Lightweight thermal insulation board prepared from construction waste recycled fine powder and preparation method thereof

A technology for recycling fine powder and construction waste, which is applied in the recycling of waste resources and the field of green building materials, can solve the problems of not being able to comprehensively utilize construction waste, not being able to play a role in strengthening aggregates, and destroying the overall structure of cement, etc., to achieve Accelerate the alkali excitation speed, improve product market competitiveness, and improve the effect of foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, a kind of method that prepares novel light-weight heat-insulation board with construction waste regenerated fine powder:

[0033] The formula is: construction waste regenerated fine powder (through 80 mesh sieve, sieve residue ≤ 5%, SiO in chemical composition 2 、Al 2 o 3 50 parts of sodium silicate water glass (modulus 1.5, Baume degree 50°Bé), 20 parts of slag (S95 grade), 3 parts of industrial hydrogen peroxide (concentration 38%), stearic acid Calcium 0.2 parts, water 50 parts.

[0034] Industrial hydrogen peroxide is used as a foaming agent, and calcium stearate is used as a foam stabilizer.

[0035] The production process is to carry out the following steps in sequence:

[0036] (1) Add solid raw materials such as construction waste regenerated fine powder, slag, and foam stabilizer to the mixing tank according to the amount, mix for 5 minutes, and rotate at 200 rpm;

[0037] (2) Add water glass and water to the resultant of step (1), add foamin...

Embodiment 2

[0041]Embodiment 2, a kind of method that prepares novel light-weight heat-insulation board with the regenerated fine powder of construction waste:

[0042] The formula is: construction waste regenerated fine powder (through 80 mesh sieve, sieve residue ≤ 5%, SiO in chemical composition 2 、Al 2 o 3 Content sum 60%) 100 parts; Sodium silicate water glass (modulus 1.2, Baume degree 50°Bé) 10 parts, slag (S95 grade) 40 parts, industrial hydrogen peroxide (concentration 38%) 5 parts, stearic acid Sodium 0.5 parts, water 70 parts.

[0043] Industrial hydrogen peroxide is used as a foaming agent, and sodium stearate is used as a foam stabilizer.

[0044] Production process is equal to embodiment 1.

[0045] Sheet properties: dry apparent density 700kg / m 3 , compressive strength 5MPa, thermal conductivity 0.11W / (m·K).

Embodiment 3

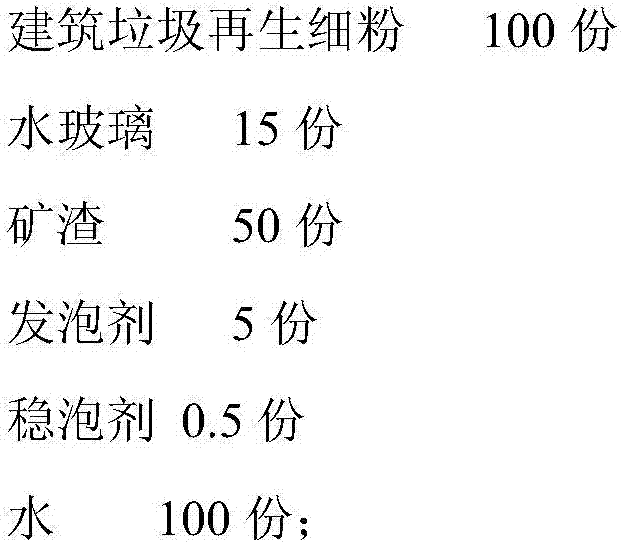

[0046] Embodiment 3, a kind of method that prepares novel light-weight heat-insulation board material with regenerated fine powder of construction waste:

[0047] The formula is: construction waste regenerated fine powder (through 80 mesh sieve, sieve residue ≤ 5%, SiO in chemical composition 2 、Al 2 o 3 Content sum 65%) 100 parts; Sodium silicate water glass (modulus 1.0, Baume degree 40°Bé) 15 parts, slag (S95 grade) 50 parts, industrial hydrogen peroxide (concentration 38%) 4 parts, stearic acid Sodium 0.4 parts, water 80 parts.

[0048] Industrial hydrogen peroxide is used as a foaming agent, and sodium stearate is used as a foam stabilizer.

[0049] Production process is equal to embodiment 1.

[0050] Sheet properties: dry apparent density 600kg / m 3 , compressive strength 6MPa, thermal conductivity 0.08W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com