Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3701 results about "Pitch blende" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt warm-mix agent and asphalt mixture mixed by same as well as preparation methods thereof

ActiveCN101899218AWith viscosity reductionWith foamClimate change adaptationBuilding insulationsChlorideRoad surface

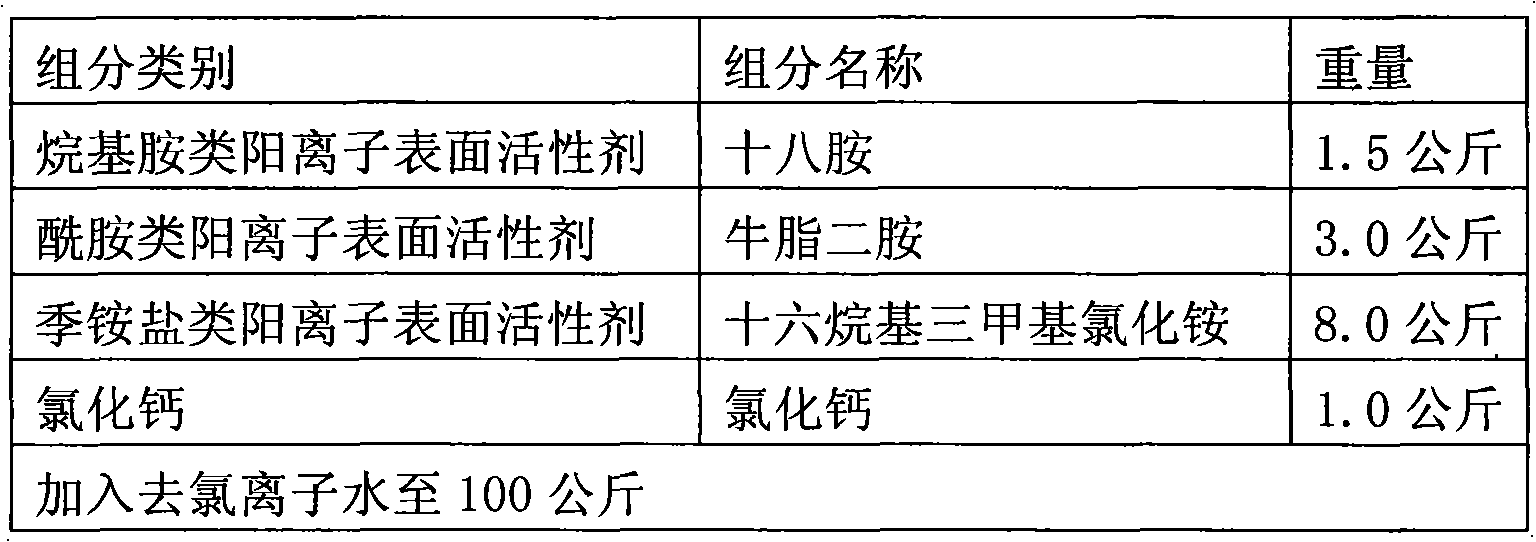

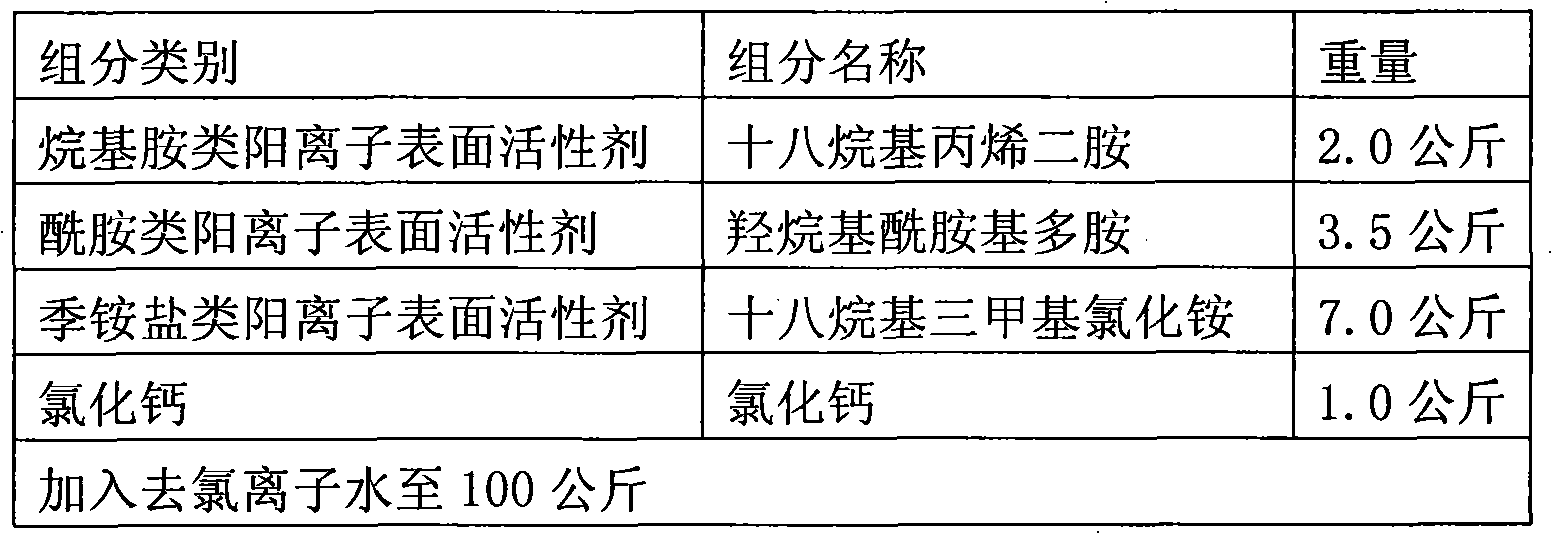

The invention relates to an asphalt warm-mix agent, comprising the following components in percentage by weight: 1.0-2.0% of alkylamine type cationic surfactant, 3.0-5.0% of amide type cationic surfactant, 5.0-10.0% of ammonium salt type cationic surfactant, 1.01.5% of calcium chloride, and water with residual percentage. The invention also relates to an asphalt mixture with the pavement applicability basically same as the traditional hot-mix asphalt mixture and the mixing and construction temperature lower than 20-50 DEG C; the purposes of energy saving, emission reduction, longer construction season, asphalt aging reduction and easier compaction are realized by reducing the mixing temperature; the indexes of the compaction degree, the water stability, the high-temperature performance, the low-temperature performance and the like of the pavement after paving the asphalt are not lower than those of hot-mix asphalt mixture at the same stage; and the service life of the asphalt pavement is efficiently guaranteed.

Owner:天津市市政工程研究院 +1

Method for treating and regenerating reuse building waste

ActiveCN101099974AAvoid excessive cement slurry contentAvoid Excessive Water DemandSolid waste managementSolid waste disposalPrillBrick

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

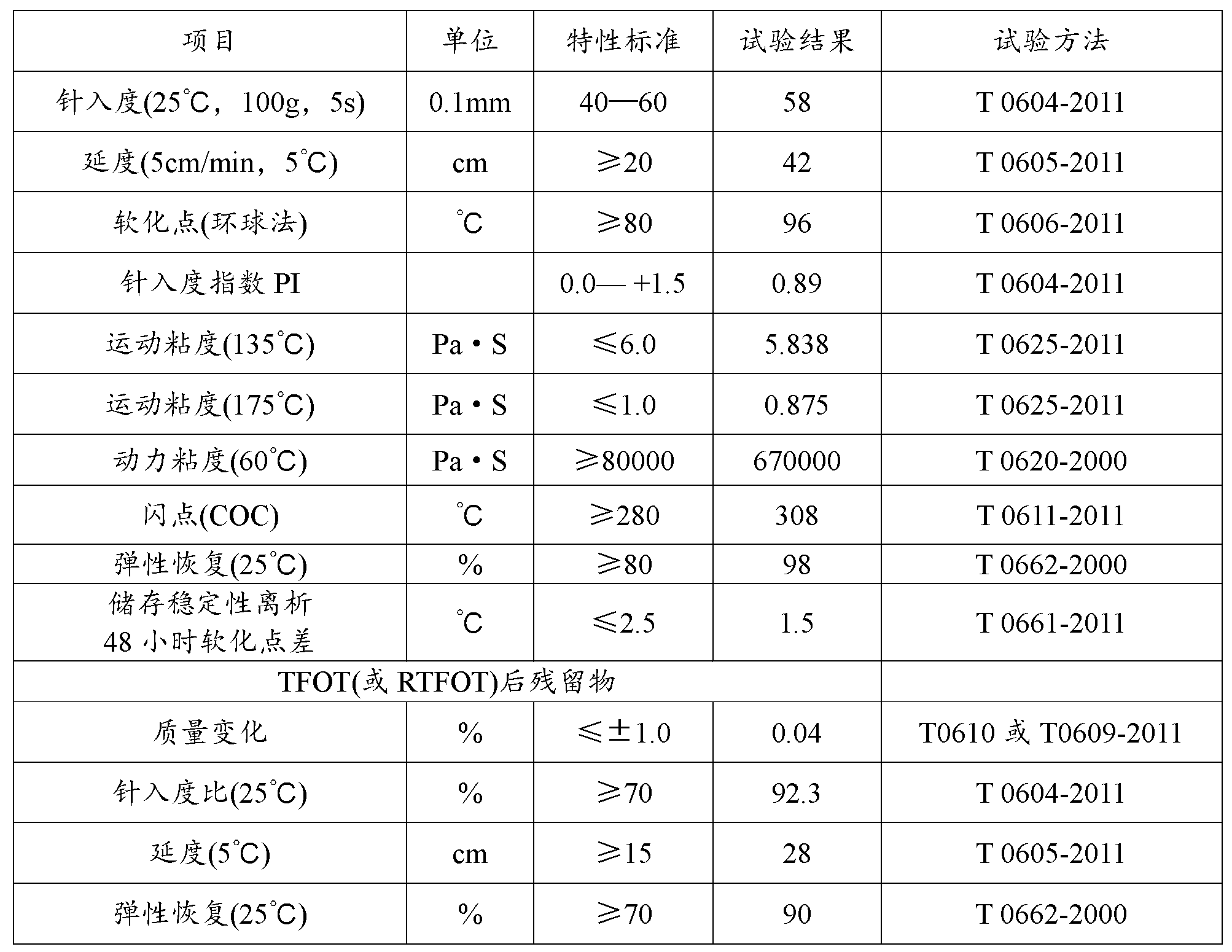

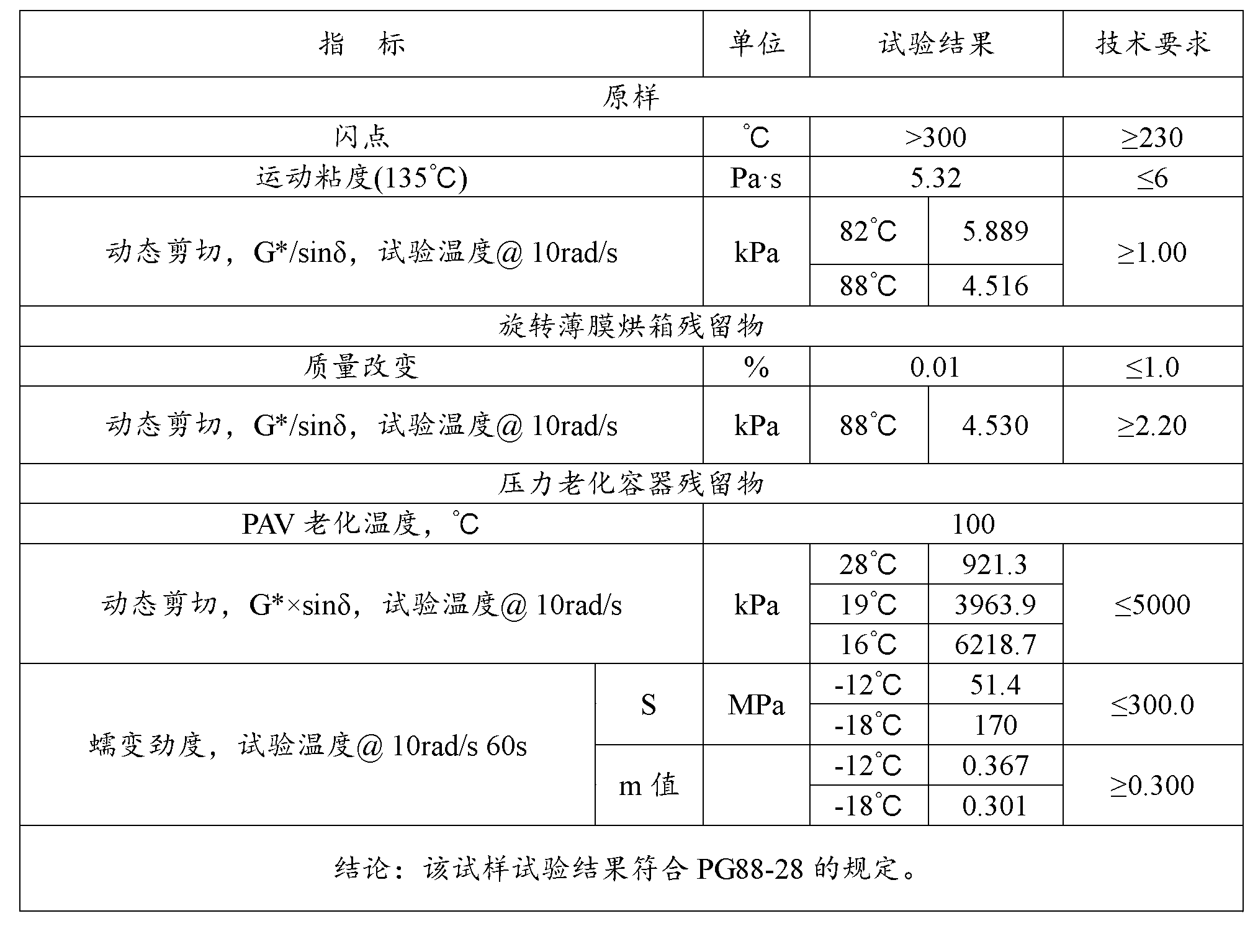

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

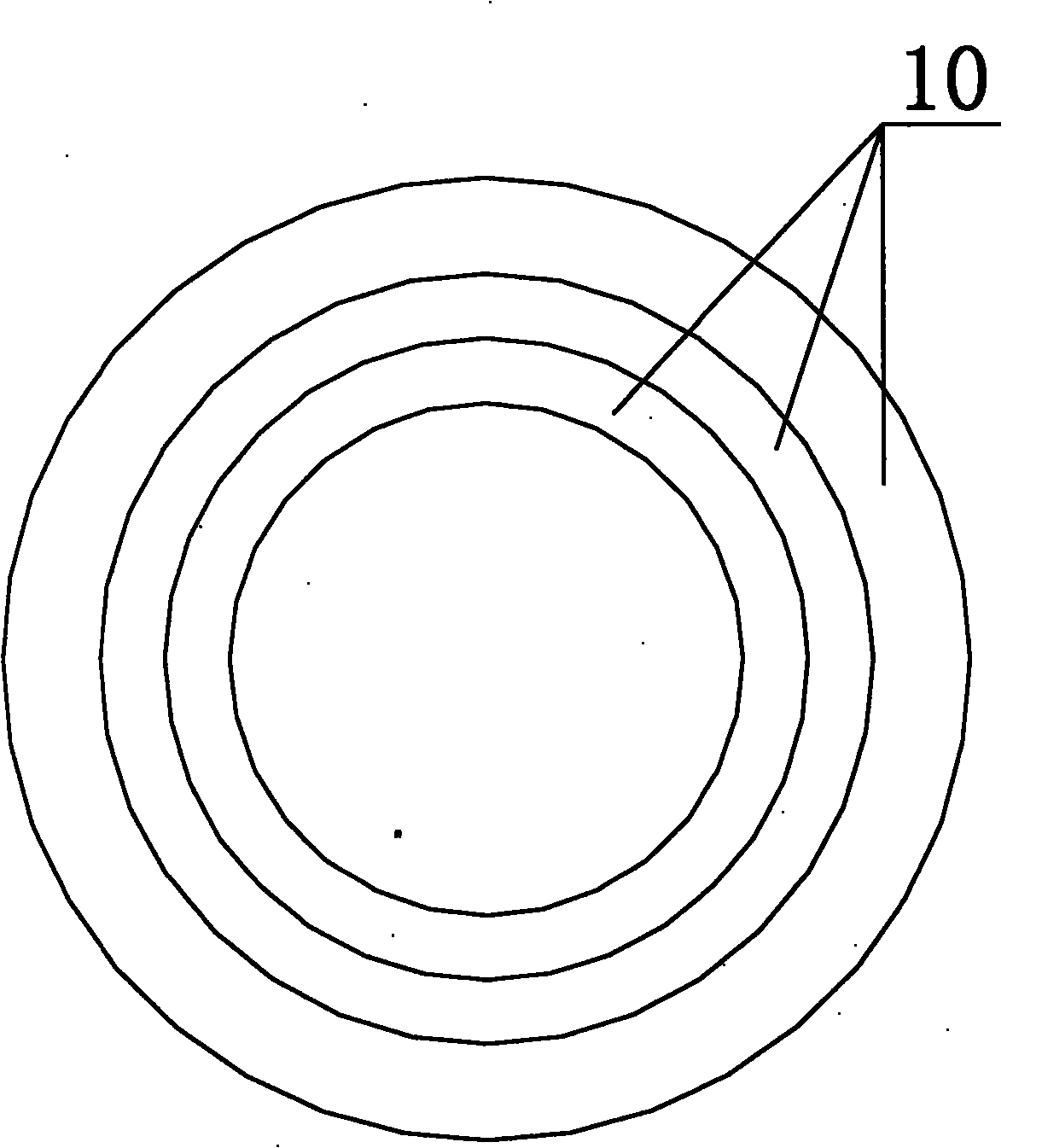

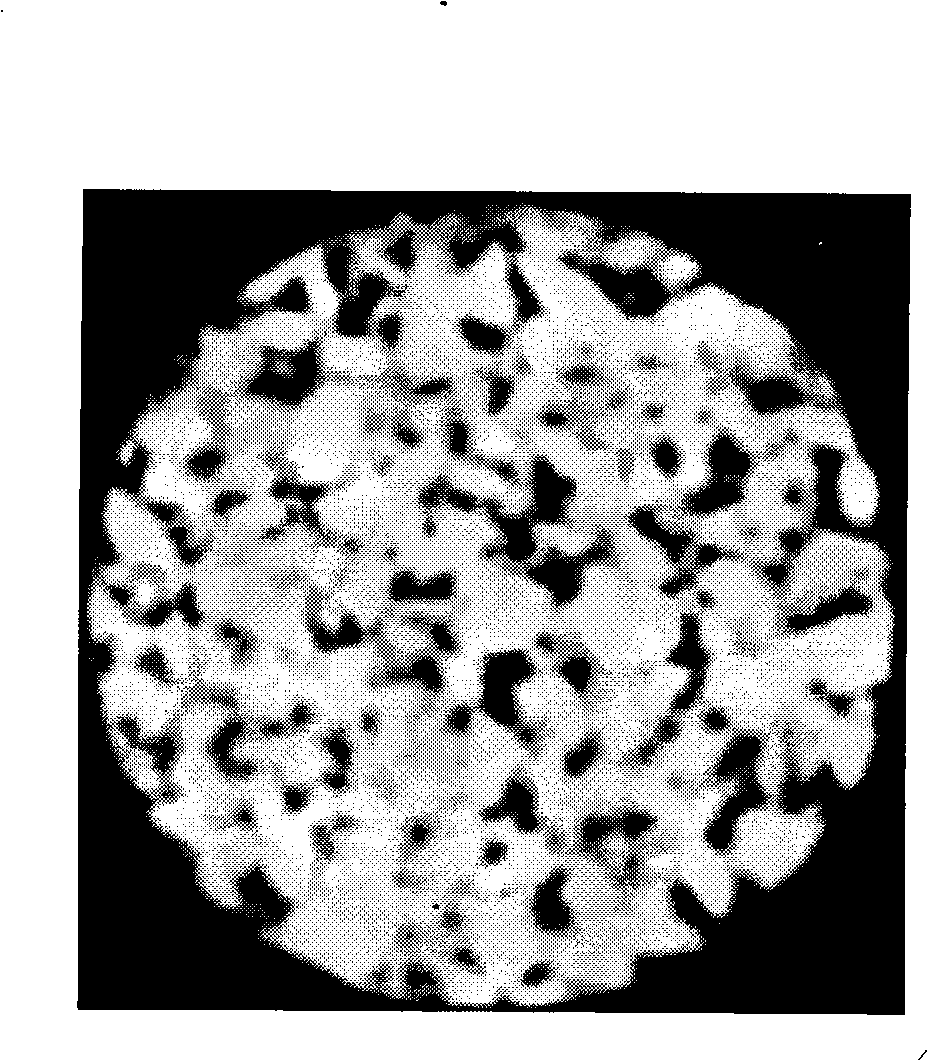

Method and system for detecting asphalt mixture

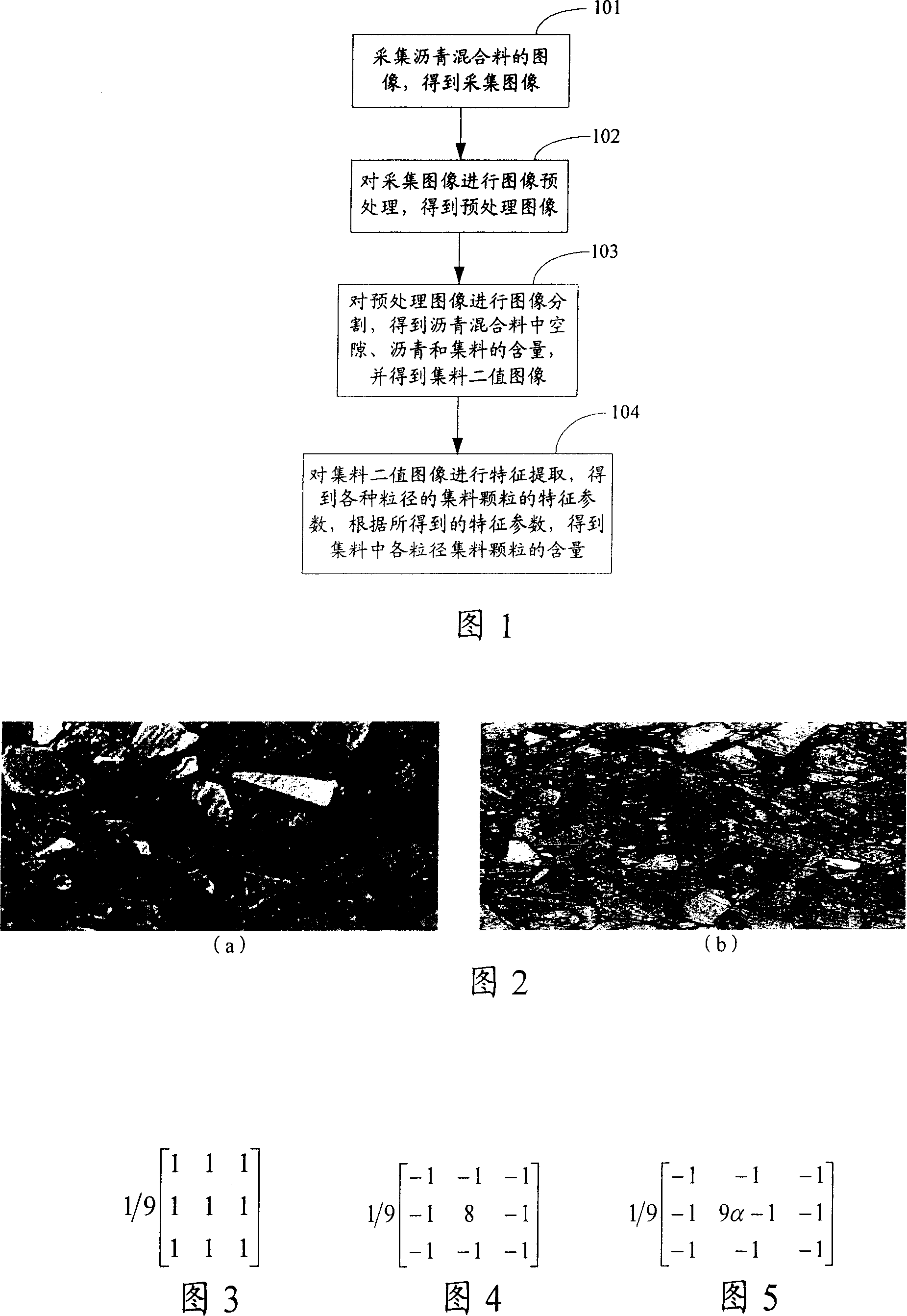

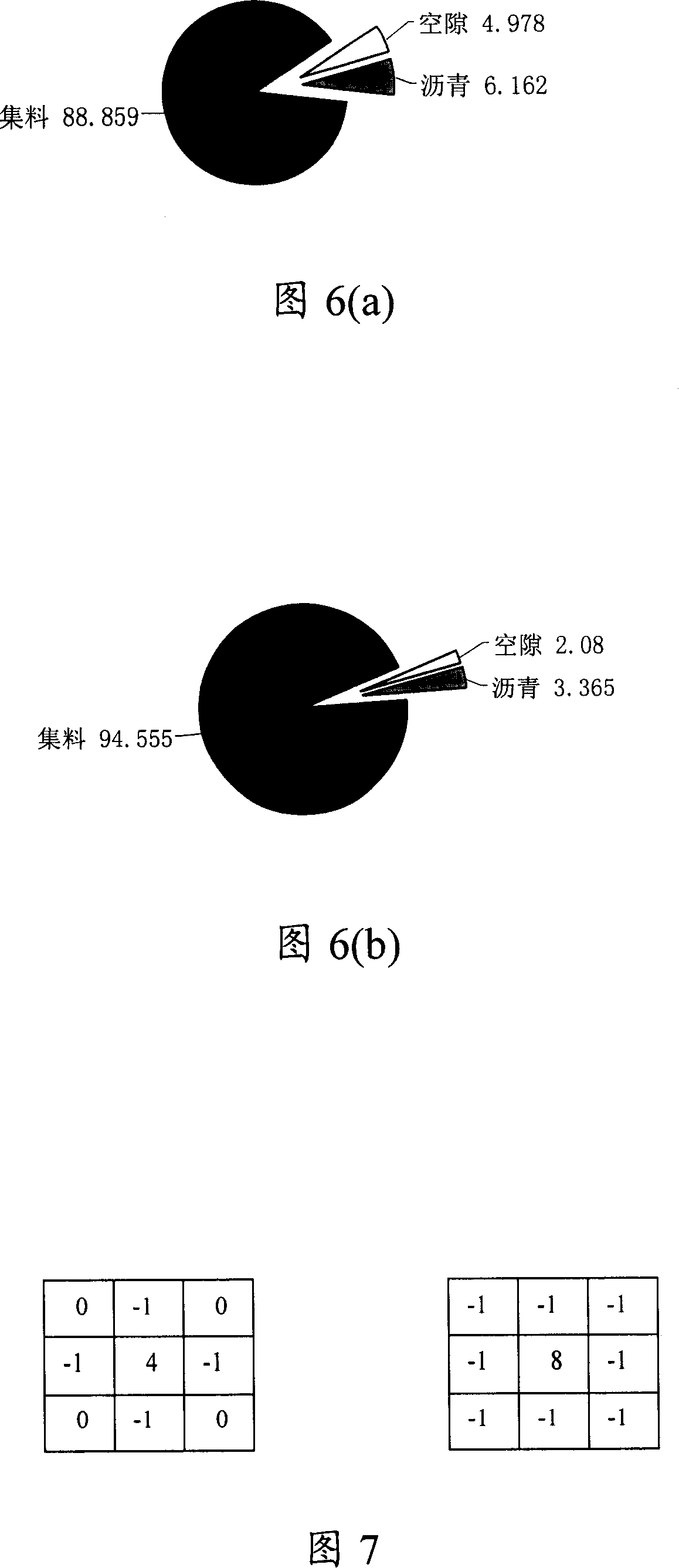

InactiveCN101153850AEfficient automatic detectionLow costImage enhancementMaterial analysis by optical meansImaging processingPavement engineering

The invention discloses a detection method of bituminous mixture, including the following steps: digital image collection of bituminous mixture is completed; image processing of the acquired digital image is completed to obtain the content of compositions of the bituminous mixture. Moreover, the invention also discloses a detection system for the bituminous mixture. Both the method and the system can complete effective separation and extraction of bitumen, airgap, aggregate and aggregate particle of different particle diameter and realize direct determination and calculation of volumetric composition characteristic parameter of the bituminous mixture through converting the obtained characteristic parameter into volume ratio; moreover, the invention improves the mechanical property of the bituminous mixture and provides reliable basis for the scientificity in bituminous pavement engineering research.

Owner:CHANGAN UNIV

Device and method for testing shear performance of asphalt mixture

InactiveCN101788431AFree disassemblyThe testing process is simplePreparing sample for investigationMaterial strength using steady shearing forcesTemperature controlStress ratio

The invention discloses a device and a method for testing shear performance of an asphalt mixture. The shear strength and shear fatigue life of the asphalt mixture under different temperature conditions are tested by adopting a circular ring shearing test. The method comprises that: before the test, an asphalt mixture test-piece is subjected to heat preservation in a temperature control box at a preset test temperature for over 6 hours; in the test, the asphalt mixture test-piece is arranged on a circular ring, and is loaded through a pressure head to cause shear failure so as to form a conical shear failure surface, and the shear strength of the asphalt mixture is calculated; and according to requirements, a specific load in a range of 0.1 to 0.9 time of failure load is selected to perform a repeated loading fatigue test on parallel test-pieces, the loading waveform is sine waves, the frequency is 10Hz, and the shear fatigue life of the asphalt mixture at different stress ratios is read out. The test method has important significance for studying the shear performance of the asphalt mixture and designing and evaluating the material of the asphalt mixture.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

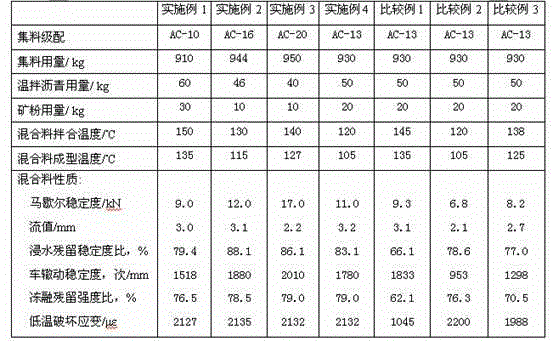

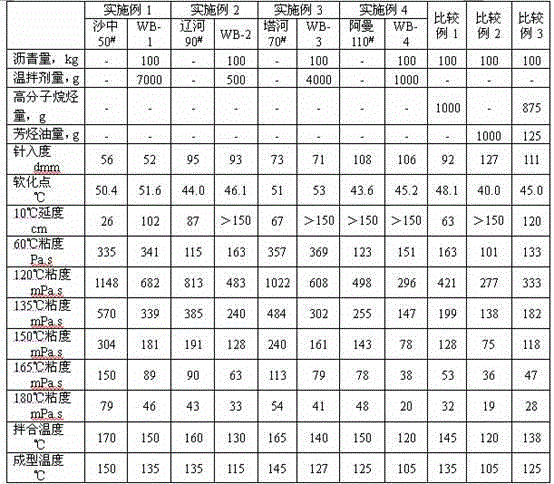

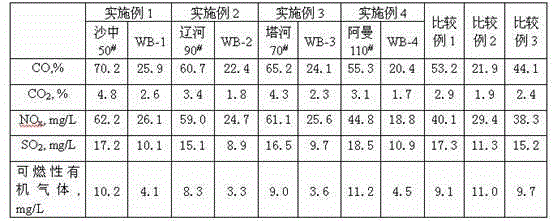

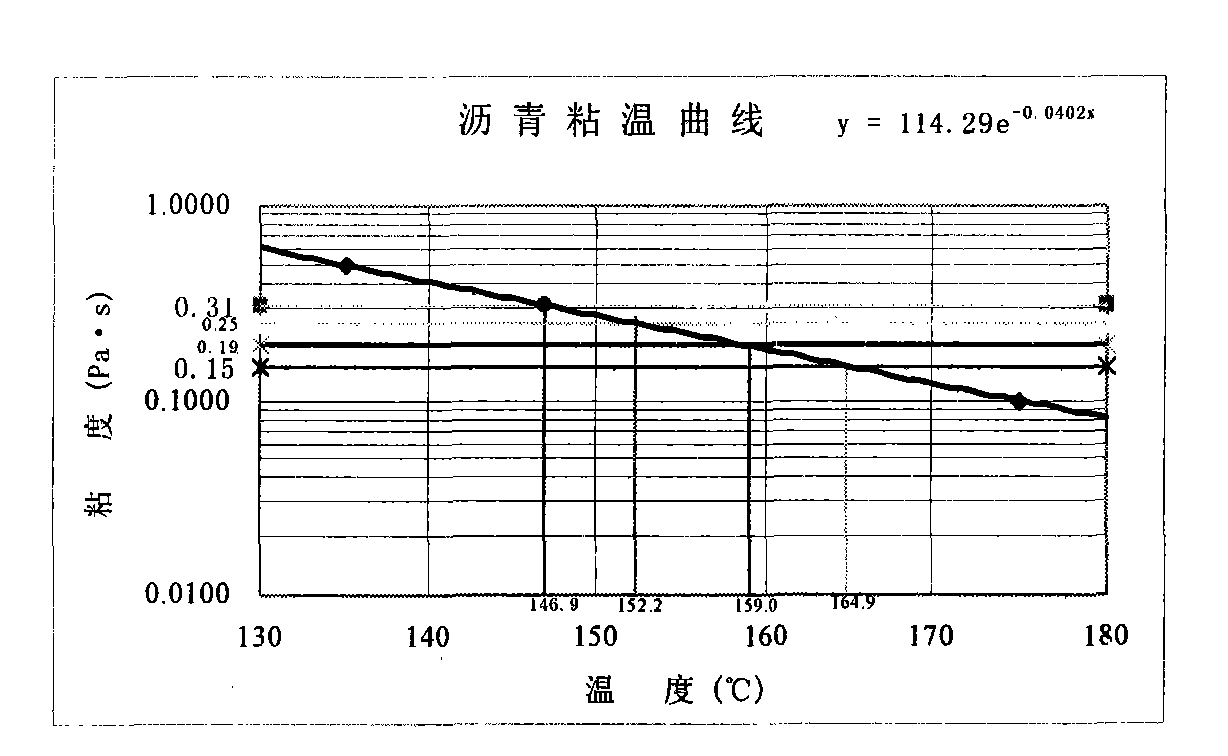

Warm-mix asphalt mixture and preparation method thereof

The invention discloses a warm-mix asphalt mixture. The warm-mix asphalt mixture comprises the following components in percentage by mass: 4.0-6.0% of warm-mix asphalt, 1.0-3.0% of mineral powder and 91.0-95.0% of aggregate; the warm-mix asphalt is prepared by the warm-mix agent. The warm-mix agent is prepared by the high polymer alkane, halogen, aromatic oil and catalyst. The dosage of the halogen is 0.3-0.5 times of the mole number of the high polymer alkane. The weight ratio of the high polymer alkane and the aromatic oil is (1-7):(7-1). The dosage of the catalyst is 0.3-0.9% of the content of the arene in the aromatic oil. The mixing and forming temperature can be reduced for the warm-mix asphalt mixture, the harmful gas generation amount is reduced, the warm-mix asphalt mixture is friendly to the environment, and the high and low temperature performance of the asphalt mixture can be improved.

Owner:辽宁兆利高新路面材料有限公司

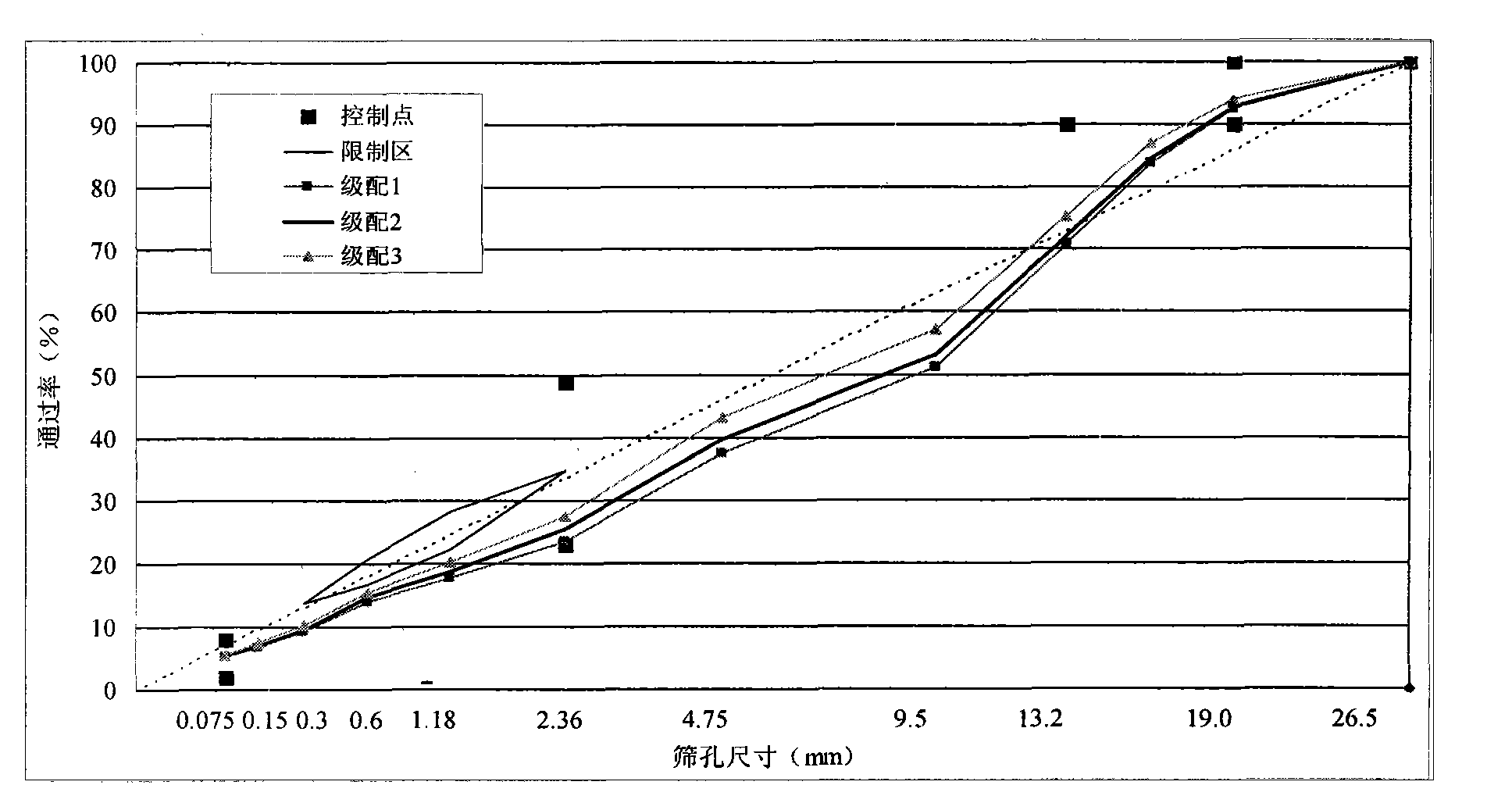

Hot in-plant reclaimed asphalt mixture

ActiveCN101654347AIncrease dosageImprove high temperature performanceSolid waste managementEconomic benefitsRoad surface

The invention relates to a hot in-plant reclaimed asphalt mixture. The mixture includes the following components by mass percent: 30 to 50 percent of milling materials, 44 to 67 percent of newly collected materials, 1.5 to 4 percent of mineral powder, 1.5 to 4 percent of new asphalt, and ARA regenerant which is 0 to 10 percent of the mass of the recycled asphalt contained in the milling materials.The processing method includes the following steps: (1) extraction and analysis of the milling materials; (2) asphalt performance test; (3) regenerant addition; (4) formation of mixture of the recycled asphalt; (5) Marshall test or rotary compacting test; and (6) mixture performance test. The proportion of milling material RAP reaches as high as 50 percent in the engineering application of the hot recycled asphalt mixture, the milling material RAP can be applied to a middle layer, and the proportion is higher than the proportions of other hot recycled mixtures by more than 20 percent. The mixture can be applied to various grades, such as the AC type, SUPERPAVE, and the like, and the RAP proportion can respectively reach 30 percent or even more than 50 percent. When the mixture is used forpaving a road surface, the road performance can respectively meet the requirements on performance of a newly proportioned asphalt mixture, and the high temperature performance is even superior to thenewly proportioned asphalt mixture. Therefore, the invention has obvious economic benefit.

Owner:JIANGSU HUAIAN TRAFFIC SURVEY & DESIGN INST

Process for preparing bitumen compositions with reduced hydrogen sulfide emission

InactiveUS20050145137A1Reduce evolutionEmission reductionRefining with metalsRefining with metal saltsScavengerCadmium Cation

In methods of preparing asphalt including asphalt / elastomeric polymer compositions, it has been discovered that the emission or evolution of H2S can be reduced by adding certain H2S scavengers to the asphalt mixture, but that not every known H2S scavenger can be effective in this method. Particularly helpful H2S scavengers include inorganic metal salts. Suitable inorganic or organic metal salt H2S scavengers include, but are not necessarily limited to those where the metal of the salt is zinc, cadmium, mercury, copper, silver, nickel, platinum, iron, or magnesium, and mixtures of these salts.

Owner:FINA TECH

Anti-rut asphalt modifier and preparation method thereof and modified asphalt and application thereof

InactiveCN101857393AGood storage stabilityReduce energy consumptionBuilding insulationsPolyolefinThermoplastic elastomer

The invention discloses a traffic anti-rut asphalt modifier and a preparation method thereof; the asphalt modifier is prepared from the following components in parts by weight: 20 to 200 parts of thermoplastic elastomer, 5 to 450 parts of polyolefin, and 5 to 400 parts of rubber powder. Simultaneously, the invention also discloses modified asphalt which contains the asphalt modifier and application of the modified asphalt in asphalt mixture. The invention can significantly improve the high-temperature performance and the anti-rut capability of the asphalt mixture, improves anti-water damage and anti-low temperature cracking and other performance, and has high cost performance. Compared with asphalt modification, the invention does not need to add asphalt modification equipment, can significantly reduce energy consumption and loss in the production process, can realize long-termed inventory, prevents the problem of the poor storage stability of modified asphalt, does not affect the mixing proportion design, does not change the gradation of the asphalt mixture under any content, only finely adjusts the asphalt-aggregate ratio, has simple construction process, and realizes random adding through a direct feeding method.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +3

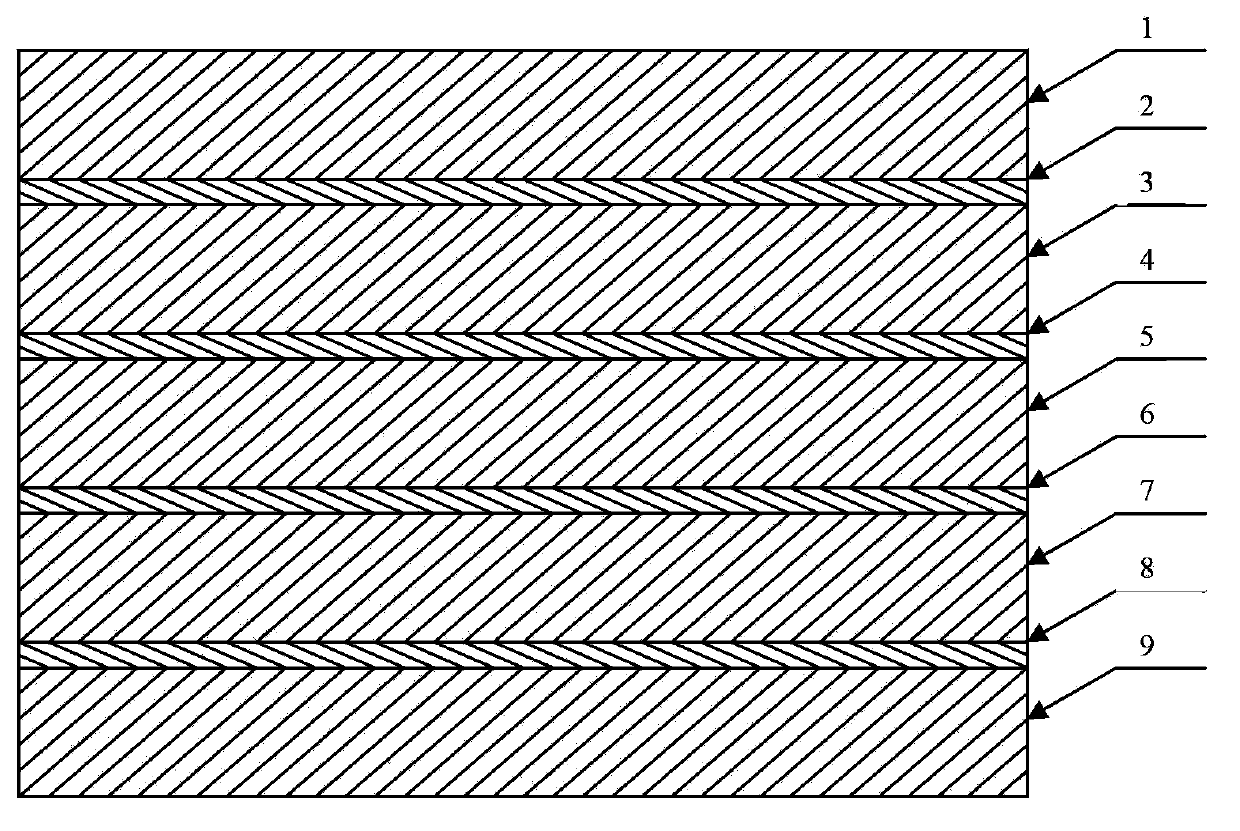

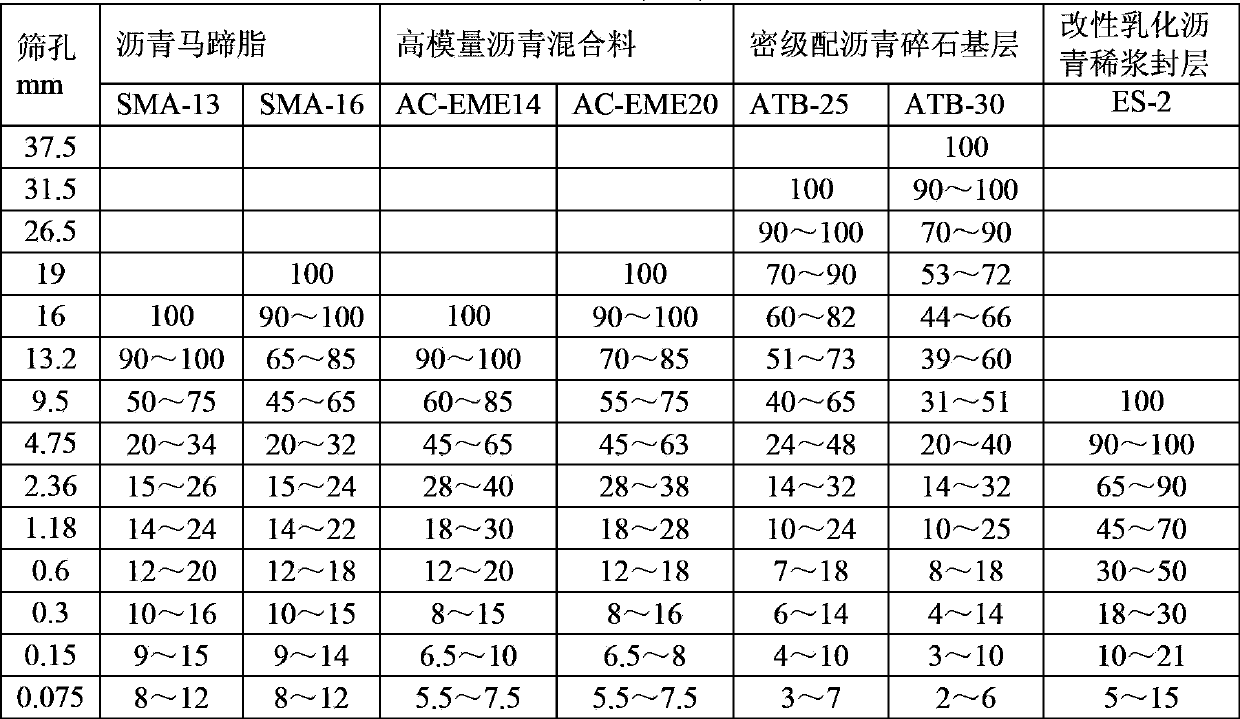

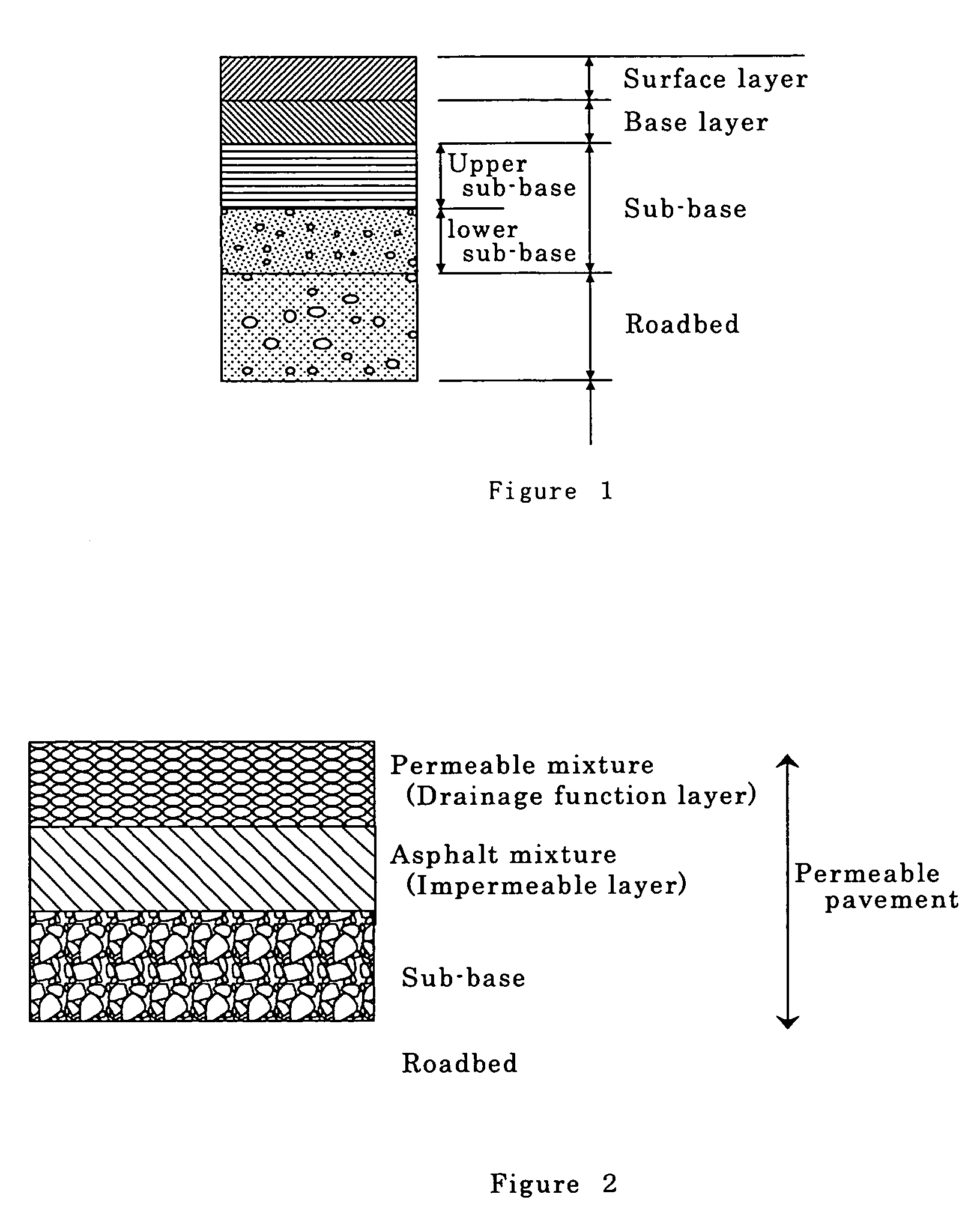

Semi-flexible heavy-duty pavement paving structure

ActiveCN103866667AImproves rutting resistanceImprove fatigue resistanceIn situ pavingsSurface layerLower grade

The invention relates to a semi-flexible heavy-duty pavement paving structure. The semi-flexible heavy-duty pavement paving structure comprises a surface layer having a thickness of 4-6cm and made of a high-viscosity modified asphalt mixture of SMA-13 or SMA-16, a middle surface layer having a thickness of 6-10cm and made of a high-modulus asphalt mixture of AC-EME14 or AC-EME20, a lower surface layer having a thickness of 10-12cm and made of a low-grade asphalt mixture of ATB-25 or ATB-30, and a semi-flexible base layer having a thickness of 6-12cm and made of skeleton solid cement-emulsified asphalt concrete; a high-viscosity modified asphalt bonding layer is arranged between the surface layer and the middle surface layer, between the middle surface layer and the lower surface layer and between the lower surface layer and the semi-flexible base layer, and the spreading quantity of the high-viscosity modified asphalt bonding layer per unit area is 0.6-0.8kg / m<2>; and an ES-2 modified emulsified asphalt slurry is arranged between the semi-flexible base layer and a bottom base layer, and has a suitable thickness of 6-10mm. The structure improves the rut resistance and the fatigue resistance of a pavement, and prolongs the service life of the pavement.

Owner:PETROCHINA CO LTD +1

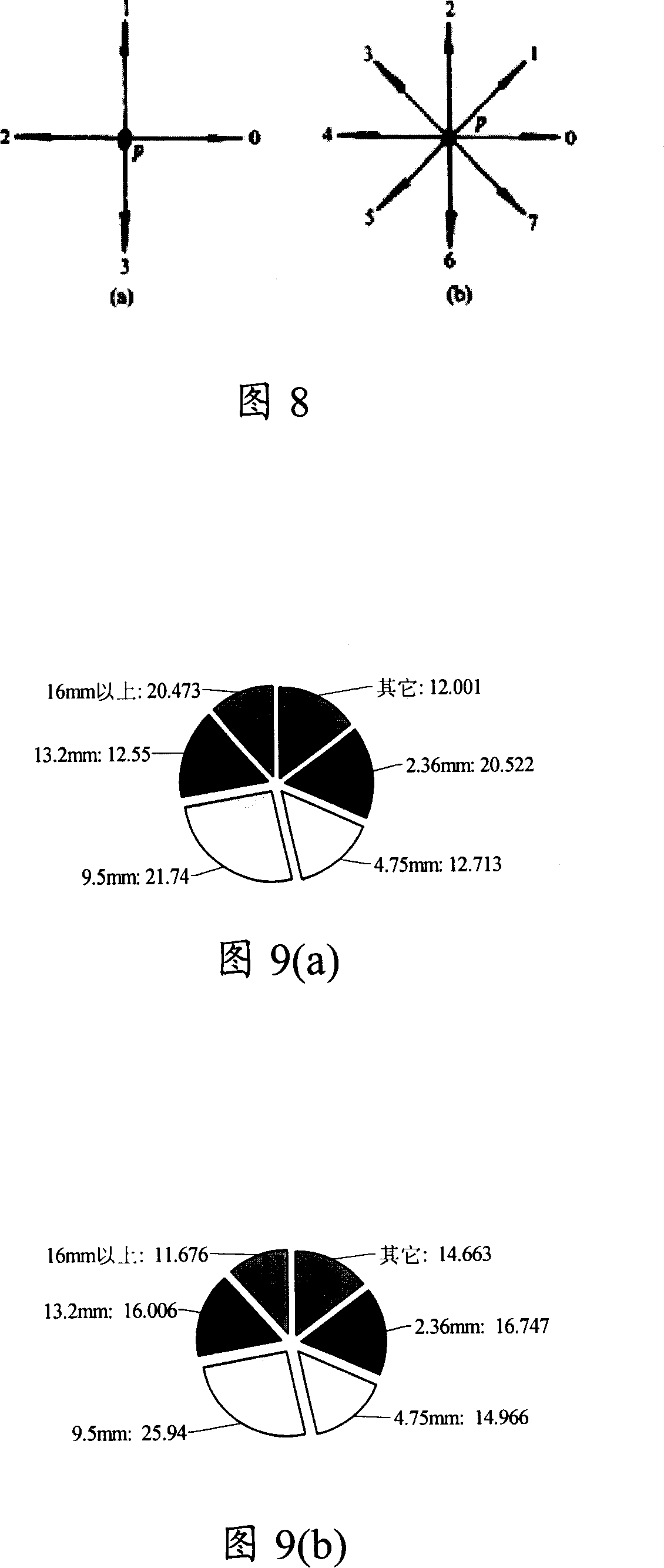

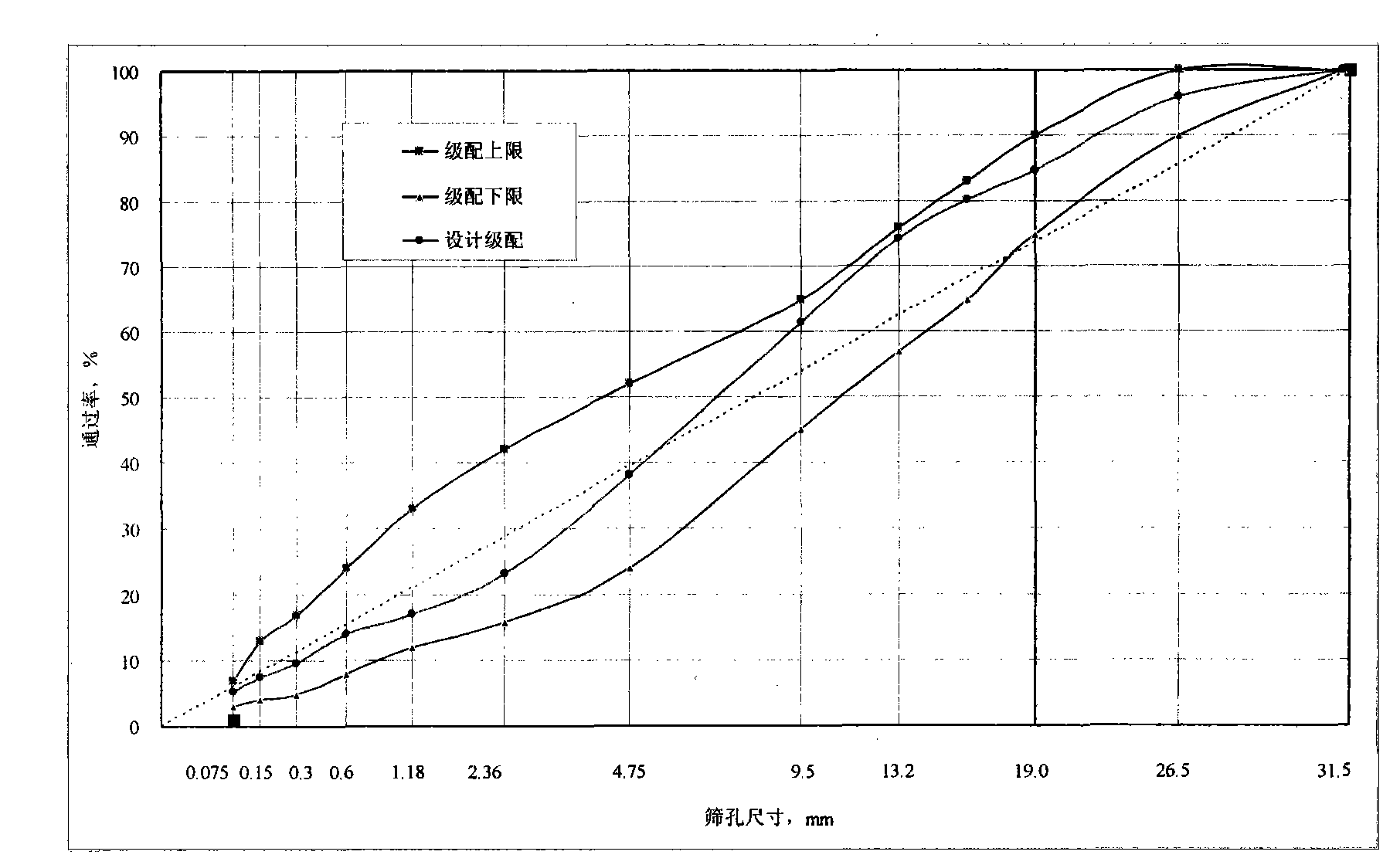

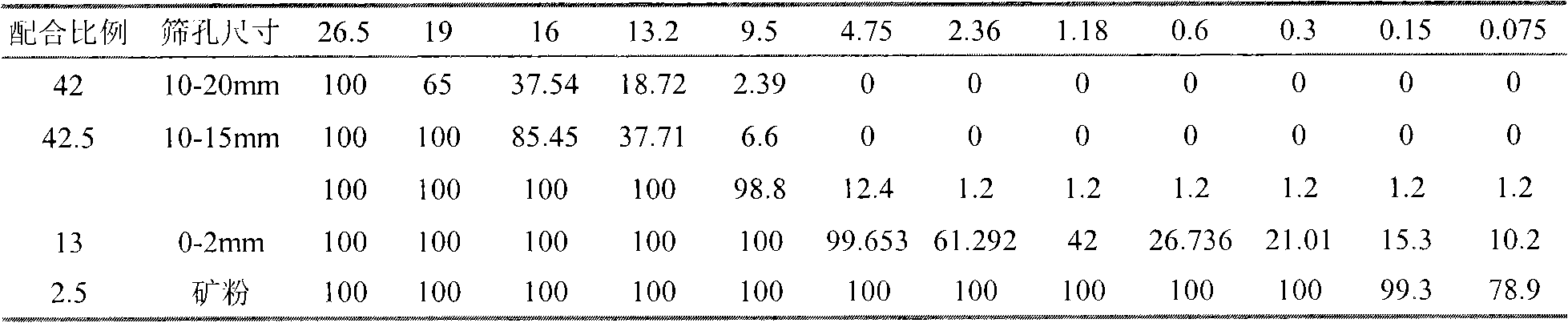

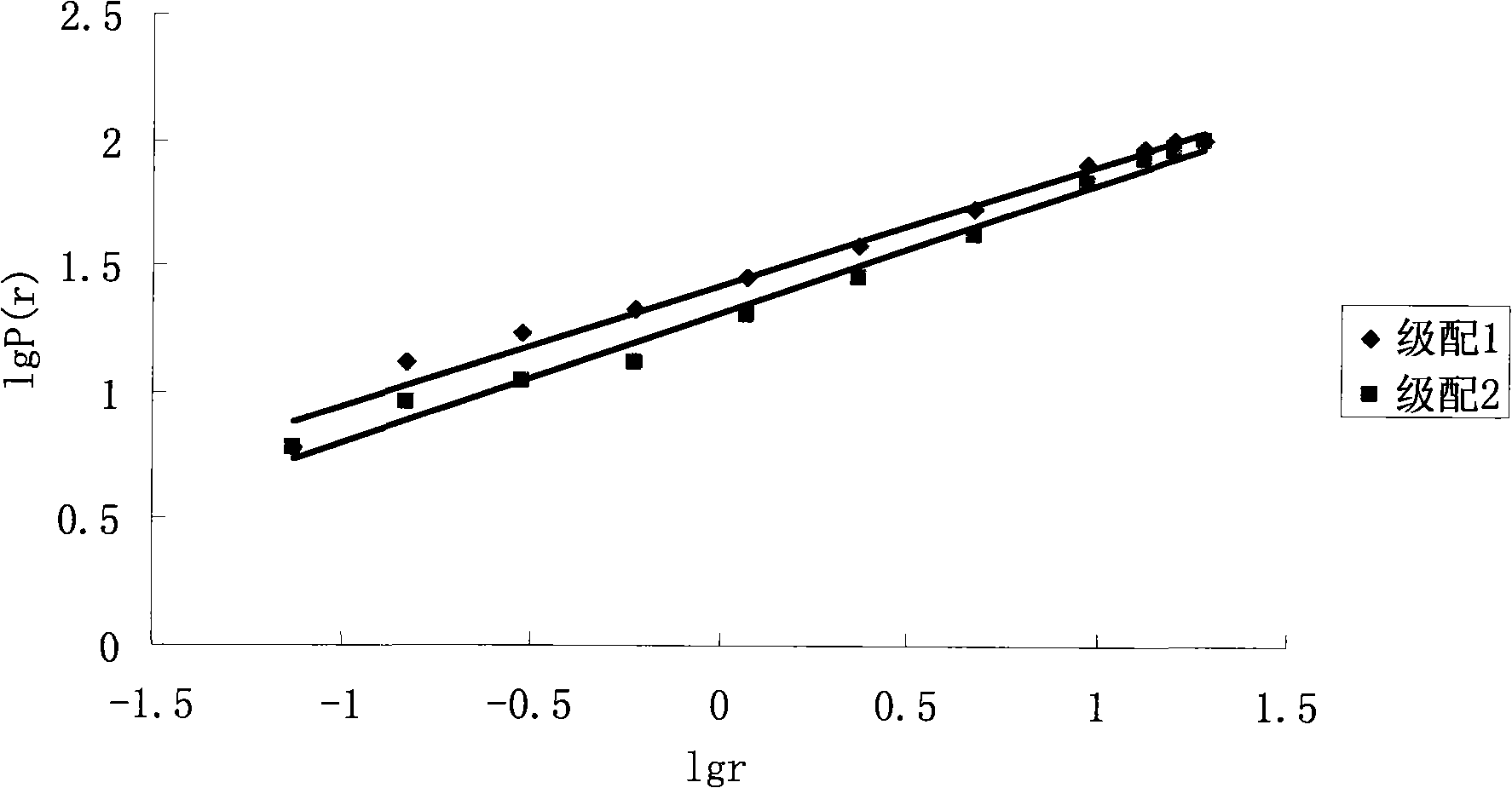

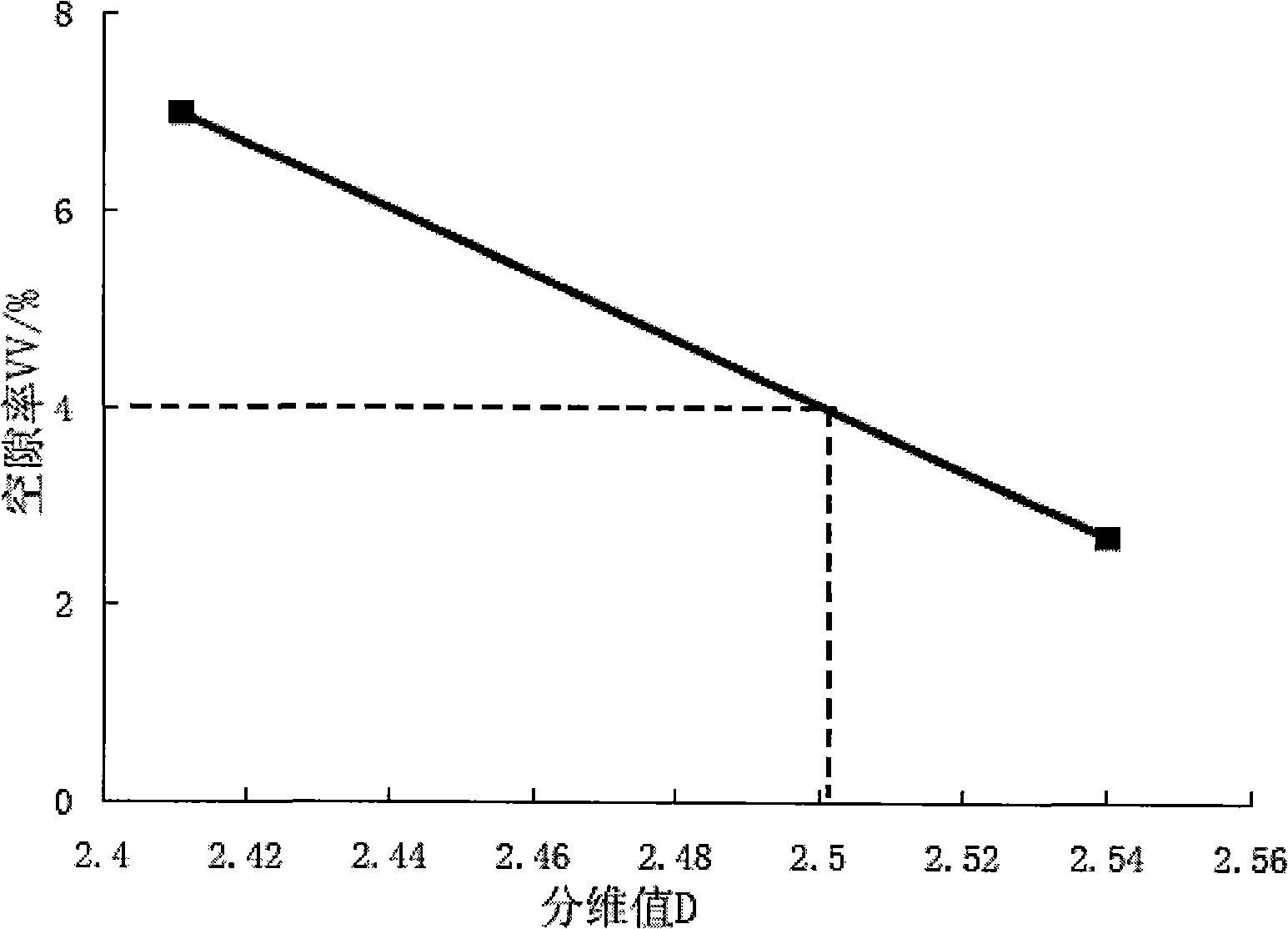

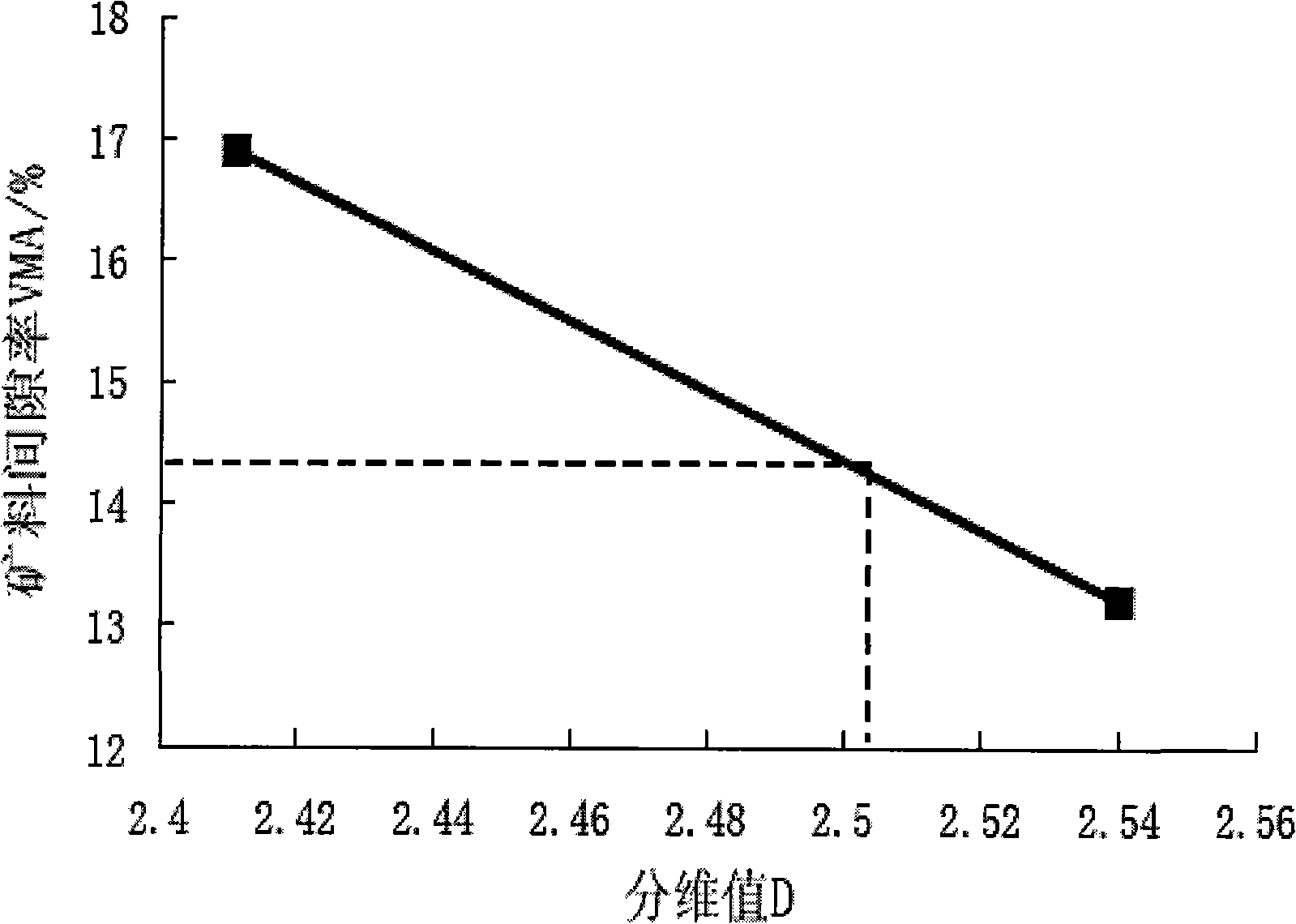

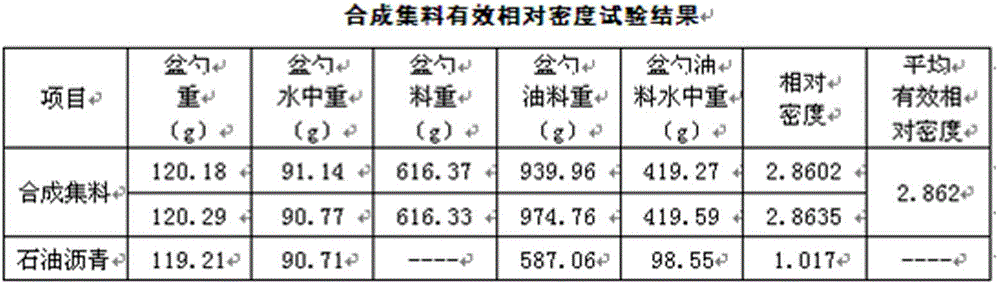

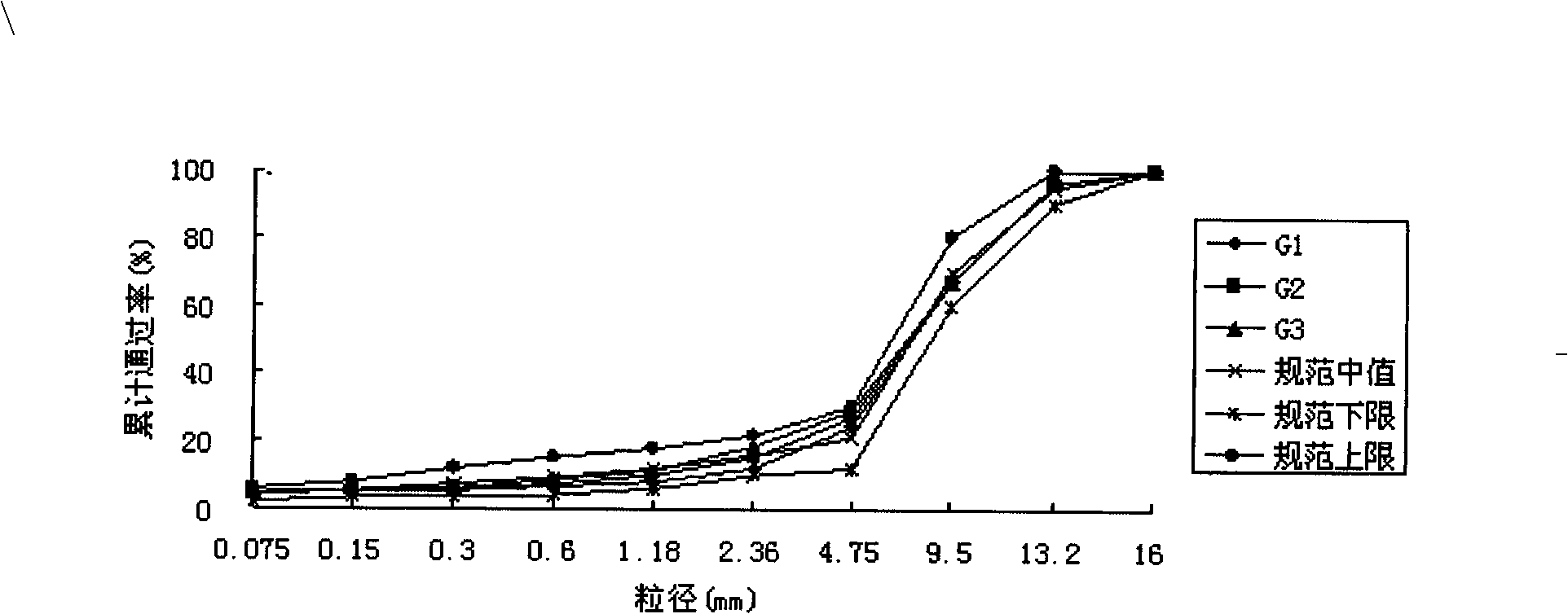

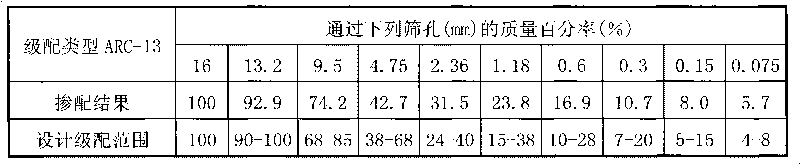

Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

InactiveCN101318794AImprove road performanceSimple internal structureSolid waste managementCeramic shaping apparatusMathematical modelTest sample

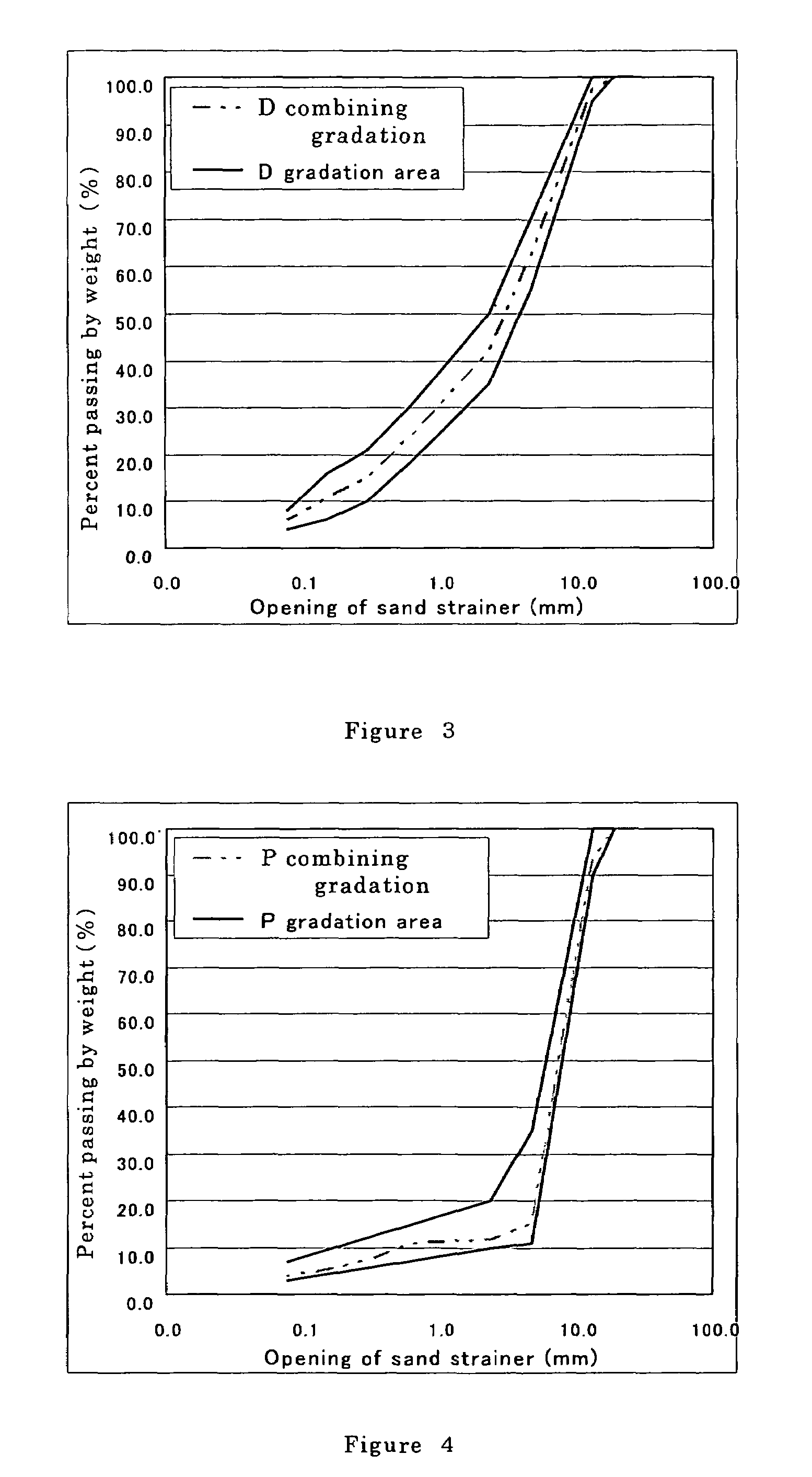

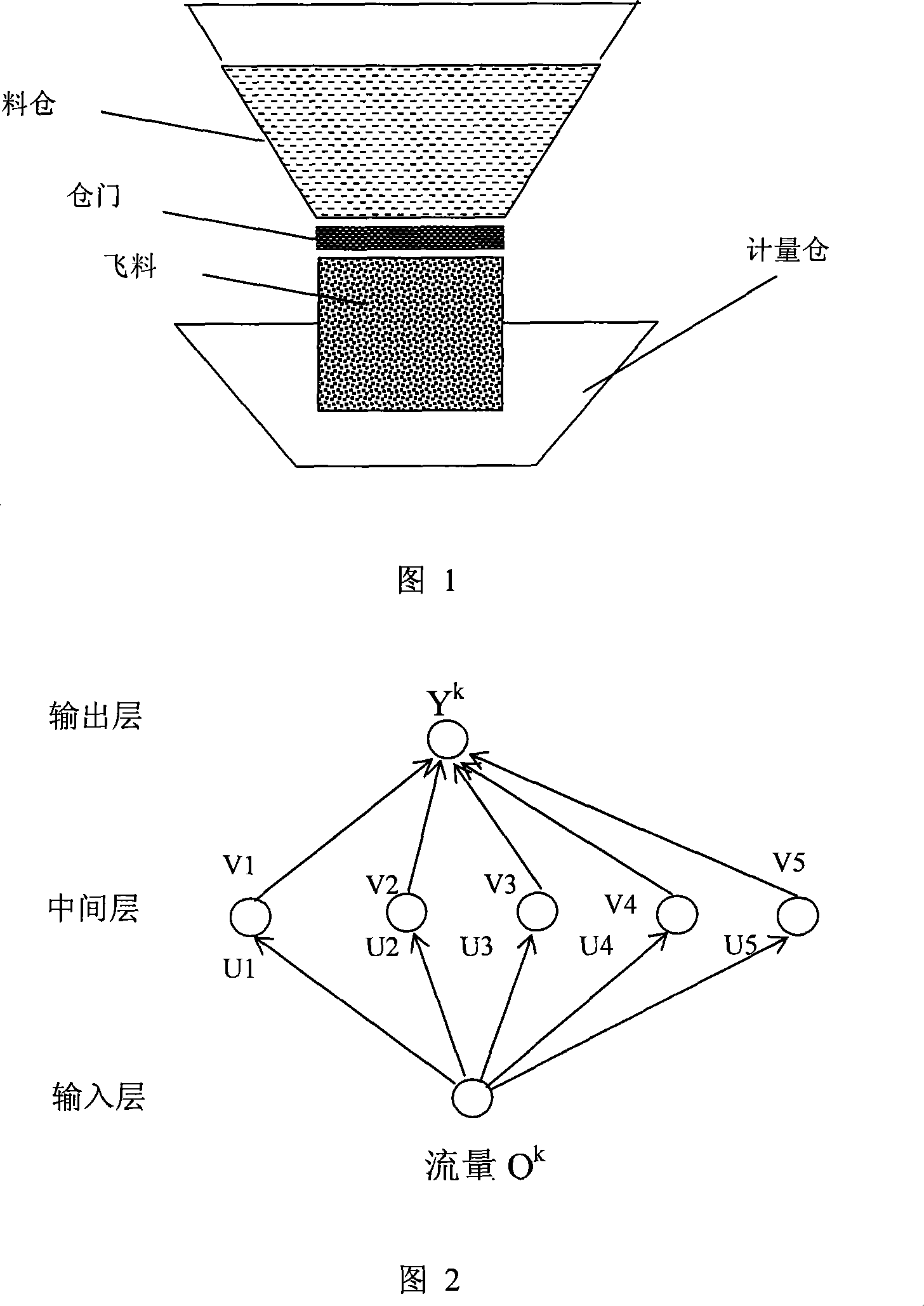

The invention relates to a method of designing a mixed ratio for a bitumen mixture based on fractal and distributional features of ore materials. The method comprises the following steps: (1) mathematical models for particle diameter distribution and mass distribution of the ore materials are set up respectively; (2) the type and the grading limit of the bitumen mixture are determined; (3) raw materials are selected and checked; (4) graduations of two arbitrary groups of the ore materials are determined and corresponding fractal dimension values(D) are worked out; (5) the use level of the bitumen is worked out; (6) the bitumen mixture is prepared by stirring; (7) a Marshall test sample is made, the relative density of the bulk volume of the test sample is determined, the theoretical maximum relative density is determined, and the volume index is worked out; (8) relationship curves between the fractal dimension values(D) and the volume indexes are drawn; (9) the graduation of the ore materials and the optimum use level of the bitumen are determined; (10) the road performance of the bitumen mixture is tested; and (11) the construction mixed ratio of the bitumen mixture is determined. The invention utilizes the fractal theory to set up the mathematical models, and in the process of designing the mixed ratio of the bitumen mixture, the optimum bitumen use level and the optimum graduation of the ore materials meeting and regulating all design rules of the bitumen mixture can be quickly determined.

Owner:LANZHOU JIAOTONG UNIV

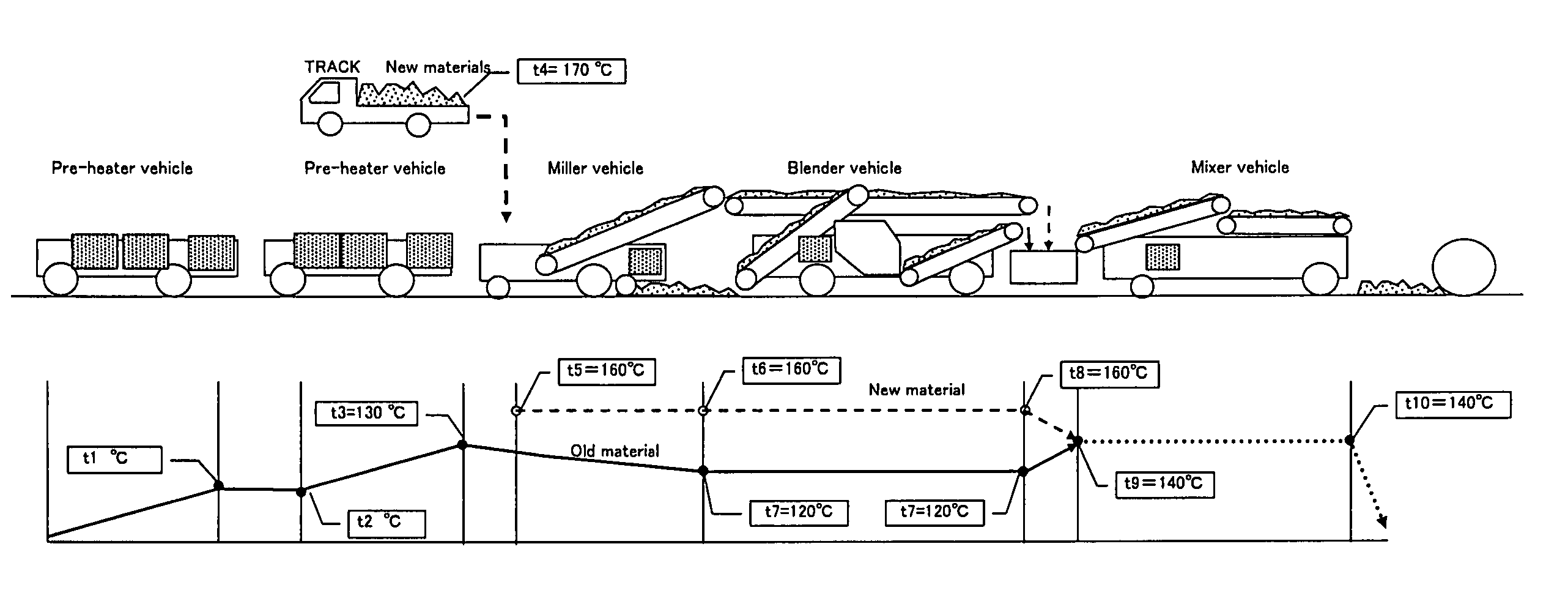

Method for continuous on-site recycling of an asphalt mixture layer of a pavement and a motor-driven vehicle system therefor

A method for recycling in place an asphalt mixture layer of a paved road continuously, while moving a self-propelled vehicle system, which comprises a step of heating and softening the asphalt mixture layer, a step of scraping and breaking said hot and softened asphalt mixture layer and keeping the softened mixture at a temperature sufficient not to form an aggregate, to prepare an asphalt mixture having a single-grained structure, a sieving step of classifying said asphalt mixture having a single-grained structure into a plurality of grain size groups, a step of designing mix proportions for converting said asphalt mixture to a recycled asphalt mixture by the use of said plurality of grain size groups classified, a step of mixing uniformly said recycled asphalt mixtures having designed mix proportions, and a step of spreading and compacting said recycled asphalt mixtures having been mixed uniformly, to thereby form a recycled asphalt mixtures layer.

Owner:NIHON KENKI CO LTD +1

Robust control method for asphalt mixing plant batching error

InactiveCN101226377AImprove batching accuracyImprove control effectMixing operation control apparatusRoads maintainenceProcess dynamicsArtificial neural network model

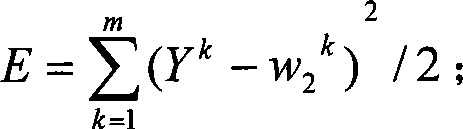

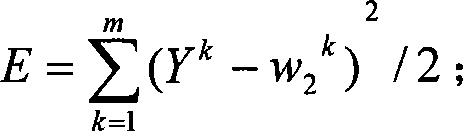

The invention discloses a robust control method of burden error of pitch concrete stirring device, which comprises first building an input / output artificial neutral network model of three-layer structure, while the input layer has one neuron, the middle layer has five neurons and the output layer has one neuron, processing dynamic prediction and learning. The invention builds the non-linear model of flux and fly ash amount to be compared with a linear model of fixed parameters via continuous learning and adjustment, to adapt the change of external parameters, thereby effectively controlling the burden error of pitch mixture stirring device, reaching +-2% burden error as maximum and improving the burden accuracy of pitch mixture stirring device.

Owner:NANJING UNIV OF SCI & TECH +1

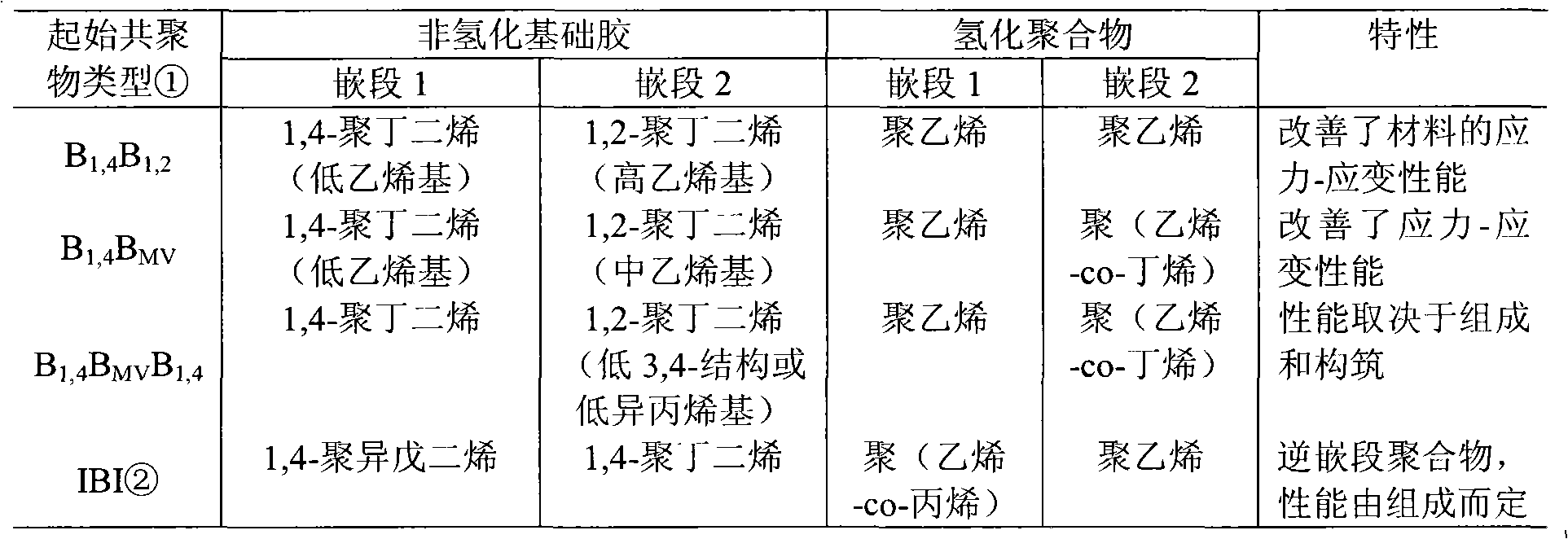

Bitumen modifier for traffic tracking resistance and modified bitumen and mixer thereof

ActiveCN101063000AGood storage stabilityReduce energy consumptionIn situ pavingsBuilding insulationsPolyolefinThermoplastic elastomer

The invention discloses a pitch modifier for traffic anti-rut, modified asphalt and bituminous mixture, which is characterized by the following: allocating 20-200 wt thermoplastic elastomer ethenyl aromatic hydrocarbon-conjugated diene block copolymer and 5-950 wt polyolefin; setting the thermoplastic elastomer ethenyl aromatic hydrocarbon-conjugated diene block copolymer as SBS, SIS, SEBS and or SEPS; setting the polyolefin as PE, PP, EVA, APP, APAO, POE, HDPE, LDPE and or LLDPE; setting the mass percent of adding basic pitch at 1%-7%; increasing high-temperature behavior and anti-rut ability distinctively; modifying anti-water damage and anti-low temperature property. This craft is simple, which avoids the problem of bad stability of modified asphalt storage.

Owner:深圳前海海川新材料科技有限公司

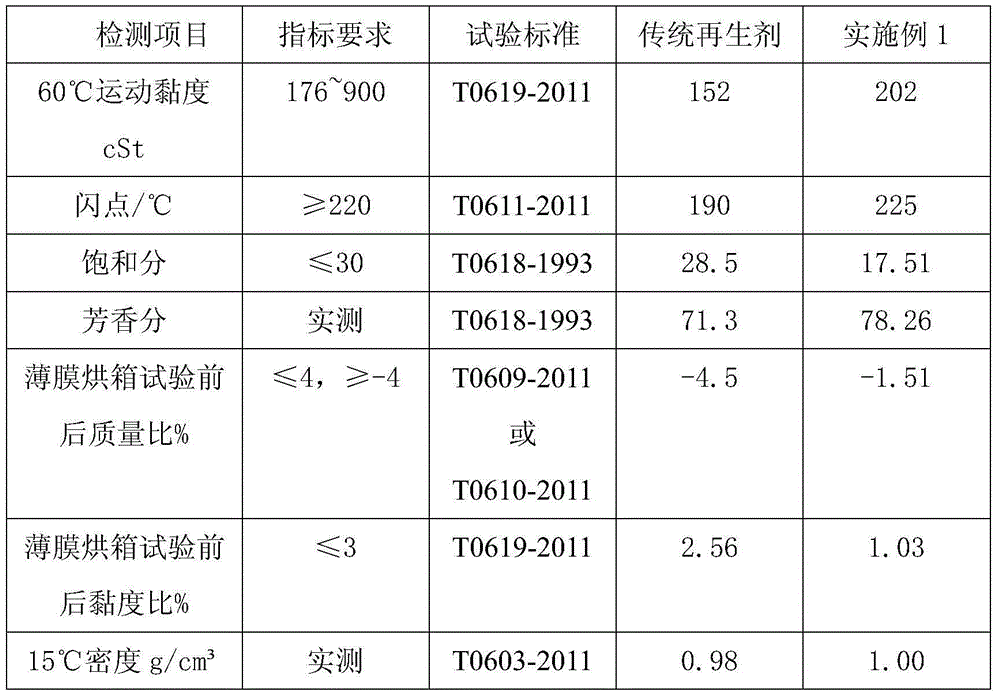

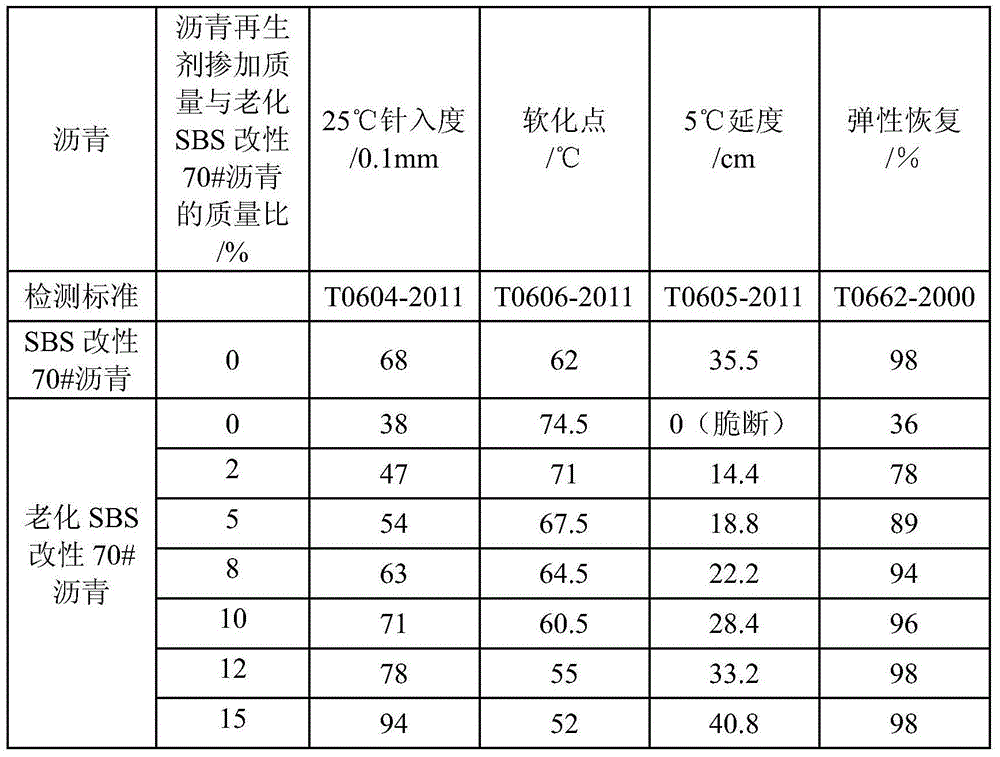

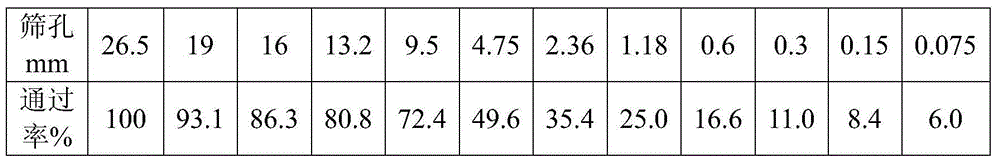

Asphalt regeneration agent as well as preparation method and application thereof

ActiveCN104610768AReduce manufacturing costAchieve reuseClimate change adaptationBuilding insulationsPlasticizerMixed materials

The invention discloses an asphalt regeneration agent which is prepared from the following raw materials in percentage by mass: 65-80% of plant asphalt, 3-5% of an interface reinforcing modifier, 15-30% of a plasticizer, 0.3-1% of a penetrating agent and 0.5-1% of an anti-aging agent, wherein the interface reinforcing modifier is one or a mixture of more than two of epoxy aliphatic polyethylene polyamine, epoxy silicon resin and epoxy resin in any ratio; the content of the epoxy group in the interface reinforcing modifier is 10-40%. In addition, the invention further provides a preparation method of the asphalt regeneration agent, an asphalt mixed material prepared from the asphalt regeneration agent, and a preparation method of the asphalt mixed material. When the asphalt mixed material is prepared from the asphalt regeneration agent, the anti-rutting performance, the anti-water damage property and the low-temperature anti-cracking property can be greatly improved, and waste resources can be recycled.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

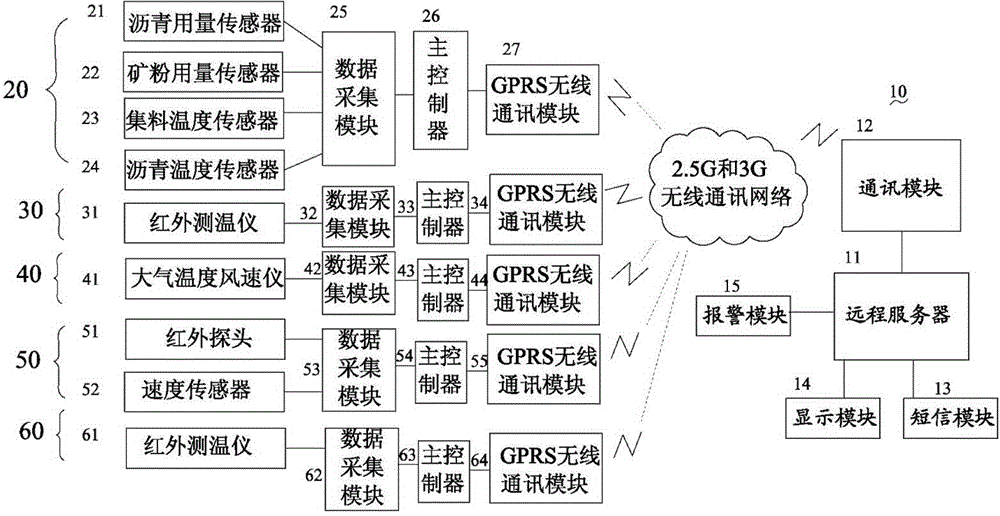

System and method of dynamic management for construction quality of asphalt concrete pavement

InactiveCN103336499ARealize dynamic controlPrevent fraudulent behaviorTotal factory controlProgramme total factory controlData informationTransmission technology

The invention discloses a system and a method of dynamic management for construction quality of an asphalt concrete pavement. The system gathers a plurality of subsystems of the dynamic management for the construction quality of the asphalt concrete pavement and a remote quality monitoring and controlling system, wherein the subsystems are composed of a production mix proportion monitoring subsystem, a discharging temperature monitoring subsystem, a construction environment monitoring subsystem, a pave data monitoring subsystem, and a rolling data monitoring subsystem. The technical scheme is that the sensing technology based on the architecture of the Internet of Things and the transmission technology base on 2.5 G and 3G are fully utilized to report data information of a manufacturing process, a construction process, and the like of asphalt mixture to a remote server through a communicating module, so as to dynamically and truthfully reflect the construction quality condition. The idea of the system and the method is to track and observe project processes, and compare the observation result with a planned value, and once a deviation is found, the rectification is performed for prevention.

Owner:ZHONGSHAN TOPWARE ELECTRONICS TECH

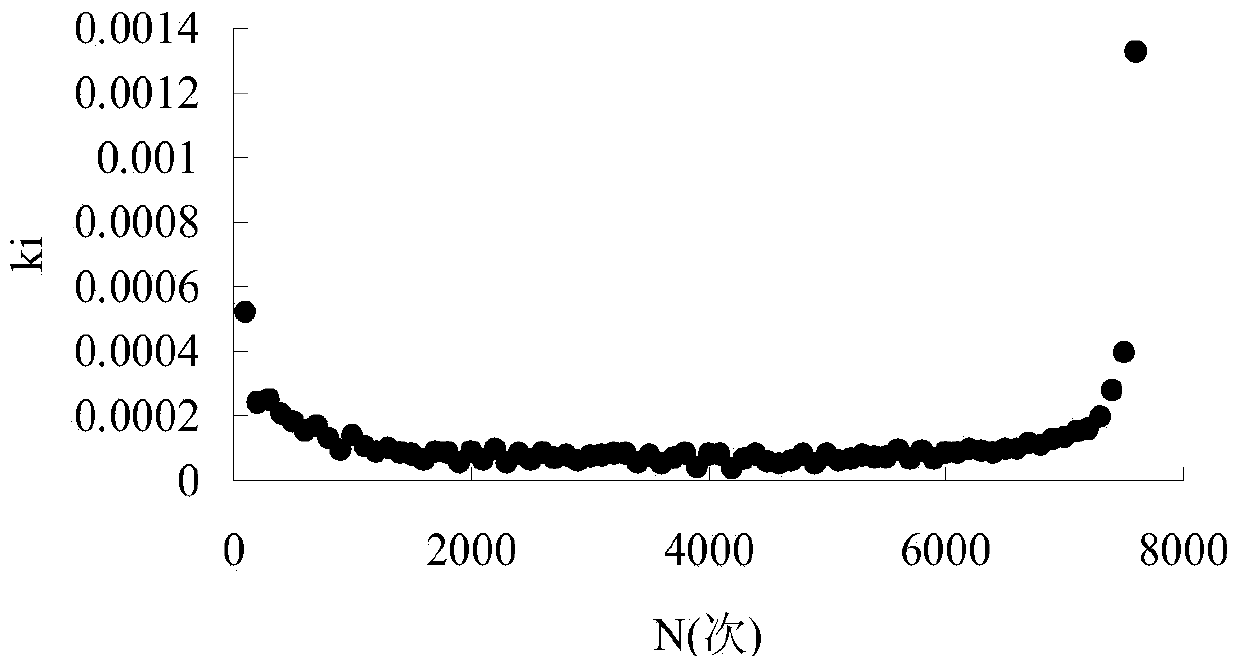

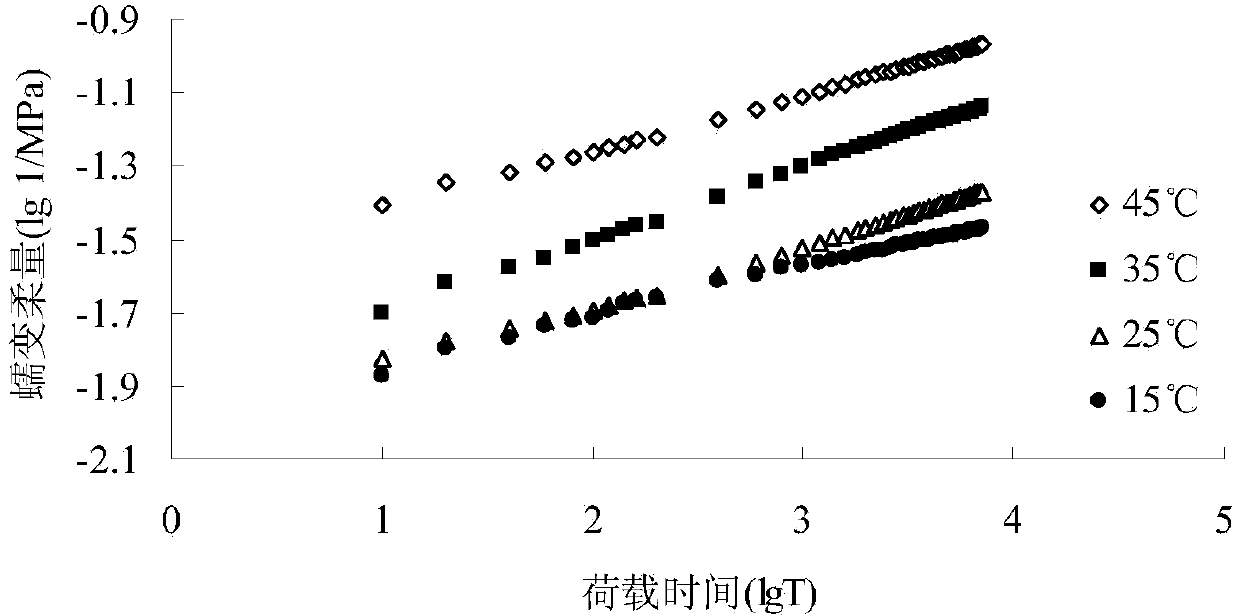

Asphalt mixture life prediction method considering fatigue-creep interaction damage effect

InactiveCN103630450AImprove scienceEasy to determineMaterial strength using repeated/pulsating forcesFatigue damageRoad engineering

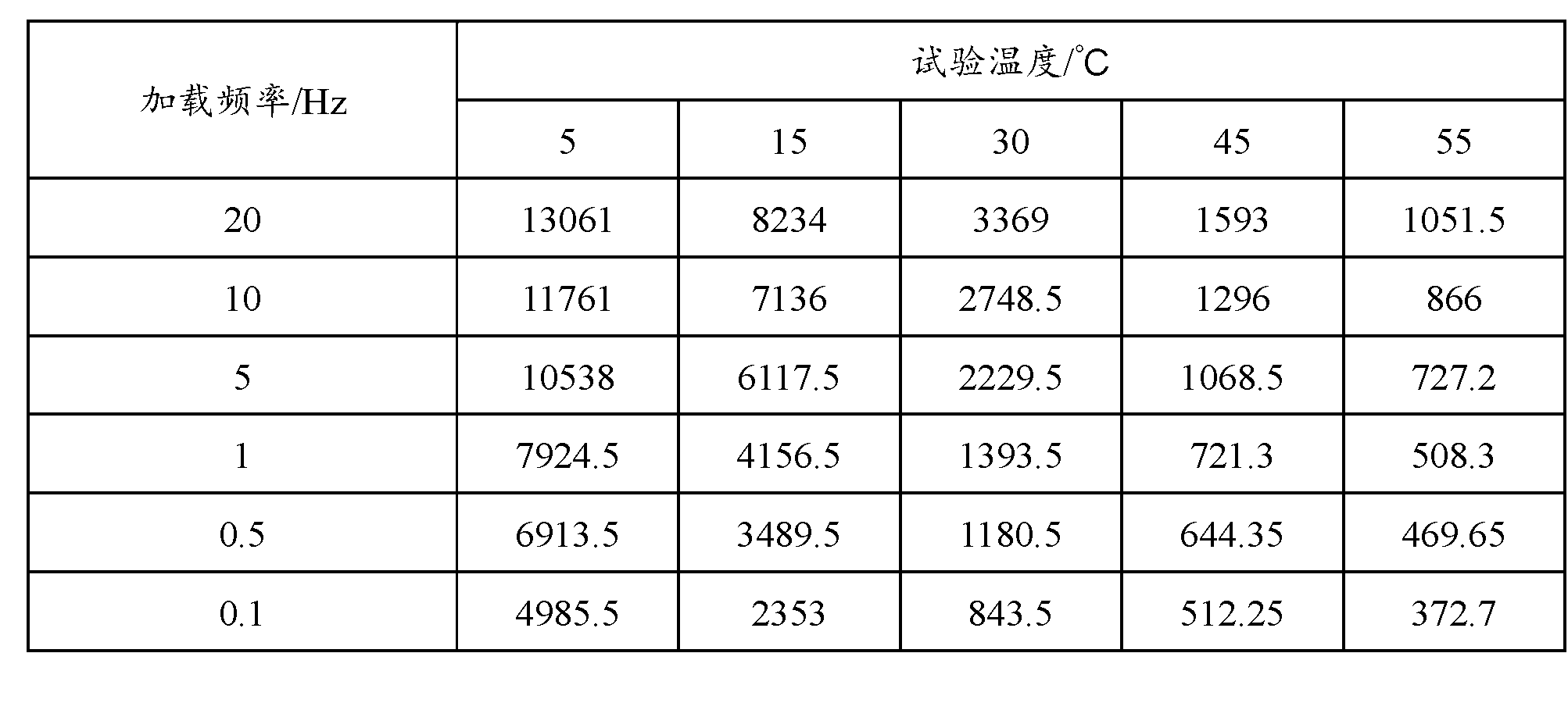

The invention relates to an asphalt mixture life prediction method considering a fatigue-creep interaction damage effect, and belongs to the field of road engineering. The method comprises the following steps: (1) determining a complex modulus of an asphalt mixture under the action of a period load; (2) determining a damage variable of the asphalt mixture; (3) building a creep damage equation and a fatigue damage equation of the asphalt mixture respectively; (4) building an asphalt mixture life prediction model under the combined action of creep damage and fatigue damage. Compared with a conventional asphalt mixture life prediction method, the viscoelastic behavior of the asphalt mixture is considered and a more accurate prediction model is built. The method accurately describes asphalt mixture damage failure process and rule, has the advantages of wide application range and reliable calculation results, and provides a more reliable method for structural design of an asphalt pavement.

Owner:云南交投集团公路建设有限公司

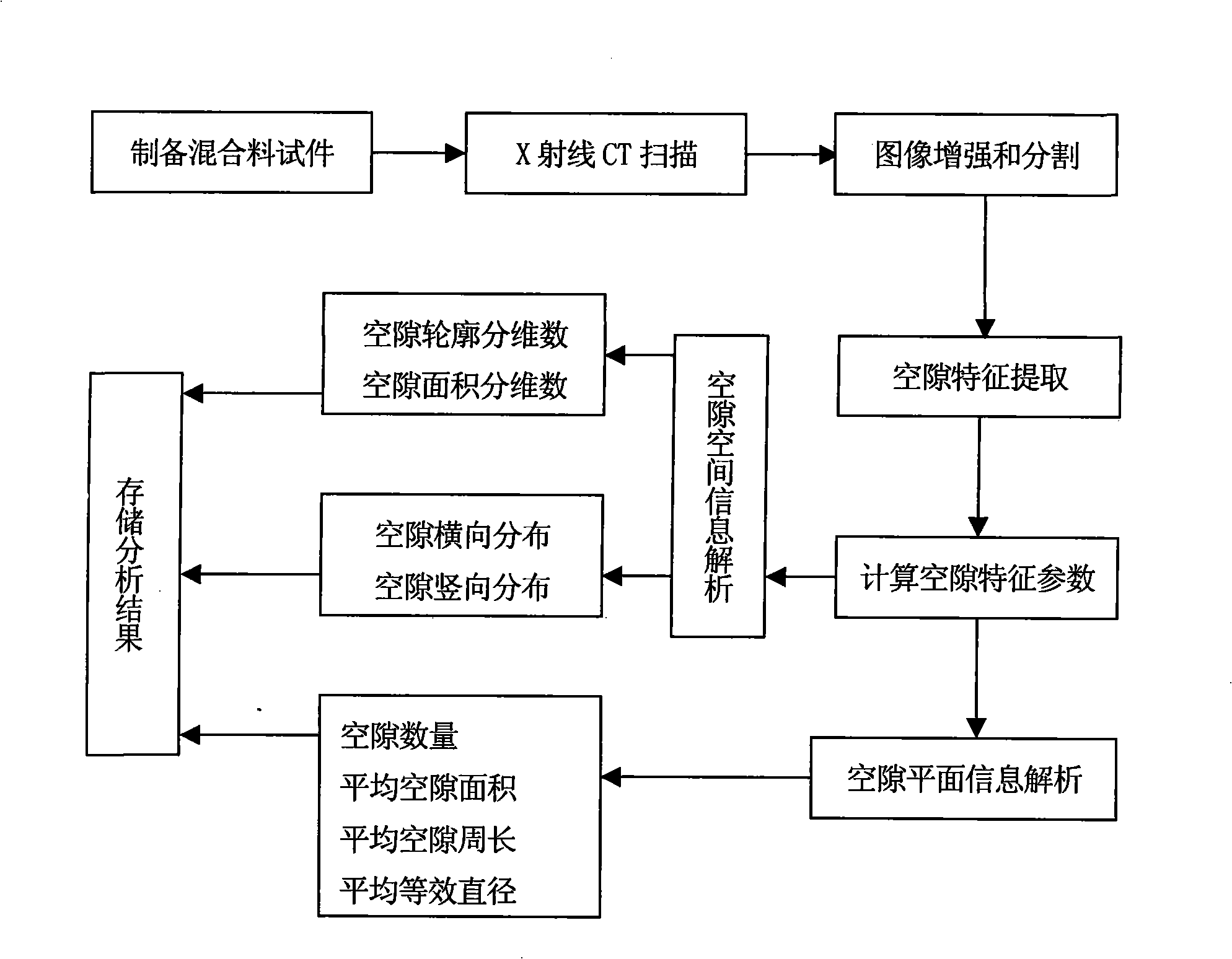

Method for analyzing porous asphalt mixture gap structure by using CT technology

InactiveCN101403683AAccurate acquisitionEasy accessImage enhancementPermeability/surface area analysisX-rayPorous asphalt

The invention provides a method used for analyzing the porous asphalt mixture void structure by adopting a CT technique, comprising the steps of: preparing porous asphalt mixture specimens, scanning the porous asphalt mixture specimen by an X-ray CT machine, reinforcing and cutting CT images, extracting void characteristic, calculating the characteristic parameter of the void structure, analyzing void plane information, analyzing void space information and memorizing the analysis result. The method adopts the CT scanning technique, can exactly and quickly obtain the digital images of the porous asphalt mixture, reinforces and cuts the images, extracts the corresponding characteristic parameters of the void, carries out the quantitative description on the structural characteristic of the void by a fractal theory by virtue of the parameters, comprehensively reflects the void structure information, and avoids the effects of all characteristics of the porous asphalt mixture on the void evaluation. The parameters lays the foundation for further researching the effect rule of the void structure on the splitting tensile strength and the permeability of the porous asphalt mixture and for researching the void decay behavior of the porous asphalt mixture.

Owner:CHANGAN UNIV

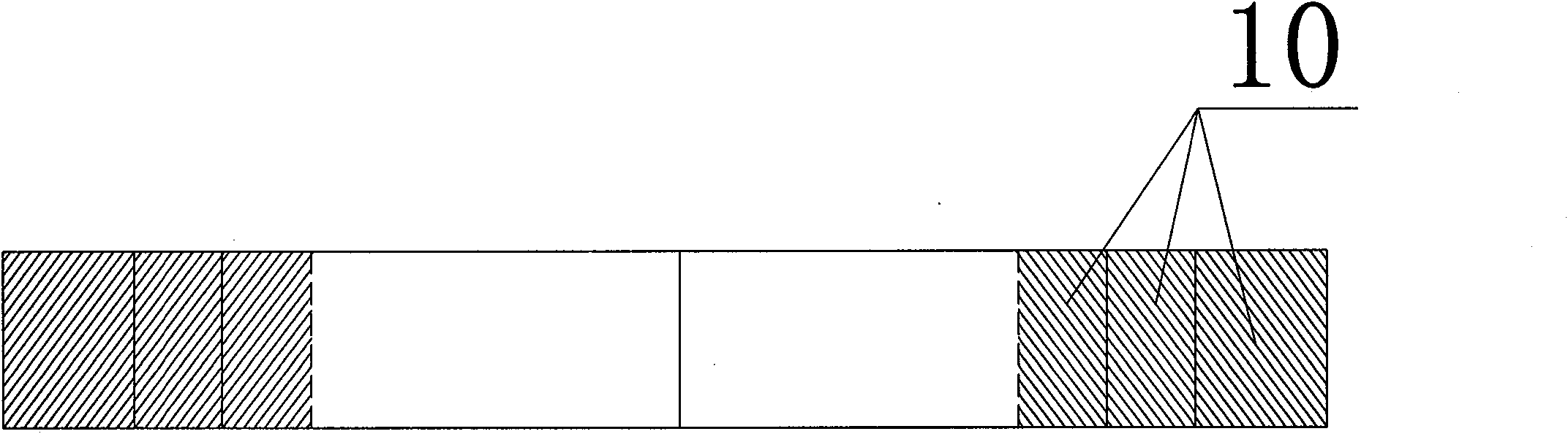

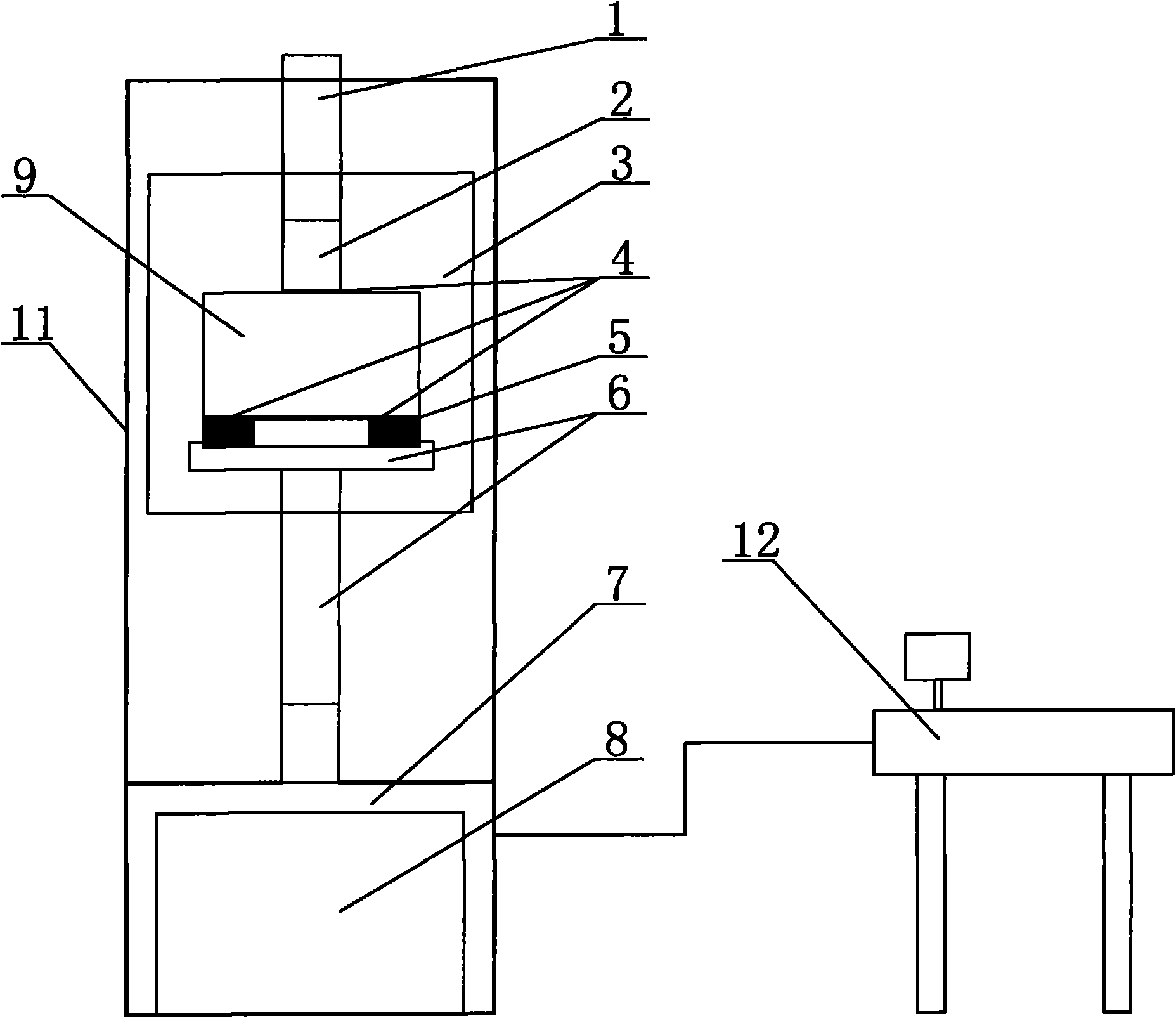

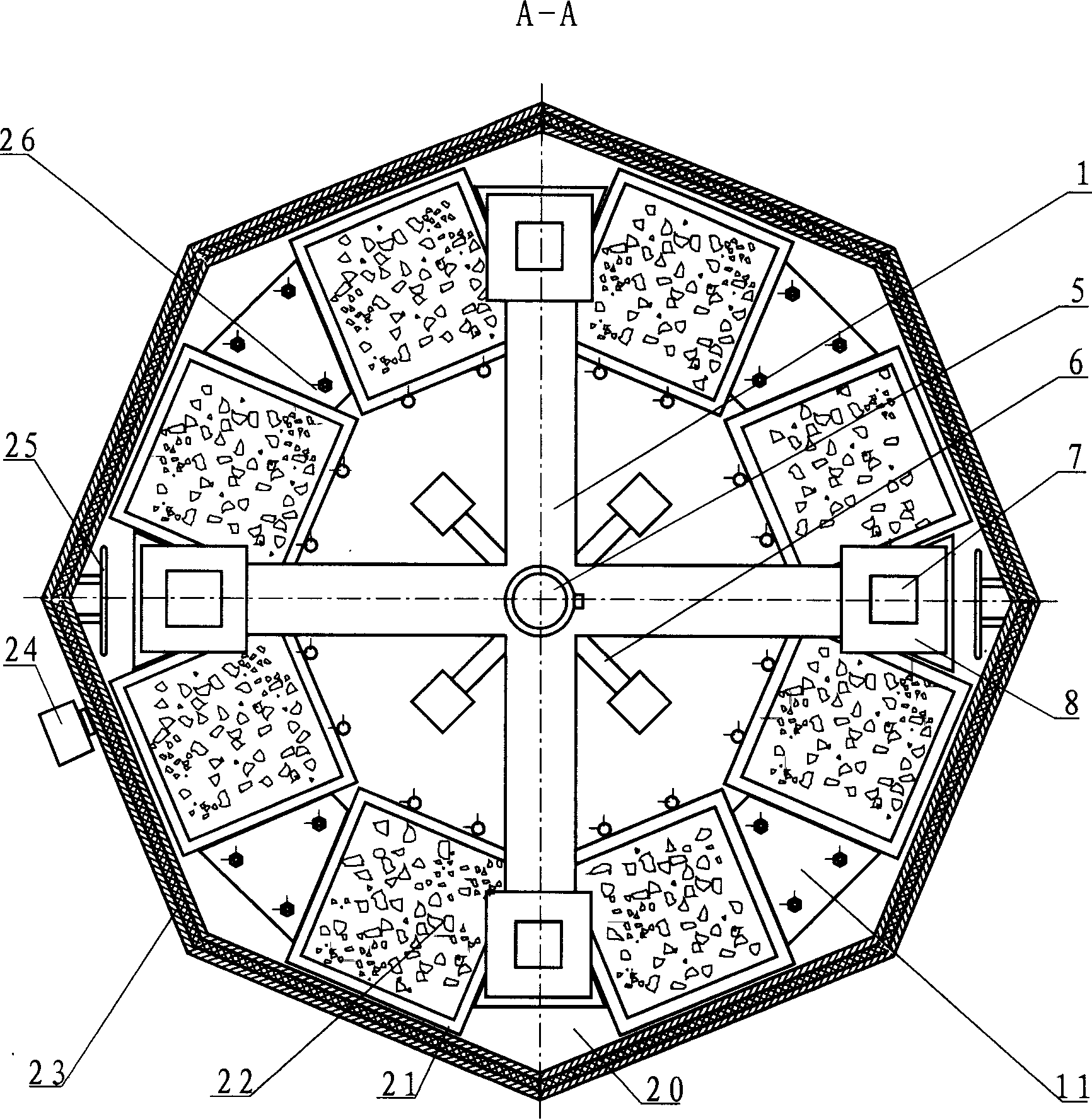

Indoor rotary wheel rutting test machine for asphalt mixture

InactiveCN1789961AShorten test timeShort test timeMaterial testing goodsInvestigating material hardnessDrive shaftTar

The invention discloses a tracking tester of indoor rotary tar hybrid material, which is characterized by the following: the rotary rack with rotary shaft is set on the floor of experimental table and in the environmental box; the top of rotary table pillar connects the experimental table panel; the speed adjustment motor contains electric rack, bearing support seat and heating pipe, which connects the rotary shaft through driving structure; the bottom of driving shaft is set on the bearing support seat; the rotary bearing is set between the rotary shaft and bearing support seat; the rotary bridge is set on the rotary shaft; the bearing sleeve and bearing are set between the rotary bridge and rotary shaft; rubber tyre column slide cylinder within at least one rubber tyre column is set on the rotary bridge; the weight block holder is set on the rubber tyre column to load the weight block and the rubber tyre is set on the bottom; the limitation column and at least two steel molds are set on the experimental table panel to assemble test piece of tar hybrid material with pad board among steel molds; the temperature controller is set on the exterior of environmental box. The invention shortens the test time and improves the efficiency, which can be used in the tracking-proof experiment of tar hybrid material pavement.

Owner:CHANGAN UNIV

Method for enhancing bituminous mixture by adopting chopped basalt fibers

InactiveCN101712803AImprove high temperature stabilityFix rutsBuilding insulationsCrack resistanceWhole-life cost

The invention relates to a method for enhancing bituminous mixtures by adopting chopped basalt fibers, belonging to the technical field of novel compound materials. According to the invention, continuous basalt protofilaments or twistless rovings the surfaces of which are expanded into fibers in certain length, and then the fibers are used for enhancing the bituminous mixtures in a certain doping proportion and can be respectively used for maintaining the bituminous mixtures used for new construction and reconstruction and extension of highways and SMA and OGFC bituminous mixtures as well as fiber seals. In addition, the fibers can also be used for the enhancement of high-speed railway packing layer CA mortar and relevant hydraulic architectures. The chopped basalt fiber plays roles of enhancing, toughening and elasticizing the cracking prevention, crack resistance and reinforcement and 'bridging' in the enhanced bituminous mixtures, can obviously increase the anti-rutting ability of highways of the enhanced bituminous mixtures and reduces the whole life costs of the enhanced bituminous mixtures; if the fibers are used for high-speed railway plate-type ballastless tracks and CA mortar, the bending strength and the deformation resistance can be increased, i.e. the fibers play a role of crack prevention and crack resistance; in addition, the fibers have better anti-water leakage action if being used for Hydraulic and Hydro-Power Engineering.

Owner:ZHEJIANG GBF BASALT FIBER +1

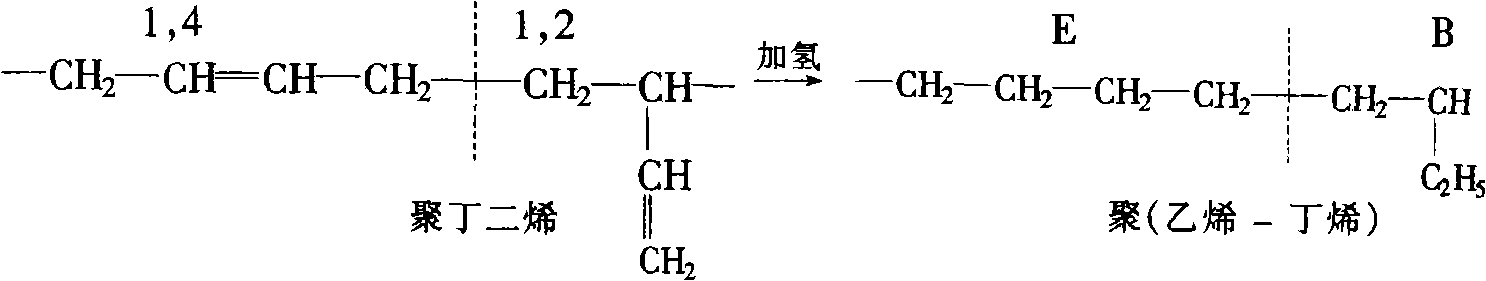

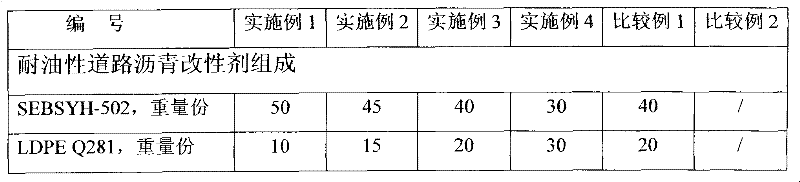

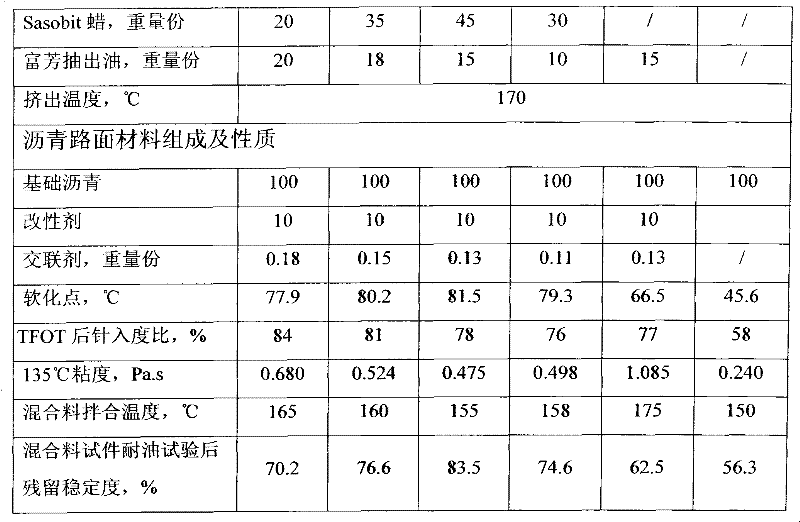

Oil-resistant road asphalt modifier and preparation method thereof

ActiveCN102443239AImprove high temperature stabilityImprove temperature sensitivityBuilding insulationsWaxPolyolefin

The invention discloses an oil-resistant road asphalt modifier and a preparation method thereof. The oil-resistant road asphalt modifier comprises the following components in parts by weight: 20-50 parts of styrene-ethylene / butylene-styrene segmented copolymer (SEBS), 10-30 parts of polyolefin resin, 15-45 parts of polymer wax and 10-30 parts of extract oil with rich aromatics by weight. The preparation method comprises the following steps of: feeding the materials in proportion to a dual-screw extruder to stretch and granulate, extruding at a temperature of 120-200 DEG C and preparing the oil-resistant road asphalt modifier. With adoption of the modifier disclosed by the invention, the anti-aging performance, the high-temperature usability and the oil resistance can be remarkably improved while the production process for the oil-resistant road asphalt modifier can be simplified; moreover, the modifier can be used for lowering hot mixing and construction temperature of the asphalt mixture, reducing energy consumption, reducing the discharging of harmful gases such as smog and reducing pollution to the environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

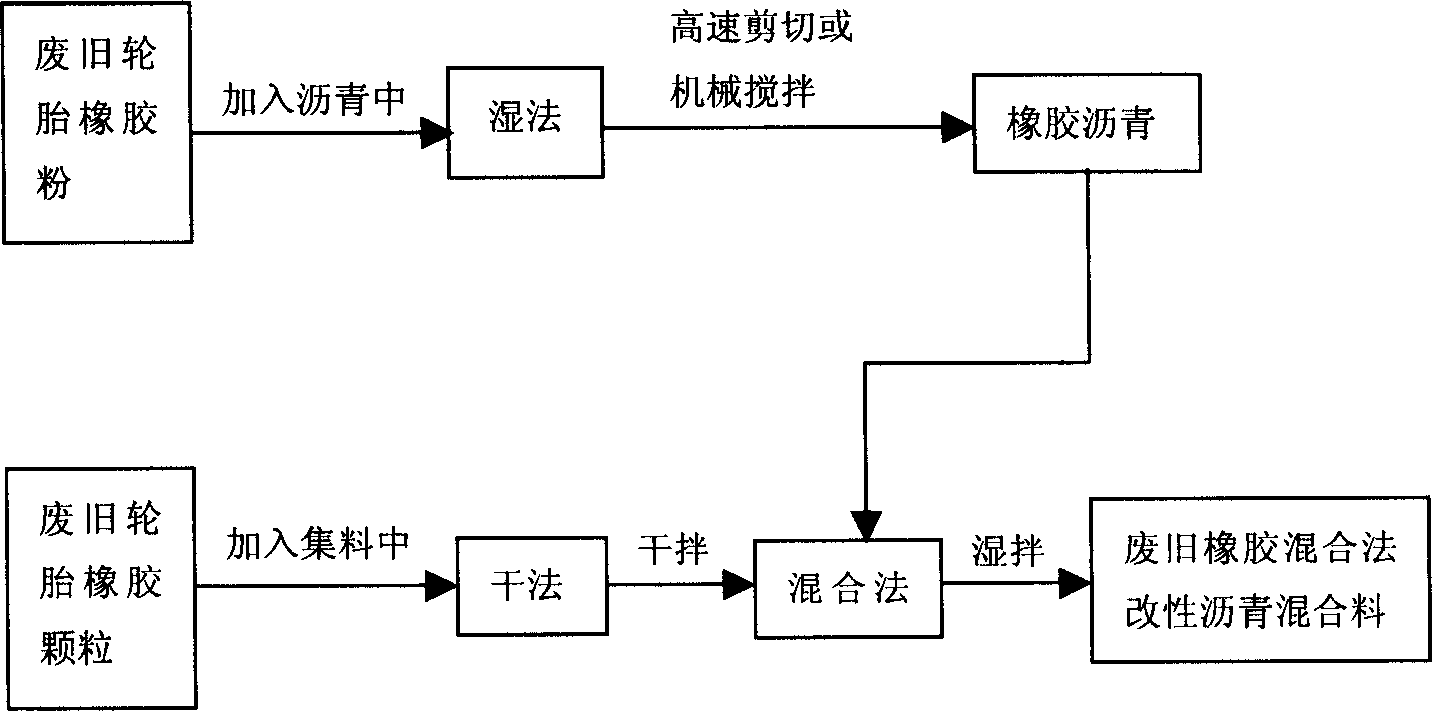

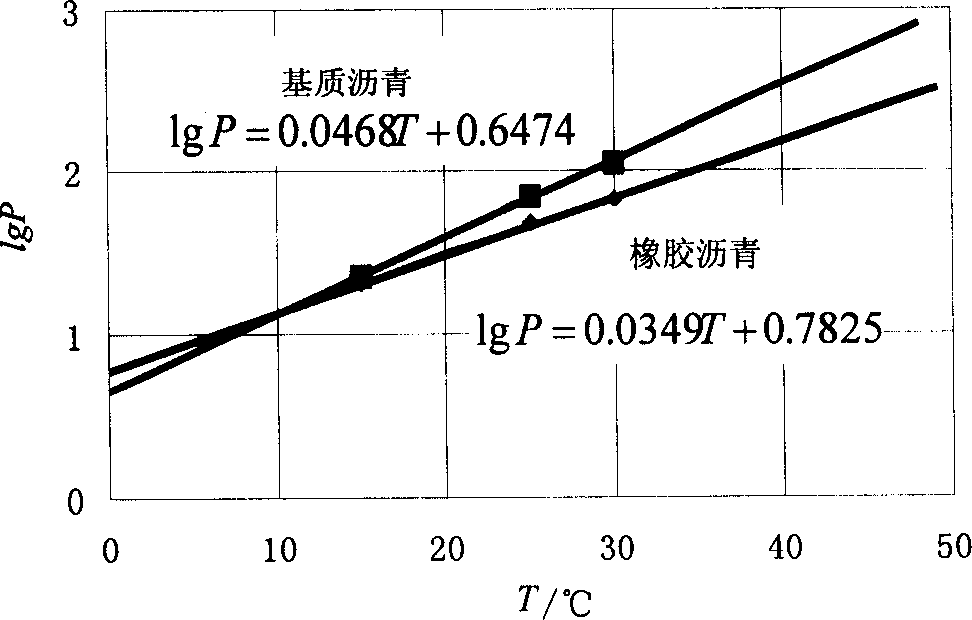

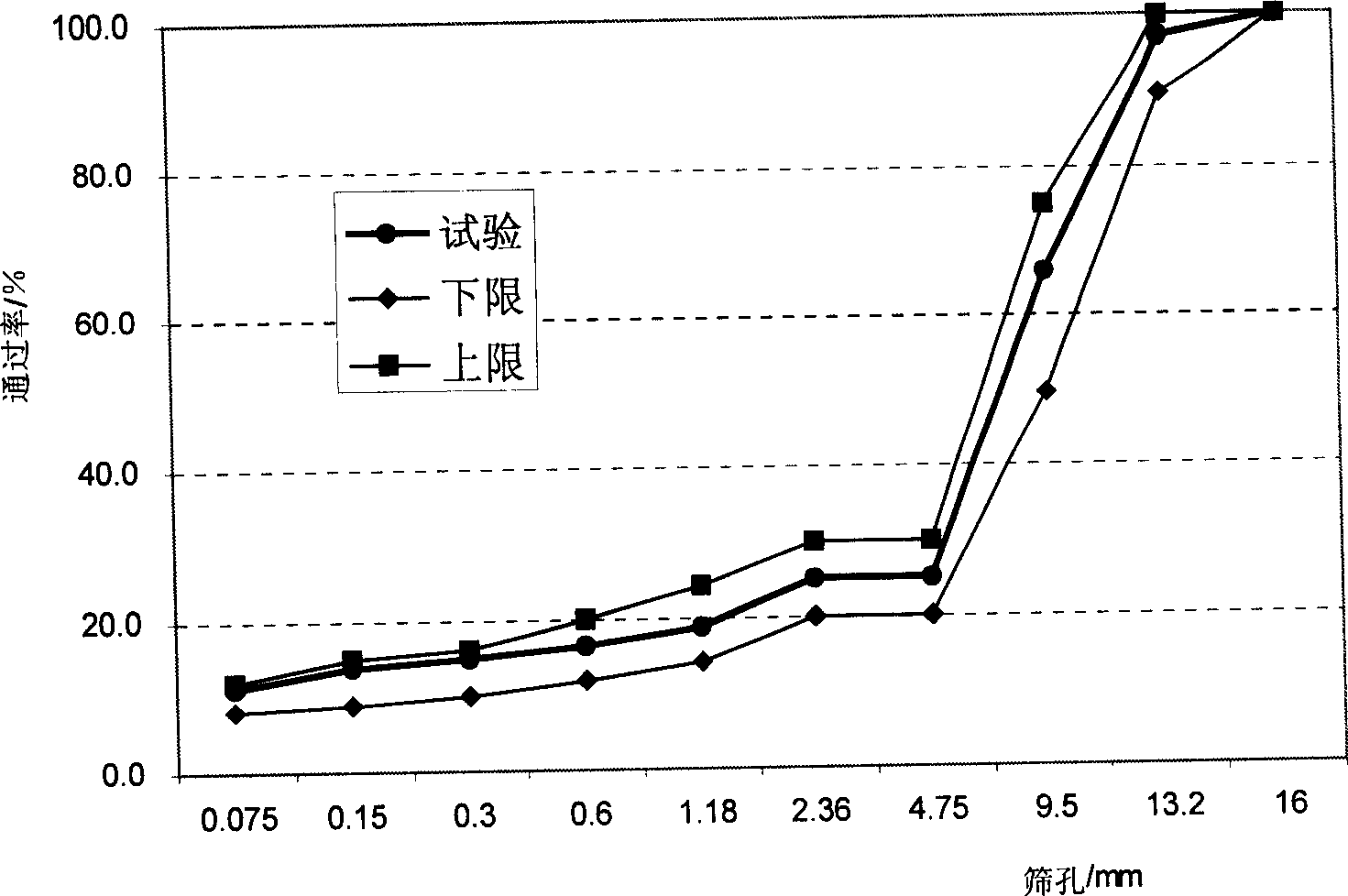

Method for preparing modified asphalt mixture using waste and old tyre and hybrid method

InactiveCN1807514AExtended service lifeReduce pollutionIn situ pavingsBuilding insulationsTraffic noiseEngineering

This invention relates to the field of engineering material technical, and it is specificly related to the method for preparing a kind of modified bituminous mixture with worn tyre. It is made as follows: mill worn tyre to powder, mix the owder with base bitumen and agitate to get rubber bitumen; gap-graded aggregate, screen the aggregates and get coarse, fine aggregates; mix rubber particles with the coarse and fine aggregates, agitate, then add rubber bitumen and agitate, lastly add powdered ore and mix to get needed production. This invention blends dry and wet processes together to exert each advantage sufficiently, and attained both the aims of consumping much worn tyre and improve pavement performance. With this invention, we can greatly improve high and low temperature behavior of bitumen and its mixture, we can longer pavement life and abate environmental pollution. The pavement paved by this mixture has the behavior of lowering traffic noise. Popularization of this achievement is economic, society, environmental and engineering benefit.

Owner:TONGJI UNIV

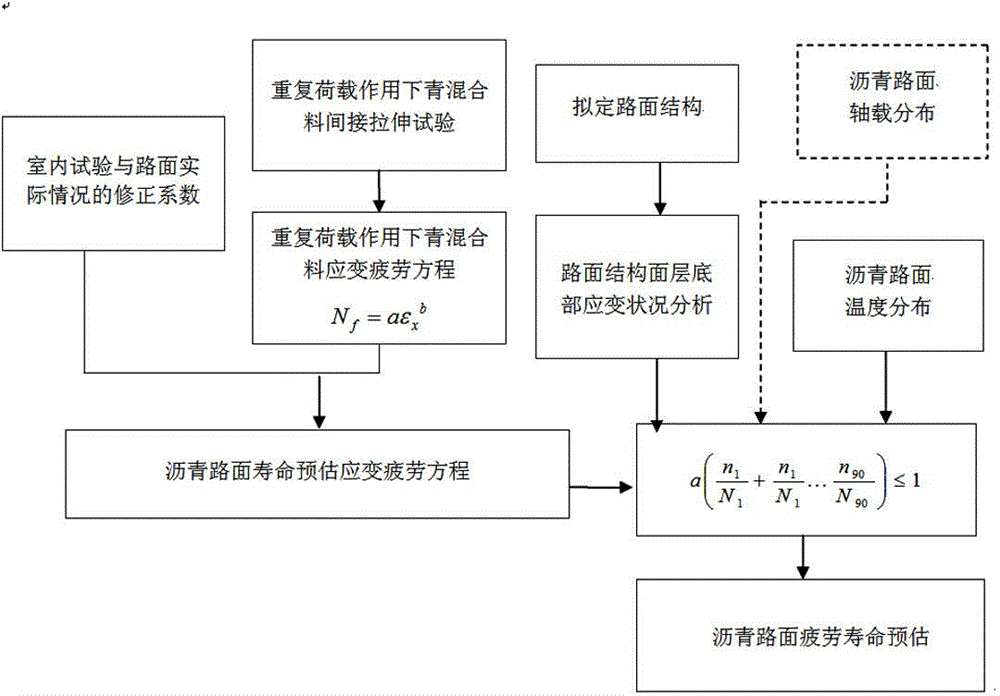

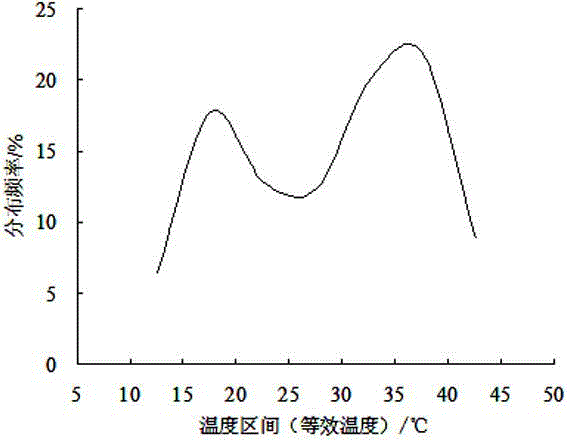

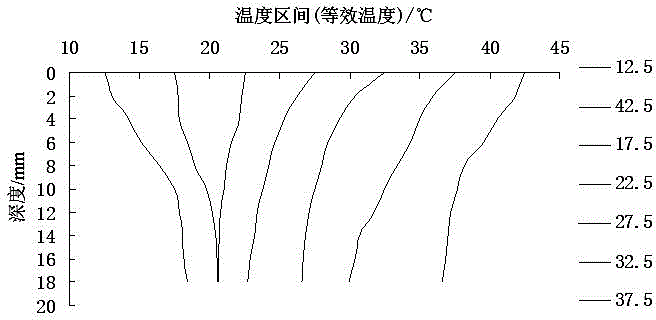

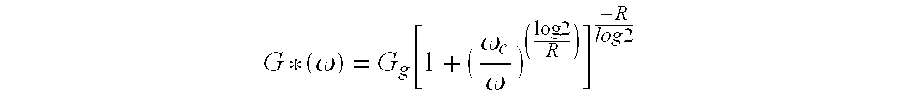

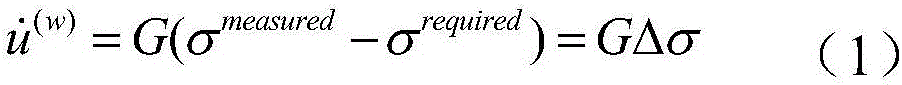

Fatigue life prediction method for high-modulus asphalt mixture pavement

InactiveCN104462843AAccurately describe attenuationAccurately describe the lawSpecial data processing applicationsUltrasound attenuationElement model

The invention provides a fatigue life prediction method for a high-modulus asphalt mixture pavement. The method comprises the steps that structural temperature distribution, pavement material dynamic modulus and temperature axle load distribution of the high-modulus asphalt mixture pavement serve as basis parameters; a fatigue strain equation is fit according to an indirect tension fatigue test result; ANSYS software is adopted to construct a pavement structure finite element model, and maximum tension strain of a bottom layer at different axle load levels in different temperature regions is calculated; according to the Miner fatigue cumulative damage rule, fatigue cumulative damage results of a high-modulus asphalt mixture at different axle loads and different temperatures are calculated according to the formula: . The fatigue life prediction method for the high-modulus asphalt mixture pavement has the technical advantages that temperature gradients and axle load distribution of the asphalt mixture pavement are fully considered, an accurate prediction model is established, the process and law of fatigue attenuation of the asphalt mixture are accurately described, the application range is wide, and calculation results are reliable, so a more reliable method is provided for structural design of the asphalt pavement.

Owner:CHONGQING JIAOTONG UNIVERSITY

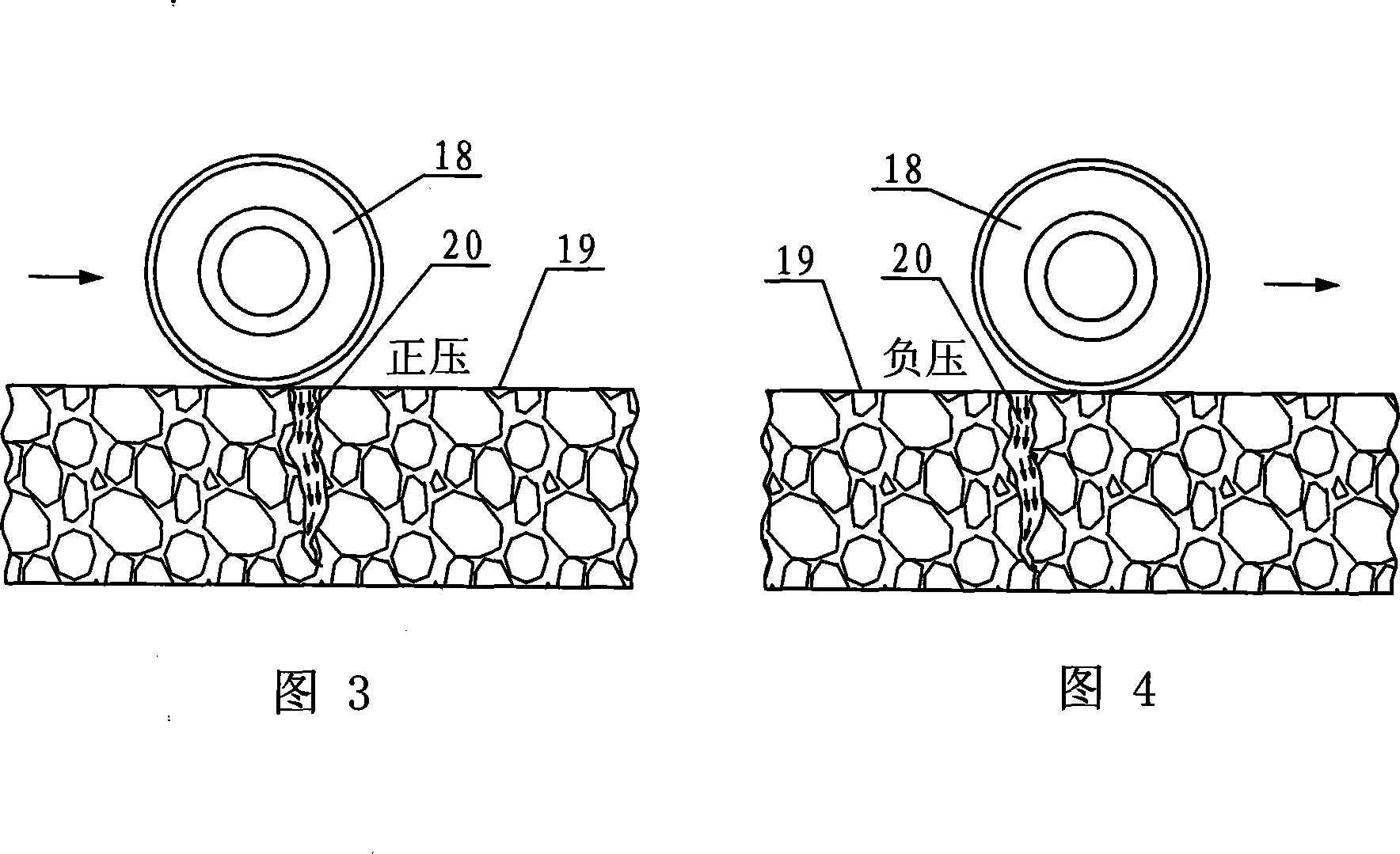

Asphalt mixture hydrodynamic pressure scouring test methods and apparatus

InactiveCN101216401AHigh simulationUsing mechanical meansVehicle tyre testingPositive pressureRoad surface

Owner:SOUTH CHINA UNIV OF TECH

Rejuvenation of reclaimed asphalt

ActiveUS20140338565A1Low cloud and pour pointImprove thermal stabilityIn situ pavingsSolid waste managementCrack resistanceFatty acid

Asphalt compositions comprising reclaimed asphalt and a rejuvenating agent are disclosed. The reclaimed asphalt comprises aggregate and an aged binder. The rejuvenating agent, which has a cyclic content of at least 5 wt. %, comprises an ester or ester blend derived from an acid selected from aromatic acids, fatty acids, fatty acid monomers, fatty acid dimers, fatty acid trimers, rosin acids, rosin acid dimers, and mixtures thereof. The rejuvenating agent revitalizes the aged bitumen binder of reclaimed asphalt and restores its physical properties to those of the original performance-grade bitumen. Improvements include desirable softening, low-temperature cracking resistance, better fatigue cracking resistance, good elevated temperature performance, improved miscibility, and restored temperature sensitivity. The rejuvenating agents enable the use of higher levels of recovered asphalt, particularly RAP, in asphalt mixtures, reduce binder and aggregate costs, and help the road construction industry reduce its reliance on virgin, non-renewable materials.

Owner:KRATON CHEM LLC

Ultra-thin wearing layer of pavement

The invention belongs to the technical field of a building material used in road engineering, and specifically relates to drainage asphalt mixture for an ultra-thin wearing layer. The mixture comprises aggregated material, stuffing, high-performance asphalt and warm mixing additive; the maximal nominal size of the mixture is 6.7mm; the thickness of a pavement layer is 10-20mm; the aggregated material is basalt or dolerite; the used stuffing is mixture of limestone powder and common silicate cement, and the used high-performance asphalt is prepared from general modified asphalt by adding waste tire rubber powder which is 20-28% of weight of the asphalt and modifying. An ultra-thin finishing coat and low-temperature construction are realized by the asphalt mixture by adding the warm mixing additive; the ultra-thin wearing layer has the advantages of low construction cost, convenience in construction and the like, and is suitable for building of an asphalt concrete pavement and function-improving works of the pavement.

Owner:上海砼仁环保技术发展有限公司

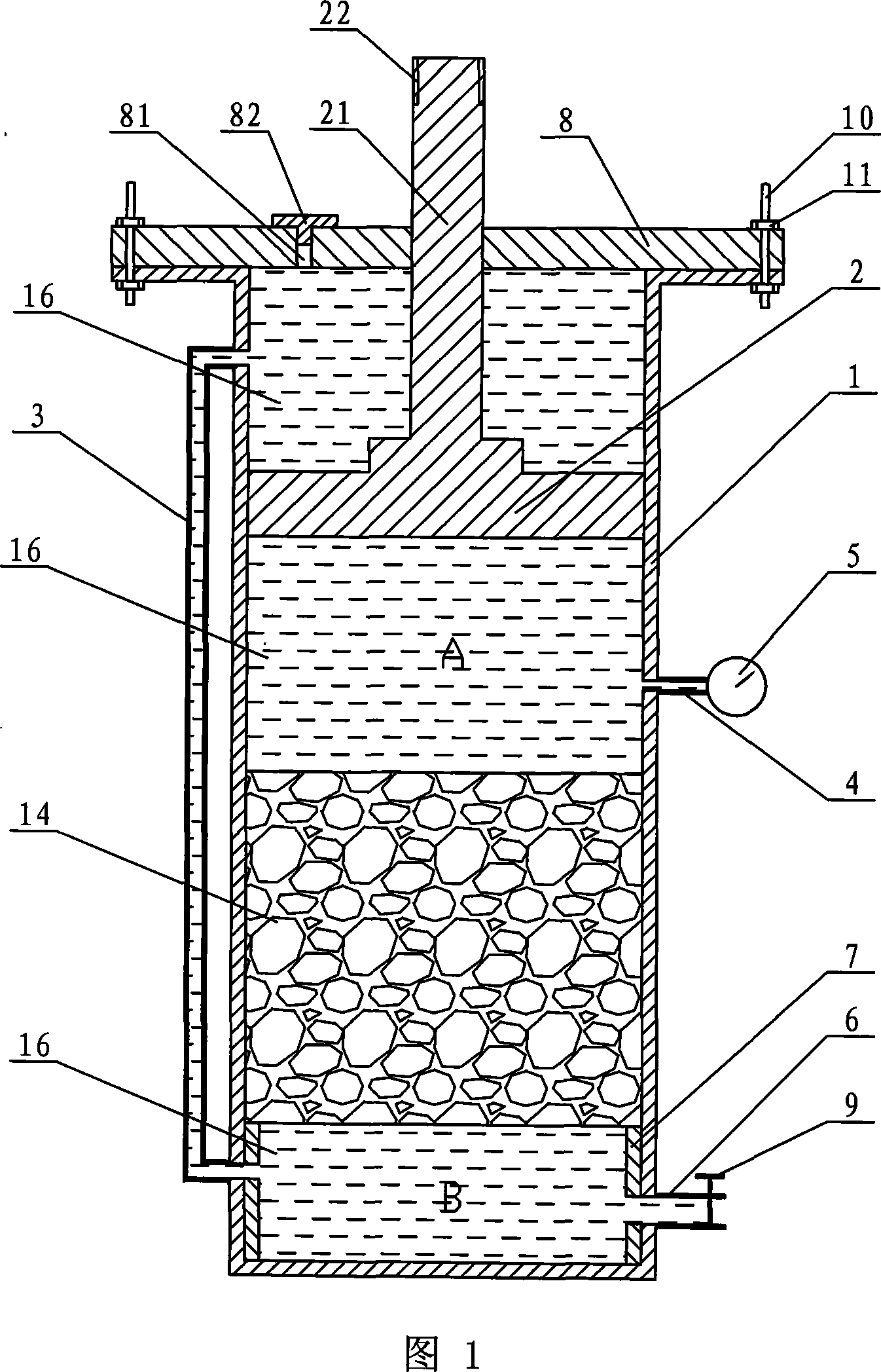

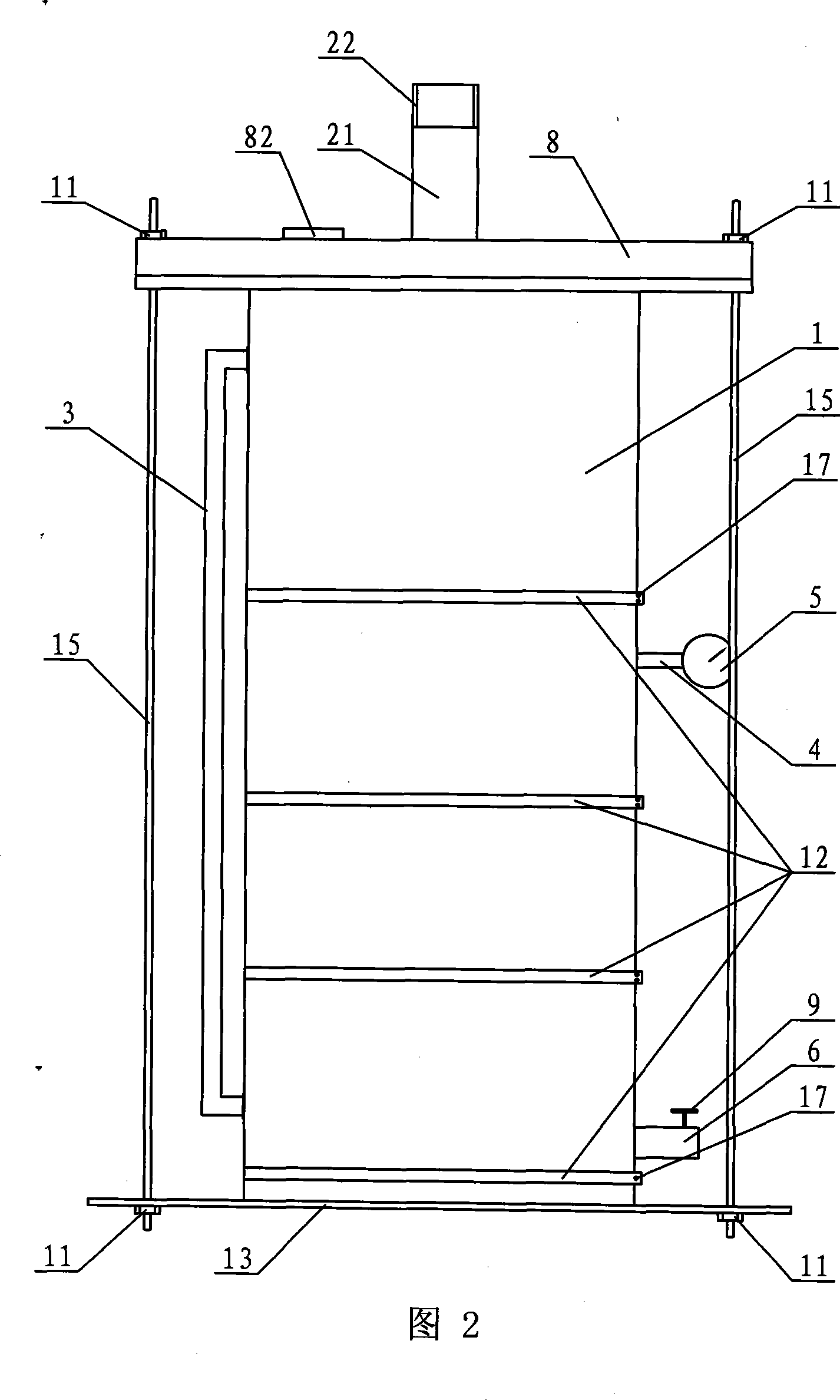

Test device for asphalt mixture resisting moving water scouring

InactiveCN101210870AWeather/light/corrosion resistanceMaterial testing goodsPore water pressureWashout

The invention relates to a test device, specifically to a flowing water washout prevention test device for asphalt mixture. The invention aims to solve the problem that no test device is available for evaluating the washout effect of flowing water on asphalt mixture. In the inventive device, a pedestal is disposed at the bottom of the inner cavity of a washout barrel (1), a piston (2) is disposed on the inner cavity of the washout barrel (1), an upper cover is disposed at the top end of the washout barrel (1), a conduit (3) and an upper water pipe (4) are disposed at the side wall of the washout barrel (1), a pressure meter (5) is disposed on the upper water pipe (4), and a lower water pipe (6) is disposed in the lower part of the side wall of the washout barrel (1) and provided with a valve (9). The invention can simulate the effect of flowing water pressure arising from vehicle traveling on the asphalt concrete pavement on the asphalt pavement under different temperature conditions.

Owner:HARBIN INST OF TECH

Cold-regenerated emulsified asphalt mixture and method of cold-regenerated emulsified asphalt mixture for road surface reconstruction

ActiveCN101748677AThe damage is correct and reasonableCorrect and reasonable damageRoads maintainenceSpecial data processing applicationsRoad surfaceMaterials science

The invention provides a cold-regenerated emulsified asphalt mixture and a method of the cold-regenerated emulsified asphalt mixture for road surface reconstruction. In the method, the damage condition of a structural layer below a surface layer is measured on the spot, and then quantitative evaluation is carried out on the bearing capacity so as to obtain actual mechanics and structural parameters; the production of the regenerated asphalt mixture is carried out in a cold mixing factory after milling materials on the asphalt surface layer of an old road, cement, emulsified asphalt and water mixed together; the regenerated asphalt mixture passes the forming test piece detection; the mixture obtained by the above steps is used for a to-be-reconstructed road surface structure, including the laying of a roadbed, a base layer and the surface layer. Moreover, the cold-regenerated asphalt mixture used for the above method has the following characteristics: mineral materials which are mainly composed of the milling materials of the asphalt surface layer of the old road, asphalt cementing materials and residual gaps form a multi-phase disperse system structure with a space network structure; the material property is granular; and the mechanics strength is reached by the cohesive force and the inner frictional resistance of the asphalt mixture.

Owner:JIANGXI GANYUE EXPRESSWAY

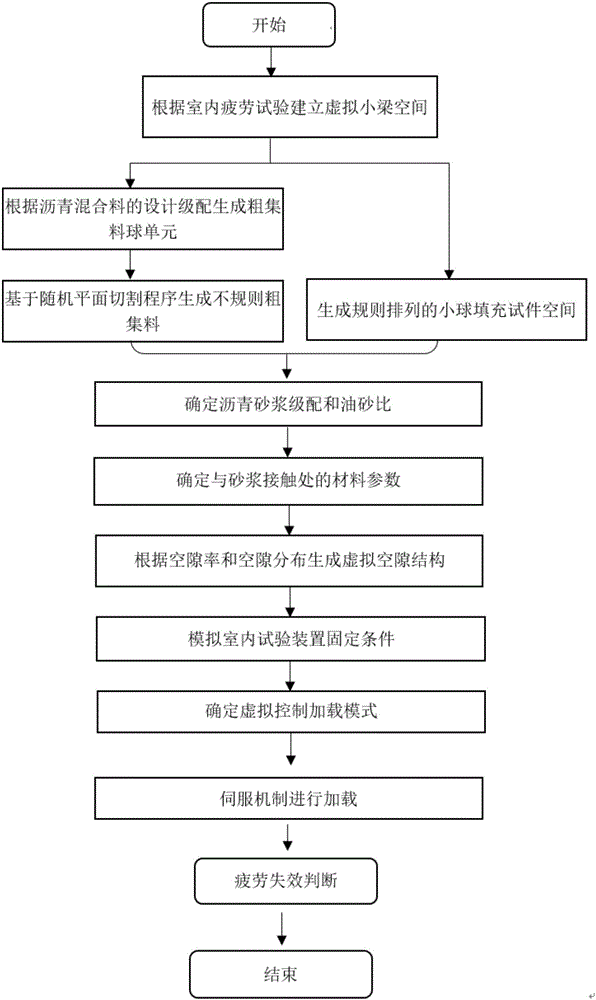

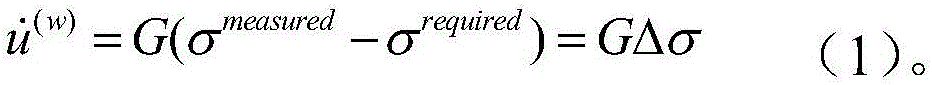

Asphalt mixture fatigue test numerical simulation method based on random generation

InactiveCN106126820AImprove efficiencyImprove accuracyDesign optimisation/simulationSpecial data processing applicationsUnit sizeVoid ratio

The invention discloses an asphalt mixture fatigue test numerical simulation method based on random generation. The method comprises the steps of randomly generating a test piece; determining the particle number, grading and irregular shape of coarse aggregates according to the test piece to be formed; determining that the coarse aggregates are not overlapped; generating irregular coarse aggregates; determining the minimum discrete unit size of bituminous mortar; filling the bituminous mortar; determining bituminous mortar grading and the dosage of asphalt in bituminous mortar according to the grading of an asphalt mixture; acquiring relative material parameters according to a bituminous mortar creep test and a spitting test; determining void ratio and void distribution and generating voids; conducting fatigue test numerical simulation; determining a virtual loading mode; conducting loading with a servo mechanism; conducting fatigue failure judgment. Through random test piece generation, three-dimensional configuration reconstruction of the asphalt mixture is achieved. By the adoption of the method, three-dimensional reconstruction of various grading levels, various void ratios and various asphalt mixtures can be achieved, and digital test piece reconstruction efficiency and accuracy are improved greatly.

Owner:SOUTHEAST UNIV

Warm mix asphalt modifier and preparation method thereof, warm mixed asphalt and warm mix asphalt mixture

InactiveCN104327520AReduce agingReduce risk of water damageClimate change adaptationBuilding insulationsSurface-active agentsSolvent

The present invention discloses a warm mix asphalt modifier and a preparation method thereof, the warm mix asphalt modifier comprises the following components: 75-95 parts of solvent oil and 3-25 parts of a surface active agent. The warm mix asphalt modifier using oil base surface active technology effectively reduces the risk of water damage of a warm mix asphalt mixture, improves the low-temperature anti-craking performance of the warm mix asphalt mixture; at the same time, the warm mix asphalt modifier greatly reduces the mix temperature of the asphalt mixture, has the advantages of simple process, environmental protection, energy saving, low cost and the like. In addition, the invention also discloses warm mix asphalt and the warm mix asphalt mixture.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com