Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

403 results about "Reactive polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The use of reactive polymers enables manufacturers to make chemical changes at a late stage in the production process, which, in turn, cause changes in performance and properties. Material selection and control of the reaction are essential to achieve optimal performance.

Cysteine variants of erythropoietin

The growth hormone supergene family comprises greater than 20 structurally related cytokines and growth factors. A general method is provided for creating site-specific, biologically active conjugates of these proteins. The method involves adding cysteine residues to non-essential regions of the proteins or substituting cysteine residues for non-essential amino acids in the proteins using site-directed mutagenesis and then covalently coupling a cysteine-reactive polymer or other type of cysteine-reactive moiety to the proteins via the added cysteine residue. Disclosed herein are preferred sites for adding cysteine residues or introducing cysteine substitutions into the proteins, and the proteins and protein derivatives produced thereby.

Owner:BOLDER BIOTECH

Cysteine variants of erythropoietin

The growth hormone supergene family comprises greater than 20 structurally related cytokines and growth factors. A general method is provided for creating site-specific, biologically active conjugates of these proteins. The method involves adding cysteine residues to non-essential regions of the proteins or substituting cysteine residues for non-essential amino acids in the proteins using site-directed mutagenesis and then covalently coupling a cysteine-reactive polymer or other type of cysteine-reactive moiety to the proteins via the added cysteine residue. Disclosed herein are preferred sites for adding cysteine residues or introducing cysteine substitutions into the proteins, and the proteins and protein derivatives produced thereby.

Owner:BOLDER BIOTECH

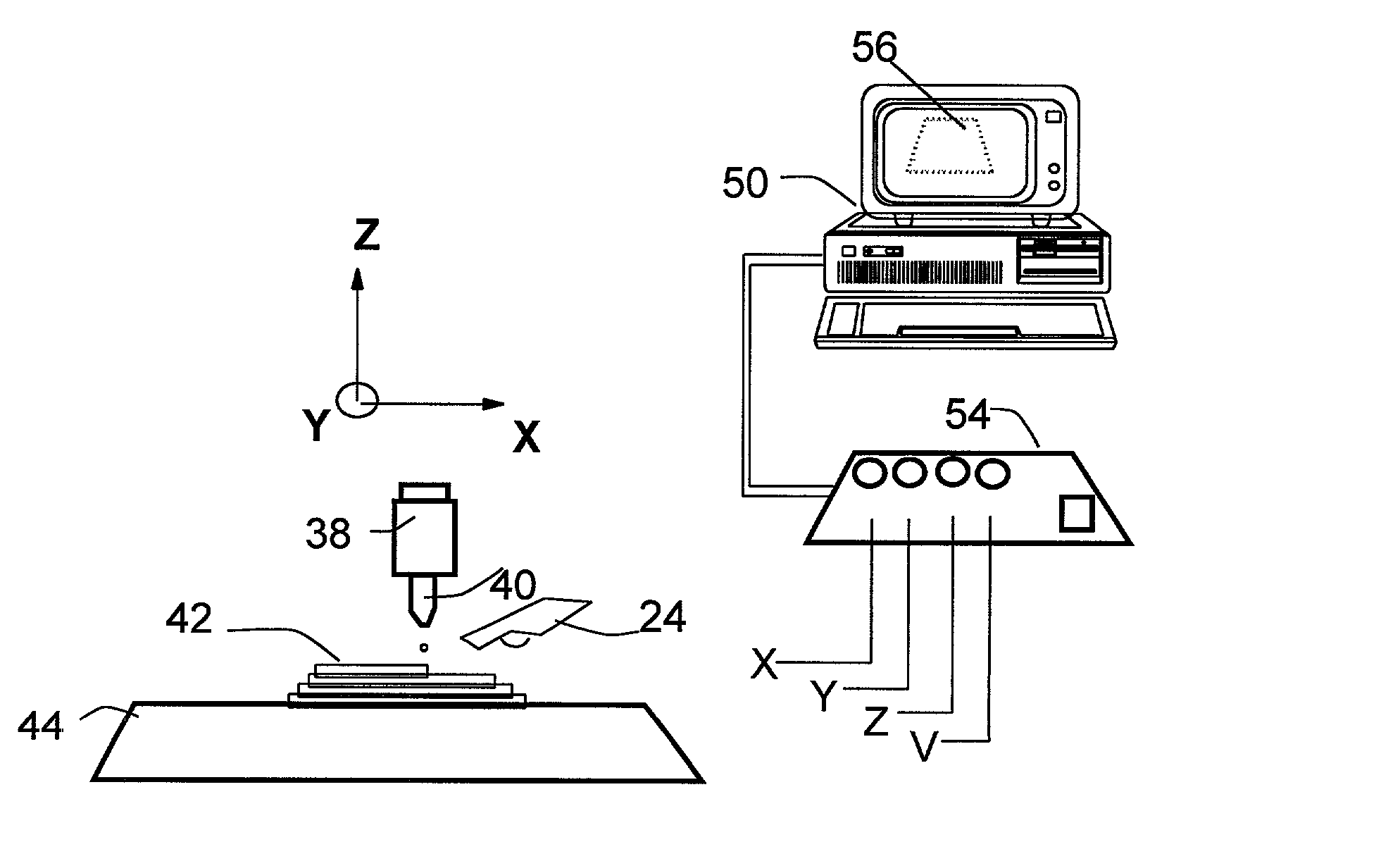

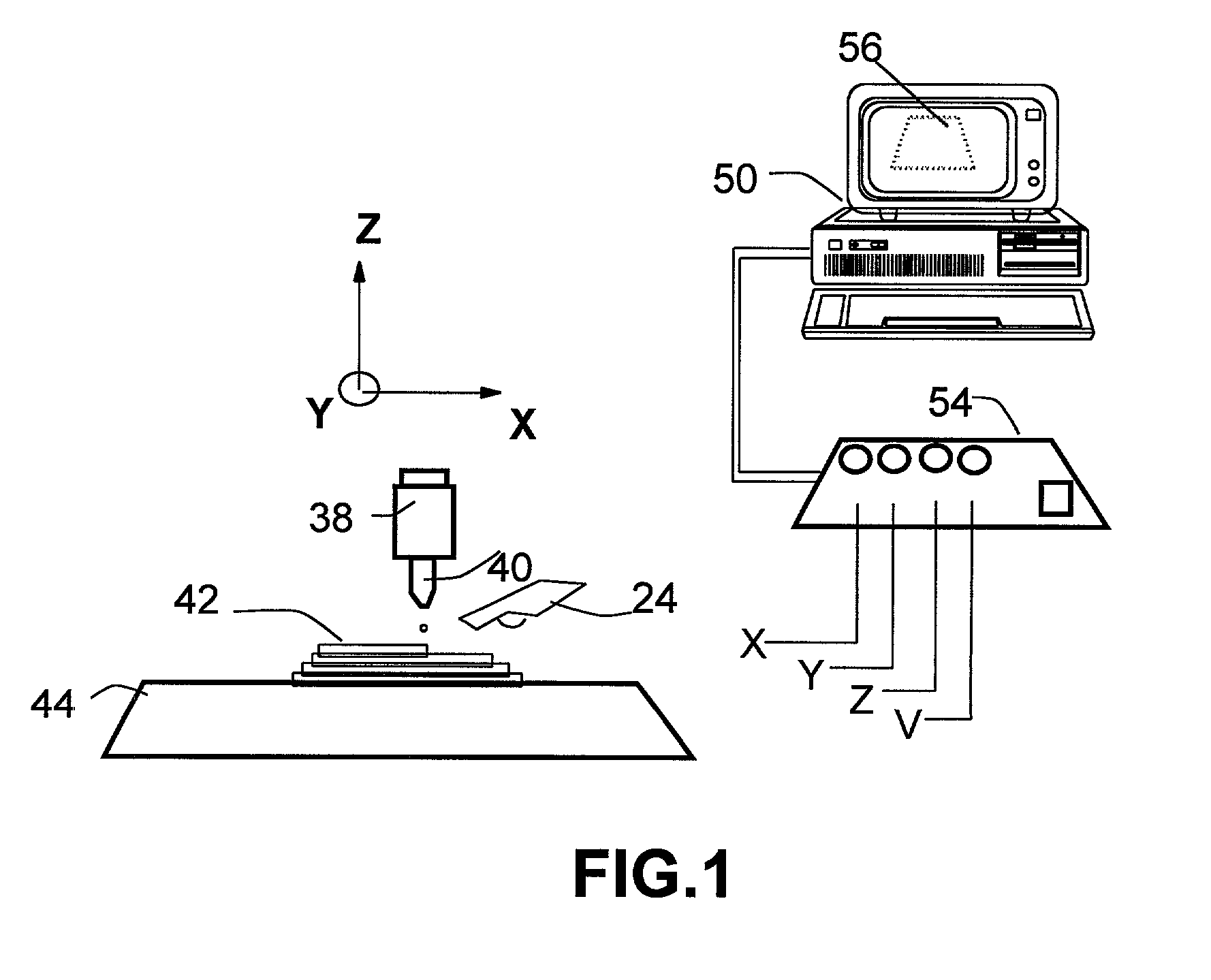

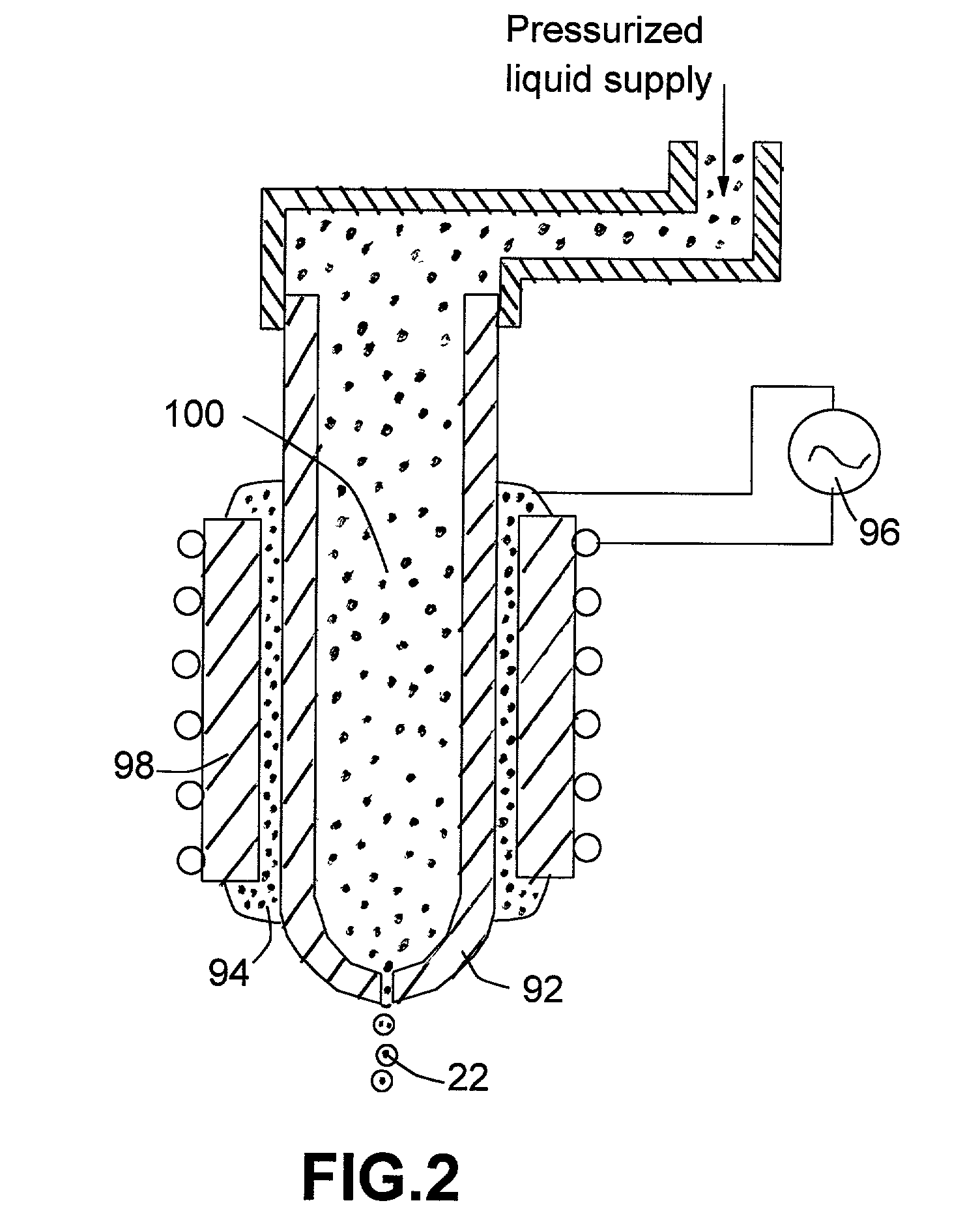

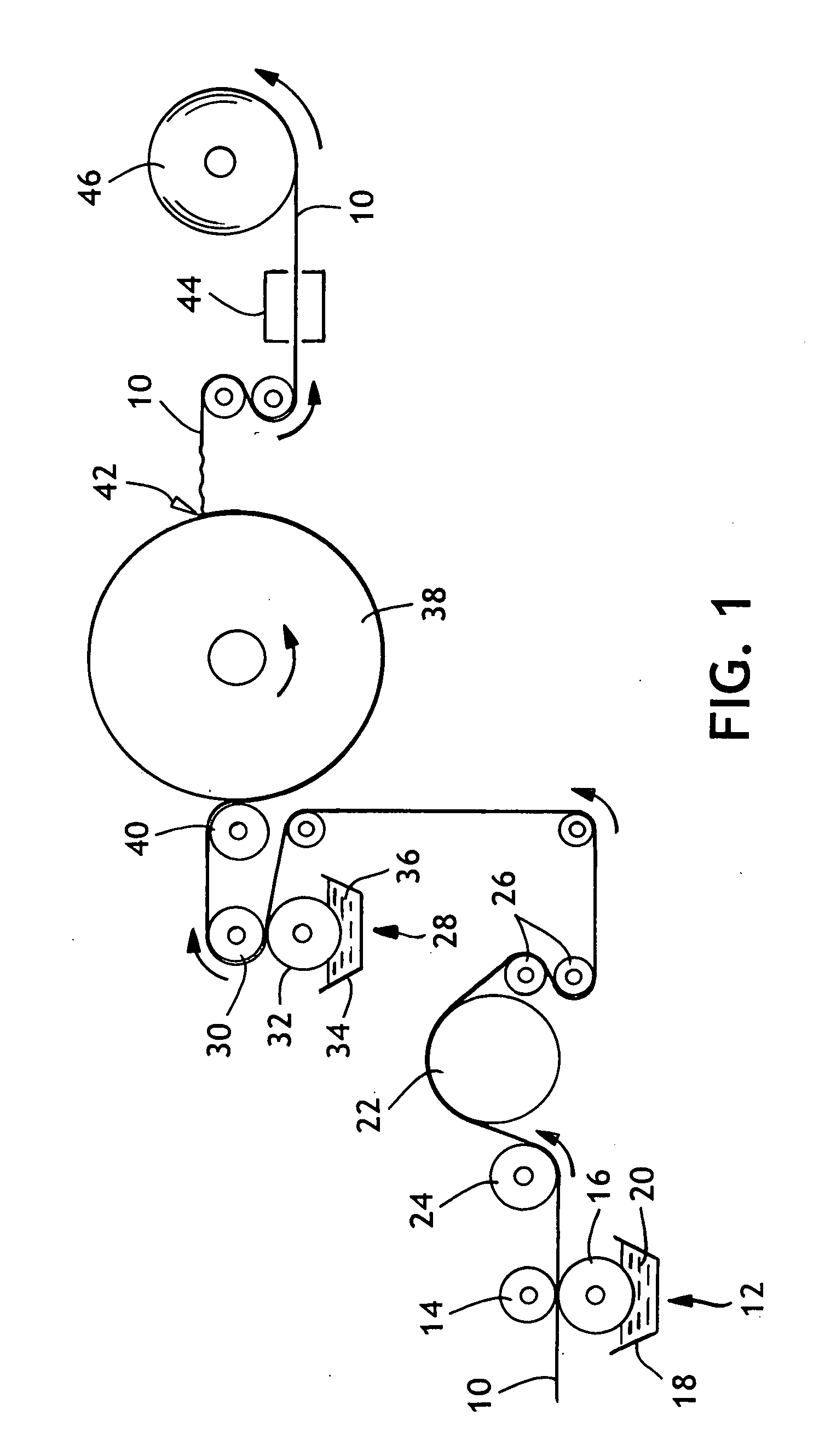

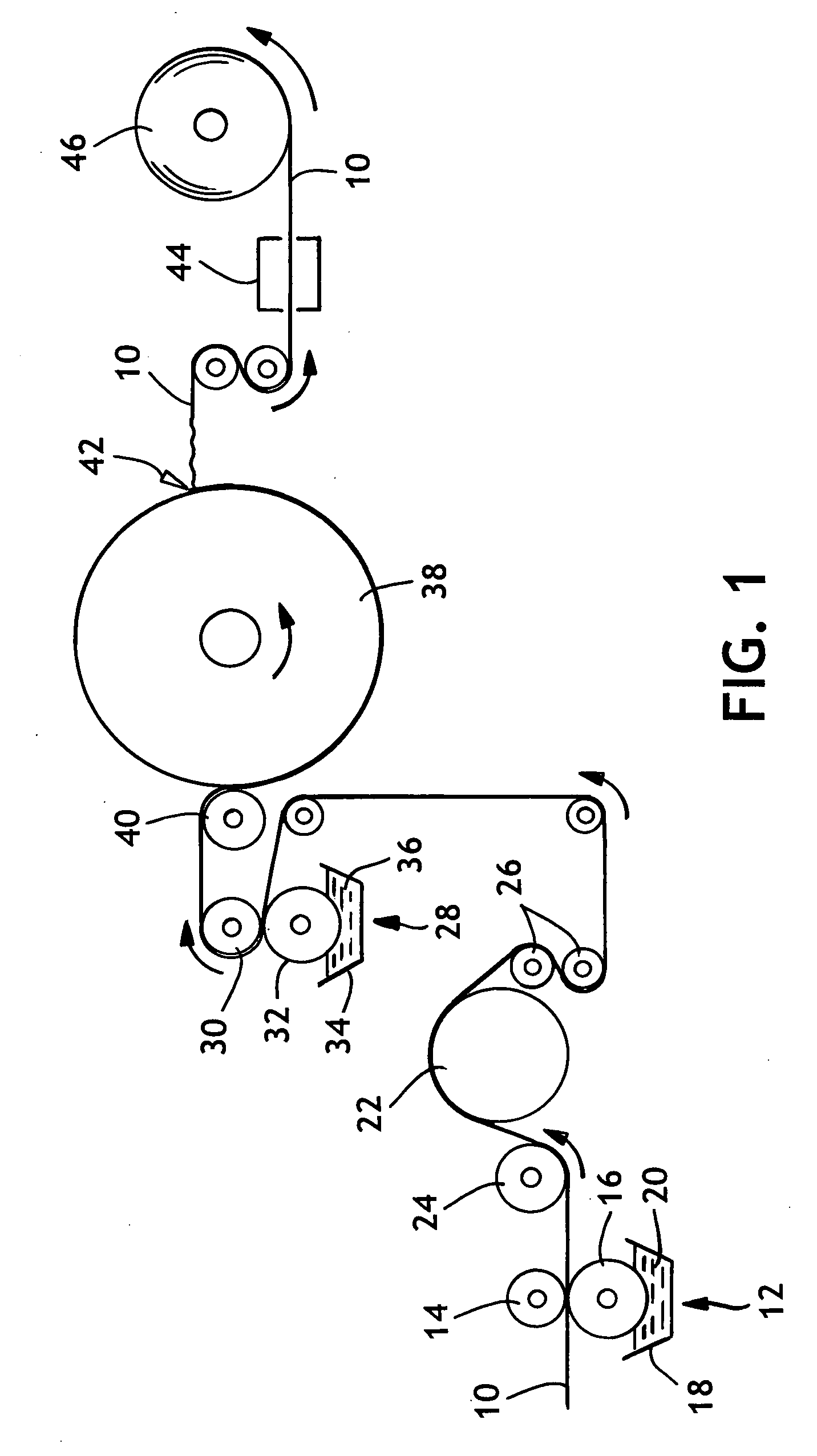

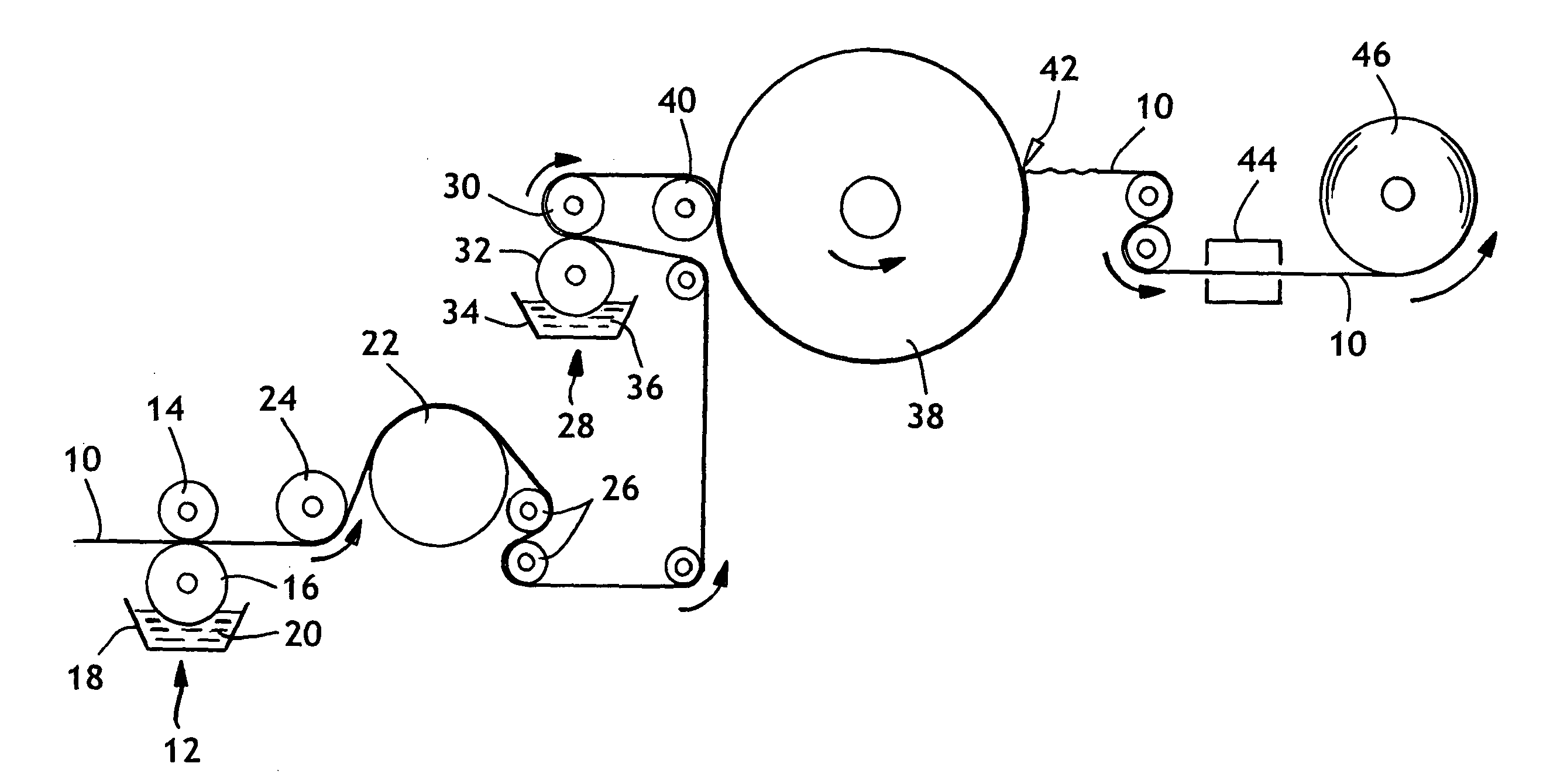

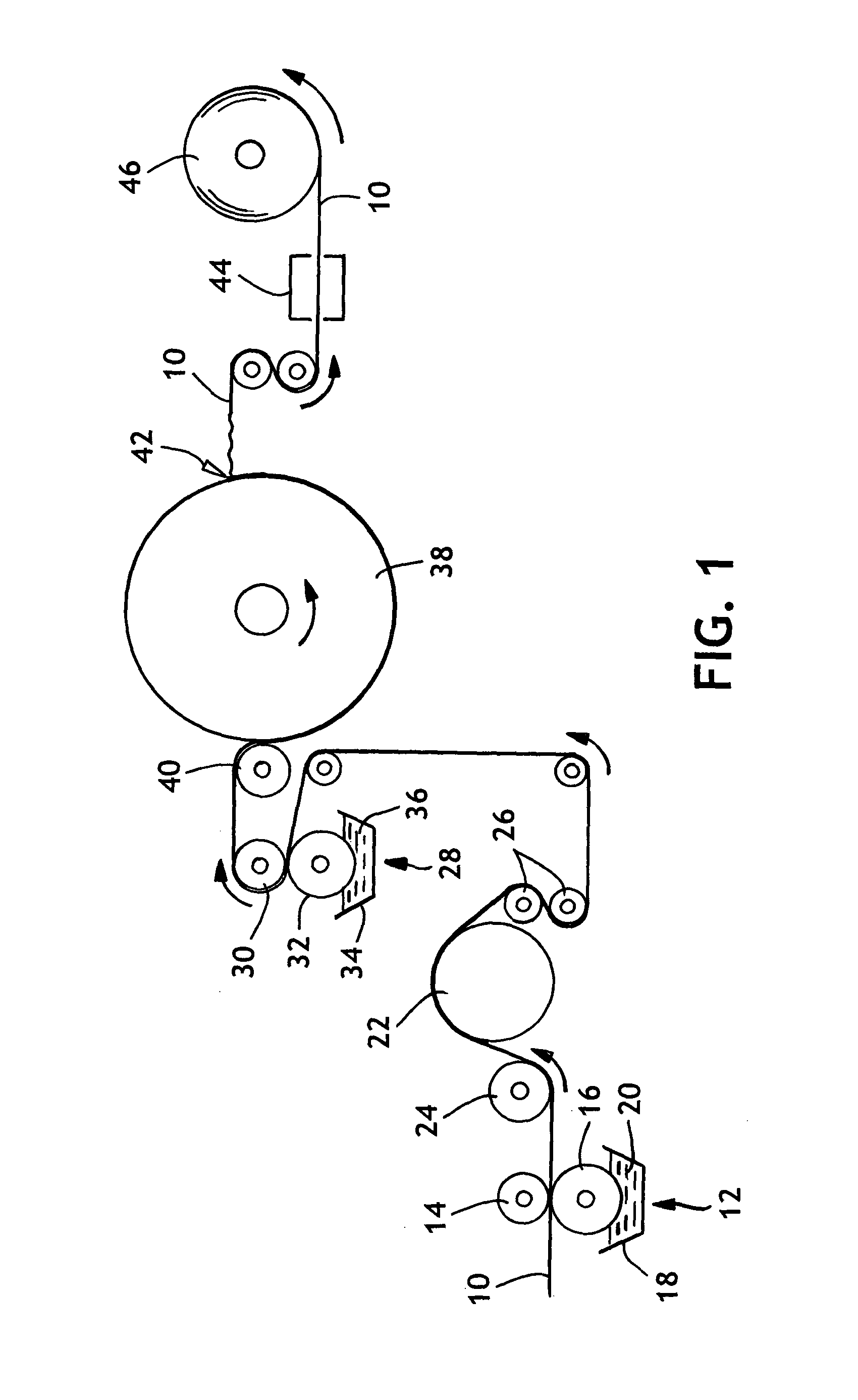

Droplet deposition method for rapid formation of 3-D objects from non-cross-linking reactive polymers

InactiveUS20020111707A13D object support structuresSpecial data processing applicationsThermoplasticControl signal

A droplet deposition-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a droplet dispensing head for dispensing droplets of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing head relative to the support member and for controlling the droplet dispensing of the material composition to construct the 3-D object.

Owner:LI ZHIMIN +3

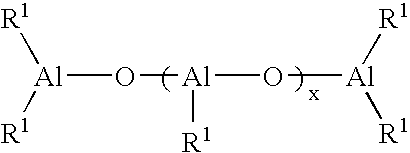

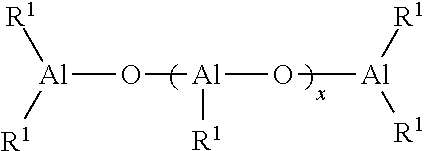

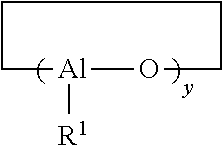

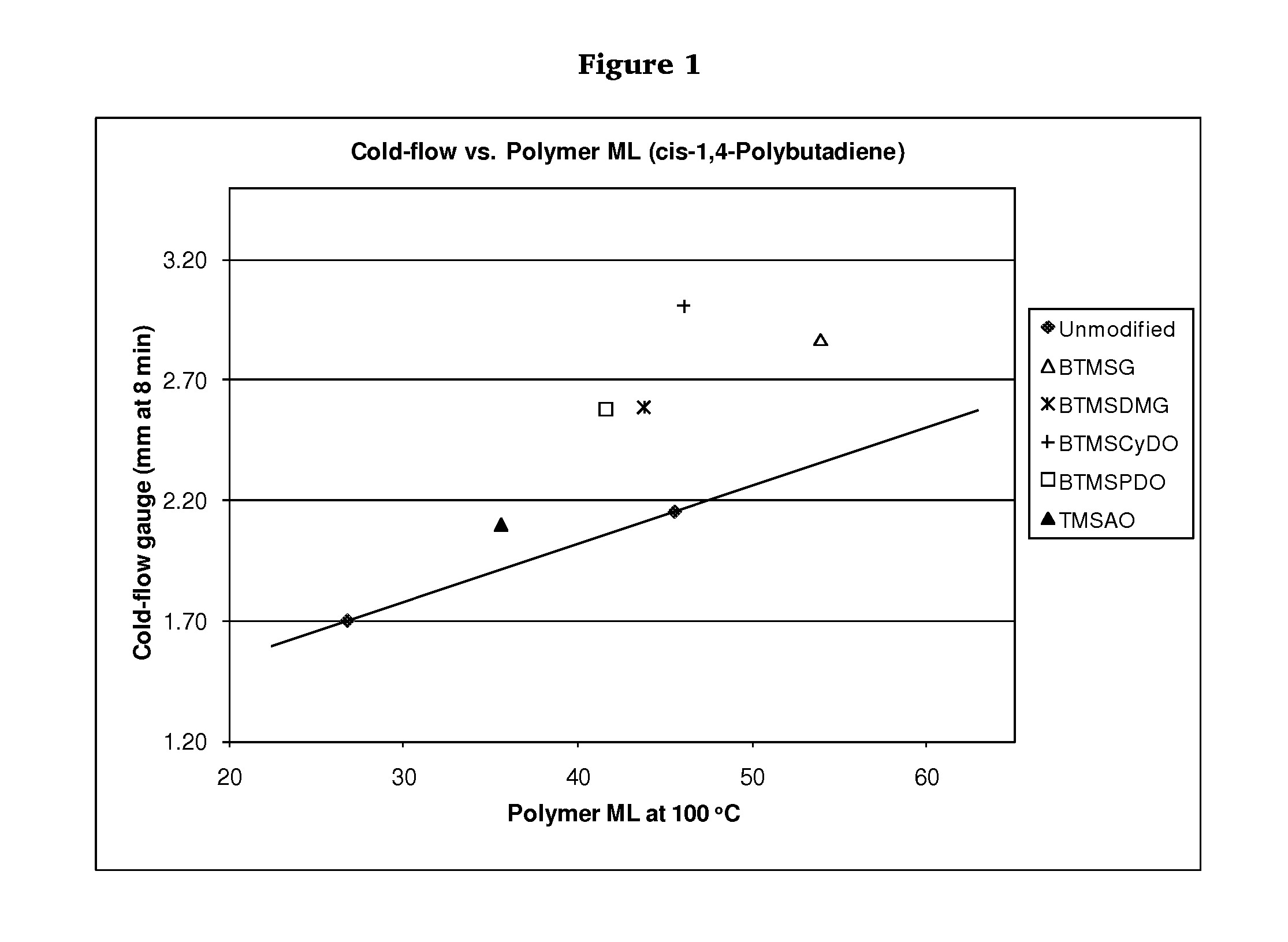

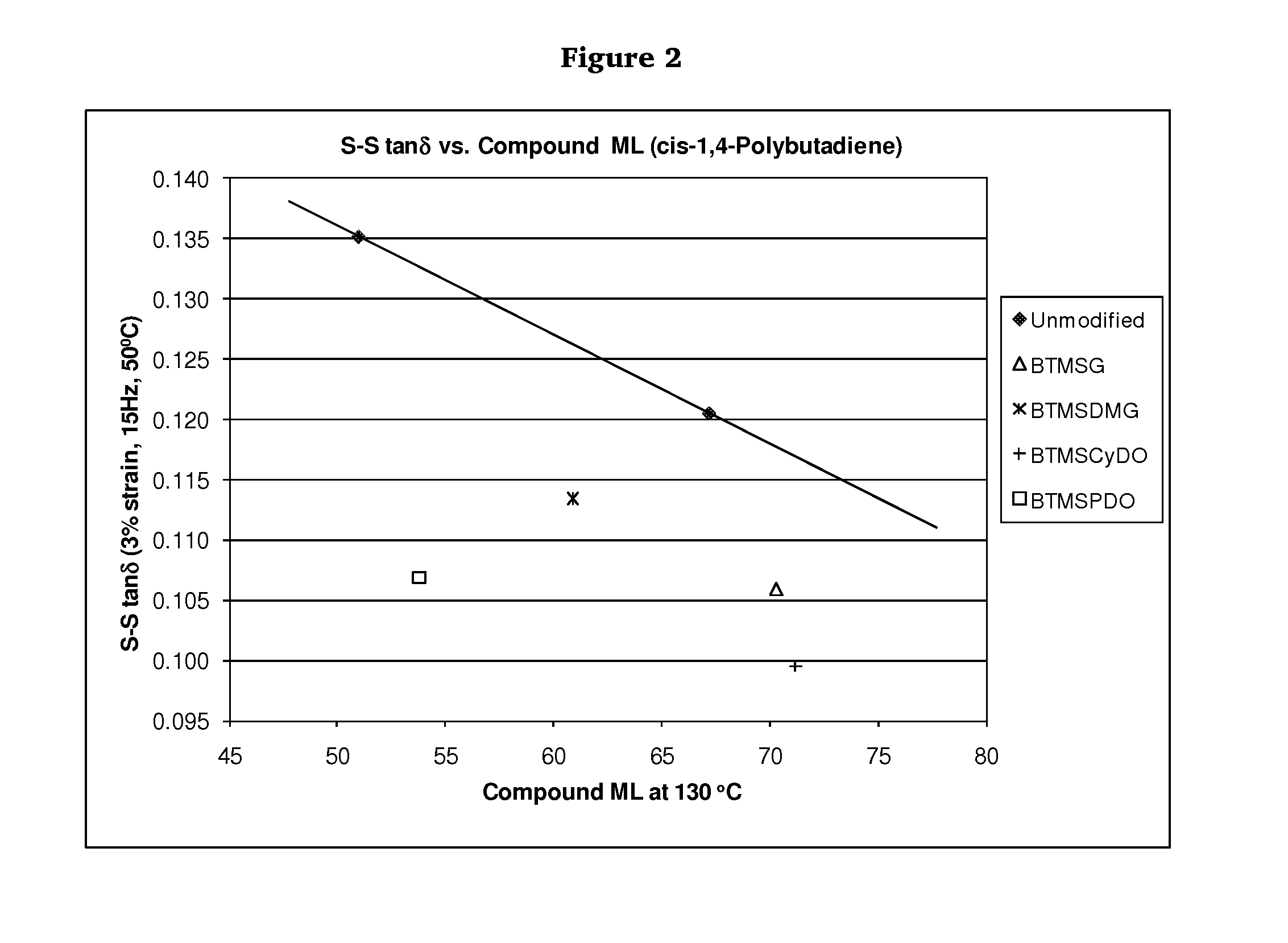

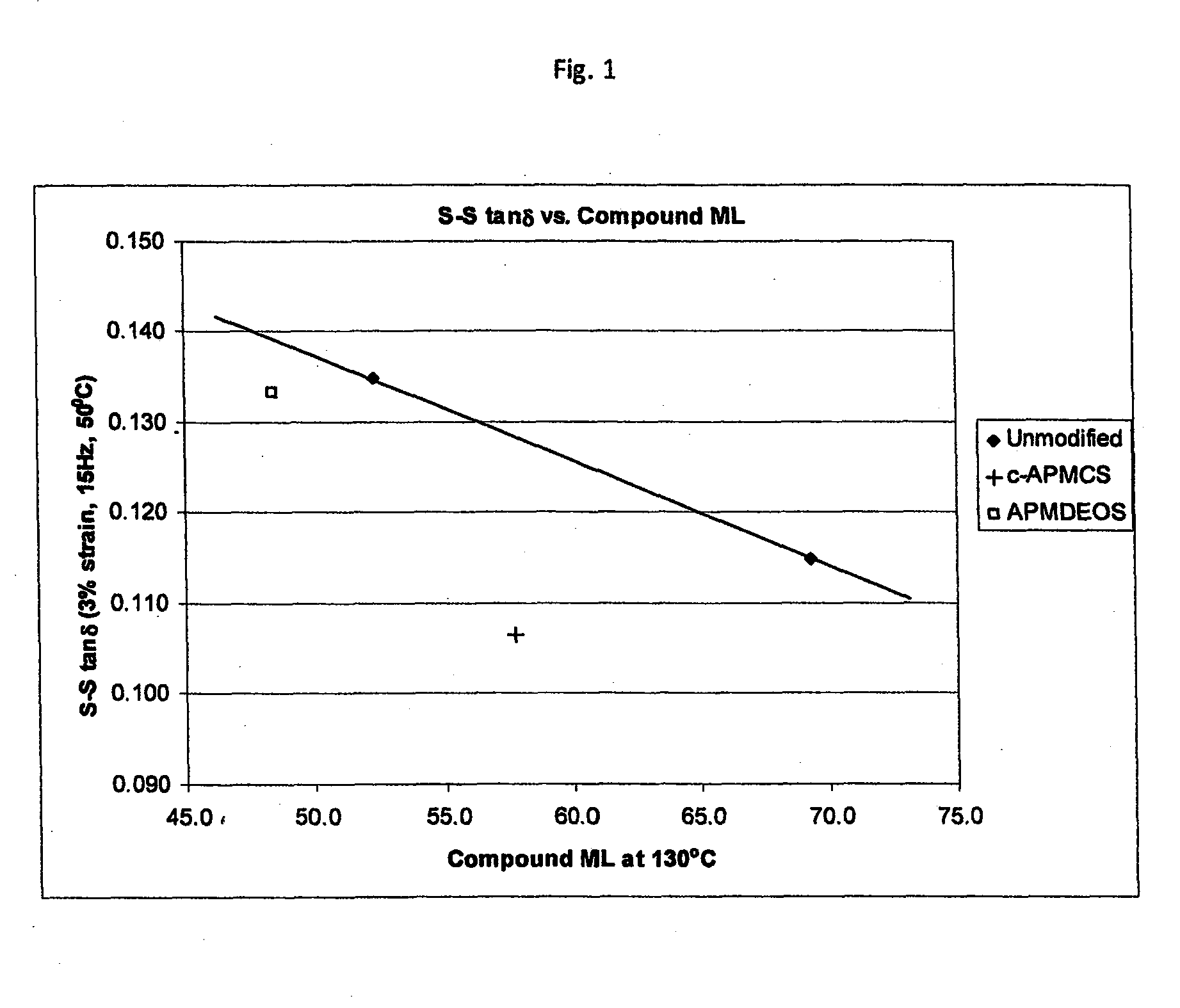

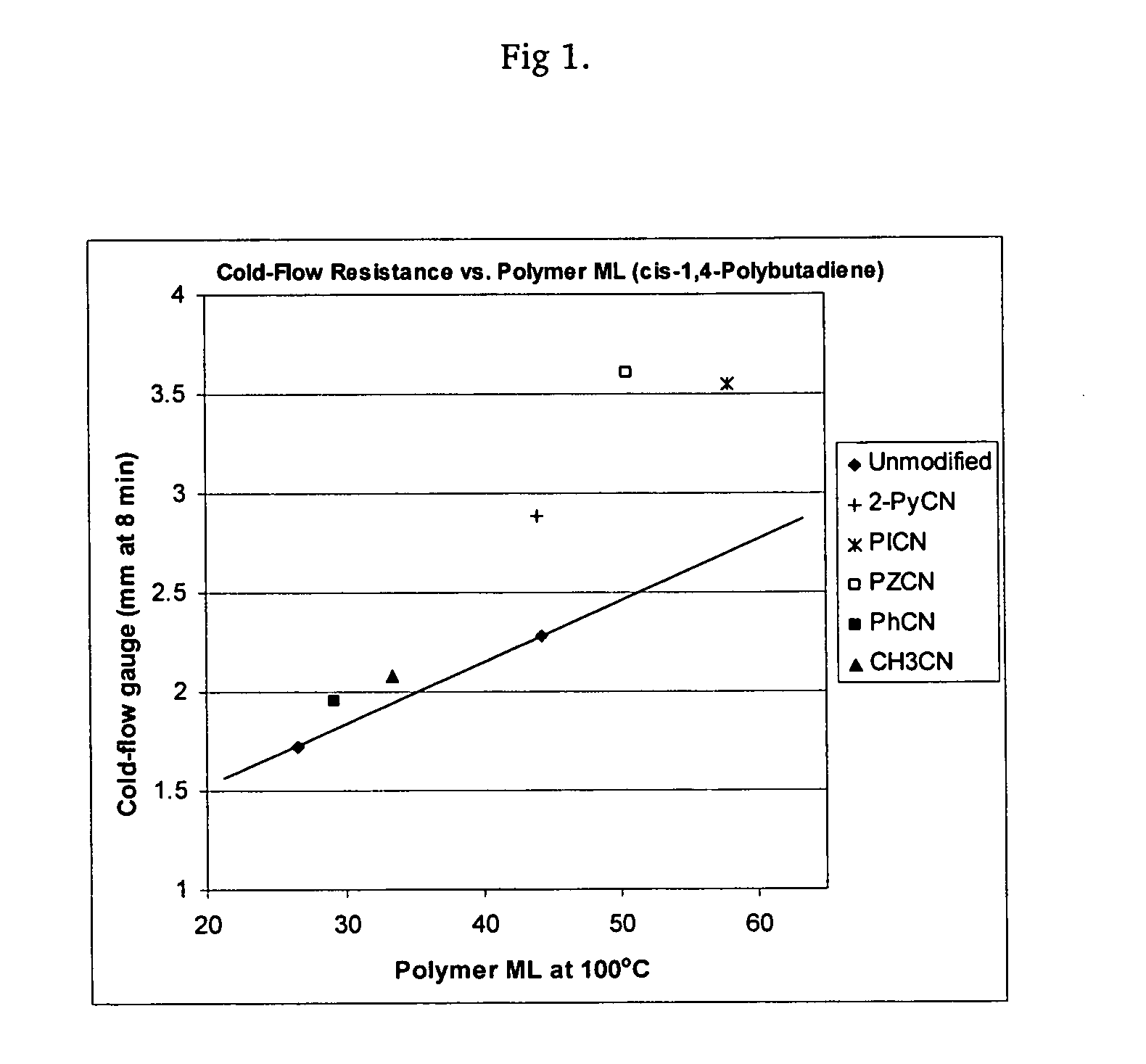

Method for producing functionalized cis-1,4-polydienes having high cis-1,4-linkage content and high functionality

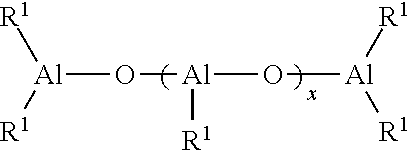

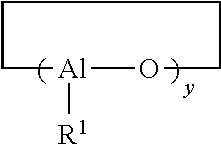

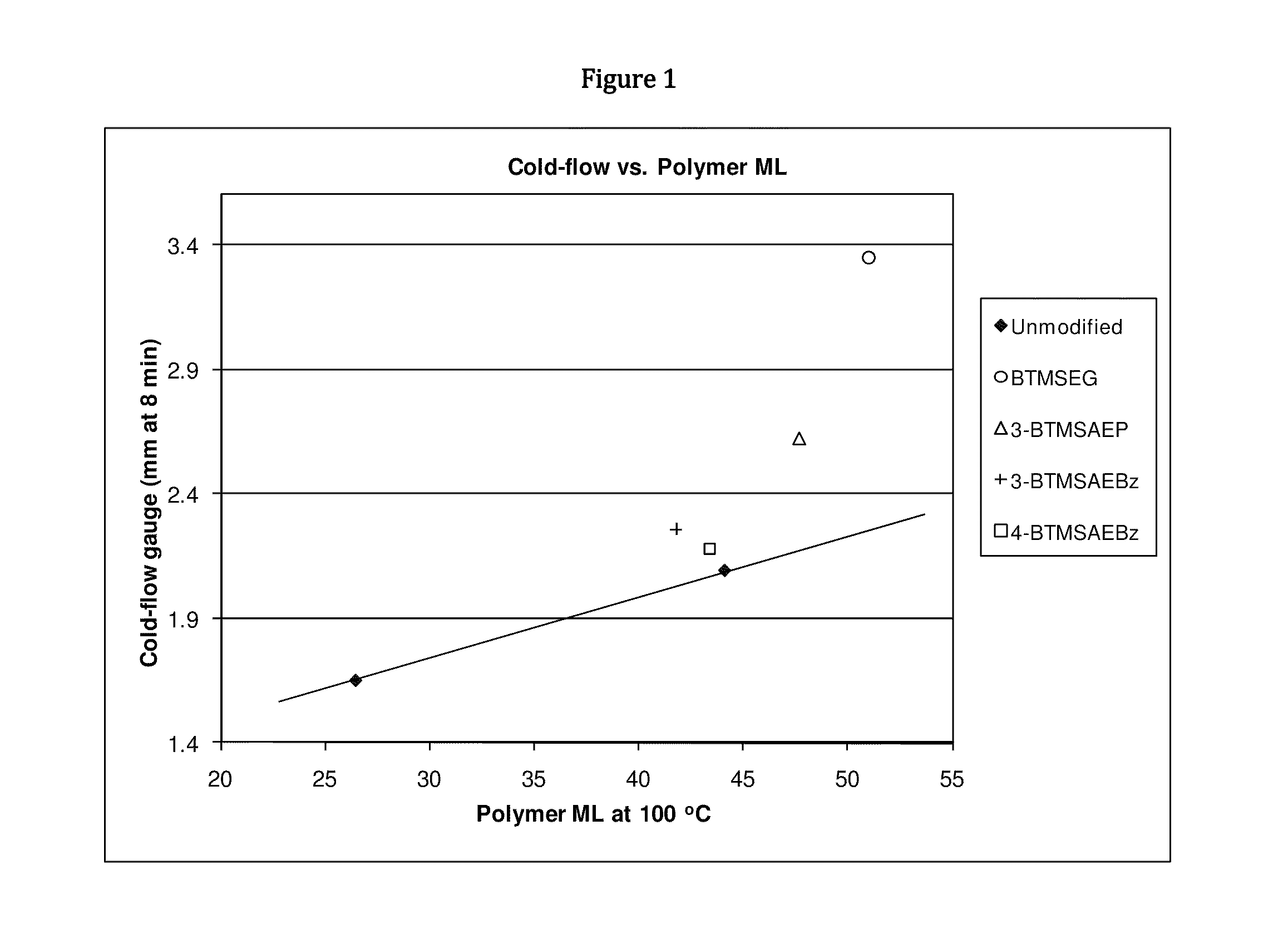

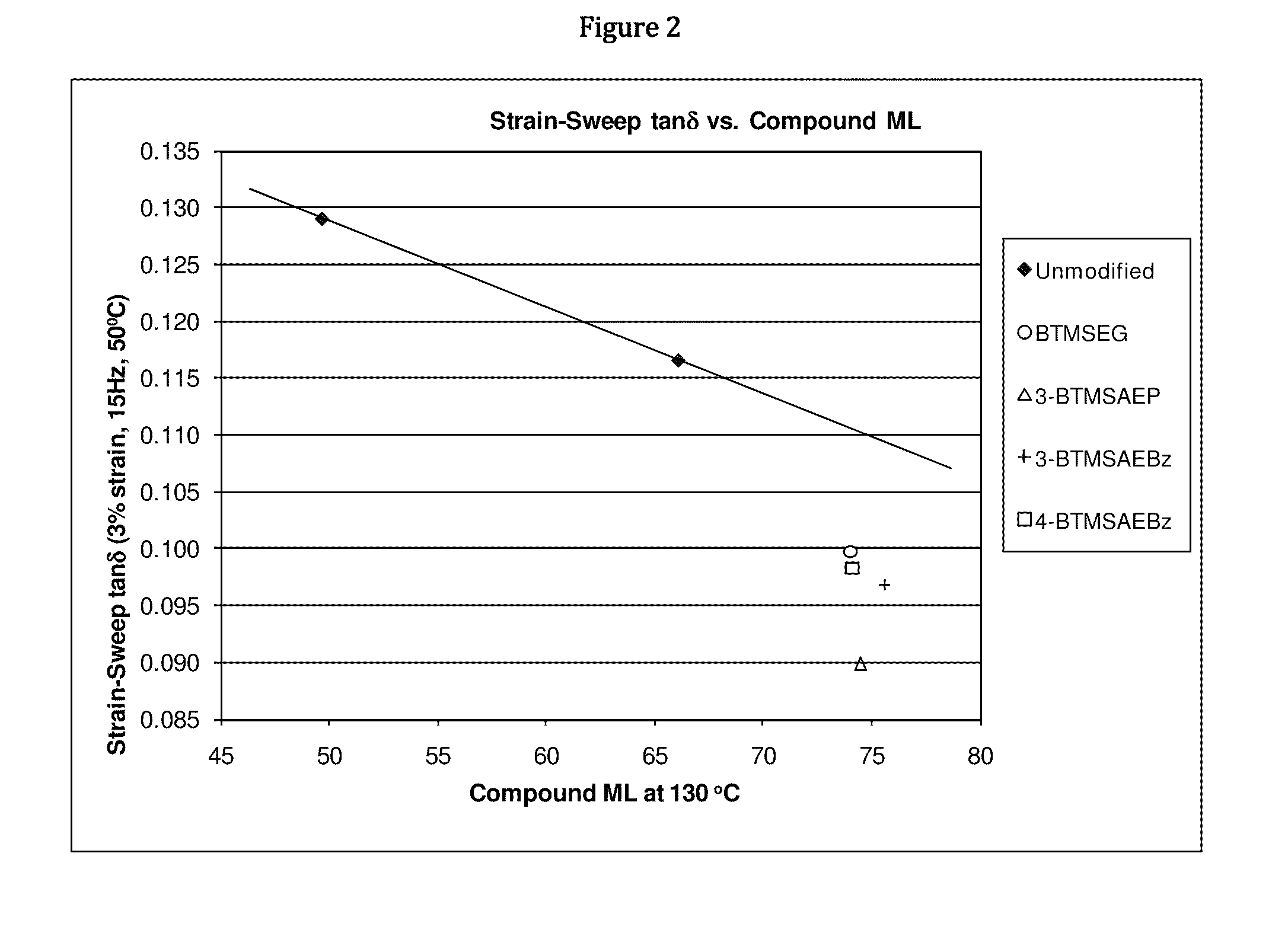

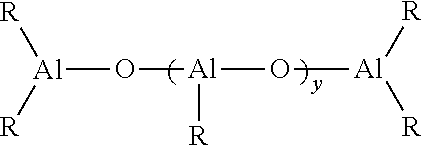

This invention relates to a method for producing functionalized cis-1,4-polydienes having a combination of a high cis-1,4-linkage content and a high functionality, the resulting polymers and the vulcanized products containing the polymers. The functionalized cis-1,4-polydienes of the present invention are produced by a method comprising the steps of: (1) preparing a reactive polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst in the presence of less than 20% by weight of organic solvent based on the total weight of monomer, organic solvent, and resulting polymer, where the lanthanide-based catalyst is the combination of or reaction product of (a) a lanthanide compound, (b) an aluminoxane, (c) an organoaluminum compound other than an aluminoxane, and (d) a halogen-containing compound; and (2) contacting the reactive polymer with a functionalizing agent.

Owner:BRIDGESTONE CORP

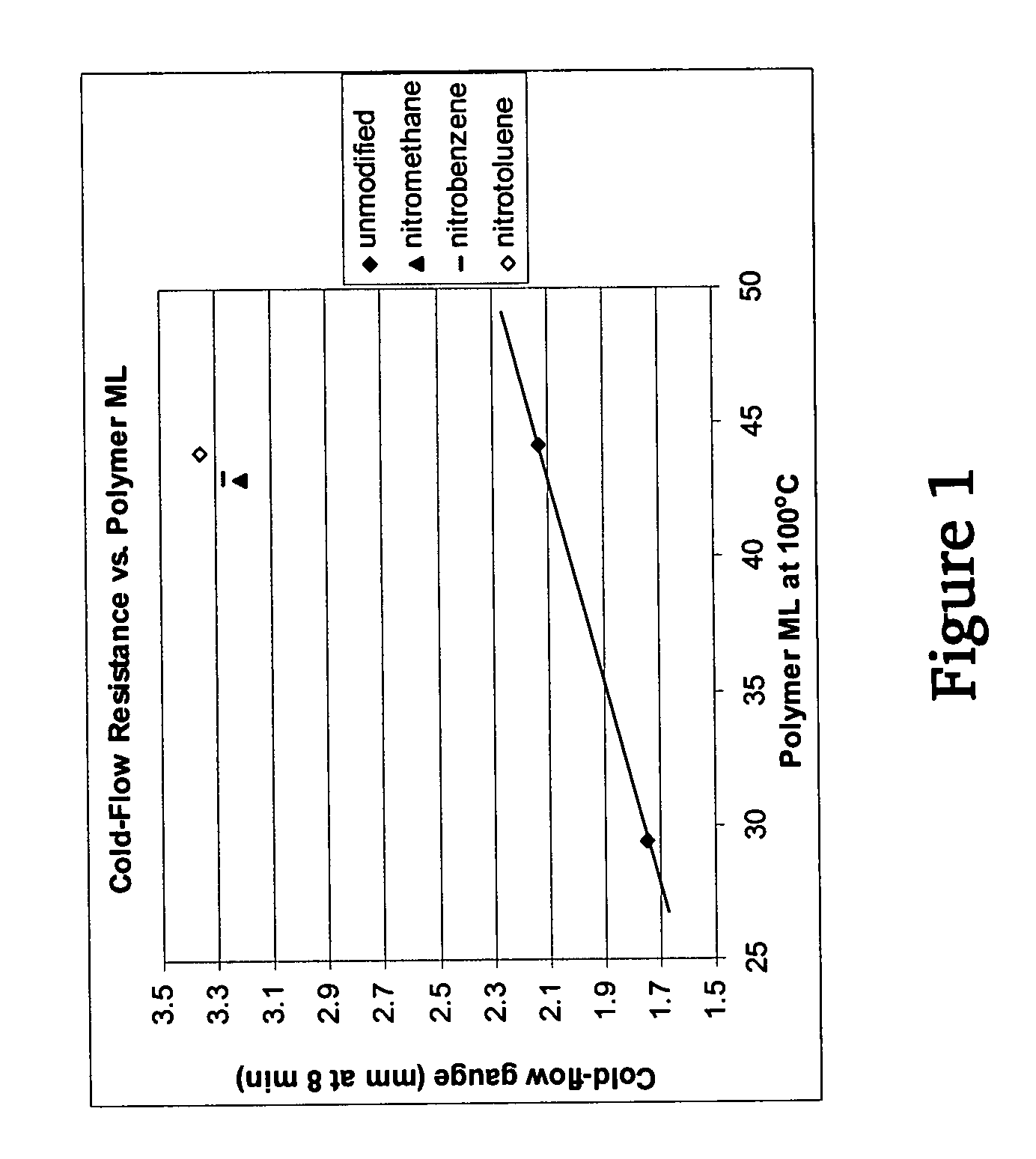

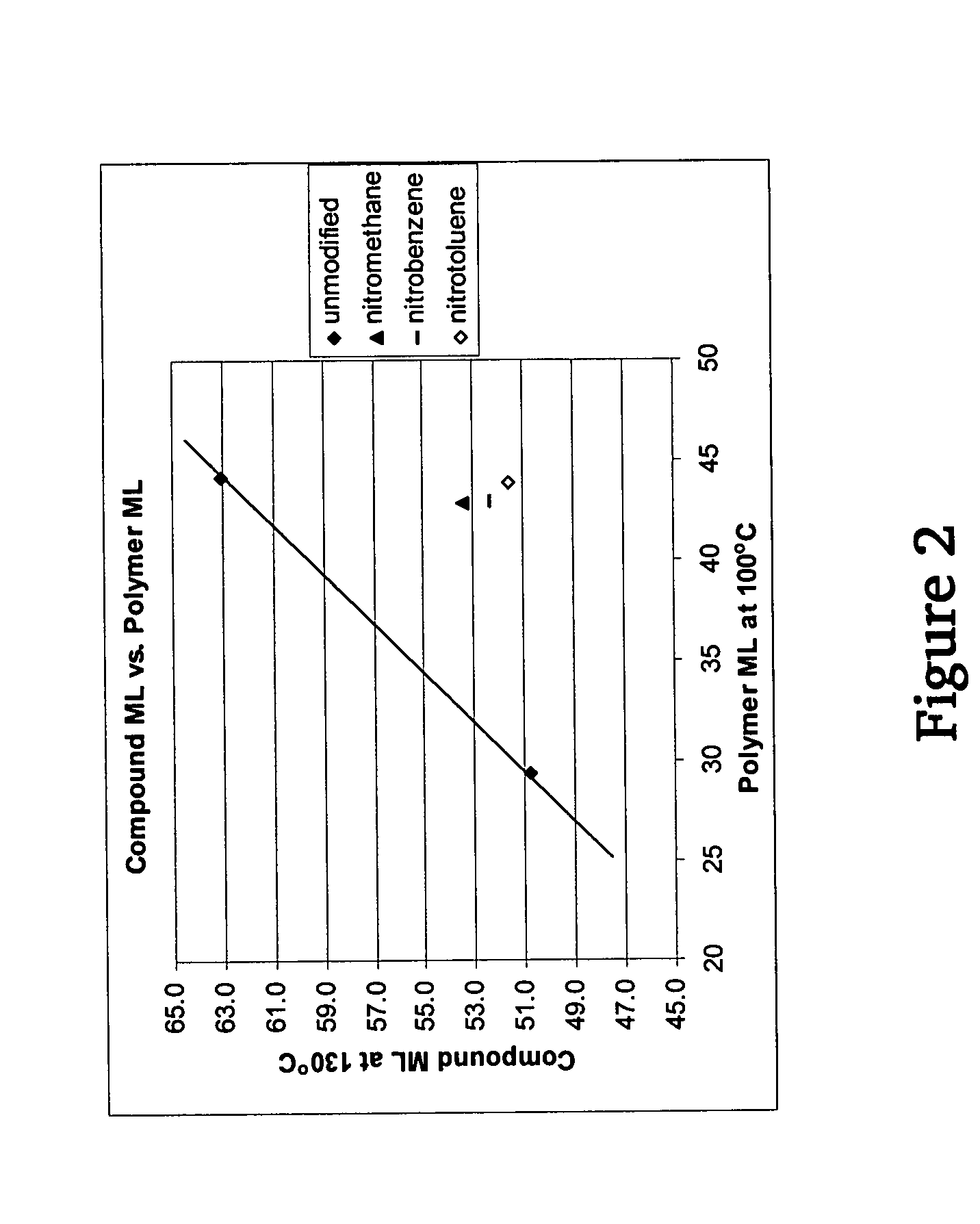

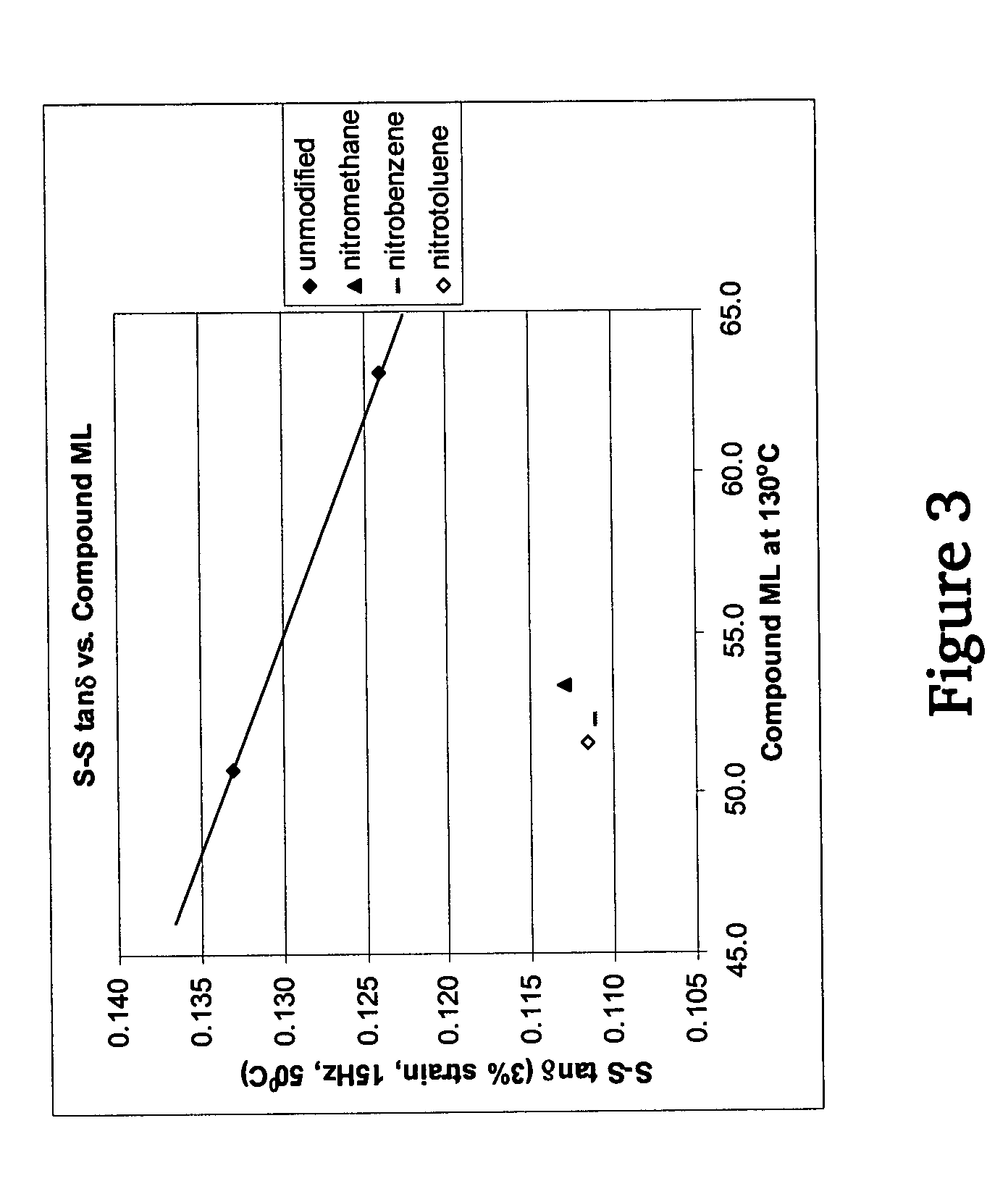

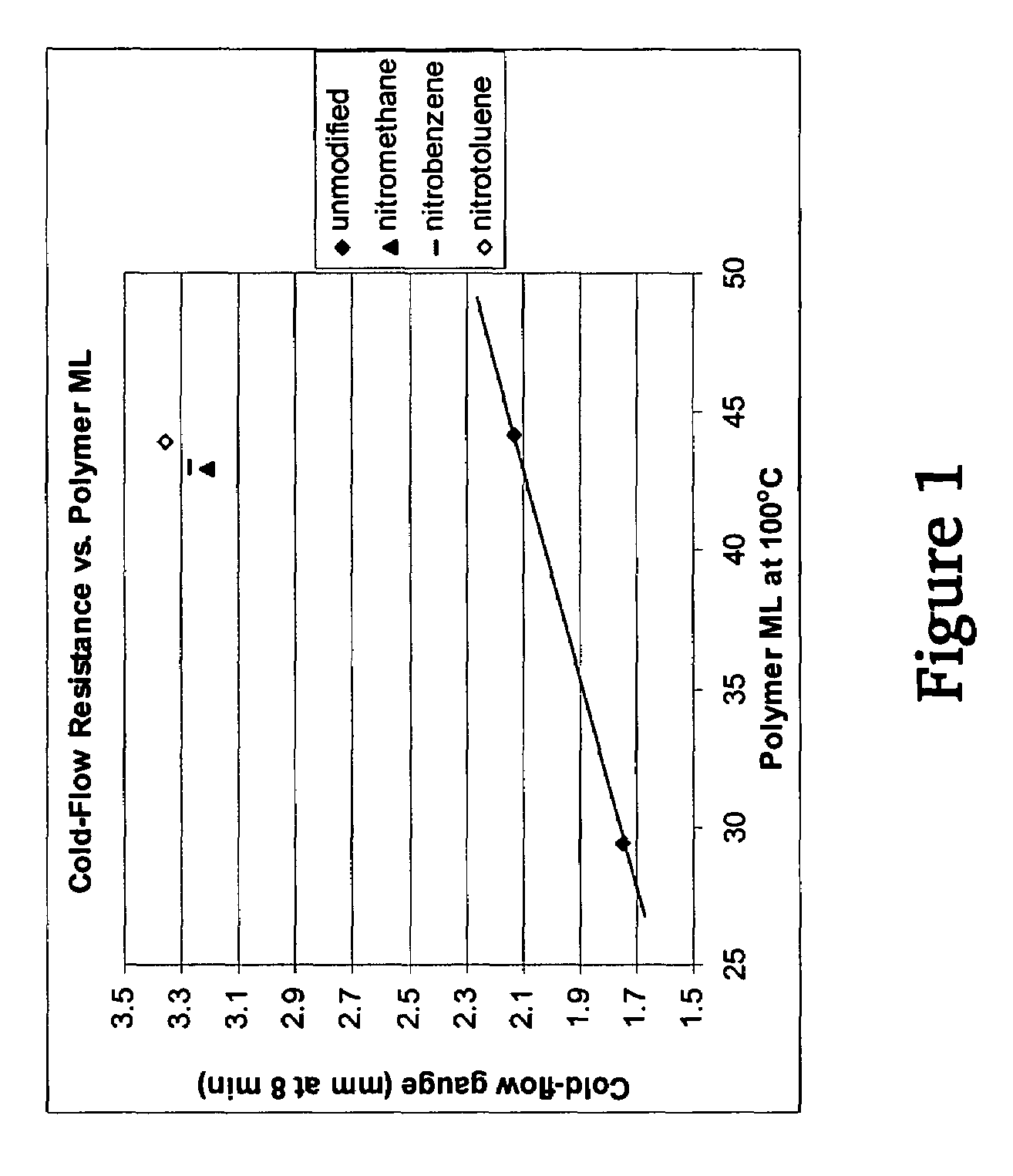

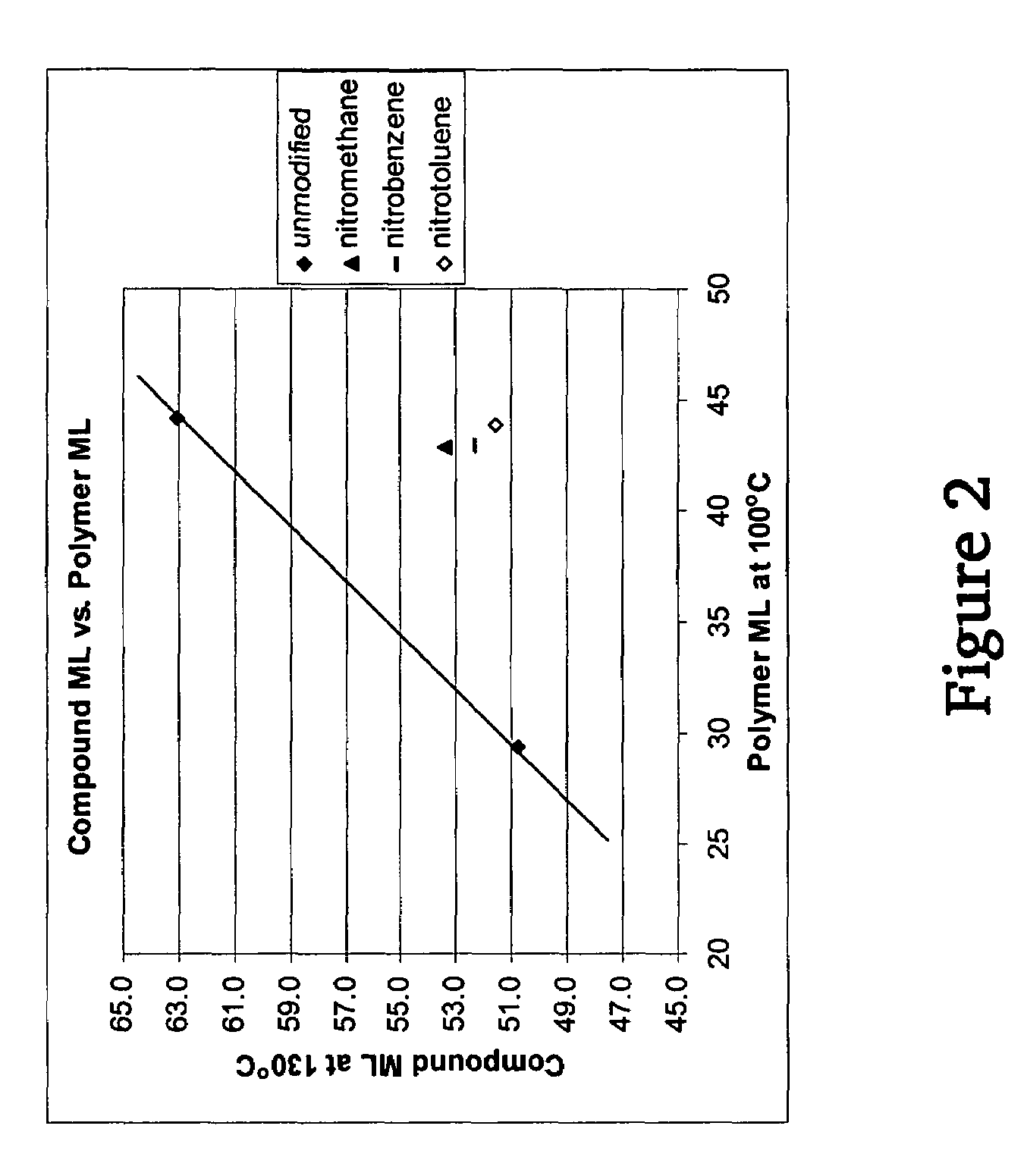

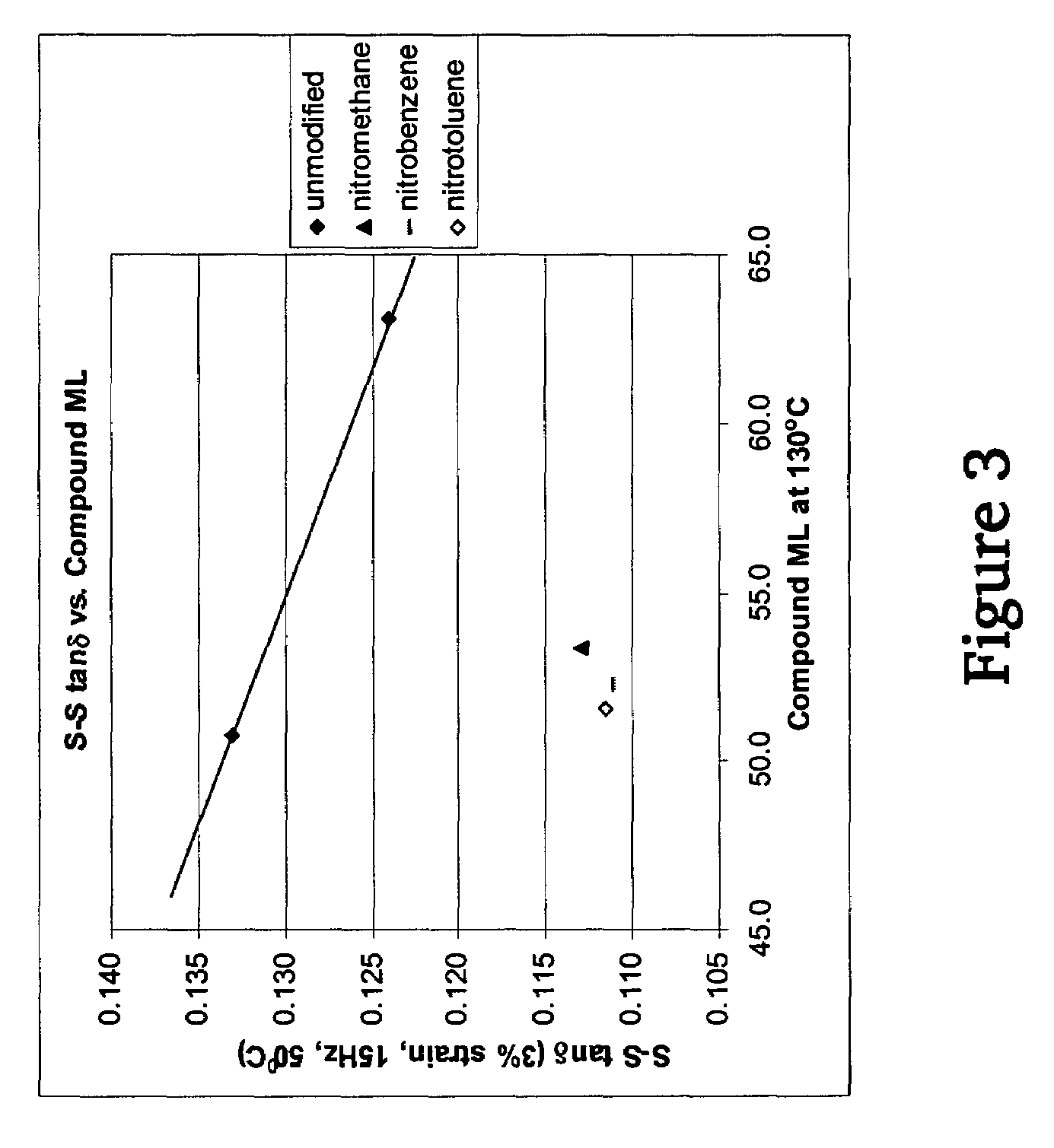

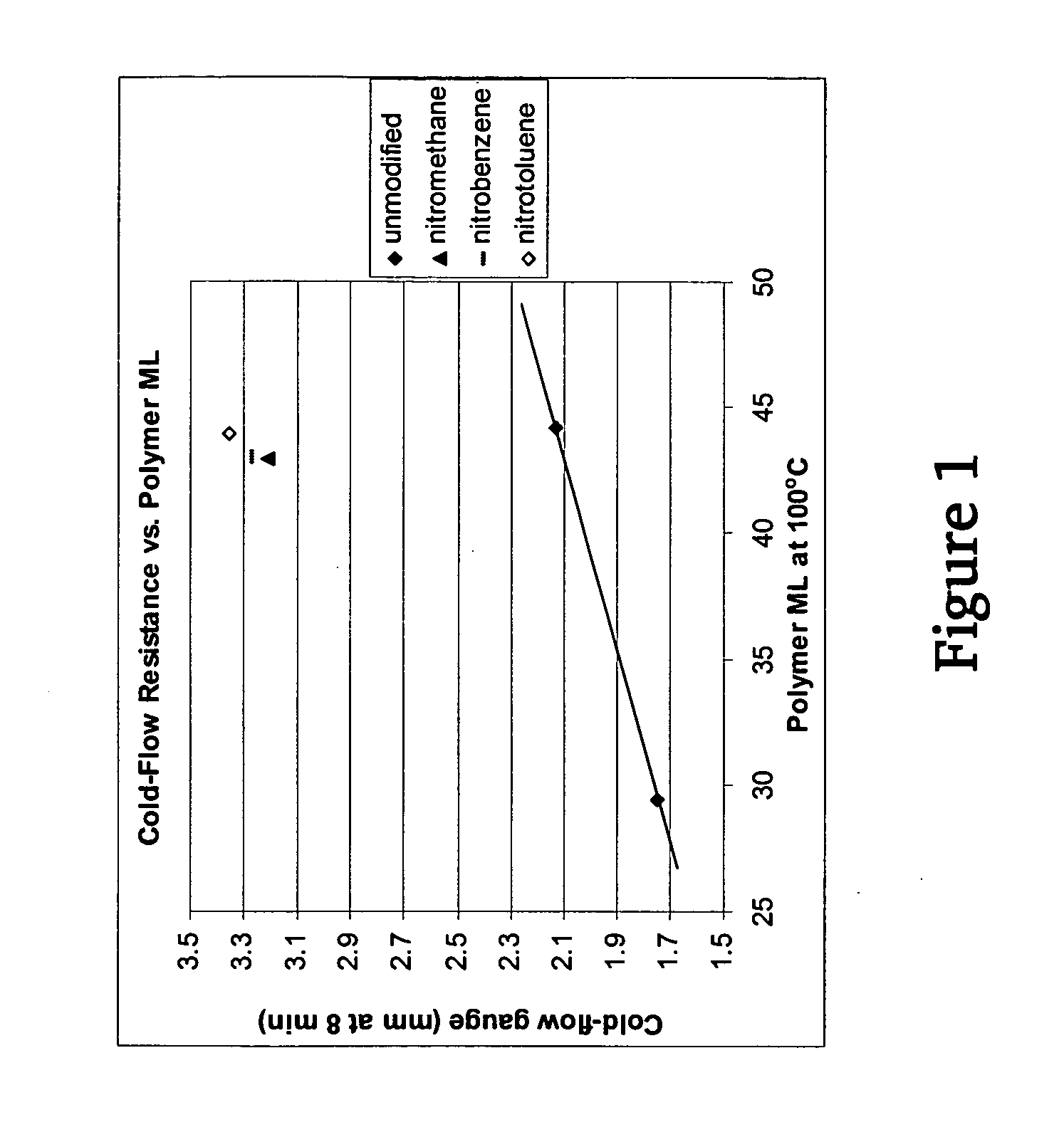

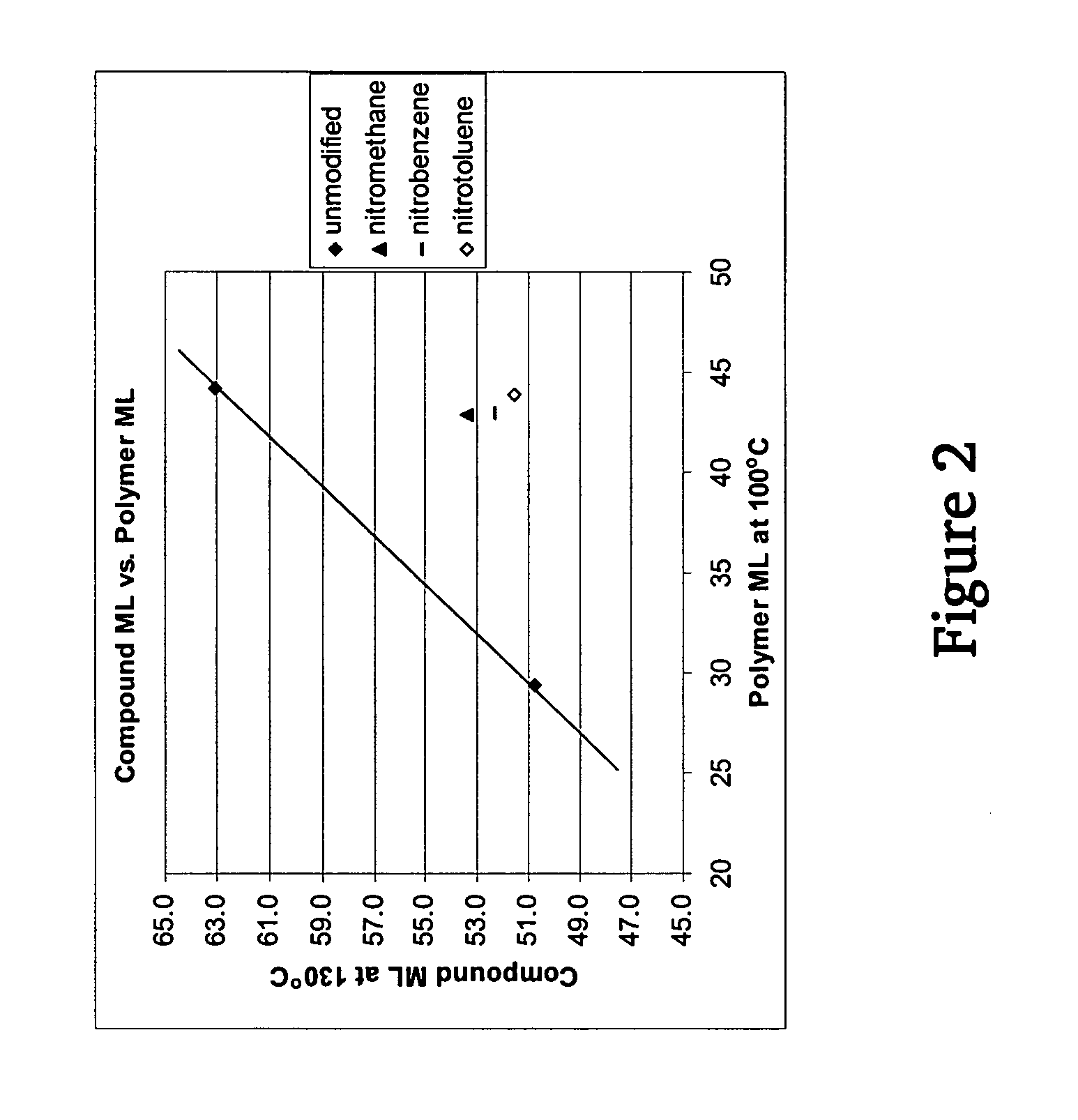

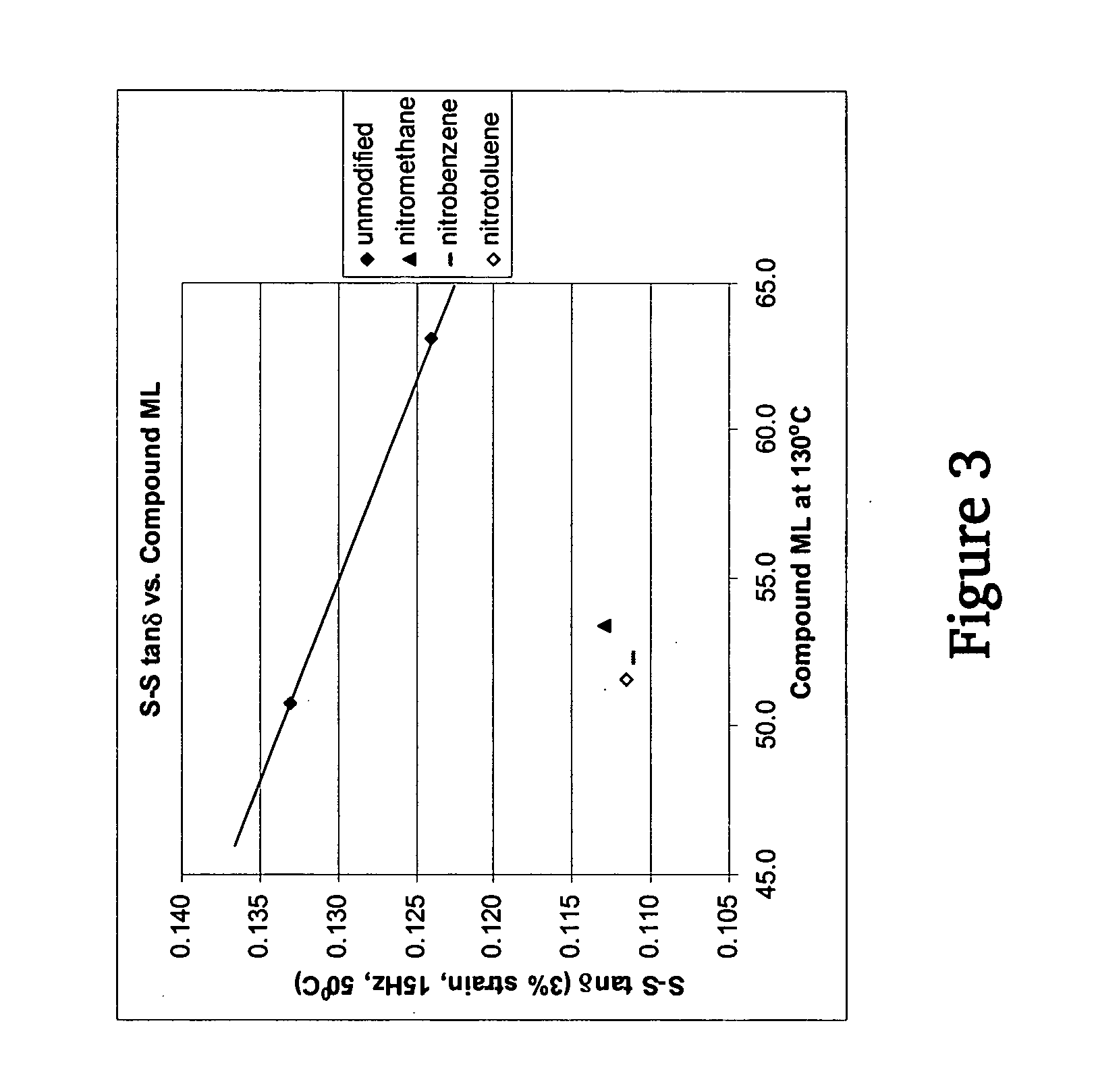

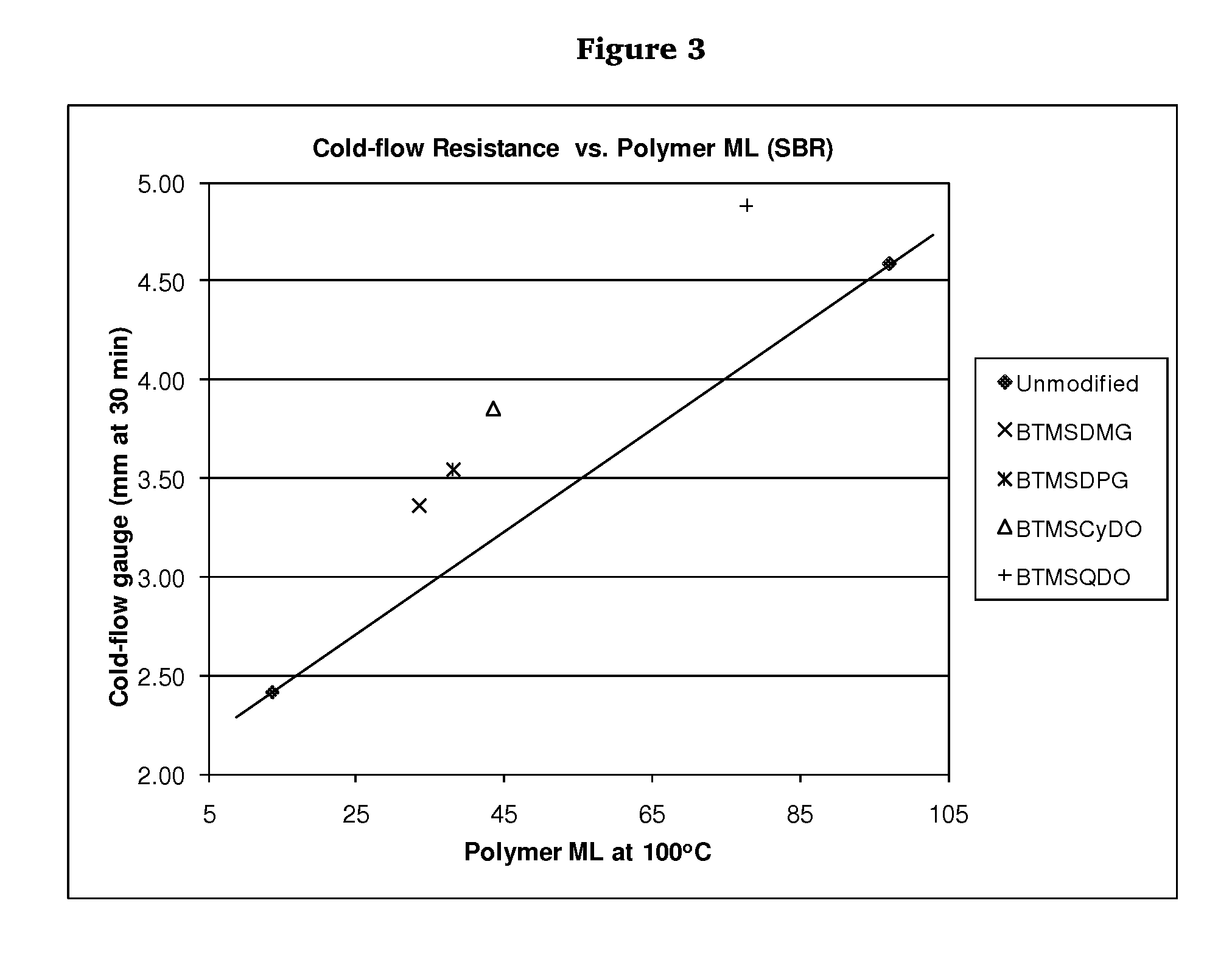

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

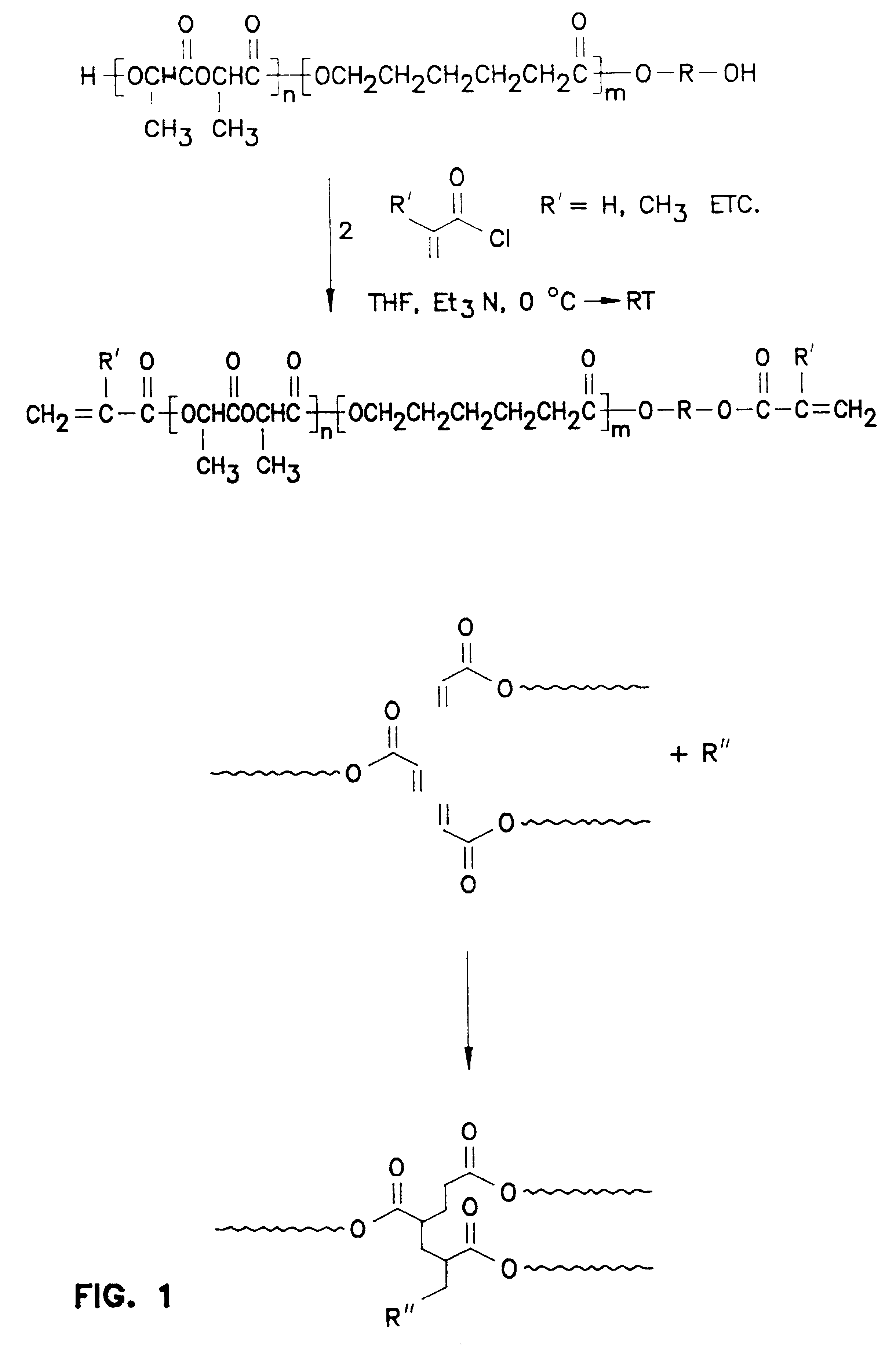

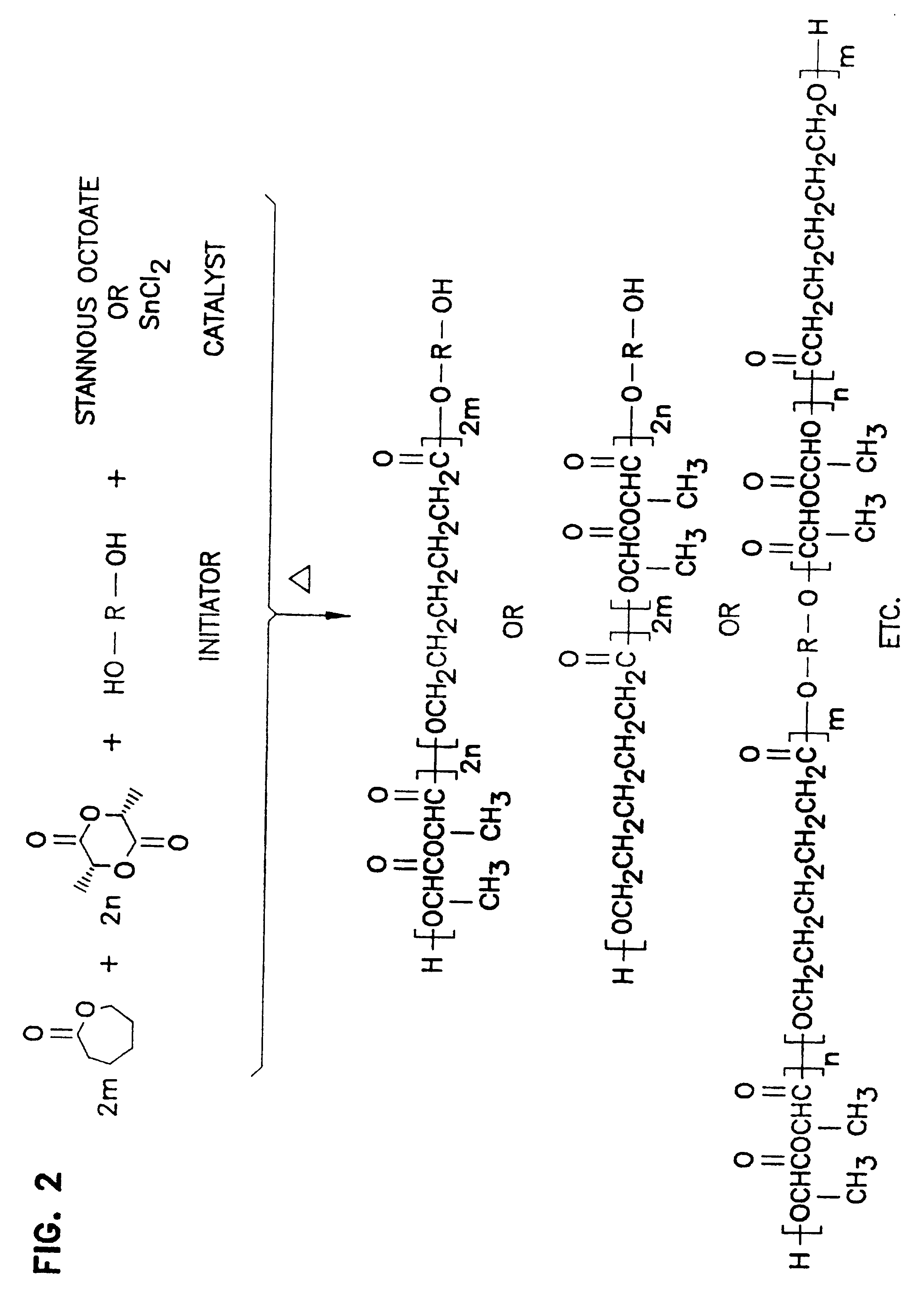

Biodegradable in-situ forming implants and methods of producing the same

A biodegradable polymer is provided for use in providing syringeable, in-situ forming, solid biodegradable implants for animals. The polymer is placed into the animal in liquid form and cures to form the implant in-situ. A thermoplastic system to form said implant comprises the steps of dissolving a non-reactive polymer in biocompatible solvent to form a liquid, placing the liquid within the animal, and allowing the solvent to dissipate to produce the implant. An alternative, thermosetting system comprises mixing together effective amounts of a liquid acrylic ester terminated, biodegradable prepolymer and a curing agent, placing the liquid mixture within an animal and allowing the prepolymer to cure to form the implant. Both systems provide a syringeable, solid biodegradable delivery system by the addition of an effective level of biologically active agent to the liquid before injection into the body.

Owner:ATRIX LAB

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

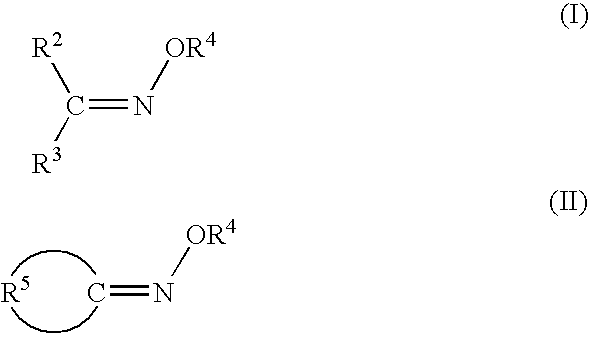

Polymers functionalized with protected oxime compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a protected oxime compound.

Owner:BRIDGESTONE CORP

Method for producing functionalized cis-1,4-polydienes having high cis-1,4-linkage content and high functionality

This invention relates to a method for producing functionalized cis-1,4-polydienes having a combination of a high cis-1,4-linkage content and a high functionality, the resulting polymers and the vulcanized products containing the polymers. The functionalized cis-1,4-polydienes of the present invention are produced by a method comprising the steps of: (1) preparing a reactive polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst in the presence of less than 20% by weight of organic solvent based on the total weight of monomer, organic solvent, and resulting polymer, where the lanthanide-based catalyst is the combination of or reaction product of (a) a lanthanide compound, (b) an aluminoxane, (c) an organoaluminum compound other than an aluminoxane, and (d) a halogen-containing compound; and (2) contacting the reactive polymer with a functionalizing agent.

Owner:BRIDGESTONE CORP

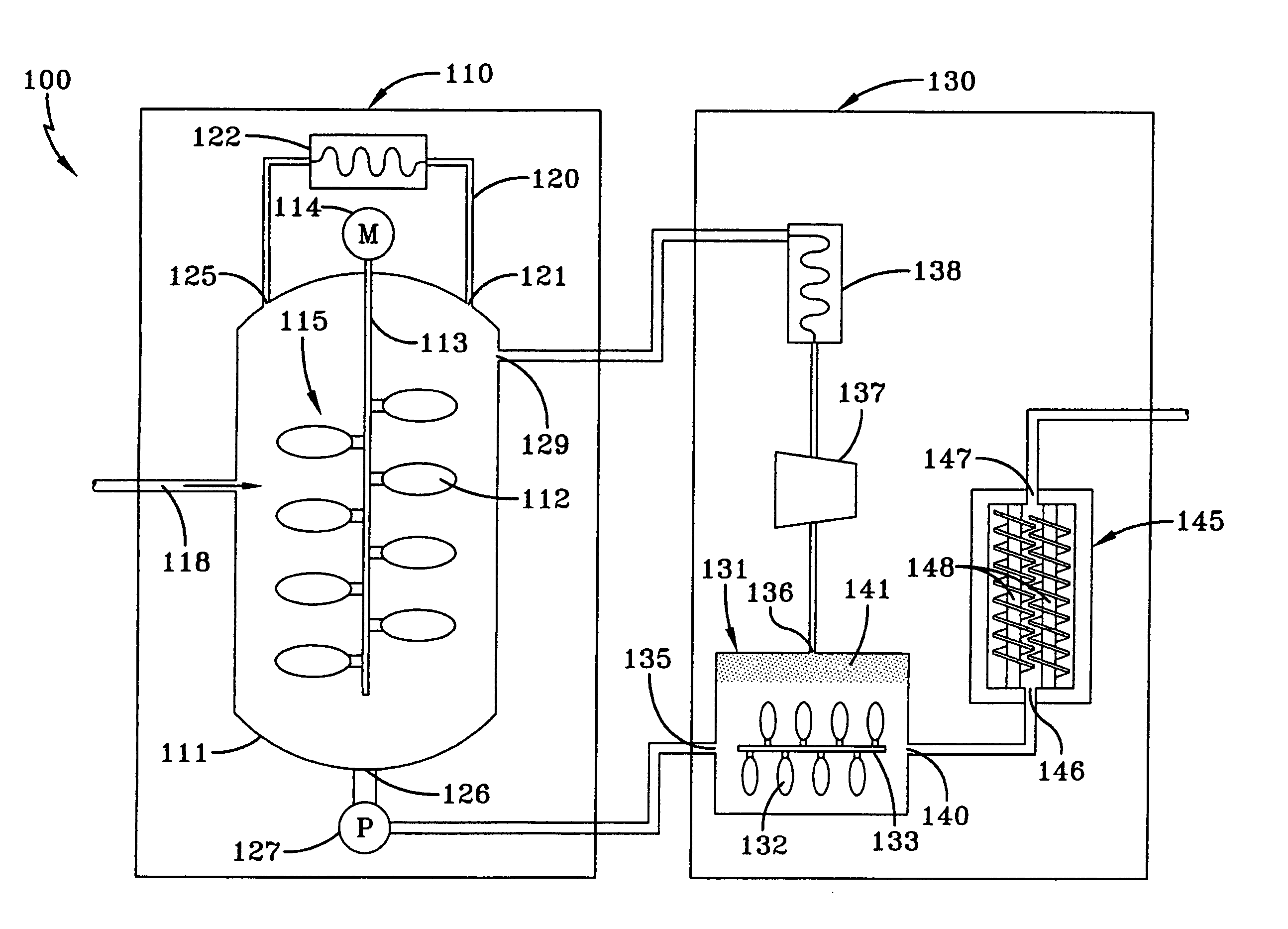

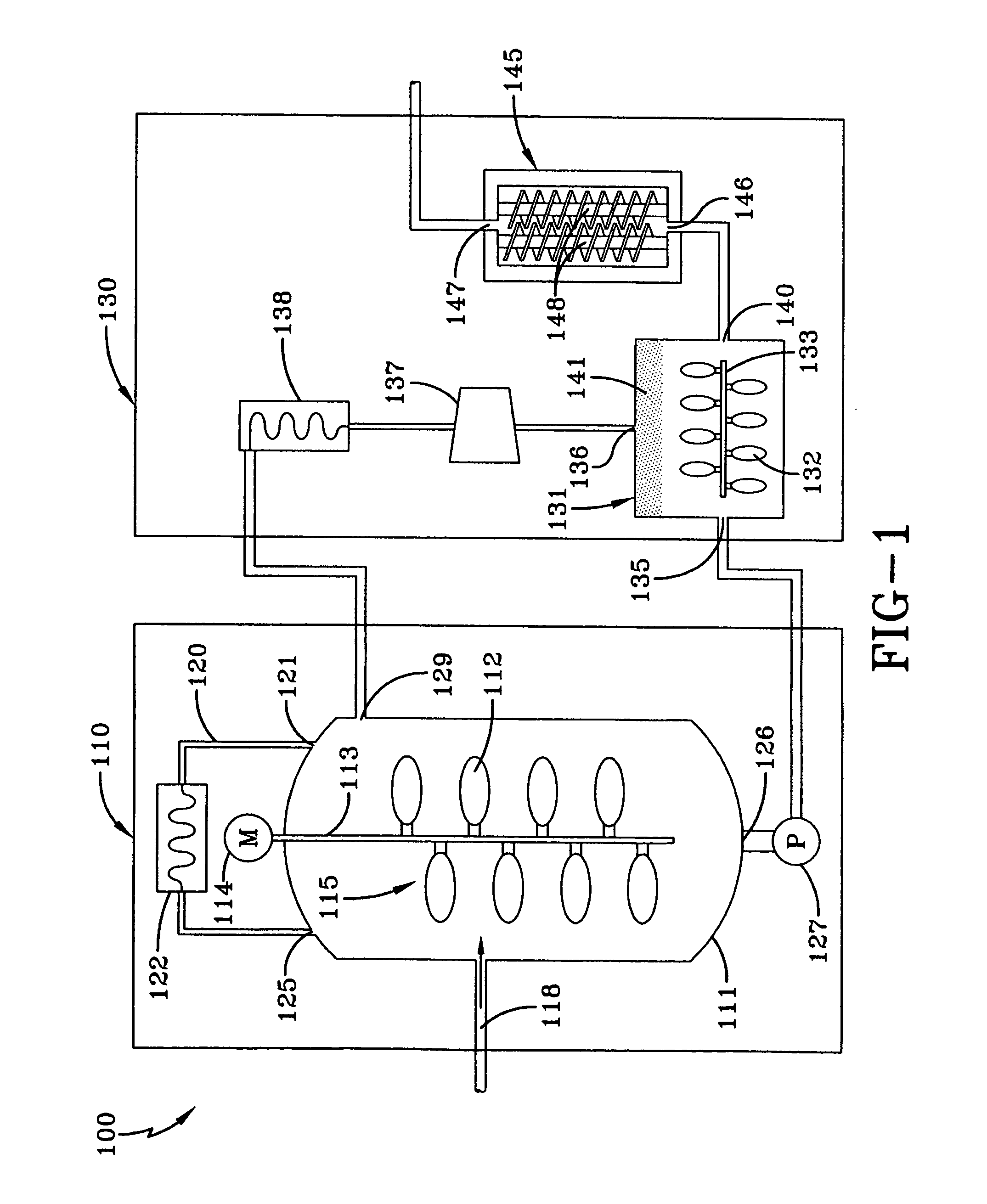

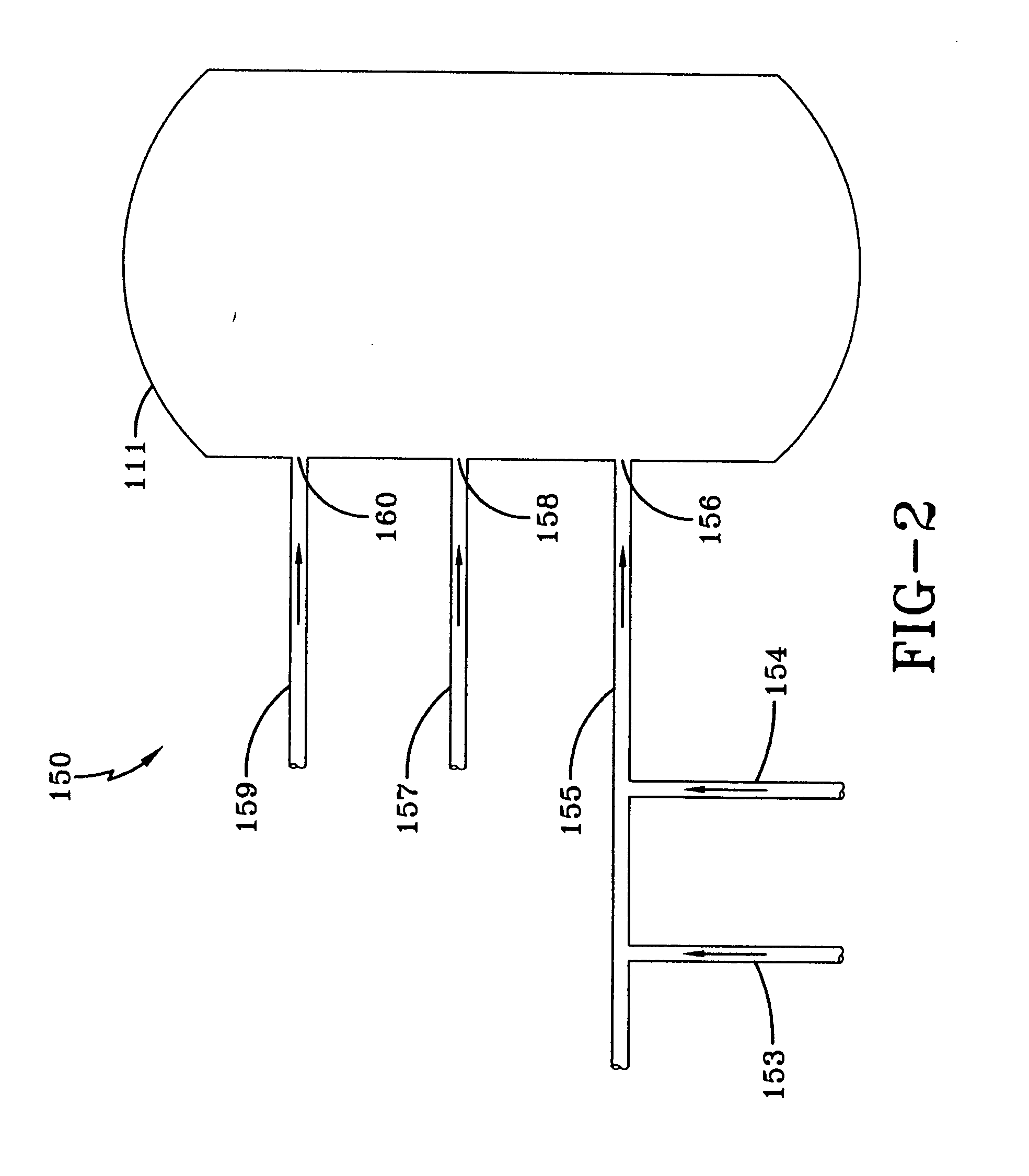

Bulk polymerization process

A method for the continuous production of polydienes, the method comprising the steps of (a) charging a mixture of one or more monomer, catalyst system, and less than 50% weight percent organic solvent based on the total weight of the monomer, catalyst and solvent, into first vessel, (b) polymerizing the monomer to a conversion of up to 20% by weight of the monomer to form a mixture of reactive polymer and monomer, (c) removing the mixture of reactive polymer and monomer from the vessel, and (d) terminating the reactive polymer prior to a total monomer conversion of 25% by weight.

Owner:BRIDGESTONE CORP

Low odor binders curable at room temperature

InactiveUS20050045294A1Easy to storePromote hydrolysisNon-fibrous pulp additionNatural cellulose pulp/paperPolymer sciencePaper towel

Topically-applied binder materials for imparting wet strength to soft, absorbent paper sheets, such as are useful as household paper towels and the like, include an epoxy-reactive polymer, such as a carboxyl-functional polymer, and an epoxy-functional polymer. These binder materials can be cured at ambient temperature over a period of days and do not impart objectionable odor to final product when wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Functionalized polymers and methods for their manufacture

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing monomer with a coordination catalyst to form a reactive polymer; and (ii) reacting the reactive polymer with a carboxylic or thiocarboxylic ester containing a silylated amino group.

Owner:BRIDGESTONE CORP

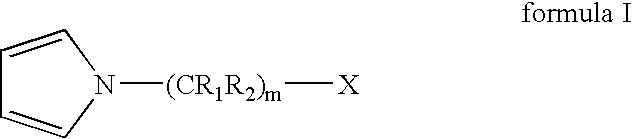

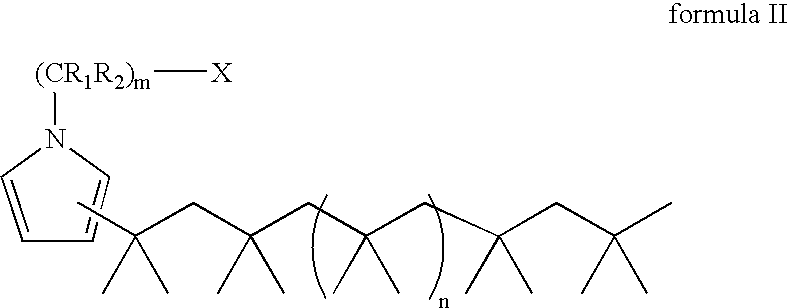

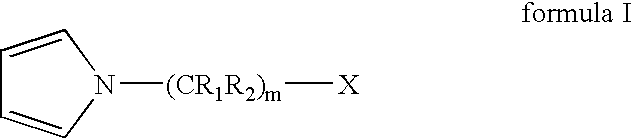

Living and quasiliving cationic telechelic polymers quenched by N-substituted pyrrole and methods for their preparation

InactiveUS6969744B2Organic compounds purification/separation/stabilisationHydrocarbon purification/separationActive polymerChloride

Disclosed is a method of preparing terminally functionalized telechelic polymers using a cationic living polymer product or a terminal tert-chloride chain end of a carbocationic quasiliving polymer product, which comprises quenching the polymer product with an N-substituted pyrrole to thereby functionalize the N-substituted pyrrole at the terminal reactive polymer chain end(s). Also disclosed are the terminal functionalized polyisobuyl N-substituted pyrrole compounds where the polyisobutyl group is substituted at the 2 and 3 position of the N-substituted pyrrole.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

Low odor binders curable at room temperature

InactiveUS20050045295A1Easy to storePromote hydrolysisNon-fibrous pulp additionNatural cellulose pulp/paperPolymer sciencePaper towel

Topically-applied binder materials for imparting wet strength to soft, absorbent paper sheets, such as are useful as household paper towels and the like, include an epoxy-reactive polymer, such as a carboxyl-functional polymer, and an epoxy-functional polymer. These binder materials can be cured at ambient temperature over a period of days and do not impart objectionable odor to final product when wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

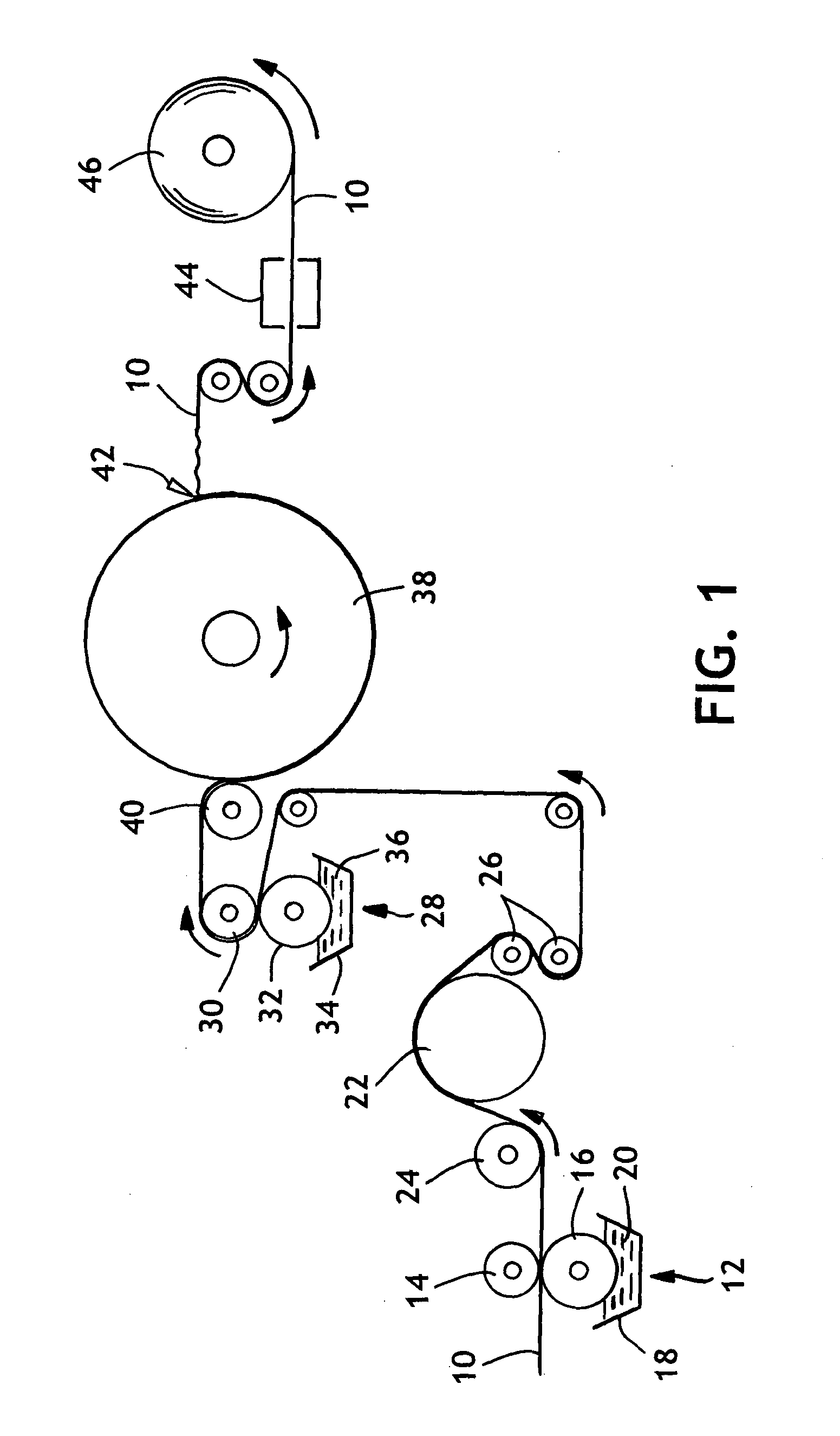

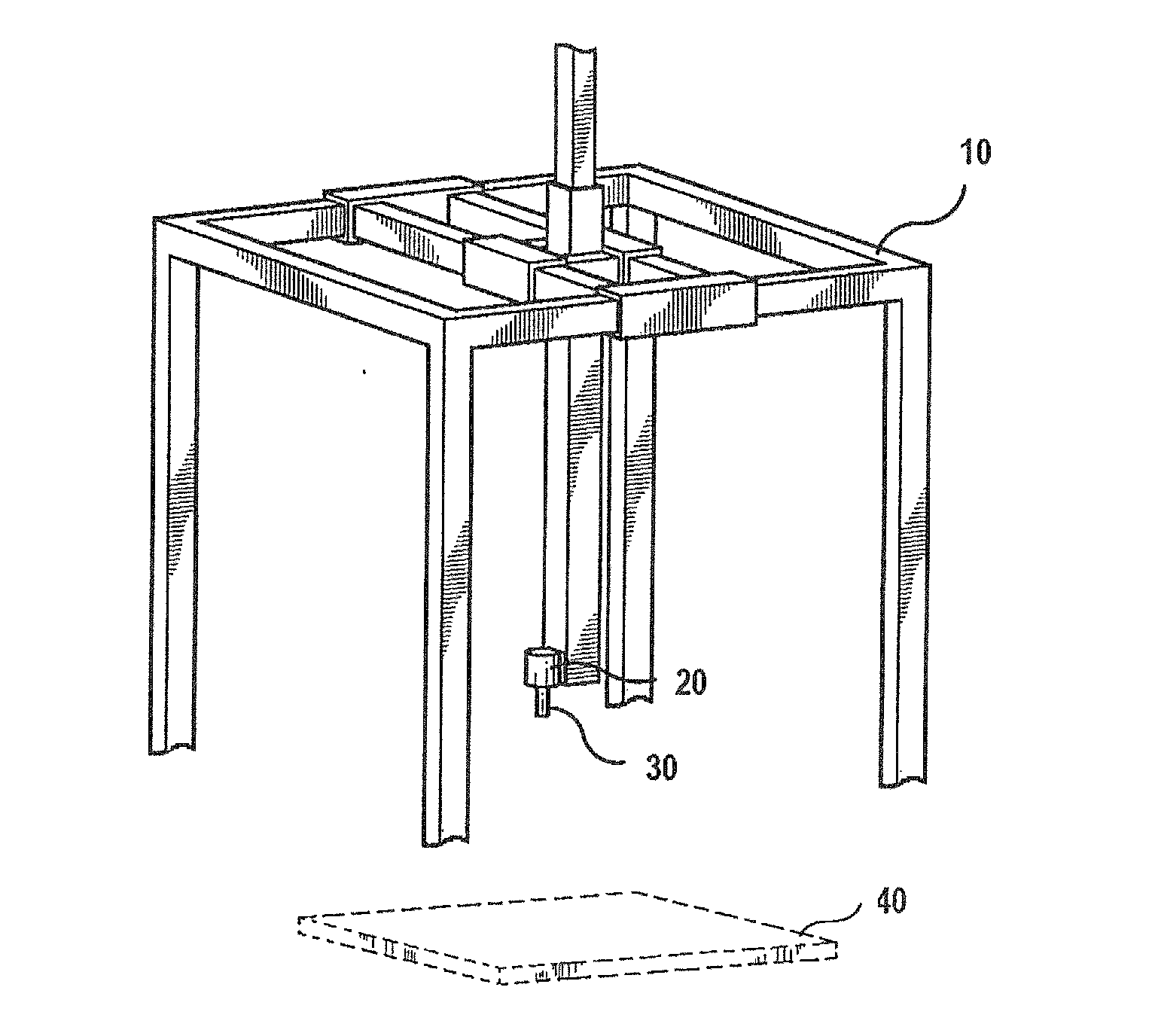

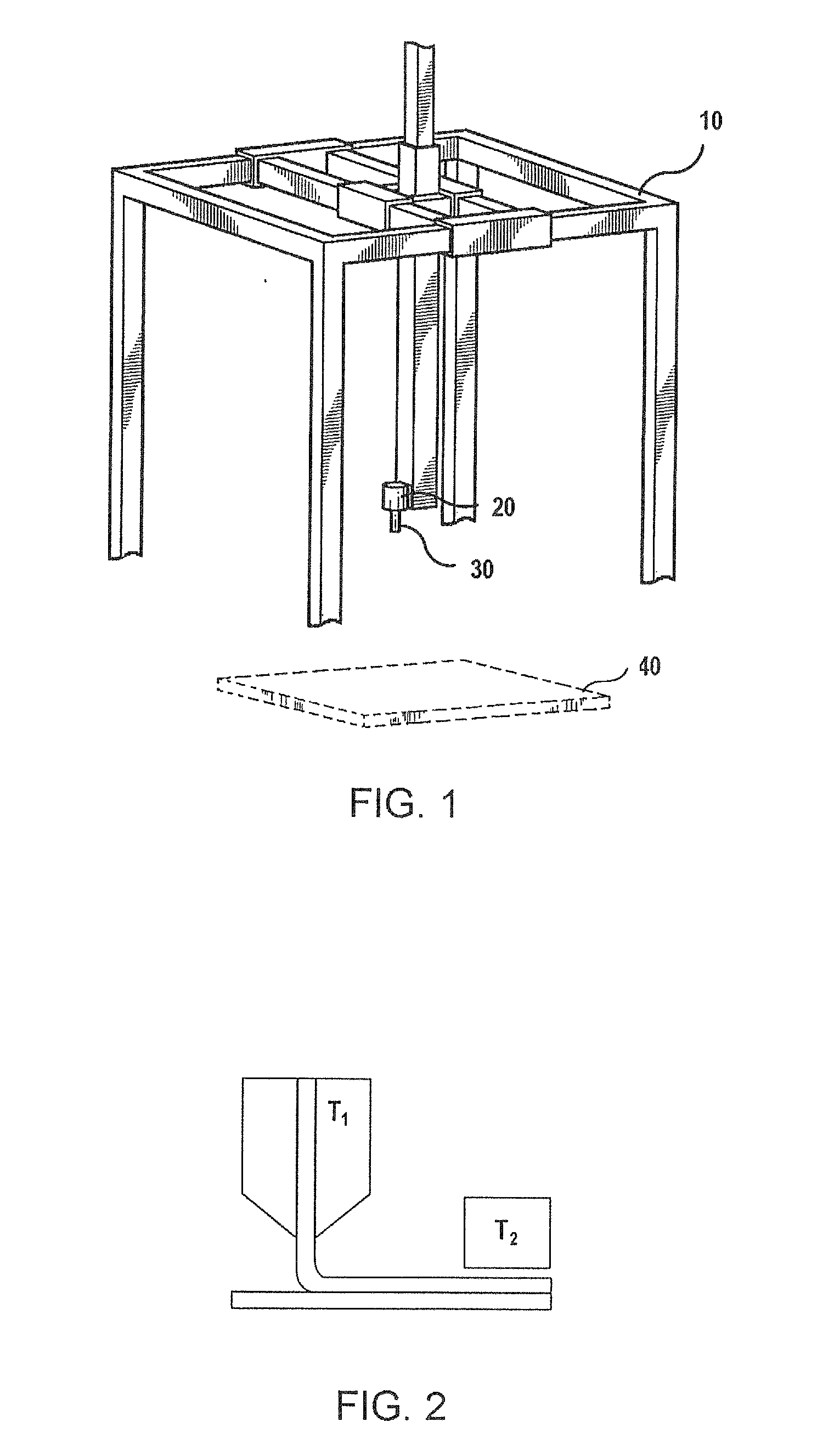

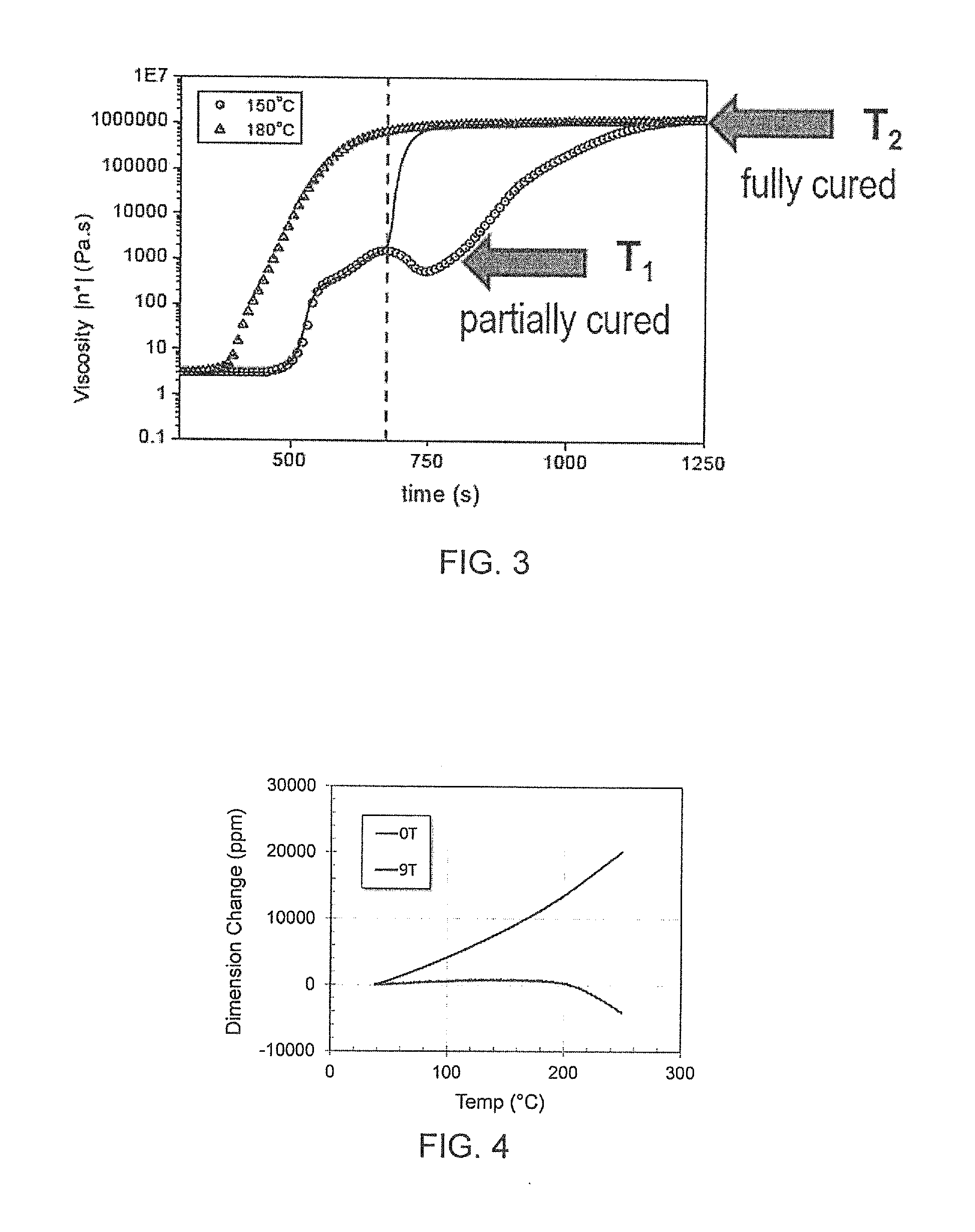

Reactive polymer fused deposition manufacturing

ActiveUS20150291833A1Improve bindingHigh mechanical strengthAdditive manufacturing apparatusElectric discharge heatingEpoxyCross-link

Methods and compositions for additive manufacturing that include reactive or thermosetting polymers, such as urethanes and epoxies. The polymers are melted, partially cross-linked prior to the depositing, deposited to form a component object, solidified, and fully cross-linked. These polymers form networks of chemical bonds that span the deposited layers. Application of a directional electromagnetic field can be applied to aromatic polymers after deposition to align the polymers for improved bonding between the deposited layers.

Owner:UT BATTELLE LLC

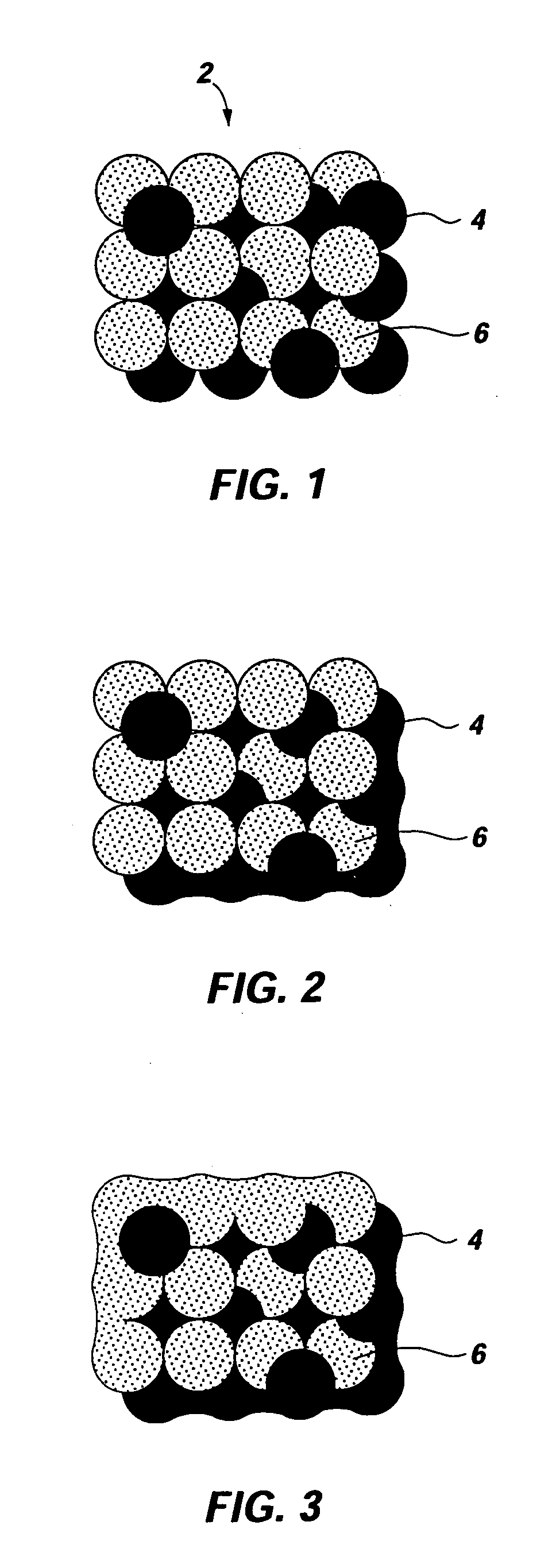

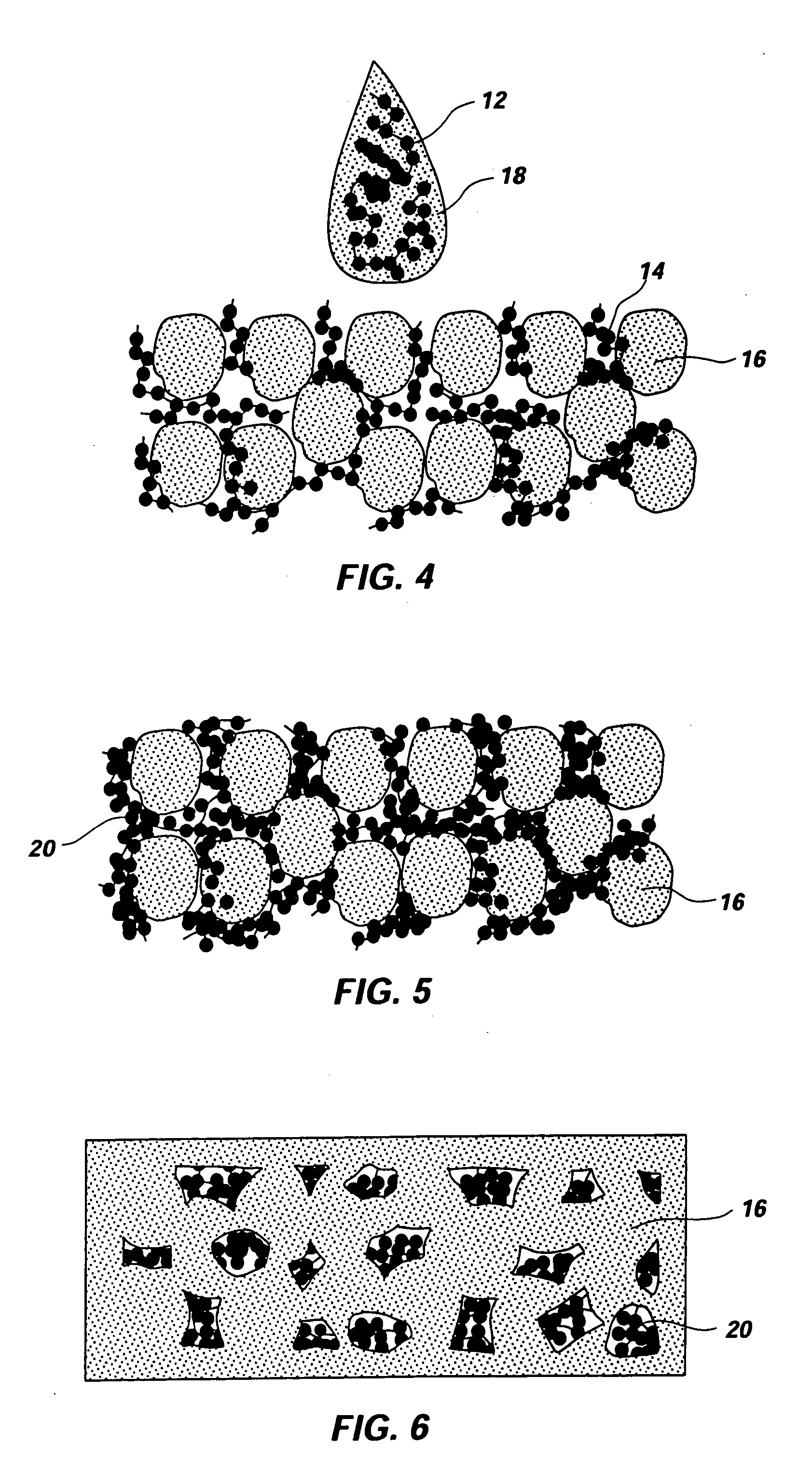

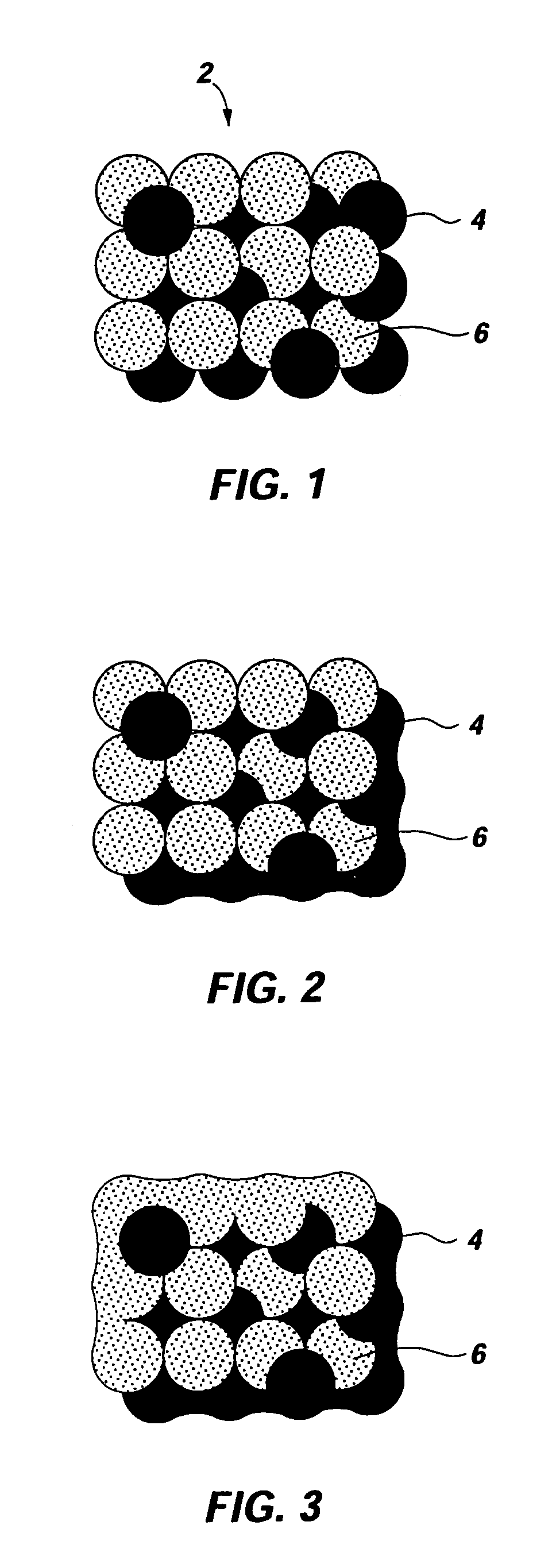

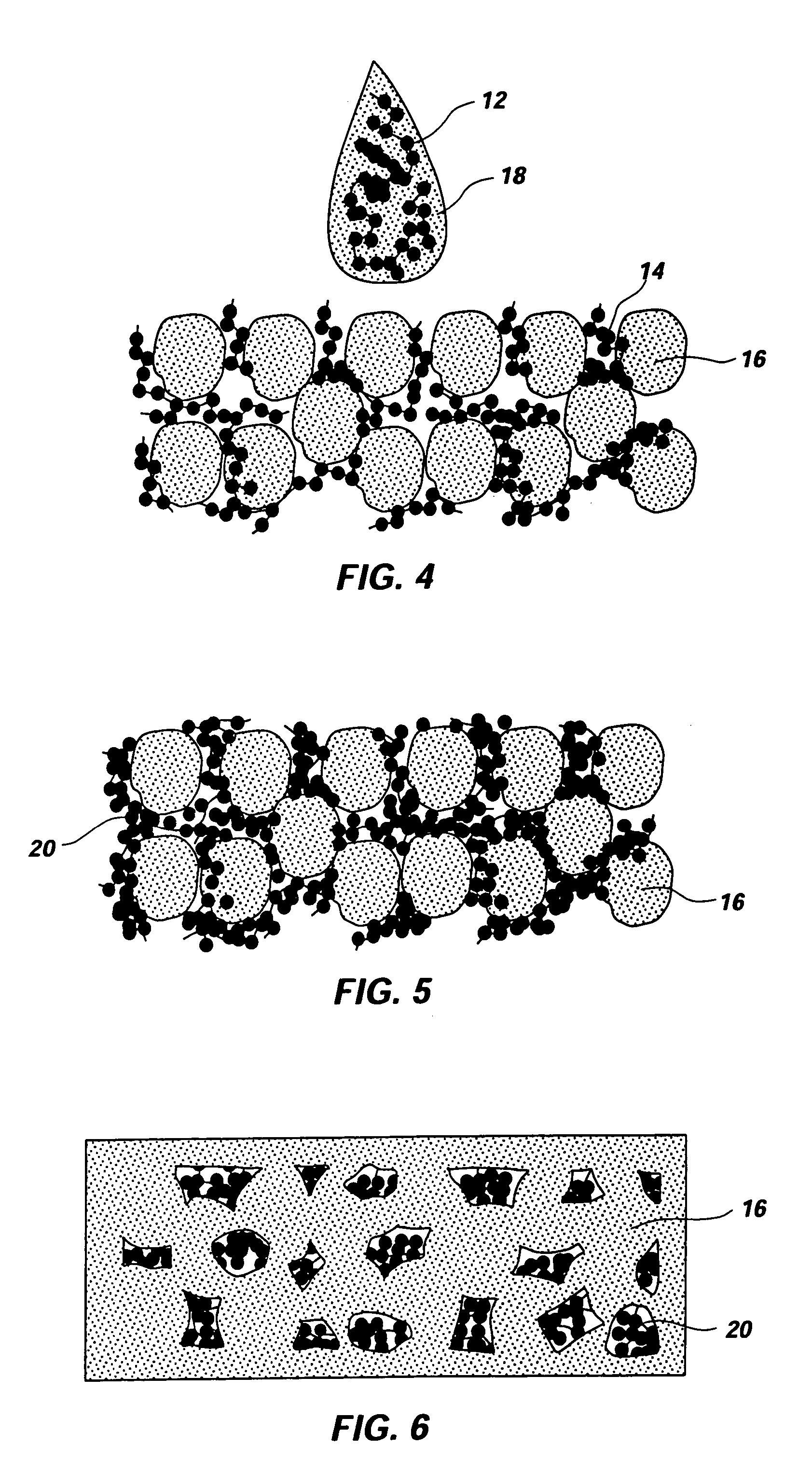

Polymer systems with reactive and fusible properties for solid freeform fabrication

ActiveUS20050080191A1Additive manufacturing apparatusAdditive mnaufacturing with solid and fluidPolymer scienceGlass transition

A powder system for use in solid freeform fabrication. The powder system includes at least one polymer having reactive properties and fusible properties. The at least one polymer is reactive with a liquid binder and is fusible at a temperature above the melting point or glass transition temperature of the at least one polymer. The at least one polymer may be a single co-polymer having at least one reactive portion and at least one fusible portion or may be a mixture of polymers including at least one reactive polymer and at least one fusible polymer. A method of forming an object by solid freeform fabrication is also disclosed.

Owner:HEWLETT PACKARD DEV CO LP

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

Polymer systems with reactive and fusible properties for solid freeform fabrication

InactiveUS7365129B2Additive manufacturing apparatusAdditive mnaufacturing with solid and fluidGlass transitionPolymer chemistry

A powder system for use in solid freeform fabrication. The powder system includes at least one polymer having reactive properties and fusible properties. The at least one polymer is reactive with a liquid binder and is fusible at a temperature above the melting point or glass transition temperature of the at least one polymer. The at least one polymer may be a single co-polymer having at least one reactive portion and at least one fusible portion or may be a mixture of polymers including at least one reactive polymer and at least one fusible polymer. A method of forming an object by solid freeform fabrication is also disclosed.

Owner:HEWLETT PACKARD DEV CO LP

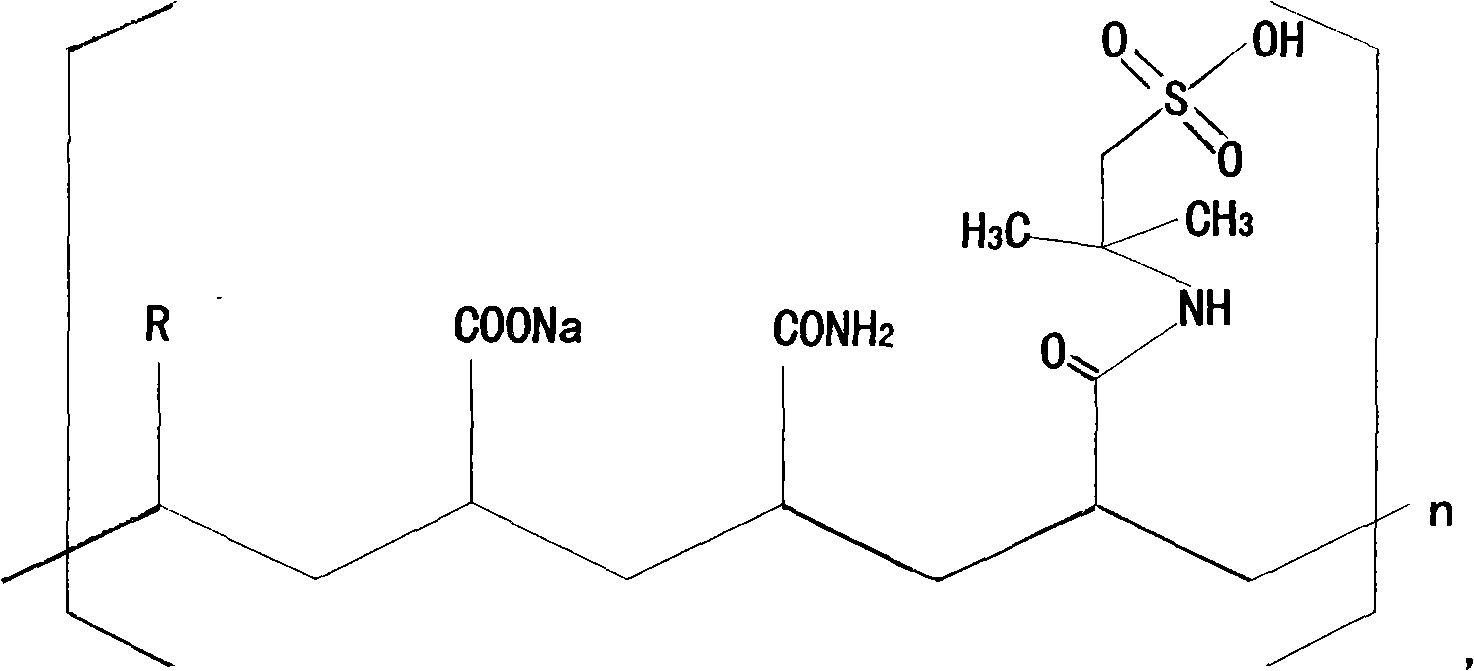

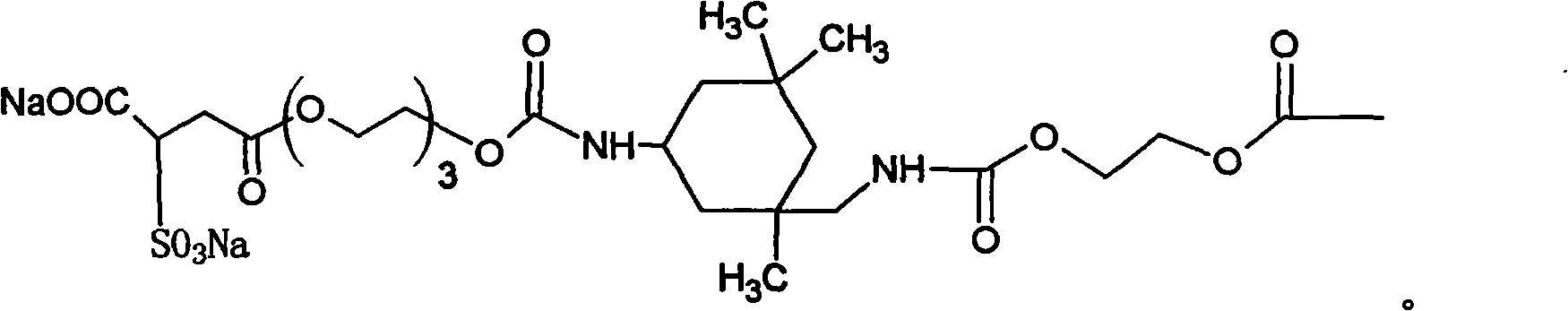

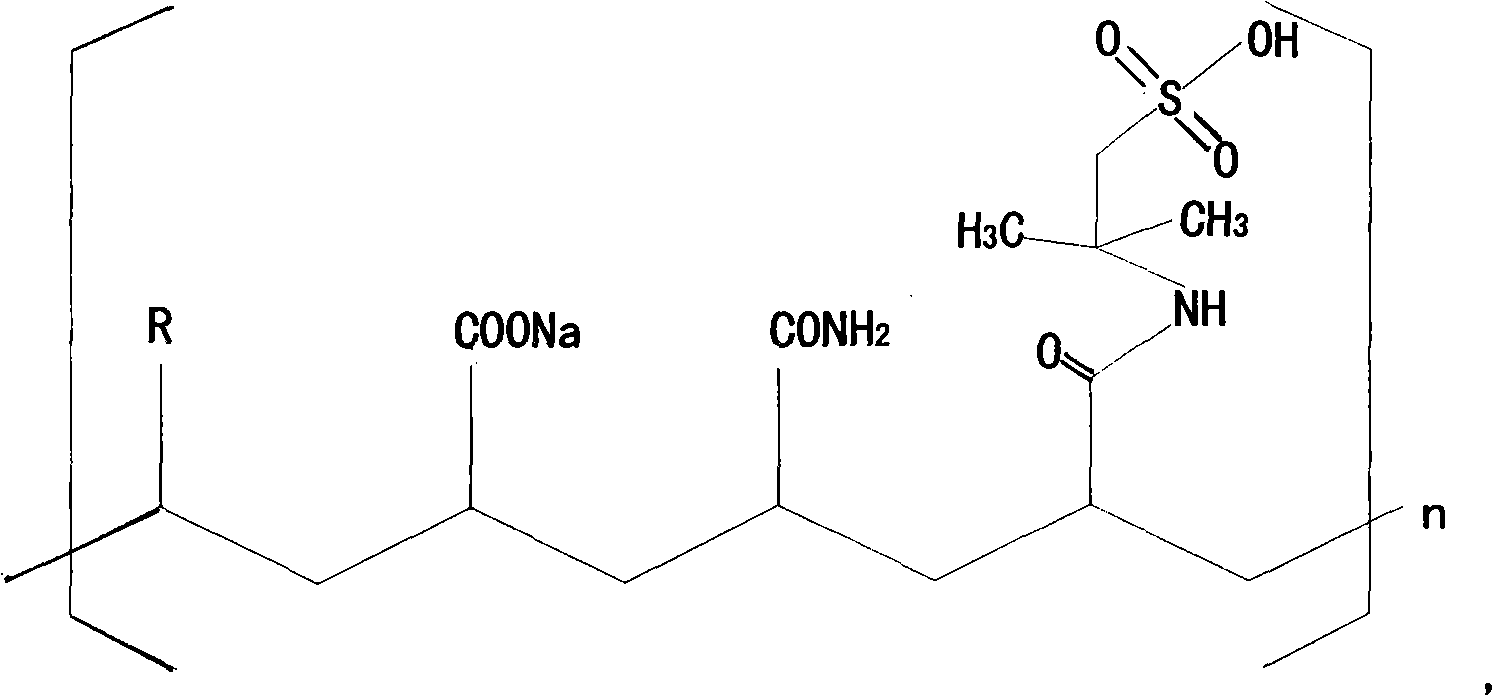

Comb-type structure activity polymer and its preparation technique and application

InactiveCN101260171AGood water solubilityHigh molecular weightDrilling compositionFunctional monomerHigh surface

The invention discloses a comb-type structural reactive polymer with the molecular weight ranging between 1x10<5> and 5x10<6>, wherein the main chain of the reactive polymer is obtained through the copolymerization of acrylamide monomer and functional monomers such as 2-acrylamido-2-methylpropanesulfonic acid and acrylic acid sodium salt, etc., which endues polymer aqueous solution with higher apparent viscosity and better temperature resistance and salt resistance; and the branched chain of the reactive polymer consists of unsaturated macromonomer molecule, which endues the polymer aqueous solution with higher surface activity. The invention also discloses a preparation method for the polymer, comprising the following steps: firstly, through process operation including esterification, prepolymerization and sulfonation, polyurethanes active macromonomer with a novel structure is prepared; then, under the action of oxidation reduction initiator, the copolymerization reaction of the active macromonomer and other functional micromolecule monomers is initiated quickly at low temperature. The comb-type structural reactive polymer can be used as oil displacement agent and has the advantages of high molecular weight and low surface tension, etc.

Owner:SHANDONG UNIV

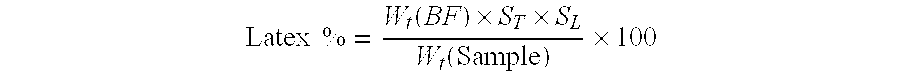

Binders curable at room temperature with low blocking

ActiveUS20060014884A1Without imparting objectionable odorEasy to prepareNatural cellulose pulp/paperPaper after-treatmentRoom temperaturePaper towel

Topically-applied binder materials for imparting wet strength to soft, absorbent paper sheets, such as are useful as household paper towels and the like, include an azetidinium-reactive polymer, such as a carboxyl-functional polymer, an azetidinium-functional polymer and, optionally, a component useful for reducing sheet-to-sheet adhesion (blocking) in the product. These binder materials can be cured at ambient temperature over a period of days and do not impart objectionable odor to final product when wetted.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Polymers functionalized with polyoxime compounds and methods for their manufacture

A method for preparing a functionalized polymer, the method comprising the steps of polymerizing monomer to form a reactive polymer, and reacting the reactive polymer with a protected polyoxime compound.

Owner:BRIDGESTONE CORP

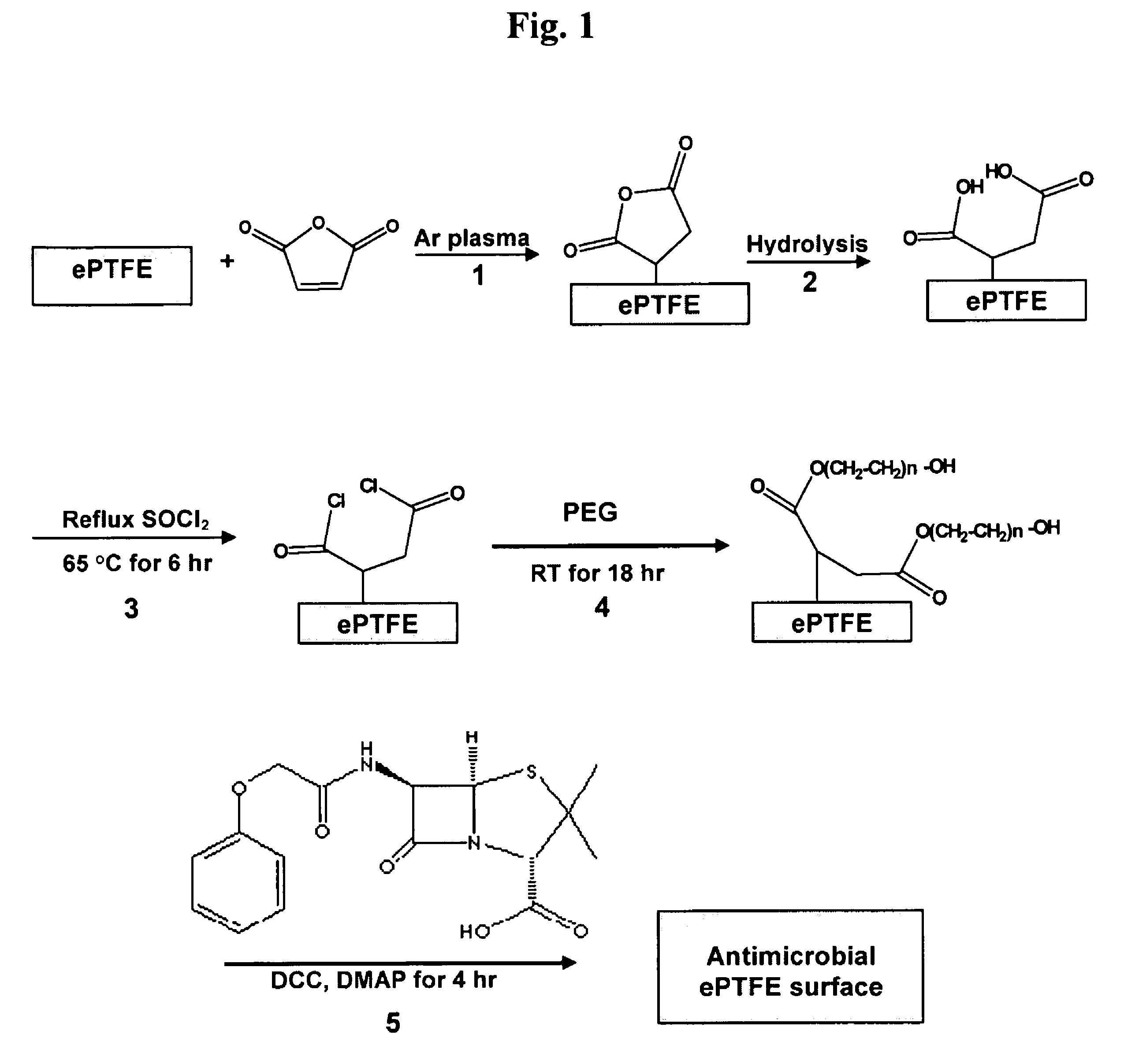

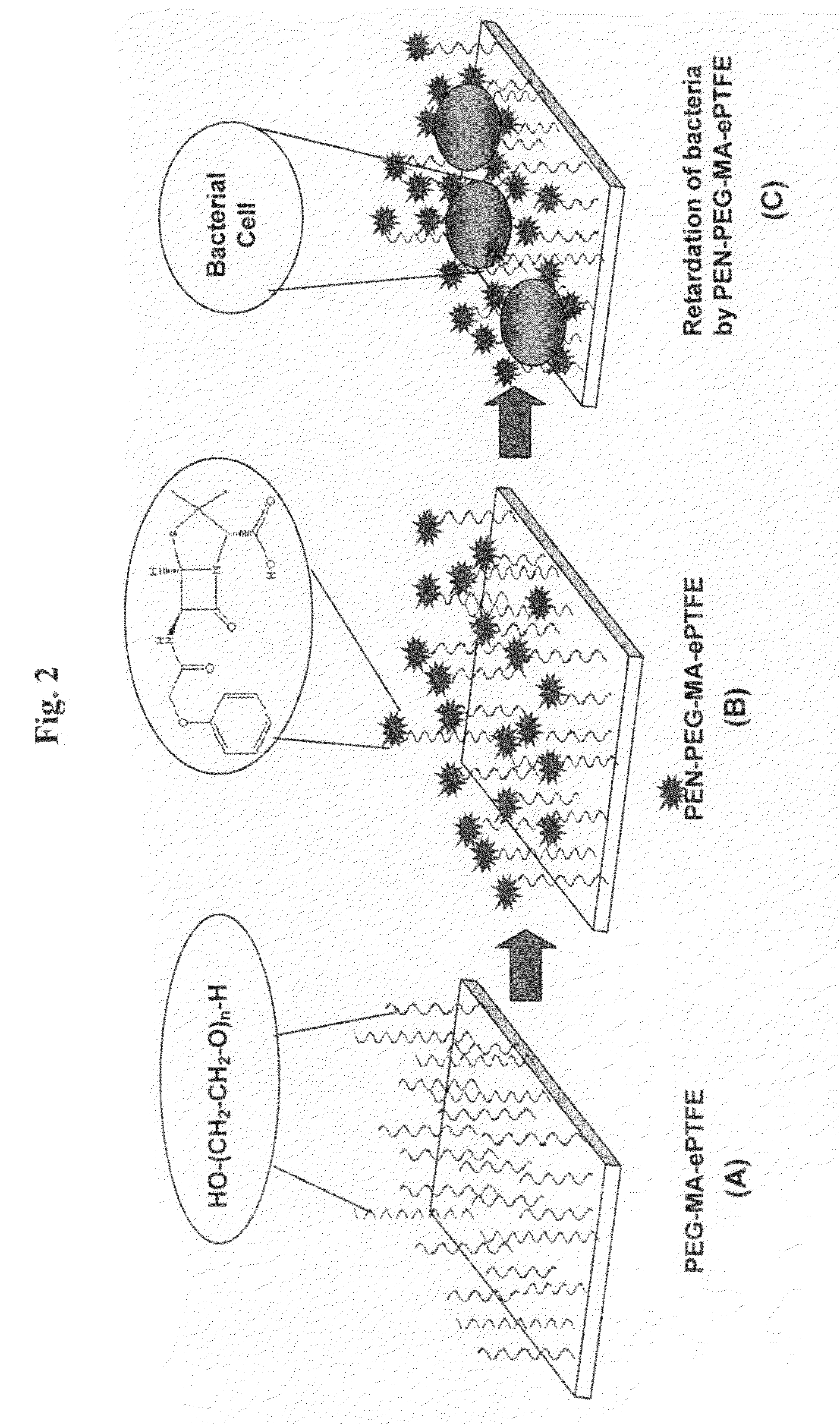

Method of attaching drug compounds to non-reactive polymer surfaces

Polymers are disclosed that are chemically modified to retard bacterial growth. Such modified polymers (e.g. ePTFE and polypropylene) are produced by first creating acid groups on the polymer surface through reactions with an anhydride. The acid groups are then linked to polyethylene glycol (PEG) through esterification or other reactions such as amidation. Preferably, at least two different molecular weight PEG species are employed. The antimicrobial surface is completed by linking antibiotics (e.g. β-lactam antibiotics) to the PEG extensions. One preferred embodiment of such a modified polymer is produced using ePTFE, maleic anhydride (MA), and penicillin (PEN) to yield PEN-PEG-MA-ePTFE, which inhibits gram-positive bacteria. The PEG spacer is critical for PEN function in this context, since PEN-ePTFE is ineffective against bacterial growth. Another preferred embodiment incorporates ampicillin (AMP) and a heterobifunctional PEG, HOOC—(CH2—CH2—O)n—NH2, to yield AMP-PEG-MA-ePTFE. This latter example inhibits both gram-negative and gram-positive bacteria.

Owner:SOUTHERN MISSISSIPPI THE UNIV OF

Low odor binders curable at room temperature

InactiveUS7189307B2Easy to storePromote hydrolysisNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceRoom temperature

Owner:KIMBERLY-CLARK WORLDWIDE INC

Reactive polymer waterproofing coiled material

ActiveCN101871248AHigh hardnessImprove cohesive strengthRoof covering using flexible materialsFilm/foil adhesivesCross-linkPolymer science

The invention discloses a reactive polymer waterproofing coiled material which comprises a fetal membrane layer, a reactive composite rubber layer and an anti-sticking isolation film layer; the reactive composite rubber layer is covered on the surface of the fetal membrane layer, and the anti-sticking isolation film layer is covered on the other surface of the reactive composite rubber layer; thereactive composite rubber comprises the following components in percentage by weight: 85.0 to 92.0 percent of SIS hot melt adhesive, 3.0 to 5.0 percent of talcum powder, 2.0 to 3.5 percent of composite ore powder, 1.0 to 2.5 percent of gaseous silica, 0.5 to 2.0 percent of silane coupling agent, and 0.5 to 2.0 percent of nano calcium carbonate. The waterproofing coiled material can have chemical cross-linking reaction and be cured with a cast-concrete matrix, fundamentally avoids 'watermoving between layer', and has the advantages of high strength, high toughness, aging resistance, long service life and the like.

Owner:KESHUN WATERPROOF TECH CO LTD

Polymers functionalized with nitroso compounds

A method for preparing a functionalized polymer, the method comprising the steps of: (i) polymerizing monomer with a coordination catalyst to form a reactive polymer; and (ii) reacting the reactive polymer with a nitroso compound.

Owner:BRIDGESTONE CORP

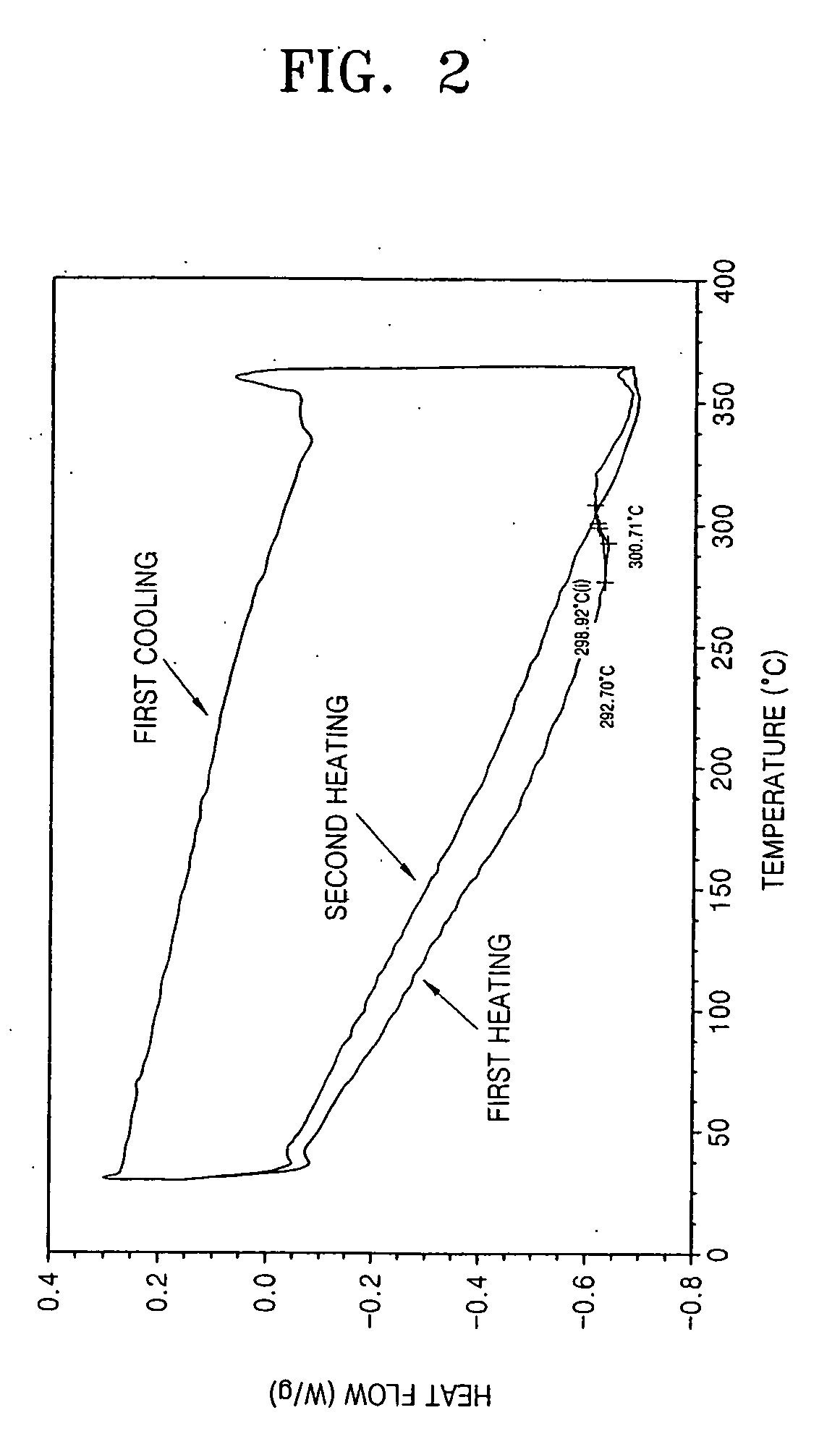

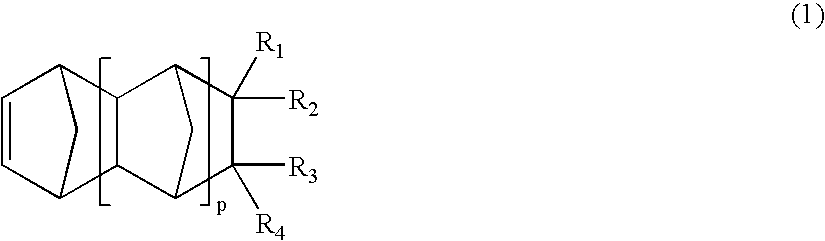

Photoreactive polymer and process of making the same

ActiveUS20060160970A1Improve thermal stabilityImproved photoreaction rateOrganic chemistryOrganic compound preparationPolymer scienceLiquid-crystal display

Provided are a photo reactive polymer that includes a multi-cyclicmulticyclic compound at as its main chain and a method of preparing the same. The photoreactive polymer exhibits excellent thermal stability since it includes a multi-cyclicmulticyclic compound having a high glass transition temperature at as its main chain. In addition, the photoreactive polymer has a relatively large vacancy so that a photoreactive group can move relatively freely in the main chain therein. As a result, a slow photoreaction rate, which is a disadvantage of a conventional polymer material used to form an alignment layer for a liquid crystal display device, can be overcome.

Owner:LG CHEM LTD

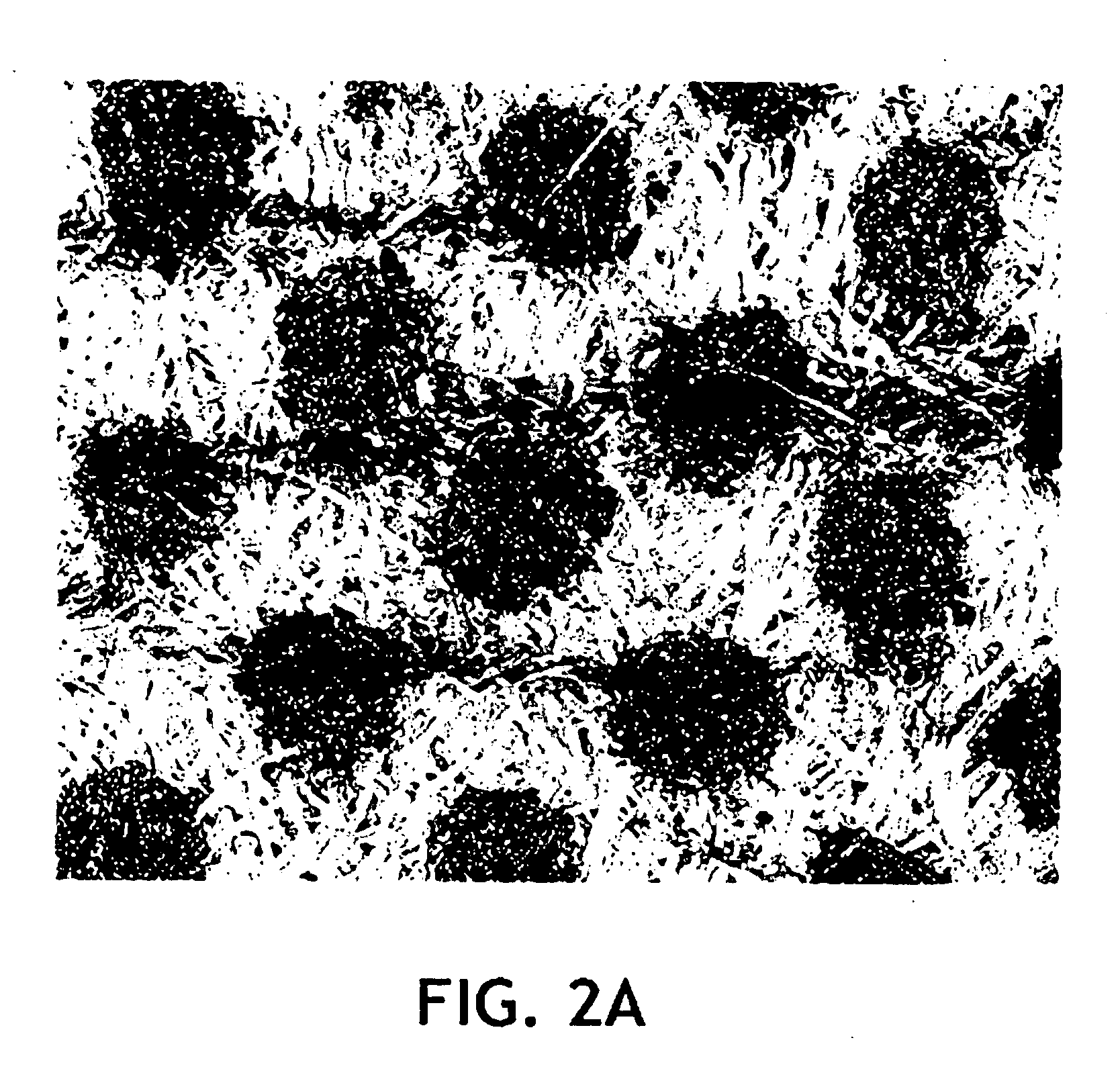

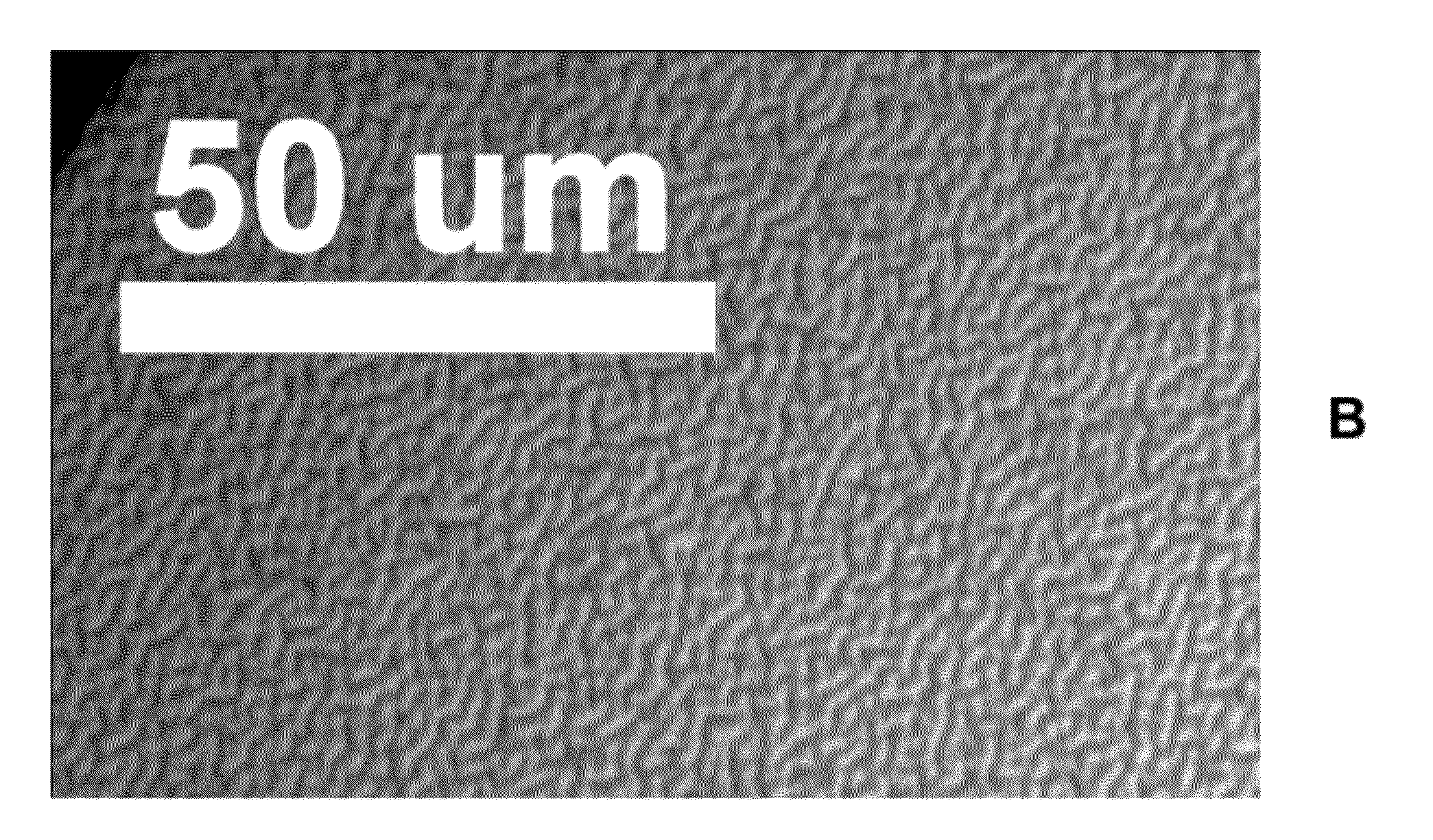

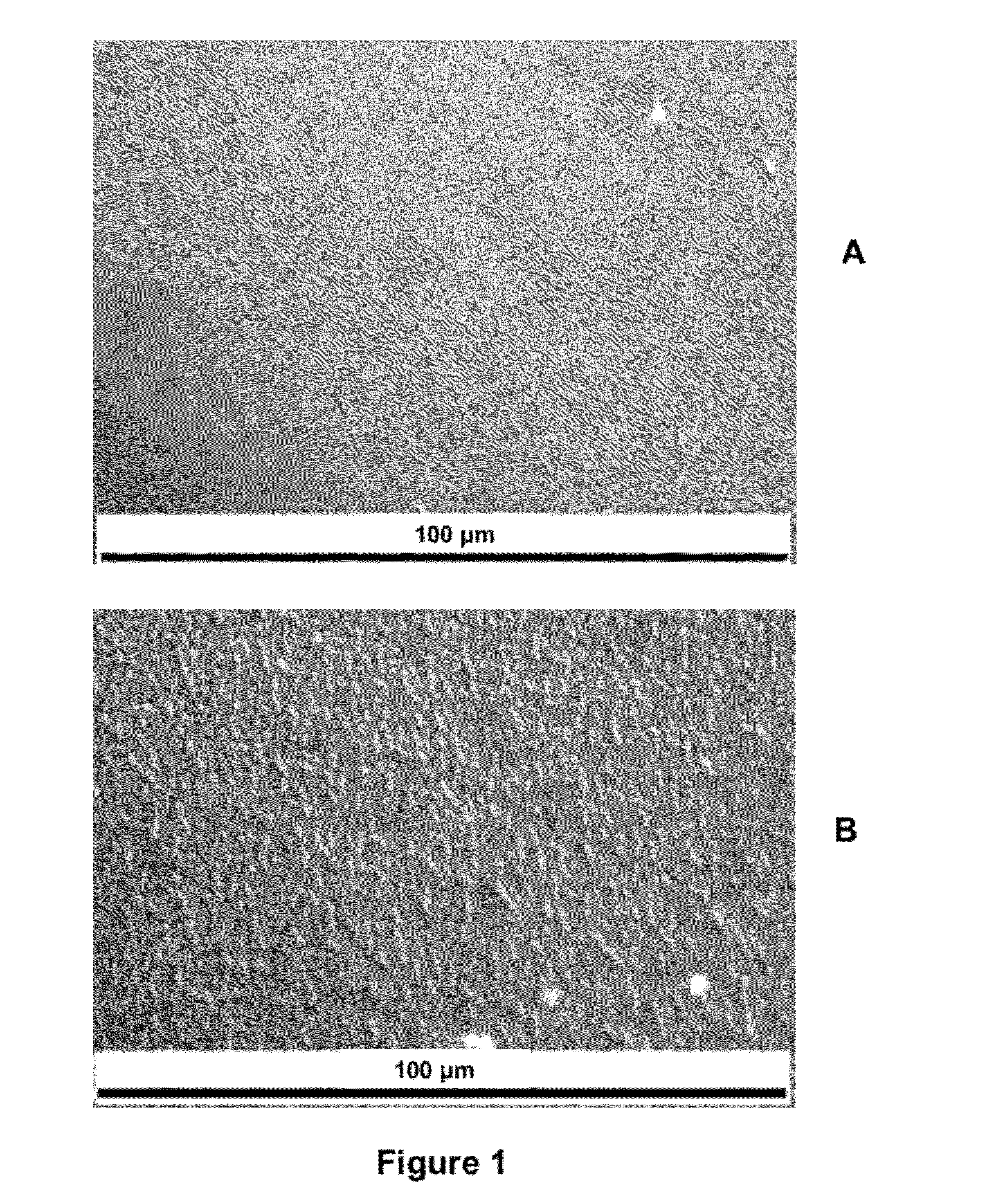

Silicone hydrogel lenses with nano-textured surfaces

ActiveUS20120314185A1Increase surface areaNo or minimal adverse effects upon the light transmissibility of the contact lensSpectales/gogglesOptical articlesPolymer scienceHydrophilic polymers

The invention is related to a method for making a silicone hydrogel contact lens having a nano-textured surface which mimics the surface texture of cornea of human eye. A method of the invention comprises creating a prime coating having nano-textures through controlled imbibition and / or depositions of a reactive polymeric coating material and fixing the nano-textures by crosslinking a hydrophilic polymeric material onto the prime coating to form a crosslinked polymeric coating that perserves the nano-textures of the prime coating and provides a nano-textured surface to the contact lens.

Owner:ALCON INC

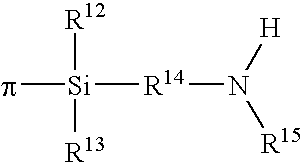

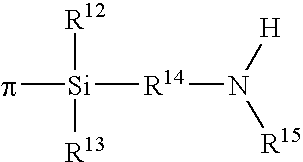

Polymers functionalized with halosilanes containing an amino group

ActiveUS20100317818A1Silicon organic compoundsOther chemical processesSilane compoundsFunctionalized polymer

A method for preparing a functionalized polymer, the method comprising the steps of preparing a reactive polymer, and reacting the reactive polymer with a halosilane compound containing an amino group.

Owner:BRIDGESTONE CORP

Cysteine variants of alpha interferon-2

The growth hormone supergene family comprises greater than 20 structurally related cytokines and growth factors. A general method is provided for creating site-specific, biologically active conjugates of these proteins. The method involves adding cysteine residues to non-essential regions of the proteins or substituting cysteine residues for non-essential amino acids in the proteins using site-directed mutagenesis and then covalently coupling a cysteine-reactive polymer or other type of cysteine-reactive moiety to the proteins via the added cysteine residue. Disclosed herein are preferred sites for adding cysteine residues or introducing cysteine substitutions into the proteins, and the proteins and protein derivatives produced thereby. Also disclosed are therapeutic methods for using the cysteine variants of the invention.

Owner:BOLDER BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com