Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

736results about How to "Fine particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

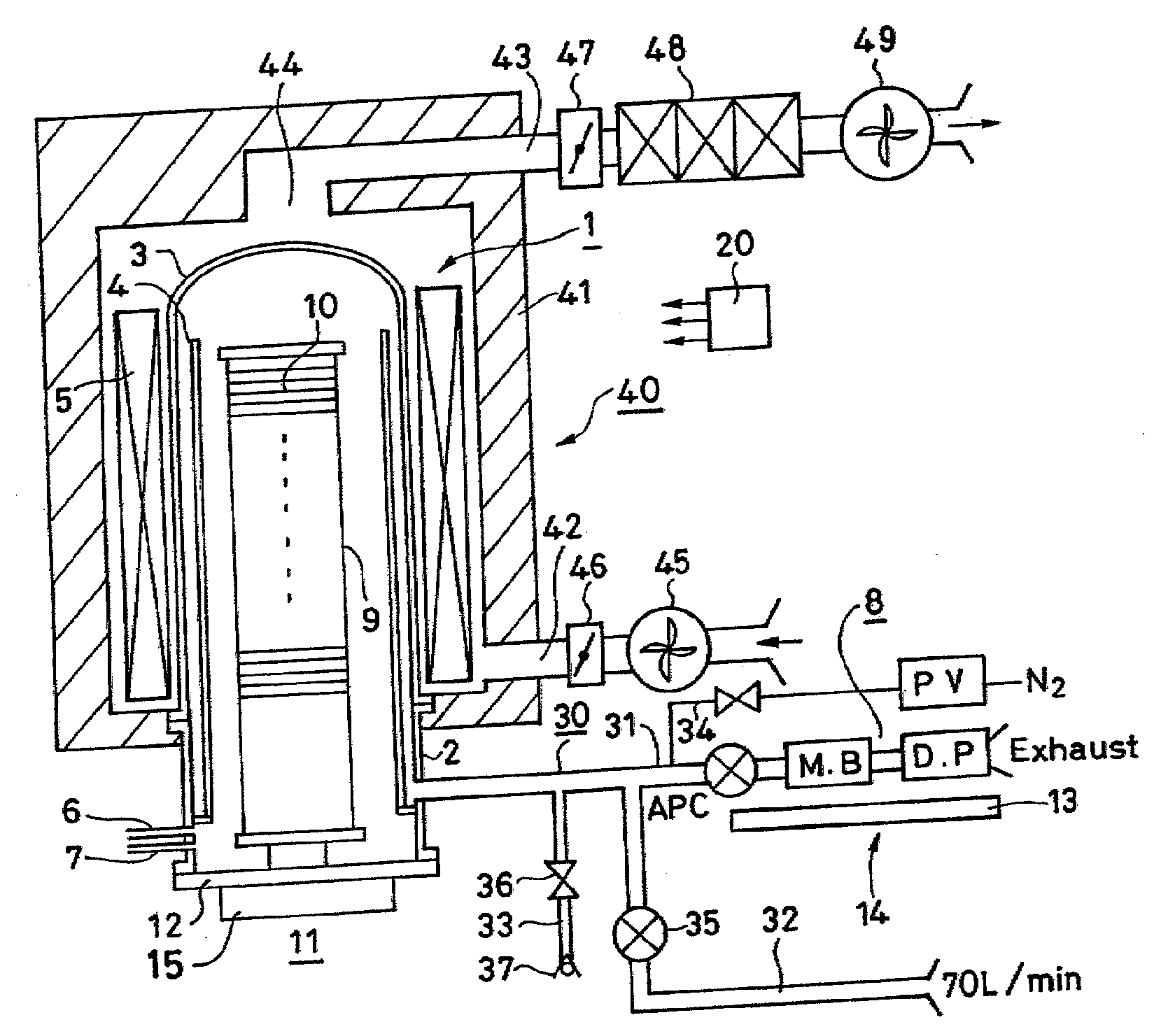

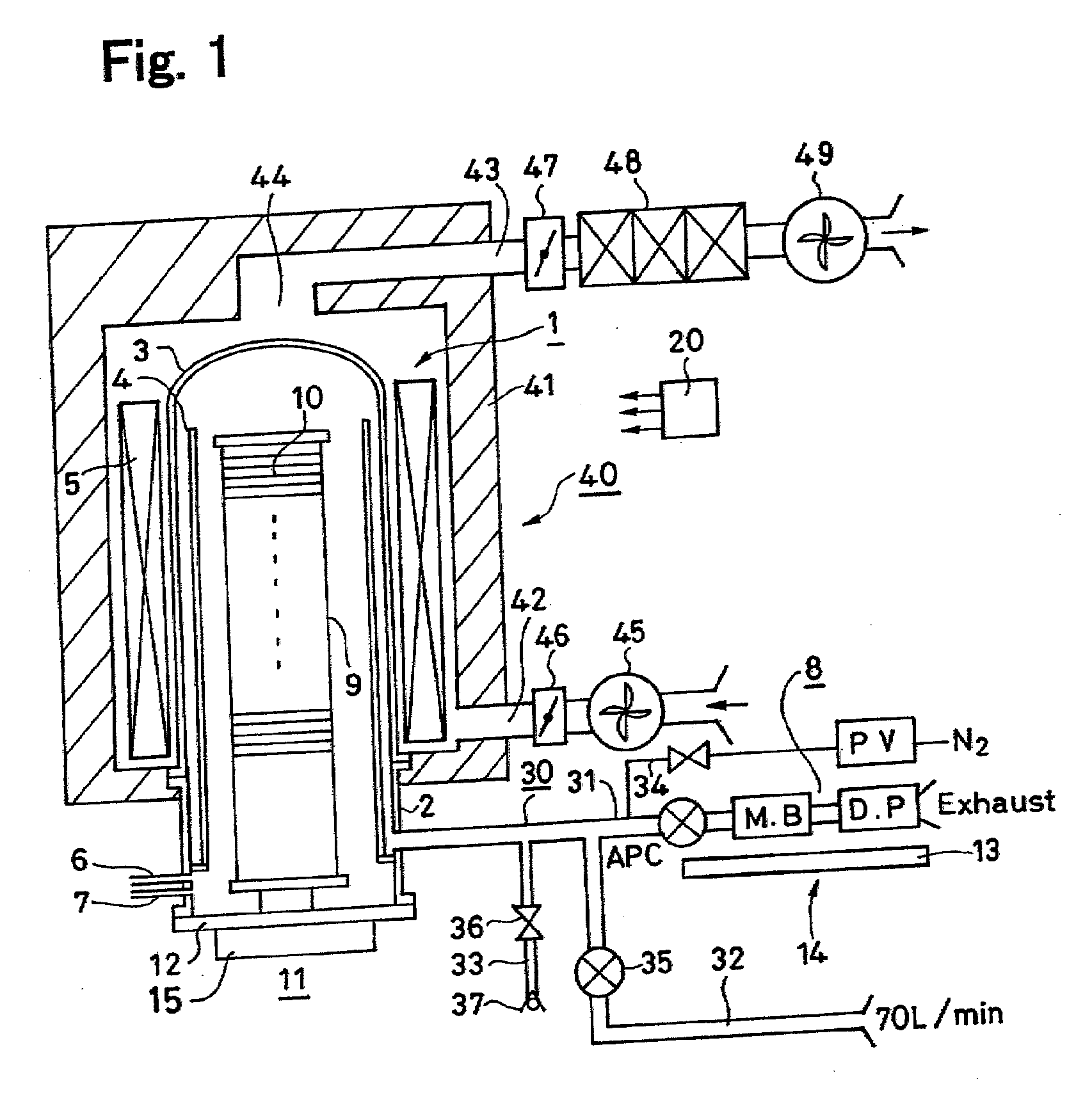

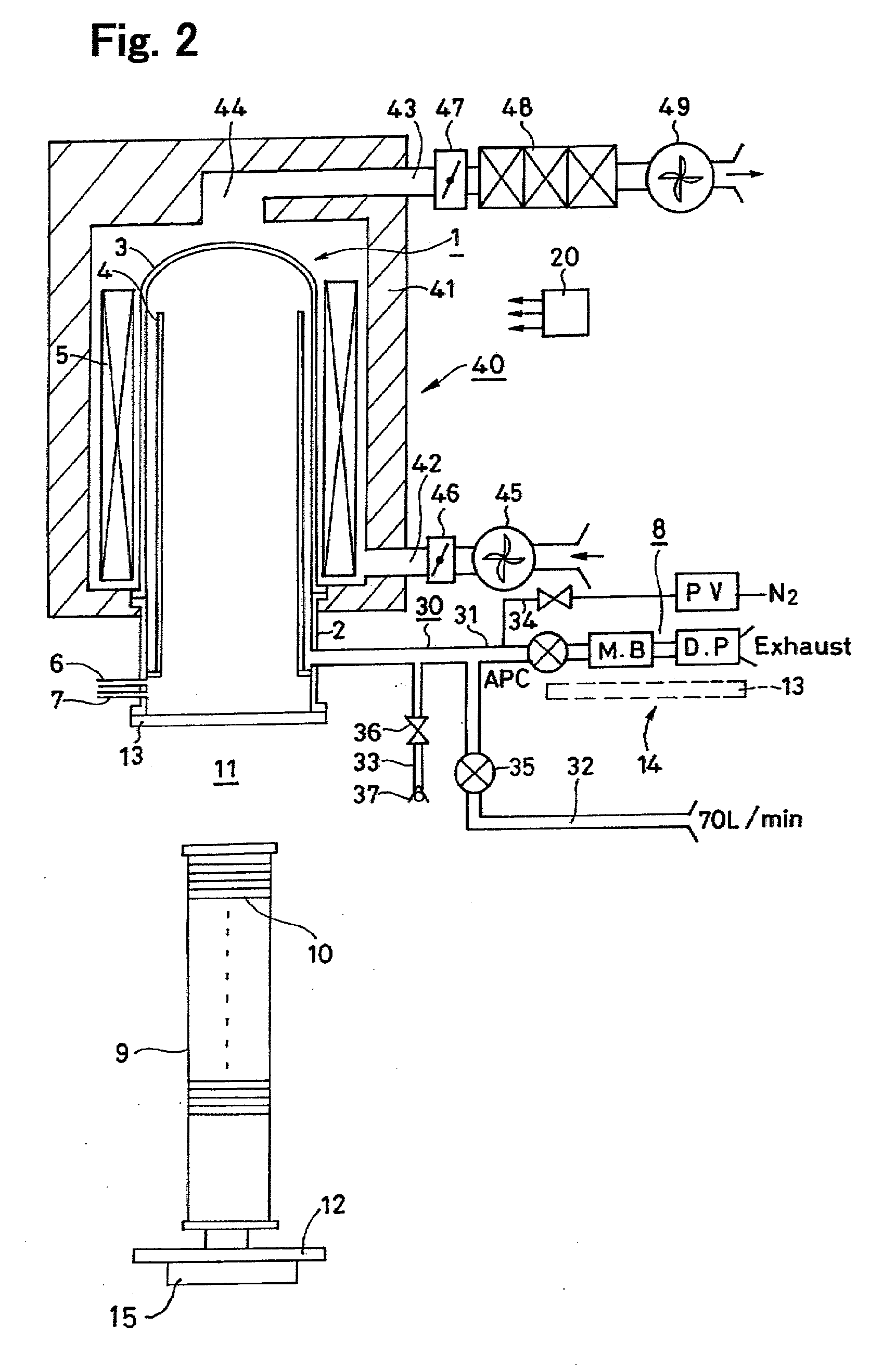

Producing method of semiconductor device and substrate processing apparatus

ActiveUS20090239386A1Reducing effect is lowReduced availabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSemiconductor

Disclosed is a producing method of a semiconductor device, comprising: loading a substrate into a reaction furnace; forming a film on the substrate in the reaction furnace; unloading the substrate from the reaction furnace after the film has been formed; and forcibly cooling an interior of the reaction furnace in a state where the substrate does not exist in the reaction furnace after the substrate has been unloaded.

Owner:KOKUSA ELECTRIC CO LTD

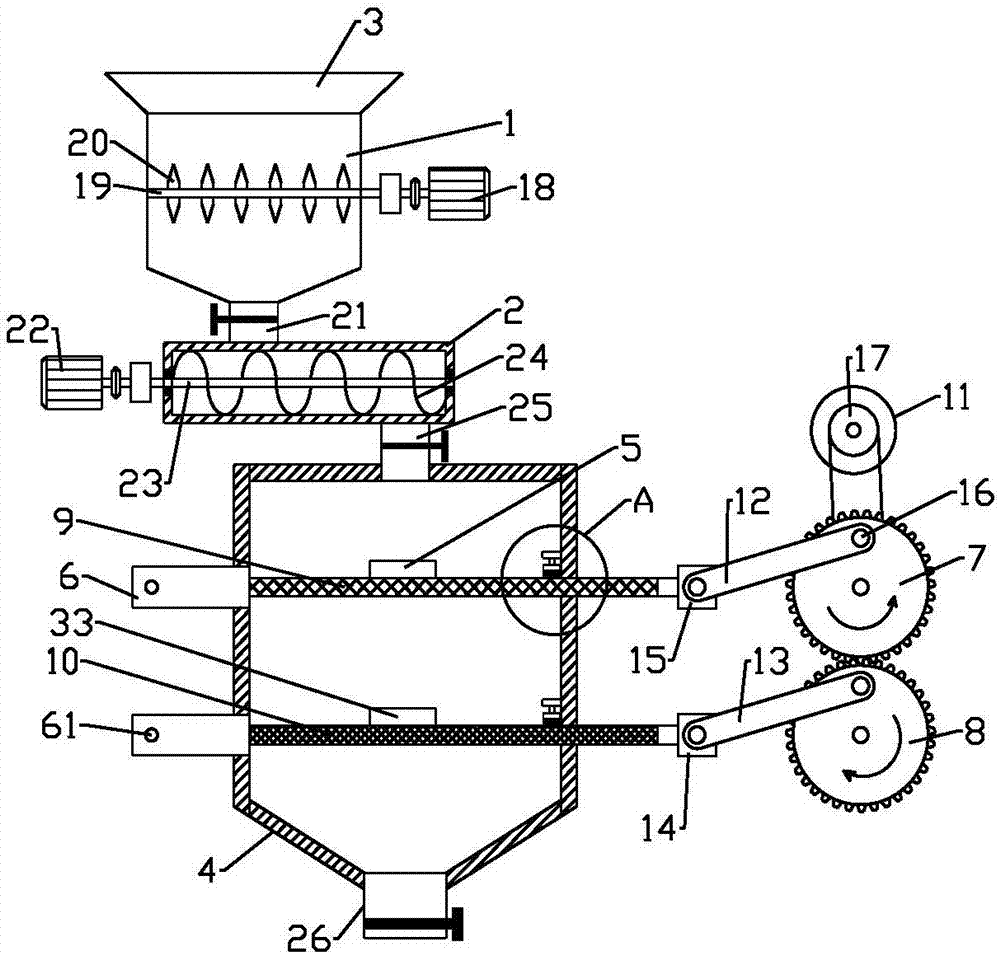

River sand classified screening device for building construction

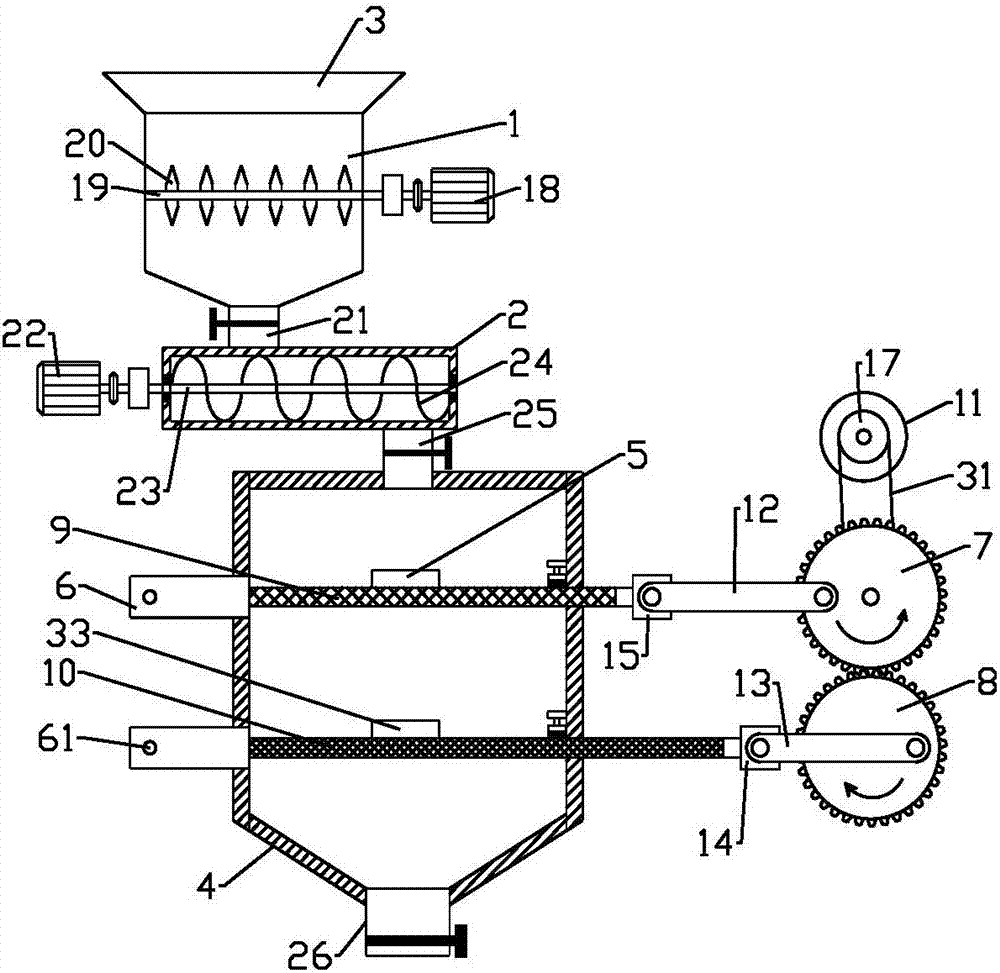

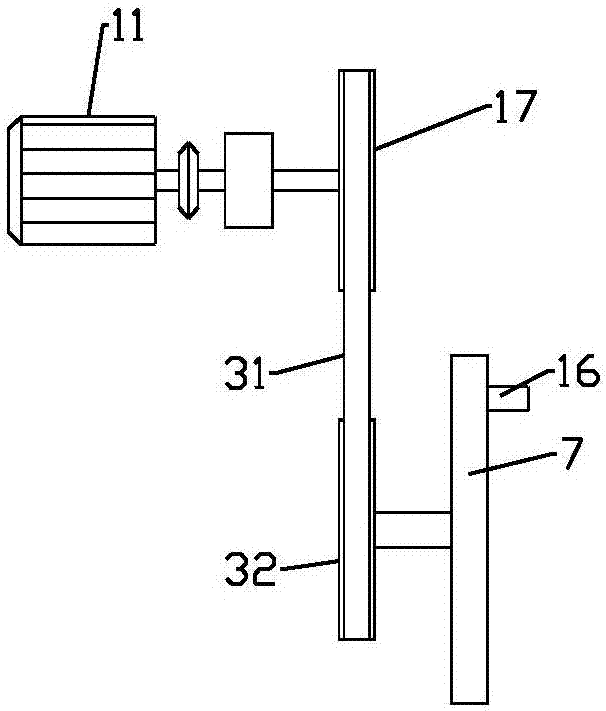

The invention discloses a river sand classification and screening device for building construction, which comprises a sand box, a feeding box, a screening box, a supporting sliding sleeve, a first gear, a second gear, a primary sieve plate, a secondary sieve plate, a No. The connecting rod and the No. 2 connecting rod, the inside of the sandbox is equipped with a crushing device, and the inner cavity of the feeding box is equipped with a screw feeding device. A drop pipe is connected, and the upper inner cavity of the screening box and the right inner cavity of the feeding box are connected through the second dropping tube. The inside of the screening box is respectively horizontally slidingly provided with a first-level sieve plate and a second-level sieve plate. The transmission connection between the first gear and the first-stage sieve plate is through the No. 1 connecting rod, and the transmission connection between the second gear and the second-stage sieve plate through the No. 2 connecting rod. device. The invention has the advantages of simple structure, convenient use, long service life, good screening effect on river sand, saving manpower and material resources, and improving work efficiency.

Owner:段华勇

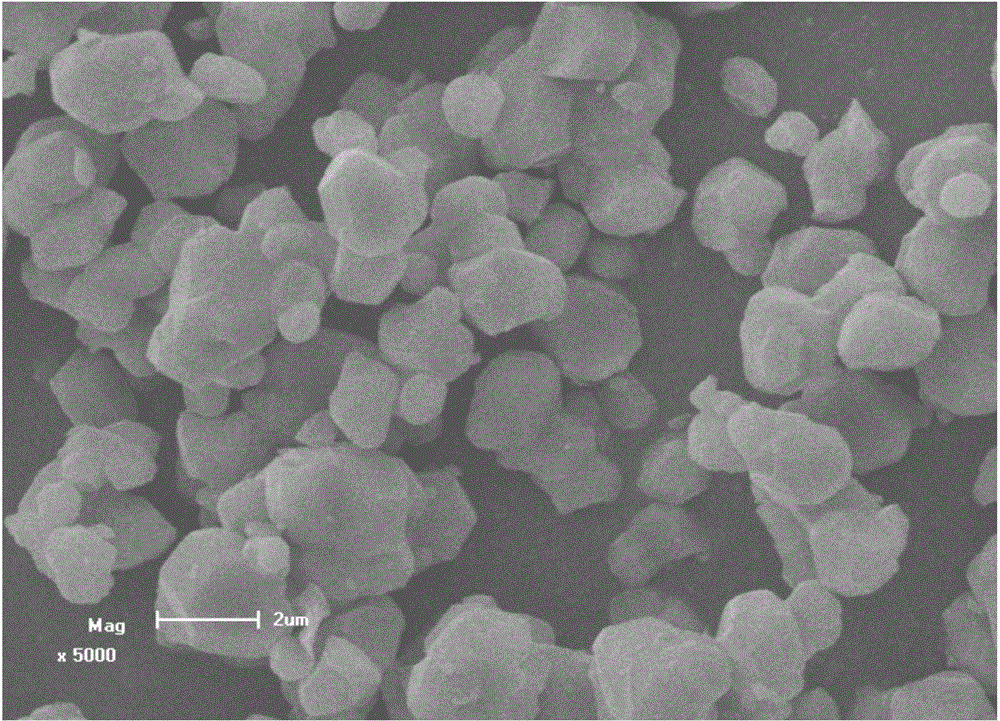

Preparation method of high dispersed white carbon black

ActiveCN102229758AIncreased dispersionReduce forcePigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsDispersityFiltration

The invention discloses a preparation method of high dispersed white carbon black. According to a new method and technology, a synthesis reaction of liquid soluble glass and concentrated sulfuric acid is carried out in two steps by first preparing fine seeds, and then carrying out a synthesis reaction, wherein the synthesis reaction is a precipitation reaction carried out under effects of an organic surfactant SDS and a composite silane coupling agent. The high dispersed precipitated white carbon black specially used in high-performance tyres is obtained through particle surface cladding, modification treatment, press filtration, washing, pulping and pressure drying. The method improves a traditional white carbon black production technology of a precipitation method by optimizing technological parameters and using an optimized auxiliary agent to meet a requirement of enhanced product dispersiveness; besides the method overcomes defects of an ordinary precipitation method, such as crude particles, wide distribution, strong hydrophilism and weak mixing dispersion. A prepared product has characteristics of fine primary particles, low surface hydroxyl content, increased lipophilicity,high bonding force with rubber high molecules and high wettability, and is an ideal reinforcing filling material specially used in high-performance tyres.

Owner:FUJIAN ZHENGSHENG INORGANIC MATERIAL

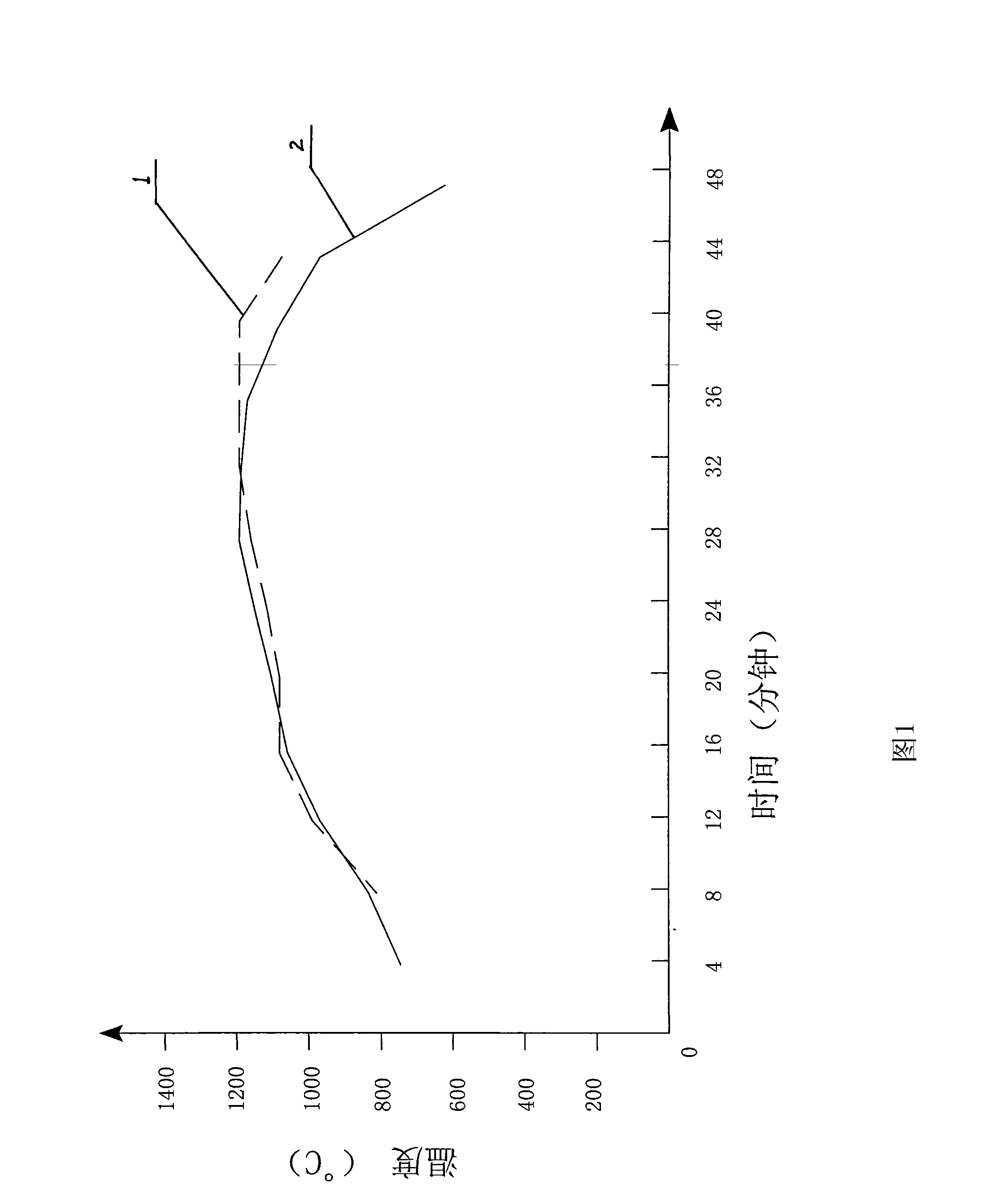

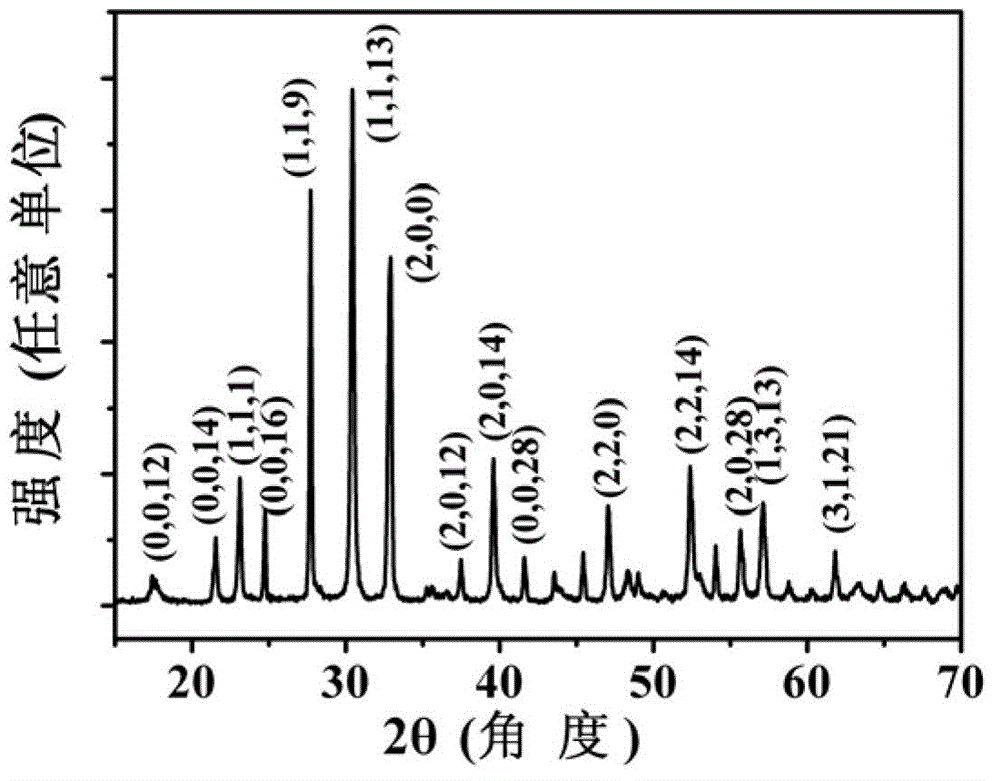

Preparation method of high-purity AlON transparent ceramic powder

InactiveCN105622104AInhibition of agglomerationThe original microscopic shape is maintainedWater basedMetallurgy

The invention belongs to the technical field of synthesis and preparation of ceramic material powder, and in particular, relates to preparation of a high-purity gamma-AlON transparent ceramic powder. The preparation includes the following steps: (1) weighing raw material; (2) preparing a pre-mixed solution; (3) preparing a slurry; (4) carrying out freeze drying; (5) carrying out low temperature calcination; and (6) carrying out high temperature reaction synthesis, to obtain the gamma-AlON transparent ceramic powder. By using the freeze drying technology, water is sublimated at lower temperature, so that nano powder agglomeration in a water-based system can be effectively inhibited, an initial micro-morphology of the raw material can be maintained, and the mixed powder with fluffy organizational structure is obtained; compared with traditional spray drying, the freeze drying technology can reduce the loss of the raw material powder, can improve the utilization rate of the powder, and reduces the preparation cost.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

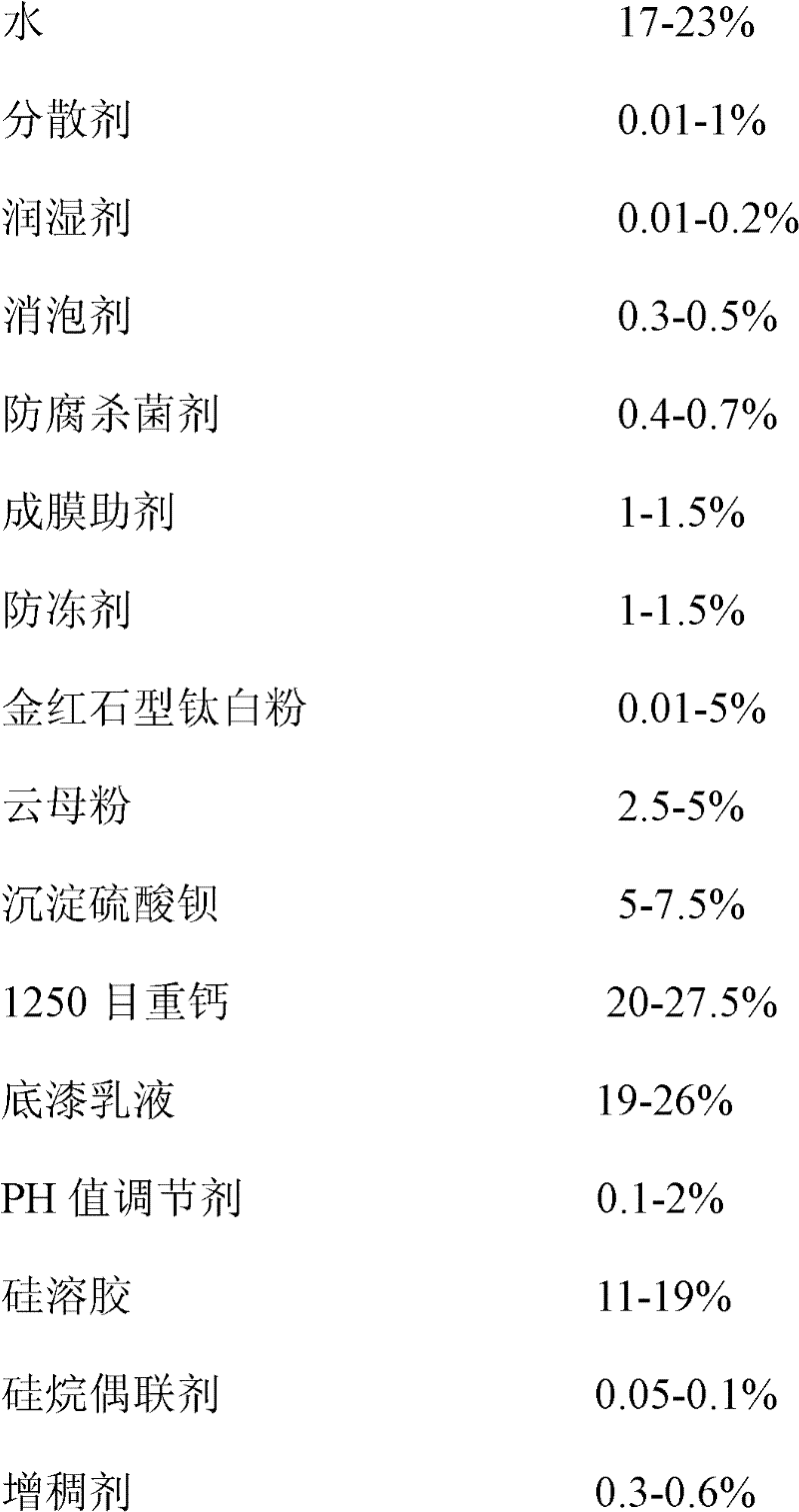

Silicasol-acrylate emulsion compound primer

ActiveCN102417775AHigh hardnessLow priceAntifouling/underwater paintsPaints with biocidesEmulsionRutile

The invention discloses a silicasol-acrylate emulsion compound primer, which comprises: 17-23% of water; 0.01-1% of dispersants; 0.01-0.2% of wetting agents; 0.3-0.5% of defoamers; 0.4-0.7% of anticorrosion bactericides; 1-1.5% of film-forming additives; 1-1.5% of antifreezing agents; 0.01-5% of rutile titanium dioxide; 2.5-5% of mica powder; 5-7.5% of precipitated barium sulfate; 20-27.5% of 1250-mesh heavy calcium; 19-26% of primer emulsion; 0.1-2% of pH adjusting agents; 11-19% of silicasol; 0.05-0.1% of silane coupling agents; 0.3-0.6% of thickening agents; wherein the percents are weight percents. The primer has low cost, and is not easy to peel or flake.

Owner:肇庆千江高新材料科技股份公司

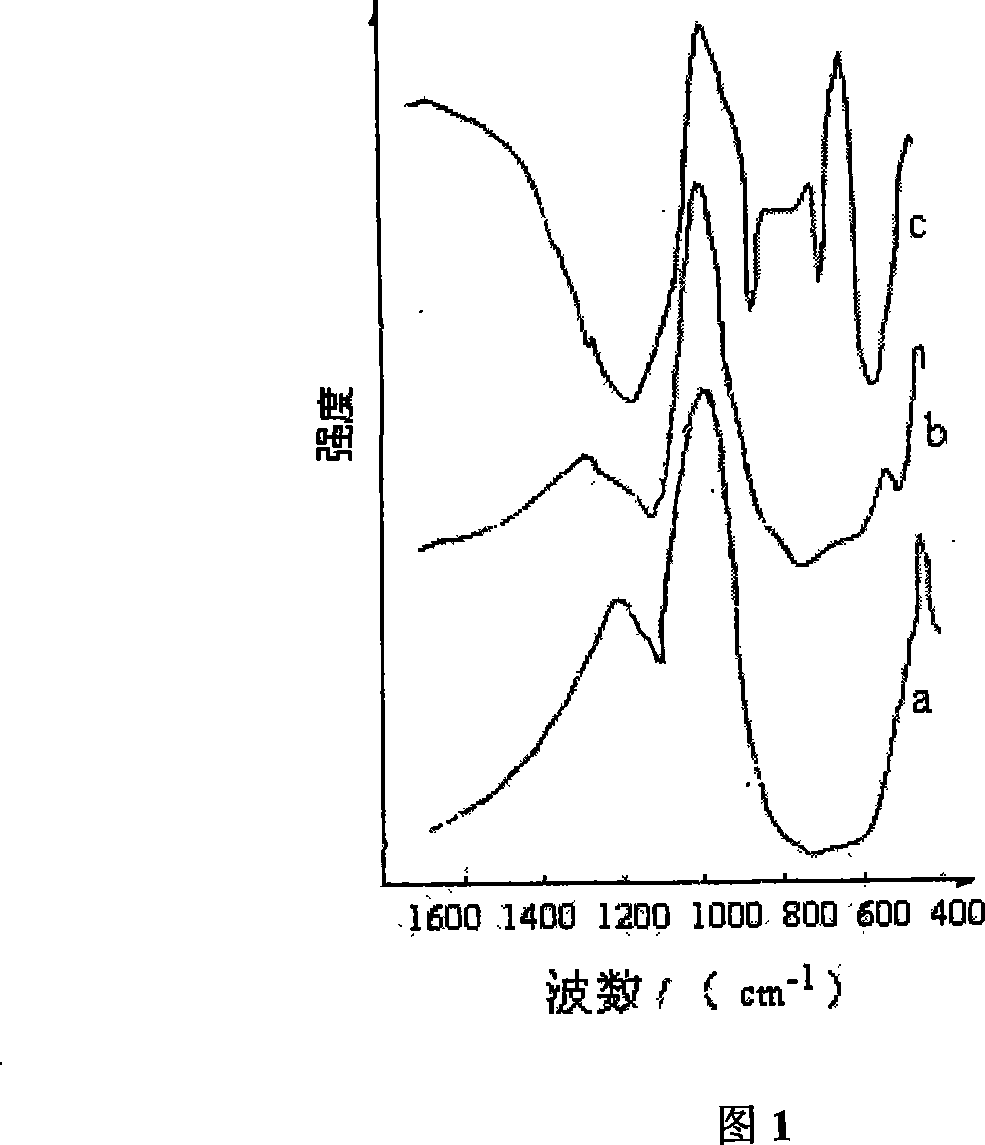

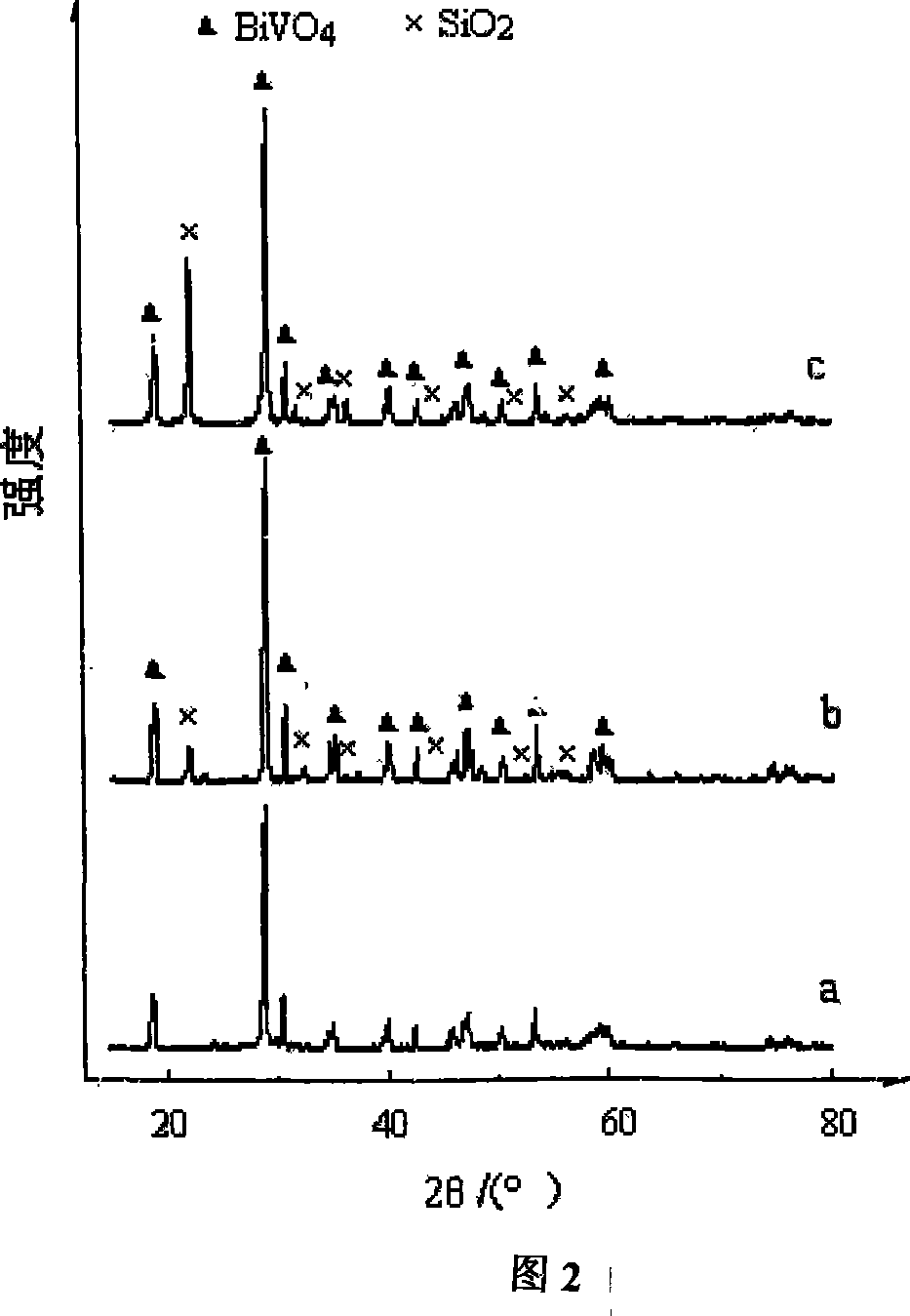

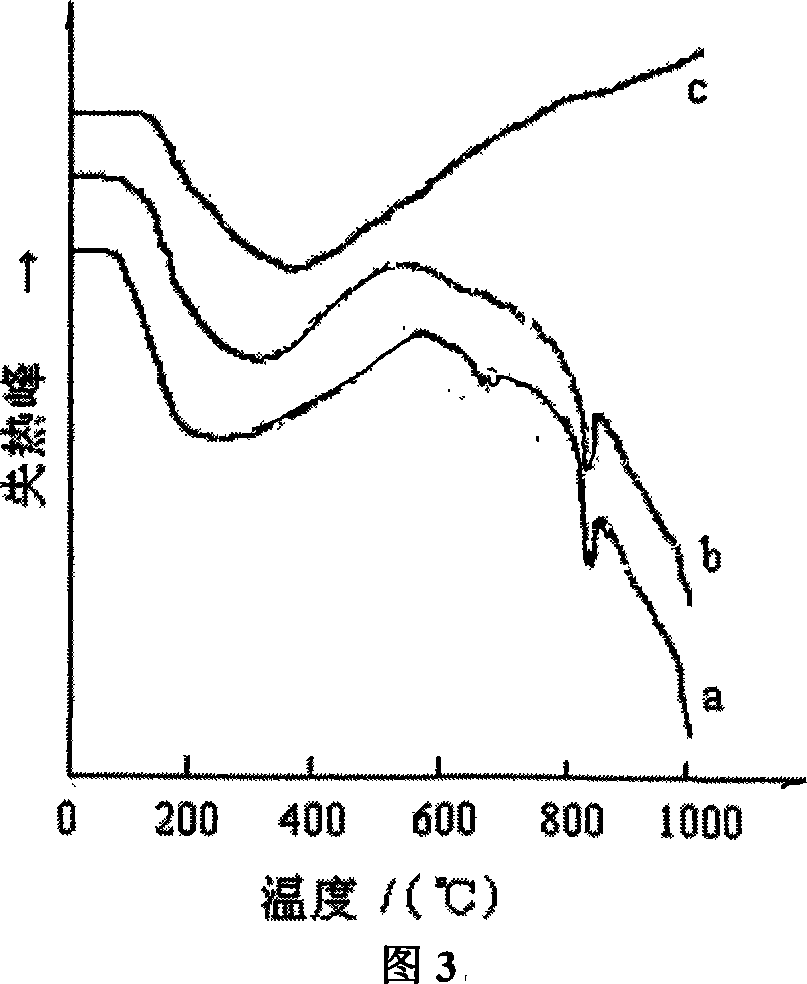

Production process of high-temp resistant bismuth vanadate yellow ceramic pigment

This invention relates to production process of pucherite yellow ceramic pigment, which takes sodium silicate as raw material to coat silicon dioxide. It takes sodium silicate as silicon source, coat silicon dioxide on surface of pucherite. For the strong inertia of silicon dioxide, it be able to withstand 1000 deg high temperature, and keep bright-colored after annealing of 1000 deg. This invention can eliminate harm to human body and pollution to environment in the process of production, solve the problem of heavy metal content are overproof in the export ceramic product of our country.

Owner:SHIJIAZHUANG UNIVERSITY

Formulation of anti-dazzle glass product etching liquid and etching technique

The invention relates to a formula of etching liquid of anti-dazzle glassware and an etching process. Raw materials of the formula proportion by weight comprise: ammonium fluoride holding 17-24 parts or ammonium hydrogen fluoride holding 8.5-12 parts, ammonium sulfate holding 2.5-3 parts, potassium sulfate holding 2.5-3 parts, calcium fluoride holding 2.5-3 parts, sulfuric acid holding 8-12.5 parts or hydrochloric acid holding 24-37.5 parts and water holding 60-75 parts. The process comprises: (1) weighing the raw materials according to the formula of the etching liquid, then mixing, uniformly stirring and ageing to formulate the etching liquid, (2) rinsing and drying pre-etched glass by organic solvent mixed by glycerol, (3) shielding one face of the rinsed glass needing not be etched and (4) immersing the glass in the formulated etching liquid for soak, then taking out the glassware and preparing anti-dazzle glass finished products after washing by clear-water and drying. The invention has the advantages of simple process, easy operation, labor saving, subtle granular surface of the prepared glassware, high penetration rate, good anti-glare effect, durable service and the like.

Owner:DONGHUA UNIV

Polypropylene nucleator and its prepn process

InactiveCN1432594AHigh transparencyRaise the crystallization temperatureOrganic phosphatesLithium compound

The present invention is polypropylene nucleator and its preparation process with alkyl metal phosphate as material. The nucleator is prepared with organic phosphate and its derivative, superfine inorganic oxide, aluminium-lithium compound and high level aliphatic salt as material. The organic phosphate includes alkyl methylene di(2,4-bialkyl phenoxy) phosphate and di[alkyl methylene di(2,4-bialkyl phenoxy)] phosphate. The preparation process includes mixing, grinding and sieving and obtains polypropylene nucleator to 0.5-100 micron diameter.

Owner:YANGZI PETROCHEM

Method for preparing high quality lead dioxide with plumbum mud in waste lead acid accumulator

The invention relates to a method for preparing high-quality lead dioxide through lead slime of waste lead acid storage batteries, comprising the following steps that: the lead slime in the waste lead acid storage batteries is taken out, washed repeatedly to neutrality, dried, and crushed into lead slime powder the granularity of which is over 200 meshes; the lead slime powder is mixed with a water solution which contains a dispersant and a desulfurizer according to a certain proportion, and then the mixture is fully stirred and desulfurized for 1 to 24 hours at a room temperature of 90 DEG C; separation is performed to remove a liquid part, and lead-bearing solid materials obtained are fully dried; the lead-bearing solid materials are mixed with a water solution which contains oxidant according to a certain proportion, and the mixture is fully stirred and oxidized for 1 to 2 hours at a room temperature of 90 DEG C; and separation is performed to remove a liquid part, and a solid part obtained is the lead dioxide after washing and drying. The method prepares the lead dioxide through the lead slime in the waste lead acid storage batteries, and has low cost and energy consumption, simple equipment, and high lead recovery rate and product quality of the lead dioxide.

Owner:HUNAN UNIV

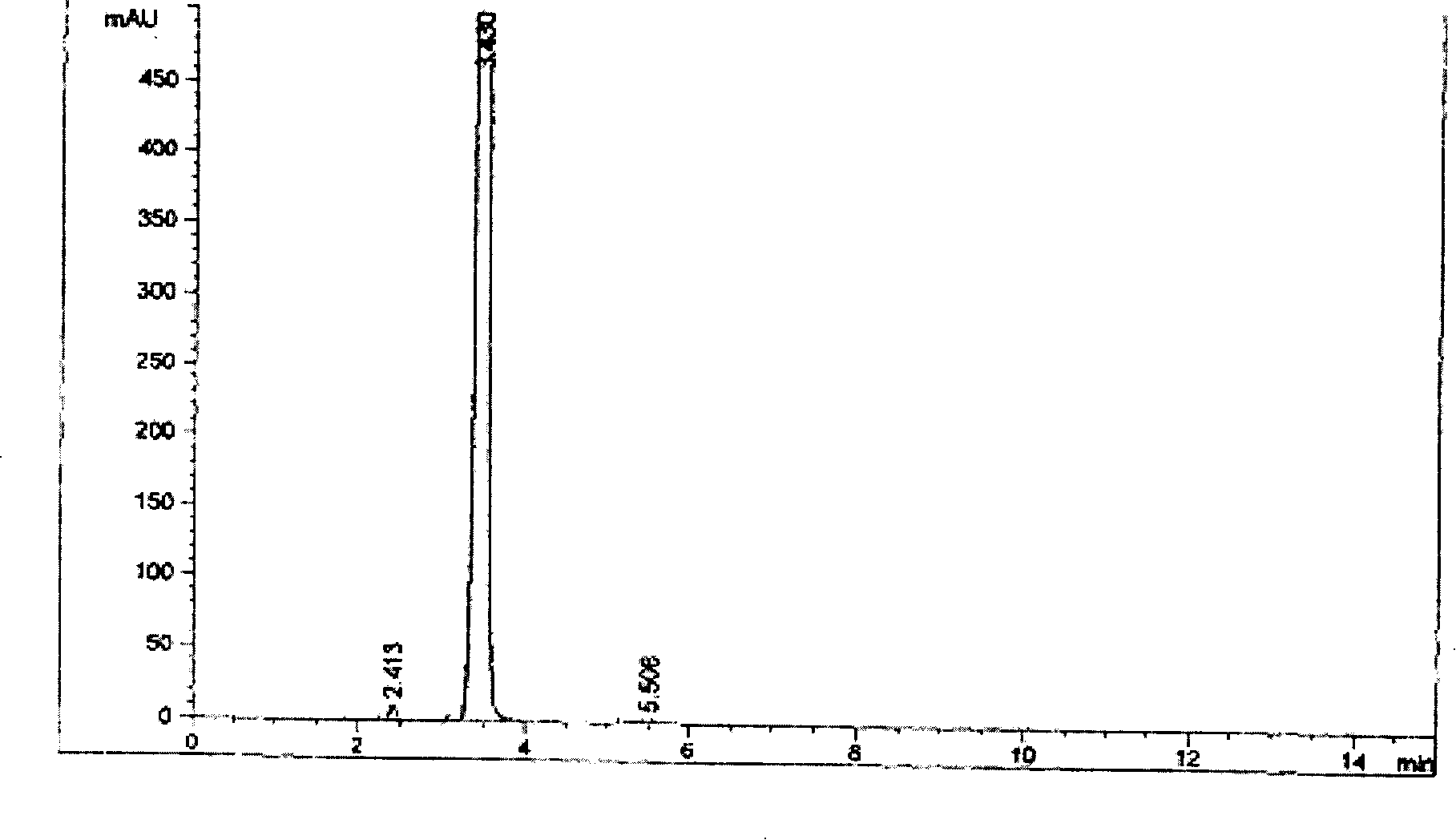

Hydroxyl carthamus tinctorius yellow colour A, preparation method and application thereof

ActiveCN101195647AGood product qualityFine particleOrganic active ingredientsSugar derivativesCarthamusChemistry

The invention relates to a hydroxysaffloryellow A extracted from Chinese medicinal material safflower, a relative preparation method and application thereof. The inventive extraction method of hydroxysaffloryellow A is stuffed into chromatography column according to different diameter-height ratios, the invention uses the upper sample to process column chromatography according to different ratios between upper sample volumes and bed volumes, to separate and purify safflower extract. The invention has simple process, few steps, low cost, high yield, no environment pollution and suitability for industrialized and large-scale production. The yield of extracted hydroxysaffloryellow A is higher than 50%, while the hydroxysaffloryellow A content tested by high-effect liquid hydroxysaffloryellow A reaches 99.5%. The drug prepared from the hydroxysaffloryellow A can effectively prevent and treat cerebrovascular diseases as cerebral infraction and hypertensive cerebral hemorrhage or the like.

Owner:山西德元堂药业有限公司

Open arc overlaying wire material with strong abrasive resistance for grinding roller and grinding disk

InactiveCN101658980AReduce splashFine particleWelding/cutting media/materialsSoldering mediaTitanium nitrideNanometre

The present invention provides an open arc overlaying wire material with strong abrasive resistance for a grinding roller and a grinding disk, which consists of a steel sheet and powder arranged in the steel sheet. A nano additive (A) is added into the powder, wherein the nano additive (A) can be one or any combination of three of nano TiN (titanium nitride), nano SiN (silicon nitride) and nano SiC (silicon carbide). The powder contains 3 to 5 weight percent of the nano additive (A). The nano additive (A) has the functions of strengthening dispersion of nano ceramic phases, improves cohesion strength, rupture strength and combination strength of a cladding layer material and has good high-temperature stability; and the nano additive (A) improves self lubricity of the material, improves theabrasive resistance of cladding layer metals and prolongs service life of the grinding roller and the grinding disk processed by overlaying. The service life of the grinding roller and the grinding disk processed by the overlaying is improved by 1.5 to 2 times than that processed by open arc overlaying; and the cladding efficiency is improved by 10 to 20 percent so as to save the overlaying wirematerial. The open arc overlaying wire material has light fume and less molten metal spatter in the process of overlaying, and a weld pass is smooth after the material is molded.

Owner:JIANGXI HENGDA HI TECH CO LTD

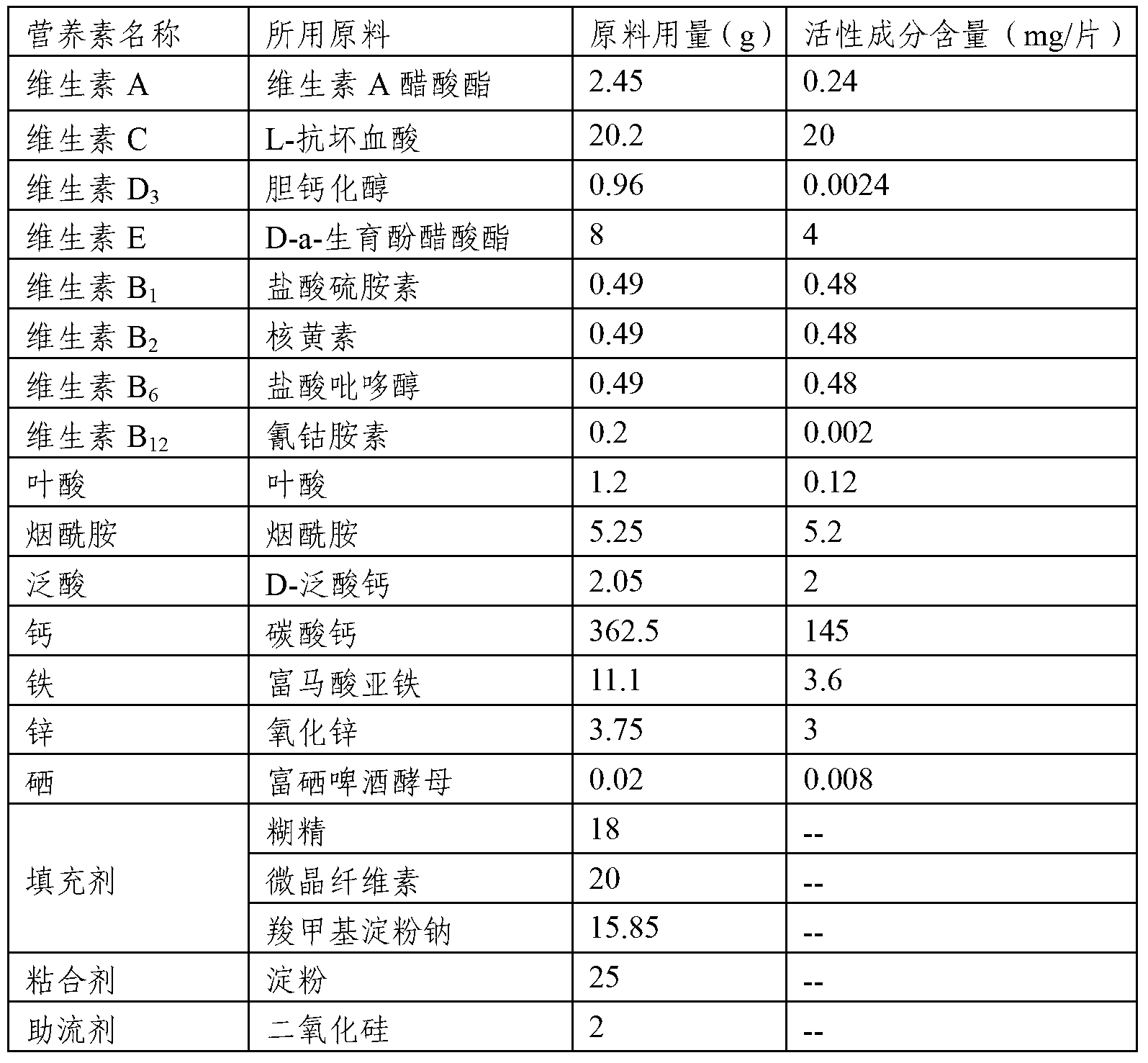

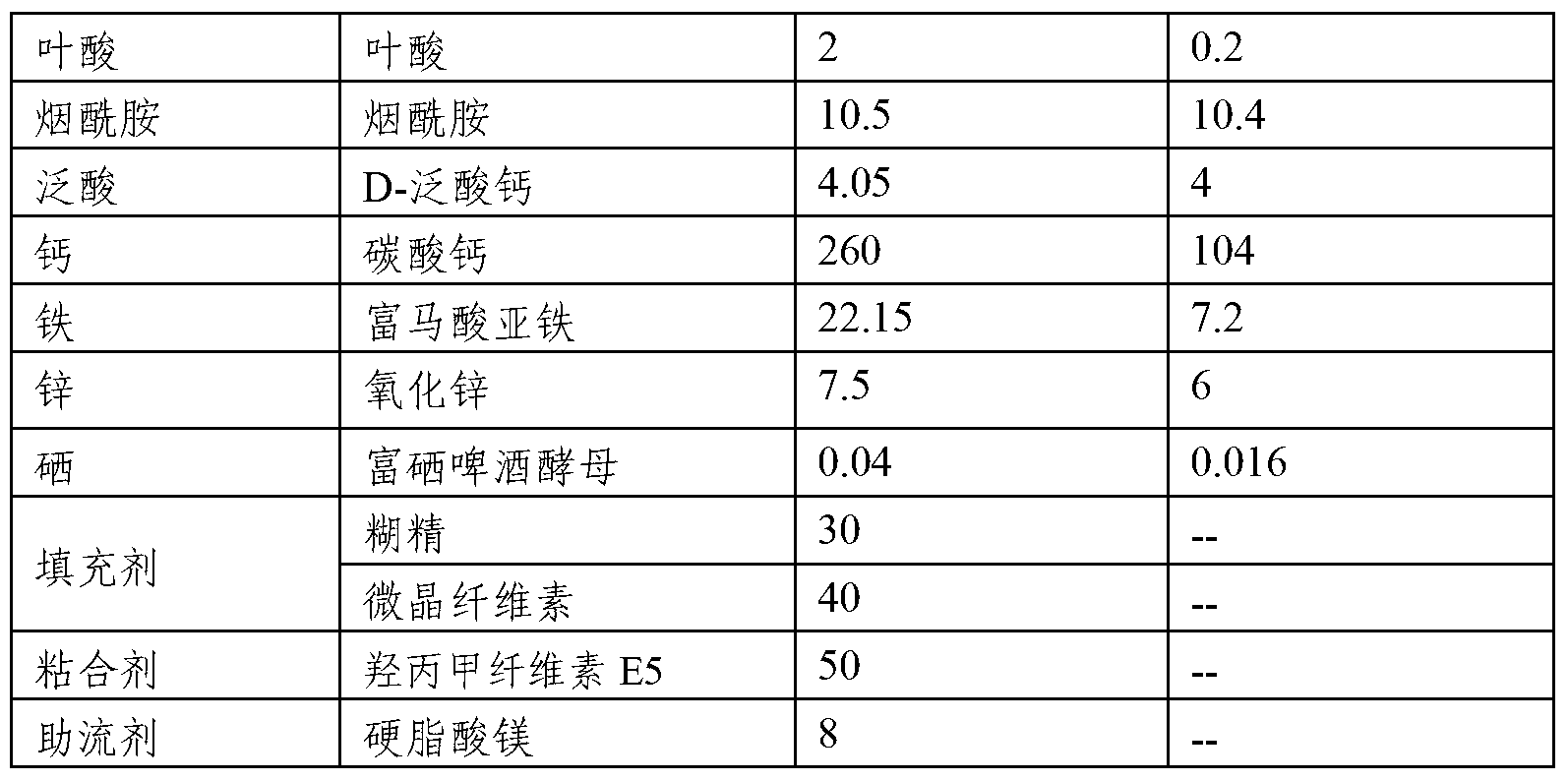

Composition comprising a plurality of vitamins and mineral substances

InactiveCN103284164AAvoid destructionIncrease mineralsFood preparationAdditive ingredientPantothenic acid

The invention relates to a composition comprising vitamins and mineral substances. The composition comprises the vitamins and the mineral substances, wherein the vitamins include vitamin A, vitamin C, vitamin D3, vitamin E, vitamin B1, vitamin B2, vitamin B6, vitamin B12, folic acid, nicotinic acid amide and pantothenic acid, and the mineral substances include calcium, iron, zinc, and selenium. According to the composition, the amounts of the vitamins and the mineral substances are reasonably proportioned strictly according to the needing amounts of a human body; the mineral substance iron is supplied by ferrous fumarate, so that the destroy on the active substances, such as vitamins, by the addition of the inorganic iron can be effectively prevented; the mineral substance selenium is provided by selenium enriched beer yeast, the toxic and side effects of chemical selenium (such as sodium selenite) on the human body and intestines and stomach stimulation are eliminated, and therefore the selenium can be absorbed and utilized by the human body more efficiently and safely.

Owner:HARBIN ZHENBAO PHARMA

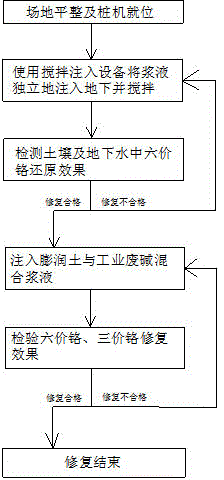

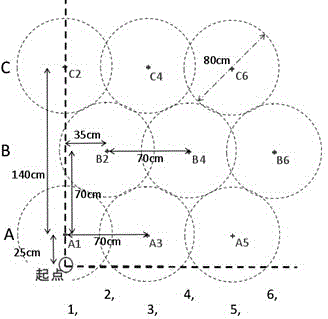

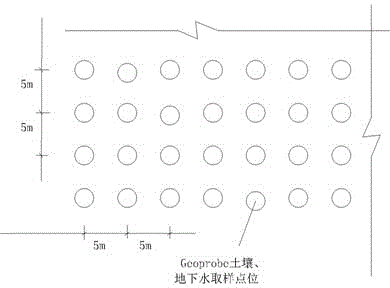

Remediation method for hexavalent chromium polluted soil and underground water

ActiveCN104624632AComplete restorationEfficient removalWater contaminantsContaminated soil reclamationSodium BentoniteInjection equipment

The invention discloses a remediation method for hexavalent chromium polluted soil and underground water. The remediation method comprises the following steps: step (10): putting a pile machine in place; step (20): independently injecting acidified bentonite slurry loaded with active carbon powder and bentonite slurry loaded with zero-valent iron powder into the ground by using stirring and injection equipment and stirring; step (30): detecting the reduction effect of hexavalent chromium in the soil and the underground water; step (40): injecting bentonite and industrial waste alkali mixed slurry; and step (50): detecting the remediation effect of hexavalent chromium and trivalent chromium. By virtue of the remediation method, remediation chemicals can be in direct and sufficient contact with the soil and the underground water to react, so that the hexavalent chromium in the soil and the underground water can be completely reduced; meanwhile, an indissolvable stable compound is formed by the trivalent chromium and the useless loss of the remediation chemicals can be reduced; the potential of hydrogen of a stratum is balanced; and the remediation method is suitable for the large-area hexavalent chromium polluted stratums different in potential of hydrogen and moisture content.

Owner:SOUTHEAST UNIV

Method of preparing foam glass based on boric sludge

InactiveCN101058480AConducive to circular economy and sustainable developmentFine particleQuenchingSolvent

The invention discloses a making method of foam glass based on boron mud in the functional inorganic material technical domain, which comprises the following steps: blending the broken waste glass and magnesium-stripping boron-mud according to proportion; grinding into raw material; heating and fusing the raw material; quenching; drying; grinding into glass powder; adding foamier and booster solvent to form the foam glass mating slurry; placing the mating slurry into the mould; pressing; shaping; heating; foaming; stabilizing the foam; annealing; obtaining the foam glass; adjusting the foam-pore structure according to the adjusted component and technique condition; reaching the goal of insulation, silence or water-retaining.

Owner:DALIAN UNIV OF TECH

Ultra-thin ceramic outside-wall brick and production method thereof

The invention relates to an ultra-thin ceramic external tile and the preparation method. The components and contents of the ceramic external tile are as follows: 12 to 18 parts by weight of clay, 4 to 8 parts by weight of binder, 12 to 18 parts by weight of kaolin, 17 to 22 parts by weight of sodium feldspar and the potassium feldspar respectively, 37 to 41 parts by weight of quartz feldspar tailings and 4 to 6 parts by weight of lithium feldspar. The ultra-thin ceramic external tile prepared by adopting the composition of the present invention is about 3.5mm to 4.6mm thick, reducing the weight from 13kg / m<2> of the conventional products to 6kg / m<2>. The invention has the advantages that the thickness is reduced, however, the strength is highly increased, moreover, the energy is saved, the cost is reduced, the weight of the tile on unit area is greatly reduced, the energy is saved and transportation cost is reduced.

Owner:福建省晋江协隆陶瓷有限公司

Preparation method of high purity aluminium oxide powder

InactiveCN1903728AHigh chemical purityReduce sodiumAluminium oxide/hydroxide preparationWater bathsAluminium hydroxide

The present invention relates to a preparation method of high-purity aluminium oxide powder body. It is characterized by that it adopts aluminium sheet whose purity is 99.9999% and organic alkal; and makes them be mutually reacted in hot water bath to obtain the precipitate of aluminium hydroxide, then the precipitate is calcined at 1100-1200deg.C and ground so as to obtain high-purity ultrafine aluminium oxide powder body. The described organic alkal; includes any one of choline, hexamethohydrotetramine and dopamine.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

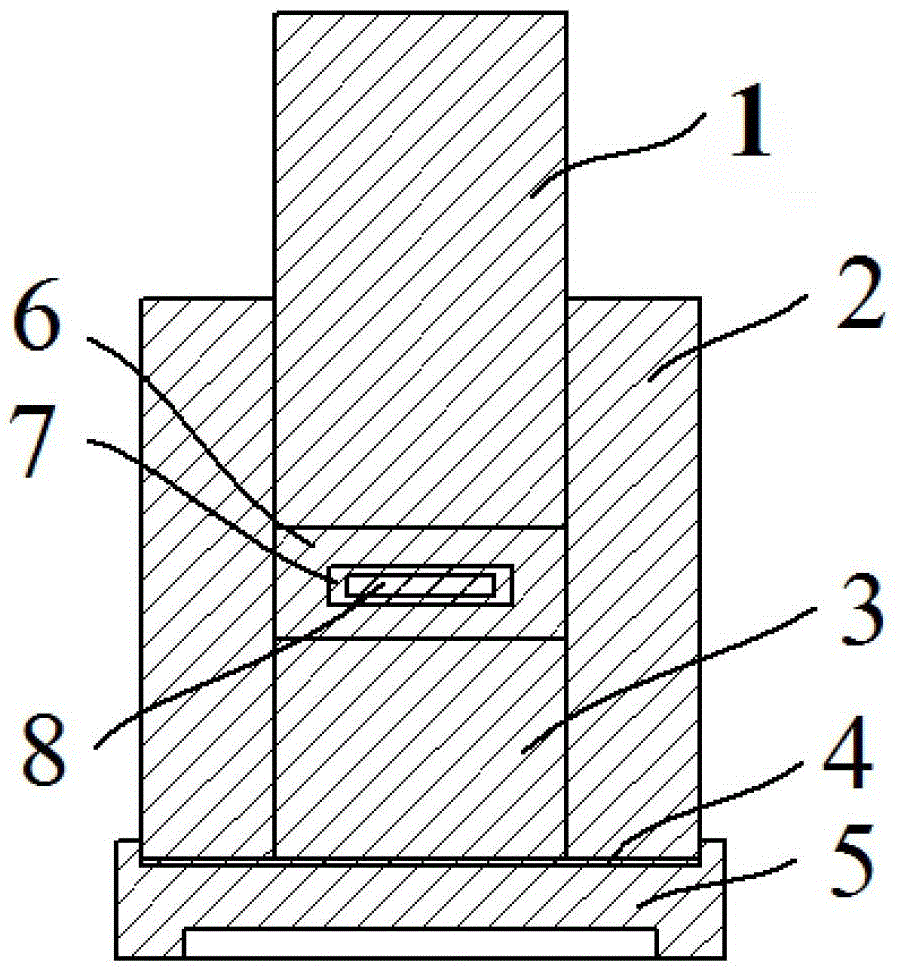

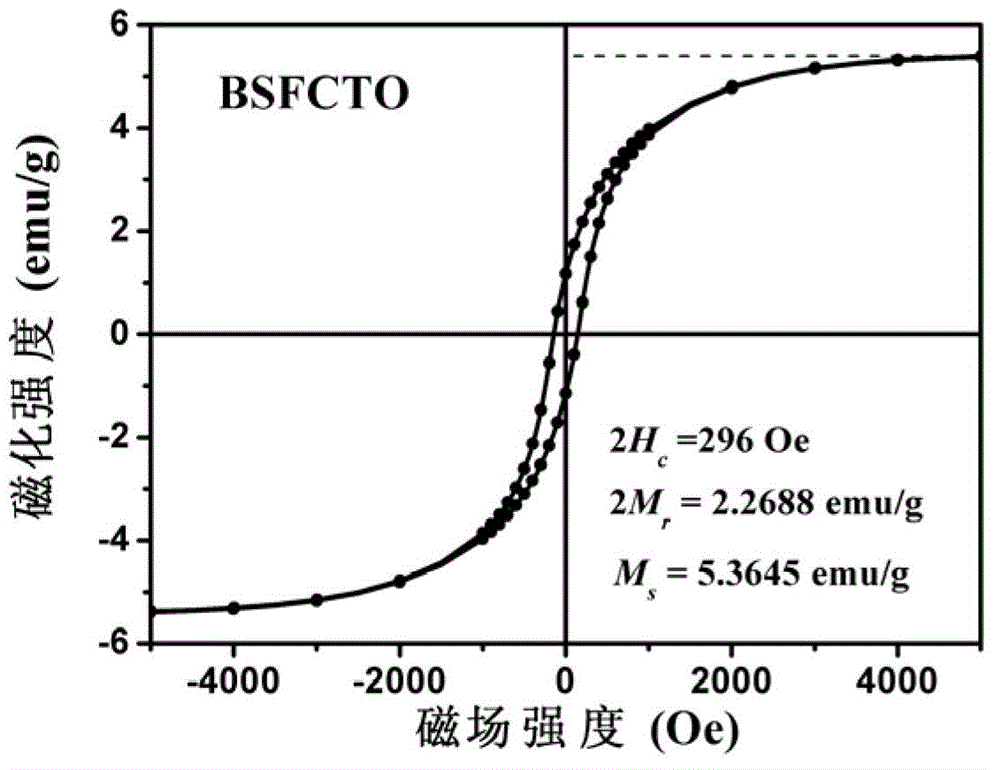

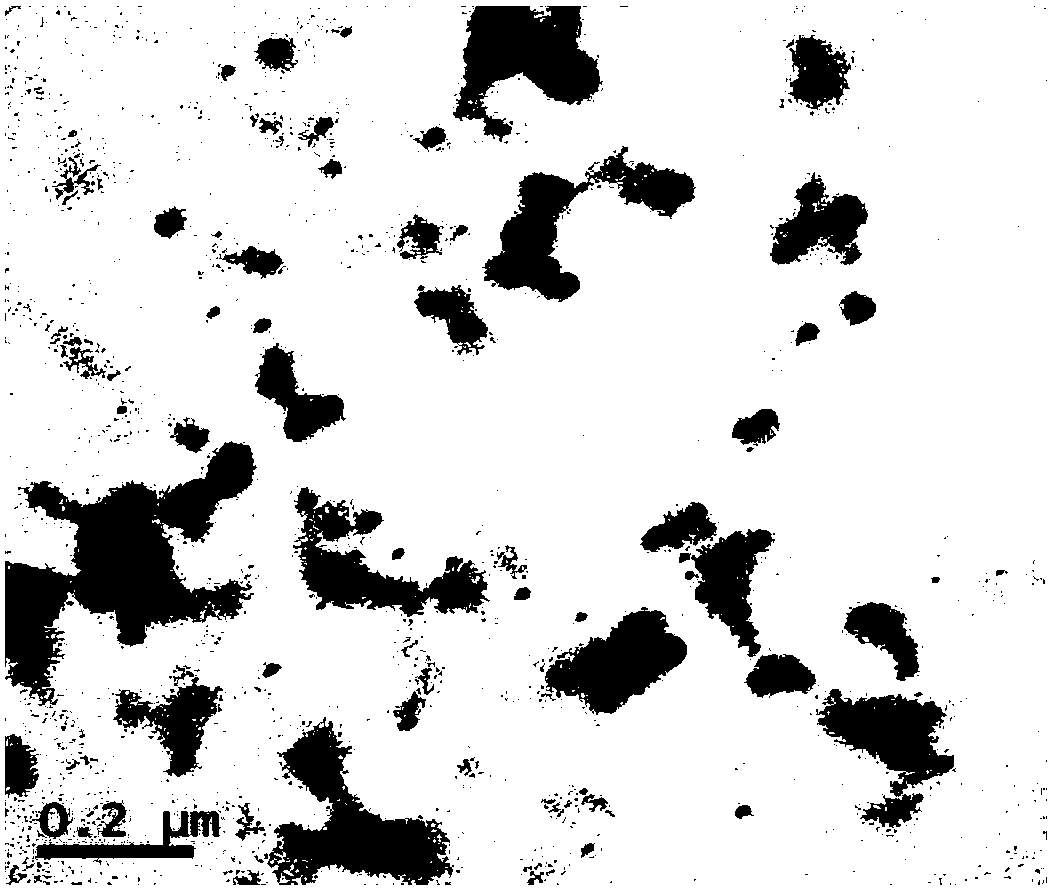

Layered perovskite structural ceramic and preparation method thereof

The invention provides layered perovskite structural ceramic and a preparation method thereof. The preparation method includes mixing well titanate compounds, bismuth compounds, strontium compounds, iron compounds, cobalt compounds and complexing agent in solvent, heating, drying and combusting to obtain powder, and presintering to obtain powder; performing the powder, and performing hot-pressing sintering to obtain the structural ceramic in in a formula (I). Compared with ceramics prepared in the prior art by solid phase sintering process, the structural ceramic in the formula (I) is prepared by solution process and hot pressing sintering. The preparation method has the advantages that less volatile low-valence strontium ions are introduced, increased leakage current due to volatilization of the strontium ions is improved, and ferroelectric properties are improved; the raw materials are evenly spread by the solution process, the power is even in component and has high reactivity, and Fe-Co ions are coupled fully; and the materials processed by hot pressing sintering are high in density and orientation, and the layered perovskite structural material can be obtained, namely Bi(n+1-x)SrxF3(n-3) / 2Co(n-3) / 2Ti3O3(n+1) (I).

Owner:UNIV OF SCI & TECH OF CHINA

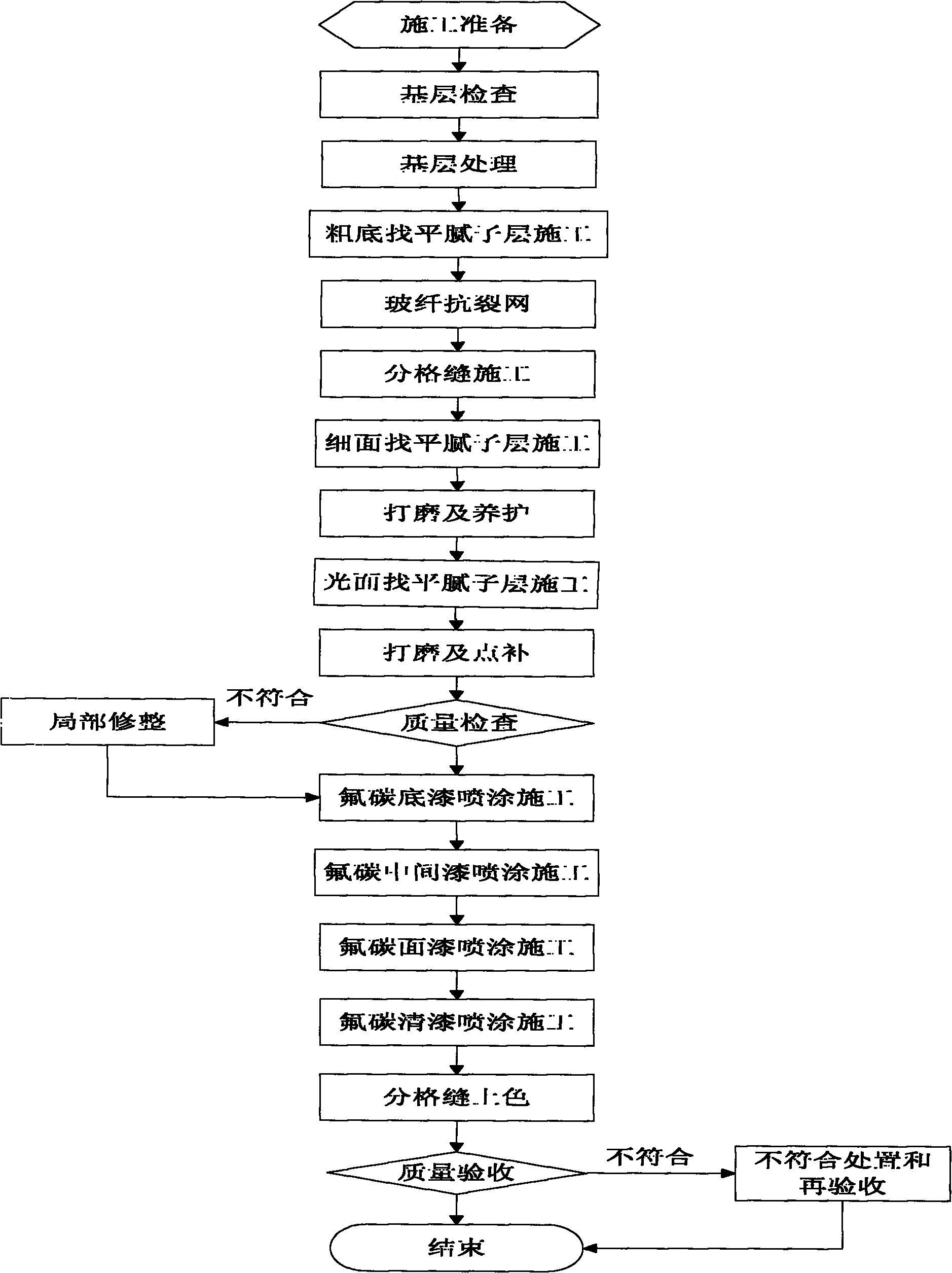

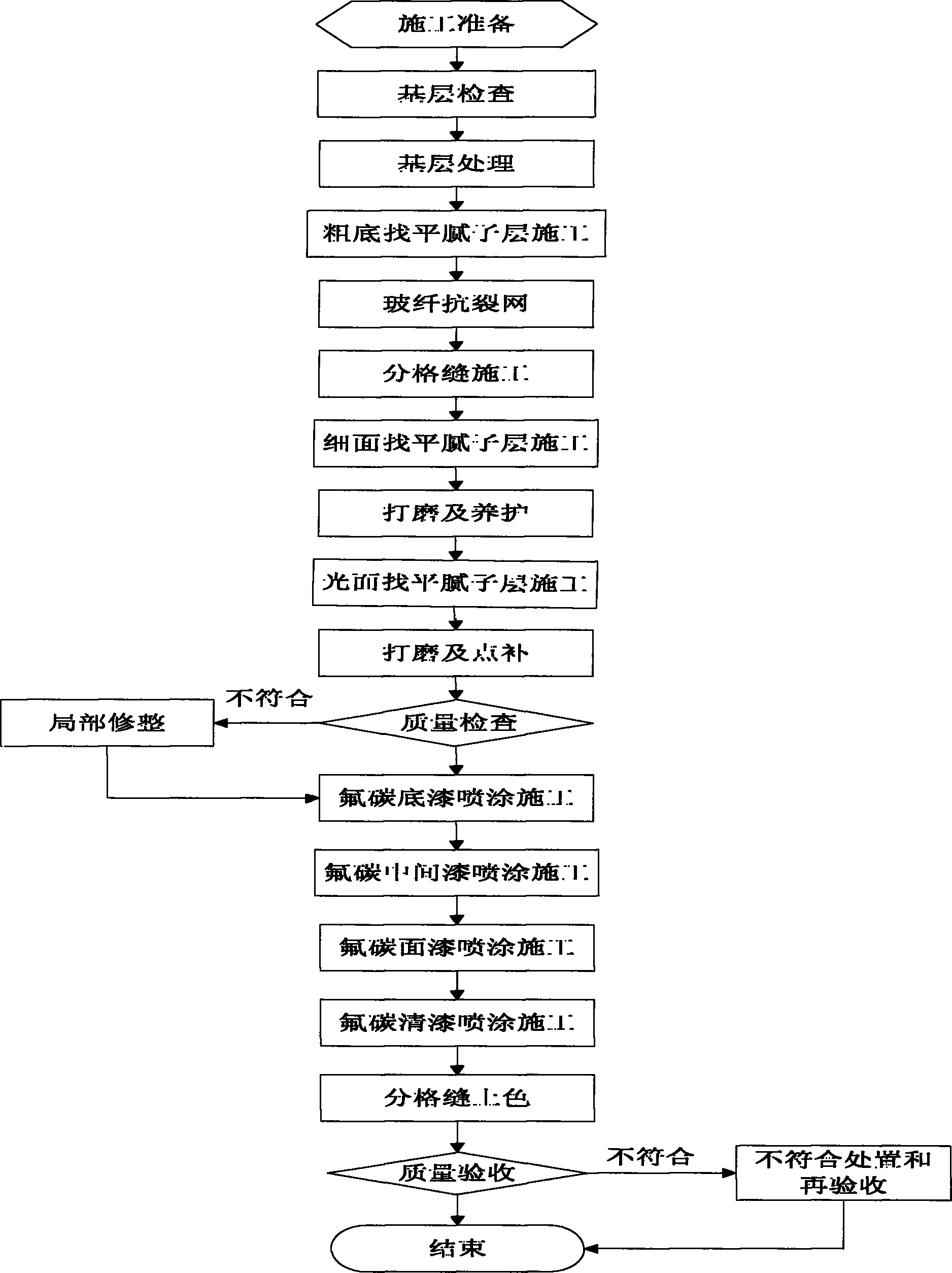

Construction process for outer wall metal fluorocarbon coating

InactiveCN101832015ASimplify construction stepsEasy to operateBuilding constructionsGlass fiberLacquer

The invention discloses a construction process for an outer wall metal fluorocarbon coating. The construction process comprises the following steps of: 1, checking a base layer; 2, treating the base layer; 3, performing coarse bottom leveling putty layer construction, wherein the used outer wall leveling coarse bottom putty is a finished putty special for the outer wall and a proper amount of quartz sand is added into the finished putty; 4, laying a glass fiber crack resistant net; 5, performing dividing joint construction; 6, performing fine surface leveling putty layer construction to ensure that the glass fiber crack resistant net is clamped between the coarse bottom leveling putty layer and the fine surface leveling putty layer; 7, polishing and maintaining; 8, performing polished side leveling putty layer construction; 9, performing fluorocarbon primer spraying construction; 10, performing fluorocarbon intermediate coating spraying construction; 11, performing fluorocarbon finish paint spraying construction; 12, performing fluorocarbon varnish spraying construction; and 13, coloring dividing joints. The construction process for the outer wall metal fluorocarbon coating has the advantages of simple construction steps, reasonable design, convenient operation, low construction cost, high construction quality, and excellent use efficiency, and can prevent the hollowness, delamination, crack and other quality defects on the surface of the outer wall metal fluorocarbon coating.

Owner:陕西建工第二建设集团有限公司

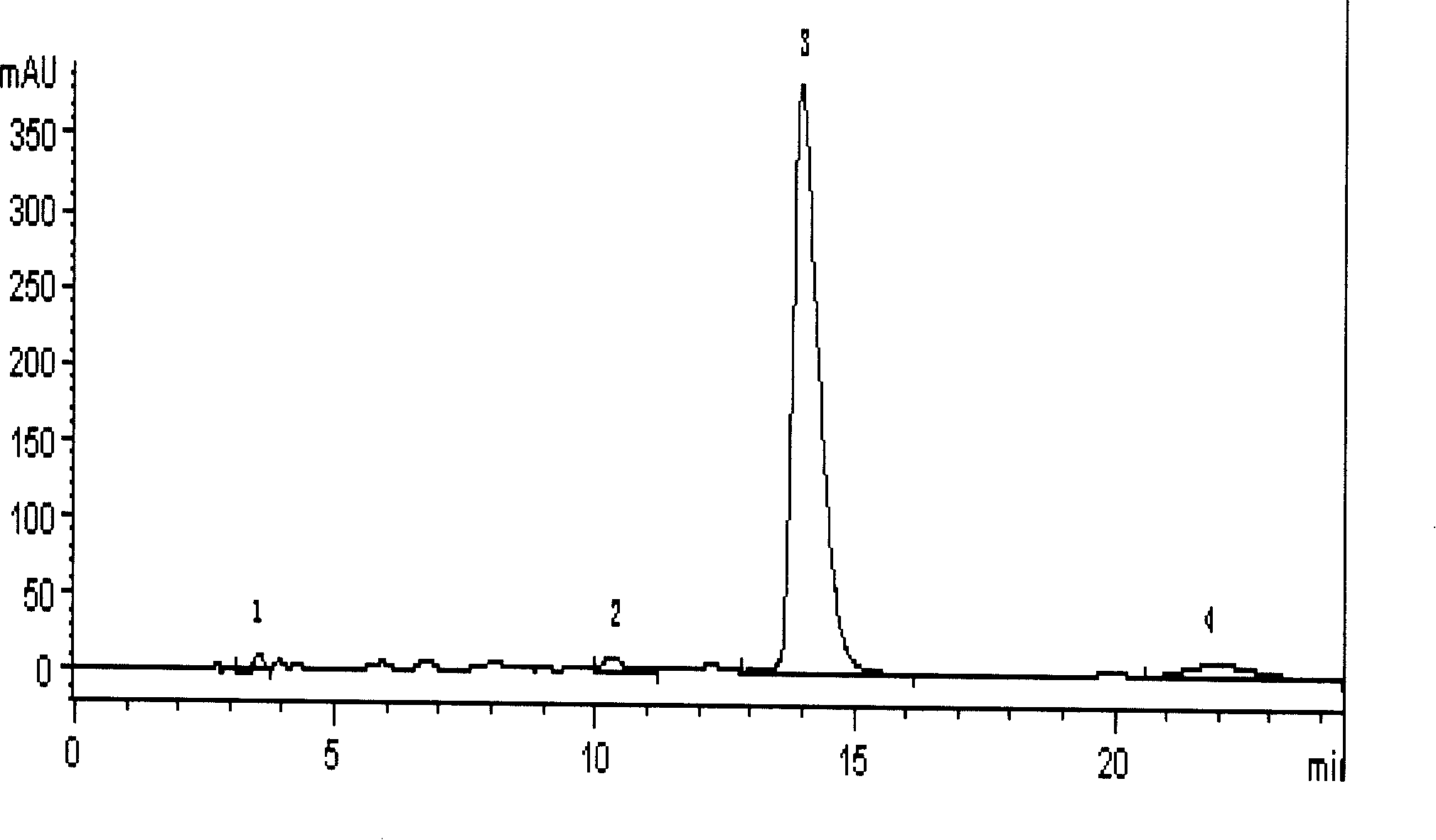

Method for preparing lithium carbide/lithium sulfide composite anode material of lithium-sulfur battery by performing carbon thermal reduction on lithium sulfate

InactiveCN106229487AReduce manufacturing costSimplify complex processesCell electrodesLi-accumulatorsMaterials preparationLithium–sulfur battery

The invention relates to a method for preparing a lithium carbide / lithium sulfide (Li2S) composite anode material of a lithium-sulfur battery by performing carbon thermal reduction on lithium sulfate (Li2SO4), and belongs to the technical field of lithium-sulfur batteries. The lithium carbide / lithium sulfide composite material is prepared by performing the carbon thermal reduction on a lithium sulfate-containing composite material serving as a precursor under a condition of inert atmosphere protection, and is applied to an anode of the lithium-sulfur battery. The lithium sulfide composite material preparation method disclosed by the invention is a novel method for in-situ synthesis of the anode material of the lithium-sulfur battery; and the prepared lithium carbide / lithium sulfide composite material is high in active substance dispersivity and stable in structure, and has the advantages of high specific capacity, excellent circulating and rate capability and the like when used as an anode material of the lithium-sulfur battery. The method is easy to operate, low in preparation cost and favorable for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

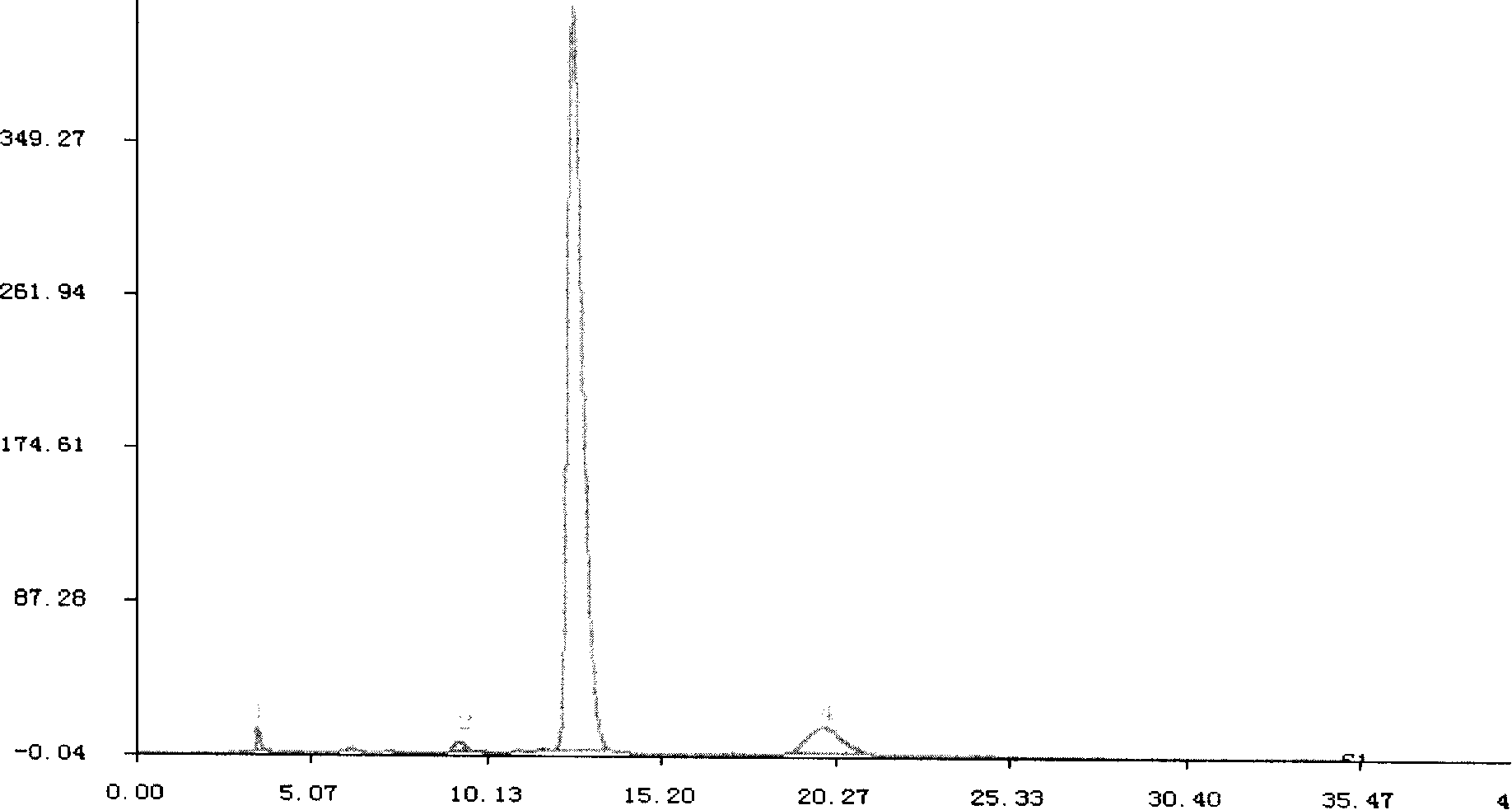

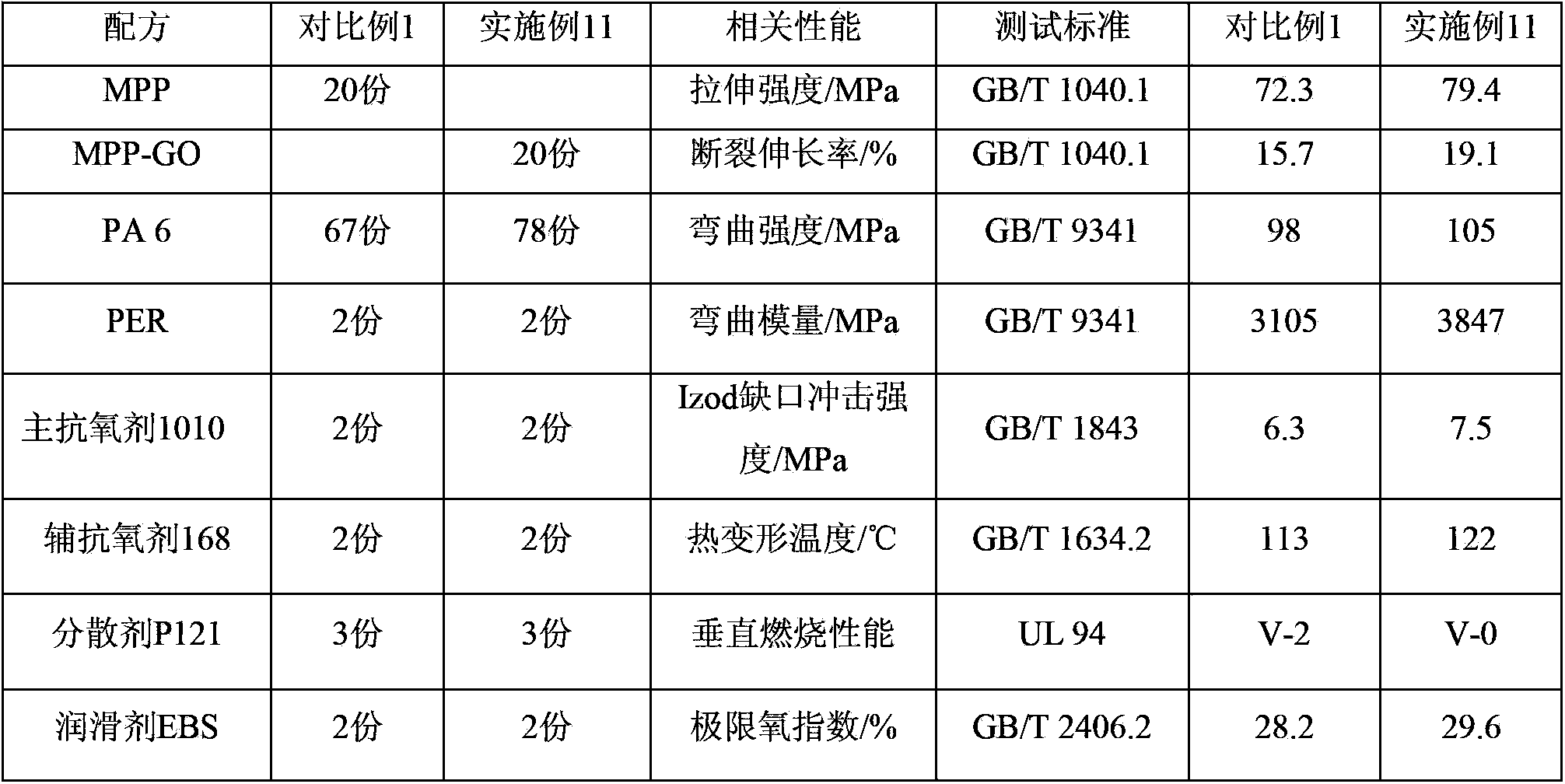

Method for modifying melamine pyrophosphate fire retardant by grafting oxidized graphene

The invention belongs to the material technical field, and relates to a preparation method for modifying a melamine pyrophosphate fire retardant by grafting oxidized grapheme, which comprises the following steps: adding melamine and anhydrous sodium pyrophosphate in distilled water, fully stirring for uniformly dispersing a system; adding an oxidized grapheme colloidal solution through ultrasonic dispersion in the above system, adding a protonic acid dilute solution of a stabilizing agent for catalysis drop by drop, adjusting pH value of the reaction system, heating, stirring, after the reaction is completed, performing pumping filtration on the reaction products, washing, and drying products to obtain the melamine pyrophosphate fire retardant. The preparation method has the advantages of high efficiency, easy operation and environmental protection, and the prepared halogen-free expansion-type fire retardant has the advantages of small particle size and high thermostability, can be used in a halogen free system of polyolefin, and can be used for polyamide, polyester, rubber and intumescent fire retardant paint.

Owner:HEFEI GENIUS NEW MATERIALS

Method for preparing barley seedlings green juice powder and wheat green flour

InactiveCN101167571ABig color changeBright green colorDough treatmentFood preparationNutritive valuesFiber

The invention provides a process for preparing barley grass green powder, and comprises sorting, cleaning and sterilizing, cutting into sections, blanching, cooling, drying, and low-temperature airflow comminuting. The invention can fully utilize nutritional substances which exist in the barley grasses. The invention has extensive usages, which not only can be used as beverages, but also can be used as the natural pigment and plant fiber extender to be charged in the flour, and improves the nutritive value of flour and vitamin contents. The invention further provides the process for preparing barley green flour.

Owner:SICHUAN XIANGZHEN ENTERPRISE

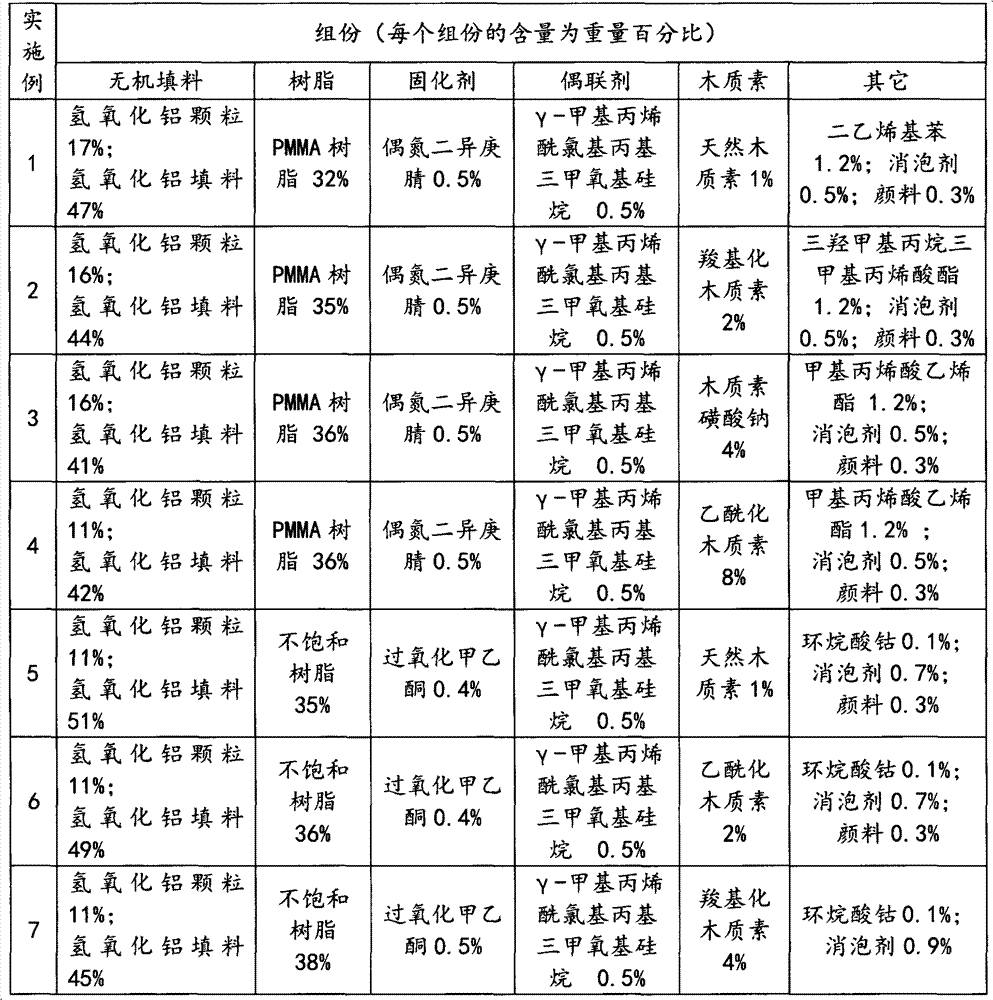

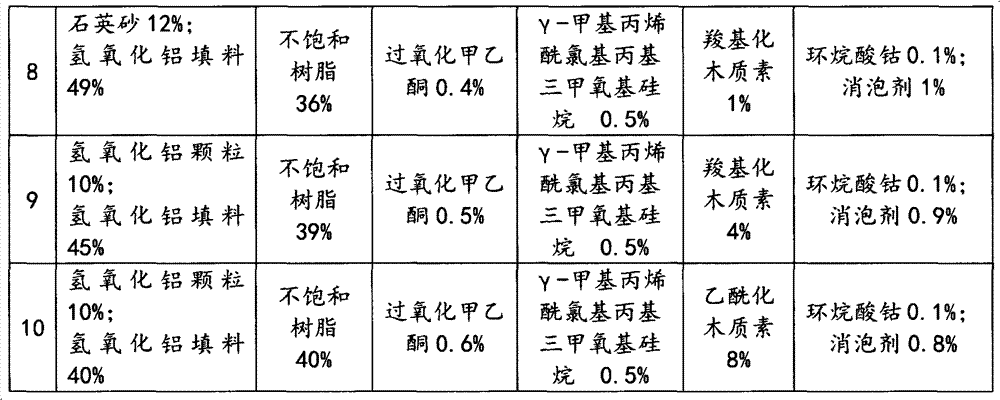

Biobased artificial stone and production process thereof

A biobased artificial stone and a production process thereof are disclosed. The artificial stone includes the following components: inorganic filler, resin, a curing agent, an accelerating agent, a crosslinking agent, a coupling agent, an antifoaming agent, lignin and a pigment. The formula of the artificial stone includes by weight: 10-85% of the inorganic filler; 3-60% of the resin; 0.03-3% of the curing agent; 0-2% of the accelerating agent; 0.05-2% of the coupling agent; 0.05-5% of the crosslinking agent; 0-3% of the antifoaming agent; 0.01-40% of the lignin; and 0-2% of the pigment. According to the invention, the lignin is used in the artificial stone, the lignin is turned into wealth from waste, the environmental pollution of the lignin is reduced, the cost of the artificial stone is reduced, and at the same time the weather resistance and light stability of the artificial stone are improved, thus the artificial stone has antibacterial ability, is green and environmental-friendly, and is suitable for building decoration of living environments.

Owner:SUZHOU TOPOLINE TECH

Method for preparing wall and floor tile adhesive mortar by using mill tailings

The invention relates to a method for preparing wall and floor tile adhesive mortar by using mill tailings. The wall and floor tile adhesive mortar comprises the following components in part by weight: 50 to 250 parts of silicate cement, 20 to 150 parts of coal ash, 100 to 650 parts of iron tailing sand or copper tailing sand, 1 to 18 parts of re-dispersible latex powder and 0.2 to 0.6 part of water reducer. The preparation method comprises the following steps of: drying the iron tailing sand or copper tailing sand to ensure that the moisture content is 1 to 6 percent; and then mixing the iron tailing sand or copper tailing sand and the silicate cement, the coal ash, the water reducer and the re-dispersible polymer latex powder uniformly by using an agravic mixer to obtain the dried powder mortar products. A large number of industrial and mineral solid wastes such as the iron tailing sand or copper tailing sand, the coal ash and the like are utilized to be combined with the re-dispersible polymer latex powder, so that the properties of the mortar, in particular the adhesive property, are improved, and high-performance environmentally-friendly wall and floor tile adhesive mortar is prepared.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing corn seed coat dietary fiber

The invention relates to a method for preparing corn seed coat dietary fiber, which comprises the following steps of: crushing corn seed coats, performing ultrasonic treatment and microwave treatment on the crushed corn seed coats by using water as an extraction agent respectively, cooling the solution, adding a mixed enzyme preparation of alpha-amylase and protease into the solution, and performing enzymolysis on the solution for 20 to 50 minutes at the pH of between 4.0 and 6.0; and after the solution is filtered after the enzymolysis, washing the filter residue by using deionized water, concentrating the filtrate, removing protein from the filtrate and washing the concentrate by using alcohol, drying the two samples respectively, and performing ultra-fine pulverization on the two dried samples to obtain the corn seed coat dietary fiber. The yield of the dietary fiber prepared by the method reaches 87.4 percent; and the dietary fiber granules are fine and light yellow, have no special smell, and can be used as a dietary fiber nutrition enhancer of multiple food products.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

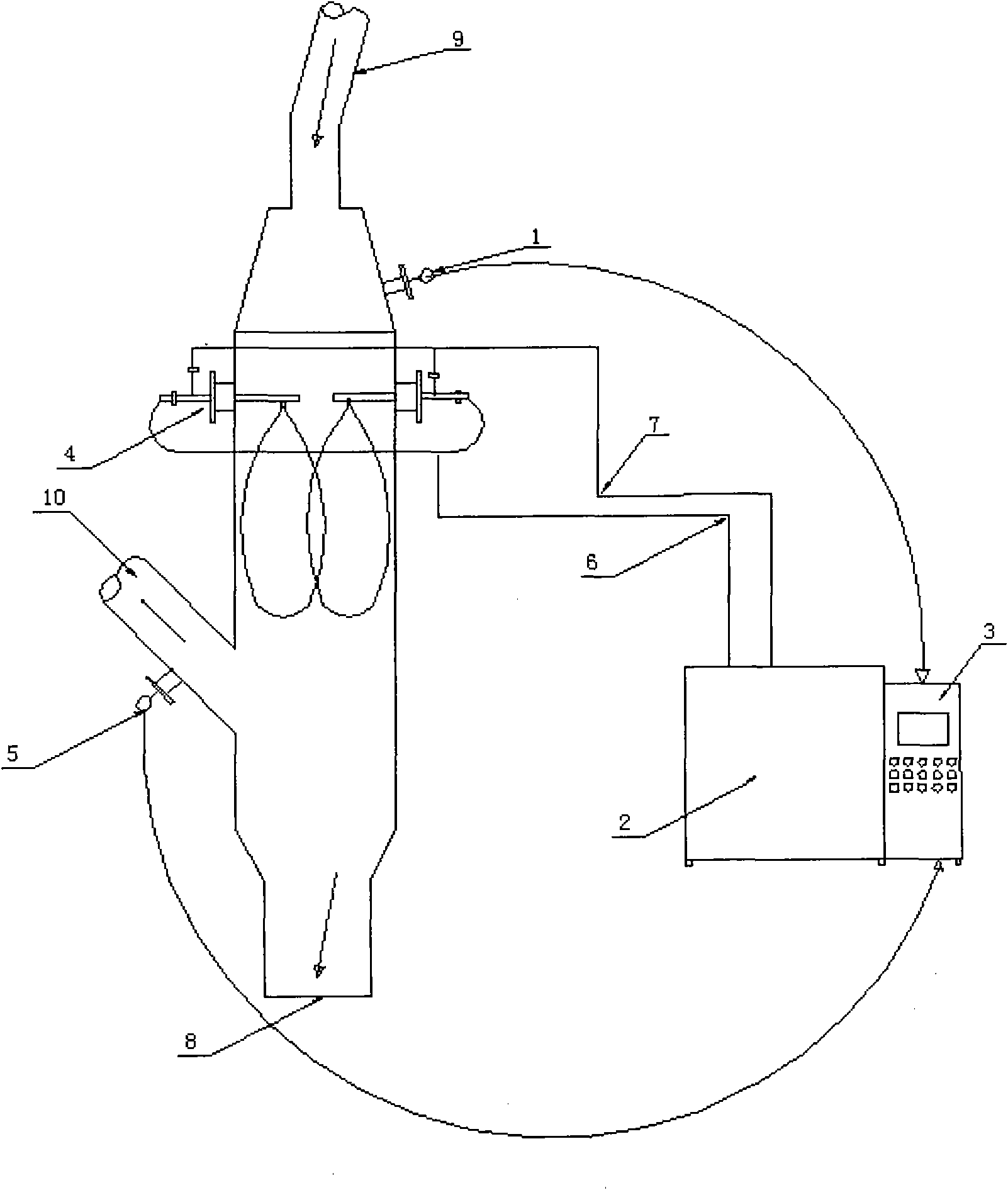

Quenching and tempering device for cooling high-temperature fume

InactiveCN101596389AEmission reductionReduce energy consumptionAuxillary pretreatmentEfficient regulation technologiesFrequency changerAir pump

The invention discloses a quenching and tempering device for cooling high-temperature fume, comprising a two-fluid electrical appliance controller, a water path and an air path arranged between a high-temperature fume inlet and a high-temperature fume outlet. The device of the invention is characterized in that a low pressure pump is arranged in the air path, a low pressure air path is combined into a water pipeline before a spray gun, two transducers are arranged to adjust the pressure and flow of a water pump and an air pump, the nozzle bore diameter is phi 6-7mm, and the spray particle diameter is smaller than 300 micrometers; a temperature sensor is respectively arranged at a wetting tower inlet and the fume outlet, and the outlet temperature is controller to 130-150 DEG C; an operation program is controlled to calculate the temperature difference of the fume inlet temperature and the fume outlet temperature, tower volume and spray fall height; two transducers are used for controlling the water pump and the air pump to automatically adjust operation power when low air pressure is 0.4-0.6MPa, and air flow quantity and water flow quantity are 5-25T / H. the particle diameter of sprayed water spray is small and even, which can better realize precise control to temperature and reduces atomization particle residence time and wet bottom danger. The dust removal device designed by the invention increases fume density and volume, lowers speed and improves dust removal function. In particular, the spray granularity is small, which can obviously control temperature and humidity, lower discharge Dioxin and furan mixed in dust and reduce environment protection cost.

Owner:SHENYANG XINCHENG TECH

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

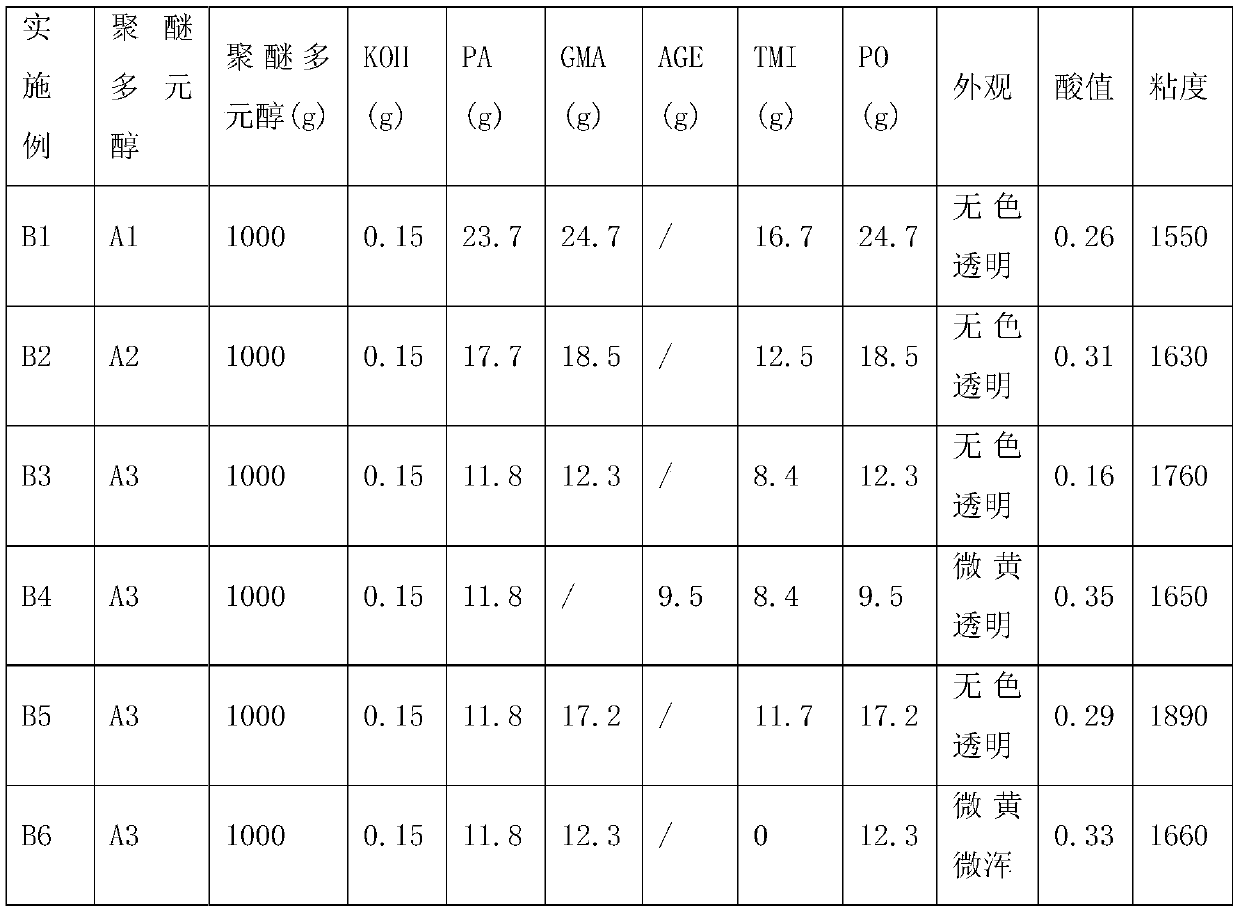

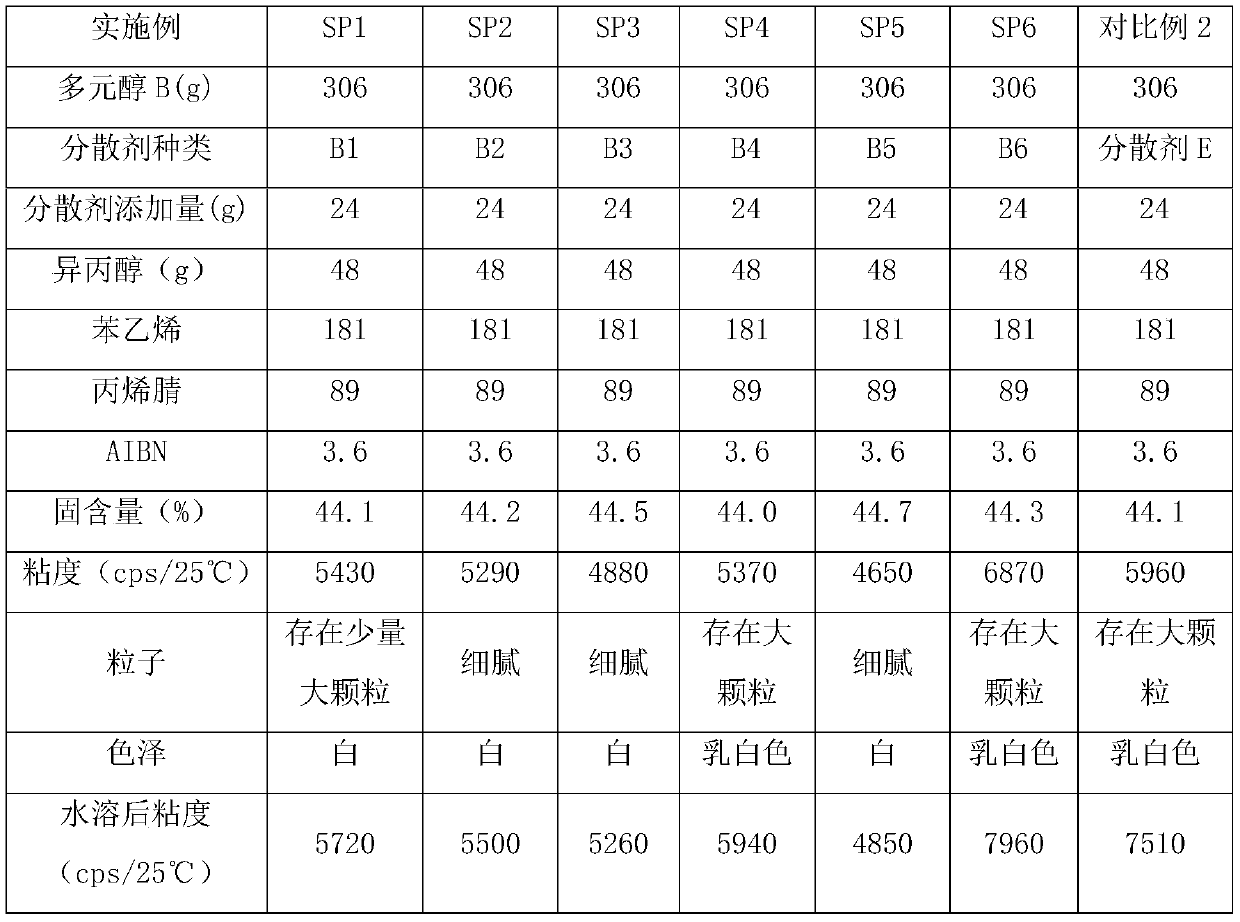

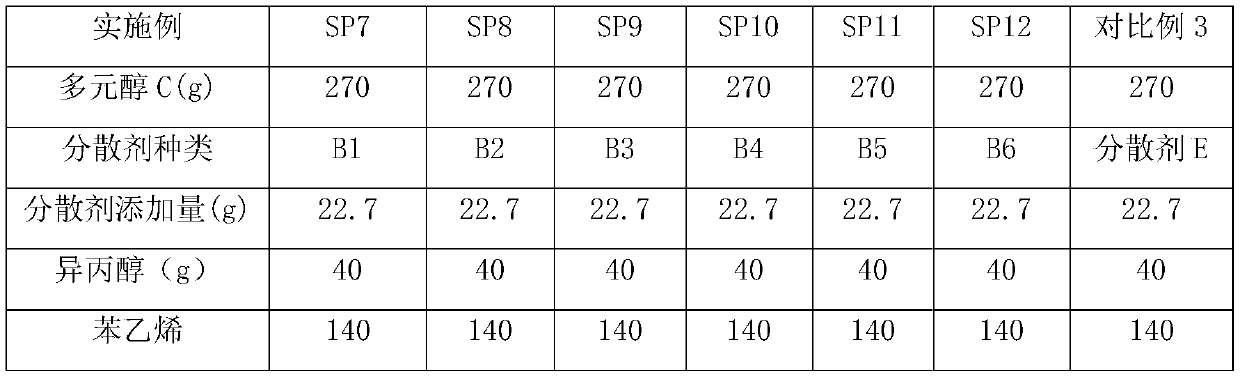

Dispersing agent for polymer polyol and preparation method of polymer polyol

InactiveCN110577636ALow viscosityFine particleTransportation and packagingMixingSolubilityPolymer science

The invention discloses a dispersing agent for polymer polyol and a preparation method of the polymer polyol. The dispersing agent is a copolymer macromolecule which is prepared from epoxypropane andethylene oxide and has an average molecular weight of 6000 to 20000, and each molecule of the dispersing agent at least contains a rigid benzene ring and a polymerizable carbon-carbon double-bond or triple-bond polymer. The preparation method of the dispersing agent comprises the following steps: synthesizing basic polyether polyol, introducing cyclic dicarboxylic acid anhydride into the polyetherpolyol, reacting the polyether polyol with an epoxy compound having polymerizable double bonds, and carrying out terminating with epoxide to obtain the dispersing agent. The polymer polyol is prepared from basic polyether polyol, unsaturated vinyl monomer styrene and acrylonitrile, a polymerization initiator, the dispersing agent and an optional chain transfer agent, wherein the basic polyether polyol is polyether polyol having a functionality of 3 to 8. The dispersing agent prepared in the invention is stable, colorless and transparent; and the polymer polyol prepared from the dispersing agent has relatively low viscosity, fine particles, high whiteness and good water solubility.

Owner:HUAIAN BUD POLYURETHANE SCI & TECH CO LTD

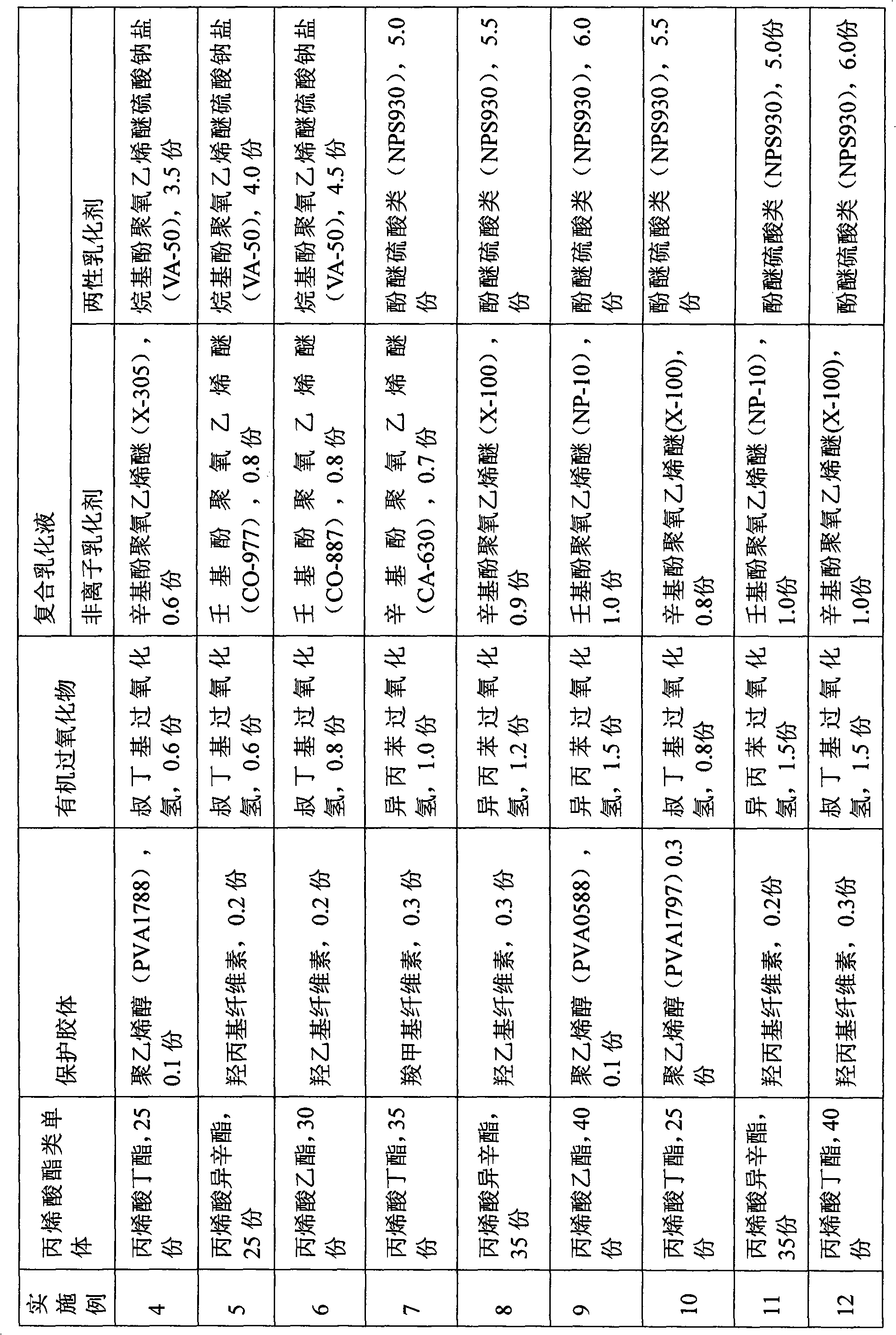

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood water resistanceStrong adhesionMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsSurface energyWaterproofing

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance and preparation method of adhesive film

ActiveCN107502232AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkMechanical property

The invention relates to a solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance. The solar cell encapsulating EVA adhesive film is characterized in that the thickness of the EVA adhesive film is 0.8 mm-1.1 mm, and the EVA adhesive film is prepared from raw materials in parts by weight as follows: 100 parts of EVA resin, 0.5-2.5 parts of a plasticizer, 0.1-0.3 parts of a photoelectric conversion rate enhancer, 1-4 parts of an anti-aging agent, 1.5-2.5 parts of a blocking agent, 1-2 parts of a dispersing agent, 1-3 parts of a coupling agent and 1-3 parts of a cross-linking agent. Firstly, the raw materials are added to a mixer proportionally and mixed into uniform components, the components are subjected to melt mixing by a banbury mixer and then subjected to extrusion and pelletizing, and the EVA adhesive film is obtained. According to the prepared EVA adhesive film, the light transmittance of the adhesive film is not influenced and the mechanical properties are greatly improved while properties and photoelectric conversion efficiency of the adhesive film are improved with addition of multiple additives.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

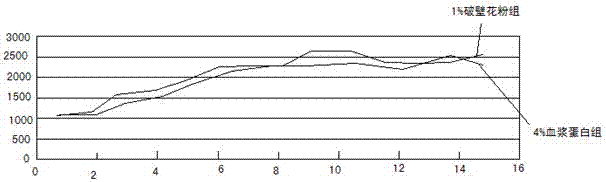

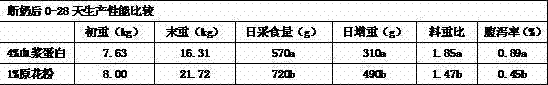

Preparation method of wall-breaking and enzymolysis bee pollen

InactiveCN103039709AFacilitated releasePromote precipitationAnimal feeding stuffAntigenHeat sensitive

The invention provides a preparation method of wall-breaking enzymolysis bee pollen. The preparation method is characterized by specifically comprising the following steps: 1) removing impurities; 2) sterilizing; 3) mechanically breaking the wall; and 4) carrying out biological enzymolysis. The preparation method of the wall-breaking enzymolysis bee pollen has the following advantages that (1) the wall-breaking effect is remarkable, and the benefits are provided for releasing and separating the nutritional components in the bee pollen such as the fatty acid, flavonoid and polysaccharide; (2) the sensitization of antigen protein is removed, the enzymolysis is carried out on alkaline glutelin, and the bioavailability is improved; (3) the dietary fibers such as lignin are obviously reduced, the absorption performance of animals to liposoluble substances is improved, the energy utilization rate is raised, and the animal production achievement is improved; (4) the particles are fine, good in flavor and comfortable in taste, and the animal ingestion and favorite are obviously improved; and (5) the action condition is mild, and little damage is brought to the heat sensitive nutritional substances.

Owner:江西旺大动物科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com