Casting-molded square crucible and preparation method therefor

A casting molding and crucible technology, applied in the field of refractory products, can solve the problems of poor corrosion resistance, easy cracks, easy peeling, etc., and achieve the effects of strong thermal shock resistance, increased strength, and good resistance to rapid cooling and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

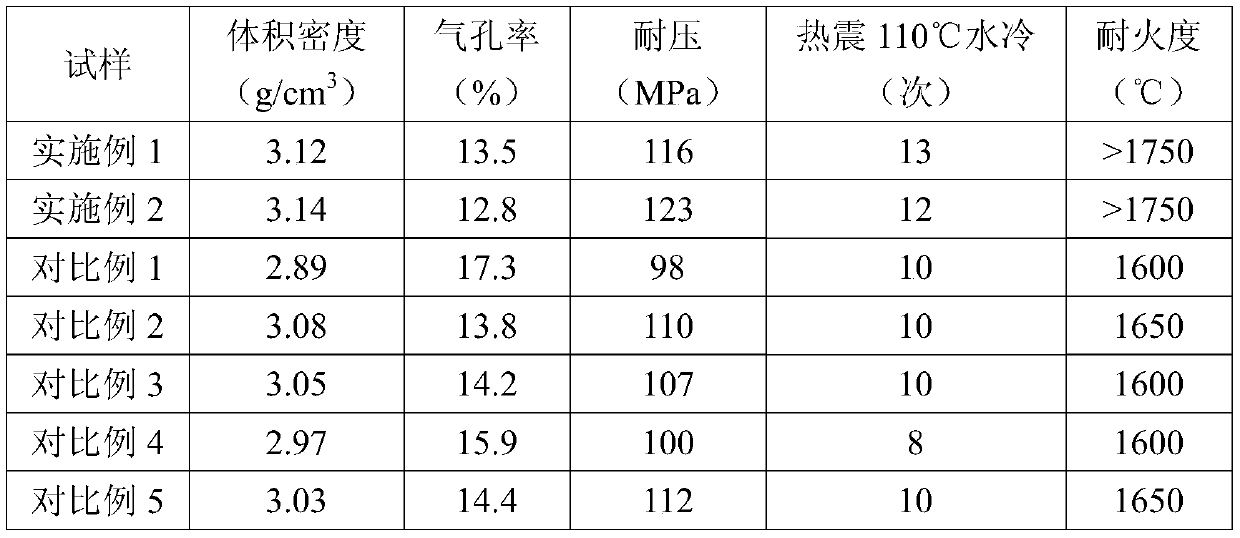

Examples

Embodiment 1

[0029] A casting-molded square crucible, the square crucible comprising the following raw materials in parts by weight: 15 parts of alumina powder, 10 parts of corundum powder, 18 parts of 3mm-1mm plate-shaped corundum, 13 parts of 20-mesh corundum particles, and 36-mesh corundum 10 parts of granules, 8 parts of 80-mesh corundum granules, 15 parts of 180-mesh fused mullite, 6 parts of 400-mesh quartz fine powder, and 5 parts of sodium tripolyphosphate.

[0030] The preparation method of this square crucible comprises the following steps:

[0031] 1) Iron removal: all kinds of raw materials are magnetically separated by a powerful magnetic separator to remove iron;

[0032] 2) Stirring: Weigh various raw materials according to the ratio, mix the raw materials with 8 parts of water, use a vacuum mixer to evacuate while stirring, and the stirring time is 30 minutes to form a slurry;

[0033] 3) Pouring: vibratingly pour the stirred mud into the plaster model of the square crucib...

Embodiment 2

[0038] A casting-formed square crucible, the square crucible comprising the following raw materials in parts by weight: 20 parts of alumina powder, 15 parts of corundum powder, 18 parts of 3mm-1mm plate-shaped corundum, 12 parts of 20-mesh corundum particles, and 36-mesh corundum 8 parts of granules, 7 parts of 80 mesh corundum particles, 14 parts of 180 mesh fused mullite, 10 parts of 400 mesh quartz fine powder, 3 parts of kaolin powder, and 9 parts of sodium tripolyphosphate.

[0039] The preparation method of this square crucible comprises the following steps:

[0040] 1) Iron removal: all kinds of raw materials are magnetically separated by a powerful magnetic separator to remove iron;

[0041] 2) Stirring: Weigh various raw materials according to the ratio, mix the raw materials with 7 parts of water, use a vacuum mixer to evacuate while stirring, and the stirring time is 25 minutes to form a slurry;

[0042] 3) Pouring: vibratingly pour the stirred mud into the plaster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com