Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

417 results about "Reliability design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

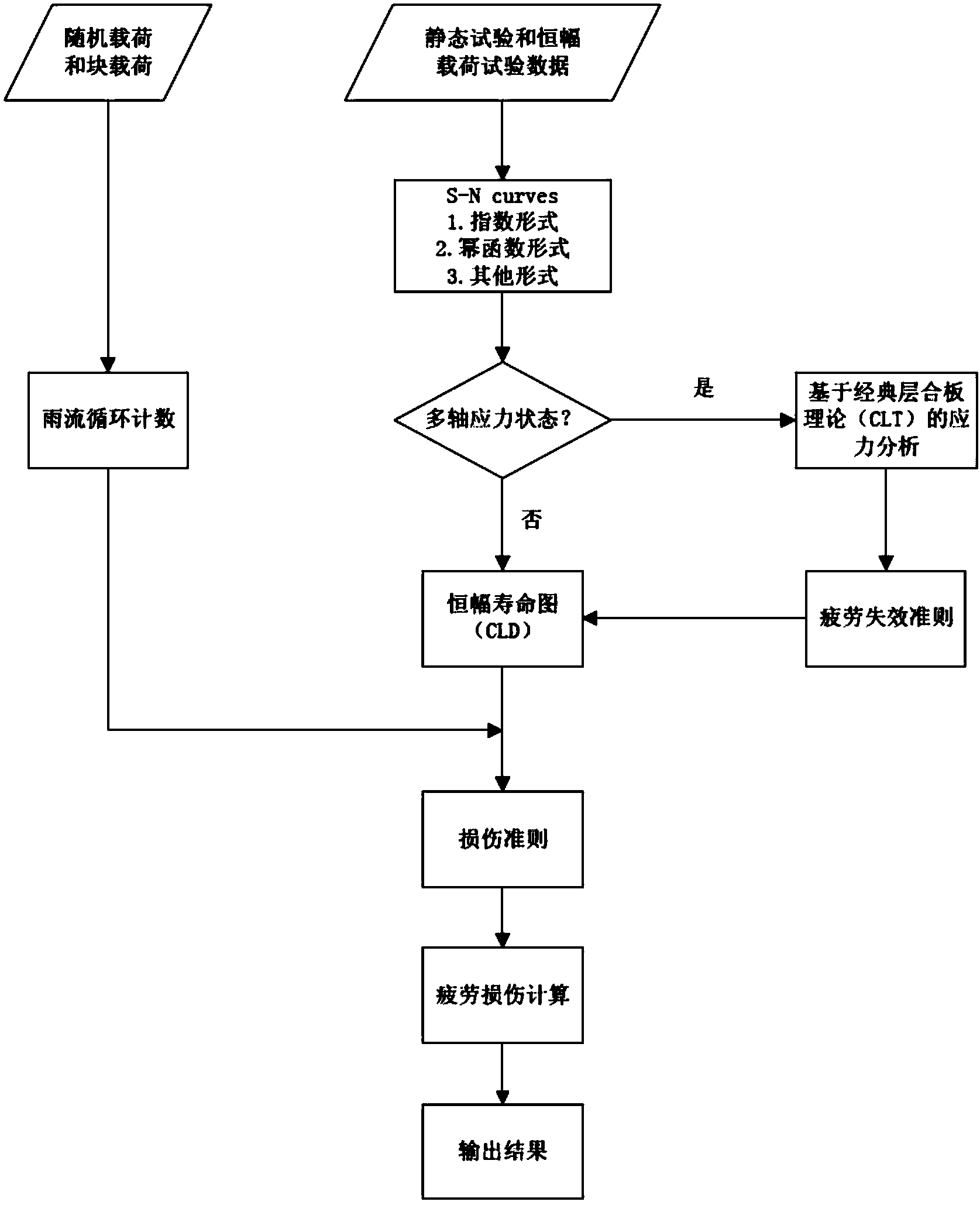

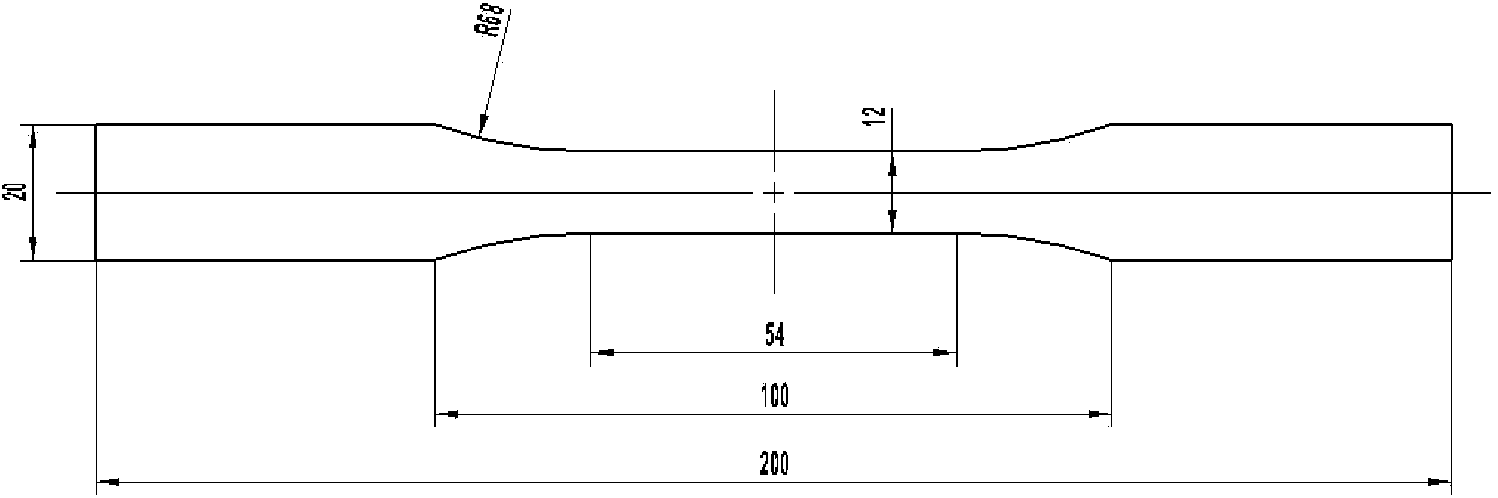

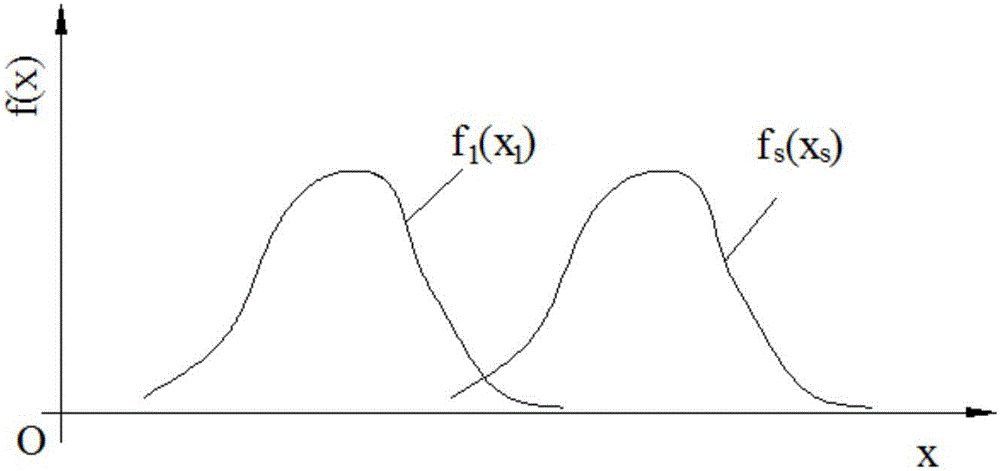

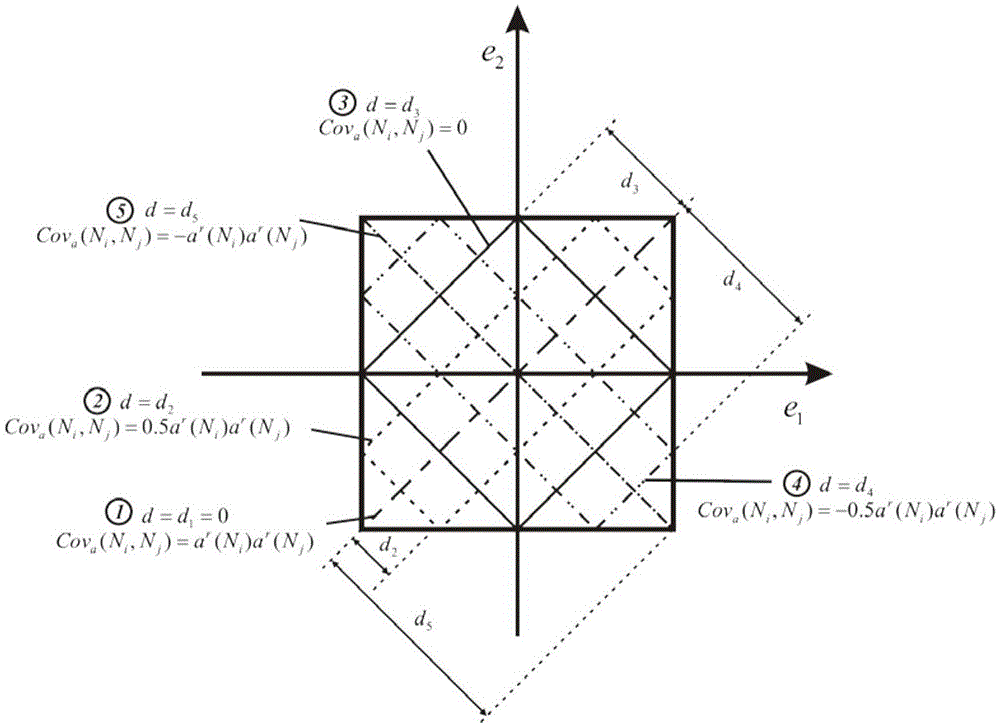

Carbon fiber composite material fatigue life estimating method based on stress ratio influences

InactiveCN103942441AAccurate lifeAccurate Damage AssessmentSpecial data processing applicationsStrength propertiesFinite element techniqueDispersity

The invention belongs to the technical field of composite materials, and discloses a carbon fiber composite material fatigue life estimating method based on stress ratio influences. Structural response calculation is carried out by means of a finite element technology. A finite element model is based on a classical laminate plate theory, and a umat subprogram taking tension and compression asymmetry into consideration is built. By carrying out constant-amplitude fatigue tests under different stress ratios, an equation of an influence mechanism of average stress on prediction of the service life of a carbon fiber composite material structure is built and is popularized to a block load and a spectrum load. A service life estimating model built through the method is based on the classical laminate plate theory and takes influences of the average stress and a variable-amplitude load into consideration, dispersity of a prediction result is little, accuracy is high, theoretical guidance is provided for reliability design of parts made of carbon fiber composite materials, and the technical problems that existing carbon fiber composite material structure fatigue life is only estimated through a test method, and accordingly cost is high and consumed time is long are solved.

Owner:SHANGHAI JIAO TONG UNIV

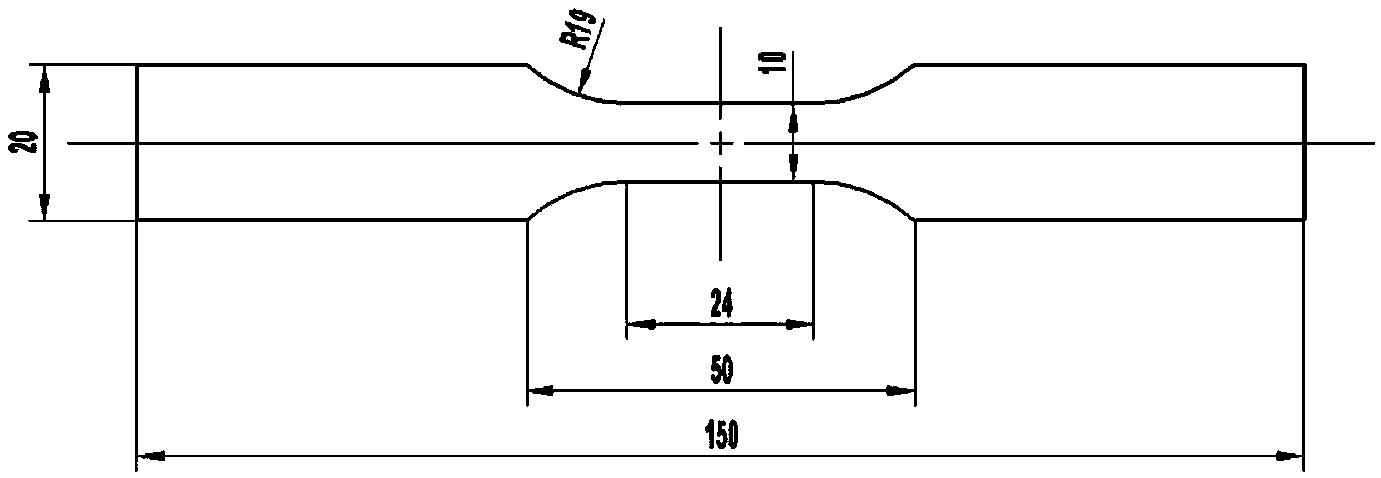

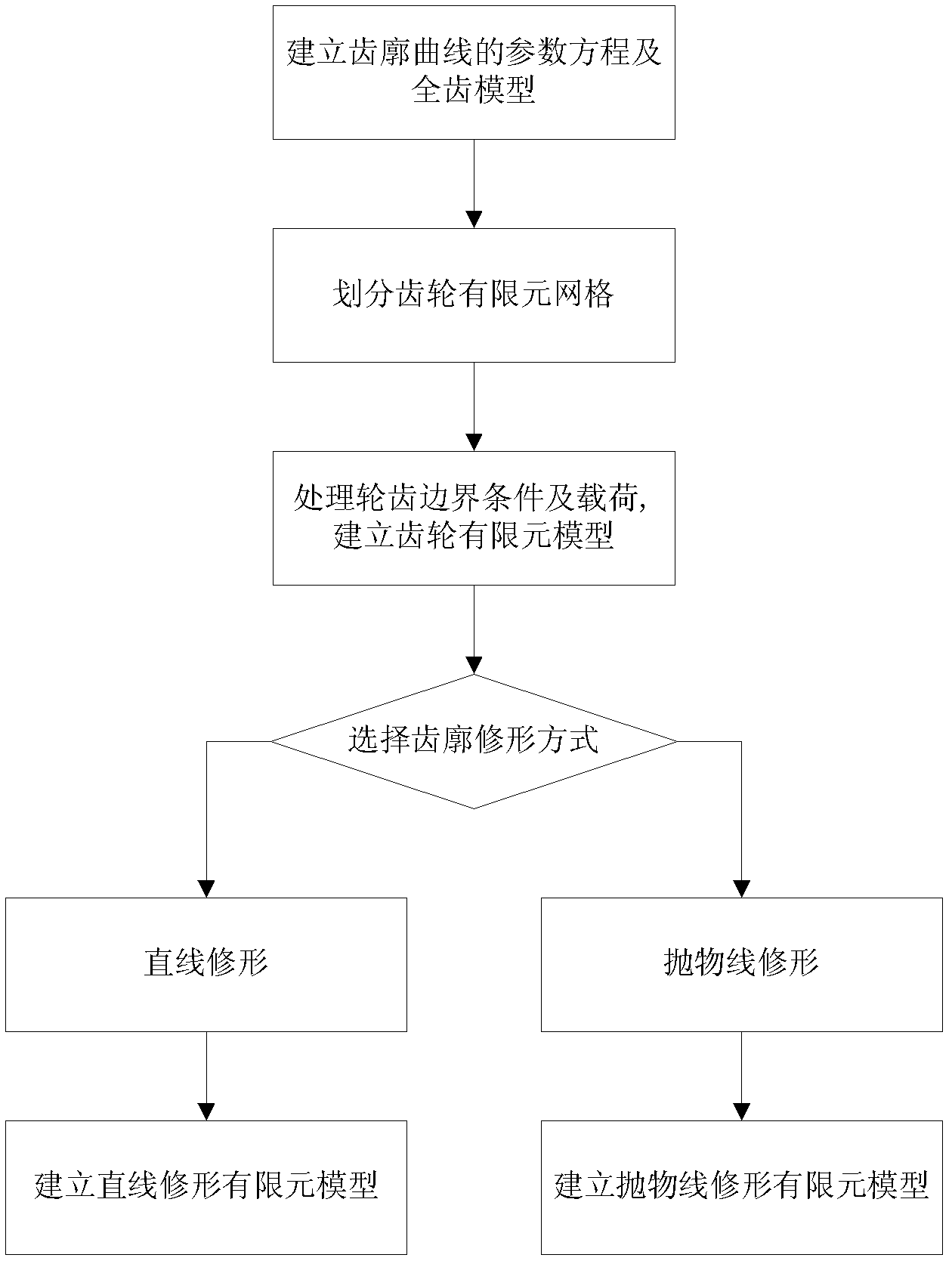

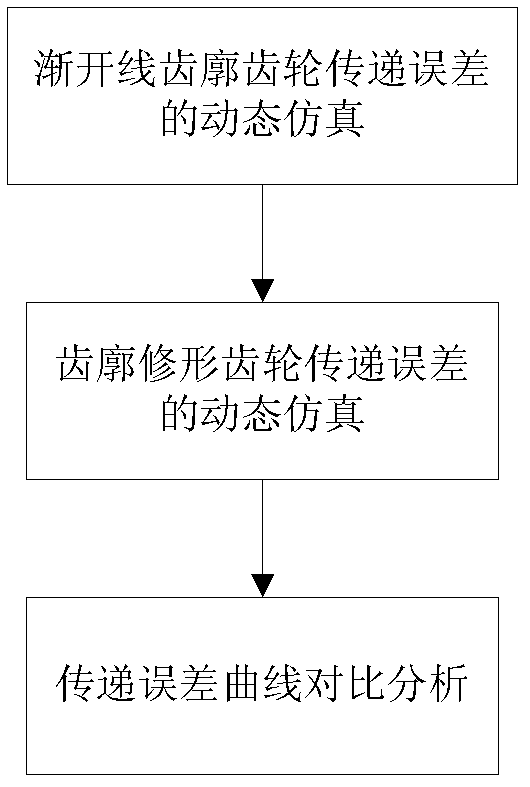

Gear profile modification method based on vibration reliability and genetic algorithm

InactiveCN102314534AImprove transmission error reliabilityEliminate shockSpecial data processing applicationsGear systemGenetic algorithm

The invention discloses a gear profile modification method based on vibration reliability and a genetic algorithm, belonging to the technical field of reliability designs. The gear profile modification method can not only reduce meshing impact due to elastic deformation and manufacturing errors, but also reduce the meshing excitation of a gear so that a gear system has smooth transmission, the vibration and the noises are reduced, and the reliability and service life of the gear system can be improved. The gear profile modification method comprises the following steps of: (1), establishing an elastic modification virtual prototype for meshing between a gear and a modifying gear; (2) carrying out dynamic simulation on gear transmission errors in the process of an involute profile and the profile modification; (3) analyzing the reliability sensitivity of the transmission errors at the time of gear pair random parameter meshing; (4) determining optimal parameters of the gear profile modification by utilizing the genetic algorithm; and (5) verifying the correctness of the parameters.

Owner:NORTHEASTERN UNIV LIAONING +1

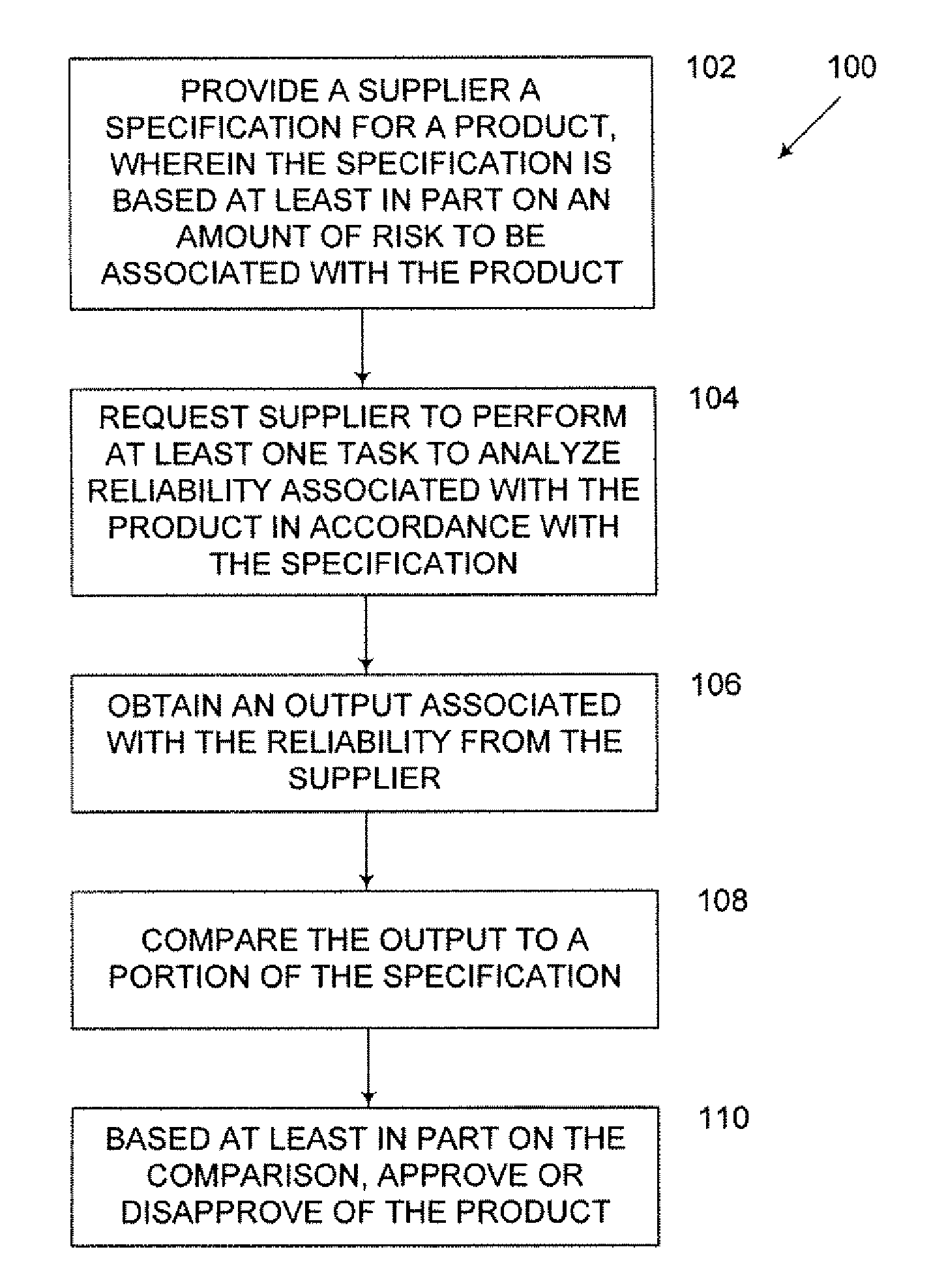

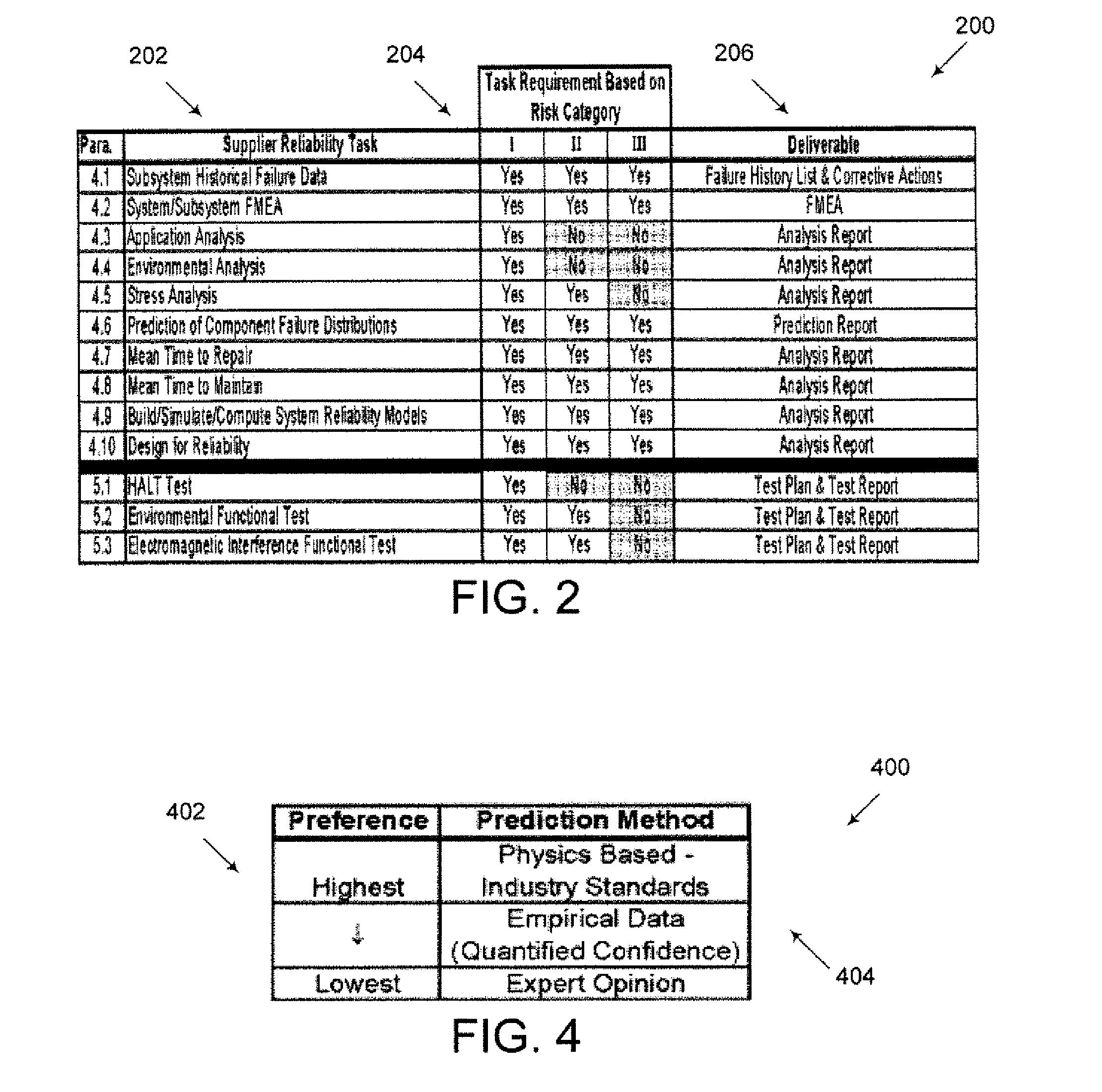

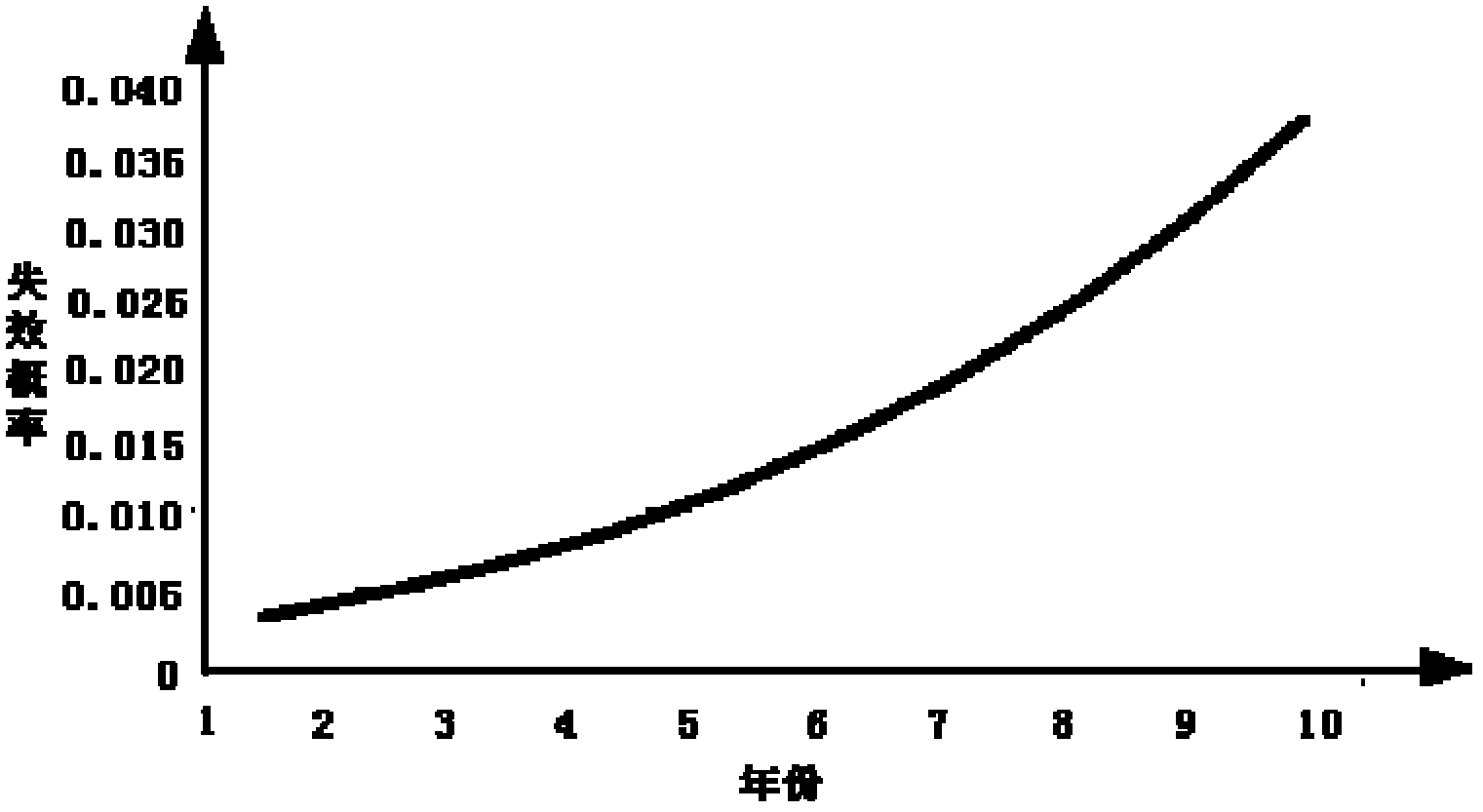

Systems and Methods for Providing Risk Methodologies for Performing Supplier Design for Reliability

Owner:GENERAL ELECTRIC CO

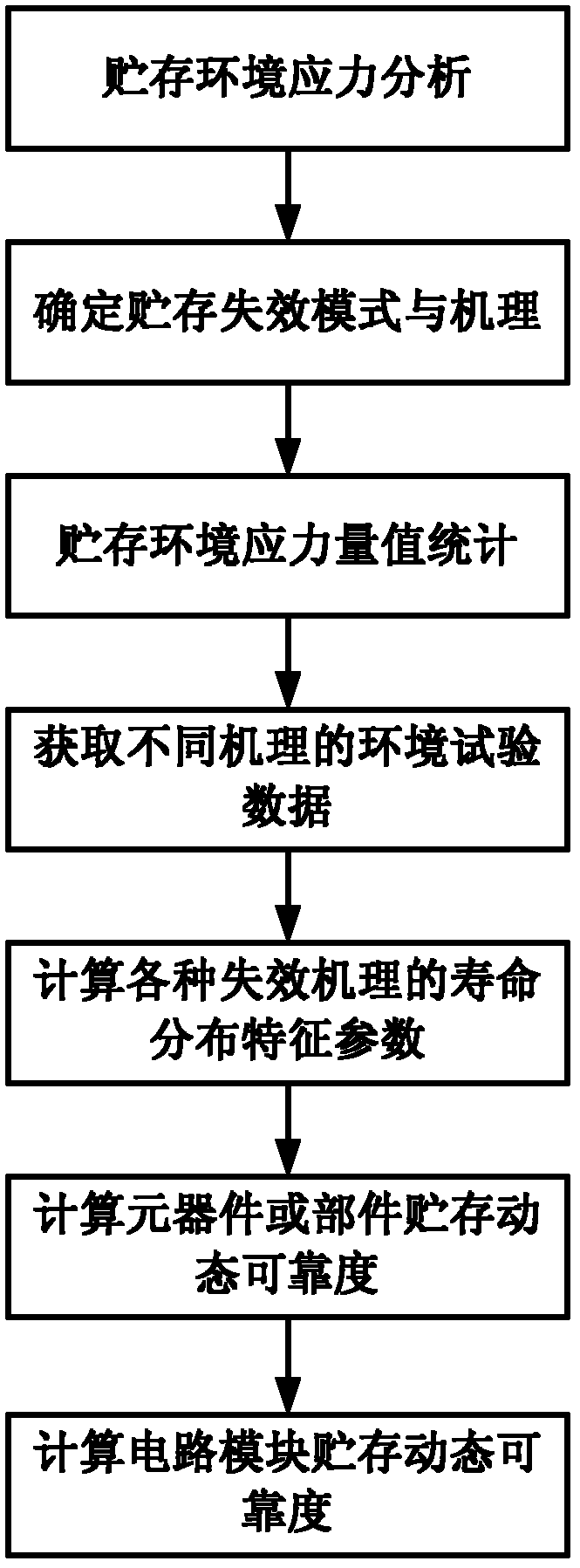

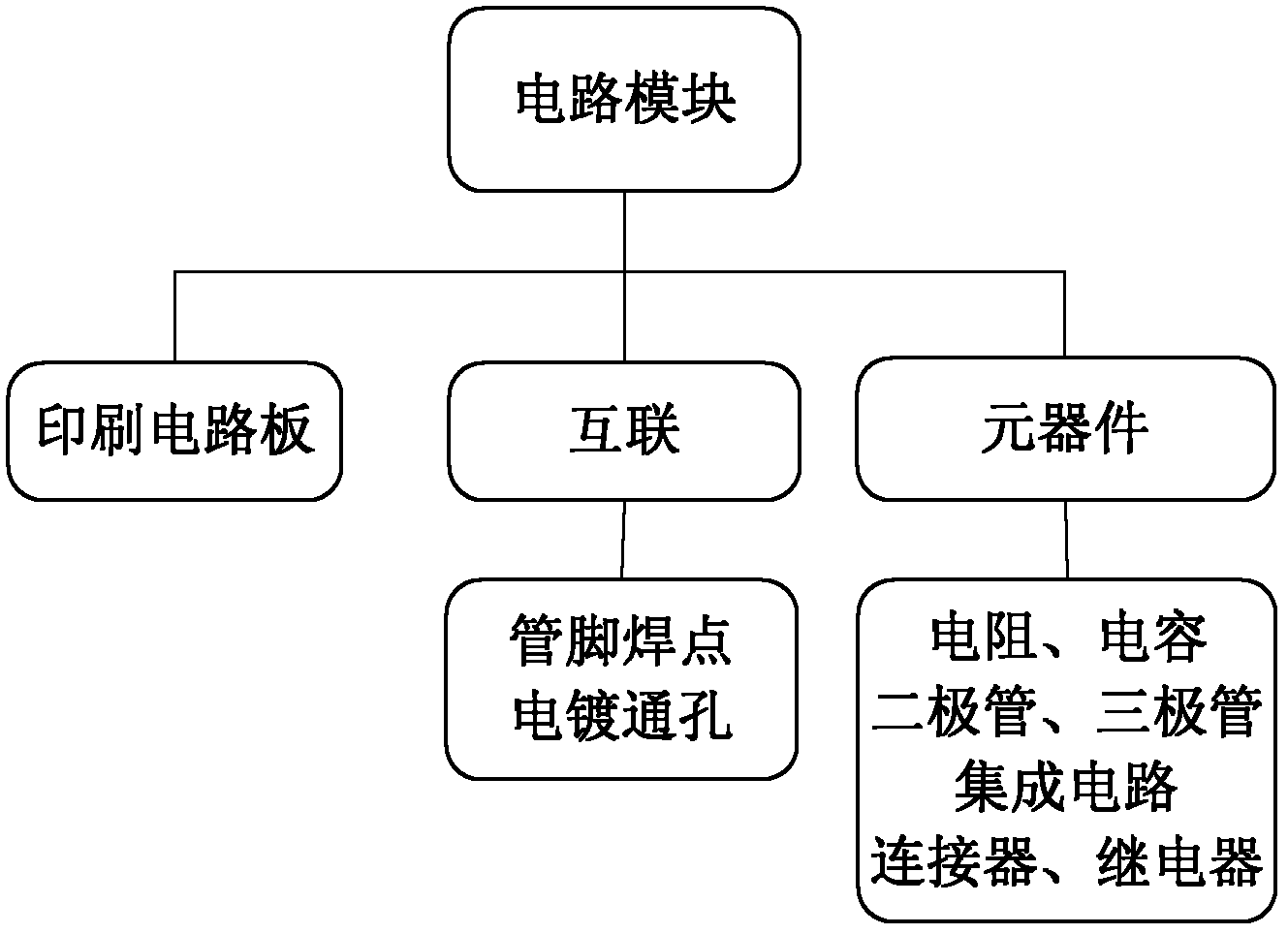

Computing method of storage dynamic reliability for aviation drive circuit module

ActiveCN102592052AIn line with engineering practiceAvoid Storage TestsSpecial data processing applicationsAviationStatistical analysis

Disclosed is a computing method of storage dynamic reliability for an aviation drive circuit module. The computing method includes steps of selecting, classifying and statistically analyzing main storage environmental stress; determining storage failure modes and failure mechanisms of the aviation drive circuit module; statistically analyzing storage environmental stress magnitudes; obtaining environmental test data of a component or a part on the premise that the failure mechanisms remain unchanged while the test environmental stress changes; computing life distribution characteristic parameters of various failure mechanisms in the module storage process; computing the life distributions of various failure mechanisms in the whole storage period; and obtaining an expression of the life distributions due to the life distribution characteristic parameters are known, integrating life distribution functions of various failure mechanisms in the storage period to obtain a failure probability F p (t) and a R p(t) reliability of various failure mechanisms at various times. According to the computing method of the storage dynamic reliability for the aviation drive circuit module, a more precise assessment result can be obtained on the premise of saving of test costs, and evidence can be provided for the reliability design of the aviation drive circuit module.

Owner:厦门蓝威可靠性系统工程研究院有限公司

Reliability acceleration test method of electronic products

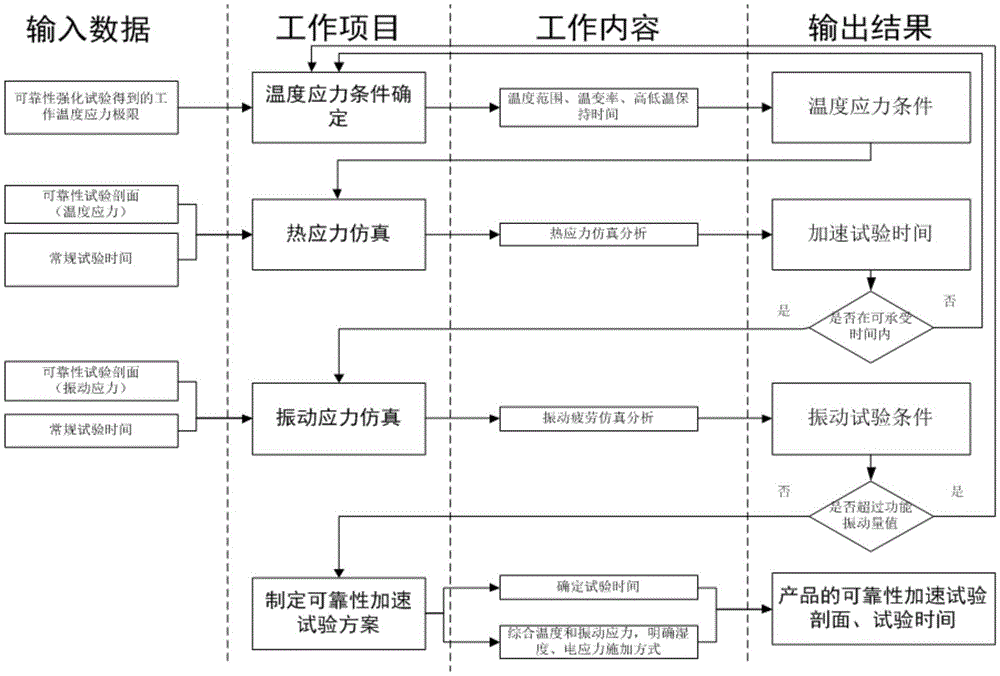

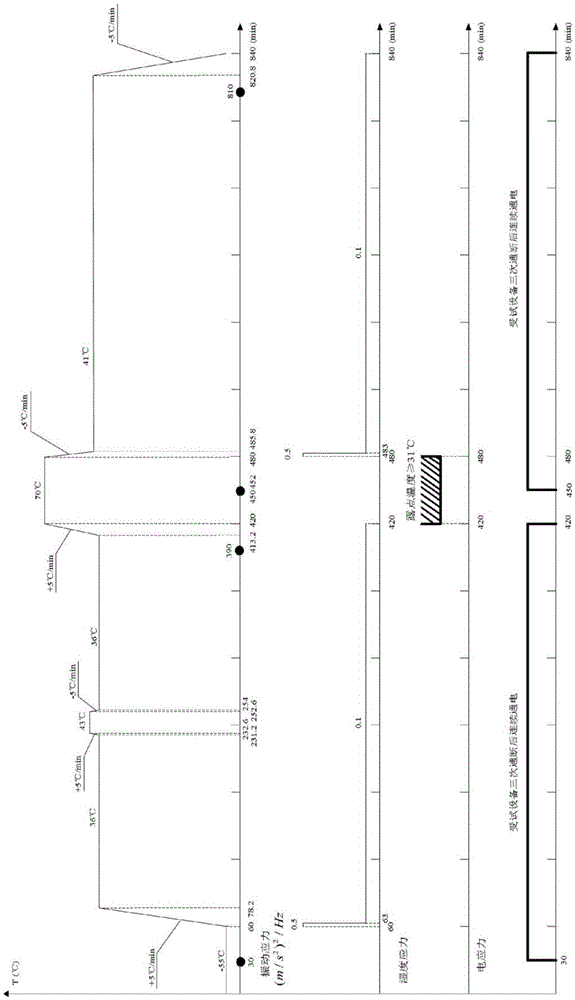

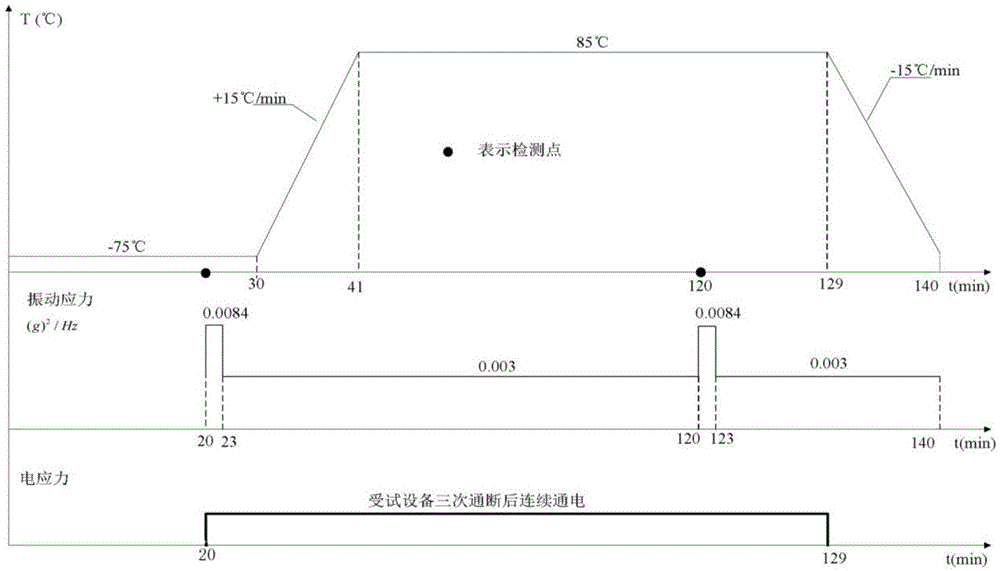

ActiveCN105572498ASolve engineering problems that are difficult to test and identify indicatorsSynthetic Stress Conditions for Growth TestsEnvironmental/reliability testsTemperature stressAcceleration factor

The invention discloses a reliability acceleration test method of electronic products, and belongs to the field of reliability designing and testing. The method comprises steps of firstly presetting an acceleration test temperature change curve boundary according to working stress limit obtained via a routine test for reliability of an electronic product, carrying out simulating calculation of temperature acceleration factors, and modifying and determining initial acceleration test temperature stress change curves; and secondly, calculating vibration acceleration factors according to the initial acceleration test temperature stress change curves and a test profile of the routine test for the reliability of the original electronic product, calculating acceleration test vibration stress change curves according to the vibration acceleration factors, and according to the acceleration test vibration stress change curves, determining the final temperature stress change curves and determining acceleration test time. According to the invention, by following the thought of testing and examining working stress of a product and properly increasing test stress level, test time is shortened; a reliability test of the electronic product can be accelerated; and diversity and controllability of the acceleration factors are achieved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Spacecraft autonomous health management architecture based on comprehensive electronic platform

ActiveCN103217974AClear task interfaceAdapt to health management needsElectric testing/monitoringComputer moduleDependability

A spacecraft autonomous health management architecture based on a comprehensive electronic platform divides spacecraft faults into five classes, a different detection method and a different restoration strategy are adopted by each class of faults, and a classified and layered health management architecture is formed. Zero-class faults are guaranteed through self-reliability design of one machine, health management of first-class faults is completed through a platform load integrated service unit health management module, a control integrated service health management module and an FDIR central control task module, a relevant fault health management module completes health management of second-class faults, and a special detection and module control module completes health management of third-class faults and fourth-class faults. The spacecraft autonomous health management architecture is based on the comprehensive electronic platform, has generality, and can meet health management requirements of spacecrafts of different types.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

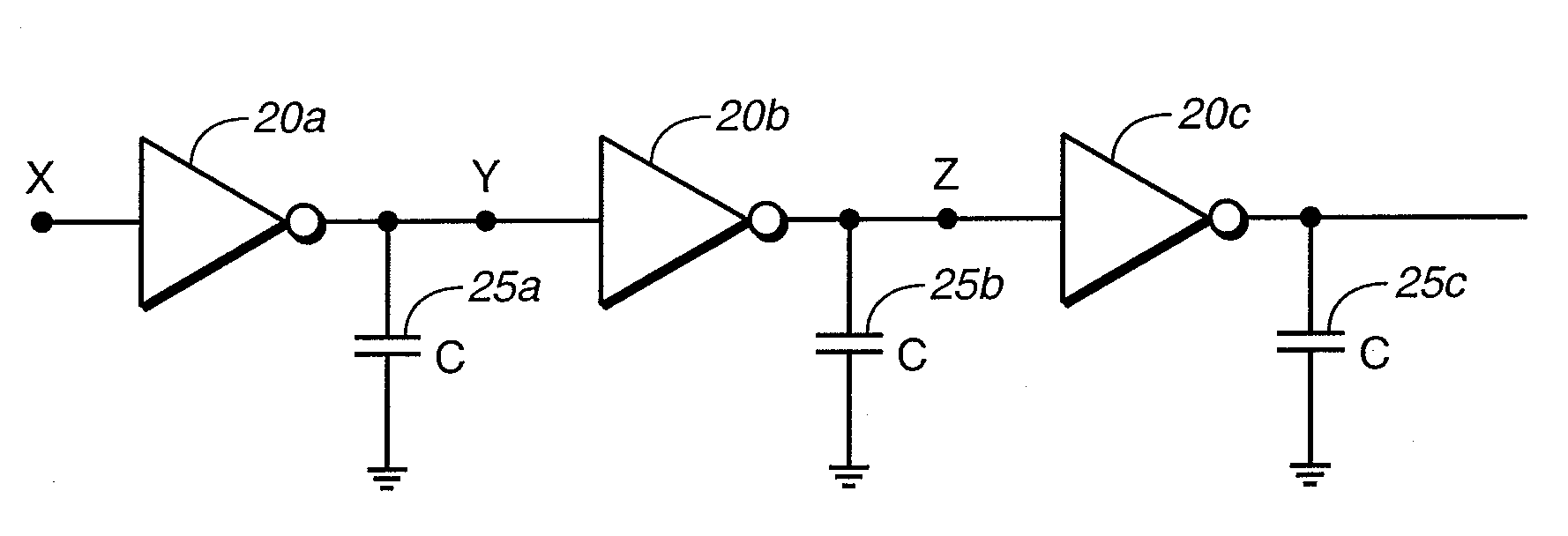

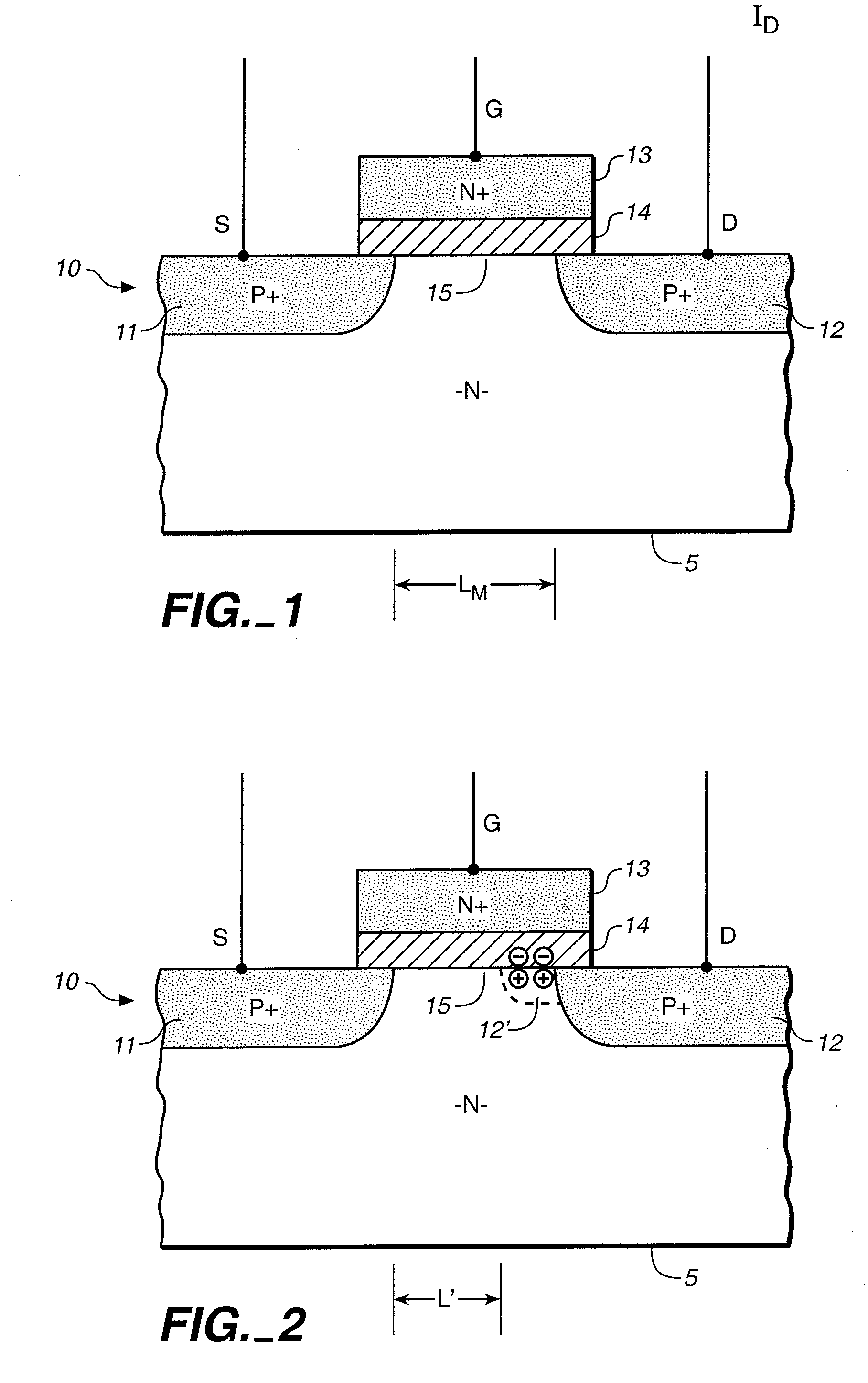

Hot-carrier reliability design rule checker

InactiveUS7219045B1Detecting faulty computer hardwareComputer aided designDevice typeComputer architecture

The present invention is directed to methods for reliability simulations in aged circuits whose operation has been degraded through hot-carrier or other effects by allowing design rules on degradation to be included in the netlist. Once the hot-carrier circuit simulation is launched, the rules are checked and the reliability design rule violations are reported. The process can be performed on either the layout or schematic window. The design rule criteria can be any device parameter and can be expressed in absolute or relative terms. The criteria can be based on device type, model card name, instance geometry, or temperature. Additionally, values can be set prior to beginning the simulation.

Owner:CADENCE DESIGN SYST INC

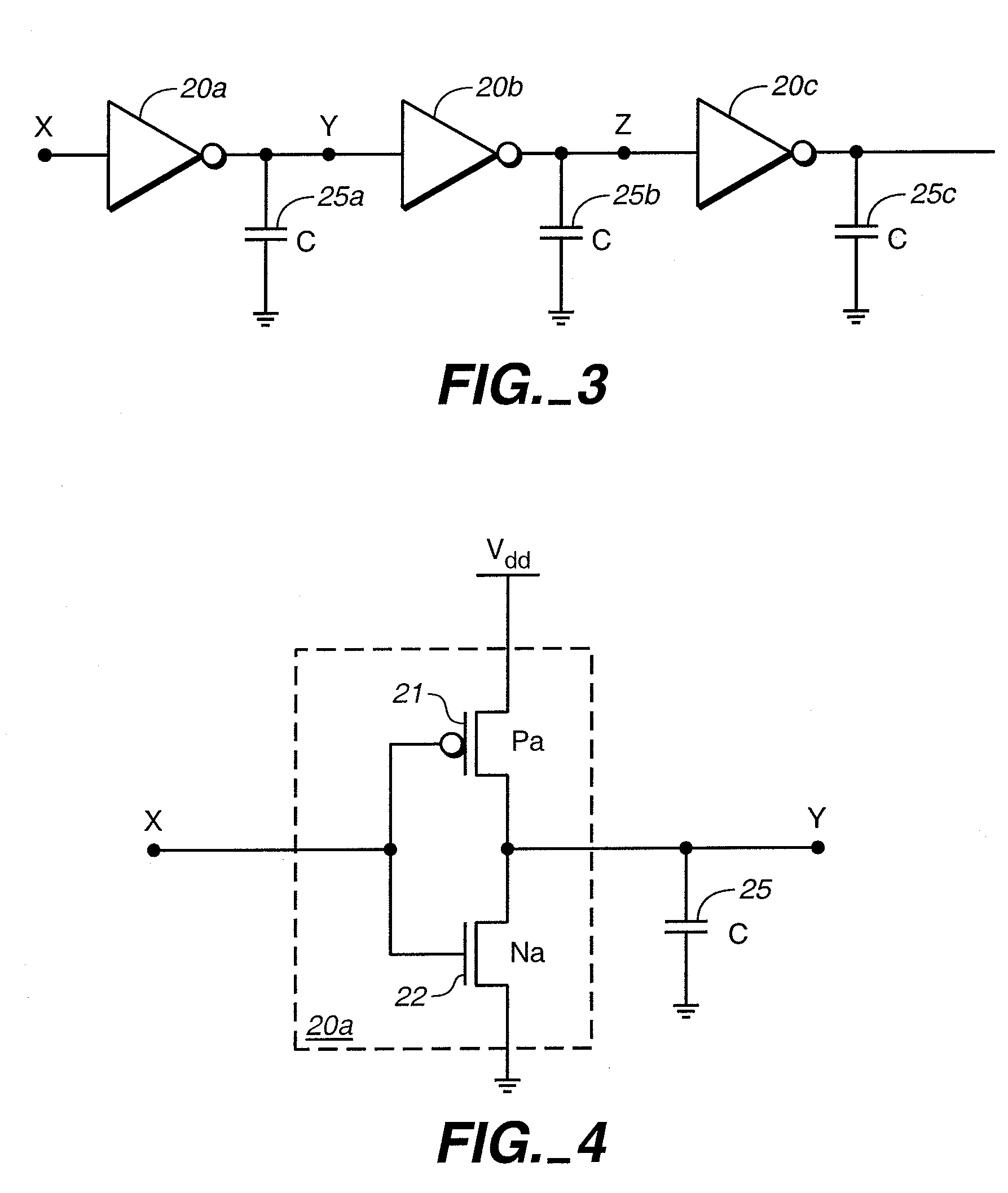

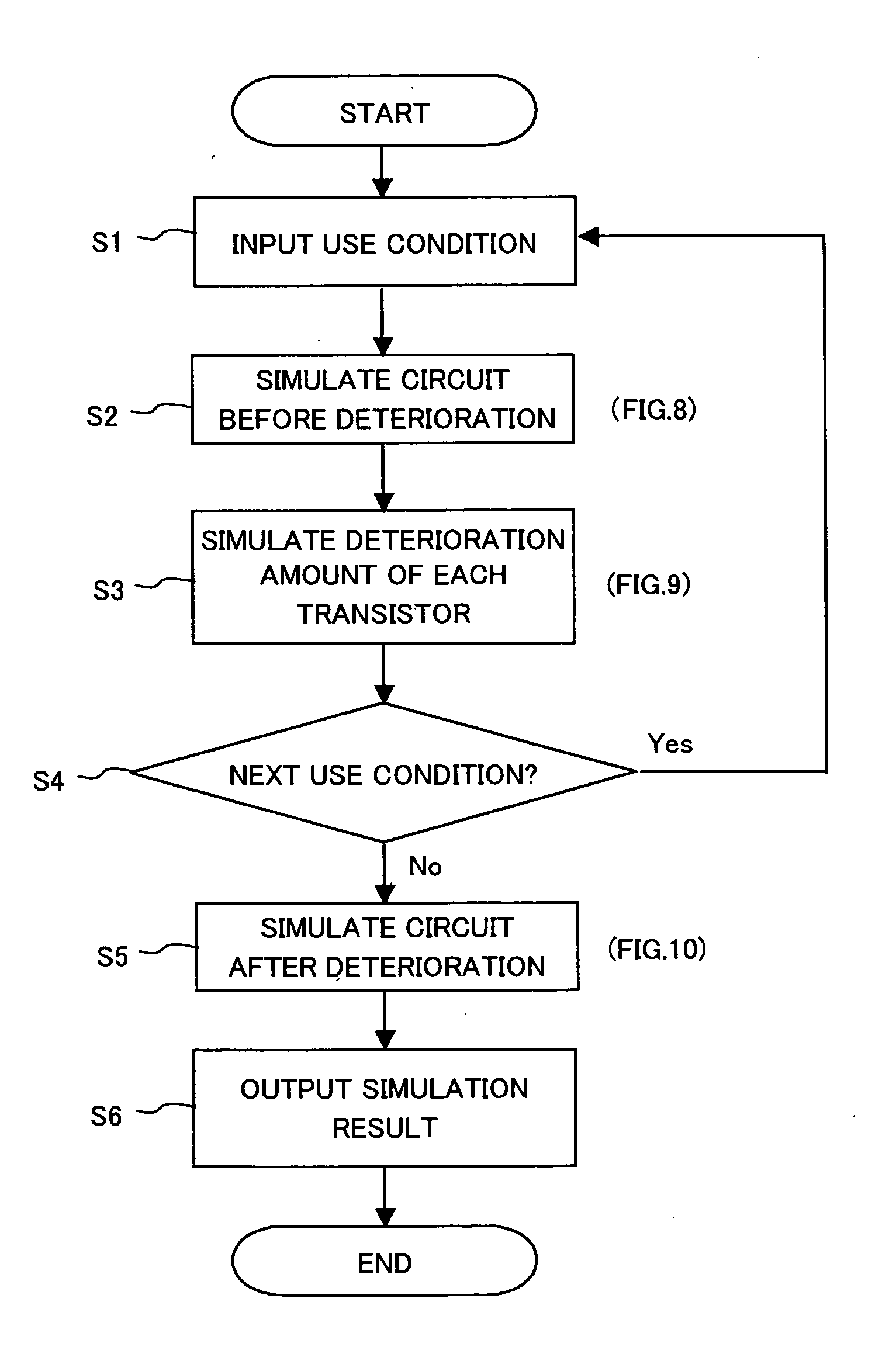

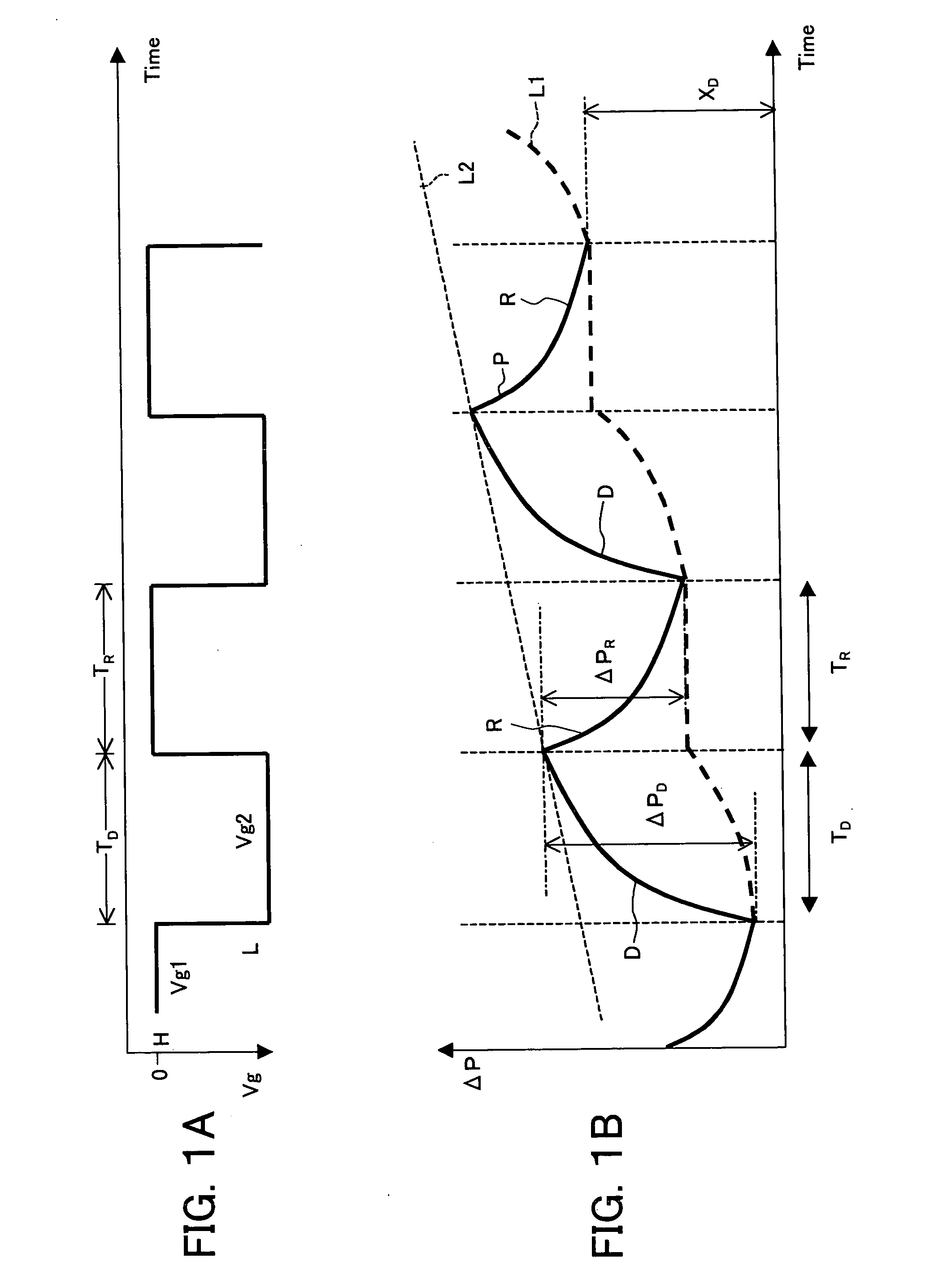

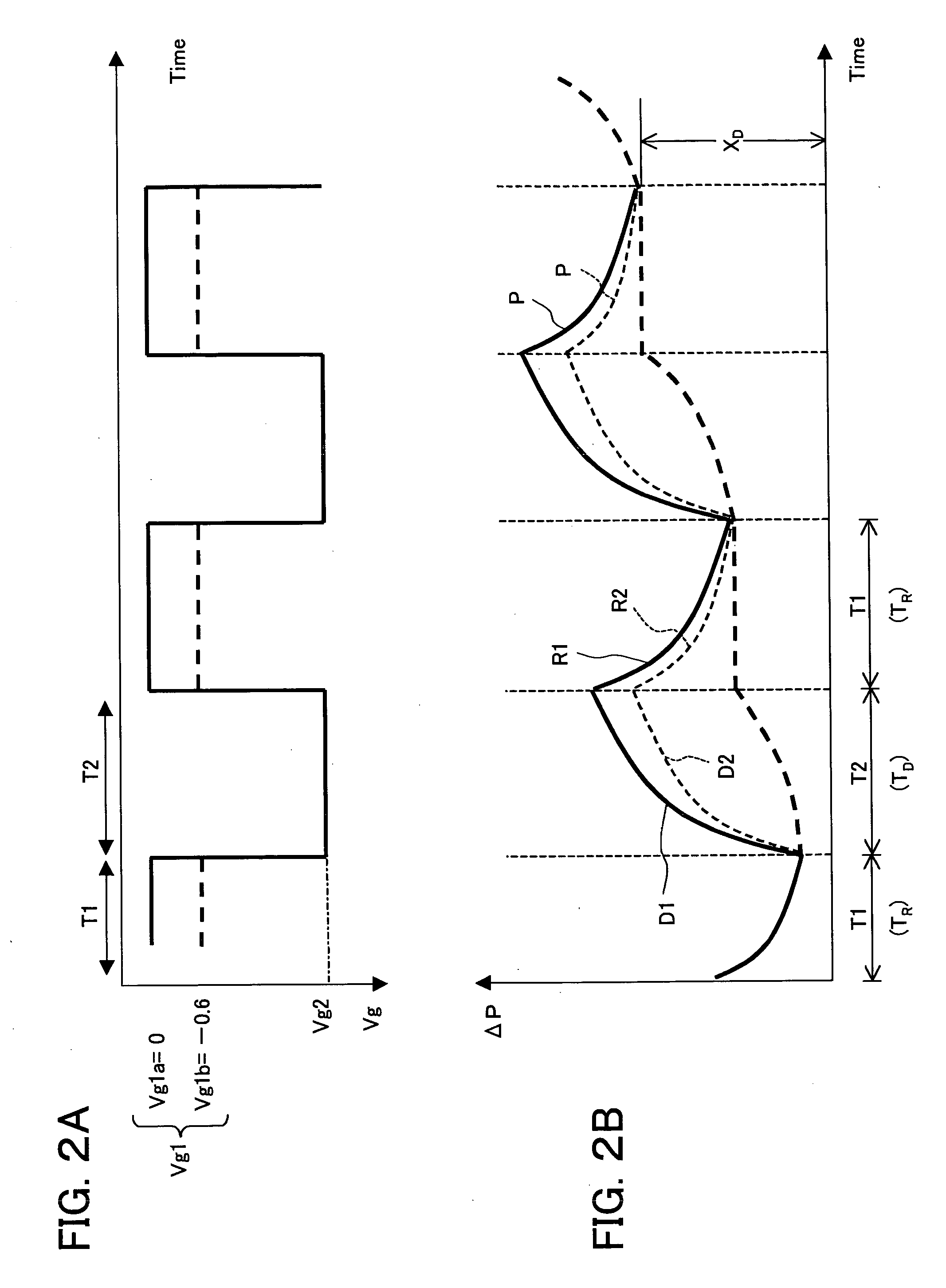

Semiconductor circuit device simulation method and semiconductor circuit device simulator

InactiveUS20050138581A1Accurate estimateSimulation is accurateTransistorAnalogue computers for electric apparatusDevice materialRecovery period

A simulator for accurately simulating a deterioration amount and a recovery amount of transistor characteristics, by which a semiconductor device can be designed with high reliability, and the method are provided. When a gate voltage of a negative level (a negative bias voltage) “Vg” is applied to a gate of the transistor, characteristics of the transistor are deteriorated. When application of the negative level gate voltage “Vg” is terminated (when applying a bias free voltage), the deteriorated transistor characteristics are recovered. In a deterioration period and a recovery period, a logarithm “log(t)” is obtained for an application time “t” of the gate voltage, a deterioration amount ΔPD(t)=CD+BD·log(t) is calculated by using constants CD and BD depending on the negative bias voltage, a recovery amount ΔPR(t)=CR+BR·log(t) is calculated by using constants CR and BR depending on the bias free voltage, and the deterioration amount (ΔPD), the recovery amount (ΔPR) and a basic deterioration amount (XD) are summed up. Preferably, passage of time is divided, and a deterioration amount and a recovery amount are obtained for each time zone by using different deterioration and recovery functions for each time zone.

Owner:SONY CORP

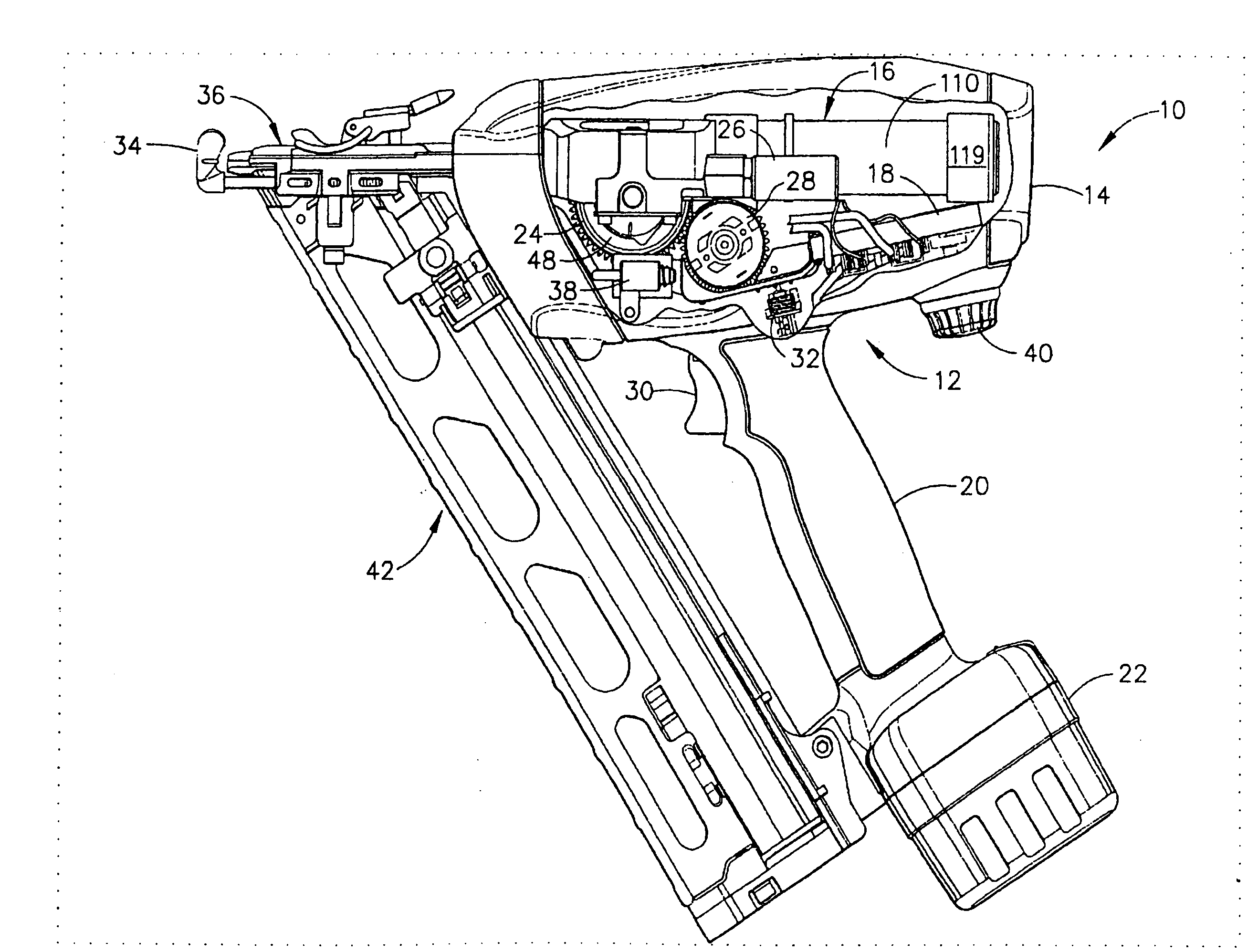

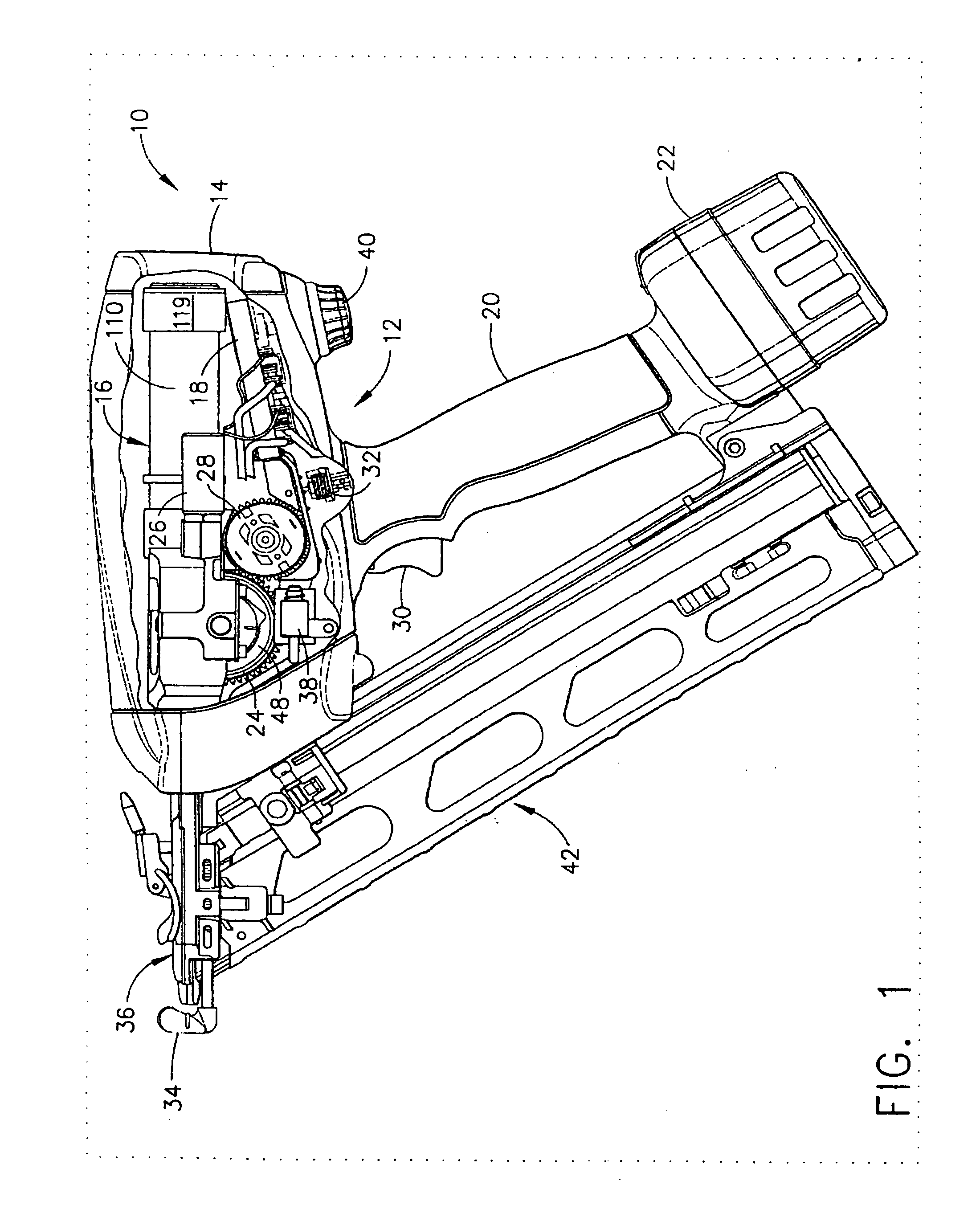

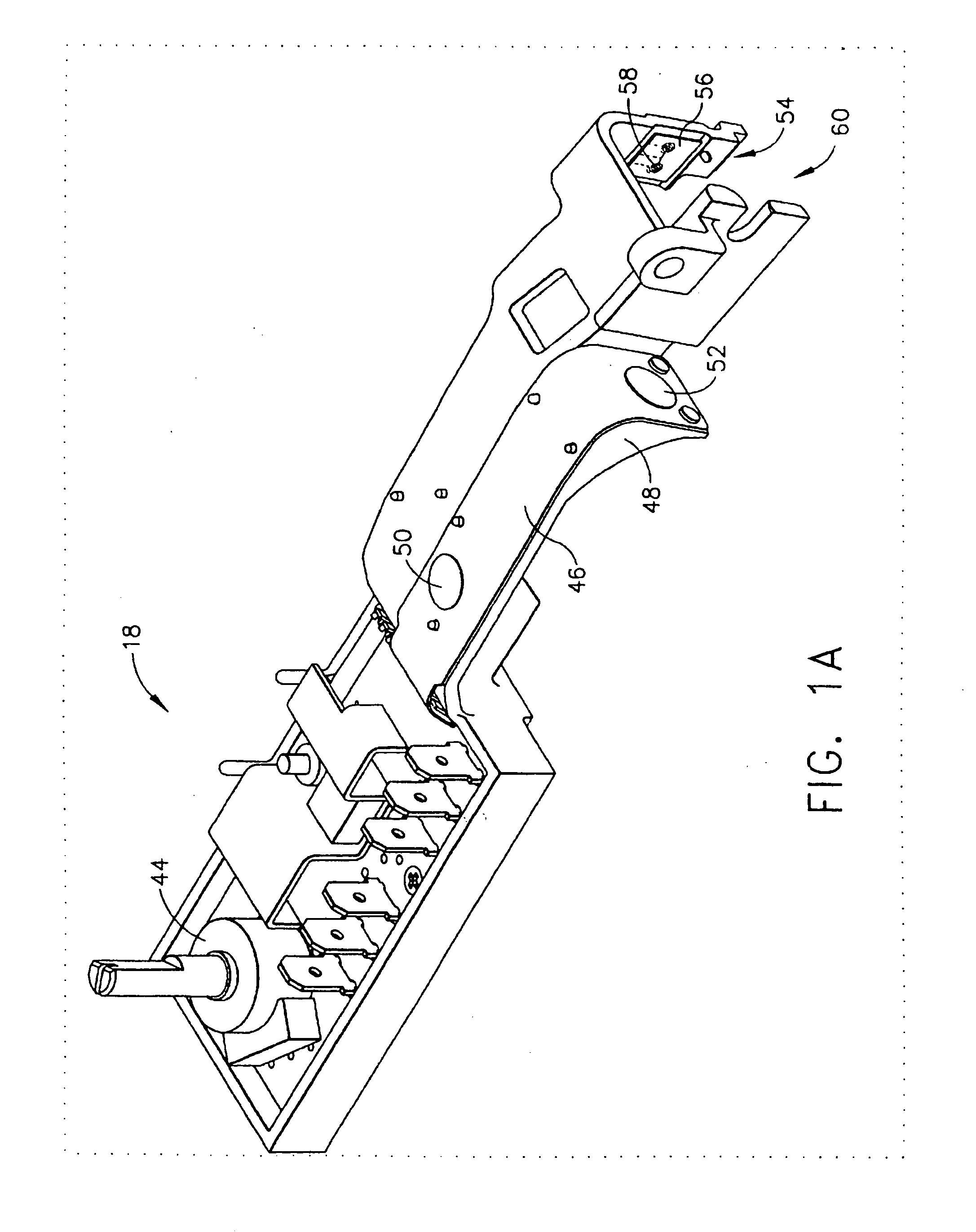

Control module for flywheel operated hand tool

InactiveUS20050040206A1Avoid human errorConsistent controlStapling toolsAC motor controlFlywheelReliability design

A control module advantageously reduces cost and enhances reliability, design flexibility, ease of assembly, and performance of a flywheel operated hand tool. The control module includes a thin film printed circuit with non-contact speed sensing of a flywheel to more accurately set the target speed and control transfer kinetic energy thereof to a fastener, achieving a desired depth regardless of variations in component performance and battery voltage. The printed circuit also includes long service life thin film switches for responding to trigger and safety inputs. Furthermore, the control module responds to a user speed selection and to preset speed selection ranges to reconfigure the controls as appropriate to constraints of a fastener drive assembly and to user preferences.

Owner:SENCO BRANDS

Fire fighting system reliability analysis and calculation method

InactiveCN102419799AObjective analysisFailure rate to be analyzedSpecial data processing applicationsTask analysisMean time to repair

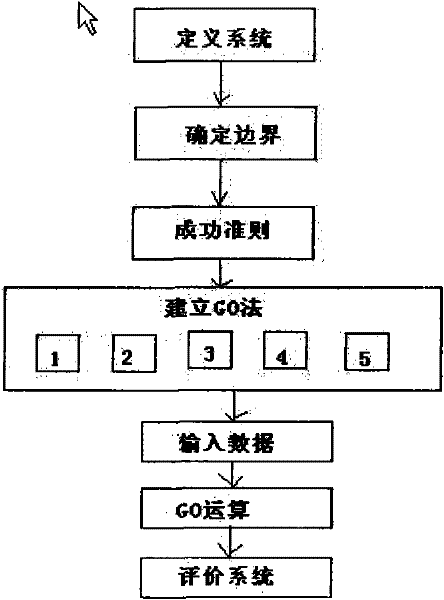

The invention belongs to application of a reliability analysis technology to the technical field of fire engineering, and ensures that the using reliability of a fire fighting system is accurately analyzed and calculated. A fire fighting system reliability analysis and calculation method comprises the following steps of: establishing a fire fighting system reliability model and determining reliability units according to the working principle of the fire fighting system, forming a GO chart for establishing the fire fighting system according to the boundary of the fire fighting system and success criteria, and determining a fault judgment method for the reliability units of the fire fighting system according to task analysis of the system and fire code requirements; and substituting fault statistical data of the reliability units of the fire fighting system into a GO model of the fire fighting system to calculate corresponding reliability indexes of the fire fighting system, such as a fault rate, average maintenance time, availability and the like. By the method, the reliability of the fire fighting system can be objectively qualitatively evaluated or accurately quantitatively evaluated, and the method can be widely applied to reliability design, reliability manufacture, fault analysis and system evaluation of the fire fighting system.

Owner:杜玉龙

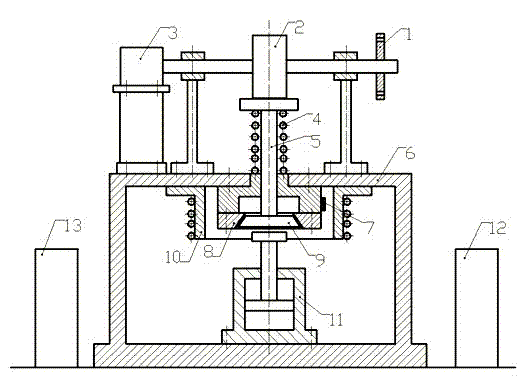

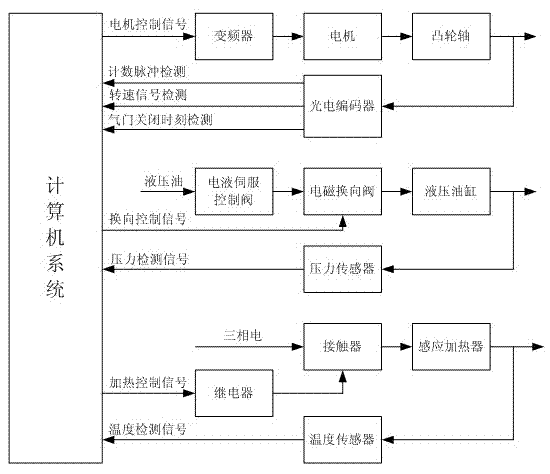

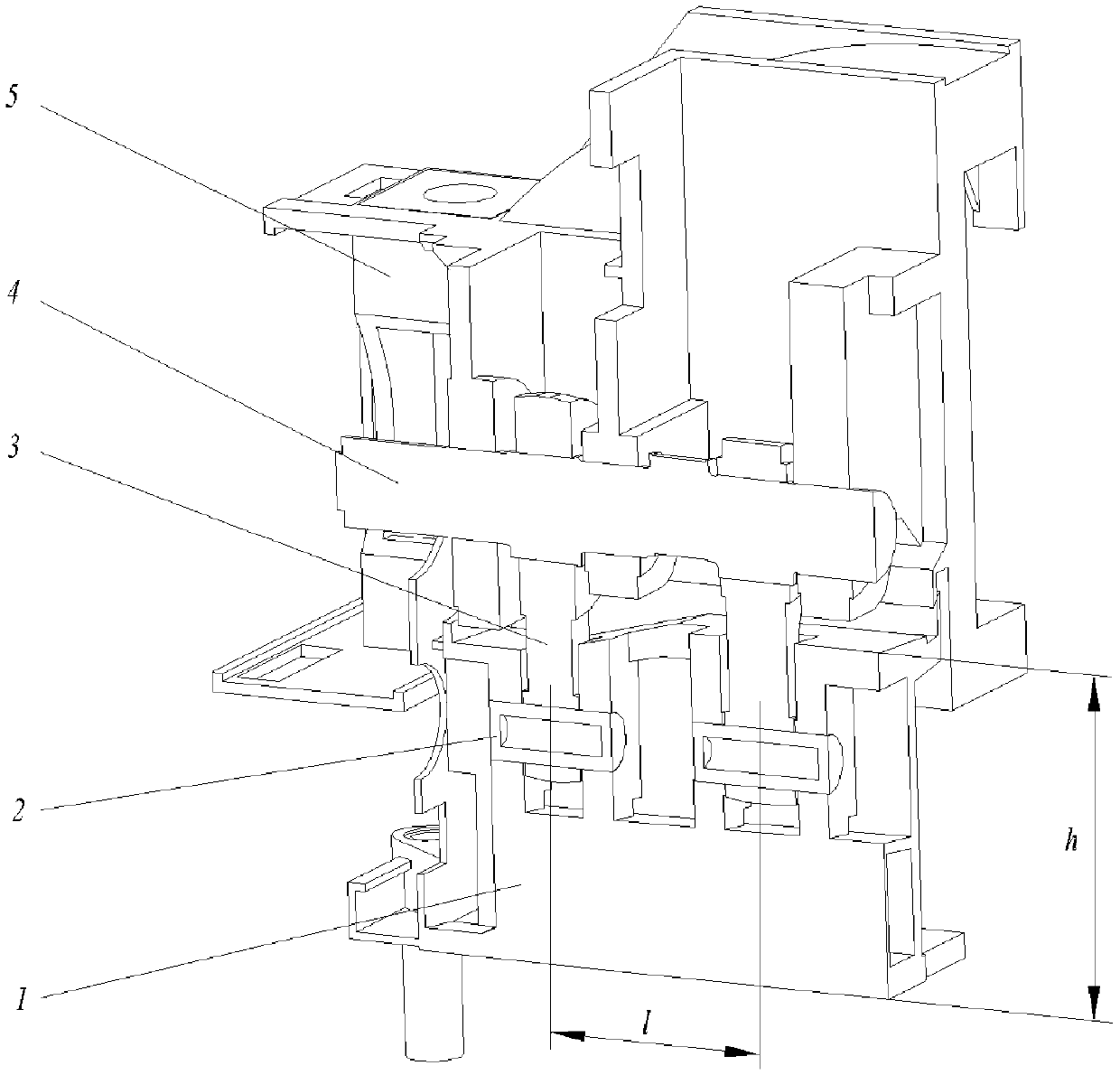

Quick wear test device of engine valve seat ring

ActiveCN102829962AImprove independent research and development capabilitiesImprove reliabilityMachine part testingShock testingBench testElectric machinery

The invention relates to a quick wear test device of an engine valve seat ring. Evaluation of a wear life of the existing engine valve and seat ring is only completed by an overall reliability bench test at present, the period is long, and the expense is high. The quick wear test device is characterized in that a motor is arranged on a stander, wherein the motor is used for driving a cam shaft, the end of the motor is provided with a photoelectric coder, the top end of a valve rod is contacted with the cam shaft, and the bottom end of the valve rod stretches into the stander and provided with a valve body; and a seat ring which is matched with the valve body is arranged inside the stander, and the valve rod outside the stander is also provided with a valve spring. The bottom inside of the stander is provided with a hydraulic oil cylinder, and the position of the hydraulic oil cylinder is opposite to the valve body. The periphery of the valve seat ring is provided with a sensing heater, and the valve seat ring is also provided with a temperature sensor. The quick wear test device is used for researching a reliability design technology of an engine air distribution mechanism component and has important significance on improving the independence research and development capacity of air distribution mechanism component manufacturers in China and improving the overall design reliability of an engine.

Owner:海宁鼎丞智能设备有限公司

Vehicle-mounted measurement device of three-dimensional deformation monitoring of subway tunnels based on reference transmission

PendingCN108917638ATimely warningHigh precisionTransmission systemsUsing optical meansMeasurement deviceReliability design

The invention belongs to the technical field of three-dimensional detection of subway tunnels, and discloses a vehicle-mounted measurement device of three-dimensional deformation monitoring of subwaytunnels based on reference transmission. A rotatable laser distance measurement system for high-speed distance measurement and angle measurement is integrated by a laser range finder, an inclination angle sensor, a high-precision turn table and a PLC controller together; a tunnel section outline is measured in a discrete multi-point mode; meanwhile, in combination with a photoelectric encoder installed on a distance measurement wheel at the bottom of a tunnel detection vehicle, a fixed displacement amount of the detection vehicle between a starting position and a travelling position on an axial direction of the tunnel is obtained, a program is triggered, and the detected data of the specific position in the tunnel are transmitted to an upper computer by a wireless communicator. The vehicle-mounted measurement device disclosed by the invention makes breakthroughs in the practical technical innovation of the online monitoring of the tunnel structure safety, lays a foundation for forminga technical system for the reliability design, analysis, test and evaluation of rail transit facilities, and has practicality in many fields.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

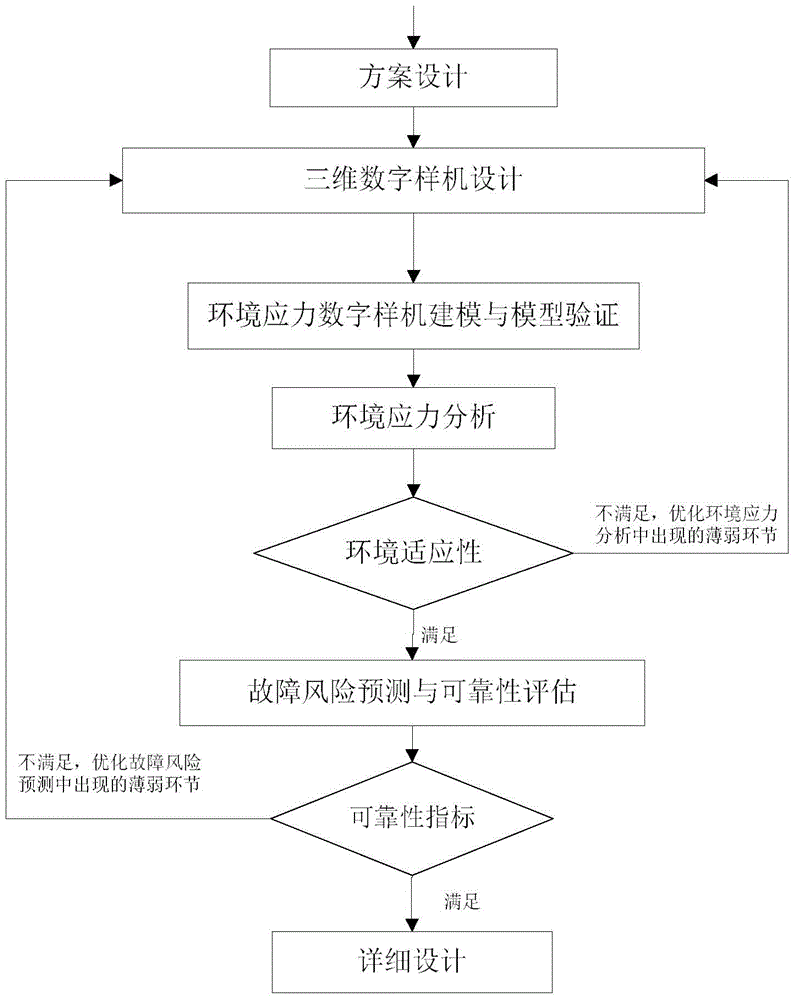

Reliability design optimization method for avionic device

InactiveCN105677991AShorten the development cycleReduce R&D costsSpecial data processing applicationsAviationDesign information

The invention provides a reliability design optimization method for an avionic device. By means of the reliability design optimization method for the avionic device, the reliability index of the device can be practically and effectively promoted in the design stage. According to the technical scheme, the method comprises the following steps that three-dimensional digital prototype modeling is conducted according to an avionic device design scheme; on the basis of a three-dimensional digital prototype, environmental stress digital prototype modeling is conducted according to a device working load, an environmental load and design information relevant to device characteristics, and a model is corrected and verified; thermal environment stress, mechanical environment stress and the like of the avionic device are analyzed by referring to environmental conditions, environmental stress weak links of the device are searched, and corresponding avionic device design optimization is conducted; a fault physical digital prototype model is built, environmental stress analysis results are introduced to conduct device fault risk prediction, avionic device design optimization is conducted aiming at the reliability weak links occurring in the analysis process, and the reliability level of the avionic device is evaluated according to the optimized fault risk distribution situation.

Owner:10TH RES INST OF CETC

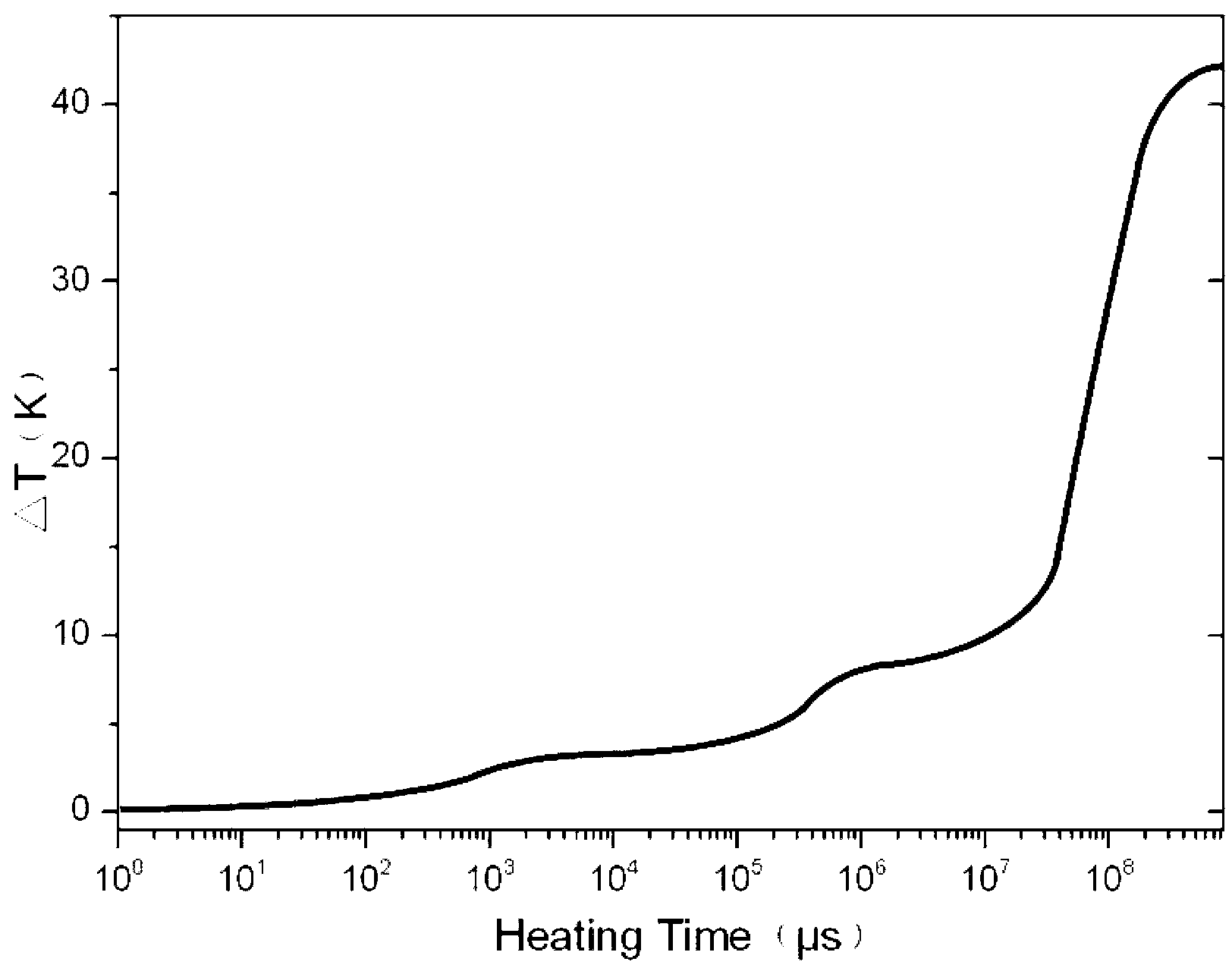

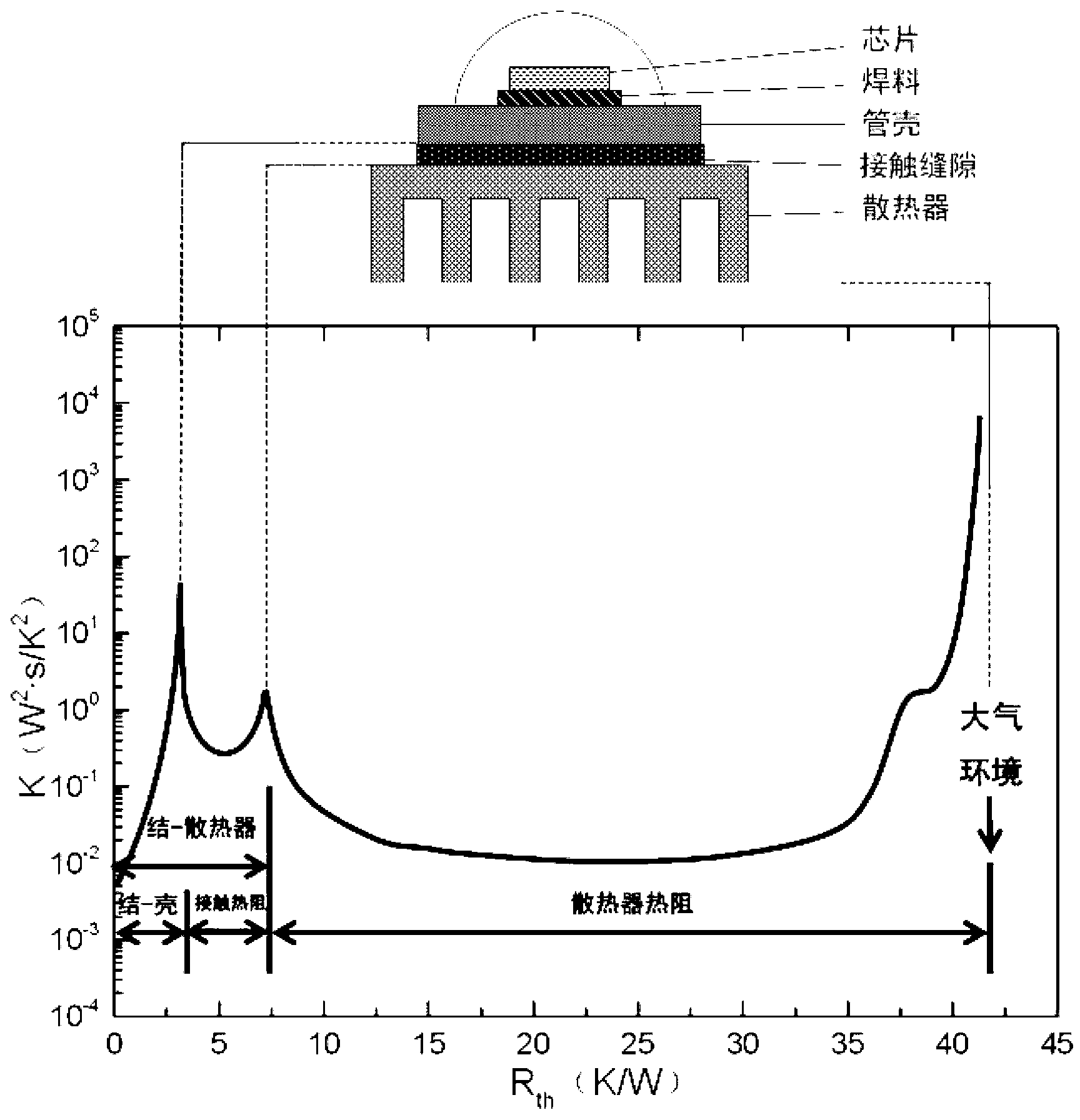

Thermal resistance composition test device and method for LED (light emitting diode) lamp

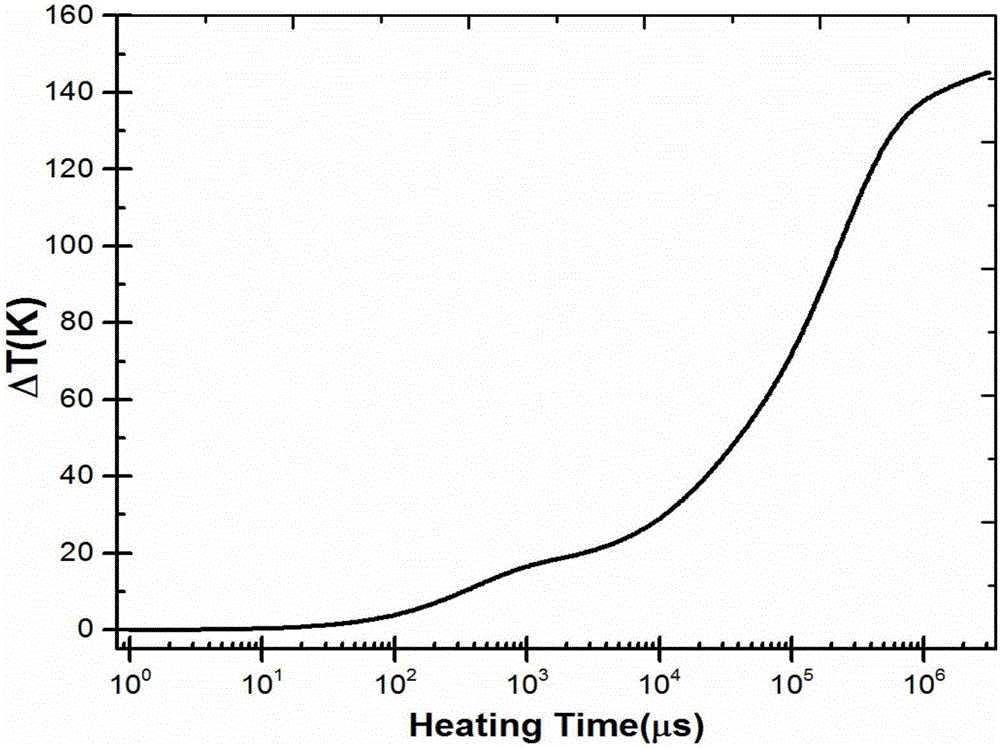

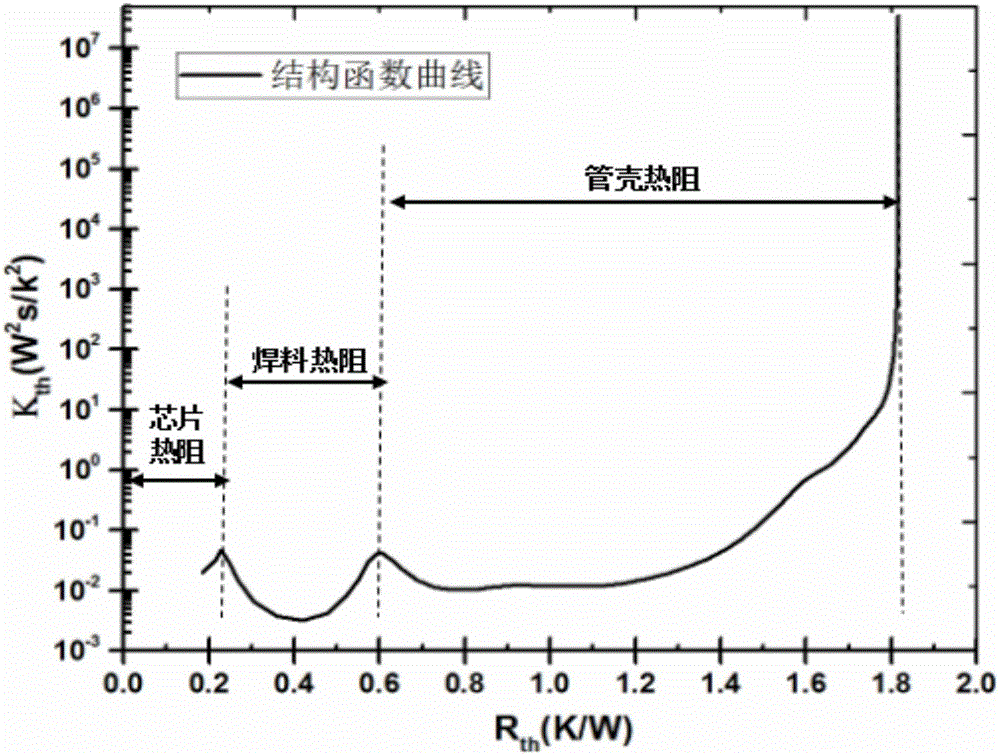

ActiveCN103076551AGuaranteed thermal resistance compositionGuaranteed measurement of thermal resistance constitutesMaterial thermal conductivityIndividual semiconductor device testingJunction temperatureEngineering

The invention relates to a thermal resistance composition test device and a thermal resistance composition method for an LED (light emitting diode) lamp, and belongs to the technical field of semiconductor LED illumination and display reliability design and checking. The device and the method provided by the invention have the main invention points that in the actual LED lamp, partial LEDs are selected and isolated to be used as temperature measuring elements, synchronous switching modes and devices for controlling an external lamp power supply are designed, the transient state temperature rise process curve collection line and methods are utilized, and the real thermal resistance composition of the LED lamp is measured on line. When the LED lamp adopts different heat radiators or the contact between the heat radiator and an LED device is poor, the heat resistance of each part is different, the heat radiation design of the LED lamp can be optimized through measuring the thermal resistance composition in different designs and equipment, the highest junction temperature of the lamp is reduced, and the service life and the quality of the LED lamp are ensured. The device and the method provided by the invention are mainly used for fast determining the thermal resistance composition of the LED lamp in a nondestructive way.

Owner:BEIJING UNIV OF TECH

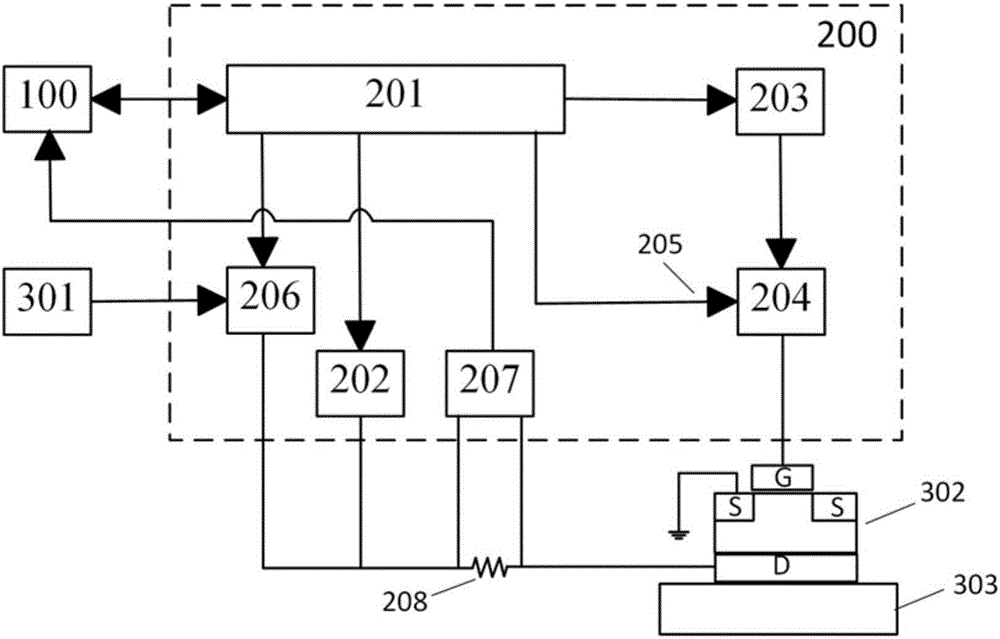

Power MOS device temperature rise and thermal resistance component test device and method

ActiveCN106443401AGet goodLossless acquisitionIndividual semiconductor device testingTest powerStructure function

The invention relates to a power MOS device temperature rise and thermal resistance component test device and method and belongs to the power MOS device reliability design and test field. According to the test device and method of the invention, a fast switching switch of drain-source voltage and gate-source voltage signal control of a tested power MOS device and a fast switching switch of drain-source high-current work are designed; and an FPGA is adopted to design the acquisition and setting function of drain-source voltage, gate-source voltage and drain-source current. In a testing process, a temperature-sensitive parameter curve is obtained at first; operating current is applied to the device, so that the temperature of the device can rise; after the output power of the device achieves a steady state, the operating current is cut off, and test current is switched on; the junction voltage of the drain-source parasitic diode of the power MOS device is acquired, so that the junction temperature curve of the device can be obtained correspondingly; processing analysis is carried out through adopting a structural function method, so that the thermal resistance components of the power MOS device can be obtained. With the power MOS device temperature rise and thermal resistance component test device and method of the invention adopted, the problems of high prices of test instruments, complicated operation of measurement technologies and long measurement period can be solved.

Owner:BEIJING UNIV OF TECH

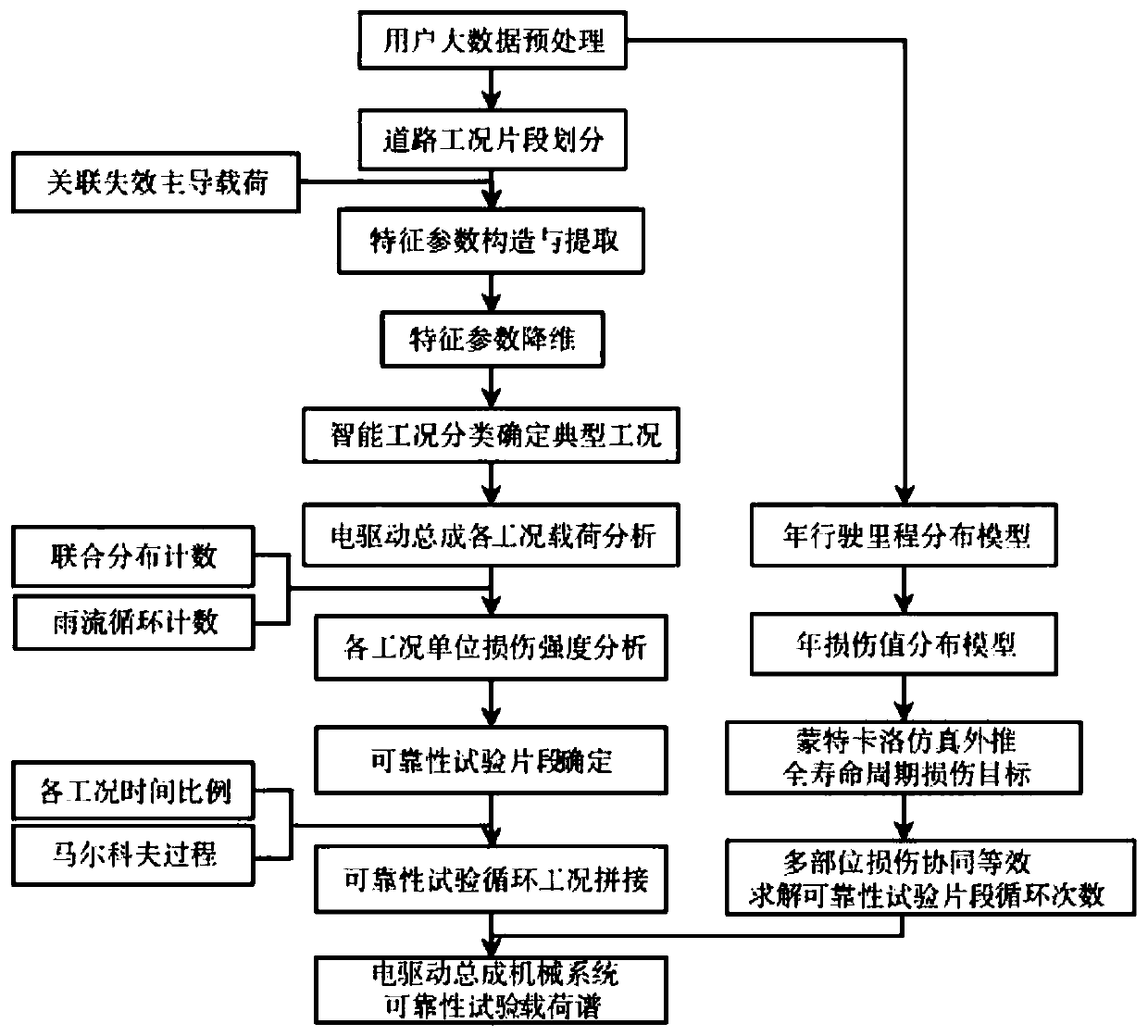

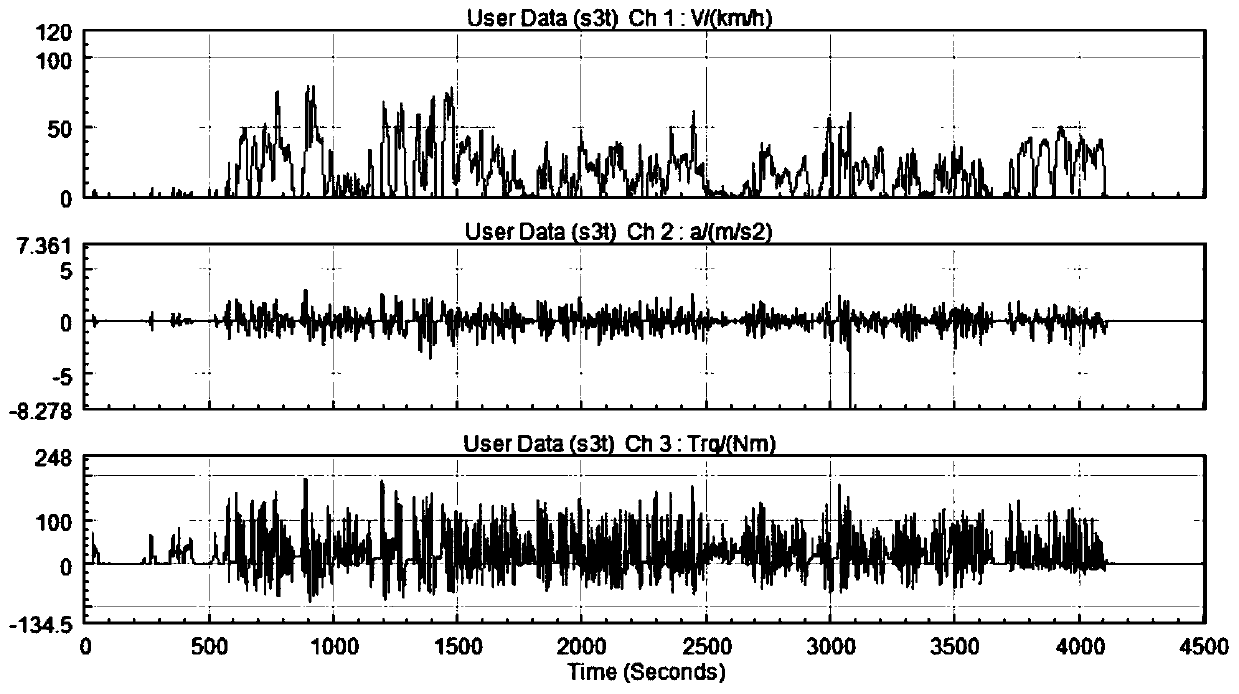

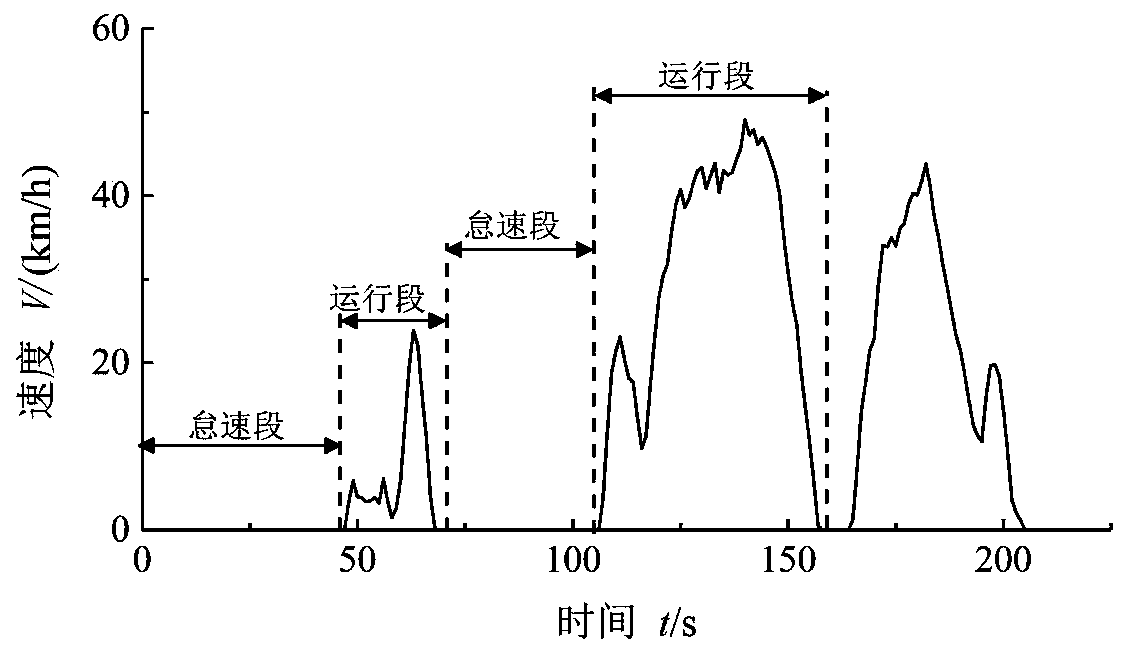

Compilation method for reliability test load spectrum of electric drive assembly mechanical system

ActiveCN111581893AAccelerated test processShorten test timeGeometric CADDesign optimisation/simulationElectric driveReliability design

The invention provides a compilation method for a reliability test load spectrum of an electric drive assembly mechanical system, and the method comprises the following steps: step 1, collecting userload data, carrying out preprocessing, and dividing road condition segments; step 2, determining five typical working conditions; step 3, selecting a reliability test cycle segment of each typical working condition; step 4, adopting Monte Carlo simulation to extrapolate damage targets of all parts in the full life cycle; step 5, calculating the number of cycles of each reliability test cycle segment covering multiple damage targets by using a multi-objective optimization method; step 6, splicing the reliability test cycle segments to obtain a reliability test cycle condition; and step 7, compiling to obtain a reliability test load spectrum according to the cycle index of the reliability test cycle segment and the reliability test cycle working condition. The load spectrum compiled by the method is associated with user load data and covers high damage strength, and reference and basis are provided for reliability design and verification of the electric drive assembly.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

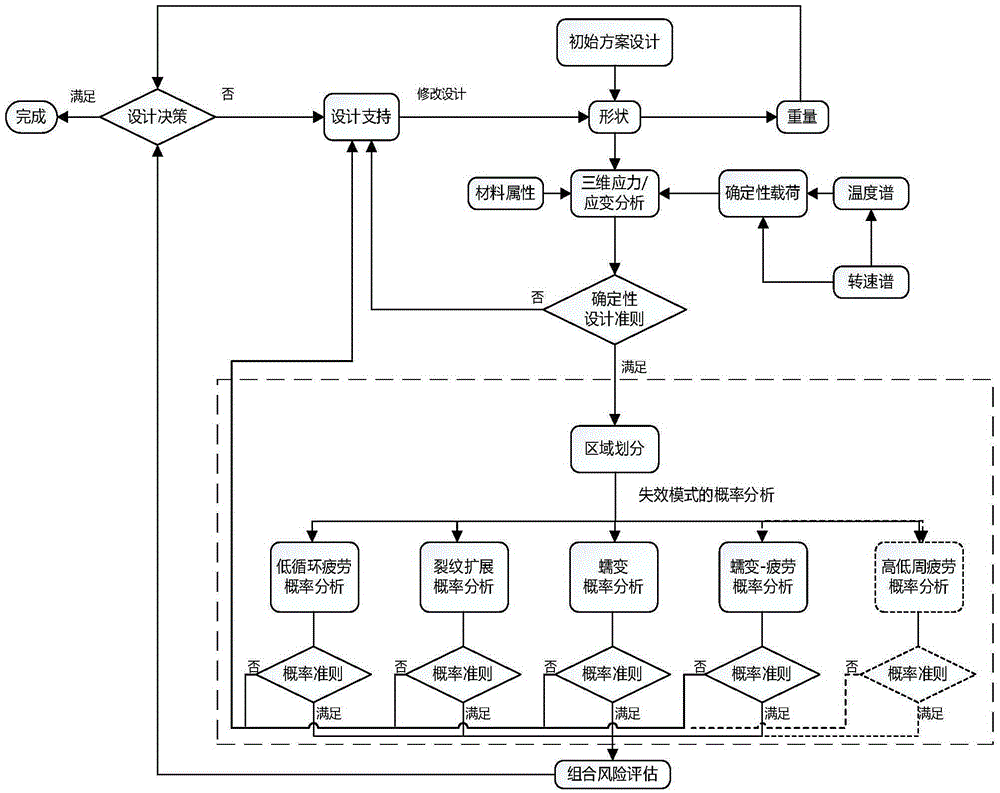

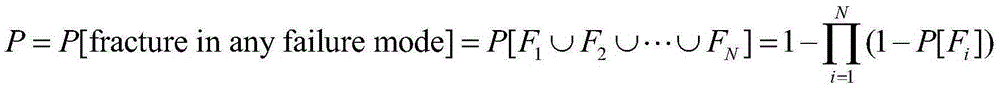

Turbine blade disc structure service life reliability design method

ActiveCN105404756AQuantify Failure RiskGeometric CADSpecial data processing applicationsStructural reliabilityRisk level

The invention relates to a turbine blade disc structure service life reliability design method. An initial scheme for a turbine blade disc structure is determined according to a traditional strength and service life analysis method, a geometrical shape of the structure is determined and weight of the structure is calculated; determinacy load of the structure is acquired and detailed 3D stress / strain analysis is conducted; a determinacy design criteria is designated to be an optimized constraint condition, and the design is returned to design support when the result does not meet the criteria demand; influence of the turbine blade disc structure is analyzed and the turbine blade disc is partitioned; structure reliability under each failure mode is calculated and a service life reliability analysis result is evaluated with the combination of the service life probability criteria; the design support is required when the structure reliability result does not meet the criteria demand; combined risk evaluation is conducted to a risk level of each failure mode and overall failure probability of the turbine blade disc structure is calculated; each technical index is determined whether to meet demands; and design support is required when the demands are not met or modifications are conducted to the size or the material.

Owner:BEIHANG UNIV

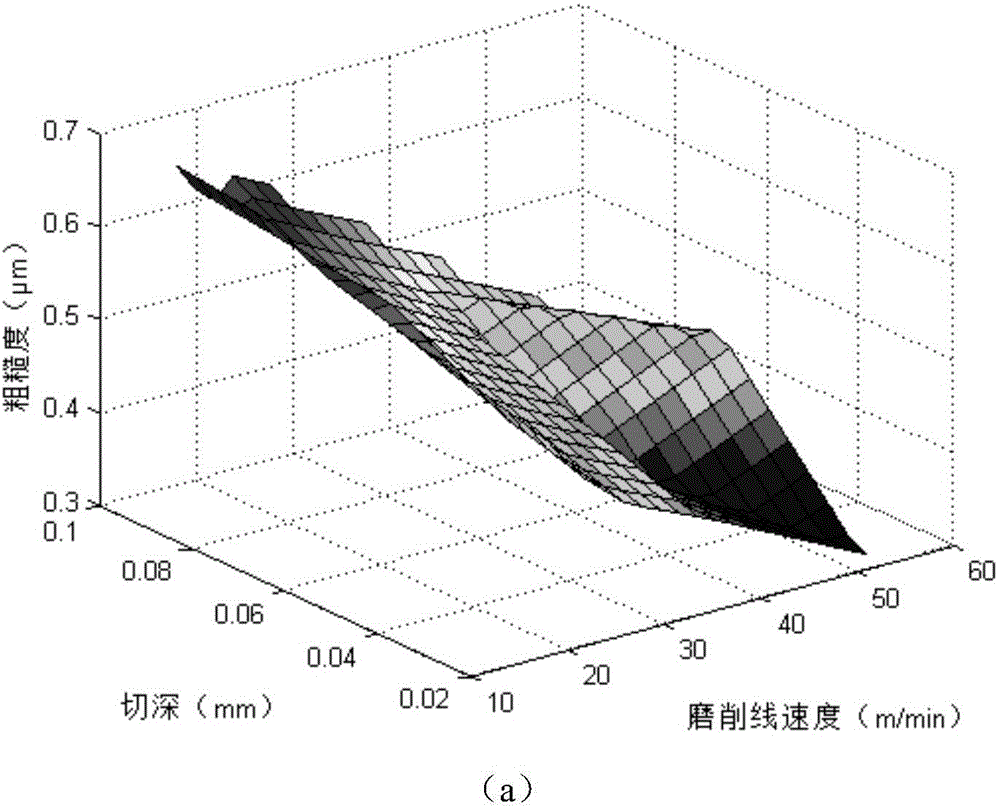

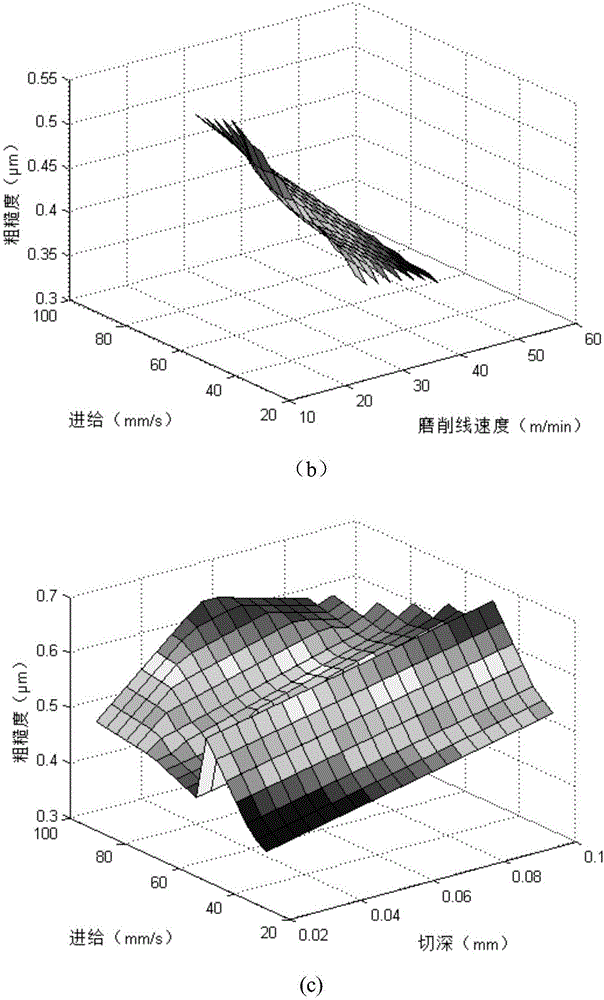

Spiral bevel gear long-life drive fatigue reliability design method based on grinding and heat treatment

ActiveCN106503350AReduce manpowerReduce material resourcesDesign optimisation/simulationSpecial data processing applicationsMultiple failureEngineering

The invention provides a spiral bevel gear long-life drive fatigue reliability design method based on grinding and heat treatment. The method includes the steps that 1, influence laws of grinding process parameters on gear surface roughness and residual stress are studied; 2, influence laws of heat treatment process parameters on gear surface hardness and depth of carburizing are studied; 3, influence laws of the gear surface roughness, the residual stress, the gear surface hardness and the depth of carburizing on all parameters in a spiral bevel gear fatigue contact and fatigue bending strength and stress calculation formula are studied; 4, influence laws of the grinding and treatment process parameters on all the parameters in the spiral bevel gear fatigue contact and fatigue bending strength and stress calculation formula are obtained; 5, distribution laws of the heat grinding and treatment process parameters are studied; 6, a reliability calculation program under Monte Carlo method spiral bevel gear multiple failure modes is compiled, and the grinding and treatment process parameters serve as input for spiral bevel gear reliability calculation. The spiral bevel gear long-life drive fatigue reliability design method has important significance in practical application of gears.

Owner:BEIHANG UNIV

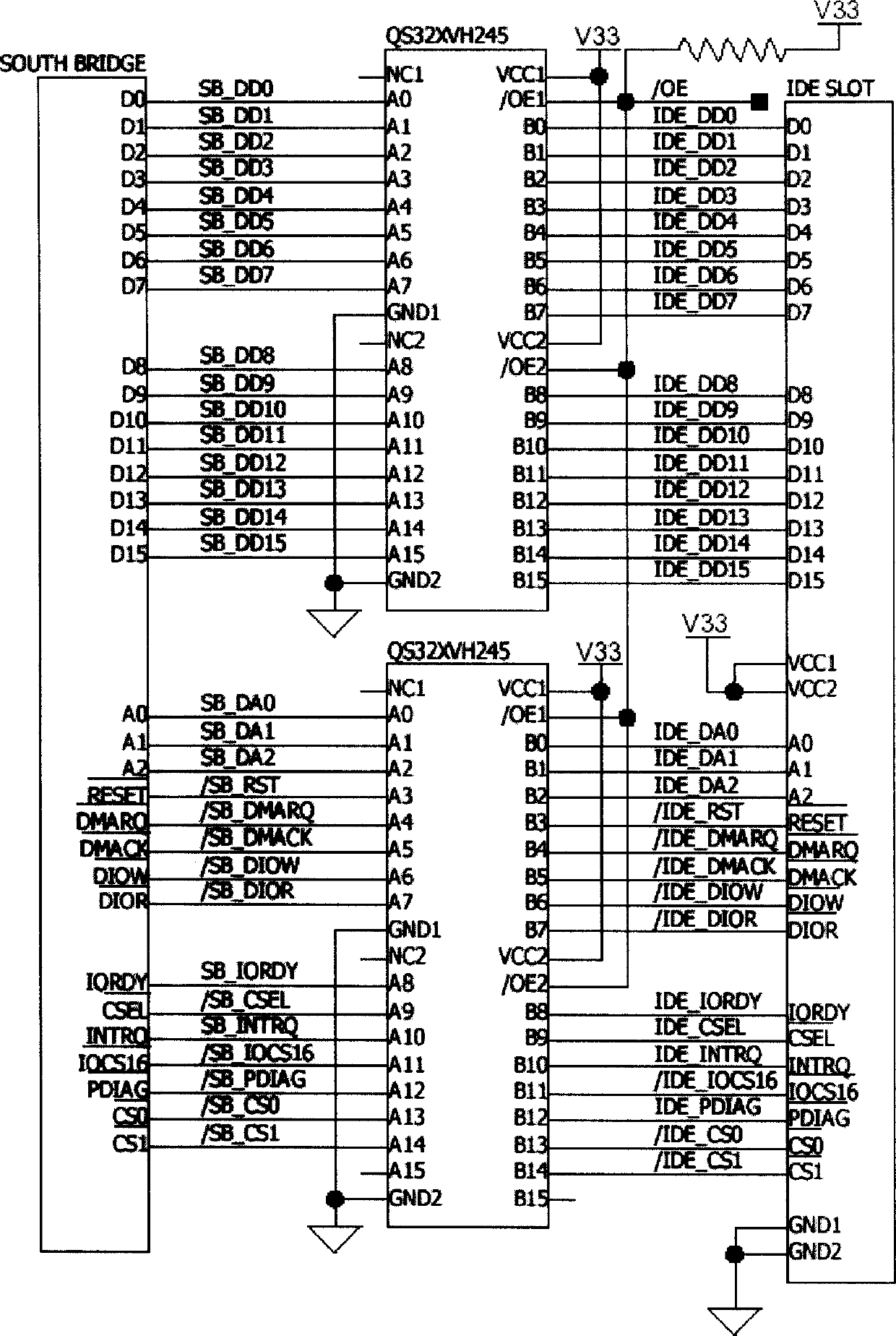

Harddisk hot-swap protection system and method

ActiveCN1731362AAvoid latch-upAvoid Physical Damage FactorsError detection/correctionInductorReliability design

The invention discloses a hardware hot drawing preserving system, which comprises; inserting the signal control apparatus on the interface circuit plate of the hardware, wherein the interface circuit is connected with the CPU of the core processing plate, which can control the connection of the hard disk signal wire according to the CPU order; pulling out the signal inductor on the interface circuit plate of the hardware, wherein the interface circuit is connected with the CPU of the core processing plate, which can induct weather the hardware can be safely pulled out according to the CPU order.

Owner:NEW H3C TECH CO LTD

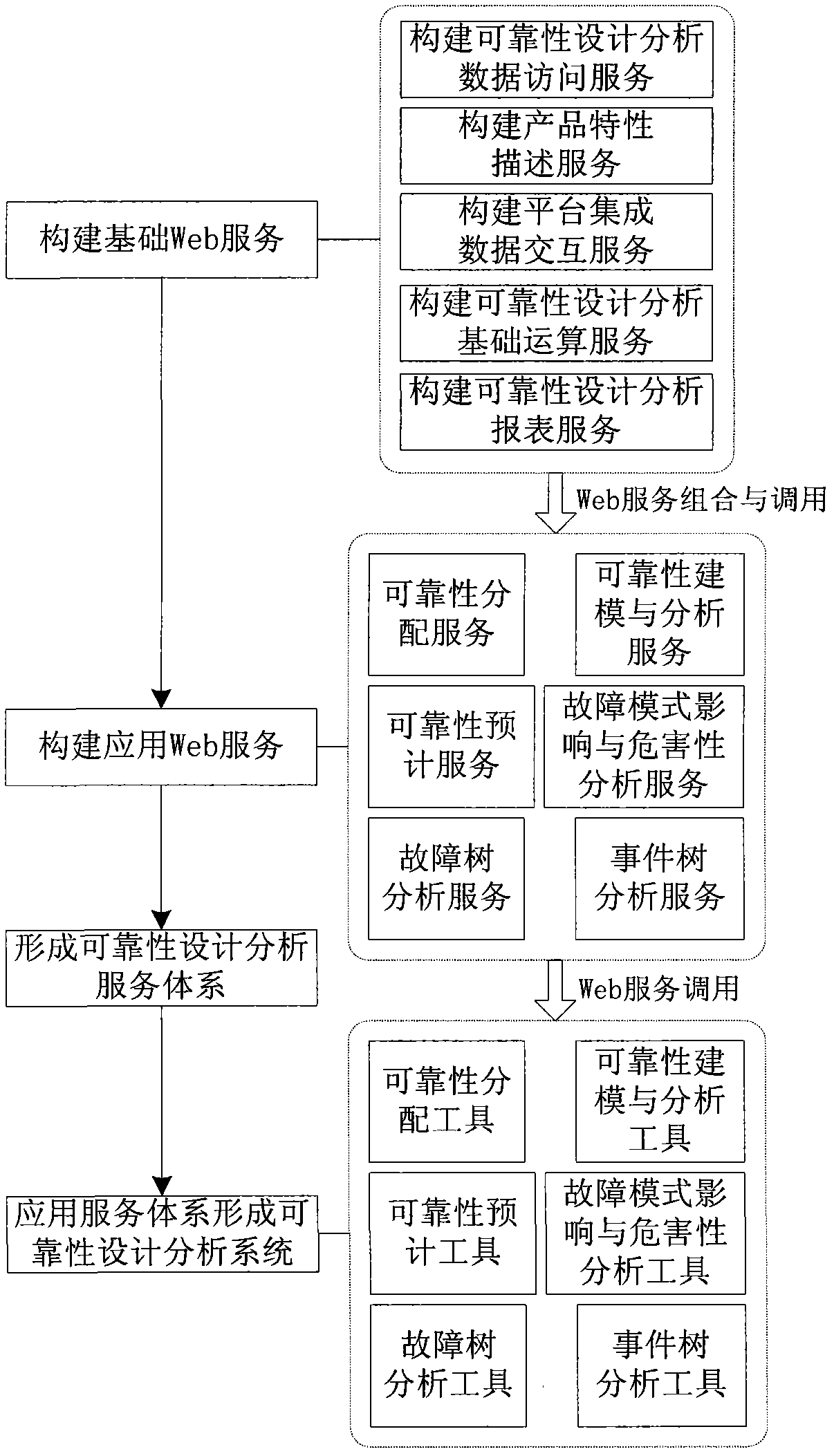

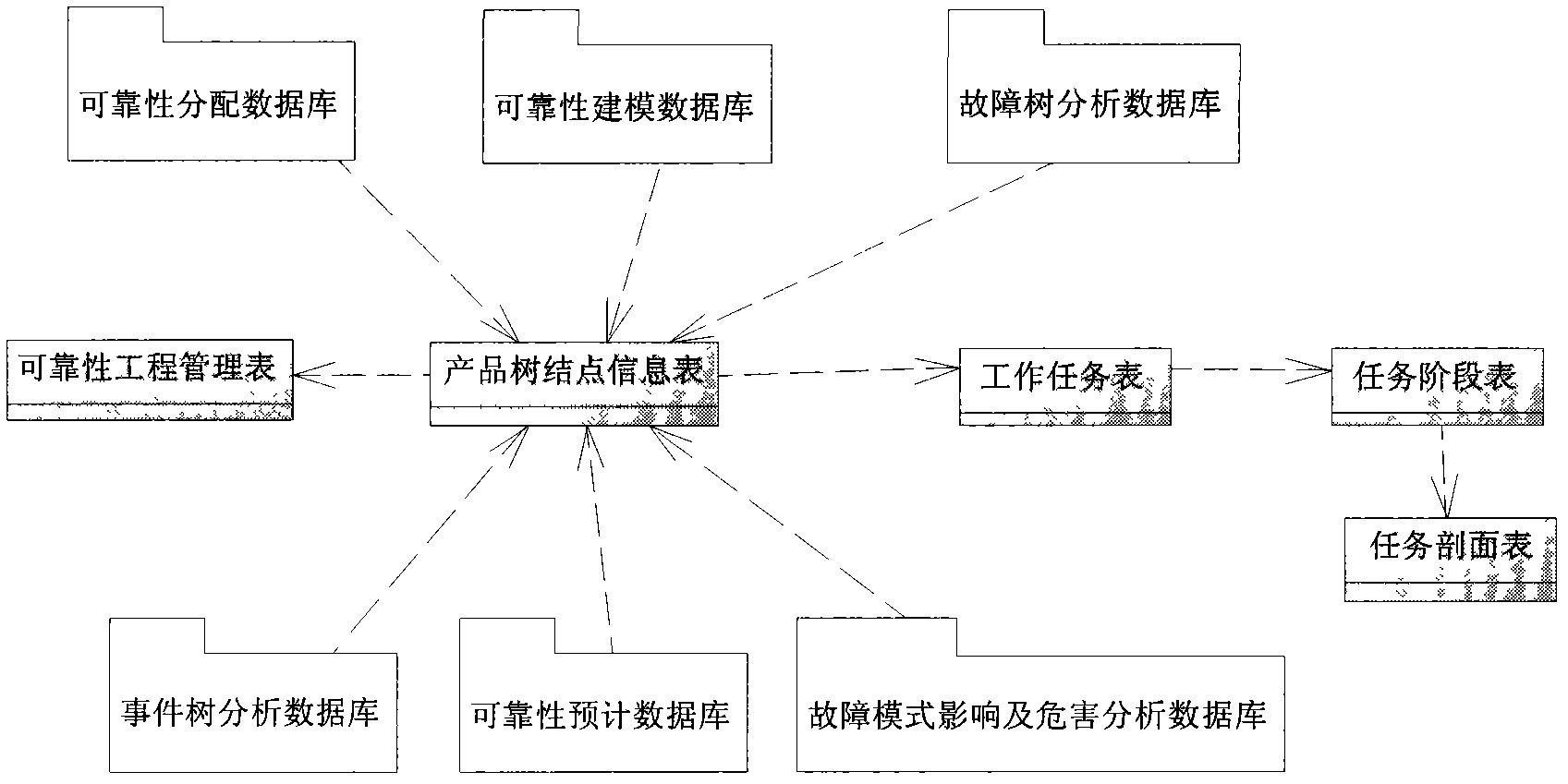

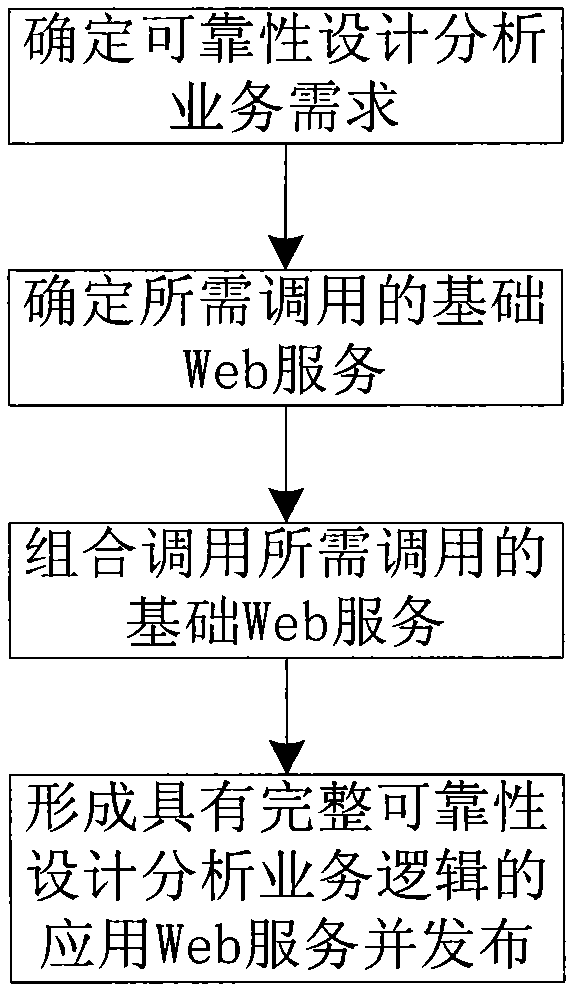

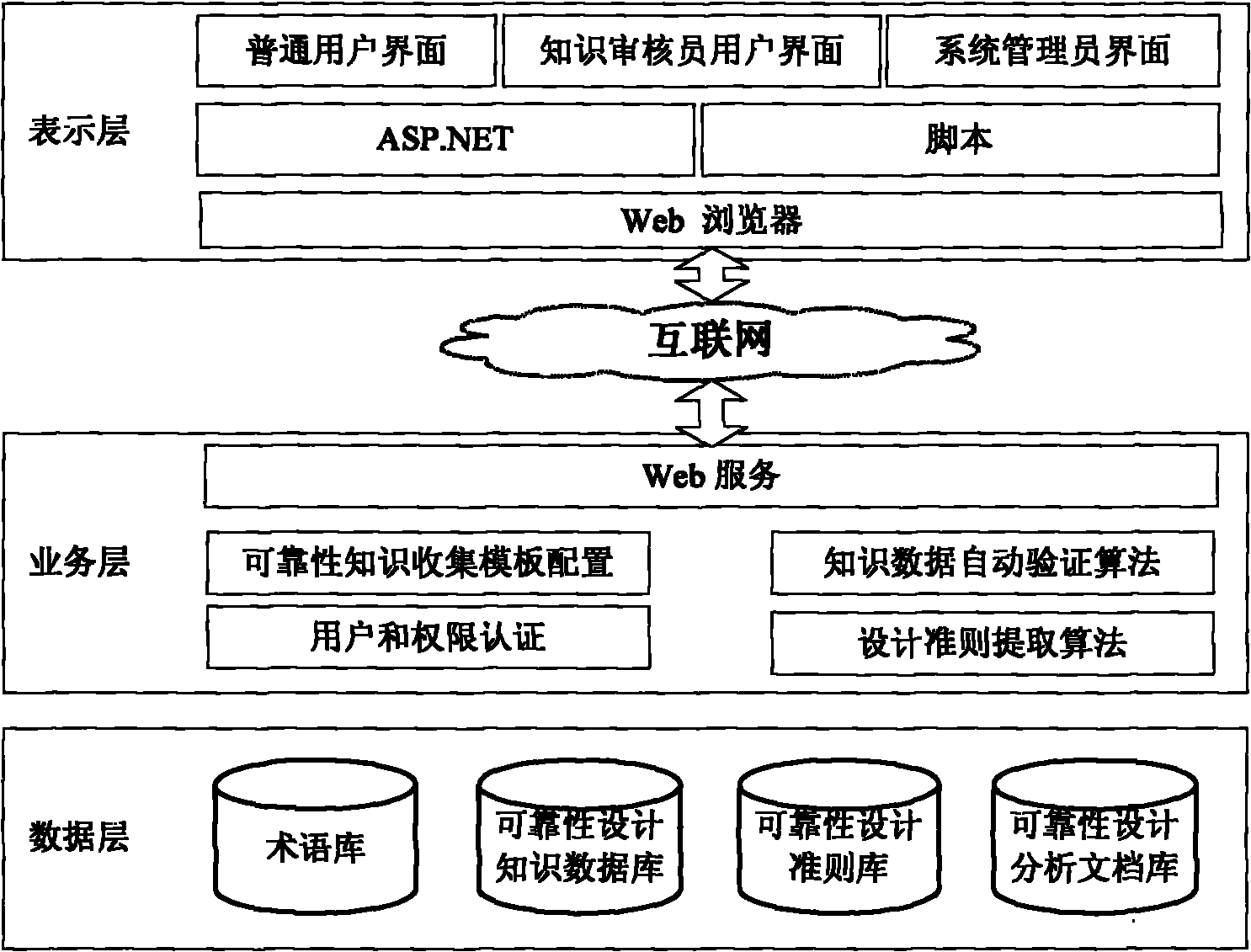

Constructing method of reliability design analysis service system of service oriented architecture

ActiveCN102024204AImprove efficiencyGood effectData processing applicationsSpecial data processing applicationsData accessComputer access

The invention relates to a constructing method of a reliability design analysis service system of a service oriented architecture, which comprises the following steps: 1) constructing basic Web services comprising basic business logic services of product characteristic description, data access, basic algorithm, report generation and platform integrated data interaction; 2) constructing an application Web service which is formed by combining the basic Web services and has complete reliability design analysis business logic; and 3) forming a reliability design analysis service system, and realizing a complete reliability design analysis software tool by combining a client showing technology. The Web services provided by the invention can be developed by any program language supporting Web service development. The Web services can be deployed on any server in an enterprise wide area network and can be accessed by any computer in the network, so as to realize cross-regional synergistic reliability design analysis, wherein the algorithm service having higher requirements for operation can be deployed on an operation server, so as to realize distributed computation; and the Web services can be integrated with other design platforms by the platform integrated data interaction service, thus realizing integration of performance and reliability design.

Owner:北京可维创业科技有限公司

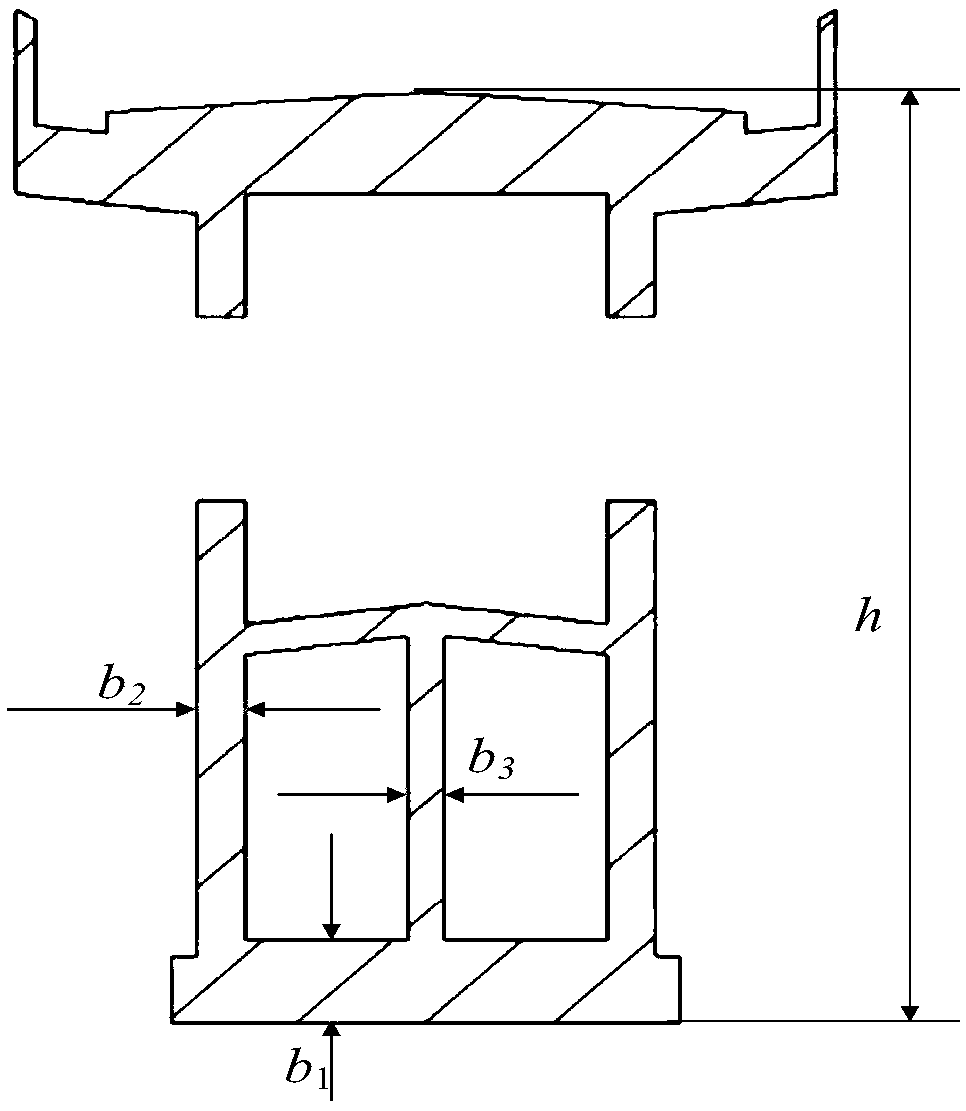

Reliability design method for upper crossbeam of high-speed pressure machine

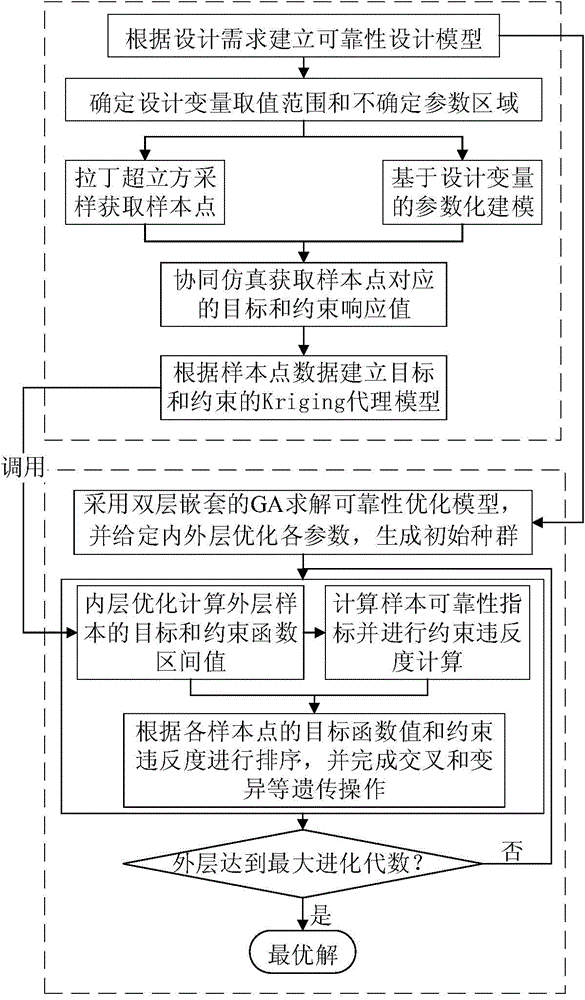

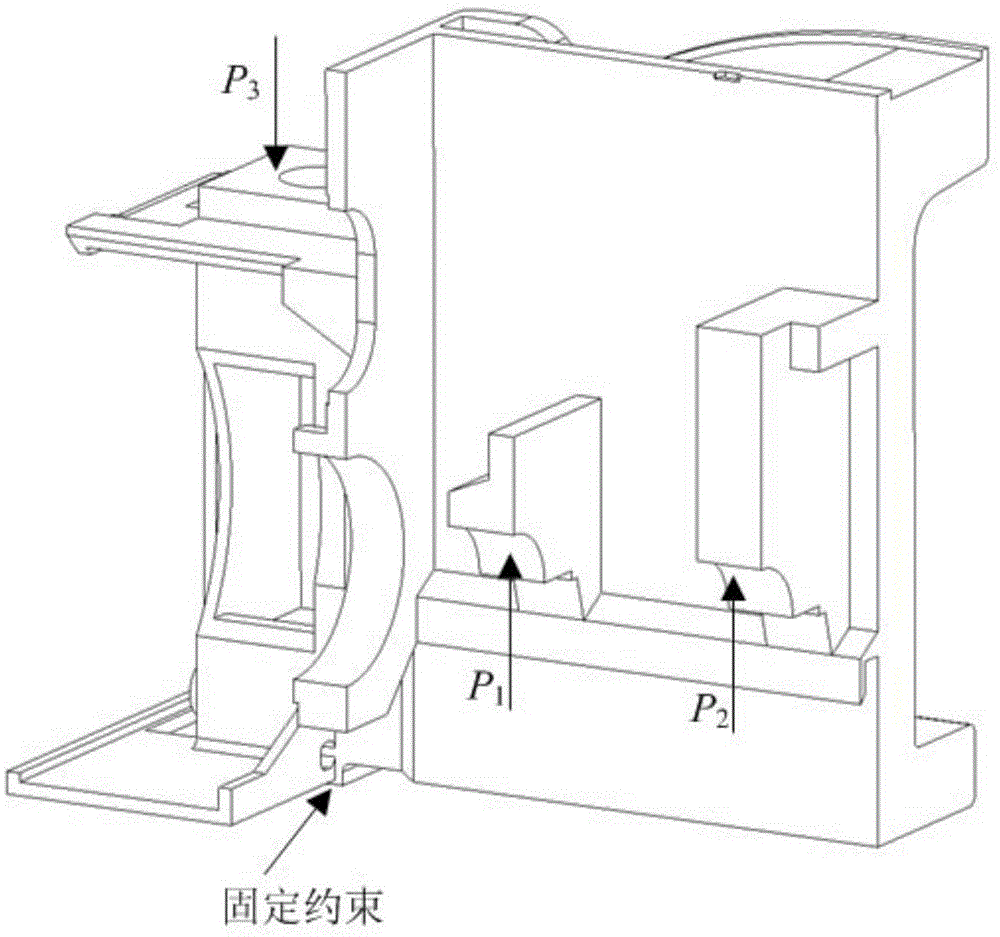

ActiveCN104636563AEasy to set upImplement two-way transmissionSpecial data processing applicationsGenetic algorithmCo-simulation

The invention discloses a reliability design method for an upper crossbeam of a high-speed pressure machine. The method includes the steps: selecting design variables according to reliability requirements in practical upper crossbeam design to establish a reliability design model for the upper crossbeam of the high-speed pressure machine, wherein uncertainty factors are described by intervals; in an experimental design, acquiring sample points required for Kriging fitting by means of LHS (Latin hypercube sampling), acquiring an objective function and a constraint function corresponding to each sample point by means of collaborative simulation to construct a Kriging model; calculating reliability constraint values in the reliability design model on the basis of uniform interval dominance degrees; adopting a double-layer nested genetic algorithm based on interval constraint violation degrees to search an optimal design scheme meeting the reliability requirements. According to the practical reliability requirements of the upper crossbeam of the high-speed pressure machine, reliability index values are calculated according to uniform interval dominance degrees in the reliability design, and the design scheme, meeting the reliability requirements, of the upper crossbeam of the high-speed pressure machine can be acquired conveniently and quickly.

Owner:ZHEJIANG UNIV

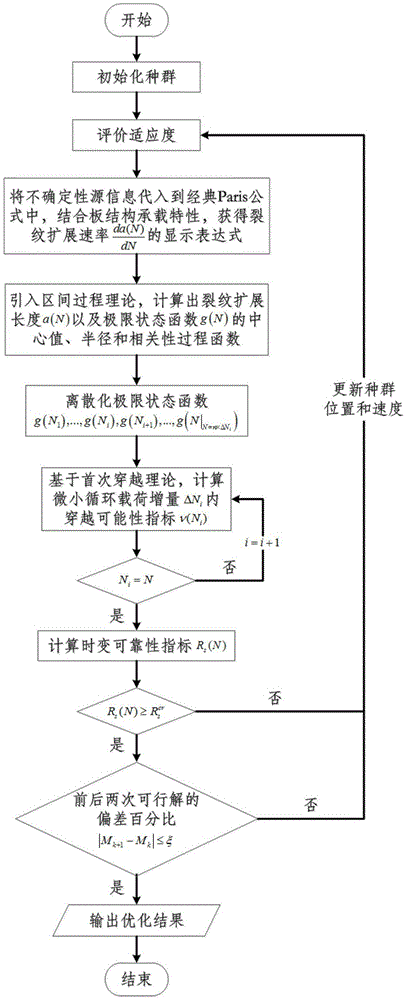

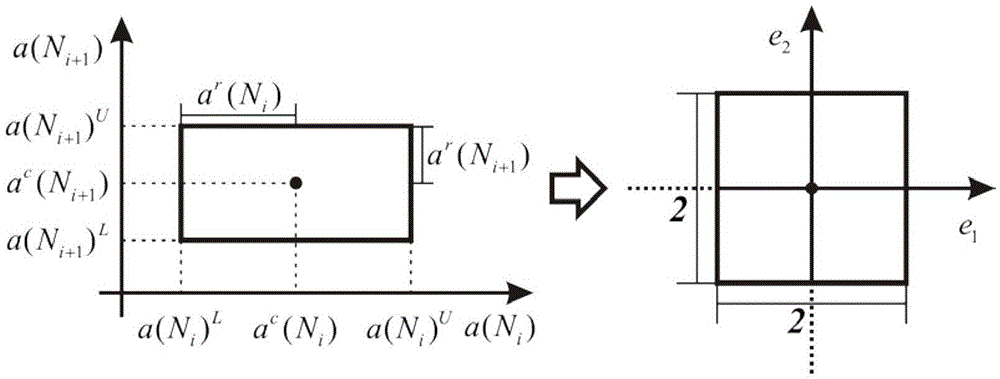

Time-variant reliability design method for rectangular plate structure with initial defects

ActiveCN105653794AMake up for and perfect limitationsReduce dependenceSpecial data processing applicationsReliability designOptimal design

The invention discloses a time-variant reliability design method for a rectangular plate structure with initial defects. The method comprises the steps of firstly, according to stress characteristics of the defected plate structure, considering indeterministic effects of parameters such as a load, material characteristics, a design permissible value and the like under a finite sample condition, and establishing a non probability interval process model of crack expansion length of the rectangular plate structure; secondly, based on a classic Paris damage evolution formula and a first passage theory, constructing a time-variant reliability measurement model of the structure with the initial defects; and finally, by taking the reliability as a constraint condition, the weight reduction as an optimization target and the plate thickness as a design variable, performing repeated iterations to obtain an optimal design scheme of the structure within a set service time. According to the method, the comprehensive influence of indeterminacy on power safety of the structure with the initial defects within a set life cycle is reasonably characterized in an optimization design process, and the weight can be effectively reduced, thereby ensuring the safety and economy of the design.

Owner:BEIHANG UNIV

Reliability design method of high-speed press force-applying components considering multi-type uncertainties

ActiveCN109063234AIn line with engineering practiceGeometric CADDesign optimisation/simulationFuzzy uncertaintyGenetic algorithm

The invention discloses a reliability design method of a force applying component of a high-speed press considering multiple types of uncertainties. The method includes the following steps: considering the random, interval and fuzzy uncertainties of high-speed press force components, choosing the minimum reliability value under the influence of three uncertainties as reliability index, establishing the stochastic model of high-speed press force components, and establishing the stochastic model of high-speed press force components; interval-Fuzzy mixed reliability design model; according to theconservation principle of entropy and '3 sigma criterion', a simplified stochastic-interval reliability design model; adopting Latin hypercube sampling and cooperative simulation technology, the Kriging model of function and objective function is constructed. The simplified reliability design model is decoupled from the reliability analysis to form a two-loop optimization solution. The inner loopuses adaptive step-size iterative method for reliability analysis, and the minimum value of reliability index is obtained. The outer loop uses genetic algorithm to optimize the design vector, and judges the feasibility of the design vector according to the reliability analysis results. When the maximum evolutionary algebra or convergence threshold is reached, the optimal solution is output.

Owner:ZHEJIANG UNIV

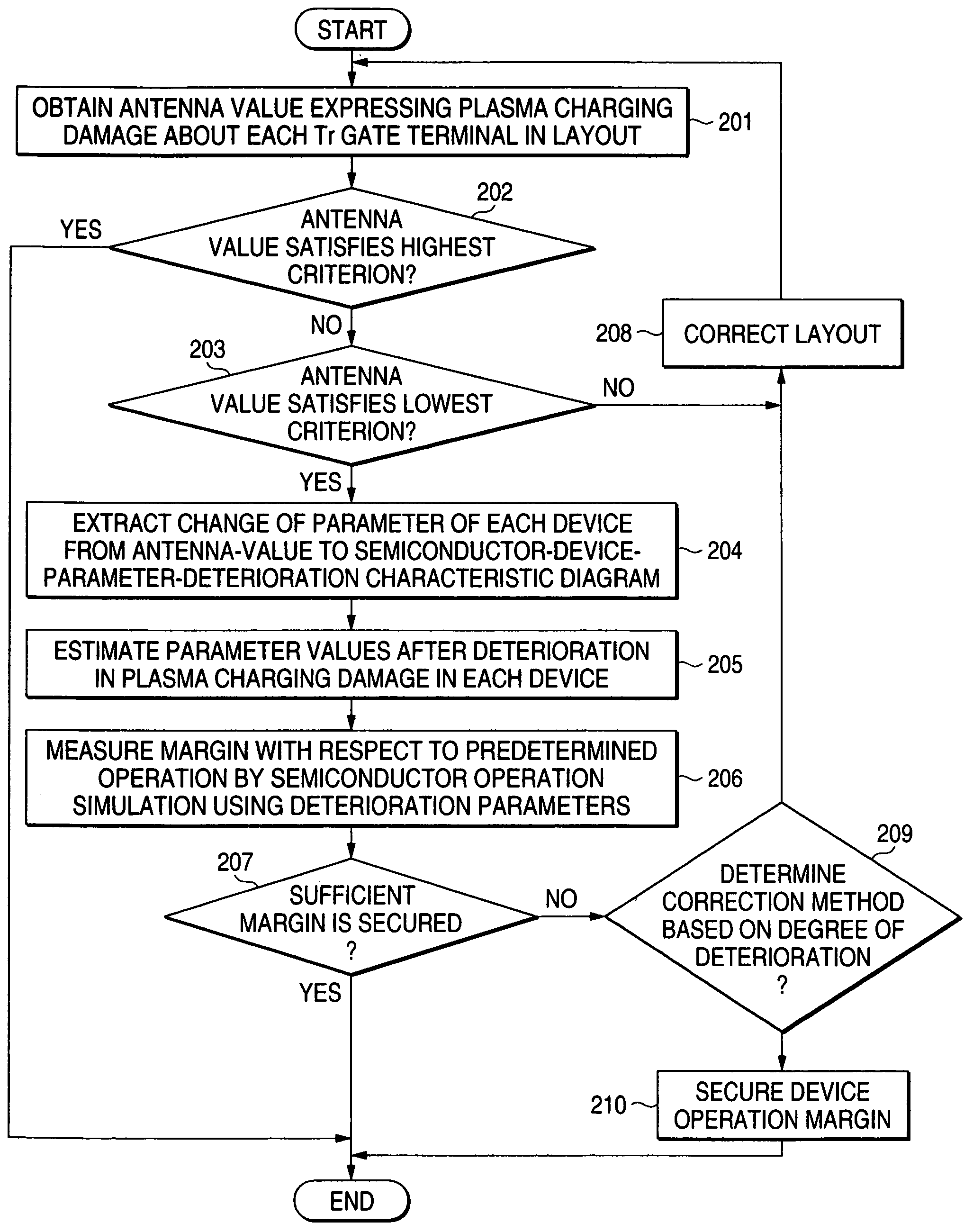

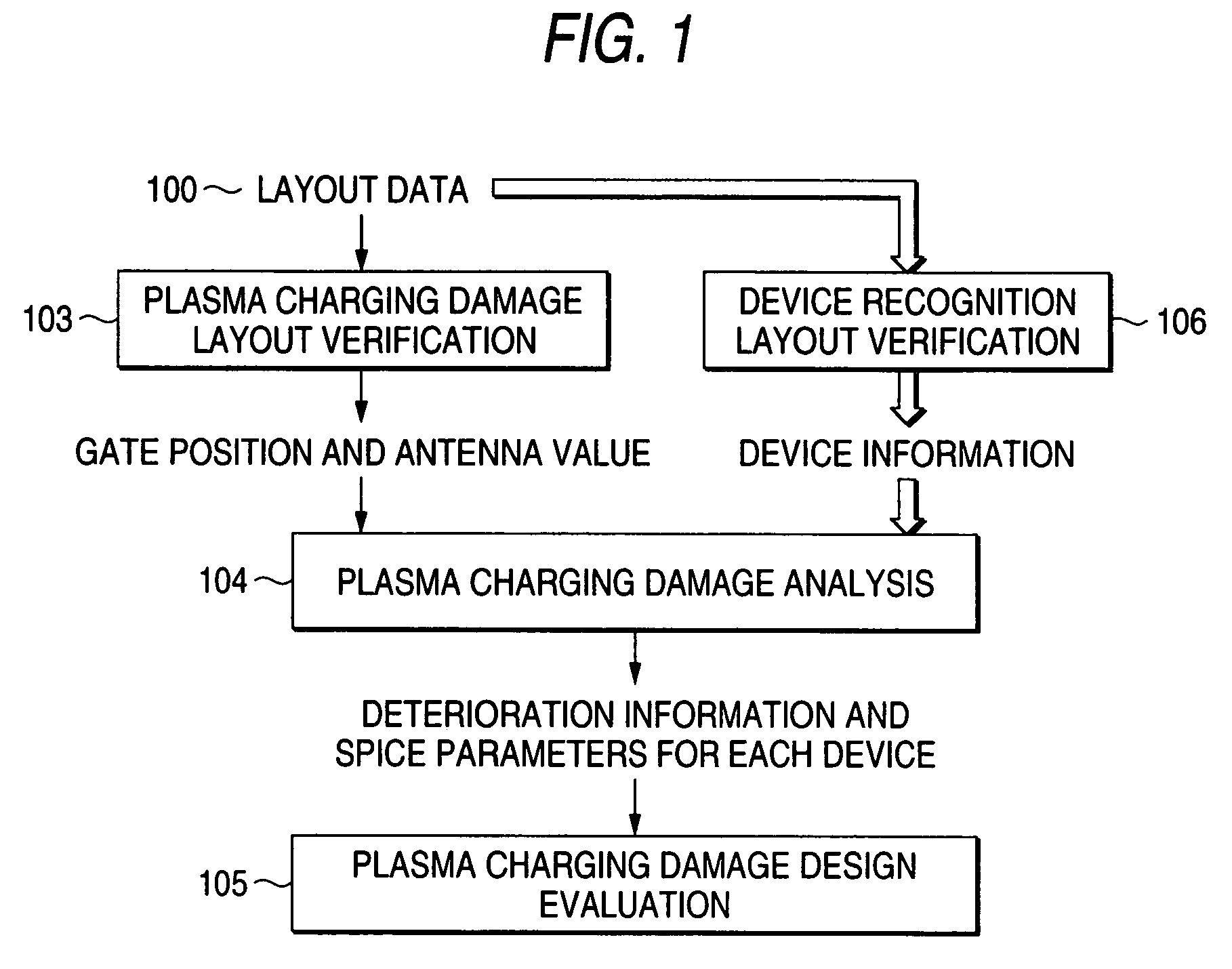

Layout verification method and method for designing semiconductor integrated circuit device using the same

InactiveUS7174527B2Accurately detecting damageHigher-reliabilitySemiconductor/solid-state device testing/measurementSolid-state devicesValidation methodsEngineering

To provide a layout verification method capable of accurately detecting damage to be given to a gate, and to provide a higher-workability and higher-reliability design method to accurately detect damage to be given to a gate and to determine an approach for design correction to avoid damage, the layout verification method according to the invention is characterized in that an antenna value which is an estimated value of transistor gate damage is output based on an antenna ratio, and a fluctuation of plasma charging damage due to the layout near the transistor gate.

Owner:SOCIONEXT INC

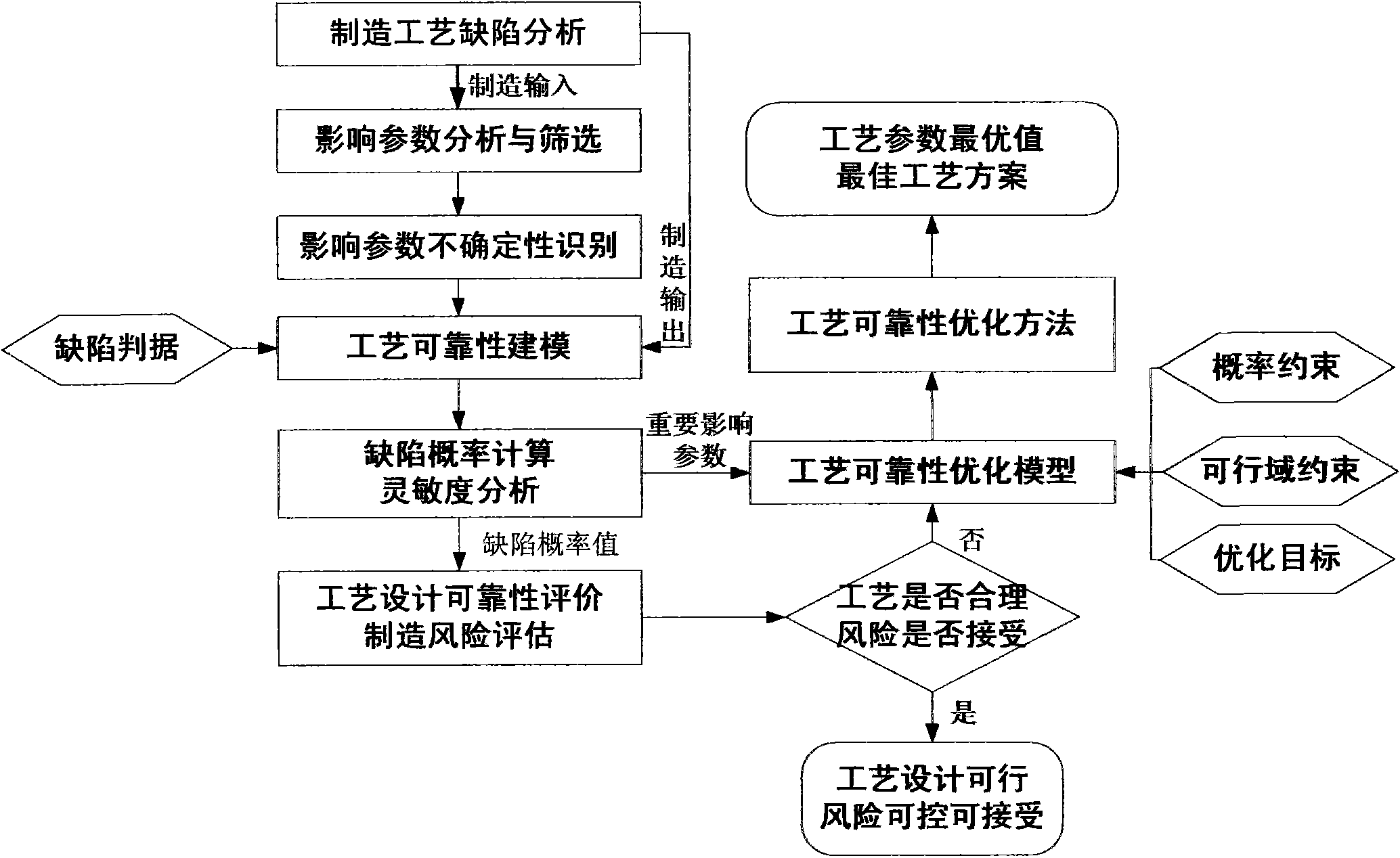

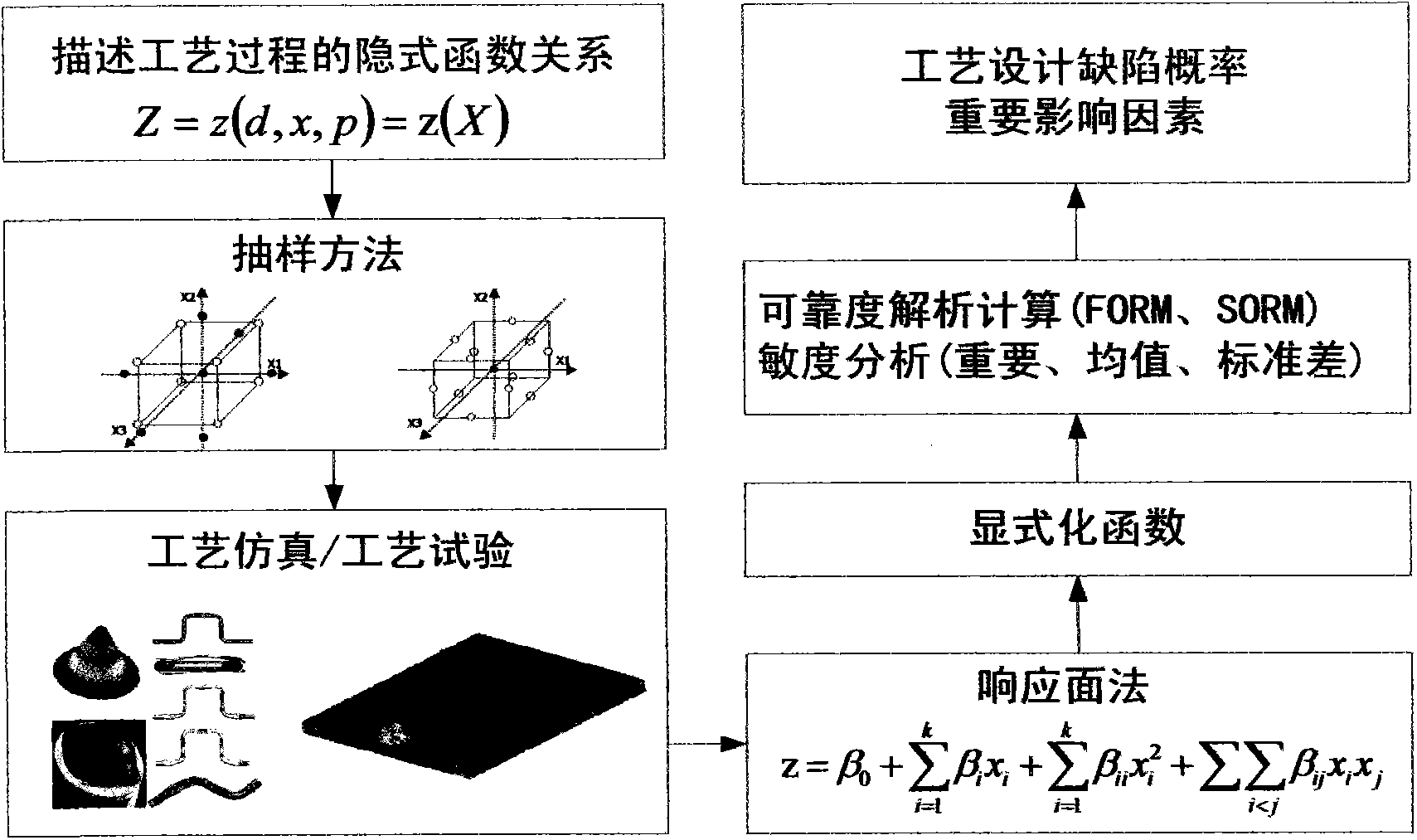

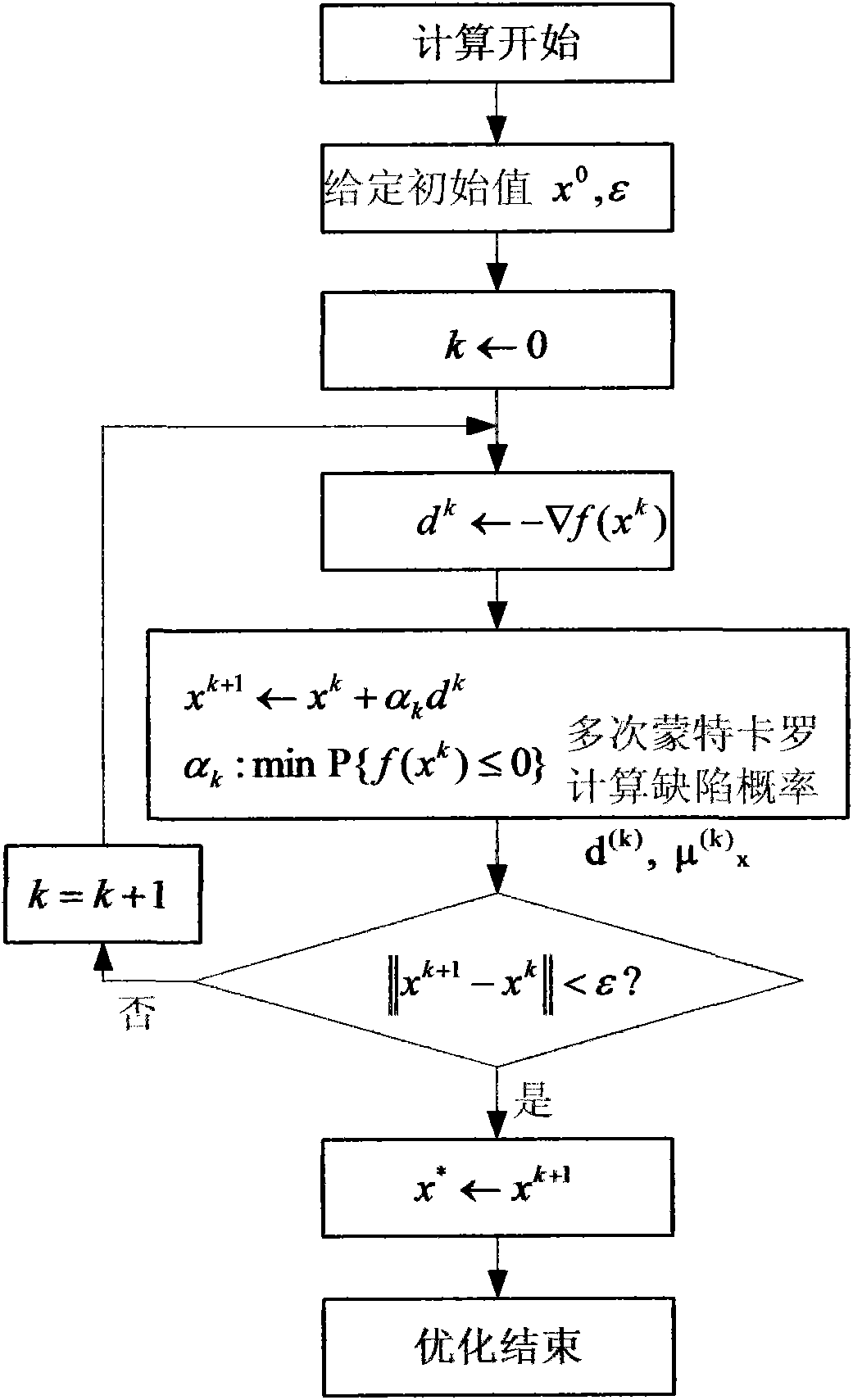

Method for process analysis and design optimization based on defect probability

InactiveCN103530467AIncreased process reliabilitySimple methodSpecial data processing applicationsProcess optimizationReliability design

The invention provides a quantitative method for conducting reliability analysis evaluation and reliability optimization in a process design stage. Through reliability analysis evaluation, advantages and disadvantages of different process schemes can be compared, the manufacturing risks are evaluated, and important parameters influencing a manufacturing result can be found out; more reliable parameter optimal values can be obtained through reliability design optimization. The method mainly comprises the 5 steps that manufacturing process defects are analyzed and the influencing parameters are screened; the indeterminacy of the manufacturing process is identified; process reliability analysis and manufacturing risk evaluation are conducted on the basis of an approximate model; process optimization modeling is conducted on the basis of the reliability; a solution to a process reliability optimization model is obtained.

Owner:中国兵器科学研究院

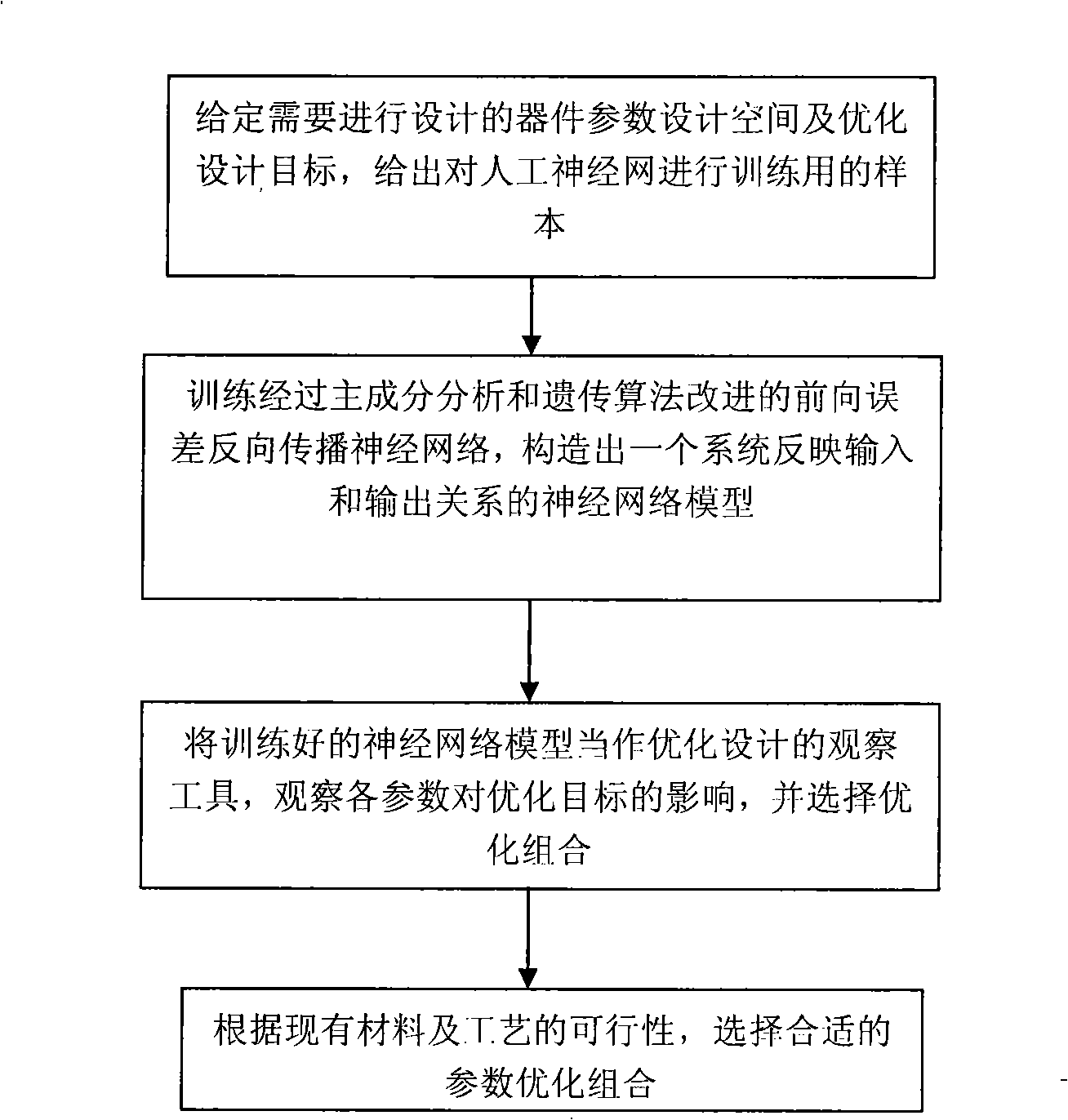

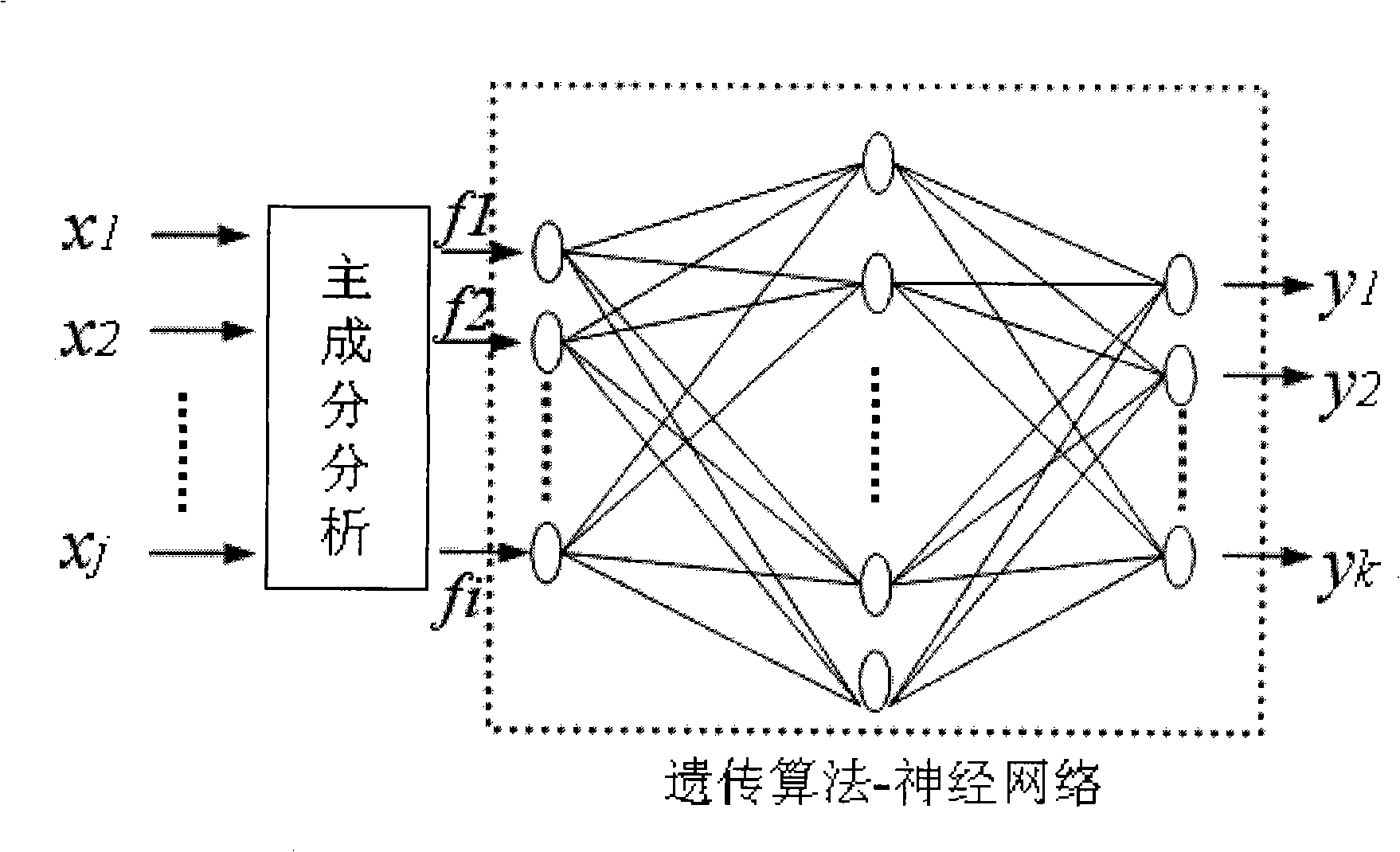

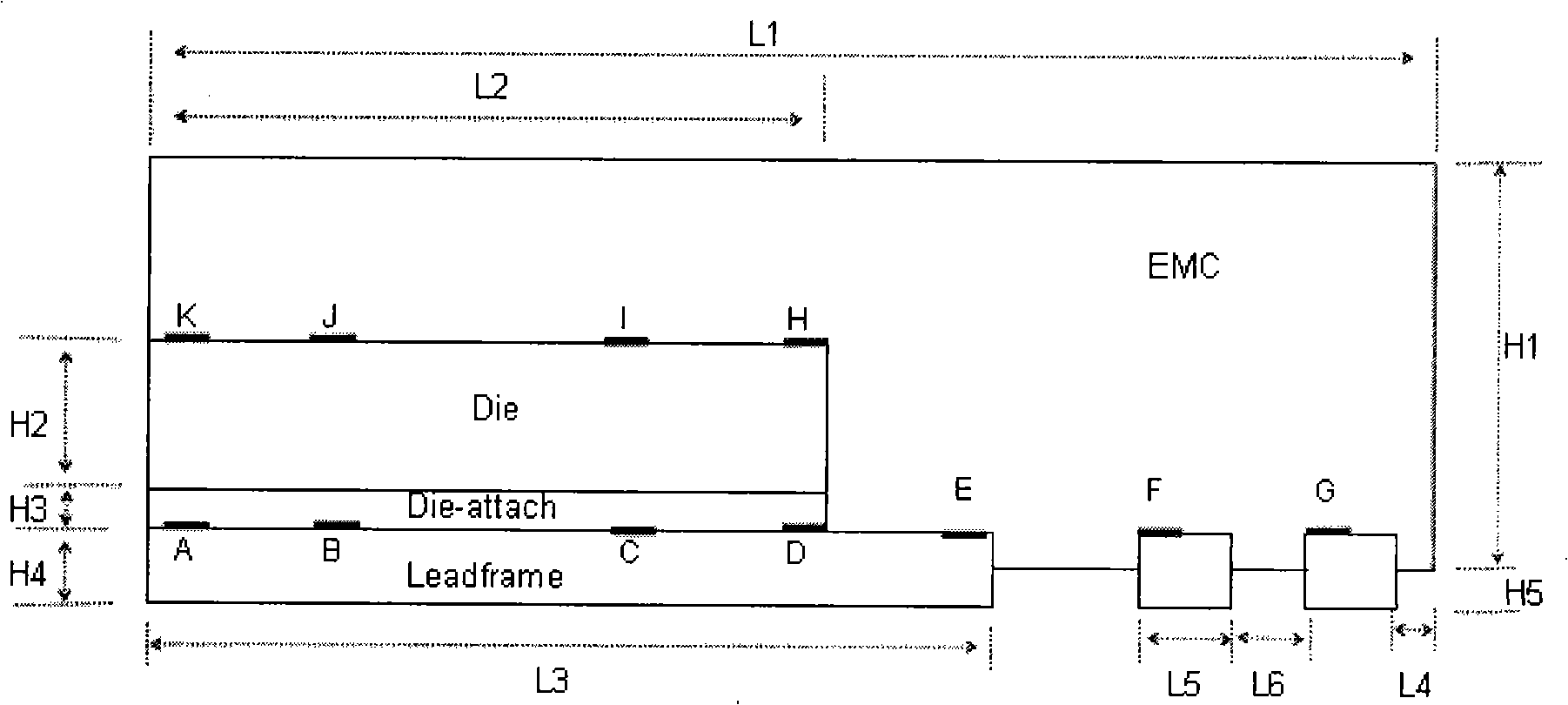

Optimization design method of micro-electron packaging device based on artificial neural network

InactiveCN101320400ASimplify the design processEasy programmingPhysical realisationSpecial data processing applicationsNerve networkAlgorithm

The present invention discloses an optimum design method of micro-electronic packaging device, based on an artificial neural network. The method comprises the following steps: (1) the user provides the parameter design space and the optimum design objective of the device to be designed, and the sample used for training the artificial neural network; (2) the training adopts a neural network of forward error and converse transmission, which is improved by main component analysis and genetic algorithm, and constructs a neural network model with a system reflecting the relation between the input and the output; (3) the trained neural network model is used as an observation tool of optimum design for observing the influence of the parameters on the optimum objective and selecting the optimum combination; (4) the proper optimum combination of the parameters is selected according to the feasibility of materials and technologies. The optimum design method solves the design problem of reliability of material collocation and size collocation, suits the optimum design of different types of packaging devices, and can be applied to the field of optimum design of various categories of multi-objective or multi-factor complex systems.

Owner:GUILIN UNIV OF ELECTRONIC TECH

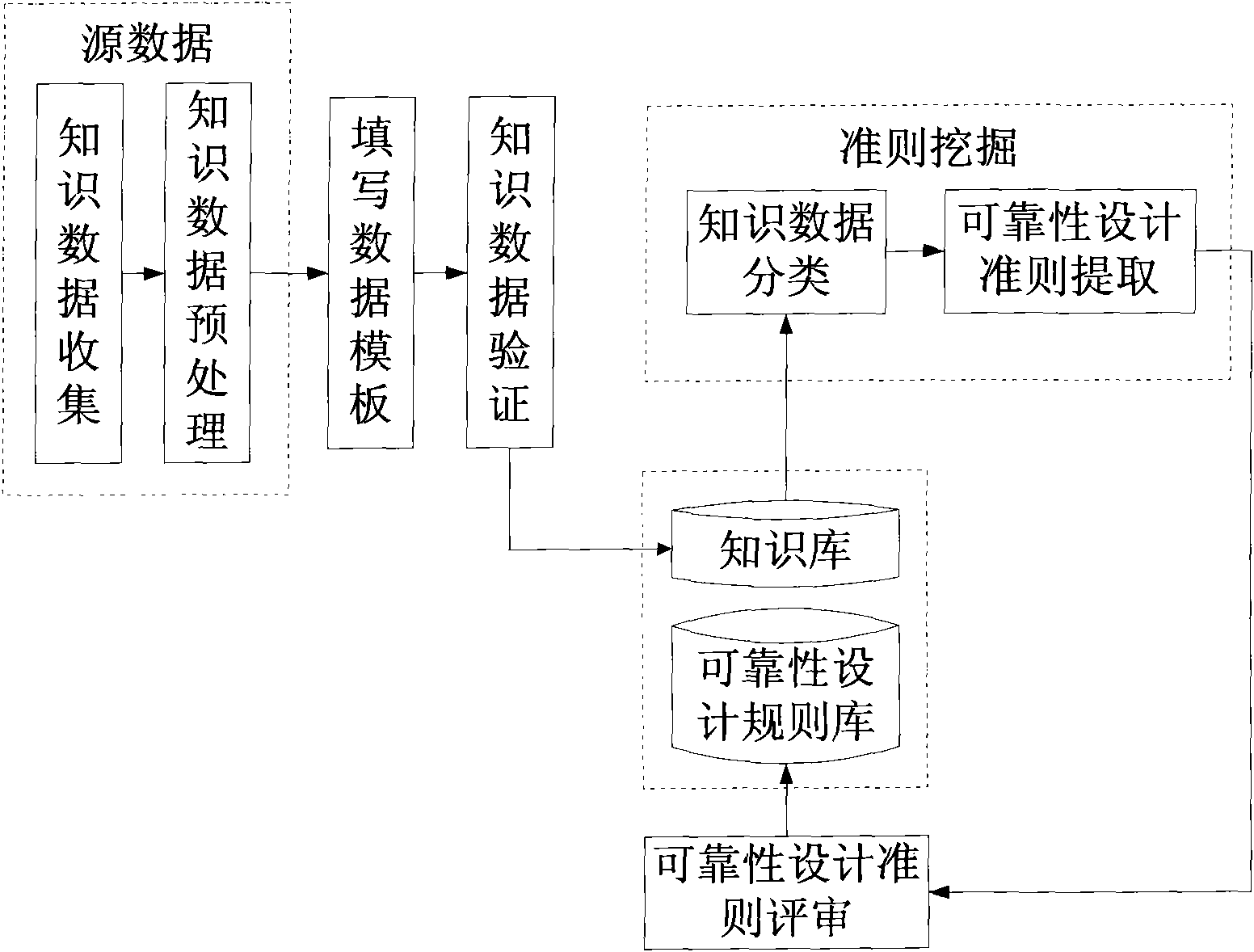

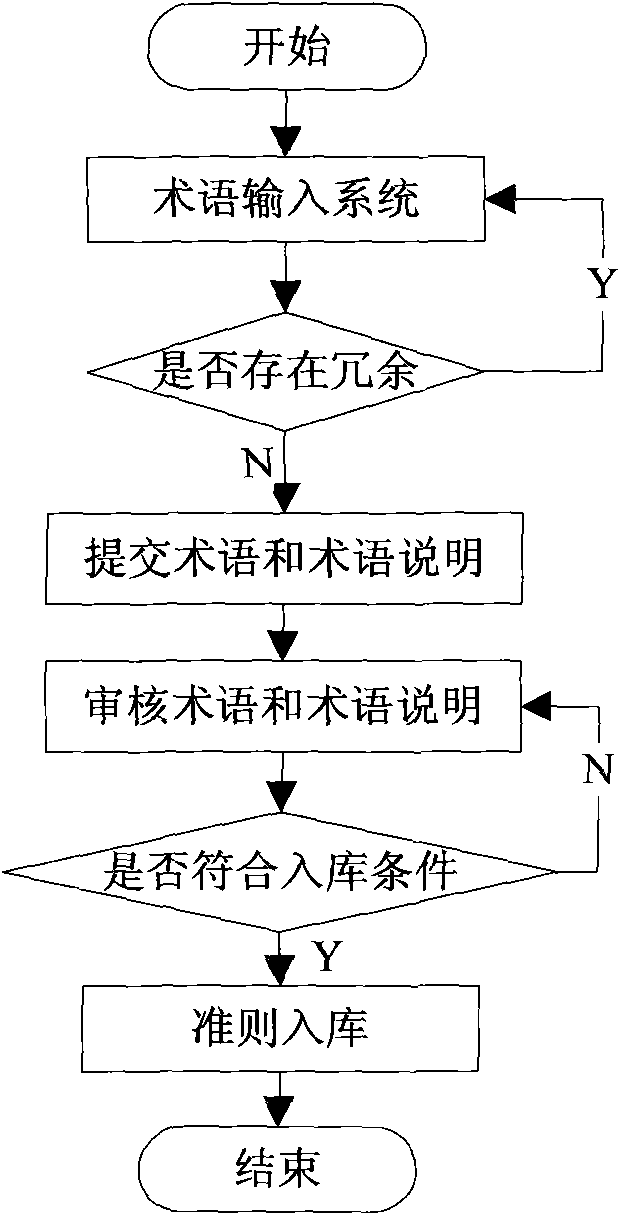

Knowledge acquisition template for product reliability design and criteria extracting method

InactiveCN102044018AAccurate collectionEasy accessSpecial data processing applicationsFeature vectorGuideline

The invention discloses a knowledge acquisition template for product reliability design and a criteria extracting method. The method comprises the following steps of: 1, determining reliability design knowledge data acquisition principles, and describing the reliability design knowledge acquisition principles by using a feature vector representation method; 2, pre-processing knowledge data by using the reliability design knowledge acquisition principles, and standardizing the identified identification features; 3, performing integrity verification and redundancy verification on the pre-processed reliability design knowledge data, and storing the audited data in a knowledge base; and 4, automatically extracting initial reliability design criteria from the reliability design by using a program, then judging the reliability design criteria by a manual judgment method, and storing the reliability design criteria passing the judgment in a criteria base.

Owner:BEIHANG UNIV

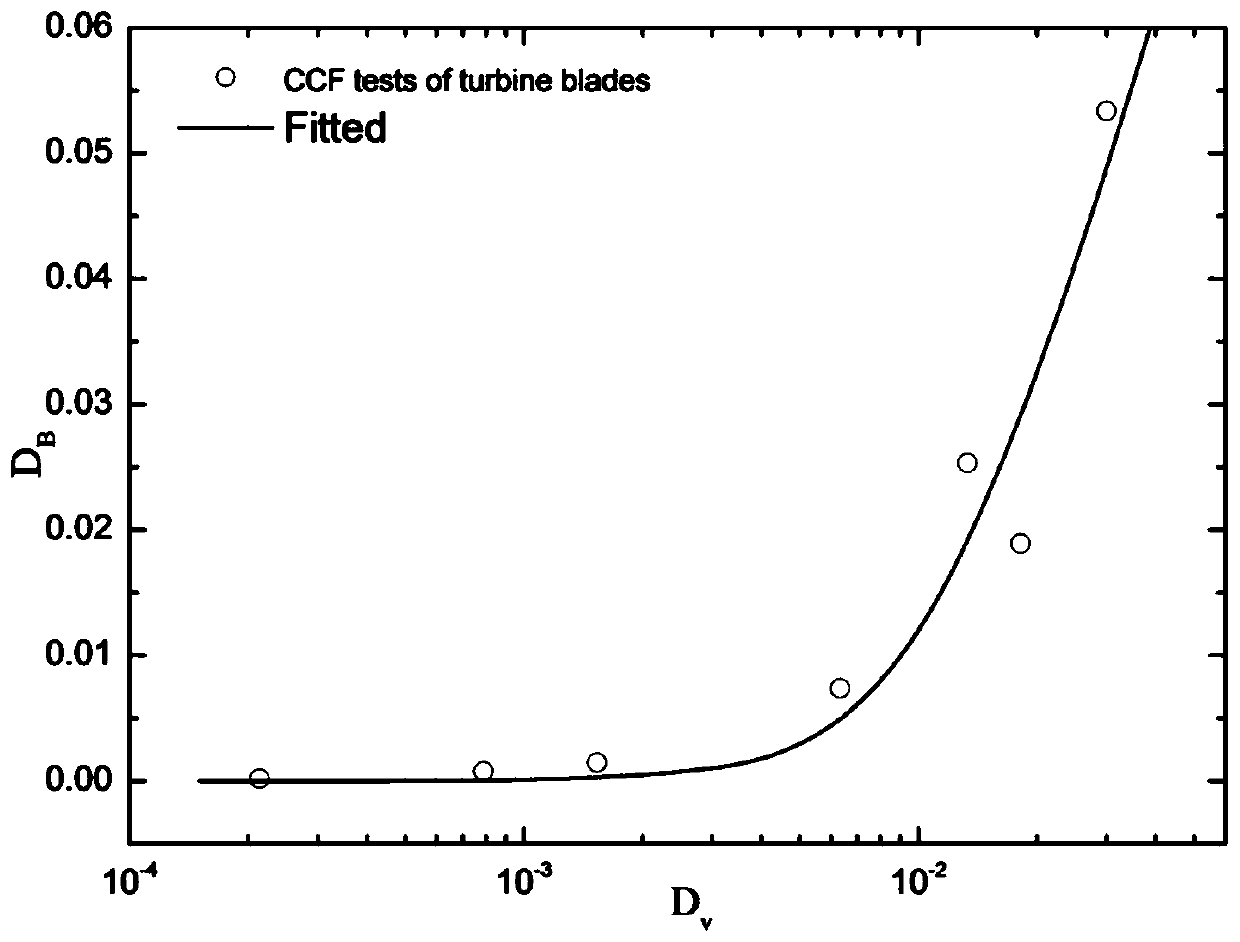

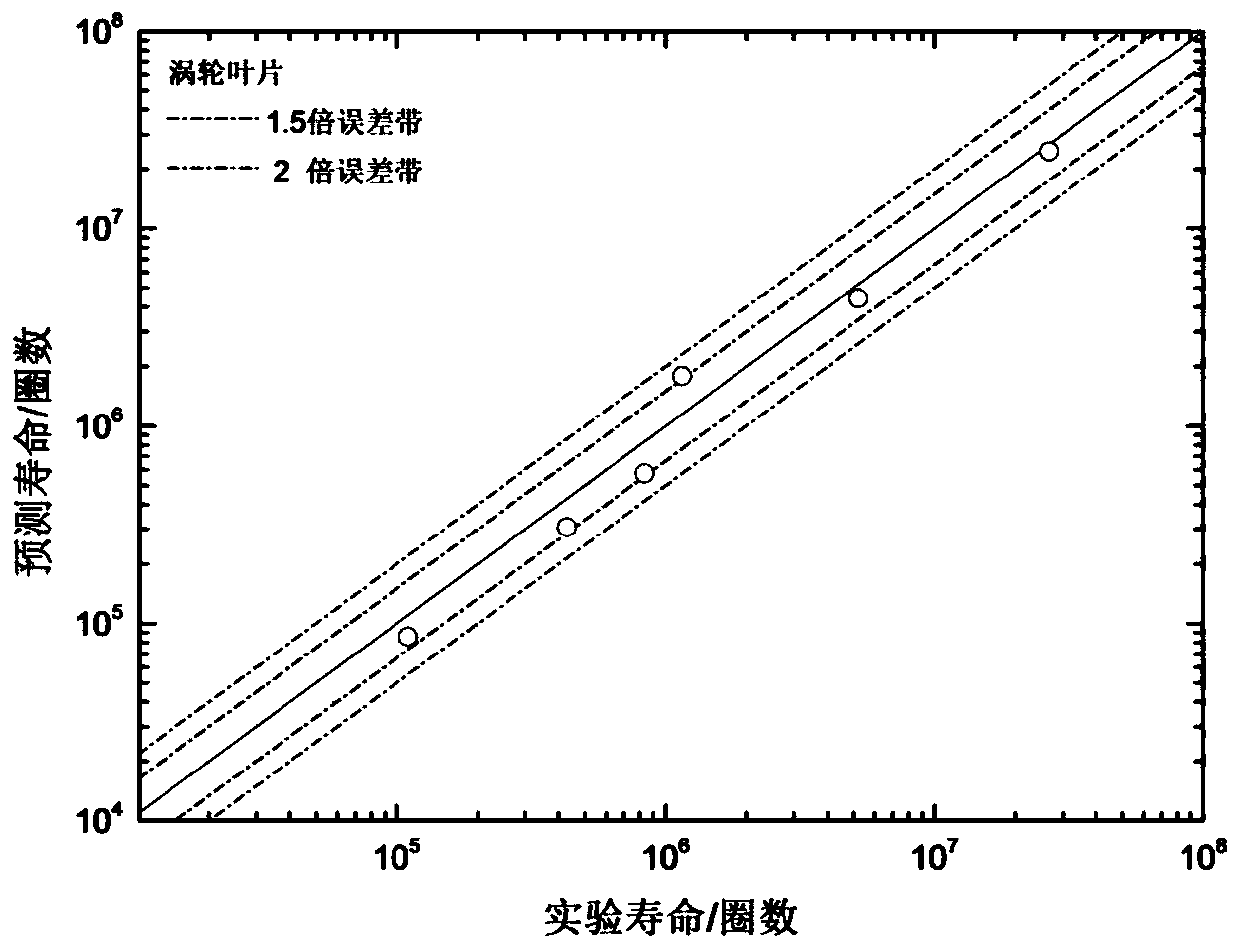

A high-low cycle composite fatigue life prediction method for an aero-engine turbine blade

ActiveCN109885920AFast characterization and prediction of fatigue lifeMachine part testingEngine testingFatigue damageAviation

The invention discloses a high-low cycle composite fatigue life prediction method of an aero-engine turbine blade, which comprises the following steps of correcting composite fatigue damage into highcycle fatigue damage, low cycle fatigue damage and coupling damage based on a linear cumulative damage model; defining high-cycle damage and coupling damage as variable damage based on service load characteristics of the aero-engine; determining variable damage as a function of high-cycle fatigue life and four characteristic parameters according to the high-cycle and low-cycle composite test loadspectrum, obtaining an expression of the variable damage, introducing an equivalent force amplitude ratio, establishing a high-cycle and low-cycle composite fatigue life prediction model, and predicting the composite fatigue life of the high-cycle and low-cycle composite fatigue life prediction model. According to the method, the fatigue life of the turbine blade under the composite loading condition can be rapidly measured by the aero-engine, and the theoretical reference is provided for reliability design and evaluation of metal materials and the turbine blade.

Owner:XIDIAN UNIV

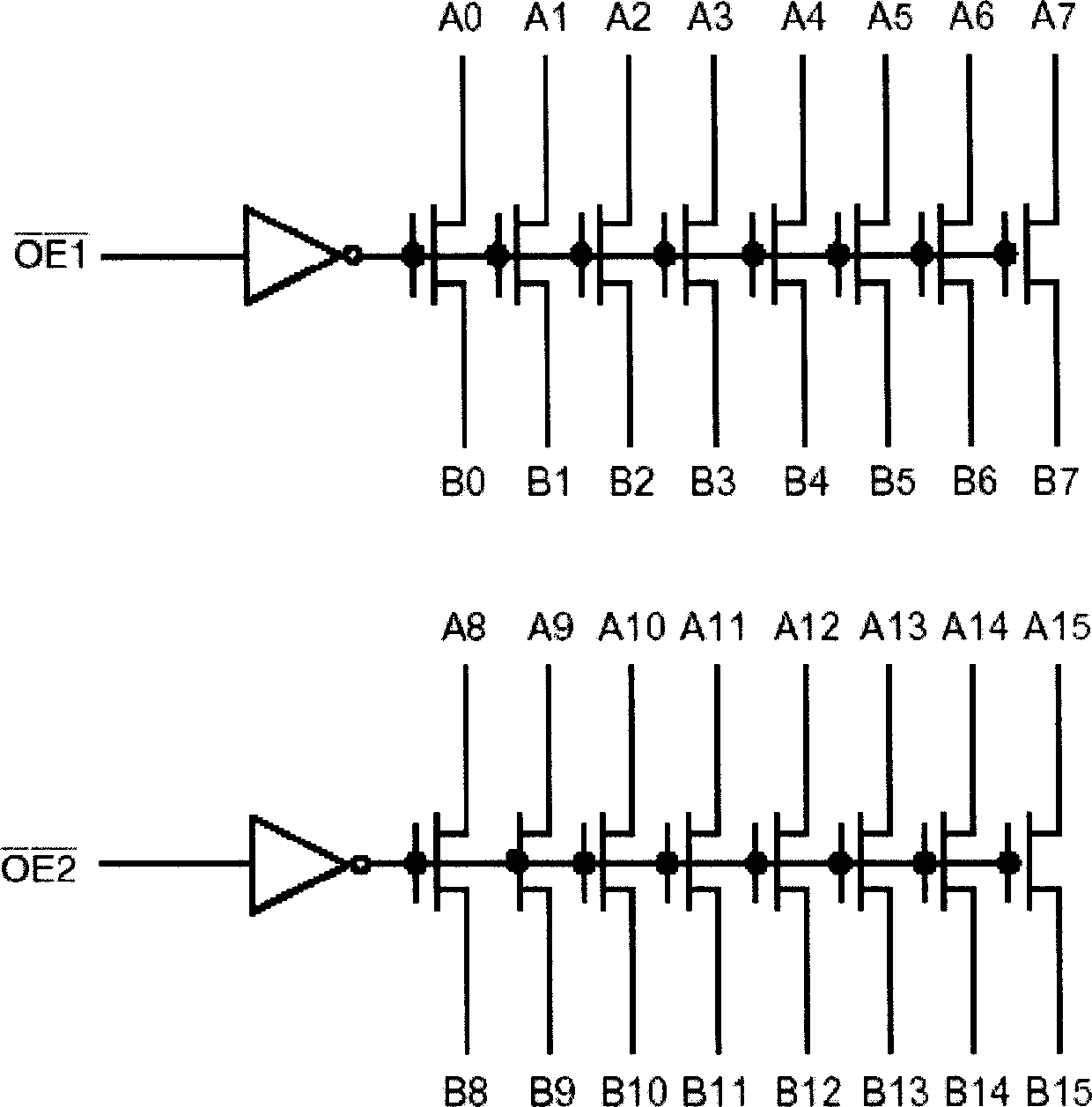

Spaceborne-software reliability design system and method based on software redundancy

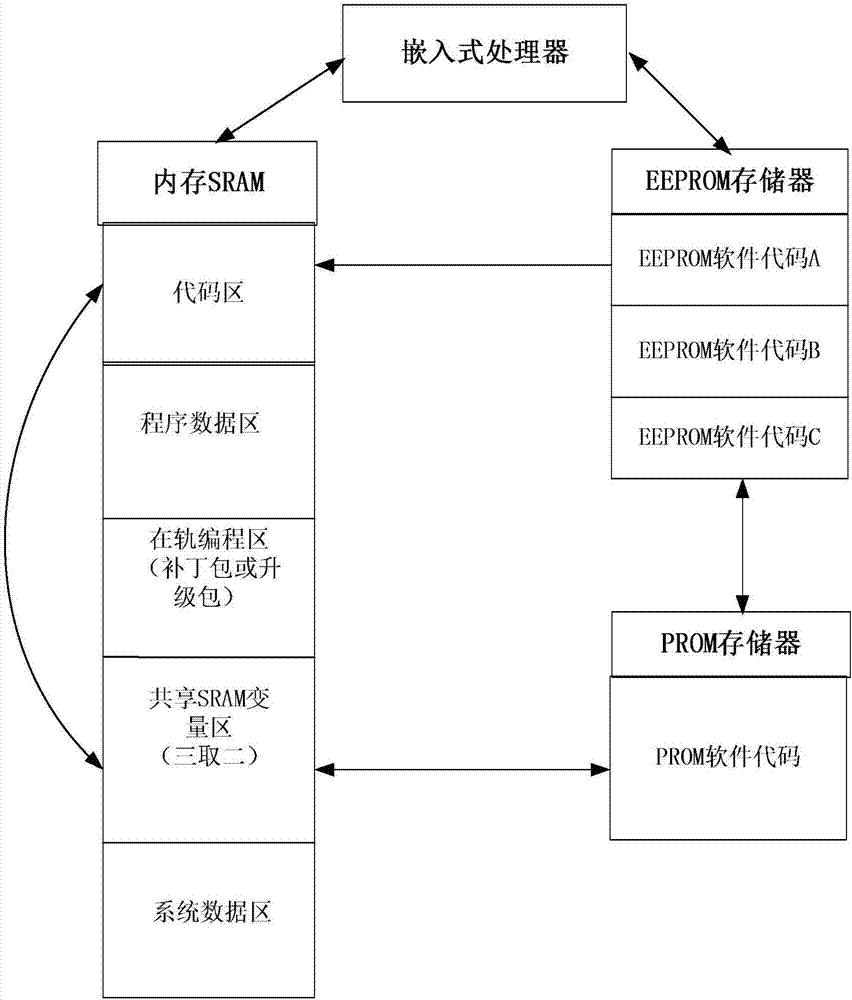

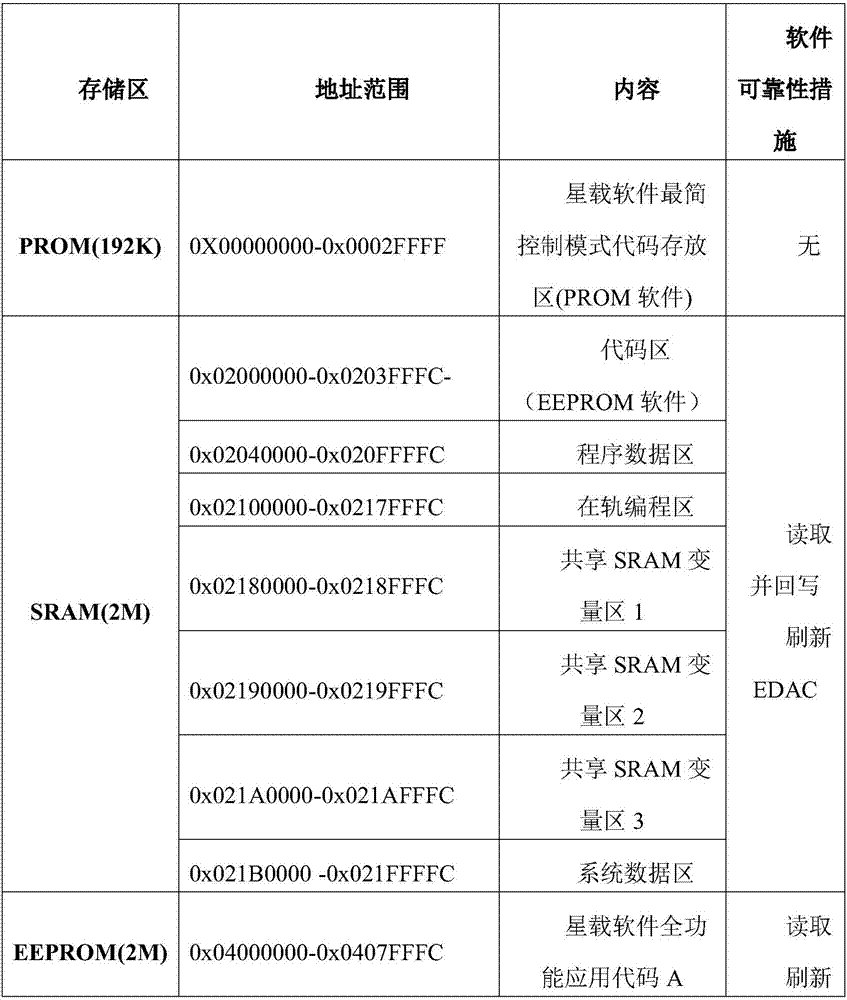

InactiveCN107515800AImprove reliabilityMeeting on-orbit maintainability needsRedundant operation error correctionProcessing InstructionMaintainability

The invention discloses a spaceborne-software reliability design system and method based on software redundancy. The spaceborne-software reliability design system based on the software redundancy includes an embedded processor, an EEPROM, a PROM and an SRAM. The EEPROM is used for storing full-function application code of spaceborne software. The PROM is used for storing a simplest-control-mode application code of the spaceborne software. The embedded processor is used as a hardware core, and for accessing and processing instructions or data in the various memories. The SRAM is used for statically and randomly accessing data in the embedded processor. According to the spaceborne-software reliability design system and method based on the software redundancy of the invention, breakdown of spaceborne-computer functions is avoided, reliability of the software is improved, and an on-orbit maintainability requirement of the software is satisfied at the same time. The system and method adapt to a development trend that satellite application functions can be upgraded on orbit.

Owner:SHANGHAI SATELLITE ENG INST

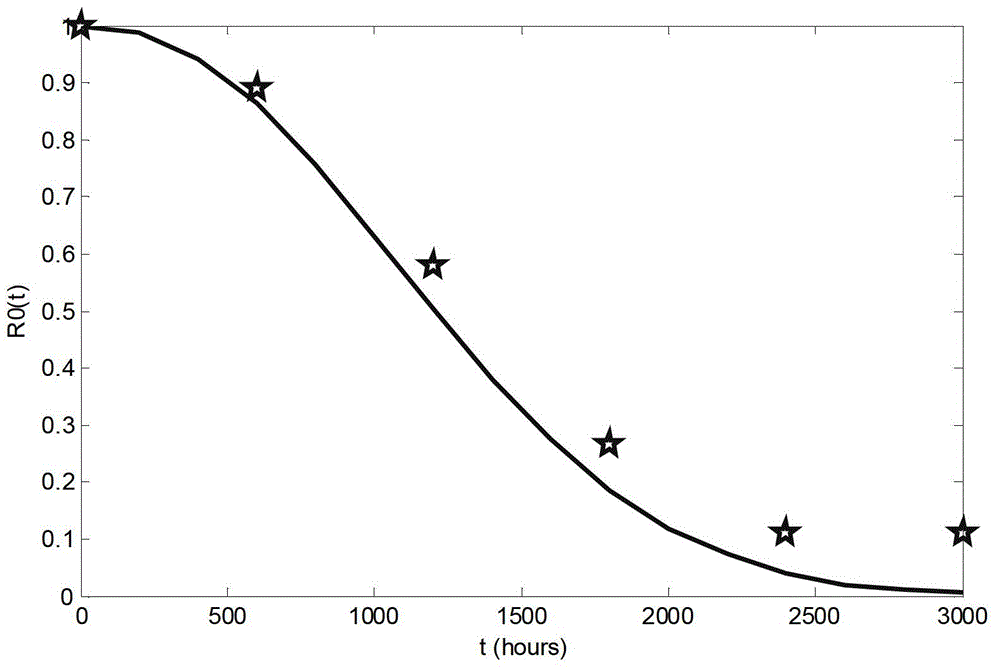

Dynamic reliability model updating method based on Bayes factor optimization

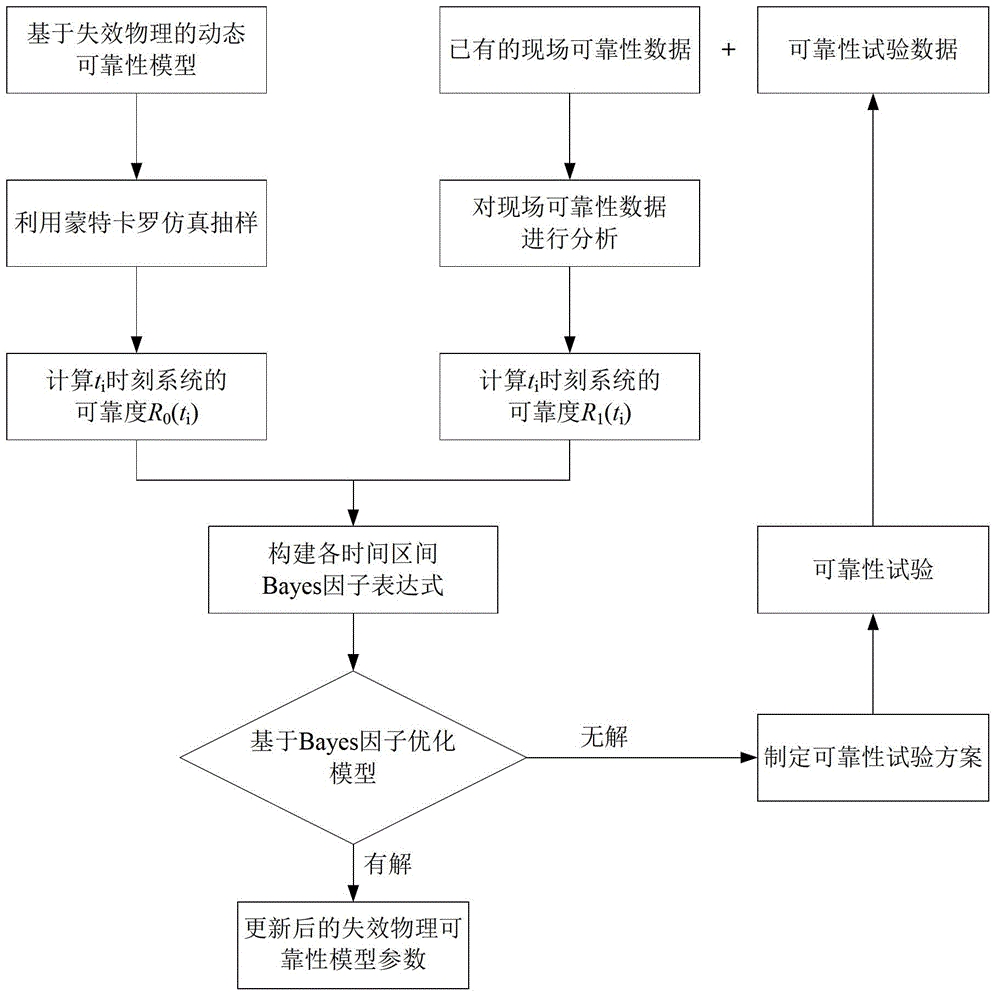

InactiveCN102982208AShorten the development cycleReduce maintenance costsSpecial data processing applicationsSmall sampleReliability design

The invention relates to a dynamic reliability model updating method based on Bayes factor optimization. The dynamic reliability model updating method comprises the following steps that 1, the failure physics of a product is analyzed, a failure physics reliability model of the product is built, and reliability degree R0 (ti) at some given time points is estimated; 2, the relevant reliability information of the product is collected in sites, the reliability information is subjected to statistics and physical property analysis, a statistics reliability model is built, and reliability degree at some given time points is estimated; and 3, the failure physics reliability model is used as a selection model, in-site reliability data and reliability test data are combined, and a Bayes factor expression at different time intervals is built. The dynamic reliability model updating method has the beneficial effects that the dynamic reliability model updating at small samples is realized, and meanwhile, higher practical values and higher engineering significance are realized on the reliability design optimization of new generation products of new technology and new materials.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com