Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1438results about "Alkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rheology modification of settled solids in mineral processing

InactiveUS6365116B1Low viscosityIncrease speedRotary stirring mixersTransportation and packagingEngineeringSlurry

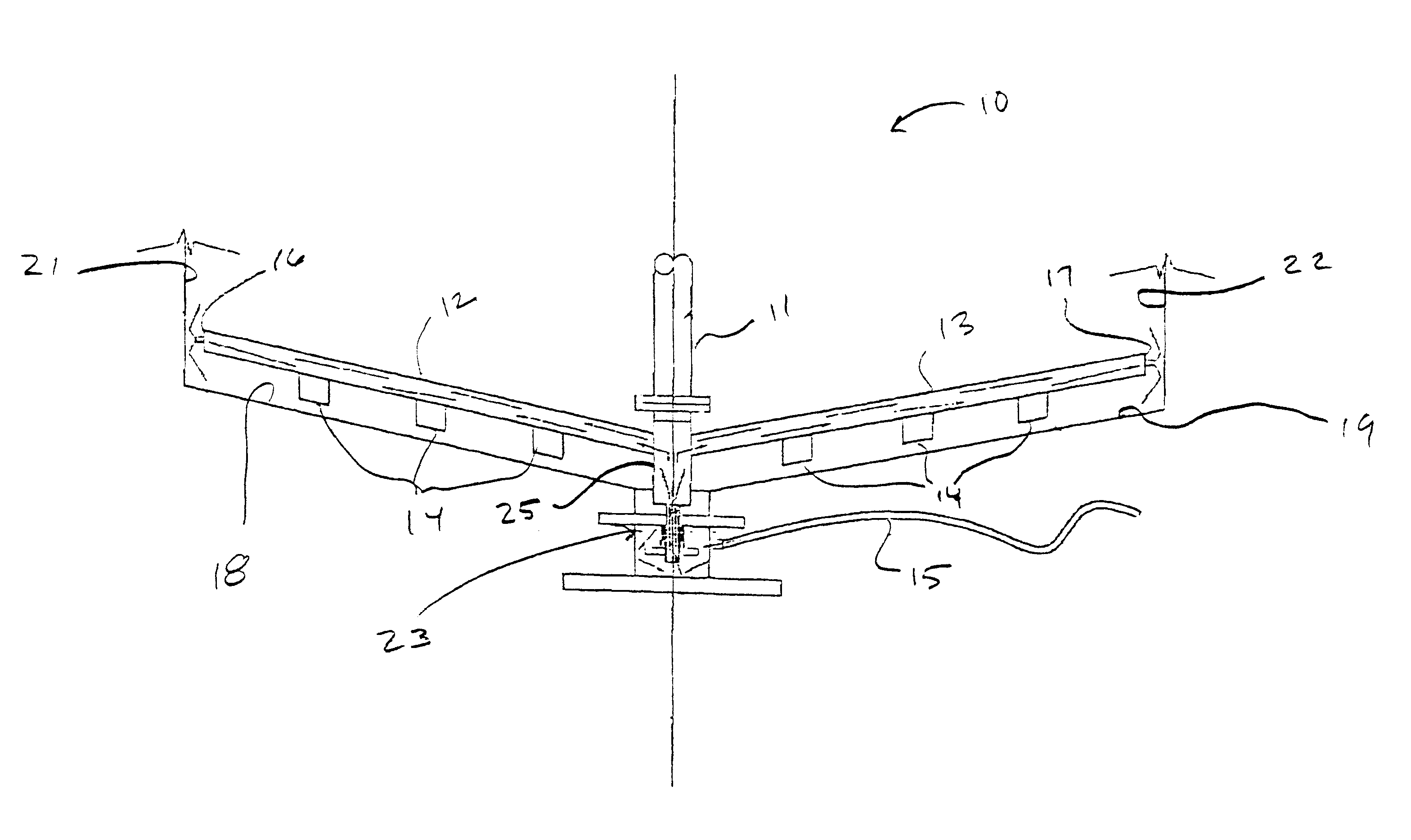

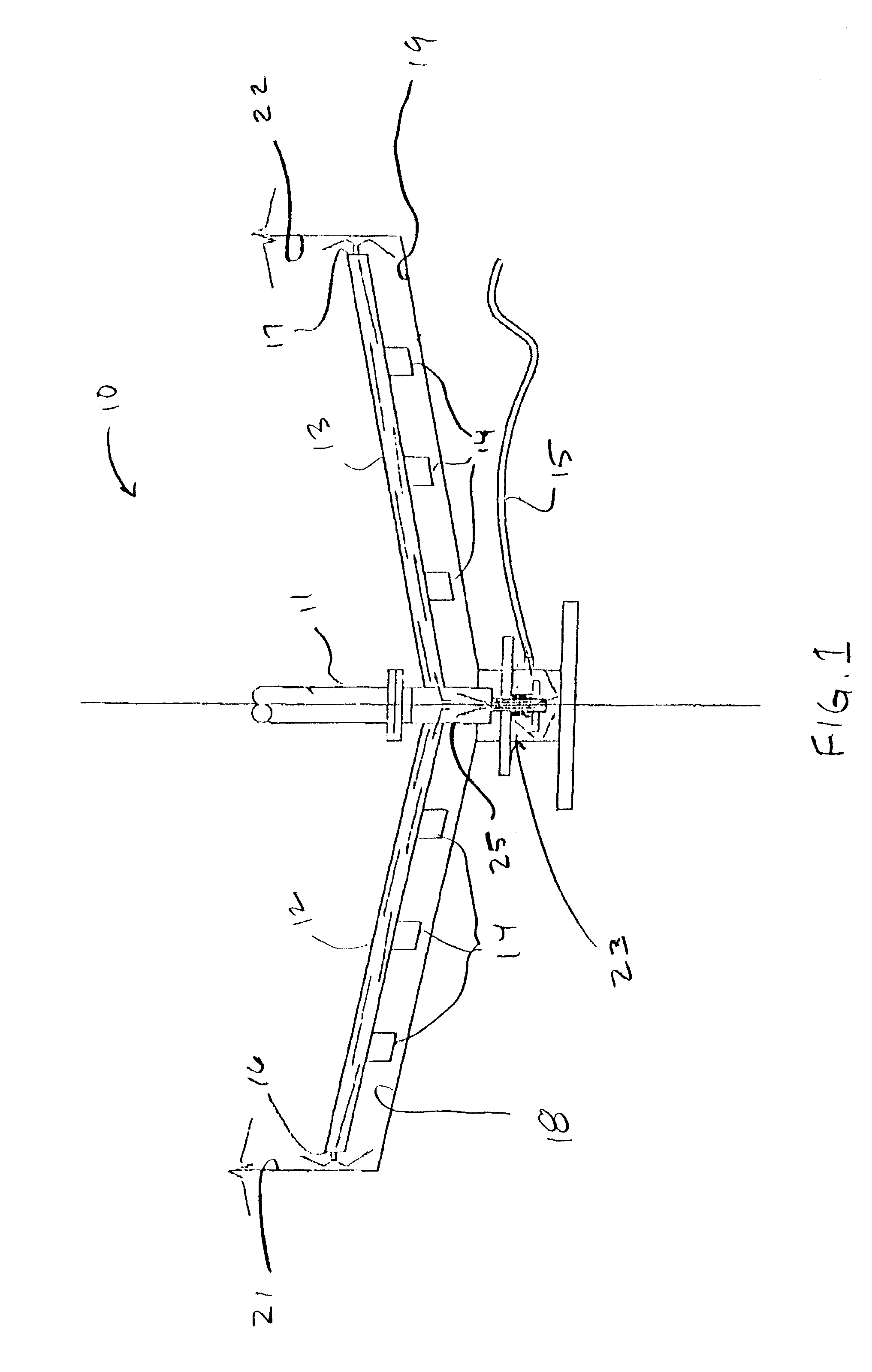

The present invention comprises a method for reducing the viscosity of the settled mud or underflow of a raked thickener thereby reducing the torque necessary to move the rake blade through the settled mud. The method includes the step of delivering a viscosity modifier to the settled mud and in front of the rake blade by pumping the viscosity modifier down the rake arm to an area in front of the rake blade. The method also includes an improved rake mechanism that includes a means for delivering viscosity modifier to the settled mud and in front of the rake blade. The present invention also includes a method for increasing the rate of consolidation of flocculated solids in a slurry.

Owner:ECOLAB USA INC

Al2O3-Y2O3-ZrO2/HfO2 materials, and methods of making and using the same

InactiveUS7507268B2Facilitates formation and homogeneityEliminates and minimizes heat transferPigmenting treatmentGlass drawing apparatusFiberThermal insulation

Al2O3—Y2O3—ZrO2 / HfO2 ceramics (including glasses, crystalline ceramics, and glass-ceramics) and methods of making the same. Ceramics according to the present invention can be made, formed as, or converted into glass beads, articles (e.g., plates), fibers, particles, and thin coatings. The particles and fibers are useful, for example, as thermal insulation, filler, or reinforcing material in composites (e.g., ceramic, metal, or polymeric matrix composites). The thin coatings can be useful, for example, as protective coatings in applications involving wear, as well as for thermal management. Certain ceramic particles according to the present invention can be are particularly useful as abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

Process for extracting aluminium hydroxide from flyash

InactiveCN1792802AAchieve recyclingEffective leachingAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

A process for extracting aluminum oxide from powdered coal ash includes such steps as grinding, calcining, mixing with H2SO4 solution, heating while reaction for extracting aluminum oxide, boiling in water, concentrating, cooling while educing out aluminum sulfate crystals, heating for dewatering, heating for decomposing to obtain gamma-Al2O3, and further preparing metallurgy-class aluminum oxide.

Owner:朔州市人民政府 +2

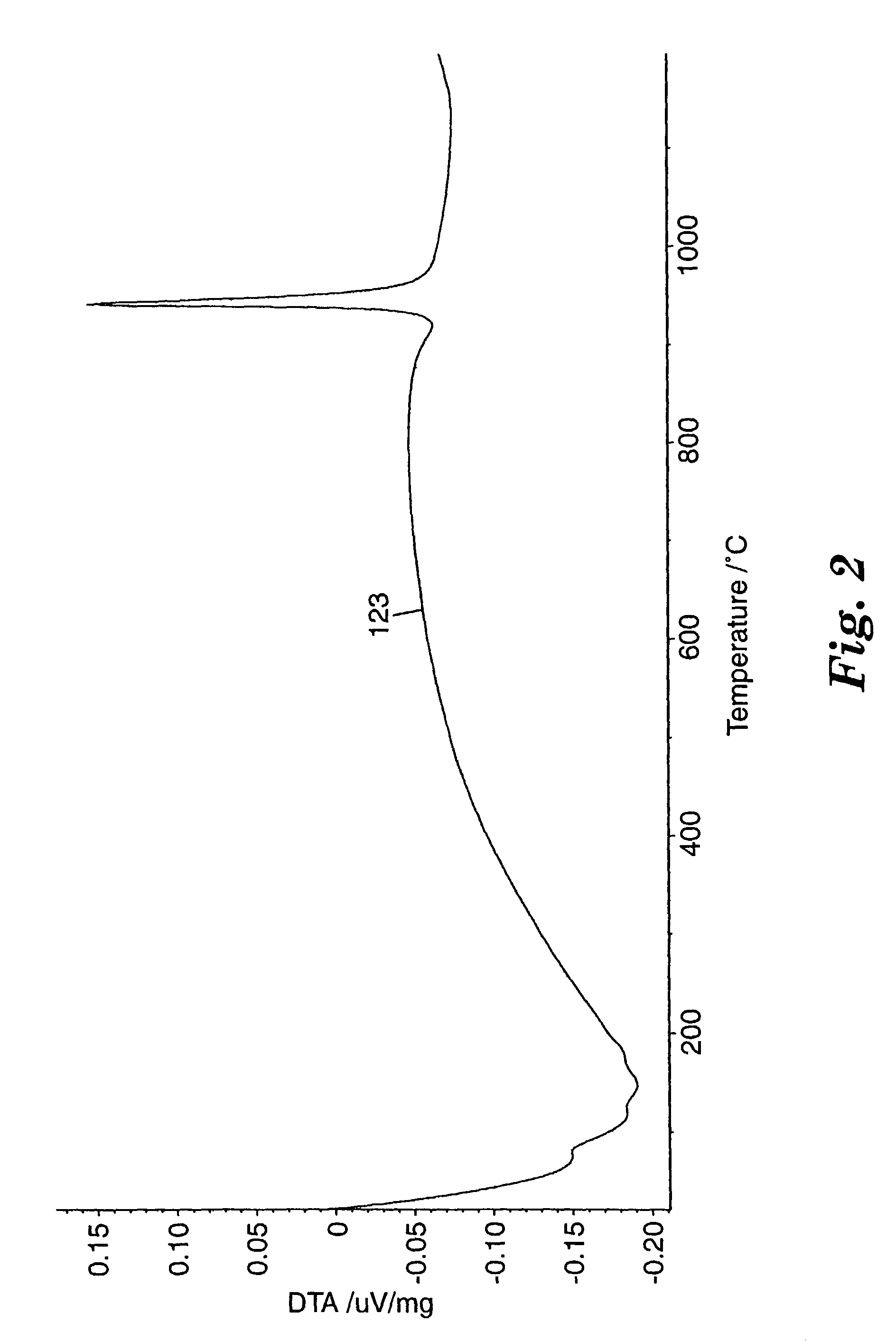

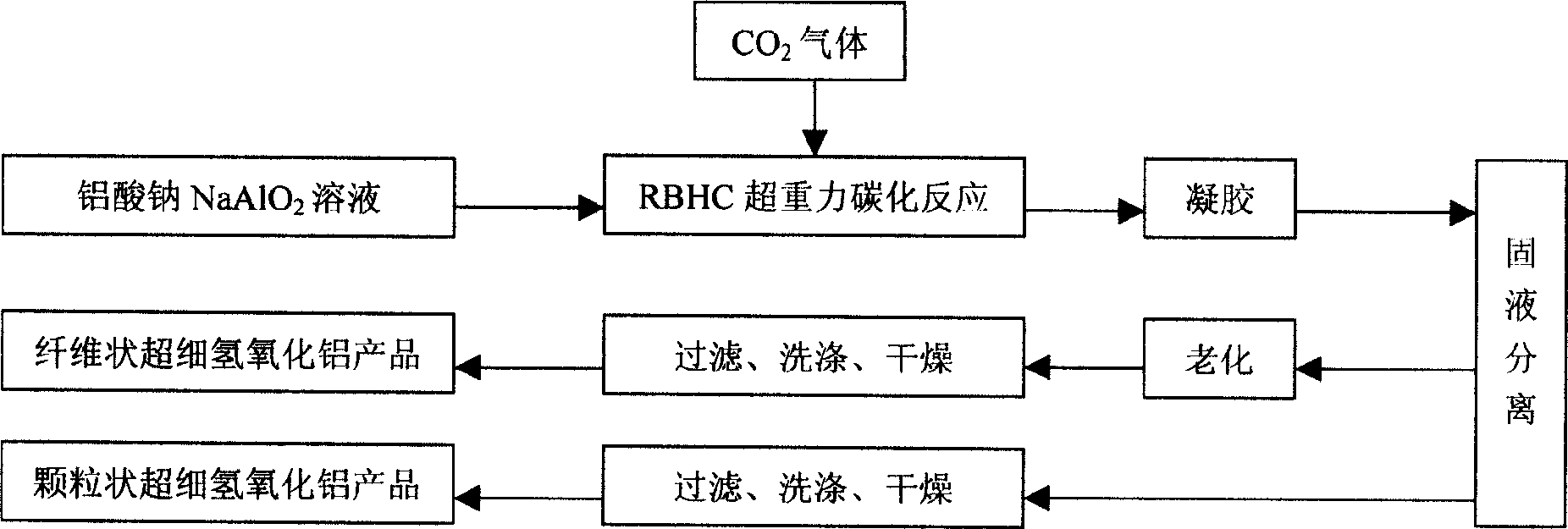

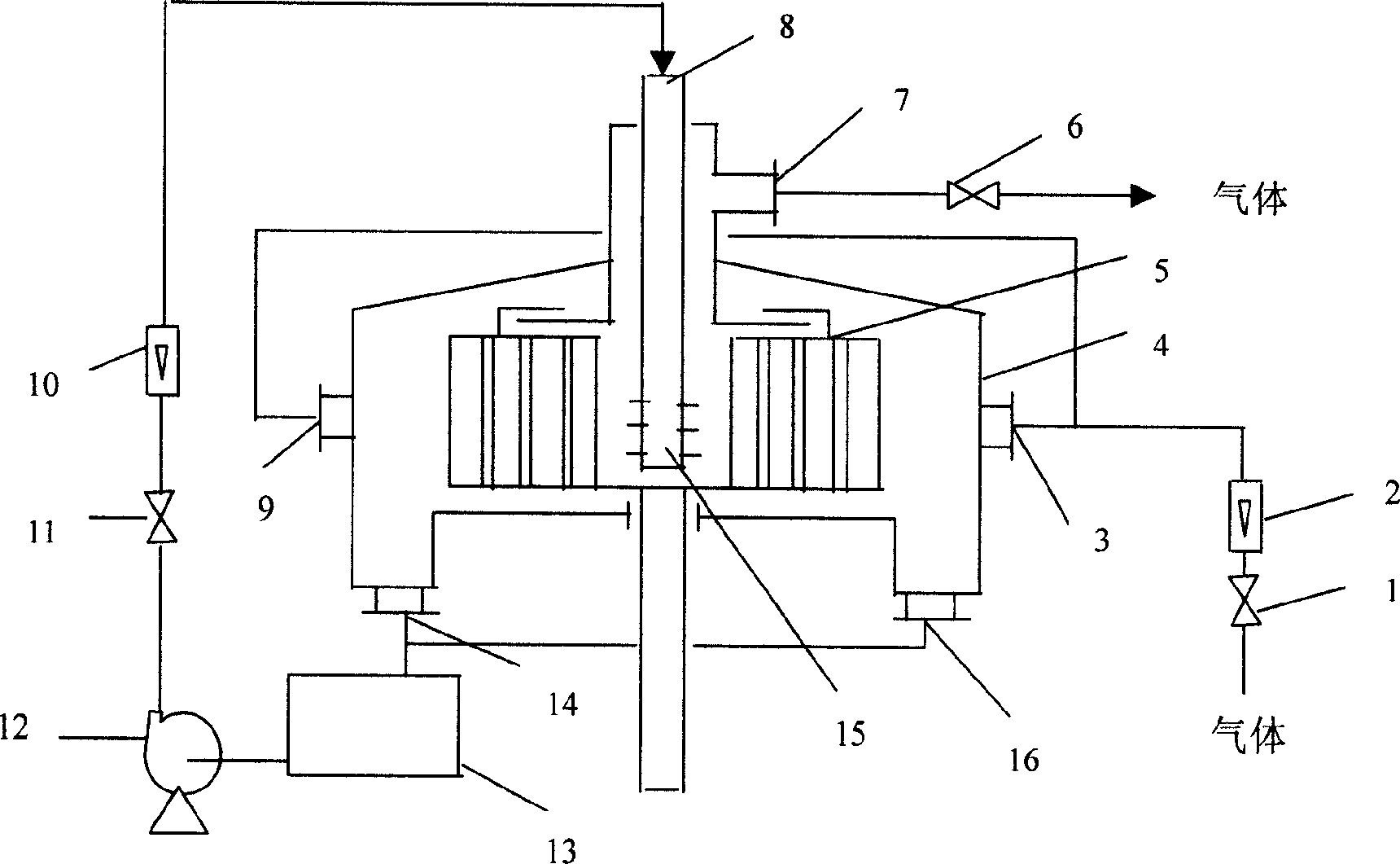

Preparation method of ultrafine aluminium hydroxide

InactiveCN1752006ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNanoparticleAluminium hydroxide

A process for preparing superfine aluminium hydroxide includes such steps as carbonifying reaction between NaAlO2 solution and the gas containing CO2 in gravitation condition to obtain aluminium hydroxide gel, preparing superfine aluminium hydroxide, filtering, washing, and drying. The product (nanofibers or nanoparticles of aluminium hydroxide) can be used as inorganic flame-retarding agent or for preparing catalyst.

Owner:XIANGTAN UNIV

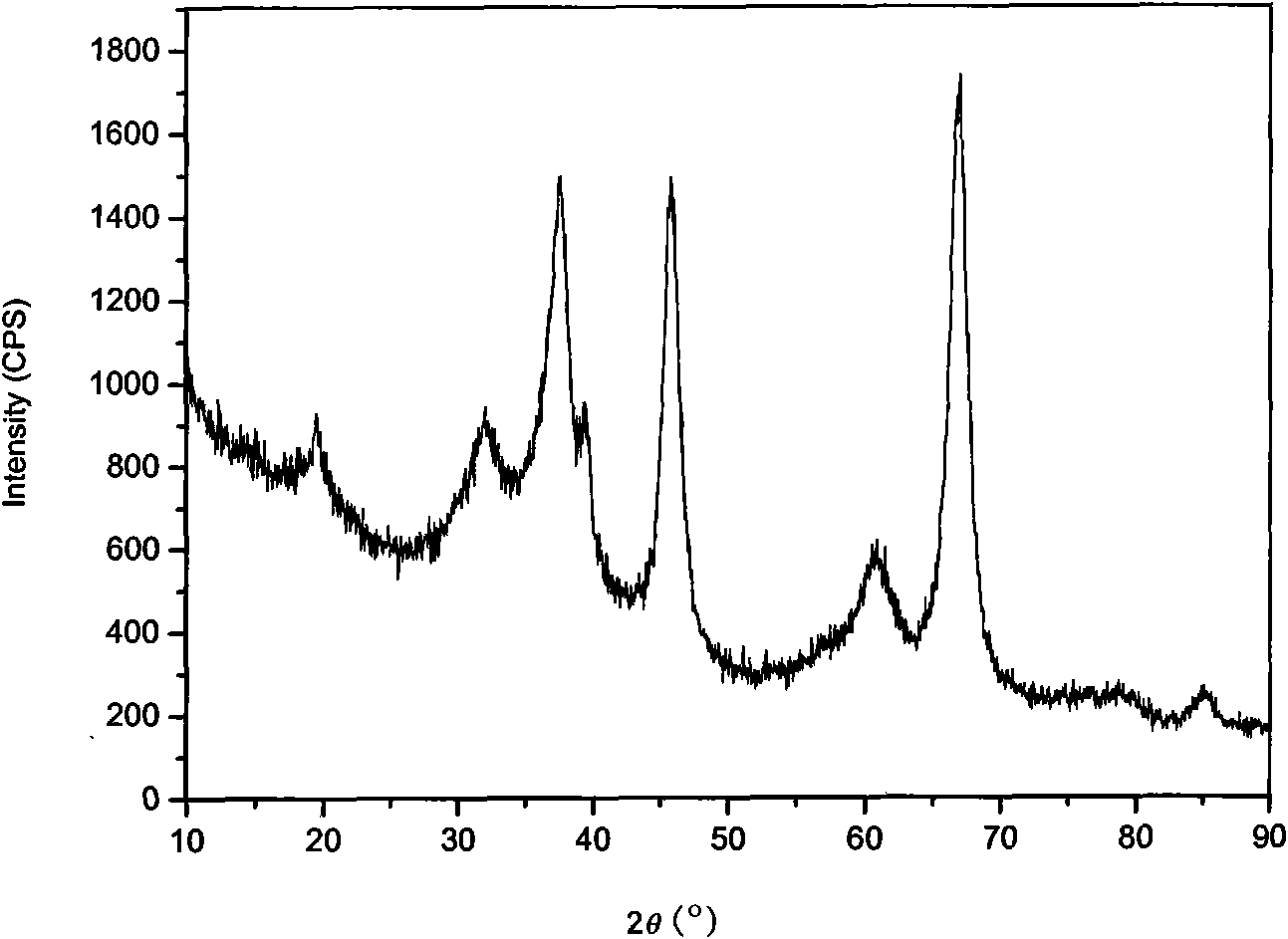

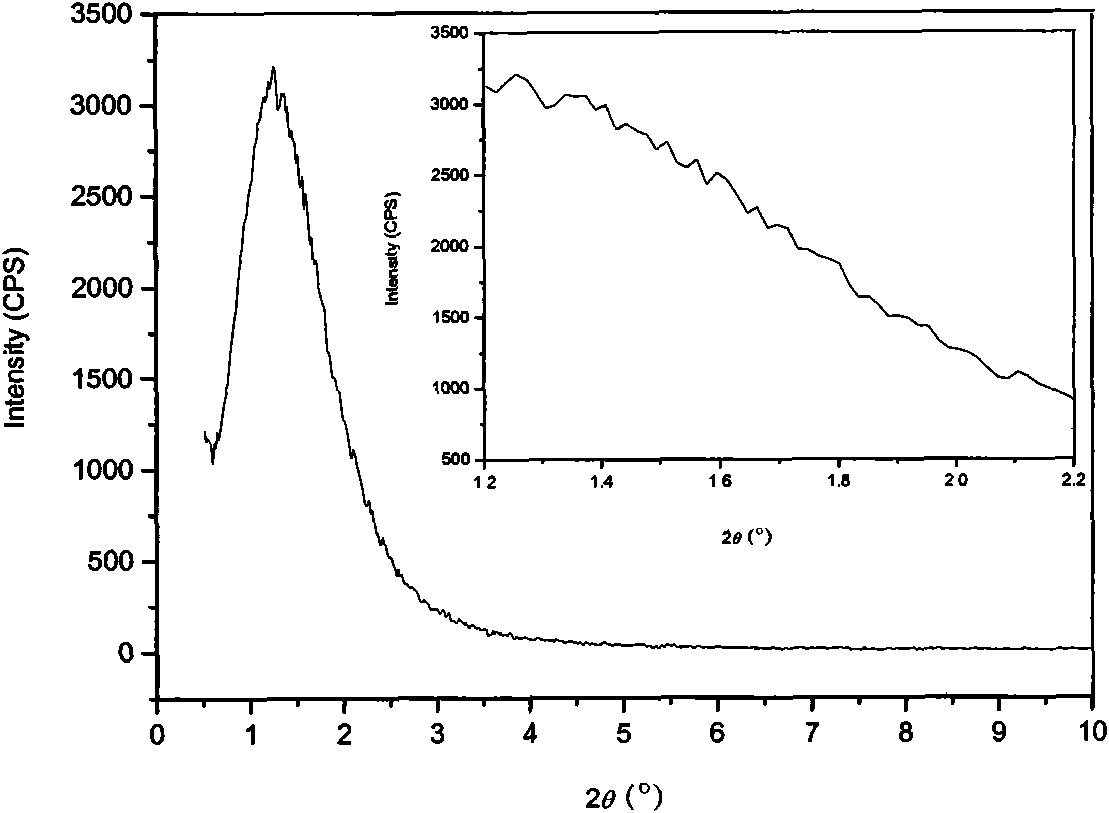

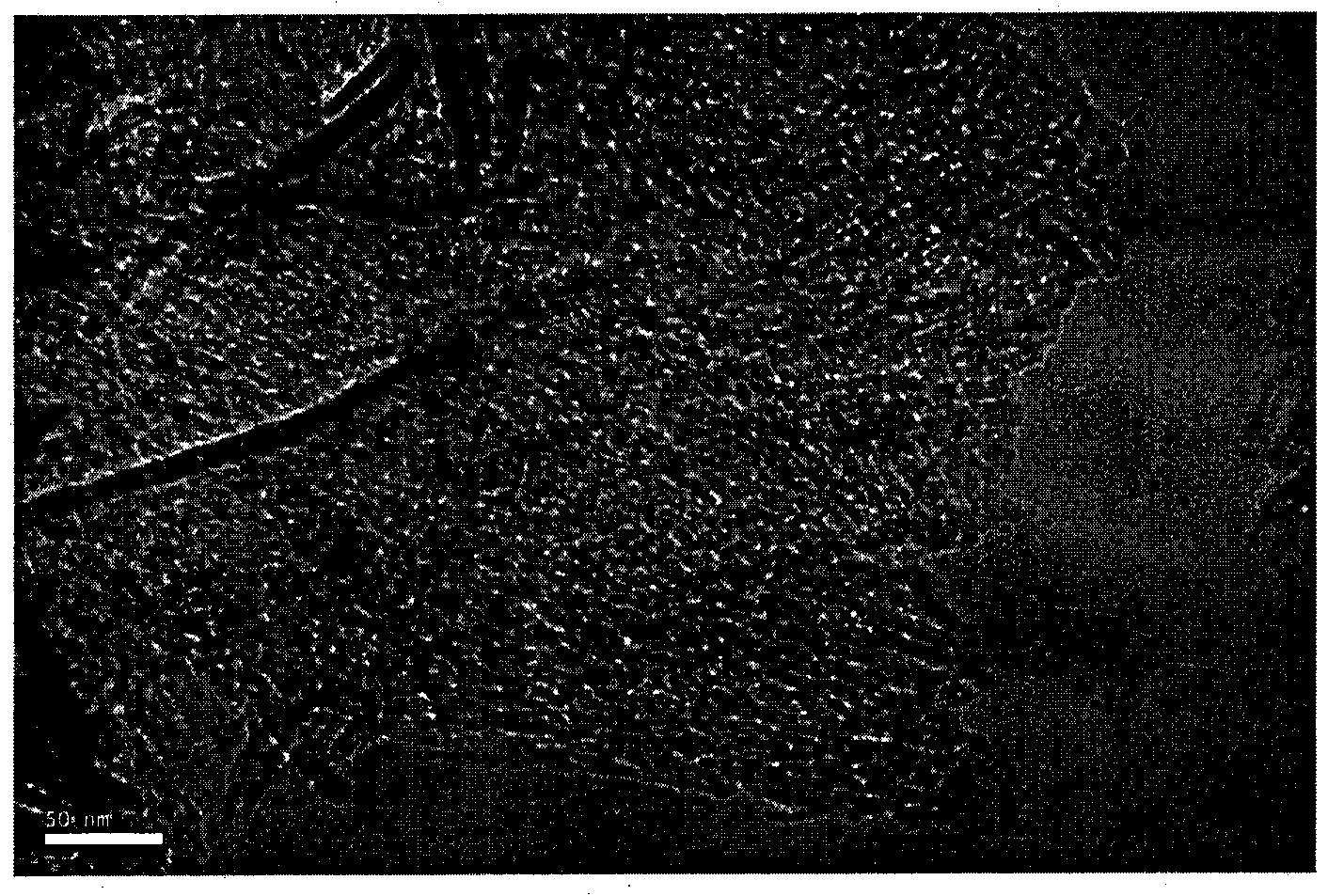

Superficially Porous Metal Oxide Particles, Methods For Making Them, and Separation Devices Using Them

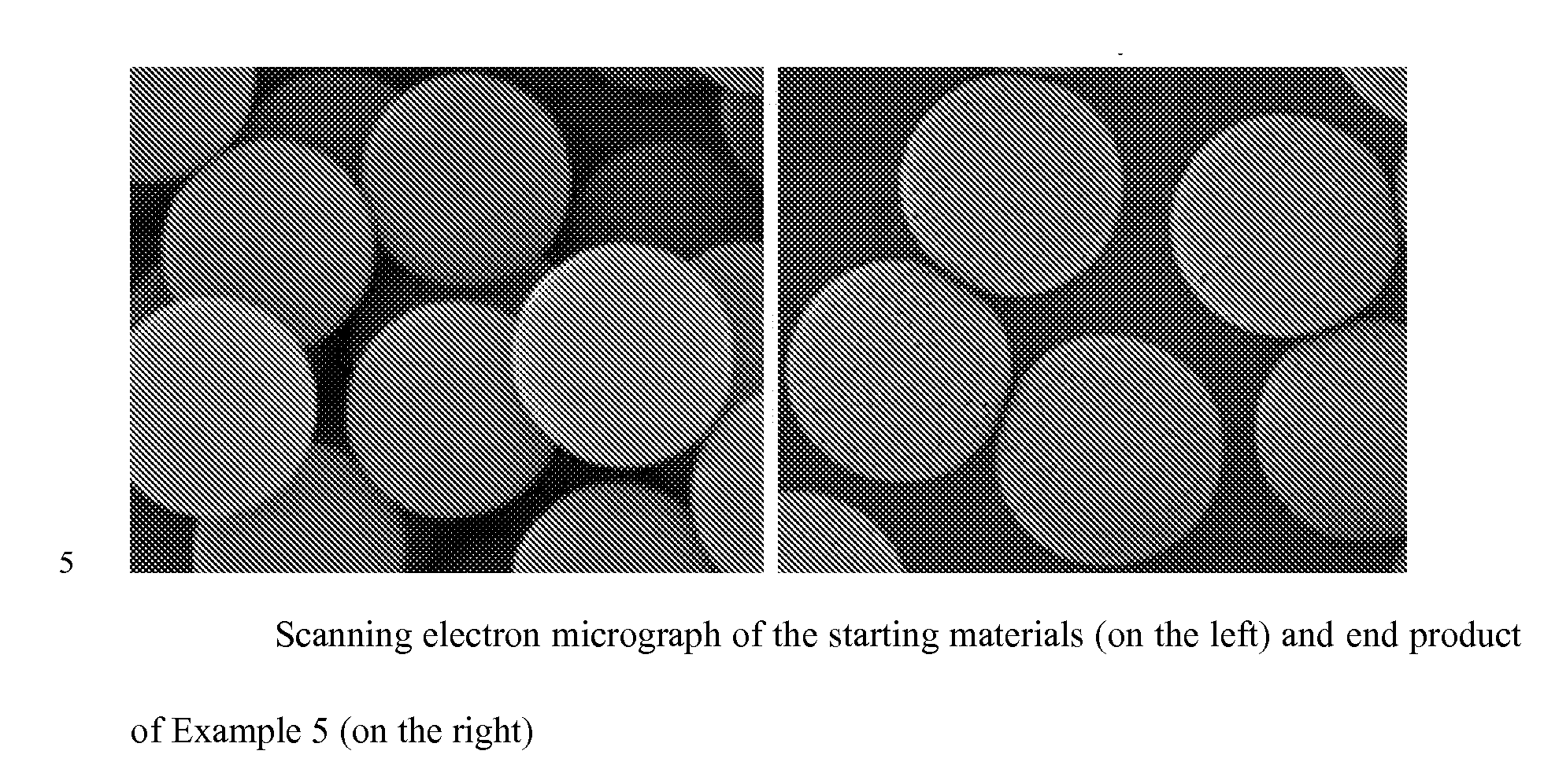

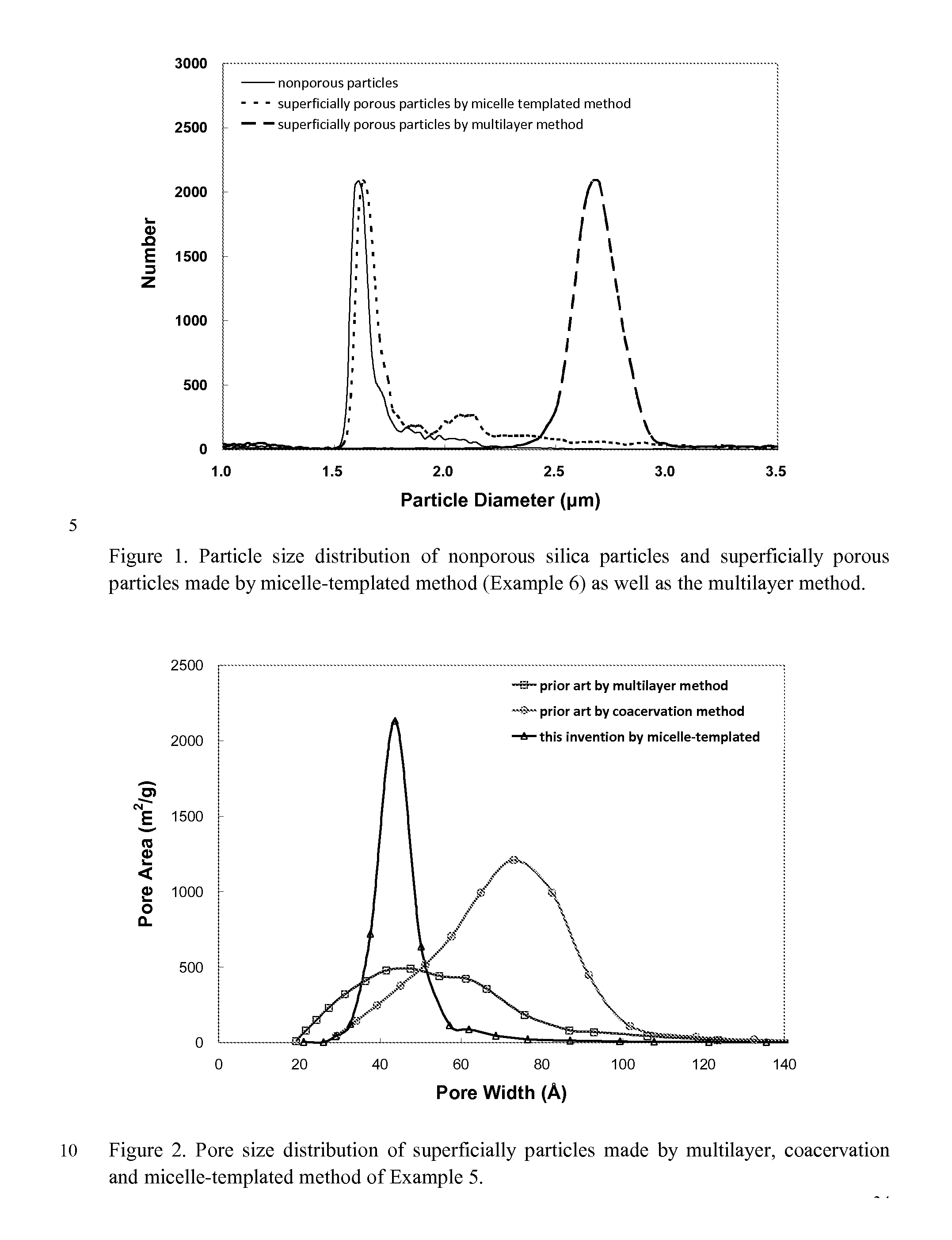

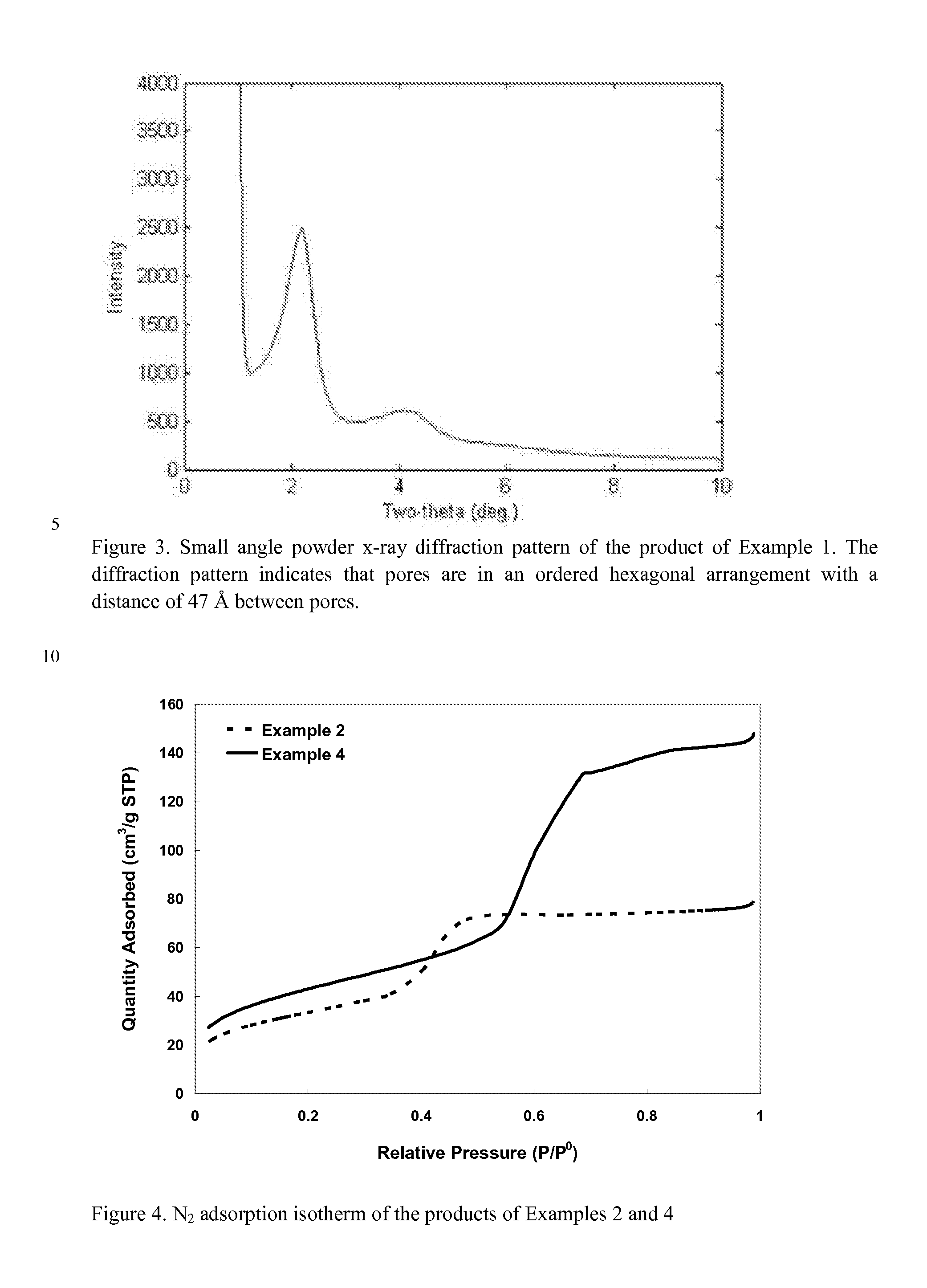

Micelle-templated superficially porous particles having a solid core and an outer porous shell with ordered pore structures and a narrow particle size distribution, such as about ±5% (one sigma), and a high specific surface area of about 5 to about 1000 m2 / g.

Owner:AGILENT TECH INC

Process for preparing active alumina

InactiveCN1420082AIncrease profitAvoid or suppress generationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationHigh concentrationPorosity

A process for preparing the active aluminium oxide includes preparing the solution of sodium metaaluminate from powdered aluminium hydroxide and sodium hydroxide, introducing high-concentration CO2 gas mixture, colloidizing at 20-70 deg.C, regulating pH=9-11, filtering, washing the filtered cake, drying at 60-100 deg.C to obtain alpha-AlO(OH), and calcining at 500-700 deg.C. Its advantages are high reaction speed, low CO2 consumption and low cost.

Owner:XIAMEN UNIV

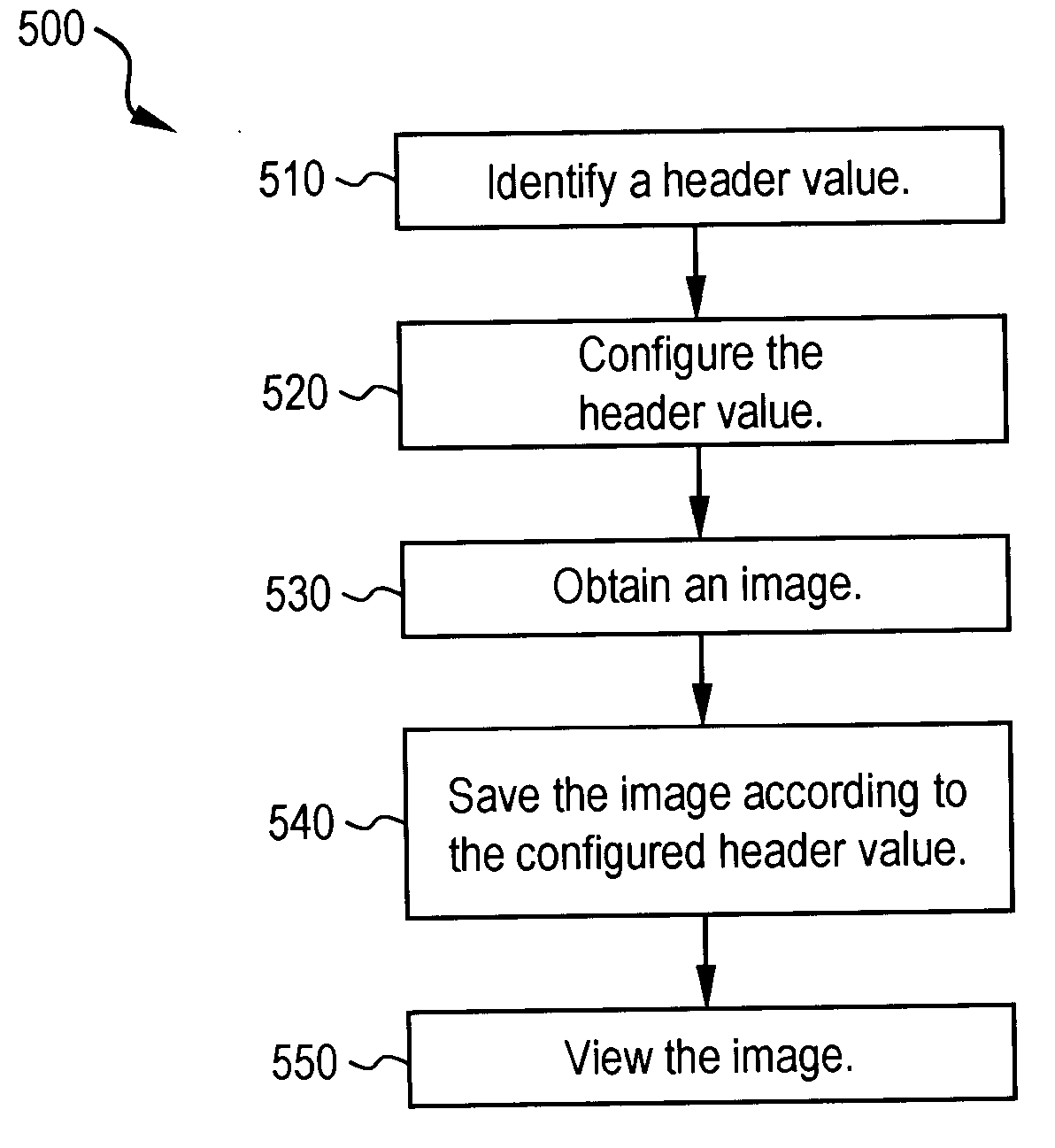

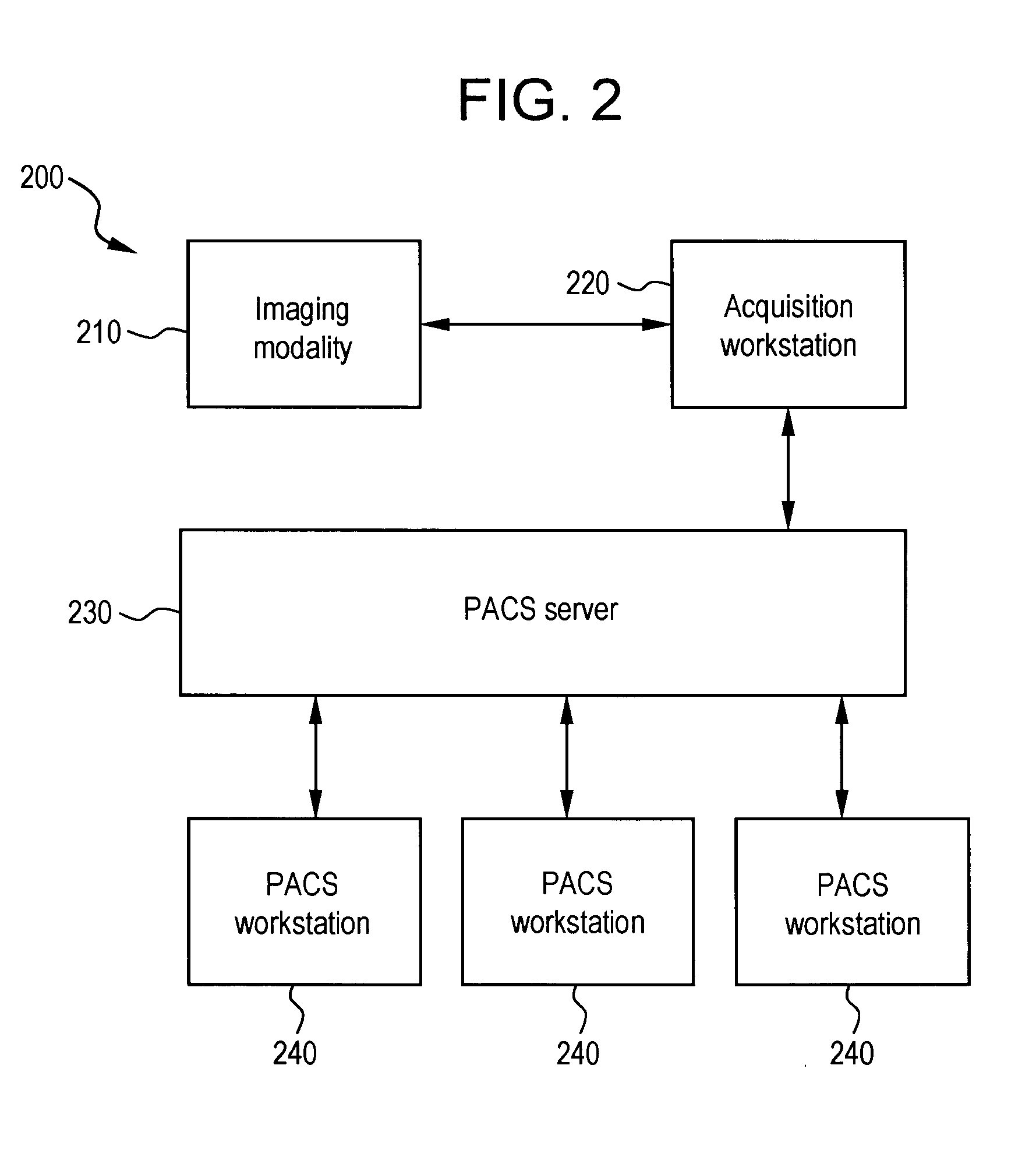

System and method for definition of DICOM header values

InactiveUS20060239589A1Aluminates/aluminium-oxide/aluminium-hydroxide purificationCharacter and pattern recognitionDICOMComputer vision

Certain embodiments of the present invention provide an improved system and method for image file header configuration. Certain embodiments of the method include retrieving one or more criterion for configuration of an image orientation parameter, configuring the image orientation parameter based on the one or more criterion, obtaining image data, and storing the image data in an image file. The image file has a header portion including the image orientation parameter. In an embodiment, the image orientation parameter may be modified from a default configuration. The one or more criterion may include user preference, modality restriction, system preference, and / or rule, for example. The method may further include saving the image file with the configured image orientation parameter. Additionally, the method may include displaying an image according to the configured image orientation parameter. The image may be automatically oriented for display based on the configured image orientation parameter.

Owner:GENERAL ELECTRIC CO

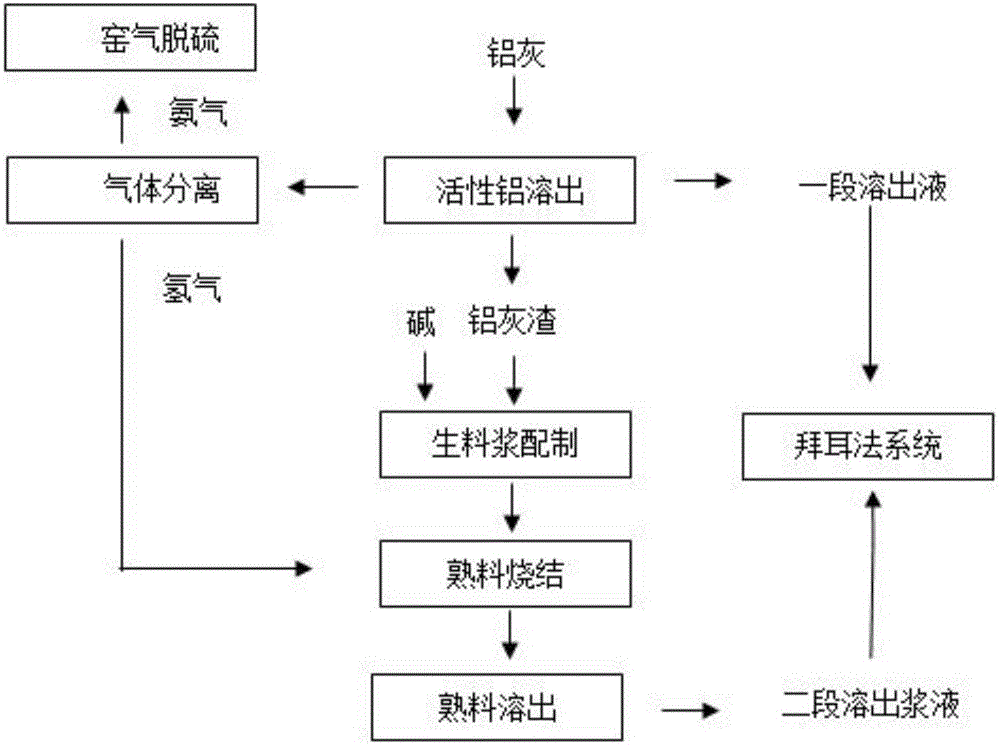

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

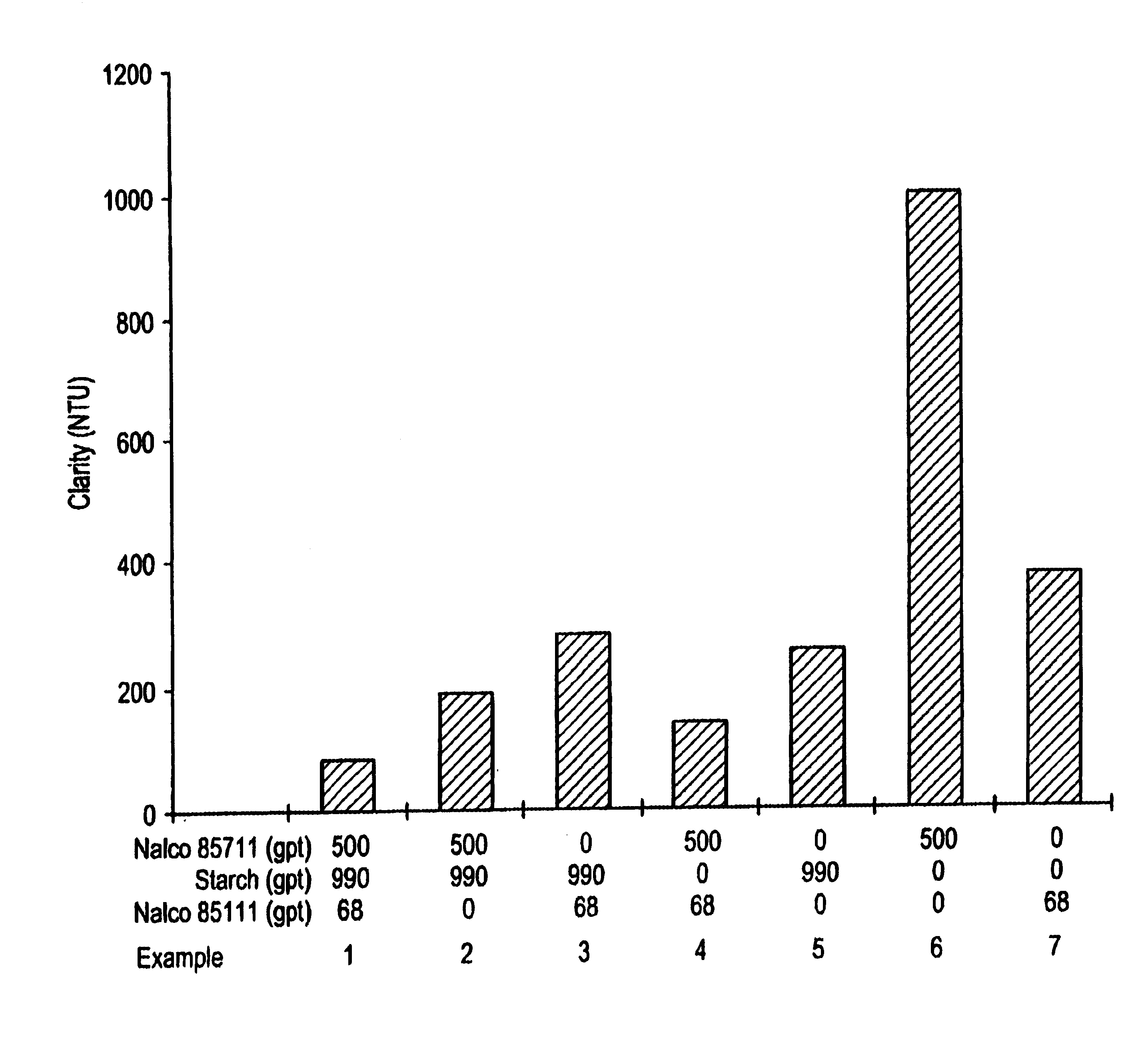

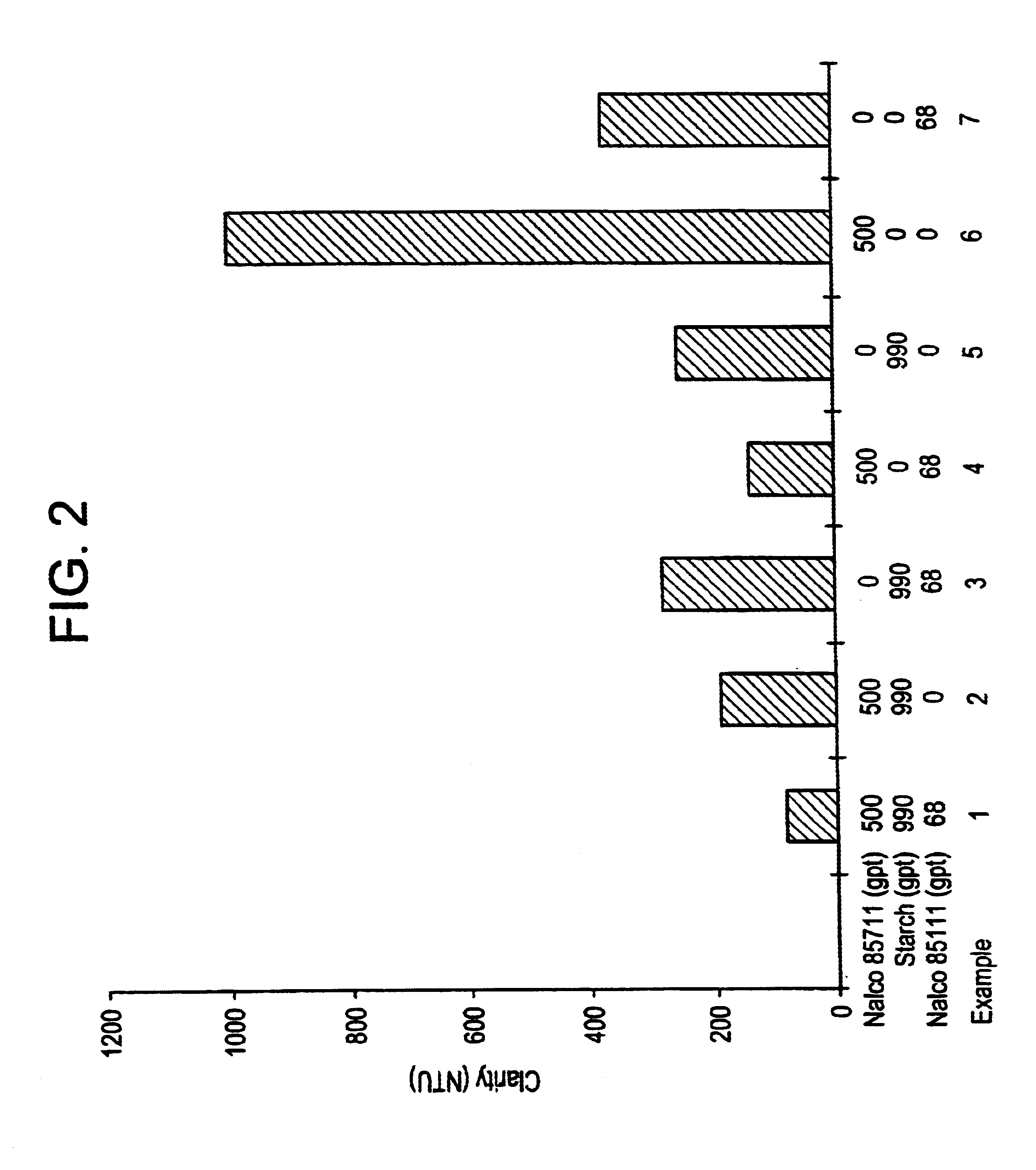

Dextran starch and flocculant combination for improving red mud clarification

InactiveUS6726845B1Easy to separateGallium/indium/thallium compoundsCentrifugal force sediment separationFiltrationCentrifugation

The claimed invention is a method for separating Bayer process red mud from a Bayer process liquor which comprises adding to a Bayer process liquor containing red mud an effective amount of a water soluble synthetic flocculant, dextran and starch combination. The flocculant is added anywhere in the slurry containing the red mud suspended in Bayer process liquor, or in a liquor slurry containing bauxite prior to or during digestion. Once the flocculant combination is added, it is mixed sequentially with the Bayer process liquor and the red mud contained in the Bayer process liquor is removed by sedimentation, centrifugation or filtration.

Owner:ECOLAB USA INC

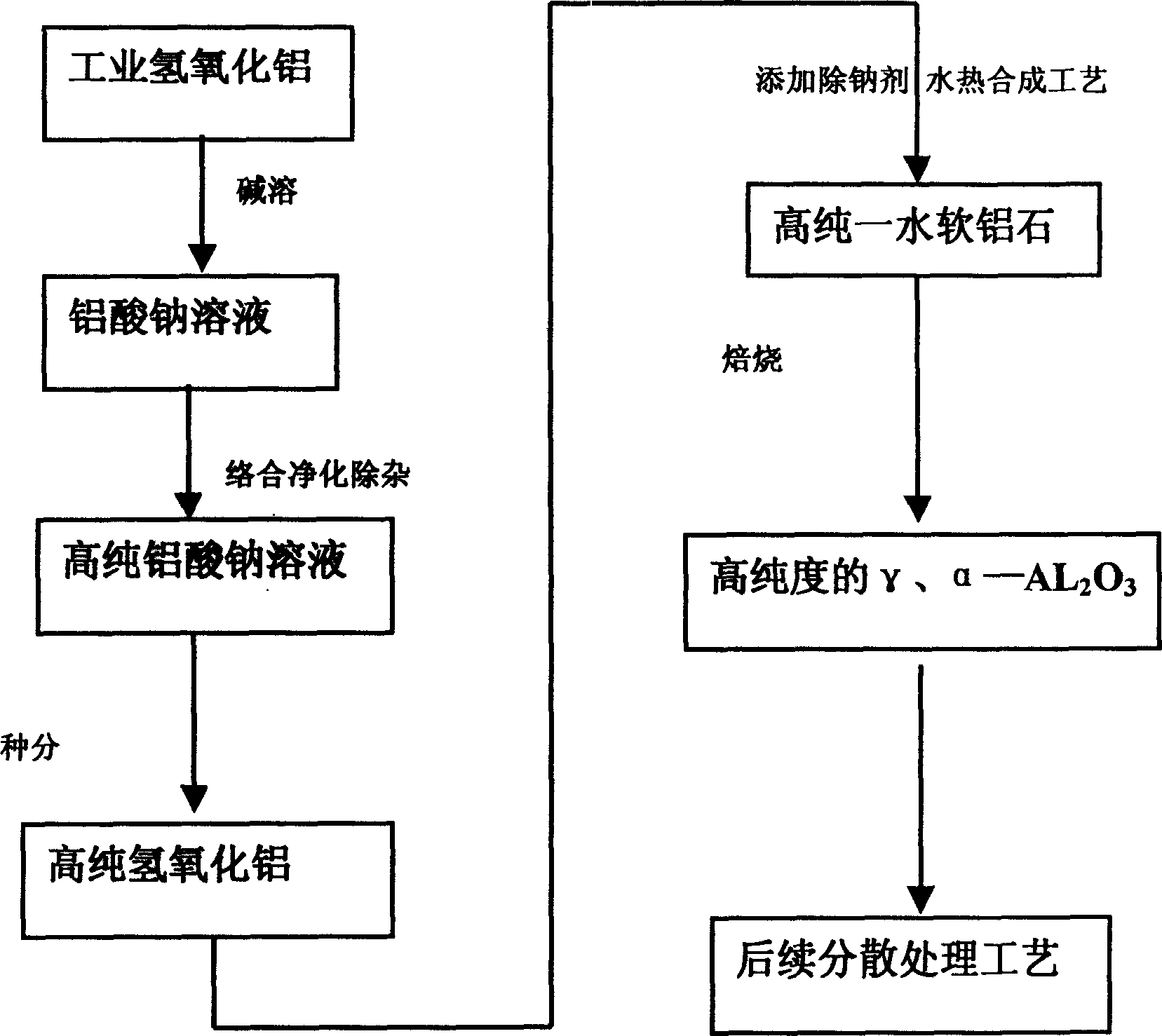

Method for preparing high-pruity alumina powder

ActiveCN1579941ALow costNo pollution in the processAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium oxide/hydroxide preparationAluminium hydroxideFluorescence

The invention discloses a method to produce highly pure Alumina powder. The steps are as follows: deploying Aluminium hydroxide which is produced in the process of manufacturing alumina using sintering process to be solution, disposing of impurity, adding seed crystal to prepare highly pure aluminium hydroxide; removing Na in the solution, getting highly pure bodhmite after hydrothermal synthesis; and after washing and baking, highly pure Alumina can be obtained. The cost is about 15 thousand per ton, which is far less than current market price, 40-60 thousand per ton. It can put into production in a large scale and it is easy to reach 1-5 thousand ton per year. With a low cost, no pollution and high purity (over 99.99 percent), the production is widely used in rare earth fluorescence materials, high voltage Na lamp and other relative special Alumina fine ceramics field.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Synthetic ferro-aluminum spinel and its preparation method

InactiveCN1762895ALow priceSimple processAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPorosityAdhesive

The present invention relates to Fe-Al spinel and its preparation process. The technological scheme of the present invention is the Fe-Al spinel preparing process including the steps of: mixing Al containing compound and Fe containing compound in the molar Al / Fe ratio of 2 and adhesive in 1-6 wt% for 5-180 min; forming and drying at 90-120 deg.c for 20-30 hr; heating in carbon atmosphere and temperature raising speed of 0.5-10 deg.c / min at 1100-1700 deg.c for 5-600 min; and naturally cooling. The present invention has the advantages of simple technological process, low reaction temperature and cheap material. Under the sintering temperature, all the Al and Fe components are converted into FeAl2O4, and the sintered product has apparent porosity lower than 5 %.

Owner:WUHAN UNIV OF SCI & TECH

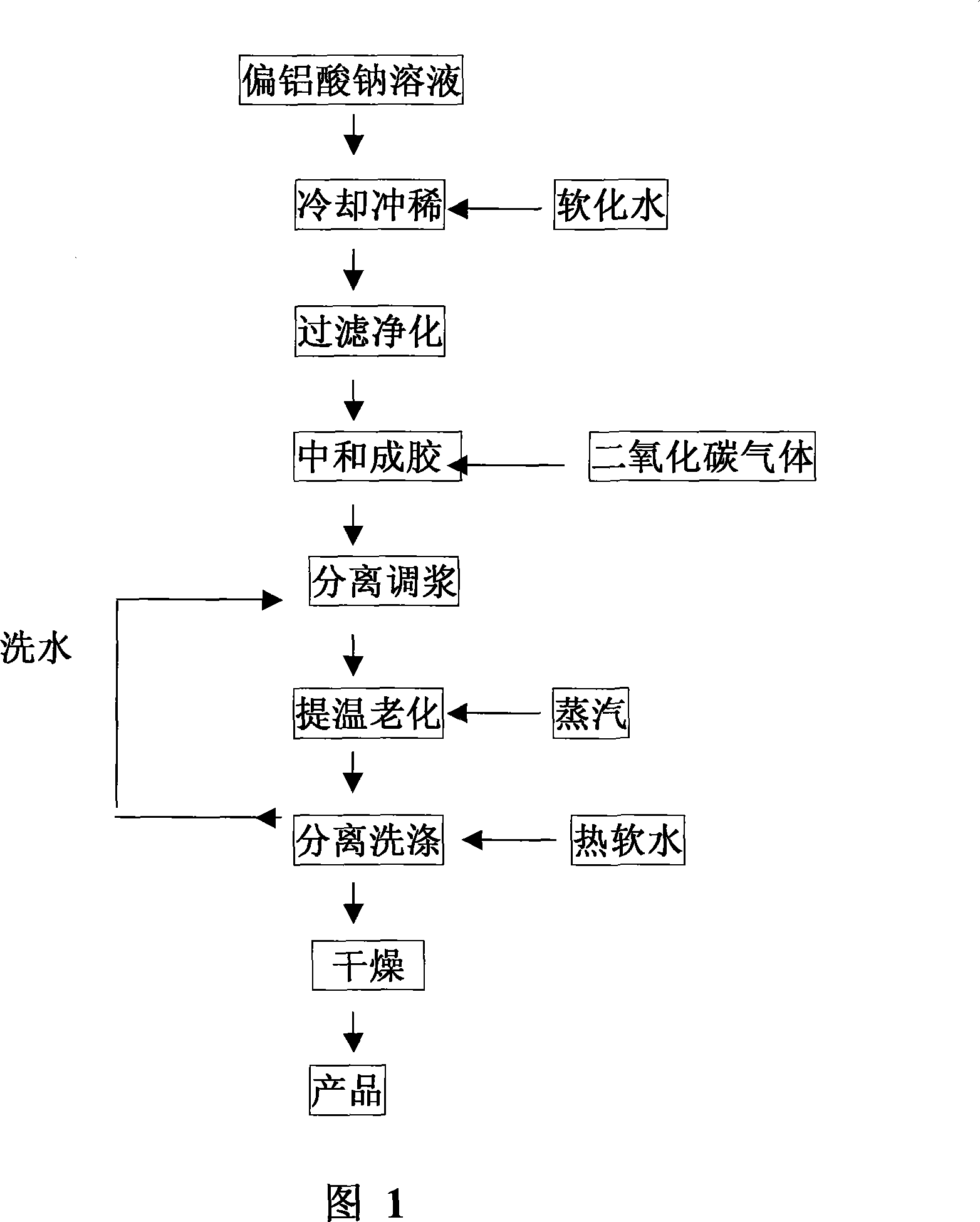

Method of producing pseudo boehmite

ActiveCN101172631AGood effectAchieving low alkali agingAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesSlurryCarbonation

The invention relates to a preparative method of pseudo-boehmite, belonging to the field of the preparative technology of alumina exclusive of metallurgical usage. The method comprises the steps as follows: sodium metaaluminate solution is carbonated into mucus, aging, separating, washing and drying. The invention is characterized in that after the sodium metaaluminate solution becomes mucus, pulp-liquid separation is carried out primarily; filter cake is added; heating and aging are performed after water washing and mixed pulping. The invention has the advantages of low washing water consumption, low production cost, easy control of product quality and good practicality.

Owner:中铝山东新材料有限公司

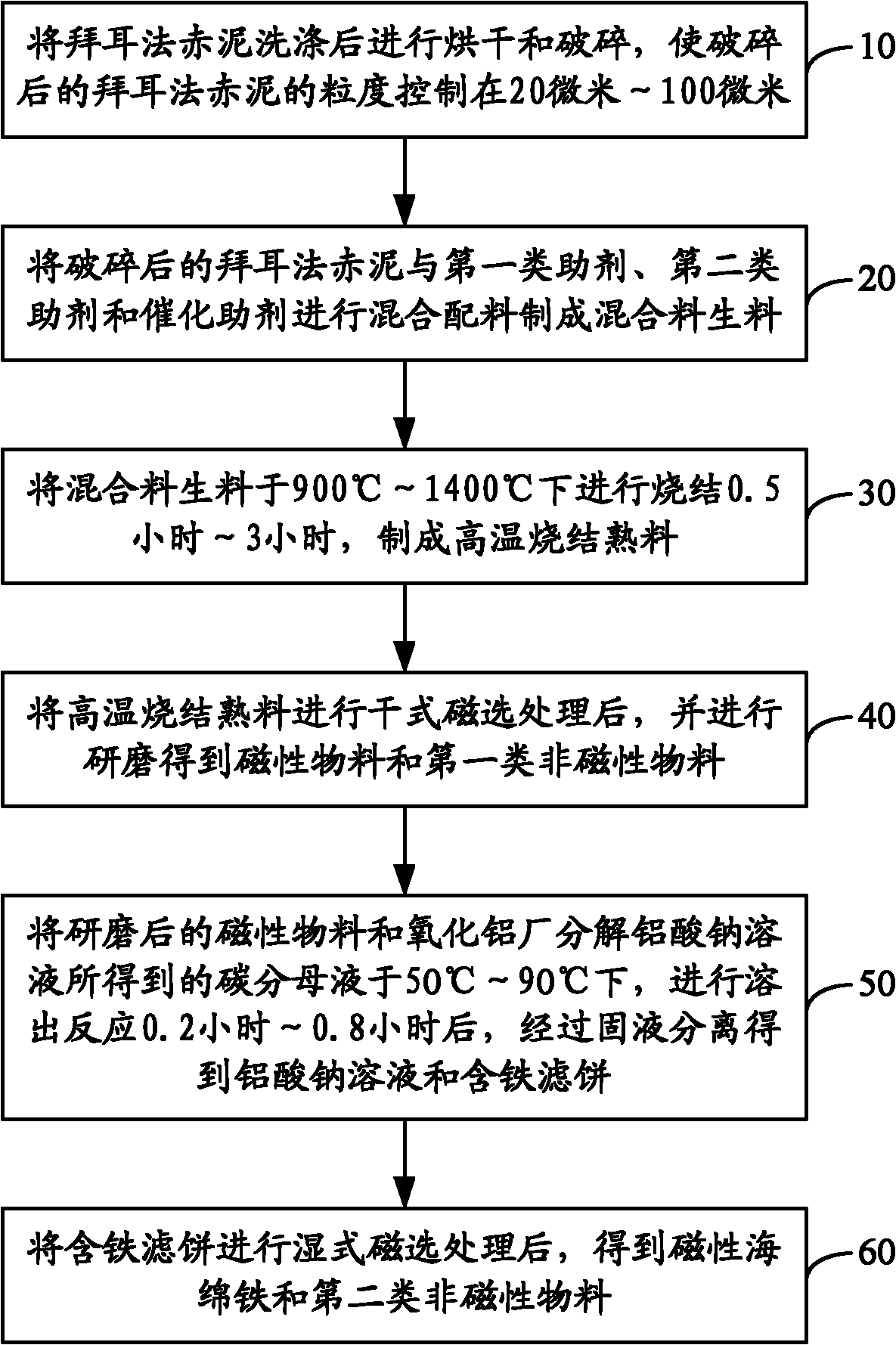

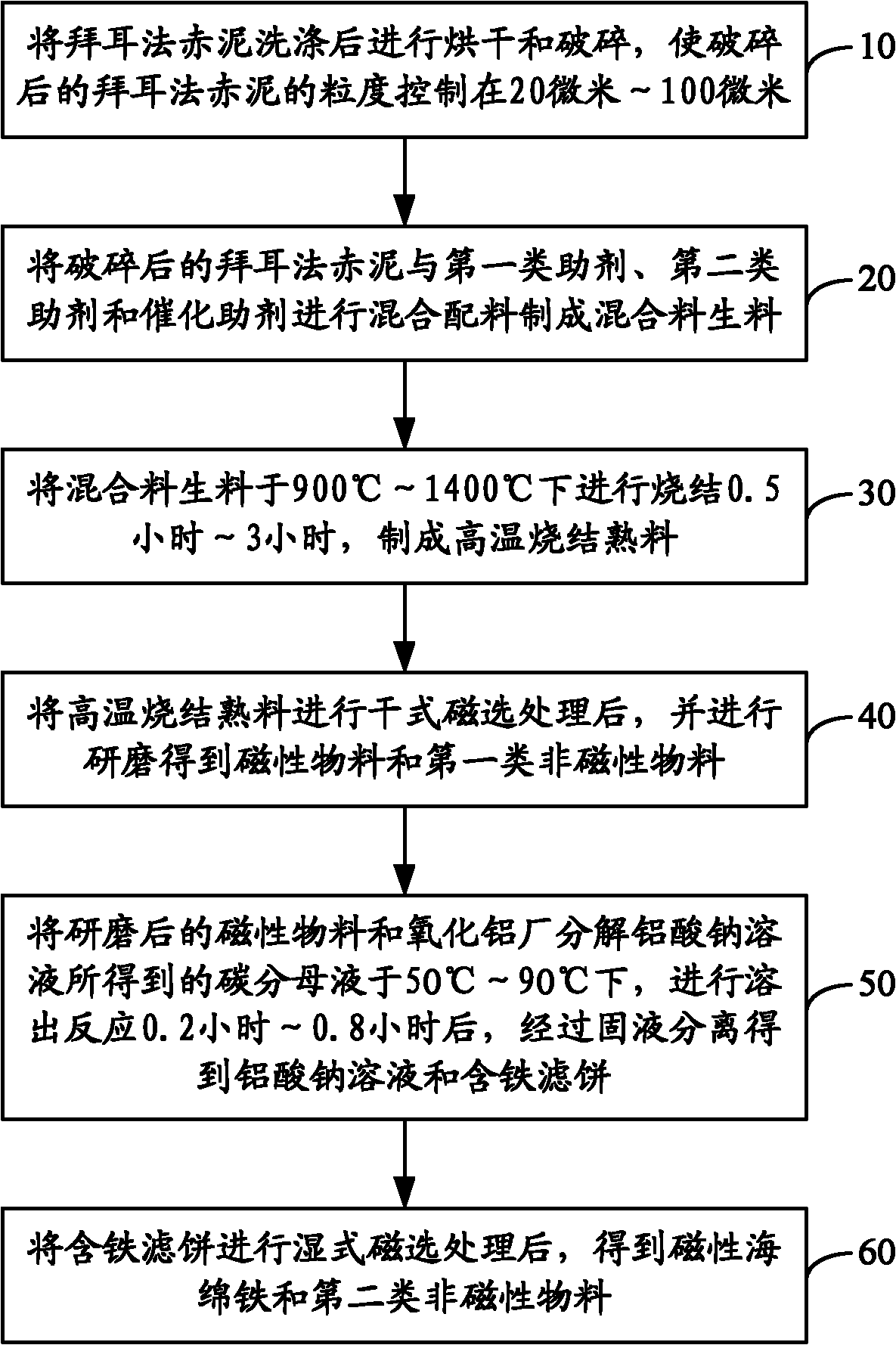

Method for producing sponge iron co-production sodium aluminate solution by using Bayer process red mud

ActiveCN101831520AReduce manufacturing costIncrease production capacityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationChemistryRefinery

The invention relates to a method for producing sponge iron co-production sodium aluminate solution by using Bayer process red mud. The method comprises the following steps of: washing the Bayer process red mud, and then drying and crushing the washed Bayer process red mud; mixing the crushed Bayer process red mud with a first type auxiliary agent, a second type auxiliary agent and a catalytic auxiliary agent so as to prepare a mixed green stock; sintering the mixed green stock to prepare a high-temperature sintered clinker; performing dry magnetic separation on the high-temperature sintered clinker, and then grinding the high-temperature sintered clinker to obtain a magnetic material and a first type non-magnetic material; performing dissolution reaction on the magnetic material and a carbon content mother liquor which is obtained by decomposing the sodium aluminate solution in an alumina refinery to obtain the sodium aluminate solution and a ferruginous filter cake; and performing wet magnetic separation on the ferruginous filter cake to obtain a magnetic sponge iron and a second type non-magnetic material. The method for producing the sponge iron co-production sodium aluminate solution by using the Bayer process red mud uses waste materials generated in an alumina production process, changes the waste materials into valuable, and reduces pollutions to the environment because of the deposition of the red mud.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for mfg. alumina nanofibre

InactiveCN1401576ASimple processInorganic material artificial filamentsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationFiberAluminium hydroxide

Owner:西安华创纳米化合物技术研究发展有限责任公司

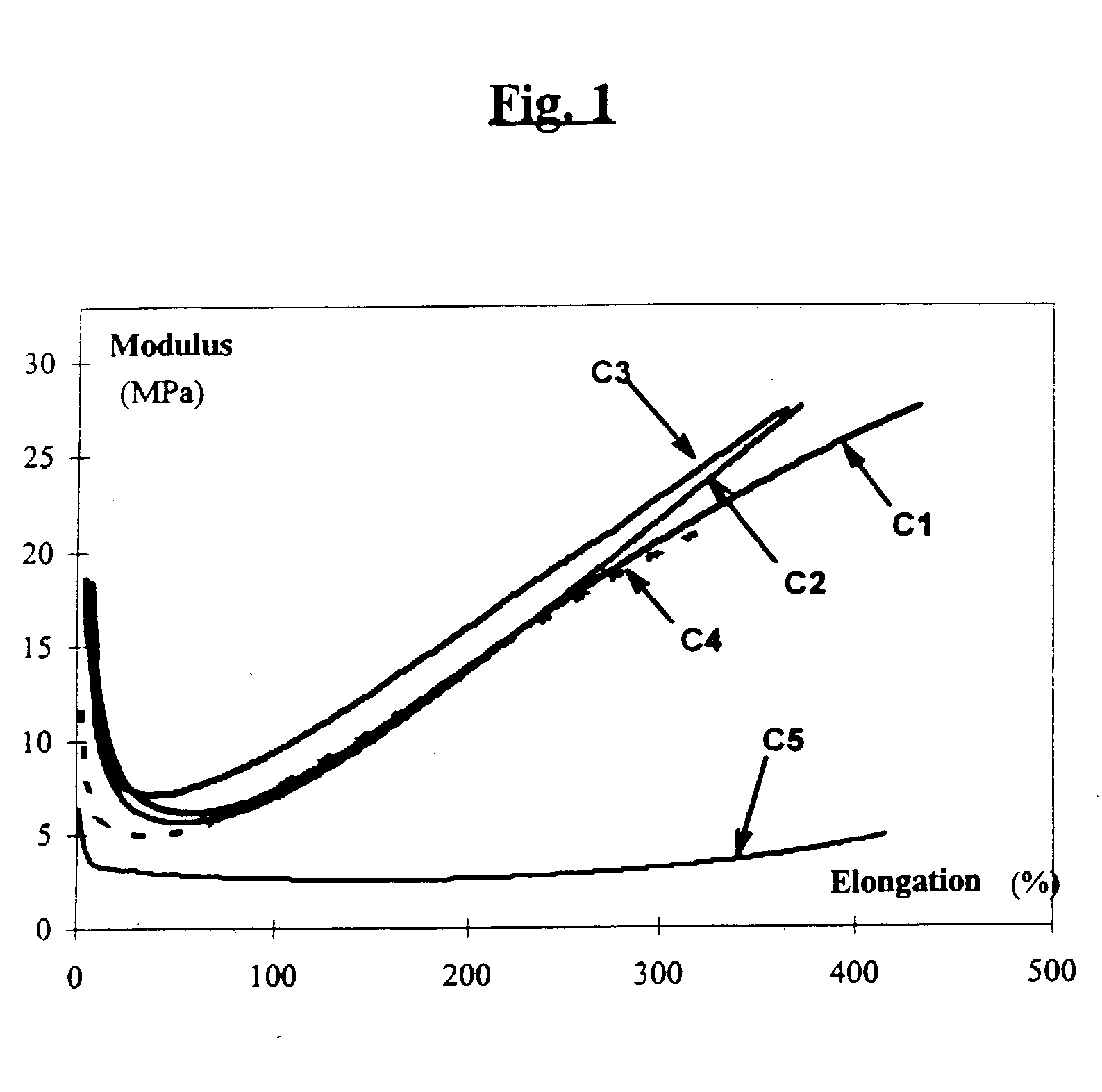

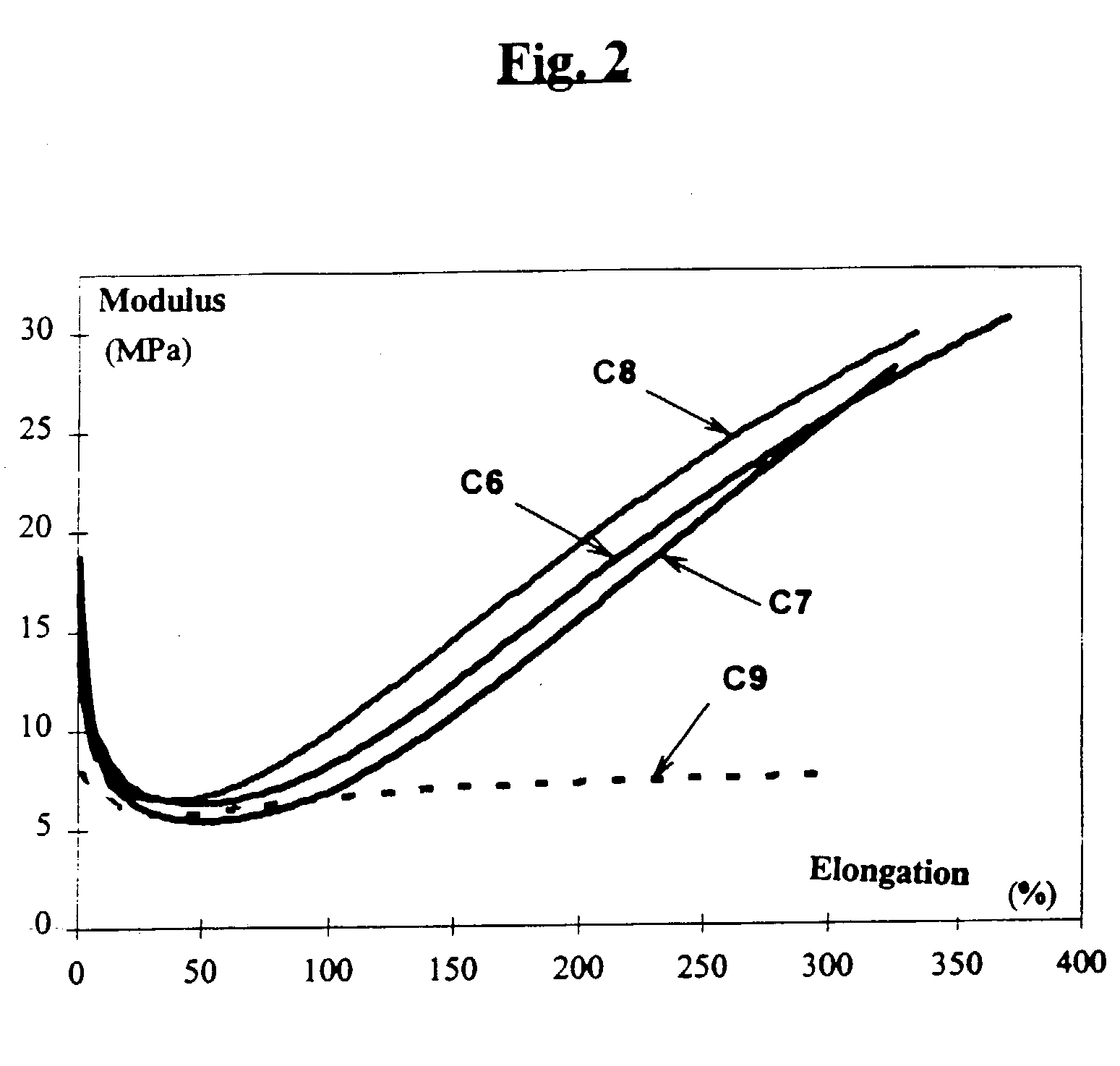

Reinforcing aluminum-based filler and rubber composition Comprising such a filler

A reinforcing aluminum-based filler which can be used for reinforcing diene rubber compositions intended for the manufacture of tires, comprising an aluminum (oxide-)hydroxide corresponding, with the exception of any impurities and the water of hydration, to the general formula (a and b being real numbers): Al(OH)aOb, with 0<a<=3 and b=(3-a) / 2, (I) the specific BET surface area of which is between 30 and 400 nm<2> / g, the average particle size (by mass) dw of which is between 20 and 400 nm and the disagglomeration rate, alpha, of which, measured via an ultrasound disagglomeration test at 100% power of a 600-watt ultrasonic probe, is greater than 5x10<-3 >mum<-1> / s is provided. A rubber composition suitable for the manufacture of tires comprising said aluminum-based filler as reinforcing filler.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

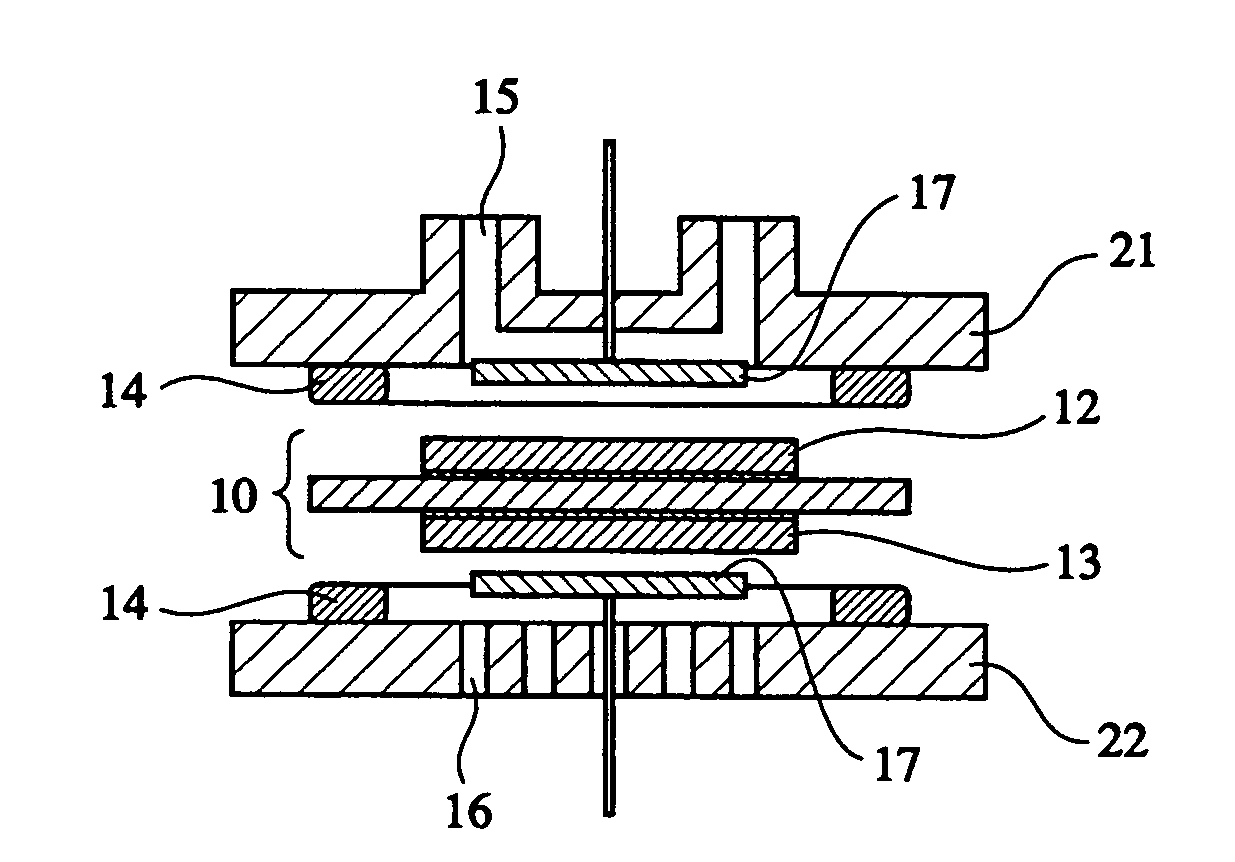

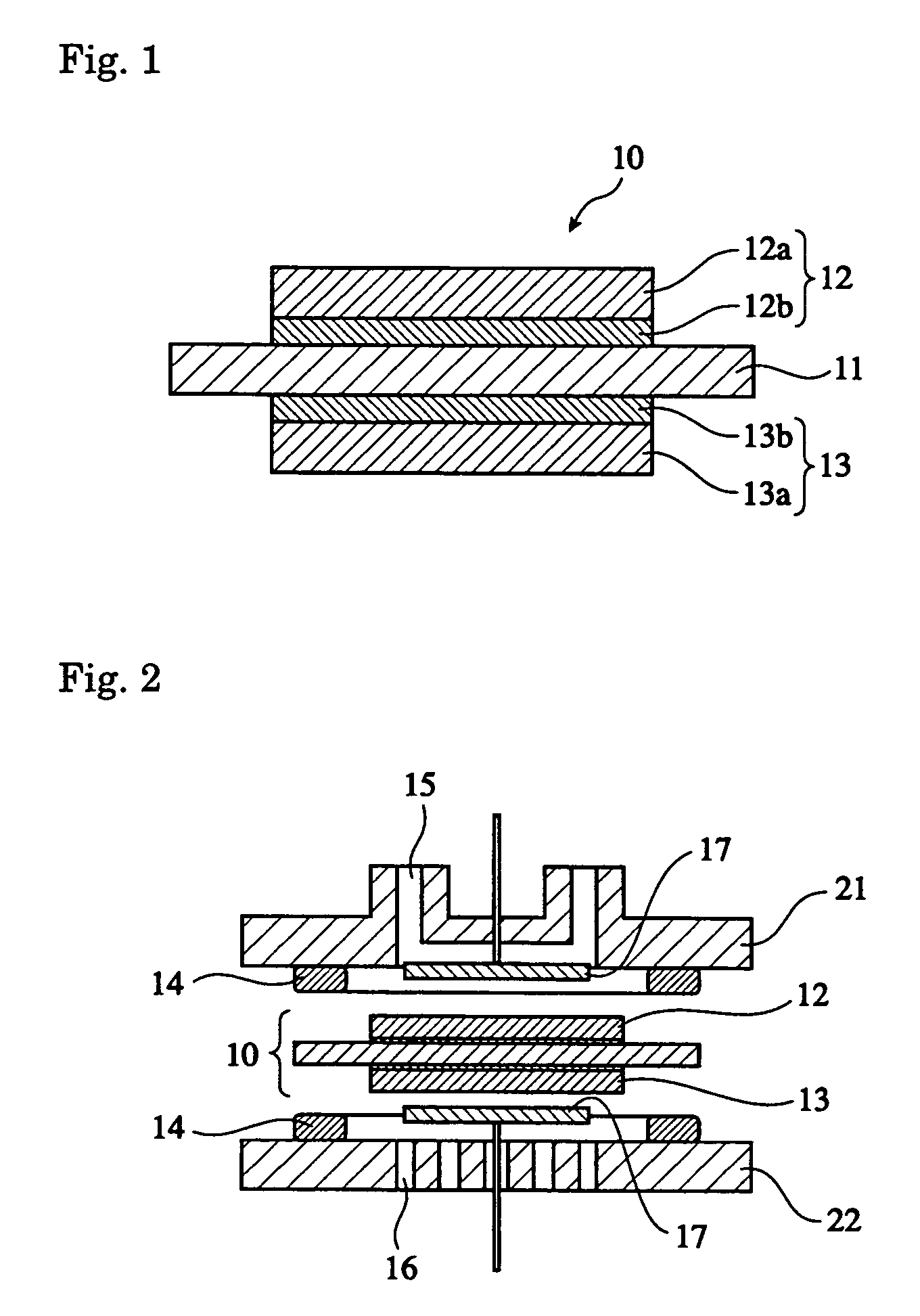

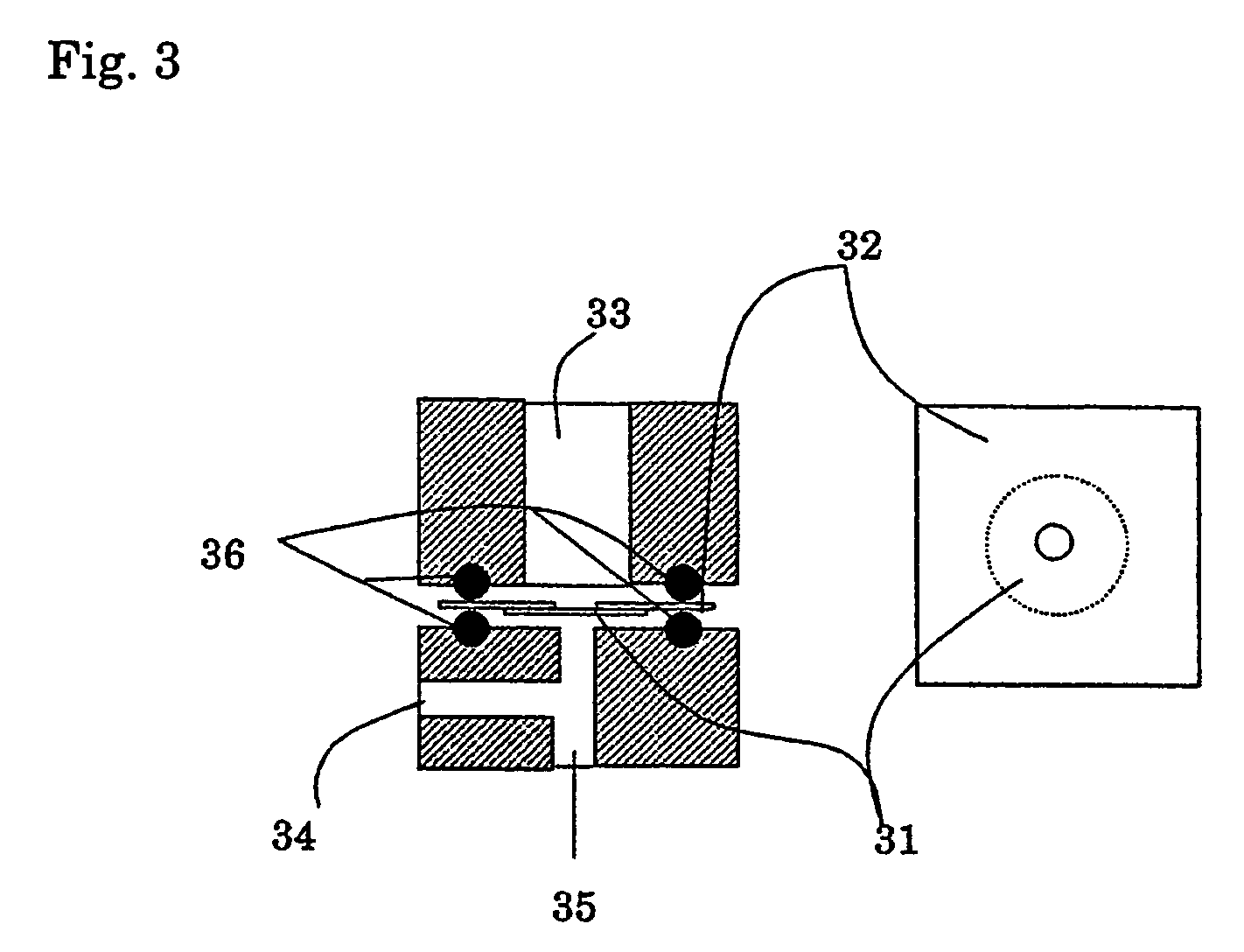

Silica sol composition, membrane electrode assembly with proton-exchange membrane, and fuel cell

InactiveUS7371480B2Process stabilityLow methanol permeabilityIon-exchanger regenerationConductive materialSilicon oxygenMethanol crossover

Provided are a proton-exchange membrane of which the ionic conductivity is high and the methanol crossover is low, and a fuel cell of high power that comprises the proton-exchange membrane. The proton-exchange membrane has a structure of mesogen-containing organic molecular chains and a proton-donating group-containing group covalent-bonding to a silicon-oxygen three-dimensional crosslinked matrix, in which at least a part of the organic molecular chains are oriented to form an aggregate thereof; and the fuel cell comprises the membrane.

Owner:FUJIFILM HLDG CORP +1

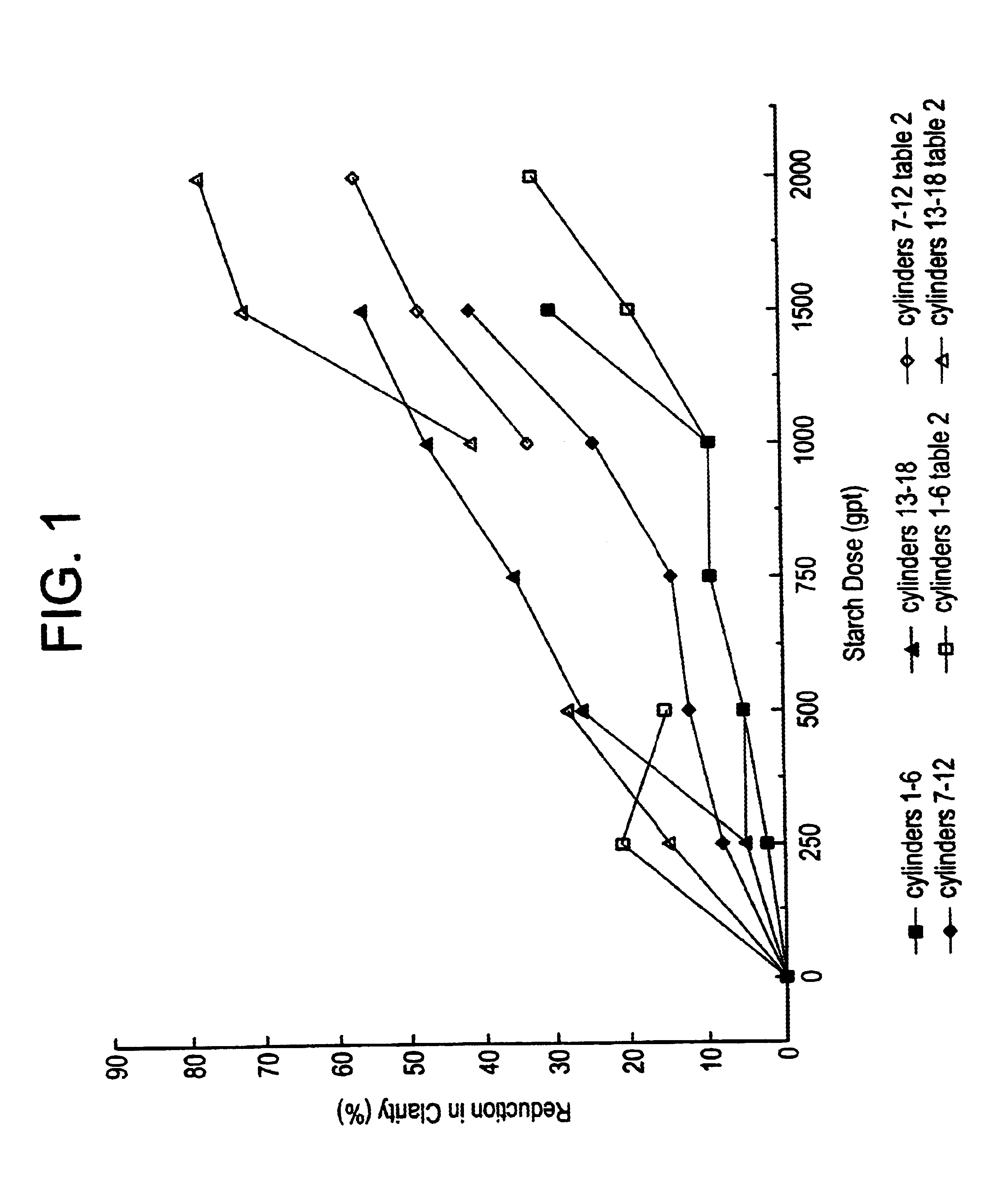

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS8298508B2Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

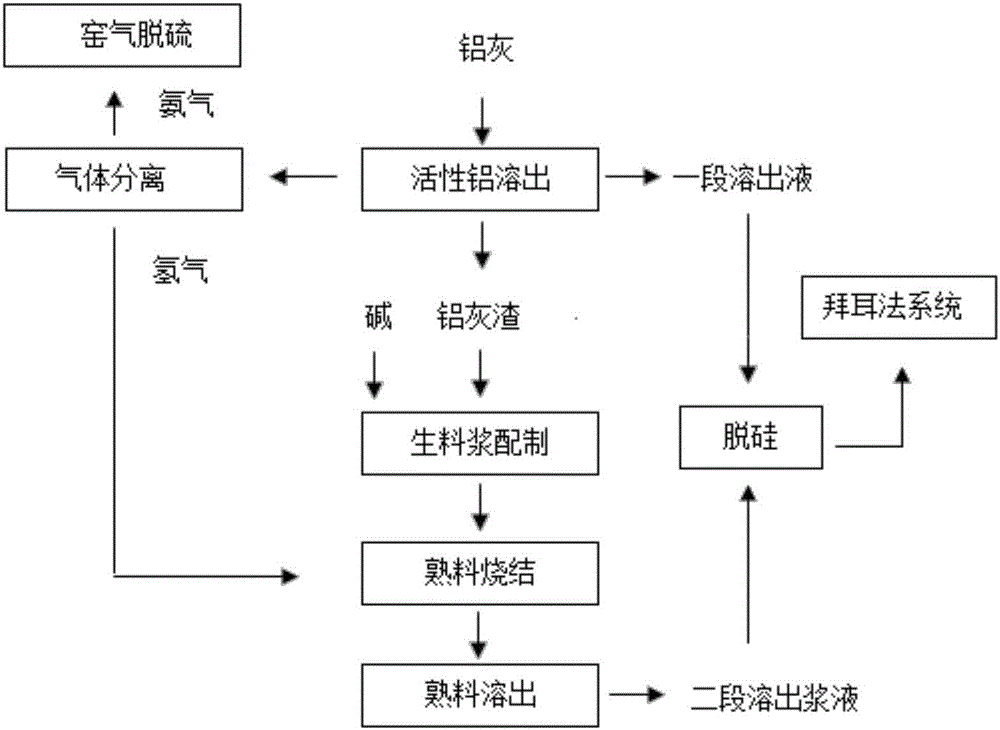

Method for safely and efficiently producing sand-like alumina from aluminum ash

ActiveCN106830030AReduce processingImprove economyChemical industryHydrogen productionHydrogenSodium aluminate

The invention provides a method for safely and efficiently producing sand-like alumina from aluminum ash. The method comprises the steps as follows: 1) aluminum ash is added to a sodium aluminate to react with the sodium aluminate solution, then solid-liquid separation is performed, a first-section digestion liquid and aluminum ash residues are obtained, and hydrogen and ammonia gas are comprehensively utilized; 2) alkali and an additive are added to the aluminum ash residues, raw slurry is obtained, and thus chlorine and fluorine elements are prevented from entering tail gas; 3) the raw slurry is sintered and clinker is obtained; 4) the clinker is added to an adjustment liquid for digestion, and second-section digestion slurry is obtained; 5) the first-section digestion liquid and the second-section digestion slurry are mixed in a Bayer process digestion slurry dilution system for production of the sand-like alumina by the Bayer process system. Nitrogen, fluorine, chlorine, hydrogen and other harmful elements in the aluminum ash are disposed safely, the concentration of organic matter in a Bayer process solution is decreased, and aluminum components are recovered efficiently and economically; for the aluminum ash, the method has the characteristics of safety, high efficiency, low cost and the like; for the Bayer process system, the yield is increased, the solution is purified, and the production efficiency is significantly improved.

Owner:CENT SOUTH UNIV +1

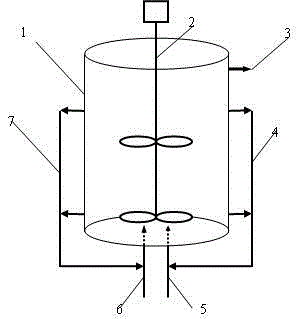

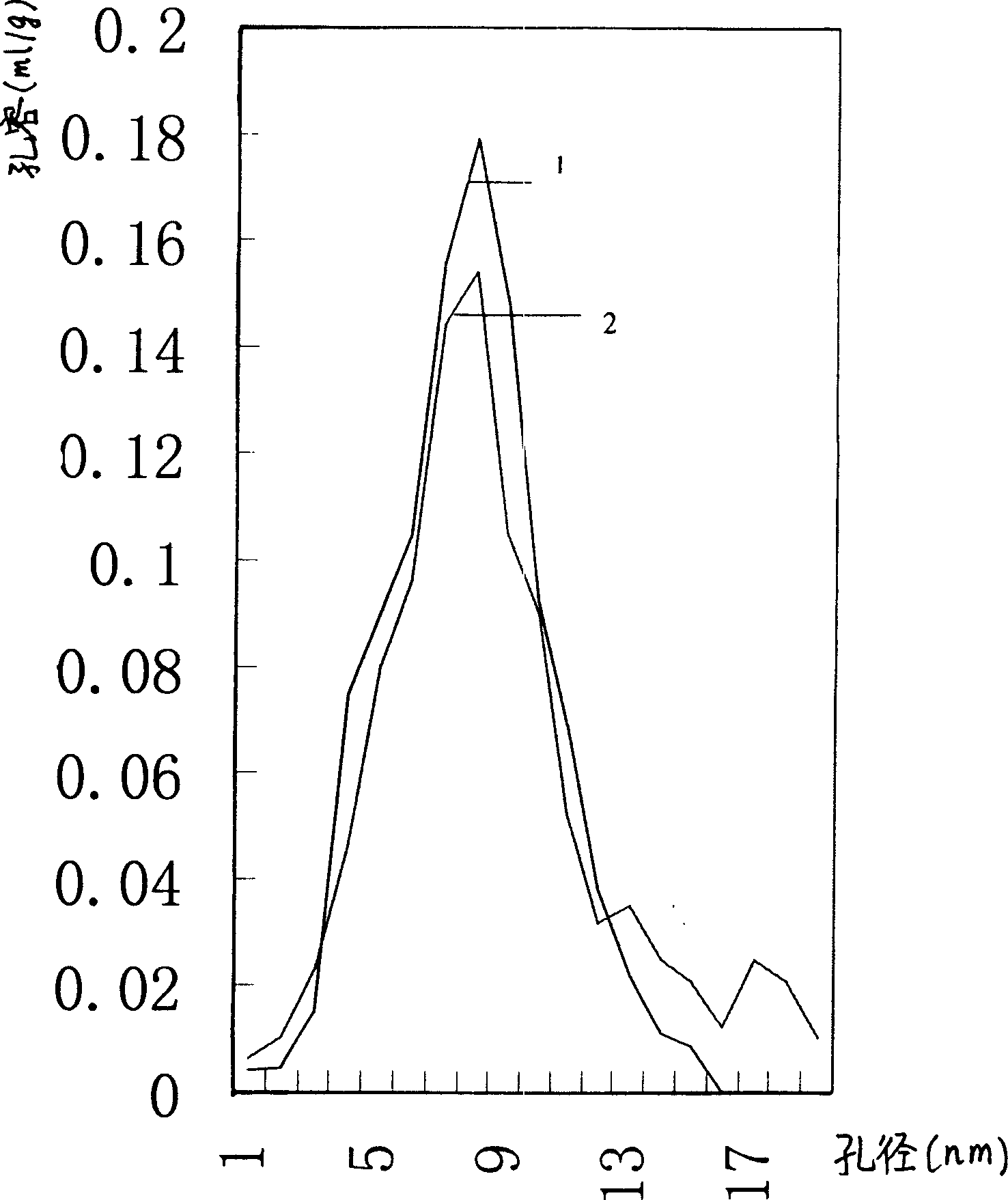

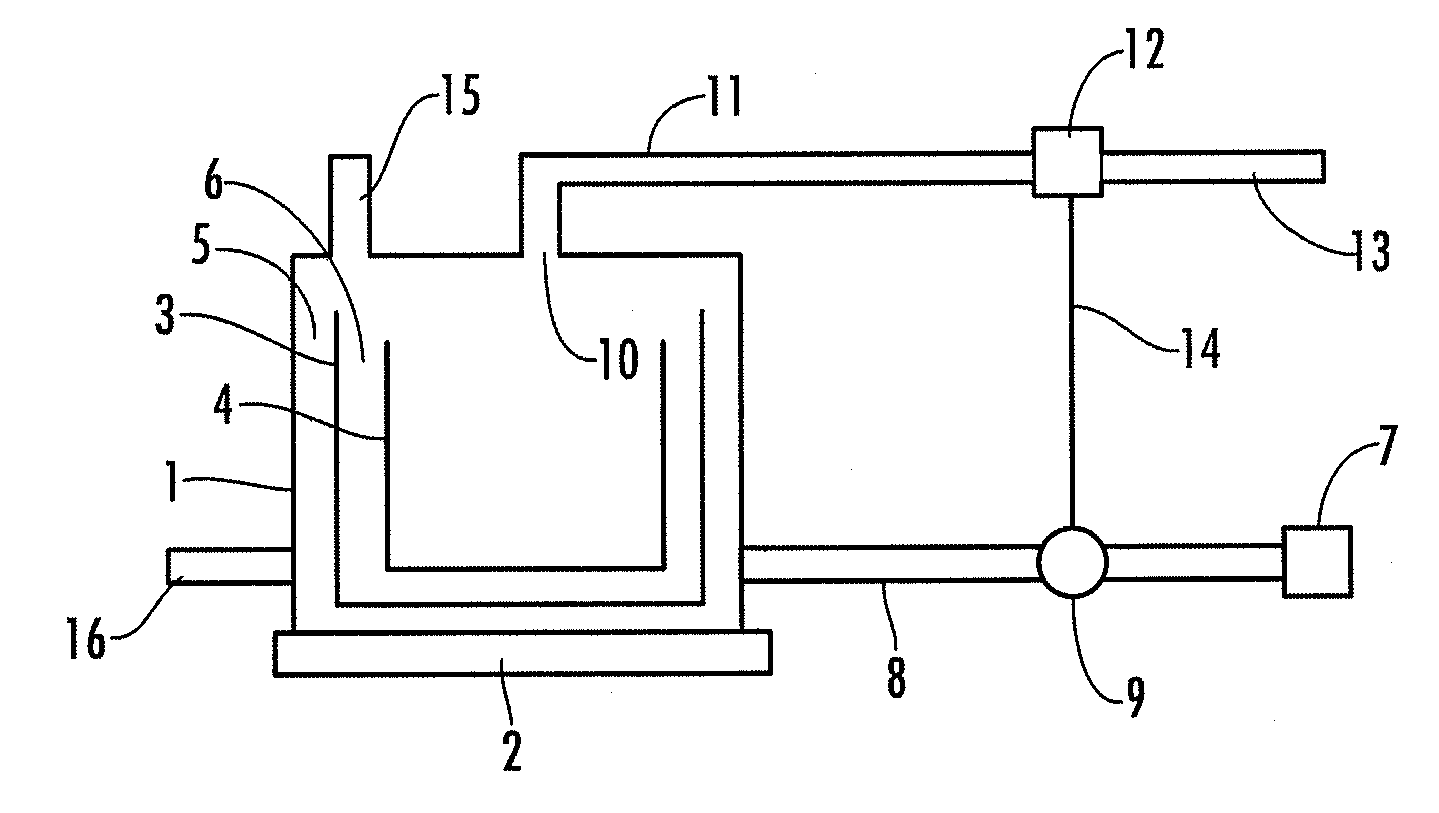

A method of preparing pseudoboehmite

ActiveCN104671265AStable in natureUniform particle sizeAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPseudoboehmitePore distribution

A method of preparing pseudoboehmite is disclosed. The method includes preparing aluminium hydroxide precipitate, ageing, washing and drying. The preparation of the aluminium hydroxide precipitate adopts a reactor, wherein the reactor comprises a reactor cylinder and is provided with a stirrer inside, the bottom of the reactor cylinder is provided with two feeding ports, two material circulating pipelines are disposed outside the reactor cylinder, each of the material circulating pipelines is provided with at least one outlet, circulating material outlets are in the upper part of the reactor cylinder, inlets of the two material circulating pipelines are respectively connected to the two feeding ports through pipelines, and the upper part of the reactor cylinder is provided with an overflow port that is higher than the circulating material outlets. Pseudoboehmite particles prepared by the method are uniform in particle size, so that prepared aluminum oxide is large in pore volume, large in pore diameter and centralized in pore distribution, and the prepared aluminum oxide is uniform and constant in properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS20120034142A1Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

Preparation of pseudo thinolite

ActiveCN1583568AUniform particlesConcentrated pore size distributionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium oxides/hydroxidesSlurryCarbonation

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for inorganically synthesizing organized mesoporous alumina

InactiveCN101993102ALow costLarge specific surface areaOther chemical processesCatalyst activation/preparationAluminium chlorideNano structuring

The invention belongs to the field of inorganic nano structure materials, in particular to a method for inorganically synthesizing organized mesoporous alumina, which is characterized in that inorganic matters of sodium aluminate and aluminum chloride are in acid-base pairing to prepare mesoporous alumina which has large specific surface area, narrow pore-size distribution, organized pore channel and high hydrothermal stability; and methyl cellulose which is used as a template agent in a synthesizing process has thermosensitivity and is beneficial to recycle. The method for inorganically synthesizing organized mesoporous alumina has the characteristics that raw materials have low cost, the template agent can be recycled, the technology is simple and easy to control, and the like. The method for inorganically synthesizing organized mesoporous alumina is easy to realize industrial production, and the obtained organized mesoporous alumina has wide application prospect in the fields of catalytic reaction, adsorption, separation, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

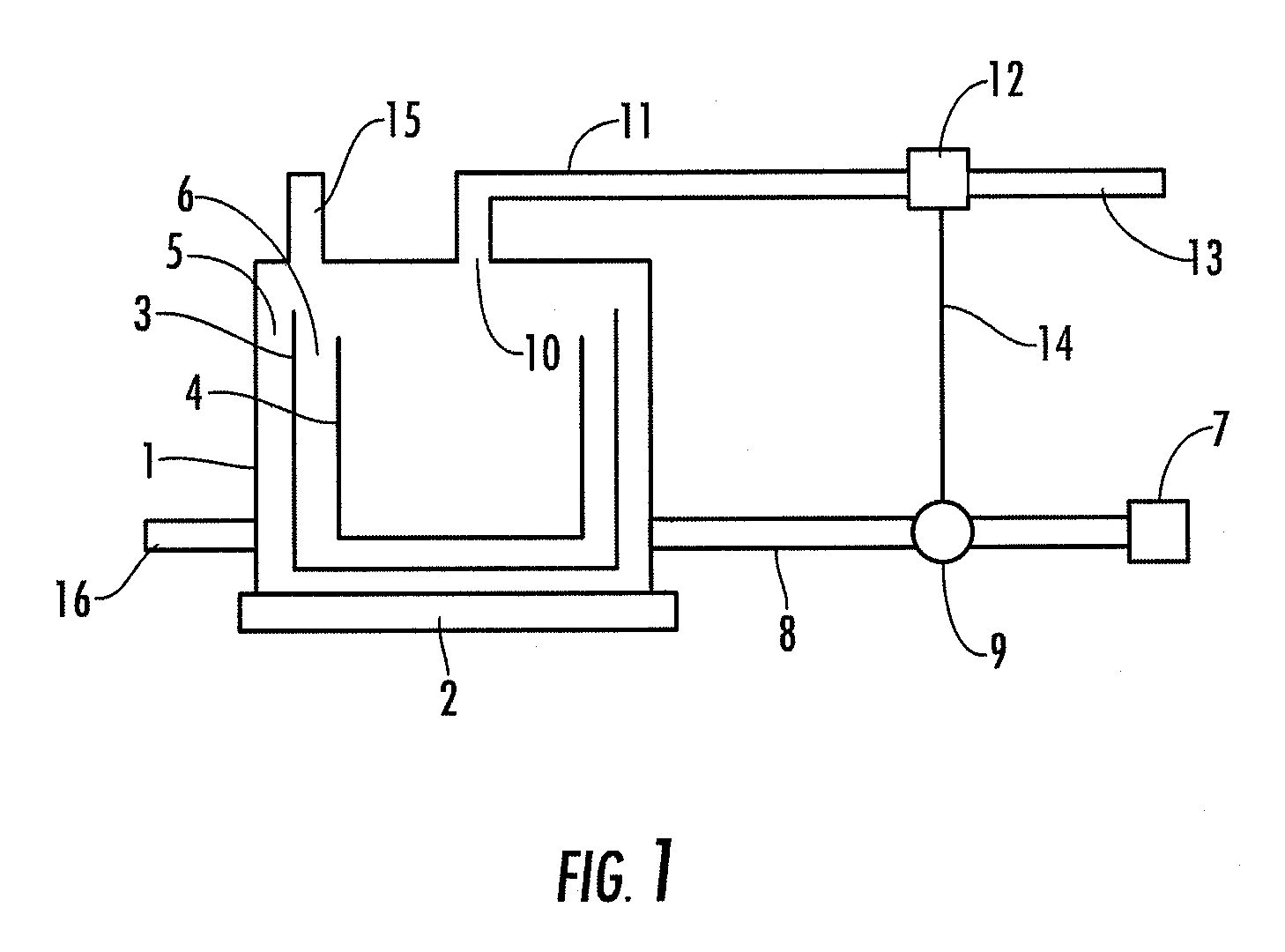

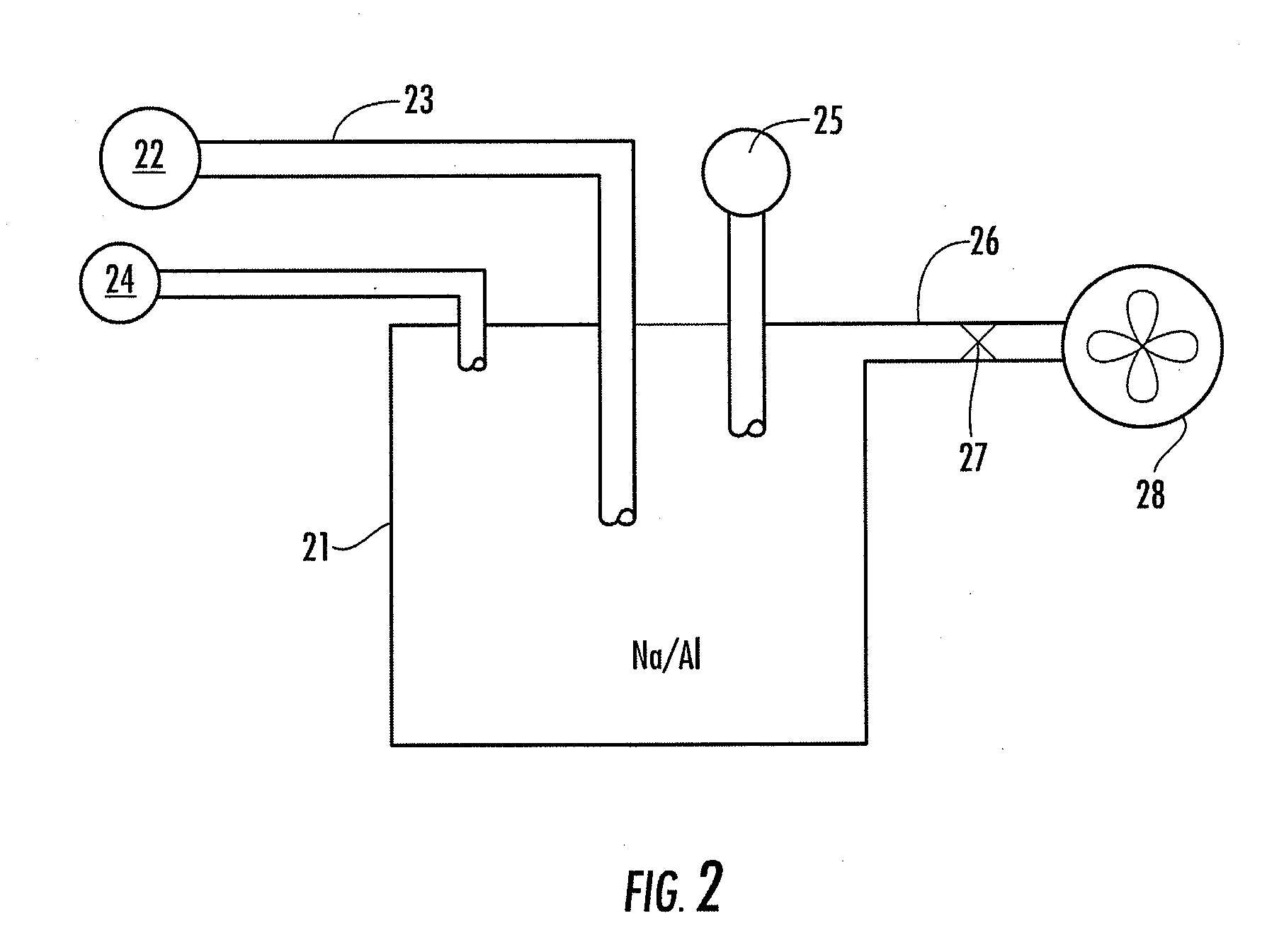

Hydrogen production and use

InactiveUS20100061923A1Sufficient supplyControl over violent natureGaseous chemical processesPressurized chemical processLiquid waterLiquid state

Sodium is reacted with water to form hydrogen, sodium hydroxide and heat, and the sodium hydroxide is reacted with aluminum to produce hydrogen and sodium aluminate, while the violent nature of the reactions is modulated by employing the exothermic heat of the reactions to convert solid sodium to liquid sodium and to convert liquid water to steam. The pressurized hydrogen generated is used to drive one or more power generators which utilize pressure to generate power. The reactions take place in a reaction chamber in which a water reservoir is disposed in open communication with a main reaction chamber.

Owner:REDDY ALLA V K

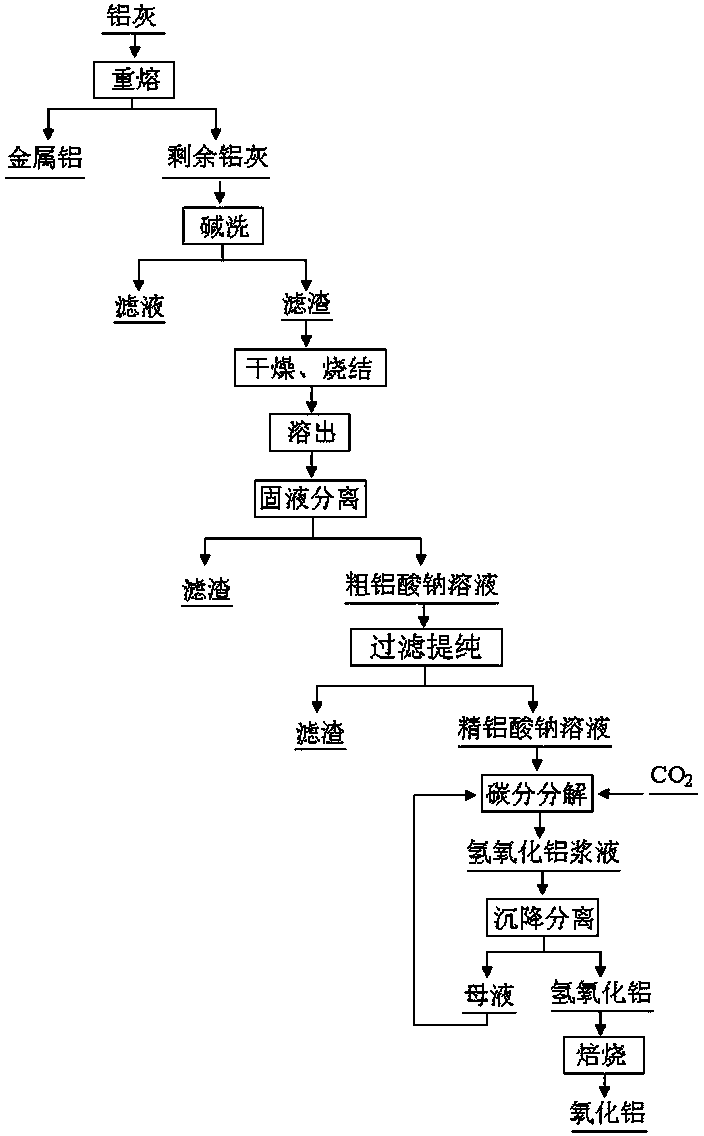

Method for harmlessly treating aluminum ash and preparing sandy alumina

ActiveCN104261445ARealize recycling of resourcesHarmlessAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium electrolysisAluminium hydroxide

The invention discloses a method for harmlessly treating aluminum ash and preparing sandy alumina. The method disclosed by the invention mainly comprises the following main steps of remelting, alkaline washing, drying and sintering, dissolving out, filtrating and purifying, carbon component decomposition, and roasting, and is specifically implemented by taking aluminum ash produced in the processes of aluminum electrolytic smelting and coarse aluminum refining as a raw material through the process post-treatment steps of recovering metallic aluminium, carrying out alkaline wash for removing impurities, sintering sodium carbonate, dissolving out sintered clinker, carrying out deep impurities removal on a sodium aluminate solution, separating and washing carbon components and aluminum hydroxide, roasting aluminum hydroxide, evaporating carbon component mother liquor, and the like, so that a sandy alumina product is obtained. Fluorine in aluminum ash, after being discharged in silicon fluoride form, is absorbed by using an aqueous solution. The method disclosed by the invention realizes the harmless treatment of aluminum ash, the method is simple in process and low in production cost, and the environmental pollution and the resource wastes caused by the aluminum ash are avoided.

Owner:KUNMING METALLURGY INST

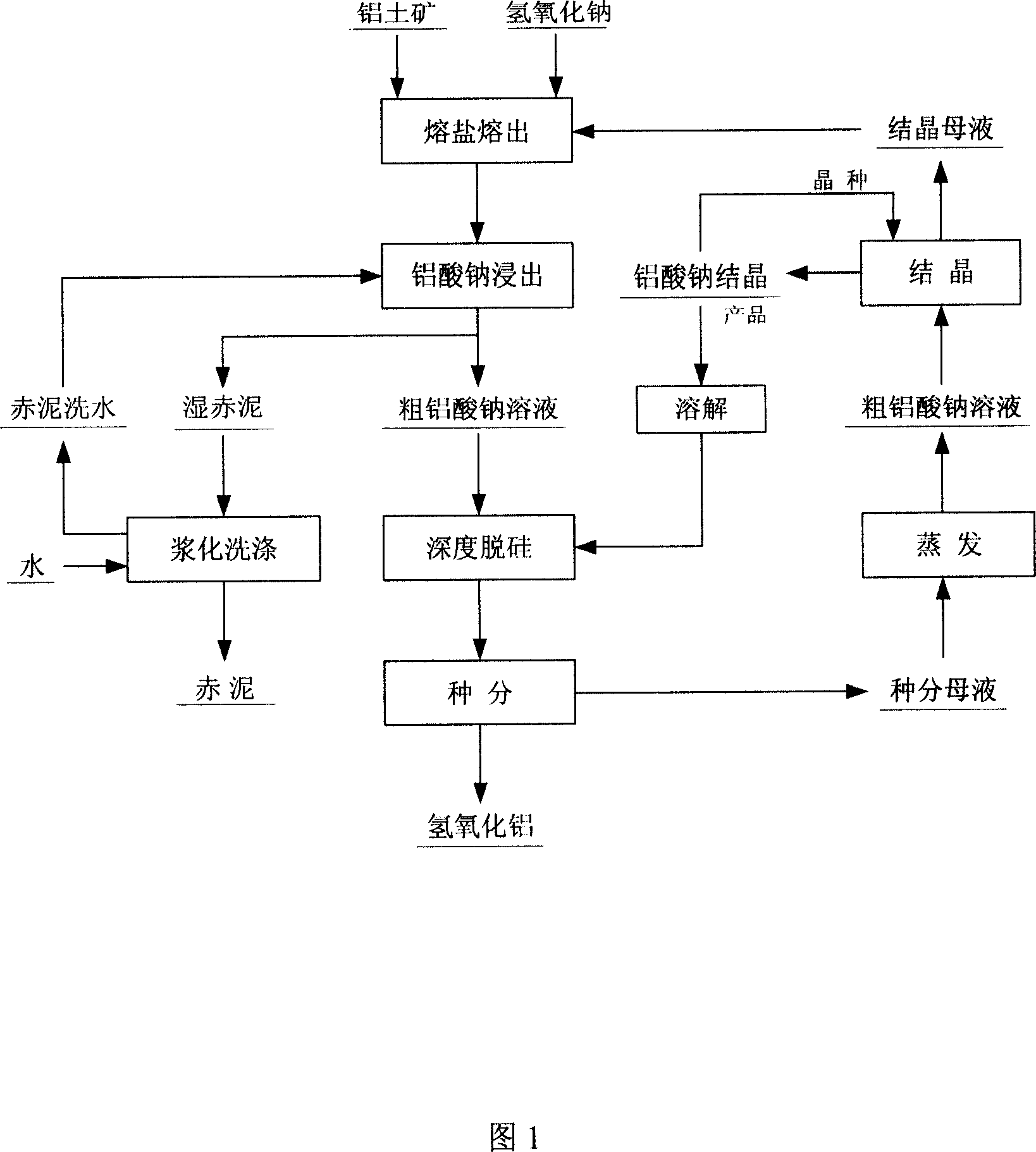

Technique for processing bauxite to produce hydroted alumina with sodium hydroxide molten salt growth method

InactiveCN101108740AReduce energy consumptionSimple processAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRed mudAluminium hydroxide

The invention relates to a process that the sodium hydroxide molten salt method is adopted to treat the bauxite to produce the aluminium hydroxide, which comprises that the sodium hydroxide solution blended evenly and the bauxite are heated to carry out the molten salt stripping reaction; the stripping grog is leached and the red mud is separated to gain the sodium aluminate solution which carries out deep desilication; the sodium aluminate solution seeds are decomposed to gain the aluminium hydroxide crystal and seeded precipitation spent liquor; the seeded precipitation spent liquor is evaporated and crystallized and the crystallized mother liquor returns to the molten salt stripping step; the sodium aluminate crystallization returns to the seeded precipitation step after dissolved by adding water. The invention has the advantages that: the digestion temperature is 500 DEG C. to 800 DEG C. lower than that of the traditional sintering method, which can greatly reduce the energy consumption; the invention is operated under normal pressure with simple flow and convenient operation; the invention can process middle-low grade-diasporite bauxite, which conforms to the realistic need of aluminium oxide development in our country; the dissolving rate of the aluminium oxide is high; any accessories are not added and the red mud amount is small, thereby the sodium loss and the aluminum loss are small and valuable metals inside are easily recycle; the product has good quality.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing high-whiteness aluminium hydroxide micropowder from Bayer process sodium aluminate solution

ActiveCN102502742AAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideSodium aluminate

A method for preparing high-whiteness aluminium hydroxide micropowder from Bayer process sodium aluminate solution is disclosed, which comprises the following steps of: (1) performing purification and decoloration on Bayer process high-concentration sodium aluminate solution at first; (2) preparing high-whiteness seed crystal by the purified and decoloured sodium aluminate solution; (3) adding the high-whiteness seed crystal slurry prepared in the step (2) in the high-concentration sodium aluminate solution purified and decoloured in the step (1), and performing seed precipitation to prepare high-whiteness aluminium hydroxide micropowder; and (4) performing surface modification on the filtered and washed high-whiteness aluminium hydroxide micropowder, so as to prevent the agglomeration of the aluminium hydroxide micropowder during drying process. In the method for preparing high-whiteness aluminium hydroxide micropowder from Bayer process sodium aluminate solution disclosed by the invention, the high-whiteness aluminium hydroxide micropowder is prepared by using high-concentration sodium aluminate solution during production process for alumina using Bayer process, leading out the high-concentration sodium aluminate solution via a lateral line, and performing the processes of purification and decoloration for solution, preparation for active seed crystal, seed precipitation for the high-concentration sodium aluminate solution and the like, and seed precipitation mother solution is returned to the present production process for alumina simultaneously.

Owner:河南能源集团研究总院有限公司 +1

Method for preparing alumina in fire resistant and high specific surface

InactiveCN1562753ASimple processLarger than surfacePhysical/chemical process catalystsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSoluble glassSilicon oxide

In the invention, meta-aluminate and soluble glass are used as raw materials to preparate aluminum oxide with high-temp. resistant and high specific surface by techonlogy that using sol-gel process to prepare aluminium oxide humidity gel and using supercritical fluid drying method to prepare aluminum oxide xerogel. The aluminum oxide contains silicon oxide (wt% is 0.1-10), the aluminum oxide xerogel is processed for 4h on 500 deg.c temp., its specific superficial area is more than 365 m2 / g, then it is processed for 4h, its specific superfical area is more than 165 m2 / g.

Owner:ZHEJIANG UNIV

Method for preparing nano material

InactiveCN102030352AThe method is scientific and reasonableImprove product qualityZinc oxides/hydroxidesNanotechnologyChemical reactionDecomposition

The invention relates to a method for preparing a nano material, which comprises the step of: preparing a nano material precursor and a nano material. The method for preparing the nano material precursor comprises the step of: placing reacting raw materials in a supergravity filed reactor for gas-liquid reaction or liquid-liquid reaction to obtain the nano material precursor. The method for preparing the nano material comprises the step of heating and roasting the nano material precursor with a microwave field to ensure that the nano material precursor generates decomposition or recrystallization to obtain the nano material. The method for preparing the nano material precursor also comprises the step of: in a process of accelerating and enhancing the mass transfer with the supergravity filed, enabling a metal salt water solution in the reactor to be uniformly mixed with a liquid precipitator or gas precipitator in a molecule size manner for chemical reaction to obtain the nano material precursor of carbonate materials or nano oxyhydrate materials or hydrous oxide materials of the metal, wherein the prepared nano material is used as a nano metal oxide. The method has the advantagesof scientific and reasonable structure, high quality of products, energy saving, no secondary pollution and the like.

Owner:XIANGTAN UNIV

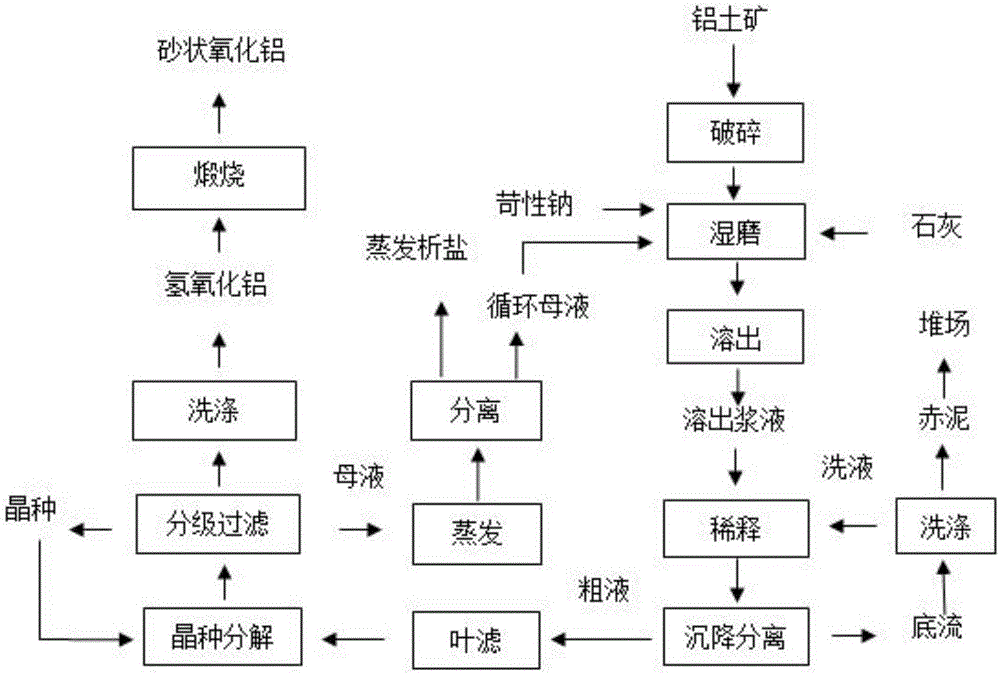

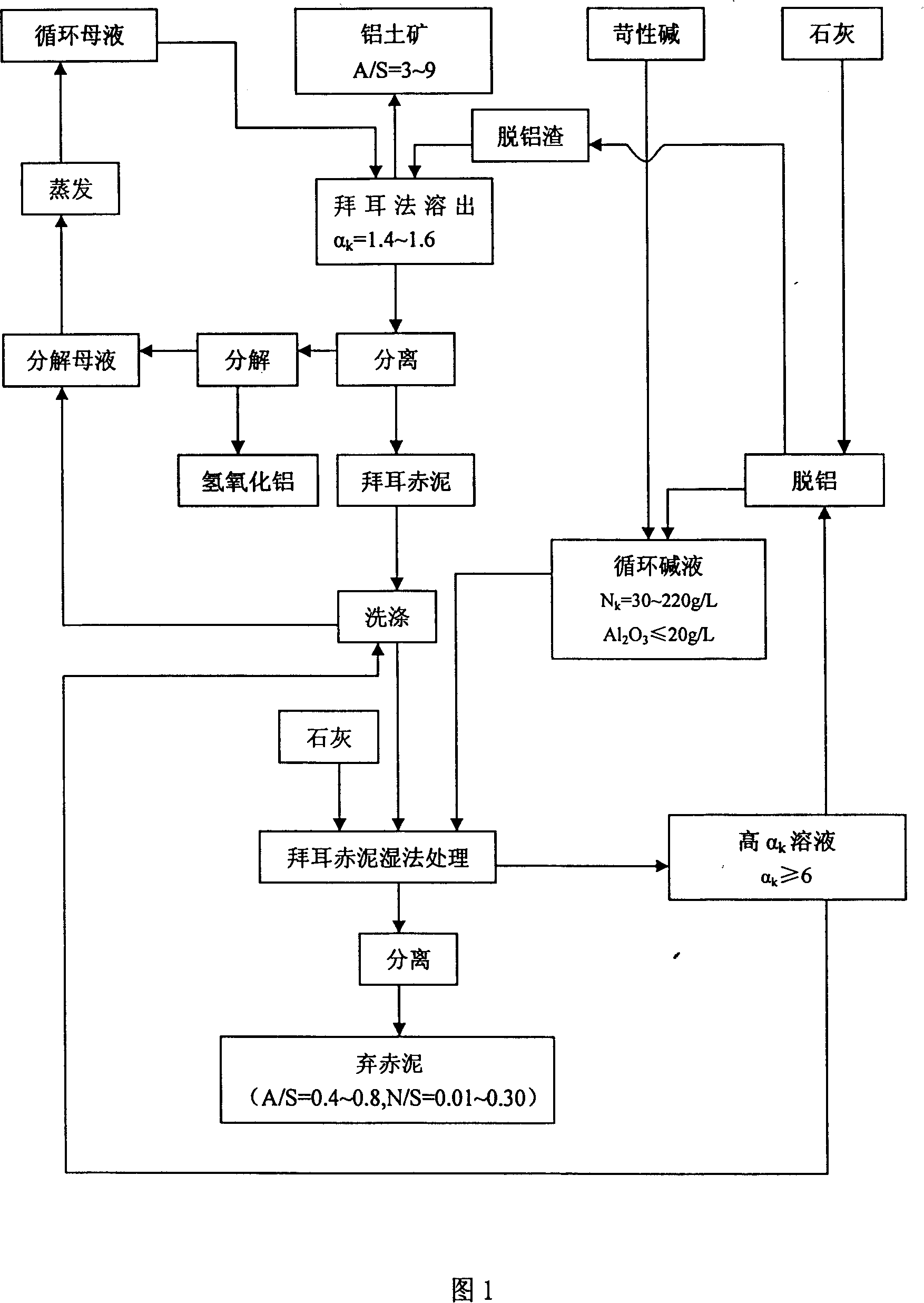

Method for producing aluminium oxide by middle-low grade alumyte

ActiveCN101113001AReduce energy consumptionReasonable processAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateResource utilization

A method to produce aluminum oxide with middle-low bauxite relates to a method to produce aluminum oxide with middle-low bauxite by the means of Bayer-method. The invention is characterized in that: during the Bayer-method process, digestion process is to add dealuminization slag instead of lime as additive in middle-low bauxite to do Bayer process digestion; after digestion and backward washing of red mud, the red mud is mixed with recycle alkaline liquor, the lime is added, the digestion reaction is done, the red mud is separated from the slurry and discharged outside, the solution part obtained oppositely washes with Bayer-method, is sent to Bayer-method system to supplement alkali after digesting the red mud, the lime is added partly and is reacted, then, dealuminization slag and recycle alkaline liquor that goes through Bayer-method red mud wet treatment are gotten and dealuminization slag calcium aluminate hydrate instead of lime is added into the Bayer process digestion. The method of the invention belongs to all wet treatment, has simple process, low energy consumption, low alkali consumption and high recovery rate of aluminum oxide and is suitable for treating Chinese bauxite that is mainly middle-low bauxite; besides, the resource utilization is high, the amount of discharged red mud is low and the red mud is easy to be utilized comprehensively.

Owner:中铝郑州有色金属研究院有限公司

Preparation method of aluminium hydroxide micro powder

ActiveCN1927719APerfect crystal developmentFine granularityAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium sulfateAluminium hydroxide

The present invention relates to technological process of producing fine aluminum hydroxide powder as fire retardant stuffing, and is especially technological process of producing fine aluminum hydroxide powder with high crystallization degree. The gel seed prepared with sodium aluminate solution through CO2 introducing carbon process and with sodium aluminate solution through aluminum sulfate neutralization process is converted via a special process into fine pure alpha-aluminum hydroxide powder without beta-aluminum hydroxide. The fine pure alpha-aluminum hydroxide powder is coated, modified and stoved to obtain submicron level pure alpha-aluminum hydroxide powder. Or, the completely converted fine powder slurry is added into sodium aluminate solution directly or after being concentrated and further decomposed to obtain fine aluminum hydroxide powder with excellent fire retarding performance.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com