Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

798 results about "Foam glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

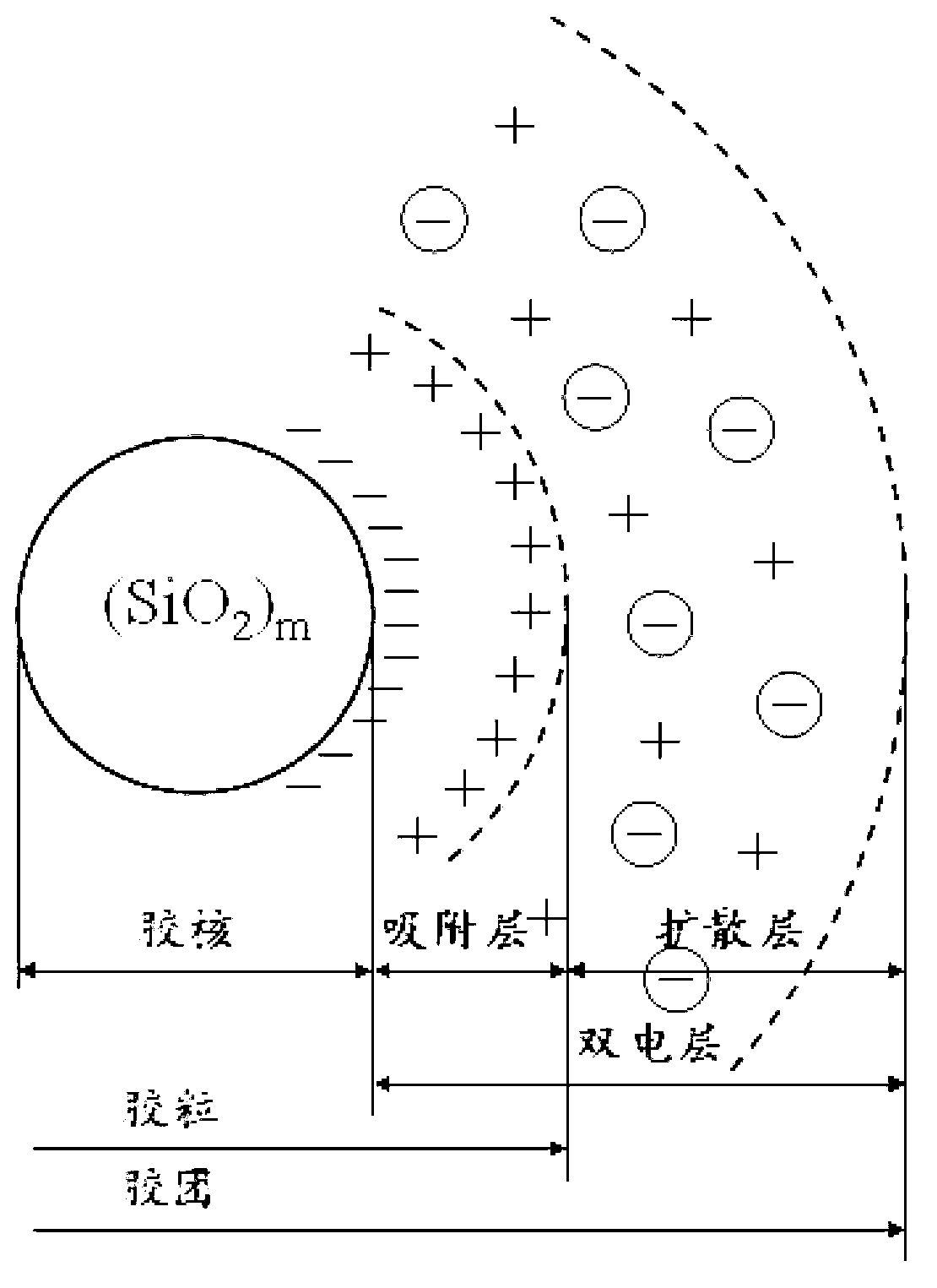

Foam glass is a porous glass foam material. Its advantages as a building material include its light weight, high strength, and thermal and acoustic insulating properties. It is made by heating a mixture of crushed or granulated glass and a blowing agent (chemical foaming agent) such as carbon or limestone. Near the melting point of the glass, the blowing agent releases a gas, producing a foaming effect in the glass. After cooling the mixture hardens into a rigid material with gas-filled closed-cell pores comprising a large portion of its volume.

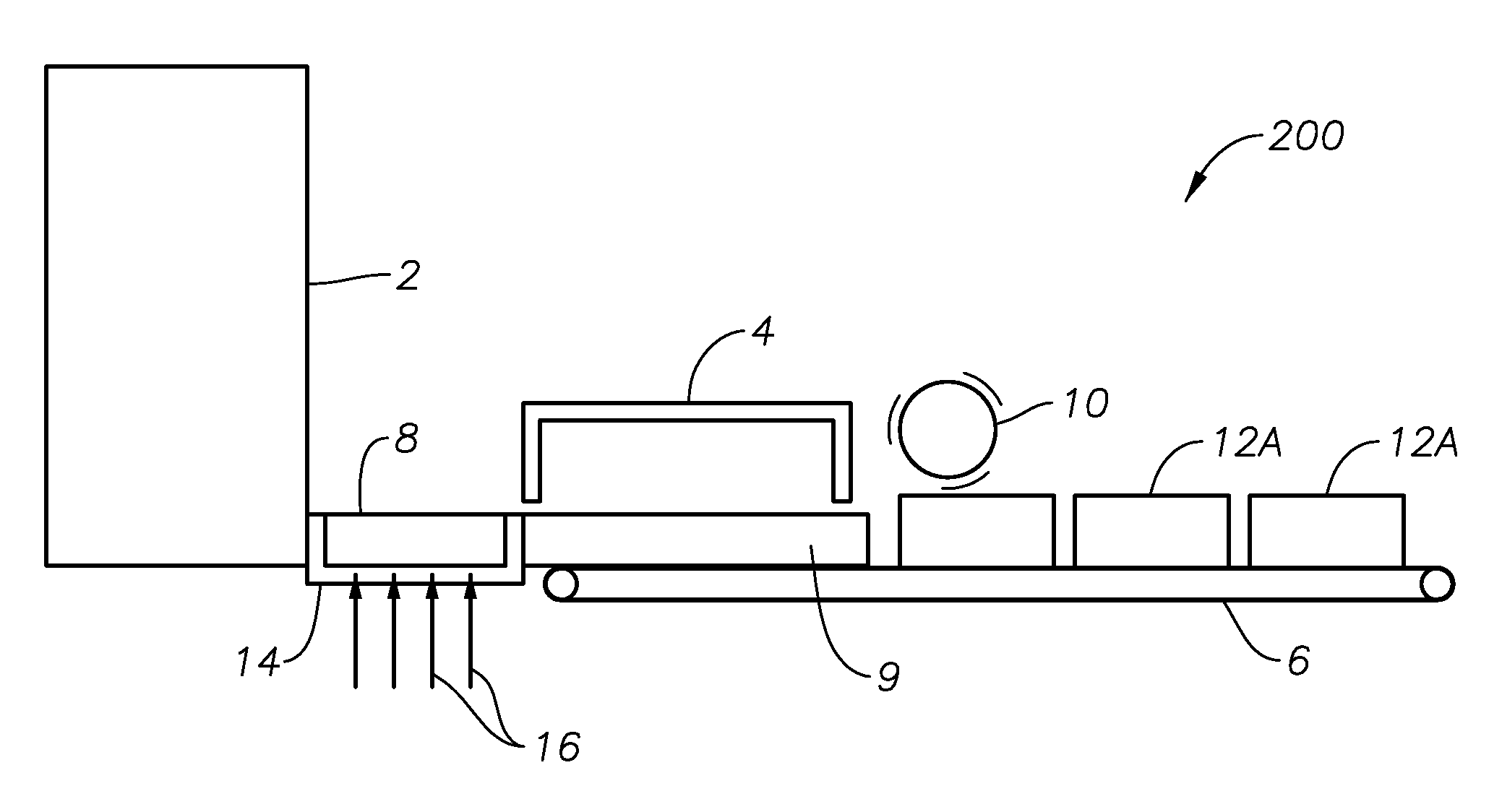

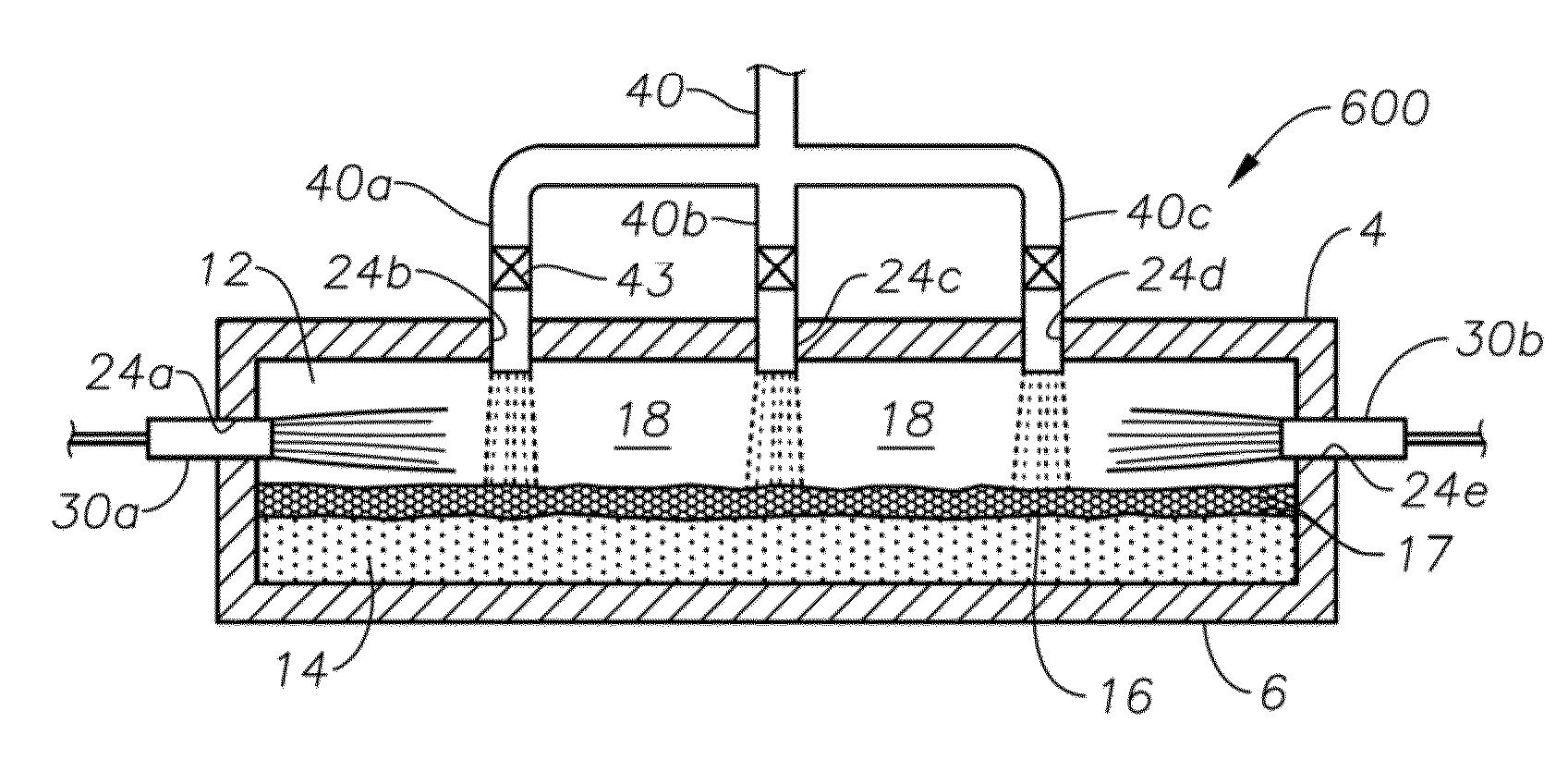

Systems and methods for making foamed glass using submerged combustion

ActiveUS20130086944A1High densityLow densityRibbon machinesGlass furnace apparatusCombustion systemDownstream processing

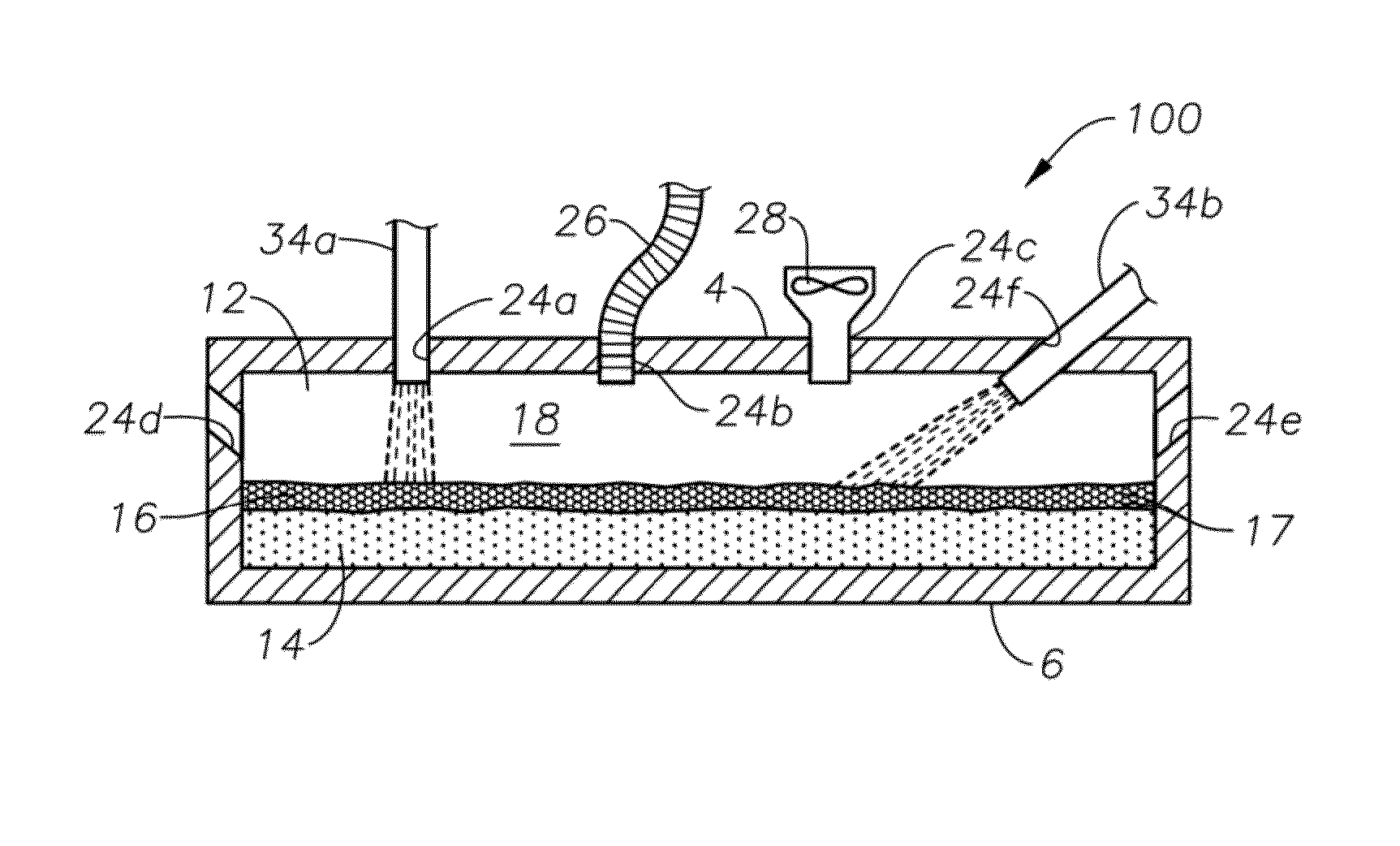

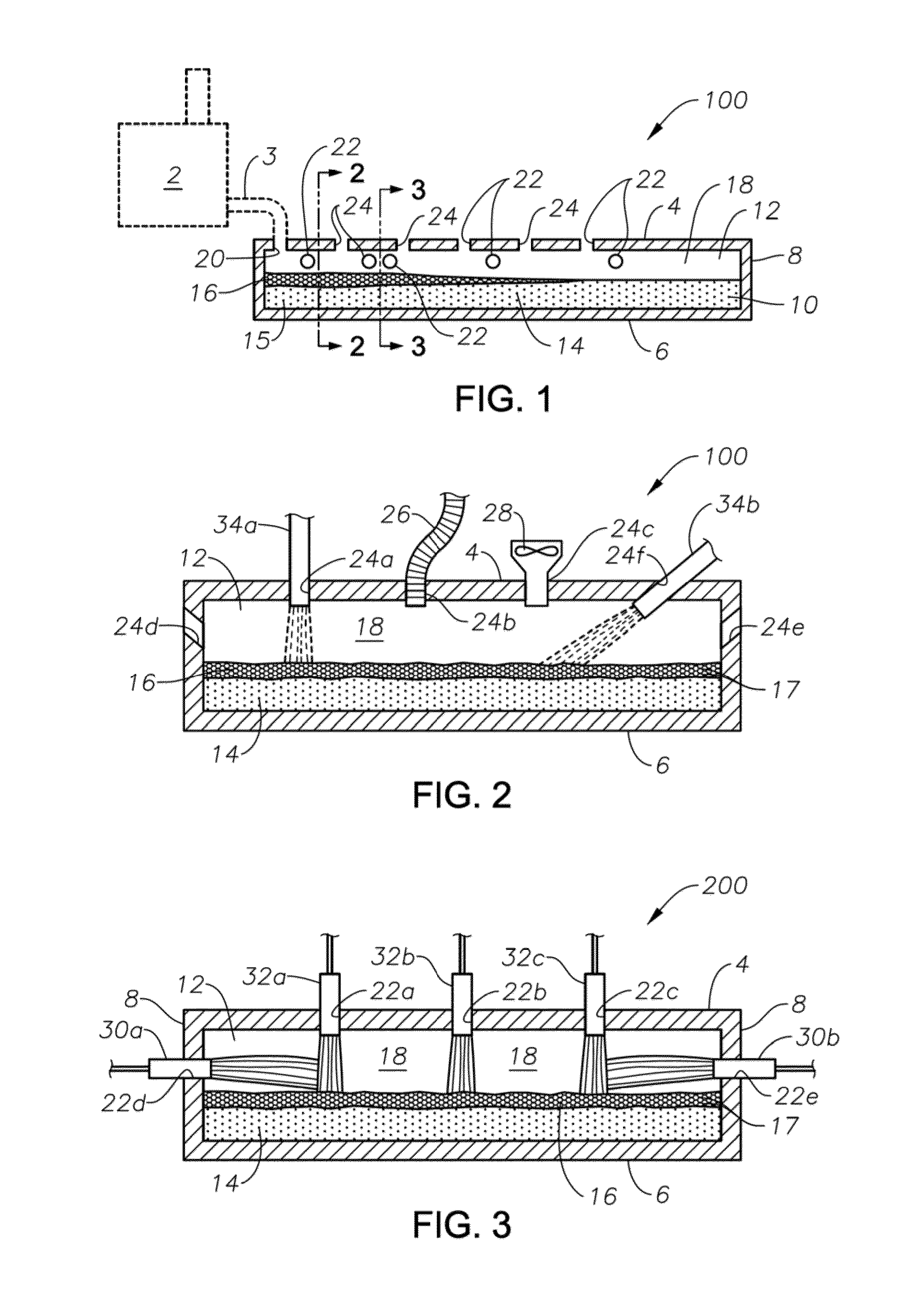

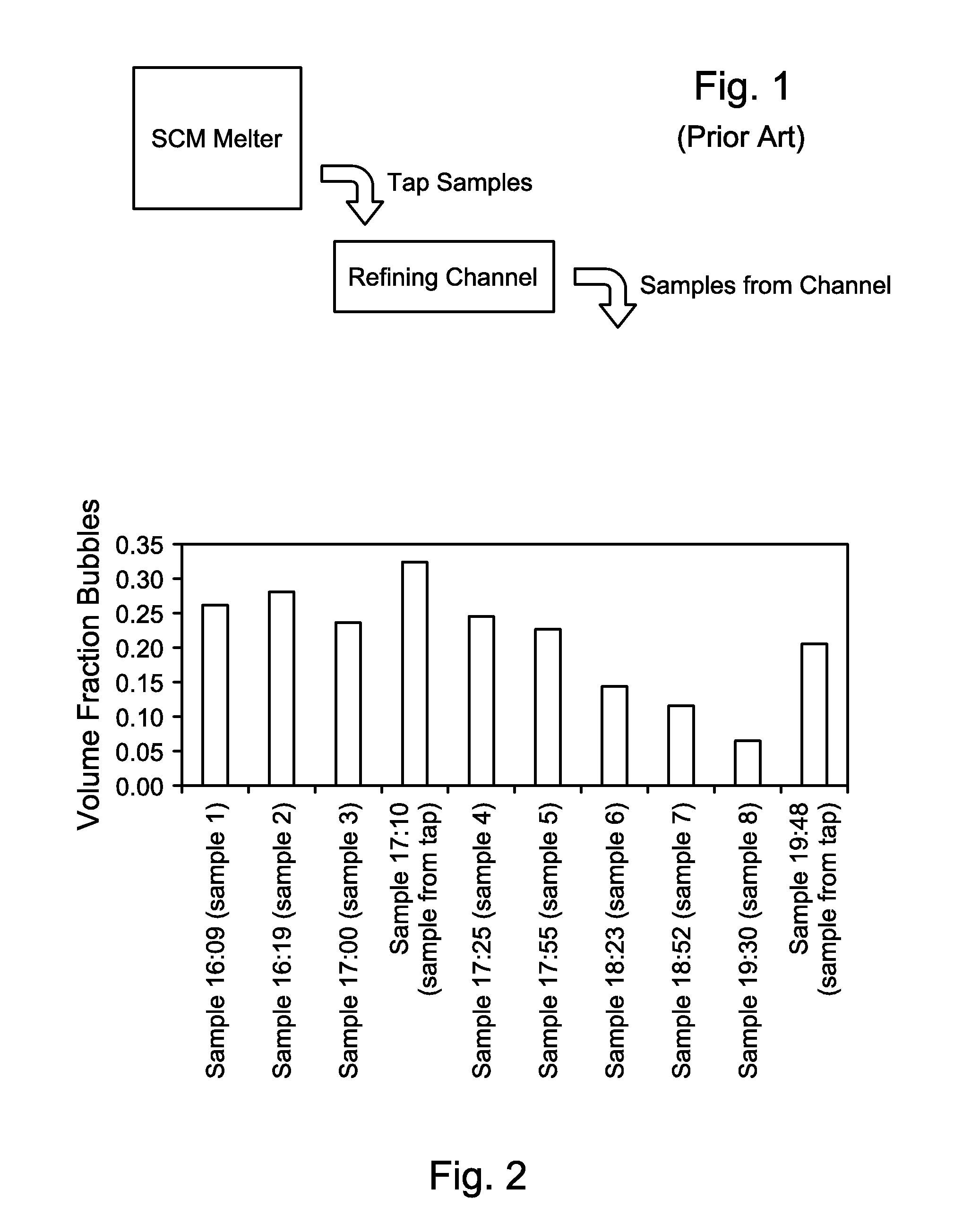

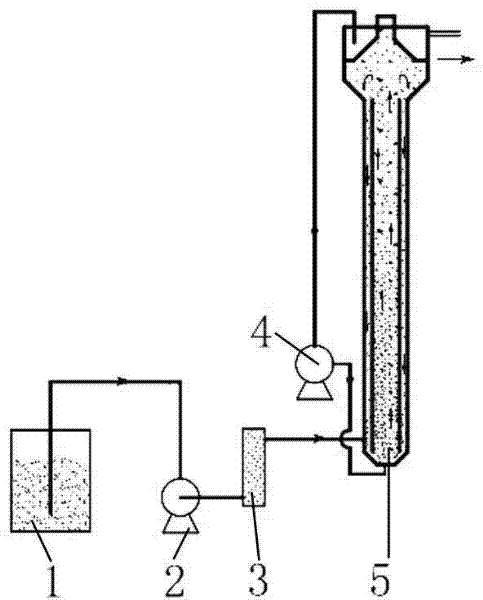

Submerged combustion systems and methods of use to produce foamed glass. One system includes a submerged combustion melter having an outlet, the melter configured to produce an initial foamy molten glass having a density and comprising bubbles filled primarily with combustion product gases. The initial foamy molten glass is deposited directly onto or into a transport apparatus that transports the initial foamy molten glass to a downstream processing apparatus. An intermediate stage may be included between the melter and the transport apparatus. One intermediate stage is a channel that includes gas injectors. Another intermediate stage is a channel that produces an upper flow of a less dense glass and a relatively more dense glass lower flow. The upper flow may be processed into foamed glass products, while the more dense flow may be processed into dense glass products.

Owner:JOHNS MANVILLE CORP

Method for stably incorporating substances within dry, foamed glass matrices

Owner:QUADRANT DRUG DELIVERY

Method for preparing borosilicate foam glass

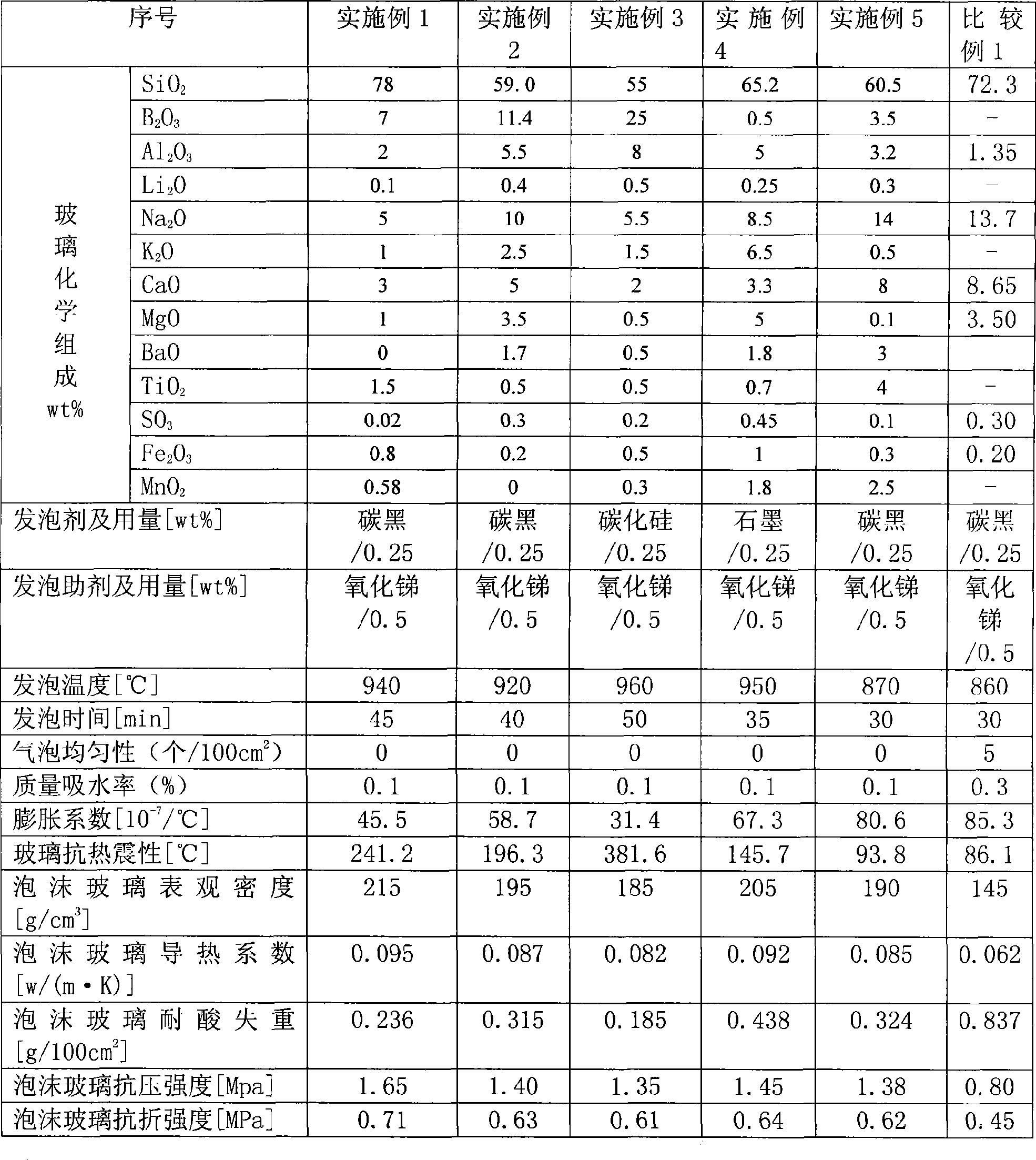

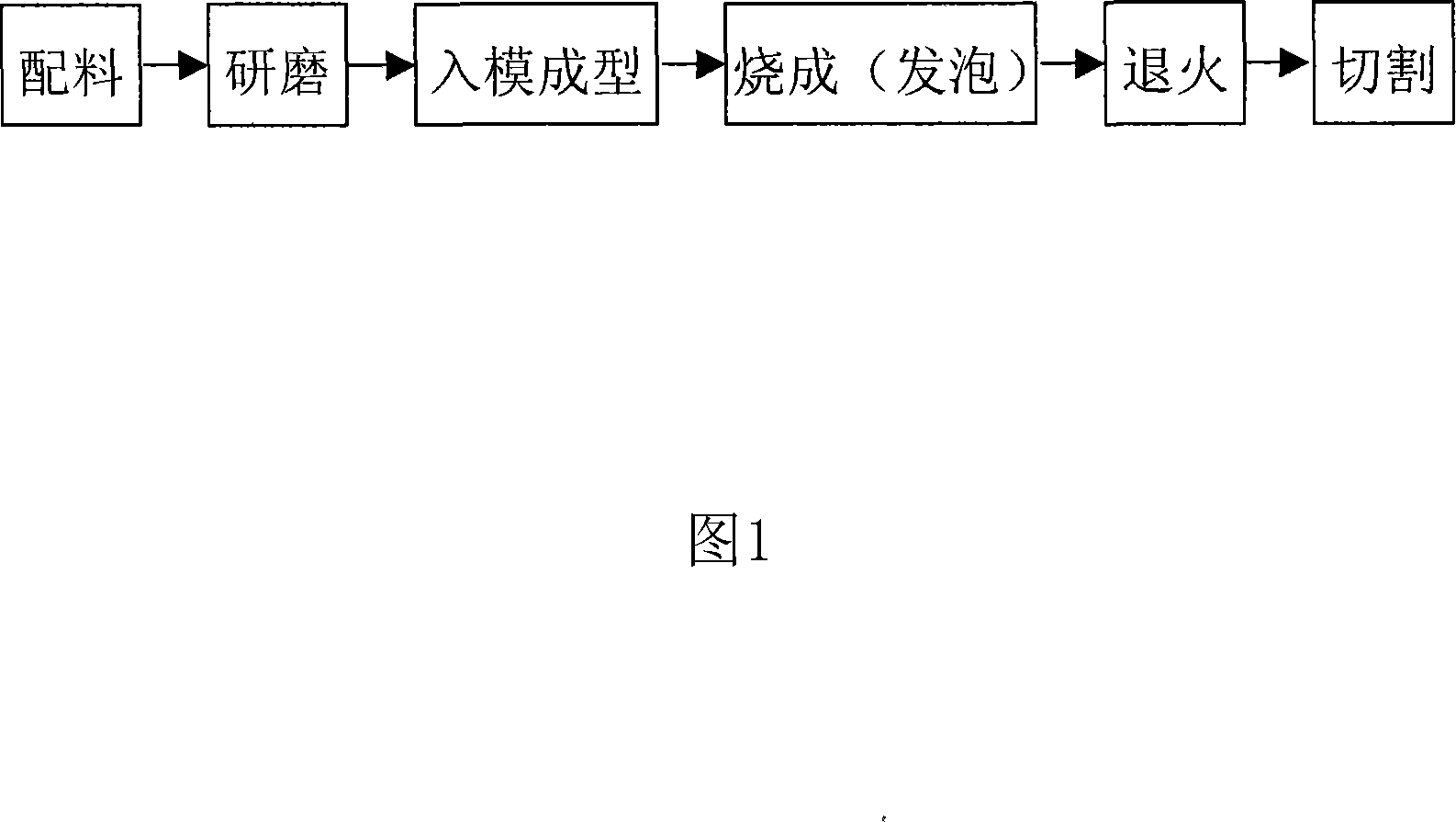

The invention relates to a method for preparing borosilicate foam glass, comprising the following steps: glass raw materials, foaming agent and blowing promoter are finely ground and evenly mixed to form batch mixture; the batch mixture is placed in a heat resistant mould; the batch mixture is prepared into multiaperture glass materials after the processes of preheating, sintering, frothing, annealing and the like; the method is characterized in that the chemical composition(wt%) of the glass materials is: SiO2: 55-78, B2O3: 0.5-25, Al2O3: 2-8, Li2O: 0.1-0.5, Na2O: 5-14, K2O: 0.5-6.5, MgO: 1-5, CaO: 3-8, BaO: 0-3, TiO2: 0.5-4, SO3: 0.02-0.45, Fe2O3: 0.2-1.0, MnO2: 0-2.5. the glass material belongs to the system of borosilicate glass and can be prepared into foam glass product featuring good acid fastness, good thermal shock stability, high mechanical strength, good scour resistance, low heat conducting coefficient and even aerated structure by adopting carbon blowing agents(carbon black, graphite, carborundum) and blowing promoter material.

Owner:BEIJING UNIV OF TECH

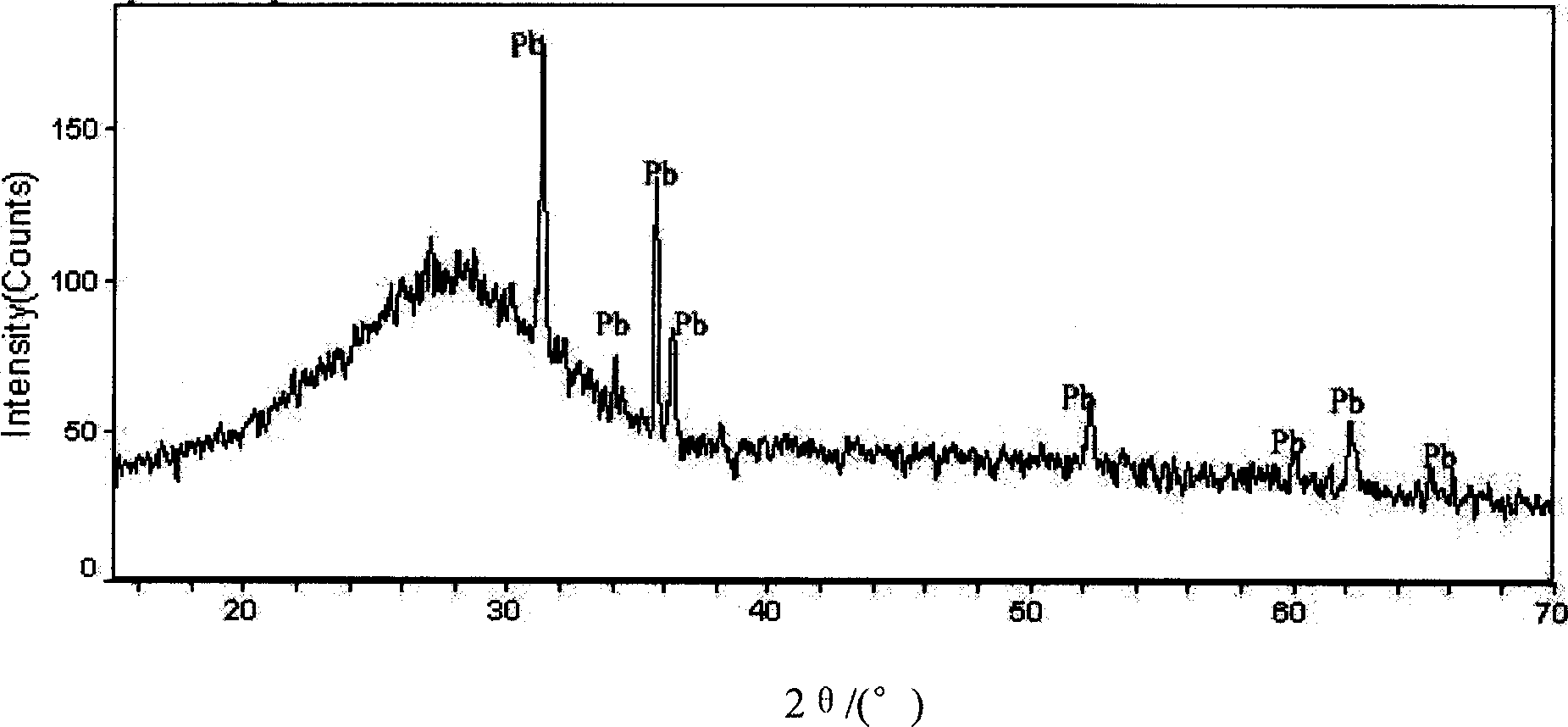

Method for preparing microcrystalline foamed glass by titanium-containing blast furnace slag

ActiveCN101323503ASolve the problem of difficult utilization of titanium-containing blast furnace slagReduce manufacturing costSlagFoam glass

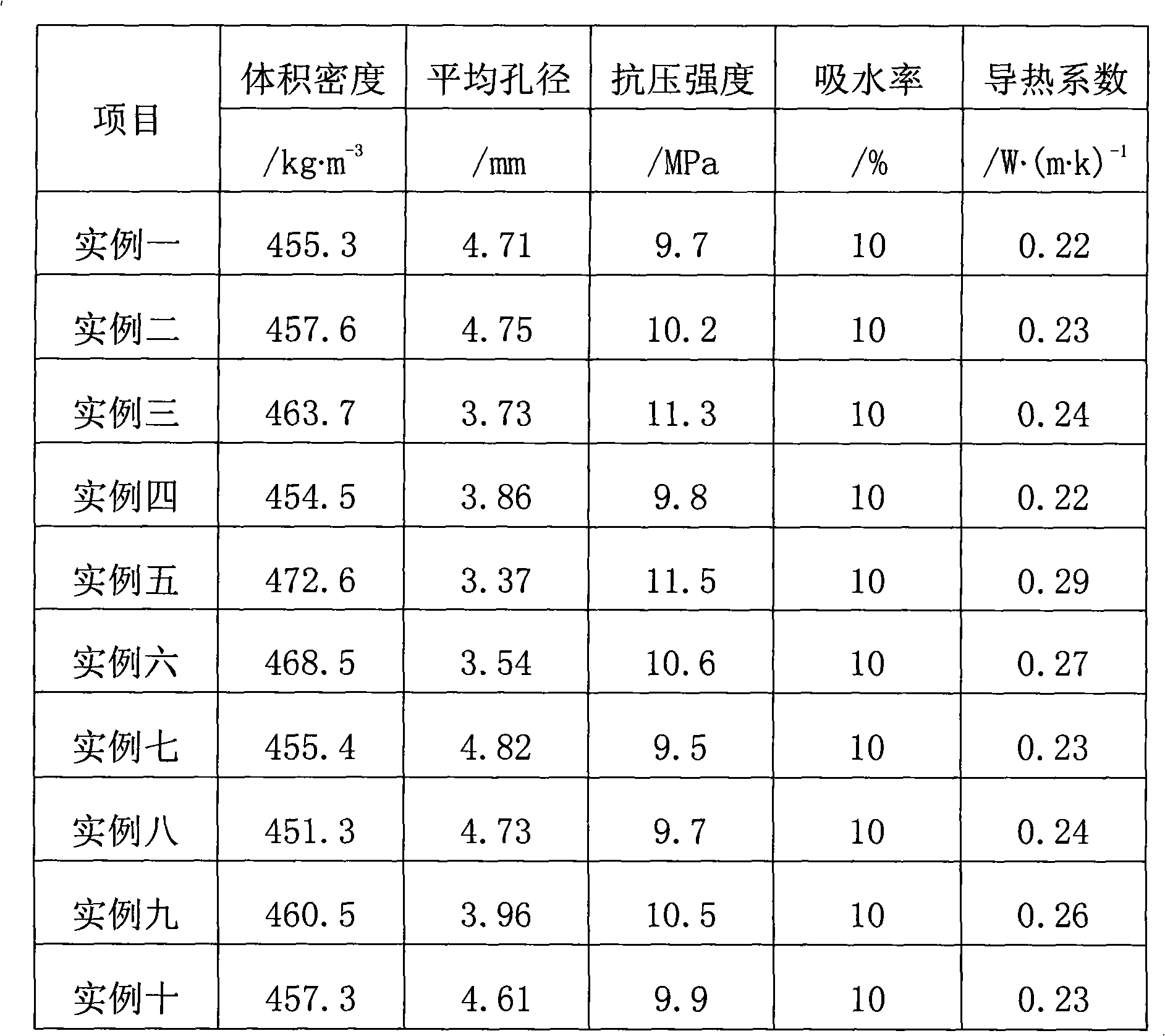

The invention provides a method adopting the blast-furnace slag containing titanium to prepare foam glass, belonging to the metallurgy source comprehensive utilization and material preparation filed. The invention mainly adopts the blast-furnace slag containing 14 to 29 percent of TiO2 as the basic material, and properly adopts silicon materials to generate glass substances, and then adds foaming agent, foam stabilizer and fusing assistant to prepare foam glass-ceramic according to a special heat disposal system. The invention has the advantages that the manufacturing cost is low; the product quality is better; the manufacturing operation is simple; the second-time contamination can be avoided and the product volume density is low, etc.

Owner:NORTHEASTERN UNIV

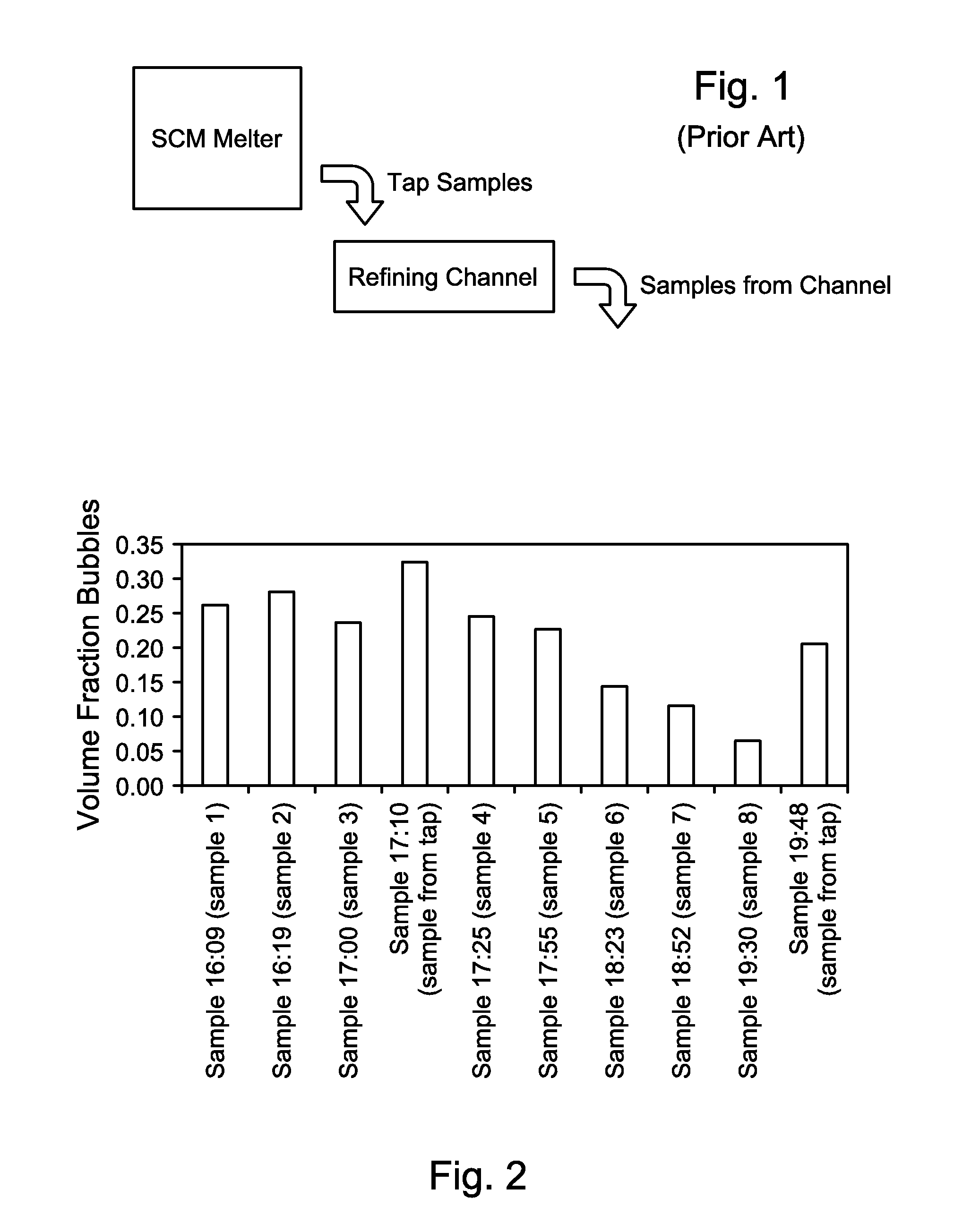

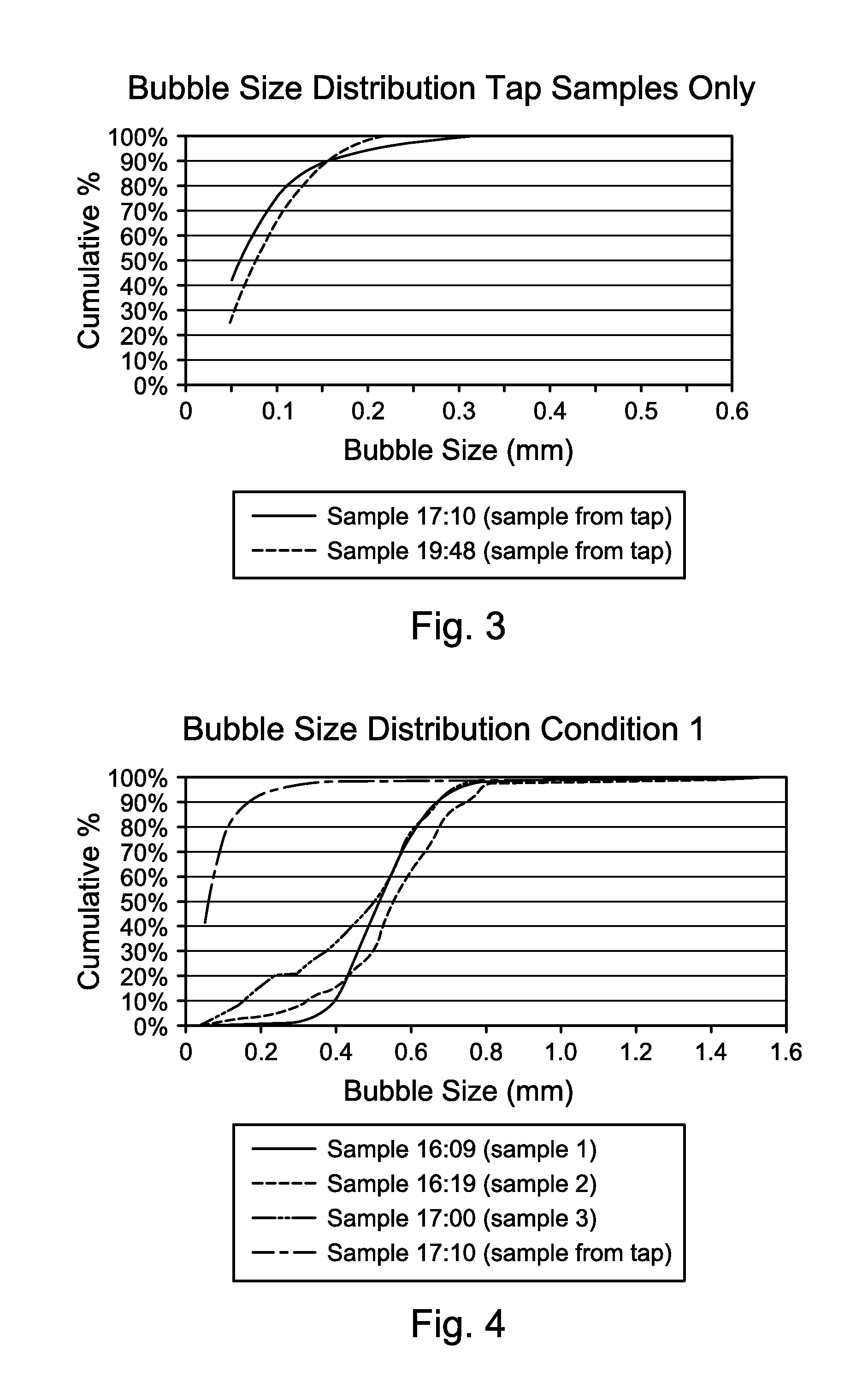

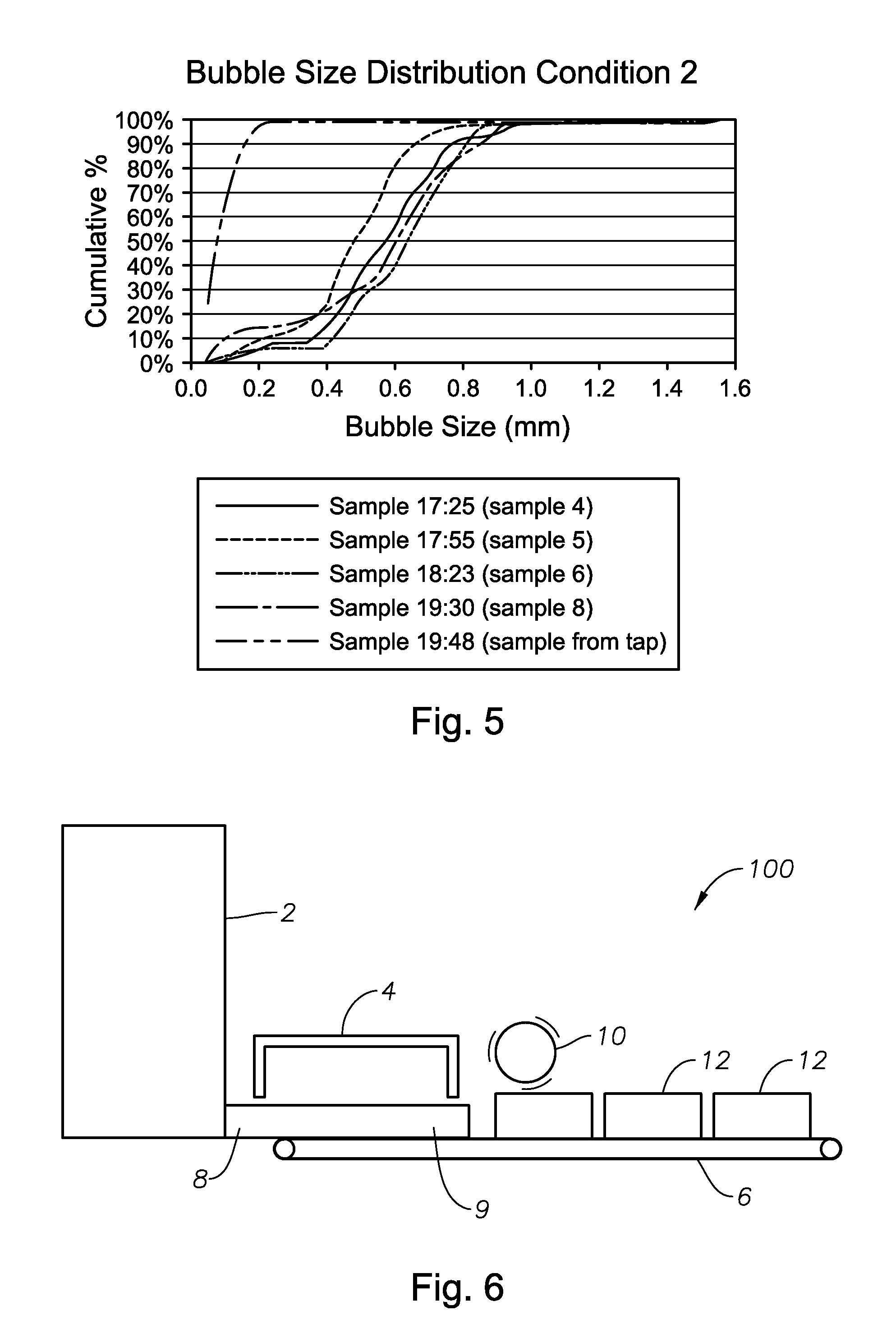

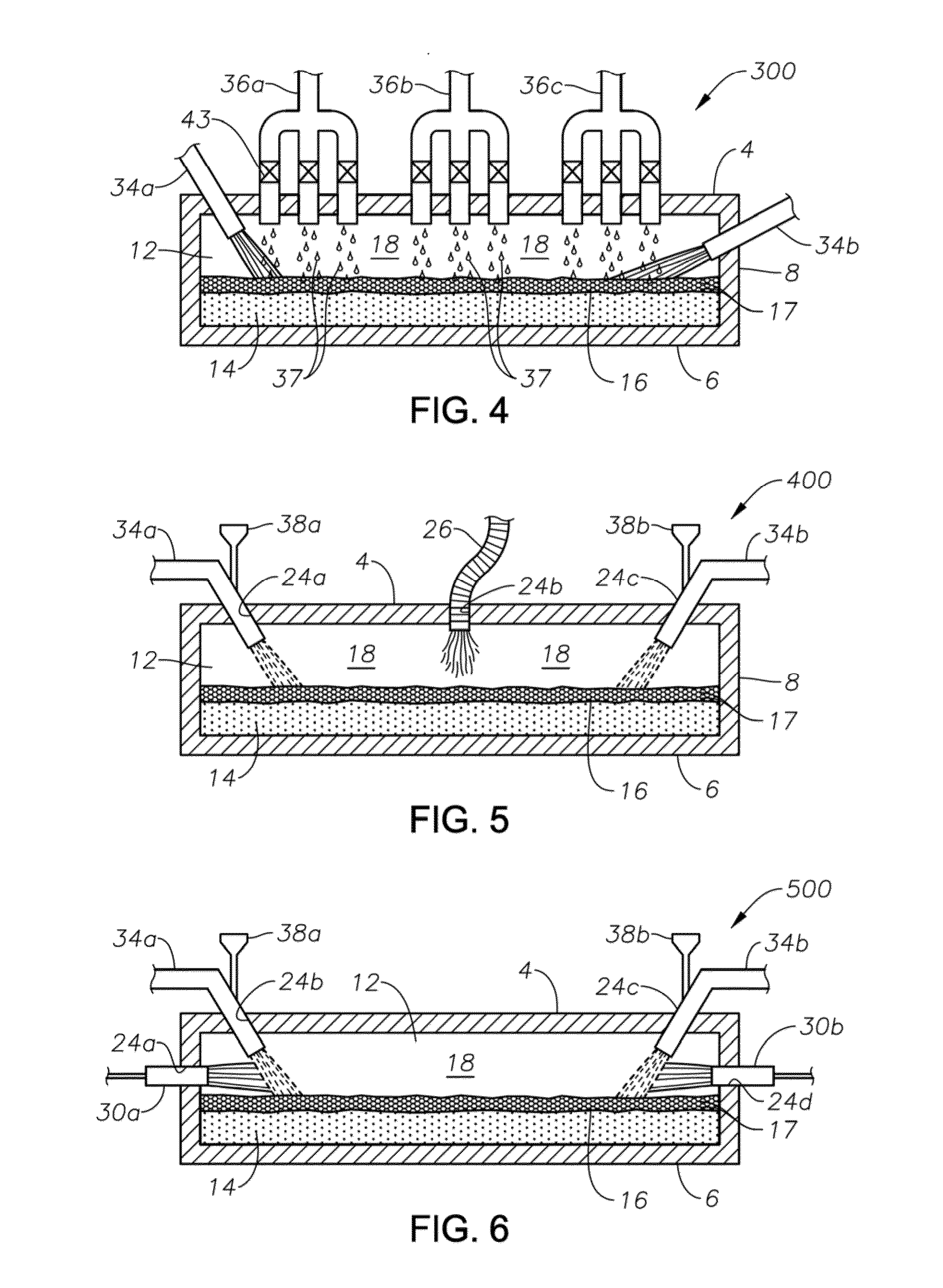

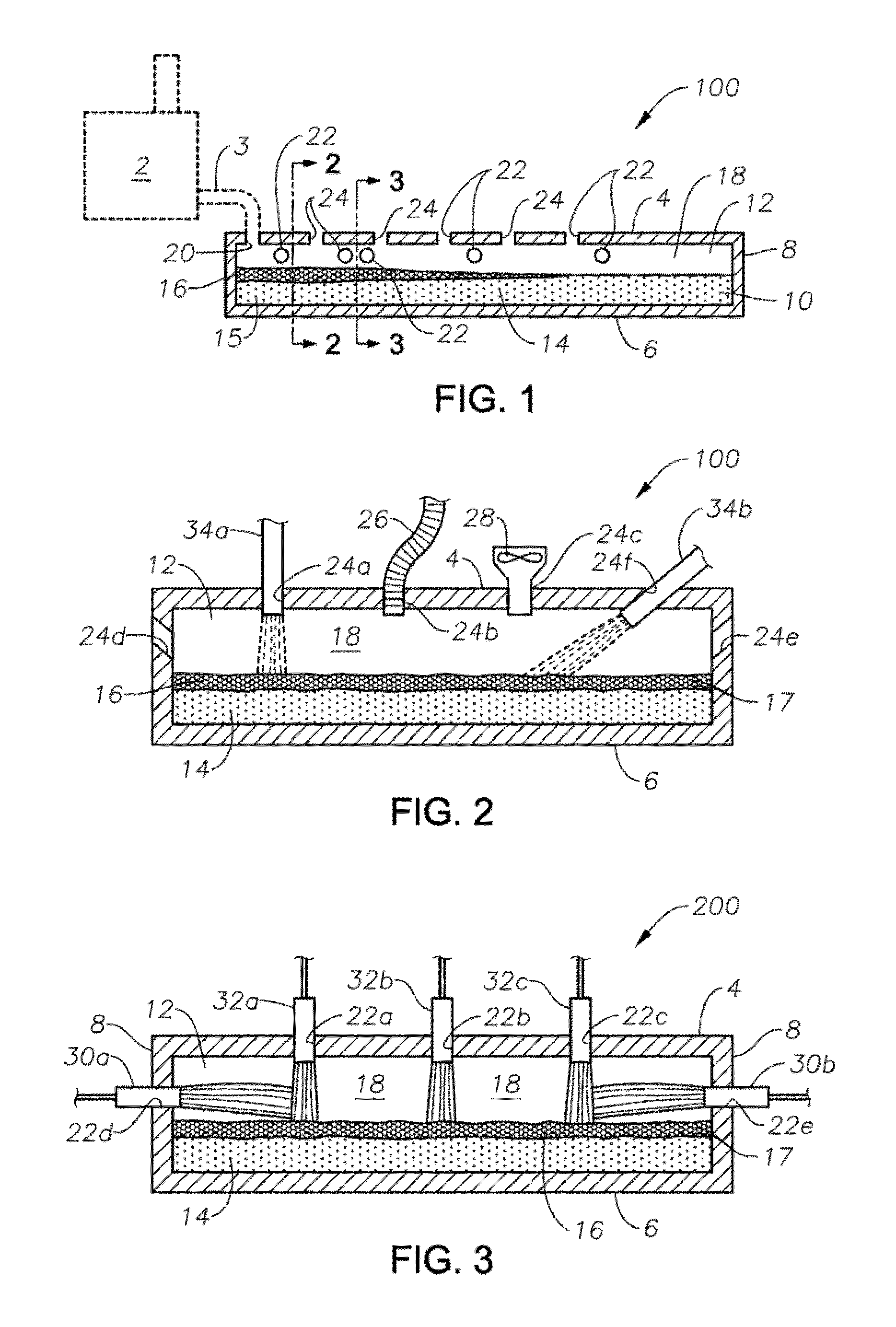

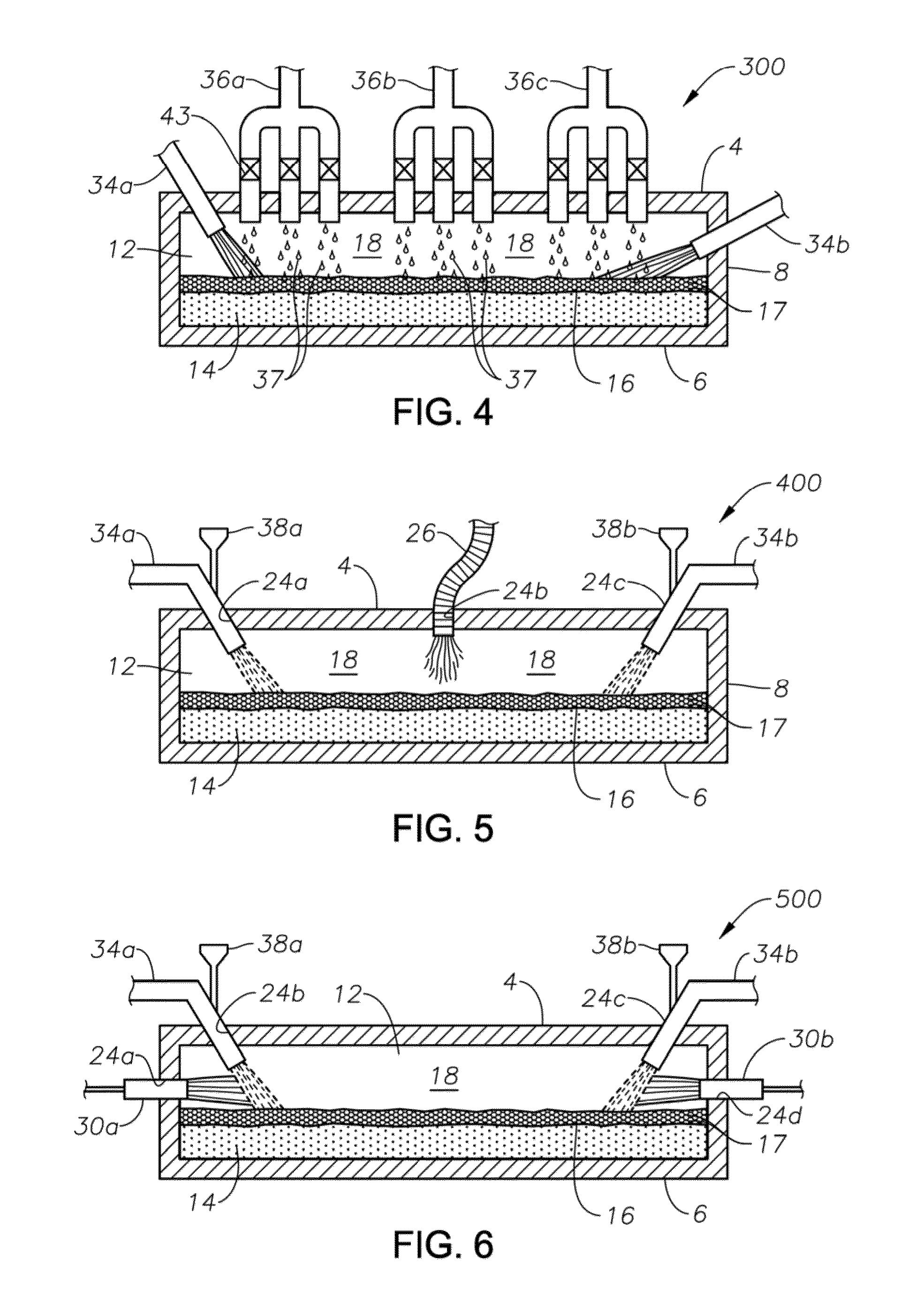

Methods and systems for controlling bubble size and bubble decay rate in foamed glass produced by a submerged combustion melter

ActiveUS20140090421A1Increase reduction rateGlass furnace apparatusGlass melting apparatusCombustionGaseous atmosphere

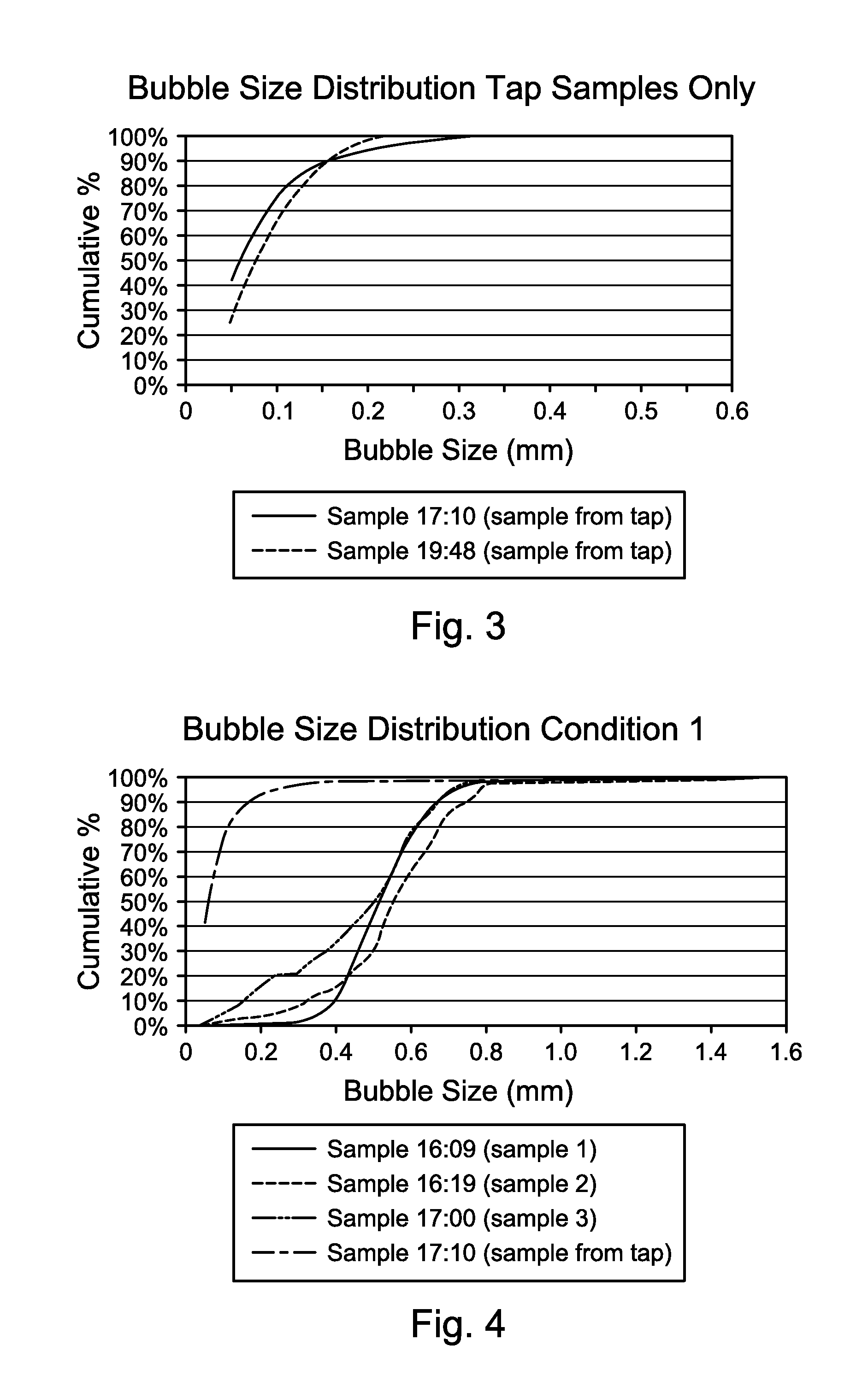

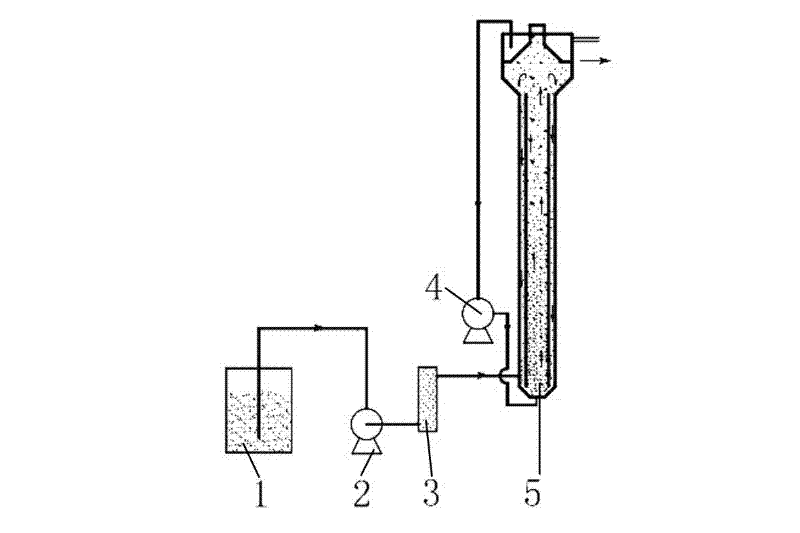

Methods and systems for controlling bubble size and bubble decay rate of glass foams formed during submerged combustion melting. Flowing a molten mass of foamed glass comprising molten glass and bubbles entrained therein into an apparatus downstream of a submerged combustion melter. The downstream apparatus has a floor, a roof, and a sidewall structure connecting the floor and roof. The foamed glass has glass foam of glass foam bubbles on its top surface, and the downstream apparatus defines a space for a gaseous atmosphere above and in contact with the glass foam. The downstream apparatus includes heating components to heat or maintain temperature of the foamed glass. Adjusting composition of the atmosphere above the glass foam, and / or contacting the foam with a liquid or solid composition controls bubble size of the glass foam bubbles, and / or foam decay rate.

Owner:JOHNS MANVILLE CORP

Preparation method of foam glass

The invention discloses a foam glass and a preparation method thereof. The main technique steps are that fly ash and waste glass are mixed and rubbed; the promoters composited by calcium carbonate, potassium nitrate, sodium nitrate, sodium carbonate, lithium carbonate, water glass and fibrin are added; the powder that has been rubbed into mould to mold is put; shaped product is sent to kiln to be dried and fired under high temperature, is annealed and finally cut, after the steps, the foam glass is made. The preparation technique is simple, and the production cost is reduced by choosing fly ash and waste glass instead of pearl rock, pumice, isinglass and other non-mine material, and the technique improves the use of solid wastes and is beneficial to environment protection.

Owner:内蒙古自治区建筑材料工业科学研究设计院

Strong, high density foam glass tile having a small pore size

InactiveUS20050019542A1Absorb energyImprove mechanical strengthCovering/liningsGlass shaping apparatusHigh densityVolumetric Mass Density

A strong, high density foam glass tile having a small pore size which can be used as a facade on both exterior and interior building walls. The foam glass tile of the present invention is strong enough that it can also be used as a structural member for a building. The foam glass tiles are very strong, and have a compression strength of 6000 psi (lb. / sq. in.) or greater, and more particularly of 8000 lb. / sq. in. or greater, and even more particularly of 10,000 lb. / sq. in. or greater, and even more particularly of 12,000 lb. / sq. in. or greater, and even more particularly of 14,000 lb. / sq. in. or greater. These foam glass tiles will absorb more energy from an explosion, withstand higher heat and wind loading and other mechanical forces. The tiles of the present invention may have an average pore size of 1.0 mm or less, and preferably 0.7 mm or less, and more preferably 0.6 mm or less, and even more preferably 0.5 mm or less, and even more preferably 0.4 mm or less, and even more preferably 0.3 mm or less. The density of the foam glass tile of the present invention is increased from the commercially recommended density of 9.5 lb. / cu. ft. to have a higher density of between 30-100 lb. / cu. ft., and more particularly greater than 40 lb. / cu. ft., and even more particularly greater than 50 lb. / cu. ft. and even more particularly greater than 60 lb.cu. ft. The weight of the foam glass tile of the present invention is over 10 lbs., and more particularly over 20 lbs., and even more particularly over 30 lbs., and more particularly 35 lbs. or greater, and even more particularly 40 lbs. or greater, and even more particularly 50 lbs. or greater, and even more particularly 65 lbs. or greater, and even more particularly 100 lbs. or greater. The tile of the present invention may also have a closed pore structure.

Owner:PEDRO M BUARQUE DE MACEDO

Fluoropolymer organic lining anticorrosive material for chimney, flue and other pipelines and containers and construction method thereof

ActiveCN101891993AImprove temperature resistanceImprove acid resistanceBio-packagingLarge containersVulcanizationAdhesive

The invention provides an anticorrosive material for a chimney, a flue and other containers and pipelines and an anticorrosive construction process. The construction method of the anticorrosive material comprises the following steps: using crude rubber with higher fluorine content as a raw material, then adding curing agent, stabilizer, special stuffing and other components, and mixing to form precuring gross rubber; dissolving the rubber by using low-molecular weight esters and ketones as the solvent to form a putty type rubber paste; and finally, adding special additives, uniformly mixing, coating to the inner walls of a chimney, a flue and a chemical container, and curing into the polymerized fluororubber organic lining under the room-temperature condition. The material can be independently used as the anticorrosive material, and can also be used for protecting common foam glass bricks (ceramic bricks) and adhesive for anticorrosive purpose in the domestic chimney (flue) at present. The invention well solves the technical problems of fluororubber room-temperature curing and difficult anticorrosive construction, can be used in a high-temperature environment of more than 230 DEG C, and can endure high-concentration sulfuric acid, nitric acid, hydrochloric acid, phosphoric acid, hydrofluoric acid, corresponding salts and a mixture thereof. The anticorrosive lining material is economically affordable, has extremely high comprehensive anticorrosive properties such as temperature resistance, acid resistance and the like, and is applicable to the anticorrosive treatment of a cured chimney.

Owner:重庆大众防腐股份有限公司

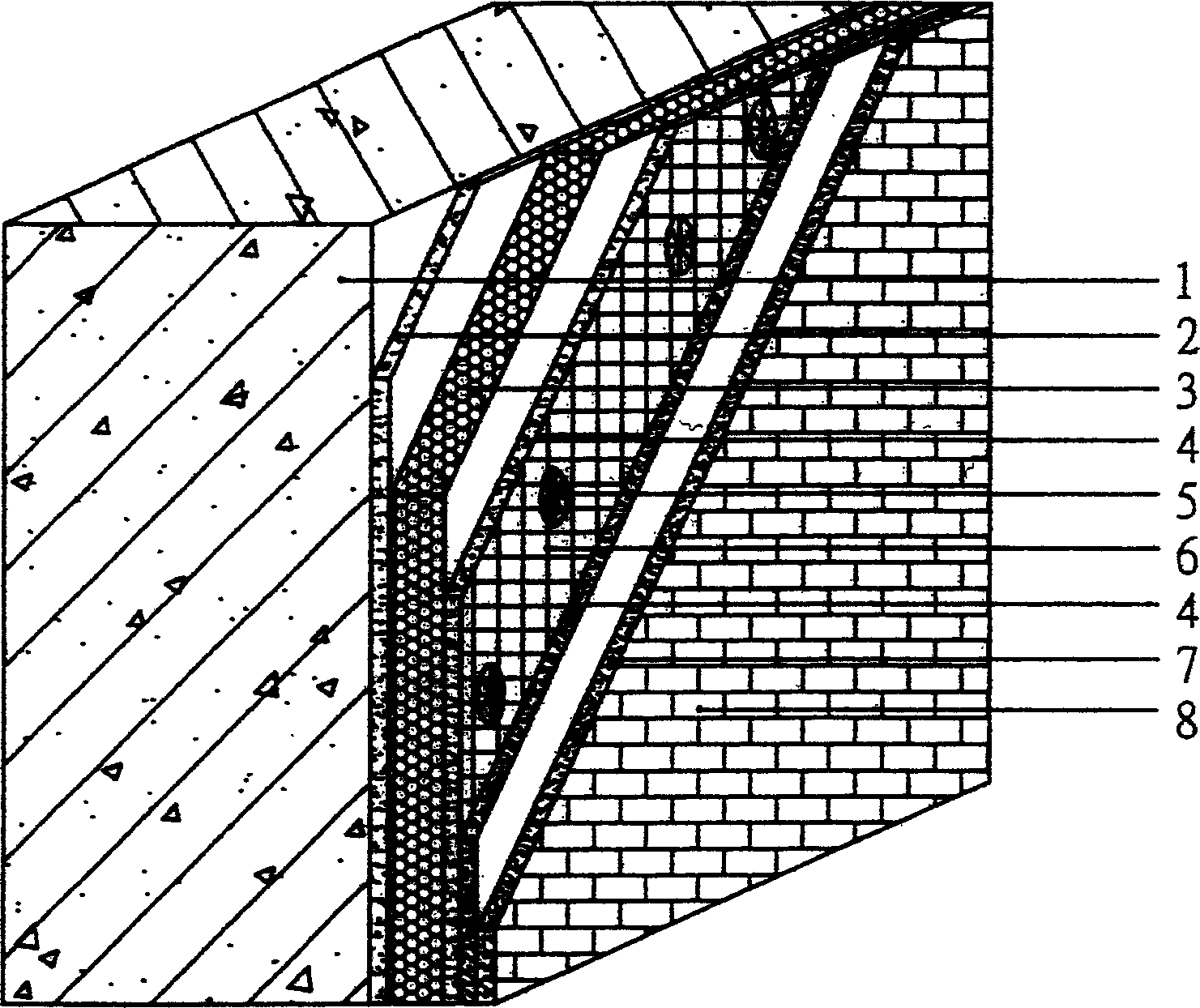

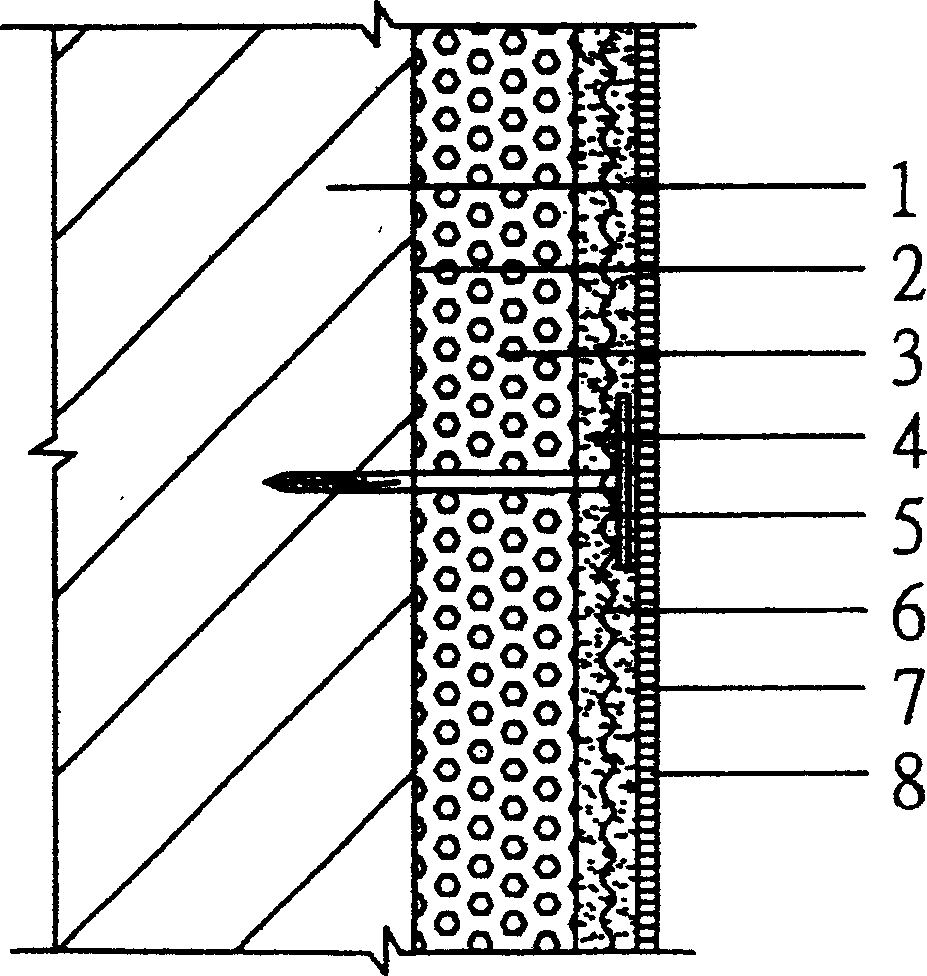

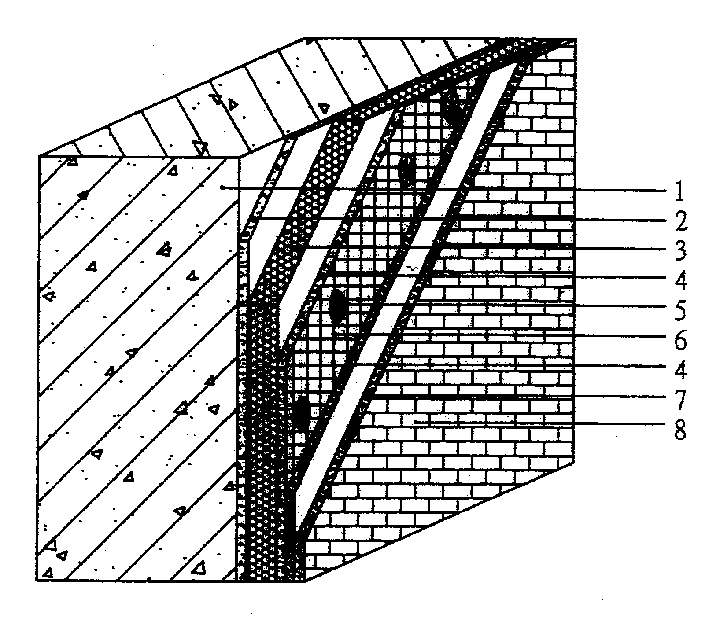

Outer heat insulating wall with anchored and adhered tile and its construction process

InactiveCN1458366AFirmly connectedRich materialCovering/liningsHeat proofingBrickReinforced concrete

The construction process includes the steps of: base wall treatment, brushing interface mortar, scribing, constructing the heat insulating layer and leveling, painting the first layer of anti-cracking polymer mortar, spreading galvanized steel wire net and anchoring expanding bolt, painting the second layer of anti-cracking polymer mortar, adhering the facing tile and pointing joint. The galvanized steel wire net is fixed with special anchoring expansion bolts. The base wall may be reinforced concrete wall, solid brick wall, hollow brick wall, porous brick wall, air-entraining concrete block wall, etc. The heat insulating layer may be polystyrene particle layer, foamed polyurethane layer, foamed glass layer, polystyrene board, etc. The present invention makes it possible to apply heat insulting facing tile to various building wall, including wall of less compactness material.

Owner:北京振利高新技术有限公司

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

Systems and methods for making foamed glass using submerged combustion

Submerged combustion systems and methods of use to produce foamed glass. One system includes a submerged combustion melter having an outlet, the melter configured to produce an initial foamy molten glass having a density and comprising bubbles filled primarily with combustion product gases. The initial foamy molten glass is deposited directly onto or into a transport apparatus that transports the initial foamy molten glass to a downstream processing apparatus. An intermediate stage may be included between the melter and the transport apparatus. One intermediate stage is a channel that includes gas injectors. Another intermediate stage is a channel that produces an upper flow of a less dense glass and a relatively more dense glass lower flow. The upper flow may be processed into foamed glass products, while the more dense flow may be processed into dense glass products.

Owner:JOHNS MANVILLE CORP

Production raw material of foamed glass and process for producing foamed glass

The invention relates to raw materials for producing foam glass and a method for applying the same to produce the foam glass. The compositions by weight portion of the raw materials are: 380 to 580 portions of quartz sand, 105 to 250 portions of potassium feldspar, 130 to 270 portions of albite, 115 to 200 portions of dolomite, 5 to 25 portions of calcite, 150 to 250 portions of calcined soda, 0.5 to 30 portions of glauber salt, 1.0 to 12 portions of magnesium carbonate and 1.0 to 8.5 percent of potassium carbonate. The method comprises the following steps that: firstly, various raw material compositions are mixed into uniform glass mixture; secondly, the glass mixture is melted and cooled into cullet; thirdly, ball milling, foaming and annealing of the cullet are performed, and then foam glass is obtained. The method can automatically control and adjust the chemical compositions of the glass and add various functional compositions as required to meet the demand of producing the foam glass with different performances by adoption of common mineral and chemical raw materials of the natural world.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

Method for preparing microcrystalline porous foam glass tube

The invention relates to a method for preparing a microcrystalline porous foam glass tube. The method comprises the following steps of: firstly, preparing base glass, and obtaining base glass powder by mixing, melting, cooling and crushing; then preparing a microcrystalline porous foam glass raw material; then filling the raw material into a mold for molding; and finally, firing to obtain the microcrystalline foam glass tube. The method can prepare porous foam microcrystalline glass tube with light weight, heat preservation, abrasion resistance, corrosion resistance and high strength. The tube may have different colors and can be optionally cut and machined into needed tube components.

Owner:TSINGHUA UNIV

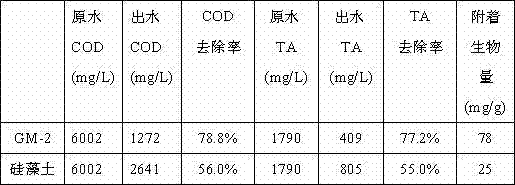

Multi-hole foam glass carrier for fast mass transfer biological fluidized bed and preparation method and application thereof

InactiveCN102515551AEvenly distributedImprove chances of interphase contactTreatment with anaerobic digestion processesBiocompatibilityFoam glass

The invention relates to a multi-hole foam glass carrier for a fast mass transfer biological fluidized bed and a preparation method and application thereof, which belong to sewage disposal technology. The multi-hole foam glass carrier is prepared by using waste glass as a raw material to be composited with volcanic rocks, coal ash, coal gangue, furnace clinker, iron powder, aluminum powder, binding agents, foaming agents, foam stabilizer and fluxing agents by weight, and multi-hole foam glass is obtained by stages of preheating, fast sintering, foaming, fast cooling and annealing. The preparation process of the multi-hole foam glass carrier is simple in route, easy to control and low in cost, and the prepared carrier is stable in performance, high in porosity, large in specific surface area, resisting in impact, good in mechanical performance, high in biocompatibility, favorable to efficient fixing of the microorganism, and suitable to the fast mass transfer biological fluidized bed. The multi-hole foam glass carrier solves the problem that biological immobilization carriers in the prior art are easy to abrade, small in bio-film formation amount, low in mass transfer effects and the like in the fast mass transfer biological fluidized bed. The preparation method opens up new approaches for preparing the biological carriers, and fills blank spaces in using of foam glass materials in sewage disposal.

Owner:NANJING UNIV OF TECH

Methods and systems for controlling bubble size and bubble decay rate in foamed glass produced by a submerged combustion melter

ActiveUS8991215B2Increase reduction rateGlass furnace apparatusGlass melting apparatusCombustionGaseous atmosphere

Methods and systems for controlling bubble size and bubble decay rate of glass foams formed during submerged combustion melting. Flowing a molten mass of foamed glass comprising molten glass and bubbles entrained therein into an apparatus downstream of a submerged combustion melter. The downstream apparatus has a floor, a roof, and a sidewall structure connecting the floor and roof. The foamed glass has glass foam of glass foam bubbles on its top surface, and the downstream apparatus defines a space for a gaseous atmosphere above and in contact with the glass foam. The downstream apparatus includes heating components to heat or maintain temperature of the foamed glass. Adjusting composition of the atmosphere above the glass foam, and / or contacting the foam with a liquid or solid composition controls bubble size of the glass foam bubbles, and / or foam decay rate.

Owner:JOHNS MANVILLE CORP

Large high density foam glass tile

InactiveUS6964809B2High densityHigh strengthCovering/liningsGlass shaping apparatusShock waveHigh density

A large, high density foam glass tile which can be used as a facade on both exterior and interior building walls. The foam glass tile can also be used with other materials to form a panel or a composite. The present invention may be used on the critical surfaces of buildings at high risk for terrorist attacks, in combination with cement, steel or other high strength building materials. The present invention may also be used in surfaces of typical buildings. The present invention has the advantage of absorbing a substantial portion of a shock wave caused by an explosion. The present invention also has the advantage of being more resistant to earthquakes.

Owner:BUARQUE DE MACEDO PEDRO M

Foam glass product

InactiveUS20050031844A1Low thermal conductivityHigh compressive strengthFireproof paintsAntifouling/underwater paintsVolumetric Mass DensityCompressive strength

Improved foam glass products prepared from natural glasses, such as unexpanded fine perlite ore and expanded fine perlite, methods of producing the improved foam glass products, and methods of use thereof are provided. The improved foam glass product made from natural glasses has, for example, a thermal conductivity less than 0.70 Btu.in / hr.F.ft2 (0.101 W / m° K) at 73° F.(296° K), a compressive strength greater than 100 PSI (689 kPa) and a density less than 20 lb / ft3 (320 kg / m3). The improved foam glass product made from natural glasses may be used in a variety of applications including thermal and acoustic insulation applications.

Owner:ADVANCED MINERALS

Process for preparing foamed glass form titan-containing blast furnace slag

The invention provides a method for preparing foam glass by utilization of titaniferous blast furnace slag, belonging to the metallurgical resource comprehensive utilization and material preparation field. The method mainly is to take the blast furnace slag containing 14 to 29 percent of TiO2 as base material, to adequately introduce silicious raw materials to generate vitreous substances, to add foaming agent, foam stabilizer and fluxing agent, and to prepare the foam glass with a specified heat treatment system. The method solves the problems that the prior titaniferous blast furnace slag is difficult to utilize and process and the utilization rate of the titaniferous blast furnace slag in the material preparation field is low, not only creates a novel path for utilization of the titaniferous blast furnace slag but also finds very cheap raw materials for production, and has the advantages of low production cost, good product quality, simple production operation, no secondary pollution and so on.

Owner:NORTHEASTERN UNIV

Micro-pore foaming glass pumice stone and preparation method thereof

ActiveCN103073184AGreen planting soil improvementLight weightGlass shaping apparatusPumice dustOptoelectronics

The invention relates to a micro-pore foaming glass pumice stone, which is characterized by being prepared by carrying out high-temperature heating and foaming, and cooling on a foaming mixture of components according to weight percentage of 85-95 of waste glass grains, 1-10 of marble powder and 1-10 of quick lime. The diameter of a micro-pore of the micro-pore foaming glass pumice stone is 0.23-5mm. The invention further relates to a preparation method of the micro-pore foaming glass pumice stone. The micro-pore foaming glass pumice stone is obtained by regenerating and utilizing waste glass and is a novel material; and the micro-pore foaming glass pumice stone has the advantages of no pollution, light weight, water permeability, water-retaining property, ventilation, fire resistance (non-combustibility and fireproof property), heat insulation property and long-period effectiveness.

Owner:江苏晶瑞特环保新材料有限公司

Preparation method for high-intensity foam glass

The invention relates to a preparation method for high-intensity foam glass. Broken glass powder, CaCO3, borax, NaNO3 and flame-resistant fiber are added in a mill pot to be milled and mixed evenly; then the mixture is put in a mould and moved into a foaming furnace for preheating, foaming, foam stabilizing, quick cooling and annealing so as to obtain the foam glass. High-intensity fiber with high flame resistance is added to the foam glass, which is in favor of improving the mechanical property of the foam glass. Therefore, the foam glass prepared by the invention has high mechanical intensity, wider range of application than that of common foam glass and long service life. The foam glass can be combined with cement, steel or other high-intensity construction materials and has the advantages of durability and rigid structure. The foam glass can absorb the main part of explosion energy when facing shock wave.

Owner:SHAANXI UNIV OF SCI & TECH

Methods for stably incorporating substances within dry, foamed glass matrices and compositions obtained thereby

The invention provides methods for producing foamed glass and the compositions obtained thereby. The compositions are suitable for stable storage of a wide variety of substances, particularly biological and pharmaceutical.

Owner:QUADRANT DRUG DELIVERY

Low-temperature foam glass thermal insulation material and preparation method thereof

InactiveCN102795781ALow water absorptionHigh mechanical strengthThermal insulationAlkali metal oxide

The invention relates to a low-temperature foam glass thermal insulation material and a preparation method thereof, and the foam glass thermal insulation material comprises the following components by mass fraction: 40-80% of SiO2, 0-16% of B2O3, 0-10% of Al2O3, and 10-40% of R2O, wherein R2O is alkali metal oxide; the preparation method comprises the following steps: (1) well mixing water glass with one or more than one of boron-containing raw materials, aluminium-containing raw materials, and an alkali of ROH under stirring so as to obtain a sol system without gelation; (2) drying the sol system to obtain an intermediate material with a water content of 25-50%; (3) performing fragmentation processing of the obtained intermediate material, and then performing foaming heat treatment under a closed condition. The low-temperature foam glass of the invention has good mechanical strength, low water absorption, and a small coefficient of heat conductivity, and can be used as an excellent thermal insulation material; the preparation technology of the invention is simple in process, low in cost, energy saving and environment-friendly, and applicable to industrial production.

Owner:宁波荣山新型材料有限公司

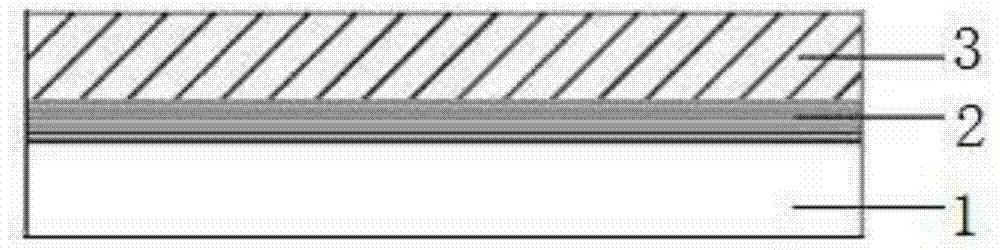

Ceiling with indoor air purification function and manufacturing method thereof

InactiveCN103924756AWith air purification functionCovering/liningsSynthetic resin layered productsSystem integrationFireproofing

The invention discloses a ceiling with an indoor air purification function comprising a heat-insulating and noise-reducing layer (1), a contaminant absorption layer (2) and an air purifying layer (3) sequentially from interior to exterior. The heat-insulating and noise-reducing layer is a foam glass ceramic board, the contaminant absorption layer is an inorganic mineral coating with an absorption function, and the air purifying layer is a photocatalyst coating. According to the indoor ceiling with the air purification function, by means of factorial production, the foam glass ceramic board with fireproofing, heat-insulating and noise-reducing functions, the aqueous mineral coating with the function of contaminant absorption and the photocatalyst coating with the air purification function are compounded, the indoor air-purifying ceiling is obtained, and using function compounding, construction mounting component basing and construction system integration of environment-friendly building materials are realized.

Owner:山东鲁蒙低碳技术研究有限公司

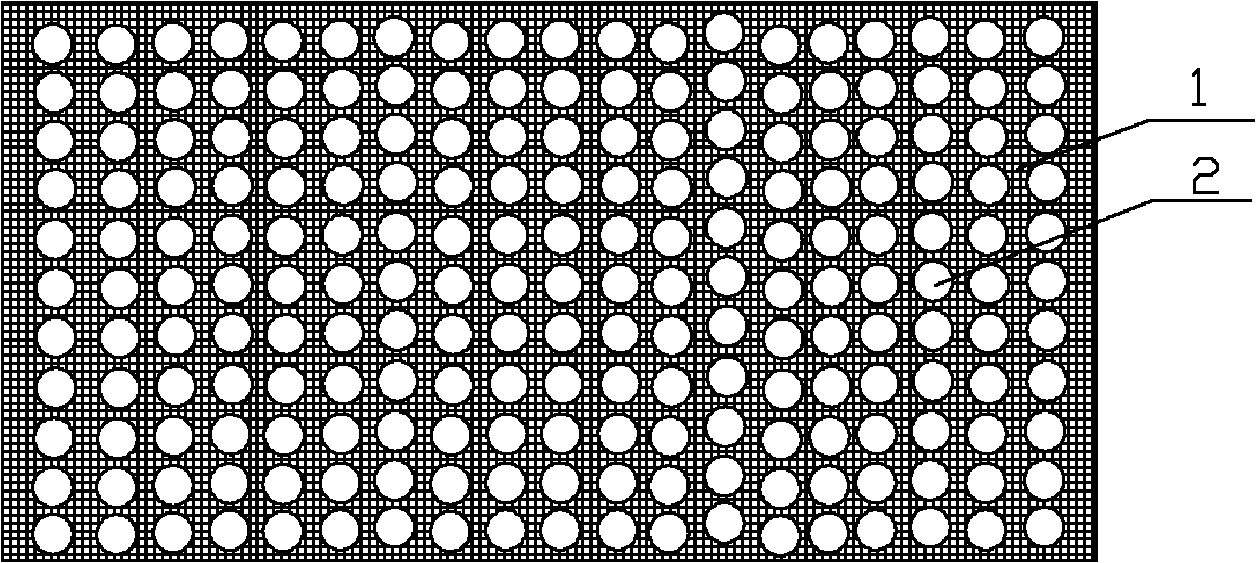

Preparation method of foam glass particles

The invention relates to a preparation method of foam glass particles, which comprises the following steps of: milling glass balls to 200 meshes for forming glass powder; mixing the glass powder, sodium nitrate, manganese dioxide, ferric oxide and sodium silicate to be made into mixed materials; uniformly drilling a plurality of cylindrical grooves on the surface of a foaming template to obtain the particular foaming template; uniformly injecting the mixed materials into the cylindrical grooves of the particular foaming template; firing the mixed materials in a roller kiln; and pouring out specimens from the particular foaming template to obtain foam glass particles. The invention uses a template method for producing the foam glass particles, and the prepared foam glass particles have narrow dimension distribution, uniform granularity and high production efficiency. The foam glass particles prepared according to the preparation method have good structural intensity, low water absorption rate, low heat conduction coefficient and high sealing porosity, and can be used as good thermal isolation and heat insulation materials. The preparation process has simple operation process, low cost and energy saving and environment protection effect and is applicable to industrial mass production.

Owner:SHAANXI UNIV OF SCI & TECH

Multifunctional environment-friendly foam glass product and preparation method thereof

The invention relates to a multifunctional environment-friendly foam glass product and a preparation method thereof, in particular relates to an environment-friendly foam glass product which is applied to a wall body of a building, a freezing device and the like for heat insulating and sound absorbing, and a preparation method of the environment-friendly foam glass product, and belongs to the technical field of glass products. The preparation method comprises the following steps: getting waste glass and an inorganic nonmetal solid mixture as the main raw materials; adding a complex solubilizer, a foaming agent, a foam stabilizing agent and an accelerator; breaking; mixing and performing ball milling in a dry manner; adding an inorganic fiber material; transferring the mixture into a die; sintering and modeling; then cooling to obtain the foam glass product. The preparation method is simple in process operation, energy-saving, environment-friendly and outstanding in product performance; the density of the foam glass product is 100 to 600kg / m<3>, and the compressive strength is 4 to 15MPa; the multifunctional environment-friendly foam glass product has the characteristics of being light in weight, absorbing sound, being high in mechanical strength, small in thermal conductivity, stable in thermal performance, flame retardant, anticorrosive and waterproof, and the like.

Owner:ZHEJIANG AOQIANG ENVIRONMENT PROTECTION TECH

Preparation method of crystallite foam glass

The preparation method for microcrystal foam glass comprises: clearing the glass surface of waste CRT without electron gun, removing the fluorescent layer and grid to smash and grind; putting the glass powder and SiC power into a ball grinder for grinding and mixing to load into mold tool; preheating with 8Deg / min speed from room temperature to 650Deg; heating with 10~12Deg / min from 650Deg to 840~900Deg, holding for 30~40min; then, foaming and cooling with 20Deg / min speed to 550Deg, holding for 20~60min; finally, annealing slowly with 1Deg / min speed to room temperature. The product has high mechanical strength and well physical properties. This invention is benefit to environment protection.

Owner:SHAANXI UNIV OF SCI & TECH

Microcrystal foam glass prepared by kerosene shale ash and manufacturing method thereof

The invention relates to a microcrystalline foam glass made by oil shale ash and a preparation method thereof. The oil shale ash is used as main material. The basic glass is made by adding a certain quantity of calcium carbonate, basic magnesium carbonate, borax and sodium carbonate to the main material, then adding foaming agent, foam stabilizer, fluxing agent. By adopting powder firing technique, the microcrystalline foam glass is made. The surface volume consistency of the glass is 875-1030 kg.m-3; absorbing capability is 8-15 percent; compressive strength is 11-23 MPa; bending strength is 10-17MPa; and heat conductive coefficient is 0.21- 0.32w(m.k)-1.The producing steps comprise the following techniques that first-time material proportioning; high temperature melting; basic glass making; second-time material proportioning; foaming; foam stabilizing; annealing, etc. The microcrystalline foam glass is a novel multi-functional material, which has remarkable meaning on improvement of the added value of oil shale rock resources and on environment protection.

Owner:NORTHEASTERN UNIV

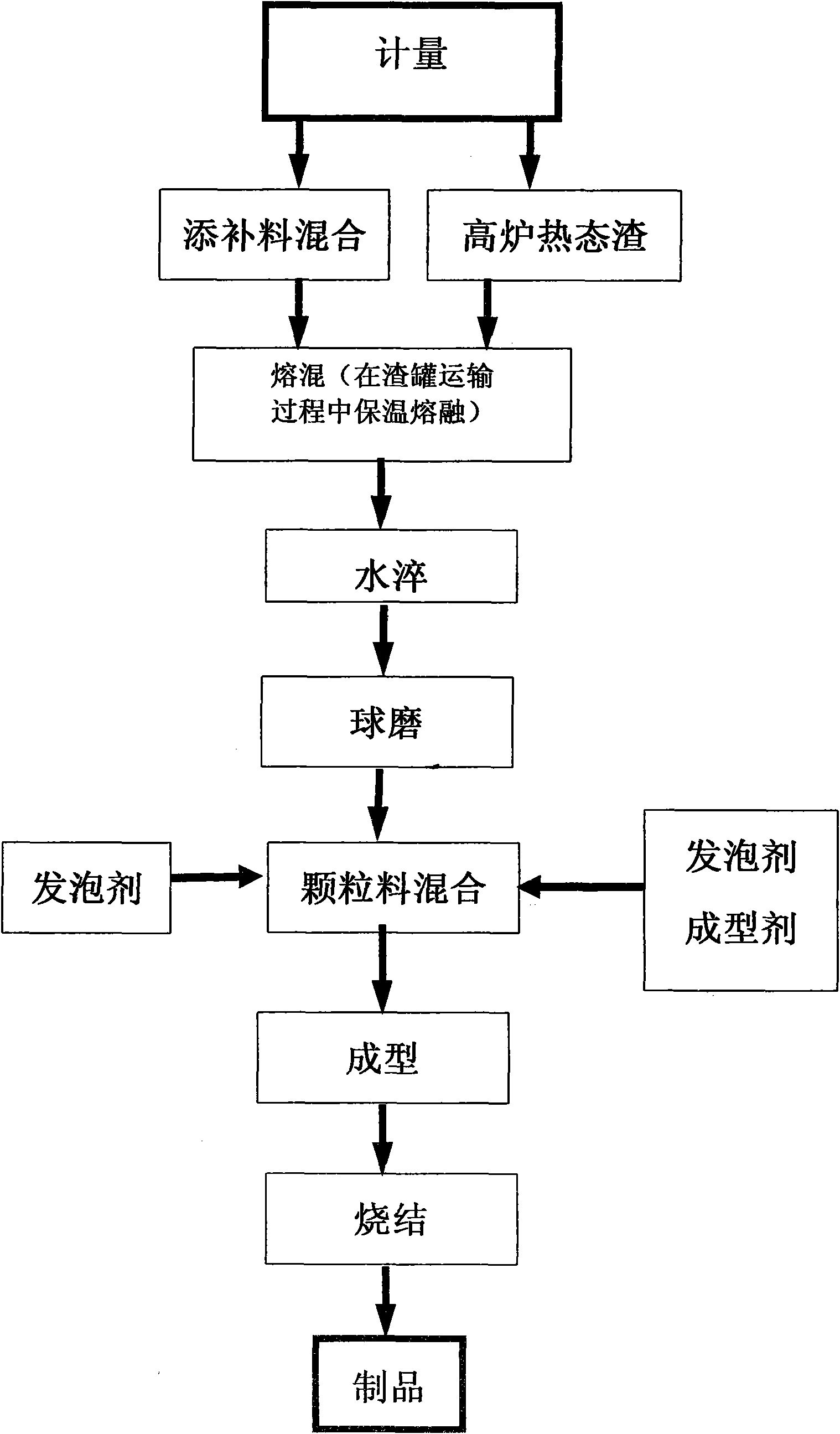

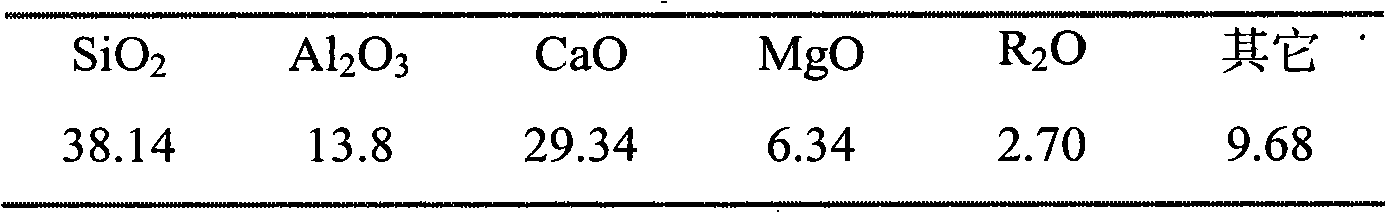

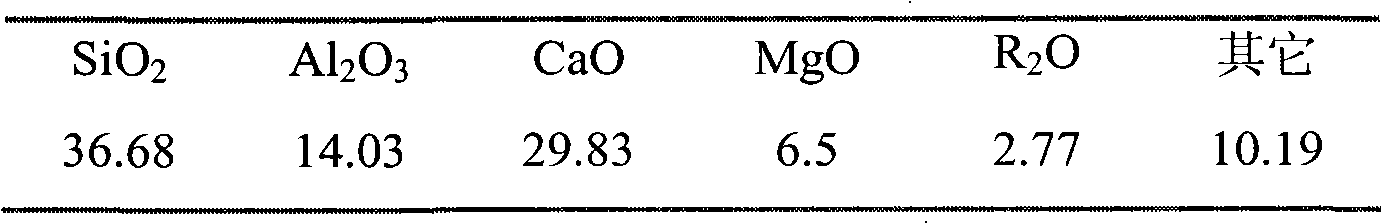

Foam glass ceramic and preparation method thereof

The invention relates to a foam glass ceramic prepared from blast furnace hot melting slag and a preparation method of the foam glass ceramic, belonging to the field of inorganic materials. In the preparation method, steeling blast furnace hot melting slag is used as a main raw material, coal ash, borax, calcined soda, rear sorted tail ore, quartz sand and the like are respectively measured, evenly mixed and then baked into porous blocks, the porous blocks are added in a slag ladle, smelting is carried out by using the blast furnace hot melting slag, a melting material is subject to water quenching to obtain glass water quenching materials with different particle sizes; and the glass water quenching materials are dried and ball-milled, a foaming agent is added to be mixed with the dried and ball-milled glass water quenching materials, press forming or spreading forming is carried out, and then the foam glass ceramic is prepared by nucleating, crystallization and sintering. In the invention, a large amount of heat energy stored in the blast furnace hot melting slag is effectively utilized, and production cost is lowered; and the prepared foam glass ceramic has the characteristics of low thermal conductivity, small density, high temperature resistance, corrosion resistance and high compression resistance and breaking strength, has strong adaptable property on high-low temperature variation of smoke, and can be widely used as a multi-cylinder type and sleeve type lining material for discharging smoke by wet desulphurization in a heat-engine plant, thermal equipment insulation, heat-insulating materials and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

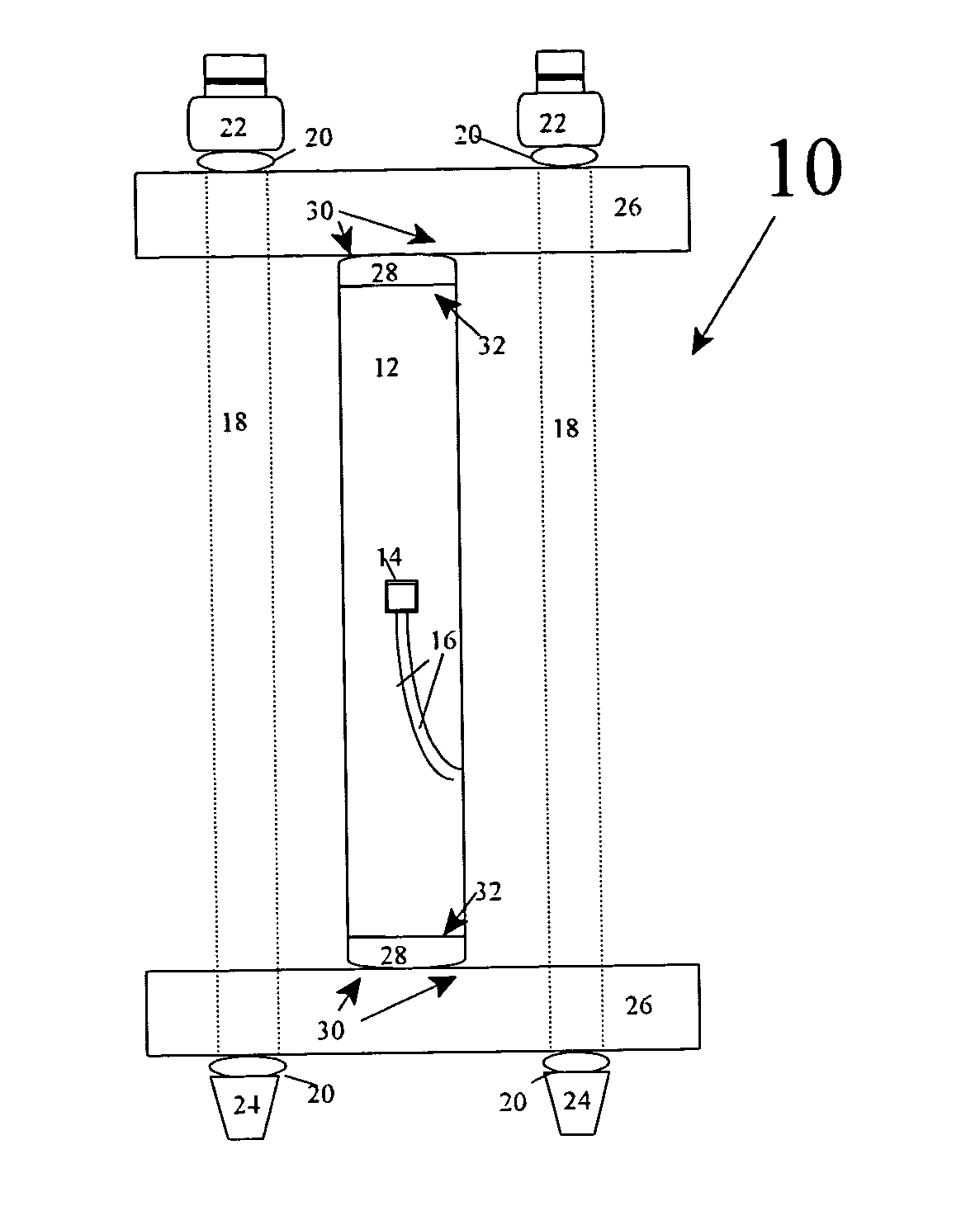

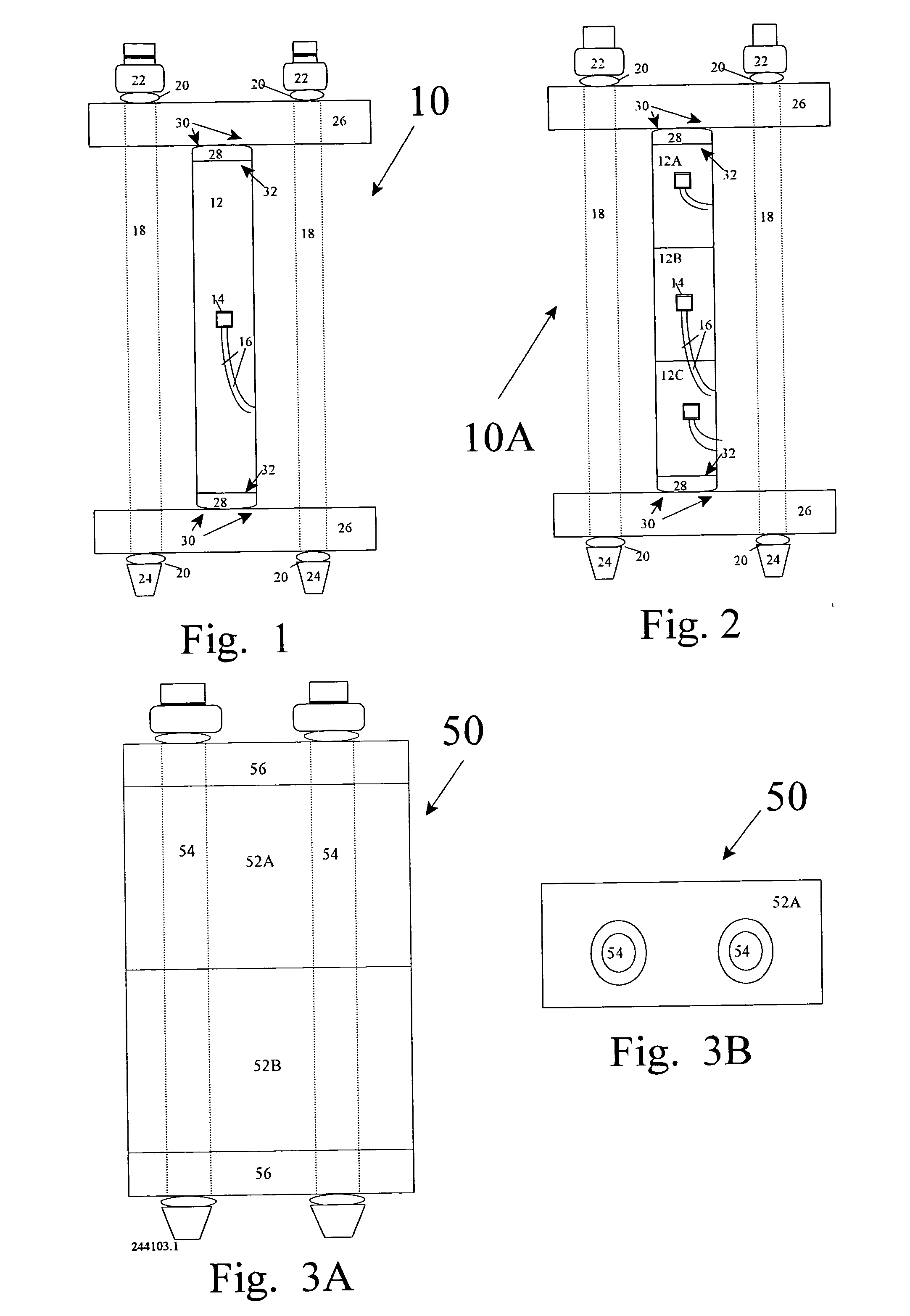

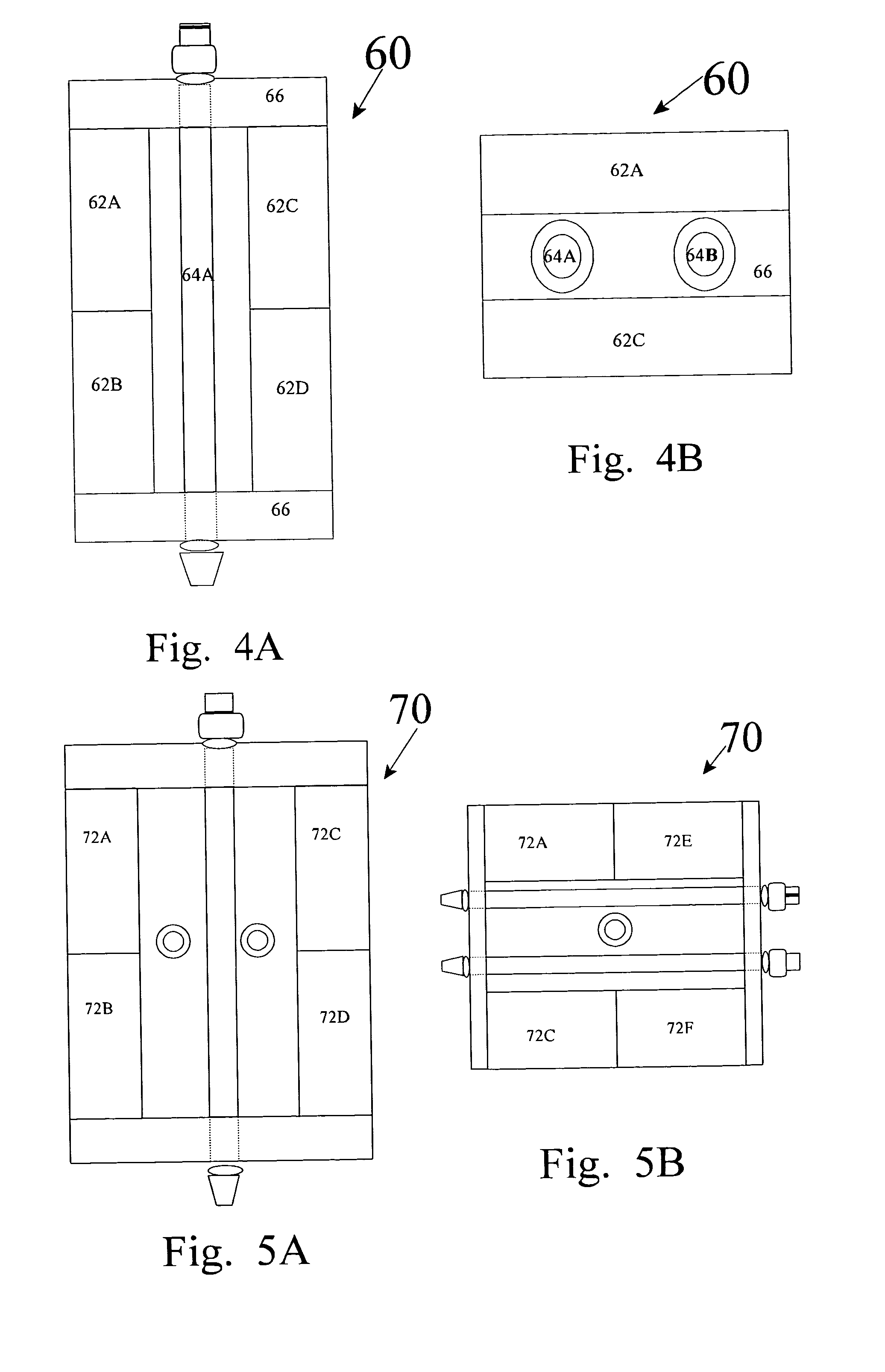

Prestressed, strong foam glass tiles

InactiveUS20050016093A1High compressive strengthMore energyWindow/door framesLoad-supporting elementsBrickHigh intensity

A prestressed, strong foam glass tile for use in construction. The prestressed, strong foam glass tiles of the present invention are capable of withstanding relatively large prestressing as a result of their relatively high compression strength. These prestressed, foam glass tiles will absorb and / or withstand more energy from an explosion, withstand higher heat and wind loading and other mechanical forces than traditional foam glass tiles. The foam glass tile of the present invention is strong enough that it can be prestressed over 1000 psi (lb. / sq. in.), and more preferably over 2,000, 3,000, 4,000 and even more preferably over 5,000 psi. The prestressed, strong foam glass tiles of the present invention maybe included as part of a prestressed assembly. Said prestressed assembly may be comprised of two metal members, one or more prestressed foam glass tiles, and a tension member such as a tension bolt and / or wires.

Owner:BUARQUE DE MACEDO PEDRO M

Method for preparing microporous foam glass by use of waste glass

The invention discloses a method for preparing microporous foam glass by use of waste glass, belonging to the technical field of inorganic nonmetallic material forming. The method comprises the following steps: grinding the waste glass and levigating into glass micropowder; proportionally mixing the glass micropowder with water and a dispersing agent, and performing ball milling; after the ball milling, adding certain amount of room-temperature foaming agent and stirring to prepare stable foam slurry with high solid content; adding the foam slurry into centrifugal atomization drying equipment to prepare hollow microsphere blanks; collecting the microsphere blanks and heating in a high-temperature furnace, and preserving heat so as to foam the microsphere blanks; and sintering to prepare high-quality microporous foam glass with low density, high strength and low heat coefficient, wherein the diameter of the micropores is uniform and controllable. Without adding a high-temperature foaming agent and a reducing agent, the method has a short sintering heat cycle, does not need annealing and is generally applicable to glass powder and suitable for large-scale continuous production while the cost is low.

Owner:HEBEI YL BANGDA NEW MATERIALS LTD CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com