Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Good crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

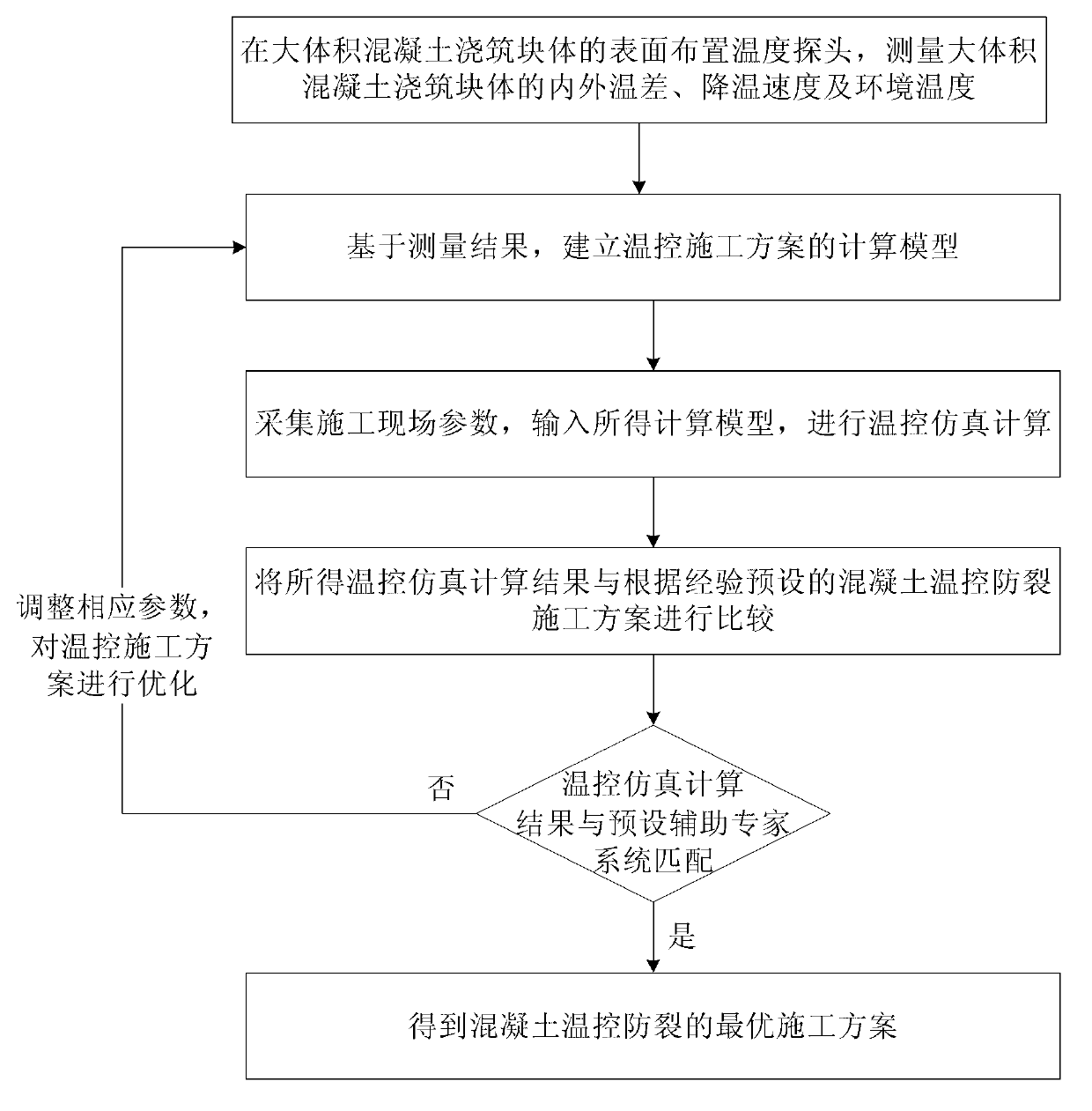

Temperature-controlled crack prevention construction method for concrete structure

ActiveCN102979307AOvercoming easy cracksOvercoming reliabilityFoundation engineeringBuilding material handlingTemperature controlTemperature difference

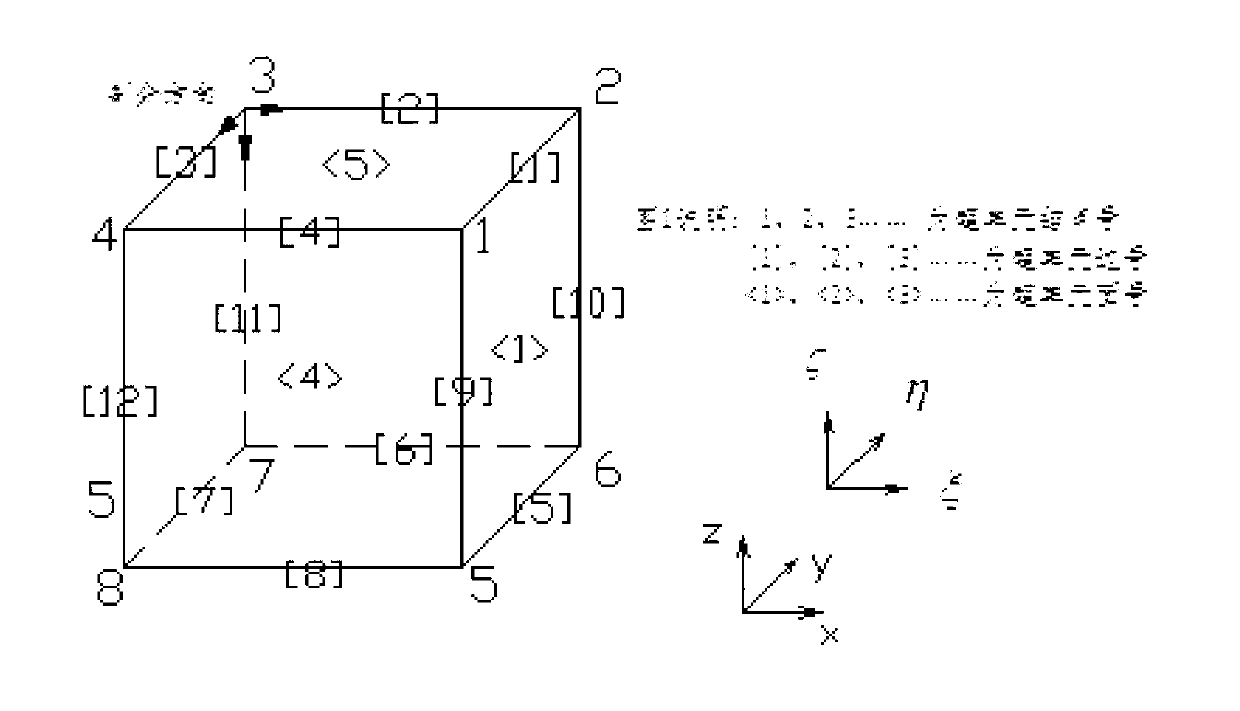

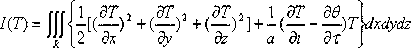

The invention discloses a temperature-controlled crack prevention construction method for a concrete structure. The method comprises the steps of (1) arranging temperature probes on the surface of a large-size concrete pouring block to measure the temperature difference between inside and outside, the cooling rate of the large-size concrete pouring block and the environment temperature; (2) establishing a calculation model for the temperature-controlled construction scheme based on the obtained measuring result; (3) collecting the construction site parameters, and inputting the parameters into the obtained calculation model for temperature-controlled simulation calculation; and (4) comparing the temperature-controlled simulation calculation result obtained in the step (3) with the preset auxiliary expert system, repeating the step (2) to adjust the corresponding parameters when the temperature-controlled simulation calculation result obtained in the step (3) and the preset auxiliary expert system mismatch, and optimizing the temperature-controlled crack prevention construction scheme for concrete preset based on experience until the optimal temperature-controlled crack prevention construction scheme for the concrete is obtained. The temperature-controlled crack prevention construction method for the concrete structure disclosed by the invention has the advantages that the concrete is not prone to crack, the crack prevention reliability is high, and the crack prevention commonality is good.

Owner:JINLAI CONSTR ENG TECH RES & DEV CO LTD OF THE XINJIANG PRODION & CONSTR CORPS

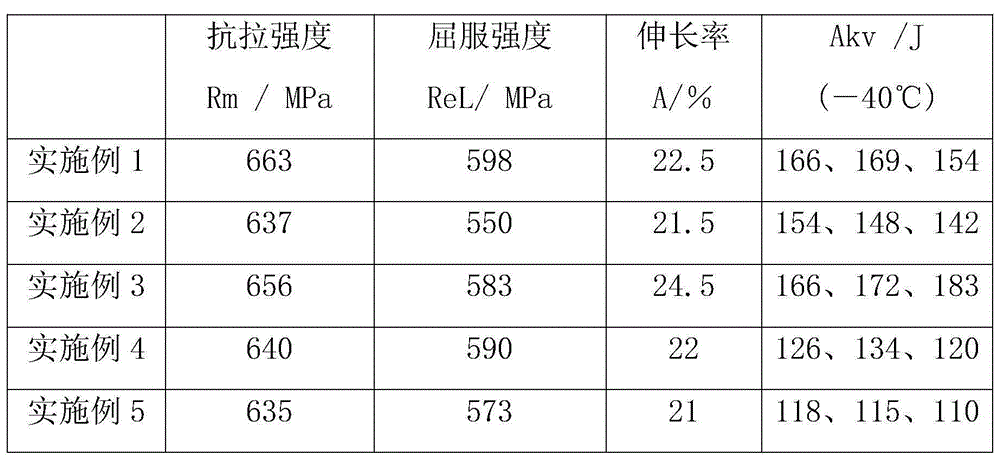

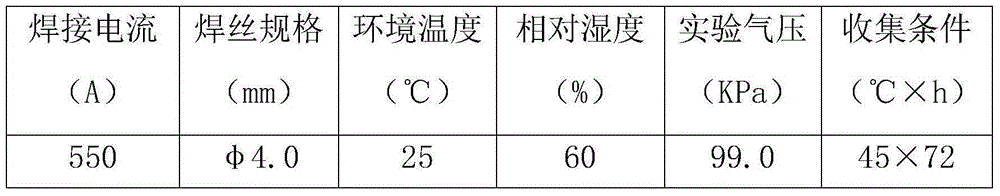

High tenacity and low hydrogen type agglomerated flux for ocean engineering and preparation method thereof

ActiveCN105081615AGood crack resistanceLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaImpact energyMetal

The invention provides high tenacity and low hydrogen type agglomerated flux for ocean engineering. The high tenacity and low hydrogen type agglomerated flux is composed of, by weight, 18%-23% of MgO, 28%-32% of CaF2, 18%-22% of Al2O3, 1%-5% of TiO2, 18%-22% of SiO2, 3%-7% of CaO, 2%-5% of Na3AIF6, 2%-6% of MnO, 0-0.015% of S and 0-0.025% of P. By means of the high tenacity and low hydrogen type agglomerated flux, weld metal has good welding process properties such as sediment separation and pore resistance and a good anti-cracking property; the Charpy impact energy is relatively high at the temperature of -40 DEG C and the content of diffusible hydrogen meets the requirement of ultra-low-hydrogen.

Owner:武汉铁锚焊接材料股份有限公司

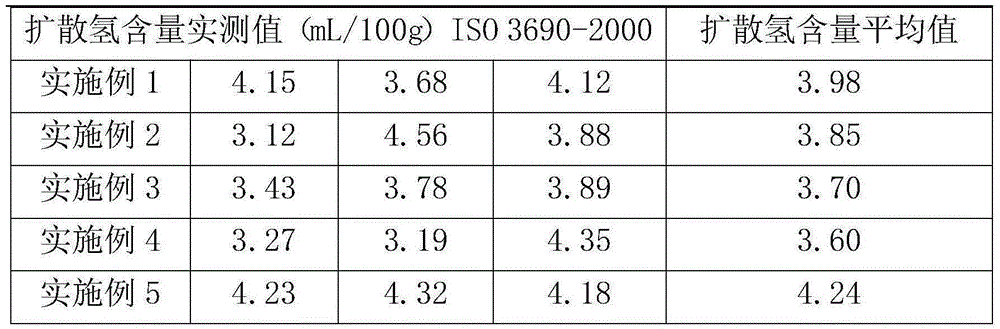

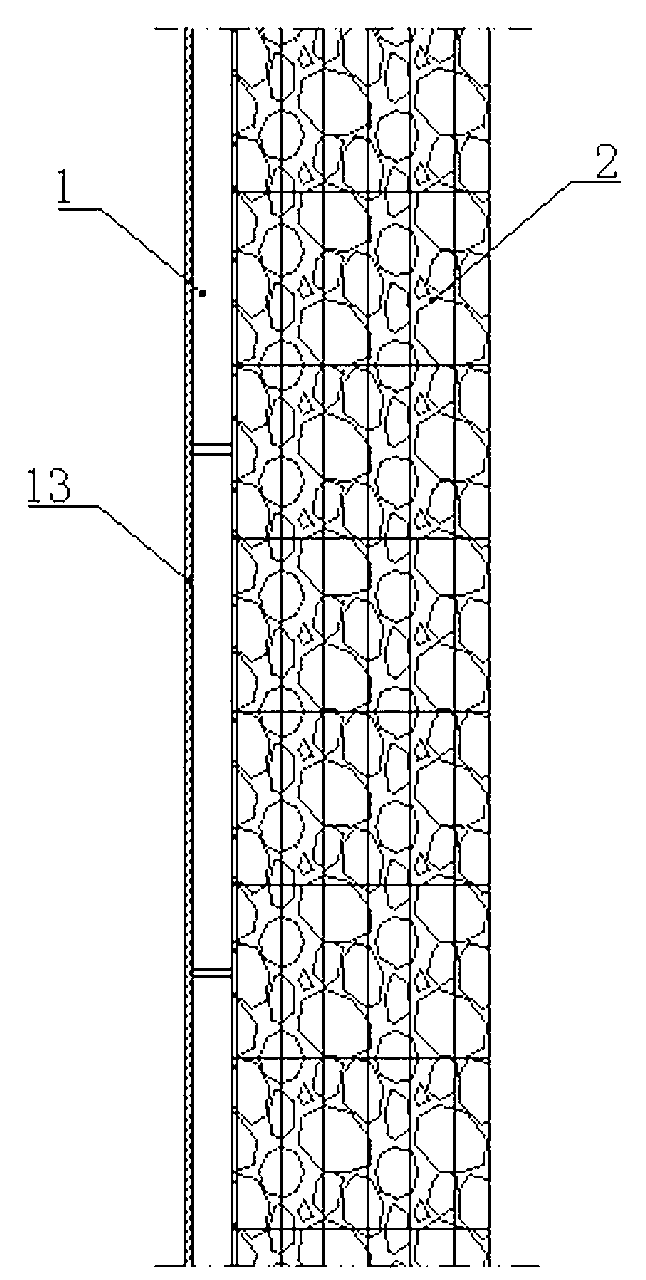

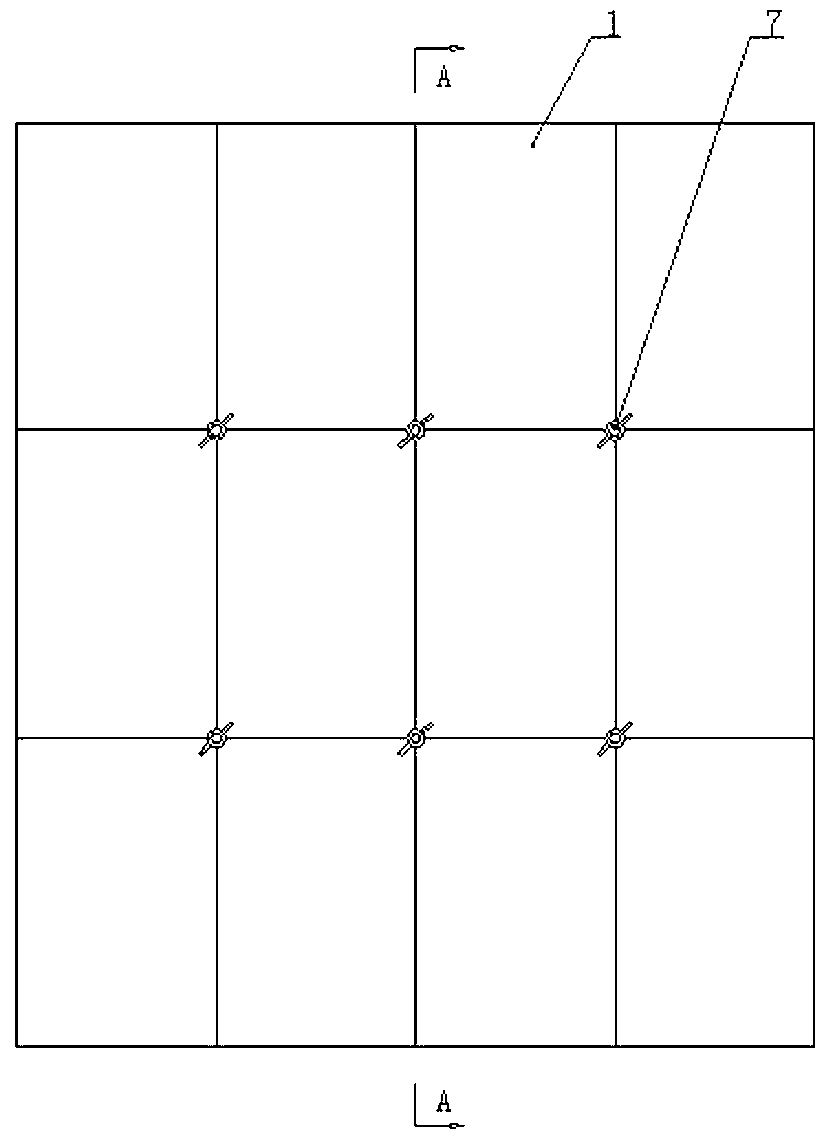

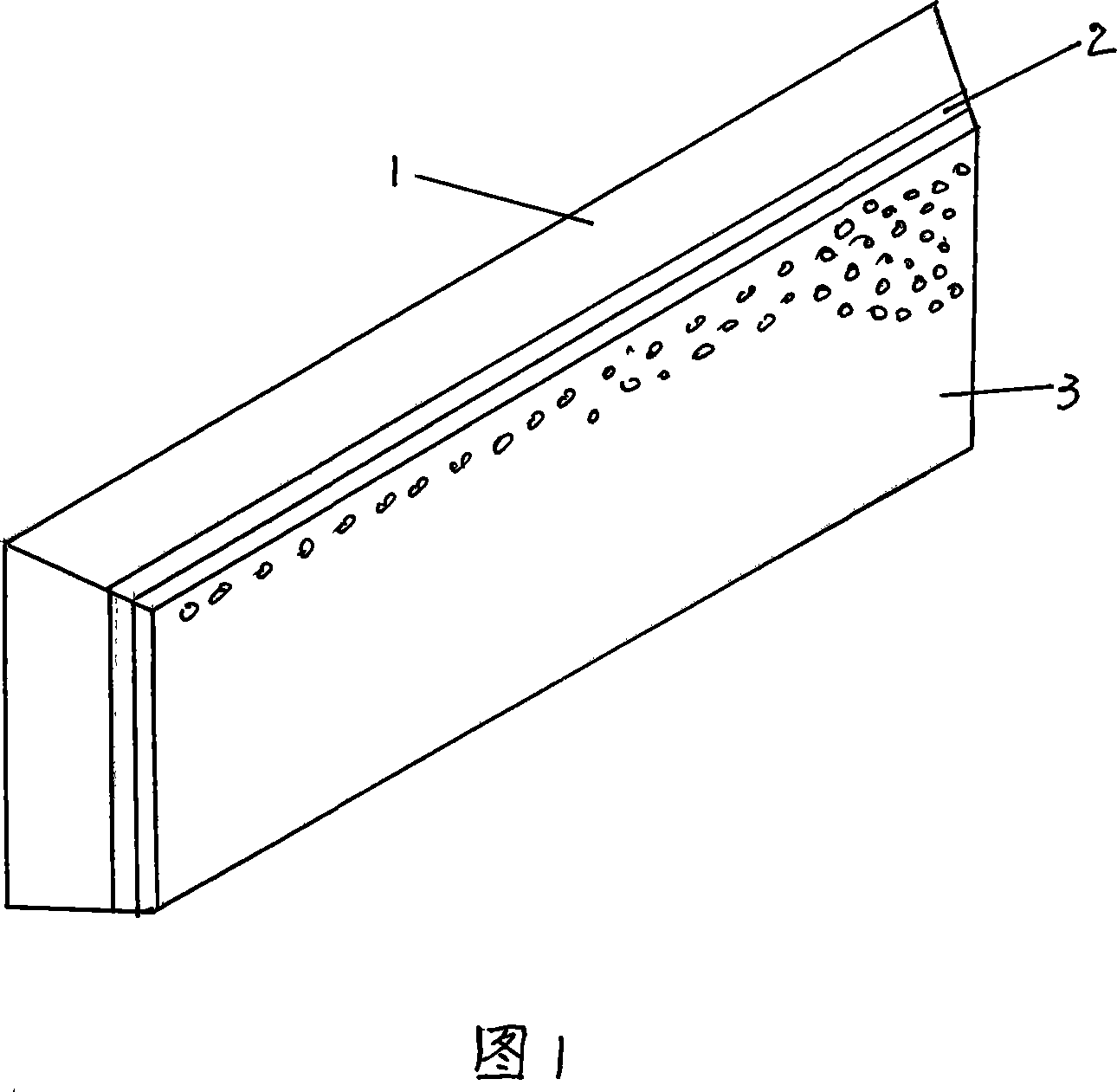

Ultra-thin heat insulation composite insulation board and cast-in-place concrete composite wall and construction method

ActiveCN103015573ASimple constructionGood crack resistanceWallsClimate change adaptationRebarReinforced concrete

The invention relates to an ultra-thin heat insulation composite insulation board and cast-in-place concrete composite wall, which is characterized by comprising an ultra-thin heat insulation composite insulation board, a reinforced concrete wall body and a finish coat, and the cast-in-place reinforced concrete wall body and the ultra-thin heat insulation composite insulation board outside are adhered into a whole; and the finish coat is arranged at the outer side of the ultra-thin heat insulation composite insulation board. The ultra-thin heat insulation composite insulation board and cast-in-place concrete composite wall provided by the invention has the advantages of simple construction, safety, work saving, labor saving, economy, good crack resistance, high adhesion with the wall body and long service life. The hand feeling operation and installation mode of hand smearing is eliminated, the industrialization of external insulation installation is realized, the labor intensity is reduced, and the economic and social benefits are good.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Outer wall heat preservation dry-powder mortar for construction

An out wall heat preservation dry powder sand pulp for architecture is characterized in that it is made up of the raw materials as following weight shares: cement 500-700, heavy calcium carbonate 200-300, gray calcium carbonate 100-2200, re-dispersed gelatine powder 15-25, hydroxypropyl methylcellulose 2-4, lignocellulose 0.5-1.5, polypropylene fibre 0.5-1.5. The out wall heat preservation dry powder sand pulp for architecture adopts the combination of the cement binder and polymer binder with a good crack resistance, a good elasticity and flexibility and a long service life. The face work will not appear crack, knob and abscission. It can be constructed in lamina, thus it reduces the material and the waste, meanwhile, it improves the life of the building and saves the energy of about 60% compared to the conventional sand pulp and increases the working efficiency. The producing process and the using process is innocuous, flavourless, safe, healthful, easy to transport, waterproof, water conservation, not sagging and have the water as the solvent.

Owner:宋连伟

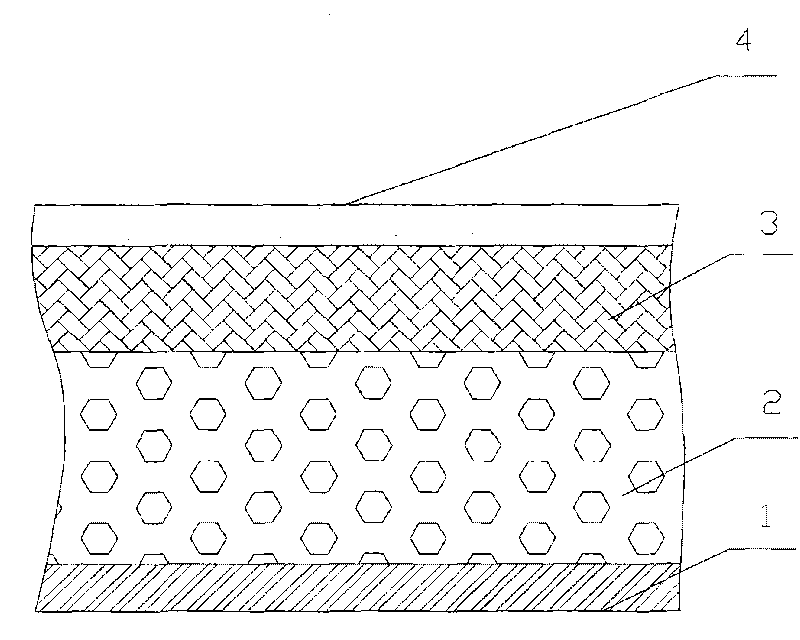

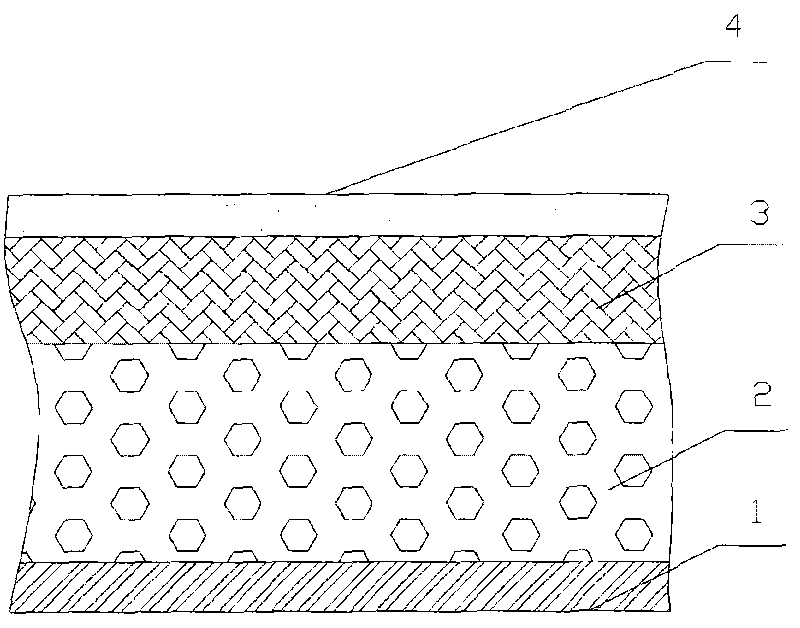

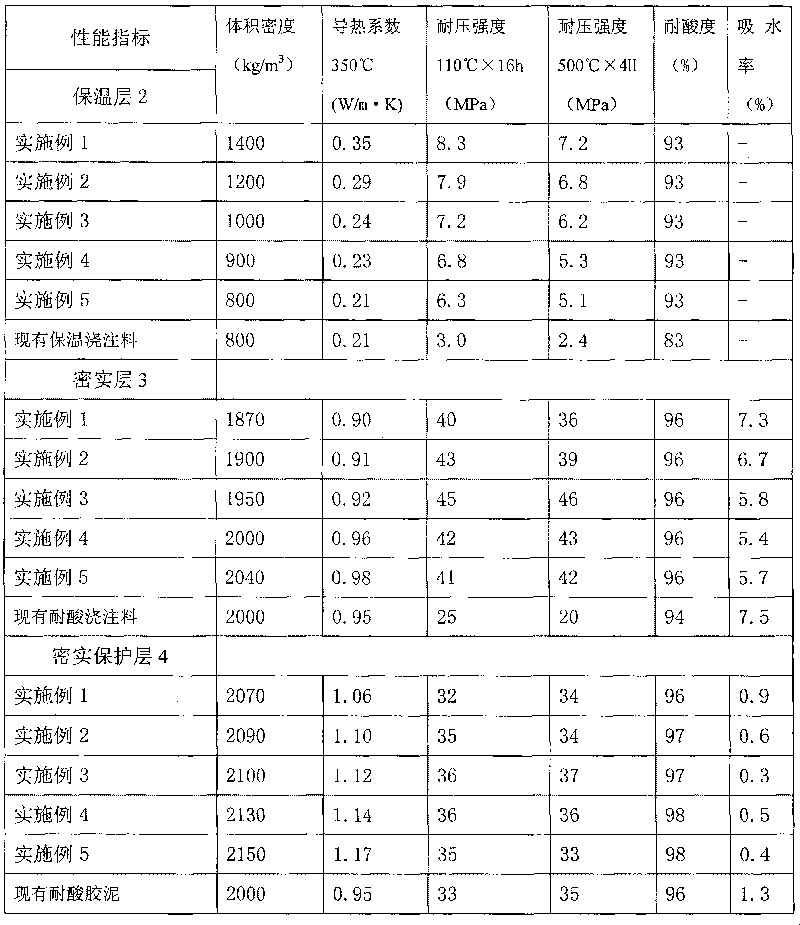

Crack resistance amorphous acid-proof pouring material, crack resistance acid-proof heat preservation protective layer and manufacturing method thereof

ActiveCN101704659AGood crack resistanceGood insulation performanceSodium fluosilicateFurfuryl alcohol

The invention provides a crack resistance amorphous acid-proof pouring material applied to afterheat recycling equipment or chemical engineering equipment, and a heat preservation protective layer formed by using the pouring material and a manufacturing method thereof. The pouring material uses water glass as binding agent, sodium fluosilicate or condensed aluminium phosphate powder as curing agent, ceramsite and pearlite grains as heat preservation material, diabase powder and quartz sand as filling material, furfuryl alcohol as modifier, and glass fiber yarn as crack resistance reinforcing material. The heat preservation protective layer comprises a porous heat preservation layer and a dense impervious layer, preserves heat and prevents seepage of acid liquor. The pouring material can proof sulfuric acid, hydrochloric acid and the like of various concentration, has excellent crack resistance and can endure a temperature as high as 500 DEG C.

Owner:NANJING SHENGNUO HEAT PIPE

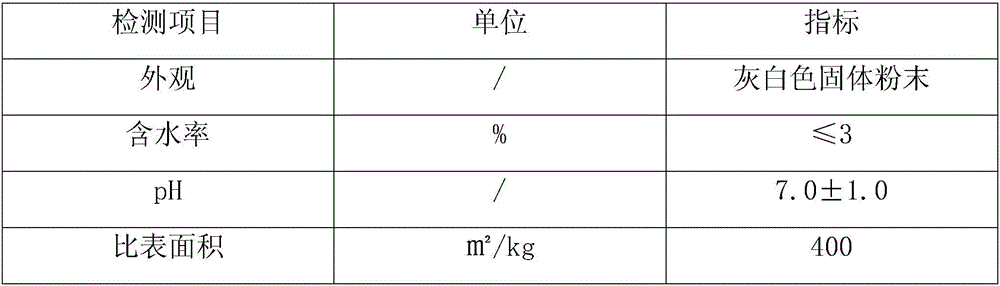

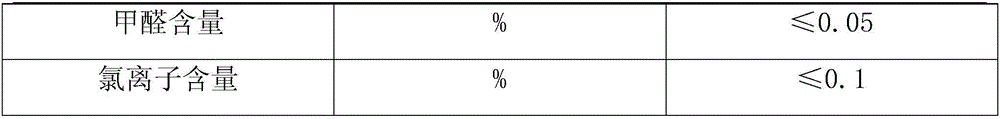

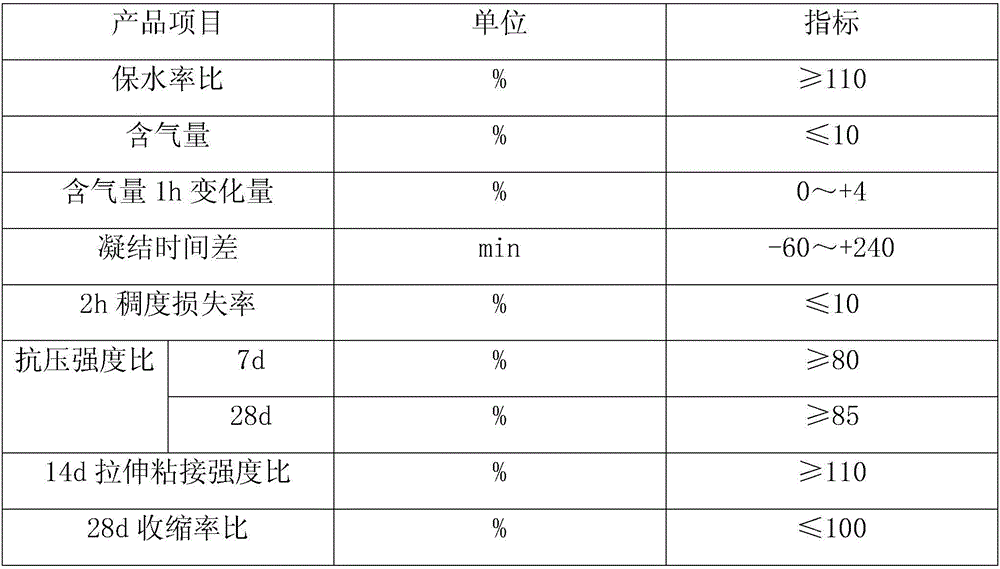

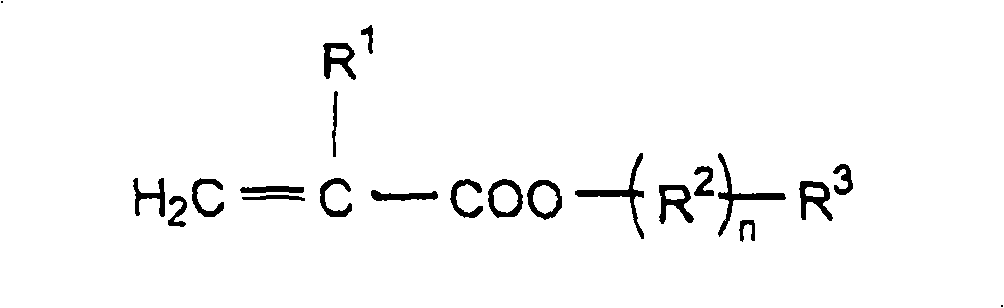

Efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as preparation method and application method thereof

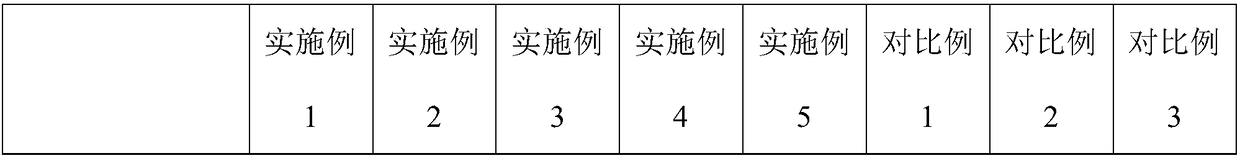

The invention discloses an efficient-spraying type dry-mixing and wet-mixing mortar plasticizer composition as well as a preparation method and an application method thereof. The composition comprises the following components in percentage by weight (100% in total): 1%-5% of a plasticizer, 15%-30% of a thickening agent, 30%-50% of a retarder, 10%-25% of an anti-cracking agent, 1-5% of a water-retaining agent, 5%-10% of an enhancer, and 1%-5% of a binding agent. By utilizing the composition, the workability, water-retaining property, adhesive property and cracking resistance of coating mortar can be remarkably improved, the cracking, hollowing and falling of the mortar are avoided, and various performance indexes such as the strength and permeability resistance of the mortar can be improved; and furthermore, cement can be saved, and the disadvantages of easiness in ash blasting, high shrinkage, low strength and the like of the cement mixed mortar are overcome.

Owner:四川巨星新型材料有限公司

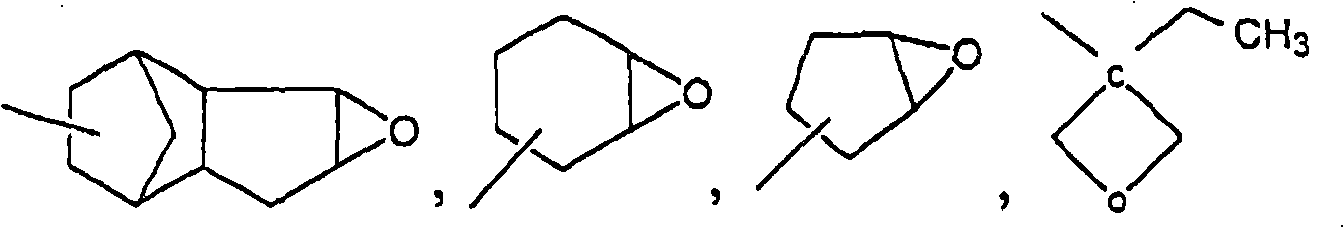

Inorganic filler and organic filler-containing curable resin composition, resist film coated printed wiring board, and method for producing the same

ActiveCN101402775AGood crack resistanceImprove functionalityPrinted circuit aspectsPrinted circuit manufactureElastic modulusResist

A curable resin composition comprises: (I) 100 parts by-weight of a curable resin; (II) 10 to 1200 parts by weight of an inorganic filler; and (III) 1 to 100 parts by weight of an organic filler having an elastic modulus of 1 to 2000 (MPa) and an average particle diameter of 0.01 to 10 mum, wherein a content weight ratio of the components (II) and (III) is 1 to 41.

Owner:SANEI KAGAKU KK

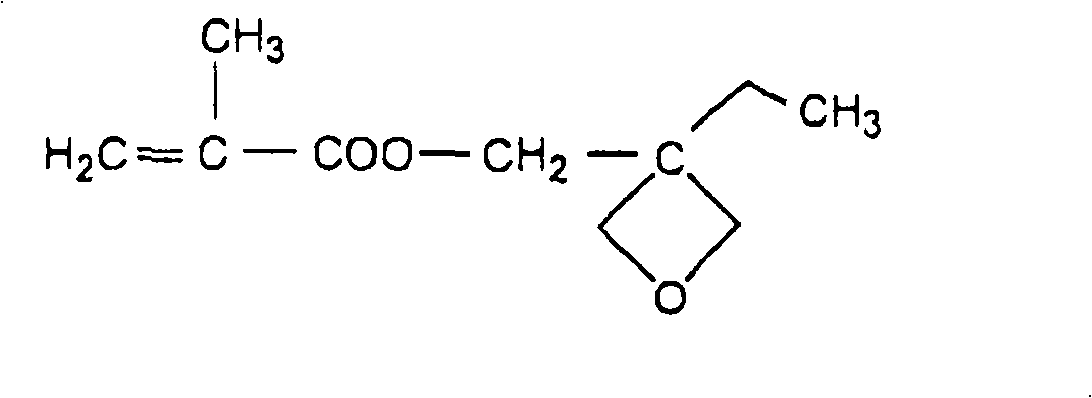

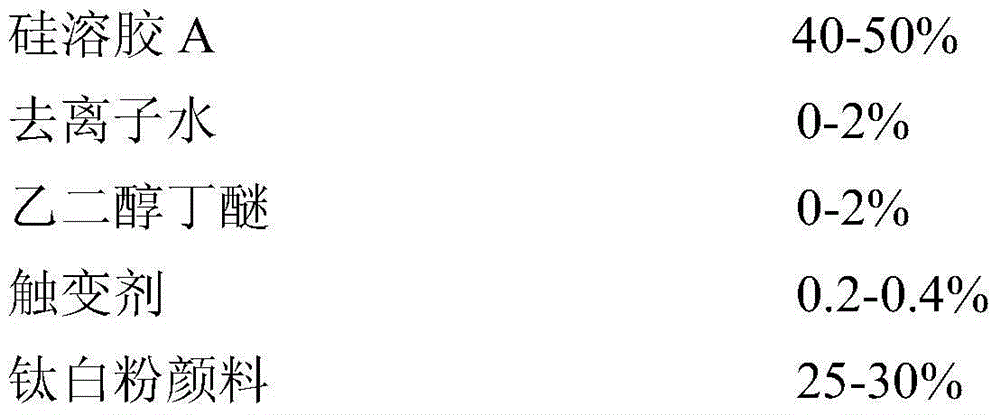

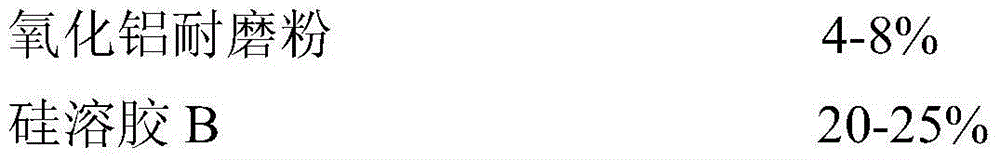

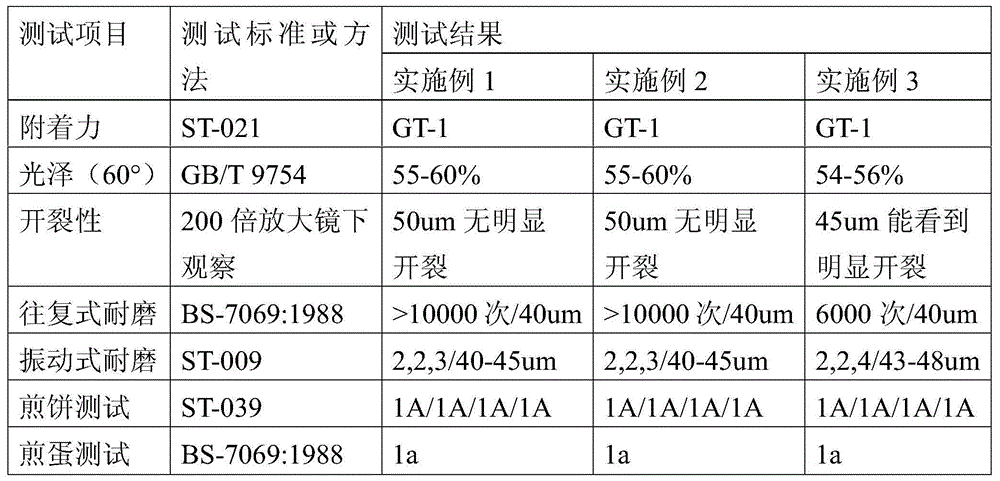

High-wear-resistant and crack-resistant ceramic paint and preparation method thereof

The invention discloses a high-wear-resistant and crack-resistant ceramic paint and a preparation method thereof. The high-wear-resistant and crack-resistant ceramic paint is composed of a component A as a main agent, a component B as a curing agent and a component C as a catalyst, wherein the weight ratio of the component A to the component B to the component C is equal to (2-3) to (1-2) to 0.01. The preparation method comprises the steps of mixing all the components according to a certain ratio, and curing to obtain a finished product of the paint. If being matched with silica sols with different particle sizes, the paint has the characteristics of excellent crack resistance and good wear resistance, and is convenient to construct and environmental friendly.

Owner:卡秀万辉(无锡)高新材料有限公司

Composite flame-resistant material for wire and cable sheaths

InactiveCN104031309AGood crack resistanceStable productionInsulated cablesInsulatorsSilicon nitrideCarbon black

The invention belongs to the technical field of wires and particularly relates to a composite flame-retardant material for wire and cable sheaths. The composite flame-retardant material for wire and cable sheaths is characterized by being prepared from, by weight, 65 parts to 75 parts of polyethylene resin, 22 parts to 28 parts of ethylene-vinyl acetate copolymer, 5 parts to 10 parts of epoxy resin, 2 parts to 4 parts of polyethylene wax, 1 part to 3 parts of ammonium polyacrylate, 2 parts to 4 parts of nano-silicon nitride or nano-silicon carbide or nano-zirconium oxide or nano-aluminum oxide, 30 parts to 40 parts of dioctyl oxalate, 10 parts to 20 parts of polyester type plasticizer with the commercially available model number of PN-850, 3 parts to 5 parts of trimellitic anhydride, 30 parts to 40 parts of magnesium hydroxide or aluminum hydroxide, 6 parts to 10 parts of carbon black and 1 part to 2 parts of antioxidant with the commercially available model number of T501. The composite flame-retardant material for wire and cable sheaths has the main advantages of being better in torsional property, processability and environmental suitability, lower in density, and better in tensile strength, elongation at break and other performance.

Owner:滨州东力电力设计有限公司

Novel material integrating decoration, anti-crack, water-proof and heat preserving function, and its producing method

InactiveCN101173549AGood crack resistanceGood waterproof effectCovering/liningsInsulation layerBeautification

The invention discloses a new type material integrating decoration, waterproof and heat insulation and the preparation method, which is characterized in that: the new type material comprises a heat preservation and insulation layer; an anti-crack and protective waterproof layer is combined between the heat preservation and insulation layer and a decoration waterproof layer; the invention adopts the preparation steps that: the heat preservation and insulation layer is combined with the anti-crack and protective waterproof layer, and the anti-crack and protective waterproof layer is combined with the decoration waterproof layer. The invention has the advantages that: two waterproof layers and one heat insulation layer are provided; the first waterproof layer is made of one of the metal plate, polymerization cement mortar or the anti-crack and waterproof powder crack sealer; the decoration waterproof layer is coated on the metal plate, polymerization cement mortar or anti-crack and waterproof powder crack sealer, which forms the second waterproof layer; a color sand finish is formed by an external surface, integrating three functions of beautification and decoration, crack resistance and waterproof and heat insulation; the wall surface or the house surface has good waterproof, anti corrosive and anti-crack effects; the color sand facing is a flexible waterproof layer, and the house surface or the wall surface with high strength is wholly crack resistant.

Owner:天津市禹红建筑防水材料有限公司

Anti-cracking concrete

The invention discloses an anti-cracking concrete. The anti-cracking concrete comprises the following raw materials in parts by weight: 55-68 parts of cement, 70-100 parts of quartz sand, 20-40 partsof pottery sand, 0.5-1.1 parts of composite fibers, 3-8 parts of cordierite, 0.9-2.7 parts of light calcined magnesia, 7-15 parts of silica fume, 1.8-2.8 parts of zeolite, 4-8 parts of agstone, 1-3 parts of lead-zinc tailings composite powder, 0.2-1.3 parts of steel slag powder, 1.2-3.5 parts of rice husks, 0.5-2 parts of alumina hollow balls, 0.5-2 parts of calcite in powder, 0.1-0.28 part of epoxy resin latex, 1-1.8 parts of a waterproofing agent, 20-28 parts of water, 0.6-2.6 parts of a water-reducing agent and 0.1-0.32 part of sludge. The anti-cracking concrete is high in strength, good intoughness, anti-cracking and long in service life.

Owner:蚌埠市方阵商品混凝土有限公司

Seam binding agent with modified fatty amine as epoxy curing agent resin

ActiveCN102816501AGood crack resistanceRapid prototypingNon-macromolecular adhesive additivesEpoxy resin adhesivesPliabilityPhysical density

The invention relates to a seam binding agent with modified fatty amine as epoxy curing agent resin. The agent is suitable for easy-cracking positions in indoor and outdoor decorations. The agent is filled into seams of same or different materials such as wood, brick and stone, gypsum board, calcium silicate, and the like, for providing an excellent anti-cracking effect. The agent can also be used as a binding agent for roof leakage repairing, wood, and plastic. The agent can be used in crack sealing and water proofing of various grouting projects, bridges, and tunnels. According to the invention, a novel nano fiber binding technology is adopted. When the product is cured, nano fibers in the product form a high-molecular high-density net-shaped film at a seam position, wherein the physical density of the film is close to that of wood board or gypsum board. The film can expand or contract synchronically with the board when weather is changed, and has good cracking resistance, adhesive force, and flexibility. The seam binding agent is advantaged in fast shaping, easy construction, and low sagging.

Owner:SKSHU PAINT

High-strength glass fiber reinforced plastic

The invention discloses a high-strength FRP, which is made of the following raw materials in parts by mass: 40-50 parts of epoxy resin, 25-30 parts of silicon dioxide, 14-16 parts of kaolin, 3-5 parts of aluminum oxide, silicon dioxide 6-8 parts of calcium oxide, 2-4 parts of titanium dioxide, 1-3 parts of magnesium oxide, 5-7 parts of calcium oxide, 4-5 parts of barium hydroxide, 11-13 parts of glass fiber, and 10-12 parts of nano-carbon fiber. The invention has high strength, good crack resistance, high temperature resistance, corrosion resistance, economy and environmental protection.

Owner:青岛燕园海洋生物科技有限公司

Submerged-arc welding wire for CO2 (Carbon Dioxide) corrosion resistant high-strength pipeline steel

InactiveCN103143856AGood crack resistanceGood impact toughnessWelding/cutting media/materialsSoldering mediaSubmerged arc weldingCorrosion resistant

The invention relates particularly to a submerged-arc welding wire for CO2 (Carbon Dioxide) corrosion resistant high-strength pipeline steel. The technical scheme is that the submerged-arc welding wire for the high-strength pipeline steel comprises the following chemical components: 0.02-0.06 wt% of C, 0.20-0.40 wt% of Si, 1.20-2.00wt% of Mn, 3.00-8.00wt% of Cr, and 0.20-0.40wt% of Cu, 0.04-0.10 wt% of (V+Ti+B), not more than 0.001 wt% of S, not more than 0.002 wt% of P, and the remain of Fe and inevitable impurities. The submerged-arc welding wire for the high-strength pipeline steel provided by the invention is matched with an SJ101-G soldering flux for use, requirements of intensity, tenacity and CO2 corrosion resistance of a welding joint formed by the welded submerged-arc welding wire for the CO2 corrosion resistant high-strength pipeline steel can be met by mechanical property and corrosion resistance of formed weld metal; moreover, the property of the welding joint is matched with base metal, so that technical requirements of oil and gas pipelines prepared by welding can be met; and the welding joint is good in CO2 corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

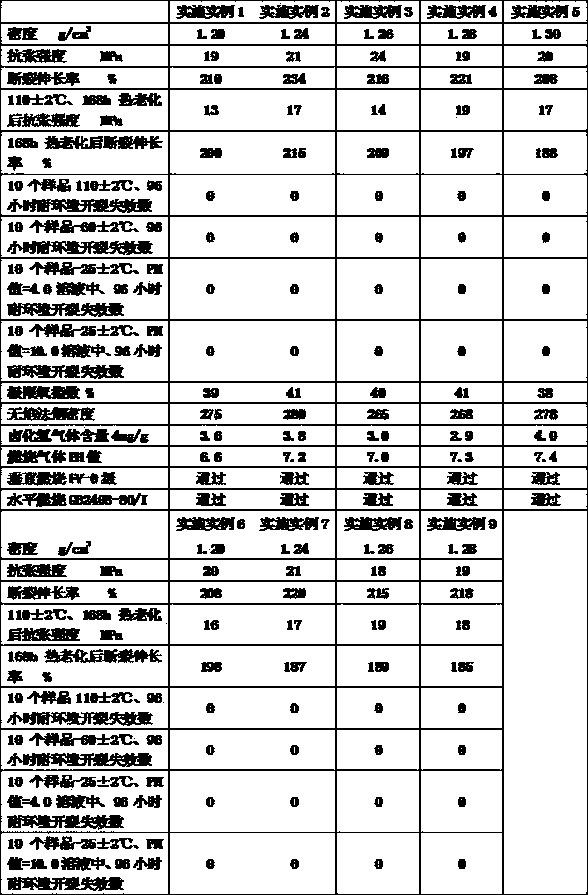

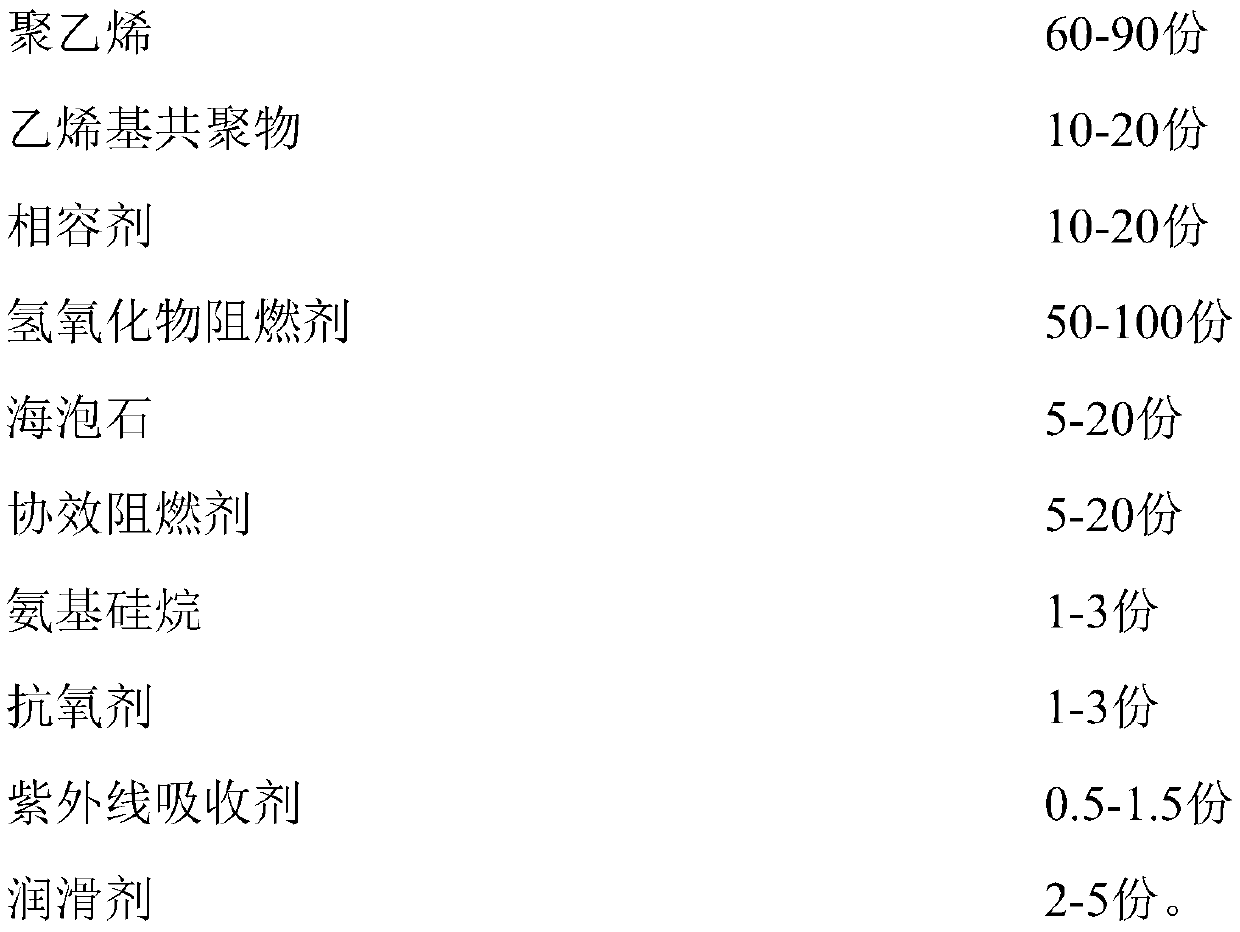

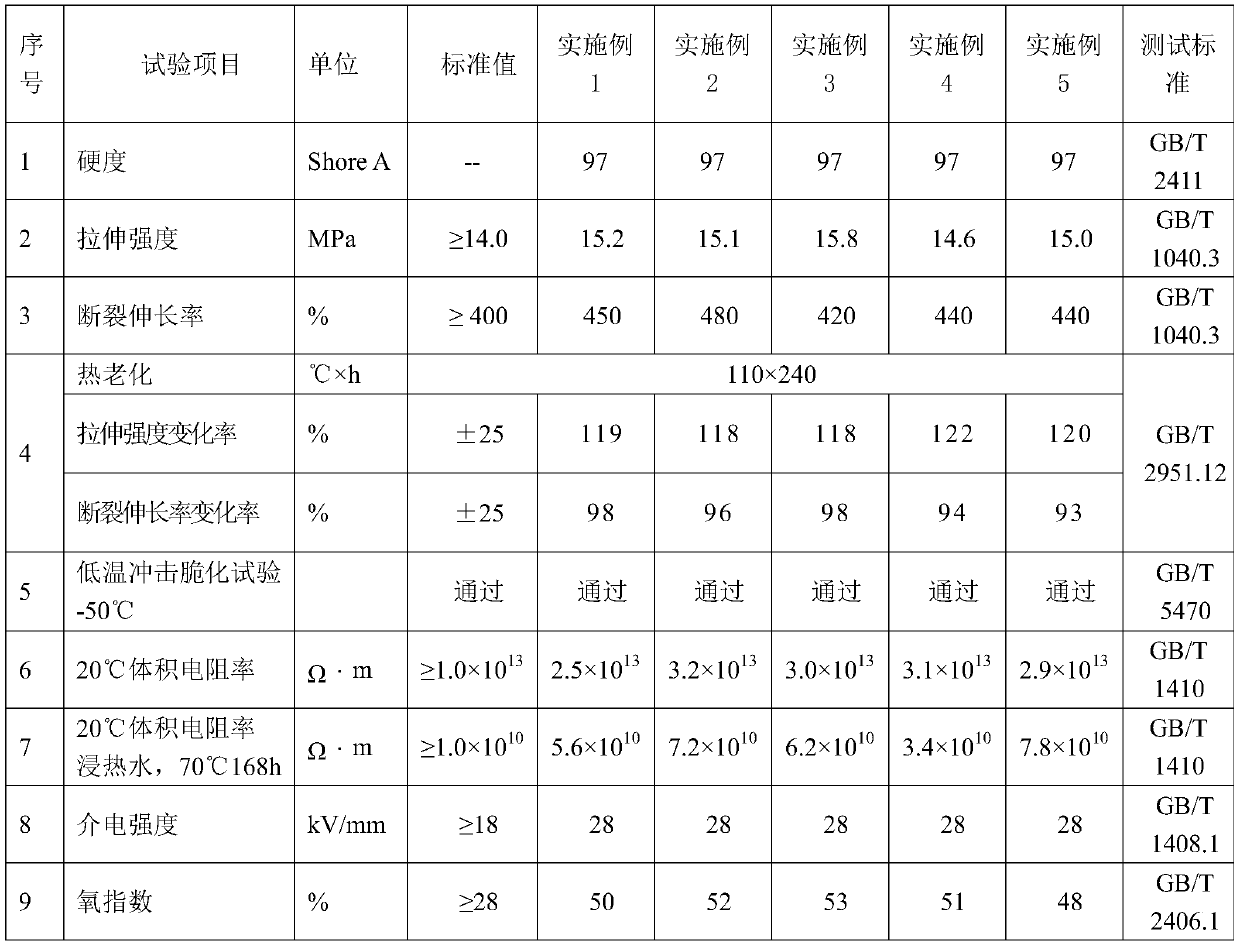

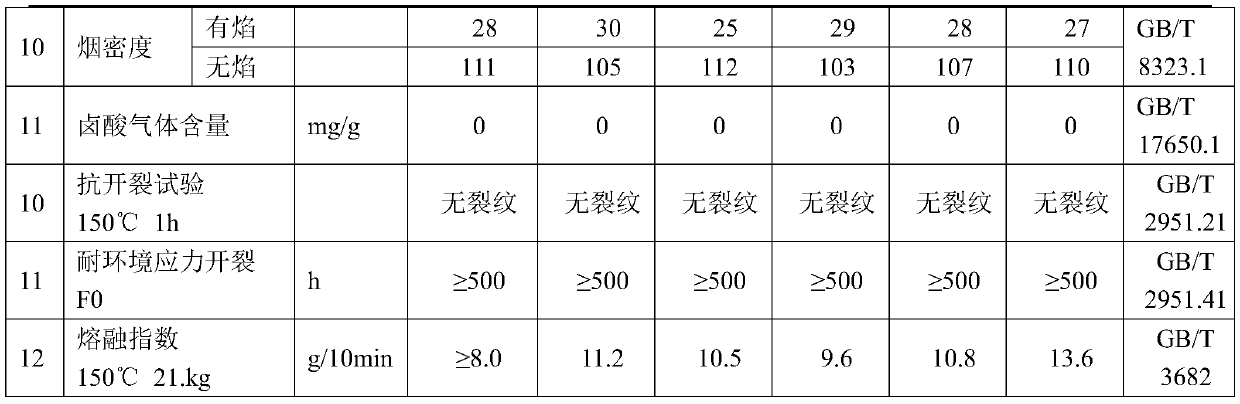

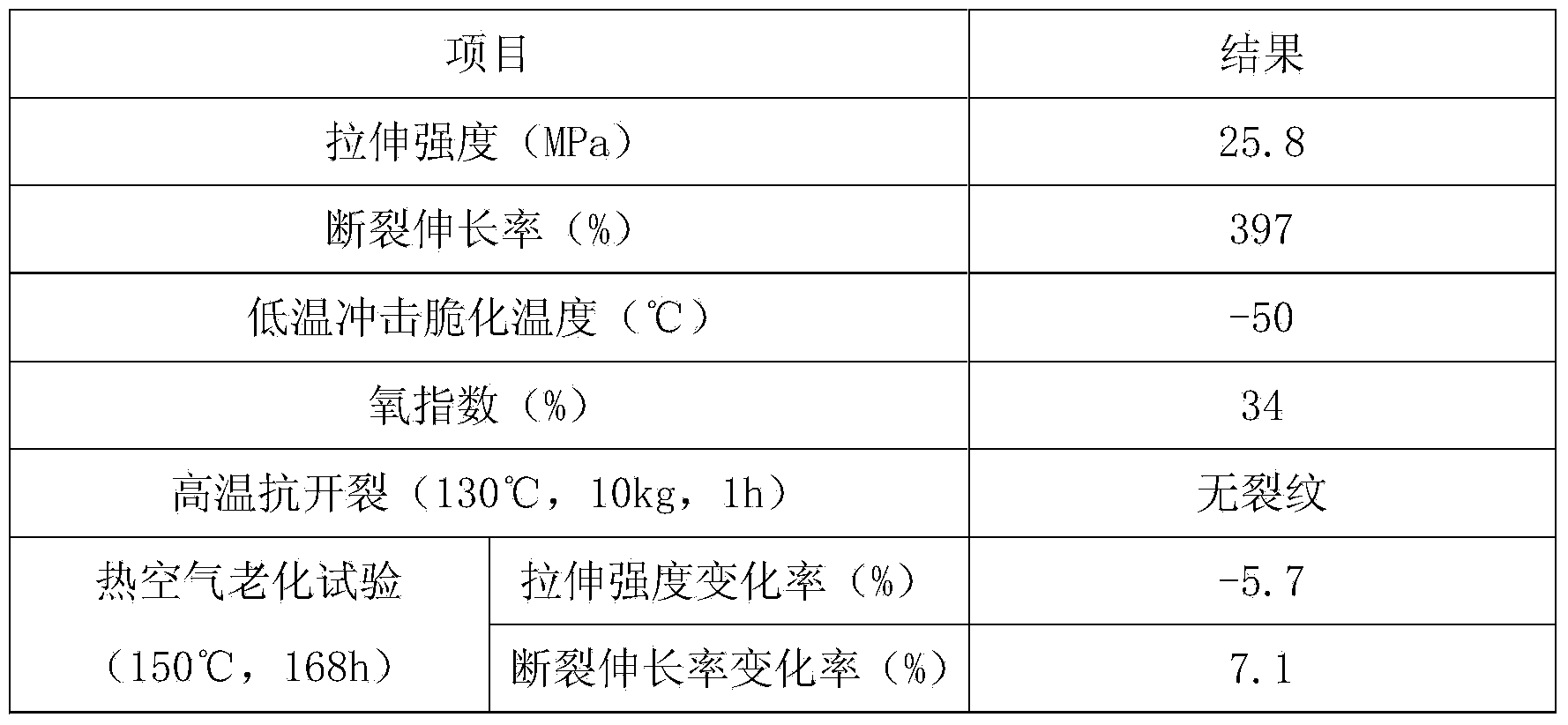

90DEG C cracking-resistant moisture-proof and flame-retardant polyethylene cable material and preparation method thereof

PendingCN110903538AGood crack resistanceGood flame retardant performancePlastic/resin/waxes insulatorsChemistryUv absorber

The invention discloses a 90DEG C cracking-resistant moisture-resistant and flame-retardant polyethylene cable material and a preparation scheme thereof. The cable material is composed of the following components by weight: 60-90 parts of polyethylene, 10-20 parts of a vinyl copolymer, 10-20 parts of a compatilizer, 50-100 parts of a hydroxide flame retardant, 5-20 parts of sepiolite, 5-20 parts of a synergistic flame retardant, 1-3 parts of aminosilane, 1-3 parts of an antioxidant, 0.5-1.5 parts of an ultraviolet light absorber and 2-5 parts of a lubricant. The 90-DEG C cracking-resistant moisture-resistant and flame-retardant polyethylene cable material disclosed by the invention has the characteristics of resistance to a low temperature of -50DEG C, outstanding cracking resistance, insulativity and moisture resistance (volume resistivity of 70DEG C*168h after immersion), good flame retardance, low smoke, no toxicity and the like, also has the advantages of fast extrusion processingspeed, difficult generation of air holes, etc., and can be widely applied to an outer sheath layer of a 1kV-220kV cable.

Owner:中广核三角洲(江苏)塑化有限公司

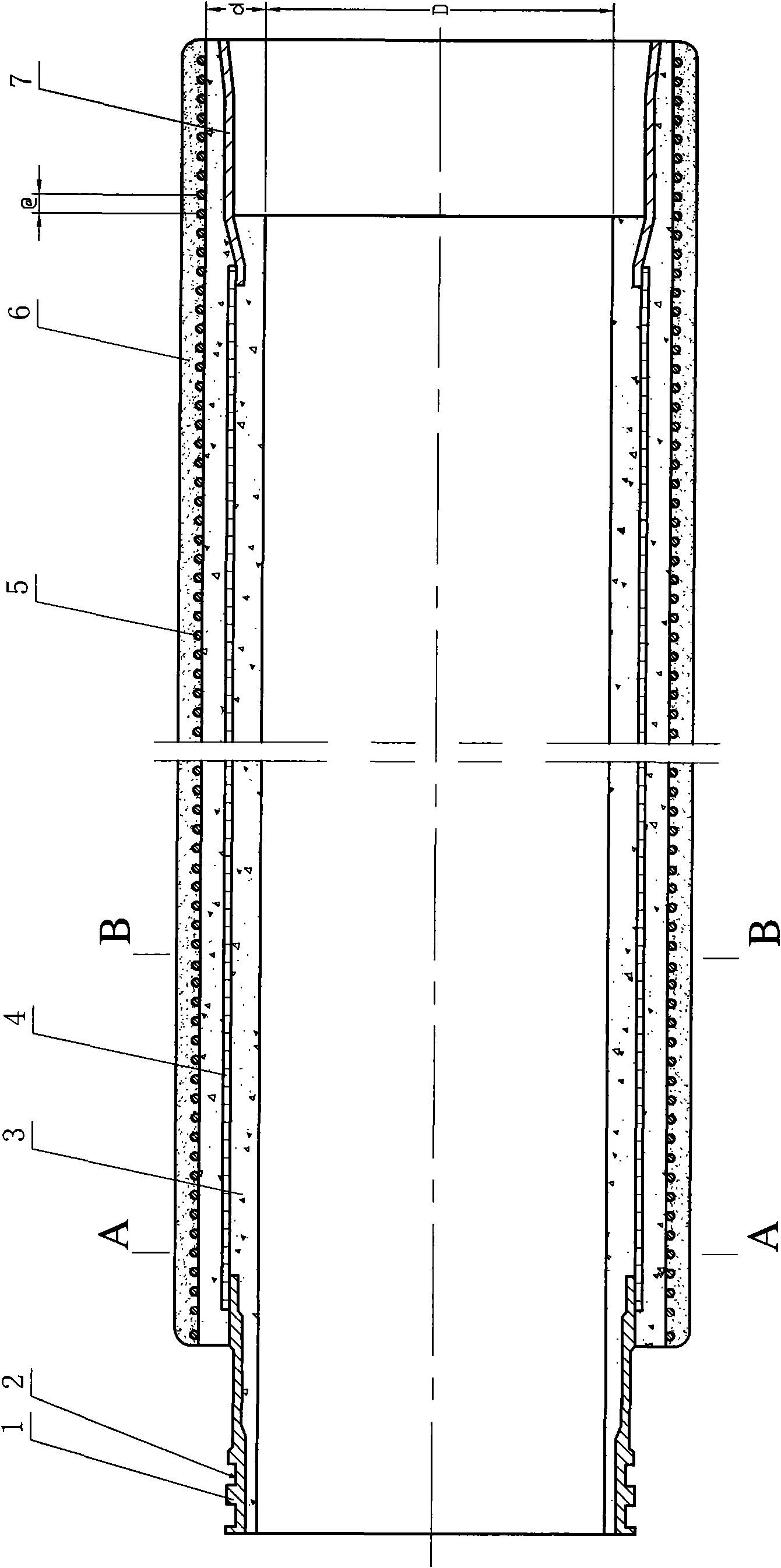

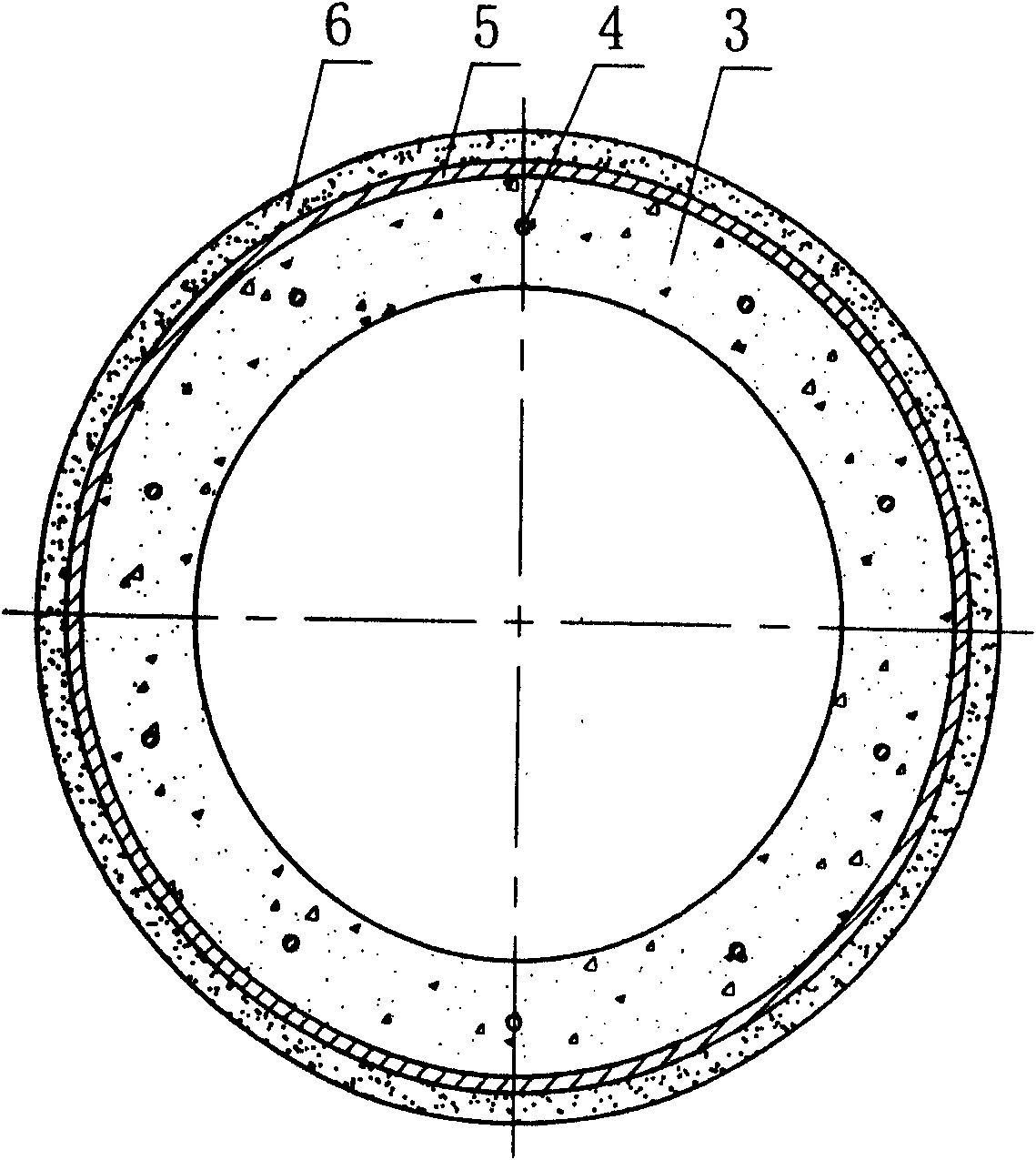

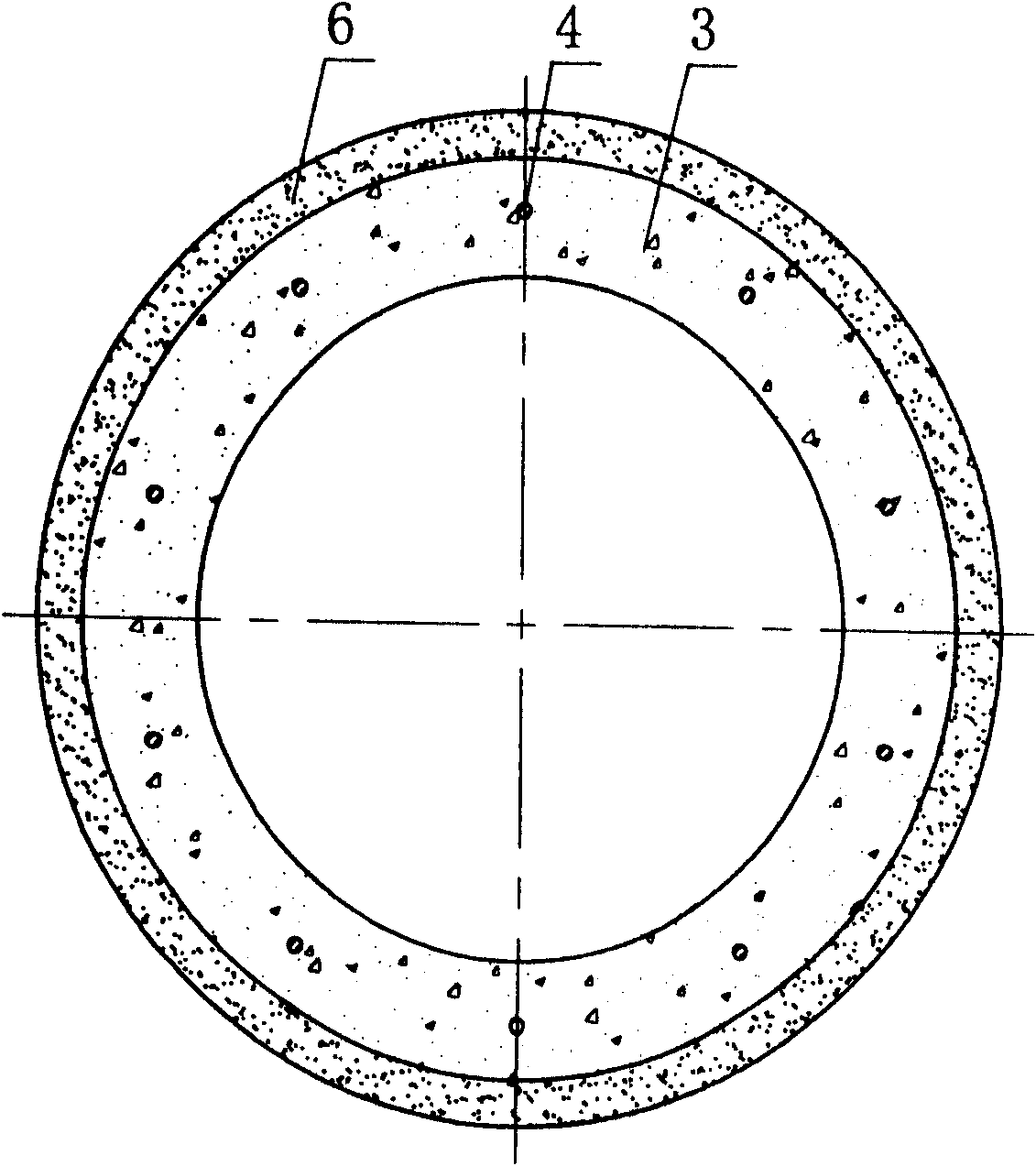

Ultrathin steel-socket prestress longitudinal bar steel-fiber concrete pipe

InactiveCN101592270AGood resistance to external pressure loadsGood crack resistancePipe-jointsRigid pipesEngineeringPre stress

The invention relates to an ultrathin steel-socket prestress longitudinal bar steel-fiber concrete pipe which comprises a socket, a faucet, a longitudinal bar, a steel-fiber concrete pipe core, a prestress steel wire and a protective layer, wherein the longitudinal bar is embedded in the steel-fiber concrete pipe core, and both ends of the longitudinal bar are fixedly arranged on the socket and the faucet respectively; the specific value of the wall thickness d of the steel-fiber concrete pipe core and the inner diameter D of the pipe core is mu, and mu is lager than or equal to 1 / 60 and smaller than or equal to 1 / 32; the prestress steel wire has a thread pitch of @mm and a diameter of phi mm, and @ is larger than or equal to 2phi and smaller than or equal to 50. The ultrathin steel-socket prestress longitudinal bar steel-fiber concrete pipe has scientific and reasonable structure design, raw material conversation, thinner wall thickness of the pipe core, better permeability and crack resistance, convenient hoisting and transport and lower construction cost.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

Rare earth heat-preserving material

InactiveCN102229480AGood crack resistanceLow thermal conductivitySolid waste managementPearliteAluminium silicate

The invention relates to a rare earth heat-preserving material. The rare earth heat-preserving material is characterized by being prepared by compounding the following raw materials in percentage by weight: 35 to 41 percent of pearlite, 5 to 10 percent of fly ash, 5 to 6 percent of aluminium silicate cellucotton, 5 to 6 percent of rock wool, 15 to 17 percent of asbestos wool, 15 to 17 percent of bentonite, 3 to 4 percent of polyacrylamide, 5 to 6 percent of penetrating agent and 0.03 to 0.3 percent of rare earth additive. The rare earth heat-preserving material has the advantages of high temperature resistance, high corrosion resistance, high sound insulation, high ageing resistance, high cracking resistance, low thermal conductivity coefficient and light dry unit weight, wherein the highest temperature is 1,000 DEG C; the lowest temperature is -30 DEG C; and particularly, the fire resistance reaches A1 level.

Owner:内蒙古宜龙节能环保科技股份有限公司

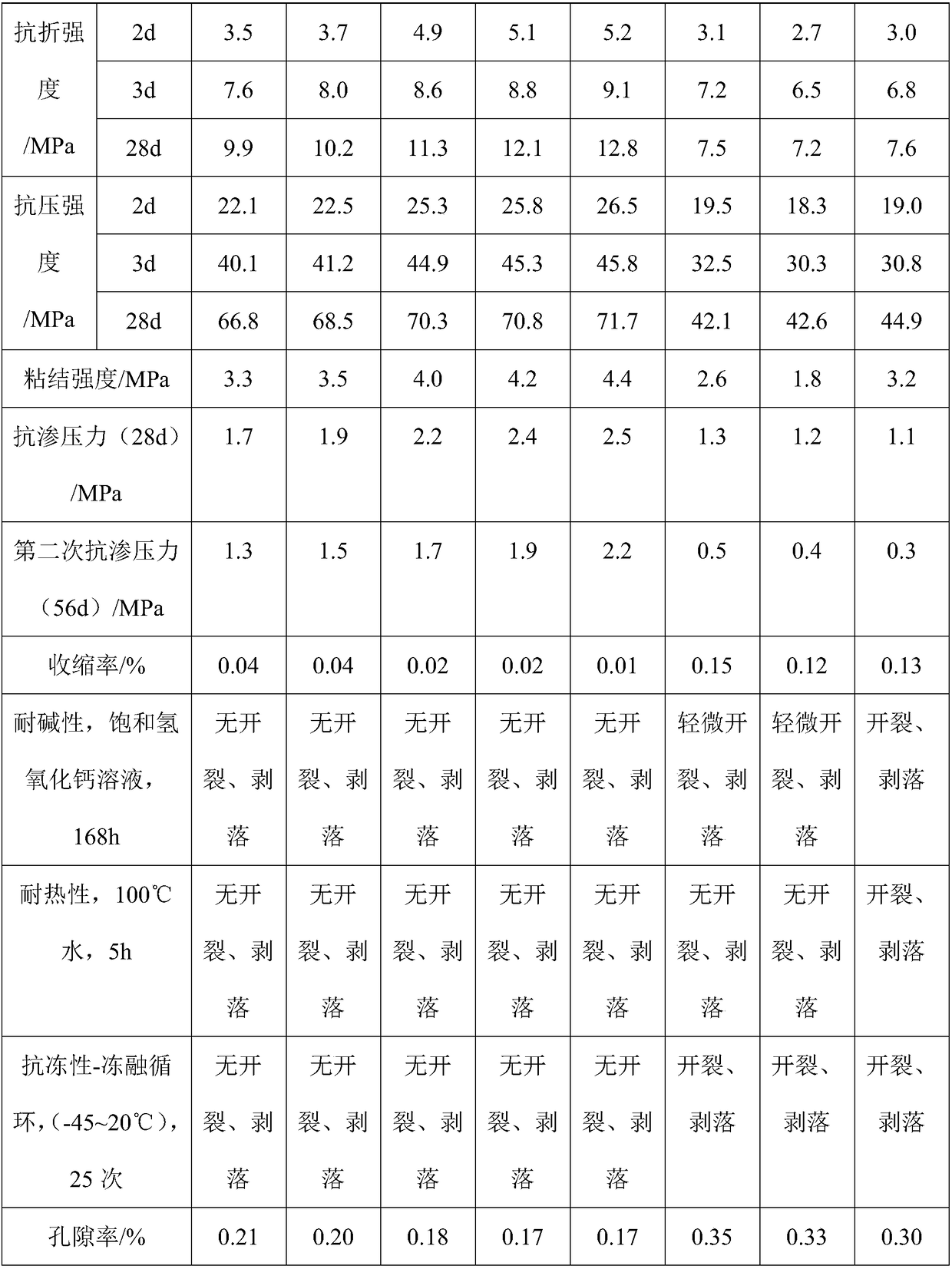

Concrete additive and concrete thereof

The invention discloses a concrete additive and concrete thereof, belonging to the technical field of concrete. The concrete additive comprises the following raw materials by weight: 5 to 15 parts of bentonite, 1 to 9 parts of silicon dioxide powder, 5 to 15 parts of polypropylene fiber, 2 to 8 parts of calcium powder, 2 to 8 parts of calcium lignosulphonate powder, 1 to 9 parts of dispersion emulsion powder and 5 to 15 parts of an acrylic emulsion. The concrete additive provided by the invention can improve toughness, compressive strength and service life of the concrete; and the concrete prepared by using the concrete additive in the invention has the advantages of good tensile, flexural and anticracking performances, low price, simple production process, low cost, and applicability to large-scale production.

Owner:广西路佳道桥勘察设计有限公司

Water-based paint highly simulating granite and marble and preparation method thereof

The invention discloses a water-based paint highly simulating granite and marble. The water-based paint is characterized by being prepared by mixing dispersed particles and a dispersed medium of emulsion in a mass ratio of 5:10, and stirring at a rotating speed of 60-80 rpm until both are uniformly mixed. The water-based paint has high weather resistance and dirt resistance, and has high simulation of granite and marble textures.

Owner:DALIAN SHENGHE TECH DEV

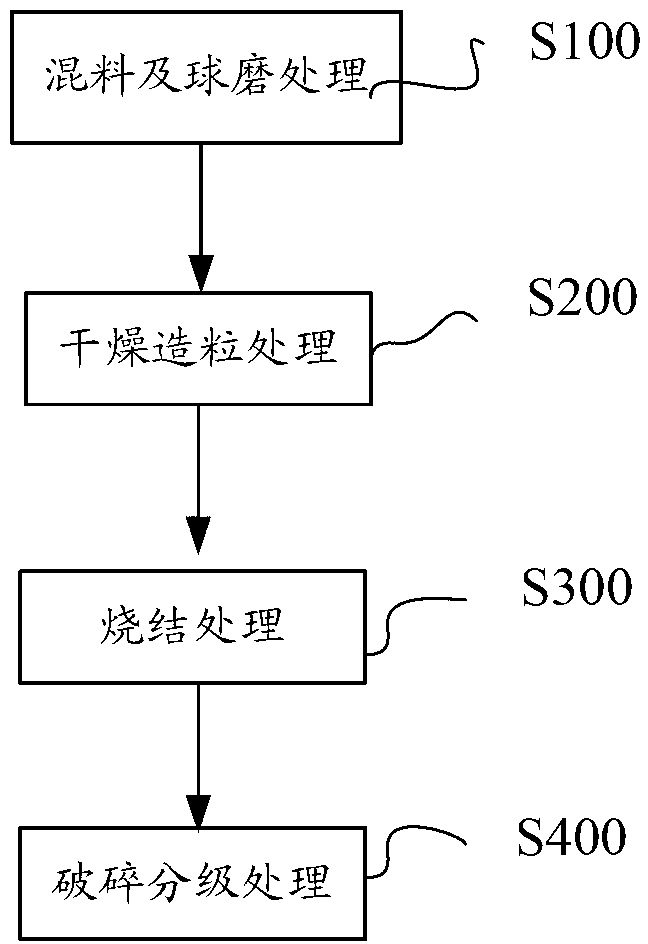

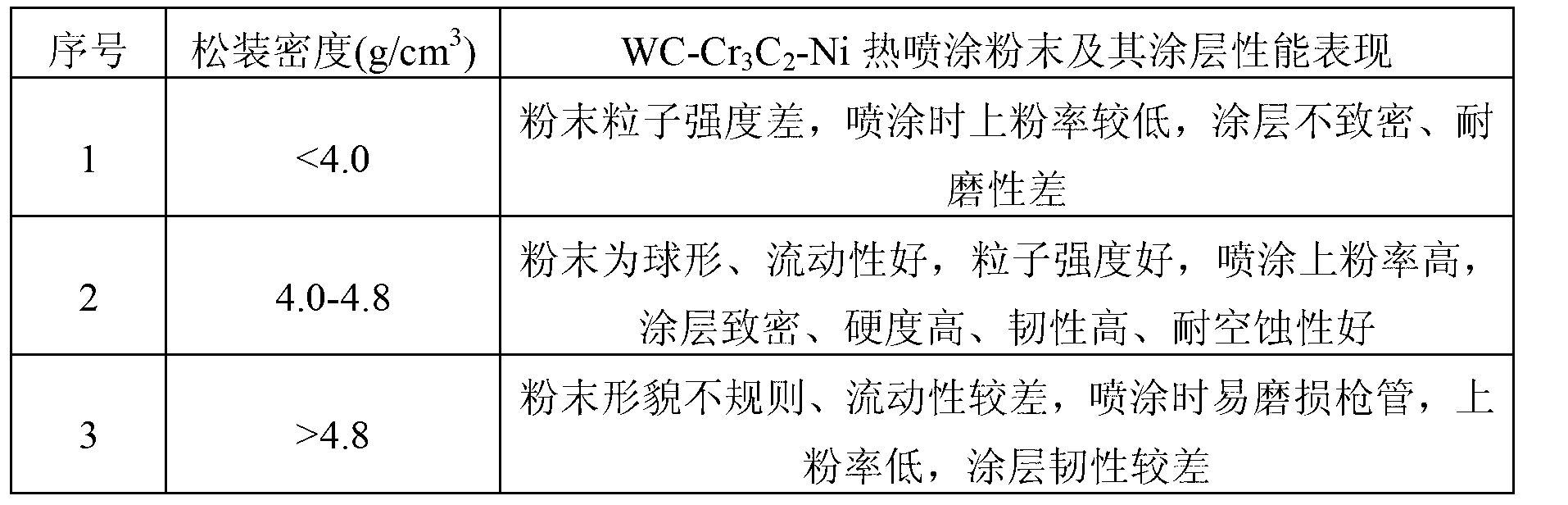

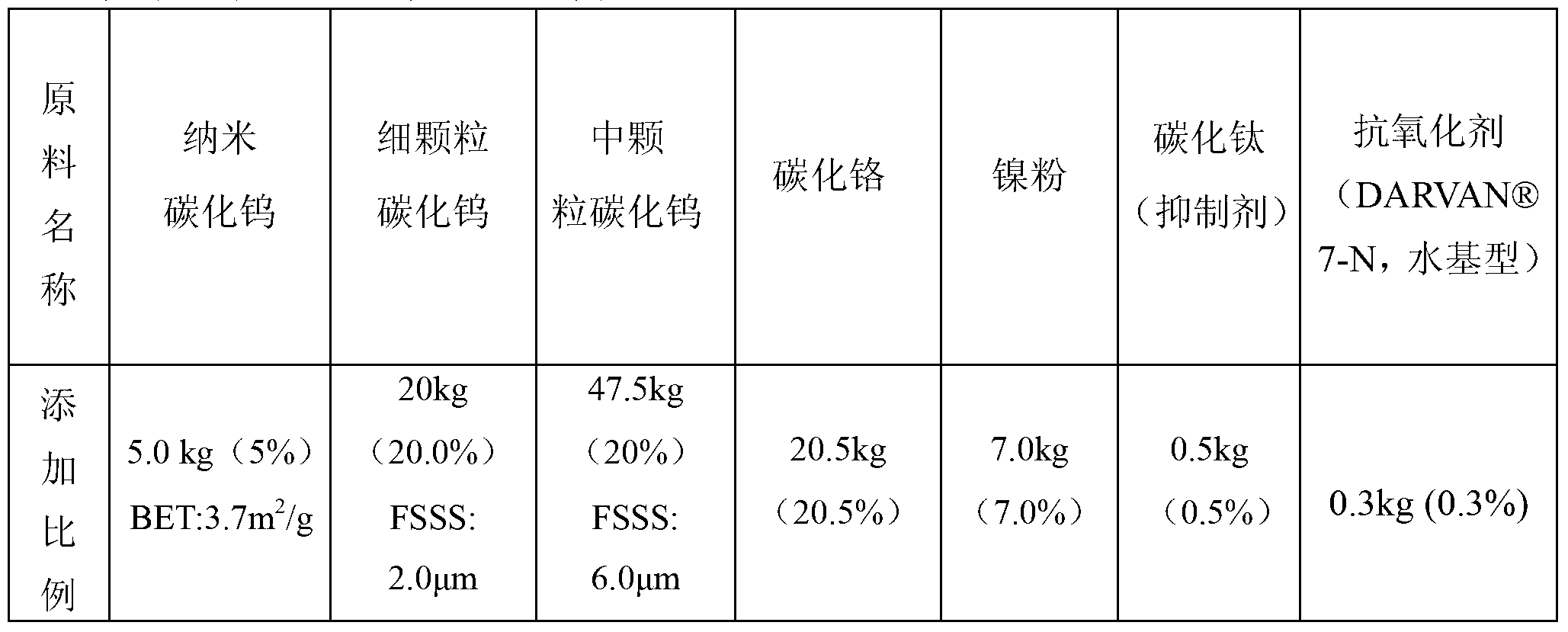

WC-Cr3C2-Ni thermal spraying powder, and preparation method and applications thereof

ActiveCN103266293AGood wear resistanceGood coating toughnessMolten spray coatingChromium carbideTitanium carbide

The invention discloses a WC-Cr3C2-Ni thermal spraying powder, and a preparation method and applications thereof Wherein, the WC-Cr3C2-Ni thermal spraying powder comprises: 72.5 parts by weight of tungsten carbide mixture; 20.5 parts by weight of chromium carbide; 7.0 parts by weight of nickel; 0.5 parts by weight of titanium carbide; and 0.3 parts by weight of organic anti-oxidant; wherein the tungsten carbide mixture comprises: 5-26.5 parts by weight of tungsten carbide with granularity being 0.05-0.2mum; 10-30 parts by weight of tungsten carbide with granularity being 1.5-2.5mum; and 12.5-57.5 parts by weight of tungsten carbide with granularity being 4.0-9.0mum. The WC-Cr3C2-Ni thermal spraying powder can improve relative performances of coating after thermal spraying, can not only make sure the coating to have excellent wear resistance, high temperature antioxidation performance and cavitation erosion resistance, but also obtains good coating toughness, and has wide application range.

Owner:GANZHOU ACHTECK TOOL TECH +1

Method for welding dissimilar steel plate of 45 steel and ZG275-485 steel

InactiveCN105108283AGood crack resistanceImprove welding qualityArc welding apparatusWelding/soldering/cutting articlesSteel platesNondestructive testing

The invention discloses a method for welding a dissimilar steel plate of 45 steel and ZG275-485 steel, and relates to the technical field of steel welding. The method mainly comprises three steps of pre-welding preparation, welding and post-welding thermal treatment. According to the welding method, welding joints are good in anti-cracking ability; the welding quality of a component is high; the nondestructive testing of a weld line area is high in qualification rate; and the welding requirement is met.

Owner:ANHUI FUHUANG STEEL STRUCTURE

Anti-flaming thermal-insulation environmentally-friendly polymeric foaming material and method for producing the same

The invention discloses an anti-flaming thermal-insulation environmentally friendly polymeric foaming material and a method for producing the material. The method comprises the following steps: preparing a urea resin foam adhesive by successively adding 37 % of formaldehyde, polyvinyl alcohol and glycerin in a reaction kettle and stirring to heat up and then adding urea, hexamethylene tetramine, stabilizer and thiourea, preparing a foaming agent by firstly adding water in a stirring tank, successively adding nekal and nonylphenol polyoxylethylene ether with stirring, heating up for completely dissolving, and then adding phosphoric acid, glycerin and sodium phosphate, uniformly stirring until completely dissolving, and discharging and packaging, and preparing a foamed product by taking the urea resin adhesive, urea and the foaming agent, mixing and stirring uniformly, putting in a foaming machine to foam, and carrying out foaming, extrusion molding, drying and packaging. The invention can be widely applied in thermal insulation of building facilities, thermal insulation of venue decoration, shock absorption, replacement of benzene plate flexible package without anti-flaming property, and the like.

Owner:王喆

Repair material for quickly repairing pavement as well as preparation method and application thereof

The invention discloses a repair material for quickly repairing a pavement as well as a preparation method and application thereof. The repair material comprises the following raw materials in parts by weight: 38-46 parts of Portland cement, 17-25 parts of fine sand, 9-17 parts of vinyl acetate resin, 3-7 parts of polyoxyethylene ether, 13-21 parts of a mixture of rice chaffs and husks and 15-25 parts of hexamethylenetetramine. The preparation method comprises the following steps: mixing the vinyl acetate resin and the mixture of rice chaffs and husks, then crushing, increasing the temperatureto 58-62 DEG C, heating and stirring for 20-25 minutes at the temperature of 58-62 DEG C, then increasing the temperature to 76 DEG C, adding a hexamethylenetetramine solution and hermetically heating and stirring for 0.9-1 hour at the temperature of 76 DEG C to prepare a mixture; mixing and uniformly stirring the Portland cement, the fine sand and the polyoxyethylene ether, then adding the mixture and stirring for 1.9-2 hours to obtain the repair material. The repair material as well as the preparation method and the application thereof, disclosed by the invention, has the benefits that therepair material is suitable for repairing cracks and joints of the cement concrete pavement under very cold weather conditions, the pavement can be open to traffic after being repaired for 0.5 hour, the traffic opening time can be greatly shortened, and the repeated repairs are not needed after one-time repair.

Owner:贵州雷氏兄弟建材有限公司

Plant-fiber wall surface coating with antifungal and mould-proof functions

ActiveCN106189864AGood crack resistanceExcellent performanceAntifouling/underwater paintsCellulose coatingsAntimicrobialWater soluble

The invention discloses a plant-fiber wall surface coating with antifungal and mould-proof functions. The plant-fiber wall surface coating is prepared from, by weight, 60%-90% of plant fibers and 10%-40% of water-soluble vegetable glue, and 0.1%-1.0% by weight of a silver inorganic antifungal agent is added. The plant-fiber wall surface coating has good wear resistance and crack resistance, and also has good antifungal and mould-proof performance.

Owner:莆田市蔓贝尔环保产品有限公司

Caulking desulphurization gypsum

The invention discloses caulking desulfurization gypsum. The caulking desulfurization gypsum comprises the following components in percentage by weight: 0.1-8% of conditioning agent, 1-25% of pulverized fuel ash, 0.3-1% of water-retaining agent, 0.01-0.2% of adhesive agent, 0.01-0.5% of retarder and balance of construction desulfurization gypsum. In the invention, the caulking desulfurization gypsum is produced by making full use of two industrial solid wastes the desulfurization gypsum and the pulverized fuel ash of a fuel electric plant. Besides, the caulking desulfurization gypsum has higher intensity, and the maximum folding strength can reach 4.0 MPa, while the folding strength of the caulked joint of natural gypsum is generally in the range of 3.0-3.4 MPa. In addition, the caulking desulfurization gypsum has good cracking resistance and is detected according to the experimental requirements of ASTM C475 / C475M-02. The caulking desulfurization gypsum has no cracks in any form, while the caulked joint of the natural gypsum can generate some fine cracks within the index range generally.

Owner:BEIJING NEW BUILDING MATERIAL

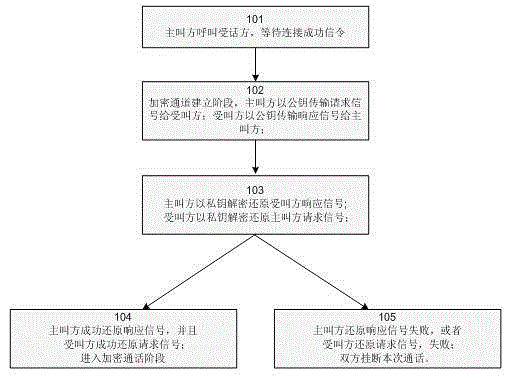

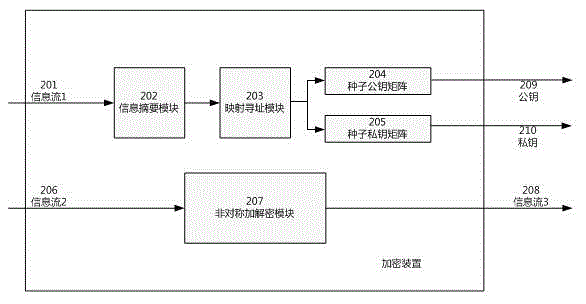

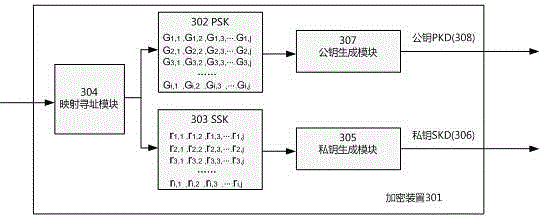

Communication encryption method and device for GSM (global system for mobile communications) mobile phones

InactiveCN104955037AGood communication security and implementation convenienceGood crack resistanceSecurity arrangementSpeech soundGlobal system

The invention discloses a communication encryption method and device for GSM (global system for mobile communications) mobile phones. The method comprises steps as follows: an encryption communication is initialized by a communication call from a calling party to a called party, and after establishment of voice service connection of the two parties, an encryption channel establishment request process is performed; in the encryption communication process, the calling party sends a local voice signal to the called party in an encrypted manner, decrypts a received encrypted voice signal of the called party and reduces the signal to a plaintext voice signal; in the encryption communication process, the called party sends a local voice signal to the calling part in an encrypted manner, decrypts a received encrypted voice signal of the calling party and reduces the signal to a plaintext voice signal. The implementation method ensures that a public key is not transmitted during encryption communication processing and has good communication safety and implementation convenience.

Owner:3525 SCI & TECH BEIJING

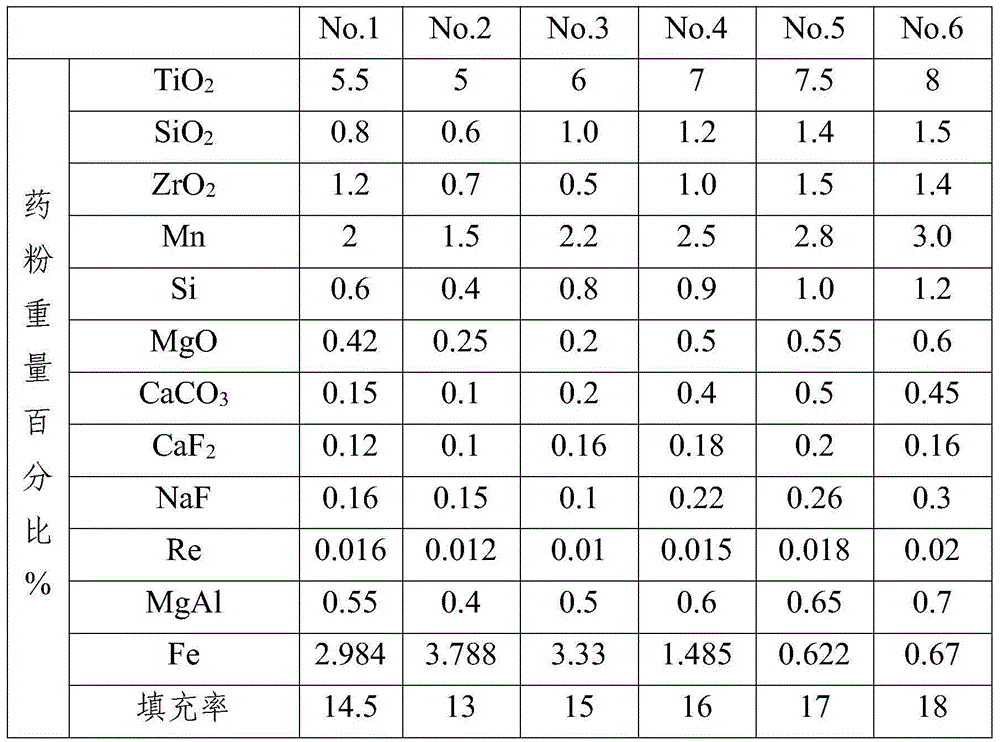

No-nickel flux-cored wire and preparation method and application thereof

ActiveCN104827201AHigh toughness and crack resistanceGood crack resistanceWelding/cutting media/materialsSoldering mediaCarbon steelSteel plates

The invention discloses a no-nickel flux-cored wire and a preparation method and application thereof. The no-nickel flux-cored wire consists of a carbon steel cover and medicine powder filled in the cover; the filling rate is 13.0-18.0%; the medicine powder comprises the following components in percentage by mass: 5.0-8.0% of TiO2, 0.6-1.5% of SiO2, 0.5-1.5% of ZrO2, 1.5-3.0% of Mn, 0.4-1.2% of Si, 0.20-0.60% of MgO, 0.10-0.50% of CaCO3, 0.10-0.20% of CaF2, 0.10-0.30% of NaF, 0.010-0.020% of Re, 0.40-0.70% of magnesium aluminum alloys, and the balance of Fe. The flux-cored wire has high toughness and excellent crack resistance, can be welded in all positions, and is specifically suitable for steel plates with yield strength equal to or higher than 390 MPa.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

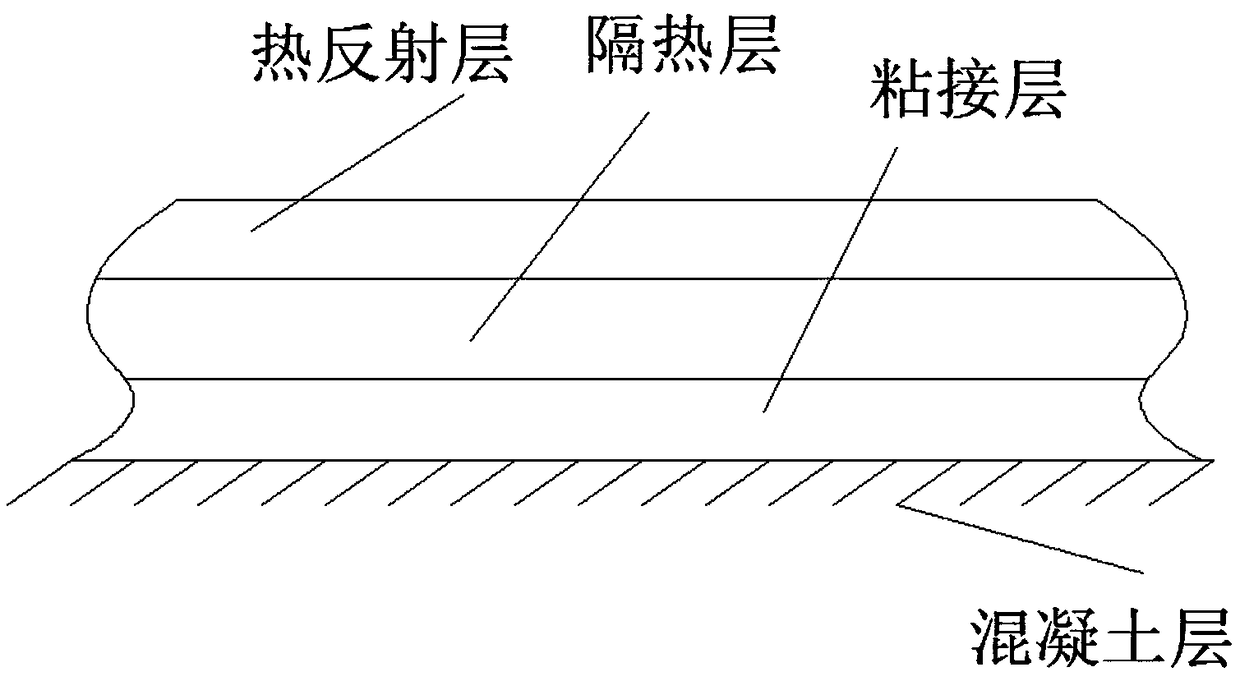

Concrete bridge protection structure layer with heat insulation and cooling functions and construction method of structure layer

ActiveCN109457594AGood adhesionGood crack resistanceBridge structural detailsBridge erection/assemblyThermal insulationEngineering

The invention discloses a concrete bridge protection structure layer with heat insulation and cooling functions. The concrete bridge protection structure layer comprises a bonding layer, a heat insulation layer and a hot reflection layer; a construction method of the concrete bridge protection structure layer comprises the steps that 1, a coating area of a to-be-coated bridge is ground and completely swept; 2, the edge of the coating area of the bridge is pasted through adhesive tape and subjected to edge sealing; 3, a rolling brush is used for coating the coating area with a heat insulation coating; 4, after the heat insulation coating is hardened, a detector is used for detecting the evenness of the heat insulation coating, and the thin part is subjected to secondary coating; 5, the coating area is swept. The coating has the functions of heat insulation and water prevention and is good in bonding performance, excellent in crack resistance and simple in construction technology.

Owner:云南交通运输职业学院

Anti-cracking high density polyethylene cable material and preparation method thereof

InactiveCN103881207AGood crack resistanceGood mechanical propertiesInsulated cablesInsulatorsMaleic anhydrideDicumyl peroxide

The invention discloses an anti-cracking high density polyethylene cable material and a preparation method thereof. The anti-cracking high density polyethylene cable material is prepared from the following raw materials in parts by weight: 50-70 parts of high density polyethylene, 20-30 parts of ethylene-vinyl acetate copolymer, 15-20 parts of ethylene-tetrafluoroethylene copolymer, 10-15 parts of methyl methacrylate-acrylonitrile-butadiene-styrene copolymer, 5-10 parts of ethylene-vinyl acetate copolymer graft maleic anhydride, 10-15 parts of magnesium hydroxide, 5-10 parts of red phosphorus, 4-6 parts of zinc borate, 3-5 parts of ethylene bis stearamide, 2-3 parts of calcium stearate, 10-15 parts of activated aluminum oxide, 2-4 parts of dicumyl peroxide, 1-2 parts of di-n-butyltin dilaurate, 15-20 parts of epoxidized soybean oil, 10-15 parts of nano wollastonite, 5-10 parts of coarse whiting powder, 4-8 parts of basic magnesium sulfate whisker, 1-2 parts of antioxidant 1035, 1-2 parts of antioxidant DSTP and 3-6 parts of compound filler. The cable material disclosed by the invention has excellent anti-cracking performance, good mechanical property, high / low-temperature resistance and bending property, can work for a long period of time in the working environment of -50 to 130 DEG C without cracking, can bear various bends, is durable and has broad application prospect.

Owner:ANHUI WANGDA COPPER DEV

Polypropylene fiber dry-mixed mortar for construction of outer wall

The invention discloses polypropylene fiber dry-mixed mortar for the construction of an outer wall. The dry-mixed mortar comprises 0.8 to 1.2 weight parts of cement, 5 to 6 weight parts of fine sand, 0.4 to 0.8 weight part of addition, 0.1 to 0.3 weight part of admixture, 1 to 1.5 weight parts of water; and 0.8 to 1 kilogram of polypropylene fiber is doped into per cubic meter of the dry-mixed mortar, and the mixture is stirred for 2 to 4 minutes. By the polypropylene fiber dry-mixed mortar for the construction of the outer wall, the integrity, the flexibility, the continuity and the durability can be improved substantially. The polypropylene fiber dry-mixed mortar has high comprehensive performance such as crack resistance, permeability resistance, shock resistance, seismic resistance, freezing resistance, erosion and abrasion resistance, burst resistance, workability and water retention. The polypropylene fiber dry-mixed mortar is easily, conveniently and quickly constructed, is easy to operate and is suitable for plastering construction of all the outer walls.

Owner:CHINA CONSTR FOURTH ENG DIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com