On-line anode connecting method and structure for prebaked anode aluminium electrolysis

A prebaked anode and aluminum electrolysis technology, which is applied in the field of electrolytic aluminum production, can solve the problems of inconvenient use, large changes in the structure of anode carbon blocks and steel claws, etc., and achieve the effects of improving electrical conductivity, reducing load-bearing requirements, and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

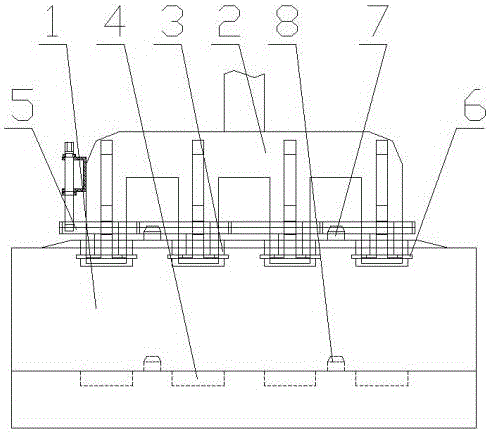

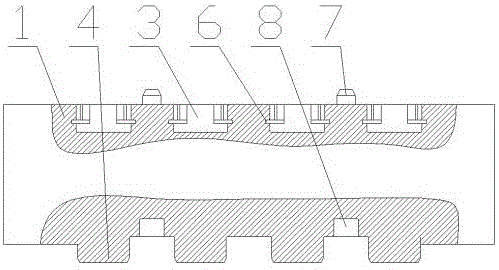

[0025] Example 1. The structure of prebaked anode aluminum electrolysis connected to the anode online, including the carbon block body 1 of the anode, the top of the carbon block body 1 is provided with a carbon bowl 3, and the bottom is provided with a fixed protrusion 4, and the old and new carbon block bodies 1 pass through the carbon bowl 3 and the fixed protrusion. Header 4 positioning connections.

[0026] The top and bottom of the carbon block body 1 are respectively provided with bumps 7 and grooves 8 .

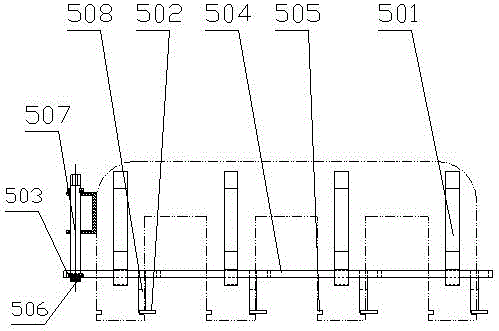

[0027] Also comprise steel claw 2, be provided with tensioning mechanism 5 on steel claw 2, as Figure 3-7 As shown, the tensioning mechanism 5 includes a clip 501 connected to the steel claw 2 . The clip 501 is provided with a fastening block 502 inserted into the carbon bowl. The clip 501 is connected to a bracket 504 for moving the fastening block 502 . The clip 501 and the fastening block 502 are placed in the installation groove 505 in the steel claw 2 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com