Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4223 results about "Calcium silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium silicate is the chemical compound Ca₂SiO₄, also known as calcium orthosilicate and is sometimes formulated as 2CaO·SiO₂. It is also referred to by the shortened trade name Cal-Sil or Calsil.

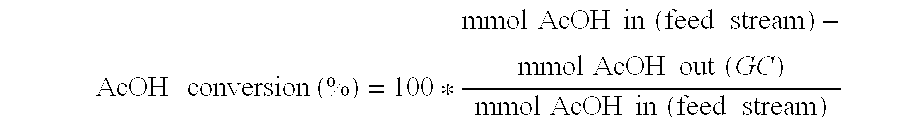

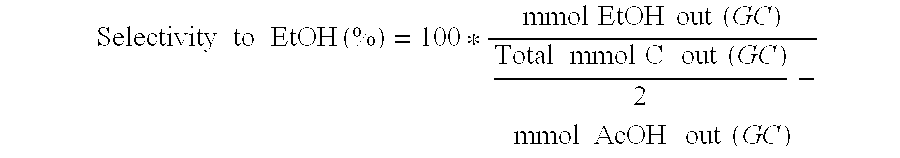

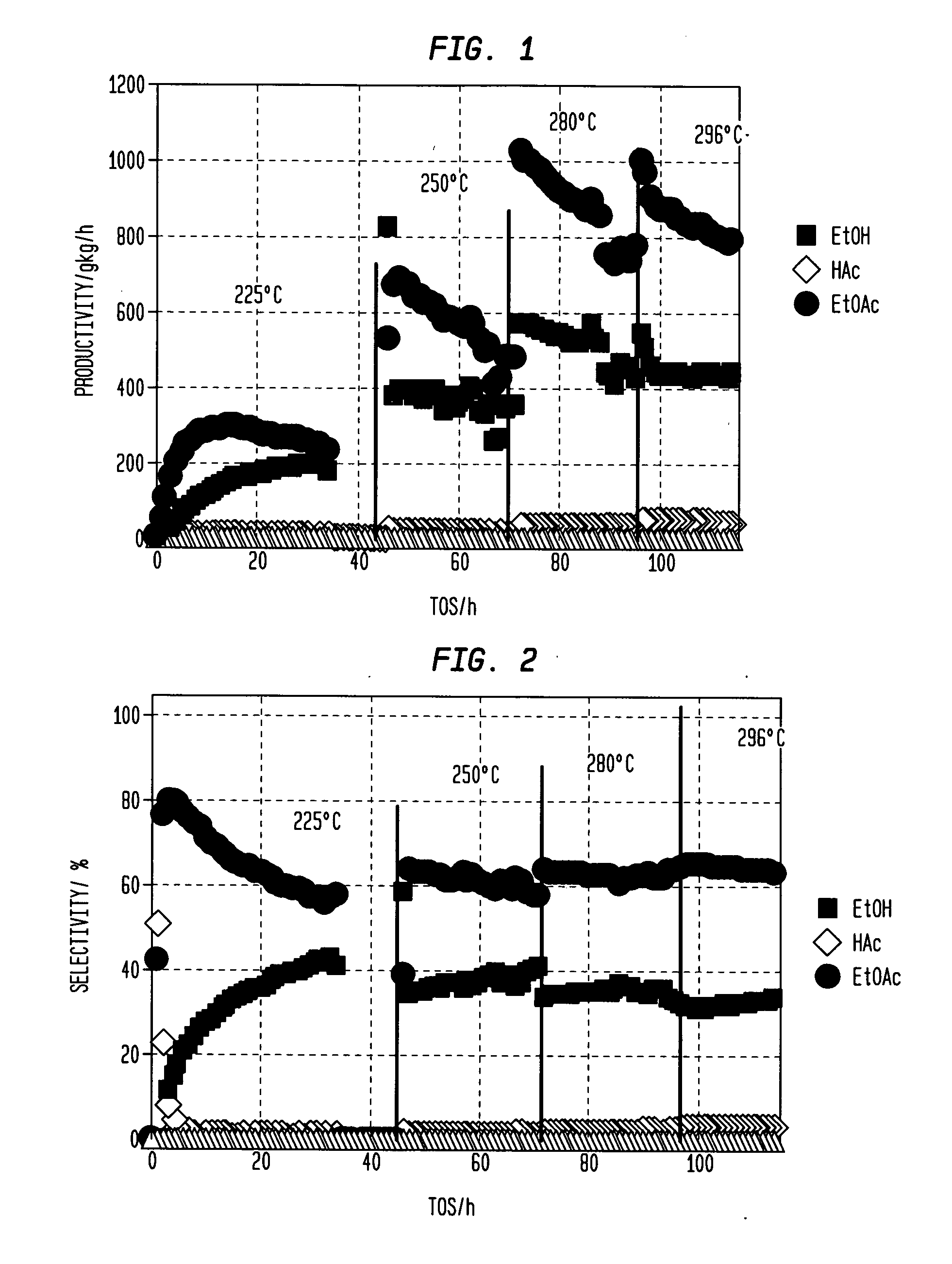

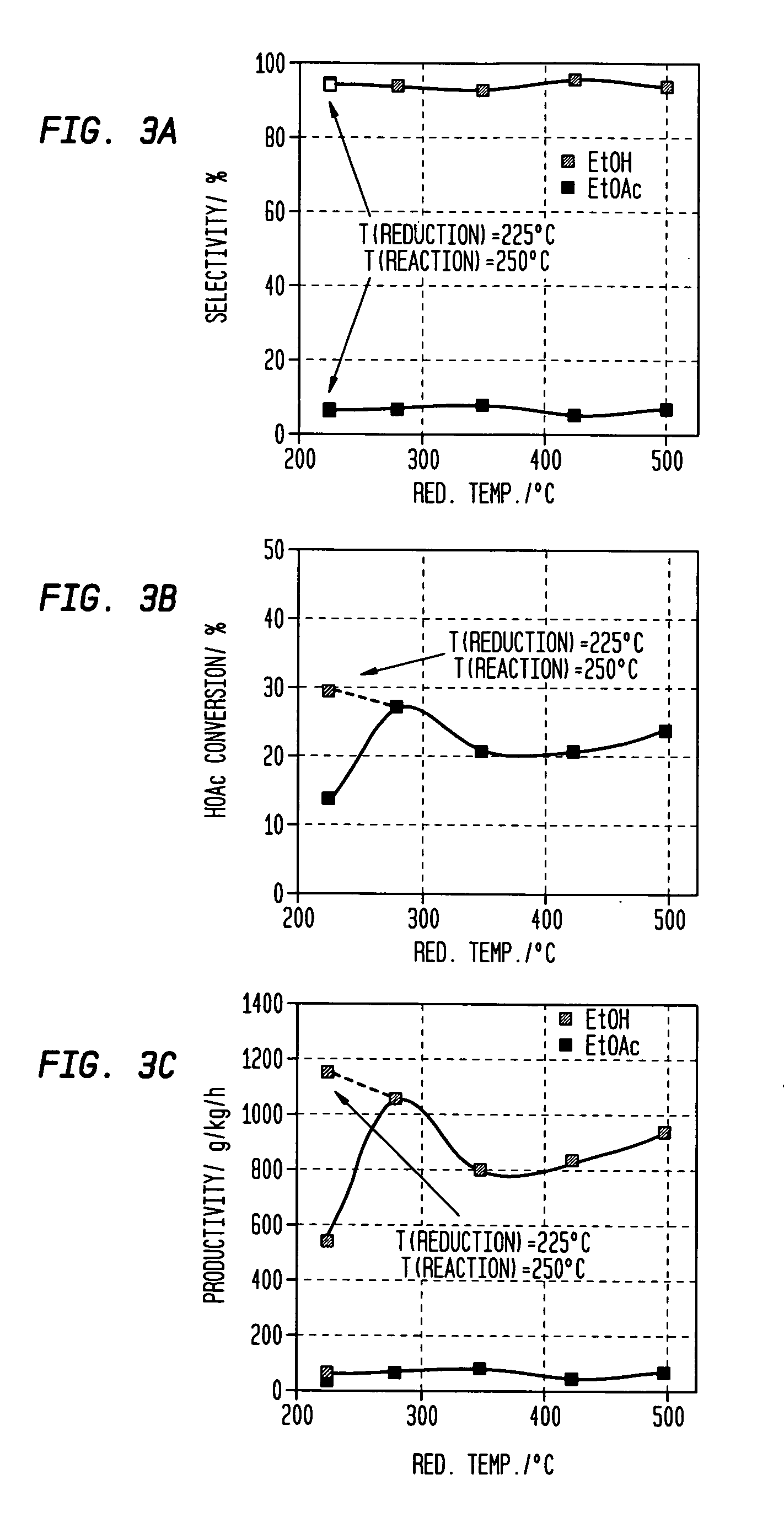

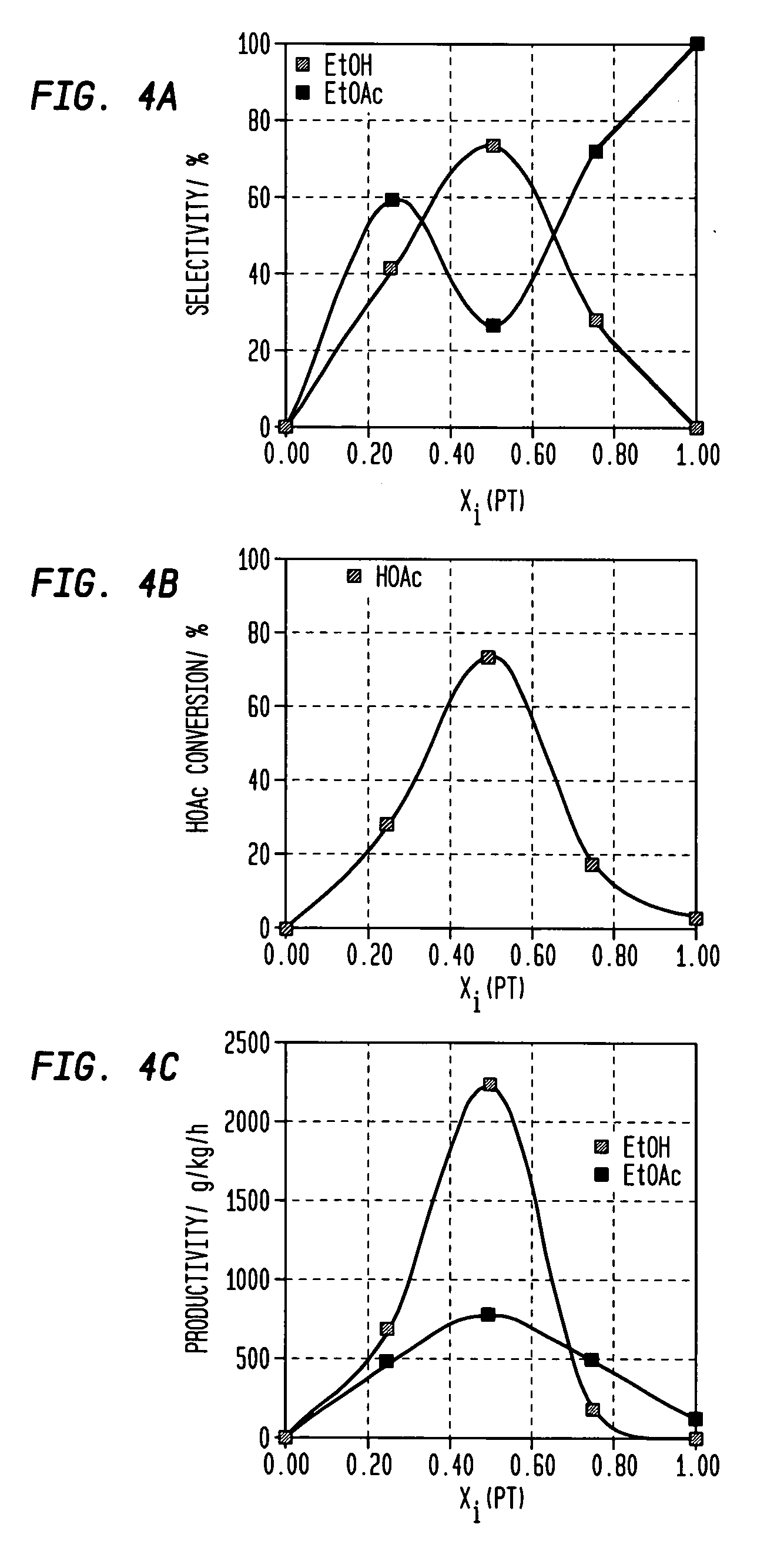

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS7863489B2High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicateAcetic acid

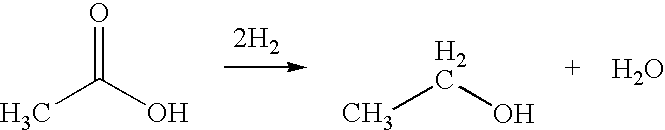

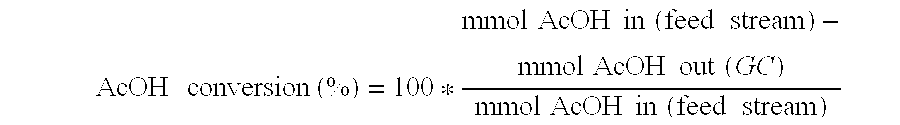

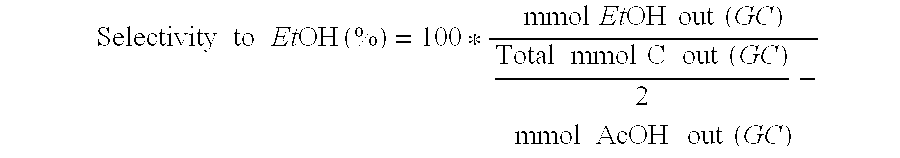

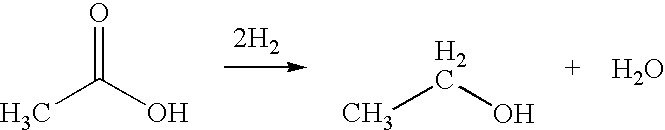

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

Direct and selective production of ethanol from acetic acid utilizing a platinum/tin catalyst

InactiveUS20100029995A1High selectivityHigh yieldOrganic compound preparationOxygen compounds preparation by reductionCalcium silicatePlatinum

A process for the selective production of ethanol by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethanol is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over a platinum and tin supported on silica, graphite, calcium silicate or silica-alumina selectively produces ethanol in a vapor phase at a temperature of about 250° C.

Owner:CELANESE INT CORP

Tunable catalyst gas phase hydrogenation of carboxylic acids

InactiveUS20100121114A1High selectivityExcessive loss of activityOrganic compound preparationHeterogenous catalyst chemical elementsPlatinumAcetic acid

A process for selective formation of ethanol from acetic acid includes contacting a feed stream containing acetic acid and hydrogen at an elevated temperature with catalyst comprising platinum and tin on a high surface area silica promoted with calcium metasilicate. Selectivities to ethanol of over 85% are achieved at 280° C. with catalyst life in the hundreds of hours.

Owner:CELANESE INT CORP

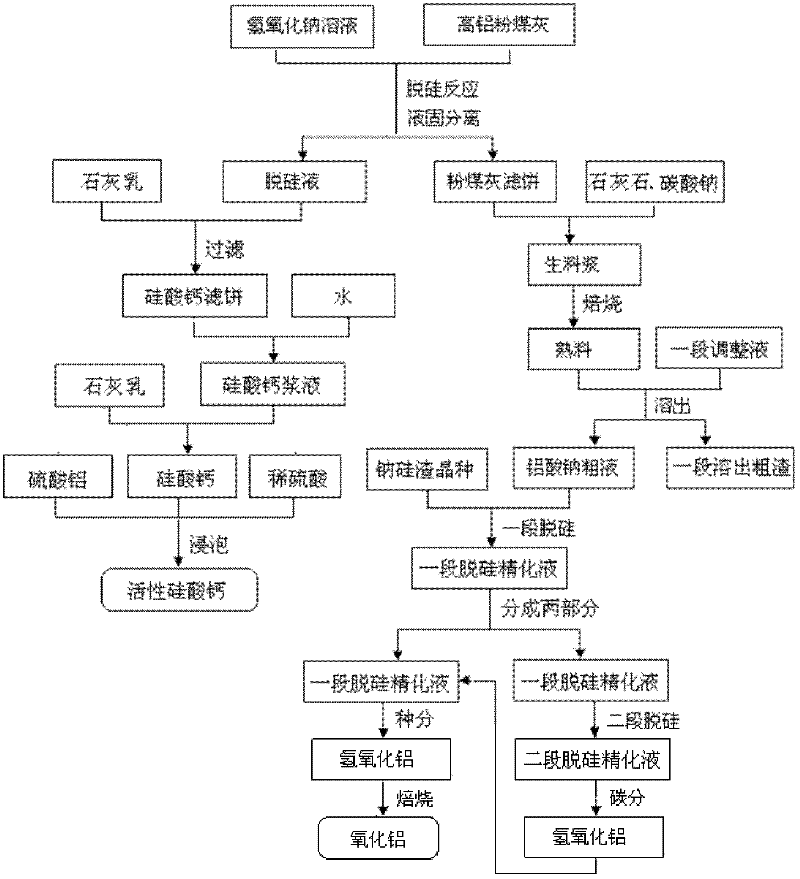

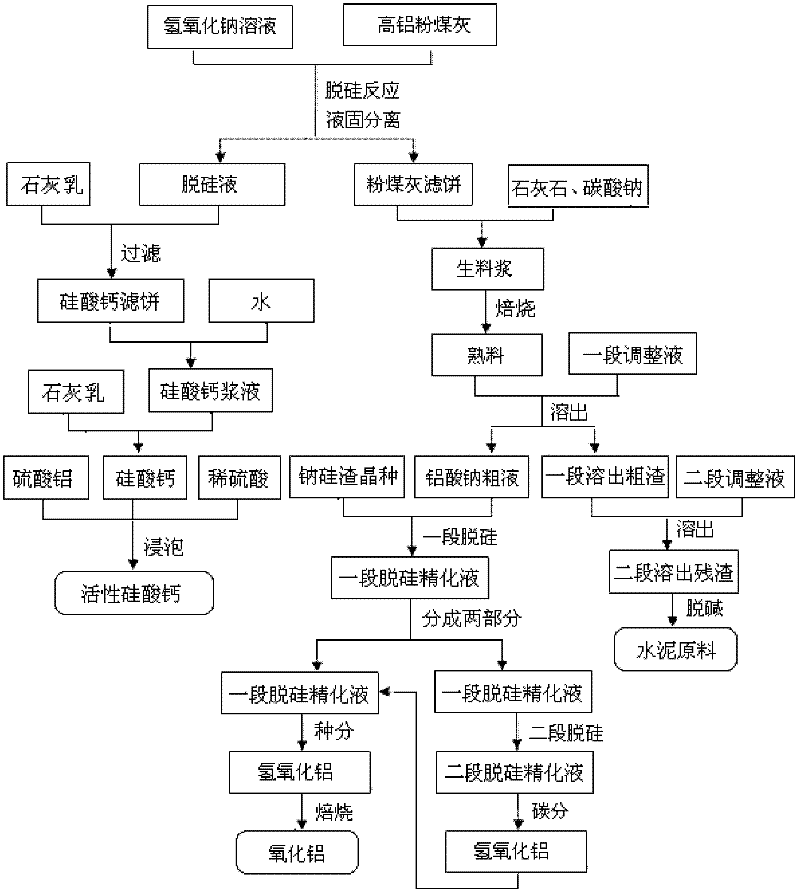

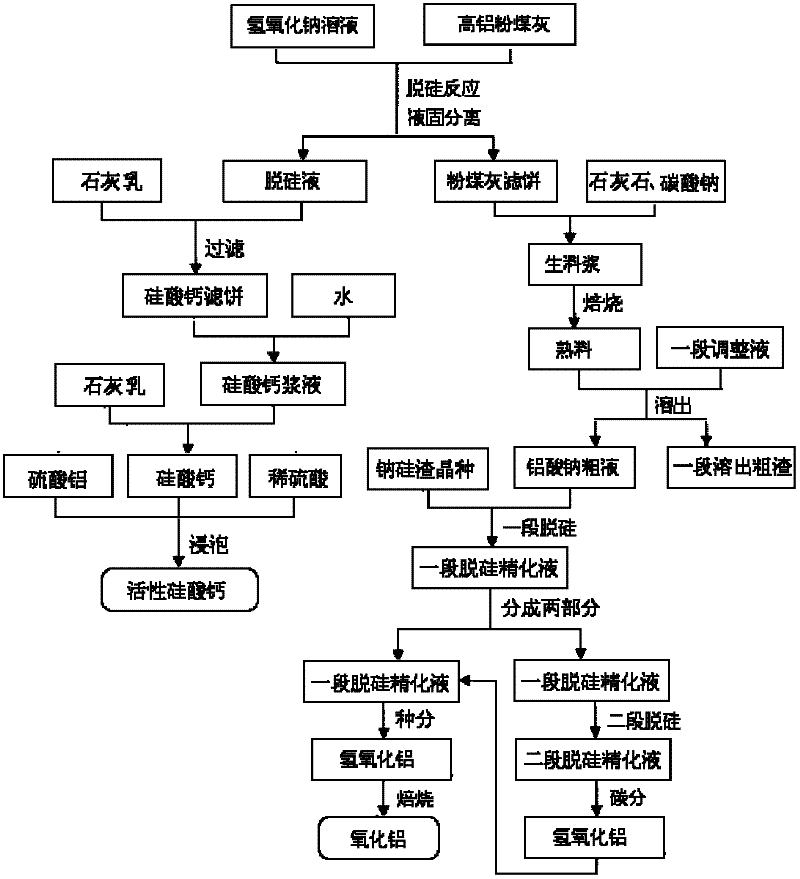

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Orodispersible tablets

ActiveUS20100297031A1Short disintegration timeGood mechanical resistanceBiocideNervous disorderCalcium silicateOrally disintegrating tablet

This invention relates to a an orally disintegrating tablet obtainable by direct compression of a dry powdered mixture, said mixture comprising up to 15% by weight of calcium silicate, at least 50% of a diluent, a disintegrant agent and an active ingredient. It also relates to a process for preparing the tablets by homogeneous blending the specific excipients in powder form and subsequent direct compression of the mixture. Said tablets disintegrate quickly in the cavity of the mouth, in particular in less than 15 seconds.

Owner:LAB LESVI SL

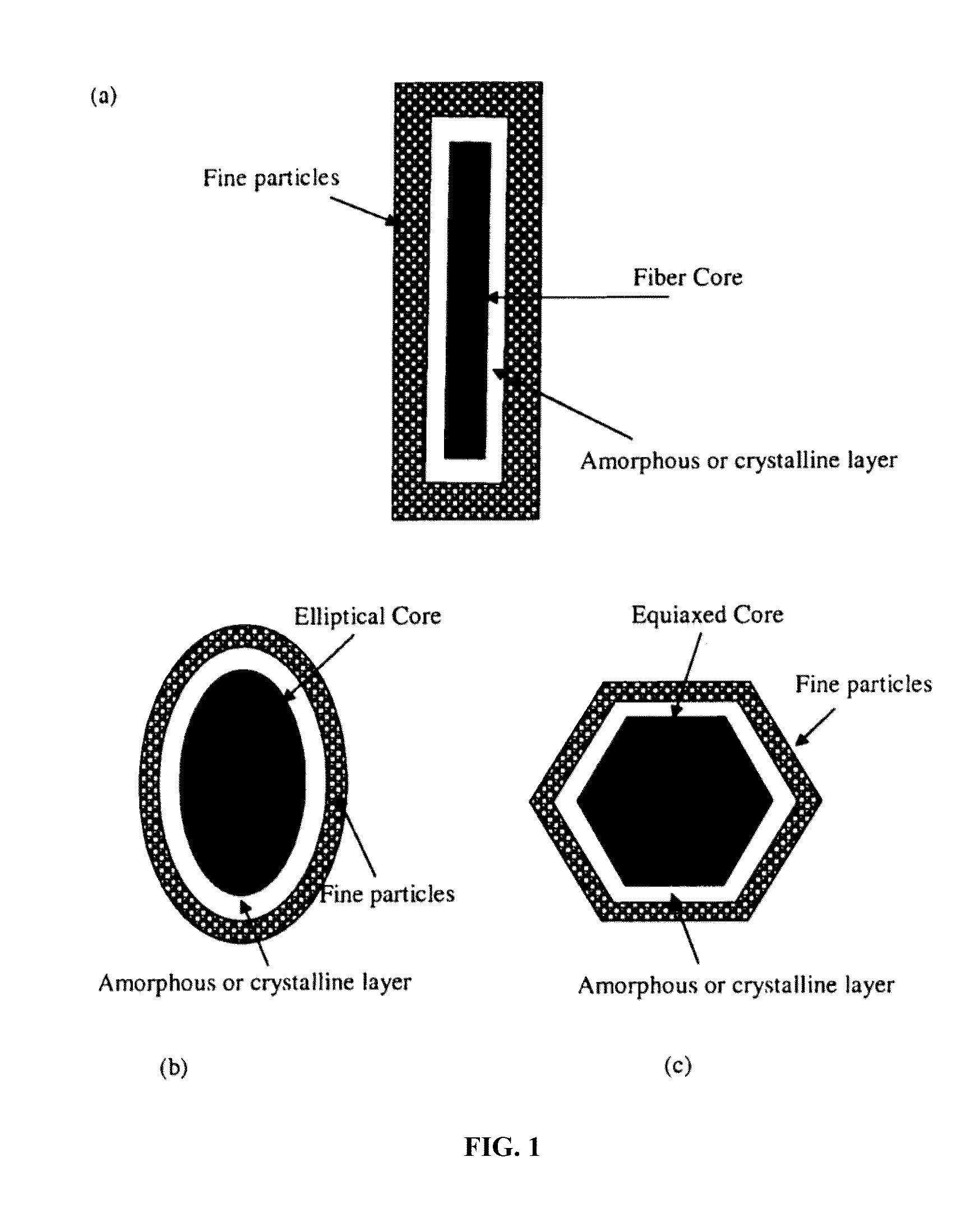

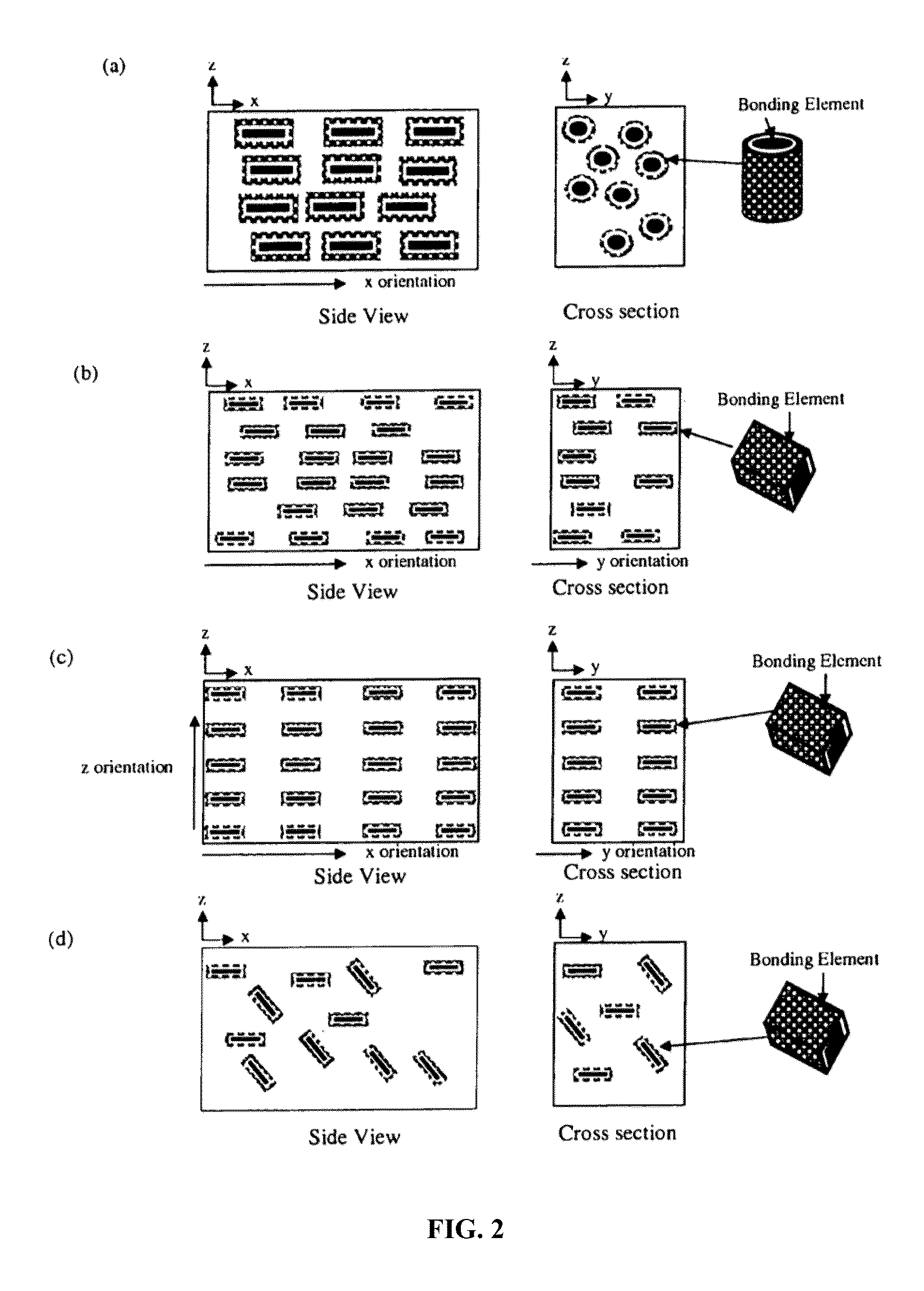

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

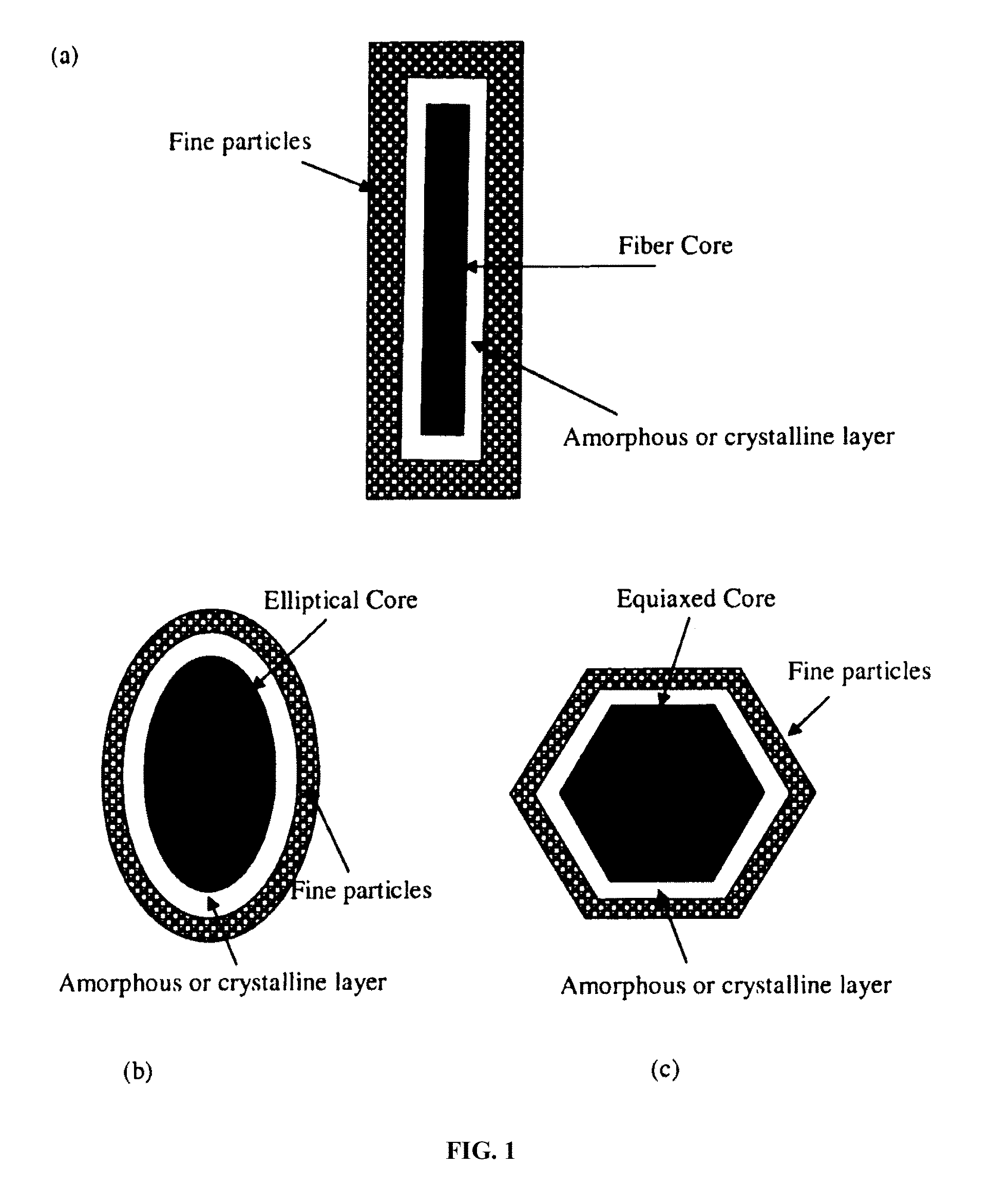

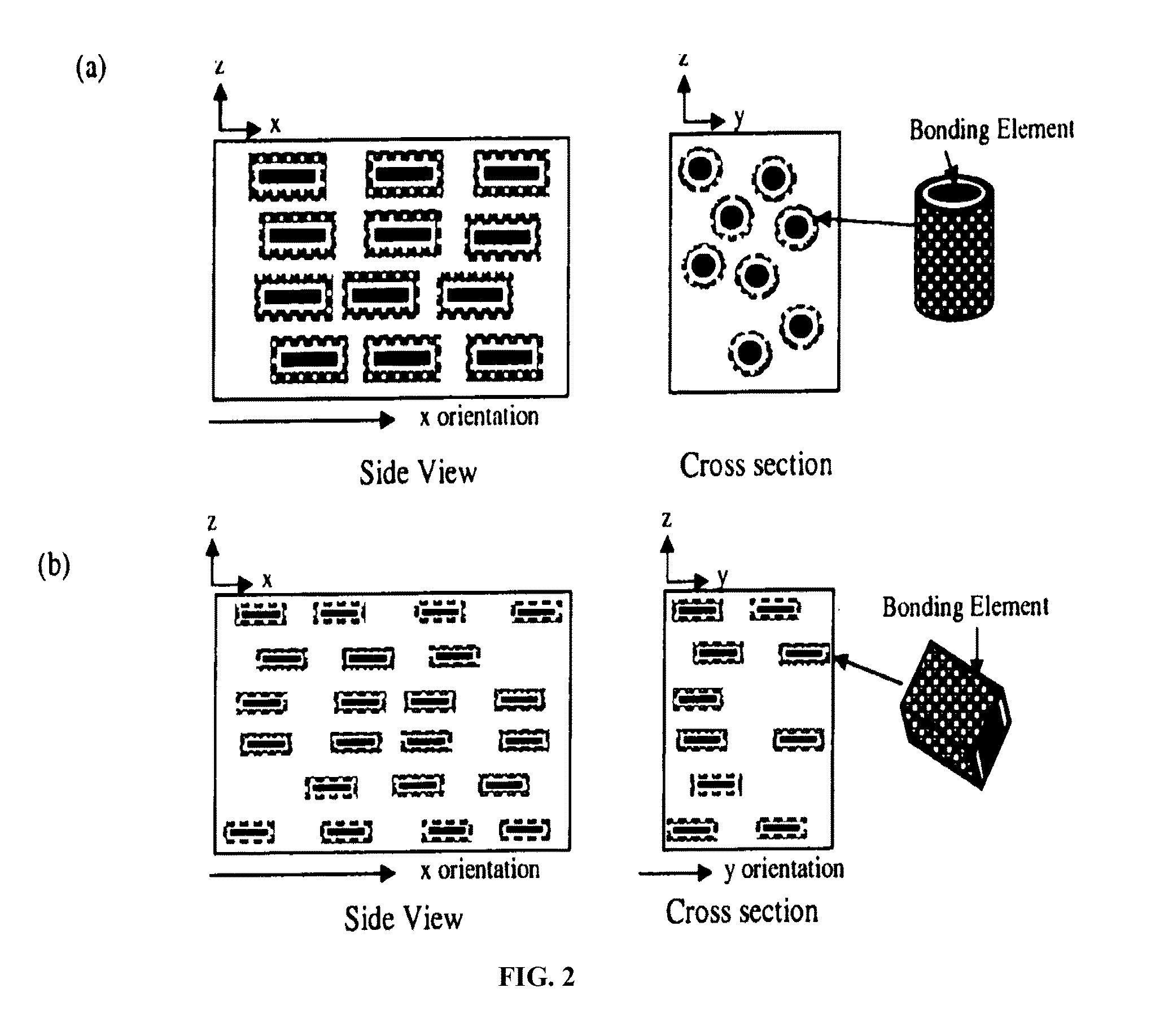

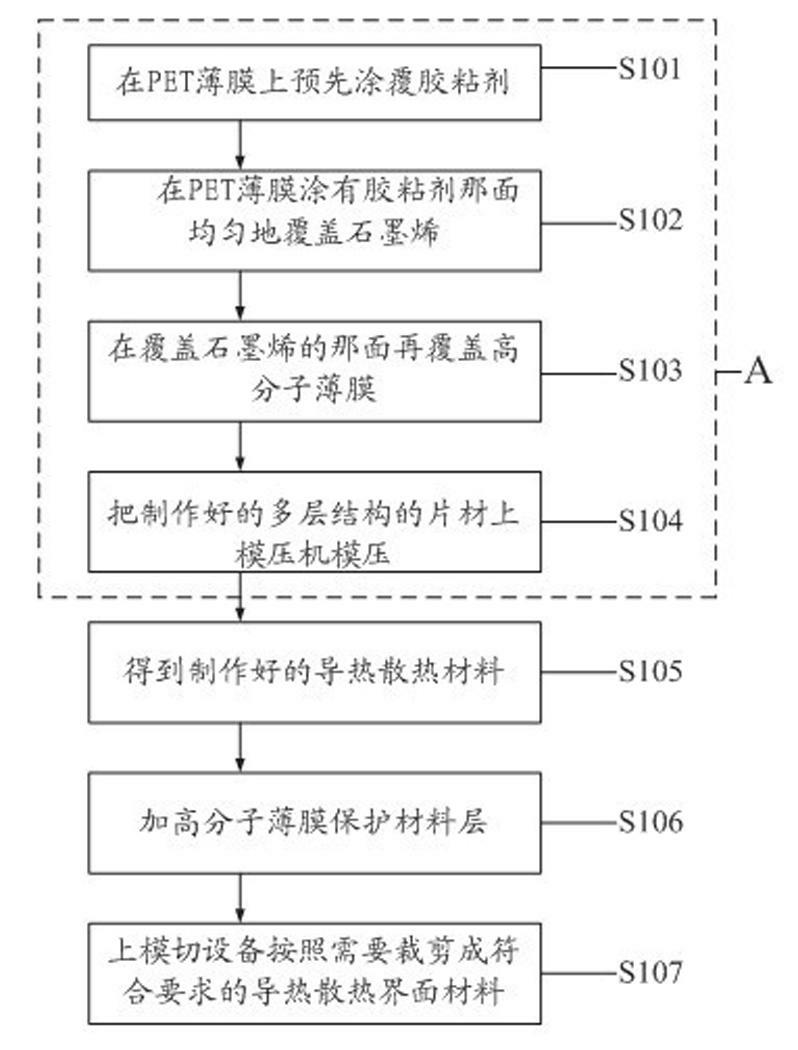

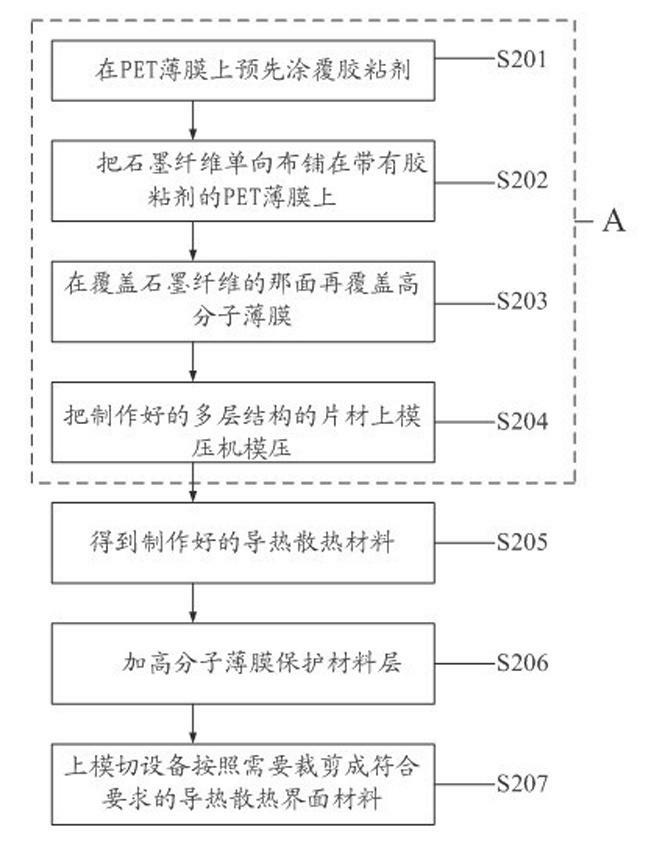

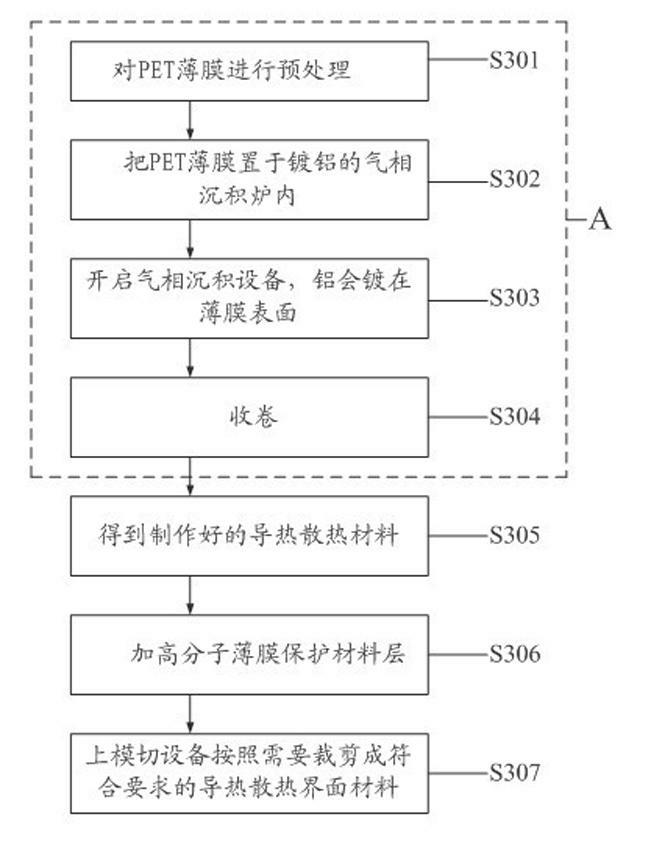

Heat-conduction heat-dissipation interface material and manufacturing method thereof

ActiveCN102651961AReduce volumeThe overall thickness is thinLayered productsCooling/ventilation/heating modificationsMetal fiberCalcium silicate

The invention provides a heat-conduction heat-dissipation interface material and a manufacturing method thereof, wherein the heat-conduction heat-dissipation interface material is applied to the field of heat dissipation of electronic products. The heat-conduction heat-dissipation interface material comprises a heat-conduction heat-dissipation layer and a surface protective material layer, wherein the heat-conduction heat-dissipation layer consists of one or more of graphite, nano graphite, crystalline flake graphite, graphene, pyrolytic carbon, pyrolytic graphite, graphite powder, carbon nano tubes, carbon fibers, graphite fibers, resin, ceramic fibers, quartz fibers, metal fibers, zirconia, boron nitride, silicon nitride, boron carbide, silicon carbide, magnesia powder, metasillicio acid fibers, calcium silicate aluminum fibers, aluminium oxide fibres, copper power, aluminium power, silver power, tungsten power and molybdenum power; and the surface protective material layer is a polymeric membrane. The heat-conduction heat-dissipation interface material manufactured according to the materials and the method provided by the invention has the advantages of effectively improved heat-dissipation performance, small volume, light weight and small thickness, can be used for prolonging the service life of an electronic component, and simultaneously is easy to produce and process.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Light-weight calcium silicate plate and preparation method thereof

The invention relates to a light-weight calcium silicate plate and a preparation method thereof. The light-weight calcium silicate plate comprises the following components in percentage by mass: 11-44.4% of siliceous filler, 30-40% of cement, 4.4% of calcific filler, 6-10% of fiber material, 3-5% of inorganic filler and 3-10% of reaction assistant, wherein the siliceous filler contains a light-weight siliceous material accounting for 22.2-44.4% of the total mass of the light-weight calcium silicate plate; and the sum of the mass percents of the components is 100%. According to the invention, the light-weight calcium silicate plate having low density and high strength is prepared through a slurry flow process by completely using high-activity amorphous kieselguhr instead of the traditional quartz sand as the siliceous material; and the process is simple and can be completed according to the existing technical process without changing the original calcium silicate plate production line and production conditions, and the production process does not increase the cost and can still achieve favorable effect.

Owner:WUHAN BUILDING MATERIAL IND DESIGN & RES INST

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS20050229809A1Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateFire retardant

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described

Owner:BONE SOLUTIONS INC

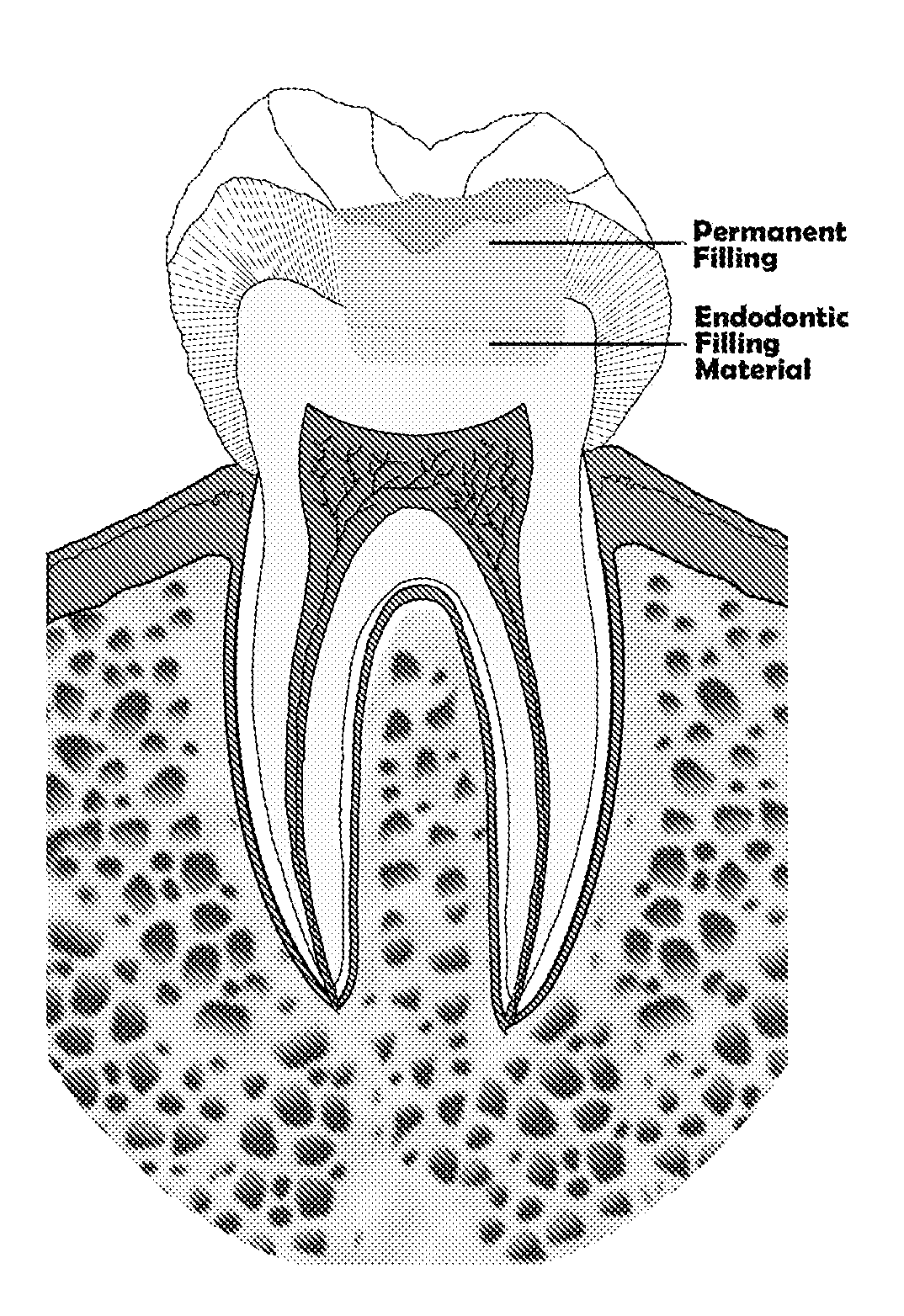

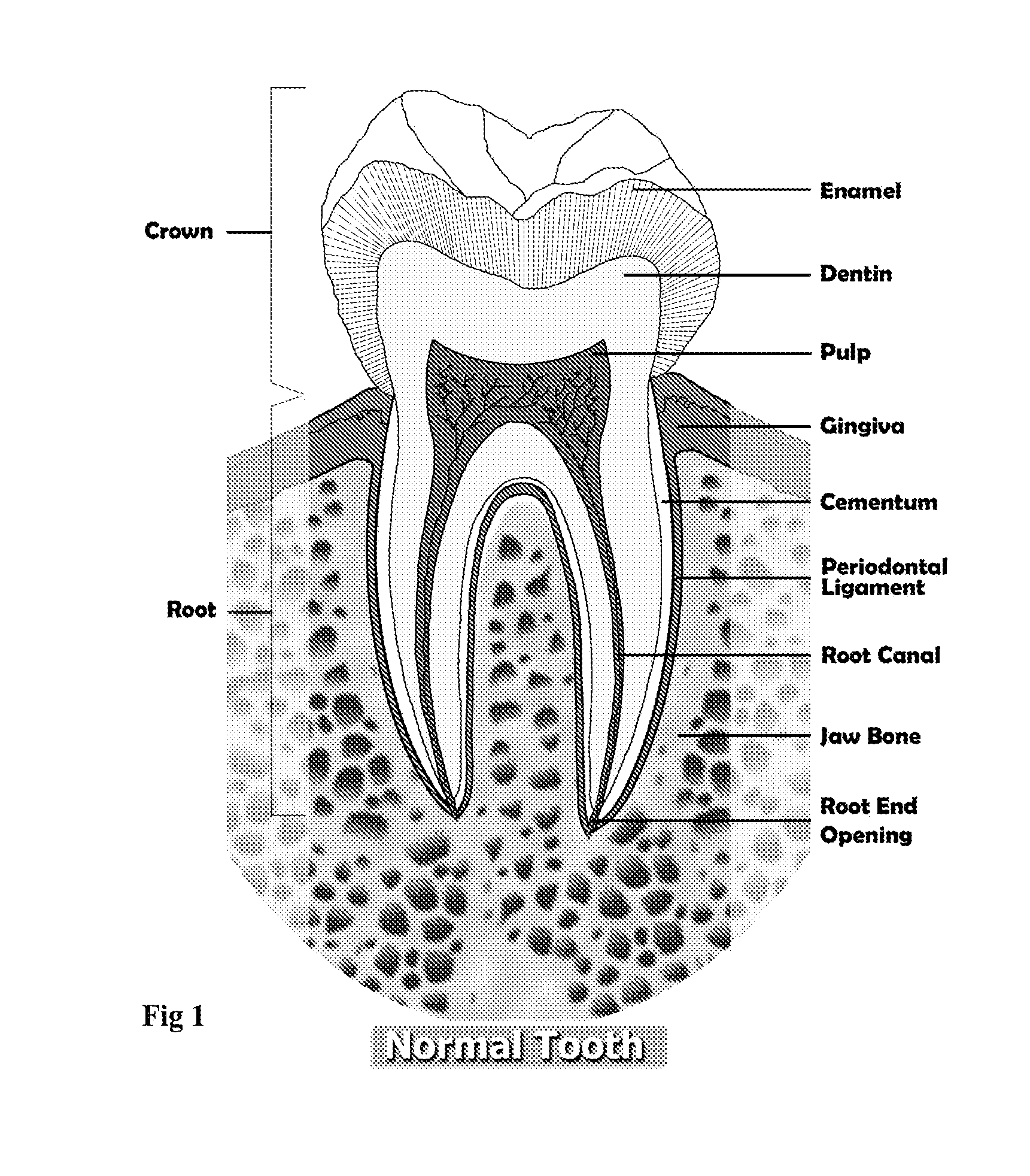

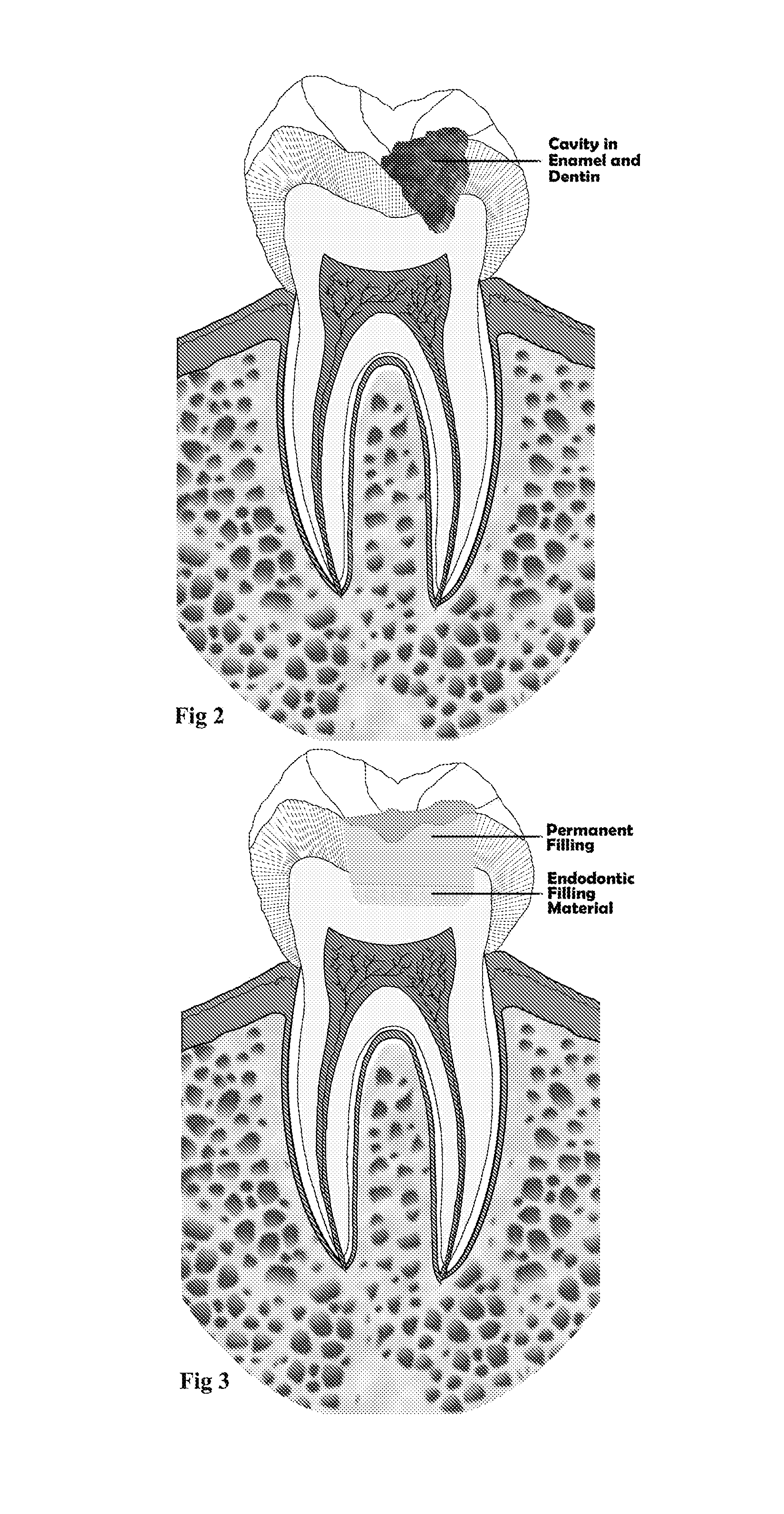

Endodontic filling material

InactiveUS20080206716A1Improve sealingEasily manipulationAntibacterial agentsOther chemical processesCalcium silicateHigh concentration

The present invention is a bioactive endodontic material and its use for filling the tooth and bone cavities. The present invention, by using calcium salt, calcium oxide, calcium silicate, and calcium phosphate compounds as essential constituents, and mixing them with a water base solution, prepares a bioactive calcium and phosphate enriched material. The enriched material (cement) comprises high concentration of water-soluble calcium and phosphate, and immediately forms hydroxyapatite during and after setting. The cement is biocompatible, antibacterial, capable to form an effective seal against reentrance of microorganisms into the filled cavity, compatible to handle and set in an aqueous environment, and able to stimulate hard tissue healing.

Owner:ASGARY SAEED

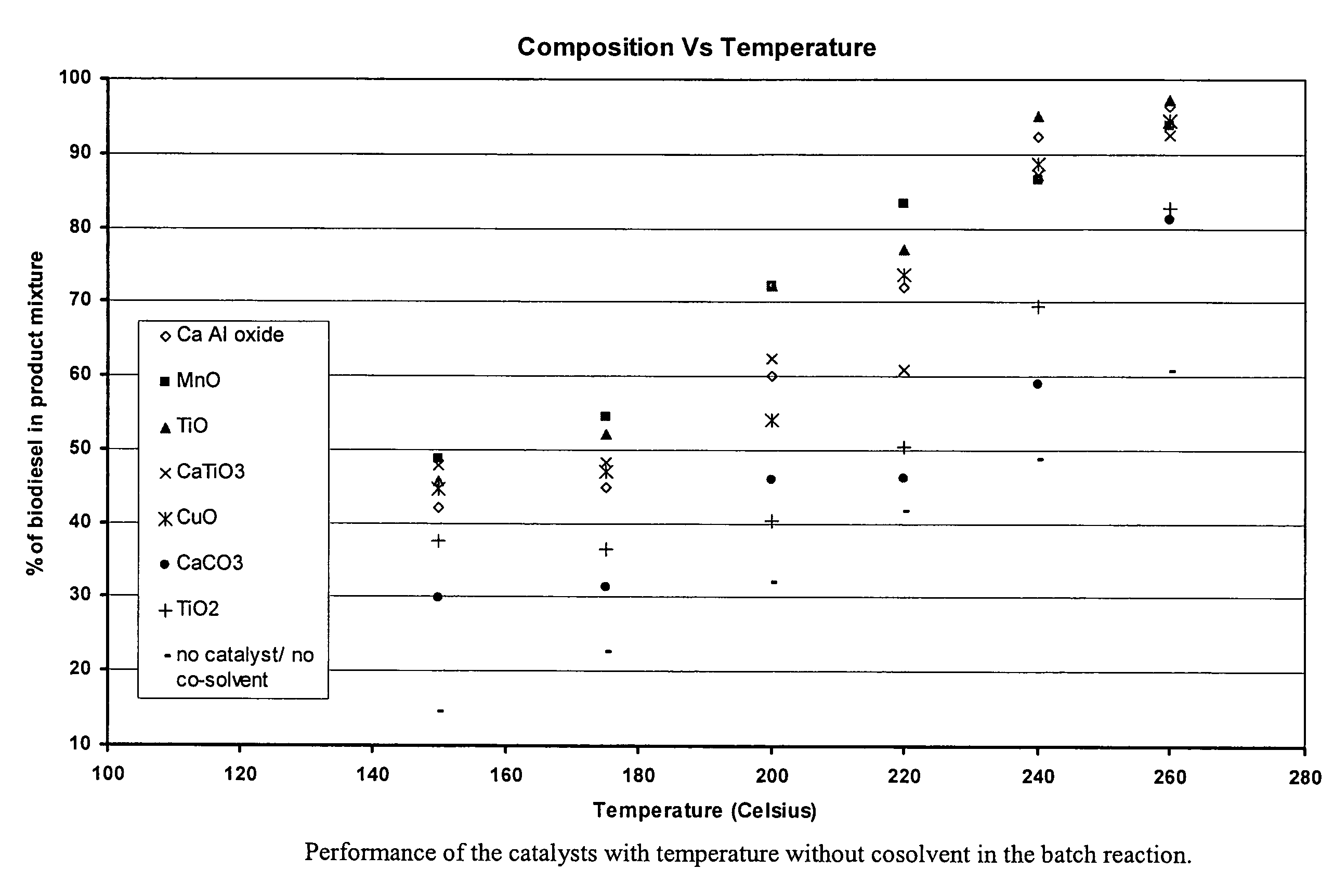

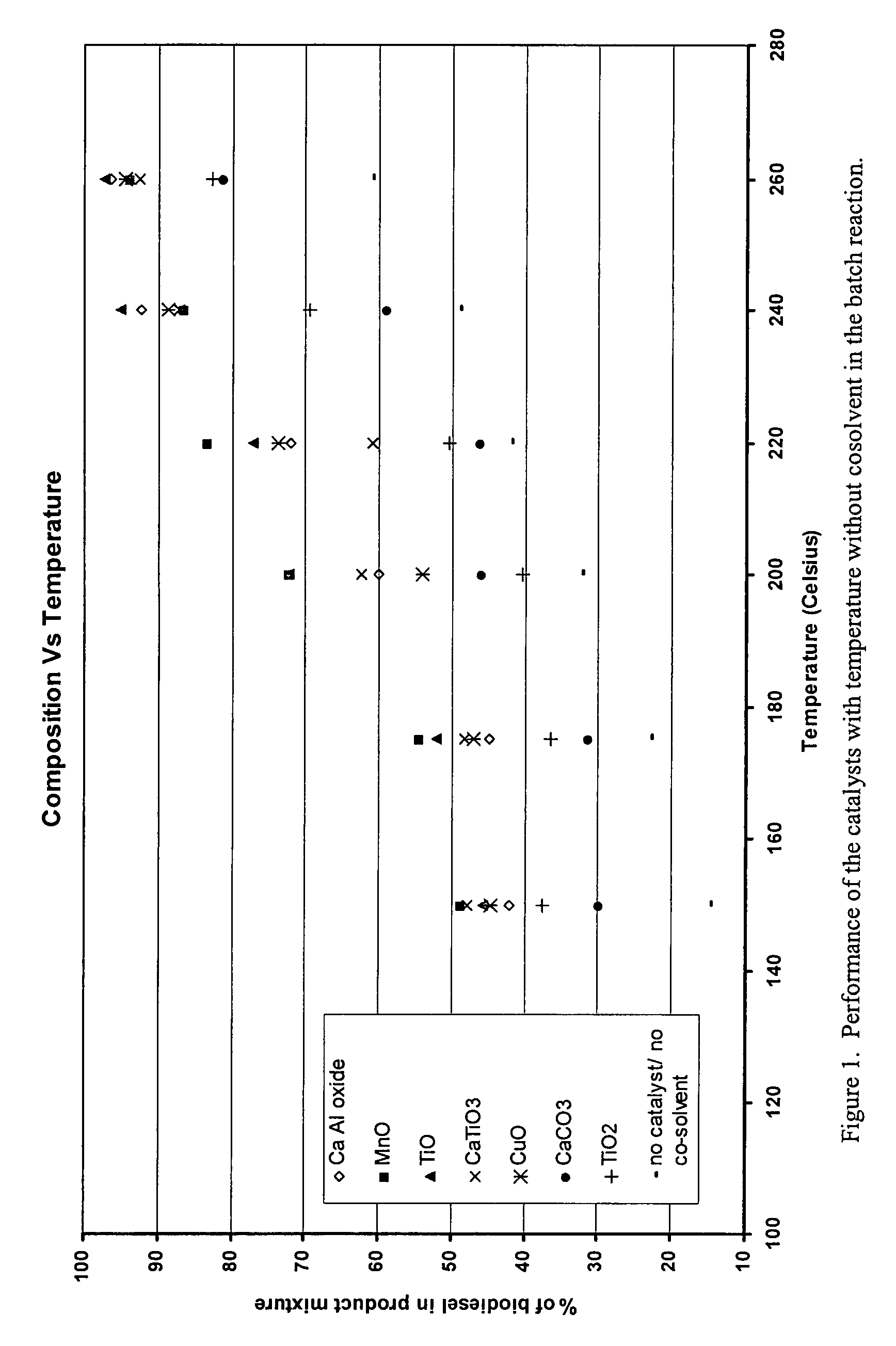

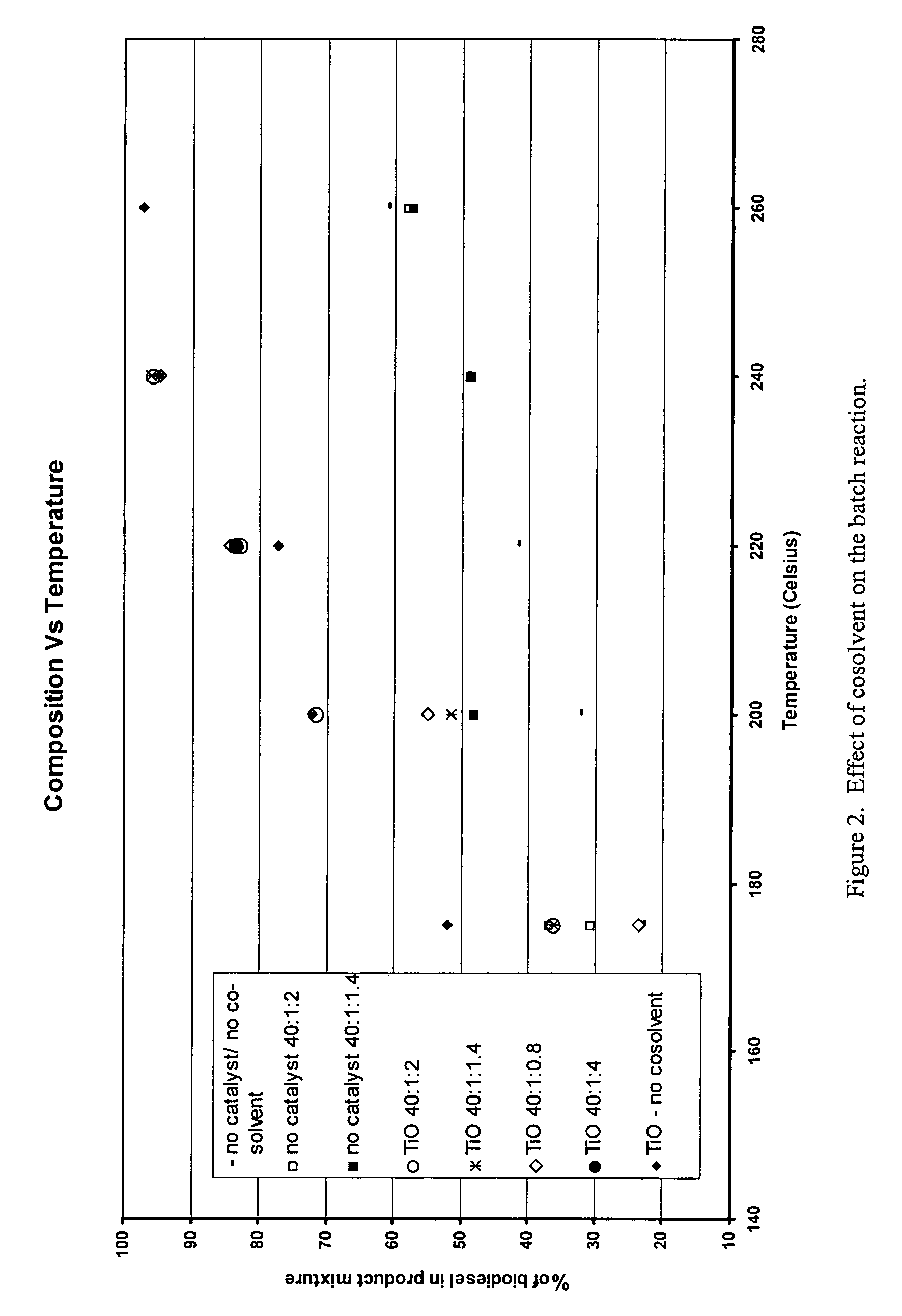

Green biodiesel

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

Process for removal of catalyst residues from poly-alpha-olefins

ActiveUS20050101761A1Reduce raw material usageOperation efficiency can be improvedHydrocarbonsAdsorption purification/separationCalcium silicateHalogen

A method is disclosed for reducing levels of residual halogen and Group IIIb metals in a crude poly(α-olefin) polymerized in the presence of a catalyst comprising the halogen and Group IIIb metals, wherein the method comprises: A) washing the crude poly(α-olefin) with water; B) separating the aqueous and organic phases; C) then adding an adsorbent selected from the group consisting of magnesium silicates, calcium silicates, aluminum silicates, aluminum oxides, and clays to the organic phase to form a slurry; D) heating the slurry under reduced pressure at a temperature of at least about 180° C. for at least about thirty minutes; and then E) separating the adsorbent from the slurry.

Owner:CHEMTURA CORP

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Process for preparation of nano multiporous silicon dioxide aerogel block

The process of producing silica aerogel block adopts the materials including polysiloxane E-40 as Si source, ethanol, water and hydrofluoric acid; and includes preparing silica aerogel grain via sol-gel and surface modification process at normal pressure, mixing the grain with calcium silicate slurry, rutile type titanium dioxide powder, ceramic fiber, glass fiber and porous cement via powerful stirring, and pressing into block with aerogel content greater than 90 vol%. High strength skeleton may be embedded into the block if necessary. The present invention may be used in insulation, sound isolation and adsorption.

Owner:TONGJI UNIV

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

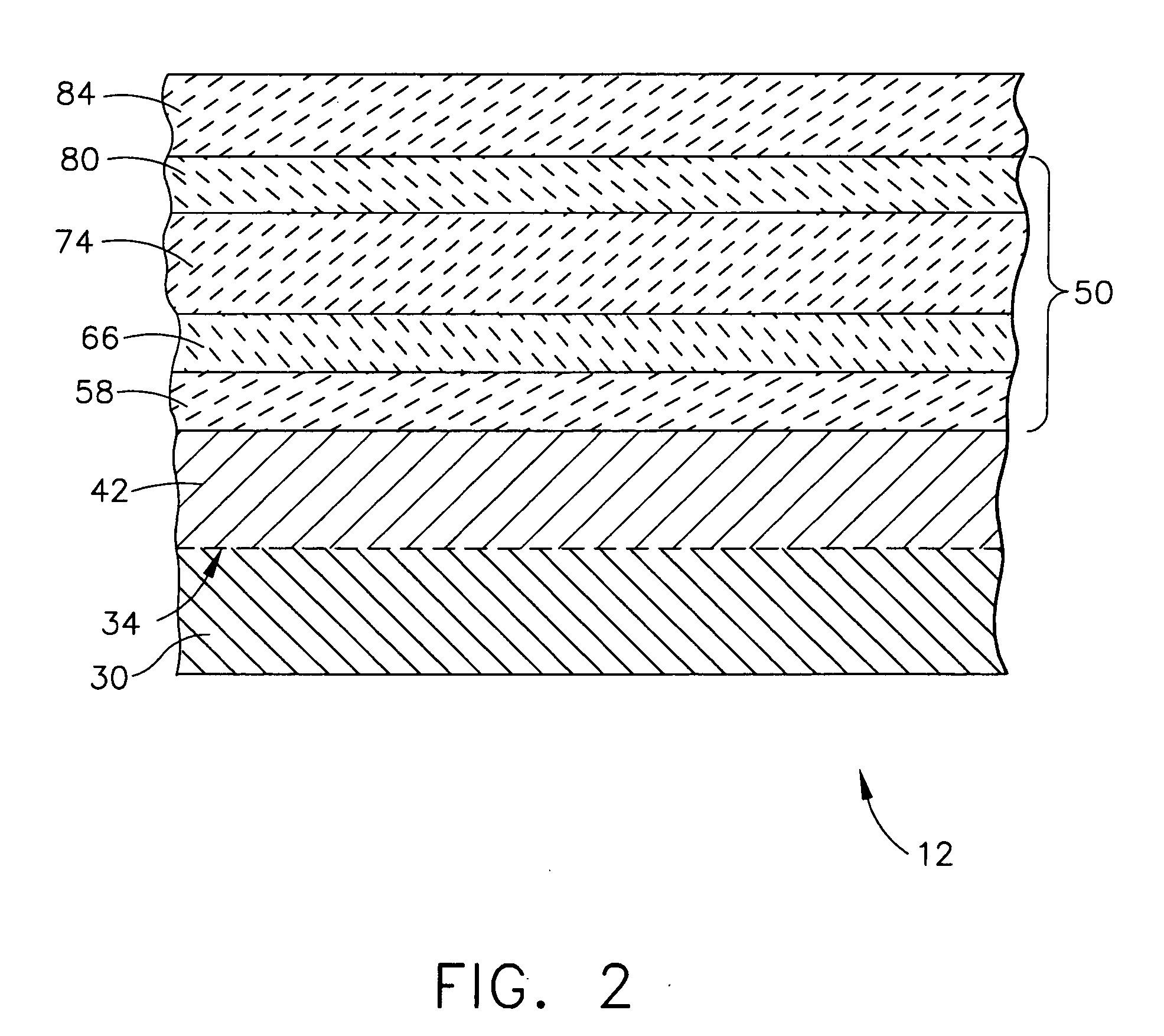

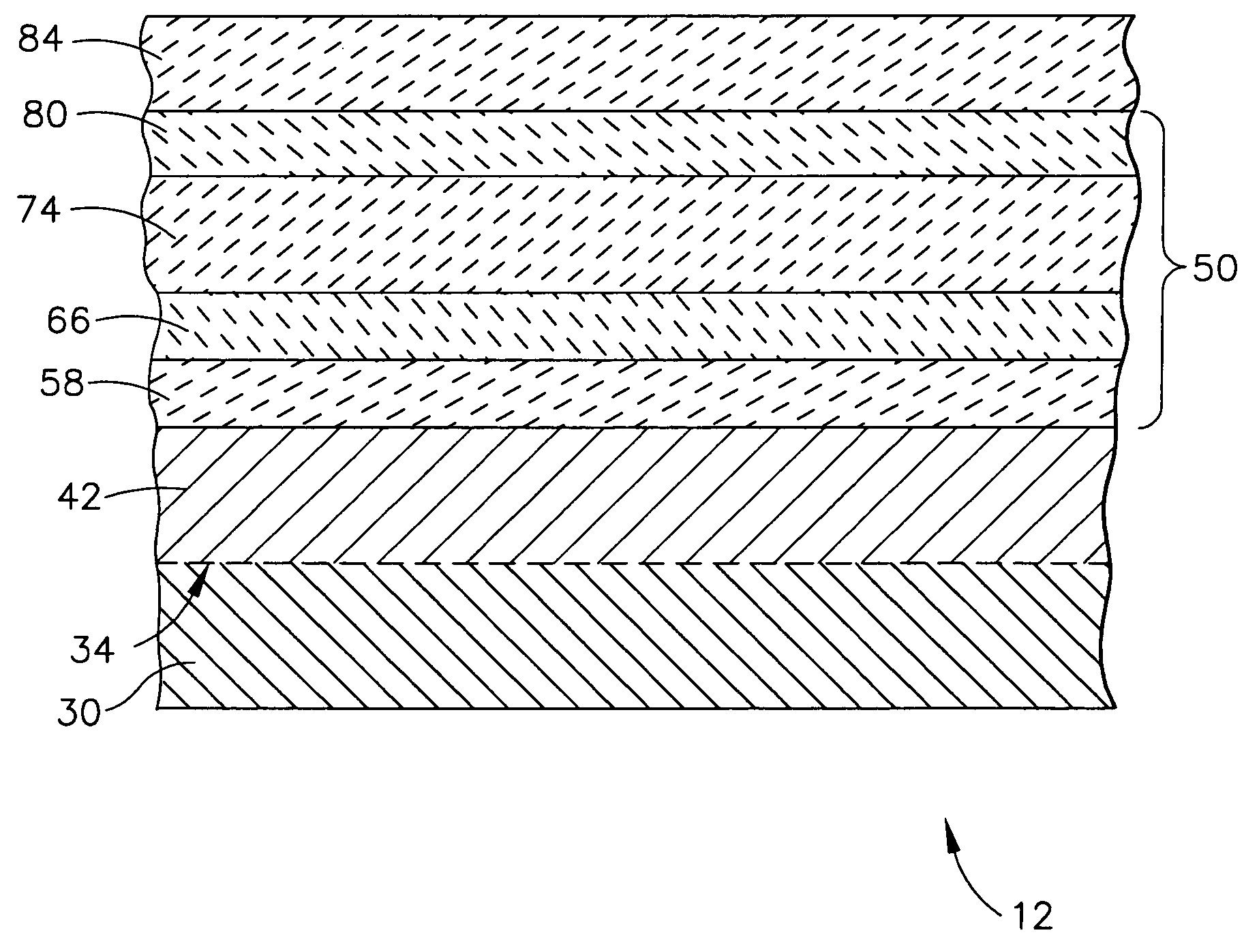

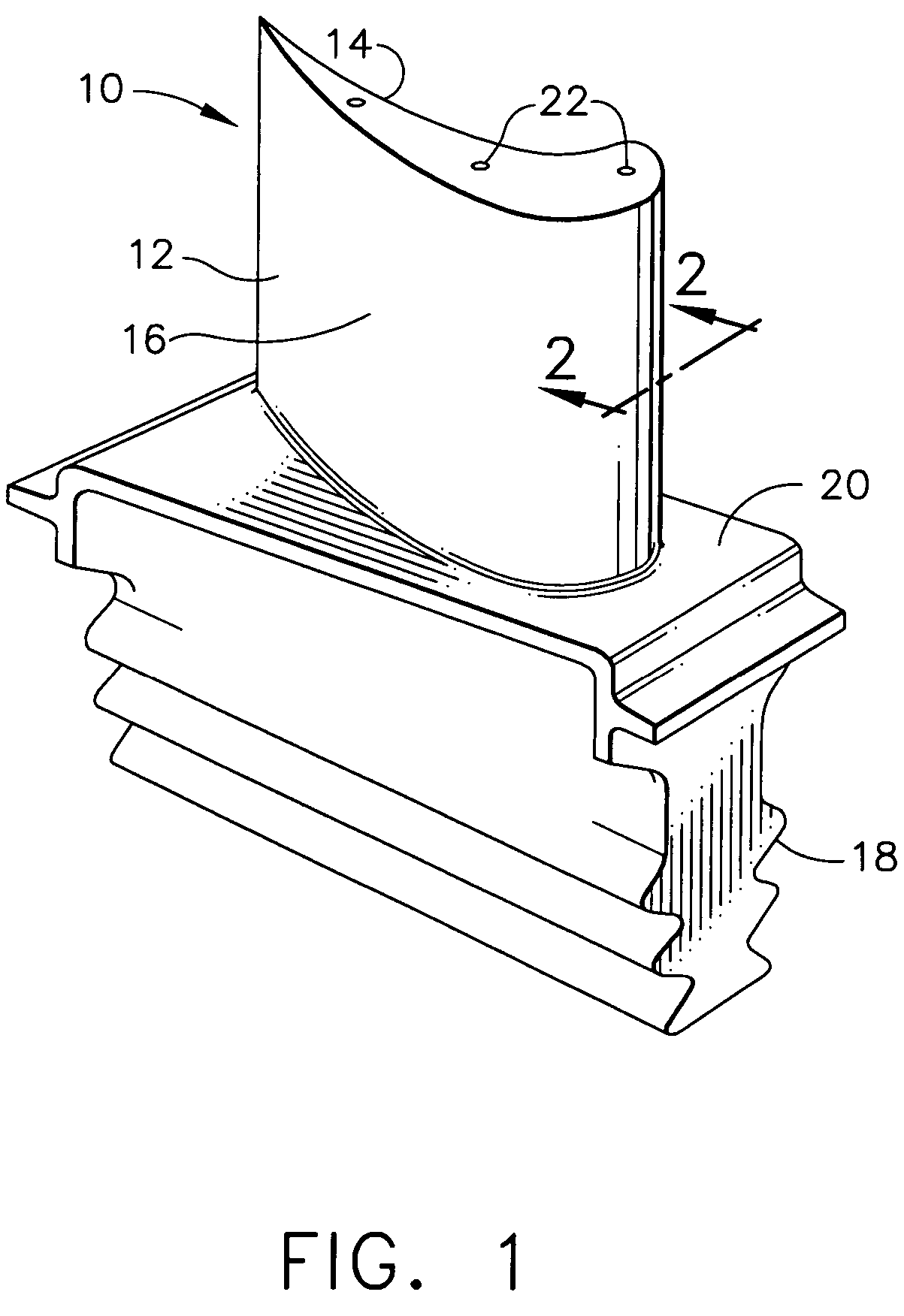

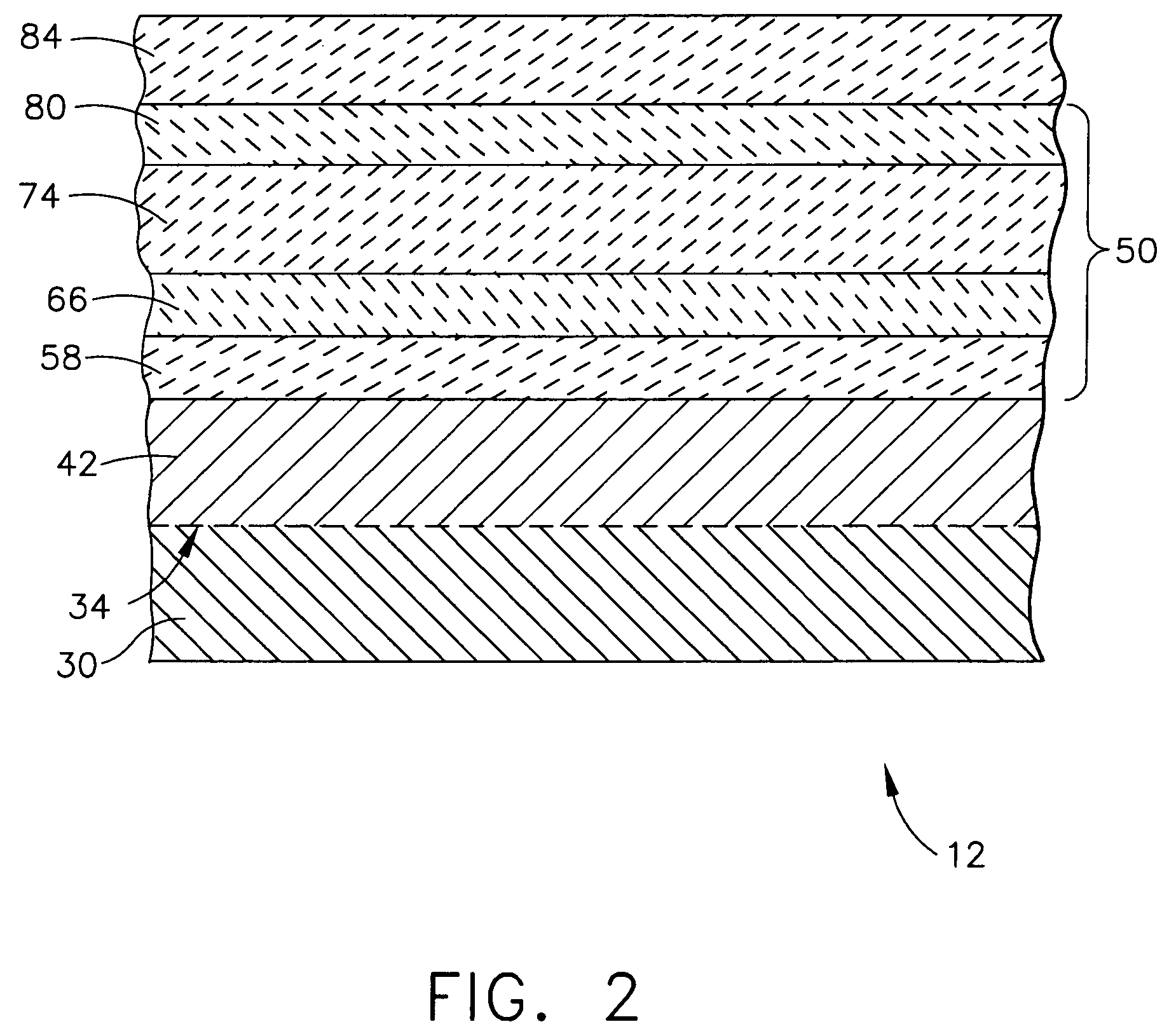

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS20060280953A1Improve adhesionHigh melting pointLiquid surface applicatorsMolten spray coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

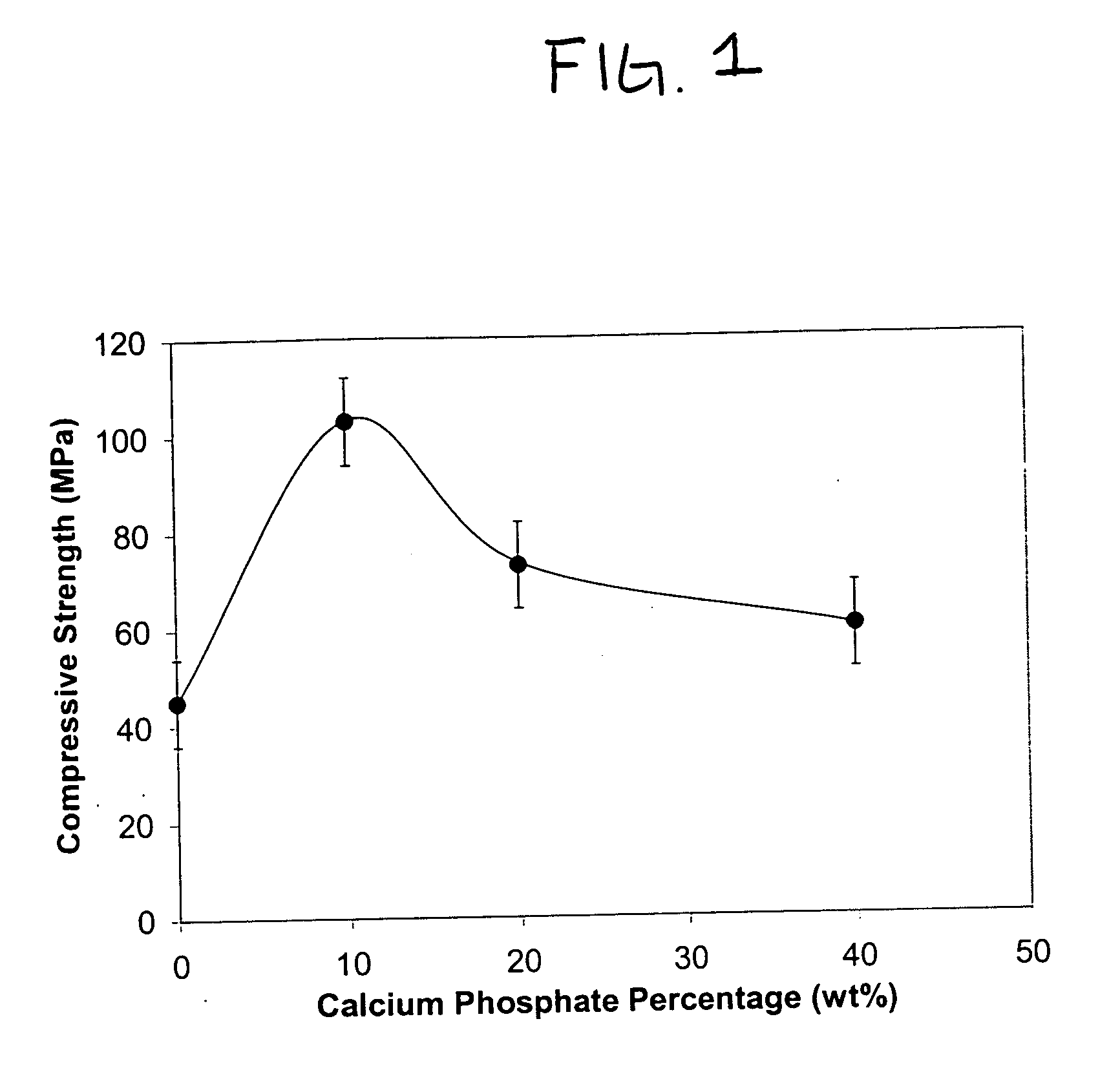

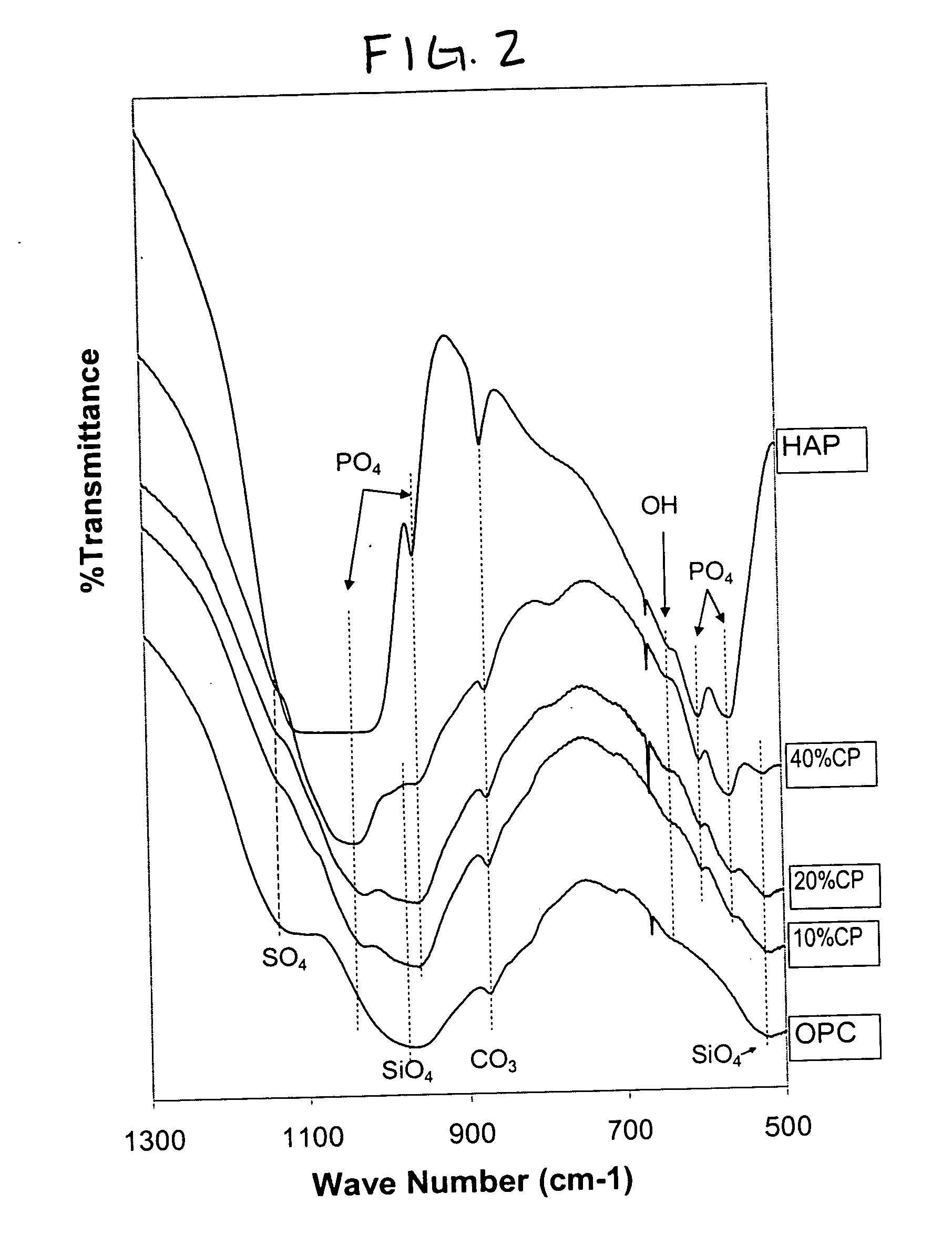

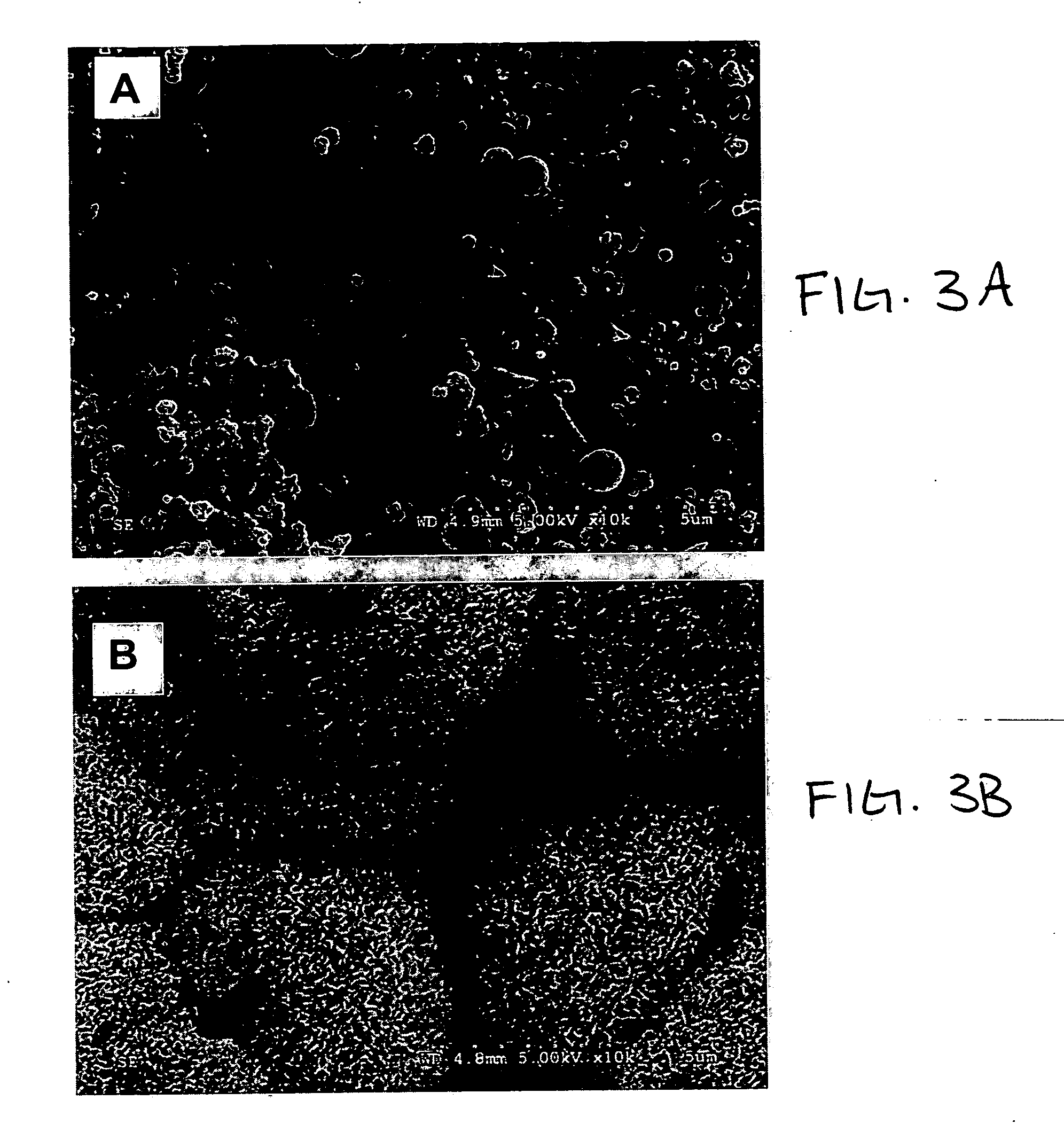

High strength biological cement composition and using the same

ActiveUS20070098811A1High mechanical strengthImprove biological activityBiocideSurgical adhesivesCalcium silicateApatite

A hydraulic cement for biomedical applications. The cement sets in-situ, hardening when exposed to water to produce nano-dispersed composite of calcium-silicate-hydrate gel mixed with hydroxyapatite. In comparison with prior cements, the composition provides high biocompatibility, high bioactivity and high biomechanical strength, due to the composite structure of the calcium silicate hydrate reinforced with co-precipitated particles of hydroxyapatite. Biocompatibility is also increased due to an absence of aluminum and magnesium in the composition. The cement is suitable for variety of applications, including dental implants, bone fixation, and bone repair.

Owner:INNOVATIVE BIOCERAMIX

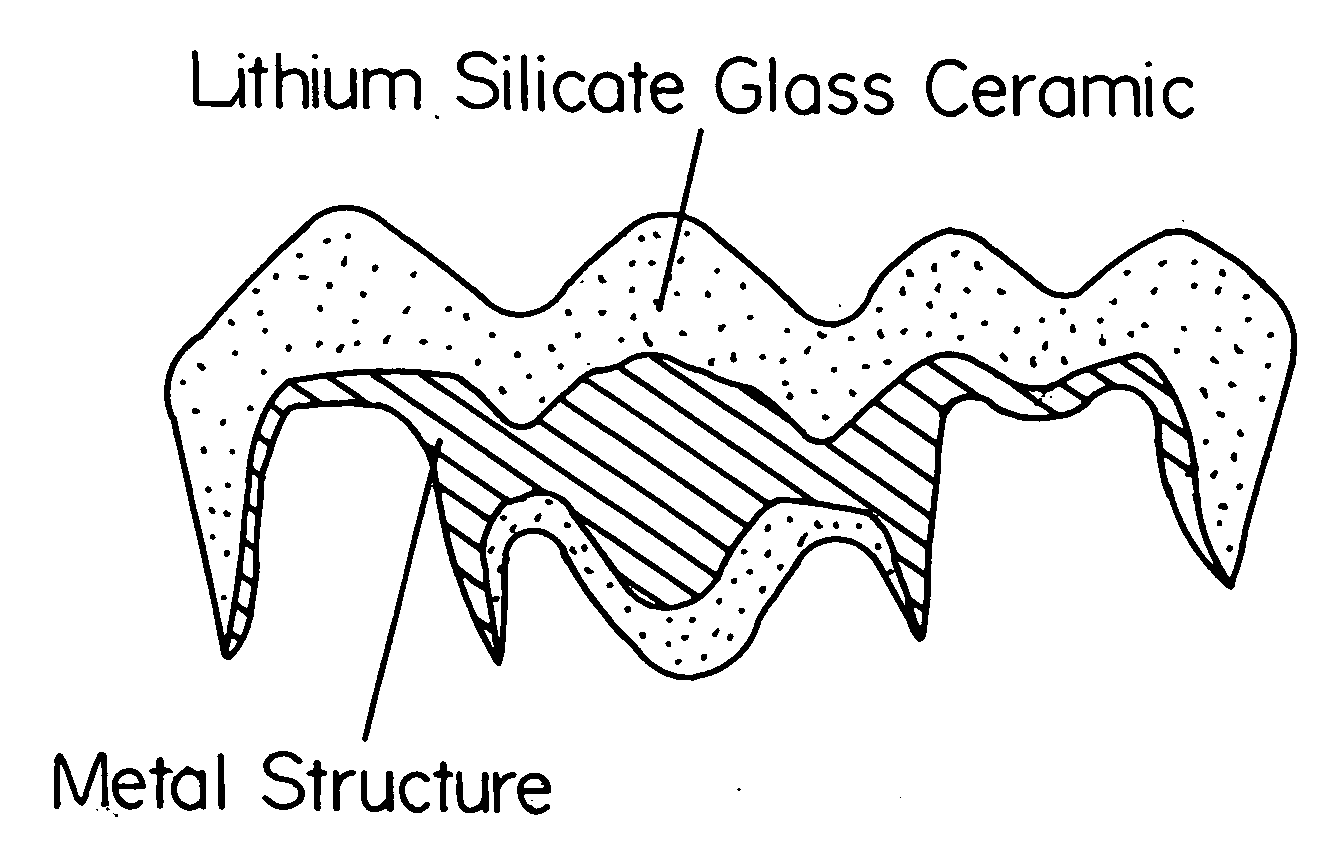

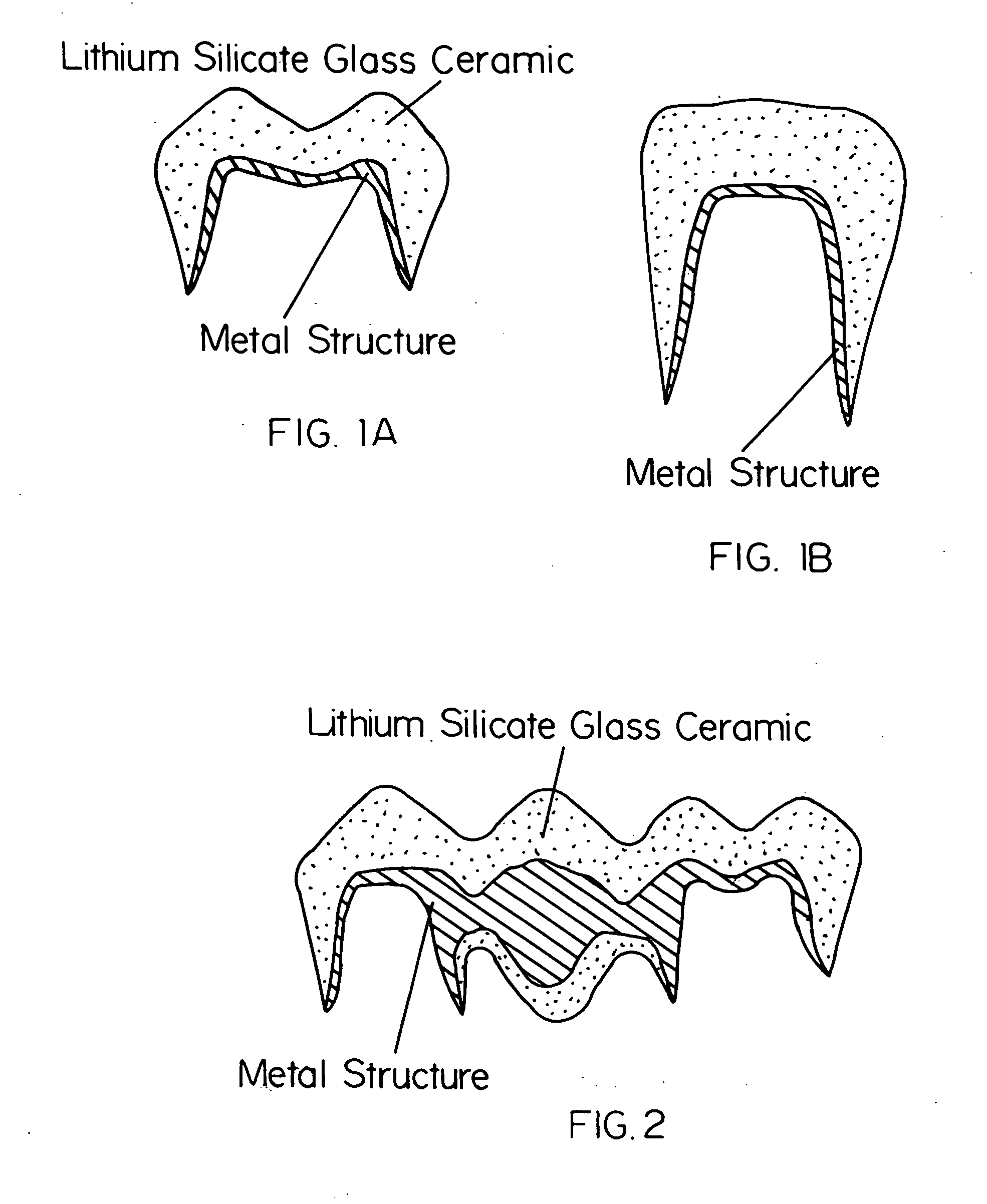

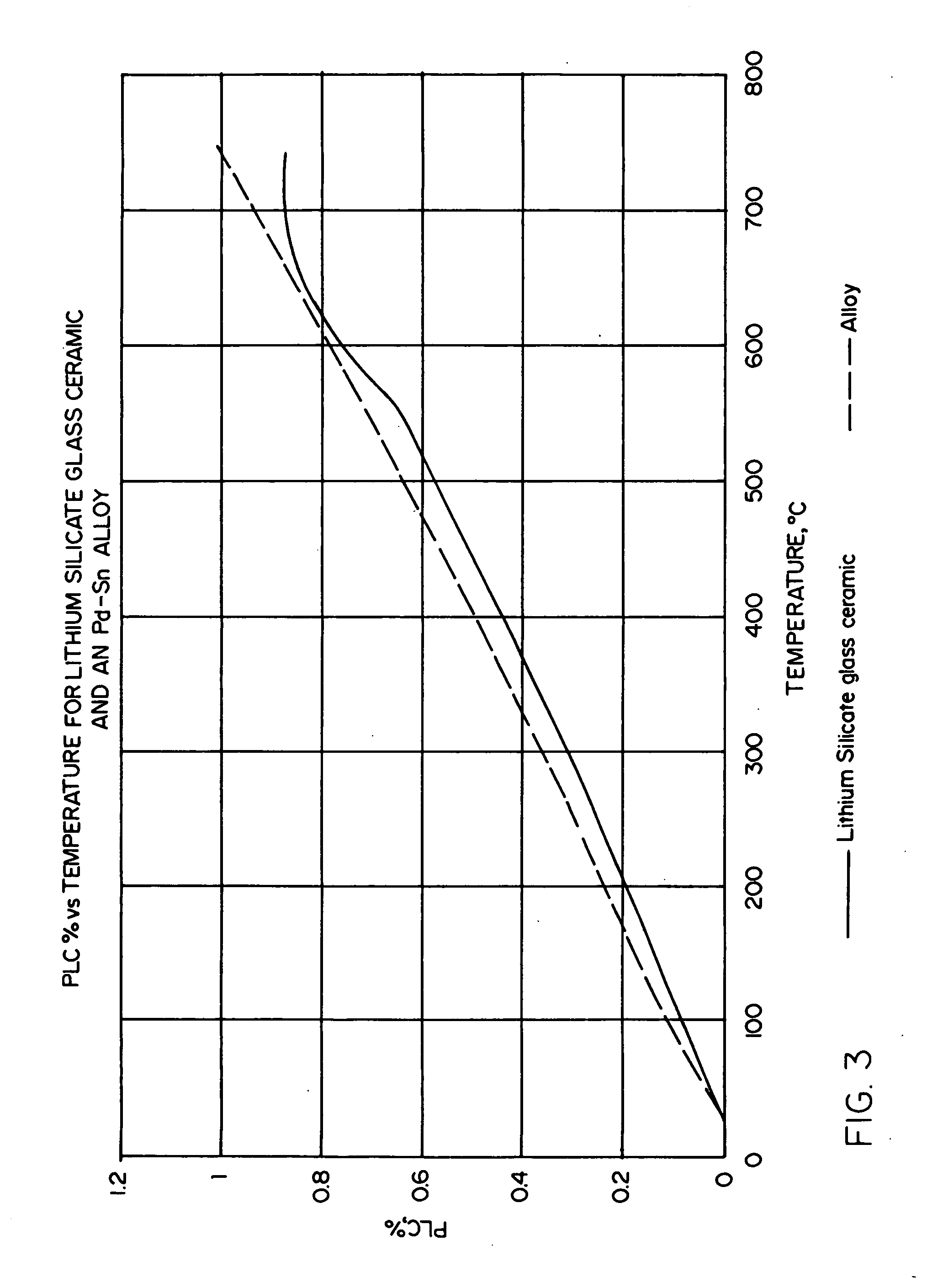

Indirect restoration technology

InactiveUS20120148988A1Easy to pressReduce the possibilityGlass pressing apparatusTooth crownsCalcium silicateThermal expansion

Dental restorations such as crowns, are made from lithium silicate glass ceramic that is heated and pressed onto a metal substrate, the latter being shaped to an impression or scan of the area of the mouth to receive the restoration. The metal substrate is made from an alloy selected to exhibit a coefficient of thermal expansion which is slightly greater than the CTE of the lithium silicate. In a preferred embodiment, the CTE of the lithium silicate glass ceramic is in the range of 11.5 to 12.5 and the alloy is selected to have a CTE of 12 to 13.5. A palladium tin alloy provides that CTE in the preferred embodiment.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

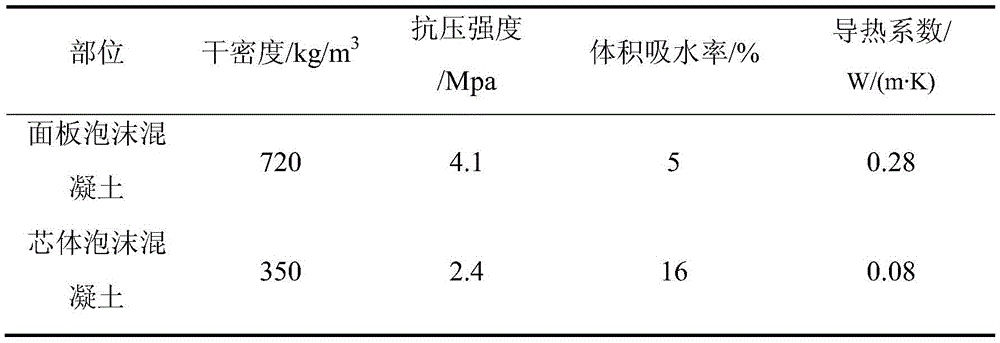

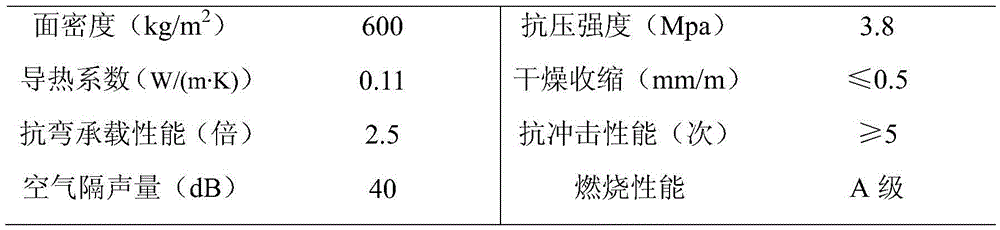

Foam concrete composite lightweight partition batten and preparation method thereof

ActiveCN105601323ALimit drying shrinkageSolve the shortcomings of high hygroscopicityConstruction materialCeramicwareCalcium silicateFoam concrete

The invention discloses a foam concrete composite lightweight partition batten, which comprises a panel foam concrete and a core foam concrete. The panel foam concrete is symmetrically arranged on both sides of the core foam concrete, and has the bulk density of 600-900kg / m<3>; and the core foam concrete has density of 150-500kg / m<3>. The present invention uses foam concrete layers with different densities and functions to design the composite lightweight partition batten, uses foam concrete with high density and high strength grade to substitute a traditional calcium silicate board panel structure, uses the core foam concrete with relatively low density and low strength to fill the middle of the composite wall. The method can effectively reduce the use of calcium silicate board, reduce the production cost of lightweight composite partition batten, and simplify the production process; and the obtained foam concrete composite lightweight partition batten has excellent performances of waterproofness, thermal insulation, fireproofness, sound insulation and phase change energy storage, and has broad application prospects.

Owner:THE FIRST SINCERITY CONSTR TECH CO LTD

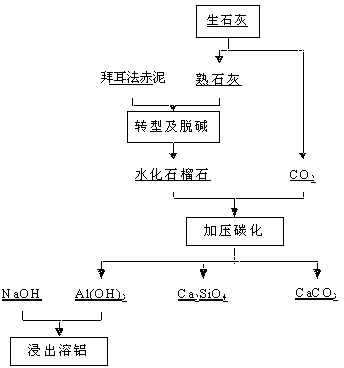

Method for dissolving Bayer process red mud

ActiveCN102757060AMeet industrial requirementsReduce sodiumCalcium/strontium/barium carbonatesSludge treatmentCalcium silicateAluminium hydroxide

The invention discloses a method for dissolving red mud. The method comprises the following specific steps of: mixing Bayer process red mud with white lime in the mass ratio of 1:(0.3-0.9); stirring at the temperature of 80-140 DEG C for reacting for 1-15 hours for calcifying, transforming and dealkalizing; mixing calcified, deformed and dealkalized Bayer process red mud with clear water or a low-concentration sodium aluminate solution in an enclosed container; introducing CO2 into the container to obtain calcified slag containing calcium silicate, calcium carbonate and aluminum hydroxide serving as main components; and extracting aluminum hydroxide from the calcified slag by using a sodium hydroxide solution or an aluminum hydroxide solution. In the method disclosed by the invention, the structure and composition of red mud are changed by adopting calcification transformation and pressurizing calcification transformation methods, so that dealkalization and extraction of aluminum can be realized; and iron is extracted properly, so that the structure and the composition of red mud can meet the requirements of cement production, and the aim of dissolving red mud on a large scale at low cost is fulfilled.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Pavers and block composite materials and methods of preparation thereof

ActiveUS20140314990A1Acceptable compressive strengthLow costRecord information storageCeramic shaping apparatusCalcium silicateCOLORED MATERIAL

The invention provides novel paving stones and construction block composite materials and methods for preparation thereof. The paving stones and construction block composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves compacting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which can comprise silicon dioxide-rich materials. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These paving stones and construction block composite materials exhibit visual patterns similar to stone as well as display compressive strength and water absorption equal to or better than that of stone.

Owner:SOLIDIA TECH

Bond coat for silicon-containing substrate for EBC and processes for preparing same

ActiveUS7442444B2Improve adhesionHigh melting pointMolten spray coatingVacuum evaporation coatingCalcium silicateAlkaline earth metal

An article comprising a silicon-containing substrate, a silicide-containing bond coat layer overlying the substrate, and typically an environmental barrier coating overlaying the bond coat layer. An article is also provided wherein the environmental barrier coating comprises: (1) an optional inner silica scale layer overlaying the bond coat layer; (2) intermediate layer overlaying the inner silica scale layer, or the bond coat layer in the absence of the inner silica scale layer, and comprising mullite, or a combination of mullite with a barium strontium aluminosilicate, a yttrium silicate, or a calcium aluminosilicate; and (3) an outer steam-resistant barrier layer overlaying the intermediate layer and consisting essentially of an alkaline earth silicate / aluminosilicate. Processes are also provided for forming the silicide-containing bond coat layer over the substrate, followed by forming the environmental barrier coating over the bond coat layer.

Owner:GENERAL ELECTRIC CO

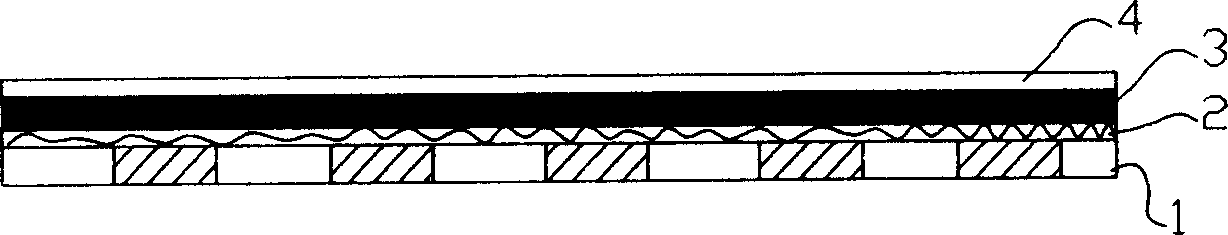

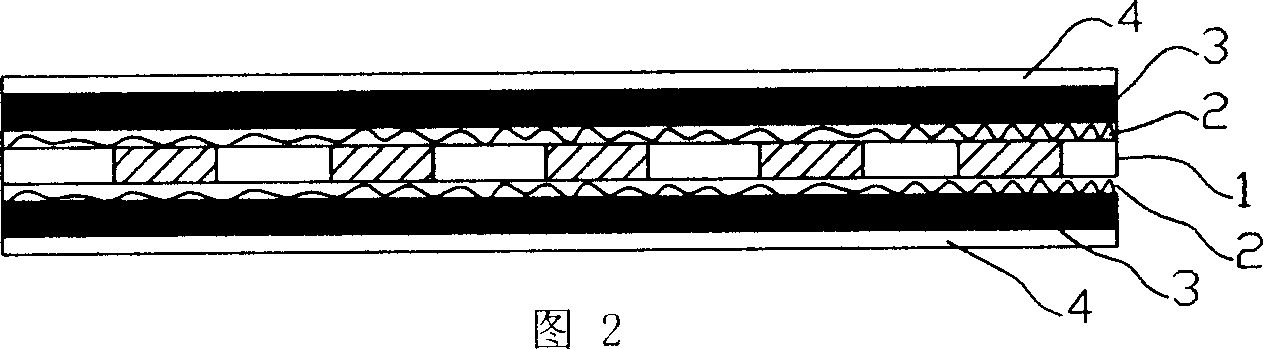

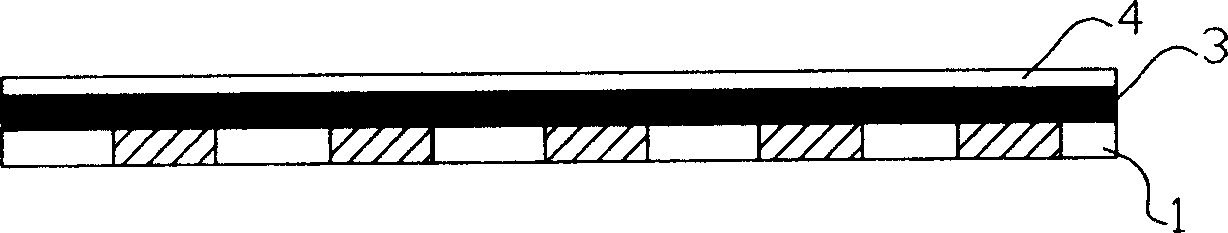

Self adhesive and high molecule self adhesive water-proof coil and producing process

InactiveCN1900207AEliminate pollutionThe process of dispensing glue is simpleOther chemical processesFilm/foil adhesivesCalcium silicateCross-link

The self adhesive consists of cross-linked asphalt, SBS rubber and tackifier, as well as SIS rubber, maleic anhydride, aluminum trichloride, thiram, magnesium chloride and calcium silicate. The self adhesive is cpddd with chemically modified cross-linked asphalt as main material at 150-170 deg.c, and has less pollution and low power consumption. It may be adhered to plasma modified polymer material and wet concrete. The present invention also discloses one kind of self adhering waterproof polymer coil made with the self adhesive and its production process, and the self adhering waterproof polymer coil has high adhesion strength between the adhesive and the main material layer.

Owner:珠海华兴防水科技有限公司

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

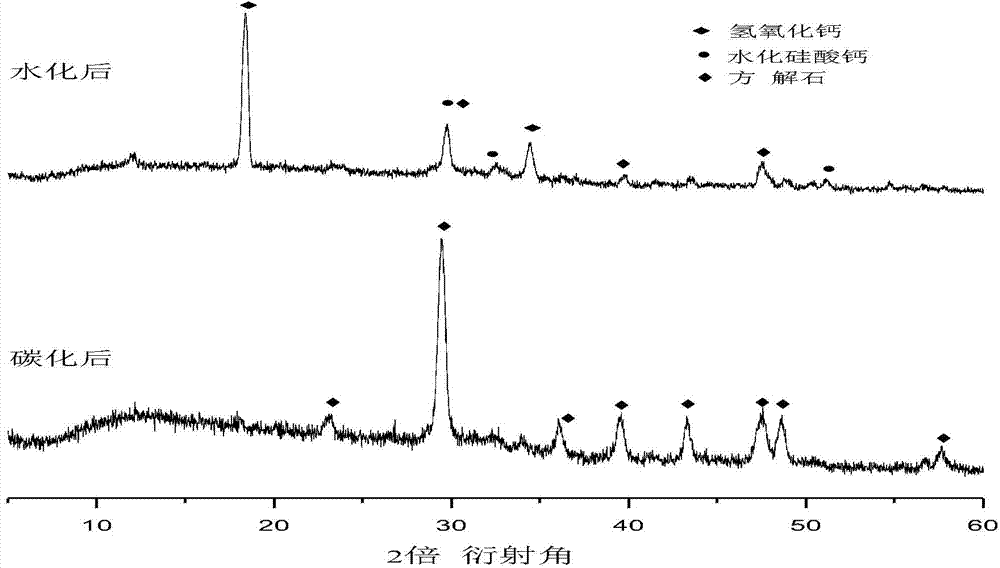

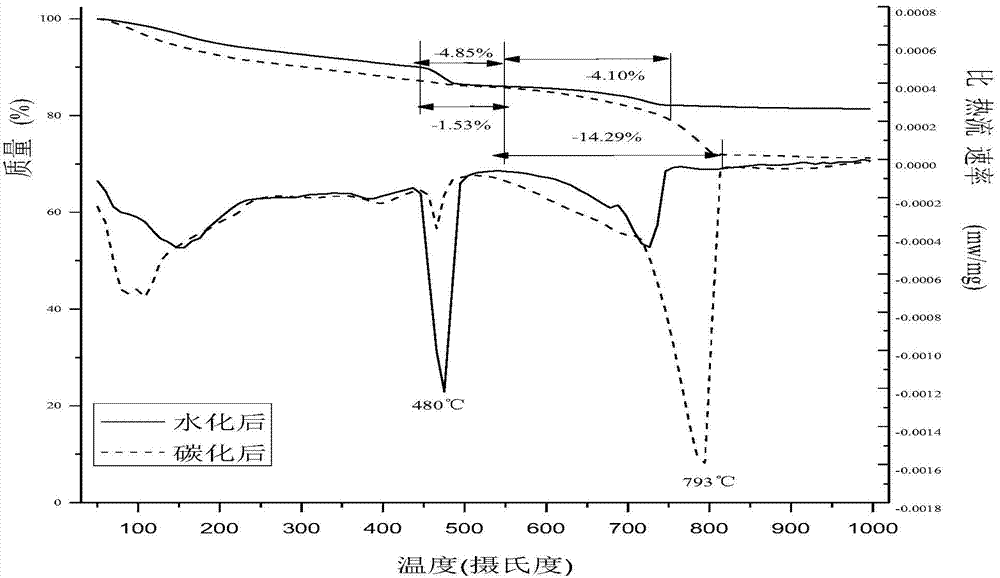

Method for preparing building material products through hydration-carbonation coupling technique

The invention belongs to the technical field of building materials, and provides a method for preparing building material products through processing industrial solid waste by hydration-carbonation coupling technique. The method comprises steps of uniformly mixing the industrial waste comprising at least one of calcium oxide, calcium hydroxide, dicalcium silicate, tricalcium silicate and tobermorite with alkaline excitation material and proper amount of water so as to prepare the blank of the building material product, wherein the industrial waste comprises steel slag, mineral waste residue, furnace slag, coal ash or coal gangue, the alkaline excitation material comprises carbide slag, lime, Portland cement or waste cement; maintaining for a period through hydration, then maintaining through carbonation so as to obtain the carbonate-based building material product. The coupling technique can effectively use the industrial solid wastes such as steel slag, mineral waste residue, furnace slag, coal ash, coal gangue, carbide slag and the like, so that emission of greenhouse gases is reduced, the greenhouse effect is relieved, furthermore, the method can be used for producing the building material products with good properties, effectively uses the waste and is environmentally friendly.

Owner:DALIAN UNIV OF TECH

Extruded polymer foam with filler particles and method

InactiveUSRE37095E1High quality dispersionAvoid reactionFlat articlesCalcium silicatePolyisocyanurate

A thermosetting foam, preferably polyisocyanurate or polyurethane foam, is prepared in an extruder which permits the incorporation of high levels of filler particles. The method includes introducing polyol, isocyanate and filler particles to an extruder screw for mixing. In conjunction with extruding, a catalyst is added. The catalyst may be added either in a last extruder barrel or with the extruder head. Foam with filler particle content in excess of 12% made be readily made. Filler particles, such as aluminum trihydrate, perlite, carbon black, diatomaceous earth, polyiso powders, ammonium phosphate, fly ash, barium sulfate, calcium silicate, and calcium carbonate, may be used. The process described is preferably used for making foam boards or bunstock.

Owner:IP RIGHTS

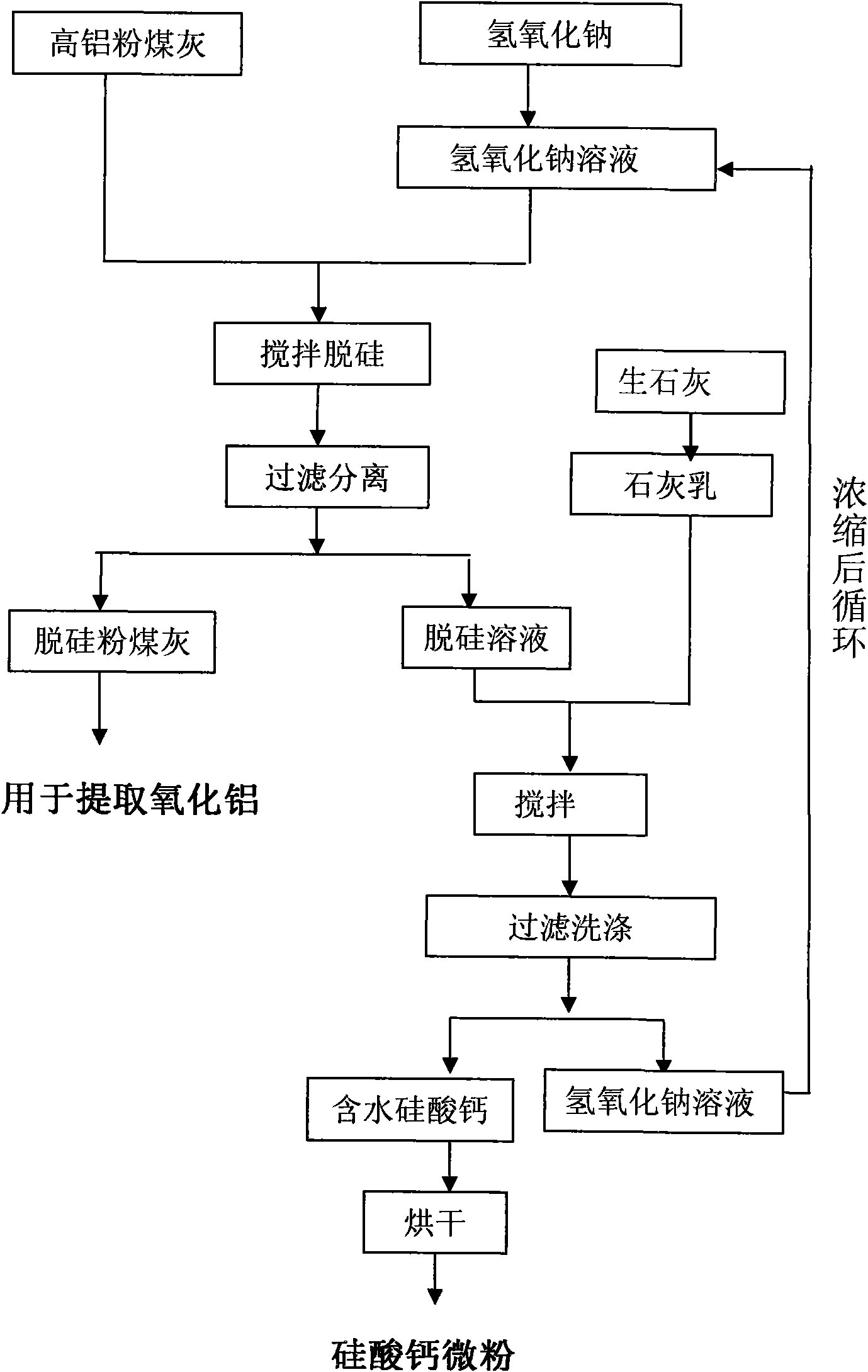

Method for preparing calcium silicate micro power by using high alumina fly ash

The invention discloses a method for preparing calcium silicate micro power by using high alumina fly ash, relating to the technical field of material and chemistry. The method comprises the steps as follows: 1. adding dry raw material high alumina fly ash into sodium hydroxide solution and stirring to carry out desiliconization reaction; 2. filtering and separating the mixture processed by desiliconization reaction, washing the filter cake to obtain desiliconized solution and desiliconized fly ash, and adding water to quicklime and stirring to obtain slurry lime cream; and 3. adding the lime cream into the desiliconized solution, stirring for reaction, filtering and washing to obtain watery calcium silicate and NaOH solution, drying the watery calcium silicate to obtain calcium silicate micro powder, and concentrating the NaOH solution for cycle use for step 1. Compared with the prior art, the method of the invention is simple in operation, low in investment, low in production cost and low in energy consumption, and the prepared calcium silicate micro power is uniform in physical and chemical performances, low in impurity content and extremely high in whiteness.

Owner:TONGFANG ENVIRONMENT

Dentifrice compositions containing calcium silicate and a basic amino acid

ActiveUS20120141588A1Reduce and inhibit formationPromote remineralizationAntibacterial agentsCosmetic preparationsCalcium silicateMedicine

An oral care composition includes an effective amount of a basic amino acid in free or salt form; and an effective amount of calcium silicate particles. The calcium silicate particles have an average diameter of less than about 5 microns, such that they can occlude dentinal tubules of the teeth. An oral care method includes applying the composition to an oral cavity of a subject to reduce or inhibit hypersensitivity of the teeth and to achieve other benefits.

Owner:COLGATE PALMOLIVE CO

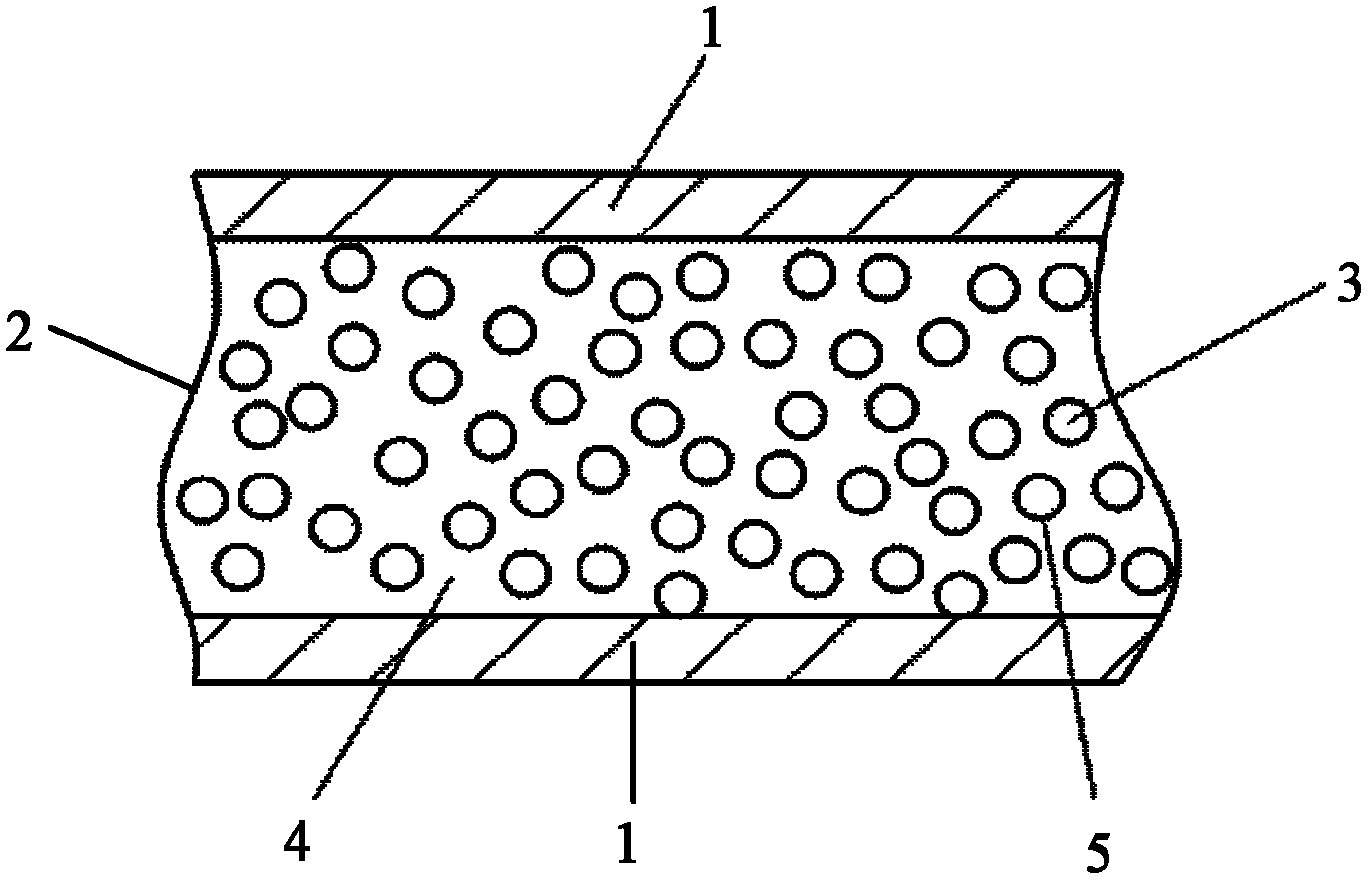

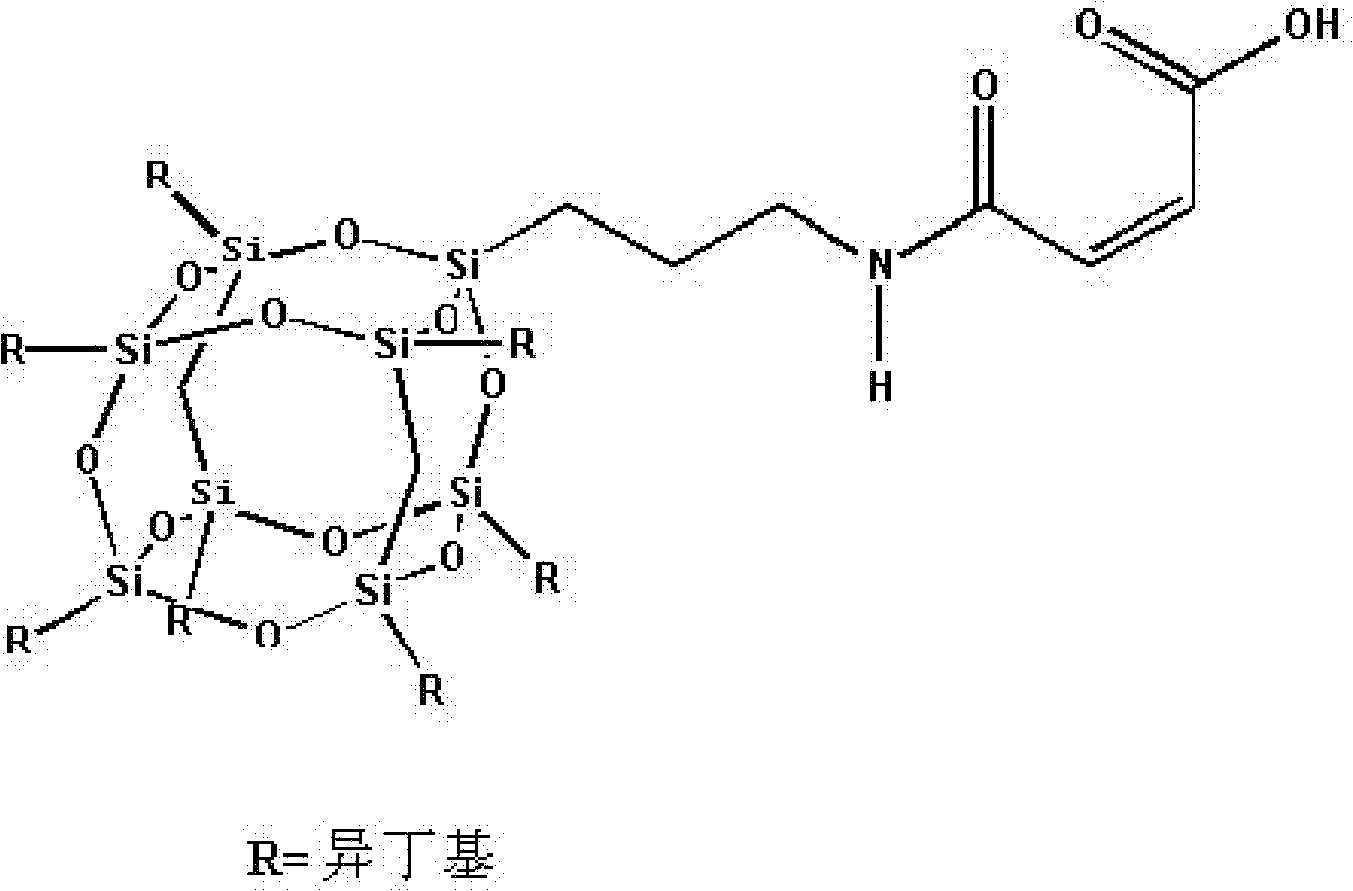

Composite heat-insulating wallboard and preparation method thereof

InactiveCN102505798AImprove interface compatibilityImprove physical and mechanical propertiesClimate change adaptationCeramic shaping apparatusCalcium silicateEmulsion

The invention discloses a composite heat-insulating wallboard and a preparation method thereof and relates to a heat-insulating wallboard. The heat-insulating wallboard is provided with two layers of calcium silicate plates, wherein a heat-insulating core material is clamped between the two layers of calcium silicate plates and is prepared from cement, coal ash, gypsum, expandable polystyrene (EPS), Maleamic Acid-Isobutyl Polyhedral Oligomeric Silsesquioxane (POSS), emulsion powder, a water reducing agent, a foaming agent and an early strength agent. Dry POSS powder is dissolved in normal hexane and then the solution is sprayed onto the surface of EPS particles to obtain substance A; the cement, the coal ash, the gypsum and the emulsion powder are drily stirred, water is added into the mixture, the mixture is stirred into paste, the substance A is added into the paste to form a slurry B; the foaming agent solution is stirred through a stirrer to form foam C; the slurry B and the foam C are mixed to obtain a heat-insulating core material slurry; the surfaces of the calcium silicate plates are brushed and washed, the calcium silicate plates are placed on the two sides of a fixed mold, the heat-insulating core material slurry is poured into the middle of the two calcium silicate plates, and the mold is vibrated to mold the slurry; and the mold is de-molded, and after watering to maintain, the wallboard is obtained.

Owner:XIAMEN UNIV +1

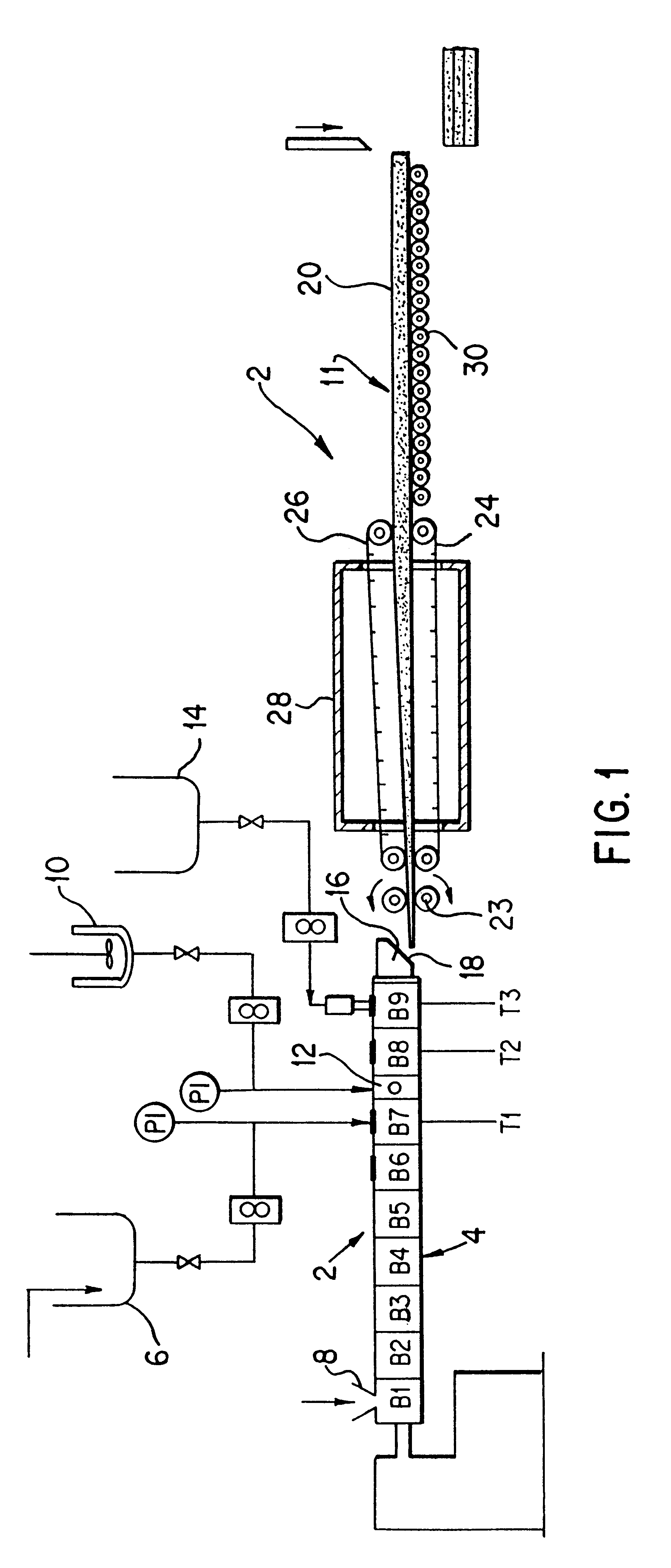

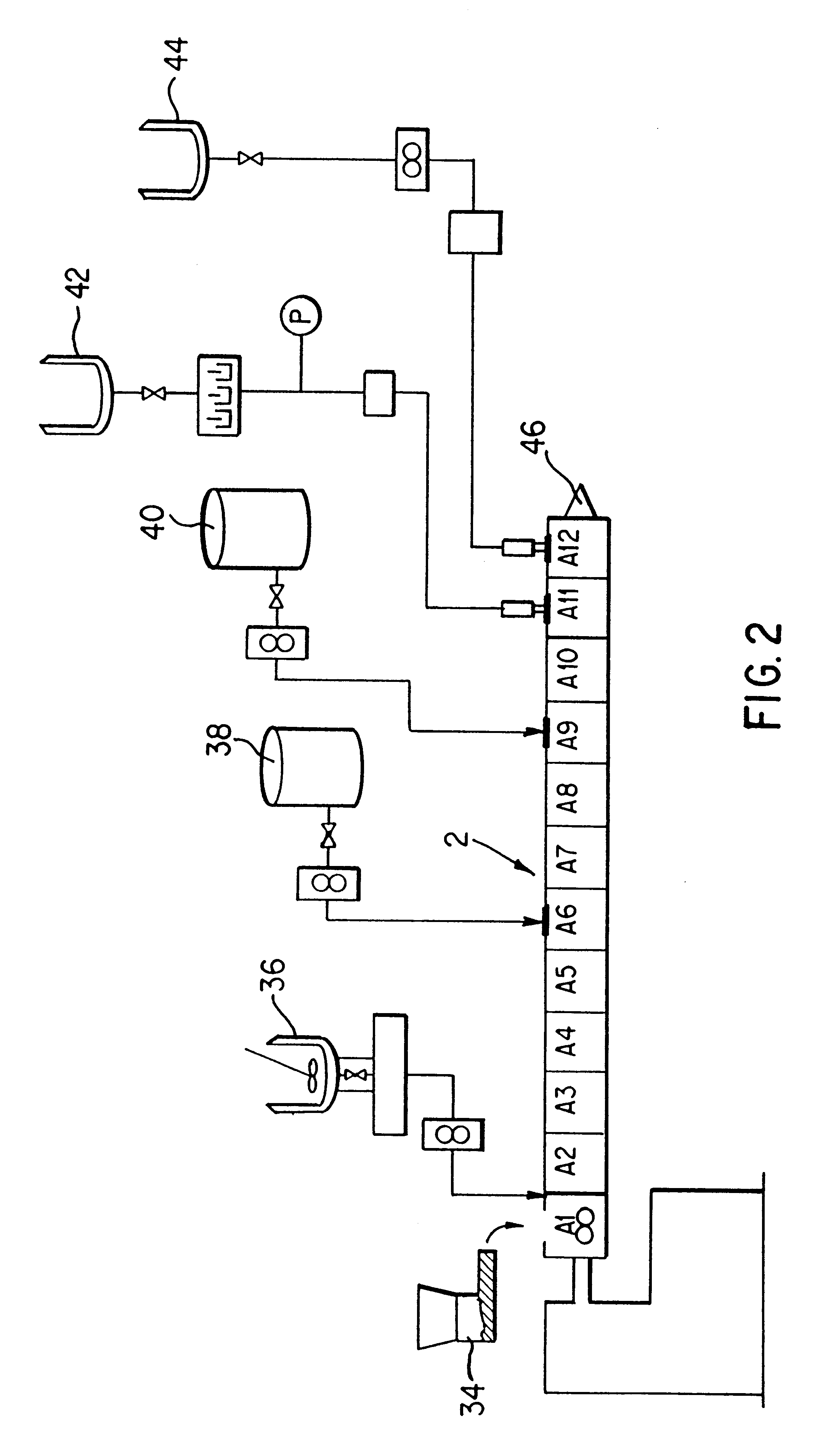

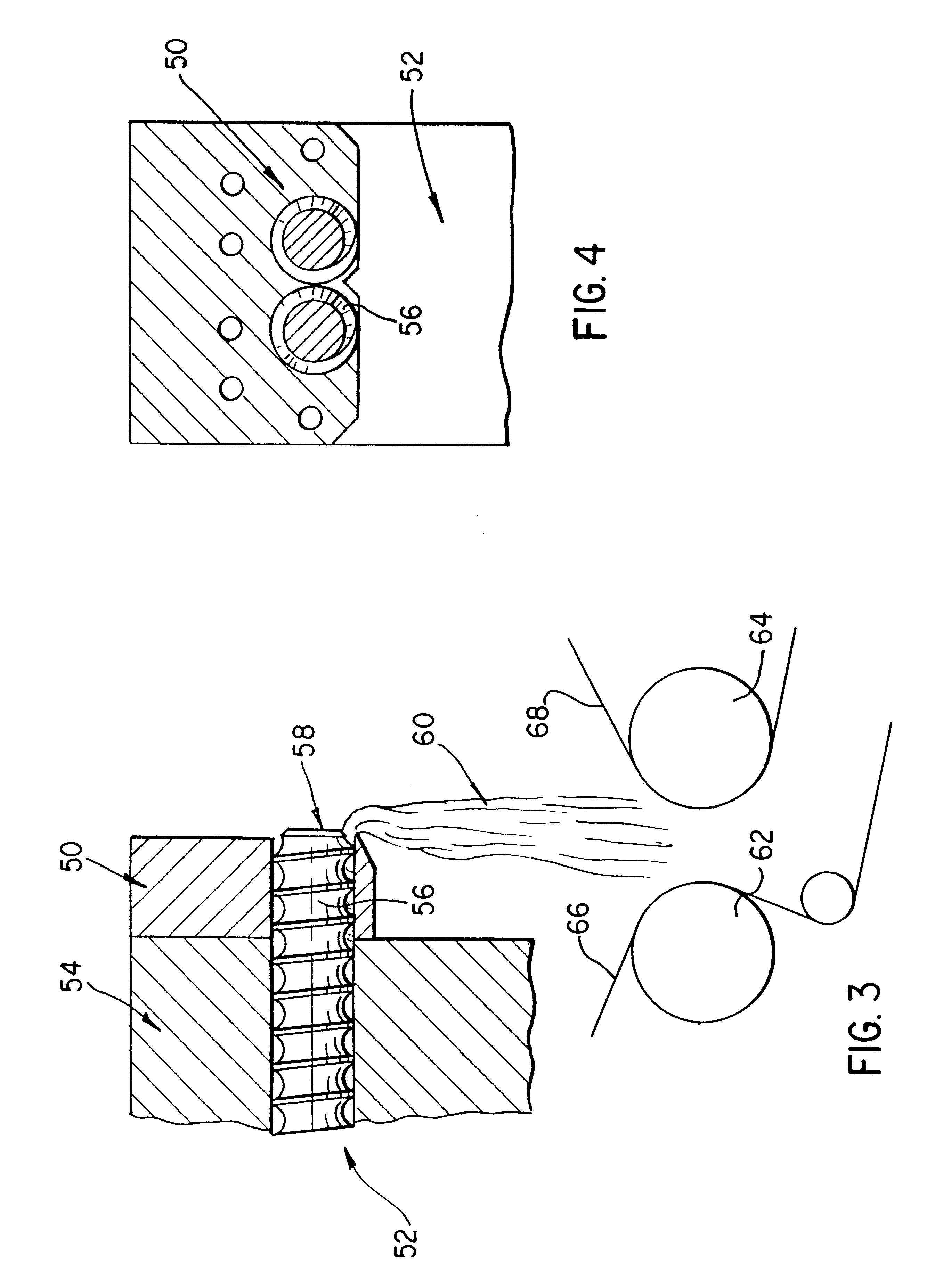

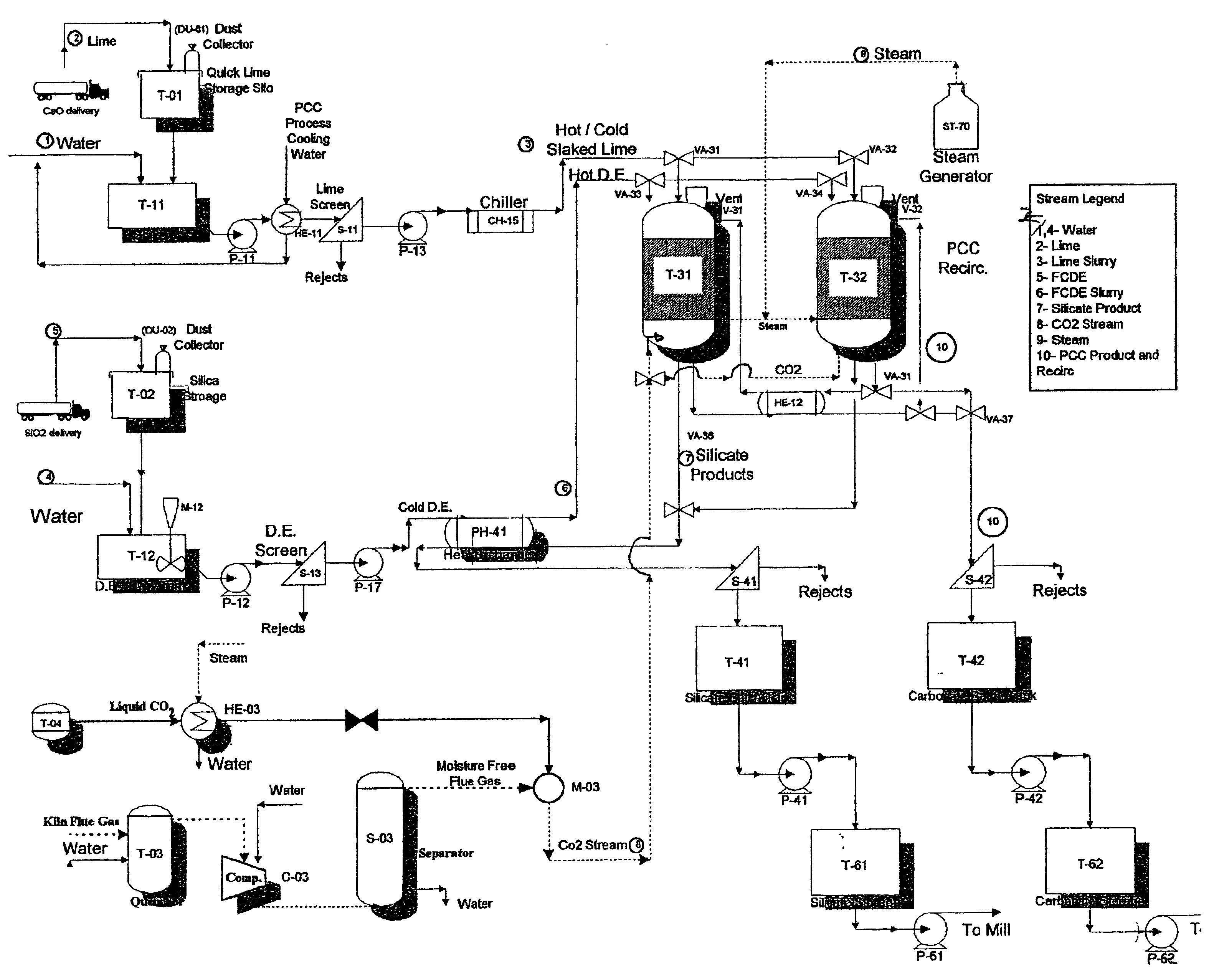

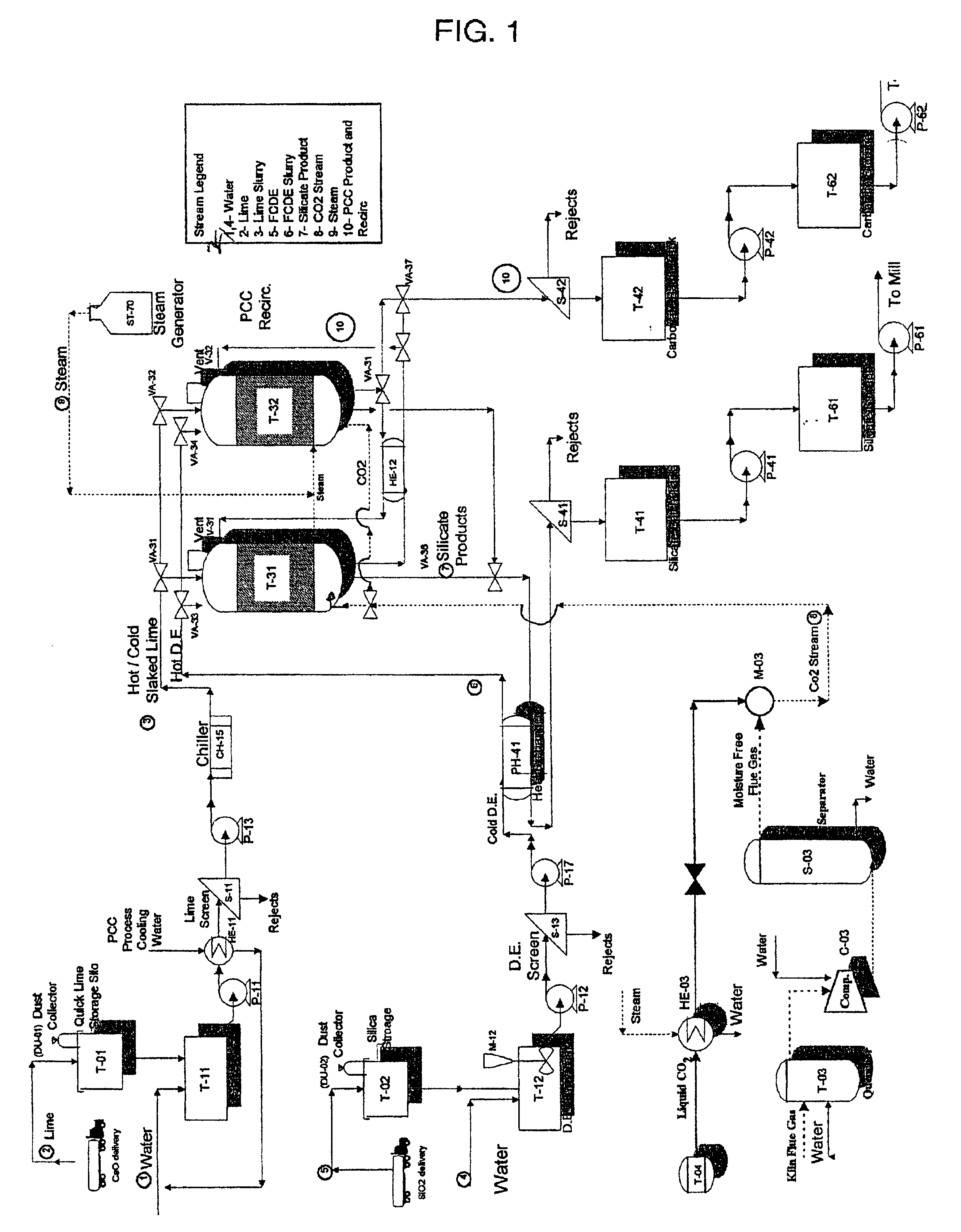

Method and apparatus for production of precipitated calcium carbonate and silicate compounds in common process equipment

InactiveUS7048900B2Increase brightnessHigh opacityCalcium/strontium/barium carbonatesPulp liquors combustionCalcium silicateProcess equipment

A method and apparatus for the production of calcium carbonate and calcium silicate in common superatmospheric reactors. Multiple reactors can be provided for switching production between reactors, and advantageously utilizing process waste heat. On site production of both PCC and Calcium Silicate Hydrates is thus achieved in a paper mill.

Owner:PACIFIC NANO PROD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com