Warm mix asphalt modifier and preparation method thereof, warm mixed asphalt and warm mix asphalt mixture

A technology of warm mix asphalt and modifier, which is applied in building thermal insulation materials, building components, climate change adaptation and other directions, can solve the problems of not being able to directly prepare warm mix asphalt, lowering the mixing temperature of the mixture, and high comprehensive use cost, and achieving The effect of reducing the risk of water damage, improving low temperature performance, saving energy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

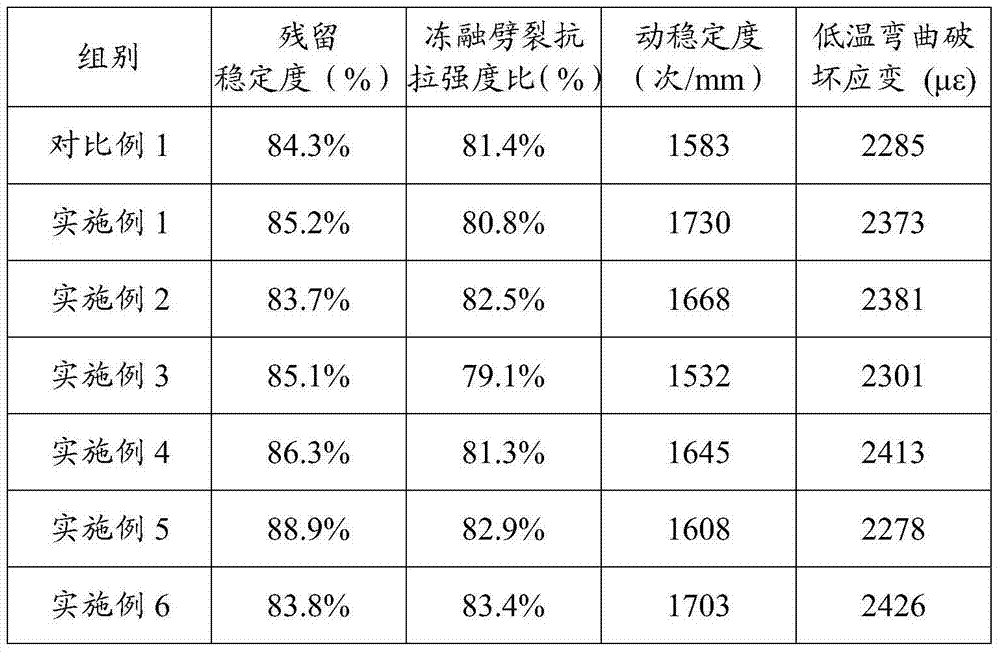

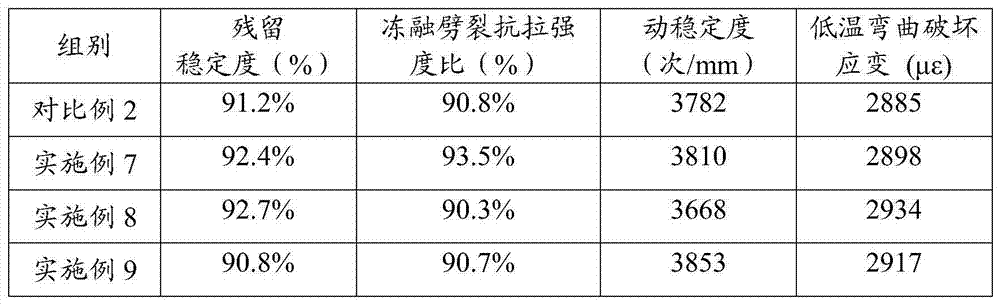

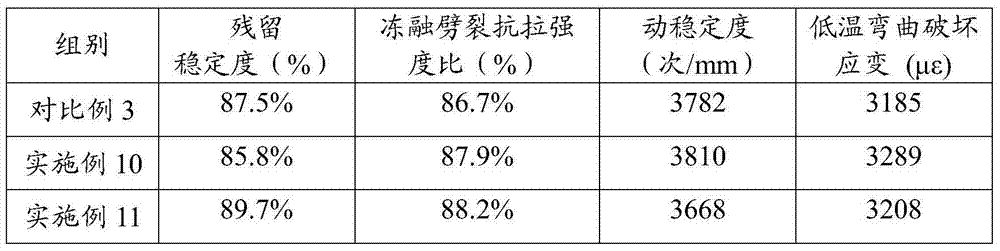

Examples

preparation example Construction

[0037] In addition, the present invention also provides a preparation method of the above-mentioned warm mix asphalt modifier, comprising the following steps:

[0038] (1) Weigh 75 to 95 parts of solvent oil in parts by weight and heat to 60 to 75°C;

[0039] (2) Add 3 to 25 parts of ionic surfactants into the above solvent oil, turn on the vacuum device and carry out mechanical stirring, and stir for 30 to 40 minutes; wherein, the vacuum degree of the vacuum device is controlled at 10 to 50 Pa;

[0040] (3) Control the temperature to drop to 30°C-45°C, turn off the vacuum device, continue stirring for 10-15min, and cool to room temperature to obtain the warm-mix asphalt modifier.

[0041] Further, the present invention also provides a kind of warm mix asphalt, which uses the above-mentioned warm mix asphalt modifier and base asphalt as raw materials, wherein the base asphalt is straight-run asphalt, oxidized asphalt, semi-air-blown asphalt, heavy traffic polymer modified One...

Embodiment 1

[0053] (1) Take 75 parts of lubricating oil base oil by weight and heat to 60°C;

[0054] (2) 20 parts of saturated C 12 ~C 18 Alkyl polypropylene polyamine and 5 parts of polyamine were added to the above-mentioned lubricating base oil respectively, the vacuum device was turned on and mechanically stirred, stirred for 30 minutes, and the vacuum degree was 50Pa;

[0055] (3) Control the temperature down to 45°C, turn off the vacuum device, continue to stir for 10 minutes, and cool to room temperature to obtain the warm mix asphalt modifier.

[0056] Preparation of warm-mix asphalt: Add warm-mix asphalt modifier with an asphalt weight of 1‰ to molten 70# petroleum asphalt, heat to 140°C and stir for 20 minutes to obtain warm-mix asphalt.

[0057] Preparation of warm mix asphalt mixture: heat warm mix asphalt and aggregate to a certain temperature; then add 4% warm mix asphalt and various graded aggregates into the mixing pot, and mix to prepare warm mix asphalt Mixture.

[...

Embodiment 2

[0060] (1) Take 95 parts of pyrolysis tar by weight and heat it to 75°C;

[0061] (2) Put 4 copies of C 12 ~C 18 Add fatty amidoamine and 1 part of polyamine to the cracked tar respectively, turn on the vacuum device and carry out mechanical stirring, stir for 40min, and the vacuum degree is 10Pa;

[0062](3) Control the temperature down to 30°C, turn off the vacuum device, continue stirring for 15 minutes, and cool to room temperature to obtain a warm-mix asphalt modifier.

[0063] Preparation of warm-mix asphalt: add 6‰ of asphalt weight of warm-mix asphalt modifier into molten 70# petroleum asphalt, heat to 150°C and stir for 20 minutes to obtain warm-mix asphalt.

[0064] Preparation of warm mix asphalt mixture: heat warm mix asphalt and aggregate to a certain temperature; then add 5% warm mix asphalt and various graded aggregates to the mixing pot, and mix to prepare warm mix asphalt Mixture.

[0065] The specific technical indicators of the obtained warm mix asphalt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com