Magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and production method

A technology of out-of-furnace refining and magnesia-calcium-zirconium bricks is applied in the field of basic refractory materials, which can solve problems such as damage of magnesia-calcium bricks, and achieve the effects of improving corrosion resistance, reducing costs and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

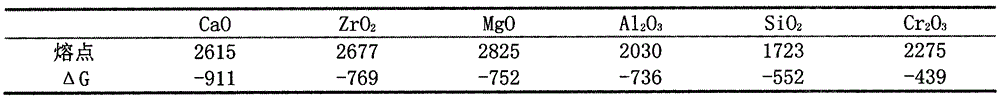

Problems solved by technology

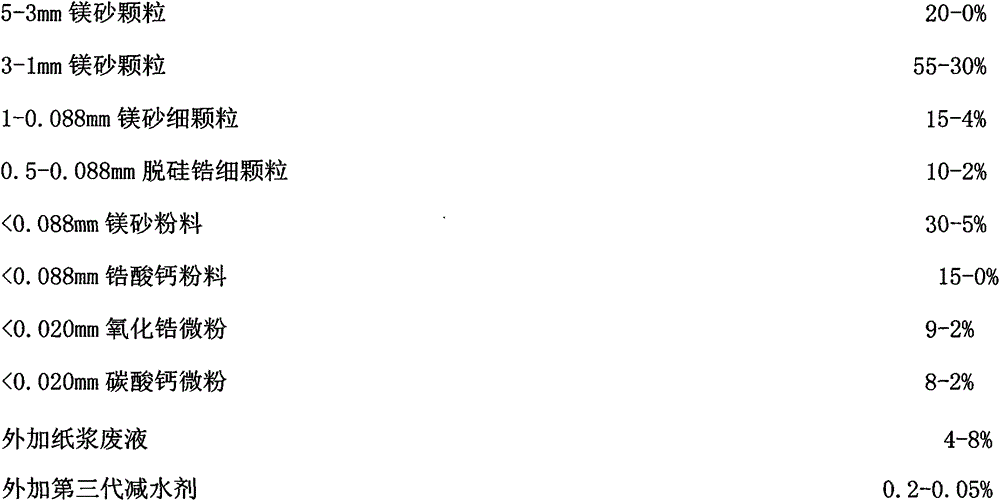

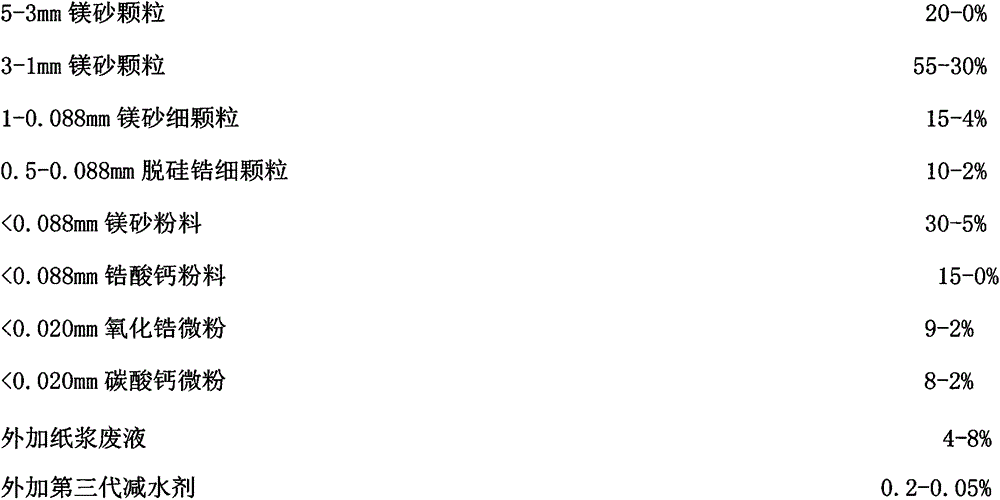

Method used

Image

Examples

Embodiment 1

[0028]The ratio used is: 3-1mm magnesia 55%, 1-0.088mm magnesia 10%, 0.5-0.088mm desiliconized zirconium 3%, 3 , Apparent porosity 14.0%, compressive strength 52MPa, load softening temperature 1700°C, thermal shock stability 1100°C water cooling 7 times, the product has certain thermal shock resistance.

Embodiment 2

[0030] The ratio used is: 5-3mm magnesia 17%, 3-1mm magnesia 35%, 1-0.088mm magnesia 6%, 0.5-0.088mm desiliconized zirconium 5%, 3 , Apparent porosity 13.0%, compressive strength 55MPa, load softening temperature 1680°C, thermal shock stability 1100°C water cooling 12 times, the product has good thermal shock resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com