Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

778 results about "Functionalized polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functionalized polyolefins are olefin polymers with polar and nonpolar functionalities attached onto the polymer backbone.

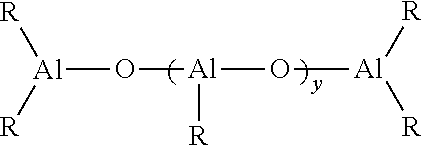

Modified polymers prepared with lanthanide-based catalysts

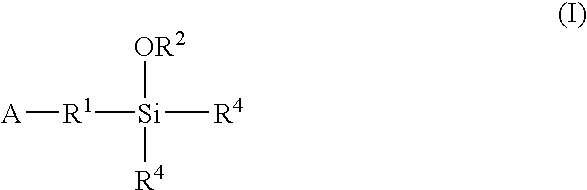

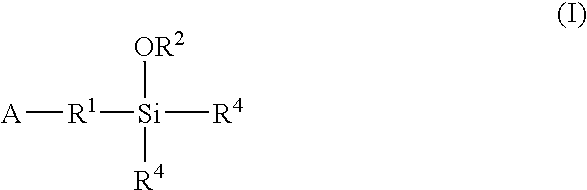

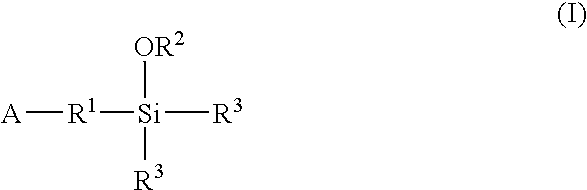

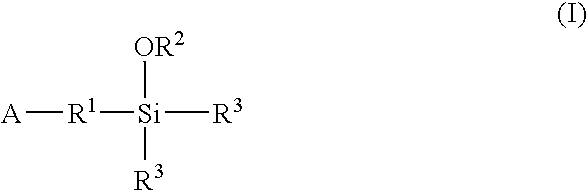

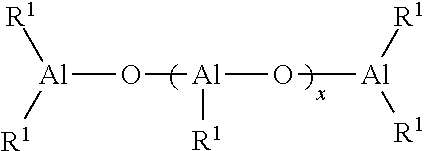

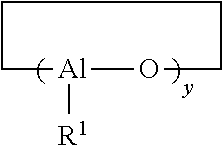

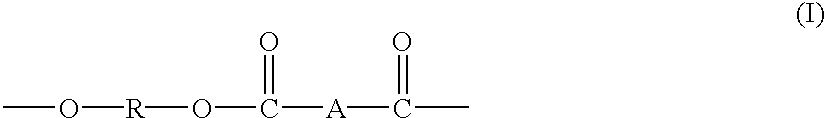

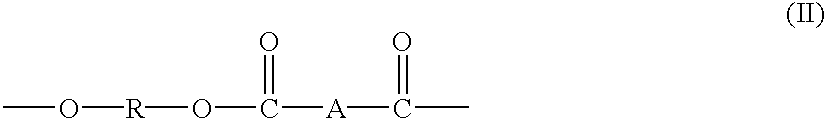

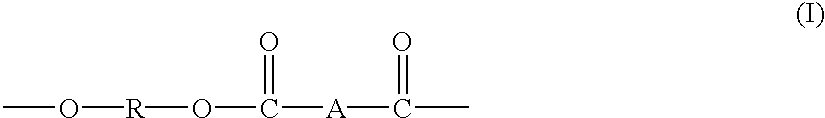

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) where A is a substituent that will undergo an addition reaction with a pseudo-living polymer, R1 is a divalent organic group, R2 is a monovalent organic group, and each R4, which may be the same or different, is a monovalent organic group or a substituent defined by —OR5 where R5 is a monovalent organic group, with the proviso that A, R1, R2, R4, and R5 are substituents that will not protonate a pseudo-living polymer. Also, the functionalized polymer and a vulcanizable composition containing the polymer.

Owner:BRIDGESTONE CORP

Modified polymers prepared with lanthanide-based catalysts

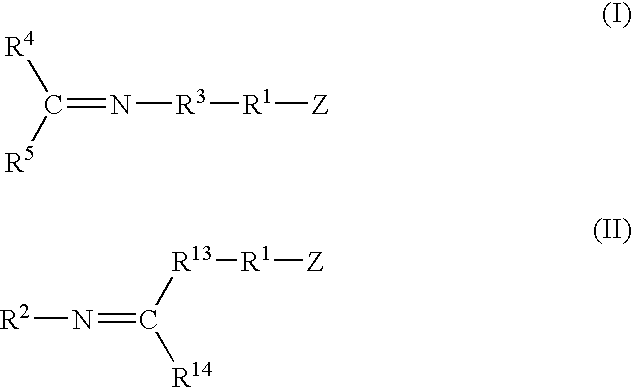

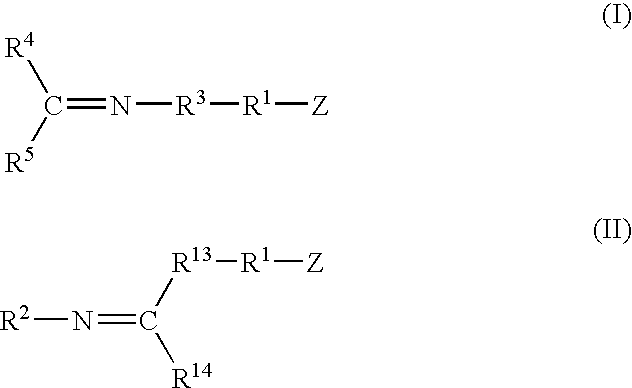

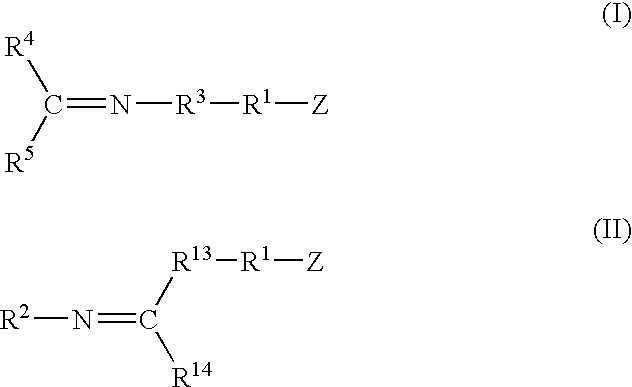

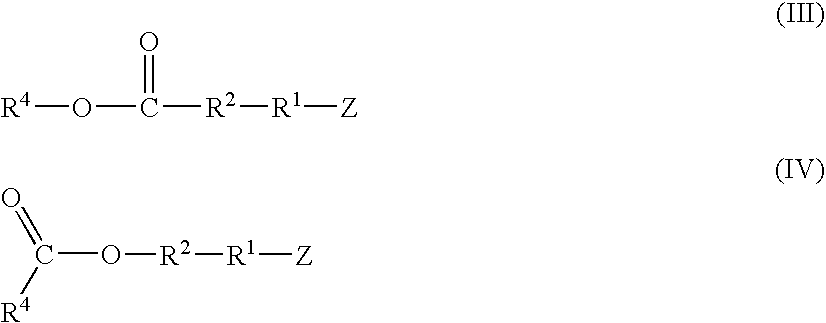

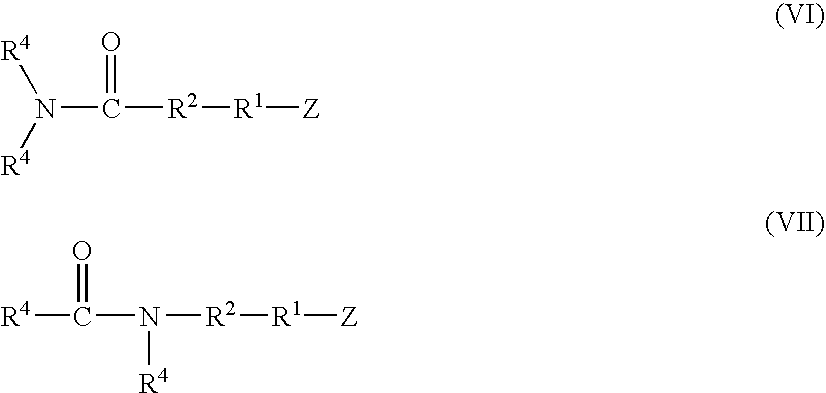

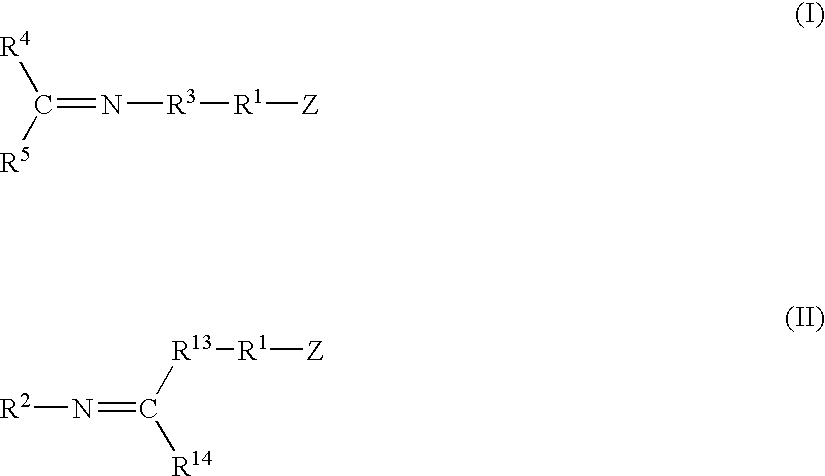

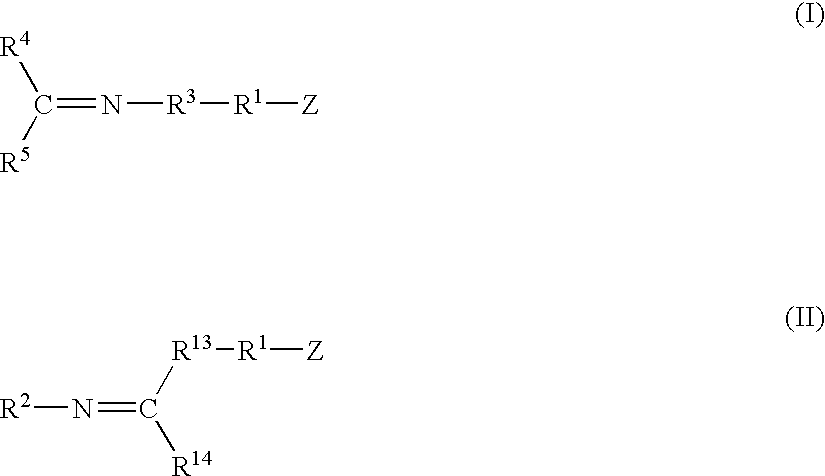

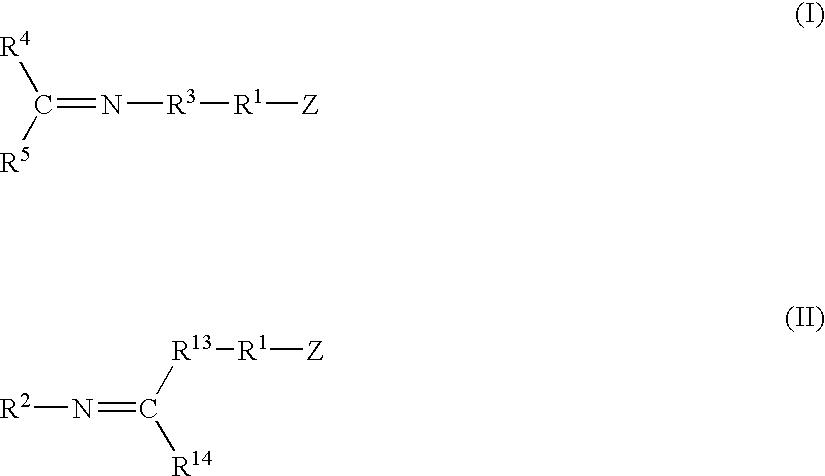

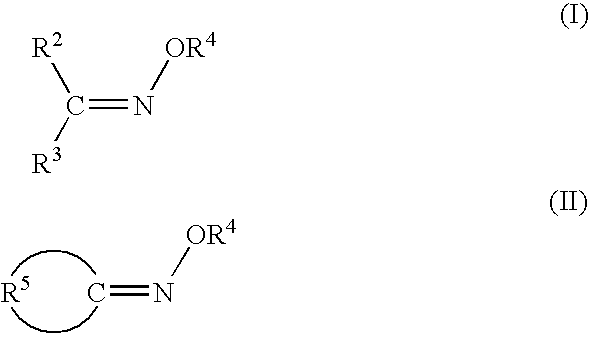

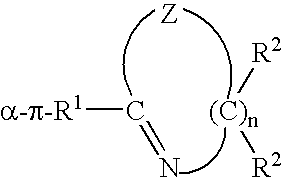

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2, R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

Modified polymers prepared with lanthanide-based catalysts

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) where A is a substituent that will undergo an addition reaction with a pseudo-living polymer, R1 is a divalent organic group, R2 is a monovalent organic group, and each R4, which may be the same or different, is a monovalent organic group or a substituent defined by —OR5 where R5 is a monovalent organic group, with the proviso that A, R1, R2, R4, and R5 are substituents that will not protonate a pseudo-living polymer. Also, the functionalized polymer and a vulcanizable composition containing the polymer.

Owner:ENEOS MATERIALS CORP

Functionalized high cis-1,4-polybutadiene prepared using novel functionalizing agents

InactiveUS20060004131A1High ci microstructureLower glass transition temperatureInksActive polymerPolymer science

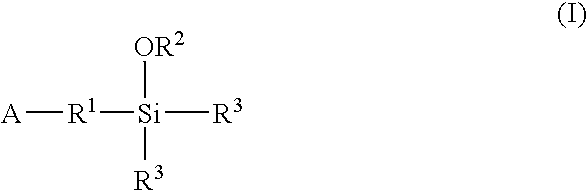

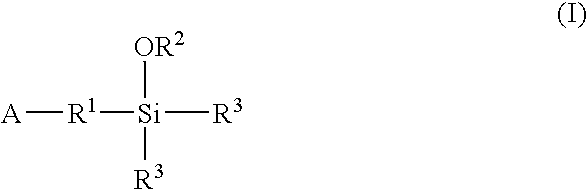

A functionalized polymer prepared by a process comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated monomer with a lanthanide-based catalyst, and reacting the pseudo-living polymer with a functionalizing agent defined by the formula (I) A-R1-Z (I) where R1 is a divalent bond or divalent organic group comprising from 0 to about 20 carbon atoms, A is a substituent that will undergo an addition reaction with a pseudo-living polymer, and Z is a substituent that will react or interact with silica or carbon black reinforcing fillers, with the proviso that A, R1, and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

Modified polymers prepared with lanthanide-based catalysts

A method for preparing a functionalized polymer comprising the steps of preparing a pseudo-living polymer by polymerizing conjugated diene monomer with a lanthanide-based catalyst, where said pseudo-living polymer is characterized by having greater than about 85 percent of the polymer in the cis microstructure and less than about 3 percent of the polymer is in the 1,2- or 3,4-microstructure, and reacting the pseudo-living polymer with at least one functionalizing agent defined by the formula (I) or (II) where Z is a substituent that will react or interact with organic or inorganic fillers; R1 is a single bond or a divalent organic group; R2 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R13 or R14; R3 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R4 or R5; R13 is a single bond, a divalent organic group, or a trivalent organic group that forms a cyclic organic group with R2 or R14; R4 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R5; R14 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R2 or R13; and R5 is a monovalent organic group or a divalent organic group that forms a cyclic organic group with R3 or R4; with the proviso that each group attached to the imino carbon is attached via a carbon atom and R1, R2 R3, R4, R5, R13, R14 and Z are substituents that will not protonate a pseudo-living polymer.

Owner:BRIDGESTONE CORP

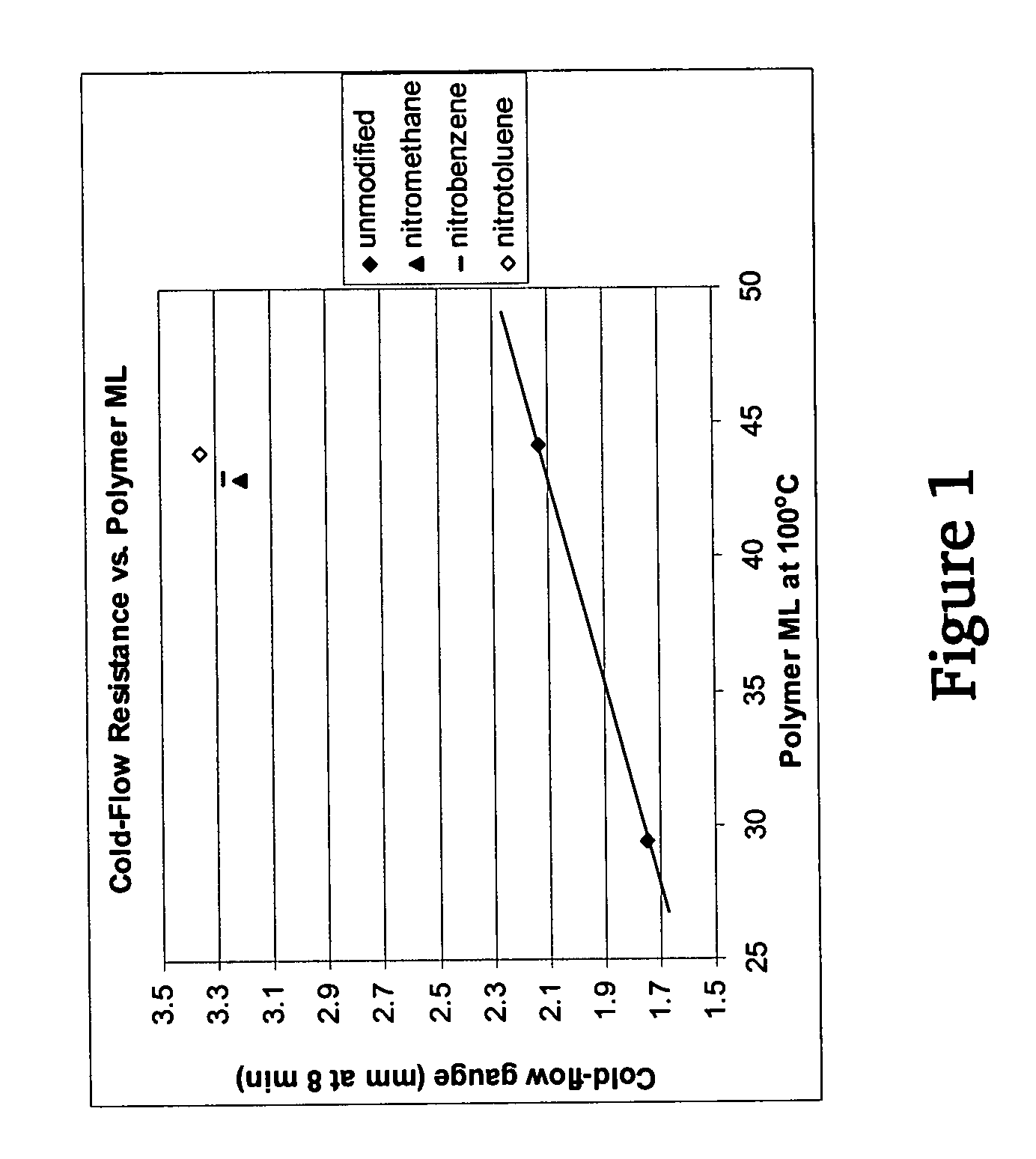

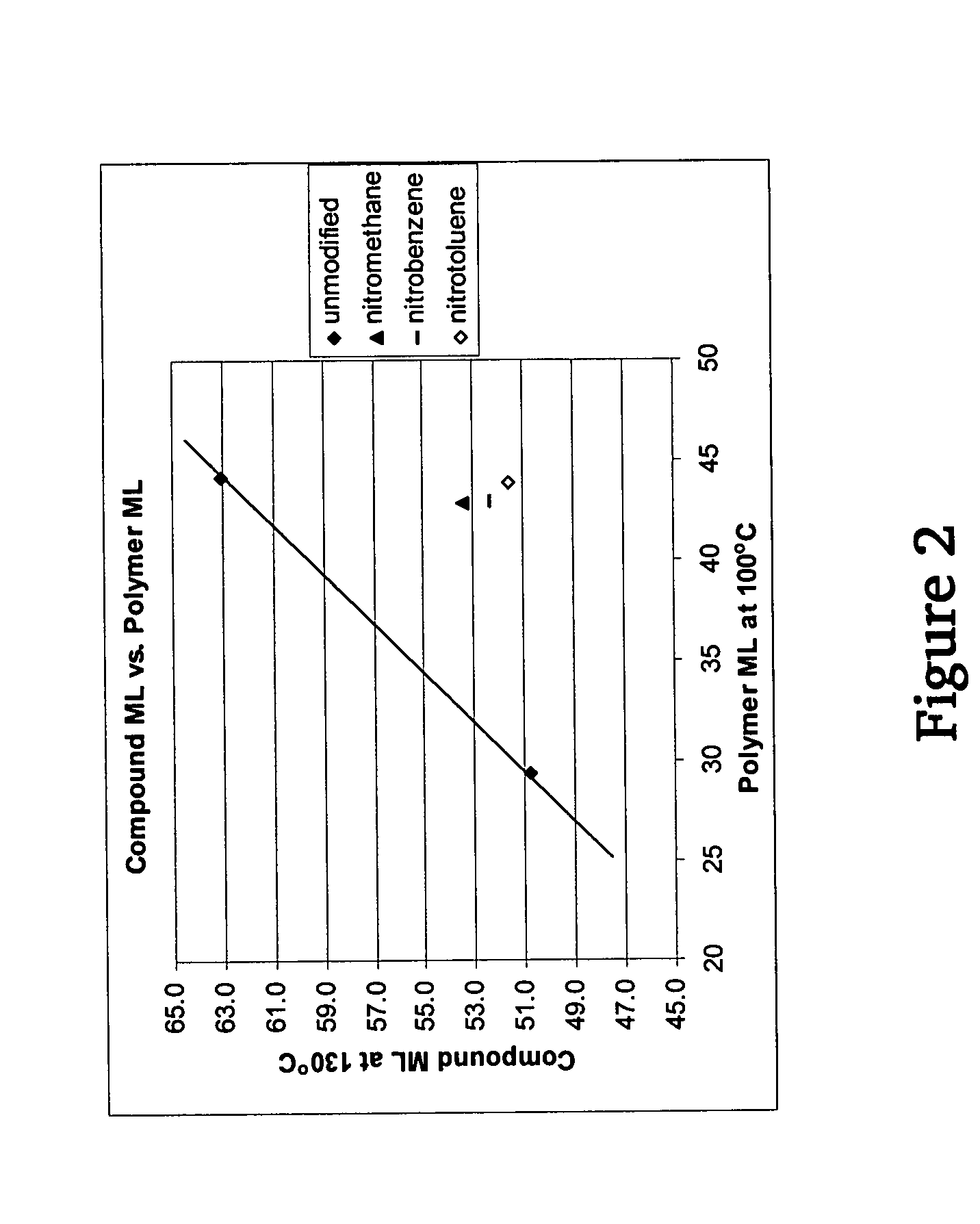

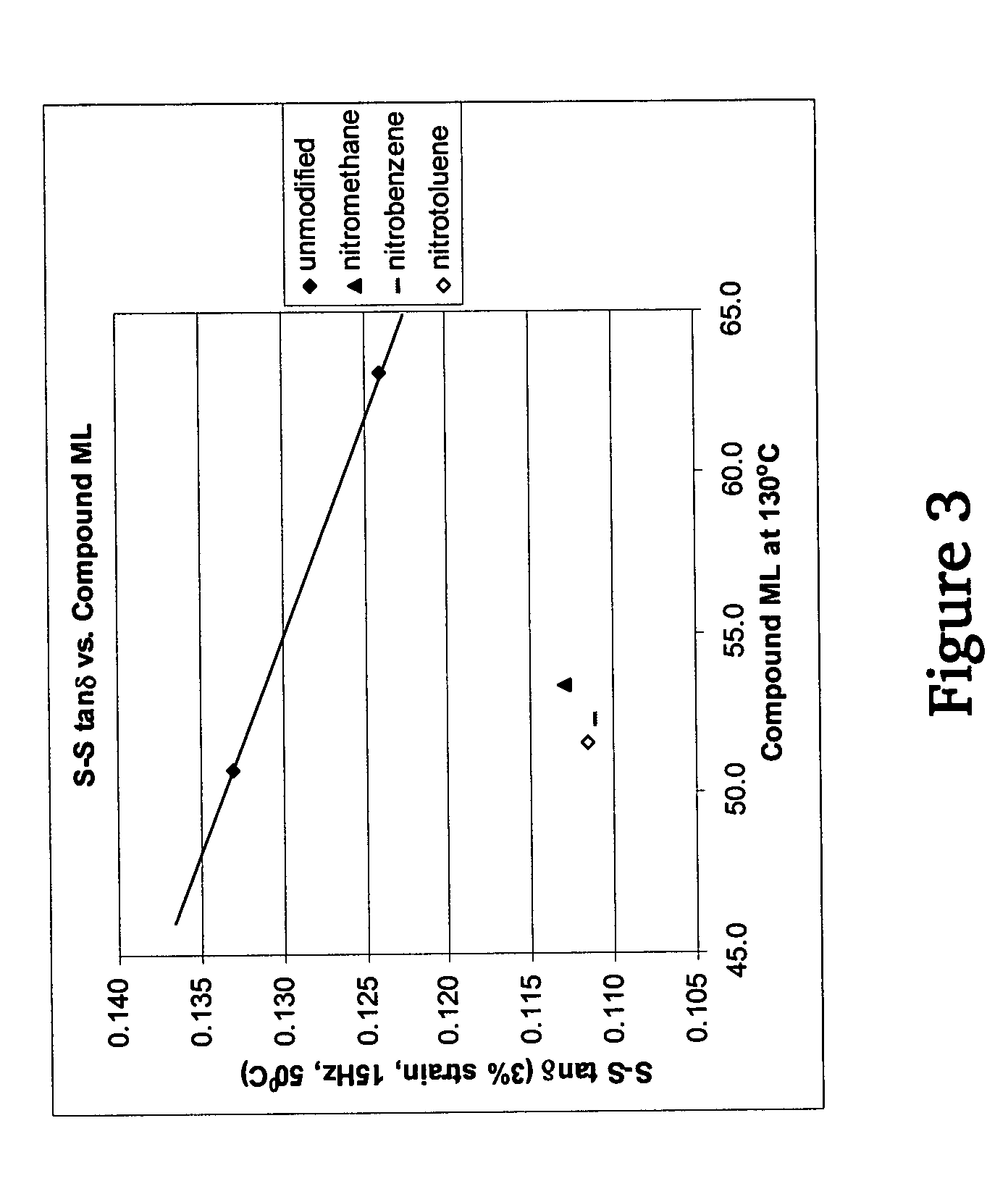

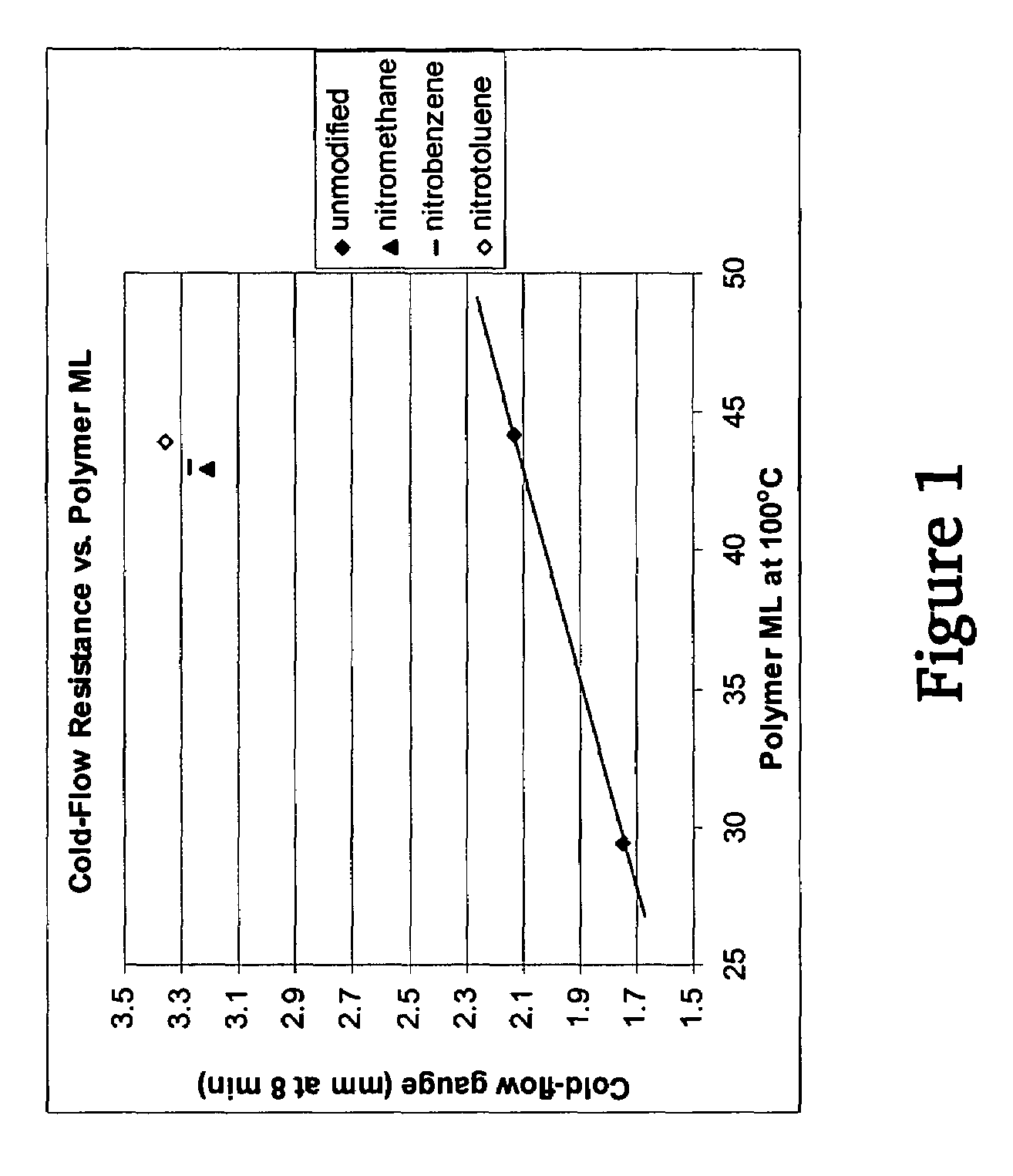

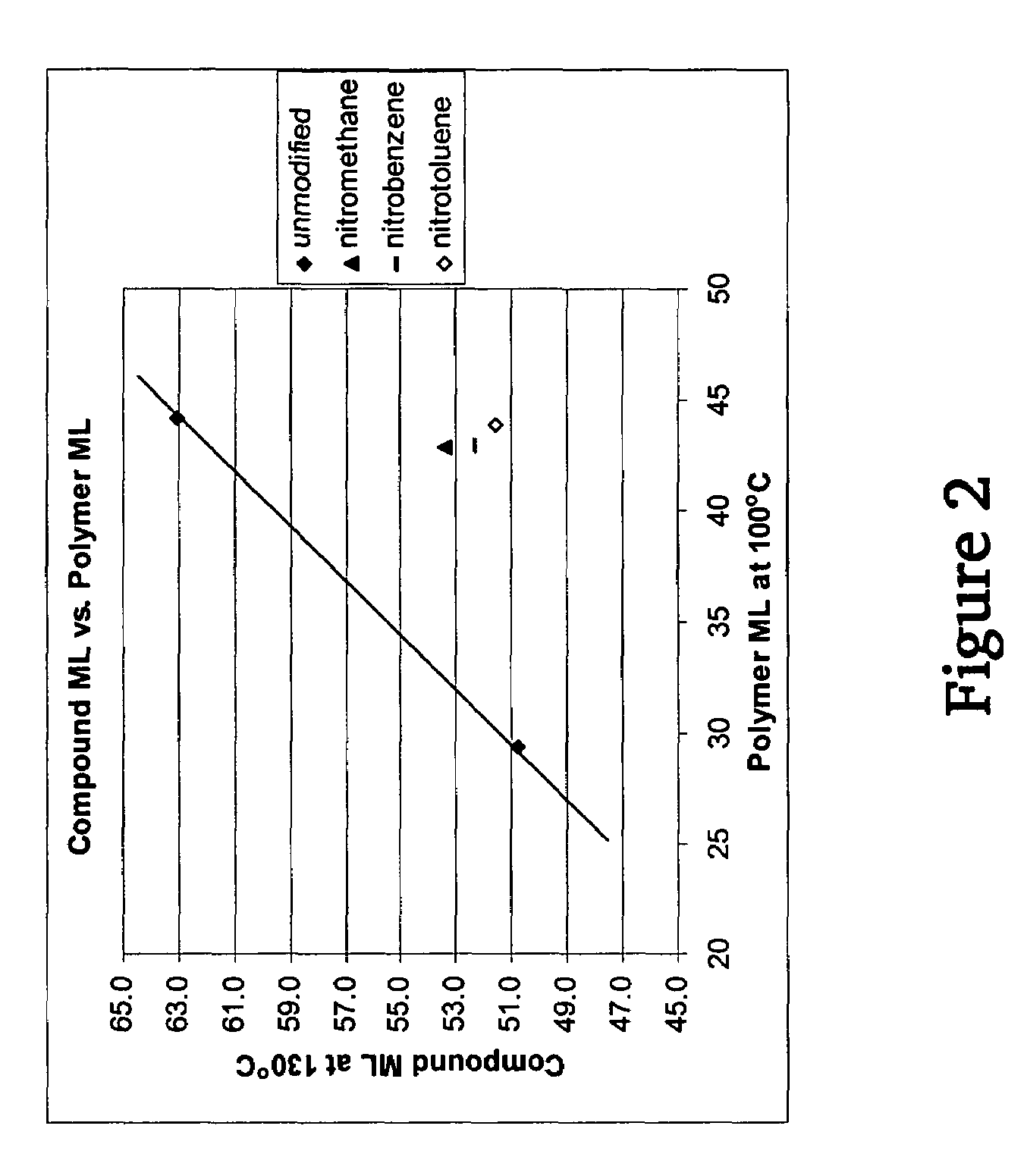

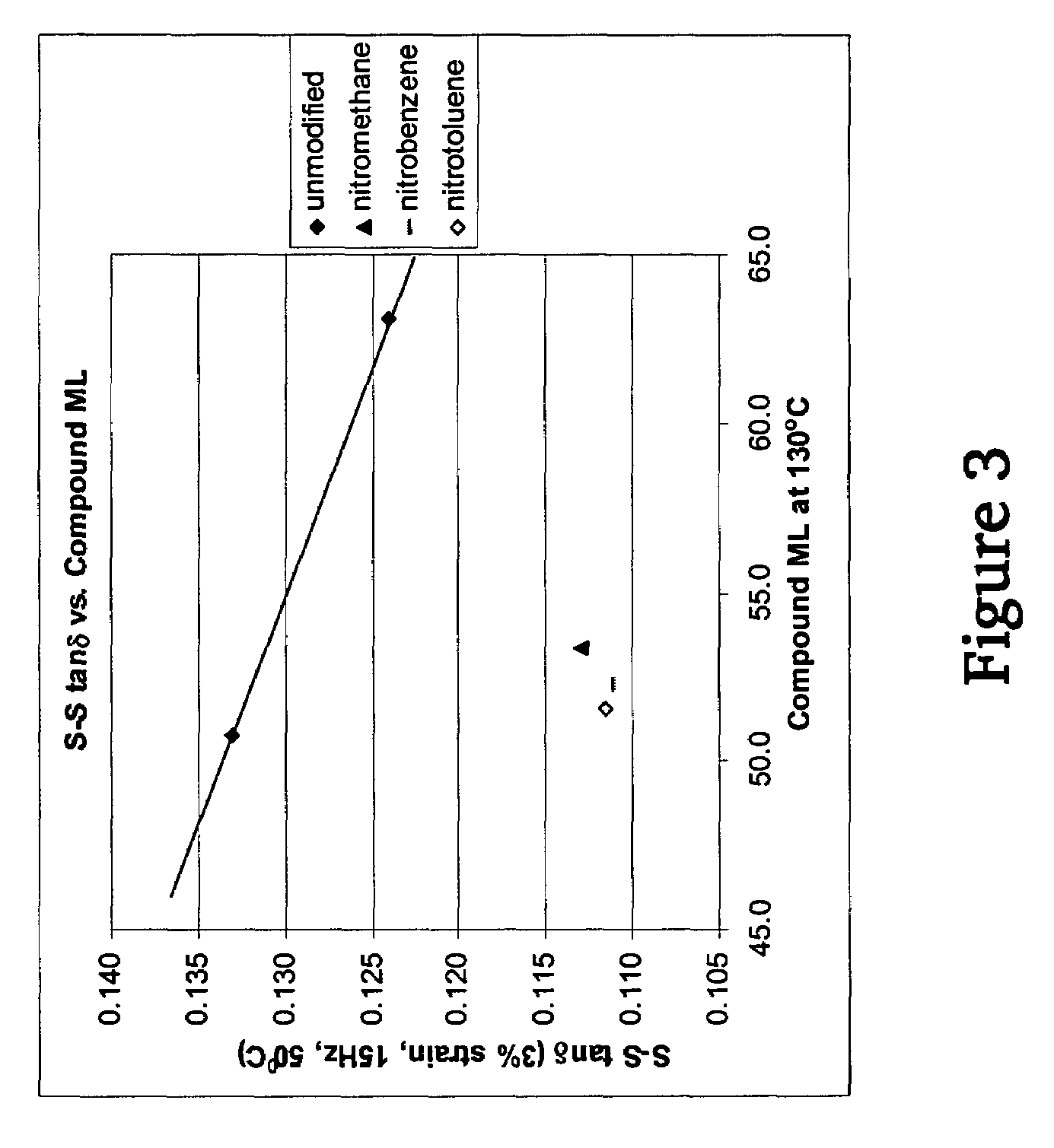

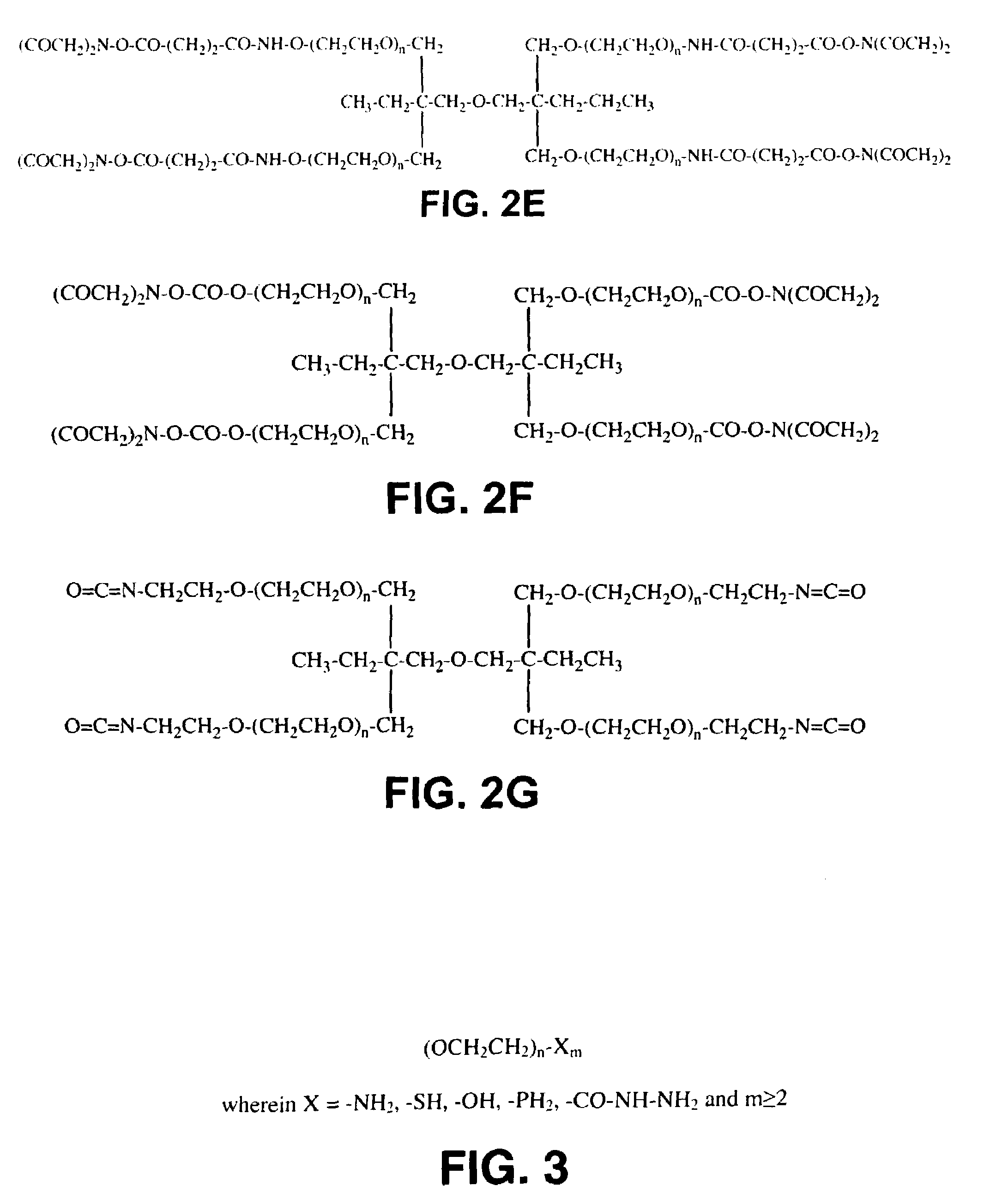

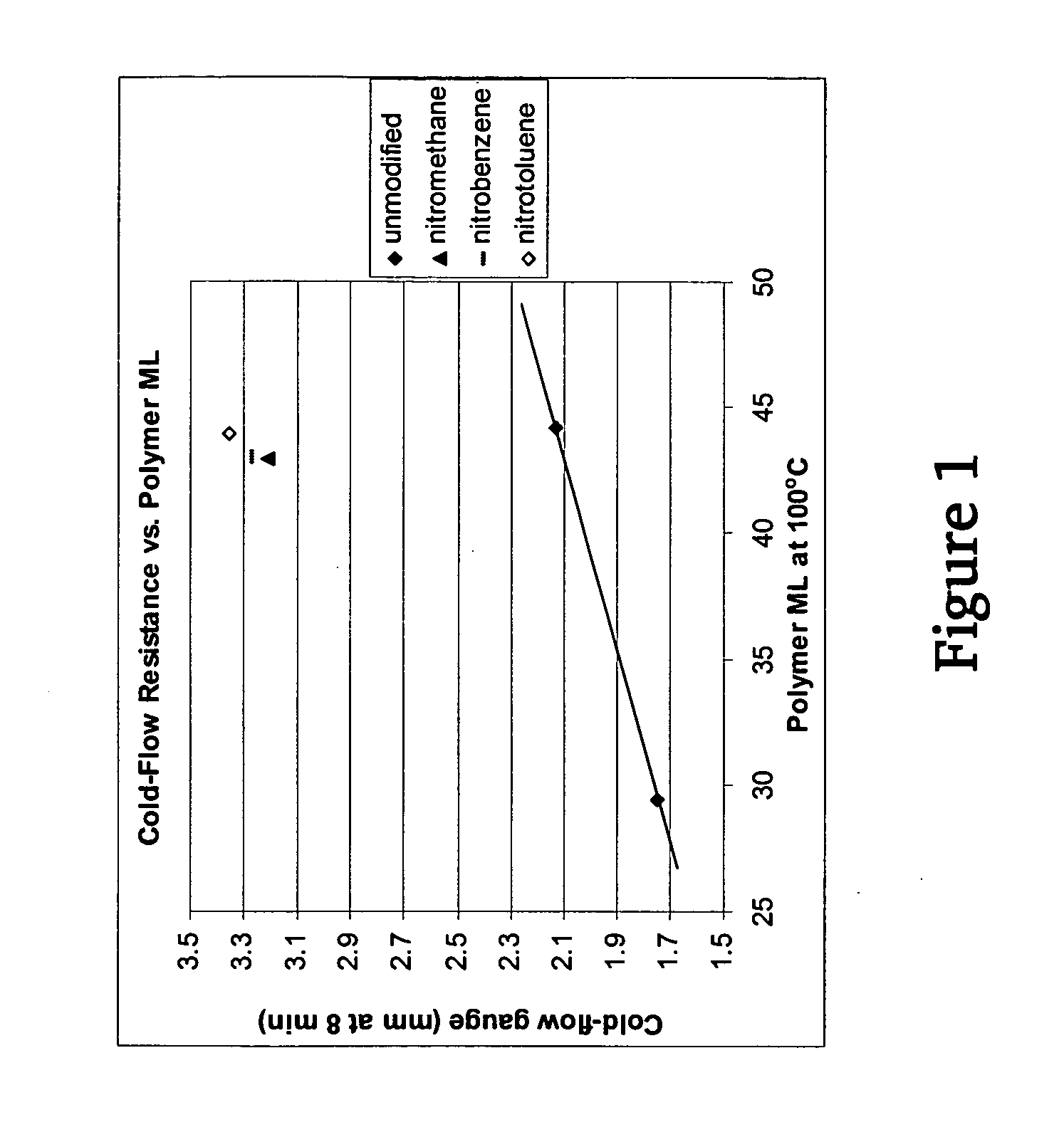

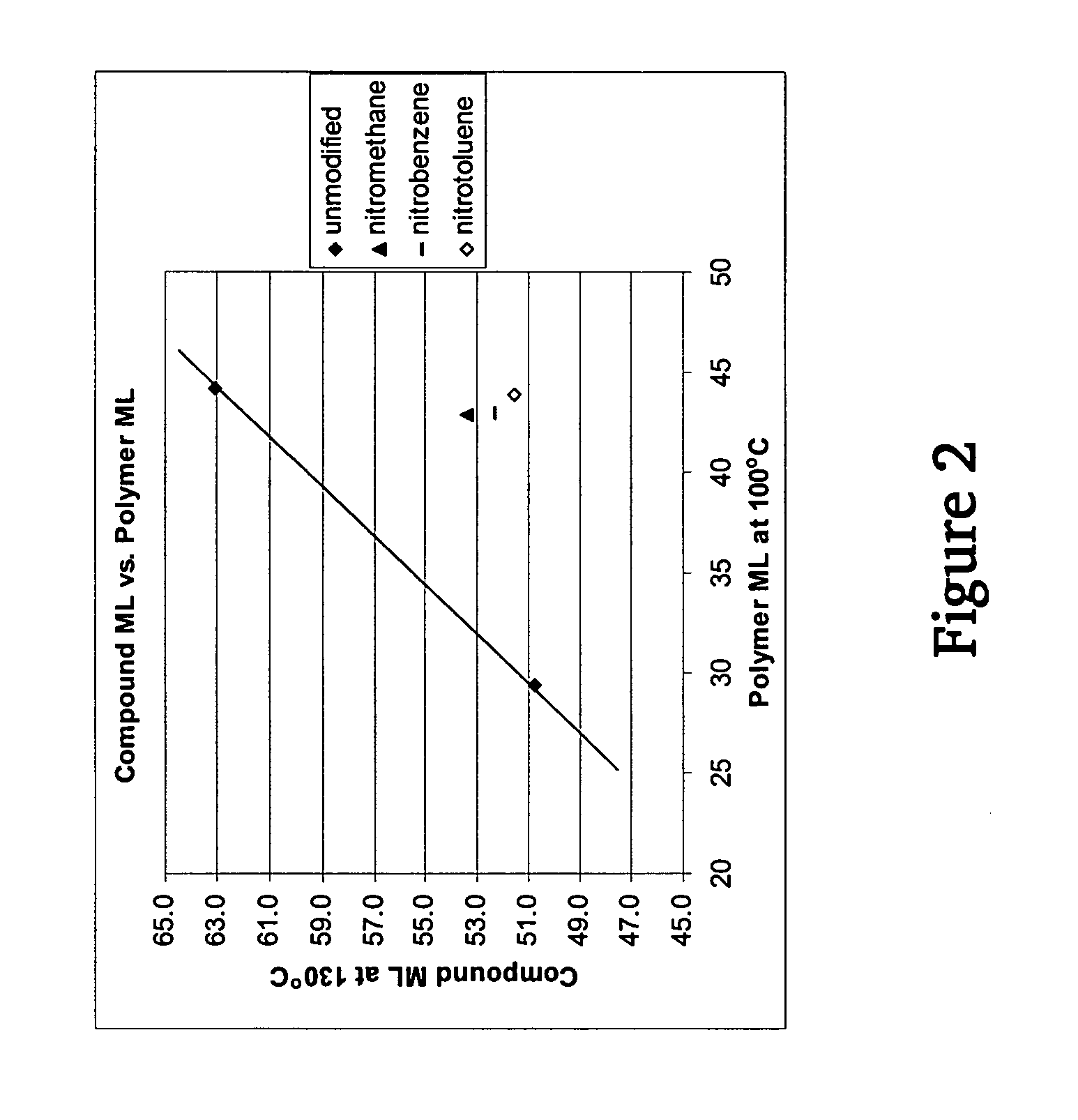

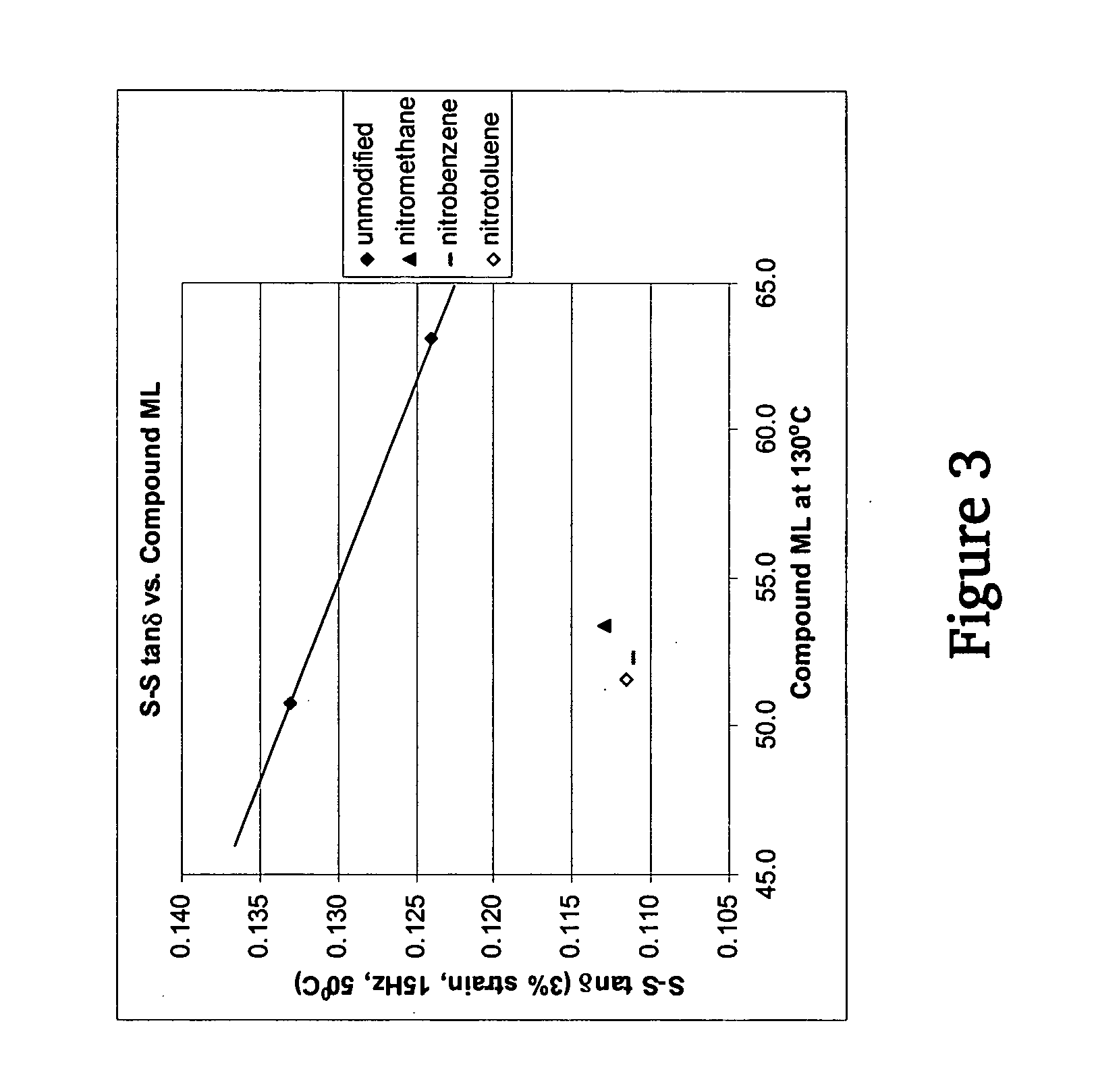

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

Multifunctional and biologically active matrices from multicomponent polymeric solutions

The present invention relates to a biologically active functionalized electrospun matrix to permit immobilization and long-term delivery of biologically active agents. In particular the invention relates to a functionalized polymer matrix comprising a matrix polymer, a compatibilizing polymer and a biomolecule or other small functioning molecule. In certain aspects the electrospun polymer fibers comprise at least one biologically active molecule functionalized with low molecular weight heparin. Examples of active molecules that may be used with the multicomponent polymer of the invention include, for example, a drug, a biopolymer, for example a growth factor, a protein, a peptide, a nucleotide, a polysaccharide, a biological macromolecule or the like. The invention is further directed to the formation of functionalized crosslinked matrices, such as hydrogels, that include at least one functionalized compatibilizing polymer capable of assembly.

Owner:UNIVERSITY OF DELAWARE

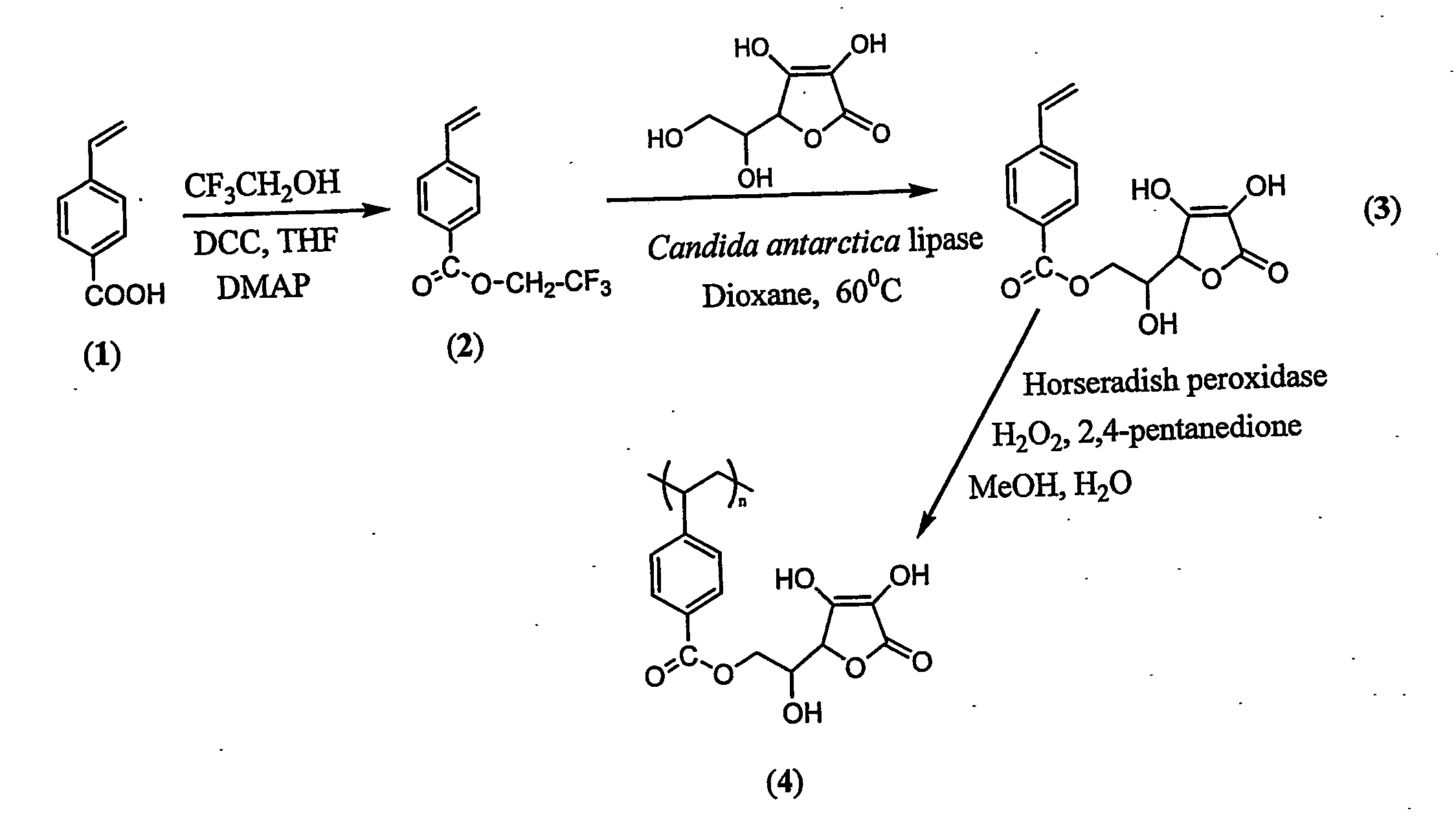

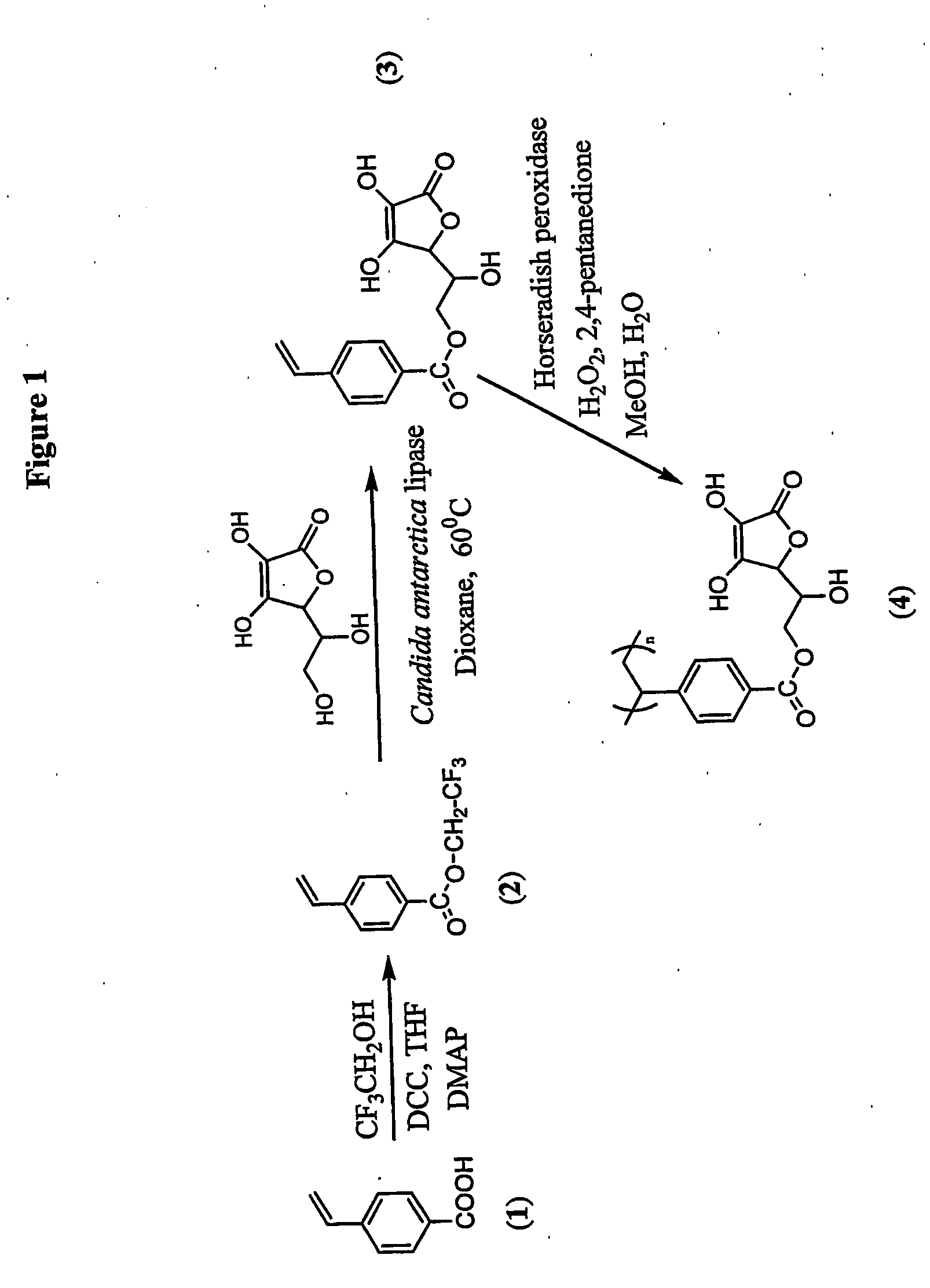

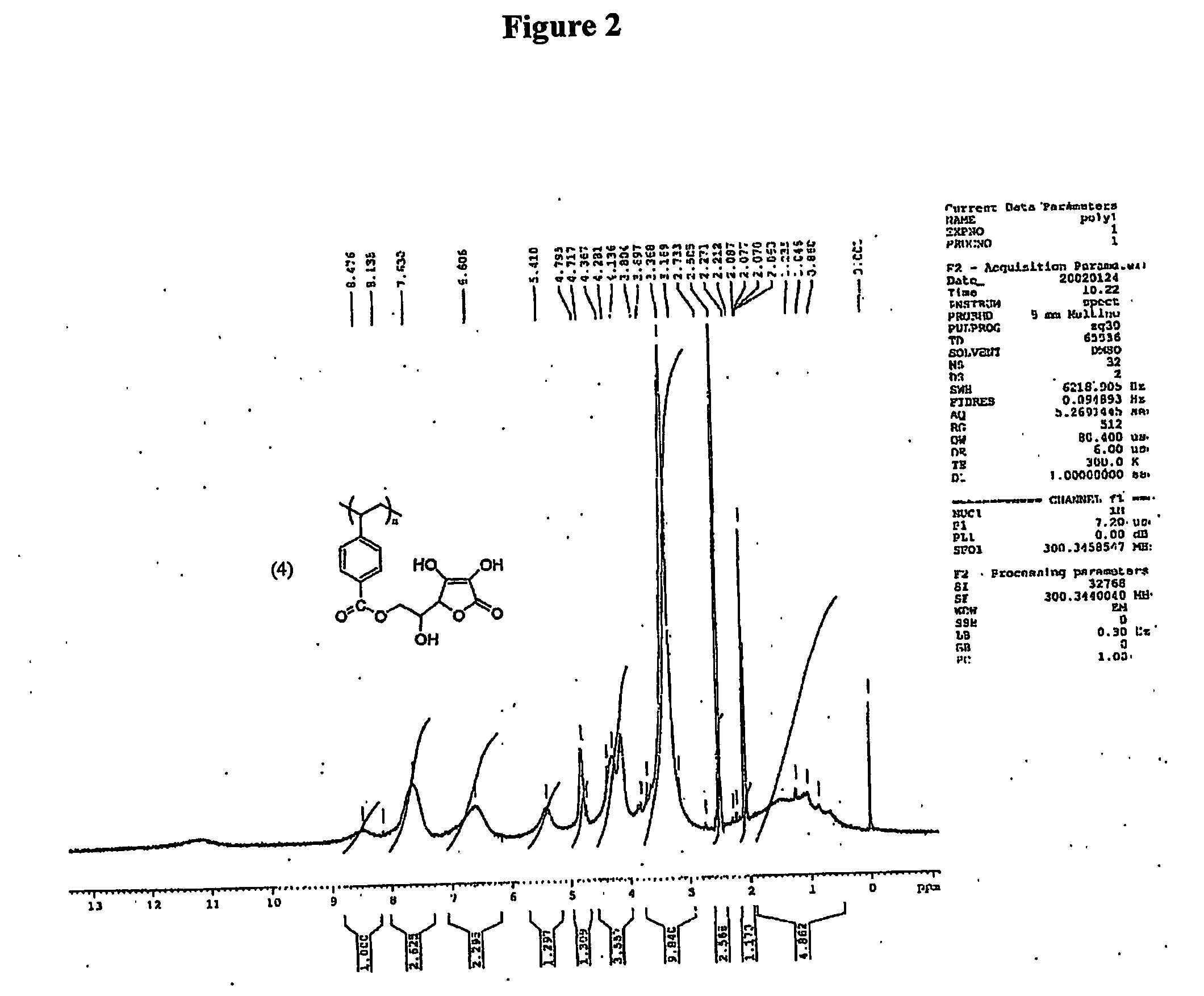

Antioxidant-functionalized polymers

InactiveUS20070010632A1Low yieldReduce sensitivitySuture equipmentsOrganic chemistryAntioxidantOxygen

Methods and compositions are disclosed for the preparation of free radical scavenging polymers and polymer films functionalized with antioxidants. Enzymatic and chemical tailoring of monomers with antioxidants followed by enzymatic polymerization is described. These antioxidant functionalized polymers can increase shelf life and quality of food products, as well as, increase effectiveness of pharmaceutical agents when used as packaging or as coatings on packaging for oxygen sensitive materials. The novel enzymatic covalent coupling of antioxidants to a polymer enhances the free radical scavenging ability of packaging while also inhibiting the escape of the antioxidants, and thus limiting exposure and / or absorption by an individual. In addition to its use in food or pharmaceutical packaging, methods are disclosed for using the antioxidant coupled polymers in a variety of applications including as coatings on the inside of medical devices, such as stents and catheters, which would substantially reduce free radical damage and / or oxygen depletion during medical procedures. Furthermore, through the coupling of antioxidants to biodegradable polymers, controlled delivery and sustained release of an antioxidant to a subject is possible.

Owner:TRUSTEES OF TUFTS COLLEGE

Polymer colloid-containing ink-jet inks for printing on non-porous substrates

ActiveUS20050176847A1Improve adhesionMeasurement apparatus componentsDuplicating/marking methodsPorous substrateParticulates

The present invention is drawn toward an ink-jet ink, comprising an aqueous liquid vehicle having acid-functionalized polymer colloid particulates and polymer-attached pigment colorants dispersed in the liquid vehicle. The liquid vehicle can include at least one volatile co-solvent, each volatile co-solvent present having a boiling point at or below about 285° C. The total amount of volatile co-solvent present in the ink-jet ink can be from 5 wt % to 50 wt %. These ink-jet inks can be printed on traditional as well as non-porous substrates. Optionally, heat can be applied to an image printed with the ink-jet ink to drive off at least a portion of the volatile co-solvent(s).

Owner:HEWLETT PACKARD DEV CO LP

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

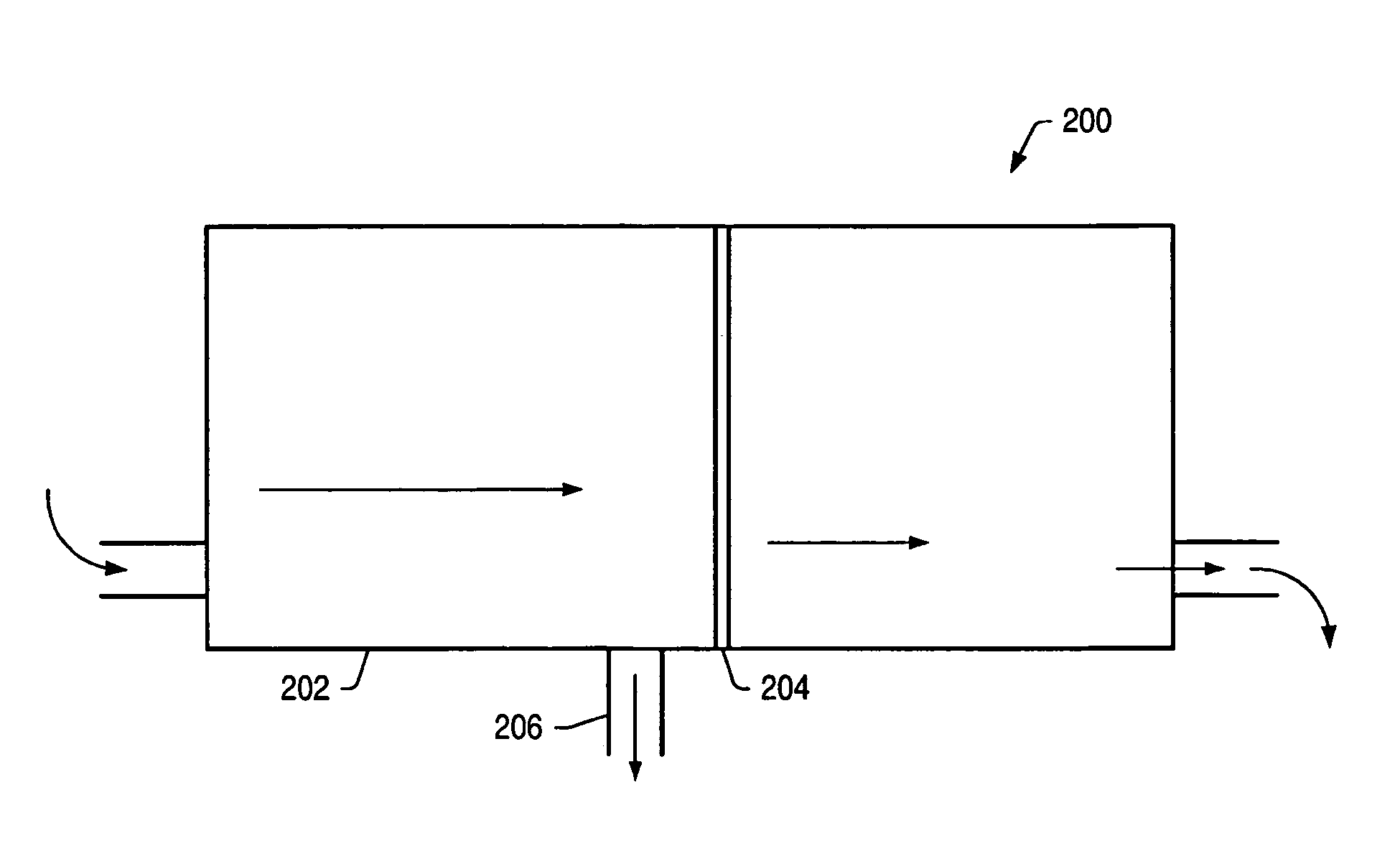

Method of using aldehyde-functionalized polymers to enhance paper machine dewatering

InactiveUS20050161181A1Accelerates the dehydration processNatural cellulose pulp/paperSpecial paperFiberPaper sheet

A method of enhancing the dewatering of a paper sheet on a paper machine comprising adding to the paper sheet about 0.05 lb / ton to about 15 lb / ton, based on dry fiber, of one or more aldehyde functionalized polymers comprising amino or amido groups wherein at least about 15 mole percent of the amino or amido groups are functionalized by reacting with one or more aldehydes and wherein the aldehyde functionalized polymers have a molecular weight of at least about 100,000.

Owner:ECOLAB USA INC

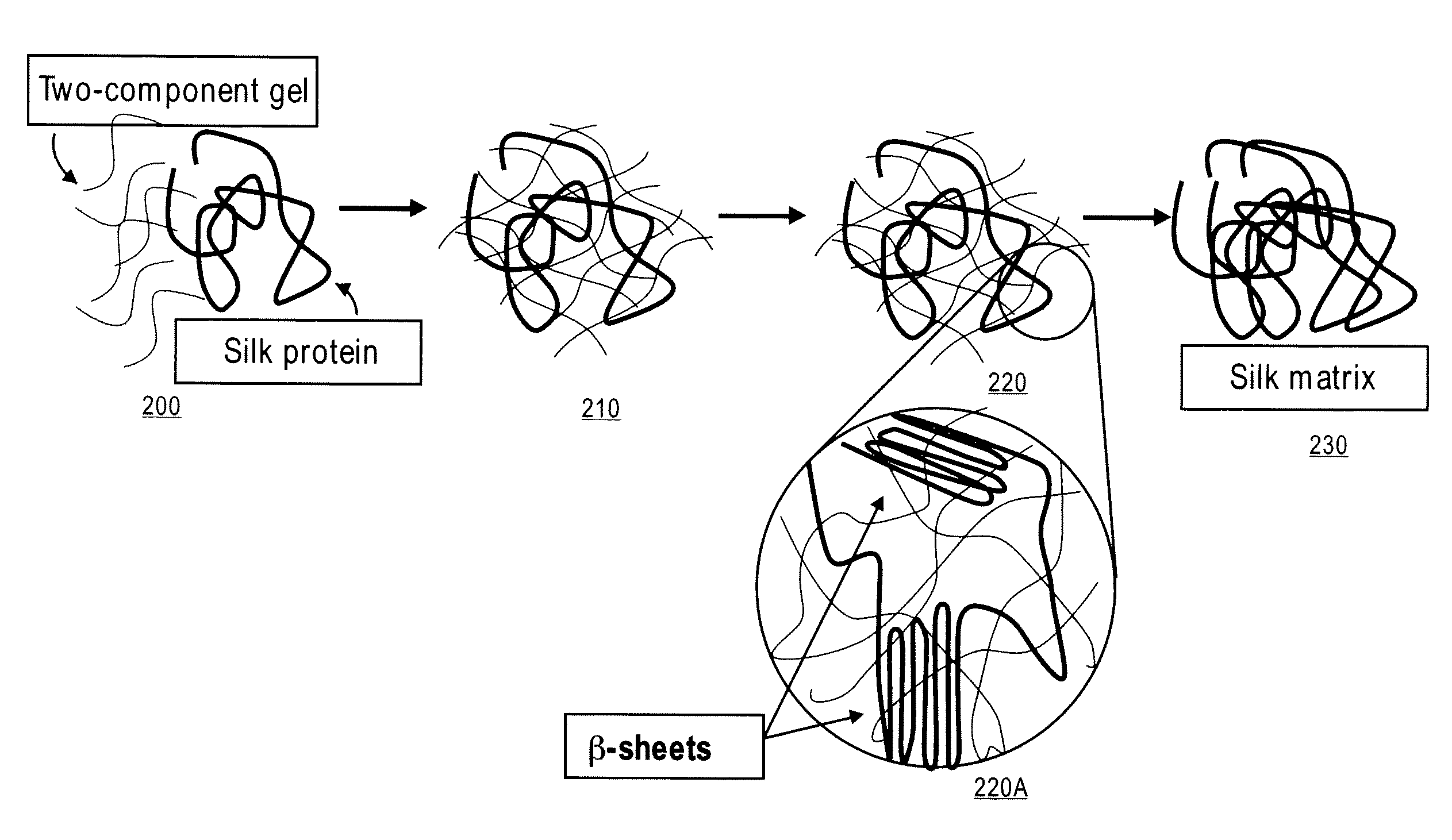

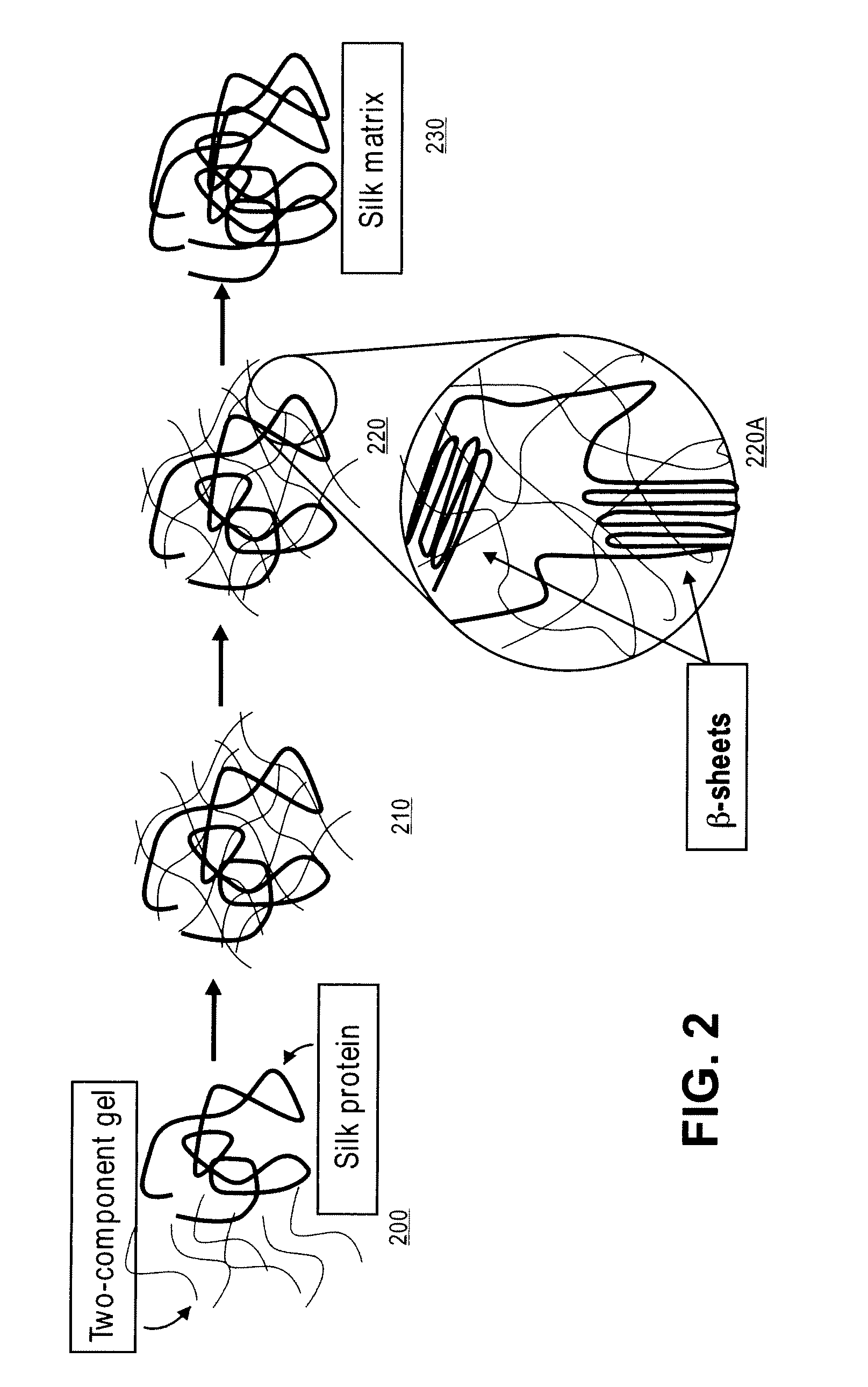

Methods and Compositions for Treating Tissue Using Silk Proteins

Compositions for forming a self-reinforcing composite biomatrix, methods of manufacture and use therefore are herein disclosed. Kits including delivery devices suitable for delivering the compositions are also disclosed. In some embodiments, the composition can include at least three components. In one embodiment, a first component can include a first functionalized polymer, a second component can include a second functionalized polymer and a third component can include silk protein or constituents thereof. In some embodiments, the composition can include at least one cell type and / or at least one growth factor. In some embodiments, the composition can include a biologic encapsulated, suspended, disposed within or loaded into a biodegradable carrier. In some embodiments, the composition(s) of the present invention can be delivered by a dual lumen injection device to a treatment area in situ, in vivo, as well as ex vivo applications.

Owner:ABBOTT CARDIOVASCULAR

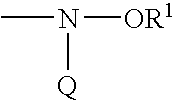

Polymers functionalized with protected oxime compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a protected oxime compound.

Owner:BRIDGESTONE CORP

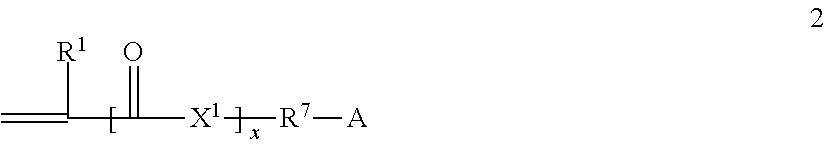

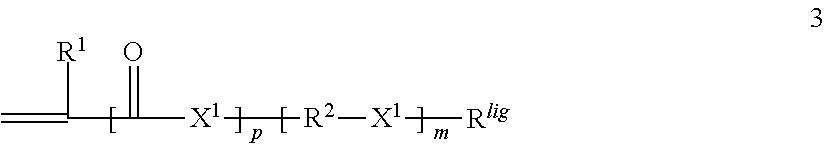

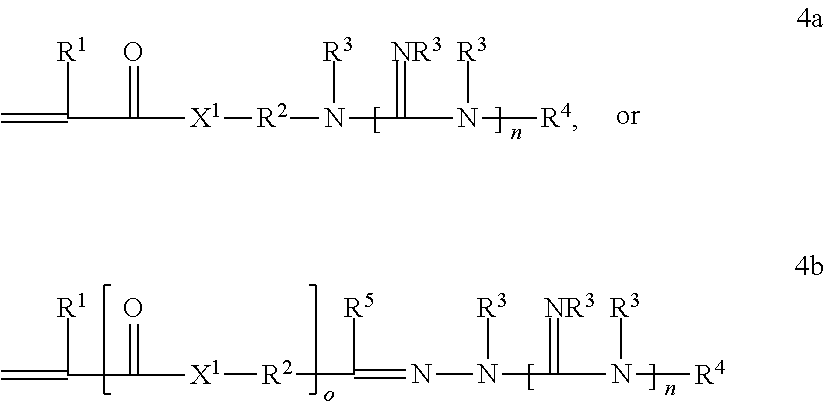

Ligand functional substrates

A substrate comprising a crosslinked polymer primer layer, and grafted thereto a ligand-functionalized polymer is provided. The grafted polymer has the requisite affinity for binding neutral or negatively charged biomaterials, such as cells, cell debris, bacteria, spores, viruses, nucleic acids, and proteins, at pH's near or below the pI's of the biomaterials.

Owner:3M INNOVATIVE PROPERTIES CO

Polylactic acid fibers

A biodegradable fiber that is formed from a thermoplastic composition that contains polylactic acid, a plasticizer, and a compatibilizer is provided. The compatibilizer includes a polymer that is modified with a polar compound that is compatible with the plasticizer and a non-polar component provided by the polymer backbone that is compatible with polylactic acid. Such functionalized polymers may thus stabilize each of the polymer phases and reduce plasticizer migration. By reducing the plasticizer migration, the composition may remain ductile and soft. Further, addition of the functionalized polymer may also promote improved bonding and initiate crystallization faster than conventional polylactic acid fibers. The polar compound includes an organic acid, an anhydride of an organic acid, an amide of an organic acid, or a combination thereof. Such compounds are believed to be more compatible with the generally acidic nature of the polylactic acid fibers.

Owner:KIMBERLY-CLARK WORLDWIDE INC

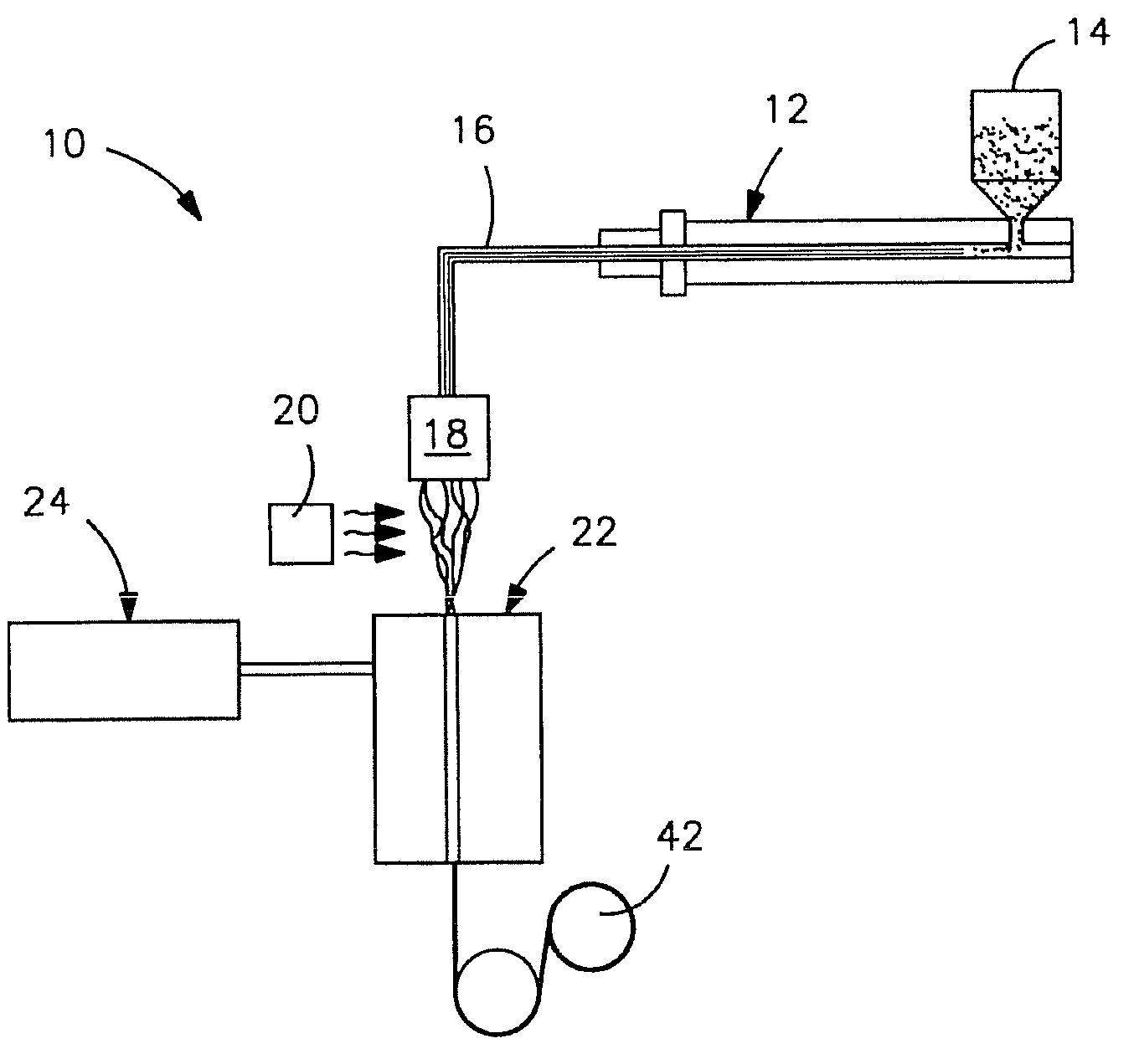

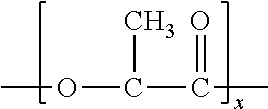

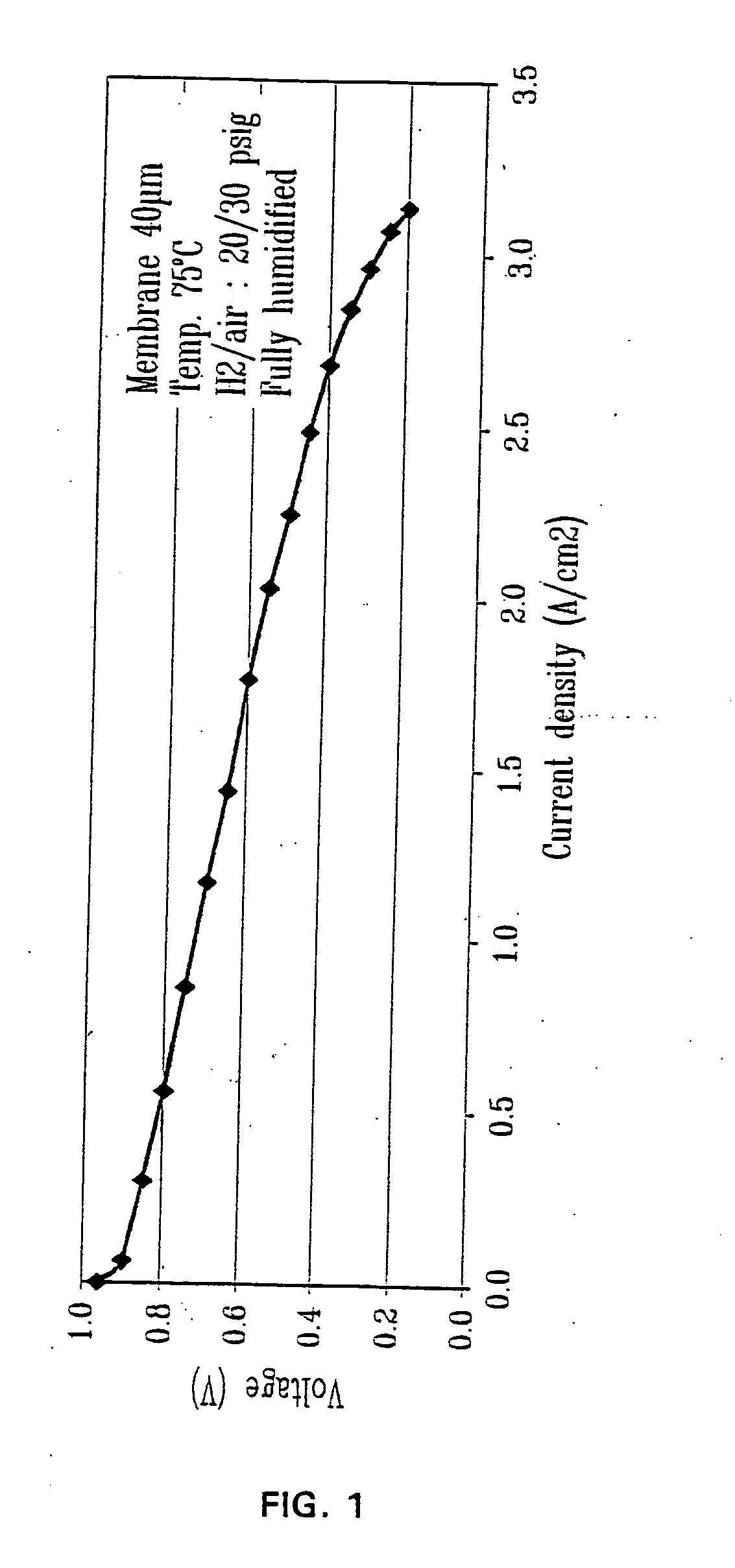

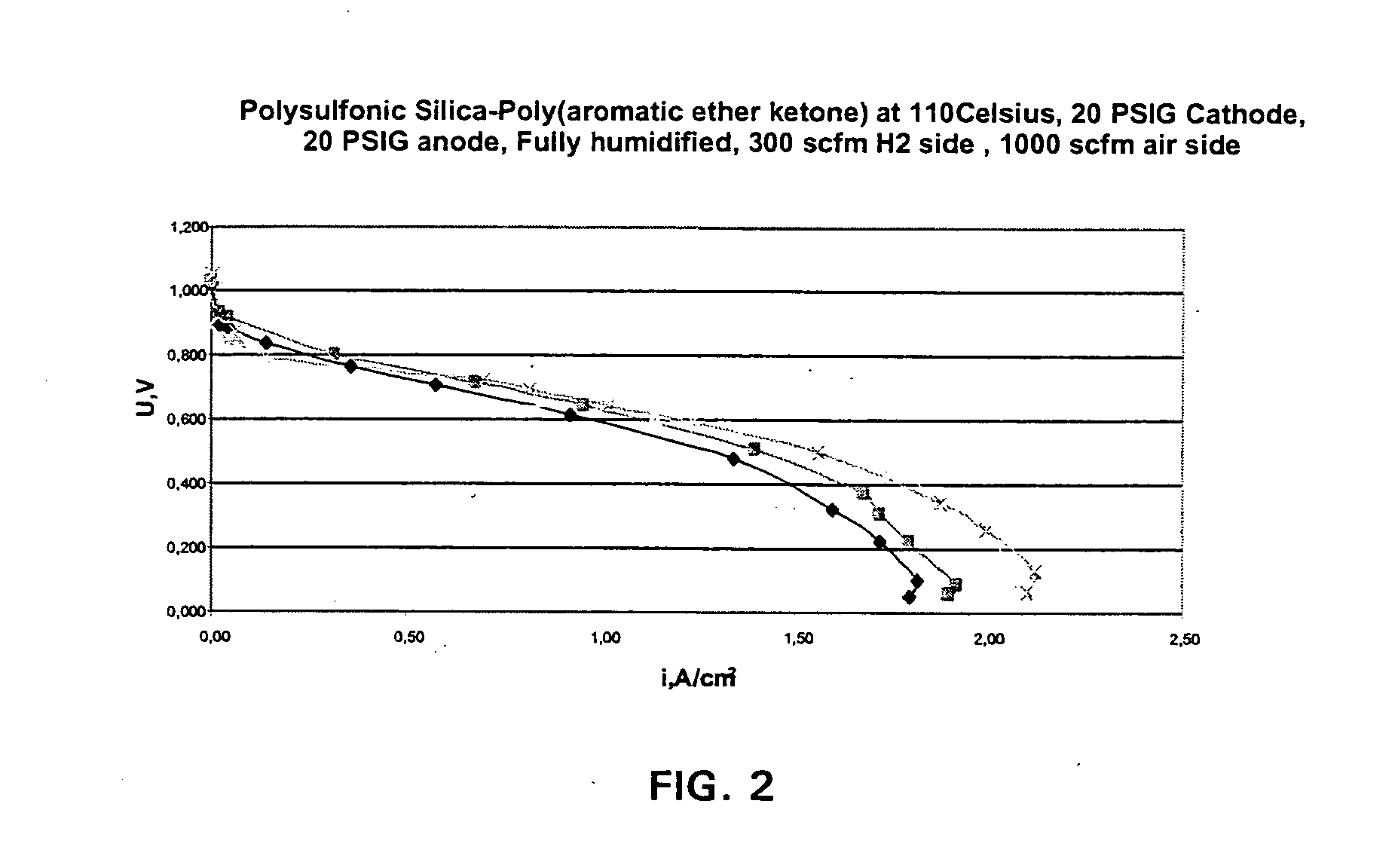

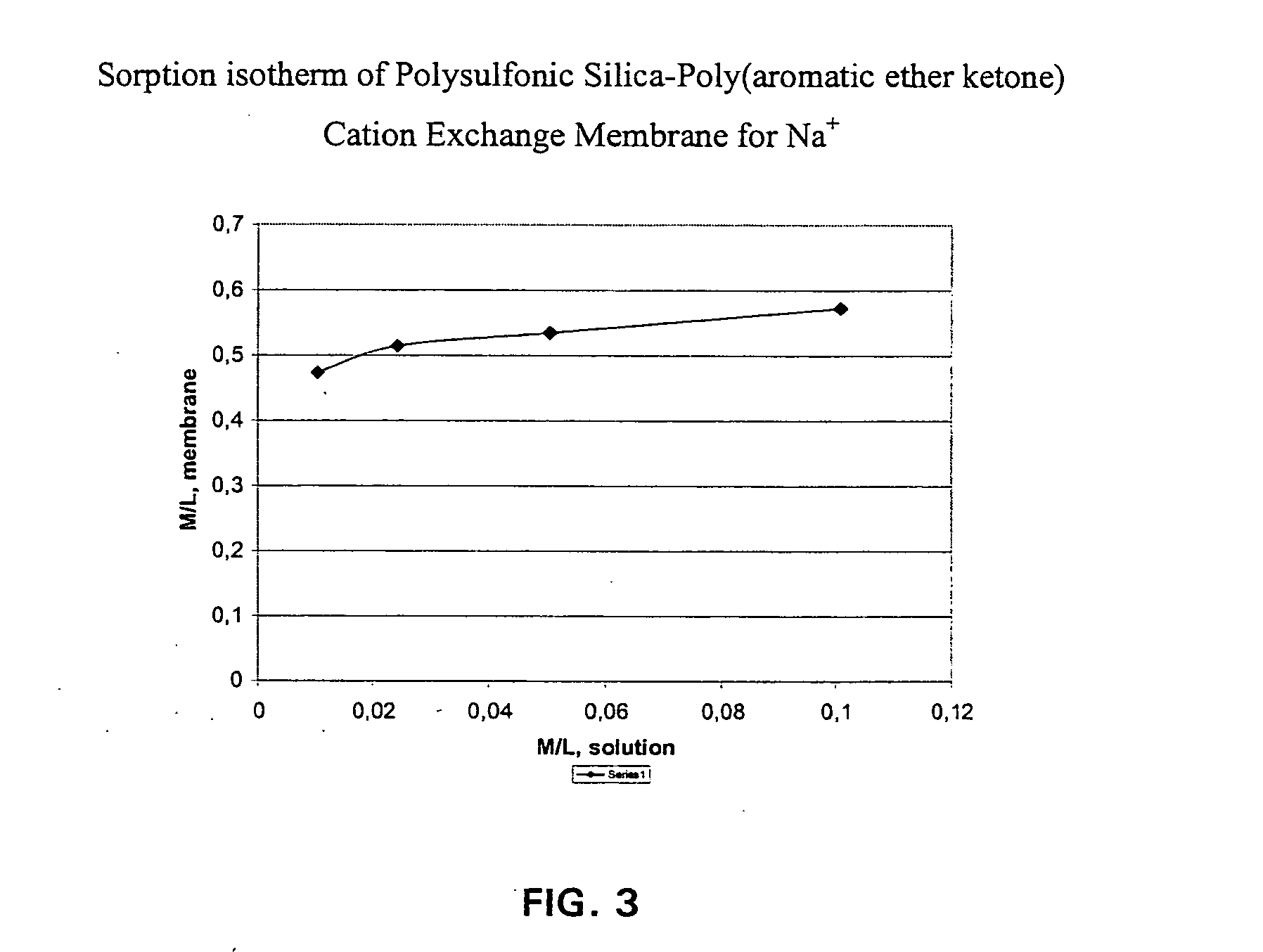

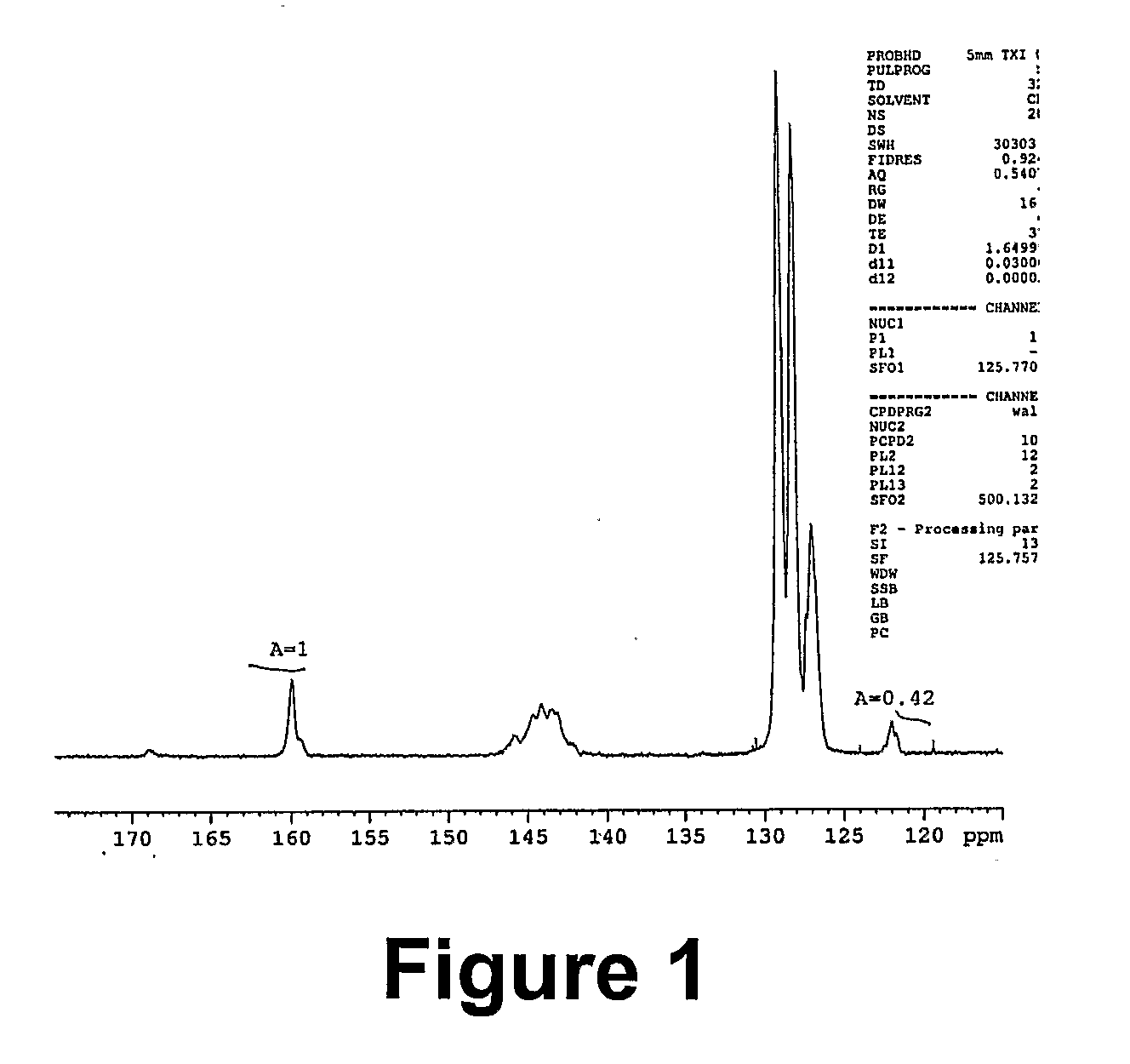

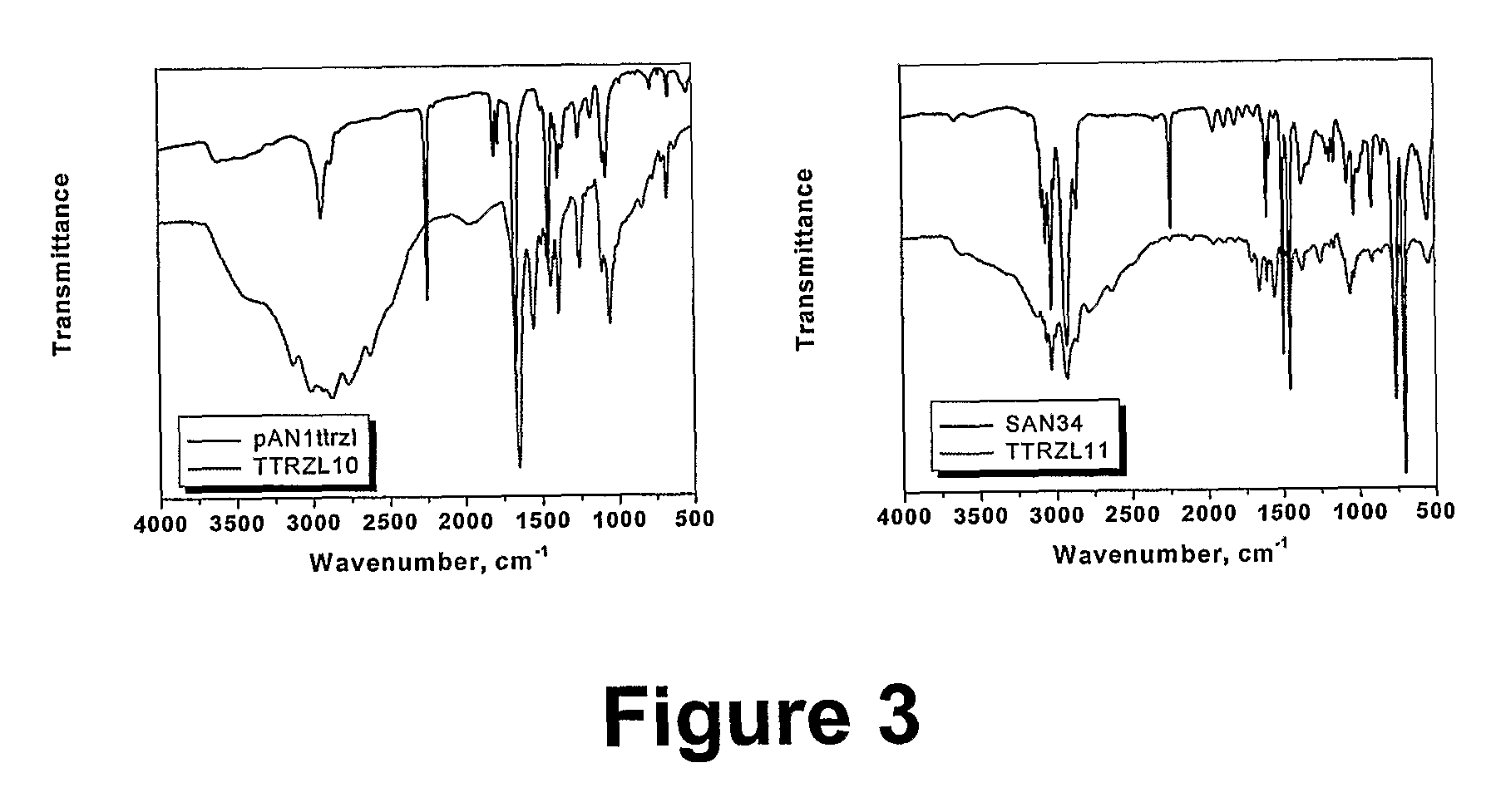

Ion exchange composite material based on proton conductive functionalized inorganic support compounds in a polymer matrix

InactiveUS20050053818A1Improve mechanical propertiesImprove impermeabilitySemi-permeable membranesSolid electrolytesIon exchangeLiquid fuel

The composite material comprise acid functionalized inorganic supports such as silica dispersed in a functionalized and / or non-functionalized polymer matrix that is based on numerous polymers such as poly(aromatic ether ketones), or poly(benzoyl phenylene), or derivatives thereof. The composite material is characterized by good water retention capabilities due to the acidic functions and the hydrophilicity of the silica particles. Moreover, a good impermeability to gas and liquid fuels commonly used in fuel cell technology, like hydrogen gas or methanol solution, is also obtained due to the presence of silica particles. Good mechanical properties of the composite material let the material to be formed easily in thin film or membrane form. In that form, the composite material is usable for proton exchange membrane for fuel cells, for drying or humidifying membrane for gas or solvent conditioning, or as acid catalytic membrane.

Owner:SIM COMPOSITES INC

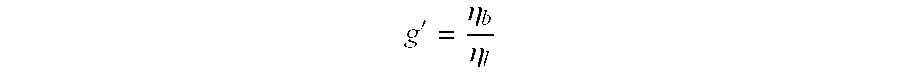

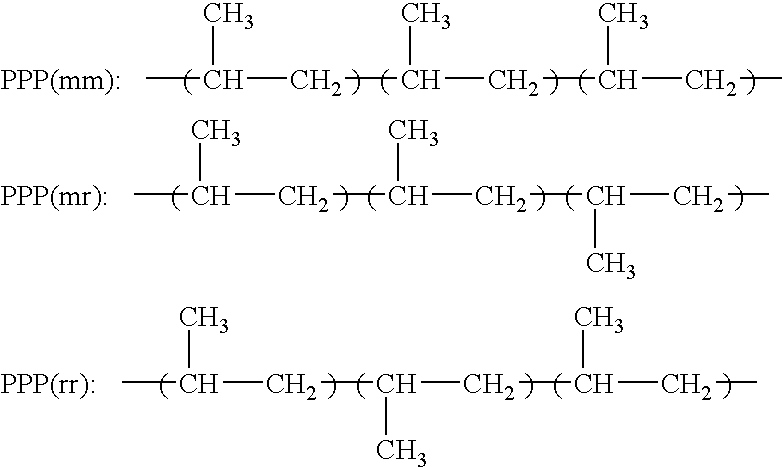

Functionalized olefin polymers

This invention relates to a composition comprising a functionalized C3 to C40 olefin polymer comprising at least 50 mol % of one or more C3 to C40 olefins, and where the olefin polymer, prior to functionalization, has:a) a Dot T-Peel of 1 Newton or more on Kraft paper;b) an Mw of 10,000 to 100,000; andc) a branching index (g′) of 0.98 or less measured at the Mz of the polymer when the polymer has an Mw of 10,000 to 60,000, or a branching index (g′) of 0.95 or less measured at the Mz of the polymer when the polymer has an Mw of 10,000 to 100,000; and where the C3 to C40 olefin polymer comprises at least 0.001 weight % of an functional group, preferably maleic anhydride. This invention further relates to blends of such functionalized polymers with other polymers including non-functionalized C3 to C40 olefin polymers as described above.

Owner:EXXONMOBIL CHEM PAT INC

Preparation of Functional Polymers

The process of the present invention is directed toward conducting highly selective, high yield post polymerization reactions on polymers to prepare functionalized polymers. An embodiment of the present invention comprises conducting click chemistry reactions on polymers. Preferably, the polymers were prepared by controlled polymerization processes. Therefore, embodiments of the present invention comprise processes for the preparation of polymers comprising conducting a click chemistry reaction on a functional group attached to a polymer, wherein the polymer has a molecular weight distribution of less than 2.0. The functional polymers may be prepared by converting an attached functional unit on the polymer thereby providing site specific functional materials, site specific functional materials comprising additional functionality, or chain extended functional materials. Embodiments of the process of the present invention include functionalization reactions, chain extensions reactions, to form mock copolymer linking reactions, and attaching side chains to form graft copolymers, for example.

Owner:CARNEGIE MELLON UNIV

Block copolymers from macrocyclic oligoesters and dihydroxyl-functionalized polymers

InactiveUS6436549B1Lactams stabilisationSynthetic resin layered productsPolyesterPolymerization catalysts

Block copolymers are prepared from polymerization of a macrocyclic oligoester and a dihydroxyl-functionalized polymer at an elevated temperature in the presence of a polymerization catalyst.

Owner:LIQUID THERMO PLASTICS

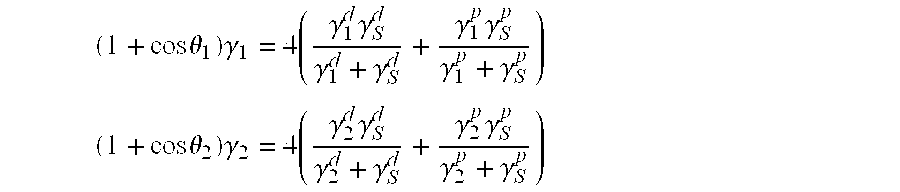

Plasticized functionalized propylene copolymer adhesive composition

Disclosed herein is an adhesive composition comprising: a random propylene polymer component having a heat of fusion of between 1 and 70 J / g and an mm triad tacticity index of at least 75%; and a functionalized polymer component comprising a C2-C20 olefin comprising at least 0.1 wt % of a functional group; wherein the adhesive composition has a T-Peel adhesion on a polar substrate at 20° C. of at least 175 N / m (1 lb / in) and a T-Peel adhesion on a non-polar substrate at 20° C. of at least 175 N / m Pa (1 lb / in) and where the polarity of the polar substrate is at least 0.10 units higher than the polarity of the non-polar substrate. Methods to produce the adhesive and articles comprising the adhesive are also disclosed.

Owner:EXXONMOBIL CHEM PAT INC

Method of using aldehyde-functionalized polymers to enhance paper machine dewatering

A method of enhancing the dewatering of a paper sheet on a paper machine comprising adding to the paper sheet about 0.05 lb / ton to about 15 lb / ton, based on dry fiber, of one or more aldehyde functionalized polymers comprising amino or amido groups wherein at least about 15 mole percent of the amino or amido groups are functionalized by reacting with one or more aldehydes and wherein the aldehyde functionalized polymers have a molecular weight of at least about 100,000.

Owner:ECOLAB USA INC

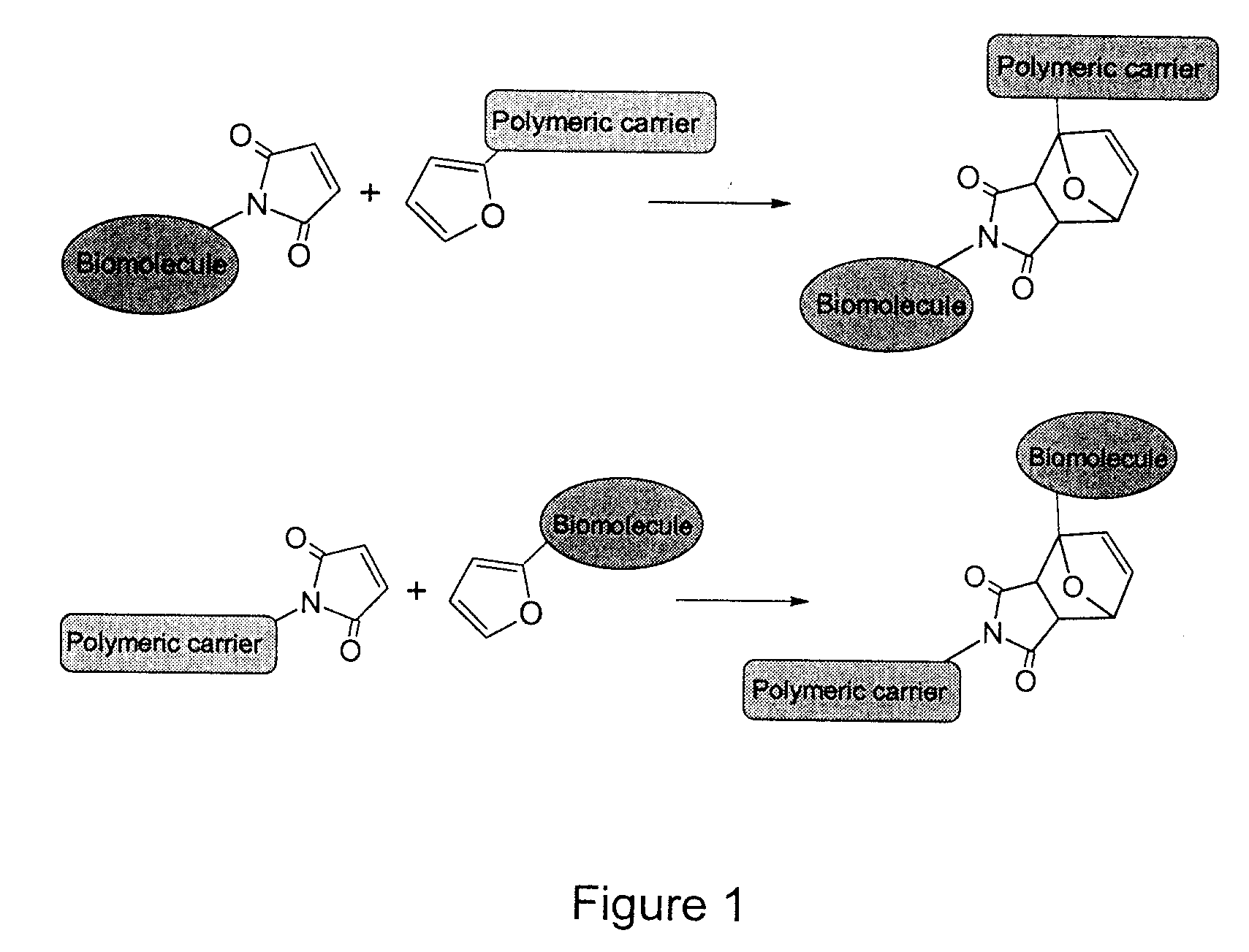

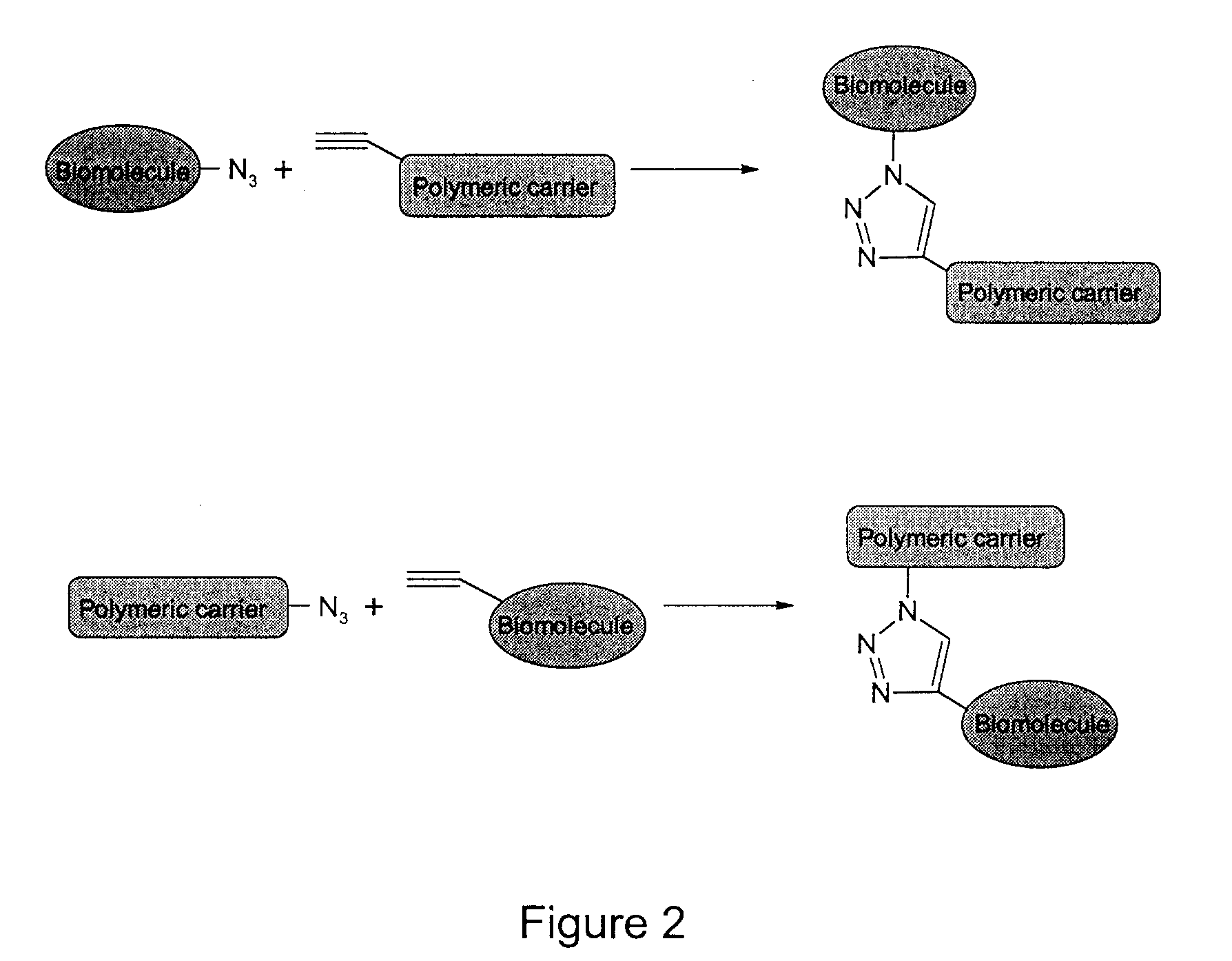

Method of Biomolecule Immobilization On Polymers Using Click-Type Chemistry

ActiveUS20090297609A1Improve efficiencyProcess environmental protectionBiocideOrganic active ingredientsFuranAlkyne

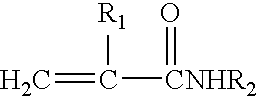

The present invention provides a method for the covalent immobilization of biomolecules on polymers for delivery of the biomolecules, which has the advantage of being simple, highly efficient, environmentally friendly and free of side products relative to traditional immobilization techniques. The invention provides a modified micro / nanoparticle system, which uses a functionalized polymer formed into micro or nanoparticles to bind a molecule to the particles using uses facile chemistry, the Diels-Alder cycloaddition between a diene and a dienophile with the polymer being functionalized with one of them and the molecule with the other, or the Huisgen 1,3-dipolar cycloaddition between a terminal alkyne and an azide to bind the molecule to the particle. The molecules and / or other therapeutic agents may be encapsulated within the polymer particles for intravenous therapeutic delivery. The invention also provides a novel synthetic biodegradable polymer, a furan / alkyne-functionalized poly(trimethylene carbonate) (PTMC)-based polymer, whose composition can be designed to meet the defined physical and chemical property requirements. In one example, the particle system self-aggregates from functionalized PTMC-based copolymers containing poly(ethylene glycol) (PEG) segments. The composition of the copolymers can be designed to meet various particle system requirements, including size, thermodynamic stability, surface PEG density, drug encapsulation capacity and biomolecule immobilization capacity.

Owner:SHOICHET MOLLY S +2

Preparation of functional polymers

Owner:CARNEGIE MELLON UNIV

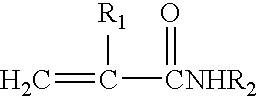

Functionalized polymers and methods for their manufacture

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing monomer with a coordination catalyst to form a reactive polymer; and (ii) reacting the reactive polymer with a carboxylic or thiocarboxylic ester containing a silylated amino group.

Owner:BRIDGESTONE CORP

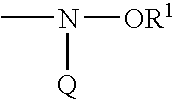

Amine functionalized polymer

A functionalized polymer includes a polymer chain and, bonded thereto, a functional group having the general formula —NQOR1 where R1 is a hydrogen atom or —CH2Z where Z is a hydrogen atom or a substituted or unsubstituted aryl, alkyl, alkenyl, alkenaryl, aralkenyl, alkaryl, or aralkyl group and where Q is a moiety connected to the nitrogen atom of the functional group through a C, N, O, or S atom. The material can be the reaction product of a living polymer and a compound that includes nitroso functionality. The functional group can interact with particulate filler such as, e.g., carbon black.

Owner:BRIDGESTONE CORP

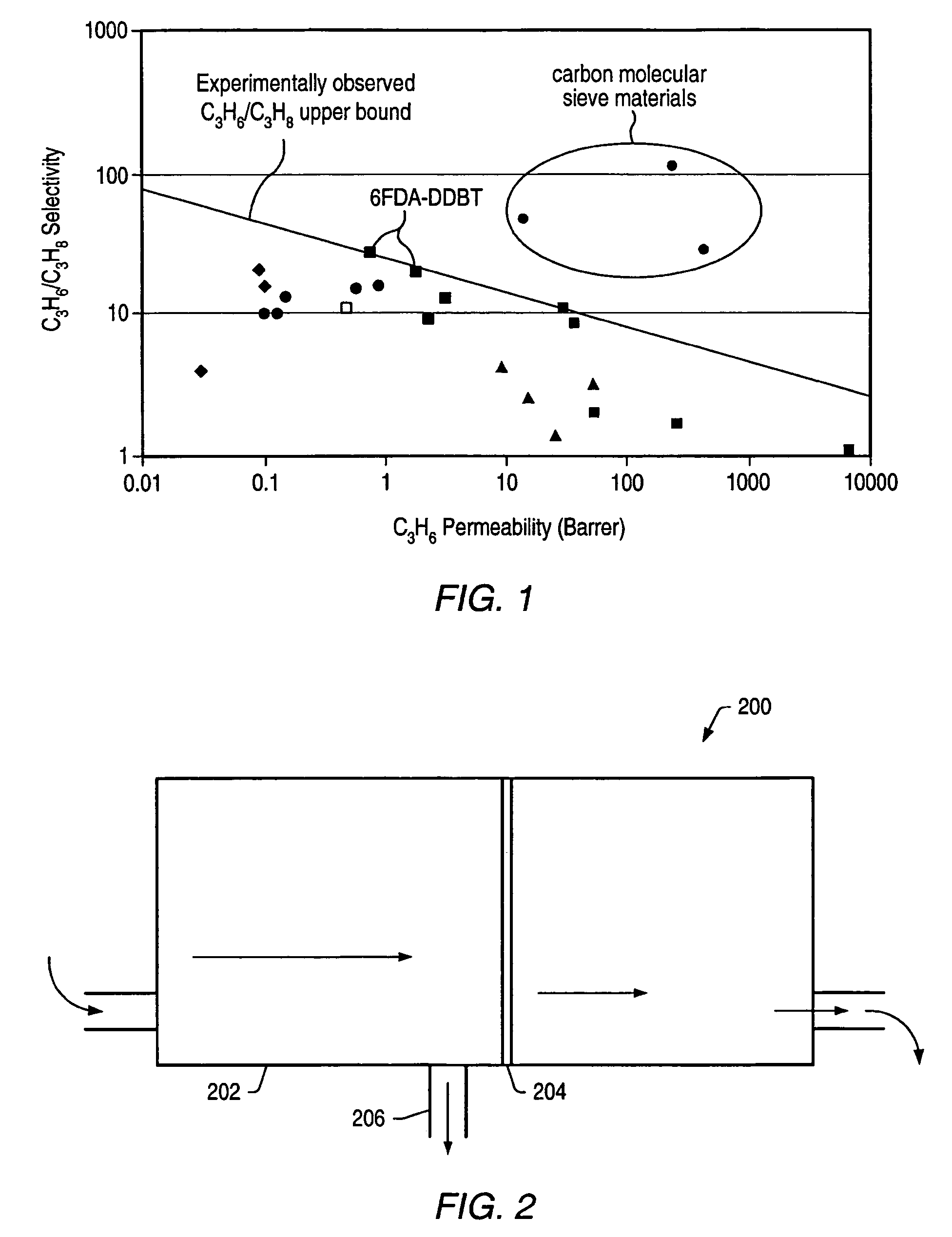

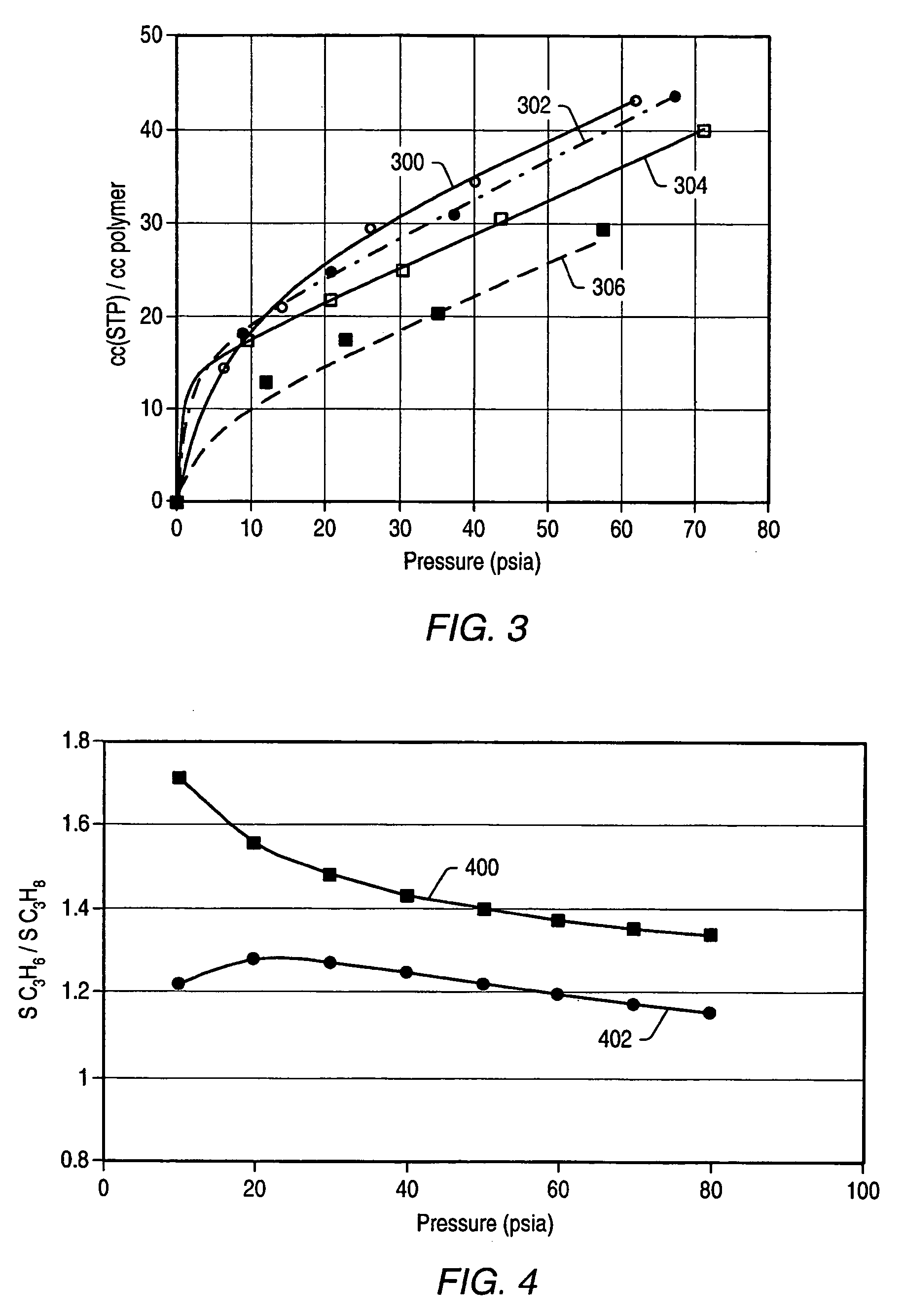

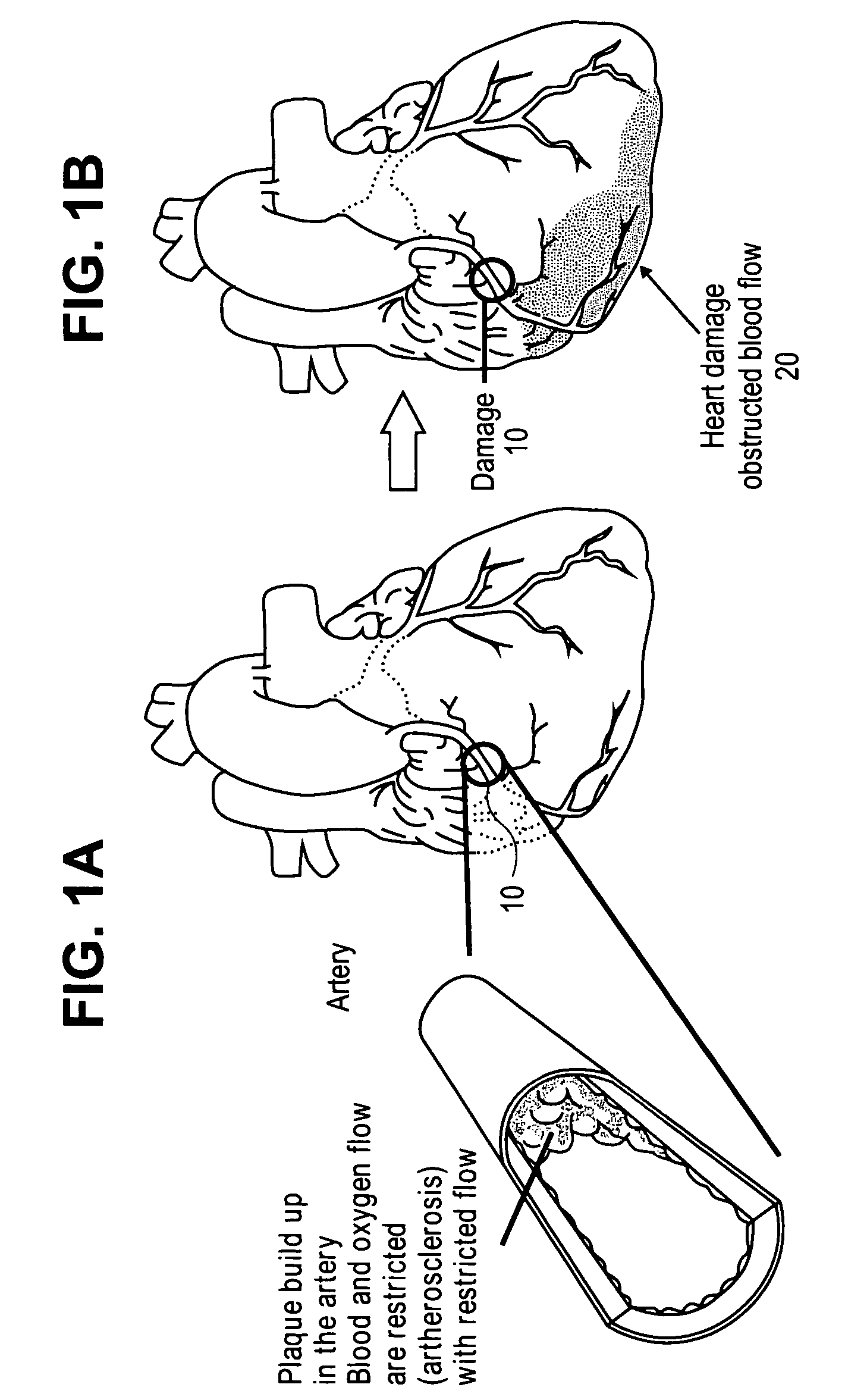

Dithiolene functionalized polymer membrane for olefin/paraffin separation

InactiveUS7160356B2Easy to separateYield maximizationSemi-permeable membranesMembranesImideSolubility

A polymeric composite may be used for forming fluid separation membranes. The membranes may be formed from polyimide, polyamide or poly (pyrrolone-imide) materials. Polyamides may be formed by the condensation of a tetraamine, a tetraacid, and a diamine. Polyimides and poly (pyrrolone-imides) may be formed by the cyclization of a polymer precursor. A polymeric composite may include a dithiolene or a mixture of dithiolenes. A polymer matrix incorporating dithiolenes may exhibit an olefin / paraffin solubility selectivity. A solubility selectivity may be between about 1.1 and about 2.0.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

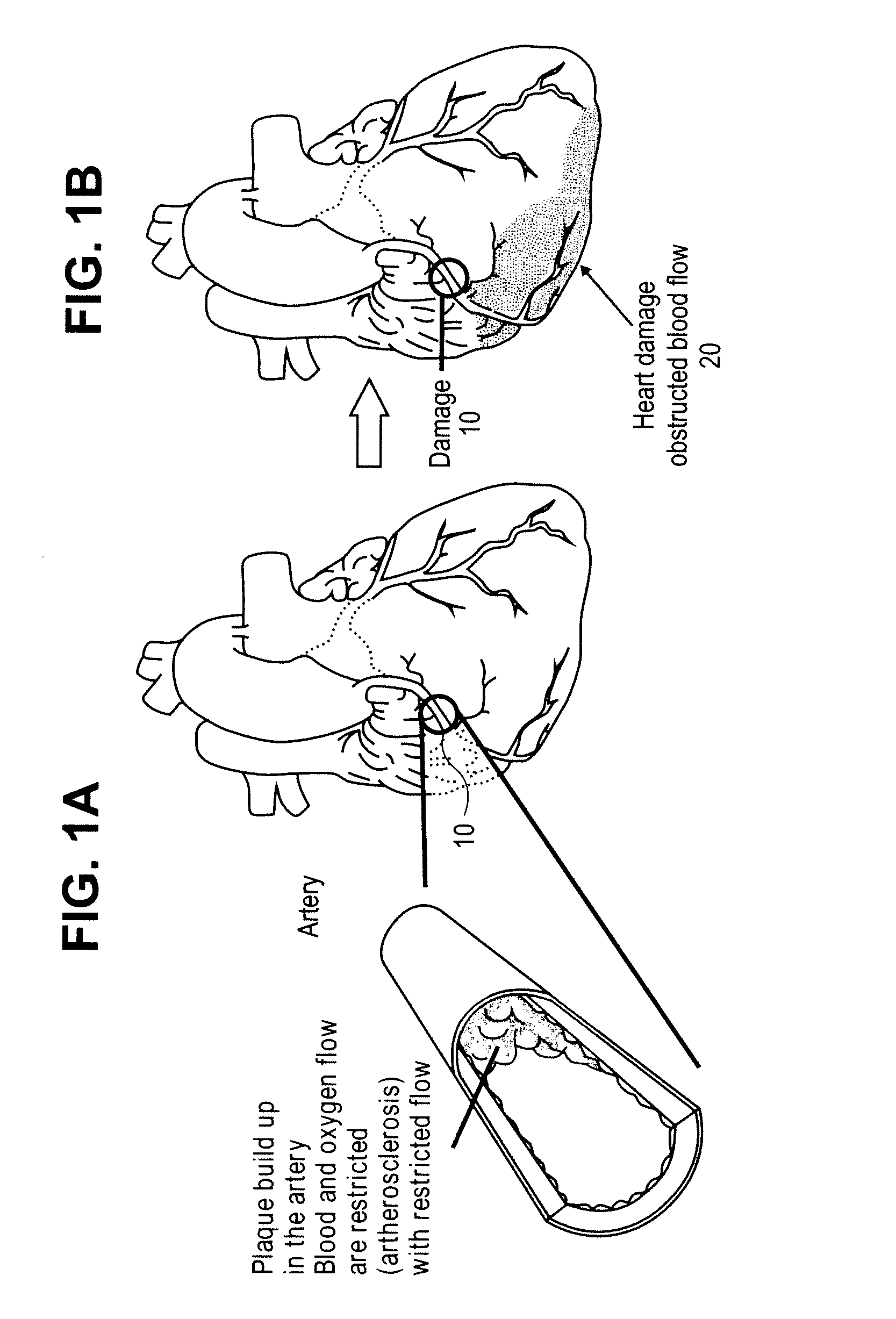

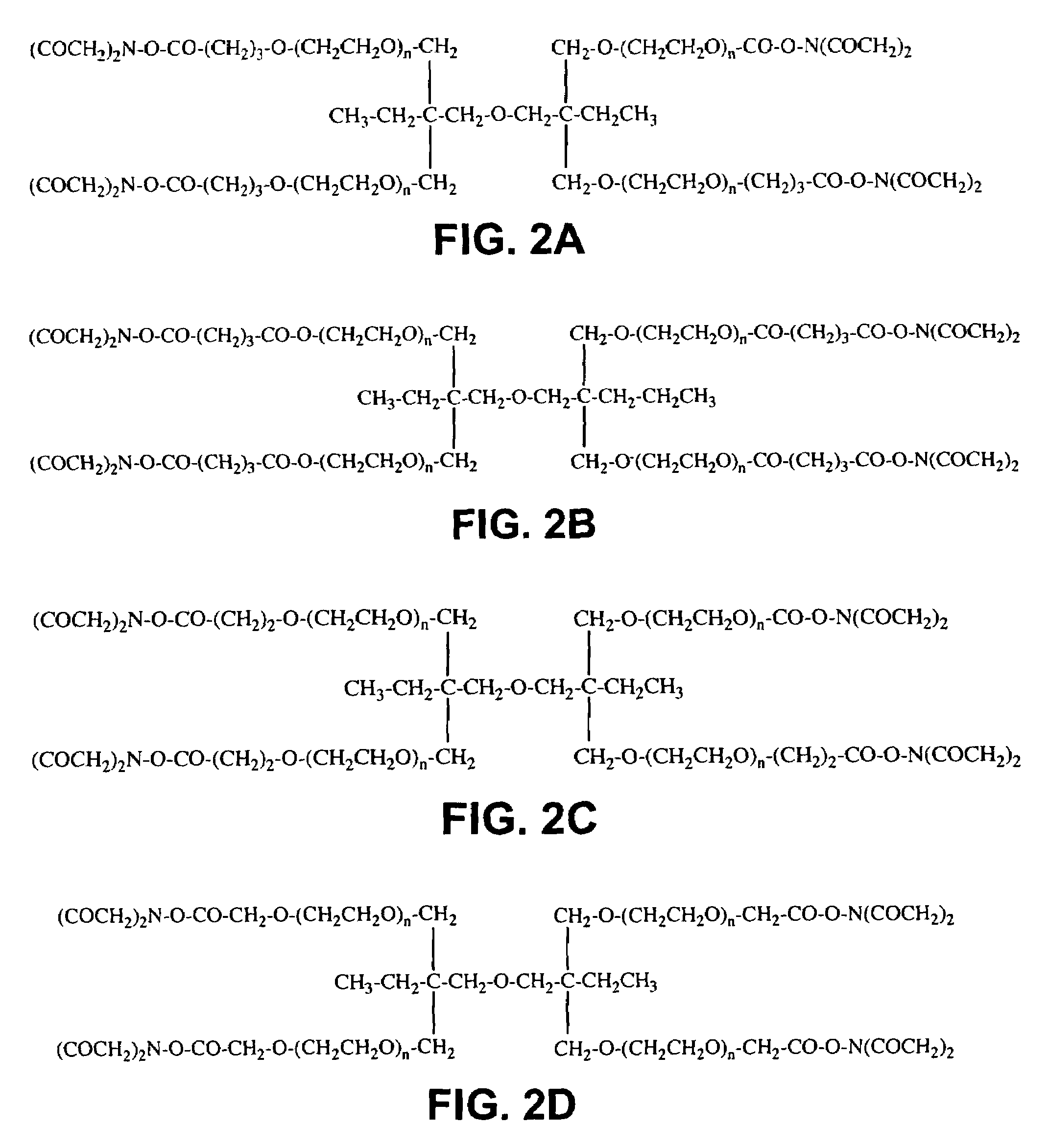

Modified two-component gelation systems, methods of use and methods of manufacture

Compositions, methods of manufacture and methods of treatment for post-myocardial infarction are herein disclosed. In some embodiments, the composition includes at least two components. In one embodiment, a first component can include a first functionalized polymer and a substance having at least one cell adhesion site combined in a first buffer at a pH of approximately 6.5. A second component can include a second buffer in a pH of between about 7.5 and 9.0. A second functionalized polymer can be included in the first or second component. In some embodiments, the composition can include at least one cell type and / or at least one growth factor. In some embodiments, the composition(s) of the present invention can be delivered by a dual bore injection device to a treatment area, such as a post-myocardial infarct region.

Owner:ABBOTT CARDIOVASCULAR

Rubber Composition Containing Functionalized Polymer Nanoparticles

Owner:BRIDGESTONE CORP

Polymers functionalized with nitro compounds

A method for preparing a functionalized polymer, the method comprising the steps of (i) polymerizing conjugated diene monomer by employing a lanthanide-based catalyst to form a reactive polymer, and (ii) reacting the reactive polymer with a nitro compound.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com