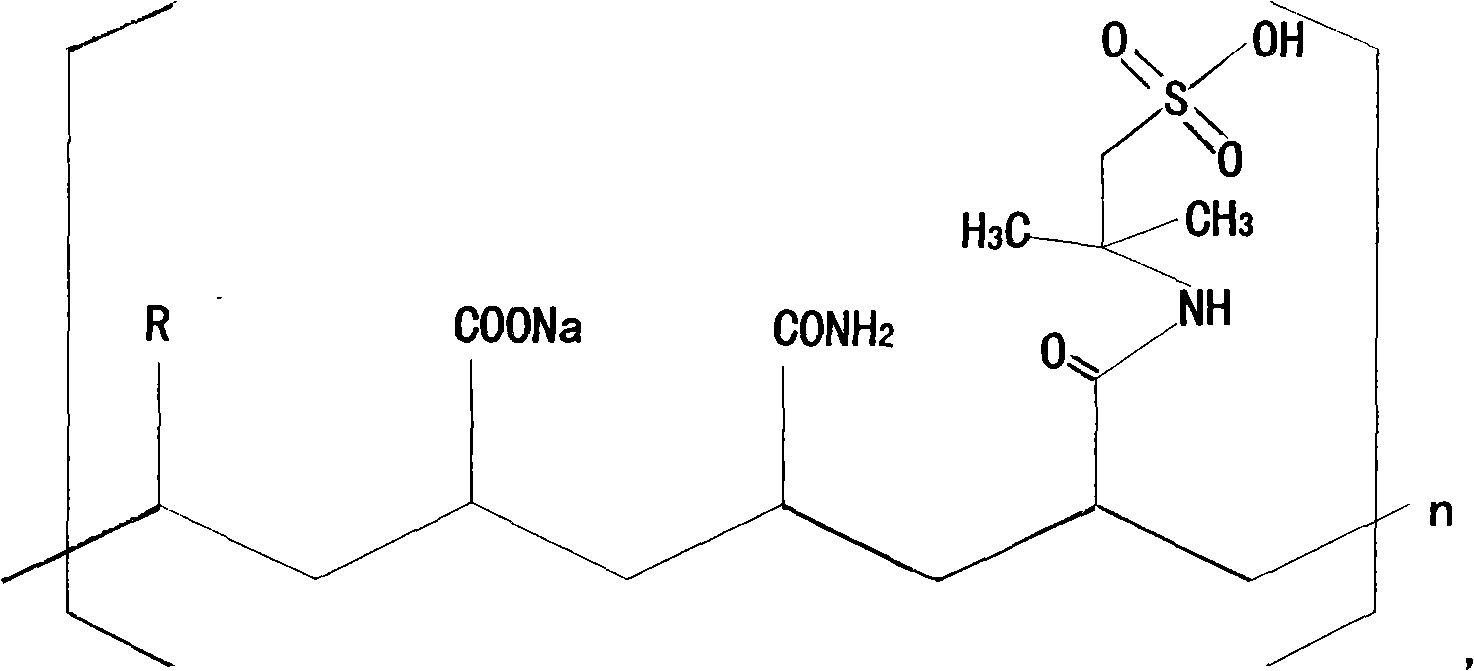

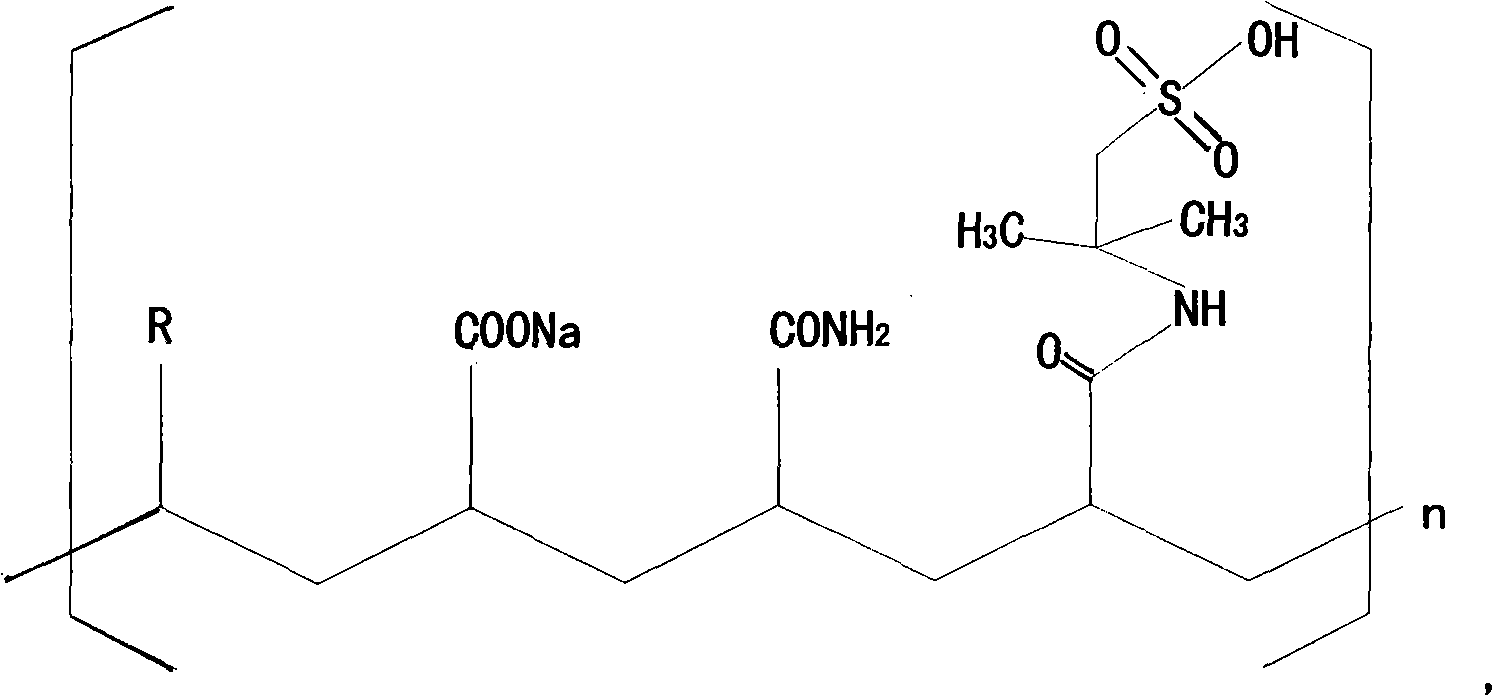

Comb-type structure activity polymer and its preparation technique and application

A kind of active polymer and preparation technology, applied in the field of polyurethane structural active polymer, can solve the problems of limited thickening ability of aqueous solution, weak foaming power and penetrating power, poor surface tension ability, etc., and achieve good water solubility and molecular weight The effect of high and high temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

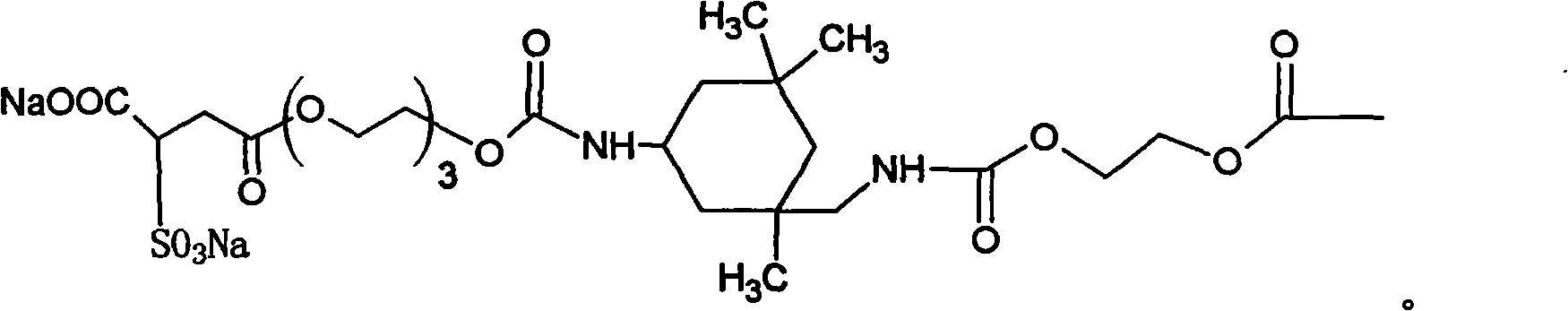

[0031] Embodiment 1: Preparation of comb-shaped structure active polymer: adopting a four-mouth vessel with stirring, heating and cooling equipment as the reaction device, the steps are:

[0032] (1) Under nitrogen atmosphere, maleic anhydride and triethylene glycol were fully mixed and stirred, and reacted at 75° C. for 1 hour;

[0033] (2) Add the catalyst dibutyltin dilaurate dropwise to the above reaction system, then add isophorone diisocyanate, and react at 85° C. for 2 hours to obtain a prepolymer whose end group is isocyanate;

[0034] (3) Add hydroxyethyl acrylate dropwise to the above reaction system, react at 75° C. for 1 h, and react the hydroxyl group of hydroxyethyl acrylate with the isocyanate of the above prepolymer;

[0035] (4) After the above reaction is completed, the temperature is lowered to 70°C, and an aqueous solution of sodium sulfite is added to cause a nucleophilic addition reaction to obtain an active macromonomer with an α-sodium sulfonate group; ...

Embodiment 2

[0044] Embodiment 2: Preparation of comb-shaped structure active polymer: using a four-mouth container with stirring, heating and cooling equipment as the reaction device, the steps are:

[0045] (1) Under nitrogen atmosphere, maleic anhydride and triethylene glycol were fully mixed and stirred, and reacted at 50°C for 1.5h;

[0046] (2) Add the catalyst dibutyltin dilaurate dropwise to the above reaction system, then add isophorone diisocyanate, and react at 95° C. for 1 hour to obtain a prepolymer whose end group is isocyanate;

[0047] (3) Add hydroxyethyl acrylate dropwise to the above reaction system, and react at 85° C. for 0.5 h, so that the hydroxyl group of hydroxyethyl acrylate reacts with the isocyanate of the above prepolymer;

[0048] (4) After the above reaction is completed, the temperature is lowered to 60 ° C, and an aqueous solution of sodium sulfite is added to cause a nucleophilic addition reaction to obtain an active macromonomer with an α-sodium sulfonate...

Embodiment 3

[0057] Embodiment 3: Preparation of comb-shaped structure active polymer: adopting a four-mouth vessel with stirring, heating and cooling equipment as a reaction device, the steps are:

[0058] (1) Under nitrogen atmosphere, maleic anhydride and triethylene glycol were fully mixed and stirred, and reacted at 60°C for 0.5h;

[0059] (2) Add the catalyst dibutyltin dilaurate dropwise to the above reaction system, then add isophorone diisocyanate, and react at 90°C for 1.5h to obtain a prepolymer whose end group is isocyanate;

[0060] (3) Add hydroxyethyl acrylate dropwise to the above reaction system, and react at 80° C. for 1 h, so that the hydroxyl group of hydroxyethyl acrylate reacts with the isocyanate of the above prepolymer;

[0061] (4) After the above reaction is completed, the temperature is lowered to 75° C., and an aqueous solution of sodium sulfite is added to cause a nucleophilic addition reaction to obtain an active macromonomer with an α-sodium sulfonate group; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com