Method for process analysis and design optimization based on defect probability

A defect probability and optimized design technology, applied in calculation, special data processing applications, instruments, etc., can solve problems such as the difficulty in establishing the quantitative relationship between process parameters and product reliability, and the inconsistency of the concept and connotation of process reliability. Strong practical value, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

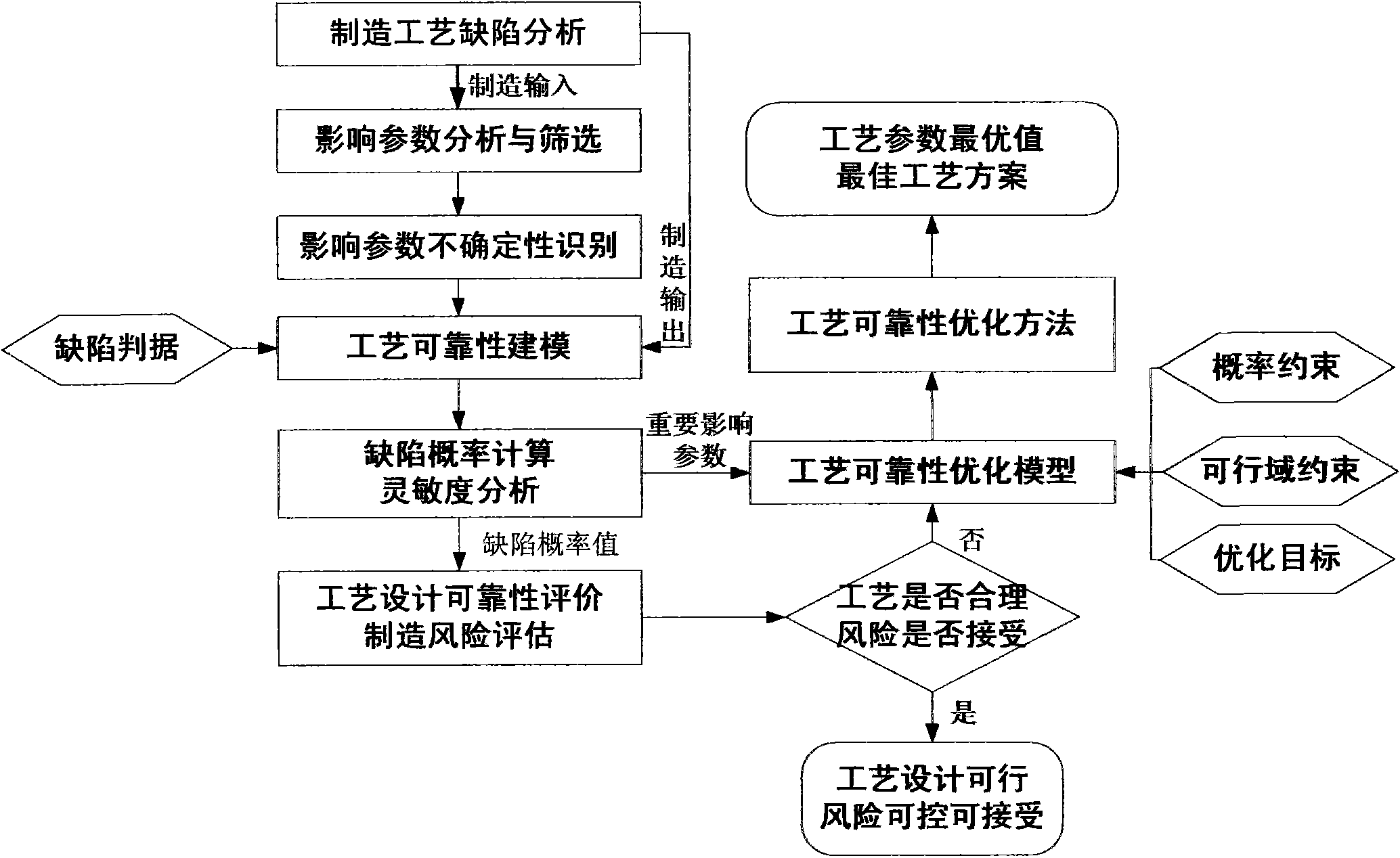

[0016] The flow chart of the present invention is as figure 1 shown, including the following steps:

[0017] 1 Manufacturing process defect analysis and influencing parameter screening.

[0018] According to the characteristics of a certain manufacturing process and its process defects, identify the characterization parameters of process defects, consider the influencing parameters of the manufacturing process from the three aspects of blank size, blank material, and process parameters as much as possible, and use the factor screening method to conduct a preliminary screening of these influencing parameters , the important parameters that affect the formation of defects obtained after the primary screening are used as the input of the second and third steps.

[0019] (1) Identification of process defect characterization parameters. Defining process design defects in a broad sense can include three situations: the product design requirements are not met, the expected technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com