Modified asphalt as well as preparation method thereof

A technology for modifying asphalt and asphalt, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of unstable performance of modified asphalt, high mixing temperature, poor storage performance, etc., to improve the softening point and low temperature. The effect of ductility, good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

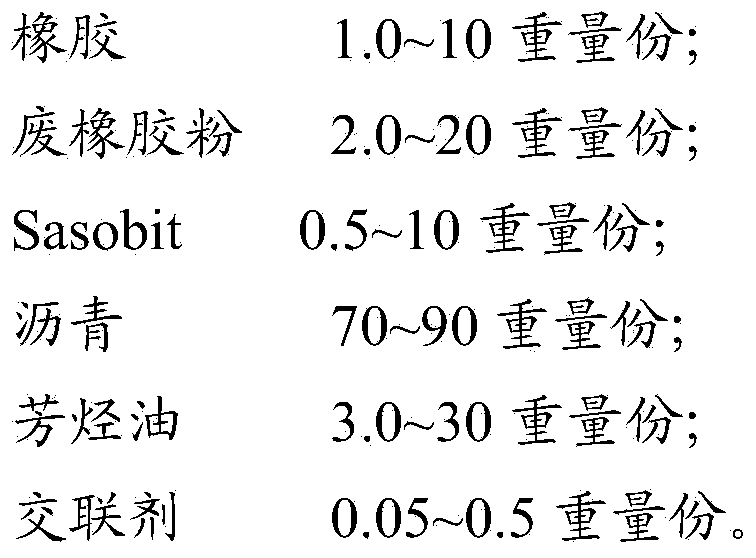

[0033] The present invention also provides a method for preparing the above modified asphalt, comprising: A) mixing 70-90 parts by weight of asphalt, 3.0-30 parts by weight of aromatic oil, 2.0-20 parts by weight of waste rubber powder, 1.0-10 parts by weight of Rubber, 0.5-10 parts by weight of Sasobit and 0.05-0.5 parts by weight of cross-linking agent are mixed and heated, and stirred to obtain modified asphalt.

[0034] Wherein, the asphalt, aromatic oil, waste rubber powder, rubber, Sasobit and crosslinking agent are all the same as above, and will not be repeated here.

[0035]According to the present invention, the step A) is specifically as follows: mixing and heating 70-90 parts by weight of asphalt and 3-30 parts by weight of aromatic oil, and performing heat preservation and stirring for the first time; adding 2.0-20 parts by weight of waste rubber powder, Carry out the second thermal insulation stirring; add 1.0-10 weight parts of rubber to carry out the third ther...

Embodiment 1

[0047] Heat 81 parts by weight of 90A asphalt to 120°C, add 8 parts by weight of furfural oil, heat to 155°C, keep stirring for 30min, add 5 parts by weight of waste rubber powder, keep stirring at 155°C for 40min, add 5 parts by weight SBS SBR, keep stirring at 155°C for 40 minutes, add 1 part by weight of Sasobit, keep stirring at 155°C for 40 minutes, then add 0.05 parts by weight of NH4L type crosslinking agent, heat up to 170°C, keep stirring for 20 minutes, and then grind with a colloid mill, After grinding for 50 minutes, the temperature was lowered to 140° C., and stirred for 70 minutes to obtain modified asphalt.

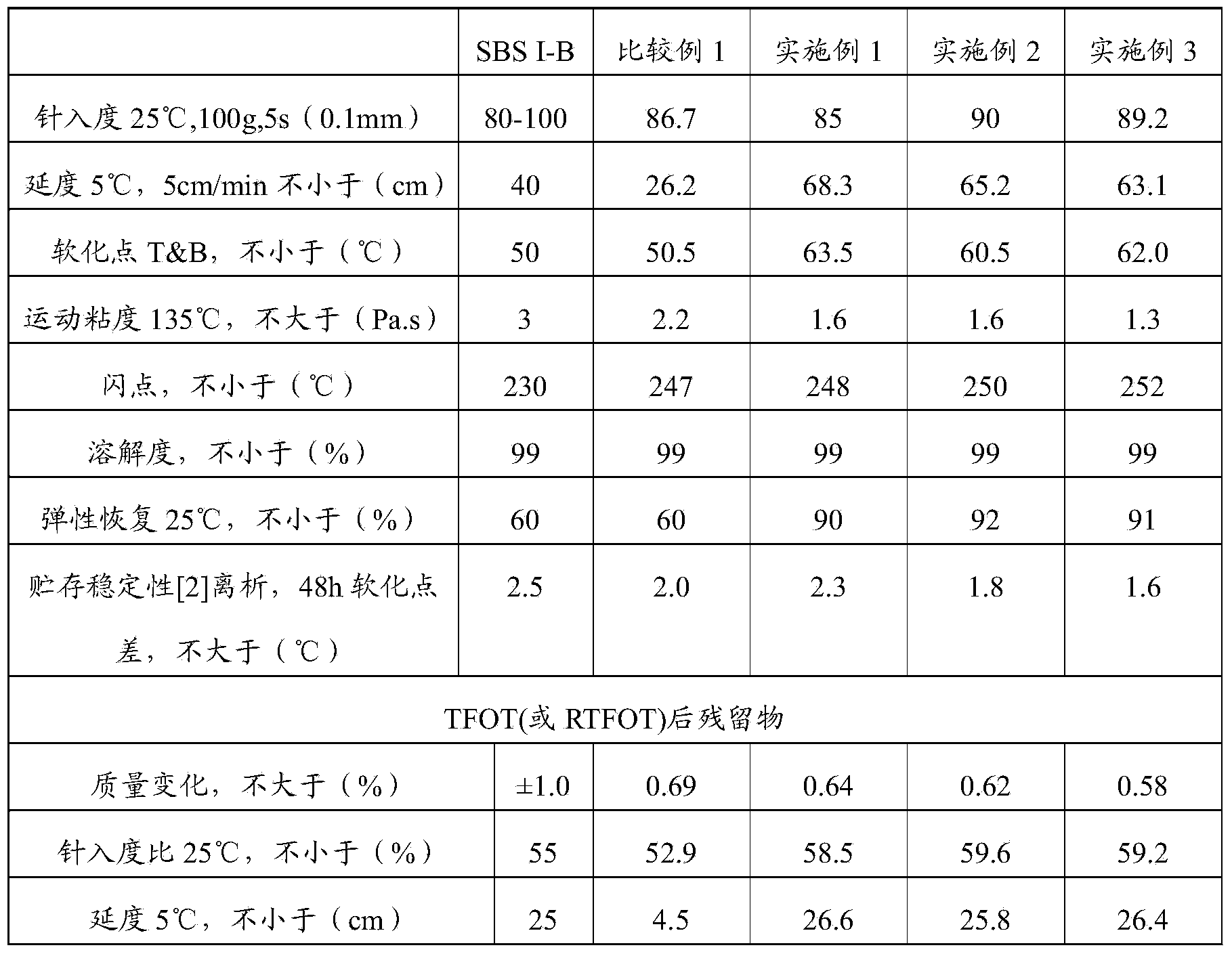

[0048] The modified asphalt obtained in Example 1 was tested for performance, and the results are shown in Table 1.

Embodiment 2

[0050] 78.5 parts by weight of 90A asphalt was heated to 120°C, 8 parts by weight of furfural oil was added, heated to 155°C, kept stirring for 30 minutes, 8 parts by weight of waste rubber powder was added, kept stirring at 155°C for 40 minutes, and 4.5 parts by weight of SBS was added. Styrene-butadiene rubber, keep stirring at 155°C for 40 minutes, add 1 part by weight of Sasobit, keep stirring at 155°C for 40 minutes, then add 0.06 parts by weight of NH4L type crosslinking agent, heat up to 170°C, keep stirring for 20 minutes, and then grind with a colloid mill, After grinding for 50 minutes, the temperature was lowered to 140° C., and stirred for 70 minutes to obtain modified asphalt.

[0051] The modified asphalt obtained in Example 2 was tested for performance, and the results obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com