Layered perovskite structural ceramic and preparation method thereof

A perovskite structure and layered technology, applied in the field of ceramic materials, can solve the problems of high sintering temperature, unimproved ferroelectric properties, and difficulty in obtaining a single-phase layered perovskite structure, achieving high reactivity and composition The effect of uniformity, high density and orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

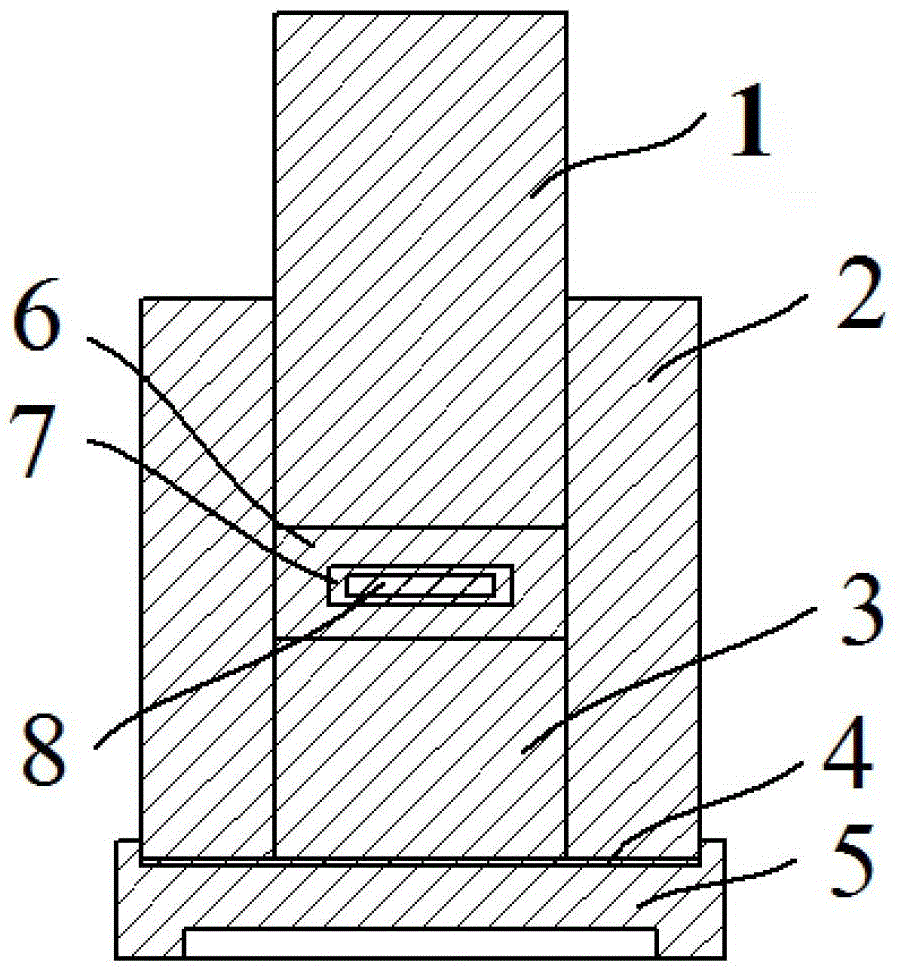

[0034] The present invention also provides a corresponding preparation method for the layered perovskite structure ceramics, including the following steps: A) dissolving titanate compounds, bismuth source compounds, strontium source compounds, iron source compounds and cobalt source compounds in proportion Solvent, add complexing agent and mix and stir, adjust the pH value to 4~7, heat, evaporate to dryness and burn into powder, and pre-calcine to obtain powder; B) Press the powder into tablets, perform hot pressing and sintering to obtain layer perovskite-structured ceramics.

[0035] In order to clearly illustrate the present invention, the experimental processes of step A and step B are described in detail below respectively.

[0036] The step A is specifically: dissolving the bismuth source compound, strontium source compound, iron source compound, cobalt source compound and titanate compound in the solvent according to the ratio of the amount of substances, adding a compl...

Embodiment 1

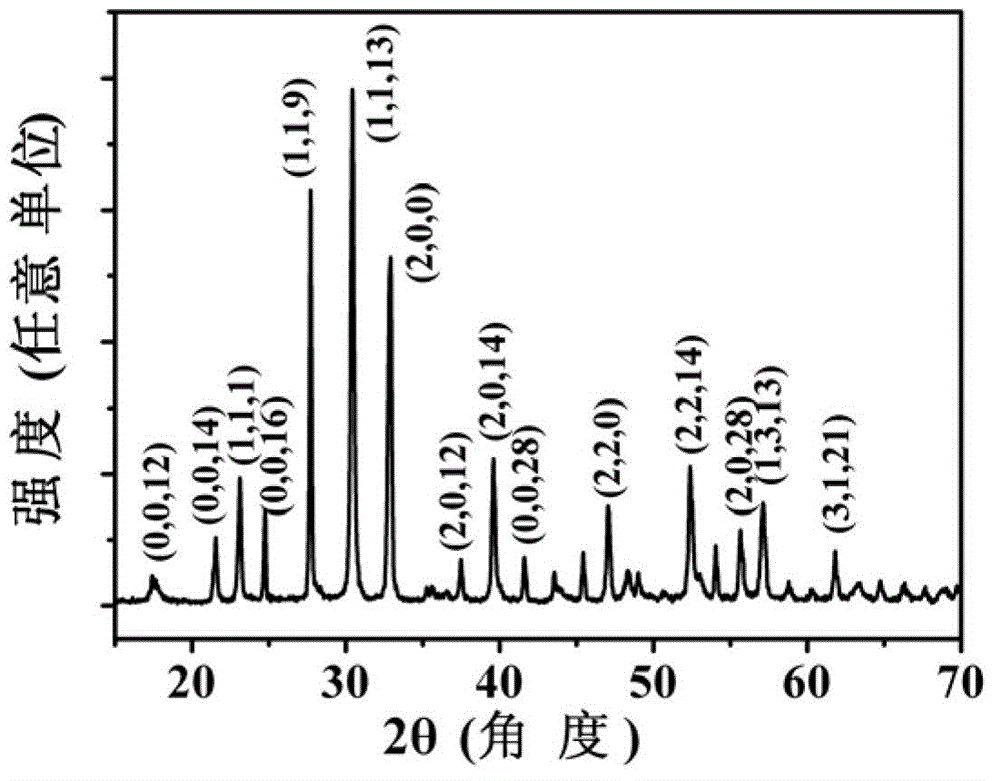

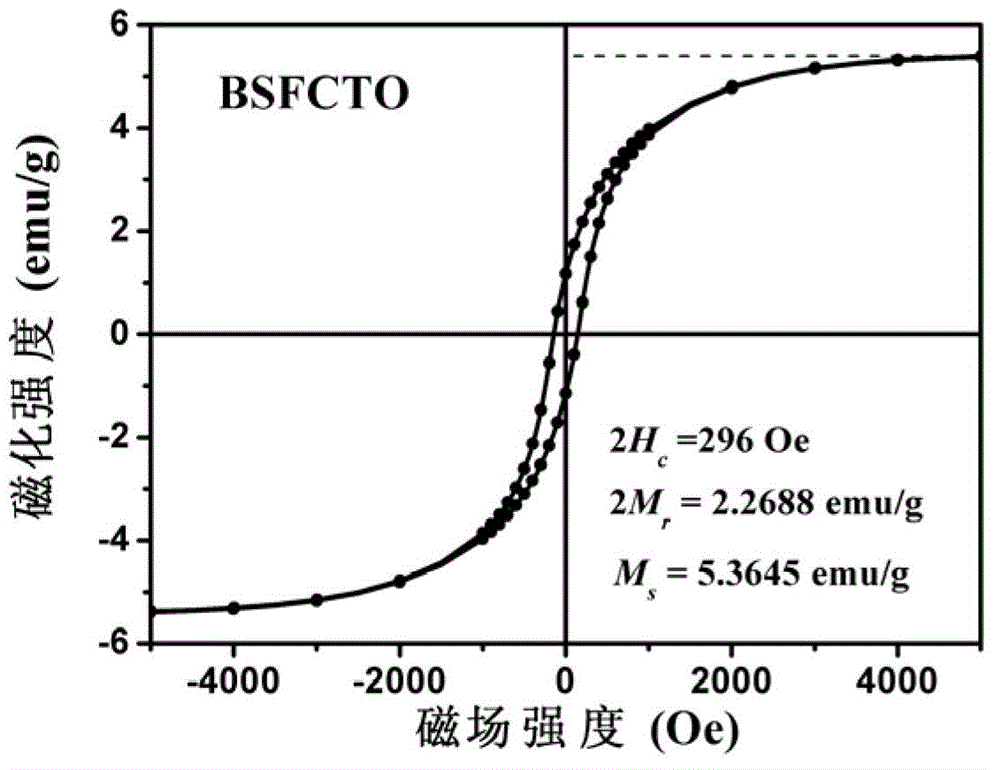

[0052] 1.1 Mix bismuth nitrate pentahydrate, strontium nitrate, iron nitrate nonahydrate, cobalt nitrate hexahydrate and n-butyl titanate according to the molar ratio Bi:Sr:Fe:Co:Ti=6.75 (1+0.05):0.25:1.5:1.5 Dissolve in nitric acid at a ratio of :3, add complexing agents ethylenediaminetetraacetic acid (EDTA) and citric acid, the molar ratio of EDTA, citric acid and metal ions is 0.7:1:1, mix and stir, add ammonia water dropwise to adjust the solution The pH value was 7, and a clear solution was obtained, which was heated and concentrated in a ceramic evaporating dish until the solution was evaporated to dryness, then burned into powder, and pre-fired in a muffle furnace at 750°C for 3 hours to obtain a powder.

[0053] 1.2 Grind the powder obtained in 1.1 for 30 minutes, and shape it into a disc with a diameter of 25 mm and a thickness of 4 mm with a manual dry press (Tianjin Keqi Company Model 40C) under a pressure of 120 MPa. The outer layer of the disc is 15% bismuth eleme...

Embodiment 2

[0058] 2.1 Mix bismuth nitrate pentahydrate, strontium nitrate, iron nitrate nonahydrate, cobalt nitrate hexahydrate and n-butyl titanate according to the molar ratio Bi:Sr:Fe:Co:Ti=6.5 (1+0.05):0.5:1.5:1.5 Dissolve in nitric acid at a ratio of :3, add complexing agents ethylenediaminetetraacetic acid (EDTA) and citric acid, the molar ratio of EDTA, citric acid and metal ions is 0.7:1:1, mix and stir, add ammonia water dropwise to adjust the solution The pH value was 7, and a clear solution was obtained, which was heated and concentrated in a ceramic evaporating dish until the solution was evaporated to dryness, then burned into powder, and pre-fired in a muffle furnace at 750°C for 3 hours to obtain a powder.

[0059] 2.2 Grind the powder obtained in 2.1 for 30 minutes, and form it into a disc with a diameter of 25 mm and a thickness of 4 mm with a manual dry press (Tianjin Keqi Company Type 40C) under a pressure of 120 MPa. The outer layer of the disc is 15% bismuth in excess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com