Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Anti-stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt warm-mix agent and asphalt mixture mixed by same as well as preparation methods thereof

ActiveCN101899218AWith viscosity reductionWith foamClimate change adaptationBuilding insulationsChlorideRoad surface

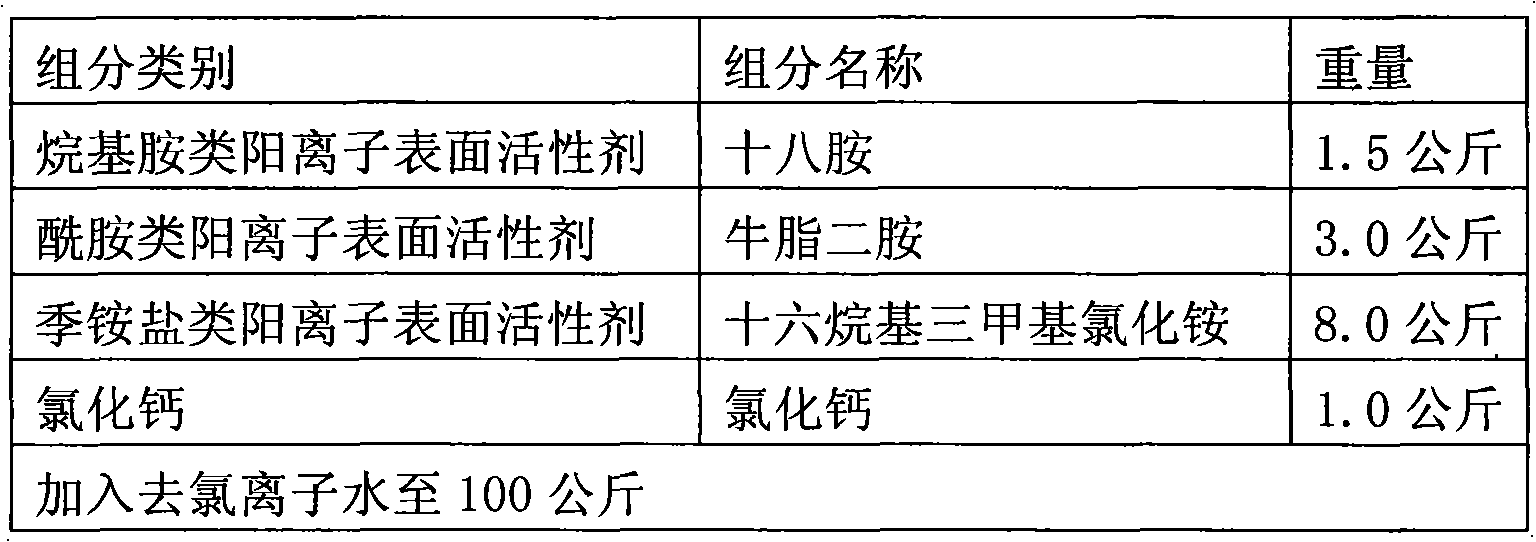

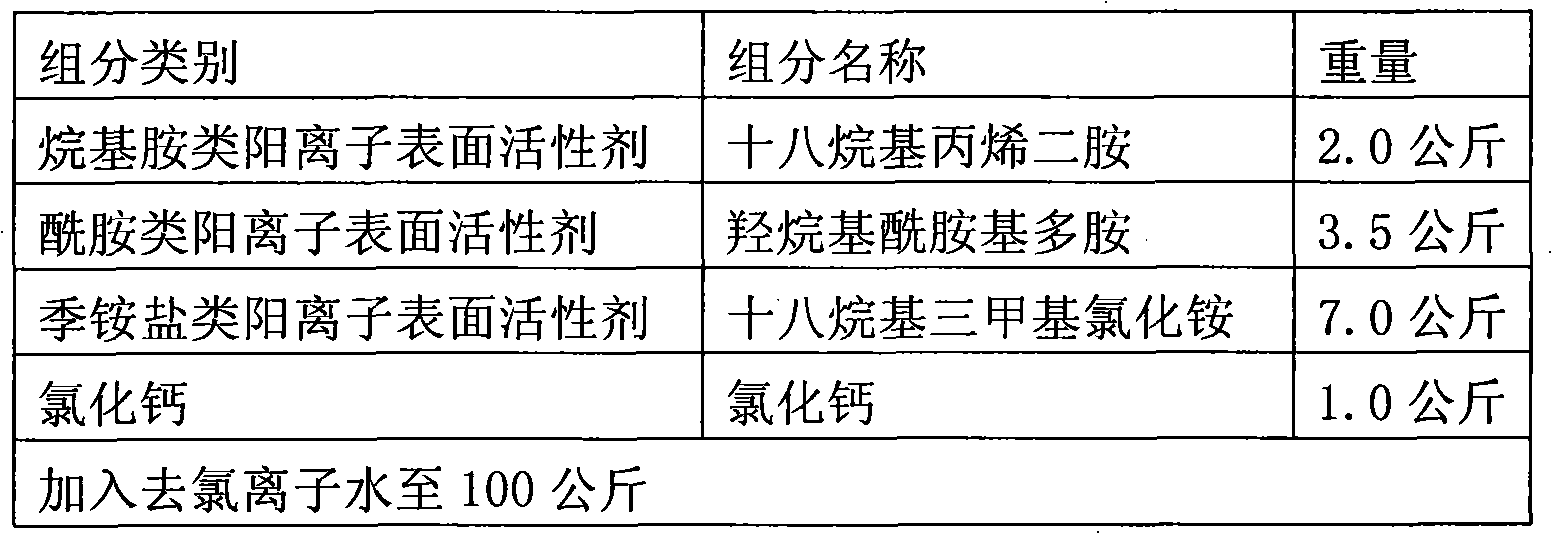

The invention relates to an asphalt warm-mix agent, comprising the following components in percentage by weight: 1.0-2.0% of alkylamine type cationic surfactant, 3.0-5.0% of amide type cationic surfactant, 5.0-10.0% of ammonium salt type cationic surfactant, 1.01.5% of calcium chloride, and water with residual percentage. The invention also relates to an asphalt mixture with the pavement applicability basically same as the traditional hot-mix asphalt mixture and the mixing and construction temperature lower than 20-50 DEG C; the purposes of energy saving, emission reduction, longer construction season, asphalt aging reduction and easier compaction are realized by reducing the mixing temperature; the indexes of the compaction degree, the water stability, the high-temperature performance, the low-temperature performance and the like of the pavement after paving the asphalt are not lower than those of hot-mix asphalt mixture at the same stage; and the service life of the asphalt pavement is efficiently guaranteed.

Owner:天津市市政工程研究院 +1

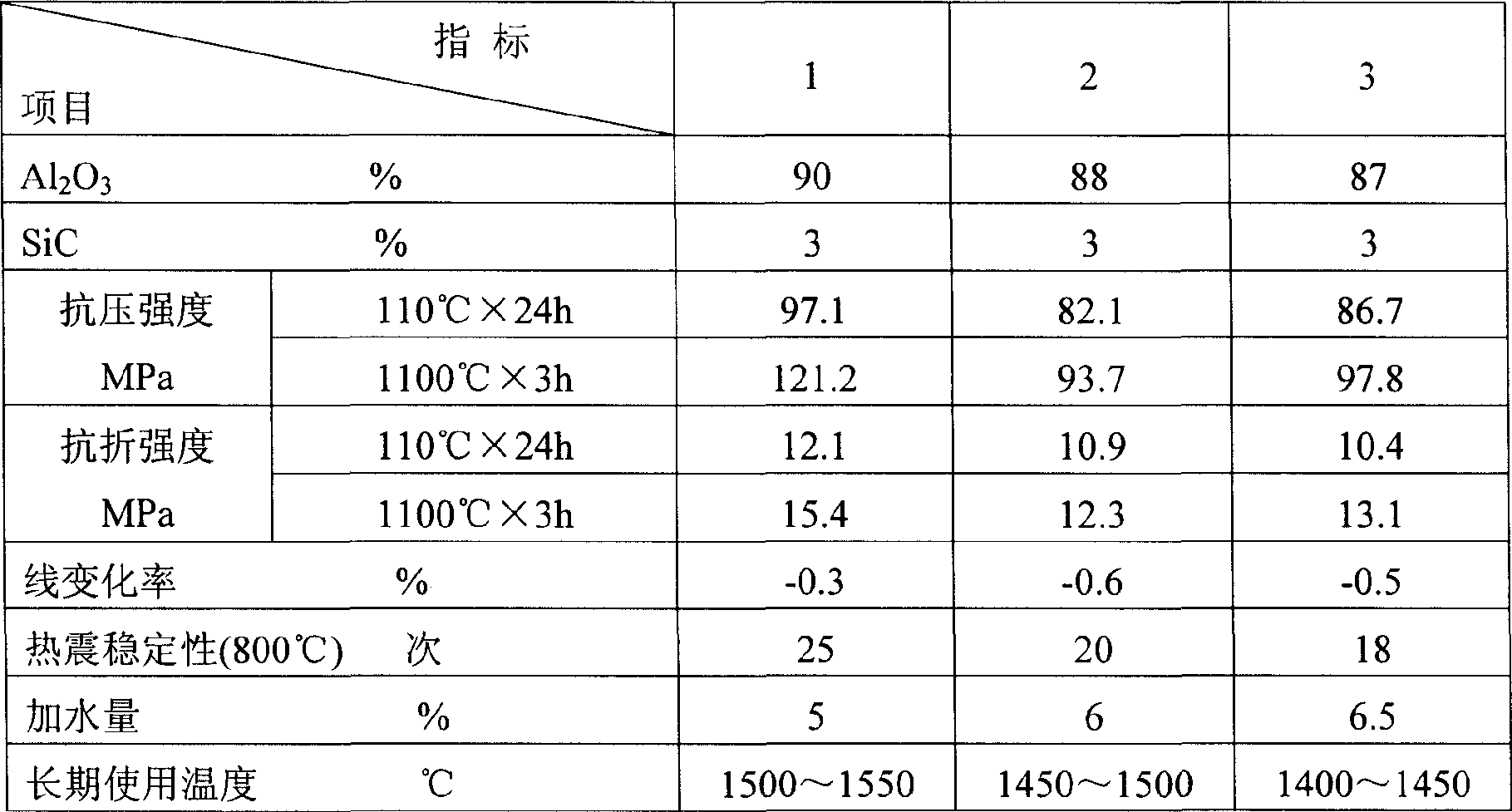

Silicon carbide corundum pouring material

The silicon carbide corundum pouring material as a kind of refractory material consists of first grade white corundum, fine corundum powder, alumina powder silica powder, fine silicon carbide powder, cement, sodium tripolyphosphate, steel fiber and RE water reducing agent in certain proportion. The poured refractory material has high strength, high fire resistance and high wear strength, and is suitable for laying various kinds of high temperature industrial furnaces and kilns.

Owner:宜兴市泰科耐火材料有限公司

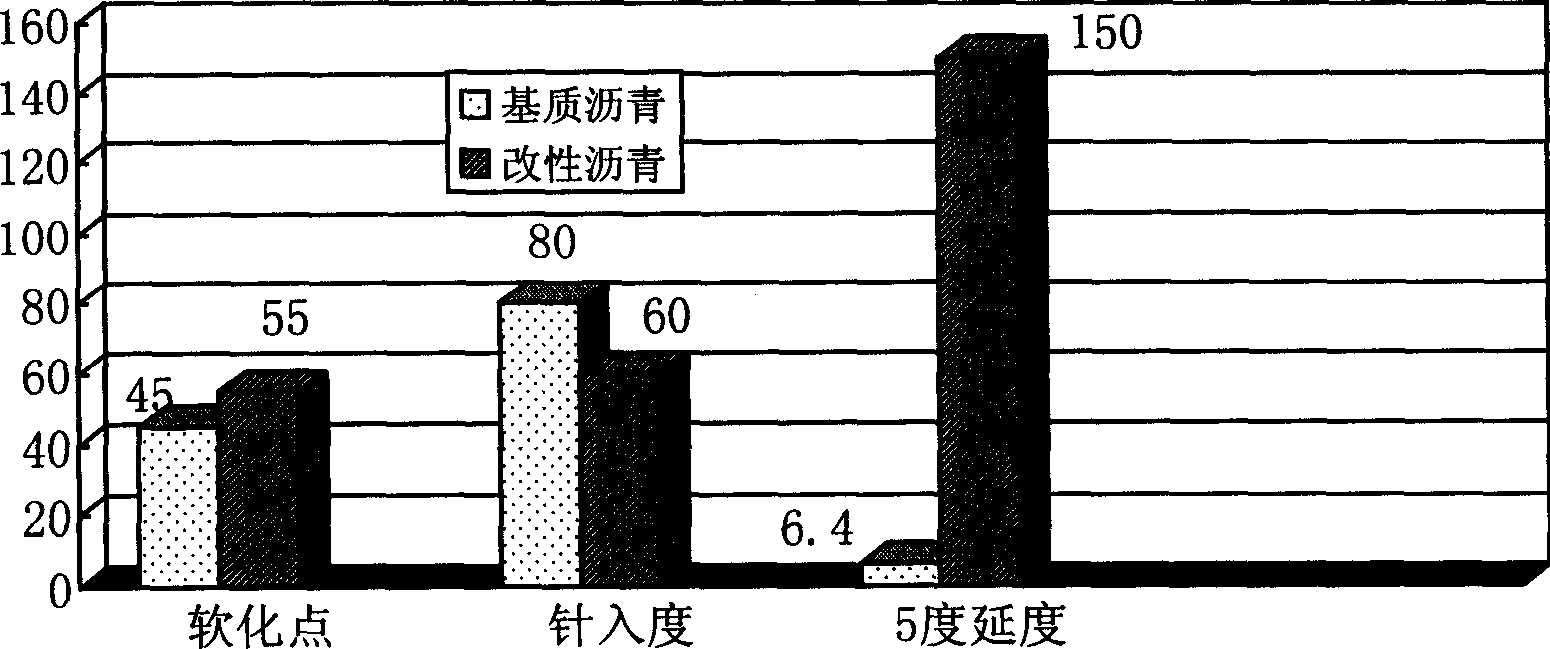

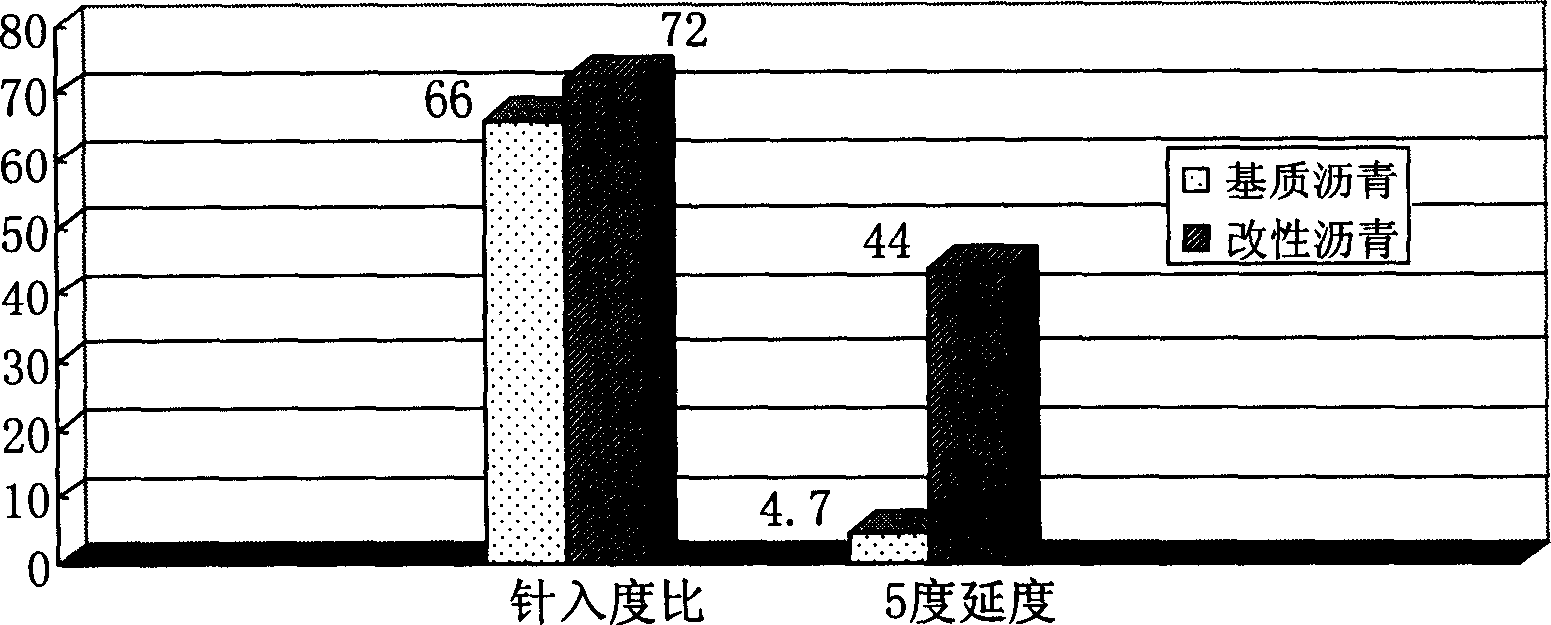

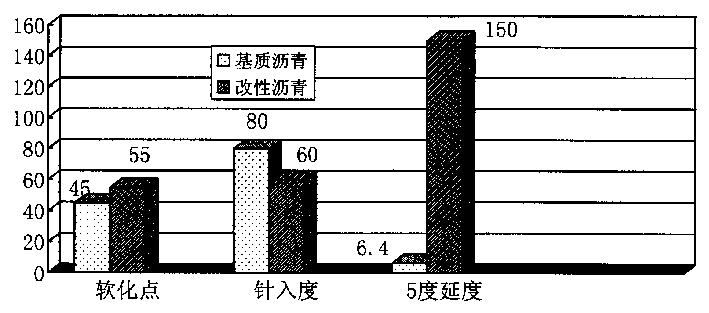

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

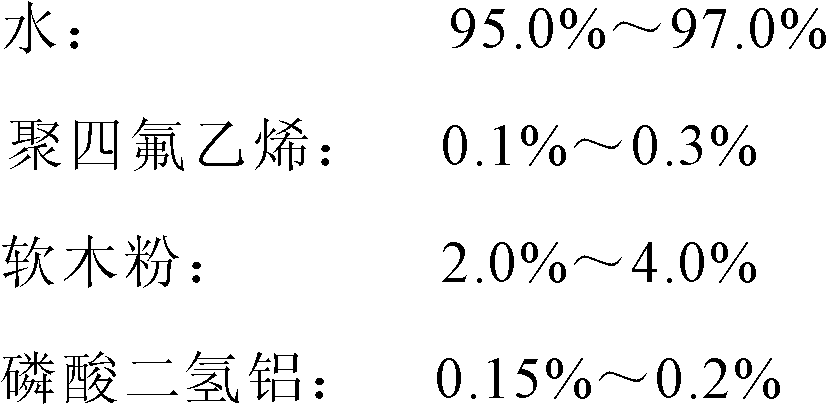

Grid mould release agent

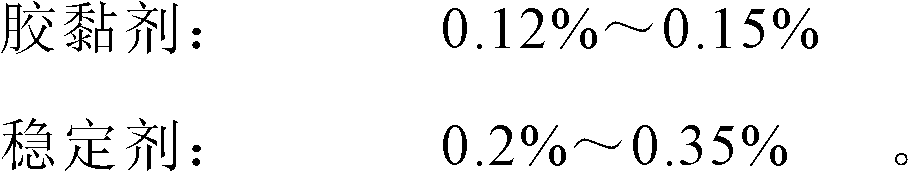

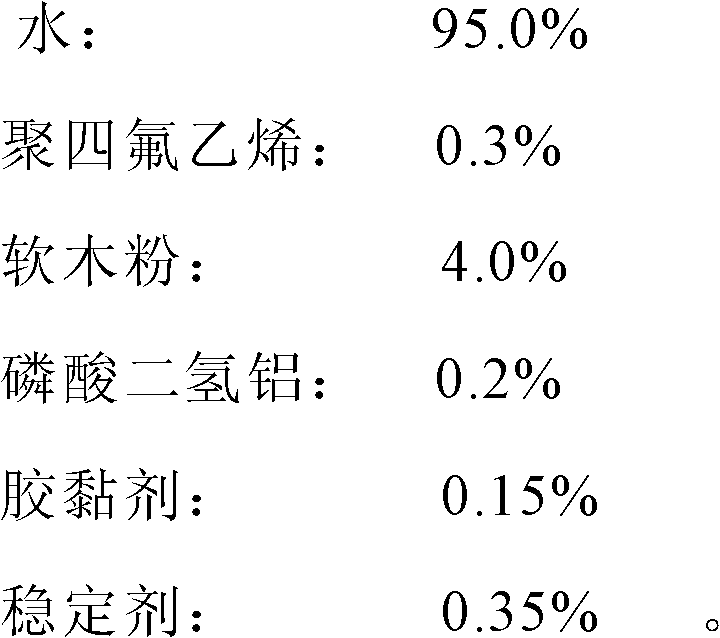

The invention discloses a grid mould release agent, which comprises the following components in percentage by mass: 95.0-97.0 percent of water, 0.1-0.3 percent of polytetrafluoroethylene, 2.0-4.0 percent of cork powder, 0.15-0.2 percent of aluminum dihydrogen phosphate, 0.12-0.15 percent of adhesive and 0.2-0.35 percent of stabilizer. The mould release agent provided by the invention has the advantages of easiness in spray coating, superior adhesion, high temperature resistance, small surface tension, high pressure resistance, smooth exhaust and the like, is extremely suitable for a lead calcium alloy grid cast through gravity at a high temperature; phenomena of blowhole, cracks and the like of the grid can be extremely effectively reduced; meanwhile, mould spray frequency in a unit time can be reduced; and the production efficiency and the product quality are improved.

Owner:CHAOWEI POWER CO LTD

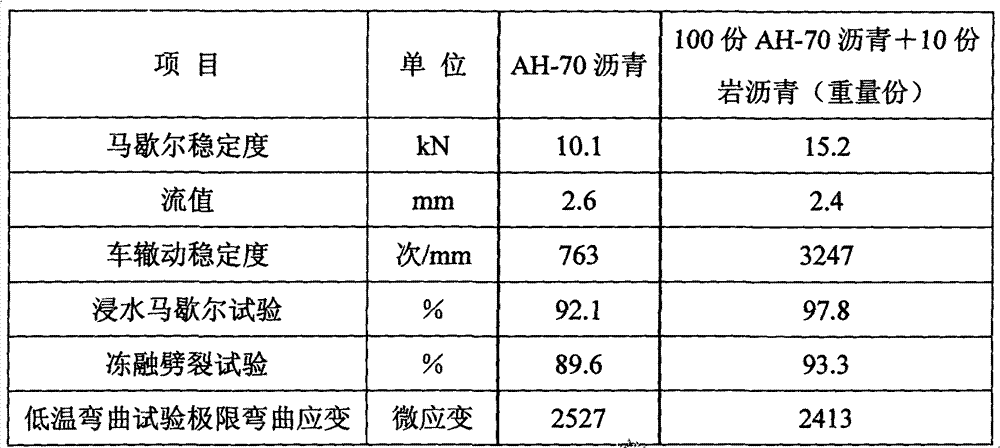

Rock asphalt modified asphalt and preparation method thereof

InactiveCN102952406ASimple production processReduce energy consumptionBuilding insulationsColloidColloid mill

The invention discloses rock asphalt modified asphalt and a preparation method thereof. The rock asphalt modified asphalt comprises 100 parts of matrix asphalt and 5-10 parts of rock asphalt. The preparation method includes: adding rock asphalt into matrix asphalt, and stirring at 150-170 DEG C for 30-60 minutes to obtain rock asphalt modified asphalt, wherein the rock asphalt is imported. Compared with the prior art, the rock asphalt modified asphalt has the advantages of stripping resistance, durability, rutting resistance at high temperature, aging resistance and the like. In addition, the rock asphalt modified asphalt is simple in production process and low in energy consumption and production cost, and needs no special equipment such as colloid mill.

Owner:SHANGHAI SENRUI ROAD ENG TECH

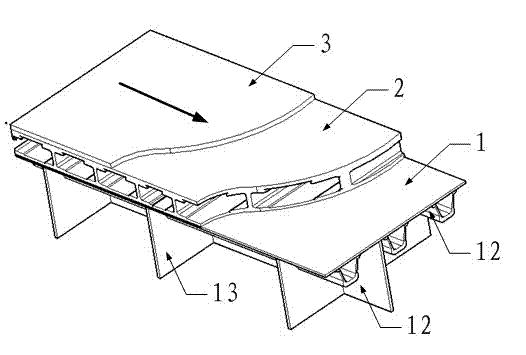

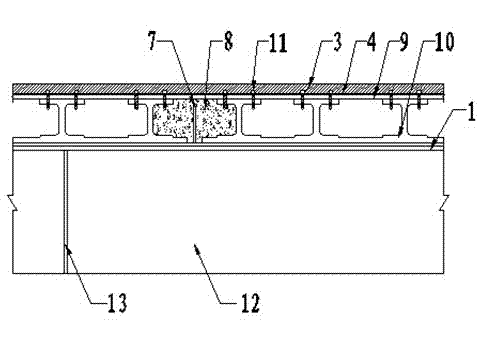

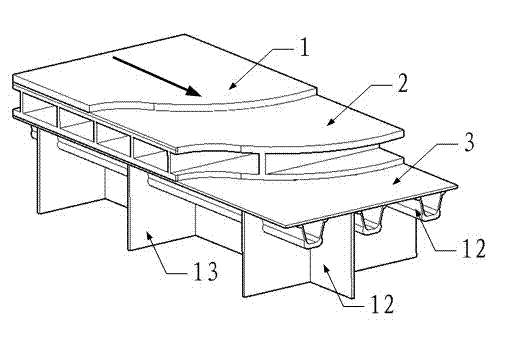

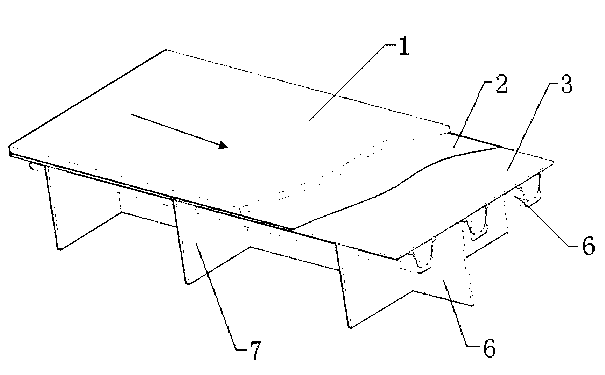

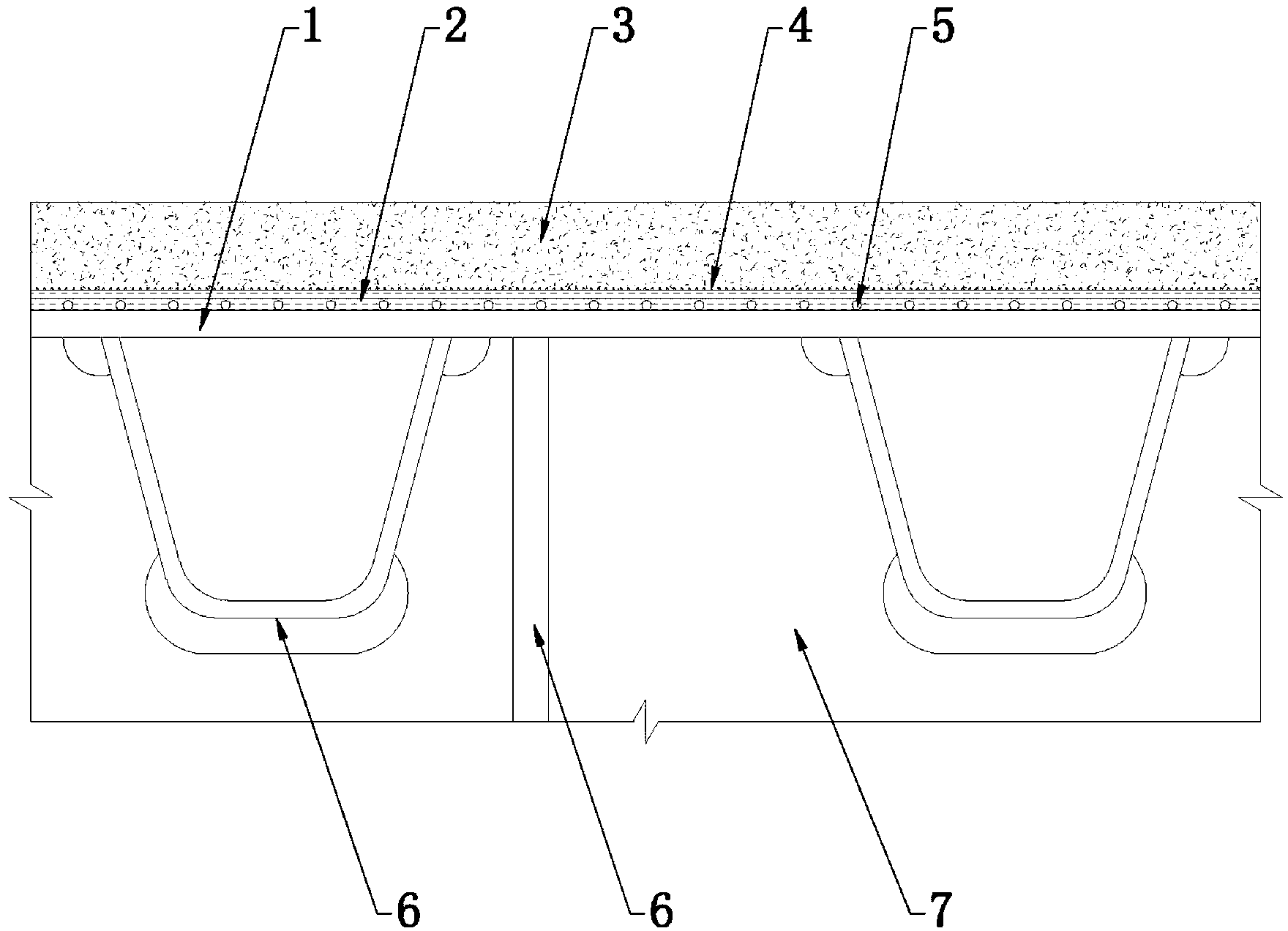

Orthotropic steel plate-composite material hollow slab combined bridge floor structure

InactiveCN103114527AReduce thicknessCorrosion resistantBridge structural detailsRough surfaceCrack resistance

The invention discloses an orthotropic steel plate-composite material hollow slab combined bridge floor structure. The bridge floor structure comprises an orthotropic steel plate, a composite material hollow slab and a wearing layer, wherein the upper side of the orthotropic steel plate is sequentially provided with the composite material hollow slab and the wearing layer; the composite material hollow slab is connected with the orthotropic steel plate on the lower side through a structural adhesive; the top of the composite material hollow slab is provided with a rough surface layer; the wearing layer is poured on the upper side of the rough surface layer; the composite material hollow slab comprises two parts, namely a top plate and a bottom plate; and the top plate and the bottom plate are connected through cement and bolts to form the composite material hollow slab. The orthotropic steel plate-composite material hollow slab combined bridge floor structure has the advantages of light weight, high strength, high rigidity, high peel strength, moisture protection, corrosion resistance, stable high-temperature stability and low-temperature crack resistance; and meanwhile, the orthotropic steel plate-composite material hollow slab combined bridge floor structure has the obvious characteristics of simple, convenient and rapid construction assembly, water resistance, pavement layer cracking resistance, orthotropic steel bridge floor surface corrosion and the like and is suitable for construction and repair of various steel bridge floor structures.

Owner:NANJING UNIV OF TECH

Preparation method of lateral insulating layer of high-gradient zinc oxide voltage-sensitive valve plate

ActiveCN103325512AReduced edge current densityAvoid punch-throughResistor manufactureHigh resistancePhosphate

The invention relates to a preparation method of a lateral insulating layer of a high-gradient zinc oxide voltage-sensitive valve plate, and belongs to the technical field of an electrical material. The method comprises the following steps: firstly, dispersing Bi2O3, Sb2O3, SiO2, Fe2O3 into mixing solution of polyvinyl alcohol water solution and ethanol to form even size; applying the obtained size at the side of a varistor valve plate billet, and firing to obtain a high-resistance layer in which Zn2SiO4 is taken as a main ingredient, Fe is dissolved and Zn7Sb2O12 is used as a secondary ingredient at the side of the zinc oxide varistor valve plate; evenly mixing the solution obtained by dissolving powder aluminium dihydrogen phosphate into normal-temperature water with SiO2 at normal temperature, and then evenly spraying the mixture at the side of the resistor plate and carrying out constant-temperature treatment, so as to obtain an inorganic glaze layer with high bonding strength; then drying the zinc oxide varistor plate, so as to obtain white and smooth lateral insulating layer at the side of the varistor plate. By adopting the preparation method, lateral insulation of a high-voltage gradient varistor plate with heavy shock current tolerance and high insulating strength can be obtained.

Owner:TSINGHUA UNIV

Hot repair mat for molten iron desulphurization

InactiveCN103183514AGood adhesion at high temperatureHigh bonding strengthThermal shockBonding strength

The invention aims to disclose a hot repair mat for molten iron desulphurization, which comprises the following components in percentage by weight: 10 to 24 percent of special-grade flint clay, 40 to 54 percent of bauxite chamotte, 5 to 10 percent of silicon carbide fine powder, 4 to 8 percent of alumina submicron powder, 5 to 10 percent of binding clay, 4 to 8 percent of expanding agent, 0.5 to 1.5 percent of additive and 10 to 15 percent of additional bonding agent. Compared with an existing product, the hot repair mat for molten iron desulphurization has the technical characteristics of good high temperature adhesivity, high bonding strength, good thermal shock resistance, antistrip performance, resistance to erosion and wear, good plasticity and the like, can meet the requirement of different molten iron desulphurization equipment on rapid hot repair, adopts easily obtained raw materials, is low in cost, has a long service life and fulfills the aim of the invention.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

New technology for preparing high-performance polyester fiber based on waste clothes

InactiveCN104452310AAnti-strippingAntistaticFibre typesMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a new technology for preparing high-performance polyester fiber based on waste clothes. The new technology comprises the following steps: firstly, classifying recovered waste clothes, and removing impurities on the clothes; crushing the waste clothes in a pulverizer; conveying the pulverized materials into a foaming machine for foaming; conveying the foamed materials into a rotary drum for mixing and stirring; drying the materials; performing color proportioning according to practical products after the drying is completed, and conveying the materials into an extruder and extruding; conveying the molten materials into a melt filter for filtering, introducing the filtered materials into a wire drawing die head, and performing wire drawing; integrating the drawn wires into wire strands, winding in a manner of small rolls, then integrating to form one strand, rolling through a gear and winding into large rolls; stretching wires on the large rolls so as to be lengthened, then destaticizing wire strands through a destaticizing device, entering a curling roll through a traction roll, and further curling; and after curling is completed, drying the wire strands, and cutting and packaging after the drying is completed.

Owner:安徽园创新材料有限公司

Magnesium-chromium composite spinelle brick

The invention discloses a magnesium-chrome composite spinel brick which is made from synthetical magnesium-chrome spinel sand, magnesia, chromium concentrate and chrome oxide according the weight percentages as follows: taking 65 percent to 70 percent of MgO, 20 percent to 25 percent of Cr2O3, 0.5 percent to 1.2 percent of SiO2, 4 percent to 6 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.5 percent to 1.2 percent of CaO to the material of the number one synthetical magnesium-chrome spinel sand; taking 55 percent to 60 percent of MgO, 30 percent to 35 percent of Cr2O3, 0.5 percent to 1.2 percent of SiO2, 4 percent to 6 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.5 percent to 1.2 percent of CaO to the material of the number two synthetical magnesium-chrome spinel sand; taking 70 percent to 75 percent of MgO, 14 percent to 19 percent of Cr2O3, 0.8 percent to 1.2 percent of SiO2, 4.5 percent to 7 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.8 percent to 1.5 percent of CaO to the material of the number three synthetical magnesium-chrome spinel sand; taking 97 percent to 98.5 percent of MgO, 0.5 percent to 1.3 percent of SiO2, 0.5 percent to 1.3 percent of CaO and 0.2 percent to 0.5 percent of Fe2O3 to the material of the magnesia; taking 50 percent to 60 percent of Cr2O3, 9 percent to 15 percent of MgO, 0.3 percent to 1.5 percent of SiO2, 15 percent to 25 percent of Fe2O3 and 8 percent to 15 percent of Al2O3 to the material of the chromium concentrate; taking 92 percent to 96 percent of Cr2O3 and 4 percent to 8 percent of ZrO to the material of the chrome oxide. The invention has the advantage of having the characteristics of compact structure, thermal shock resistance, anti-scaling off, erosion resistance etc.

Owner:ZHENGZHOU HUAWEI REFRACTORIES

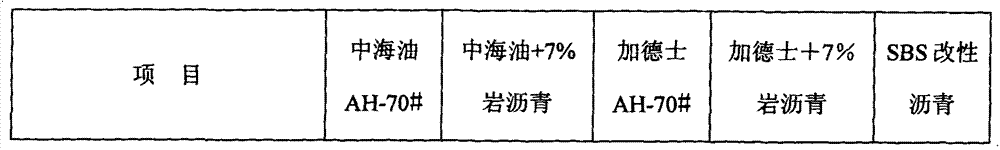

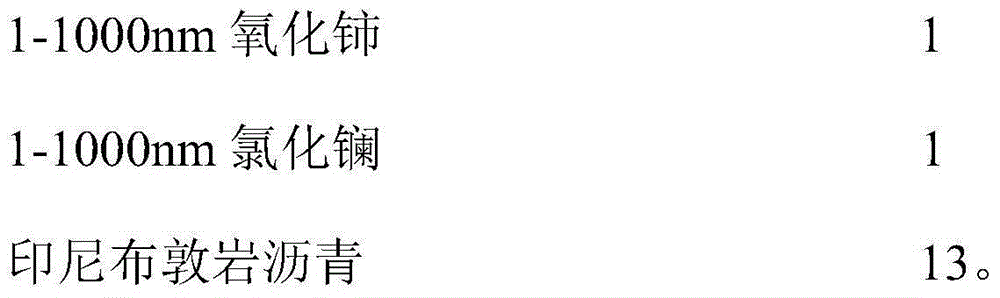

Rare-earth modified asphalt and preparation method thereof

The invention relates to rare-earth modified asphalt and a preparation method thereof. The rare-earth compound modified asphalt is prepared from, by weight, 80-95 parts of matrix asphalt, 0.1-3 parts of rare-earth compounds and 4.9-20 parts of rock asphalt. The rare-earth compound modified asphalt has the advantages of being insensitive to temperature changes, free of cracks at low temperature and long in service life, resisting to tracks at high temperature, resisting to ageing, resisting to stripping and the like, the production process is simple, energy consumption is low, and cost is low. The modified asphalt has wide application prospects in building of roads and bridges.

Owner:王新航 +1

Production technology of regenerated polyester fiber filaments

InactiveCN104975373AAnti-strippingAntistaticElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentFiltrationHigh pressure

A production technology of regenerated polyester fiber filaments comprises the following steps: 1) burdening: various waste polyester plastics are selected as main raw materials in cooperation with a nano-additive and an inorganic monomer; 2) mix-screening: different raw materials are fully mixed uniformly according to technological requirements; 3) conveying: pulse conveyance is carried out; 4) storage: raw materials are sent into an overhead bunker; 5) crystallization-drying: main raw materials undergo crystallization-drying; 6) addition of the nano-additive; 7) high-temperature melting; 8) high-pressure extrusion: melts are sent into a filter through a high-pressure screw extruder; 9) two-stage filtration; 10) uniform mixing of melts: filtered melts are further mixed uniformly; 11) high-pressure spinning: a spinning module ejects the melts; 12) cooling and oiling: the melts are gradually changed from a liquid to a solid state; 13) high-speed winding: tows ejected from the spinning step are wound into a cylinder; 14) poy filaments: wound filaments are named poy filaments; 15) tensile deformation; 16) grading; and 17) product warehousing for sale.

Owner:ANHUI DONGJIN RESOURCE REGENERATION SCI & TECH

High abrasion-proof anti-heat vibration high-alumina brick and preparation thereof

The invention discloses a high abrasion-resistance and thermal shock-resistance high alumina brick, comprising the following compositions, by weight: 5 to 15 parts of 3 to 5mm special grade bauxite aggregate, 30 to 40 parts of 1 to 3mm special grade bauxite aggregate, 10 to 20 parts of 0 to 1mm special grade bauxite aggregate, 20 to 30 parts of special grade bauxite fine powder, 5 to 7 parts of zircon sand fine powder, 1 to 3 parts of Suzhou No.2 mud, 8 to 10 parts of complex binding agent and 4 to 6 parts of water. The invention also discloses a manufacturing method of the high abrasion-resistance and thermal shock-resistance high alumina brick. The high abrasion-resistance and thermal shock-resistance high alumina brick has properties of high intensity, refractoriness and high abrasion-resistance and thermal shock resistance. The high alumina brick and the manufacturing method are applied to circulating fluidized bed boiler cyclone separator flues, cyclone separator straight sections and cones, return feeders, metallurgical industrial furnaces and other heat equipment, and have advantages of simple manufacturing process and easy realization.

Owner:江苏耐基炉衬有限公司

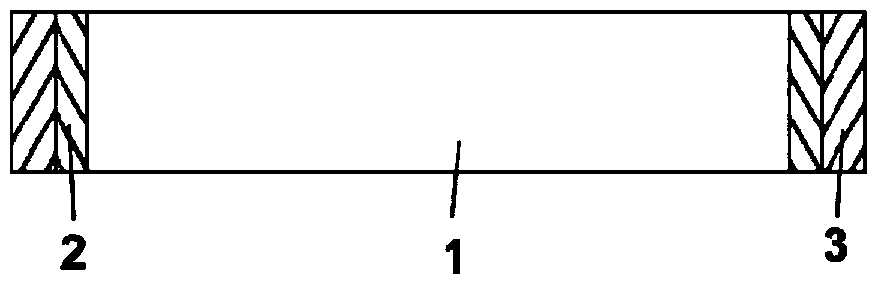

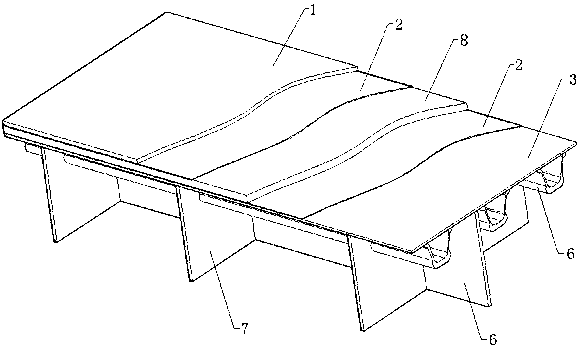

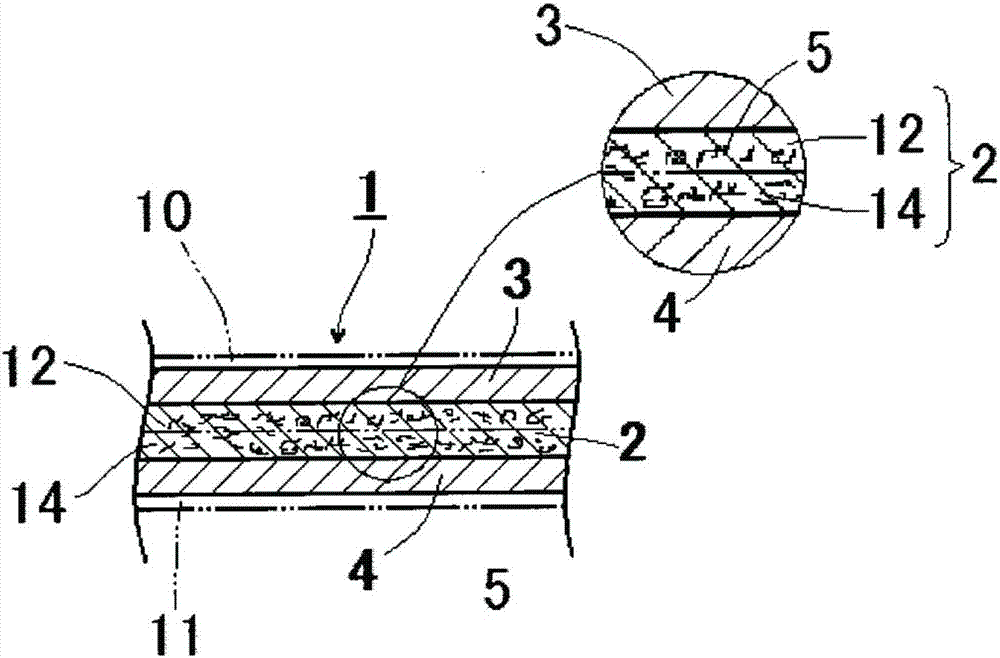

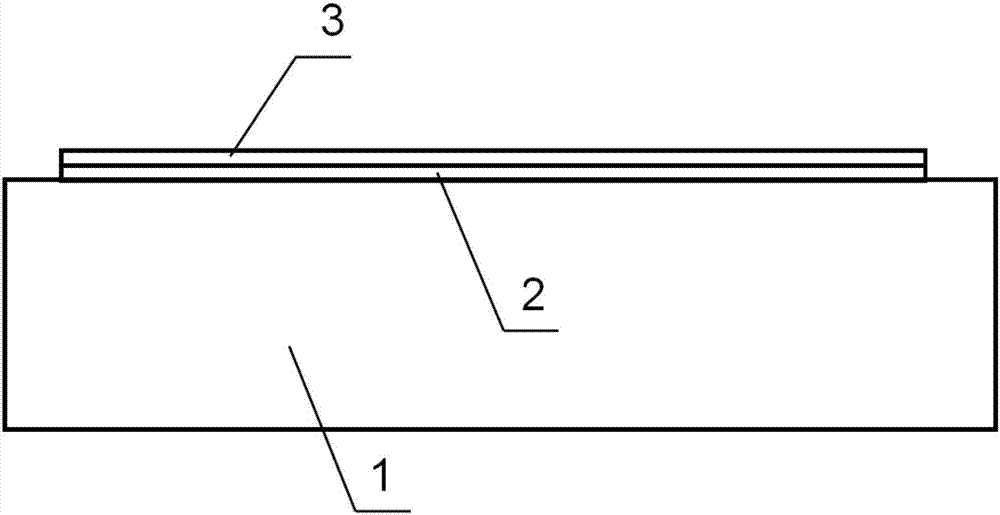

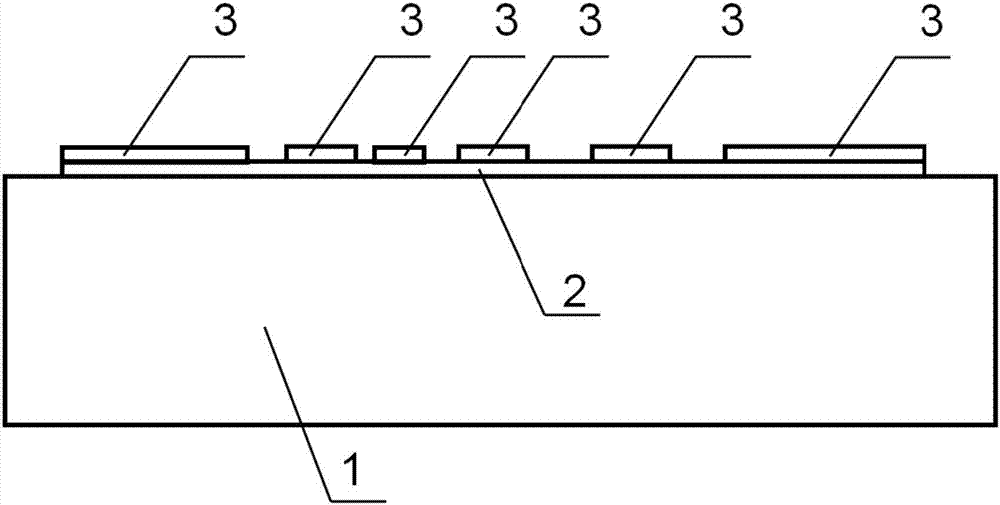

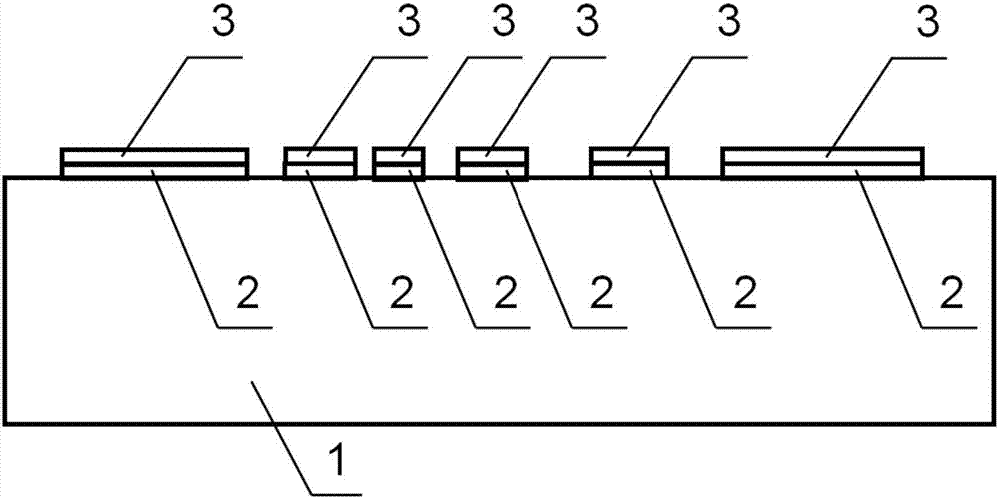

Factory-made orthotropic steel plate and composite combined deck structure

InactiveCN103015317AReduce thicknessCorrosion resistantBridge structural detailsRough surfaceSheet steel

The invention discloses a factory-made orthotropic steel plate and composite combined deck structure. The deck structure comprises an orthotropic steel plate (1), a composite layer (2) and a wearing layer (3), wherein the upper side of the orthotropic steel plate (1) is provided with the composite layer (2) and the wearing layer (3) in sequence; the composite layer (2) is mutually connected with the orthotropic steel plate (1) below the lower side of the composite layer (2) through resin; the top face of the composite layer (2) is provided with a rough surface layer (4); and the wearing layer (3) is cast at the upper side of the rough surface layer (4). Through additionally installing the composite layer between the orthotropic steel plate and the wearing layer, the deck structure disclosed by the invention is light in weight, high in strength, high in rigidity, good in peeling resistance, moisture resistance and corrosion resistance and high in high-temperature stability and low-temperature anti-cracking performance and has the outstanding features that assembly construction is simple and rapid; water is resisted; a pavement layer is prevented from being cracked; and the orthotropic steel deck structure is prevented from being corroded. The factory-made orthotropic steel plate and composite combined deck structure is suitable for building and repairing various steel deck structures.

Owner:NANJING UNIV OF TECH

Preparation method for periclase composite spinel brick used for cement kiln clinkering zone

The invention discloses a preparation method for a periclase composite spinel brick used for a cement kiln clinkering zone. The method comprises the following steps: firstly, preparing a magnesium sand granule material, a ferric oxide powder and an alumina powder; and synthetizing into hercynite granule material and pleonaste granule material at a certain ratio; weighing the above materials as follows: 6-15 parts of synthetized hercynite granule material, 40-55 parts of synthetized pleonaste granule material, 35-45 parts of magnesium sand granule material, 1-3 parts of ferric oxide powder and 1-2 parts of alumina powder; adding 2-5 parts of magnesium chloride solution or sulphurous acid paper pulp solution in the above materials for milling; then pressing the mixture in a press to obtain a green brick; and after drying, sintering and forming. The preparation method has the advantages that the sintered finished brick has the characteristics of compact tissue structure, high strength, excellent alkali corrosion resistance and thermal shock stability, good spalling resistance and is an ideal product for a large cement kiln clinkering zone and kiln coating is easy to hung. The product fills up the national blank, reaches the international leading level and can replace the same type of imported products.

Owner:ZHENGZHOU HUAWEI REFRACTORIES

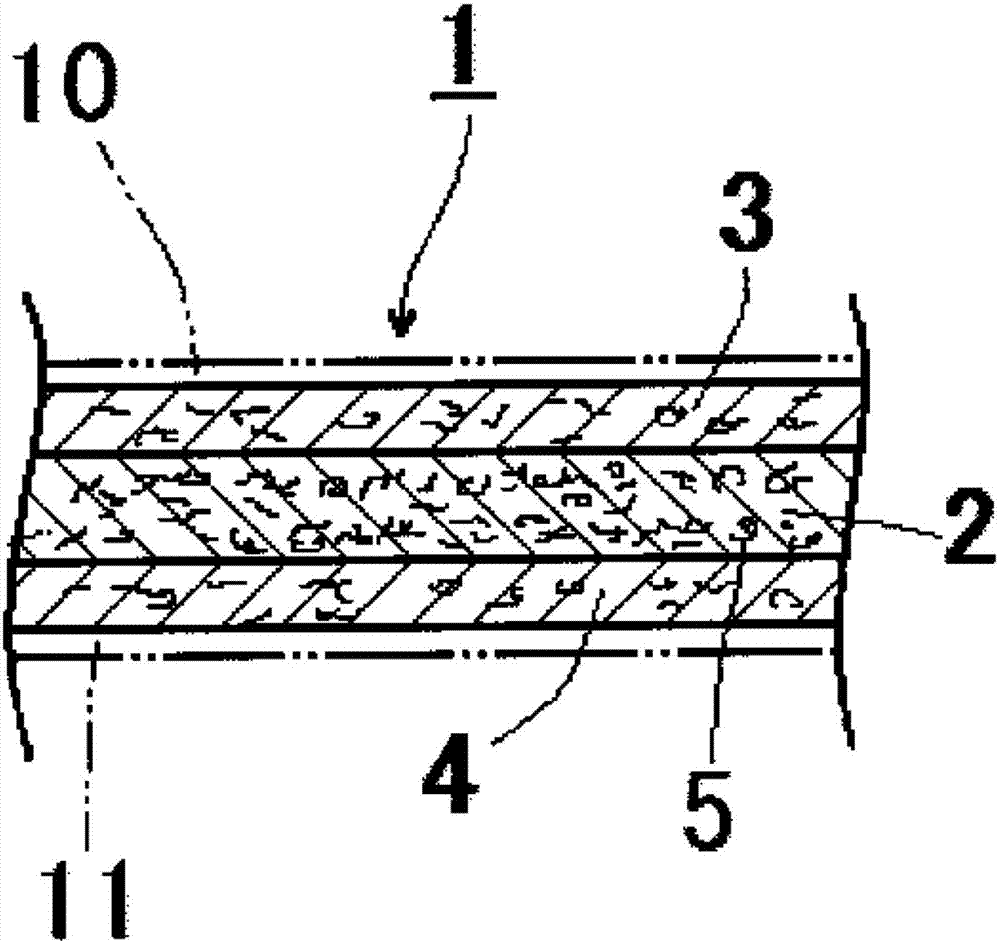

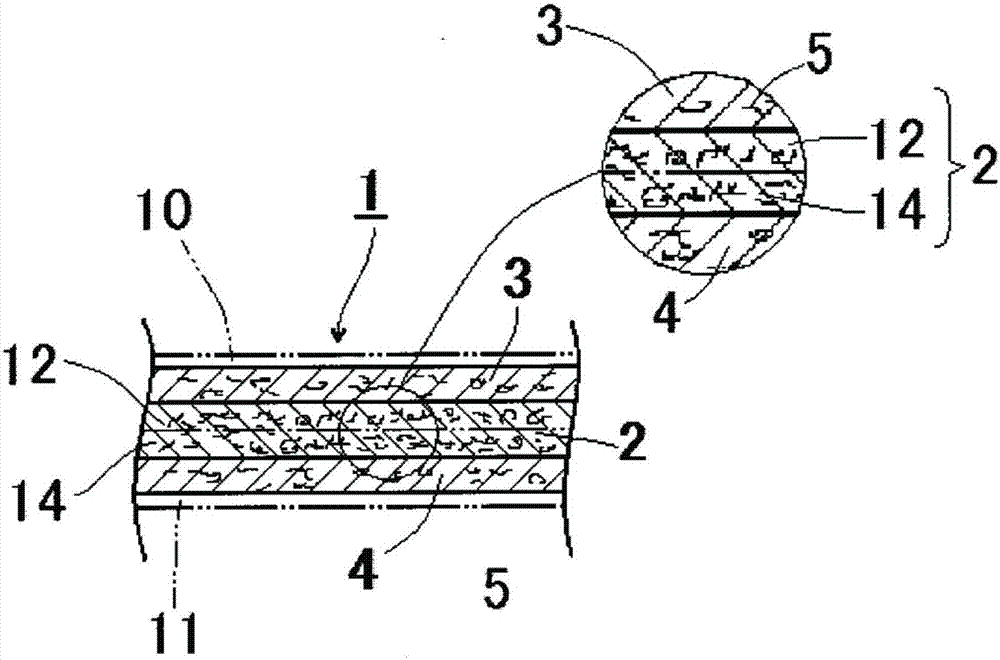

Baseless double-sided adhesive sheet or tape, and method for manufacturing the same

ActiveCN107418458AHigh fiber densityAnti-strippingLayered product treatmentPolyureas/polyurethane adhesivesAdhesiveEngineering

The invention provides a baseless double-sided adhesive sheet or tape configured to prevent seepage of an adhesive during a storage period or during cutting into a predetermined dimension, represent an expected performance of anti-peeling cohesion, and avoids sacrifice of an initial bonding intensity, and a method for manufacturing the same. In the baseless double-sided adhesive sheet or tape, an adhesive layer formed from an adhesive serves as a center layer, and adhesive layers and formed from an adhesive are layered onto a front face and a rear face of the adhesive layer serving as the center layer. Fibers are least dispersed in the adhesive layer serving as the center layer, and the adhesive layer serving as the center layer between the adjacent adhesive layers has a relatively high fiber density and relatively low flowability.

Owner:KYODO GIKEN CHEM

High-abrasion high-alumina brick with heat shock resistance and manufacturing method thereof

InactiveCN104030707AImprove erosion resistanceImprove thermal shock resistanceCycloneChromium carbide

The invention discloses a high-abrasion high-alumina brick with heat shock resistance. The high-abrasion high-alumina brick comprises the following components in parts by weight: 5-15 parts of 3-5mm super alum aggregate, 30-40 parts of 1-3mm super alum aggregate, 10-20 parts of 0-1mm super alum aggregate, 20-30 parts of super alum powder, 5-7 parts of zirconium carbide fine powder, 2 parts of chromium carbide powder, 1-3 parts of Suzhou mud NO.2, 8-10 parts of compound binder and 4-6 parts of water. The invention also discloses a manufacturing method of the high-abrasion high-alumina brick with heat shock resistance. The high-abrasion high-alumina brick with heat shock resistance disclosed by the invention has high strength, refractoriness, high abrasion and heat shock resistance, and is applicable to a circulating fluid bed boiler cyclone separator flue, cyclone separator straight section and cone body, a return feeder, a metallurgical furnace and other thermal equipment. The high-abrasion high-alumina brick is simple in manufacturing process and easy to realize.

Owner:张婷

Solid-color quick-drying water-based nail polish

InactiveCN104352360AAnti-strippingLarge particle sizeCosmetic preparationsToilet preparationsWater basedMixing ratio

The invention relates to solid-color quick-drying water-based nail polish. The solid-color quick-drying water-based nail polish is characterized by comprising the following components: a pigment and filler, water-based emulsion, a film-forming auxiliary agent and a functional auxiliary agent, wherein the pigment and filler is one or a mixture of titanium dioxide, kaolin and a colorant paste; the water-based emulsion is water-based polyurethane emulsion; the film-forming auxiliary agent is one or a mixture of DPM, DPnB and medical alcohol; the functional auxiliary agent is a mixture of a wetting agent, a defoamer, a dispersant and an anti-settling directional agent in a mixing ratio of (0.1-0.2)% : (0.1-0.3)% : (0.2-0.4)% : (0-1.5)%. A preparation method of the solid-color quick-drying water-based nail polish is characterized by comprising the following steps: sufficiently and uniformly dispersing the pigment and filler, the water-based emulsion, the film-forming auxiliary agent and the functional auxiliary agent till the fineness of the mixture is smaller than 15 microns, and packaging to obtain a finished product. The solid-color quick-drying water-based nail polish has the advantages as follows: the solid-color quick-drying water-based nail polish has good wear resistance, water resistance, fullness and peeling resistance and excellent drying speed; the solid-color quick-drying water-based nail polish is simple in nail beautifying process, can be dried within 5 minutes at room temperature or dried within one minute by a dryer, and is simple and safe to use; the solid-color quick-drying water-based nail polish can be widely applied to nail beautification.

Owner:上海展辰涂料有限公司 +4

Casting-molded square crucible and preparation method therefor

The invention relates to the technical field of refractory products and particularly relates to a casting-molded square crucible and a preparation method therefor. The square crucible is prepared fromthe following raw materials in parts by weight: 10-30 parts of powdered alumina, 5-20 parts of corundum powder, 15-20 parts of 3mm-1mm slabby corundum, 10-20 parts of corundum granules with the particle size of 20 meshes, 5-20 parts of corundum granules with the particle size of 36 meshes, 10-10 parts of corundum granules with the particle size of 80 meshes, 10-20 parts of electrofused mullite with the particle size of 180 meshes and 5-10 parts of dispersant. The method comprises the steps of iron removal, stirring, casting, demolding, baking and firing. The square crucible disclosed by the invention has the characteristics of high-temperature resistance, high strength, stripping resistance, erosion resistance and good thermal shock resistance; and the preparation method has the characteristics that the operation is simple, a large-sized molding press is not required, and the investment is small.

Owner:山东铭特陶瓷材料有限公司

Anti-seepage coated fabric manufacturing method

ActiveCN106120359AStrong tensile breaking strengthHigh tear strengthWoven fabricsCoatingsPolyesterGram

The invention relates to an anti-seepage coated fabric manufacturing method which includes the steps of base fabric weaving, coating agent preparation, primary coating, secondary coating, plasticizing or plasticizing and surface treatment. High-strength polyester fibers with the fineness of 1000-1500D are used as raw materials and woven into a polyester base fabric by a Panama weaving method, the gram weight of each inch (14-20)*(14-20) is 244-540g / m<2>, the coated amount of front coating is 480-700g / m<2>, and the coated amount of back coating is 220-380g / m<2>. The thickness of a manufactured product is far larger than that of a conventional product, various physical and mechanical performances can still be ensured, surfaces are compact and even, defects are fewer, and the product has the advantages of seepage resistance, mildew prevention, bacterial inhibition, environmental protection, aging resistance, stripping resistance and the like. The grade of the product is higher than that of a common waterproof fabric for an awning, and the product can be applied to waterproof engineering of drinking water containers, small swimming pools, tunnels, dams, roofs and the like, and accordingly has high market and vitality.

Owner:HAININ JINDA COATING

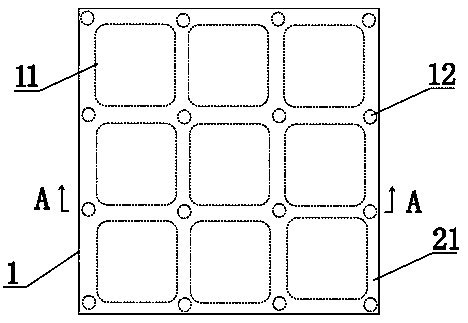

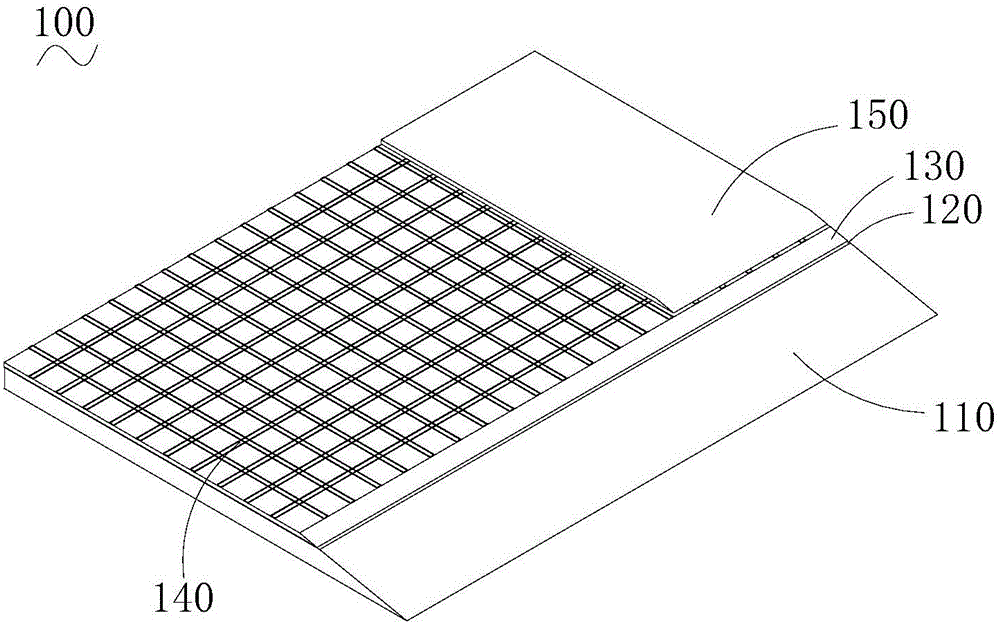

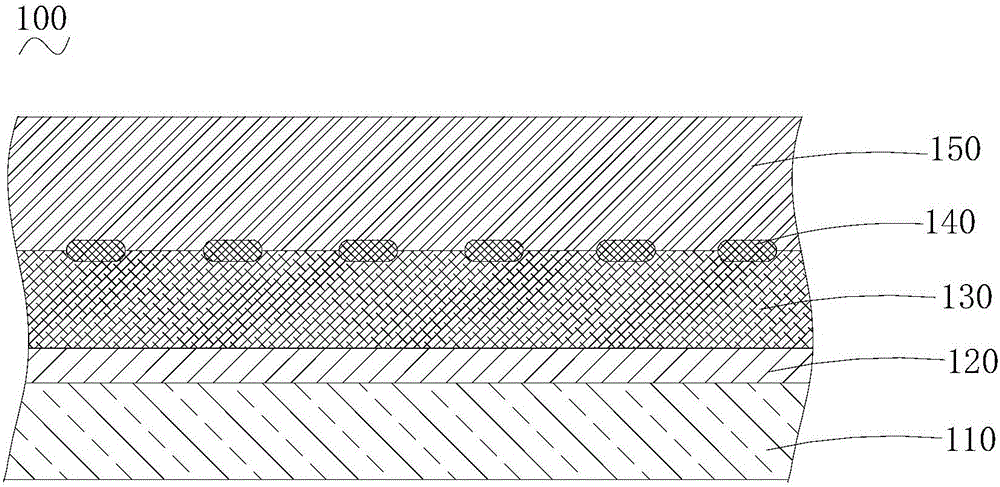

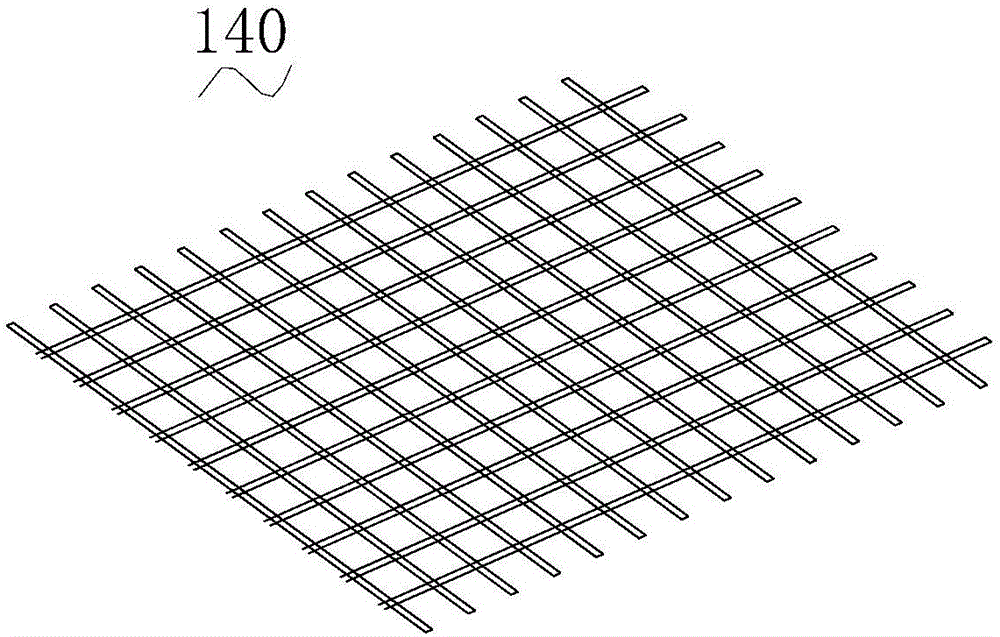

Interlayer type composite material wallboard

InactiveCN103866899AReduce weightHigh strengthConstruction materialSynthetic resin layered productsFiberUltimate tensile strength

The invention discloses an interlayer type composite material wallboard. The wallboard comprises an interlayer layer and surface boards, the upper surface and the lower surface of the interlayer layer are both provided with latticed recessed grooves, through holes are arranged in the joint parts of the grooves in the thickness direction of the interlayer layer, resin is filled in the through holes so as to form resin columns; the upper surface and the lower surface of the interlayer layer are both covered by a surface board, each surface board is prepared by curing resin on a fiber cloth layer, and the outer surfaces of the surface boards are both provided with a functional coating. The interlayer type composite material wallboard has the characteristics of light weight, high strength, damp resistance, corrosion resistance, peeling resistance, heat insulation, and energy saving, can be used to outer walls, inner wall wallboard, and baffle plate of concrete frame structure composed of steel and wood, can even be applied to bearing walls, and is capable of enhancing the anti-seismic performance of buildings.

Owner:甘婷婷

Novel process for efficient, energy-saving and green preparation of distinctive fibers by waste old clothes

The invention provides a novel process for efficient, energy-saving and green preparation of distinctive fibers by waste old clothes. The novel process comprises the following steps: classifying the waste clothes; cutting off buttons and zippers and putting the waste clothes into an impregnation solution; impregnating for 3-6 hours; fishing out the clothes and draining for later use; crushing the drained clothes into block-shaped or strip-shaped crushed cloth; conveying the crushed cloth into drying equipment and braking at a low temperature for 2-3 hours; taking out the baked crushed cloth and cooling to a room temperature; conveying the crushed cloth into low-temperature freezing equipment and freezing for 2-3 times, wherein the freezing time of each time is 1-3 hours and the freezing temperature ranges from -5 DEG C to 0 DEG C; putting the frozen crushed cloth into a self-made solution and impregnating for 12-24 hours; fishing out and draining; airing under a natural environment; crushing the treated crushed cloth to form bubble-buddle materials; conveying the bubble-buddle materials into a smelting furnace to be smelted to obtain granulated semi-finished-product raw materials; conveying the granulated semi-finished-product raw materials into a granulating machine to be granulated to obtain grain-shaped fiber materials; and smelting the grain-shaped fiber materials into a macromolecular solution according to preparation requirements of a down-stream product, and drawing to obtain the distinctive fibers.

Owner:安徽园创新材料有限公司

Preparation method of anti-erosion silicon brick

The invention belongs to the technical field of refractory materials, and specifically relates to a preparation method of an anti-erosion silicon brick. According to the preparation method, dry raw materials are prepared and stirred according to a formula, and water is added for stirring, wherein the raw materials comprise high-alumina bauxite clinker, silicon oxide micropowder, silicon carbide powder, andalusite powder, nano-sized metal aluminum powder and a binder; the mixed materials after trapping are pressed into a brick blank by a high pressure press; and the dried brick blank is sent toa tunnel kiln for firing. The preparation method of the anti-erosion silicon brick has the characteristics of abrasion resistance, flaking resistance, strong acid and alkali resistance and excellentthermal stability, is small in thermal conductivity and light bulk density, and can reduce the temperature outside a cylinder; and the preparation method of the silicon brick is scientific and simple,free of pollution in the implementation process and suitable for industrial promotion.

Owner:无锡远能耐火材料有限公司

Method for improving oxidation ablation resistant performance of material based on surface micro-structure modifying

ActiveCN106884165AEffectively Contains AblationAvoid churnMetallic material coating processesMicro structureAluminium

The invention discloses a method for improving oxidation ablation resistant performance of a material based on surface micro-structure modifying. The surface of the matrix material is coated with aluminium dihydrogen phosphate, and then the specific surface micro-structure morphology is formed. The aluminium dihydrogen phosphate structure has strong adhesivity with the matrix material and has the characteristics of high temperature resistance, vibration resistance, peeling resistance, high-temperature air flow scour resistance and the like. Flowing of liquid reactants on the surface can be obstructed effectively under high-temperature and high-speed air flows, and accordingly the oxidation ablation resistant performance of a matrix is improved.

Owner:TSINGHUA UNIV

Building strengthening structure and building strengthening method

The invention relates to the field of construction, and specifically discloses a building reinforcement structure, which comprises: a building base; an interface agent layer, which is covered on the surface of the building base; and a first polymer mortar layer, which is covered on the interface agent layer; A composite grid, partially embedded in the first polymer mortar layer; and a second polymer mortar layer, overlying the first polymer mortar layer and the composite grid; the composite grid includes a fiber grid skeleton and attached to it glue layer. The reinforcement structure of the building adopts the method of sandwiching fiber grids between two layers of polymer mortar, and the thickness of the repair layer is small, which improves the utilization rate of structural space; and can also significantly enhance the reinforcement strength. In addition, the composite grille is used to make the fiber grille and the polymer mortar layer have greater adhesion, forming a good synergistic effect; improving the binding force of the fiber grille and the main material, further improving the building reinforcement structure. Reinforced performance. The invention also discloses a building reinforcement method.

Owner:ZHANGJIAGANG YINGHUA MATERIAL TECH CO LTD

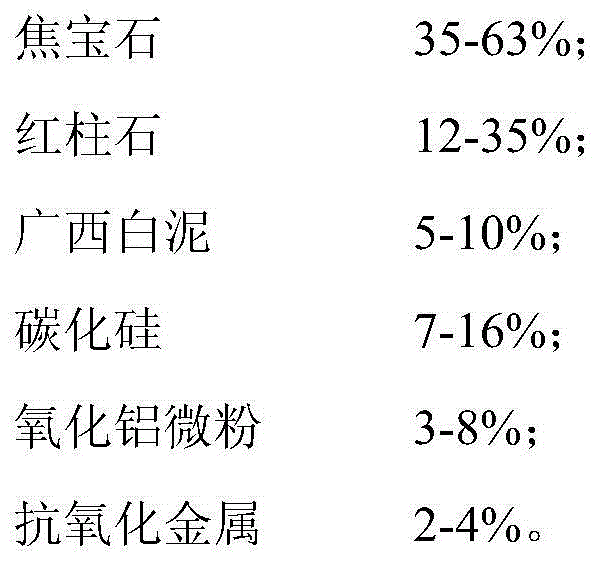

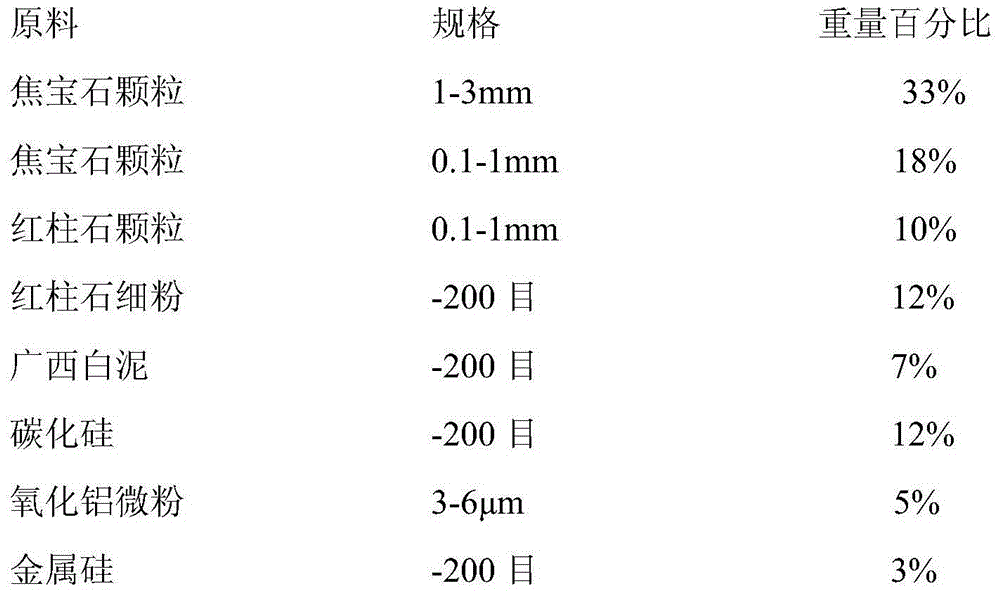

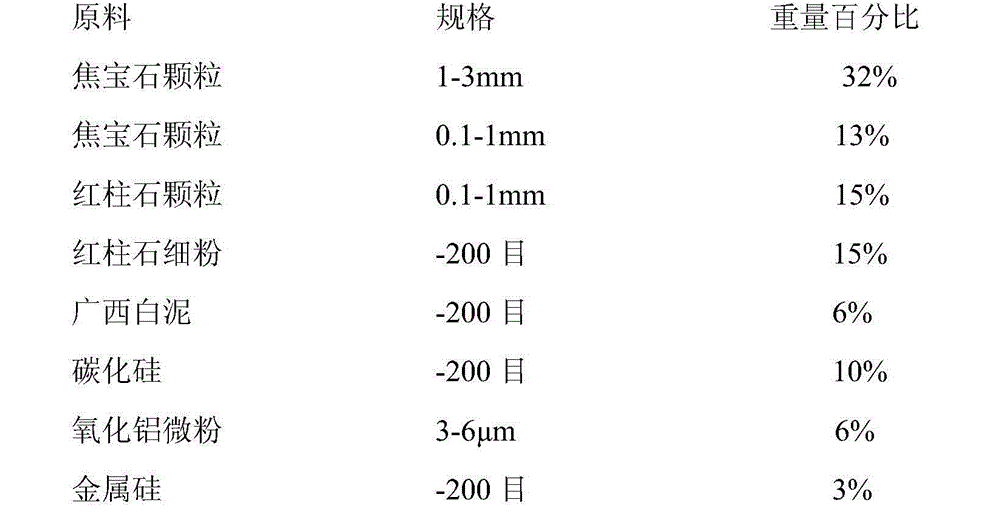

Refractory material used for ladle and preparation method of refractory material

The invention belongs to the technical field of refractory materials, and particularly relates to a refractory material used for a ladle and a preparation method of the refractory material. The refractory material is prepared from the following materials in percentage by weight: 35-63% of flint clay, 12-35% of andalusite, 5-10% of Guangxi white mud, 7-16% of silicon carbide, 3-8% of alumina micro powder and 2-4% of anti-oxidant metal. The refractory material has the characteristics of good size stability, peelingresistance, anti-corrosion, no adhering slag and good thermal insulation. The preparation method is simple in process and easy to conduct.

Owner:山东硒拓新材料科技有限公司

Vertical wedge-shaped refractory brick for rotary limestone kiln

A vertical wedge-shaped refractory brick for a rotary limestone kiln consists of a port wedge-shaped brick body of a wedge-shaped structure, kiln body wedge-shaped brick bodies and a tail end wedge-shaped brick body and is characterized in that the port wedge-shaped brick body consists of a wedge point and a wedge bottom, one side of the port wedge-shaped brick body is a wedge-shaped end face, and steps matched with the kiln body wedge-shaped brick bodies are arranged on one side of the wedge point and the wedge bottom; each kiln body wedge-shaped brick body consists of a wedge point building block and a wedge bottom building block which form an integrated structure, and the ends of the wedge point building block and the wedge bottom building block are respectively provided with steps matched with the port wedge-shaped brick body, another kiln body wedge-shaped brick body or the tail end wedge-shaped brick body; the tail end wedge-shaped brick body consists of a wedge point stopper block and a wedge bottom stopper block, one side of the tail end wedge-shaped brick body is a wedge-shaped tail face, and steps matched with the kiln body wedge-shaped brick bodies are arranged on one side of the wedge point stopper block and the wedge bottom stopper block. The vertical wedge-shaped refractory brick has the advantages of being convenient to lay, high in construction speed and flat in butt joint face.

Owner:刘伟

High-alumina brick and manufacturing method thereof

InactiveCN104003743AGood wear resistance and thermal shock resistanceImproved erosion and thermal shock resistanceFlueStraight segment

The invention discloses a high-alumina brick. The high-alumina brick comprises, by weight, 5-15 parts of 3 mm-5 mm super alumina aggregate, 30-40 parts of 1 mm-3 mm super alumina aggregate, 10-20 parts of 0 mm-1 mm super alumina aggregate, 20-30 parts of super alumina powder, 5-7 parts of zirconium carbide powder, 1-3 parts of Guangxi mud, 8-10 parts of composite bonding agents and 4-6 parts of water. The invention further discloses a manufacturing method of the high-alumina brick. The high-alumina brick is of high strength, high refractoriness, high abrasion resistance and high thermal shock resistance and is applicable to a cyclone separator flue, a cyclone separator straight segment and a cone of a circulating fluidized bed boiler, a back-feeder, a metallurgical industrial furnace and other thermal equipment. The manufacturing process of the high-alumina brick is simple and easy to implement.

Owner:张婷

Electrode antioxidant coating

The invention discloses an electrode antioxidant coating, and the antioxidant coating comprises the following components: boron carbide, aluminium dihydrogen phosphate, metal powder, and conductive carbon black; The manufacturing method comprises the following steps: proportionally weighing boron carbide, aluminium dihydrogen phosphate, copper powder or nickle powder, and conductive carbon black into a vessel, stirring for one hour at normal temperature, allowing the mixture to stand for 30 min, and brushing the mixture on a surface of a graphite electrode repeatedly by a hairbrush. The coating brushed on the surface of the graphite electrode has protective effect, can decrease the oxidation consumption of the electrode side surface by above 50% during application, can greatly decrease the consumption of the graphite electrode per ton of zinc or steel, and can solve the problem of electrode fracture caused by the oxidation consumption of the electrode side surface.

Owner:孙振光

Fire-resistant composite material for investment casting lining as well as preparation method thereof

The invention discloses a fire-resistant composite material for investment casting lining as well as a preparation method thereof. The fire-resistant composite material for investment casting lining comprises the following raw materials in parts by weight: 10 to 20 parts of compound metal powder, 8 to 14 parts of silicon powder adhesive, 5 to 9 parts of inorganic adhesive, 15 to 25 parts of mineral powder, 9 to 13 parts of modified composite filled earth, 8 to 16 parts of modified quartz powder and 3 to 5 parts of flake graphite. The fire-resistant composite material for investment casting lining has the characteristics of high volume stability, anti-stripping property, erosion resistance, avoidance of slag hanging and high heat-insulating property, and can withstand erosion and scouring of molten steel and furnace slag to avoid damage when being applied to the lining material; meanwhile, the raw material components are safe and reliable, the raw materials are easily available, the cost is low, the process is simple, operation is facilitated, industrialized production is realized easily, and high practical value and good application prospect are achieved.

Owner:合肥聪亨新型建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com