Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7118 results about "Sodium salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

While sodium is a component of salt, they are not one in the same. In fact, sodium is a mineral found naturally in almost all foods.

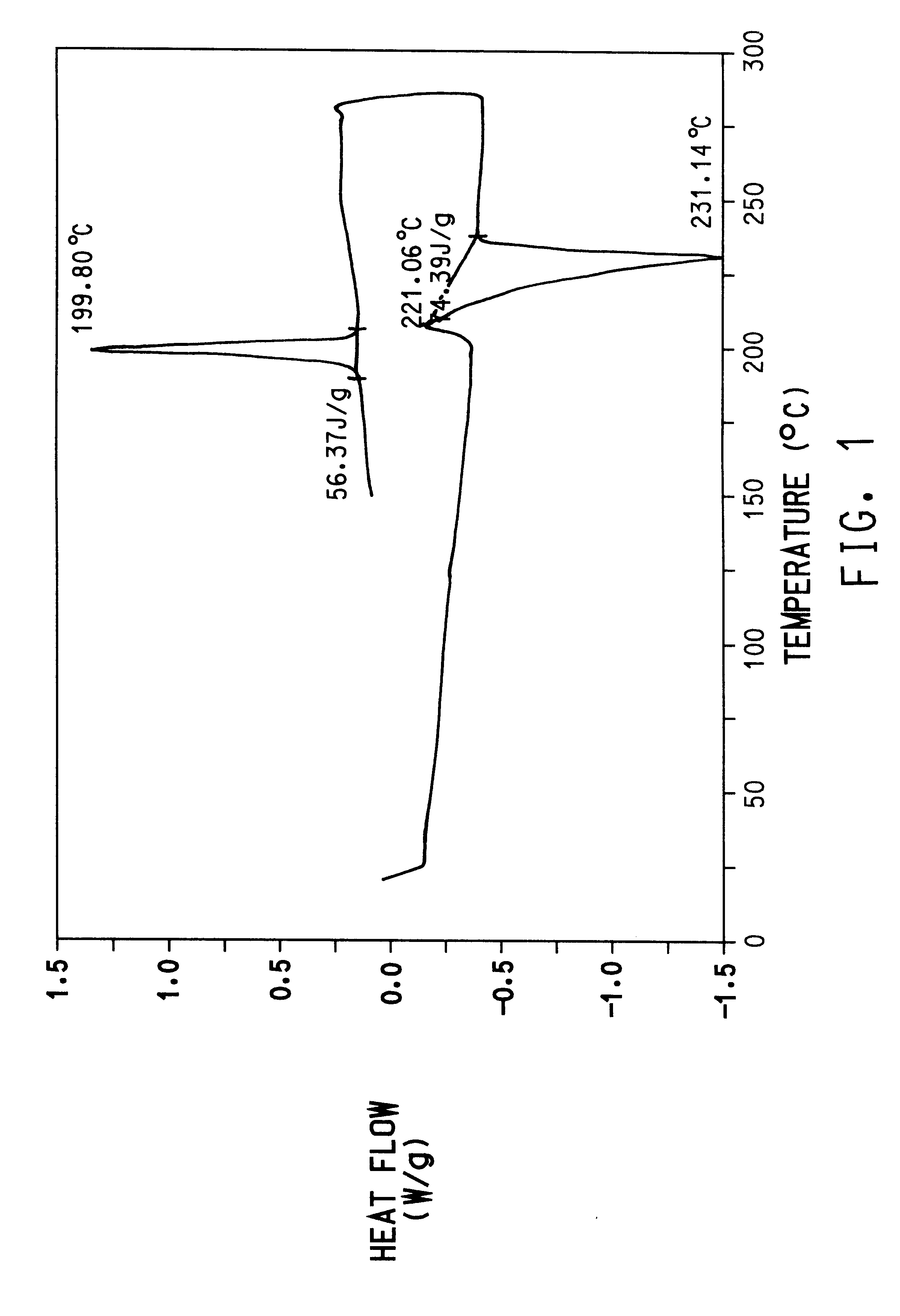

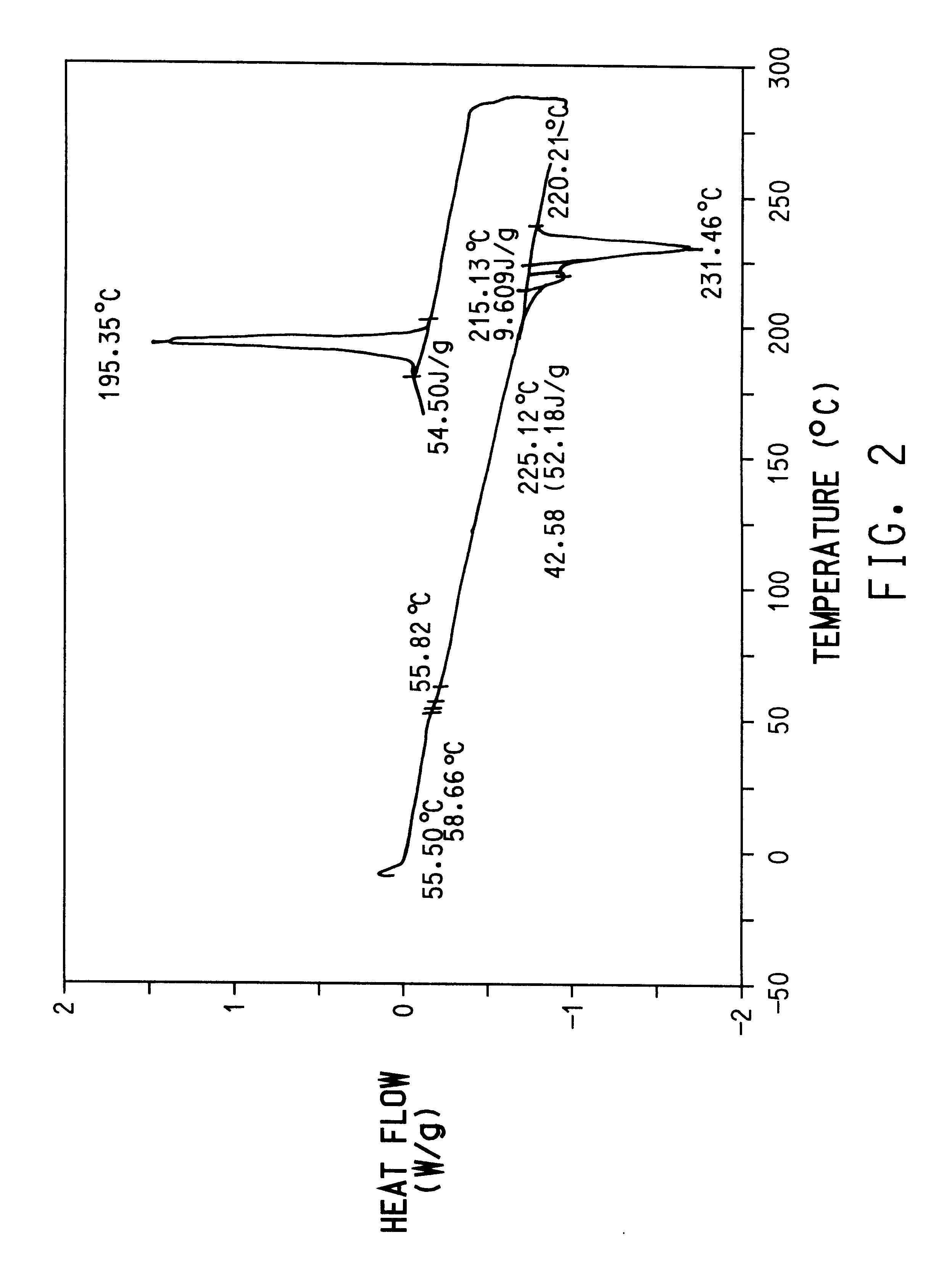

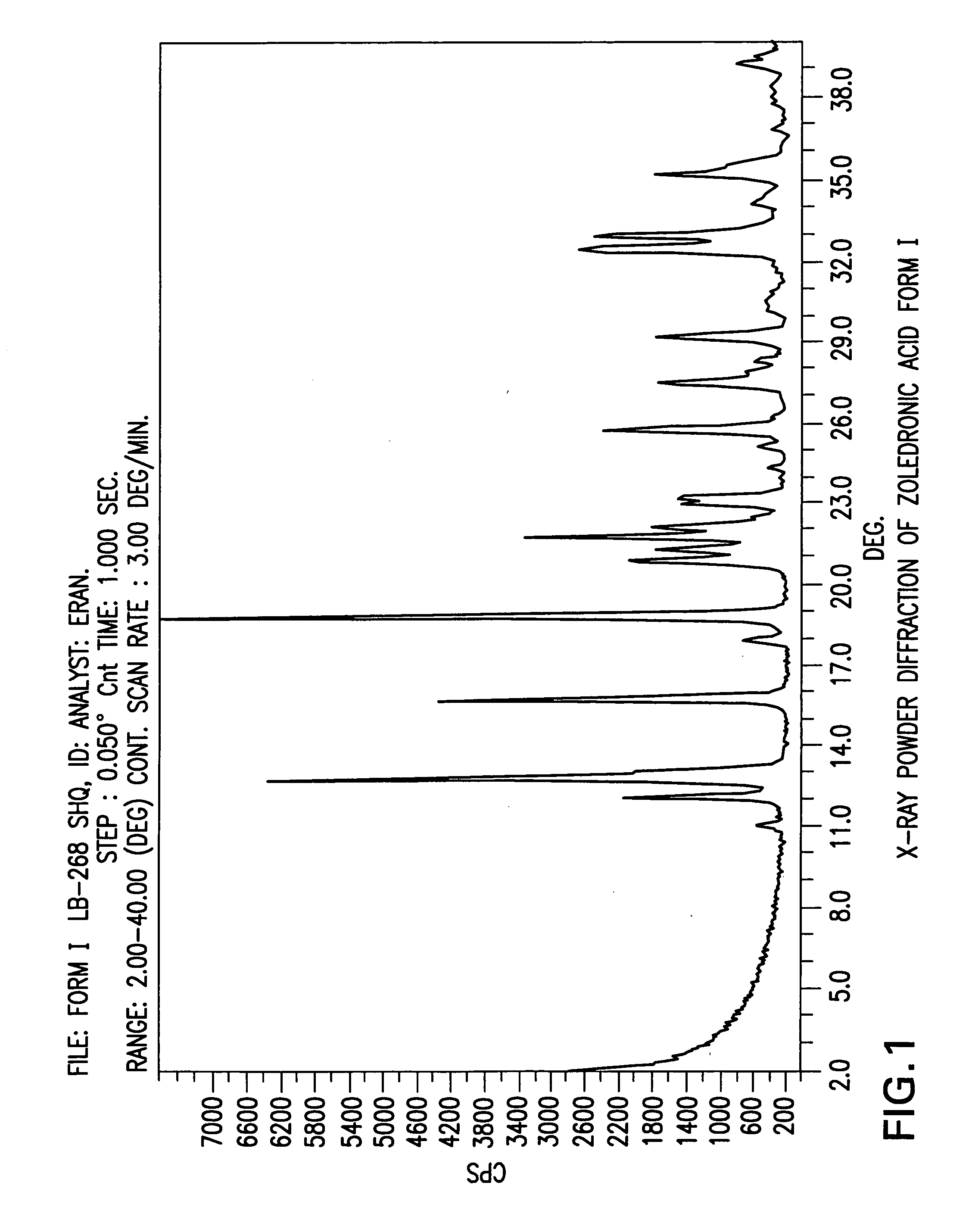

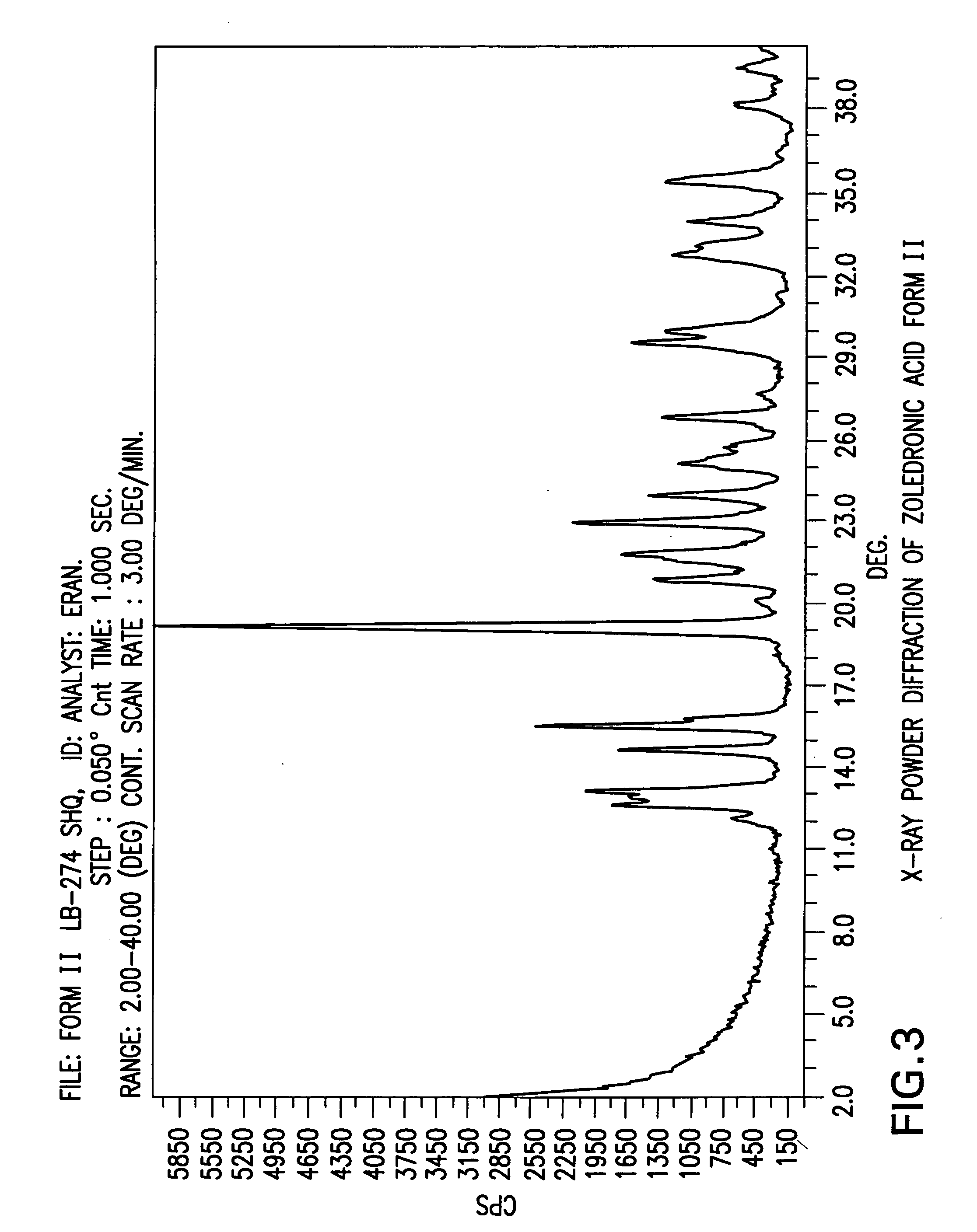

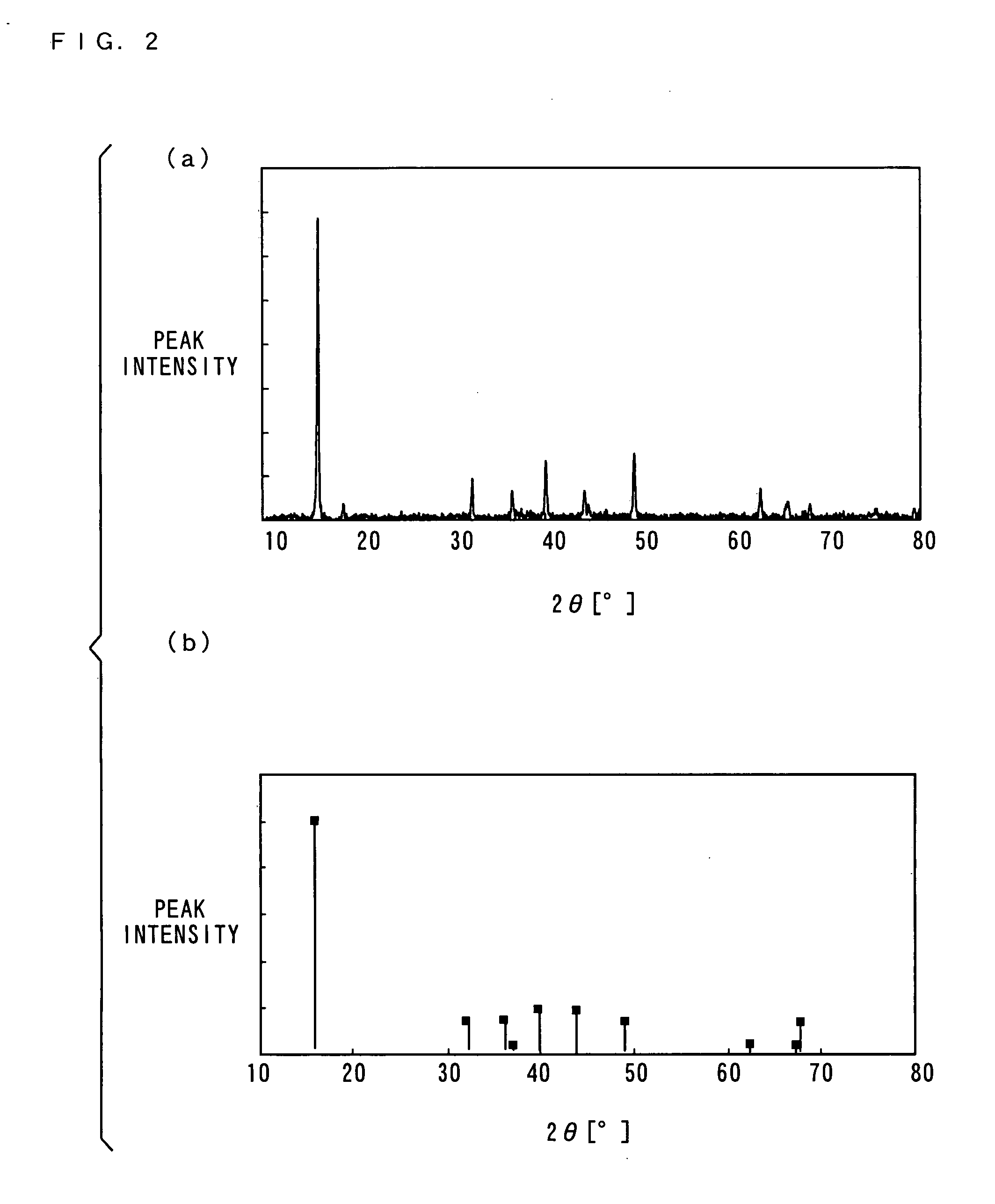

Zoledronic acid crystal forms, zoledronate sodium salt crystal forms, amorphous zoledronate sodium salt, and processes for their preparation

InactiveUS20050054616A1BiocideOrganic active ingredientsPharmaceutical SubstancesMedicinal chemistry

The invention relates to polymorphs of zoledronic acid and zoledronate sodium salts, amorphous zoledronate sodium salt, processes for making the polymorphs and amorphous zoledronate sodium salt and pharmaceutical compositions containing the polymorphs and amorphous zoledronate sodium salt.

Owner:TEVA PHARM USA INC

Reduced sodium salty taste composition, process for its preparation and food systems containing such composition

A reduced sodium salty taste composition for reduction of sodium chloride in food contains sodium chloride, at least one of a food acid and a salt of a food acid, at least one of an amino acids and a salt of an amino acid, and can additionally contain potassium chloride, yeast extract, sweeteners, and flavors. A food containing the reduced sodium salty taste composition and a process for making the reduced sodium salty taste composition are disclosed.

Owner:MCCORMICK & CO INC

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

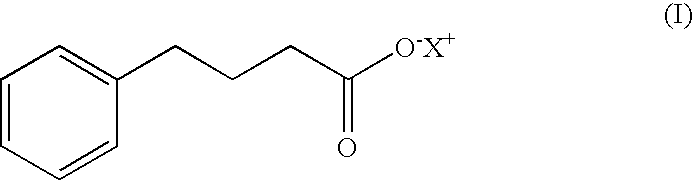

4-phenylbutyric acid controlled-release formulations for therapeutic use

InactiveUS20060045912A1Low costReduce the amount requiredBiocideNervous disorderHalf-lifeNeuro-degenerative disease

Controlled-release formulations and dosage forms containing 4-phenylbutyric acid sodium salt, or other pharmaceutically acceptable salts, esters or prodrugs, and a controlled release material for use in the treatment of diseases and disorders including neoplastic disorders and neurodegenerative diseases The formulations provide extended release and extended half-life.

Owner:LUNAMED

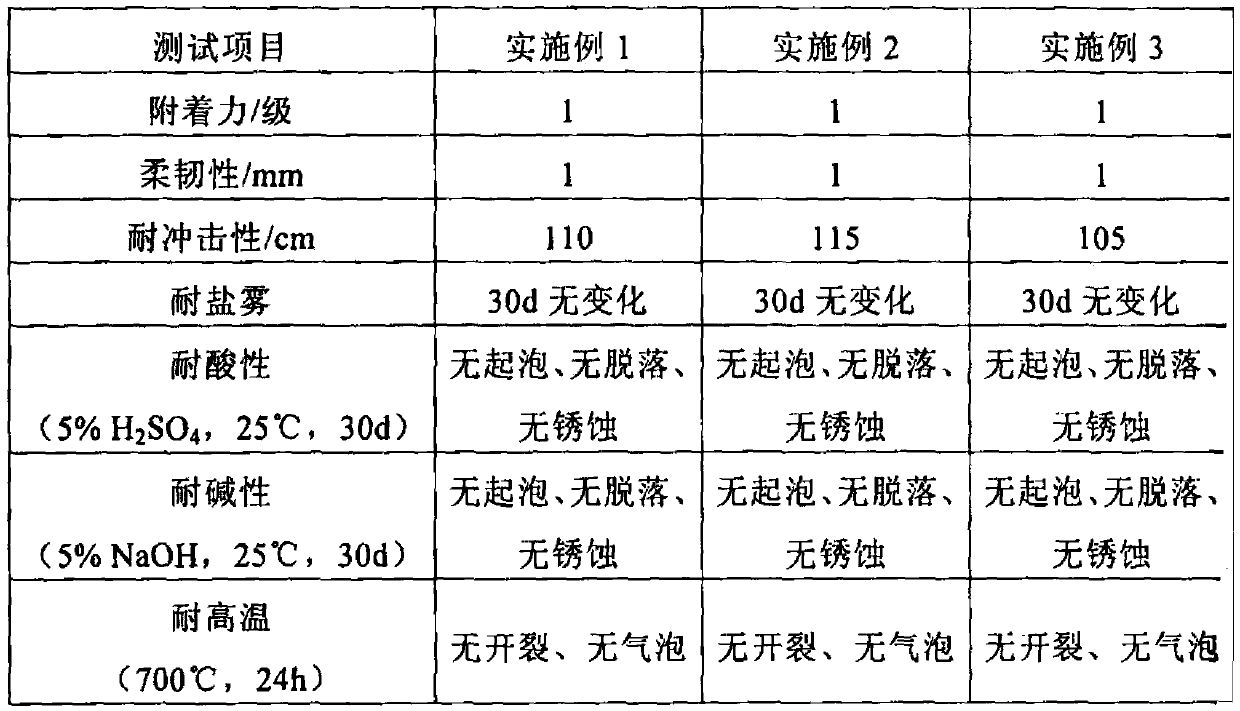

High temperature resistant anticorrosion coating based on graphene and preparation method thereof

InactiveCN103589281AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to a high temperature resistant anticorrosion coating based on graphene and a preparation method thereof. The high temperature anticorrosion coating comprises the following components by the mass percentage: 5-60% of epoxy resin, 3-30% of polyphenylene sulfide resin, 3-30% of amino resin, 1-10% of a pigment, 1-20% of graphene, 3-50% of n-butyl alcohol, 0.1-0.3% of a defoaming agent, 0.1-10% of polyhydroxy acid sodium salt, 0.1-5% of benzenedicarboxylic acid dibutyl ester, 0.5-1.0% of bentonite, and 0.2-0.5% of a leveling agent. Compared with the prior art, the prepared coating has the advantages of quite excellent waterproof and anticorrosion performance, high temperature resistance, weather resistance, alkali resistance, impact resistance, artificial aging resistance and the like, and the preparation method has the advantages of good controllability, simple operation, low production cost, and easy industrialized production.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

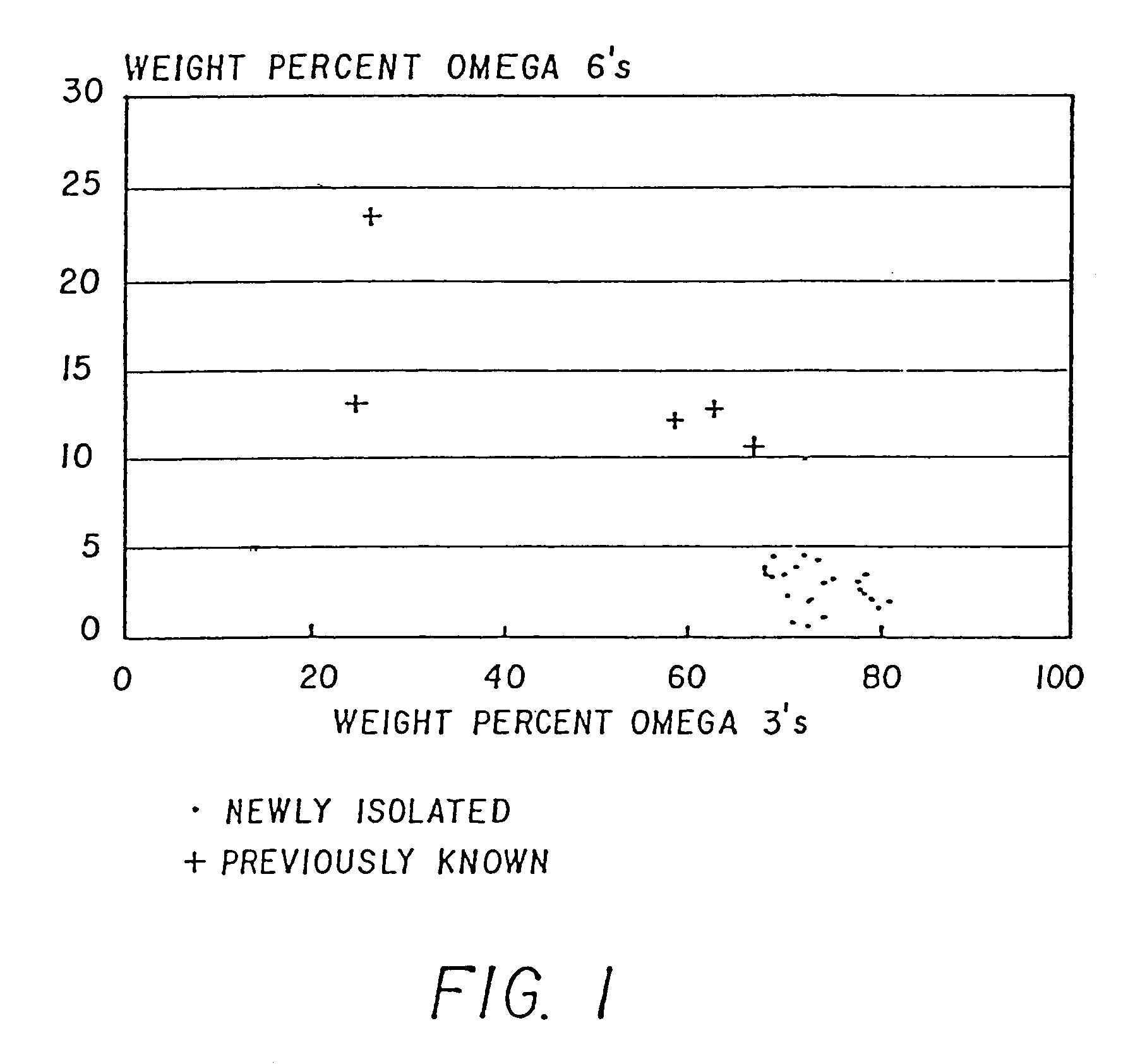

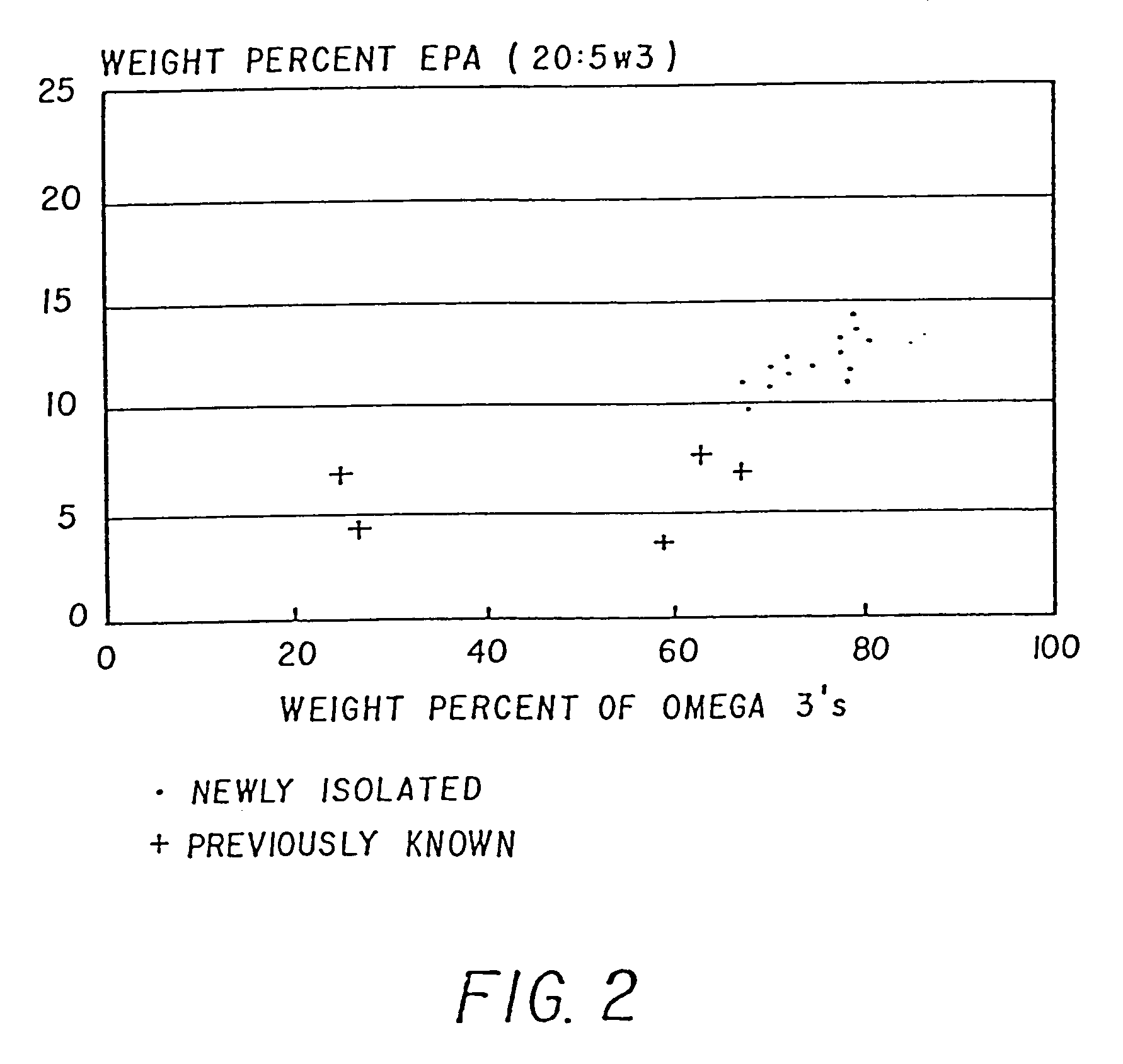

Method of producing lipids by growing microorganisms of the order thraustochytriales

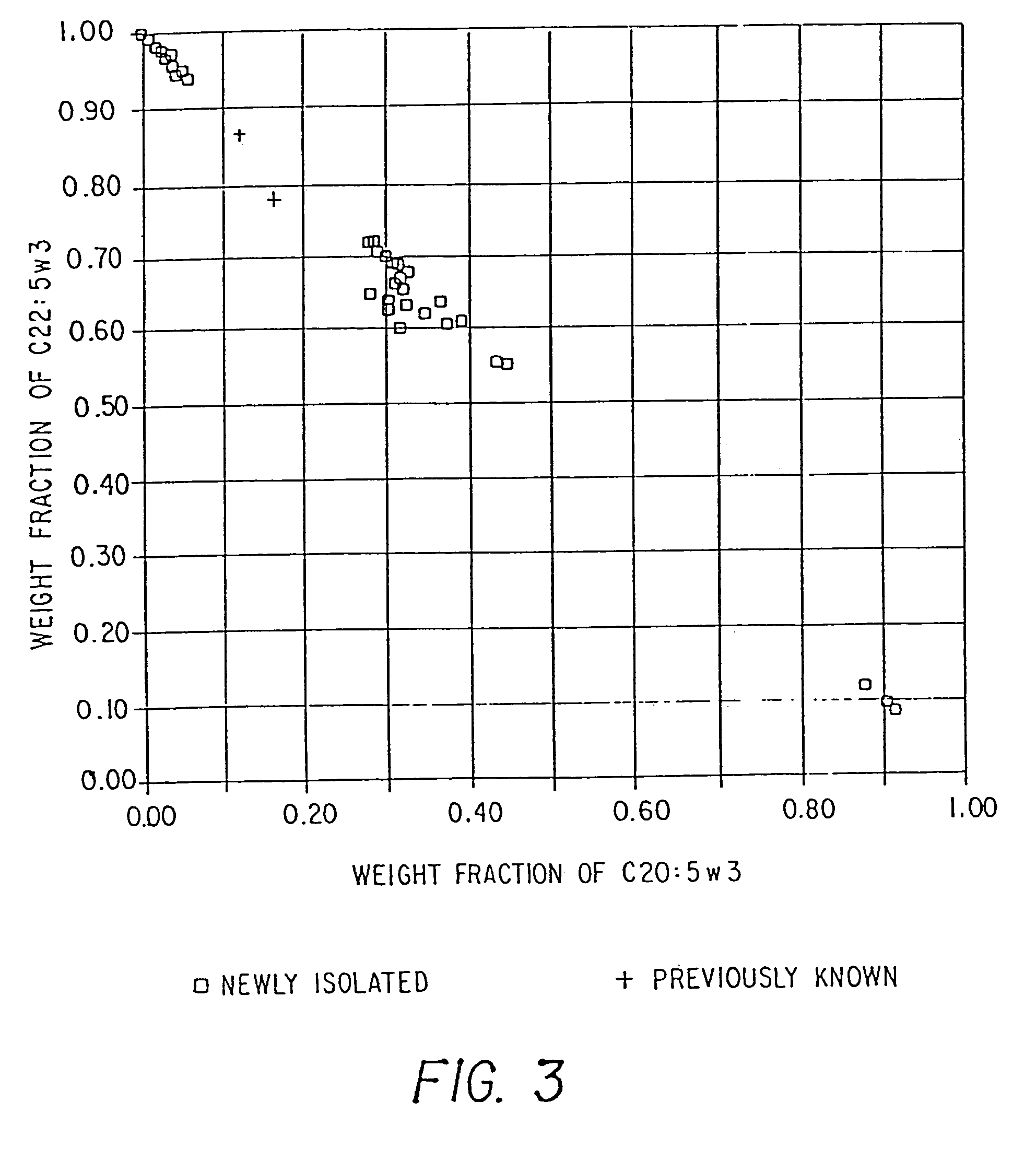

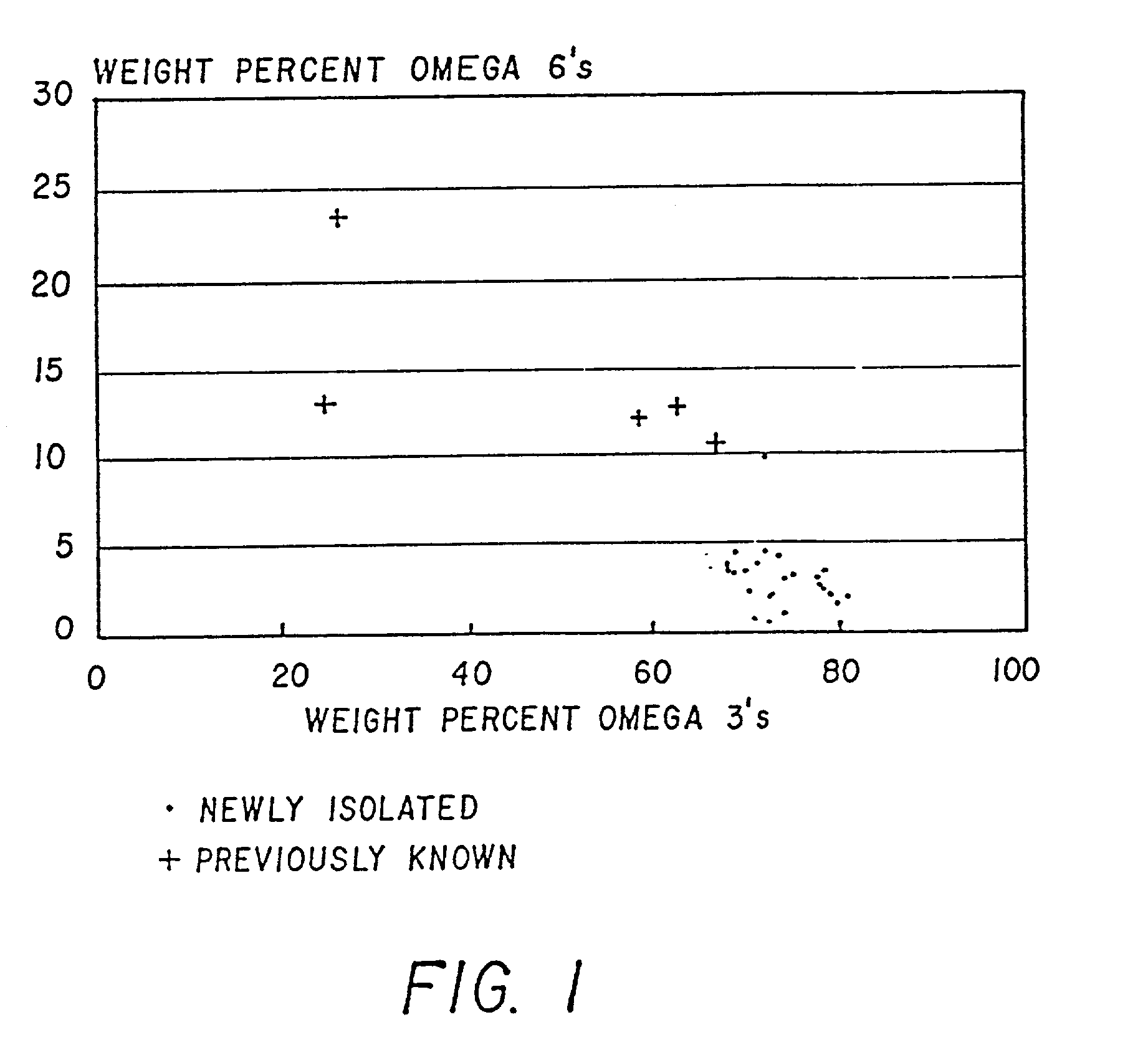

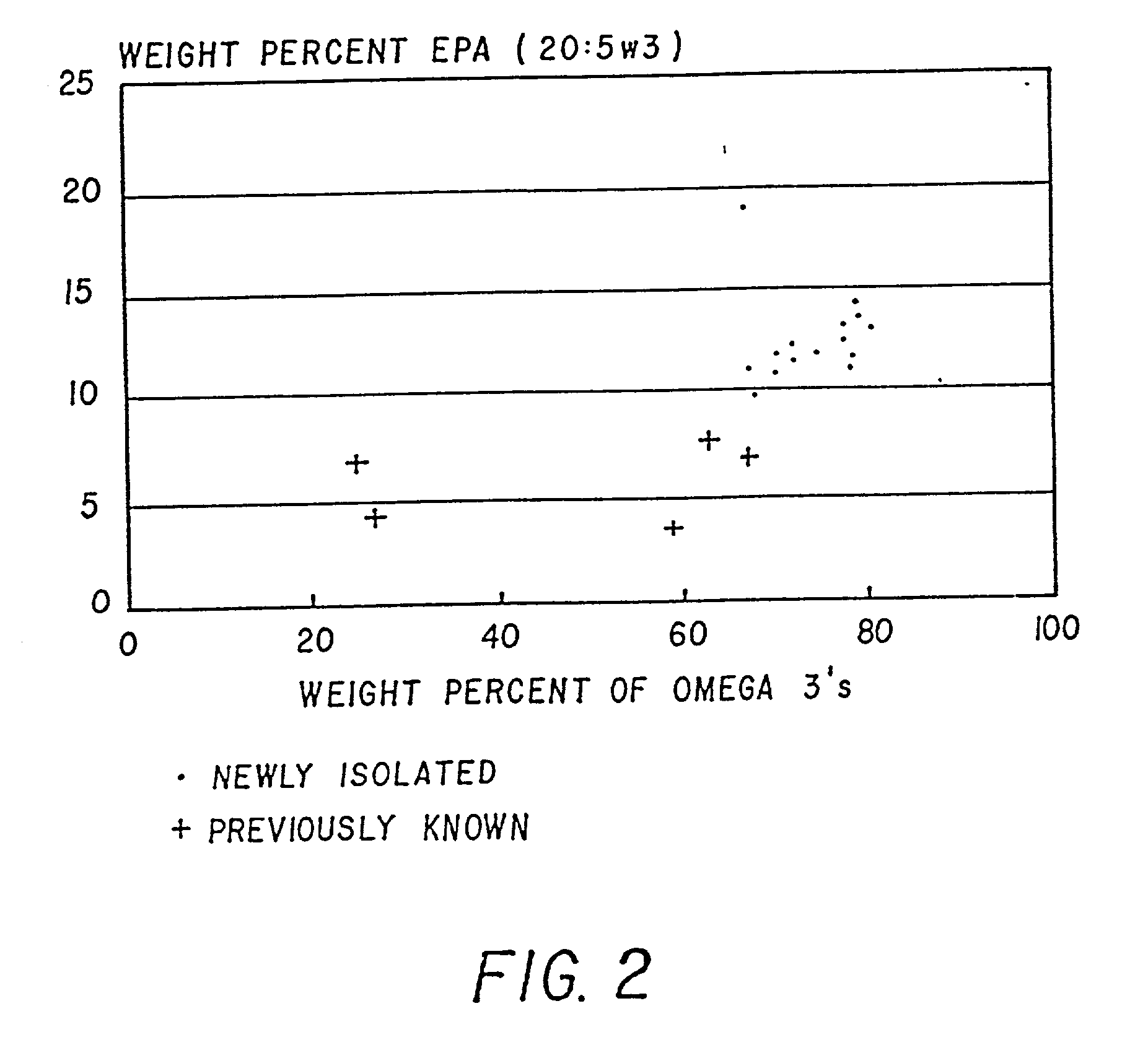

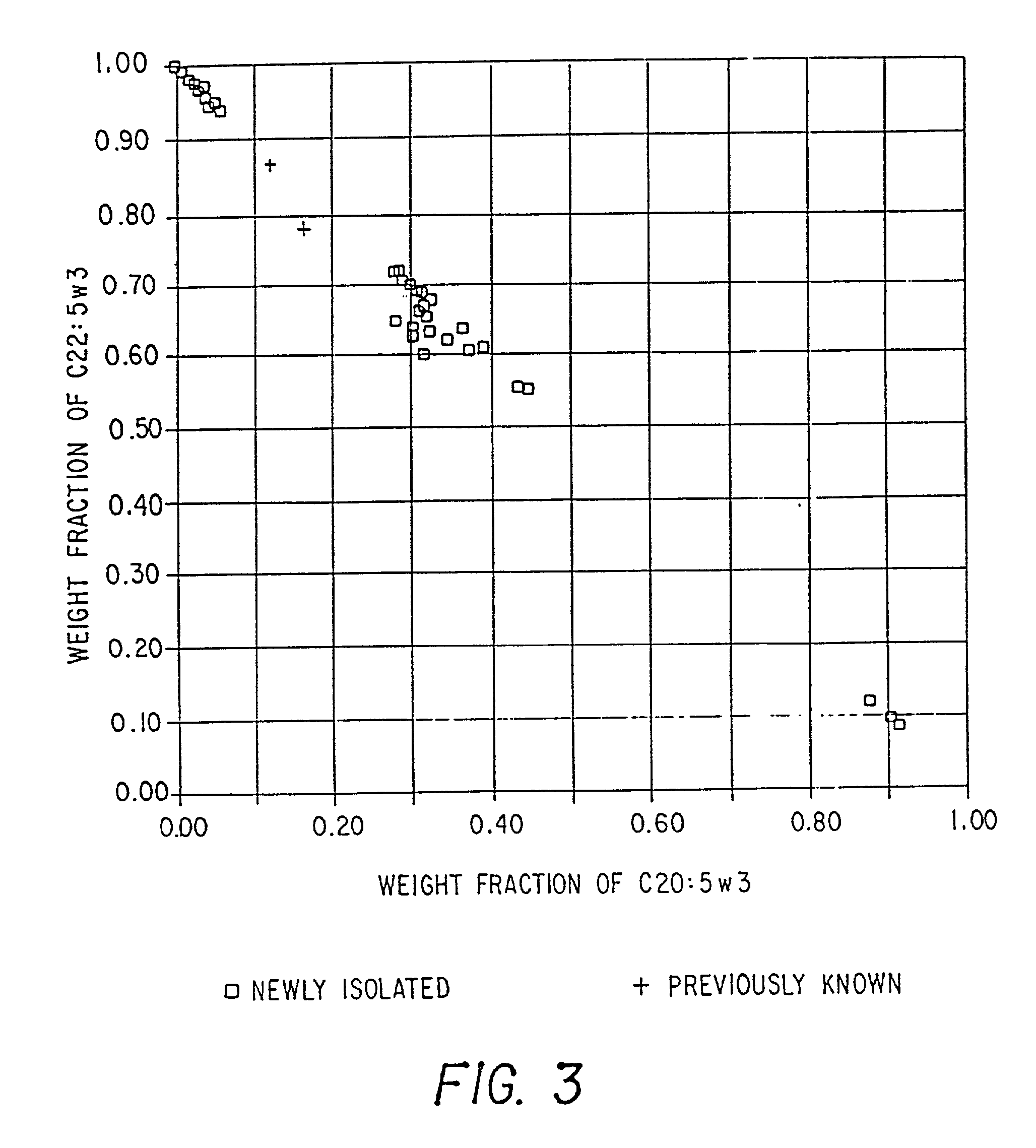

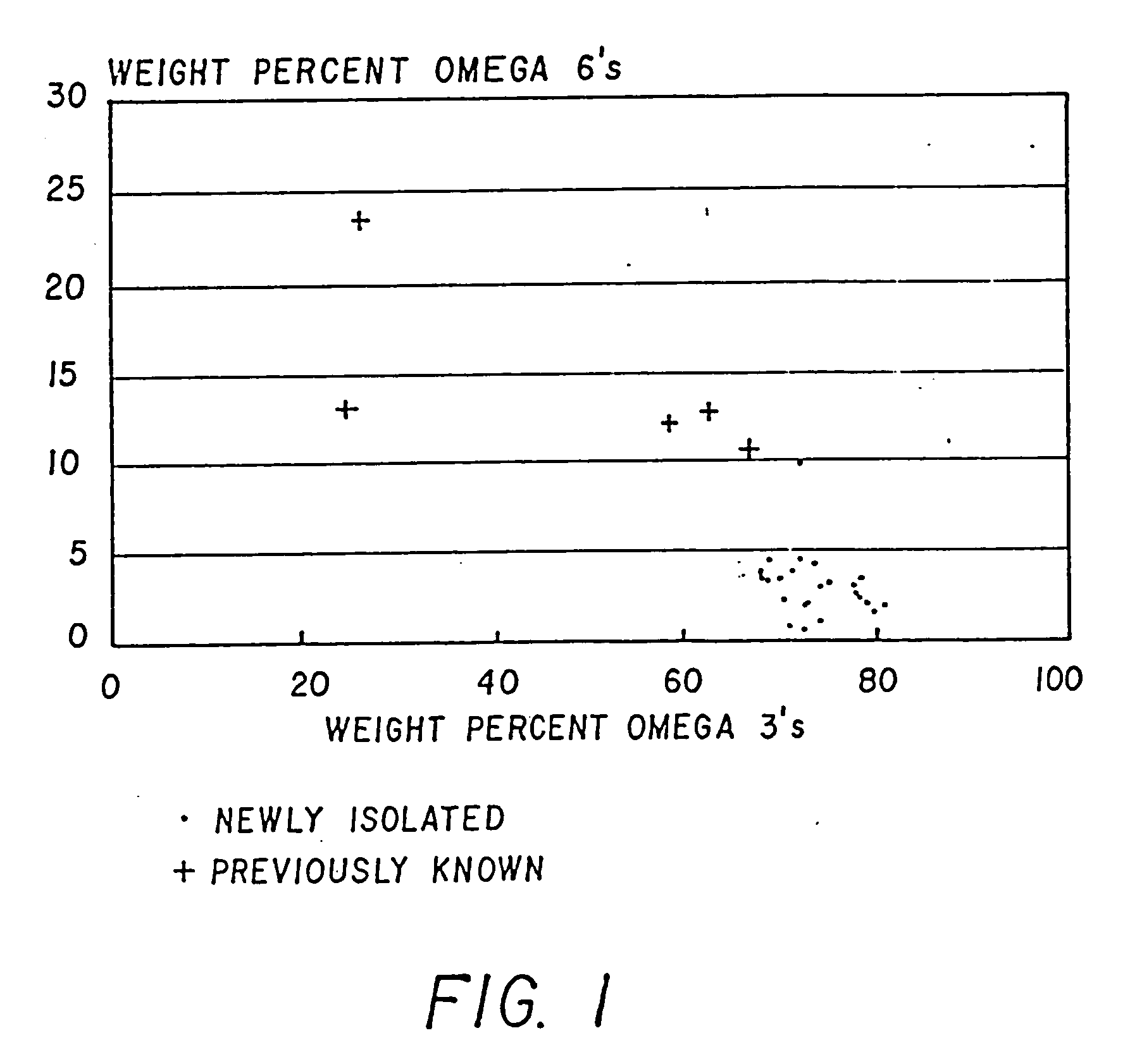

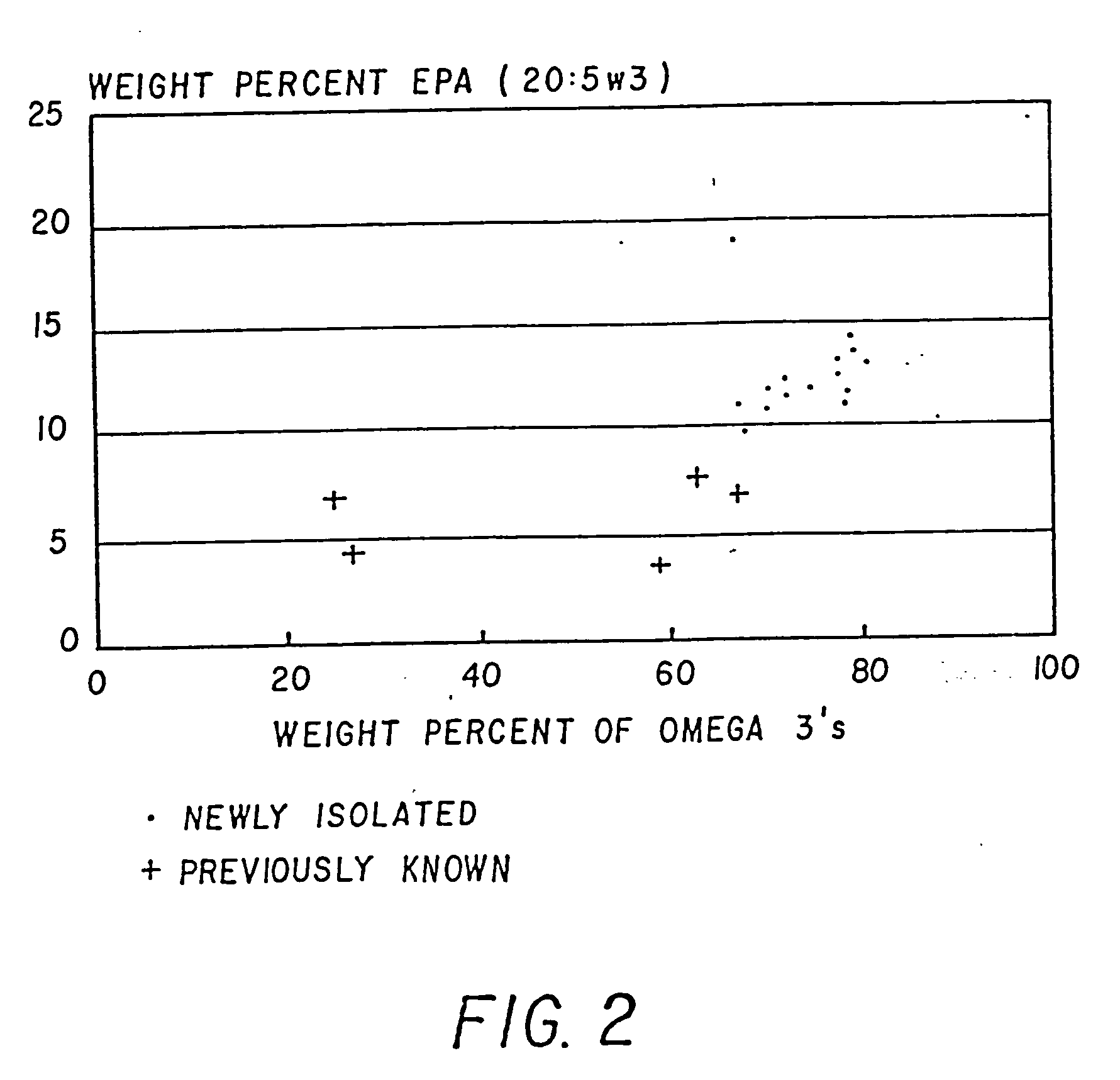

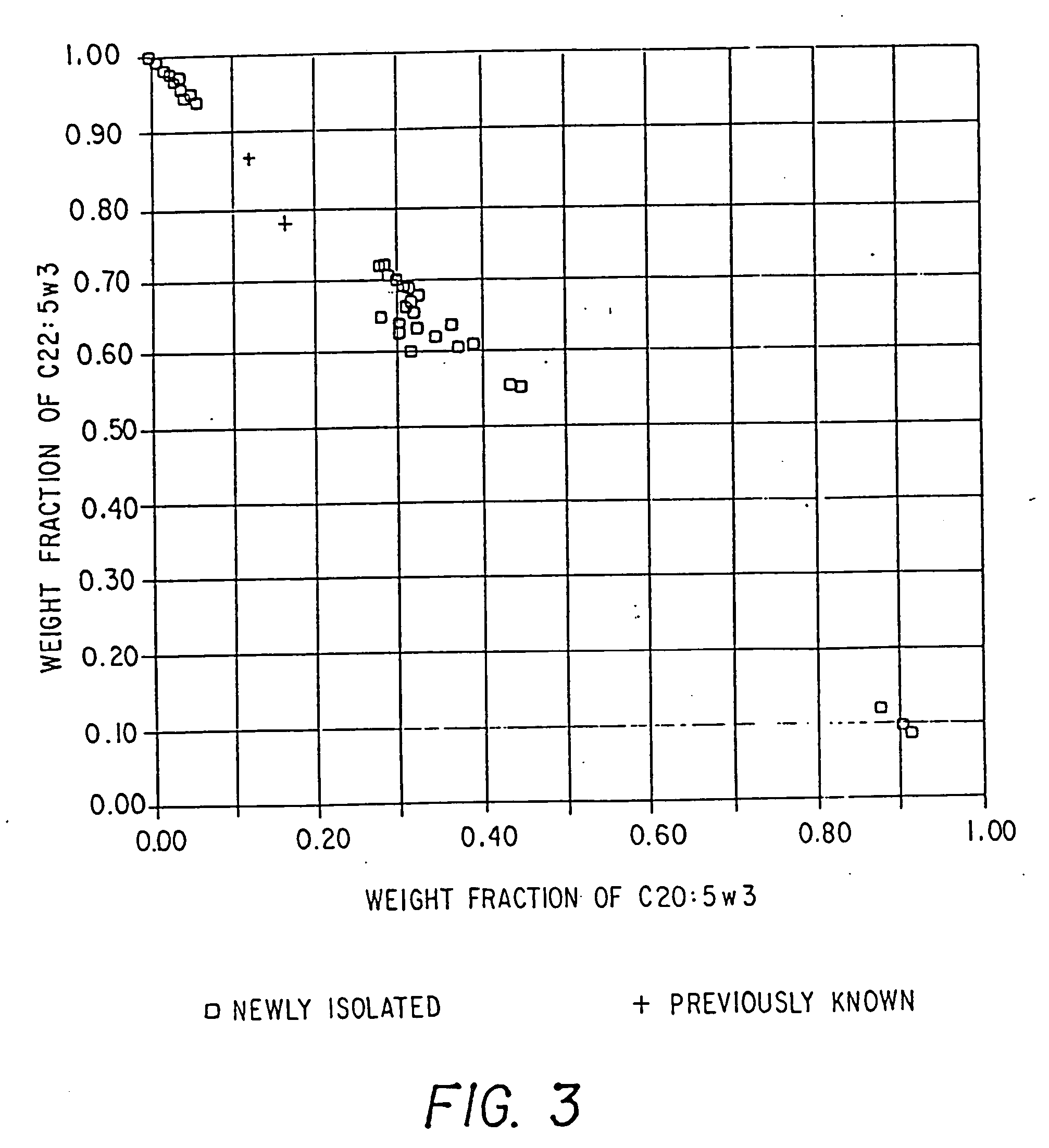

Disclosed is a process for growing the microflora Thraustochytrium, Schizochytrium, and mixtures thereof, which includes the growing of the microflora in fermentation medium containing non-chloride containing sodium salts, in particular sodium sulfate. In a preferred embodiment of the present invention, the process produces microflora having a cell aggregate size useful for the production of food products for use in aquaculture. Further disclosed is a food product which includes Thraustochytrium, Schizochytrium, and mixtures thereof, and a component selected from flaxseed, rapeseed, soybean and avocado meal. Such a food product includes a balance of long chain and short chain omega-3 highly unsaturated fatty acids. In an embodiment, lipids are produced by growing microorganisms of the order Thraustochytriales in a medium and extracting the lipids.

Owner:DSM IP ASSETS BV

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

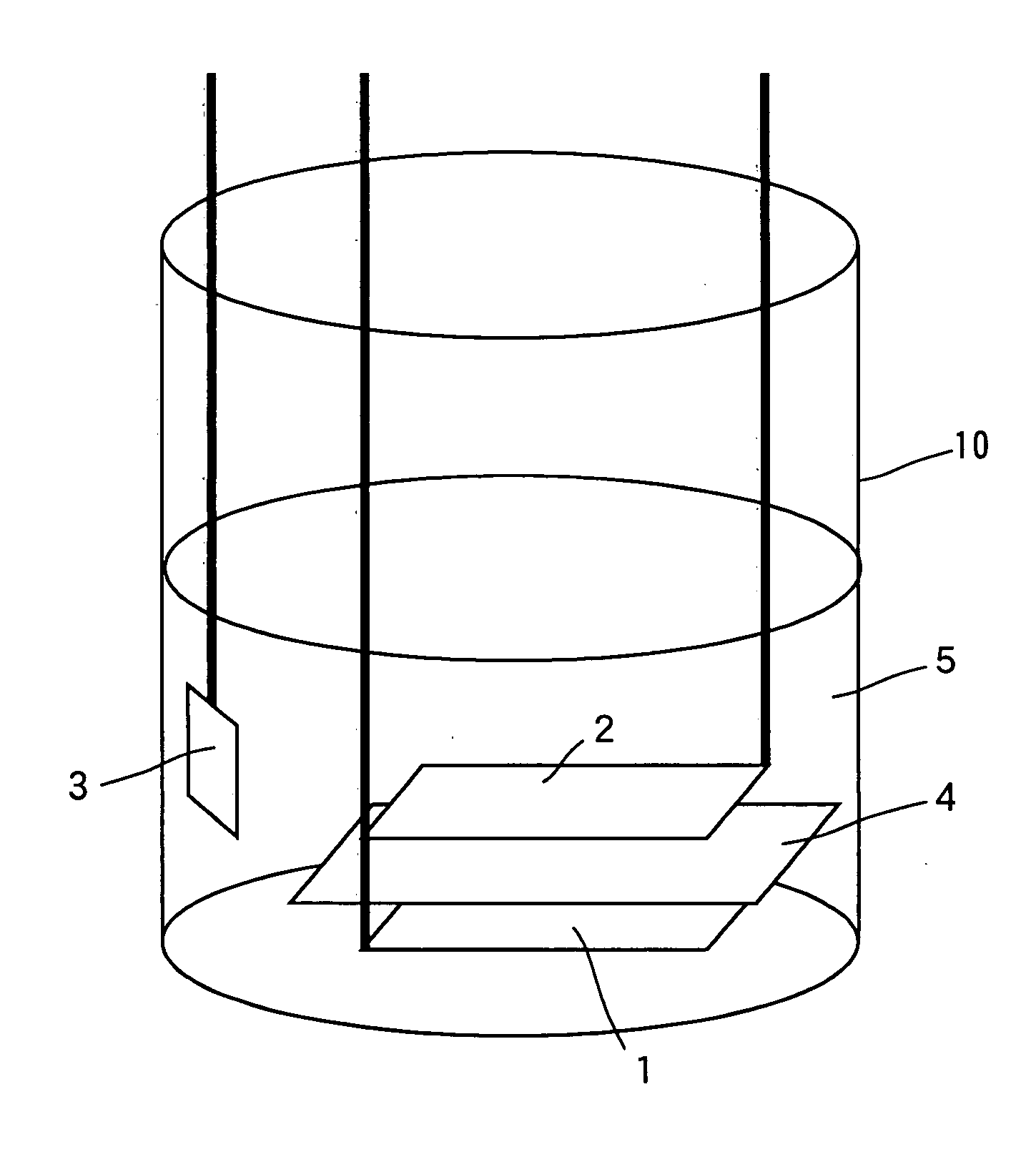

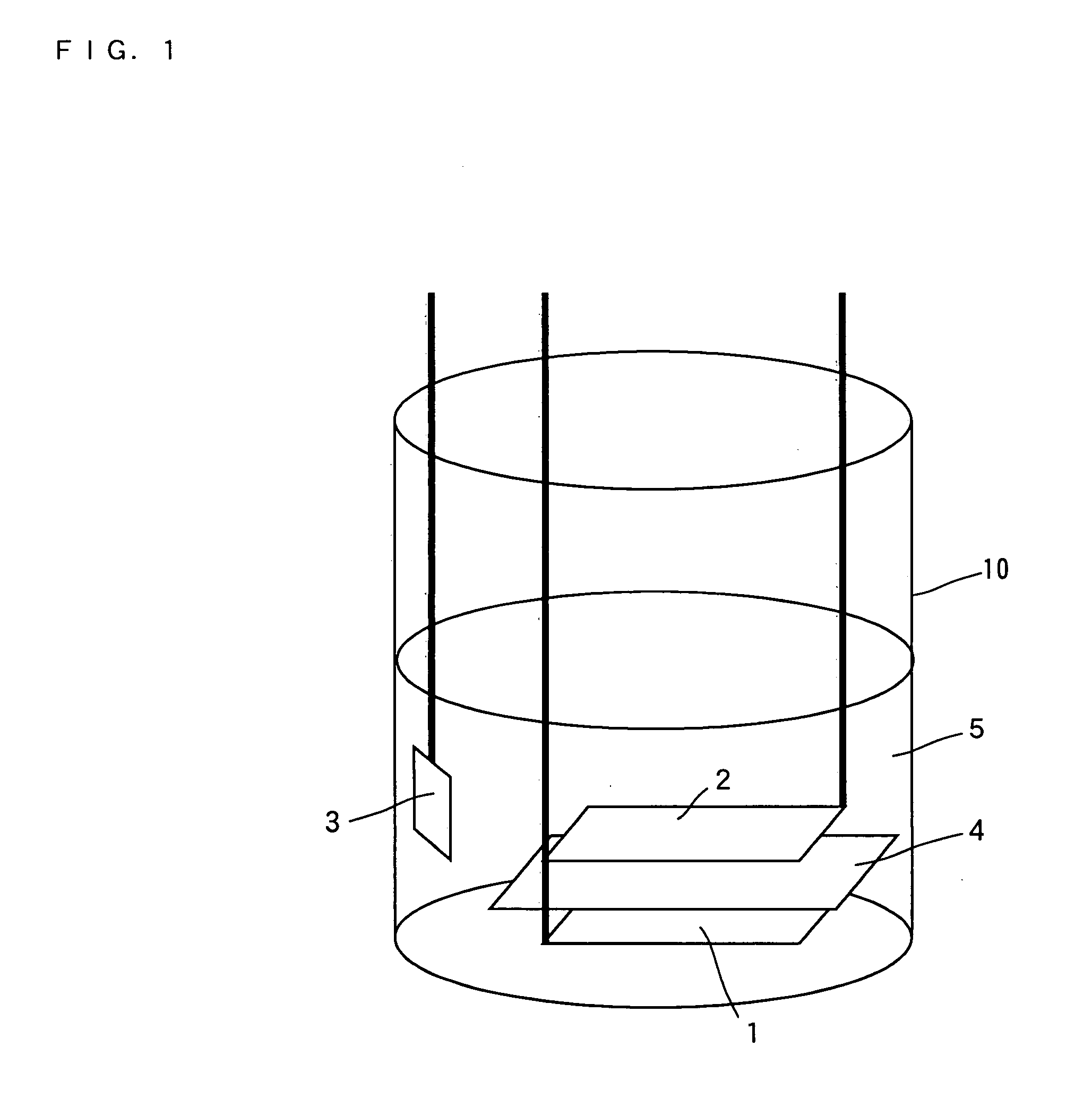

Sodium ion secondary battery

ActiveUS20070218361A1High densityNon-aqueous electrolyte accumulatorsSolid electrolyte cellsCyclic etherManganese

The positive electrode active material of a positive electrode includes a sodium-containing transition metal oxide (NaaLibMxO2±α). The M includes at least two of manganese (Mn), iron (Fe), cobalt (Co), and nickel (Ni). For a negative electrode, a sodium metal or a metal that forms an alloy with sodium is used. A non-aqueous electrolyte produced by dissolving an electrolytic salt (sodium salt) in a non-aqueous solvent is used. Examples of the non-aqueous solvent may include a cyclic carbonate, a chain carbonate, esters, cyclic ethers, chain ethers, nitrites, amides and a combination thereof.

Owner:SANYO ELECTRIC CO LTD

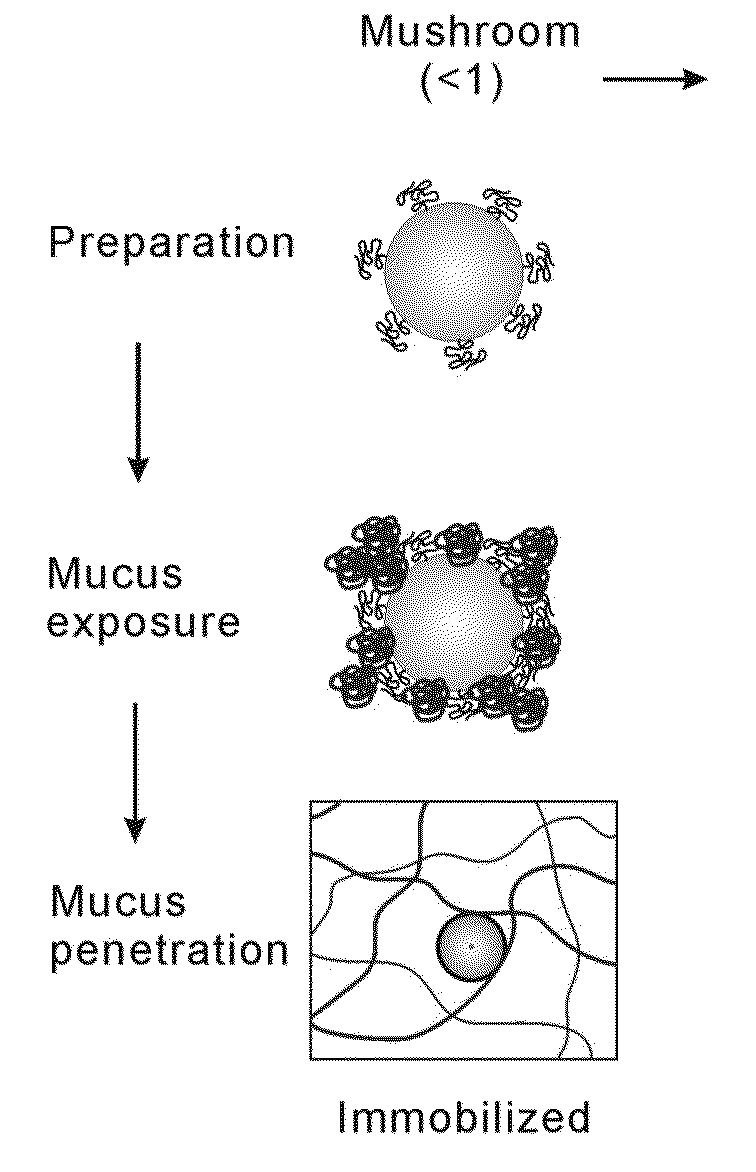

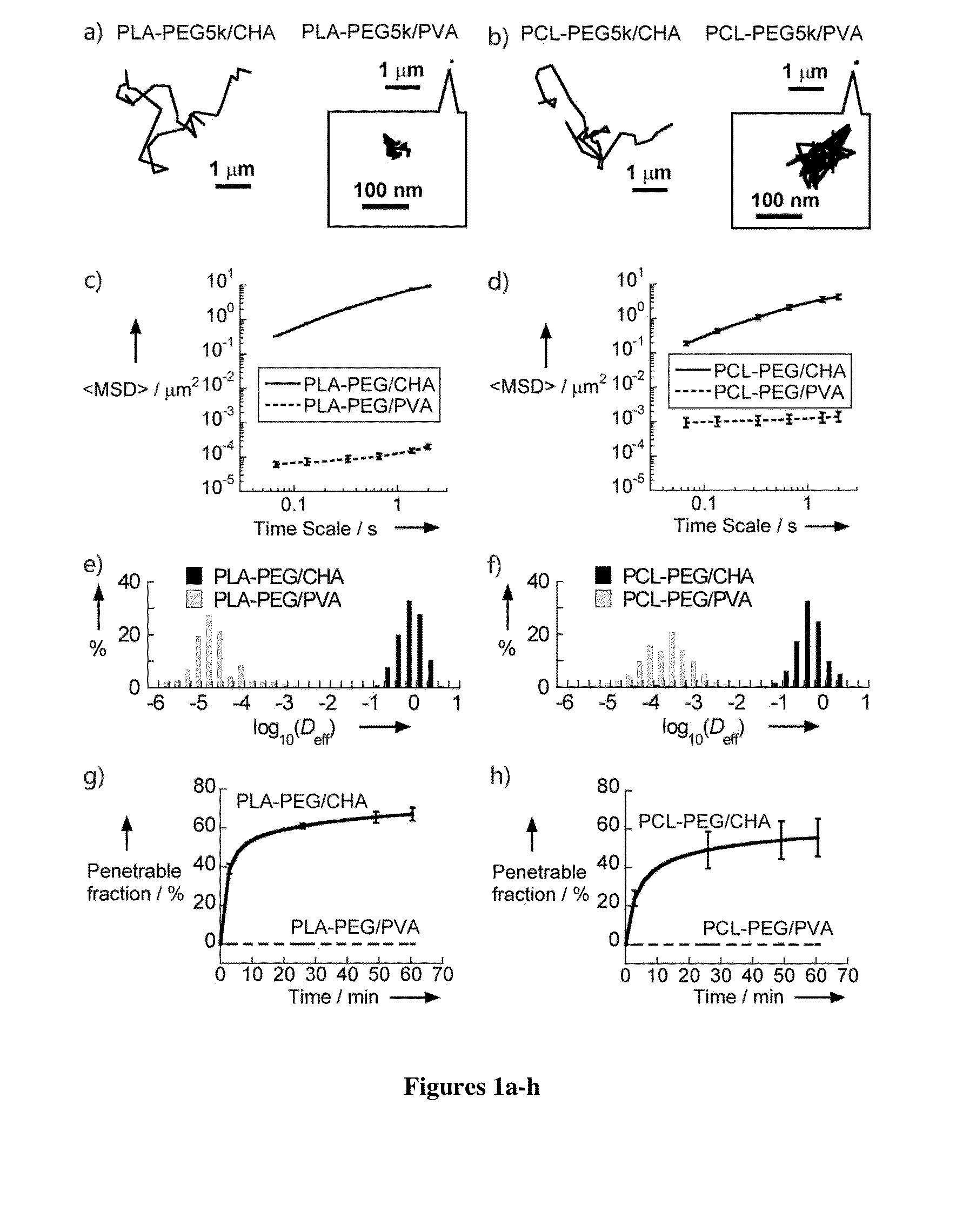

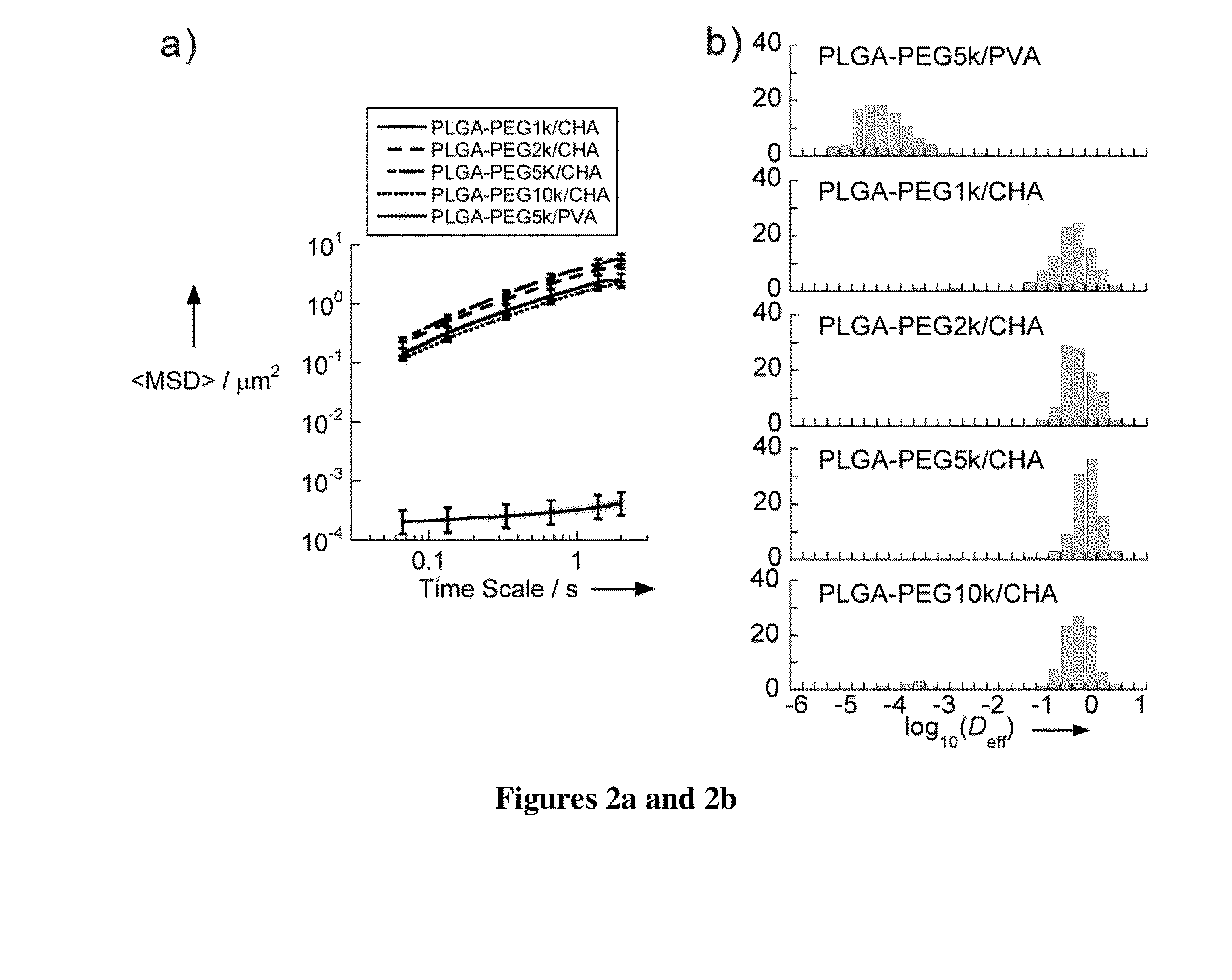

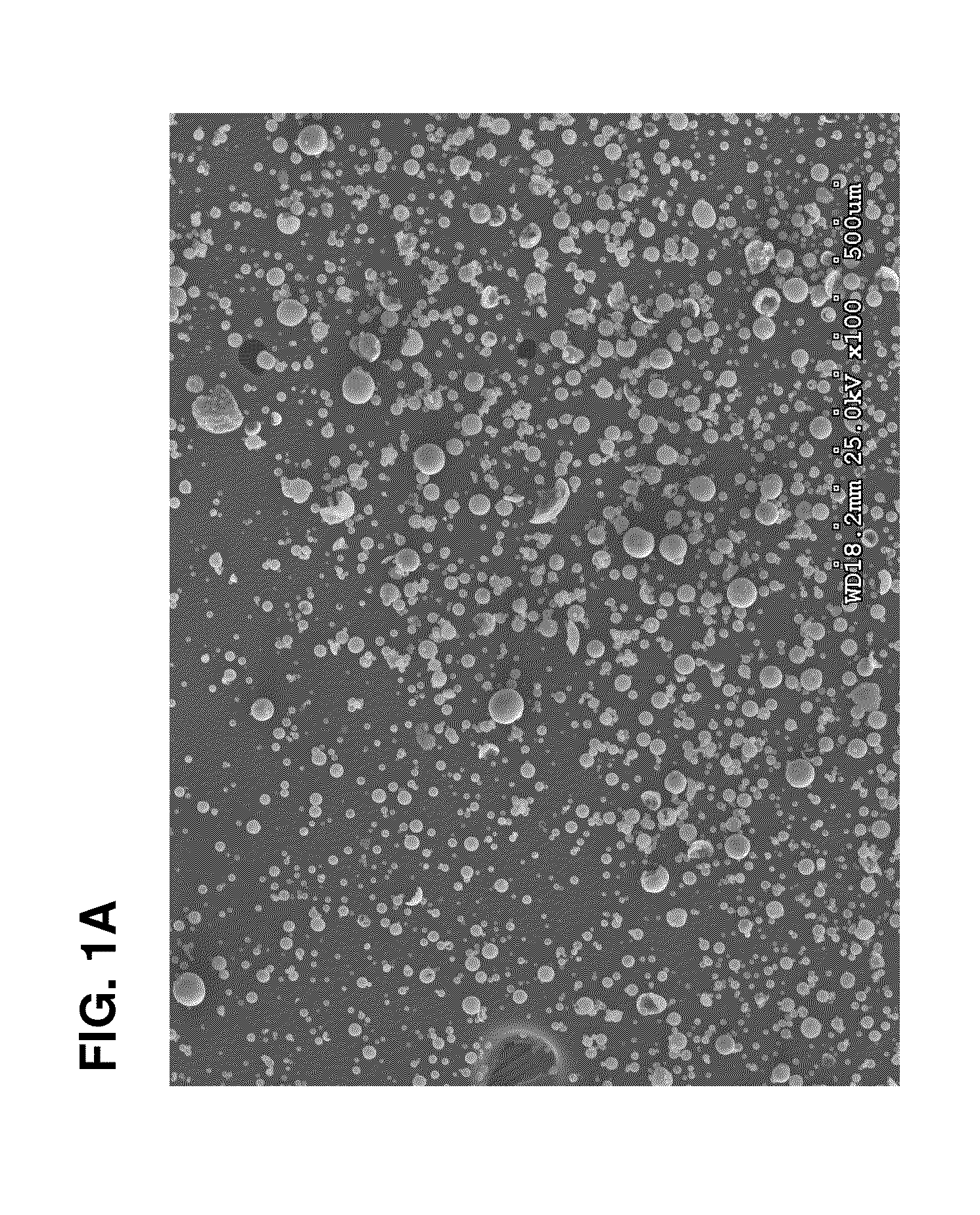

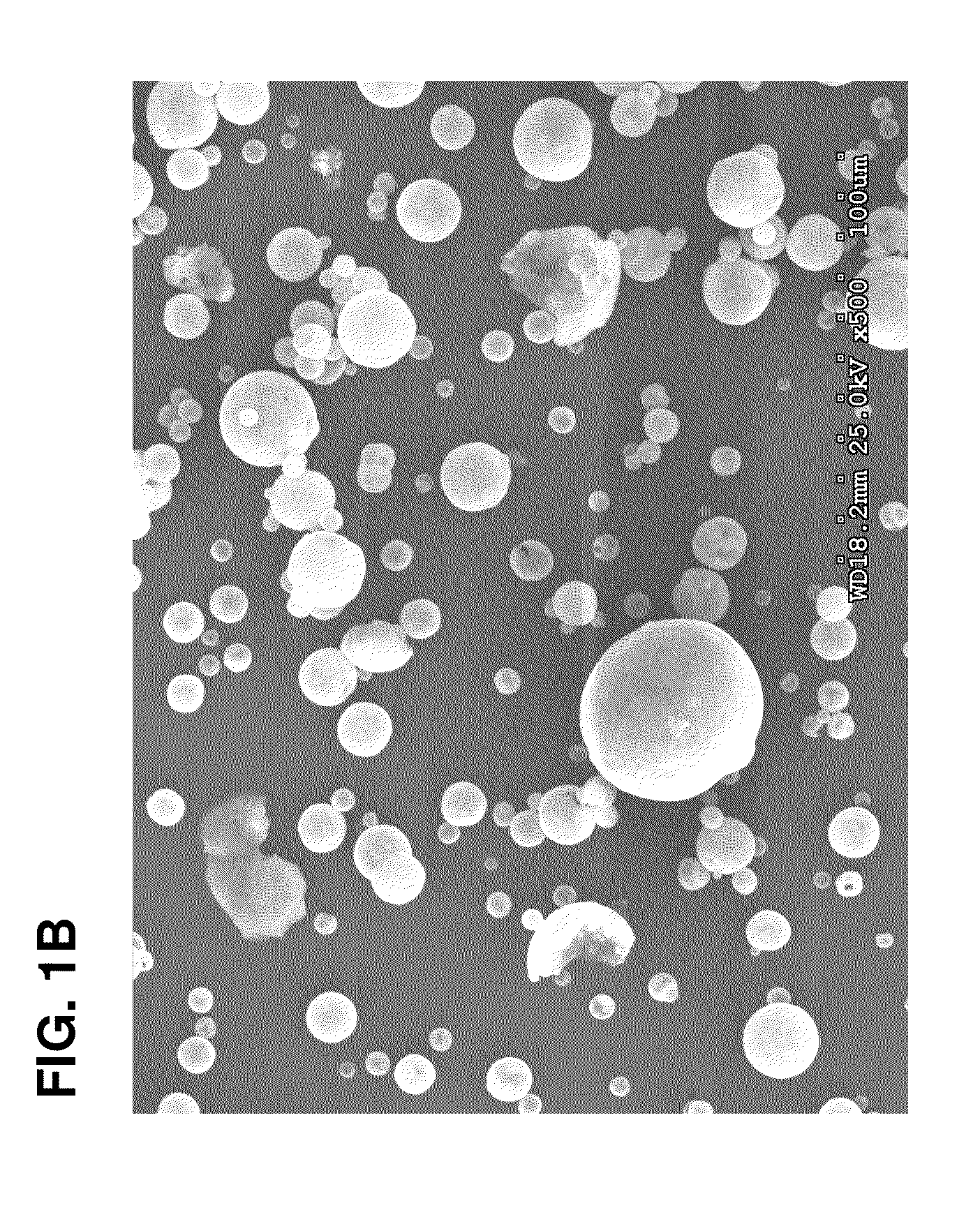

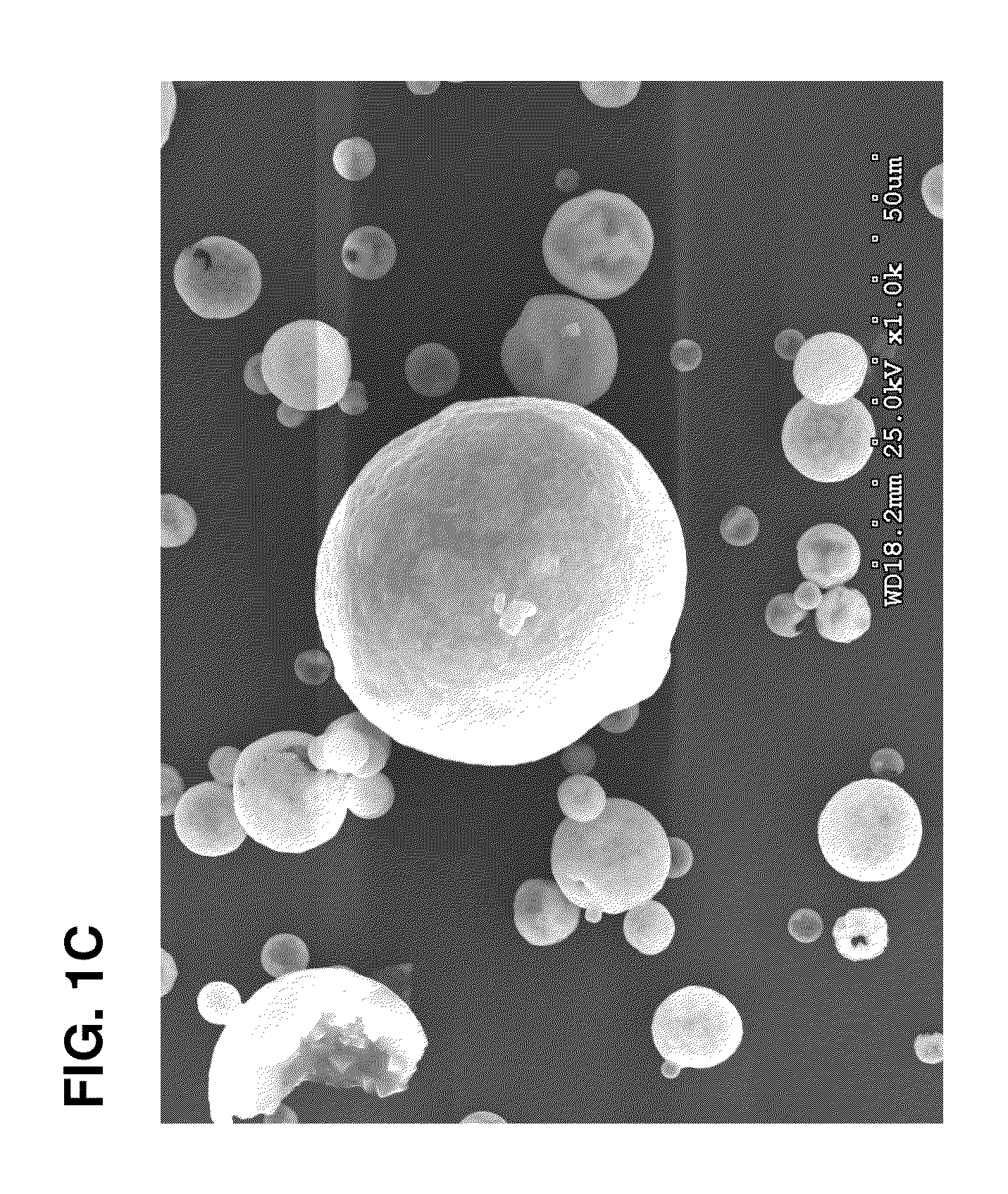

Nanoparticles with enhanced mucosal penetration or decreased inflammation

Nanoparticles formed by emulsion of one or more core polymers, one or more surface altering materials, and one or more low molecular weight emulsifiers have been developed. The particles are made by dissolving the one or more core polymers in an organic solvent, adding the solution of the one or more core polymers to an aqueous solution or suspension of the emulsifier to form an emulsion, and then adding the emulsion to a second solution or suspension of the emulsifier to effect formation of the nanoparticles. In the preferred embodiment, the molecular weight of the emulsifiers is less than 1500, 1300, 1200, 1000, 800, 600, or 500 amu. Preferred emulsifiers include cholic acid sodium salt, dioctyl sulfosuccinate sodium, hexadecyltrimethyl ammonium bromide, saponin, TWEEN® 20, TWEEN® 80, and sugar esters. The surface altering materials are present in an amount effective to make the surface charge of the particles neutral or essentially neutral when the one or more emulsifiers are charged. The emulsifiers have an emulsification capacity of at least about 50%, preferably at least 55, 60, 65, 70, 75, 80, 85, 90, or 95%.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

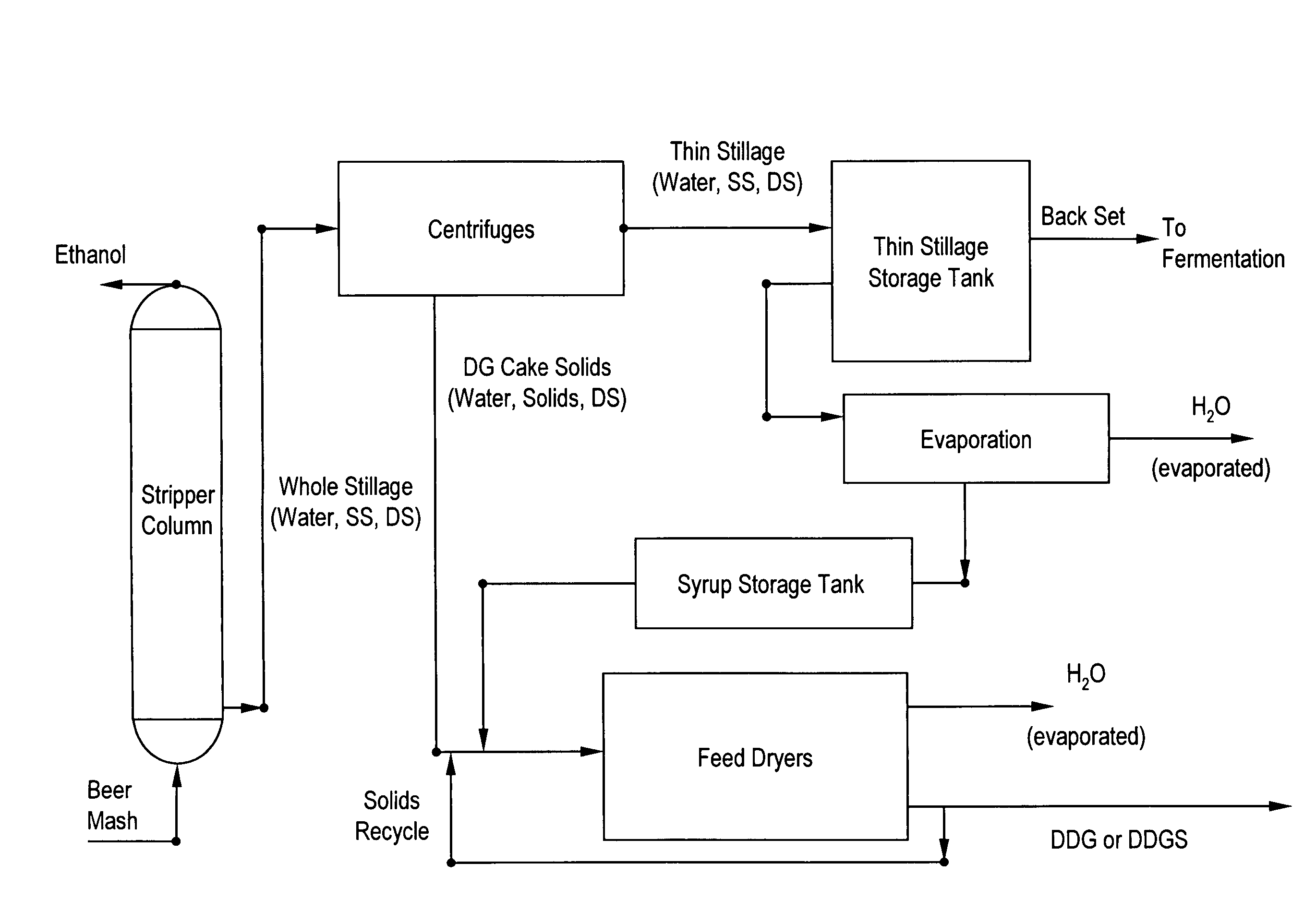

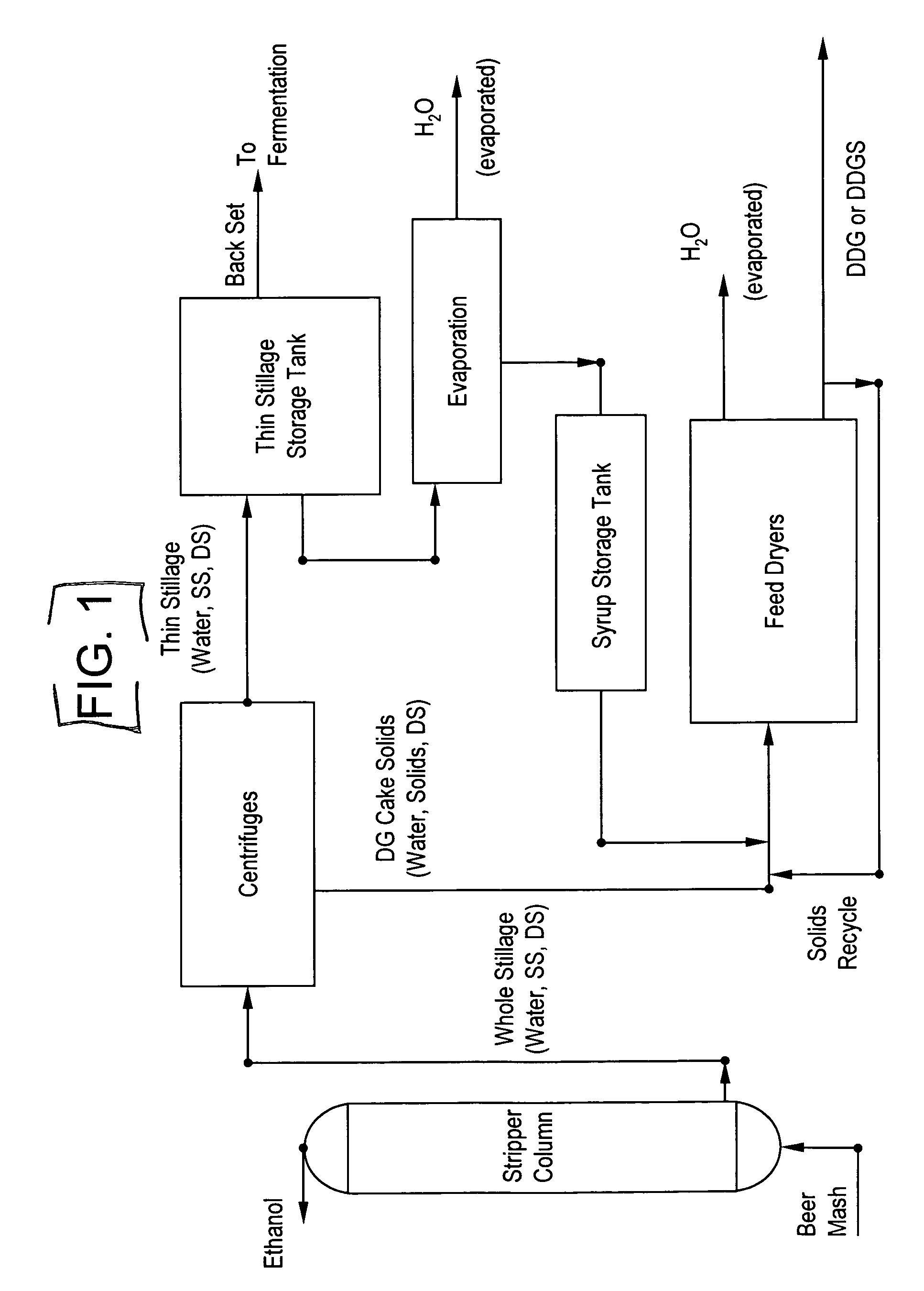

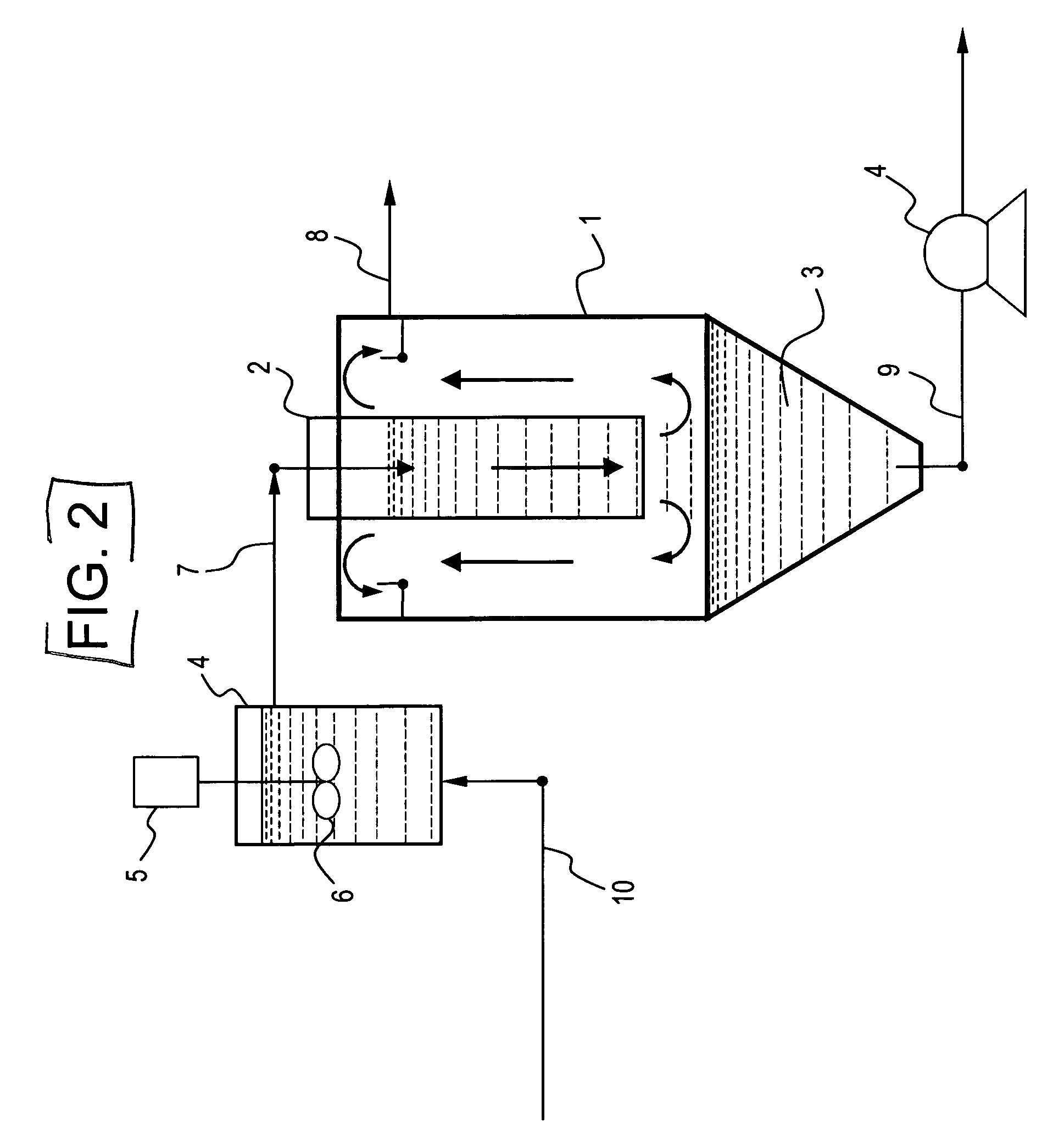

Method of dewatering thin stillage processing streams

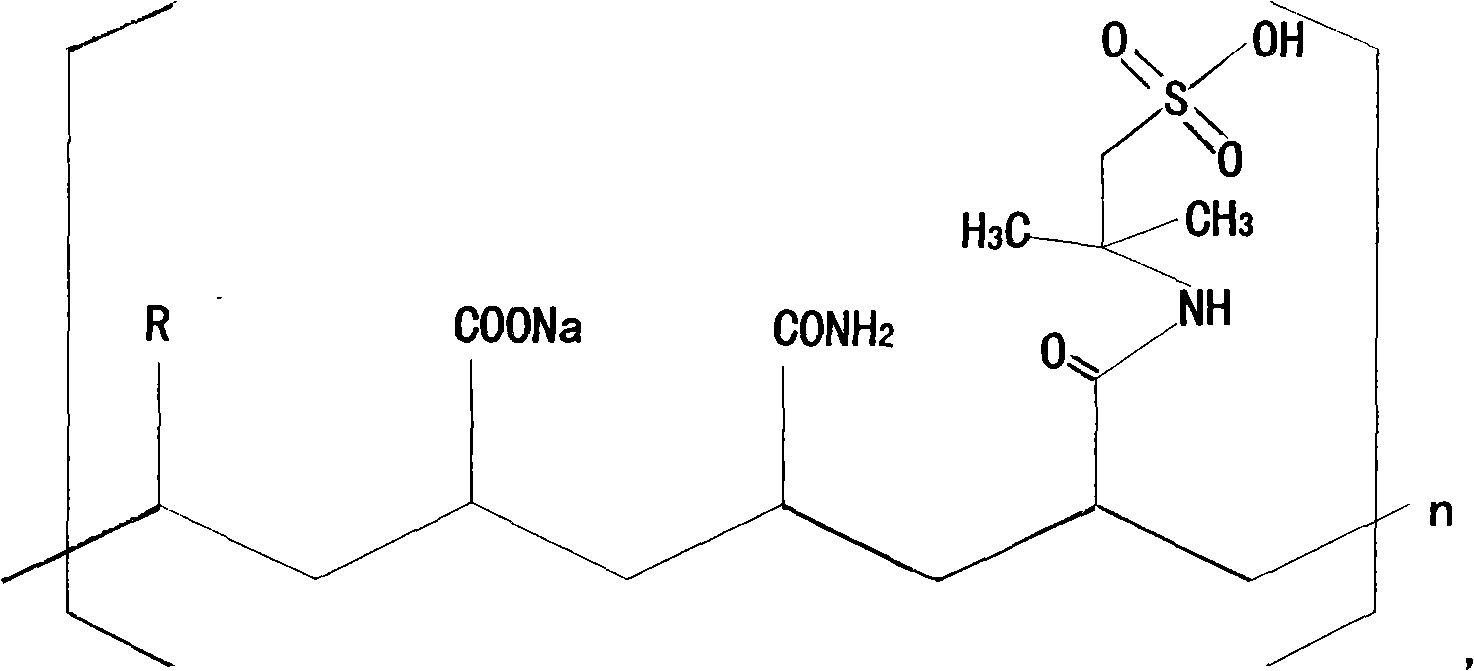

InactiveUS20060006116A1Improve agglomerationAbility to withstandBy-product recoveryWater treatment parameter controlAcryditeSodium methacrylate

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective coagulating and flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and coagulated and flocculated solids; and separating the water from the coagulated and flocculated solids using a dewatering device.

Owner:NALCO CO

Liquid infusion method for producing linaloe on aquilaria sinensis trees

ActiveCN101755629AIncrease productionShorten the production cycleBiocidePlant growth regulatorsInfusion methodMedicine

The invention belongs to biological technical field, in particular to a liquid infusion method for producing linaloe on aquilaria sinensis trees. The method includes of drilling on the aquilaria sinensis trunk, gradually dropping a linaloe catalyst into the aquilaria sinensis tree body through the liquid infusion method; the operation is repeated every 2-3 months, after 6-12 months, the chocolatebrown oil-like material and the yellowish-brown discolored eaglewood formed in the trunk is cut and is dried to obtain the linaloe; the linaloe catalyst is mixed up by a phytohormone solution and a chemical reagent solution; the chemical reagent is ferric salt or sodium salt. The process of the invention has simple technique, convenient operation, can greatly increase production quantity of the linaloe and greatly shorten the production period of the linaloe through the inducing method, has good linaloe-forming effect, can effectively ease the contradiction between supply and demand for sinensis, is applicable to large-scale standardization and commercialization production, provides a new effective path for protecting, developing and utilizing the aquilaria sinensis tree resources, and has important economical, social and ecological benefits.

Owner:INST OF MEDICINAL PLANT DEV CHINESE ACADEMY OF MEDICAL SCI HAINAN BRANCH

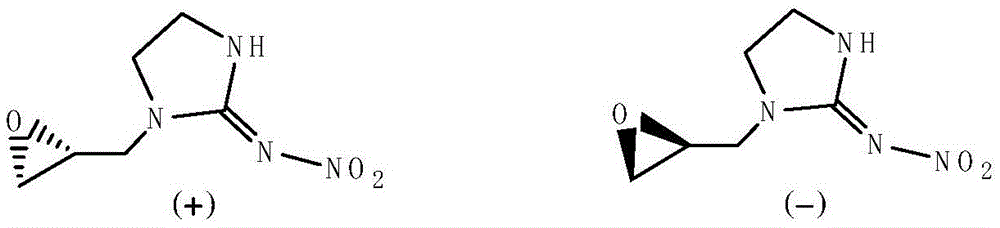

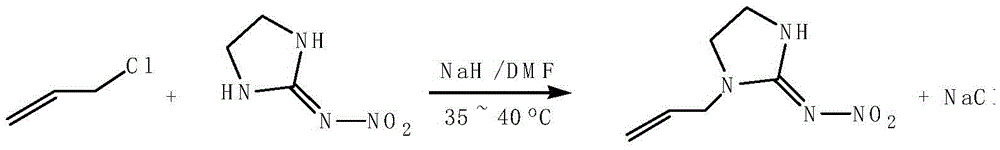

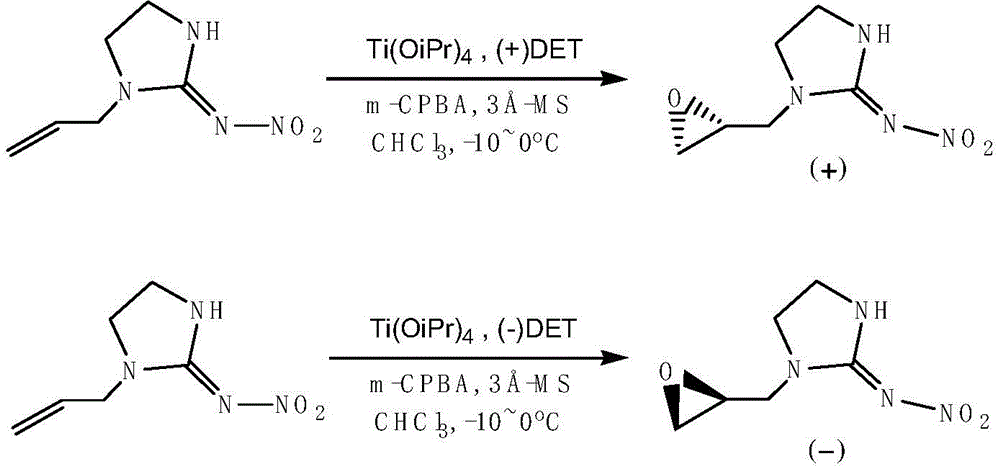

Preparation method for cycloxylidin enantiomer with photoactivity

InactiveCN105481839APrevent self-aggregationMild thermal conditionsOrganic chemistry methodsHydrogenResonance

The invention discloses a preparation method for a cycloxylidin enantiomer with photoactivity, which belongs to the technical field of asymmetric catalytic synthesis of medicines with optical activity. The method comprises a first step of synthesizing 1-allyl-N-2-nitroiminoimidazolidine and a second step of synthesizing the 1-(1,2-glycidyl)-N-2-nitroiminoimidazolidine enantiomer. The method employs sodium hydride to effectively completely remove hydrogen with weak acidity in a resonance structure of N-nitroiminoimidazolidine and convert the hydrogen into a sodium salt, wherein organic by-products are not produced; through asymmetric epoxidation, levorgyrate or dextrorotary enantiomer products with high yield can be obtained; and the method prepares high-purity enantiomer products, substantially improves insecticidal activity of the products and reduces environmental pollution.

Owner:安徽千和新材料科技发展有限公司

Electrolyte purgative

ActiveUS20050271749A1Reduce the amount requiredIncreased tonicityOrganic active ingredientsBiocideMagnesium saltPotassium

The invention relates to compositions for use in purgatives, to purgatives comprising such compositions, and to methods for inducing purgation of the colon. The composition may comprise at least one water-soluble sodium salt; at least one water-soluble minimally degradable sugar in an amount, by weight, of from about 1 to about 3 times the weight of sodium ions in said composition; at least one water-soluble potassium salt in an amount, by weight, of from about 0.05 to about 1 time the weight of said sodium salt in said composition; and at least one water-soluble magnesium salt, wherein the weight of magnesium ions in said composition is from 0.1 to about 10 times the weight of sodium ions in said composition.

Owner:RITE PREP PTY LTD AS TRUSTEE FOR THE RITE PREP UNIT TRUST

Methods and compositions for the treatment of diseases characterized by calcification and/or plaque formation

The invention provides methods and compositions that include a nutraceutical supplement, antibiotic, and metal chelating agent that is administered to a patient to treat or prevent pathological calcification and or plaque formation as associated with Nanobacteria Calcifying Nano-Particles and / or diseases caused there-from, The method includes the administration of a therapeutically effective nutraceutical supplement, tetracycline HCL, and ethylenediaminetetraacetic acid calcium di-sodium salt to a patient in order to prevent and treat calcific disease.

Owner:CIFTCIOGLU NEVA

Massive bodies containing free halogen source for producing highly converted solutions of chlorine dioxide

InactiveUS7182883B2Increase conversion rateImprove permeabilityBiocideOrganic chemistryHalogenLiquid water

A massive body, e.g., a tablet, for producing a solution of chlorine dioxide when the massive body is added to liquid water. The massive body comprises a metal chlorite such as sodium chlorite, an acid source such as sodium bisulfate and a source of free halogen such as the sodium salt of dichloroisocyanuric acid or a hydrate thereof. The concentration of free halogen in the solution will be:(a) less than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.25:1 by weight; or(b) equal to or greater than the concentration of chlorine dioxide in said solution on a weight basis and the ratio of the concentration of chlorine dioxide to the sum of the concentrations of chlorine dioxide and chlorite anion in said solution is at least 0.50:1 by weight.

Owner:ENGELHARD CORP

Low Sodium Salt Composition

The present invention relates to a low sodium salt composition and the methods used to make it. In particular, the invention relates to the combined processing of sodium and potassium chloride to produce a low sodium salt composition. The low sodium salt composition includes sodium chloride and a modified chloride salt composition. The modified chloride salt composition includes a homogenous amalgamation of chloride salts, food grade acidulant, and carrier.

Owner:S & P INGREDIENT DEV

Method of producing lipids by growing microorganisms of the order thraustochyriales

Disclosed is a process for growing the microflora Thraustochytrium, Schizochytrium, and mixtures thereof, which includes the growing of the microflora in fermentation medium containing non-chloride containing sodium salts, in particular sodium sulfate. In a preferred embodiment of the present invention, the process produces microflora having a cell aggregate size useful for the production of food products for use in aquaculture. Further disclosed is a food product which includes Thraustochytrium, Schizochytrium, and mixtures thereof, and a component selected from flaxseed, rapeseed, soybean and avocado meal. Such a food product includes a balance of long chain and short chain omega-3 highly unsaturated fatty acids. In an embodiment, lipids are produced by growing microorganisms of the order Thraustochytriales in a medium and extracting the lipids.

Owner:DSM IP ASSETS BV

Chemical composition for treatment of nitrate and odors from water streams and process wastewater treatment

InactiveUS20020011447A1Efficient processSolid sorbent liquid separationWater softeningSodium BentoniteBisulfide

Owner:MAXICHEM

Inspissated oil emulsion viscidity reducer

ActiveCN1778862AStrong resistance to mineral saltHigh emulsifying colloidDrilling compositionPhosphateOil emulsion

A thickened oil emulsifying viscosity reducer consists of anion surface activator, non-ionic-anion surface activator, demulsifier and water in proportion by 1:0.1-50:0.01-20 and water content is 0.2-5000 times of the sum of a, b and c. Anion surface activator comprises sodium salt and calcium salt of petroleum sulfoacid salt methyl condensate and sulfonated lignin; non-ionic-anion surface activator is chosen organic phosphate salt, sulfuric ester salt , carboxylate and sulfosalt of alkylphenol or fatty alcohol-polyoxyethylene ether; demulsifier is copolymer of alkyl ammonium halide cation demulsifier, polyethylene glycol polyoxytrimethylene polylol ether non-ionic demulsifier or polyethylene glycol polyoxytrimethylene polyethylene polyamines block. It has strong emulsifying ability and low thickened oil viscosity,

Owner:CHINA PETROLEUM & CHEM CORP +1

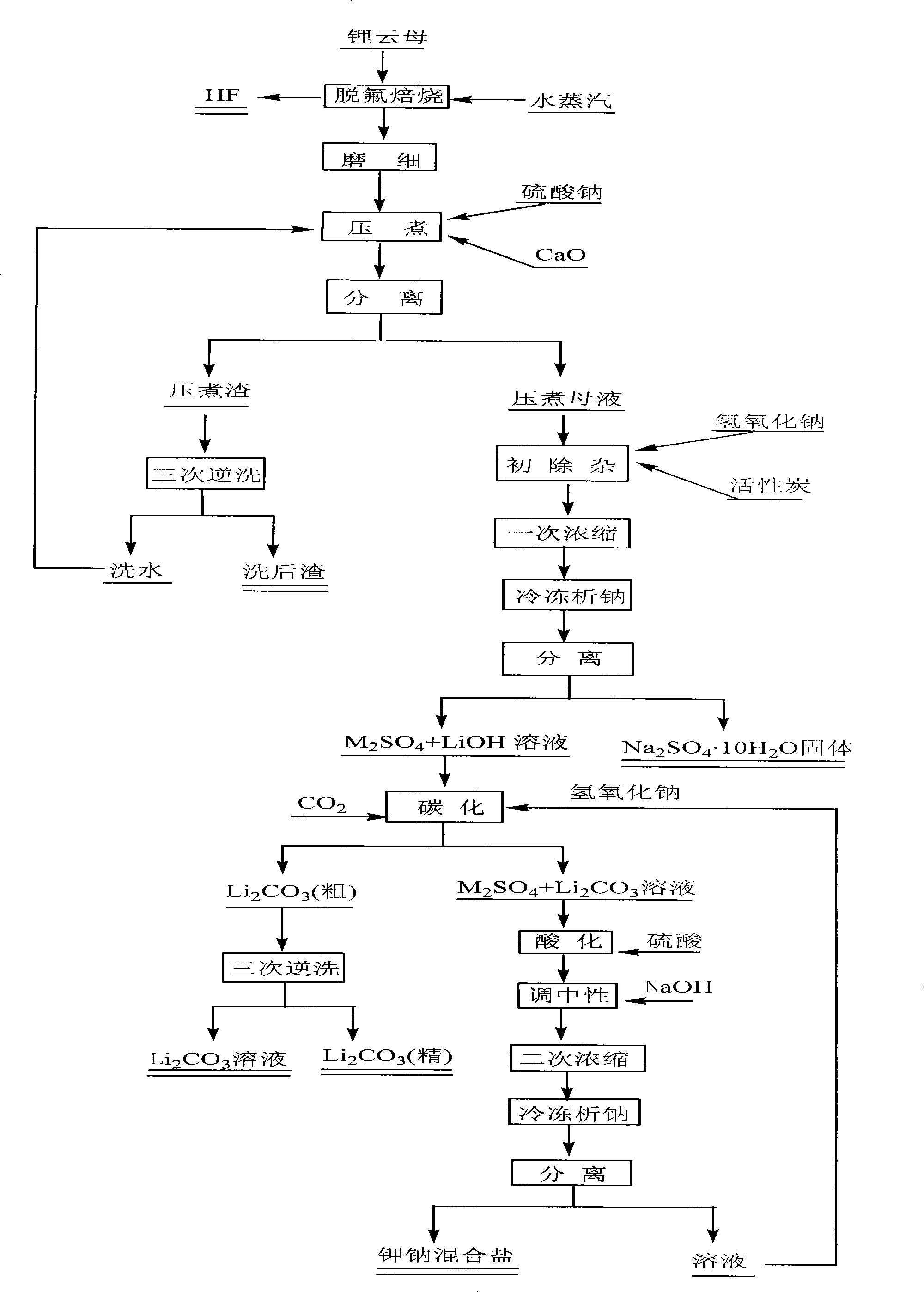

Method for preparing lithium carbonate by extracting lithium from lepidolite

ActiveCN101302018AImprove leaching rateIncrease concentrationLithium carbonates/bicarbonatesCarbonizationIon exchange

Owner:GANFENG LITHIUM CO LTD

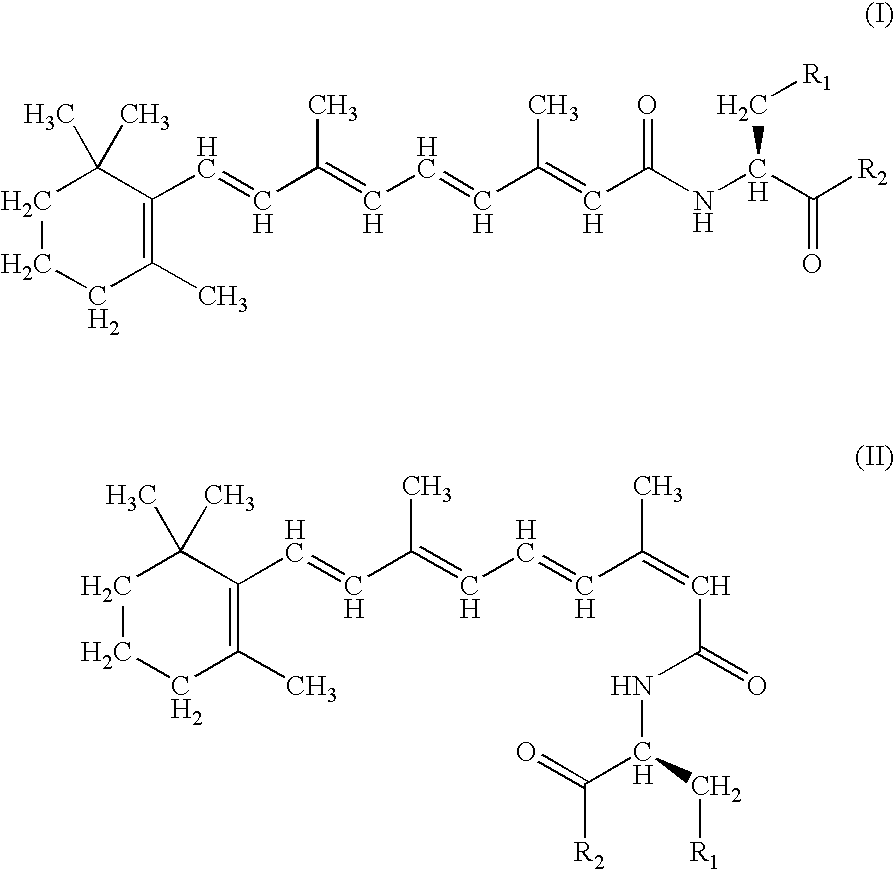

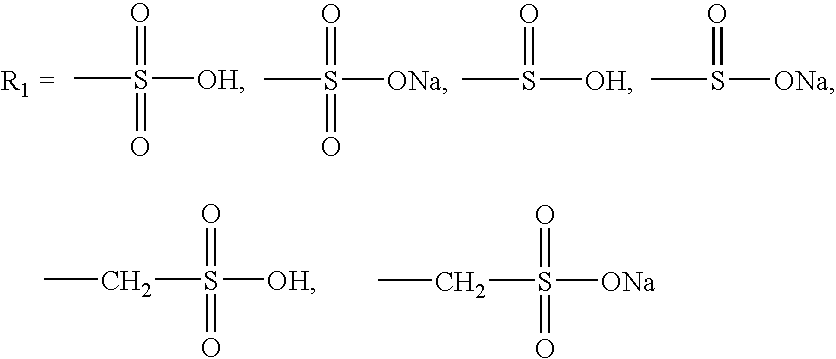

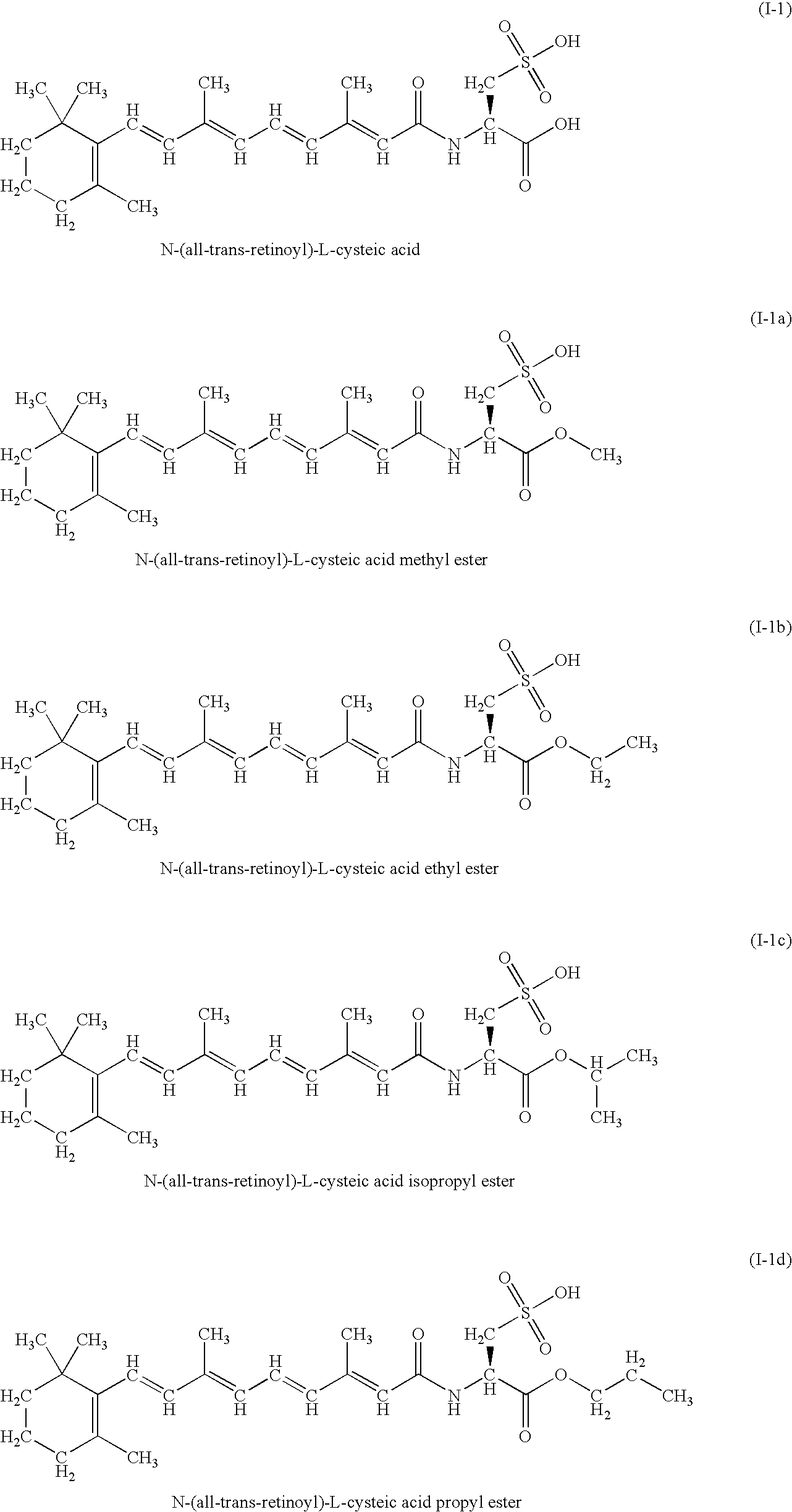

Therapeutic compounds

InactiveUS20040048923A1Improve pharmacological activityGood curative effectBiocideOrganic compound preparationDocetaxel-PNPTreatment effect

A group of new compounds, N-(all-trans-Retinoyl)-L-cysteic acid, N-(13-cis-Retinoyl)-L-cysteic acid, N-(all-trans-Retinoyl)-L-cysteinesulfinic acid, N-(13-cis-Retinoyl)-L-cysteinesulfinic acid, N-(all-trans-Retinoyl)-L-homocysteic acid, N-(13-cis-Retinoyl)-L-homocysteic acid, and sodium salts of these compounds, including sodium salts of their esters and amides, is shown to exhibit therapeutic effects per se, and which compounds in combination with cytotoxic compounds, such as docetaxel, paclitaxel, doxorubicin and mitoxantrone, exhibit a synergistic effect. These compounds make it possible to manufacture new formulations of poorly soluble pharmaceutical compounds, and the present invention discloses a process of manufacturing water-soluble formulations of such compounds, exemplified by docetaxel, and paclitaxel, exhibiting enhanced pharmacological activity, and formulations of water-soluble pharmaceuticals exemplified by doxorubicin and mitoxantrone, exhibiting improved therapeutic efficacy.

Owner:VIVESTO AB

Comb-type structure activity polymer and its preparation technique and application

InactiveCN101260171AGood water solubilityHigh molecular weightDrilling compositionFunctional monomerHigh surface

The invention discloses a comb-type structural reactive polymer with the molecular weight ranging between 1x10<5> and 5x10<6>, wherein the main chain of the reactive polymer is obtained through the copolymerization of acrylamide monomer and functional monomers such as 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid sodium salt, etc., which endues polymer aqueous solution with higher apparent viscosity and better temperature resistance and salt resistance; and the branched chain of the reactive polymer consists of unsaturated macromonomer molecule, which endues the polymer aqueous solution with higher surface activity. The invention also discloses a preparation method for the polymer, comprising the following steps: firstly, through process operation including esterification, prepolymerization and sulfonation, polyurethanes active macromonomer with a novel structure is prepared; then, under the action of oxidation reduction initiator, the copolymerization reaction of the active macromonomer and other functional micromolecule monomers is initiated quickly at low temperature. The comb-type structural reactive polymer can be used as oil displacement agent and has the advantages of high molecular weight and low surface tension, etc.

Owner:SHANDONG UNIV

Method of dewatering thin stillage processing streams

ActiveUS7497955B2Improve agglomerationAbility to withstandWater treatment parameter controlWater treatment compoundsSodium methacrylateSodium salt

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and flocculated solids; and separating the water from the flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

Aliphatic diol-based polycarbonates, method of making, and articles formed therefrom

Owner:SABIC INNOVATIVE PLASTICS IPBV

Synthesis method of drilling fluid filtrate reducer

InactiveCN101805595ANo pollution in the processFast polymerization rateDrilling compositionSynthesis methodsOil phase

The invention relates to a synthesis method of drilling fluid filtrate reducer. The method comprises: a, nonionic compound emulsifying agent is dissolved in oil and oil phase is made up; a first monomer chosen from fumaric acid, maleic acid, itaconic acid or crylic acid, a second monomer chosen from N, N- dimethylacrylamide, N, N-diethylacrylamide or acrylamide and a third monomer chosen from 4-vinylbenzenesulfonic acid sodium salt, sodium allylsulfonate, 3-allyloxy-2-dydroxy-1-sodium allylsulfonate, 2- methacryloxypropyl-2-methyl propanesulfonic acid, 2-acrylamido-2-methyl propanesulfonic acid or SMAS are dissolved in water with the molar ratio of 1:1 to 5:1 to 5, the pH value of the solution is adjusted to be between 8 and 11, evocating agent is added and water phase solution is made up; and b, the water solution is added to the oil phase solution and the temperature rises to 40 to 70 DEG C for polymerization. The method of the invention has the advantages of fast polymerization speed, high outcome molecular weight and high outcome stability, good filtrate reducing performance, high temperature resistance and high salt resistant performance.

Owner:BEIJING UNIV OF CHEM TECH

Process for the heterotrophic production of microbial products with high concentrations of omega-3 highly unsaturated fatty acids

InactiveUS20060160203A1Improve filtering effectLipid content can be increasedFungiBacteriaHigh concentrationRapeseed

Disclosed is a process for growing the microflora Thraustochytrium, Schizochytrium, and mixtures thereof, which includes the growing of the microflora in fermentation medium containing non-chloride containing sodium salts, in particular sodium sulfate. In a preferred embodiment of the present invention, the process produces microflora having a cell aggregate size useful for the production of food products for use in aquaculture. Further disclosed is a food product which includes Thraustochytrium, Schizochytrium, and mixtures thereof, and a component selected from flaxseed, rapeseed, soybean and avocado meal. Such a food product includes a balance of long chain and short chain omega-3 highly unsaturated fatty acids.

Owner:DSM IP ASSETS BV

Method for recovering tungsten component from selective catalytic reduction denitrification catalyst

The invention relates to a method for recovering a tungsten component from a selective catalytic reduction denitrification catalyst, belonging to the technical field of waste catalyst recovery. The invention achieves the purpose of separating and purifying a tungsten component by high-temperature sodium salt roasting, organic phase extraction, ammonia water back extraction and other operations. According to the invention, tungsten trioxide in a catalyst can be separated from other acidic metal oxide, the contained tungsten element can be selectively extracted, no effect can be made on the recovery of other metal elements, and the recovery of the tungsten component can be realized basically.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

Process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt

InactiveCN103436720ASolve the problem of ammonia nitrogen pollutionRealize green miningProcess efficiency improvementAmmoniacal nitrogenCalcium hydroxide

The invention relates to a process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt. The process comprises the step of replacing ammonium salt by taking a mixture of calcium, magnesium and sodium salts as a leaching agent and taking non-ammonium salts, such as calcium hydroxide, magnesium hydrate or sodium hydroxide as a precipitator. According to the process disclosed by the invention, the ammonia nitrogen pollution problem in exploitation of ion-adsorption type rare earth is radically solved; environmental-friendly exploitation of the ion-adsorption type rare earth can be realized; the process disclosed by the invention has higher economic benefit and social benefit.

Owner:LONGNAN COUNTY NANYU RARE EARTH RESOURCES COMPREHENSIVE UTILIZATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com