Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

488results about How to "Improves rutting resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

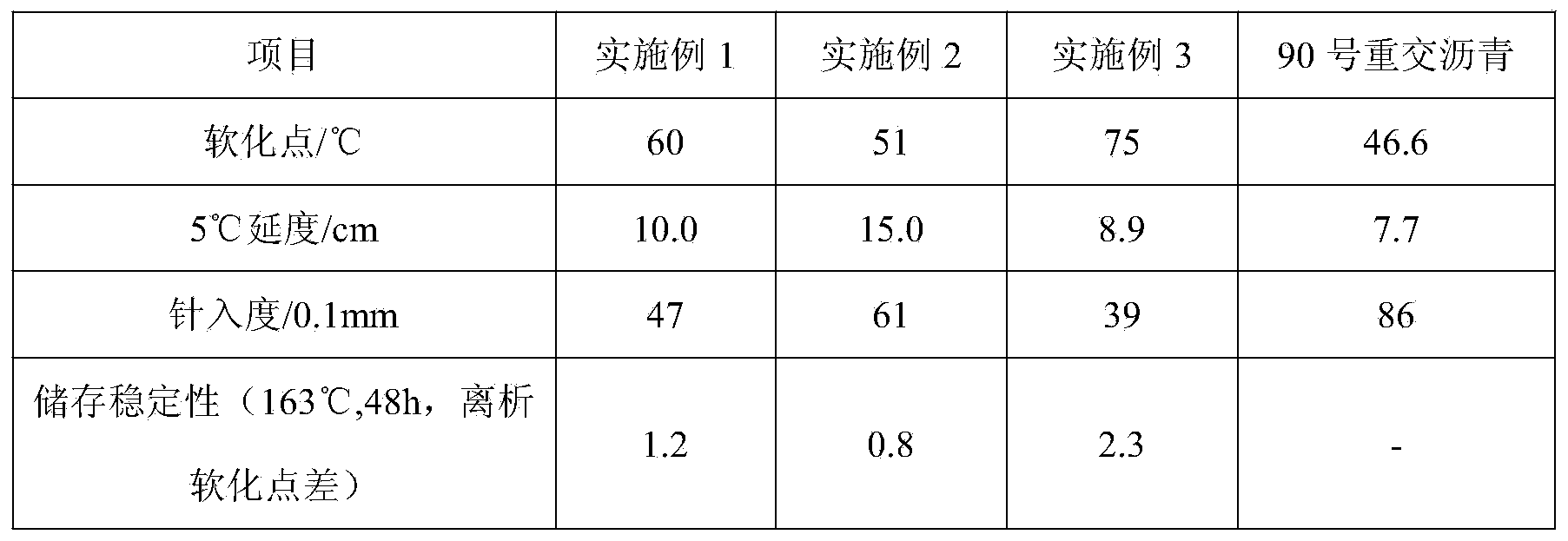

Graphene oxide modified asphalt and preparation method thereof

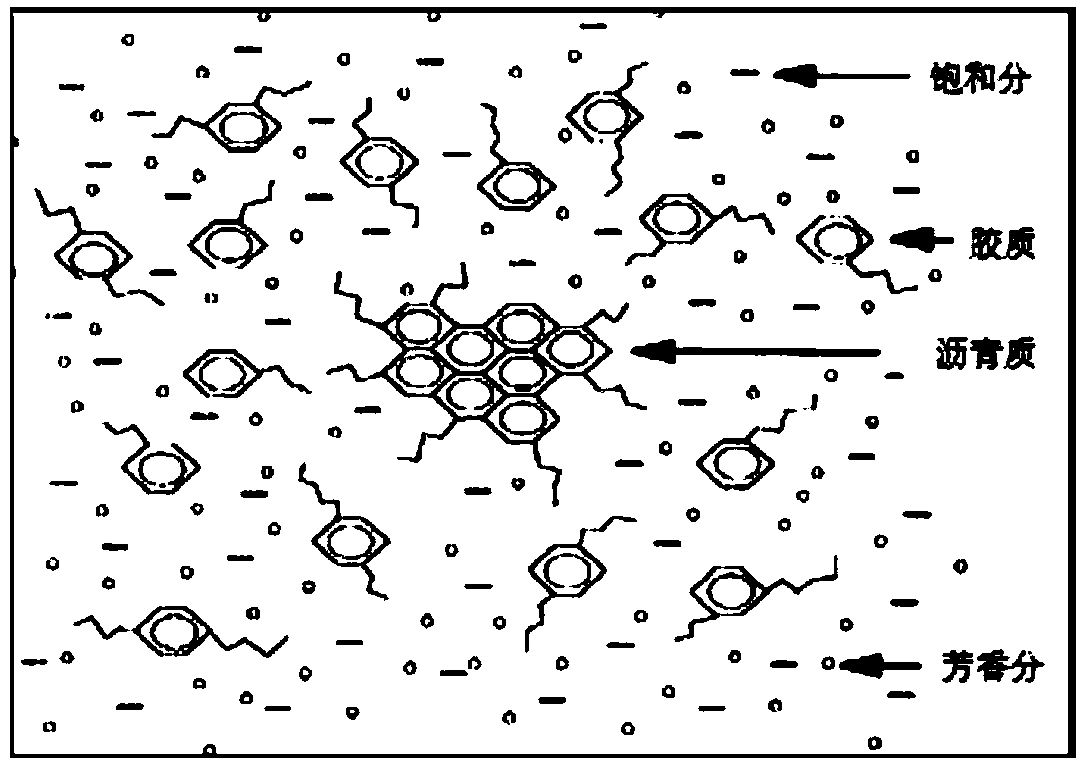

ActiveCN103819915AImprove high temperature performanceImproves rutting resistanceBuilding insulationsGraphite oxidePitch blende

The invention provides graphene oxide modified asphalt, comprising, by mass, 0.5 to 15% of graphene oxide and 85 to 99.5% of matrix asphalt, wherein the above mentioned mass percent sums to 100%. A preparation method for the graphene oxide modified asphalt comprises the following steps: heating and fusing matrix asphalt, maintaining a temperature to be 120 to 200 DEG C, adding graphene oxide, carrying out artificial stirring for 20 to 40 min, then carrying out stirring with a shearing machine for 20 to 120 min, cooling an obtained mixture to 100 to 150 DEG C and standing the mixture for 20 to 50 min so as to allow the mixture to be fully swollen; and subjecting the asphalt mixture to shearing on the shearing machine again for 80 to 100 min until graphene oxide is uniformly dispersed in asphalt. The graphene oxide modified asphalt provided by the invention uses graphene oxide as a modifier for modification of asphalt, can substantially improve high temperature performance and anti-deformation capability of matrix asphalt and greatly improves anti-tracking capability of a bituminous pavement.

Owner:浙江威克新材料科技发展有限公司

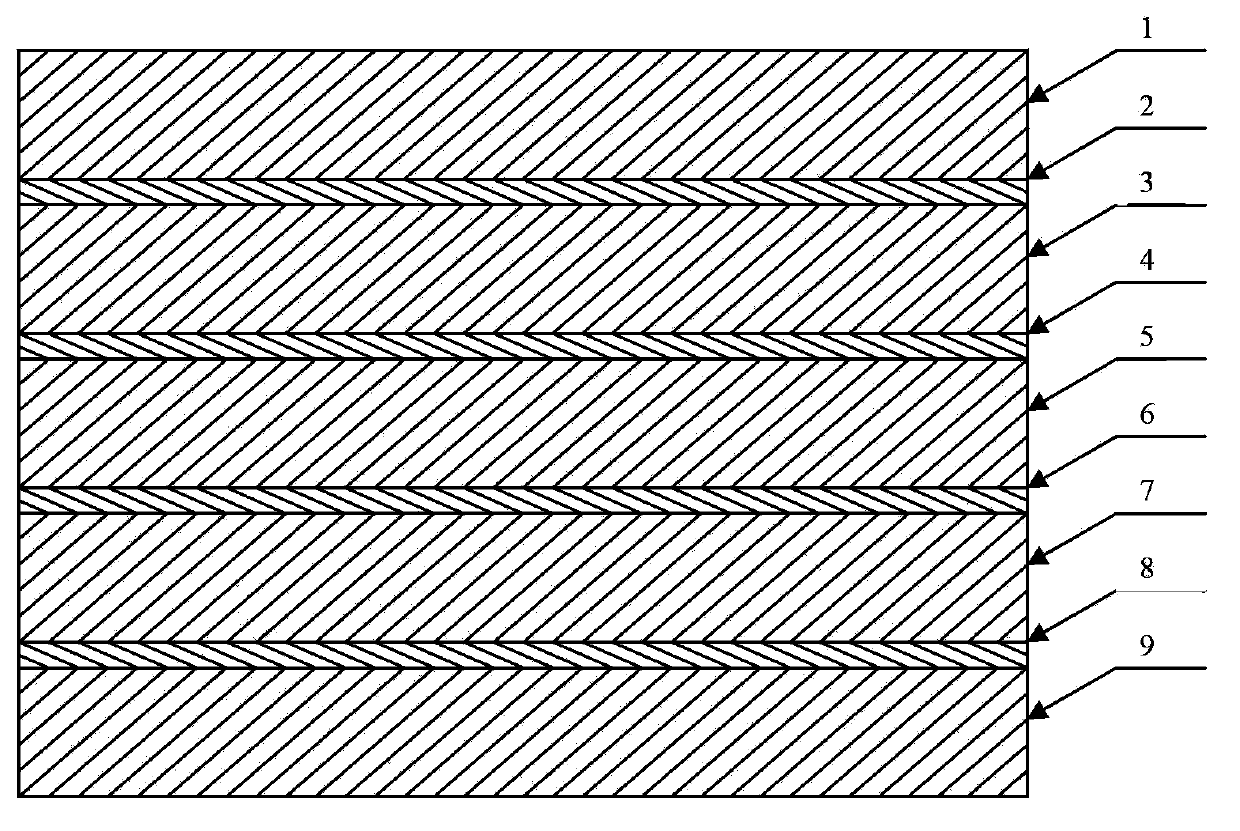

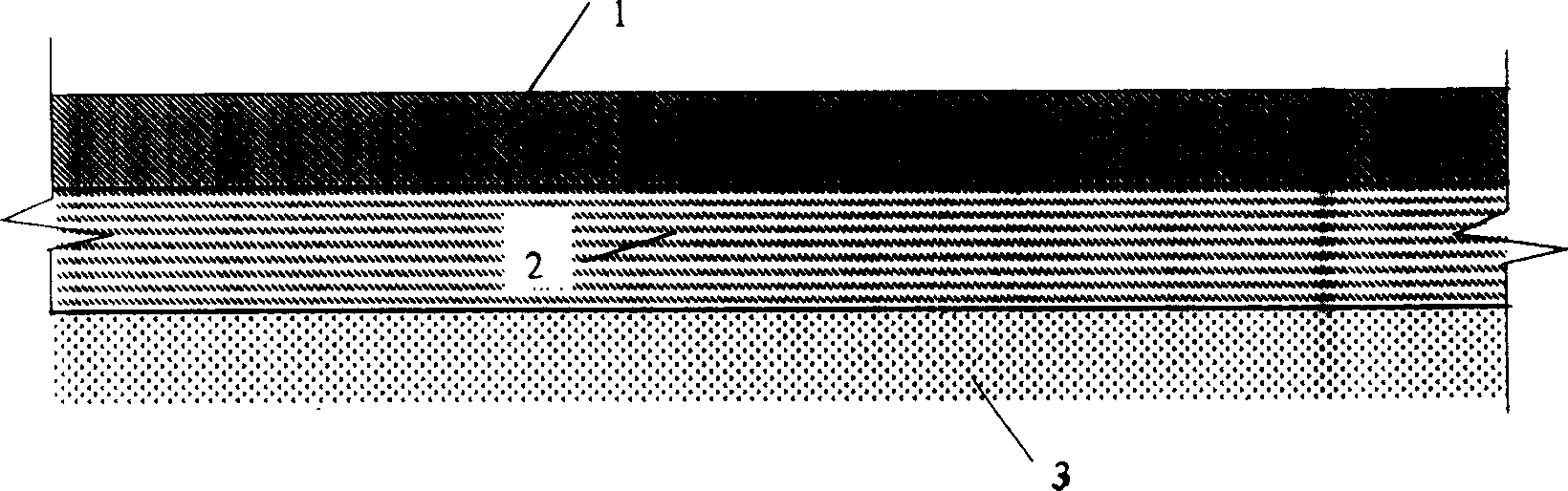

Semi-flexible heavy-duty pavement paving structure

ActiveCN103866667AImproves rutting resistanceImprove fatigue resistanceIn situ pavingsSurface layerLower grade

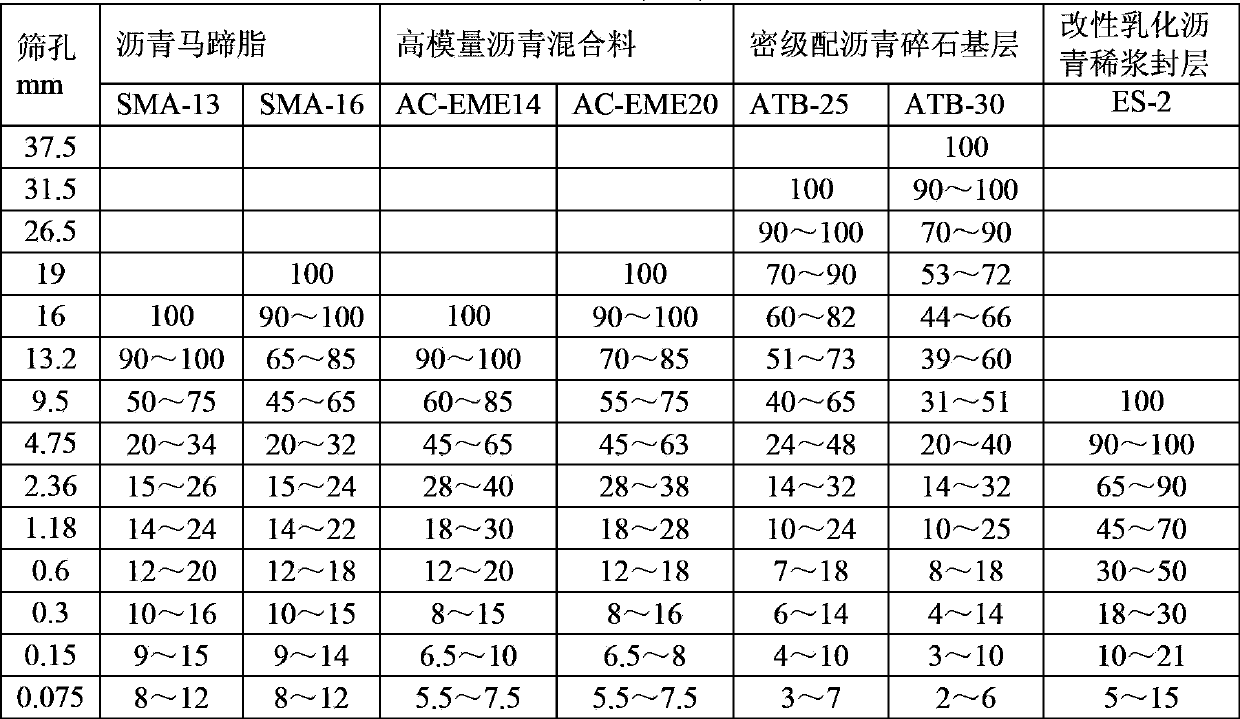

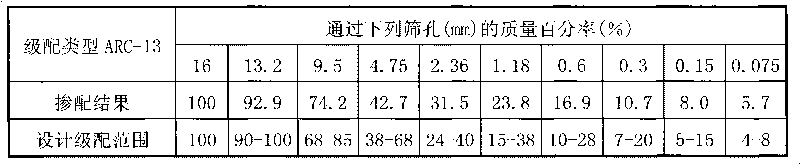

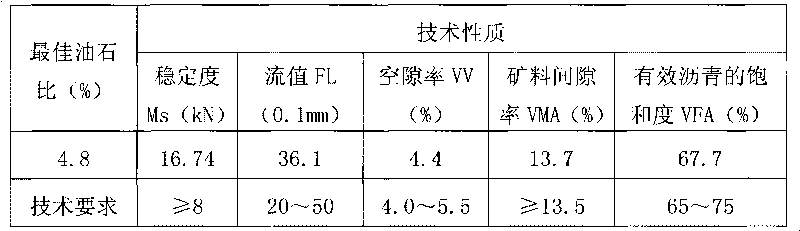

The invention relates to a semi-flexible heavy-duty pavement paving structure. The semi-flexible heavy-duty pavement paving structure comprises a surface layer having a thickness of 4-6cm and made of a high-viscosity modified asphalt mixture of SMA-13 or SMA-16, a middle surface layer having a thickness of 6-10cm and made of a high-modulus asphalt mixture of AC-EME14 or AC-EME20, a lower surface layer having a thickness of 10-12cm and made of a low-grade asphalt mixture of ATB-25 or ATB-30, and a semi-flexible base layer having a thickness of 6-12cm and made of skeleton solid cement-emulsified asphalt concrete; a high-viscosity modified asphalt bonding layer is arranged between the surface layer and the middle surface layer, between the middle surface layer and the lower surface layer and between the lower surface layer and the semi-flexible base layer, and the spreading quantity of the high-viscosity modified asphalt bonding layer per unit area is 0.6-0.8kg / m<2>; and an ES-2 modified emulsified asphalt slurry is arranged between the semi-flexible base layer and a bottom base layer, and has a suitable thickness of 6-10mm. The structure improves the rut resistance and the fatigue resistance of a pavement, and prolongs the service life of the pavement.

Owner:PETROCHINA CO LTD +1

Method for enhancing bituminous mixture by adopting chopped basalt fibers

InactiveCN101712803AImprove high temperature stabilityFix rutsBuilding insulationsCrack resistanceWhole-life cost

The invention relates to a method for enhancing bituminous mixtures by adopting chopped basalt fibers, belonging to the technical field of novel compound materials. According to the invention, continuous basalt protofilaments or twistless rovings the surfaces of which are expanded into fibers in certain length, and then the fibers are used for enhancing the bituminous mixtures in a certain doping proportion and can be respectively used for maintaining the bituminous mixtures used for new construction and reconstruction and extension of highways and SMA and OGFC bituminous mixtures as well as fiber seals. In addition, the fibers can also be used for the enhancement of high-speed railway packing layer CA mortar and relevant hydraulic architectures. The chopped basalt fiber plays roles of enhancing, toughening and elasticizing the cracking prevention, crack resistance and reinforcement and 'bridging' in the enhanced bituminous mixtures, can obviously increase the anti-rutting ability of highways of the enhanced bituminous mixtures and reduces the whole life costs of the enhanced bituminous mixtures; if the fibers are used for high-speed railway plate-type ballastless tracks and CA mortar, the bending strength and the deformation resistance can be increased, i.e. the fibers play a role of crack prevention and crack resistance; in addition, the fibers have better anti-water leakage action if being used for Hydraulic and Hydro-Power Engineering.

Owner:ZHEJIANG GBF BASALT FIBER +1

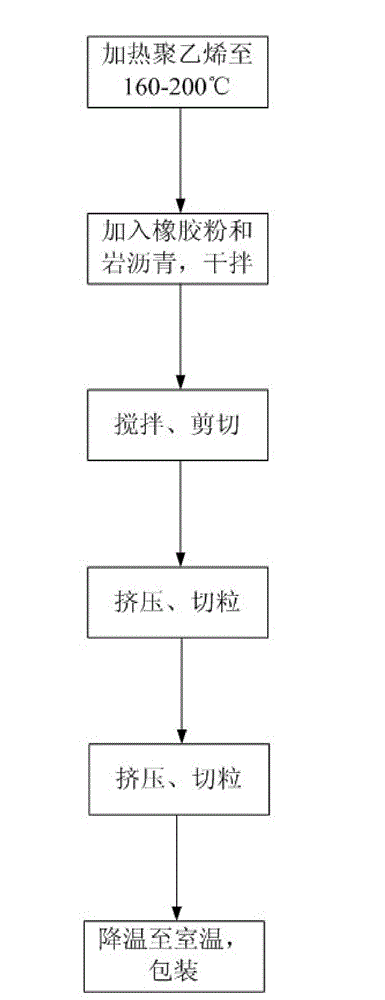

Direct-casting type anti-track agent and preparation method

ActiveCN102585522AImprove plasticityHigh modulus at room temperatureBuilding insulationsWaxPolyester

The invention discloses a direct-casting type anti-track agent, which is formed by the following components by weight in mixing mode: 20 to 40 parts of regenerative polyolefine plastic, 10 to 20 parts of regenerative polyester plastic, 2 to 10 parts of regenerative wax, 2 to 10 parts of organic powder body with small particle size and 5 to 10 parts of gilsonite. A preparation method of the direct-casting type anti-crack agent and a method for preparing asphalt mixture by adopting the direct-casting type anti-crack agent are further disclosed. Particles of the direct-casting type anti-crack agent can be directly cast in hot aggregate on construction sites to be mixed with the hot aggregate in drying mode, intermittent construction can be conducted, and the direct-casting type anti-track agent lowers or reduces probability of separation of modified asphalt in the cooling, transporting and storing processes, and break through limit and restraint brought by continuous production and construction.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

High-modulus bituminous mixture additive and preparation method thereof

ActiveCN103773006AImprove dynamic stabilityImprove static modulusBuilding insulationsPolymer sciencePavement engineering

The invention discloses a high-modulus bituminous mixture additive and a preparation method thereof. The high-modulus bituminous mixture additive is composed of a modifying main agent, butadiene styrene rubber, polyethylene paraffin, a filling material, an anti-aging component, and a plasticizing component according to a mass percentage of 100:(10-30):(15-40):(40-80):(2-6):(5-20); wherein the modifying main agent consists of one or more components selected from waste PE, polypropylene, and EVA. The preparation method comprises the following steps: evenly mixing the modifying main agent, butadiene styrene rubber and polyethylene paraffin at a temperature of 160 to 190 DEG C, adding the filling material, anti-aging component and plasticizing component into the mixture, evenly mixing under a certain rotation speed, then extruding the mixture by a screw extruder, cooling at the room temperature, and finally cutting into particles. The high-modulus bituminous mixture additive is mainly applied to pavement projects such as new construction and reconstruction of high grade roads and heavy traffic roads, can improve the dynamic stability, static modulus, dynamic modulus and shearing resistant performance of bituminous mixture, thus prominently reduces the damages of rut, displacement, or the like, and can improve the low-temperature anti-cracking performance of high-modulus bituminous mixture at the same time.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Polyurethane/nano-composite modified asphalt and preparation method thereof

ActiveCN103834185AImprove high temperature performanceImprove deformation resistanceBuilding insulationsRoad surfaceTwo step

The invention provides polyurethane / nano-composite modified asphalt. The polyurethane / nano-composite modified asphalt comprises the following components in percentage by mass: 2%-15% of polyurethane, 0.1%-5% of graphene oxide and 80%-97.9% of matrix asphalt, wherein the sum of the mass percentage of the components is 100%. A preparation method of the polyurethane / nano-composite modified asphalt comprises the following steps: heating and melting the matrix asphalt, maintaining temperature at 150-200 DEG C, adding the polyurethane and the graphene oxide, manually mixing for 20-40 minutes, then stirring for 80-100 minutes by using a shearing machine, cooling to 100-150 DEG C, standing for 20-50 minutes, and shearing an asphalt mixture by using the shearing machine again for 80-100 minutes till the polyurethane and the graphene oxide are uniformly dispersed in the asphalt, thus obtaining the polyurethane / nano-composite modified asphalt. The preparation method has the advantages that the polyurethane and the graphene oxide are used as modifying agents, a two-step method modification technology is adopted so as to give full play to good performances of the polymer and nanometer materials, and the high-temperature performance and anti-modification capacity of the matrix asphalt and the anti-rutting capacity of asphalt pavements are obviously improved.

Owner:XIAN UNIV OF TECH

Road surface structure of felexiable fibre emulsifying asphalt stable material as base and construction method thereof

InactiveCN100999890AReduce dosageSave energy resourcesPaving reinforcementsIn situ pavingsFrostSurface layer

The present invention relates to road structure and construction technology, and is especially road structure with flexible fiber and emulsified asphalt stabilized aggregate layer as the base layer and its construction process. The road structure includes one bottom layer; one base layer and one paved surface layer, and the base layer of rolled flexible fiber and emulsified asphalt stabilized aggregate is formed through mixing flexible fiber, emulsified asphalt, cement and water to form cementing material, adhering aggregate, stuffing, admixture, etc with the cementing material, and rolling. The rolled flexible fiber and emulsified asphalt stabilized aggregate has improved early plastic shrinking, dry shrinking and hot shrinking performance, obviously raised anticracking performance, toughness, impact strength, frost resistance, erosion resistance and water stabilty, and doubled antifatigue performance. The road with the said base layer has raised performance and increased service life.

Owner:马银华 +3

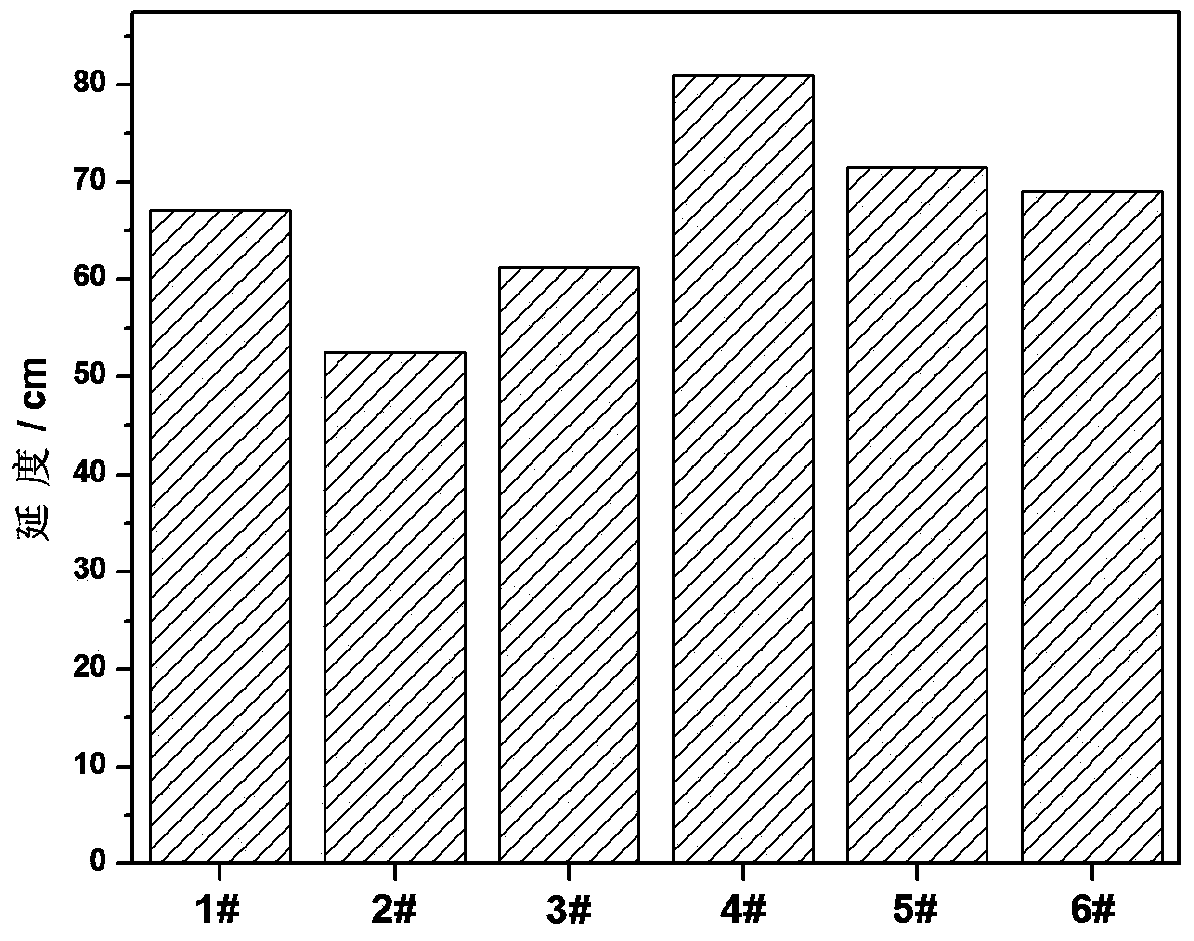

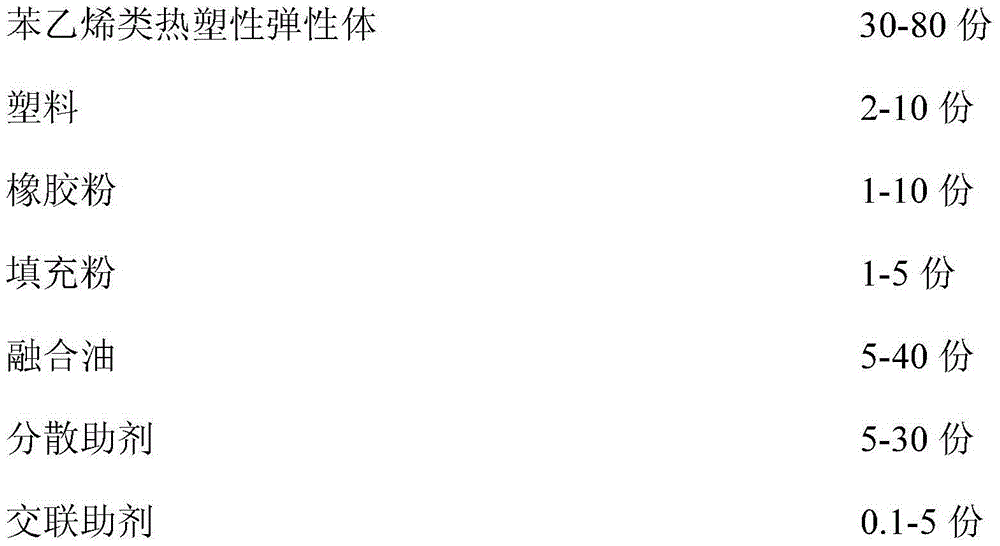

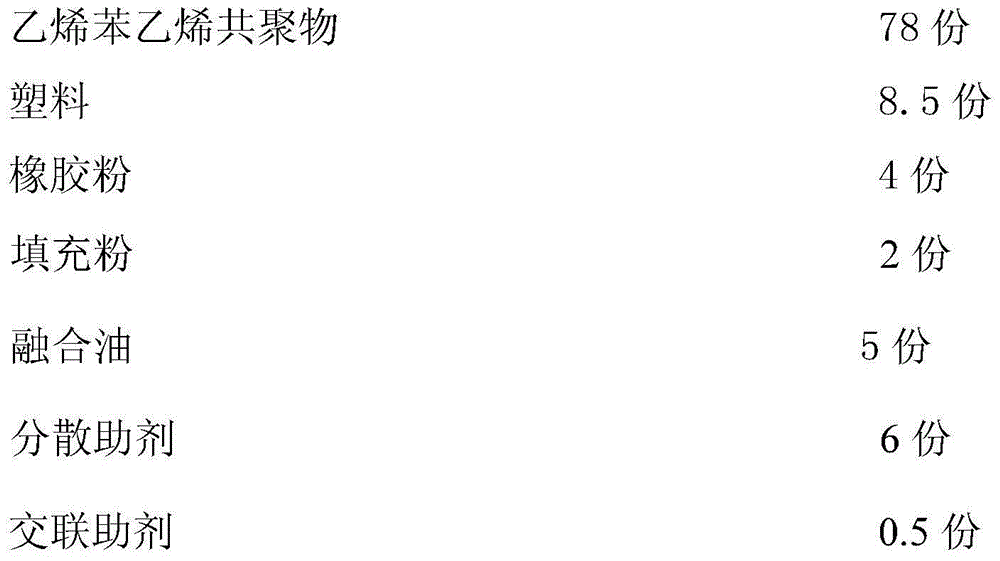

Direct vat set modifier of cast asphalt mixture and preparation method

InactiveCN103980650AImprove performanceLess production equipmentBuilding insulationsUltrasound attenuationThermoplastic elastomer

The invention discloses a direct vat set modifier of a cast asphalt mixture and is characterized in that the modifier is composed of the following components, by weight, 30-80 parts of a styrenic thermoplastic elastomer, 10-20 parts of plastic, 1-10 parts of rubber powder, 1-5 parts of a packing powder, 5-40 parts of fuser oil, 5-30 parts of a dispersing auxiliary agent and 0.1-5 parts of a crosslinking auxiliary agent. The invention also discloses a preparation method of the modifier and an asphalt mixture prepared from the modifier. The material can be directly put into a mixing plant cylinder to produce modified asphalt concrete. The produced asphalt concrete completely satisfies engineering needs. In comparison with a traditional SBS modification process, the method provided the invention has the following advantages: the step of producing modified asphalt in a traditional method is saved; production equipment of modified asphalt is save; there is no need in hot storage of modified asphalt; performance attenuation and separation of modified asphalt under hot storage condition are avoided; and positive contributions are made to low temperature and fatigue performance of the asphalt mixture.

Owner:CHONGQING SINO CANADA ASPHALT TECHN SERVICE

Laminated silicate clay nano modified alphalt and its preparing method

InactiveCN1775865AEvenly dispersedIncrease layer spacingBuilding insulationsPhysical chemistryAsphalt

The invention supplies a method to make phyllo-silicate clay nm modification asphalt that is made up of 0.1-20% of phyllo-silicate clay and 80-99.9% of asphalt. The process includes the following steps: using the phyllo-silicate clay as modification agent for road petroleum asphalt; adding the clay into asphalt maintaining the temperature between 100 degree centigrade and 200 degree centigrade, whisking for 0.5-8 hours at the rotating speed between 1000-6000rpm / min and the modification asphalt would be gained. The invention has simple technology and has high price performance ratio.

Owner:WUHAN UNIV OF TECH

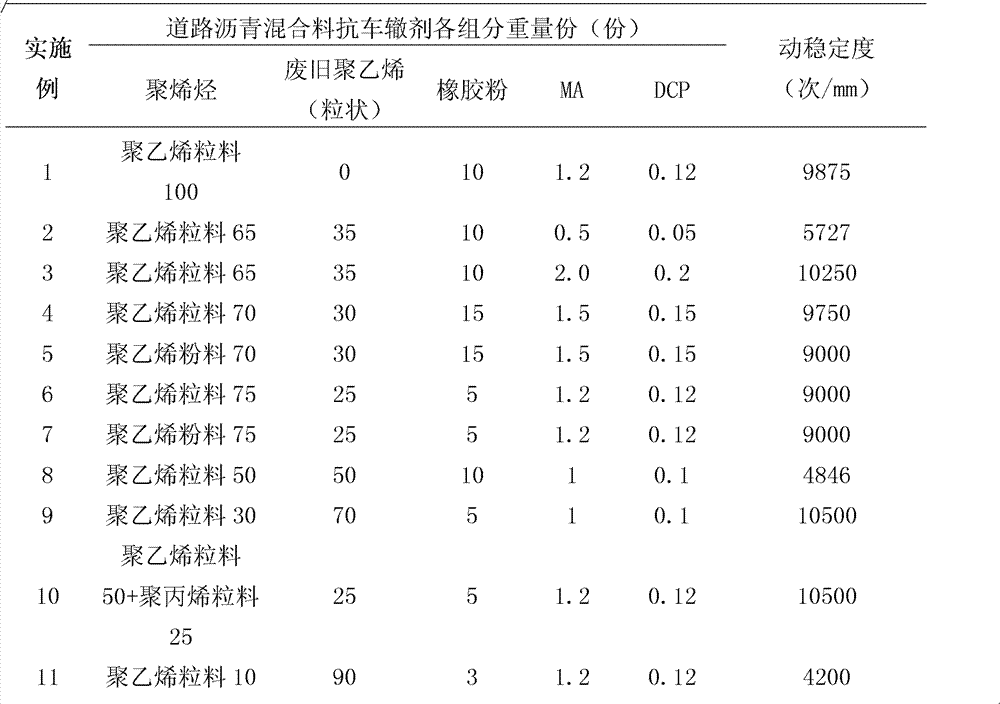

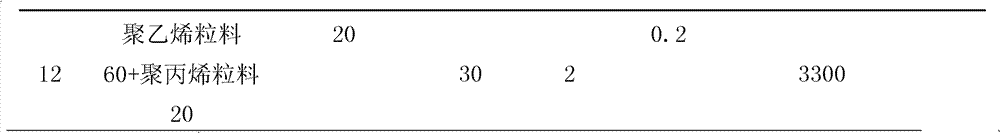

Road asphalt mixture rut resisting additive and preparation method thereof

InactiveCN102964525AImproves rutting resistanceLow costBuilding insulationsMaleic anhydridePolyolefin

Belonging to the technical field of road asphalt mixture additives, the invention relates to an asphalt mixture rut resisting agent and a preparation method thereof. A road asphalt mixture rut resisting additive is characterized in that it is prepared by: mixing the following raw materials, and conducting melt extrusion, grain cutting, as well as drying. The raw materials consist of, by weight: 100 parts of polyolefin, 3-30 parts of waste rubber powder, 0.5-2 parts of maleic anhydride, and 0.05-0.2 part of dicumyl peroxide. The additive prepared by the method can significantly improve the rut resistance of an asphalt mixture.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

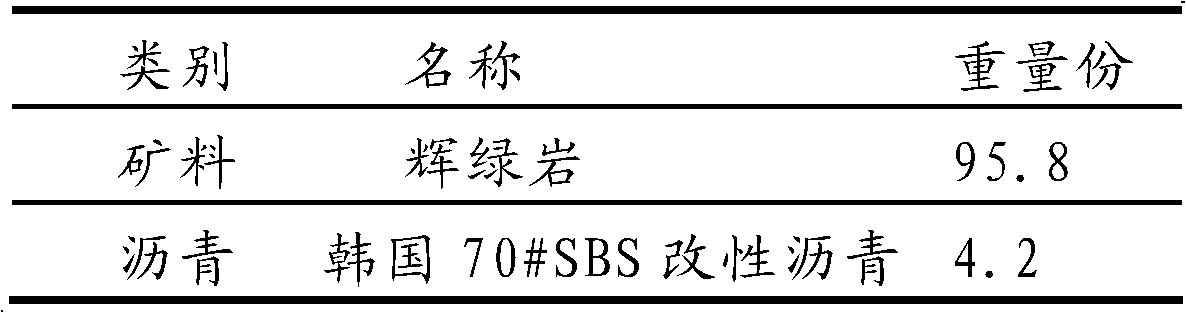

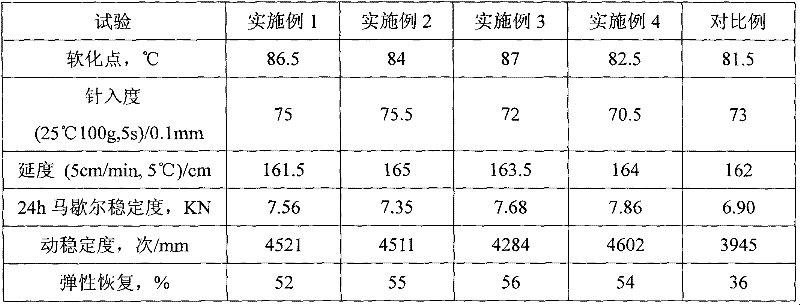

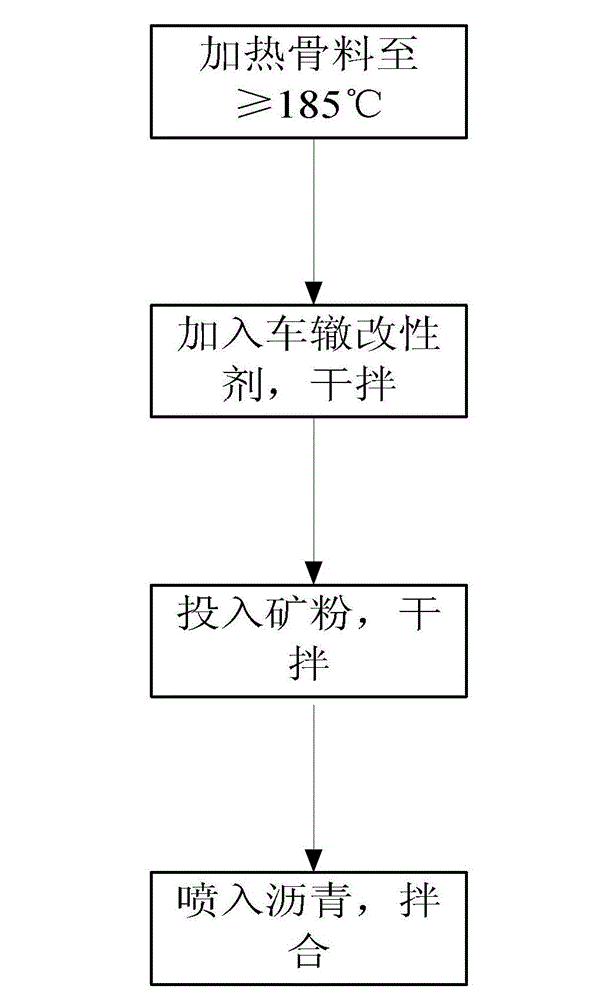

Rock asphalt composite modifier and its preparation method and use

The invention discloses a rock asphalt compound modifier and a preparation method and use of the rock asphalt compound modifier. The rock asphalt compound modifier is composed of rock asphalt and polymer, wherein, the amount of the rock asphalt is 10 percent to 90 percent and the amount of the polymer is 10 percent to 90 percent in weight percentage. The preparation method is that the rock asphalt and the polymer are mixed together by a twin screw extruder in proportion, and then are granulated by a cold bracing and granulating equipment. The use of the rock asphalt compound modifier is that the rock asphalt compound modifier is put into an asphalt mixture mixing plant to be mixed with hot mineral aggregation for 5 to 20 seconds, and then basic asphalt is sprayed in to be mixed with the hot mineral aggregation for 20 to 60 seconds, at last the compound modified asphalt mixture is prepared. The rock asphalt compound modifier is in granular shape and has the advantages of accurate adding measurement, fine dispersion, uniform mixing and convenient construction. The compound modified asphalt mixture is suitable for paving the roads in high grade with further improved performance.

Owner:交通部公路科学研究院 +1

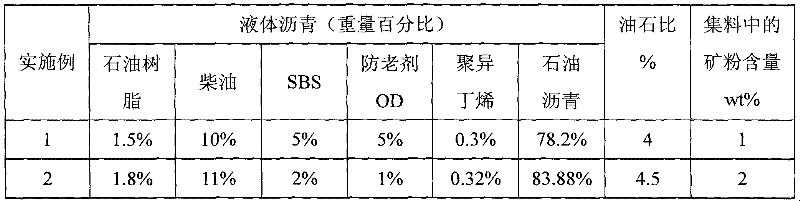

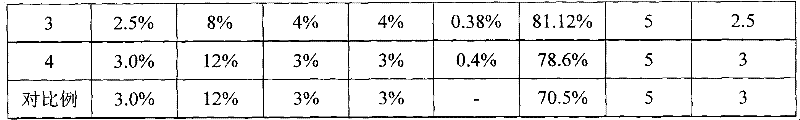

Hot-mix-cold-laid SBS (styrene butadiene styrene) modified asphalt mixture

The invention provides hot-mix-cold-laid SBS (styrene butadiene styrene) modified asphalt mixture, which is characterized by comprising SBS modified asphalt and aggregates; the aggregates comprise coarse aggregates, fine aggregates and mineral powder; and the SBS modified asphalt comprises the following components by weight percentage: 1.5-3 percent of petroleum resin, 8-12 percent of thinner, 2-6 percent of SBS, 5-10 percent of anti-aging agent, 0.3-0.4 percent of stabilizer and the rest being petroleum asphalt. The hot-mix-cold-laid SBS modified asphalt mixture can be stored for a long time at normal temperature and also has a stable performance. In addition, the invention also has the advantages that the hot-mix-cold-laid SBS modified asphalt mixture has a high softening point and good anti-rutting performance.

Owner:上海道柯特沥青科技有限公司

Anti-rutting modifying agent used for asphalt pavement and asphalt mixture containing anti-rutting modifying agent

ActiveCN103059587ASolve technical problemsRealize repeated recyclingBuilding insulationsPolymer scienceEngineering

The invention relates to an anti-rutting modifying agent. The anti-rutting modifying agent comprises (a) high-density low-pressure polyethylene, (b) rubber powder and (c) rock asphalt. The anti-rutting modifying agent is good in low-temperature cracking resistance, high in bonding strength, high in water damage resistance, good in non-deformability, low in cost, simple in preparation technology, convenient to operate and convenient to add in asphalt mixture.

Owner:北京中交路通科技发展有限公司

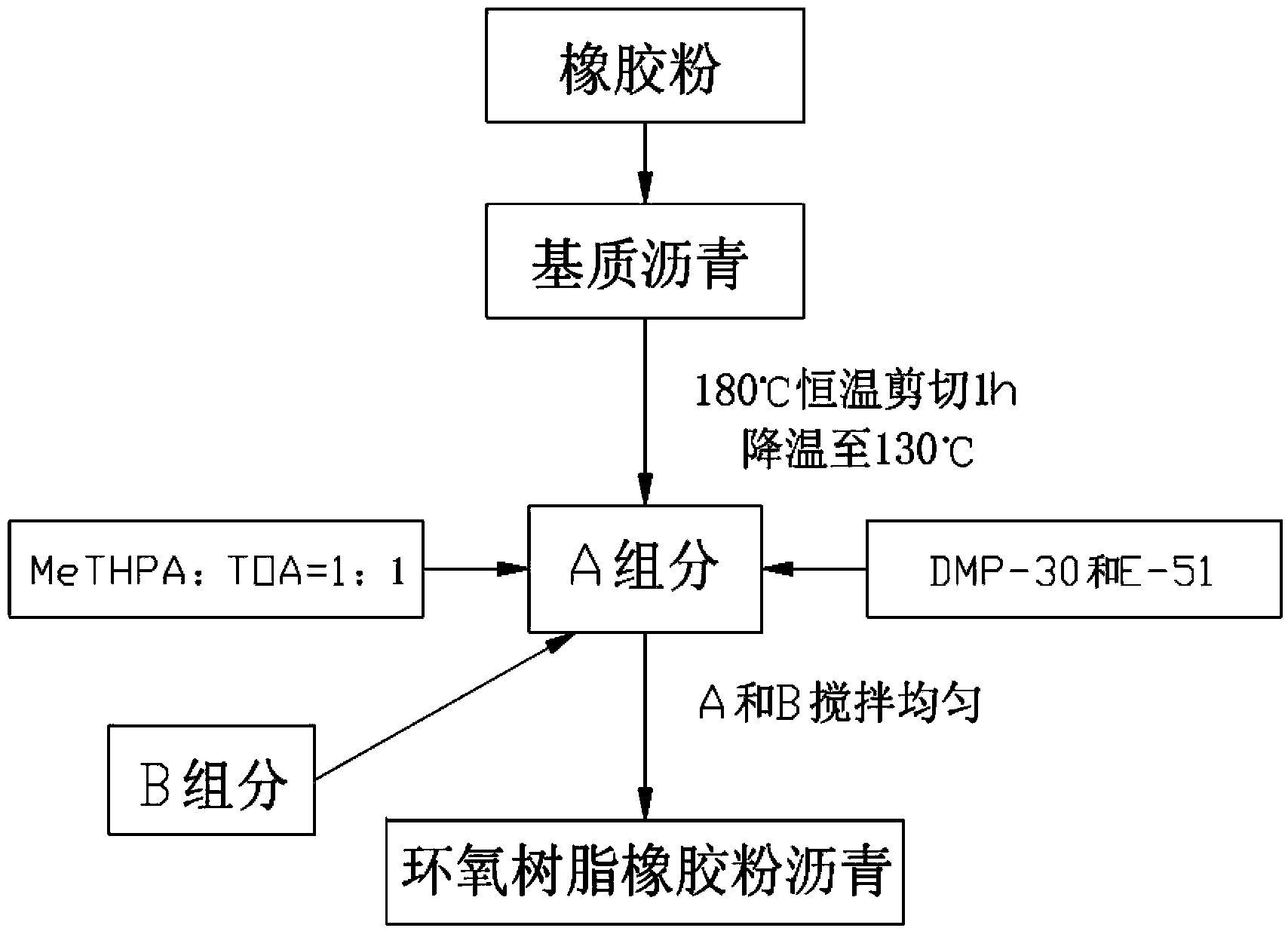

Epoxy resin-modified rubber asphalt

InactiveCN103351630AImproves rutting resistanceLess stress damageBuilding insulationsEpoxyPolymer science

The invention discloses epoxy resin-modified rubber asphalt which is a mixture comprising a component A and a component B, wherein the component A is prepared by adding rubber powder with the weight accounting for 18% of that of matrix asphalt into the matrix asphalt at the temperature of 170-180 DEG C, cutting and stirring for 1 hour, cooling to 130 DEG C, adding a compound curing agent with the weight accounting for 40% of that of the matrix asphalt, 2,4,6-tri(dimethylaminomethyl) phenol with the weight accounting for 5% of that of the matrix asphalt and a bulking agent with the weight accounting for 5% of that of the matrix asphalt into rubber asphalt obtained by cutting at a speed of 6000 r / min; the component B is E-51 epoxy resin; and the component A and the component B are mixed for 20 minutes at the temperature of 120 DEG C according to a weight ratio of 2 to 1 to obtain the epoxy resin-modified rubber asphalt. The epoxy resin-modified rubber asphalt is high in tensile strength, high in breaking elongation rate and good in fatigue resistance and fatigue durability, so that the epoxy resin-modified rubber asphalt is good in anti-rutting performance and is capable of remarkably reducing the stress damage and prolonging the service life of asphalt pavements.

Owner:杨林江

High-elasto-viscosity stress absorbing layer and top facing construction process thereof

ActiveCN104294732AImprove adhesionEfficient decompositionIn situ pavingsBridge structural detailsStress concentrationPolymer modified

The invention belongs to the technical field of road and bridge maintenance and discloses a high-elasto-viscosity stress absorbing layer and a top facing construction process thereof. The high-elasto-viscosity stress absorbing layer is arranged between an old cement concrete pavement and an overlay above the old cement concrete pavement, and composed of polymer modified asphalt, limestone, fine river sand and aggregate chips. The top facing construction process of the high elasto-viscosity stress absorbing layer comprises three steps in order: designing the mixing proportion of the high-elasto-viscosity stress absorbing layer; determining the plane position, and performing preparation before construction; and mixing a polymer modified asphalt-concrete mixed material, transporting, paving and rolling. The high-elasto-viscosity stress absorbing layer has the powerful stress absorption capacity, high caking capacity and excellent waterproofness, and is capable of generating a delaying effect on cracks of a polymer modified asphalt-concrete surface layer due to stress concentration, and therefore, the anti-rutting performance of a pavement is greatly improved, and the water damage of a base layer as pavement water seepage enters the base layer also can be prevented.

Owner:CCCC SHEC DONGMENG ENG CO LTD

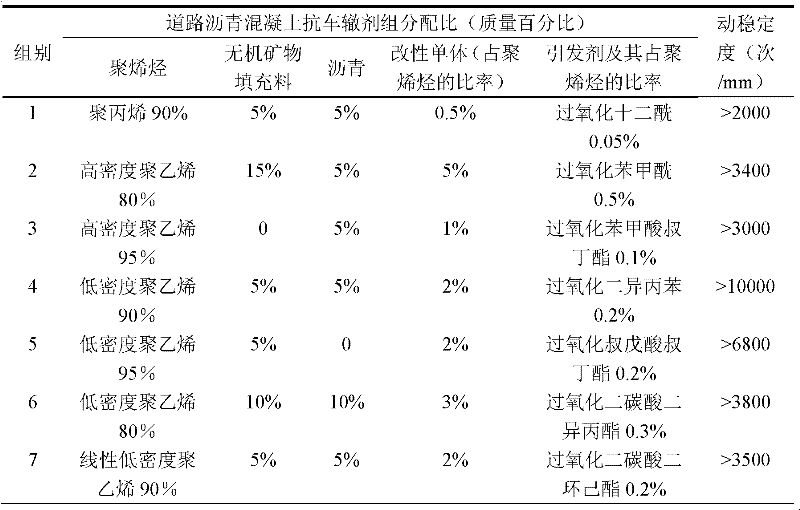

Method for preparing asphalt concrete anti-rutting agent for road by in-situ graft modification

ActiveCN102250287AImproves rutting resistanceAchieve in-situ graft modificationBuilding insulationsPolyolefinMelt extrusion

The invention belongs to the technical field of asphalt concrete additives for roads, and in particular relates to a method for preparing an asphalt concrete anti-rutting agent for a road by in-situ graft modification. The method comprises the following steps of: uniformly mixing polyolefin, an inorganic mineral filler, asphalt, graft modification monomers and an initiator fully; and adding the mixture into a screw extruder for melt extrusion to obtain the asphalt concrete anti-rutting agent for the road. The asphalt concrete anti-rutting agent for the road, which is prepared by the method, can obviously improve the anti-rutting performance of the asphalt concrete.

Owner:HUAZHONG UNIV OF SCI & TECH

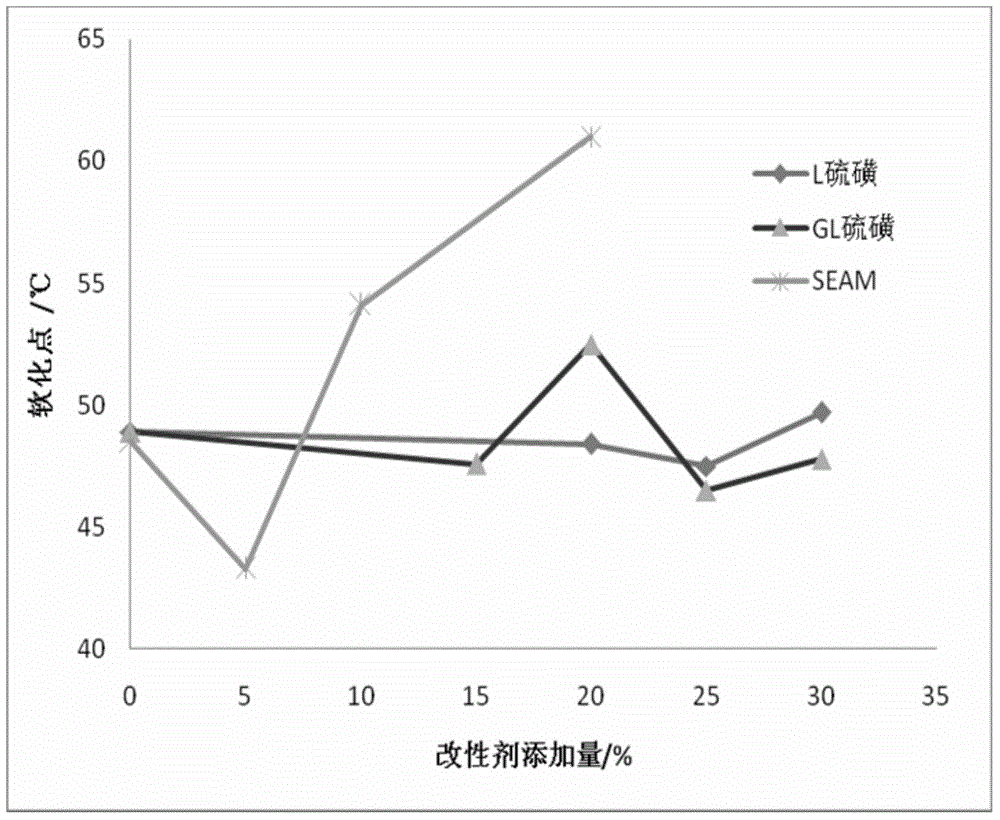

Asphalt modifier and industrial production method and application thereof

The invention discloses an asphalt modifier and an industrial production method and application thereof. The asphalt modifier is prepared by uniformly mixing modified sulfur and red mud particles. The industrial production method comprises the following steps: 1, preparing the modified sulfur, namely performing sulfur fusion and sulfur modification; and 2, adding the red mud particles. In the industrial production method, the modified sulfur is prepared in a way that an olefin modifier and a sulfur modification additive are added into sulfur for modifying sulfur; a weight ratio of the olefin modifier to sulfur is 2-6:100, and a weight ratio of the red mud particles to the sulfur is 10-30:100. The application process of the asphalt modifier comprises the following steps: I, preheating raw materials; and II, mixing, namely mixing the preheated asphalt modifier, mineral aggregate and matrix asphalt. The asphalt modifier adopted in the production method is simple in production process, low in construction cost, incombustible, safe to use and excellent in performance, the amount of discharged atmospheric pollutants in the production and application process is small, comprehensive performance of the modified asphalt concrete is excellent, and industrial waste red mud can be effectively utilized.

Owner:XIAN UNIV OF SCI & TECH

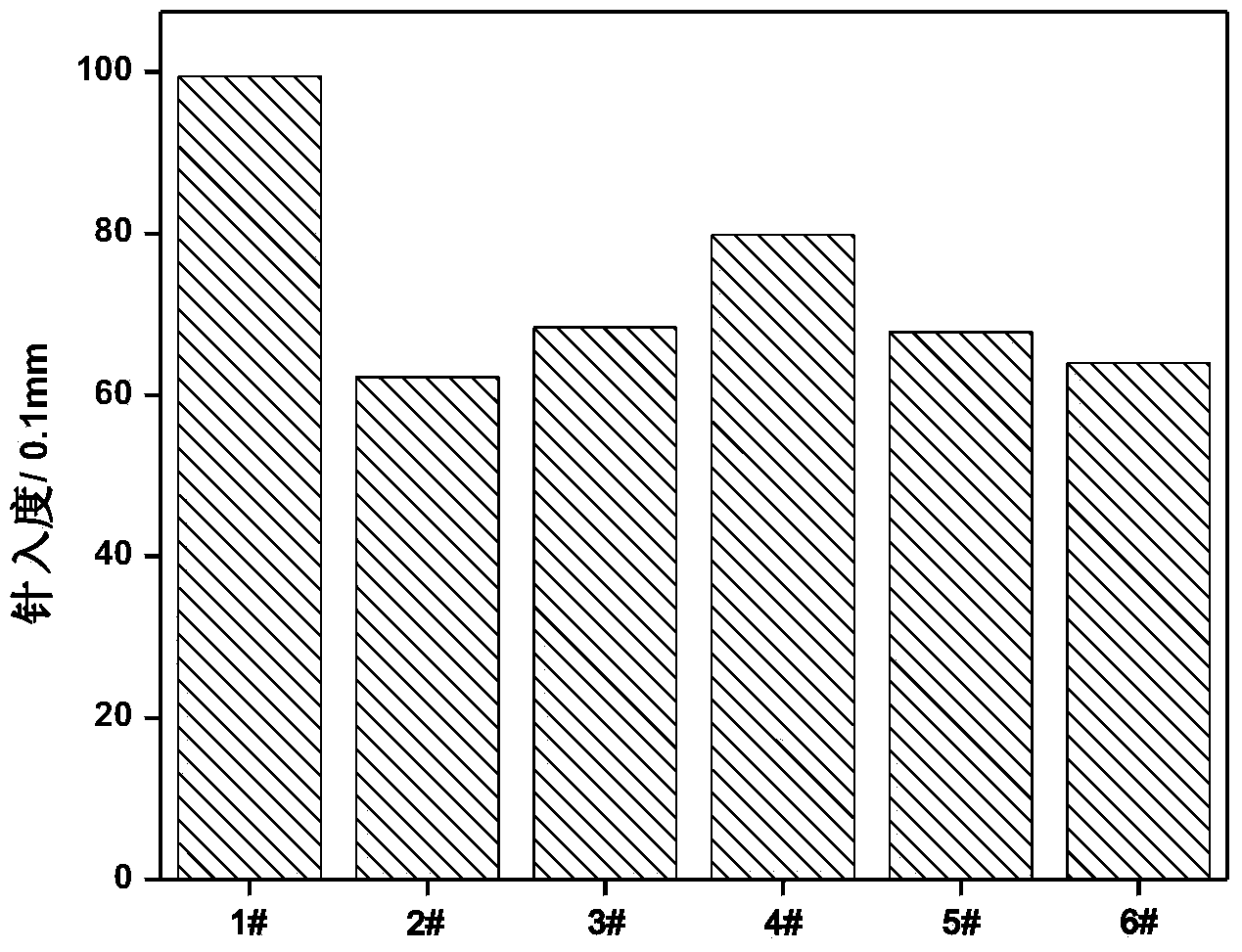

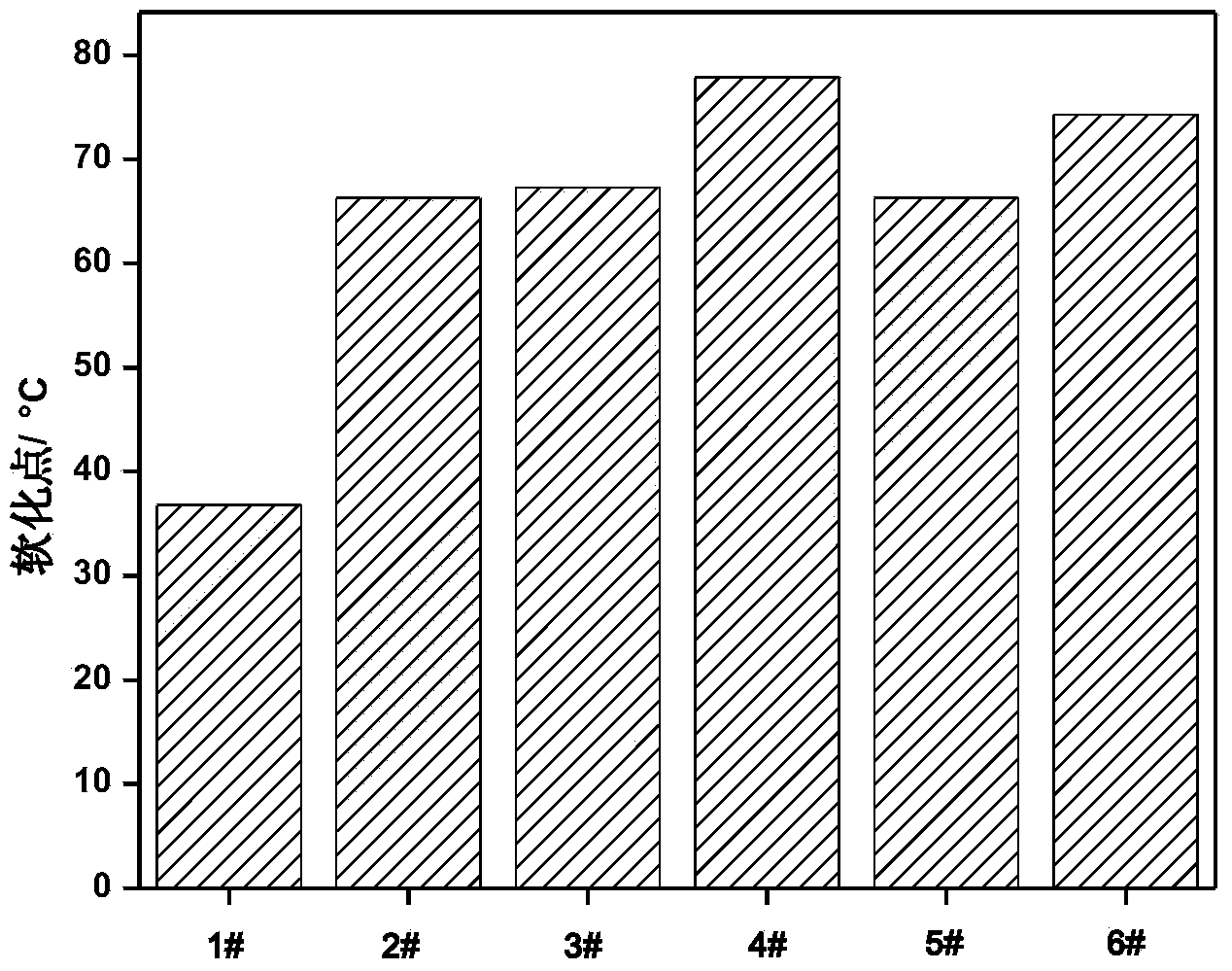

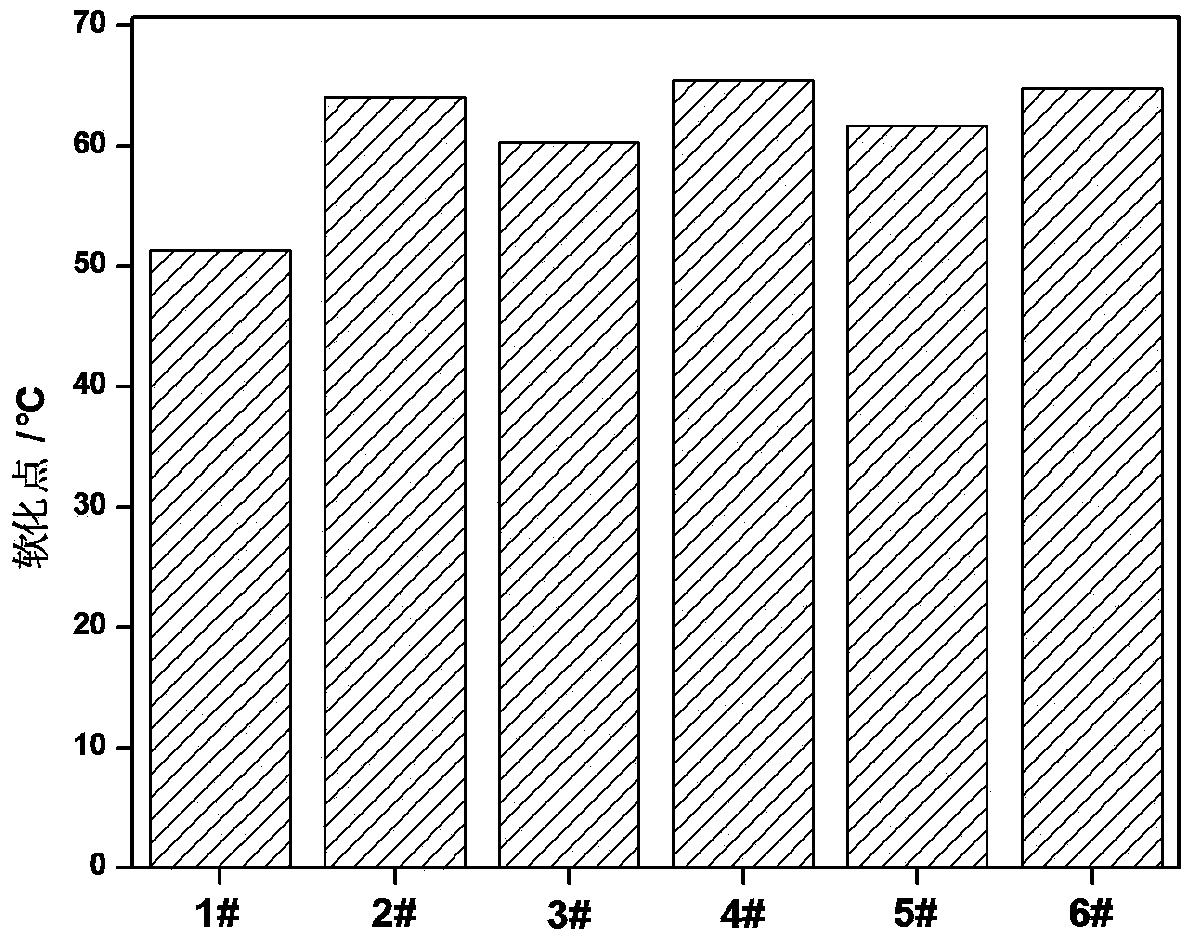

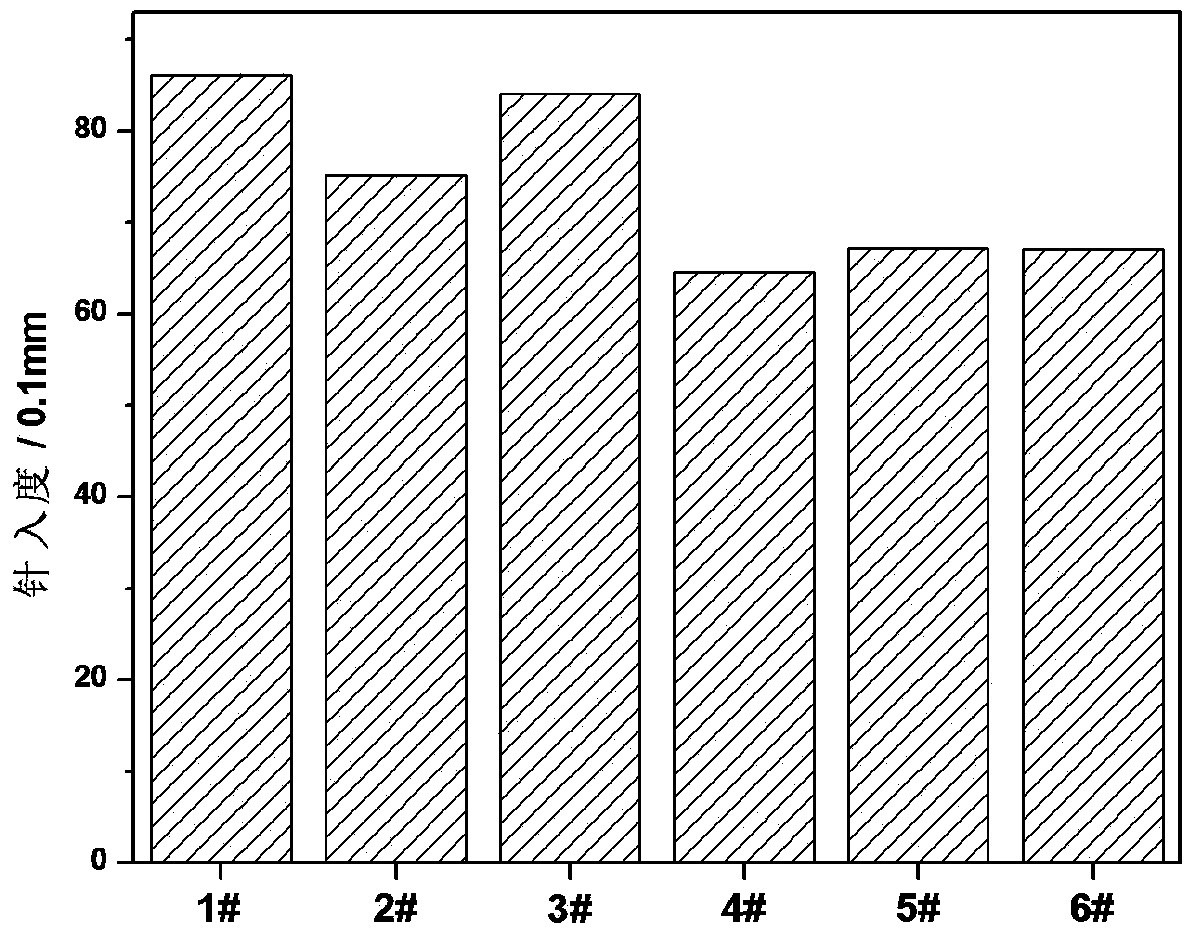

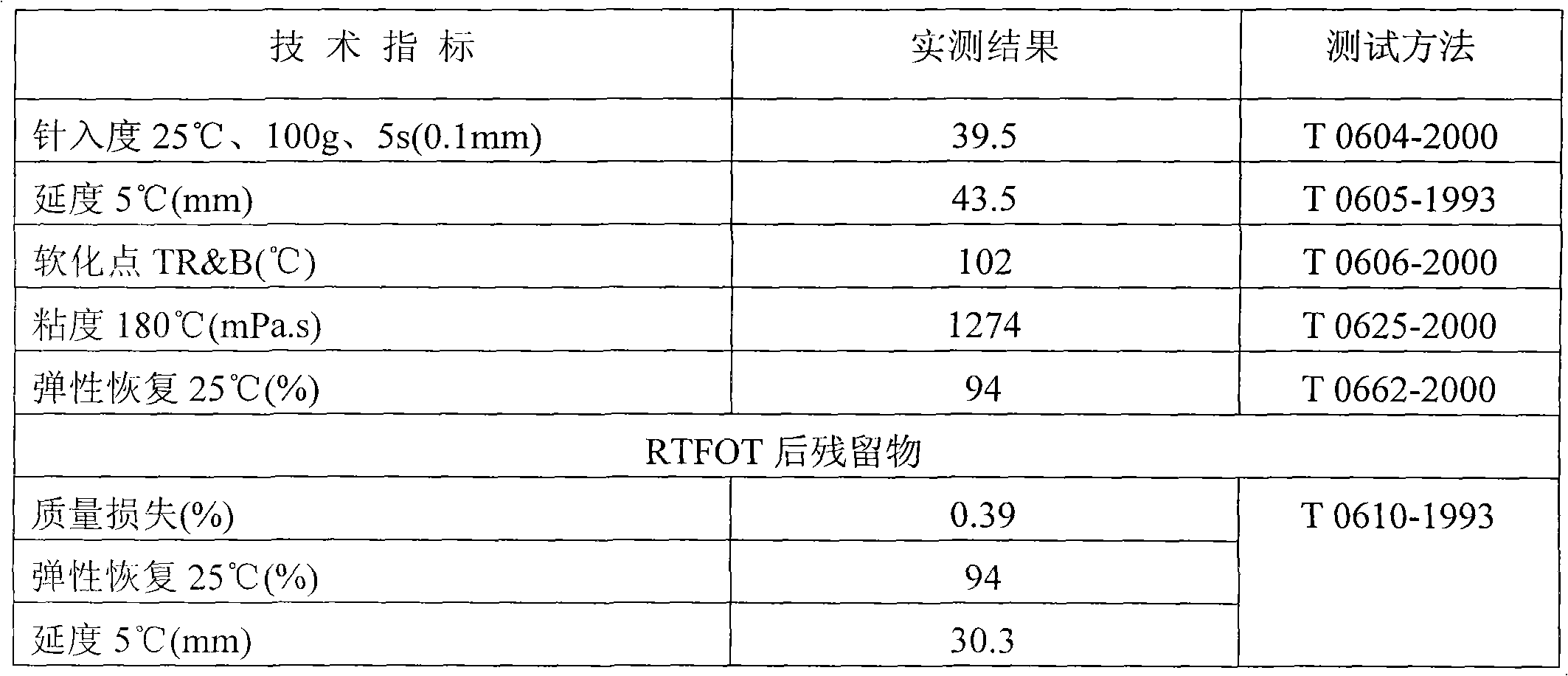

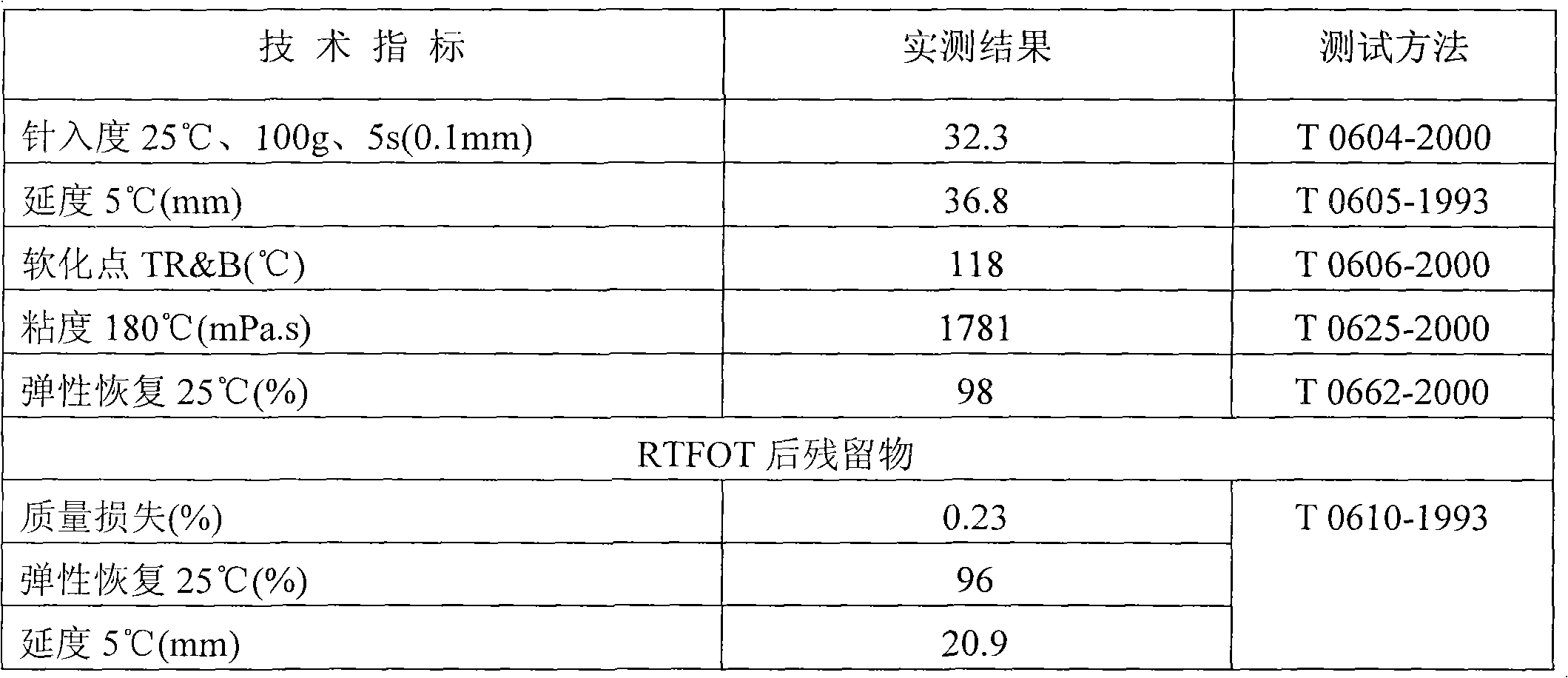

High intensity asphalt modifier for cast asphalt concrete and preparation method thereof

ActiveCN101851426AImprove high temperature performanceImprove the state of stressBuilding insulationsPolymer scienceRecovery performance

The invention discloses a high intensity asphalt modifier for cast asphalt concrete and a preparation method thereof. The asphalt modifier comprises the following components by weight percent: 20-50% of modifier, 5-20% of reinforcing agent and 30-60% of viscosity breaker. The product of the invention is used as the modifier to prepare high intensity modified asphalt, and the obtained asphalt has higher softening point and hardness (lower penetration degree) and excellent elastic recovery performance and thermal aging property.

Owner:CHONGQING ZHONGJIAO ROAD & BRIDGE TECH

Modified graphene based composite asphalt modifier and preparation method and application of modified graphene based composite asphalt modifier

ActiveCN108117714AImprove plasticityImprove elastic propertiesBuilding insulationsPotassium peroxodisulfateButadiene-styrene rubber

The invention discloses a modified graphene based composite asphalt modifier. The modified graphene based composite asphalt modifier is prepared from modified graphene and an SBS (Styrene Butadiene Styrene) modifier; the modified graphene is prepared by adding a styrene monomer and lauryl sodium sulfate into an oxidized graphene microchip solution, conducting ultrasonic concussion on the obtainedmixed solution, adding potassium peroxodisulfate, reacting in an oil bath, then adding hydrazine hydrate, raising the temperature to 100 DEG C at the same time, reacting for 4-6 hours, cooling, filtering through a microfiltration membrane, washing and drying. The invention further discloses a preparation method and application of the modified graphene based composite asphalt modifier. The high-and-low temperature performance and the plastic property of the modified asphalt prepared by using the composite asphalt modifier are obviously improved, the anti-rutting performance and the elastic property are greatly improved, the defects of not high durability and not good high temperature property of the SBS modified asphalt are effectively improved, and compared with the graphene microchip notmodified, the dispersibility and the stability of the modified graphene microchip in the asphalt are greatly improved.

Owner:GUANGXI UNIV

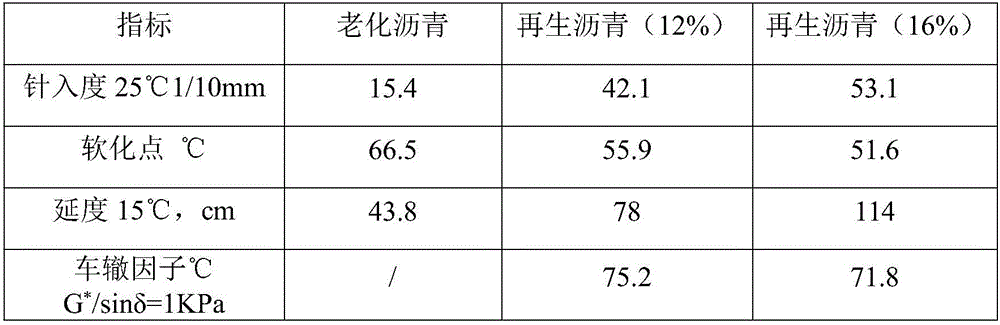

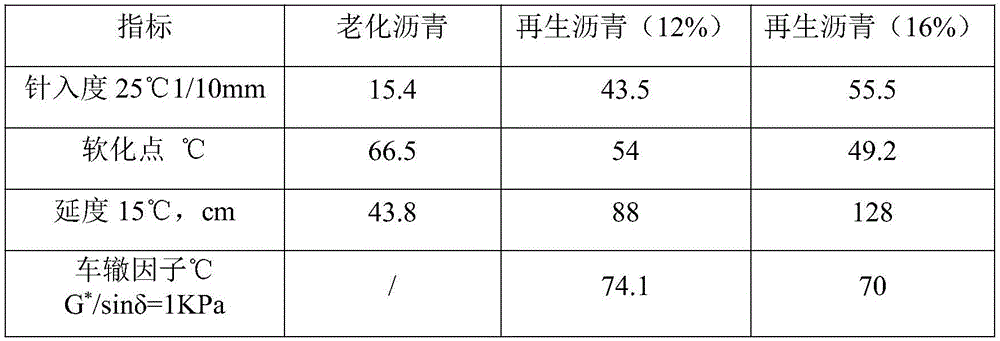

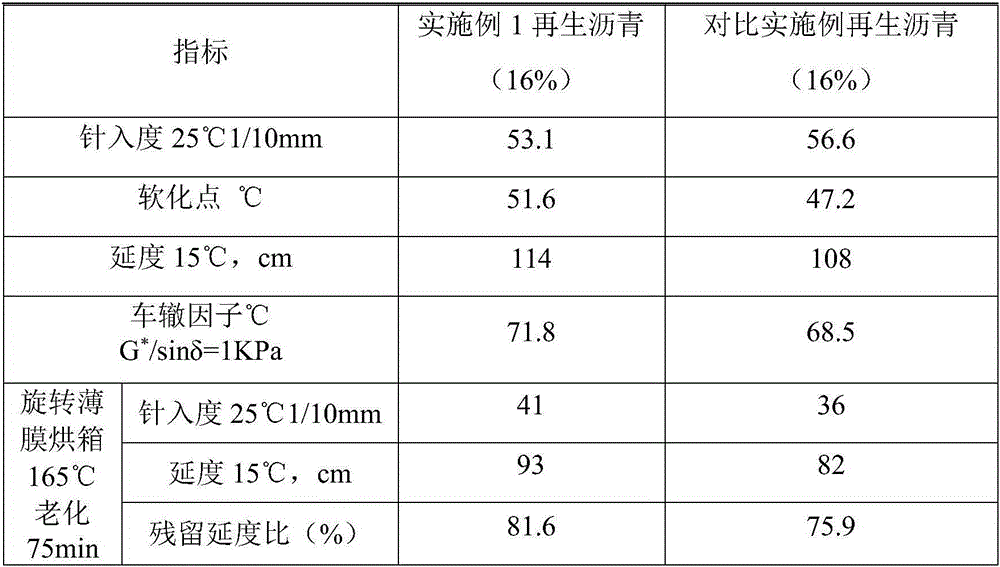

Asphalt regenerant as well as preparation method and application thereof

ActiveCN105754356ARestore physical performanceGood physical propertiesPlastic recyclingBuilding insulationsPlasticizerMontmorillonite

An asphalt regenerant is mainly prepared from 40-60 parts of a regeneration component, 15-30 parts of nano organic montmorillonite modified asphalt, 15-30 parts of a plasticizer and 1-5 parts of a penetrant; the regeneration component is mixed oil mainly formed by mixing light oil and heavy oil in proportion. The preparation method of the asphalt regenerant comprises steps as follows: a reaction kettle is preheated and heated, the regeneration component is added to the reaction kettle, the nano organic montmorillonite modified asphalt is added in parts by mass after stirring, the temperature is controlled within 130-160 DEG C, the temperature is decreased to 80-120 DEG C after stirring, the penetrant and the plasticizer are added, the mixture is stirred continuously, and the asphalt regenerant is obtained after cooling. During usage, the reaction kettle is preheated, waste aged asphalt is added, the temperature is decreased gradually after quick stirring, then a certain proportion of asphalt regenerant is added, and regenerated asphalt is obtained after quick stirring. The product performance is good, the cost is low, and the technology is simple, controllable and environment-friendly.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

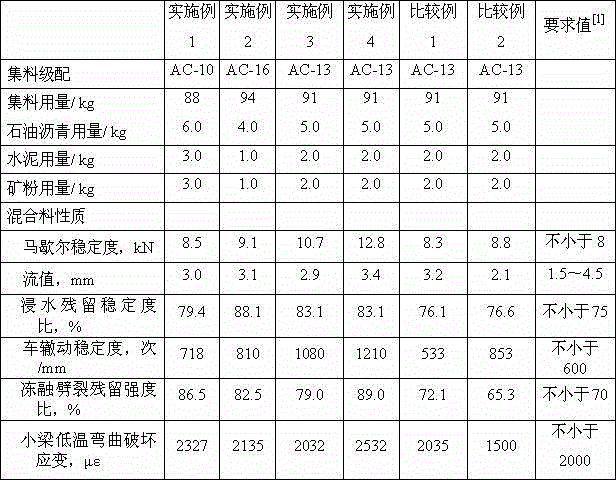

Asphalt mixture and preparation method thereof

The invention discloses an asphalt mixture and a preparation method thereof, and particularly relates to an anti-track and anti-upheaval asphalt mixture and a preparation method thereof. The asphalt mixture comprises the following components in percentage by weight: 4.0-6.0% of special road oil asphalt, 1.0-3.0% of cement, 1.0-3.0% of mineral powder and 88.0-94.0% of aggregates. The preparation method comprises the following steps: (1) a stirring kettle and the aggregates are heated to reach 130-180 DEG C for standby, and the special road oil asphalt is heated to a melted state for standby; (2) the aggregates, the cement and the mineral powder are added into the stirring kettle simultaneously and are uniformly stirred; (3) the special road oil asphalt is added into the stirring kettle and is uniformly stirred and mixed with the aggregated, the cement and the mineral powder which are uniformly mixed in the stirring kettle in advance to obtain the asphalt mixture. Due to the fact that the special road oil asphalt is used for the asphalt mixture, the track dynamic stability of the mixture is substantially improved, the anti-track performance of an asphalt road surface can be obviously improved, and the asphalt mixture is particularly suitable for asphalt roads with heavy traffic load and asphalt roads where tracks are likely to occur in high-temperature areas of the southern area of China.

Owner:CHINA PETROLEUM & CHEM CORP +1

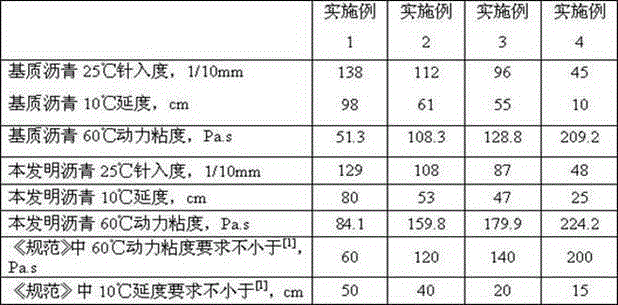

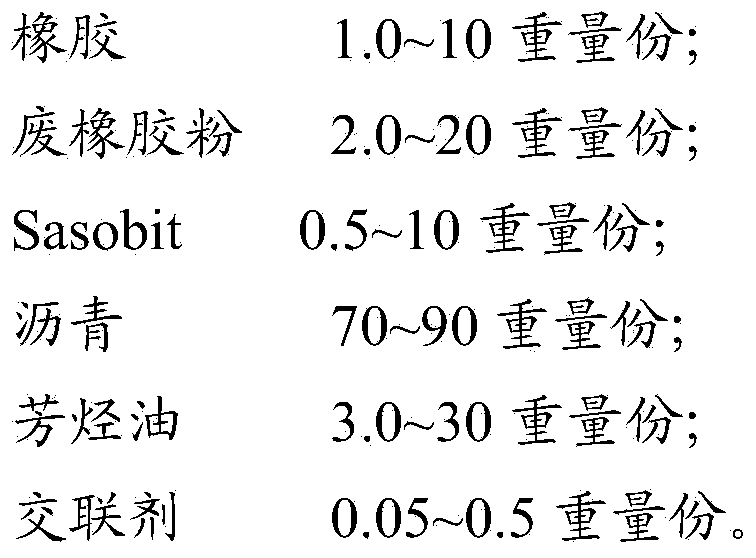

Modified asphalt as well as preparation method thereof

ActiveCN103468010AImprove low temperature performanceImprove low temperature ductilityBuilding insulationsHigh temperature storageSwelling capacity

The invention provides modified asphalt as well as a preparation method thereof. The preparation method comprises the following step: mixing, heating and stirring 70-90 parts of asphalt, 3.0-30 parts of aromatic hydrocarbon oil, 2.0-20 parts of waste rubber powder, 1.0-10 parts of rubber, 0.5-10 parts of Sasobit and 0.05-0.5 part of a crosslinking agent to obtain the modified asphalt. Compared with the prior art, polymer rubber, waste rubber powder, aromatic hydrocarbon oil, Sasobit and the crosslinking agent are adopted to jointly modify the asphalt. The rubber has better low temperature performance and can improve the low temperature ductility of the asphalt, and meanwhile, does not damage other pavement performances of the asphalt. The aromatic hydrocarbon oil has higher swelling capacity to the rubber and the waste rubber powder, so that the compatibility of the asphalt and modification materials is improved. The crosslinking agent can further improve the high temperature storage stability of a finished product so as to prevent separation. Sasobit can reduce the construction temperature of the asphalt.

Owner:SHANDONG JINSHI BITUMEN CO LTD

Environment-friendly asphalt pavement anti-rut agent and preparation method thereof

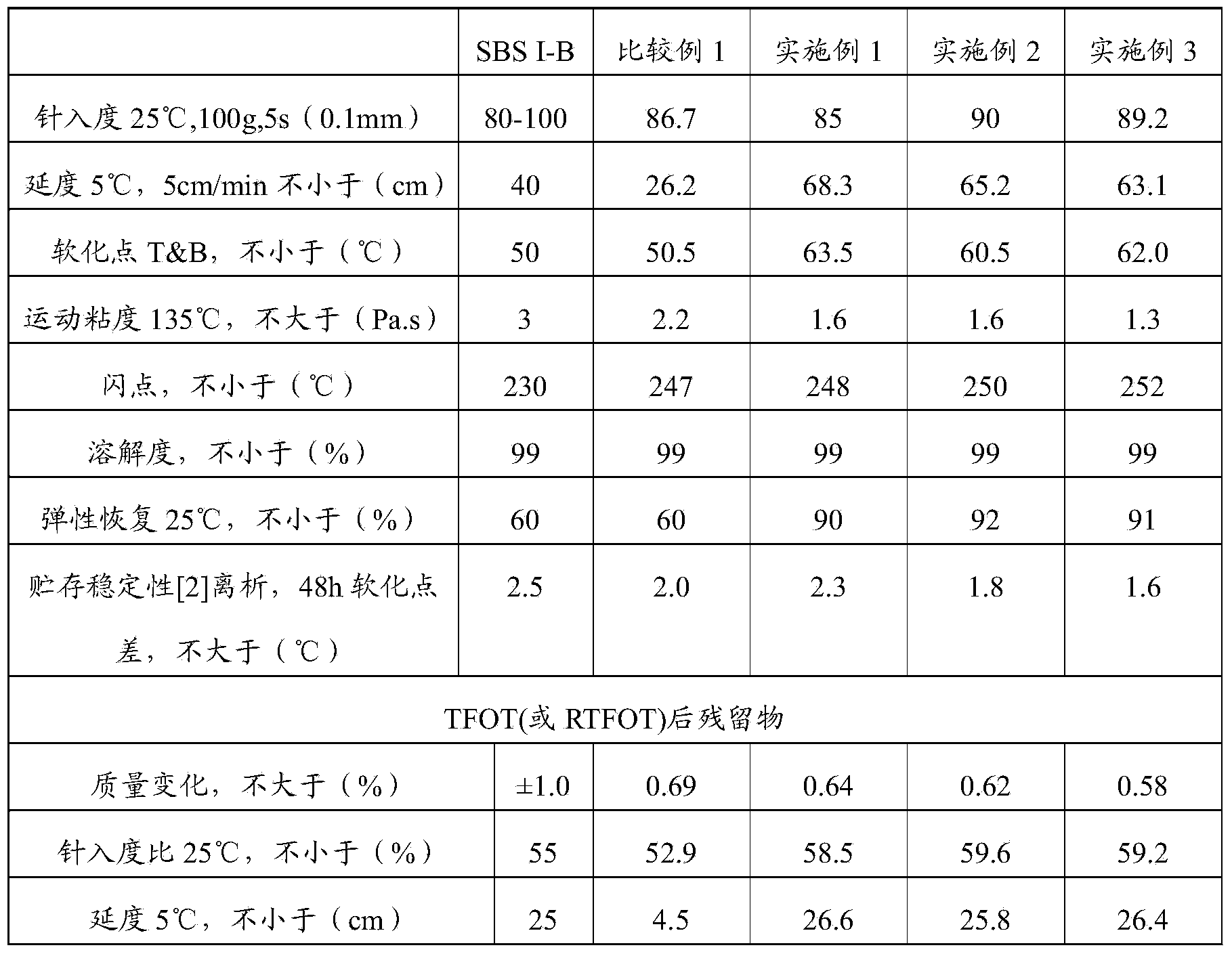

ActiveCN102702600AImprove protectionNo displacementBuilding insulationsLow-density polyethyleneMicrosphere

The invention discloses a preparation method of an environment-friendly asphalt pavement anti-rut agent and an application thereof. The method comprises the following steps of: mixing and stirring 45-80 percent of polyethylene and 15-30 percent of petroleum resin derived from 'plastic waste', 5-15 percent of polymethyl methacrylate, 5-15 percent of an asphalt material and 0-10 percent of an inorganic mineral filling material at a high speed; and extruding at a high temperature to prepare the environment-friendly asphalt pavement anti-rut agent. Due to the adoption of the environment-friendly asphalt pavement anti-rut agent, the performance of an asphalt pavement is enhanced, the service life of the pavement is prolonged, 'white waste' is recycled, and environmental pollution is lowered. Polyethylene serving as a major component is either or both of industrial production low-density polyethylene and industrial recycled waste polyethylene; the industrial recovered waste polyethylene is recovered polyethylene or regenerated low-pressure polyethylene or regenerated PE (Polyethylene); the molecular weight of the petroleum resin is 300-3,000; the molecular weight of the polymethyl methacrylate is 80,000-120,000; the asphalt material is one or more of natural asphalt, coal tar asphalt and petroleum asphalt; and the inorganic mineral filling material is one or over two of calcium carbonate of 500-800 meshes, talc powder, quartz sand, glass hollow microspheres and kaolin.

Owner:SHENZHEN KEZHONGDA POLYMER MATERIAL RES INST

Asphalt-treated permeable-base (ATB) construction process

The invention relates to an asphalt-treated permeable-base (ATB) construction process. The ATB construction process is characterized in that: each raw material is obtained in a way that: coarse aggregate comprises crushed limestone produced by an impact crusher, fine aggregate comprises the crushed limestone with the particle sizes of less than 2.36mm, and a filler is produced by levigating hydrophobic stones such as highly-basic rocks and the like in limestone or magmatite; the asphalt distribution of a prime coat is 0.6 to 1.2 L / m<2>, and the asphalt distribution of a seal coat is 0.8 to 1.0 L / m<2>; when an asphalt mixture is mixed, asphalt is heated at the temperature of 155 to 165 DEG C, the mineral aggregate is heated at the temperature of 170 to 190 DEG C, the mixture is produced at the temperature of 155 to 170 DEG C, and reduction in the mixture storage temperature is not more than 10 DEG C; when the asphalt mixture is transported and charged, a vehicle is required to be moved forwards and backwards to realize balanced charging, and the temperature of the mixture is not lower than 150 DEG C when arriving at a pavement site; the temperature of an asphalt mixture paver screed is not lower than 80 DEG C, and the mixture is paved at the temperature of not lower than 140 DEG C at the pavement speed of 3 to 5 m / min; and rolling compaction is performed by three rolling compaction stages. The ATB construction process is simple and convenient to construct, and ensures relatively lower cost and high performance.

Owner:CCCC SHEC DONGMENG ENG CO LTD

Polyethylene/rubber powder blend modified asphalt and preparation method thereof

InactiveCN103709770AReasonable priceEasy to operateBuilding insulationsCrack resistanceAging resistance

The invention provides a polyethylene / rubber powder blend modified asphalt which is composed of a matrix asphalt and a polyethylene / rubber powder blended substance, wherein the polyethylene / rubber powder blended substance is composed of the following components in percentage by weight: 40-52% of polyethylene, 45-59% of rubber powder and 1-3% of crosslinking agent; and the weight ratio of the polyethylene / rubber powder blended substance to the matrix asphalt is (5-15):100. According to the polyethylene / rubber powder blend modified asphalt, the softening point is enhanced, the penetration degree is lowered, and the anti-rut property of the asphalt mixture is enhanced; the ductility is enhanced, and the low temperature ductility is improved; the aging resistance is improved; and the storage stability of the modified asphalt is enhanced, and the storage and transportation properties of the modified asphalt are improved. The polyethylene / rubber powder blend modified asphalt provides flexibility, fatigue resistance and cracking resistance for the asphalt pavement, thereby prolonging the service life of the pavement.

Owner:中华人民共和国泰州出入境检验检疫局

Open-graded basalt fibre and asphalt mixture and preparation method thereof

ActiveCN108863172AImprove high temperature stabilityImprove tensile propertiesDry mixingBasalt fiber

The invention discloses an open-graded basalt fibre and asphalt mixture and a preparation method thereof. The mixture comprises SBS modified asphalt, basalt fibres and mineral aggregate, wherein the mineral aggregate comprises an aggregate material and mineral powder, and the aggregate material is divided into three groups according to the grain size of 10-15 mm, 5-10 mm and less than or equal to3 mm. The preparation method for the mixture comprises the steps of drying the raw materials to the constant weight separately, carrying out dry mixing on the basalt fibres and the coarse and fine aggregate material for 30 s at the mixing temperature, adding the constant-temperature SBS modified asphalt, carrying out wet mixing for 3 min, adding the mineral powder, carrying out mixing for 90 s soas to obtain the mixture. According to the open-graded basalt fibre and asphalt mixture, the pavement performance can be greatly improved, the operation is simple and convenient, and the cost is low.

Owner:泰州学院 +1

Polyolefin-based asphalt mixture additive and preparation method thereof

InactiveCN106280505AImprove high temperature stabilityImproves rutting resistanceBuilding insulationsPolyolefinPolymer science

The invention relates to a polyolefin-based asphalt mixture additive and a preparation method thereof. The anti-rutting additive is prepared from the following raw materials in percentage by weight: 70-85% of modified polyolefin granules, 10-25% of inorganic salt whisker, 1-5% of nano silica, 0.1-0.5% of a plasticizer and 0.1-0.5% of an antioxidant. All the raw material components are uniformly mixed at normal temperature and normal pressure and then are added into a twin-screw extruder, melting extrusion is carried out under the conditions that temperature of barrel is 180-230 DEG C, rotating speed of a main engine is 30-50r / min and feeding rate is 30-60r / min, and then grain-sized dicing and drying are carried out, so that the polyolefin-based asphalt mixture additive is obtained. The prepared road asphalt anti-rutting additive can effectively improve anti-rutting and anti-aging properties of asphalt mixture, so that high temperature anti-rutting property of the asphalt mixture can be greatly improved.

Owner:WUHAN UNIV OF TECH

Asphalt mixture and production method thereof

ActiveCN109180077AImproves rutting resistanceImprove stress resistanceBuilding insulationsAsphaltPolymer chemistry

The invention discloses an asphalt mixture and a production method thereof and relates to the field of building materials. The asphalt mixture solves the problem that the existing asphalt mixture forthe airport runway has poor stability and anti-rutting ability, and comprises 4 to 12 wt% of modified asphalt, 72 to 88 wt% of aggregate, 5 to 10 wt% of a filler, 0.5 to 3 wt% of a fiber stabilizer and 0.5 to 3 wt% of an anti-rutting agent and has an asphalt-aggregate ratio of 5.6 to 14%. The modified asphalt comprises matrix asphalt and SBS and the weight of the SBS is 5-8 wt% that of the matrixasphalt. The asphalt mixture has the advantages of high dynamic stability, high temperature stability, strong rutting resistance and good water stability, and is suitable for airport runways.

Owner:厦门市政沥青工程有限公司 +2

Durable tunnel paving structure

InactiveCN104863032AGood flexibilityImprove waterproof performanceIn situ pavingsClimate change adaptationRoad surfaceFire safety

The invention discloses a durable tunnel paving structure, which sequentially comprises a rubber asphalt gravel sealing layer, a pouring-type semi-flexible mixture paving lower layer, a modified emulsified asphalt bonding layer and a high-modulus warm mixing flame-retardant asphalt mixture paving upper layer from bottom to top. The durable tunnel paving structure provided by the invention has the advantages that the anti-track capability and anti-crack performance of the pavement are obviously enhanced; the durability is greatly improved; the anti-slip function of the paving surface is ensured; the problem of potential fire safety hazards of asphalt pavement is solved; the asphalt pavement construction temperature is lowered; energy sources are saved; emission is reduced; the construction simplicity is improved; only the surface maintenance and repair are needed in daily life; the integral repeated repair is avoided; and the investment is reduced in the whole life cycle.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

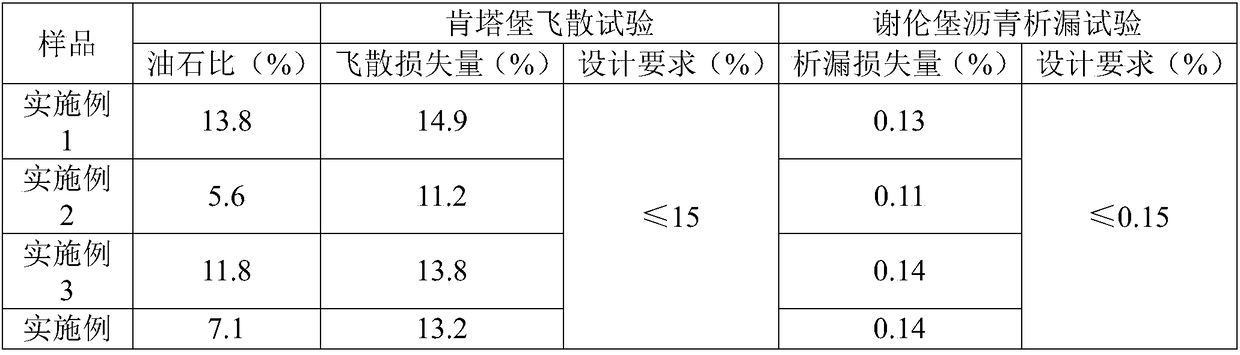

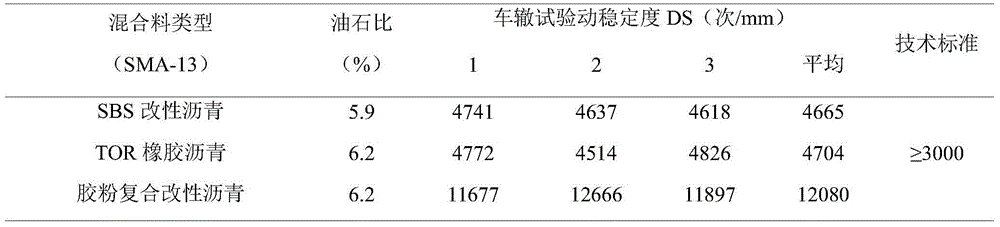

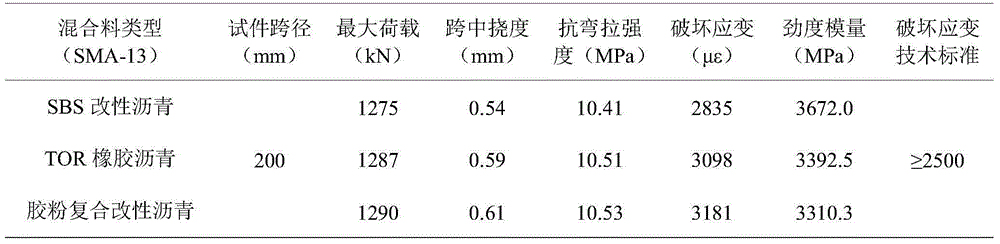

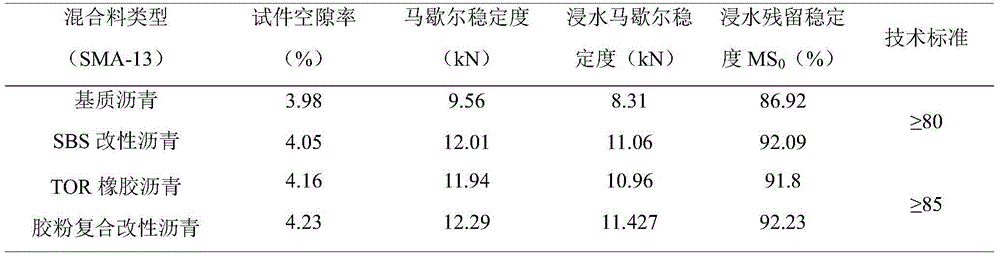

Composite modified asphalt mixture of rubber powder with high anti-rutting performance and preparation method thereof

ActiveCN104446157AImproves rutting resistanceSimple processSolid waste managementPolymer scienceMass ratio

The invention relates to a composite modified asphalt mixture of rubber powder with a high anti-rutting performance and a preparation method thereof. The mixture is mainly characterized in that in a dry process moulding preparation method, the mass ratio of tans-polyethylene rubber (TOR), rubber powder, asphalt, mineral aggregate to a complexing agent is (0.038-0.041): (0.841-0.919): (4.671-5.106): (93.337-94.052): (0.399-0.596); in a wet process moulding preparation method, the mass ratio of tans-polyethylene rubber (TOR), rubber powder, asphalt, mineral aggregate to a complexing agent is (0.016-0.035): (0.780-0.855): (4.335-4.918): (93.671-94.652): (0.217-0.492). According to the mixture provided by the invention, the anti-rutting performance of an asphalt rubber pavement is improved to a great extent, the dynamic stability is obviously increased compared with an SBS modified asphalt mixture, and the low temperature anti-cracking performance and the water stability are slightly improved. The composite modified asphalt mixture provided by the invention is simple in process, has huge social and economic benefits, and meets the characteristics of green ecology and sustainable development.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com