Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

256 results about "Stress ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress ratios are the ratios between under and over stress with regard to a particular type of load, such as torque. Here R = -1 and defines a pure alternating stress ratio, R = 0 defines a pure pulsating stress ratio.

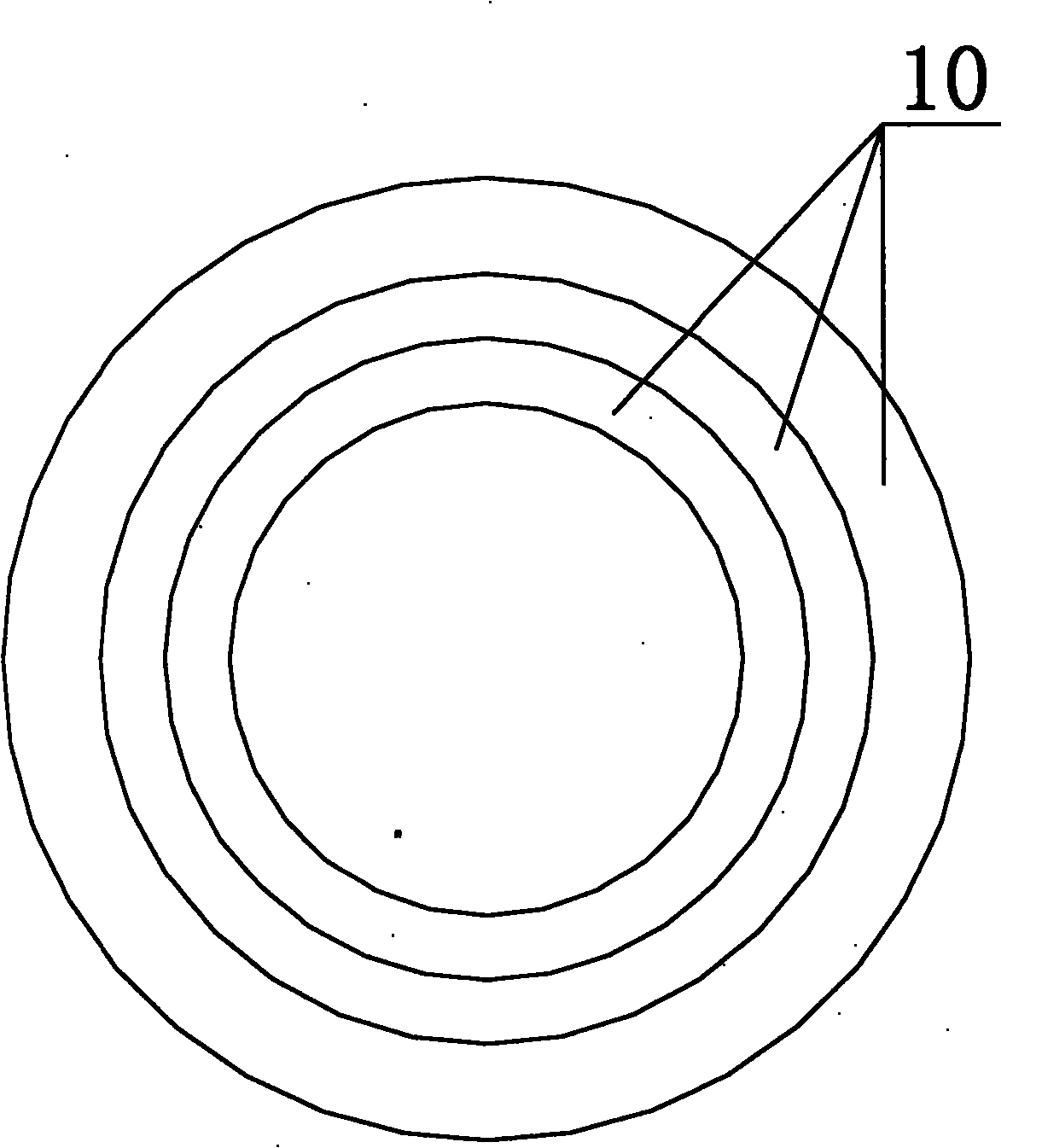

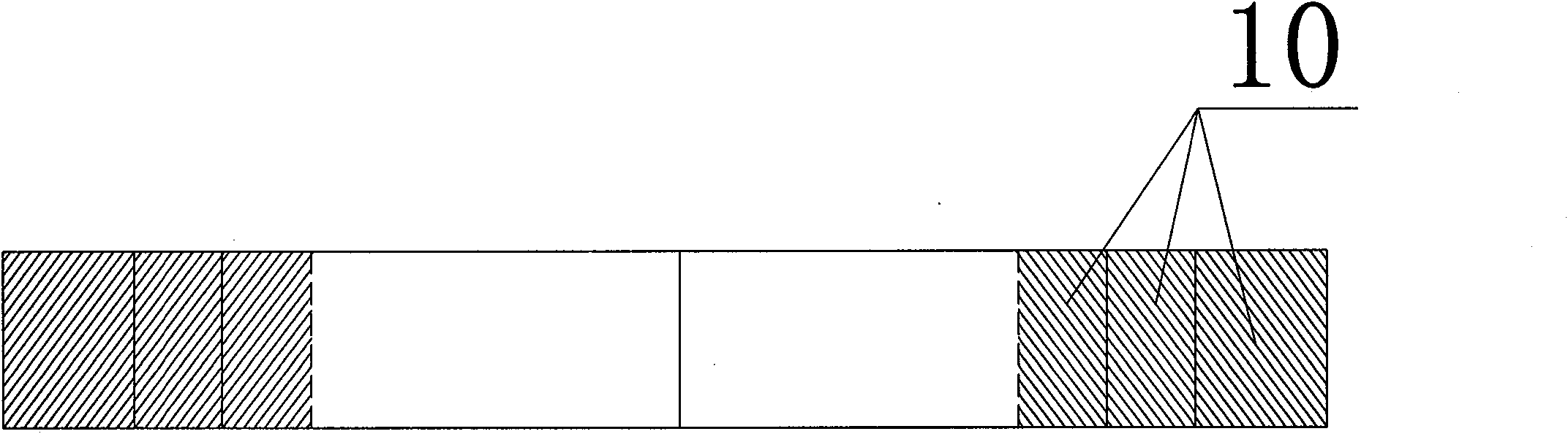

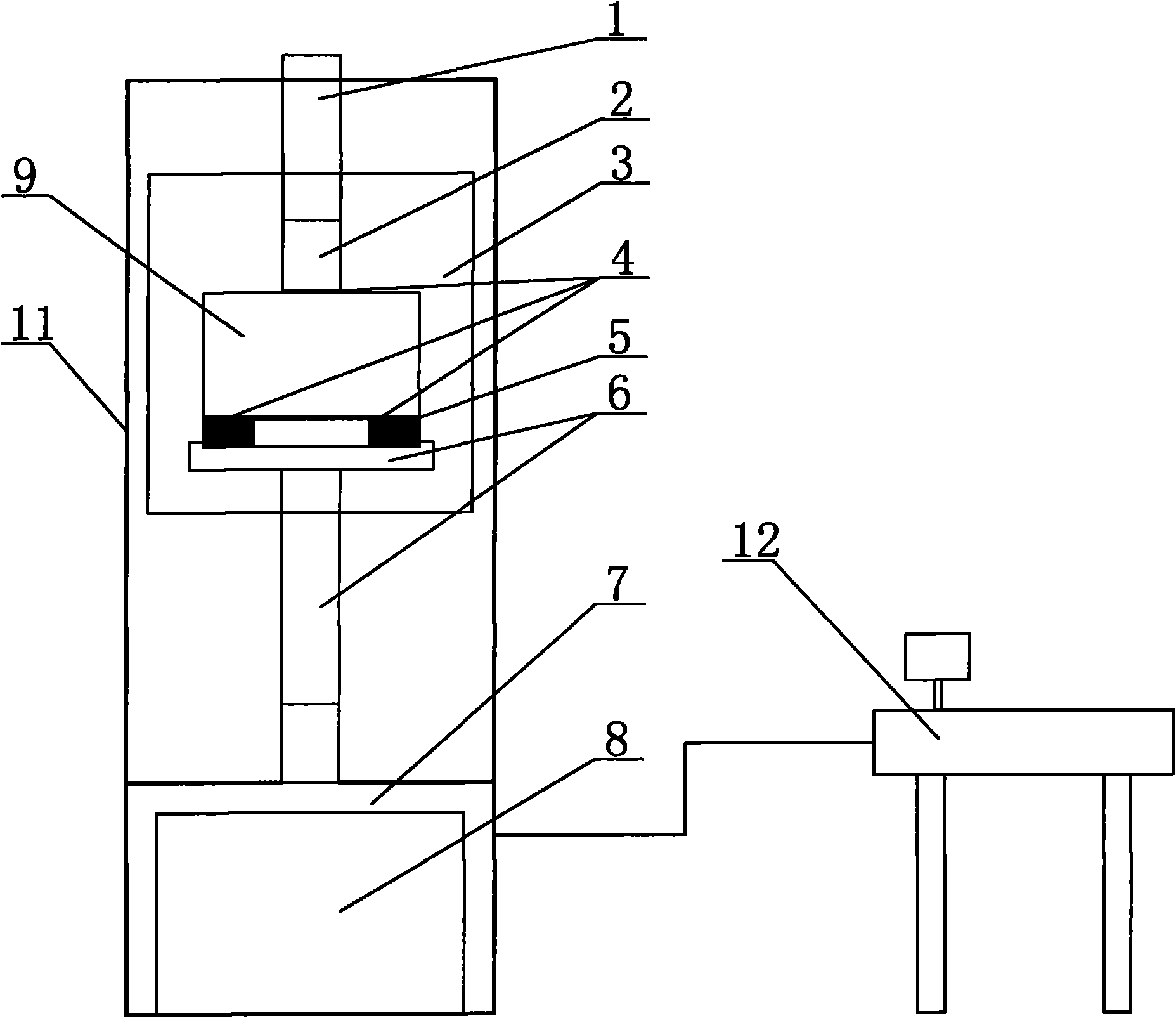

Device and method for testing shear performance of asphalt mixture

InactiveCN101788431AFree disassemblyThe testing process is simplePreparing sample for investigationMaterial strength using steady shearing forcesTemperature controlStress ratio

The invention discloses a device and a method for testing shear performance of an asphalt mixture. The shear strength and shear fatigue life of the asphalt mixture under different temperature conditions are tested by adopting a circular ring shearing test. The method comprises that: before the test, an asphalt mixture test-piece is subjected to heat preservation in a temperature control box at a preset test temperature for over 6 hours; in the test, the asphalt mixture test-piece is arranged on a circular ring, and is loaded through a pressure head to cause shear failure so as to form a conical shear failure surface, and the shear strength of the asphalt mixture is calculated; and according to requirements, a specific load in a range of 0.1 to 0.9 time of failure load is selected to perform a repeated loading fatigue test on parallel test-pieces, the loading waveform is sine waves, the frequency is 10Hz, and the shear fatigue life of the asphalt mixture at different stress ratios is read out. The test method has important significance for studying the shear performance of the asphalt mixture and designing and evaluating the material of the asphalt mixture.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

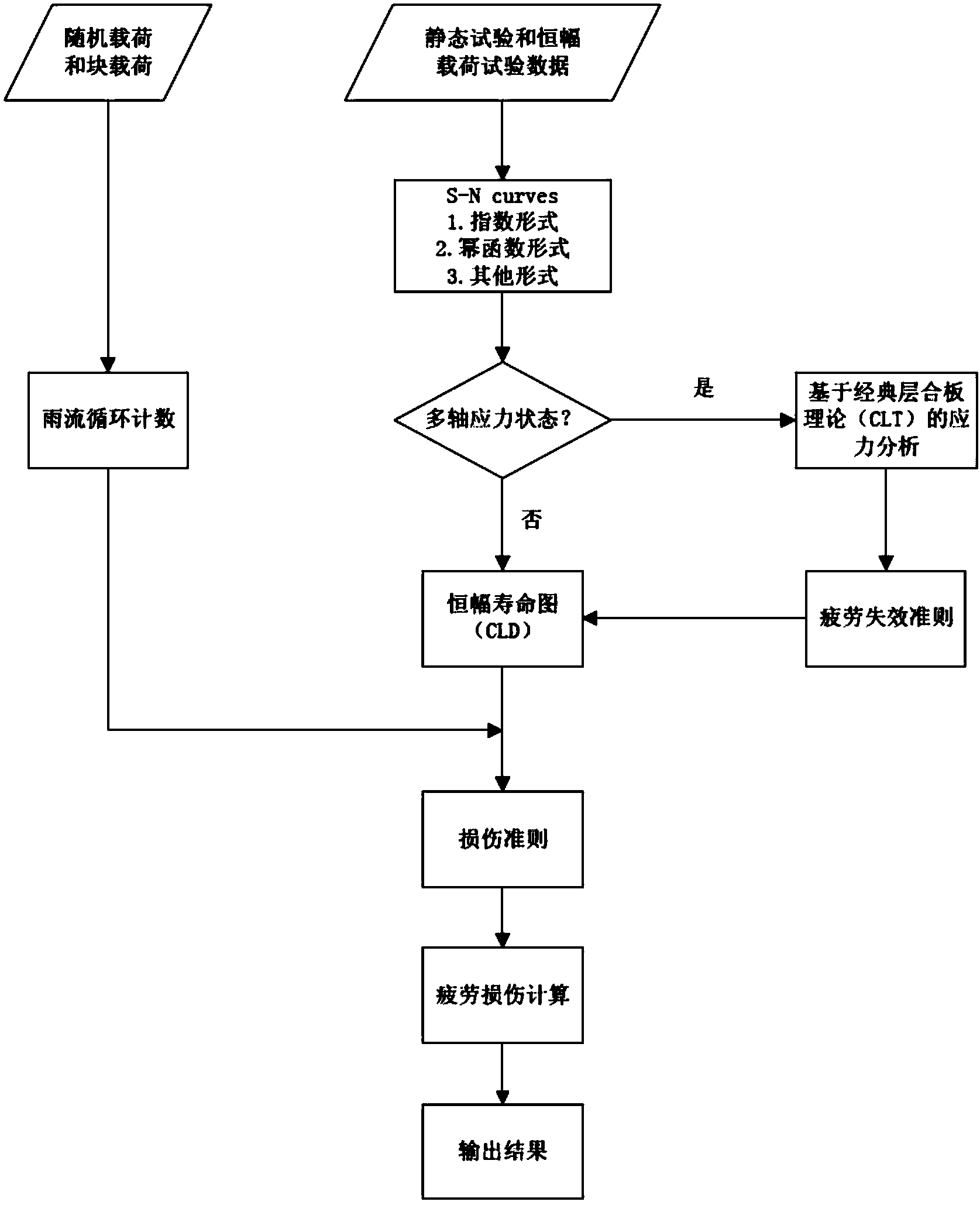

Carbon fiber composite material fatigue life estimating method based on stress ratio influences

InactiveCN103942441AAccurate lifeAccurate Damage AssessmentSpecial data processing applicationsStrength propertiesFinite element techniqueDispersity

The invention belongs to the technical field of composite materials, and discloses a carbon fiber composite material fatigue life estimating method based on stress ratio influences. Structural response calculation is carried out by means of a finite element technology. A finite element model is based on a classical laminate plate theory, and a umat subprogram taking tension and compression asymmetry into consideration is built. By carrying out constant-amplitude fatigue tests under different stress ratios, an equation of an influence mechanism of average stress on prediction of the service life of a carbon fiber composite material structure is built and is popularized to a block load and a spectrum load. A service life estimating model built through the method is based on the classical laminate plate theory and takes influences of the average stress and a variable-amplitude load into consideration, dispersity of a prediction result is little, accuracy is high, theoretical guidance is provided for reliability design of parts made of carbon fiber composite materials, and the technical problems that existing carbon fiber composite material structure fatigue life is only estimated through a test method, and accordingly cost is high and consumed time is long are solved.

Owner:SHANGHAI JIAO TONG UNIV

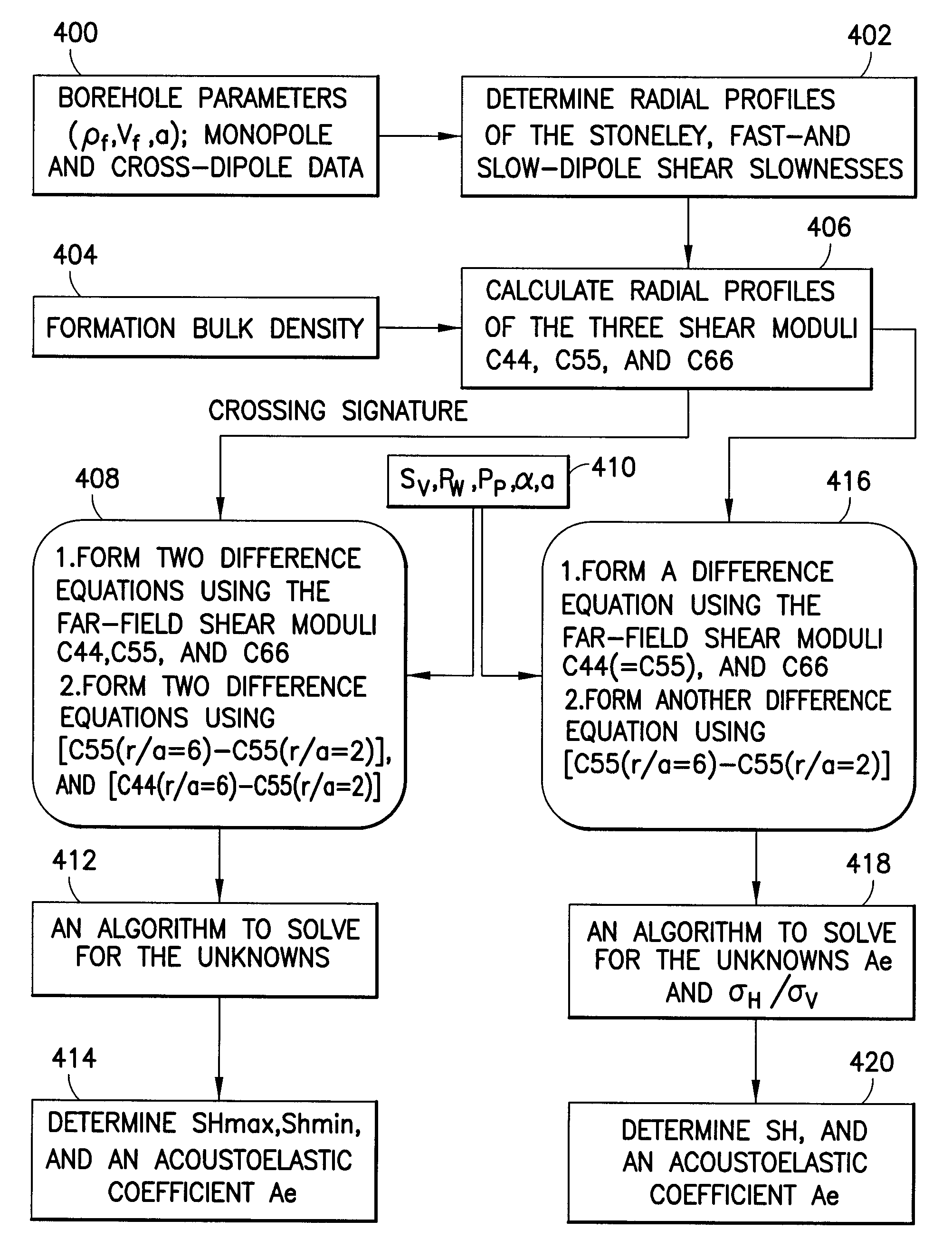

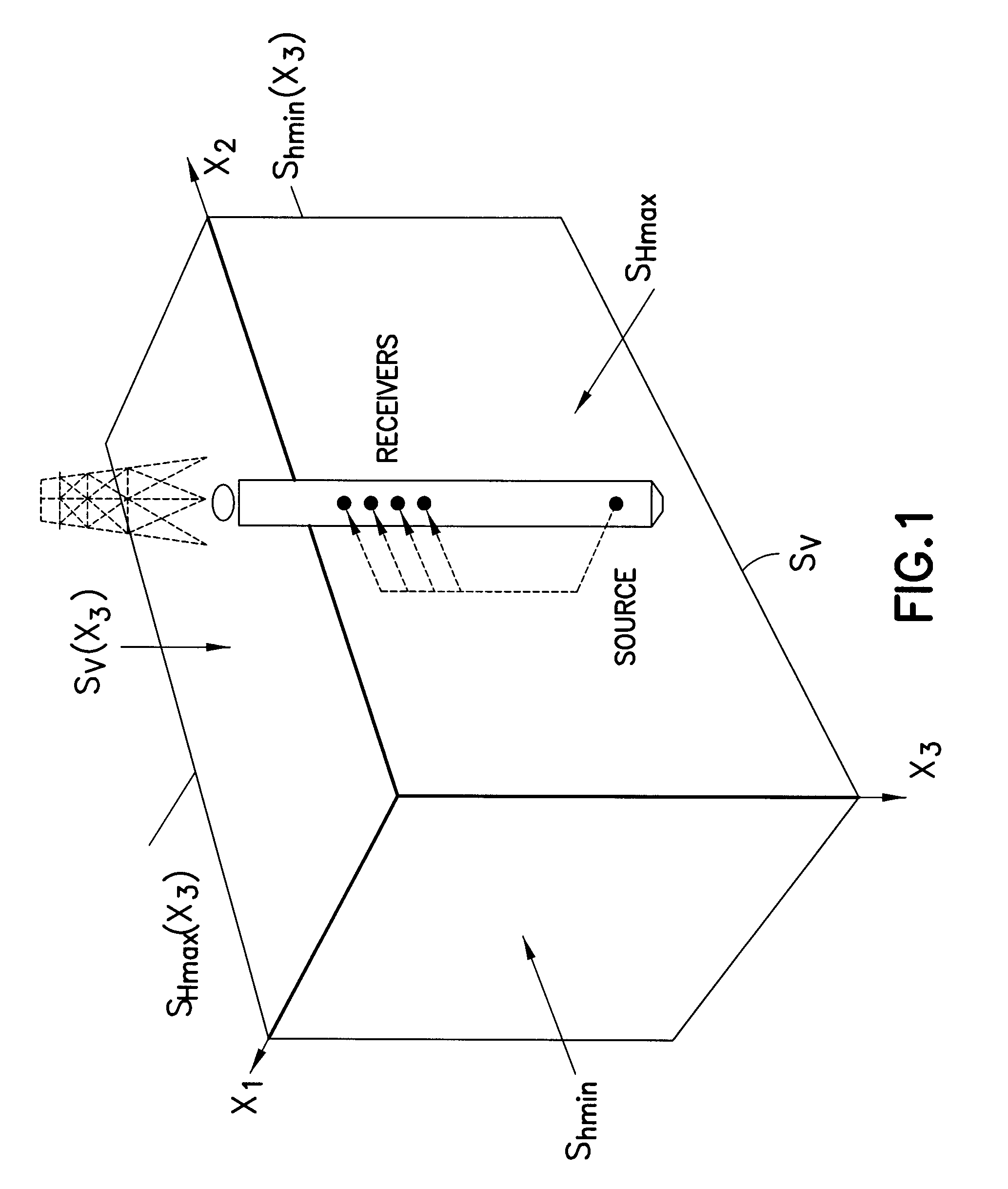

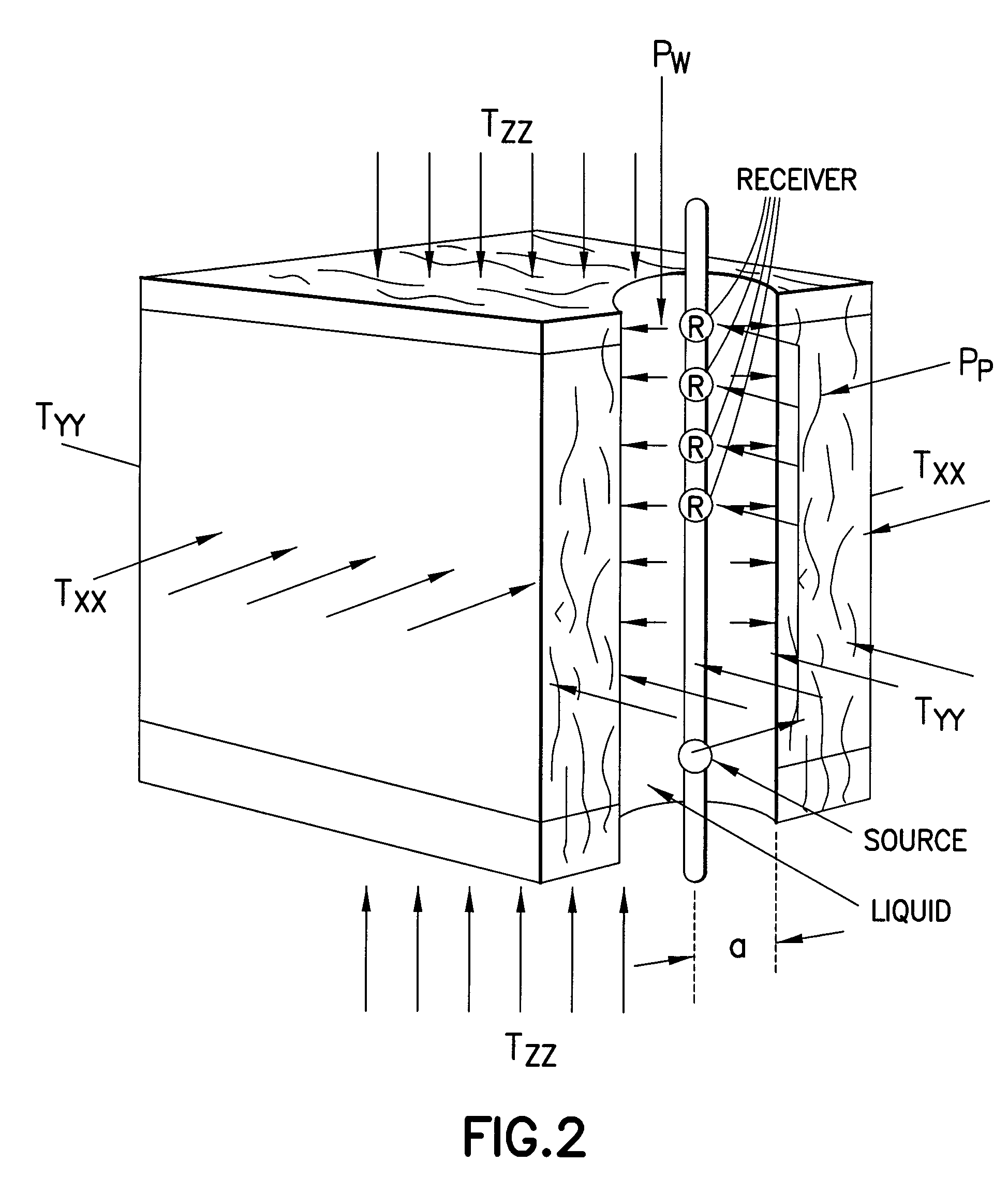

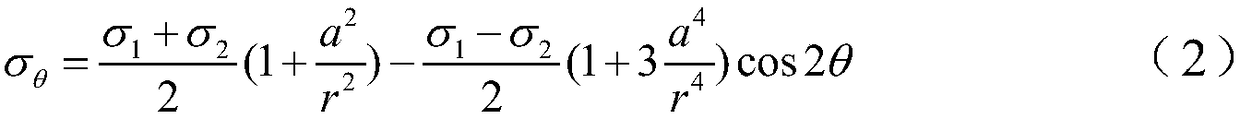

Estimating formation stresses using radial profiles of three shear moduli

ActiveUS20100020642A1Seismic signal processingSeismology for water-loggingStress concentrationShear modulus

Maximum and minimum horizontal stresses, and horizontal to overburden stress ratio, are estimated using radial profiles of shear moduli. Inversion enables estimation of maximum and minimum horizontal stresses using radial profiles of three shear moduli associated with an orthogonal set of axes defined by the three principal stress directions. Differences in the far-field shear moduli are inverted together with two difference equations obtained from the radial profiles of the dipole shear moduli C44 and C55, and borehole stresses in the near-wellbore region. The horizontal to overburden stress ratio is estimated using differences in the compressional, dipole shear, and Stoneley shear slownesses at two depths in the same lithology interval where the formation exhibits azimuthal isotropy in cross-dipole dispersions, implying that horizontal stresses are nearly the same at all azimuths. The overburden to horizontal stress ratio in a formation with axial heterogeneity may also be estimated using the far-field Stoneley shear modulus C66 and dipole shear modulus C55 together with the radial variation of the dipole shear modulus C55 caused by near-wellbore stress concentrations.

Owner:SCHLUMBERGER TECH CORP

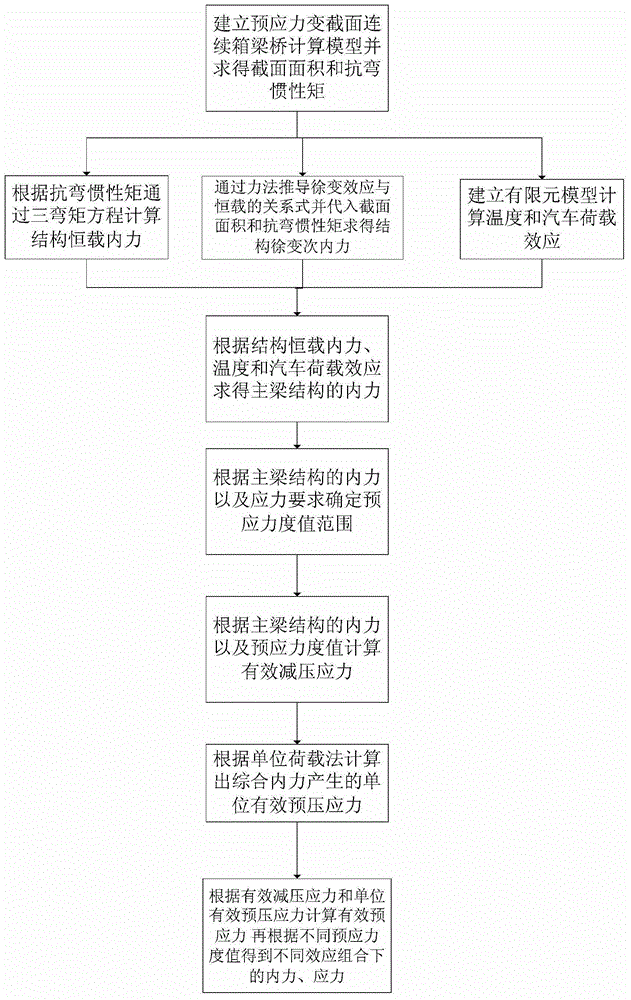

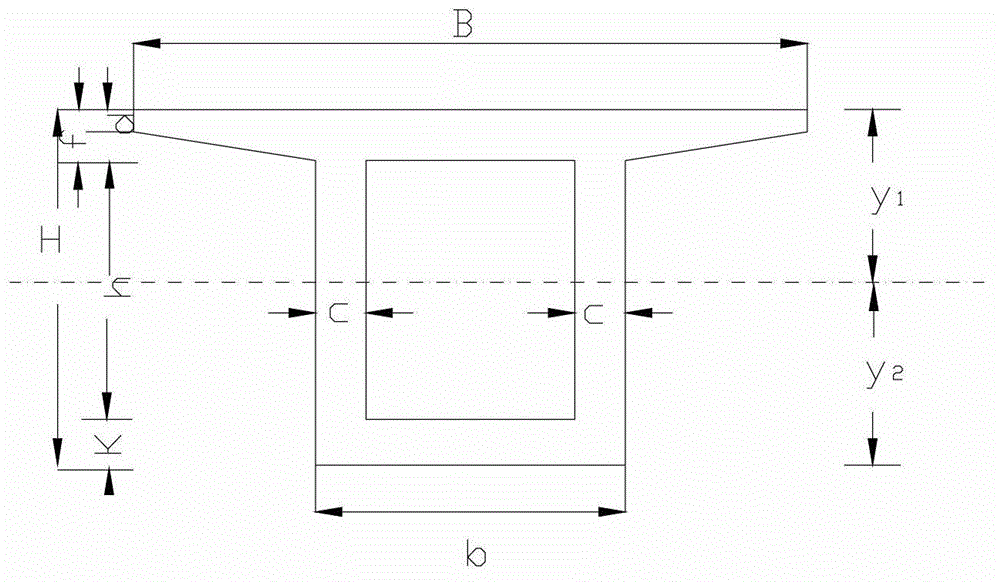

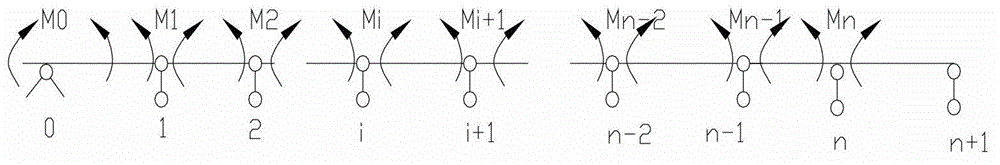

Design method for longitudinal pre-stressing tendons of variable-cross-section pre-stressed concrete continuous bridge

InactiveCN103065035ADevelop longitudinal prestressDevelopment of Analytical Computational MethodsSpecial data processing applicationsBridge materialsStress ratioPre stressing

The invention discloses a design method for longitudinal pre-stressing tendons of a variable-cross-section pre-stressed concrete continuous bridge. The optimization design method for the longitudinal pre-stressing tendons of the pre-stressed concrete continuous bridge is built based on the design principle of the pre-stressed degree and through combining an analytic method with a finite element method and compressively considering dead load and live load action effects. A three moment equation of the variable-cross-section pre-stressed concrete continuous box girder bridge is established to solve the internal force of the structure under the action of the self weight on the basis of the average bending moment method. A calculation formula of pre-stressed effective pre-pressure is built through a load equal effect method and a unit load method; a creep effect calculation formula is built through a force method; the temperature effect and the automobile load effect are calculated through the finite element method; and a variable-cross-section statically indeterminate structure pre-stressing tendon reinforcement calculation formula is obtained through combination of the stress ratio with the definition of the competitive pre-stressed degree.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

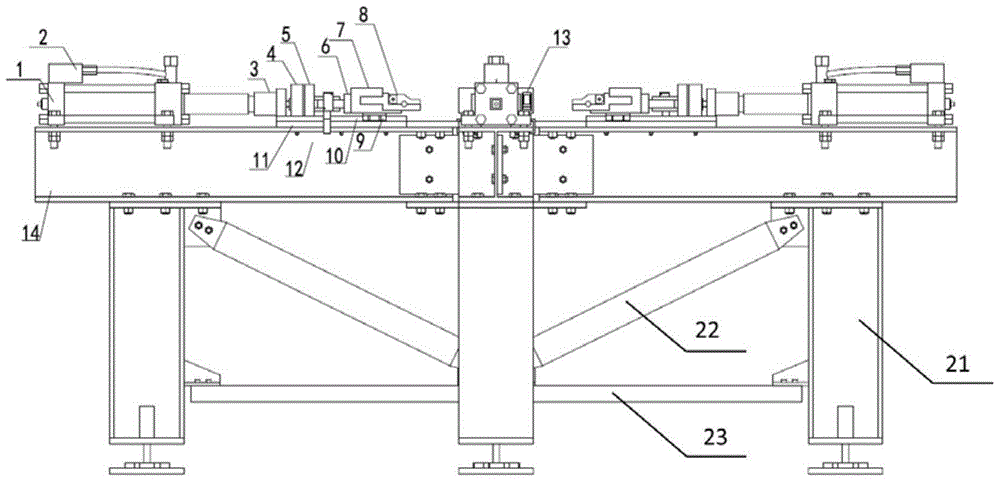

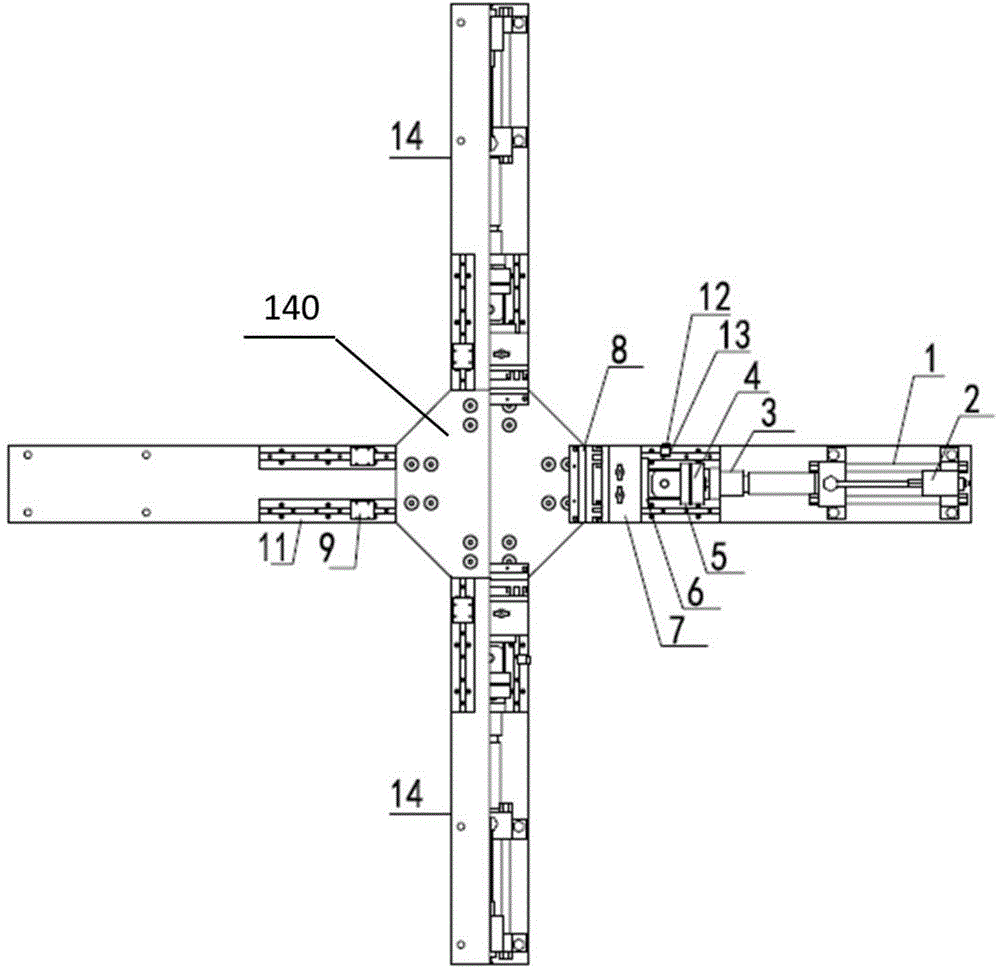

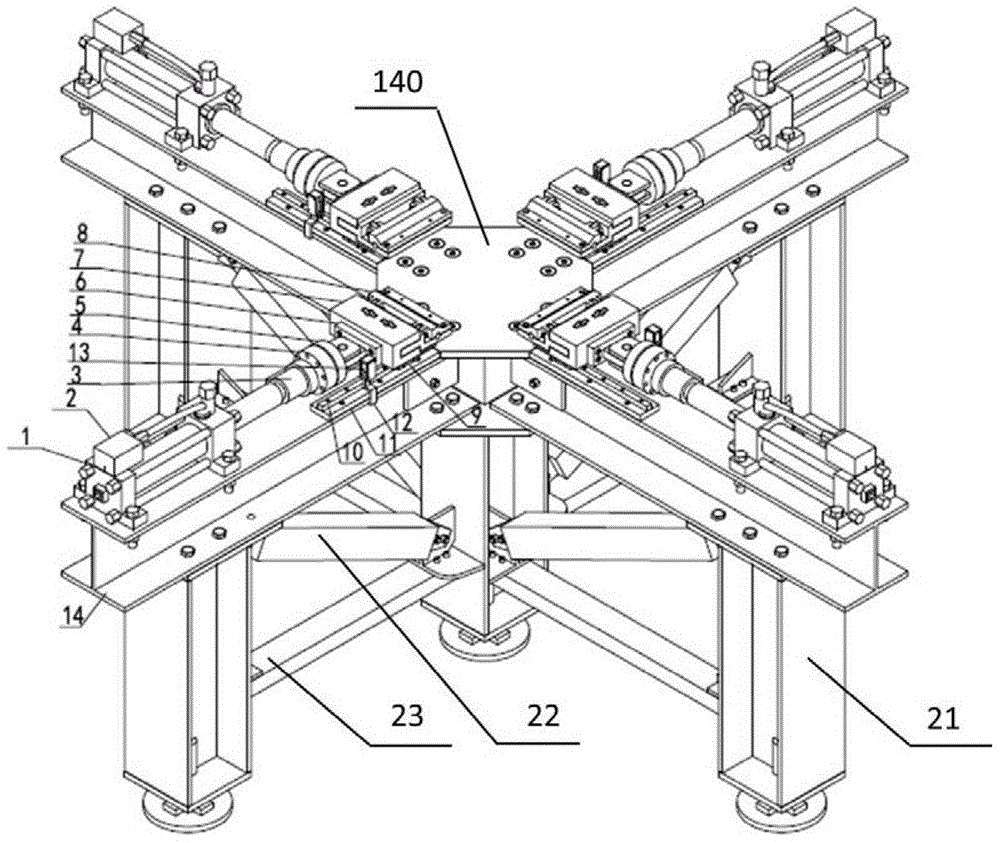

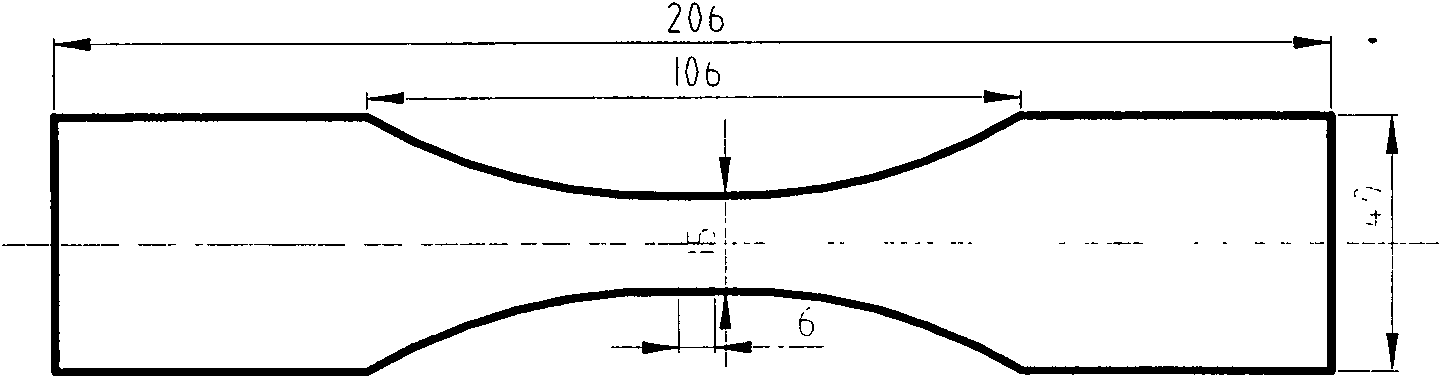

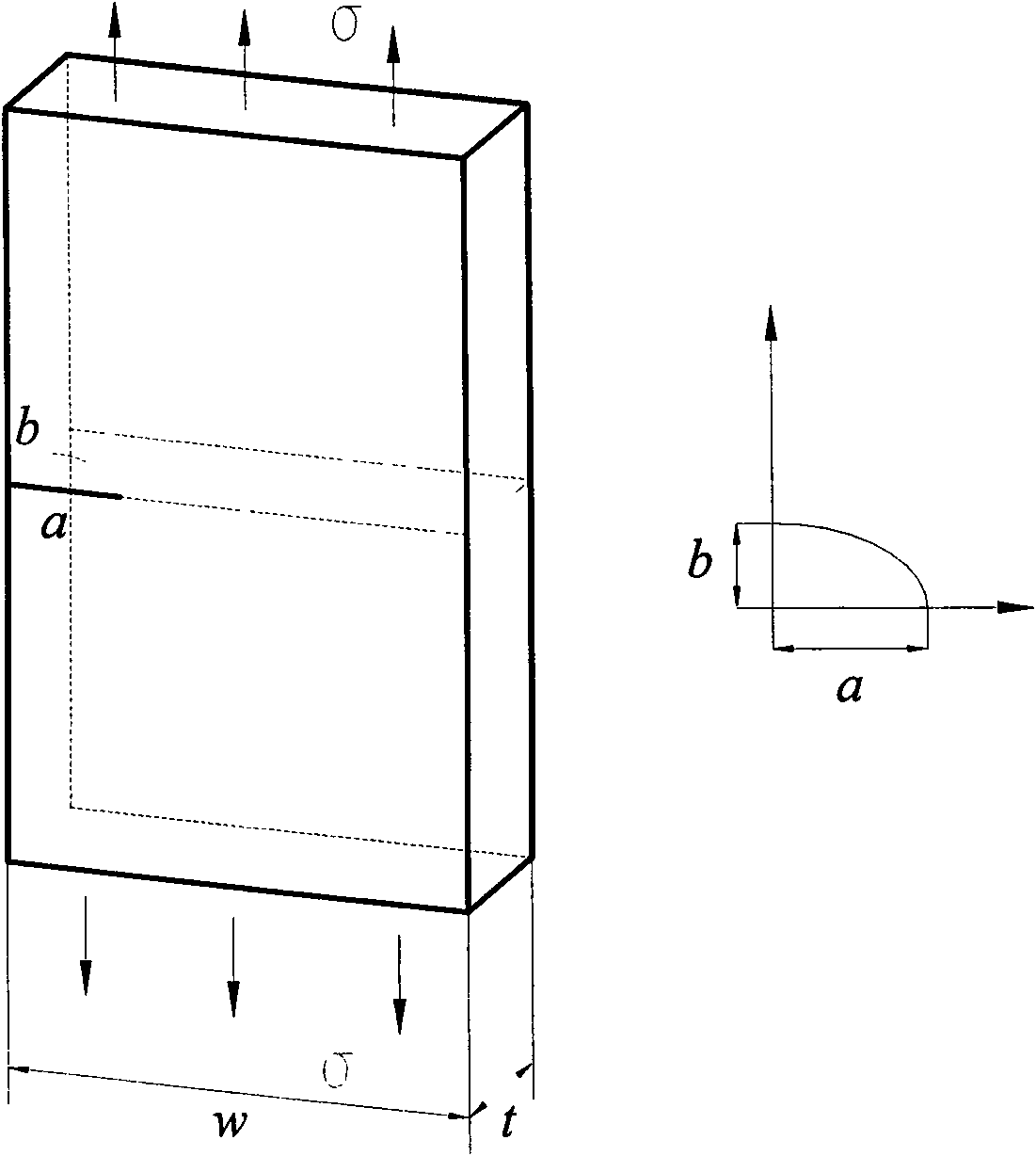

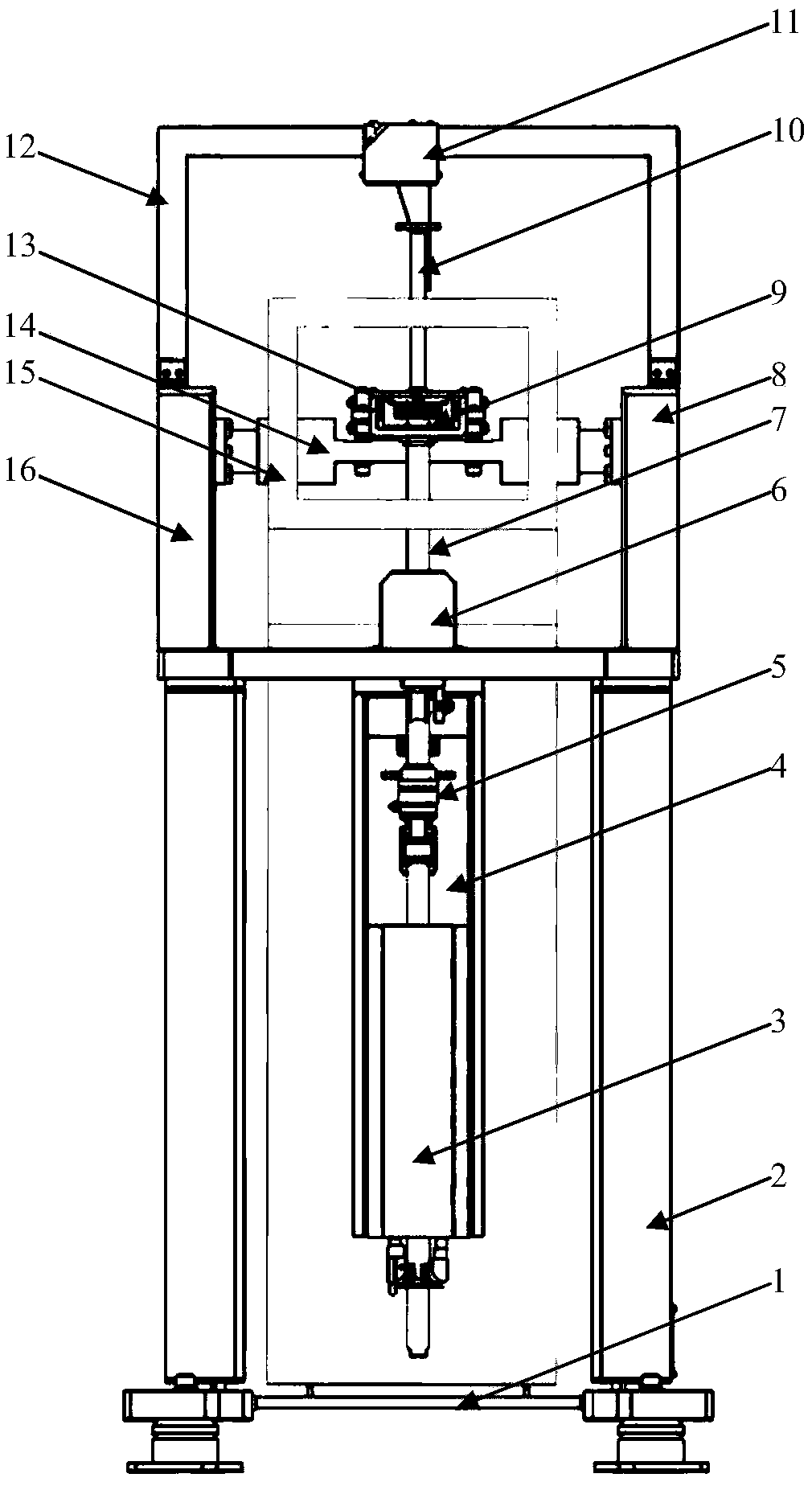

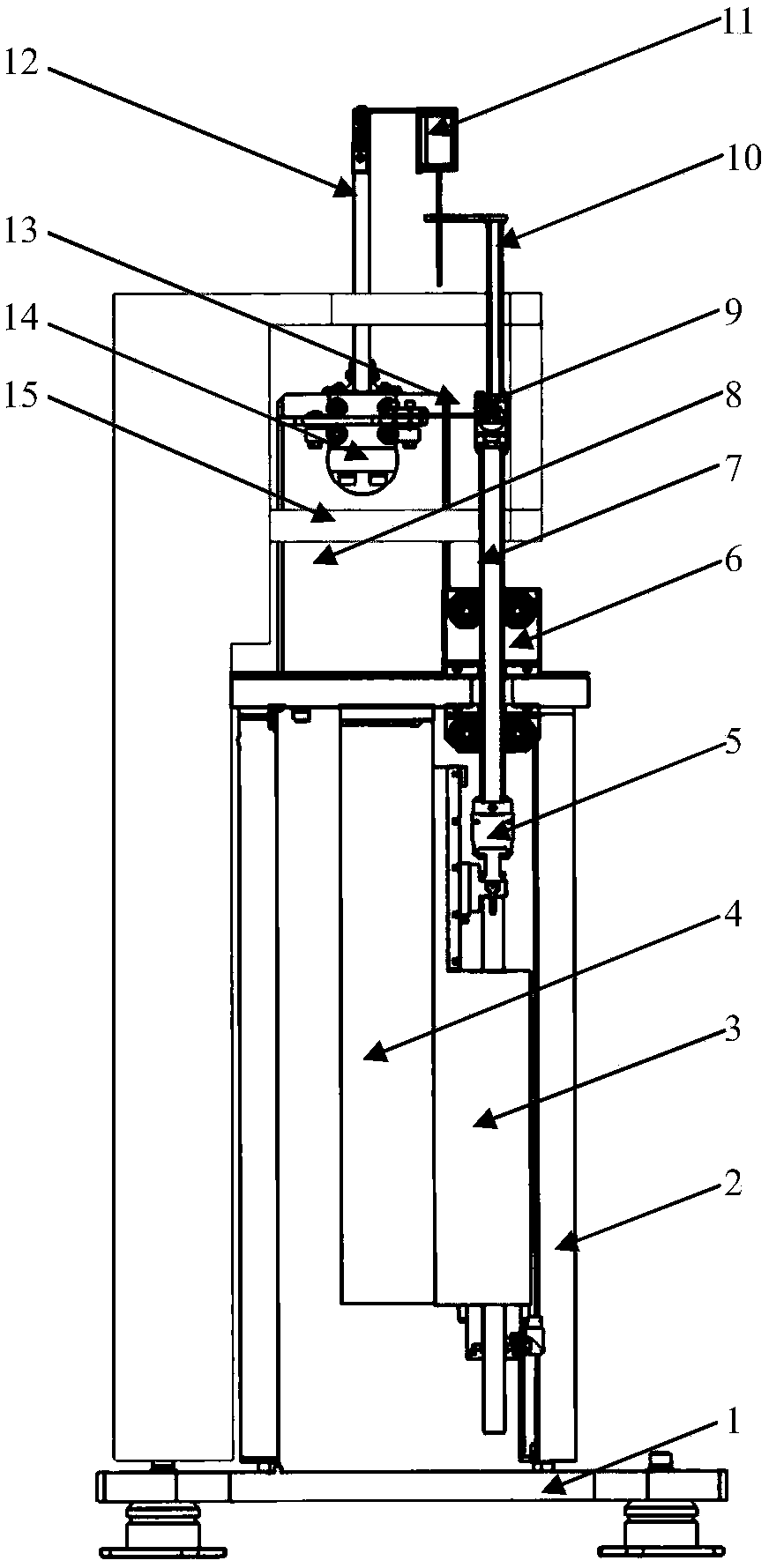

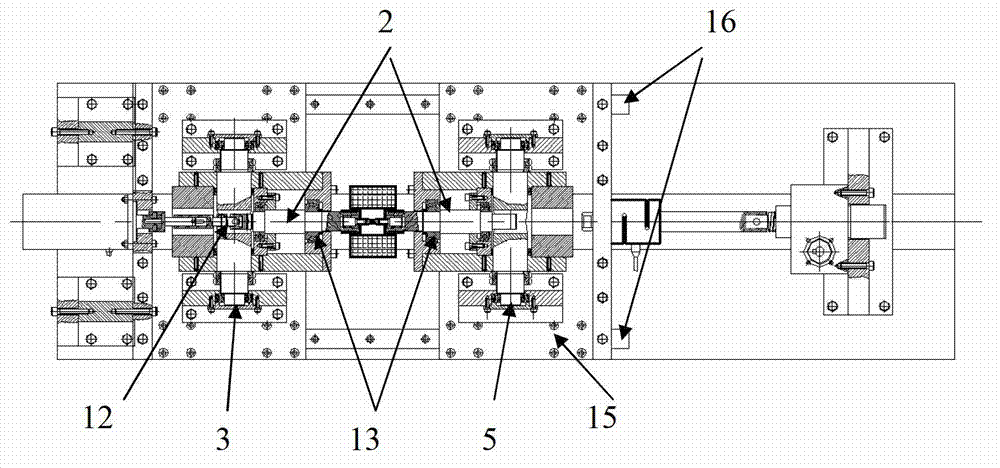

Biaxial extension test device

ActiveCN104568591ACompact structureWell formedMaterial strength using tensile/compressive forcesStress ratioEngineering

The invention discloses a biaxial extension test device. The biaxial extension test device comprises a horizontal rack which is an orthogonal cross, wherein a servo-cylinder is mounted at the end part of each of four arms of the horizontal rack and sequentially connected with a tension sensor and a combined fixture; a linear guide rail is arranged on the surface of each of the four arms of the horizontal rack; and the combined clamps are arranged on the linear guide rails, can move along the linear guide rails and are used for clamping test pieces. The invention also provides a method for the biaxial extension test device to perform biaxial extension test, and the method comprises a plurality of steps. The biaxial extension test device is compact in structure, concise in format, stable in operation and high in precision, has various test functions (unidirectional static extension, low-cycle reciprocating extension, bidirectional static tensile strength and optional biaxial stress ratio low-cycle reciprocating extension), and can be applied to uniaxial tensile test machines, biaxial tensile test machines and the like.

Owner:SHANGHAI JIAO TONG UNIV

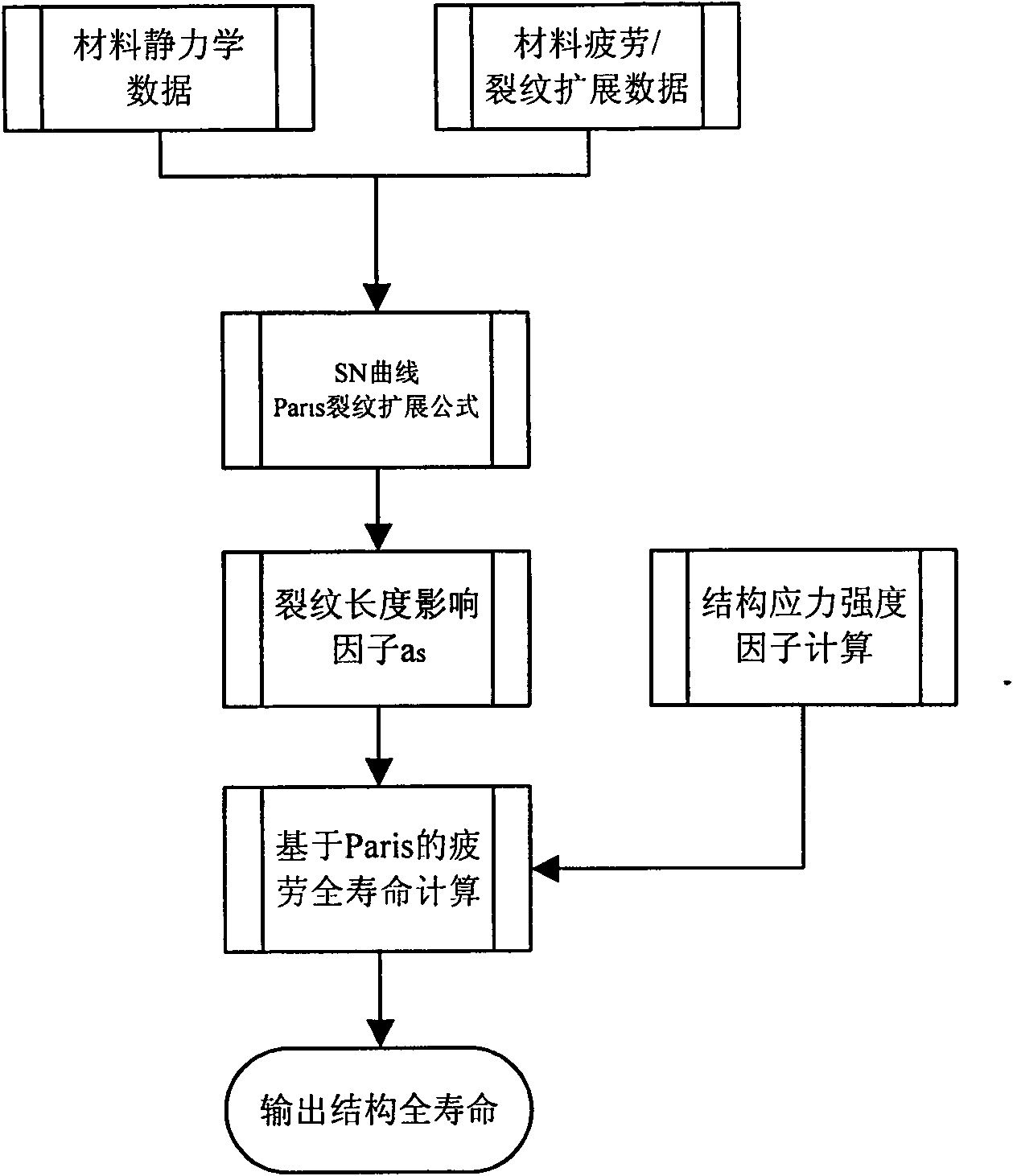

Fatigue life analyzing method based on Paris formula

InactiveCN102129512AAvoid Experimental MeasurementsRealize fatigue life calculationSpecial data processing applicationsStress intensity factorStress ratio

The invention discloses a fatigue life analyzing method based on a Paris formula, comprising the following steps of: acquiring the mechanical property data and a fatigue SN (Serial Number) curve of materials as well as the Paris material constants of the materials when stress ratio R=0 and a stress intensity factor curve of a suture, and then calculating the influence factors of a crack length; and carrying out crack propagation life integral calculation from an initial crack length to a critical crack length by adopting a fatigue life-cycle calculation formula based on the Paris so as to obtain and output a final structure fatigue life-cycle. In the invention, only the basic common material constants are needed, therefore, the test measurement of a large quantity of material constants is prevented; and the prevention of the test measurement of the large quantity of material constants is very important for the structure life-cycle analysis of engineering application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-temperature fatigue property characterization and life estimation method

The invention discloses a low-temperature fatigue property characterization and life estimation method. The method comprises three major steps of step 1, through considering the influence of a stress ratio, deriving an S-N-R curved surface characterizing the fatigue property by adopting a Goodman equilife curve based on a three-parameter power function expression, and performing data processing by virtue of a linear regression theory; step 2, through considering an interaction effect of loads under spectrum loading, proposing a corrected spectrum loading fatigue life estimation model based on a Willenborg / Chang model and a crack tip plastic zone theory, and giving out a fatigue damage increment representation method; and step 3, calculating the low-temperature spectrum loading fatigue life of a material by adopting an accumulative damage theory. The method is simple and practical; and a low-temperature fatigue property characterization model can be constructed only by a constant-load fatigue property curved surface and an actually measured flight load spectrum of the material in a low-temperature environment, and the spectrum loading fatigue life is estimated, so that the method has important academic meanings and engineering application values.

Owner:BEIHANG UNIV

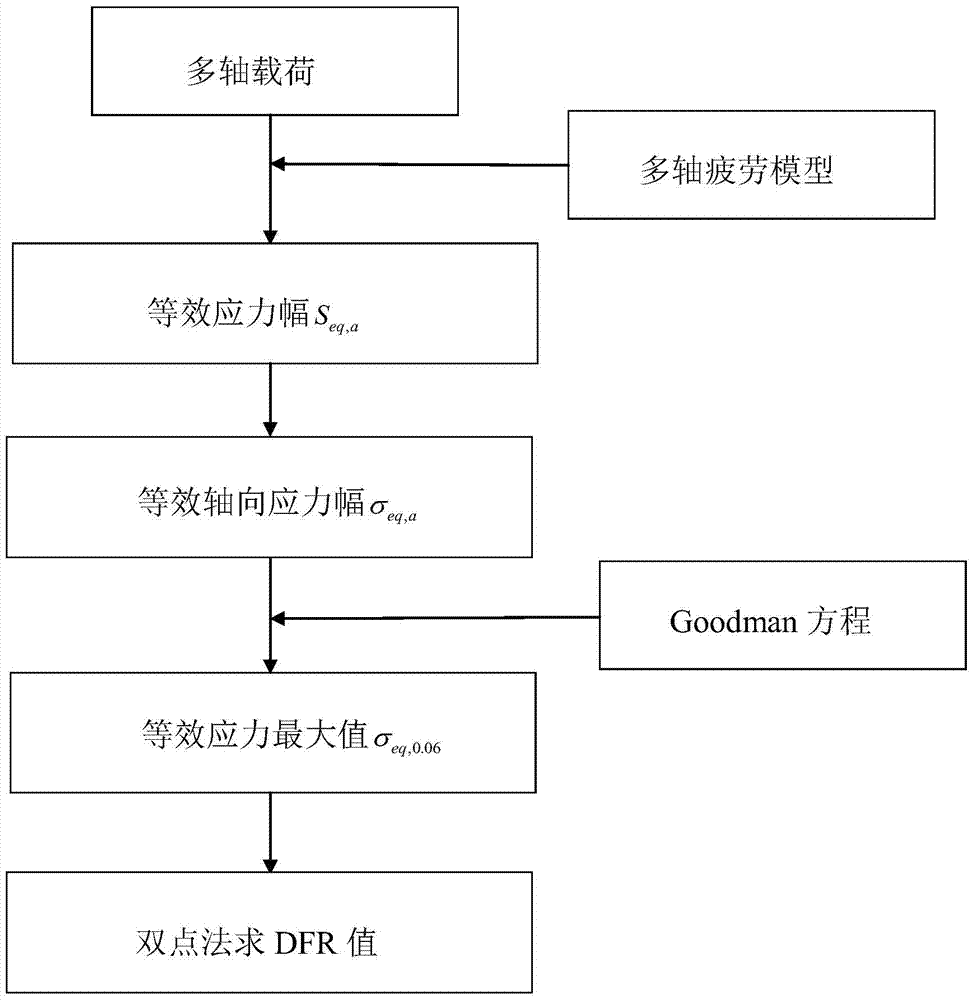

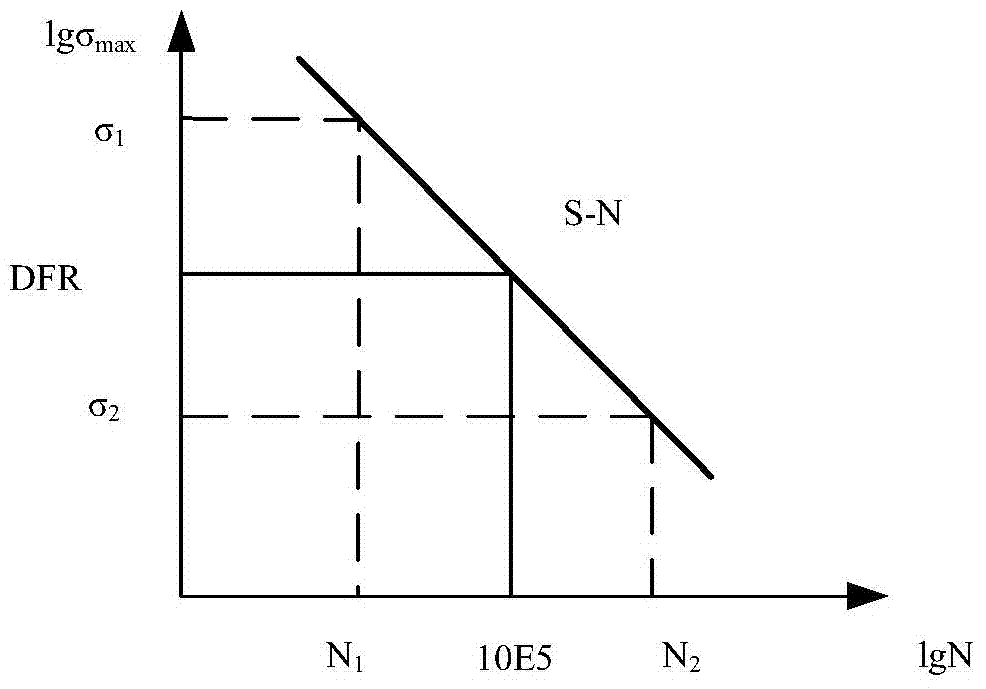

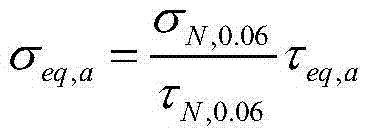

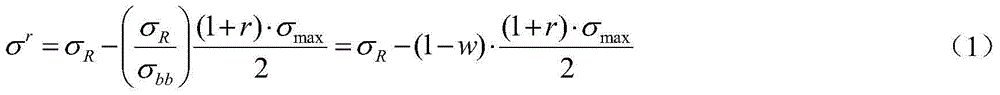

Method for determining specific fatigue strength rated value under multi-axial loading condition

The invention provides a method for determining the specific fatigue strength rated value under the multi-axial loading condition, and relates to the field of fatigue strength. The method comprises the first step of converting a multi-axial load into equivalent stress through an existing high-cycle multi-axial fatigue model, the second step of converting the equivalent shearing stress amplitude into the equivalent axial stress amplitude if the converted equivalent stress is a shearing type model, the third step of converting the equivalent axial stress amplitude sigma eq,a into the maximum stress sigma eq,0.06 when the stress ratio is 0.06 based on the Goodman equation, and the fourth step of calculating the DFR value based on the double-point method. The method is used for calculating the DFR value under the multi-axial loading condition, and the predicting result shows that the DFR value under the multi-axial loading condition can be calculated with the method.

Owner:BEIJING UNIV OF TECH

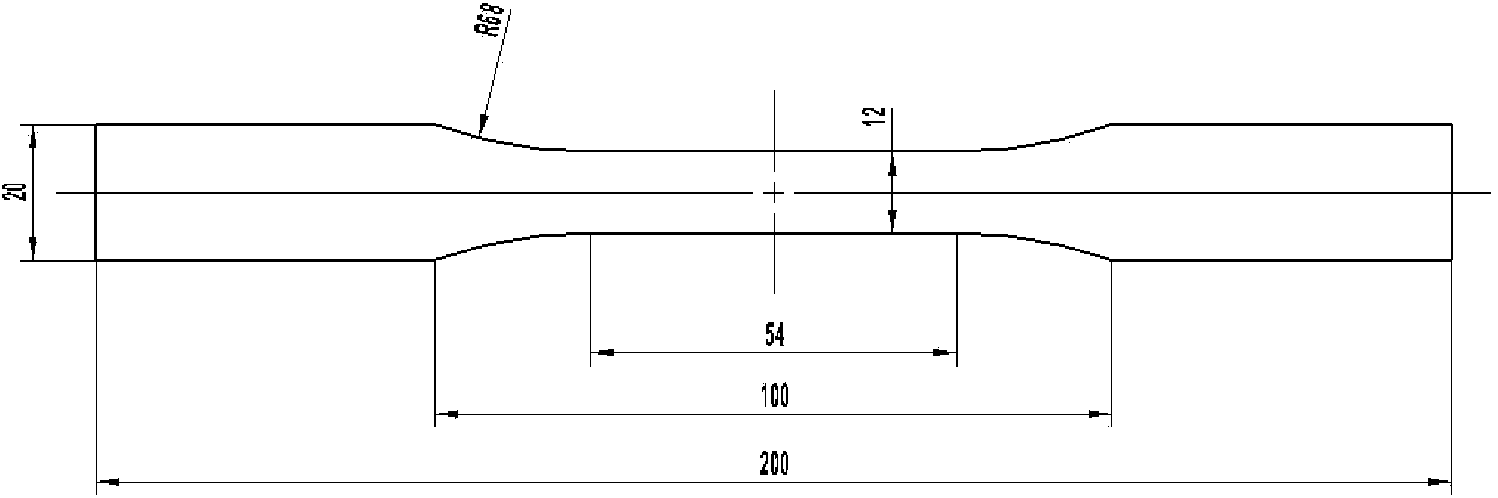

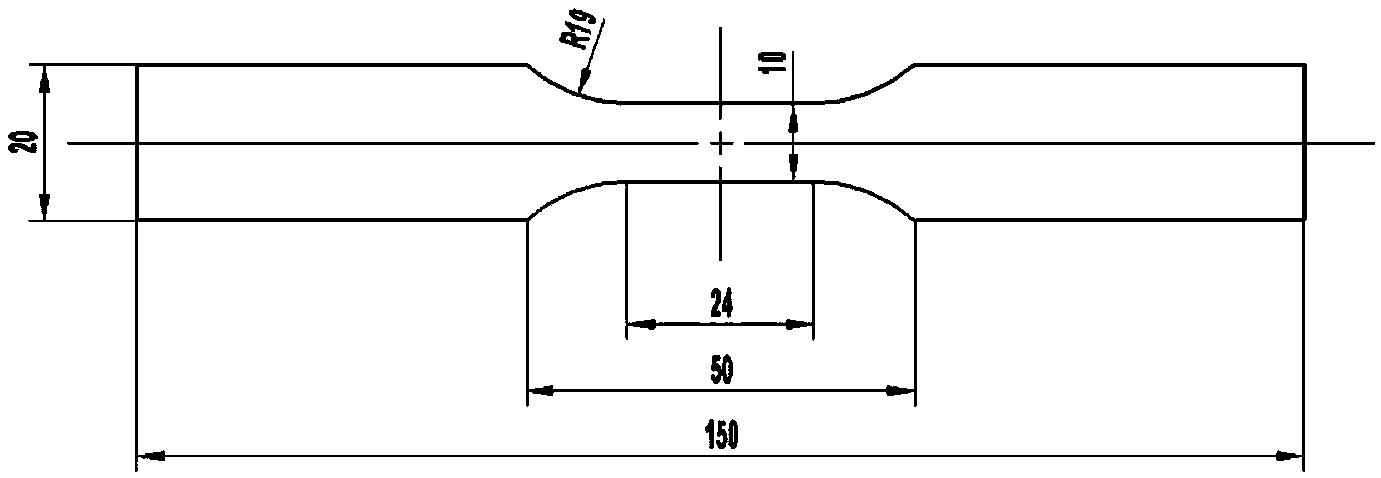

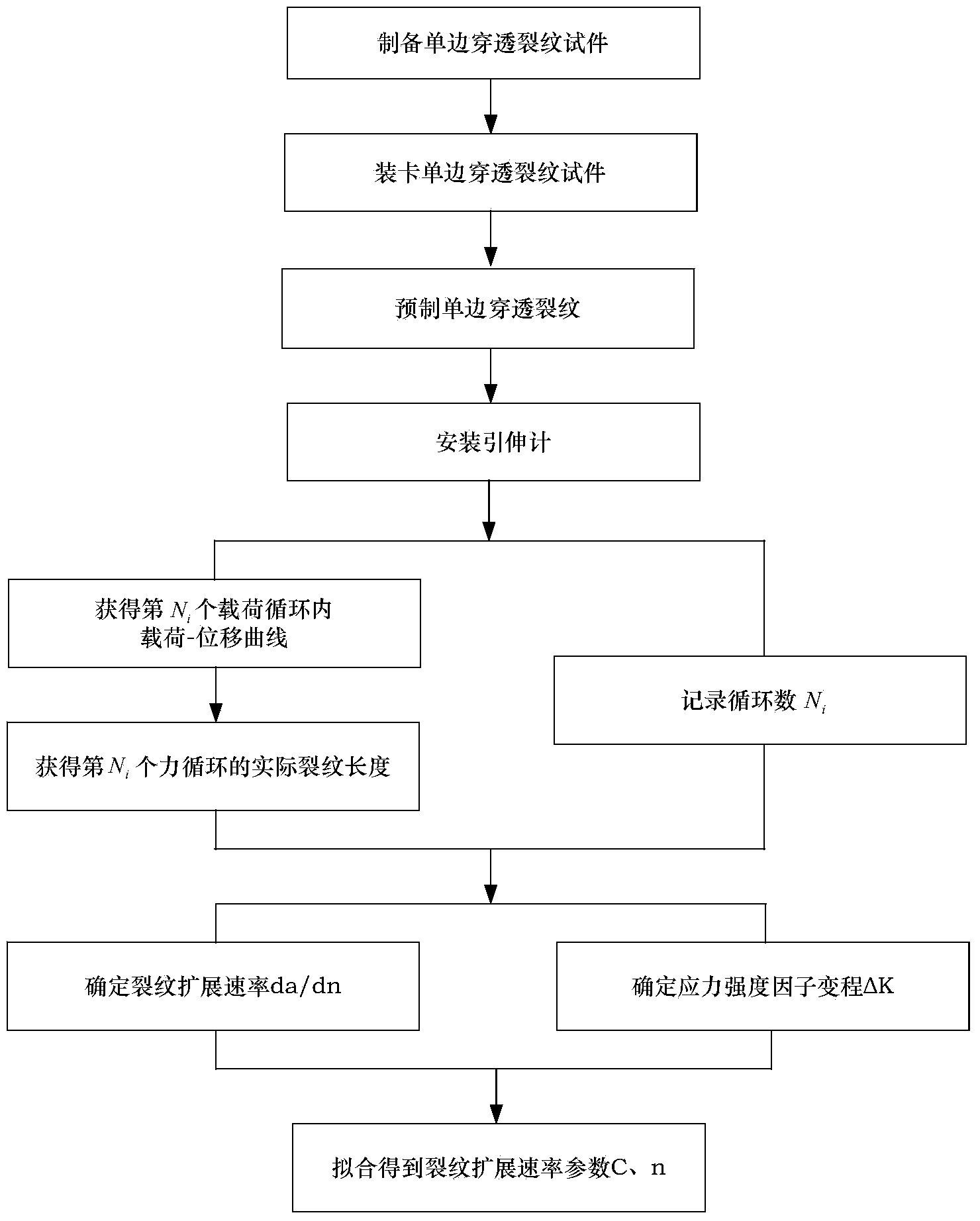

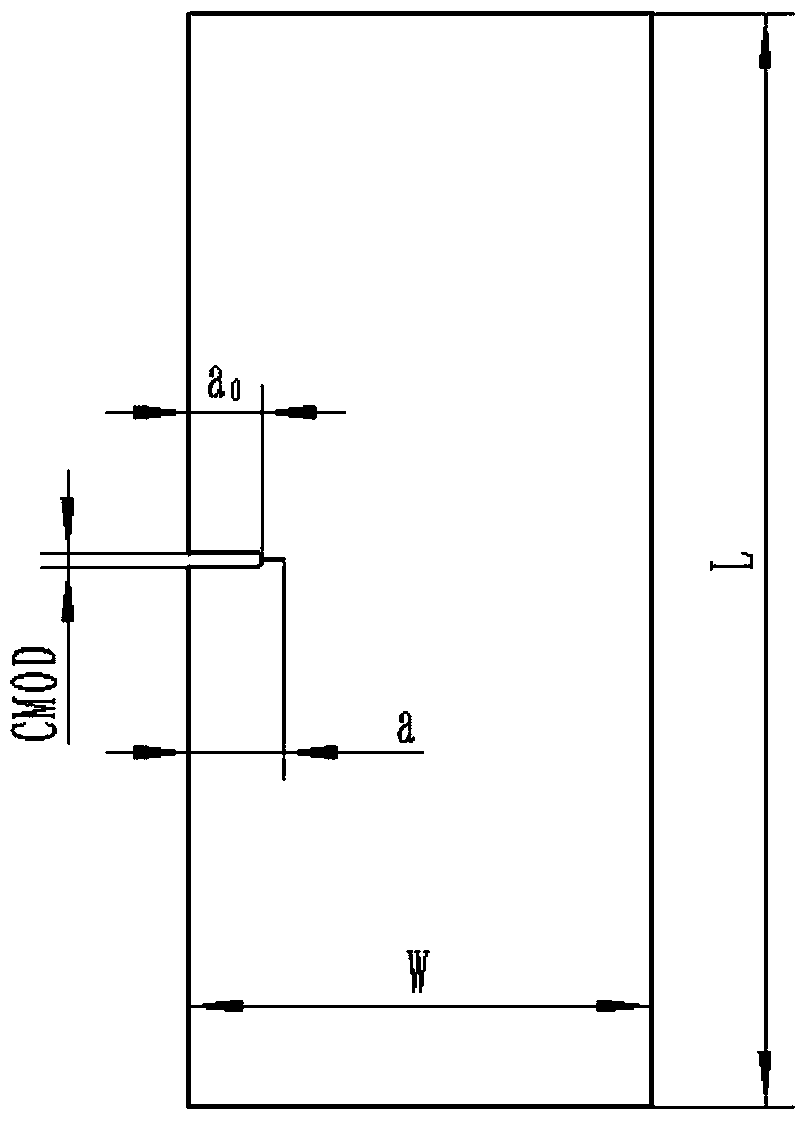

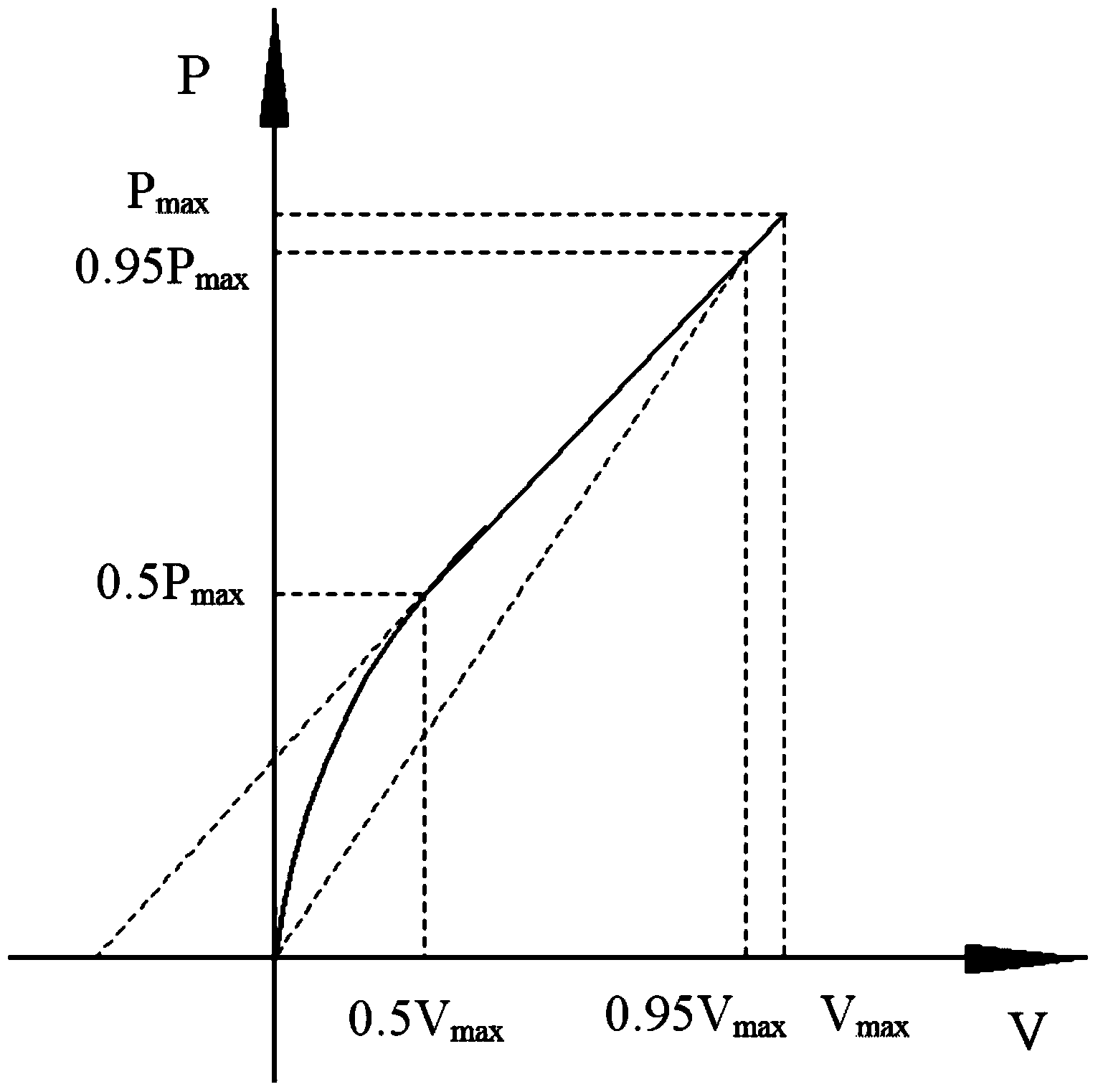

Crack propagation rate measurement method

InactiveCN103674741AAvoid invalid situationsSave materialMaterial strength using repeated/pulsating forcesStress intensity factorStress ratio

The invention discloses a crack propagation rate measurement method. The method comprises the steps of applying alternating load to a test piece with a single-side penetrated crack by a testing machine; measuring load-displacement curves at an interval of certain loading cycles and fitting a linear segment to obtain the non-dimensional flexibility value of the test piece; acquiring the length of the crack according to the relation of the non-dimensional flexibility value of the single-side penetrated crack and the length of the crack under a clamped boundary condition; recording the number of the current loading cycles to obtain a crack length-load cycle number curve, and determining the crack propagation rate; and calculating the corresponding stress intensity factor, acquiring discrete data and fitting to obtain the parameters of the crack propagation rate. The method has the advantages that the method is suitable for measuring the crack propagation rate under positive and negative stress ratios and can be used for measuring the crack length automatically; and the measurement system has wide application range and is particularly suitable for measuring the crack propagation rate of novel materials such as a metal laminated board, a metal / composite material laminated board, a ceramic matrix composite material, a welding material.

Owner:BEIHANG UNIV +1

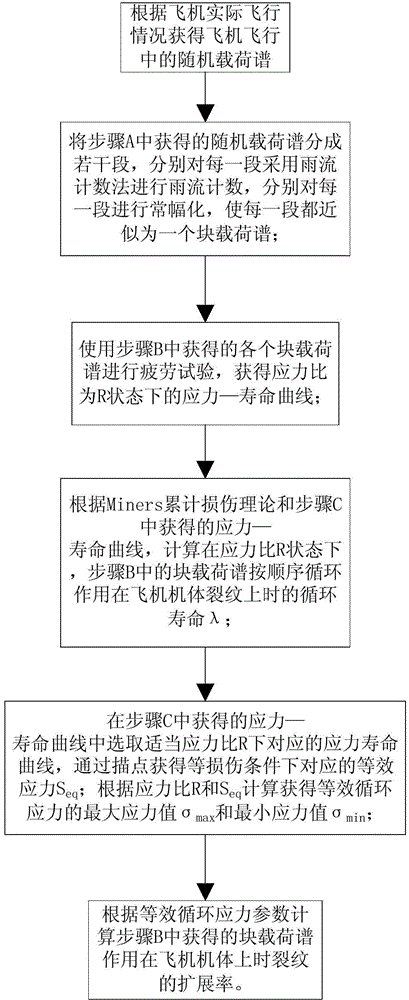

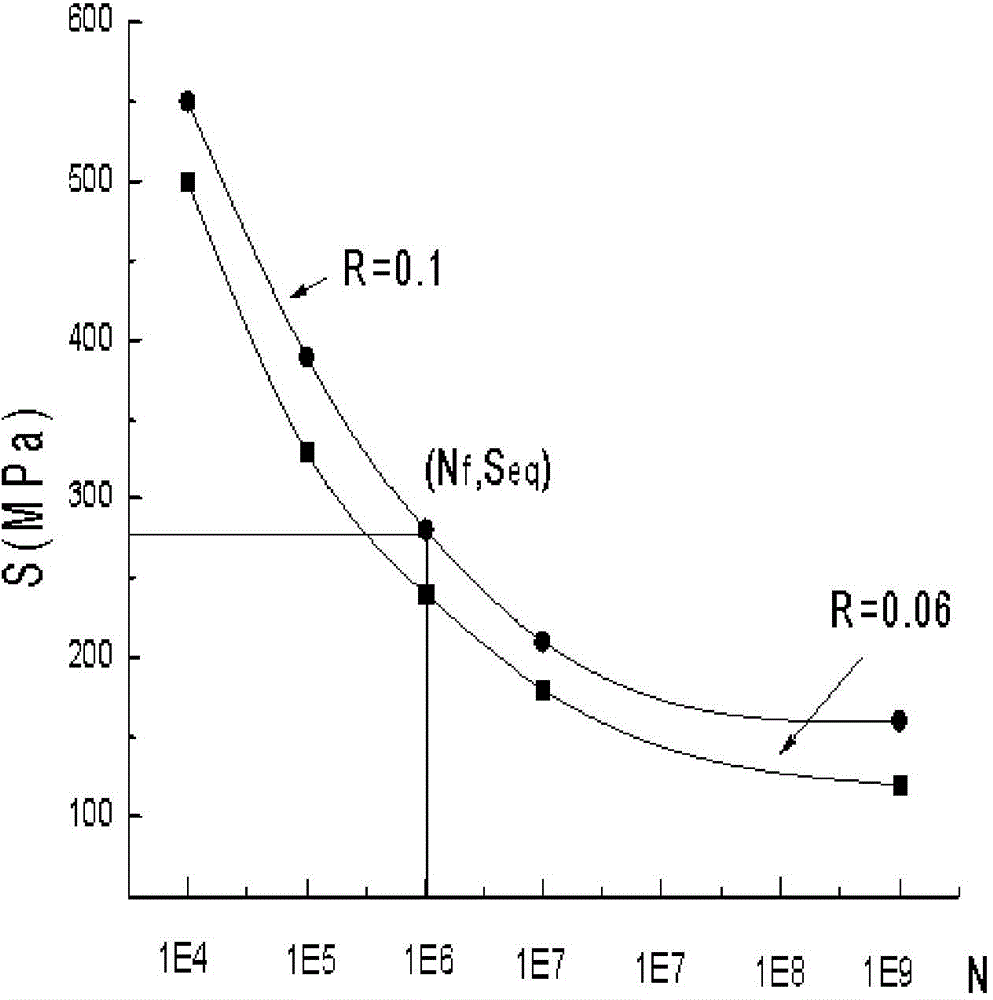

Prediction method of crack propagation life of aircraft body

ActiveCN104792633AAvoid frequent updatesAvoid repartitioningMaterial strength using repeated/pulsating forcesStress ratioEngineering

The invention discloses a prediction method of a crack propagation life of an aircraft body. The prediction method comprises the following steps: obtaining a random loading spectrum of an aircraft in flight according to the practical flight situation of the aircraft; dividing the obtained random loading spectrum into a plurality of sections, and respectively performing rain-flow counting and constant amplitude on each section, so that each section is approximated as a block loading spectrum; according to an Miners progressive damage theory, calculating a cycle life lambda effected on a crack of each block loading spectrum under the state of a corresponding stress ratio R, performing a fatigue test under the suitable stress ratio, and obtaining a corresponding stress-life curve; according to an equal defect theory, selecting the correspondence life curve under the suitable stress ratio R in the stress-life curve, and obtaining the equivalent stress Seq corresponding to the same life by a point tracing method; then, according to the R and the Seq, obtaining a maximum stress value sigma max and a minimum stress value sigma min of the equivalent cyclic stress; according to parameters of the equivalent cyclic stress, calculating the propagation rate of the crack when the obtained block loading spectrum is acted on the aircraft body.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Steel wire for high strength spring excellent in workability and high strength spring

ActiveUS20060201588A1Excellent fatigue propertiesImprove sag resistanceSolid state diffusion coatingStress ratioManganese

A steel wire has tempered martensite, comprises, as essential components, by mass, C: 0.53 to 0.68%; Si: 1.2 to 2.5%; Mn: 0.2 to 1.5%; Cr: 1.4 to 2.5%; Al: 0.05% or less; further comprises, as a selective component, Ni: 0.4% or less; V: 0.4% or less; Mo: 0.05 to 0.5%; or Nb: 0.05 to 0.5%; and further comprises remainder essentially consisting of Fe and inevitable impurities, wherein the grain size number of prior austenite is 11.0 or larger, and the proof stress ratio (σ0.2 / σB), namely, a ratio of 0.2% proof stress (σ0.2) to tensile strength (σB) is 0.85 or lower. Satisfying the above requirements makes it possible to produce a steel wire for high-strength spring excellent both in workability (cold workability), and in sag resistance and fatigue properties.

Owner:KOBE STEEL LTD +2

Sample preparation device for remoulded soil with different stress ratios

InactiveCN103033406ALimit contractionUniform moisture contentPreparing sample for investigationStress ratioEngineering

The invention provides a sample preparation device for remoulded soil with different stress ratios. The device comprises a clamping unit, an upper fixing plate, a lower fixing plate, a confining pressure cover, an elastic membrane, a force transmission element, a first water-permeable element and a second water-permeable element, wherein the clamping unit comprises an upper clamping plate and a lower clamping plate; the upper clamping plate is provided with a hole; the upper fixing plate is provided with an upper hole matched with the hole; the lower fixing plate is provided with a lower hole having the same diameter as the upper hole; the two ends of the confining pressure cover are fixed on the upper fixing plate and the lower fixing plate respectively; the two ends of the elastic membrane are fixed at the peripheries of the upper hole and the lower hole in a defining manner respectively; and an outer wall of the force transmission element is clung to the elastic membrane. According to the sample preparation device for the remoulded soil with the different stress ratios, thin mud is poured into the sample preparation device, the force transmission element applies vertical pressure on the thin mud in the elastic membrane, and water in the confining pressure cover applies lateral pressure on the thin mud in the elastic membrane, so that the different stress ratios are controlled, a soil sample is solidified, and a remolded soil test sample with the uniform water content is obtained.

Owner:SHANGHAI JIAO TONG UNIV

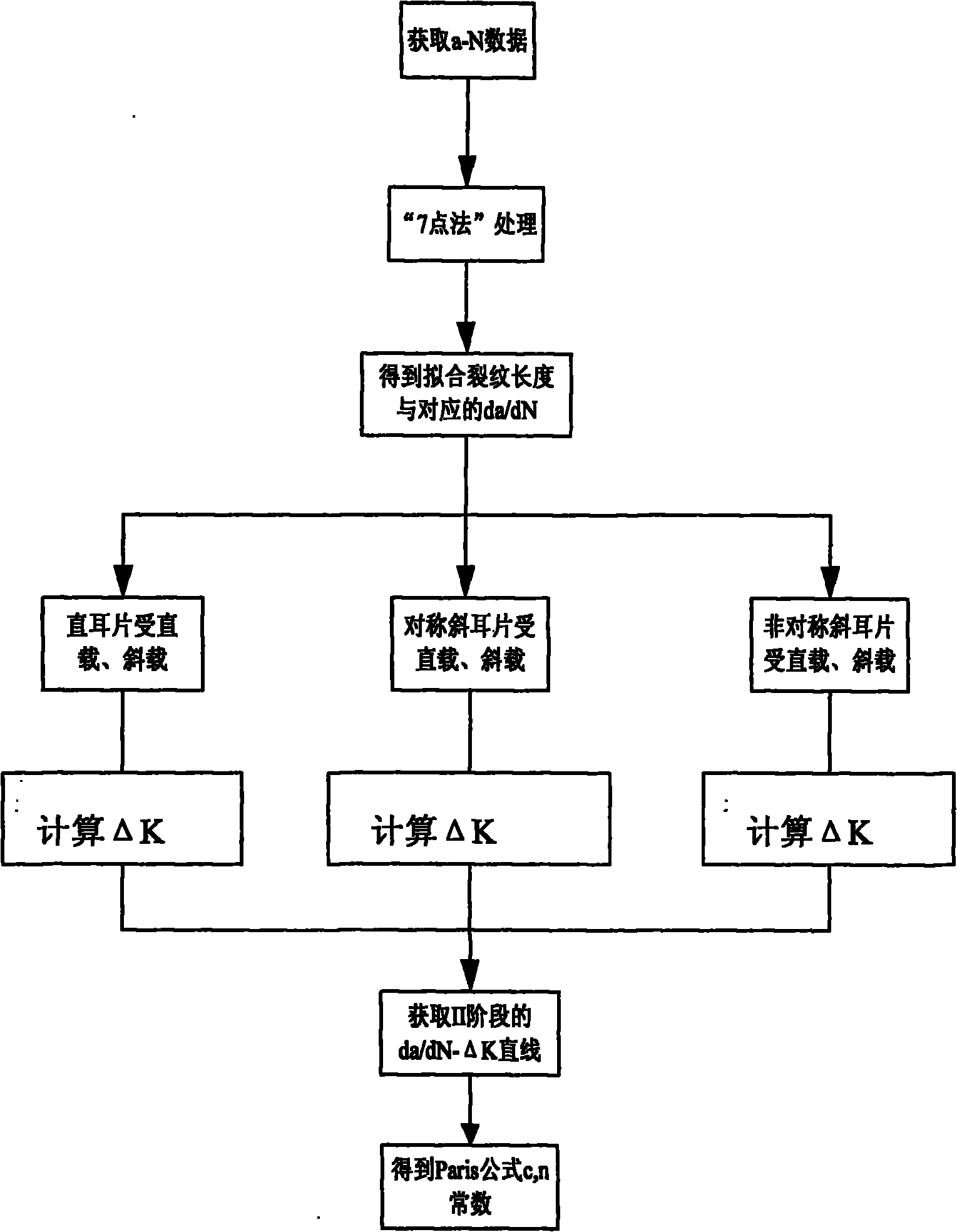

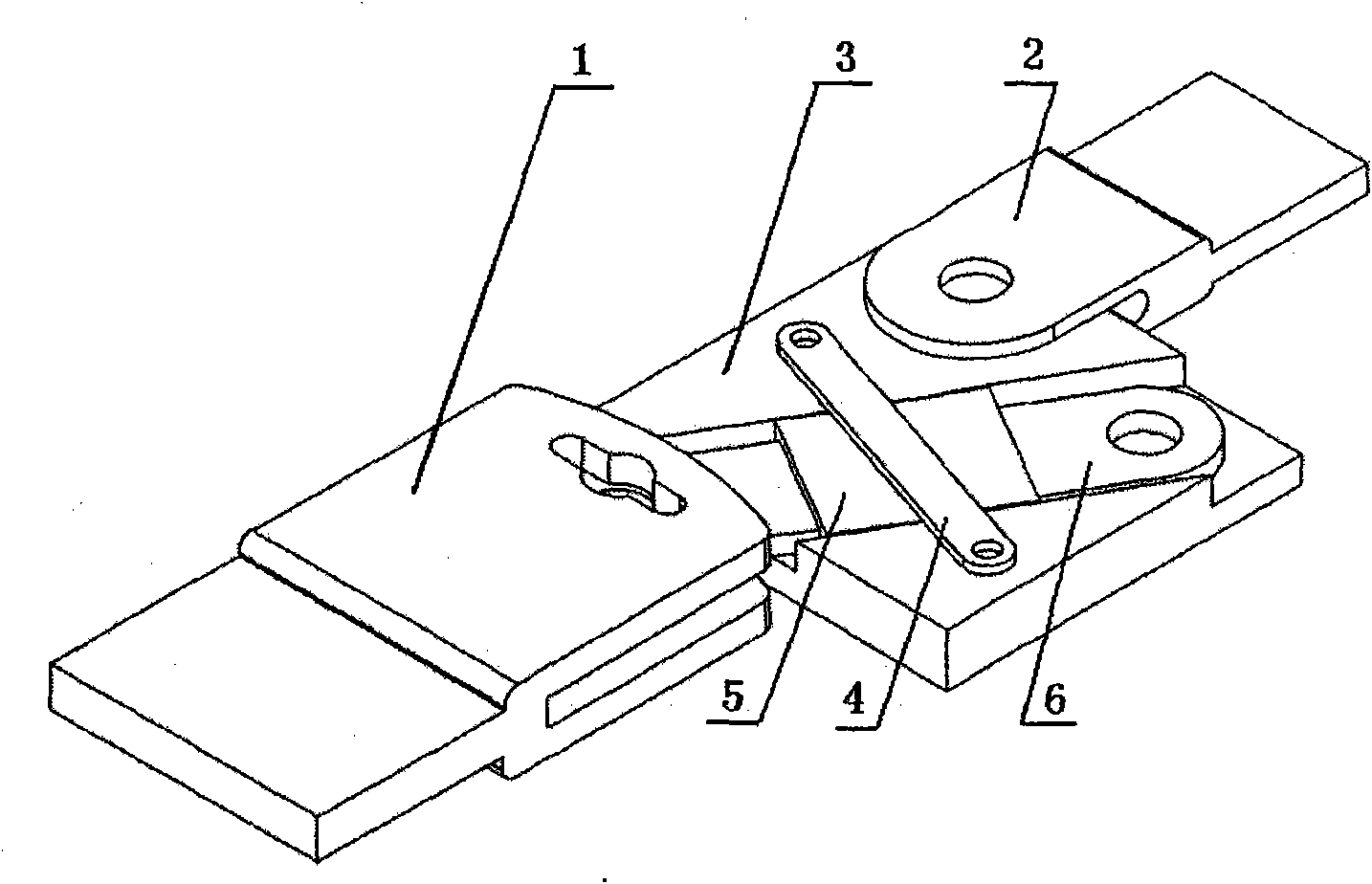

Test analysis method for bolt connecting piece fatigue crack expanding

InactiveCN102023116AClear principleWide applicabilityMaterial strength using tensile/compressive forcesStress intensity factorStress ratio

The invention relates to a test analysis method for lug connecting piece fatigue crack expanding, which is technically characterized by installing a test lug on a testing machine; then loading and producing fatigue crack on the lug; adopting a stress intensity factor comprising a straight lug pulled and loaded lengthwise, the straight lug loaded obliquely smaller than 45 degrees, a symmetrical oblique lug pulled and loaded lengthwise, the symmetrical oblique lug loaded obliquely smaller than 45 degrees, an asymmetrical oblique lug pulled and loaded lengthwise and the asymmetrical oblique lug loaded obliquely smaller than 45 degrees to the corresponding delta K; taking a slope factor of 1g(da / dN)-1g(delta K) line as a constant n in the Paris formula, an intercept of a straight line and axis y as a constant C in the Paris formula, and obtaining the Paris formula when the stress ratio is R; and the lug fatigue crack expanding life NC is estimated according to the obtained Paris formula. The invention has the advantages that the applicability is wide, and the test analytical method plays a directive role in researching the lug hole edge fatigue crack expanding properties under various pulling and loading conditions.

Owner:AIR FORCE UNIV PLA

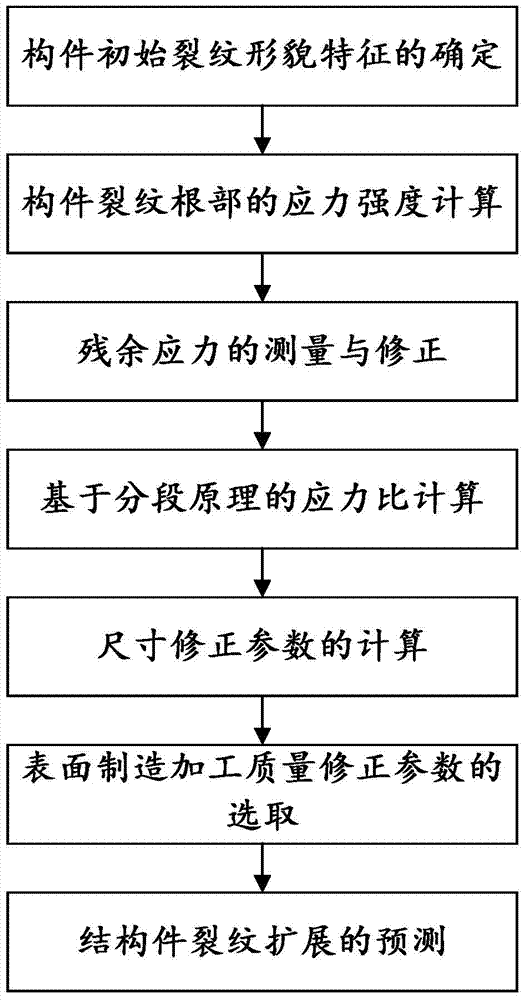

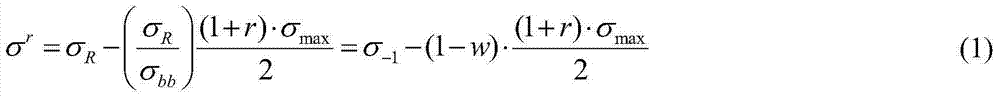

Structural member crack propagation prediction method based on multi-factor fusion correction

ActiveCN104850691AGood prediction accuracyAccurate and Effective PredictionSpecial data processing applicationsStress ratioMaterials science

The invention discloses a structural member crack propagation prediction method based on multi-factor fusion correction. Under the consideration of various factors with impacts on crack propagation of a structural member, the structural member crack propagation prediction method comprises: measurement and correction of initial crack morphology features of the structural member, stress intensity of the crack root of the structural member and the residual stress; calculation of a stress ratio; calculation of dimension correction parameters; selection of correction parameters of surface manufacturing quality. With the adoption of the structural member crack propagation prediction method, the precision of the prediction result is greatly improved. Therefore, the crack propagation of the structural member can be accurately and effectively predicted.

Owner:南京市特种设备安全监督检验研究院 +1

Anti-large deformation steel for X80 pipeline and production method hereof

The invention discloses anti-large deformation steel for an X80 pipeline which consists of the following components in percentage by weight: 0.050-0.085% of C, 0.20-0.45% of Si, 1.75-1.90% of Mn, less than or equal to 0.012% of P, less than or equal to 0.0015% of S, 0.15-0.35% of Mo, 0.25-0.50% of Cr, less than or equal to 0.03% of Cu, 0.045-0.080% of Nb, less than or equal to 0.01% of V, 0.005-0.030% of Ti, 0.02-0.05% of Al, less than or equal to 0.010% of N and 0.0010-0.0050% of Ca. The production steps of the anti-large deformation steel comprises smelting and continuous casting into blank, cast blank heating, rough rolling, finish rolling, two-section cooling and air cooling to room temperature and straightening. According to the invention, the uniform elongation A, the stress ratio and the deformability of steel are obviously improved through accurate duplex structure control; and by adopting low-temperature heating and two-section cooling, relaxation after rolling is canceled, the rolling holding time is shortened, the low-temperature toughness and structure of the pipeline steel are improved, and the performance is stable.

Owner:武汉钢铁有限公司

Fatigue crack spreading rate normalization forecasting method

ActiveCN103308381ASimple methodWell formedSpecial data processing applicationsStrength propertiesApplicability domainStress ratio

The invention relates to the field of forecast of a fatigue crack spreading rate of a material, and in particular relates to a fatigue crack spreading rate normalization forecasting method based on the energy release rate. The method comprises the following steps of: drawing a data map for setting a metal material to be under different stress ratios; constructing a fatigue crack spreading rate calculation formula for the metal material under the stress ratio of R:i of 1:1, FORMULA, and expressing the formula as a function; determining experiment constants and curves of the expression under the stress ratio of R:i of 1:1; constructing normalization method expressions of experiment data under different stress ratios that R is not equal to i, and obtaining the normalization method expressions, FORMULA; determining the value Alpha and a math expression Alpha=f(R), and determining an expression of a stress ratio normalization coefficient M and an expression of a data normalization method; and forecasting normalized data through the fatigue crack spreading rate formula under the determined stress ratio of R:i of 1:1. The method has the characteristics of simplicity, wide application range and the like and is favorable for engineering application.

Owner:HEFEI GENERAL MACHINERY RES INST

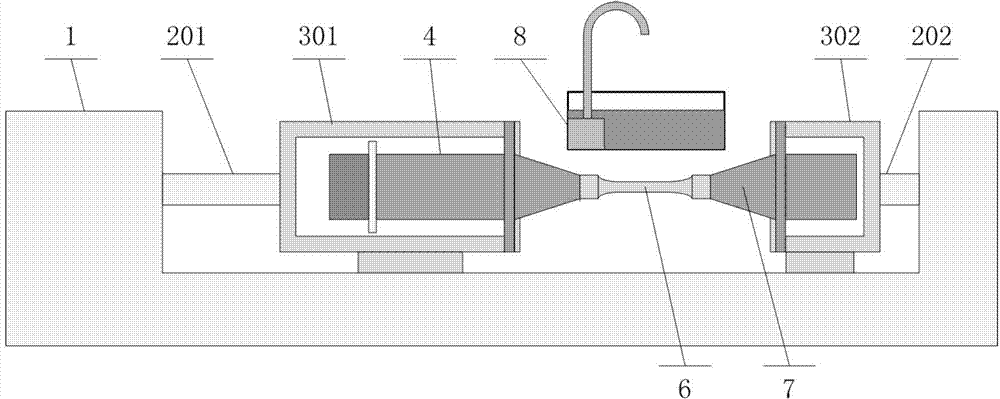

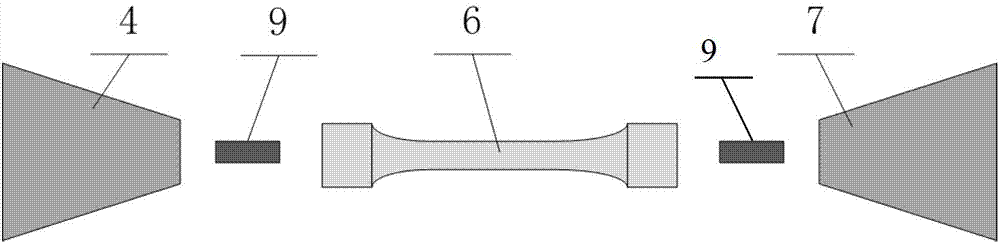

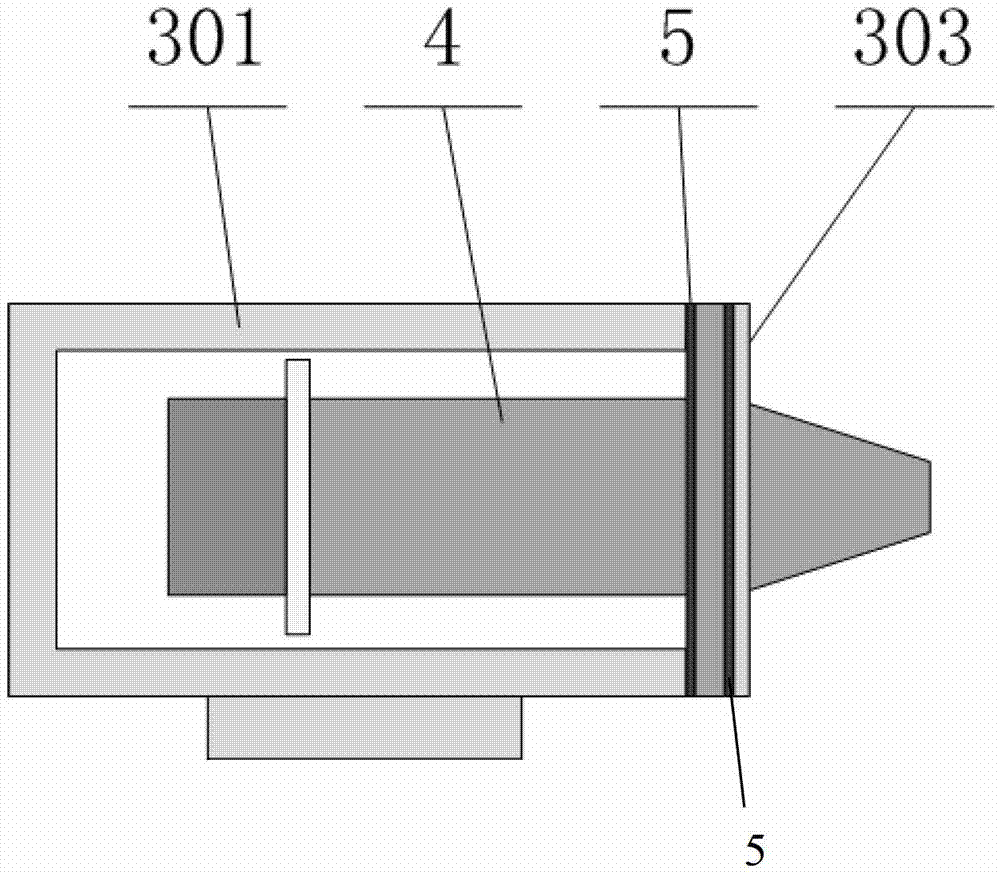

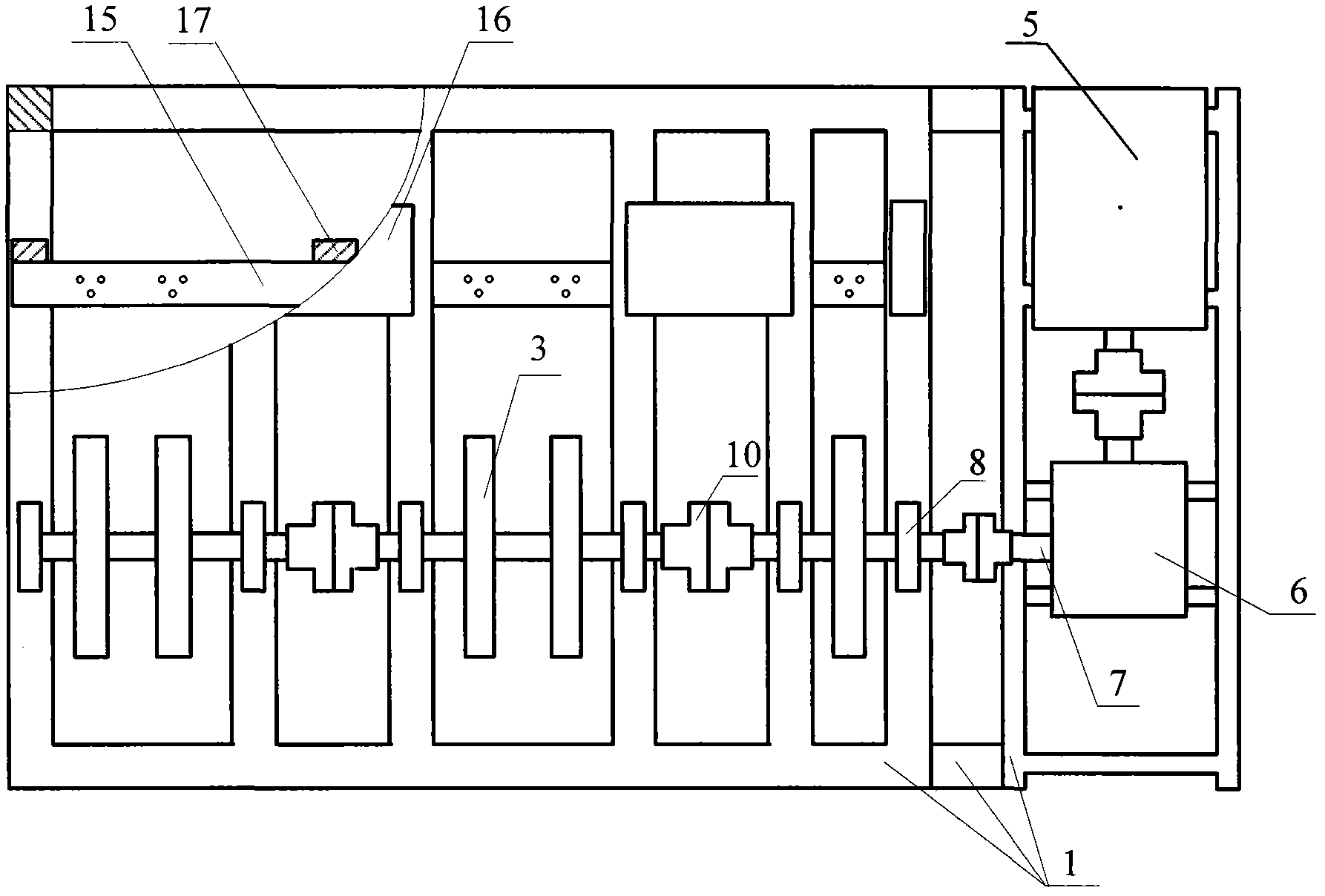

Sub-ultrasonic high-frequency fatigue testing machine

ActiveCN103091184AReduce frequencySmall sizeMaterial strength using repeated/pulsating forcesStress ratioTransformer

The invention discloses a sub-ultrasonic high-frequency fatigue testing machine. An energy converter used as a driving force source, the energy converter, a tested sample and a driven amplitude transformer form a resonance system, and a prearranged static loading mechanism provides static load for a test piece. The energy converter can be a full-wavelength energy converter or a half-wavelength energy converter. The energy converter converts an electric signal into mechanical vibration under the driving of an external alternating voltage, so the whole system is in a resonance state, and the tested sample has resonance vibration and a stress, thereby the fatigue detection can be realized. The energy converter can be a piezoelectric energy converter or a giant magnetostrictive energy converter. The sub-ultrasonic high-frequency fatigue testing machine allows the sub-ultrasonic high-frequency fatigue tests of the test piece under different stress ratios to be carried out according to the system prearrangement state; compared with traditional high-frequency fatigue testing machines, the sub-ultrasonic high-frequency fatigue testing machine has the advantages of simple structure, small volume, test period shortening, high efficiency and energy saving; and compared with present ultrasonic fatigue testing machines, the sub-ultrasonic high-frequency fatigue testing machine has the advantage of reduction of the frequency effect and the dimension effect to the material fatigue performances.

Owner:天津益普科技发展有限公司

Structural part remaining life predicting method based on multi-factor fusion correction

ActiveCN104809311AGood prediction accuracyAccurate and Effective PredictionSpecial data processing applicationsStress concentrationStress ratio

The invention discloses a structural part remaining life predicting method based on multi-factor fusion correction. By taking multiple factors influencing the structural part remaining life into account, the structural part remaining life predicting method comprises the following steps: measuring and correcting stress intensity and residual stress of a structural part, calculating stress ratio, calculating size correcting parameters, selecting stress concentration correcting parameters and surface manufacturing quality correcting parameters, and the like. By the structural part remaining life predicting method, the accuracy of a prediction result is greatly improved, so that accurate and effective prediction of the structural part remaining life is achieved.

Owner:SOUTHEAST UNIV

IC layout adjustment method and tool for improving dielectric reliability at interconnects

ActiveUS20150379188A1Increase wiring spacePrevent rejectionComputer aided designTotal factory controlElectricityStress ratio

Method for adjusting a layout used in making an integrated circuit includes one or more interconnects in the layout that are susceptible to dielectric breakdown are selected. One or more selected interconnects are adjusted to increase via to wire spacing with respect to at least one via and one wire of the one or more selected interconnects. Preferably, the selecting analyzes signal patterns of interconnects, and estimates the stress ratio based on state probability of routed signal nets in the layout. An annotated layout is provided that describes distances by which one or more via or wire segment edges are to be shifted. Adjustments can include thinning and shifting of wire segments, and rotation of vias.

Owner:RGT UNIV OF CALIFORNIA

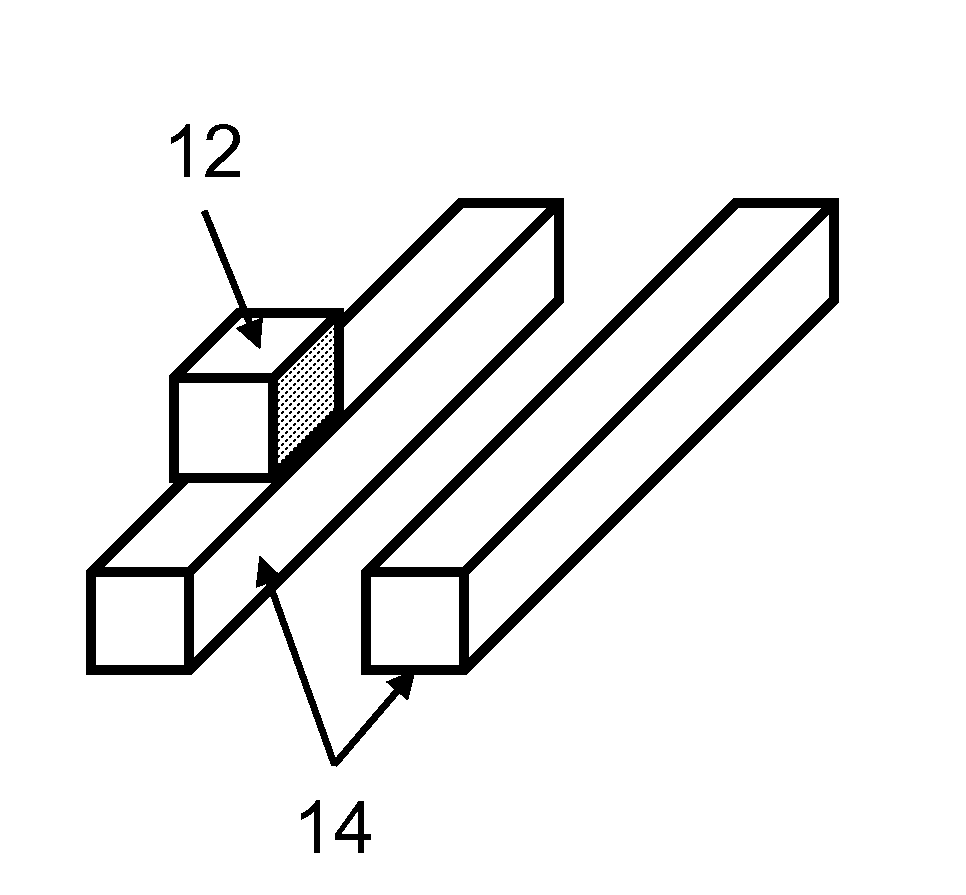

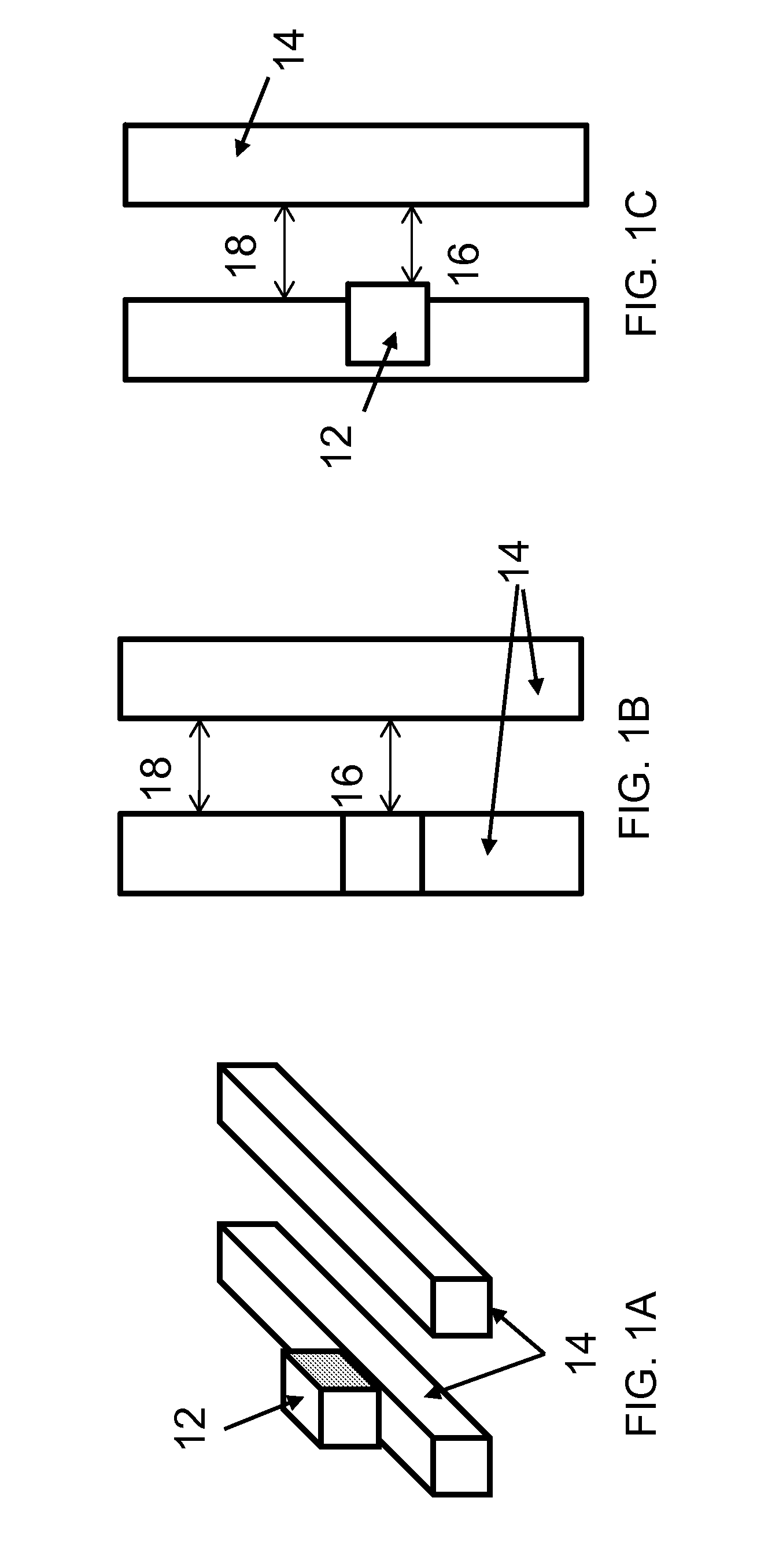

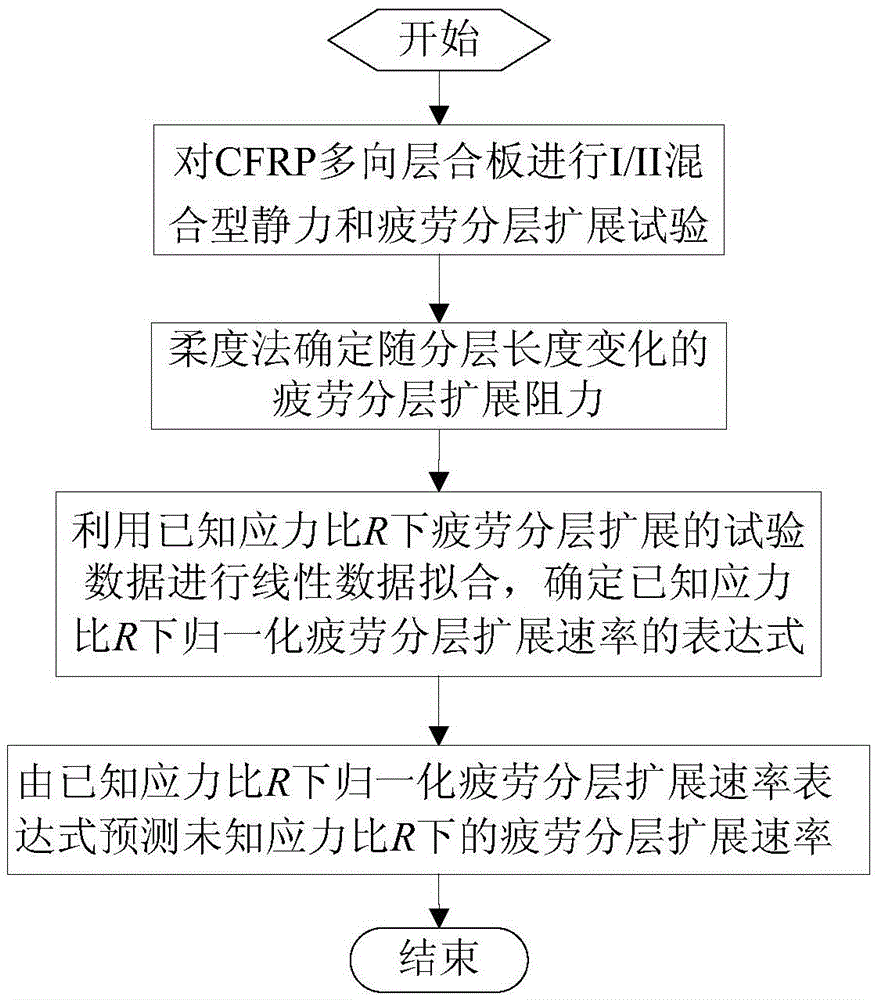

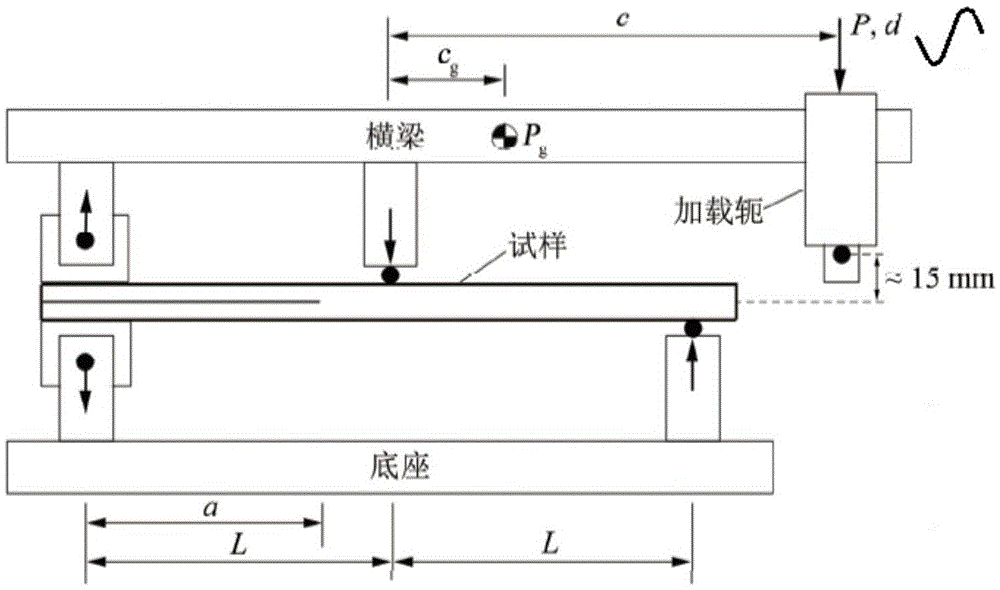

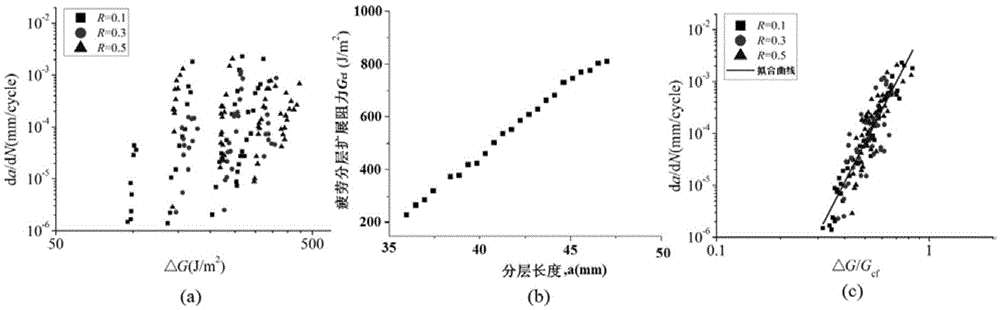

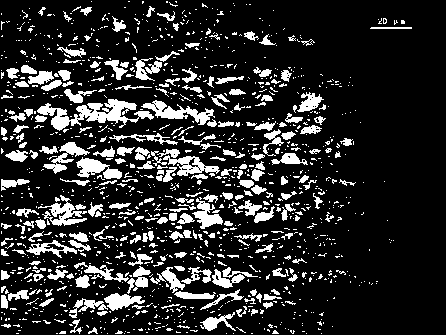

Prediction method for normalized fatigue delamination propagation rate of CFRP (carbon fiber-reinforced plastic) multi-directional laminated plate

ActiveCN105488310AReduce workloadReduce testing workloadGeometric CADSpecial data processing applicationsFiberHybrid type

The invention discloses a prediction method for a normalized fatigue delamination propagation rate of a CFRP (carbon fiber-reinforced plastic) multi-directional laminated plate. The method comprises steps as follows: (1) fatigue delamination tests are performed on the CFRP multi-directional laminated plate under I / II mixed type static force and in different stress ratios; (2) fatigue delamination propagation resistance Gcf(a) changing with the delamination length is determined with a flexibility method; (3) a ratio of energy release rate variation amplitude deltaG and the fatigue delamination propagation resistance Gcf(a) is used as a normalized fatigue delamination propagation rate control parameter, and an expression of the normalized fatigue delamination propagation rate da / dN is corrected and established on the basis of a Paris formula; fitting parameters in the expression are obtained through linear fitting of fatigue delamination test data in a known stress ratio; (4) the fatigue delamination propagation rate in an unknown stress ratio is predicted by the aid of the expression of the fatigue delamination propagation rate in the known stress ratio. According to the method, the fatigue delamination propagation rate in the unknown stress ratio is predicted by the aid of the expression of the normalized fatigue delamination propagation rate of the CFRP multi-directional laminated plate in the known stress ratio, the test cycle can be significantly shortened, and the test cost can be reduced.

Owner:CHONGQING UNIV +1

Tower weak component location method based on finite element dynamic analysis

ActiveCN102930103AAccurate locationFailure warningSpecial data processing applicationsThree dimensional simulationStress ratio

The invention discloses a tower weak component location method based on finite element dynamic analysis and belongs to the field of online monitoring of disaster prevention and reduction of a power transmission line. The method includes building a three-dimensional simulation model according to a tower structure, utilizing an orthogonal test method to select a load set, simulating all possible dynamic loads in operation of the tower, conducting finite element dynamic calculation, obtaining axial stress ratio of tower components according to simulation results under each load combination and selecting weak components according to the axial stress ratio. The tower weak components can be accurately located by means of the method. The method can be used for online monitoring of disaster prevention and reduction of the power transmission line and is capable of directly conducting effective early warning on effect failure of the tower components.

Owner:WUHAN UNIV

Novel method for forecasting calendar life of metal structure of aging aircraft

ActiveCN104978490ACalendar life getsFew parametersSpecial data processing applicationsFatigue loadingStress ratio

A novel method for forecasting a calendar life of a metal structure of an aging aircraft. The method comprises five steps of: S1, establishing a prior-corroded metal material fatigue property S-N-t curve surface representation model; S2, according to a relative coefficient optimization method, establishing a prior-corroded metal material fatigue property S-N-t curve surface parameter fitness method; S3, establishing a prior-corroded metal material fatigue S-N-t curve surface model in a random stress ratio; S4, establishing a calendar life calculating formula for the metal structure of the aging aircraft under a spectrum load; and S5, substituting material fatigue properties with different prior-corrosion life limits, which are measured by testing, and a fatigue load spectrum counting processing result into the calendar life calculating formula to determine the calendar life of the metal structure of the aging aircraft. The novel method is simple and practical; a small number of model parameters need to be measured by testing; and the calendar life of the metal structure of the aging aircraft can be determined only by substituting the material corrosion fatigue properties with different prior-corrosion life limits and fatigue load spectrum data into the calendar life calculating formula.

Owner:北京睦邦仁科技有限公司

Large-strain X80 dual-phase steel plate produced by virtue of process at low temperature and under high pressure

The invention belongs to the field of the low-alloy high-strength pipeline steel and more specifically relates to a large-strain X80 dual-phase steel plate produced by virtue of a process at a low temperature and under a high pressure. The large-strain X80 dual-phase steel plate is composed of the following components in percentage by weight: 0.05-0.07% of C, 0.25-0.35% of Si, 1.40-1.80% of Mn, less than or equal to 0.01% of P, less than or equal to 0.003% of S, 0.01-0.04% of Nb, 0.01-0.02% of Ti, less than or equal to 0.035% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.035% of Cr, less than or equal to 0.030% of Ni, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 1.2ppm of H and the balance of Fe and inevitable impurities. The large-strain X80 dual-phase steel plate has the beneficial effects that the steel plate is subjected to accelerated cooling by virtue of high-pressure water in the adopted rolling process so that the crystalline grain are effectively refined and the production efficiency is improved, and multi-pass cooling and rolling at a low temperature and under high pressure are not carried out in a non-recrystallization zone, and finally, a proeutectoid ferrite-lath bainite structure is obtained, the obtained steel plate has the yield strength Rt0.5 of 480-560MPa, the tensile strength Rm of 770-800MPa, the yield ratio Rt0.5 / Rm being less than or equal to 0.75, the Charpy impact energy at -20 DEG C being greater than or equal to 350J, the drop shear area at -15 DEG C being greater than or equal to 95% and the Uniform elongation UEL being greater than or equal to 12, and the steel plate is high in anti-deforming capability, and furthermore, the stress ratios of the steel plate are as follows: Rt2.0 / Rt1.0 is greater than or equal to 1.09 and Rt1.5 / Rt0.5 is greater than or equal to 1.15.

Owner:JIGANG GRP

Underground cavern group layout method

ActiveCN103291331AReduce deformation and damageReduce the cost of reinforcement supportUnderground chambersUnderground cavernTransformer

The invention discloses a large-scale underground cavern group layout method applied to water conservancy and hydropower engineering and underground storage cavern engineering. The underground cavern group layout method can give overall consideration to major factors having influences on underground cavern adjoining rock stability, particularly gives overall consideration to the crucial factor of the rock strength-stress ratio, enables a large-scale underground cavern group layout designing scheme to be scientific, and is overall in considered factors. The method includes the following steps: firstly, determining the positions of main caverns, then determining the axis directions of the main caverns, determining the thickness of a rock pillar between the main caverns, and finally determining cavern shapes of the main caverns. When the cavern shapes of the main caverns are determined, each main cavern is divided into an underground main power house, a main transformer chamber and a tail water surge chamber according to functions, the hole shape of each underground main power house and the hole shape of each main transformer chamber are in circular arch straight wall shapes or egg shapes, and each tail water surge chamber is in a cylinder shape or a gallery shape.

Owner:POWERCHINA CHENGDU ENG

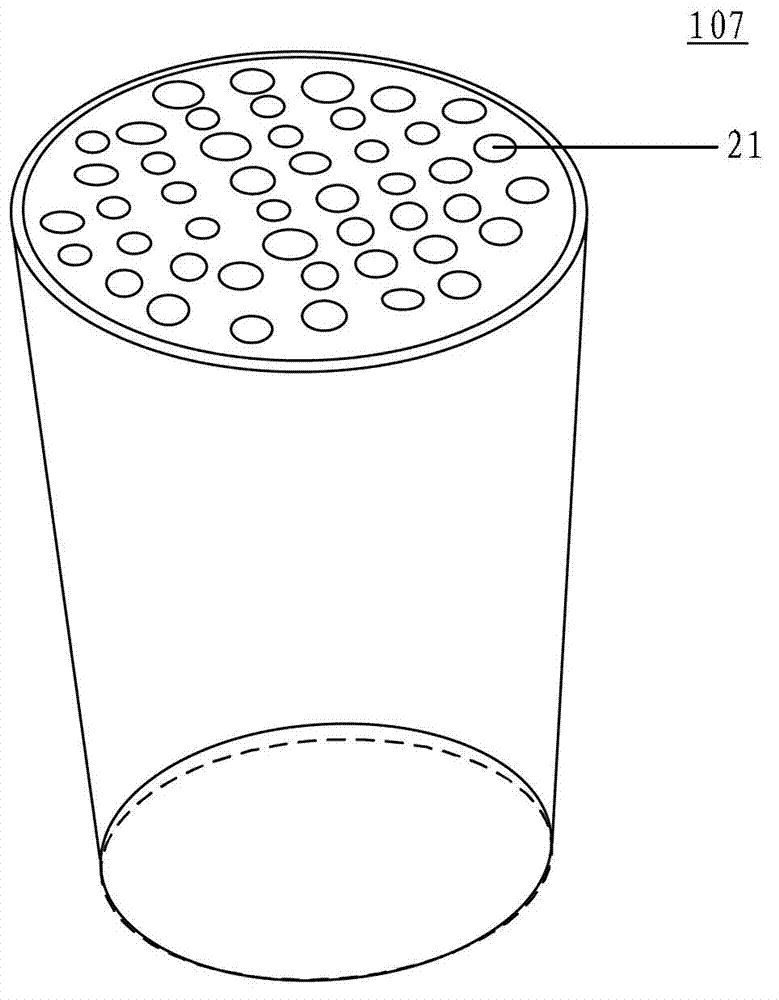

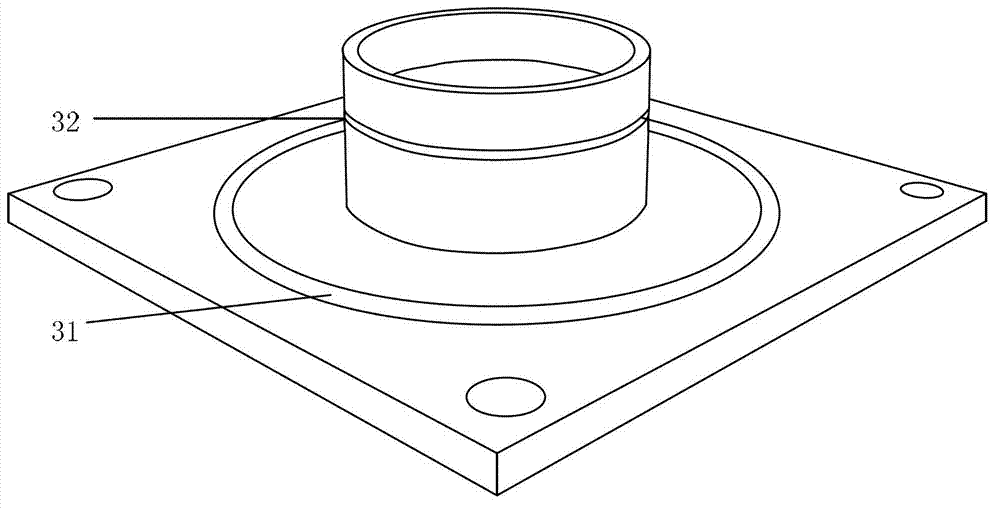

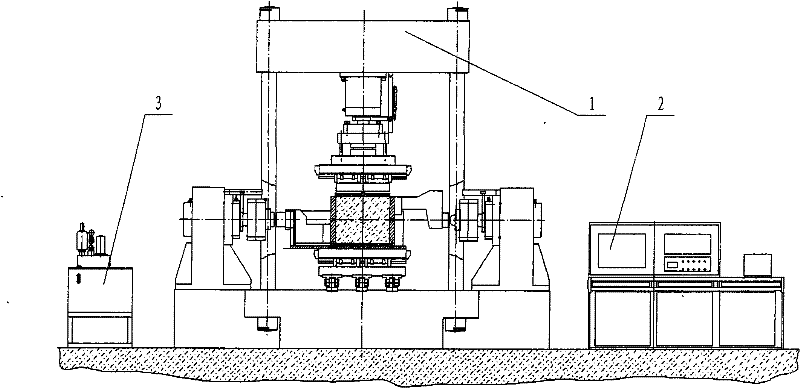

Microcomputer control electro-hydraulic servo large bidirectional direct shear apparatus

InactiveCN102478473ANo bending momentHigh precisionUsing mechanical meansMaterial strength using steady shearing forcesComing outExperimental research

The invention discloses a microcomputer control electro-hydraulic servo large bidirectional direct shear apparatus. The direct shear apparatus can satisfy a sample with larger size, can apply higher stress ratio, can simulate practical condition really, and is suitable for experimental research on the mechanical properties of contact faces of a plurality of materials. The direct shear apparatus comprises a host machine (1), a hydraulic system (2) and an electro-hydraulic servo control system (3). The host machine (1) comprises a bearing machine frame, a vertical servo loading oil cylinder (103), an upper shearing test table (104), horizontal bearing brackets (106, 106'), horizontal shearing servo loading oil cylinders (105, 110), a lower shearing test table (108) and a combined shearing box device (109), wherein the bearing machine frame consists of a bearing cross beam (101), four upright posts (102) and a machine base (107); the horizontal shearing servo loading oil cylinders (105, 110) are arranged on the horizontal bearing brackets (106, 106') and have consistent central height; the lower shearing test table (108) comes in and comes out of a test position through a linear guide rail arranged on the machine base; and the combined shearing box device (109) is arranged on the lower shearing test table (108).

Owner:TIANSHUI HONGSHAN TESTING MACHINE

Large bury depth cavern extrusion surrounding rock large deformation discrimination method

ActiveCN108871262AAccurate and quick judgmentImprove stabilityMeasurement devicesPrincipal stressStress ratio

The invention discloses a large bury depth cavern extrusion surrounding rock large deformation discrimination method which can quickly and reliably predict large deformation of the calculation point of the deep buried cavern engineering surrounding rock. The method comprises the steps that the in-situ ground stress test is performed and the lateral pressure coefficient lambda and the maximum principal stress value sigma0max are acquired; the rock core is drilled and processed into the cylindrical rock sample; the uniaxial compression test is performed on the rock sample so as to acquire the rock uniaxial compressive strength sigmac under the natural water content; the self-weight stress field is calculated according to the stress environment of the underground cavern or the rock strength-to-stress ratio SSR under the stress field is constructed; and occurrence of surrounding rock extrusion large deformation is judged according to the acquired self-weight stress field or the rock strength-to-stress ratio SSR under the constructed stress field. The method is used for judgment and prediction of large bury depth cavern surrounding rock extrusion large deformation and can be used for stability evaluation of the bury depth cavern and optimization of the permanent support design.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

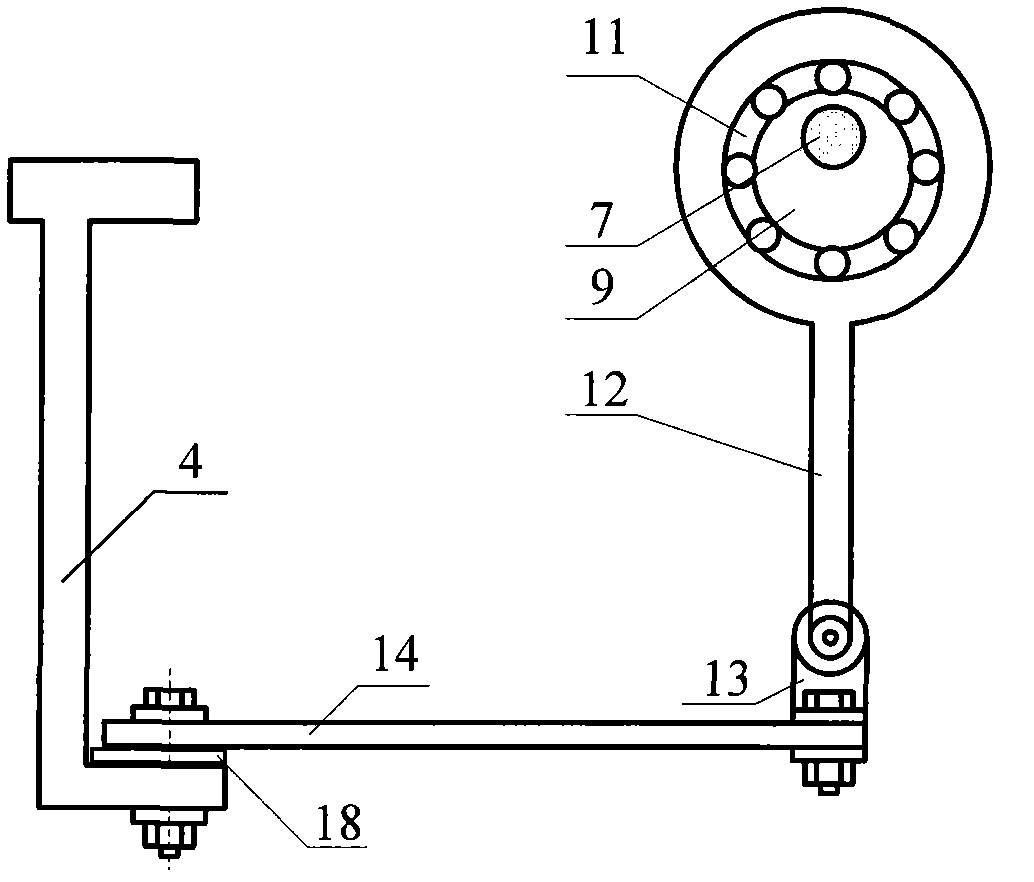

Reciprocating bending corrosion fatigue testing machine

InactiveCN102156077AImproving Experimental Efficiency for Low-Frequency Corrosion FatigueReduce labor intensityWeather/light/corrosion resistanceMaterial strength using steady bending forcesTemperature controlReduction drive

The invention discloses a reciprocating bending corrosion fatigue testing machine which manly comprises a steel frame, a power mechanism, eccentric wheel mechanisms and an adjusting bracket mechanism. An exciting motor with controllable rotation speed is connected with a speed reducer through a coupler; the speed reducer reverses by 90 degrees through the coupler to drive a rotation shaft to rotate; the rotation shaft is fixed in the length direction of the steel frame through a bearing pedestal; the five eccentric wheel mechanisms are arranged on the rotation shaft, and each eccentric wheel mechanism comprises an eccentric wheel as well as a bearing and a connecting rod which are sleeved outside; the stress of a sample can be adjusted through the eccentricity of the eccentric wheel; the connecting rod of each eccentric wheel mechanism is connected with one end of the sample through a T-shaped block, and the other end of the sample is fixed on a bottom plate of an adjusting bracket; the distance between the adjusting bracket and the rotation shaft can be adjusted to test the sample of different size; and the thickness of a gasket arranged between the sample and the bottom plate of the adjusting bracket can be adjusted to adjust the cyclic load stress ratio. The reciprocating bending corrosion fatigue testing machine has the functions of medium temperature control, motor start / stop control, automatic counting and remote alarm.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Small device for load bending fatigue testing and method

ActiveCN109357962AReasonable structural designVersatileMaterial strength using repeated/pulsating forcesControl systemStress ratio

The invention discloses a small device for load bending fatigue testing and a method. The device comprises a base, a gantry, a linear motor module, a linear motor module bracket, a load sensor, a thrust rod guide wheel assembly, a thrust rod, a specimen fixed end clamp right support table, a specimen cantilever end clamp assembly, a displacement sensor test connective rod, a displacement sensor, adisplacement sensor bracket, a fatigue specimen, a specimen fixed end clamp assembly, an environmental chamber, a specimen fixed end clamp left support table, and control system. The small device forload bending fatigue testing and the method provided by the invention can realize fatigue testing of stress control, strain control, and stress / strain hybrid control, and achieve a bending fatigue performance testing with a stress ratio greater than zero, equal to zero, or less than zero. The advantages of the device are reasonable in structure design, complete in function, and convenient in operation.

Owner:CIVIL AVIATION UNIV OF CHINA

Rotating bending fatigue test device and method with axial load control function

InactiveCN102866066AControl load amplitudeImplementing Uniaxial Tensile TestingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesStress ratioTest sample

The invention discloses a rotating bending fatigue test device and a rotating bending fatigue test method with an axial load control function. The device comprises a rotating bending fatigue loading device and an axial load application and control device for applying axial force to a test sample. The axial load application and control device is additionally arranged on the basis of the conventional rotating bending fatigue test device and the conventional rotating bending fatigue test method, and the sample is subjected to the action of an axial load under a rotating bending fatigue loading condition, so that rotating bending fatigue tests under different stress ratio conditions are realized. The axial load is controlled to be changed along with a time cycle, so that combined fatigue under the action of two different frequency loads is realized. Rotation is stopped, a bending load is removed, and the axial load is controlled to be monotonically increased, so that a monotonic tensile test is realized. The rotating bending fatigue test device with the axial load control function is simple in structure, low in energy consumption, low in manufacture and using cost and suitable for high-cycle and ultrahigh-cycle fatigue tests under an average tensile stress load condition.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Layout design method of underground cavern group

ActiveCN103266902AReduce damage and deformationReduce the cost of reinforcement supportUnderground chambersDesign planUnderground cavern

The invention discloses a layout design method of an underground cavern group applied to a water conservancy and hydropower project and an underground storage. According to the layout method, main factors influencing the stability of surrounding rock of the underground caverns, especially, the rock strength stress ratio which is the essential factor can be fully taken into consideration. The method comprises the following steps of: firstly determining the positions of main caverns, determining the axial line directions of the main caverns, determining the thicknesses of rock pillars among the main caverns, and finally determining the shapes of the main caverns, wherein in the process of determining the thicknesses of the rock pillars among the main caverns, the thicknesses of the rock pillars are 1.0-2.5-time mean than excavation span between two adjacent main caverns and are 0.5-0.8 times that of the height of the big one in the adjacent two main caverns. Compared with the layout design with a design plan provided by a using traditional layout method, the layout design with the layout method disclosed by the invention is more scientific; and especially, in a highland stress environment and in a condition with relatively low surrounding rock strength, the phenomena of the deformation and destruction of the surrounding rock after the surrounding rock of the underground cavern group is excavation-unloaded can be greatly reduced or the deformation and destruction degrees of the surrounding rock can be reduced.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com