Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4212results about How to "Improve impermeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

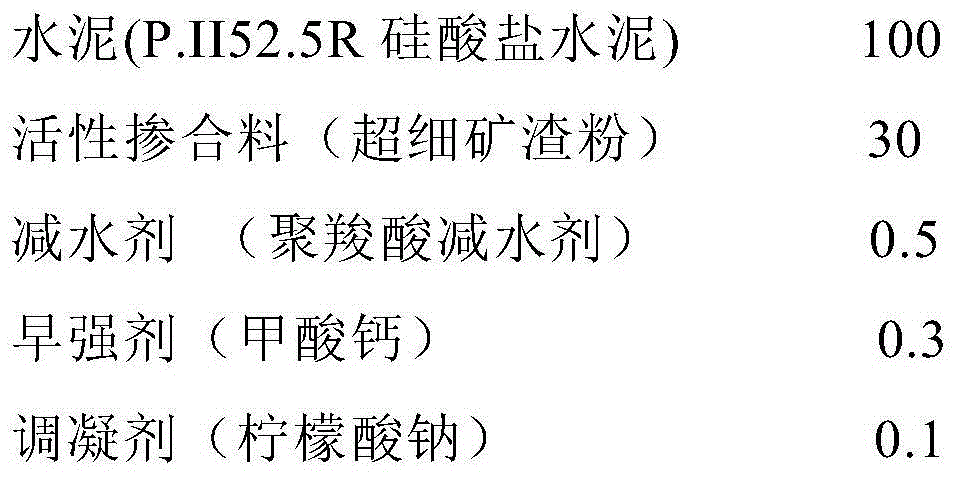

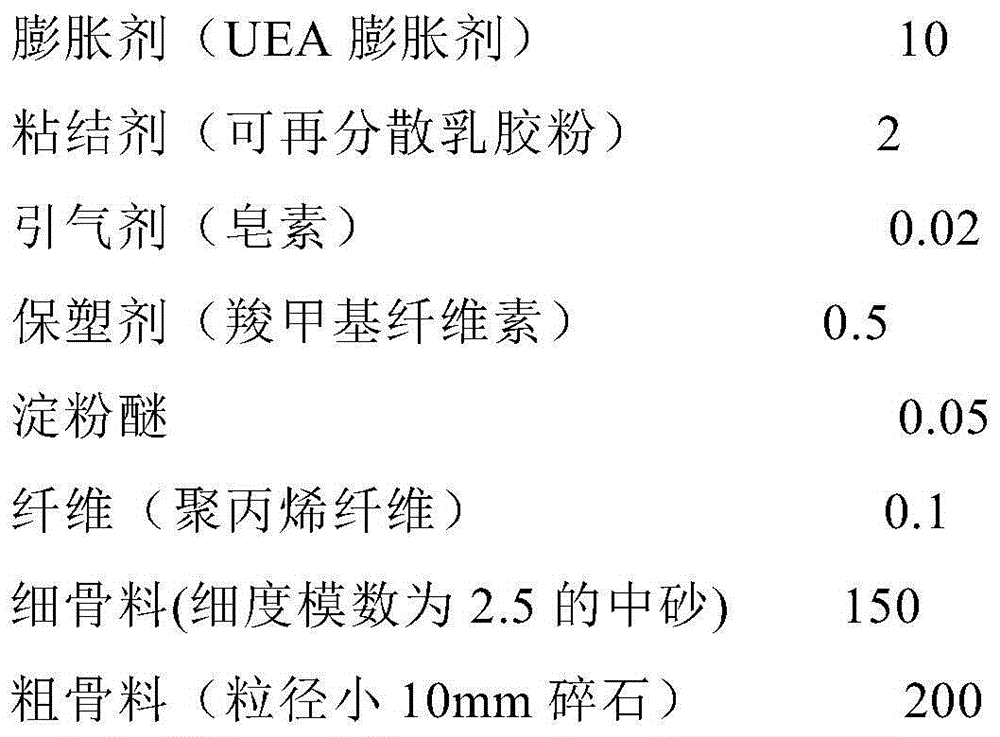

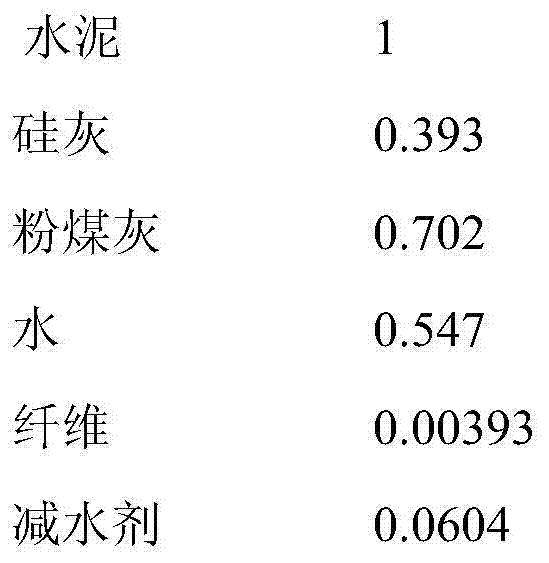

3D printing cement-based material and preparation method thereof

The invention relates to a 3D printing cement-based material and a preparation method thereof. The 3D printing cement-based material is composed of a powder form gelling material and an aggregate, the powder form gelling material is composed of cement, an active admixture, a water reducer, a hardening accelerator, an adjustable solidification agent, an expanding agent, a binder, an air-entrainer, a plasticity-maintaining agent, a water repellent, starch ether, a powder filling material and fiber, and the aggregate is composed of a fine aggregate and a crude aggregate. Compared with prior art, the 3D printing cement-based material has the advantages of good work performance, constructability performance, mechanical property and endurance performance.

Owner:TONGJI UNIV

Multifunctional coatings and preparation method thereof

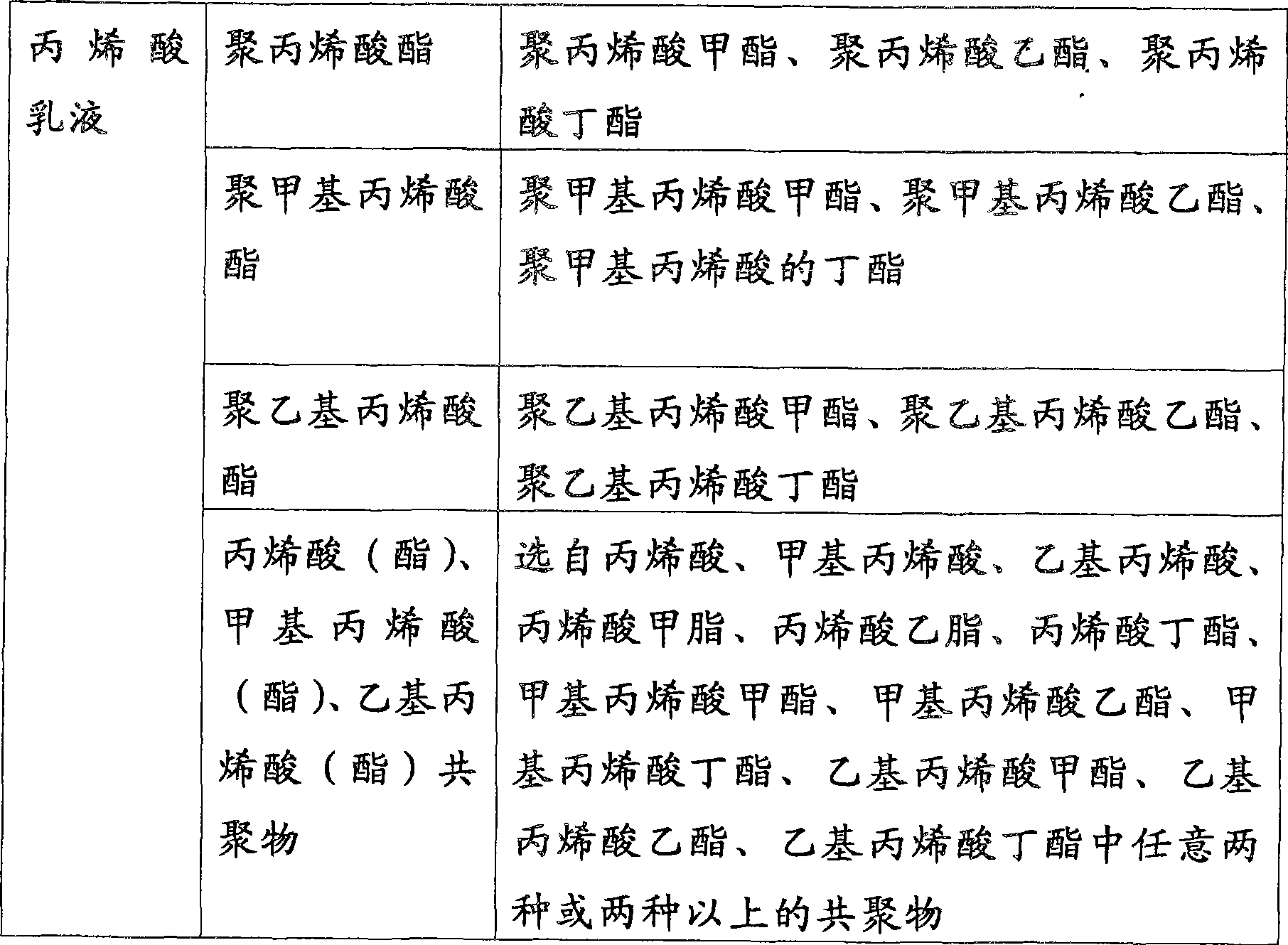

ActiveCN101386719AGood film formingImprove impermeabilityFireproof paintsLuminescent paintsFire retardantStorage garage

The invention relates to multifunctional paint with the functions of water and fire prevention, lighting, noise reduction, safe escape and decoration and a preparation method thereof. The multifunctional paint comprises a polymer emulsion, a filler, a flame retardant, a long afterglow luminescent material, an addition agent and water, and the paint comprises raw materials in weight percentage: 10 to 50 percent of the polymer emulsion, 5 to 30 percent of the filler, 10 to 30 percent of the flame retardant, 10 to 60 percent of the long afterglow luminescent material, 0.1 to 5 percent of the addition agent and 1 to 50 percent of the water. The multifunctional paint is applied to a highway tunnel, an underground garage, an underground urban traffic passage, a civil defence engineering, an underground fortification, an underground warehouse, an underground production workshop and other underground buildings, can well meet the requirements of waterproof and fireproof functions and has obvious energy-saving effect; and with the characteristic of the long afterglow of the luminescent paint, the multifunctional paint exerts the function of illumination after power failure and is used to guide personnel to safely evacuate the scene of an accident. In addition, the multifunctional paint also has certain functions of noise absorption and noise reduction.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

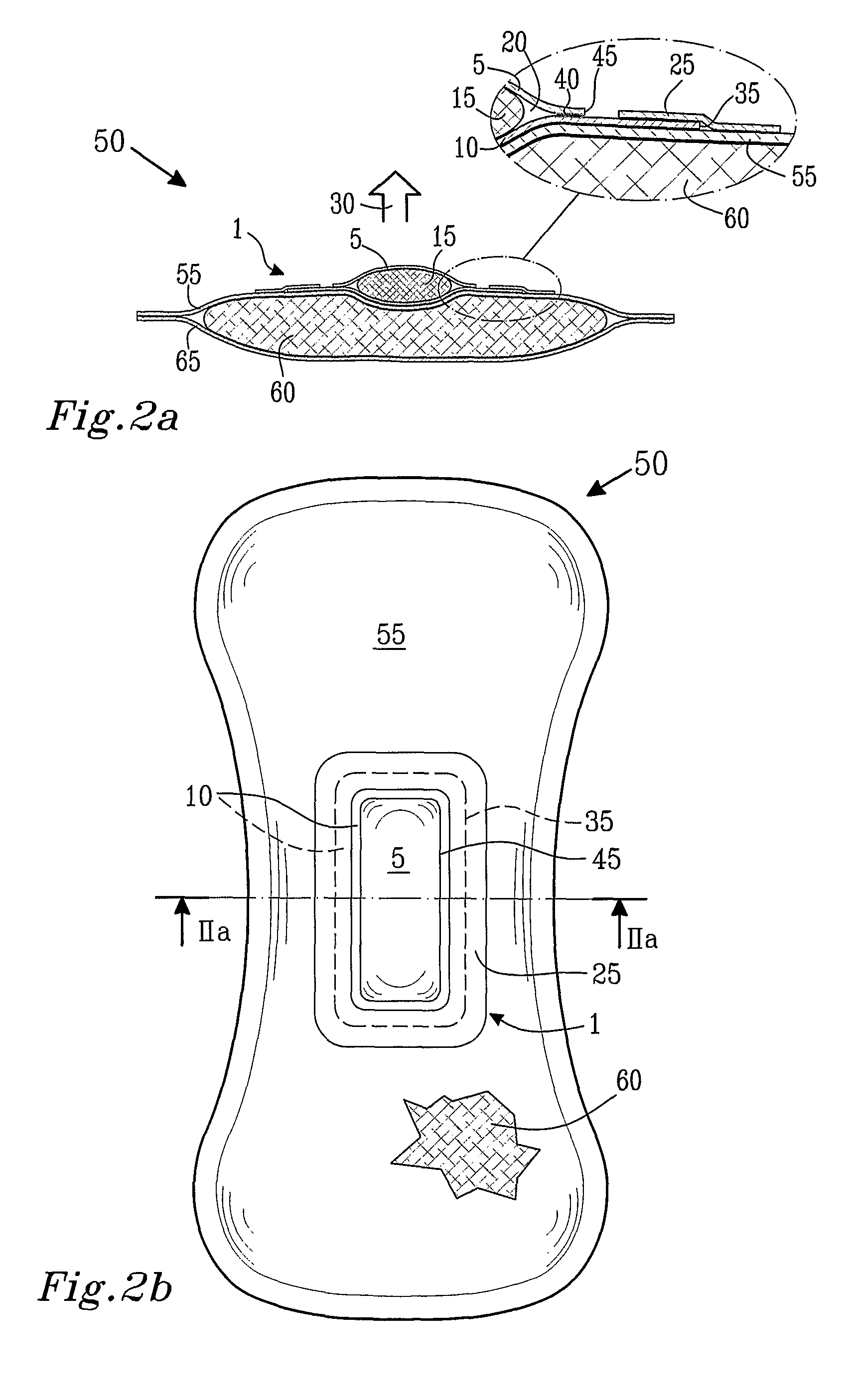

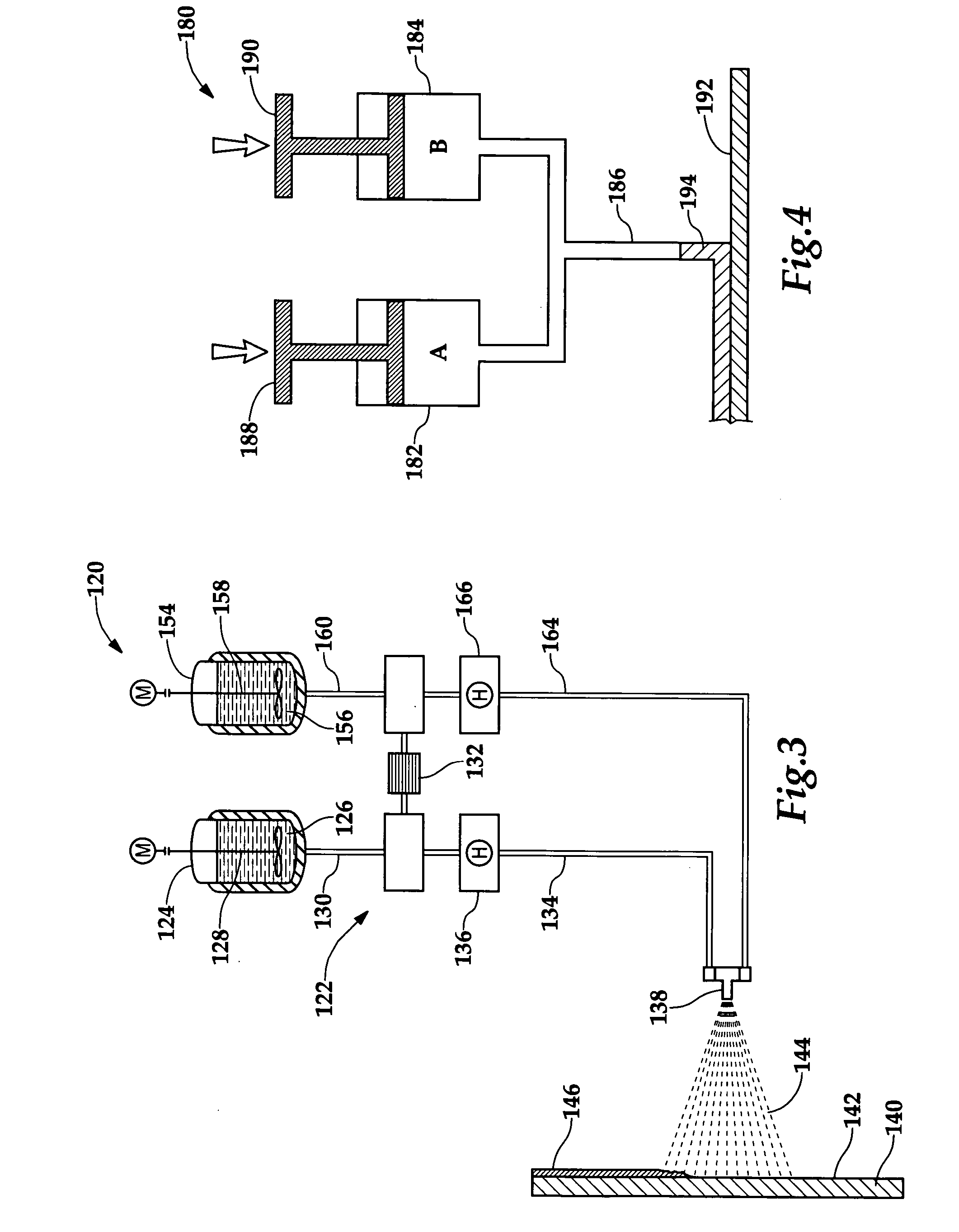

Delivery device

Owner:ESSITY HYGIENE & HEALTH AB

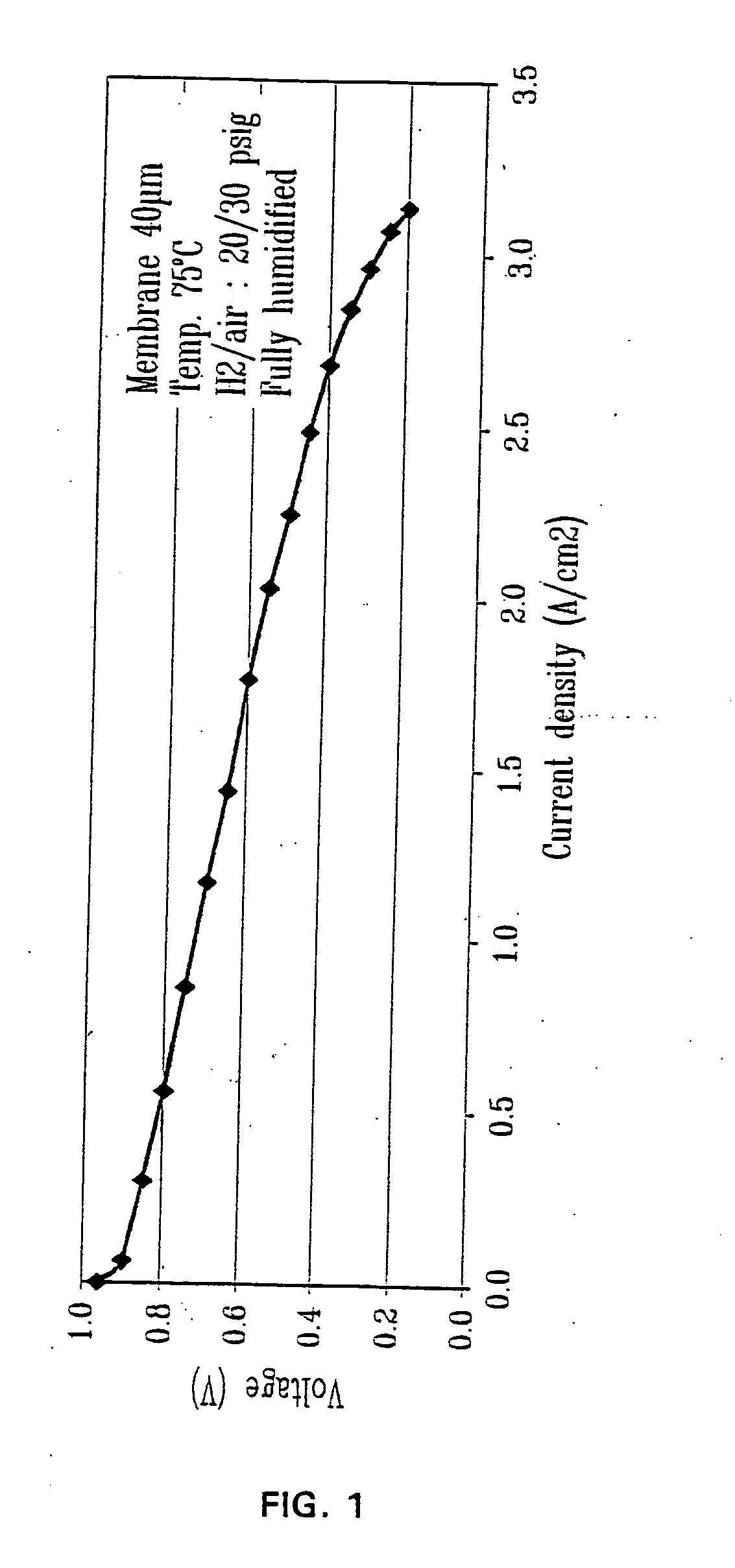

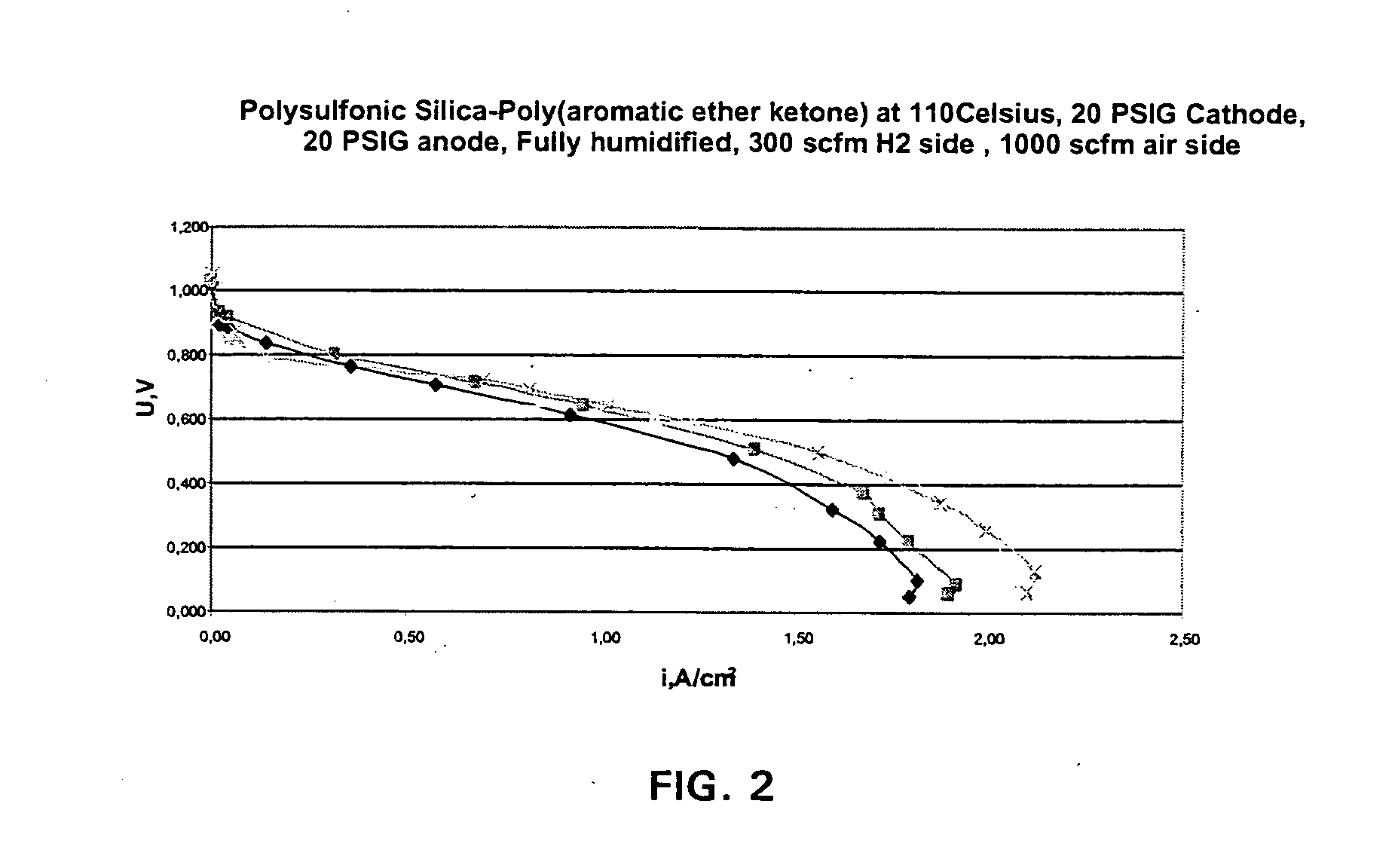

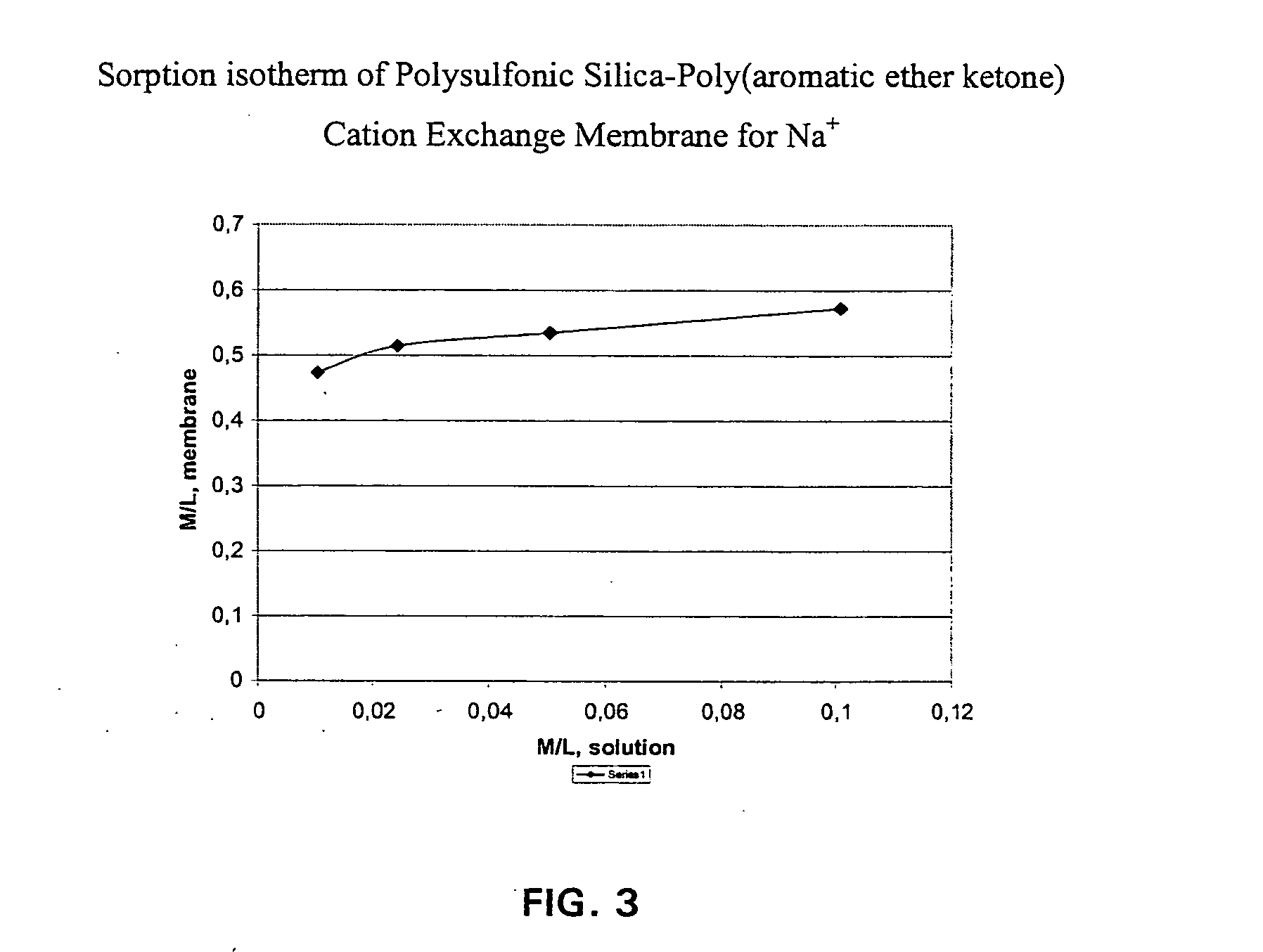

Ion exchange composite material based on proton conductive functionalized inorganic support compounds in a polymer matrix

InactiveUS20050053818A1Improve mechanical propertiesImprove impermeabilitySemi-permeable membranesSolid electrolytesIon exchangeLiquid fuel

The composite material comprise acid functionalized inorganic supports such as silica dispersed in a functionalized and / or non-functionalized polymer matrix that is based on numerous polymers such as poly(aromatic ether ketones), or poly(benzoyl phenylene), or derivatives thereof. The composite material is characterized by good water retention capabilities due to the acidic functions and the hydrophilicity of the silica particles. Moreover, a good impermeability to gas and liquid fuels commonly used in fuel cell technology, like hydrogen gas or methanol solution, is also obtained due to the presence of silica particles. Good mechanical properties of the composite material let the material to be formed easily in thin film or membrane form. In that form, the composite material is usable for proton exchange membrane for fuel cells, for drying or humidifying membrane for gas or solvent conditioning, or as acid catalytic membrane.

Owner:SIM COMPOSITES INC

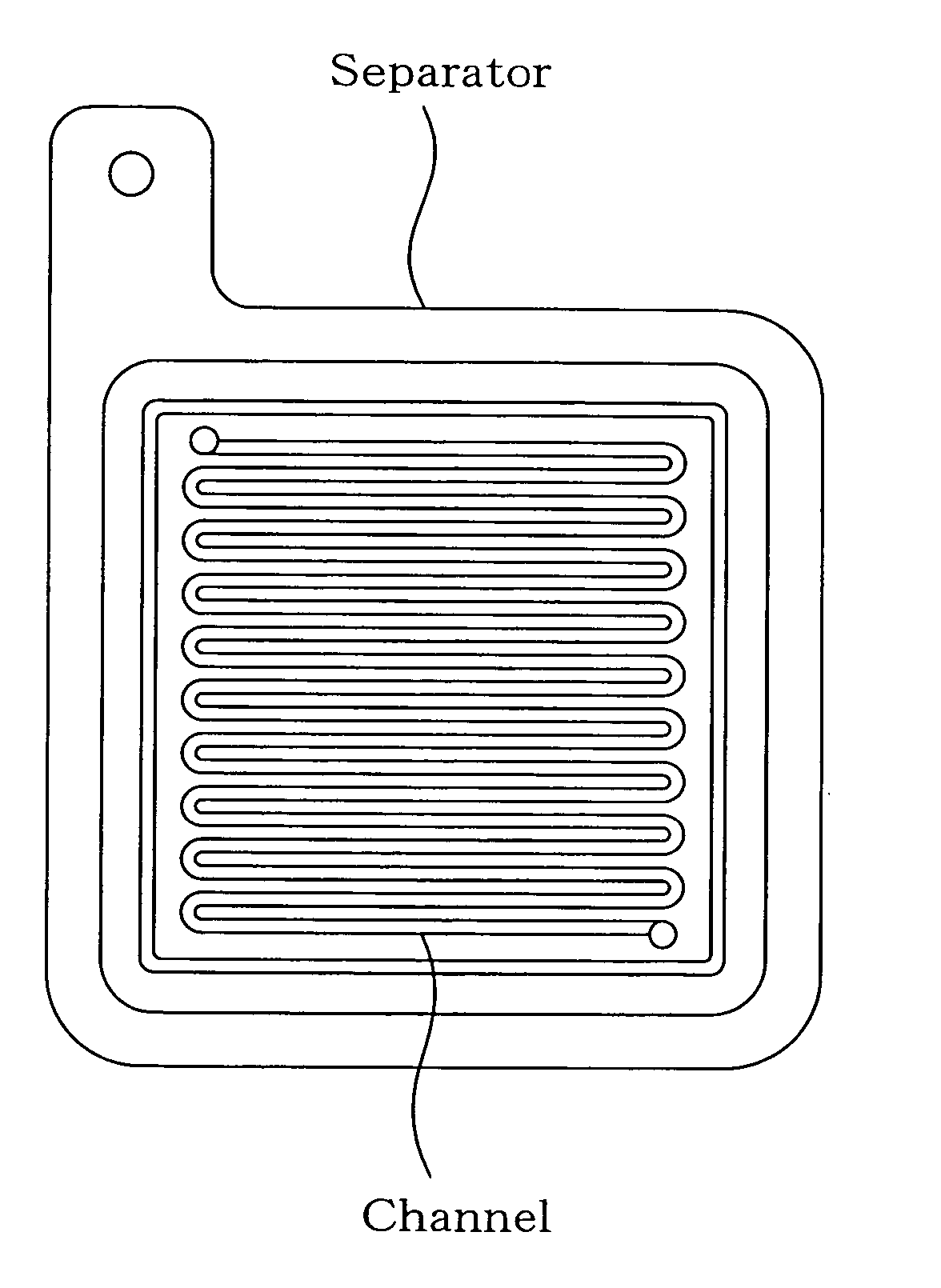

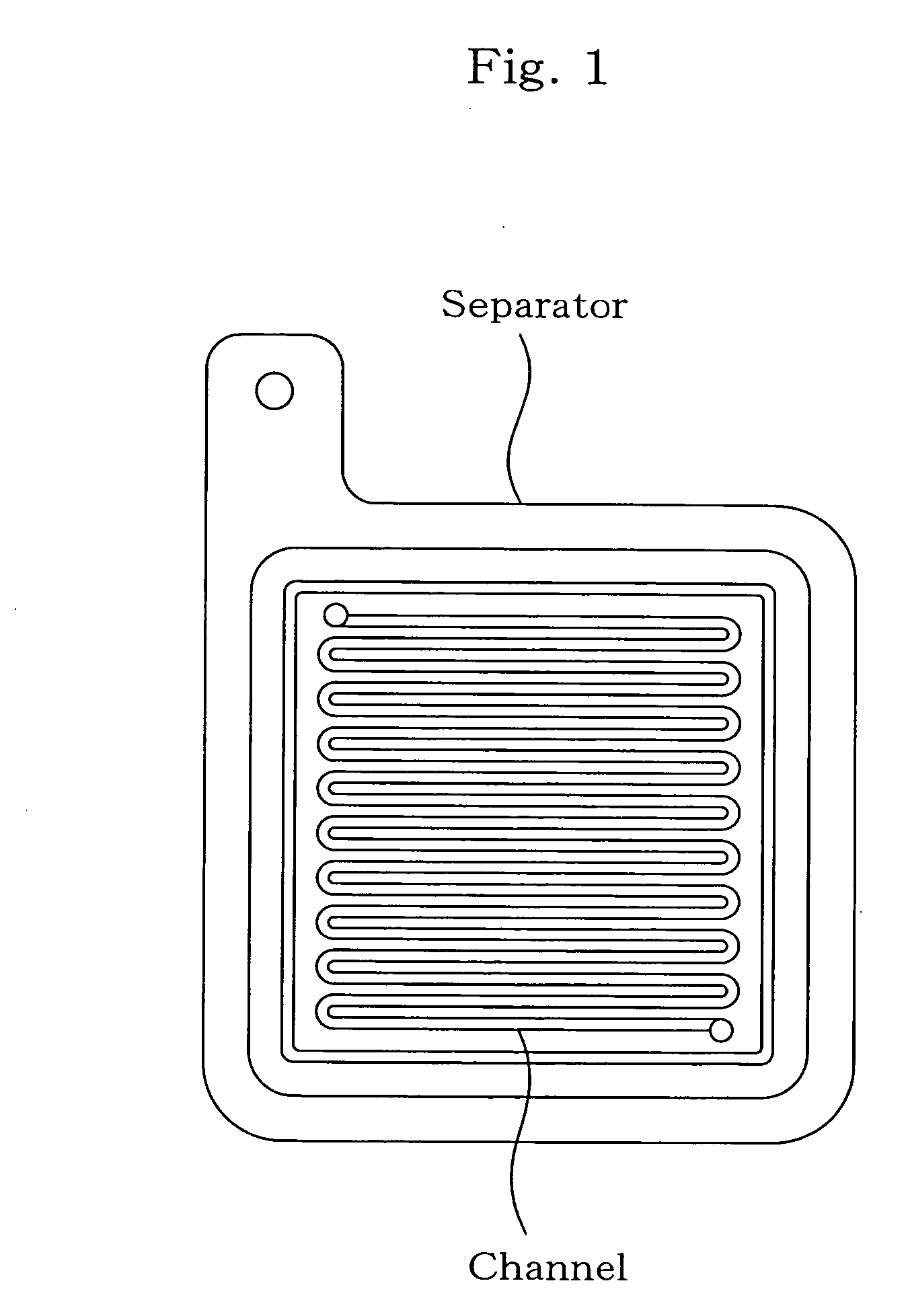

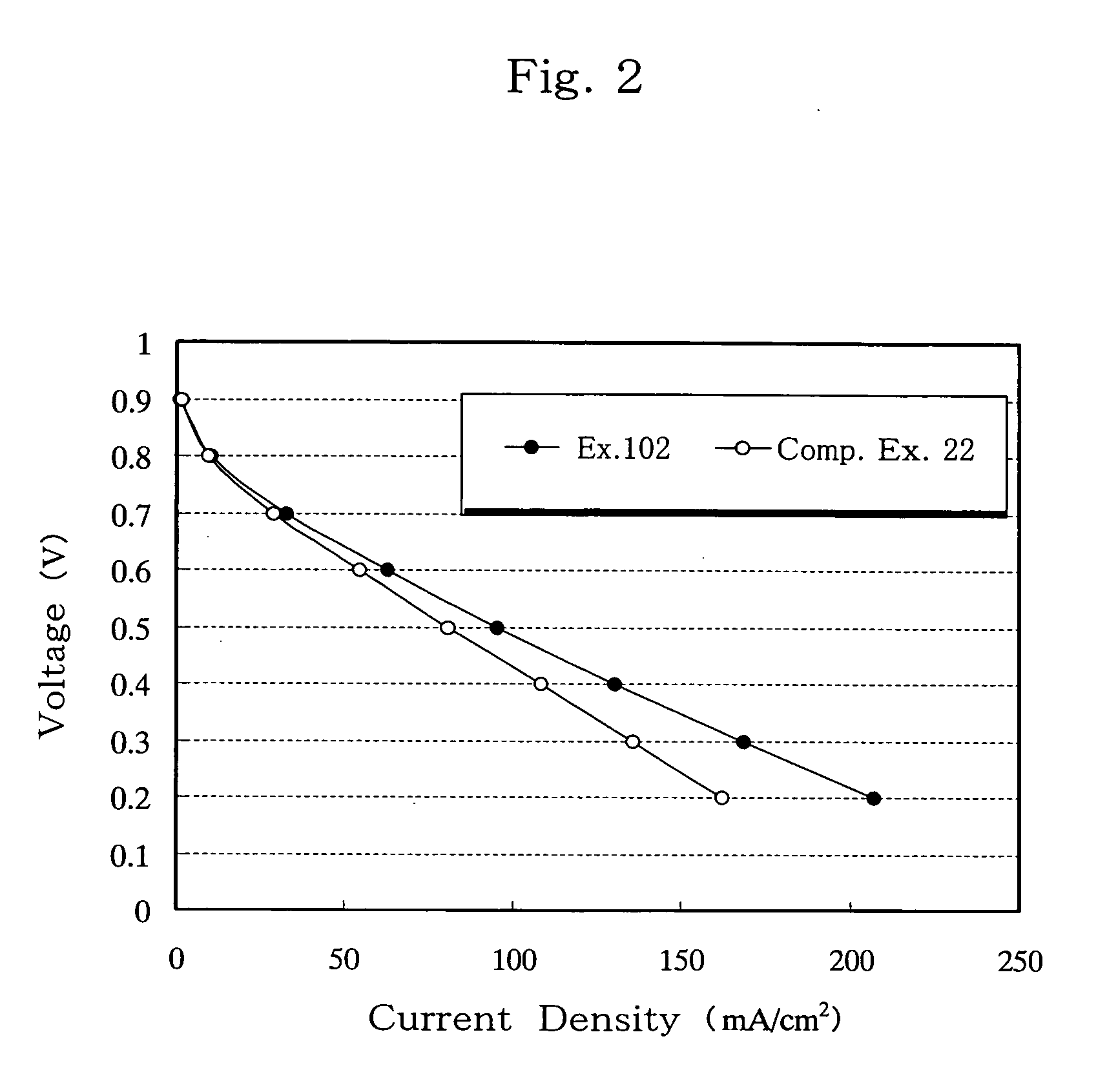

Separator for fuel cell, method for producing the same, and fuel cell using the same

InactiveUS20050142413A1Excellent in electroconductivityExcellent in gas impermeabilityNon-metal conductorsElectrode carriers/collectorsFuel cellsConductive materials

The present invention provides a fuel cell separator obtainable by hot-molding an electroconductive resin composition that comprises a thermosetting resin (A) which comprises a compound with a dihydrobenzoxazine ring (a), a compound (b) reactive with a phenolic hydroxyl group formed by opening of a dihydrobenzoxazine ring, and a latent curing agent (c), and an electroconductive material (B); a process for producing the separator; and a fuel cell comprising the separator.

Owner:SANSHO KAKOU +1

Dry-type heat-insulating waterproof coating

InactiveCN101648794AGood heat insulation and waterproof effectImprove waterproof performancePliabilityTalc

The invention relates to a dry-type heat-insulating waterproof coating which comprises the following raw materials in percentage by weight: 0-5.5 dispersible polymer powder, 10-20 hollow filling beads, 5-20 sepiolite powder, 5-10 mica powder, 5-30 heavy calcium carbonate powder, 5-15 light calcium carbonate powder, 0.5-1.5 rutile titanium dioxide, 10-20 talc powder and 10-40 white cement. A coat formed by the coating of the invention has favorable heat-insulating waterproof effect (lowers indoor temperature by 4-20 DEG C) and excellent flexibility, impermeability, weathering resistance and bonding strength to a substrate as well as high strength, good brightness, uniform luster, smooth and tender touch feeling, waterproof washing and rubbing, and the like. The dry-type coating has the advantages of simple production process, convenient transportation, long storage time, convenient construction, and the like, no toxicity or pollution, environment-friendly trend suitability, low cost, low VOC and high performance, thereby becoming a new-generation building coating product.

Owner:吕海涛

Lightweight aggregate foam concrete and production method thereof

The invention discloses a lightweight aggregate foam concrete which is composed of the following materials in parts by weight: 100-300 parts of cement, 1-150 parts of admixture, 60-250 parts of water, 1-10 parts of additive and 1-11 parts of foaming agent, as well as a lightweight material by a dosage accounting for 5%-60% of the total volume. The admixture comprising PC32.5 cement, coal ash and the like is produced from industrial waste materials such as coal ash, slag powder and clinker, so that discharge and bulk deposition of the industrial waste materials are effectively reduced and the environmental pollution is greatly reduced; therefore, good environmental protection benefit and social benefit are achieved. More importantly, expensive sulfoaluminate cement is replaced by low-cost materials, so that the cost of producing the lightweight aggregate foam concrete is greatly reduced; the performance effect of the product is extremely obvious and the physical properties of the cement is greatly improved; as a result, the outside erosion resisting capability of the concrete is effectively improved.

Owner:河南华泰新材科技股份有限公司

Moisture curable sealer and adhesive composition

ActiveUS20050107499A1Low costExcellent propertyRoof covering using flexible materialsBituminous material adhesivesIsocyanatePliability

A low cost moisture curable sealer and adhesive composition containing a polymer having reactive silyl groups and a bituminous material and having many advantages over conventional moisture cure sealer compositions, including greater elastomeric properties, improved flexibility and pliability, lower durometer, faster and deeper cure, low temperature cure. The composition is also free of carcinogens such as coal tar, toxic isocyanates, and volatile solvents.

Owner:CHEMLINK

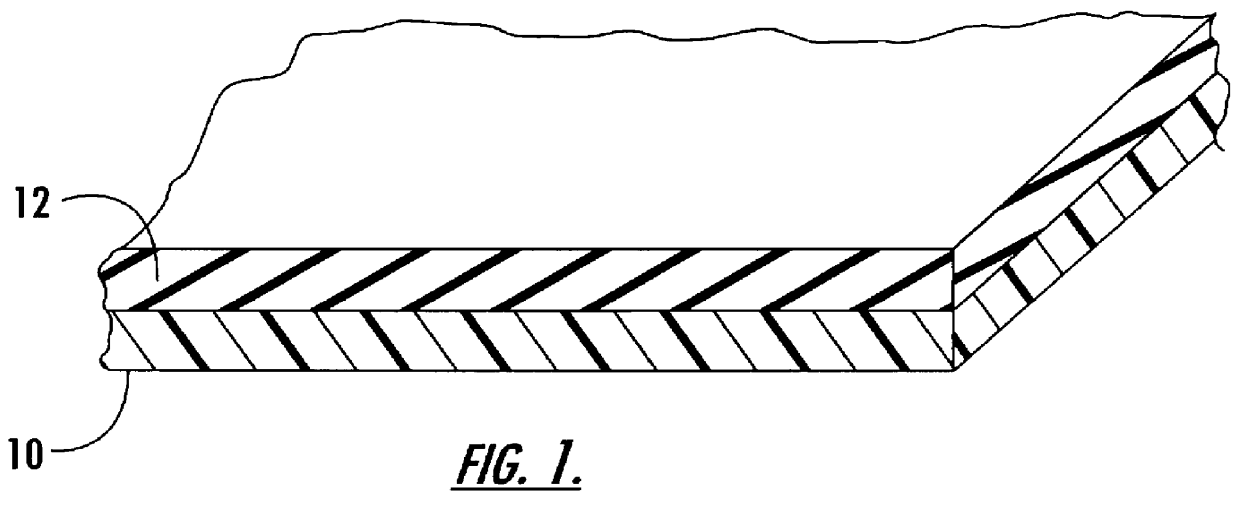

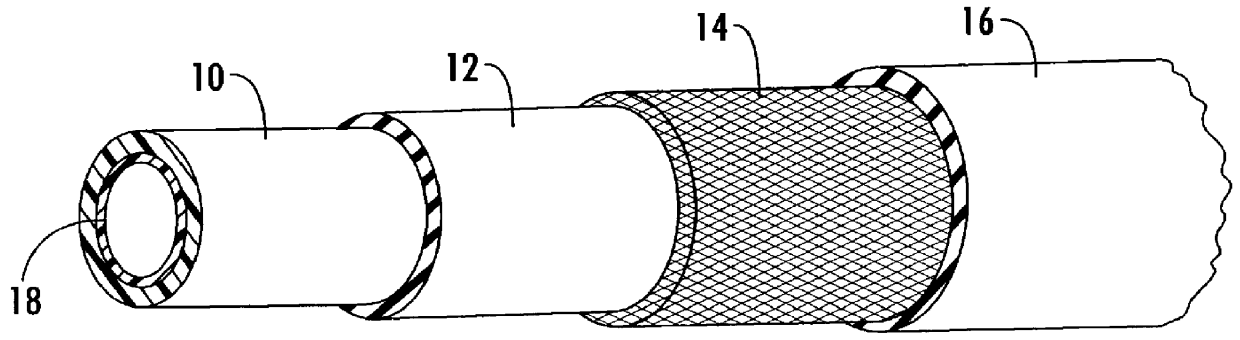

Thermoplastic-elastomer composite product, such as a pipe for conveying coolant in an air conditioning circuit, for example

InactiveUS6068026AImprove impermeabilitySynthetic resin layered productsVehicle heating/cooling devicesMaleic anhydrideThermoplastic

A thermoplastic and elastomer composite product, in particular a pipe for conveying coolant fluid in a motor vehicle air conditioning circuit, the product comprising an inside layer made of a mixture of a polyamide 6 and at least one modifying agent such as a grafted poly(1,2-vinylbutadiene), a polyoctene, a brominated isobutylene-p-methylstyrene, a silane, or an ethylene and acrylic acid copolymer, and a layer of an elastomer such as a brominated butyl rubber modified by a grafted poly(1,2-vinylbutadiene), a silane, an ethylene and acrylic acid copolymer, or a copolymer of ethylene and of propylene grafted with maleic anhydride, there being total adhesion between the thermoplastic and the elastomer.

Owner:HUTCHINSON SA

Pneumatic radial tire and process for producing retreaded tire

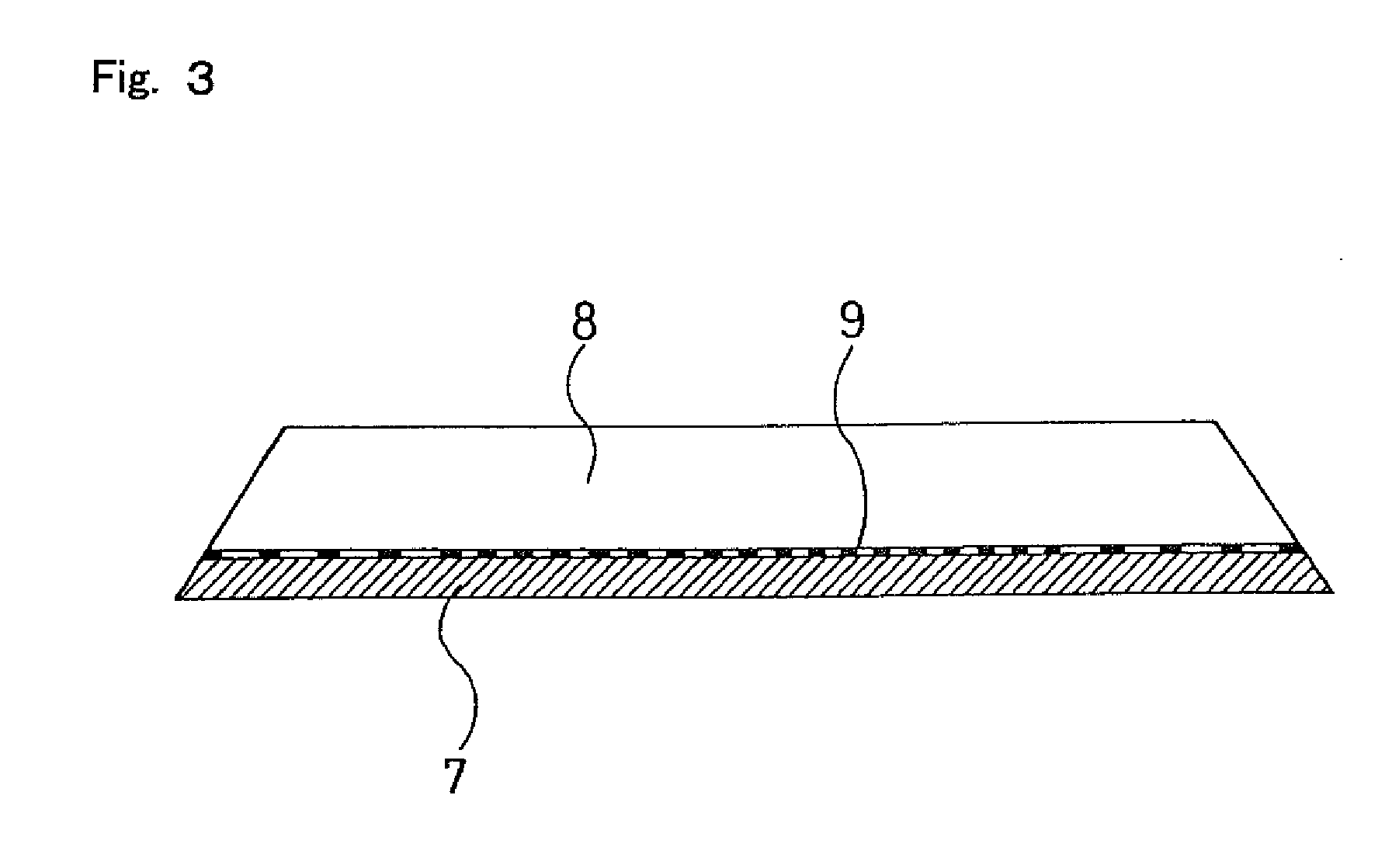

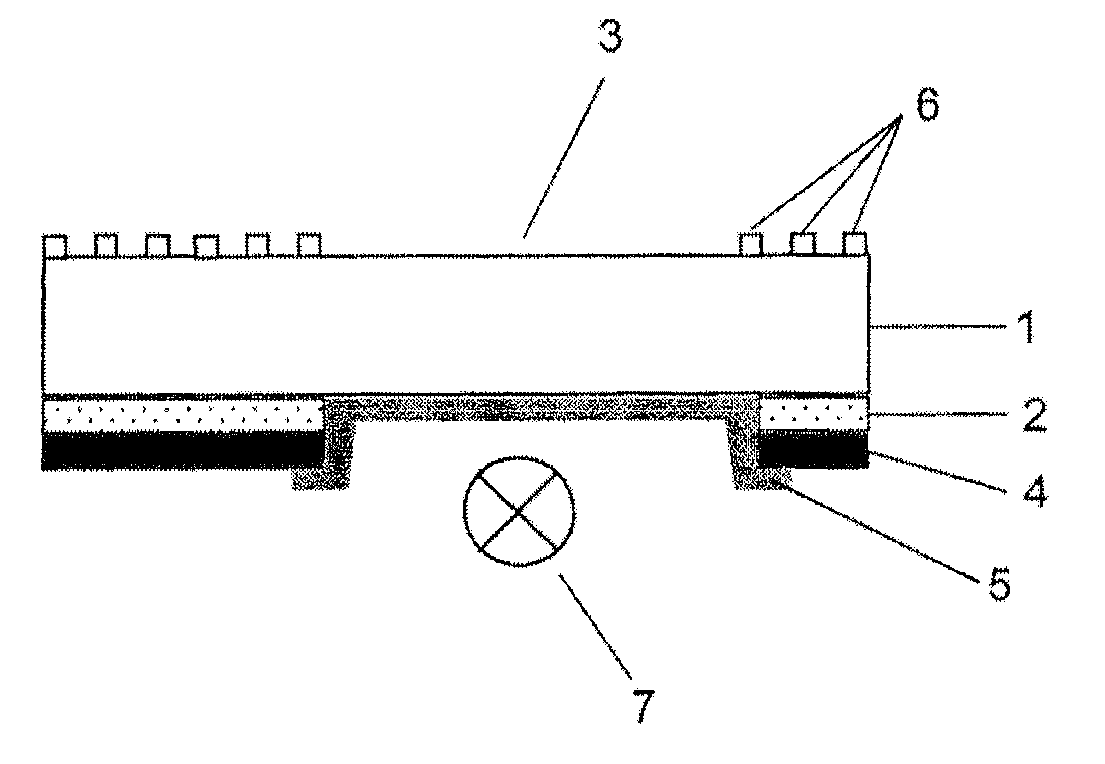

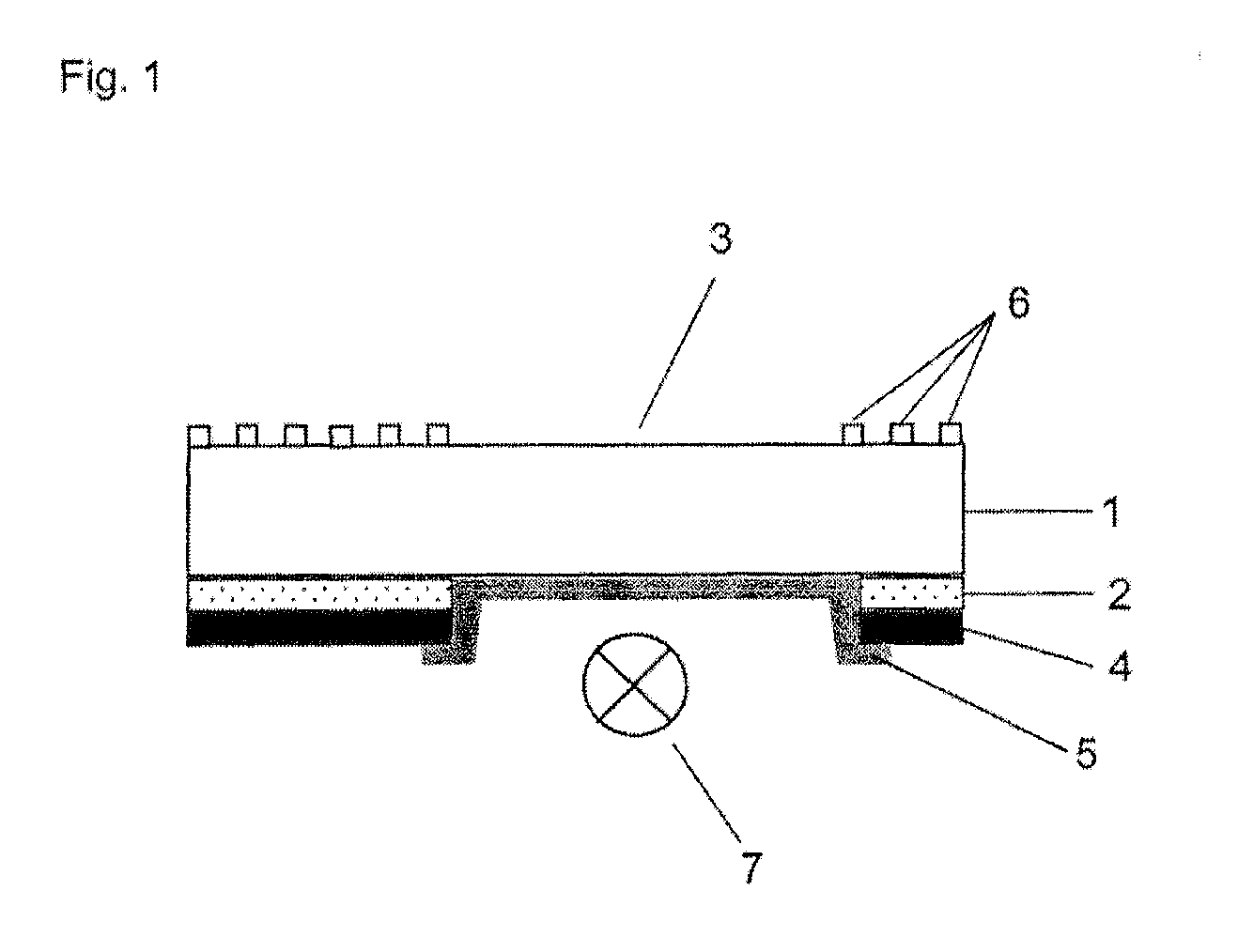

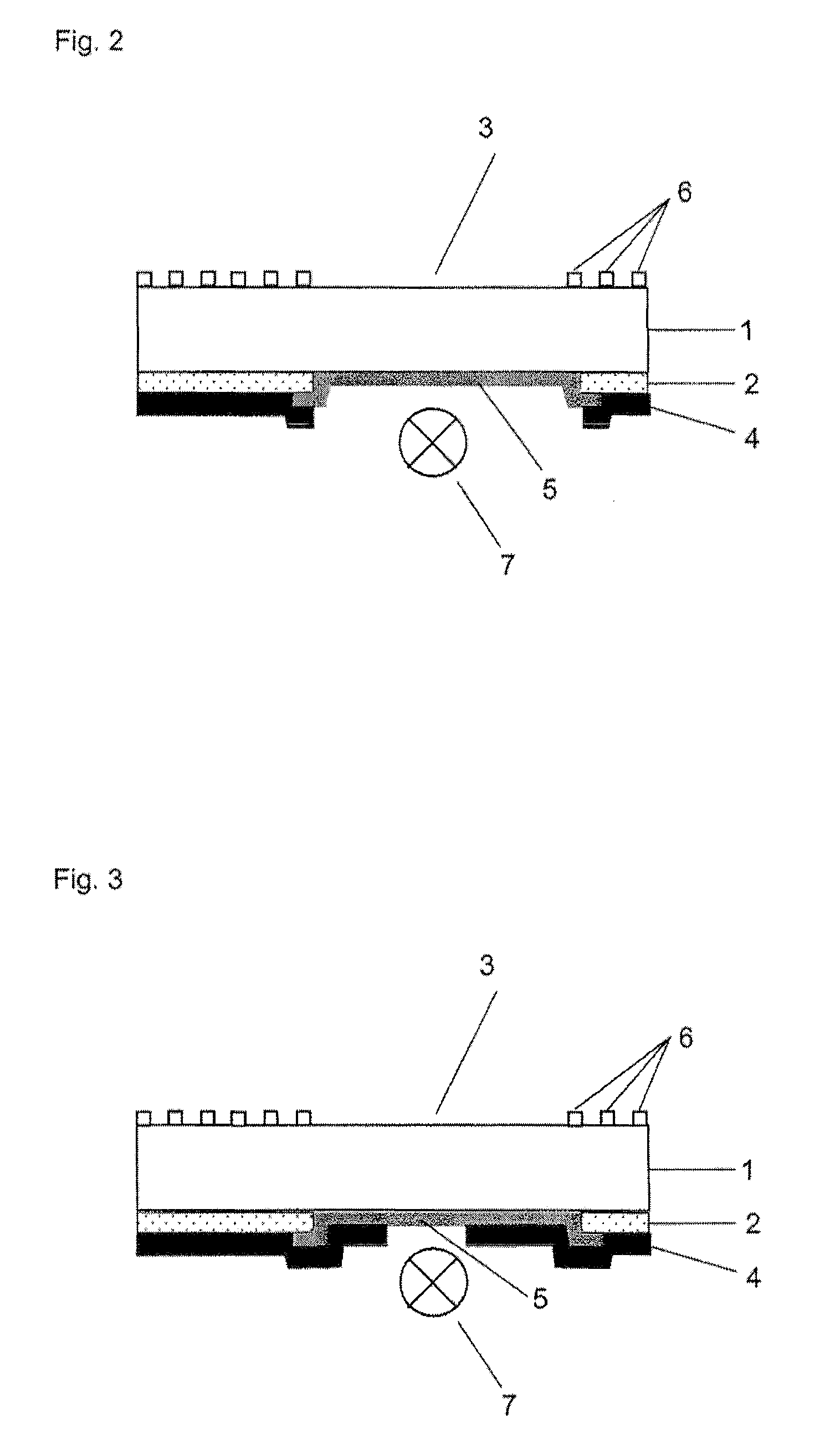

InactiveUS20110056603A1Easy to separateImprove productivityTyresInflatable tyresElastomerThermoplastic elastomer

A pneumatic radial tire includes: at least one carcass layer suspended across left and right bead parts; a belt layer arranged on an outer circumferential side of the carcass layer; and a tread arranged on an outer circumferential side of the belt layer. The tread has a laminated structure in which a thermoplastic film layer of a thermoplastic resin or a thermoplastic elastomer composition is interposed between a tread-side rubber layer and a belt layer-side rubber layer. The thermoplastic elastomer composition is obtained by blending an elastomer in a thermoplastic resin. A process for producing a retreaded tire includes the steps of: forming a base tire from the pneumatic radial tire by softening the thermoplastic film layer through heating so as to separate and remove the tread-side rubber layer, the pneumatic radial tire having the tread worn away; and subsequently bonding a new tread-side rubber layer onto the base tire.

Owner:YOKOHAMA RUBBER CO LTD

Waterborne heat-insulating flame-retardant multifunctional nano coating and preparation method thereof

InactiveCN101824270AImprove performanceSimple preparation processFireproof paintsPolyurea/polyurethane coatingsTin dioxideMicrosphere

The invention relates to a waterborne heat-insulating flame-retardant multifunctional nano coating and a preparation method thereof. The coating consists of the following components in part by weight: 48 to 52 parts of waterborne resin and 30 to 50 parts of nano pigment fillers (nano titanium dioxide, nano titanium dioxide-coated hollow glass microspheres, nano titanium dioxide-coated hollow ceramic microspheres and nano antimony-doped tin dioxide (ATO) particles), size and auxiliary materials such as film-forming additive and coupling agent. The preparation method includes the steps that: the nano fillers and the size are first dipped into the waterborne resin, the auxiliary materials are then sequentially added and stirred, and thereby the heat-insulating flame-retardant multifunctional nano coating is obtained. The processing technique is simple, the component proportion is reasonable, and the prepared coating has the advantages of high heat resistance, high reflectivity, high radiative heat conductivity, certain fire resistance, high-efficient heat insulation, excellent mechanical and chemical properties, environment-friendliness, stain resistance, flame retardance and energy saving. The coating can be coated on outside facilities such as outer walls and building roofs.

Owner:长沙新凯化工有限公司

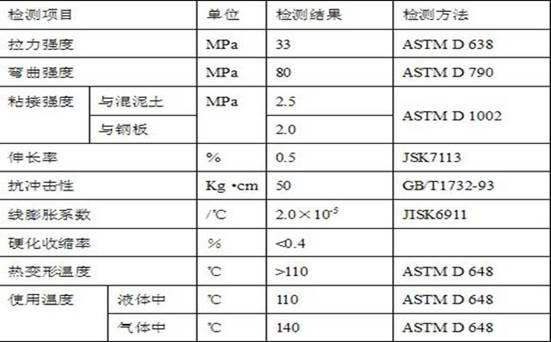

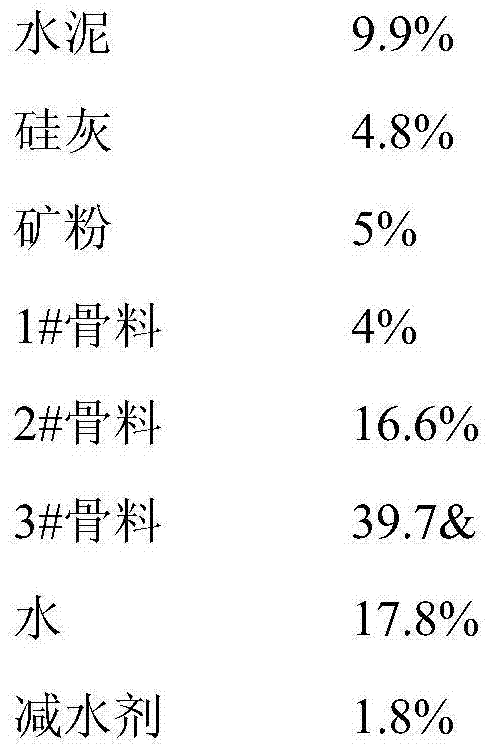

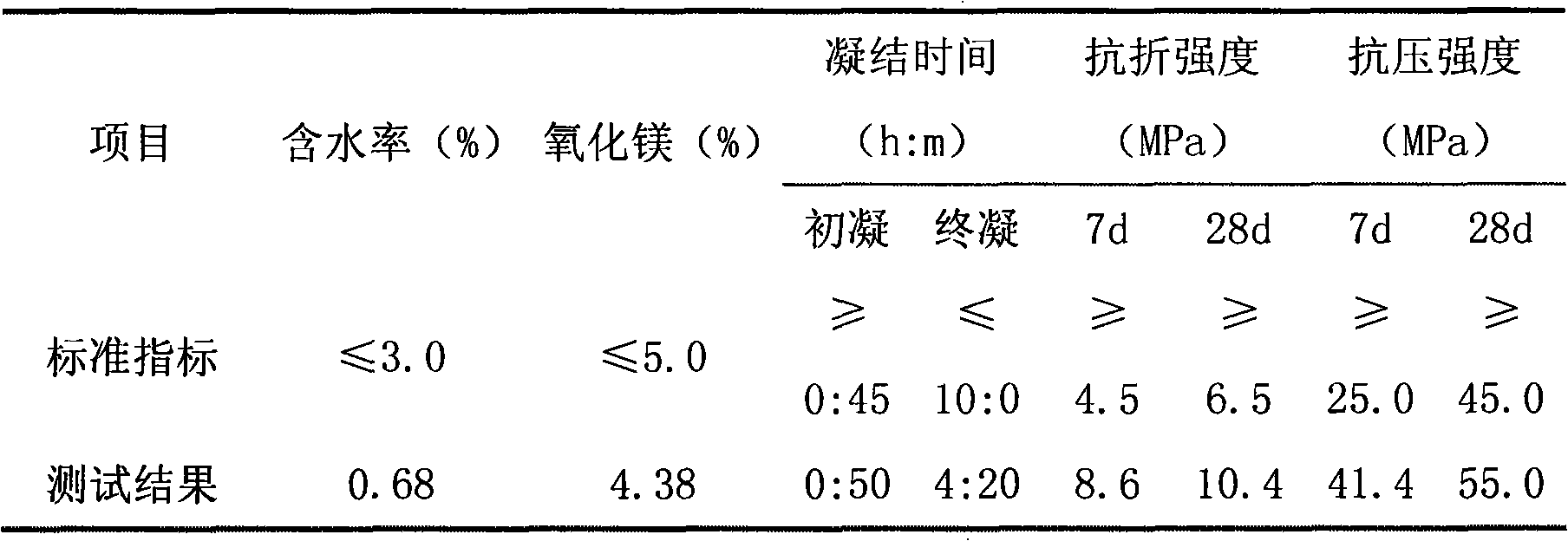

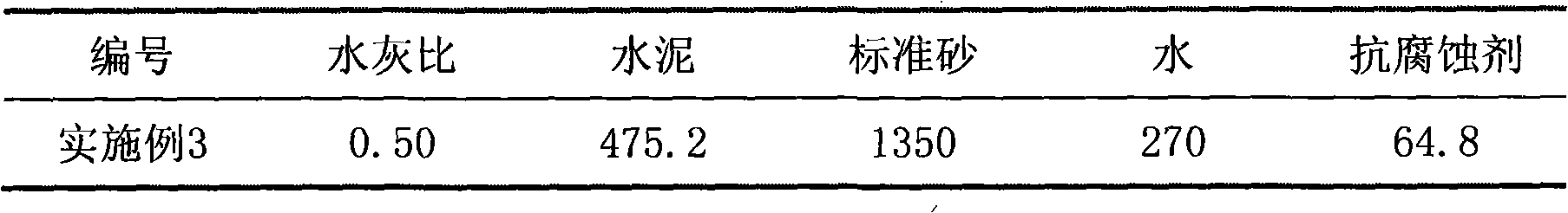

Preparation method of high-performance anti-corrosion repairing mortar

A preparation method of high-performance anti-corrosion repairing mortar including following components, by weight: 150-250 parts of cement, 280-725 parts of quartz sand, 50-200 parts of mineral powder, 50-150 parts of fly ash, 0-50 parts of silicon ash, 5-10 parts of barium nitrate, 0.1-1 part of an early strength agent, 1-4 parts of PP fibers, 0.5-20 parts of latex powder, 0.5-5 parts of cellulose ether, 0.5-2 parts of a water repellent agent, 0.001-0.1 parts of an air entraining agent, 0.1-2 parts of a water reducing agent, 0-1 part of a defoaming agent, and 100-250 parts of water. The invention, aiming to the characteristic of sulphate attack and the performance requirement of repairing mortar, discloses the repairing mortar which can repair the surface of damaged concrete with a protective film formed thereon to prevent the concrete form being corroded again. The repairing mortar is good in construction performance, can be used for coating the surface of the damaged concrete or filling damaged positions of the concrete. The repairing mortar is high in bonding strength and strength, is good in anti-permeability and flexibility, is simple in preparation process, is especially suitable for repairing the concrete subjected to sulphate attack, is great in market prospect and is good in practicability.

Owner:潍坊德霖建材科技有限公司

Coating for one or more display areas on a glass or glass-ceramic plate, process for producing said coating, and uses thereof

ActiveUS20100219176A1High surface resistancePrevent electrical conductivityDoors for stoves/rangesDomestic stoves or rangesSol-gelMedicine

The transparent coating for one or more display areas of a glass or glass-ceramic plate is made by a process using a sol-gel paint containing alkyl silicates as binding agents. The transparent coating is provided on areas of the glass or glass-ceramic plate that have been left uncoated by a color-imparting opaque coating and is formed by applying the sol-gel paint to the areas left open and then thermally treating the sol-gel paint so as to cross-link reactive groups of the alkyl silicates. The coating has organic, non-hydrolyzable groups bound directly to silicon. A process for making the coating and the uses of the coated glass or glass-ceramic plate are part of the invention.

Owner:SCHOTT AG

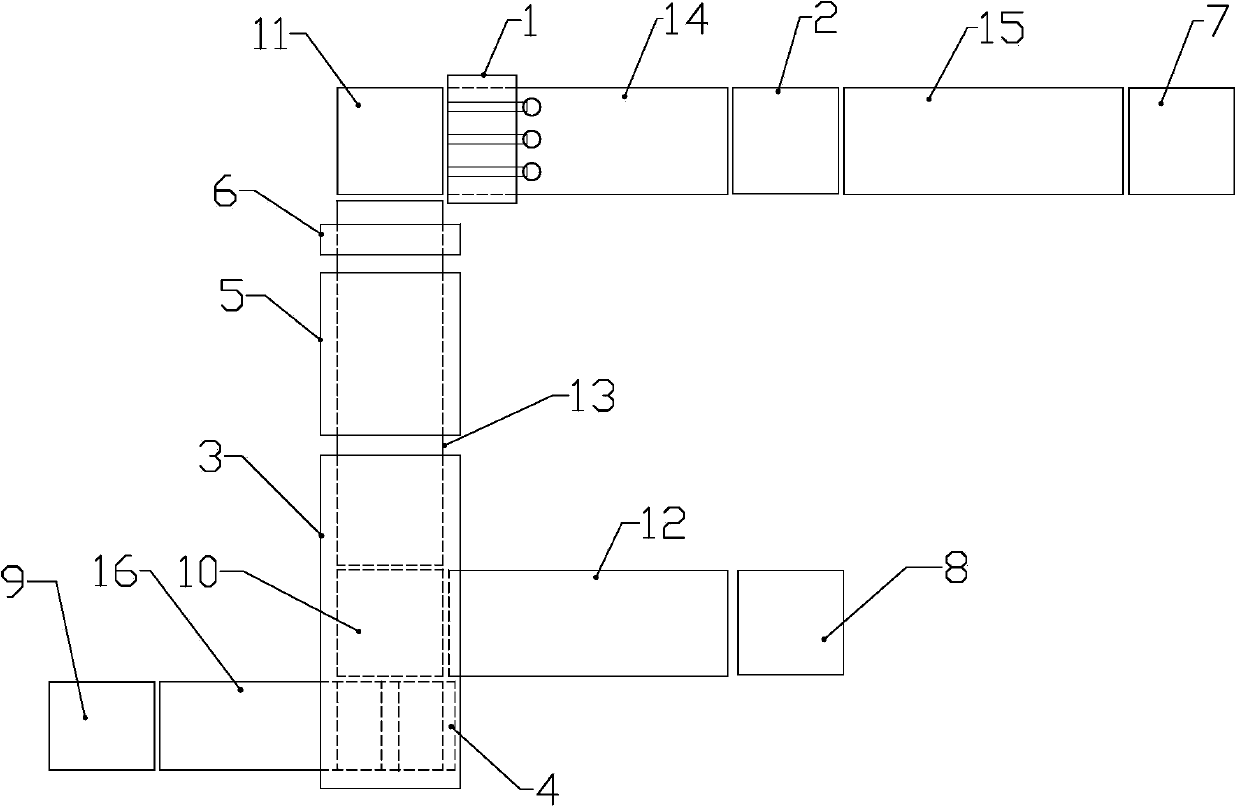

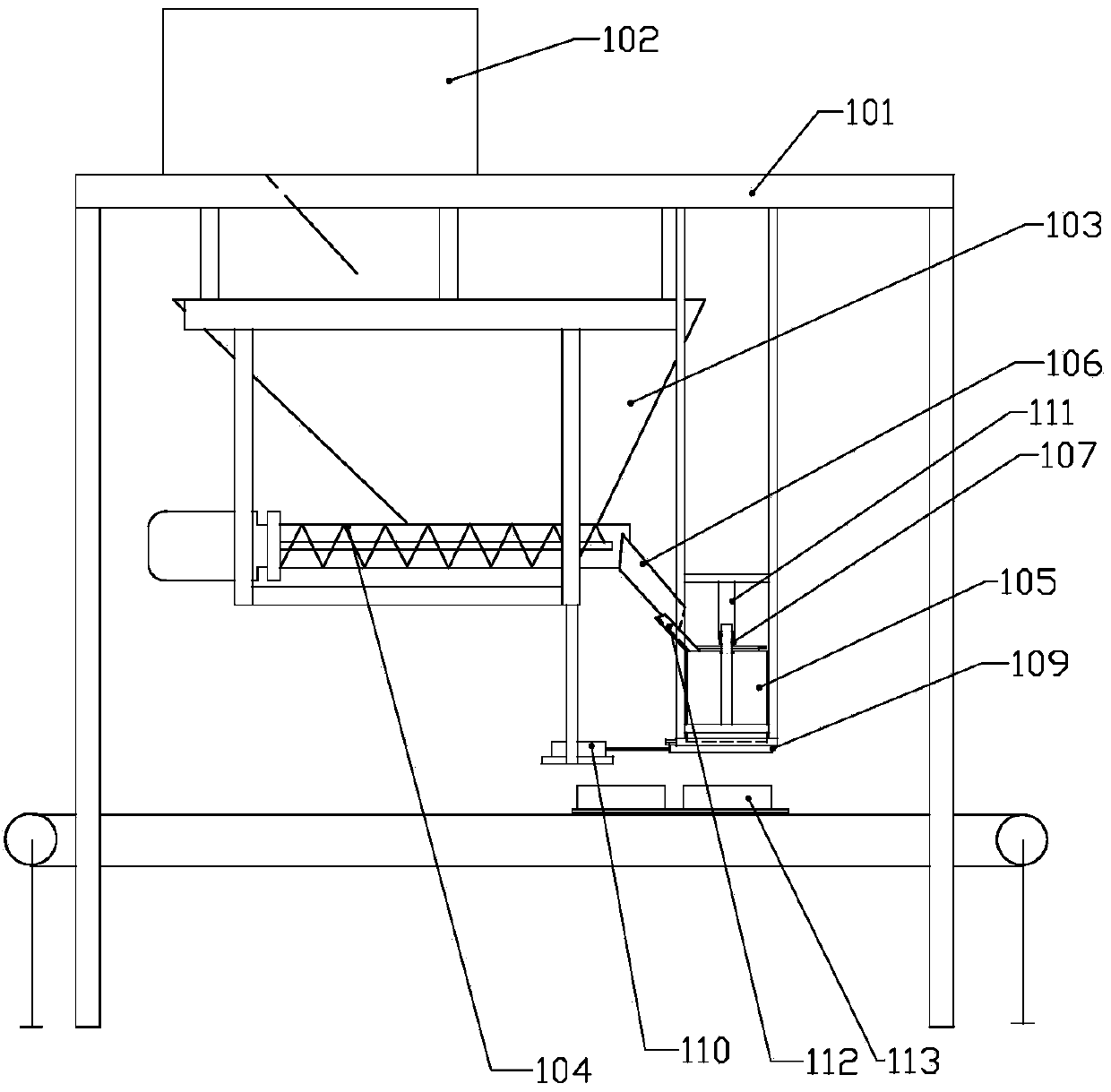

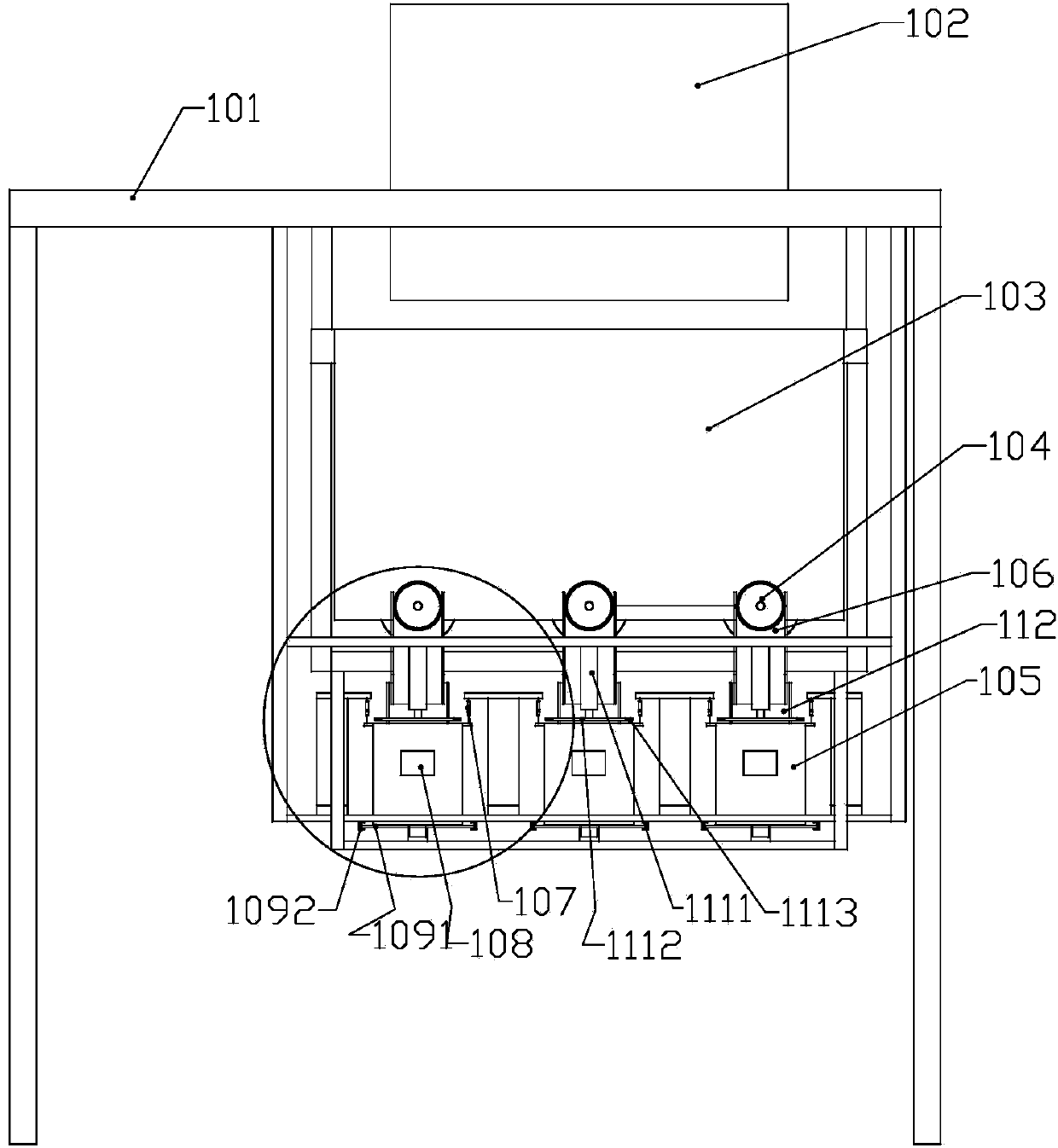

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

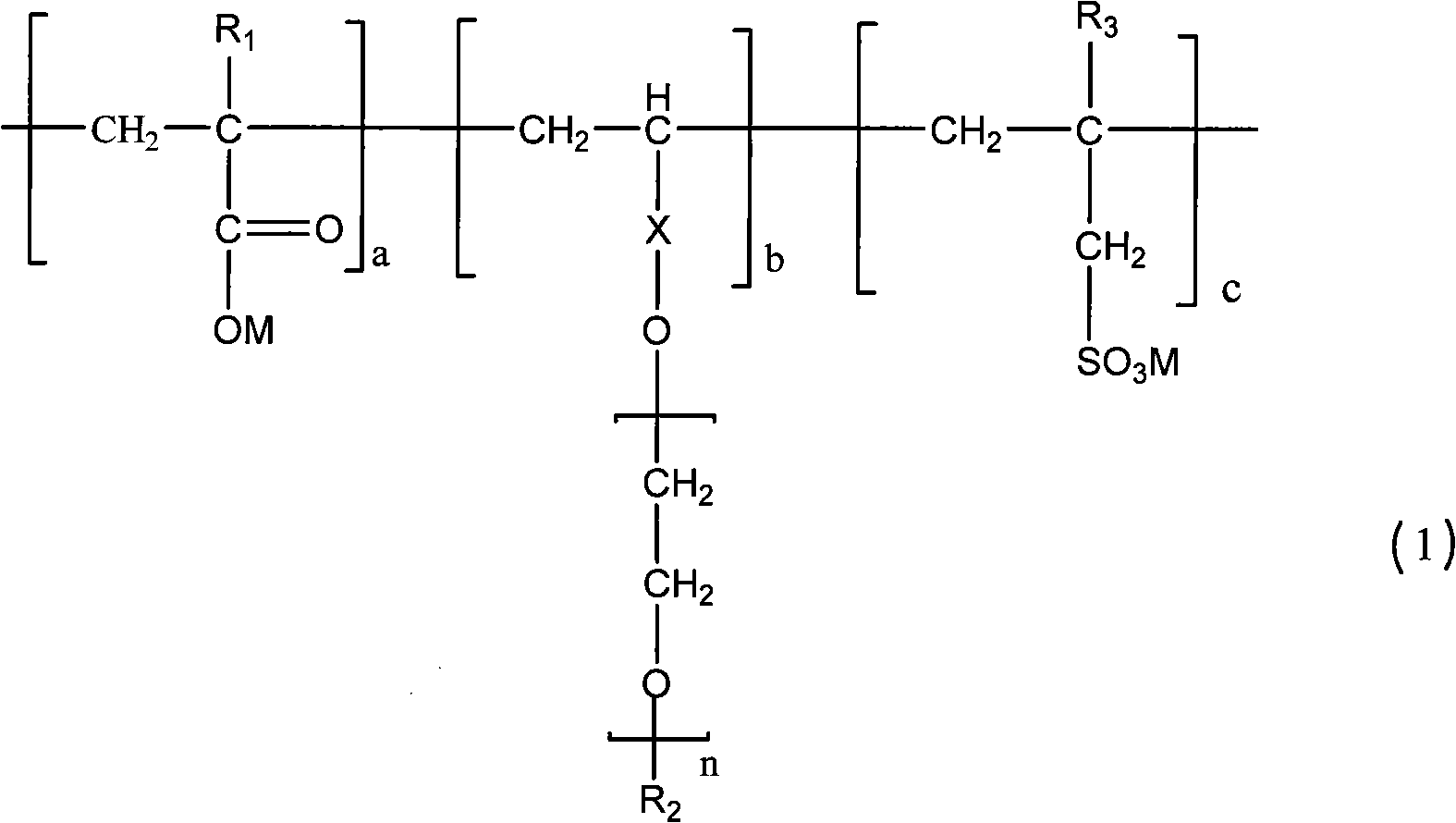

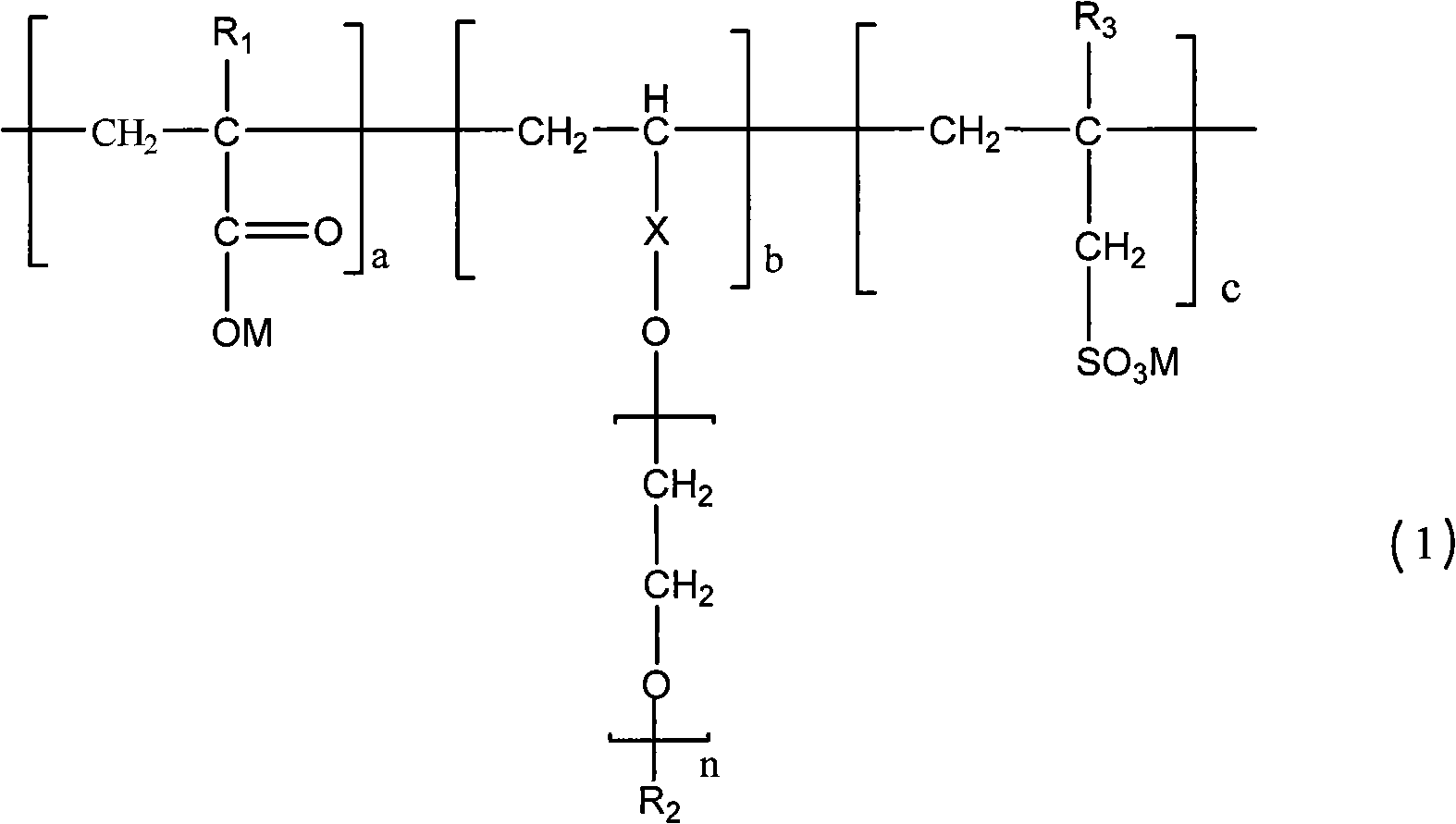

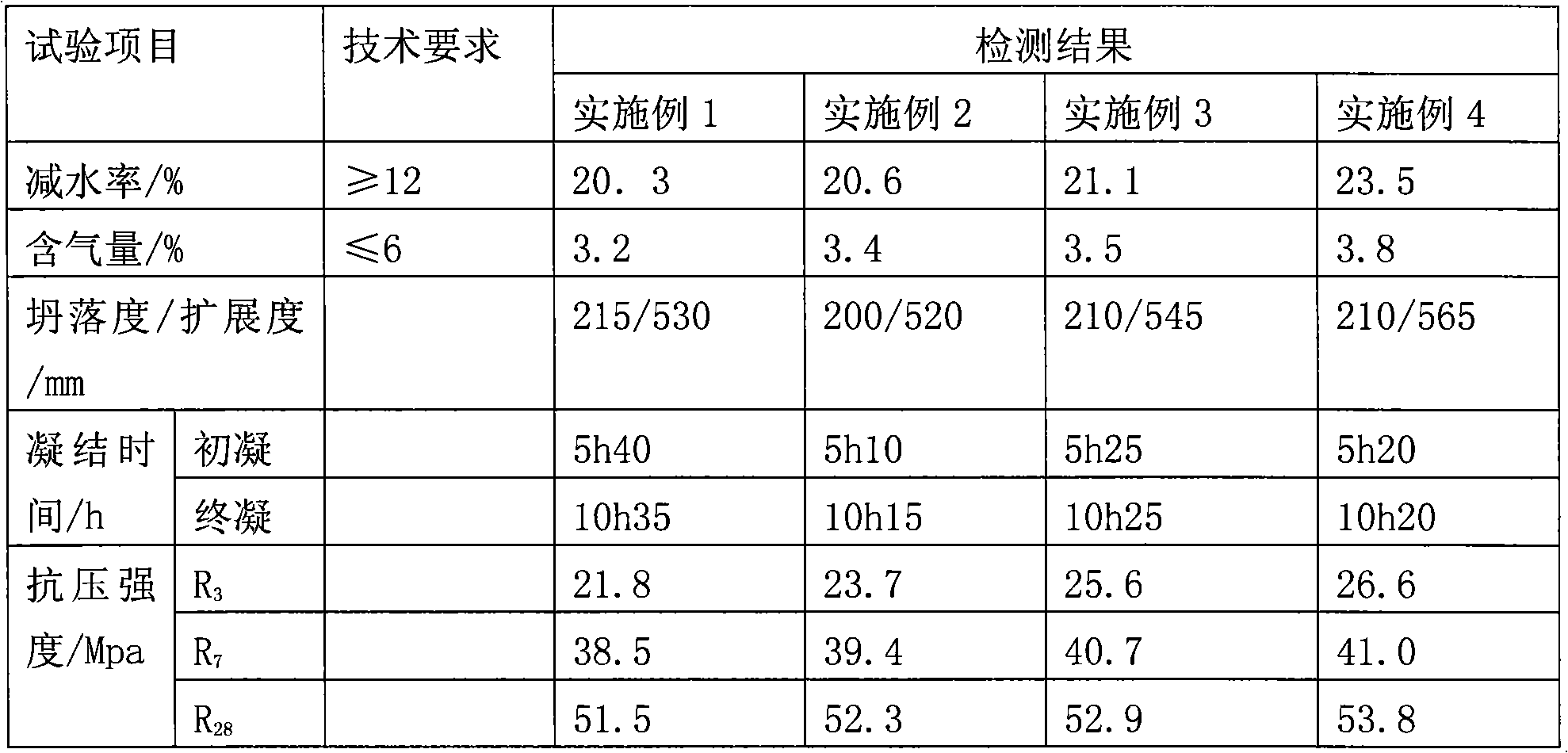

Polycarboxylate composite water reducing agent suitable for low-cementitious material concrete and preparation method thereof

The invention relates to a polycarboxylate composite water reducing agent suitable for low-cementitious material concrete and a preparation method thereof. The polycarboxylate composite water reducing agent suitable for the low-cementitious material concrete is characterized by comprising the following components in percentage by mass: 15 to 25 percent of polycarboxylic high-performance water reducing agent, 1 to 5 percent of retarder, 0 to 0.10 percent of defoaming agent, 0.01 to 0.3 percent of air entraining agent, 0.3 to 0.5 percent of preservative and the balance of water, wherein the mass solid content of the polycarboxylic high-performance water reducing agent is 40 percent. The polycarboxylate composite water reducing agent is applied to the concrete, and has the water reducing rate over 20 percent by comparing the concrete with reference concrete; and the prepared concrete has the advantages of good workability, no dissociation or bleeding, and good freezing resistance and infiltration resistance, and can be used for preparing concrete with various strength grades between C20 and C40.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Heavy-duty anticorrosive coating for flue gas desulphurization equipment and preparation technology thereof

InactiveCN102690586AStrong adhesionImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses a heavy-duty anticorrosive coating for flue gas desulphurization equipment and a preparation technology thereof. The heavy-duty anticorrosive coating comprises components of a novolac epoxy vinyl ester resin, a plasticizer, a diluent, a curing agent, a promoter, glass flakes, rutile titanium dioxide, nano-silica, alumina powder, silicon carbide, talcum powder and auxiliary agents. The preparation technology comprises that the components are dispersed by a high-speed dispersion kettle and then are mixed into the heavy-duty anticorrosive coating. The heavy-duty anticorrosive coating is convenient for construction, can be cured at a normal temperature, has good mechanical properties and excellent anti-permeability performances, is stable in an acid medium for a long time and has good protection effects on a matrix material.

Owner:BEIJING UNIV OF CHEM TECH

Mortar for concrete base surface repair, and preparation method thereof

The present invention belongs to a building mortar, and particularly relates to a mortar for concrete base surface repair, and a preparation method thereof. The mortar comprises the following raw materials by mass: 20-80 parts of silicate cement, 20-100 parts of sulphoaluminate cement, 80-190 parts of aggregate, 40-100 parts of a mineral admixture, 30-80 parts of an aqueous epoxy emulsion, 0.2-0.5 part of cellulose ether, 0.1-0.5 part of anti-cracking fibers, and 20-85 parts of water. The mortar of the present invention has characteristics of strong adhesion, excellent cracking resistance, excellent compression resistance, high bonding strength, and low price.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

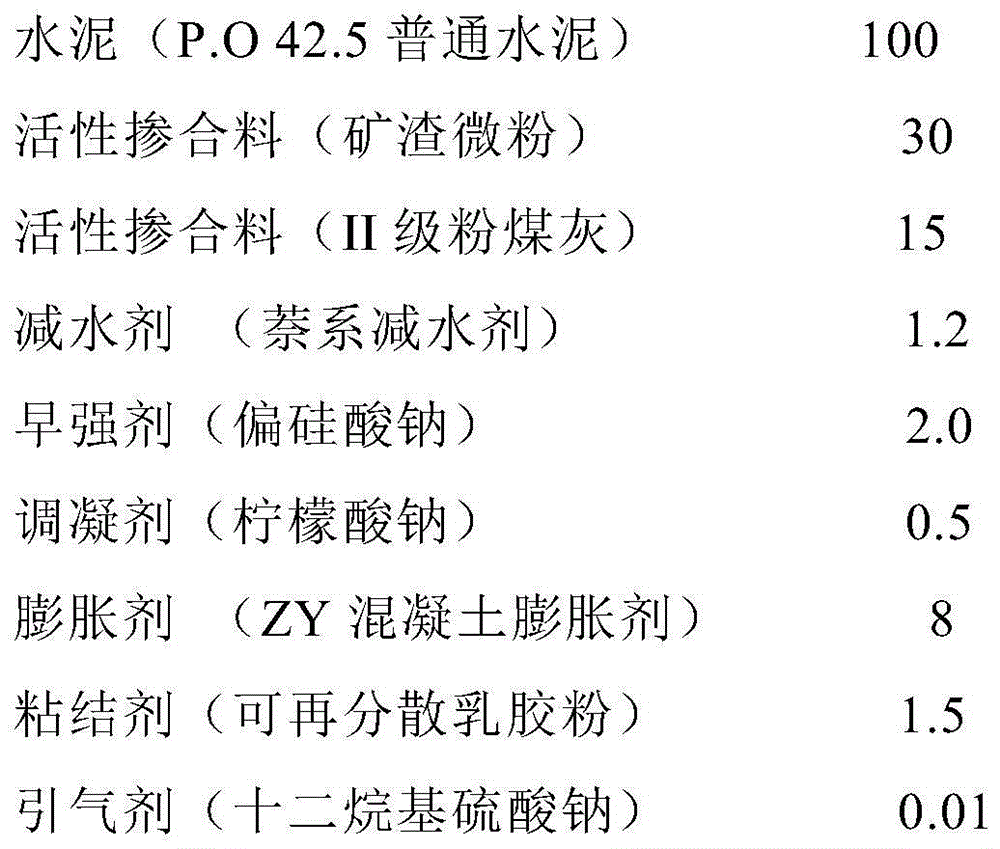

Method for synthesizing carboxyl butadiene-styrene latex used for cement group water-proofing material

ActiveCN101139413AAvoid pollutionReduce energy consumptionAntifouling/underwater paintsPaints with biocidesSodium bicarbonateEthylenediamine

This invention relates to a synthesis method for carboxylated styrene-butadiene latex used in the cement-based waterproof coating. The preparation method involves 30 to 50 shares of butadiene or isoprene isoprene, 30 to 55 shares of styrene, 0.1 to 5 shares of methyl acrylate , 1 to 5 shares of itaconic acid, 1 to 8 shares of n-butyl acrylate butyl acrylate, 1.2 to 2.8 hares of emulsifier, 0.3 to 1.2 hares of initiator potassium supersulphate, 0.2 to 0.8 shares of molecular weight regulator, 0.01 to 0.5 shares of pH buffer sodium bicarbonate, 0.01 to 5 shares of electrolyte, 0.01 or 5 shares of chelating agent ethylenediamine tetraacetic acid or endrate disodium and 100 to 150 shares of soft water for polymerization. The electrolyte is the combination of potassium phosphate and disodium hydrogen phosphate, with the ratio of 3 to 2: 1; in the polymerization reaction, monomer and a variety of agents are added with intermission. And reaction temperature control adopts the two-step laddered control. When the conversion rate reaches 99.0 percent, the mixture experiences the vacuum degassing treatment. The latex produced by the present invention is of good compatibility with the additives as the paint during the paint preparation. The prepared paint is of excellent fluidity, water retention and machinery stability under the high-cut condition. The improved mortar has the advantages of good permeability, high bond strength and so on.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

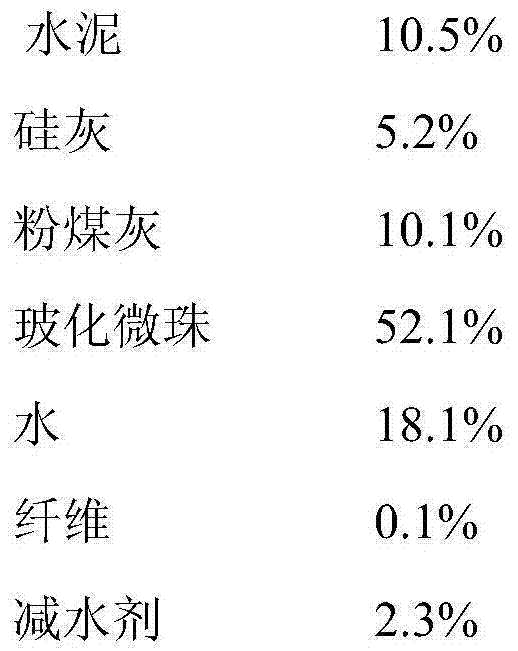

Lightweight high-strength cement based composite material

InactiveCN103896527AMeet the requirements of construction mobilityThe material surface is denseSolid waste managementChemical admixtureUltimate tensile strength

The invention relates to a lightweight high-strength cement based composite material. The grain composition of a multivariate cementing material and grain composition of aggregate are optimized, anddue to use of additives such as water reducing agent and thickener, the material can obtain high compressive strength of over 20MPa while obtaining the unit weight which is significantly lower than that of common concrete. The material has the technical advantages that the compressive strength of 28d standard curing is greater than or equal to 20MPa when the unit weight is smaller than or equal to 1650kg / m<3>; the requirements of the construction liquidity can be met by grain composition of the optimized gel material and the grain composition of the aggregate; the hardened material has a dense surface, and has excellent endurance performances such as anti-permeability, carbonation resistance, resistance to chloride ion erosion and the like.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

Concrete corrosion resistant additive for sea construction

InactiveCN101337787AAchieve high performanceImprove corrosion resistanceSolid waste managementCrack resistanceHazardous substance

The invention relates to a concrete corrosion proof additive for maritime work. The concrete corrosion proof additive is characterized in that the concrete corrosion-proof additive is prepared with the following components by weight: 40 to 80 percent of a sulfoaluminate micro-expanding agent, 0.1 to 2.0 percent of synthetic fiber, 1 to 10 percent of anticorrosive composition, 10 to 40 percent of fleur, and 0 to 12 percent of a water reducer. In the invention, the sulfoaluminate micro-expanding agent, the synthetic fiber, the anticorrosive composition, the fleur, the water reducer and so on are matched and compounded properly, thus forming the mutual superimposed effect. In this way, the crack resistance and the impermeability of concrete can be significantly improved; and chloride ions, vitriol and other hazardous substance can be effectively prevented from entering the concrete, thus preventing seawater and hazardous substance contained in seawater from eroding the concrete, protecting steel bars from being eroded, and improving the service life of concrete structure in maritime work.

Owner:南京派尼尔科技实业有限公司

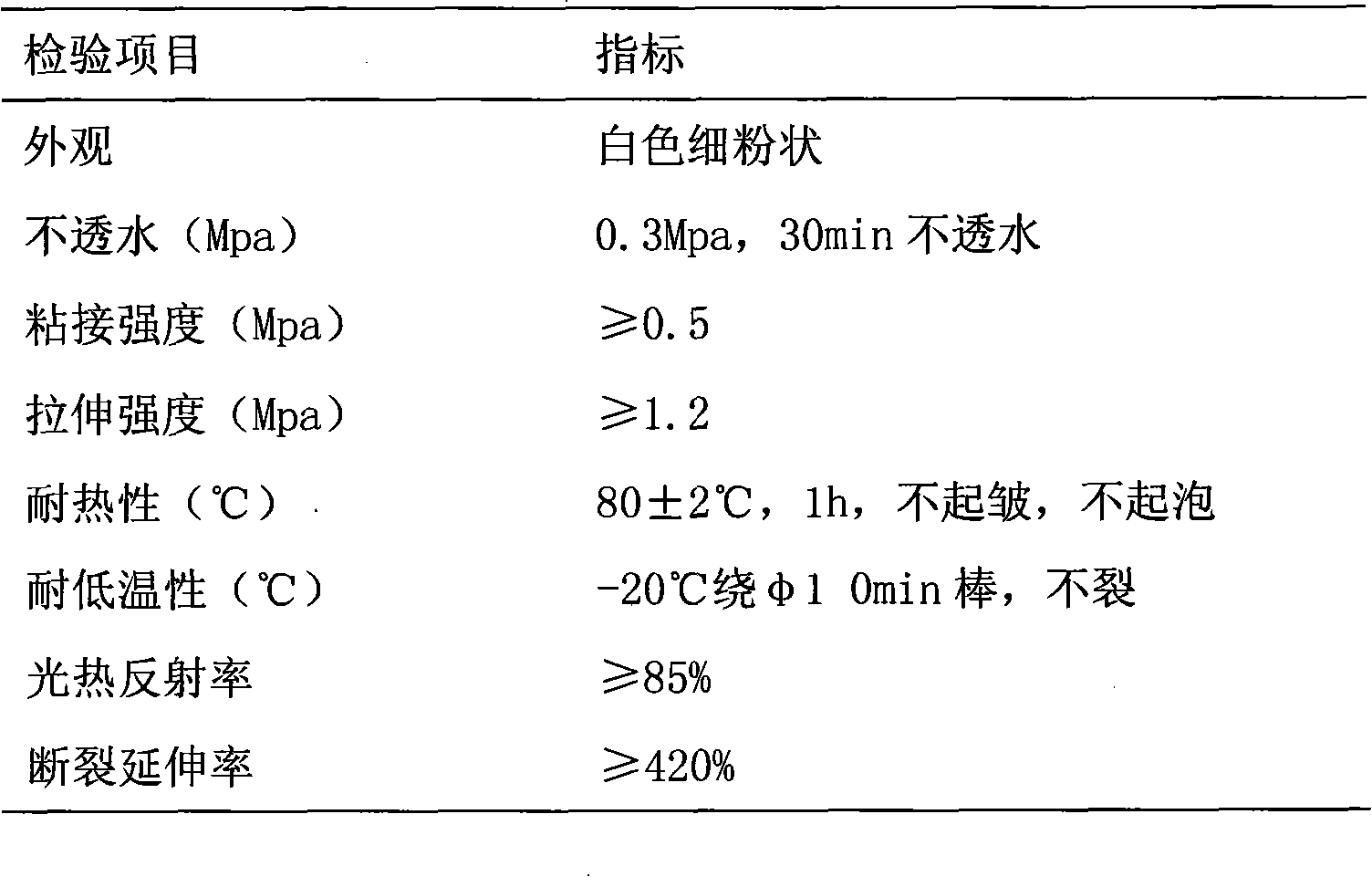

Inorganic powder capillary crystalline waterproof coating material

InactiveCN101362867AImprove impermeabilityImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater reducerQuartz

The invention discloses an inorganic powder infiltration crystalline water-proof material which consists of 45 to 55 portions of 600#silicate cement, 20 to 25 portions of ultra-thin quartz sands, 25 to 30 portions of master batches, 1 to 5 portions of effective retarding water reducers and 1 to 5 portions of macromolecular tougheners and is manufactured by feeding the materials into a stirrer to be uniformly stirred. The inorganic powder infiltration crystalline water-proof material is characterized by having the advantages of secondary anti-permeability capacity, durable water-proof performance, high sticking performance, acid resistance and alkali matter resistance; besides, the inorganic powder infiltration crystalline water-proof material have the capacity of growing an insoluble crystal in the pores and the micro cracks of a concrete substrate to plug the pores and the micro cracks, thereby improving the anti-permeability capacity of the concrete and achieving the goals of anti-permeability and anti-leakage. The inorganic powder infiltration crystalline water-proof material can be broadly applied to the water-proof projects of railways, roads, ports and docks, culverts, dams and pools as well as large underground projects.

Owner:天津市耀新科技发展有限公司

High-durability high-activity powder concrete electrical pole

InactiveCN101033658ANo lossImprove impermeabilitySolid waste managementMixing operation control apparatusPattern matchingPre stress

The invention relates to a RPC electric pole. Percentage of its quality quotient is: 100-140 portion thin round steel fiber with a diameter of 0.22mm, a length of 12-15mm and copperized surface, 21-25 portion water reducing agent, 170-190 portion water and 1110-1190 portion slender quartz grain with a grain size of 0.16-1.25mm. The steel fiber and slender quartz grain are added into agitator for homogenization, add cement and silicon powder for homogenization, then, add water reducing agent and residue water for homogenization to get RPC. Prime RPC into pattern matching prestressed reinforcement and centrifugate it. The finishsed product is conserved in 70-80deg.C steam for 48 hours and demould to achieve high endurance high intensity RPC electric pole. Its compression strength is above 200MPa, tensile strength is 15MPa and impermeability is above P16.

Owner:NORTHEAST DIANLI UNIVERSITY

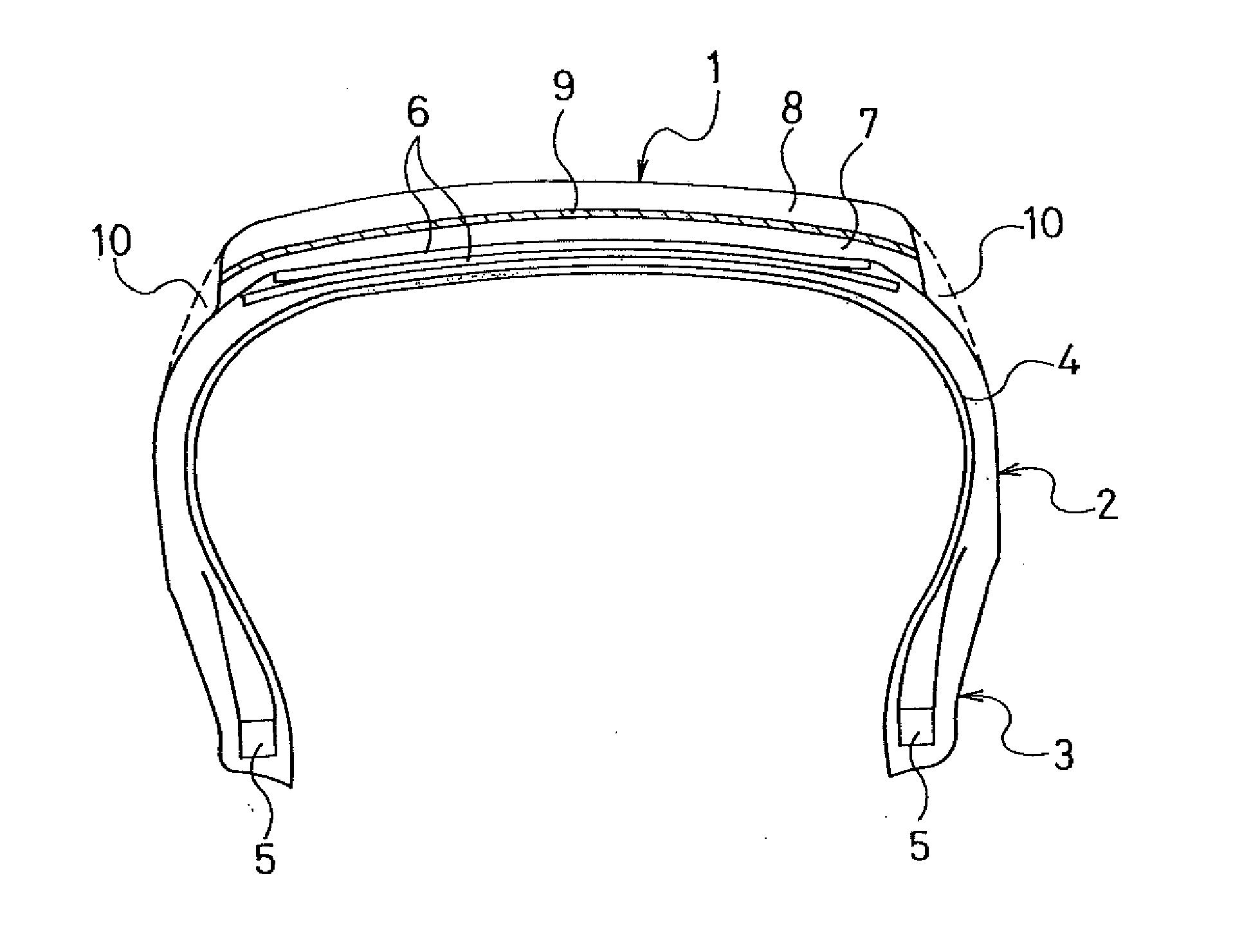

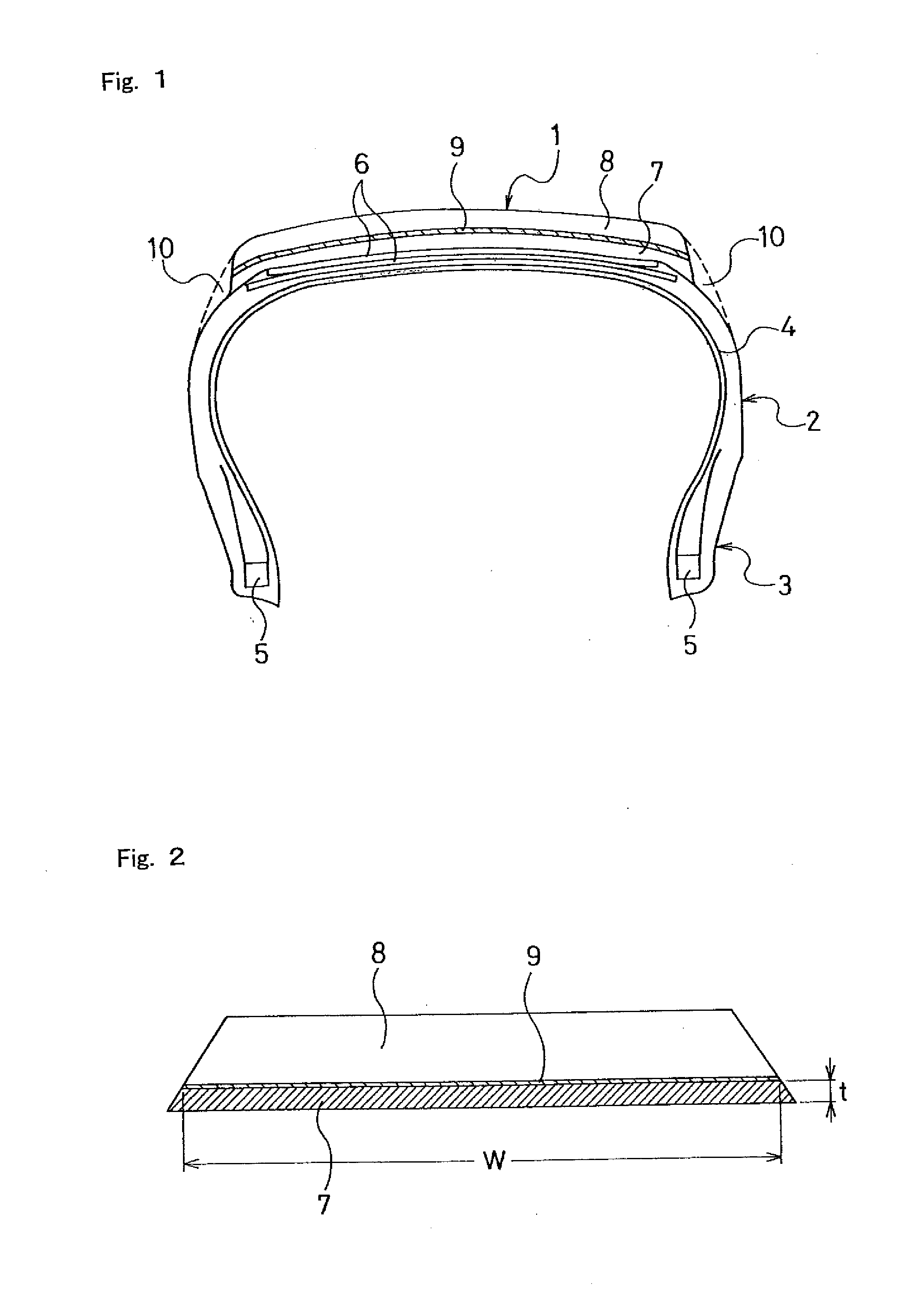

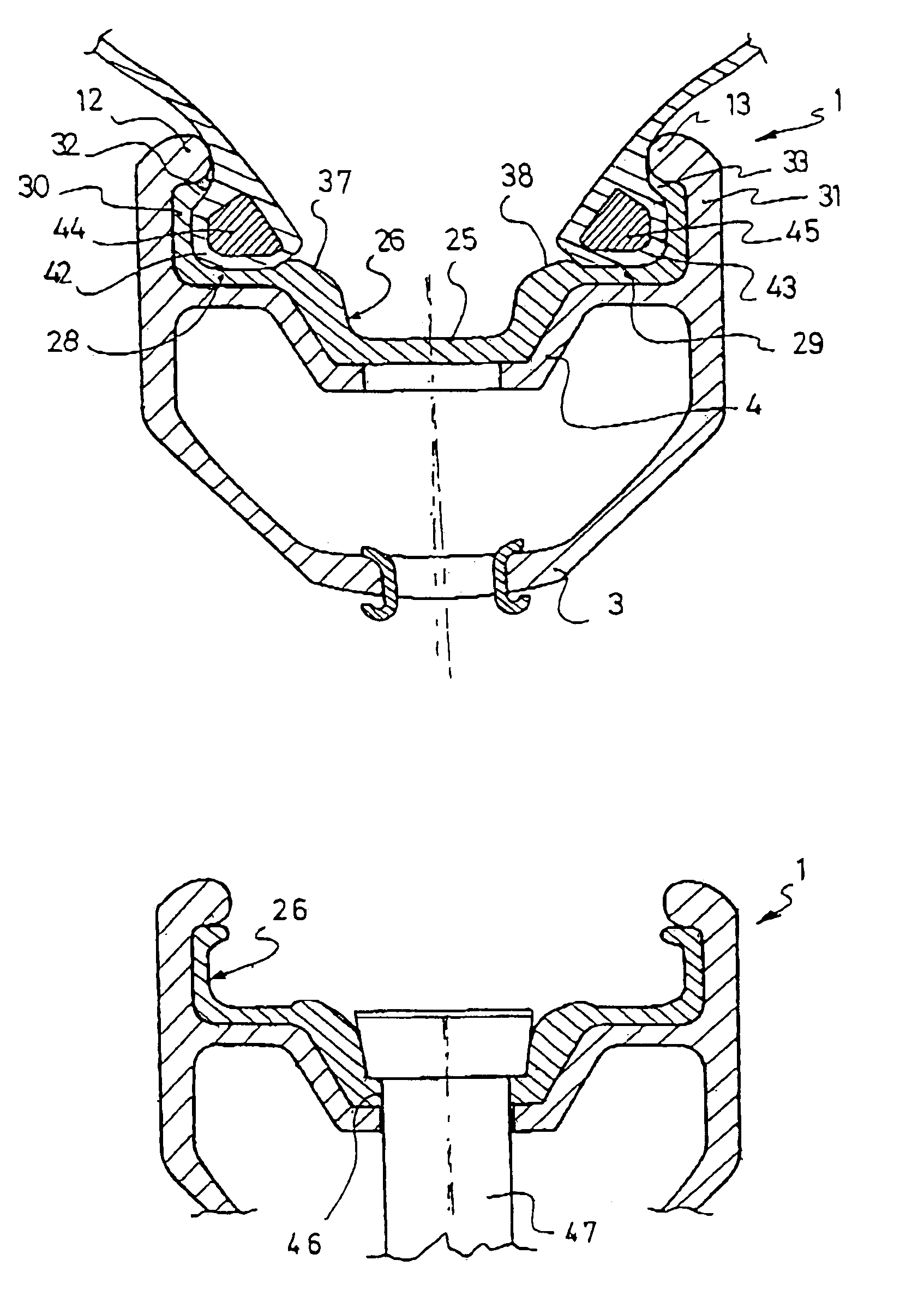

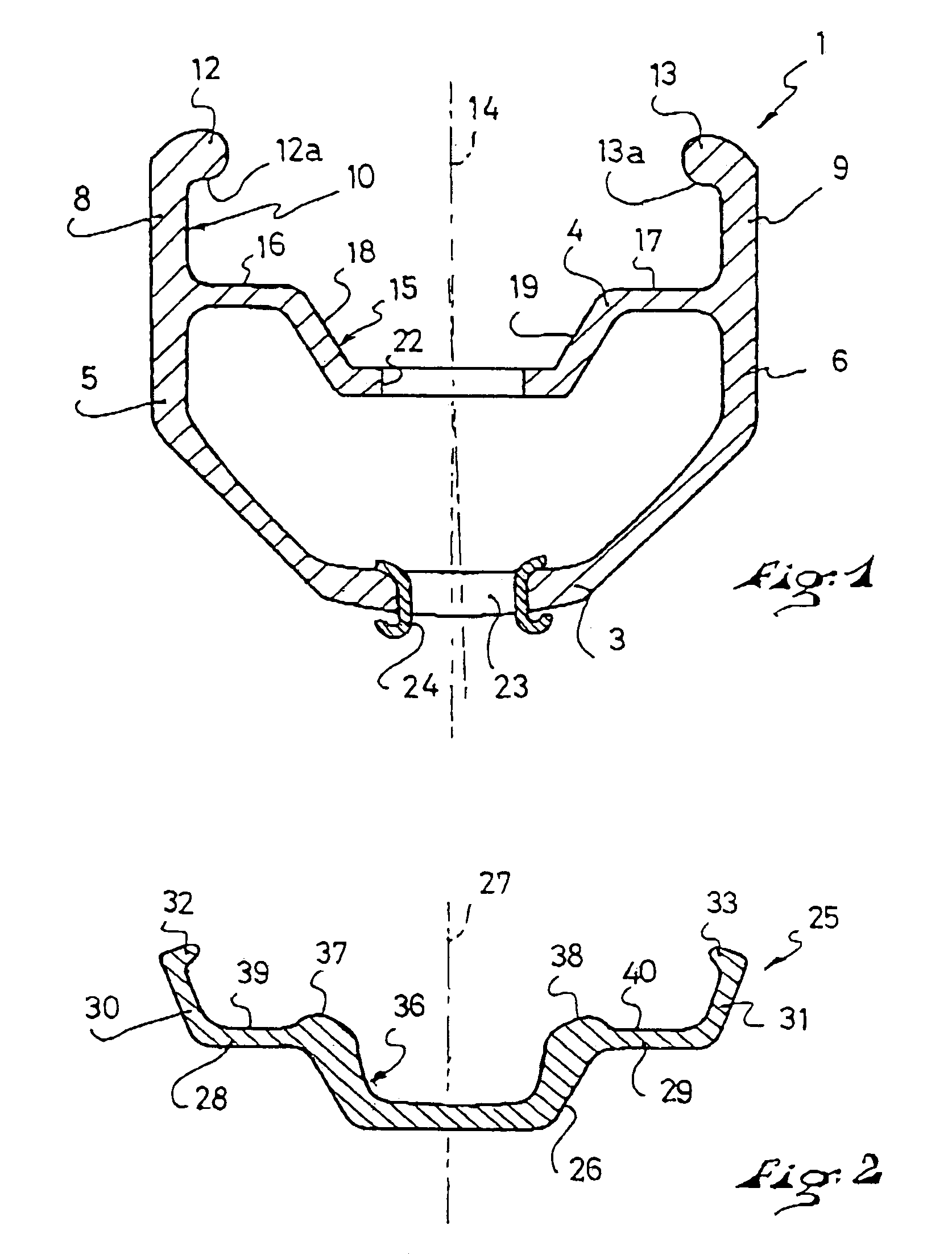

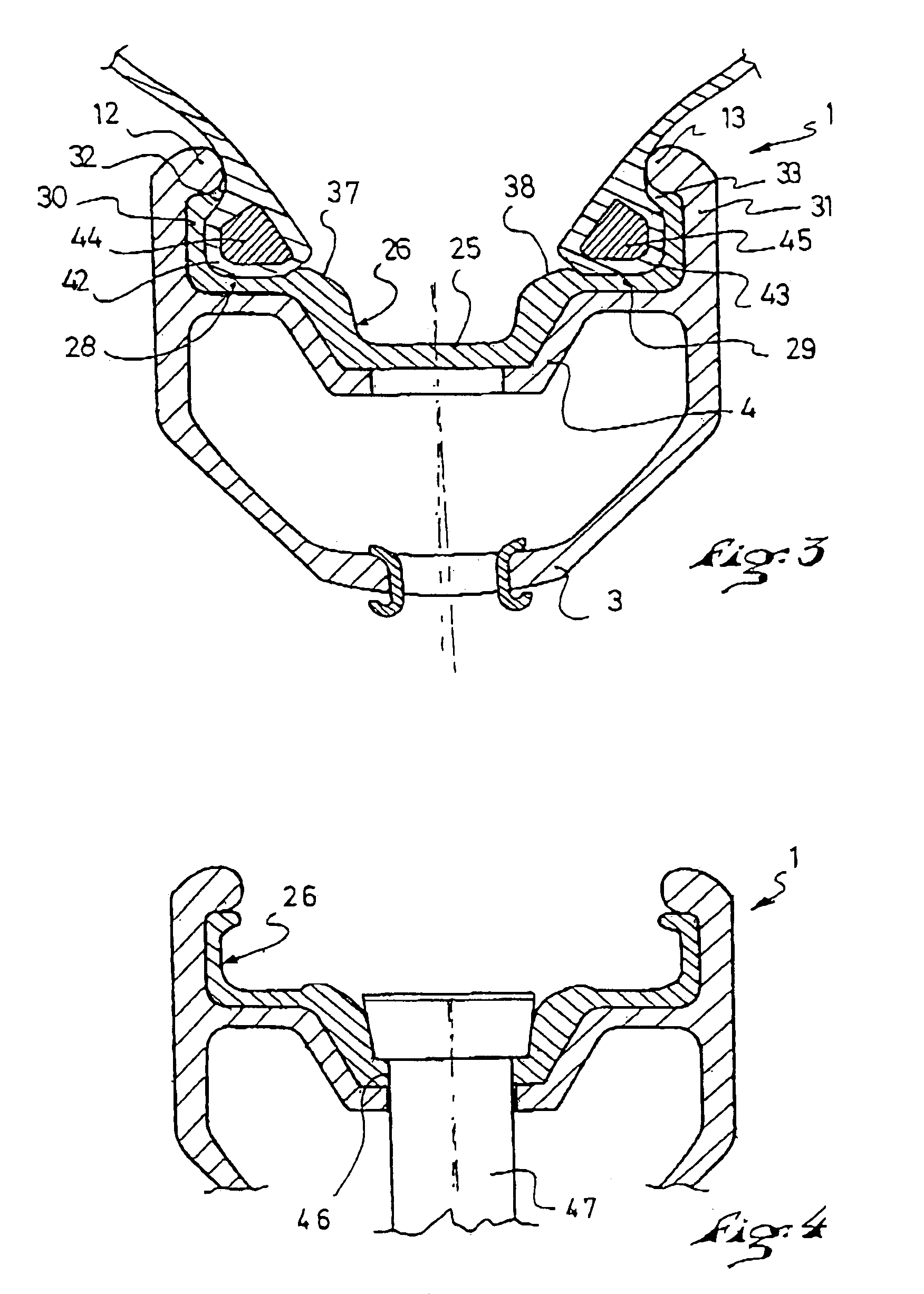

Sealing strip for a rim of a wheel and a rim having a sealing strip

InactiveUS7104300B2Improve impermeabilityImprove performanceRimsInflatable tyresEngineeringLateral extension

Owner:MAVIC SA

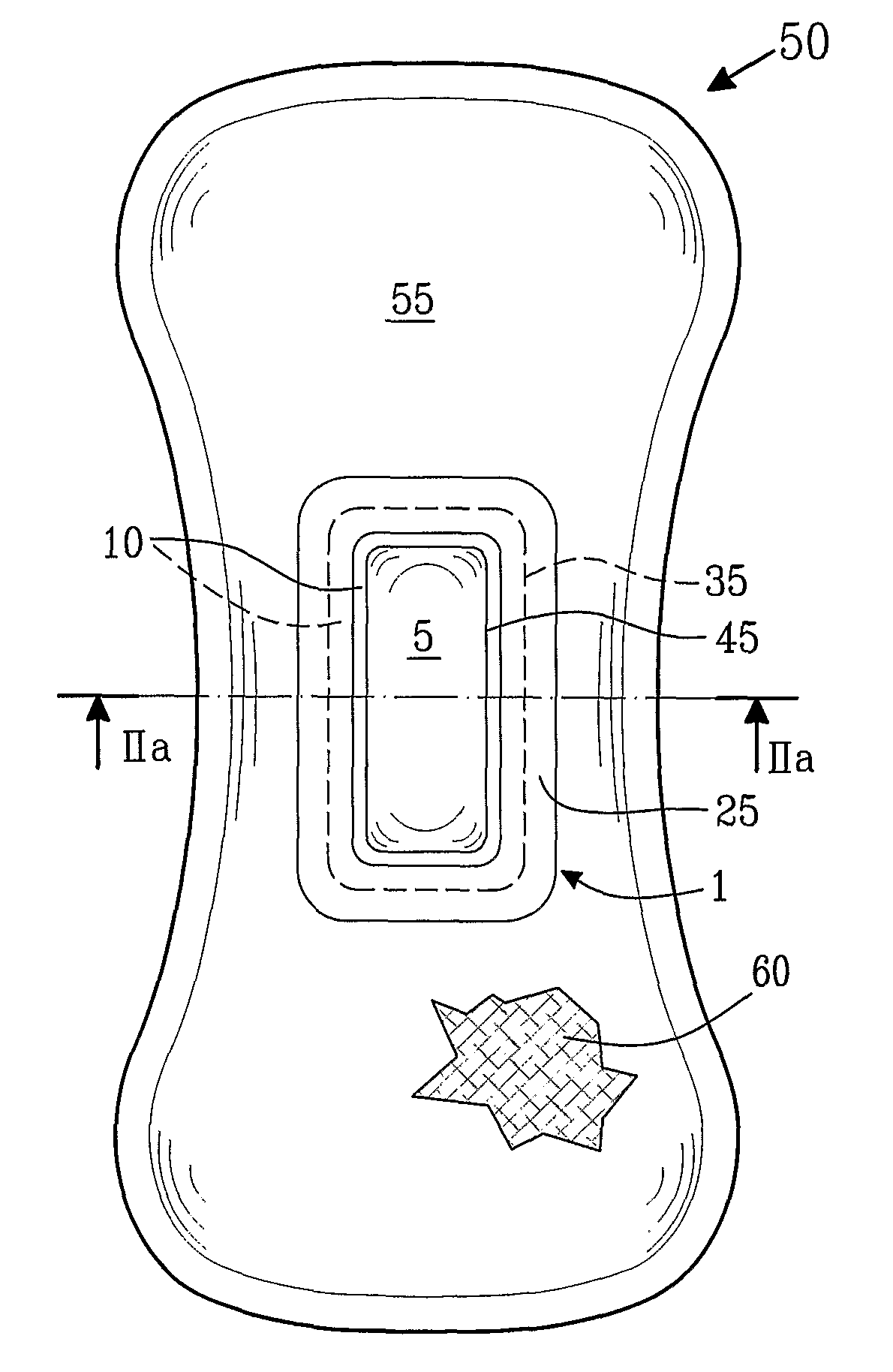

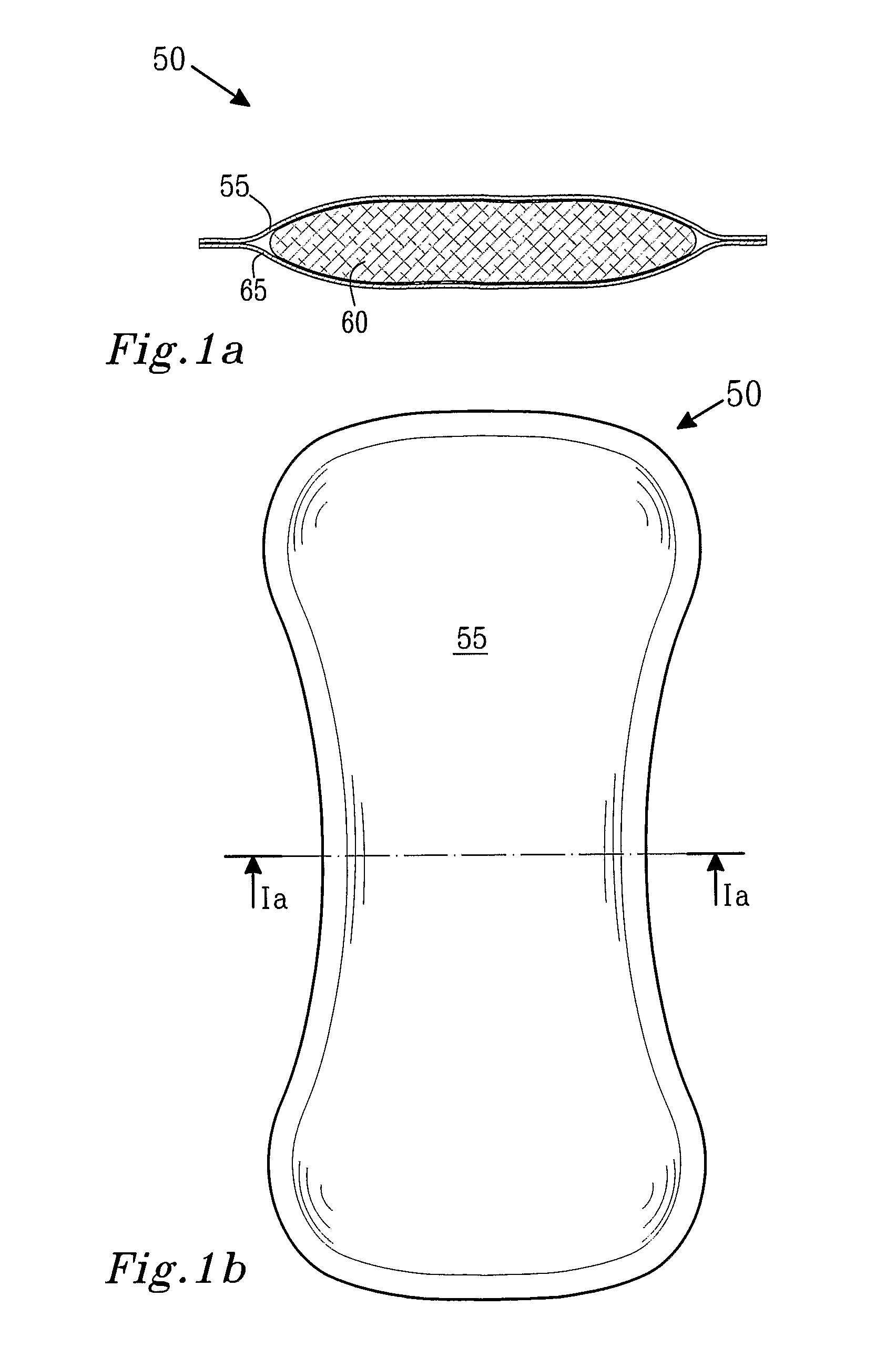

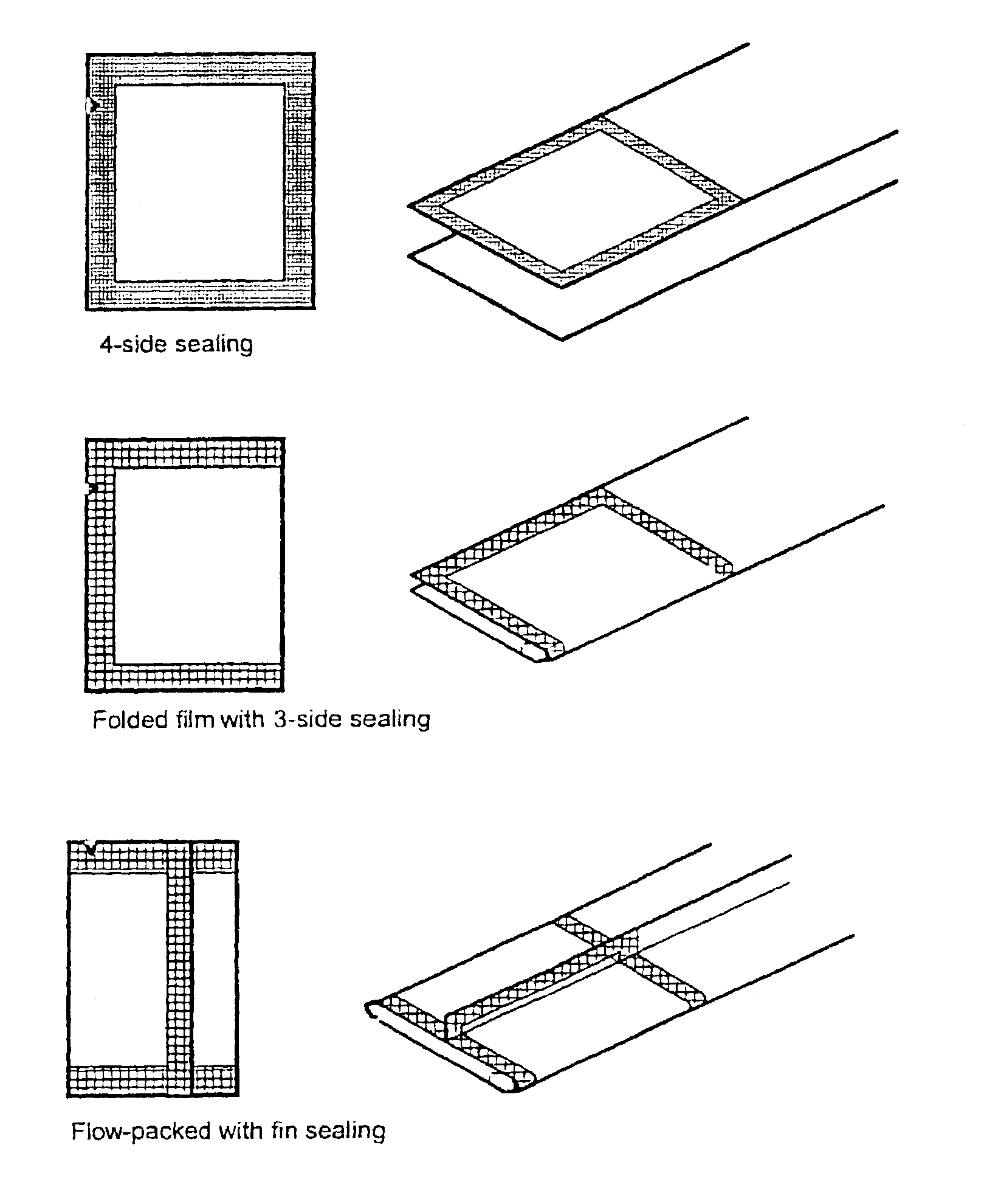

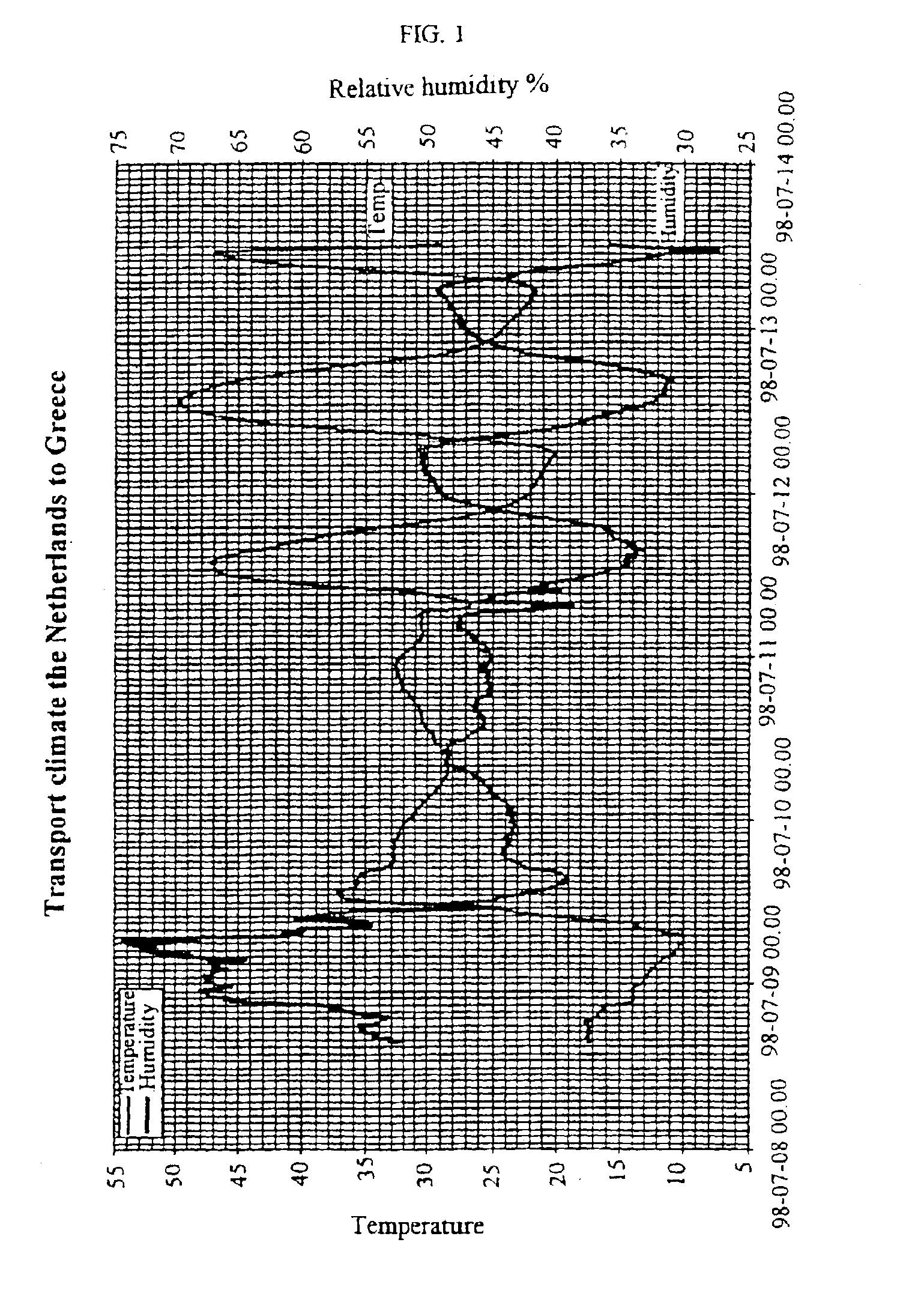

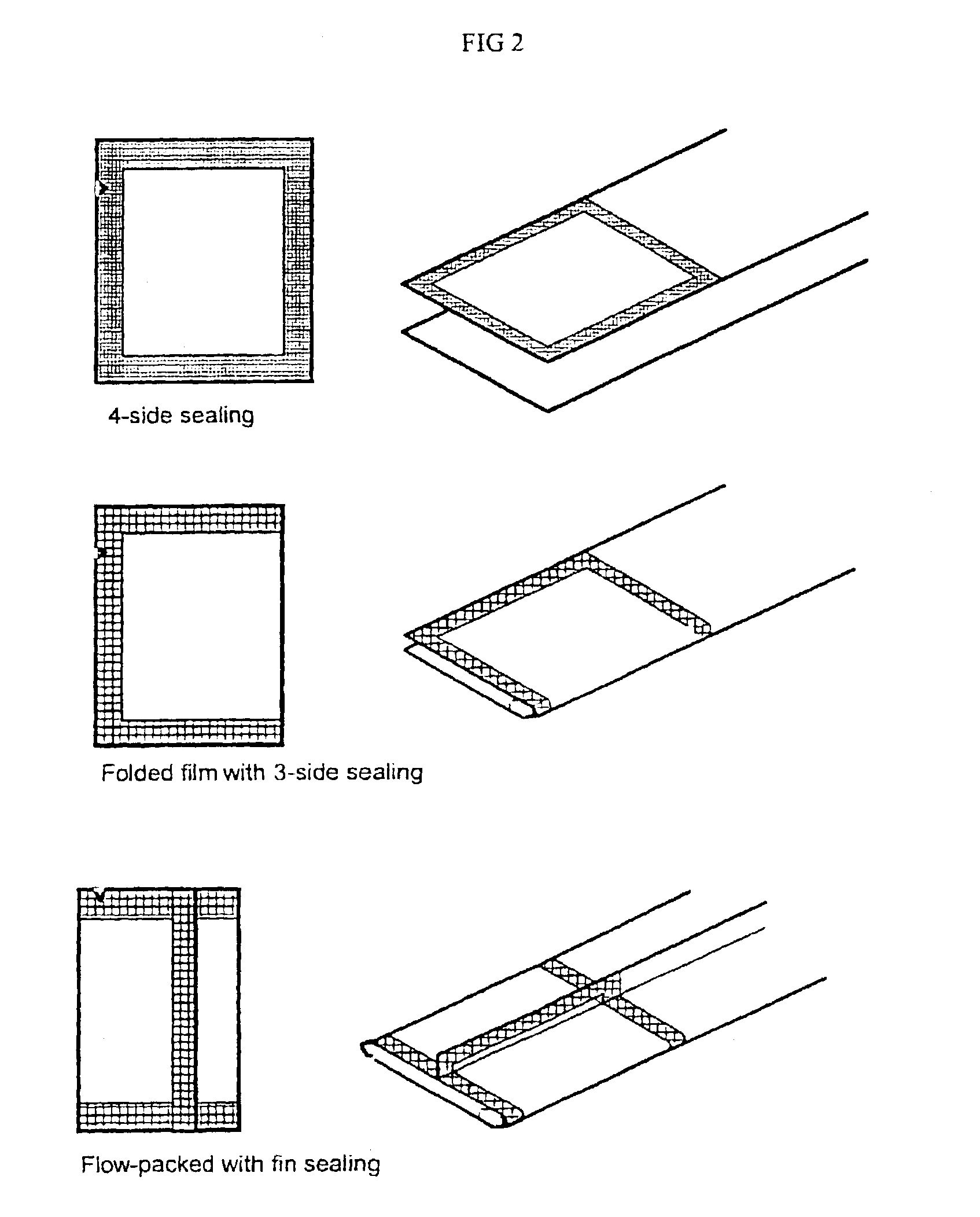

Use of moisture impervious packaging units and package for absorbent articles comprising moisture-sensitive additives

InactiveUS6854600B1Good effectImprove impermeabilityContainers for flexible articlesFlexible coversEngineeringTampon

Active additives in absorbent articles, such as sanitary napkins, panty liners, tampons, incontinence protectors and diapers have been found to lose their properties due to taking-up moisture during storage and transportation for instance, when conventional packaging materials are used. The invention relates to the use of a moisture impervious film material for packaging an absorbent article comprising one or more active moisture-sensitive additives. Packaging is effected in film material that has low vapor and gas permeability and in packaging unites that have tight joins or seams.

Owner:ESSITY HYGIENE & HEALTH AB

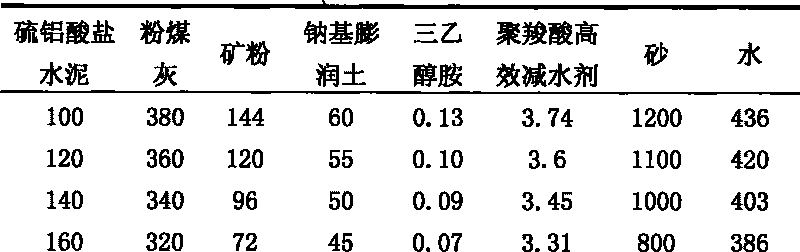

Sulphoaluminate cement base synchronous slip casting material and preparation method

InactiveCN101693615AFulfil requirementsEarly strengthSolid waste managementSodium BentoniteCarboxylic acid

The invention relates to a synchronous slip casting material and a preparation method for tunnels, in particular to a sulphoaluminate cement base synchronous slip casting material, which is characterized in that the sulphoaluminate cement base synchronous slip casting material is prepared by a basal body component and an externally-mixing component, wherein the basal body component comprises sulphoaluminate cement, coal ash, powdered ore, sand and water, the externally-mixing component comprises polycarboxylic acids highly-effective water reducing agent, sodium bentonite and triethanolamine early-strength admixture, the proportioning (kg / m3) of each component is that sulphoaluminate cement: 100-200, coal ash: 300-400, powdered ore: 45-455, sand: 700-1200, water: 350-500, polycarboxylic acids highly-effective water reducing agent: 3.0-4.0, sodium bentonite: 40-60, and triethanolamine early-strength admixture: 0.05-0.2. The synchronous slip casting material prepared by the method has the characteristics of excellent early-stage intensity, underwater non-dispersibility, permeability-resisting and corrosion resistance, and can be used in large-scale river-sea-crossing tunnels or underground engineering.

Owner:武汉市商品混凝土管理站

High-permeability multi-effect concrete water-proofing agent and preparation method thereof

The invention discloses a high-permeability multi-effect concrete water-proofing agent and a preparation method thereof. The water-proofing agent is a colorless transparent alkaline mixed solution of which the pH value is 10-12 and the solid content is 15.4-35 percent. The method comprises the following preparation steps of: adding 0.1-0.5 part by weight of a fluorocarbon surfactant, 0.1-1 part by weight of a nonionic surfactant, 0.1-1 part by weight of an inhibiting agent and 0.1-2.5 parts by weight of a modified into 21-42 parts by weight of deionized water in sequence; uniformly stirring; adding 10-20 parts by weight of alkali metal silicate, and then adding 5-33 parts by weight of organic silicon into 21-42 parts of water; and stirring till organic silicon is fully hydrolyzed, and adding into an organic matter active penetrating fluid. The water-proofing agent has the outstanding advantage of excellent permeation capability and the advantages of maximum permeation depth of 30 millimeters, great increase in the thickness of a water-proof layer, lowering in the complexity of double-component formula construction due to the adoption of a single-component formula, saving in construction cost, nontoxicity and environmental friendliness.

Owner:SOUTH CHINA UNIV OF TECH

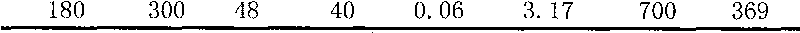

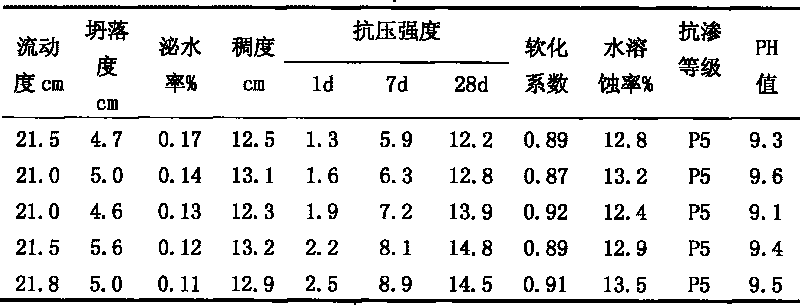

System and method for coating a substrate

InactiveUS20060057394A1Improve impermeabilityIncrease resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsCoating systemReactive components

A system and method are disclosed that provide for coating a substrate. In one embodiment, the coating system includes a polyurethane-polyurea polymer disposed on a surface of the substrate. The polyurethane-polyurea polymer has a mercaptan content of about 0.5% to about 5.0% and is the reaction product of a polyisocyanate prepolymer component and an isocyanate-reactive component.

Owner:SPECIALTY PRODS

Mining foam paste filling material prepared by utilizing synergistic foaming method and preparation method thereof

ActiveCN103449837AReasonable allocation of resourcesLower filling costsCeramicwareFoaming agentActive component

The invention discloses a mining foam paste filling material prepared by utilizing a synergistic foaming method and a preparation method thereof, which are widely suitable for filling of coal mine gob areas, closure of laneways and construction of underground firewalls. The filling material comprises a component A and a component B, wherein the component A comprises an active component, a fine aggregate, a mineral foaming agent, an activating agent, a coagulant and the like; and the component B comprises a foaming agent, a foam stabilizing agent, a water reducing agent and the like. The key point is as follows: after fly ash is activated, the fly ash can be used for replacing part of cement for being used as a cementing material; and in addition, a concrete foaming technology is applied to the filling material, and the mineral foaming agent is innovatively applied to work in coordination with a concrete foaming agent for foaming, so that the foaming expansion performance, pumping performance and anti-seepage performance of the filling material are improved on the original basis, a gob area with a larger space can be filled under the condition of low cement consumption, and low consumption, environmental friendliness, energy conservation and easiness in pumping are realized.

Owner:ANHUI UNIV OF SCI & TECH

Ready-mixed concrete with phosphorus slag powder

InactiveCN101798207AImprove impermeabilityReduce heat of hydrationSolid waste managementSolid waste disposalTensile strainReady mixed concrete

The invention relates to a ready-mixed concrete with phosphorus slag powder, which is characterized in that the composition ratio and the weight ratio comprise the following parts: 120-150 parts of cement, 100-250 parts of phosphorus slag powder, 0-120 part(s) of fly ash, 0.5-20 part(s) of water reducing agent, 0-0.5 part of air entraining agent, 0-0.02 part of water retention agent, 50-17000 parts of coarse aggregate, 20-9000 parts of fine aggregate and 100-300 parts of water. The invention takes the industrial waste residue i.e. the phosphorus slag powder as the admixture part of the concrete to replace the cement to dope in the ready-mixed concrete, thereby reducing the use amount of the cement, uses the retarding characteristic of the phosphorus slag to reduce the gelled material cost of the concrete and the manufacture cost the of concrete pumping aid, simultaneously gives full play to the characteristic of the phosphorus slag so as to reduce the hydration heat and the adiabatic temperature rise of the concrete, decreases the elasticity modulus and improves the ultimate tensile strain capacity of the concrete, the strength growth rate is high, and the durability is significantly improved; and the invention can changes the waste into the valuable and turns the harmful into the beneficial.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com