Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Reduce construction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt warm-mix agent and asphalt mixture mixed by same as well as preparation methods thereof

ActiveCN101899218AWith viscosity reductionWith foamClimate change adaptationBuilding insulationsChlorideRoad surface

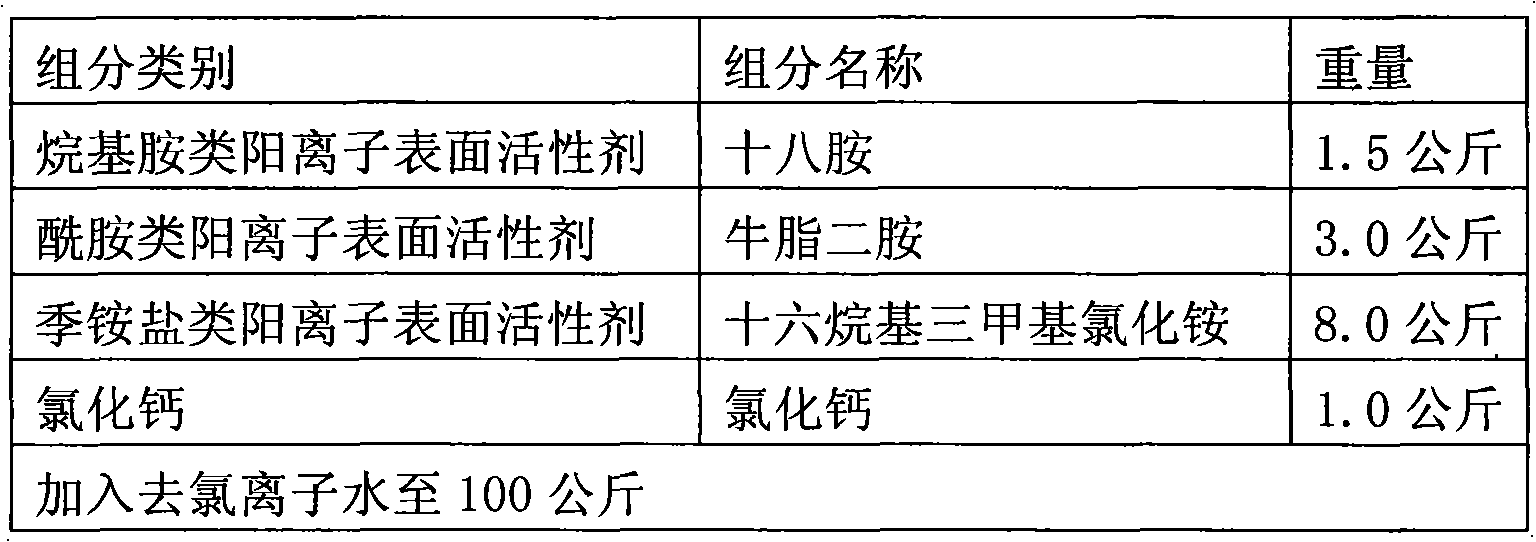

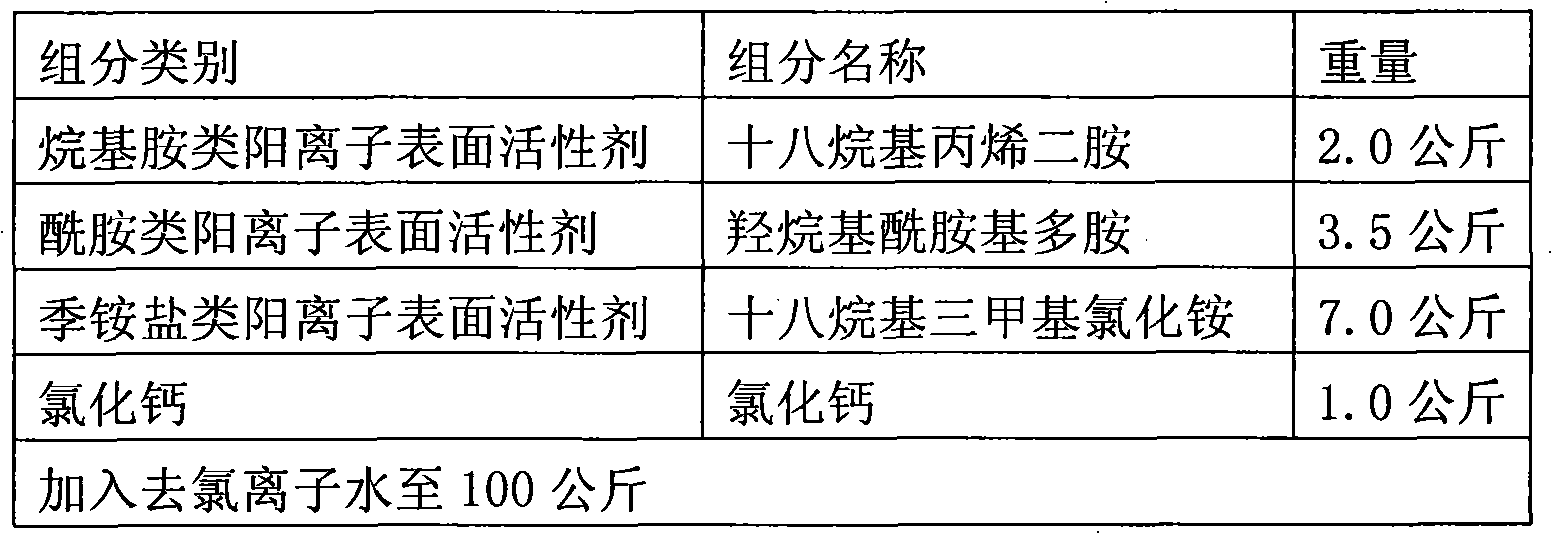

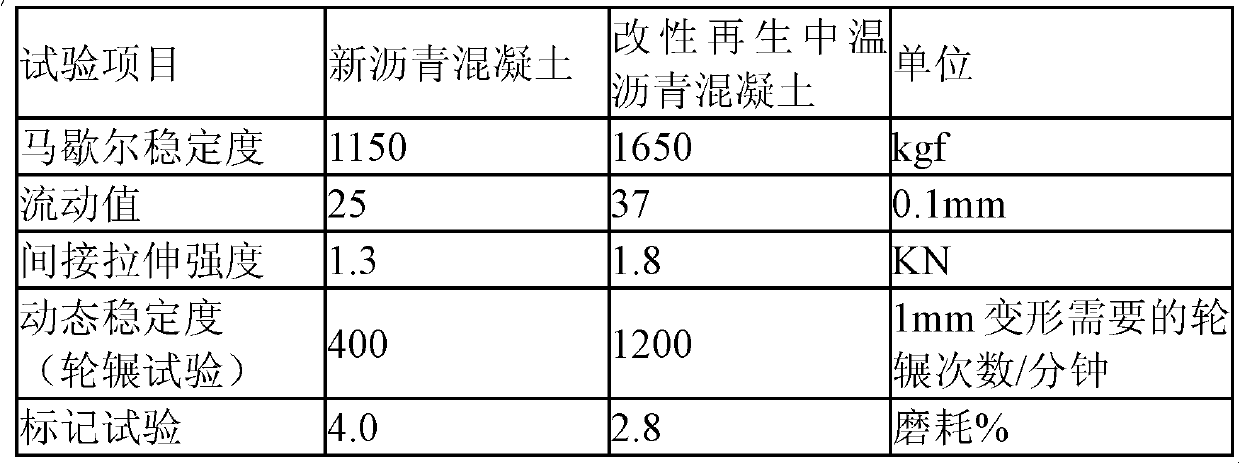

The invention relates to an asphalt warm-mix agent, comprising the following components in percentage by weight: 1.0-2.0% of alkylamine type cationic surfactant, 3.0-5.0% of amide type cationic surfactant, 5.0-10.0% of ammonium salt type cationic surfactant, 1.01.5% of calcium chloride, and water with residual percentage. The invention also relates to an asphalt mixture with the pavement applicability basically same as the traditional hot-mix asphalt mixture and the mixing and construction temperature lower than 20-50 DEG C; the purposes of energy saving, emission reduction, longer construction season, asphalt aging reduction and easier compaction are realized by reducing the mixing temperature; the indexes of the compaction degree, the water stability, the high-temperature performance, the low-temperature performance and the like of the pavement after paving the asphalt are not lower than those of hot-mix asphalt mixture at the same stage; and the service life of the asphalt pavement is efficiently guaranteed.

Owner:天津市市政工程研究院 +1

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

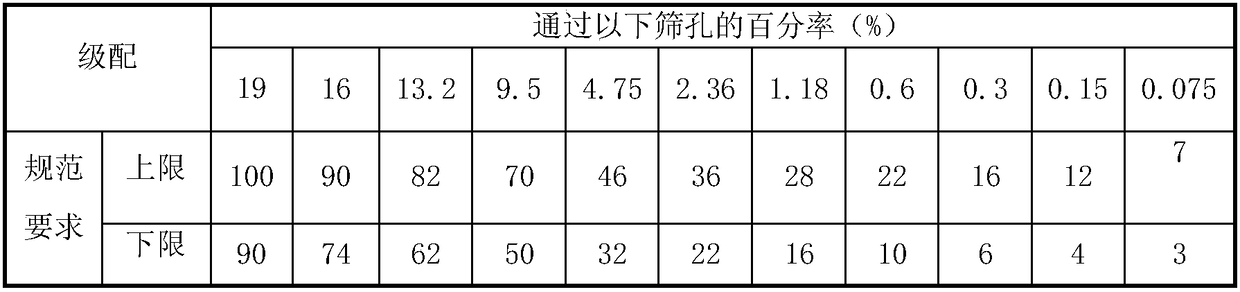

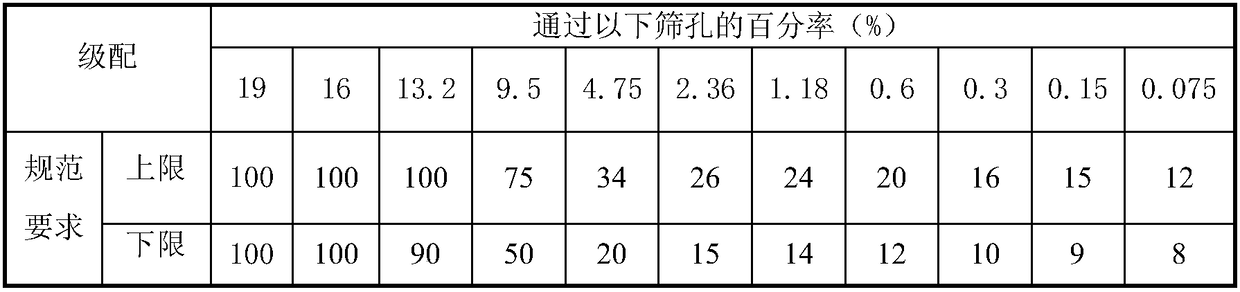

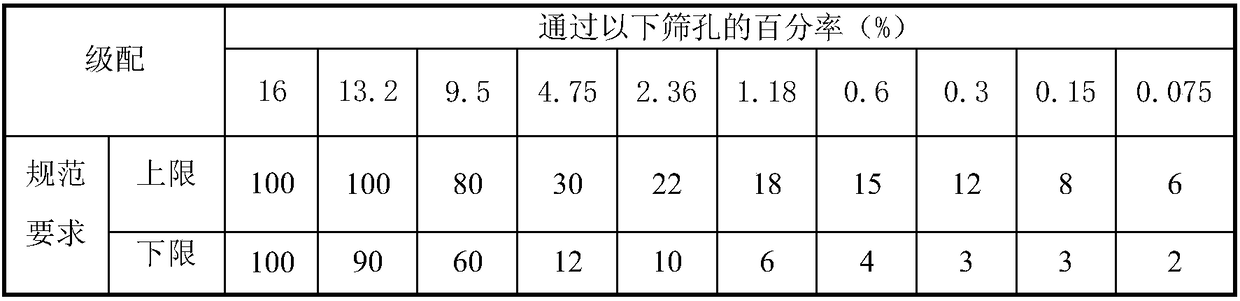

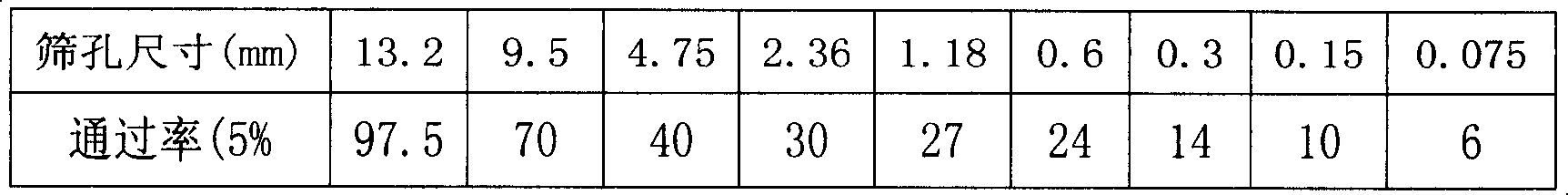

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

Poured epoxytar concrete material and its prepn process

InactiveCN101020601AImprove low temperature performanceReduce construction temperatureRoadwaysEpoxyEther

The present invention relates to poured road surface laying material, and is especially one kind of poured epoxy asphalt concrete material with low construction temperature, high flowability and construction convenience and its preparation process. The poured epoxy asphalt concrete material consists of component A and component B in the weight ratio of 8-50 as well as stone material in the amount of 3-9 times the component A. The component A consists of asphalt 45-90 weight portions, epoxy resin 4.5-36 weight portions, modified alkylphenol 9-27 weight portions and glycidol ether 0-3 weight portions, and the component B is curing agent. The poured epoxy asphalt concrete material is prepared through mixing the materials of the component A, stirring at 120-160 deg.c, adding stone material, and final adding the heated curing agent and maintaining the temperature for 0-120 min.

Owner:重庆市智翔铺道技术工程有限公司

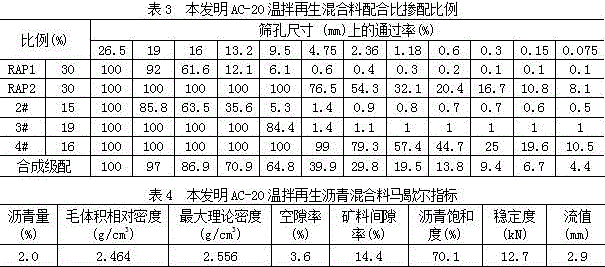

Warm mix recycled asphalt mixture with high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and preparation method of warm mix recycled asphalt mixture

InactiveCN106186837AHigh strengthImprove fatigue resistanceSolid waste managementClimate change adaptationLow emissionMaterials science

The invention provides a warm mix recycled asphalt mixture with a high RAP (Reclaimed Asphalt Pavement) mixing amount and high performance and a preparation method of the warm mix recycled asphalt mixture, and belongs to the technical field of highway construction materials. The mixture is prepared from the following components in percentage by mass: 50 to 70 percent of RAP material, 28.2 to 47.2 percent of aggregate and 1.8 to 2.8 percent of newly-doped asphalt and warm mix regenerant; the content of the warm mix regenerant is 0.3 to 0.5 percent of the mass of the newly-doped asphalt. The preparation method comprises the following steps of reclaiming and stacking of the RAP material, crushing and screening of a reclaimed material, stacking and detection of a reference material in different bins, and preparation of the warm mix recycled asphalt mixture. The RAP material, the aggregate, the asphalt and the warm mix regenerant are taken according to the requirement of raw material proportioning and are subjected to mixing treatment according to a conventional production technique of a hot-mixed asphalt mixture, wherein the mixing temperature is 120 to 140DEG C, and the mixing time is 20 to 35s, and finally the recycled asphalt mixture is obtained. The warm mix recycled asphalt mixture has the advantages of high RAP mixture ratio, low heating and constructing temperature, good constructability, easiness and pavement performance, low energy consumption, low emission and the like.

Owner:云南省公路科学技术研究院

Chromatic bituminous cement improving workability

InactiveCN101205371AReduce construction temperatureEasy constructionBuilding insulationsPetroleum resinRoad surface

The invention discloses a colorful asphalt binder. The component of the colorful asphalt binder of the invention calculated by weight percentage comprises 20-65 per cent of petroleum resin, 30-79 per cent of lubricant refined extract oil and 1-5 per cent of polyethylene wax. By pulling a little of polyethylene wax into conventional colorful asphalt binder, temperature of mixing, spreading and rolling of asphalt mixture can be greatly reduced and negative influence on final colorful asphalt pavement is not caused, which allows an easy construction. As the same time, the reduction of construction temperature and odor emitted by the binder are decreased, which are in favor of environment protection. As the same time, addition of SEBS, SIS and SBR allows the colorful asphalt binder to be provided with better high-temperature stability.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

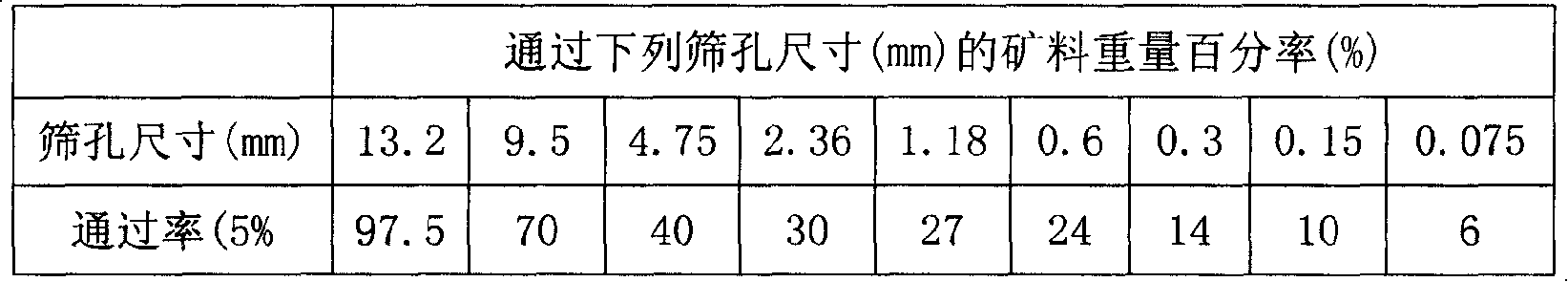

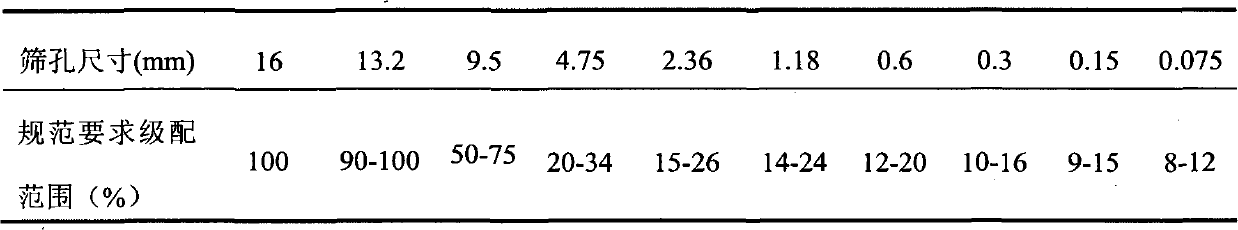

Warm mixing shape memory alloy (SMA) asphalt mixture and preparation method thereof

The invention discloses a warm mixing shape memory alloy (SMA) asphalt mixture. The warm mixing SMA asphalt mixture comprises styrene-butadiene-styrene (SBS) modified asphalt, aggregate, fiber, mineral powder and warm mixing agent, wherein the warm mixing agent is inorganic silico-aluminate of which the water content is 18 to 23 percent; based on 1 weight part of SBS modified asphalt, the mixture contains 10 to 18 parts of aggregate, 0.01 to 0.08 part of fiber, 0.5 to 1.5 parts of mineral powder and 0.02 to 0.08 part of warm mixing agent; and the invention discloses a preparation method for the warm mixing SMA asphalt mixture, and adding sequence, control temperature and mixing time of the materials are described in the method. According to the warm mixing SMA asphalt mixture, the mixing temperature of the SMA asphalt is effectively reduced, the problem that the SMA asphalt mixture is difficult to compact is solved, emission of toxic gases such as 'asphalt fume' is reduced to a great extent, damage to the environment and harm to health of constructors are reduced, and storage type production is facilitated.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Modified asphalt viscosity decreasing agent

ActiveCN101781468AReduce high temperature viscosityImprove low temperature crack resistanceBuilding insulationsCasting typesEngineering

The invention provides a modified asphalt viscosity decreasing agent which relates to a paving material for roads, bridges and tunnels. The viscosity decreasing agent is prepared from the following components in parts by weight: 4-20 parts of organic acid, 1-30 parts of surface active agent, 5-80 parts of synthesis paraffin, and 1-30 parts of compatilizer. After the viscosity decreasing agent is doped, the high-temperature viscosity of the modified asphalt is greatly decreased, while other various indexes are not changed. Simultaneously, compared with the common modified asphalt, after the viscosity decreasing agent is doped, the concrete stirring temperature, low-temperature property and fatigue property of the casting type asphalt are greatly improved. The invention is mainly used for road petroleum asphalt and SBS modified asphalt.

Owner:重庆市智翔铺道技术工程有限公司

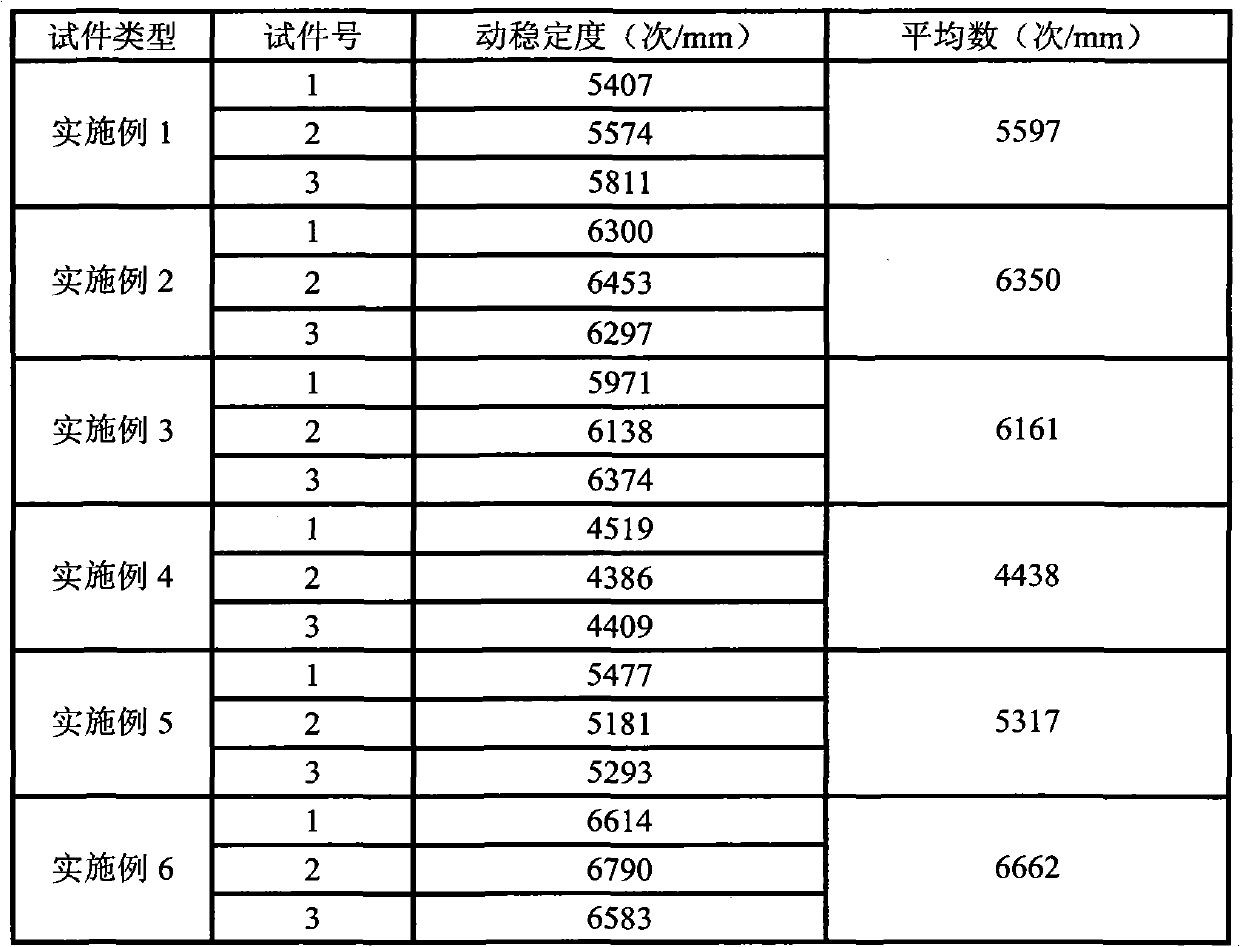

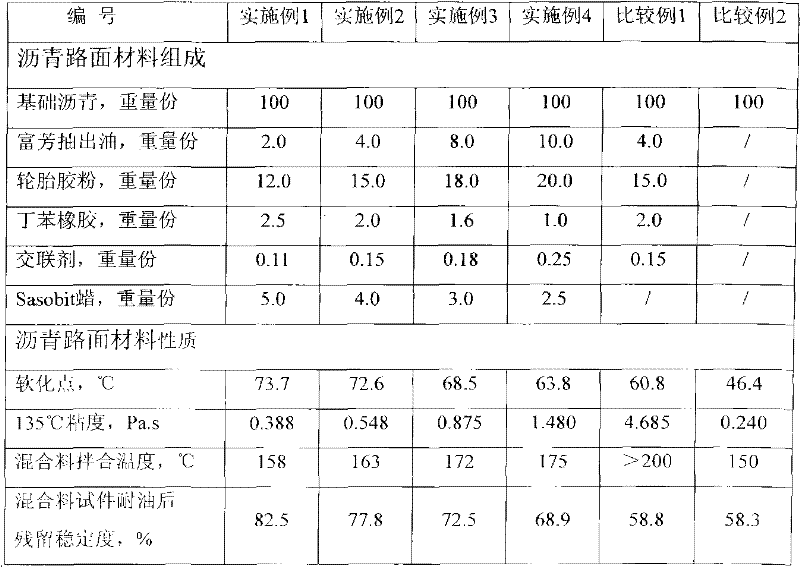

Environment-friendly oil-resistant asphalt pavement material and preparation method thereof

InactiveCN102453335AGood oil resistanceImprove temperature sensitivityIn situ pavingsBuilding insulationsWaxPolymer science

The invention discloses an environment-friendly oil-resistant asphalt pavement material and a preparation method thereof. The oil-resistant pavement material comprises the following components in part by weight: 100 parts of base asphalt, 5 to 25 parts of waste tyre rubber powder, 0.5 to 5.0 parts of styrene butadiene rubber (SBR), 1 to 10 parts of macromolecular wax, and 0.1 to 0.3 part of crosslinking agent. The preparation method comprises the following steps of: adding the macromolecular wax into molten base asphalt in the weight proportion, stirring for reaction, adding the waste tyre rubber powder and the SBR, keeping temperature for swelling, and finally adding the crosslinking agent and grinding fully to obtain the environment-friendly oil-resistant asphalt pavement material. The waste tyre rubber powder is used as an asphalt modifier and matched with the SBR and the macromolecular wax, and the environment-friendly oil-resistant asphalt pavement material has high oil resistance and low cost and is favorable for reducing environmental pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

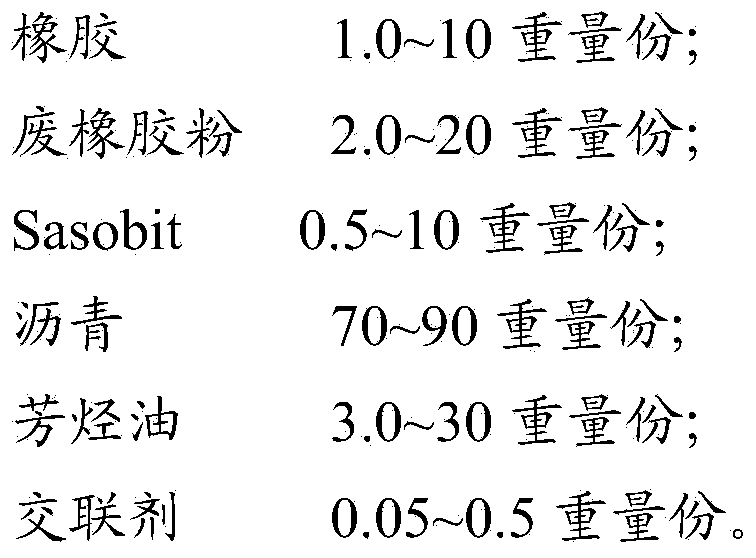

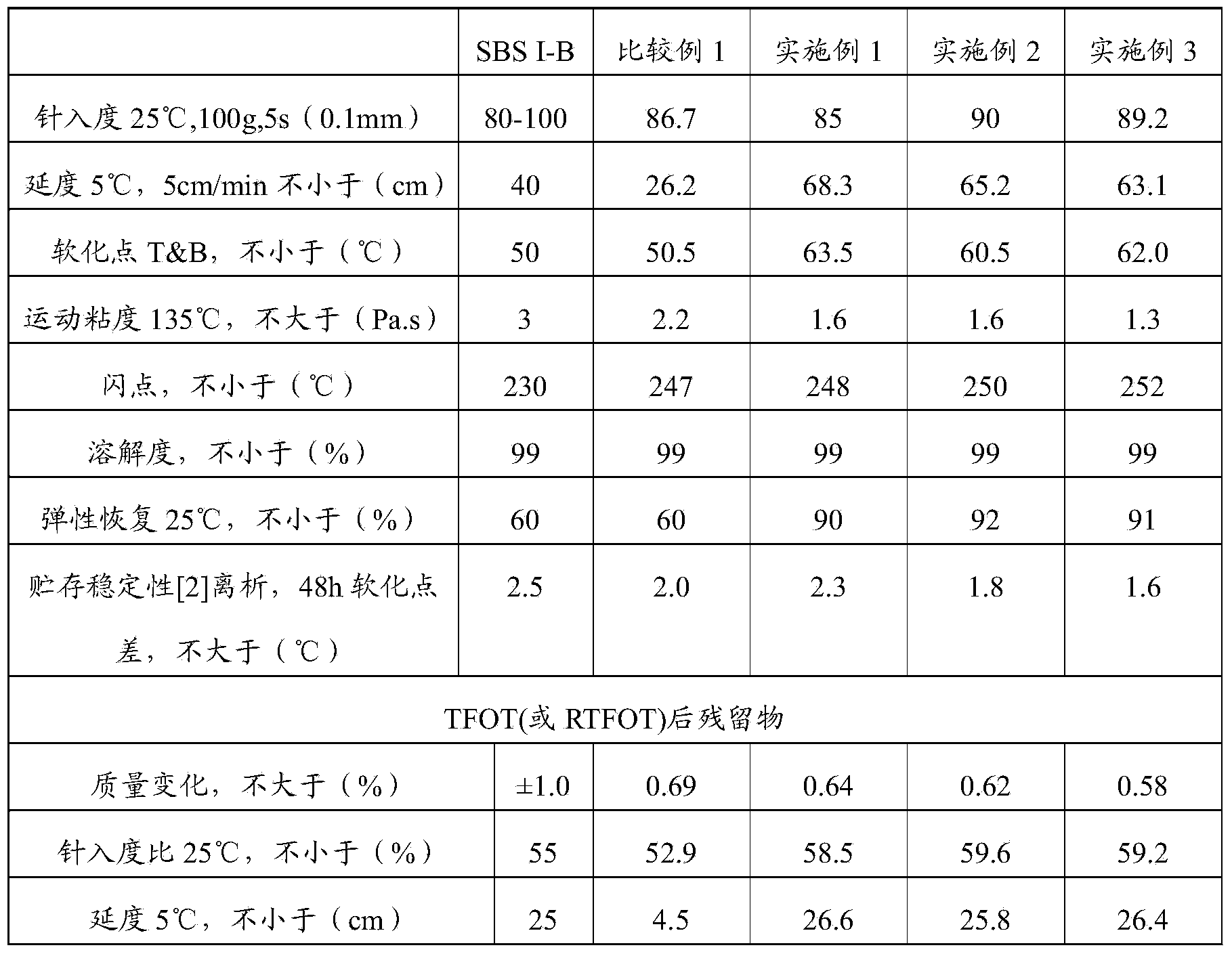

Modified asphalt as well as preparation method thereof

ActiveCN103468010AImprove low temperature performanceImprove low temperature ductilityBuilding insulationsHigh temperature storageSwelling capacity

The invention provides modified asphalt as well as a preparation method thereof. The preparation method comprises the following step: mixing, heating and stirring 70-90 parts of asphalt, 3.0-30 parts of aromatic hydrocarbon oil, 2.0-20 parts of waste rubber powder, 1.0-10 parts of rubber, 0.5-10 parts of Sasobit and 0.05-0.5 part of a crosslinking agent to obtain the modified asphalt. Compared with the prior art, polymer rubber, waste rubber powder, aromatic hydrocarbon oil, Sasobit and the crosslinking agent are adopted to jointly modify the asphalt. The rubber has better low temperature performance and can improve the low temperature ductility of the asphalt, and meanwhile, does not damage other pavement performances of the asphalt. The aromatic hydrocarbon oil has higher swelling capacity to the rubber and the waste rubber powder, so that the compatibility of the asphalt and modification materials is improved. The crosslinking agent can further improve the high temperature storage stability of a finished product so as to prevent separation. Sasobit can reduce the construction temperature of the asphalt.

Owner:SHANDONG JINSHI BITUMEN CO LTD

Warm mix asphalt and preparation method thereof

The invention discloses warm mix asphalt and a preparation method thereof. The warm mix asphalt comprises asphalt, aggregate, mineral powder and warm mixing agent, wherein the warm mixing agent is inorganic silico-aluminate of which the water content is 18 to 23 percent; based on 1 weight part of asphalt, the warm mix asphalt contains 15 to 30 parts of aggregate, 0.5 to 1.5 parts of mineral powder and 0.05 to 0.01 part of warm mixing agent; and the invention discloses the preparation method for the warm mix asphalt, and adding sequence, control temperature and mixing time of the materials are detailed in the method. According to the warm mix asphalt, the mixing temperature of the asphalt is effectively reduced, consumption of fuel and emission of harmful gases are reduced, damage to the environment and harm to health of constructors are reduced, and storage type production is facilitated; and by the preparation method for the warm mix asphalt, the production procedures of the mixture are simplified, the warm mix asphalt can be produced in the conventional equipment, and equipment input and maintenance cost are reduced.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

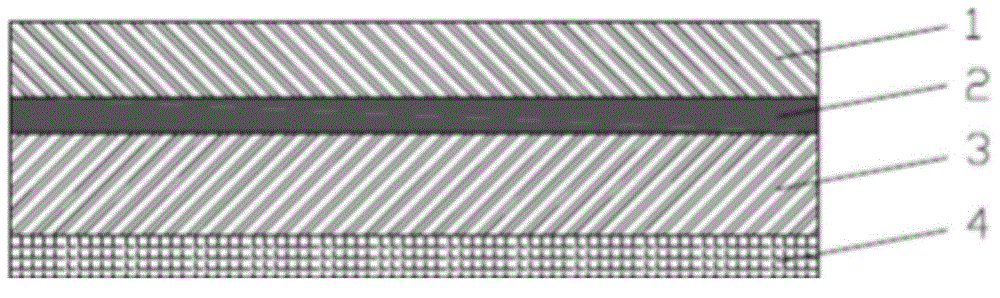

Durable tunnel paving structure

InactiveCN104863032AGood flexibilityImprove waterproof performanceIn situ pavingsClimate change adaptationRoad surfaceFire safety

The invention discloses a durable tunnel paving structure, which sequentially comprises a rubber asphalt gravel sealing layer, a pouring-type semi-flexible mixture paving lower layer, a modified emulsified asphalt bonding layer and a high-modulus warm mixing flame-retardant asphalt mixture paving upper layer from bottom to top. The durable tunnel paving structure provided by the invention has the advantages that the anti-track capability and anti-crack performance of the pavement are obviously enhanced; the durability is greatly improved; the anti-slip function of the paving surface is ensured; the problem of potential fire safety hazards of asphalt pavement is solved; the asphalt pavement construction temperature is lowered; energy sources are saved; emission is reduced; the construction simplicity is improved; only the surface maintenance and repair are needed in daily life; the integral repeated repair is avoided; and the investment is reduced in the whole life cycle.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

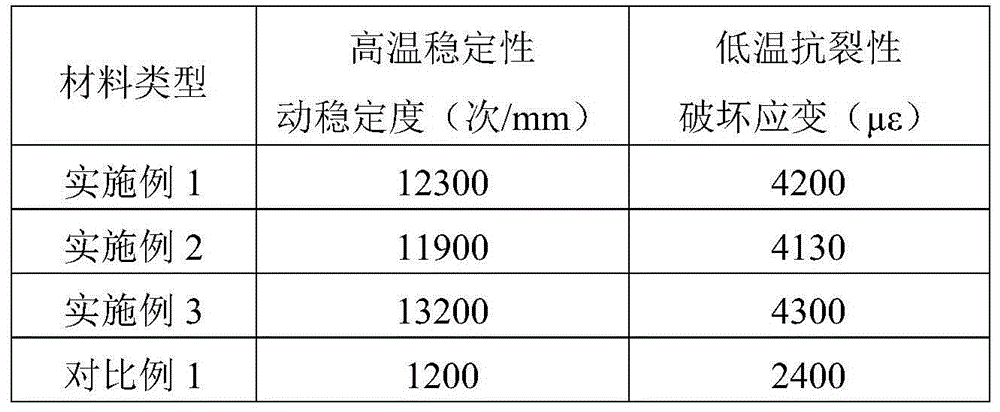

Warm-mix modified asphalt and method for preparing asphalt mixture by using same

InactiveCN102504553AImprove high temperature stabilityHigh temperature stability hasClimate change adaptationBuilding insulationsPolyolefinAsphalt

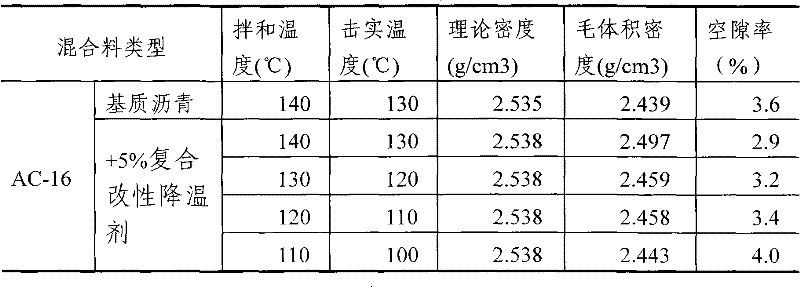

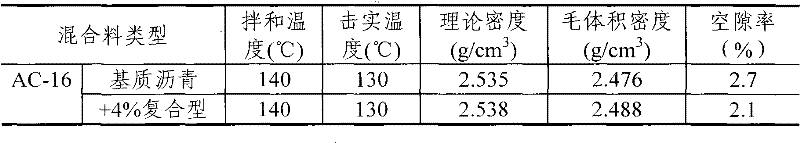

The invention discloses warm-mix modified asphalt and a method for preparing asphalt mixture by using the same. The warm-mix modified asphalt comprises matrix asphalt and a composite modified cooling agent, the adding weight of the composite modified agent is 3% to 6% of the weight of the matrix asphalt, and the composite modified agent is a polyolefin cooling agent. The method for preparing the asphalt mixture by using the warm-mix modified asphalt includes the following steps: the asphalt is heated to 110 DEG C to 130 DEG C and dehydrated, mineral aggregate is heated, hot mineral aggregate with 85%-90% weight ratio and hot matrix asphalt with 7% to 9% weight ratio are put into a mixing cylinder to be mixed, the mixing time is T1 5 seconds to 30 seconds, the polyolefin cooling agent with the weight occupying 3% to 6% of the weight of the matrix asphalt is added and mixed, the mixing time is T2 2 minutes to 5 minutes, and the mixture of the warm-mix asphalt is obtained. The warm-mix modified asphalt and the mixture of the same have low mixing, paving and compacting temperature, and can effectively retain the original performance of hot mix asphalt mixture while solving the problems of environment pollution, large energy consumption, aging and decline of the asphalt and the like.

Owner:JIANGYIN TAIFU ASPHALTUM

Special rubber powder for non-cured rubber asphalt waterproof coating and preparation method thereof

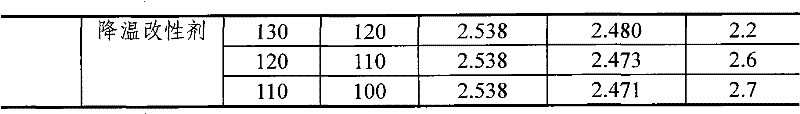

The invention discloses special rubber powder for a non-cured rubber asphalt waterproof coating and a preparation method thereof. The special rubber powder is prepared from, by weight parts, 50-65% of tire rubber powder, 20-40% of butyl rubber powder, 0.1-1.5% of activator, 0.1-1.0% of viscosity reducer and 5-15% of separant. The preparation method comprises the following steps: 1) stirring the tire rubber powder and the butyl rubber powder; 2) heating the activator and spraying the activator to the rubber powder obtained in the step 1), and then performing stirring and pre-activation; 3) mixing the pre-activated rough rubber powder obtained in the step 2) with the viscosity reducer and the separant, forming fine rubber powder through grinding, sieving the fine rubber powder, and performing packaging to obtain the finished product. Through the compounding of the waste tire rubber powder and the butyl rubber powder, the performance can meet the creep property, cohesiveness, self-healing property and ageing resistance requirements of the non-cured rubber asphalt waterproof coating. The added amount of plasticizer and polymerization modifiers is reduced effectively, and the cost can be reduced by over 10%.

Owner:GUANGXI YUANJING RUBBER TECH

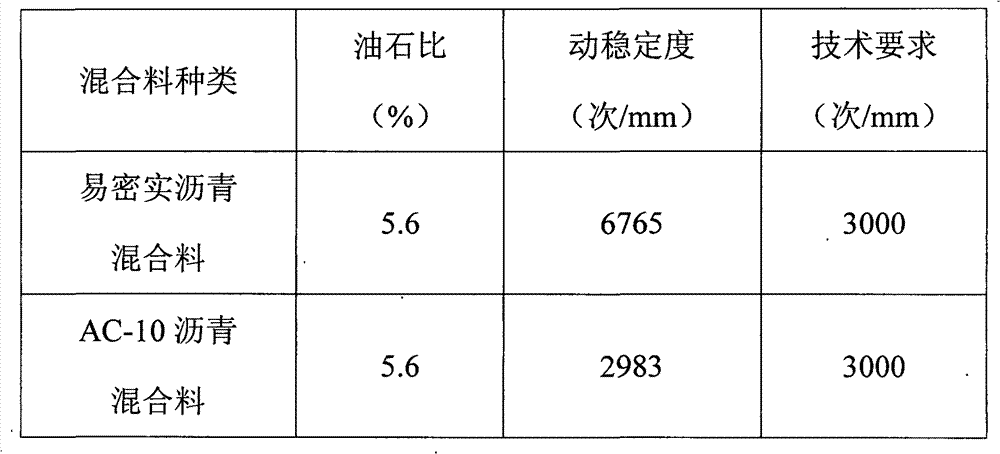

Easy compact asphalt mixing material and preparation method of easy compact asphalt mixing material

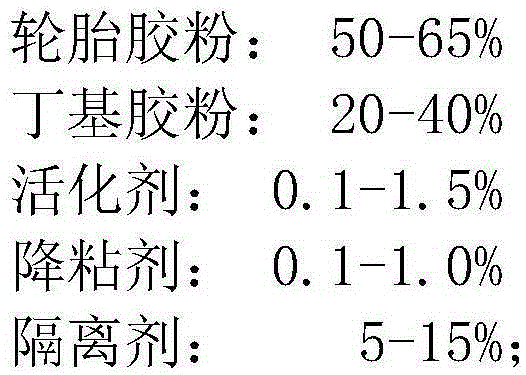

The invention discloses an easy compact asphalt mixing material and temperature and time control parameters in the preparation process of the easy compact asphalt mixing material. The easy compact asphalt mixing material comprises 100 parts of ore materials, 5.8 to 6.4 parts of modified asphalt, 0.2 to 0.3 parts of polyester fibers and 0.3 parts of easy compact agents, wherein the ore materials comprise the following ingredients in weight proportioning: 50 percent to 60 percent of 8-11mm macadam, 10 percent to 15 percent of 5-8mm macadam, 25 percent to 35 percent of manufactured sand and 3 percent to 8 percent of limestone ore powder. The ore materials are heated to 150 DEG C to 160 DEG C and is then subjected to dry stirring with polyester fibers for 5 to 10s, the modified asphalt is heated to 165 DEG C to 175 DEG C, the easy compact agents start to be sprayed after the modified asphalt is sprayed for 3s, the total time for spraying the asphalt and the easy compact agents is controlled to be within 13s, the ore powder is added after the wet stirring for 6s, the total time of the stirring and the mixing is not lower than 60s, the cylinder discharge temperature is controlled to 135 to 155 DEG C, and the easy compact asphalt mixing material is obtained. The mixing material is easy to compact, the rutting resistance capability is high, the construction temperature is reduced to 30 to 50 DEG C, heating energy sources are saved by about 22 percent, the emission of asphalt smoke and greenhouse gas such as CO2 is reduced, the effects of energy saving, emission reduction and environment protection are obvious, meanwhile, the construction quality is improved, the effective construction time is prolonged, and the work period is shortened.

Owner:中石化胜利建设工程有限公司

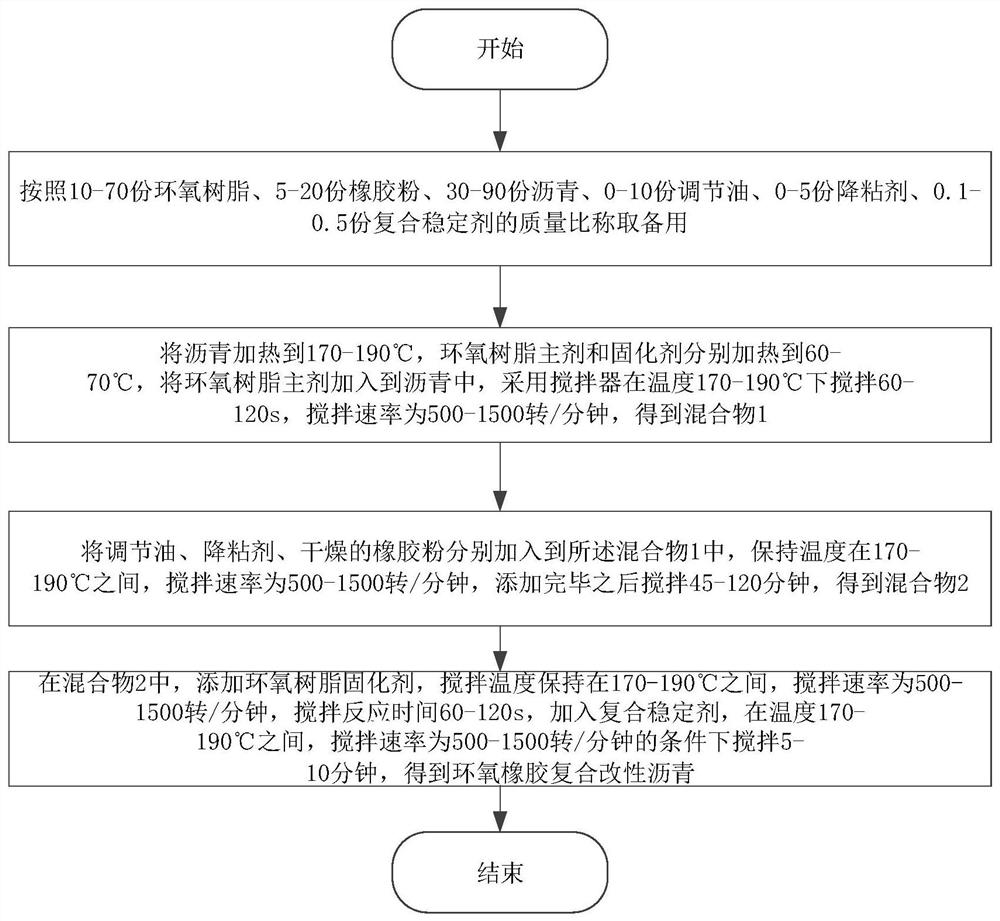

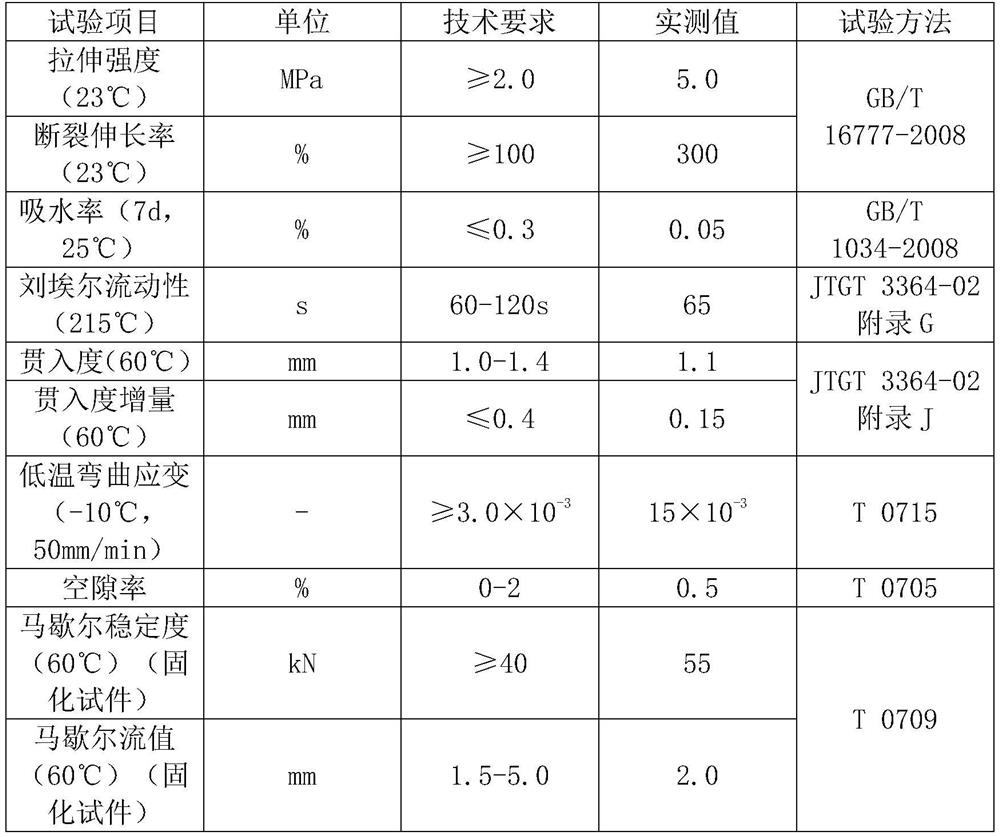

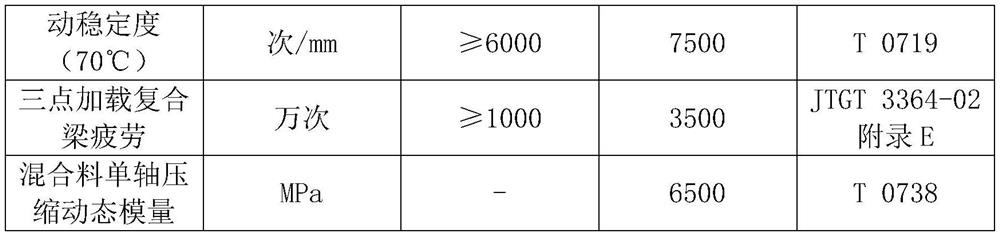

Epoxy rubber composite modified asphalt and preparation method thereof

The invention provides epoxy rubber composite modified asphalt and a preparation method thereof. The epoxy rubber composite modified asphalt comprises the following components in parts by weight: 10-70 parts of epoxy resin, 5-20 parts of rubber powder, 30-90 parts of asphalt, 0-10 parts of regulating oil, 1-5 parts of a viscosity reducer and 0.1-0.5 part of a composite stabilizer. The epoxy rubber composite modified asphalt has the remarkable technical characteristics of being adjustable in rigidity, low in viscosity in the construction process, high in viscosity and elasticity under the service condition, good in high-temperature stability, high in durability, energy-saving and environment-friendly.

Owner:JIANGYIN TAIFU ASPHALTUM

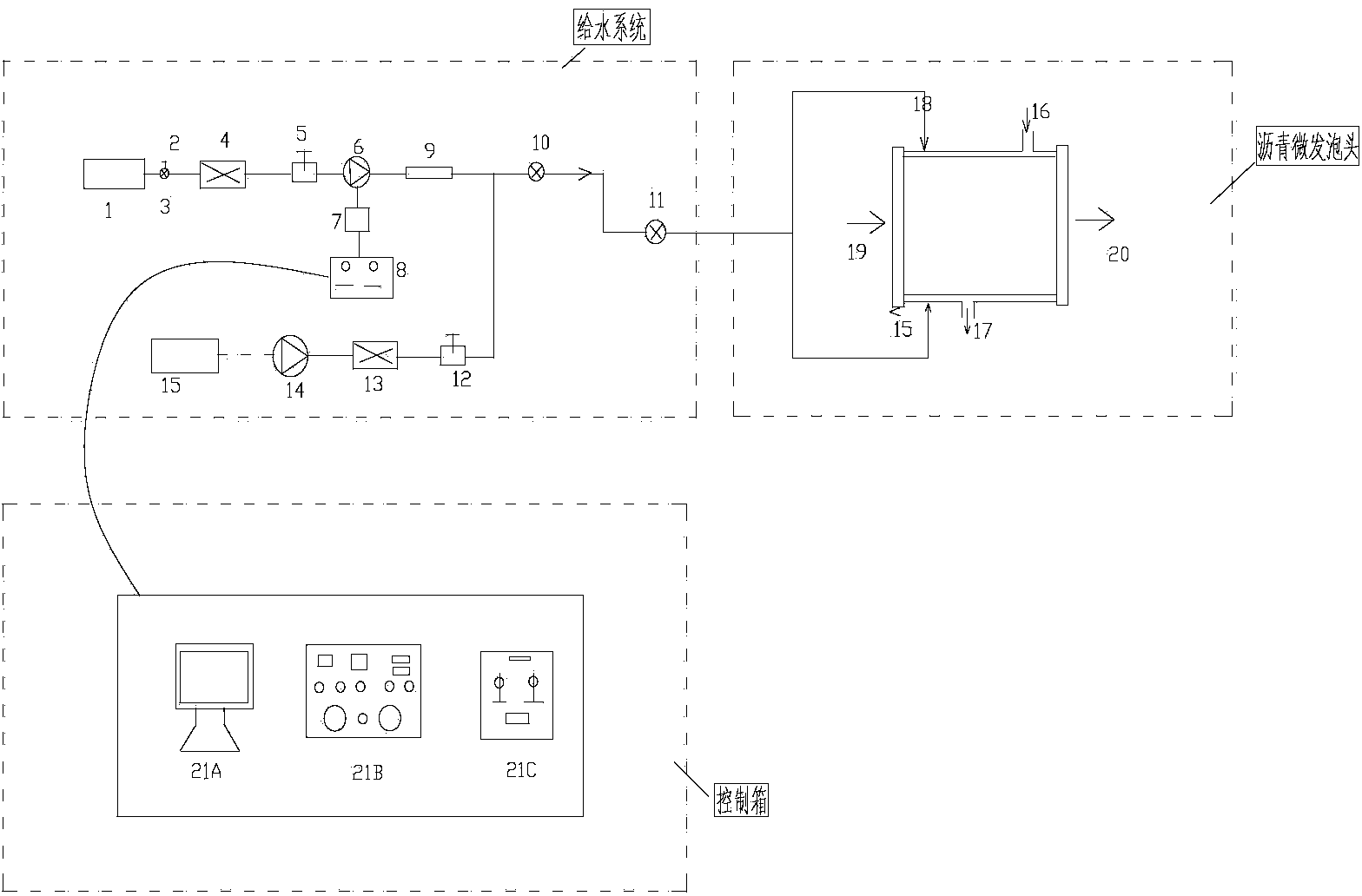

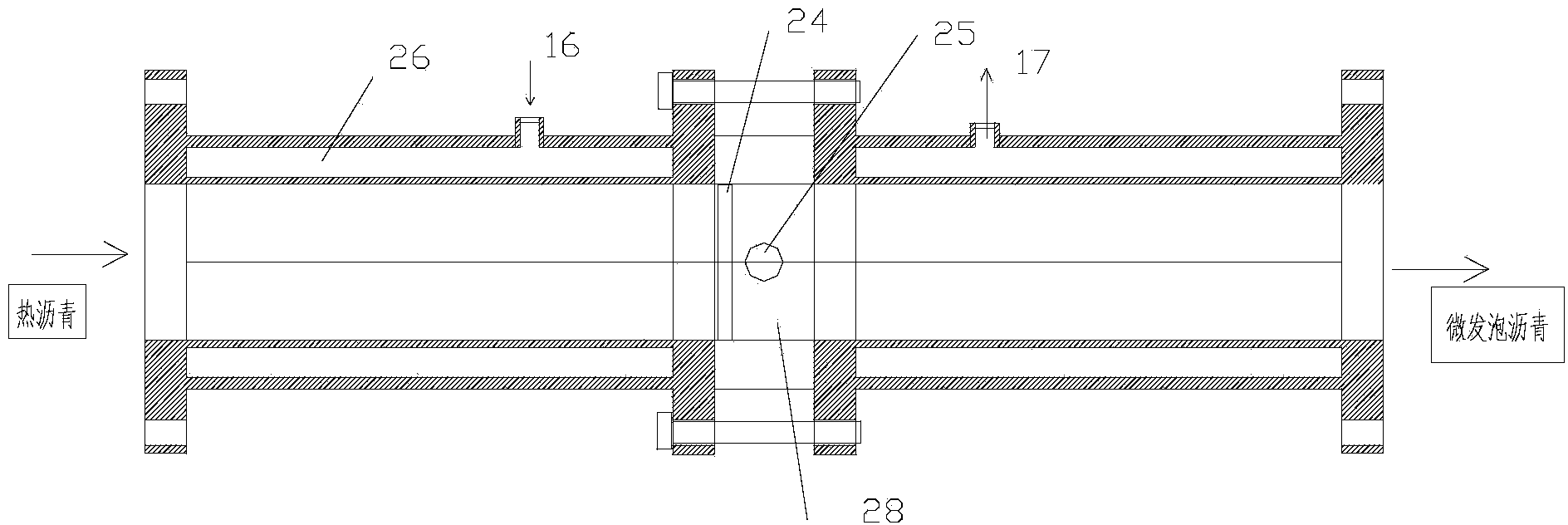

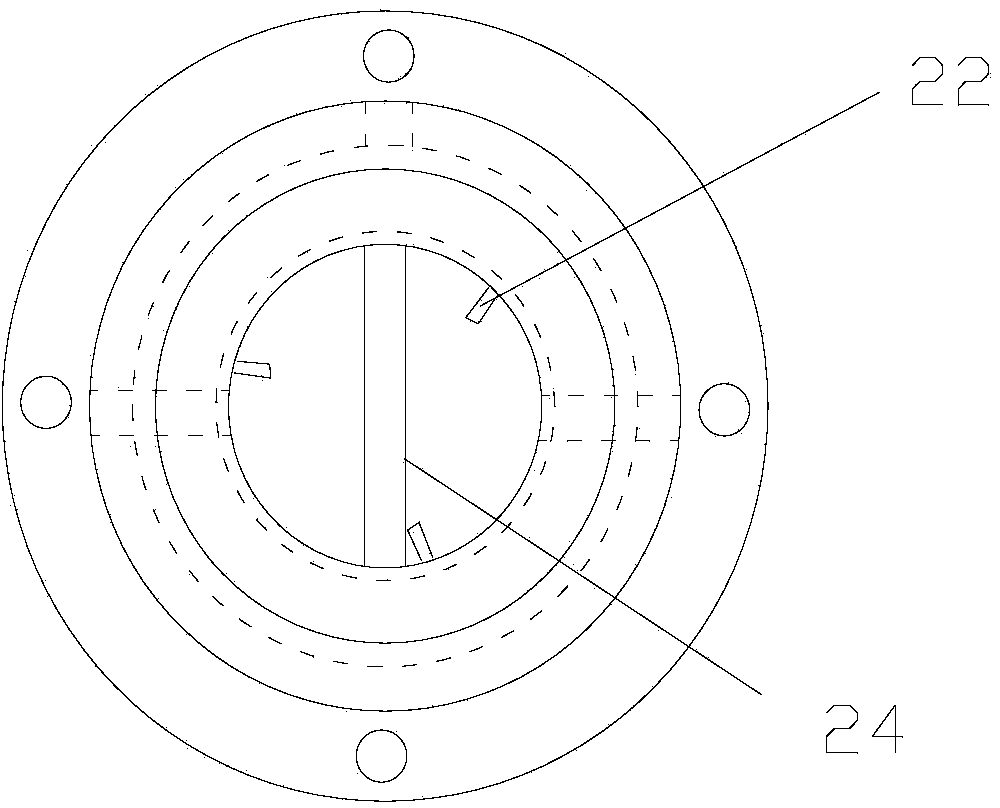

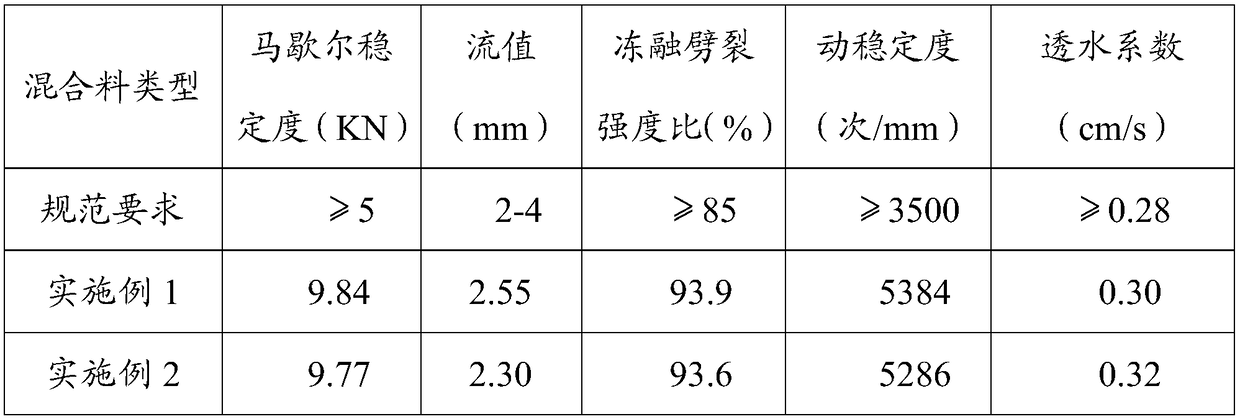

Micro-foamed warm mix asphalt mixture as well as preparation method and equipment thereof

ActiveCN104355568AReduce consumptionEmission reductionClimate change adaptationRoads maintainenceViscosityAsphalt

The invention relates to a warm mix asphalt mixture as well as a preparation method and equipment thereof, in particular to a micro-foamed warm mix asphalt mixture as well as a preparation method and equipment thereof, and belongs to the technical field of engineering. An asphalt micro-foaming formula and the equipment are matched for use. During mixture production, by the aid of the equipment, asphalt is fully foamed, a binder is sprayed into a mixing cylinder in the form of foamed asphalt and mixed with aggregate to form the warm mix asphalt mixture, the foamed asphalt is lower than the asphalt in viscosity and higher in workability and can fully cover the aggregate at the lower temperature, the mixing temperature of the warm mix asphalt mixture is reduced, and the micro-foamed warm mix asphalt mixture is produced. The micro-foamed warm mix asphalt mixture as well as the preparation method and the equipment thereof have benefits as follows: warm mixing of the warm mix asphalt mixture is realized by the aid of micro-foaming equipment, the cost for purchasing the equipment is only input once, and a small amount of water is sprayed in production. The production cost of the warm mix asphalt mixture is reduced, the once-and-for-all effect can be realized, and the method is more energy-saving and environment-friendly when compared with a traditional technology that warm mix materials are added for warm mixing.

Owner:江苏东交工程设计顾问有限公司

Green and environment-friendly permeable asphalt mixture for cold regions and method for preparing green and environment-friendly permeable asphalt mixture

InactiveCN109354441AHigh strengthGood water permeabilityClimate change adaptationEnvironmental resistanceSlag

The invention discloses a green and environment-friendly permeable asphalt mixture for cold regions. The green and environment-friendly permeable asphalt mixture comprises, by weight, 210-230 parts ofsteel slag, 8.80-9.53 parts of SBS (styrene-butadiene-styrene block copolymer) modified asphalt, 6.14-6.36 parts of limestone mineral powder, 1.14-1.27 parts of diatomaceous earth, 0.70-0.95 part ofrubber powder, 0.53-0.76 part of TPS (toughened polystyrene) asphalt high-viscosity agents, 0.25-0.30 part of warm mixing agents and 0.47-0.94 part of basalt fibers. The invention further provides a method for preparing the green and environment-friendly permeable asphalt mixture for the cold regions. The green and environment-friendly permeable asphalt mixture and the method have the advantages that the green and environment-friendly permeable asphalt mixture is sufficient in strength, water stability, durability, frost resistance and water permeability, rainwater can be immediately permeatedinto spaces below pavements, accordingly, the driving safety can be greatly guaranteed, driving noise can be lowered, and urban water logging can be reduced; the construction temperatures further canbe reasonably lowered, the construction difficulty can be lowered, and the green and environment-friendly permeable asphalt mixture and the method have important engineering application values.

Owner:JILIN UNIV

Safe and environment-friendly asphalt for road and preparation method thereof

ActiveCN103911007AHigh oxygen indexReduce pollutionClimate change adaptationBuilding insulationsCombustionRoad engineering

The invention specifically relates to a safe and environment-friendly asphalt for a road and a preparation method thereof, belonging to the technical field of road engineering materials. The asphalt comprises, by mass, 80 to 85 parts of heavy duty pavement petroleum asphalt, 9 to 10 parts of hyperviscous modifier, 2 to 3 parts of Sasobit warm mix asphalt modifier and 2 to 5 parts of fire retardant. Compared with the prior art, through addition of the fire retardant, the safe and environment-friendly asphalt provided by the invention has a high oxygen index, produces a small amount of black smoke during combustion and reduces pollution to the environment; moreover, addition of a warm mixing agent enables viscosity and construction temperature of the asphalt to be reduced and secondary pollution to the environment to be decreased. Thus, the safe and environment-friendly asphalt has wide application prospects and good social and economic benefits in construction of tunnel pavements.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Energy-saving emission-reducing type asphalt mixture and preparation method thereof

ActiveCN103601423AReduced durabilityLow production temperatureClimate change adaptationNitric oxideRoad surface

The invention relates to an energy-saving emission-reducing type asphalt mixture and a preparation method thereof and belongs to the technical field of engineering. By adopting the energy-saving emission-reducing type asphalt mixture, the demands of the asphalt mixture on environment temperature can be reduced, the annual construction time can be prolonged, better compaction function can be provided, the service life of a pavement is prolonged and effective guarantee for safe driving is provided; by adopting the energy-saving emission-reducing type asphalt mixture, a lot of fuel oil can be saved, and the discharge of greenhouse gas is reduced, so that the environment protection cost can be reduced and economical effect is more obvious; in addition, by applying the energy-saving emission-reducing type asphalt mixture, good social effect for establishing Chinese resources-saving society is provided, the discharge of carbon dioxide can be reduced, poisonous gases such as carbon monoxide, sulfur trioxide and nitric oxide also can be greatly reduced, and extremely important practical significances for saving social sources and protecting environment are provided.

Owner:JIANGSU EASTTRANS INTELLIGENT CONTROL TECH GRP CO LTD

Odorless asphalt mixture and preparation method thereof

The present invention provides an odorless asphalt mixture, which comprises the following raw materials by weight: 40-60 parts of asphalt, 850-950 parts of aggregate, 20-100 parts of mineral powder, 0.2-1 part of an odor inhibitor, and 0.1-0.5 part of an interface active agent. According to the present invention, the odorless asphalt mixture acts through the odor inhibitor and the interface activeagent so as to effectively inhibit the formation and volatilization of H2S, SO2, NOX and other asphalt flue gases during asphalt mixture production and construction and significantly eliminate the odor, wherein the asphalt performance is not significantly changed; and the odorless asphalt mixture has characteristics of environmental protection, energy saving, consumption reducing, high cost performance ratio, convenient construction and the like. The present invention further provides a preparation method of the odorless asphalt mixture.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

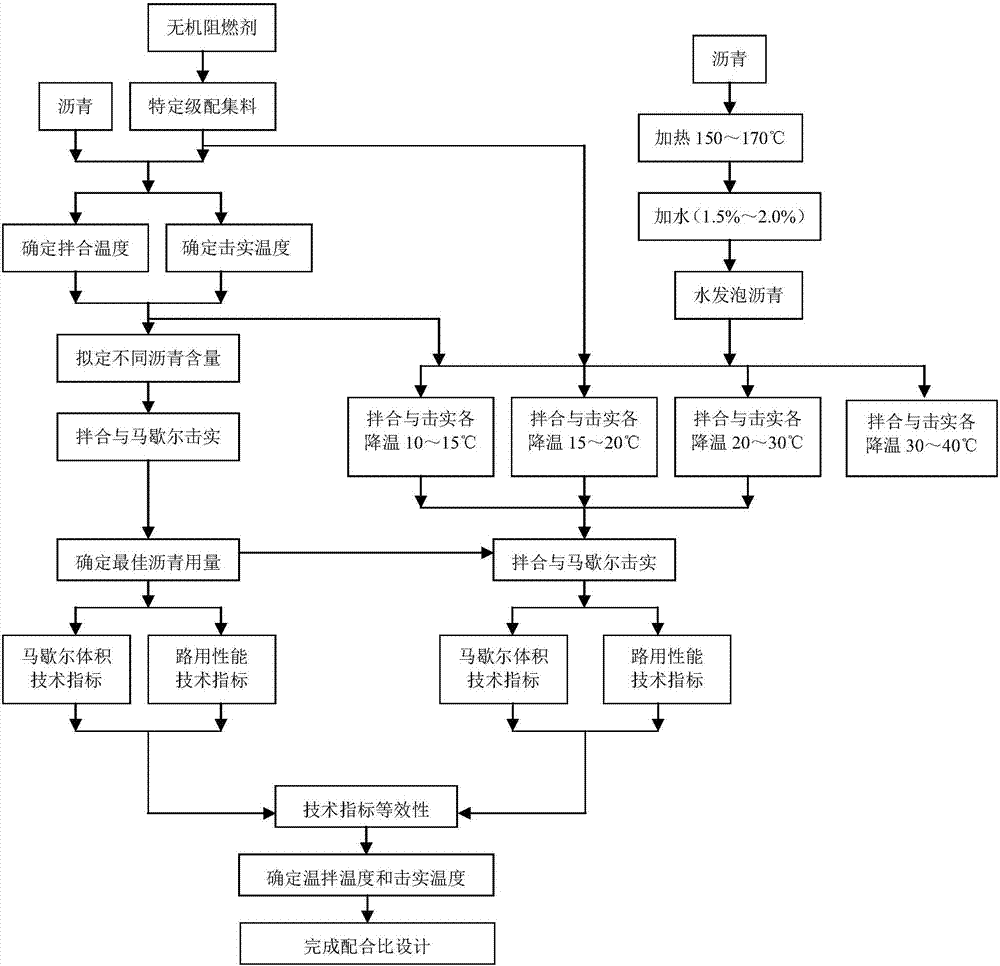

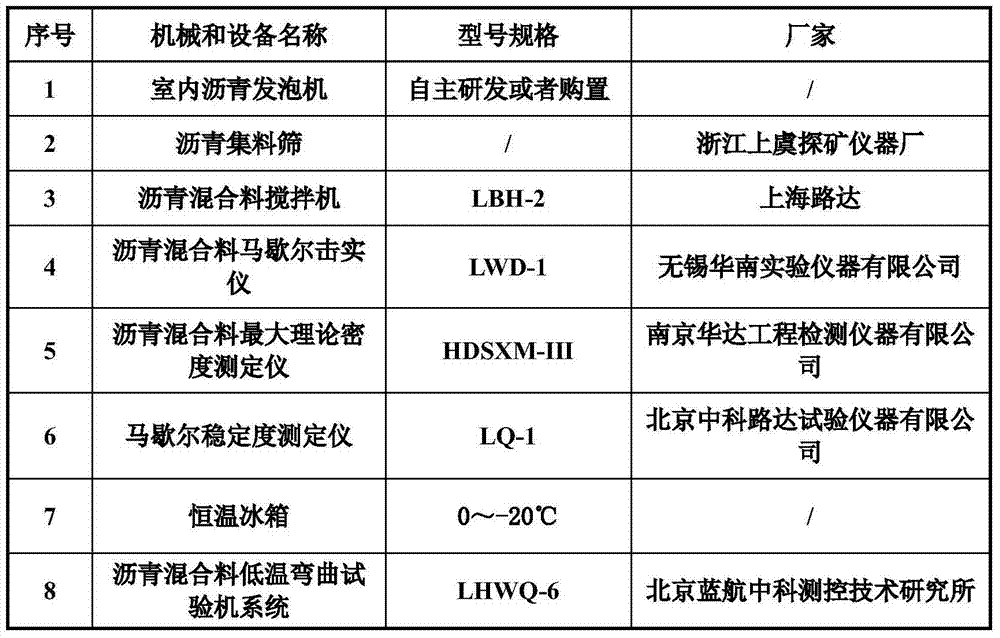

Water-blown warm-mix flame-retardant asphalt mixture, and preparation and design method thereof

The invention discloses a water-blown warm-mix flame-retardant asphalt mixture and a preparation method thereof. According to the invention, through comprehensive utilization of a water-blown asphalt warm-mixing technology and an asphalt flame-retardation technology, construction temperature of an asphalt pavement is effectively reduced, the safety factor of a tunnel asphalt pavement is increased, and the advantages of energy conservation, emission reduction, greenness, environmental protection, reduction in construction cost, improvement of warm-mixing construction technology for tunnel flame-retardant asphalt pavements and the like are obtained. The invention also provides a design method for the water-blown warm-mix flame-retardant asphalt mixture. The method utilizes the concept of equivalent design of basic mix ratios and technique indexes to improve the traditional design method for the warm-mix flame-retardant asphalt mixture, provides bases for the design of the water-blown warm-mix flame-retardant asphalt mixture and fills a gap in the design method for the water-blown warm-mixed flame-retardant asphalt mixture.

Owner:SUZHOU UNIV OF SCI & TECH

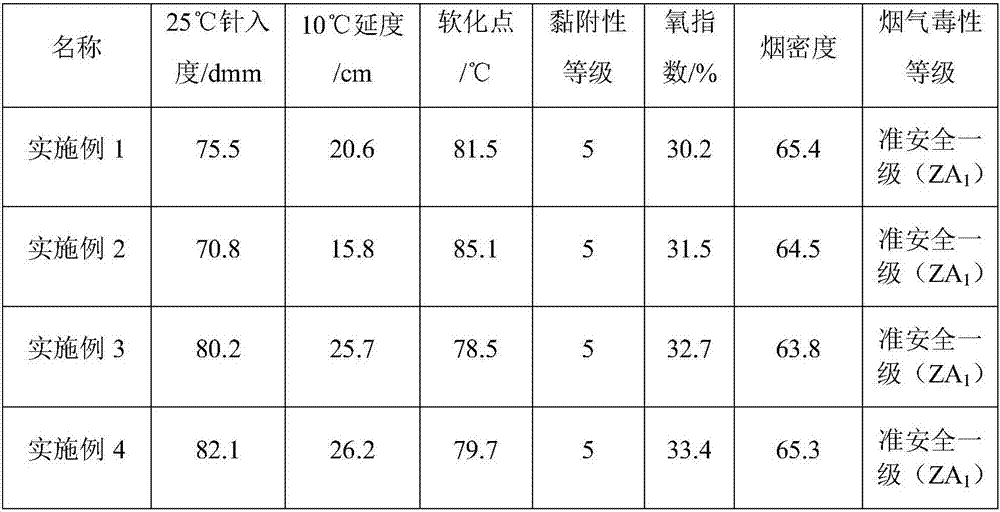

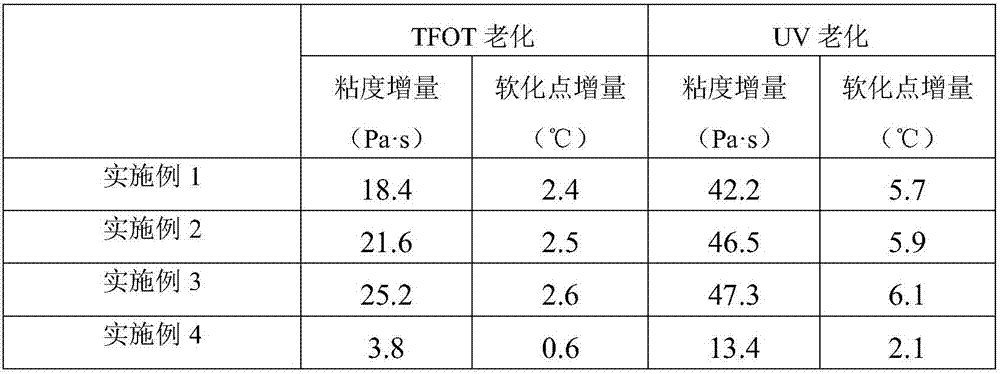

Warm-mixing anti-ultraviolet aging asphalt and preparation method thereof

ActiveCN108276788AGood anti-ultraviolet aging performanceImprove high temperature resistanceClimate change adaptationBuilding insulationsButadiene-styrene rubberAsphalt

The invention discloses warm-mixing anti-ultraviolet aging asphalt and a preparation method thereof. The asphalt is prepared from the following raw materials in parts by weight: 100 parts of SBS (Styrene-Butadiene-Styrene) modified asphalt, 1 to 4 parts of light stabilizing agent, 0.1 to 0.5 part of absorbent and 0.5 to 2.5 parts of warm-mixing agent. The warm-mixing anti-ultraviolet aging asphaltprepared by the preparation method of the warm-mixing anti-ultraviolet aging asphalt has remarkable anti-ultraviolet aging performance and also has good high-temperature-resisting performance and low-temperature anti-cracking performance; the service life of an asphalt road surface can be greatly prolonged and the construction temperature also can be effectively reduced; in a construction process, energy source consumption is saved and the environment protection is facilitated.

Owner:PETROCHINA CO LTD +1

Non-curable rubber modified asphalt waterproof coating material and fabrication process and construction method thereof

InactiveCN106318211AImprove stabilityReduce construction temperatureBuilding insulationsBituminous coatingsPolymer sciencePolymer modified

The invention relates to a non-curable rubber modified asphalt waterproof coating material and fabrication process and construction method thereof. The non-curable rubber modified asphalt waterproof coating material currently available on the market either has bad resistance to high temperature or can only be workable in a temperature above 150 DEG C with high pollution. The invention of non-curable rubber modified asphalt waterproof coating material comprises, by weight, 59-64.5 parts of asphalt, 17-20 parts of aromatic oil, 3-5 parts of polymer modifiers, 9-11 parts of rubber particles, 2.5 parts of tackifier. The invention also relates to the fabrication process and environment-friendly construction method of the non-curable rubber modified asphalt waterproof material. The invention of the non-curable rubber modified asphalt waterproof material achieves the energy-saving, environment-friendly features and the advantages of anti-sagging under 100 DEG C which makes it suitable to be used in various kinds of waterproof projects.

Owner:SHANDONG LECRON CONSTR ENERGY SAVING TECH CO LTD

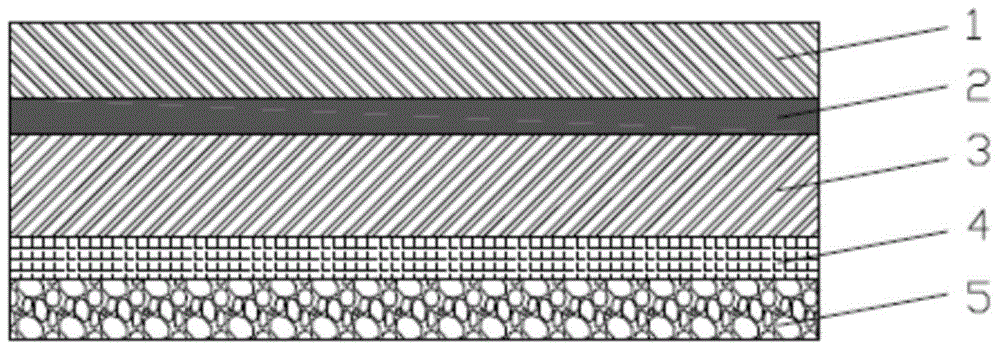

Paving method of durable tunnel pavement

InactiveCN104947564AGood flexibilityImprove waterproof performanceIn situ pavingsClimate change adaptationChipsealSand blasting

The invention discloses a paving method of a durable tunnel pavement. The paving method comprises the following steps: (1) carrying out sand blasting treatment on a cement concrete plate, spreading rubber asphalt and gravel on the surface of the cement concrete plate, and grinding to form a rubber asphalt and gravel seal coating; (2) grinding to form an asphalt mixture substrate on the rubber asphalt and gravel seal coating, pouring cement-based mortar, and naturally curing to form a poured semi-flexible paving lower layer; (3) spreading modified emulsified asphalt so as to form a modified emulsified asphalt layer; and (4) paving a fine-grain type asphalt mixture or a medium-grain type asphalt mixture to form a high-modulus warm mixing inflaming-retarding asphalt mixture paving upper layer. According to the invention, the paving method is strong in universality and simple in construction process, adopts a relatively conventional material, is strong in operability, and has good construction peaceability; with the whole paving structure, design service life can be obviously prolonged and can achieve 20-30 years, and good fireproofing, skid resistance, safety, as well as energy conservation and environment protection effects are achieved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

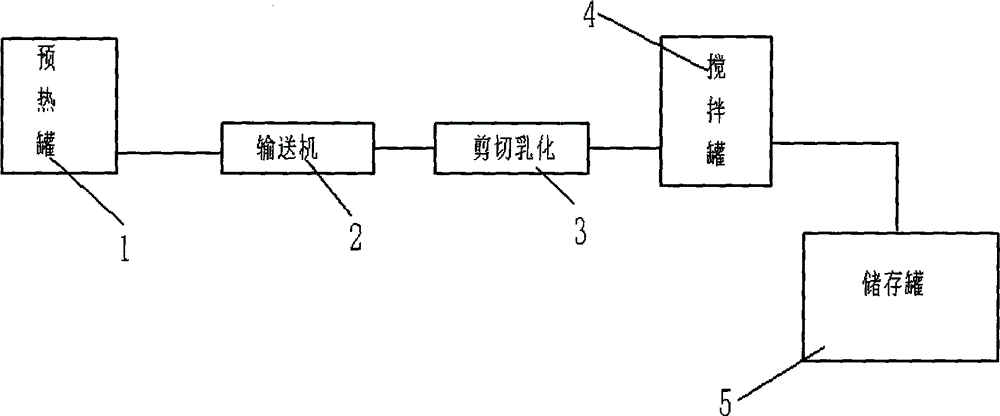

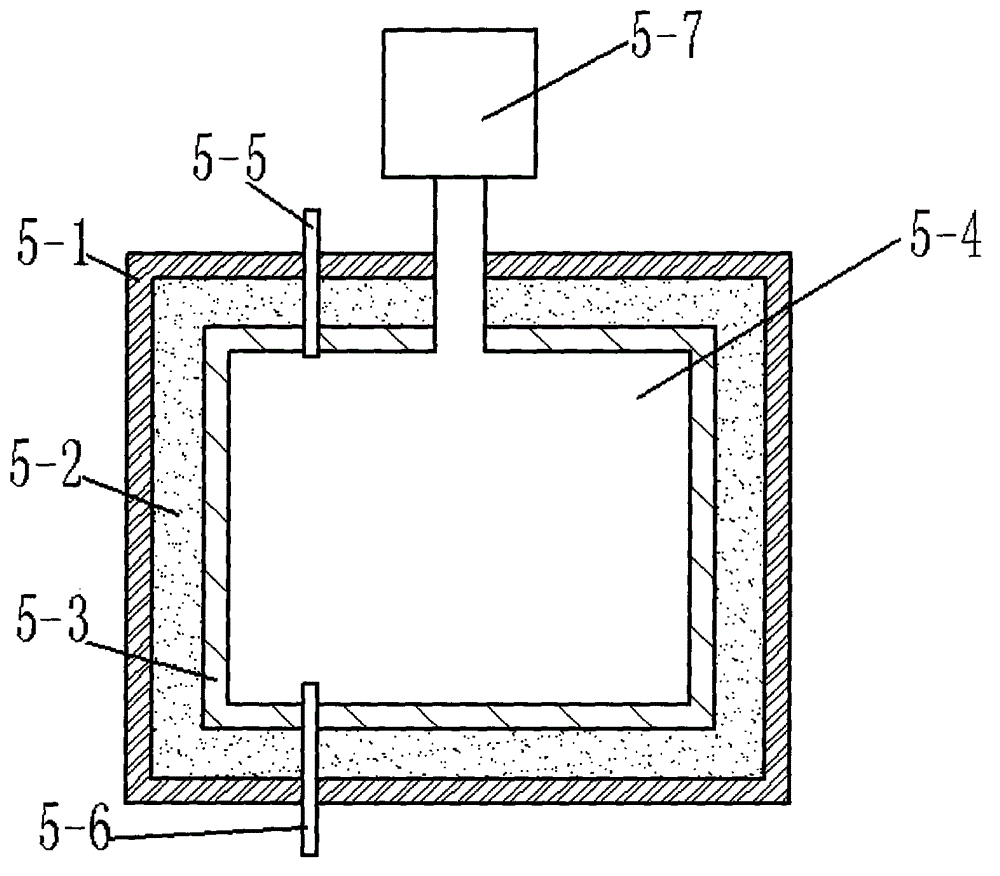

Warm-mix asphalt and production device thereof

ActiveCN105316991AEmission reductionLow costClimate change adaptationRoads maintainenceControl systemAsphalt

The invention discloses warm-mix asphalt and a production device thereof. The warm-mix asphalt is prepared from 70# matrix asphalt or SBS asphalt, a warm-mix modifier and other additives. A preparation method of the warm-mix asphalt includes the steps that the matrix asphalt is preheated, the modifier is added at the constant temperature of 140 DEG C, and the mixture is stirred at a low speed through a machine to obtain the warm-mix asphalt. The production device of the warm-mix asphalt comprises an asphalt preheating tank, a constant-temperature stirring tank, an asphalt storage tank and a motor control system, wherein the asphalt is preheated and stirred through the asphalt preheating tank and conveyed to the stirring tank at the constant temperature of 140 DEG C through a pressure system, the warm-mix modifier is added, stirring continues till the warm-mix asphalt is obtained, and finally the obtained warm-mix asphalt is conveyed to the asphalt storage tank. The warm-mix asphalt can obviously lower the emission of dust, waste and other pollutants and is low in construction temperature. The asphalt production device is simple in structure and low in cost, meets production requirements and saves energy.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Chromatic bituminous cement and preparation method thereof

InactiveCN101205373AReduce construction temperatureEasy constructionBuilding insulationsPetroleum resinRoad surface

The invention discloses a colorful asphalt binder. The component of the colorful asphalt binder of the invention calculated by weight percentage comprises that: 20 per cent-65 per cent of petroleum resin, 30 per cent -79 per cent of lubricant refined extract oil and 1 per cent -5 per cent of polyethylene wax. By pulling a little of polyethylene wax into conventional colorful asphalt binder, temperature of mixing, spreading and rolling of asphalt mixture can be greatly reduced and negative influence on final colorful asphalt pavement is not caused. As the polyethylene wax is added, a reasonably low construction temperature can be obtained, which allows an easy construction. At the same time, the lowering of construction temperature decreases correspondingly the odor emitted by the asphalt binder, which is in favor of environmental protection. Simultaneously, the adding of SBR allows the colorful asphalt binder to be provided with a better high-temperature stability.

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

Coal pitch mixture and preparation method thereof

ActiveCN102649632AImprove adhesionImprove high temperature performanceBuilding insulationsRoad surfacePetroleum

The invention discloses a coal pitch mixture, which comprises road coal pitch and mineral aggregate, wherein the weight ratio of the road coal pitch to the mineral aggregate is 6-3:94-97; the road coal pitch consists of the following components in percentage by mass: 10-80 percent of coal pitch, 15-76 percent of petroleum pitch, 3-8 percent of alkyl acid or alkyl acid salt and 2-6 percent of low molecular weight polyethylene. The invention also discloses a preparation method of the coal pitch mixture. The temperature of the coal pitch mixture is reduced by 20-30 DEG C during mixing and construction compared with hot mixed pitch mixture; the emission of pitch gas can be obviously reduced and the effect of suppressing the toxicity of the coal pitch is achieved; and thermo-oxidative aging ofthe pitch is reduced and the aims of energy conservation and emission reduction are fulfilled. The obtained coal pitch mixture is easier to compact; and indexes such as compactness, water stability, high temperature performance and low temperature performance of a paved pavement are not less than those of the hot mixed pitch mixture of the same grade.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +1

Cementing material, preparation and use thereof

The invention discloses a cementing agent, the preparation and application thereof. The cementing agent has the components with the weight percentage: 30-55% of C9 petroleum resin, 1-3% of N, N'-ethylidene bi-oleamide, 3-8% of SIS, and the rest of aromatic hydrocarbon oil. The cementing agent needs low construction temperature, and has better adhesiveness since the N, N'-ethylidene bi-oleamide is added into the cementing agent.

Owner:广州大象超薄路面技术开发有限公司

Bio-based flame-retardant modified asphalt and preparation method thereof

ActiveCN107987541AExcellent performanceReduce construction temperatureBuilding insulationsEnvironmentally friendlyPlasticizer

The invention belongs to the technical field of asphalt materials, and relates to bio-based flame-retardant modified asphalt and a preparation method thereof. The bio-based flame-retardant modified asphalt comprises 100 parts of hard asphalt, 0.5-5 parts of a warm mixing agent, 1-5 parts of a plasticizer, 1-5 parts of a stabilizer, 1-50 parts of modified plant asphalt, 1-5 parts of an antiaging agent and 1-20 parts of a microcapsule flame retardant. Compared with the prior art, the bio-based flame-retardant modified asphalt has the advantages as follows: with the hard asphalt and the bio-basedplant asphalt as raw materials, own advantages of the hard asphalt and the bio-based plant asphalt are fully combined to form a combined effect of softness and hardness; meanwhile, supplemented by additives and modifying measures for making up own defects, bio-based modified asphalt with excellent performance is finally prepared; meanwhile, through addition of the microcapsule flame retardant, the bio-based flame-retardant modified asphalt has flame-retardant and smoke-suppressing functions. In the preparation process, used materials are environmentally friendly, wastes are turned into treasures, and the obtained flame-retardant modified asphalt not only has various excellent performance, but also can achieve flame retardance and smoke suppression, and is of great advantage to reducing casualties and material loss in a fire disaster.

Owner:山西省交通科技研发有限公司

Primer applicable to security door and preparation method of primer

ActiveCN104962179AReduce construction temperatureShorten construction timeEpoxy resin coatingsEpoxyFire risk

The invention relates to a primer applicable to a security door and a preparation method of the primer. The primer is prepared from the following raw materials in percentage by weight: base stocks: 30%-50% of aqueous epoxy ester resin and 6%-10% of amino resin; aids: 3%-5% of a cosolvent, 1%-3% of a neutralizer, 10%-15% of deionized water, 0.5%-2% of a wetting dispersant, 0.1%-0.5% of a defoaming agent and 0.1%-0.3% of a base material wetting agent; pigments and fillers: 15%-25% of a red pigment free of heavy metal, 5%-10% of compound zinc phosphate, 5%-10% of compound ferrotitanium powder and 1%-5% of nanoscale precipitated barium sulphate. According to the preparation method, an aqueous coating is used as a solvent, so that the fire risk during construction is eliminated, the atmospheric pollution is alleviated, and the working environment condition is improved; a coating process of existing security doors is not changed, the workability of the product is relatively good, and the aqueous coating can be used for direct coating construction in humid environment on a wet surface and is well adaptive to the surface of the material; a coating tool can be washed by water, so that the consumption of a cleaning solvent is greatly reduced.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com