Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Strong resistance to slag erosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

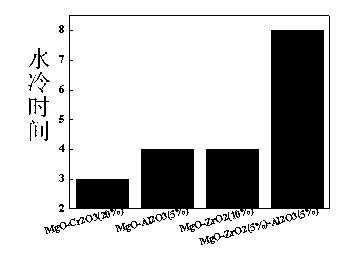

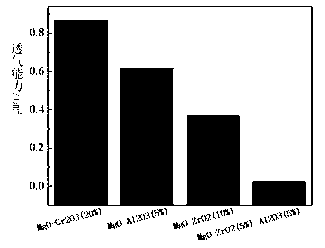

Magnesium-zirconium brick with high erosion resistance and thermal shock resistance for RH furnace and production technology thereof

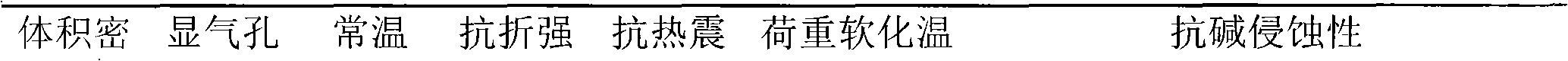

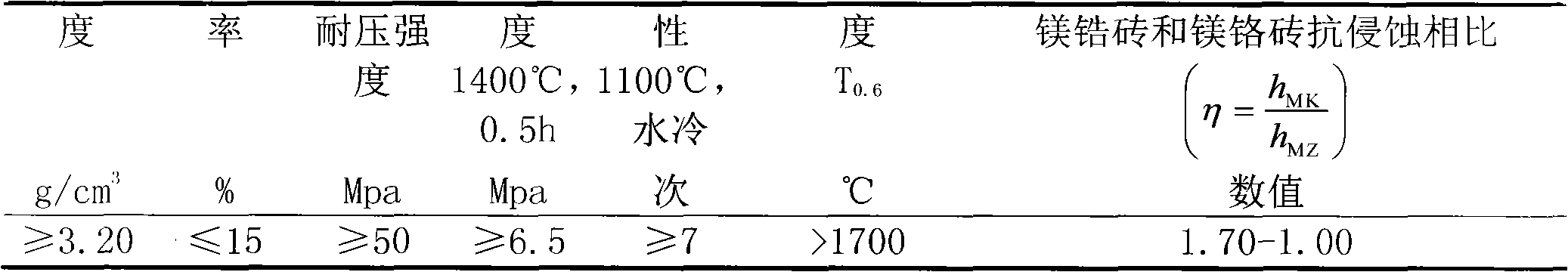

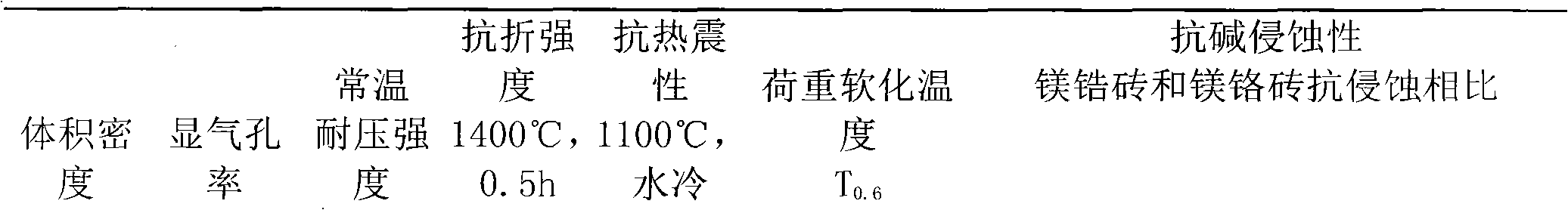

The invention relates to a magnesium-zirconium brick with high erosion resistance and thermal shock resistance for an RH furnace and a production technology thereof. The brick comprises the following components by weight percent: 76-90% of MgO and 5-21% of ZrO2; and the firing temperature of the brick is 1680-1840 DEG C. The production technology comprises the following steps: pretreating magnesia and zirconia, synthesizing the magnesia and zirconia into magnesium-zirconium sand; crushing synthesized magnesium-zirconium sand and fused magnesia to 5-3mm, 3-1mm and 1-0mm particles; homogenizing under strong force and mixing the granular materials, 150-200 mesh magnesia and magnesium-zirconium sand powder, 200-250 mesh zirconia powder, additives CaO and Y2O3 and binder paper pulp water liquid and performing compression moulding; baking at 120 DEG C for 24-72 hours; and heating to 1680-1840 DEG C and maintaining the temperature for 3-5 hours. The linear change of the finished brick is within the range of + / -0.5%; and after being baked, the brick has no surface chap defect caused by the phase change of zirconia and has excellent refinery cinder erosion resistance and thermal shock resistance.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Light-weight corundum-spinel castable and preparation method thereof

The invention relates to a light-weight corundum-spinel castable and a preparation method thereof. The preparation method includes following steps: (A) employing 60-75 wt% of equal-diameter micro-porous corundum spheres as an aggregate, and employing 8-12 wt% of electric-fused white corundum fine powder, 2-8 wt% of electric-fused magnesite fine powder, 2-8 wt% of magnesium aluminate spinel fine powder, 6-12 wt% of [alpha]-Al2O3 micro powder, 0.5-2.5 wt% of chromium oxide powder and 3-7 wt% of an aluminum silicone gel powder as substrate materials, wherein the aggregate and the substrate materials form a raw material in total; (B) employing organic fibers accounting for 0.02-0.08 wt% of the raw material and a polycarboxylate water reducer accounting for 0.05-0.12 wt% of the raw material as additive materials, pre-mixing the substrate material with the additive materials and adding the aggregate with uniform mixing; (C) adding water accounting for 3-5 wt% of the raw material, stirring the mixture and performing cast moulding; and (D) maintaining the temperature at 110-200 DEG C for 12-48 h, roasting the moulded product at 800-1200 DEG C for 24-72 h to obtain the light-weight corundum-spinel castable. The light-weight corundum-spinel castable is low in apparent porosity, is low in volume density, is low in heat conductivity, is strong in anti-slag-erosion capability and is long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Ladle bottom castable and preparation method thereof

The invention relates to a ladle bottom castable and a preparation method thereof. The technical scheme is as follows: 60-70wt% of titanium-iron slag particles are taken as aggregate, and 25-35wt% of titanium-iron slag fine powder, 1-4wt% of zirconia micro powder and 2-5wt% of titanium oxide micro powder are taken as substrate materials; according to the content of the aggregate and the substrate materials, the substrate materials are uniformly mixed firstly, and then the uniformly mixed substrate materials are added to the aggregate to be uniformly mixed; silica sol accounting for 3-7wt% of the sum of the substrate materials and the aggregate is added, and the mixture is uniformly stirred, subjected to vibratory compaction, cured for 6-12 h under the condition of room temperature and finally subjected to heat preservation for 12-24 h under the condition of 90-110 DEG C to prepare the ladle bottom castable. The ladle bottom castable and the preparation method have the characteristics of low cost and simple process, and the prepared ladle bottom castable has good high-temperature volume stability and good corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH +1

Micro closed-cell light-weight corundum refractory aggregate and preparation method thereof

The invention relates to a micro closed-cell light-weight corundum refractory aggregate and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: by using 45-65 wt% of gamma-Al2O3 fine powder, 30-50 wt% of alpha-Al2O3 micropowder and 1-10 wt% of nano aluminum oxide micropowder as raw materials, adding water accounting for 40-80 wt% of the raw materials, and carrying out wet milling with a planet ball mill for 0.5-3 hours; putting the slurry subjected to wet milling in a mold, standing at room temperature for 12-24 hours, and stripping; and drying at 110-200 DEG C for 12-36 hours, and keeping the temperature at 1750-1900 DEG C for 1-8 hours to obtain the micro closed-cell light-weight corundum refractory aggregate. The micro closed-cell light-weight corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, low volume density, small average pore size, lower heat conductivity and high molten slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Molten-slag-resistant spray paint for lade and application method thereof

The invention provides molten-slag-resistant spray paint for a ladle. The molten-slag-resistant spray paint comprises the following components in percentage by weight: 70-80 percent of aggregate, 16-25 percent of a bonding agent, 1-10 percent of a molten-slag-resistant functional additive and 0.01-1 percent of an additional additive, wherein the bonding agent is a composite bonding agent, and comprises silica powder, silicate cement, sodium silicate powder and bentonite. A method for applying the spray paint comprises the following steps: firstly, preparing a mixture in the weight ratio; secondly, adding water in an amount of 5-8 percent based on the weight of the mixture under strong stirring; and lastly, spraying the mixture onto a molten slag resisting position on the ladle through a spray gun. Compared with the prior art, the molten-slag-resistant spray paint provided by the invention has the advantages of high strength, high molten slag resistance, molten slag erosion resistance, oxidation resistance and high thermal shock resistance. Moreover, a waste sliding plate reclaimed material is taken as a main component for the aggregate of the molten-slag-resistant spray paint, so that the production cost of the molten-slag-resistant spray paint is lowered greatly, and high comprehensive benefit is achieved.

Owner:北京利尔高温材料股份有限公司

Modified high-purity magnesium aluminate spinel composite brick and preparation method thereof

The invention belongs to the technical field of a high-grade refractory matter for metallurgy, coloring, glass and cement kilns, and preparation thereof, and particularly relates to a modified high-purity magnesium aluminate spinel composite brick and a preparation method thereof. Aggregate is prepared from the following raw materials in parts by weight: 65 to 80 parts of high-purity magnesia and 15 to 35 parts of high-purity magnesium aluminate spinel; powder materials are prepared from the following raw materials in parts by weight: 1 to 5 parts of fused magnesia powder, 1 to 5 parts of fused magnesia-alumina spinel, 1 to 3 parts of fused magnesia-alumina spinel micro powder, 1 to 3 parts of desilicication zirconia, 1 to 3 parts of titanium oxide, 0.1 to 0.5 part of sintering agents, 1 to 3 parts of active aluminum oxide micro powder and 3 to 4 parts of combining agents. The modified high-purity magnesium aluminate spinel composite brick has the advantages that the purity is high; the density is great; the strength is high; the high-temperature thermal shock stability is good; the corrosion resistant performance is high; the molten metal resistant and antioxidation capability is high; no harmful gas is exhausted; green refractory material standards are conformed. The preparation method is simple; the cost is low; no carbon and no chrome are discharged; no pollution occurs; practical applicability is realized.

Owner:大石桥市中建镁砖有限公司

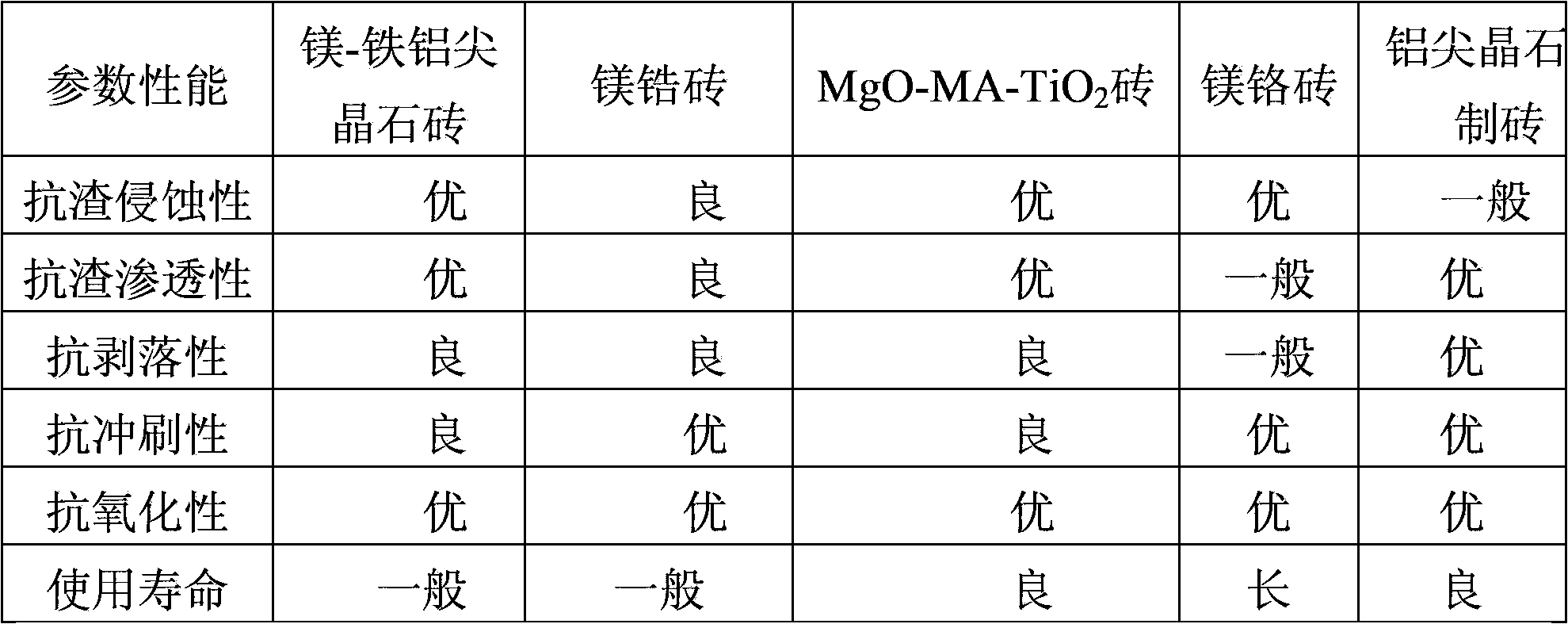

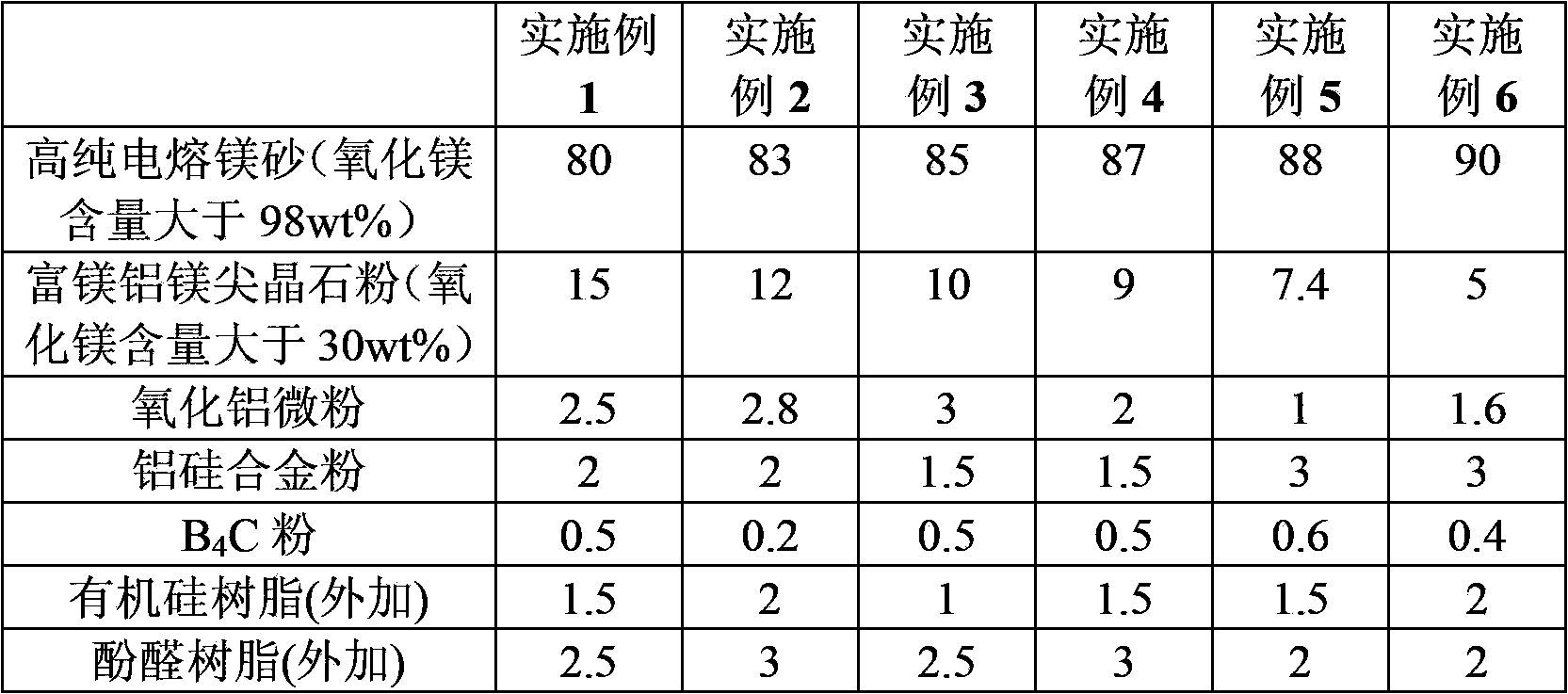

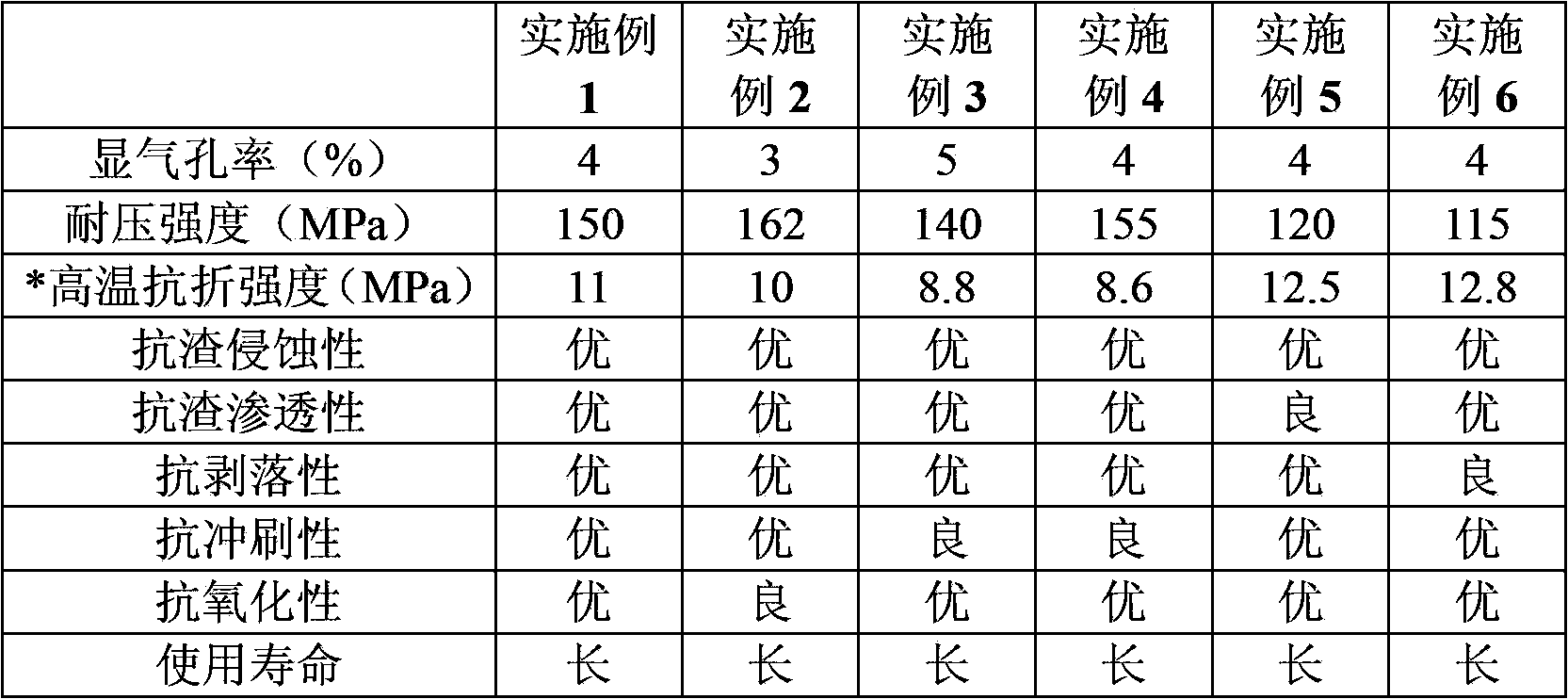

Unfired magnesia-alumina spinel brick

The invention discloses an unfired magnesia-alumina spinel brick. The unfired magnesia-alumina spinel brick comprises the following chemical components by mass: 80 to 90% of fused magnesia, 5 to 15% of magnesium-rich magnesia-alumina spinel, 1 to 3% of micro alumina powder, 1 to 3% of aluminum-silicon alloy powder and 0.2 to 0.6% of B4C. The chemical components are bonded together by using 3.5 to 5 wt% of an added binder. The content of magnesium oxide in the fused magnesia is greater than 98 wt%, and the content of magnesium oxide in the magnesium-rich magnesia-alumina spinel is greater than 30 wt%. The unfired magnesia-alumina spinel brick provided by the invention has excellent slag reaction resistance, slag penetration resistance, anti-stripping performance, anti-scouring performance, resistance to oxidation and a long service life, does not include the harmful element--chromium, avoids pollution and harm to human beings and the environment, needs low production cost and has a wide application scope.

Owner:BAOSHAN IRON & STEEL CO LTD

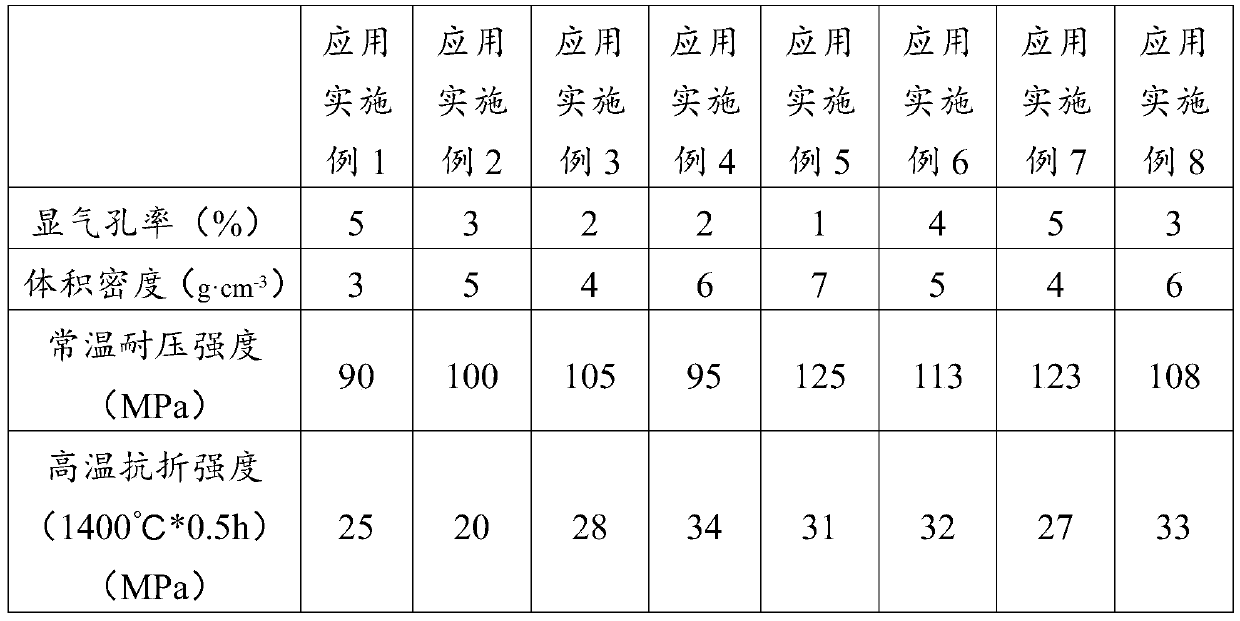

MgAlON combined aluminum magenisum permeable brick and preparation method thereof

The invention particularly relates to an MgAlON combined aluminum magenisum permeable brick and a preparation method of the MgAlON combined aluminum magenisum permeable brick. The technical scheme comprises the following steps of: taking 55-65 wt% of sintered corundum grains, 25-35 wt% of aluminum oxide fine powder, 2-10 wt% of metal aluminum powder and 2-10 wt% of fused magnesite fine powder as raw materials; then, additionally adding phenolic resin which is 2-6 wt% of the raw materials and grinding and agitating; carrying out mechanical pressing; drying under the condition of 180-220 DEG C for 12-24 hours; raising the temperature to 1500-1700 DEG C by a temperature-rising speed of 2-5 DEG C / min; and keeping the heat for 3-5 hours to prepare the MgAlON combined aluminum magenisum permeable brick. The prepared MgAlON combined aluminum magenisum permeable brick has the characteristics of high density, larger high-temperature strength, good thermal shock resistance, capability of being not wetted by liquid steel and strong corrosion resistance to slag.

Owner:WUHAN UNIV OF SCI & TECH

Sailon corundum refractory material for permeable ladle stopper and its prepn process

The refractory sialon corundum brick material for permeable ladle stopper is prepared with corundum 65-75 wt%, metal silicon powder 5-12 wt%, alumina powder 3-10 wt%, silica powder 1-5 wt%, pure calcium aluminate cement 0-8 wt%, dispersed alumina 0-10 wt%, water reducing agent 4-6 wt% and water 4-6 wt%, and through stirring, vibration forming, pouring to form permeating pre-fabricated part, drying, and nitrogenating and sintering directly in nitrogen atmosphere. The present invention has simple preparation process, low treating temperature, cheap material, and the prepared refractory material has excellent slag resistance, excellent molten iron fuse loss resistance, high heat shock stability, high wear resistance and high finished product rate.

Owner:WUHAN UNIV OF SCI & TECH

High-density ultrahigh-purity magnesia-calcium brick and preparation method thereof

The invention discloses a high-density ultrahigh-purity magnesia-calcium brick and a preparation method thereof. The high-density ultrahigh-purity magnesia-calcium brick is prepared from 9 to 16% of magnesia-calcium sand having particle sizes of 5-7mm, 9 to 16% of magnesia-calcium sand having particle sizes of 3-5mm, 9 to 16% of magnesia-calcium sand having particle sizes of 1-3mm, 13 to 32% of magnesia-calcium sand having particle sizes of 0.5-1mm, 5 to 25% of magnesia-calcium sand having particle sizes less than or equal to 0.5mm, 5 to 10% of high-purity magnesia sand fine powder having particle sizes less than or equal to 0.044mm, 2 to 5% of tar resin or paraffin, and 2 to 5% of fused zirconia. The preparation method comprises the following steps of raw material proportioning, raw material blending, mixing, molding, sintering, waxing and vacuum aluminium foil package. The high-density ultrahigh-purity magnesia-calcium brick has a high product compact degree and excellent hydration resistance. The high-density ultrahigh-purity magnesia-calcium brick has high purity and thus high slag corrosion resistance and high flushing resistance are obtained. Compared with other like products, the high-density ultrahigh-purity magnesia-calcium brick has better thermal shock resistance. The high-density ultrahigh-purity magnesia-calcium brick contains a large amount of dissociative CaO and thus the high-density ultrahigh-purity magnesia-calcium brick has excellent molten steel cleaning performances and is especially suitable for production of high cleanliness steel such as stainless steel.

Owner:PERFECT WORLD CO LTD

Ladle kerb casting material and ladle kerb preparation method thereof

The invention relates to ladle kerb casting material and a ladle kerb preparation method by the ladle kerb casting material. The casting material comprises the following components in weight percentage: 60-82% of ladle lining waste having a grain size of 1-8mm, 10-20% of bauxite grain size of 0.044-1mm, 2-10% of silicon dioxide superfine(less than or equal to 0.02mum), 5-10% of magnesium oxide fine powder grain size of 0.044-0.088 and 0.01-1% of sodium polyphosphate. The preparation method comprises ladle kerb lining waste selecting, crushing, mixing evenly and adding water while stirring, casting, maintaining, baking and the like. The waste ladle kerb casting material is recycled by the preparation method so that the production cost of the fireproof materials and the steel-making cost can be obviously reduced, the economic benefit is improved and the social meaning of protecting environment and saving energy can be realized; the ladle kerb prepared by the ladle kerb casting material has the advantages of good high-temperature volume stability, enough common / medium / high temperature strength, strong anti-slag corrosion and anti erosion-corrosion, thus satisfying the requirements for maintaining the normal running of the ladles.

Owner:HENAN GENGSHENG REFRACTORIES

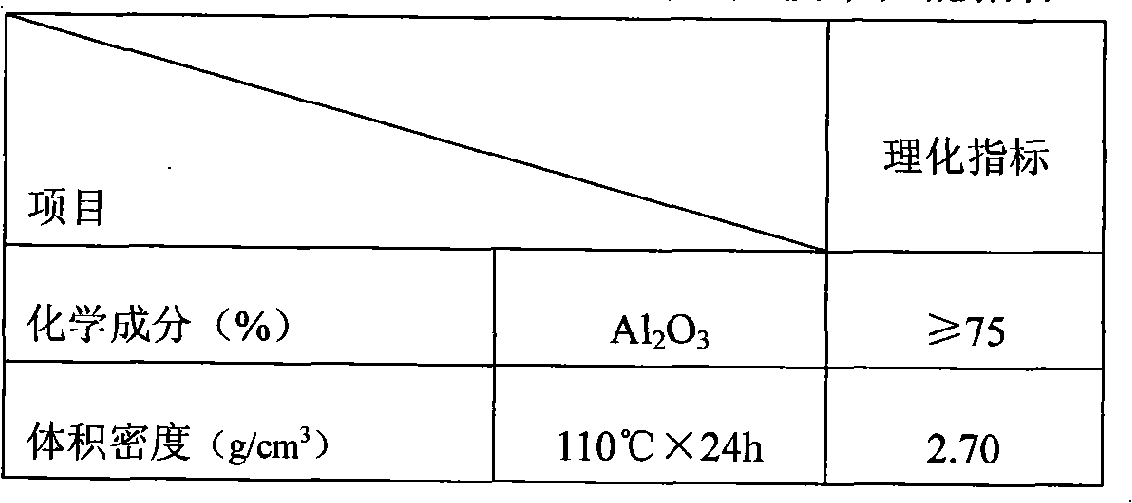

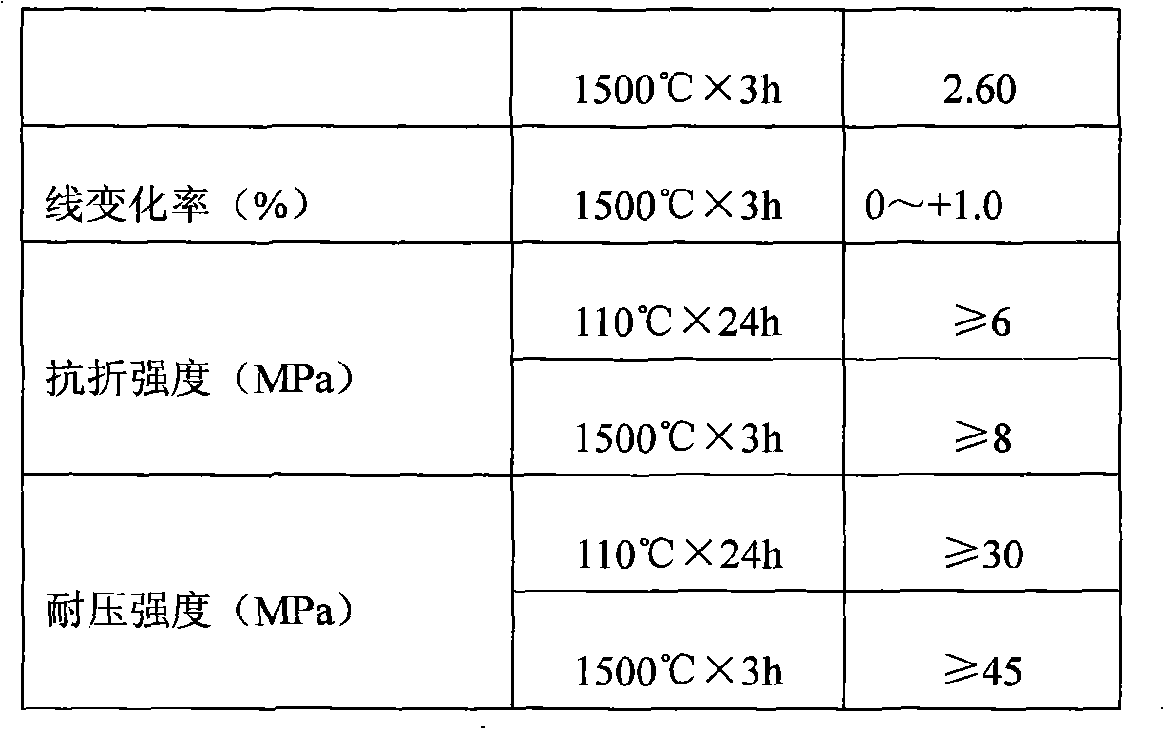

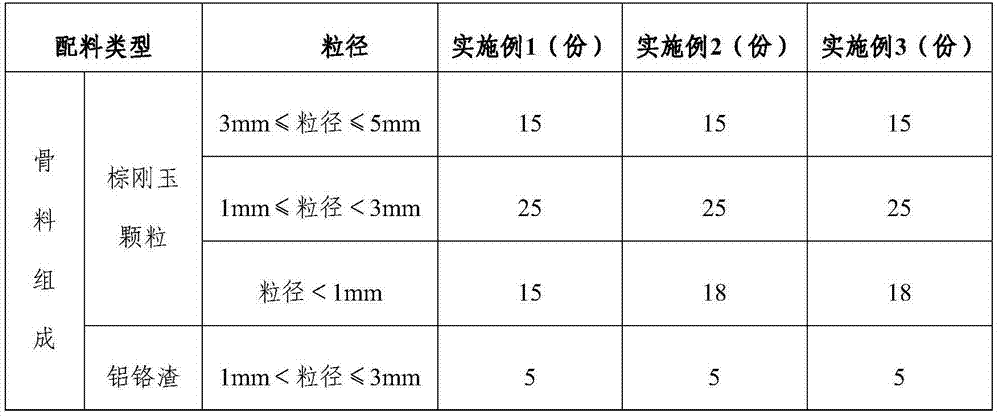

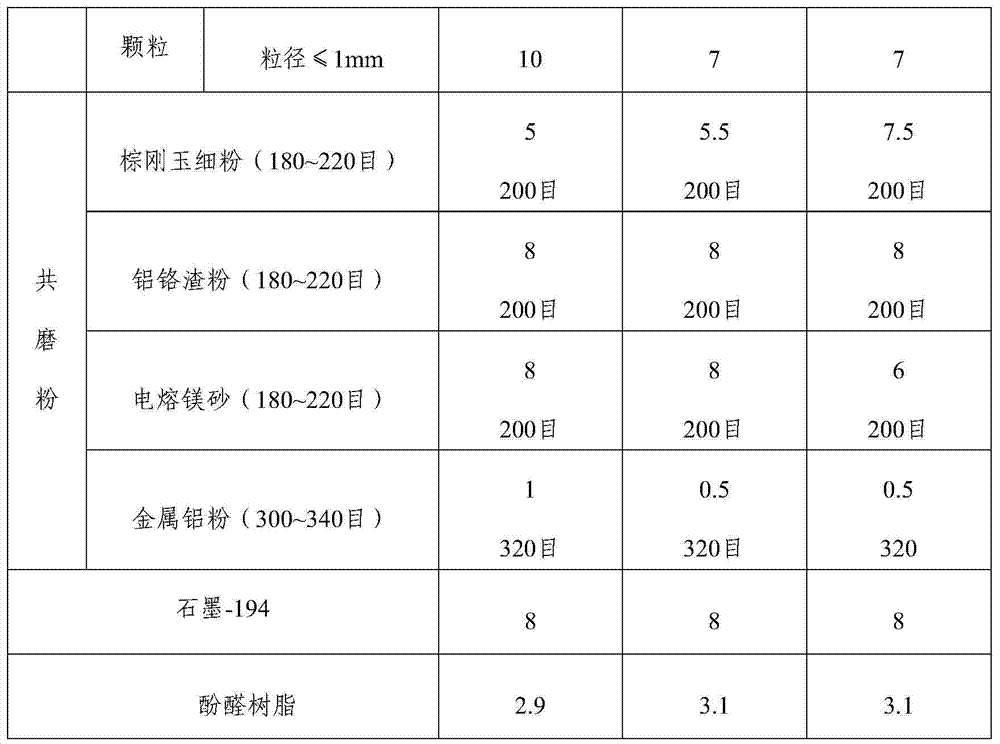

Alumina-spinel-carbon brick containing aluminachrome slag and preparation method of alumina-spinel-carbon brick

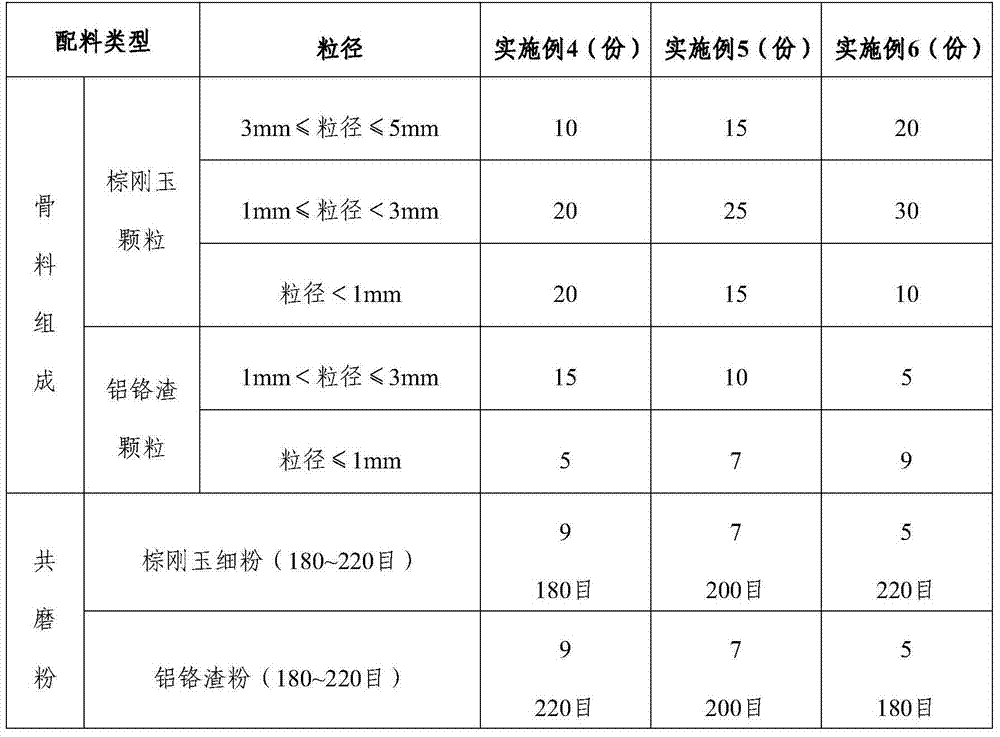

The invention relates to a refractory matter, and particularly relates to an alumina-spinel-carbon brick containing aluminachrome slag and a preparation method of thee alumina-spinel-carbon brick. The alumina-spinel-carbon brick is prepared from the following raw materials in parts by weight: 50-65 parts of brown fused alumina particles with the particle sizes of smaller than or equal to 5mm, 5-20 parts of aluminachrome slag particles with the particle sizes of smaller than or equal to 3mm, 5-15 parts of 180-220meshbrown aluminum oxide powder, 5-10 parts of 180-220mesh aluminachrome slag powder, 6-15 parts of 180-220mesh fused magnesite powder, 0.3-1.0 part of 300-340mesh metal aluminum powder, 6-12 parts of graphite and 2-4 parts of a binding agent. The alumina-spinel-carbon brick provided by the invention is high in strength, stable in chemical property, and excellent in slag corrosion resistance; and the aluminachrome slag component is added, and reacts with magnesia powder at a high temperature, so as to form a spinel structure, so that the anti-erosion properties and slag resistance of the alumina-spinel-carbon brick are enhanced.

Owner:北京利尔高温材料股份有限公司

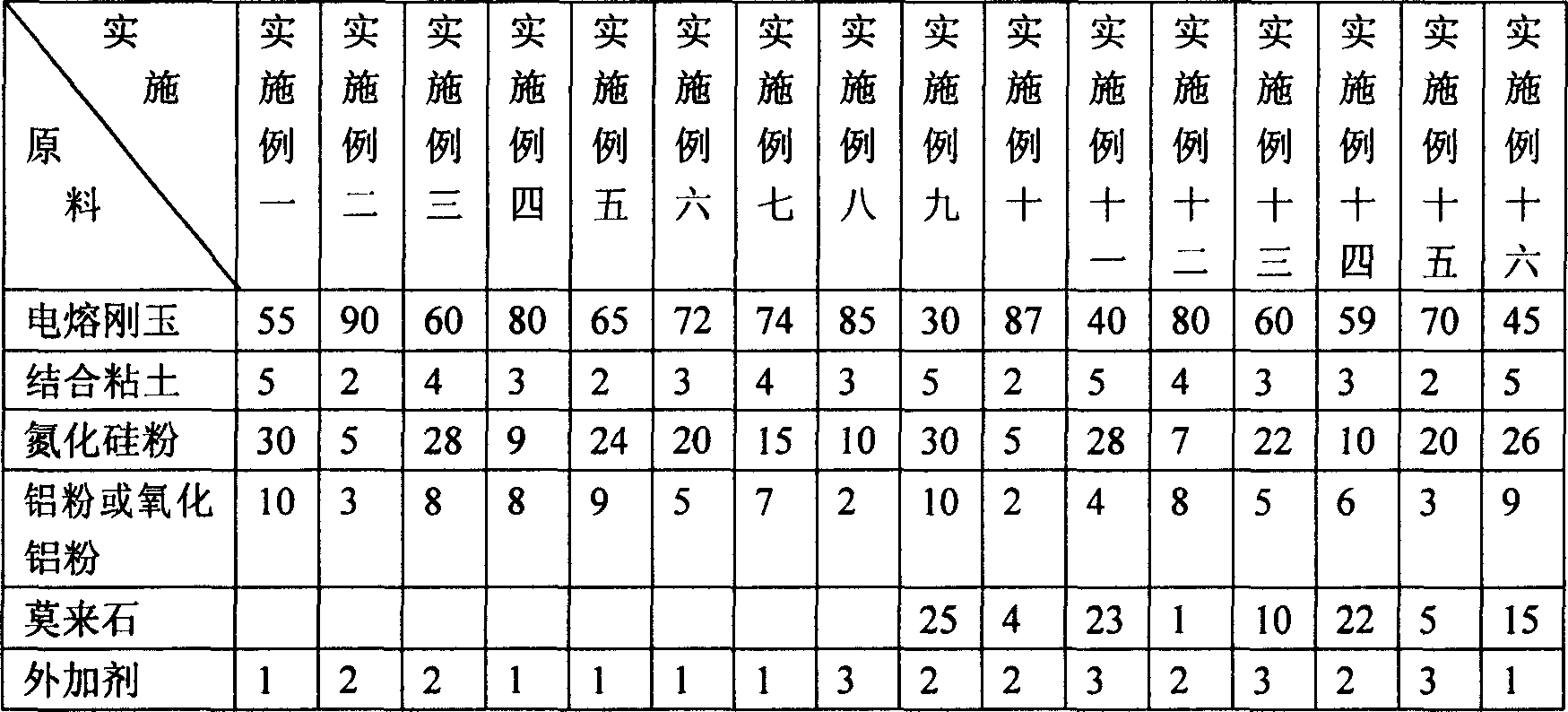

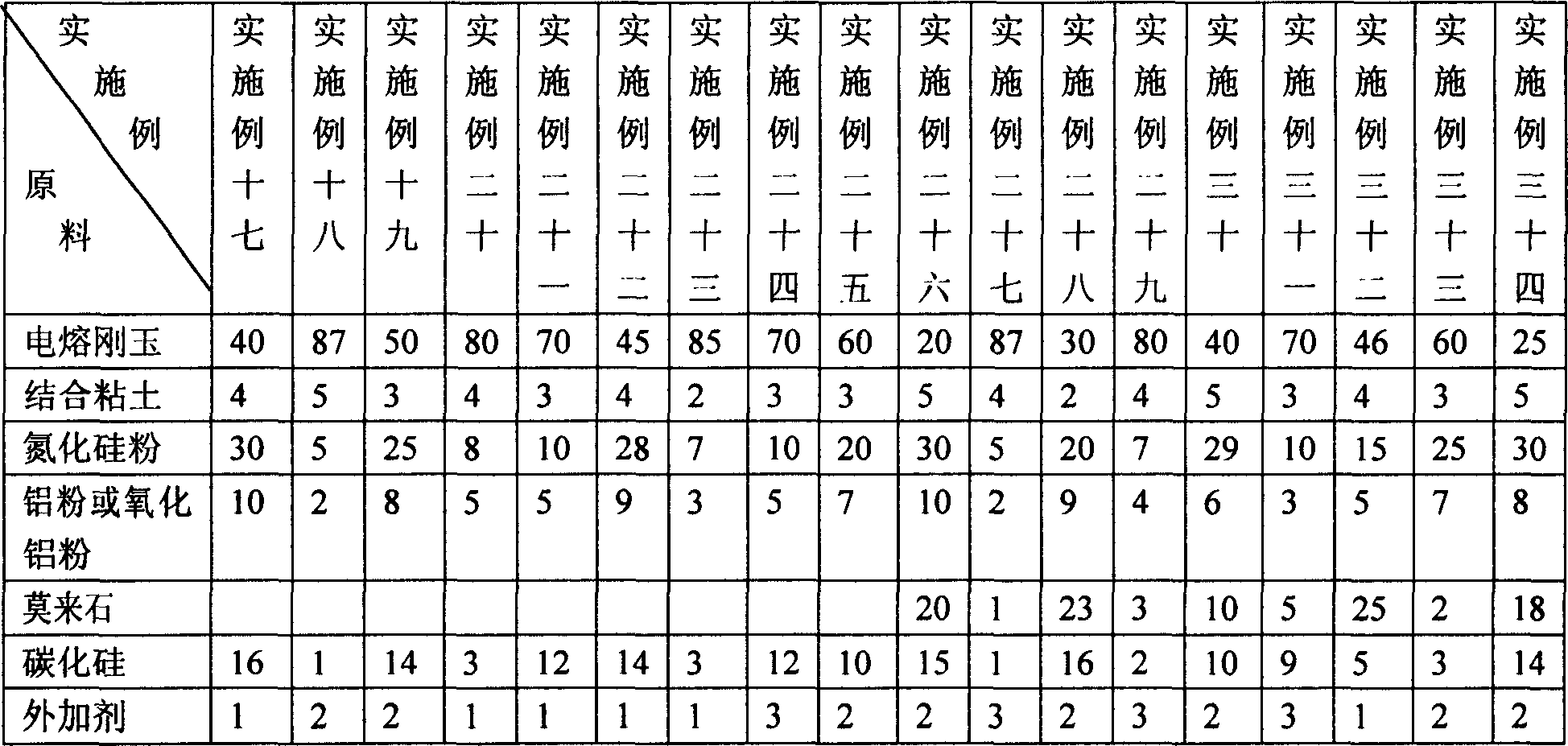

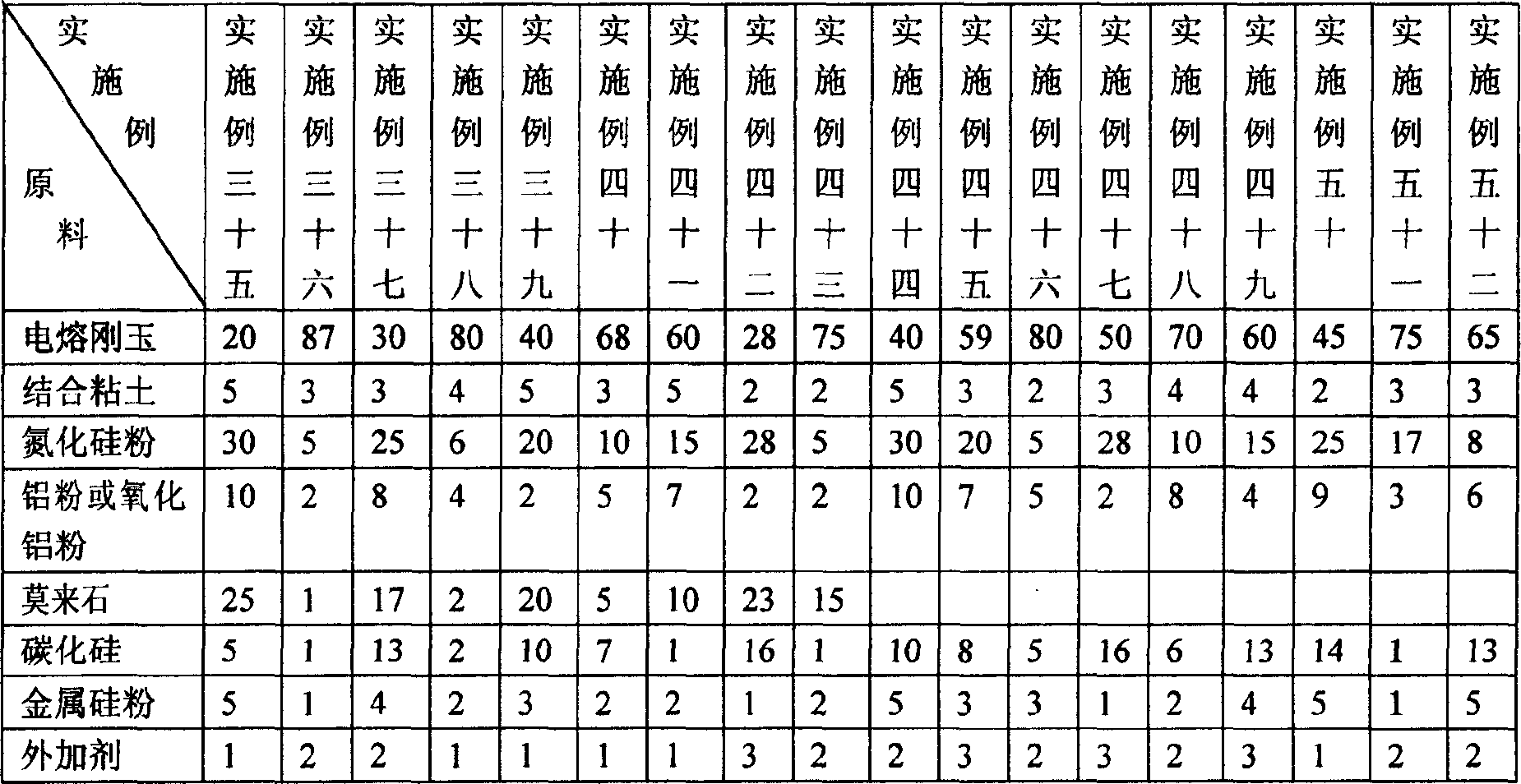

Compound Sialon-corundum fire brick series and its production process

InactiveCN1810724AImprove antioxidant capacityExtended service lifeCeramic shaping apparatusSlagNitrogen gas

The production process of compound sialon-corundum fire brick includes mixing the materials comprising fused corundum of 0.088-5 mm granularity 55-90 wt%, 180-mesh binding clay 2-5 wt%, 240-1000 mesh aluminum powder or active alumina powder 2-10 wt%, 200-500 mesh silicon nitride powder 5-30 wt% and binding agent 1-3 wt%; pressing to form; drying; and sintering in a kiln in nitrogen atmosphere or reducing atmosphere. The compound sialon-corundum fire brick has high heat performance and priority of resisting chemical corrosion of molten iron, slag, alkali, etc, and may be used widely in the work layer in large and middle sized blast furnace to prolong the life of blast furnace and purify molten iron.

Owner:郑州华宇高炉工程技术有限公司

Rotary blowing rotor produced with combination of plumbago and ceramic

InactiveCN101270414AGood high temperature oxidation resistanceImprove thermal shock resistanceMovable spraying apparatusCeramic compositeSlag

A rotor of rotary impeller of compositing graphite and ceramic belongs to the field of the purification treatment of aluminum melt. The invention comprises a graphite nozzle and a graphite-ceramic composite nozzle. The graphite nozzle is connected with the graphite-ceramic composite nozzle. The graphite-ceramic composite nozzle comprises two parts, and the internal part is a graphite tube which is covered with a ceramic bushing. The internal part of the graphite-ceramic composite nozzle is a through hole which is a gas channel. The graphite nozzle is equipped with a jet orifice for gas ejection. The ceramic material is silicon nitride bonded silicon carbide material, and the component and the weight percent are: 45 to 70 percent of silicon nitride and 30 to 55 percent of silicon powder. The ceramic material of the invention has the advantages of the good high temperature oxidation resistance, the good thermal shock resistance, the strong slag corrosion resistance, the high strength and the wear resistant, preventing from the erosion and oxidation of the graphite tube from aluminum liquid and air, thereby achieving the longer service life of the rotor of rotary impeller of compositing graphite and ceramic than that of the original rotor of rotary impeller with full graphite material.

Owner:SHANGHAI JIAO TONG UNIV

Unfired modified high-purity magnesium-aluminum spinel composite bricks and preparation method

The invention belongs to the technical field of high-grade fireproof materials for metallurgy, non-ferrous metal, glass and cement kilns and preparation methods thereof, and in particular relates to unfired modified high-purity magnesium-aluminum spinel composite bricks and a preparation method thereof. The unfired modified high-purity magnesium-aluminum spinel composite bricks take high-purity magnesia powder with the magnesium content of 99 percent as a raw material; a complexed magnesium-aluminum cementing agent and rare-earth oxide are used for modifying the magnesium-aluminum spinel composite bricks for the first time; a preparation process adopts an electric energy low-temperature drying technology to prepare at 200 DEG C. The unfired modified high-purity magnesium-aluminum spinel composite bricks provided by the invention have the advantages of high purity, great density, high strength, good high-temperature thermal shock durability, high corrosion resistance and high molten metal resistance and anti-oxidization capability, no emission of harmful gas and accordance with green refractory standards and the like; the preparation method is simple and high-temperature firing is not needed; the cost is low and no carbon and no chromium are discharged by the raw materials; magnesium-carbon bricks and magnesium-chromium bricks, which are used for a steel ladle, are replaced, and carbon-free and chromium-free emission is realized; the preparation method has no pollution and zero emission; molten steel is cleaned, energy saving and emission reduction are realized and the preparation is safe.

Owner:沈阳罗泰智能系统有限公司

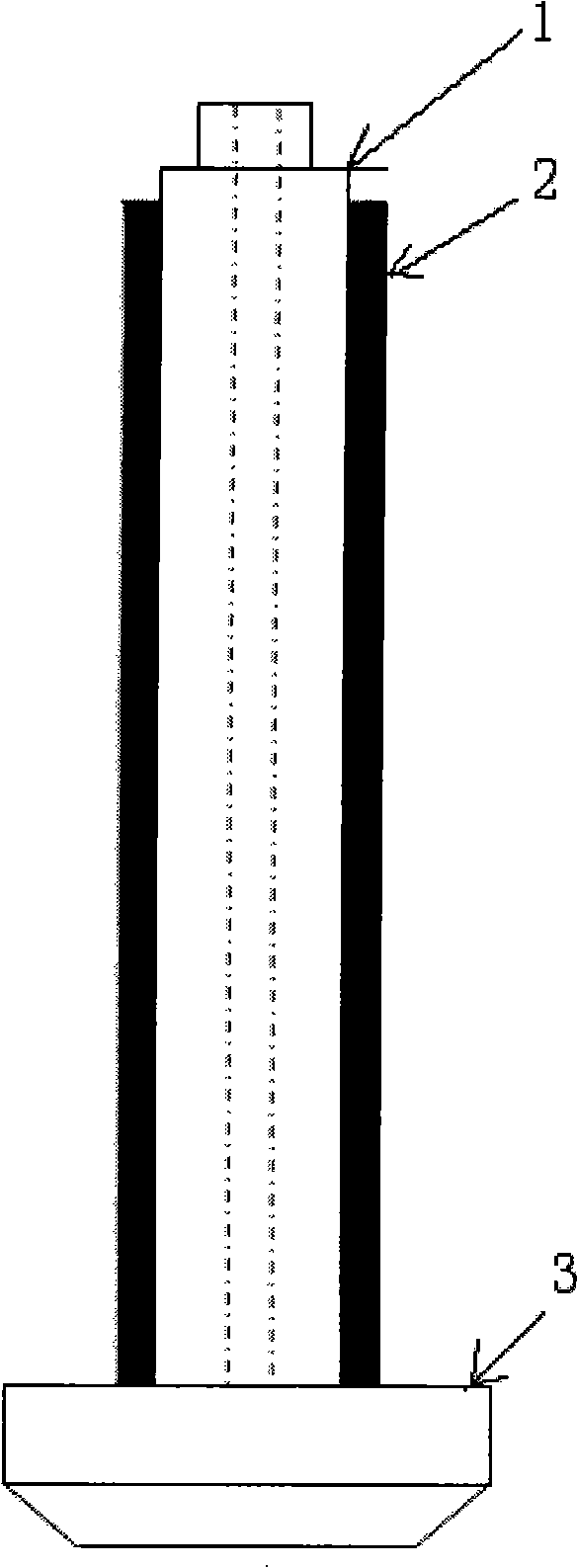

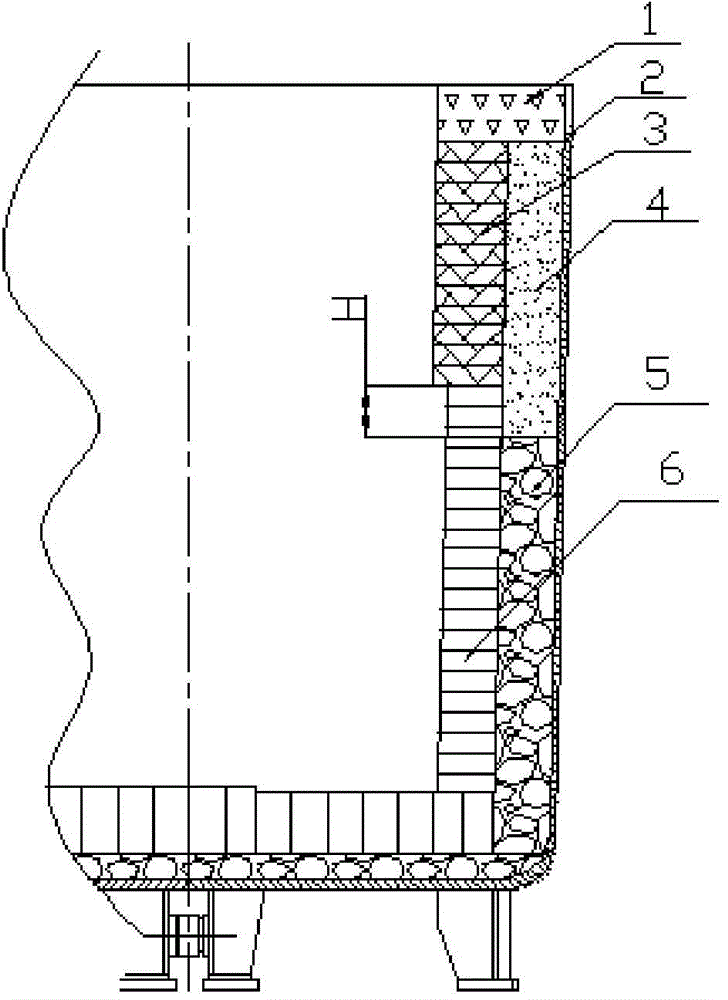

Combined type steel ladle permanent layer casting body

ActiveCN104972103AImprove securityStrong resistance to slag erosionMelt-holding vesselsMelting tankSlag

The invention discloses a combined type steel ladle permanent layer casting body which comprises an upper casting body portion and a lower casting body portion. The combination position of the upper casting body portion and the lower casting body portion is lower than that of a work layer of a slag line and a work layer of a molten pool, and the height difference H of the combination positions is equal to 500 mm to 600 mm. The upper casting body portion is formed by casting magnesium-chromium castable. The lower casting body portion is formed by casting alumina-magnesia castable prepared from corundum reclaimed materials. The upper portion and the lower portion of a steel ladle permanent layer are formed by casting castable of different materials in a combined mode, and the magnesium-chromium fireproof castable is adopted in the upper portion; the excellent scouring preventing performance, molten steel washing preventing performance and high-temperature use strength are achieved; slag corrosion and washing of molten steel can be effectively resisted, and then the use safety coefficient of a steel ladle is improved by 5-8 times. The alumina-magnesia castable prepared from the corundum reclaimed materials is adopted in the lower portion; the service life is long, and meanwhile manufacturing cost is greatly lowered, and cost performance is improved; the problem that fireproof material resources are in short supply is effectively solved.

Owner:WUGANG REFRACTORY CO LTD

Environment-friendly metallurgical magnesite and preparation method thereof

The invention discloses an environment-friendly metallurgical magnesite and a preparation method thereof. The environment-friendly metallurgical magnesite comprises the following raw materials in percent by weight: 25%-35% of forsterite, 10%-20% of 92-fused magnesite, 20%-30% of medium magnesia, 10%-25% of medium magnesia powder, 5%-10% of brown fused alumina powder, 3%-8% of a binding agent and 0.3%-0.4% of additive. The environment-friendly metallurgical magnesite is prepared from the raw materials, including forsterite, magnesia, brown aluminum oxide, silica powder, and the like; the environment-friendly metallurgical magnesite has the advantages of high compactness, high strength, excellent anti-scouring property and high construction liquidity; nontoxic and pollution-free binding agent is used for replacing chromic anhydride, so that the prepared metallurgical magnesite meets the construction and use requirements and is environment-friendly.

Owner:云南濮耐昆钢高温材料有限公司

Unfired alumina-magnesite carbon brick and preparation method thereof

The invention belongs to the technical fields of advanced fireproof materials for electric furnaces, converter linings and steel ladle linings and preparation thereof, and relates to an unfired alumina-magnesite carbon brick and a preparation method thereof. The unfired alumina-magnesite carbon brick is prepared from aggregate, powder, an additive and a binding agent in parts by weight: 60 to 70 parts of brown aluminum oxide and / or special alumina; 1 to 3 parts of magnesium aluminate spinel, 9 to 11 parts of high-purity magnesia, and 11 to 13 parts of sub-white corundum; 2 to 4 parts of the additive; 5 to 7 parts of graphite, 1 to 3 parts of high-temperature pitch, 0.2 to 0.5 part of rare earth oxide, 3 to 5 parts of a ceramic binding agent, 3 to 4 parts of a complexing magnalium grouting agent and 1 to 3 parts of water. The unfired alumina-magnesite carbon brick has the advantages that the preparation method is simple and safe, the cost is low, high-temperature firing is not needed, the density is large and the strength is high.

Owner:大石桥市冠诚耐火材料有限公司

Copper smelting converter tuyere brick and preparation method thereof

The invention relates to a copper smelting converter tuyere brick and a preparation method thereof. According to the technical scheme, 60-65wt% of fused magnesite chrome particles serve as aggregate, and 15-20wt% of fused magnesite fine powder, 11-16wt% of Cr7C3 fine powder, 4-7wt% of zirconia micro powder and 1-3wt% of yttria micro powder serve as matrix materials; the matrix materials are evenly mixed according to the contents of the aggregate and the matrix materials and then added into the aggregate, and the matrix materials and the aggregate are evenly mixed; then, zirconia sol accounting for 8-10wt% of the sum of the matrix materials and the aggregate is added and evenly mixed, forming is carried out, and the mixture is cured for 12-24 h at 25-30 DEG C and dried for 12-18 h at 110-120 DEG C; finally, the mixture is put into a muffle and heated to 1550-1580 DEG C at the heating rate of 4-5 DEG C / min, heat preservation is carried out for 2-3 h, furnace cooling is carried out, and the copper smelting converter tuyere brick is obtained. The process is simple; the prepared copper smelting converter tuyere brick is large in strength, high in slag corrosion resistance, excellent in thermal shock resistance and good in volume stability.

Owner:WUHAN UNIV OF SCI & TECH

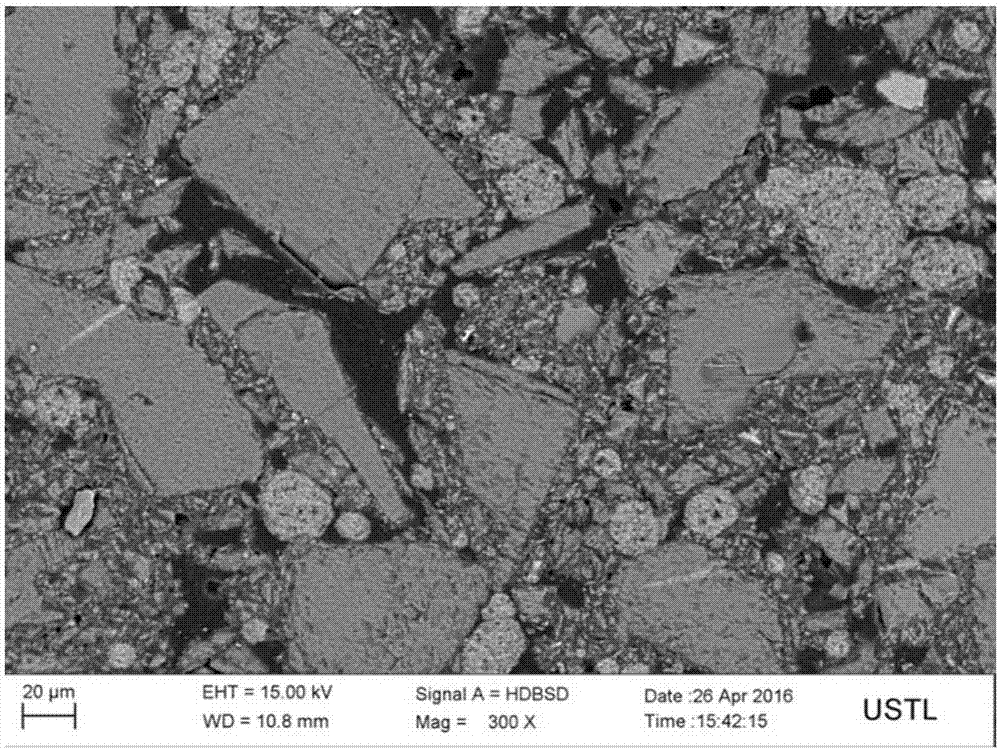

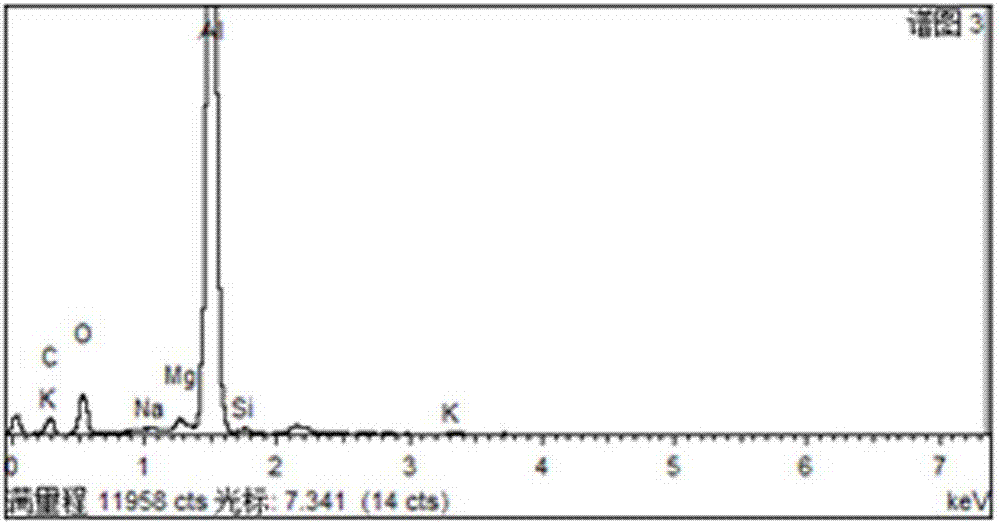

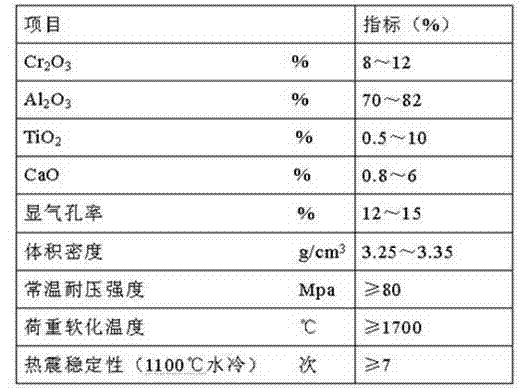

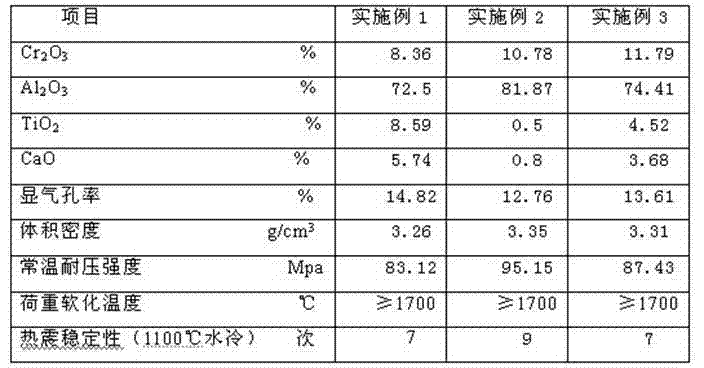

Chrome corundum-titanium brick and production method thereof

ActiveCN103896608APromote densificationImproved thermal shock stabilityCompression moldingO-Phosphoric Acid

The invention provides a production method of a chrome corundum-titanium brick. The production method comprises the steps of mixing chrome corundum materials with grain sizes of 5-3mm, 3-1mm, 1-0mm, 180 meshes and 325 meshes, adding phosphoric acid, stirring the materials uniformly, and putting the materials for not less than 24 hours; adding titanium dioxide or high titanium slag to the chrome corundum mixture subjected to ageing to be mixed, then adding lime and mixing the materials uniformly, thus obtaining a mixture; then adding aluminium dihydrogen phosphate to carry out mulling; carrying out compression molding and high-temperature firing, thus obtaining the chrome corundum-titanium brick. The production method has the advantages that the production method is simple in process, is low in cost, can improve the thermal shock stability of the product, and ensures a good slag corrosion resistance effect; calcium titanate is generated by adopting titanium oxide and calcium oxide at high temperature, the melting point is as high as 1850 DEG C, and the slag corrosion resistance capacity is strong; the thermal shock stability of the produced chrome corundum-titanium brick is not less than seven times, so that the chrome corundum-titanium brick can meet the using requirements of special parts of non-ferrous metallurgical furnaces.

Owner:锦州集信高温材料有限公司

Light-weight composite corundum refractory aggregate, and preparation method for light-weight composite corundum refractory aggregate

The invention relates to a light-weight composite corundum refractory aggregate, and a preparation method for the light-weight composite corundum refractory aggregate. According to the technical scheme, the preparation method comprises the following steps: taking 80-95 wt% of gamma-Al2O3 fine powder, 1-10 wt% of Al(OH)3 micro powder, 1-10 wt% of a glycopolymer and 0.1-5 wt% of an antifreeze protein as raw materials, adding 20-60 wt% of water, and conducting wet grinding; pelleting slurry obtained after wet grinding into particles with the grain sizes being 1-2.5 mm through a disk, freezing, drying, and keeping the temperature for 3-6 h at the temperature of 300-800 DEG C to obtain porous corundum particles; then taking 80-97 wt% of alpha-Al2O3 micro powder, 2-10 wt% of nanometer aluminium oxide sol, and 1-5 wt% of MgO micro powder as mixtures, adding 30-50 wt% of organic alcohol, and conducting mixed grinding; pelleting the slurry obtained through mixed grinding and the porous corundum particles into particles of which the grain sizes are 3-10 mm, drying, and sintering for 1-5 h at the temperature of 1,700-1,900 DEG C, so as to obtain the light-weight composite corundum refractory aggregate. The light-weight composite corundum refractory aggregate product prepared by the invention is low in volume density, high in closed porosity, and high in slagging corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Composite lining material and application and application method thereof

The invention belongs to the technical field of refractory materials, and provides a composite lining material. After Al2O3-ZrO2 composite powder is added into the composite lining material, Al2O3 reacts with MgO in the low-carbon magnesium-carbon material to generate spinel. Spinel has the advantages of good slag corrosion resistance, thermal shock resistance, high high-temperature strength and the like, and is beneficial to improving the performance of the low-carbon magnesium-carbon material. The invention also provides application of the composite lining material in preparation of a refractory material. According to the composite material, the dependence on raw materials is reduced while the comprehensive performance of the refractory product is improved, the refractory material with excellent performance can be obtained through fewer raw materials, mineral resources are saved, and the energy consumption is reduced.

Owner:北京利尔高温材料股份有限公司

Seam jointing material for laying magnesia-carbon bricks and alumina-magnesia-carbon bricks

ActiveCN1830905AMake full use of the ability to resist slag erosionImprove corrosion resistanceBrickAlcohol

A jointing material for Mg-C bricks and Al-Mg-C bricks is prepared from solid powder which is the mixture of Mg sand, flaky graphite, solid resin, SiC, high-temp asphalt and metallic Si, and the liquid adhesive which is the mixture of furan resin, alcohol and washing oil through proportional mixing and stirring.

Owner:WUHAN WINNING TECH

Intermediate-frequency electric furnace liner patching material and method of use thereof

The invention provides a patching material for intermediate frequency electric furnace lining and a use method thereof. The invention is characterized in that the patching material is prepared by mixing the following raw materials according to percentage by weight: 1%-7% of waste glass powder, 25%-55% of electroquartz, 15%-35% of electroquartz micro powder, 17.5%-27.5% of chromic oxide micro powder, 5%-10% of zirconium oxide micro powder, and 0.5%-1.5% of boric anhydride. The use method is spraying on the furnace wall with a conventional spray gun at a temperature between 1000 DEG C and 1200 DEG C in the furnace to patch the furnace lining. The material of the invention can realize fast spraying and fast sintering, and can extensively prolong the service life of the furnace lining.

Owner:ZIBO ZHUYOU FIREPROOF FURNACE MATERIAL

Preparation method of magnesium spinet zirconium brick

The invention discloses a preparation method of a magnesium spinet zirconium brick. The preparation method comprises the following steps of: fully mixing 30% of electro-fused magnesite, 30% of alpha-Al2O3 micropowder and 40% of electro-fused monocline zirconium, then adding a binding agent, pressing into blocks under 200MPa, sintering into co-crystallizing sand during insulating the temperature of 1720-1815 DEG C for 12-14hours, grinding the co-crystallizing sand into fine powder with particle size of no more than 0.0425mm, taking the electro-fused magnesite as aggregate, adding 2.8-3.5% of co-crystallizing fine powder and 1-3% of monocline zirconium powder, insulating at the temperature of 1720 DEG C for 6hours in an ultrahigh-temperature tunnel kiln, and sintering for preparing a novel magnesium spinet zirconium brick. The novel magnesium spinet zirconium brick has excellent high-temperature strength, structure stripping resistance and thermal shock resistance stability, slag scouring resistance property, and is environment-friendly and safe, and the pollution of the hexavalent chromium can be thoroughly eliminated.

Owner:江苏诺明高温材料股份有限公司

Al2O3-Cr2O3 refractory aggregate and preparation method thereof

The invention belongs to the field of refractory materials and relates to an Al2O3-Cr2O3 refractory aggregate and its preparation method. The Al2O3-Cr2O3 refractory aggregate has nonuniform chemical composition. Content of Cr2O3 at peripheral position of the Al2O3-Cr2O3 refractory aggregate is greater than or equal to 20%, and content of Cr2O3 at the central position is lower than Content of Cr2O3 at the peripheral position. Porosity of the Al2O3-Cr2O3 refractory aggregate is not more than 10%. Al2O3 and Cr2O3 in the refractory aggregate form uniform solid solutions. Particles and a coating are combined tightly, and strength is high. A diffusion reaction of Al2O3 and Cr2O3 at high temperature causes Cr2O3 concentration attenuation from the surface layer to the center of the aggregate. An Al2O3-Cr2O3 refractory product prepared from the refractory aggregate has good slag corrosion resistance. Meanwhile, utilization rate of chromium resources is high.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Fabricated part for coal water slurry pressurization gasification furnace and production method thereof

The invention relates to a fabricated part for a coal water slurry pressurization gasification furnace and a production method thereof. The technical scheme is as follows: the production method comprises the following steps of: by utilizing 40-70wt% of electric melting chromium oxide particles, 10-25wt% of fused zirconia alumina particles, 5-20wt% of electric melting chromium oxide fine powder, 2-10wt% of alumina micro powder, 3-10wt% of monoclinic zirconium oxide micro powder and 1-10wt% of chromium oxide green micro powder as raw materials, mixing the raw materials, and then, adding 0.5-3wt% of pure calcium aluminate cement, 0.1-0.8wt% of isobutylene polymer, 0.1-0.2wt% of a gather carboxylate water-reducing agent and 2-6wt% of water; and uniformly stirring, vibrating to form, curing at 20-50 DEG C for 1-2 days, demoulding, drying and sintering at 1400-1600 DEG C in the air. The preparation method is simple and low in production cost; and the fabricated part for the coal water slurry pressurization gasification furnace produced by the method has a long service life, high strength and excellent thermal shock resistance and corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Sintered high-alumina refractory brick and preparation method thereof

The invention relates to a sintered high-alumina refractory brick and a preparation method thereof. The technical scheme of the preparation method comprises the following steps: mixing high-alumina bauxite in a planetary forced mixer, and screening to obtain a material A of which the granularity is 3-5mm; mixing titanium-iron slags in the planetary forced mixer, and screening to obtain a material B of which the granularity is 0.088-2.5mm; burdening material A, material B, Guangxi white clay, silicon carbide and Rho-aluminium oxide according to the weight ratio of 1 to (0.75 to 0.80) to (0.05 to 0.10) to (0.25 to 0.30) to (0.30 to 0.35), evenly stirring, adding silica solution, stirring, ageing mixture, carrying out mechanical pressing, demoulding and drying; then, keeping the temperature for 2-4 hours at the temperature of 1480-1500 DEG C in air atmosphere in a muffle furnace, and carrying out furnace cooling to the room temperature to obtain the sintered high-alumina refractory brick. The preparation method has the characteristics of simple technology and low cost, and the prepared sintered high-alumina refractory brick has the advantages of high compactness and high high-temperature breaking strength and slag corrosion resistance.

Owner:淄博恒森耐火材料有限公司

Corundum-spinel refractory brick and preparation method thereof

The invention relates to a corundum-spinel refractory brick and a preparation method thereof. The corundum-spinel refractory brick comprises 55 to 60% by weight of brown fused alumina particles as aggregates, 20 to 25% by weight of aluminum-magnesium spinel fine powder as a base material, 15 to 20% by weight of caustic calcined magnesite powder as a base material, 1 to 2% by weight of aluminum powder as a base material and 1 to 4% by weight of iron powder as a base material. The preparation method comprises uniformly mixing the base materials, adding the aggregates into the base materials, mixing the mixture for 5 to 8 minutes, adding 3 to 6 wt% of thermosetting phenolic resin into the base materials and aggregates, mixing the mixture for 10 to 15 minutes, carrying out mechanical pressing molding, carrying out maintenance at a temperature of 200-250 DEG C for 12 to 18 hours, putting the molded material into a muffle furnace, carrying out heating to 1500-1600 DEG C under nitrogen atmosphere conditions, carrying out thermal insulation for 2 to 3 hours, and carrying out furnace cooling to obtain the corundum-spinel refractory brick. The preparation method has the characteristics of low cost and simple processes. The corundum-spinel refractory brick has high sintered density, large high temperature flexural strength and strong anti-slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Recycled alumina-chrome brick for Ausmelt furnace inner liner, and making method thereof

The invention relates to a recycled alumina-chrome brick for an Ausmelt furnace inner liner, and a making method thereof. A technical scheme is characterized in that the recycled alumina-chrome brick comprises 66-76wt% of ferrochrome slag particles as aggregates, and also comprises 20-30wt% of ferrochrome slag fine powder, 1-2wt% of vanadium trioxide fine powder and 2.1-2.9wt% of yttria fine powder as a matrix. The method comprises the following steps: mixing above proportions of components of the matrix for 0.5-1h, adding the mixed matrix to the above proportion of the aggregates, and mixing the matrix and the aggregates for 5-8min; and adding alumina sol accounting for 5-7% of the total weight of the matrix and the aggregates, mixing for 8-10min, ageing the obtained mixture at 25-35DEG C for 0.3-0.5h, carrying out mechanical pressing, drying the obtained material at 100-110DEG C for 12-24h, and carrying out heat insulation at 1550-1650DEG C for 3-6h to obtain the recycled alumina-chrome brick for the Ausmelt furnace inner liner. The method has the characteristics of low cost and simple process; and the recycled alumina-chrome brick for an Ausmelt furnace inner liner, made in the invention, has good high temperature volume stability and strong slag corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com