Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

969 results about "Induction heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An induction heater is a key piece of equipment used in all forms of induction heating. Typically an induction heater operates at either medium frequency (MF) or radio frequency (RF) ranges.

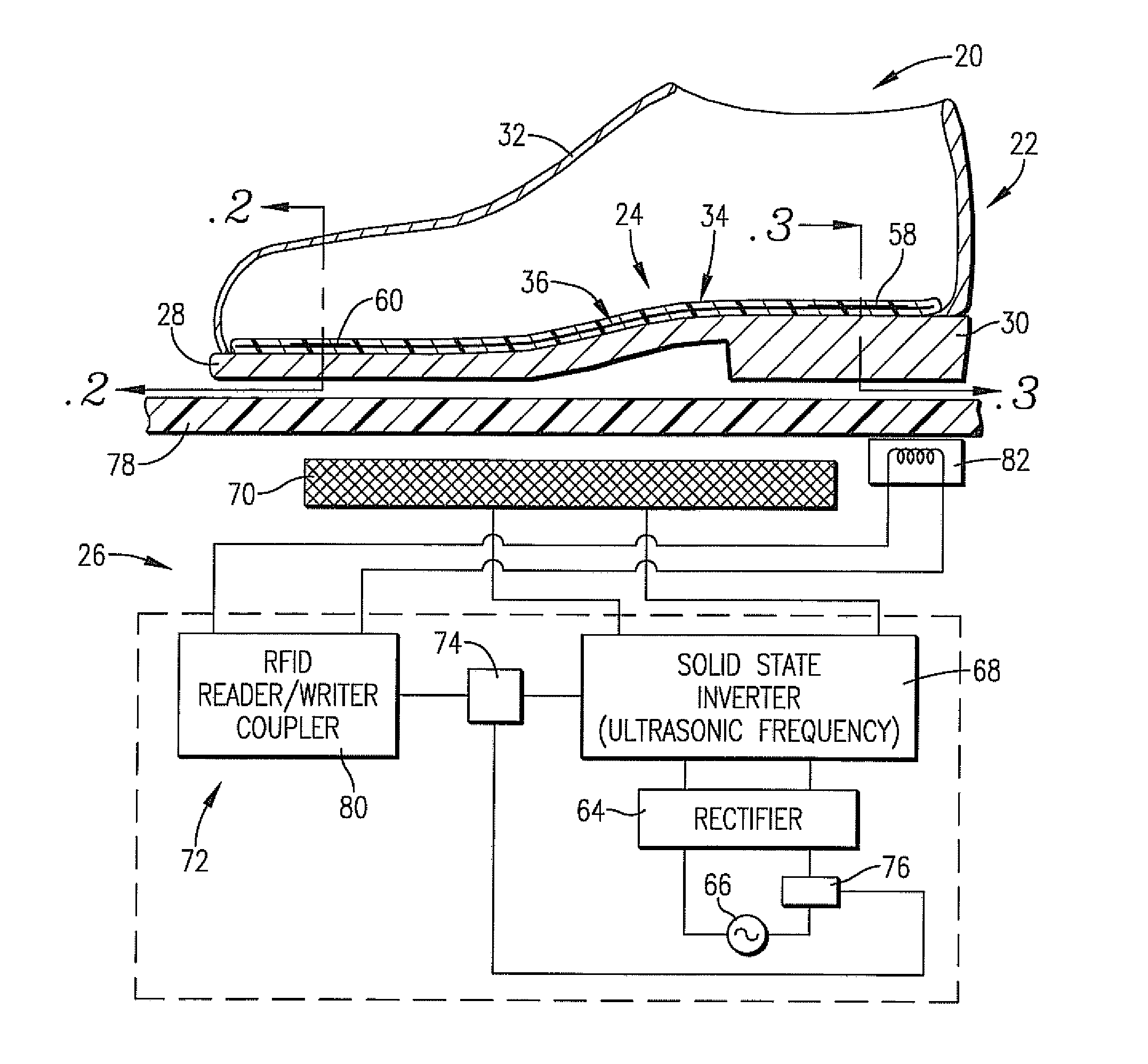

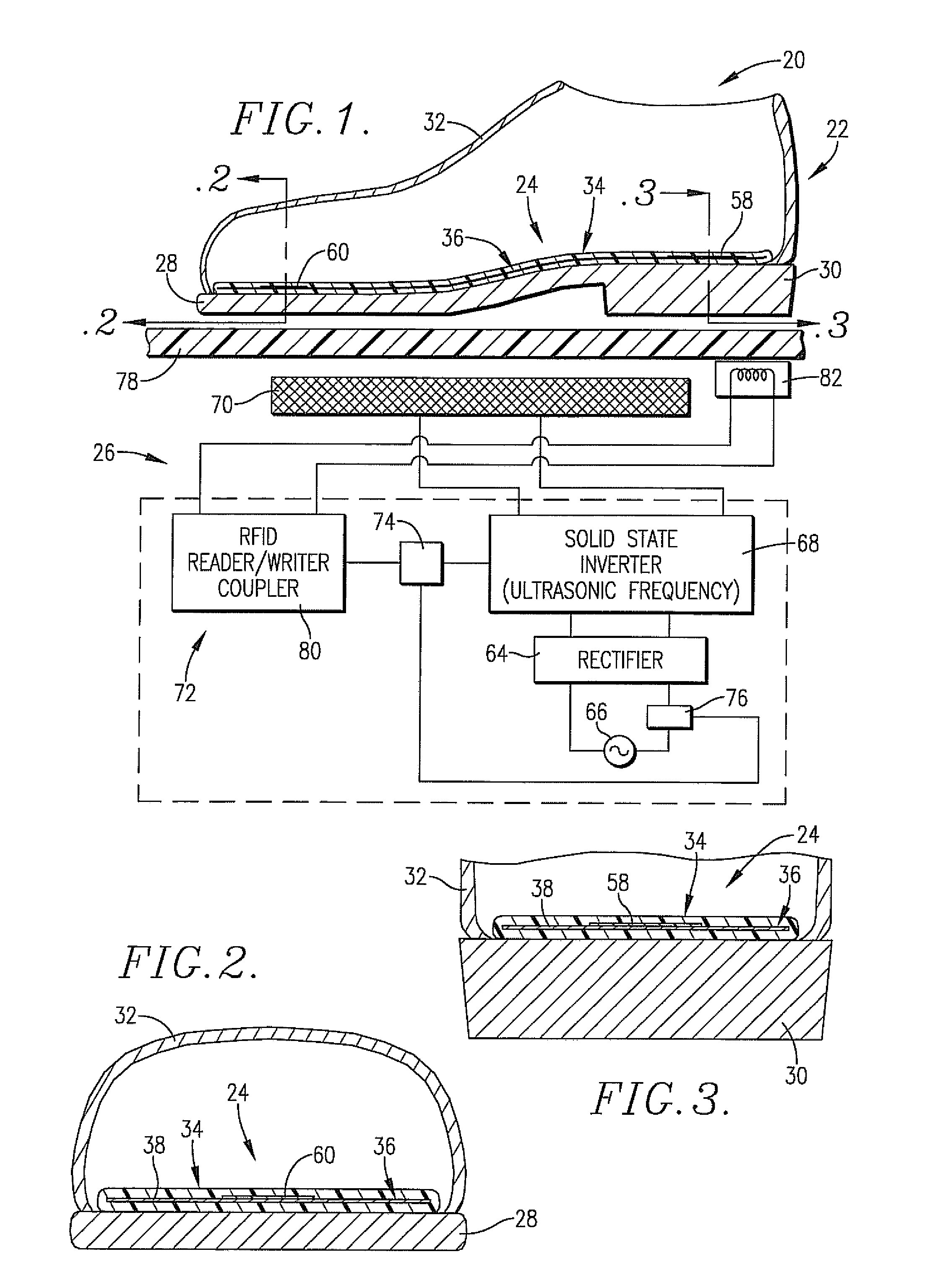

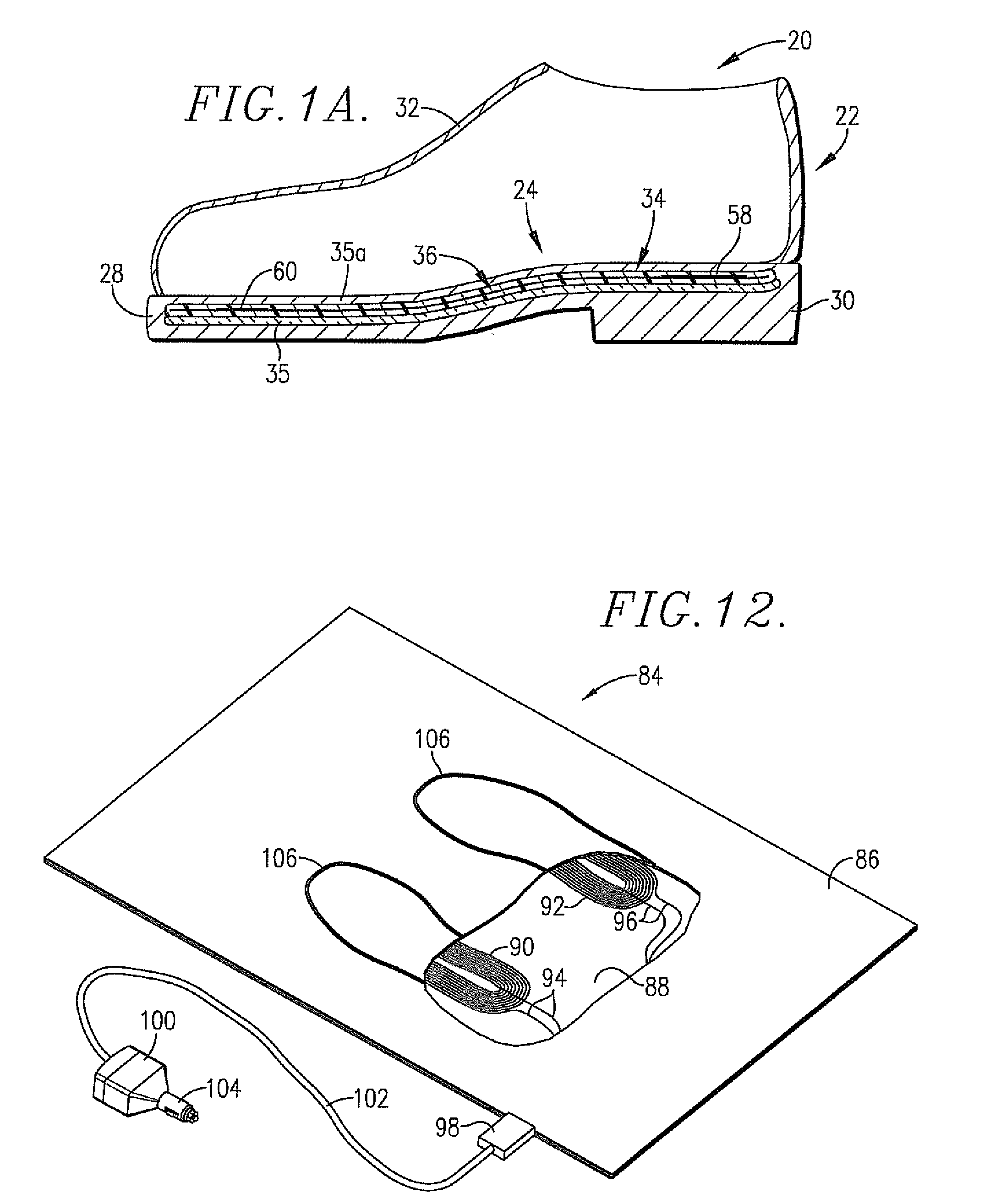

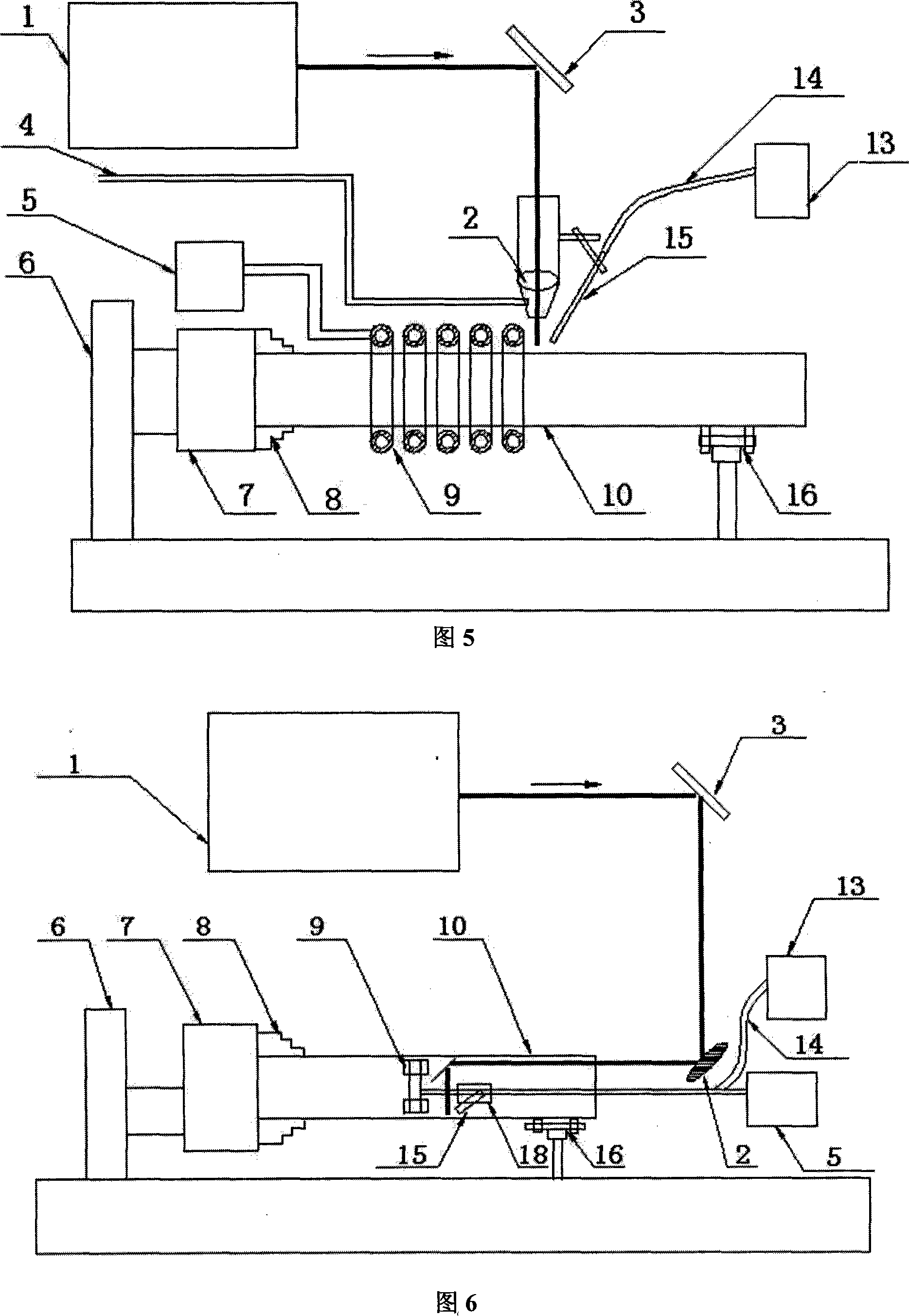

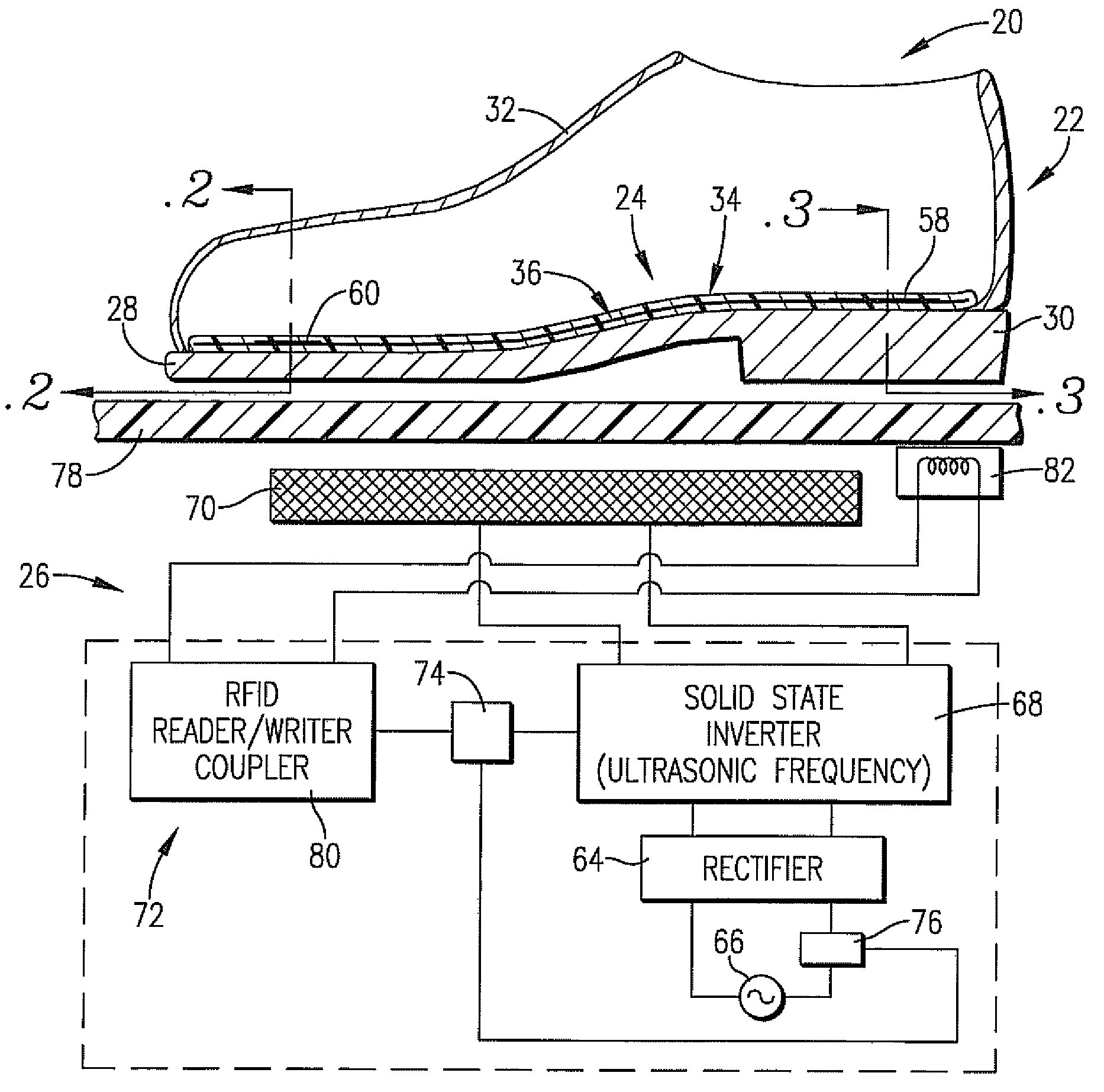

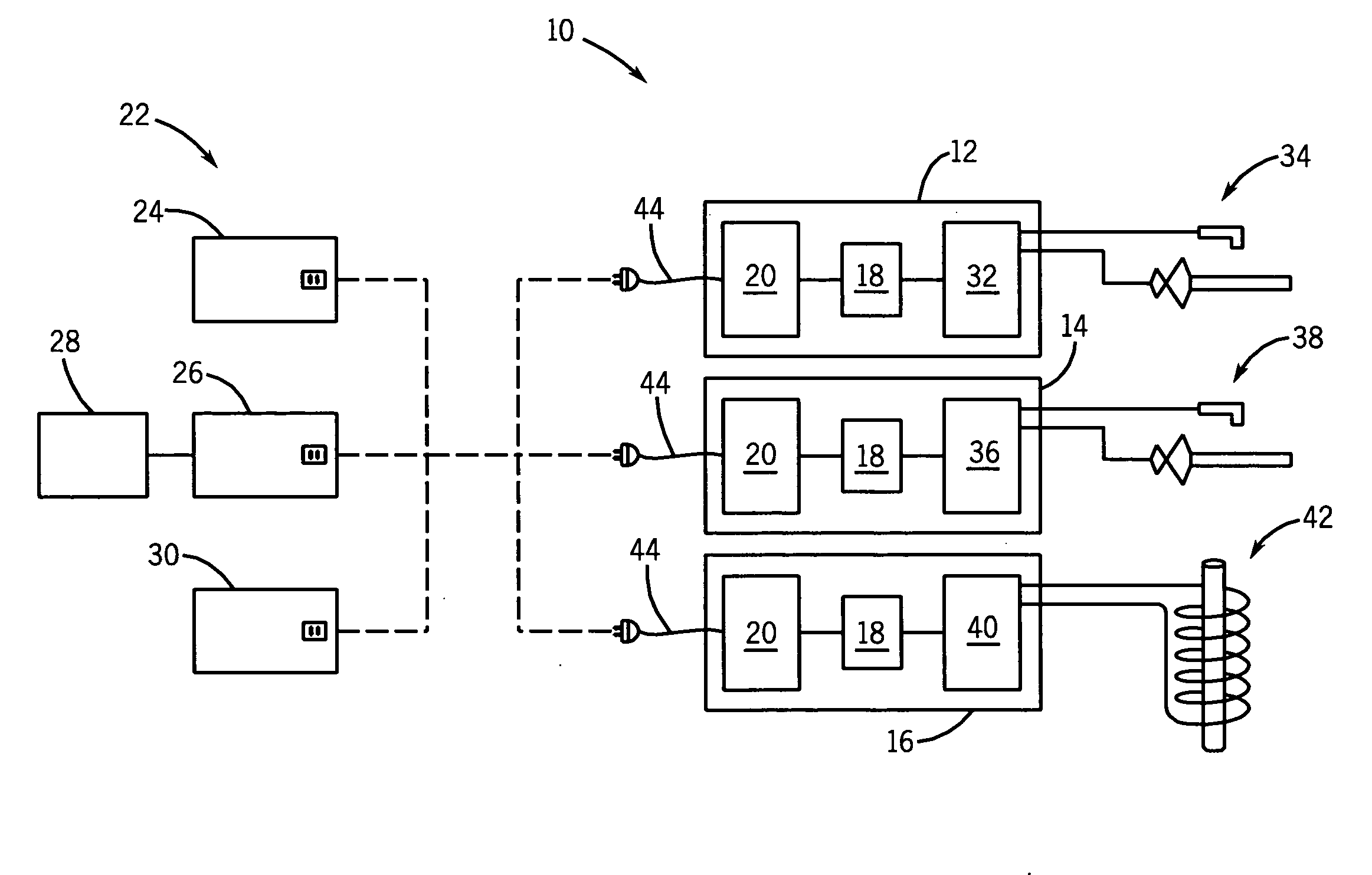

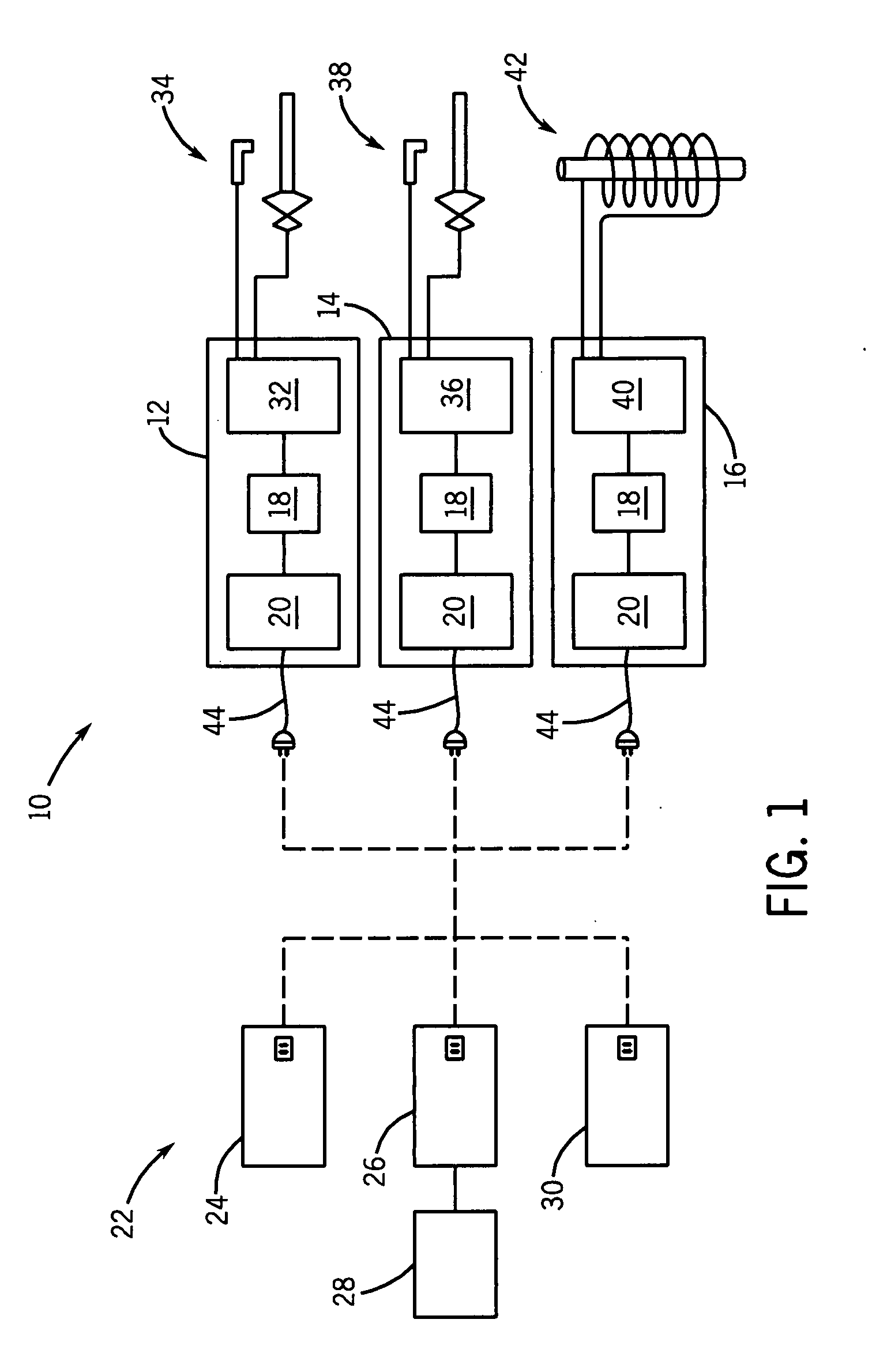

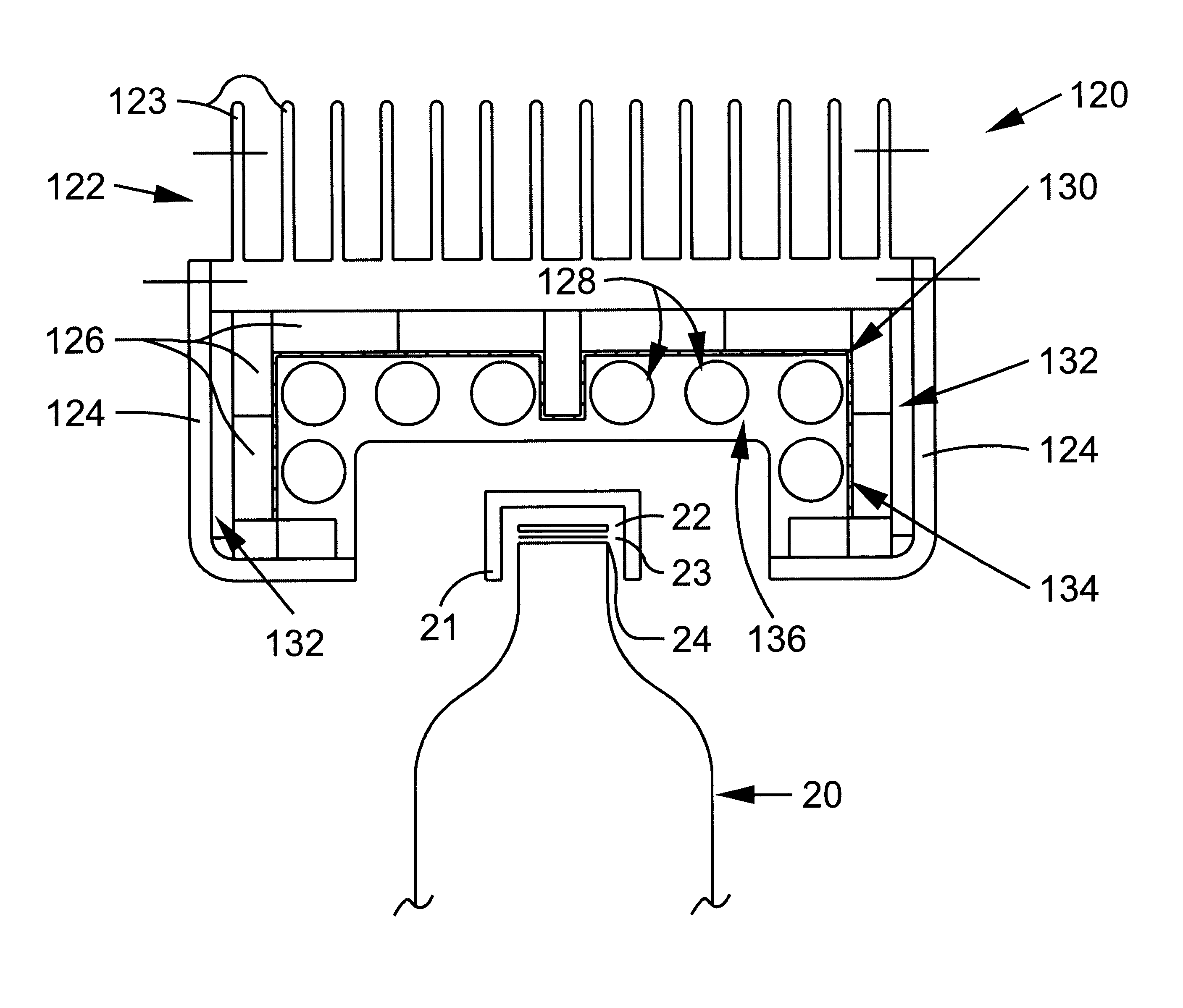

Inductively heated clothing

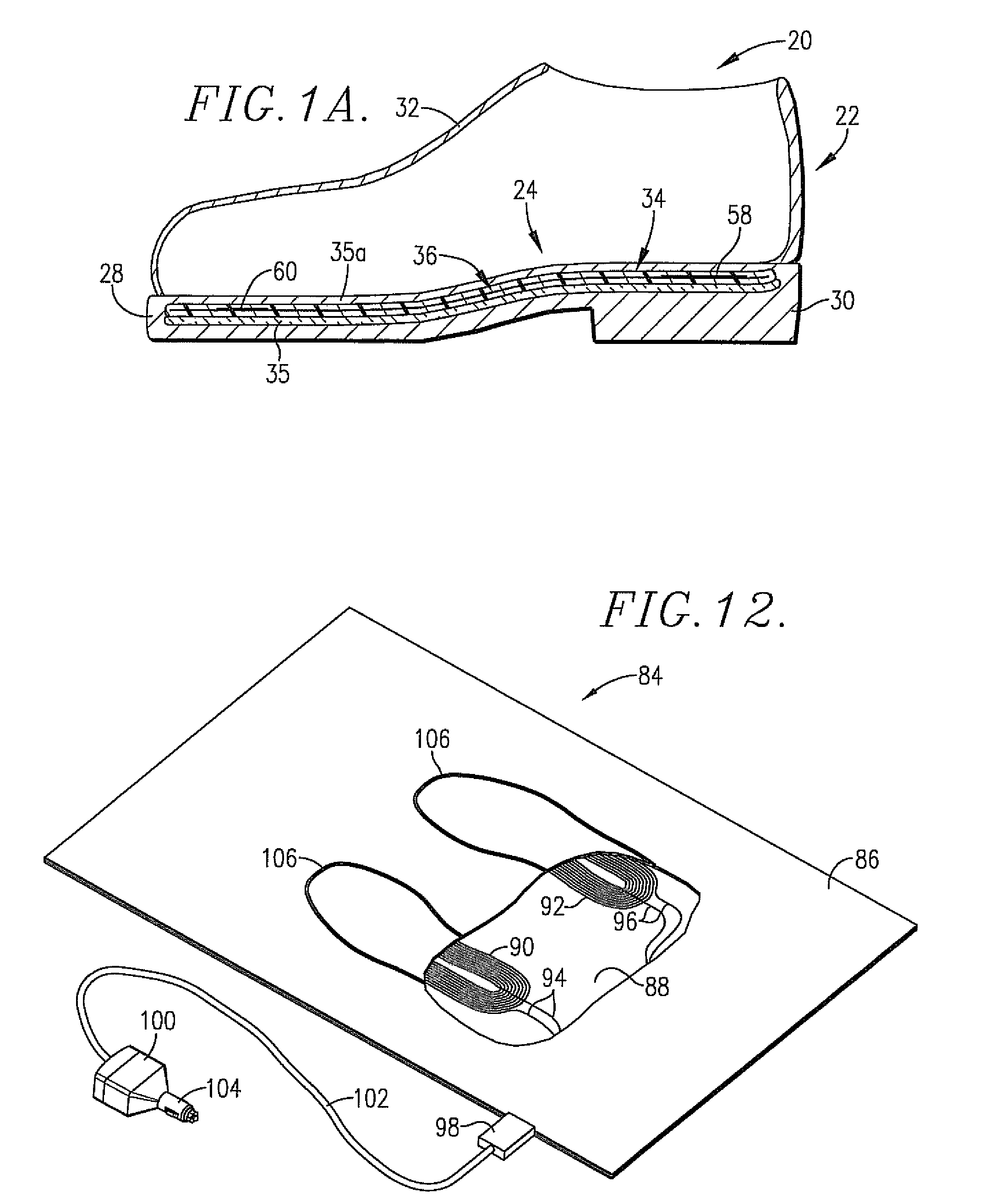

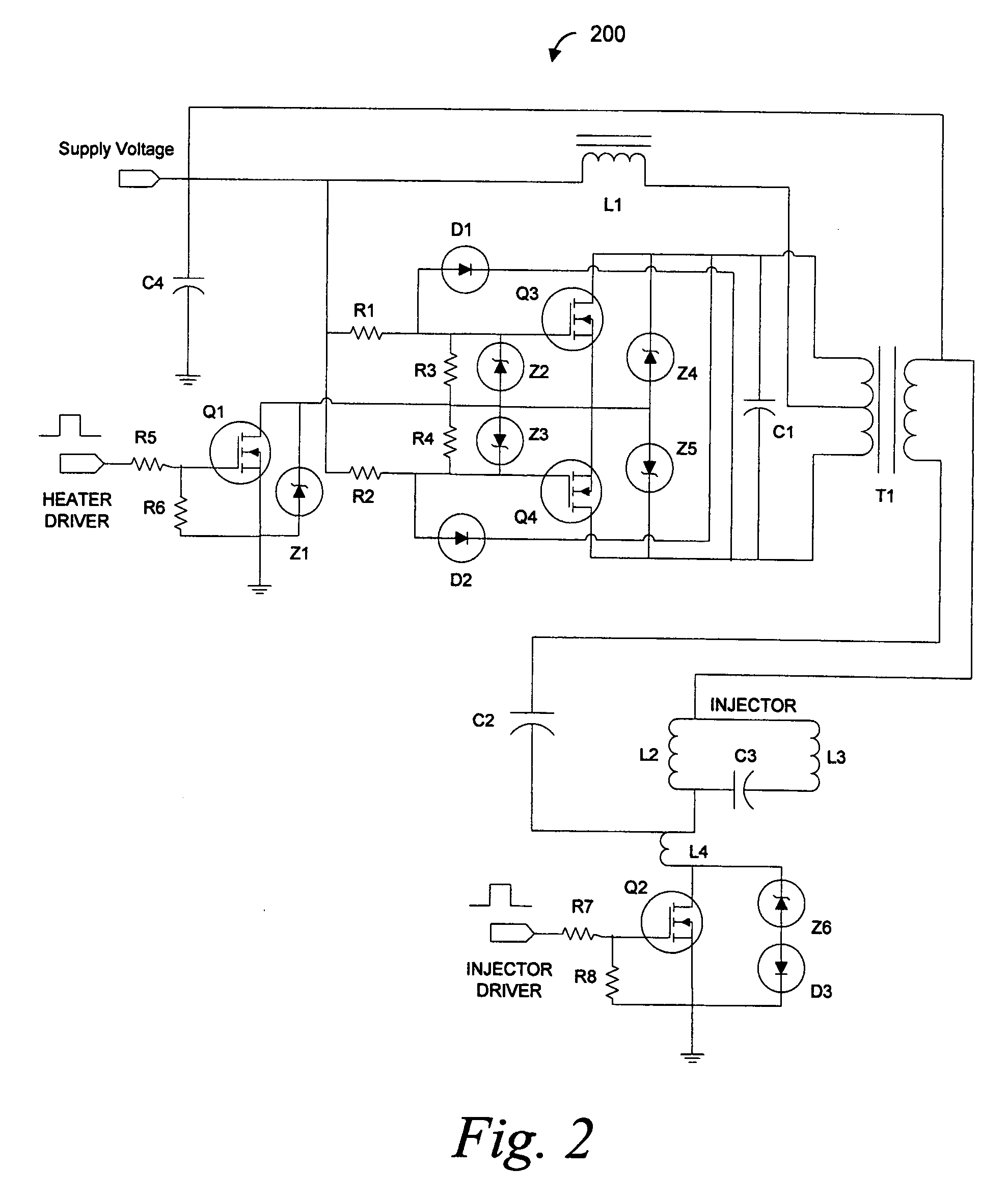

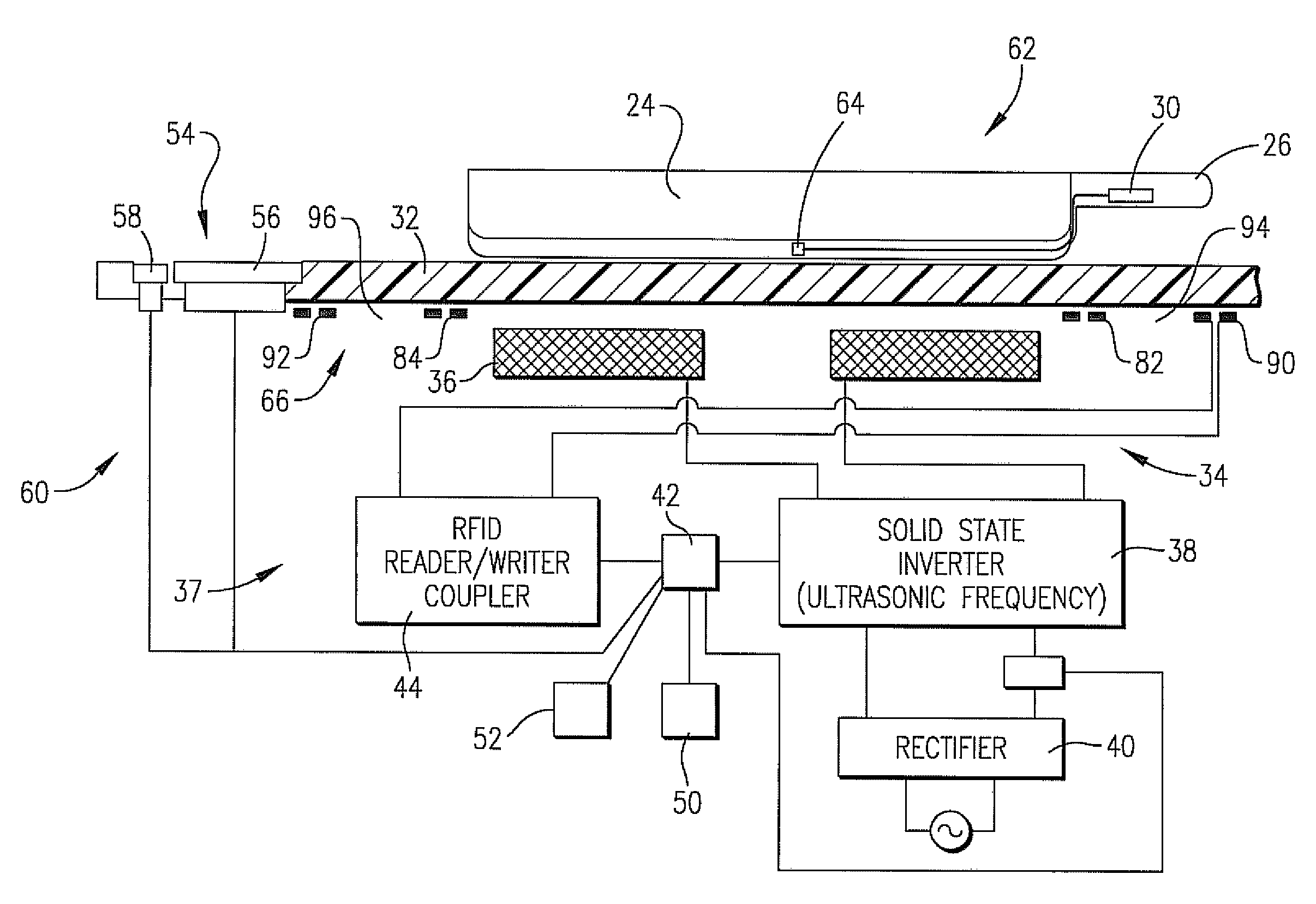

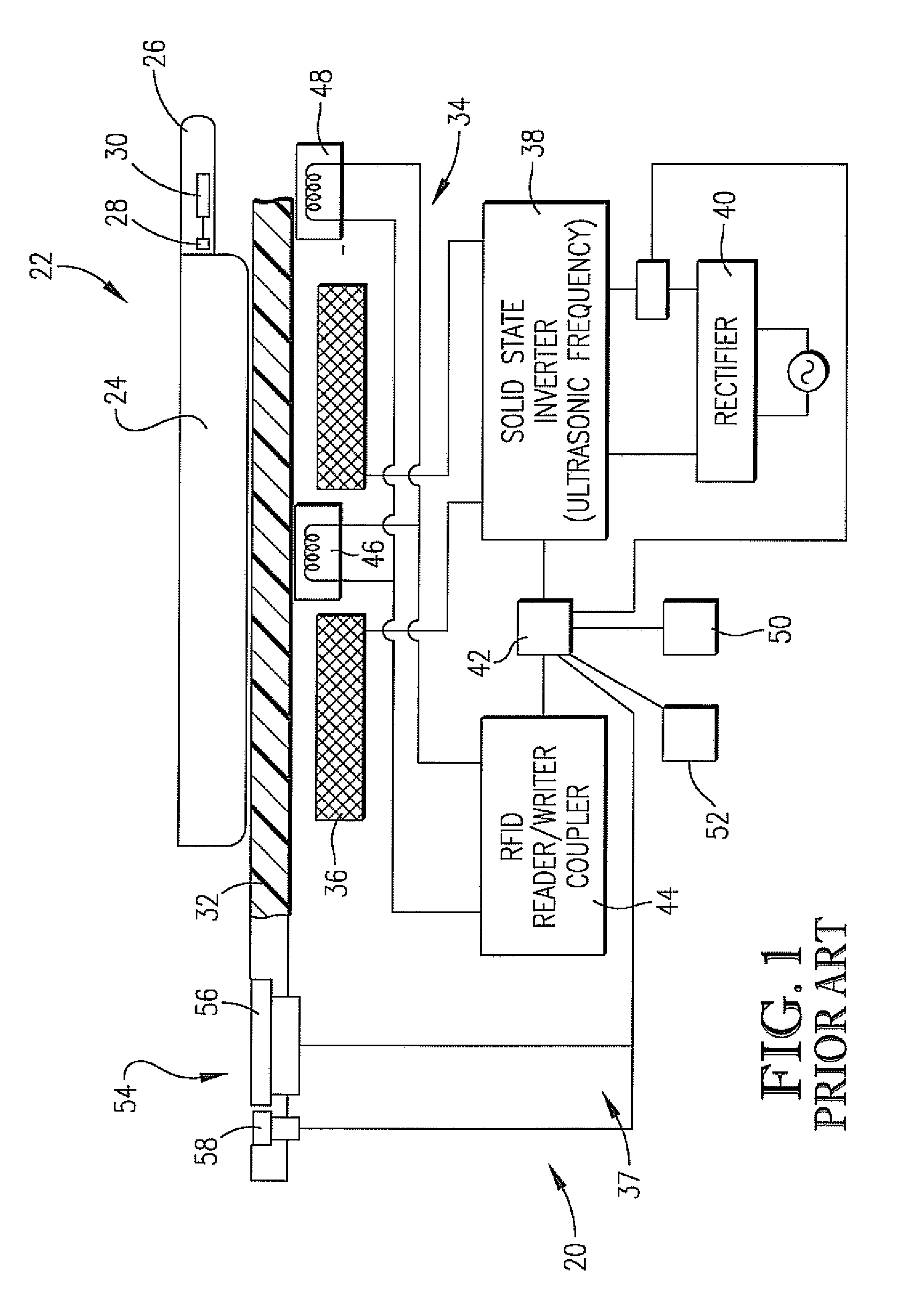

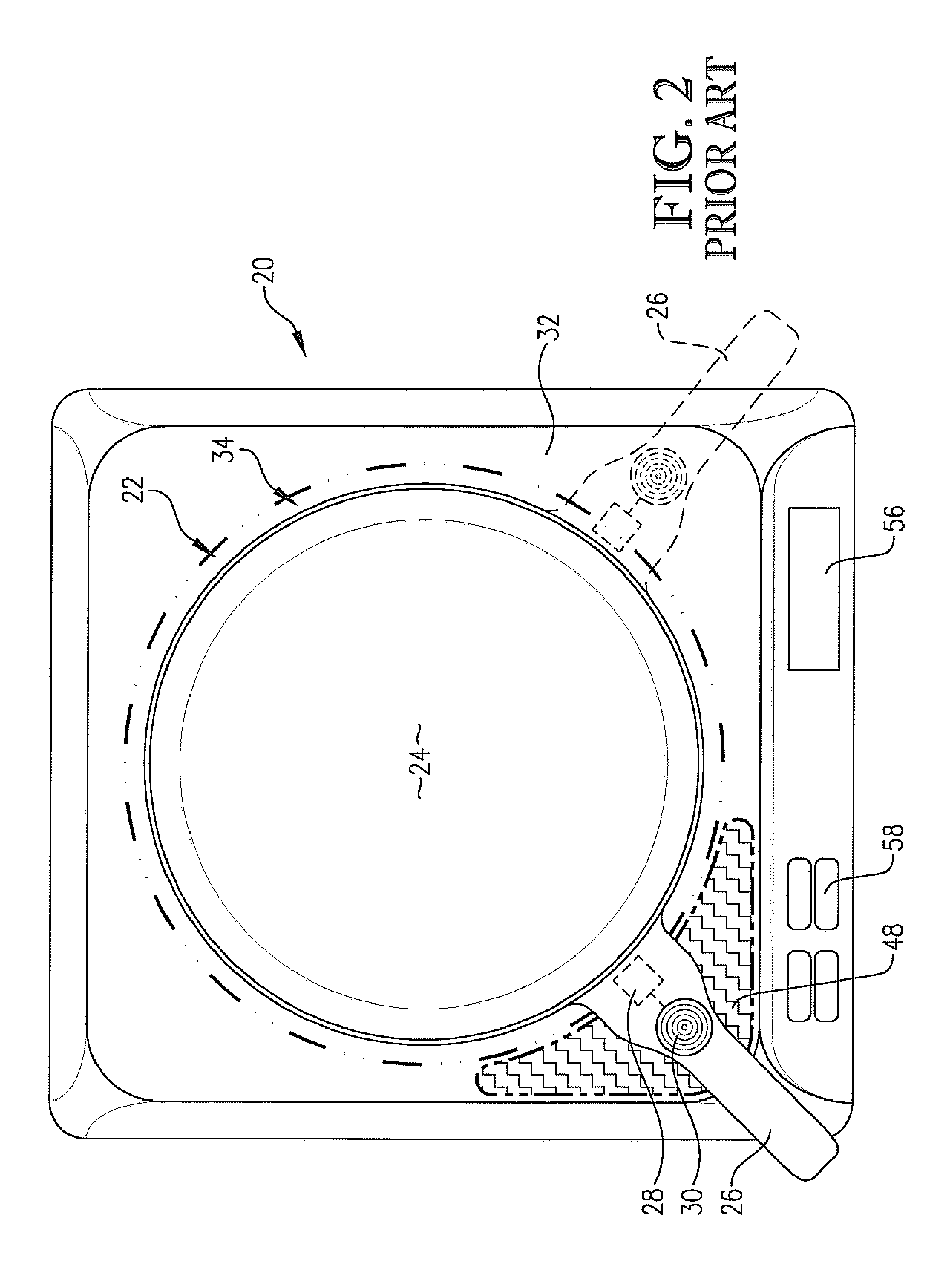

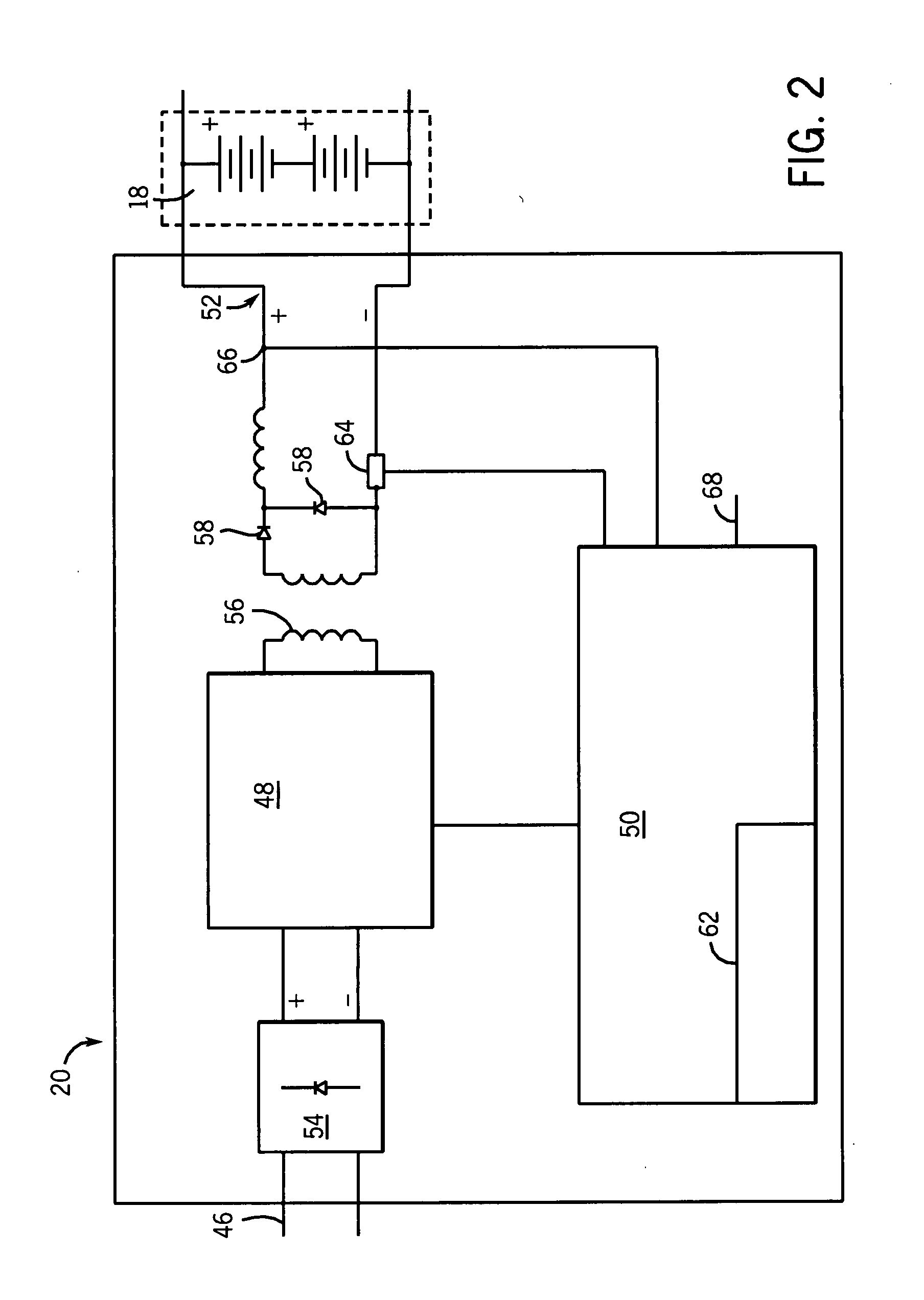

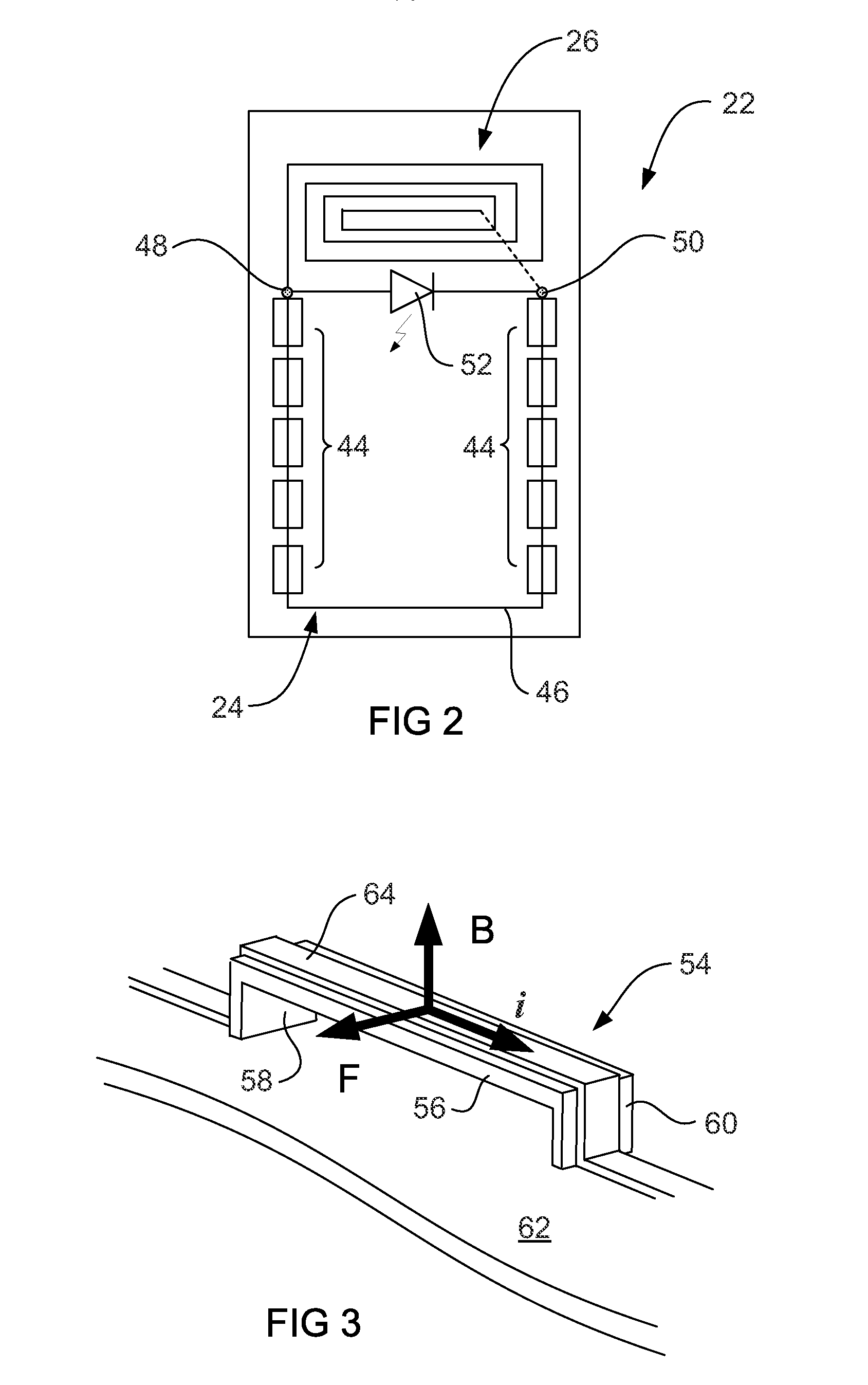

Induction heatable clothing items such as footwear (22) and apparel (160) are provided which include a clothing body having an induction heatable element (36, 108, 112, 114, 116) and preferably having heat retentive material containing phase change material, wherein the element (36, 108, 112, 114, 116) is operable to be heated when subjected to an alternating magnetic field. The clothing items (22, 160) are heated using induction heaters (26, 84). In preferred forms, wireless temperature sensing is used to control heating of the items (22, 160). To this end, the heating elements (36, 108, 112, 114, 116) may be provided with RFID tag / temperature sensor assemblies (58, 60, 110), and the induction heaters (26, 84) are equipped with correlated RFID reader / writer devices (80). Alternately, microwire temperature sensors (120) may be used with the induction heaters (26, 84) having microwire detectors. In other embodiments, temperature monitoring is achieved using impedance detection feedback control.

Owner:TSI TECH

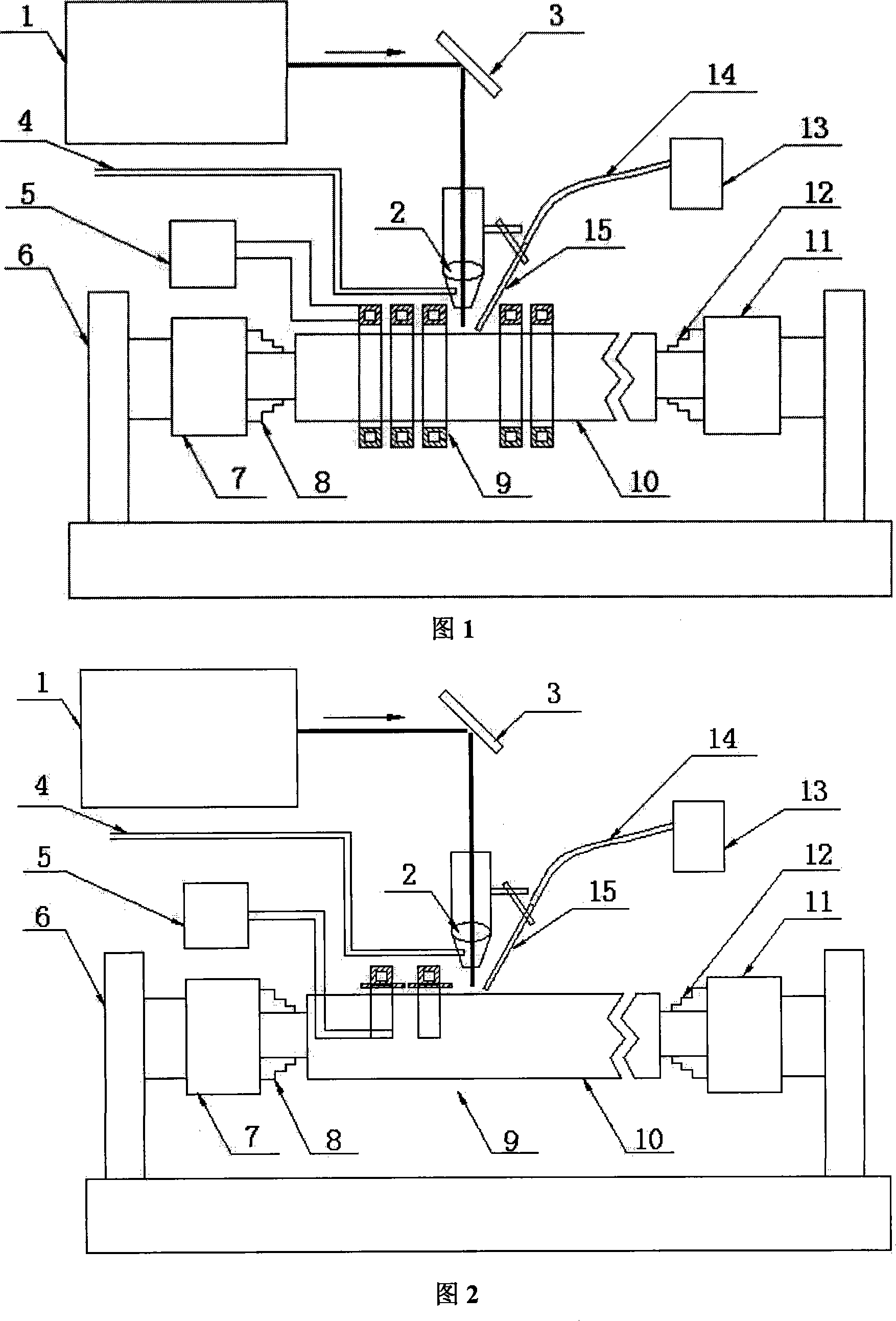

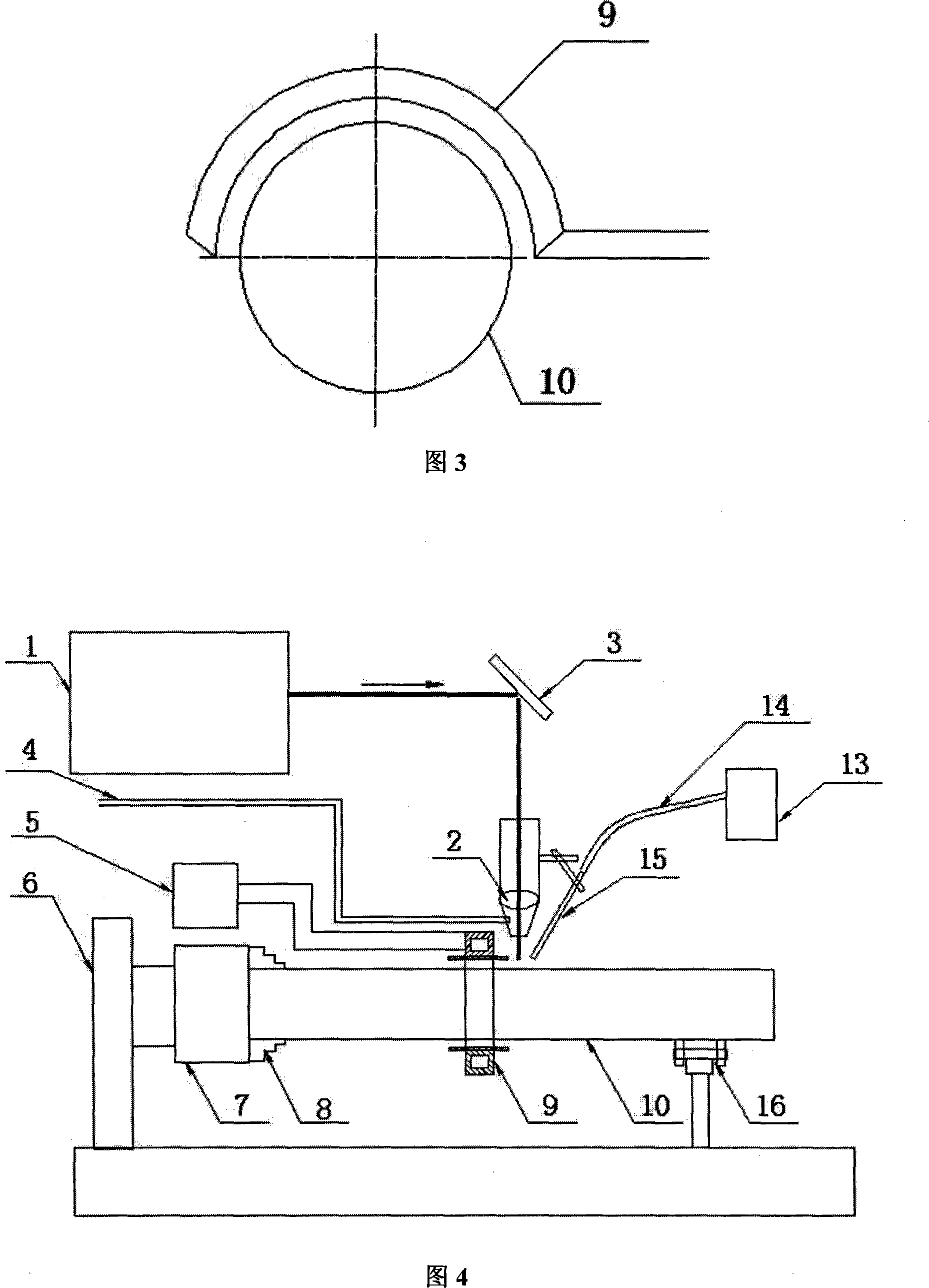

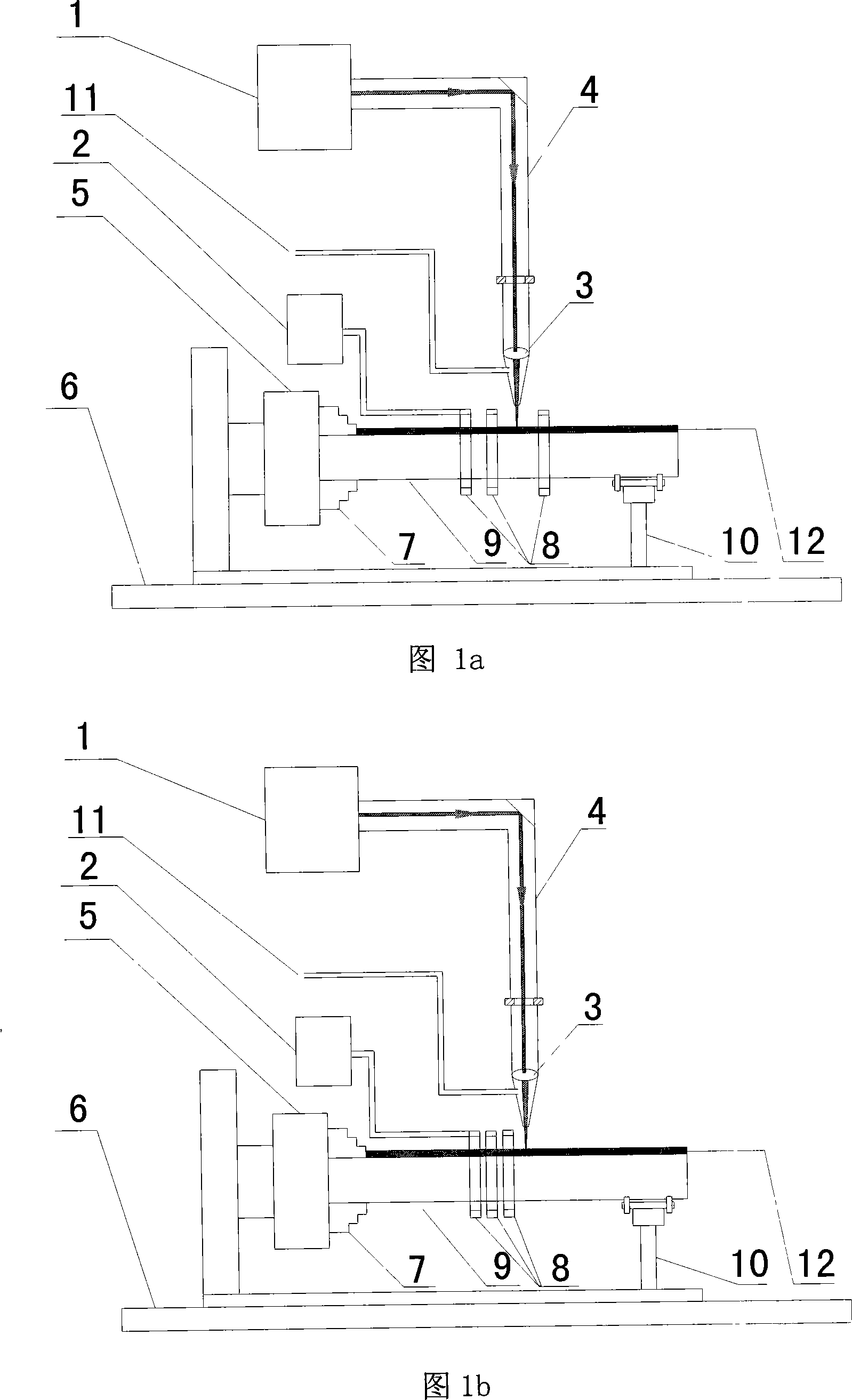

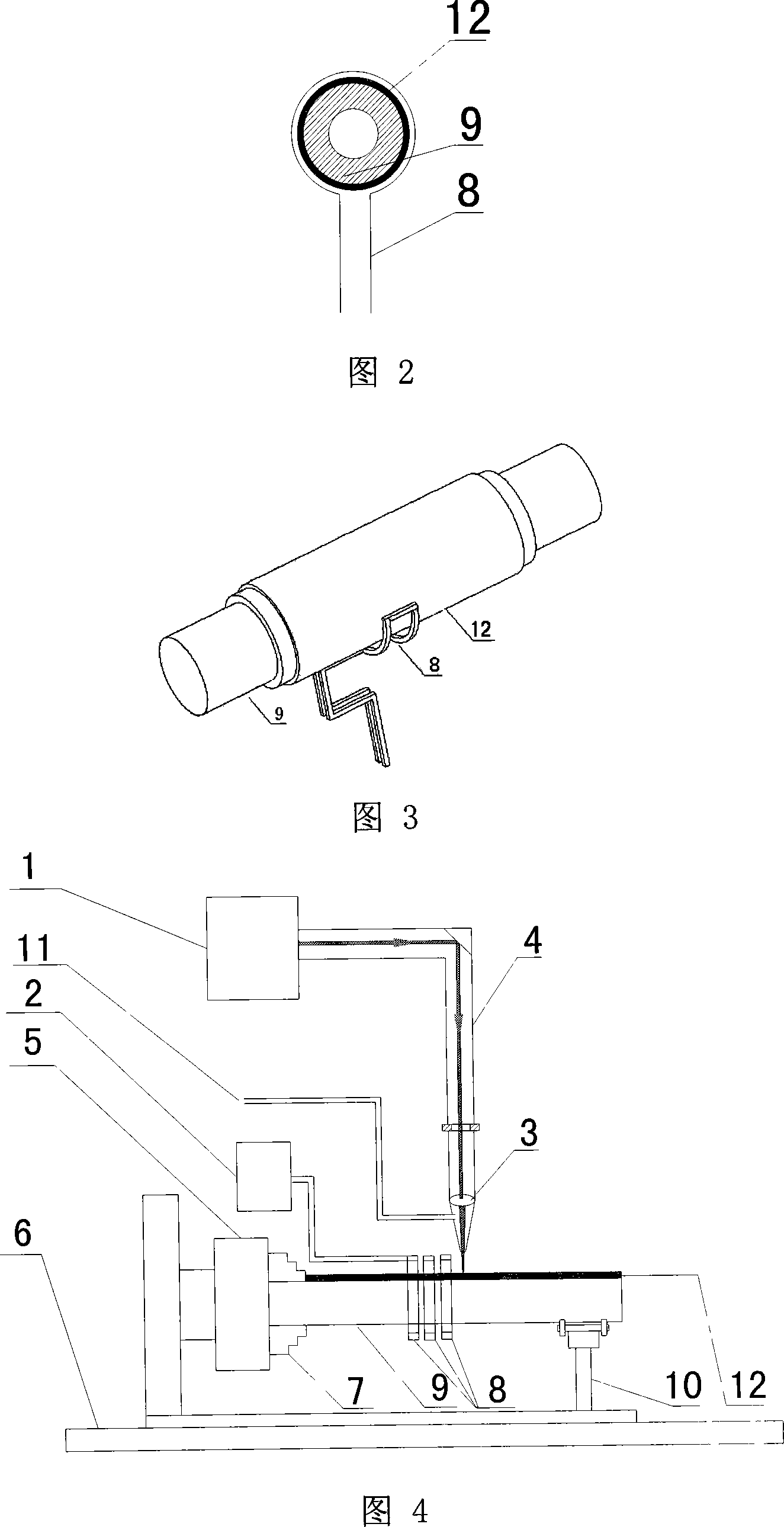

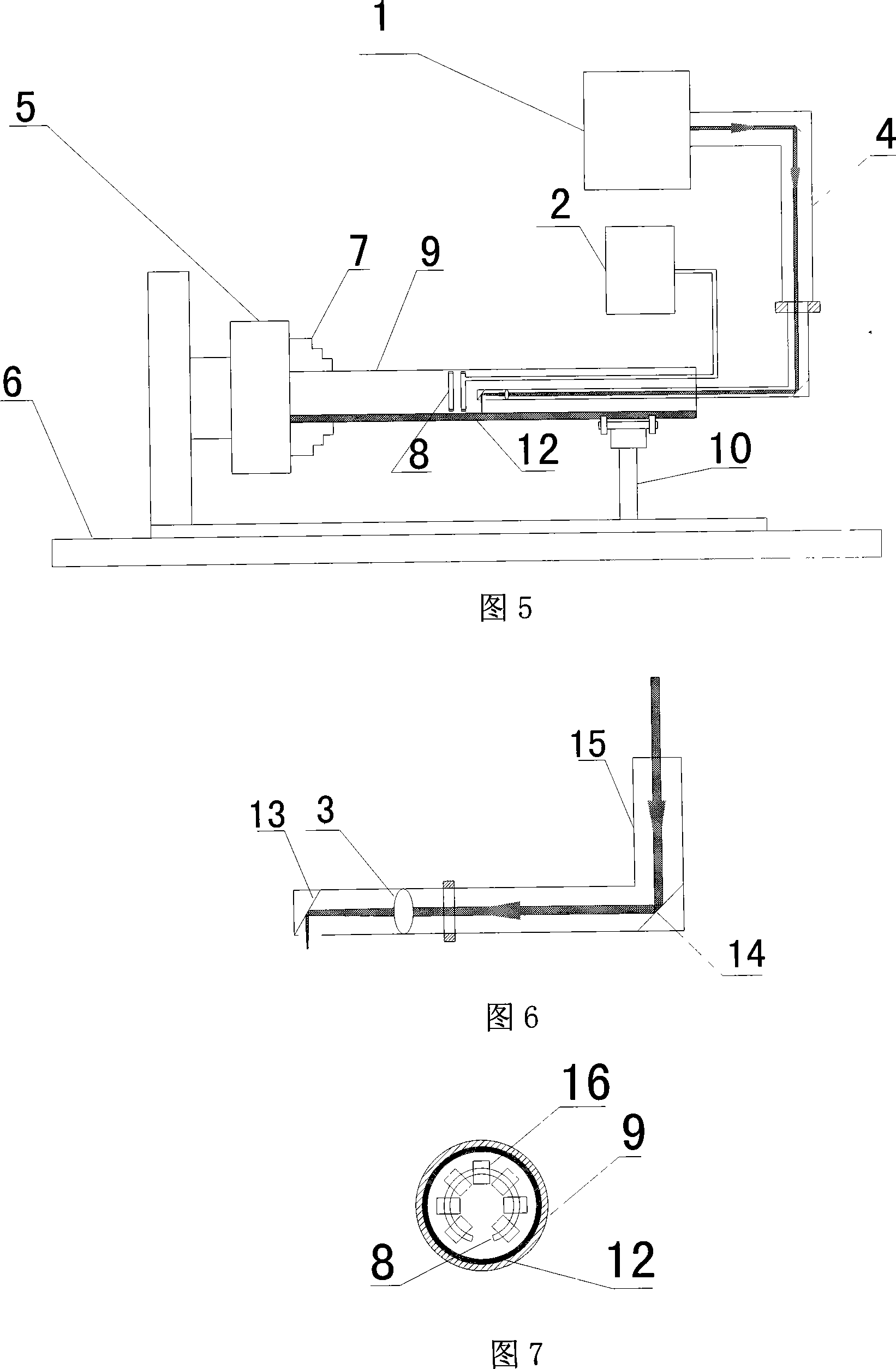

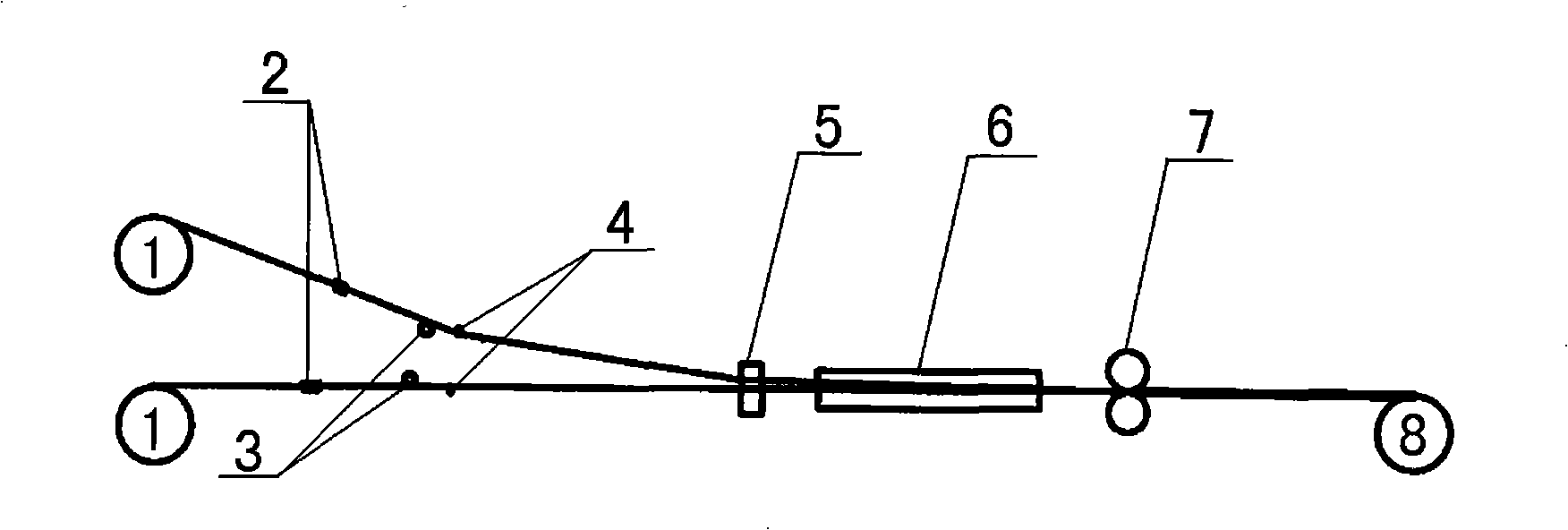

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

Inductively heated clothing

Induction heatable clothing items such as footwear (22) and apparel (160) are provided which include a clothing body having an induction heatable element (36, 108, 112, 114, 116) and preferably having heat retentive material containing phase change material, wherein the element (36, 108, 112, 114, 116) is operable to be heated when subjected to an alternating magnetic field. The clothing items (22, 160) are heated using induction heaters (26, 84). In preferred forms, wireless temperature sensing is used to control heating of the items (22, 160). To this end, the heating elements (36, 108, 112, 114, 116) may be provided with RFID tag / temperature sensor assemblies (58, 60, 110), and the induction heaters (26, 84) are equipped with correlated RFID reader / writer devices (80). Alternately, microwire temperature sensors (120) may be used with the induction heaters (26, 84) having microwire detectors. In other embodiments, temperature monitoring is achieved using impedance detection feedback control.

Owner:TSI TECH

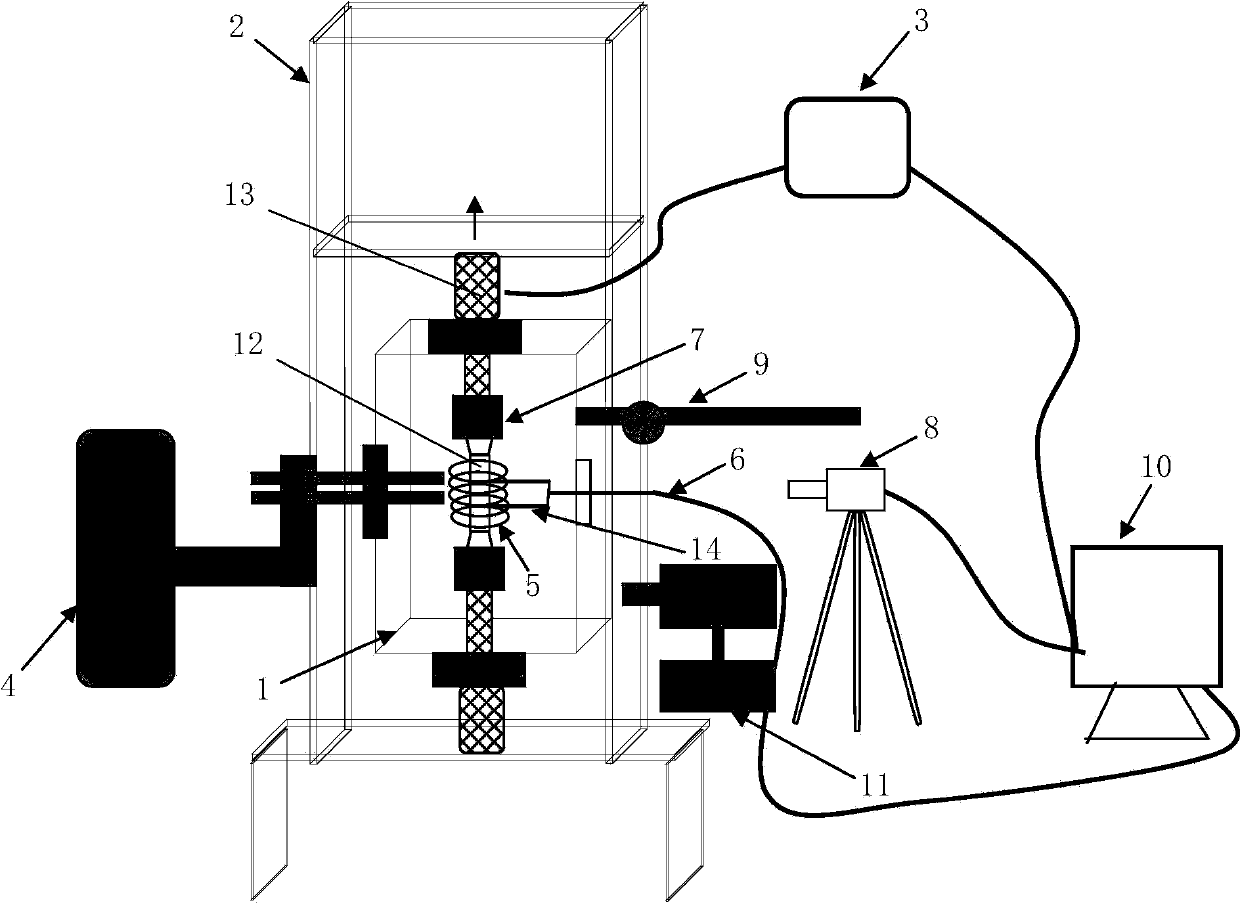

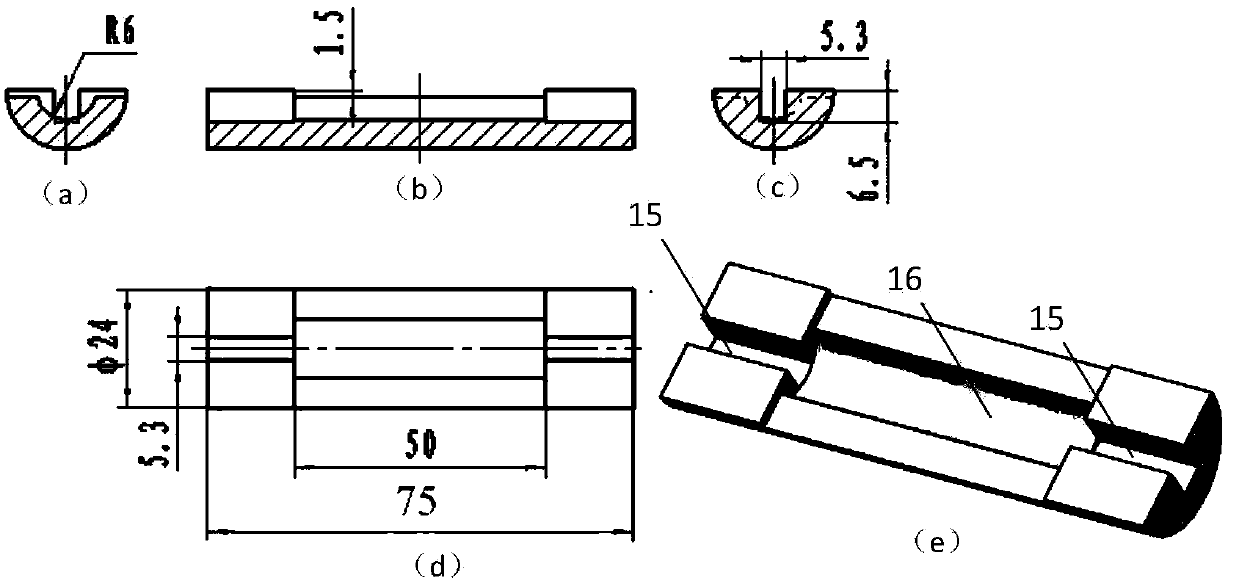

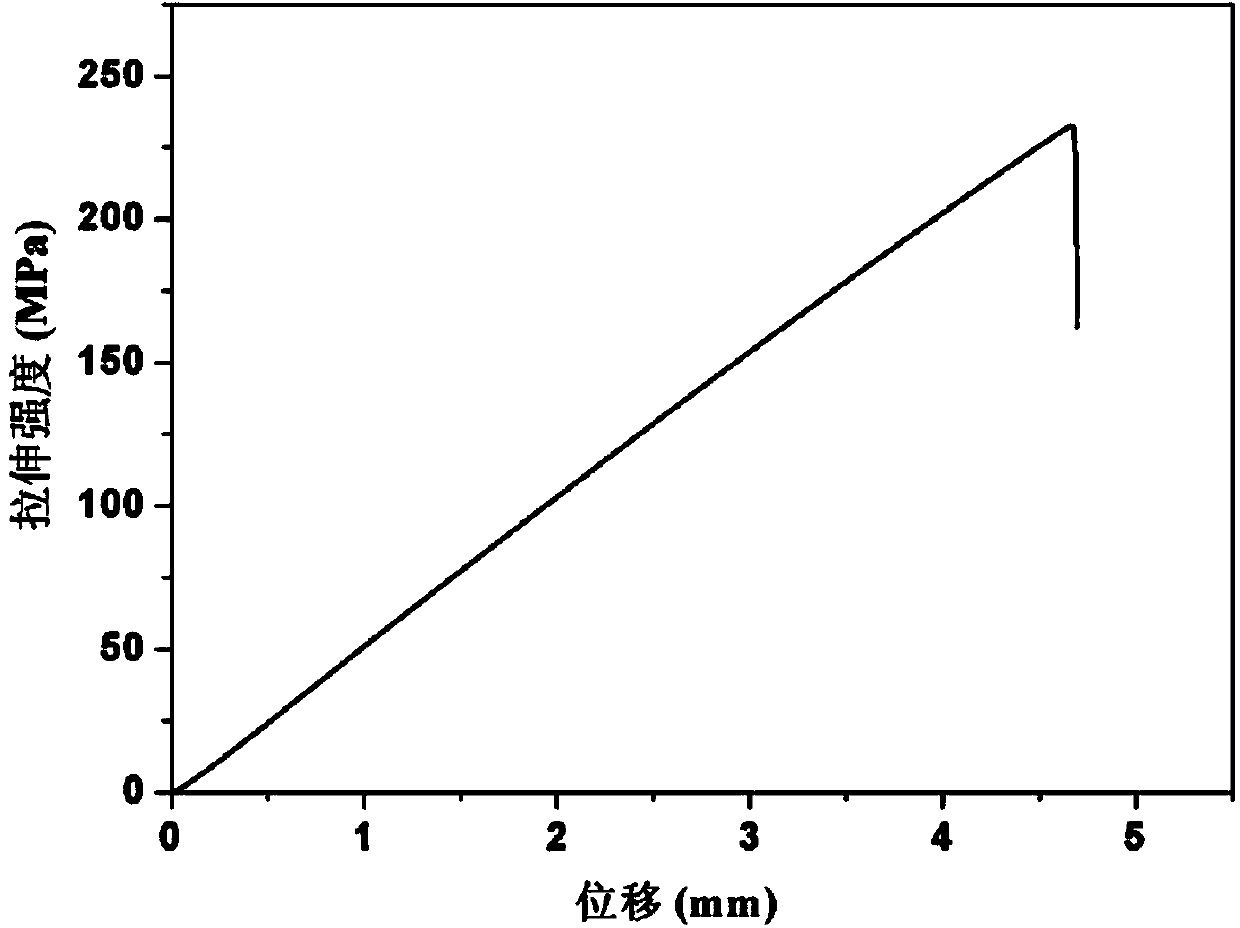

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

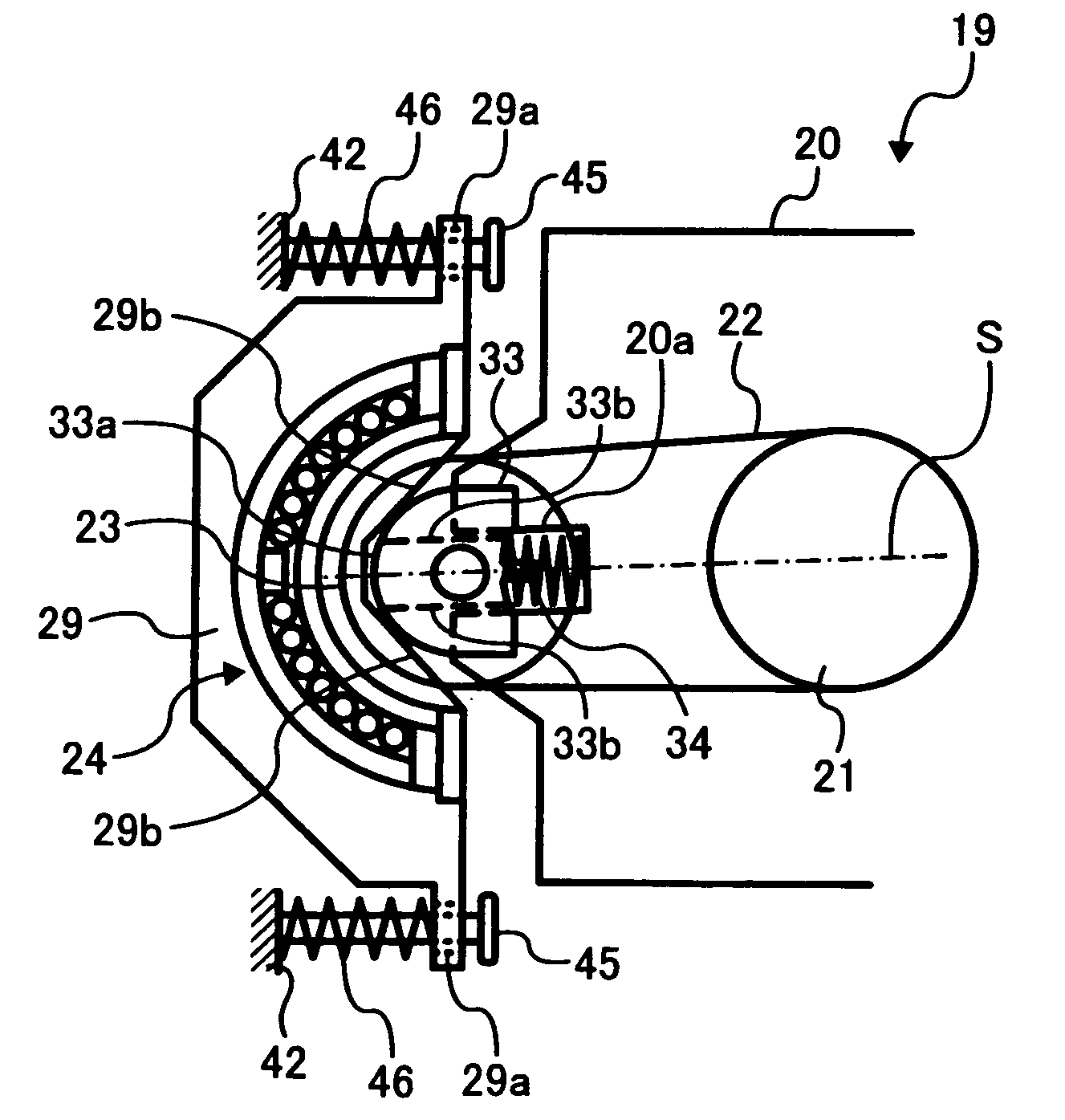

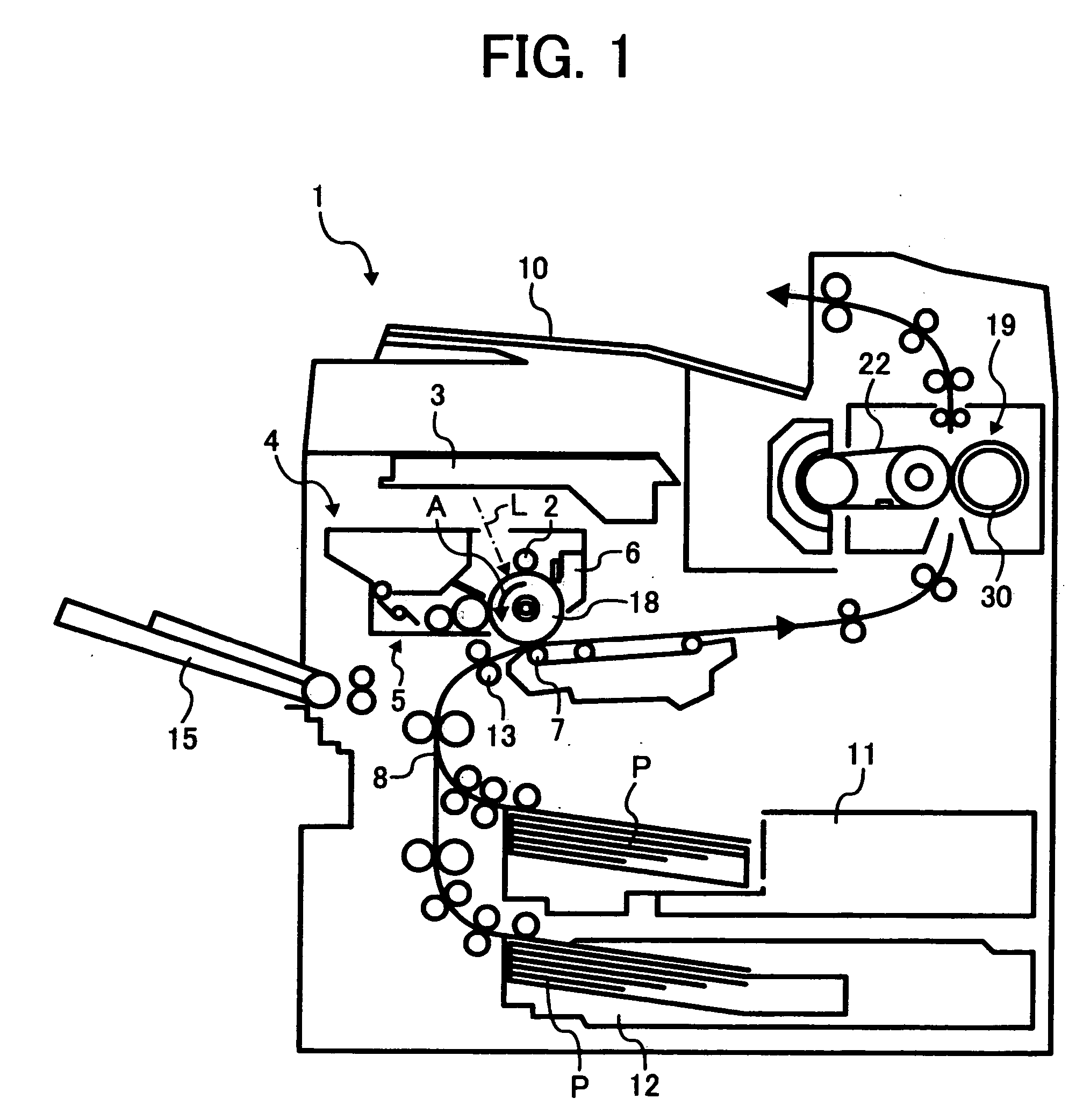

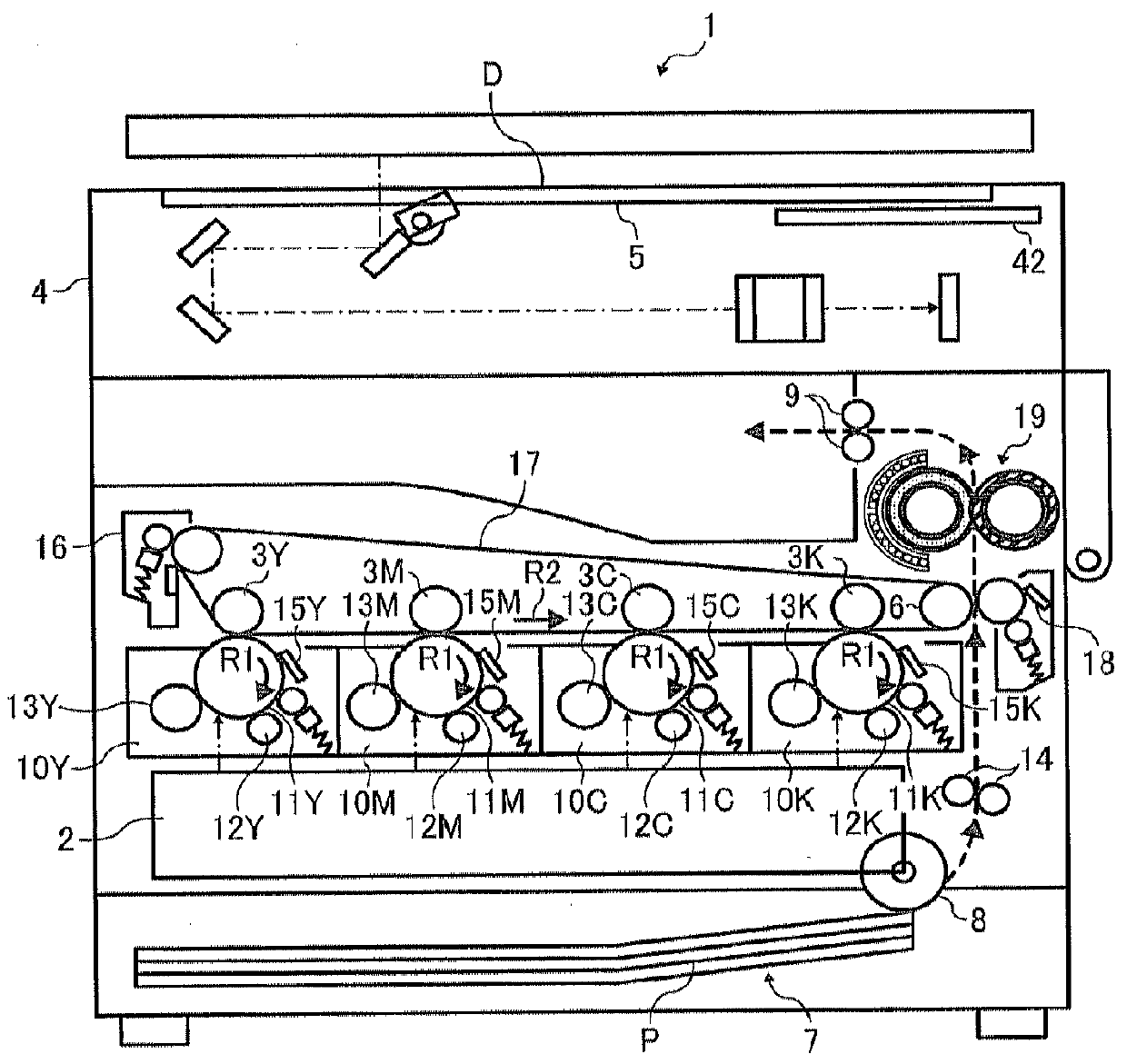

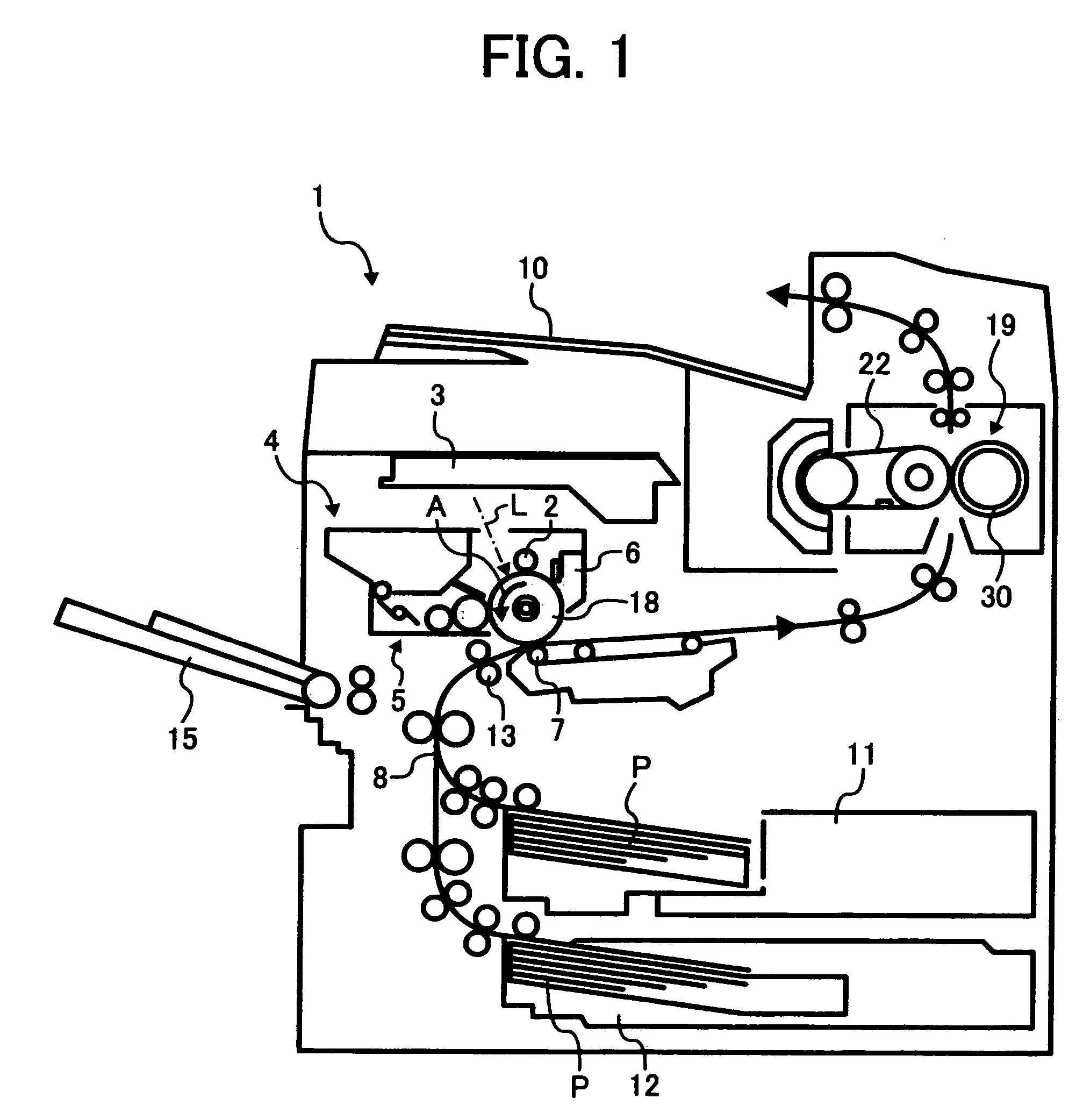

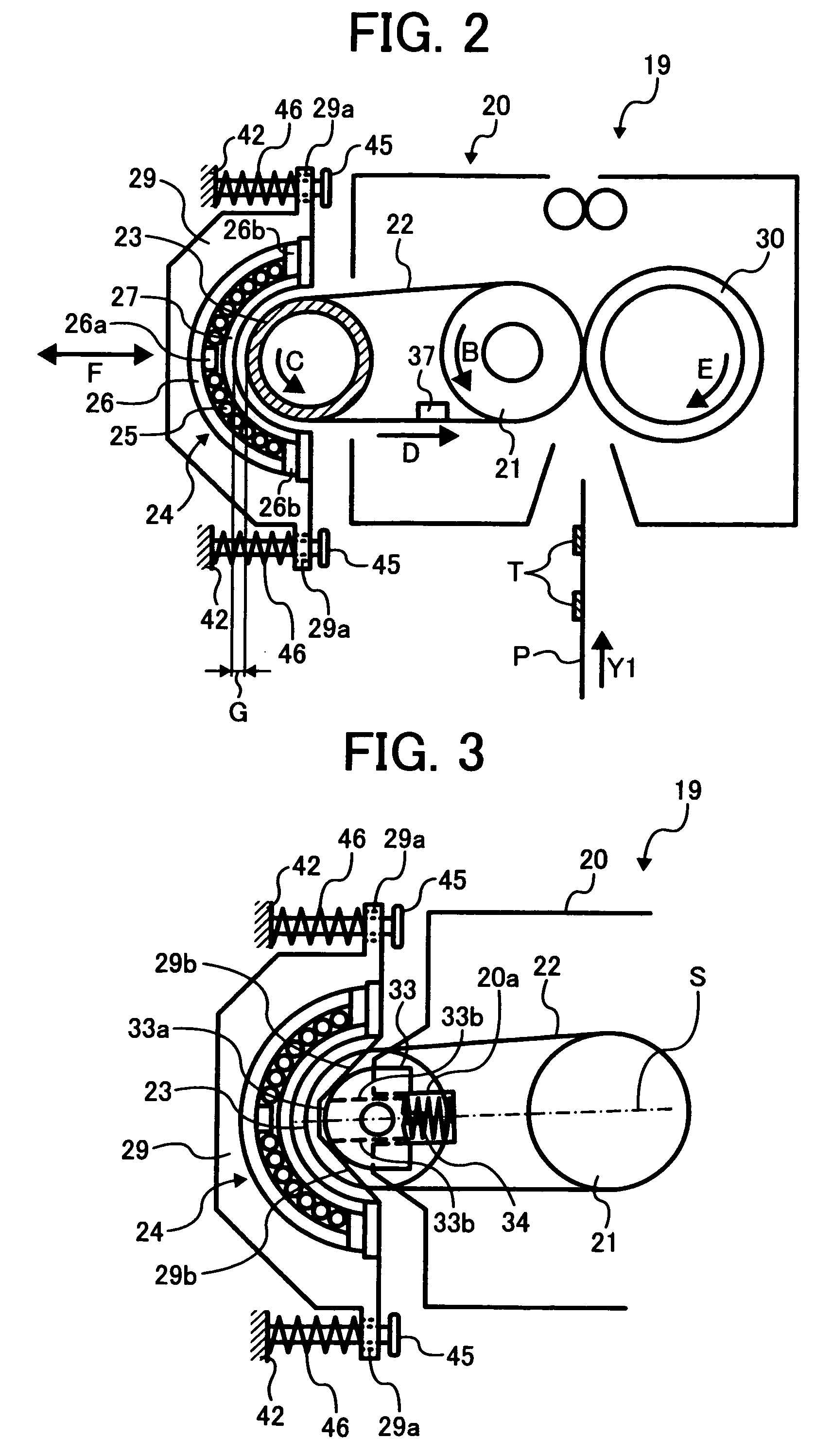

Image forming apparatus, fixing unit, and image forming method using induction heater

InactiveUS20060285893A1Electrographic process apparatusInduction heating apparatusImage formationInduction heater

An image forming apparatus includes an image forming mechanism configured to form a toner image on a recording medium according to image data and a fixing mechanism configured to fix the toner image on the recording medium. The fixing mechanism includes an induction heater, a heat generator, and a position adjusting mechanism. The induction heater is configured to generate a magnetic flux. The heat generator is disposed at a position opposite to the induction heater and is configured to generate heat by the magnetic flux generated by the induction heater. The position adjusting mechanism is configured to adjust a position of the induction heater in conjunction with a displacement of the heat generator.

Owner:RICOH KK

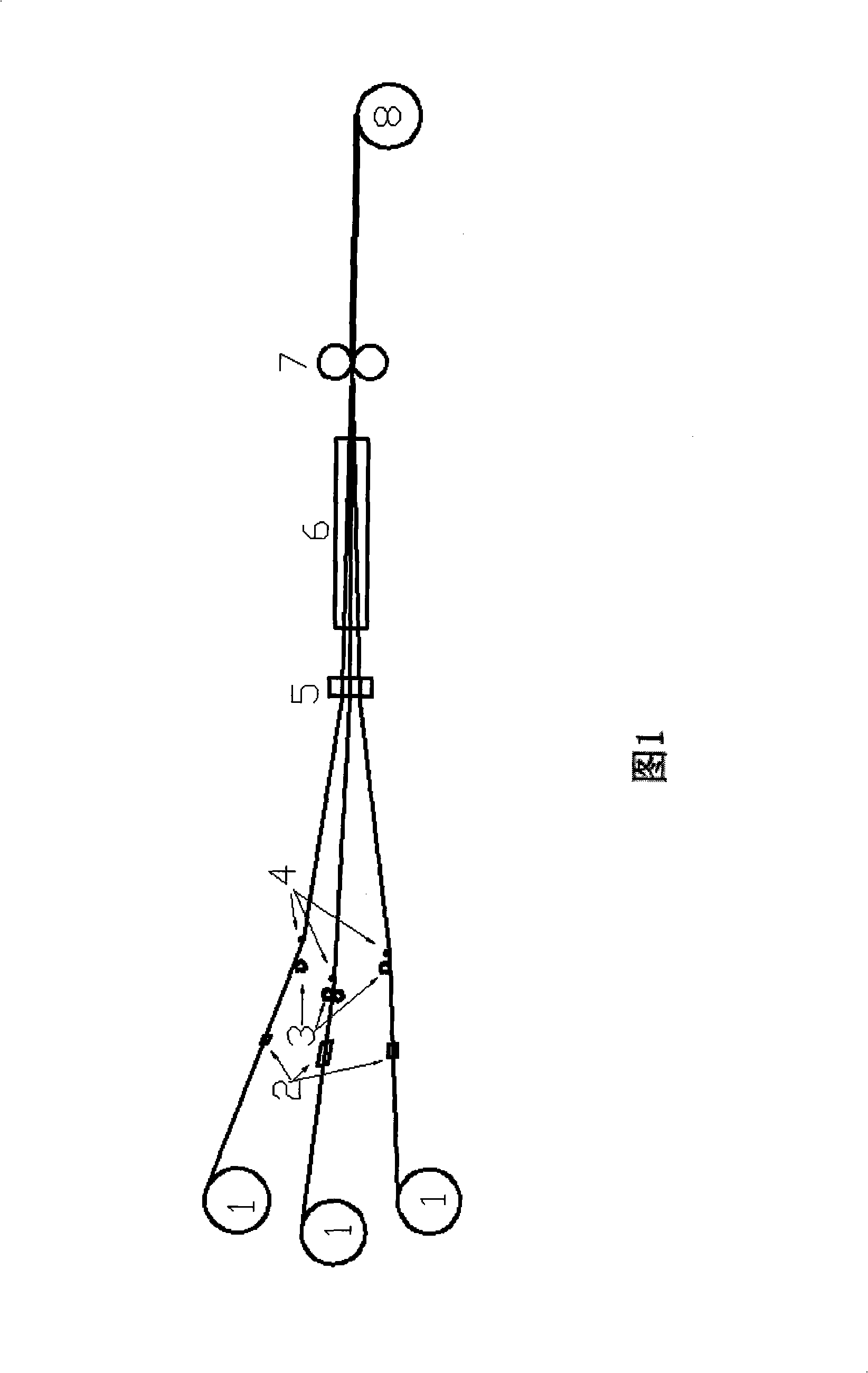

Method and apparatus for preparing material coating by laser inductive composite melt-coating

ActiveCN101070595AAvoid problems such as damageSimple structureMetallic material coating processesLaser beam welding apparatusNumerical controlOptoelectronics

The invention discloses a method and its device for laser to induce the compound melt high performance material coating. The invention heats up and coupling the laser beam and the high frequency electromagnetic induction, and realizes the process of laser compound melt with induction heating. The device includes the laser, the laser conducting device, the laser gathering device, the high frequency induction heater, numerically controlled machine tool, and the workpiece holding device. When the device works, the distance of coating of preparing to deal with workpiece surface and induction heating coil is between 1 and 10 millimeter. The versatility of the invention is strong, so it can do the surface treatment with laser to induce the compound melt high performance material coating in the surface of solid assembly of each material and inner and outer surface of tubular part. The characteristic of melt method lies in utilizing the efficiency high merit of hot spray, cold spray, or supersonic flame spray. And induction heating is done at the time of laser melt. The maximum melt linear speed amounts to 0.5-10 meters per minute, which enhances between one time and ten times to the conventional laser melt. The deposition rate of powder is improved between one time and fifteen times than existing laser melt deposition rate, moreover the melt deposit doesn't have the blowhole and the crack.

Owner:WUHAN HIVALUE INTELASER LTD

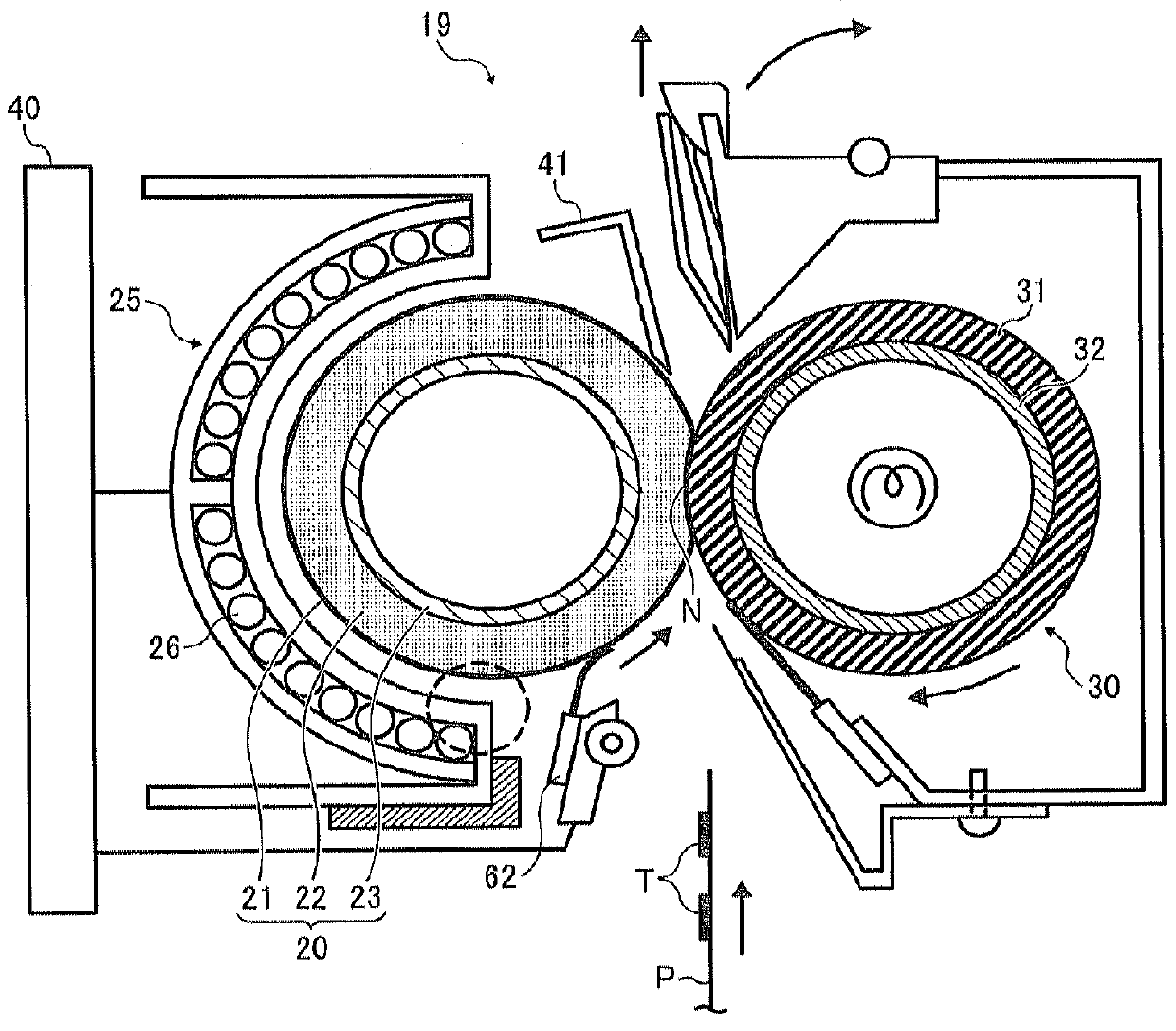

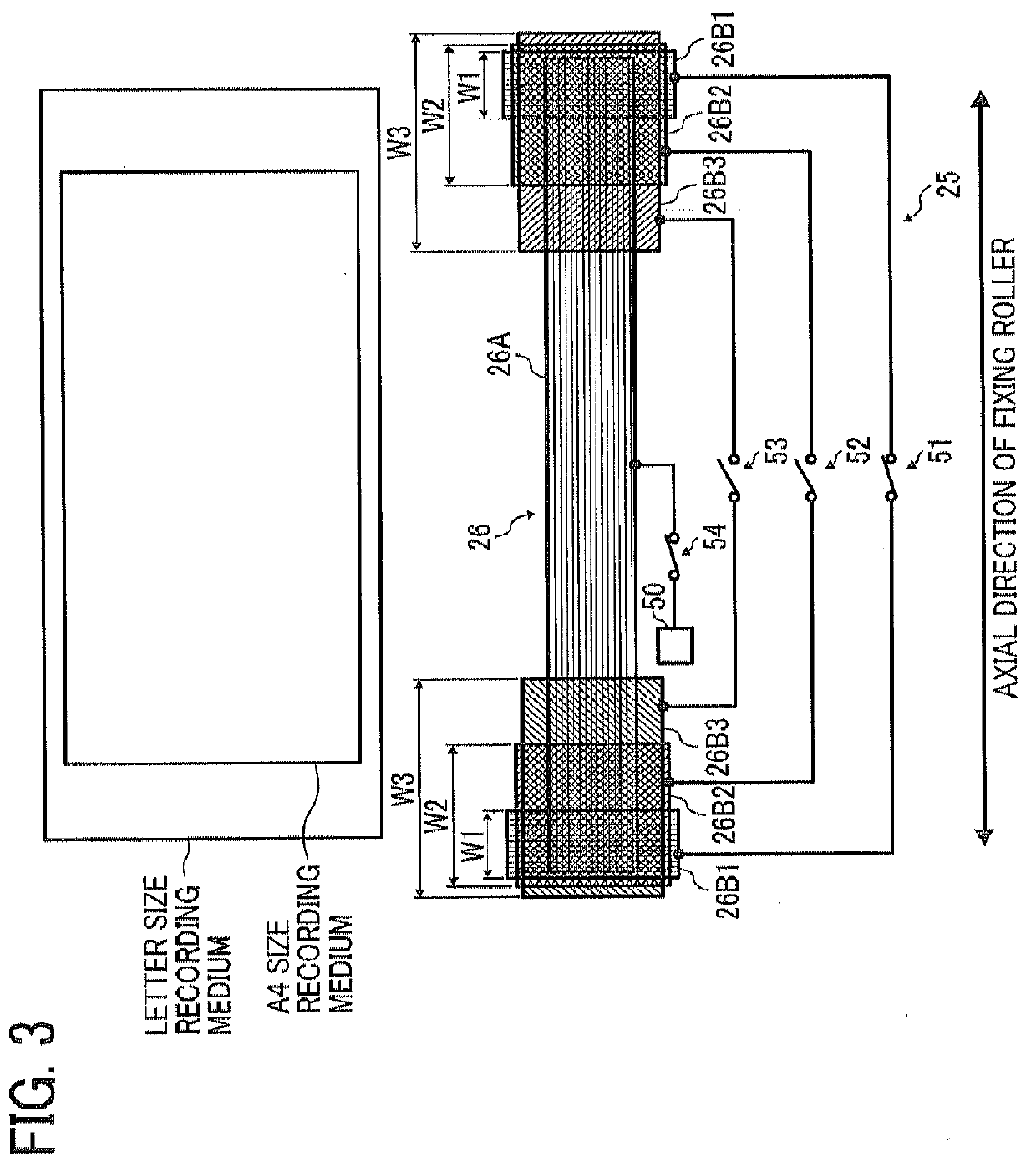

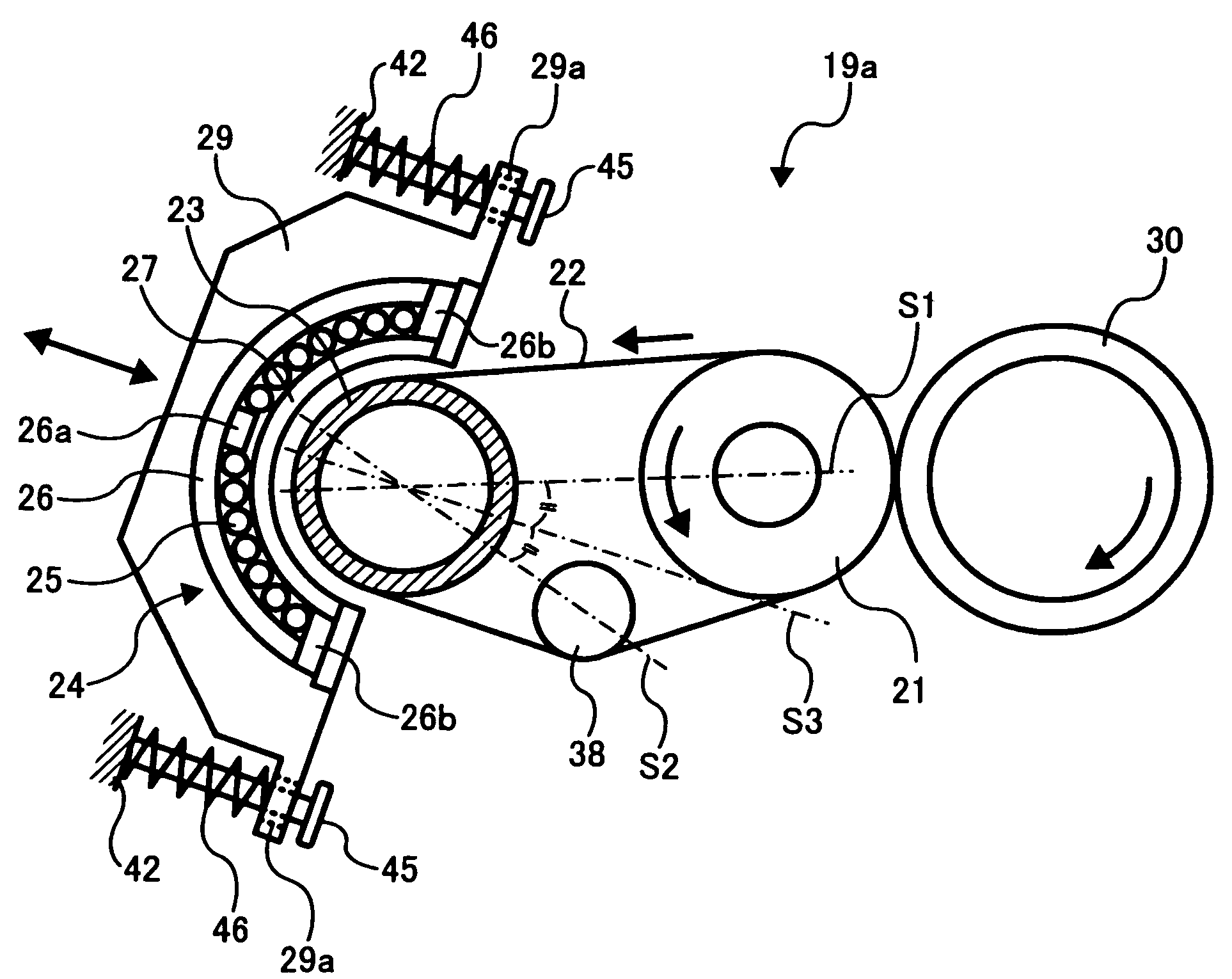

Fixing device, image forming apparatus incorporating same, and method for heating fixing rotary body

InactiveUS20120177424A1Electrographic process apparatusElectric/magnetic/electromagnetic heatingImage formationInduction heater

A fixing device includes an induction heater constructed of an exciting coil, a first pair of degaussing coils, and a second pair of degaussing coils. A controller turns off the exciting coil while the controller turns on one of the first pair of degaussing coils and the second pair of degaussing coils and at the same time turns off the other one of the first pair of degaussing coils and the second pair of degaussing coils, and then turns on the exciting coil for an extra time period corresponding to reserved power not supplied to the exciting coil while the exciting coil is turned off.

Owner:RICOH KK

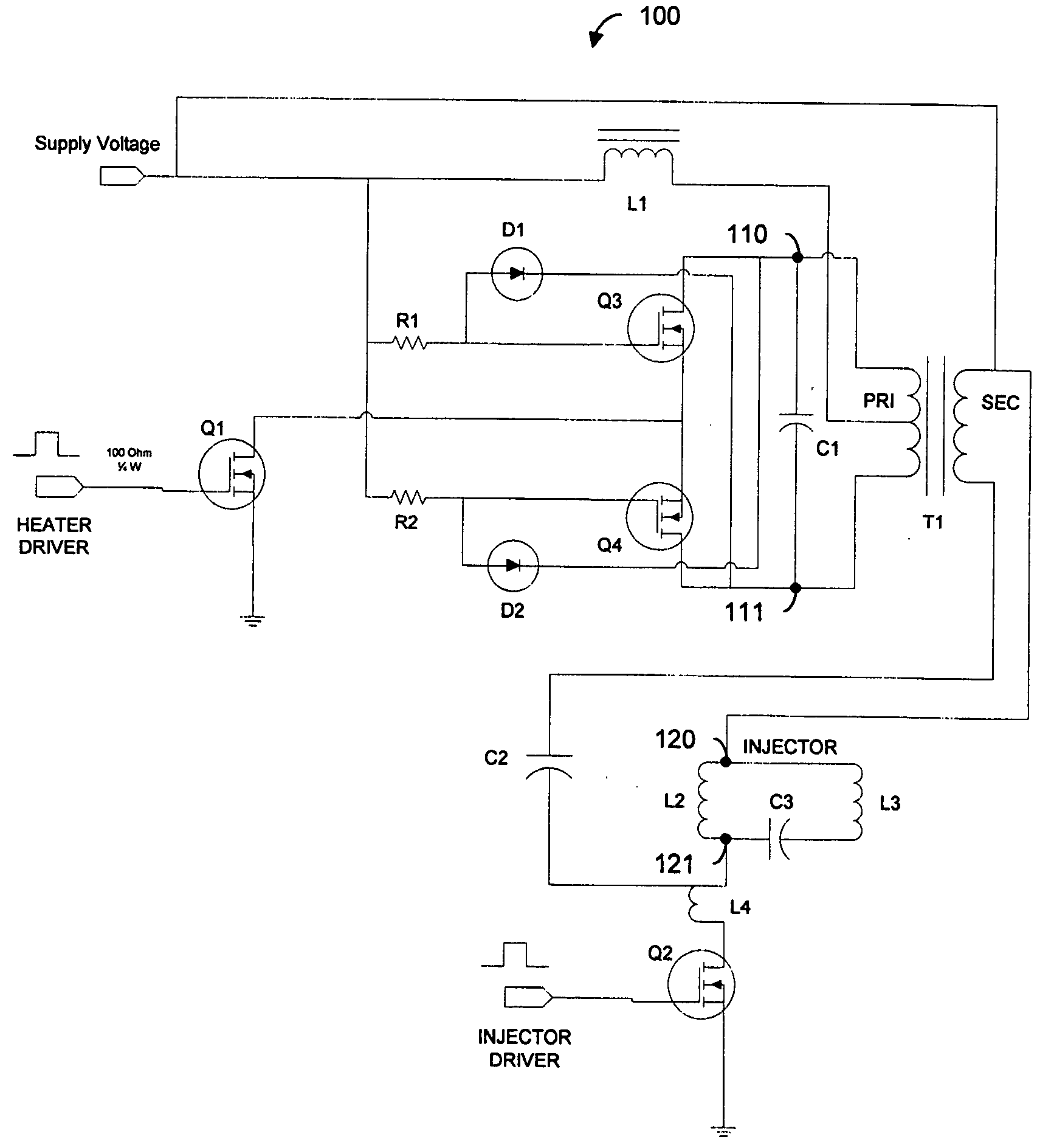

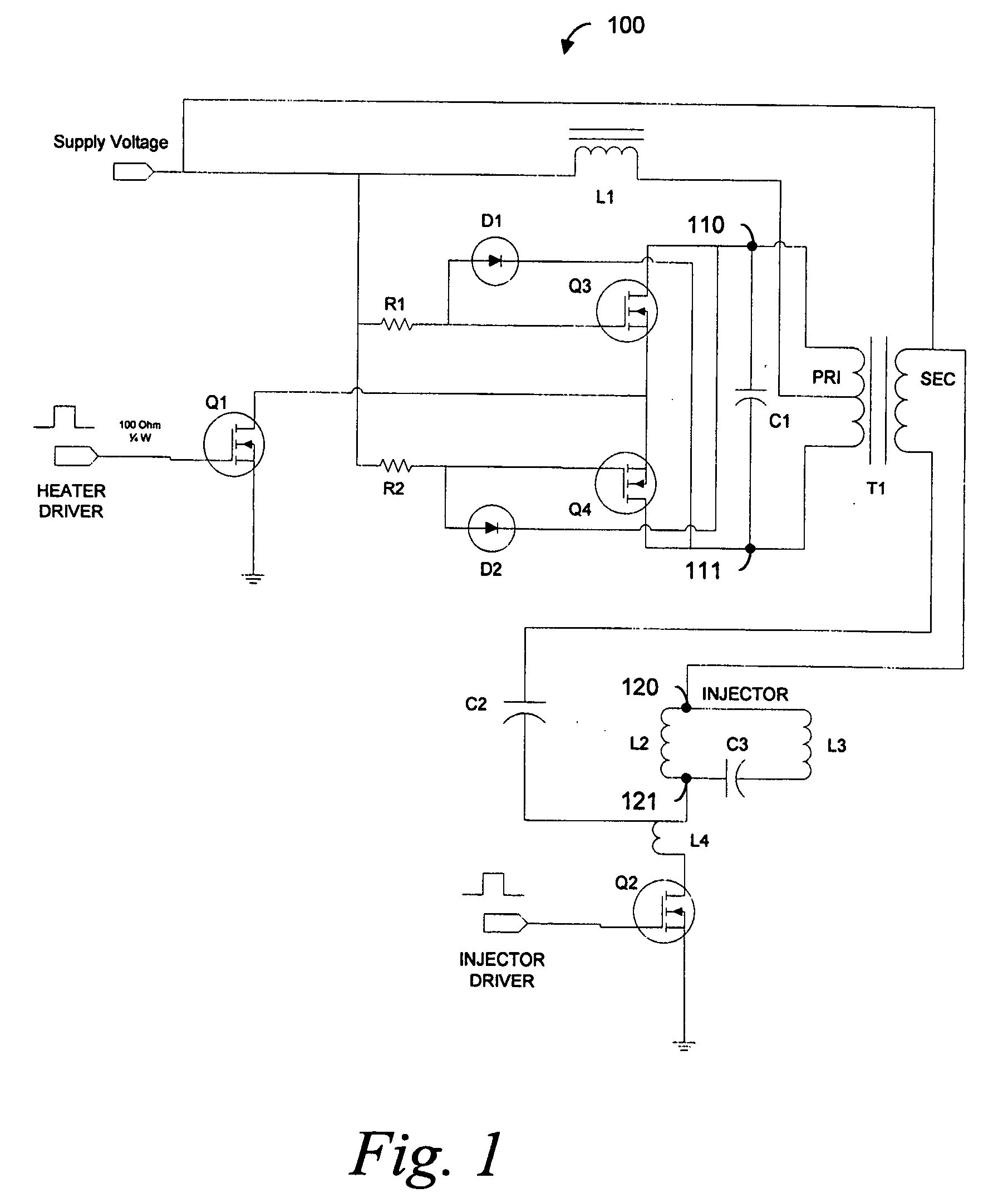

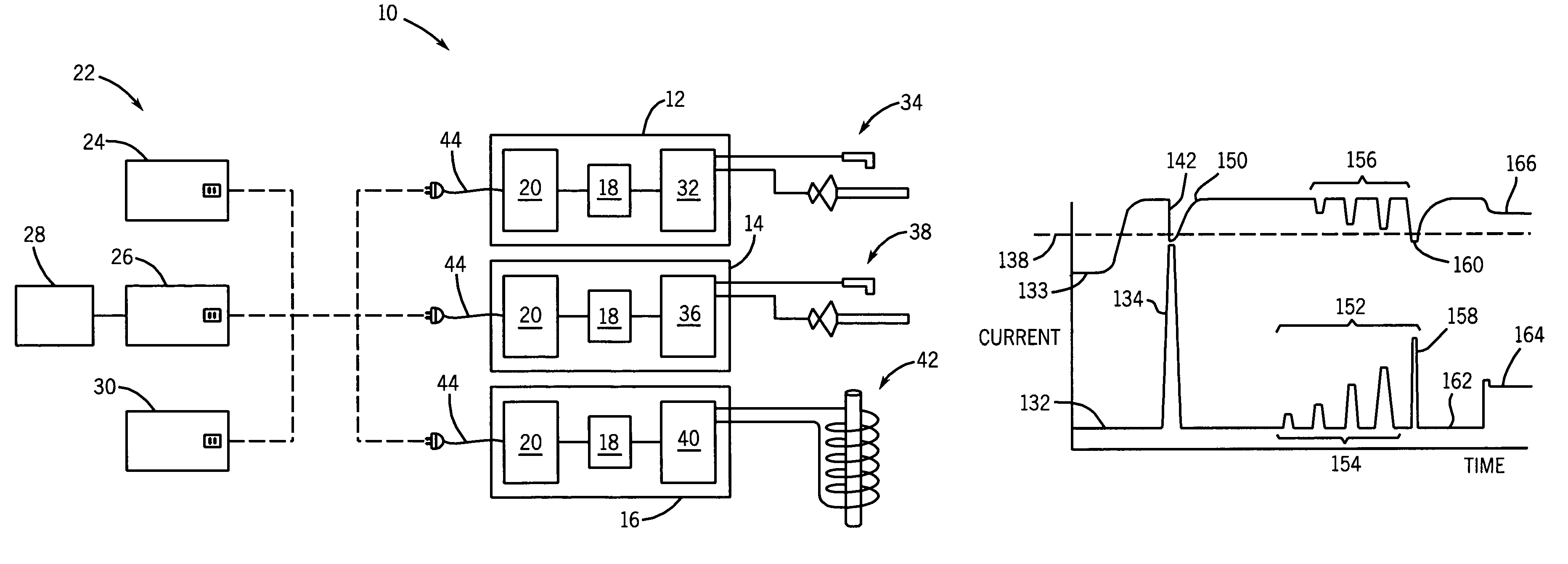

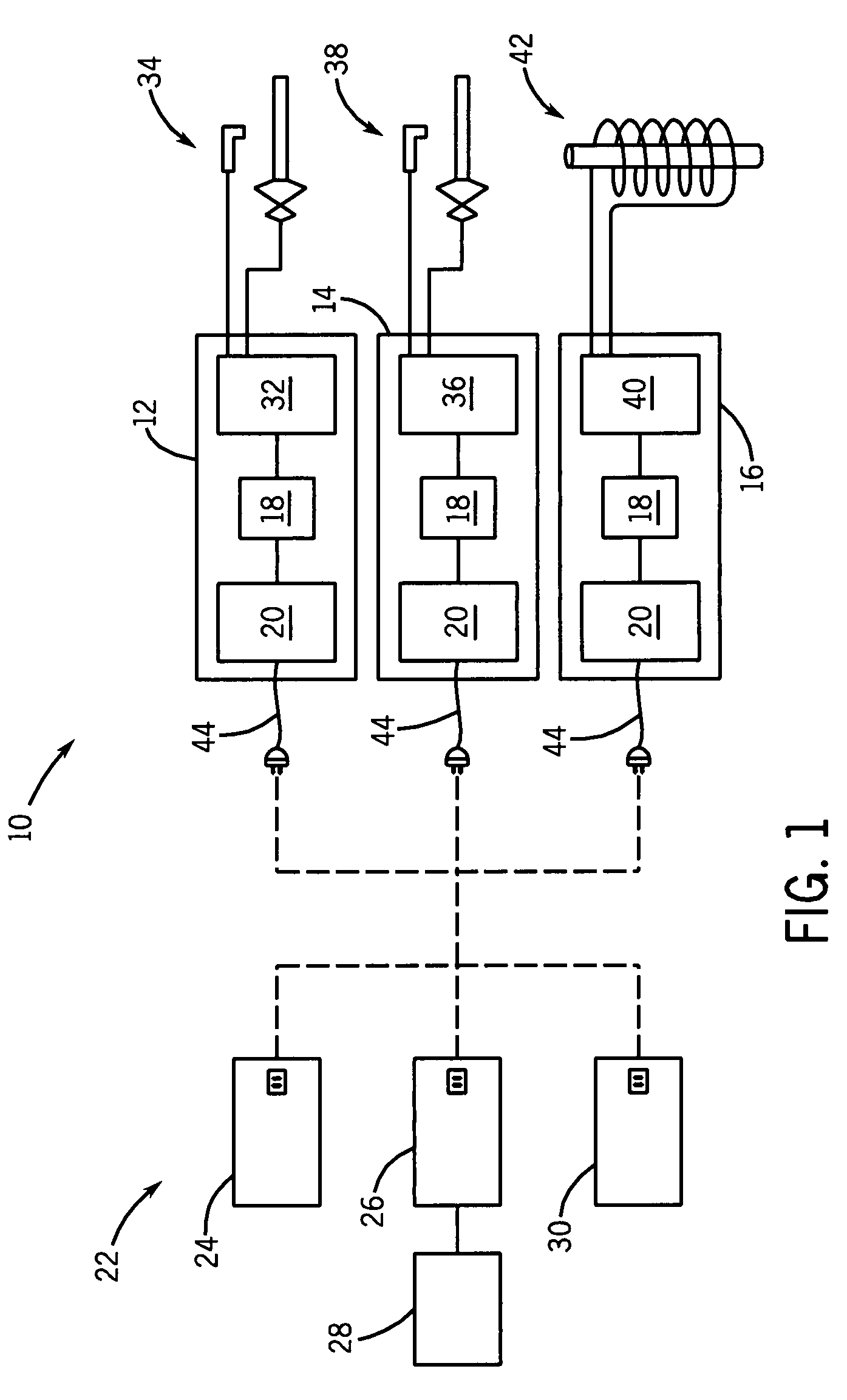

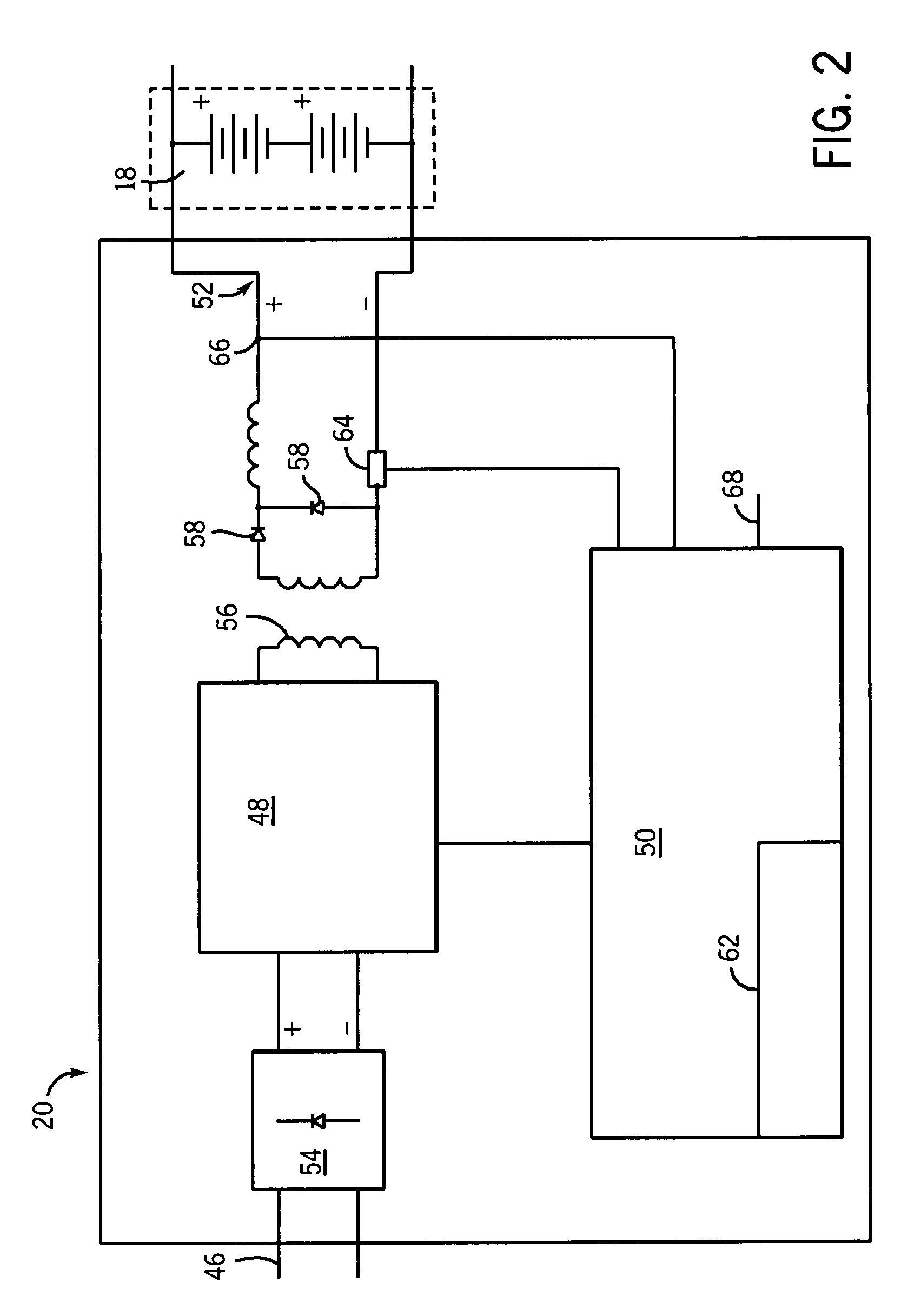

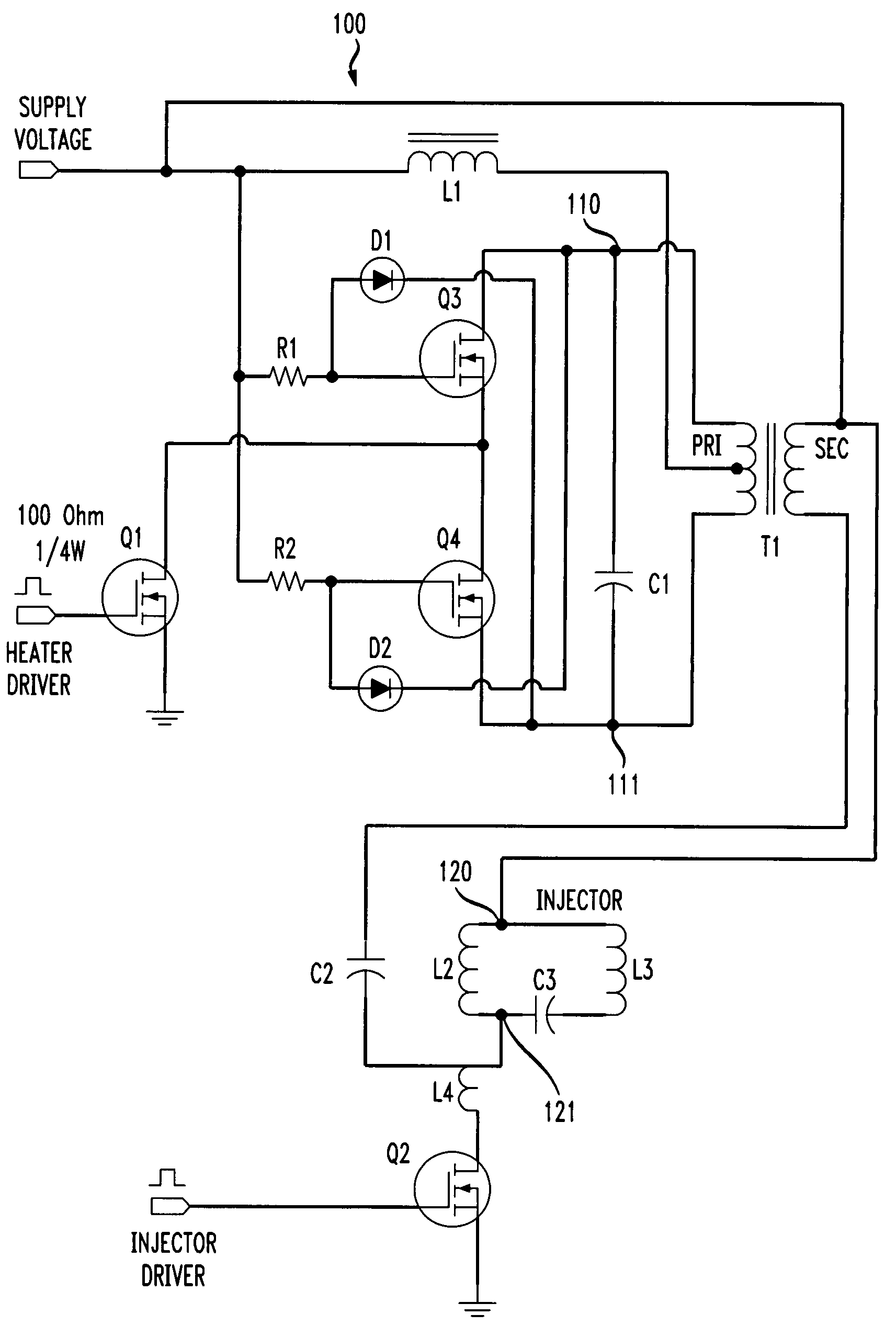

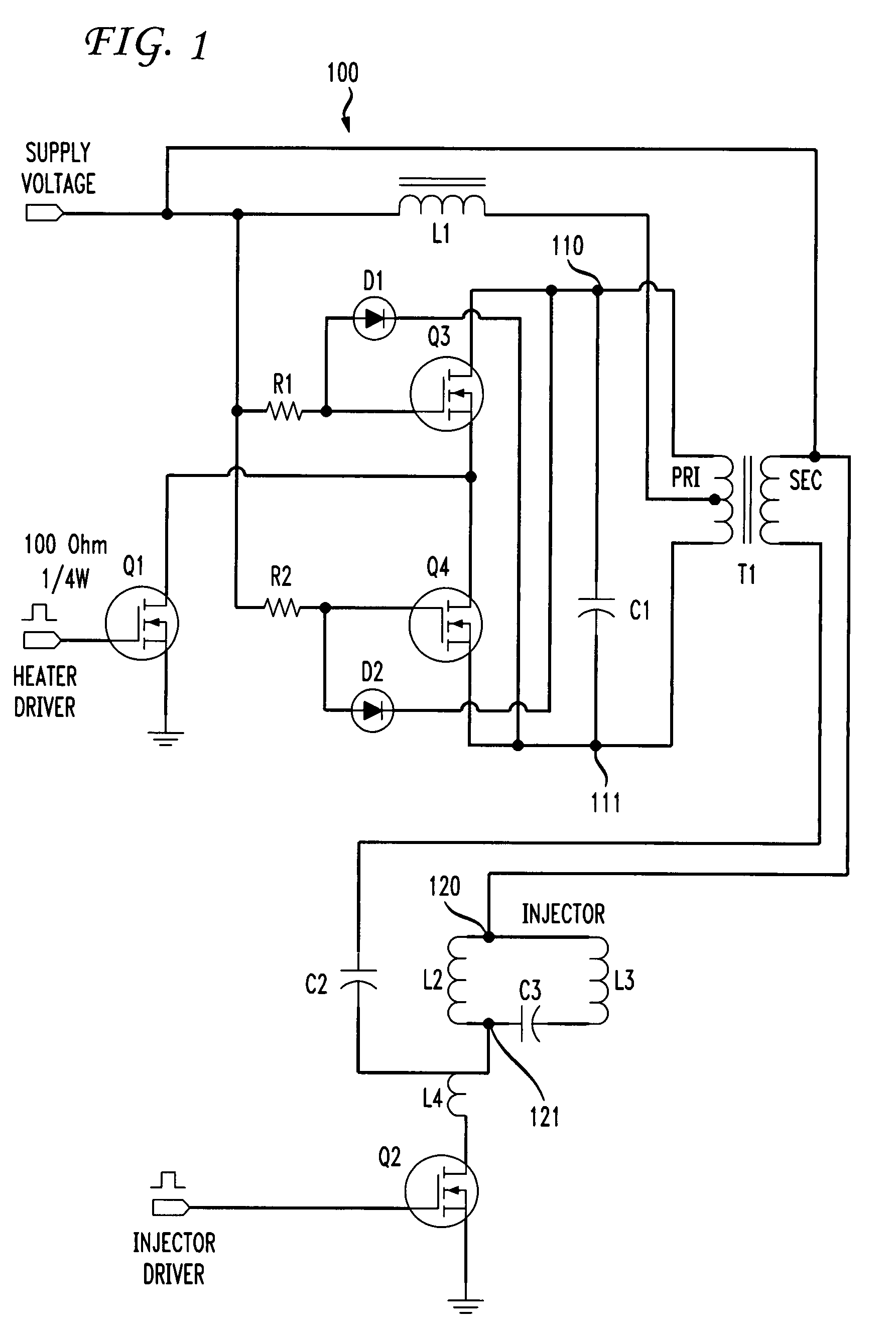

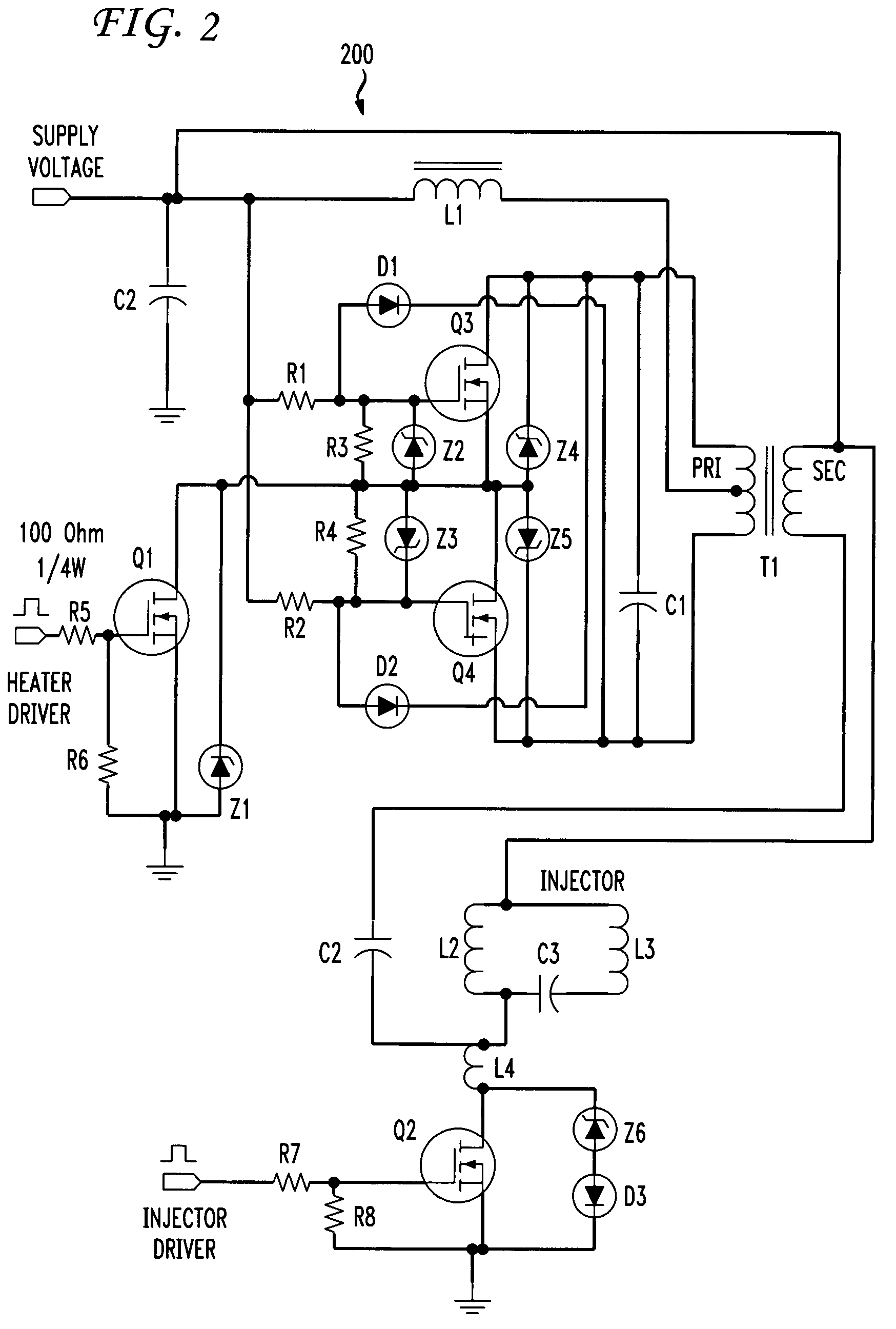

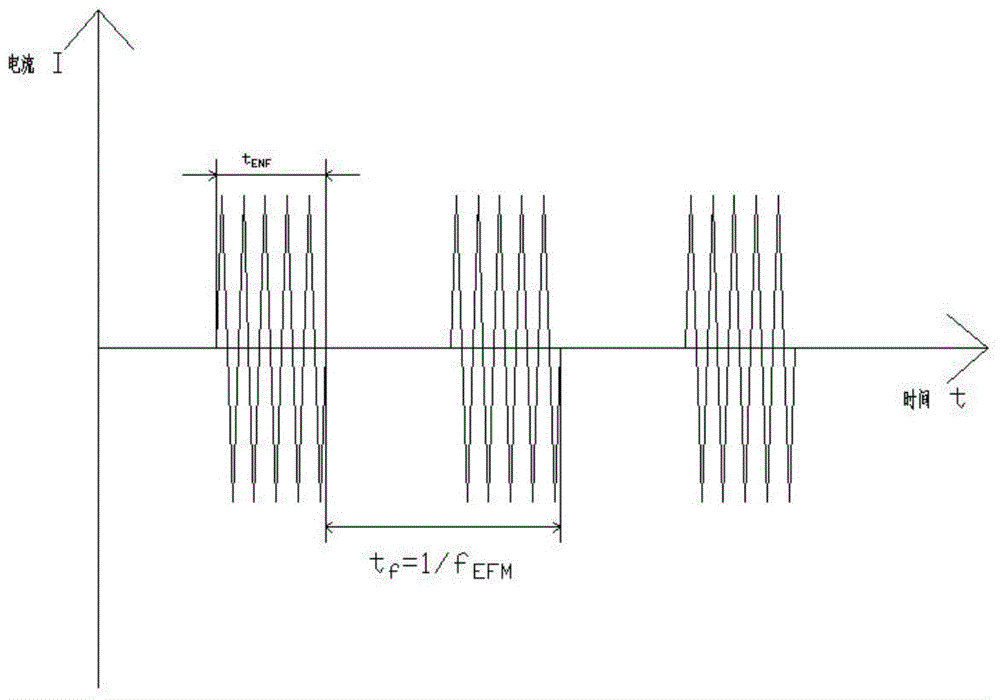

Constant current zero-voltage switching induction heater driver for variable spray injection

An electronic high frequency induction heater driver, for a variable spray fuel injection system, uses a zero-voltage switching oscillator that is impedance coupled to an imbedded multiple function signal separator and integrated with a conventionally implemented electronic fuel injector driver. The induction heater driver, upon receipt of a turn-on signal, multiplies a supply voltage through a self-oscillating series resonance, and couples the high frequency energy to a high pass filter such that the useful energy is utilized in an appropriate loss component so that fuel inside a fuel component is heated to a desired temperature.

Owner:VITESCO TECH USA LLC

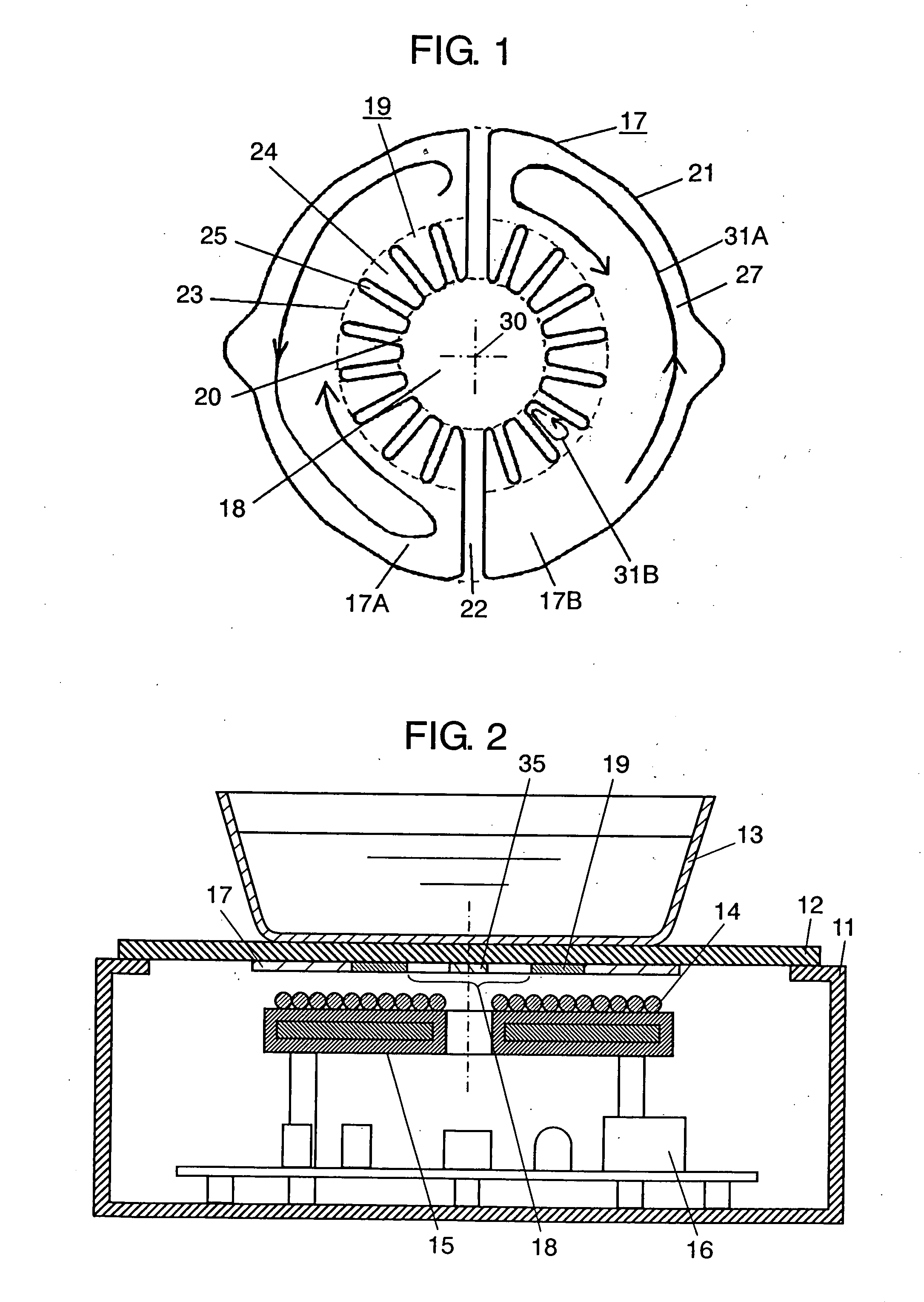

Radio frequency antenna for heating devices

ActiveUS20090194526A1Little induced voltage (noise)Reduce areaElectric signalling detailsInduction heating controlInduction heaterEngineering

The present invention provides an improved antenna assembly (66) designed to maintain RF communication between an object (22, 64, 148) to be heated, and a heating assembly (20, 60) such as an induction heater having a hob (34) equipped with an induction work coil (36). The antenna assembly (66) provides substantially continuous RF communication about the entirety of the hob (34), so that the object (22, 64, 148) can be rotated through substantially 360E, or displaced radially, without loss of RF communication. The preferred antenna assembly (66) includes an antenna (67) mounted upon a substrate (68) and presenting a plurality of continuous, conductive antenna loops (70, 72) oriented to cooperatively and substantially around the hob (34). Each of the loops (70, 72) has an inner section (82, 84) proximal to the hob (34) and defines a respective, enclosed RF communication zone (94,96) outboard of and disposed about the hob (34); the zones (94,96) cooperatively define a substantially continuous RF communication zone outboard of and disposed about the hob (34). The antenna assembly (66) also includes antenna circuitry 97 including tuning assemblies (98, 100) and a terminal network (102). In alternative forms, radiant, resistant heating, or other types of heating hobs can be used.

Owner:TSI TECH

Image forming apparatus, fixing unit, and image forming method using induction heater

InactiveUS7570910B2Electrographic process apparatusInduction heating apparatusImage formationInduction heater

An image forming apparatus includes an image forming mechanism configured to form a toner image on a recording medium according to image data and a fixing mechanism configured to fix the toner image on the recording medium. The fixing mechanism includes an induction heater, a heat generator, and a position adjusting mechanism. The induction heater is configured to generate a magnetic flux. The heat generator is disposed at a position opposite to the induction heater and is configured to generate heat by the magnetic flux generated by the induction heater. The position adjusting mechanism is configured to adjust a position of the induction heater in conjunction with a displacement of the heat generator.

Owner:RICOH KK

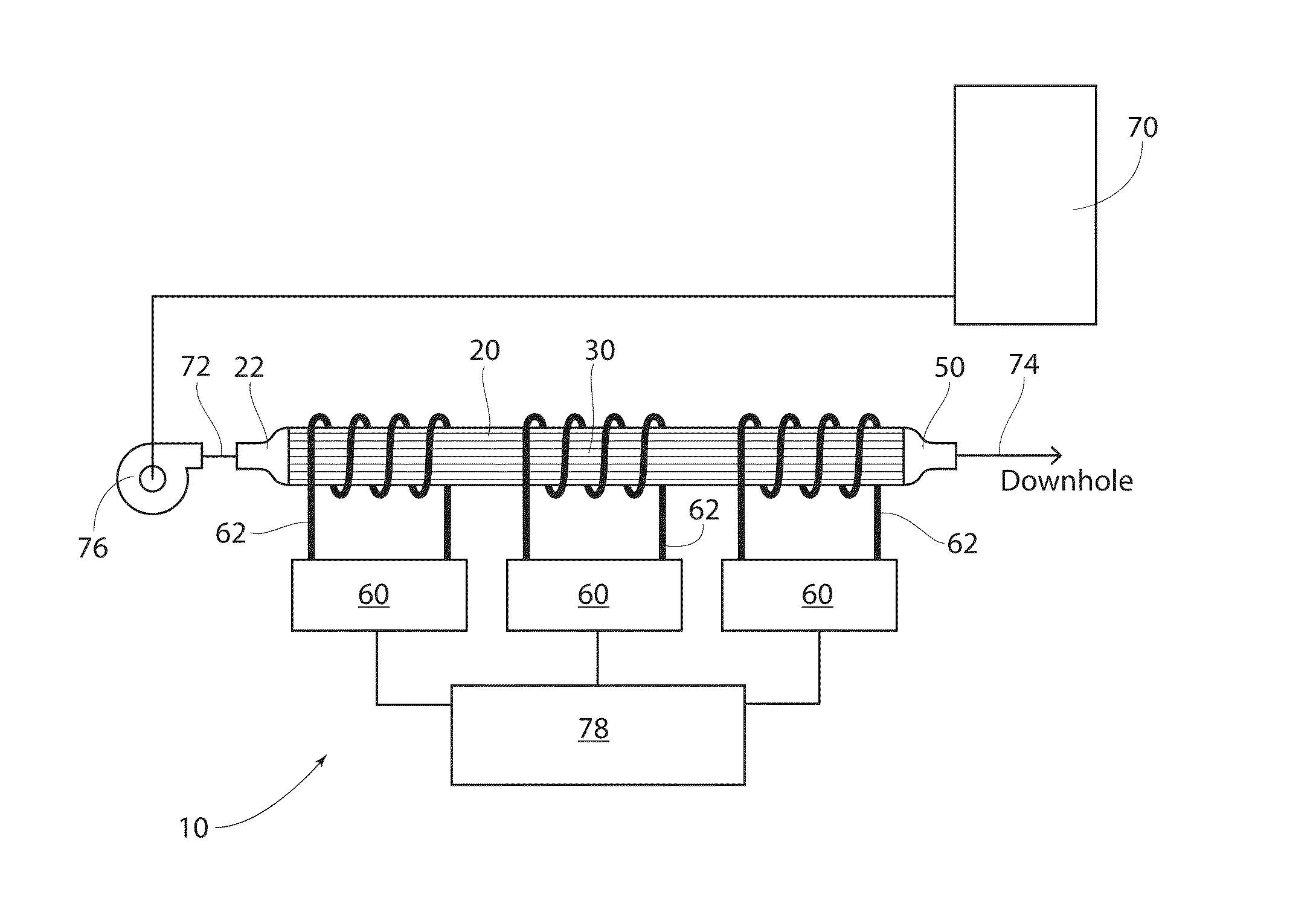

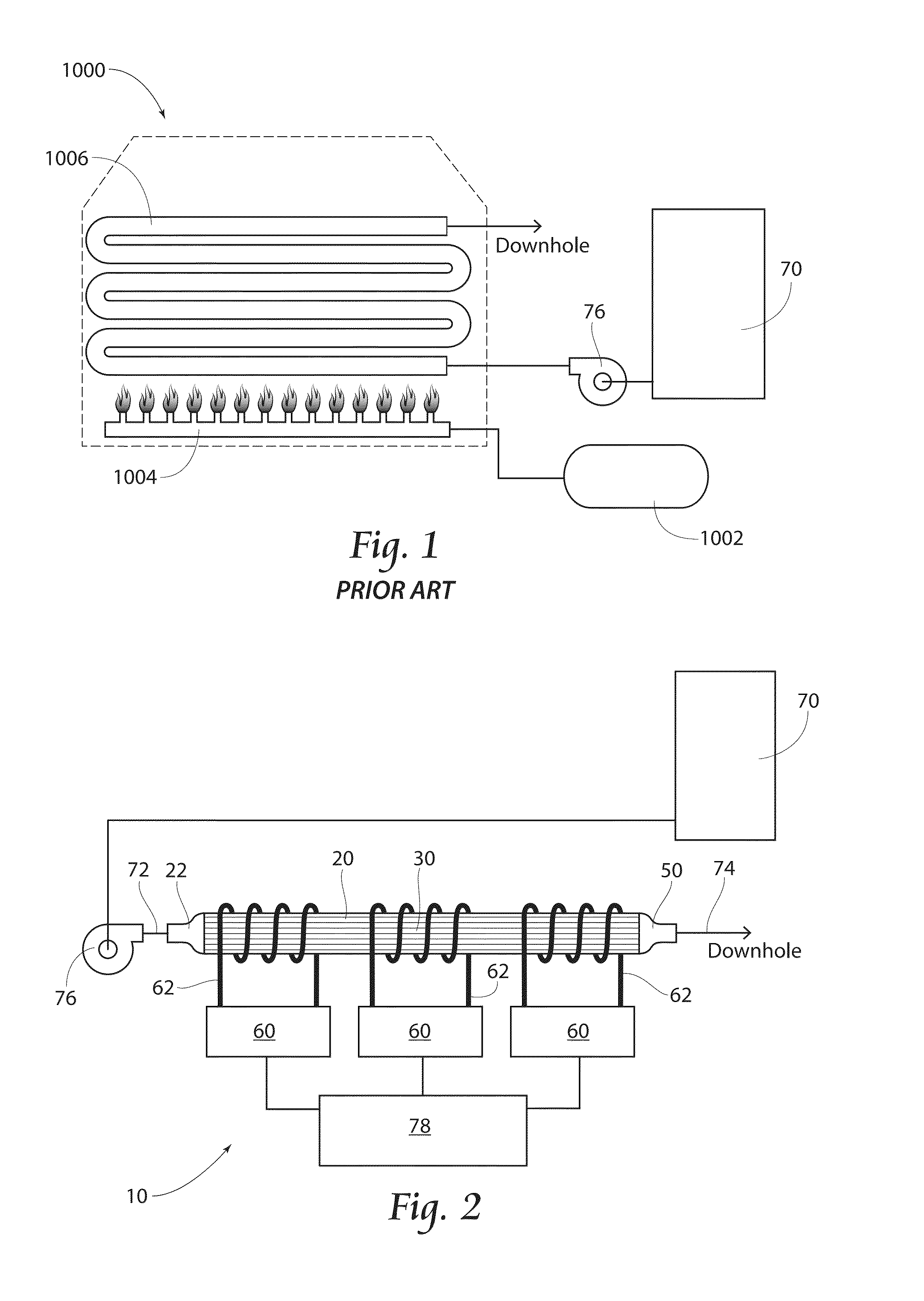

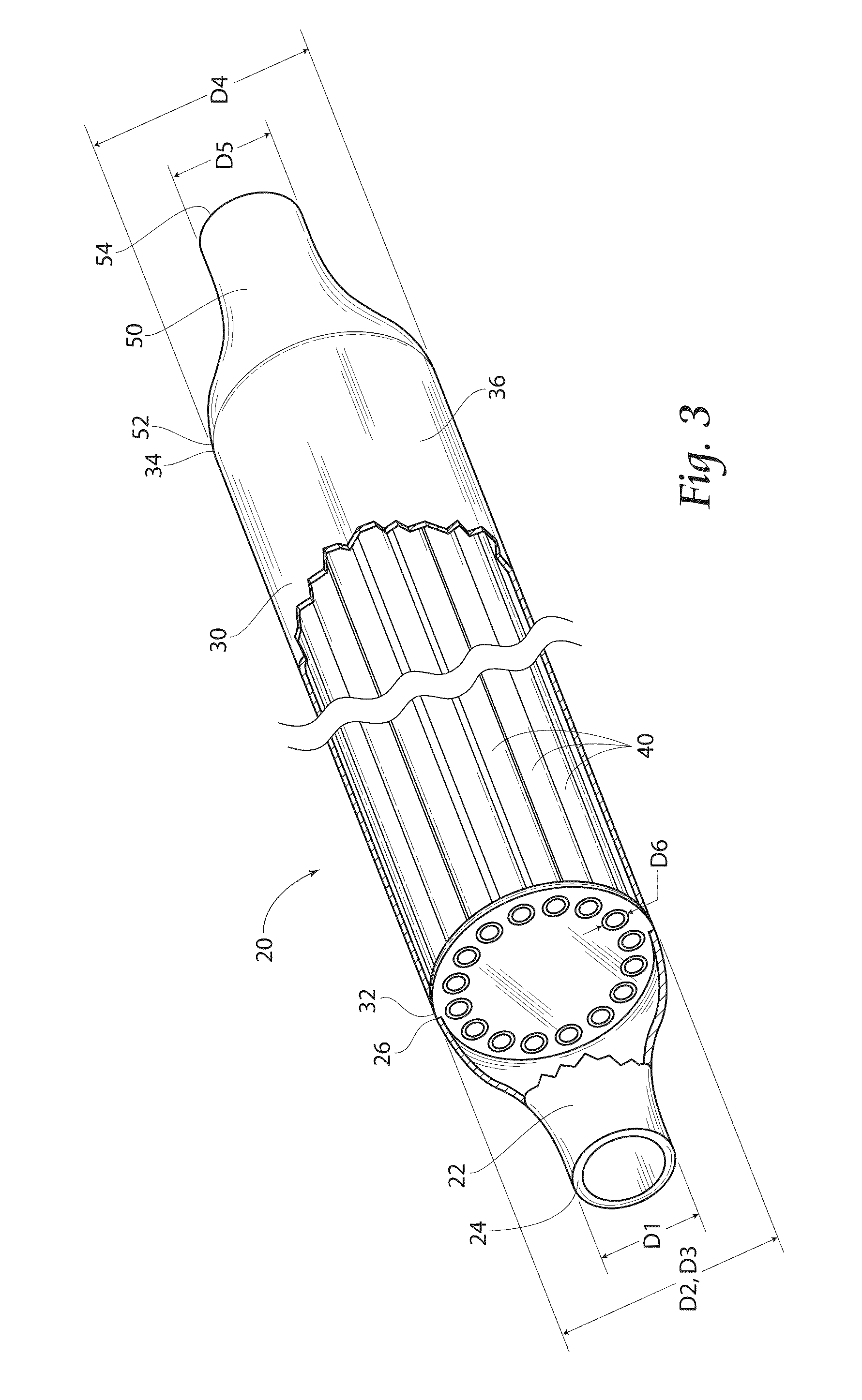

Multi-channel conduit and method for heating a fluid for use in hydraulic fracturing

System and method directed to the art of heating a fluid for use in a hydraulic fracturing system. A heat tube having a plurality of pipes disposed axially along and substantially near the periphery of a medial portion of the heat tube. The heat tube is heated by induction heaters.

Owner:FREEDOM OILFIELD SERVICES

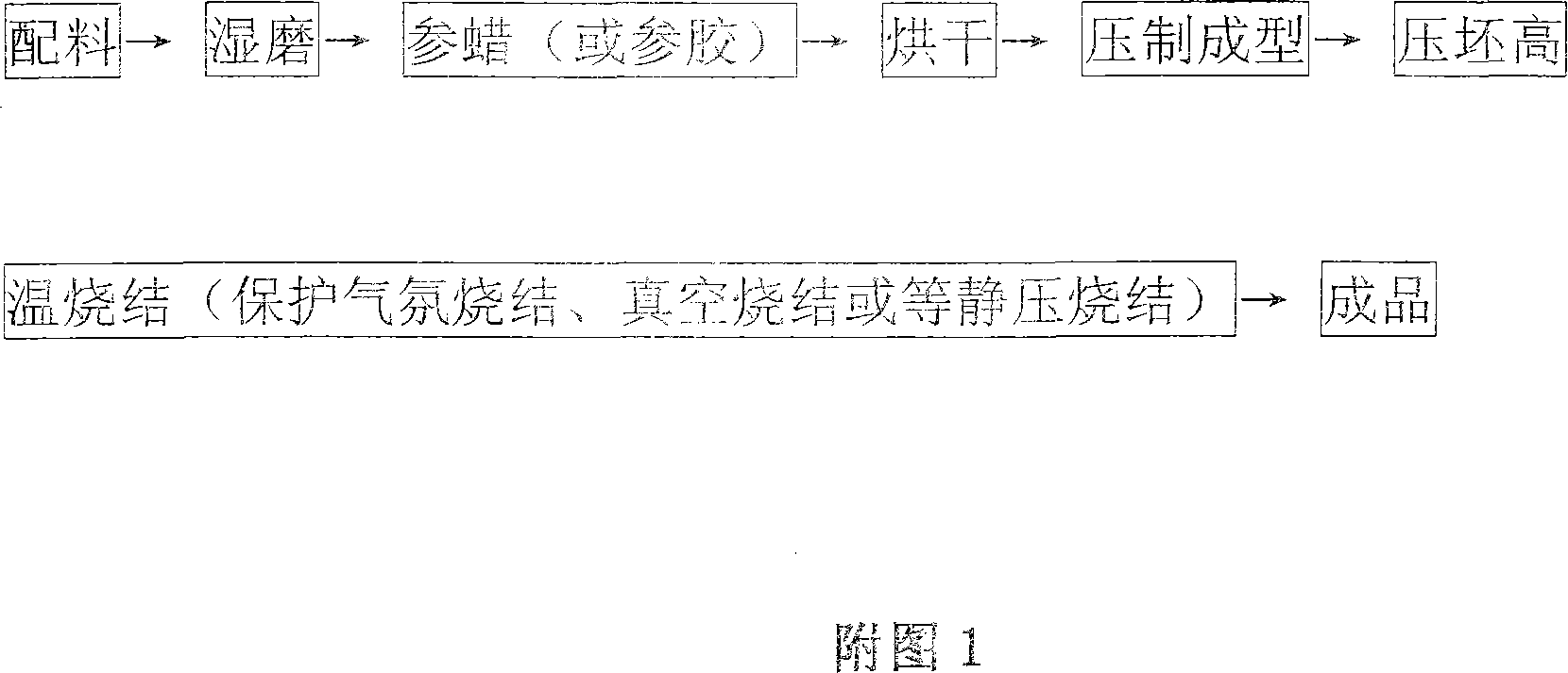

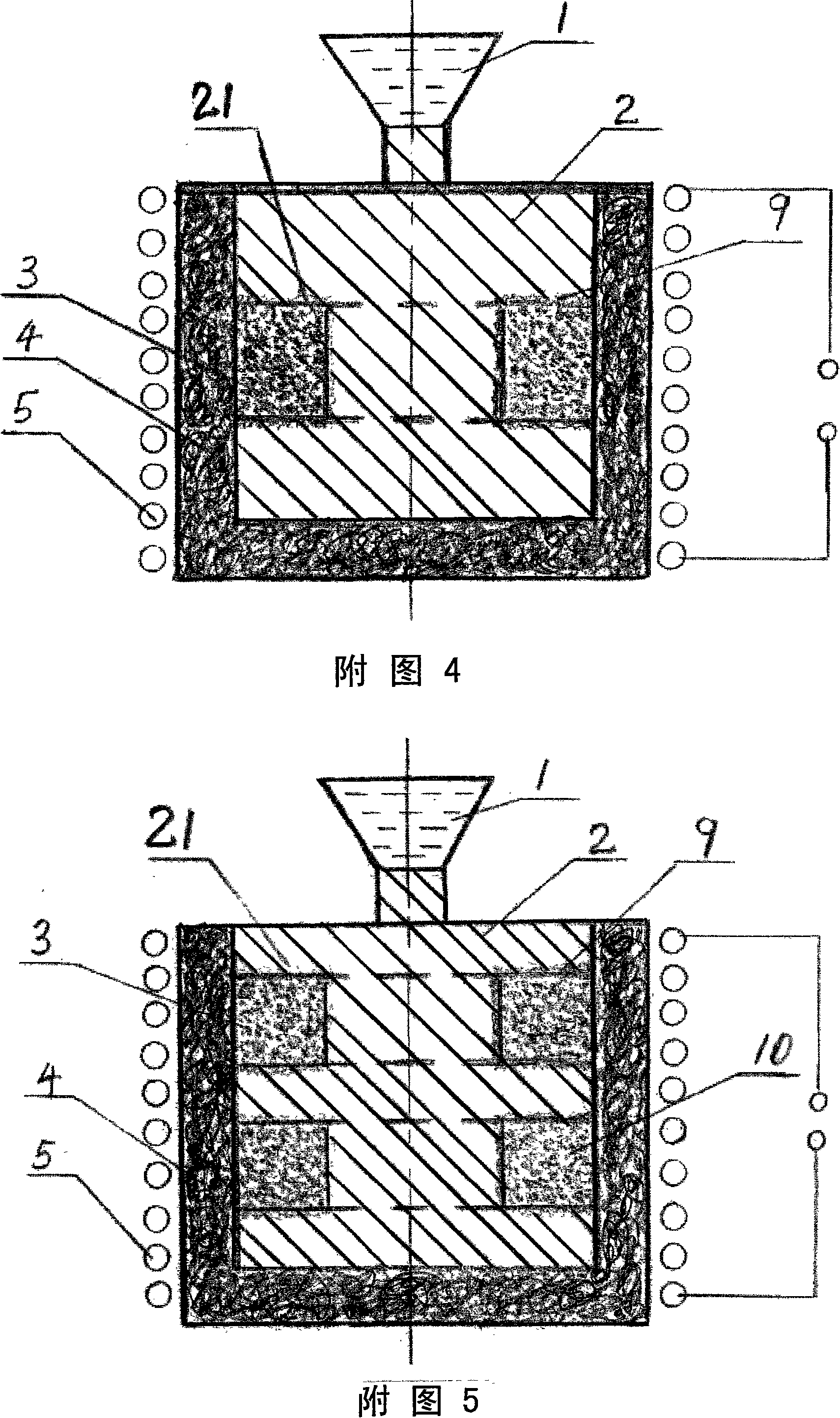

Hard alloy and double-metal composite technique and device

The utility model relates to a composite art and apparatus for hard alloy and bimetal, wherein the hard alloy is made of C with the content from 1.5 to 3.8 percent, Cr with the content from 15 to 27 percent, high chromium foundry iron with the content Fe used as binder, WC or TIC particles by the powder metallurgy technique, wherein the C and Cr are both accounted for 10-40 percent, the rest is the high chromium foundry iron, the WC or the TIC has the content from 90 to 60 percent. The hard alloy proceed composite casting with the C with the content from 1.5 to 3.8 percent, the Cr with the content from 15 to 25 percent, the rest high chromium foundry iron and spheroidal graphite cast iron in the mould provided with an electro-magnetism induction heater outside. The recombination of two materials is achieved by directly heating to the hard alloy and base metal liquid via the induction heater in the process of casting. The hard alloy produced by the invention has better wetting property and less bulking difference to the base metal, and is capable of achieving good recombination with the base metal. The invention has the advantages of simple recombination technique, easy achievement of technique, good property of the recombination products and low manufacturing costs.

Owner:丁家伟 +1

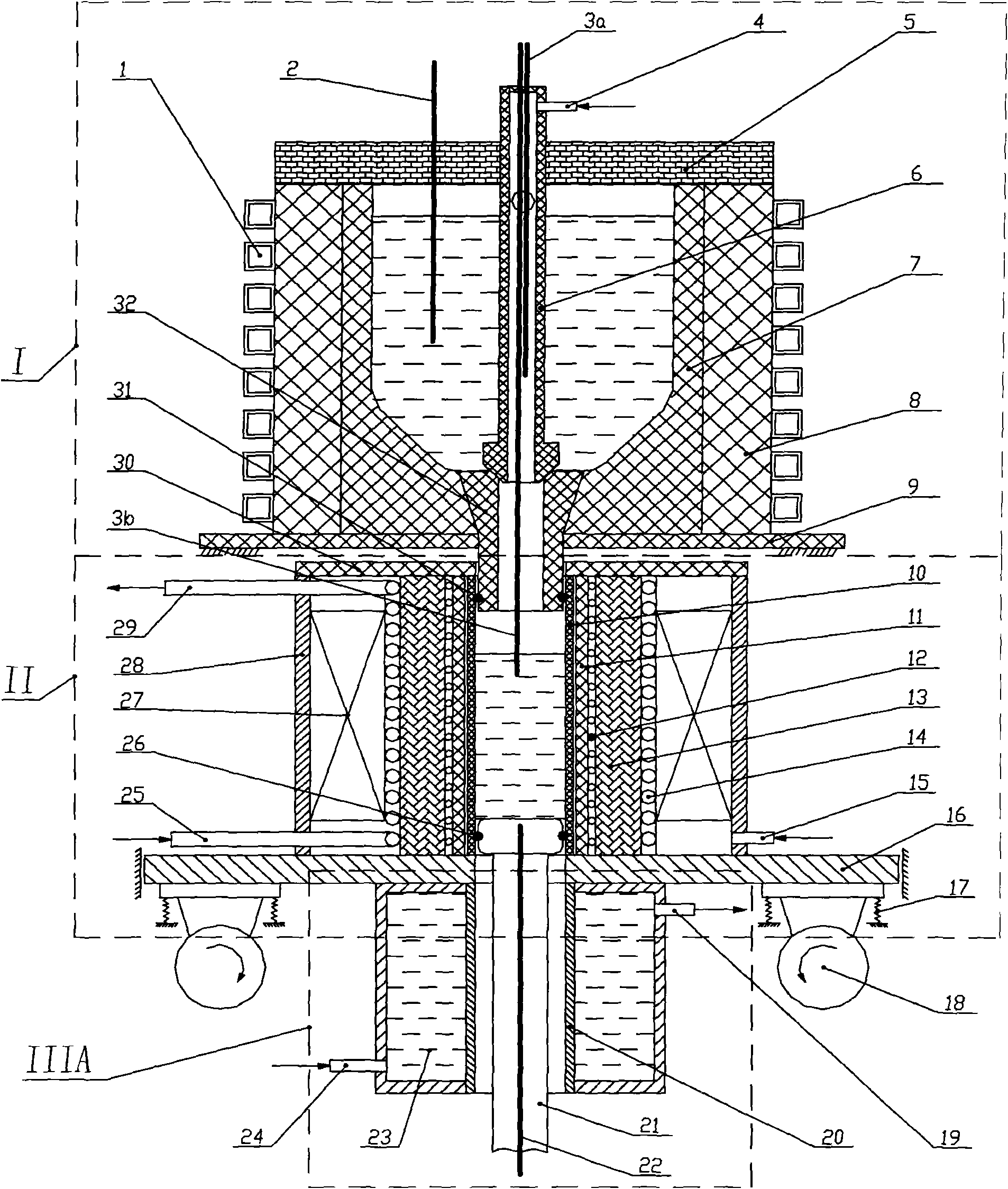

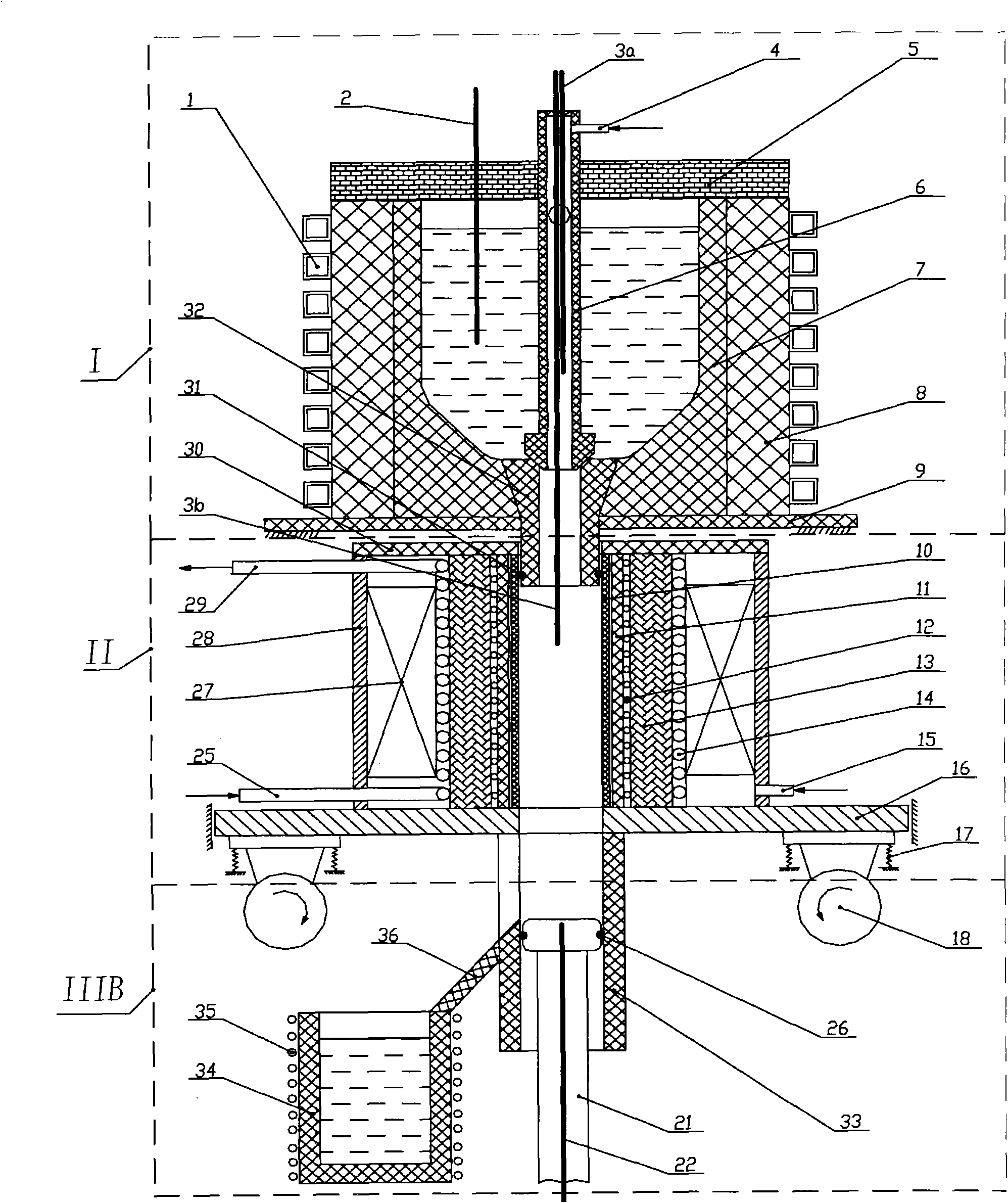

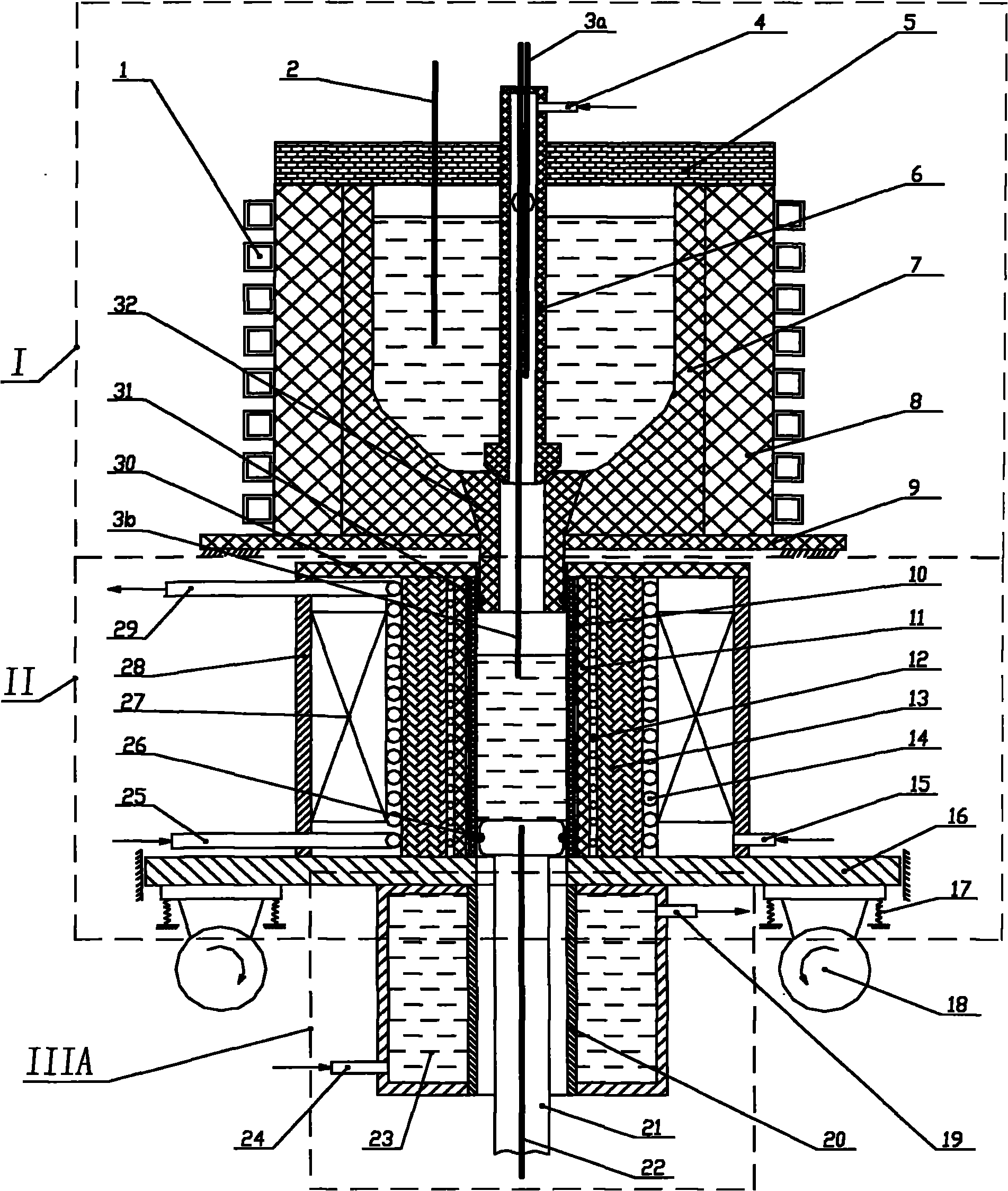

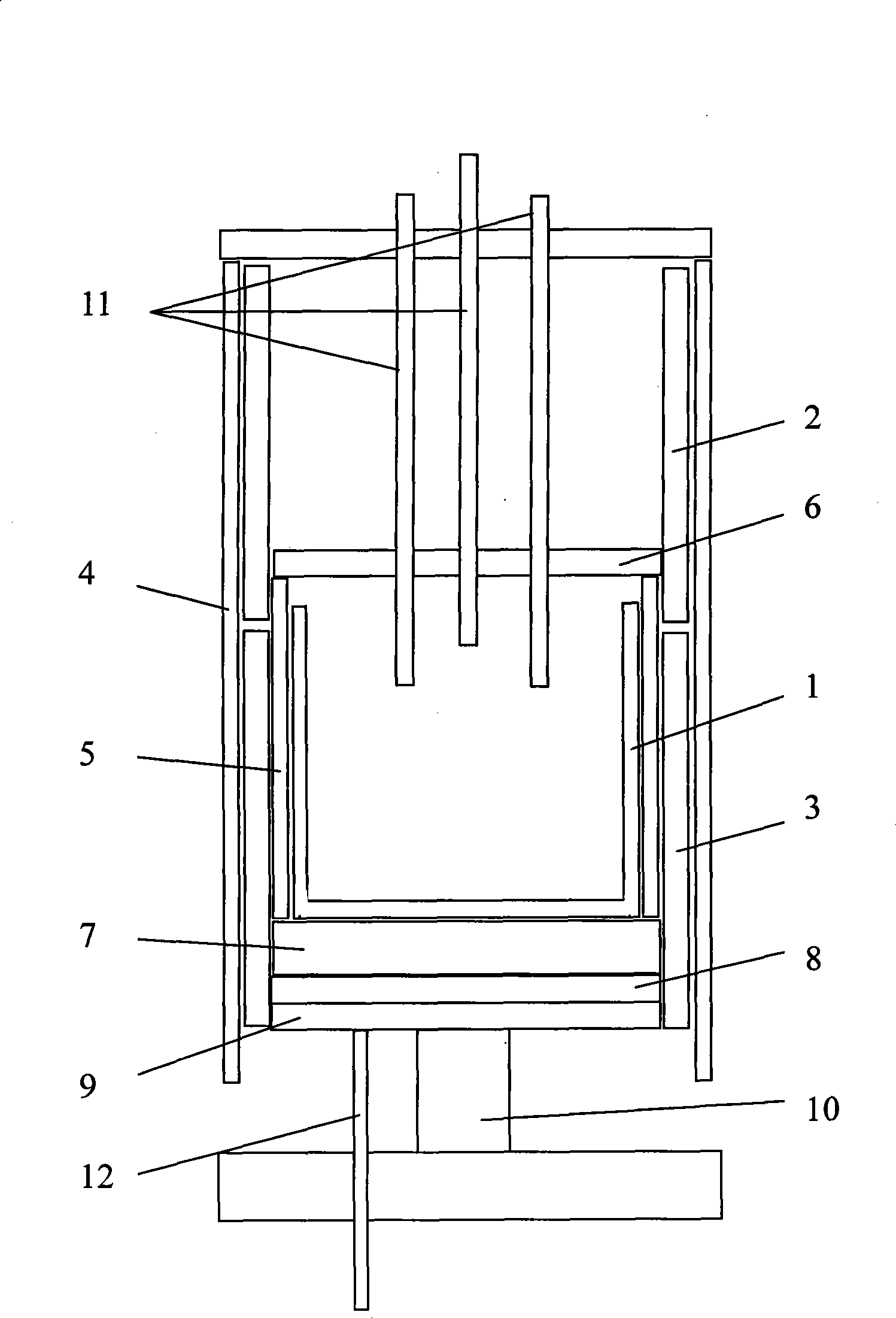

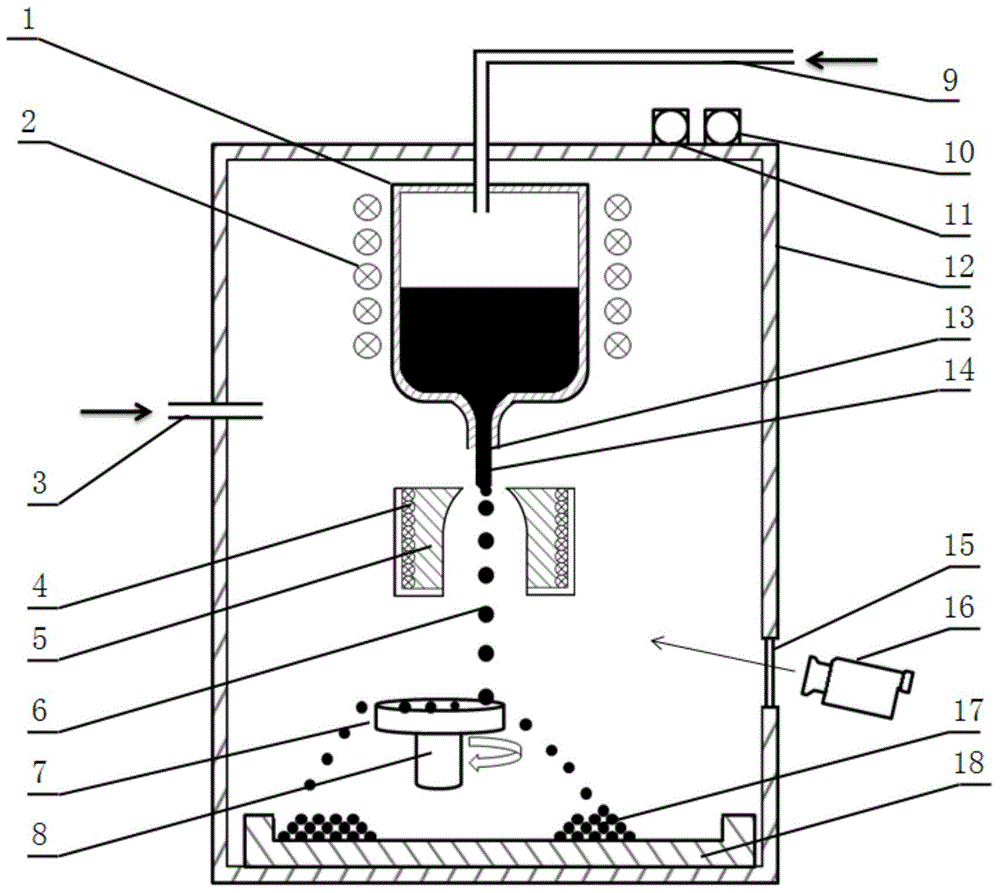

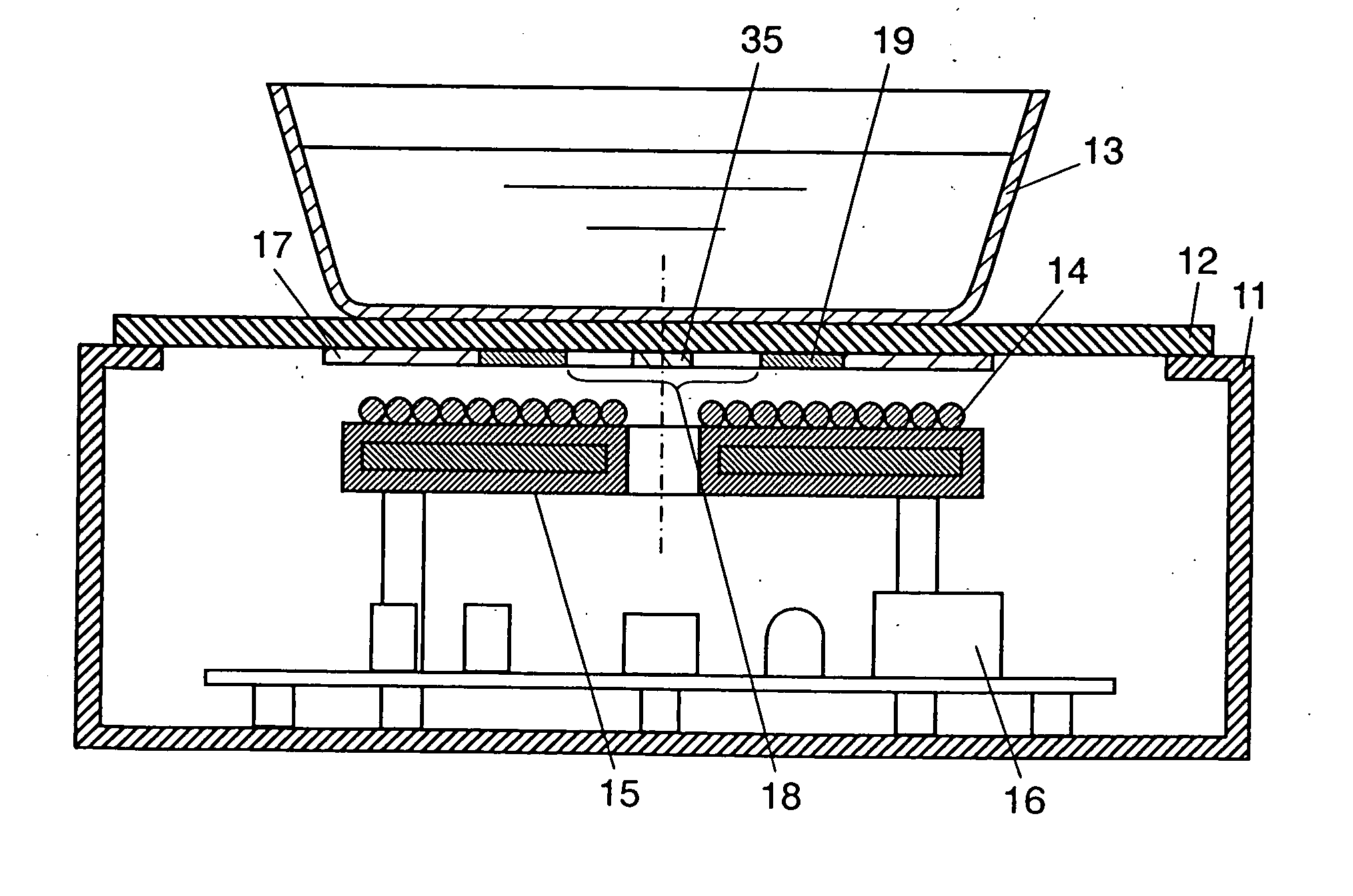

Electromagnetic stirring and vibration combined device for preparing semi-solid slurry of black metal

The invention relates to an electromagnetic stirring and vibration combined device for preparing semi-solid slurry of a black metal. The device comprises three main sections: a melting furnace, a stirring chamber, and a crystallizer or a rheologic conveyor, wherein the melting furnace is arranged at the upper part of the stirring chamber, and the crystallizer or the rheologic conveyor is arranged at the lower part of the stirring chamber. When molten metal is poured into the melting furnace, a medium-frequency induction heater is used for maintaining temperature and uniformly heating; when the temperature of the molten metal is within the liquidus temperature range, the molten metal is poured into a stirring crucible in a quantitative amount, and a non-dendritic fine equiaxial spherical or nearly spherical microstructure is obtained by electromagnetically stirring and mechanically vibrating the molten metal; and the prepared fine nearly spherical semi-solid slurry is poured into the crystallizer, then cooled and solidified into a blank, or the slurry is poured into the rheologic conveyor and then is rapidly conveyed to a forming mold for rheoforming. The device can be used for preparing semi-solid slurry of a black metal and nonferrous metal, which improves the efficiency and the quality for preparing metal semi-solid slurry and shortens the preparation time. The device is especially suitable for rheoforming.

Owner:XI AN JIAOTONG UNIV

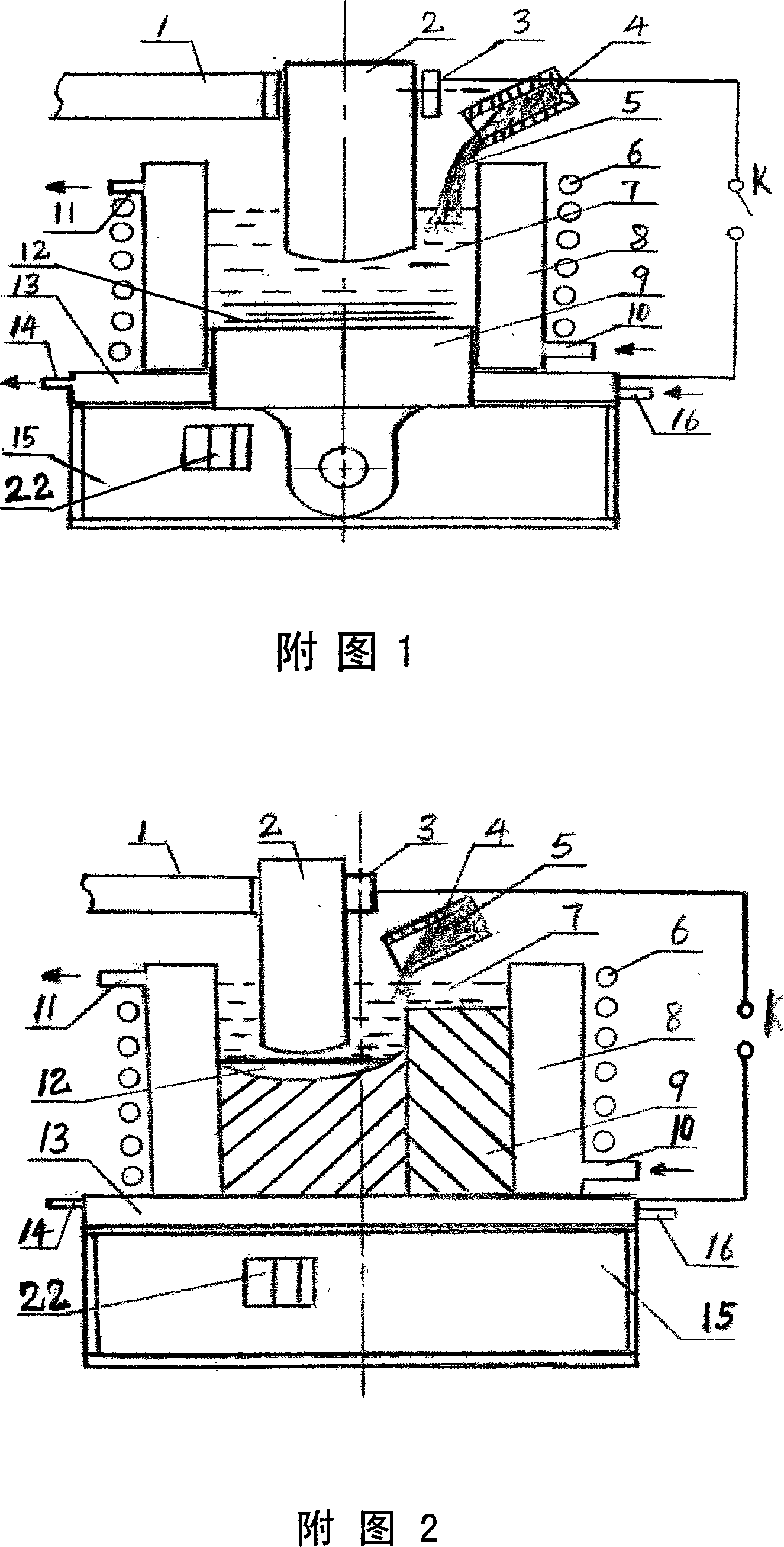

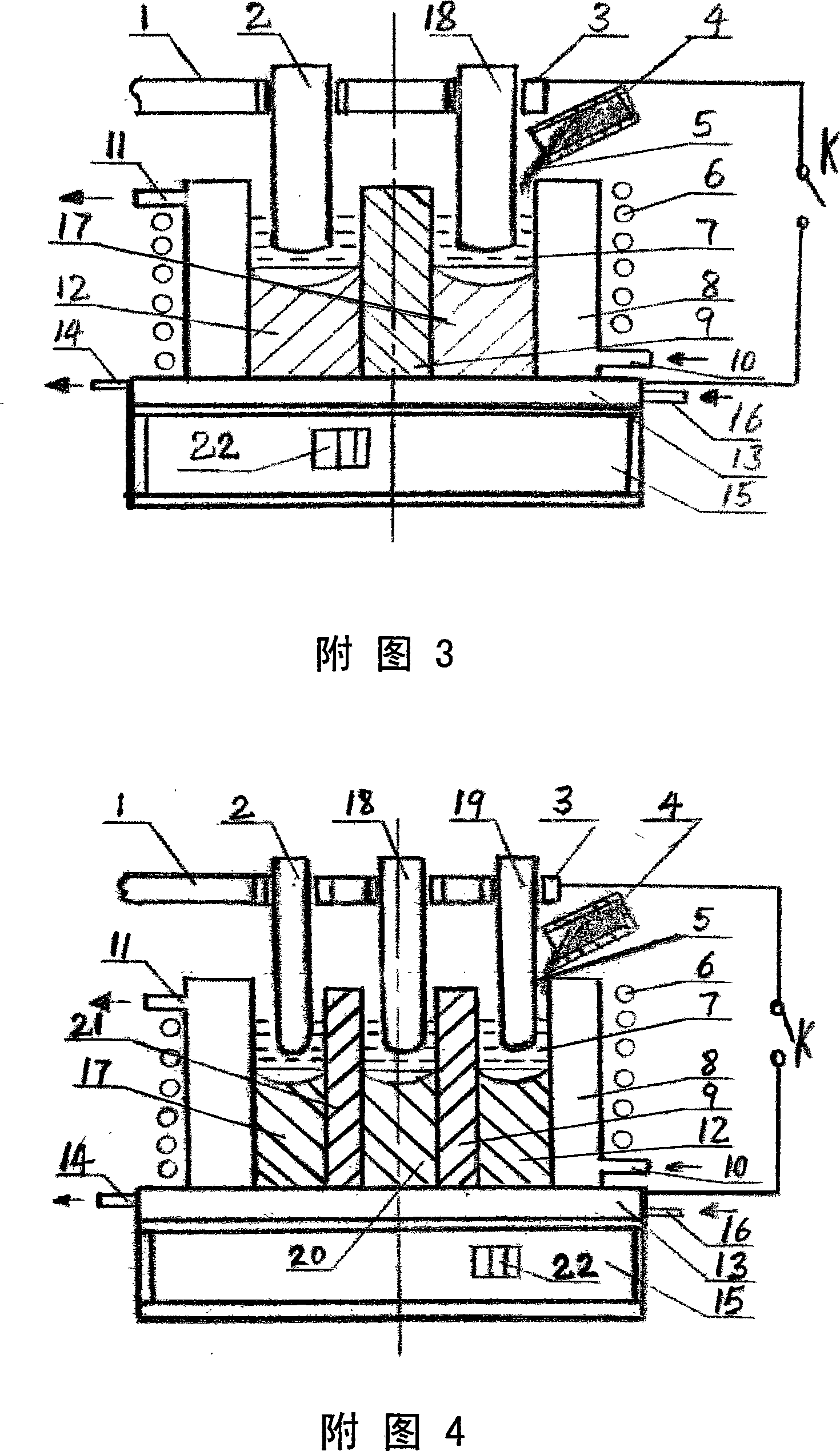

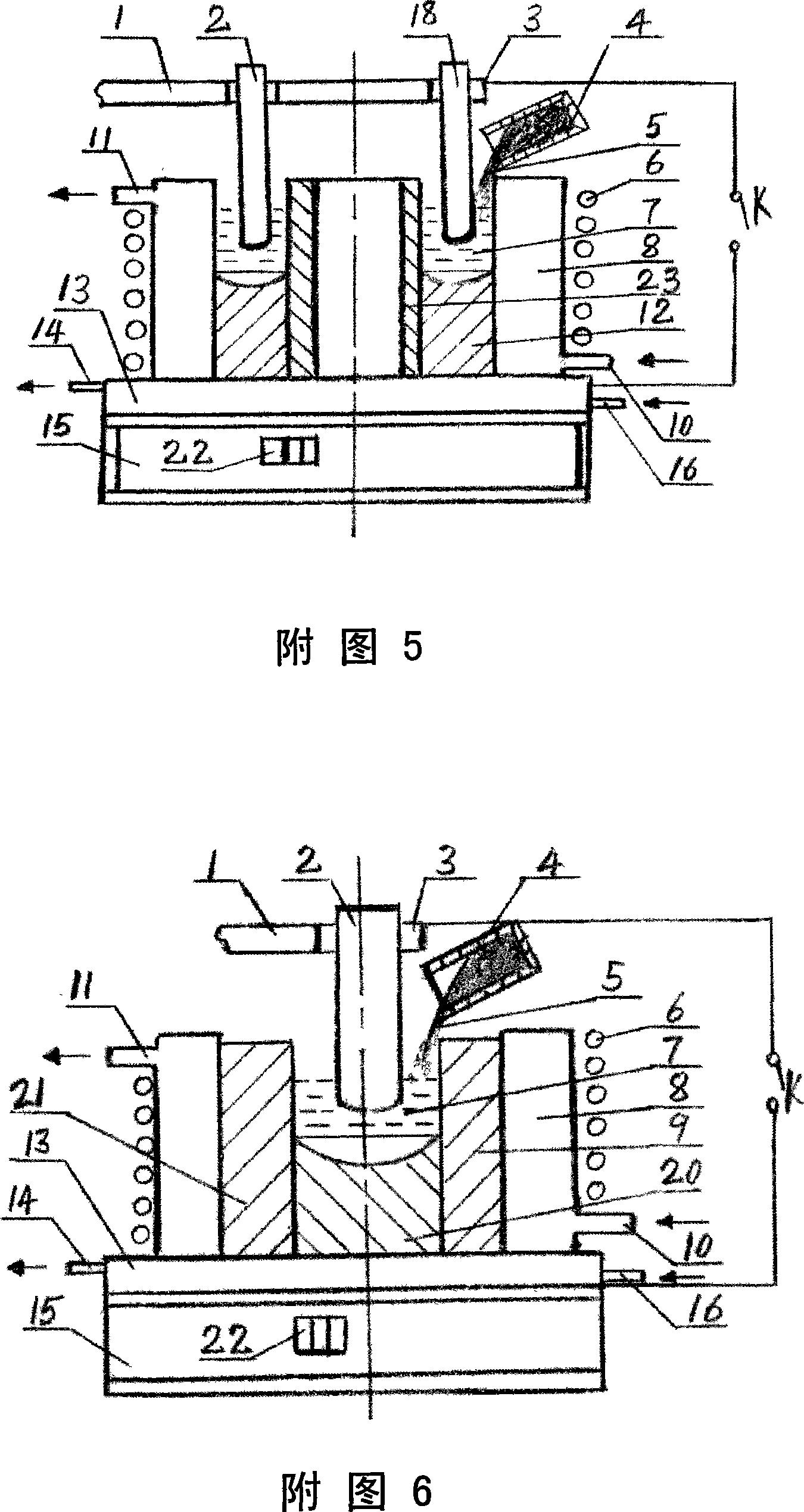

Casting method for manufacturing layered metal composite material technology and equipment

The present invention discloses a technique and relative equipment for casting laminated and composite metal material. Target material is heated to 300 DEG C to 1200 DEG C by an electromagnetic induction heater installed on exterior of a casting die or a water cooling crystallizer. Molten electroslag liquid is poured in the casting die or the water cooling crystallizer, and an electrode is inserted in for heating. The metal liquid is poured in the casting die or the water cooling crystallizer by top casting mode or bottom casting mode. After casting, the induction heater and the electrode conduct continuous heating for 3 to 20 minutes, then heating is stopped, and layered composite material with plane gradient, laminated composite material and coated composite material of all geometric shapes can be produced. The present invention can simplify production procedures of composite material and can realize the dynamic regulation of all technical parameters during composition. The interface of the composite layer is under eay control so as to achieve excelllent metallurgical combination. The present invention has wide optional range about materal of the composite layer, high productivity, simple production technique and low cost.

Owner:丁家伟 +1

Method for purifying and ingot casting multi-temperature zones silicon material and apparatus thereof

InactiveCN101423220AAvoid coolingAvoid heatingAfter-treatment apparatusPolycrystalline material growthElectrical resistance and conductanceCrucible

The invention provides a method and a device used for purifying and ingot-casting of multi-temperature area silicon material; the silicon material is added into a crucible after a fluxing medium is added; the silicon material is inductively heated, fused and vacuum-smelted; furthermore, oxidative gas is added to carry out the reaction; subsequently, temperature reducing and directional solidification are carried out to the silicon material to form silicon ingots by crystallization. The device comprises a crucible system, a lifting device, an induction heater and a resistance heater; the induction heater is arranged on the upper surface of the resistance heater so as to respectively form an induction heating area and a resistance heating area; the lifting device is arranged on the lower surface of the resistance heating area and can move up and down in the induction heating area and the resistance heating area; and the crucible system is arranged on the lifting device. The method and the device can be used for purifying and ingot-casting the silicon ingot with high purity and high purification efficiency, can complete the whole process in one furnace body and can save the time and energy resource.

Owner:PROPOWER RENEWABLE ENERGY SHANGHAI

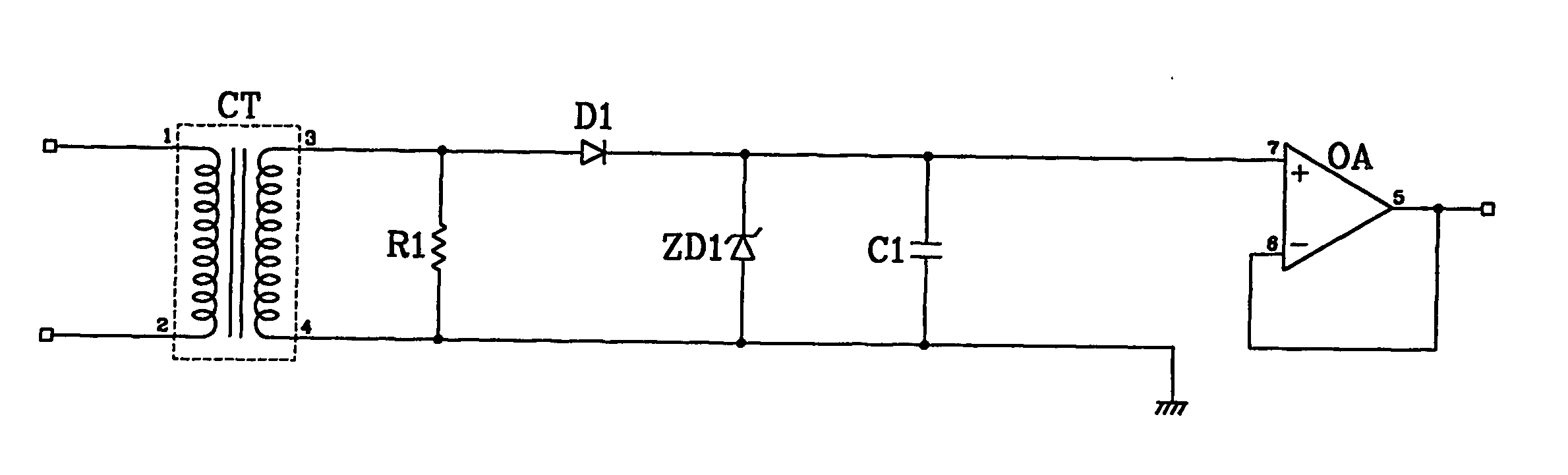

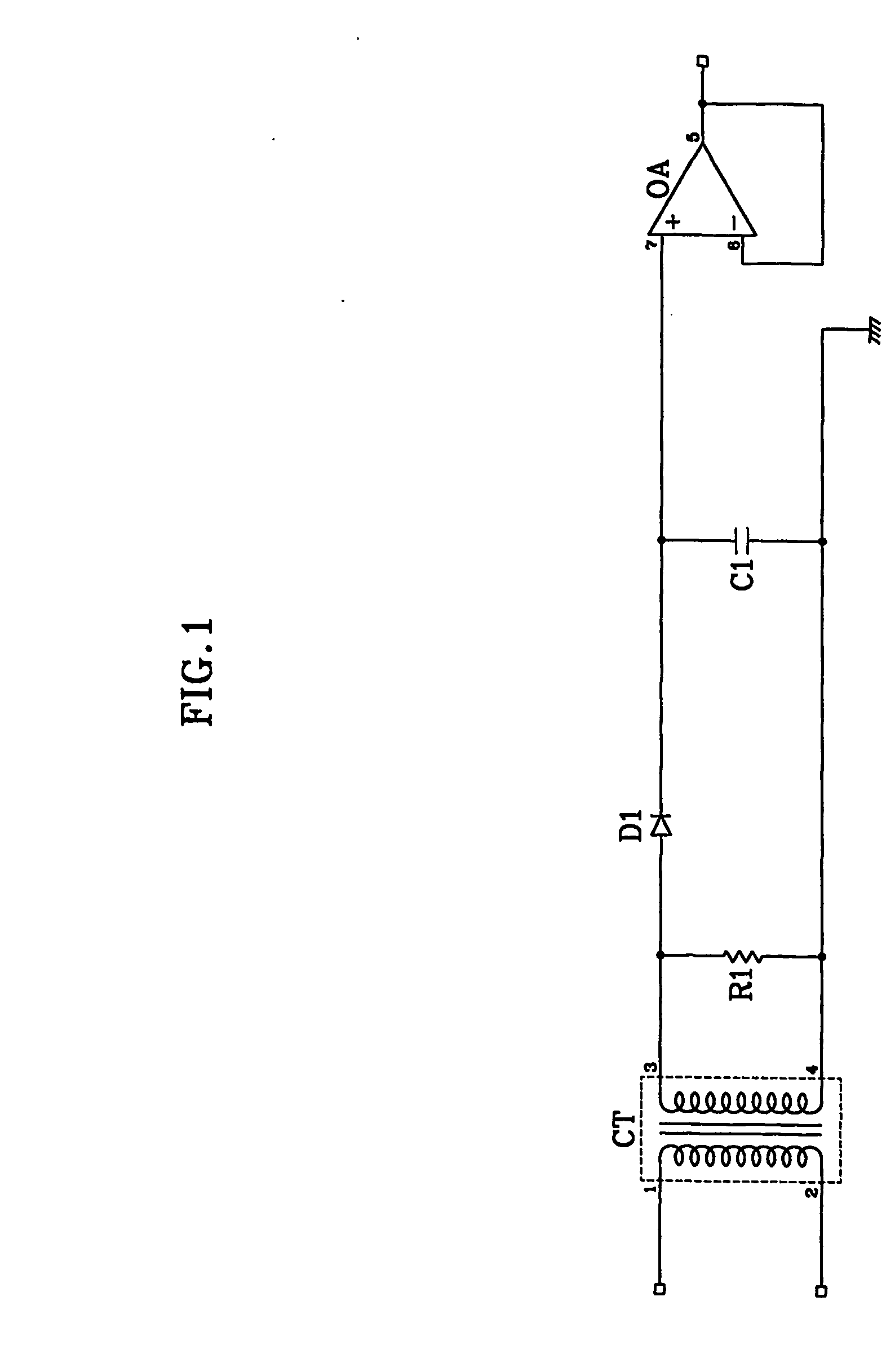

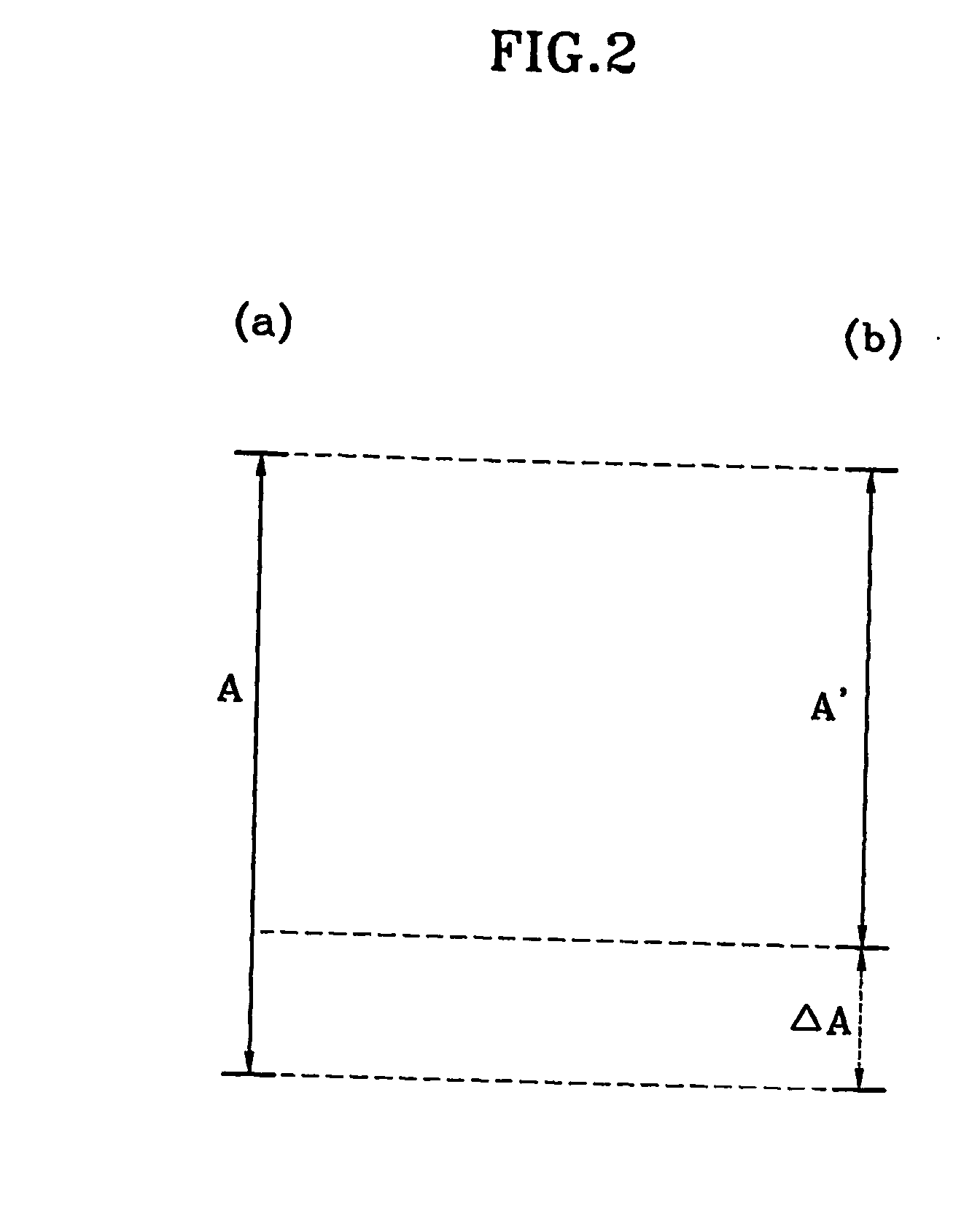

Circuit for detecting electric current

ActiveUS20060164096A1Improve accuracyImprove reliabilityResistance/reactance/impedenceAc/pulses peak value measurementsInduction heaterEngineering

A circuit for detecting an electric current by which a loss portion of a forward current caused by a backward leakage current of a diode generated by the influence of temperature increase can be compensated such that error in the peak value of a load current detected by surrounding high temperature can be minimized, and credibility reliability can be increased for electric instruments that call for an accurate control of the load current and that generate a high temperature such as induction heating cookers, induction heaters and the like.

Owner:KWON YONG JAI

Battery powered welder system utilizing vehicle powered AC inverter

A system and method, in certain embodiments, adjusts a charging output based on capabilities of various power sources. The system and method may be used to charge a variety of equipment such as welders, cutters, induction heaters, tools and so forth. For example, a charging circuit configured to change an output charge level based upon capabilities of multiple power sources configured to be coupled to the charging circuit. In some embodiments, the system and method may test the capabilities of the various power sources by evaluating an actual output versus a commanded output, and reduce the commanded output if the actual output falls below a desired level.

Owner:ILLINOIS TOOL WORKS INC

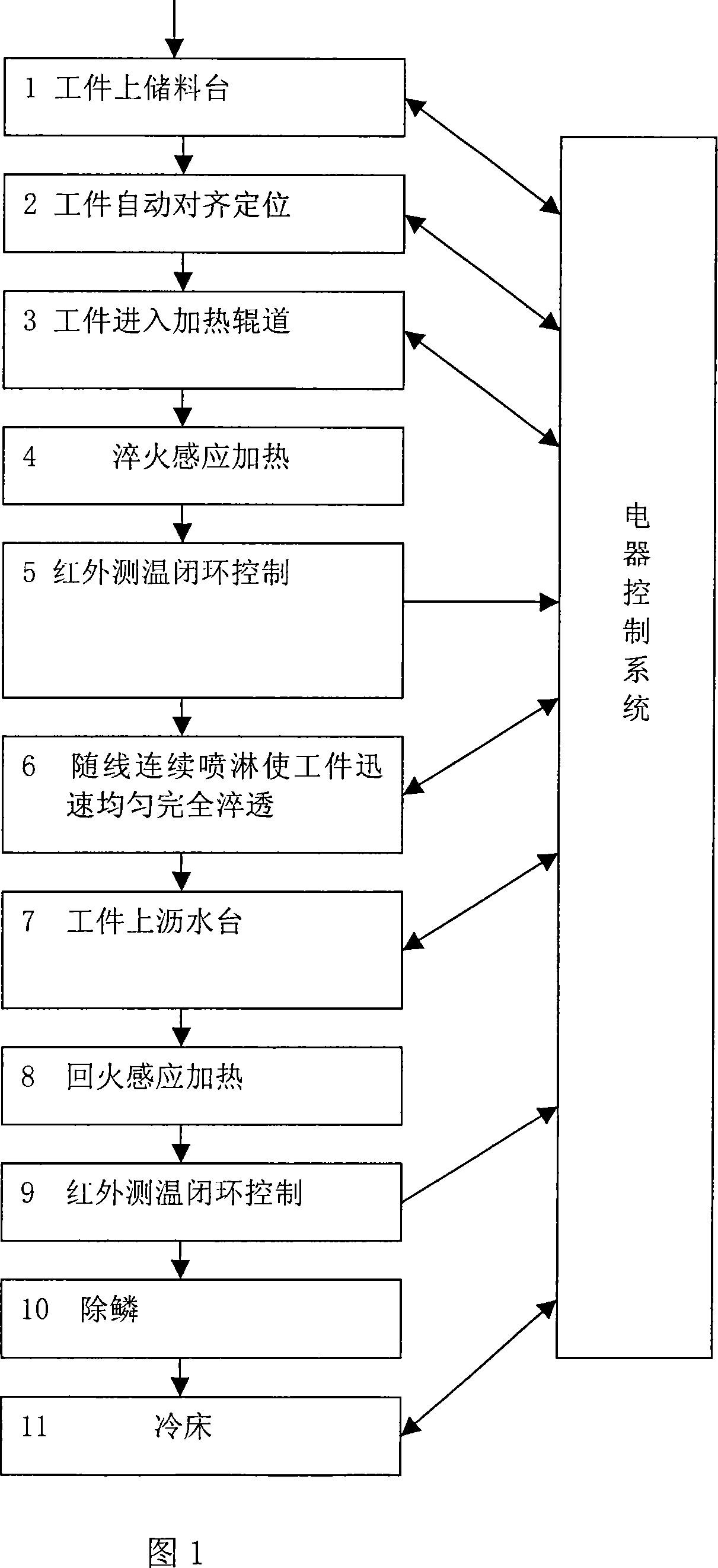

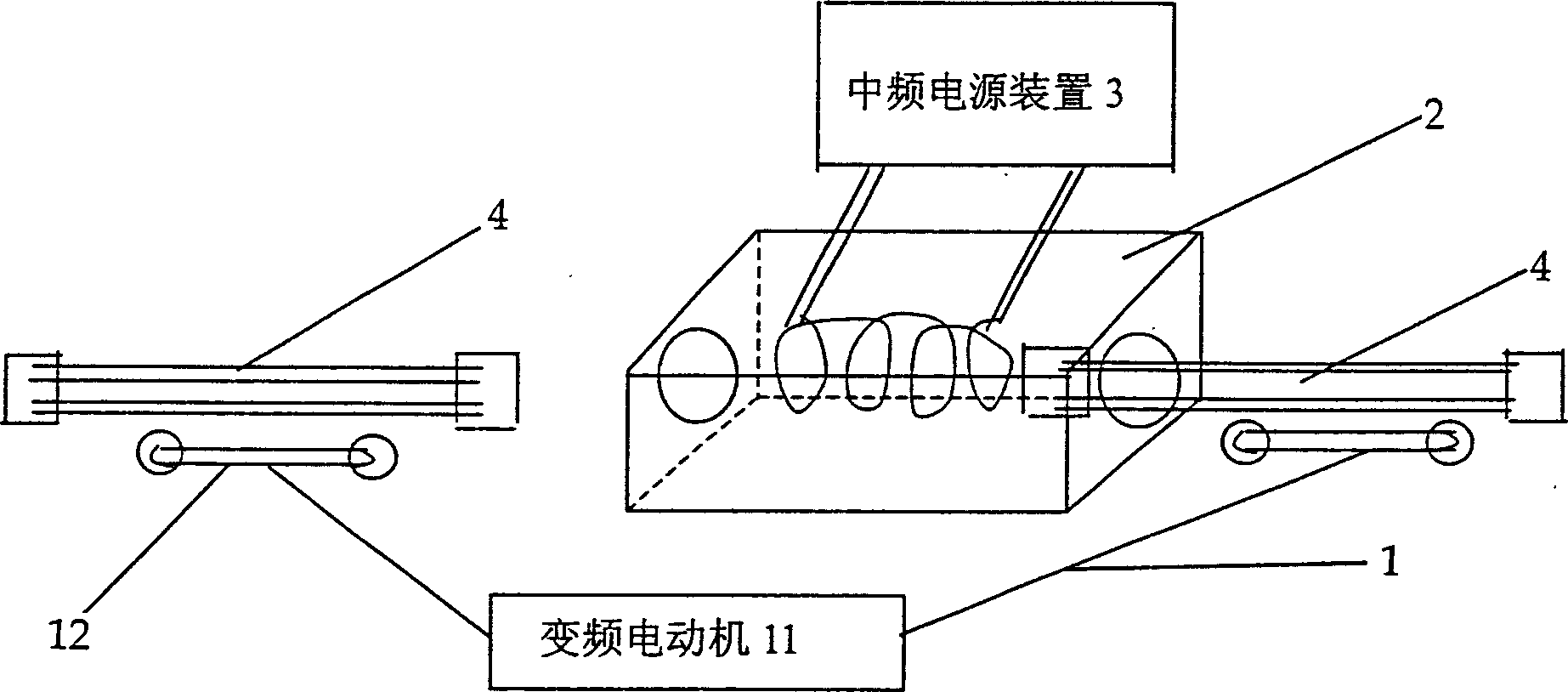

Medium frequency induction heating treatment method for steel pipe, petroleum well pipe and drill pipe

ActiveCN101078042ANo pollution in the processHeating evenlyFurnace typesIncreasing energy efficiencyClosed loopPetroleum

This invention provides a kind of main-frequency induction heating method using in the frequency treatment system of steel pipe and the tube and drill pipe of oil well. This method include put the work piece to the storage platform, the work piece automatic alignment and localization, the work piece enter the heating roller, quenching inducing heated, closed loop temperature control system, continuum spray ensure the work piece being uniformly quenched entire and quickly, the water stay in the work piece being ejected on the detearing platform, the work piece is heated by the temper inducing heater which controlled by the infrared thermometer controller, descaling device, and then enter the descaling device , the final is the cooling platform. The intermediate-frequency induction heater is using as the heating system, which is safe, no pollution and with little oxide scale. The heater roller ensure the work piece is heated uniformly and entirely, and after this process the work piece no need to be straightened which decrease the cost. The spray quenching equipment ensure the work piece could be uniformly quenched entire and quickly. The descaling device makes the surface of the work piece brightly. The detearing platform makes the work piece move automatically, which won' t influence the heating effect. And the water and steam could not enter the heating inducing loop either, which can increase the life of the loop..

Owner:朱兴发

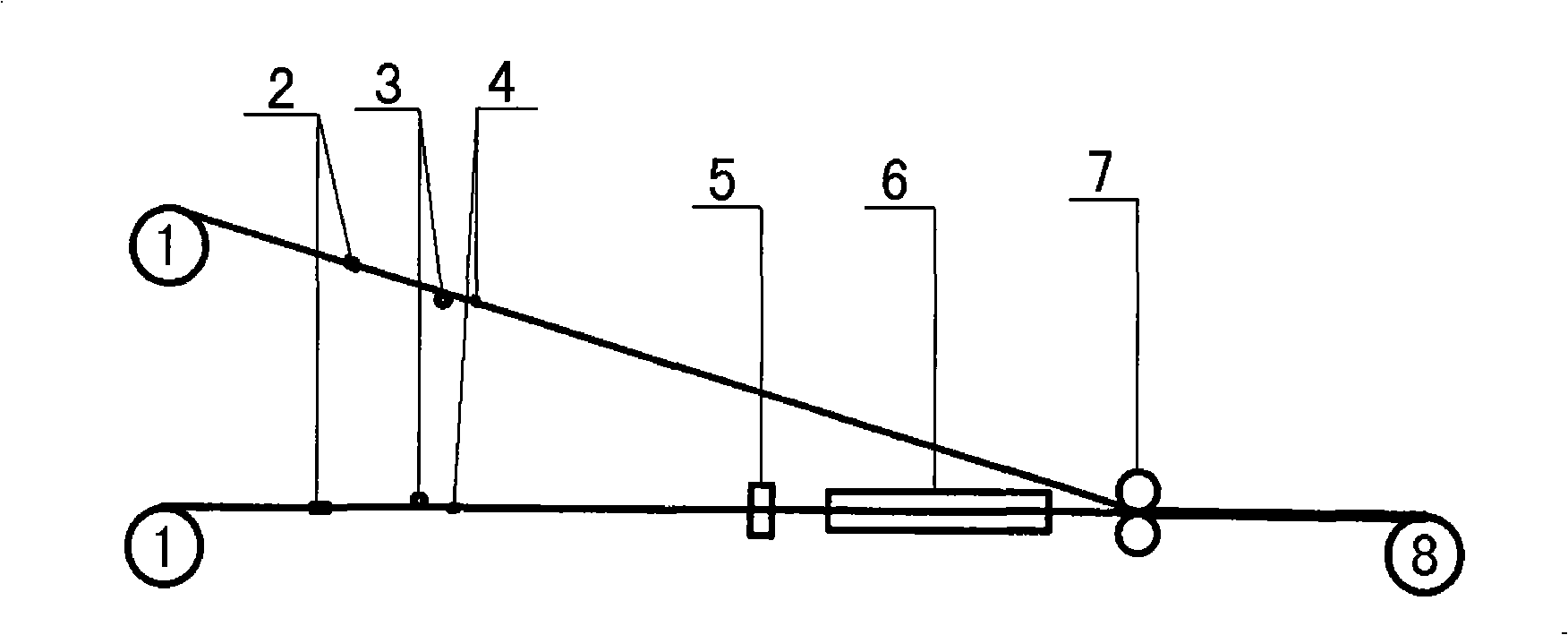

Method for preparing special-shaped composite contact tape

ActiveCN101259583AImprove your own performanceGood dimensional stabilityWork treatment devicesMetal rolling arrangementsHydrogenNitrogen

The invention discloses a preparation method of a special composite contact belt, wherein, two or more clean strips with matched properties are heated rapidly in protective atmosphere according to a certain speed by a brushing mechanism and a high frequency induction heater, continuously rolled and compounded according to a certain processing rate under the condition of atmosphere protection such as hydrogen, nitrogen, argon, etc. after a die is precisely located, and formed a long strip with two or more layers. After the long strip carries out heat treatment, the long strip is rolled to the regulated thickness and divided into a plurality of micro sized strips on a precise stripping device. The micro sized strips are prepared into special composite contact strips after being shaped, rolled and molded by a precise die. The preparation method of the invention has the advantages that close combination can be formed and at the same time performance of material is protected by making use of skin effect of the high frequency induction heating; no large rolling equipment is needed; strength of interlayer combination is high and stable; longer strips can be continuously compounded; production efficiency is high by combination of precise stripping technology, thus being suitable for production in large amount.

Owner:兰溪市金铎金属材料科技有限公司

Constant current zero-voltage switching induction heater driver for variable spray injection

An electronic high frequency induction heater driver, for a variable spray fuel injection system, uses a zero-voltage switching oscillator that is impedance coupled to an imbedded multiple function signal separator and integrated with a conventionally implemented electronic fuel injector driver. The induction heater driver, upon receipt of a turn-on signal, multiplies a supply voltage through a self-oscillating series resonance, and couples the high frequency energy to a high pass filter such that the useful energy is utilized in an appropriate loss component so that fuel inside a fuel component is heated to a desired temperature.

Owner:VITESCO TECH USA LLC

Battery powered welder system utilizing vehicle powered AC inverter

A system and method, in certain embodiments, adjusts a charging output based on capabilities of various power sources. The system and method may be used to charge a variety of equipment such as welders, cutters, induction heaters, tools and so forth. For example, a charging circuit configured to change an output charge level based upon capabilities of multiple power sources configured to be coupled to the charging circuit. In some embodiments, the system and method may test the capabilities of the various power sources by evaluating an actual output versus a commanded output, and reduce the commanded output if the actual output falls below a desired level.

Owner:ILLINOIS TOOL WORKS INC

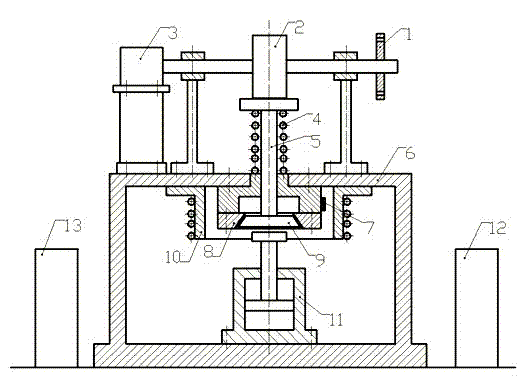

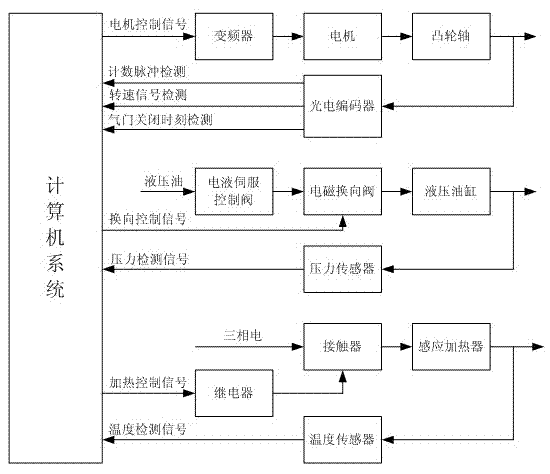

Quick wear test device of engine valve seat ring

ActiveCN102829962AImprove independent research and development capabilitiesImprove reliabilityMachine part testingShock testingBench testElectric machinery

The invention relates to a quick wear test device of an engine valve seat ring. Evaluation of a wear life of the existing engine valve and seat ring is only completed by an overall reliability bench test at present, the period is long, and the expense is high. The quick wear test device is characterized in that a motor is arranged on a stander, wherein the motor is used for driving a cam shaft, the end of the motor is provided with a photoelectric coder, the top end of a valve rod is contacted with the cam shaft, and the bottom end of the valve rod stretches into the stander and provided with a valve body; and a seat ring which is matched with the valve body is arranged inside the stander, and the valve rod outside the stander is also provided with a valve spring. The bottom inside of the stander is provided with a hydraulic oil cylinder, and the position of the hydraulic oil cylinder is opposite to the valve body. The periphery of the valve seat ring is provided with a sensing heater, and the valve seat ring is also provided with a temperature sensor. The quick wear test device is used for researching a reliability design technology of an engine air distribution mechanism component and has important significance on improving the independence research and development capacity of air distribution mechanism component manufacturers in China and improving the overall design reliability of an engine.

Owner:海宁鼎丞智能设备有限公司

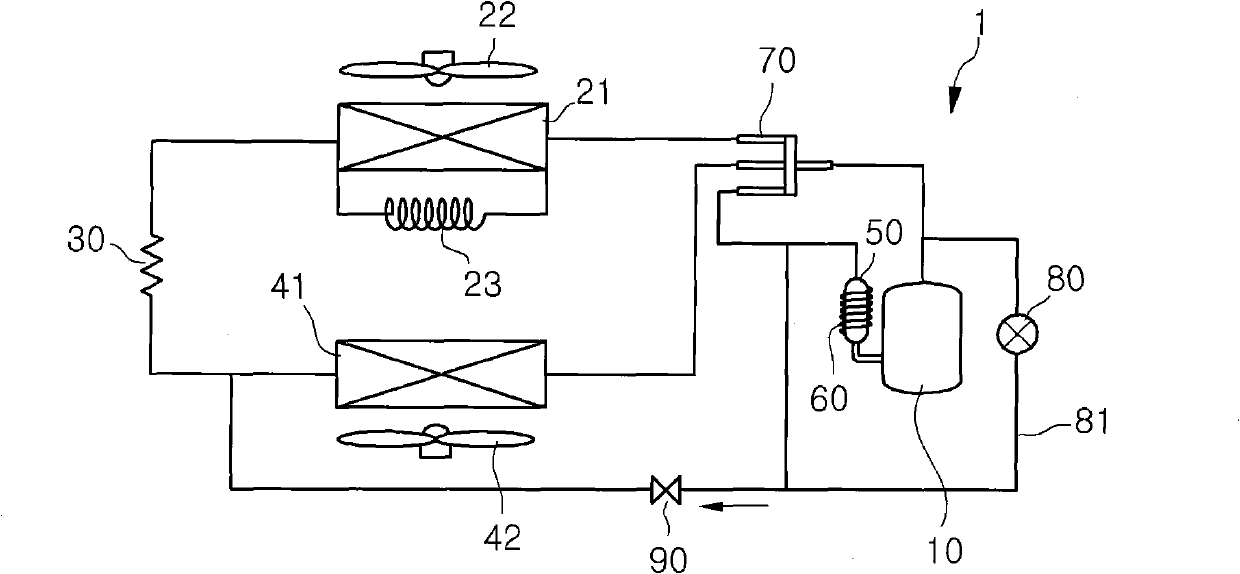

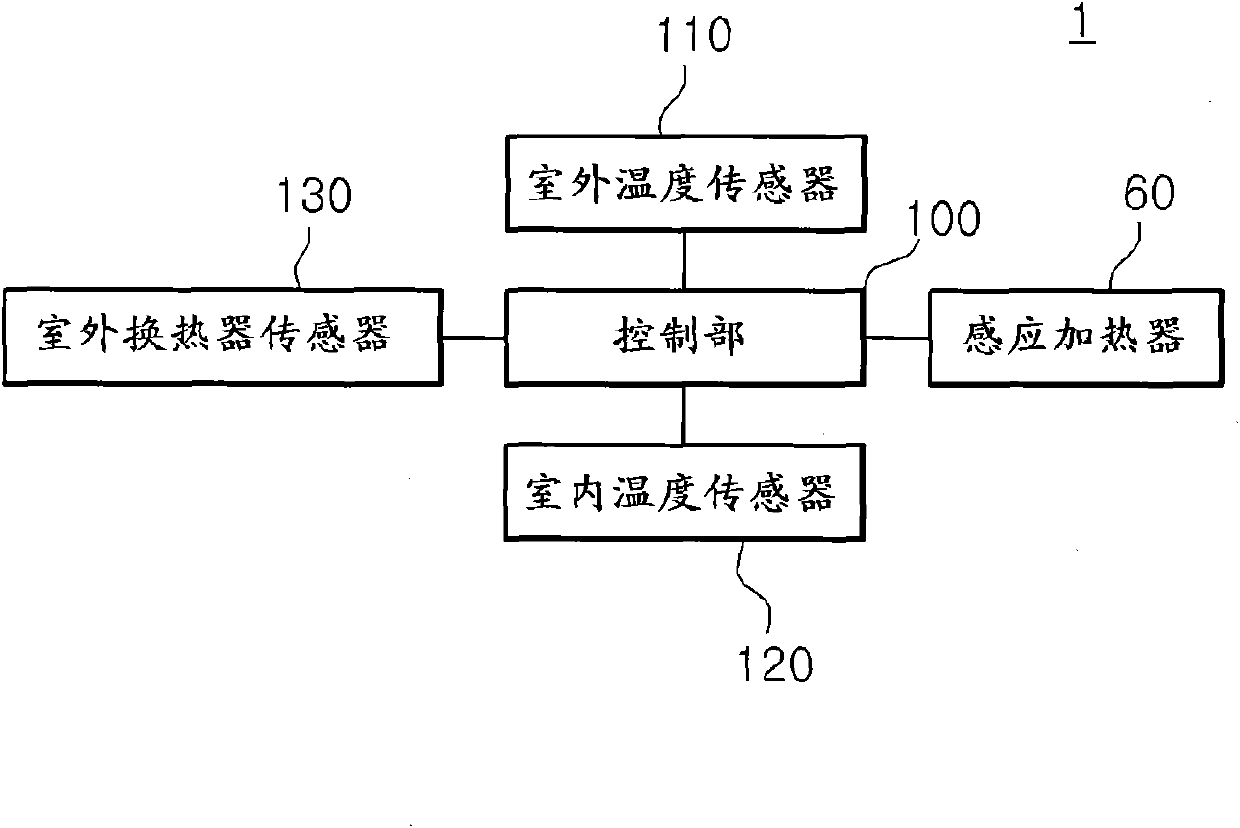

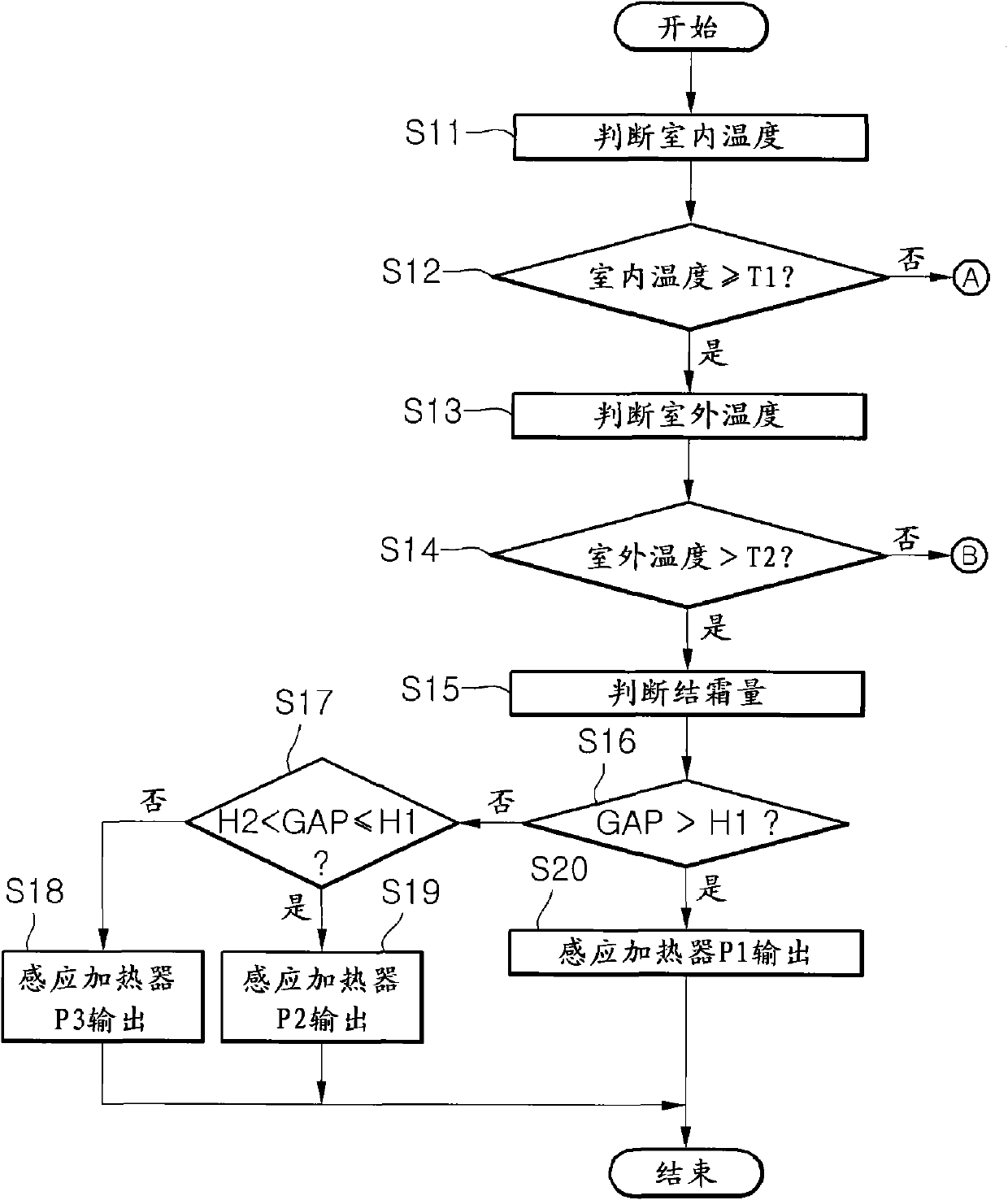

Air conditioner and method for controlling the same

InactiveCN102022807AImprove indoor heating performanceReduce power consumptionSpace heating and ventilation safety systemsSpace heating and ventilation control systemsInduction heaterTemperature difference

An air conditioner is provided. A compressor compresses refrigerant. An indoor heat exchanger performs heat exchange between the refrigerant and indoor air. An expansion device decompresses the refrigerant. An outdoor heat exchanger performs heat exchange between the refrigerant and outdoor air. Sensors sense temperature of the outdoor heat exchanger, indoor temperature and outdoor temperature. Aheater generates heat variably according to the outdoor temperature and the outdoor heat exchanger temperature. A controller determines quantity of frost on the outdoor heat exchanger by comparing a preset reference temperature with a temperature difference between the outdoor heat exchanger and the outdoor heat exchanger temperature, and controls output of the heater according to the determined frost quantity. Accordingly, frost quantity is determined according to the indoor and outdoor temperatures and the outdoor heat exchanger temperature, and heat quantity of the induction heater is accordingly varied. Therefore, power consumption can be reduced.

Owner:LG ELECTRONICS INC

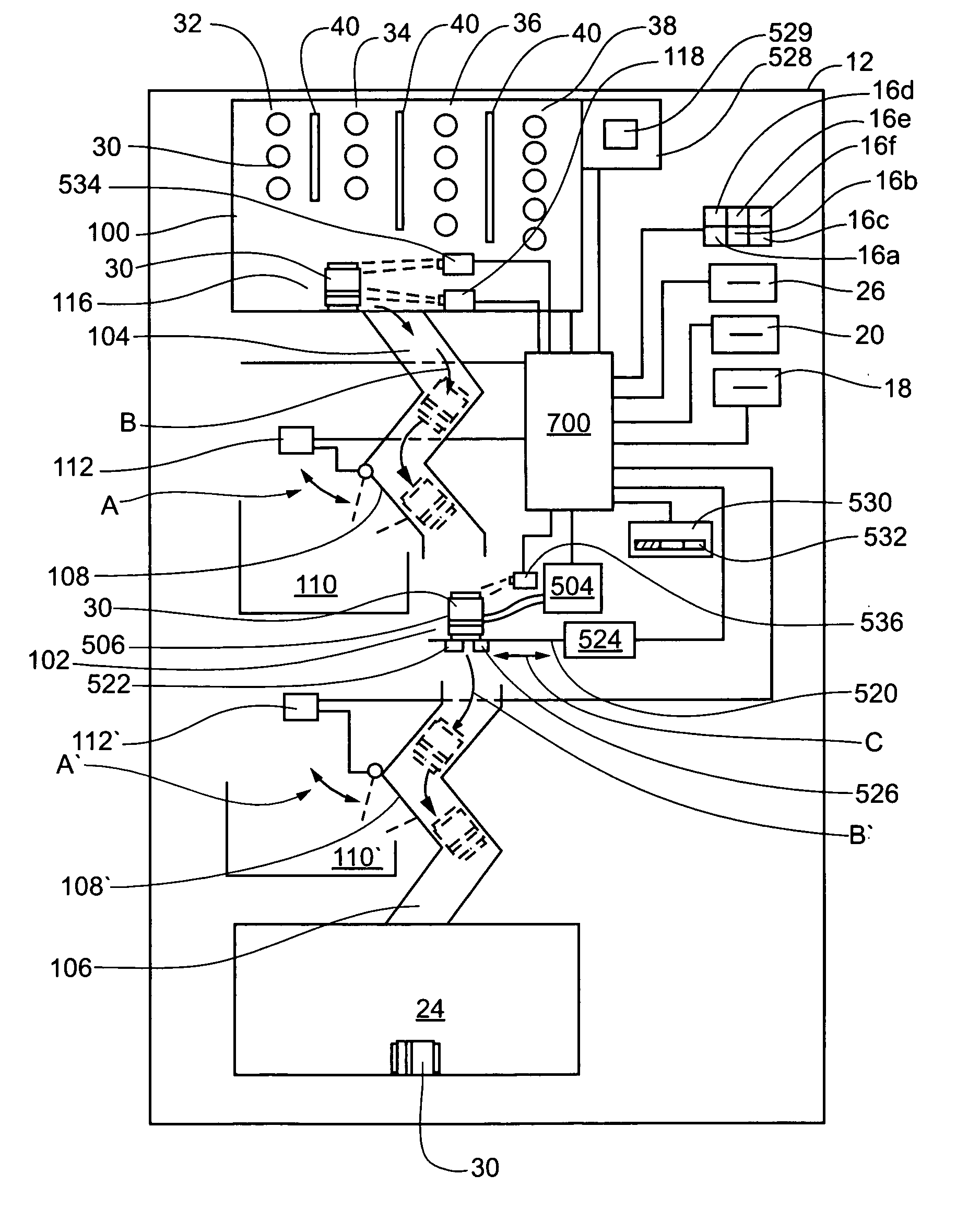

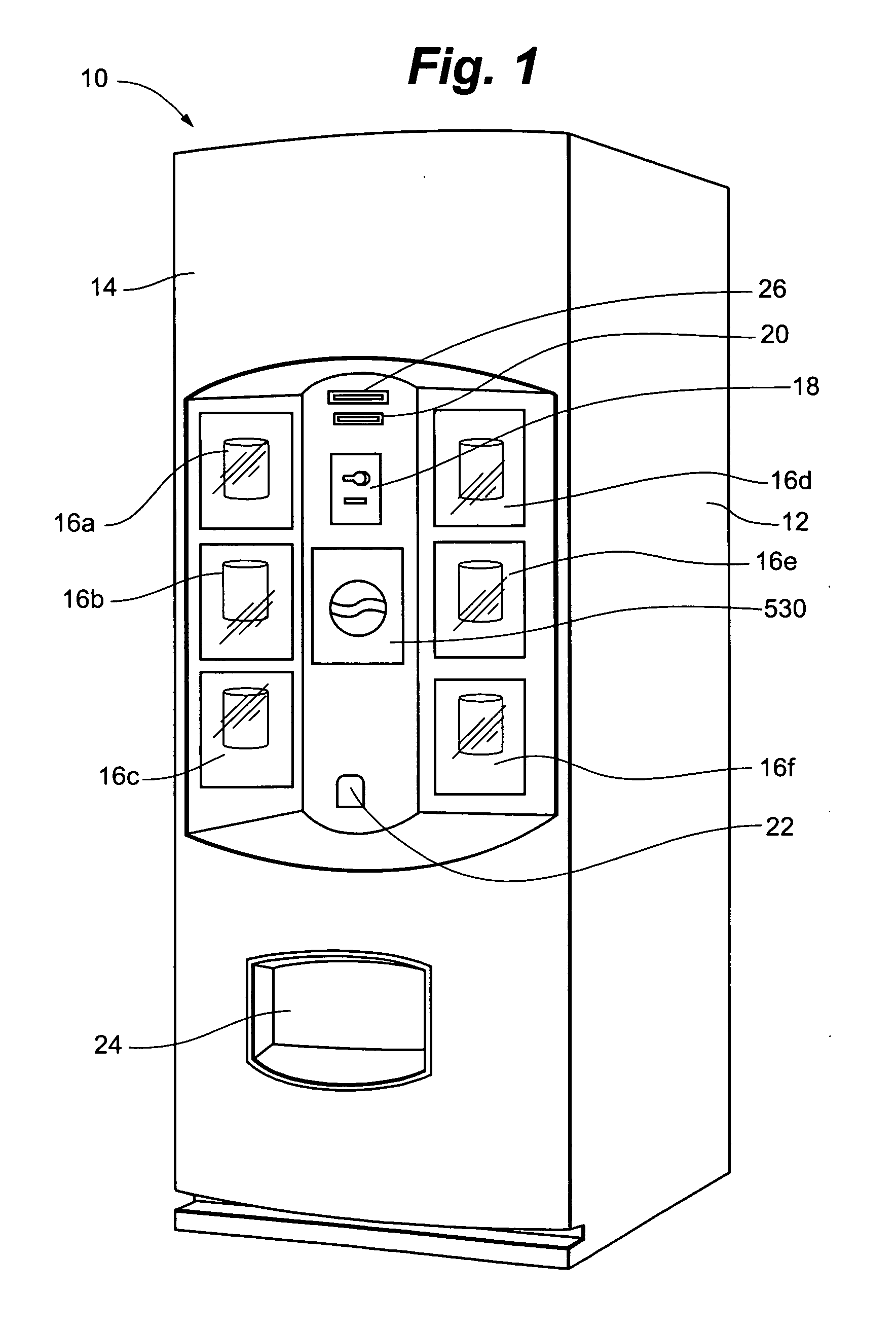

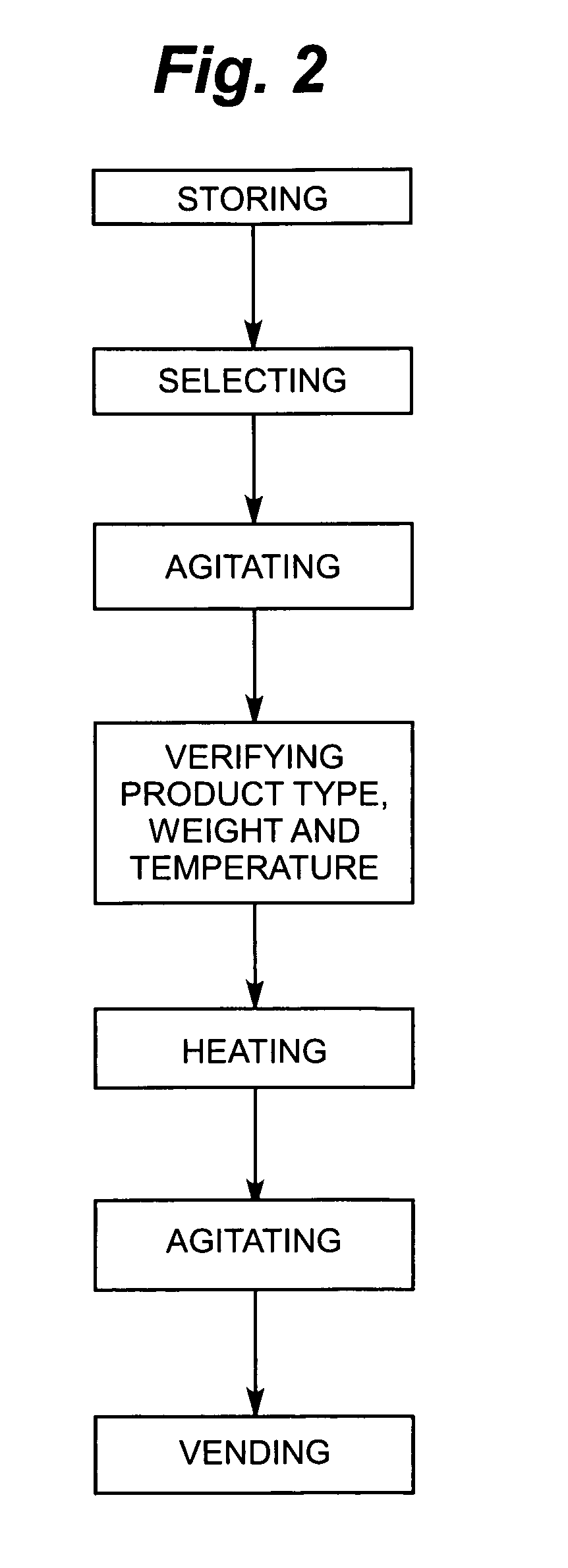

Method and apparatus for product agitation in a vending machine

InactiveUS20070170195A1Coin-freed apparatus detailsApparatus for meter-controlled dispensingProduct typeInduction heater

Heating devices and methods which are particularly useful in vending machines for hot products. Products such as beverages contained in individual containers such as cans are rapidly heated to serving temperature by induction heating for delivery to a customer. Various types of products with different heating characteristics are rapidly heated without deleterious effects on the product by varying the power and timing of the inductive heating. The type of product is identified by machine-readable indicia on the container which are automatically scanned prior to heating. The product containers are agitated before, during and / or after heating to mix the contents and distribute heat evenly. The containers are heated in a manner to safely heat the product without overheating or causing damage to the container. A power management protocol turns off non-essential components of the vending machine while the inductive heater is energized to permit the vending machine to operate on a standard 120 VAC, 15 A electrical circuit without overload.

Owner:PEPSICO INC

Device and method for efficiently preparing metal spherical ultrafine powder

The invention discloses a device for efficiently preparing metal spherical ultrafine powder. The device comprises a shell, a crucible and a powder collection area, wherein the crucible is arranged in the shell. The device is characterized in that a thermal couple is arranged inside the crucible; sensing heaters are arranged outside the crucible; the bottom of the crucible is provided with a nozzle with a small hole; a concentrator is arranged below the nozzle; the periphery of the concentrator is provided with sensing coils; the powder collection area comprises a collection disk arranged at the bottom of the shell and a rotary circular disk arranged above the collection disk. The invention further discloses a method for preparing metal spherical ultrafine powder. A technology for preparing fine particles by cutting capillary jet with electromagnetic force and a centrifugal atomizing method are combined, so that metal powder which has the advantages of narrow particle diameter distribution interval, high roundness, high fluidity, superior spreading property, uniform and controllable size and nonexistence of satellite droplets and meets the 3D printing use requirement can be prepared. The method is suitable for industrial production.

Owner:DALIAN UNIV OF TECH

Slotted induction heater

InactiveUS6412252B1Little room for errorGain of the LCR circuit is greatly reducedCoil arrangementsControl devices for conveyorsLitz wireInduction heater

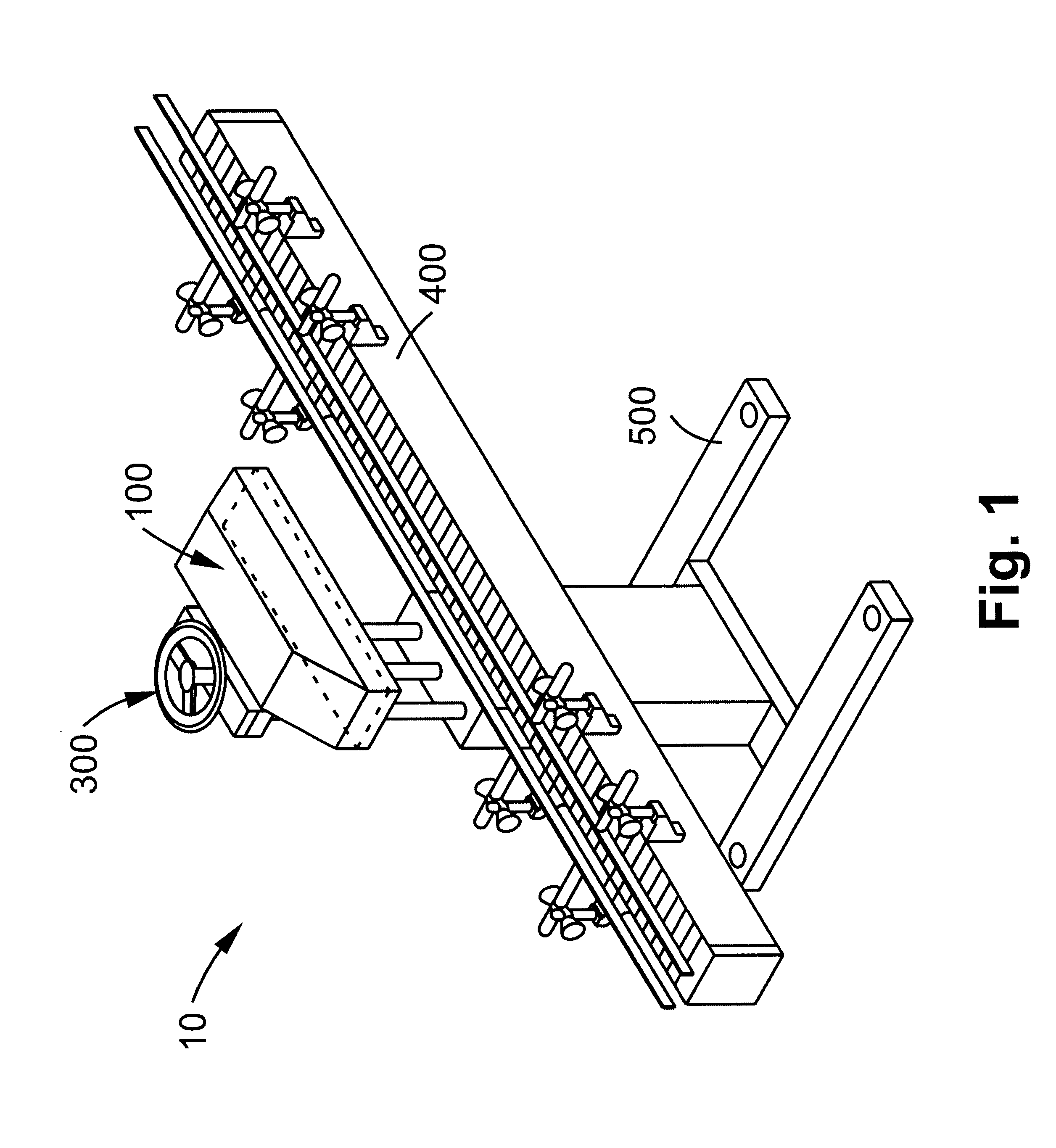

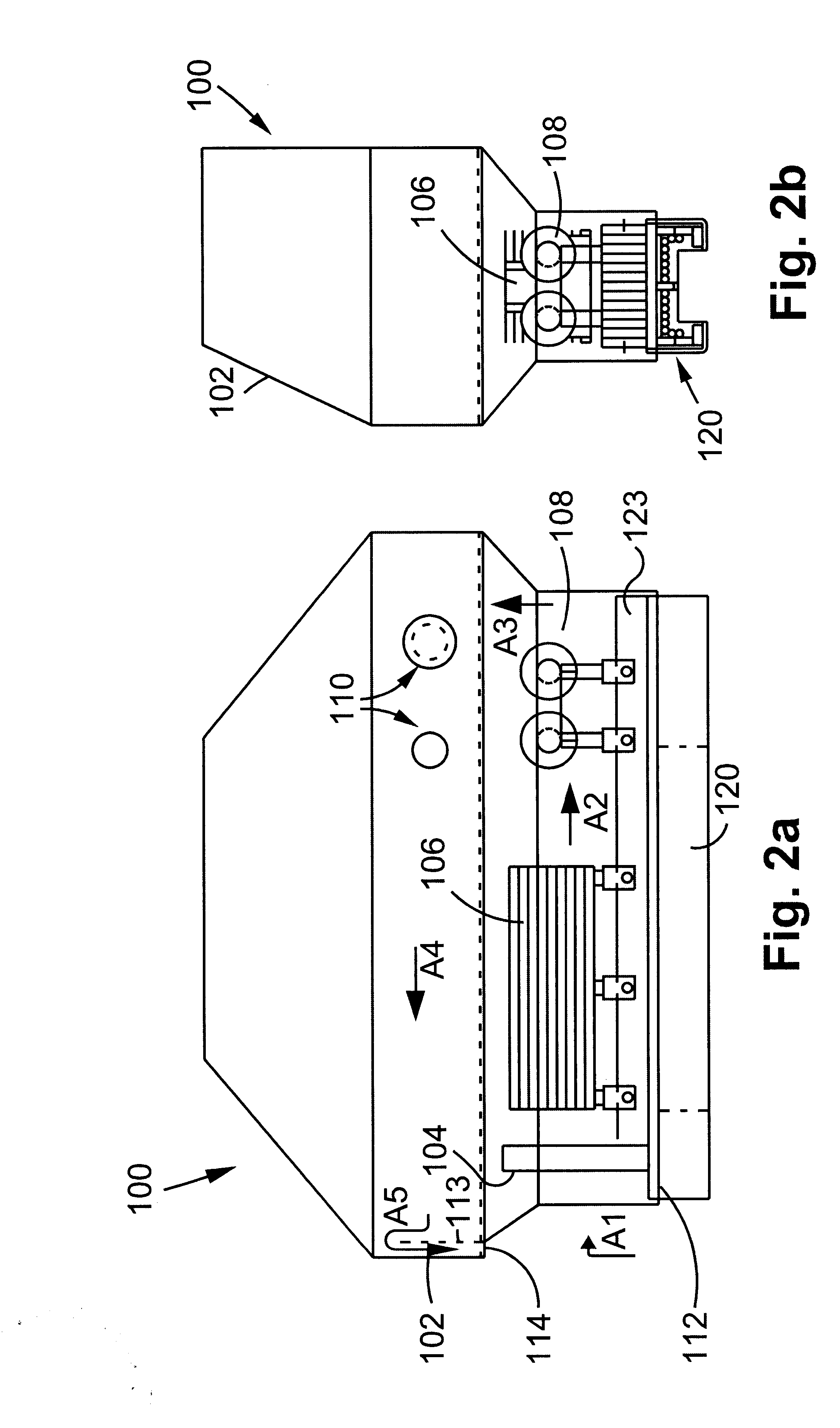

An induction sealing conveyor system includes an induction sealing unit coupled to an adjustment mechanism which adjustably positions the induction sealing unit with respect to a conveyor which moves a container to be sealed near a sealing head of the induction sealing unit. The sealing head includes ferrite cores and a litz wire coil formed on the ferrite cores which produces an electromagnetic field for hermetically sealing the container. The sealing head is entirely air cooled within the induction sealing unit.

Owner:AUTO KAPS +1

Temperature sensing and heating device

ActiveUS20140008355A1Induction current sourcesInduction heating controlInduction heaterThermal contact

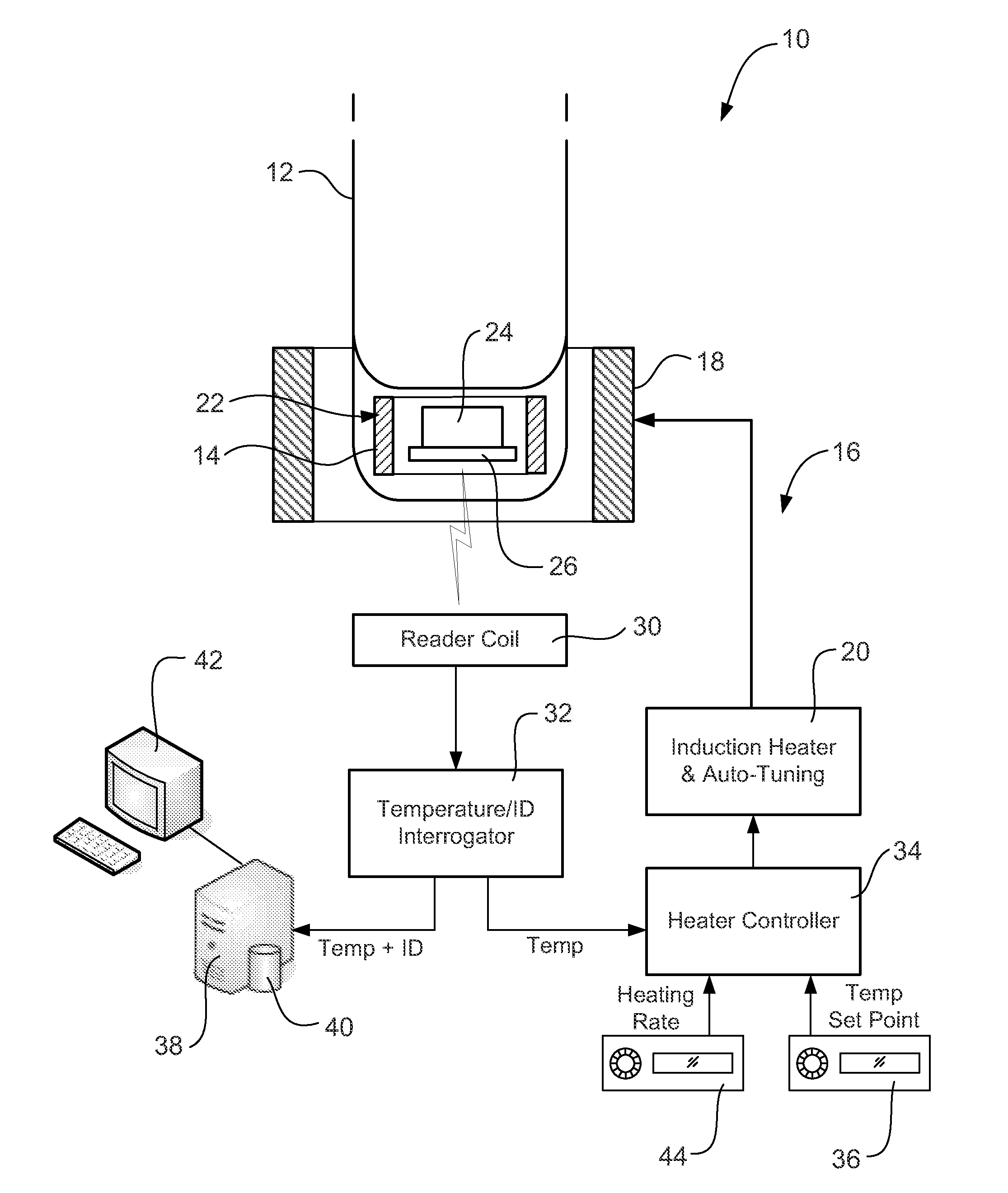

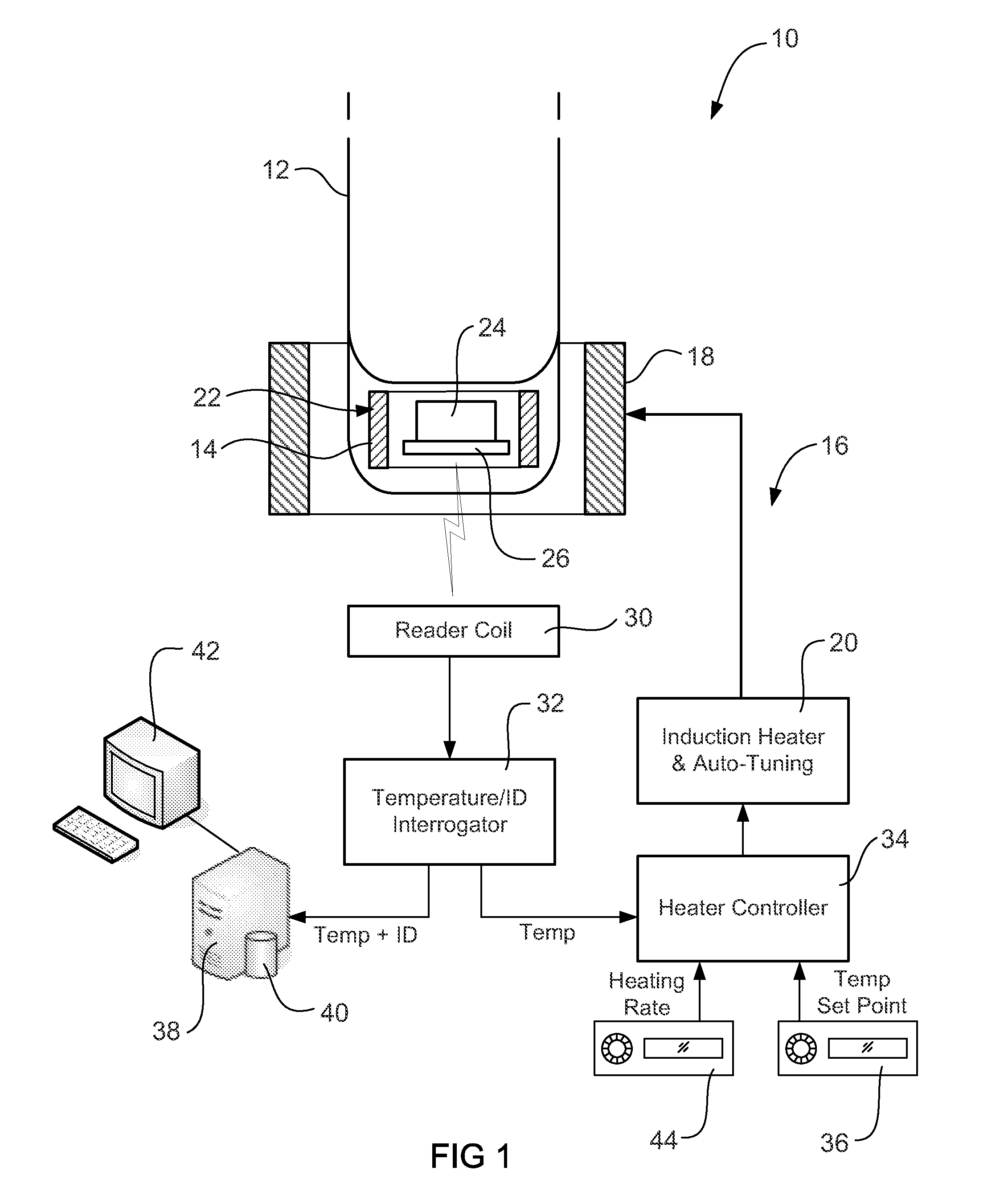

An induction heating system including a container for storing a substance; a heating element in thermal contact with the substance; a machine readable tag in thermal contact with the substance, the tag having a machine readable temperature-dependant characteristic; an interrogator for reading the temperature-dependant characteristic of the tag and for determining the current temperature of the substance; an induction heater for generating an AC magnetic field to heat the heating element; and a heater controller for controlling operation of the induction heater, in response to the substance temperature determined by the interrogator, to heat the substance.

Owner:BLUECHIIP LTD

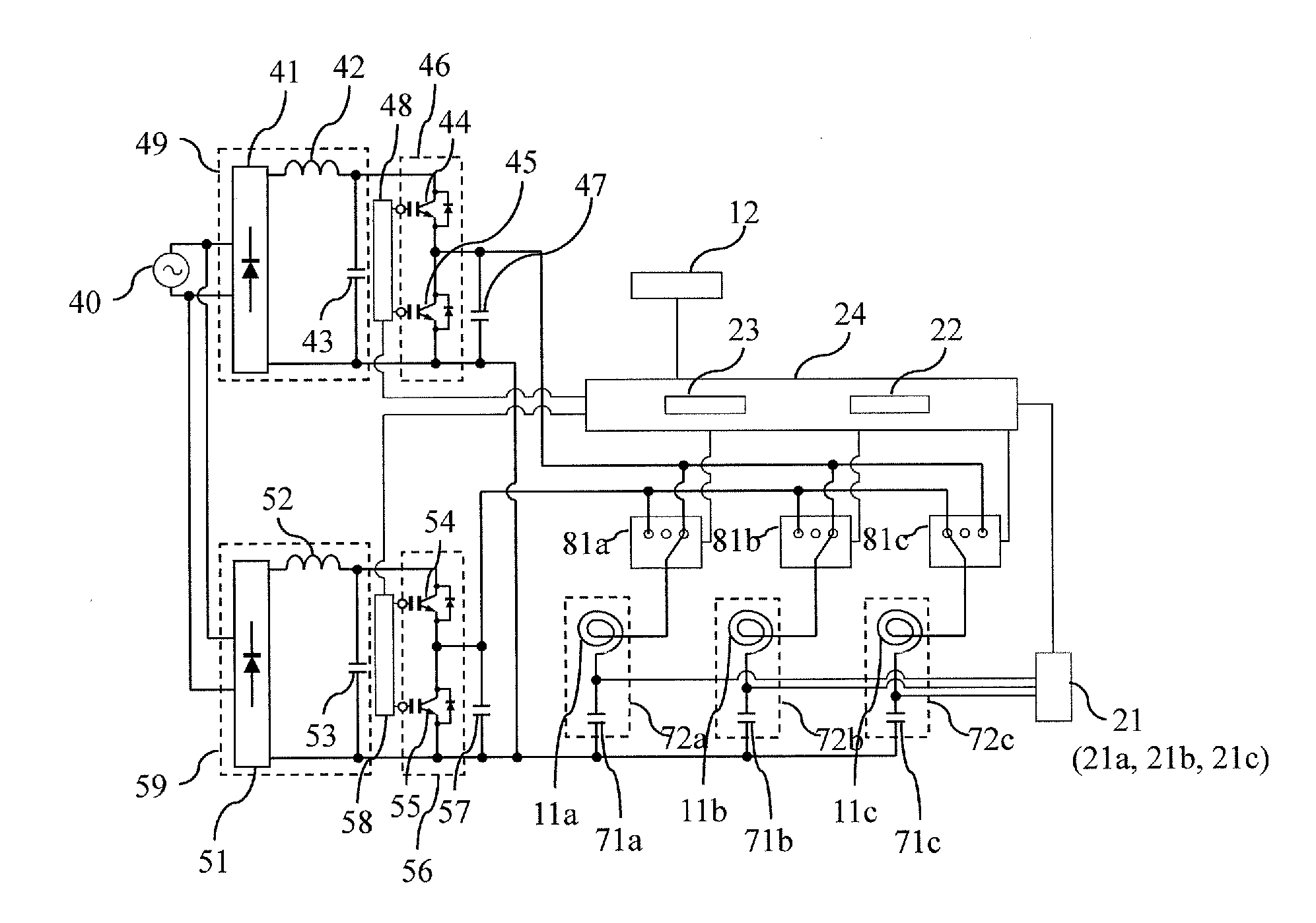

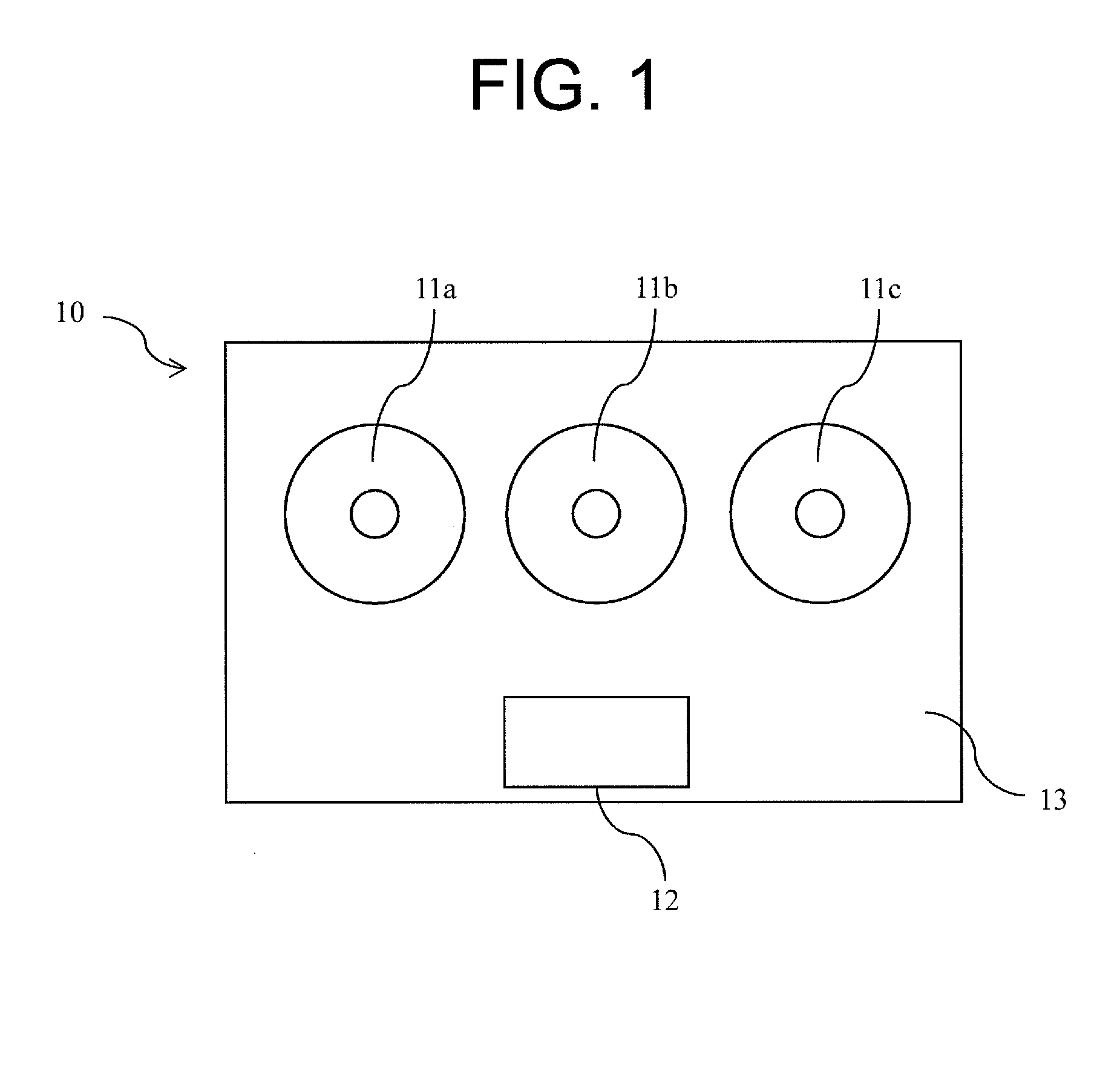

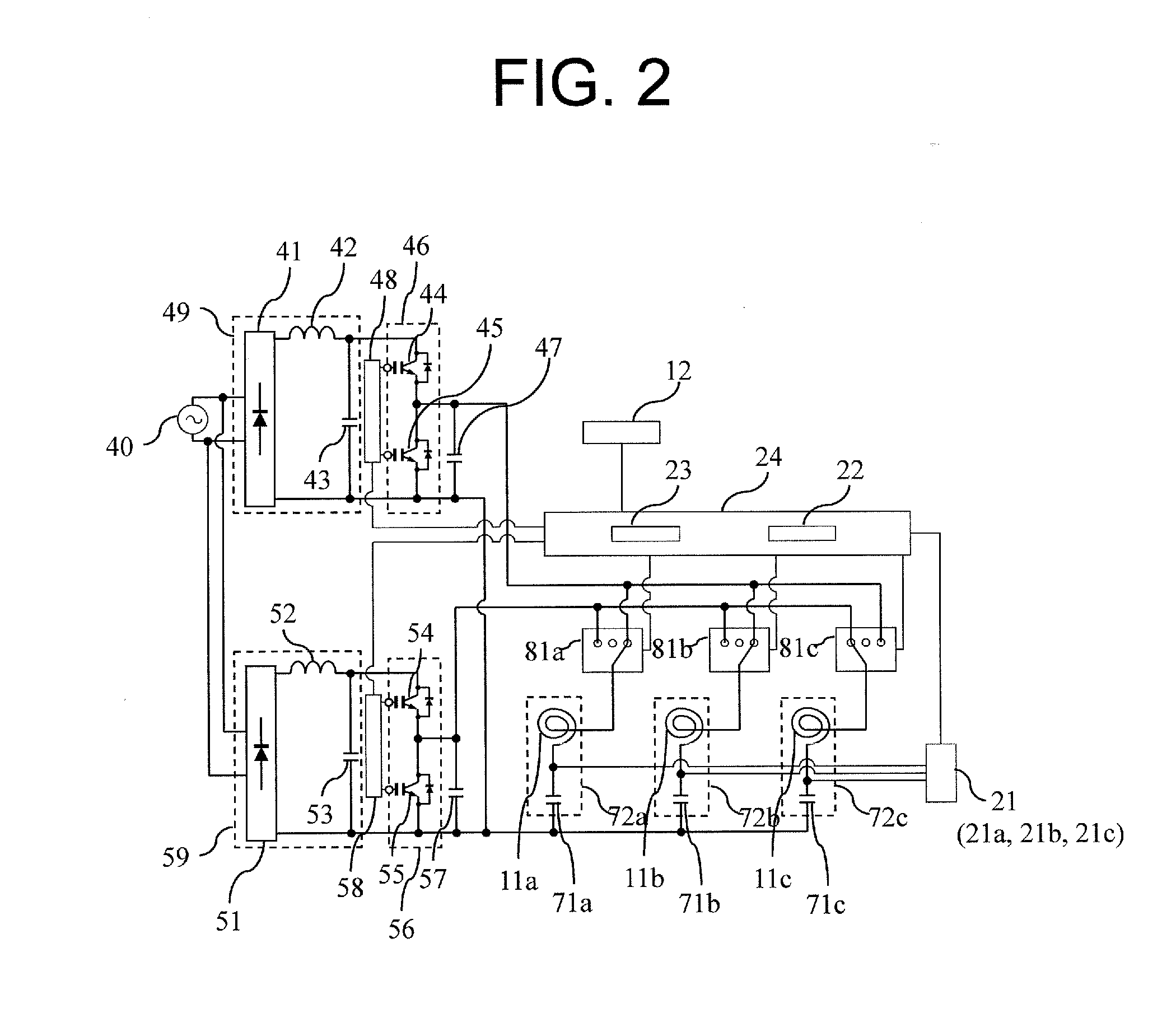

Induction heater

InactiveUS20160029439A1Avoid conduction lossSuppressing a leaked magnetic fieldCoil arrangementsInduction heating controlPower flowResonance

An induction heater includes a plurality of heating coils, a plurality of inverters, a plurality of switching circuits, command unit, sensor group, and container detection unit. The number of inverters supplying a high-frequency current to the heating coils is less than the number of heating coils. Each of the switching circuits switches an electric path of each of the heating coils such that each heating coil is connected or not connected to any of the inverters. The command unit controls driving of the inverters and switching of the switching circuits. Each sensor in the sensor group detects a response of a resonance circuit including the heating coil relative to power supply from the inverters. The container detection unit detects whether or not heating target is placed on the heating coil based on an output of the sensor. This enables to retain safety and reduce cost of the induction heater equipped with the plurality of heating coils.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

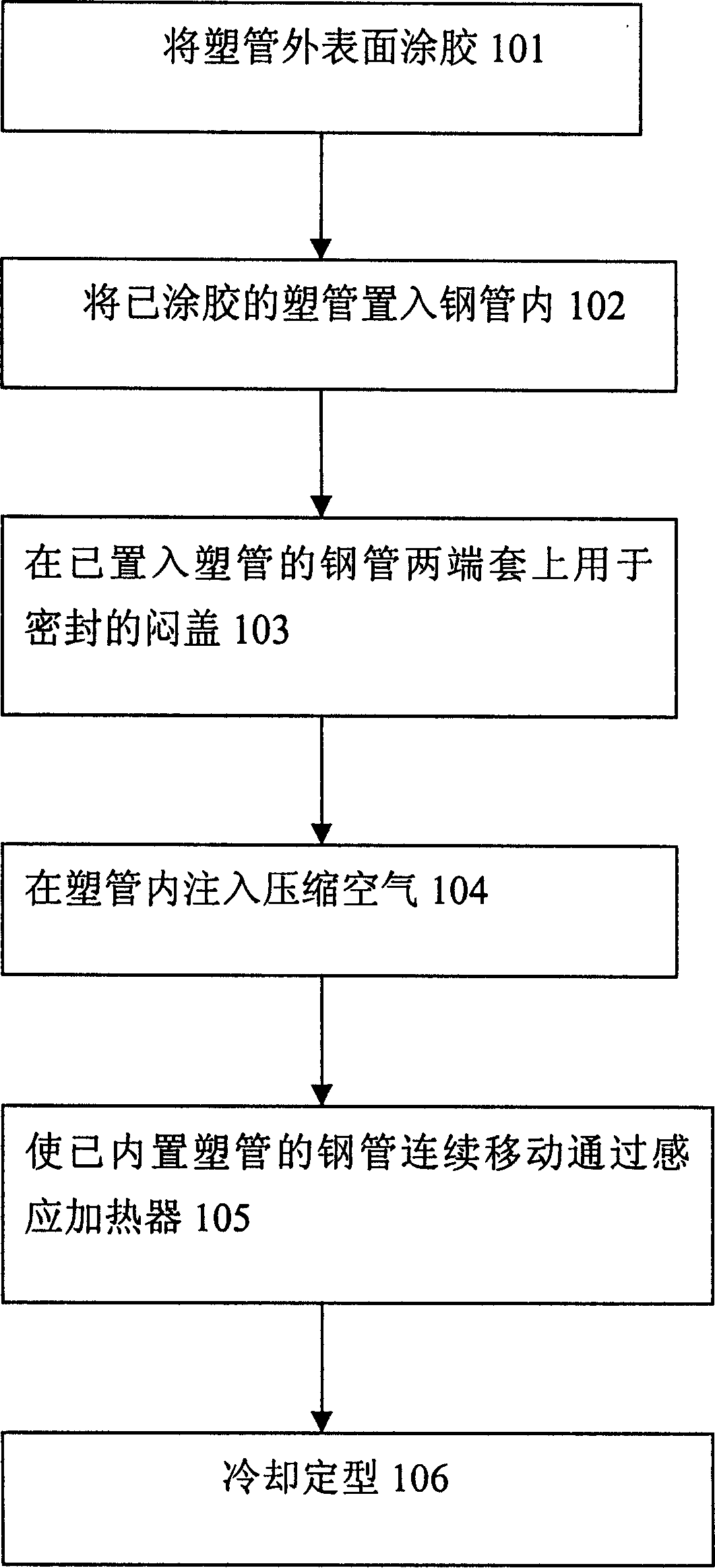

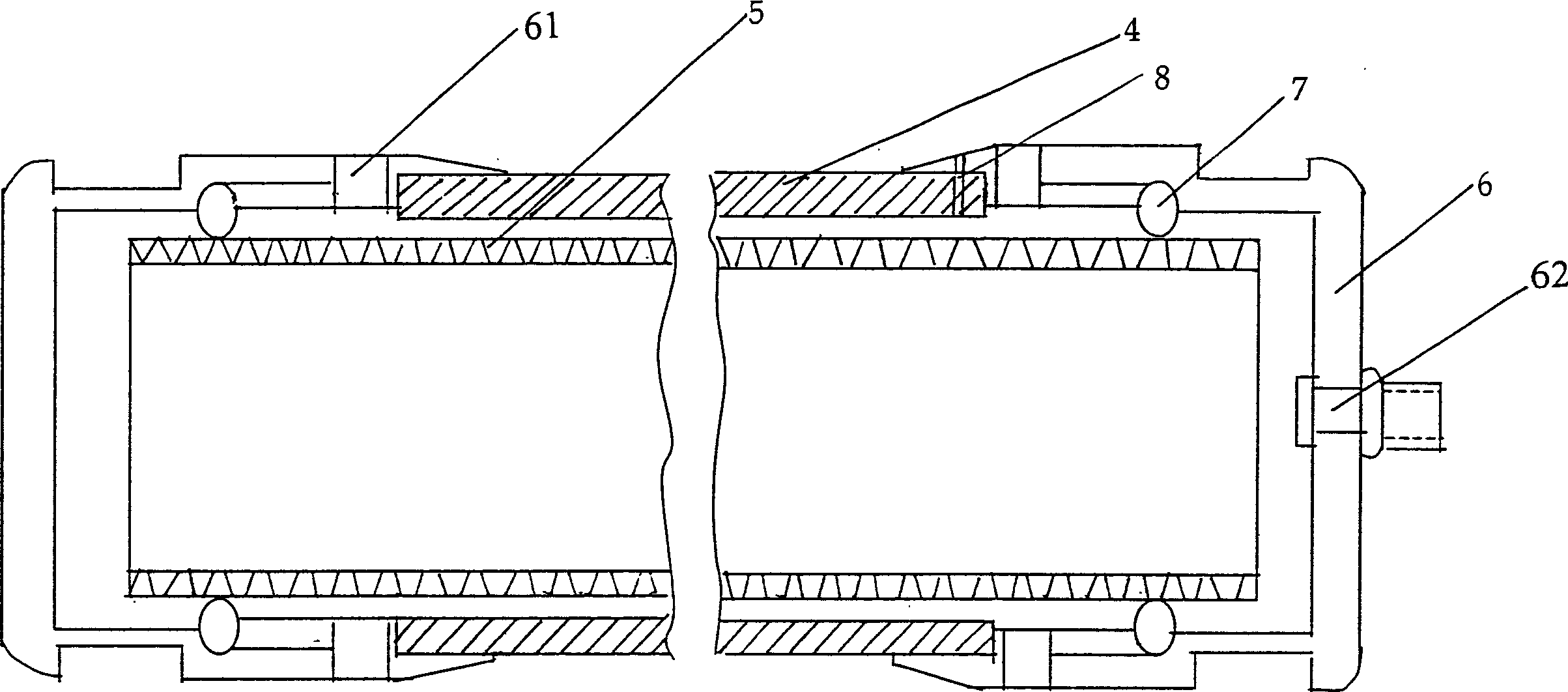

Manufacturing method plastic lining composite steel pipe and its manufacturing equipment

A technology for manufacturing plastic-lined composite steel pipe includes such steps as coating adhesive on the external surface of a plastic pipe, putting the plastic pipe in a steel pipe, sealing both ends of steel pipe by two blank covers, injecting compressed air into the plastic pipe, moving the steel pipe through an induction heater, and cooling for formation. Its advantages are high productivity and no damage to the coated zinc layer of steel pipe.

Owner:SHANGHAI WEIBANG PIPELINE

Induction heater

ActiveUS20050205561A1Reduce lifting forceImprove heating efficiencyCoil arrangementsInduction heating apparatusInduction heaterElectric current

An electric conductor provided for decreasing a lifting force exerted on an object being heated has an aperture of a small diameter in the center thereof, which leaves a large surface area to enhance reduction of the lifting force. The electric conductor is also provided with a comb section around the aperture for preventing a circling current induced in the electric conductor from flowing into an area around the aperture. This structure can thus alleviate excessive heating around the aperture, and allow the heating coil to produce a high output power for a long duration of time even when an inwardly concaved pan is used.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com