Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

654results about How to "High surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

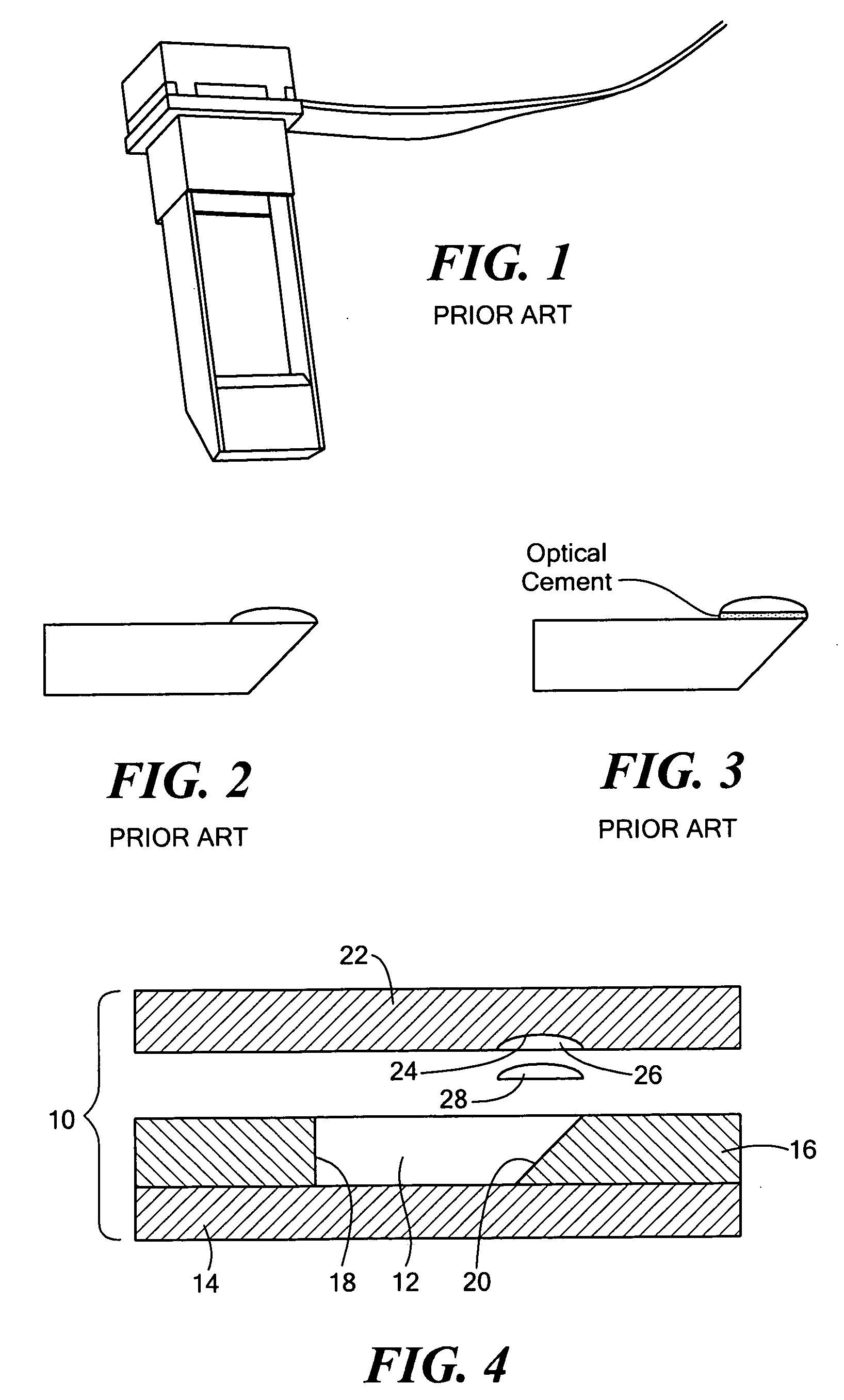

Smart recognition apparatus and method

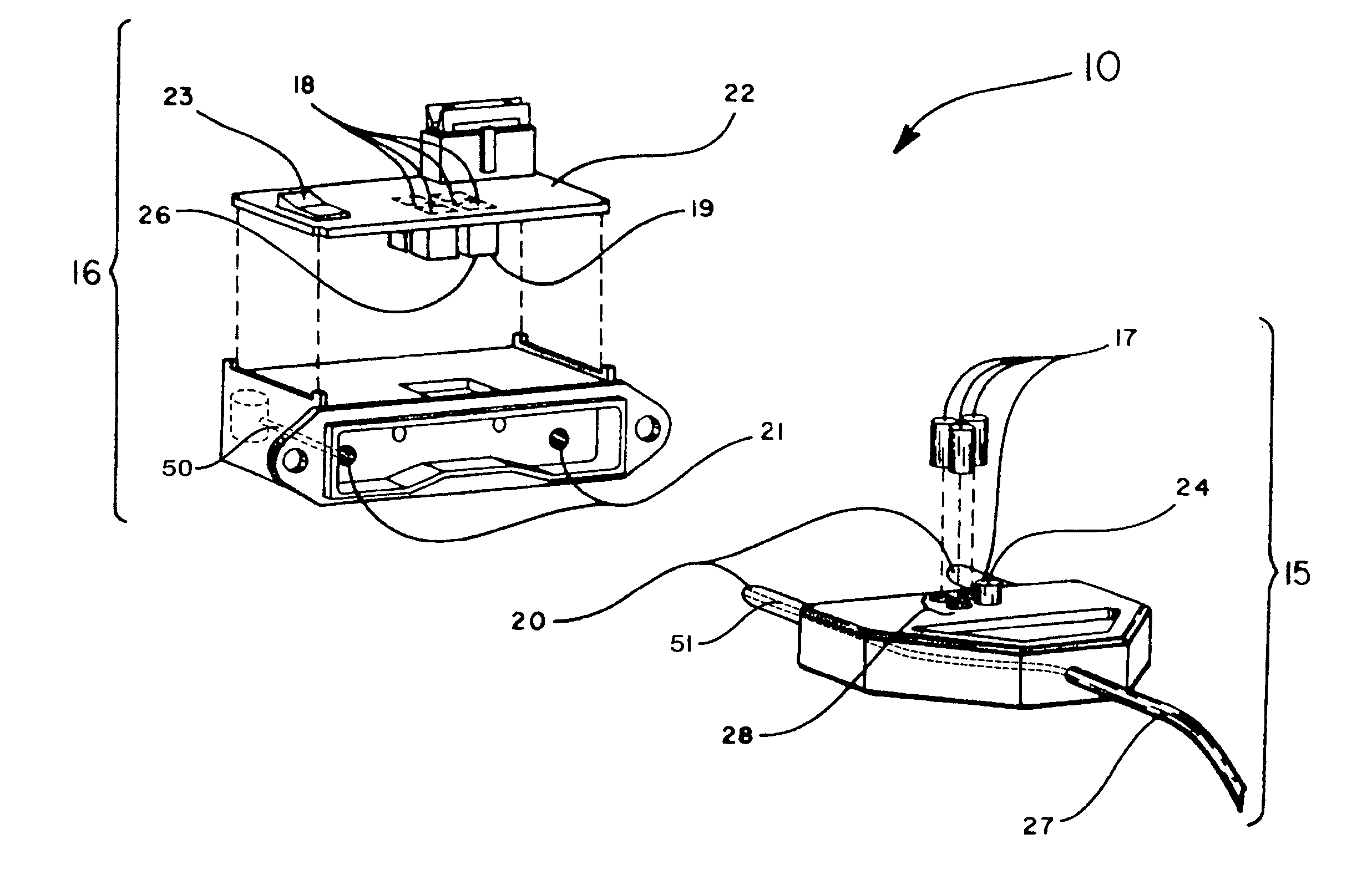

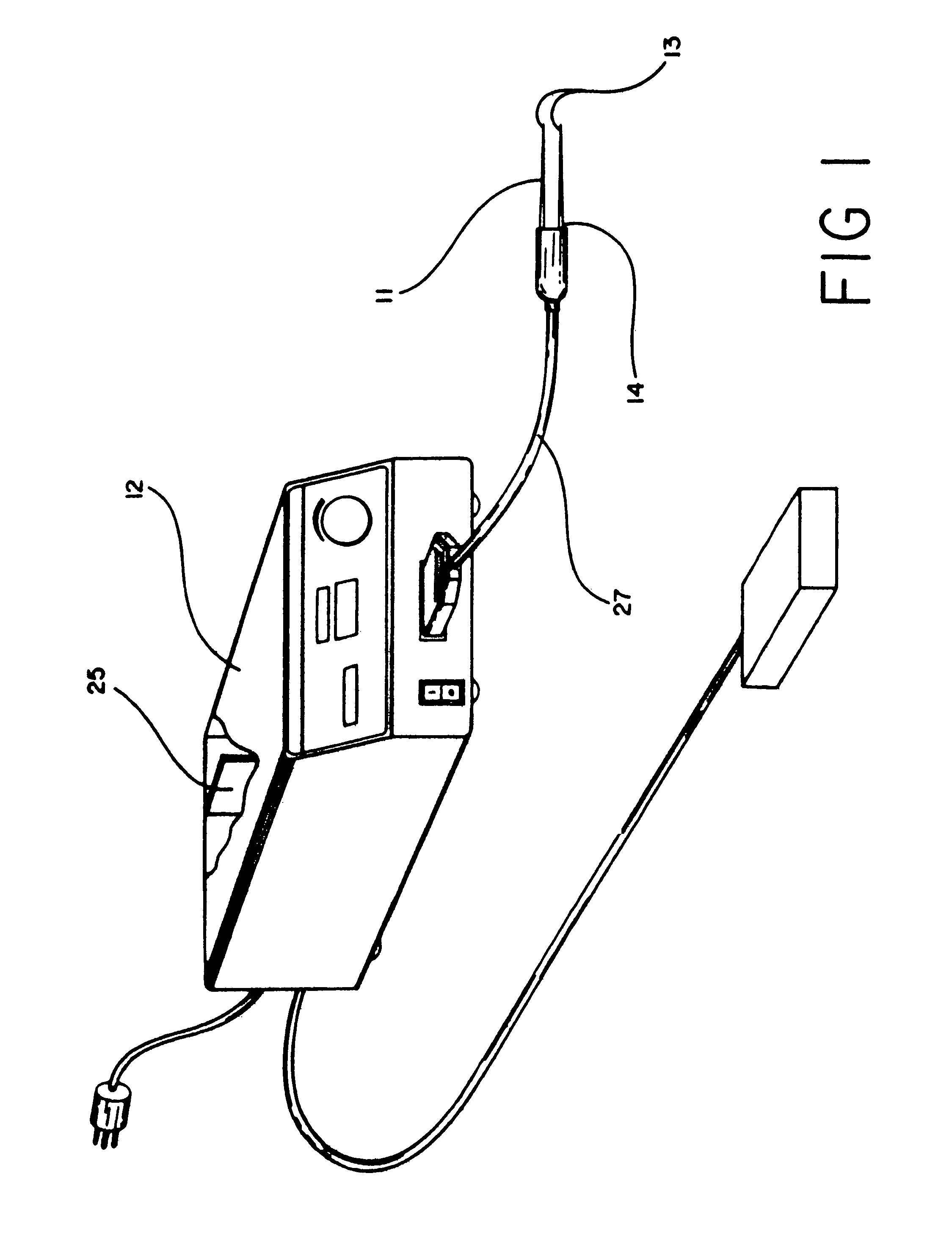

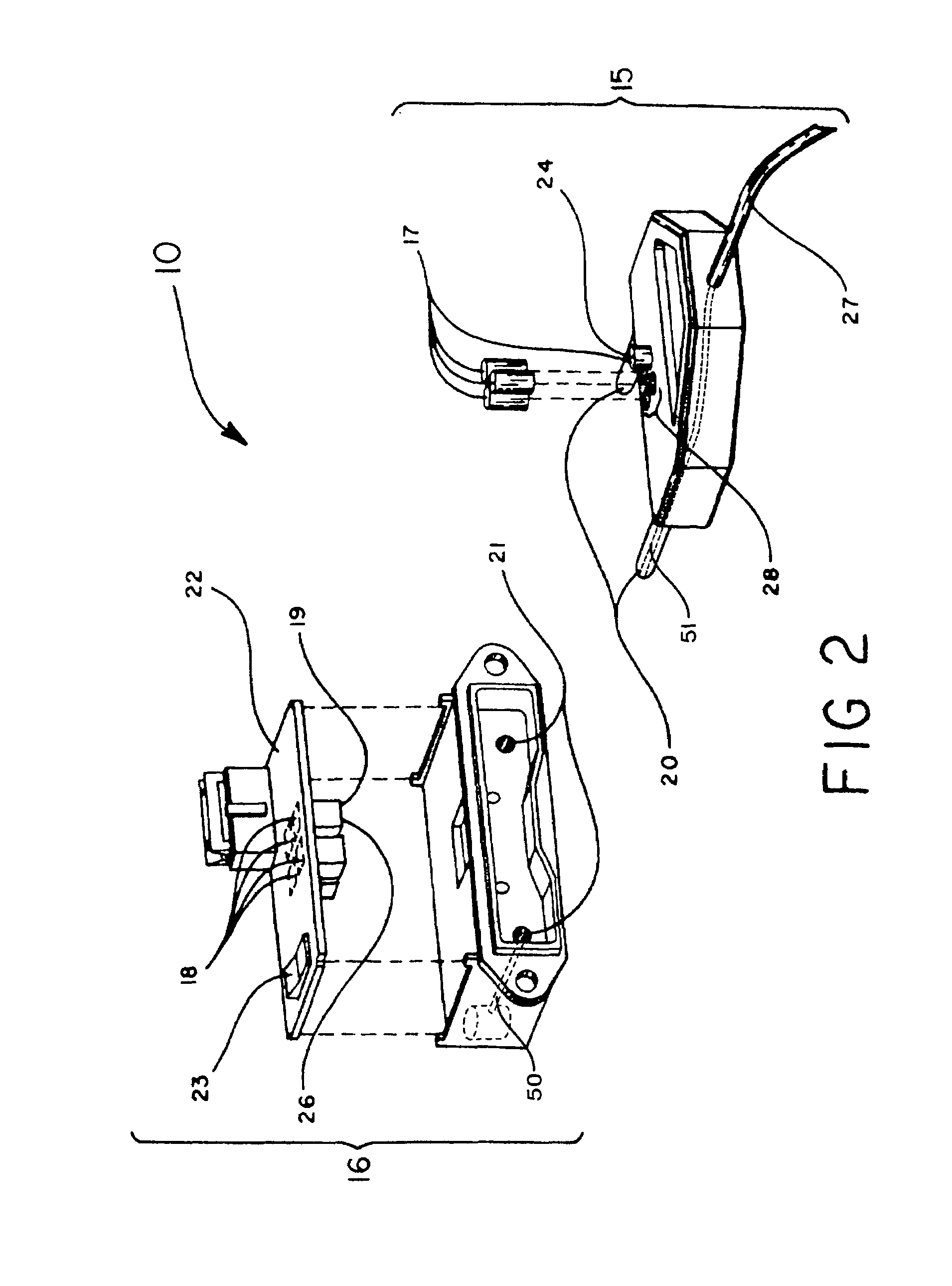

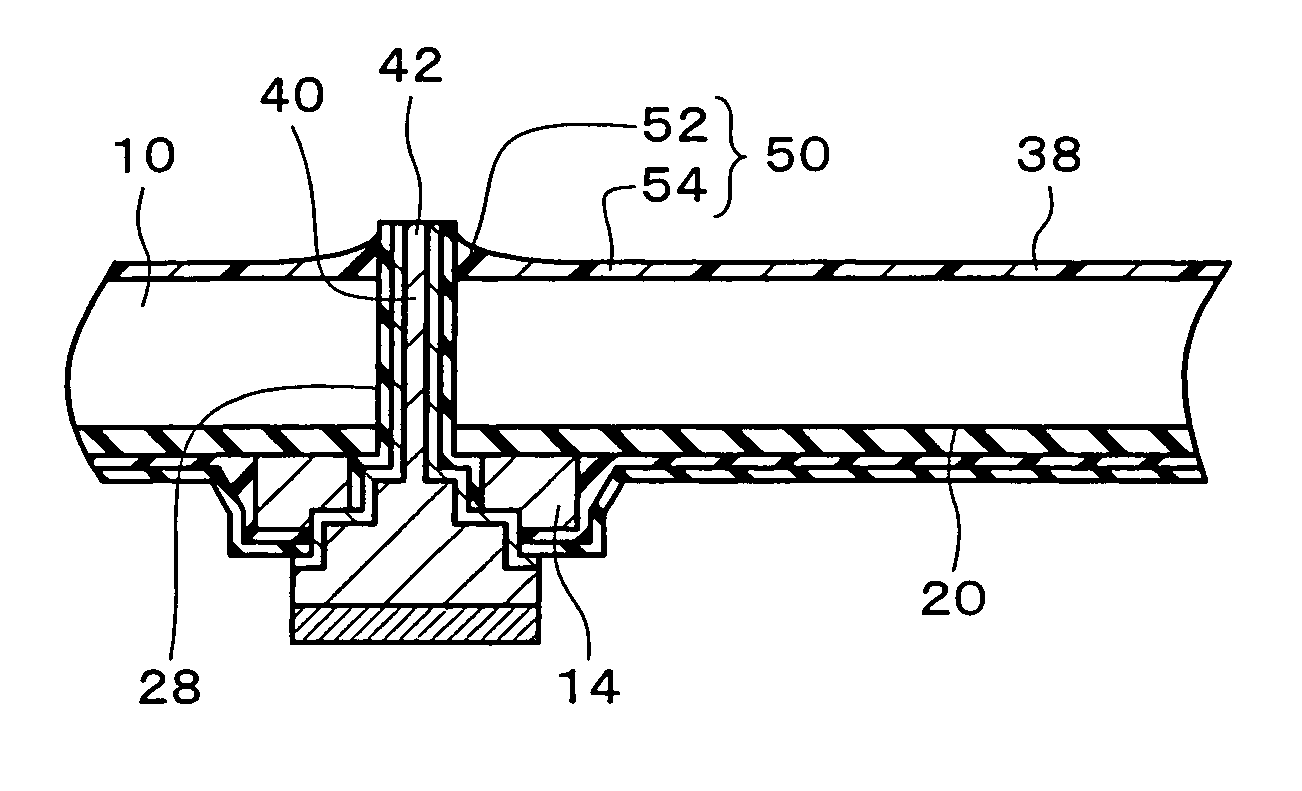

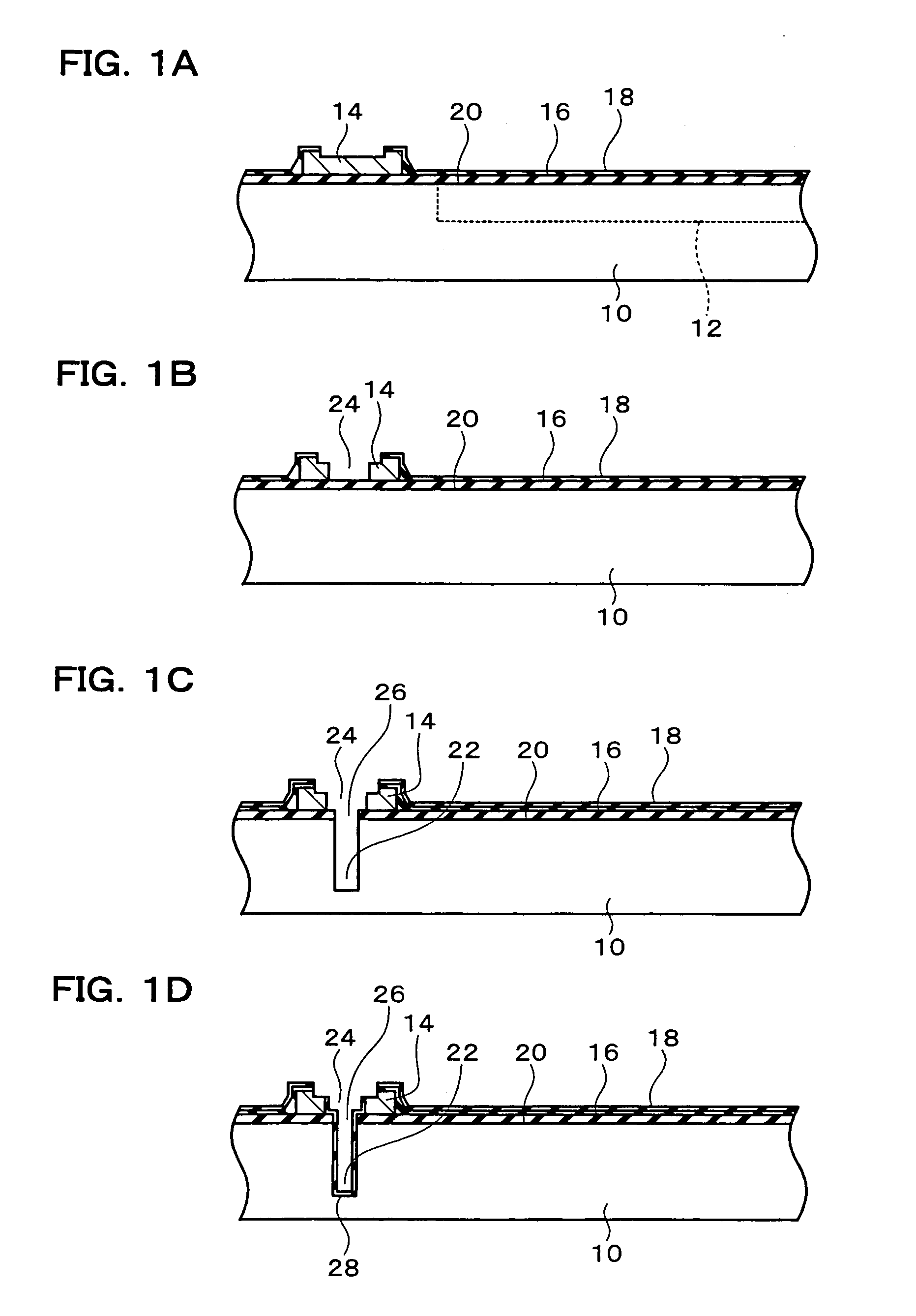

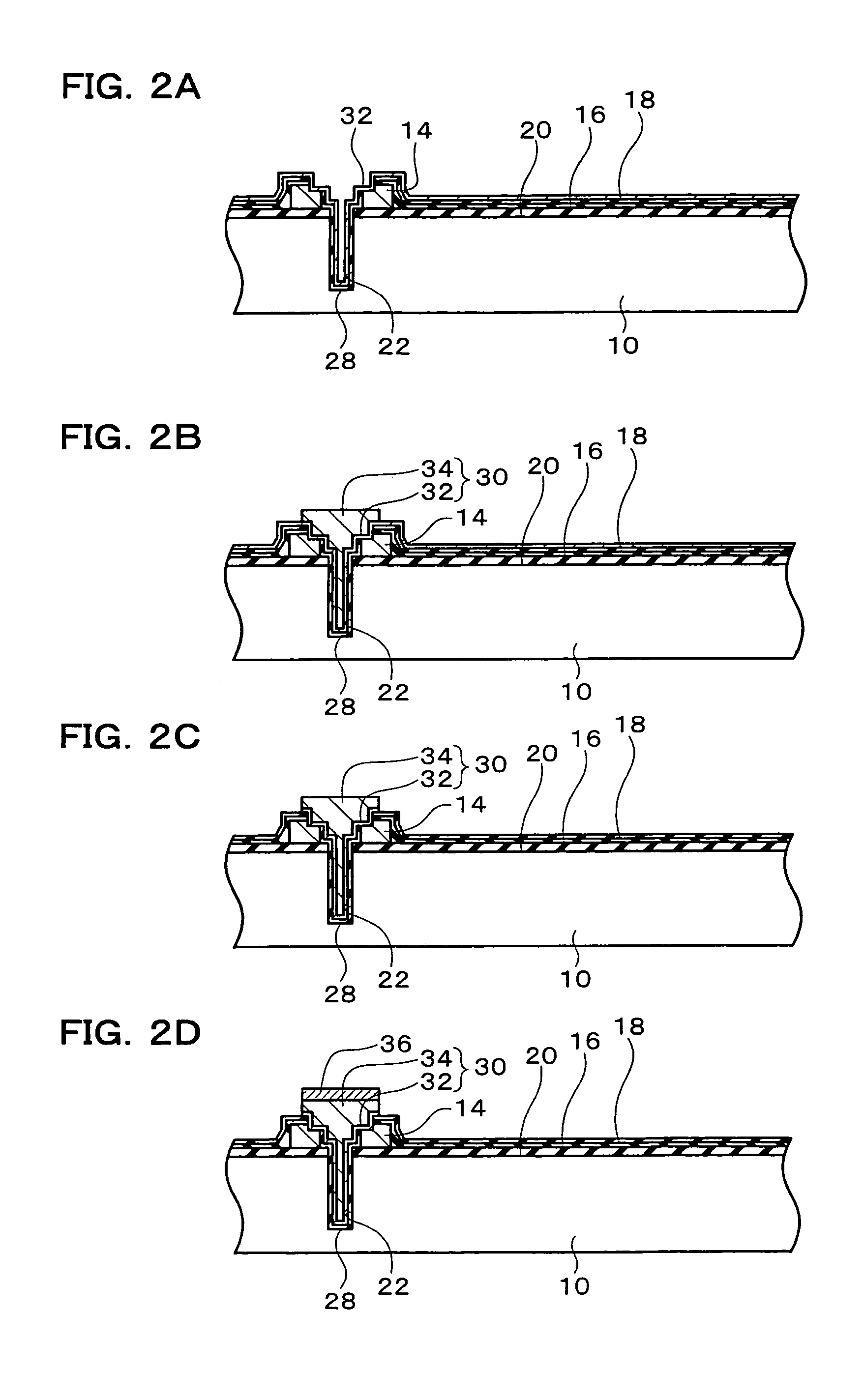

InactiveUS7044949B2Avoid problemsTight optical and mechanical toleranceDiagnosticsClose-range type systemsProximateElectrosurgery

A qualifying connection for an instrument attaches to a source of electrosurgery energy and to the instrument and has first and second parts coupled to the instrument and the source, respectively. Optical couplings on the connection transmit invisible energy to identify the instrument and are proximate on the first and second parts. A light modifier on the first part is proximal to the second part for modification of radiation in the infrared wavelengths so infrared transmitters encode signals and non-contact coded proximity detectors on the second part are the coupled detectors. Mechanical attachments include conjugating male and female portions which physically extend between the parts and matingly engage. An identifying circuit couples to the second part and responds to invisible light optically communicated across the couplings for verifying the type of instrument connected by the cable to the source. A method of using the connection has steps including juxtaposing and conjugating the parts with attachments and couplings for transmitting invisible optical energy to identify the instrument. The method includes modifying the invisible optical energy with geographically disposed proximate couplings of the parts when the attachments engage and the couplings are proximate. Passing and assessing signals of the modified energy are transmitted through the connection and to an identifying circuit in the source.

Owner:COVIDIEN AG

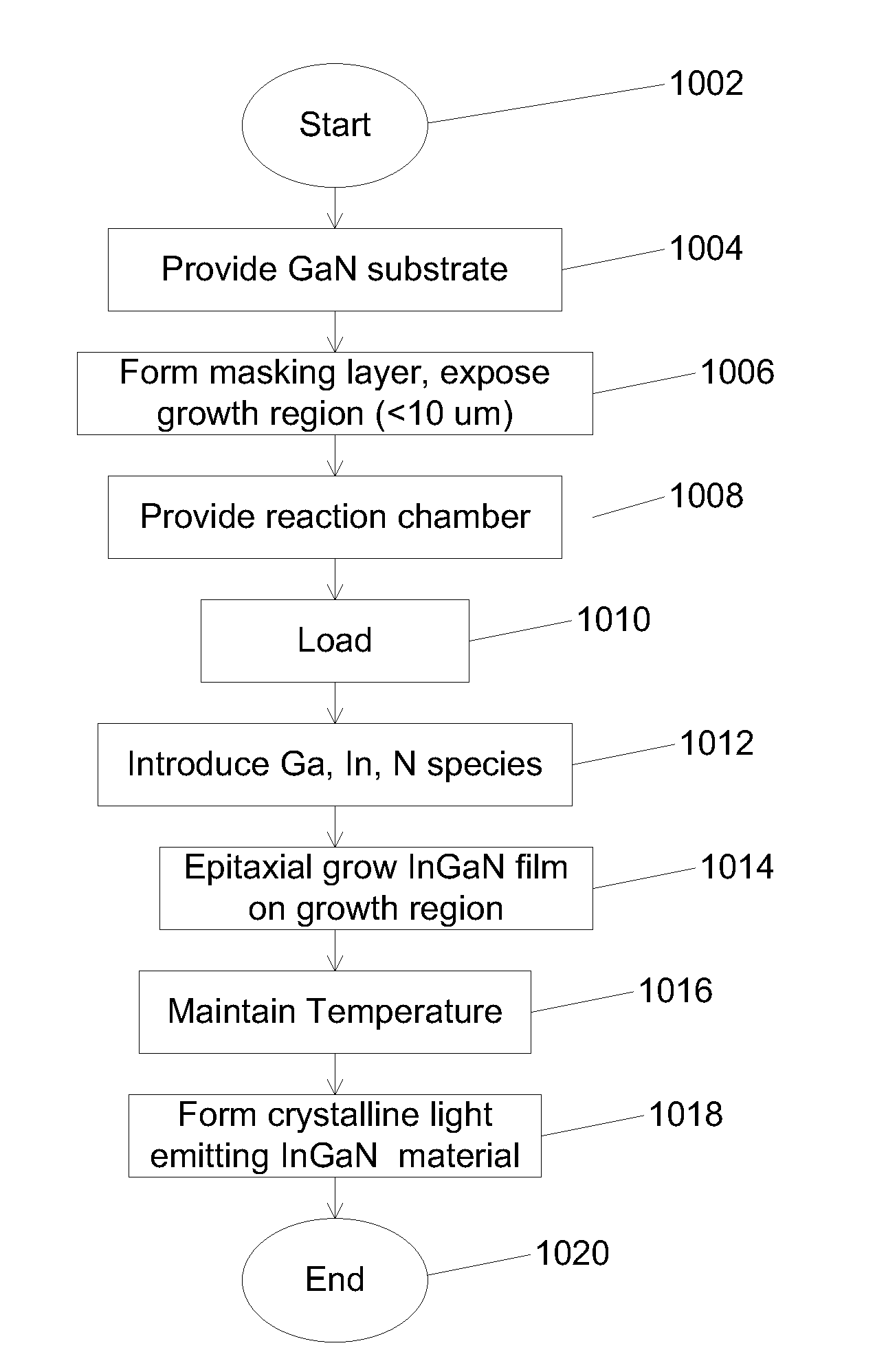

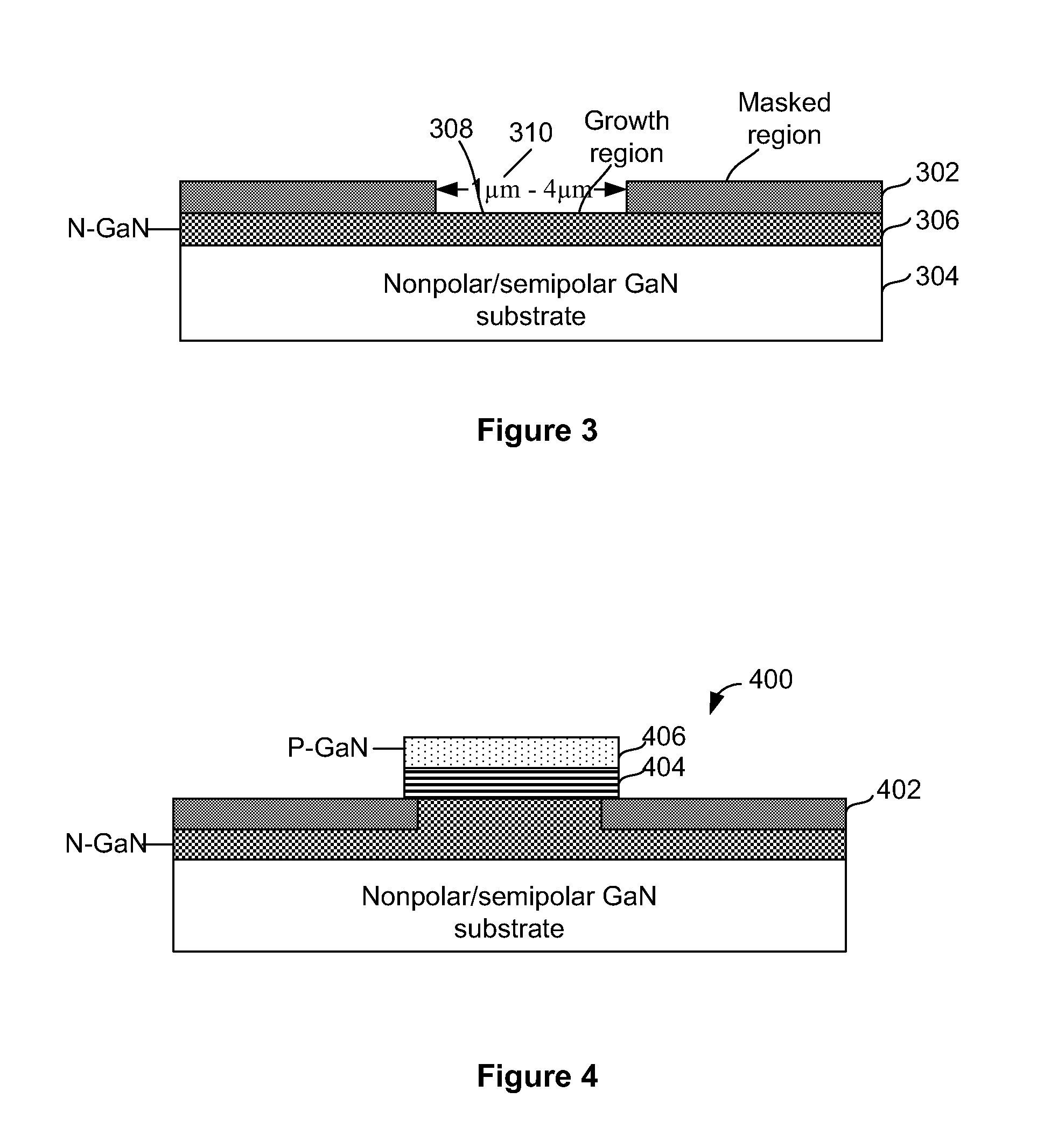

Selective area epitaxy growth method and structure for multi-colored devices

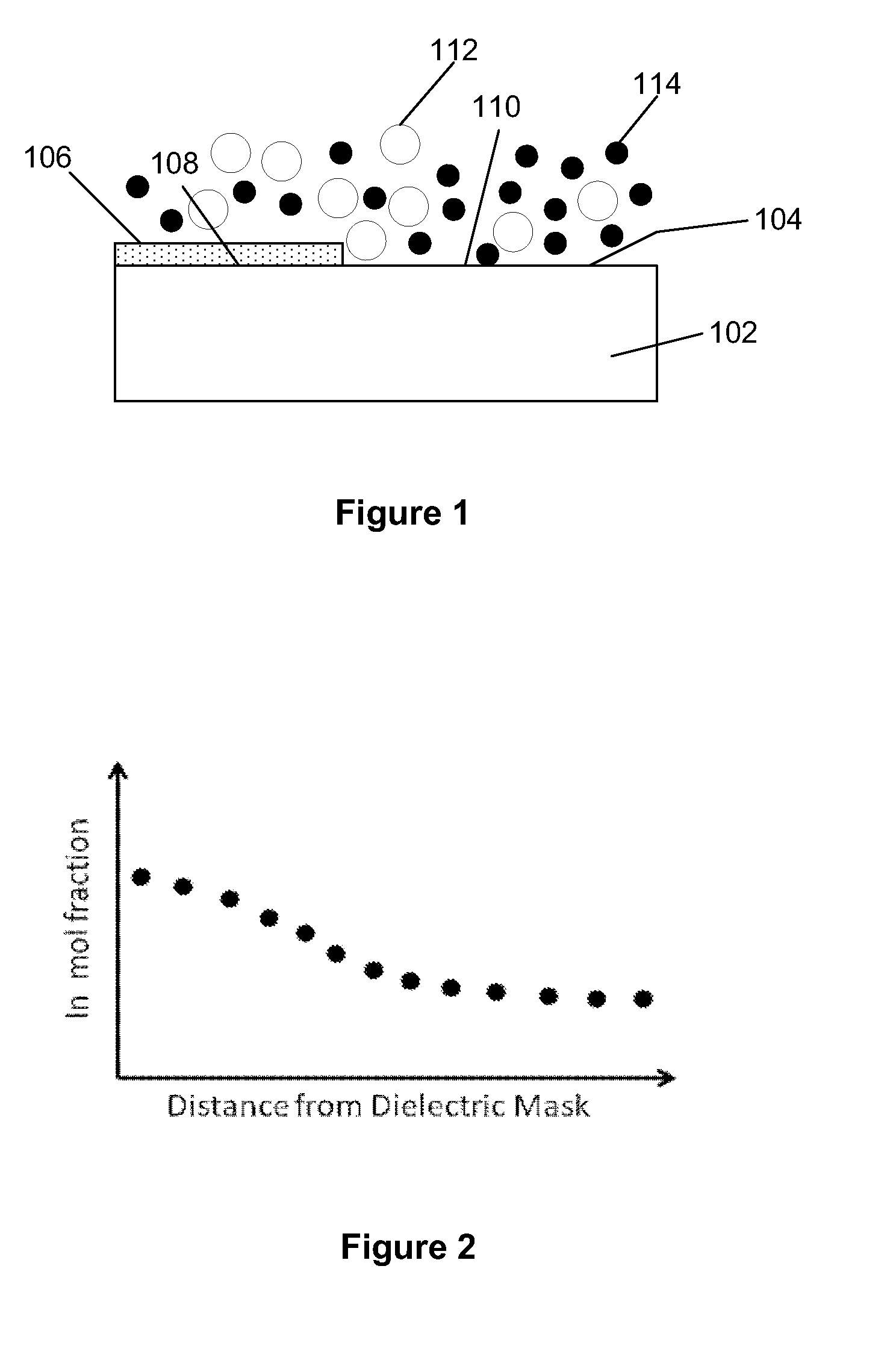

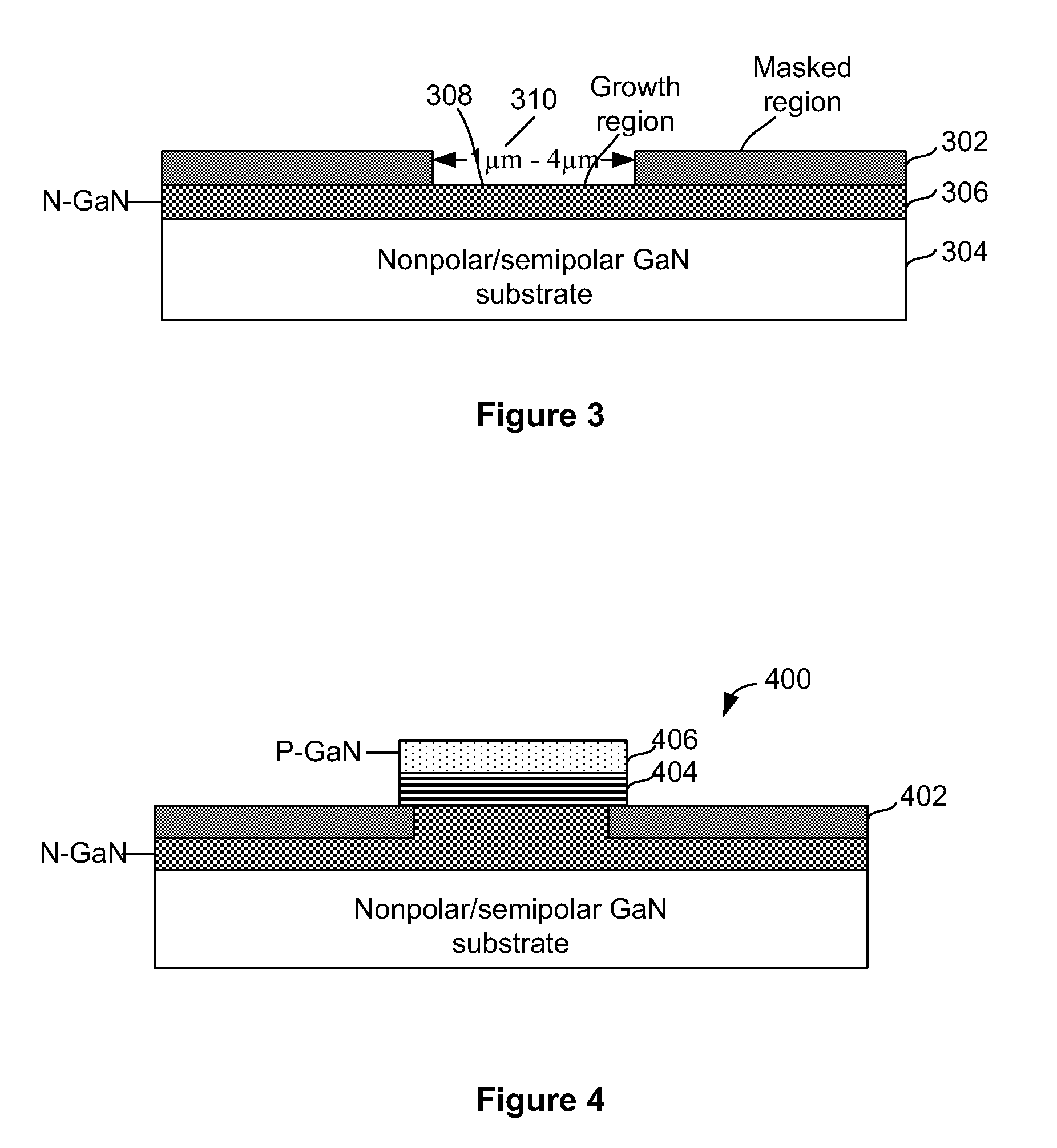

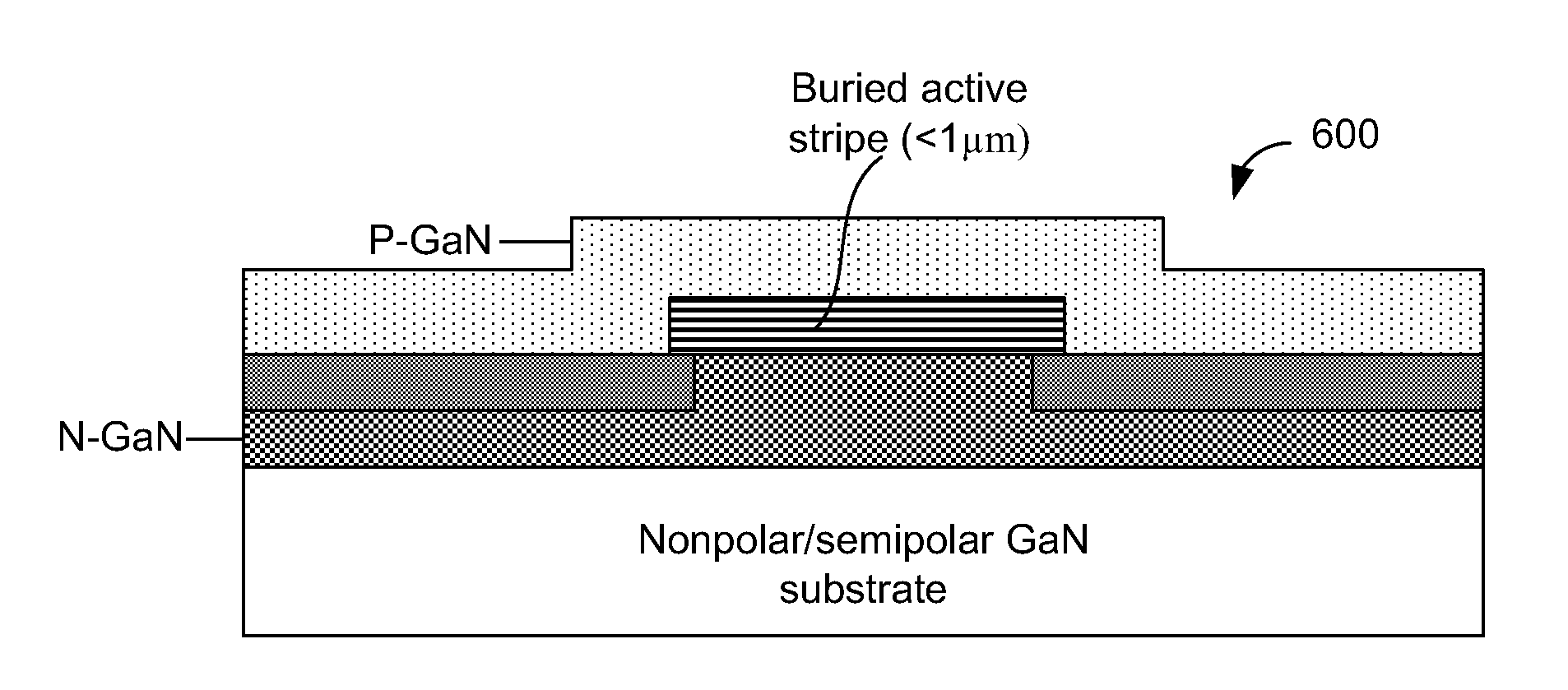

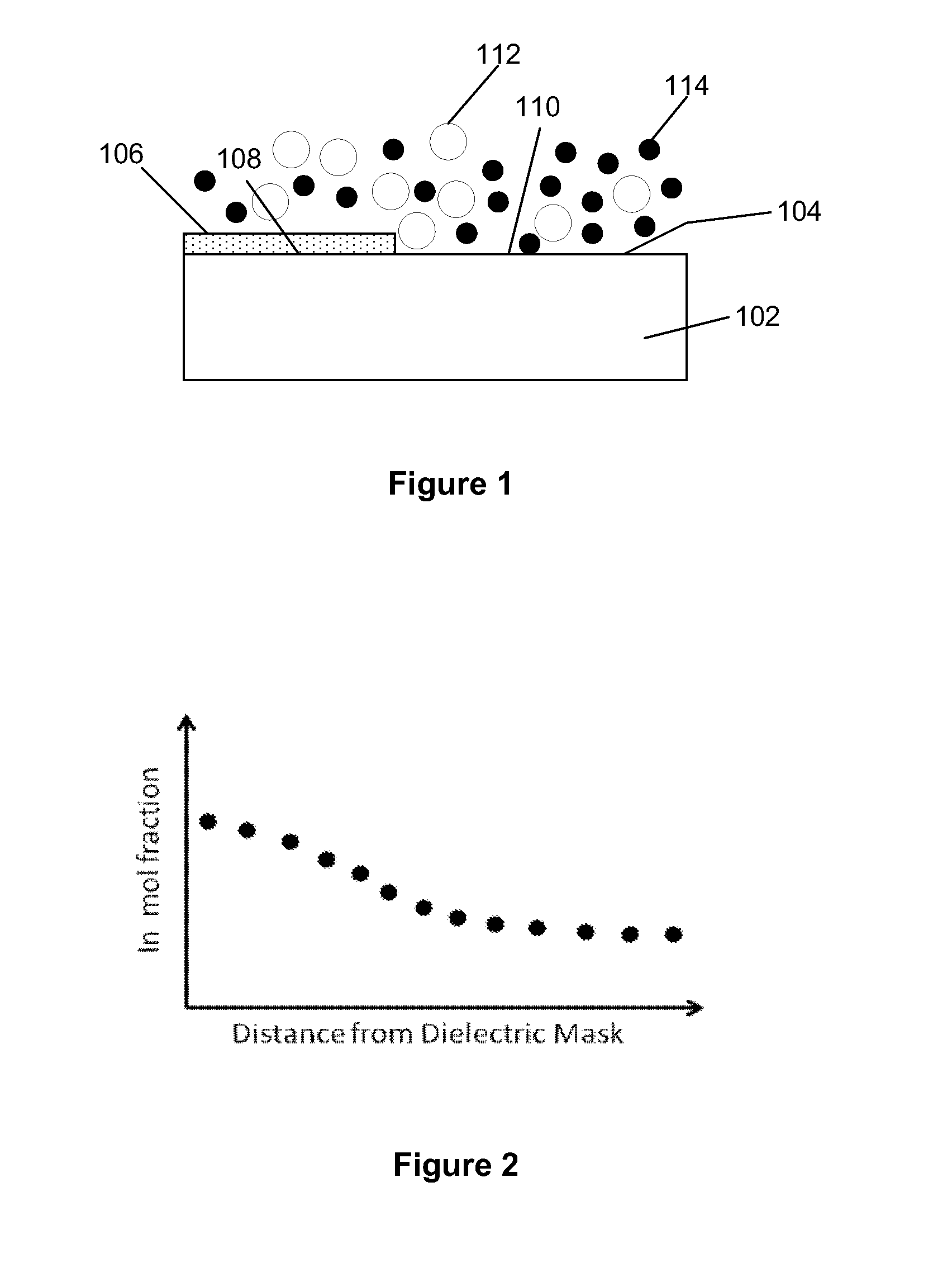

InactiveUS20090309110A1Improve the level ofImprove surface mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesIndiumSelective area epitaxy

A multicolored LED device made of a semipolar material having different indium containing regions provided on different spatial features of GaN material. Other materials such as non-polar materials can also be used.

Owner:SLT TECH

Selective area epitaxy growth method and structure

InactiveUS20090309127A1Improve the level ofSmall sizePolycrystalline material growthNanoinformaticsIndiumPhotoluminescence

A gallium containing crystalline material. The material comprises a bulk semi-polar gallium indium containing crystalline material having a thickness of about 20 nanometers to about 1000 nanometers. The material includes a spatial width dimension of no greater than about 10 microns characterizing the thickness of the bulk semi-polar gallium indium containing crystalline material. The material includes a photoluminescent characteristic of the crystalline material having a first wavelength, which is at least five nanometers greater than a second wavelength, which is derived from an indium gallium containing crystalline material grown on a growth region of greater than about 15 microns.

Owner:SORAA +1

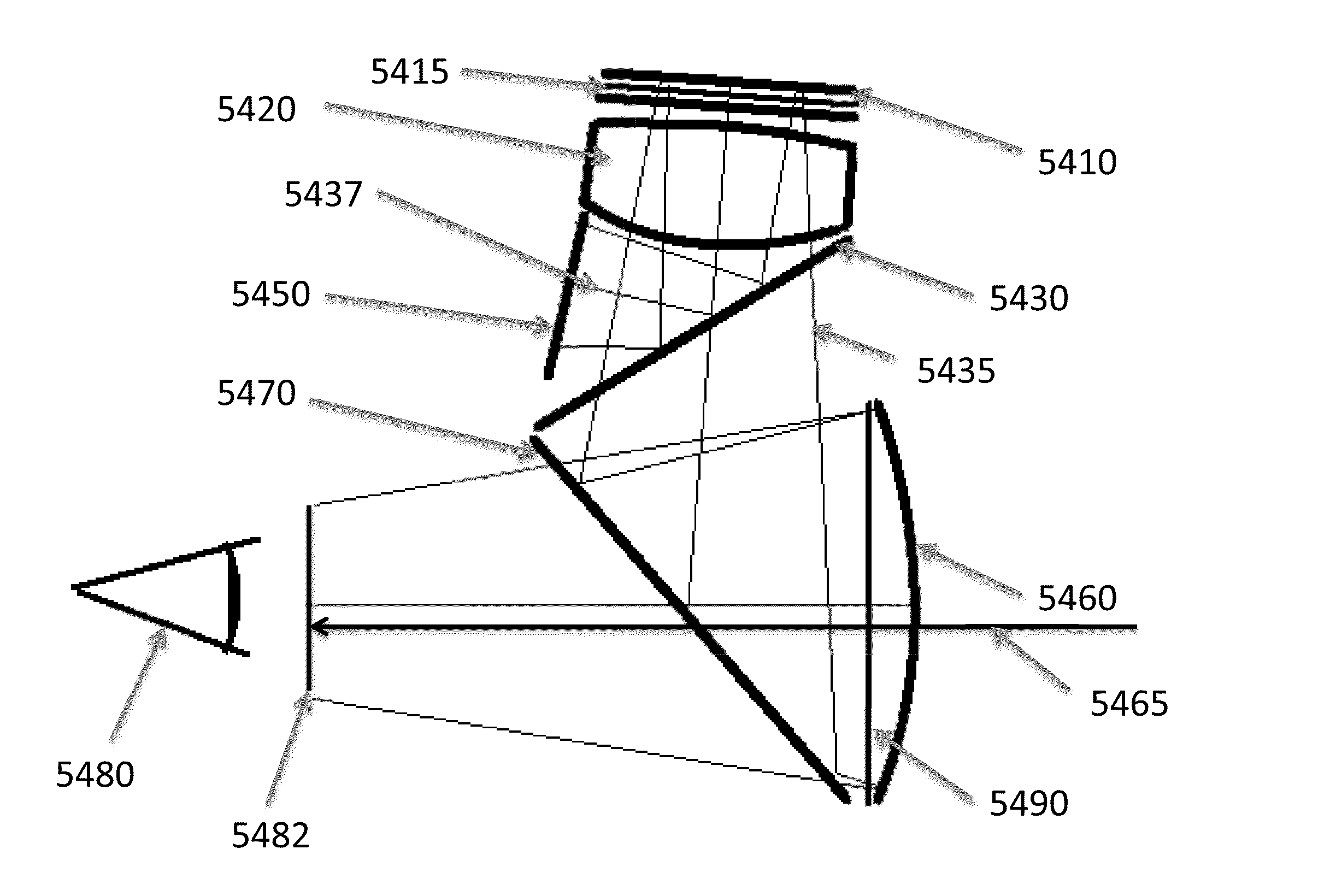

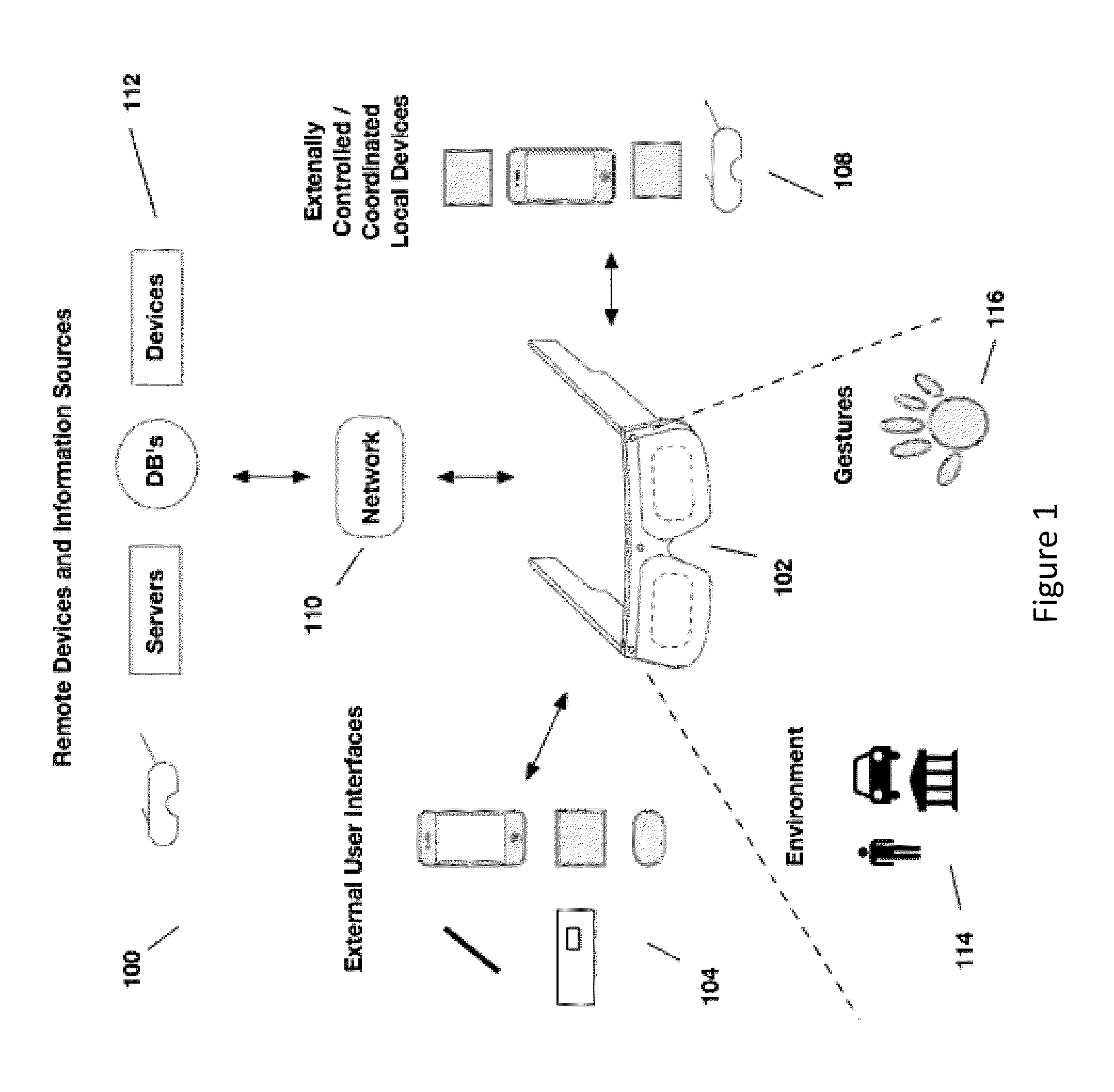

Optical systems for see-through displays

ActiveUS9366867B2Reduce weightComfortable to wearPolarising elementsCathode-ray tube indicatorsSee-through displayComputer science

Aspects of the present invention relate to methods and systems for providing a high quality display images in see-through head-worn optics.

Owner:OSTERHOUT GROUP INC

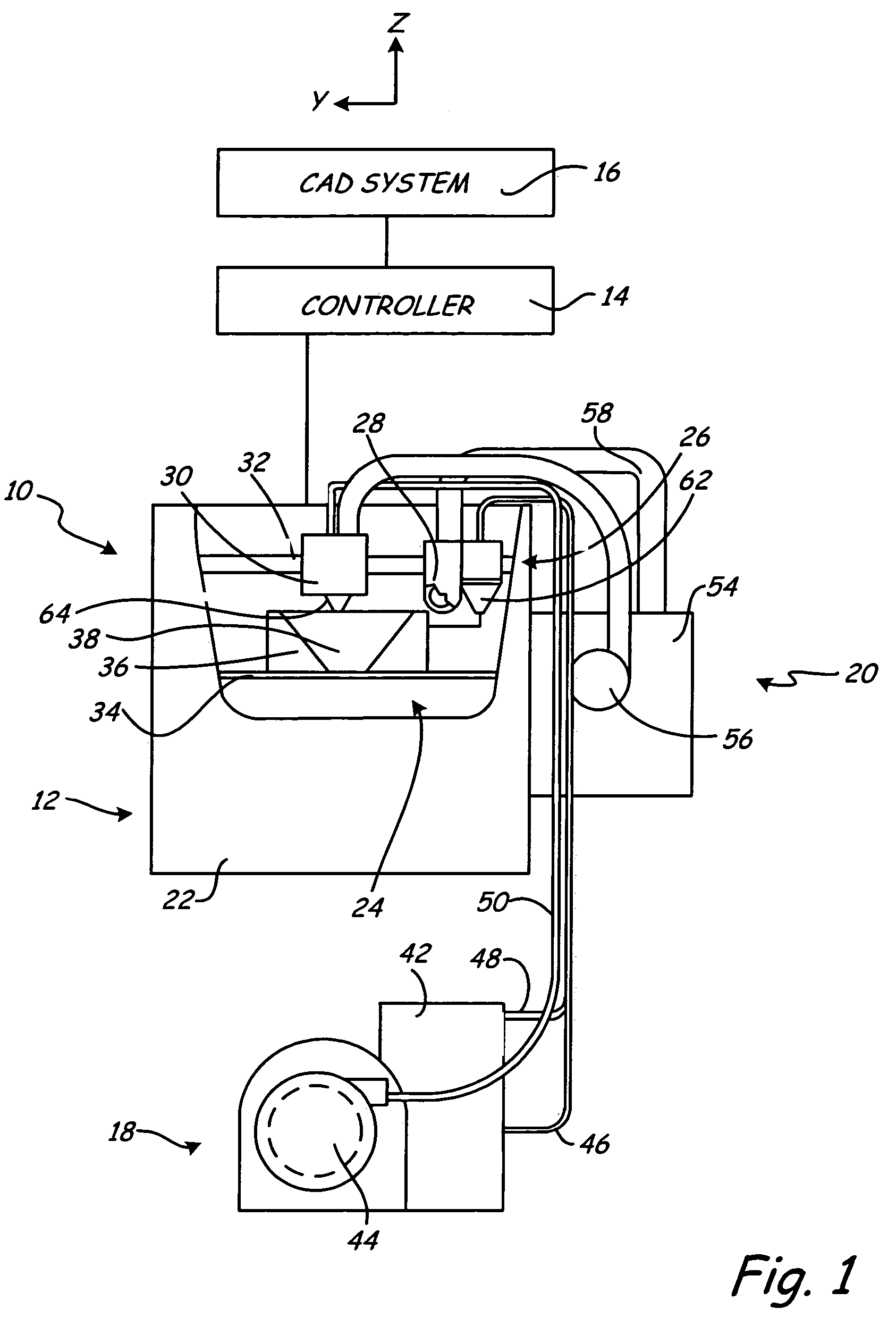

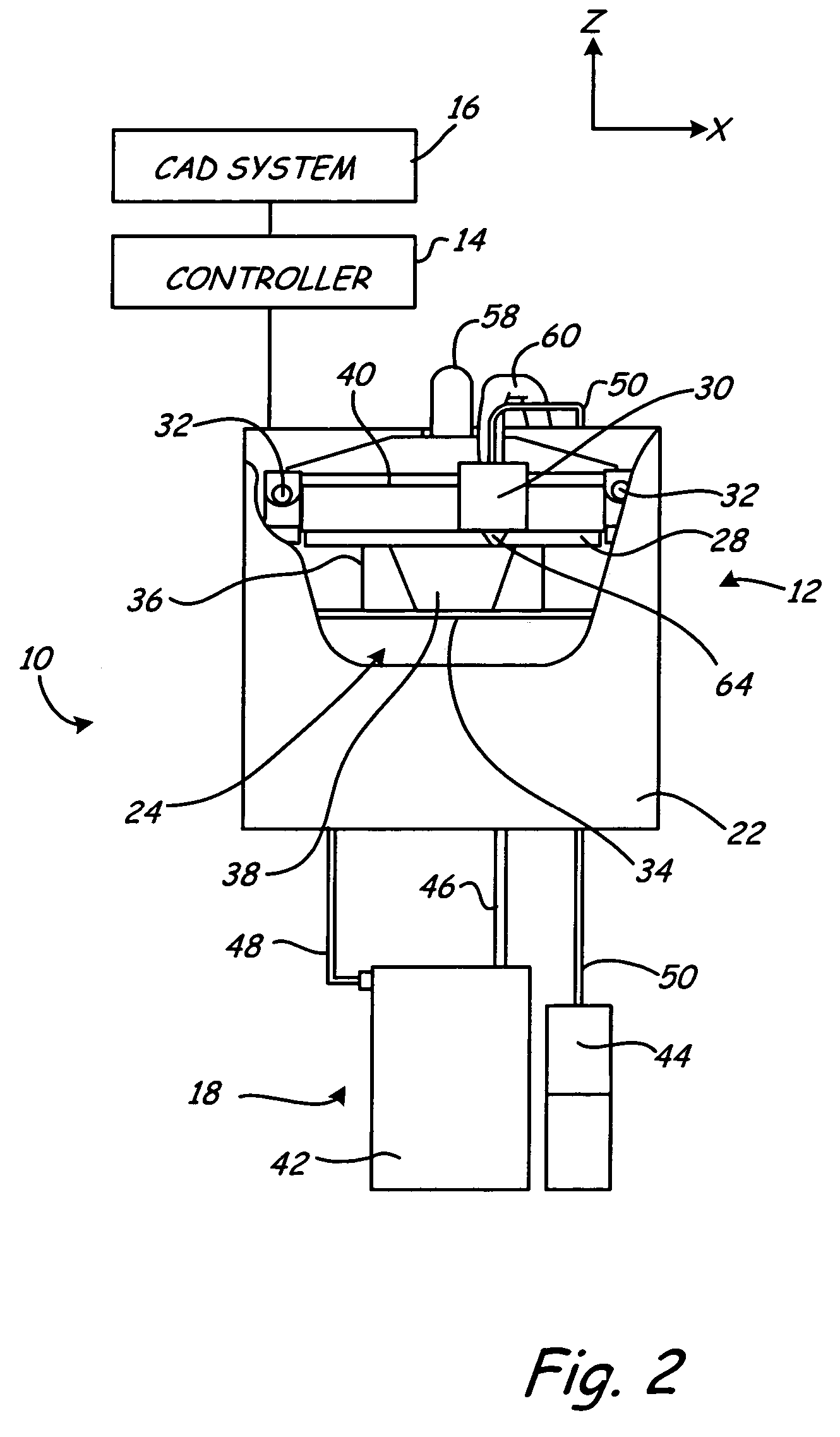

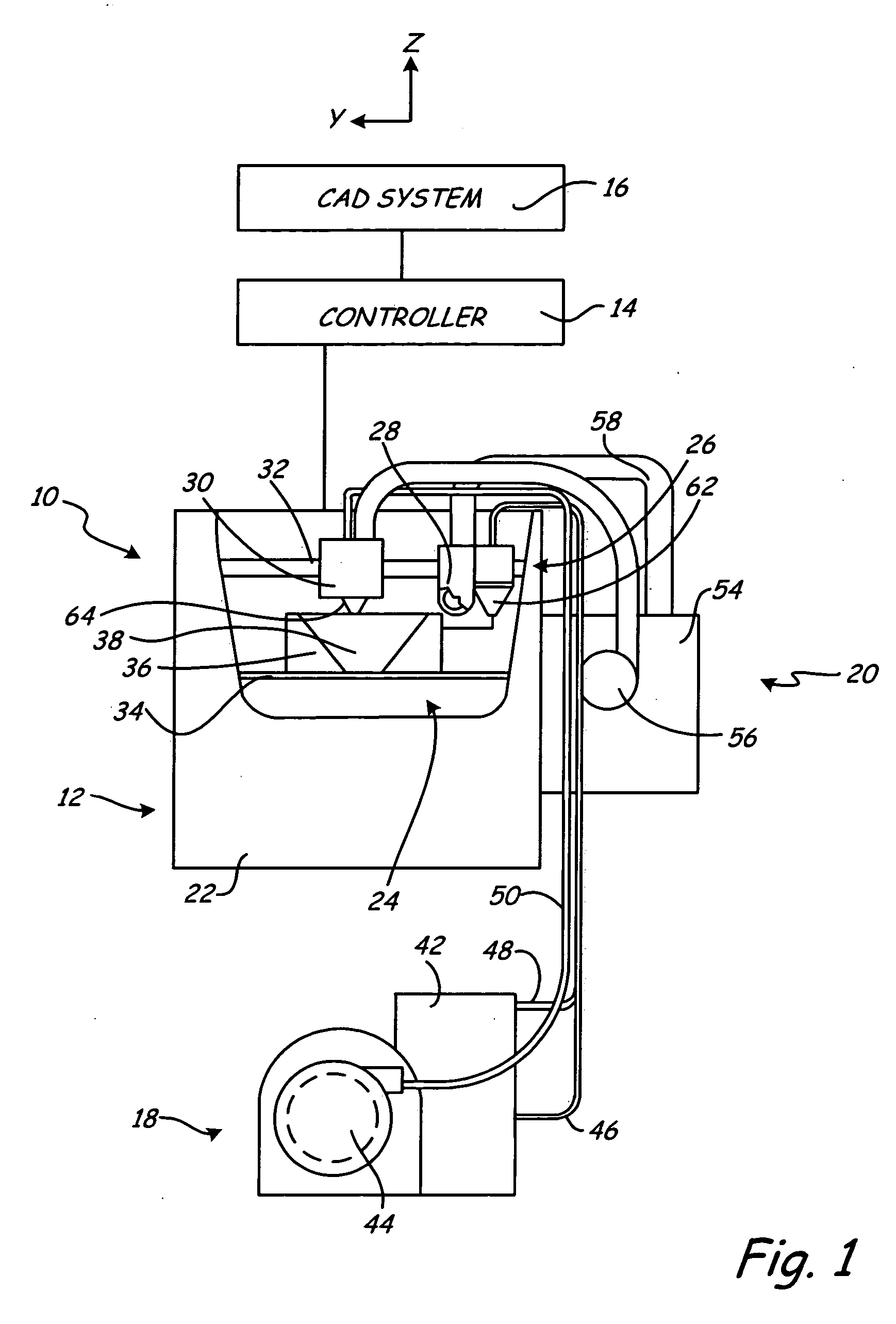

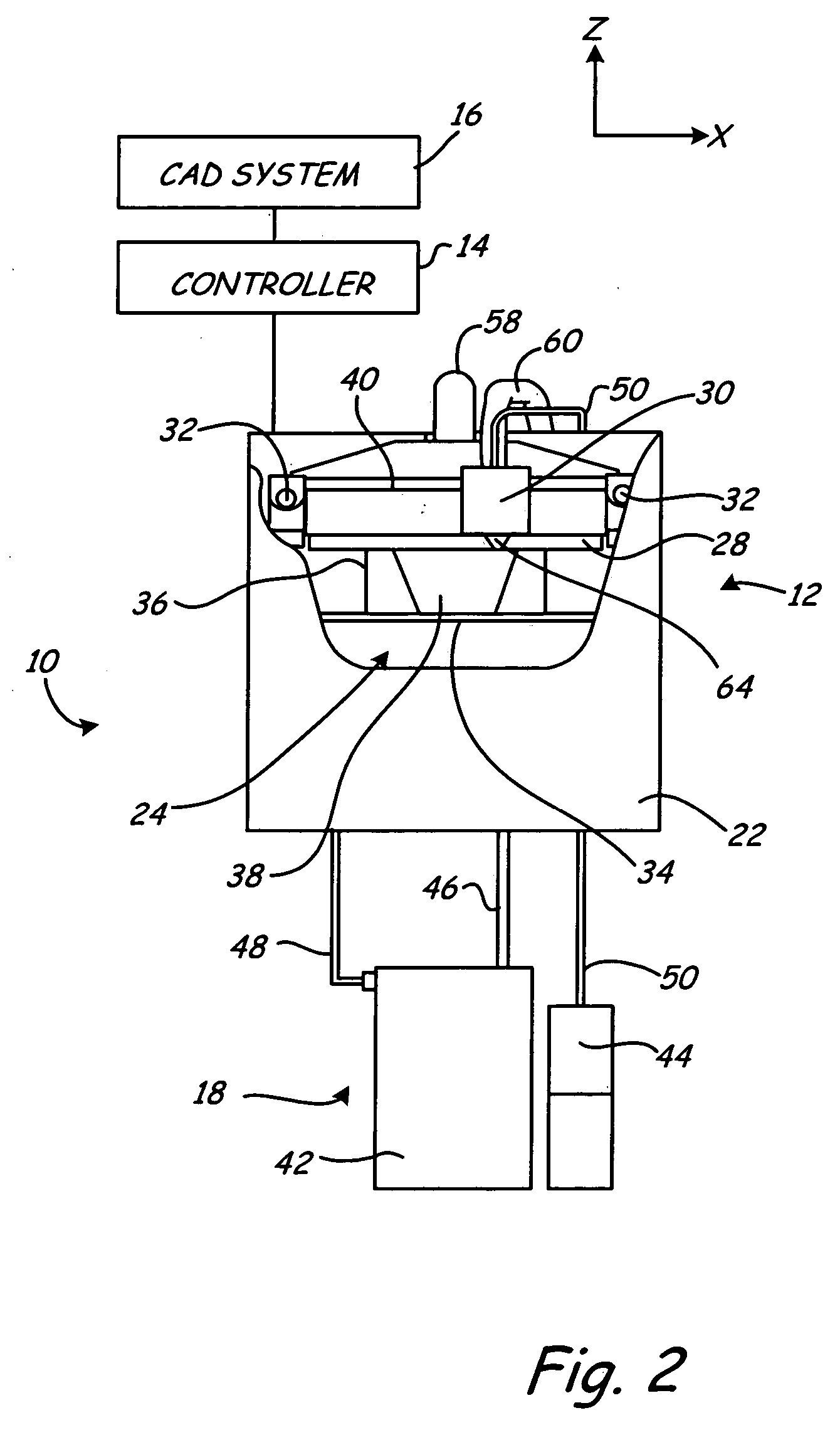

High-resolution rapid manufacturing

ActiveUS7236166B2Fast preparationGood physical propertiesAdditive manufacturing apparatusWood working apparatusStructural engineeringRapid manufacturing

The present invention is a method for forming an object, the method comprising jetting a first material to form a plurality of layers that define a support structure increment, and extruding a second material to form a layer of the object. The layer of the object substantially conforms to an interior surface of the support structure increment.

Owner:STRATSYS INC

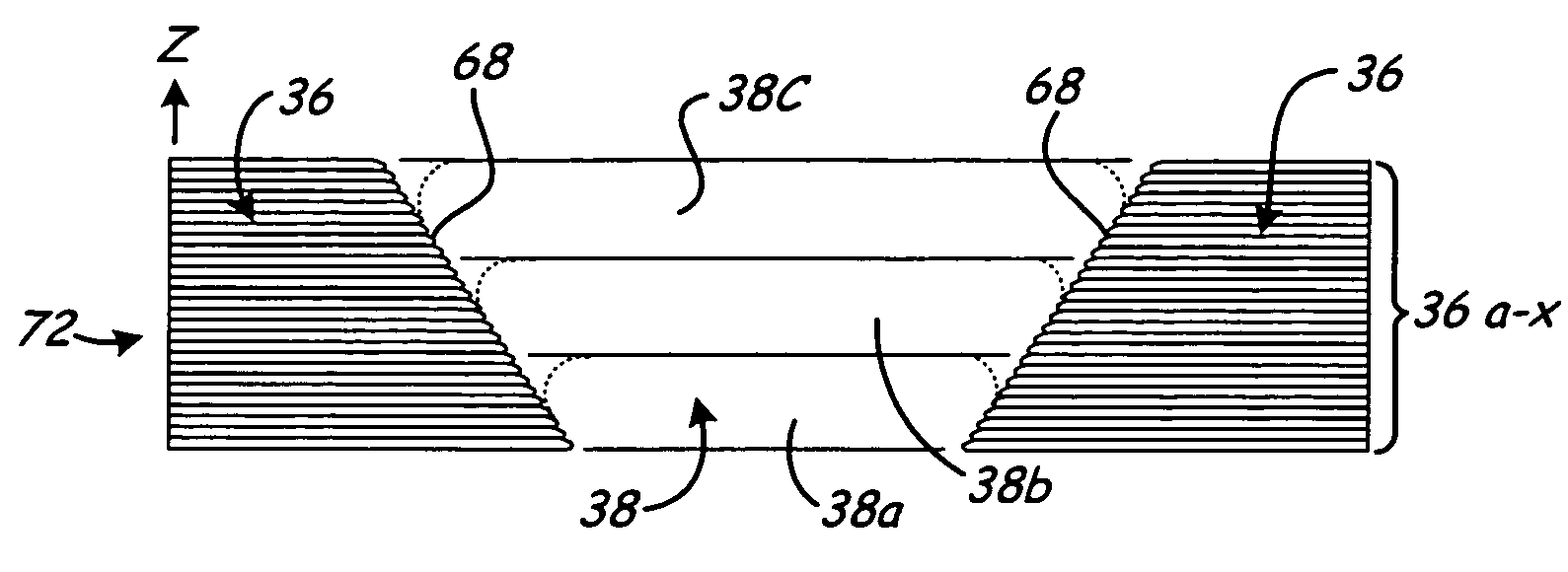

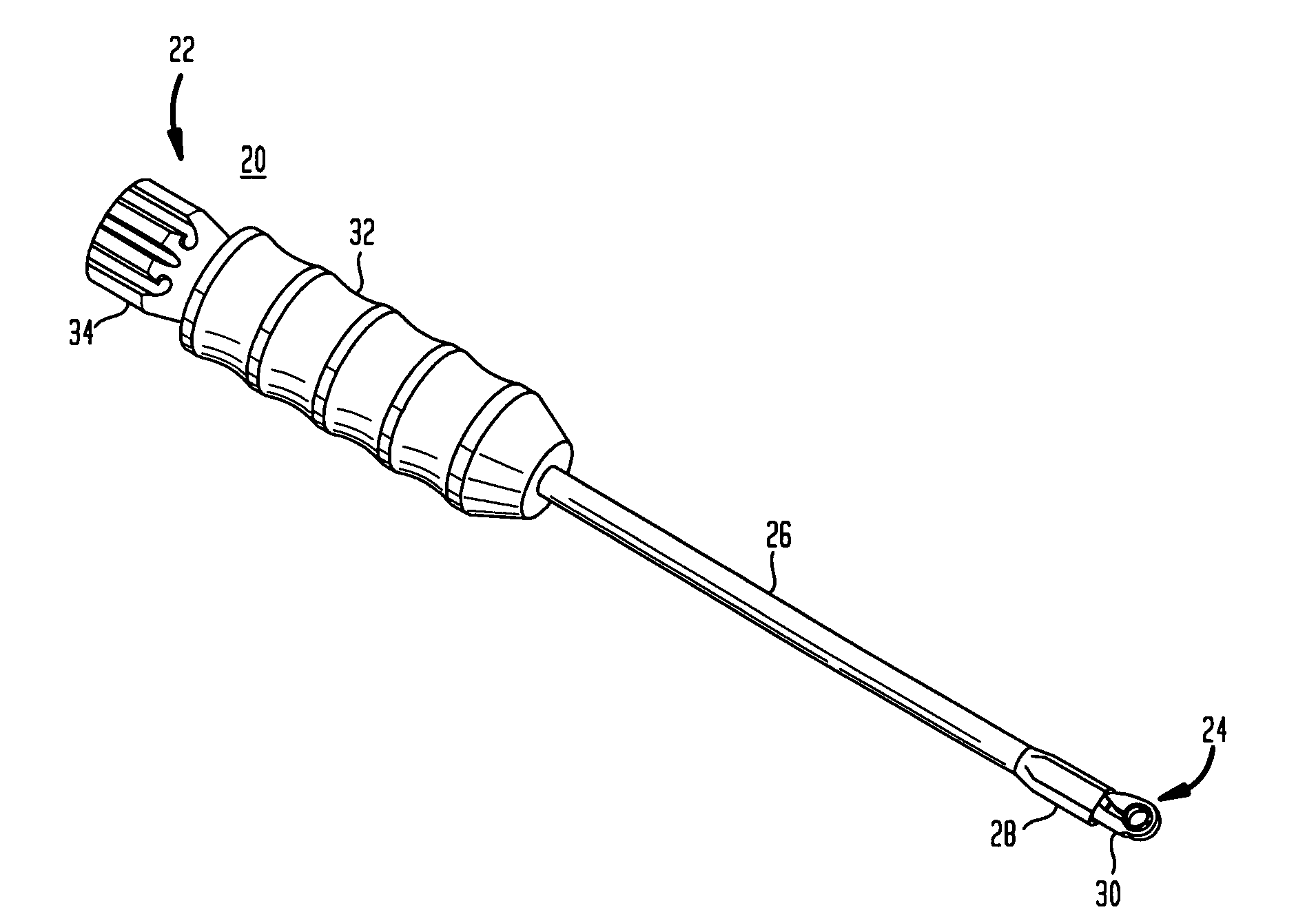

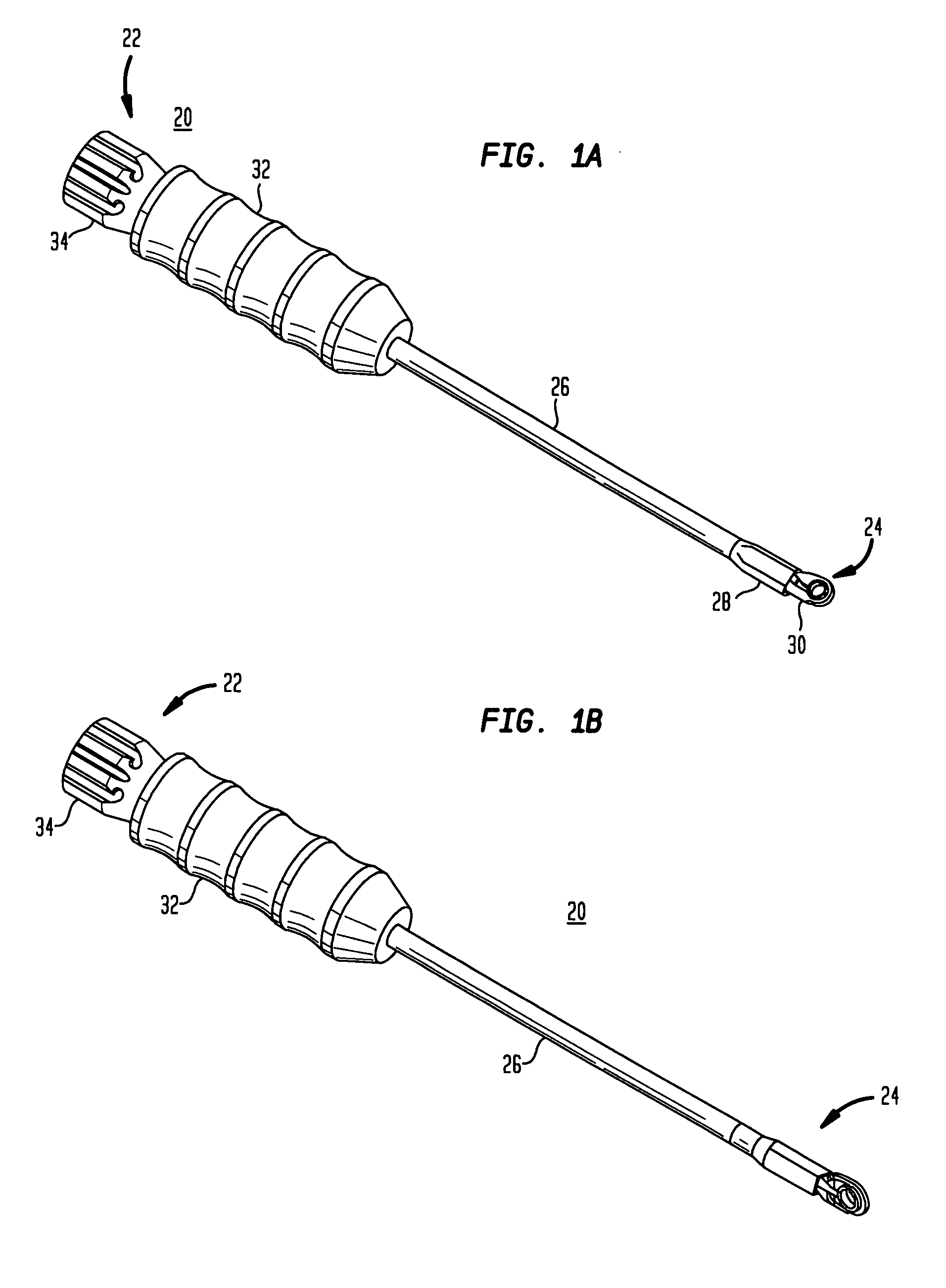

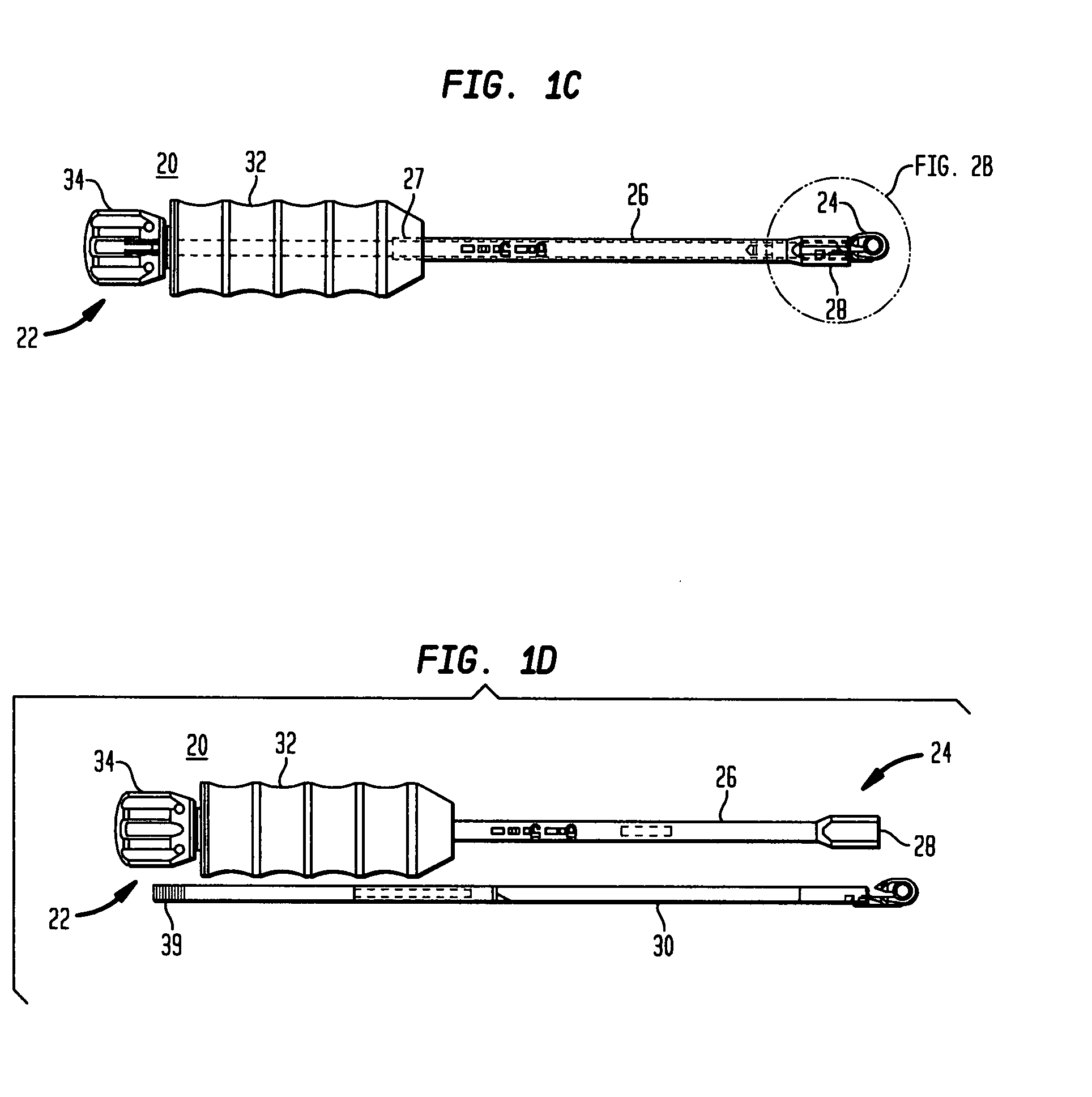

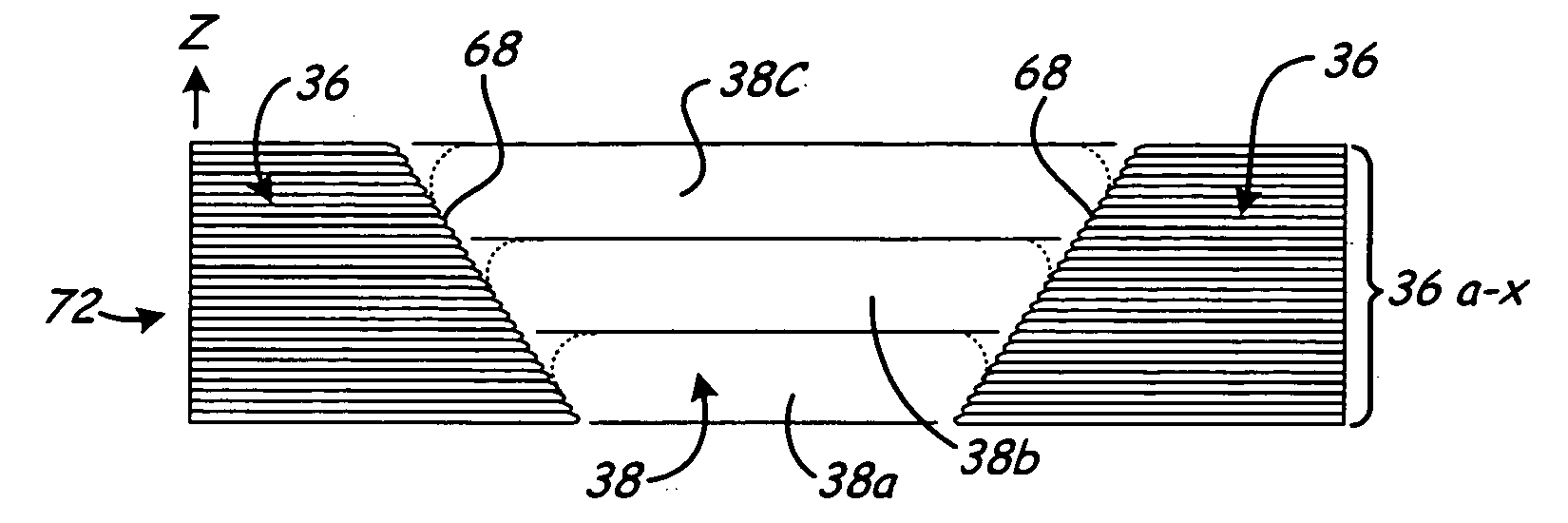

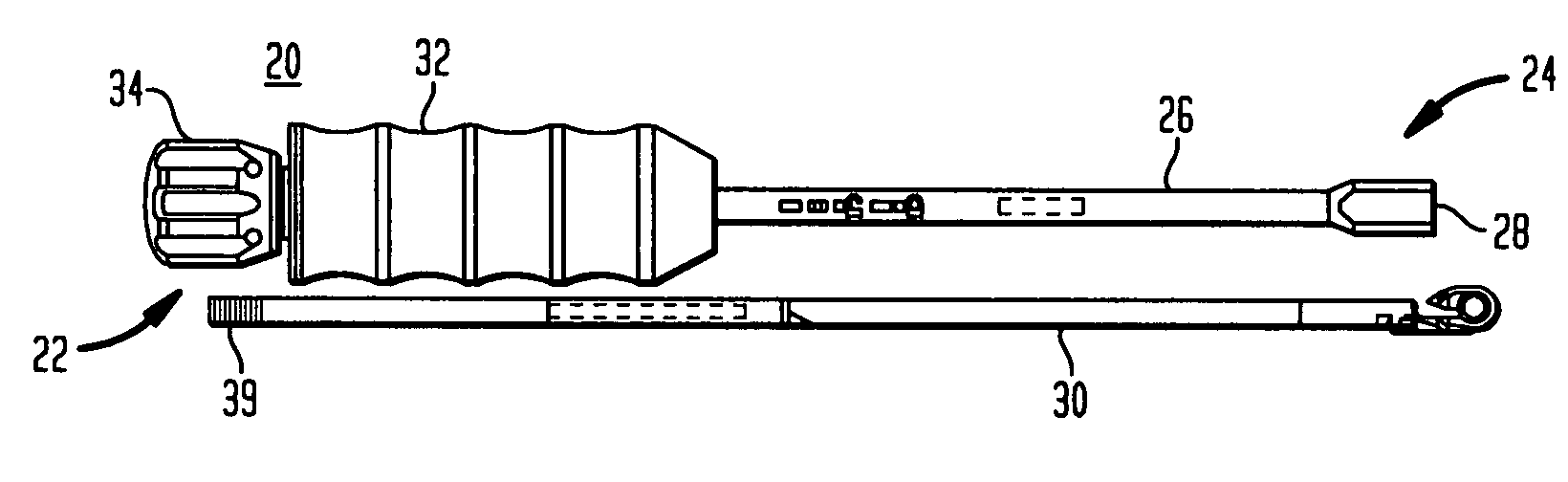

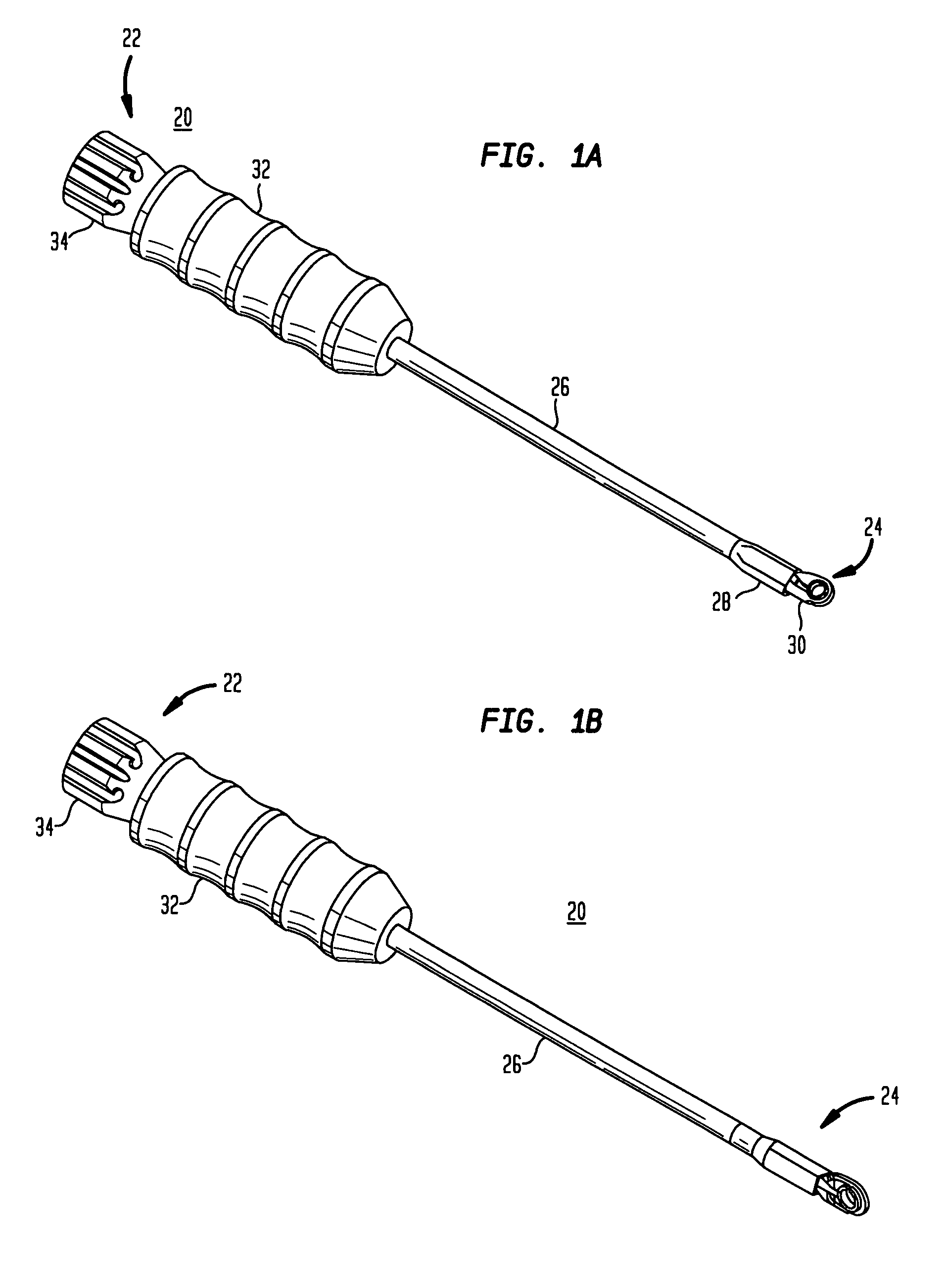

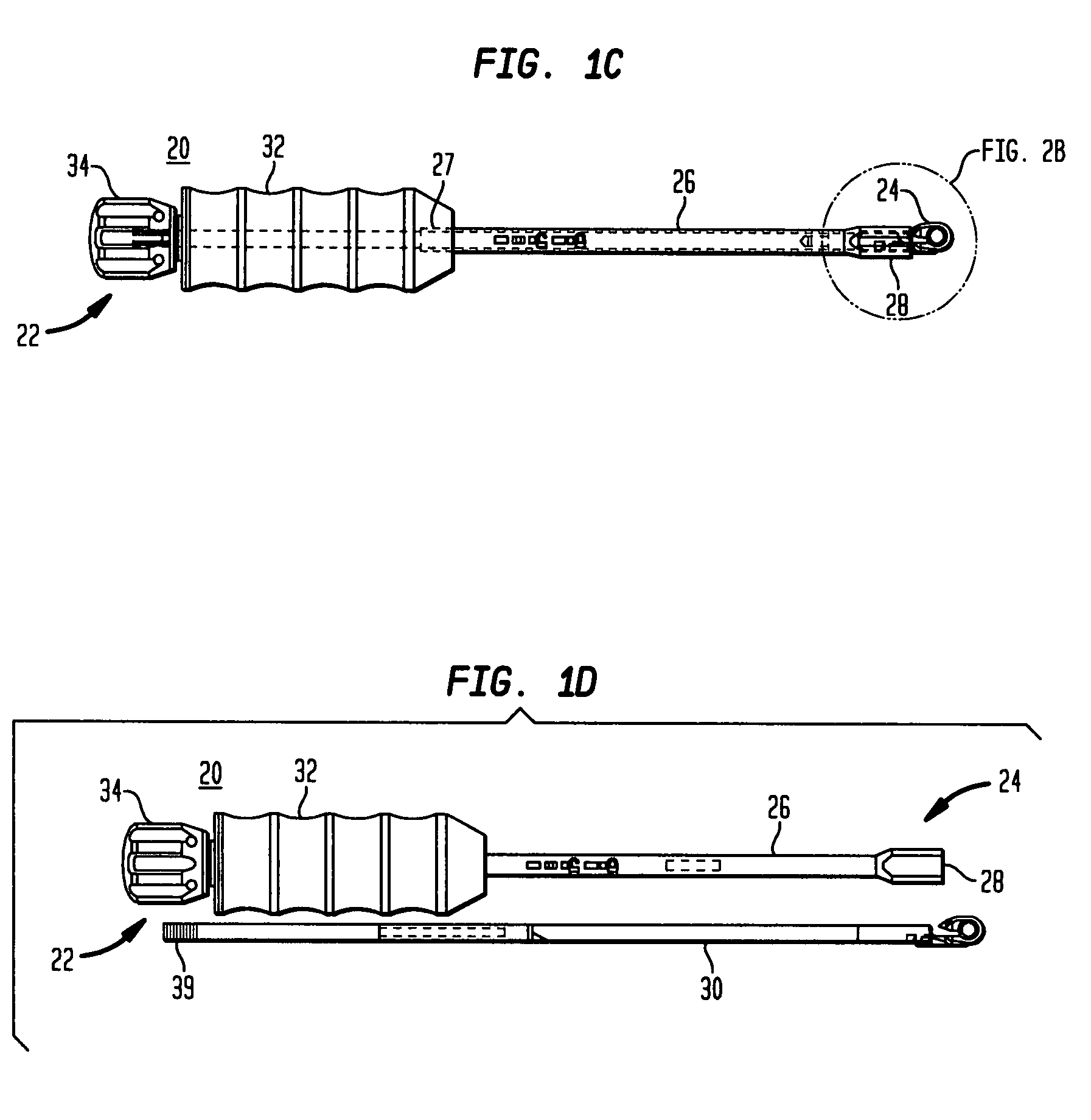

Rod inserter and rod with reduced diameter end

ActiveUS20080077136A1Facilitates percutaneous spinal rod insertionPromote recoveryInternal osteosythesisProsthesisBiomedical engineering

An inserter tool for coupling a spinal rod with an implant includes an outer shaft having a proximal end, a distal end and an elongated opening extending between the proximal and distal ends, a handle secured to the proximal end of the outer shaft, and an inner shaft having a proximal end and a distal end, the inner shaft being telescopically received within the elongated opening of the outer shaft and being adapted to move between the proximal and distal ends of the outer shaft. The tool includes a compressible clamping tip secured to the distal end of the inner shaft, the clamping tip including a first section secured to the distal end of the inner shaft, a flexible arm that extends from the first section, and an opening disposed between the first section and the flexible arm. A knob is coupled with the proximal end of the inner shaft, the knob being rotatable in a first direction for extending the clamping tip from the distal end of the outer shaft and in a second direction for retracting the clamping tip into the distal end of the outer shaft so as to compress the flexible arm of the clamping tip toward the first section of the clamping tip.

Owner:STRYKER EURO OPERATIONS HLDG LLC

High-resolution rapid manufacturing

ActiveUS20060158456A1Fast preparationGood physical propertiesAdditive manufacturing apparatusWood working apparatusStructural engineeringRapid manufacturing

The present invention is a method for forming an object, the method comprising jetting a first material to form a plurality of layers that define a support structure increment, and extruding a second material to form a layer of the object. The layer of the object substantially conforms to an interior surface of the support structure increment.

Owner:STRATSYS INC

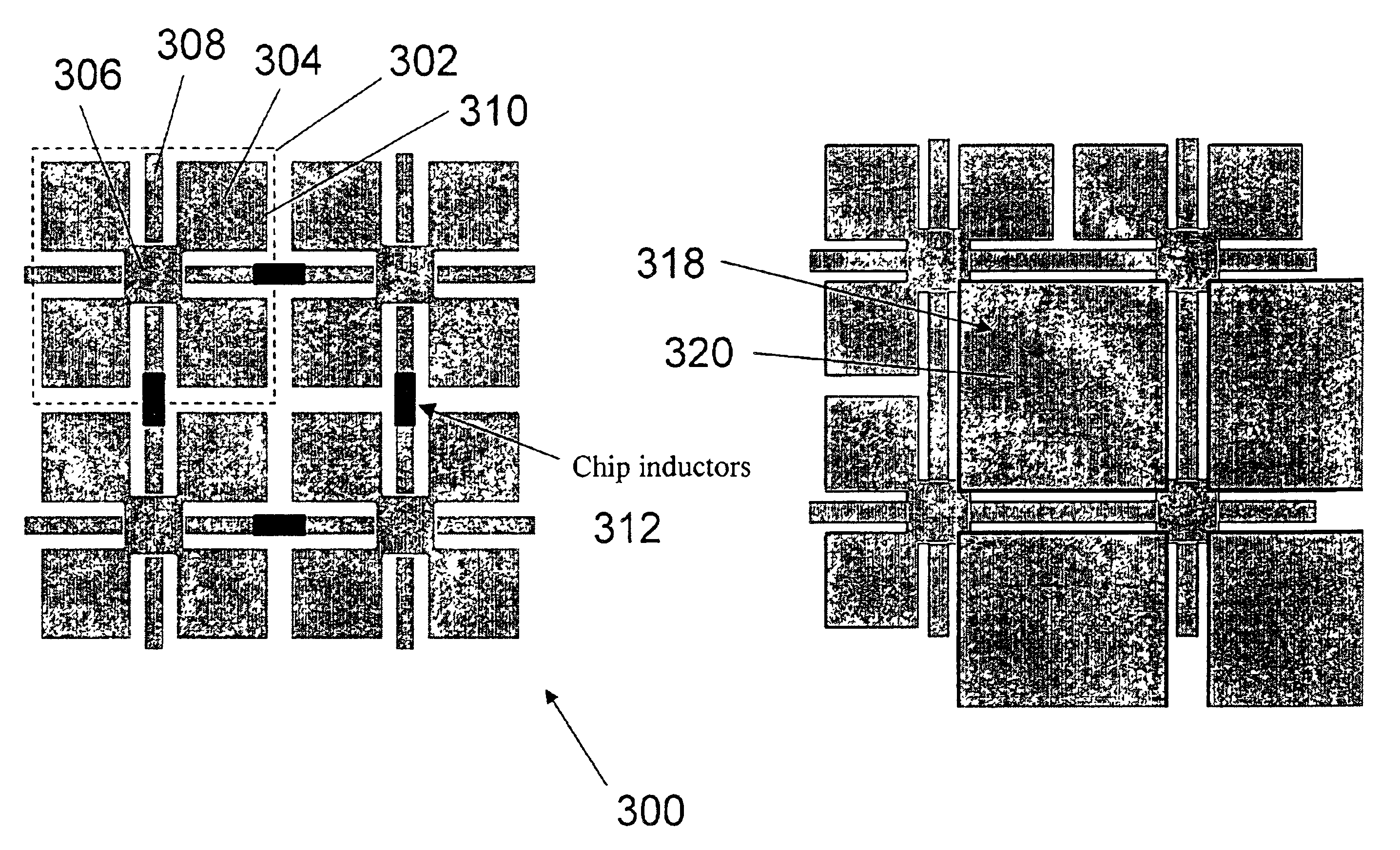

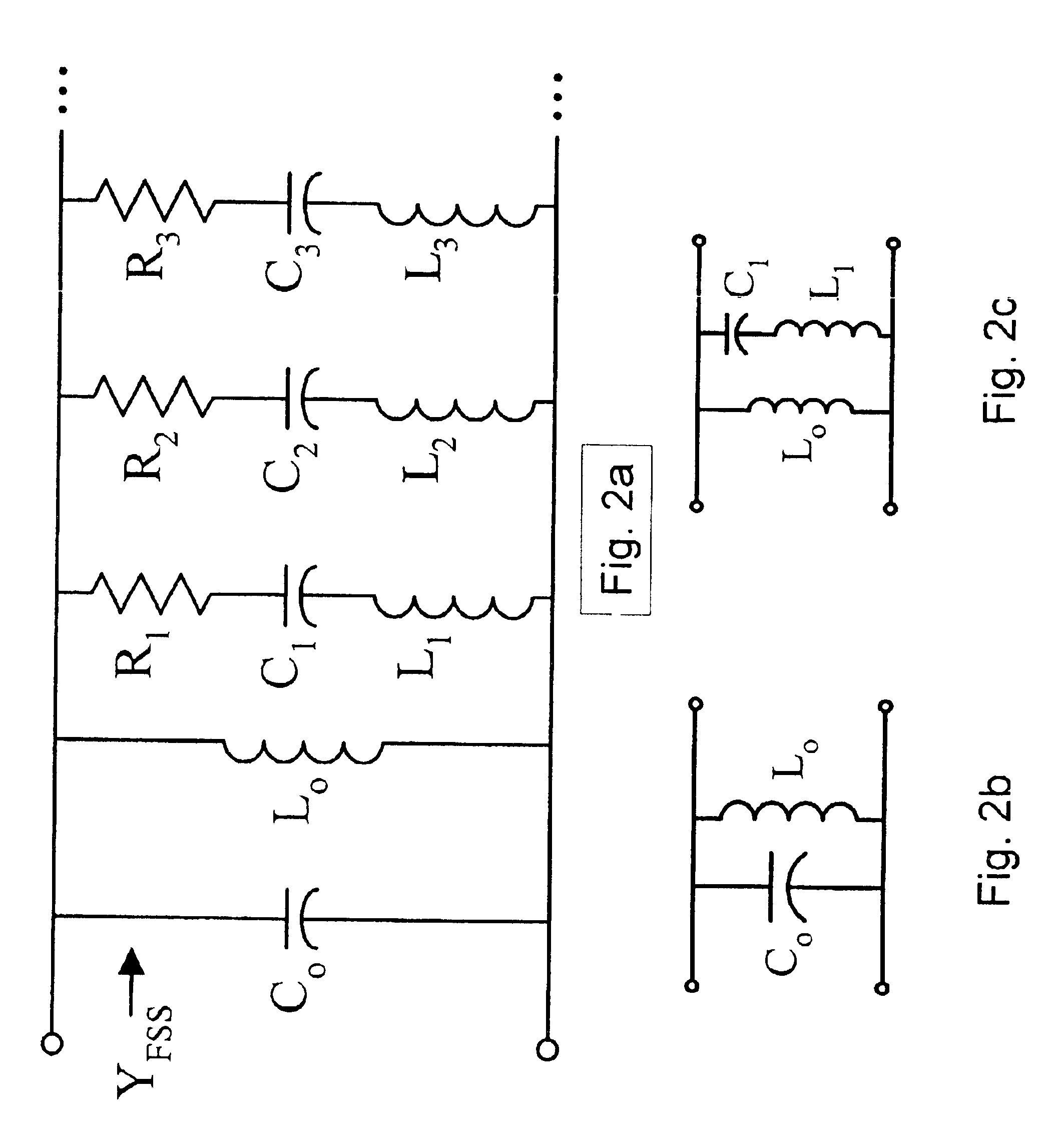

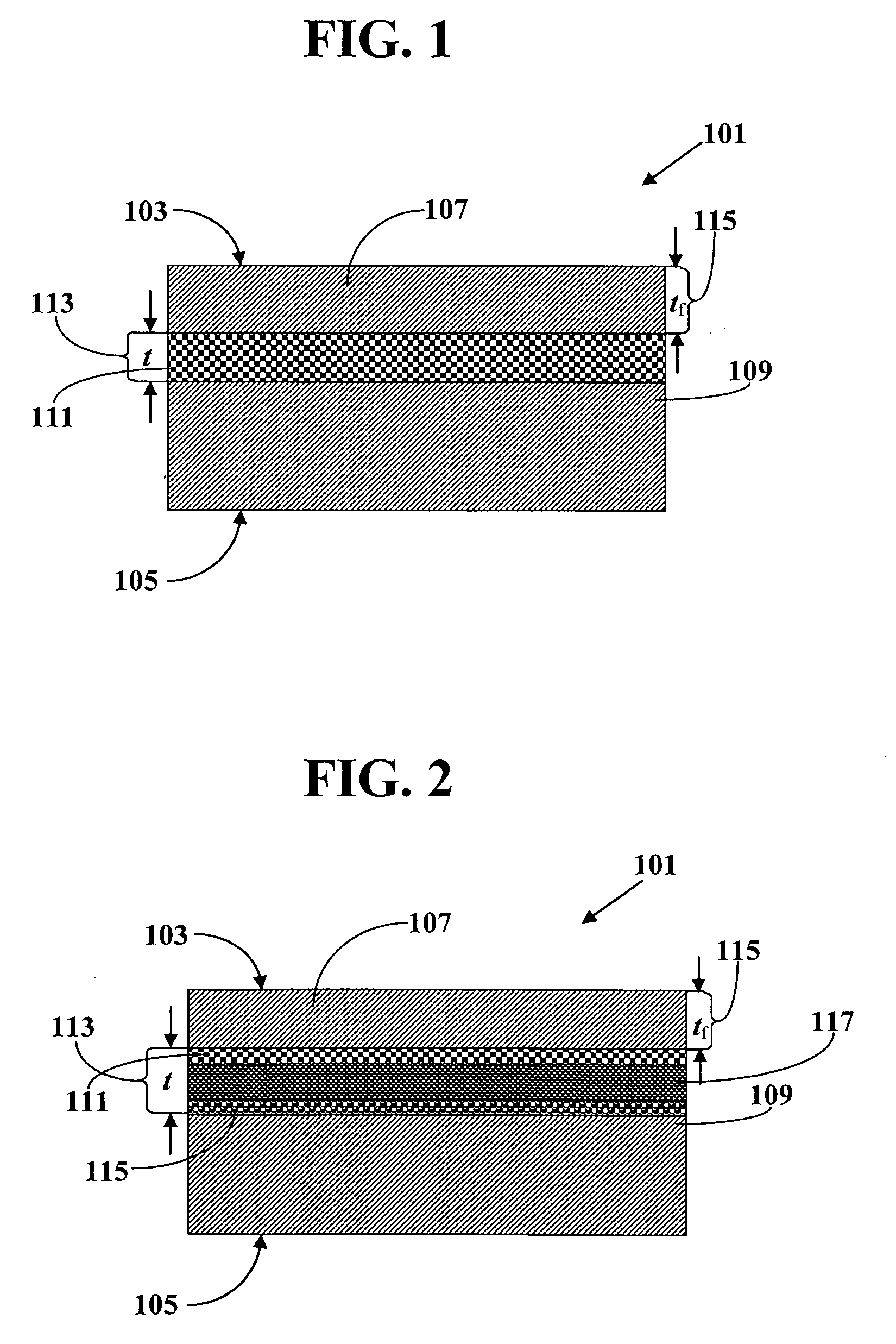

Low frequency enhanced frequency selective surface technology and applications

ActiveUS7071889B2Reduce physical sizeHigh surfaceSimultaneous aerial operationsRadiating elements structural formsWave structureCapacitance

DC inductive FSS technology is a printed slow wave structure usable for reduced size resonators in antenna and filter applications of wireless applications. It is a dispersive surface defined in terms of its parallel LC equivalent circuit that enhances the inductance and capacitance of the equivalent circuit to obtain a pole frequency as low as 300 MHz. The effective sheet impedance model has a resonant pole whose free-space wavelength can be greater than 10 times the FSS period. A conductor-backed DCL FSS can create a DC inductive artificial magnetic conductor (DCL AMC), high-impedance surface with resonant frequencies as low as 2 GHz. Lorentz poles introduced into the DCL FSS create multi-resonant DCL AMCs. Antennas fabricated from DCL FSS materials include single-band elements such as a bent-wire monopole on the DCL AMC and multi-band (dual and triple) shorted patches, similar to PIFAs with the patch / lid being a DCL FSS.

Owner:OAE TECH INC

Producing SOI structure using ion shower

InactiveUS20070281440A1Large area simultaneous ion implantationLow and no surface etchSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryIon implantation

Owner:CORNING INC

Optical configurations for head-worn see-through displays

ActiveUS20170023790A1Reduce weightComfortable to wearPolarising elementsSee-through displayDisplay device

Aspects of the present invention relate to methods and systems for providing high quality display images in see-through head-worn optics.

Owner:OSTERHOUT GROUP INC

Rod inserter and rod with reduced diameter end

ActiveUS7686809B2High surfacePrevent rotationInternal osteosythesisNon-surgical orthopedic devicesEngineeringBiomedical engineering

Owner:STRYKER EURO OPERATIONS HLDG LLC

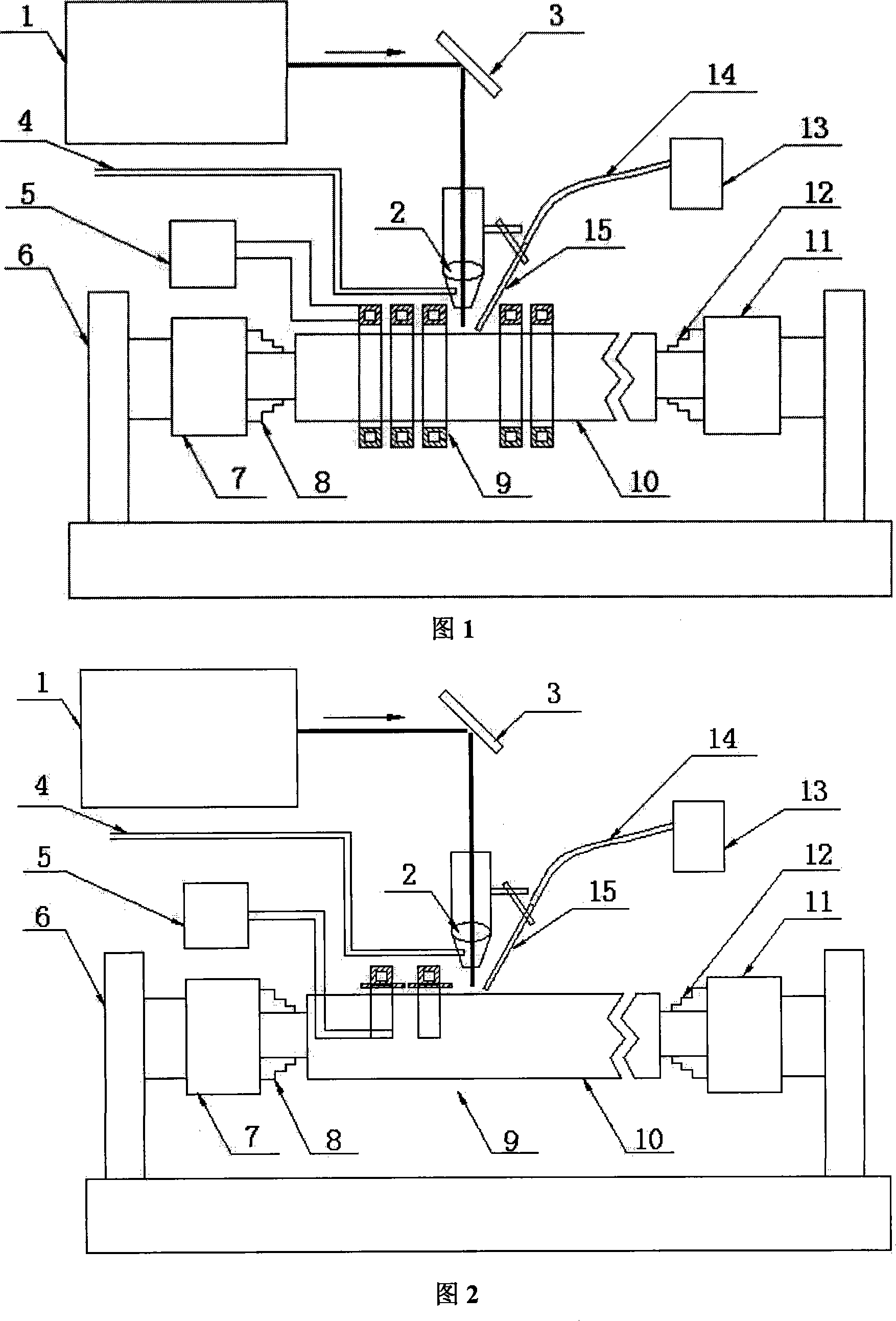

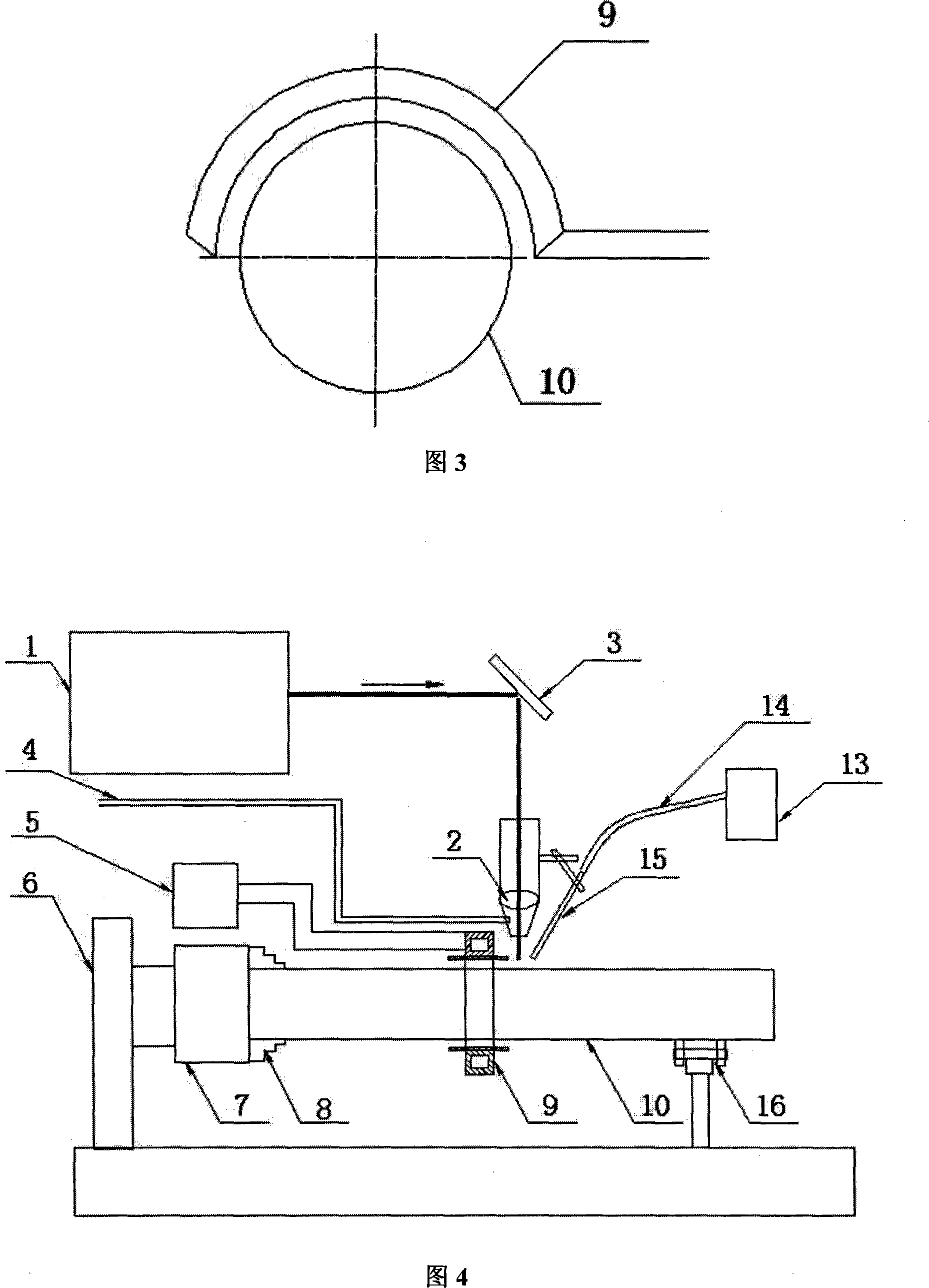

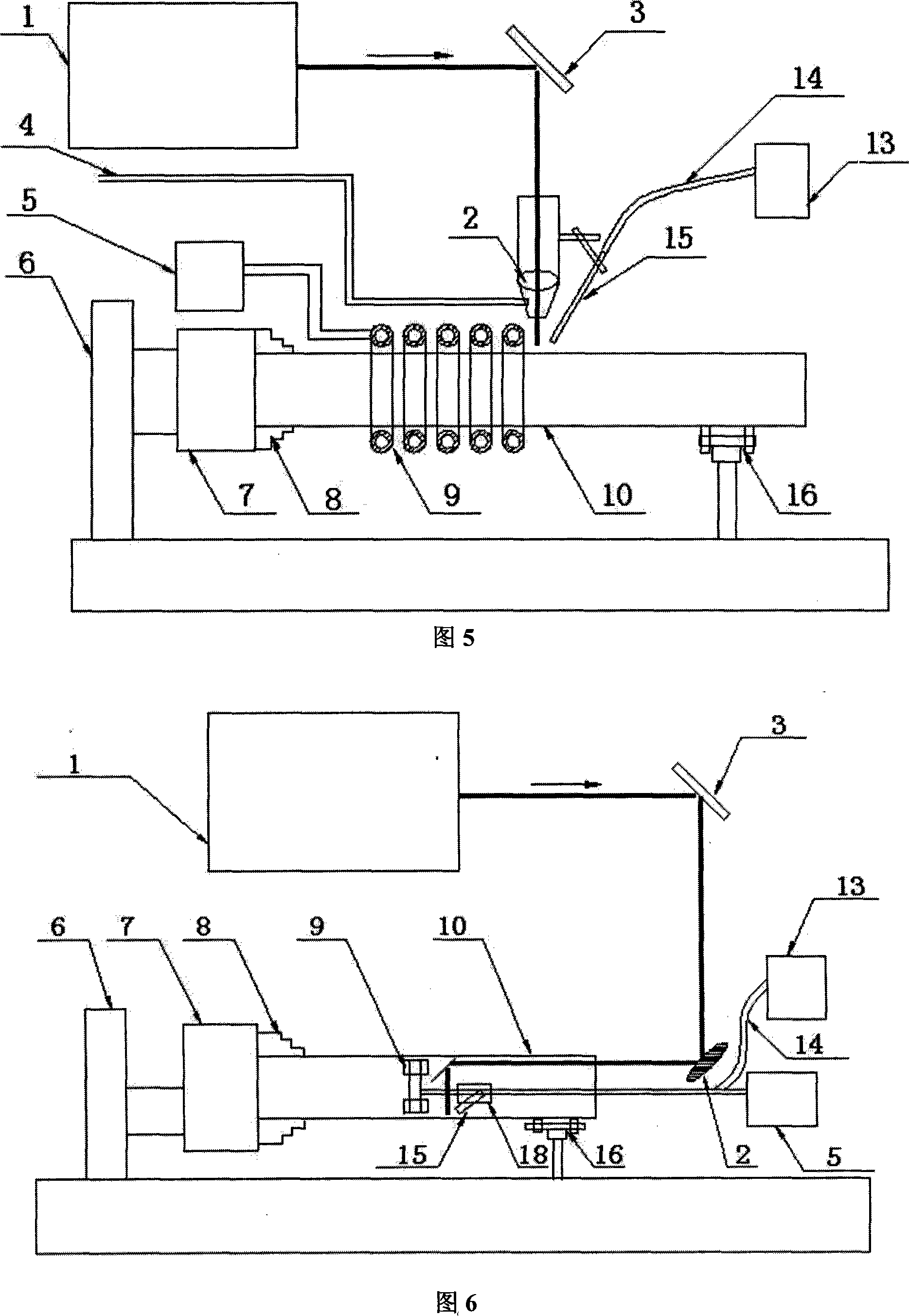

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

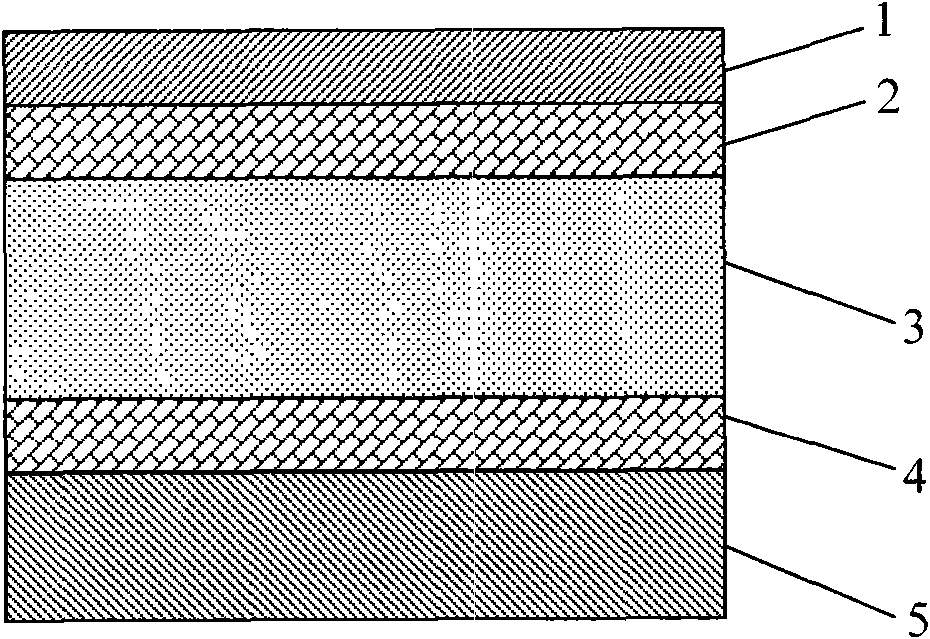

Novel solar battery backboard

ActiveCN101582458ANovel structureMaterials are readily availableSynthetic resin layered productsPhotovoltaic energy generationPolyurethane adhesiveAlloy

The invention relates to a novel solar battery backboard, which comprises the following components according to the adhesion in turn: a weathering layer, a first adhesive layer, a structure-enhancing layer, a second adhesive layer and an adhesive reflecting layer; wherein, the weathering layer is a polyvinylidene fluoride alloy layer modified by inorganic materials; the adhesive reflecting layer is a white polyethylene layer; preferably, the polyvinylidene fluoride alloy layer is a plastic alloy layer formed by the polyvinylidene fluoride and the inorganic materials with the thickness of 4-40 mum; the white polyethylene layer is a plastic alloy layer in which polyethylene is mixed with inorganic white pigment, anti-ultraviolet stabilizer and hot-oxygen ageing resistance stabilizer with the thickness of 10-300mum; the structure-enhancing layer is a polyethylene qlycol terephthalate layer; the first adhesive layer and the second adhesive layer can be one of the following three, namely, a polyurethane adhesive layer, an acrylic ester adhesive layer or an epoxy adhesive layer with the thickness of 1mum-30mum. The invention features novel structure, easily obtained materials, greatly reduced cost and good performance, conforms to the requirements of the backboard, and has important significance on solar energy industry.

Owner:SHANGHAI HIUV NEW MATERIALS

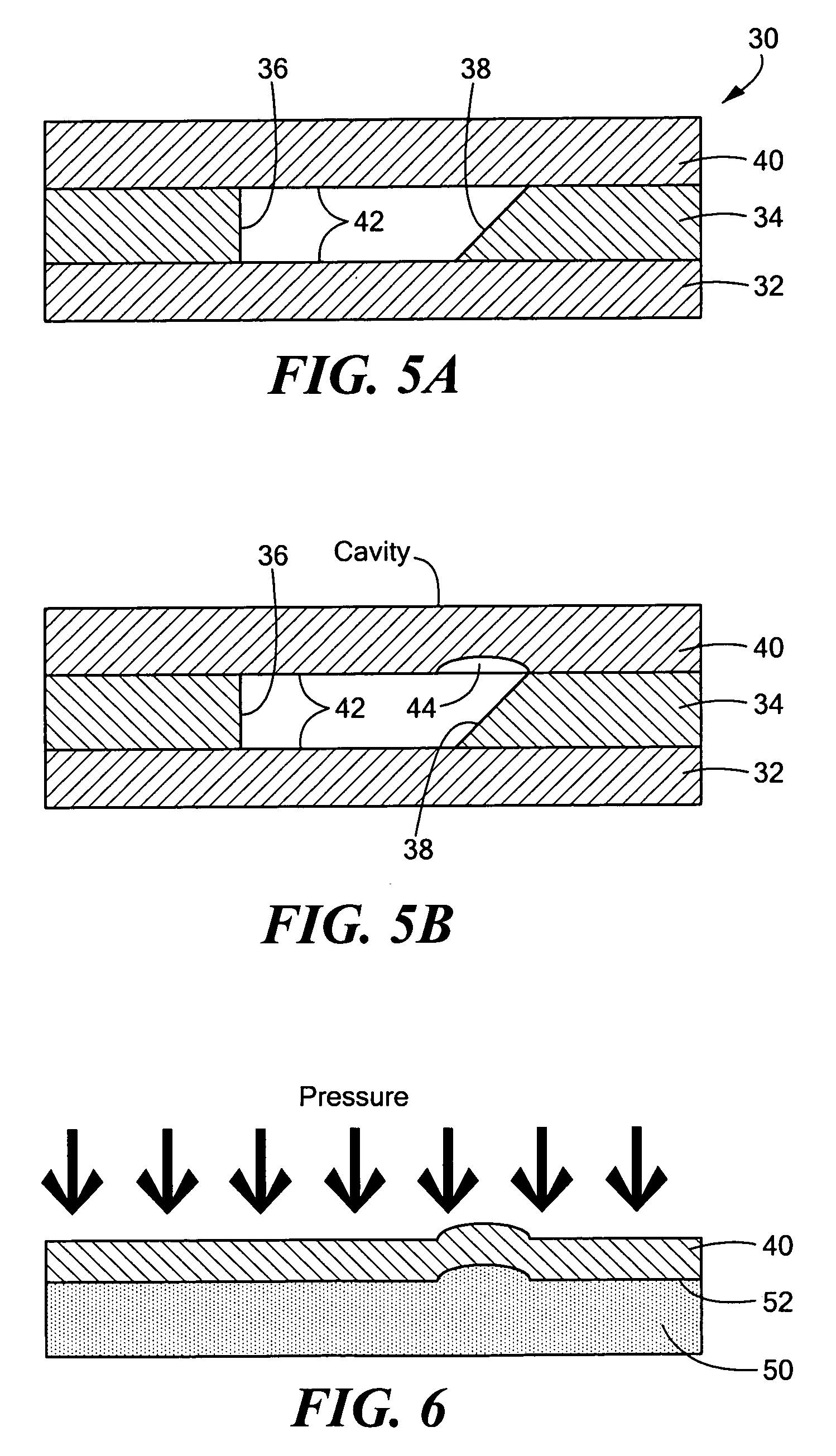

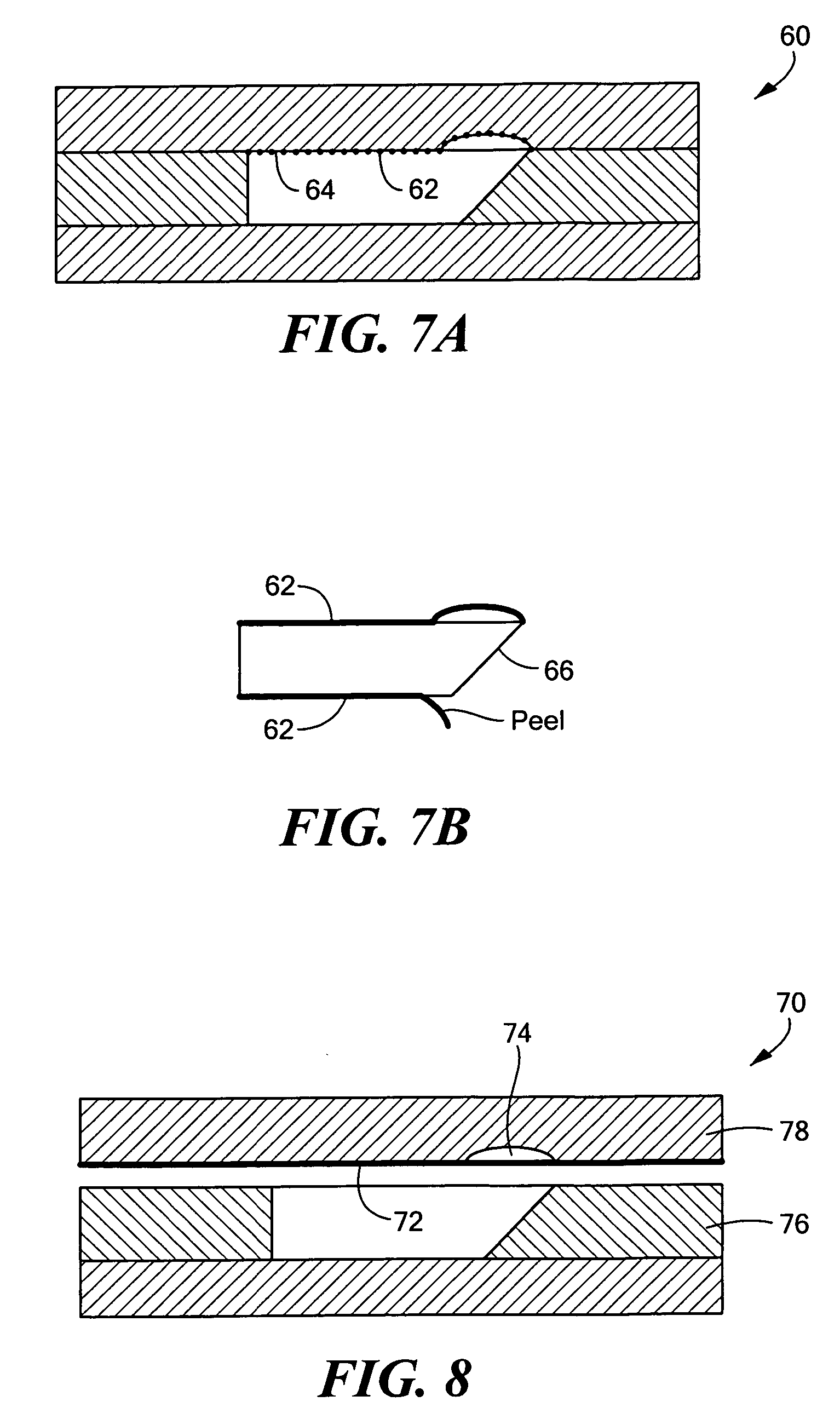

Method for producing high quality optical parts by casting

InactiveUS20060192307A1Quality improvementIncrease costOptical articlesPolymer sciencePolymer thin films

A casting method, rather than injection molding, to produce polymer optical components and systems is provided. The casting process controls shrinkage and stress, thus providing both high bulk uniformity and high quality, accurate surfaces, by incorporating polymer films into the mold. The films may remain incorporated into the part or may optionally be removed from the part after removal from the mold. In addition, the incorporation of separately produced components within the cast part is also provided, eliminating post-casting assembly manufacturing steps.

Owner:GOOGLE LLC

Producing SOI structure using high-purity ion shower

InactiveUS20070281399A1Large area simultaneous ion implantationLow and no surface etchSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryIon implantation

Owner:CORNING INC

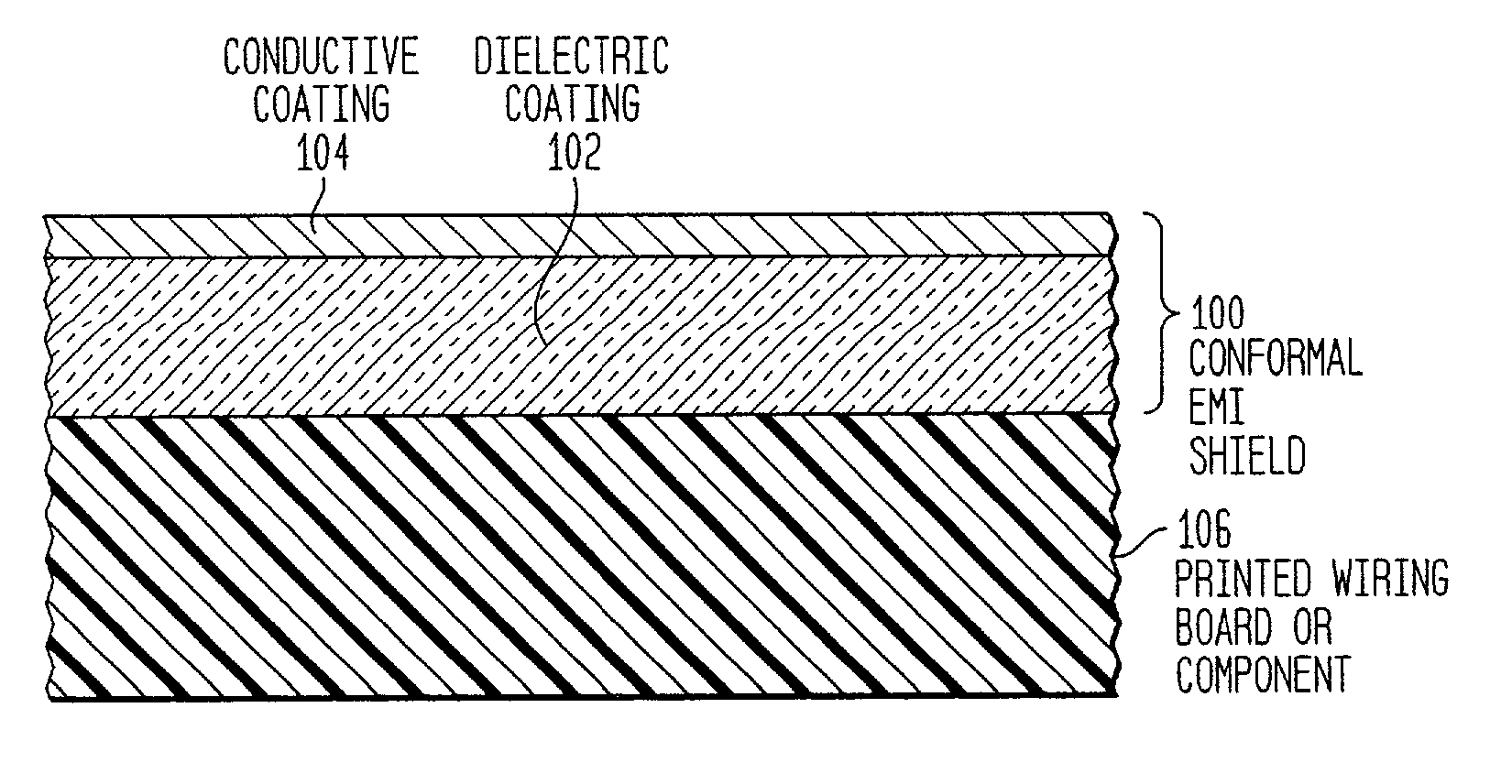

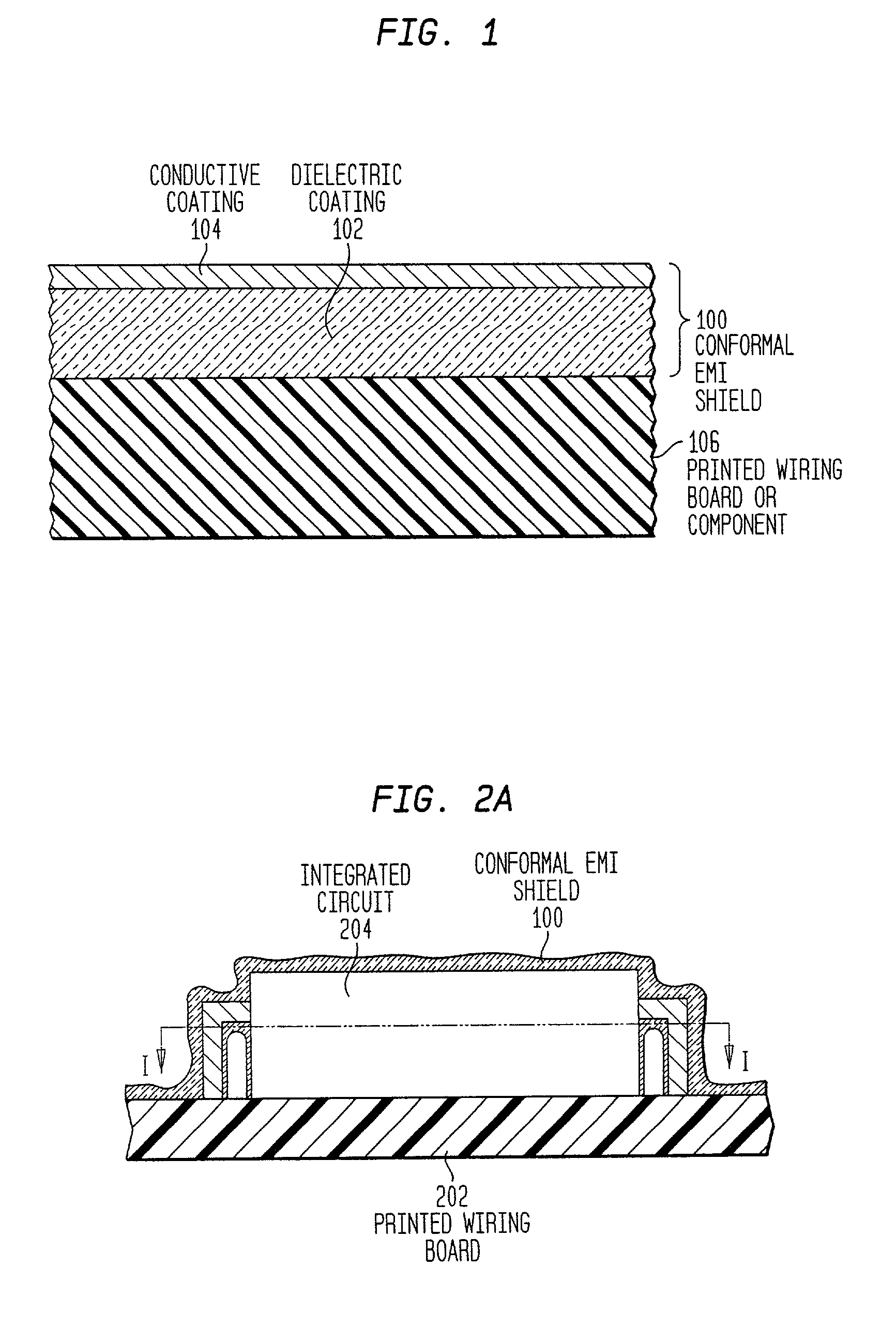

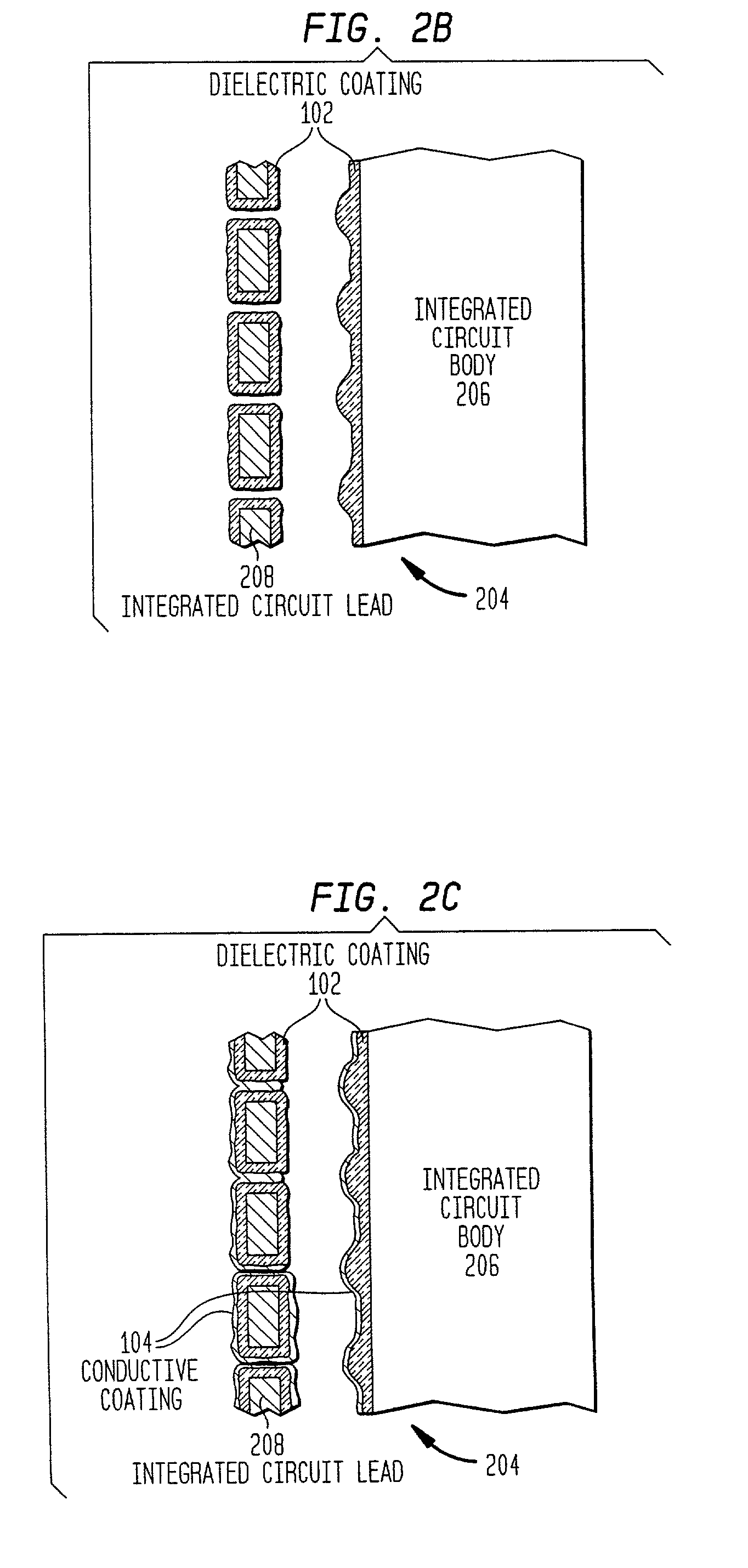

Board-level EMI shield that adheres to and conforms with printed circuit board component and board surfaces

InactiveUS20020129951A1Optimize allocationLift restrictionsElectrically conductive connectionsMagnetic/electric field screeningFilling materialsConductive coating

An electrically continuous, grounded conformal EMI protective shield and methods for applying same directly to the surfaces of a printed circuit board. The EMI shield adheres and conforms to the surface of the components and printed wiring board. The shield takes the shape of the covered surfaces while adding little to the dimensions of the surfaces. The EMI shield includes low viscosity, high adherence conductive and dielectric coatings each of which can be applied in one or more layers using conventional spray techniques. The conductive coating prevents substantially all electromagnetic emissions generated by the shielded components from emanating beyond the conformal coating. The dielectric coating is initially applied to selected locations of the printed circuit board so as to be interposed between the conductive coating and the printed circuit board, preventing the conductive coating from electrically contacting selected components and printed wiring board regions. A high viscosity, non-electrically-conductive filler material is applied to printed circuit board regions that have surfaces that are cavitatious and / or which have a highly variable slope. The filler material can be used in conjunction with conformal EMI shield board level coating. The high viscosity, electrically non-conductive filler material substantially covers each cavity such that the covered cavity is inaccessible and that the covered region of the printed circuit board has a contiguous, contoured surface. A pre-manufactured non-electrically-conductive component cover can be mounted over a corresponding component and secured to the printed wiring board. The component cover and printed wiring board surround the component, forming a sealed enclosure. The component cover has a thin cross-section and an interior surface that follows closely the surface of the component. This minimizes the volume enclosed by the component cover. In addition, the exterior surface of the component cover has a low profile, and prevents the conformal EMI shield from physically contacting the covered component. Instead, the exterior surface of the component cover is coated with the EMI shield. This enables the covered component to be removed from the printed circuit board for repair, replacement or salvage without having to risk damage to the printed wiring board or component that may occur with the removal of a conformal EMI shield applied directly to the component.

Owner:HEWLETT PACKARD DEV CO LP

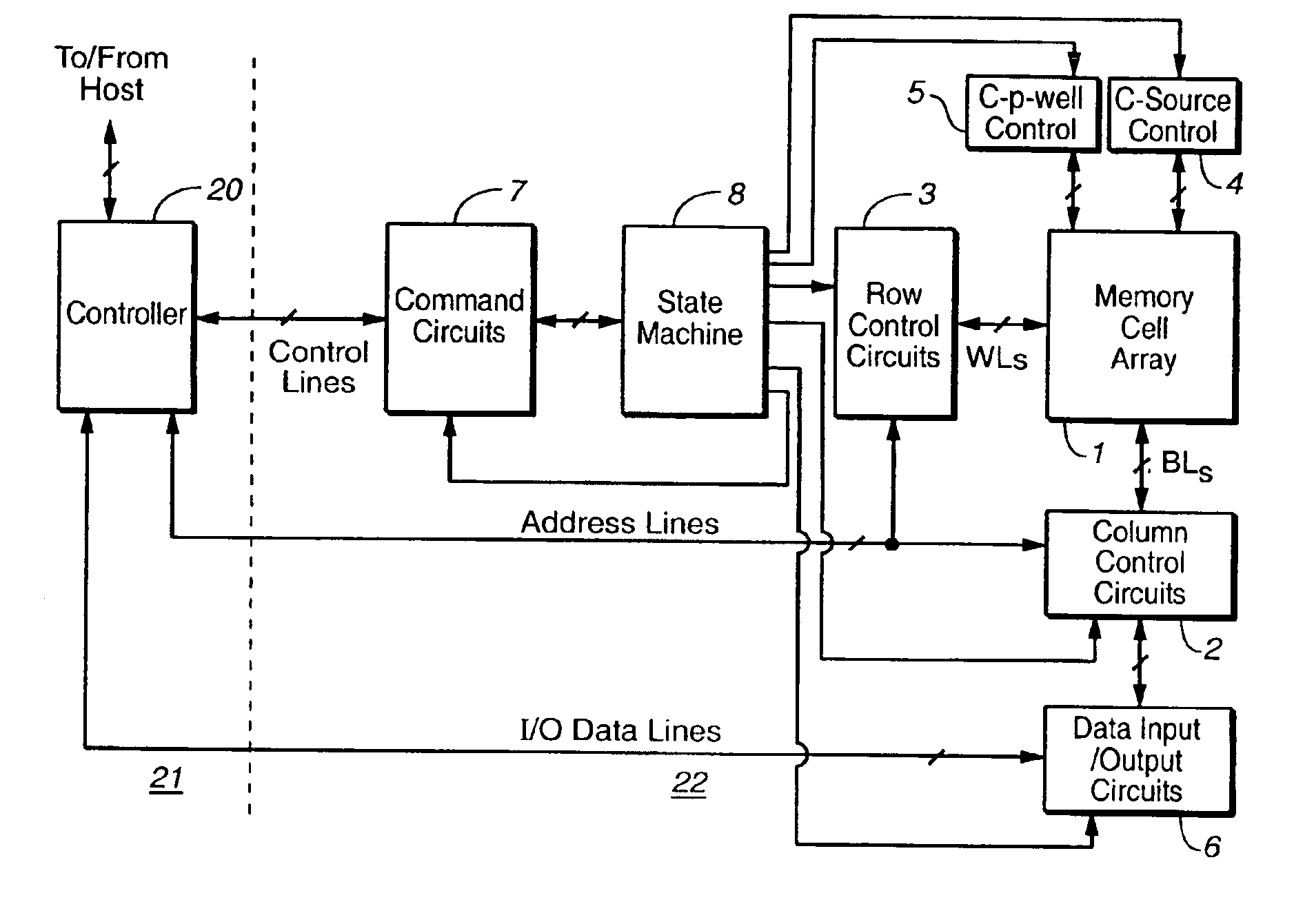

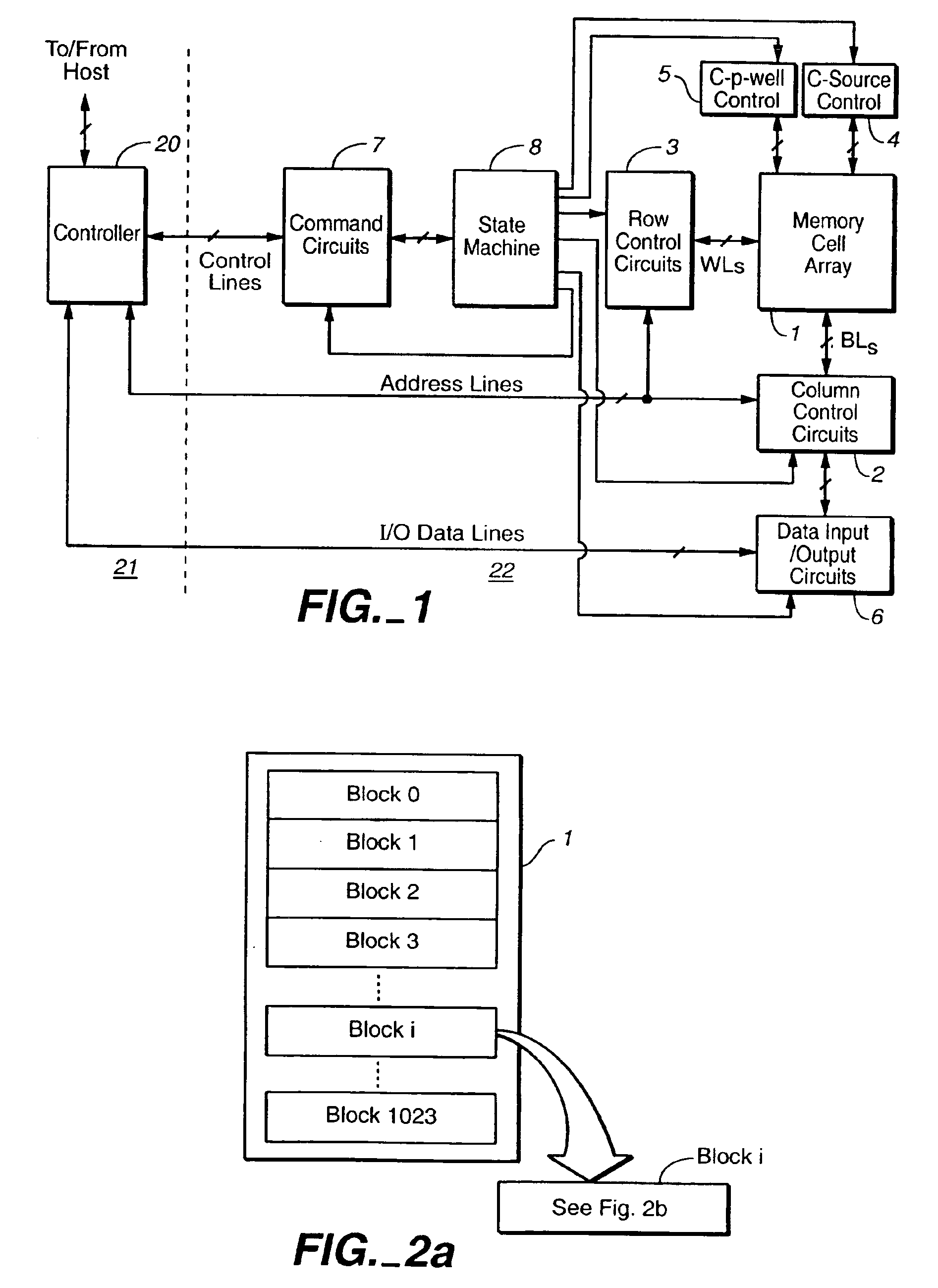

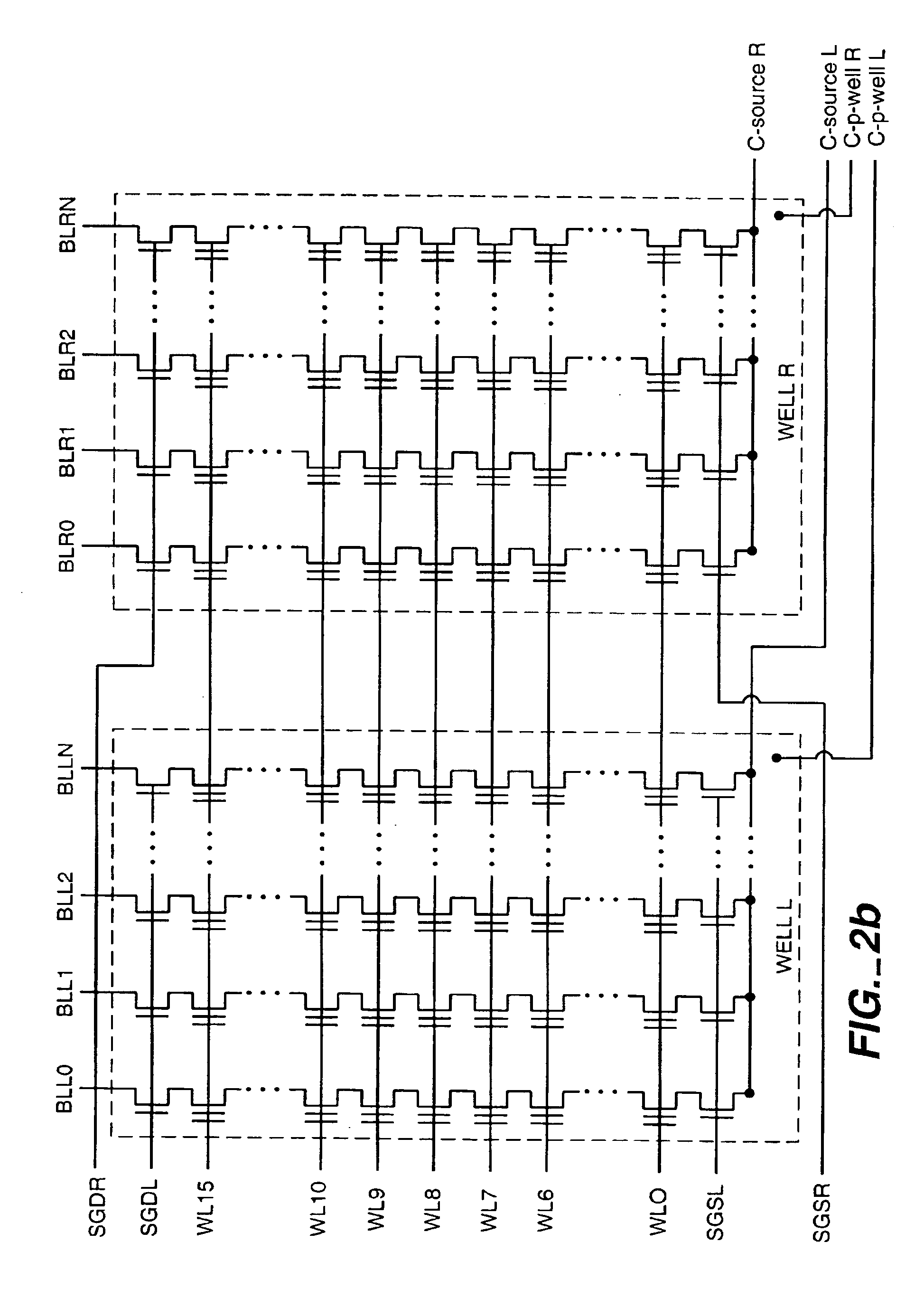

Operating techniques for reducing program and read disturbs of a non-volatile memory

InactiveUS6996003B2Reduce the amount requiredHigh surfaceTransistorSolid-state devicesLeft halfComputer architecture

The present invention presents a non-volatile memory having a plurality of erase units or blocks, where each block is divided into a plurality of parts sharing the same word lines to save on the row decoder area, but which can be read or programmed independently. An exemplary embodiment is a Flash EEPROM memory with a NAND architecture that has blocks composed of a left half and a right half, where each part will accommodate one or more standard page (data transfer unit) sizes of 512 bytes of data. In the exemplary embodiment, the left and right portions of a block each have separate source lines, and separate sets of source and drain select lines. During the programming or reading of the left side, as an example, the right side can be biased to produce channel boosting to reduce data disturbs. In an alternate set of embodiments, the parts can have separate well structures.

Owner:SANDISK TECH LLC

Thermally conductive honeycombs for chemical reactors

InactiveUS6881703B2Good catalyst compatibilityImprove thermal conductivityHydrogenChemical/physical/physico-chemical stationary reactorsChemical reactorHoneycomb

Monolithic metallic catalyst substrates offering improved heat conductivity are provided from metal powder extrusion batches of copper, tin, zinc, aluminum, iron, silver, nickel, and mixtures and alloys thereof by extrusion through a honeycomb extrusion die followed by drying and firing in a two stage firing process to oxidize organic extrusion batch components, remove residual oxides from the porous wall structure, and consolidate the metal powders to strong, integral honeycomb support structures.

Owner:CORNING INC

Grinding fluid for processing LED (light-emitting diode) substrate and preparation method thereof

InactiveCN102337084AReduce surface roughnessReduce surface scratchesPolishing compositions with abrasivesSemiconductor devicesSolventSilicon dioxide

The invention relates to a grinding fluid for processing an LED (light-emitting diode) substrate. The grinding fluid comprises a solvent, an additive and a grinding agent, wherein the grinding agent consists of diamond micropowder and non-diamond nano polishing material; the purity of the diamond micropowder is more than 99%, and the particle size of the diamond micropowder is W0.5-W20; and the non-diamond nano polishing material is any one or a mixture of any of alumina, silicon dioxide, cerium oxide and chromic oxide, the particle size of the non-diamond nano polishing material is 10-100nm, and the purity of the non-diamond nano polishing material is more than 99%. According to the invention, micron diamond is used as a grinding material while the non-diamond nano polishing material is also compositely added, thereby ensuring the grinding rate and well guaranteeing the processing quality of the surface of a workpiece.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

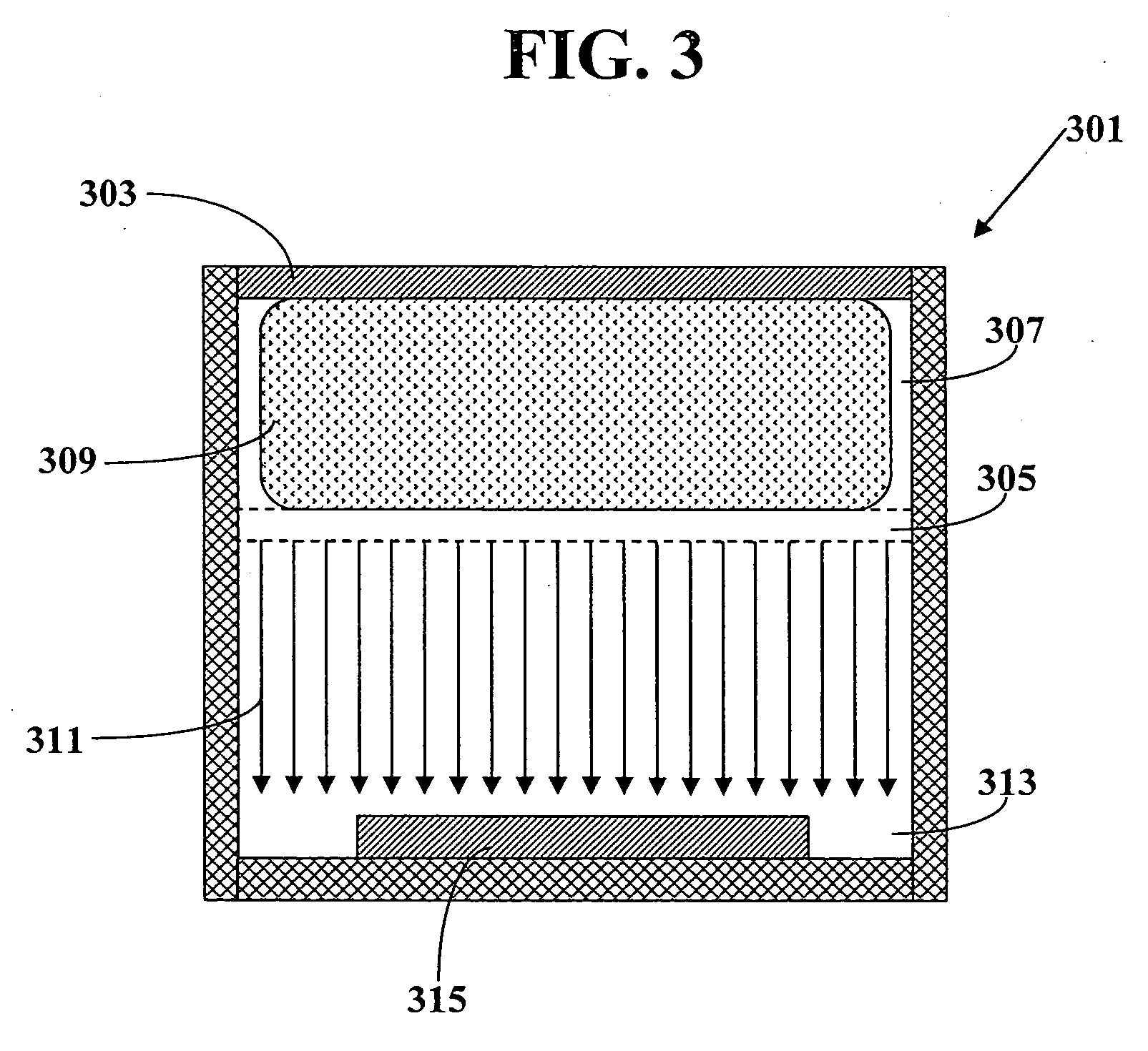

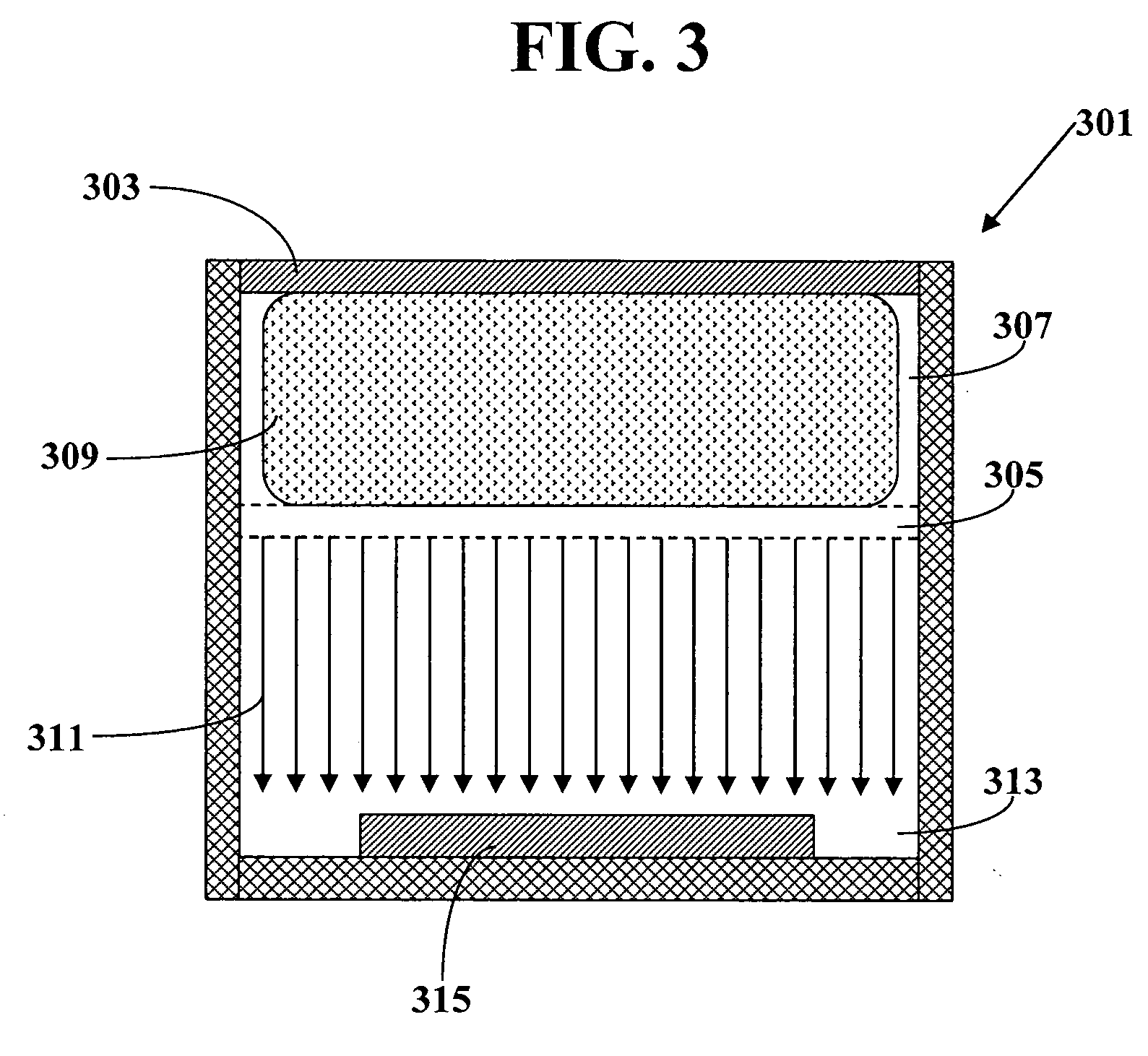

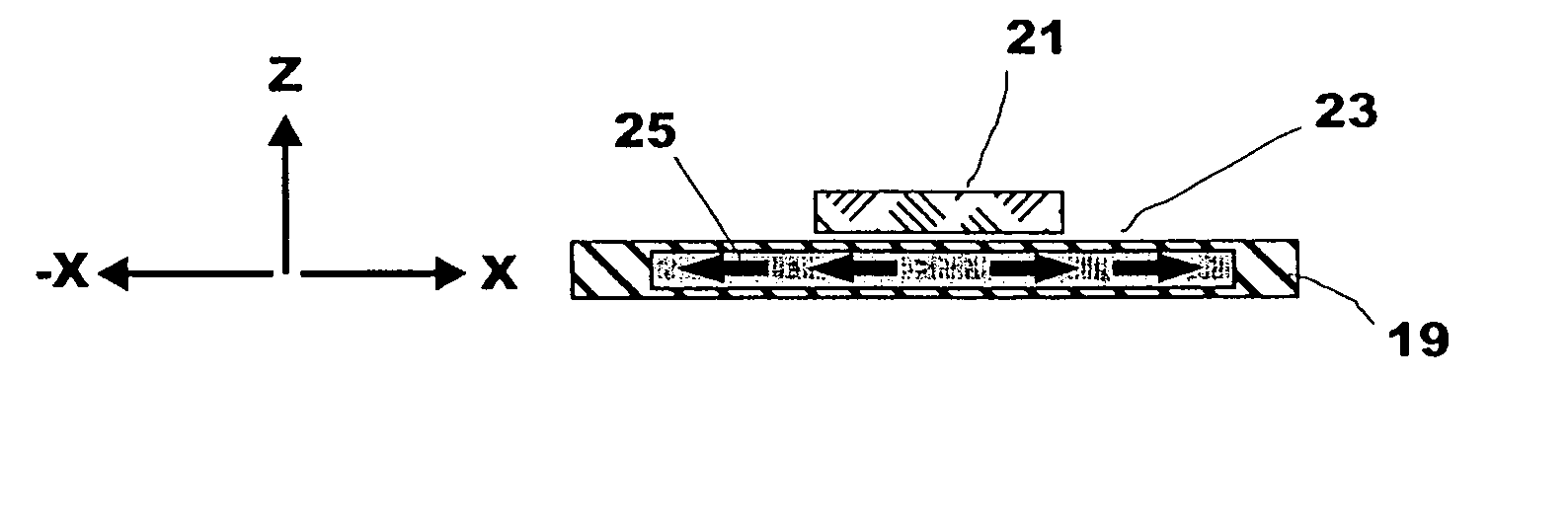

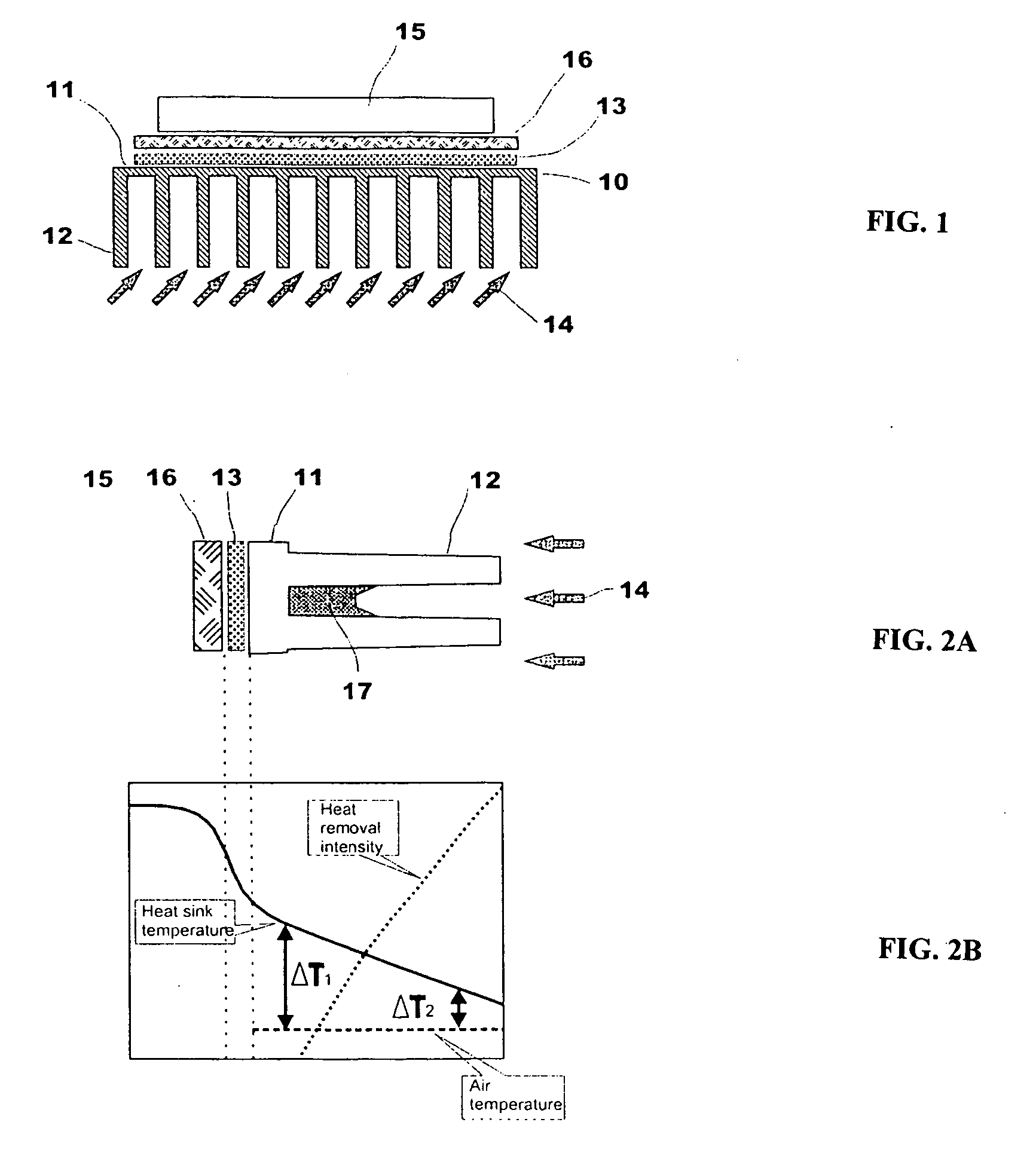

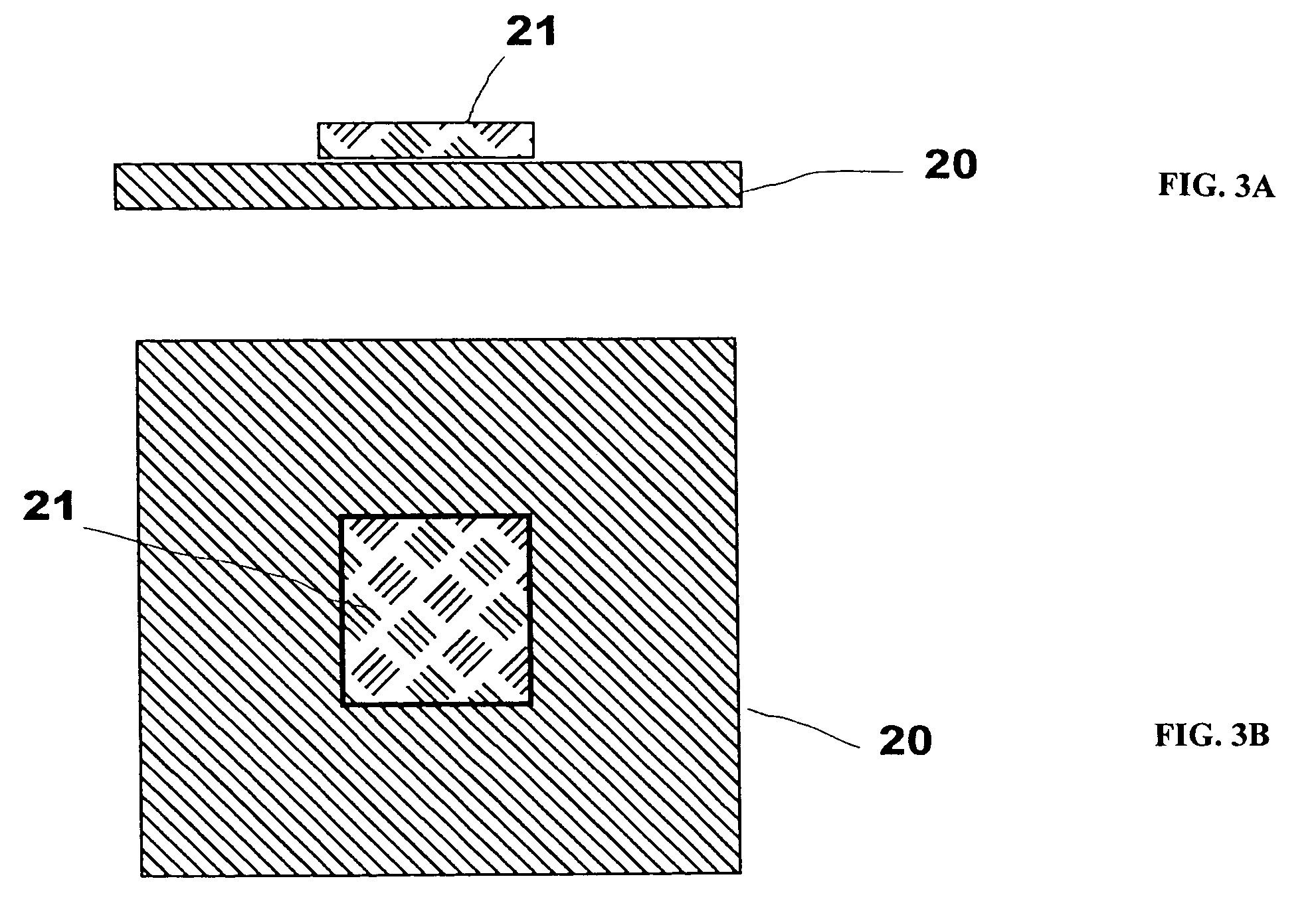

Thermal management system and computer arrangement

InactiveUS20060011336A1Increase volumeLow costInorganic phosphorous active ingredientsSemiconductor/solid-state device detailsEngineeringThermal management system

It is the object of the present invention to provide a low weight, compact, low vertical profile thermal management system for removing heat from electronic components. The thermal management system comprises of a plurality of “flow-through” type cooling devices, a source of filtered pressurized fluid suitable for use as a coolant, and a fluid delivering device that supplies the cooling devices with fluid. A preferred fluid is air, such as a filtered pressurized air. The cooling device is comprised of a high conductivity metal matrix composite heat spreader, a miniature heat sink, preferably of the same material, a permeable heat exchanger with high specific surface, and a closure that provides structural integrity of the cooling device.

Owner:FRUL VIKTOR

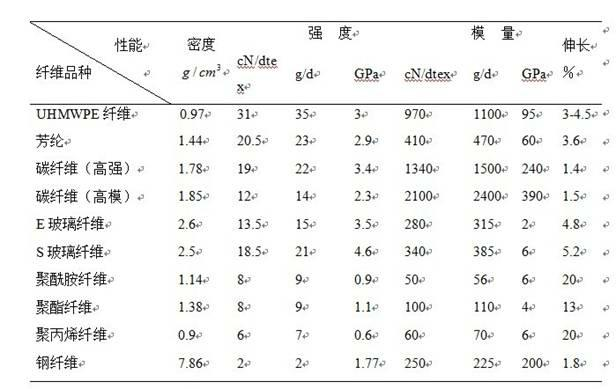

Method for improving creep resistant performance of ultra-high molecular weight polyethylene fiber

ActiveCN102493168AHigh surfaceIncrease internal cross-link pointsPhysical treatmentFibre typesFiberPolymer science

The invention relates to a method for improving the creep resistant performance of an ultra-high molecular weight polyethylene fiber; and the method is characterized by jointly triggering crosslinking by using a photosensitizer and a thermal initiating agent, thereby crosslinking points of the surface and interior of the ultra-high molecular weight polyethylene fiber are increased, the crosslinking efficiency of a cross-linking agent is improved, the relative slippage among molecules of the ultra-high molecular weight polyethylene fiber is effectively impeded and the creep resistant performance of the fiber is increased.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

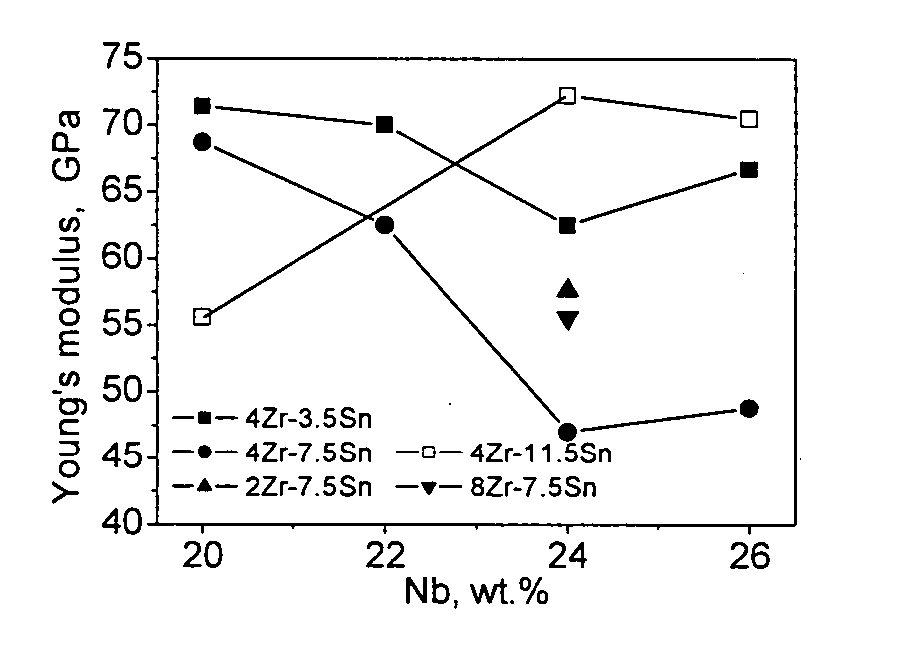

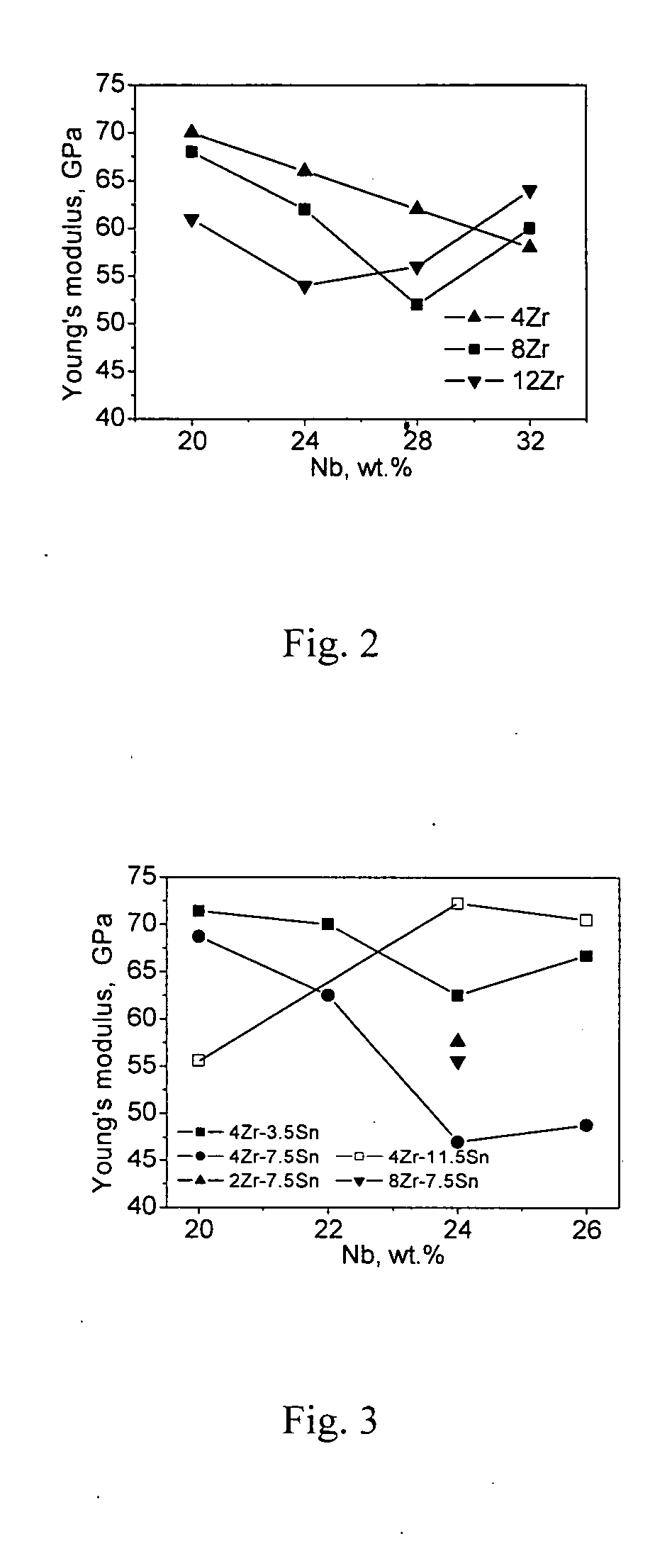

Titanium alloy with extra-low modulus and superelasticity and its producing method and processing thereof

The patent provides the titanium alloy with extra-low modulus and superelasticity containing 20˜35 wt. % niobium, 2˜15 wt. % zirconium, balanced titanium and other unavoidable impurity elements. The advantages of the invention alloy are shown as follows: The invention titanium alloy has superior cold processing capacity and low work hardening rate; It can be severely deformed by cold rolling and cold drawing; It has superelasticity, shape memory effect, damping capacity, low modulus, high strength, good corrosion resistance and high biocompatibility; The invention titanium alloy can be made into nano-size materials by cold deformation and extra high strength can be achieved by heat treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

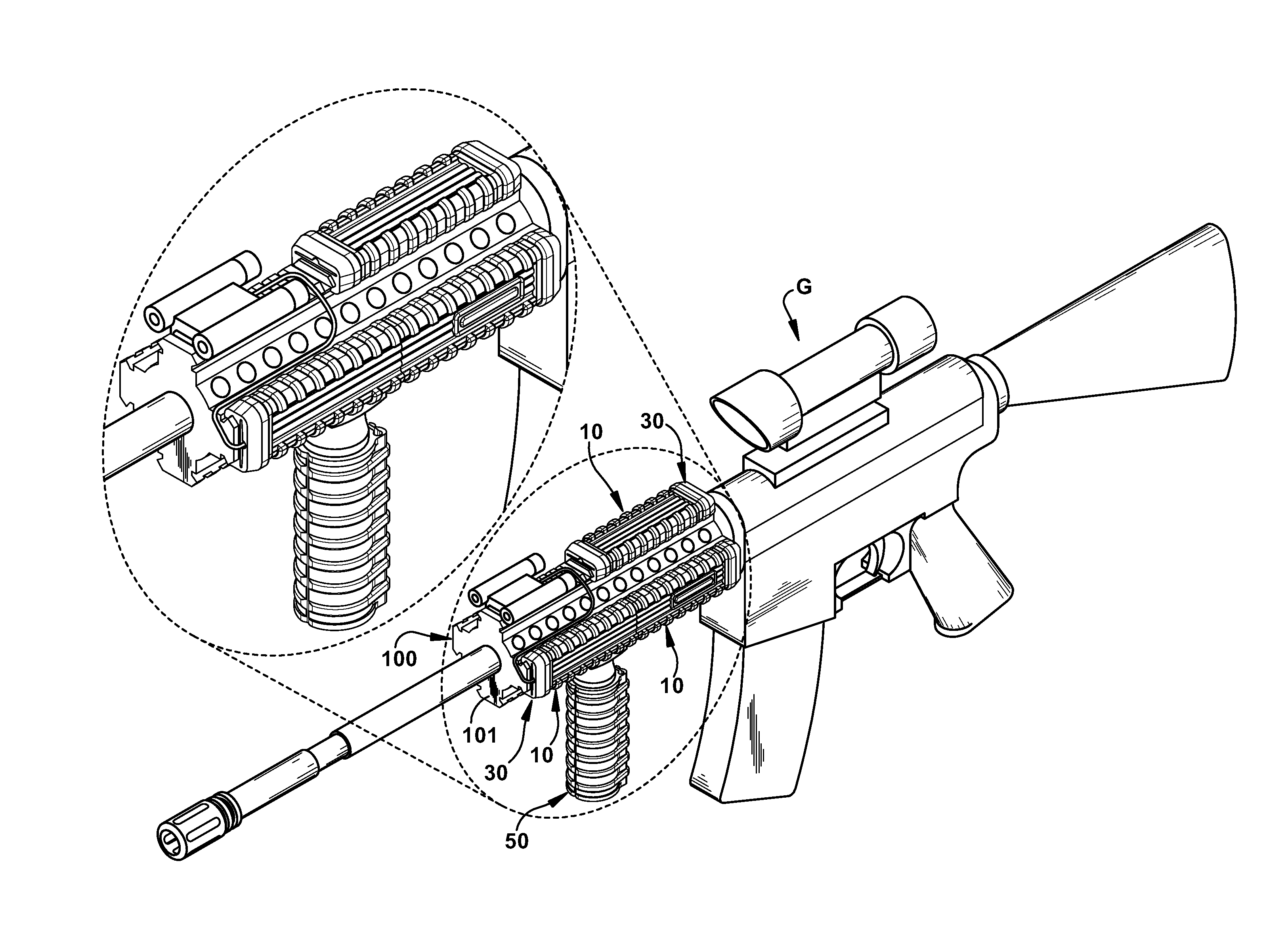

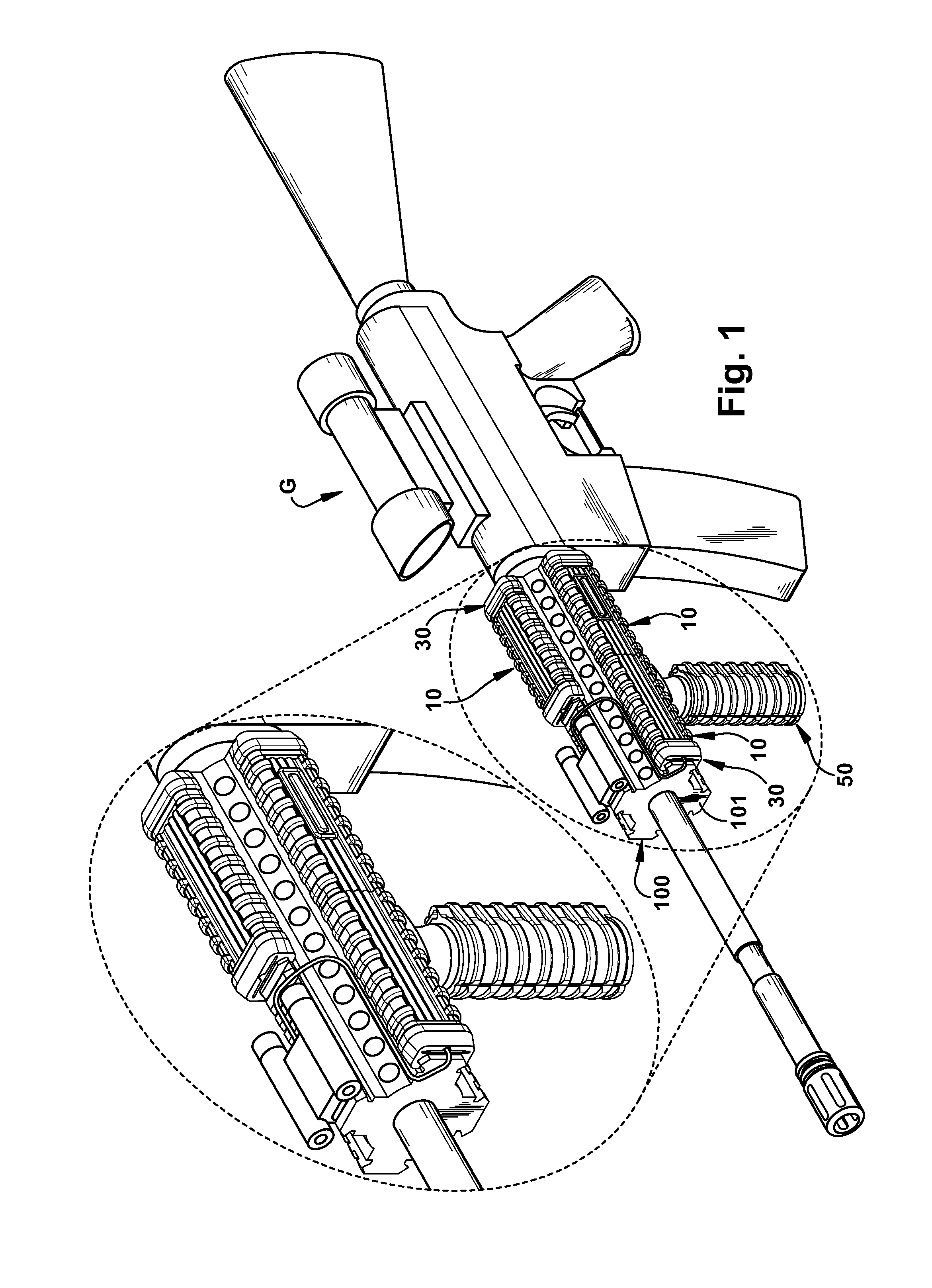

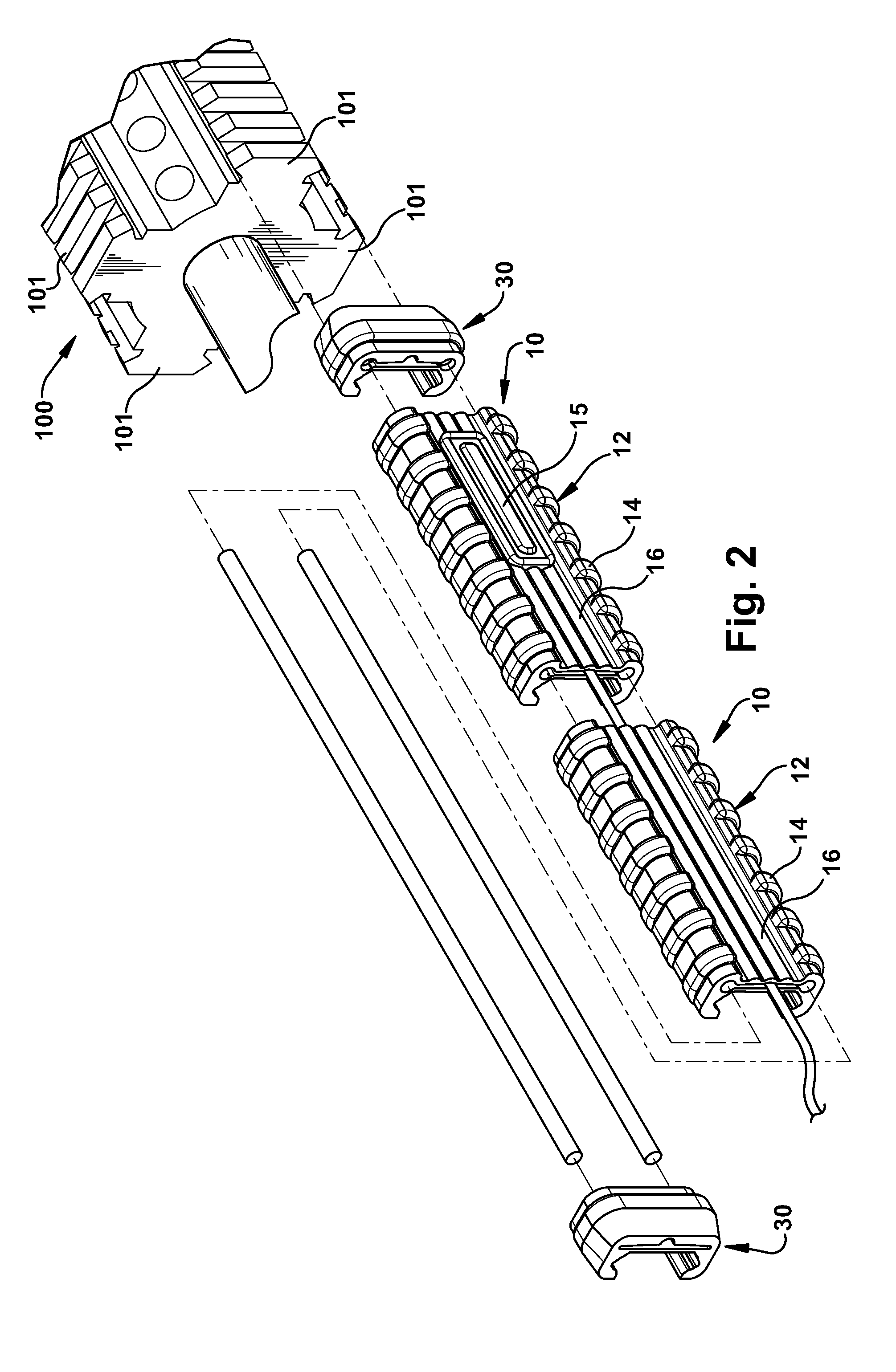

Gun rail attachments, components, accessories and systems

ActiveUS20120266514A1Improve gripHigh friction tactile gripping surfaceCartridge extractorsSighting devicesEngineeringMechanical engineering

Gun rail attachments, gun components and accessories and systems include attachment bodies made of polymeric materials with hardness ratings and ranges which are generally flexible and malleable and heat resistant. Reinforcing members are combined with the attachment bodies for secure attachment to gun rails and grips with only the polymeric attachment bodies exposed. Pockets, cavities and channels are formed in the attachment bodies for receiving wires, devices, device modules, components or accessories for guns.

Owner:AIM INC

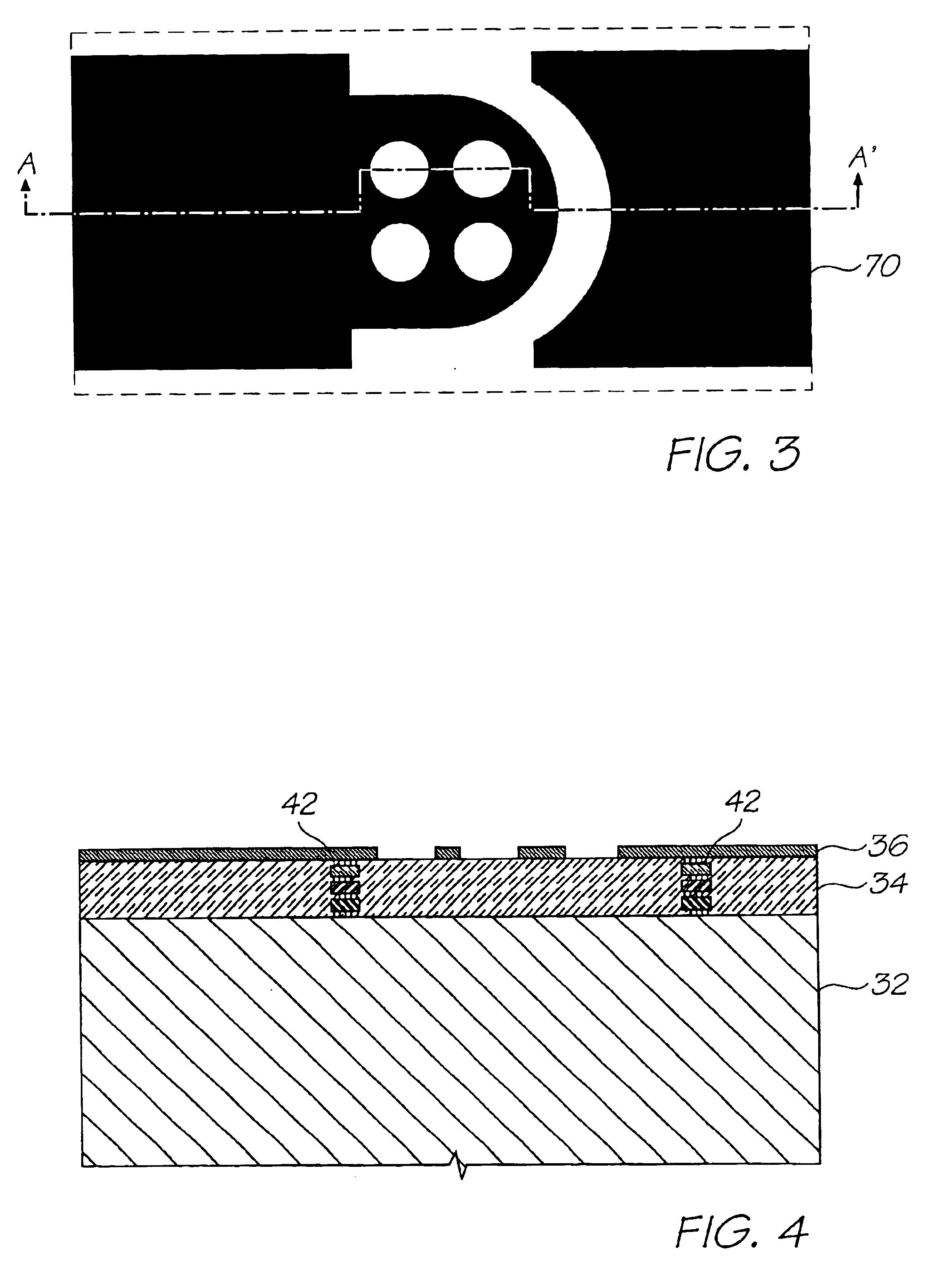

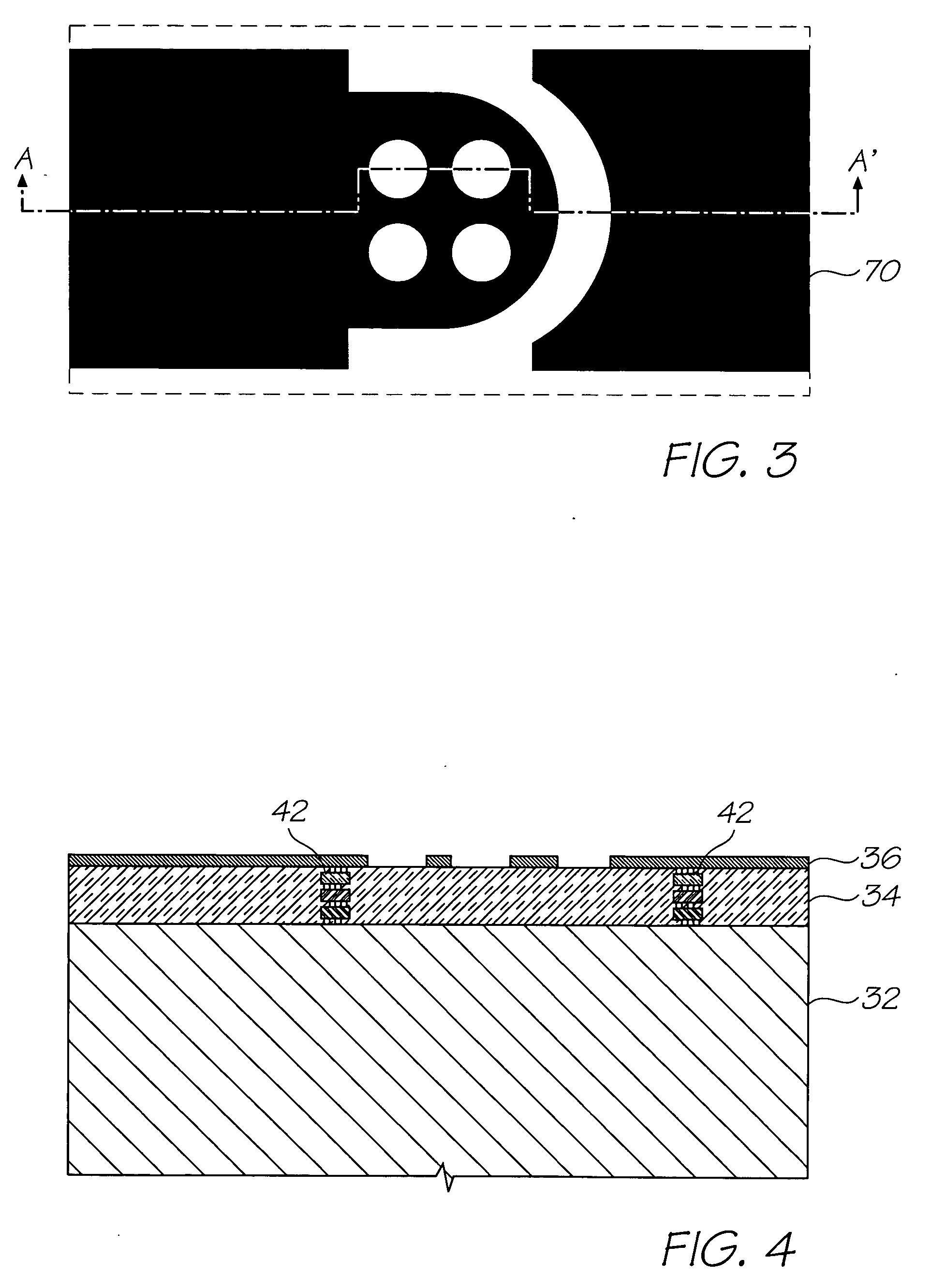

Capacitative pressure sensor with close electrodes

InactiveUS6968744B1Avoids extreme fluid pressureSmall surface area electrodeTyre measurementsMultiple fluid pressure valves simultaneous measurementCapacitive pressure sensorConductive materials

A pressure sensor (30) for harsh environments such as vehicle tires, formed from a chamber (58) partially defined by a flexible membrane (50), the chamber (58) containing a fluid at a reference pressure. In use, the flexible membrane (50) deflects due to pressure differentials between the reference pressure and the fluid pressure, the membrane being at least partially formed from conductive material. A conductive layer (36) is deposited within the chamber (58) spaced from the flexible membrane (50) such that they form opposing electrodes of a capacitor. Associated circuitry (34) is also deposited for converting the deflection of the flexible membrane (50) into an output signal indicative of the fluid pressure. The conductive layer (36) is less than 50 microns from the membrane in its undeflected state because capacitative sensors with closely spaced electrodes can have small surface area electrodes while maintaining enough capacitance for the required operating range. Furthermore, small electrodes reduce the power consumption of the sensor which in turn reduces the battery size needed for the operational life of the sensor.

Owner:PRECISION MECHATRONICS

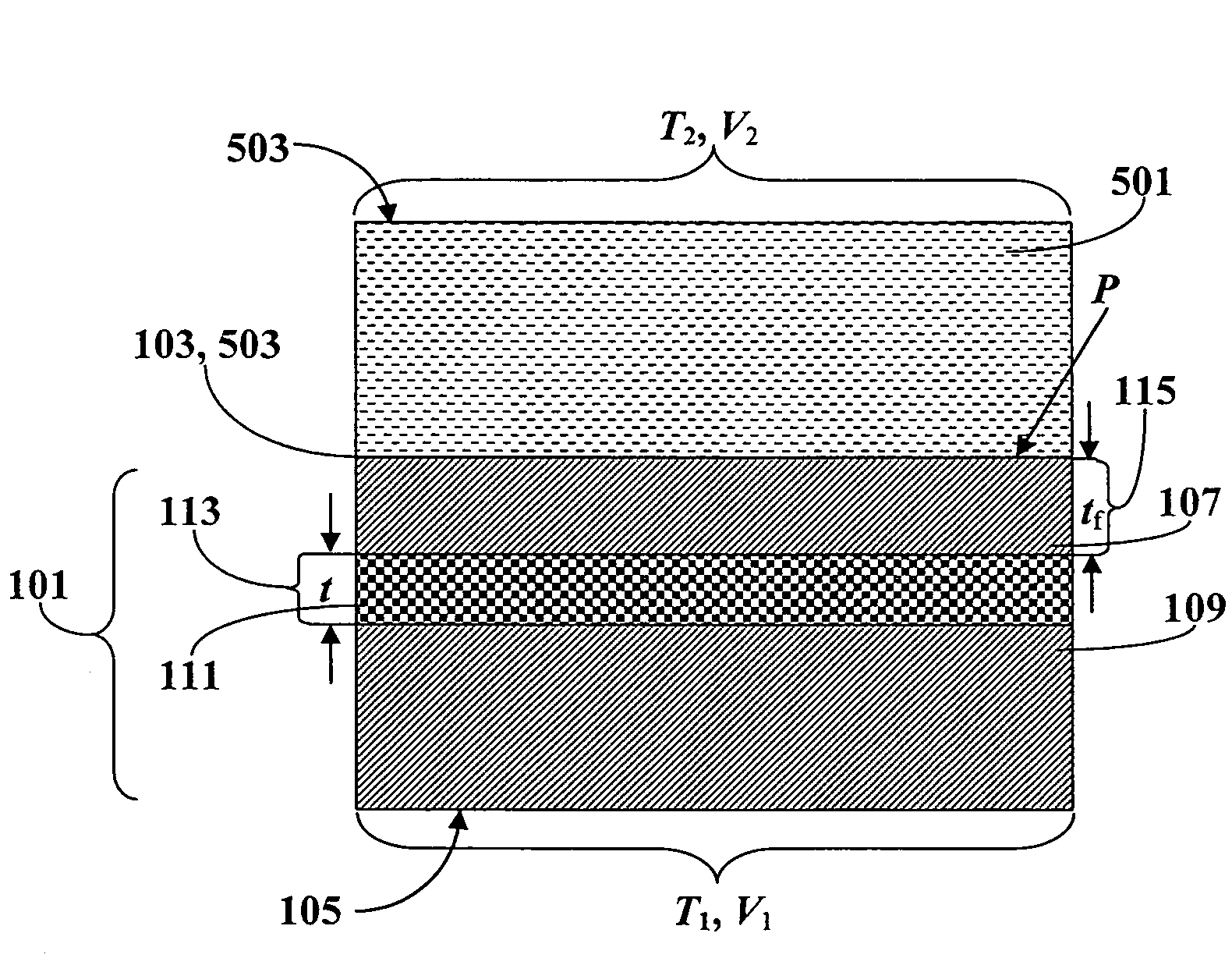

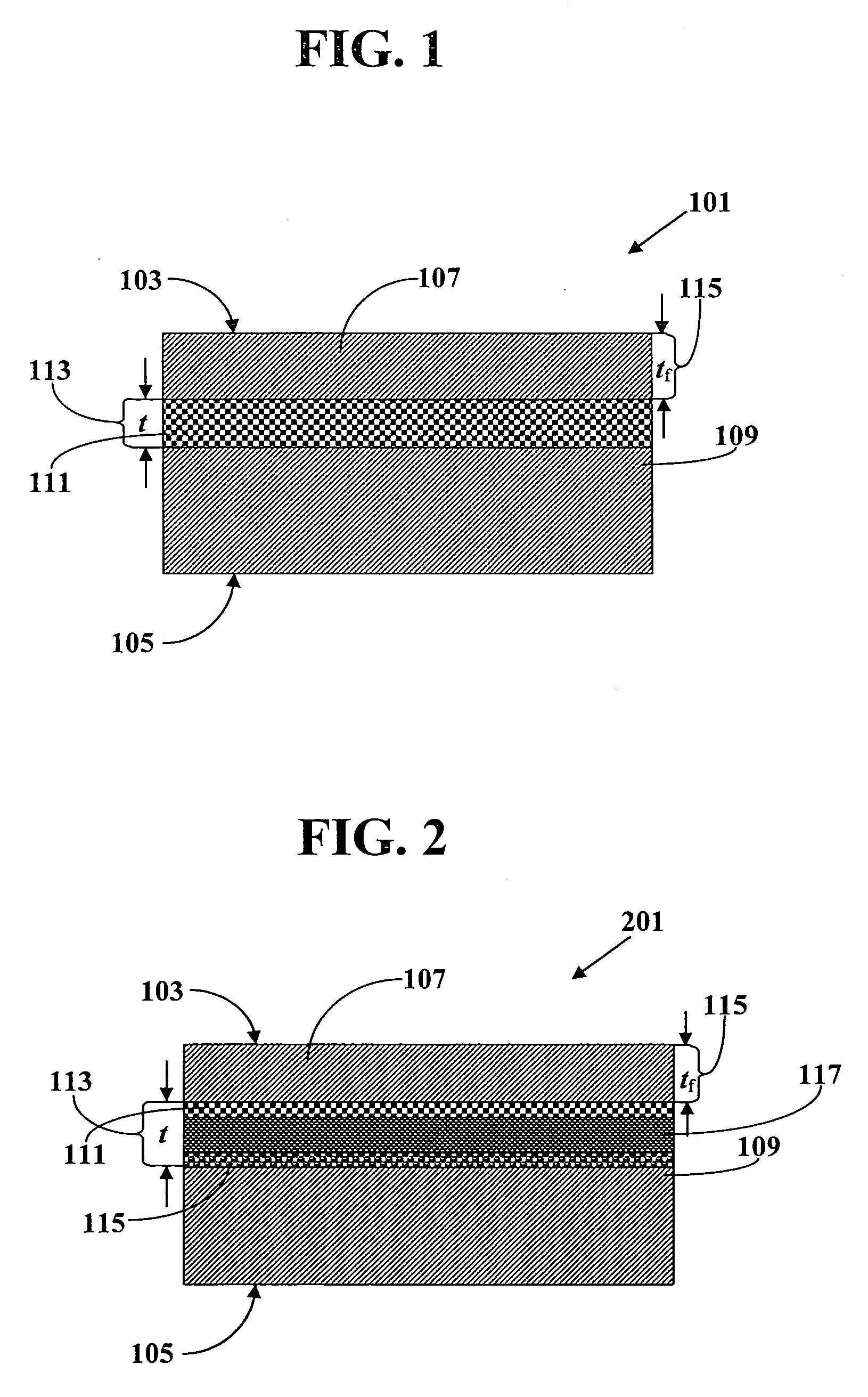

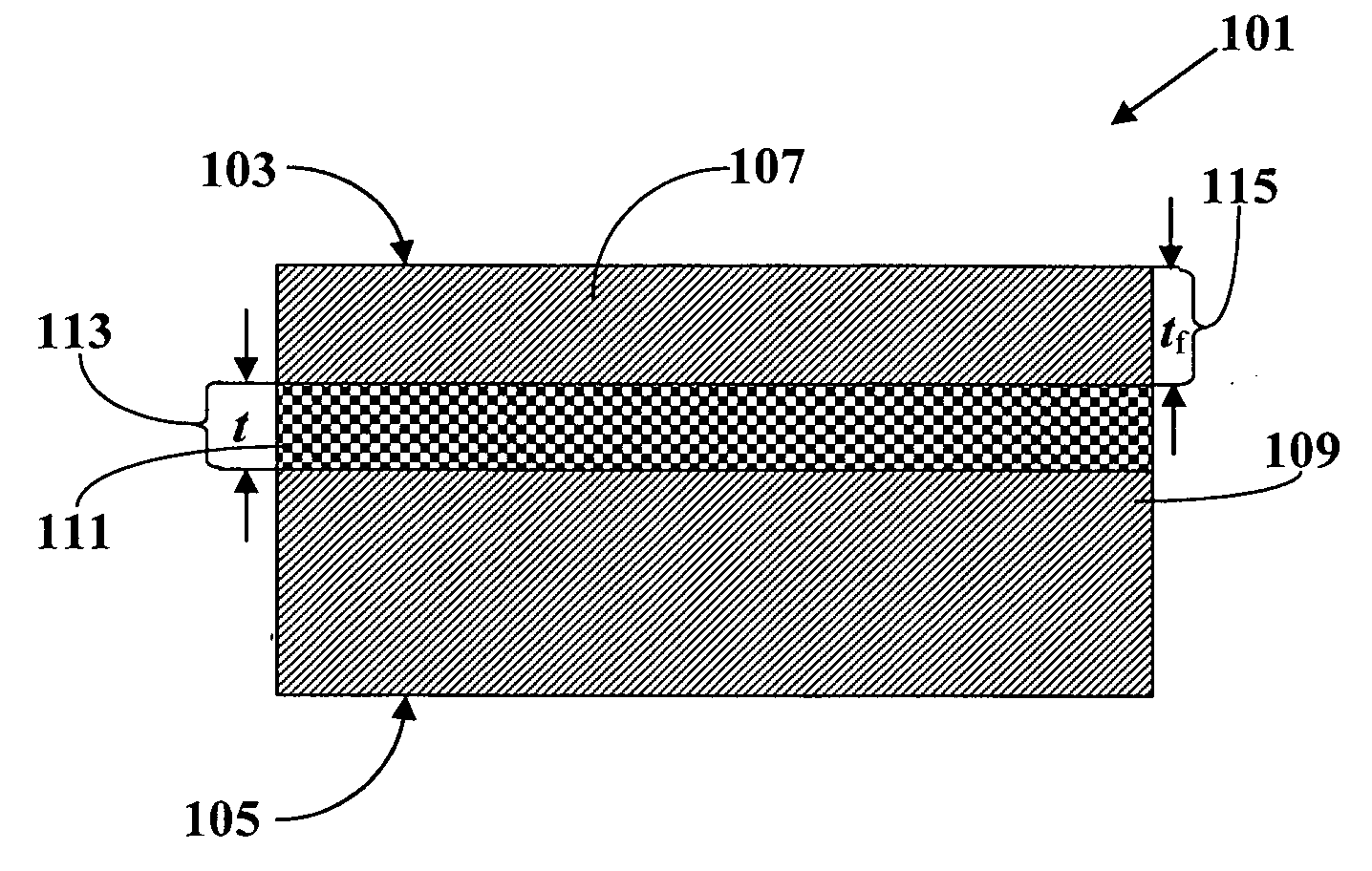

Semiconductor chip, and semiconductor wafer including a variable thickness insulating layer

ActiveUS7358602B2Rise to surfaceHigh surfacePrinted circuit assemblingSemiconductor/solid-state device detailsPhysicsSemiconductor chip

A semiconductor chip includes: a semiconductor substrate; a penetrating electrode which is formed through the semiconductor substrate from a first surface to a second surface of the semiconductor substrate and has a projection which projects from the second surface; an insulating layer formed over an entire surface of the second surface. The insulating layer includes a first insulating section formed in a region around the projection and a second insulating section other than the first insulating section. The second insulating section is formed to be thinner than a thickest area of the first insulating section.

Owner:SAMSUNG ELECTRONICS CO LTD

Metal Oxide/Hydroxide Materials

InactiveUS20070281854A1Facilitate accessibilityHigh surfaceOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsOxideHydroxide

Owner:COMMONWEALTH SCI & IND RES ORG

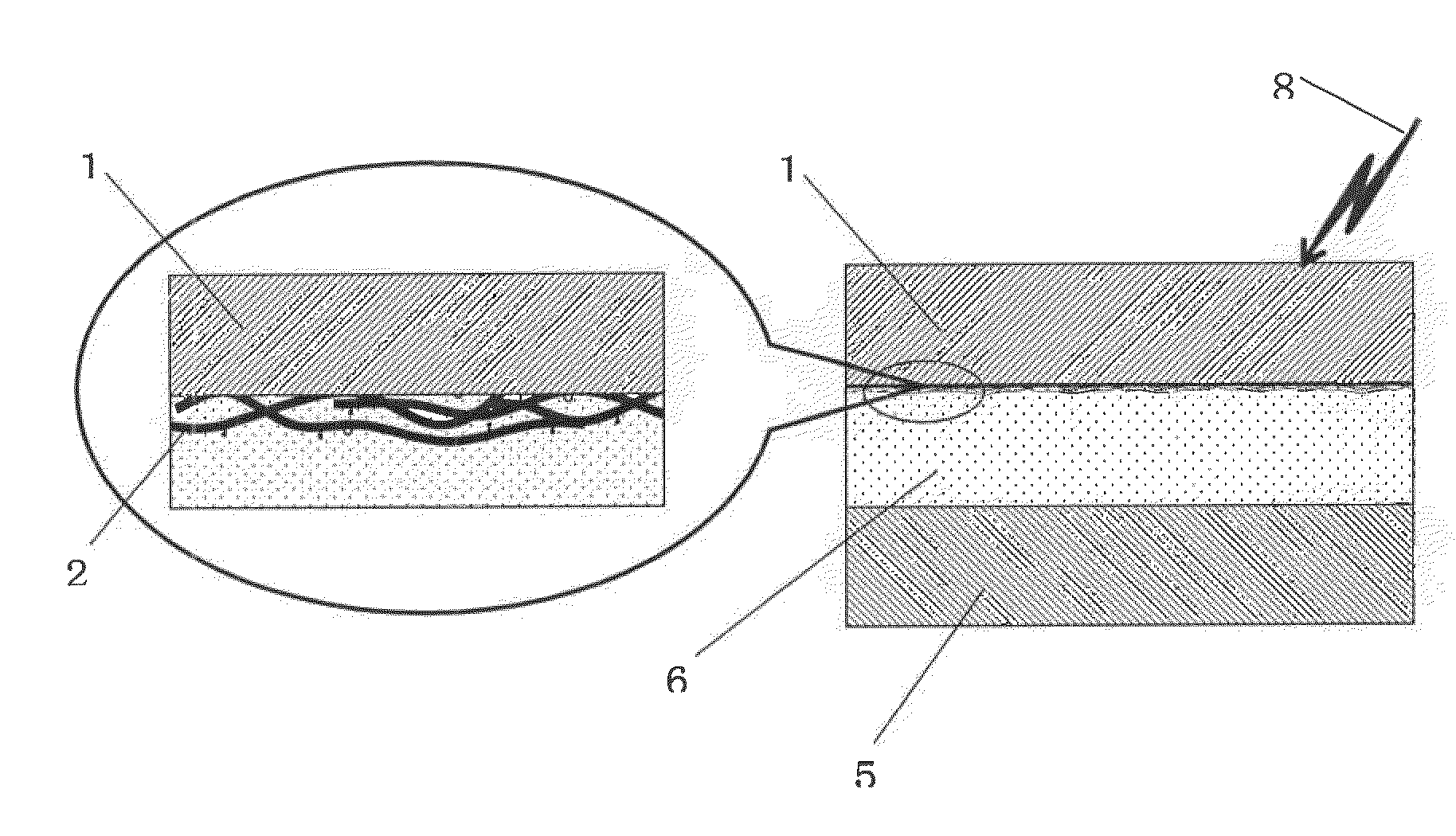

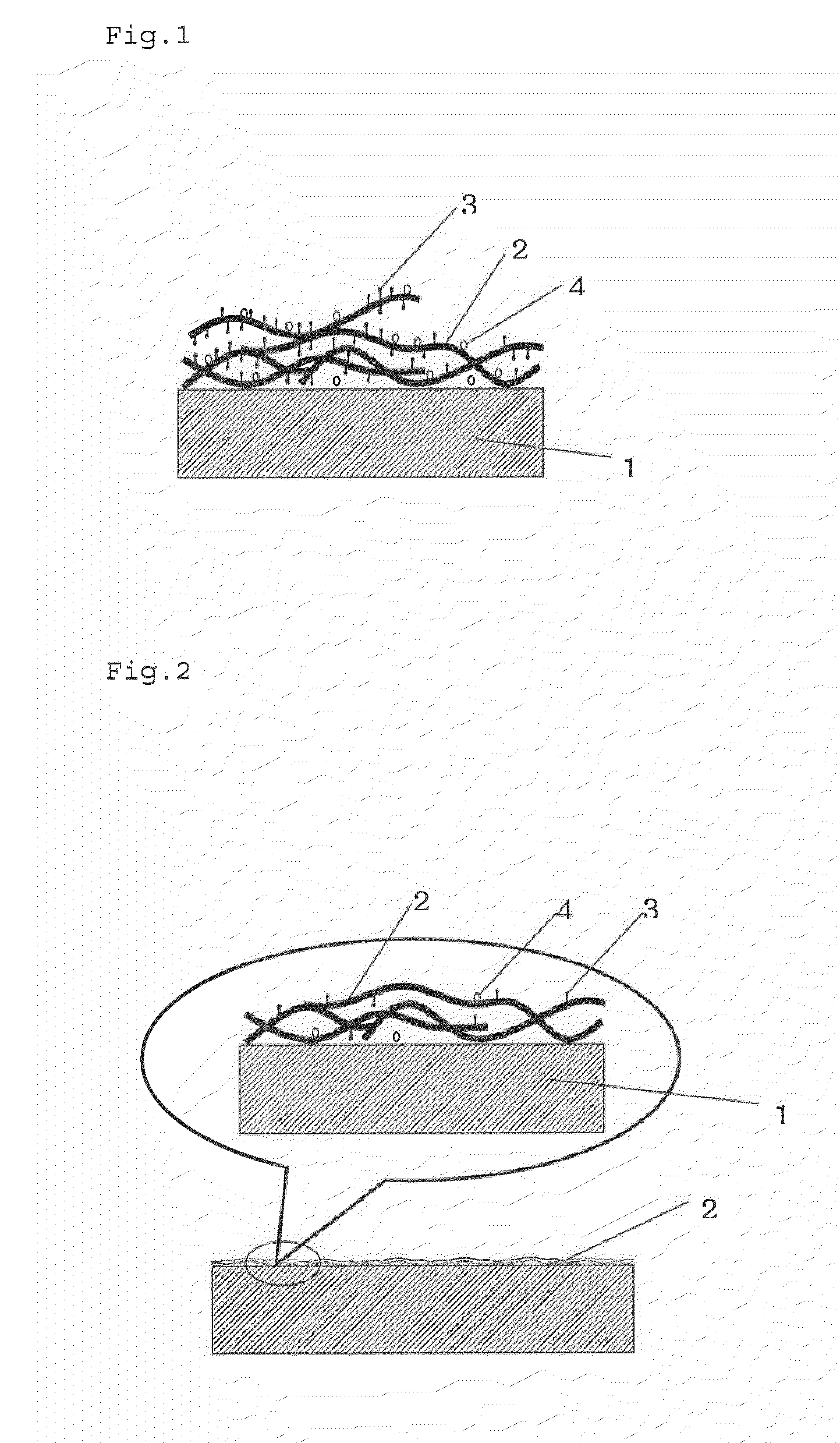

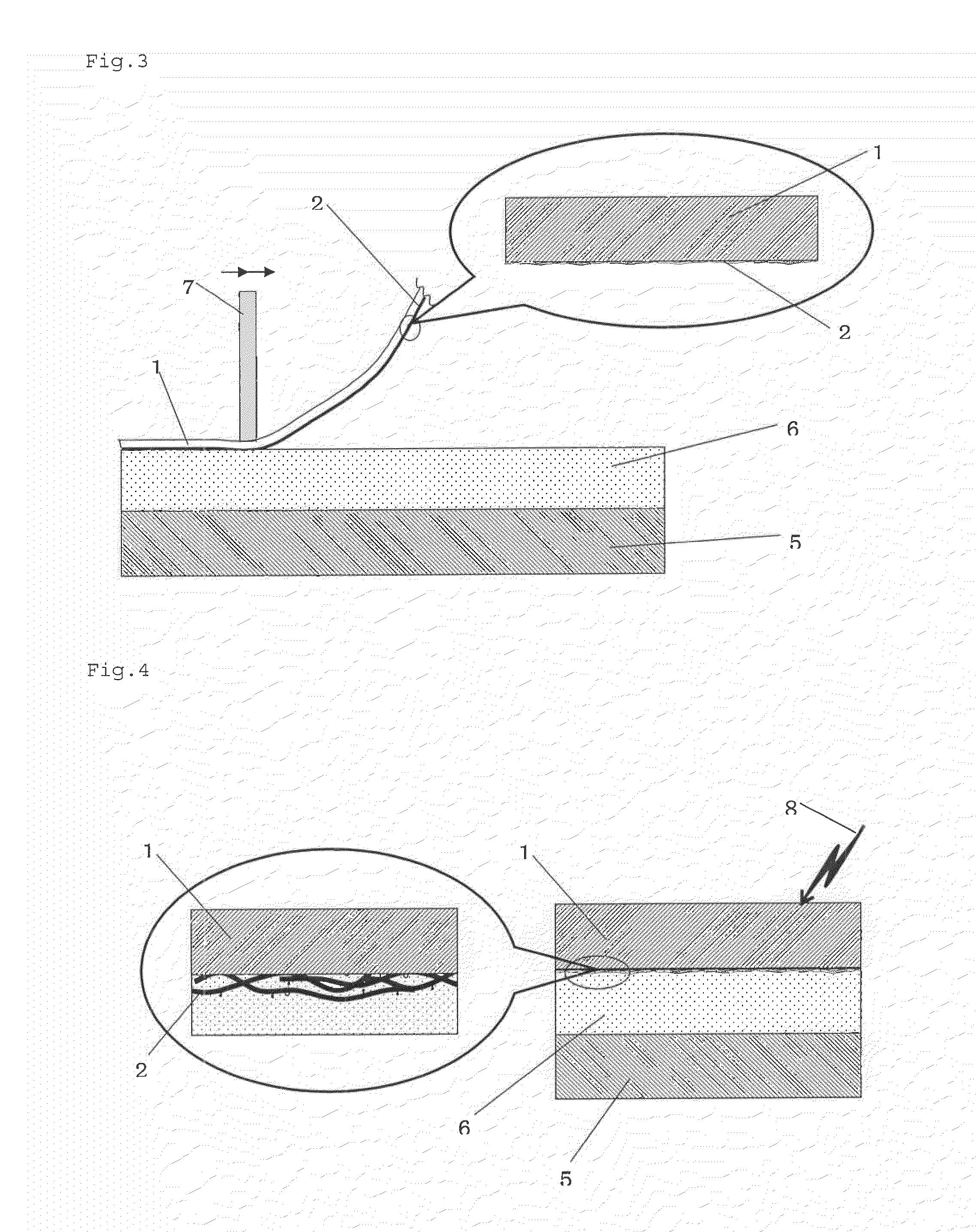

Method for producing carbon nanotube-containing conductor

ActiveUS20100252184A1High conductivityGood conductivityMaterial nanotechnologyDecorative surface effectsCarbon nanotubeLiquid resin

The invention is to provide a method for producing an inexpensive carbon nanotube-containing conductor having high transparency and high conductivity as well as excellent durability. The invention is a method for producing a carbon nanotube-containing conductor having a conductive layer on the surface of an objective substrate, and the method includes the steps of pressing a release substrate having a carbon nanotube network layer, via the carbon nanotube network layer thereon, against a transparent objective substrate coated with an electron beam-curable liquid resin composition to infiltrate the liquid resin composition into the carbon nanotube network layer; irradiating it with electron beams to cure the liquid resin composition; and peeling away the release substrate to obtain an objective substrate having a resin composition layer with carbon nanotubes embedded in the surface thereof. According to the invention, a conductor and a conductive film having high conductivity and transparency as well as excellent strength and durability are obtained.

Owner:MEIJO NANO CARBON

Inkjet ink sets for high speed printing on plain papers and glossy media

InactiveUS20090169761A1Improve image qualityLow hazeLiquid surface applicatorsInksEngineeringMagenta

An inkjet ink set comprising a cyan ink, a magenta ink and a yellow ink, wherein each of said cyan, magenta and yellow inks individually comprises at least 65% water, between 1% and 5% by weight of a dispersed pigment colorant, a surfactant that reduces static surface tension, a dynamic surface tension reducing agent distinct from the surfactant, and at least one humectant distinct from the surfactant and the dynamic surface tension reducing agent; wherein said surfactant, said dynamic surface tension reducing agent and said humectant can be the same or different between said cyan, magenta and yellow inks; and wherein each of said cyan, magenta and yellow inks is characterized by exhibiting a viscosity normalized dynamic surface tension at surface refresh ages of 0.01 s of less than 23.0 mN / (m*cP); and wherein the average viscosity normalized dynamic surface tension at a surface refresh age of 0.01 s for said cyan, magenta and yellow inks taken together is less than 22.0 mN / (m*cP).

Owner:EASTMAN KODAK CO

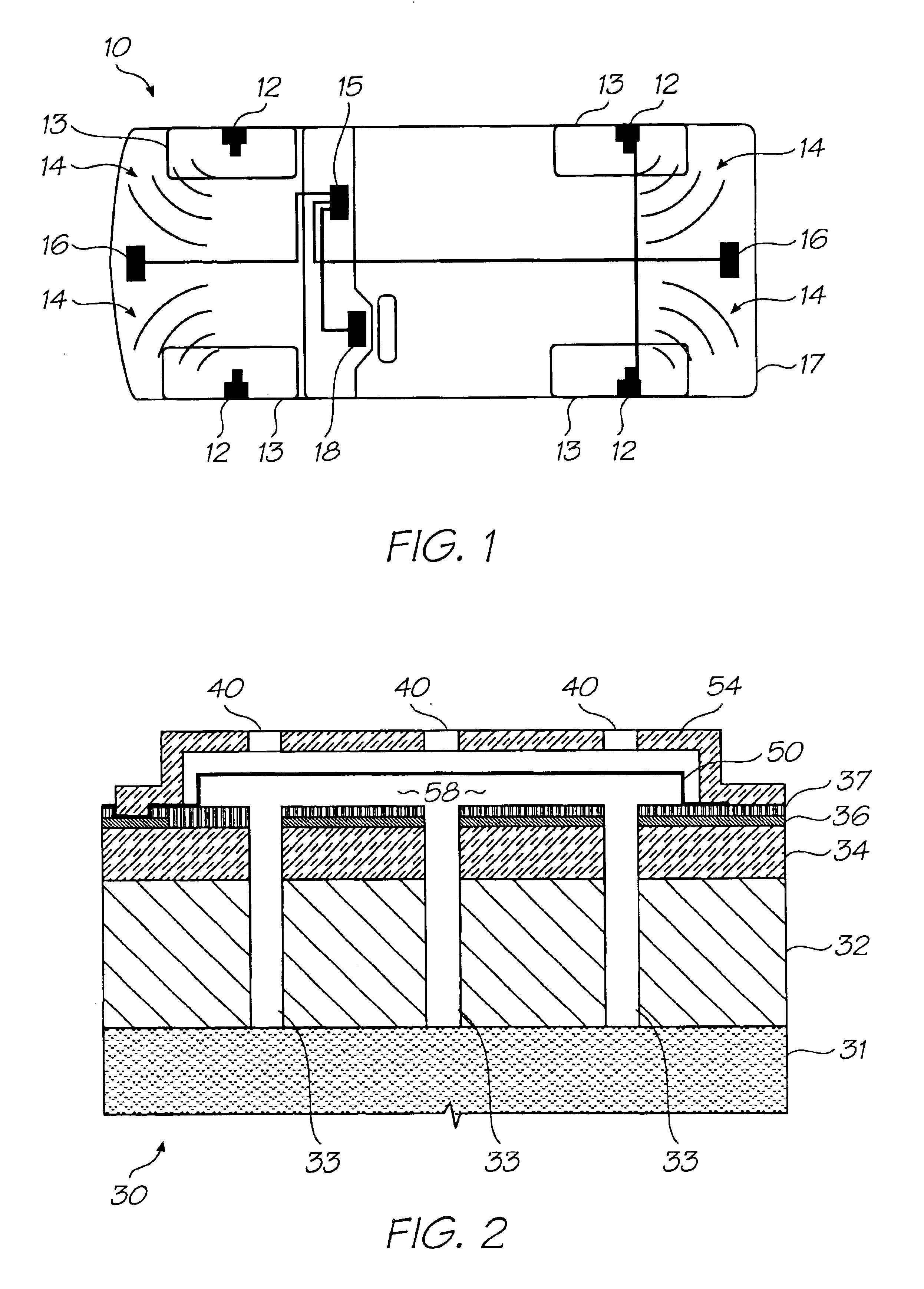

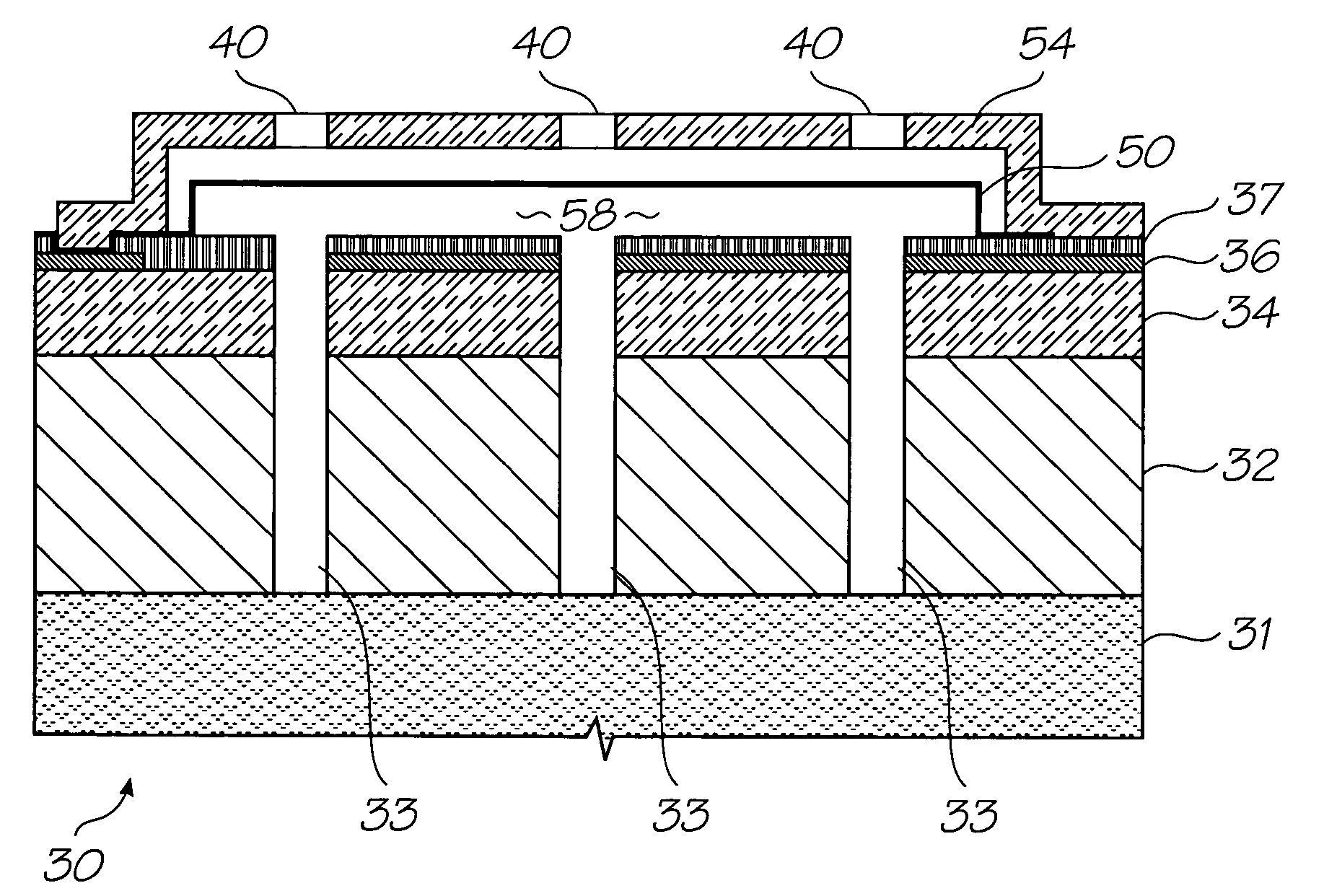

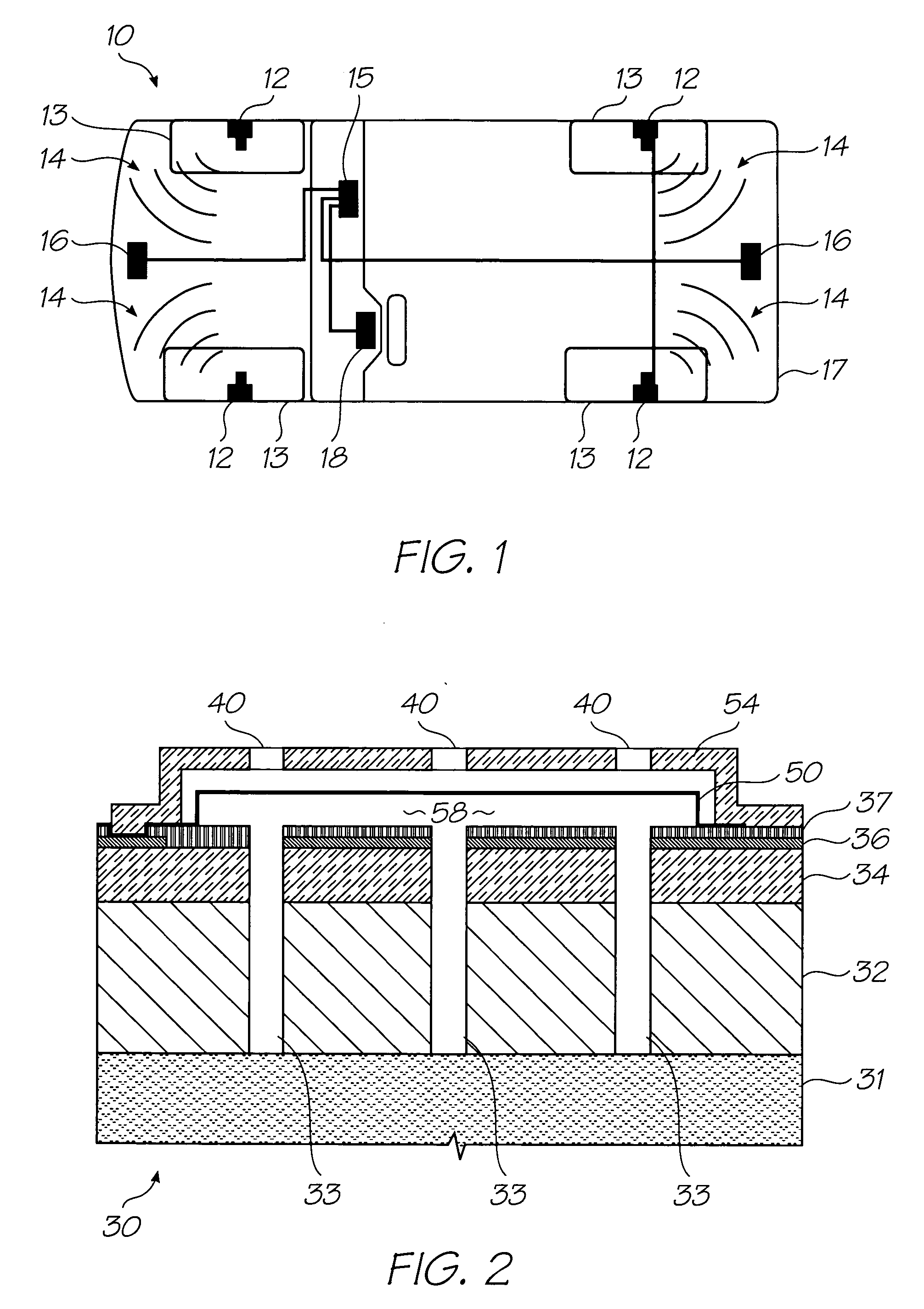

Wafer bonded pressure sensor

InactiveUS20060081062A1The material is lowAvoids high surface cleanlinessFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsHermetic sealEngineering

A pressure sensor (30) for sensing a fluid pressure in harsh environments such as the air pressure in a tire, by using a first wafer substrate (32) with a front side and an opposing back side, a chamber (58) partially defined by a flexible membrane (50) formed on the front side and at least one hole (33) etched from the back side to the chamber (58); a second wafer (31) on the back side of the first wafer (32) to seal the at least one hole (33); wherein, the chamber (58) containing a fluid at a reference pressure, such that the flexible membrane (50) deflects due to pressure differentials between the reference pressure and the fluid pressure; and, associated circuitry (34) for converting the deflection of the flexible membrane (50) into an output signal indicative of the fluid pressure; wherein, the second wafer (31) is wafer bonded to the first wafer substrate (32). Wafer bonding offers an effective non-adhesive solution. It provides a hermetic seal with only minor changes to the fabrication procedure. Skilled workers in this field will readily understand that the most prevalent forms of wafer bonding are: direct wafer, or silicon fusion, bonding; anodic, or electrostatic Mallory process bonding; and, intermediate layer bonding.

Owner:PRECISION MECHATRONICS

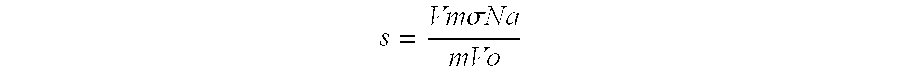

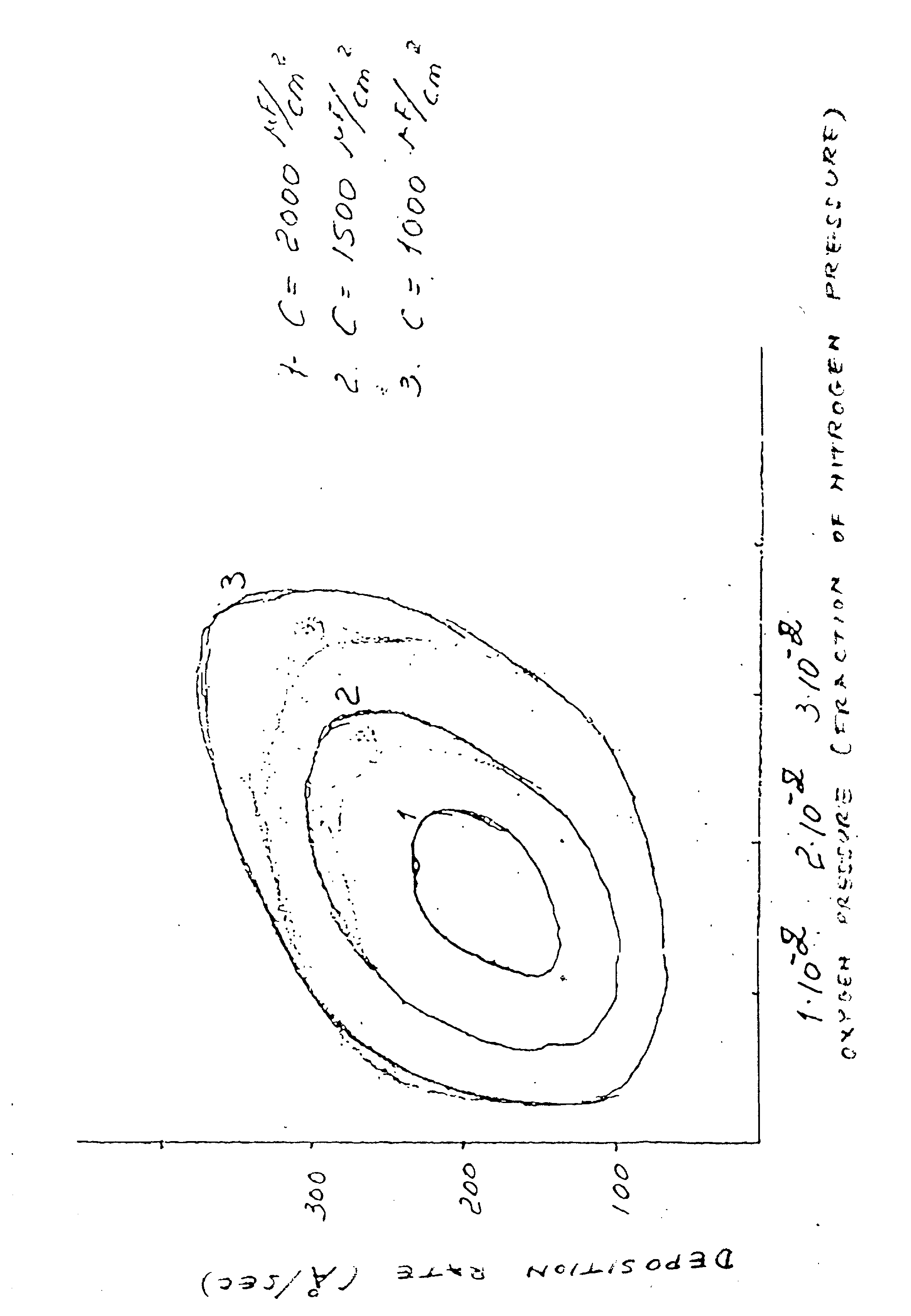

Method for producing high surface area foil electrodes

InactiveUS20010051442A1Increase capacitanceHigh surfaceFixed capacitor dielectricSynthetic resin layered productsElectrolysisMetal foil

A method for increasing the surface area of foil electrodes of electrolytic capacitors. A valve metal is deposited by evaporation on a valve metal foil in a low pressure inert atmosphere including oxygen at a pressure one to two orders of magnitude lower than the pressure of the inert gas. The resulting surface is fractal-like. The foil thus treated is suitable as such for use as a cathode. Prior to anodization to produce an anode, a discontinuous layer of a valve metal oxide is deposited on the foil, to preserve the high surface area of the fractal-like surface and otherwise promote the formation of a dielectric coating whose interface with the metal foil has a high surface area.

Owner:ACKTAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com