Method for safely and efficiently producing sand-like alumina from aluminum ash

A technology of alumina and aluminum ash, which is applied in the field of aluminum metallurgy, can solve the problems of affecting the normal operation of alumina, poor physical indicators of products, and high impurity content of products, and achieve the effects of industrial application, reduction of energy consumption, and improvement of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

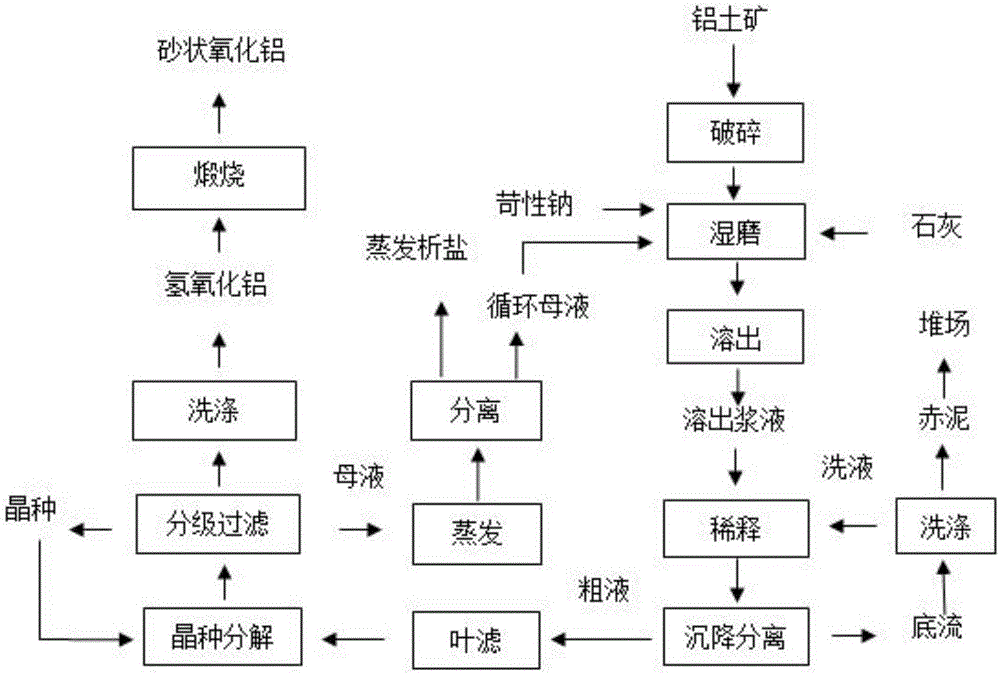

[0048] b Preparation of aluminum hydroxide: filter the crude liquid (leaf filter, leaf filter) to obtain semen, after the semen is cooled, add seed crystals to the semen to decompose [NaAl(OH) 4 Decomposed into Al(OH) 3 ] Obtain aluminum hydroxide slurry, after classification, get sandy aluminum hydroxide product and seed crystal, filter, wash product, get sandy aluminum hydroxide, lotion and mother liquor, return and continue to add to the seminal fluid of cooling for seed crystal Precipitation of aluminum hydroxide;

[0049] c Sandy alumina Preparation of alumina: Calcining sandy aluminum hydroxide to obtain sandy alumina.

[0050] Among them, the mother liquor is evaporated and concentrated to obtain the concentrated mother liquor (the recycle mother liquor prepared) and the evaporative salt containing sodium carbonate. In the pure Bayer process, water is added to dissolve and evaporate the precipitated salt, and lime is added for causticization to obtain caustic soda for...

Embodiment 1

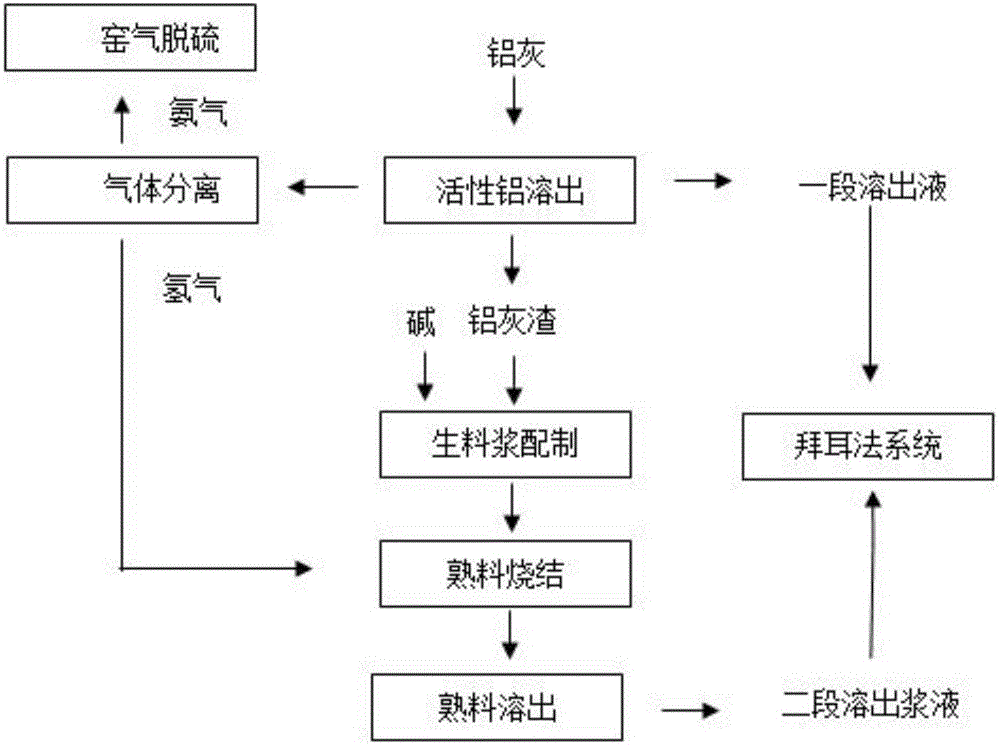

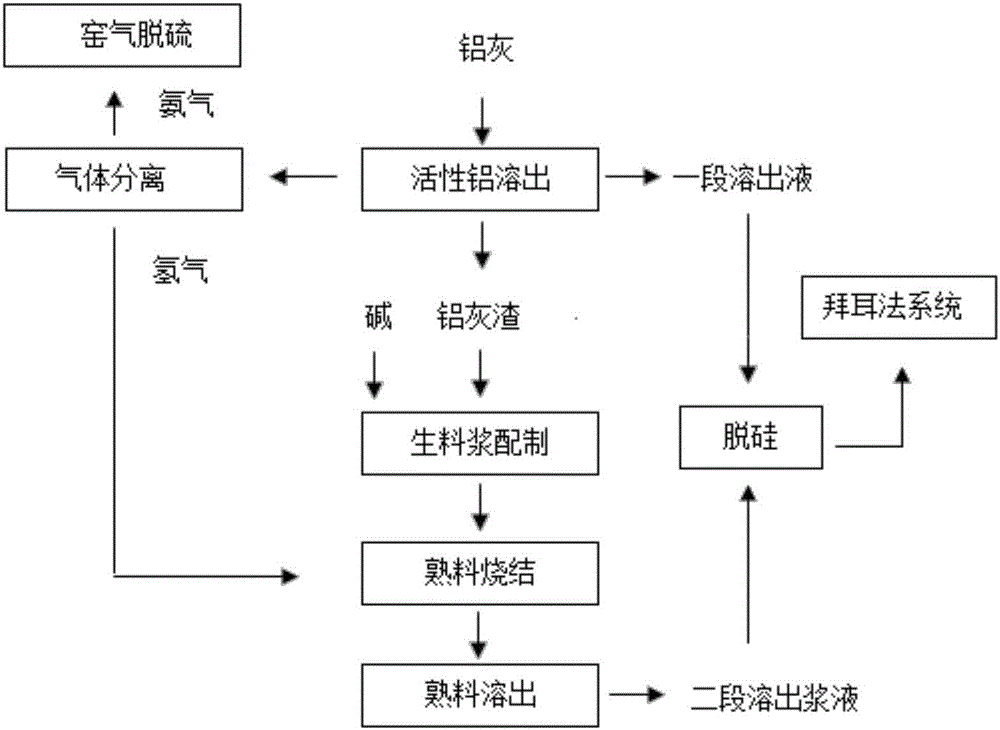

[0052] refer to figure 1 , figure 2 , a method for safely and efficiently producing sandy alumina using aluminum ash provided by the present invention, the specific steps are as follows:

[0053] 1) Take 100mL sodium aluminate solution (Na 2 o k =160g / L, Al 2 o 3 =90.8g / L, a k =2.90), add aluminum ash to the sodium aluminate solution, add aluminum ash every 5 minutes each time, the amount of each addition is 10 g / L, the total amount of aluminum ash added is 150 g / L, stir at 25 ° C for 10 h , after filtration, a section of eluate (Na 2 o k =165.7g / L, Al 2 o 3 =166.2g / L, a k =1.64, SiO 2 1.7g / L) and aluminum ash, collected hydrogen 22.5L, ammonia concentration 4.5%;

[0054] 2) Add evaporating salt in the Bayer process to the above-mentioned filtered aluminum ash (containing liquid), then add lime with 3% of the mass of aluminum ash as an additive, mix evenly to obtain raw slurry, and oxidize in the raw slurry Sodium (Na 2 o k ) to the total amount of alumina a...

Embodiment 2

[0058] refer to figure 1 , figure 2 , a method for safely and efficiently producing sandy alumina using aluminum ash provided by the present invention, the specific steps are as follows:

[0059] 1) Take 100mL sodium aluminate solution (Na 2 o k =130g / L, Al 2 o 3 =71g / L, a k =3.00), add aluminum ash to the sodium aluminate solution, add aluminum ash every 3min, the amount of each addition is 30 g / L, the total amount of aluminum ash added is 130 g / L, stir at 90°C for 10h, After filtration, a section of eluate (Na 2 o k =141.1g / L, Al 2 o 3 =158.2g / L, a k =1.47, SiO 2 =1.4g / L) and aluminum ash, collected hydrogen 14.8L, ammonia concentration 7.8%;

[0060] 2) Add the evaporating salt in the Bayer process to the above-mentioned filtered aluminum ash (containing liquid), and then add a mixture of lime, calcium aluminate and calcium-silicon slag with 5% of the mass of the aluminum ash slag as an additive and mix evenly to obtain a raw material. Sodium oxide (Na 2 ok ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com