Preparation method of ultrafine aluminium hydroxide

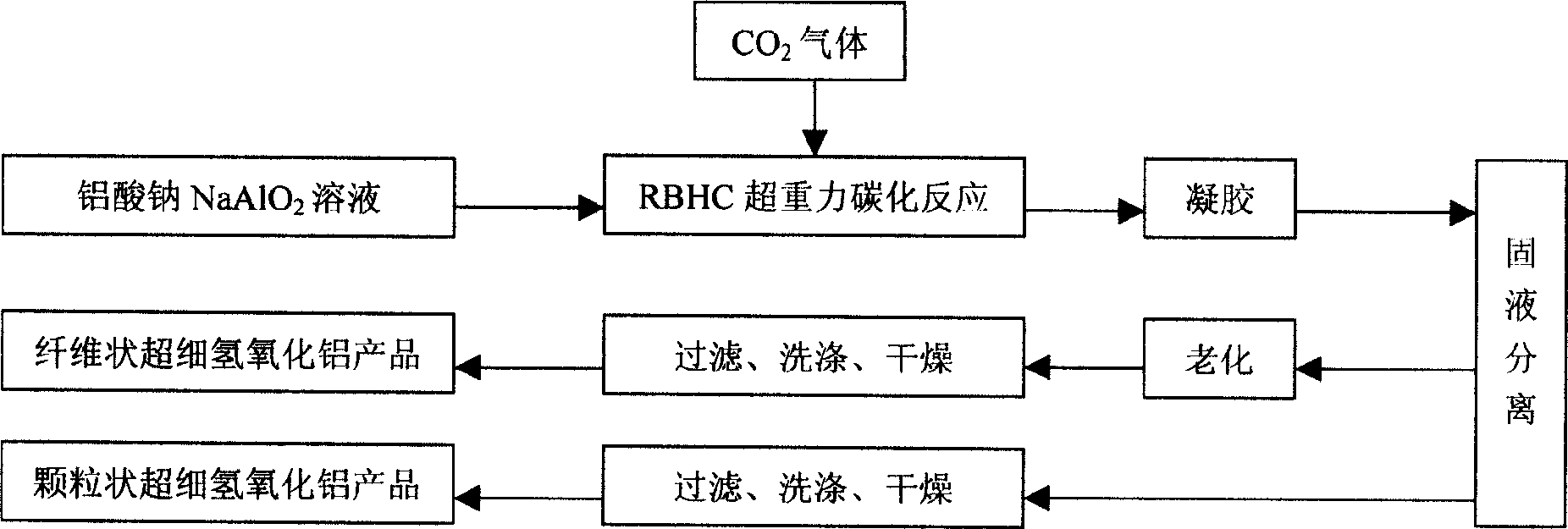

A technology of ultra-fine aluminum hydroxide and carbon dioxide, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of easy blockage of RPB devices, achieve shortened carbonization time, good quality, and large specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

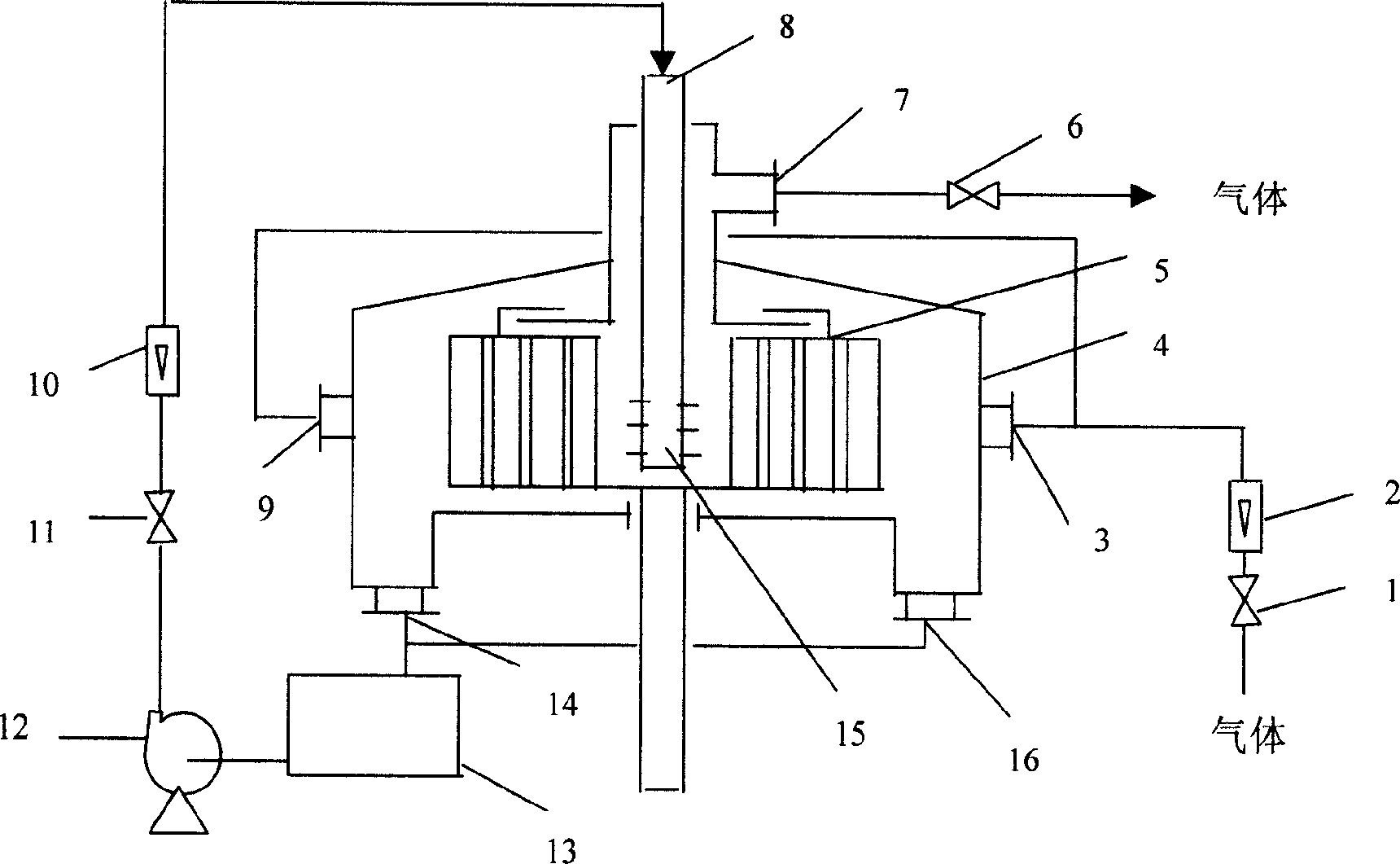

[0038] 2. The preparation of granular ultrafine aluminum hydroxide products is mainly completed by a one-step direct method under the condition of high gravity of the spiral channel type rotating bed. 3000rpm, the ratio of gas (calculated as net carbon dioxide in standard state) to liquid is 1-20, and the concentration of CO will not be higher than 30%. 2 Gas and NaAlO with a concentration of 0.05-2mol / L 2 The solution is passed into the rotor of the reactor through the air inlet and the liquid inlet pipe respectively, and an organic polymer dispersant with a mass content of 1-2% is added, and the gas-liquid-solid multiphase transfer is carried out in the spiral channel of the reactor rotor. Quality reaction, that is, carbonization reaction, the temperature of carbonization reaction is controlled at 0-100°C, the temperature and pH value are recorded regularly, and the CO2 is stopped when the pH value reaches 11-12 2 Gas, reduce the speed of reactor 4 and recirculate for a per...

Embodiment 1

[0044] Embodiment 1: adopt technological process of the present invention as figure 1 , extract a certain volume of sodium aluminate solution, filter and remove impurities, and dilute to 0.4mol / L, and place it in the circulation tank 13. The liquid port 8 enters the spiral channel of the rotor 5 through the distributor 15; the high concentration of CO 2 After the gas is decompressed from the gas source of the steel cylinder, it passes through the gas valve 1 and the gas flow meter 2 from the inlet 3 and 9 to the outside of the spiral channel and enters the spiral channel of the rotor 5 of the rotating bed RBHC. The gas-liquid volume flow ratio is 3, CO 2 Gas and sodium aluminate solution are reversely contacted in the rotating spiral channel for carbonization reaction. During the carbonization reaction, 1-2% by mass of organic polymer dispersant is added to generate nano-sized aluminum hydroxide ultrafine particles, and the remaining gas flows from the spiral The center of t...

Embodiment 2

[0045] Embodiment 2: This embodiment 2 is except identical with embodiment 1, and its different variation with embodiment 1 is: the concentration of sodium aluminate solution is 0.2mol / L, passes into the CO of high concentration 2 Gas, the rotation speed of rotor 5 is 1000rpm. After the carbonization reaction is complete, the gel is filtered and washed, then added with deionized water, placed in water at 97°C for heating and aging for 6 hours, filtered, washed and dried at 100°C with isobutanol to obtain Fibrous superfine aluminum hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com