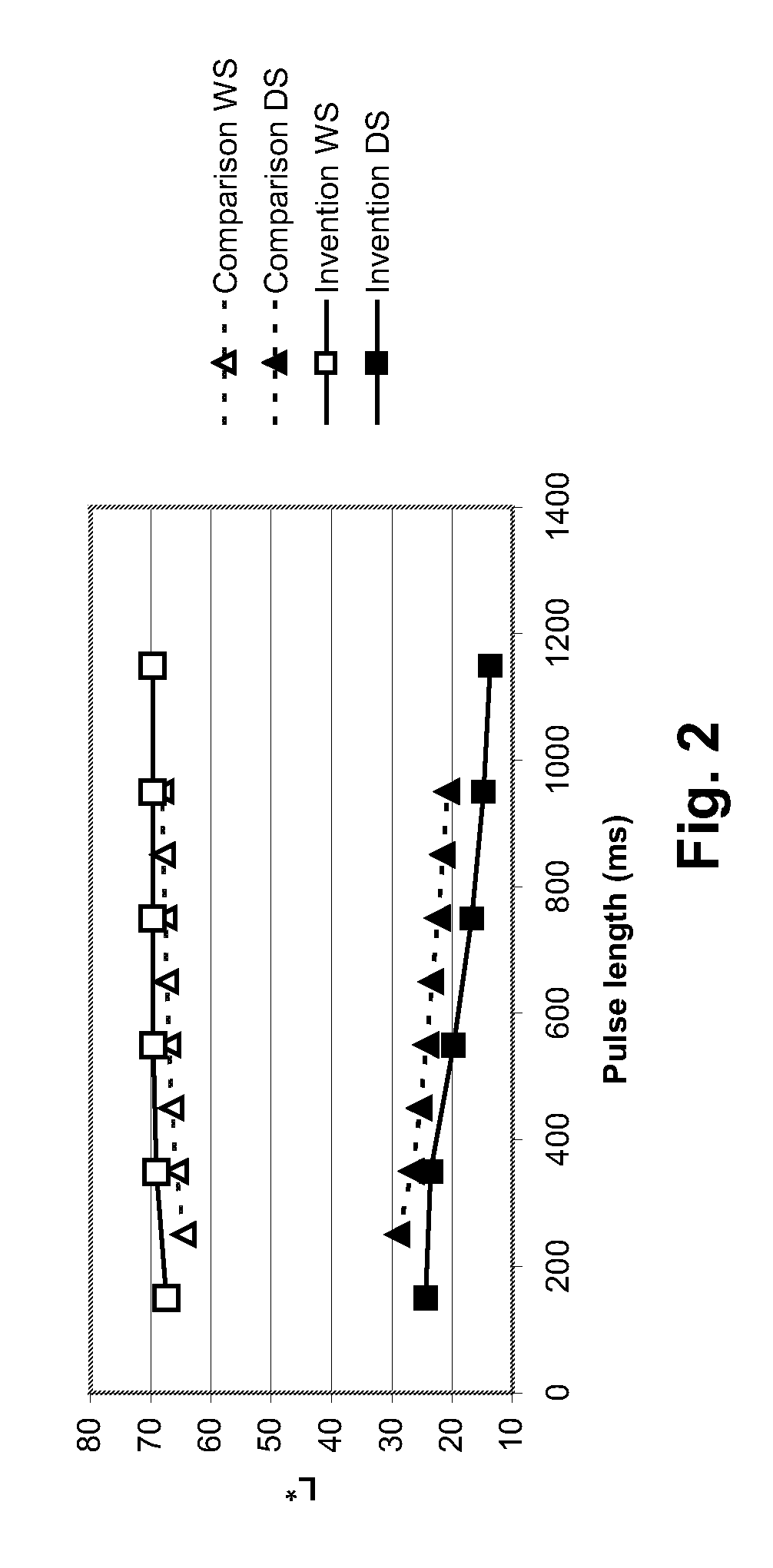

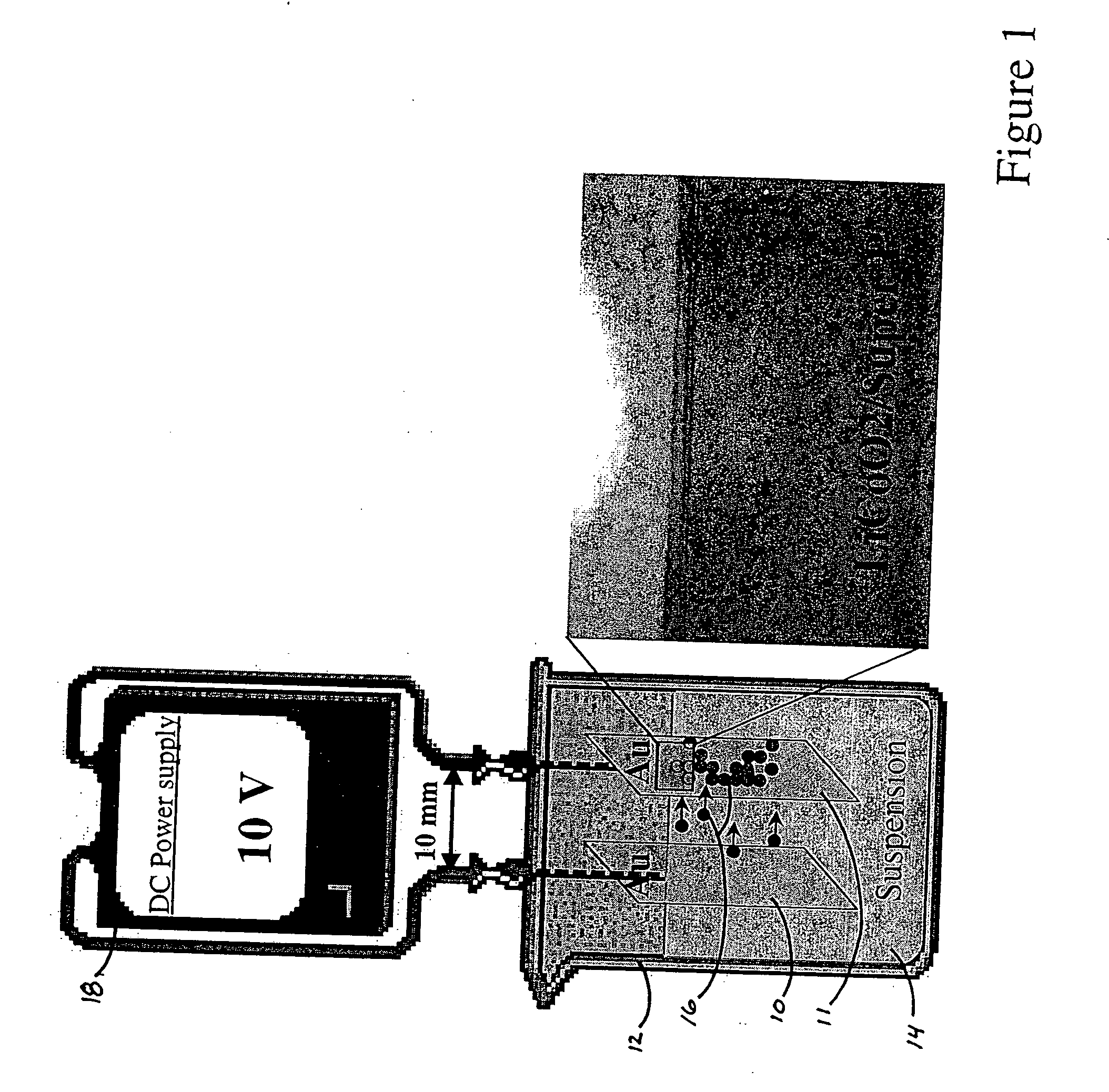

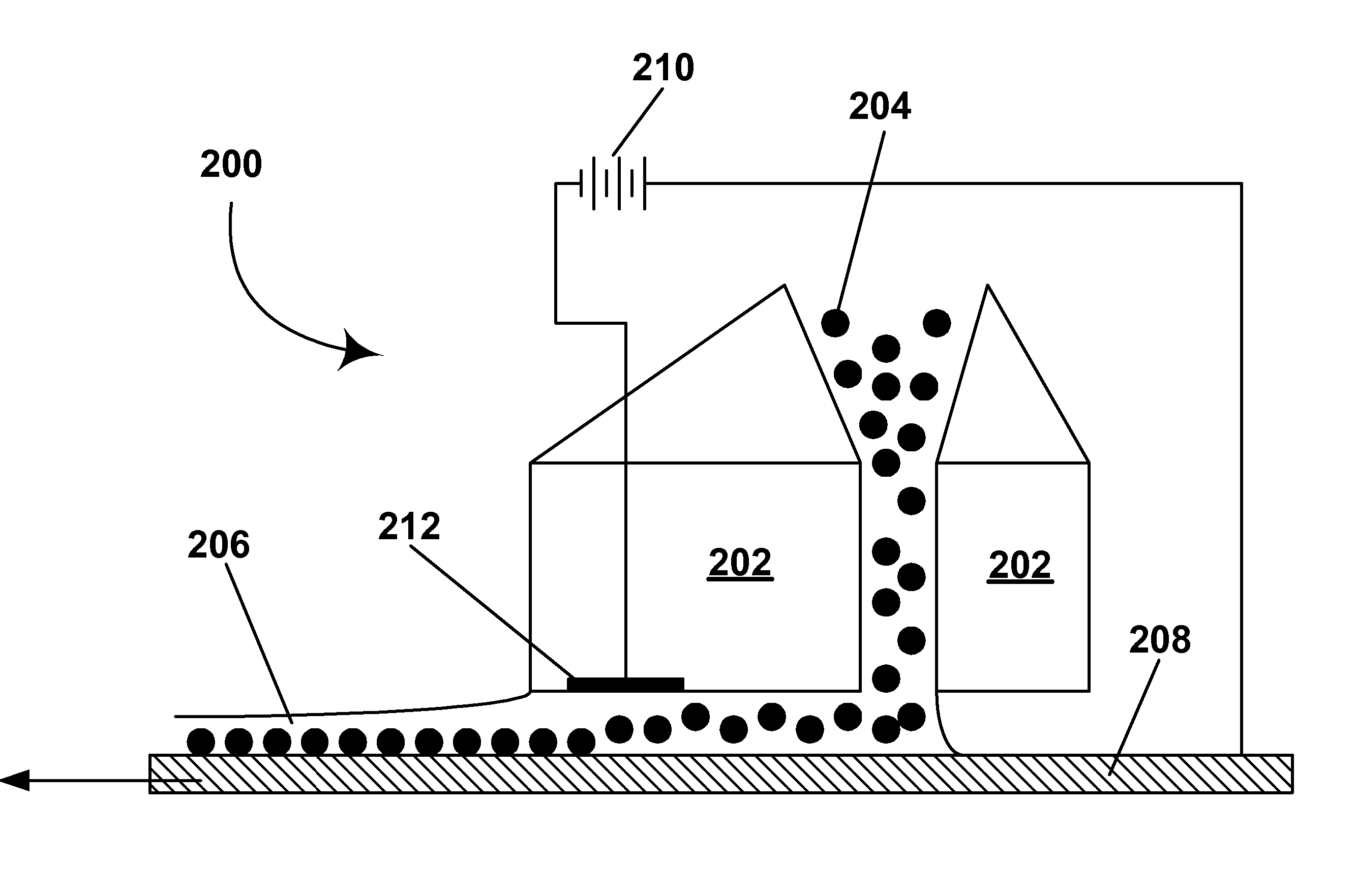

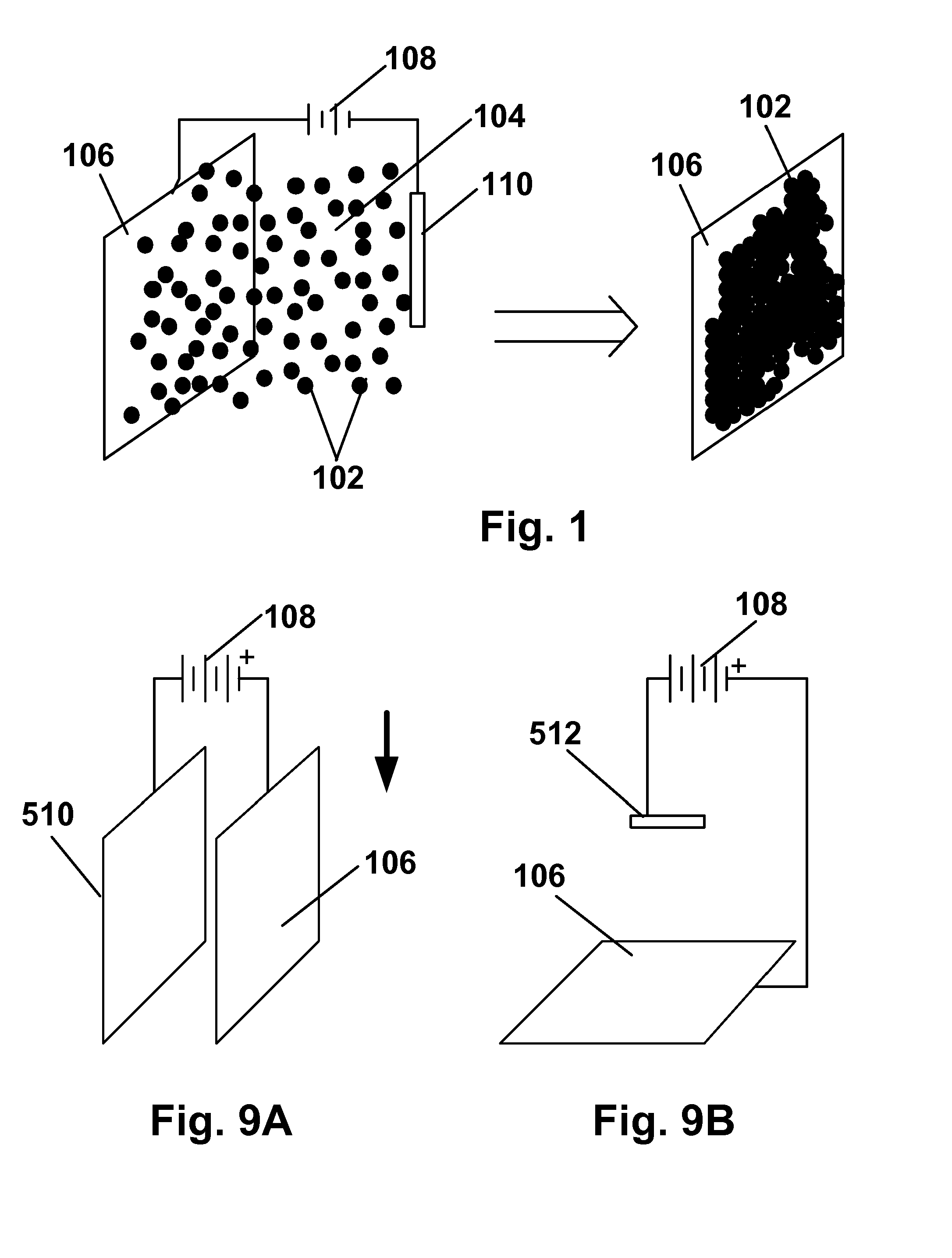

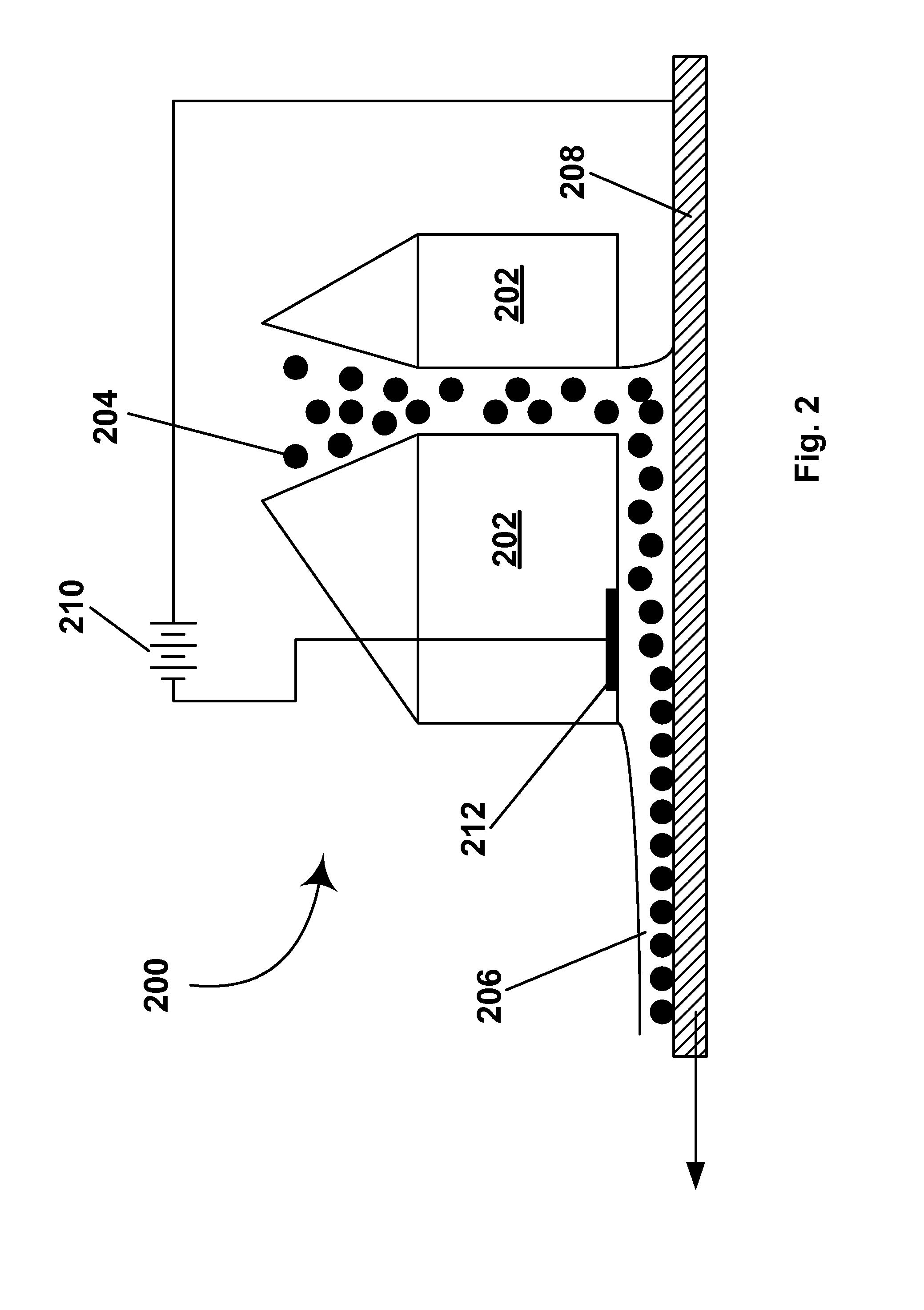

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, a patterned coating may be deposited upon a substrate containing a conductive layer by varying the conductivity of the conductive layer by radiation exposure or by coating portions of the conductive layer with an insulating layer, typically a photoresist.

Owner:E INK CORPORATION

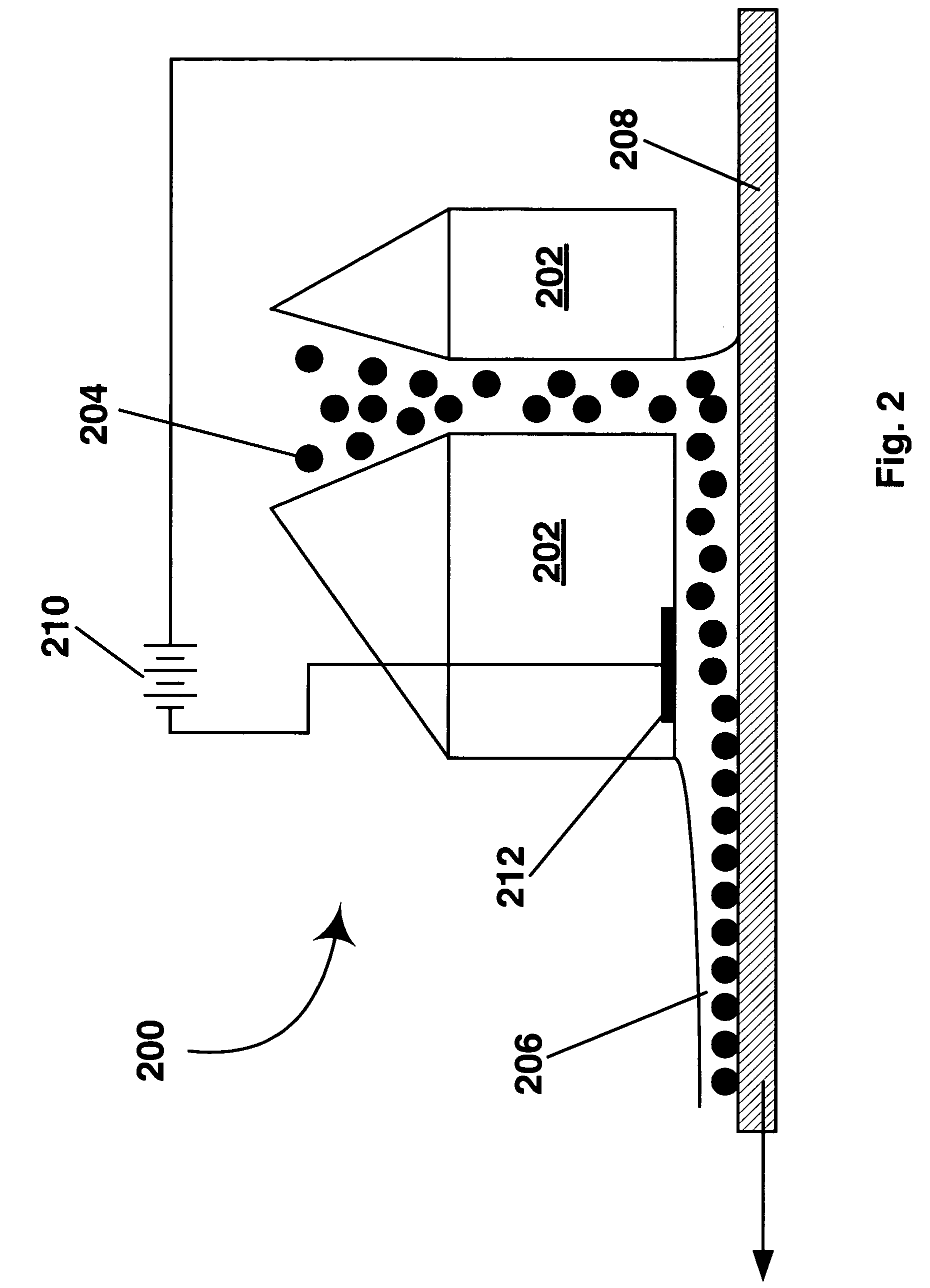

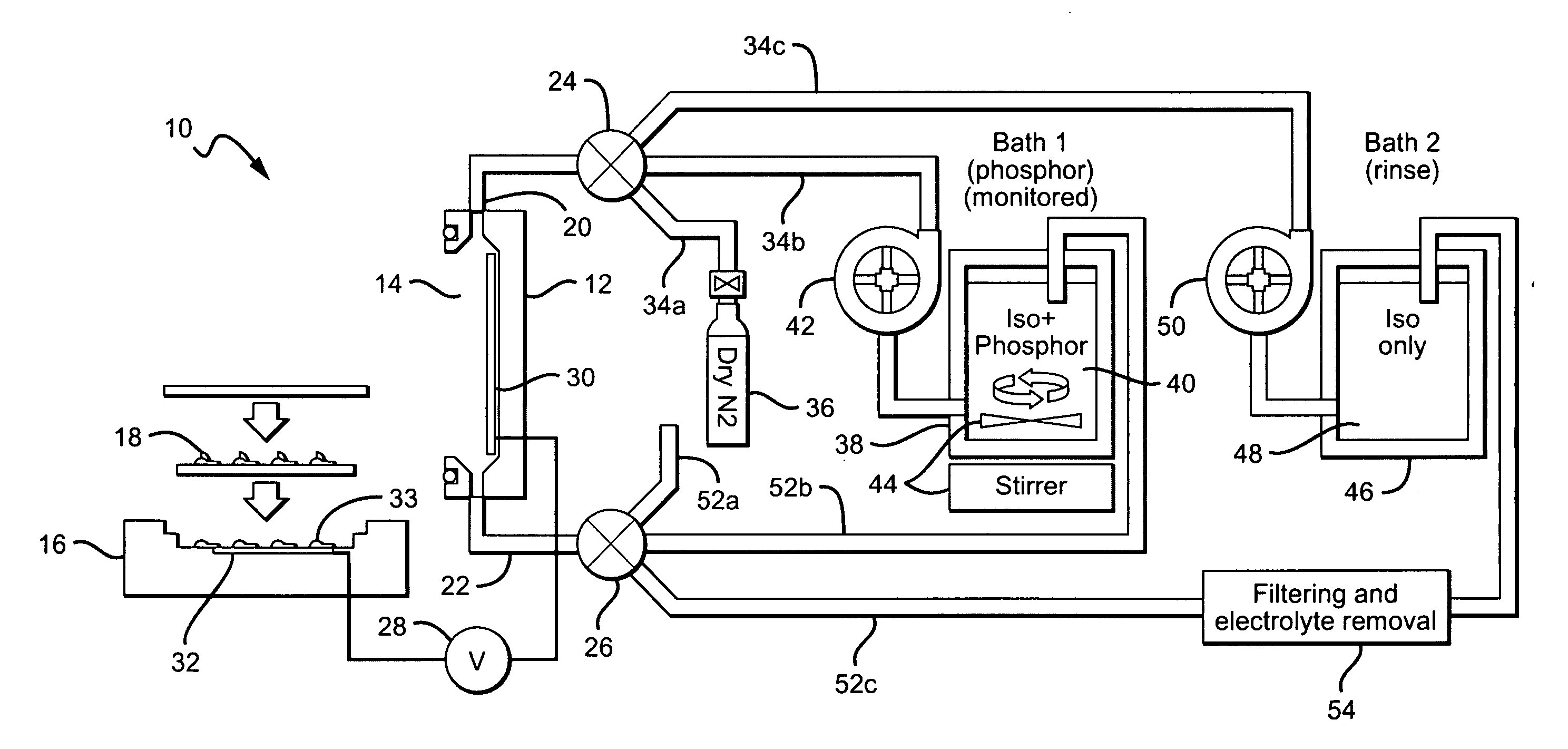

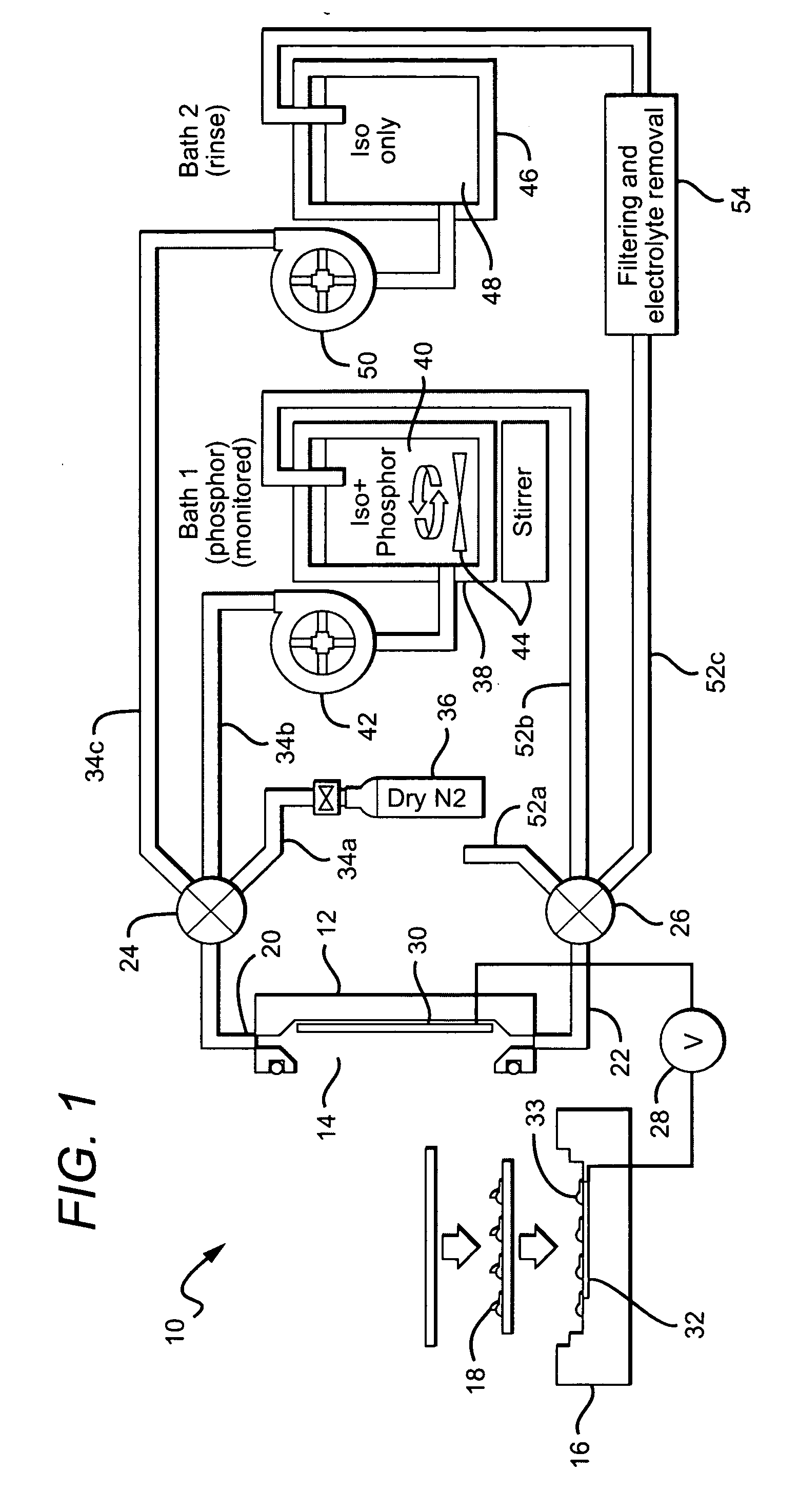

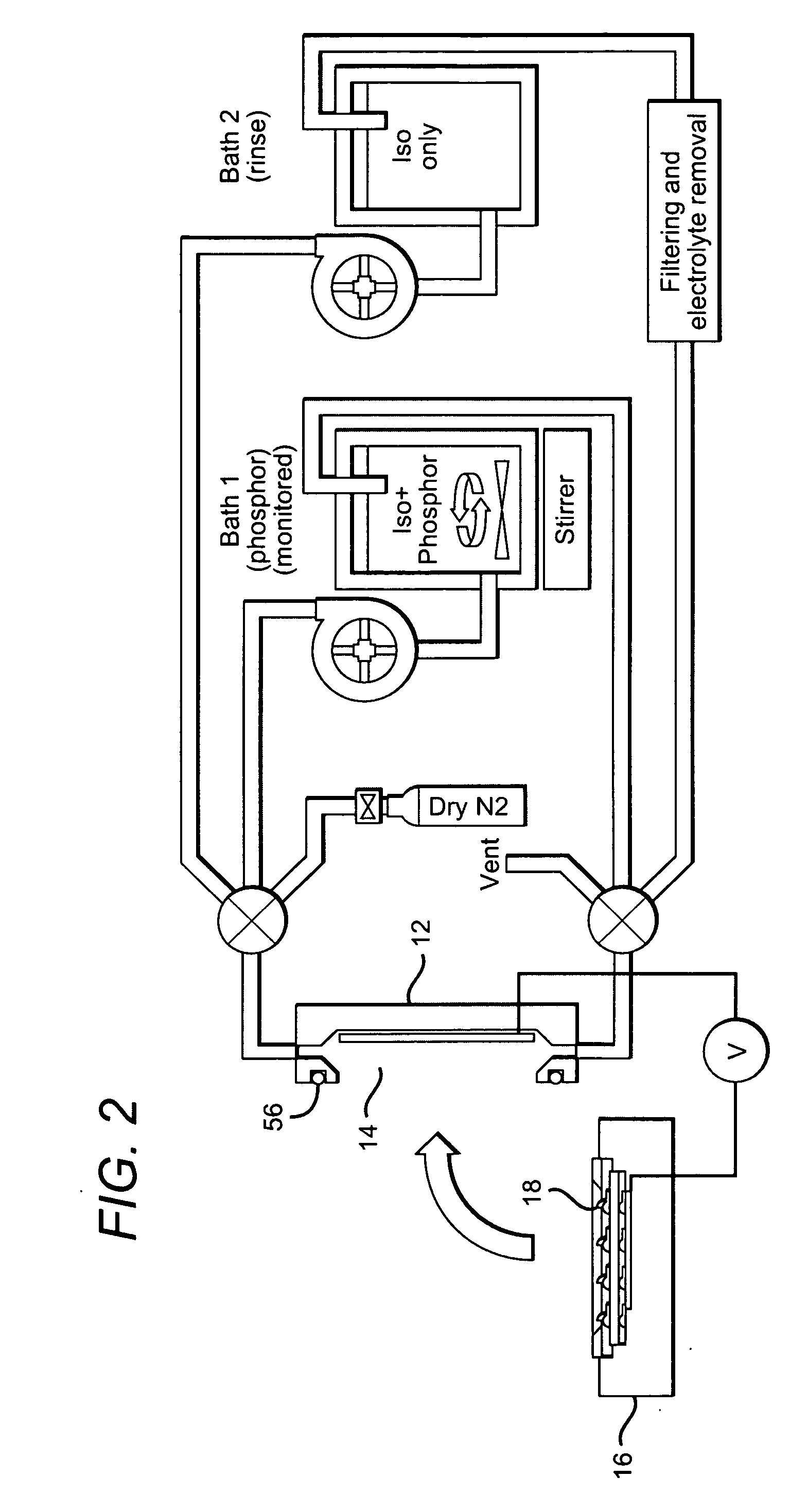

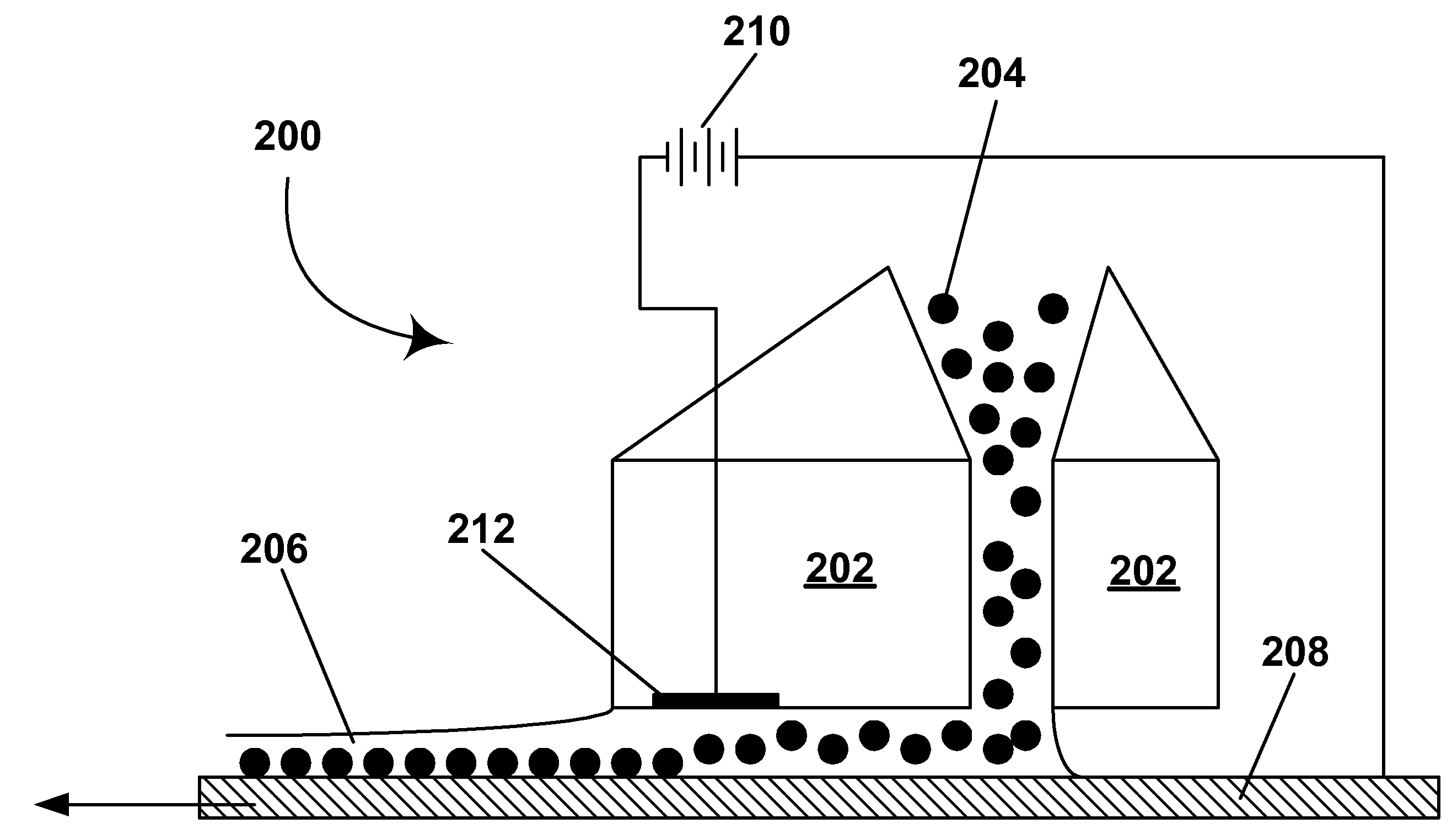

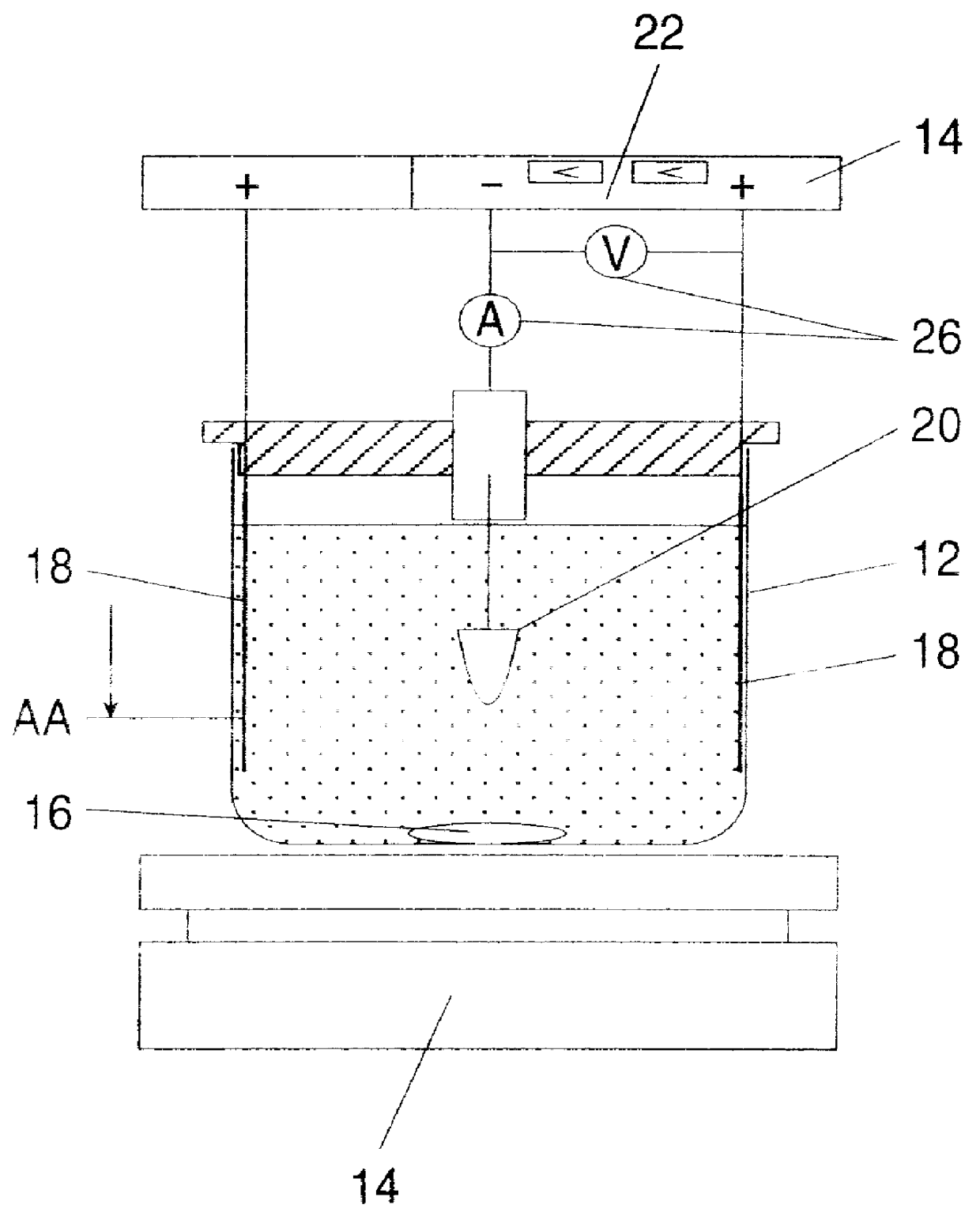

Close loop electrophoretic deposition of semiconductor devices

One close loop system and method for electrophoretic deposition (EPD) of phosphor material on light emitting diodes (LEDs). The system comprises a deposition chamber sealed from ambient air. A mixture of phosphor material and solution is provided to the chamber with the mixture also being sealed from ambient air. A carrier holds a batch of LEDs in the chamber with the mixture contacting the areas of the LEDs for phosphor deposition. A voltage supply applies a voltage to the LEDs and the mixture to cause the phosphor material to deposit on the LEDs at the mixture contacting areas.

Owner:CREELED INC

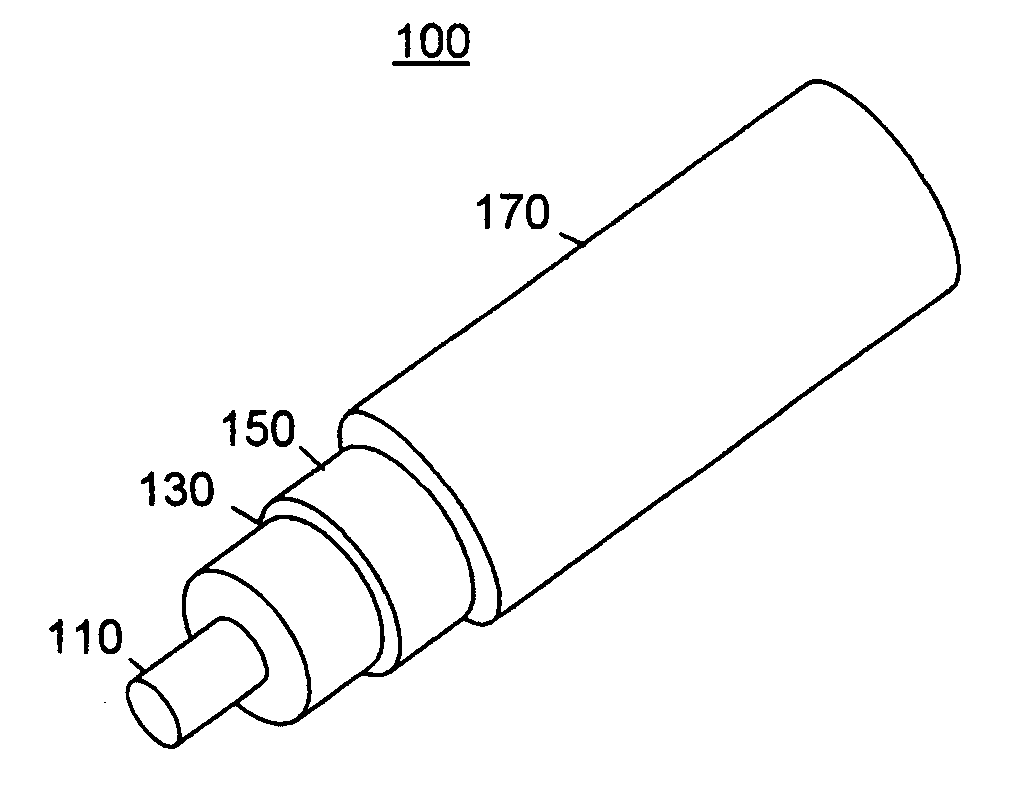

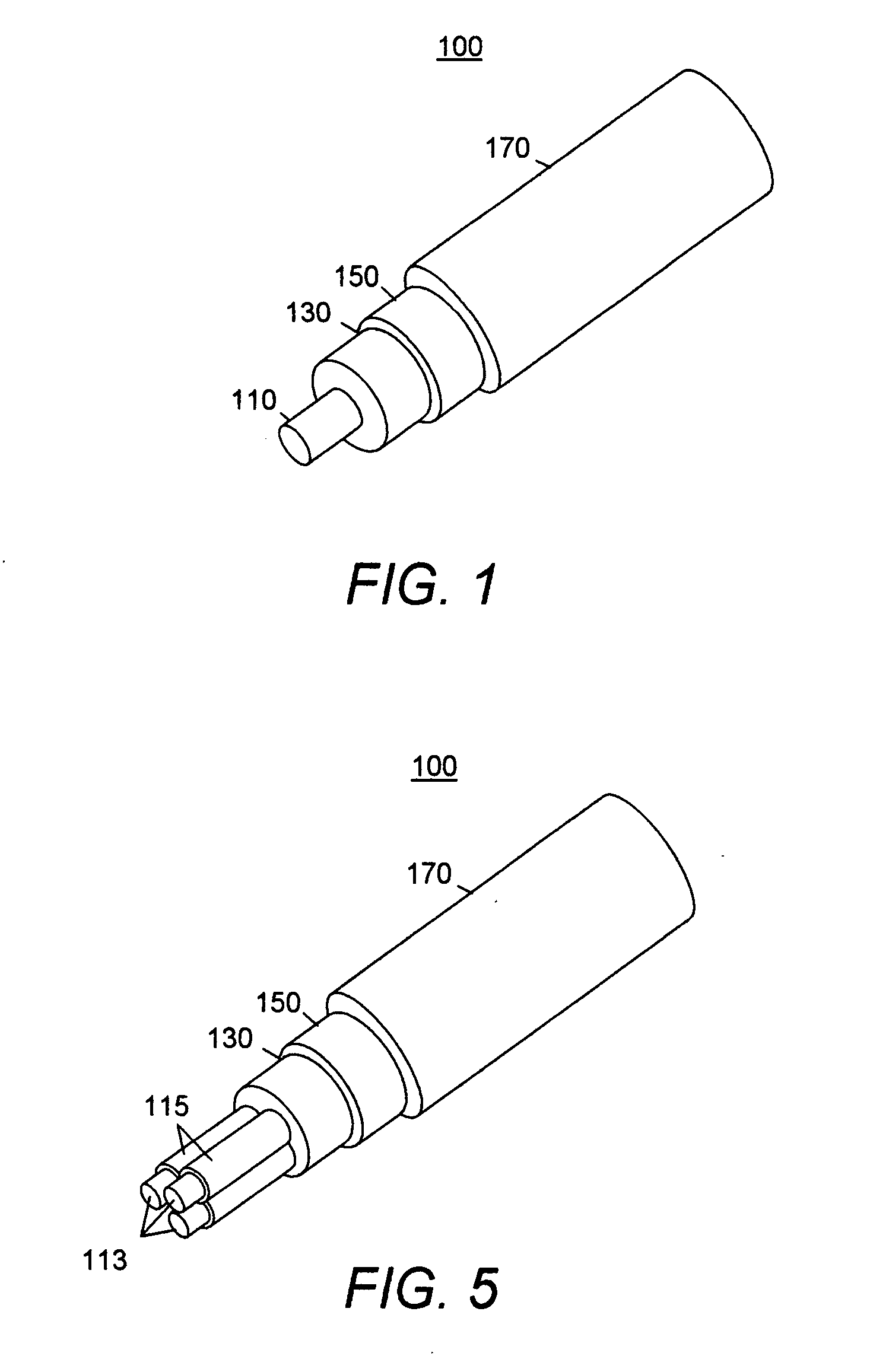

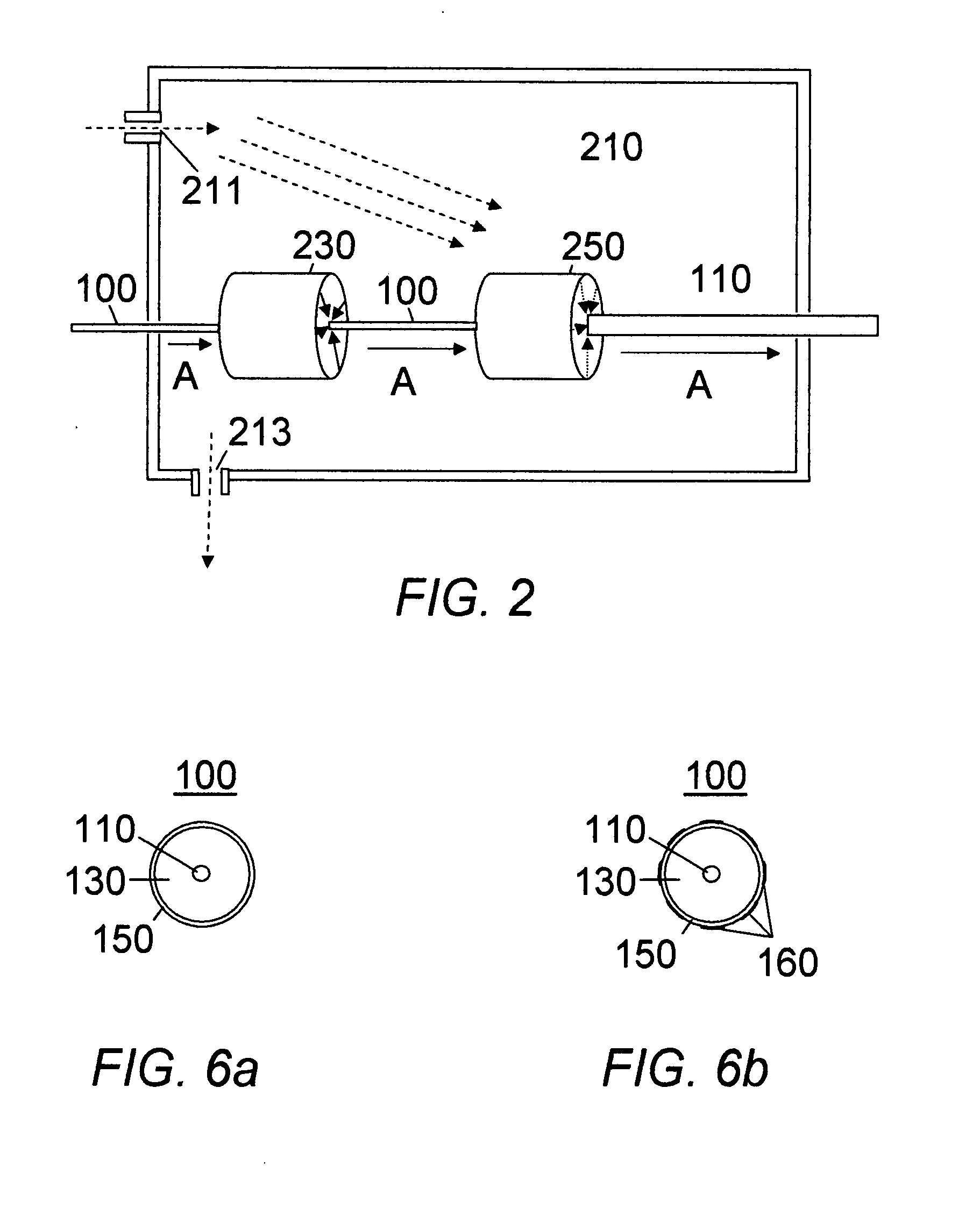

Multi-layer cable design and method of manufacture

InactiveUS20080060832A1Economically manufacturedVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsCathodic arc depositionFiber

A novel method of designing and fabricating flexible and lightweight cable [100] having a central conductor [110], a dielectric layer [130], an outer conductor [150] and an insulation coating [170] using thin film technology is disclosed. The dielectric layer [130] is ‘grown’ on dielectric layer [130] using electrophoretic deposition to a specified thickness, based upon its intended use. It may include nano-diamonds. Ion beam assisted deposition is used to metalize the cable dielectric layer [130]. This may be ion beam assisted sputtering, ion beam assisted evaporative deposition or ion beam assisted cathodic arc deposition. In an alternative embodiment, the outer conductor may be etched to provide greater flexibility, or to add a piezoelectric layer. The central conductor [110] may be created from dielectric fibers [113] which are metalized as described above. The piezoelectric layer added to create ultrasonic transducer cables.

Owner:RAZAVI ALI

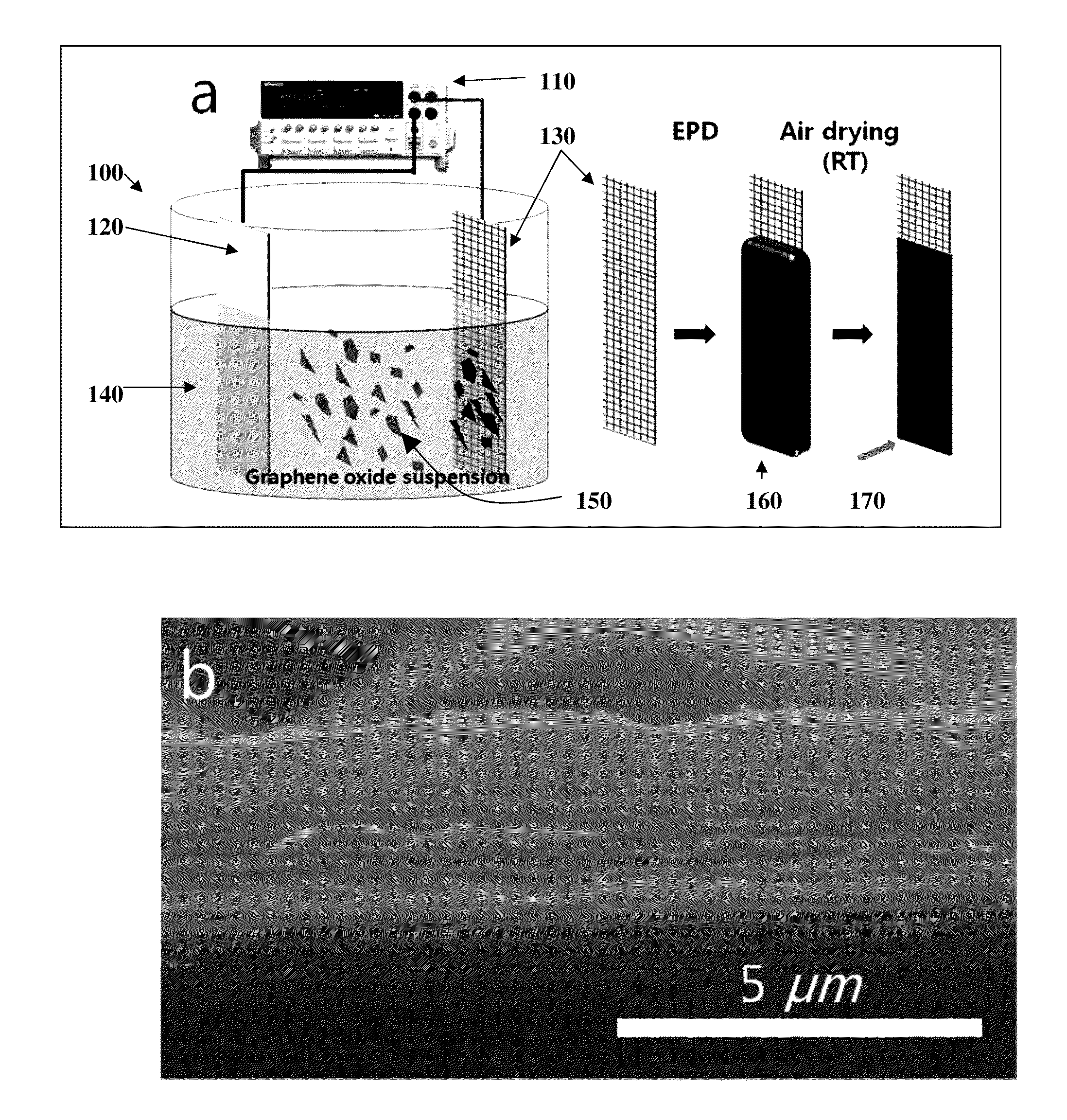

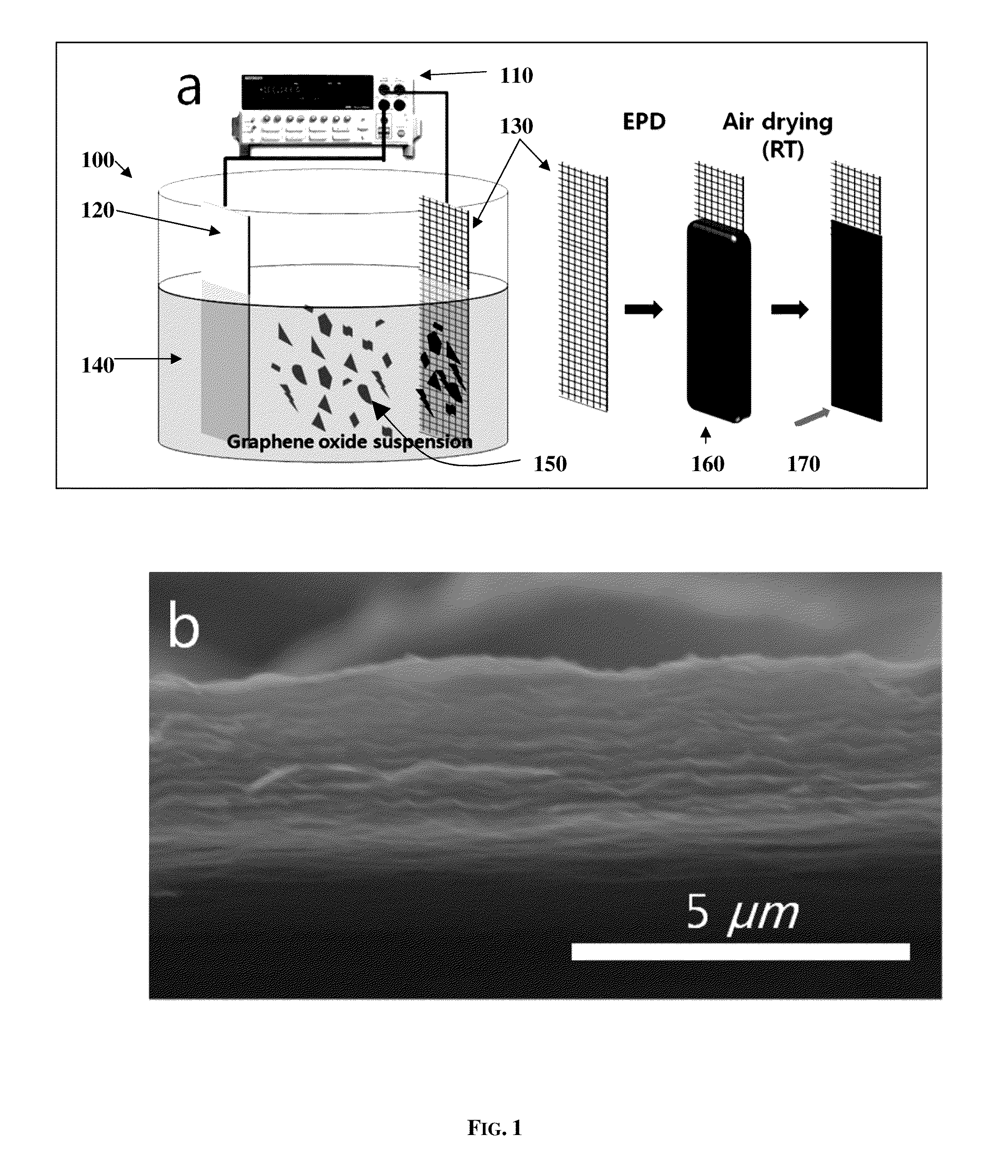

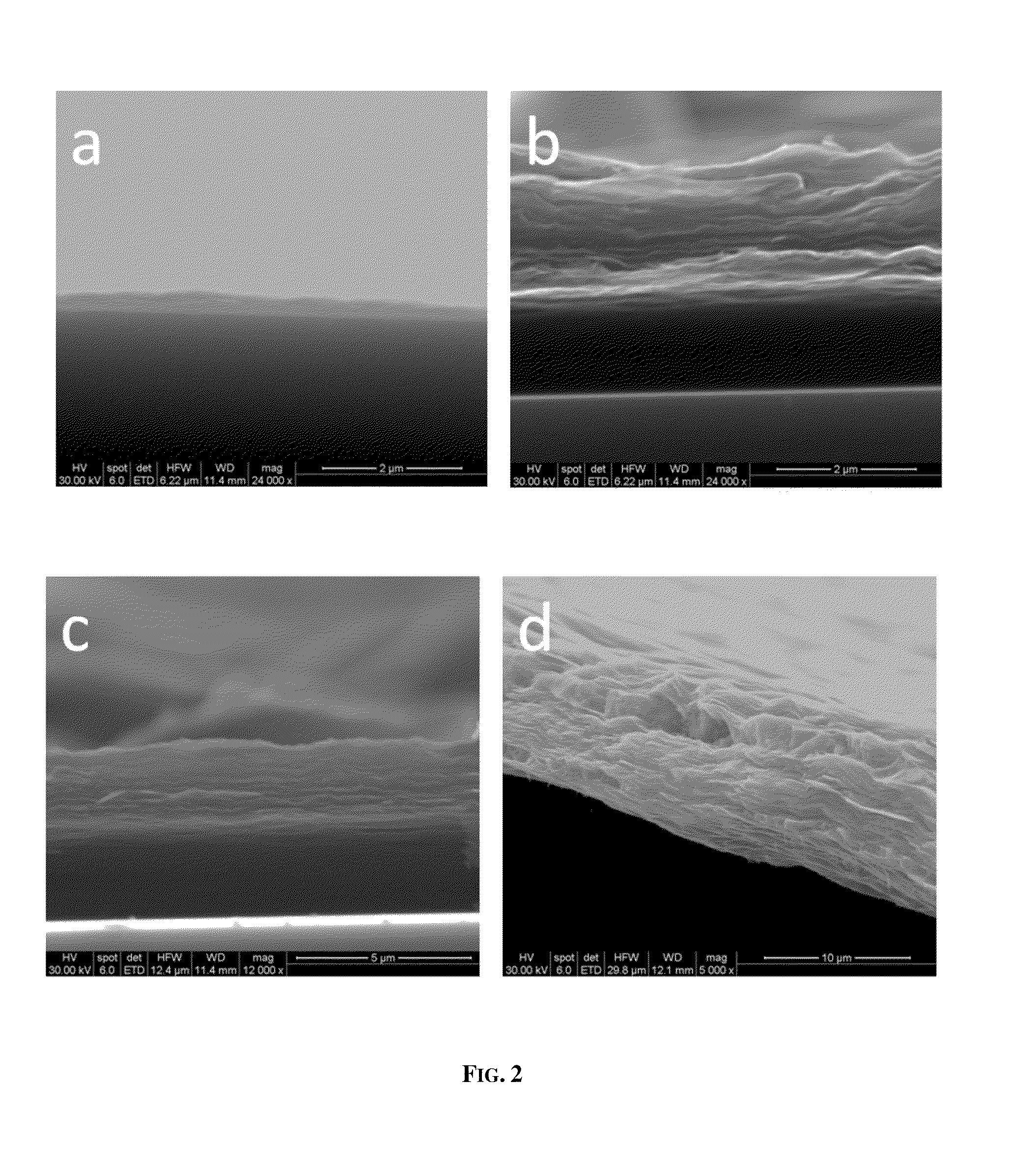

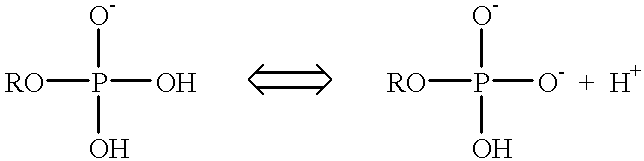

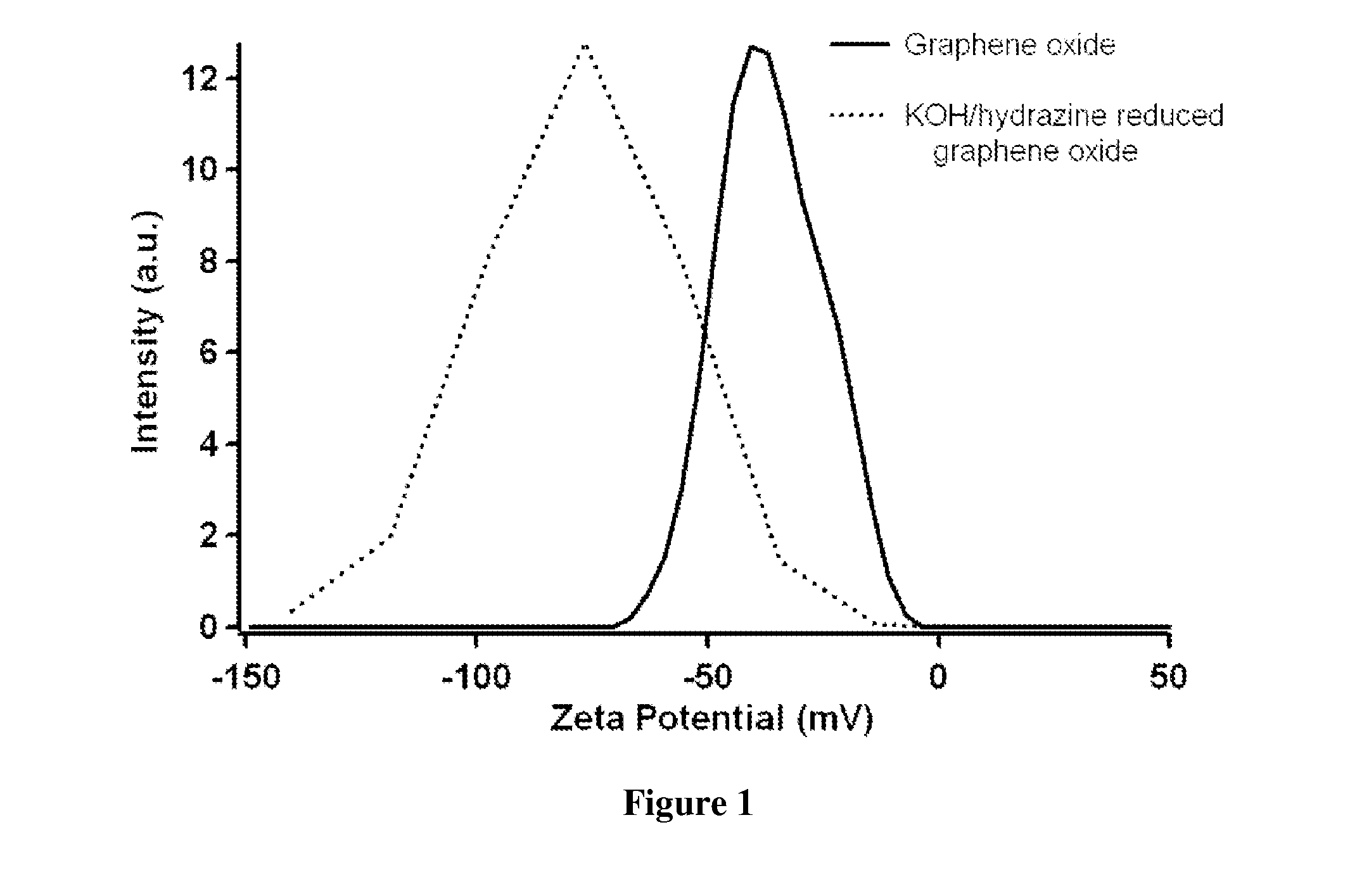

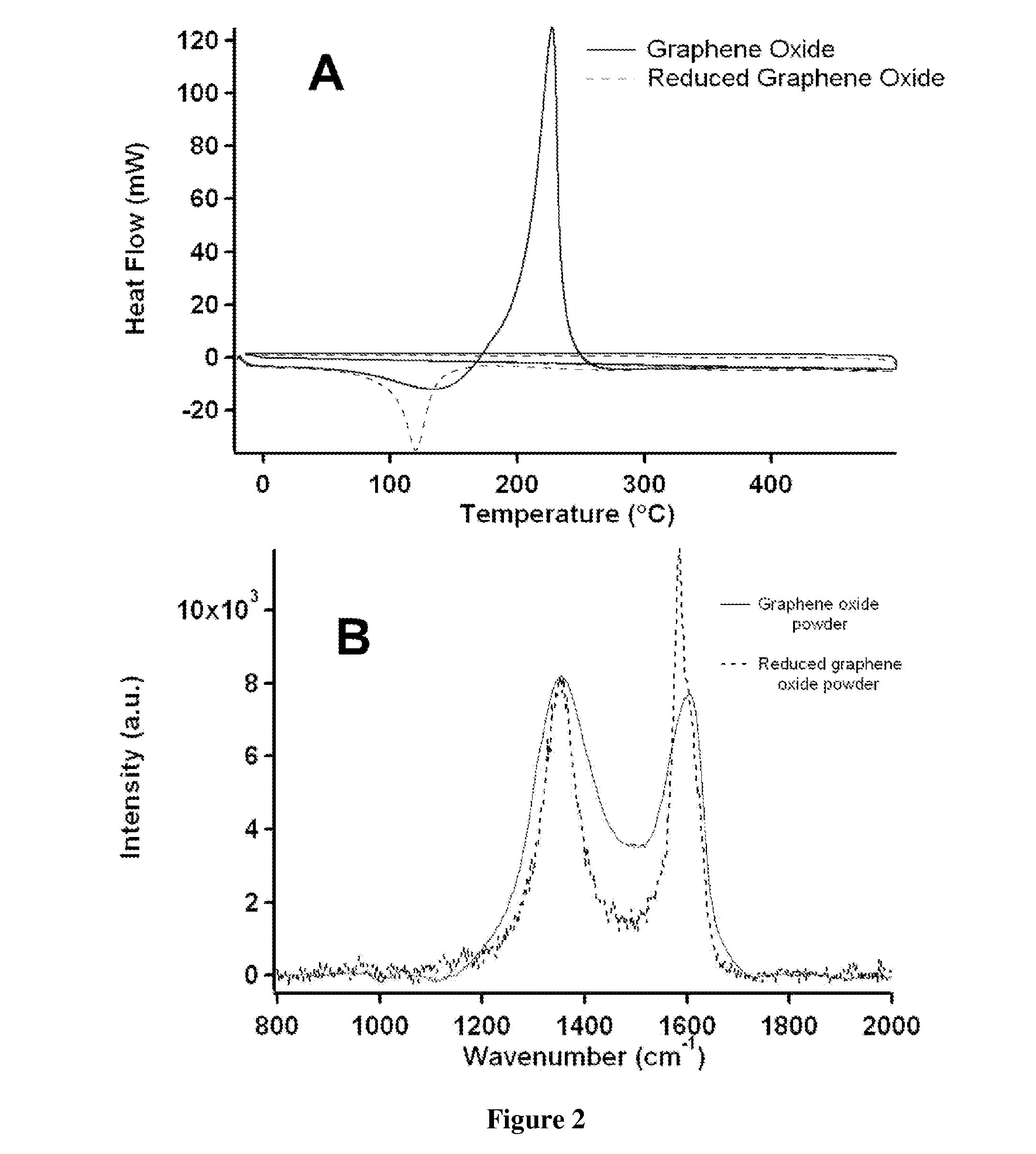

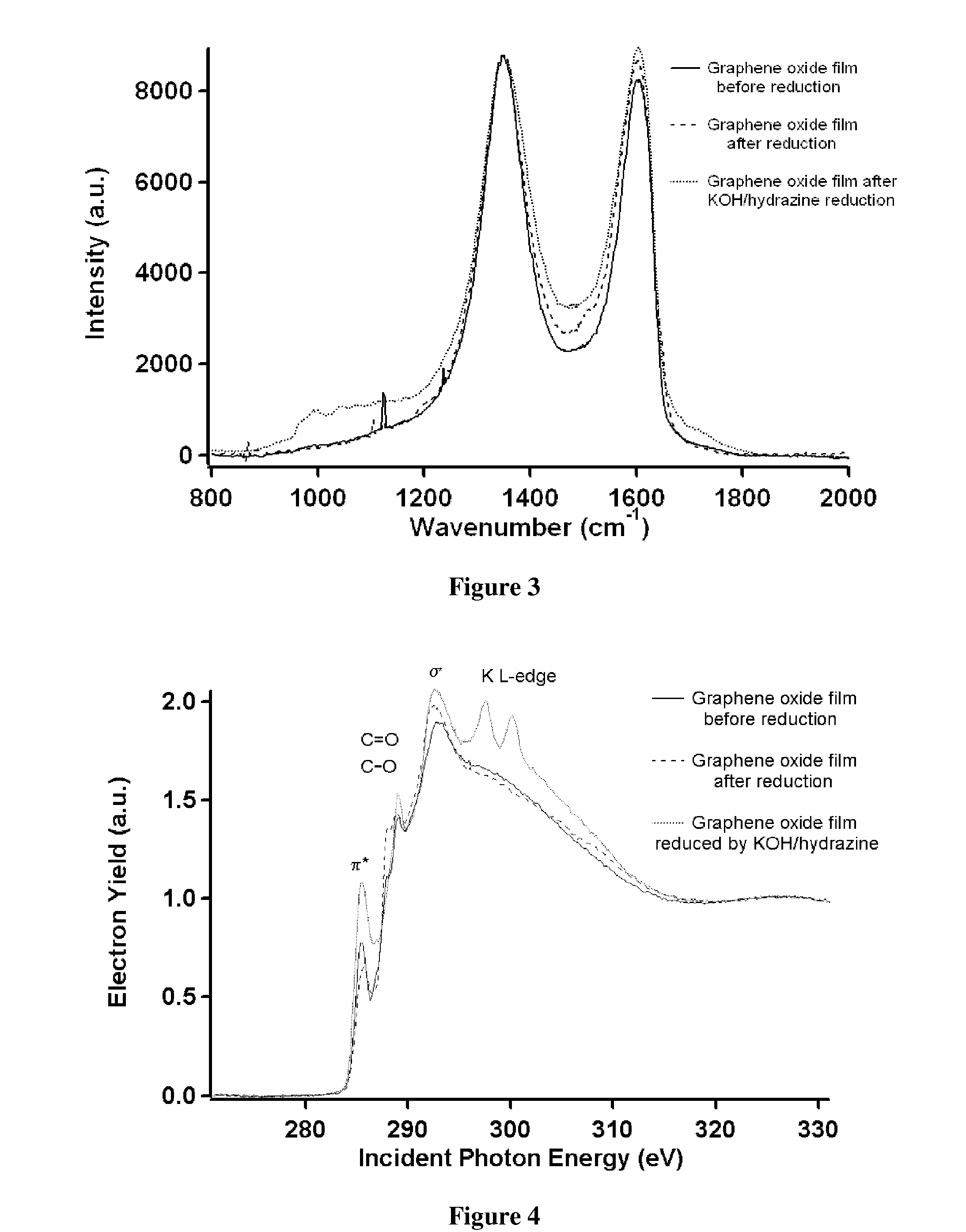

Electrophoretic deposition and reduction of graphene oxide to make graphene film coatings and electrode structures

Owner:RUOFF RODNEY S +4

Processes for the production of electrophoretic displays

ActiveUS7910175B2Electric shock equipmentsElectrophoretic coatingsPotential differenceElectrophoresis

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, patterned coatings of capsules may be formed by applying a fluid form of an electrophoretic medium to a substrate, and applying a temporally varying voltage between an electrode and the substrate. The process may be repeated to allow for deposition of full color displays.

Owner:E INK CORPORATION

Processes for the production of electrophoretic displays

ActiveUS20040226820A1Electrolysis componentsVolume/mass flow measurementElectrophoresisPotential difference

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, a patterned coating may be deposited upon a substrate containing a conductive layer by varying the conductivity of the conductive layer by radiation exposure or by coating portions of the conductive layer with an insulating layer, typically a photoresist.

Owner:E INK CORPORATION

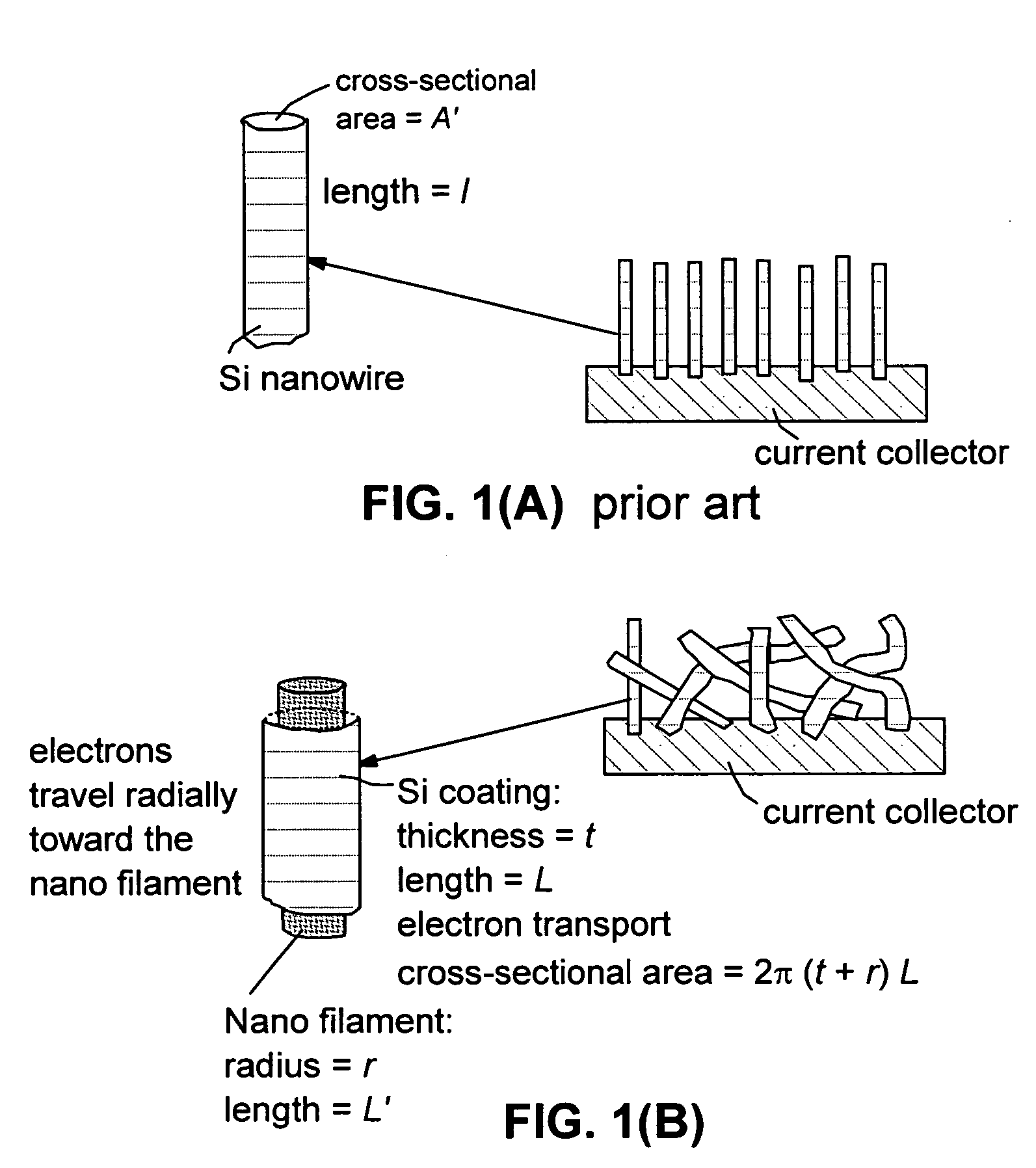

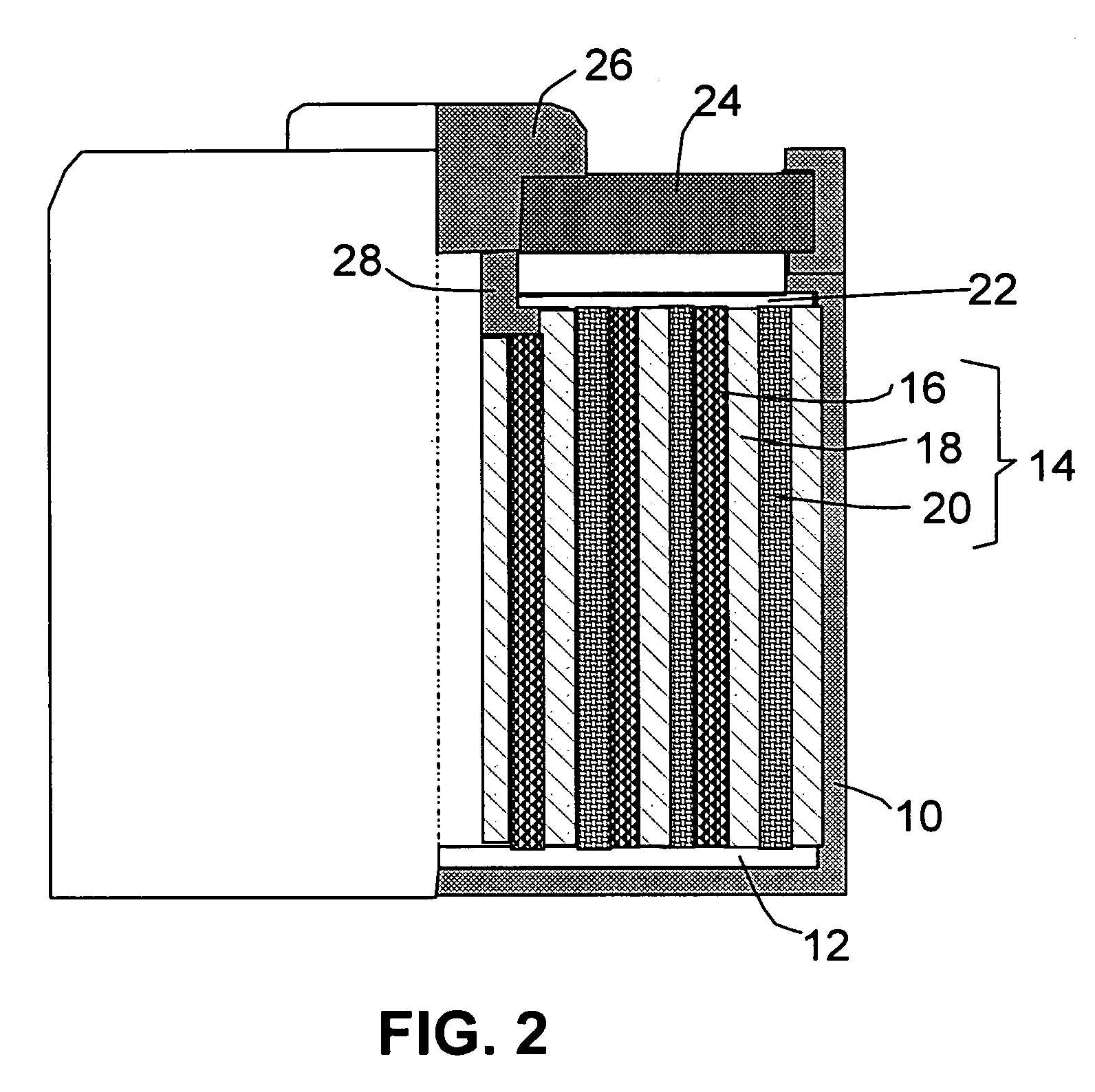

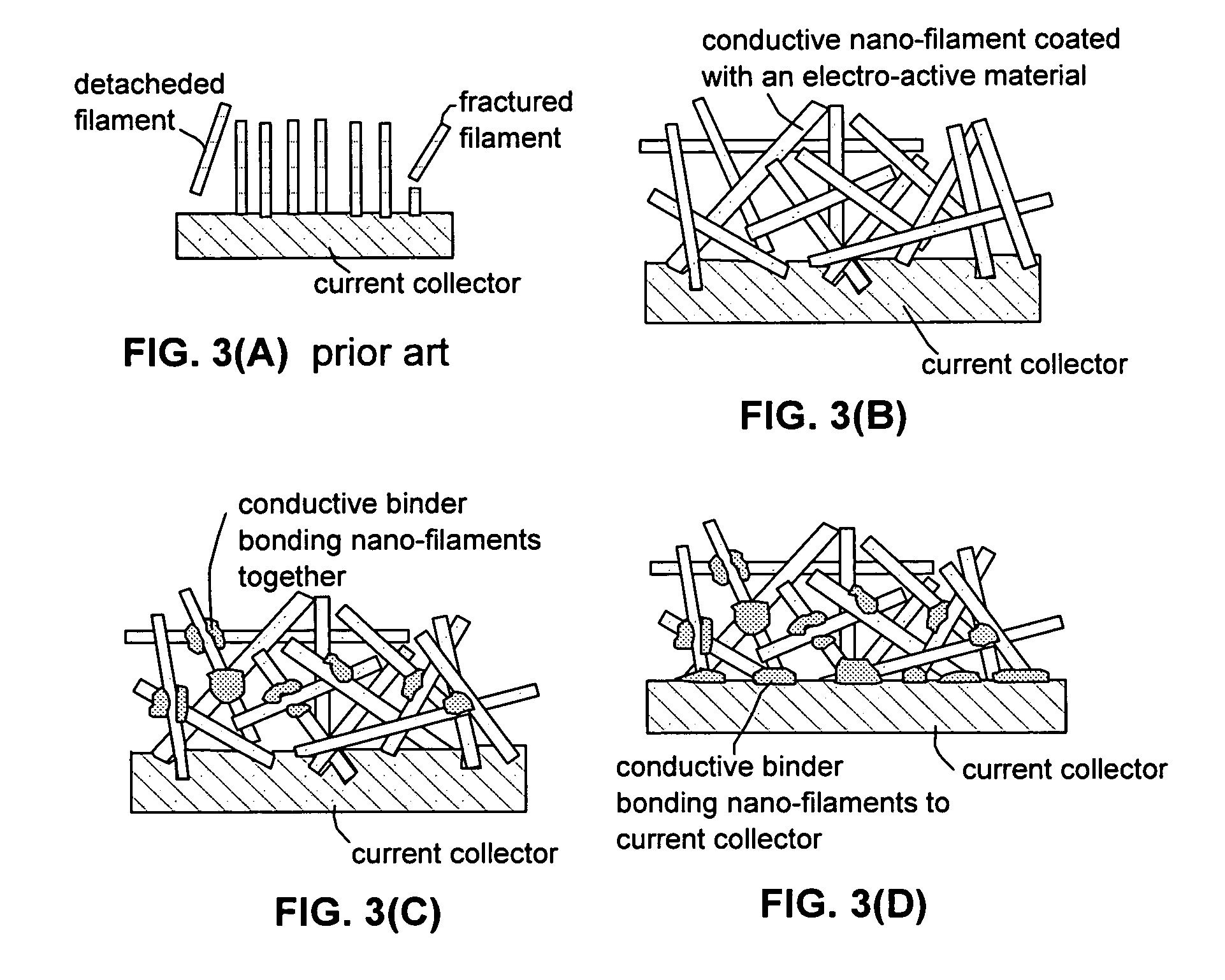

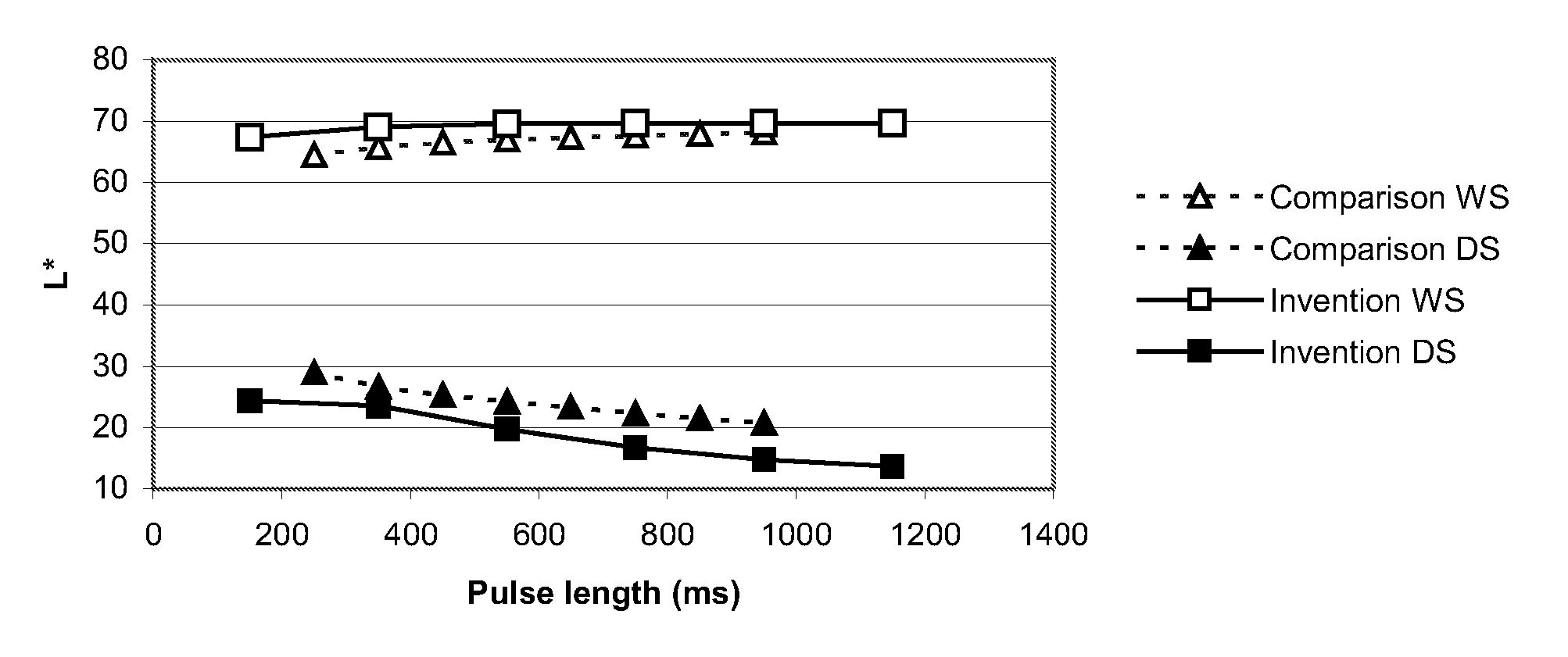

Process for producing hybrid nano-filament electrodes for lithium batteries

ActiveUS20090269511A1High reversible capacityLower internal resistanceCell electrodesFinal product manufactureNanowireElectrical battery

This invention provides a process for producing a hybrid nano-filament composition for use in a lithium battery electrode. The process comprises: (a) providing a porous aggregate of electrically conductive nano-wires that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a porous network of electrically conductive filaments, wherein the nano-wires have a diameter or thickness less than 500 nm; and (b) depositing an electro-active coating onto a surface of the nano-wires, wherein the electro-active coating is capable of absorbing and desorbing lithium ions and the coating has a thickness less than 10 μm, preferably less than 1 μm. This process is applicable to the production of both an anode and a cathode. The battery featuring an anode or cathode made with this process exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

Electrophoretic particles, and processes for the production thereof

InactiveUS20050000813A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrophoresisCopper chromite

Owner:E INK CORPORATION

Methods for coating a metal substrate and related coated substrates

ActiveUS7749368B2Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrogalvanizationMetallic substrate

Owner:PPG IND OHIO INC

Pretreatment compositions and methods for coating a metal substrate

Disclosed are methods for treating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods include contacting the substrate with a pretreatment composition that includes: (a) a group IIIB and / or IVB metal; (b) free fluorine; (c) a metal fluoride salt formed from a metal which forms a fluoride salt having a pKsp of at least 11; and (d) water.

Owner:PPG IND OHIO INC

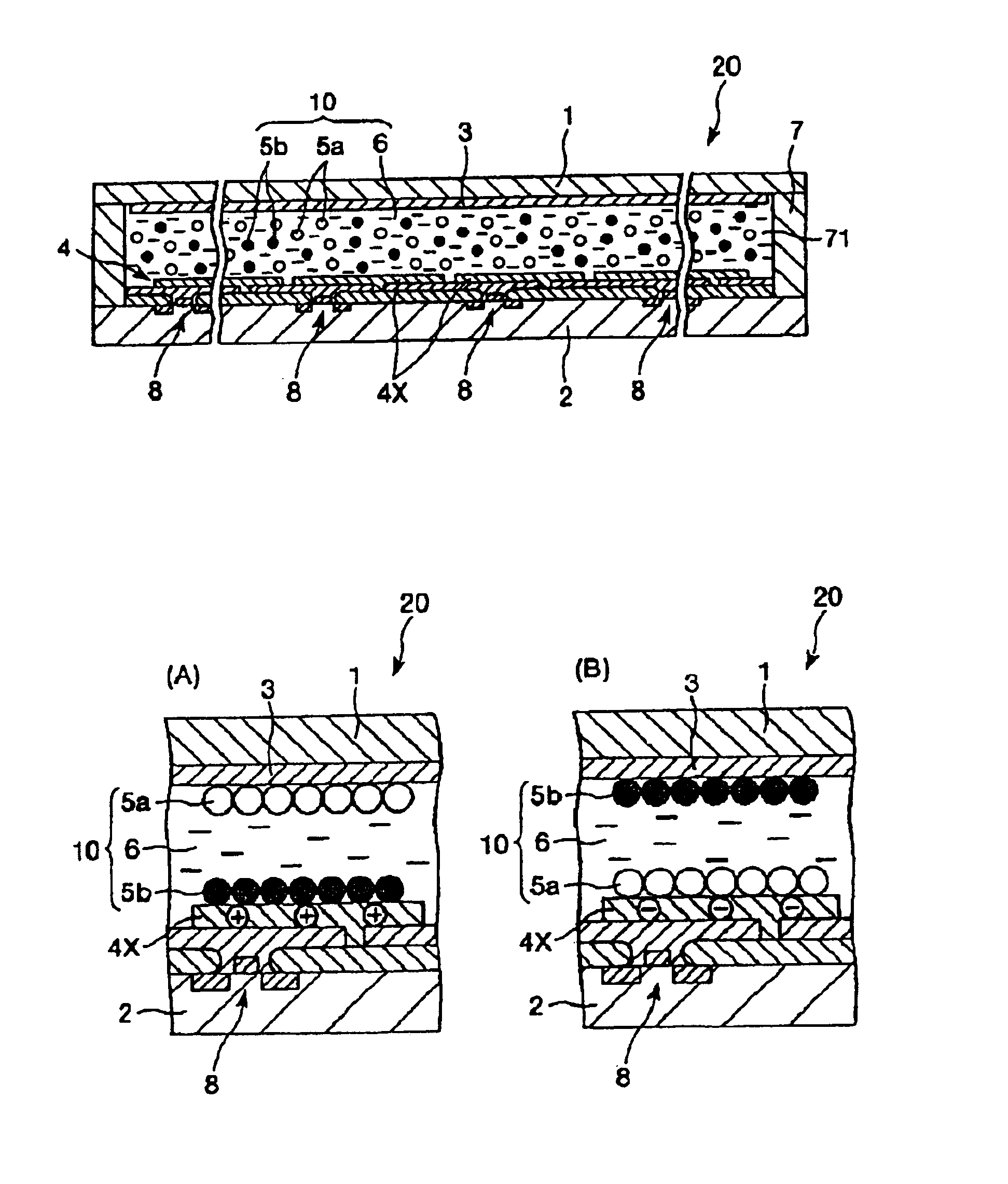

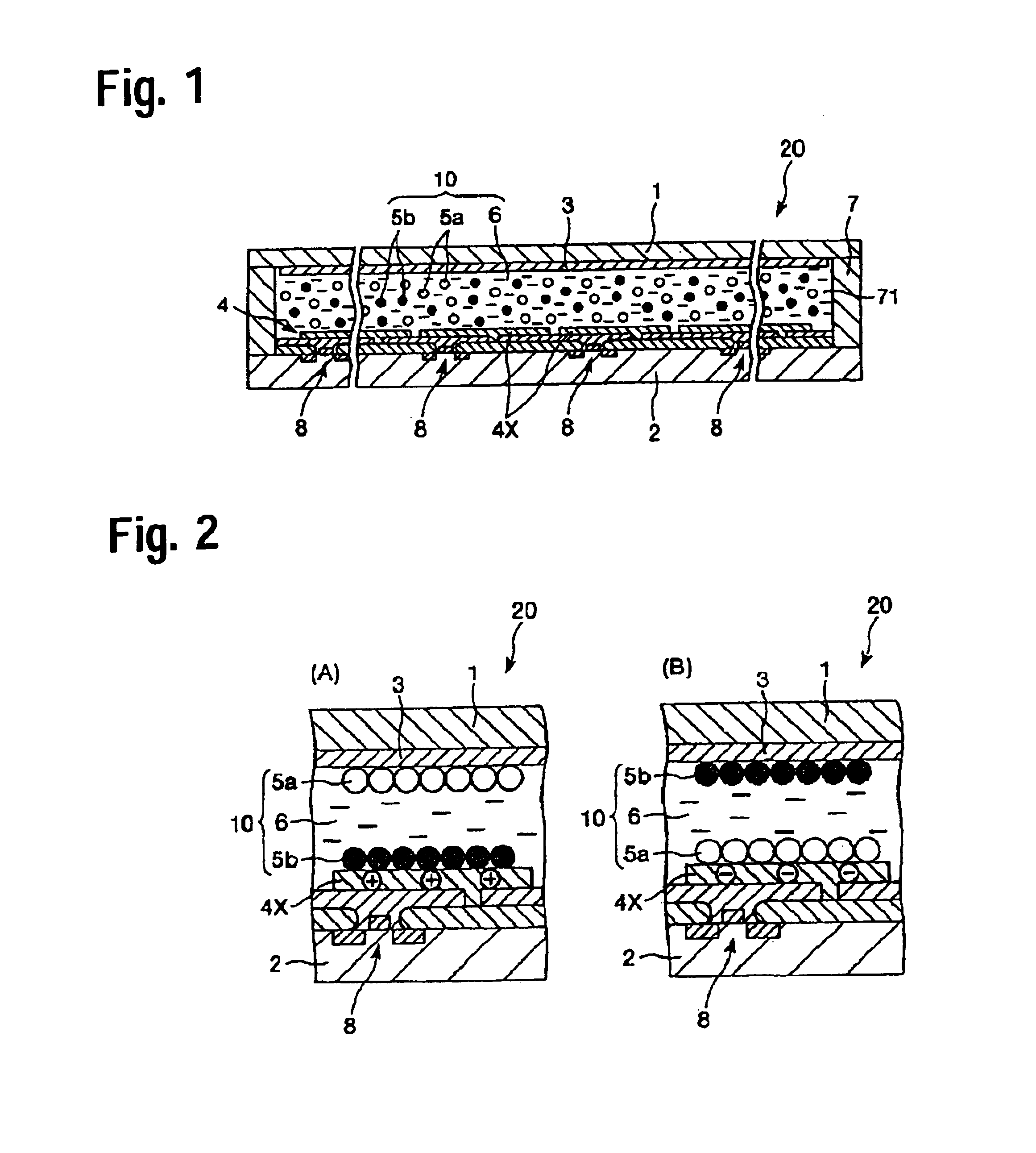

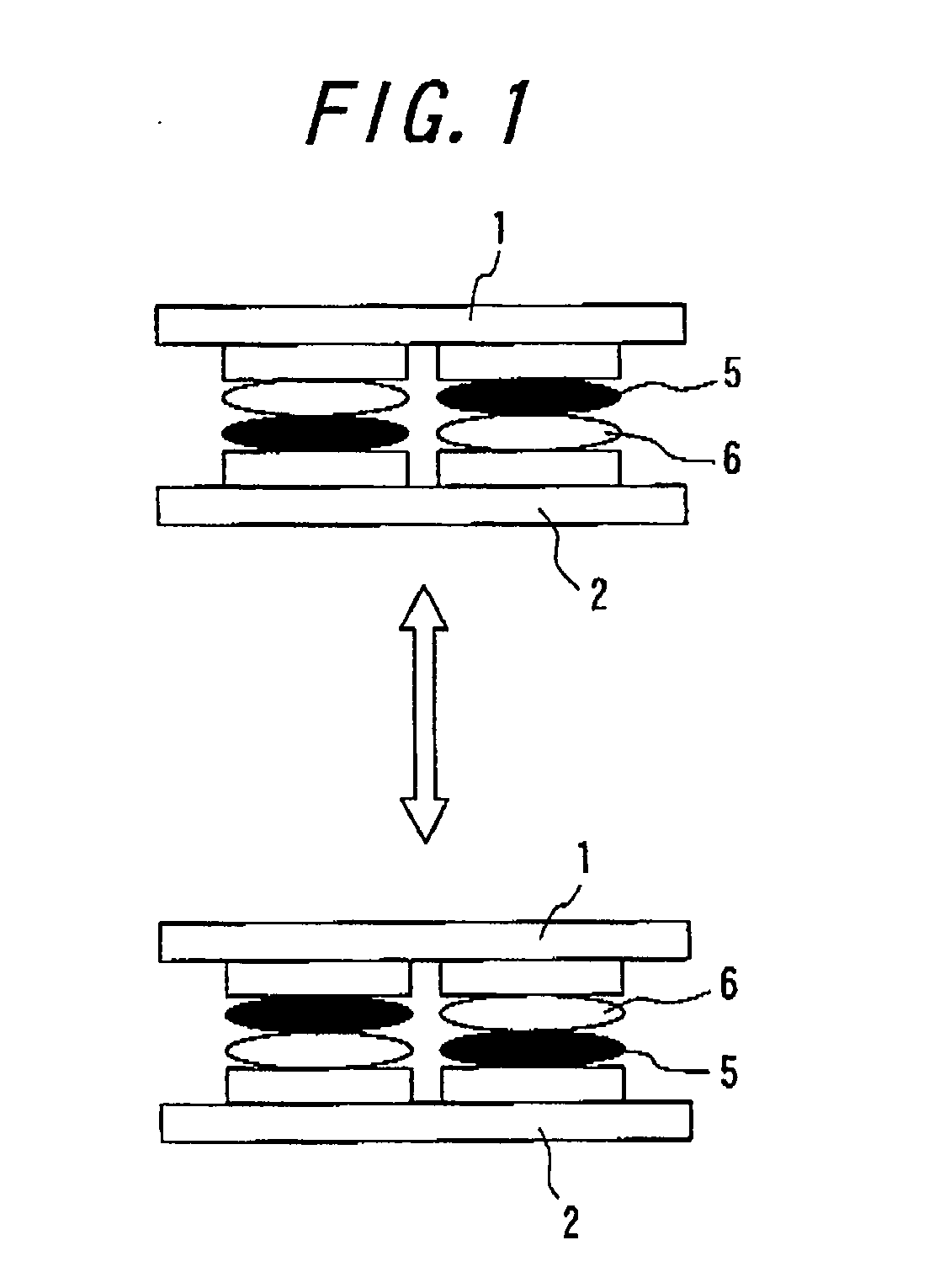

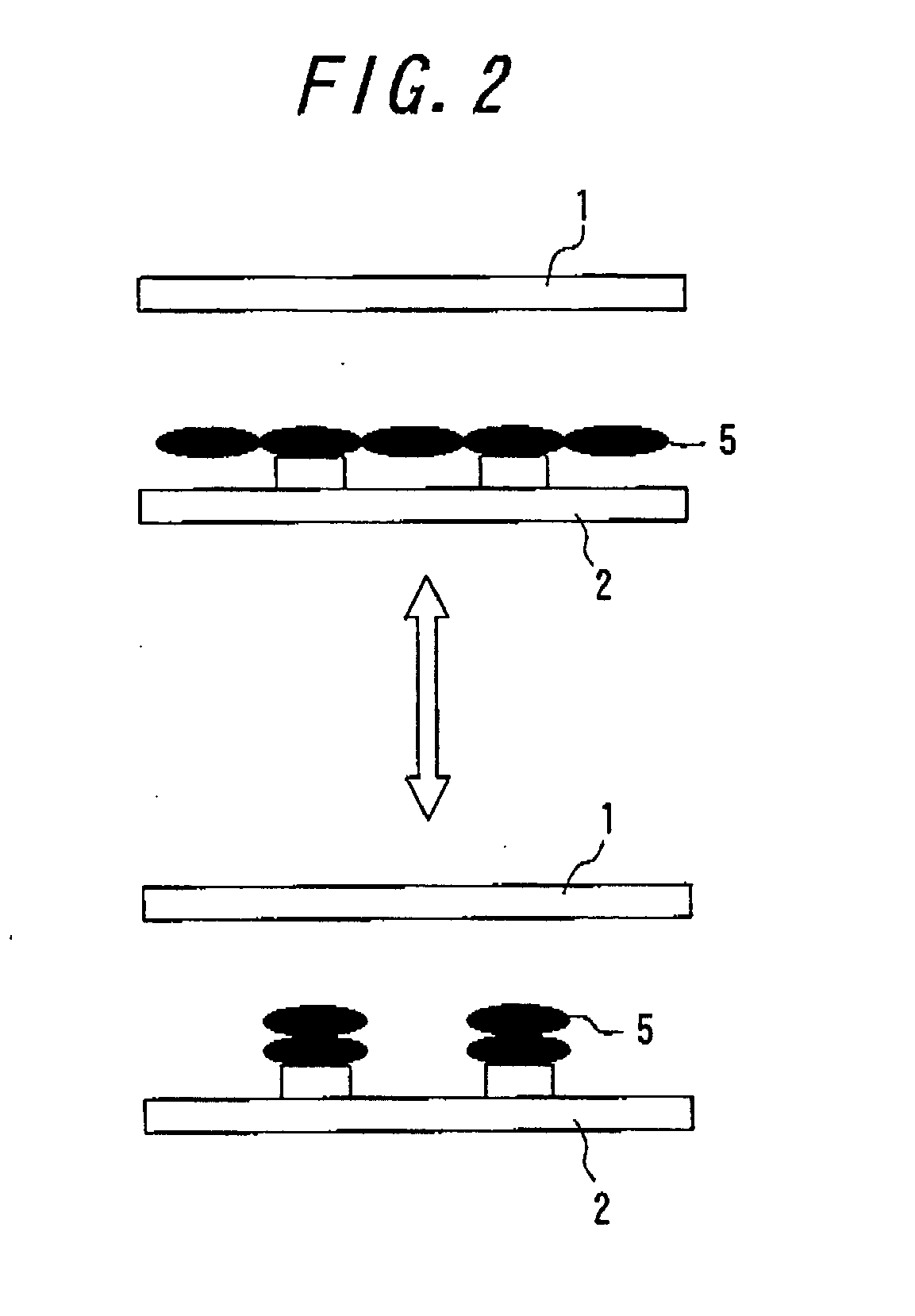

Electrophoretic dispersion, electrophoretic display device, method of manufacturing electrophoretic display device, and electronic system

ActiveUS6947203B2Reduces and prevents aggregationImprove the display effectElectrolysis componentsStatic indicating devicesInorganic particleElectronic systems

To provide an electrophoretic dispersion capable of reducing or preventing the aggregation of electrophoretic particles, an electrophoretic display device using the electrophoretic dispersion, a method of manufacturing the electrophoretic display device, and an electronic system superior in display performance; an electrophoretic display device (electrophoretic display unit) has: a first substrate with a first electrode; a second substrate with a second electrode opposite the first electrode; and an electrophoretic dispersion provided between the first substrate and second substrate. The electrophoretic dispersion (dispersion for electrophoretic display units) includes a liquid phase insulative dispersion medium and electrophoretic particles dispersed in the dispersion medium, the particles electrophoretically migrated under an influence of an electric field. Also included as the electrophoretic particles, inorganic particles and resin particles dyed a color different from that of the inorganic particles and having an electrical polarity opposite to that of the inorganic particles.

Owner:E INK CORPORATION

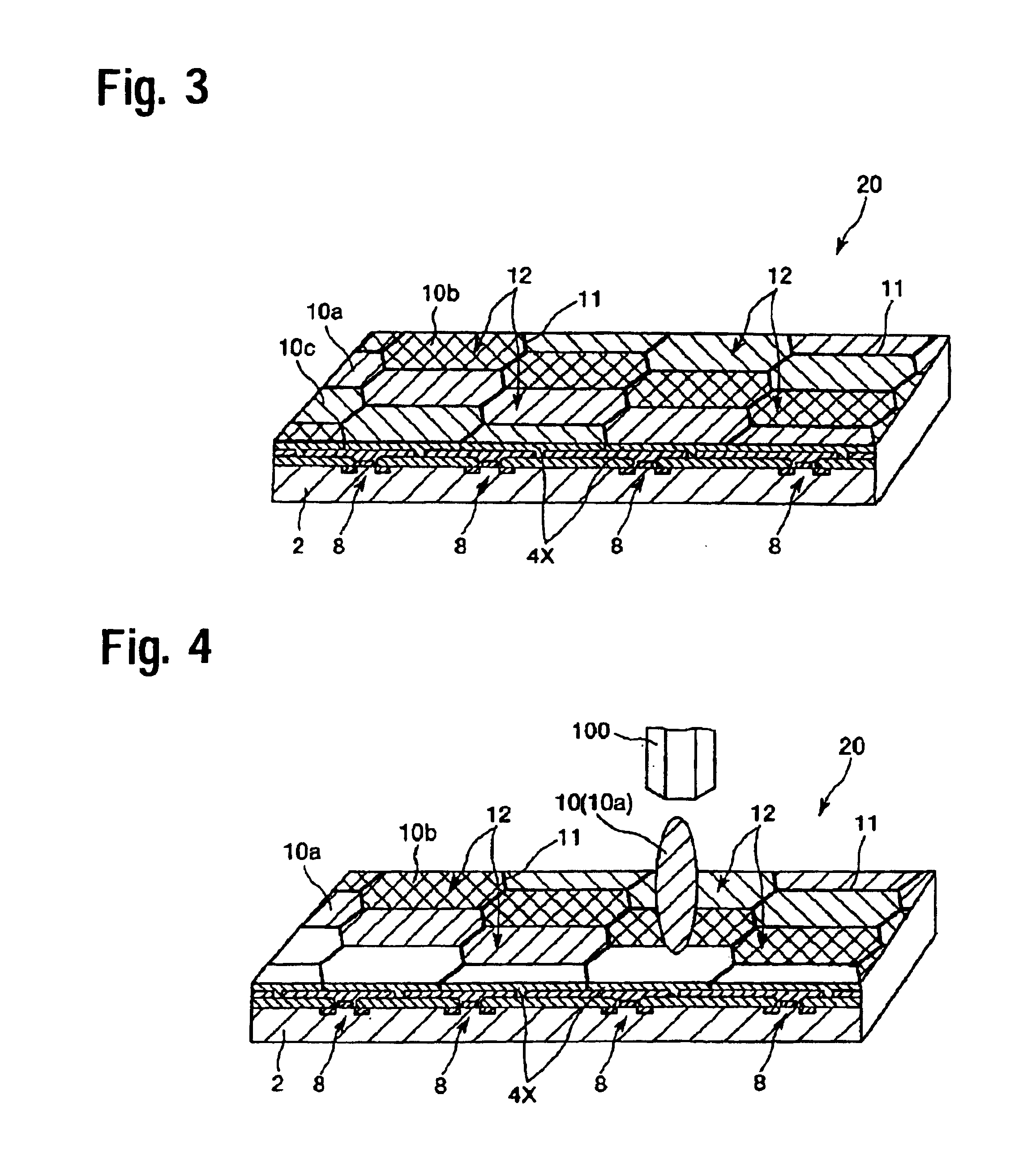

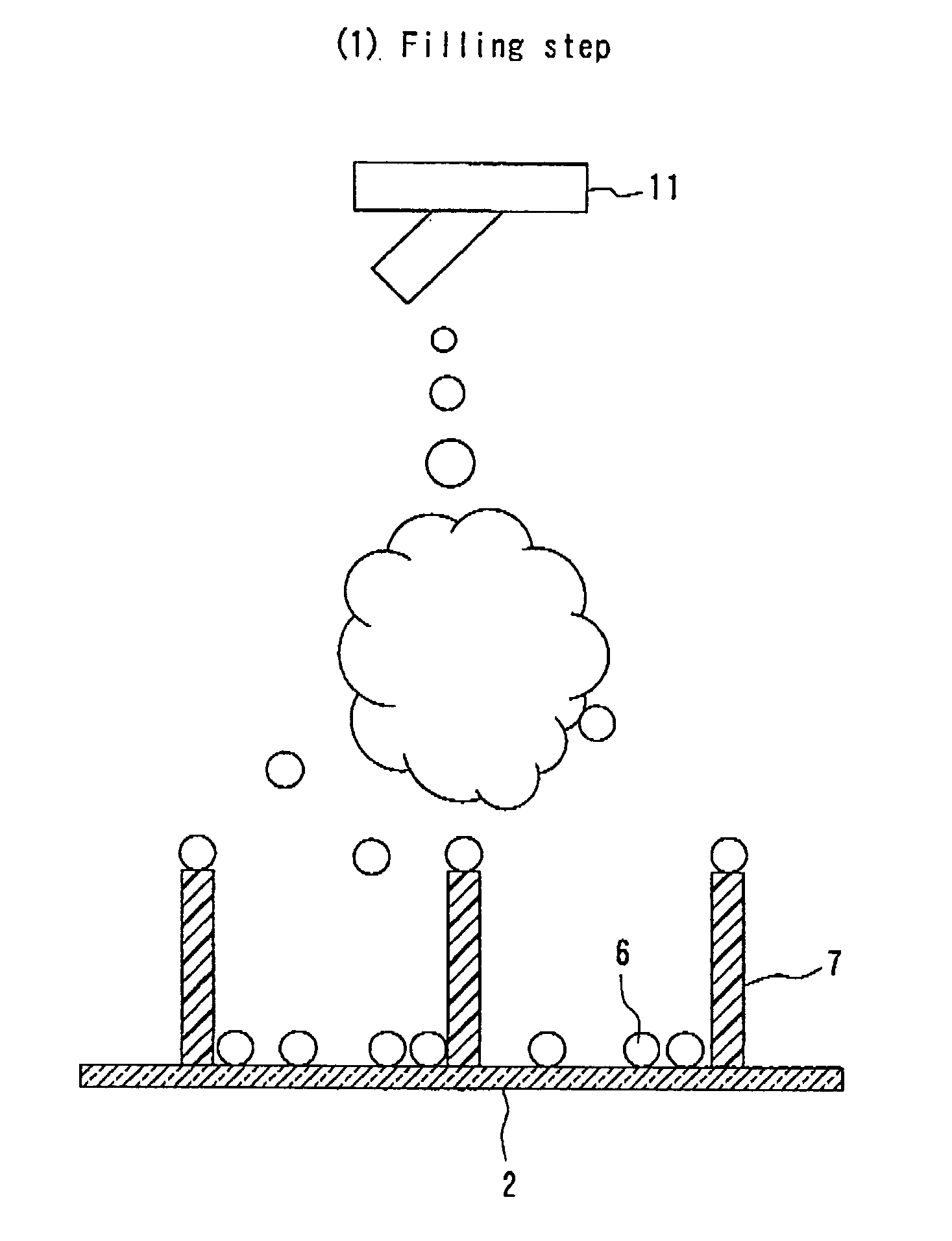

Image display panel manufacturing method, image display device manufacturing method, and image disiplay device

InactiveUS20060231401A1Drawback can be obviatedQuick responseElectrolysis componentsVolume/mass flow measurementSpray nozzleEngineering

In the case of filling and setting the liquid powders or the particles in a plurality of cells formed by the partition walls on the substrate, the method includes the steps of: setting a nozzle at an upper portion of a container; setting the substrate, on which the partition walls are arranged, at a lower portion of the container; scattering the liquid powders or the particles dispersed in a gas from the nozzle arranged at the upper portion in the container; and filling the liquid powders or the particles in the cells on the substrate arranged at the lower portion in the container. After this filling, the method further includes: a filling step for filling a predetermined amount of the liquid powders or the particles in spaces constituting the image display cells isolated by the partition walls; a removing step for removing unnecessary liquid powders or unnecessary particles remaining on the partition walls in the filling step; a substrate stacking step for stacking the transparent substrate and the opposed substrate via the partition walls and applying a sealing agent at a peripheral portion of the substrate so as to make an atmosphere between the transparent substrate and the opposed substrate uniform; and an electrode adhering step for connecting a circuit for displaying the image to the electrode so as to form a module.

Owner:BRIDGESTONE CORP

Pretreatment compositions and methods for coating a metal substrate

ActiveUS20090032144A1Sufficient amountElectrophoretic coatingsSolid state diffusion coatingPre treatmentMetal substrate

Disclosed are methods for treating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods include contacting the substrate with a pretreatment composition that includes: (a) a group IIIB and / or IVB metal; (b) free fluorine; (c) a metal fluoride salt formed from a metal which forms a fluoride salt having a pKsp of at least 11; and (d) water.

Owner:PPG IND OHIO INC

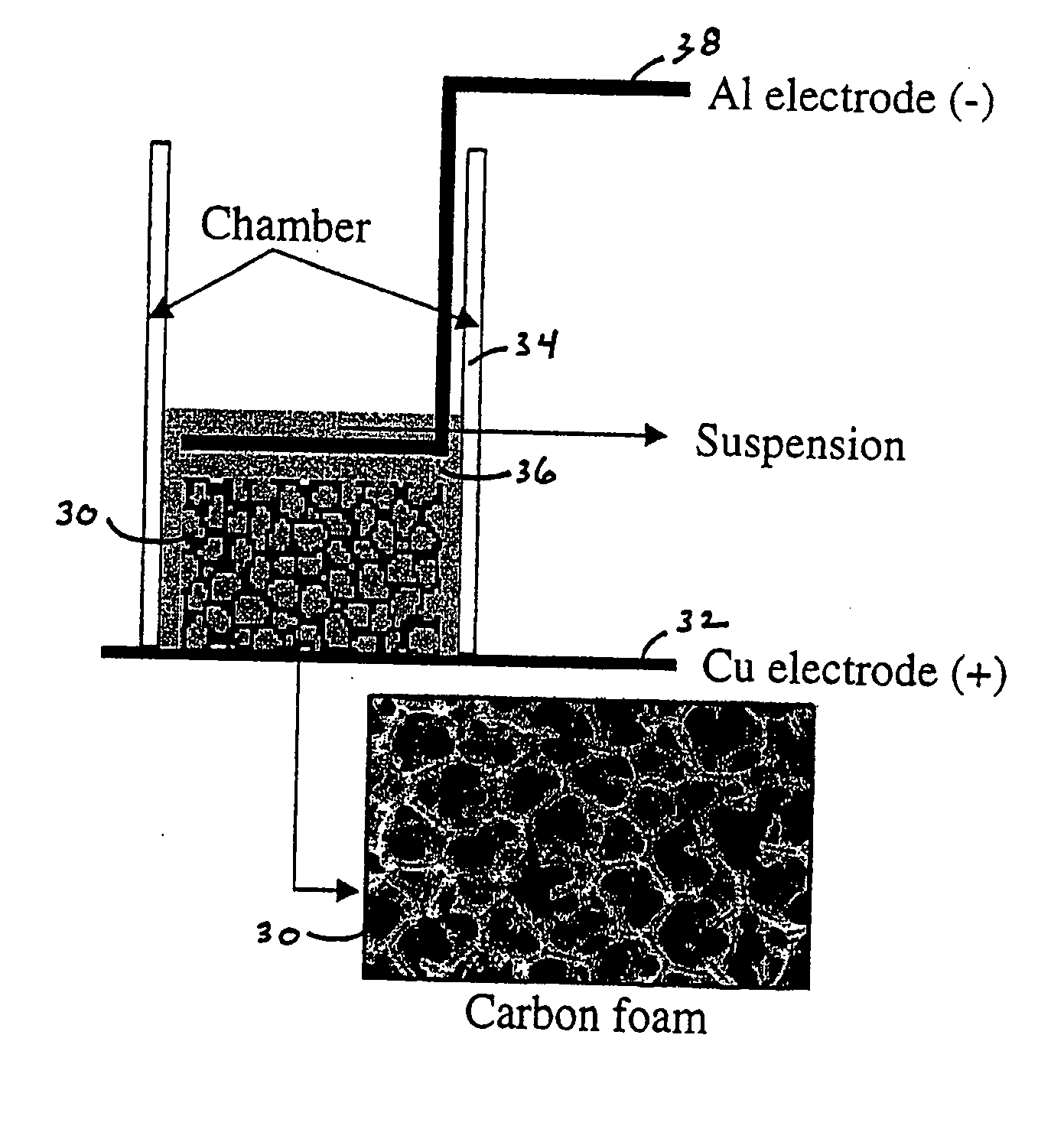

Electrophoretic diamond coating and compositions for effecting same

InactiveUS6258237B1Effective engineering evaluation of material strengthImprove adhesionElectrolysis componentsVolume/mass flow measurementSubstrate surfaceMaterials science

A method of depositing diamond particles on a surface of a substrate is provided. The method is effected by (a) charging the diamond particles by a positive charge to obtain positively charged diamond particles; and (b) electrophoretically depositing the positively charged diamond particles on the surface of the substrate, for obtaining a green diamond particles coat on the surface of the substrate.

Owner:ISCAR LTD

Graphene Films and Methods of Making Thereof

ActiveUS20130156678A1Material nanotechnologyElectrolysis componentsPlanar substrateConformal coating

Provided are methods for forming graphene or functionalized graphene thin films. Also provided are graphene and functionalized graphene thin films formed by the methods. For example, electrophoretic deposition methods and stamping methods are used. Defect-free thin films can be formed. Patterned films can be formed. The methods can provide conformal coatings on non-planar substrates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Method of electrophoretic deposition of ceramic bodies for use in manufacturing dental appliances

InactiveUS6059949AHigh strengthImprove toughnessElectrolysis componentsTeeth fillingMetallurgyElectrophoresis

A method for electrophoretic deposition of ceramic particles as a green body shaped as a dental appliance, the method comprising the steps of (a) forming a suspension of the ceramic particles in a first polar solvent, the ceramic particles constituting at least about 5% of the first suspension by weight; (b) passing a direct electrical current through the first suspension, using a deposition electrode shaped as the dental appliance to form a green body; (c) coating the green body with glass particles; and (d) sintering the resultant coated body for obtaining a glass coated all-ceramic dental appliance.

Owner:CEREL CERAMIC TECH

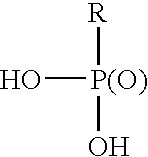

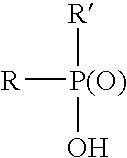

Electrodeposition coatings for use over aluminum substrates

A process for applying a coating on aluminum substrates by anionic electrodeposition of a phosphated epoxy resin made by phosphating a polyepoxide with both phosphoric acid and an organophosphonic acid and / or an organophosphinic acid. The coating has a reduced tendency to form pinholes.

Owner:PPG IND OHIO INC

Process for forming a two-coat electrodeposited composite coating the composite coating and chip resistant electrodeposited coating composition

InactiveUS6248225B1Electrolysis componentsVolume/mass flow measurementPolyurethane coatingAqueous dispersion

A process for applying two electrodeposited coatings, one on top of the other, to an electrically conductive substrate is provided. An electrically conductive first coating is applied to provide for corrosion resistance and a second polyurethane-based coating is applied to the first coating to provide chip resistance. Also, aqueous dispersions of the polyurethane coating compositions are disclosed.

Owner:PPG IND OHIO INC

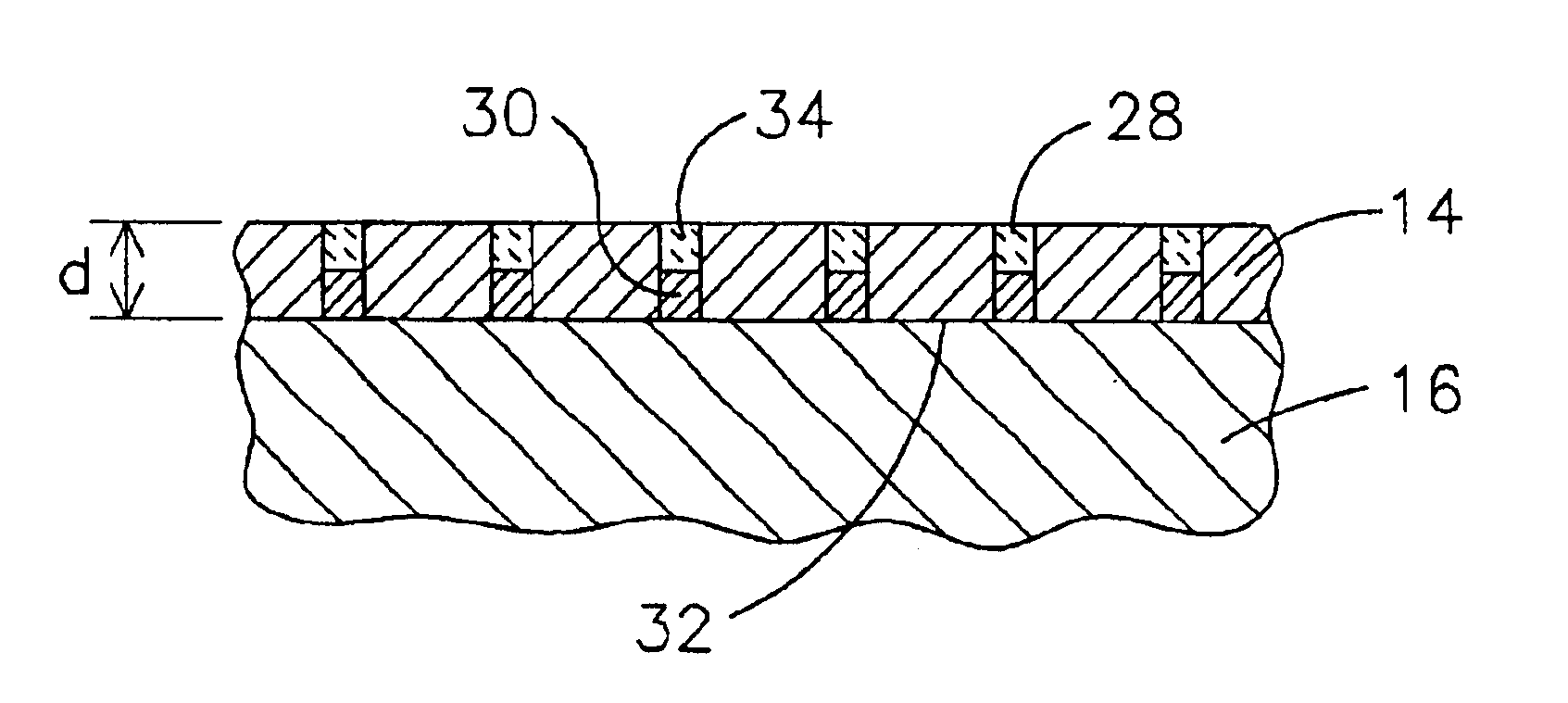

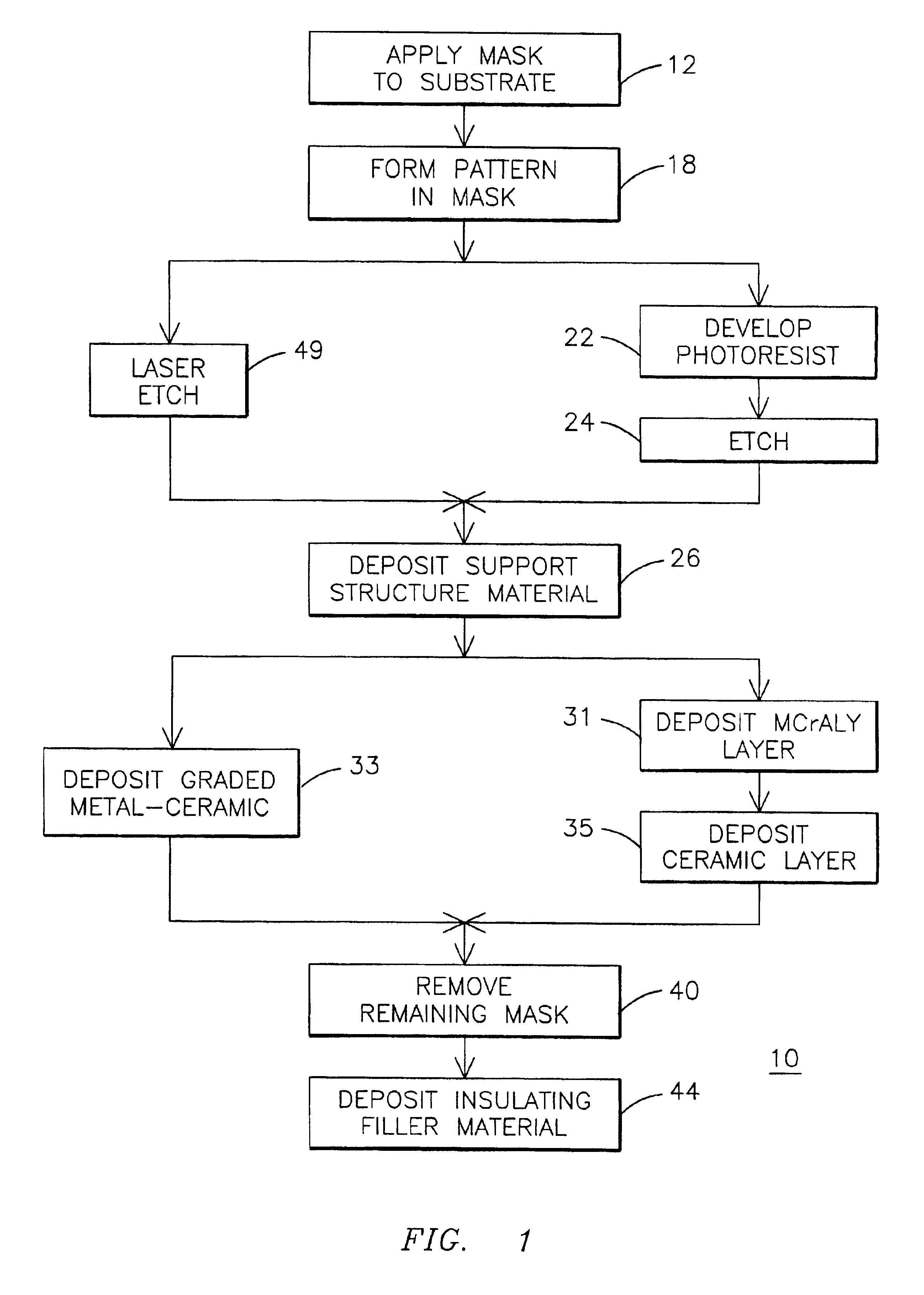

Honeycomb structure thermal barrier coating

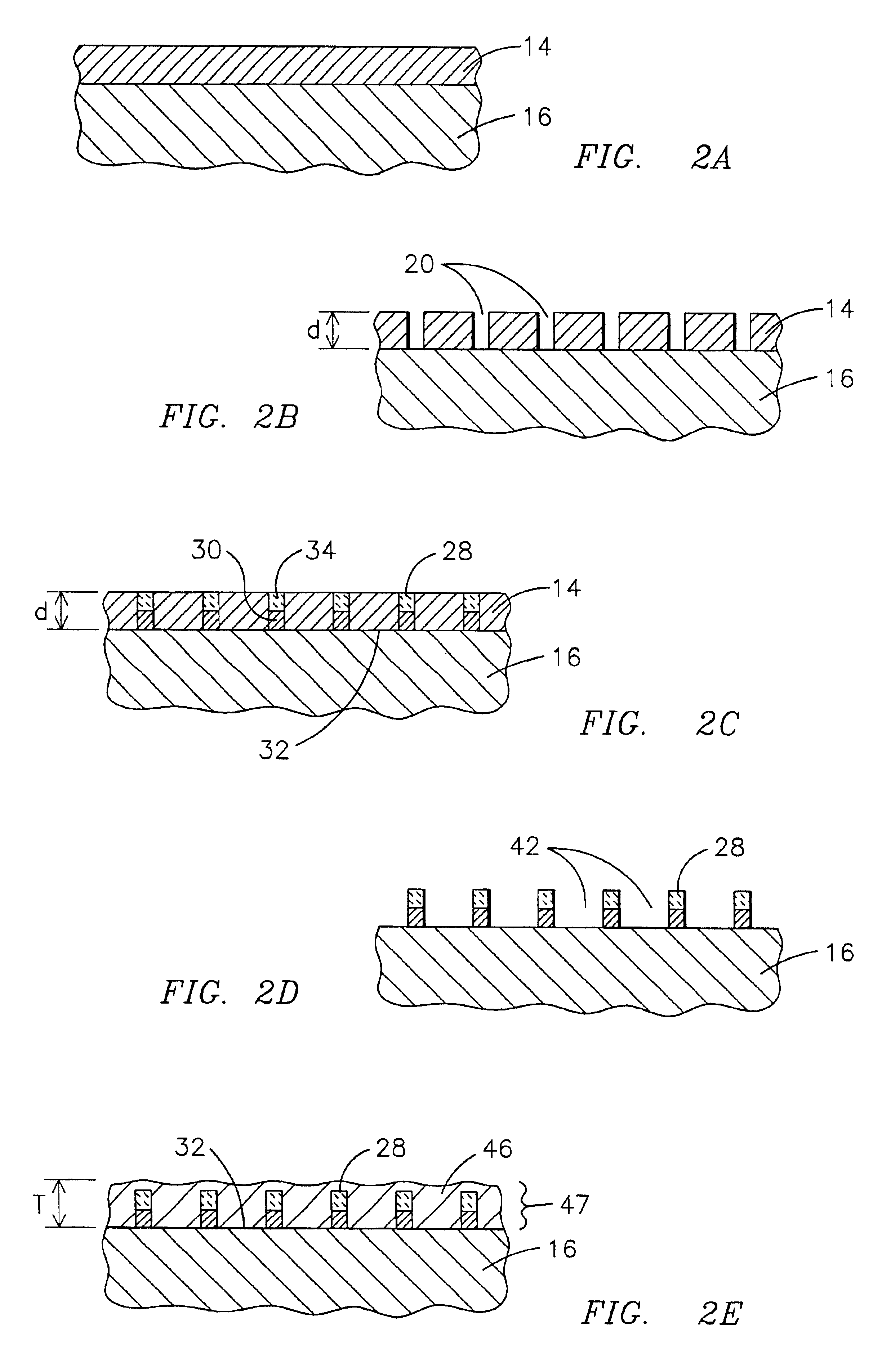

InactiveUS6846574B2Minimize heat transfer rateConvenient coatingMolten spray coatingRecord information storageForeign matterLaser etching

A device having an improved thermal barrier coating (46) and a process for manufacturing the same. A support structure (28) for retaining a ceramic insulating material (46) on a substrate (16) is formed by the deposition of a support structure material through a patterned masking material (14). The support structure can define cells into which the ceramic insulating material is deposited following removal of the masking material. The masking material may be patterned by known photolithographic techniques (22,24) or by laser etching (48). The support structure (28) may be a composite metal-ceramic material having either discreet layers (30,34) or a graded composition and may be deposited by an electro-desposition process followed by a heat treatment to form a solid state diffusion bond with the substrate. The ceramic filler material may be deposited (44) by the electrophoretic deposition of ceramic particles coated with a bonding material that is subsequently heated to oxidize and to bond the particles together. The support structure may be provided with included walls in order to improve its resistance to foreign object impact damage.

Owner:SIEMENS ENERGY INC

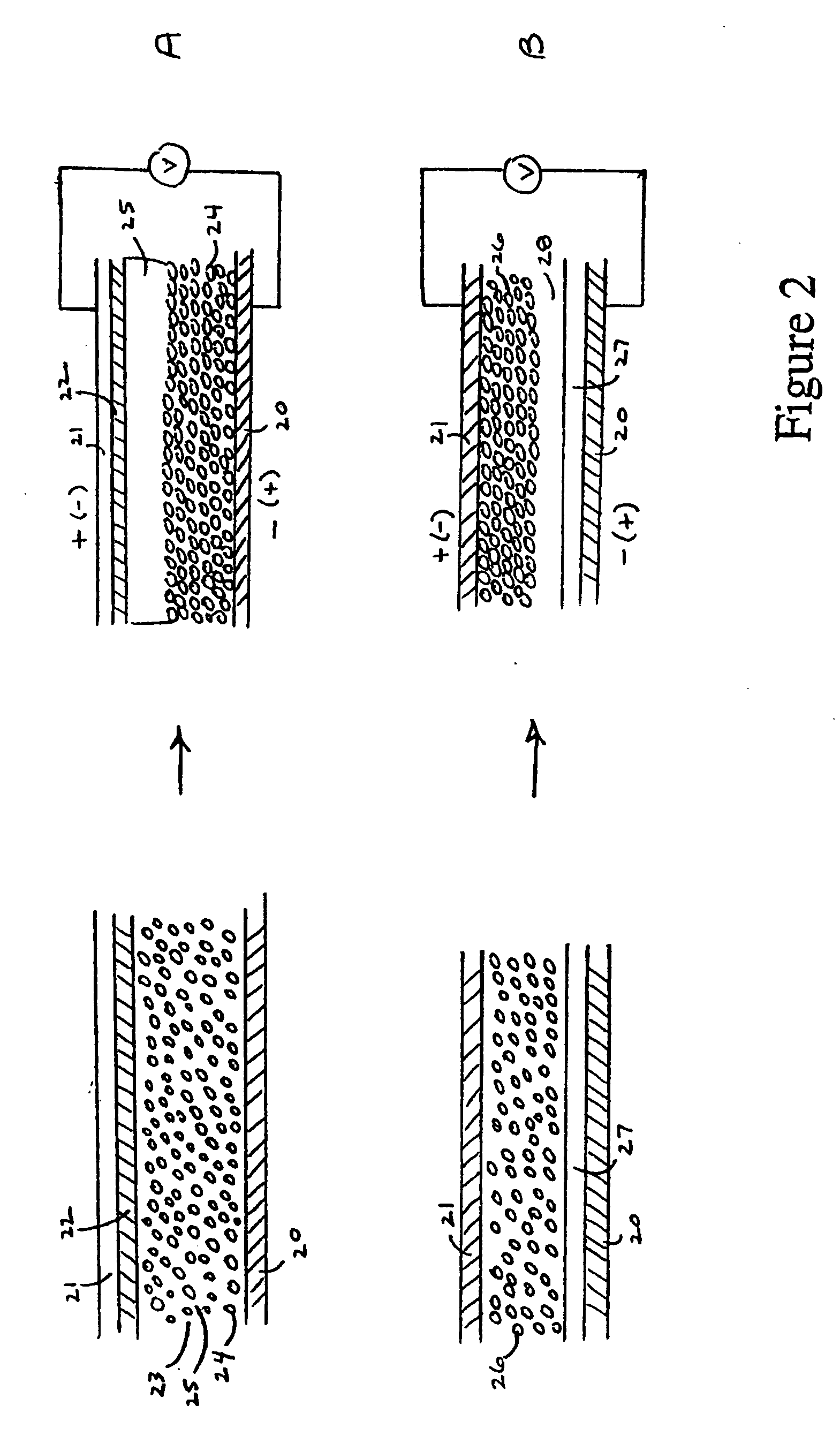

Electrophoretic assembly of electrochemical devices

InactiveUS20050272214A1Reduce manufacturing costHigh densityElectrolytic capacitorsCell electrodesElectrophoresisElectrical battery

Methods are provided for making bipolar electrochemical devices, such as batteries, using electrophoresis. A bipolar device is assembled by applying a field that creates a physical separation between two active electrode materials, without requiring insertion of a discrete separator film or electrolyte layer.

Owner:A123 SYSTEMS LLC

Processes for the production of electrophoretic displays

ActiveUS20080023332A1Liquid surface applicatorsElectrolysis componentsPotential differenceElectrophoresis

A coating of an encapsulated electrophoretic medium is formed on a substrate (106) by dispersing in a fluid (104) a plurality of electrophoretic capsules (102), contacting at least a portion of a substrate (106) with the fluid (104); and applying a potential difference between at least a part of the portion of the substrate (106) contacting the fluid (104) and a counter-electrode (110) in electrical contact with the fluid (104), thereby causing capsules (102) to be deposited upon at least part of the portion of the substrate (106) contacting the fluid (102). Patterned coatings of capsules containing different colors may be deposited in registration with electrodes using multiple capsule deposition steps. Alternatively, patterned coatings of capsules may be formed by applying a fluid form of an electrophoretic medium to a substrate, and applying a temporally varying voltage between an electrode and the substrate. The process may be repeated to allow for deposition of full color displays.

Owner:E INK CORPORATION

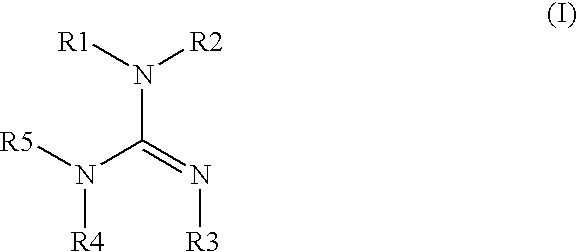

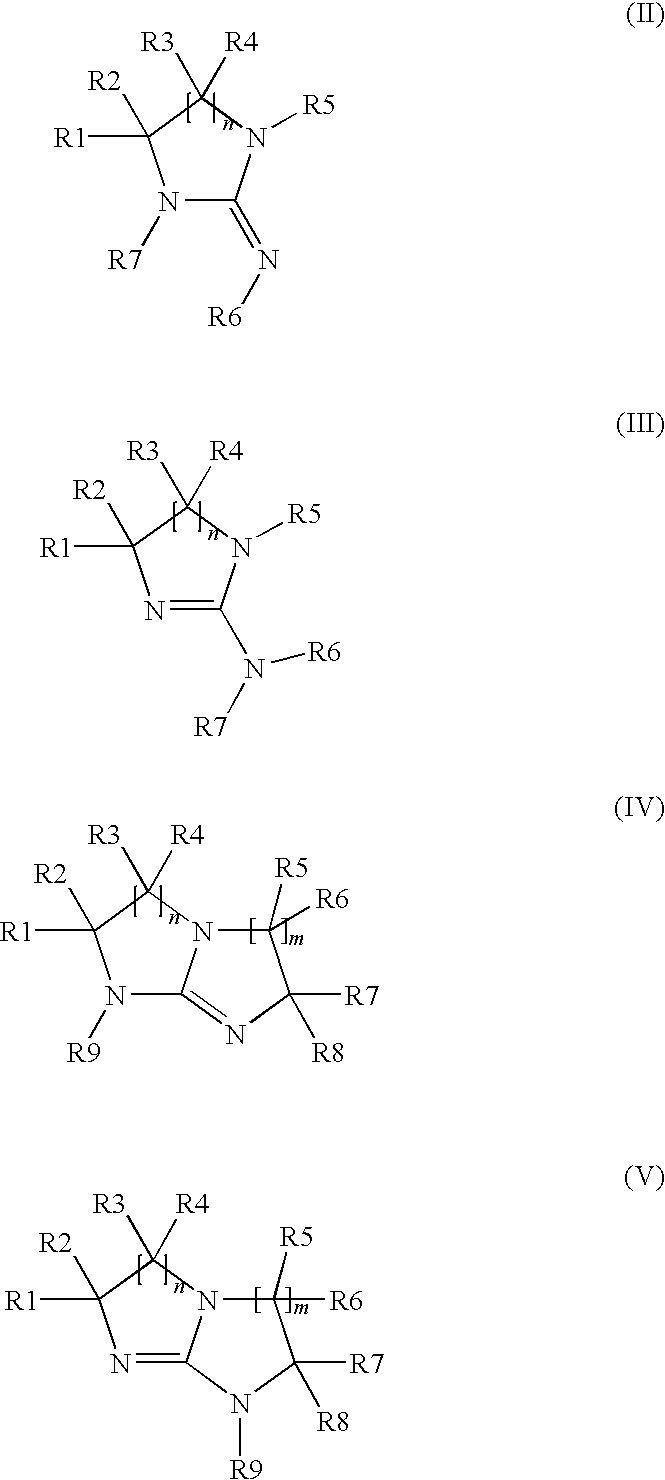

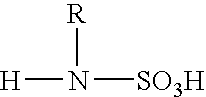

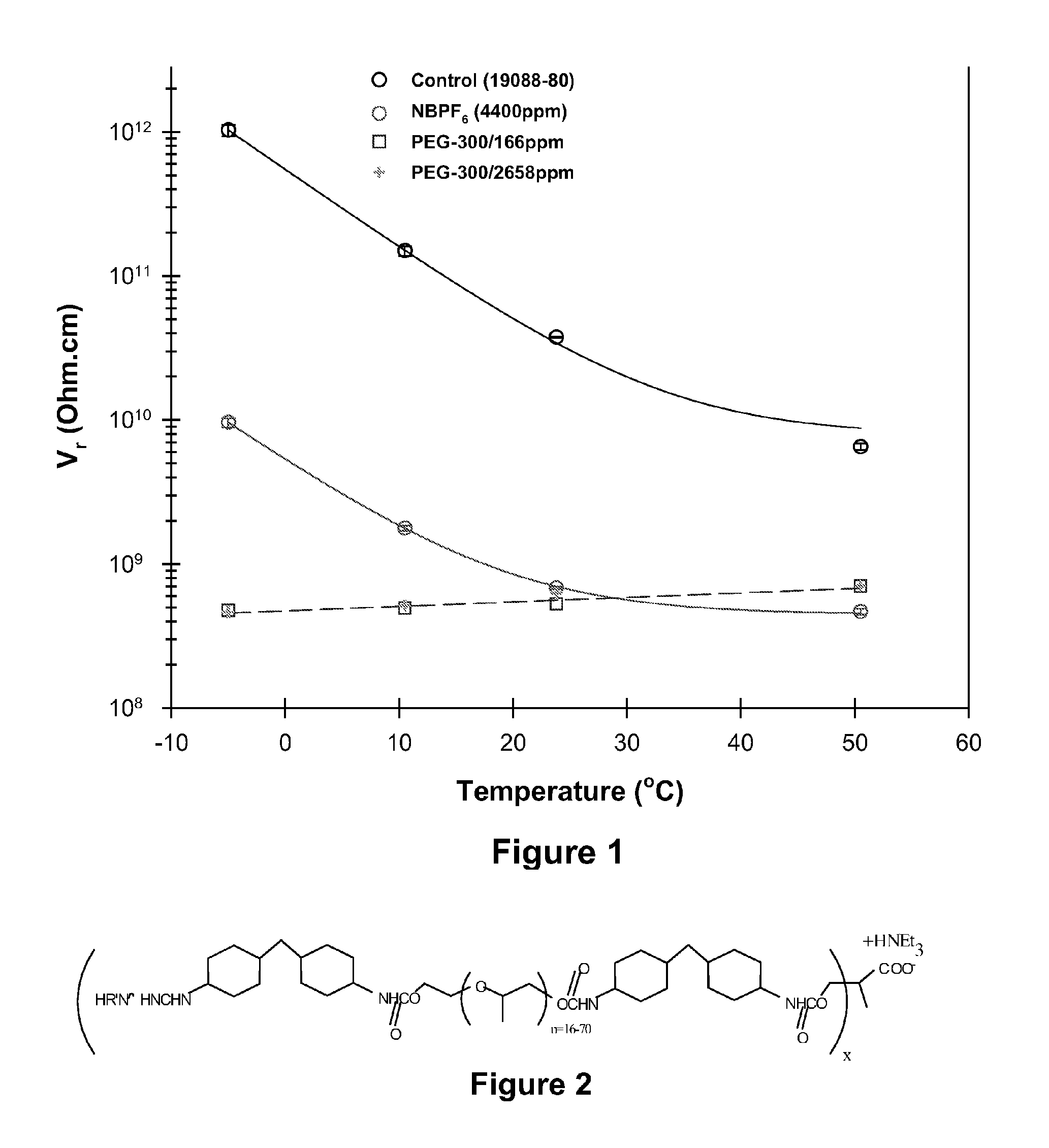

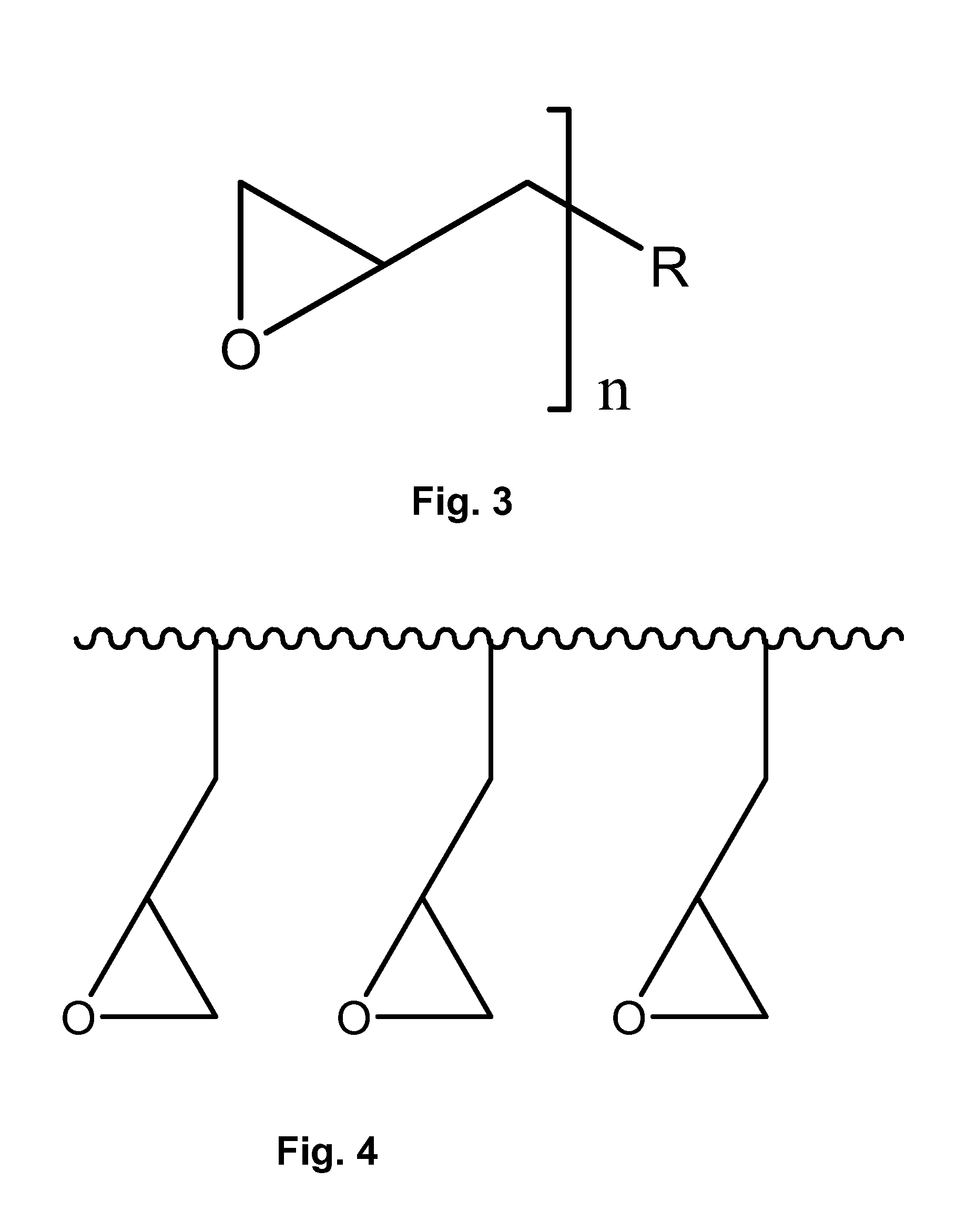

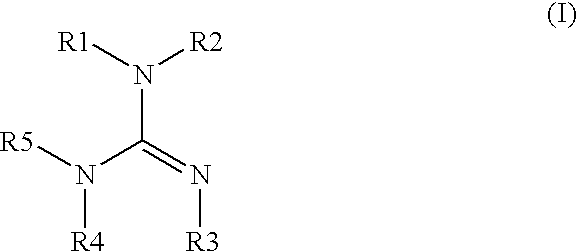

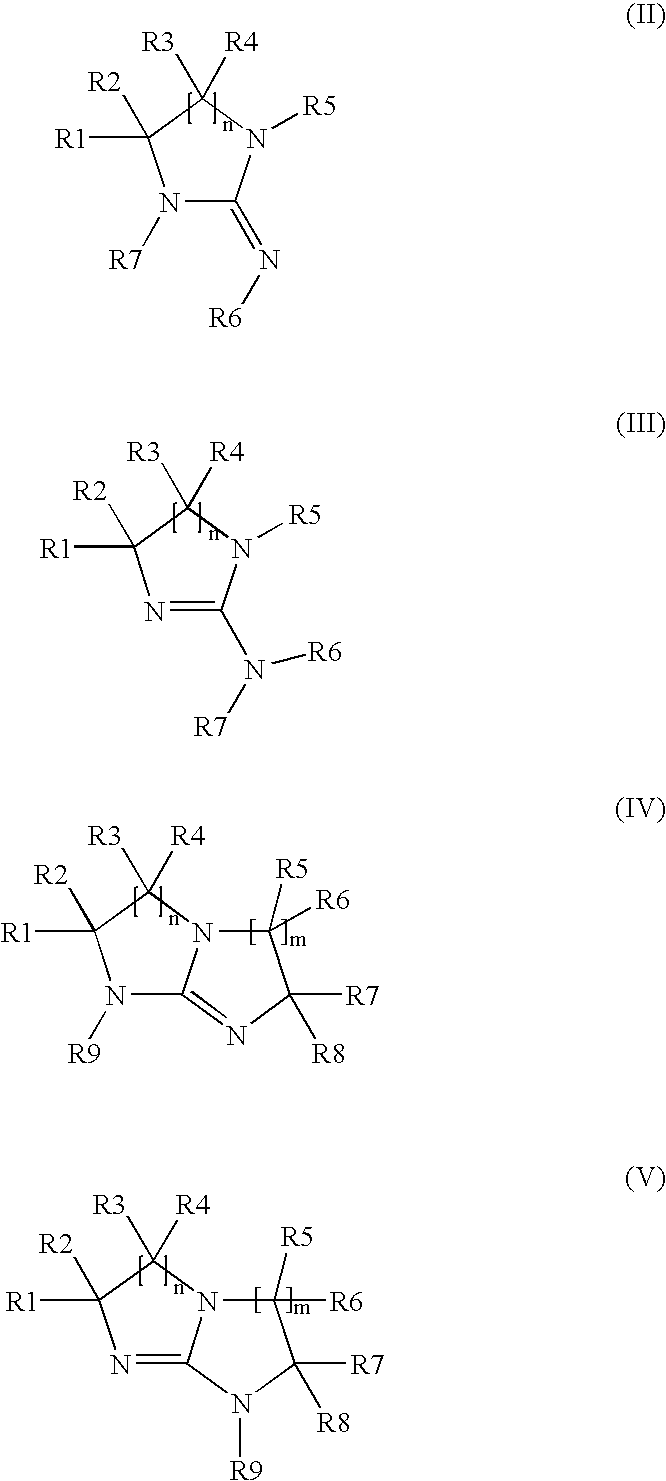

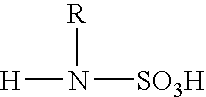

Electrodepositable coating composition containing a cyclic guanidine

The present invention is directed towards an electrocoating composition comprising a cyclic guanidine.

Owner:PPG IND OHIO INC

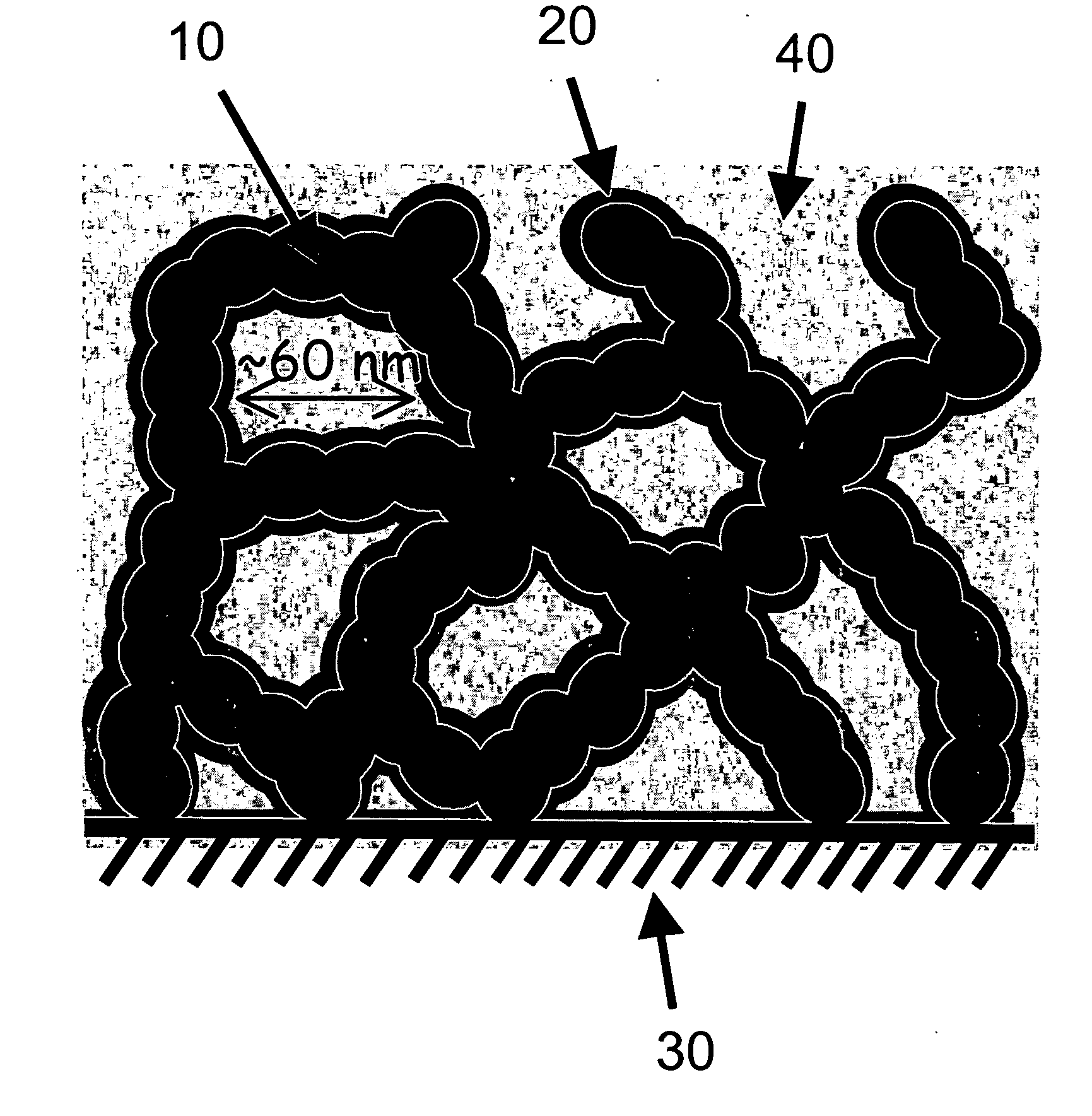

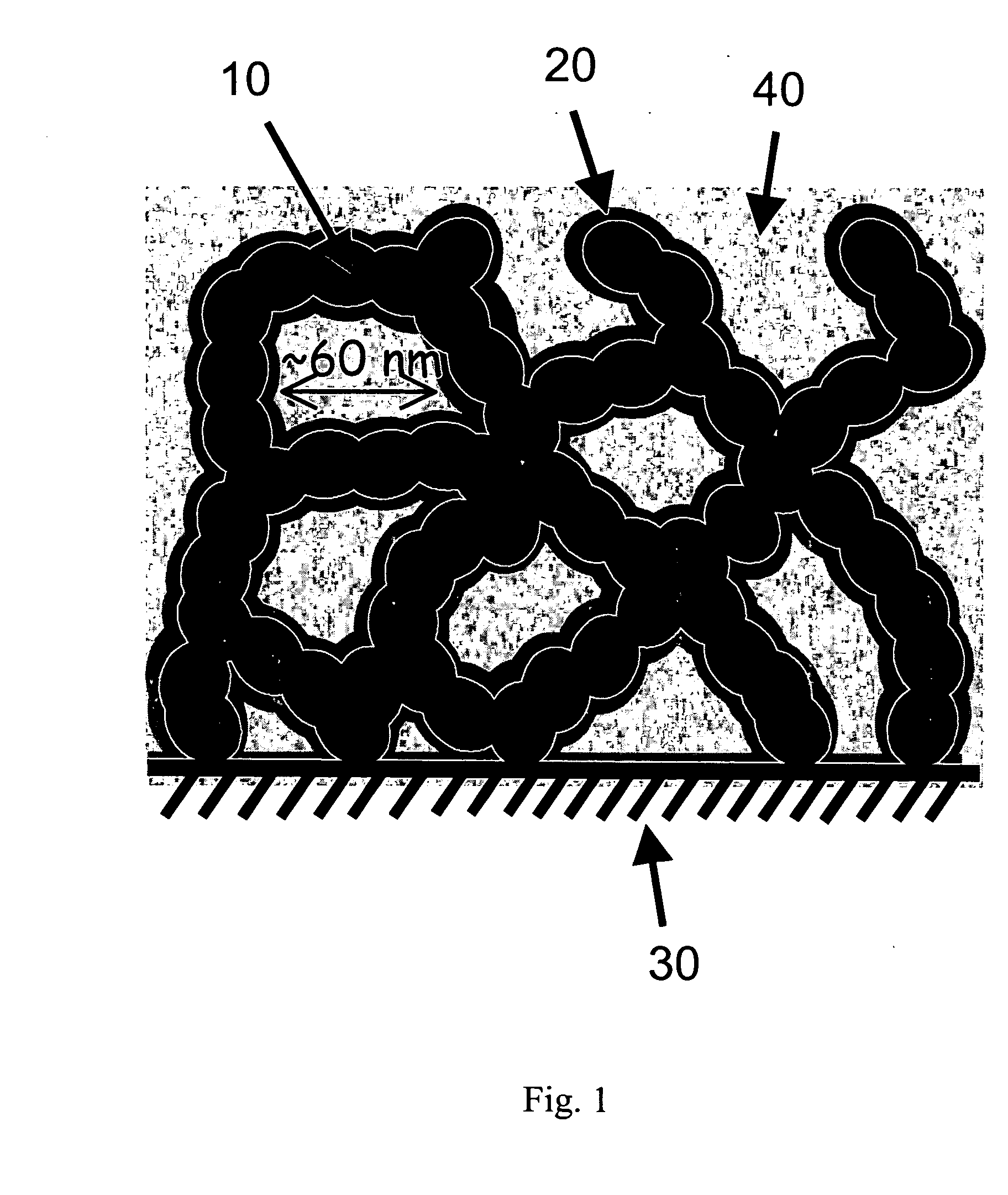

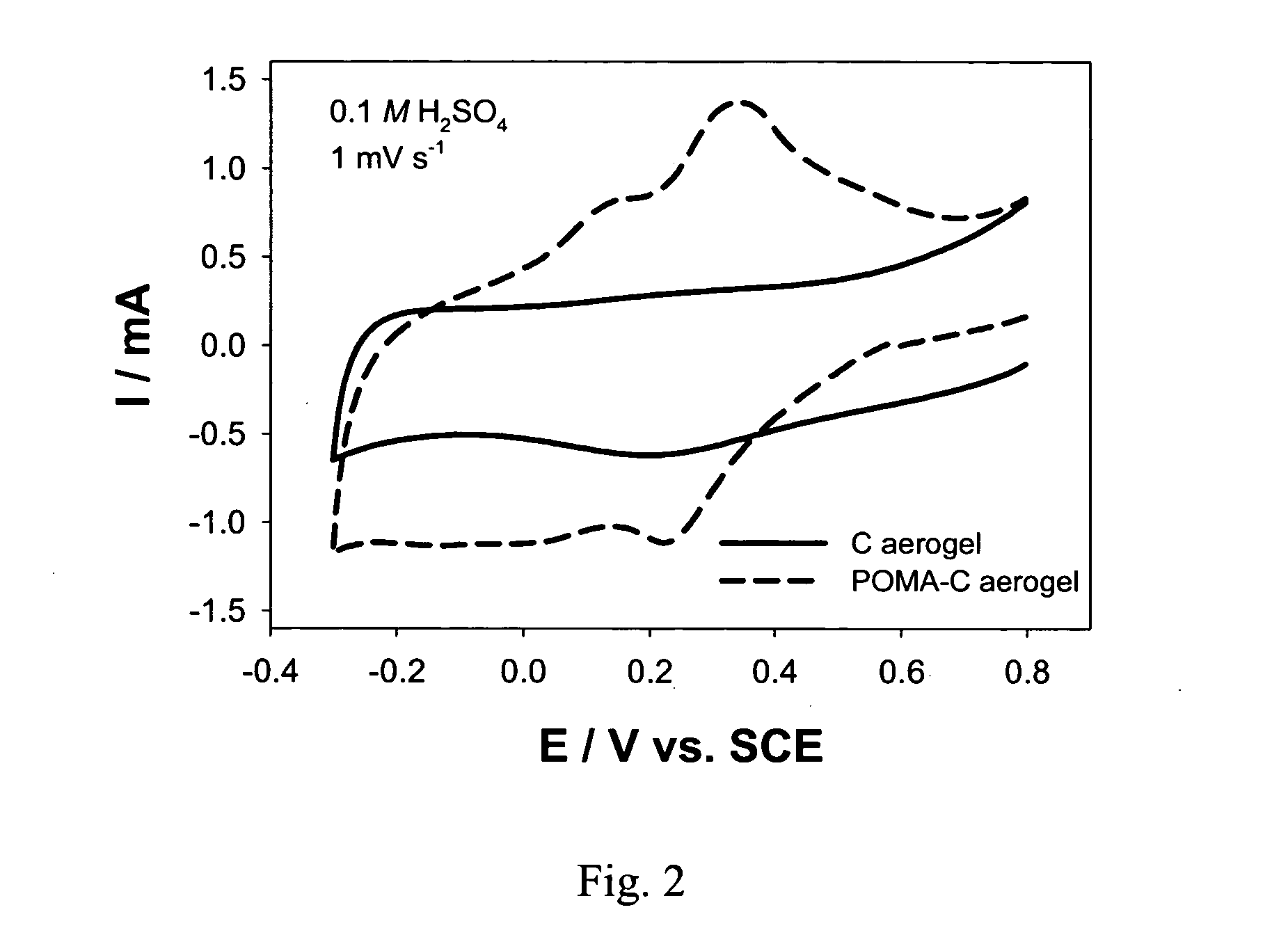

Carbon nanoarchitectures with ultrathin, conformal polymer coatings for electrochemical capacitors

ActiveUS20050153130A1Hybrid capacitor electrolytesElectrolysis componentsSelf limitingPolymer science

A composite having an electroactive polymer coating on a porous carbon structure is disclosed. The composite may be used in capacitor electrodes. The composite may be made by self-limiting electropolymerization of a monomer on the carbon structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Methods and devices for enhanced adhesion between metallic substrates and bioactive material-containing coatings

InactiveUS20070073390A1Reduce riskExcellent Adhesive PropertiesVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsMedical deviceMetallic substrate

Disclosed herein are methods to create medical devices and medical devices including bioactive composite structures with enhanced adhesion characteristics. The bioactive composite structures are prepared using anchors that are electrochemically codeposited into a metallic layer that is formed on the surface of implantable medical device followed by the adhesion of a bioactive material-containing coating to the substrate and anchors.

Owner:MEDLOGICS DEVICE CORP

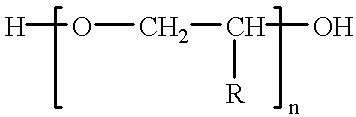

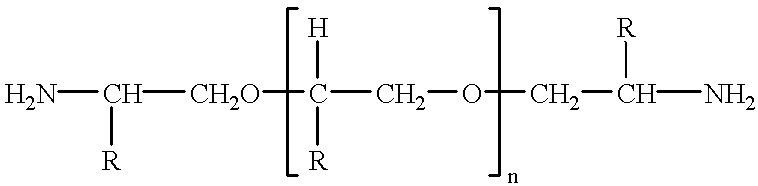

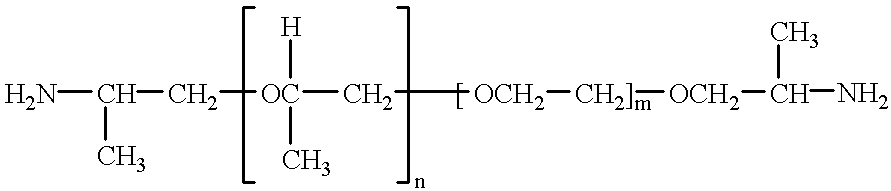

Electro-optic displays, and materials for use therein

A first electro-optic display comprises first and second substrates, and an adhesive layer and a layer of electro-optic material disposed between the first and second substrates, the adhesive layer comprising a mixture of a polymeric adhesive material and a hydroxyl containing polymer having a number average molecular weight not greater than about 5000. A second electro-optic display is similar to the first but has an adhesive layer comprising a thermally-activated cross-linking agent to reduce void growth when the display is subjected to temperature changes. A third electro-optic display, intended for writing with a stylus or similar instrument, is produced by forming a layer of an electro-optic material on an electrode; depositing a substantially solvent-free polymerizable liquid material over the electro-optic material; and polymerizing the polymerizable liquid material.

Owner:E INK CORPORATION

Methods and structures for the production of electrically treated items and electrical connections

InactiveUS20060032752A1Reduces cost and complexityReduce capacityPrinted circuit assemblingPrinted circuit aspectsConductive polymerElectrical connection

This invention involves unique electroplated items comprising electrically conductive polymers. In addition, novel processing is taught to facilitate continuous production of electrically treated items. Many embodiments employ directly electroplateable resins for particular advantage. Unique methods of establishing electroplated electrical connections are taught.

Owner:LUCH DANIEL

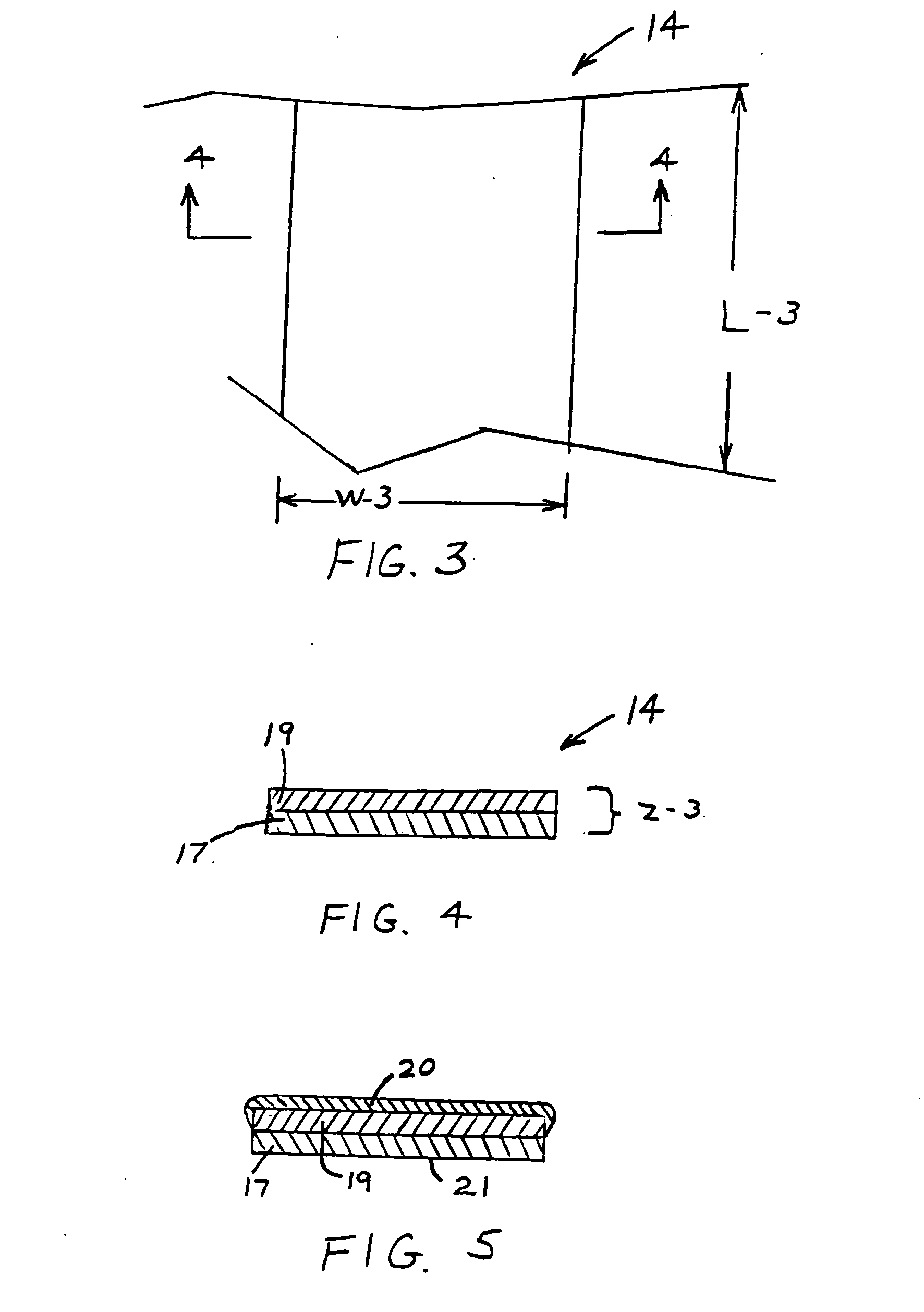

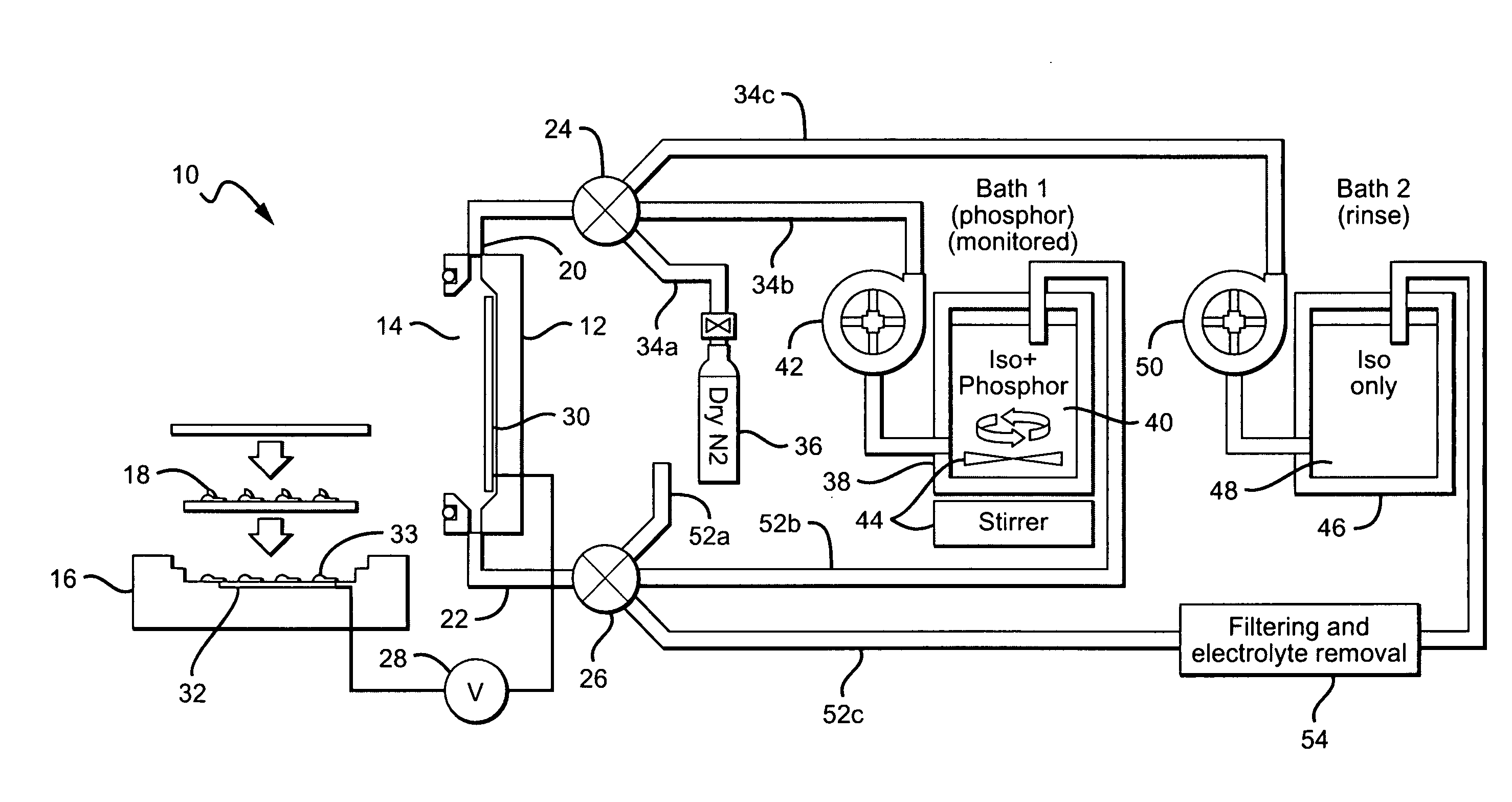

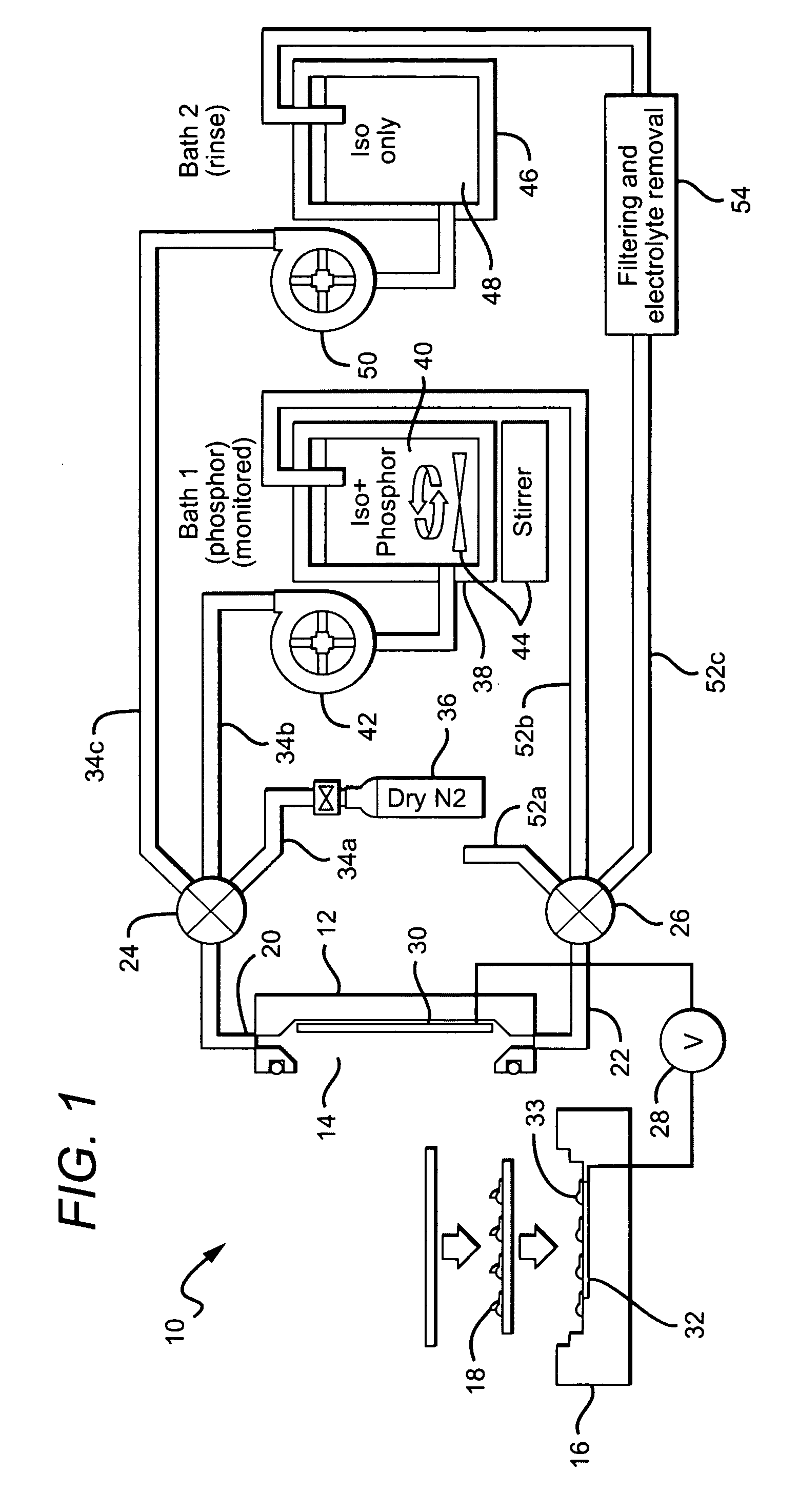

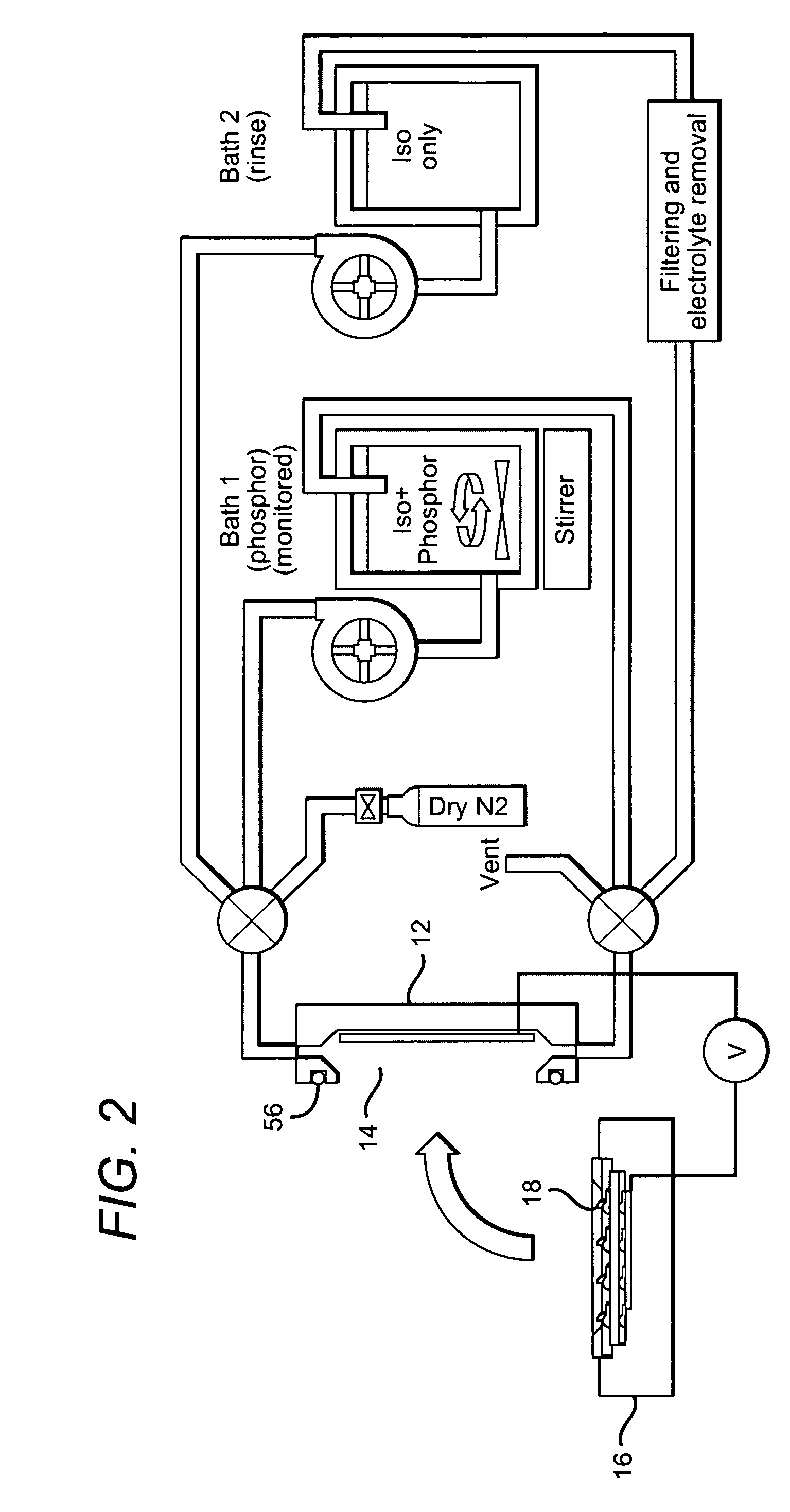

System for and method for closed loop electrophoretic deposition of phosphor materials on semiconductor devices

One close loop system and method for electrophoretic deposition (EPD) of phosphor material on light emitting diodes (LEDs). The system comprises a deposition chamber sealed from ambient air. A mixture of phosphor material and solution is provided to the chamber with the mixture also being sealed from ambient air. A carrier holds a batch of LEDs in the chamber with the mixture contacting the areas of the LEDs for phosphor deposition. A voltage supply applies a voltage to the LEDs and the mixture to cause the phosphor material to deposit on the LEDs at the mixture contacting areas.

Owner:CREELED INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com