Quick wear test device of engine valve seat ring

A technology for engine valve and wear testing, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of long cycle and high cost, and achieve improved design reliability, obvious economic and social benefits, and improved The effect of independent research and development capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

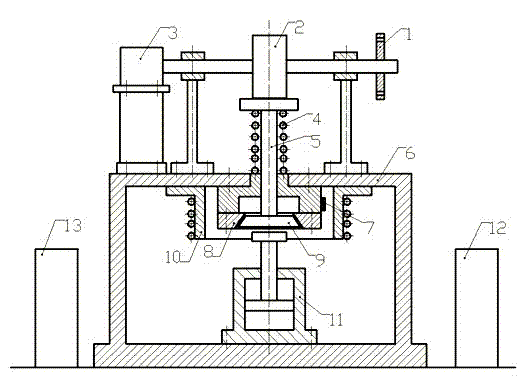

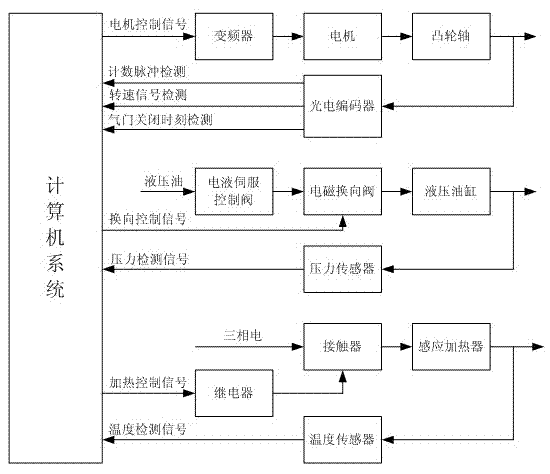

[0014] Such as figure 1 As shown, the simulated test device of the present invention consists of a photoelectric encoder 1, a camshaft 2, a motor 3, a valve spring 4, a valve stem 5, a frame 6, a temperature sensor 7, a seat ring 8, a valve body 9, an induction heater 10. It is composed of hydraulic cylinder 11, hydraulic control system 12 and test control system 13. The motor 3 drives the camshaft 2, pushes the valve rod 5 to open the valve, and the seat of the valve is pushed by the restoring force of the valve spring 4. The indicators such as the shape, size and material of the cam, valve spring, seat ring and valve body should be the same as those of the test piece. After the valve body 9 is seated, the hydraulic oil cylinder 11 rises, hits the bottom surface of the valve body 9, and applies a load, simulating the impact of the combustion pressure on the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com