Power MOS device temperature rise and thermal resistance component test device and method

A technology for MOS devices and testing devices, which is applied in the direction of single semiconductor device testing, measuring devices, instruments, etc., can solve the problems of high instrument price, complicated measurement technology operation, long measurement cycle, etc., and achieves reduction of measurement cycle and optimization of measurement operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

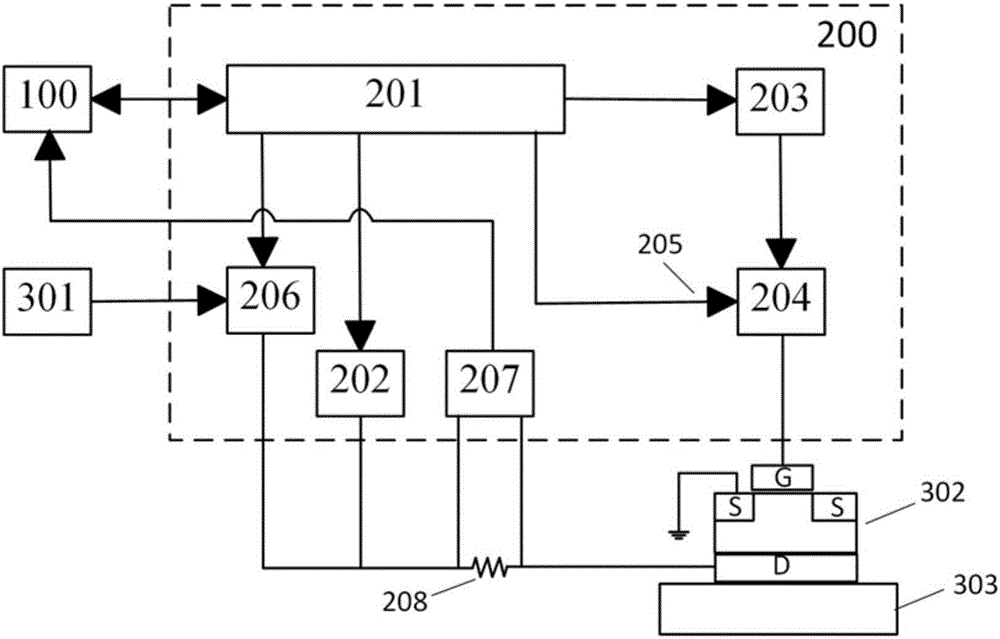

[0029] First, the power MOS device 302 to be tested is placed on a temperature-adjustable constant temperature platform 303 . After connecting the gate, source and drain wires of the power MOS device 302, the computer 100 is the control center, which realizes the transmission of signal instructions, transmission and storage of data. The computer 100 is connected to the FPGA unit 201 via USB, and the FPGA unit 201 is controlled by timing signals, respectively connected to the test current source 202, the grid-source operating voltage source 203, the grid-source operating power switch 204, the drain-source operating power switch 206, and the computer 100 is connected to the voltage and current acquisition unit 207 via USB.

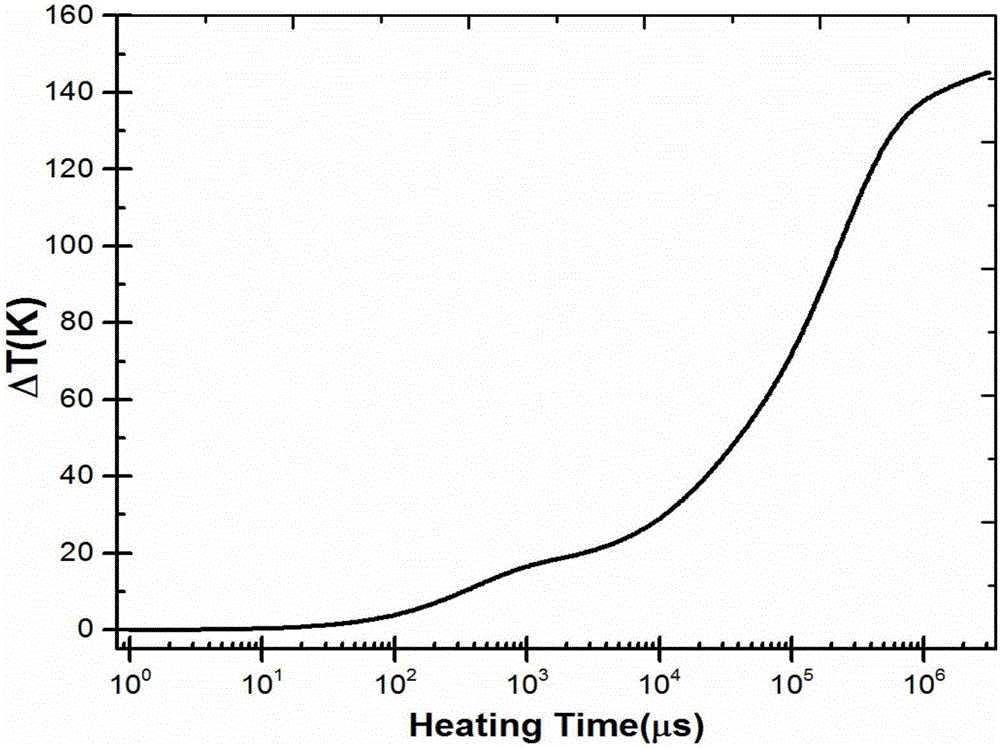

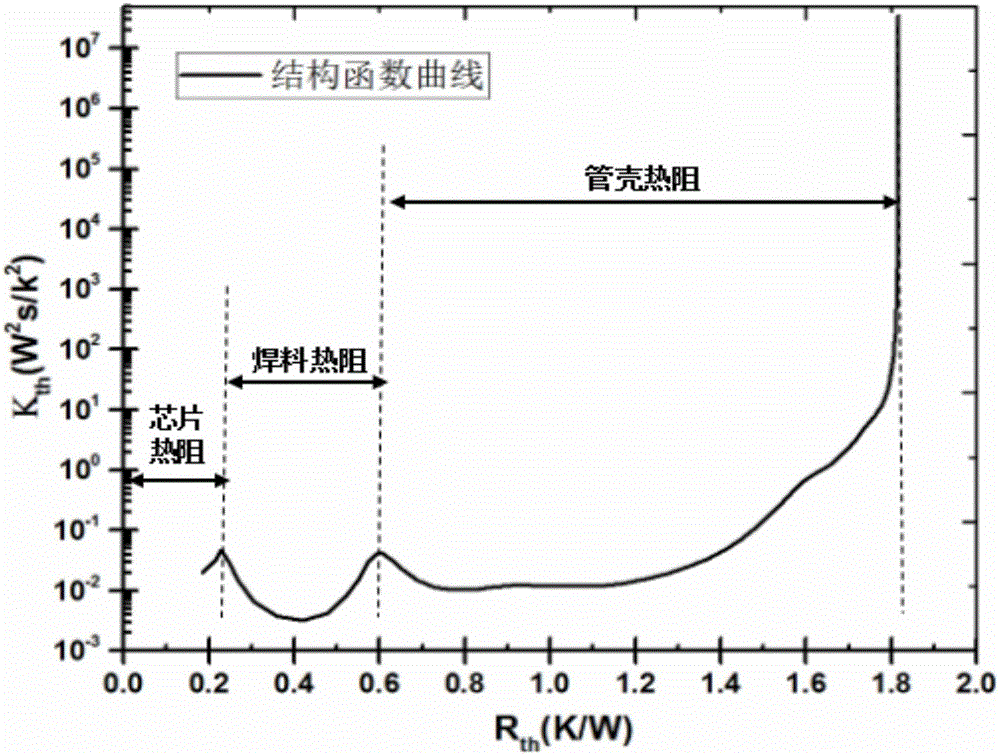

[0030] During measurement, the control computer 100 issues an instruction, and the test current source 202 produces a test current identical to the temperature coefficient of the measured power MOS device, which is connected to the drain-source two ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com