Preparation method of foam glass particles

A technology of foam glass and granules, which is applied in the field of preparation of foam glass granules, can solve the problems of limiting the use effect of excellent thermal insulation materials and filling materials, narrow particle size distribution, etc., and achieve high production efficiency, narrow size distribution, and closed pores high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the first step: the preparation of batch materials: first, the various cullets collected are cleaned, dried, broken, and ball-milled to 200 mesh to form glass powder; secondly, according to the mass fraction, 94% of the glass powder, 3% sodium nitrate, 1% manganese dioxide, 1% ferric oxide, and 1% sodium silicate are put into the mixer and mixed to a mixture whose uniformity is greater than 98%; then, to the mixer Spray 5% of the atomized water into the mixture, and then mix the mixture for 30 minutes to form a batch for preparing foam glass particles;

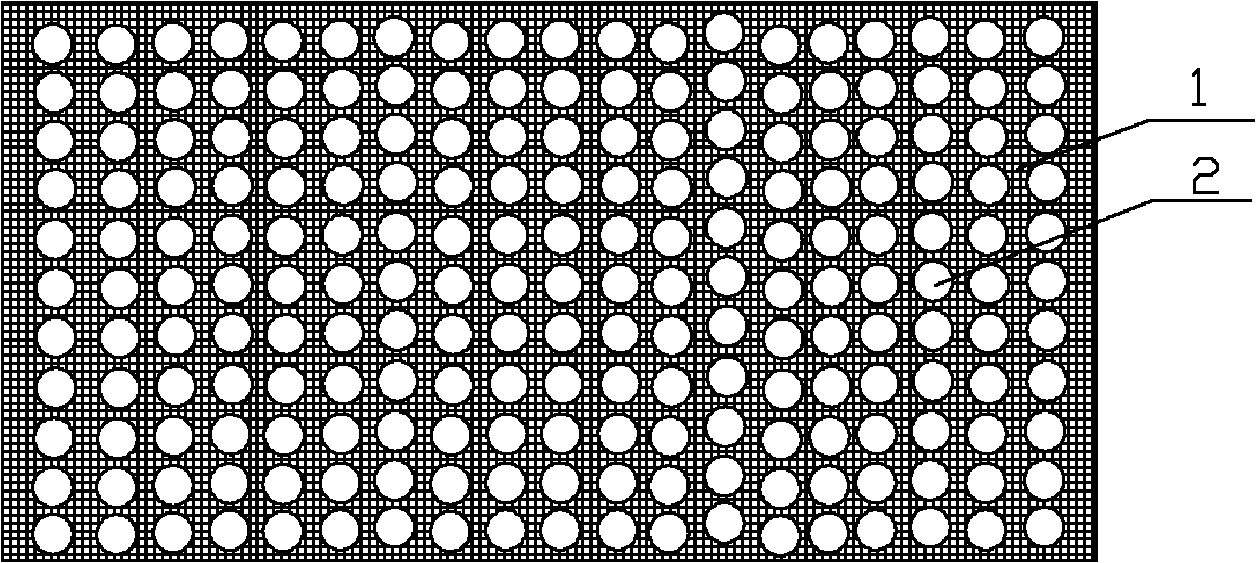

[0020] Step Two: See figure 1 , the preparation of the foamed formwork with granules: firstly, the surface of the foamed formwork 1 made of alumina with a size of 600mm×400mm×40mm was polished and smoothed; secondly, several holes with a diameter of 2mm, 2mm deep cylindrical groove 2, and clean the foam template 1 and cylindrical groove 2; then, evenly spray the alumina water grinding slurry with a partic...

Embodiment 2

[0023] Embodiment 2, the first step: preparation of batch materials: firstly, the various cullets collected are cleaned, dried, broken, and ball-milled to 200 mesh to form glass powder; secondly, according to the mass fraction, 94% of the glass powder, 3% sodium nitrate, 1% manganese dioxide, 1% ferric oxide, and 1% sodium silicate are put into the mixer and mixed to a mixture whose uniformity is greater than 98%; then, to the mixer Spray 5% of the atomized water into the mixture, and then mix the mixture for 30 minutes to form a batch for preparing foam glass particles;

[0024] Step 2: Preparation of foamed formwork with granules: firstly, the surface of the foamed formwork 1 made of sillimanite with a size of 600mm×400mm×40mm is ground and smoothed; secondly, the surface is uniformly drilled out on the flat ground surface A number of cylindrical grooves 2 with a diameter of 3 mm and a depth of 2 mm, and the foaming formwork 1 and cylindrical grooves 2 are cleaned; then, the...

Embodiment 3

[0027] Embodiment 3, the first step: the preparation of batch material: firstly, various cullets collected are cleaned, dried, crushed, and ball-milled to 200 mesh to form glass powder; secondly, according to the mass fraction, 94% of the glass powder, 3% sodium nitrate, 1% manganese dioxide, 1% ferric oxide, and 1% sodium silicate are put into the mixer and mixed to a mixture whose uniformity is greater than 98%; then, to the mixer Spray 5% of the atomized water into the mixture, and then mix the mixture for 30 minutes to form a batch for preparing foam glass particles;

[0028] Step 2: Preparation of foamed formwork with granules: First, polish the surface of the foamed formwork 1 made of silicon carbide with a size of 600mm×400mm×40mm; a cylindrical groove 2 with a diameter of 3 mm and a depth of 3 mm, and clean the foam template 1 and the cylindrical groove 2; The surface layer of the groove 2 is made into a granular foam template after natural drying;

[0029]The 400-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com