Device and method for treatment and recovery of solid wastes produced by aluminium electrolysis

A technology for recycling solid waste and aluminum, which is applied in the field of metallurgical environment, can solve environmental impact and other problems, and achieve the effect of complete separation and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

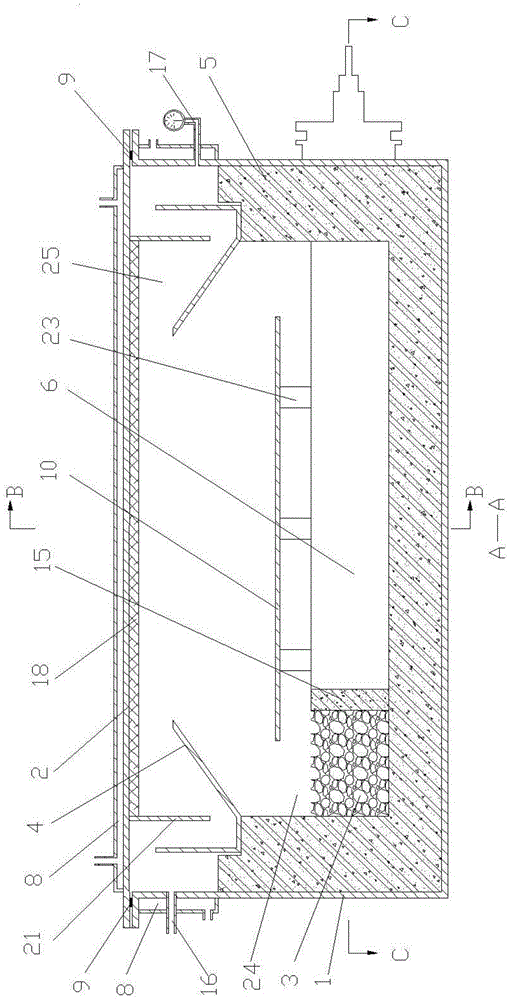

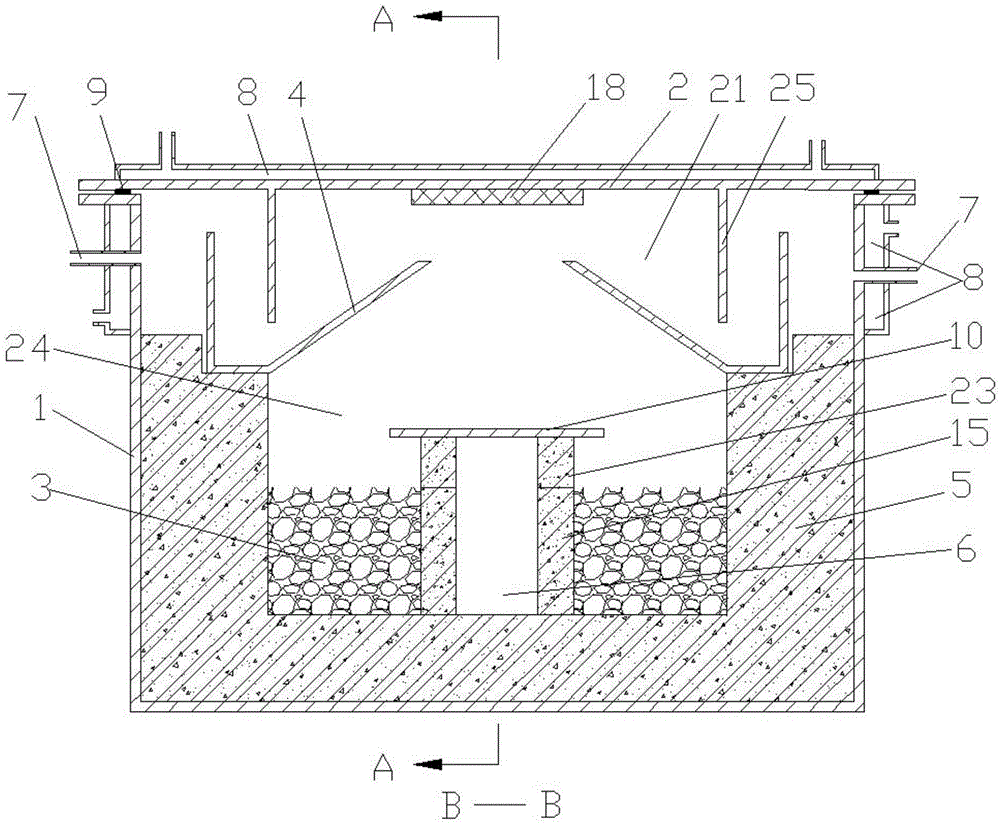

[0042] figure 1 , figure 2 , image 3 It is a box-type vacuum resistance furnace of "a device for processing and recycling aluminum electrolytic solid waste" of the present invention. 3. Refractory concrete wall 15, material chamber 6, refractory concrete cylinder 23, heat radiation baffle 10, cover type crystallizer 4, cylinder type crystallizer 21, electrolyte crystallization chamber 24, alkali metal crystallization chamber 25, heat insulation board 18. It consists of a vacuum exhaust pipe 7, an argon gas filling pipe 16, a vacuum pressure gauge 17 and an electrode 22 for inputting electric energy to the waste cathode carbon block resistance heating element.

[0043] A section of the outer wall of the furnace shell below the upper edge of the furnace shell 1 is welded with a cooling water jacket 8 .

[0044] The furnace cover 2 is made of ferrous metal material and has a flange structure. A flange is also welded on the upper edge of the metal shell. A vacuum gasket is pr...

Embodiment 2

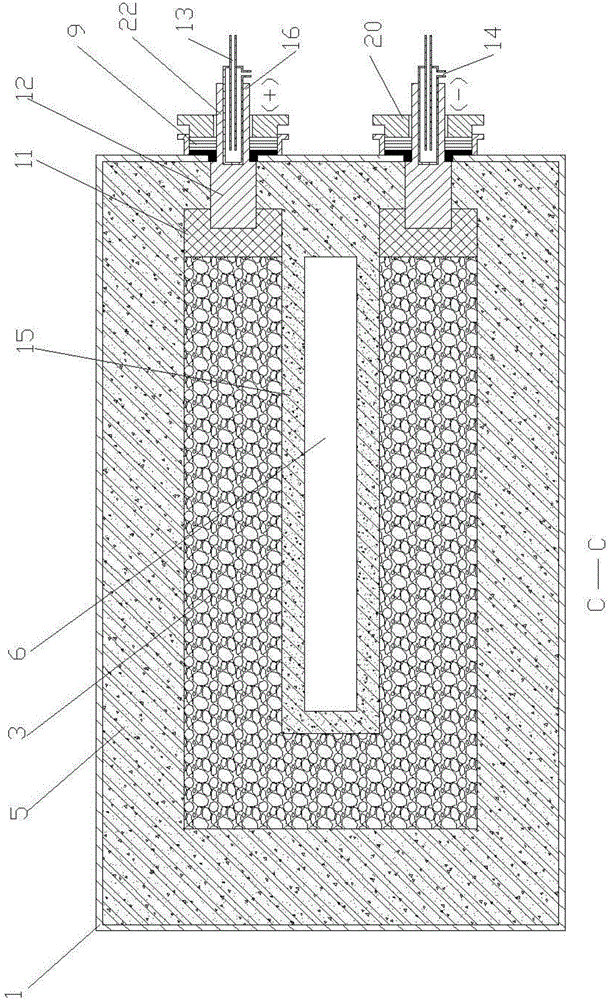

[0064] Figure 4 It is the C-C plane cross-sectional view when the resistance heating element made by the waste cathode carbon block of the aluminum electrolytic cell of the present embodiment is a U-shaped design, and the A-A plane and the B-B plane cross-sectional view are the same as in Embodiment 1, as figure 1 , figure 2 shown. The difference between this embodiment and the resistance furnace device structure of Embodiment 1 is that the resistance heating element 3 in the furnace is a U-shaped design, the upper surface of the resistance heating element is slightly higher than the upper surface of the graphite conductor by 15 cm, and the material added in the material chamber It is a mixed briquette made of grinding powder and aluminum ash for the lining of waste refractories in electrolytic cells.

[0065] Use the above-mentioned device to process and recycle aluminum electrolysis waste refractory lining grinding powder and aluminum ash mixed briquette, according to th...

Embodiment 3

[0072] Figure 5 , Image 6 It is the A-A sectional view and the C-C plane sectional view when the resistance heating element of the present embodiment is designed as two mutually parallel and independent linear shapes, and the B-B plane sectional view is the same as that of Embodiment 1, as figure 2 shown. The difference between this embodiment and the resistance furnace device structure of Embodiment 1 is that the resistance heating element 3 in the furnace is designed as two parallel and independent linear shapes, and the upper surface of the resistance heating element is flat with the upper surface of the graphite conductor. Qi, and the material added in the material chamber is the mixed compacted material of the waste refractory lining grinding material of the electrolytic cell and the Al-Fe alloy.

[0073] The resistance heating element 3 of this embodiment is designed as two mutually parallel and independent rectilinear shapes, and the two electrodes 22 of each indepen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com