Method for sorting waste aluminum electrolytic cathodes

An aluminum electrolysis and waste technology, which is applied in the comprehensive recycling and utilization of electrolytic aluminum waste cathodes, the separation and purification of electrolytic aluminum waste cathodes, can solve the problems affecting the selection index, the flotation index, and the large processing capacity, and achieves improved treatment. The effect of the effect, the production index is good, the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

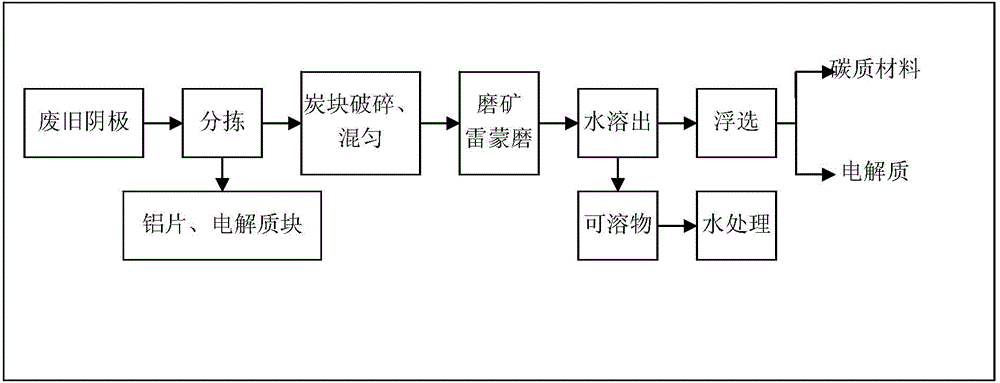

Image

Examples

Embodiment 1

[0028] Example 1: Utilization of waste cathodes in electrolytic aluminum production enterprises with an annual output of 200,000 tons of aluminum

[0029] (1) Basic information:

[0030] The electrolytic aluminum plant with an annual production capacity of 200,000 tons adopts 300kA large-scale prebaked tank electrolysis technology and prebaked anode roasting technology. The annual output of waste cathodes is 8,000 tons. The reference cathode composition is as follows: the carbon content is 33% to 65%, and the degree of graphitization is as high as 70% to 88%; the electrolyte composition content is 65% to 32%.

[0031] (2) Application method

[0032] After the collected waste cathodes are crushed and mixed, they are finely crushed and ground, and the waste cathodes are ground to less than 0.074mm, accounting for 70%.

[0033] Set up two dissolution pools (A and B pools) to operate alternately.

[0034] After ore grinding, the waste cathode powder is added to the dissoluti...

Embodiment 2

[0042] Example 2: Application of electrolytic aluminum enterprises with an annual output of 600,000 tons

[0043] (1) Basic information

[0044] The electrolytic aluminum plant with an annual production capacity of 600,000 tons adopts 300kA large-scale prebaked tank electrolysis technology and prebaked anode roasting technology. The annual output of waste cathodes is 20,000-24,000 tons. The reference cathode composition is as follows: the carbon content is 42-69%, the degree of graphitization is as high as 70-88%; the electrolyte composition content is 58-31%.

[0045] (2) Application method

[0046] Crushing equipment is used for crushing treatment, mining equipment is used for grinding treatment, and the waste cathode is ground to less than 0.074mm, accounting for 85%.

[0047] Set up two dissolution pools (A and B pools) to operate alternately. After grinding, the waste cathode powder is added to the dissolution tank A for dissolution treatment, the dissolution concen...

Embodiment 3

[0055] Embodiment 3: Application of an industrial park with an annual output of 1 million tons of electrolytic aluminum

[0056] (1) Basic information

[0057]Aluminum Industrial Park, with an annual electrolytic aluminum production capacity of 1 million tons. Adopt 200 ~ 350kA large pre-baked tank electrolysis technology and pre-baked anode roasting technology. The annual output of waste cathodes is 38,000-46,000 tons. The reference cathode composition is as follows: carbon content is 38-67%, graphitization degree is as high as 70-88%; electrolyte component content is 62'33%.

[0058] (2) Application method

[0059] Crushing equipment is used for crushing treatment, mining equipment is used for grinding treatment, and 90% of the waste cathodes are ground to below 0.074mm.

[0060] Set up two dissolution pools (A and B pools) to operate alternately.

[0061] After grinding, the waste cathode powder is added to the dissolution tank A for dissolution treatment, the dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com