Dispersing agent for polymer polyol and preparation method of polymer polyol

A polyether polyol, polyol technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc. Fineness, good water solubility and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

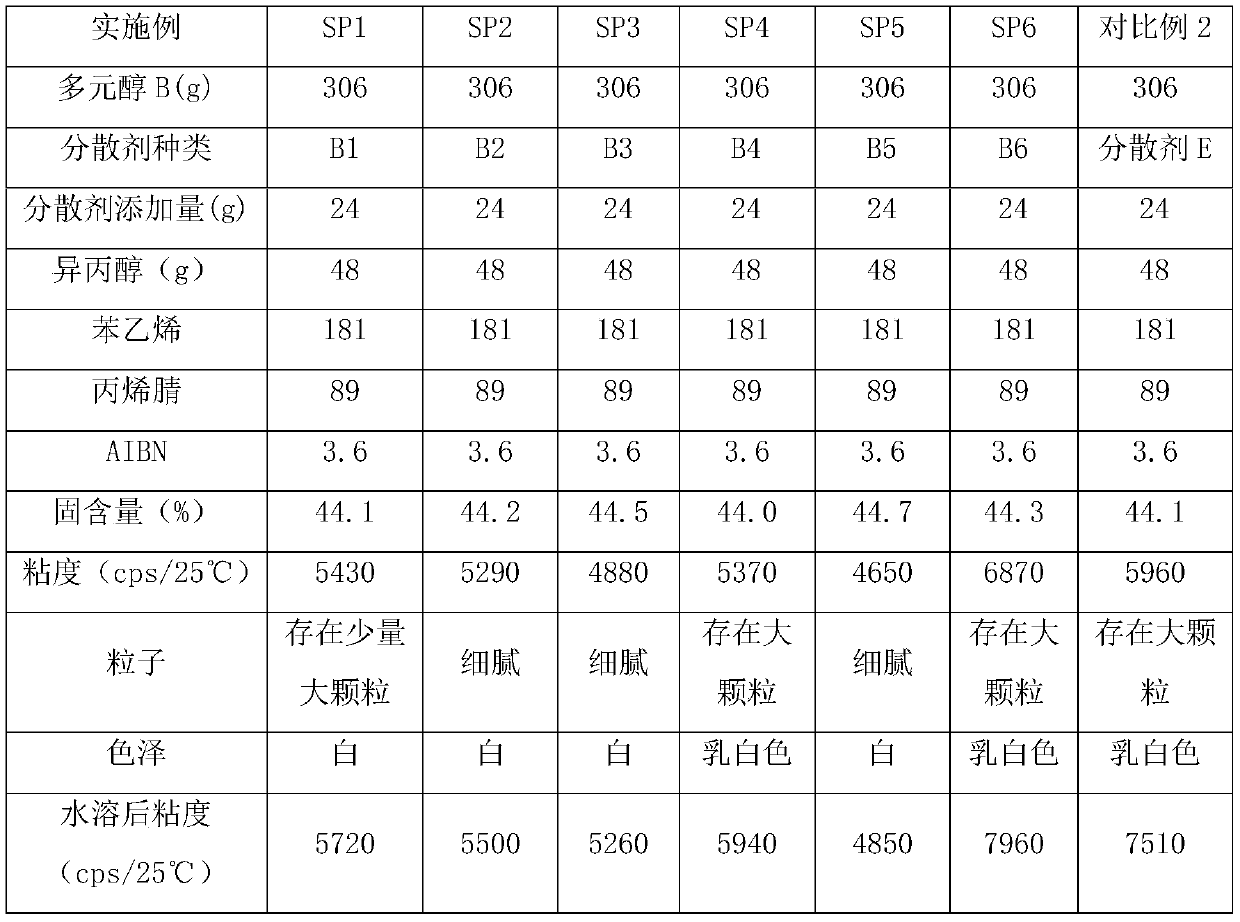

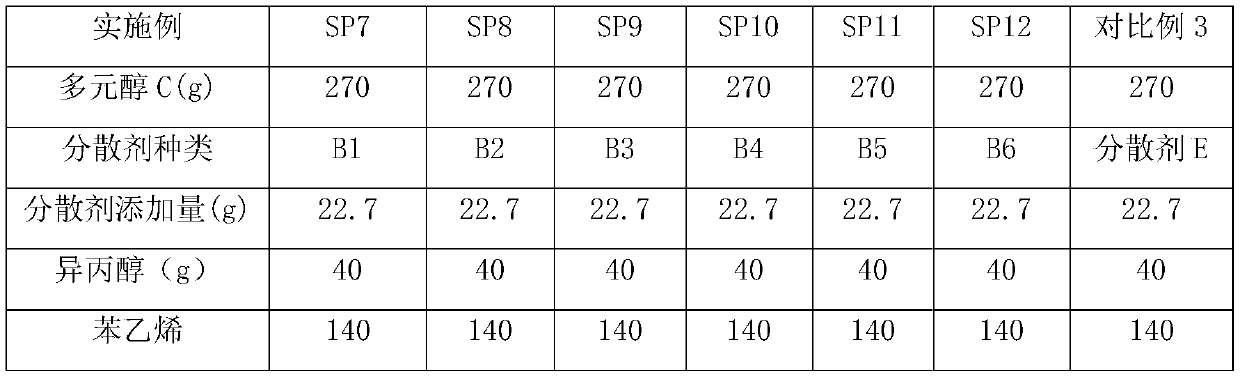

Examples

Embodiment 1

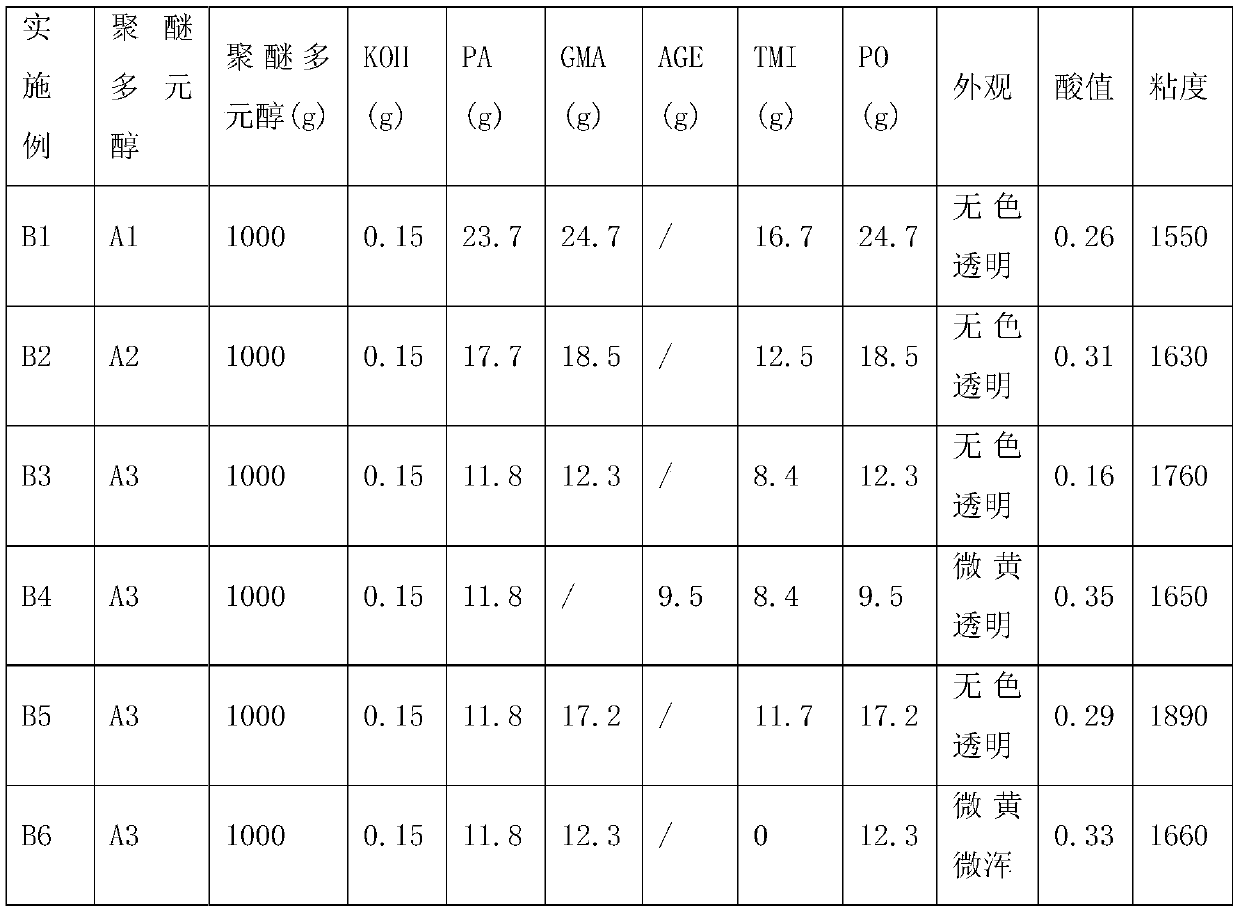

[0019] Embodiment 1: the synthesis of polymer polyol dispersant

[0020] Production of A1 polyether polyol

[0021] Potassium hydroxide was added to glycerol with a molecular weight of 92, propylene oxide was added to polymerize at a temperature of 115°C, and then capped with 15 wt% ethylene oxide to produce a trifunctional polyether polyol with a molecular weight of 6000. The product was treated with water, neutralized with phosphoric acid, and the refined preparation was adsorbed with clay, and filtered to obtain the final product A1 with a hydroxyl value of 28 mgKOH / g.

[0022] Production of A2 polyether polyol

[0023] Add potassium hydroxide to pentaerythritol with a molecular weight of 136, add a 85 / 15 mixture of propylene oxide and ethylene oxide to polymerize at a temperature of 115°C to produce a tetrafunctional polyether polyol with a molecular weight of 8000, and add water to the product Treatment, neutralization with phosphoric acid, adsorption of the refined pre...

Embodiment B2-B3

[0029] The polymer polyol dispersant was prepared in the same manner as in Example B1, except that the polyether polyol A1 was replaced with A2 and A3, as shown in Table 1.

Embodiment B4

[0031] The polymer polyol dispersant was prepared in the same manner as in Example B3, except that glycidyl methacrylate (GMA) was replaced by allyl glycidyl ether (AGE), as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com