Preparation method of amorphous iron phosphate

An iron phosphate and amorphous technology, applied in the field of preparation of amorphous iron phosphate, can solve the problems of poor electrochemical performance of lithium iron phosphate, poor batch stability and high cost, and achieve improved process reliability and product stability. , the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

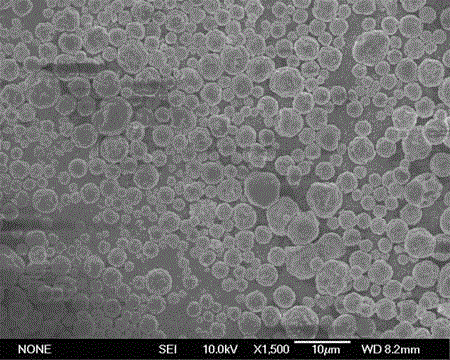

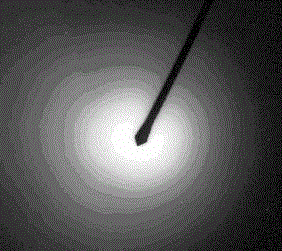

[0017] According to the stoichiometric ratio Fe:P=1:1.03, take ferric chloride and phosphoric acid to form Fe 3+ For a metal mixed solution with an ion concentration of 1.5 mol / L, prepare a 4 mol / L ammonia solution as a precipitant. First add deionized water to the reactor and adjust the pH to 1.8 with hydrochloric acid solution. The metal mixed solution was continuously fed into the 10L reactor at a flow rate of 300mL / h, and at the same time, the ammonia solution was added in parallel to control the pH=2.3 for reaction. The reaction process temperature was 50° C., and the stirring speed was 200 rpm. When the average particle size of ferric phosphate particles is D50=6-8μm and the particle size distribution is 3-20μm, adjust the flow rate of ammonia solution to control pH=3.0 and react for 30 minutes, then adjust the flow rate of metal mixed solution to restore pH=2.3 for continuous reaction. The obtained white suspension was filtered and washed, and the filter cake was drie...

Embodiment 2

[0019] According to the stoichiometric ratio Fe:P=1:1.03, take ferric chloride and phosphoric acid to form Fe 3+ For a metal mixed solution with an ion concentration of 1.5 mol / L, prepare a 4 mol / L ammonia solution as a precipitant. First add deionized water to the reactor and adjust the pH to 1.8 with hydrochloric acid solution, and the additive gelatin is added in an amount of 10mg / L. The metal mixed solution was continuously fed into the 10L reactor at a flow rate of 300mL / h, and at the same time, the ammonia solution was added in parallel to control the pH=2.3 for reaction. The reaction process temperature was 50° C., and the stirring speed was 360 rpm. When the average particle size of ferric phosphate particles is D50=6-8μm and the particle size distribution is 3-20μm, adjust the flow rate of ammonia solution to control pH=3.0 and react for 30 minutes, then adjust the flow rate of metal mixed solution to restore pH=2.3 for continuous reaction. The obtained white suspen...

Embodiment 3

[0021] According to the stoichiometric ratio Fe:P=1:1.03, take ferric chloride and phosphoric acid to form Fe 3+ For a metal mixed solution with an ion concentration of 1.5 mol / L, prepare a 4 mol / L ammonia solution as a precipitant. First add deionized water to the reactor and adjust the pH to 1.8 with hydrochloric acid solution, and the additive gelatin is added in an amount of 10mg / L. The metal mixed solution was continuously fed into the 10L reactor at a flow rate of 300mL / h, and at the same time, the ammonia solution was added in parallel to control the pH=2.3 for reaction. The reaction process temperature was 50° C., and the stirring speed was 200 rpm. When the average particle size of iron phosphate particles is D50=6-8μm and the particle size distribution is 3-20μm, adjust the flow rate of ammonia solution to control pH=3.0 and react for 120 minutes, then adjust the flow rate of metal mixed solution to restore pH=2.3 for continuous reaction. The obtained white suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com