On-line real time measuring method and measurer for aluminium electrolyzing parameters

A technology of real-time measurement and aluminum electrolysis, applied in the field of temperature measurement method and the instrument used for measurement, can solve the problems of sampling process error, inability to measure, difficulty in saving energy consumption, etc., and achieve the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

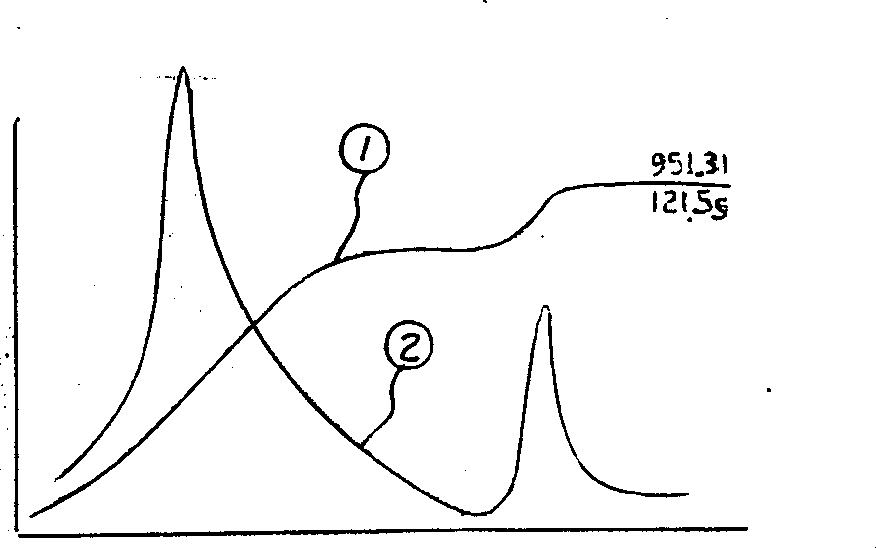

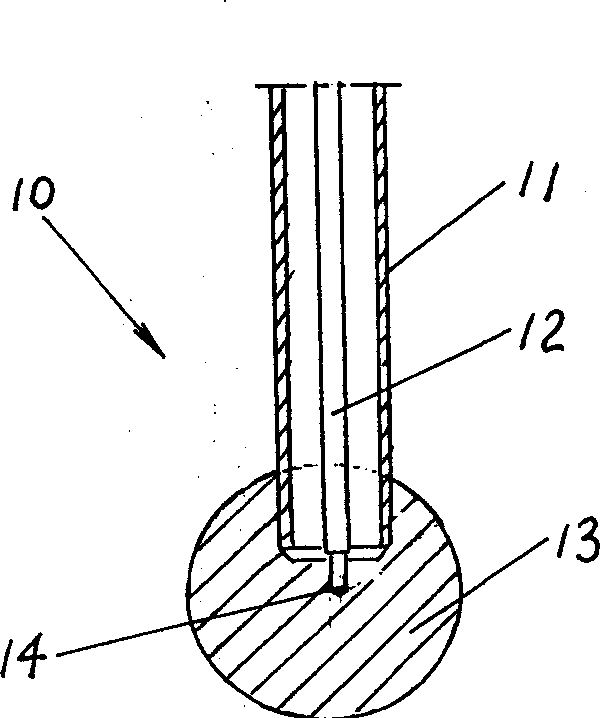

[0016] Measurement method of the present invention comprises the following steps: as figure 2 , 3 ,

[0017] (1) Determination of electrolyte temperature, primary crystal temperature of electrolyte, measuring instrument includes two parts of probe 10 and secondary instrument 20, measures 5 points altogether, inserts probe 10 of measuring instrument in the electrolytic cell, records electrolyte temperature, electrolyte The primary crystal temperature is transmitted to the measurement interface of the secondary instrument 20 as an electrical signal.

[0018] (2) Use the secondary instrument 20 of the measuring instrument to amplify and process the measurement electrical signal output by the probe 10, and calculate the parameters of the electrolysis operation according to the set mathematical model. Table 1 shows 5 points of the 60KA aluminum electrolytic cell measurement results.

[0019] dot

Electrolyte temperature ℃

Electrolyte initial crystallization temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com