Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

246results about How to "Low apparent porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air brick for magnesia carbon ladle and method for producing the same

The invention discloses an air brick used for a magnesium and carbon ladle, and a producing method thereof, aiming at producing high-quality air bricks used for the ladles. The mass percentage of the chemical compositions of the air brick is: 55 to 99 percent of MgO, 0 to 20 percent of C, 0 to 20 percent of AI2O3, 0 to 5 percent of ZrO2, 0 to 5 percent of AI, 0 to 5 percent of AI-Mg alloy, 0 to 5 percent of CaB6, and 0 to 2 percent of B4; the physical property indexes are: volume density (g / cm<3>): 3.00 to 3.15, apparent porosity (%): 1.5 to 5.0, cold compressive strength (MPa): 40 to 65, and distortion resistance at high temperature (MPa): 14.0 to 25.0. Raw materials adopted by the invention comprise fused magnesite, magnesite clinker, crystalline flake graphite, corundum, zirconia and oxidation inhibitor. The raw materials are added into a pug mill and externally added with a bonding agent for mulling. Mulled pug is added into a mould, and molded by utilizing isopressing equipment or a friction brick press or a hydraulic press. The invention obviously reduces the apparent porosity of the air brick, not only can improve the basic slag corrosion resistant capability of the air brick, but also can reduce the cost of the raw materials by more than two thirds.

Owner:UNIV OF SCI & TECH LIAONING

Light-weight corundum-spinel castable and preparation method thereof

The invention relates to a light-weight corundum-spinel castable and a preparation method thereof. The preparation method includes following steps: (A) employing 60-75 wt% of equal-diameter micro-porous corundum spheres as an aggregate, and employing 8-12 wt% of electric-fused white corundum fine powder, 2-8 wt% of electric-fused magnesite fine powder, 2-8 wt% of magnesium aluminate spinel fine powder, 6-12 wt% of [alpha]-Al2O3 micro powder, 0.5-2.5 wt% of chromium oxide powder and 3-7 wt% of an aluminum silicone gel powder as substrate materials, wherein the aggregate and the substrate materials form a raw material in total; (B) employing organic fibers accounting for 0.02-0.08 wt% of the raw material and a polycarboxylate water reducer accounting for 0.05-0.12 wt% of the raw material as additive materials, pre-mixing the substrate material with the additive materials and adding the aggregate with uniform mixing; (C) adding water accounting for 3-5 wt% of the raw material, stirring the mixture and performing cast moulding; and (D) maintaining the temperature at 110-200 DEG C for 12-48 h, roasting the moulded product at 800-1200 DEG C for 24-72 h to obtain the light-weight corundum-spinel castable. The light-weight corundum-spinel castable is low in apparent porosity, is low in volume density, is low in heat conductivity, is strong in anti-slag-erosion capability and is long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Aluminum chrome refractory material

The invention belongs to the technical field of refractory materials, in particular to an aluminum chrome refractory material, which takes white fused corundum as a body and is formed by adding scraps (the scraps are collected and crushed into the synthetic size) generated in the cold processing process of a dense chromic oxide product, Alpha-Al2O3 powder or chrome oxide green or white fused corundum powder and sintering at a high temperature in combination with an inorganic binding agent or an organic binding agent. A product obtained in the invention can be widely applied to a coal water slurry gasification furnace back lining, a hard carbon black reaction furnace inner lining, a residual oil gasification furnace inner lining in the petrochemical industry, a glass wool molten pool inner lining and the like, fully and effectively makes use of the scraps generated in the cold processing process of the dense chromic oxide product and has the characteristics of low impurity content, high refractoriness, excellent physical performance, good thermal shock resistance and strong erosion resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Micro closed-cell light-weight corundum refractory aggregate and preparation method thereof

The invention relates to a micro closed-cell light-weight corundum refractory aggregate and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: by using 45-65 wt% of gamma-Al2O3 fine powder, 30-50 wt% of alpha-Al2O3 micropowder and 1-10 wt% of nano aluminum oxide micropowder as raw materials, adding water accounting for 40-80 wt% of the raw materials, and carrying out wet milling with a planet ball mill for 0.5-3 hours; putting the slurry subjected to wet milling in a mold, standing at room temperature for 12-24 hours, and stripping; and drying at 110-200 DEG C for 12-36 hours, and keeping the temperature at 1750-1900 DEG C for 1-8 hours to obtain the micro closed-cell light-weight corundum refractory aggregate. The micro closed-cell light-weight corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, low volume density, small average pore size, lower heat conductivity and high molten slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Aluminum-magnesium lightweight refractory material and preparation method thereof

The invention relates to an aluminum-magnesium lightweight refractory material and a preparation method thereof. The technical scheme comprises the following steps of: taking 60-85wt% of microporous corundum particles as an aggregate, taking 5-30wt% of fine corundum powder, and taking 2-10% of magnesium oxide micropowder and 4-9wt% of alpha-alumina micropowder as matrix materials; adding the matrix materials into the aggregate, additionally adding an adhesive which is 3-10wt% of the sum of the aggregate and the matrix materials, stirring uniformly and then mixing and milling for 15-30 minutes by a mixing mill, and molding by a brick pressing machine; and thermally processing the molded green body for 12-24 hours at 100-220 DEG C to obtain the aluminum-magnesium lightweight refractory material. The product prepared by the preparation method has the characteristics of small volume density, low apparent porosity, small average aperture, high refractoriness, large high-temperature strength, low thermal conductivity, good thermal shock resistance and strong capability resistant against the corrosion of media such as steel slag; and the prepared product is applicable to a working lining of a high-temperature industrial furnace.

Owner:WUHAN UNIV OF SCI & TECH

Lightweight aluminum-magnesium castable and preparation method of lightweight aluminum-magnesium castable

The invention relates to a lightweight aluminum-magnesium castable and a preparation method of the lightweight aluminum-magnesium castable. The technical scheme is as follows: using 60-85wt% of microporous corundum granules as an aggregate, and using 5-30wt% of fine corundum powder, 2-10wt% of magnesium oxide micropowder and 4-9wt% of alpha-aluminum micropowder as matrix materials; premixing a polycarboxylate-type water reducer and the matrix materials firstly, wherein the polycarboxylate-type water reducer is 0.05-0.3wt% of the sum of the aggregate and the matrix materials; adding the premixed matrix materials into the aggregate; and then additionally adding a binding agent which is 3-10wt% of the sum of the aggregate and the matrix materials, and stirring uniformly to obtain the lightweight aluminum-magnesium castable. The lightweight aluminum-magnesium castable prepared by the method has the characteristics of small volume density, low apparent porosity, large high-temperature strength, good volume stability, low thermal conductivity and strong capability of resisting the corrosion of media such as steel slag; and the prepared lightweight aluminum-magnesium castable is applied to a working lining of a high-temperature industrial furnace, the energy consumption can be reduced, and the service life is long.

Owner:WUHAN UNIV OF SCI & TECH

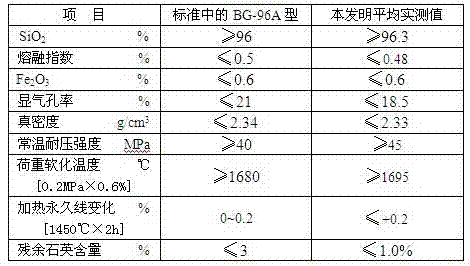

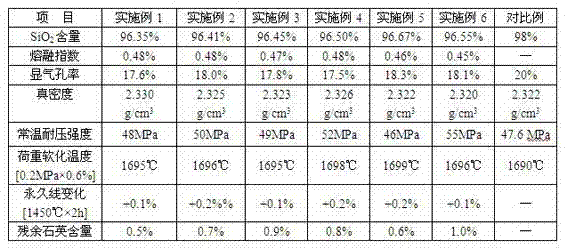

Silica brick for glass furnace

ActiveCN102515801ASmall volume expansionReduce crackingGlass furnace apparatusGlass productionPorosityBrick

The invention discloses a silica brick for a glass furnace, and belongs to the technical field of refractory materials. The silica brick for a glass furnace comprises: by weight, 30 to 45% of silica having particle sizes of 3 to 1.0mm, 5 to 25% of silica having particle sizes of 1.0 to 0.5mm, 30 to 50% of silica having particle sizes less than 0.5mm, an additive and a composite additive, wherein the weight of the additive is 5 to 15% of the total weight of the silica and the weight of the composite additive is 2 to 10% of the total weight of the silica. SiO2 content of the silica is great than or equal to 99%. Al2O3 content of the silica is less than or equal to 0.25%. Fe2O3 content of the silica is less than or equal to 0.45%. The additive is a waste silica material having SiO2 content great than or equal to 96%. The composite additive is a mixture of lime milk, mill scales and calcium lignosulphonate. The silica brick for a glass furnace has high SiO2 content, a high yield, low impurity content, low apparent porosity, good high-temperature performances and a long service life. A preparation technology of the silica brick for a glass furnace is simple and is suitable for large-scale production.

Owner:ZHEJIANG ZHAOSHAN SILICEOUS REFRACTORY MATERIAL

Lightweight micro closed cell magnesium-containing corundum refractory aggregate and preparation method thereof

The invention relates to lightweight micro closed cell magnesium-containing corundum refractory aggregate and a preparation method of the refractory aggregate. The method comprises the steps of taking 80-95wt% of gamma-Al2O3 fine powder, 1-10wt% of nano alumina powder and 1-10wt% of magnesium oxide micropowder as raw materials, adding water accounting for 40-70wt% of the raw materials, mixing, wet-milling with a planet ball mill for 0.5-3h to form slurry, putting the slurry in a mold, placing under a room temperature condition for 12-24h, removing the mold, drying a demolded green body for 12-36h at 110-200 DEG C, and carrying out heat preservation for 1-8h at 1750-1900 DEG C to form the lightweight micro closed cell magnesium-containing corundum refractory aggregate. The prepared lightweight micro closed cell magnesium-containing corundum refractory aggregate has the characteristics of low apparent porosity, high closed porosity, lower volume density, small mean pore size, lower heat conductivity, and strong washout and slag erosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Preparation technology of low-cost high-strength ceramic floor tile

InactiveCN103819176AAlleviating the crisis of scarcityReduce dependenceManufacturing technologyRed mud

The invention relates to a preparation technology of a low-cost high-strength ceramic floor tile, which comprises the following steps: 1)taking 30-40% of steel slag, 40-55% of bayer process red mud and 20-30% of talcum according to weight percentage for standby; 2)crudely crushing the steel slag into the particles with size below 10mm; 3)respectively performing ball milling on the steel slag particles and the bayer process red mud by a ball mill for 8 hours, and sieving through a sieve with 250 meshes; 4)placing the sieved raw material in a three-dimensional stereo feed mixer for mixing for 10 hours; and 5)adding water in a mixture, and preparing a green compact by an oil hydraulic press under 25MPa pressure, placing the dried green compact in a muffle furnace, and roasting to obtain the ceramic floor tile. The ceramic floor tile provided by the invention takes red mud and steel slag as main raw materials, and the red mud and steel slag substitute the rear kaolin with high cost and high quality, so that dependence of ceramic industry in our country to kaolin is reduced, and crisis of high-quality kaolin scarcity due to rapid development of industrial can be alleviated.

Owner:HENAN UNIV OF SCI & TECH

High temperature creep resistant mullite-cordierite product and preparation method thereof

The invention relates to a high temperature refractory material, and specifically relates to a high temperature creep resistant mullite-cordierite product and a preparation method thereof. The product is prepared from the main raw materials of sintered mullite, cordierite, white corundum, fused quartz, kyanite, alumina micro powder, bentonite micro powder, slaked talcum micro powder and kaolin by the steps of mixing, mixture ageing, forming-drying and final high-temperature firing. By adopting scientific mixing proportion and graduation, and using a resonable production method, the high temperature creep resistant mullite-cordierite product provided by the invention is prepared. Compared with other products, the high temperature creep resistant mullite-cordierite product provided by the invention has the advantages of low apparent porosity, high volume density, good creep resistance, excellent thermal shock resistance, long service life, and on the like, and is mainly suitable for moderate temperature material sintering, such as sintering of cobaltous oxide and ferric aluminum phosphate raw materials for automotive batteries in chemical industry.

Owner:长兴宏业高科高温耐火材料有限公司

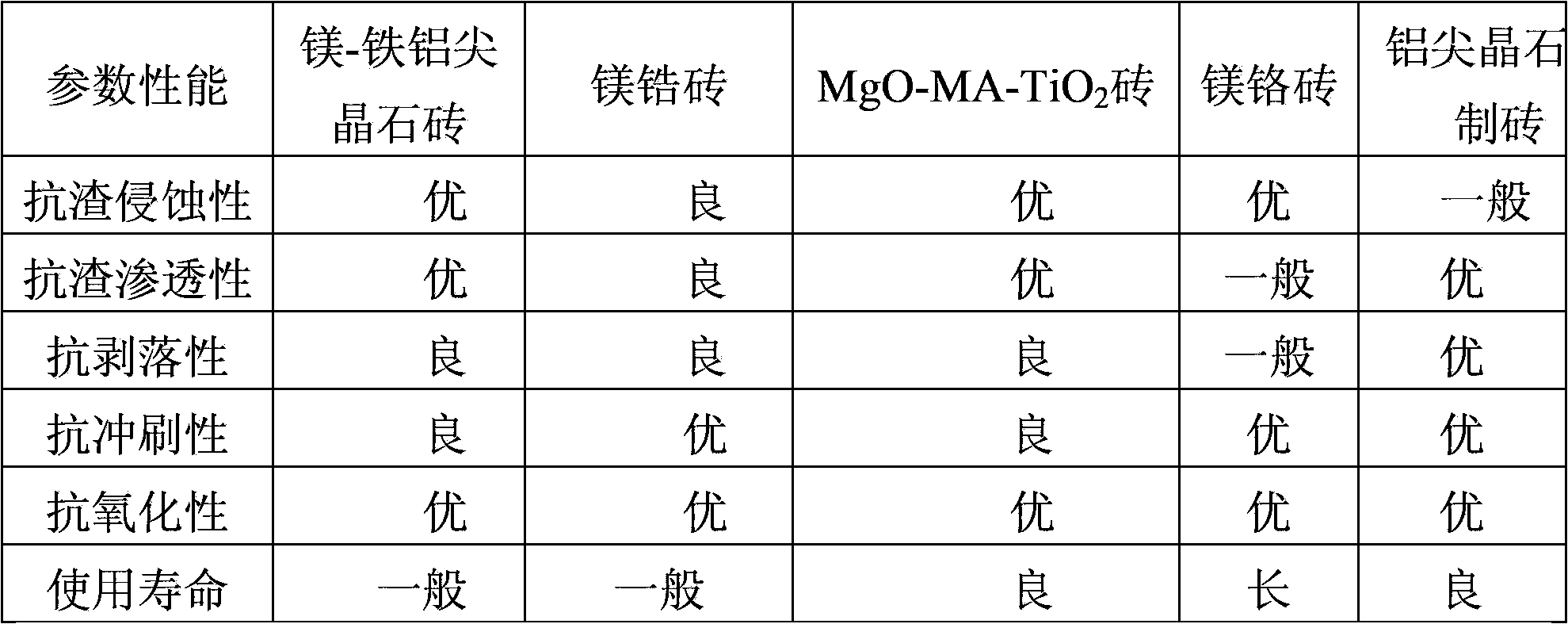

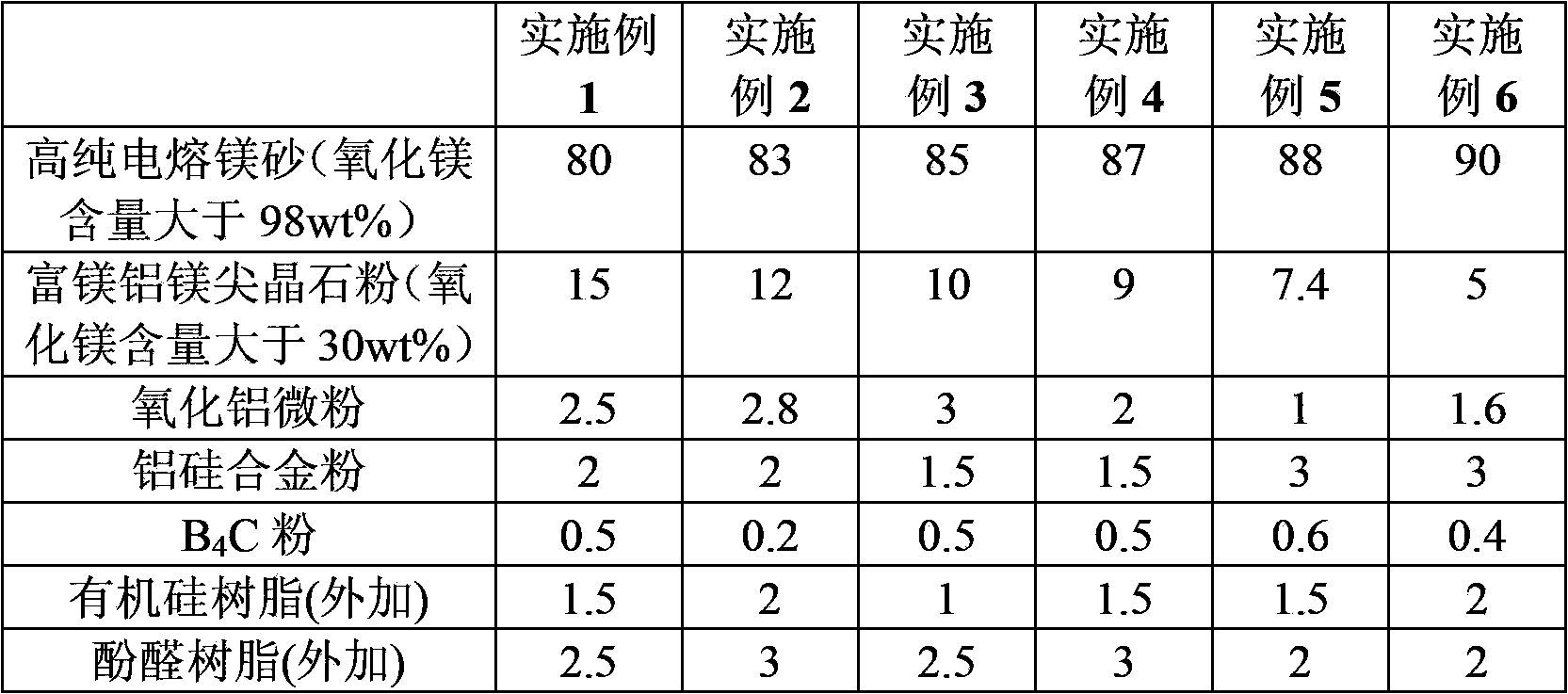

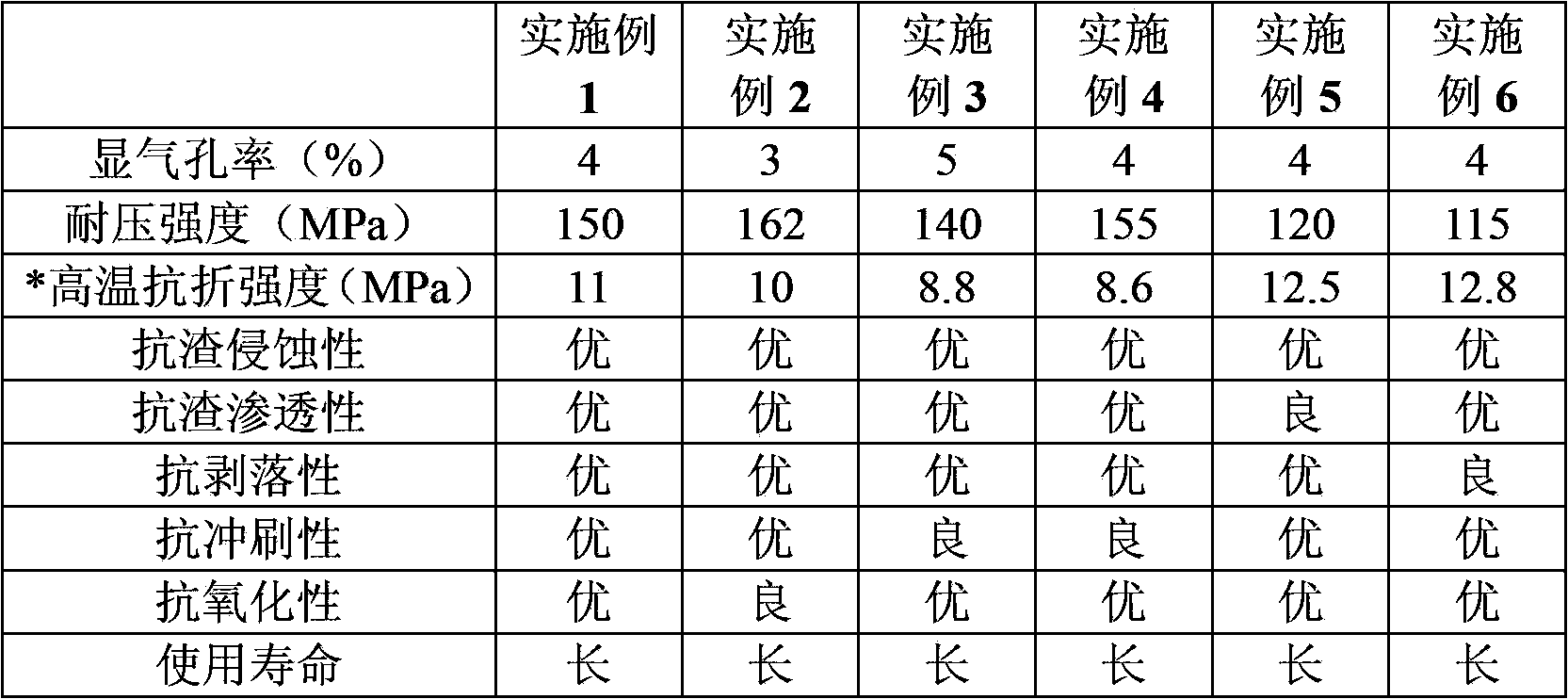

Unfired magnesia-alumina spinel brick

The invention discloses an unfired magnesia-alumina spinel brick. The unfired magnesia-alumina spinel brick comprises the following chemical components by mass: 80 to 90% of fused magnesia, 5 to 15% of magnesium-rich magnesia-alumina spinel, 1 to 3% of micro alumina powder, 1 to 3% of aluminum-silicon alloy powder and 0.2 to 0.6% of B4C. The chemical components are bonded together by using 3.5 to 5 wt% of an added binder. The content of magnesium oxide in the fused magnesia is greater than 98 wt%, and the content of magnesium oxide in the magnesium-rich magnesia-alumina spinel is greater than 30 wt%. The unfired magnesia-alumina spinel brick provided by the invention has excellent slag reaction resistance, slag penetration resistance, anti-stripping performance, anti-scouring performance, resistance to oxidation and a long service life, does not include the harmful element--chromium, avoids pollution and harm to human beings and the environment, needs low production cost and has a wide application scope.

Owner:BAOSHAN IRON & STEEL CO LTD

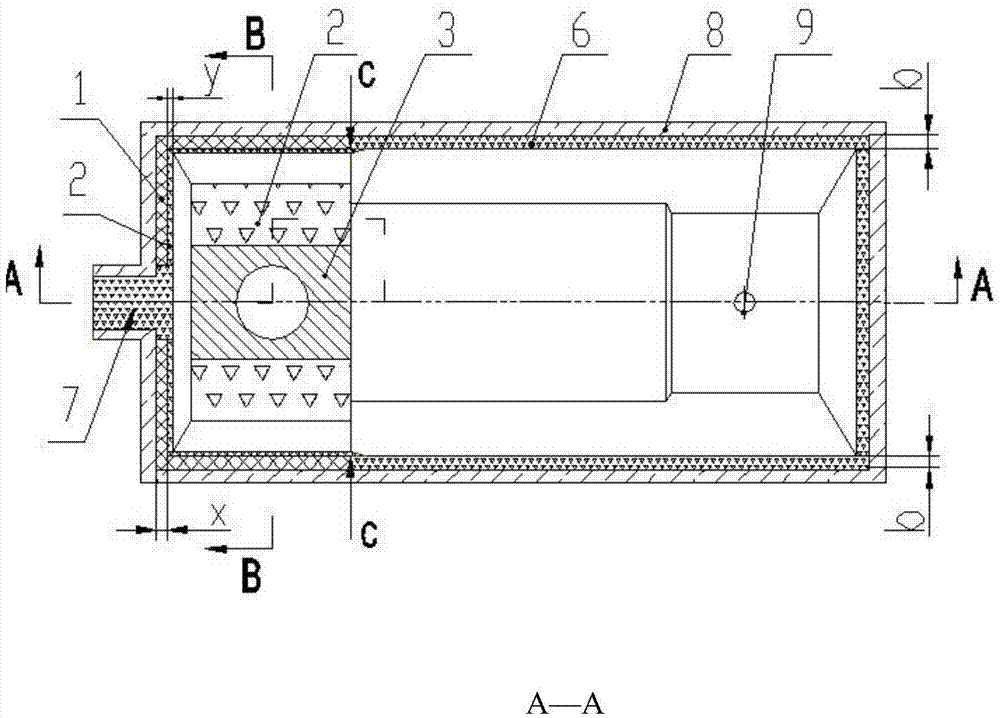

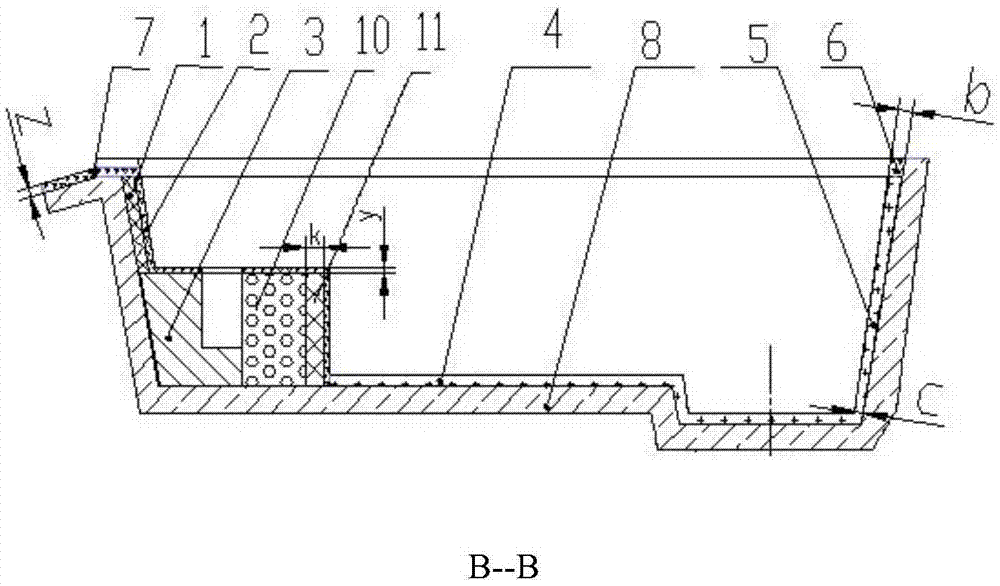

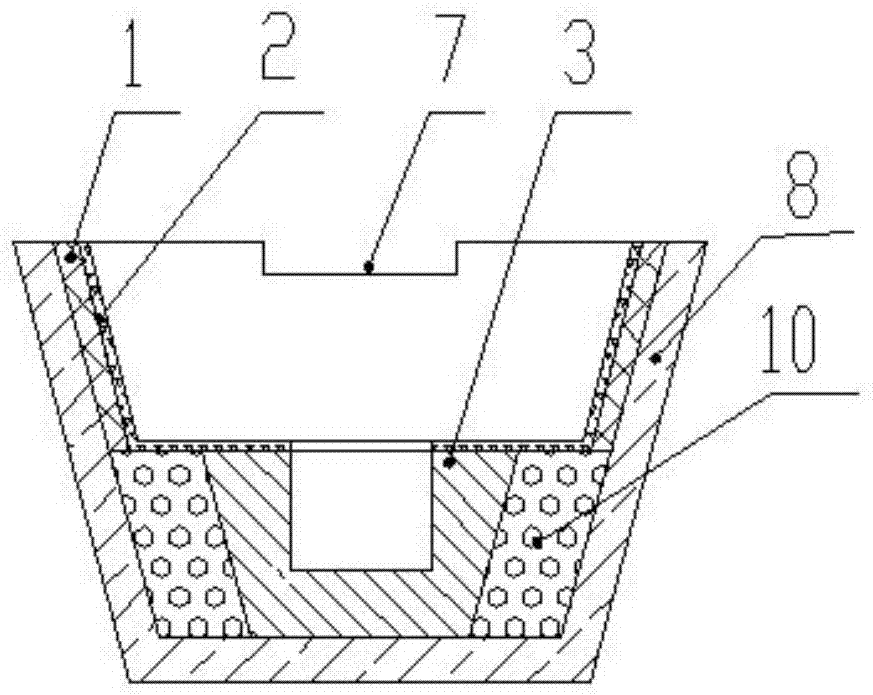

Reworked material working lining of continuous casting tundish and preparation method for reworked material working lining

ActiveCN105436492ASolve the problem of bulging cracks and even material collapseEasy to useMelt-holding vesselsBrickRefractory

The invention relates to a reworked material working lining of a continuous casting tundish and a preparation method for the reworked material working lining. The reworked material working lining is divided into an impact zone working lining and a non-impact zone working lining, which are internally attached to a permanent lining; the non-impact zone working lining sequentially comprises a ladle edge working lining, a ladle wall working lining and a ladle bottom working lining from top to bottom; the impact zone working lining is built by adopting waste magnesia-carbon bricks and regenerated coating material mud through a wet process; the ladle wall working lining and the ladle bottom working lining are built by adopting a regenerated dry material; an overflow port working lining and the lade edge working lining are built by adopting the regenerated coating material; a space between the two sides of a turbulent flow controller and the ladle wall permanent lining is filled by waste; and a regenerated coating material layer coats the outer surfaces of the waste magnesia-carbon bricks, the outer surface of the waste and the upper surface of the turbulent flow controller. By applying the reworked material working lining, the service life of a shaped blank continuous casting tundish reaches 33-38 hours, and refractory material cost of the regenerated material working lining is reduced by more than 60% year on year.

Owner:SHANDONG IRON & STEEL CO LTD

Special type composite low alumina mullite brick and preparation method thereof

The invention discloses a special type composite low alumina mullite brick which is prepared by raw materials by weight percent: 10-30% of mullite with granularity of 3-1mm, 20-40% of flint clay with granularity of 3-1mm, 10-20% of flint clay with granularity of 1-0mm, 5-15% of flint clay with granularity of -200 meshes, 10-30% of sillimanite or andalusite, and 15-25% of additive. The materials weighed according to the mixture ratio are mixed and ground, processed by ageing, extruded to be molded, dried and finally sintered, so that the special type composite low alumina mullite brick can be obtained. The special type composite low alumina mullite brick has the advantages of low apparent porosity and impurity, high strength and refractoriness under load, micro-expanded product, high mullite phase and the like, and has the function of one brick for multiple purposes. The application of the special type composite low alumina mullite brick can save a great deal of maintenance costs and energy conservation cost for steel users, thus having remarkable social and economic benefits.

Owner:GONGYI WINNA SCI & TECH DEV

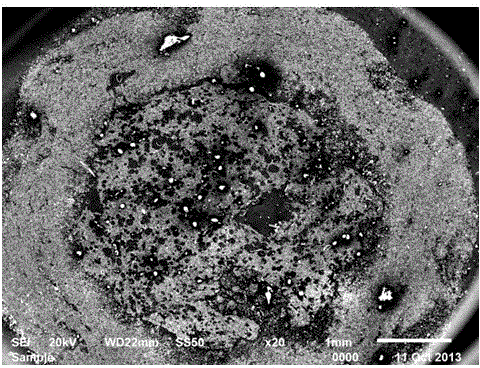

Porous corundum aggregate with core-shell structure and preparation method thereof

The invention relates to porous corundum aggregate with a core-shell structure and a preparation method thereof. The technical scheme comprises that the preparation method comprises: uniformly stirring 100 parts by mass of industrial aluminium oxide fine powder, 0.5-2.5 parts by mass of a foaming agent, 5-20 parts by mass of aluminum dihydrogen phosphate and 5-35 parts by mass of water, so as to prepare foam mud; firstly putting 100-200 parts by mass of industrial aluminium oxide fine powder into a sugarcoating machine, then putting the foam mud into the sugarcoating machine, performing wet-process pelletizing, naturally drying, and baking at 100-120 DEG C for 12-24 h; and then heating to 1600-1850 DEG C, and keeping warm for 1-3 h, so as to obtain the porous corundum aggregate with the core-shell structure. The production technology is simple, and the prepared porous corundum aggregate with the core-shell structure is low in apparent porosity, high in strength, good in thermal-shock stability and wide in application scope.

Owner:WUHAN UNIV OF SCI & TECH

Light weight microporous corundum aggregate and preparation method thereof

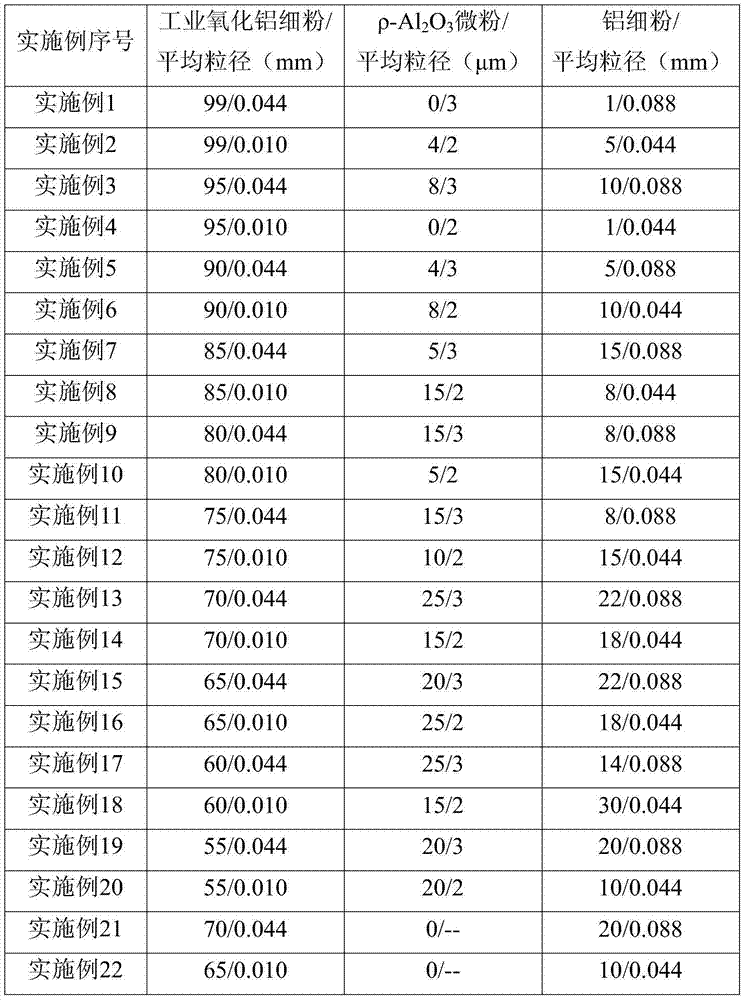

The invention discloses light weight microporous corundum aggregate and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing components of raw materials and balling, wherein the balling water addition is 5-30%; and then, insulating for 0.5-6 hours at 1600-1950 DEG C to obtain the light weight microporous corundum aggregate. The raw materials comprise the following components in parts by weight: 55-99 parts of industrial aluminum oxide fine powder, 0-30 parts of p-Al2O3 micropowder and 1-20% of aluminum micropowder. The light weight microporous corundum aggregate provided by the invention is simple in preparation method, low in apparent porosity, lower than sintered plate corundum in volume density and high in refractoriness.

Owner:浙江自立新材料股份有限公司

Tap hole reclaimed material recycled quick-dry anti-explosion castable

The invention discloses a tap hole reclaimed material recycled quick-dry anti-explosion castable which comprises the following components in parts by mass: 15-30 parts of electrically-fused dense corundum, 5-10 parts of brown fused alumina fresh material, 3-5 parts of brown fused alumina reclaimed material, 5-10 parts of mullite fresh material, 3-5 parts of mullite reclaimed material, 4-8 parts of silicon carbide, 4-6 parts of graphite, 2-5 parts of binding agent which is a mixture of pure calcium aluminate cement and nanometer silica-alumina gel powder, 3-8 parts of polycarboxylate superplasticizer, and 0.5-2 parts of compound anti-explosion agent. The tap hole reclaimed material recycled quick-dry anti-explosion castable has the beneficial effects that by adopting brown fused alumina reclaimed material and mullite reclaimed material, waste materials can be sufficiently utilized so as to reduce the cost of industrial products in the iron and steel industry, the condensation time can be effectively controlled by specially proportioning aggregate materials with different properties and particles and adding additional additives, the hardening time of the castable can be shortened, the quick-dry anti-explosion properties are good, the construction efficiency is improved, on-schedule tapping of a blast furnace can be guaranteed, and the service life of the castable can be prolonged.

Owner:CHANGXING MINGTIAN FURNACE CHARGE

Anti-thermal shock iolite fireproof kiln furniture and preparation method thereof

The invention relates to an anti-thermal shock iolite fireproof kiln furniture and a preparation method thereof. The fireproof kiln furniture comprises the raw materials of 25-37% of a matrix, 50-56% of an aggregate, 4-5% of a sintering agent and 9-14% of a fiber reinforced material, wherein the matrix is composed for 15-25% of kyanite fine powder, 15-25% of kaolin fine powder, 48-69% of and alusite fine powder, and 1-2% of magnesia fine powder, and the aggregate is composed for 60-75% of gangue and 25-40% of high bauxitic clay clinker. In the prepared fireproof material, acicular iolite and cylindrical mullite are interlaced to a net state, the particles are in a free state with uniform size, the matrix and the particles have a certain buffer area, a certain stress is absorbed, and crack dynamic expansion is avoided. An iolite-mullite multiphase is generated in the fireproof product, synchronous increase of flexural intensity and compression strength can be satisfied, and the heat stability of the final product is increased.

Owner:HENAN UNIV OF SCI & TECH

SiCf/SiC composite material flame tube and automatic preparation method thereof

ActiveCN110330353AHigh mechanical strengthCorrosion protectionContinuous combustion chamberCeramic layered productsPolymer scienceGas phase

The invention discloses an automatic preparation method of a SiCf / SiC composite material flame tube. The preparation method comprises the following steps: preparing an interface layer from SiC fibersby adopting chemical vapor deposition, so as to obtain SiC fibers with a continuous interface layer; performing unidirectional tape laying and filament winding on the SiC fibers with the continuous interface layer according to the fiber volume and fiber orientation obtained by simulation calculation, so as to obtain net size forming preform; performing densifying treatment on the obtained preformby adopting a reactive melt infiltration process and the chemical vapor deposition process; preparing an environmental barrier coating on the surface of the obtained preform; finally, continuously preparing a thermal barrier coating on the surface, thereby fully intelligently obtaining the high-density SiCf / SiC composite material flame tube. The SiCf / SiC composite material flame tube prepared withthe method disclosed by the invention has the characteristics of high temperature resistance and long service life and also has the advantages such as low thermal expansion coefficient, high thermalconductivity, high thermal shock resistance and excellent mechanical property. Meanwhile, the preparation method is high in degree of automation, short in production cycle, low in cost and controllable in quality.

Owner:CENT SOUTH UNIV

Low-porosity periclase-magnesium aluminate spinel-zirconia sintered composite refractory material and production process thereof

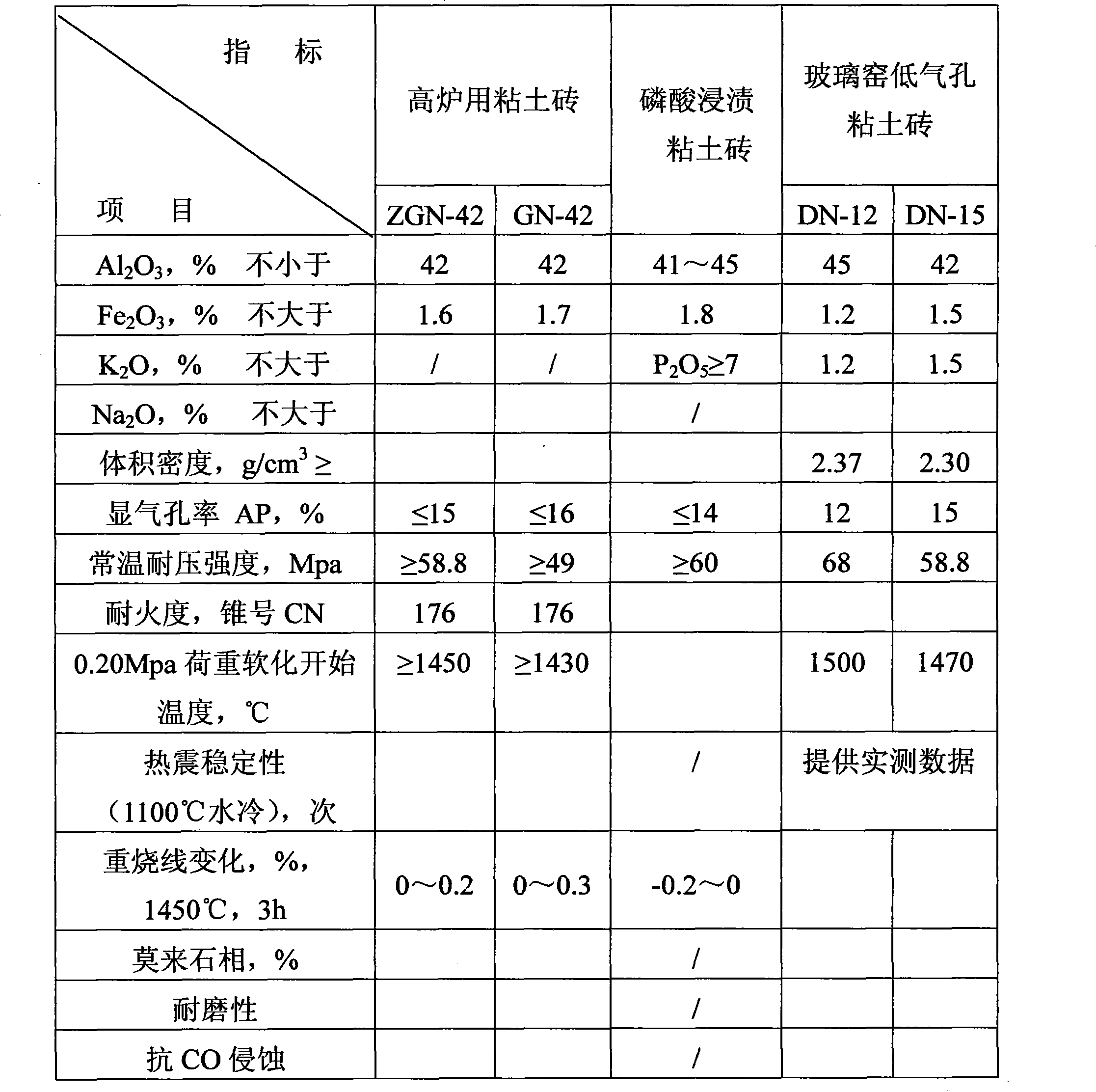

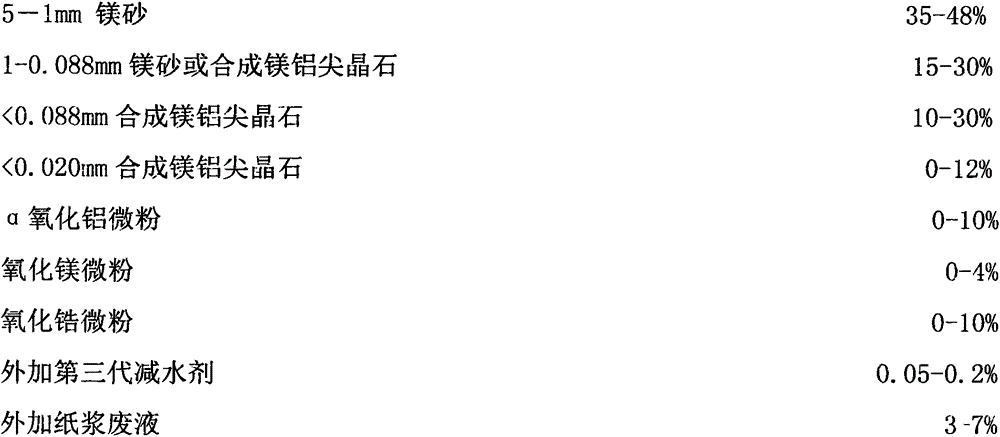

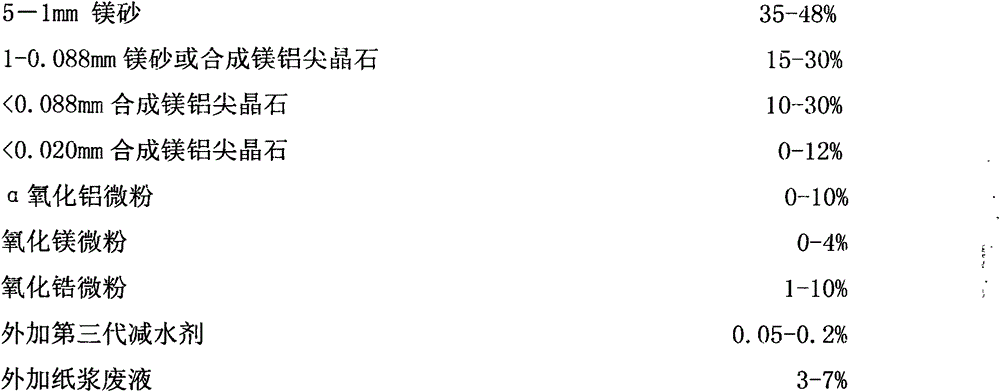

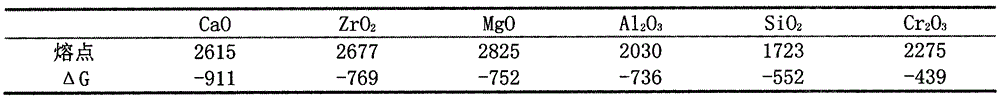

The invention provides a low-porosity periclase-magnesium aluminate spinel-zirconia sintered composite refractory material, which is prepared from the following materials: 35-48% of 5-1mm magnesia, 15-30% of 1-0.088mm magnesia or synthetic magnesium aluminate spinel, 10-30% of less than 0.088mm synthetic magnesium aluminate spinel, 0-12% of less than 0.020mm synthetic magnesium aluminate spinel, 0-10% of G alumina micro powder, 0-4% of magnesium oxide micro-powder, 1-10% of zirconium oxide micro-powder, 0.05-0.2% of external third generation water reducing agent and 3-7% of external sulfite lye. During production, the magnesia is taken as an aggregate, and the composite magnesium aluminate spinel-zirconium oxide is taken as a base material; in the base material, the synthetic magnesium aluminate spinel is taken as coarse particles, while in-situ spinel-zirconium oxide is taken as fine particles; a brick-making material is dispersed in an efficient dispersant and then formed into compact green bricks under high pressure; then the compact green bricks are sintered at high temperature to form the refractory material with a compact structure; according to the proportions of the raw materials, all the raw materials are weighed, blended, mixed, molded and dried, and then sintered in the temperature range from 1650 to 1800 DEG C for 5-10 hours, and finally, the refractory materials is obtained. The refractory material has extremely low apparent porosity, and excellent high-temperature resistance, thermal shock resistance and erosion resistance; therefore, the refractory material is applicable for the grid of the heat accumulating chamber of a glass kiln as an erosion-resistant refractory material.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Preparation method for microporous light-weight corundum fireproof aggregate

The invention relates to a microporous light-weight corundum fireproof aggregate and a preparation method thereof. According to a technical scheme in the invention, 55 to 100 wt% of industrial alumina fine powder and 0 to 45 wt% of industrial aluminum hydroxide fine powder or alpha-Al2O3 micro powder are used as raw materials, and the raw materials undergo dry grinding on a ball mill for 0.5 to 3 h at first, then balling in a ball forming mill to obtain a ball blank with a size of 20 to 30 mm and finally rapid sintering in a shaft kiln at a temperature of 1700 to 1950 DEG C so as to obtain the microporous light-weight corundum fireproof aggregate. The preparation method for the microporous light-weight corundum fireproof aggregate is simple and easy and is applicable to volume industrial production; the microporous light-weight corundum fireproof aggregate has the advantages of a small bore diameter, high strength, low thermal conductivity, anti-scouring performance, erosion resistance and the like, can be used in a part where the wall of a steel ladle directly contacts with molten steel, is also applicable to production of iron runners, slide plates, ventilating bricks and the like and to other industrial kilns used in petrochemistry, ceramics and the like and can obviously reduce energy consumption.

Owner:JIANGSU JINGXIN NEW MATERIAL

Magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and production method

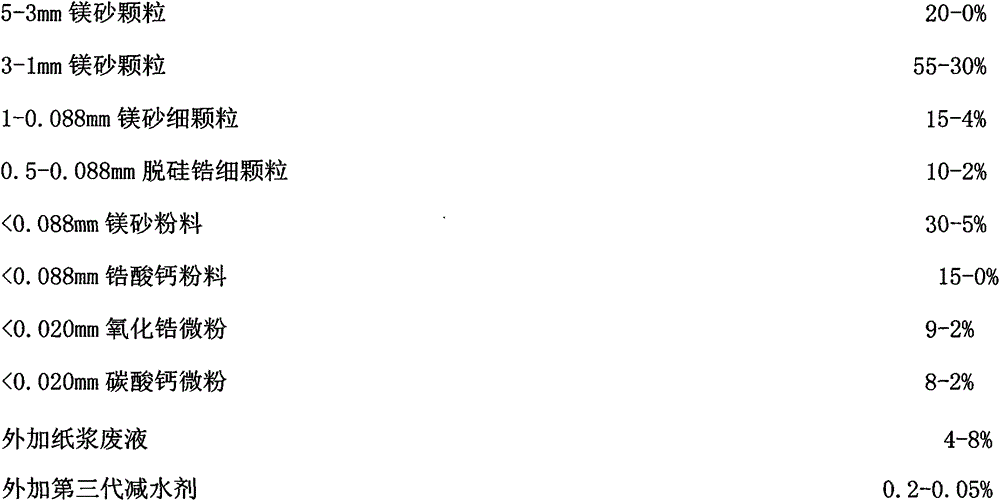

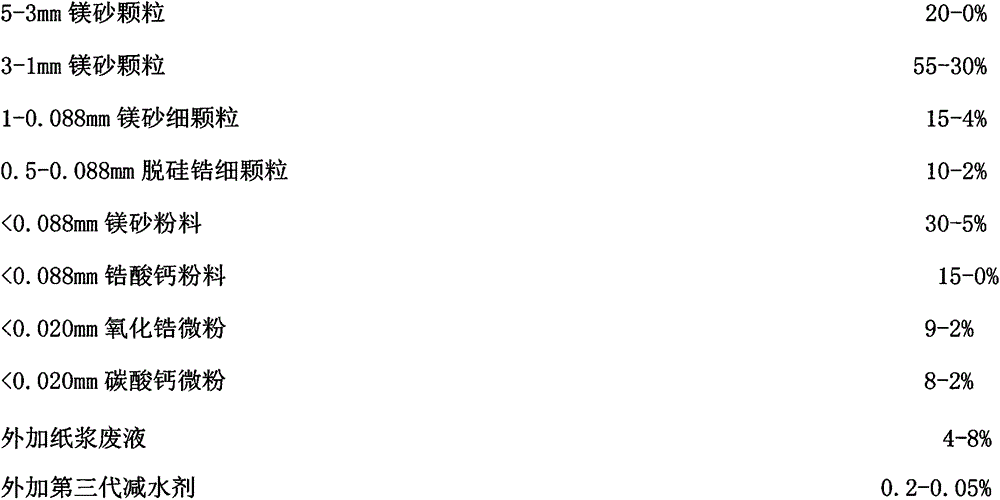

The invention relates to a magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and a production method. During manufacturing, 0-20% of 3 mm-5 mm magnesia particles, 30-55% of 1 mm-3 mm magnesia particles, 4-15% of 0.088 mm-1 mm fine magnesia particles, 2-10% of 0.088 mm-0.5 mm fine desilicated zirconia particles, 5-30% of magnesia powder with the diameter being less than 0.088 mm, 0-15% of calcium zirconate powder with the diameter being less than 0.088 mm, 2-9% of zirconia micro powder with the diameter being less than 0.020 mm, 2-8% of calcium carbonate micro powder with the diameter being less than 0.020 mm, 4-8% of additional waste pulp liquid and 0.2-0.05% of additional third-generation water reducing agents are used; during production, the adopted process includes the steps that firstly, the zirconia micro powder and the calcium carbonate micro powder are premixed; secondly, the 3 mm-5 mm magnesia particles, the 1 mm-3 mm magnesia particles and the 0.088 mm-1 mm fine magnesia particles are added to a mixing mill, and he waste pulp liquid and the third-generation water reducing agents are added to the mixing mill to be mixed; thirdly, magnesia powder with the diameter being less than 0.088 mm, calcium zirconate with the diameter being less than 0.088 mm and premixed zirconia-calcium carbonate micro powder with the diameter being less than 0.020 mm are add and mixed until the mixture is even; finally, forming, drying, 1580-1700 DEG C sintering and checking are conducted on the mixture to obtain a refractory material with periclase-calcium zirconate-baddeleyite as a main crystal phase. The magnesium-calcium-zirconium brick has the advantages of being convenient to manufacture, low in cost, simple to use and excellent in performance, has excellent anti-erosion performance and thermal shock resistance, excellent high-temperature physical and chemical stability, and is competent for the work of secondary refining to make clean steel.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Preparation method of forsterite refractory brick prepared from nickel-iron slag

The invention discloses a preparation method of a forsterite refractory brick prepared from nickel-iron slag. The nickel-iron slag is used as a raw material, and fine magnesite powder is added; the generation amount of a liquid phase in a firing process is controlled by regulating and controlling the mass ratios of all components, so that the volume density and the compression strength of the refractory brick are improved, and the sintering temperature is reduced; the mass ratios of all the components are controlled to meet the following conditions that the mass ratio of MgO to SiO2 is 0.98 to 1.67, the mass ratio of MgO to FeO is 5.87 to 7.71, the mass ratio of MgO to Al2O3 is 11.23 to 17.6, the mass ratio of Al2O3 to SiO2 is 0.087 to 0.095, and the sum of MgO and CaO to the sum of SiO2 and Al2O3 is 0.95 to 1.59; meanwhile, the preparation method comprises the following steps: additionally adding water and a binding agent, uniformly mixing, and carrying out compression moulding and drying treatment; after treatment, roasting at the temperature of 1200 to 1350 DEG C for 2 to 3.5 hours; adopting an oxidizing atmosphere in the firing process, thus obtaining the forsterite refractory brick. The preparation method disclosed by the invention has the advantages of high resource utilization rate, environment friendliness, simple process, low production cost and the like; the forsterite refractory brick prepared from the nickel-iron slag has the advantages of high compression strength, high volume density, low porosity and good thermal shock resistance.

Owner:CENT SOUTH UNIV

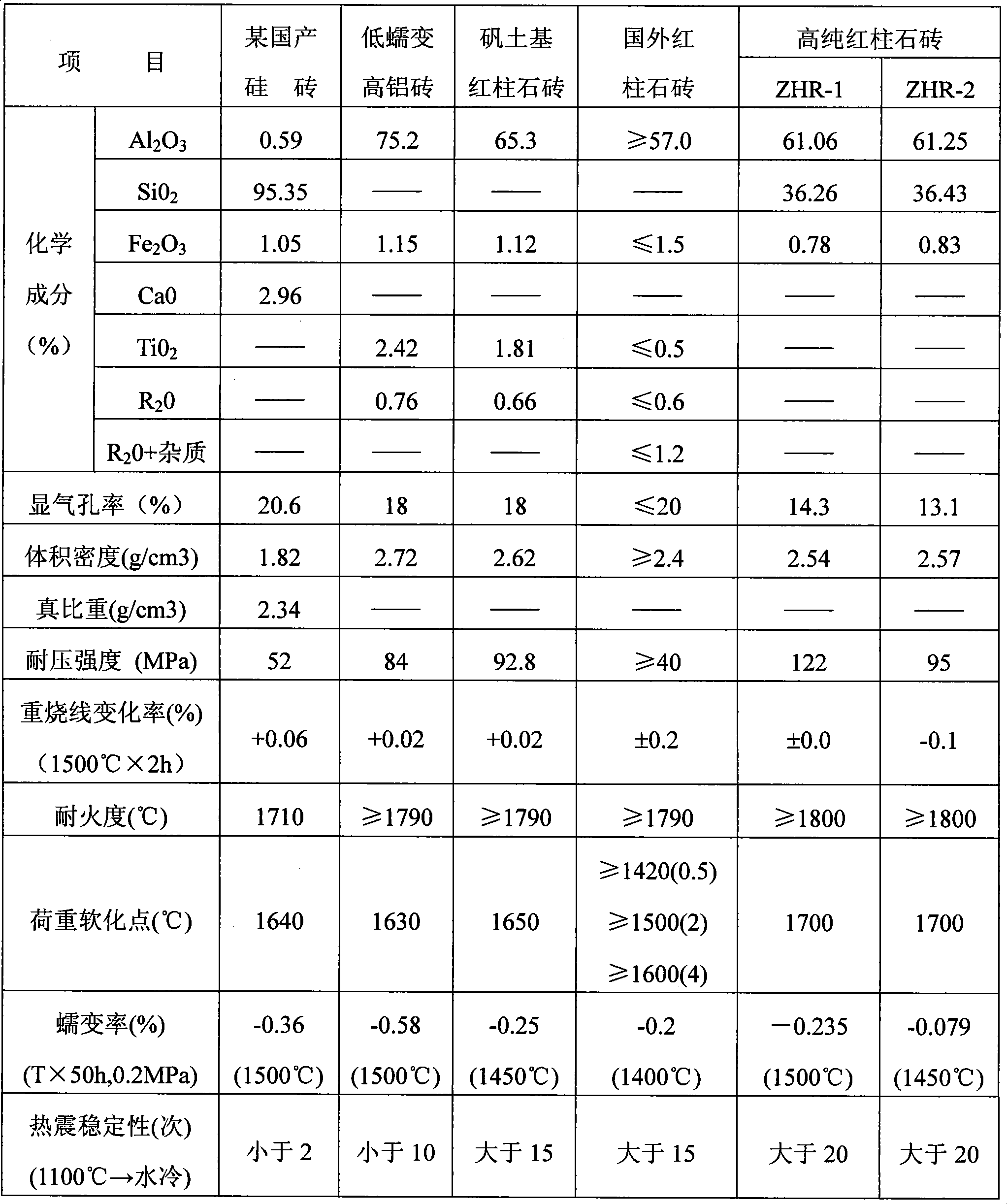

High purity andalusite brick for high blast temperature and long time type hot blast stove and preparation method thereof

The invention discloses a high pure andalusite brick for an air heating furnace with high blast temperature and long service life, and a preparation method thereof. The high pure andalusite brick is prepared by the following steps: andalusite, sillimanite sand, activated alumina powder and kaolin are taken as raw materials, andalusite powder, the activated alumina powder and kaolin powder which have the raw material particle size of between 0.088 and 0 mm are premixed into powder first, then the remaining particle materials, sulphite liquor and the prepared powder are mixed evenly to produce pug, the produced pug is pressed into a green brick, and the green brick is transferred into a high-temperature tunnel kiln for calcination to obtain a product. As a refractory material of a large-scale air heating furnace, the product has low creep rate and good thermal shock stability during use, and can apparently improve the blast temperature and the service life of the air heating furnace, thereby saving a large amount of maintenance cost and energy-saving cost for iron and steel users, and obtaining remarkable social and economical benefits.

Owner:GONGYI TONGDA ZHONGYUAN REFRACTORY TECH

Aluminum-magnesium casting material for ladle liner and preparation method thereof

The invention relates to an aluminum-magnesium casting material for a ladle liner and a preparation method thereof. ACcording to the technical scheme, the method comprises the following steps: preparing 50-65wt% of microporous alumina particles serving as aggregate; preparing 10-15wt% of fine corundum particles, 15-30wt% of fine corundum powder, 2-8wt% of magnesium oxide powder, 2-8wt% of alpha-A12O3 powder and 2-8wt% of aluminum powder silica gel which are used as base materials; adding water which accounts for 3-10wt% of the sum of the aggregate and the base materials; evenly agitating, and molding in a vibrating manner; carrying out heat preservation at 100-150 DEG C for 12-36 hours, so as to prepare the aluminum-magnesium casting material for the ladle liner. The aluminum-magnesium casting material for the ladle liner prepared by the method has excellent slag resistance and thermal shock stability, and the service life of the aluminum-magnesium casting material for the ladle liner can be effectively prolonged.

Owner:WUHAN UNIV OF SCI & TECH

Ultrahigh strength thermal shock resistance corundum/mullite product and manufacture method thereof

The invention relates to an ultrahigh strength thermal shock resistance corundum / mullite product and a manufacture method thereof. The manufacture method comprises steps of stirring 8-mesh white corundum, 80-mesh white corundum, 320-mesh tabular corundum, 24-mesh capacitance synthetic mullite, 36-mesh capacitance synthetic mullite, 280-mesh andalusite, 180-mesh sillimanite, 800-mesh aluminum oxide powder, 200-mesh kaolin and yellow dextrin for 1-3 hours, then adding 8% water so as to wring, stacking and ageing for 10 days, stirring for 15 minutes again, then molding through jolt-squeeze, naturally drying in shade, then firing for 6-8 hours at 1600 DEG C-1620 DEG C so as to obtain the ultrahigh strength thermal shock resistance corundum / mullite product. According to the manufacture method, the raw material chemical components and granularity ratio are optimized, the product is sintered fully, and the prepared corundum / mullite product has low porosity, large volume density, good strength, good thermal shock resistance, good integrated quality, and long service life up to 4-6 months.

Owner:长兴宏业高科高温耐火材料有限公司

Magnesia refractory materials property promotion method and the product produced thereby

The invention relates to a method for improving technical characteristics of magnesia refractory materials which comprises, placing the magnesia refractory materials into a vacuum plant, vacuum-pumping to -0.05~-0.1MPa, pressure maintaining 1-15 minutes, pumping in chromium-containing precursor nano collosol under vacuum state, pressurizing to 0.1-0.5 MPa, pressure maintaining 1-15 minutes, releasing pressure, taking out magnesia refractory materials, baking and drying 10-72 hours at 100-200 deg. C.

Owner:WUHAN UNIV OF SCI & TECH

Injection molding reactive sintering B4C/SiC composite ceramic material and preparation method thereof

The invention relates to an injection molding reactive sintering B4C / SiC composite ceramic material and a preparation method thereof. The composite ceramic material is prepared from the following raw materials in percentage by weight by virtue of material mixing, milling, injection, degreasing and sintering: 45-60% of boron carbide, 15-30% of silicon carbide, 1-5% of charcoal powder, 1-3% of a surfactant, 0-2% of a dispersant, 6-15% of a lubricant, and 4-12% of a binding agent, wherein the sum of the used amounts of all the components is 100%. For the reactive sintering B4C / SiC composite ceramic material prepared by the method provided by the invention, the apparent porosity is lower than 0.30%, the bending strength is 300MPa or above, the hardness is more than 3.04GPa, and the fracture toughness is more than 4.27MPa.m<1 / 2>.

Owner:SHANDONG UNIV

Magnesium carbon-based castable

The invention relates to a magnesium carbon-based castable. The magnesium carbon-based castable comprises the following components in parts by weight: 1-12 parts of surface modified graphite, 72-93.8 parts of magnesia, 3-15 parts of alumina oxide micro powder or / and aluminum-magnesium spinel micro powder or / and silicon carbide, 2-5 parts of binding agent, and 0.05-1 part of water reducer, wherein the binding agent is one or more of Rho-Al2O3, magnesium oxide micro powder, silicon micro powder and silica solution, and the water reducer comprises one or more of sodium tripolyphosphate, sodium hexametaphosphate, dispersing alumina oxide M-ADS1, and dispersing alumina oxide M-ADW1. The magnesium carbon-based castable has the advantages of less water amount for pouring, large volume density and low apparent porosity after molding, and strong oxidation resistance at high temperature, and is not easy to permeate and erode by high temperature steel slag in use.

Owner:江苏苏嘉集团新材料有限公司

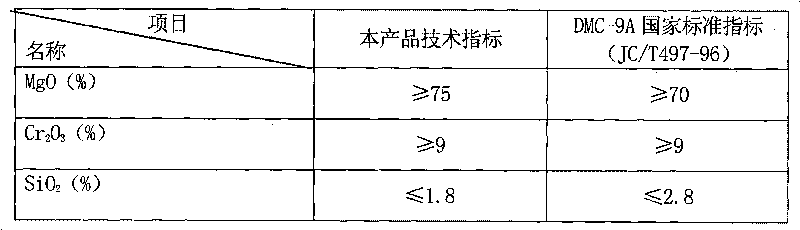

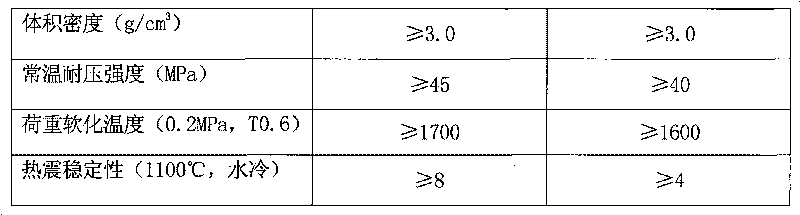

Method for producing direct-bonded magnesia-chrome brick with high refractorinees under load and high stability of thermal shock resistance

ActiveCN101734908AExtend the life cycleBreak the status quo of generally relying on importsTunnel kilnPorosity

The invention discloses a method for producing a direct-bonded magnesia-chrome brick with high refractorinees under load and high stability of thermal shock resistance, which comprises the following steps: (1) selecting 7.5 parts by weight of magnesite, 2.5 parts by weight of chrome ore and 0.5 part by weight of chromium refined powder; (2) mixing the materials evenly, putting into an edge runner mixer, adding a lignin solution with the weight 4-5% of the weight of the total material and putting into a pressing machine with the pressure greater than 630KN for molding after milling wetly to prepare a semi-finished product; and (3) after putting the semi-finished product into a dryer and drying, entering a tunnel kiln, sintering at the temperature of 1750+ / -10 DEG C and keeping the temperature for 10-12 hours under the condition of the temperature of 1750+ / -10 DEG C so as to obtain a finished product of a brick body. The brick body has high refractoriness under load, large volume density, low apparent porosity and high stability of thermal shock resistance, sets up the record of the longest use period of 456 days, replaces imported products in many large-sized cement enterprises successfully and breaks the current situation that fireproof materials used for the burning zone of a large-sized rotary cement kiln with a novel dry method generally depend on import.

Owner:郑州真金耐火材料有限责任公司

Preparation method of high temperature resistant forsterite type refractory material

The invention discloses a preparation method of a high temperature resistant forsterite type refractory material. The method comprises the following steps: using nickel-iron slag as raw materials and magnesia powder as additives, wherein the ratio of [w (MgO) + w (FeO)] to [w (Al2O3)+w (Cr2O3)] is 10.50 to 13.57, the ratio of w (MgO) to w (Cr2O3) is 34.90 to 48.12 and the ratio of w (MgO) to w (SiO2) is 1.19 to 1.61, adding binding agents and controlling calcination temperature to be 1360 DEG C to 1450 DEG C, inducing mineral phase reconstruction of the nickel-iron slag, optimizing transformation process of refractory crystal form (Mg2SiO4, MgO.Fe2O3, MgO.Al2O3, MgO.Cr2O3) to increase refractoriness of the refractory material. The refractoriness of the obtained refractory material is 1700 to 1800 DEG C, and the refractory material also has the advantages of high compressive strength, large bulk density, low apparent porosity, and can fully meet the industrial need of the refractory material. The preparation method of the high temperature resistant forsterite type refractory material has the advantages of high utilization rate of resources, high production efficiency, high added value, environment friendliness, easiness in process control, low production cost and the like.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com