Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "High closed porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro closed-cell light-weight corundum refractory aggregate and preparation method thereof

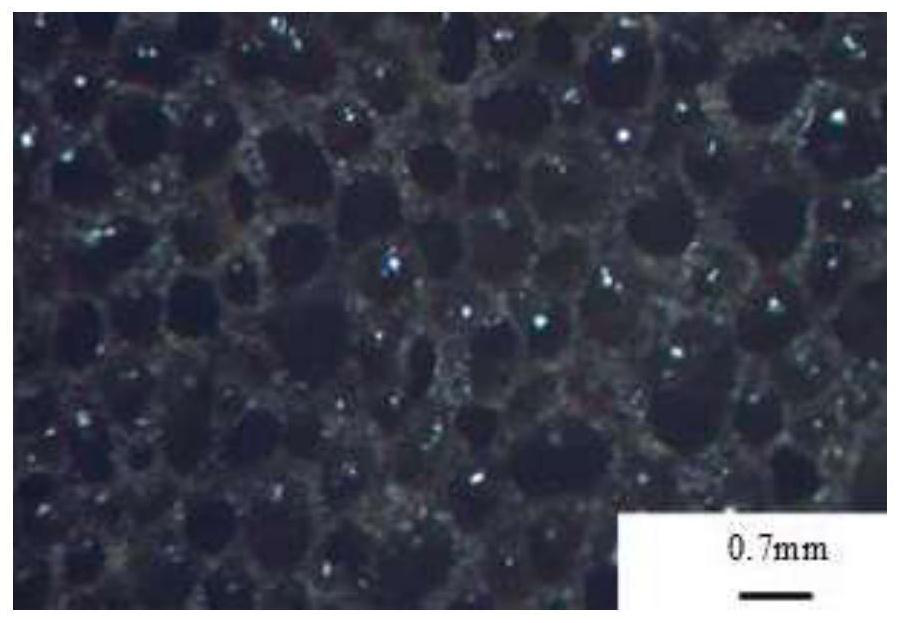

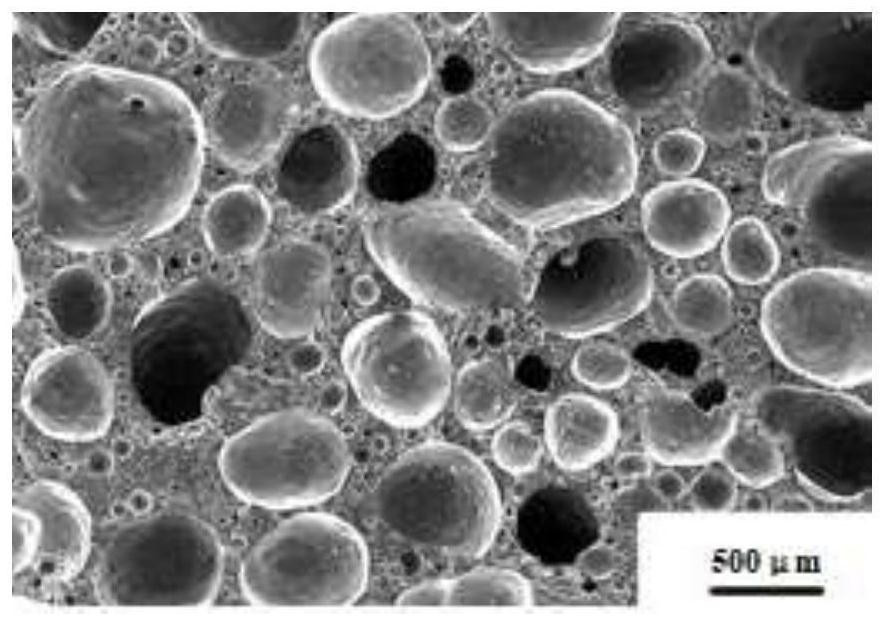

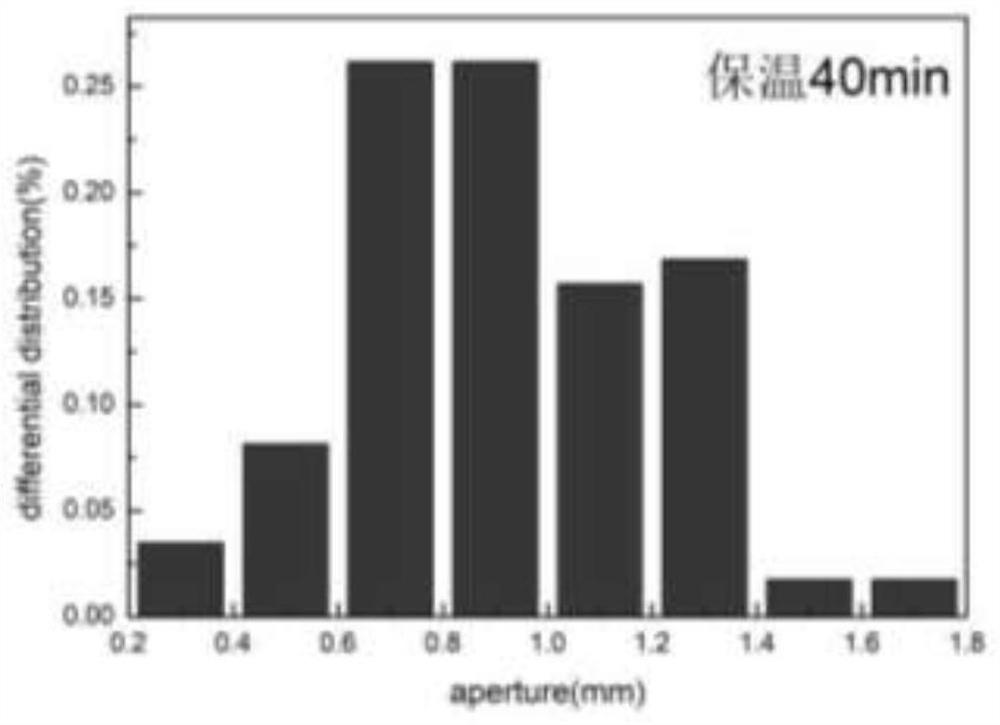

The invention relates to a micro closed-cell light-weight corundum refractory aggregate and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: by using 45-65 wt% of gamma-Al2O3 fine powder, 30-50 wt% of alpha-Al2O3 micropowder and 1-10 wt% of nano aluminum oxide micropowder as raw materials, adding water accounting for 40-80 wt% of the raw materials, and carrying out wet milling with a planet ball mill for 0.5-3 hours; putting the slurry subjected to wet milling in a mold, standing at room temperature for 12-24 hours, and stripping; and drying at 110-200 DEG C for 12-36 hours, and keeping the temperature at 1750-1900 DEG C for 1-8 hours to obtain the micro closed-cell light-weight corundum refractory aggregate. The micro closed-cell light-weight corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, low volume density, small average pore size, lower heat conductivity and high molten slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing closed pore foam ceramic

The invention discloses a method for preparing closed pore foam ceramic, which adopts a high-decomposition-temperature calcium sulfate foaming agent and a inorganic high-temperature silicon carbide oxide pore-forming agent to compositely form pores, and comprises the following steps: mixing the following ingredients in percentage by weight: 65%-75% of high-alumina refractory brick, 10%-30% of hard clay, 0.1% -2% of feldspar, 4%-6% of calcium sulfate and 4% -20% of silicon carbide micro powder; and carrying out ball-milling, carrying out filter-pressing, drying, ageing, carrying out mechanical pressing, sintering at a temperature of 1350 DEG C -1400 DEG C in air atmosphere, and cooling to the room temperature to obtain the foaming ceramic with closed porosity up to 75%. The invention adopts the high-decomposition-temperature calcium sulfate foaming agent and the inorganic high-temperature silicon carbide oxide pore-forming agent to compositely form the pores, and can obviously increase the closed porosity of the foaming ceramic to over 75% from 58%.

Owner:NANJING UNIV OF SCI & TECH

Lightweight micro closed cell magnesium-containing corundum refractory aggregate and preparation method thereof

The invention relates to lightweight micro closed cell magnesium-containing corundum refractory aggregate and a preparation method of the refractory aggregate. The method comprises the steps of taking 80-95wt% of gamma-Al2O3 fine powder, 1-10wt% of nano alumina powder and 1-10wt% of magnesium oxide micropowder as raw materials, adding water accounting for 40-70wt% of the raw materials, mixing, wet-milling with a planet ball mill for 0.5-3h to form slurry, putting the slurry in a mold, placing under a room temperature condition for 12-24h, removing the mold, drying a demolded green body for 12-36h at 110-200 DEG C, and carrying out heat preservation for 1-8h at 1750-1900 DEG C to form the lightweight micro closed cell magnesium-containing corundum refractory aggregate. The prepared lightweight micro closed cell magnesium-containing corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, lower volume density, small mean pore size, lower heat conductivity, and strong washout and slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

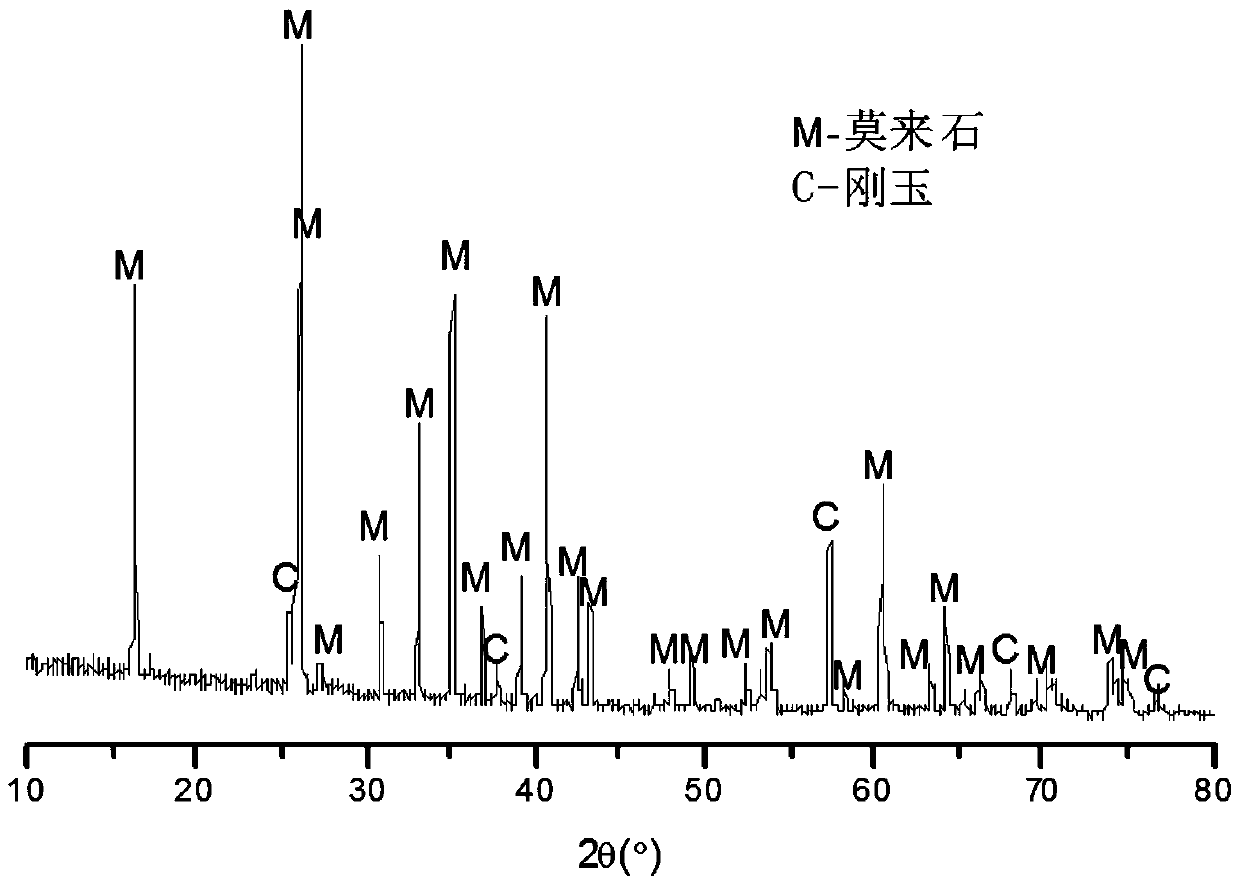

High-strength pore-closed mullite material and preparation method thereof

The invention relates to a high-strength pore-closed mullite material and a preparation method thereof. The material comprises, by weight, 30-84wt% of alumina raw material, 1-55wt% of alumina-silica raw material, 15-60% of silica raw material and 2-10wt% of additive. The preparation method includes: mixing the raw materials according to the above proportion, adding the additive, stirring well, and pouring into a die; performing mechanical pressing under 80-150MPa to obtain a blank, and drying the blank at 60-140 DEG C for 3-16h; putting the blank in a high-temperature kiln for calcining to obtain the high-strength pore-closed mullite material. Sintering in-situ pore forming technology is adopted, so that the high-strength pore-closed mullite material prepared by the method has the advantages of high closed porosity, high pressure-resistant strength and high refractoriness under load and can be used for a long time at high temperature of 1550-1700 DEG C.

Owner:ZHENGZHOU UNIV

Method for quickly preparing low-heat-conduction mullite heat-insulation brick on basis of foam processes

The invention discloses a method for quickly preparing a low-heat-conduction mullite heat-insulation bricks on the basis of foam processes. The method includes adding auxiliary materials including setting accelerators, water reducing agents, structural propping agents and water into raw materials including aluminum oxide fine powder, corundum fine powder, expansive agents, gel powder, clay, mullite powder and binding agents and mixing the auxiliary materials and the raw materials with one another to obtain first mixtures; adding foaming agents into the first mixtures and uniformly mixing the foaming agents and the first mixtures with one another to obtain second mixtures; calcining the second mixtures to obtain the low-heat-conduction mullite heat-insulation bricks. The invention further discloses the low-heat-conduction mullite heat-insulation brick prepared by the aid of the method. The method and the low-heat-conduction mullite heat-insulation brick have the advantages that the method includes simple preparation technologies and is free of environmental hazards, low in production cost and short in production cycle; good heat-insulation effects can be realized by the low-heat-conduction mullite heat-insulation brick prepared by the aid of the method, the low-heat-conduction mullite heat-insulation brick is high in thermal shock resistance, long in service life and wide in service range, and the like.

Owner:YIXING MORGAN THERMAL CERAMICS CO LTD

Light-weight composite corundum refractory aggregate, and preparation method for light-weight composite corundum refractory aggregate

The invention relates to a light-weight composite corundum refractory aggregate, and a preparation method for the light-weight composite corundum refractory aggregate. According to the technical scheme, the preparation method comprises the following steps: taking 80-95 wt% of gamma-Al2O3 fine powder, 1-10 wt% of Al(OH)3 micro powder, 1-10 wt% of a glycopolymer and 0.1-5 wt% of an antifreeze protein as raw materials, adding 20-60 wt% of water, and conducting wet grinding; pelleting slurry obtained after wet grinding into particles with the grain sizes being 1-2.5 mm through a disk, freezing, drying, and keeping the temperature for 3-6 h at the temperature of 300-800 DEG C to obtain porous corundum particles; then taking 80-97 wt% of alpha-Al2O3 micro powder, 2-10 wt% of nanometer aluminium oxide sol, and 1-5 wt% of MgO micro powder as mixtures, adding 30-50 wt% of organic alcohol, and conducting mixed grinding; pelleting the slurry obtained through mixed grinding and the porous corundum particles into particles of which the grain sizes are 3-10 mm, drying, and sintering for 1-5 h at the temperature of 1,700-1,900 DEG C, so as to obtain the light-weight composite corundum refractory aggregate. The light-weight composite corundum refractory aggregate product prepared by the invention is low in volume density, high in closed porosity, and high in slagging corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Steel ladlethermal insulationng castable as well as application thereof

The invention relates to steel ladle thermal insulationinsulating castable as well as an application thereof. The steel ladle thermal insulationinsulating castable is prepared from the following raw materials by mass percentage: 45 to 65 percent of mullite, 8 to 15 percent of flint clay, 5 to 12 percent of andalusite, 2 to 8 percent of clay powder, 4 to 15 percent of magnesite fine powder, 3 to 6percent of aluminum oxide micro powder, 2 to 6 percent of silicon oxide micro powder, 5 to 9 percent of calcium aluminate cement, 0.2 to 0.3 percent of an addition additive, and 5 to 9 percent of additionwater. The steel ladle thermal insulationinsulating castable provided inby the invention is applicable to different parts such as steel ladle furnace liners, permanent layers and ladle covers, high in pressure resisting strength, low in cost, high in closed porosity, and good in insulating effect, can reduce the heat radiation of the molten steel cooling and steel ladle shell without increasing the thickness of the furnace liner and influencing the original masonry process, can improve the stability of the molten steel temperature and the continuous casting pouring efficiency, can alleviate the high-temperature radiation damage for relevant devices, can reduce the temperature fluctuation of a refractory material, and can prolong the service life of the refractory material.

Owner:武汉钢铁有限公司

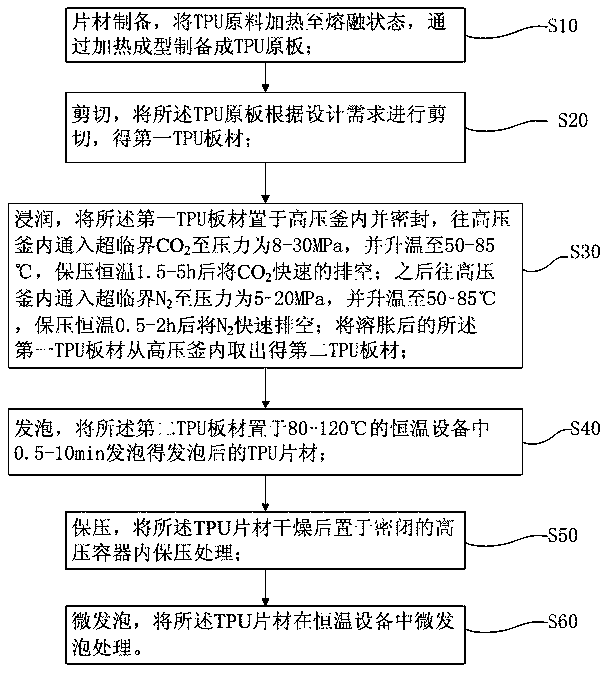

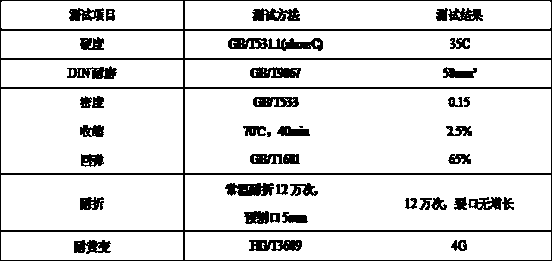

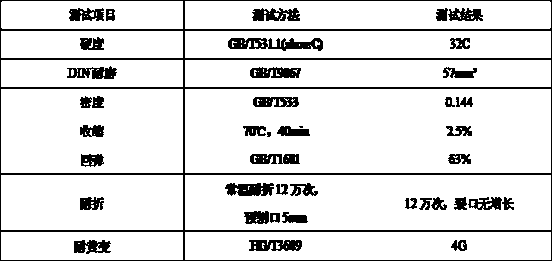

TPU sheet foaming process

The invention provides a TPU sheet foaming process which comprises the following steps: preparing a sheet to obtain a TPU raw plate; shearing to obtain a first TPU plate; soaking, namely putting the first TPU plate into a high-pressure kettle, sealing, introducing supercritical CO2 into the high-pressure kettle until the pressure is 8-30MPa, heating to 50-85 DEG C, maintaining the pressure and theconstant temperature for 1.5-5 hours, and quickly emptying CO2; introducing supercritical N2 into the high-pressure kettle until the pressure is 5-20 MPa, heating to 50-85 DEG C, maintaining the pressure and the constant temperature for 0.5-2 hours, and quickly emptying N2; taking out the swollen first TPU plate from the high-pressure kettle to obtain a second TPU plate; and foaming to obtain theTPU sheet. The invention discloses a TPU sheet foaming process. The TPU sheet is directly prepared through foaming by adopting an infiltration process combining supercritical CO2 and supercritical N2, the product prepared by adopting the process is good in flatness and plumpness, the phenomena of edge curling and the like are avoided, the production convenience is provided for downstream manufacturers, and the equipment investment of the downstream manufacturers is greatly reduced.

Owner:锋特(福建)新材料科技有限公司

Light slightly-closed hole corundum complex-phase refractory material and preparation method thereof

The invention provides a light slightly-closed hole corundum complex-phase refractory material and a preparation method thereof. The refractory material is prepared by conducting mixing and wet grinding to obtain slurry with, by weight, 95-99 parts of alpha-Al2O3 and 1-5 parts of doloma as raw materials and, by weight, 2-15 parts of nanometer alumina sol, 5-15 parts of saccharide polymers and 30-50 parts of organic alcohol as additives, placing the slurry in a mold for 6-12 hours under the temperature of 15-25 DEG C, placing the mold at the temperature of 60-90 DEG C, keeping the temperature for 6-12 hours, conducting demolding, drying a blank obtained after demolding for 24-36 hours under the condition that the temperature is 110-200 DEG C, keeping the temperature for 2-5 hours under the condition that the temperature is 1800-2000 DEG C, and obtaining the light slightly-closed hole corundum complex-phase refractory material. The invention further discloses the preparation method of the light slightly-closed hole corundum complex-phase refractory material. The light slightly-closed hole corundum complex-phase refractory material has the advantages of being low in volume density, small in average pore size, high in closed porosity, low in heat conductivity, high in thermal shock resistance, resistant to flushing and high in slag corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

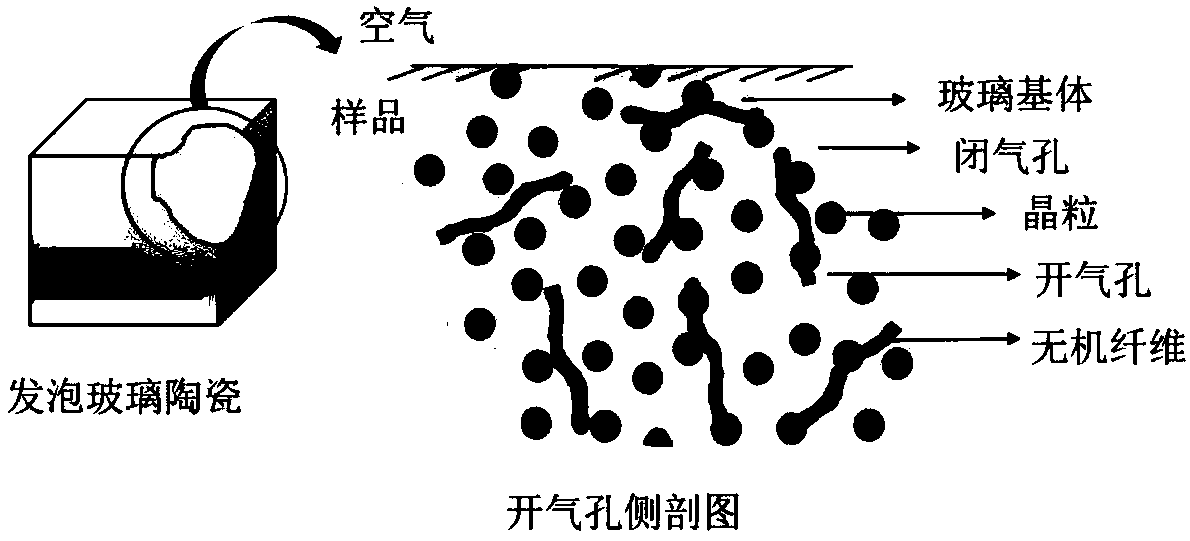

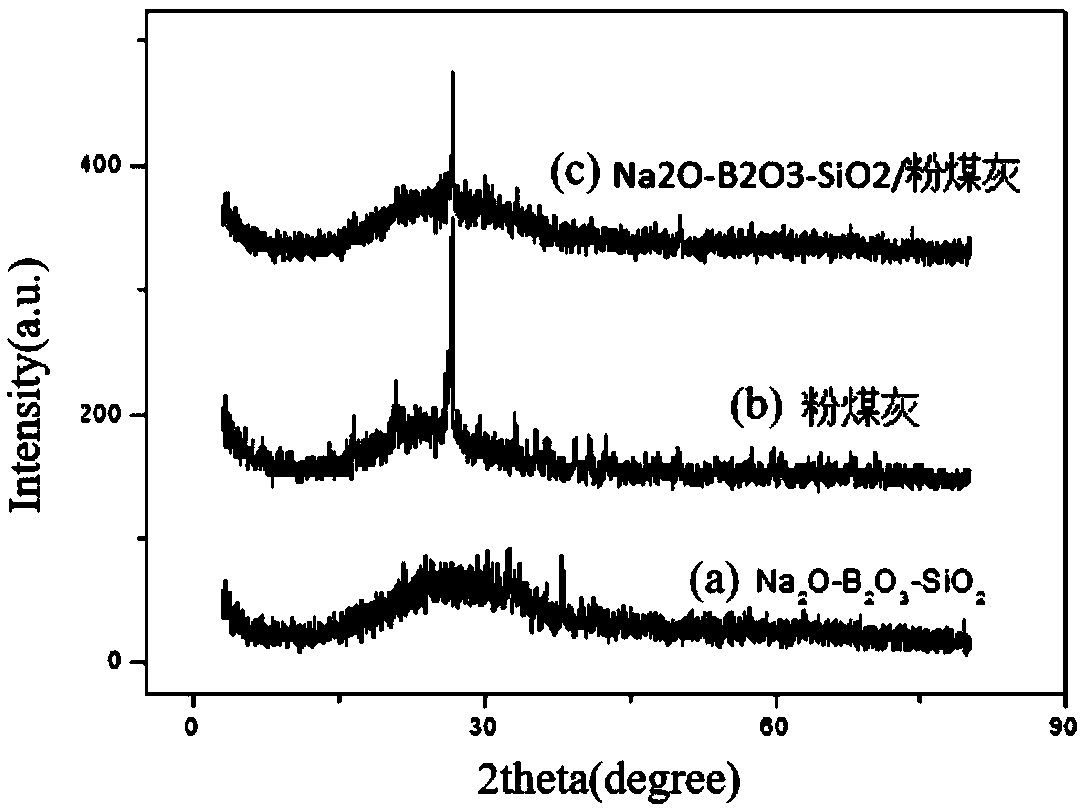

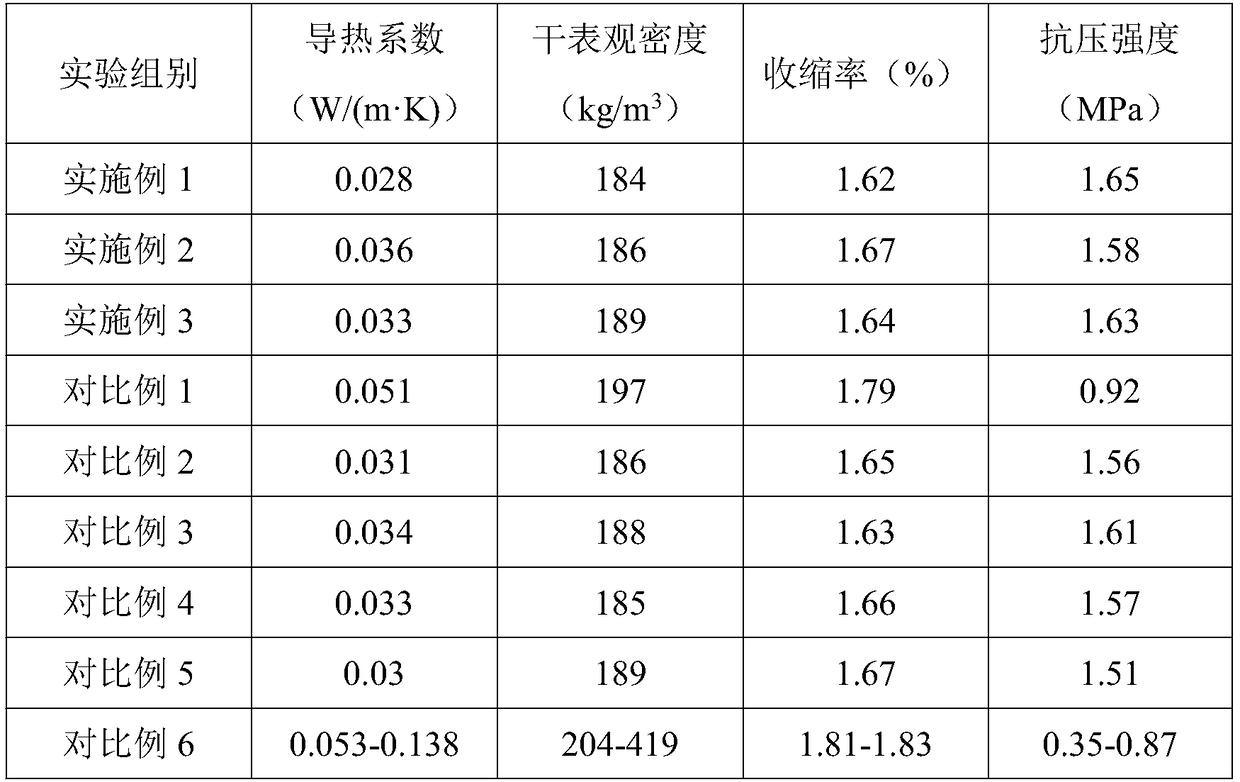

Foam glass ceramic composite building thermal insulation material and preparation method thereof

The invention relates to a foam glass ceramic composite building thermal insulation material and a preparation method thereof. The material comprises a hydrated glass substrate, a crystal phase mineral and inorganic fibers. The preparation technology includes hydrated glass substrate preparation by a wet chemical method, crystal phase mineral and inorganic fiber blending, low-temperature foaming and dehydroxylation heat treatment. The material is excellent in physical and chemical property and fireproof performance, has moderate open pore rate and breathing humidity controlling behaviors and meets grade-A non-combustible standards. Raw materials are wide in variety and low in cost, the preparation process is green and environmentally friendly, and the material is applicable to thermal insulation of building walls.

Owner:宁波荣山新型材料有限公司

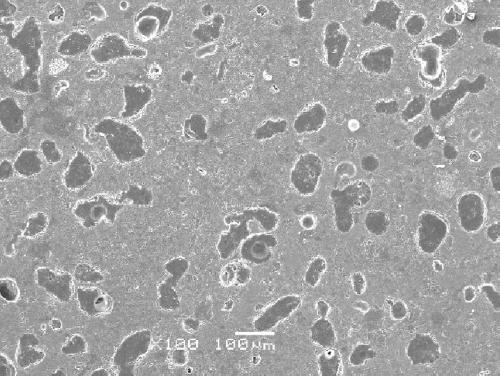

Light-weight micro-closed-pore alumina refractory aggregate and preparation method thereof

The invention relates to light-weight micro-closed-pore alumina refractory aggregate and a preparation method thereof. According to the technical scheme, the light-weight micro-closed-pore alumina refractory aggregate is obtained through the step that the temperature of blocky alumina raw materials is increased to the final temperature through a temperature-gradient method, wherein the step of increasing the temperature of the blocky alumina raw materials to the final temperature through the temperature-gradient method comprises the step that heat preservation is conducted for 1 hours to 4 hours when the temperature is increased to 300 DEG C, 400 DEG C, 500 DEG C, 600 DEG C, 900 DEG C, 1,100 DEG C, 1,200 DEG C and the final temperature separately, the final temperature ranges from 1,500 DEG C to 1,650 DEG C, and the Al2O3 content of the blocky alumina raw materials is higher than or equal to 45%. The preparation method is simple in process and low in cost, and the light-weight micro-closed-pore alumina refractory aggregate prepared through the method has the advantages of being low in apparent porosity, high in closed porosity and strength and small in average pore size.

Owner:山西明景耐火材料有限公司

Light-weight corundum refractory aggregate and preparation method thereof

The invention relates to a light-weight corundum refractory aggregate and a preparation method thereof. The preparation method comprises the following steps: using 40wt% to 60wt% of gamma-Al2O3 fine powder, 30wt% to 50wt% of alpha-Al2O3 micro powder, 1wt% to 5wt% of Al(OH)3 micro powder, 1wt% to 5wt% of nanometer aluminum oxide micro powder, 1wt% to 10wt% of saccharides polymer and 0.1wt% to 5wt% of antifreeze proteins as raw materials, adding 20wt% to 70wt% of water according to the raw materials additionally, and using a planetary ball mill for wet milling for 0.5-3 hours; putting slurry after wet milling in a mold, freezing for 6-24 hours under the condition of -30 to -90 DEG C, and demolding; then drying 12-36 hours under the condition of 110-200 DEG C, and preserving the temperature for 3-6 hours under the condition of 300-800 DEG C; and finally aluminizing so that the plating thickness is 0.1-0.5 mm, preserving the temperature for 3-6 hours under the condition of 500-900, sintering for 1-5 hours under the condition of 1600-1900 DEG C, and thus obtaining the light-weight corundum refractory aggregate. The light-weight corundum refractory aggregate prepared by the invention has the characteristics of small volume density, high closed porosity and high slag corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of low-temperature composite foam glass

InactiveCN107601903AHigh viscosityFine pore structureGlass shaping apparatusVegetable oilFoaming agent

The invention discloses a preparation method of low-temperature composite foam glass and belongs to the technical field of foam glass preparation. The preparation method comprises adding boric acid into a sodium silicate solution, carrying out uniform mixing to obtain high-viscosity liquid sol in the premise of no gelling, then adding a vegetable oil emulsion into a solution, carrying out uniformstirring, adding fermented broth obtained by fresh grape skin fermentation into the solution, adding the fermented broth into the liquid sol, drying the composite liquid sol to obtain composite solidsol, adding limestone as a foaming agent into the sol, adding borax as a cosolvent into the sol, uniformly mixing the sol, foaming agent and borax to obtain mixed sol, designing unit weight of 260-270kg / m<3>, putting the fine composite solid sol corresponding to the designed unit weight into a mold, sealing the mold, transferring the sealed mold into a heating device, carrying out preheating, carrying out melting heat-preservation foaming in an oven, carrying out cooling to the room temperature and carrying out annealing and demolding to obtain the low-temperature composite foam glass.

Owner:薛向东

Manufacturing method of artificial inorganic imitated stone texture decorative plate

The invention provides a manufacturing method of an artificial inorganic imitated stone texture decorative plate, the modified cellulose is prepared from the wheat straw and the corn straw, and the mechanical property of the decorative plate is improved through the synergistic effect of the modified cellulose, the coal ash and the white carbon black; foamed glass is prepared by uniformly coating the surfaces of hollow glass beads with a layer of graphite-like phase carbon nitride, and the foamed glass is pressed on the main body mixture to form a thermal insulation layer, so that the high temperature resistance and flame retardance of the decorative plate are improved; by adding and rographolide and radix isatidis, the mildew-proof and antibacterial properties of the decorative plate are improved; the insulating layer is coated with an imitated stone coating. The decorative plate produced by the method realizes reasonable matching of high strength, obdurability, high temperature resistance and water resistance, and has the advantages of lower production cost, higher process applicability, higher operability, controllable product quality and the like.

Owner:江苏仙野建材有限公司

Thermal insulating mortar and preparation method thereof

ActiveCN108069660AImprove responseLow thermal conductivityCeramicwareSodium BentonitePolystyrene particle

The invention discloses a thermal insulating mortar and a preparation method thereof and belongs to the technical field of preparation of building materials. The thermal insulating mortar is preparedfrom the following raw materials including silicate cement, coal ash, limestone powder, polystyrene particles, bentonite, thickener, heavy calcium carbonate powder, tackifier, carboxyethyl methylcellulose, lauryl sodium sulfate, calcium fluoride, styrene maleic anhydride copolymer and organosilicon-polyurethane copolymer, sodium carbonate and hydrochloric acid through the steps of mixing, stirringand the like. The thermal insulating mortar can improve the compressive strength and reduce dry apparent density, heat conductivity coefficient and water absorption per volume.

Owner:东至安东祥源新型建材有限公司

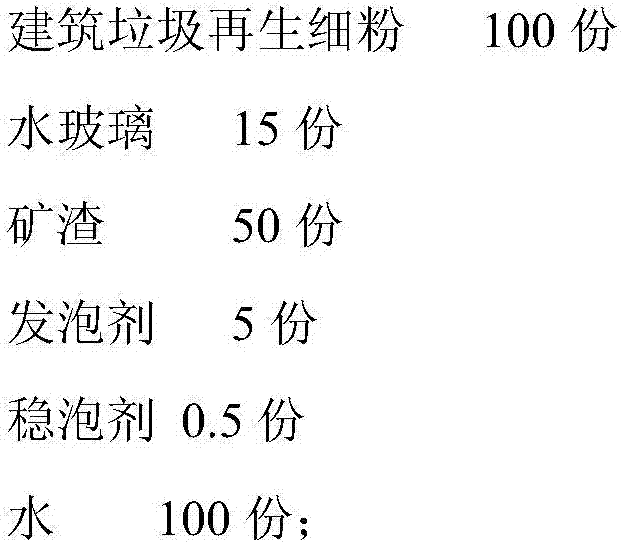

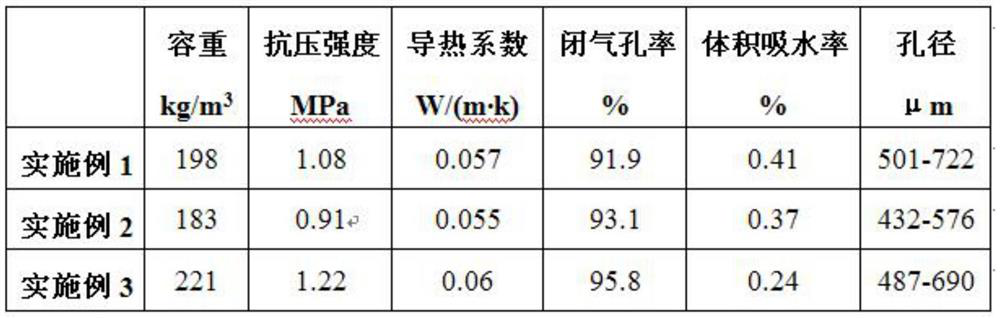

Lightweight thermal insulation board prepared from construction waste recycled fine powder and preparation method thereof

ActiveCN105645901BReduce manufacturing costAchieve recyclingSolid waste managementCeramicwareSodium stearateSlag

The invention discloses a light-weight heat insulation plate prepared from building rubbish regeneration fine powder. The light-weight heat insulation plate is prepared from the following ingredients in parts by weight: 100 parts of building rubbish regeneration fine powder, 5 to 15 parts of water glass, 20 to 50 parts of mine slag, 3 to 5 parts of foaming agents, 0.2 to 0.5 part of foam stabilizing agents and 50 to 100 parts of water, wherein the building rubbish regeneration fine powder passes through a 80-mesh sieve, the sieving residue is smaller than or equal to 5 percent, and the content sum of SiO2 and Al2O3 in chemical components is greater than or equal to 50 percent; the water glass is sodium silicate water glass; the mine slag is mine slag conforming to S95-stage standard requirements in granulated blast-furnace slag used in cement and concrete (GB / T18046-2000); the foaming agent is hydrogen peroxide; the foam stabilizing agent is calcium stearate or sodium stearate. The invention also discloses a preparation method of the light-weight heat insulation plate.

Owner:ZHEJIANG UNIV

Method for preparing aluminum oxide porous ceramics by gel-foaming method

The invention provides a method for preparing aluminum oxide porous ceramics by combining the gel-casting method and the foaming method, belonging to the technical field of porous ceramics material. The invention prepares a porous aluminum oxide ceramic with a high porosity, high strength and particularly a high closed porosity by implementing processing steps like preparing slurry, molding, drying, discharging glue and sintering. The method is a near clear dimension in-situ forming method. The prepared blank has a higher strength and can be reprocessed, and is suitable to prepare porous ceramic products with higher dimensions and complicated shapes.

Owner:KUNMING UNIV OF SCI & TECH

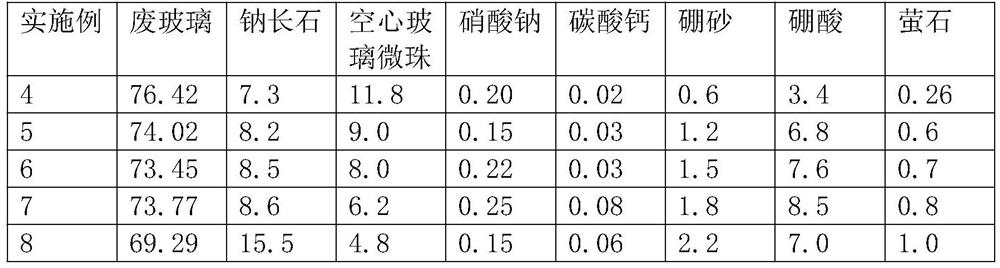

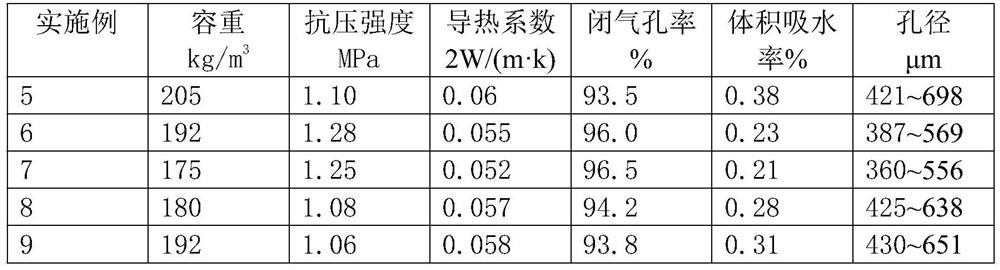

Microporous foamed glass prepared by taking waste glass as main raw material

ActiveCN112777937AReduce manufacturing costHigh value-added utilizationGlass shaping apparatusPorosityCompressive resistance

The invention discloses microporous foamed glass prepared by taking waste glass as a main raw material. The microporous foamed glass is prepared from the following components in percentage by mass: 62.8 to 77.0 percent of waste glass, 7.3 to 16.8 percent of albite, 4.0 to 11.8 percent of hollow glass beads, 0.1 to 0.3 percent of sodium nitrate, 0.01 to 0.12 percent of calcium carbonate, 0.6 to 3.0 percent of borax, 3.1 to 9.5 percent of boric acid and 0.25 to 1.2 percent of fluorite. The true density of the hollow glass beads is 0.15-0.18 g / cm<3>, and the particle size of the hollow glass beads is 10-85 [mu]m. The preparation method comprises the following steps: firstly preparing a blank material, heating the blank material in a high-temperature furnace to 780-860 DEG C at a speed of 5-8 DEG C / min, preserving heat for 30-50 minutes, and then conducting cooling along with the furnace to obtain the microporous foamed glass. The hollow glass beads are adopted as a physical foaming agent, abnormal holes in the foaming process are effectively avoided, the prepared microporous foamed glass is low in volume weight, the closed porosity is larger than or equal to 91%, and the aperture less than 80 [mu]m, and the compressive strength and the thermal insulation performance of the material are remarkably improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Method for preparing high-closed-porosity quartz-aluminum phosphate ceramics

The invention provides a method for preparing high-closed-porosity quartz-aluminum phosphate ceramics. The method is characterized by using the following steps of (1) dissolving aluminum dihydrogen phosphate and aluminum nitrate into water to be prepared into a solution; (2) dripping the prepared solution onto the surface of the porous quartz ceramics at room temperature until the porous quartz ceramics reach the adsorption saturation; (3) drying the porous quartz ceramics adsorbing the mixed solution at 50 DEG C; (4) heating the dried products in the air atmosphere to raise the temperature to1150 DEG C; performing heat insulation for 2 hours; then, performing temperature lowering and cooling at the speed of 5 DEG C / min to reach 800 DEG C; performing heat insulation for 2 hours; finally,performing natural furnacecooling to reach the room temperature to obtain the high-closed-porosity quartz-aluminum phosphate ceramics. The open porosity is not higher than 10 percent; the closed porosity rate reaches 39 percent to the highest degree.

Owner:SHANDONG UNIV OF TECH

Foamed ceramic plate based on Muyu stone tailings and preparation method thereof

PendingCN112279635AImprove the decorative effectLightweight and high strengthCeramicwarePorosityFoaming agent

The invention discloses foamed ceramic based on Muyu stone tailings. The foamed ceramic comprises the following components in percentage by mass: 60-85% of the Muyu stone tailings, 9-20% of quartz, 5-25% of feldspar and 0.1-0.4% of a foaming agent. The Muyu stone tailings are used as a main raw material, various low-grade raw materials are used as auxiliary materials, and the formula composition and the preparation process are optimally designed, so that the mechanical properties and the thermal insulation property of the obtained foamed ceramic product can be effectively considered. The obtained foamed ceramic has the advantages of being high in closed porosity, good in decorative effect, good in heat preservation, heat insulation and fireproof performance and the like, high-additional-value utilization of the high-doping-amount muyu stone tailings can be achieved, and remarkable environmental and economic benefits are achieved.

Owner:WUHAN UNIV OF TECH

A kind of thermal insulation mortar and preparation method thereof

The invention discloses a preparation method of high-strength thermal insulation mortar, and belongs to the technical field of building material preparation. The preparation method comprises the following steps: S1, mixing Portland cement, fly ash, limestone powder, polystyrene particles, bentonite, a thickening agent, heavy calcium carbonate powder, a tackifier and carboxyethyl methyl cellulose in parts by weight, and uniformly stirring to obtain slurry; S2, adding lauryl sodium sulfate into the slurry while stirring, stirring for 10 to 15min, and standing for 30 to 60min; and S3, adding calcium fluoride, a styrene-maleic anhydride copolymer or an organic silicon-polyurethane copolymer, sodium carbonate and hydrochloric acid on the basis of the step S2, and performing uniform stirring with a stirrer so as to obtain the high-strength thermal insulation mortar. The high-strength thermal insulation mortar can improve the compressive strength and reduce the dry apparent density, the heatconductivity coefficient and the volume water absorption rate.

Owner:东至安东祥源新型建材有限公司

Method for preparing high-closed-porosity cordierite-aluminium phosphate ceramic

InactiveCN108298975AImprove insulation performanceHigh closed porosityCeramicwareCordieritePhosphate

The invention provides a method for preparing high-closed-porosity cordierite-aluminium phosphate ceramic. The method is characterized by including the following steps that (1), aluminium dihydrogen phosphate and aluminium nitrate are dissolved in water, and a solution is prepared; (2), the prepared solution is dropped onto the surface of porous cordierite ceramic at room temperature till the porous cordierite ceramic achieves adsorption saturation; (3), the porous cordierite ceramic on which the mixed solution is adsorbed is dried at the temperature of 50 DEG C; (4), a dried product is heatedto 1,150 DEG C in the atmosphere and subjected to heat preservation for 2 hours, then the dried product is cooled to 800 DEG C at the speed of 5 DEG C / min and subjected to heat preservation for 2 hours, finally the product is naturally furnace-cooled to room temperature, and the high-closed-porosity cordierite-aluminium phosphate ceramic is prepared, wherein the open porosity is not higher than 10% and the closed porosity is 39% to the maximum degree.

Owner:SHANDONG UNIV OF TECH

A closed-cell alumina-based mullite material and its preparation method

The invention relates to a closed-pore bauxite based mullite material and a preparing method thereof. According to the technical scheme, by mass, 40-95wt% of bauxite rawore powder and 5-60wt% of silicon dioxide material are mixed uniformly, an additive accounting for 3-10wt% of the raw material mass is added externally and stirred uniformly to obtain a mixture, the mixture is poured into a mold and formed under the pressure of 80-150 MPa to obtain a blank, and the blank is fired for 2-12 h at the temperature of 80-160 DEG C, then put into a high-temperature furnace and calcined for 3-18 h at the temperature of 1450-1750 DEG C in the high-temperature furnace to obtain the closed-pore bauxite based mullite material. The preparing method is low in production cost and saves resources and energy, and the obtained closed-pore bauxite based mullite material is high in closed porosity, small in volume density and large in compression strength.

Owner:ZHENGZHOU UNIV

A kind of lightweight micro-closed-cell clay refractory aggregate and preparation method thereof

ActiveCN106478118BSimple production processHigh closed porosityClaywaresPhysical chemistryRefractory

The invention relates to a lightweight micro-closed-pore clay refractory aggregate and a preparation method thereof. The technical solution is: heating the bulk clay raw meal to the final temperature in stages at a heating rate of 3-10°C / min to obtain a lightweight micro-closed-cell clay refractory aggregate. The stepwise heating up to the final temperature is: when the temperature rises to 300°C, 400°C, 500°C, 600°C, 800°C, 900°C, 1100°C and the final temperature respectively, keep warm for 1-4 hours. The final temperature is 1200-1500°C. Al of the block clay raw meal 2 o 3 The content is 30~50wt%. The invention has simple process and low cost; the prepared lightweight micro-closed-cell clay refractory aggregate has the characteristics of low apparent porosity, high closed porosity, high strength, small average pore diameter and good erosion resistance to high-temperature medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing closed pore foam ceramic

InactiveCN101955371BHigh closed porositySmall apertureSolid waste disposalCeramicwareAir atmospherePorosity

The invention discloses a method for preparing closed pore foam ceramic, which adopts a high-decomposition-temperature calcium sulfate foaming agent and a inorganic high-temperature silicon carbide oxide pore-forming agent to compositely form pores, and comprises the following steps: mixing the following ingredients in percentage by weight: 65%-75% of high-alumina refractory brick, 10%-30% of hard clay, 0.1% -2% of feldspar, 4%-6% of calcium sulfate and 4% -20% of silicon carbide micro powder; and carrying out ball-milling, carrying out filter-pressing, drying, ageing, carrying out mechanicalpressing, sintering at a temperature of 1350 DEG C -1400 DEG C in air atmosphere, and cooling to the room temperature to obtain the foaming ceramic with closed porosity up to 75%. The invention adopts the high-decomposition-temperature calcium sulfate foaming agent and the inorganic high-temperature silicon carbide oxide pore-forming agent to compositely form the pores, and can obviously increasethe closed porosity of the foaming ceramic to over 75% from 58%.

Owner:NANJING UNIV OF SCI & TECH

Micro-pore dead burned high-calcium magnesite and preparation method thereof

The invention provides micro-pore dead burned high-calcium magnesite. The micro-pore dead burned high-calcium magnesite is prepared from the following raw materials: 50 to 70 weight percent of light burned magnesium powder, 25 to 40 weight percent of light-burned dolomite powder and 5 to 10 weight percent of an additive, wherein the additive is carbonate micro-powder and the D50 value of the additive is 50 to 500nm. The micro-pore dead burned high-calcium magnesite has the beneficial effects that 1) the added carbonate micro-powder is decomposed at high temprature to generate carbon dioxide and remain a lot of air pores by adopting a carbonate micro-powder in-situ decomposition method, the added micro-powder is nano-grade micro-powder, almost air pores generated by decomposition are sealedair pores and have a small air pore diameter; components of the added carbonate micro-powder are the same as main components and impurity components are not introduced; 2) the micro-pore dead burnedhigh-calcium magnesite provided by the invention is detected to find out that the volume density is 2.80 to 3.05g / cm<3>, the porosity is greater than 3.0 percent, the ratio of the closed porosity to the total porosity is greater than 60 percent and the average pore diameter is 0.05 to 0.3mum; and 3) the dead burned high-calcium magnesite provided by the invention has the characteristics of low volume density, small average pore diameter, high closed porosity, low heat conductivity, good thermal shock stability and strong washing-out resisting and molten slag erosion resisting capabilities.

Owner:UNIV OF SCI & TECH LIAONING

Light-weight equal-diameter micro-porous corundum complex-phase sphere and preparation method thereof

The invention relates to a light-weight equal-diameter micro-porous corundum complex-phase sphere and a preparation method thereof. The preparation method includes the following steps: (A) employing 90-99 wt% of Al2O3 micro-powder and 1-10 wt% of MgO micro-powder as raw materials, adding a saccharide polymer accounting for 5-15 wt% of the raw materials, and mixing the components in a planetary ball mill; (B) adding water accounting for 6-20 wt% of the raw materials, performing rotary granulation to obtain pre-fabricated spheres; (C) mixing aluminum oxide sol and [rho]-Al2O3 micro powder according to mass ratio of (0.04-0.1):1 to prepare slurry, spraying the slurry uniformly onto the surfaces of the pre-fabricated spheres, wherein a ratio of the thickness of the slurry sprayed onto the surfaces of the pre-fabricated spheres to the radials of the pre-fabricated spheres is (0.05-0.12):1; and (D) drying the spheres and calcining the spheres at 1900-2100 DEG C for 2-5 h in an ultrahigh-temperature vertical kiln to prepare the light-weight equal-diameter micro-porous corundum complex-phase sphere. The light-weight equal-diameter micro-porous corundum complex-phase sphere is low in volume density and is less in average pore diameter, is high in closed porosity, is low in heat conductivity, is good in thermal shock stability, is washing-resistant and is strong in anti-slag-erosion capability.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing high-closed-porosity aluminium oxide-aluminium phosphate ceramic

The invention provides a method for preparing high-closed-porosity aluminium oxide-aluminium phosphate ceramic. The method is characterized by including the following steps that (1), aluminium dihydrogen phosphate and aluminium nitrate are dissolved in water, and a solution is prepared; (2), the prepared solution is dropped onto the surface of porous aluminium oxide ceramic at room temperature till the porous aluminium oxide ceramic achieves adsorption saturation; (3), the porous aluminium oxide ceramic on which the mixed solution is adsorbed is dried at the temperature of 50 DEG C; (4), a dried product is heated to 1,150 DEG C in the atmosphere and subjected to heat preservation for 2 hours, then the dried product is cooled to 800 DEG C at the speed of 5 DEG C / min and subjected to heat preservation for 2 hours, finally the product is naturally furnace-cooled to room temperature, and the high-closed-porosity aluminium oxide-aluminium phosphate ceramic is prepared, wherein the closed porosity is 39% to the maximum degree.

Owner:SHANDONG UNIV OF TECH

A kind of mullite silicon carbide microporous aggregate and preparation method thereof

The invention relates to mullite-carborundum microporous aggregates and a preparation method thereof. The technical scheme of the invention is as follows: the method comprises the steps: firstly, adding a pore former, which is 0.5wt% to 5.0wt% that of raw materials, into 45wt% to 70wt% of alumina raw material and 30wt% to 55wt% of crystalline silicon cutting waste liquid which serve as the raw materials, carrying out uniform mixing, carrying out compression molding at the pressure of 20MPa to 50MPa, carrying out natural drying, and carrying out baking for 12 to 24 hours at the temperature of 60 DEG C to 110 DEG C; then, heating the baked product to the temperature of 1,350 DEG C to 1,550 DEG C, carrying out heat preservation for 1 to 12 hours, then, naturally cooling the baked product to room temperature, and carrying out crushing, thereby preparing the mullite-carborundum microporous aggregates. The crystalline silicon cutting waste liquid contains the chemical ingredients, i.e., SiC, Si and C, wherein the content of SiC is not lower than 35wt%, the content of Si is not lower than 15wt%, and the content of C is not lower than 4wt%; the content of Al2O3 in the alumina raw material is not lower than 60wt%; the grain size of the alumina raw material is smaller than 0.074mm. The mullite-carborundum microporous aggregates and the preparation method thereof have the characteristics of low production cost, simple process, resource saving and environment protection; the prepared mullite-carborundum microporous aggregates are small in coefficient of thermal conductivity, high in strength, good in wear resistance and high in erosion capability.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing high closed porosity forsterite-aluminium phosphate ceramic

The invention relates to a method for preparing a high closed porosity forsterite-aluminium phosphate ceramic. The method is characterized by comprising the following steps: (1) dissolving aluminium dihydrogen phosphate and aluminium nitrate in water to prepare a solution; (2) dropping the prepared solution on the surface of a porous forsterite ceramic at room temperature until the porous forsterite ceramic reaches adsorption and saturation; (3) drying and adsorbing the porous forsterite ceramic of the mixed solution at 50 DEG C; and (4) heating the dried product to 1,150 DEG C under the atmosphere and preserving heat for 2 h, and cooling to 800 DEG C at the speed of 5 DEG C / min and preserving heat for 2 h, and finally naturally cooling to room temperature along with a furnace, thereby preparing the high closed porosity forsterite-aluminium phosphate ceramic. The high closed porosity forsterite-aluminium phosphate ceramic is not higher than 10% in open porosity, and is 39% in maximum closed porosity.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com