Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

895 results about "Aluminium electrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphitized wetable cathode carbon block for aluminium electrolysis bath and production method thereof

InactiveCN101158048AGood electrical and thermal conductivityHigh degree of graphitizationShaping pressAluminium electrolysisGraphite

The invention relates to a graphitized wettable cathode carbon block used in an aluminum electrolytic tank and a production method thereof, and is characterized in that the graphitized wettable cathode carbon block consists of a graphitized carbon block matrix and a TiB2 compound layer integrated on the matrix. The production method of the graphitized wettable cathode carbon block is characterized in that when the cathode carbon block is produced through vibration molding, the working surface of the cathode carbon block is integrated with and molded by a TiB2 compound layer; a pressing molded greed block is roasted, leached, graphitized and processed by machine and a graphitized wettable cathode carbon block is prepared. The carbon block matrix of the graphitized wettable cathode carbon block used in the aluminum electrolytic tank of the invention has good electric and heat conductivity, and the TiB2 compound layer integrated and molded on the matrix is roasted and treated by high temperature heat process, thus the compound intensity can be effectively improved, so the graphitized wettable cathode carbon block used in aluminum electrolytic tank has excellent electrolyte corrosion resistance and aluminum liquid scouring resistance as well as good electric and heat conductivity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Alloy material suitable for inert anode of metal fused-salt electrolysis cell

InactiveCN101717969AReduce consumptionEliminate emissionsElectrodesAluminium electrolysisMolten salt

The invention relates to an alloy material suitable for an inert anode of a metal fused-salt electrolysis cell, relating to metal fused-salt electrolysis, in particular to a carbon-free metal-base alloy inert anode of an aluminium electrolysis cell. The carbon-free metal-base alloy inert anode of the aluminium electrolysis cell is characterized in that the alloy material comprises the following components in percentage by weight: 5-30% of Ni, 5-20% of Al, and the balance of Cu. The alloy material suitable for the inert anode of the metal fused-salt electrolysis cell is suitable for a lower-temperature (700 DEG C-850 DEG C) electrolyte system; in addition, the alloy inert anode has good high-temperature oxidation resistance and electrolyte corrosion resistance in the electrolytic processes, and electrolyzed aluminium products reach the quality more than 99.7 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

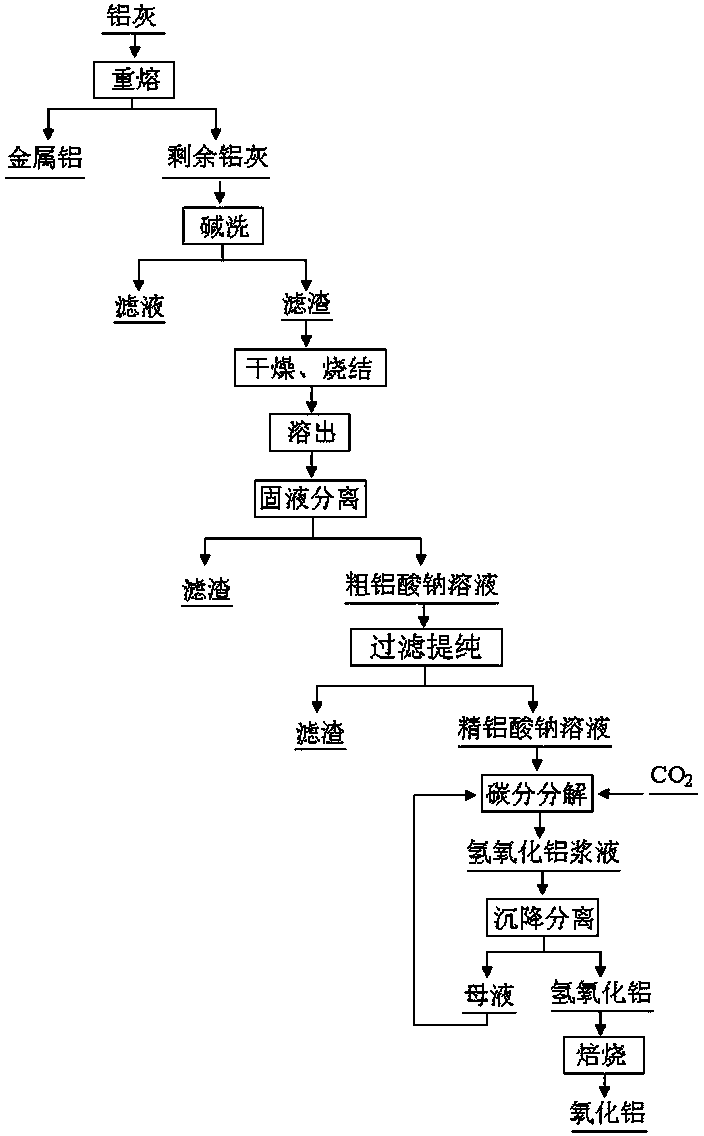

Method for harmlessly treating aluminum ash and preparing sandy alumina

ActiveCN104261445ARealize recycling of resourcesHarmlessAluminium oxide/hydroxide preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium electrolysisAluminium hydroxide

The invention discloses a method for harmlessly treating aluminum ash and preparing sandy alumina. The method disclosed by the invention mainly comprises the following main steps of remelting, alkaline washing, drying and sintering, dissolving out, filtrating and purifying, carbon component decomposition, and roasting, and is specifically implemented by taking aluminum ash produced in the processes of aluminum electrolytic smelting and coarse aluminum refining as a raw material through the process post-treatment steps of recovering metallic aluminium, carrying out alkaline wash for removing impurities, sintering sodium carbonate, dissolving out sintered clinker, carrying out deep impurities removal on a sodium aluminate solution, separating and washing carbon components and aluminum hydroxide, roasting aluminum hydroxide, evaporating carbon component mother liquor, and the like, so that a sandy alumina product is obtained. Fluorine in aluminum ash, after being discharged in silicon fluoride form, is absorbed by using an aqueous solution. The method disclosed by the invention realizes the harmless treatment of aluminum ash, the method is simple in process and low in production cost, and the environmental pollution and the resource wastes caused by the aluminum ash are avoided.

Owner:KUNMING METALLURGY INST

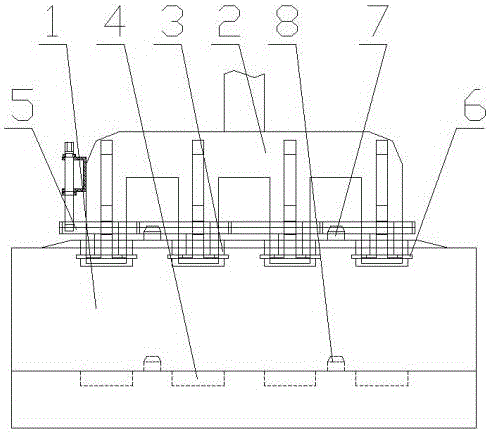

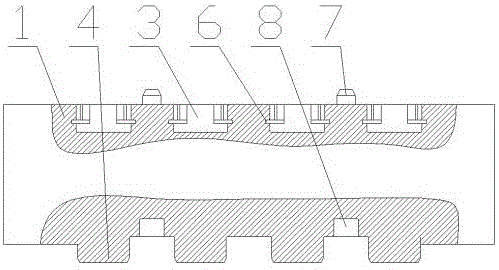

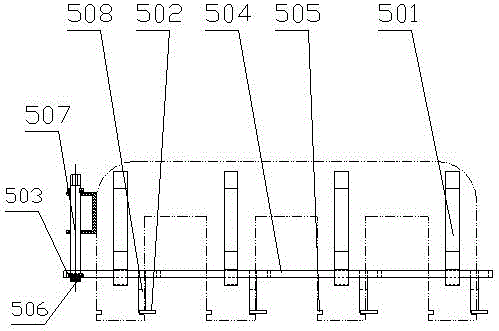

On-line anode connecting method and structure for prebaked anode aluminium electrolysis

The invention discloses an on-line anode connecting method and structure for prebaked anode aluminium electrolysis. The on-line anode connecting method is characterized in that carbon bowls (3) at the top of a carbon block body (1) of an anode is connected with a steel claw (2) through casting of aluminium water; when the carbon block body (1) in an electrolytic bath is burnt to the degree that connection with a new anode is required, aluminium water in the carbon bowls (3) of the old carbon block body (1) is molten, the steel claw (2) is taken out, and at the moment, the old carbon block body (1) bears through a covering material at the periphery of the carbon block and a condensation layer of an electrolyte; a new carbon block body (1) is placed above the old carbon block body (1); the new carbon block body (1) and the old carbon block body (1) are connected through a fixing convex head (4) at the bottom of the new carbon block body (1) and the carbon bowls (3) of the old carbon block body (1); and the steel claw (2) is fixed in the carbon bowls (3) of the new carbon block body (1) through casting of aluminium water. According to the application, the structures of the steel claw and the anode carbon blocks are further simplified, the modification cost is lowered, and the use is more convenient.

Owner:周俊和 +1

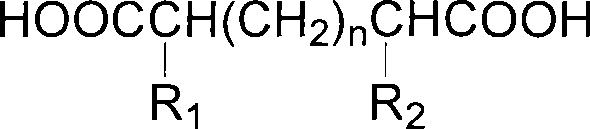

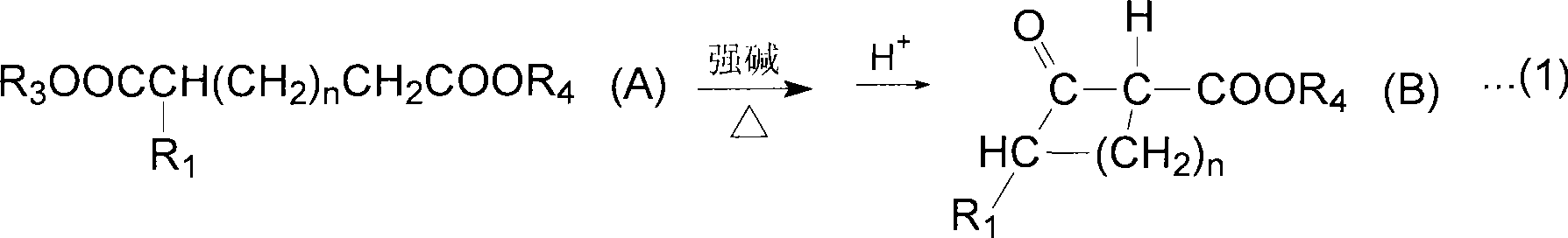

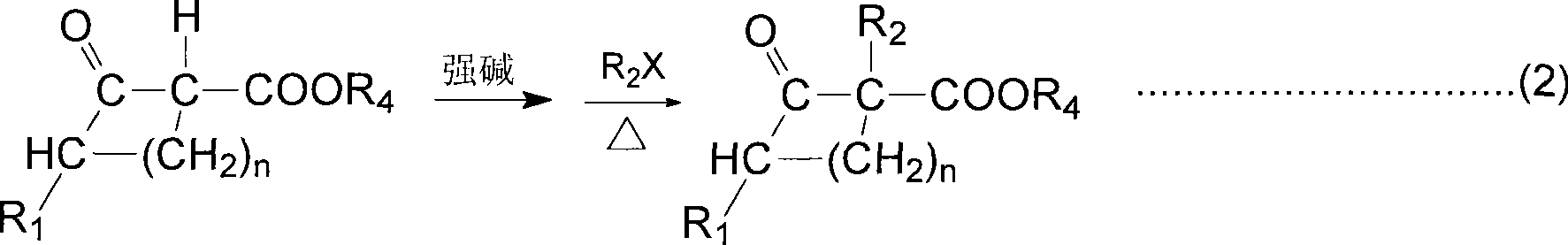

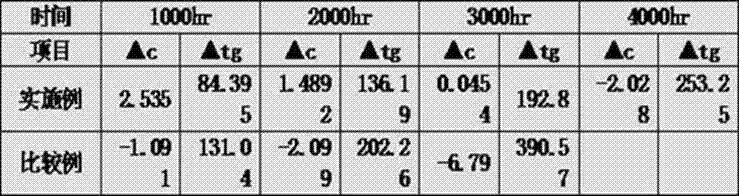

Electrolyte for aluminium electrolytic capacitor and preparation method of core solute thereof

ActiveCN101521117AImprove solubilityImprove thermal stabilityElectrolytic capacitorsPreparation from carboxylic acid esters/lactonesSolubilityCarboxylic salt

The invention relates to an electrolyte for an aluminium electrolytic capacitor and a preparation method of a core solute thereof, in particular to an electrolyte for a medium-high voltage aluminium electrolytic capacitor, which has high heat stability. The electrolyte for the medium-high voltage aluminium electrolytic capacitor comprises a solute and a solvent and is characterized in that the solute comprises alpha position dicarboxylic acid which contains branched chains or binary carboxylic salt, the solvent is one of an alcohol solvent, an alcohol ether solvent, an acid amide solvent, a sulphone solvent, a sulphoxide solvent and an ester solvent or is a mixed solvent formed by more than one of the alcohol solvent, the alcohol ether solvent, the acid amide solvent, the sulphone solvent, the sulphoxide solvent and the ester solvent, wherein the content of the alpha position dicarboxylic acid which contains the branched chains or the binary carboxylic salt is 0.1-30 percent by weight, and the preferable content is 2.5-15 percent by weight. Besides, the invention also provides a preparation method of the alpha position dicarboxylic acid which contains the branched chains and dicarboxylic acid ammonium salt. Due to the alpha position dicarboxylic acid which contains the branched chains and the binary carboxylic salt, the electrolyte inside glycol has better solubility and heat stability, and the obtained capacitor has long service life and good low-temperature property.

Owner:SHENZHEN CAPCHEM TECH

Hazard-free treatment and utilization method for aluminium electrolysis waste slot liner

ActiveCN106565120AEfficient and reasonable useAvoid wasting timeSolid waste managementAluminium electrolysisBrick

The invention relates to a hazard-free treatment and utilization method for an aluminium electrolysis waste slot liner. The hazard-free treatment and utilization method is characterized by comprising the steps of (1) performing sorting and separating on the aluminium electrolysis waste slot liner based on an aluminium electrolysis waste negative electrode carbon material and a waste fireproof material; (2) performing smashing separately; (3) performing powder grinding separately; (4) measuring content values of cyanogen and fluorine;(5) adding a solid cyanogen removal agent and a solid fluorine removal agent, and performing material mixing; (6) performing a cyanogen removal and fluorine removal and neutral reaction on the waste fireproof material; (7) performing a cyanogen removal and fluorine removal reaction on the waste negative electrode carbon material; (8) pressing and filtering material slurry obtained in the step (6), recycling the filtering liquid, and taking filtering slag for road pavement; and (9) pressing and filtering material slurry obtained in the step (7), recycling the filtering liquid, and taking filtering slag as carbon brick for manufacturing a blast furnace. By adoption of the hazard-free treatment and utilization method, different kinds of waste materials in the waste slot liner are processed, respective optimal technological parameters specific to different kinds of waste materials are selected, and the hazard-free slag can be sorted and reasonably recycled.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method used for preparing fluorine salt taking aluminium fluoride as main component from electrolyte-containing material produced in aluminium electrolysis

ActiveCN110194478AElectrolyte composition is stableEfficient recyclingIron oxides/hydroxidesAluminium fluoridesAluminium electrolysisAluminium fluoride

The invention provides a method used for preparing a fluorine salt taking aluminium fluoride as a main component from electrolyte-containing material produced in aluminium electrolysis. The method comprises following steps: the electrolyte-containing material is mixed with a soluble aluminium salt or an aluminium salt solution, and reaction is carried out at 50 to 100 DEG C; a reaction product issubjected to solid liquid separation, after separation, an obtained solid product is washed and dried so as to obtain the fluorine salt taking aluminium fluoride as a main component, and a liquid solid product obtained through separation and a solid product washing solution obtained in washing of the solid product are mixed so as to obtain a mixture, a strong basicity hydroxide or a solution of the strong basicity hydroxide is added into the mixture to remove calcium and iron impurities in the mixture; evaporation concentration desalting is carried out, and separation is carried out so as to obtain a concentrated mother liquor; a carbonate or a solution of the carbonate is added to remove Lithium-ion impurities in the concentrated mother liquor, after impurity removing, an obtained solution is adopted in diluting or washing step in the method. The method is capable of converting the excess electrolyte-containing material produced in aluminium electrolysis into aluminum fluoride, so that effective circulation of fluoride element in aluminium electrolysis enterprises is realized, and great meaning on aluminium electrolysis industry development of China is achieved.

Owner:郑州于斯新创科技有限公司

Method for extracting metal from coal ash by fused salt electrolysis method

The invention discloses a method for extracting metal from coal ash by a fused salt electrolysis method, which belongs to the technical field of metallurgy. The method I comprises the following steps: (1) mixing Na3AlF6 and AlF3 to prepare cryolite-based fused salt; (2) putting the cryolite-based fused salt into an electrolytic bath, and adding the coal ash; and (3) heating the electrolytic bath to 910-985 DEG C, then electrifying for electrolysis, depositing on a negative pole to form an aluminium-based alloy. The method II comprises the following steps: (1) mixing Na3AlF6 and AlF3 uniformly to prepare cryolite-based fused salt; (2) putting the cryolite-based fused salt into an electrolytic bath, and adding the coal ash and aluminium oxide; and (3) heating the electrolytic bath to 930-985 DEG C, then electrifying for electrolysis, and after the electrolysis is finished, depositing on a negative pole to form an aluminium-based alloy. The method disclosed by the invention has the beneficial effects that the coal ash is treated by the fused salt electrolysis method, oxides of aluminium, silicon, titanium, iron and the like are directly electrodeposited to prepare the alloy, so that the green, high-efficiency and comprehensive utilization of the coal ash is realized. The method disclosed by the invention has the advantages that the process is simple, the production can be carried out in an existing industrial aluminium electrolysis bath, the flow process is short and continuous production can be achieved.

Owner:NORTHEASTERN UNIV

Method for producing insulating bricks by utilizing aluminum-electrolyzed waste refractory materials

InactiveCN102059736AEmission reductionAdsorptiveCeramic shaping apparatusCyanide compoundAluminium electrolysis

The invention discloses a method for producing insulating bricks by utilizing aluminum-electrolyzed waste refractory materials, relating to a recovery technology of waste refractory materials during the aluminum electrolysis production, wherein the aluminum-electrolyzed waste refractory materials are mainly various refractory material mixture in which waste cathode carbon blocks and side silicon carbide are removed. The method adopts the following raw materials in percentage by weight: 5-30% of the aluminum-electrolyzed waste refractory materials, 10-50% of fly ash or fly ash drift beads, 15-30% of a cementing agent, 1-5% of additives, 3-8% of a pore-forming agent and 10-20% of water, and the method comprises the following steps of: preparing the raw materials, mixing the raw materials, extruding the mixture to mold, drying and sintering to produce the insulating bricks; and by utilizing innocuous treatment measures, the extraction contents of fluoride and cyanide of the produced insulating bricks are lower than 50mg / l and 1.0mg / l, the smoke gas is adsorbed by an aluminum oxide, and the solvable injurant and the smoke gas of the insulating bricks both meet the national environment protection emission standard; and the produced insulating bricks can be applied to the heat insulation of various pipelines and walls at a temperature lower than 1000 DEG C.

Owner:YICHUAN LONGHAI TECH INDAL

Method for recycling electrolyte in aluminium electrolysis waste tank lining through ultrasonic-assisted pressing alkaline leaching

The invention relates to a method for recycling an electrolyte in an aluminium electrolysis waste tank lining through ultrasonic-assisted pressing alkaline leaching, and belongs to the technical field of recycling of solid waste resources of aluminium electrolysis. The method comprises the steps of crushing and grinding the aluminium electrolysis waste tank lining till the particle size is 0.074 mm or below; blending the waste tank lining powder and water into slurry, and carrying out ultrasonic pretreatment; carrying out pressure leaching on the treated slurry through alkali liquor, and carrying out filtering separation; and burying filter residues, and introducing a filtrate into CO2 to separate out an electrolyte sediment. According to the method, through the synergistic effect of ultrasonic treatment and pressure leaching, soluble substances in the waste tank lining are dissolved in the alkali liquor to a maximum extent to be recycled; the method is simple in technological process, short in treatment cycle, free of secondary pollution, and suitable for treating the aluminium electrolysis waste tank lining low in carbon content; and during the entire treatment process, the electrolyte recovery rate is 96.84%, and the process cycle is 90 min.

Owner:CENT SOUTH UNIV

Aluminium electrolysis flue gas dry purification method

ActiveCN102373489AReduce pollutionImprove working environmentDispersed particle filtrationPurification methodsAluminium electrolysis

The invention relates to a flue gas purification technology and especially to an aluminium electrolysis flue gas dry purification method. The aluminium electrolysis flue gas dry purification method provided by the invention comprises the following steps of: 1) collection step by a seal gas gathering system; 2) butterfly valve unlatching step for allowing flue gas to enter into a branch smoke pipe of a horizontal smoke pipe; 3) ash removal step; 4) feeding step; 5) boiling step; 6) feeding adjustment step; and 7) flue gas purifying and dedusting step. According to the aluminium electrolysis flue gas dry purification method, the design of the technological control process is optimized, the utilization rate of energy is raised, and energy consumption is reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

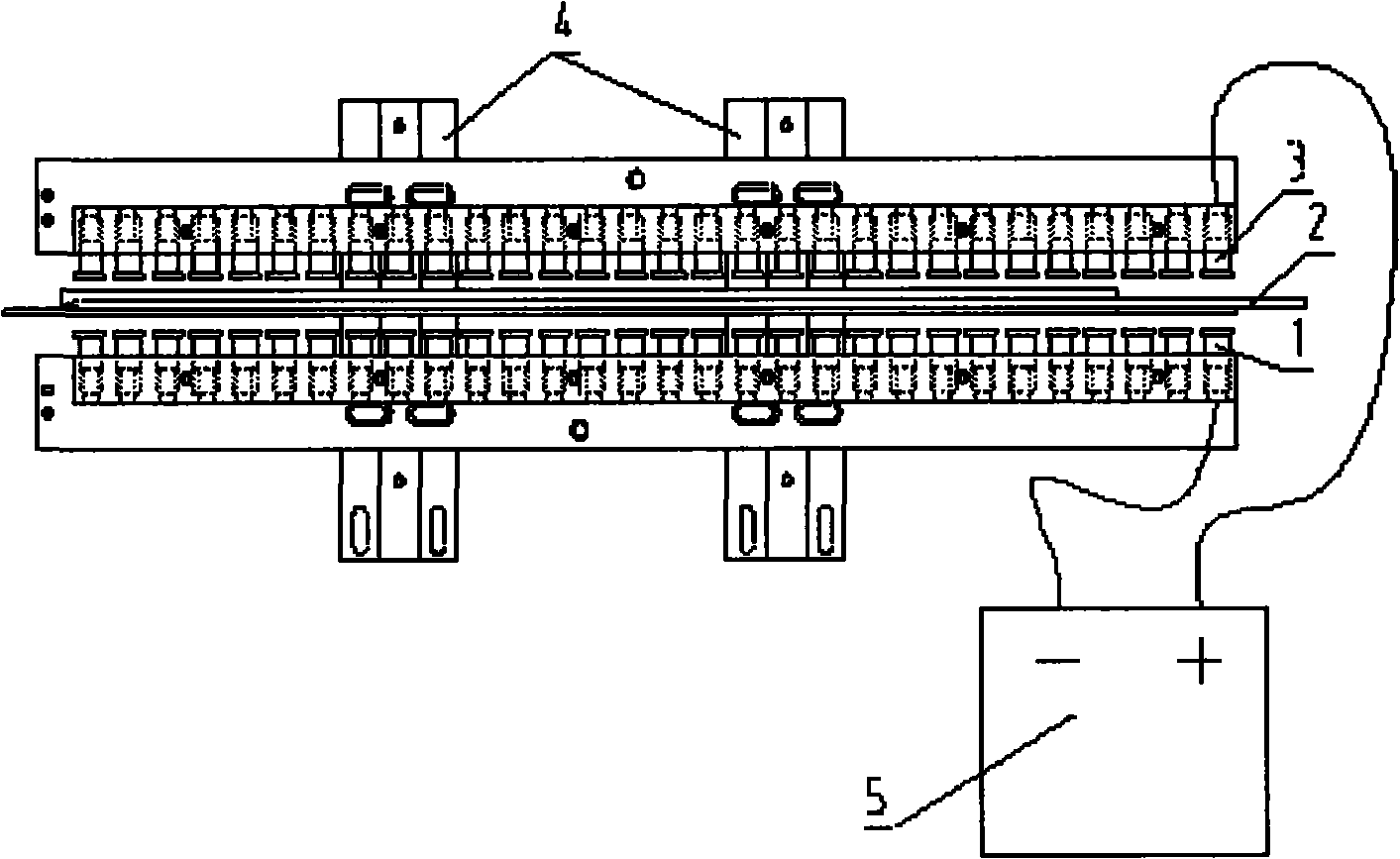

Preprocessing method and apparatus for aging aluminium electrolysis capacitor

InactiveCN101329944AAccelerated agingSpeed up agingElectrolytic capacitorsCapacitor manufactureAluminium electrolysisAge method

The invention relates to an aging method applied to processing an aluminum electrolytic capacitor and a device thereof, and provides a preprocessing method of an aluminum electrolytic capacitor before aging and a device thereof. Before aging, a charging process of the aluminum electrolytic capacitor is carried out; the current loaded to the two electrodes of the capacitor is DC current or pulse current, the current value is 30A to 150A; the voltage value is 6.3V to 120V; in the current and voltage, the burr and raw edge produced in material cutting and nail coiling processes of the aluminum electrolytic capacitor can be burned. The device of the invention consists of an anode contact (1), an isolation insulation board (2), a cathode contact (3), a sliding seat (4) of the anode and cathode contacts and a fixed power source (5). When in charge, the device can straighten the bent anode and cathode lines, thereby being conducive to aging and clipping of the capacitor. Therefore, aging speed can be increased and aging efficiency can be improved.

Owner:HUNAN AIHUA GRP

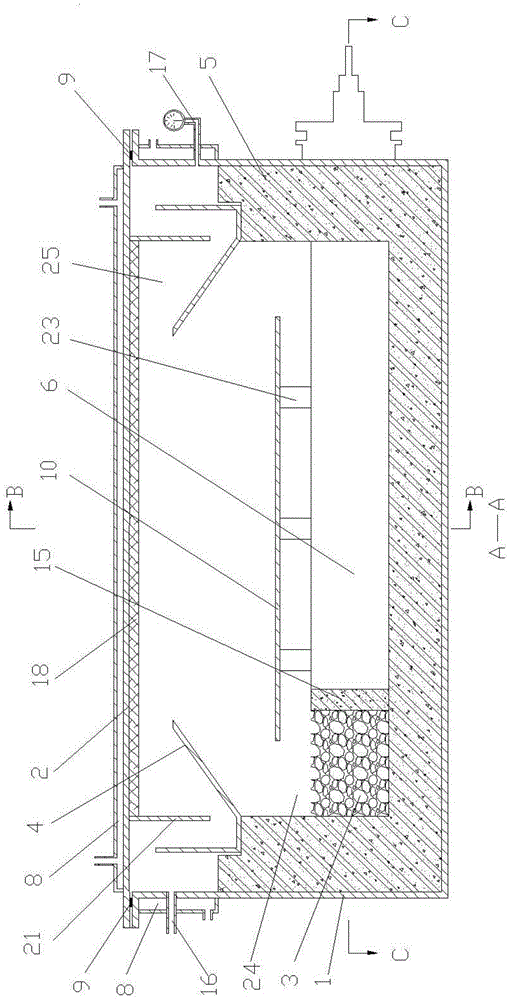

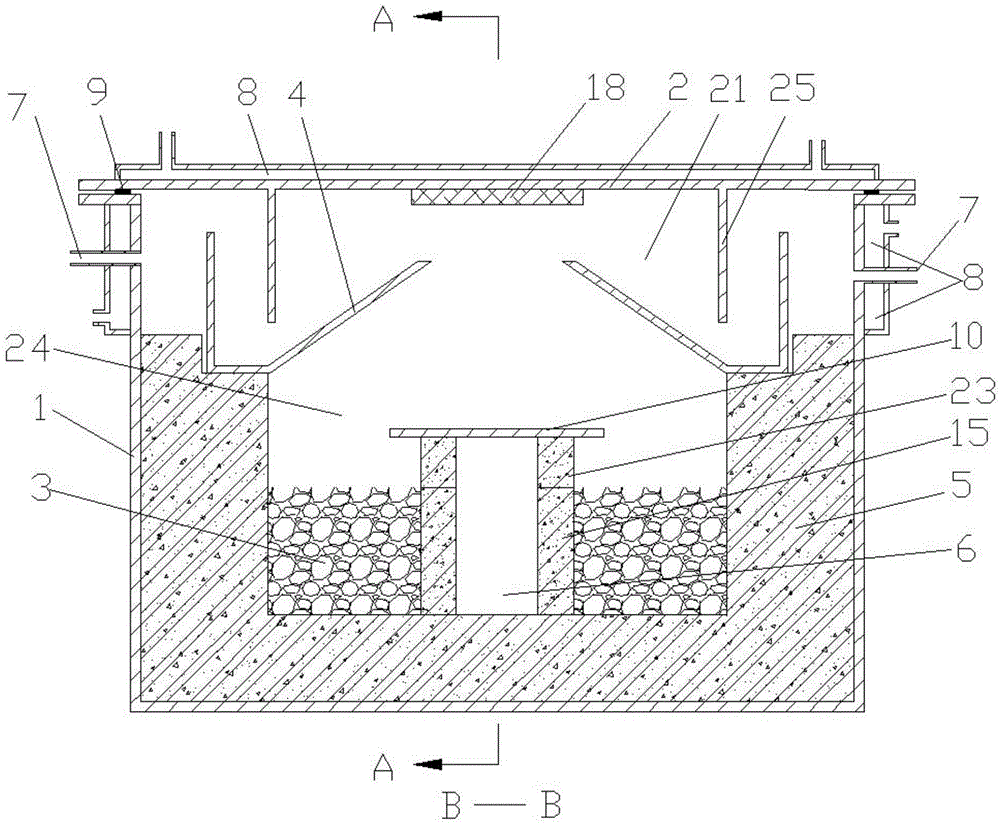

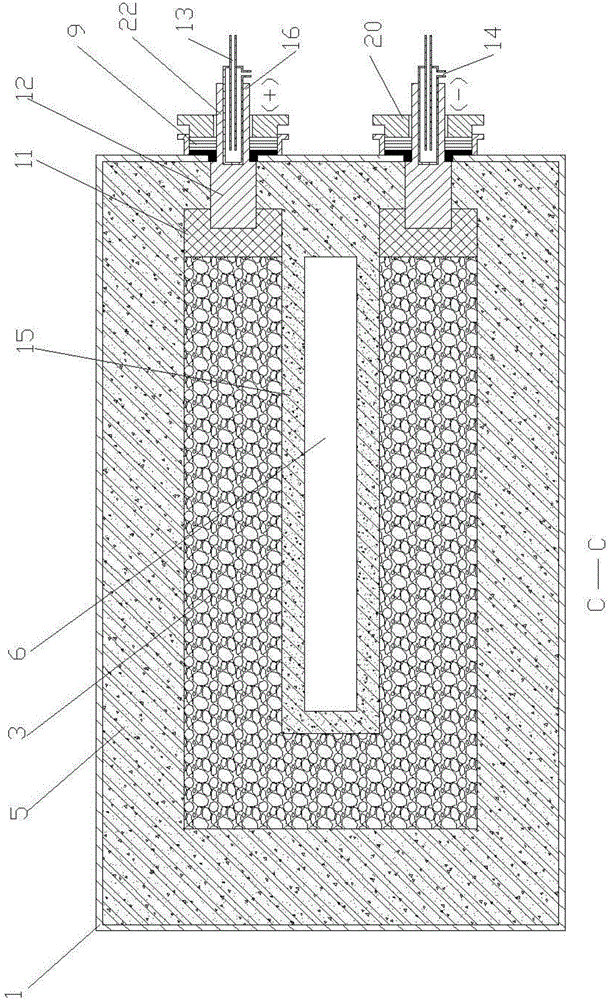

Aluminium electrolysis bath

ActiveCN101709486AGood structural sealingImprove energy utilizationAluminium electrolysisHigh energy

The invention relates to an aluminium electrolysis bath used in primary aluminium production. The aluminium electrolysis bath is characterized in that the electrolysis bath comprises an aluminium electrolysis bath body and an aluminium electrolysis bath cover plate, wherein the bath body comprises a horizontal bath bottom and vertical side bath walls connected with the bath body into a whole; and the cover plate is a horizontal cover plate which covers the upper ends of the vertical bath walls and is provided with an electrode through hole. The aluminium electrolysis bath has the advantages of ideal airtightness of bath body structure, high energy utilization rate, no pollution, small land occupation and high capacity per unit area, scientifically realizes heat preservation in a melt zone and the upper part of the electrolysis bath, and has a long service life.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

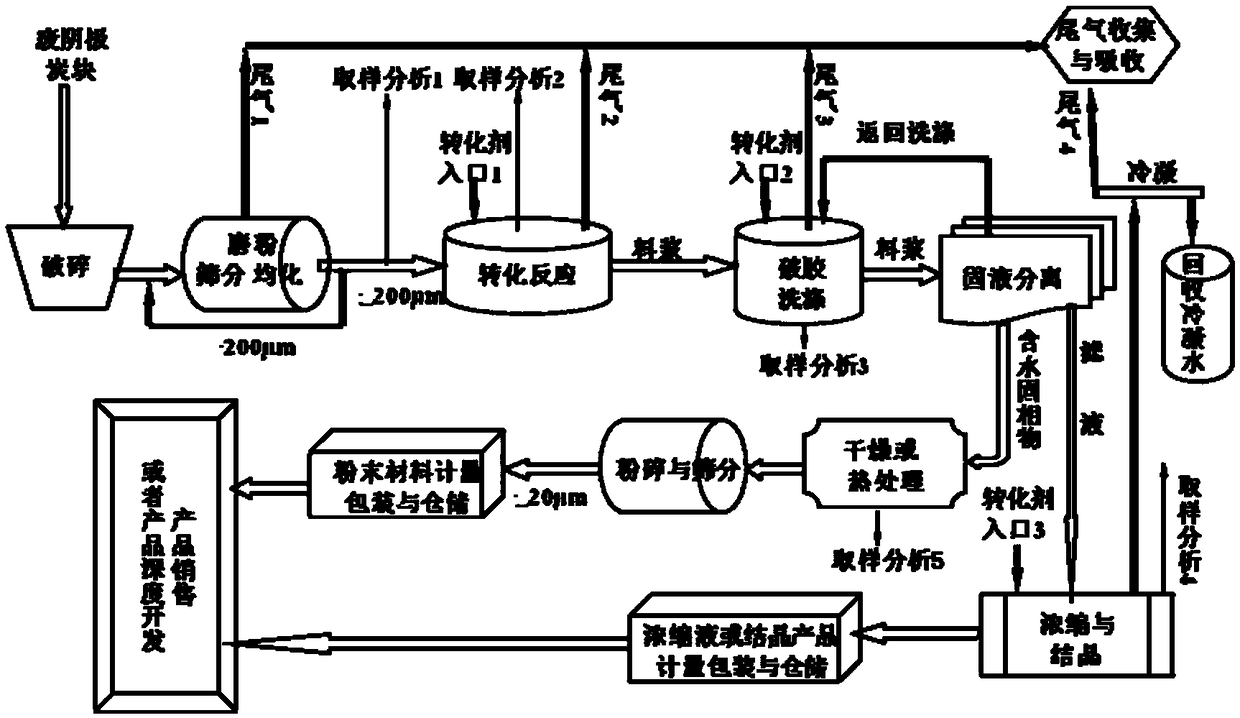

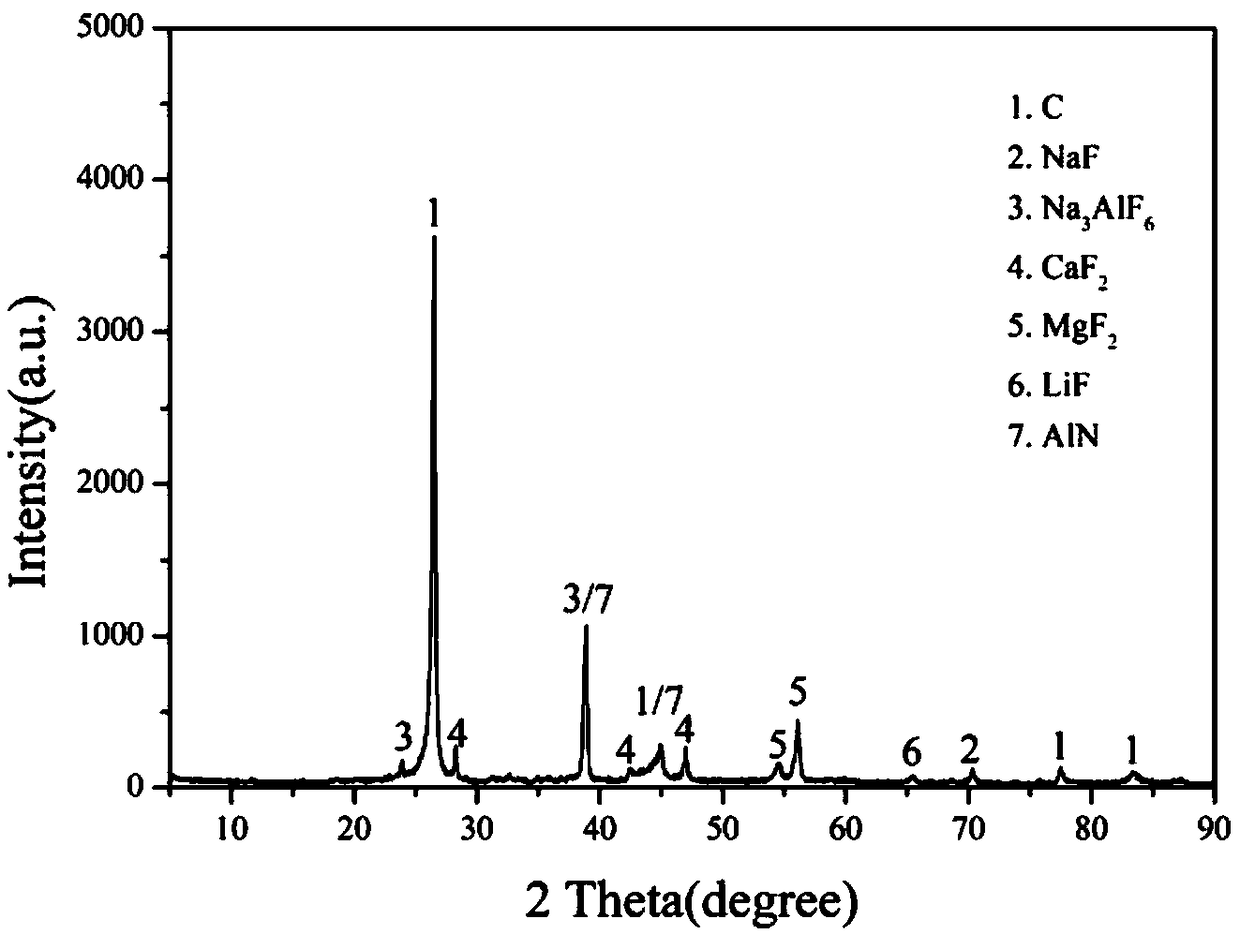

Method and system for converting sodium-containing and fluorine-containing compounds in waste cathode carbon block of aluminum electrolytic cell

ActiveCN109047285AEasy to controlEasy to industrializeMagnesium fluoridesTransportation and packagingPollutionHeat treated

The invention relates to a method and system for converting sodium-containing and fluorine-containing compounds in a waste cathode carbon block of an aluminum electrolytic cell. The conversion methodcomprises the step that a conversion agent is used for converting the sodium-containing compound in the waste cathode carbon block of the aluminum electrolytic cell into a fluorine-free soluble sodiumcompound, converting the fluorine-containing compound into an insoluble and harmless mineral fluorine compound and converting a cyanide-containing compound into harmless N2 or NH3 and CO2 in an oxidized manner through a mechanochemical conversion reaction in a conversion mill, and therefore the hazards of fluoride and cyanide in the waste cathode carbon block of the aluminum electrolytic cell arecompletely eliminated. The conversion system comprises a waste cathode carbon block crushing device, a milling device, the conversion mill, a stirred reactor and a solid-liquid separation device which are sequentially connected in series, and the solid-liquid separation device is then directly connected with a concentration or crystallization device and a drying or heat treatment device, and thedrying or heat treatment device is connected to the crushing device. By means of the method and system, the process is simple, mass production is easy, the production cost is low, pollution of three wastes is avoided, and the method and system are environmentally friendly.

Owner:XIANGTAN UNIV

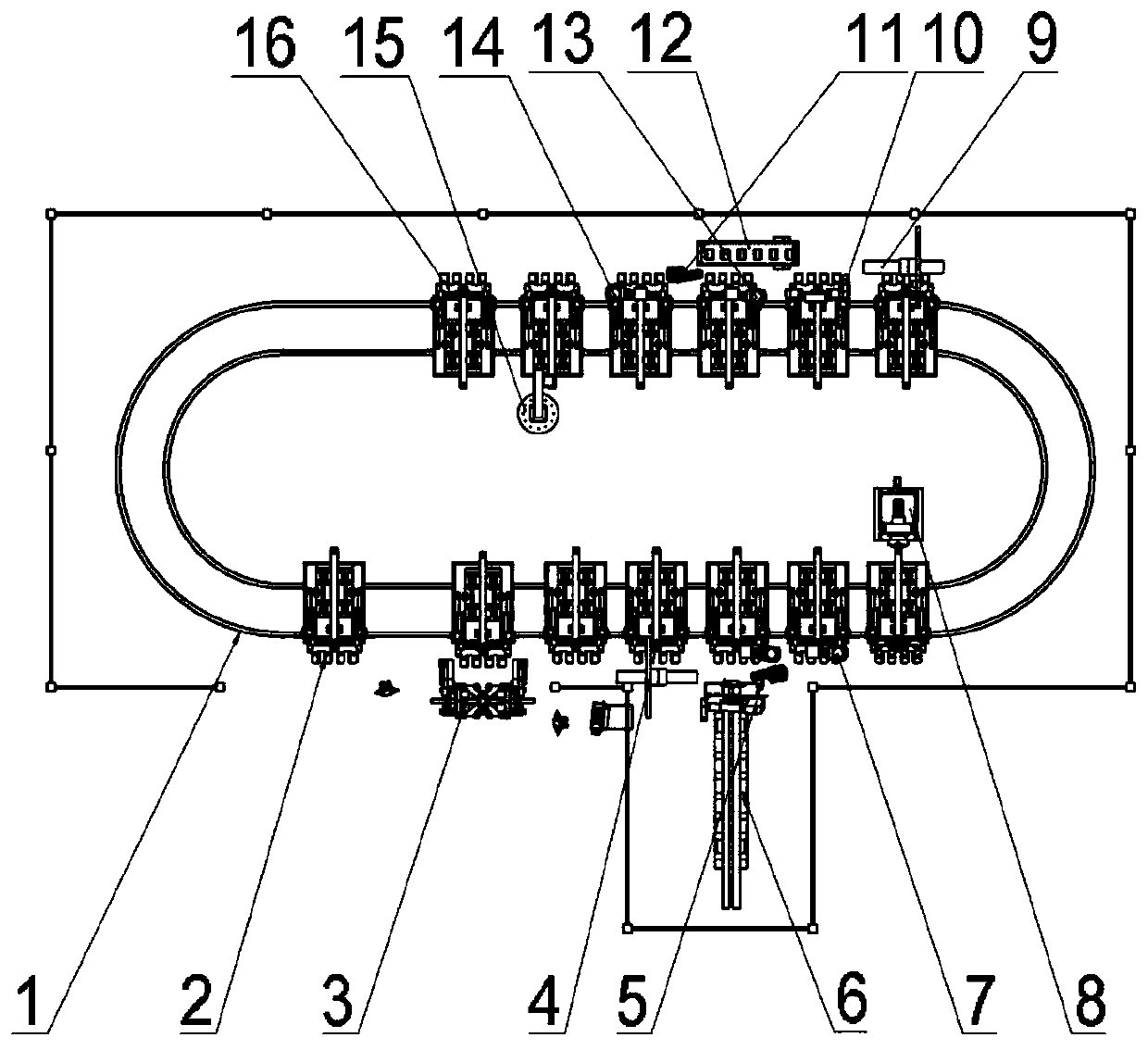

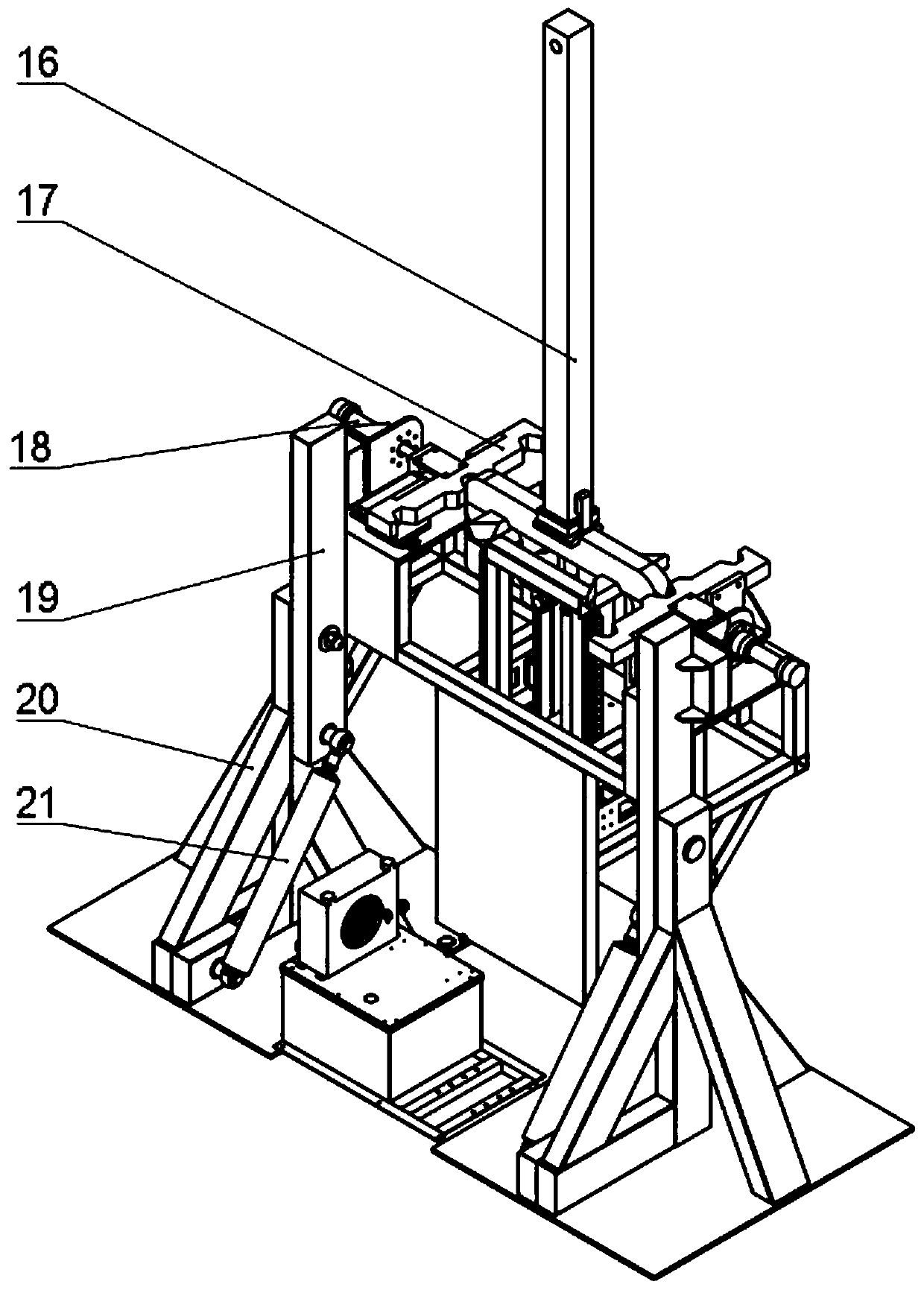

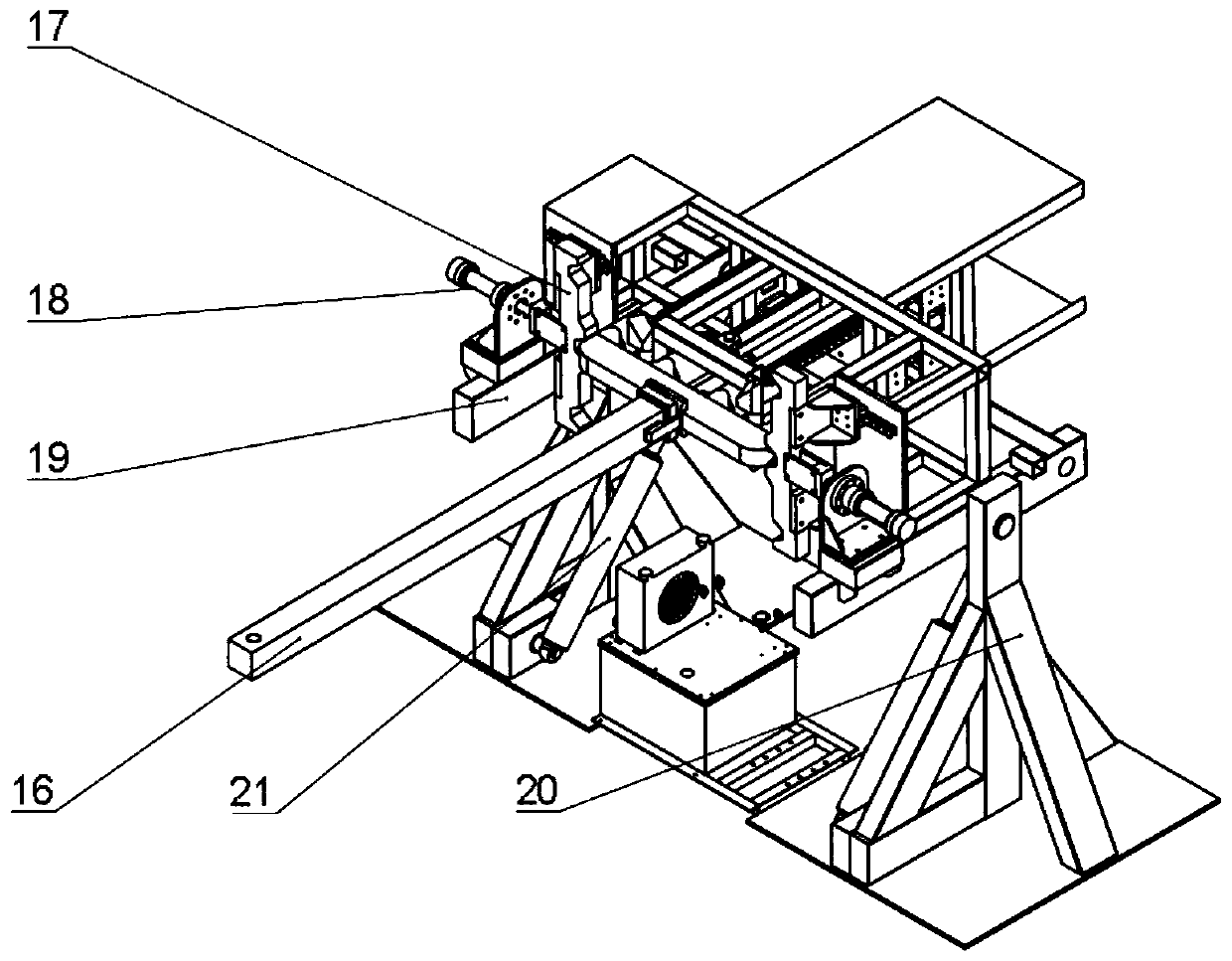

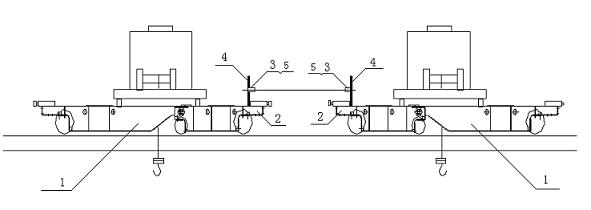

Aluminum electrolysis anode rod automatic repair annular production line and repair method

PendingCN110774009AFast and efficient operationImprove repair efficiencyOther manufacturing equipments/toolsNumerical controlProduction line

The invention discloses an aluminum electrolysis anode rod automatic repair annular production line and a repair method. The production line comprises ground circular rails laid on the ground and toolrail trolleys running on the ground circular rails and carrying anode rods, and further comprises an online turnover table, a numerical controlled flame cutting machine, a steel rod feeding robot, asteel rod feeding device, a steel jaw special welding machine, a double-anode turnover positioner, a numerical controlled flame cutting machine, a guide rod cutting machine, an explosion block feedingrobot, an explosion block feeding device, an explosion block special welding machine, a guide rod special welding machine and a guide rod planar milling device which are arranged along the ground circular rails. According to the aluminum electrolysis anode rod automatic repair annular production line, the traveling trolleys and the circular rails are used as tools for transporting and fixing theanode rods so that the anode rods can be transported quickly between operation working positions; meanwhile, the anode rods are directly repaired on the trolleys, so that the anode rods are repaired between different working positions more quickly and efficiently to form anode rod repair assembly line operation, and the anode rod repair efficiency is greatly improved.

Owner:GUIYANG AL-MG DESIGN & RES INST

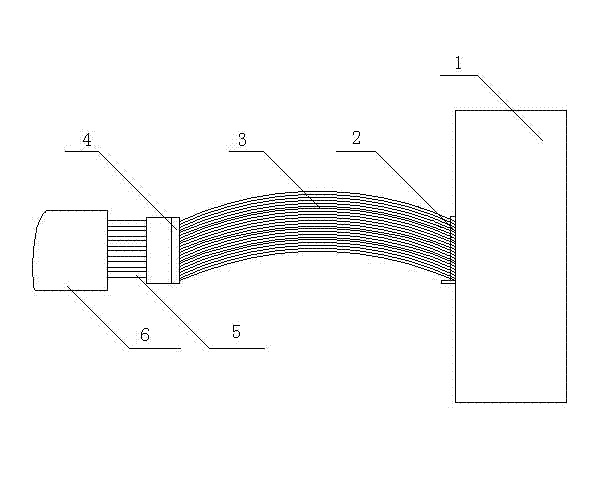

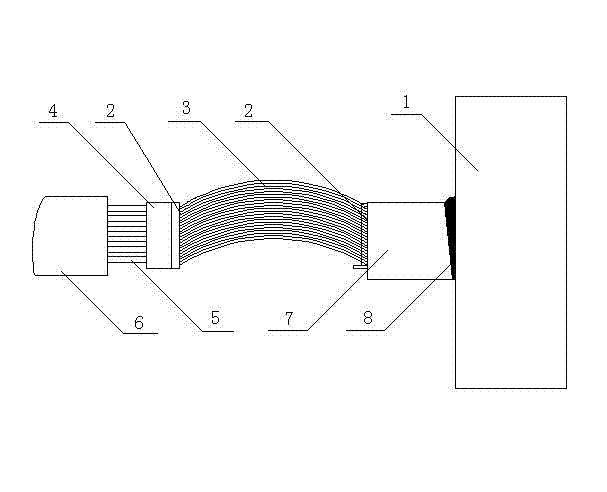

Method for welding cathode flexible bus of aluminum electrolysis cell without series power failure

ActiveCN102806425AProduction impactAchieve the purpose of repairWelding apparatusExothermic weldingAluminium electrolysis

The invention relates to the industry of electrolytic aluminum, and in particular to a method for performing repair work under the condition of no series power failure in the occurrence of damage to a cathode flexible bus of an aluminum electrolysis cell. The method provided by the invention comprises following steps: 1. steps of removing, grinding and flattening; 2. a step of welding a transition aluminum block; 3. a step of welding an explosion block; 4. a step of making preparation for welding; 5. a step of filling a heat release welding flux; 6. a step of heating a welding part; 7. a step of ignition; and 8. removing a mould after naturally cooling a cavity; performing insulation treatment on the welding part and slowing the cooling in places where the climate is cold; and after the completion of the welding, cleaning a site. With the adoption of the method provided by the invention, the cathode flexible hose of the aluminum electrolysis cell can be welded without the series power failure; due to good generality, the method is applicable for various slots; in such a way, the series power failure of the electrolytic cell is prevented, the ferrous welding under a strong magnetic field is prevented, and the condition that the heat release welding cannot be directly used for the flexible bus with a laminated structure is prevented; and therefore, the economic benefits of an aluminum electrolysis enterprise are improved, and the technical difficult in repairing the cathode flexible bus is solved for the aluminum electrolysis enterprise.

Owner:HUANGHE XINYE

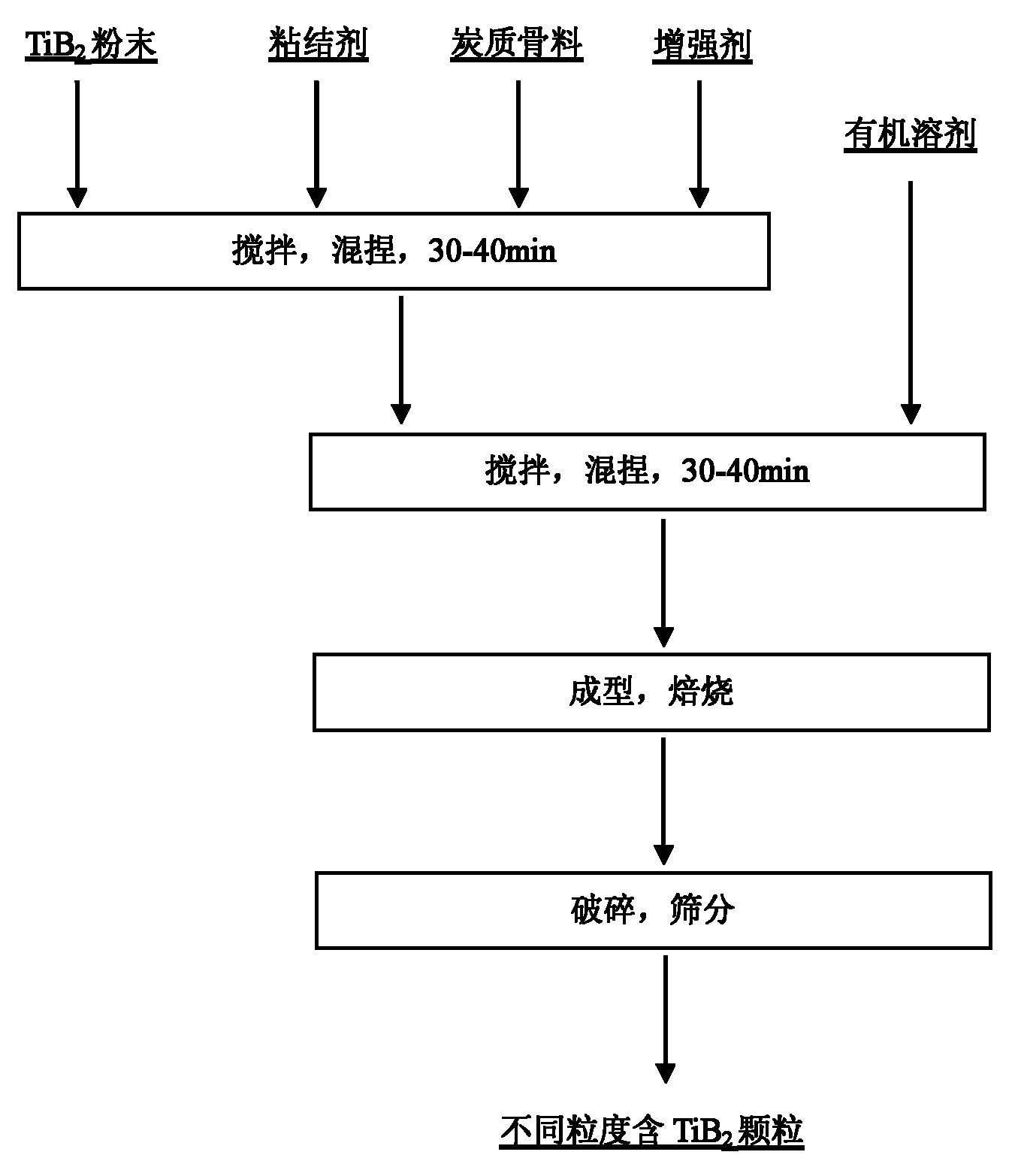

Pelleting method of titanium diboride powder

InactiveCN101844926AHigh resistance to sodium permeabilityGood resistance to sodium penetrationAluminium electrolysisGranularity

The invention provides a pelleting method of titanium diboride powder, which is suitable for preparing high-content high-strength large TiB2 particles for the wettable cathode of an aluminium electrolysis cell and is especially suitable for preparing the high-content high-strength large TiB2 particles for the wettable cathode of a deflector-type aluminium electrolysis cell. The method is characterized in that the high-content high-strength TiB2 particles are prepared by carrying out processes of kneading, shaping, roasting, crushing, sieving and the like on the titanium diboride powder as the main aggregate by adopting an organic binder or inorganic binder or a compound binder of the organic binder or the inorganic binder. The method has simple preparation process, controllable granularity and convenient application. The TiB2 particles prepared by the invention has the TiB2 content of 70-95 percent, the strength of 30-60MPa, and the resistivity of 0.5-40 muomega.m, and moreover, the TiB2 particles have small deformation and strong high temperature melt penetration resistance, can be completely wetted with aluminium liquid, realizes aluminium electrolysis production energy saving, prolongs the service life of the cathode of the aluminium electrolysis cell and reduces the aluminium electrolysis production cost.

Owner:CENT SOUTH UNIV

Electrolyte for driving of aluminum electrolytic capacitor and preparation method of main solute of electrolyte

ActiveCN102969161AImprove solubilityImprove thermal stabilityOxygen-containing compound preparationOrganic compound preparationElectrolytic agentAluminium electrolysis

The invention discloses electrolyte for driving of an aluminum electrolytic capacitor and a preparation method of dicarboxylic acid with branches in an alpha position and salt of the dicarboxylic acid. The electrolyte comprises solutes, solvents and various additives, wherein the solutes comprise major solutes and auxiliary solutes; the solvents comprise major solvents and auxiliary solvents; and the additives comprise a sparking voltage improver, a waterproof mixture and a hydrogen eliminating agent. According to the weight ratio, the major solutes account for 2%-18%, the auxiliary solutes account for 3.5%-7.5%, the main solvents account for 54.5%-82%, the auxiliary solvents account for 3%-8%, the sparking voltage improver accounts for 2%-8%, the waterproof mixture accounts for 1.5%-3%, and the hydrogen eliminating agent accounts for 1.5%-2.5%. The electrolyte has the characteristics of relatively high sparking voltage, good low-low-temperature stability and large ripple current resistance, thus being capable of prolonging the service life of the capacitor.

Owner:NANTONG SUNION ELECTRONICS

High temperature conductive binding material for aluminium electrolysis

InactiveCN1552788AHigh bonding strengthImprove conductivityElectrically-conducting adhesivesAluminium electrolysisElectrical conductor

An electric conducting refractory adhesive for the aluminium electrolysis, especially for carbon anode, carbon cathode, inertial anode and wettable TiB2 cathode, is prepared from electric conducting powder, resin adhesive, solidifying agent, solvent, reinforcing agent and additives. It has high adhesion, electric conductivity, heat shock resistance and high-temp mechanical performance.

Owner:CENT SOUTH UNIV +1

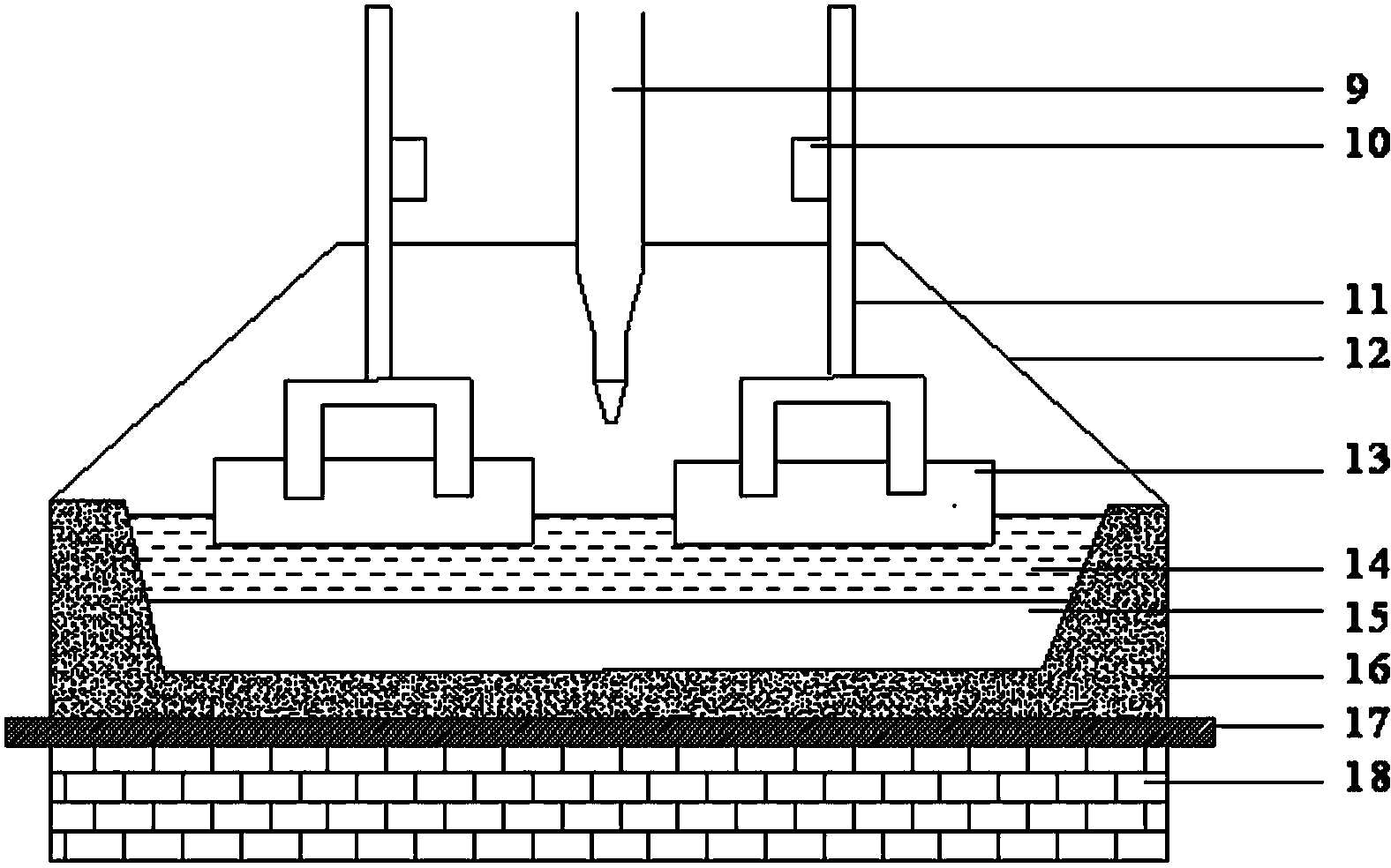

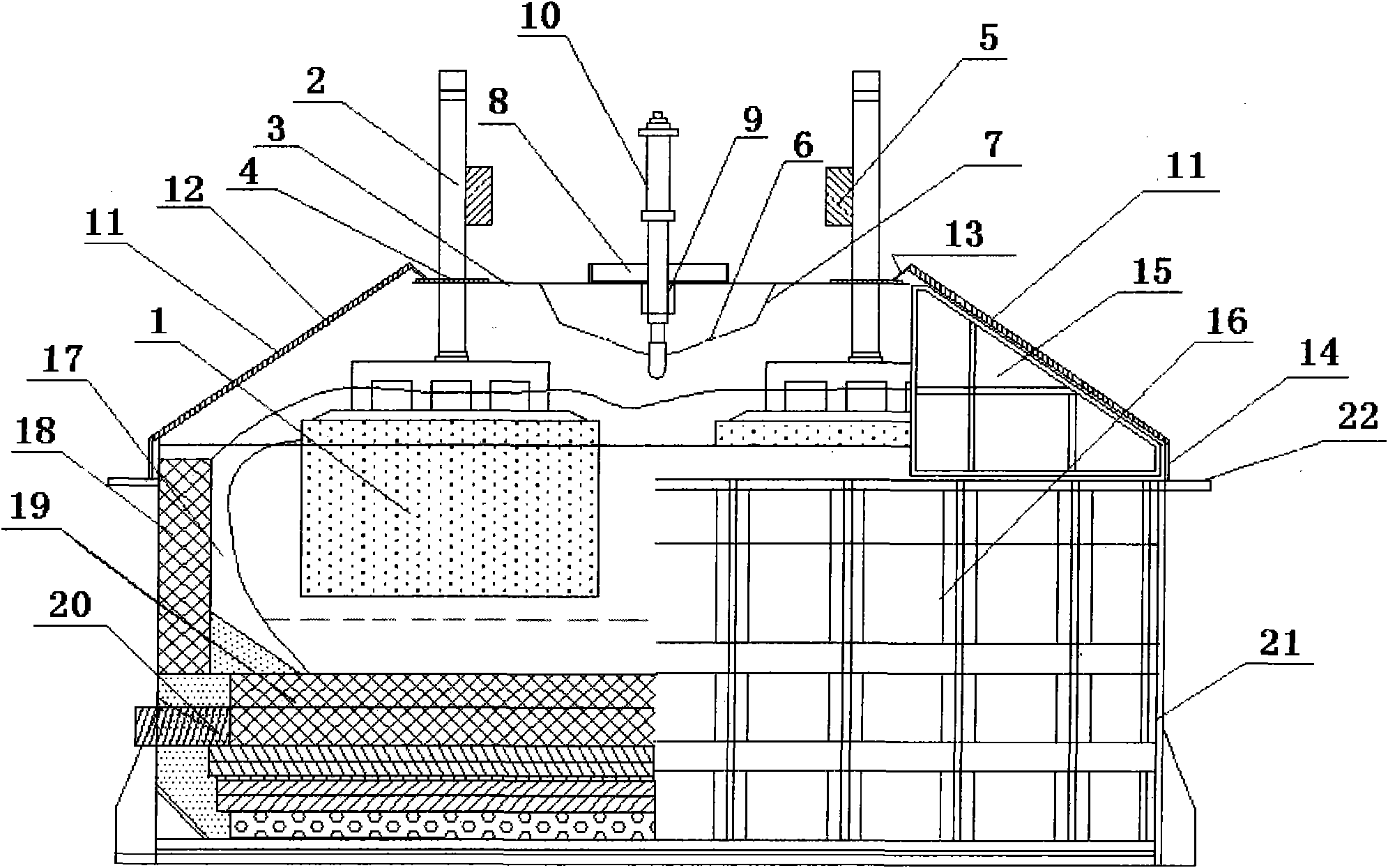

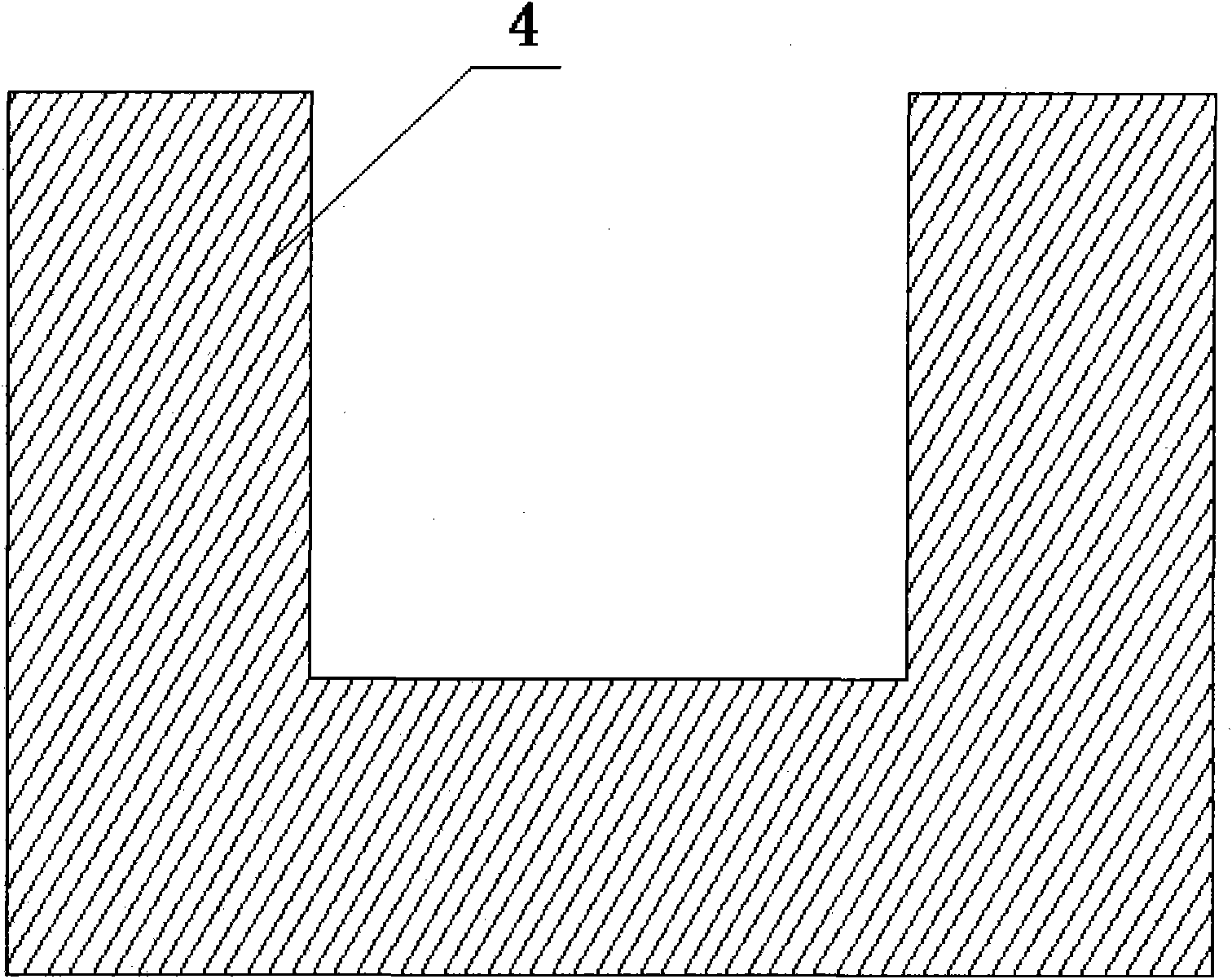

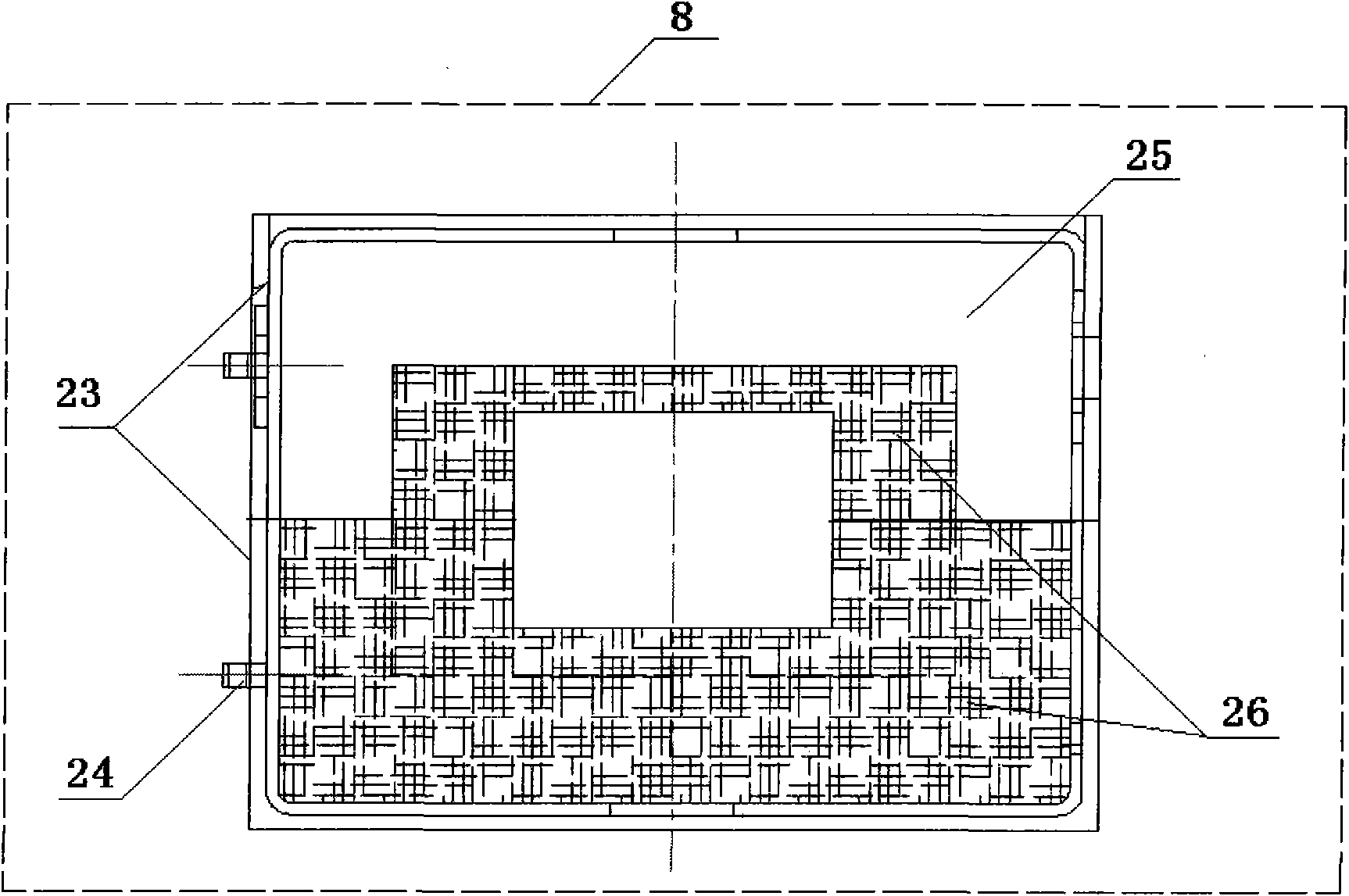

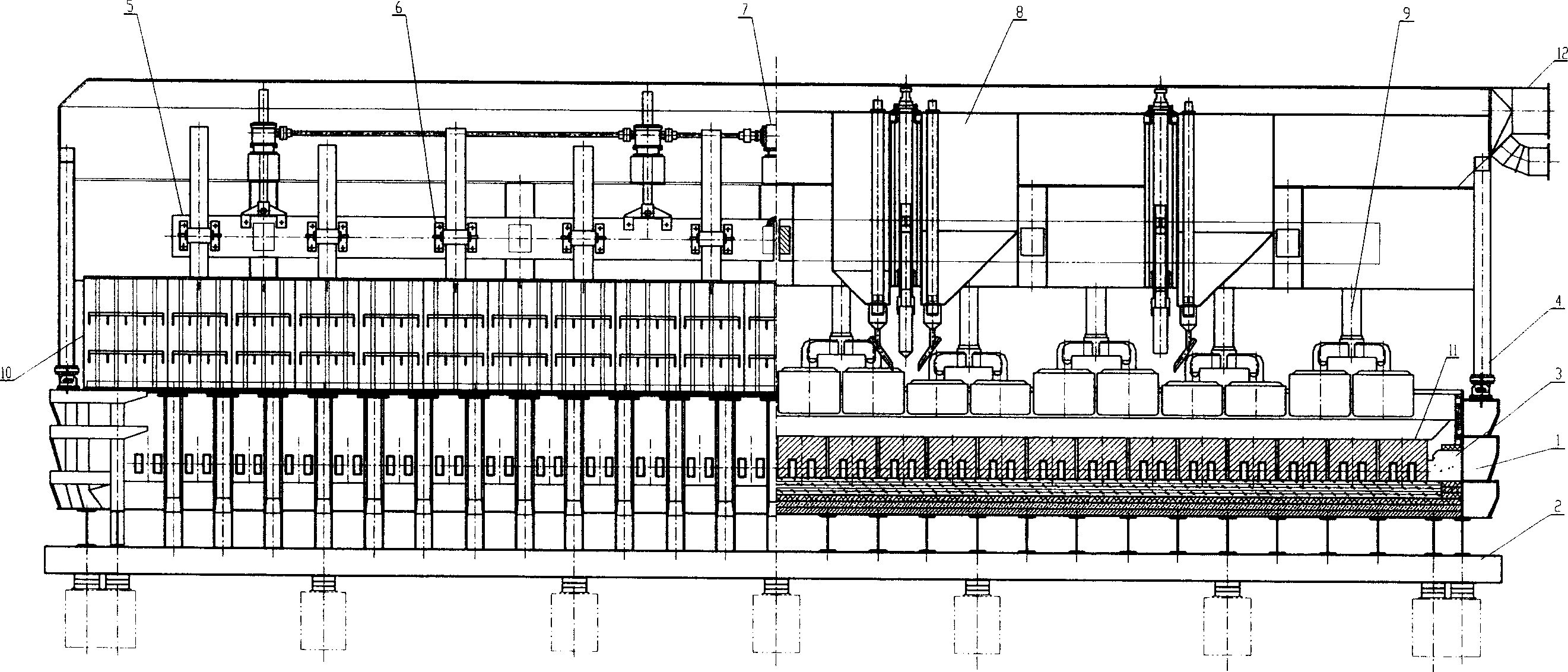

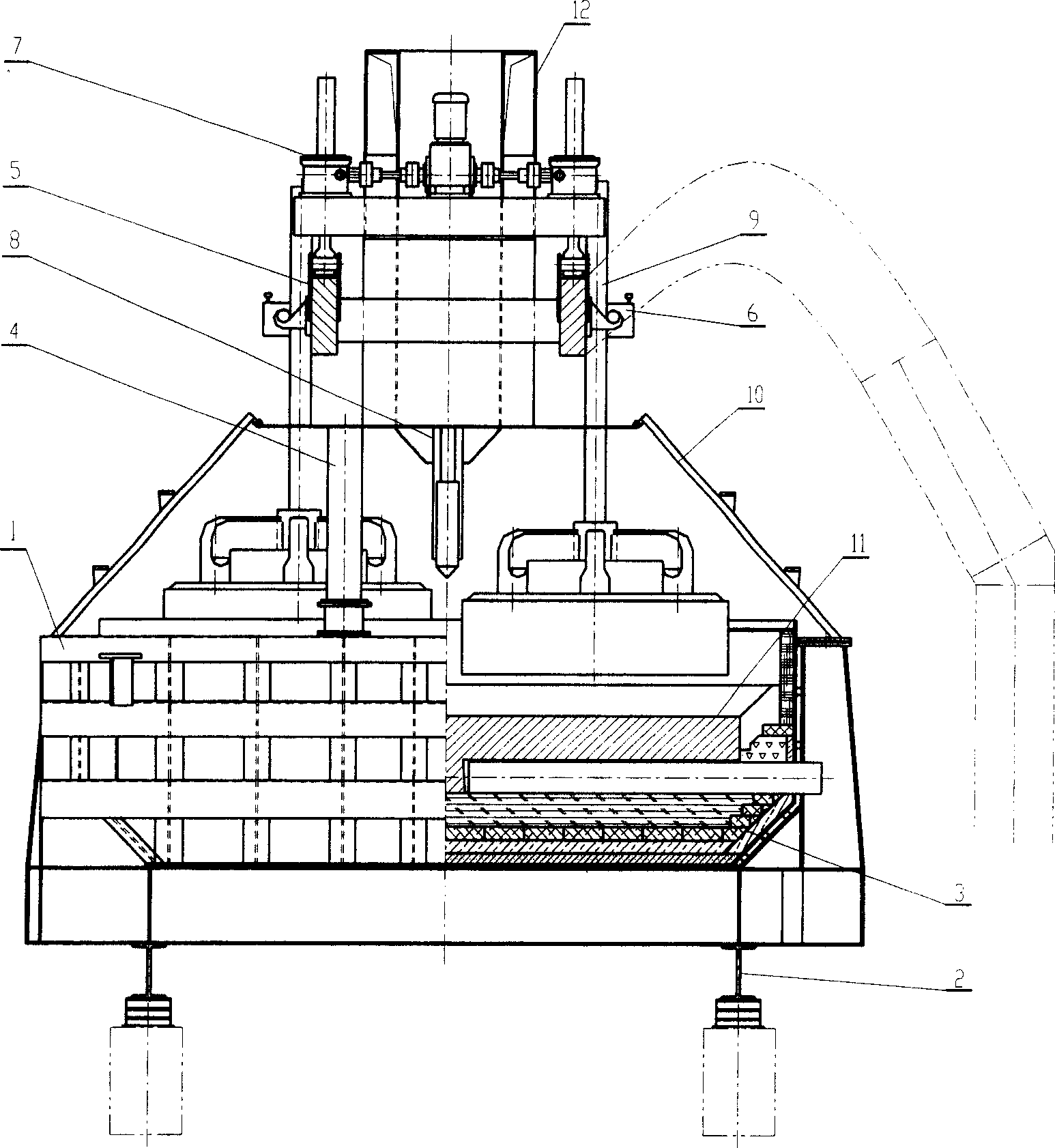

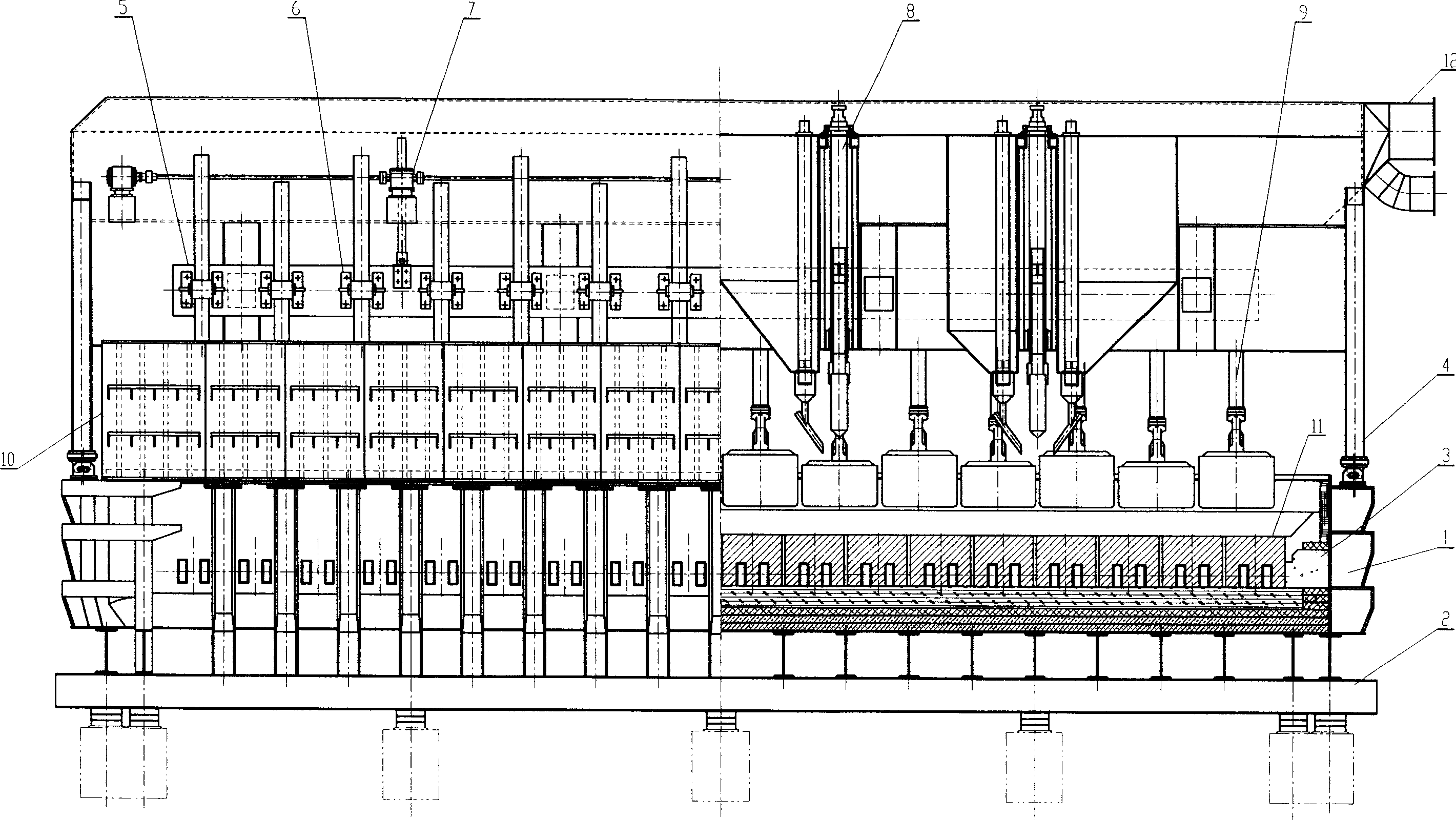

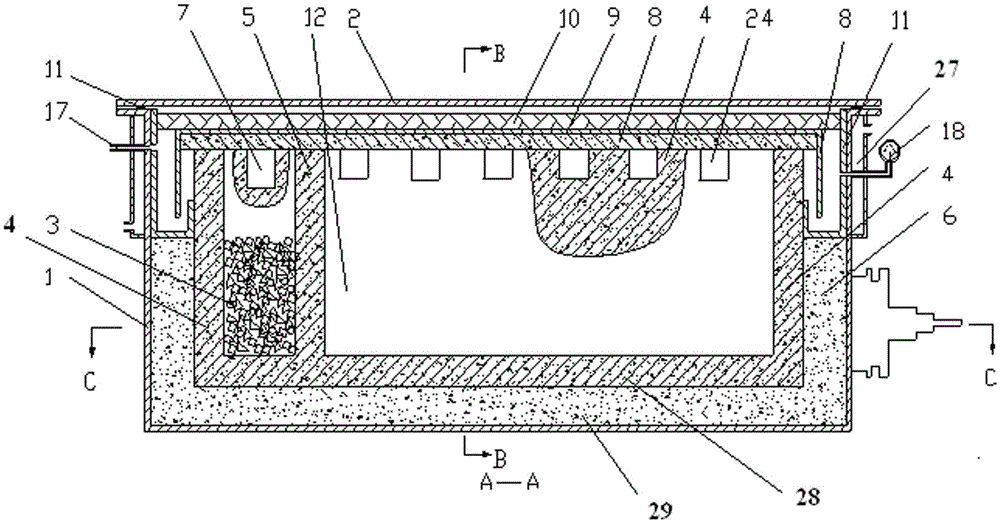

Large-scale aluminium electrolysis pre-baking tank

The large aluminum electrolyzing pre-roasting tank includes anode carbon block combination, anode bus, breaking and feeding unit, anode elevating mechanism, crossbeam and portal upright, tank sealing air exhaust system, tank casing, cathode structure and bottom heat insulating structure. It features the double anode structure comprising two anode carbon blocks assembled through aluminum rod and steel pawl; the elevator installed below the top surface of the crossbeam; the tank sealing air exhaust system set inside the crossbeam; and the cathode with surround casing, carbon block with bottom composite heat insulating layer, side silicon nitride to combine silicon carbide blocks and surrounding cast material. The present invention has improved structure resulting in raised fume collecting efficiency, reasonable gas flow distribution and smooth aluminum electrolyzing process.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

Alloy material applicable to inert anode of metal molten salt electrolytic cell

InactiveCN102994801AImprove corrosion resistanceImprove electrolysis efficiencyElectrodesAluminium electrolysisMolten salt

The invention relates to an alloy material applicable to an inert anode of a metal molten salt electrolytic cell, relates to metal molten salt electrolysis, and provides a carbon-free metal-based alloy inert anode applicable to an aluminum electrolytic cell. An alloy material is formed by following base elements in mass percentage of 37-76% of Cu, 15-30% of Ni, 5-15% of Fe and 4-8% of Al. The alloy material applicable to the inert anode of the metal molten salt electrolytic cell disclosed by the invention is applicable to a low-temperature (700-850 DEG C) electrolyte system. An alloy anode has good high-temperature anti-oxidization property and electrolyte corrosion resistance in an electrolysis process and the quality of an electrolyzed aluminum product is more than 99.7%.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method of non stopping production reparing aluminium electrolysis bath side wall

A technology for repairing the side wall of aluminium electrolyzer without stopping production includes cutting open the internal edge plate at the position where the side wall is damaged, opening the alumina shell, filling and compacting the isolating dam between said damaged side wall and anode, removing the residual substance from said side wall, mounting new side wall, welding the internal edge plate, blocking by cryolite and alumina powder, and natural calcining. Its advantages are high speed and low cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

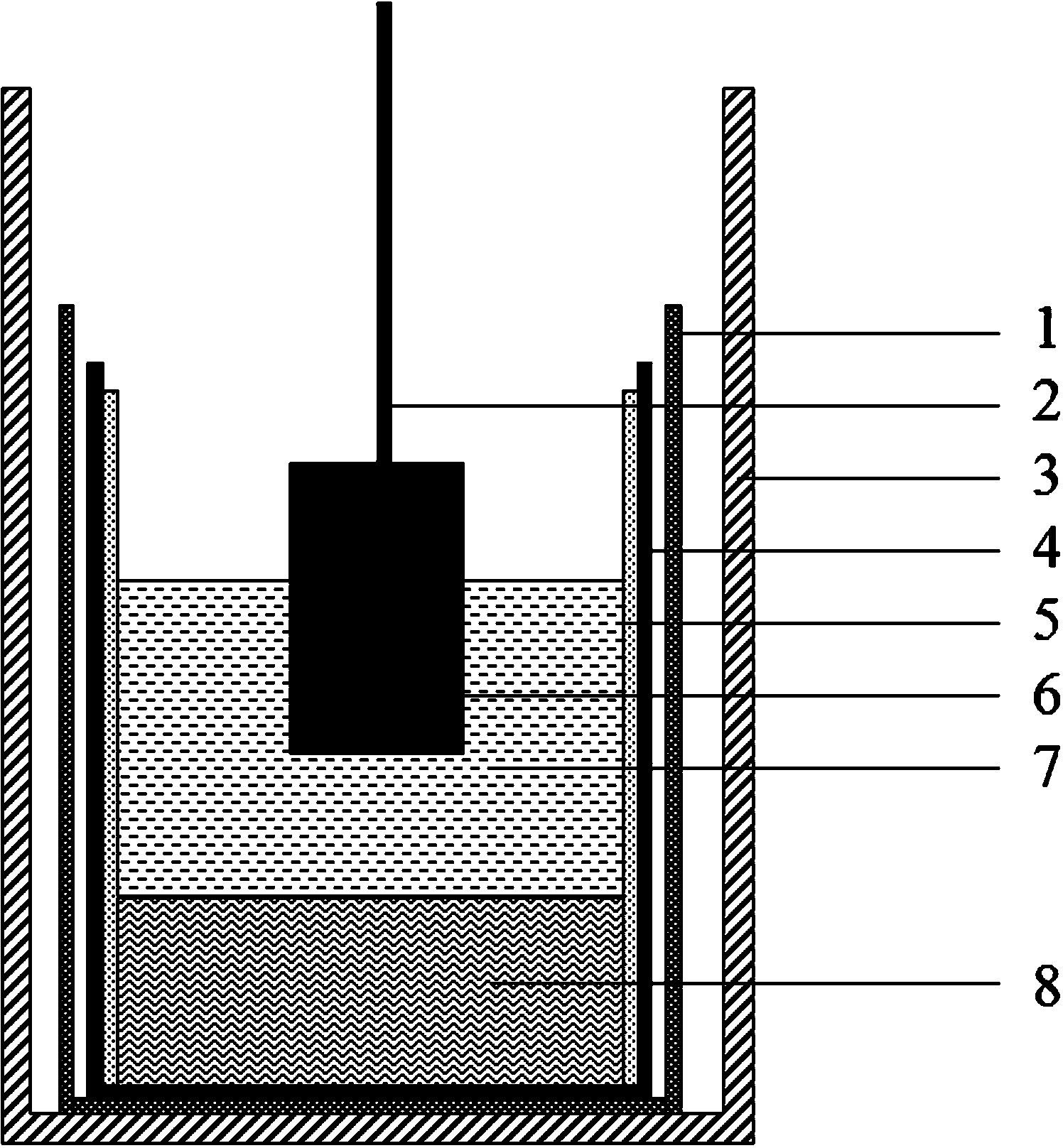

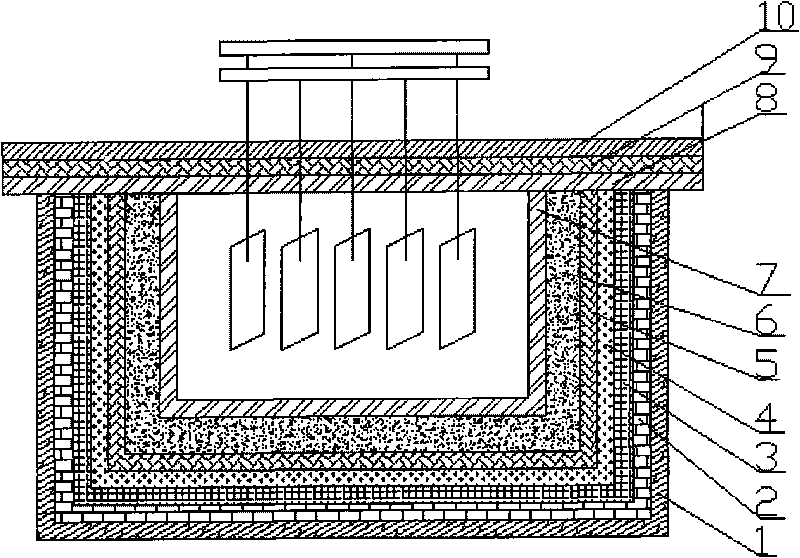

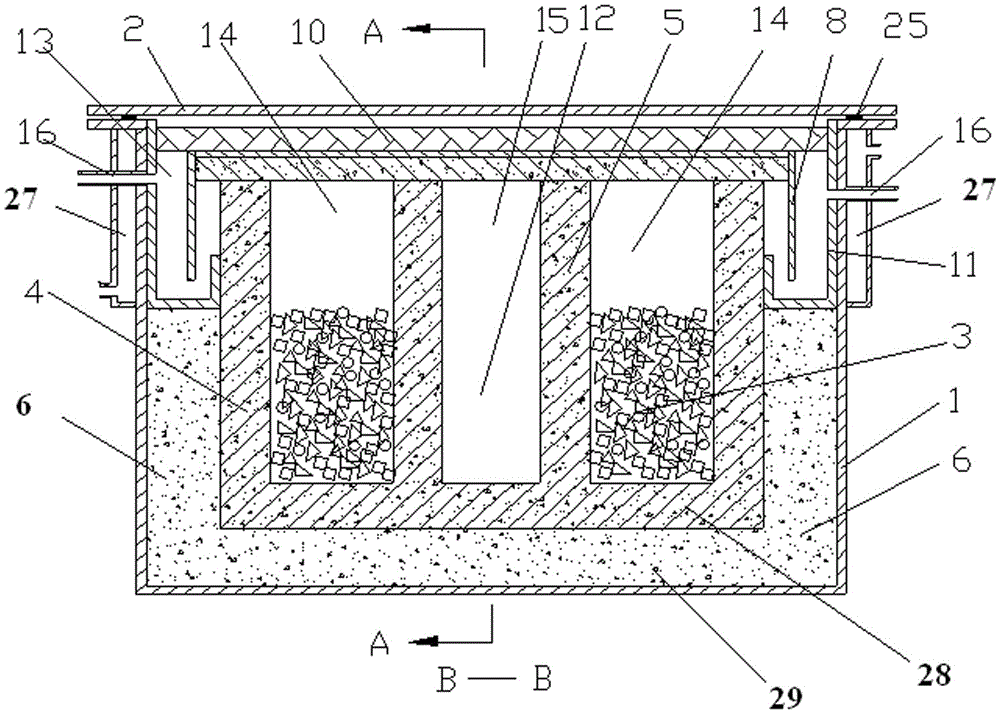

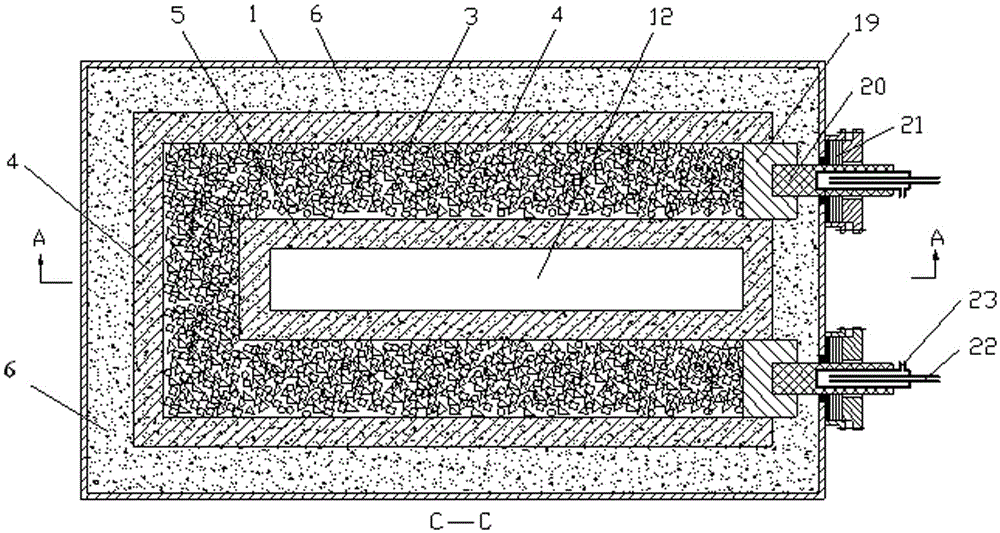

Device and method for treatment and recovery of solid wastes produced by aluminium electrolysis

The invention provides a device and method for treatment and recovery of solid wastes produced by aluminium electrolysis. The device comprises a metal shell, a furnace cover, a fire-resistant and heat-preserving furnace wall body, a fire-resistant and heat-preserving furnace bottom, a resistance heater, a refractory concrete wall body, a material chamber, a refractory concrete column body, a thermal radiation baffle, a cover type crystallizer, a cylinder type crystallizer, an electrolyte crystallization chamber, an alkali metal crystallization chamber, a thermal baffle, a vacuum suction pipe, an argon gas inflatable tube, a vacuum manometer and electrodes for supplying electric energy to the resistance heater. According to the device and method for treatment and recovery of solid wastes produced by aluminium electrolysis, high temperature is generated by resistance heat of waste cathode carbon blocks, non-carbonaceous components in the solid wastes evaporate in the form of gas and crystallize in the device at different positions, so that the thorough separation of carbon, alkali metal and electrolyte is realized, the technological operation is simple, no residue, exhaust gas or waste water is produced in the whole separation process. The device and method for treatment and recovery of solid wastes produced by aluminium electrolysis are energy-saving and environment-friendly, and are very suitable for large-scale popularization and application in industry.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

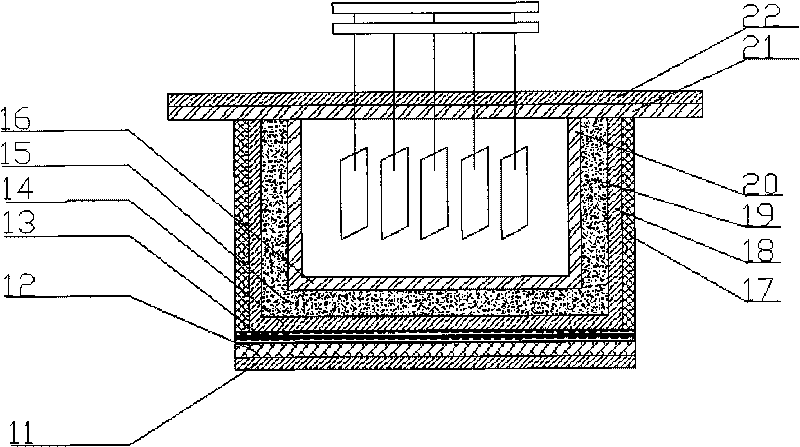

Device for treating and recycling aluminum electrolysis solid waste

A device for treating and recycling aluminum electrolysis solid waste comprises a furnace shell, a furnace cover, a furnace lining, a fire wall fireproof material wall, a furnace bottom fireproof material lining, a resistance heating body, a fireproof material wall in the middle in a furnace, an alkali metal crystallizer, a heat isolation cover plate, a metal cover, electrodes, an auxiliary material chamber, an electrolyte crystallization chamber and an alkali metal crystallization chamber. The resistance heating body is composed of waste cathode carbon block fragments with the particle diameter smaller than 10 cm. According to the device, carbon, alkali metal and electrolytes in waste cathode carbon blocks and a carbon lining can be thoroughly separated, and the device is an energy-saving and environment-friendly aluminum electrolysis solid waste treating device and is very suitable for being applied and popularized in industry on a large scale.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

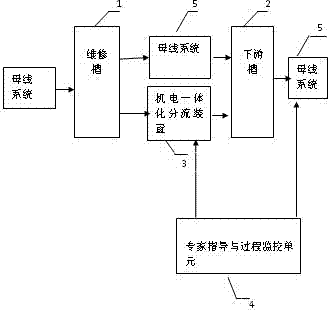

Aluminium electrolysis cell through-current body hot-line welding control system

The invention discloses an aluminium electrolysis cell through-current body hot-line welding control system, comprising a maintenance tank (1), a downstream tank (2) and a bus system (5), wherein a mechanical-electrical shunt device is arranged between the maintenance tank (1) and the downstream tank (2), the surfaces of the mechanical-electrical shunt device (3) and the bus system (5) are provided with thermoelectric sensors which are connected with an expert guiding and process monitoring unit (4) electrically. The aluminium electrolysis cell through-current body hot-line welding control system disclosed by the invention solves the problems that a thermit reaction has a high requirement on the spatial size of a welded position, a special thermit container is short in use period and high in cost, a reagent formula needs to be determined by exploration, a mode for shielding a dangerous magnetic field adopts an easily magnetized permeability material, and is not obvious in shielding effect and difficult to operate.

Owner:GUIYANG AL-MG DESIGN & RES INST

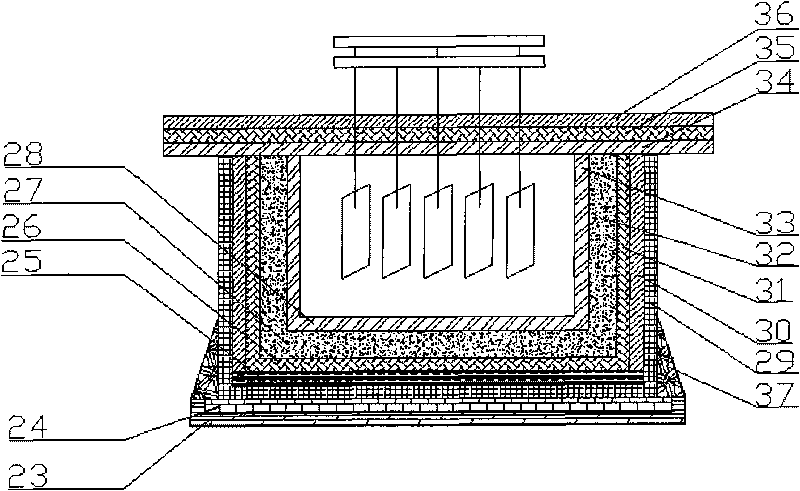

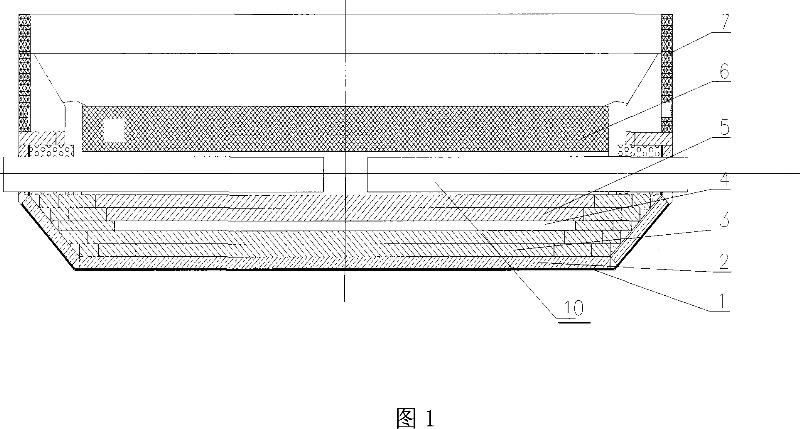

Lining structure of large-scale pre-baking aluminium electrolysis trough

InactiveCN101037775AImprove thermal conductivityLow resistivityCalcium silicateAluminium electrolysis

The invention relates to an improvement of apparatus in aluminium electrolytic industry, specially relate to a large-sized lining structure for prebaking aluminium electrolysis. The inventive lining structure has, on the bottom of electrolytic cell housing, from the bottom up, in order, asbestos plate layer, heat-insulating layer made of calcium silicate plate with heat-resisting, heat-insulating layer made of both layers light-weight bricks, impermeable layer made of one layer alumina, impermeable layer made of both layers firebricks, half-graphite-rod-cathode complex TiB2 coating, with the leteral of allotypic lateral mass. The advantages of the invention are that: (1) the structure has higher heat conductivity, lower electrical resistivity and low dilatability of electrolytic sodium, and current distribution in cathodic charcoal is more uniform; (2) impermeable layer is especially advantageous for prolonging the life of electrolytic cell; (3) allotypic lateral mass has higher thermal conductivity and lower electrical resistivity, in particular, prolonging the the life of electrolytic cell. The large-sized lining structure for prebaking aluminium electrolysis of more than 200kA is used in the invention.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

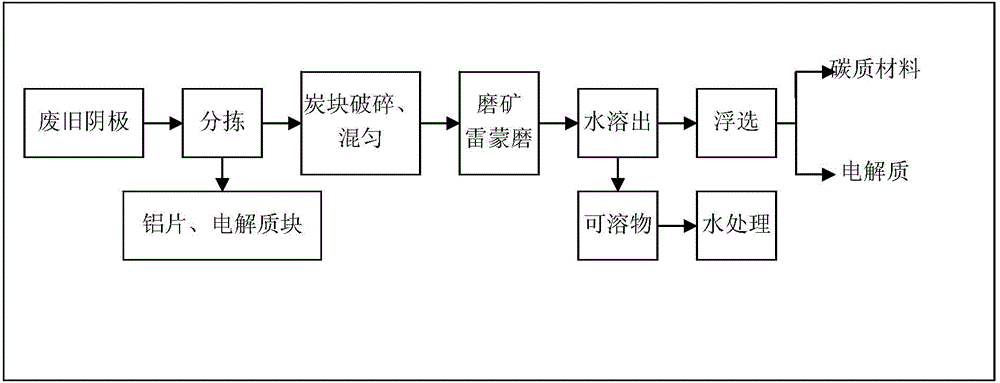

Method for sorting waste aluminum electrolytic cathodes

InactiveCN104438280AGuaranteed uniformityEasy to handleSolid waste disposalFlotationAluminium electrolysisMetallurgy

The invention relates to a method for sorting waste aluminum electrolytic cathodes. The method comprises the steps of carrying out crushing and blending treatment on sorted waste cathodes to obtain waste cathode fragments; grinding the waste cathode fragments to obtain crushed ores; soaking the crushed ores with water, and then carrying out solid-liquid separation to obtain dissolved ore bodies; and carrying out flotation treatment on the dissolved ore bodies to obtain carbon products and electrolyte products respectively. According to the method, a way of crushing, blending and then ore grinding is adopted for the waste cathodes, so that the uniformity of composition and the like of treated materials can be guaranteed, thus being beneficial to the improvement of a treatment effect; meanwhile, dissolution treatment is adopted for the ground waste cathode materials simultaneously, soluble parts are dissolved and separated to eliminate the impact of the soluble parts on subsequent flotation operation, and flotation can be carried out on the waste cathode materials directly after the dissolution treatment without adjusting the PH. The method for comprehensively recycling waste aluminum electrolytic cathodes, provided by the invention, is simple and feasible, low in production cost and good in production index.

Owner:北京森泉伟业科技有限公司

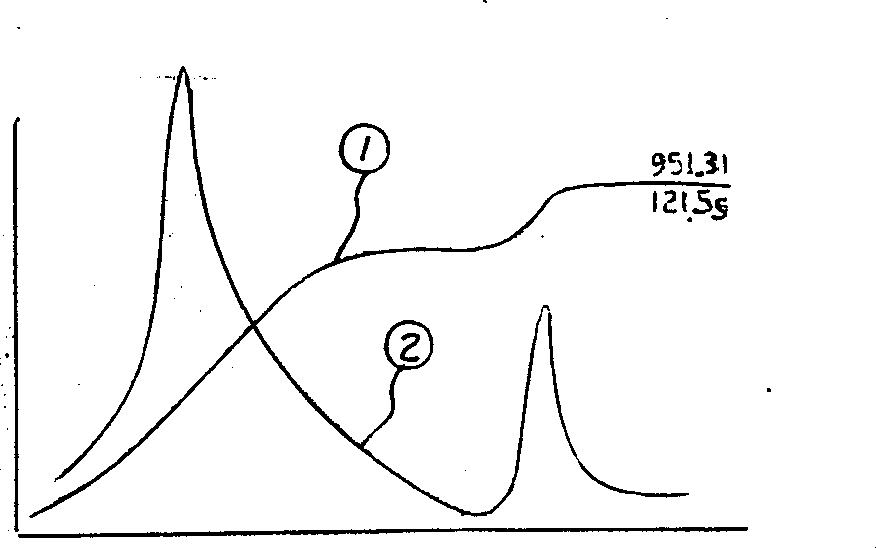

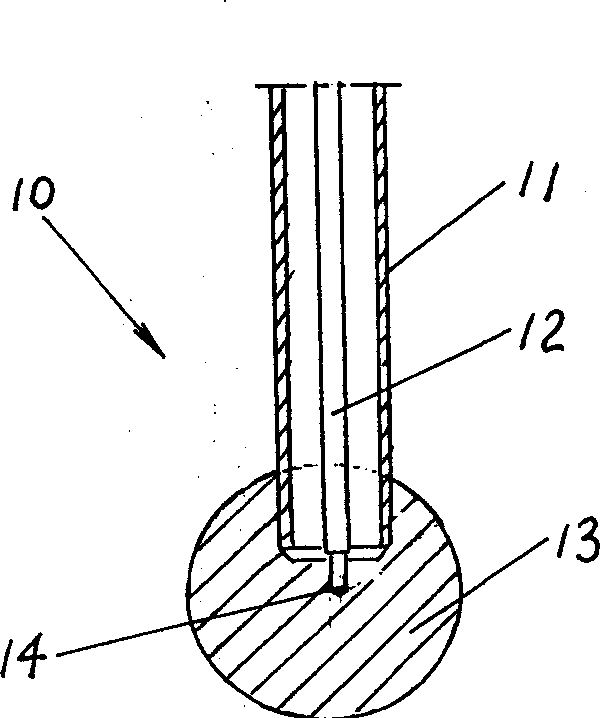

On-line real time measuring method and measurer for aluminium electrolyzing parameters

An on-line real-time aluminium electrolyzing parameters measuring process includes the steps of detecting the primary crystal temperature by inserting the measurer probe into electrolyzer and sendingout the primary crystal temperature signal; and processing the signal and calculating other electrolysis parameters according to the set mathematical model. The probe of the present invention includes thermocouple, metal ball and protecting tube, and the thermocouple inside the protection tube has its end inserted to the geometric center of the metal ball. The present invention can measure and find out important aluminium electrolyzing parameters timely and precisely, and this makes it possible to realize the autocontrol of aluminium electrolyzer for raising its current efficiency, reducing the power consumption and raising the yield.

Owner:程留恩 +1

Nickel-based alloy material suitable for inert anode of metal molten salt electrolyzer

InactiveCN102011144AGood high temperature oxidation resistanceReduce segregationAluminium electrolysisMolten salt

The invention provides a nickel-based alloy material suitable for an inert anode of a metal molten salt electrolyzer, relates to metal molten salt electrolysis, in particular to an alloy material suitable for carbon-free metal-based alloy inert anode of an aluminum electrolyzer. The nickel-based alloy material is characterized by comprising the following components in percentage by mass: 5 to 20 percent of Cu, 3 to 15 percent of Al, 15 to 50 percent of Fe, and the balance of Ni. By the invention, the alloy material suitable for the inert anode of the metal molten salt electrolyzer is obtained, and is suitable for a low-temperature (700 to 850 DEG C) electrolysis system. The alloy anode expresses excellent high-temperature oxidation resistance and electrolysis corrosion resistance in the electrolyzing process, and the quality of an electrolyzed aluminum product reaches over 99.7 percent.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

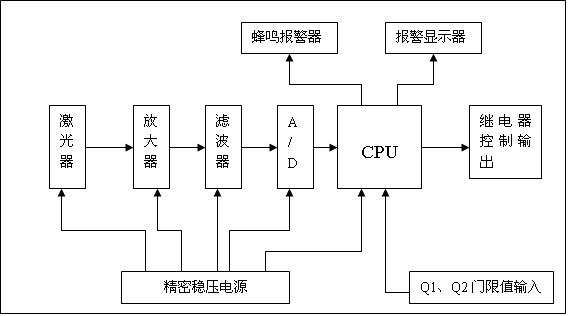

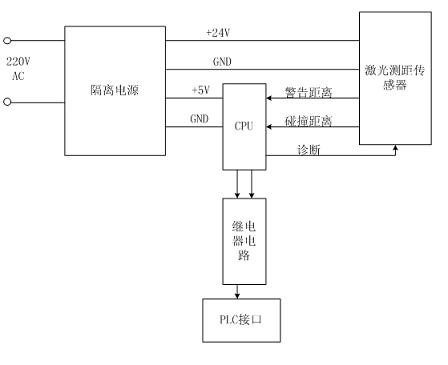

Anti-collision alignment method for aluminum electrolytic multifunctional crane

The invention relates to the technical field of aluminum electrolysis, and concretely relates to an anticollision counterpoint method of multifunctional crown blocks for aluminum electrolysis. In the invention, a laser emitter, a laser receiver, and an arithmetic control unit CPU are arranged on an end carriage at one side of a crossbeam of each multifunctional crown block; two reflecting plates are arranged on two end carriages of the adjacent multifunctional crown blocks, and the two end carriages are opposite to each other; the laser emitter, the laser receiver, and a controller are fixed by a fixed carriage and a locking spring washer; the reflecting plates are fixed by a support frame; a precise power supply which comprises three-terminal voltage regulator tubes 7805 and 7815, a capacitor and a resistor provides power for the laser emitter, the laser receiver and the controller; and detection waves emitted by the laser emitter are reflected to a low frequency amplifier 9014 triode the laser receiver by the reflecting plate to preamplify, are subjected to signal amplification and double bridge filtering processing, are input to the CPU for operation, and are sent to the controller to execute alarm or control the crown blocks to stop. The application of the method of the invention can avoid the damage of crown block parts caused by the bump generated by the opposite motion of the multifunctional crown blocks, so the operation failure rate of the crown blocks is reduced. The method of the invention is suitable for the counterpoint control of the opposite motion of the multifunctional crown blocks for aluminum electrolysis.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com