Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Baddeleyite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Baddeleyite is a rare zirconium oxide mineral (ZrO₂ or zirconia), occurring in a variety of monoclinic prismatic crystal forms. It is transparent to translucent, has high indices of refraction, and ranges from colorless to yellow, green, and dark brown. See etymology below.

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

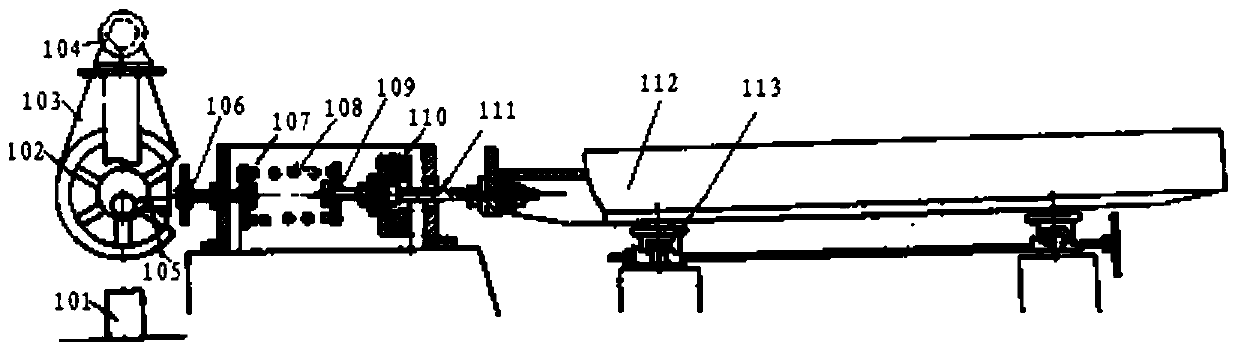

Method for uranium lead dating of baddeleyite by using secondary ion mass spectroscopy

InactiveCN102141539ASuppresses the "optical axis effect"Increased ionization yieldMaterial analysis by electric/magnetic meansFractionationMass analyzer

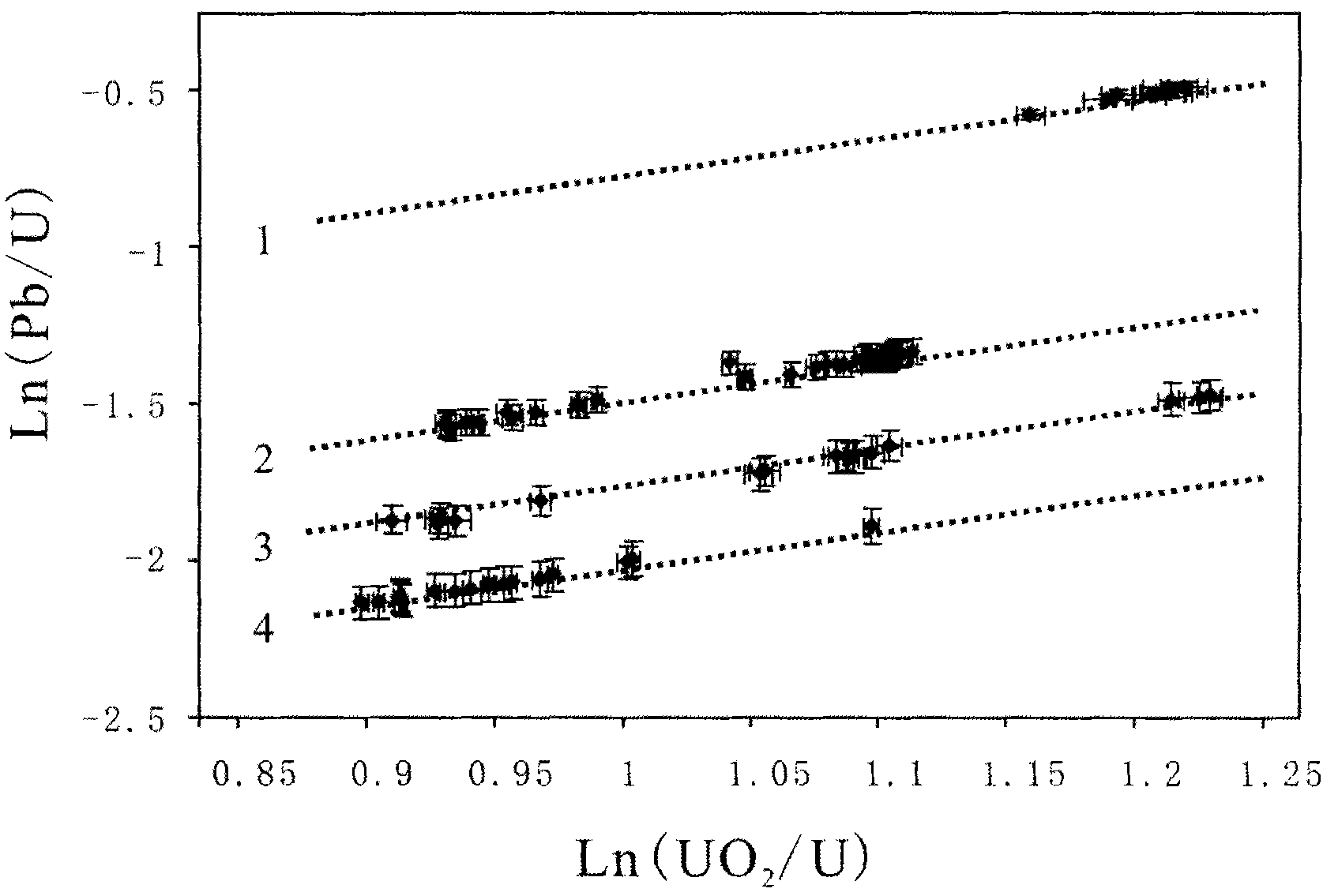

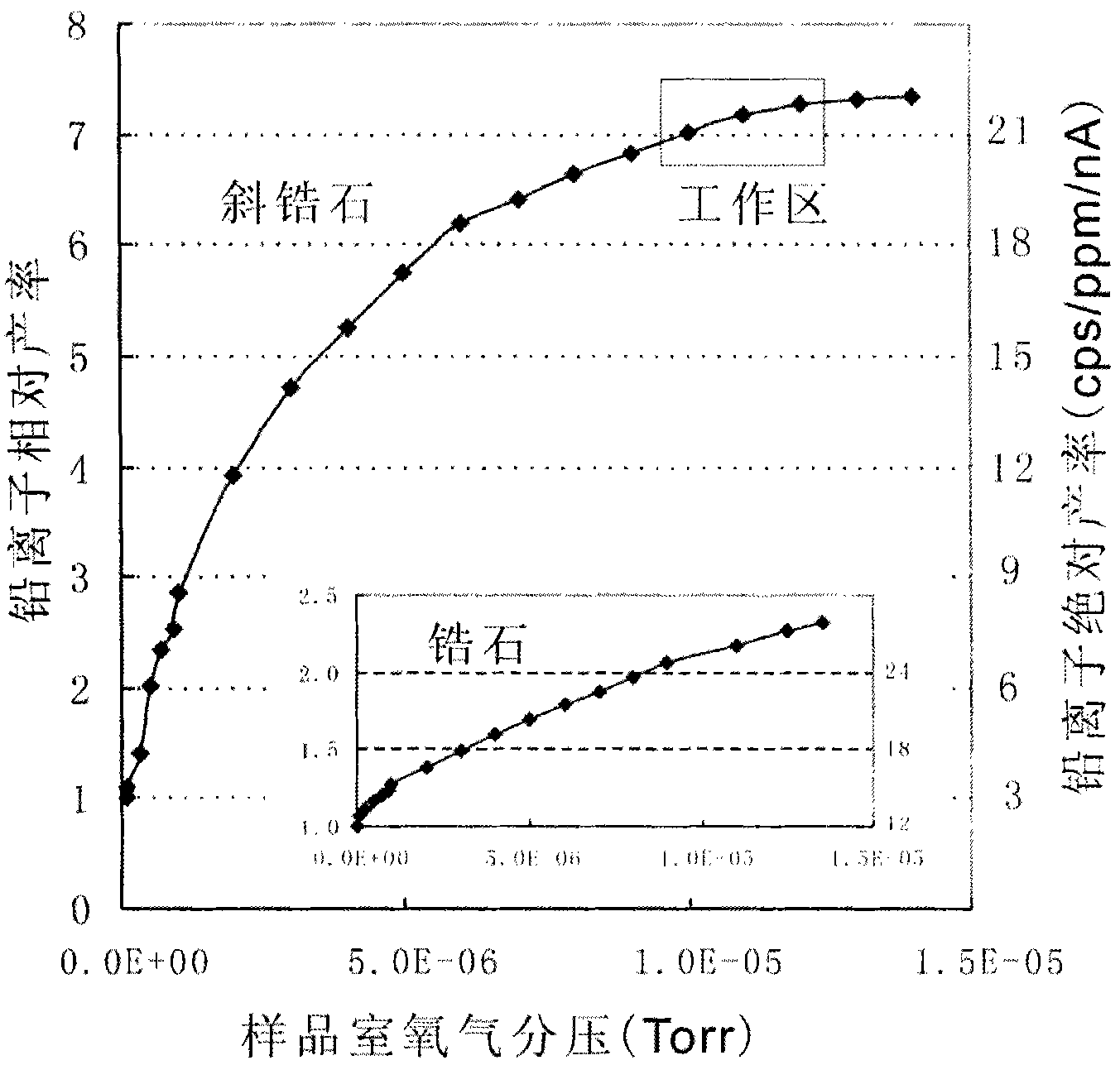

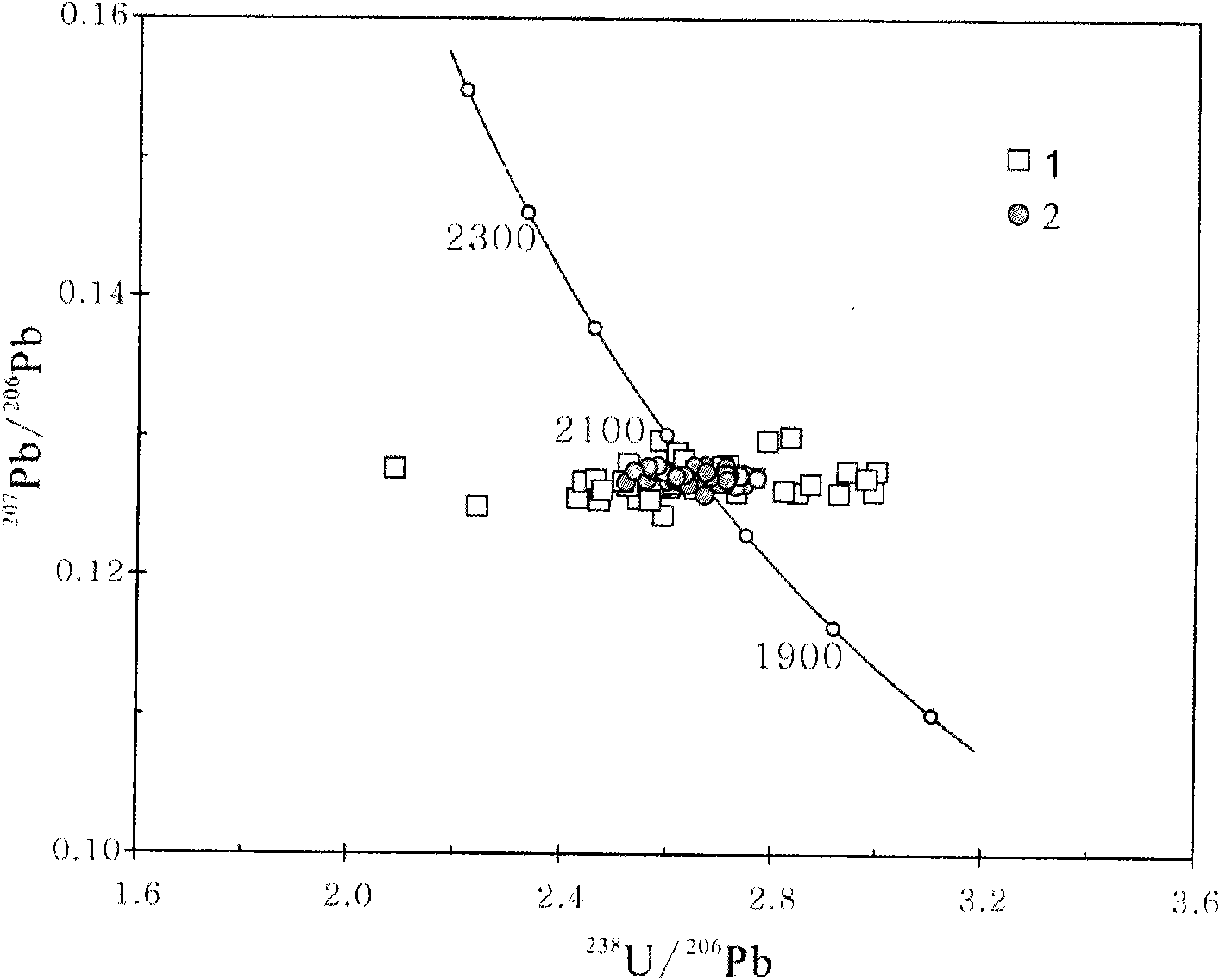

The invention discloses a method for determining uranium lead age of baddeleyite by using secondary ion mass spectroscopy, which belongs to the field of secondary ion mass spectroscopy dating method in geochronology and particularly relates to a method applied to a large secondary ion mass spectrometer having oxygen blowing conditions. In the measurement method described by the invention, the degree of vacuum in a sample cavity of the spectrometer is enabled to reach 1E-8Torr at first, and an oxygen leak valve is then opened to blow the oxygen with the purity of 99.99% to the surface of the sample so that the oxygen partial pressure of the sample cavity reaches 1E-5Torr. The method of the invention can reduce the optical axis effect, which is exhibited by secondary ion mass spectroscopy during the uranium-lead dating of baddeleyite, to be below 2%, thus the accuracy of uranium-lead age when the baddeleyite is subjected to secondary ion mass chromatographic analysis is significantly improved. After uranium-lead measurement ratio is obtained, uranium-lead fractionation correction is performed by adopting a linear relation between ln(Pb+ / U+) and ln(UO2+ / U+) in order to obtain accurate age.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Baddeleyite U-Pd dating method based on LA-ICP-(Q)MS (Laser Ablation-Inductively Coupled Plasma-(Quadrupole) Mass Spectrometer)

InactiveCN106483189AEffective controlEfficient collectionMaterial analysis by electric/magnetic meansInductively coupled plasmaQuadrupole

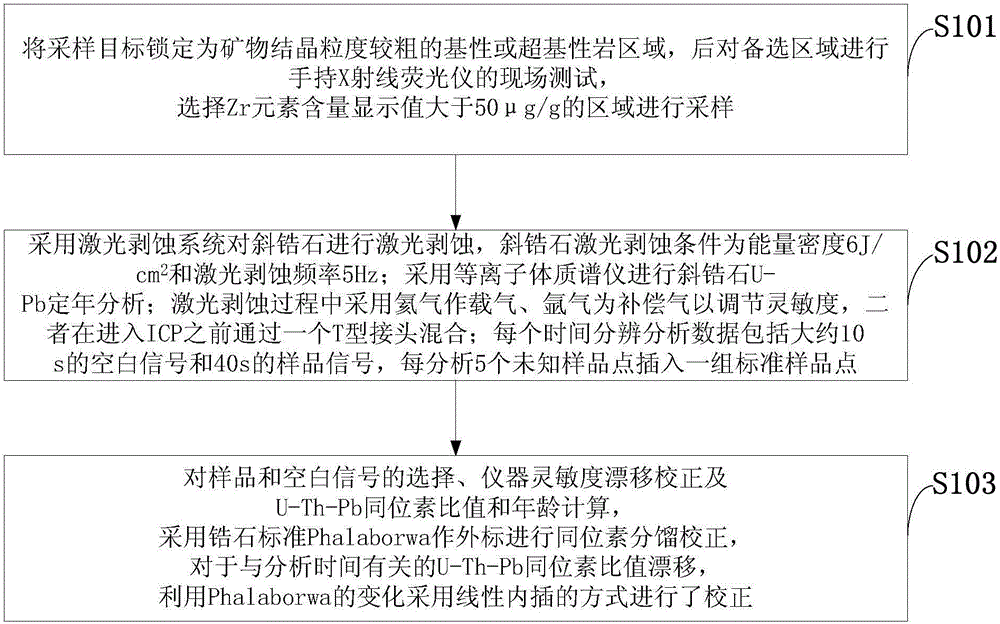

The invention discloses a baddeleyite U-Pd dating method based on a LA-ICP-(Q)MS (Laser Ablation-Inductively Coupled Plasma-(Quadrupole) Mass Spectrometer). A region of which the displayed value of the content of an element Zr is more than 50 mu g / g is selected to carry out sampling; laser ablation is carried out on baddeleyite by adopting a laser ablation system, and baddeleyite U-Pd dating analysis is carried out by adopting a plasma mass spectrometer; helium is adopted as a carrier gas and argon is adopted as a compensation gas to regulate sensitivity in a laser ablation process; a sample and a blank signal are selected, the sensitivity drift of an instrument is corrected, the U-Th-Pb isotope specific value and age are calculated, the zircon standard Phalaborwa is adopted as an external standard to carry out isotope fractionation correction, and the correction is carried out by utilizing the change of the Phalaborwa and by adopting a linear interpolation way. By using the baddeleyite U-Pd dating method based on the LA-ICP-(Q)MS, the effective collection on a baddeleyite sample and the effective control and the accurate correction on an elemental fractionation effect are realized.

Owner:XIAN CENT OF GEOLOGICAL SURVEY CGS

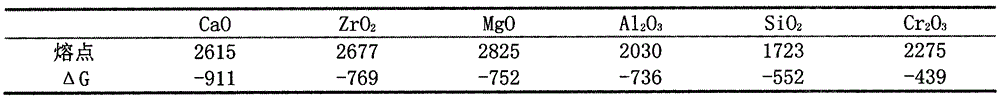

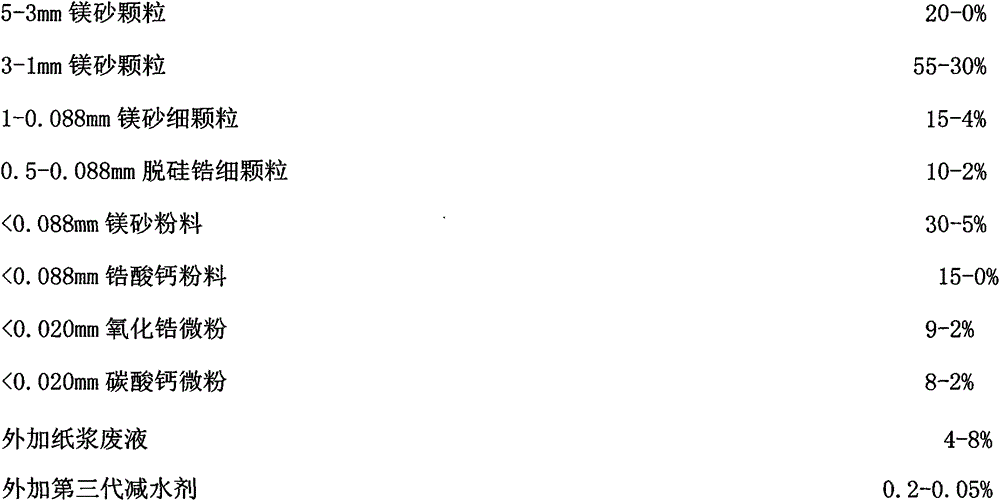

Magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and production method

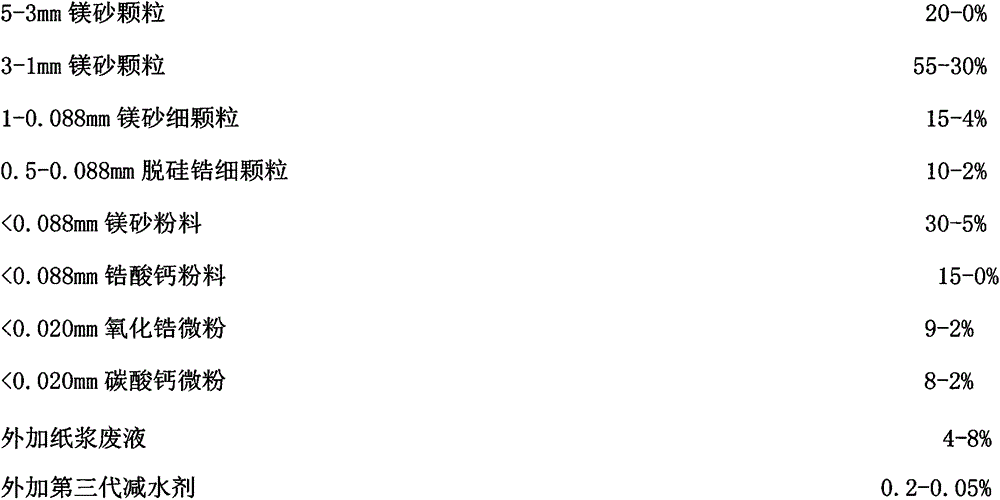

The invention relates to a magnesium-calcium-zirconium brick manufactured by means of in-situ reaction and used for secondary refining and a production method. During manufacturing, 0-20% of 3 mm-5 mm magnesia particles, 30-55% of 1 mm-3 mm magnesia particles, 4-15% of 0.088 mm-1 mm fine magnesia particles, 2-10% of 0.088 mm-0.5 mm fine desilicated zirconia particles, 5-30% of magnesia powder with the diameter being less than 0.088 mm, 0-15% of calcium zirconate powder with the diameter being less than 0.088 mm, 2-9% of zirconia micro powder with the diameter being less than 0.020 mm, 2-8% of calcium carbonate micro powder with the diameter being less than 0.020 mm, 4-8% of additional waste pulp liquid and 0.2-0.05% of additional third-generation water reducing agents are used; during production, the adopted process includes the steps that firstly, the zirconia micro powder and the calcium carbonate micro powder are premixed; secondly, the 3 mm-5 mm magnesia particles, the 1 mm-3 mm magnesia particles and the 0.088 mm-1 mm fine magnesia particles are added to a mixing mill, and he waste pulp liquid and the third-generation water reducing agents are added to the mixing mill to be mixed; thirdly, magnesia powder with the diameter being less than 0.088 mm, calcium zirconate with the diameter being less than 0.088 mm and premixed zirconia-calcium carbonate micro powder with the diameter being less than 0.020 mm are add and mixed until the mixture is even; finally, forming, drying, 1580-1700 DEG C sintering and checking are conducted on the mixture to obtain a refractory material with periclase-calcium zirconate-baddeleyite as a main crystal phase. The magnesium-calcium-zirconium brick has the advantages of being convenient to manufacture, low in cost, simple to use and excellent in performance, has excellent anti-erosion performance and thermal shock resistance, excellent high-temperature physical and chemical stability, and is competent for the work of secondary refining to make clean steel.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

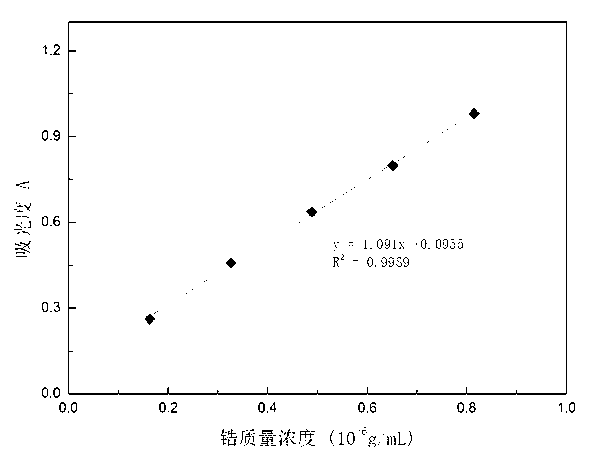

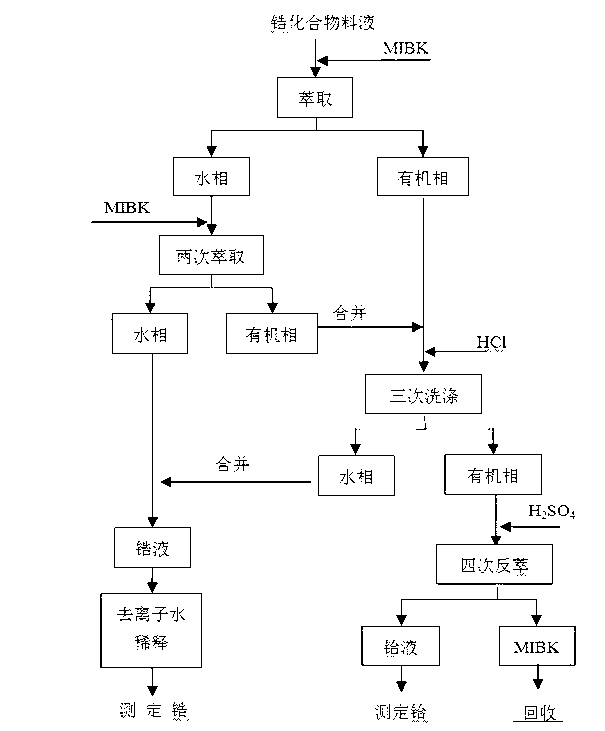

Method for accurately determining zirconium and hafnium components in zirconium compound by using extraction spectrophotometric method

InactiveCN102706871AHigh sensitivityGood choiceMaterial analysis by observing effect on chemical indicatorHafniumSolvent

The invention relates to a method for accurately determining zirconium and hafnium components in a zirconium-hafnium mixture by using an extraction spectrophotometric method. In the presence of a large amount of zirconium, the zirconium and hafnium are extracted and separated by using a methylisobutylketone-thiocyanic acid (MIBK-HSCN) system solvent, and the zirconium and hafnium components are accurately determined by combining an arsenazo III spectrophotometry. By the method, the zirconium and hafnium components in tested objects of zirconium oxychloride, baddeleyite, zircon sand, zirconium oxide, ferrozirconium and the like can be accurately determined; and the method has the advantages of high sensitivity, good selectivity, simplicity, convenience and quickness for instrument operation, accurate determination result and the like, and the test cost and the requirement on instrument equipment can be effectively reduced.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

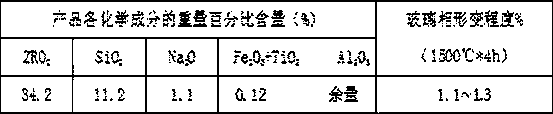

Production method of deformation-resistant fusion-cast zirconia corundum

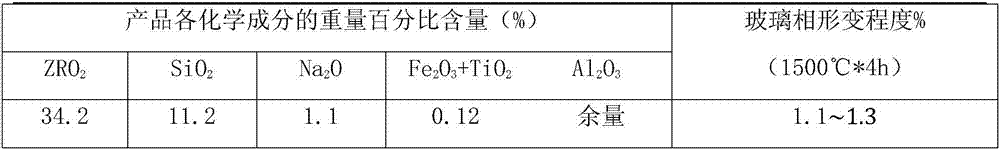

The invention provides a production method of deformation-resistant fusion-cast zirconia corundum. The deformation-resistant fusion-cast zirconia corundum is prepared by 20 to 60 percent of clinker and 40 to 80 percent of raw material, wherein the clinker is prepared from the following raw materials: 1.2 to 1.6 percent of sodium oxide, 25 to 33 percent of zirconium oxide, 17 to 19 percent of silicon oxide and 46 to 53 percent of aluminum oxide, and the raw material is prepared from the following raw materials by weight percent: 20 to 50 percent of zircon sand, 38 to 67 percent of calcined aluminum oxide powder, 6 to 20 percent of desilicated zirconia and 1 to 3 percent of sodium carbonate. A main chemical component of the fusion-cast zirconia corundum still belongs to a ternary phase diagram of Al2O3.ZRO2.SiO2, the original advantages of the fusion-cast zirconia corundum brick are sufficiently reserved; and however, by adding main components of baddeleyite and controlling the introduction of impurities, the tensile strength is improved, the deformation rate under the condition of 1500 DEG C can be reduced to 1.2 percent or smaller for 4 hours, the pollution on glass fluid is reduced, the glass quality is improved, and the production method is particularly suitable for producing and manufacturing top-grade glass.

Owner:江苏徐耐新材料科技股份有限公司

High wear resistant ceramic tool material and preparation method thereof

The invention discloses a high abrasion resistant ceramic tool material and a preparation method thereof, and the high abrasion resistant ceramic tool material is mainly prepared from silicon oxide, waste glass scraps, serpentine tailings, blast furnace slag, copper oxide, steel slag micro powder, tungsten boride, nano diamond, aluminum oxide, yttrium oxide, potassium magnesium titanate lamellas, glycerol, phenolic resin emulsion, polyvinyl alcohol, propylene glycol alginate (PGA), titanium dioxide, baddeleyite, garnet, bauxite, iron sulfide and other raw materials. By calcinations of the bauxite, serpentine tailings and other raw materials, high strength, high hardness, room temperature and high temperature friction increasing effects are fully played, by mutual cooperation of the baddeleyite, the garnet, the potassium magnesium titanate lamellas and other raw materials, friction coefficient stabilization is facilitated, wear resistance of the material is enhanced, abrasion is reduced, the titanium dioxide plays the role of increasing toughness and enhancing anti shearing ability, and the high abrasion resistant ceramic tool material has good overall abrasion resistance, high strength and long service life.

Owner:佛山市东方智柏纳米材料科技有限公司

High-hardness domestic ceramic and preparation process thereof

The invention belongs to the technical field of domestic ceramics, and particularly relates to a high-hardness domestic ceramic and a preparation process thereof. The high-hardness domestic ceramic comprises a domestic ceramic green body and a glaze layer, and the glaze layer is prepared from the following raw materials in parts by weight: 35-45 parts of kaolin, 5-10 parts of vein quartz, 3-7 parts of nepheline syenite, 3-7 parts of baddeleyite, 1-3 parts of silicon carbide fibers, 2-4 parts of zirconium oxide fibers, 3-7 parts of boron carbide fibers, 4-8 parts of carboxymethyl cellulose, 2-6 parts of sodium silicate and 25-35 parts of water. Through mutual cooperation of the components and a special heat treatment process, the prepared high-hardness domestic ceramic has relatively high hardness and bending strength.

Owner:潮州市瑞成陶瓷实业有限公司

A wear-resistant daily-use ceramic and its preparation method

The invention discloses a wear-resistant ceramic for daily use and a preparation method thereof. The wear-resistant daily-use ceramics include a daily-use ceramic body and a glaze layer, and the glaze layer is made of the following raw materials in parts by weight: 30-40 parts of zircon sand, 10-15 parts of baddeleyite, and 5-10 parts of syenite, 3-6 parts of titanium carbide powder, 3-5 parts of titanium dioxide, 4-6 parts of lutetium oxide, 2-4 parts of tungsten powder, 2-4 parts of polyvinyl alcohol with a mass fraction of 5wt% 2-4 parts of glycerin, 20-30 parts of water. The wear-resistant daily-use ceramics of the present invention are obtained through synergistic cooperation of components, and the obtained wear-resistant daily-use ceramics have a smooth glazed surface, good texture, excellent hardness and bending strength, and excellent wear resistance.

Owner:潮州市欧博瓷业有限公司

High-strength and high-temperature-resistance molding sand and preparation method thereof

InactiveCN105478654AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresBrickCalcium formate

The invention discloses high-strength and high-temperature-resistance molding sand and a preparation method thereof. The high-strength and high-temperature-resistance molding sand is prepared by the following raw materials in parts by weight: 14-22 of allophane, 24-38 of attapulgite, 12-18 of obsidian, 10-15 of baddeleyite, 8-14 of waste brick chips, 5-10 of refining slag, 16-24 of emery, 9-16 of glauconite, 7-11 of calcium formate, 5-10 of nanometer magnesium titanate, 4-7 of polyethylenimine, and 270-330 of modifying agents. The molding sand, prepared with allophane, obsidian, baddeleyite, waste brick chips, refining slag, emery and the like as main raw materials, is better in thermal stability and higher in refractoriness, and is added with calcium formate, nanometer magnesium titanate, polyethylenimine and the like to improve the green compression strength and the wet tensile strength. The prepared molding sand is excellent in breathability, fluidity, strength, collapsibility and high-temperature resistance; and a casting produced by the molding sand is smooth in surface and low in rejection rate.

Owner:安徽创奇乐智能游乐设备有限公司

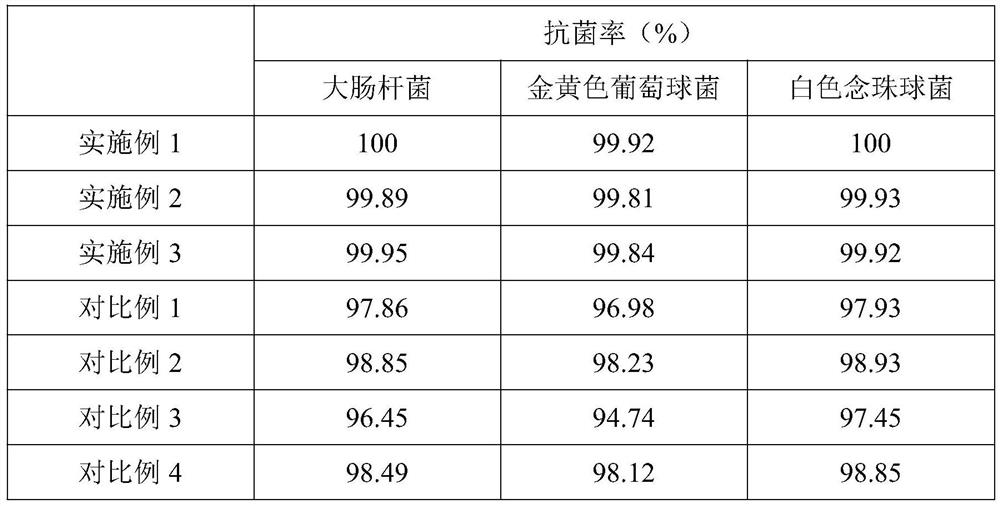

High-strength antibacterial domestic ceramic and preparation method thereof

ActiveCN113773115AImprove photocatalytic performanceImprove antibacterial propertiesCeramic materials productionClaywaresLutetiumGlaze

The invention belongs to the technical field of domestic ceramics, and particularly relates to a high-strength antibacterial domestic ceramic and a preparation method thereof. The high-strength antibacterial domestic ceramic comprises a domestic ceramic green body and a glaze layer, wherein the glaze layer is prepared from the following raw materials in parts by weight: 40-50 parts of baddeleyite, 6-12 parts of spodumene, 1-3 parts of B2O3, 5-7 parts of samarium and europium co-doped ZnO, 3-5 parts of silver powder, 0.5-2 parts of yttrium oxide, 0.5-2 parts of lutetium oxide, 3-6 parts of sodium humate, 3-6 parts of sodium polyacrylate and 20-30 parts of water. In the samarium and europium co-doped ZnO, the doping amount of samarium is 1-3 wt%, and the doping amount of europium is 1-3 wt%. According to the high-strength antibacterial domestic ceramic disclosed by the invention, through mutual matching of the components and control of the preparation method, the obtained product has excellent strength and antibacterial performance.

Owner:揭阳市栢轩顺陶瓷有限公司

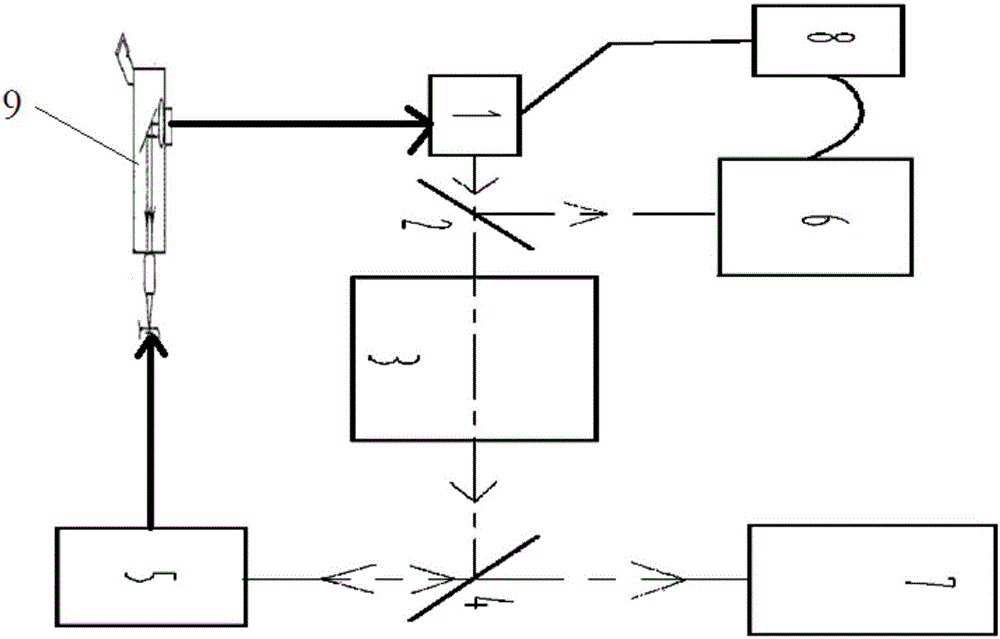

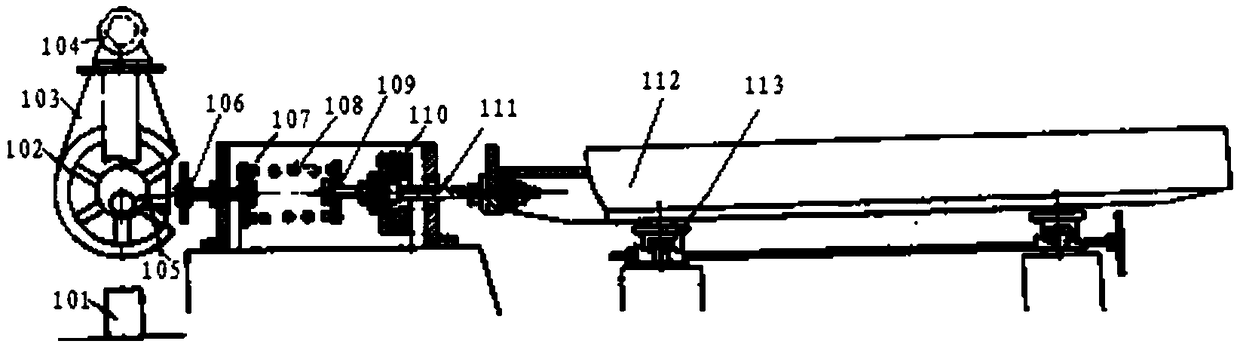

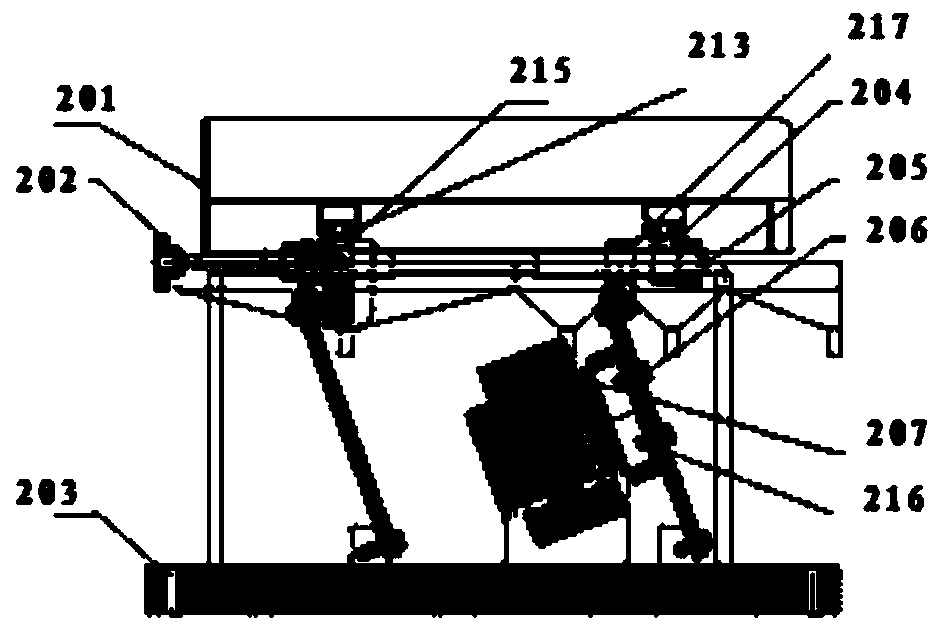

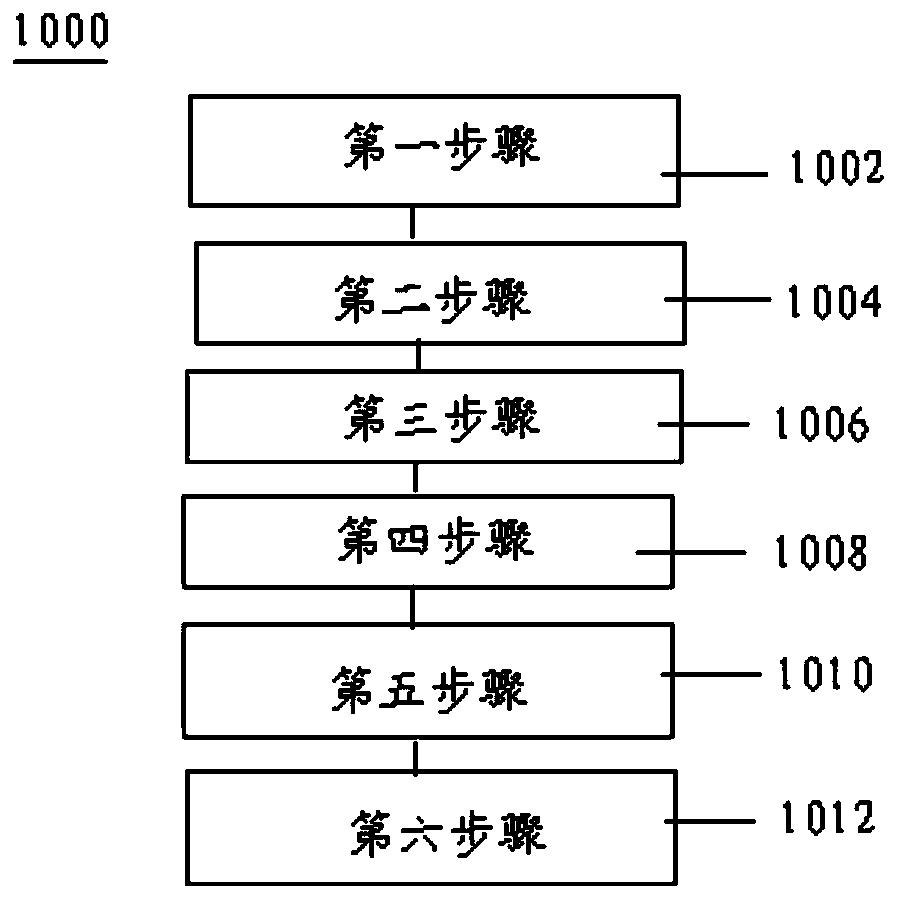

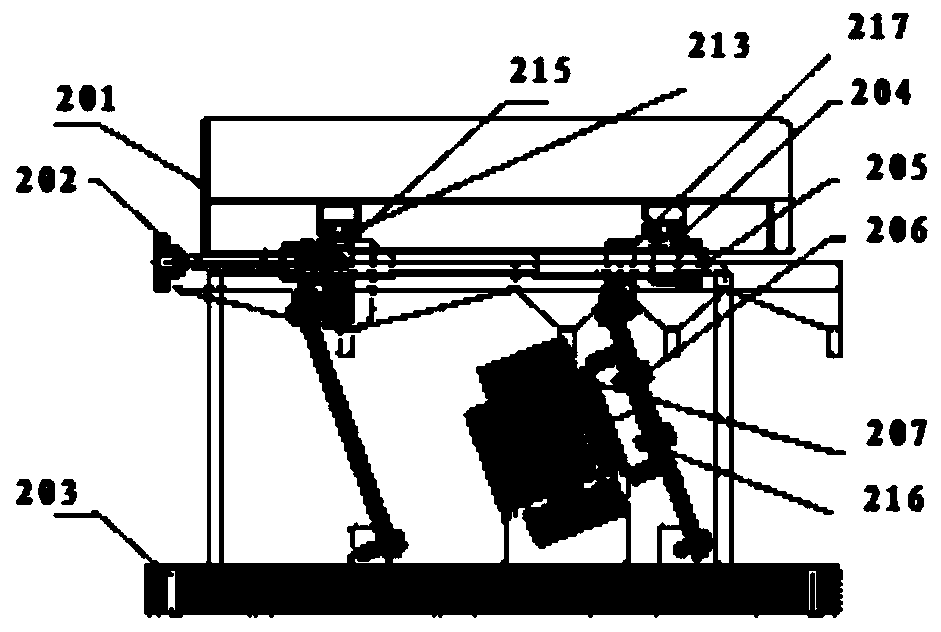

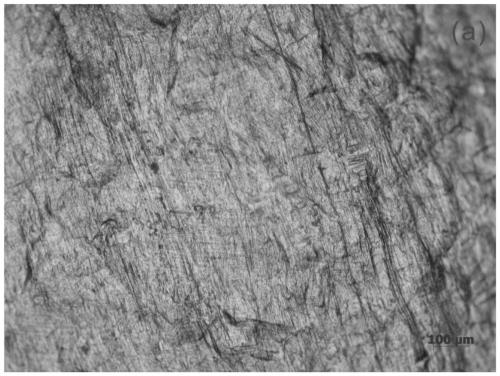

Sorting method and system of baddeleyite

The invention discloses a sorting method and system of baddeleyite. The sorting method of the baddeleyite comprises a first step, a second step, a third step, a fourth step, a fifth step and a sixth step. The sorting system of the baddeleyite comprises a first subsystem, a second subsystem, a third subsystem, a fourth subsystem, a fifth subsystem and a sixth subsystem.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Hot working method of fused zirconia corundum

The invention relates to a hot working method of fused zirconia corundum. The hot working method comprises the raw materials of 20-60% of clinker and 40-80% of raw materials by weight percent. The clinker comprises 1.2-1.6% of sodium oxide, 25-33% of zirconium oxide, 17-19% of silicon oxide, and 46-53% of aluminum oxide by weight percent. The raw material comprises 20-50% of zircon sand, 38-67% ofcalcined aluminum oxide powder, 6-20% of desiliconized zirconium, and 1-3% of sodium carbonate. The main chemical ingredients of the fused zirconia corundum still belong to an Al2O3-ZRO2-SiO2 ternary-component phase diagram, the original advantages of the fused zirconia corundum are fully kept, but as the main ingredient of baddeleyite is added and the addition of an impurity is controlled, the tensile strength is improved, the deformation rate is reduced to be 1.2% or lower under the condition of 1500 DEG C for four hours, the hot working method is favorable for reducing the pollution of molten glass and improving the quality of the glass, and is particularly suitable for the production and manufacture of the top-grade glass.

Owner:徐州东鹏工具制造有限公司

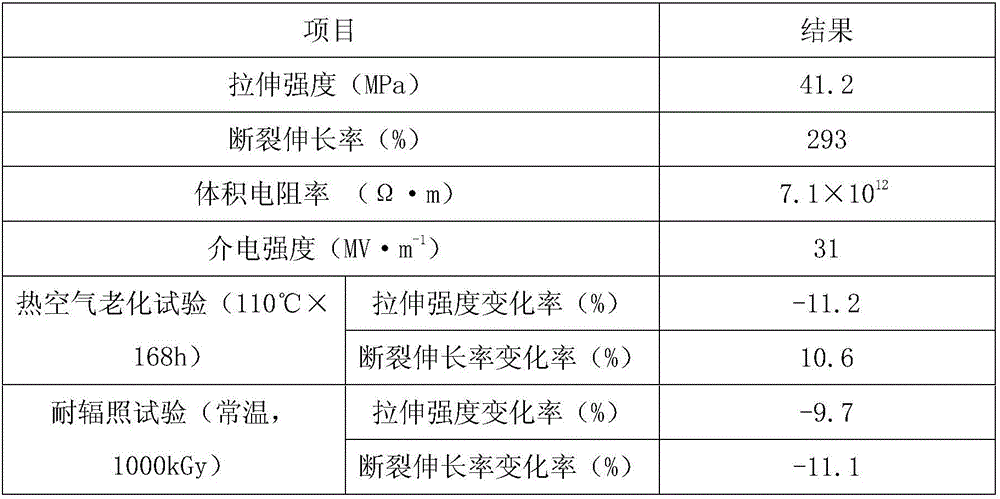

Irradiation-resistant anti-aging sheath material for communication wire harness, and preparation method of irradiation-resistant anti-aging sheath material

InactiveCN106084590AGood anti-aging performanceImprove thermal stabilityPlastic/resin/waxes insulatorsCalcium silicatePolyetherimide

The invention discloses an irradiation-resistant anti-aging sheath material for a communication wire harness, and a preparation method thereof. The irradiation-resistant anti-aging sheath material for the communication wire harness is prepared from the following raw materials in parts by weight: 34 to 48 parts of polytetrafluoroethylene, 14 to 22 parts of polyetherimide, 11 to 19 parts of polyphenylene sulfone, 5 to 10 parts of light calcined powder, 5 to 10 parts of nano barium sulphate, 12 to 18 parts of dibutyl phthalate, 2 to 3 parts of calcium ascorbate, 7 to 14 parts of a ceramic polishing waste material, 5 to 8 parts of low-molecular-weight polyisobutylene, 6 to 12 parts of calcium silicate slag tail, 5 to 10 parts of baddeleyite, 3 to 4 parts of poly(ethylene glycol) monooleate, 4 to 6 parts of behenamide, 2 to 3 parts of calcium isooctanoate, 1 to 2 parts of zinc isoocatanoate, and 4 to 5 parts of antimony pentasulfide. According to the irradiation-resistant anti-aging sheath material for the communication wire harness, and the preparation method thereof, irradiation-resistant materials, such as polyetherimide and polyphenylene sulfone are added into polytetrafluoroethylene for blending and modifying, and meanwhile, a suitable amount of inorganic fillers, such as nano barium sulphate, the calcium silicate slag tail, baddeleyite and antimony pentasulfide, are added, so that the irradiation resistance of the sheath material can be improved, and the anti-aging performance, the heat stability and the corrosion resistance of the sheath material can also be improved.

Owner:合肥得润电子器件有限公司

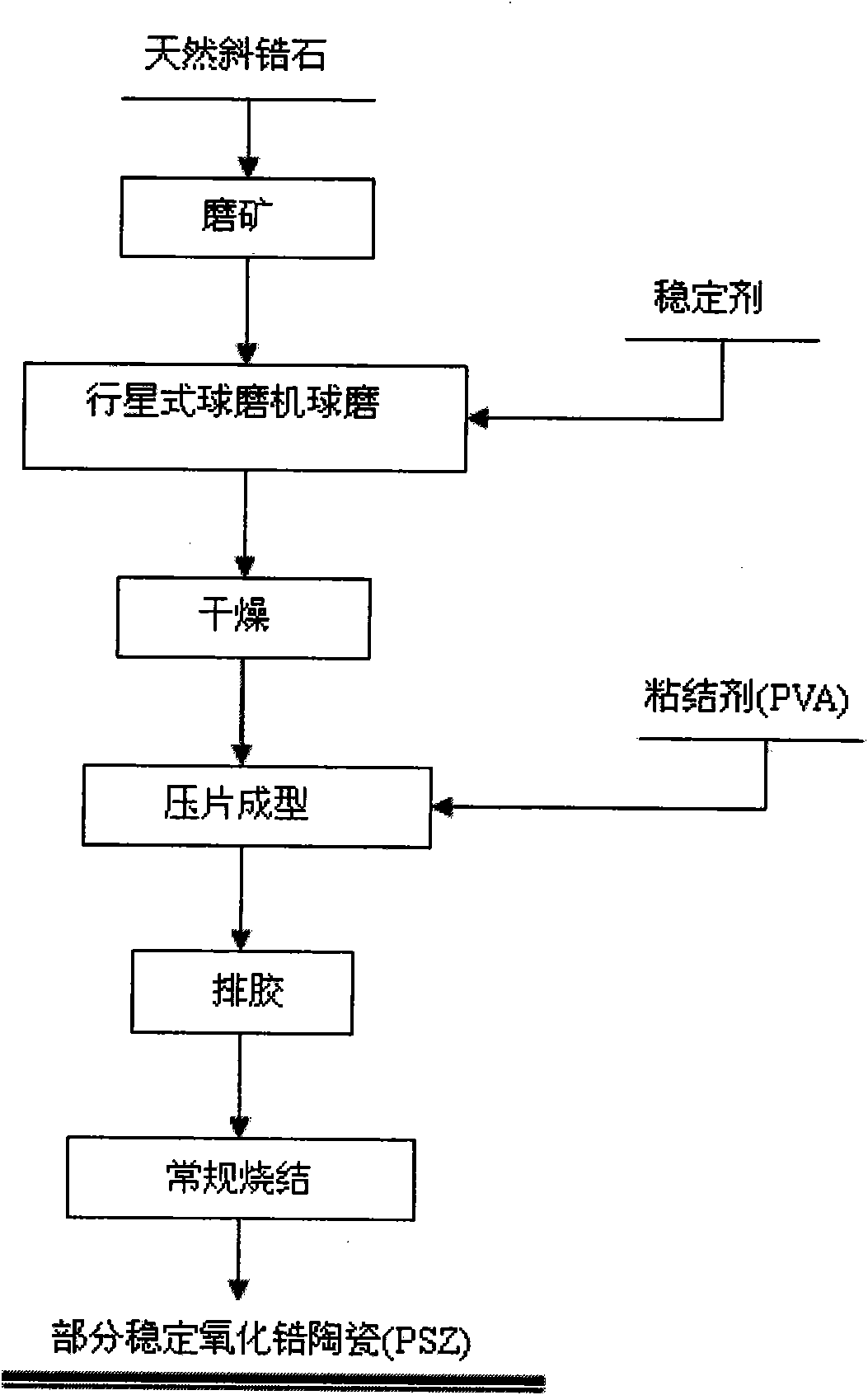

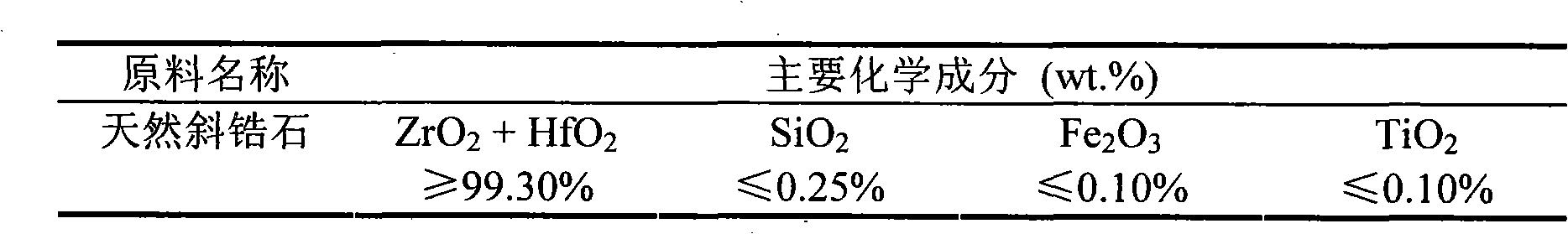

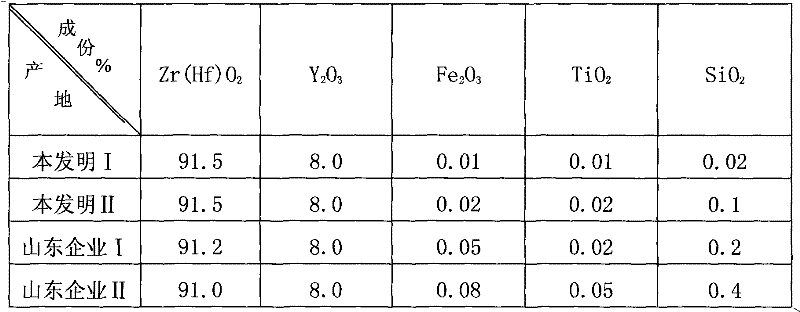

Method for preparing partially stabilized zirconia ceramics by adopting natural baddeleyite

The invention discloses a method for preparing partially stabilized zirconia ceramics by adopting natural baddeleyite. A finished product of the partially stabilized zirconia ceramics serving as a special ceramic material and a refractory material is prepared from the natural zirconia serving as a raw material by crushing, preparing materials, ball-milling, sintering at the temperature of between 1,300 and 1,600 DEG C and keeping the temperature for 2 to 6 hours. By directly adopting the natural baddeleyite obtained by beneficiation as the raw material without using a processed industrial pure raw material, so no waste residue, no waste gas or no waste liquor is generated in a process. Because the natural zirconia is used as the raw material, the partially stabilized zirconia ceramics can be prepared by only adding a certain amount of stabilizer, ball-milling, caking and sintering without performing additional treatment; process flow is short; energy consumption is reduced; and harmless treatment is realized. The partially stabilized zirconia ceramics is used as the special ceramic material or the refractory material.

Owner:KUNMING UNIV OF SCI & TECH

Fireproof anti-aging ceramic tile and preparation method thereof

The invention discloses a fireproof anti-aging ceramic tile and a preparation method thereof. The fireproof anti-aging ceramic tile is prepared from, by weight, 12-19 parts of magnesite, 16-24 parts of baddeleyite, 5-10 parts of titanium dioxide, 13-22 parts of pelite, 4-7 parts of yttrium oxalate hydrate, 18-27 parts of silica sand, 14-23 parts of carbide slurry, 15-20 parts of furnace kiln residues, 11-17 parts of carbon ferrochrome slags, 10-15 parts of satin stone, 5-10 parts of quick lime, 17-24 parts of kyanite tailings, 15-20 parts of bauxite and 14-21 parts of stone coal vanadium extracting residues. Due to the added raw materials such as magnesite and baddeleyite, the mechanical property of the ceramic tile can be improved, the refractoriness of the ceramic tile can be improved; due to the added raw materials such as stone coal vanadium extracting residues, satin stone and carbon ferrochrome slags, and the ceramic tile can have the good aging resistance and high corrosion resistance. The obtained ceramic tile has the advantages of being high in refractoriness and mechanical strength, excellent in aging resistance, good in corrosion resistance and durability and the like.

Owner:安徽省亚欧陶瓷有限责任公司

Production method of electrically melt yttrium oxide stabilized zirconia granulation powder

The invention discloses a production method of electrically melt yttrium oxide stabilized zirconia granulation powder which is profitable, green and environmentally friendly. The method comprises the following steps: adding zircon sand and Y-doped cubic zirconia powder (or Y-Zr powder) in reducing agent for mixing and electric smelting or directly adding baddeleyite for mixing and electric smelting, cooling, performing coarse crushing and fine crushing, screening, performing coarse grinding and fine grinding, performing wet grinding to generate pulp, performing surface modification, performing spray granulation, mixing evenly and packaging. The method of the invention uses Y-Zr powder as raw material, the technical process is simple and easy, the method does not discharge waste water, waste gas and waste residue; the equipment investment is less, the product quality meets user requirements, the production process does not adopt secondary electric smelting and high-temperature heat treatment and add stabilizing agent; and under the same conditions, compared with the stabilized Zr and granulation powder thereof which are produced by the current and popular technology, the granulation powder quality is higher, the performance is better and the cost is reduced by 30-40%.

Owner:王必庆

Fireproof glass micro-beads for flame-retardant reflective cloth and preparation method thereof

The invention discloses fireproof glass micro-beads for flame-retardant reflective cloth and a preparation method thereof. The fireproof glass micro-beads are prepared from the following raw materials in parts by weight: 42-59 parts of andalusite, 33-46 parts of volcanic rock, 27-39 parts of eclogite, 36-52 parts of baddeleyite, 29-44 parts of sellaite, 5-10 parts of sodium tungstate, 6-12 parts of yttrium aluminate, 10-15 parts of white clay, 16-24 parts of bauxite, 26-37 parts of flint clay, and 12-14 parts of an additive. The prepared glass micro-beads have high the refractoriness which is as high as more than or equal to 1700 DEG C, also have the advantages of good weather resistance, high compressive strength, good corrosion resistance, good flexibility, and high refractive index, and can improve high temperature resistance and fire prevention performance while ensuring light reflective performance of the flame-retardant reflective cloth.

Owner:BENGBU GAOHUA ELECTRONICS

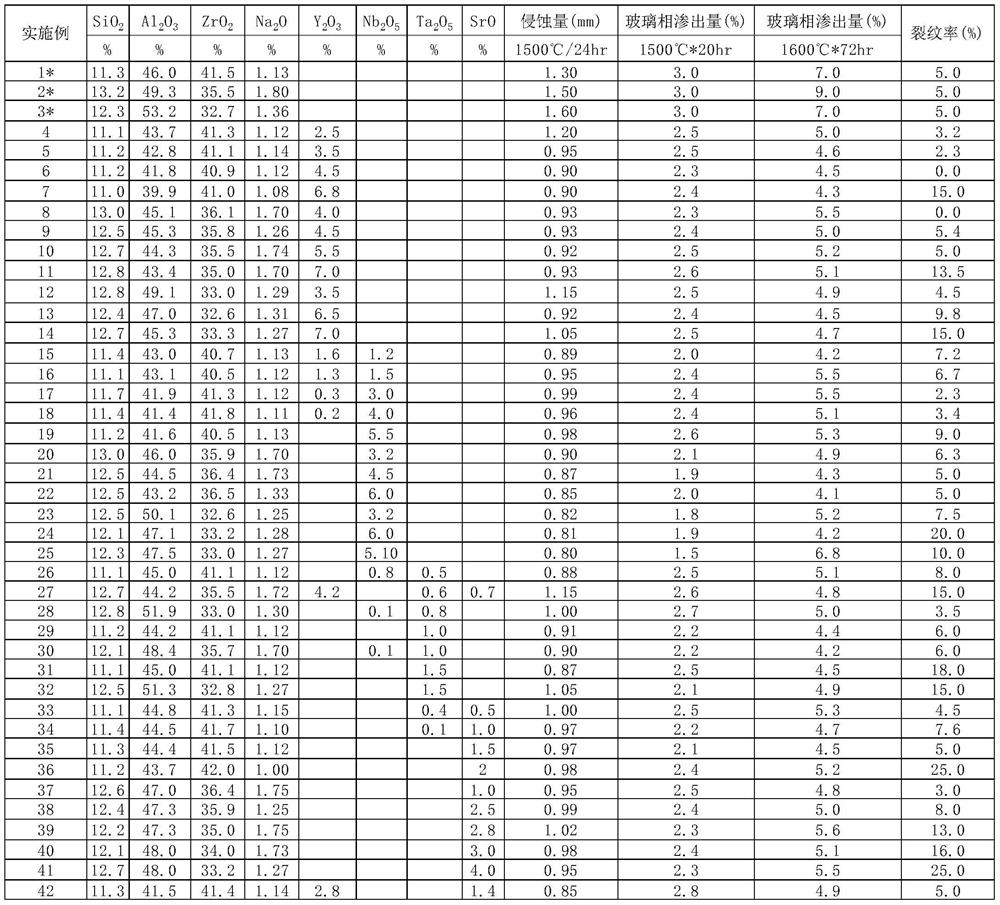

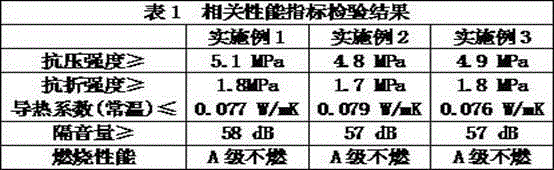

Fused azs bricks resistant to corrosion by low iron glass

ActiveCN108218192BLow Static ErosionImprove corrosion resistanceGlass furnace apparatusBrickRefractory

The invention relates to an electric fused AZS brick corrosion-resistant to low-iron glass, which belongs to the field of refractory materials. The fused AZS bricks resistant to corrosion by low-iron glass are composed of the following mass fractions: ZrO 2 : 31‑45%; SiO 2 : 9‑14%; Na 2 O: 0.6‑1.9%; doped oxide: 0.5‑16.5%, the balance being alumina. The doped oxide is Y 2 o 3 、 Ta 2 o 5 , Nb 2 o 5 Or one or more of SrO. The prepared fused AZS brick has good corrosion resistance, low porosity and high ability to withstand the stress of baddeleyite phase transformation. Compared with ordinary AZS brick, the corrosion resistance is increased by more than 30%, and the glass phase exudates rate reduced by 30%.

Owner:淄博艾杰旭刚玉材料有限公司

Molten slag corrosion-resistant refractory brick and preparation method thereof

InactiveCN106631063AImprove fire resistanceSignificant refractorinessCeramic materials productionClaywaresKyaniteALUMINUM PHOSPHATE

The invention discloses a molten slag corrosion-resistant refractory brick and a preparation method thereof. The refractory brick is prepared from the following raw materials in parts by weight: 13-24 parts of siliceous shale, 18-27 parts of base slag, 15-25 parts of kyanite, 11-19 parts of hydrargillite, 5-9 parts of cerium oxide, 15-20 parts of steel mill precipitator dust, 10-15 parts of vesuvianite, 20-30 parts of purple grit mud, 24-32 parts of bentonite, 14-22 parts of talcum, 15-25 parts of baddeleyite, 12-24 parts of superfine molybdenum powder, 8-13 parts of condensed aluminum phosphate and 4-8 parts of yttrium oxalate. The refractory brick prepared by the invention is compact in crystal structure, high in refractoriness under load, favorable in thermal shock resistance, high in normal-temperature and high-temperature mechanical strength, favorable in wear resistance and favorable in thermal conductivity; and the refractory brick has excellent molten slag corrosion resistance, is particularly suitable for resisting the corrosion and invasion of a solution and molten slag from a high-temperature smelting furnace, is wide in application range and has a favorable use effect.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

High-strength fire-proofing insulating plate for construction and preparation method thereof

The invention provides a high-strength fire-proofing insulating plate for construction. The insulating plate is prepared from the following raw materials in parts by weight: 20-25 parts of boric sludge, 16-20 parts of palygorskite, 6-8 parts of dickite, 12-15 parts of baddeleyite, 25-30 parts of gypsum powder, 2-3 parts of p-hydroxybenzenesulfonic acid, 3-4 parts of benzene sulfinic acid sodium salt, 5-7 parts of polyacrylamide, 4-6 parts of high-substituted hydroxyproxyl cellulose, 9-13 parts of lignocellulose and 30-40 parts of water. The high-strength fire-proofing insulating plate for construction has the characteristics of high tensile strength, temperature preservation and heat insulation, good fire-proofing performance, corrosion resistance, damp resistance and the like, and is very suitable for construction separators.

Owner:山西绅美陶瓷纤维股份有限公司

Zirconium self-flowing castable

The invention discloses a zircon self-flowing castable. The zircon self-flowing castable is characterized by comprising aggregate, powder and an admixture, the aggregate is prepared from high-aluminabauxite clinker, sub-white corundum, zirconite and baddeleyite which account for 70-80% of the sum of the mass of the aggregate and the mass of the powder; the powder comprises silica powder accounting for 1-6% of the sum of the mass of the aggregate and the powder, sub-white corundum powder accounting for 1-10% of the sum of the mass of the aggregate and the powder, alumina powder accounting for1-12% of the sum of the mass of the aggregate and the powder, zirconia powder accounting for 2-3% of the sum of the mass of the aggregate and the powder, white mud accounting for 1-10% of the sum of the aggregate and powder, high-alumina bauxite clinker accounting for 0-25% of the sum of agrregate and the power, the mass of the high-alumina cement accounting for 0-3% of the total mass of the aggregate and the powder, and the mass of the pure calcium aluminate cement accounting for 0-6% of the total mass of the aggregate and the powder. The zirconium self-flowing castable is stable in propertyand performance at high temperature and excellent in fire resistance, the cracking resistance can be improved by 2%-3% of zirconium oxide powder, and the fire resistance is integrally improved.

Owner:浙江攀盛冶金材料有限公司

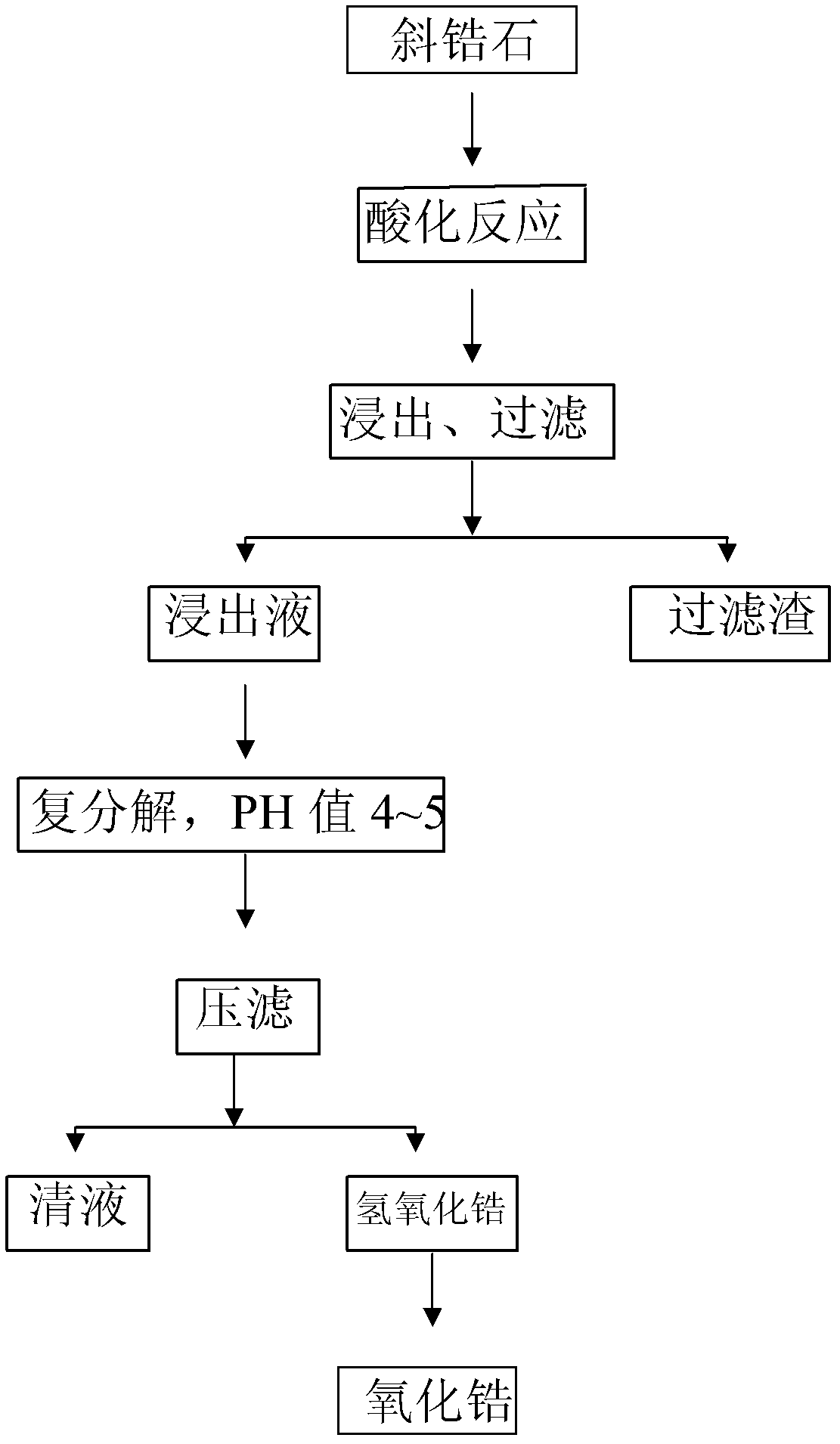

Method for purification of baddeleyite to prepare high purity zirconia

The invention relates to a purification method of high purity zirconia, particularly to a method for purification of baddeleyite to prepare high purity zirconia. The method is characterized in that: the baddeleyite is subjected to an acidification reaction to convert the zirconia component therein into zirconium sulfate, the zirconium sulfate reacts with lye to generate zirconium hydroxide, and finally after calcinations, the high purity zirconia can be obtained. The method provided in the invention has the advantages of: saving energy, simplifying the production process, improving the production efficiency, solving the environmental protection, and realizing pollution-free discharge. The obtained product has a white color, the mass content of ZrO2 is greater than or equal to 99.5%, and the impurity content is low.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

High-temperature-resistant antioxidant ceramic glaze and preparation method thereof

PendingCN114804635AGood high temperature resistance and oxidation resistanceModified mechanical propertiesOxidation resistantEthyl acrylate

The invention belongs to the technical field of ceramic glazes, and particularly relates to a high-temperature-resistant antioxidant ceramic glaze and a preparation method thereof. The glaze is prepared from the following components in parts by weight: 40 to 50 parts of baddeleyite; 4 to 8 parts of anorthite; 4-8 parts of diopside, 3-6 parts of boron carbide whiskers, 3-6 parts of silicon carbide whiskers and 1-3 parts of nano lanthanum oxide; 1-3 parts of nano praseodymium oxide; 3 to 6 parts of poly (ethyl acrylate); 4 to 8 parts of dimethyl diallyl ammonium chloride; and 25-35 parts of water. According to the high-temperature-resistant anti-oxidation ceramic glaze disclosed by the invention, through mutual matching of the components and control of the preparation method, the obtained product has excellent strength and high-temperature-resistant anti-oxidation performance.

Owner:广州力合新材料科技有限公司

Shock-resistant and break-resistant domestic ceramic and preparation method thereof

The invention belongs to the technical field of domestic ceramics, and particularly relates to a shock-resistant and break-resistant domestic ceramic and a preparation method thereof. The shock-resistant and break-resistant domestic ceramic comprises a domestic ceramic green body and a glaze layer, and the glaze layer is prepared from the following raw materials in parts by weight: 40-50 parts of baddeleyite, 4-8 parts of diopside, 4-8 parts of high bauxite, 1-3 parts of silicon carbide fiber, 1-3 parts of carbon nitride fiber, 0.5-1.5 parts of nano europium oxide, 0.5-1.5 parts of nano erbium oxide, 0.5-1.5 parts of sodium silicate, 4-8 parts of sodium polyacrylate and 35-45 parts of water. Through a specific method and mutual coordination and cooperation of the components, the prepared domestic ceramic has excellent shock resistance and other properties.

Owner:毕延格

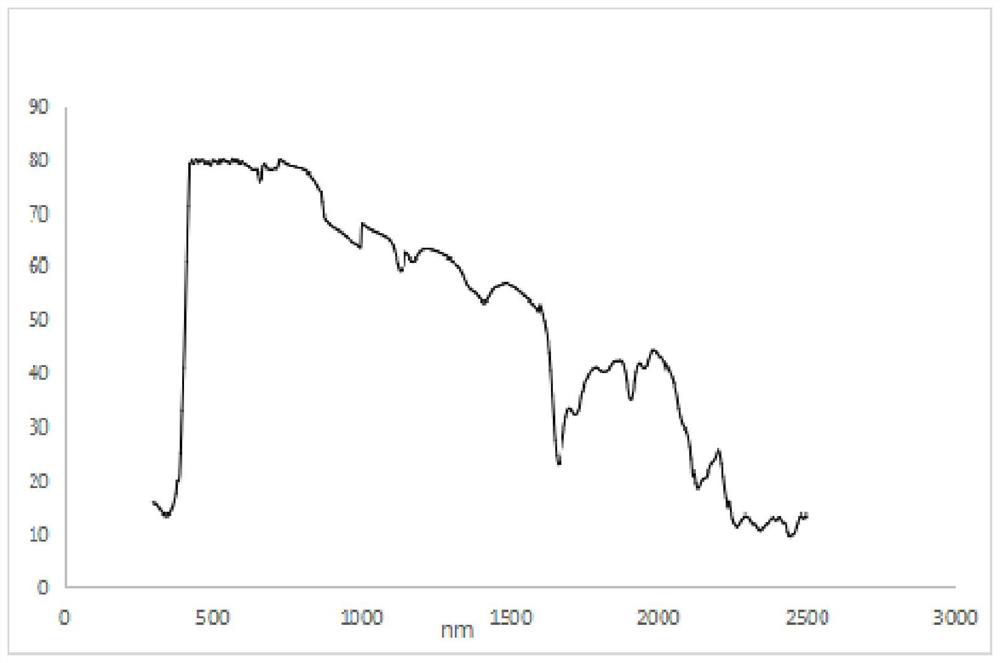

Infrared reflection alpha-PbO2 phase titanium dioxide-zirconium oxide nano composite material and preparation method thereof

ActiveCN113800559ALow costSimple process routeMaterial nanotechnologyTitanium dioxideIr reflectionCrystal system

The invention discloses an infrared reflection alpha-PbO2 phase titanium dioxide-zirconium oxide nano composite material and a preparation method thereof, and belongs to the field of infrared reflection materials. The method comprises the following steps: S1, anatase type titanium dioxide is firstly converted into alpha-PbO2 phase titanium dioxide at 5-13 GPa and can be changed into a baddeleyite structure at 3-26 GPa, but after pressure is released to normal pressure, only the alpha-PbO2 phase titanium dioxide exists, the alpha-PbO2 phase titanium dioxide is in an orthorhombic crystal system, crystal parameters of the alpha-PbO2 phase titanium dioxide are related to pressure change, the interplanar spacing of 110 and 111 is 2.8 nm, the included angle of the crystal faces is 70.3, which is better than ordinary titanium dioxide, and the reflection efficiency of light in the near-infrared wavelength range is greatly improved. The zirconium salt is adopted as a zirconium ion source, the infrared reflection alpha-PbO2 phase titanium dioxide-zirconium oxide nano composite material is prepared, the cost is low, the process route is simple and easy to implement, and the infrared reflection material can be widely applied to the fields of coatings, plastics, daily necessities, medical treatment, spinning and the like.

Owner:畅的新材料科技(上海)有限公司

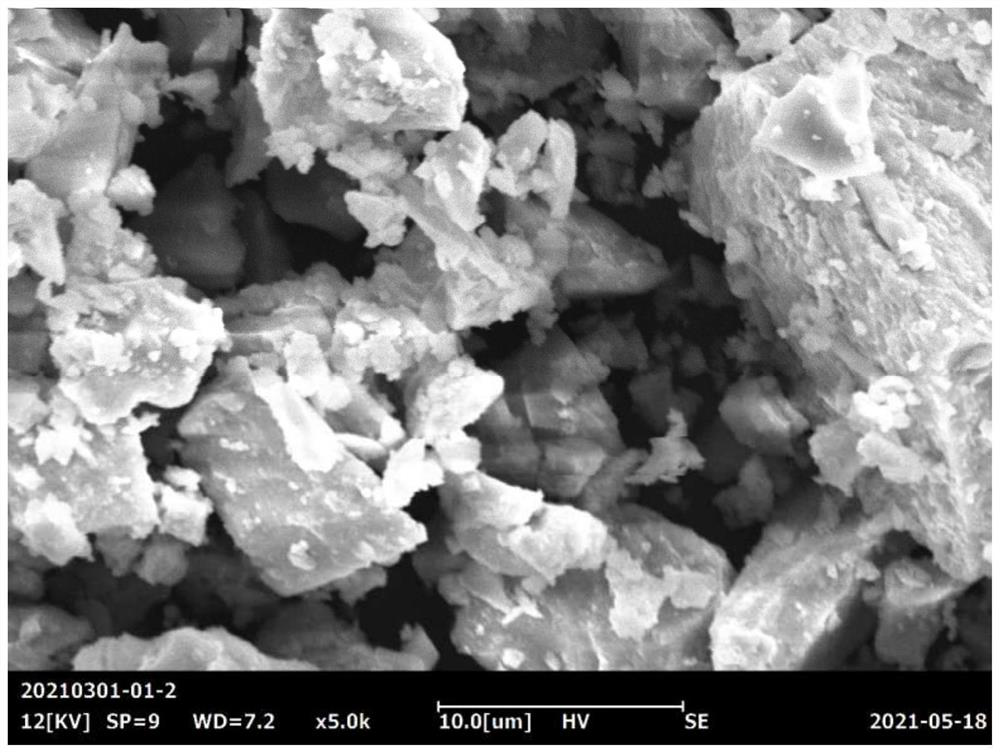

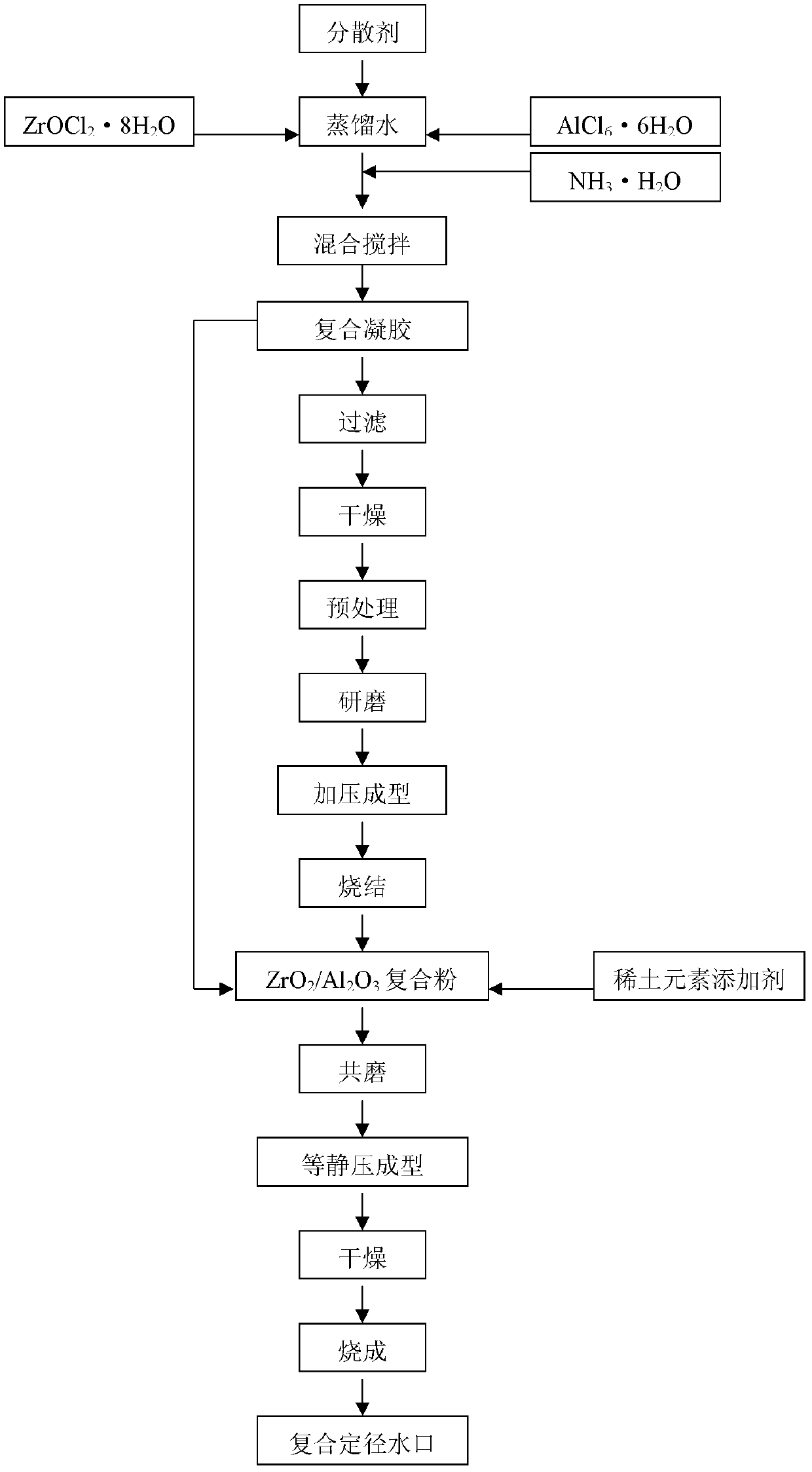

Preparation method for corundum baddeleyite eutectoid composite nonswirl nozzle inner layer

The invention discloses a preparation method for a corundum baddeleyite eutectoid composite nonswirl nozzle inner layer. The method comprises the following steps: preparing ZrO2-Al2O3 composite powder; grading the grain size of the ZrO2-Al2O3 composite powder; adding a rare earth additive; grinding for 24 to 48 hours; adding ZrO2-Al2O3 gel, in amount which is 5 to 10 percent of the total amount of the materials, serving as a binding agent; performing isostatic pressing; drying at the temperature of 105 + / - 5 DEG C for 24 hours; and sintering at the temperature of 1,700 and 1,720 DEG C to prepare the corundum baddeleyite eutectoid composite nonswirl nozzle inner layer, wherein the zirconium oxide (ZrO2) content is 45 + / - 1 percent, the ZrO2+Al2O3 is more than or equal to 95 percent, the corundum baddeleyite eutectoid content is more than or equal to 90 percent, the volume density is 4.50 to 4.60 g / cm<3>, and the cold state pressure-resistant strength is more than or equal to 300 MPa. The result of a test of an applicant shows that the service life can reach 23 hours.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A sorting method and system for baddeleyite

The invention discloses a sorting method and system of baddeleyite. The sorting method of the baddeleyite comprises a first step, a second step, a third step, a fourth step, a fifth step and a sixth step. The sorting system of the baddeleyite comprises a first subsystem, a second subsystem, a third subsystem, a fourth subsystem, a fifth subsystem and a sixth subsystem.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

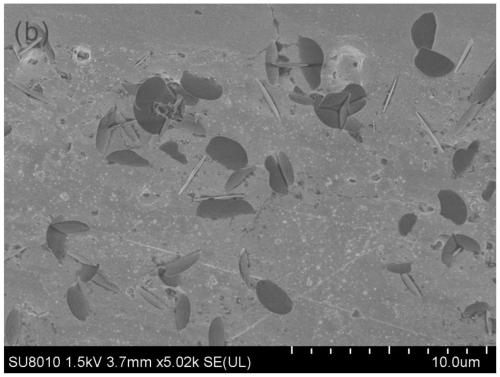

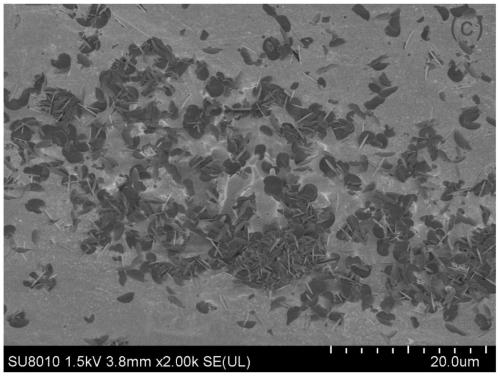

A kind of high (001) surface flaky zirconia and its preparation method

ActiveCN110203968BSelf-reactive synthesisLarge specific surface areaZirconium oxidesCrystallographyReaction temperature

The present invention provides a preparation method of high (001) plane flaky zirconia, which is prepared through hydrolysis and self-reaction of a single reagent of fluozirconic acid. According to the present invention, only two reagents, fluozirconic acid and ethanol, are used in the whole process, 5 synthetic raw materials are simple and easily available, reaction time is extremely short, and reaction temperature is low, thereby avoiding complicated procedures of reaction, calcination, cleaning and the like, and simplifying the process; and synthesized flaky zirconia particles are uniform, intact in crystal plane, high in (001) plane proportion and high in specific surface area, and thus have good application prospects such as adsorption, catalysis and sensing. Drawings x i i E Standard baddeleyite 11 11 1 o 1G2,70 3WO 45G SAG 6W3 72G Raman displacement (cm) * Warmingup * k * Eu * .- ~ * £ * *S * * * qbqh 4%44 4 4 a

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com