High-strength fire-proofing insulating plate for construction and preparation method thereof

A fire-proof insulation board, high-strength technology, applied in the field of building materials, can solve the problems of poor air permeability, air-tightness, spraying construction, etc., and achieve the effect of high compressive strength and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

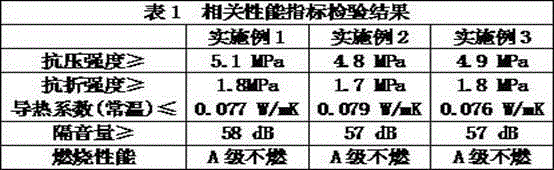

Embodiment 1

[0018] Example 1: (1) 22 kilograms of boron mud, 18 kilograms of palygorskite, 6 kilograms of dickite, and 13 kilograms of oblique zircon were crushed and ground into powder with a particle size of 2 to 4 mm, and then mixed uniformly;

[0019] (2) Mix 12 kilograms of lignocellulose with a length of 5-8mm, 6 kilograms of highly substituted hydroxypropyl cellulose, 28 kilograms of gypsum powder, and 38 kilograms of water at 62-72°C for 10 minutes.

[0020] (3) Add 2 kilograms of p-hydroxybenzene sulfonic acid, 3 kilograms of sodium benzenesulfinate, and 6 kilograms of polyacrylamide to the mixture in step (2), mix and stir for 10 minutes at 35-45°C, and then add to step (1) Stir the mixture evenly;

[0021] (4) The mixture in step (3) is transported to a press to be pressed into semi-finished insulation boards of different shapes, and the semi-finished insulation boards are sent to a drying room for natural drying;

[0022] (5) Transport the semi-finished thermal insulation board in ste...

Embodiment 2

[0023] Example 2: (1) 20 kg of boron mud, 16 kg of palygorskite, 6 kg of dickite, and 12 kg of plagioclase were crushed and ground into powder with a particle size of 2 to 4 mm, and then mixed uniformly;

[0024] (2) Mix 9 kilograms of lignocellulose with a length of 5-8mm, 4 kilograms of high-substituted hydroxypropyl cellulose, 25 kilograms of gypsum powder, and 30 kilograms of water at 62-72°C for 10 minutes.

[0025] (3) Add 2 kilograms of p-hydroxybenzenesulfonic acid, 3 kilograms of sodium benzenesulfinate, and 5 kilograms of polyacrylamide to the mixture in step (2), mix and stir for 10 minutes at 35-45°C, and then add to step (1) Stir the mixture evenly;

[0026] (4) The mixture in step (3) is transported to a press to be pressed into semi-finished insulation boards of different shapes, and the semi-finished insulation boards are sent to a drying room for natural drying;

[0027] (5) Transport the semi-finished thermal insulation board in step (4) to the tunnel kiln at 180-200...

Embodiment 3

[0028] Example 3: (1) 25 kilograms of boron mud, 20 kilograms of palygorskite, 8 kilograms of dickite, and 15 kilograms of oblique zircon were crushed and ground into powder with a particle size of 2 to 4 mm, and then mixed uniformly;

[0029] (2) Mix 13 kilograms of lignocellulose with a length of 5-8mm, 6 kilograms of high-substituted hydroxypropyl cellulose, 30 kilograms of gypsum powder, and 40 kilograms of water at 62-72°C for 10 minutes.

[0030] (3) Add 3 kilograms of p-hydroxybenzenesulfonic acid, 4 kilograms of sodium benzenesulfinate, and 7 kilograms of polyacrylamide to the mixture in step (2), mix and stir for 10 minutes at 35-45°C, and then add to step (1) Stir the mixture evenly;

[0031] (4) The mixture in step (3) is transported to a press to be pressed into semi-finished insulation boards of different shapes, and the semi-finished insulation boards are sent to a drying room for natural drying;

[0032] (5) Transport the semi-finished thermal insulation board in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com