Rock asphalt modified asphalt and preparation method thereof

A technology for modifying asphalt and rock asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of unstable thermodynamic performance, low stress transfer efficiency, complex production process, etc., and achieve good price advantages and low production costs. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

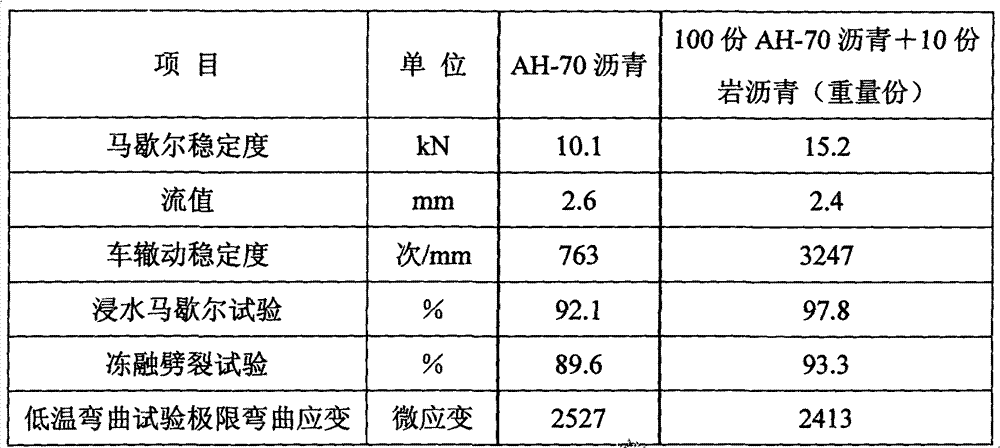

[0016] Add 10 parts by weight of imported rock asphalt to 100 parts by weight of AH-70# asphalt, stir at 150°C for a period of time and then take a sample to test the penetration (25°C), softening point, ductility (15°C) and viscosity (60°C). The mixing time and performance test results of embodiments 1~3 are as shown in table 1:

[0017] Table 1 Performance indicators of rock asphalt modified asphalt in Examples 1 to 3 with different mixing times

[0018] Stirring time (min)

[0019] Softening point (ring and ball method) ℃

[0020] It can be seen from Table 1 that as the stirring time prolongs, the penetration decreases slowly at first, and after the time is extended to 60 minutes, the slope of the line increases and the penetration decreases rapidly. Penetration characterizes the consistency of asphalt material. The trend of the penetration value in the table with the mixing time shows that the initial mixing time has little effect on the consistency of...

Embodiment 4~7

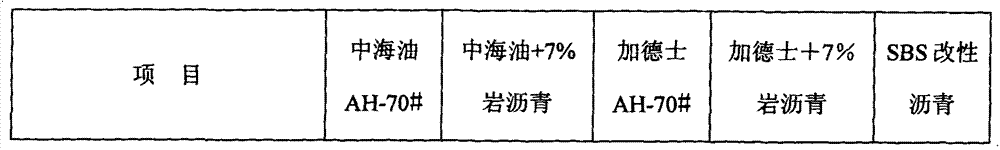

[0022] Add rock asphalt to 100 parts by weight of AH-70# asphalt, stir at 165°C for 30 minutes and then take samples to test the penetration, softening point, ductility (15°C) and viscosity (60°C). The parts by weight and performance test results of rock asphalt in Examples 4 to 7 are as shown in Table 2:

[0023] Table 2. Performance indicators of rock asphalt modified asphalt with different weight parts of rock asphalt added in Examples 4 to 7

[0024] Parts by weight of rock bitumen added

[0025] It can be seen from Table 2 that when the amount of rock asphalt added increases from 0 to 5 parts by weight, each performance index has a significant change, and the change rate is relatively large compared with the subsequent increase in the amount. That is to say, the addition of rock asphalt changes the properties of asphalt from ordinary asphalt to modified asphalt, which shows that rock asphalt can indeed be used as a modifier to effectively improve the properties ...

Embodiment 8~10

[0027] Add imported rock asphalt to 100 parts by weight of AH-70# asphalt, stir at 165°C for 30 minutes and take samples to test penetration, softening point, ductility, viscosity, dynamic shear DSR, BBR creep stiffness, creep Variable rate and SHRP. The parts by weight and performance test results of embodiment 8~10 rock asphalt are as shown in table 3:

[0028] Table 3. Performance indicators of rock asphalt modified asphalt with different weight parts of rock asphalt added in Examples 8-10

[0029]

[0030] It can be seen from Table 3 that the penetration of modified asphalt with rock asphalt is reduced, the softening point is increased, and the viscosity is increased, which shows that the high temperature performance of asphalt is significantly improved. Although the ductility has decreased, the BBR test of SHRP shows that the low-temperature creep stiffness and creep stiffness change rate of asphalt are at the same level, which shows that the addition of rock bitumen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com