Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

900 results about "Anode oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The anode is an element that loses electrons (reducing agent), thus oxidation always occurs in the anode, and the cathode is an element that gains electrons (oxidizing agent), thus reduction always occurs in the cathode. Corrosion occurs whenever there’s a difference in oxidation potential.

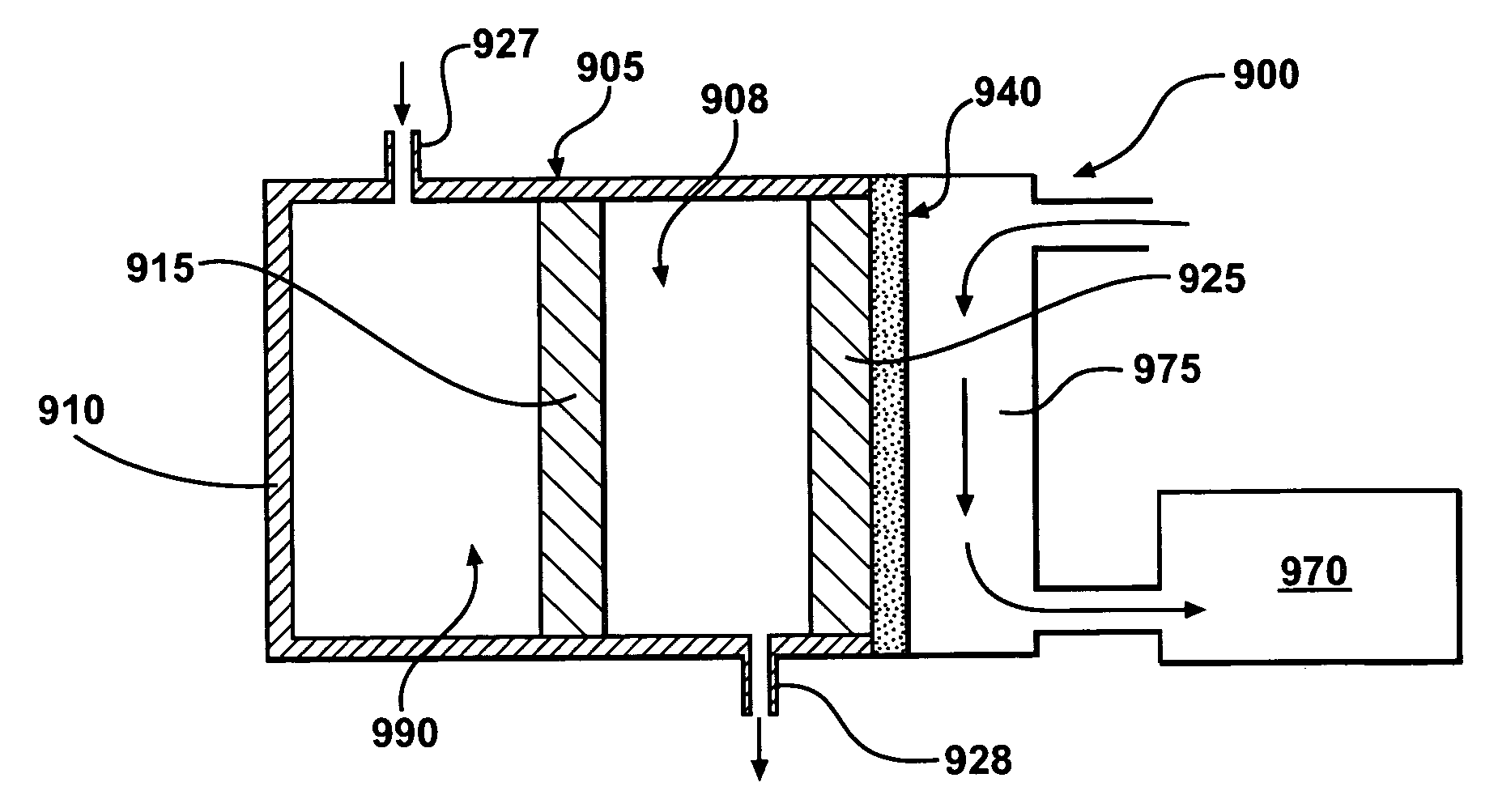

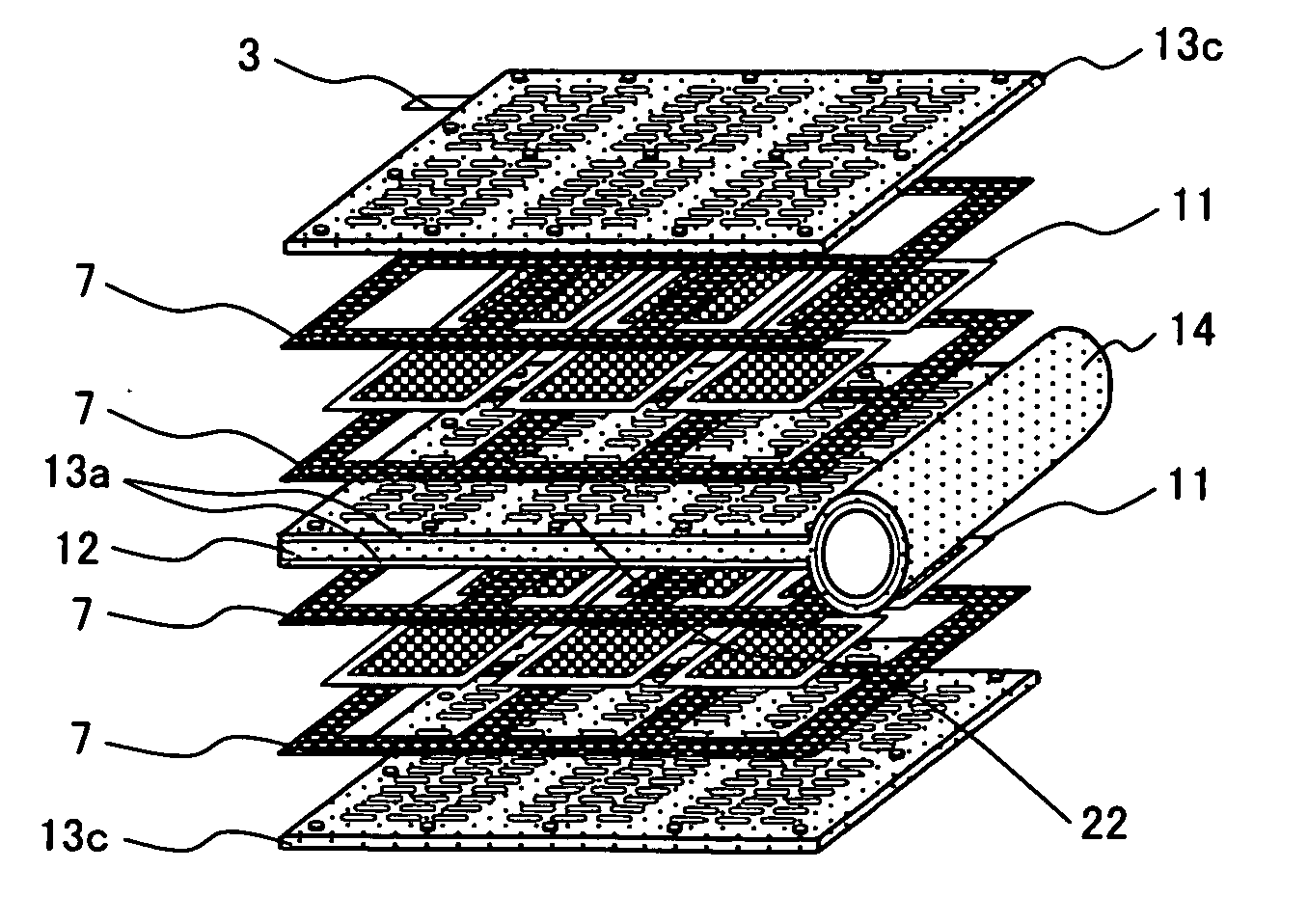

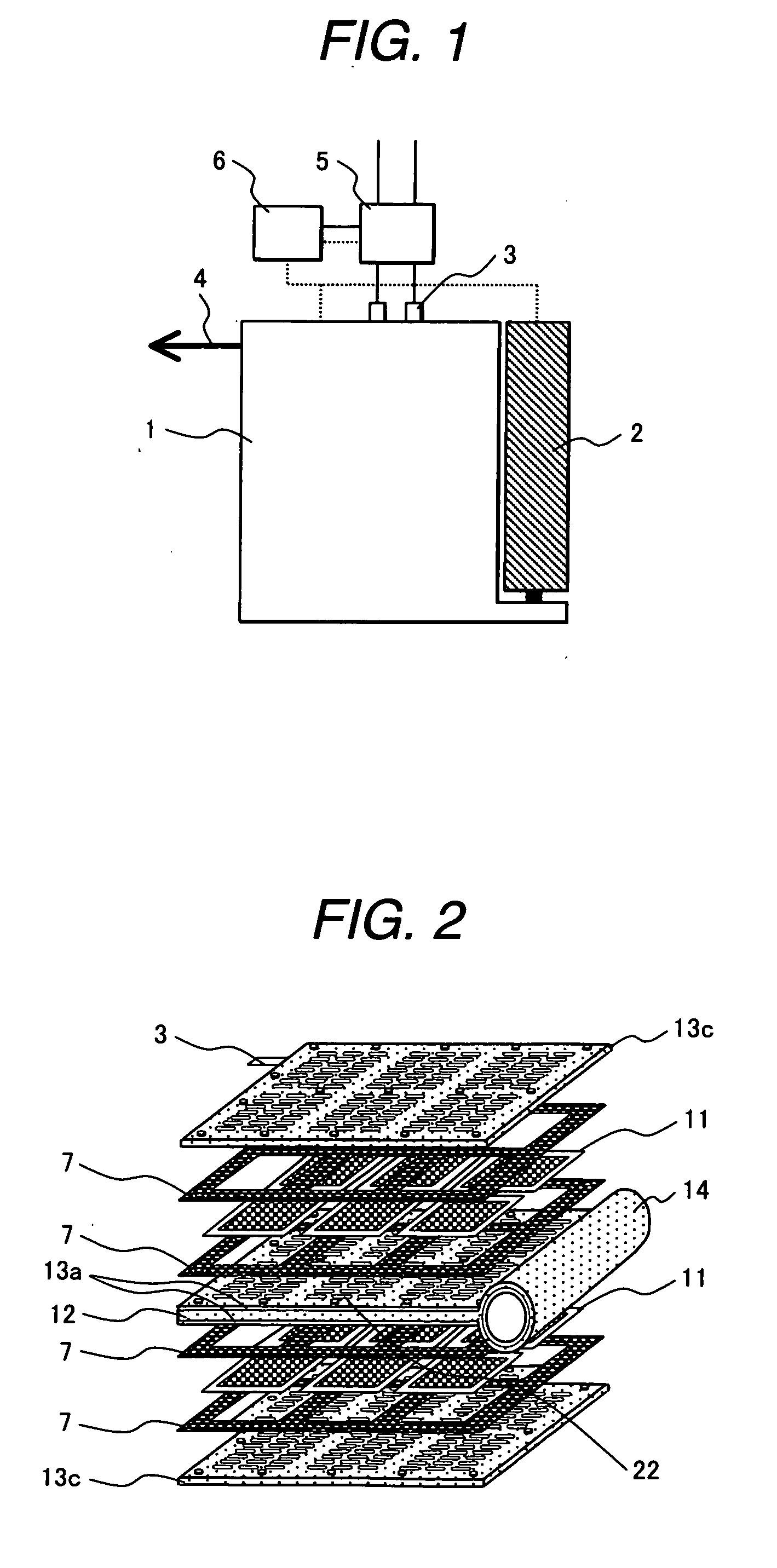

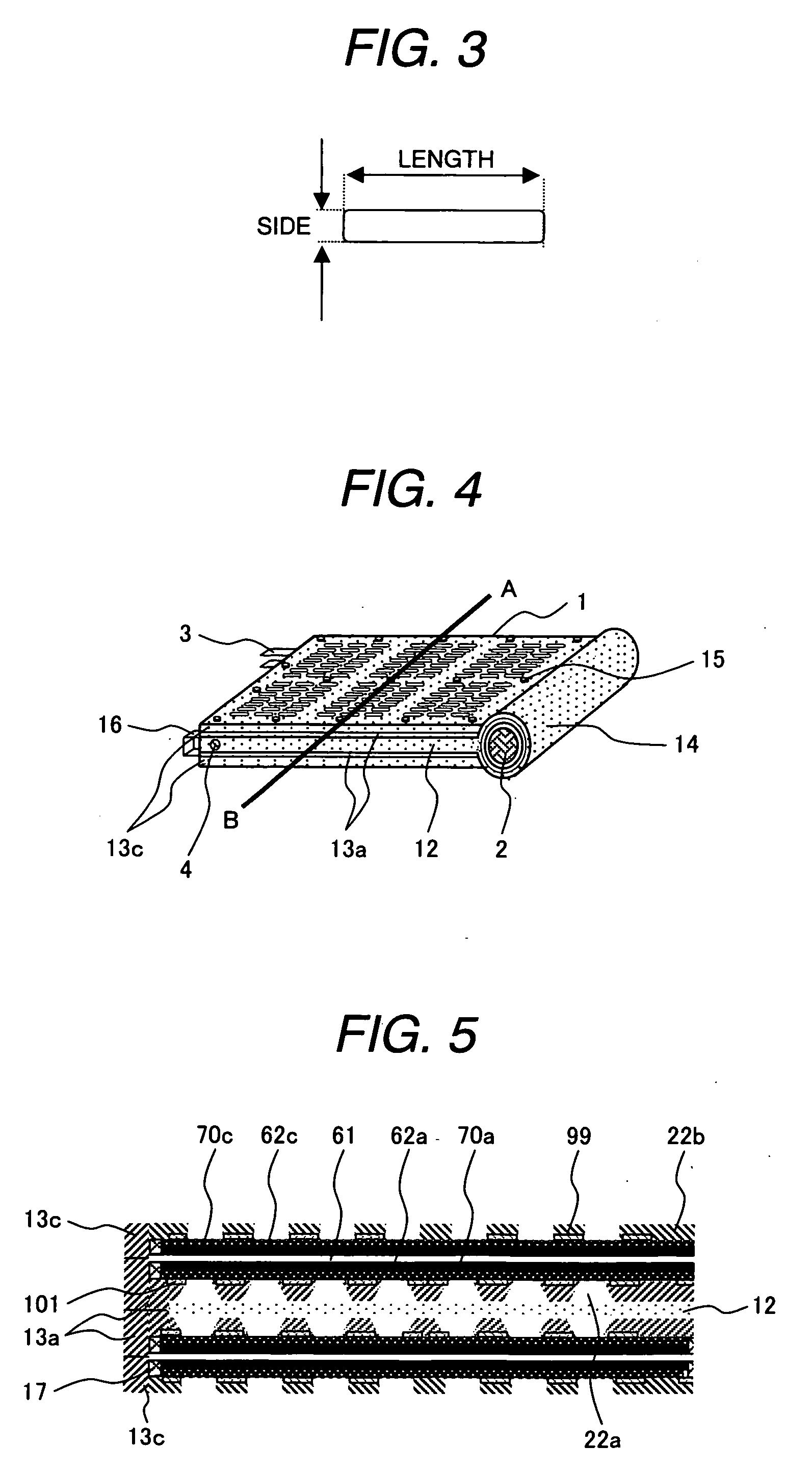

Materials and configurations for scalable microbial fuel cells

ActiveUS20070259217A1Raise the potentialTreatment by combined electrochemical biological processesActive material electrodesElectricityMicrobial fuel cell

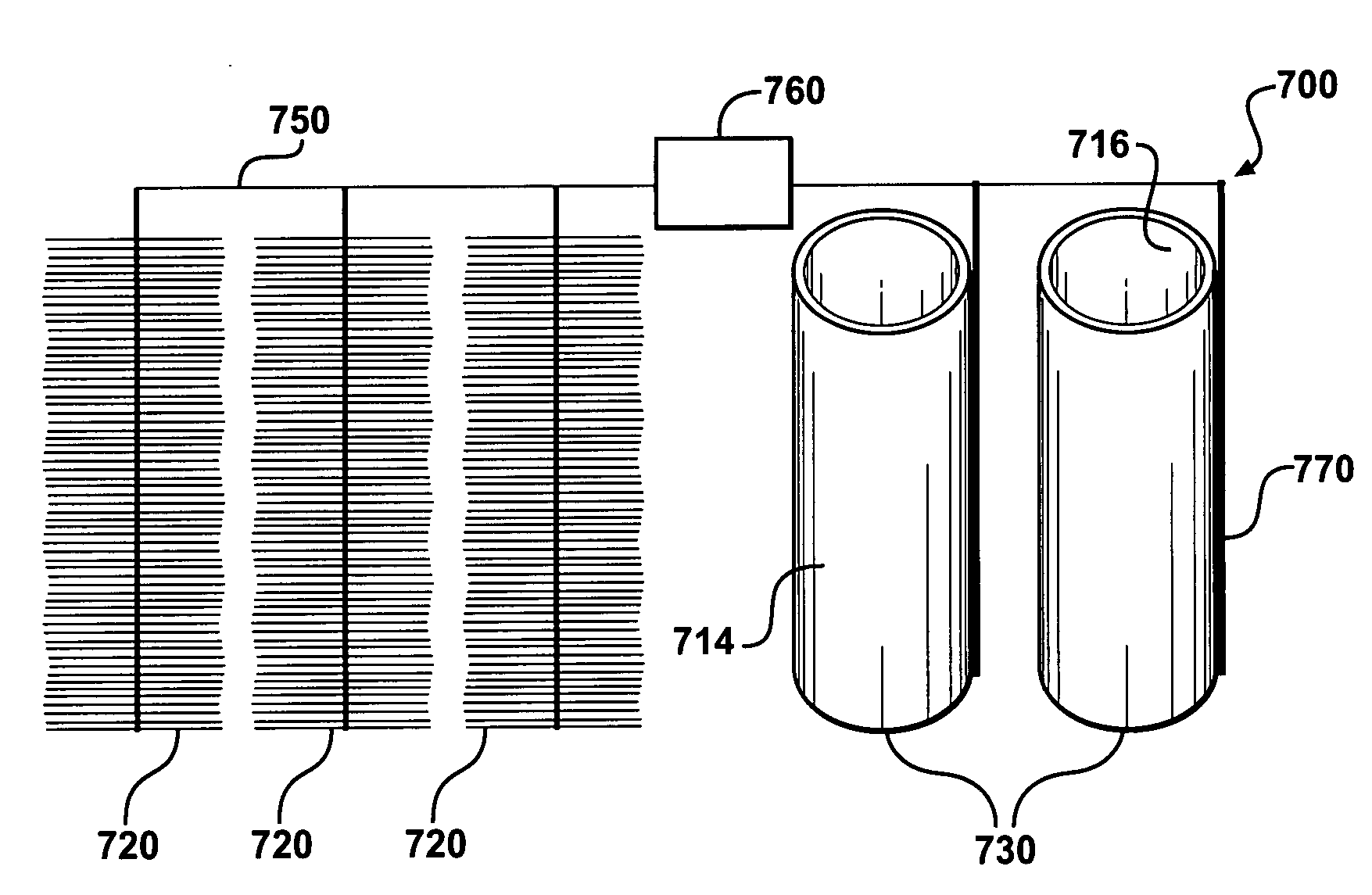

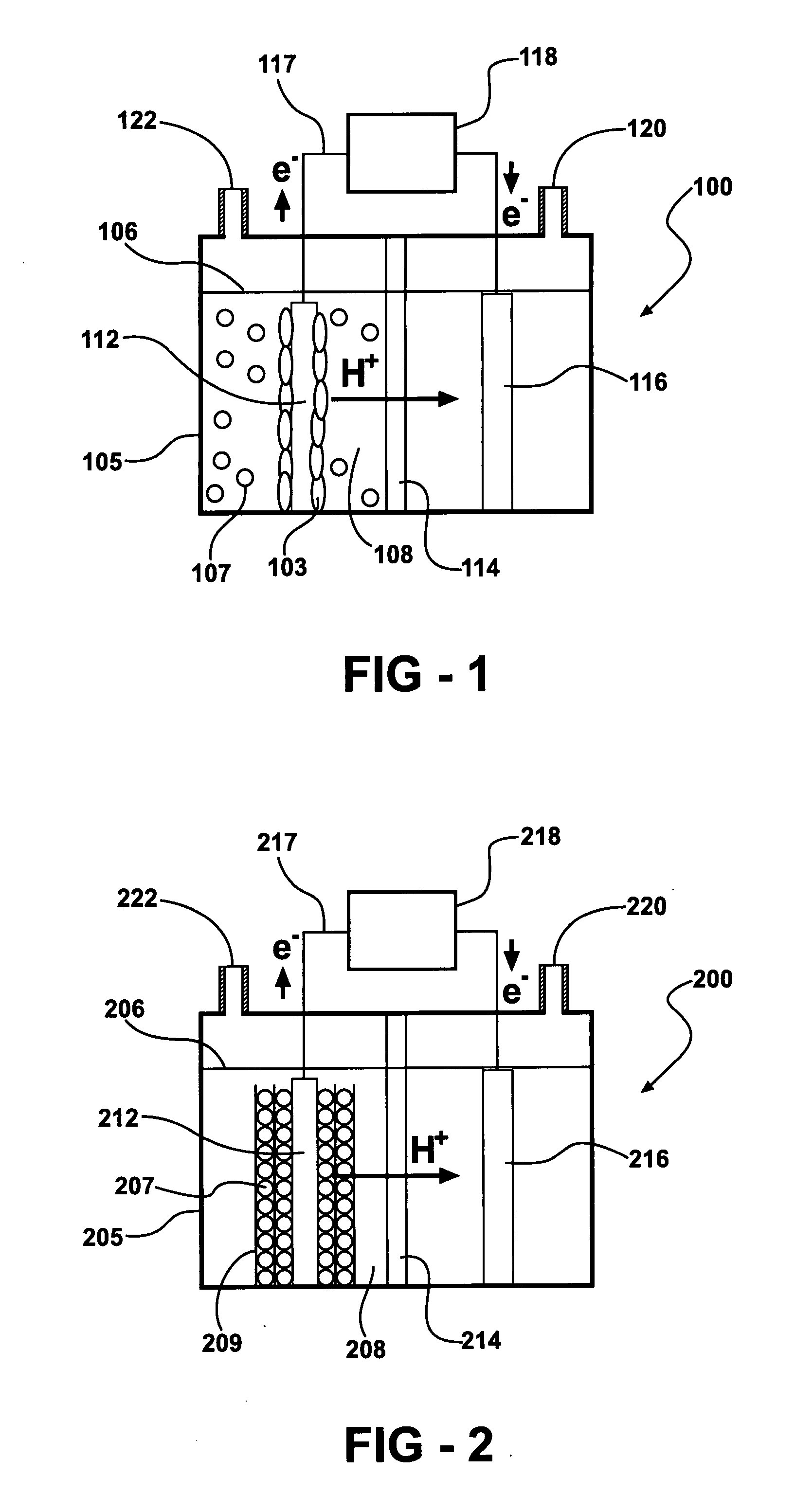

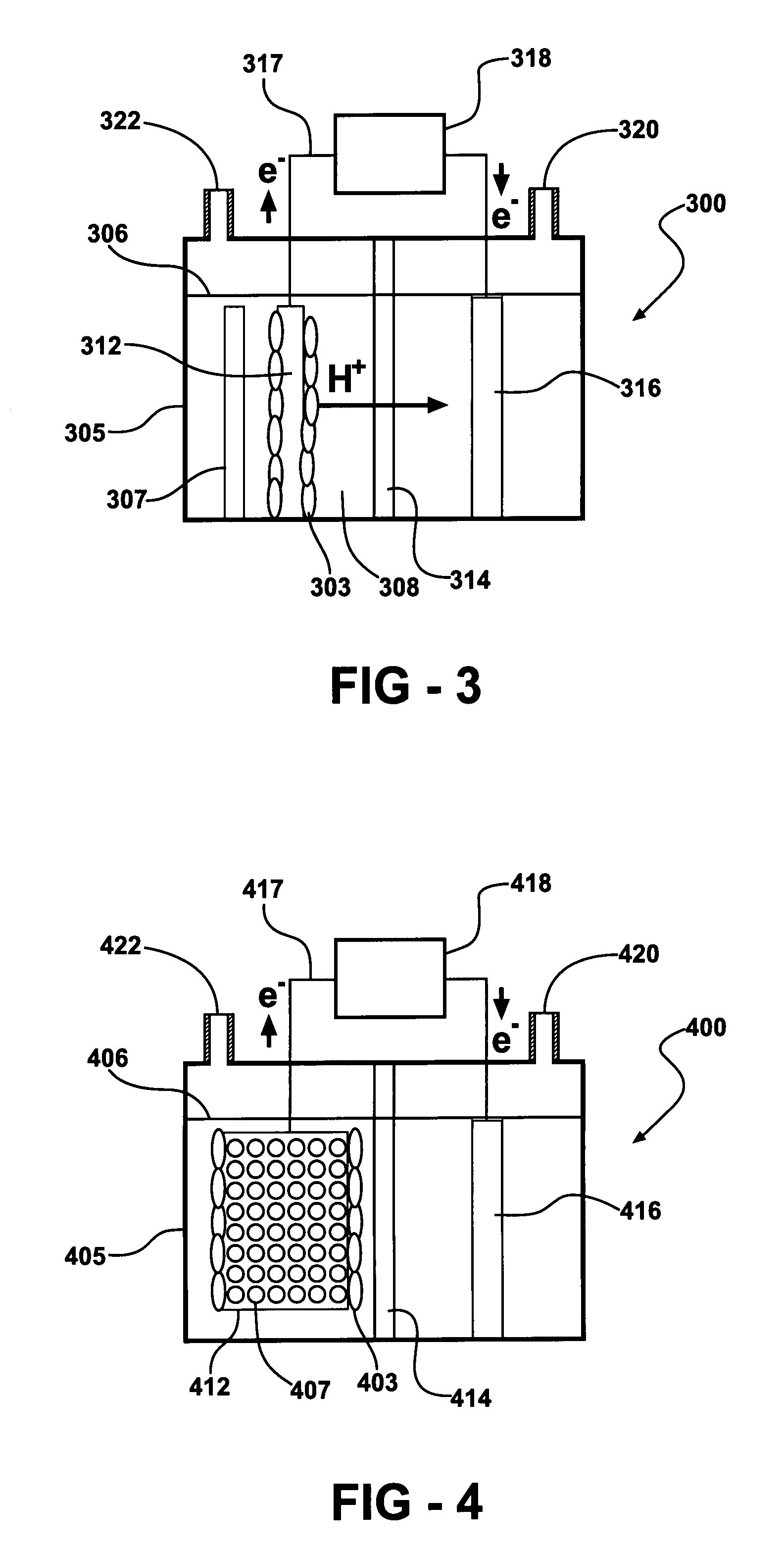

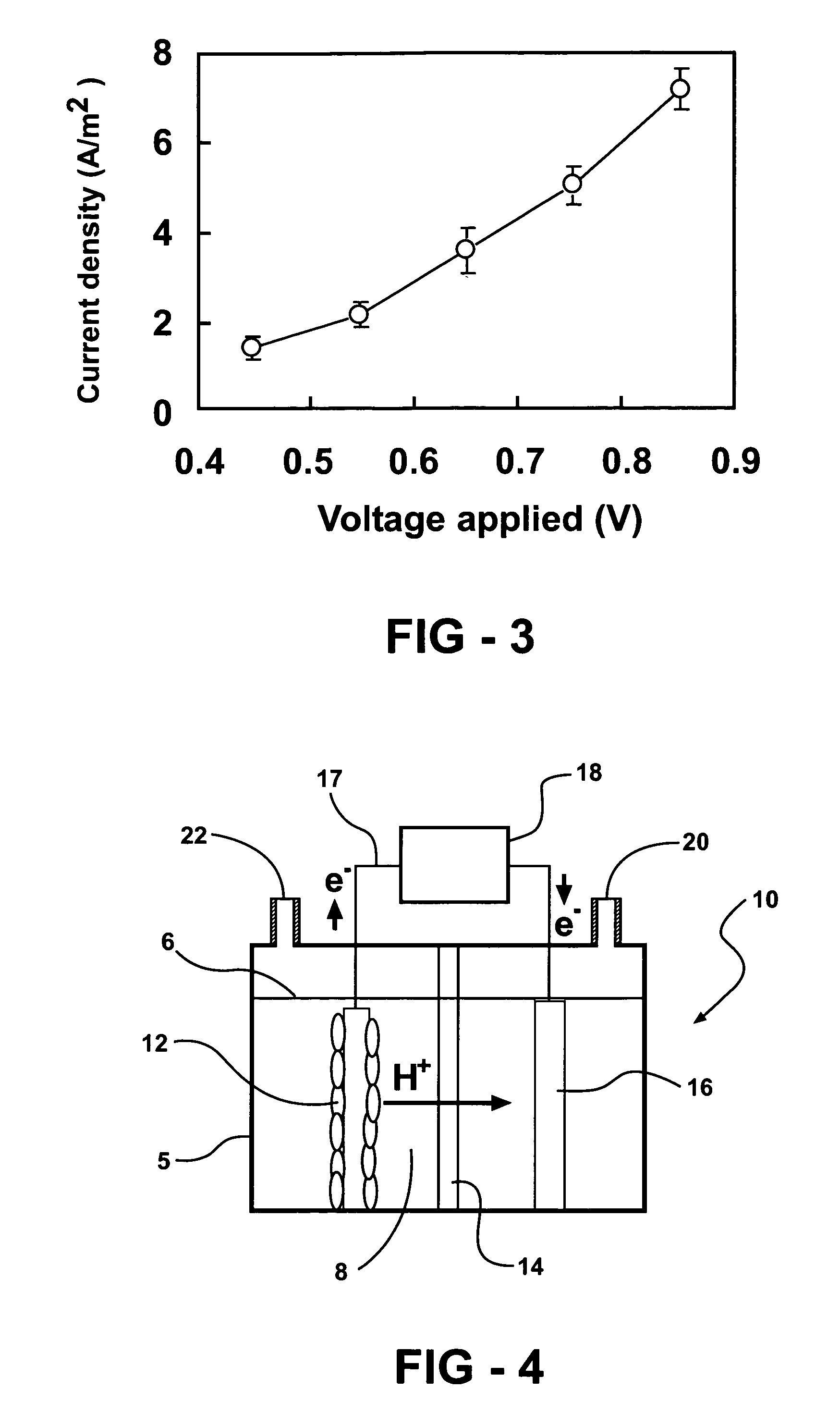

Devices for production of electricity and / or hydrogen gas are provided by the present invention. In particular, microbial fuel cells for production of electricity and modified microbial fuel cells for production of hydrogen are detailed. A tube cathode is provided which includes a membrane forming a general tube shape. An anode is provided which has a specific surface area greater than 100 m2 / m3. In addition, the anode is substantially non-toxic to anodophilic bacteria. Combinations of particular anodes and cathodes are included in microbial fuel cells and modified microbial fuel cells.

Owner:PENN STATE RES FOUND

Substrate-enhanced microbial fuel cells

A microbial fuel cell configuration of the invention includes a substrate particularly formulated for a microbial fuel cell configured to produce electricity and / or a modified microbial fuel cell configured to produce hydrogen. A substrate formulation according to one embodiment includes a solid biodegradable organic material in a package porous to bacteria. A microbial fuel cell provided according to embodiments of the present invention includes an anode, a cathode, an electrically conductive connector connecting the anode and the cathode, a housing for an aqueous medium, the aqueous medium in contact with the anode, and a solid form of a biodegradable organic substrate disposed in the aqueous medium, the solid form of a biodegradable organic substrate formulated to support electron generation and transfer to the anode by anodophilic bacteria over a selected minimum period of time.

Owner:PENN STATE RES FOUND

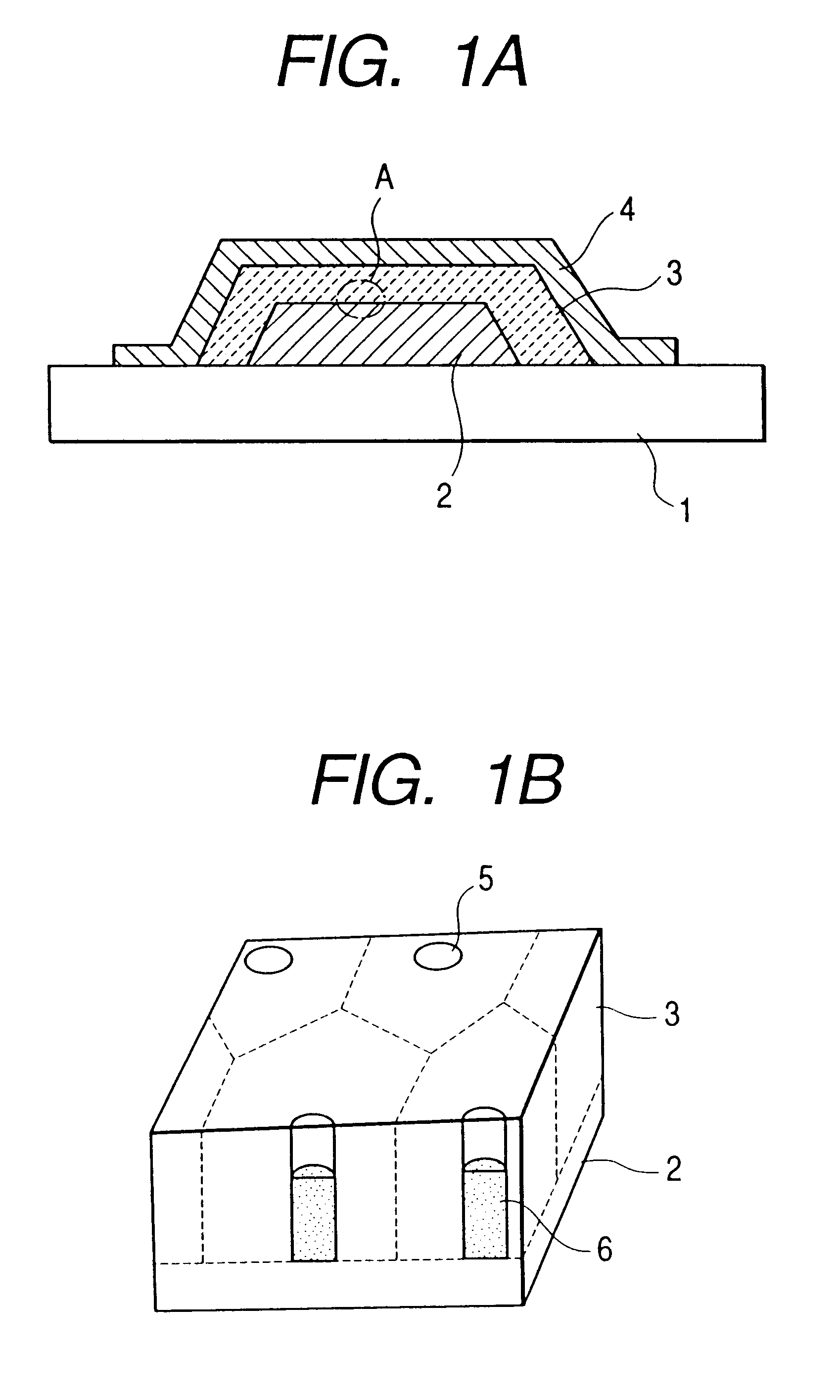

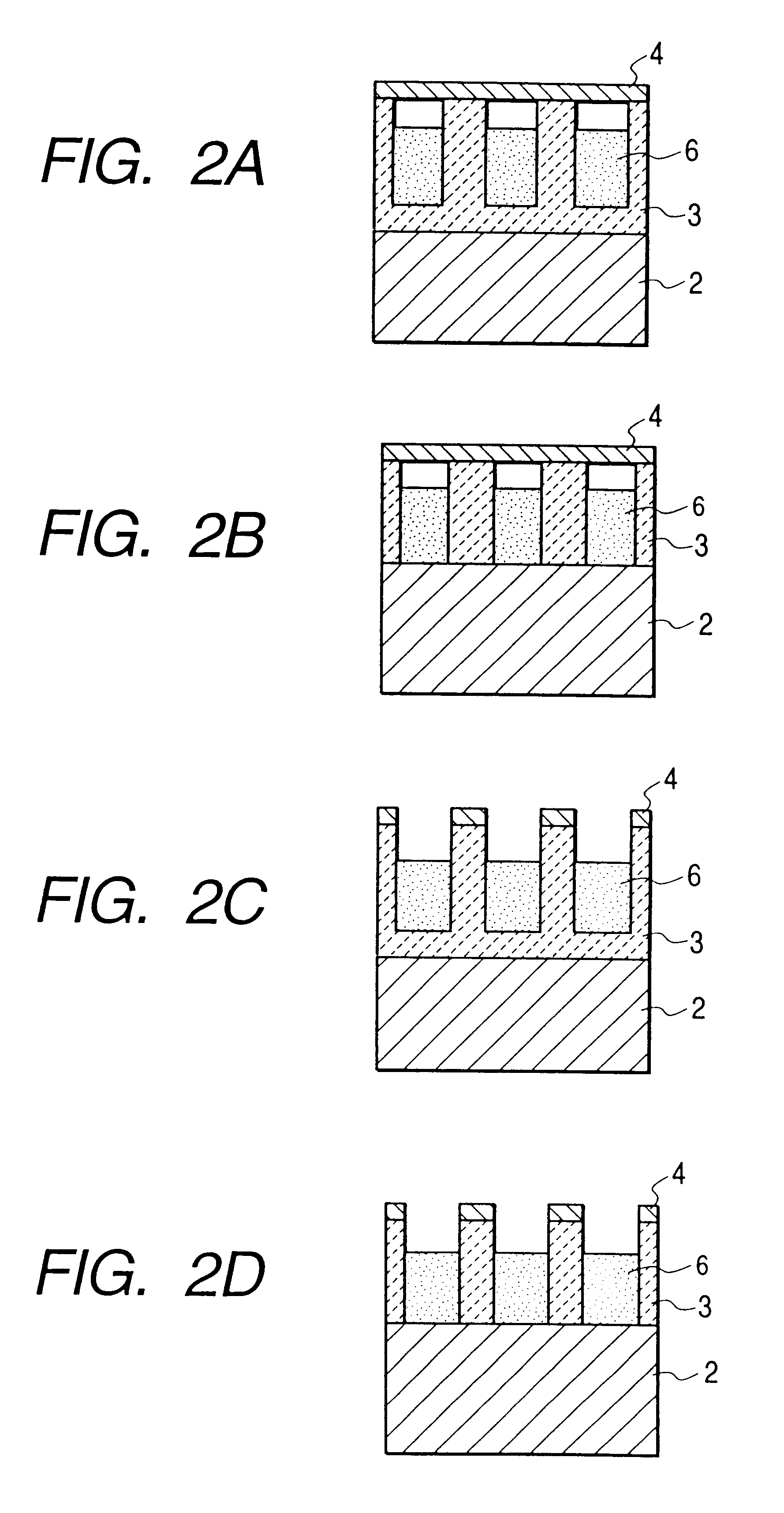

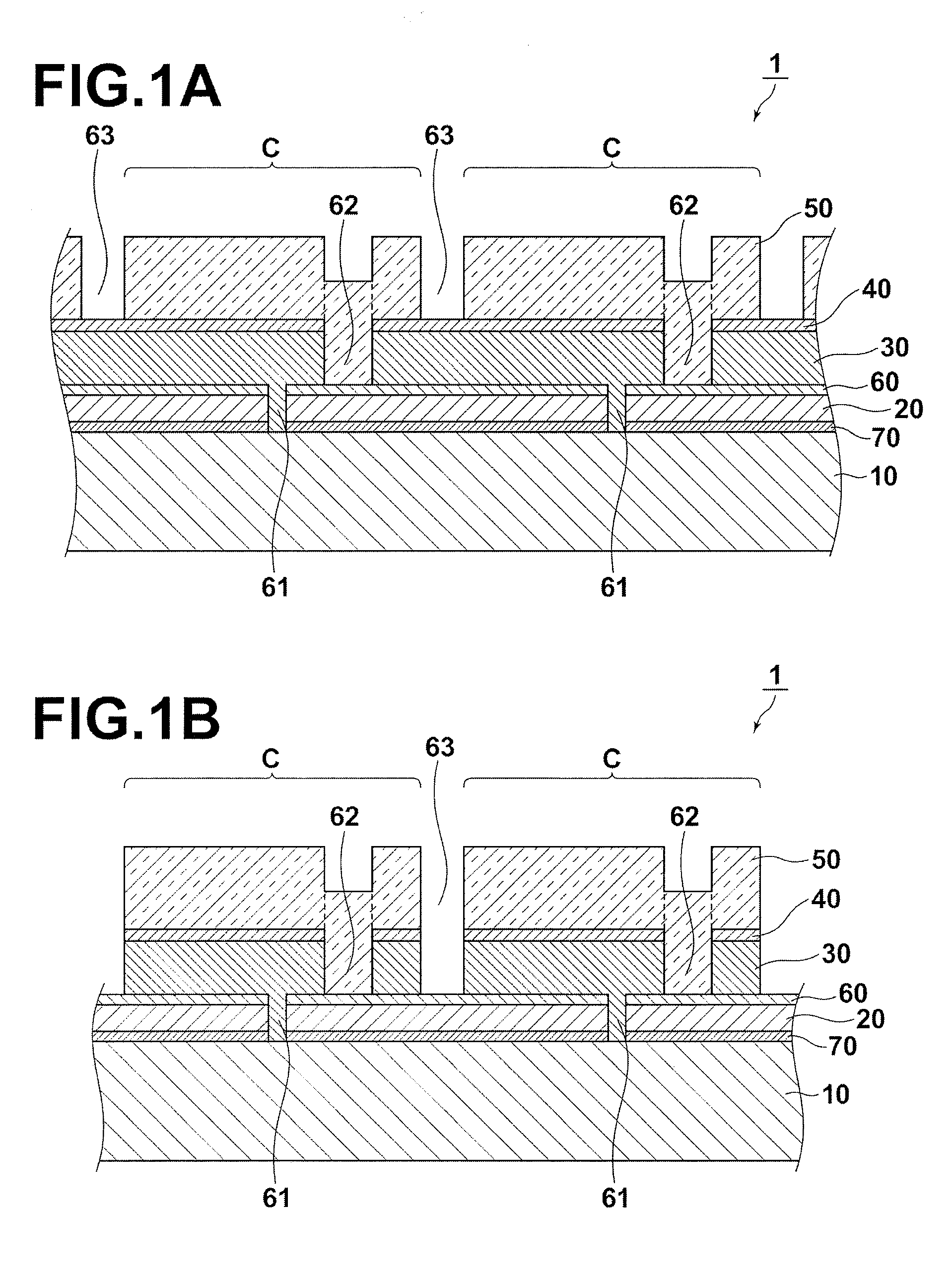

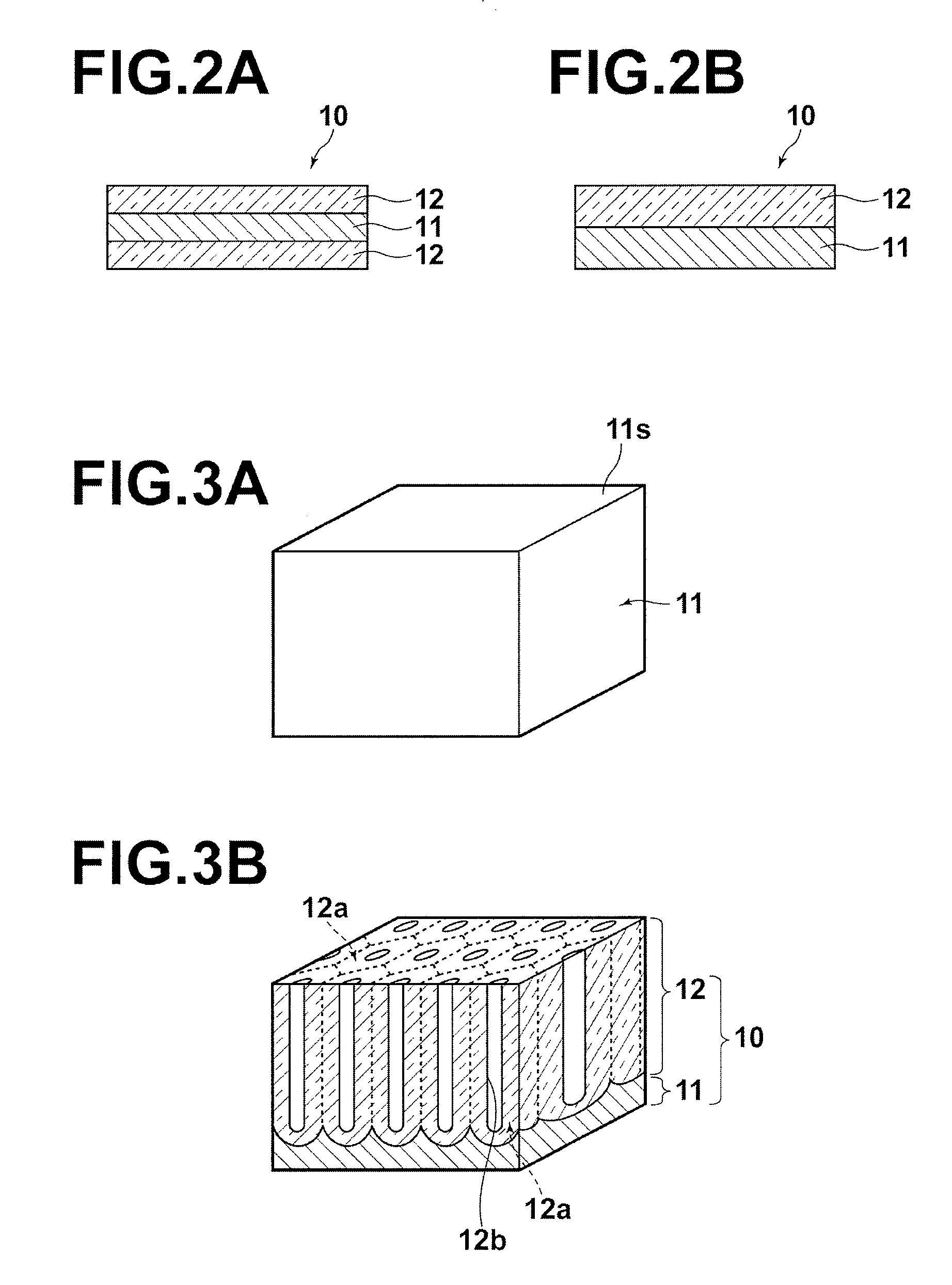

Electron-emitting device provided with pores that have carbon deposited therein

An electron-emitting device disclosed has stable electron emission characteristics with little variation, in high electron emission efficiency, in high definition, and at low driving voltage. The electron-emitting device disclosed is constructed in such structure that on a substrate there are a lower electrode, an insulating layer having pores, and an upper electrode stacked in this order, the insulating layer is an anodic oxide layer, and a carbon deposit is formed in the pores.

Owner:CANON KK

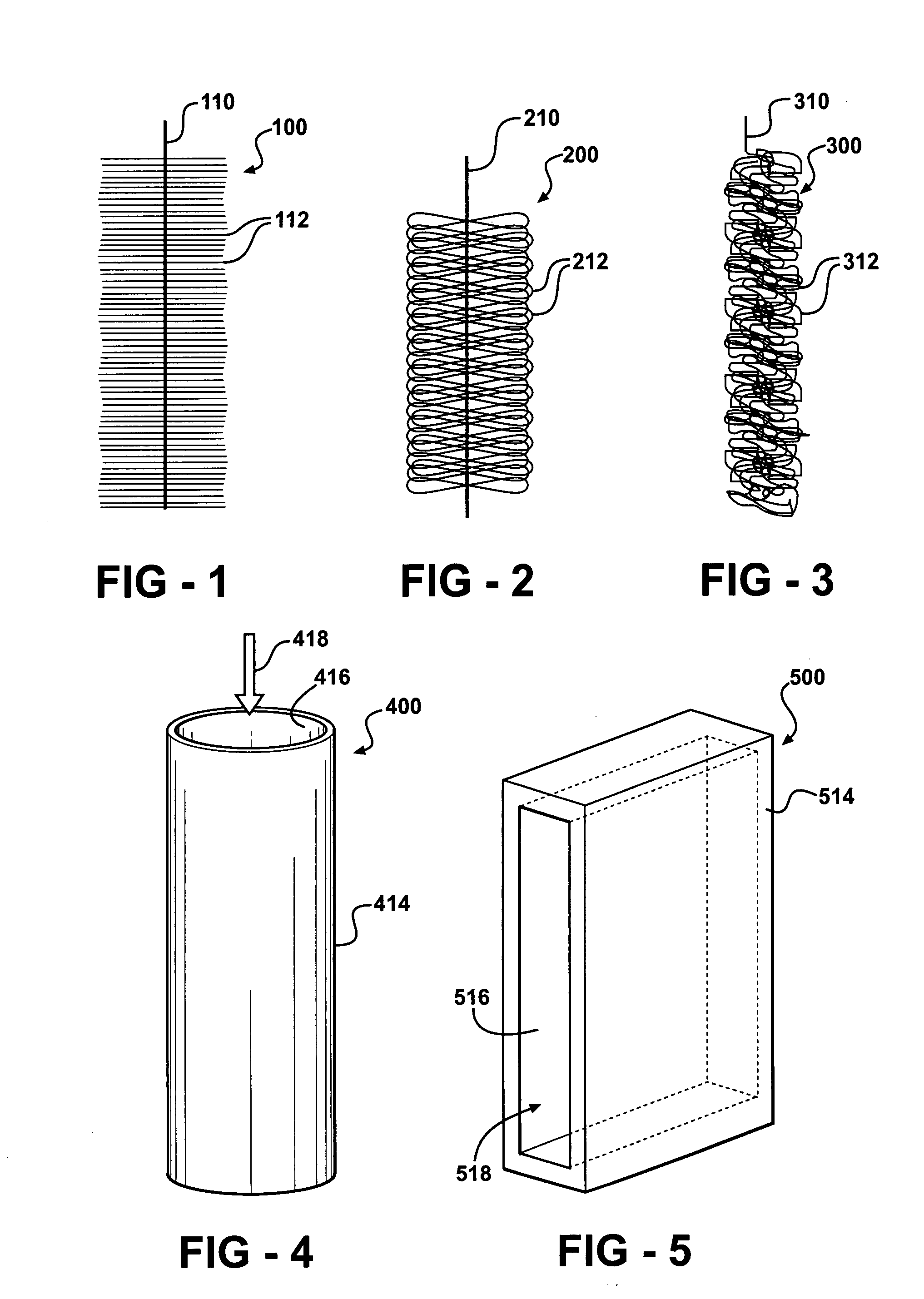

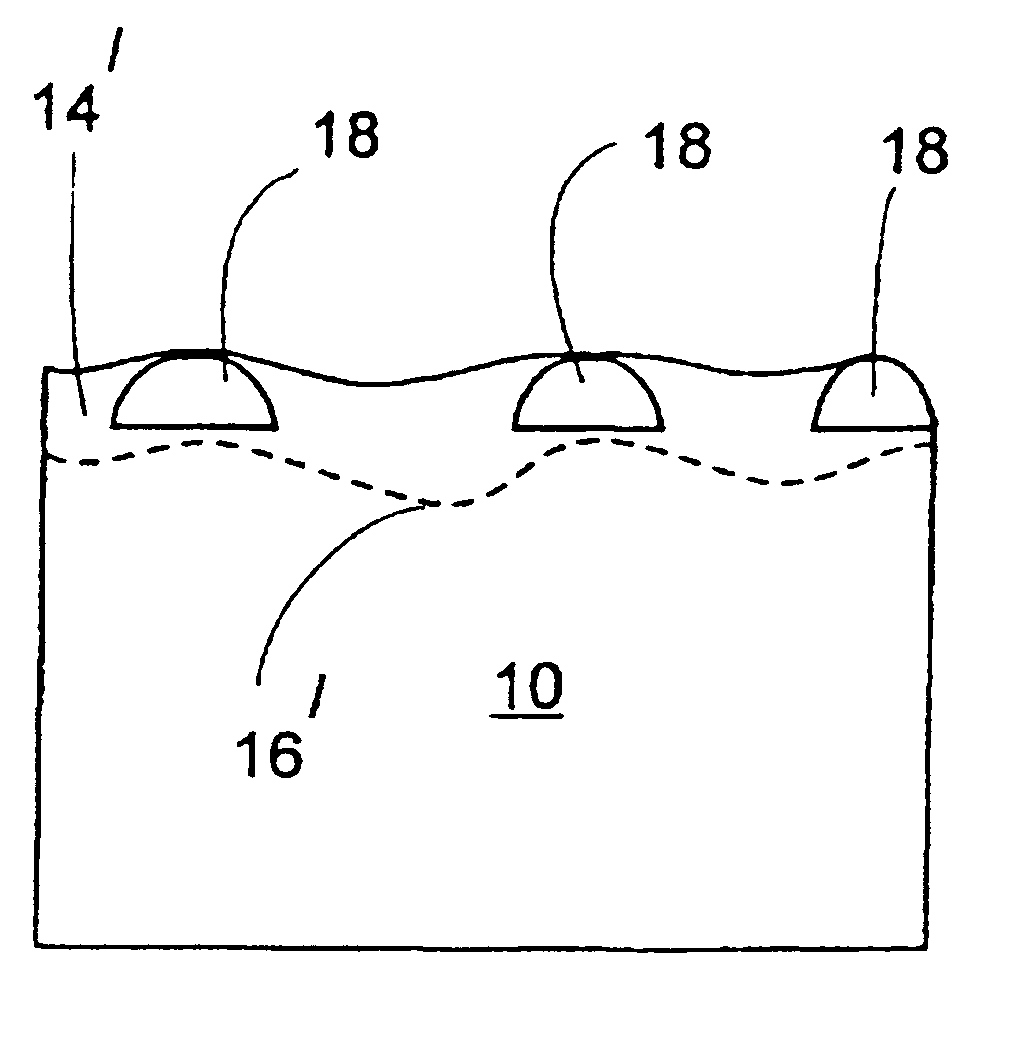

High power capacitors from thin layers of metal powder or metal sponge particles

InactiveUS20030169560A1Increase surface areaSmall sizeFixed capacitor dielectricSolid-state devicesDielectric strengthHigh surface area

An anode (14, 208, 410) and / or cathode (12, 212, 420) of a capacitor has a large surface area. The high surface area of the anode is provided by forming the anode from a thin, electrically conductive layer (16) formed from metal particles (18) or an electrically conductive metallic sponge (416). These materials provide a porous structure with a large surface area of high accessibility. The particles are preferably directional or non-directional sponge particles of a metal, such as titanium. The conductive layer hasa dielectric film (36, 236, 414) on its surface, formed by anodizing the particle surfaces. The dielectric film has a combination of high dielectric constant and high dielectric strength. The cathode (12, 212, 420) of the capacitor is either a conventional solid material or, more preferably, has a large surface provided by forming the surface from a sponge or particles analogously to the anode. The high dielectric strengths obtainable from the capacitor allow for extreme miniaturization, making the capacitor particularly suited for integrated circuit applications.

Owner:TITANIUM POWER TECH

Graphite felt watch surface modified method and modified mineral carbon felt

InactiveCN101182678AImprove wettabilityImprove charge and discharge performanceElectrode manufacturing processesPhysical treatmentFiberVanadium redox battery

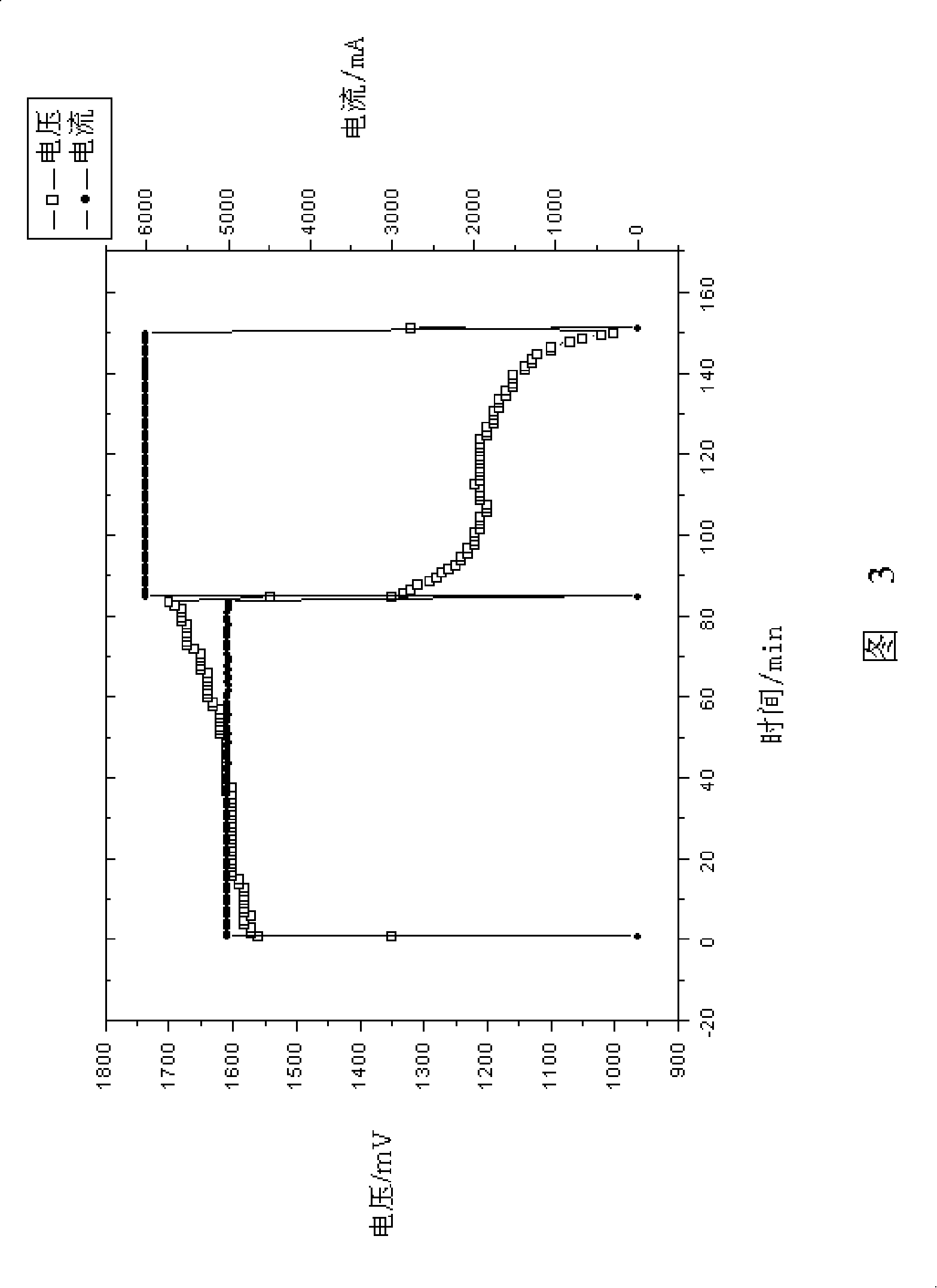

The invention relates to a graphite fiber felt surface modification method and a modified graphite fiber felt, and belongs to the all vanadium redox flow battery electrode manufacture technical field. The method step is that the electrochemical cathode modification treatment is conducted before the anode oxidation treatment. When used as an electrode, a modified graphite fiber felt greatly improves the electrochemical activity in the preparation of an all vanadium redox flow battery, promotes the voltage efficiency and the battery energy efficiency during the battery discharging, and increases the stable discharging time, so the recharging and discharging performance of the all vanadium redox flow battery is greatly improved. Moreover, the method is easy for implantation and low in the cost. No particular devices are required. The invention provides a good-performance electrode material for the battery manufacture field.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Nanoporous Drug Release Structure for Drug Elute Instruments and the Preparation Method Thereof

InactiveUS20090112310A1Reduce riskNo effect on mechanical propertySurgeryPharmaceutical delivery mechanismMicro arc oxidationPercent Diameter Stenosis

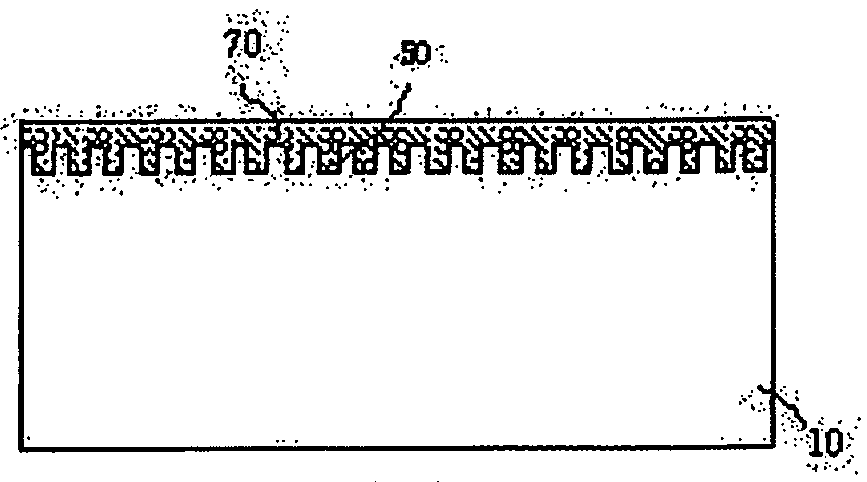

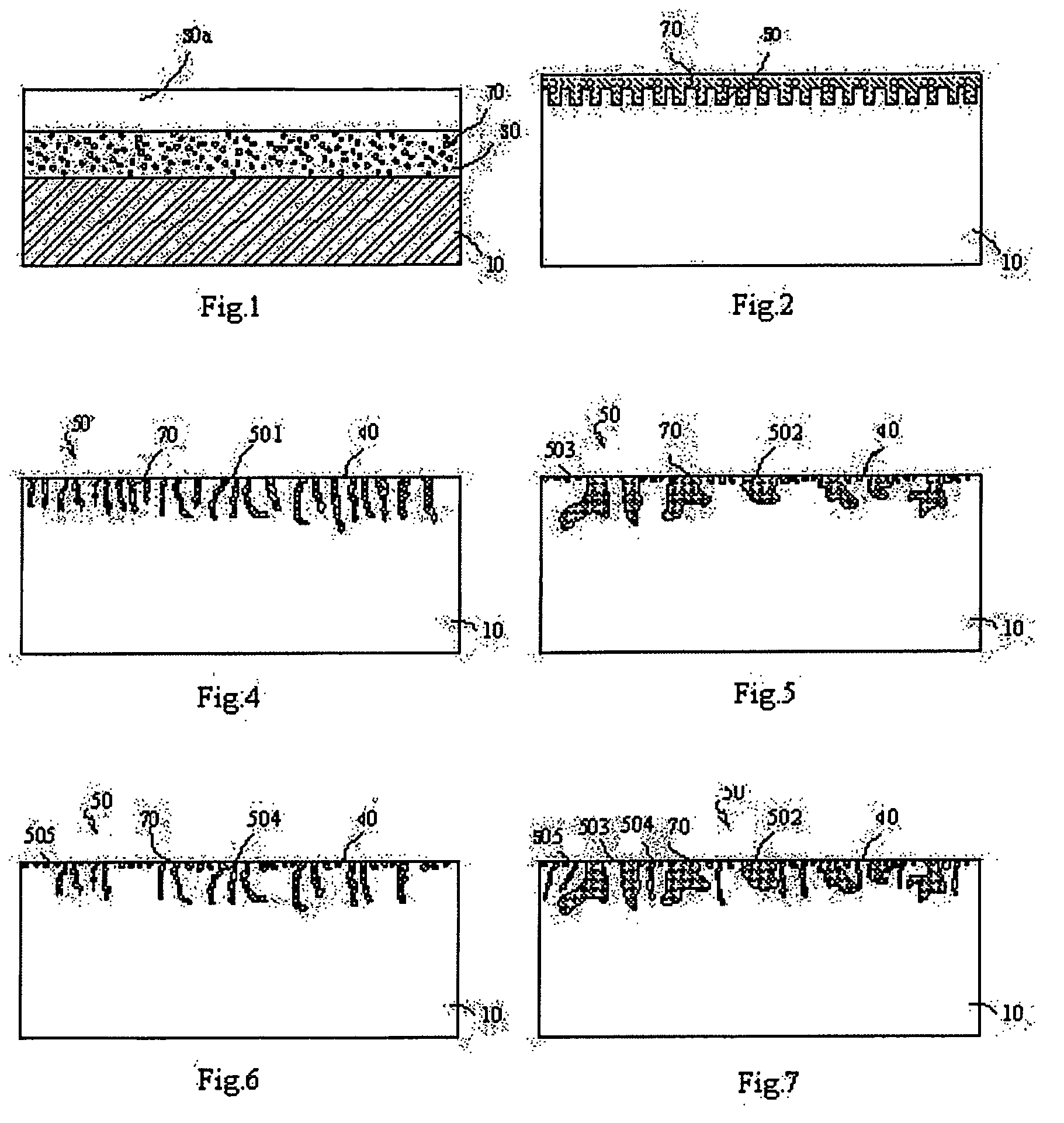

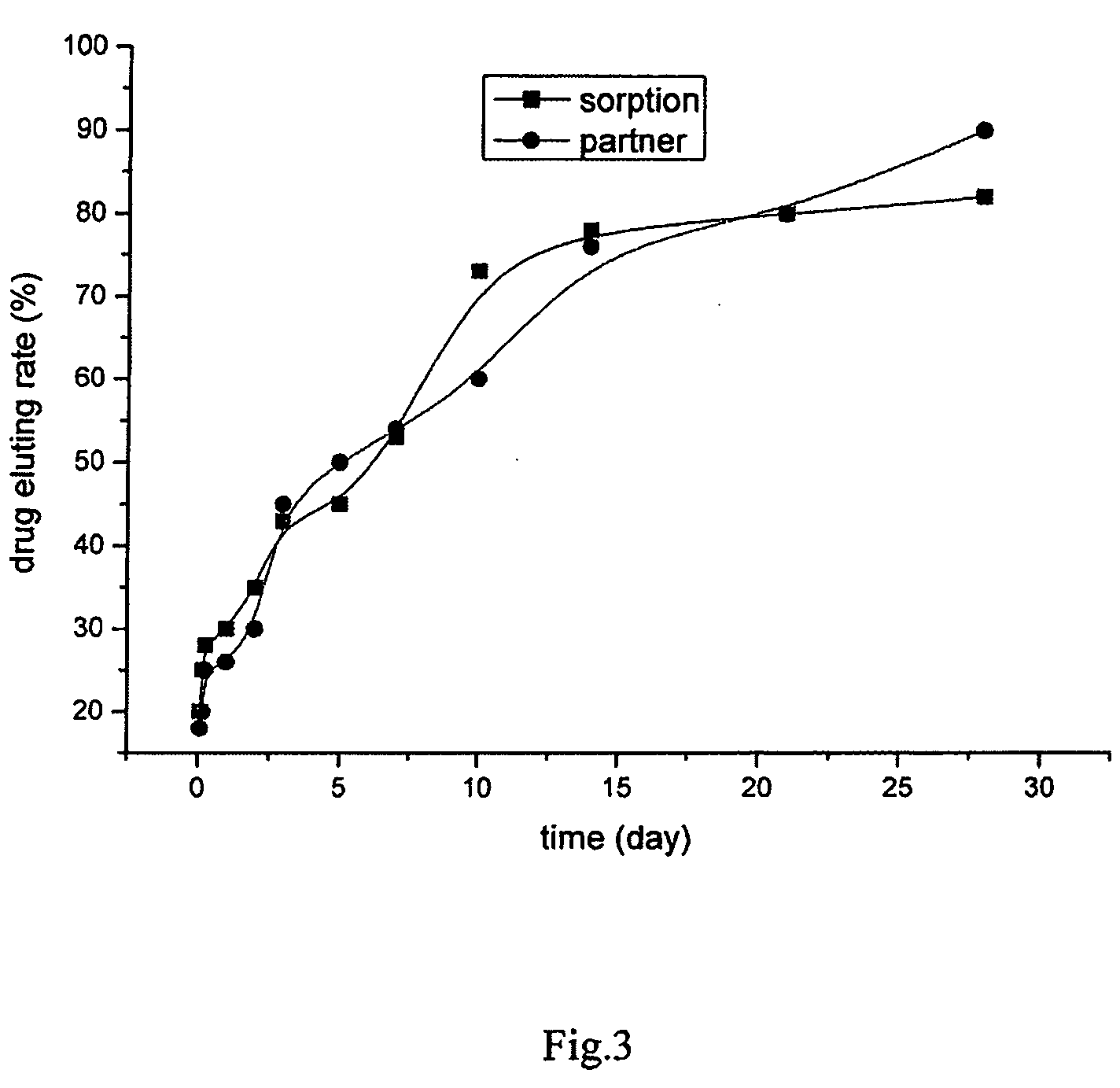

The present invention relates to a nanoporous configuration for drug release used in a drug-eluting device and its preparation, employing acid corrosion or anode oxidation to prepare pores, or employing acid corrosion to prepare pores firstly, then employing anode oxidation or micro-arc oxidation combined with micro-arc nitridation to prepare single sized or two sized or multiple sized nanopores, as well as a uniform size distributed or two or more nonuniform size distributed in pore diameter or pore depth h nanopores on the raw material of device body directly. The preparation process includes: ① Pre-treating the surface of the device body, ② Preparing pore, ③ Post-treating the surface of the device body, ④preparing drug, ⑤ Spraying drug etc. The nanoporous configuration lowers the risk of forming thrombus after the drug-delivery device with polymer carrier is implanted into the tissue. The device also controls the release rate of drug efficiently and lowers the incidence of restenosis significantly.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

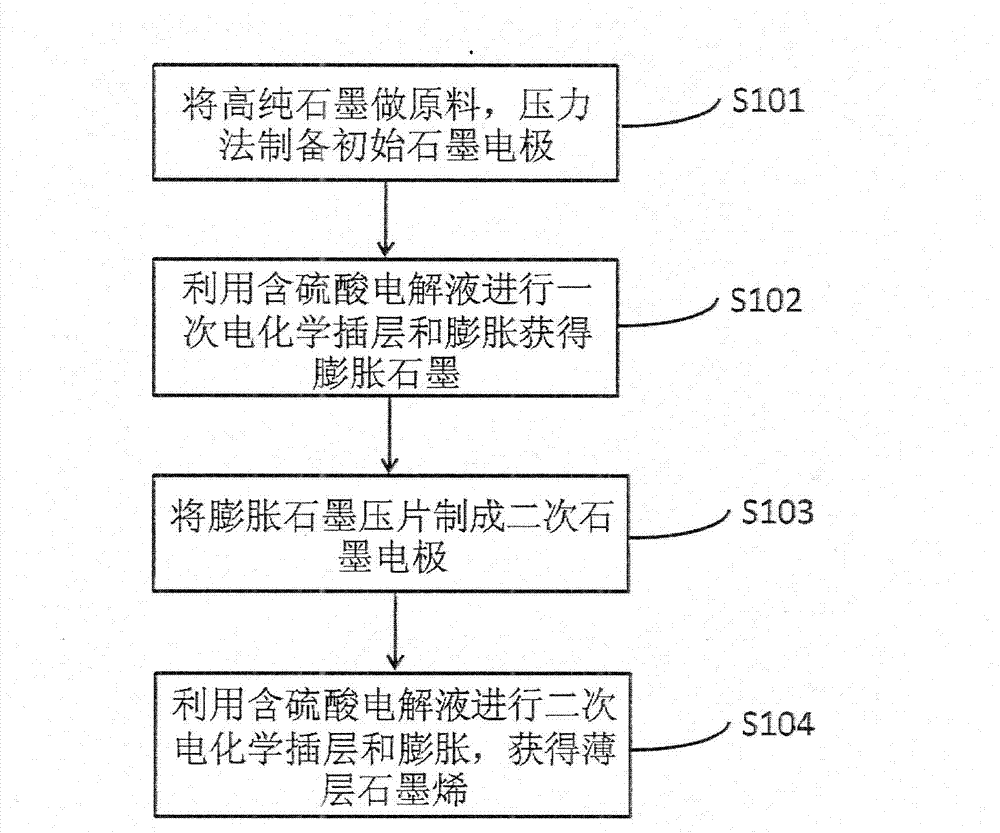

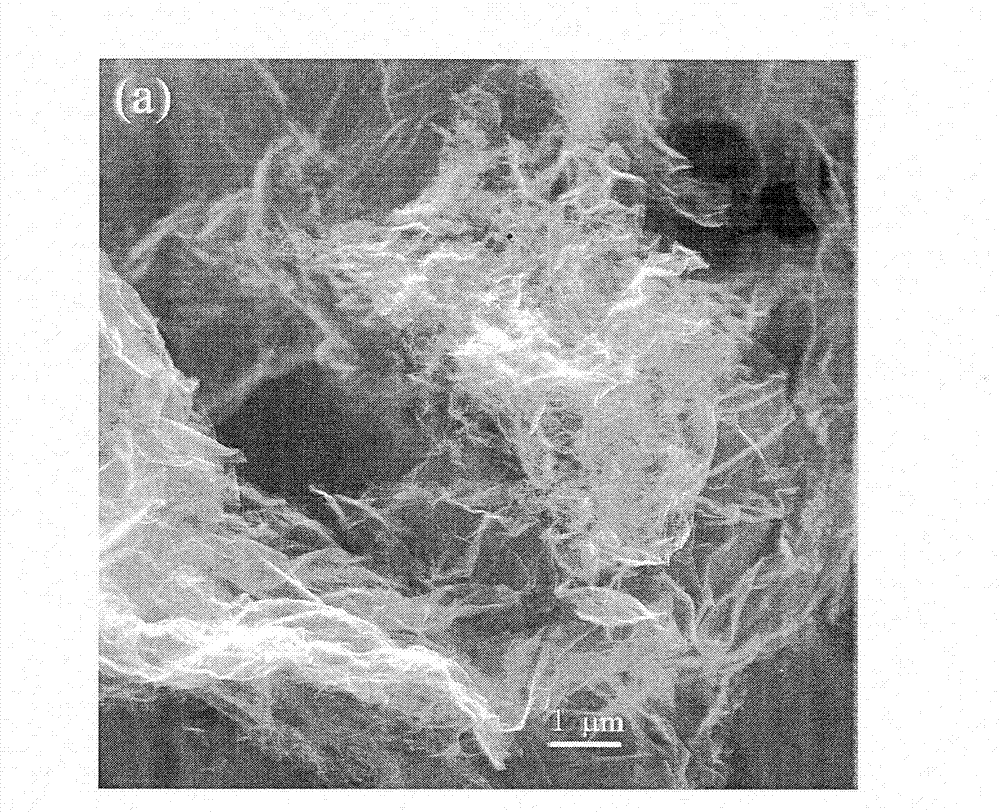

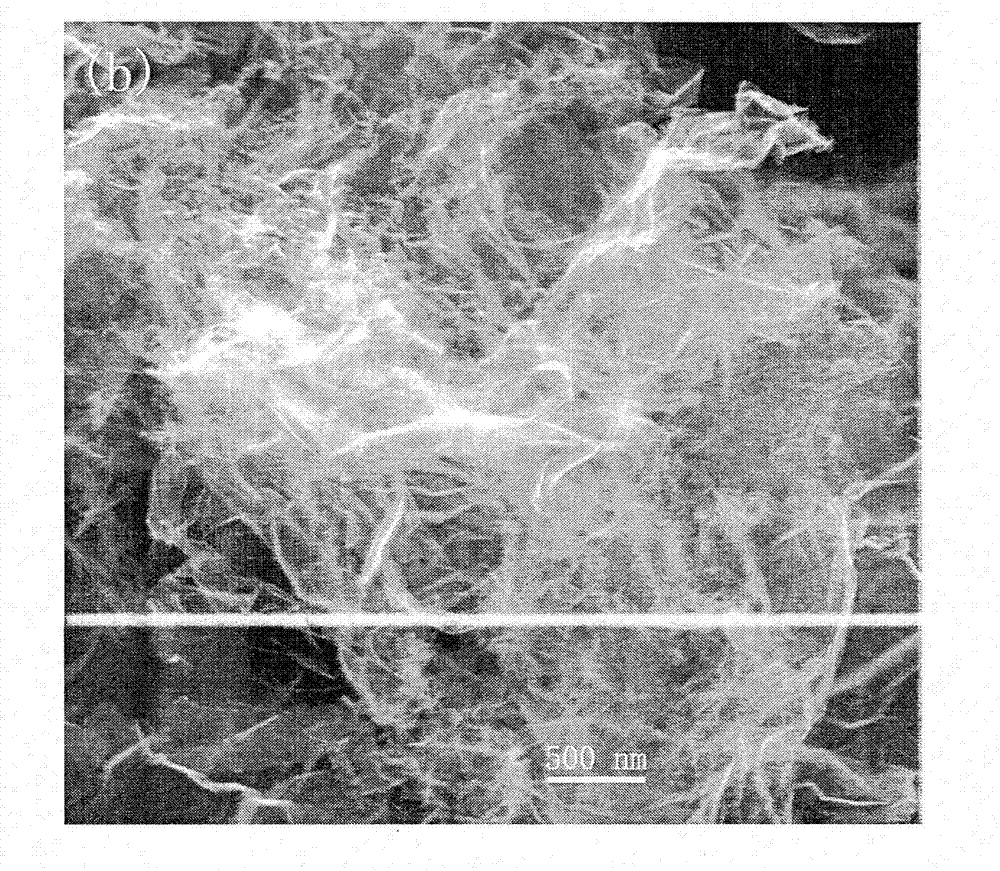

Method for electrochemically preparing graphene

The invention discloses a method for electrochemically preparing graphene, which preferably comprises the steps of pressing a high-purity graphite raw material to form a graphite electrode, carrying out anodization through the graphite electrode by using sulfuric acid aqueous solution or acetic acid and the like mixed acid solution as an electrolyte to prepare a graphite intercalation product, and obtaining expanded graphite by high temperature or microwave and other methods; and then pressing the expanded graphite to prepare a reaction electrode, and carrying out secondary electrochemical intercalation and expansion to finally obtain laminar graphene. According to the invention, in the preparing process, potassium permanganate and other strong oxidizers are not used, and the damage of the strong oxidizers to the structure and performance of graphene are avoided; alkali metal, fuming sulfuric acid oxydol and other inflammable and explosive dangerous substances are not used, and toxic or harmful substances are not introduced, so that the production is safe and environment friendly; and at the same time, the method is simple in process flow, easy to operate, low in cost, high in yield, mild in reaction conditions and low in energy consumption, and is suitable for industrialized large-scale production.

Owner:苏州格瑞丰纳米科技有限公司

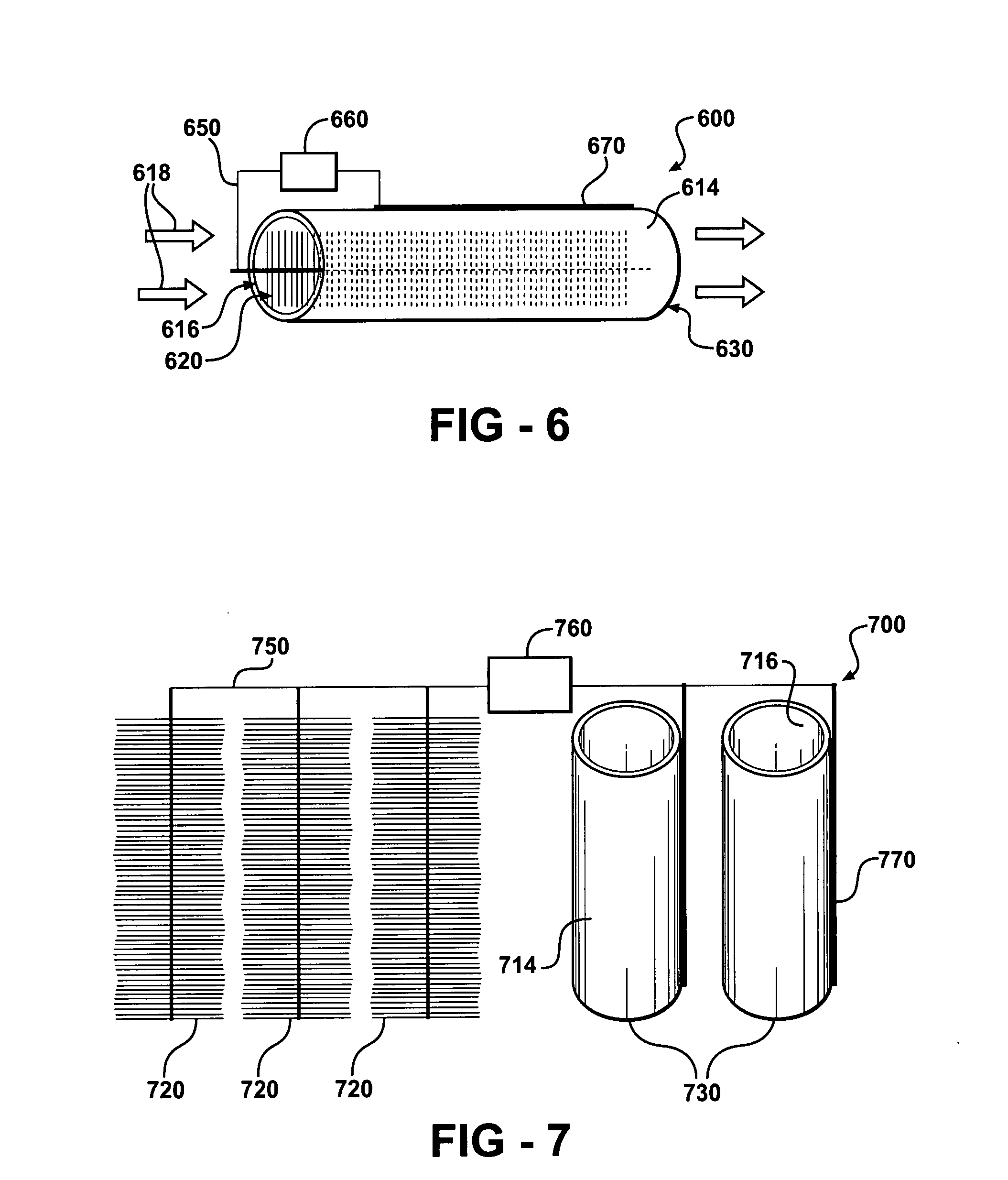

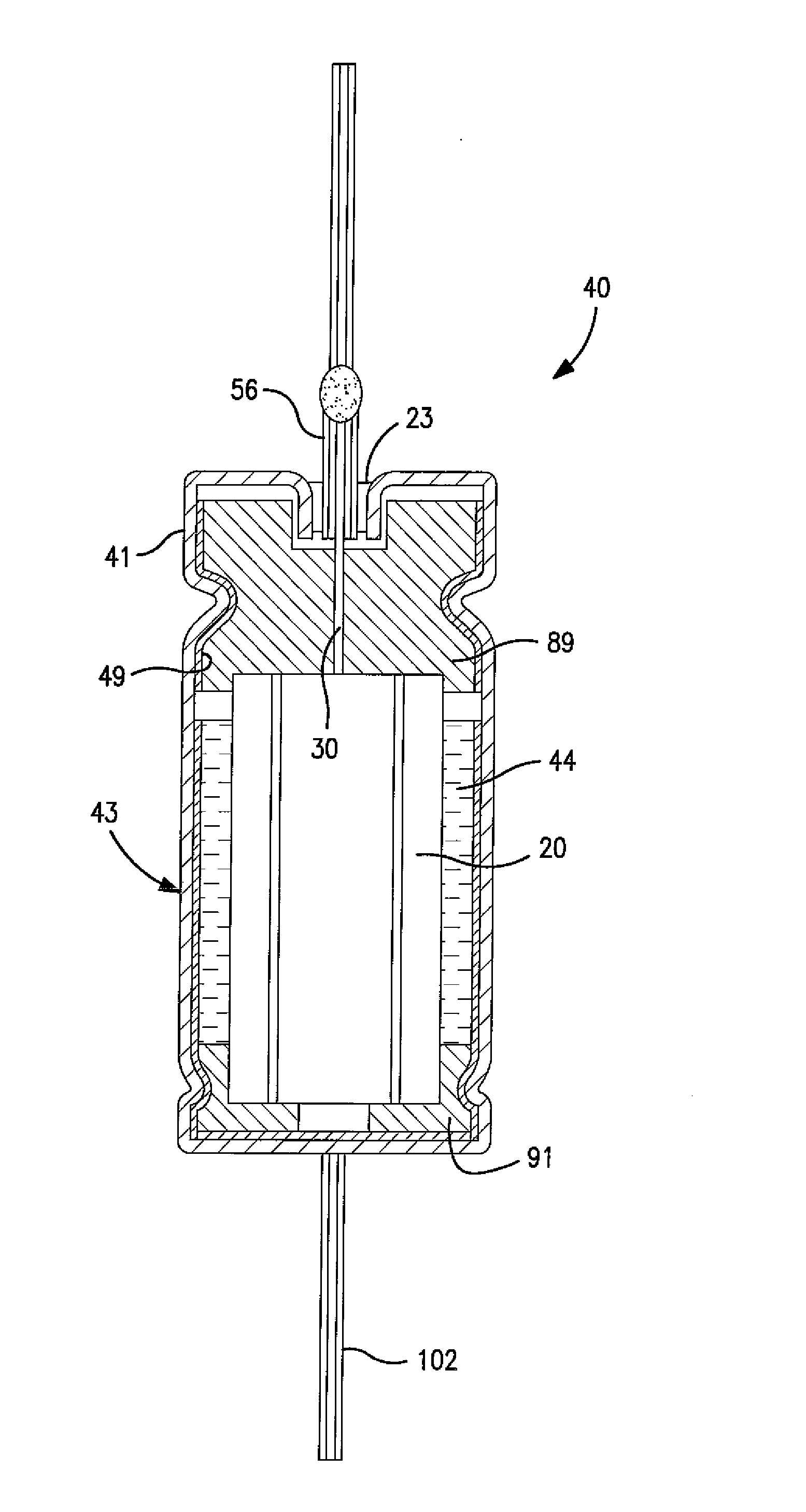

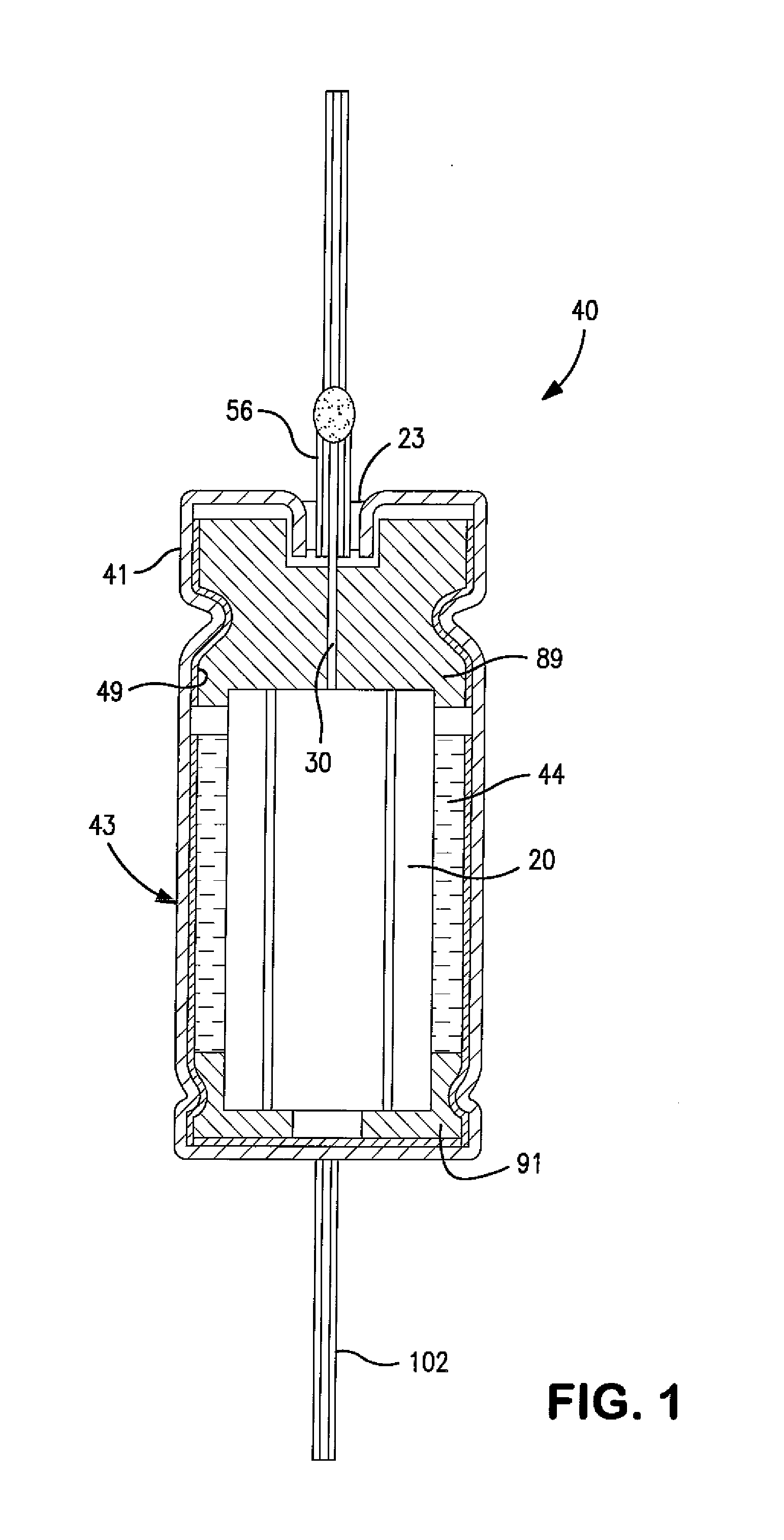

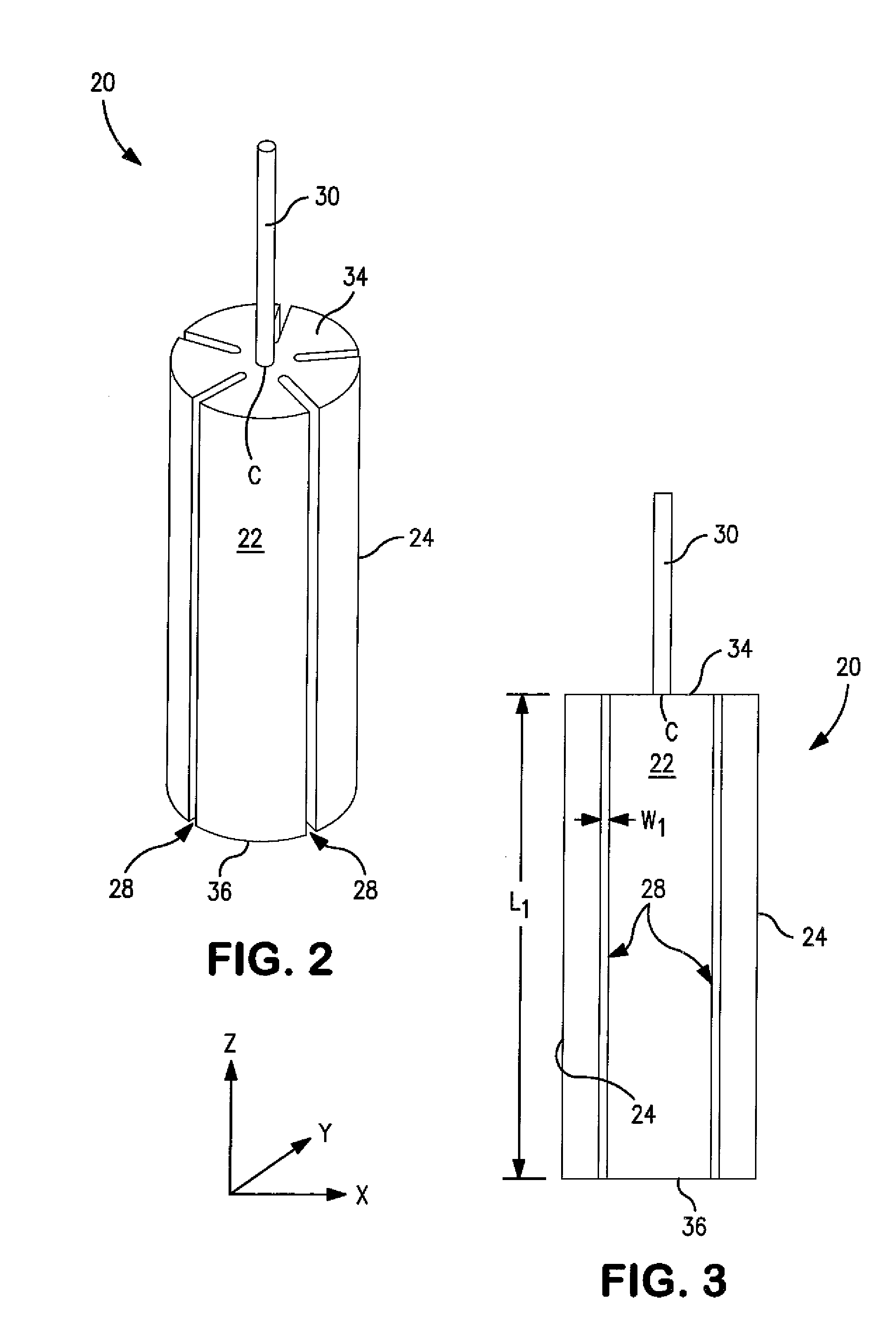

Bio-electrochemically assisted microbial reactor that generates hydrogen gas and methods of generating hydrogen gas

ActiveUS7491453B2Growth inhibitionLower internal resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsHydrogenProton

Systems and processes for producing hydrogen using bacteria are described. One detailed process for producing hydrogen uses a system for producing hydrogen as described herein, the system including a reactor. Anodophilic bacteria are disposed within the interior of the reactor and an organic material oxidizable by an oxidizing activity of the anodophilic bacteria is introduced and incubated under oxidizing reactions conditions such that electrons are produced and transferred to the anode. A power source is activated to increase a potential between the anode and the cathode, such that electrons and protons combine to produce hydrogen gas. One system for producing hydrogen includes a reaction chamber having a wall defining an interior of the reactor and an exterior of the reaction chamber. An anode is provided which is at least partially contained within the interior of the reaction chamber and a cathode is also provided which is at least partially contained within the interior of the reaction chamber. The cathode is spaced apart at a distance in the range between 0.1-100 centimeters, inclusive, from the anode. A conductive conduit for electrons is provided which is in electrical communication with the anode and the cathode and a power source for enhancing an electrical potential between the anode and cathode is included which is in electrical communication at least with the cathode. A first channel defining a passage from the exterior of the reaction chamber to the interior of the reaction chamber is also included.

Owner:PENN STATE RES FOUND +1

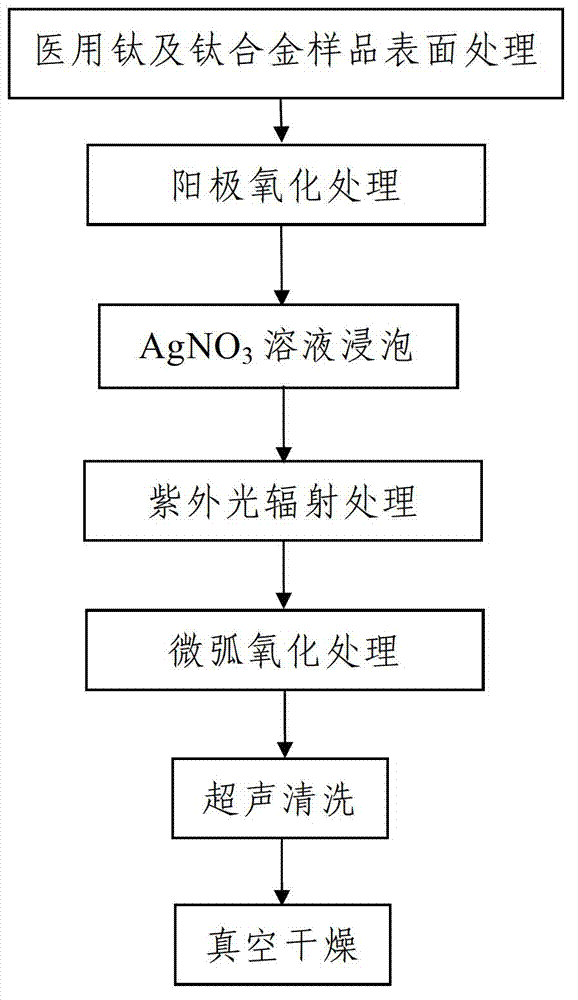

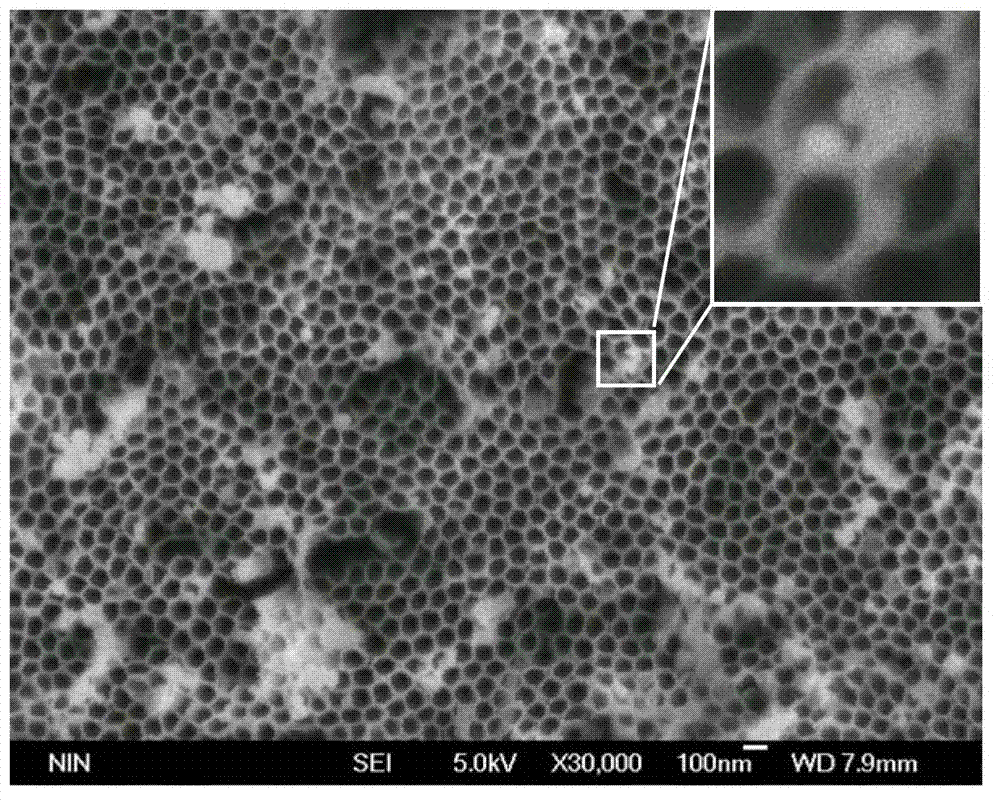

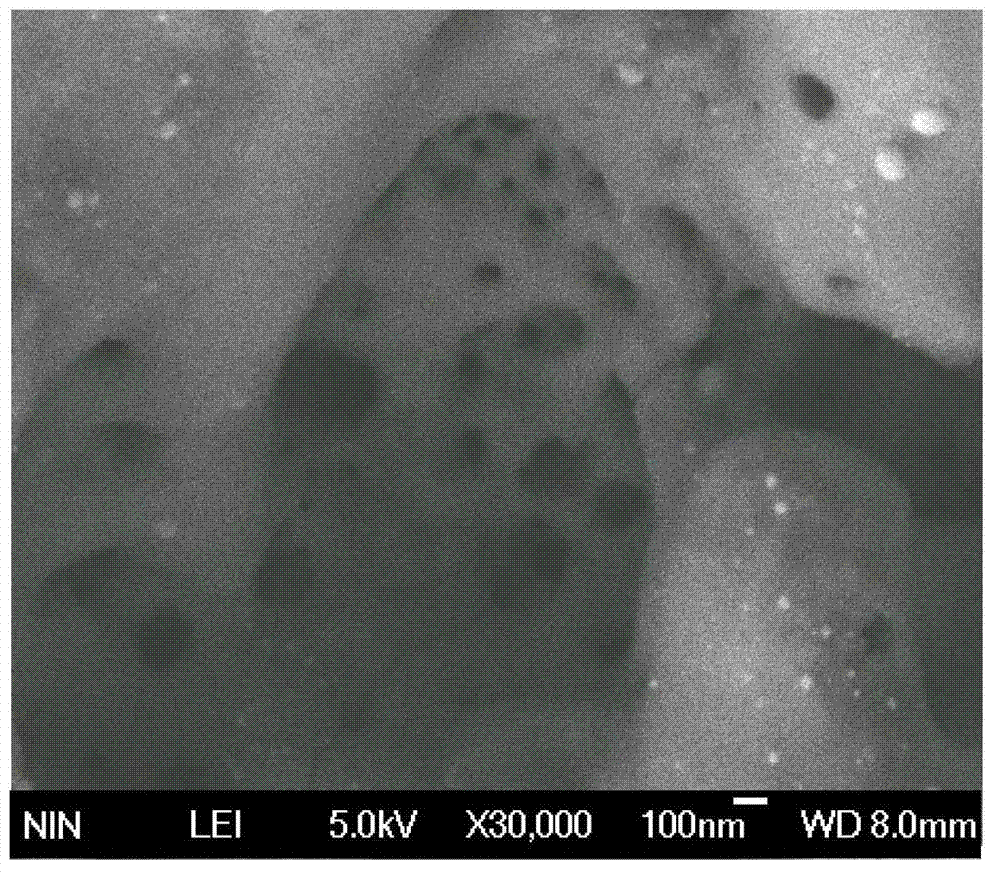

Method for preparing biomedical titanium and titanium alloy surface antibacterial coatings

ActiveCN102758202AImprove antibacterial propertiesReduce or avoid infectionSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for preparing biomedical titanium and titanium alloy surface antibacterial coatings. The method comprises steps of firstly, processing the surface of a biomedical titanium or titanium alloy sample to be processed, immersing the biomedical titanium or titanium alloy sample in a glycol aqueous solution containing soluble fluoride and performing an anode oxidation treatment; secondly, immersing the biomedical titanium or titanium alloy sample after being subjected to the anode oxidation treatment in a silver nitrate solution, taking out the biomedical titanium or titanium alloy sample, using ultraviolet light radiation to process the biomedical titanium or titanium alloy sample and obtaining the silver-carrying biomedical titanium or titanium alloy sample; and performing a micro-arc oxidation treatment for the silver-carrying biomedical titanium or titanium alloy sample, performing ultrasonic cleaning and vacuum drying and obtaining the antibacterial coatings. The nano precoating layer preparation, the silver-carrying treatment and a micro-arc oxidation technology are combined, then a large amount of silver can be fixed on the biomedical titanium and titanium alloy sample surfaces and can be released slowly for a long time, the antibacterial performance of titanium and titanium alloys is greatly improved, the antibacterial effect can be kept for a long time, and the bacterial infection caused by the fact that a titanium and titanium alloy apparatus is embedded in a human body is greatly reduced or avoided.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

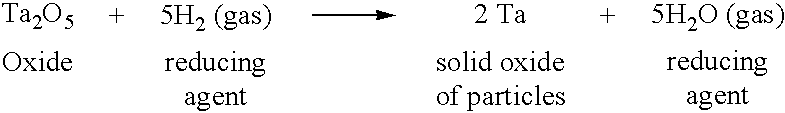

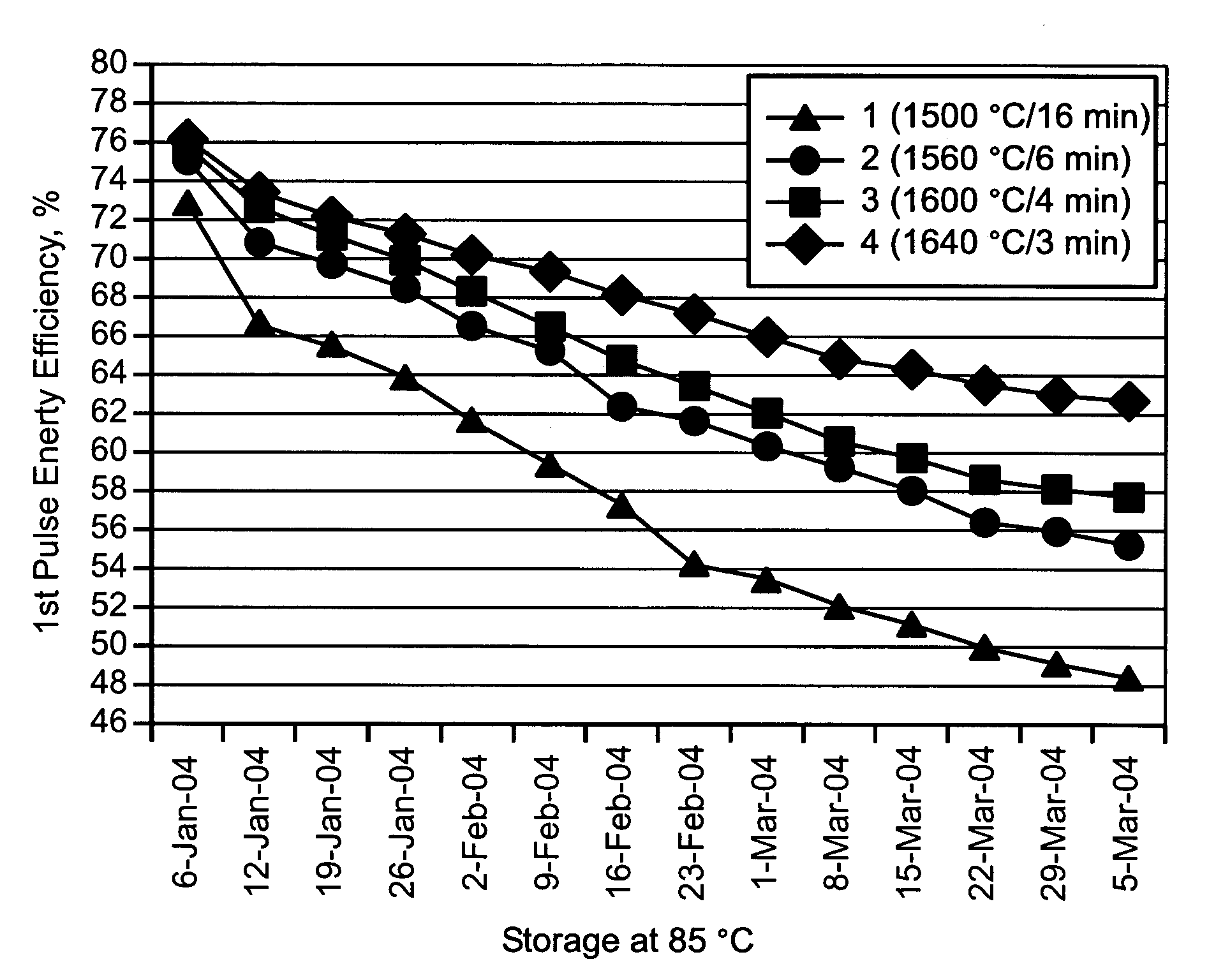

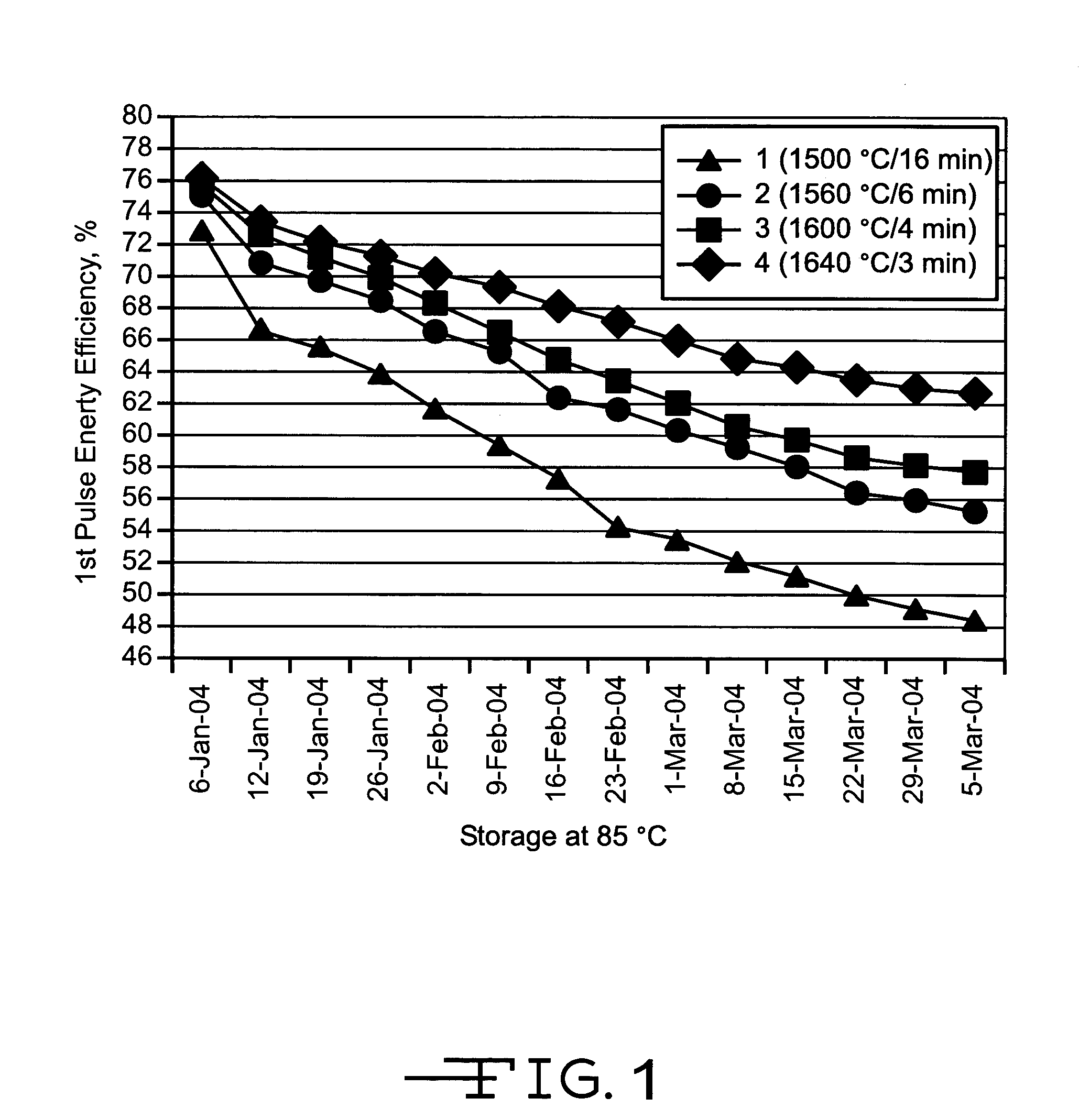

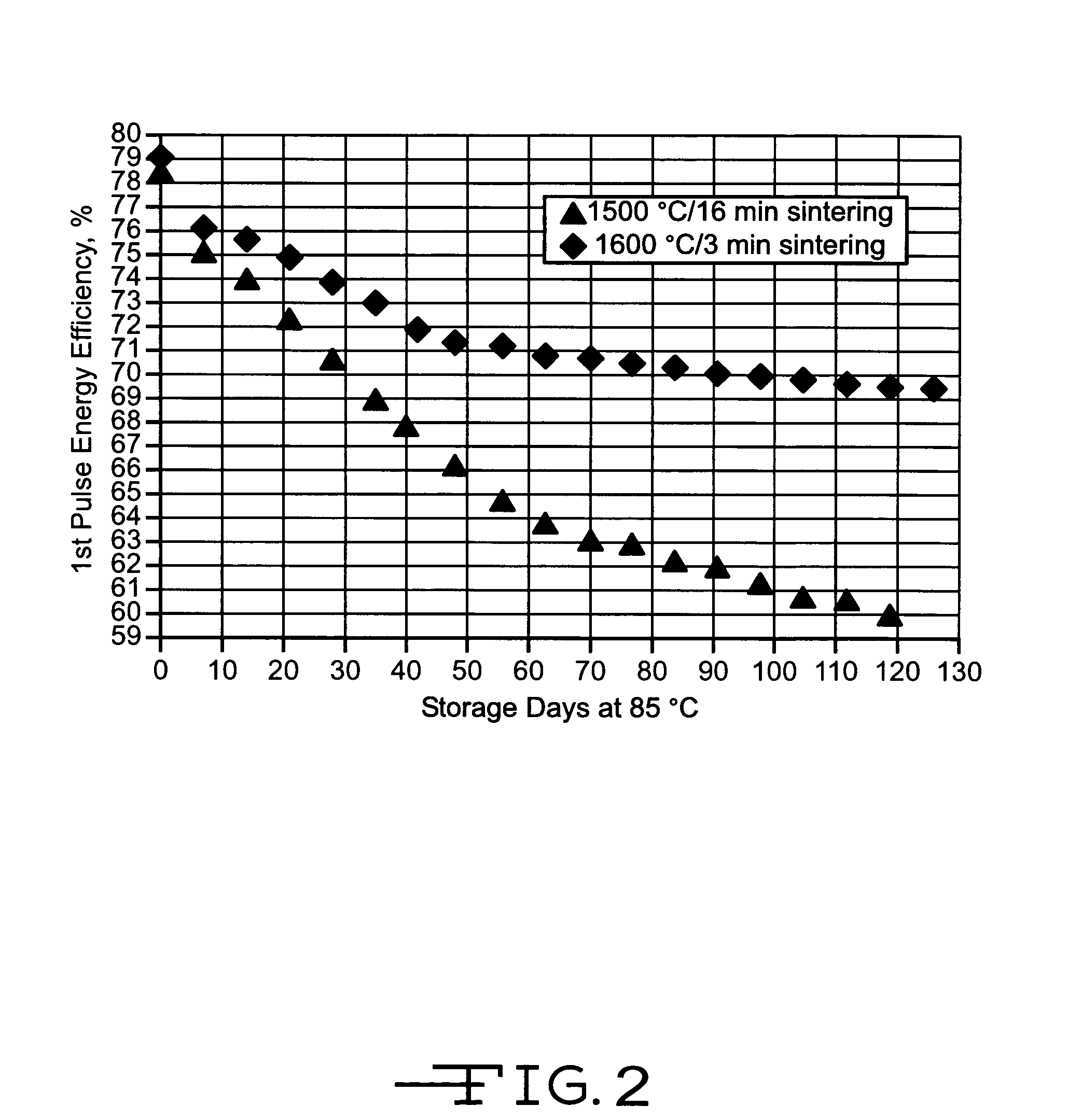

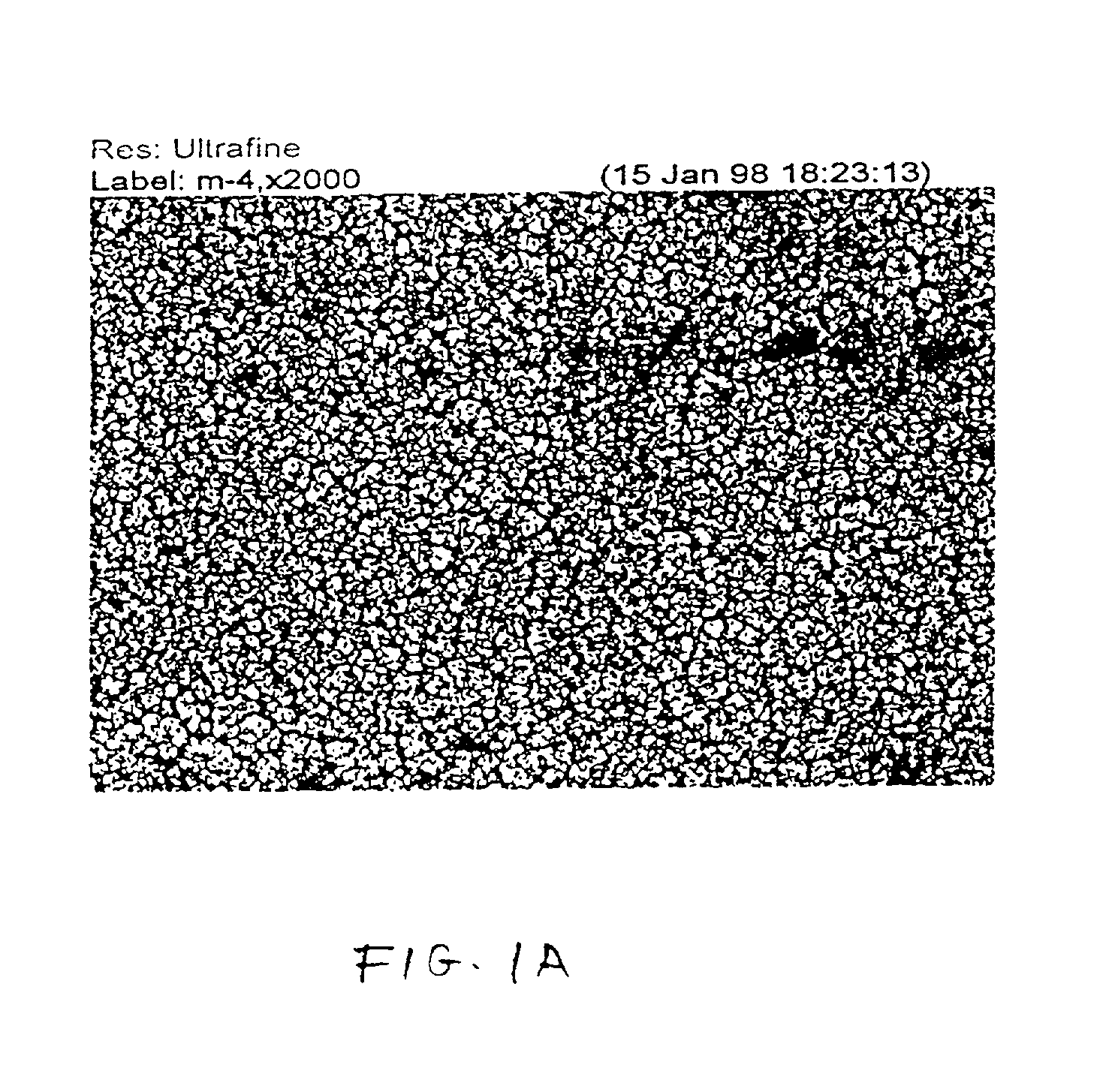

Sintered valve metal powders for implantable capacitors

ActiveUS6965510B1Short timeIncrease temperatureLiquid electrolytic capacitorsCapacitor electrodesNiobiumTitanium

A sintering method for valve metal powders, such as tantalum, niobium, aluminum, titanium, and their alloys, is described. The valve metal powders are pressed into a pellet and sintered at a relatively high temperature, but for a relatively short time. The anodized valve metal structure is then useful as an anode in an electrolytic capacitor.

Owner:WILSON GREATBATCH LTD

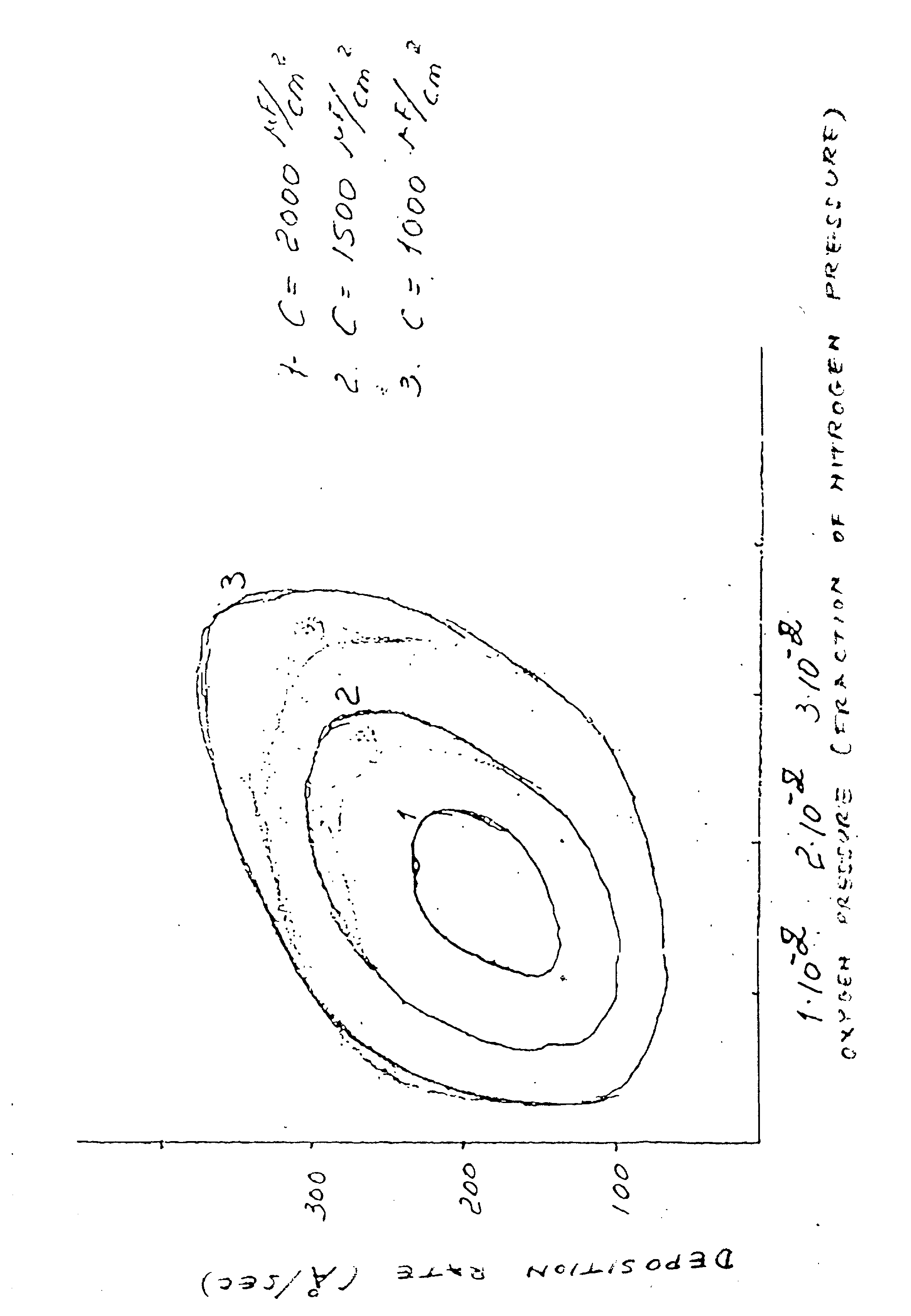

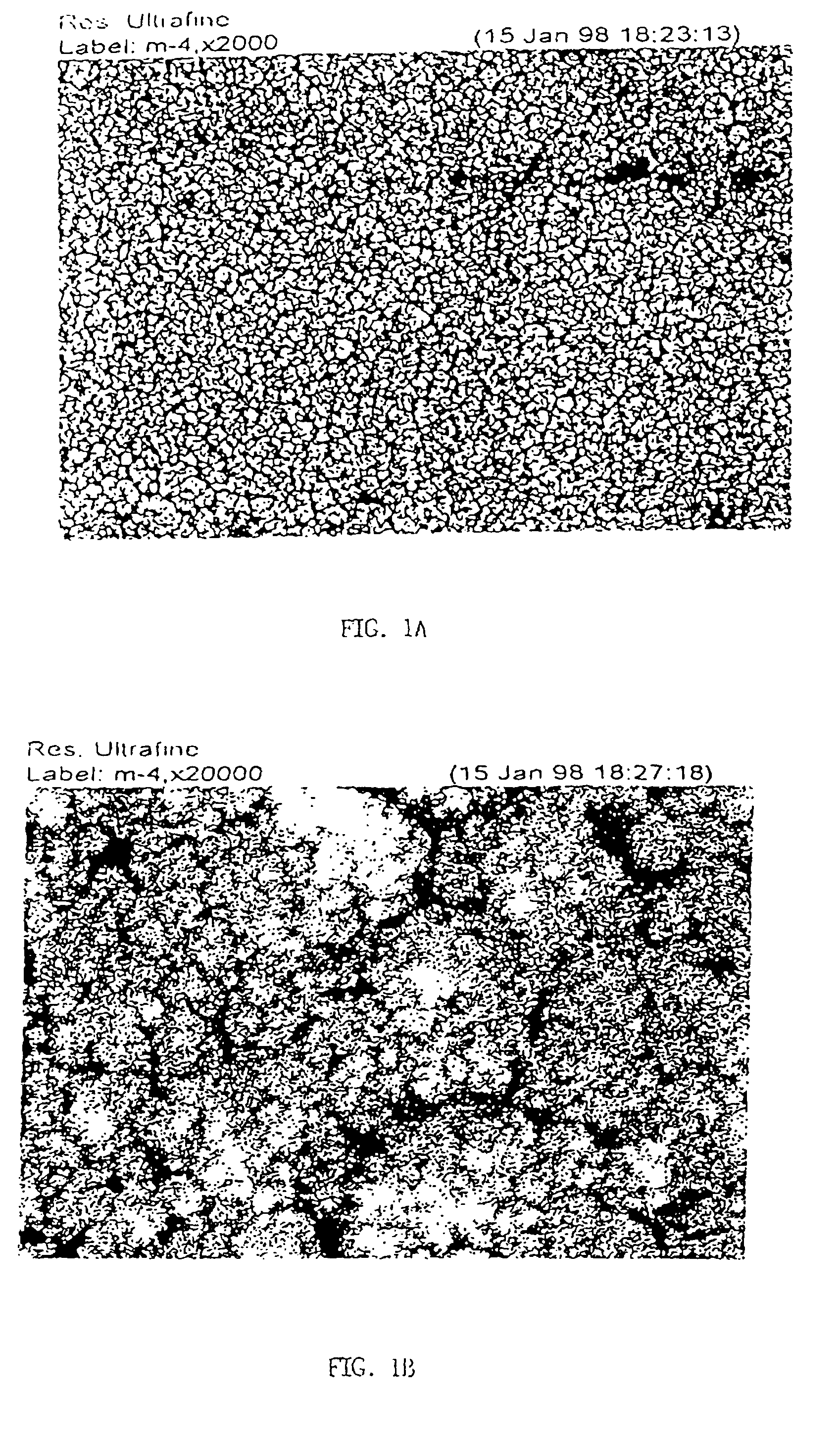

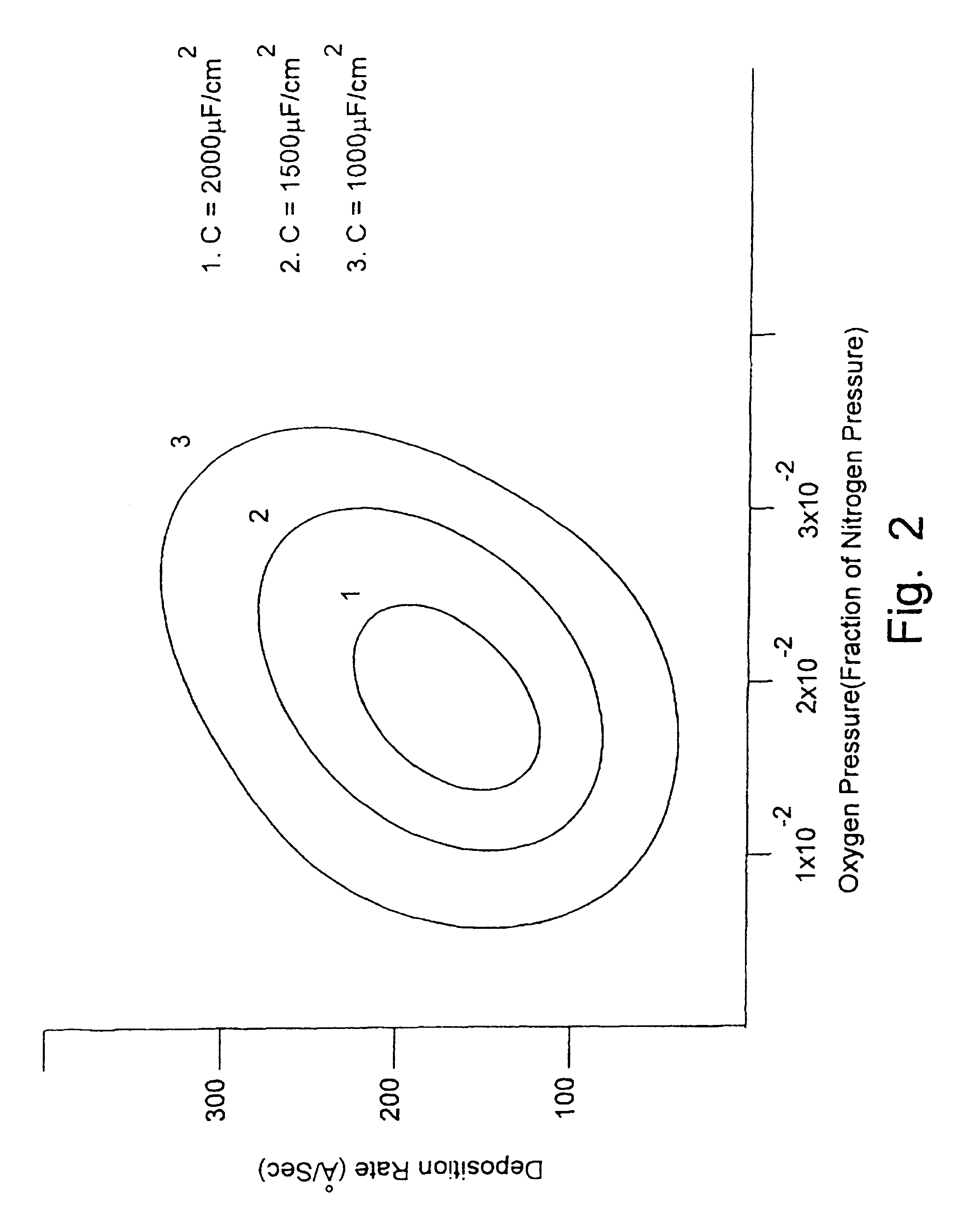

Method for producing high surface area foil electrodes

InactiveUS20010051442A1Increase capacitanceHigh surfaceFixed capacitor dielectricSynthetic resin layered productsElectrolysisMetal foil

A method for increasing the surface area of foil electrodes of electrolytic capacitors. A valve metal is deposited by evaporation on a valve metal foil in a low pressure inert atmosphere including oxygen at a pressure one to two orders of magnitude lower than the pressure of the inert gas. The resulting surface is fractal-like. The foil thus treated is suitable as such for use as a cathode. Prior to anodization to produce an anode, a discontinuous layer of a valve metal oxide is deposited on the foil, to preserve the high surface area of the fractal-like surface and otherwise promote the formation of a dielectric coating whose interface with the metal foil has a high surface area.

Owner:ACKTAR

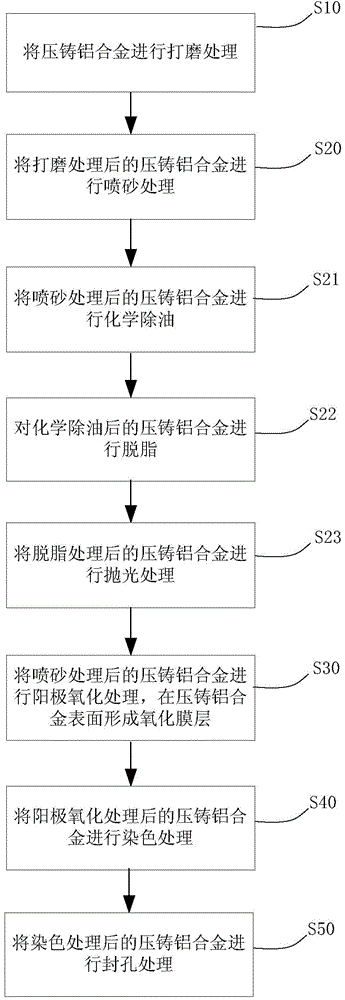

Surface treatment method for die-cast aluminum alloy

InactiveCN104805485AWith a variety of metal appearance effectsHas a metallic lookAnodisationSuperimposed coating processAnode oxidationDyeing

The invention discloses a surface treatment method for a die-cast aluminum alloy, and relates to the technical field of metal surface treatment. The surface treatment method comprises the following steps: S10, conducting polishing treatment on the die-cast aluminum alloy; S20, conducting sand-blast treatment on the polished die-cast aluminum alloy; S30, conducting anode oxidation treatment on the sand-blasted die-cast aluminum alloy, so that an oxidation film layer is formed in the surface of the sand-blasted die-cast aluminum alloy; S40, conducting dyeing treatment on the oxidized die-cast aluminum alloy; S50, conducting plugging treatment on the dyed die-cast aluminum alloy. According to the surface treatment method, the problems that the die-cast metal structure is non-uniform, black spots are easy to generate, and the anode oxidation treatment cannot be conducted because the conventional die-cast aluminum alloy contains metal ingredients such as silicon, copper and iron are solved, and die-cast aluminum alloy products with various metal appearance effects can be obtained.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

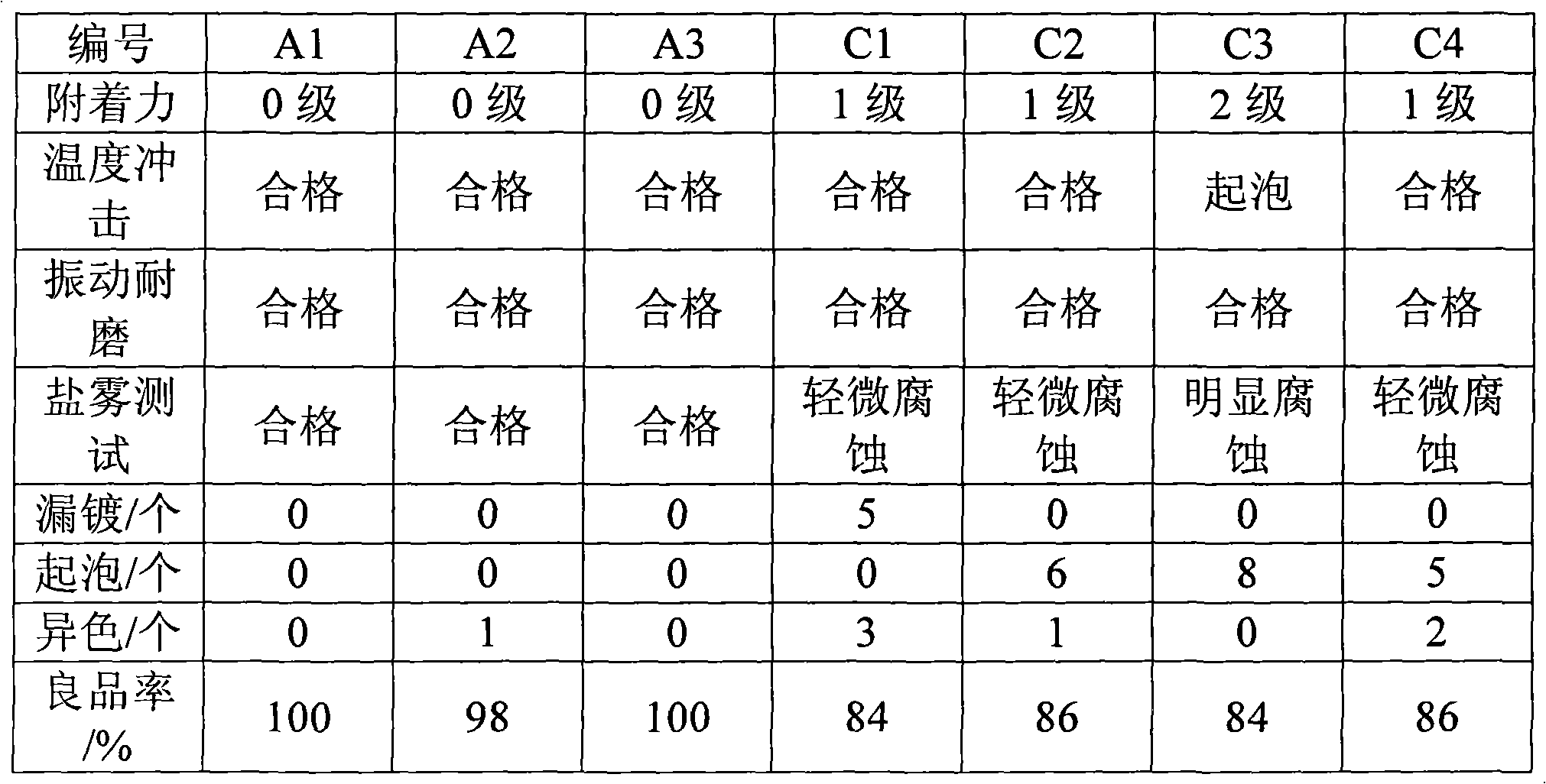

Aluminum alloy surface treatment method

InactiveCN101922010ALess prone to missing platingNot prone to foamingHot-dipping/immersion processesAnodisationAcid etchingLaser etching

The invention provides an aluminum alloy surface treatment method which comprises the steps of sequentially carrying out pretreatment, chemical plating and electroplating on an aluminum alloy matrix, wherein the pretreatment comprises the steps of sequentially carrying out anode oxidation, laser etching, erosion and acid etching on the aluminum alloy matrix. By using the method for forming electroplating texture on the surface of an aluminum alloy, the obtained product has natural texture, is not subject to skip plating, bubbling and discoloration phenomena and has a good decorative effect. Besides, the method has the advantage of simple operation, realizes the unshaded treatment and the convenient maintenance by using the technology of anode oxidation plus electroplating, and facilitates the mass production.

Owner:BYD CO LTD

Integrated dry gasification fuel cell system for conversion of soild carbonaceous fuels

InactiveUS20090004529A1Increase power generation rateFuel cell heat exchangeRegenerative fuel cellsFuel cellsOxygen

An integrated dry gas fuel cell (IDG-FC) is provided. The IDG-FC includes at least one solid oxide fuel cell having an anode, a cathode and an electrolyte membrane disposed between the anode and the cathode. The IDG-FC further includes a conversion bed, where carbon dioxide gas is provided to the conversion bed to convert carbon monoxide gas from the carbon dioxide gas. Solid carbonaceous fuel is provided to the conversion bed to promote the gas conversion. The carbon monoxide is provided as fuel to the anode, and air is supplied to the cathode to provide oxygen for oxidation of the carbon monoxide at the anode to generate electric power. This new process does not require water, and supplies the oxygen required for the oxidation reaction through an ionically selective solid oxide electrolyte membrane.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

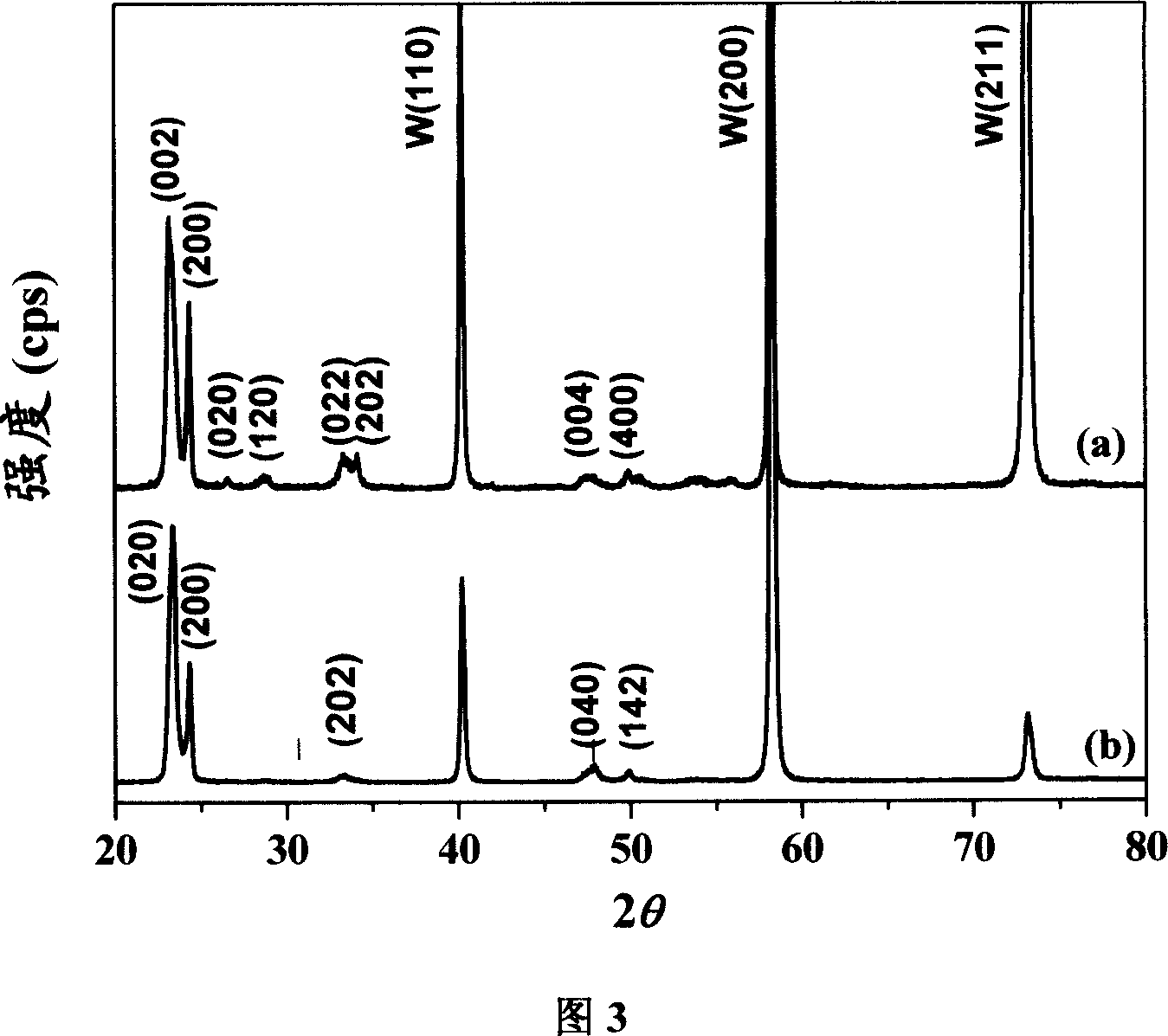

Nanometer porous tungsten trioxide material and its prepn and application

InactiveCN1974890ALower surface energyImprove surface topographyPolycrystalline material growthSurface reaction electrolytic coatingPotassium fluorideStrong acids

Owner:DALIAN UNIV OF TECH

Preparation method for multicolor oxide film

InactiveCN101619477APerformance impactAccelerated corrosionAnodisationArtistic surface treatmentWear resistanceCarving

The invention relates to a preparation method for multicolor oxide film, comprising that an anode oxide film forming step is repeatedly carried out. The anode oxide film forming step comprises: oxidizing color anode, and forming a protective layer and laser carving on a color anode oxide film. The color anode oxidation comprises anode oxidation, dyeing and hole sealing are carried out in turn on the surface of a base material so as to obtain a color anode oxide film. The protective layer is used for separating electrolyte oxidized by a color anode and a color anode oxide film formed previously. The laser carving is used for removing at least one part of color anode oxide film formed previously so as to cause the surface of parts of base material to be exposed. The integral corrosion resistance and abrasion resistance of the oxide film on the surface of the base material, which is prepared according to the method of the invention, are high, and no other macromolecule materials need to be coated, so that the texture of the oxide film is kept.

Owner:BYD CO LTD

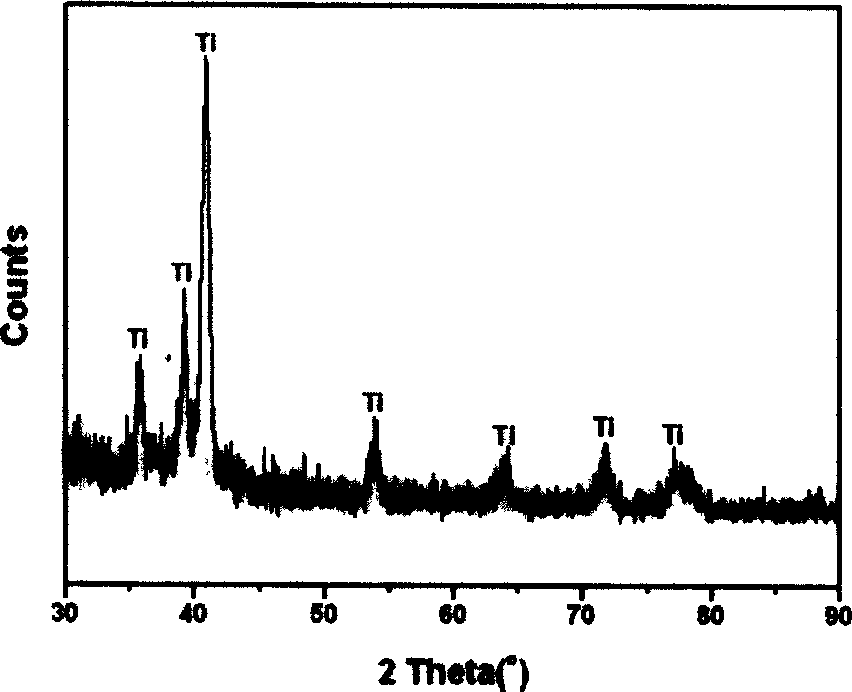

Process for anode oxidation coloration of titanium and titanium alloy surface

InactiveCN1844483ABright colorImprove the decorative effectSurface reaction electrolytic coatingTitaniumTitanium alloy

This invention relates to titanium and titanium alloy surface anode oxidation bepainting method. This invention has following steps: dealing with titanium and titanium alloy in alkali solution for 10-15min under 60-75deg C and ultrasonic condition, then rinsing, and then putting it in acid solution for 0.5-1min, and then rinsing, and then under the condition that the temperature is 15-35deg C, the current density is 5-10Am-2, the voltage is 20-90V, putting it in anode oxidation bepainting solution to bepaint for 15-30min,then rinsing, and then dealing with it closely for 15-30min in non-ionic water, and then drying for 30-60min under 110-130deg C. The advantage in this invention is that the steps are few, the operation is simple, and it is easy to maintain.

Owner:XIAMEN UNIV

Method for producing high surface area foil electrodes

InactiveUS6287673B1Increase capacitanceHigh surfaceVacuum evaporation coatingSputtering coatingElectrolysisMetal foil

A method for increasing the surface area of foil electrodes of electrolytic capacitors. A valve metal is deposited by evaporation on a valve metal foil in a low pressure inert atmosphere including oxygen at a pressure one to two orders of magnitude lower than the pressure of the inert gas. The resulting surface is fractal-like. The foil thus treated is suitable as such for use as a cathode. Prior to anodization to produce an anode, a discontinuous layer of a valve metal oxide is deposited on the foil, to preserve the high surface area of the fractal-like surface and otherwise promote the formation of a dielectric coating whose interface with the metal foil has a high surface area.

Owner:ACKTAR

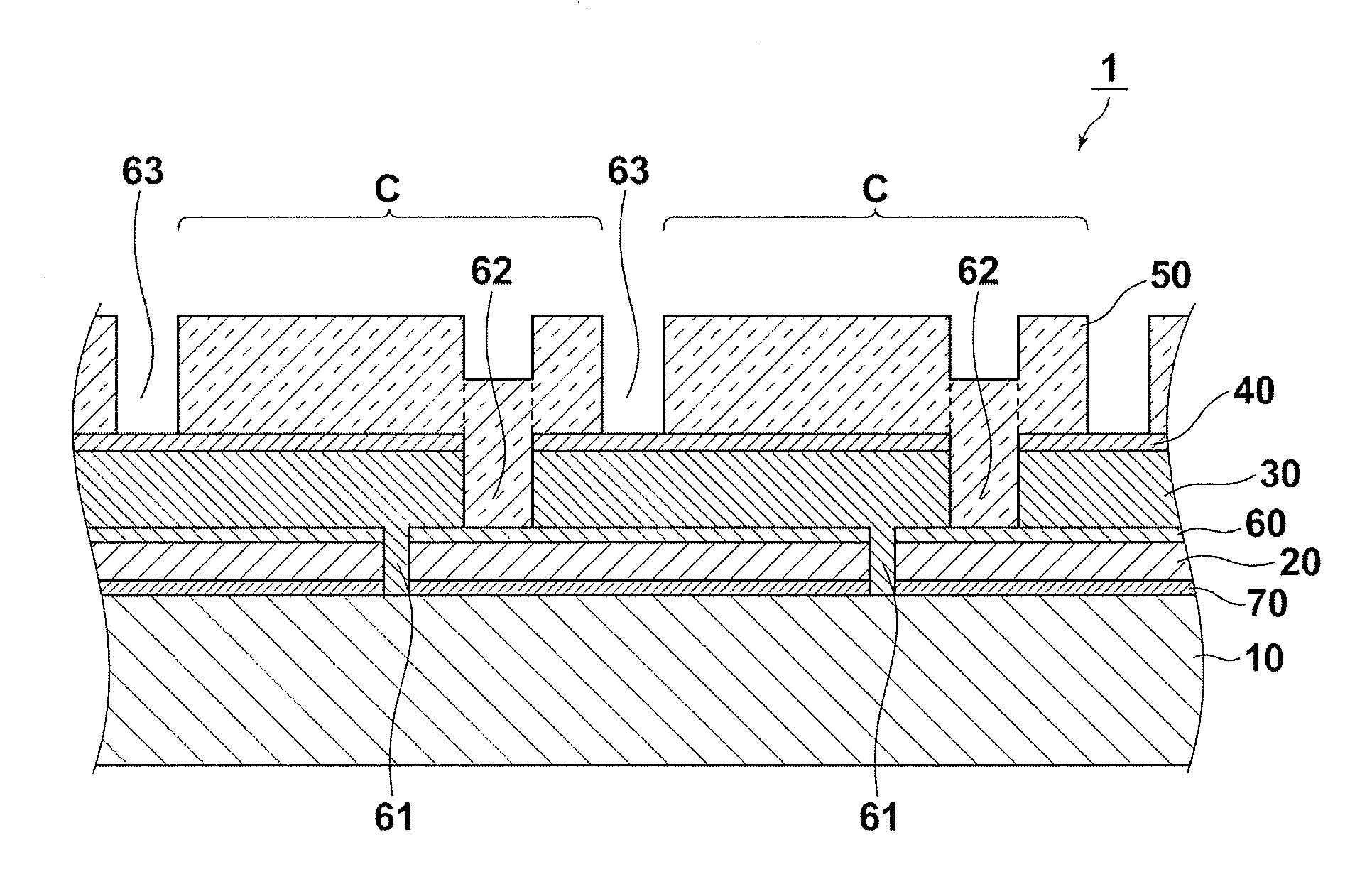

Photoelectric conversion device and solar cell using the photoelectric conversion device

InactiveUS20100224249A1Reduce manufacturing costLow cost manufacturingAnodisationFinal product manufactureAlkaline earth metalPhotoelectric conversion

A photoelectric conversion device having a laminated structure includes: an anodized substrate constituted by a metal substrate mainly containing aluminum and an anodized film formed on the metal substrate; a lower electrode mainly containing molybdenum; a semiconductor photoelectric conversion layer generating current when absorbing light; an upper electrode; a metal supply layer being formed in contact with or inside the lower electrode, containing an alkali and / or alkaline earth metal element, and supplying the alkali and / or alkaline earth metal element to the photoelectric conversion layer during formation of the photoelectric conversion layer; and a diffusion barrier layer being conductive and formed between the anodized substrate and the metal supply layer in contact with the lower electrode and / or the metal supply layer or inside the lower electrode, and suppressing diffusion, into the anodized substrate, of the alkali and / or alkaline earth metal element from the metal supply layer.

Owner:FUJIFILM CORP

Production method of lotus leaf type non-sticking cooking utensils

ActiveCN101396229ARealize the lotus leaf effectHigh hardnessCooking-vessel materialsAnodisationElectricitySpray coating

The invention provides a method for manufacturing a lotus leaf type non-sticky cooking utensil, belonging to the technical field of kitchen cooking utensils. The method solves the problems of the prior art that the existing non-sticky cooking utensil has relatively poor non-sticky effect and wear resistance of non-sticky layers and relatively difficult processing. The method for manufacturing the lotus leaf type non-sticky cooking utensil comprises the following steps: (A) drawing and forming; (B) blasting; (C). hard anode oxidation treatment; and (D). spray coating or dip coating and sintering. The cooking utensil achieves a lotus leaf effect of the cooking utensil and has excellent non-sticky effect; the surface of the non-sticky cooking utensil has high hardness, good wear resistance and high temperature resistance; the cooking utensil has excellent electric insulativity and corrosion resistance, long service life, simple manufacturing method and process, and simple processing, and can realize large-scale industrialized production.

Owner:ZHEJIANG SUPOR CO LTD

Fuel cell, fuel cell power source system and electronic devices using the same

InactiveUS20070037040A1Efficient dischargeReactant parameters controlElectrode carriers/collectorsEngineeringOxygen

Provided is a fuel cell having a membrane electrode assembly for generating power by oxidizing fuel at an anode electrode and reducing oxygen at a cathode electrode, an anode diffusion layer for allowing fuel to pass therethrough to the outside of the anode electrode of the membrane electrode assembly and transferring electrons generated by the oxidation, a cathode diffusion layer for removing water thus generated and transferring electrons to be used for the reduction to the lo outside of the cathode electrode, an anode current collector and anode endplate for transferring electrons generated by the oxidation to the outside of the anode diffusion layer, and a cathode current collector and a cathode endplate for transferring electrons to be used for the reduction to the outside of the cathode diffusion layer. The anode endplate or anode current collecting layer is hydrophilic or the end plate on the anode side has a constitution promoting discharge of a gas generated by the reaction.

Owner:HITACHI LTD

Wet Capacitor Cathode Containing a Conductive Copolymer

InactiveUS20130242464A1Liquid electrolytic capacitorsSurface reaction electrolytic coatingDielectricElectrolysis

A wet electrolytic capacitor that contains an anodically oxidized porous anode body, a cathode containing a metal substrate coated with a conductive coating, and a working electrolyte that wets the dielectric on the anode. The conductive coating contains a conductive copolymer having at least one thiophene repeating unit, as well as a pyrrole repeating unit and / or aniline repeating unit.

Owner:AVX CORP

Technique for preparing high-hardness large-aperture thick film by mixed acid anode oxidation

The invention relates to a technology of mixed acid anodizing high hardness wide-bore thick-film, first the anodizing solution is mixed with the phosphoric acid and the oxalic acid preparation; then the alkaline solution removes the oxide layer of specimen surface; and then acidic solution neutralizes the surface residue, followed by electrochemical polishing treatment; more the anode is oxidized to prepare the porous alumina, finally the specimen of anodization in the phosphoric acid solution process the reaming. The invention relates to a method of the mixed acid with the phosphoric acid and the oxalic acid as the electrolyte to form 20-45um porous alumina film; the anode is oxidized by the phosphoric acid to reaming, the aperture increased to 80-140nm; the temperature of the anodization mixed the oxalic acid is higher greatly, to save the energy; the micromesh of the mixed acid anodic alumina film fills in the PTFE, MoS2, carbon nano fibers, zinc stearate, and other solid lubricants, prepared to self-lubricating materials, the invention is worthy of spreading to application.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

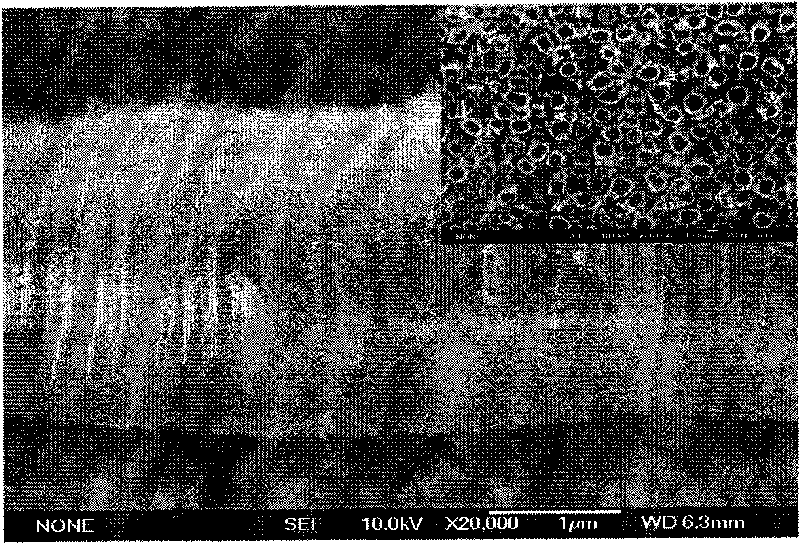

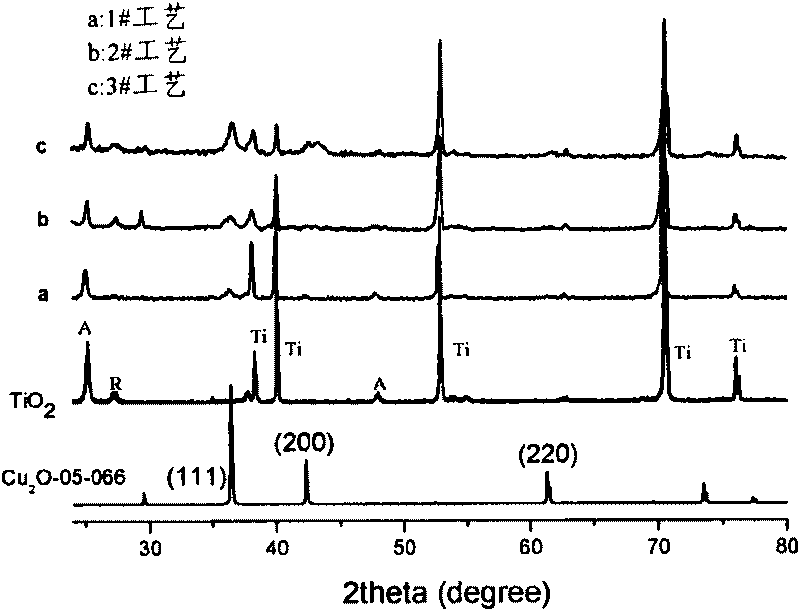

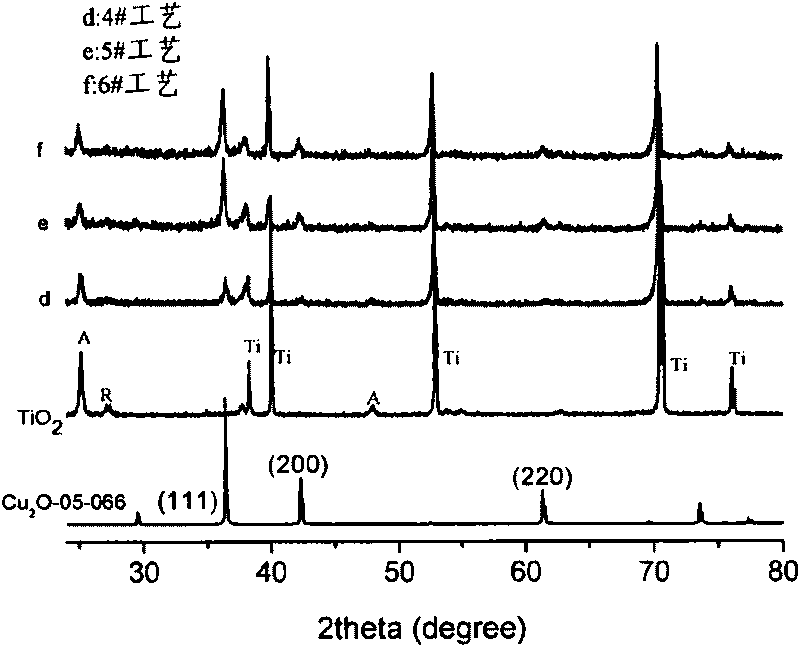

Method for preparing cuprous oxide/titanium dioxide core-shell structure array film through AC electro-deposition method

InactiveCN101717980AAvoid breakingSimple processElectrolytic inorganic material coatingSurface reaction electrolytic coatingThin film electrodeTio2 nanotube

The invention discloses a method for preparing cuprous oxide / titanium dioxide core-shell structure array film through AC electro-deposition method. The method comprises the following steps: (1) adopting anode oxidation method to prepare TiO2 nanotube array film; (2) adopting AC electro-deposition method to prepare one-dimensional Cu2O / TiO2 core-shell structure array film, dissolving CuSO4 in a mixed solution of lactic acid and water to prepare Cu2O electro-deposition solution, using TiO2 / Ti as the working electrode and graphite as the counter electrode to deposit Cu2O under the alternating voltage, washing the electrode surface of the Cu2O / TiO2 nano-array film with deionized water, and drying to prepare the one-dimensional Cu2O / TiO2 core-shell structure array film. The method of the invention has easy technology, is easy to control, is not easy to destroy the TiO2 nanotube array structure, and is possible to realize mass production with low cost.

Owner:TIANJIN UNIV

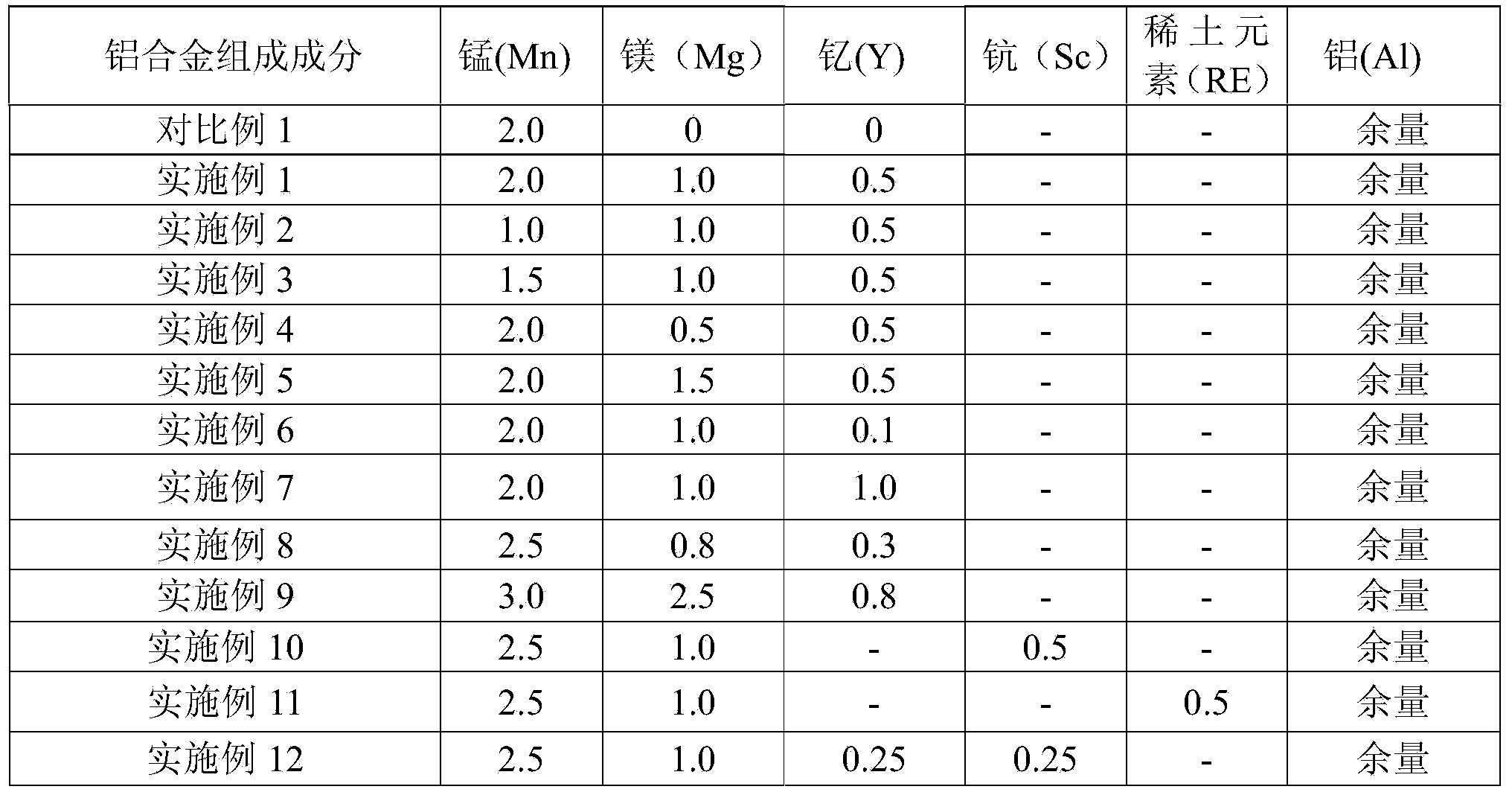

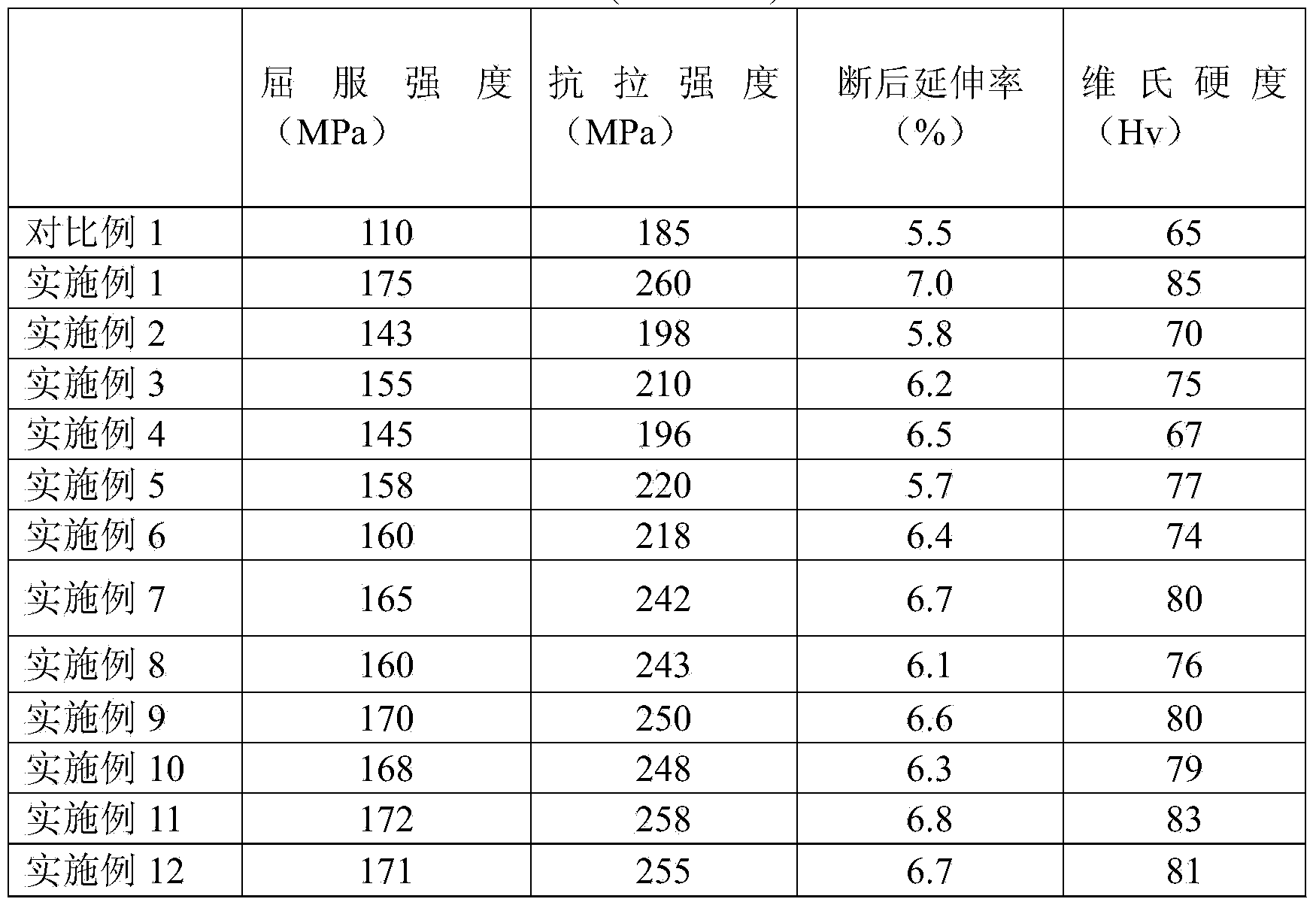

Anode-oxidable high-performance die-casting aluminum alloy and preparation method thereof

The invention provides an anode-oxidable high-performance die-casting aluminum alloy and a preparation method thereof. The die-casting aluminum alloy comprises the following components in percentage by weight: 0.5-3.0 percent of Mn, 0.5-2.50 percent of Mg, 0.1-1.0 percent of D and the balance of Al and inevitable impurities, wherein D can be one or more than two of elementary substances Y, Sc and Re; the inevitable impurities comprises the following components in percentage by weight: less than or equal to 0.10 percent of Fe, less than or equal to 0.10 percent of Si and less than or equal to 0.10 percent of Cu. The aluminum alloy is simple in composition, a high-finish surface can be obtained by means of ordinary anode oxidation and dyeing, and the comprehensive physical properties of high strength, high plasticity and the like are achieved; the anode-oxidable high-performance die-casting aluminum alloy can be colored, has high casting performance, machinability and high corrosion resistance, and can meet the use requirements of exterior parts for 3C products. The production cost is reduced, and the efficiency is increased.

Owner:SUZHOU KAI YOU ELECTRONICS SCI & TECH LTD

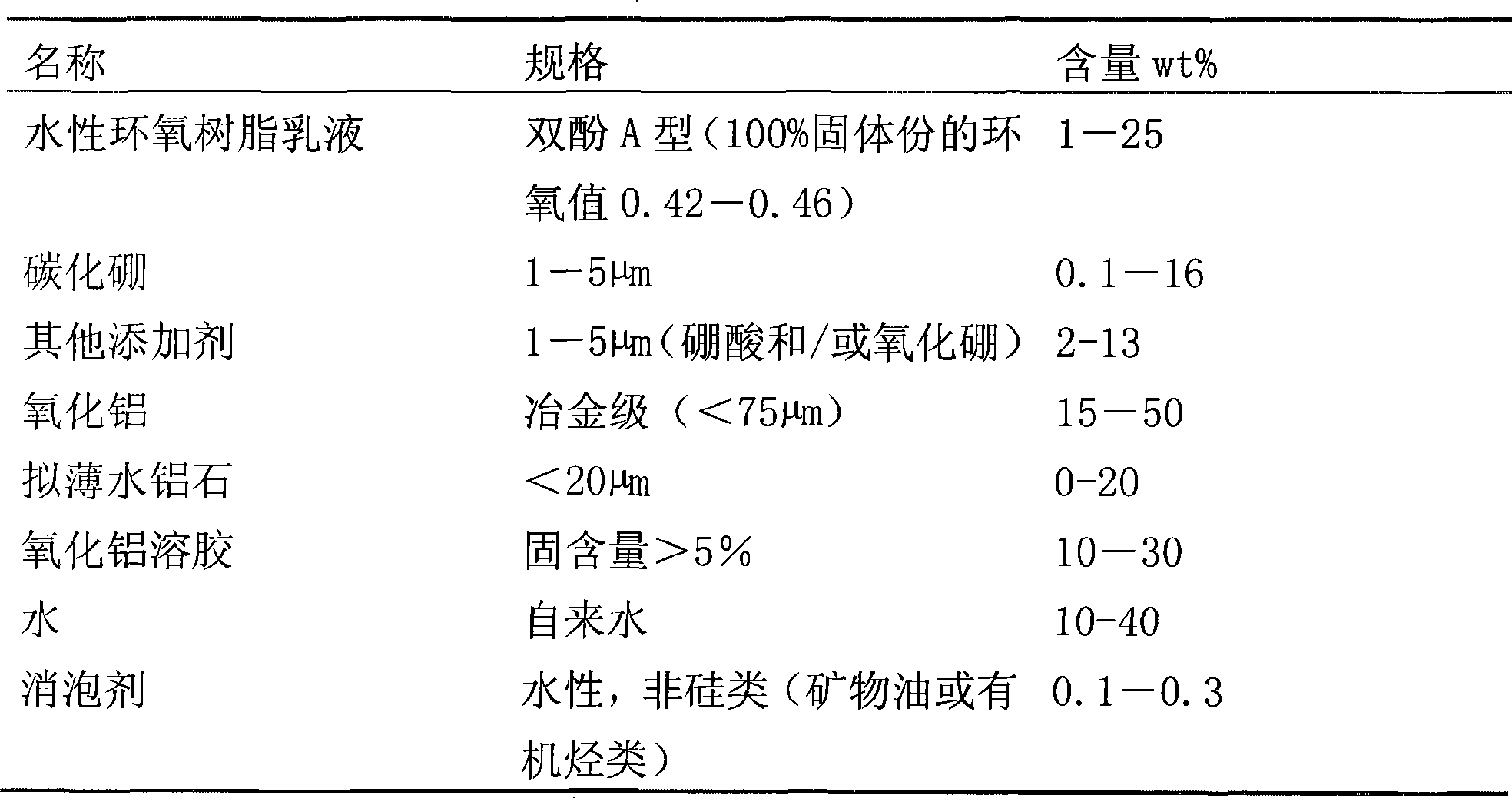

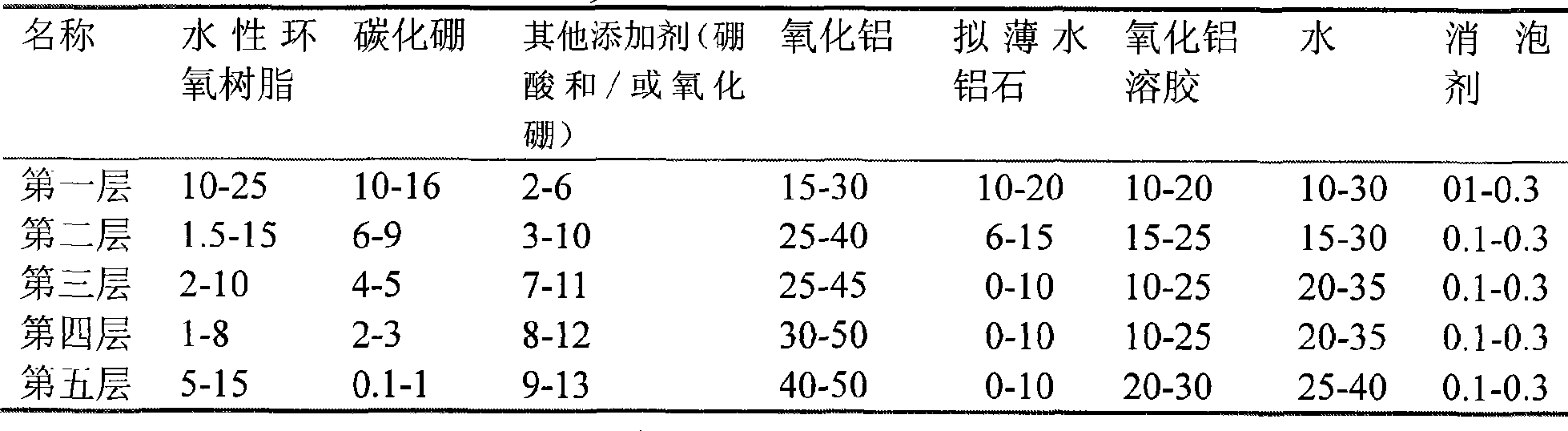

Aluminum electrolysis carbon anode oxidation coating and coating method thereof

The invention relates to an oxidation resistant coating for aluminum electrolytic carbon anode and a coating method thereof. The method is characterized in that the surface of the aluminum electrolytic carbon anode is provided with an anti-oxidation coating formed by dried and mixed coat which is sprayed on the surface of the electrode, wherein the mixed coat comprises the following compositions in weight percentage: 1 to 25 percent of bisphenol A-type waterborne epoxy resin, 0.1 to 16 percent of boron carbide, 2 to 13 percent of boric acid and / or boric oxide, 15 to 50 percent of alumina, 0 to 20 percent of pseudo-boehmite, 10 to 30 percent of alumina sol, 0.1 to 0.3 percent of foam suppressor, and the balance being water. The coating and the method adopt an alumina-based gradient boron carbide oxidation resistant coating with a multilayer structure, and effectively blocks the contact of air and CO2 with carbon anode carbon, thereby avoiding or reducing excessive consumption of the carbon anode carbon. The method can realize carbon conservation by aluminum electrolytic prebaked anode by 10 to 20 kilogram / ton-Al.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

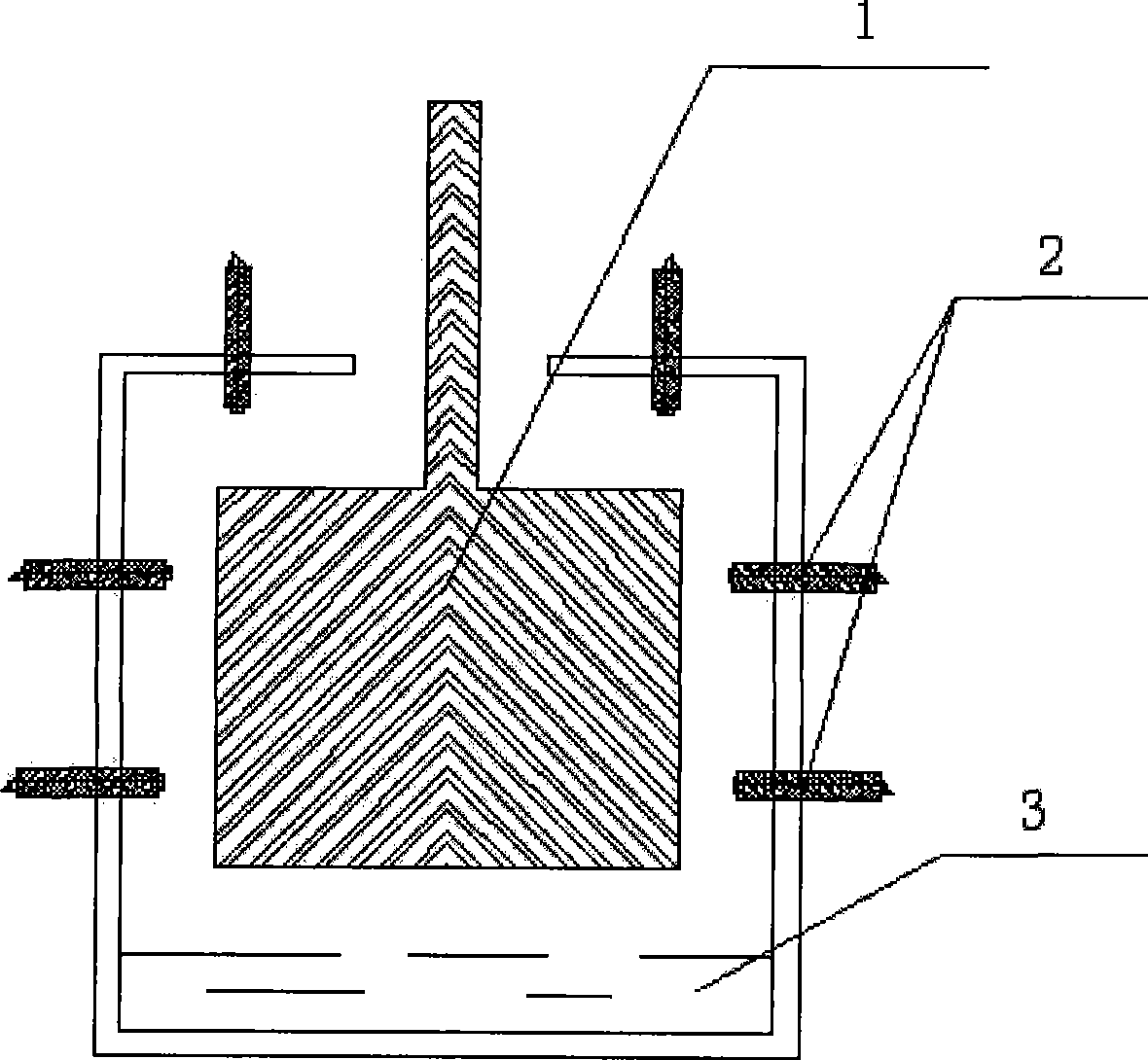

Method and device for preparing ordered porous alumina template

The invention relates to a method and a device for preparing an ordered porous alumina template, thereby being capable of realizing large-scale preparation of the ordered porous alumina templates with low cost. The method comprises the steps of: 1) removing stains and an oxide film on an aluminum sheet and polishing; and 2) using the aluminum sheet as an anode, adopting a base metal as a cathode and adopting the secondary anode oxidation method for preparing the nano-ordered porous alumina template. The cathodes and the anodes are multiple and are respectively connected in parallel by adopting guide wires, thereby controlling the anode oxidation of the aluminum sheets. The device is a cuboid groove structure, a plurality of pairs of small holes are formed on two sides and used for containing the cathodes and the anodes which are connected with a power supply, and electrolyte is contained in the groove. An magnetic stirrer and other stirring equipment can be adopted for carrying out stirring on the electrolyte during the anode oxidation process. The method and the device can realize the low-cost, large-scale and rapid preparation of a nano-pore path array with high order degree and adjustable pore size.

Owner:TONGJI UNIV

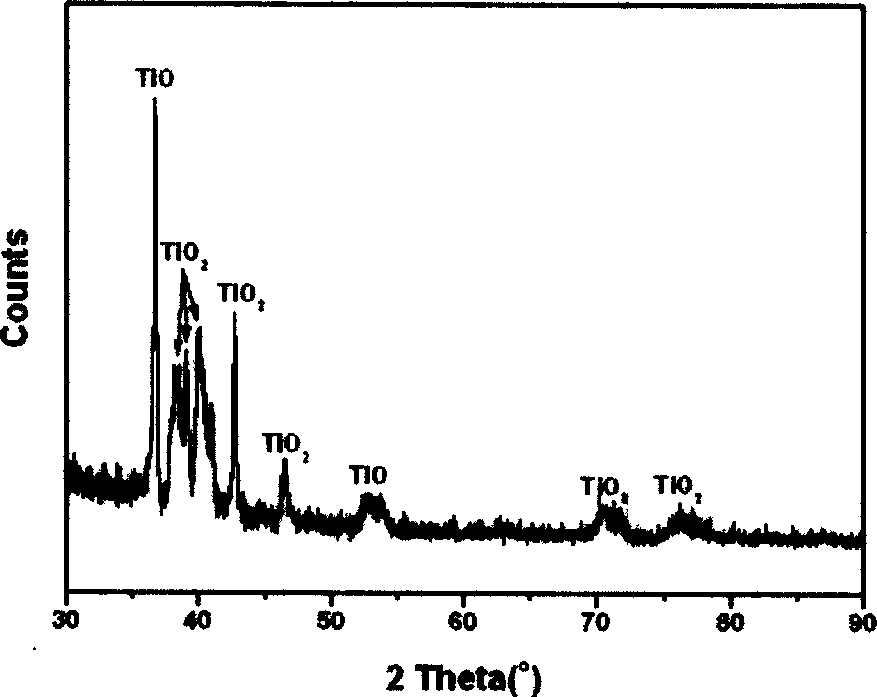

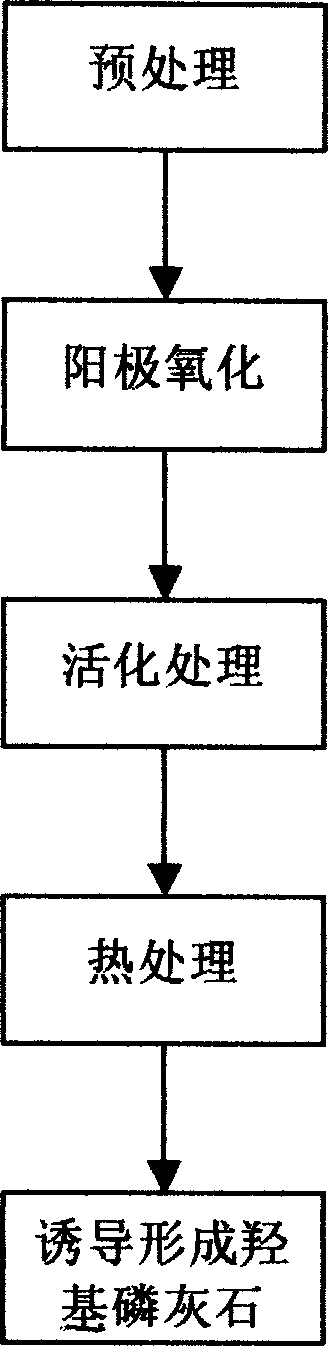

Preparation method of biologically active nanometer composite layer on medical-use metal surface

InactiveCN1769527AGood combinationImprove biological activitySuperimposed coating processApatiteBiological activation

This invention relates to a biological active nanometer compound layer making method for the medical metal surface, which includes the following steps: putting the medical metal titanium and its alloy radix into the diluent acid liquid to do corrad pretreatment; using the pretreated titanium and its alloy radix as the anode to do anode oxidation to create the compact titanium dioxide nanometer tube film on the surface of the metal; putting them into the alkali lye to do activation treatment, then doing heat treatment with them under 450íµí½650íµ for 0.5í½3 hours; Then putting them into the simulate liquid to produce hydroxyl apatite. The charater of this invention is that it provides a method that combines the anode oxidation and alkali heat treatment, and this invention impoves the biological compatibility of the medical metal greatly.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Preparation method of aluminum alloy corrosion resistant coating

ActiveCN101693995AHigh economic returnShort processing timeLiquid surface applicatorsMetallic material coating processesChemical reactionHigh energy

The invention relates to a preparation method of an aluminum alloy corrosion resistant coating, comprising the following steps: forming a passivation layer which has a certain nanometer thickness and contains cobalt element on the surface of aluminum alloy by adopting a chemical reaction method and further covering a sulfydryl organic acid compound doped oxidation polyaniline coating on the passivation layer. By adopting the method, the corrosion resistant characteristic of the surface of the aluminum alloy is realized through inhibiting electrochemical reaction. The invention solves the problems of complex process, unstable oxidation quality, high energy consumption, severe pollution and the like of the traditional anode oxidation, and is suitable for use in the fields of special aluminum alloy materials in the industries of navigation, spaceflight, ships and warships and the like. Compared with the prior art, the invention has the characteristics of simple method, short reaction time, little equipment investment and high economic return.

Owner:南京南大波平电子信息有限公司

Anode oxidation pretreatment method for aluminium alloy

InactiveCN1654714ASand fastReduce aluminum consumptionSurface reaction electrolytic coatingWaxPretreatment method

The processing method of aluminum alloy part before anode oxidizing includes the following steps: eliminating oil and wax, water washing, brightening acid pickling, low temperature polishing, water washing, eliminating ash, and water washing. The said method has the advantages of powerful mechanical ripple eliminating ability, low aluminum loss, complete elimination of acid pickling ash, etc. and can make the processed surface have no ripple, ash and fine sand and be bright.

Owner:熊映明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com