Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41 results about "Physical density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Density is a physical property because its measurement or observation does not alter the chemical composition of a substance. Other physical properties include color, texture, melting point and volume. When a chemical property, such as flammability or oxidation, is observed, one substance changes into another.

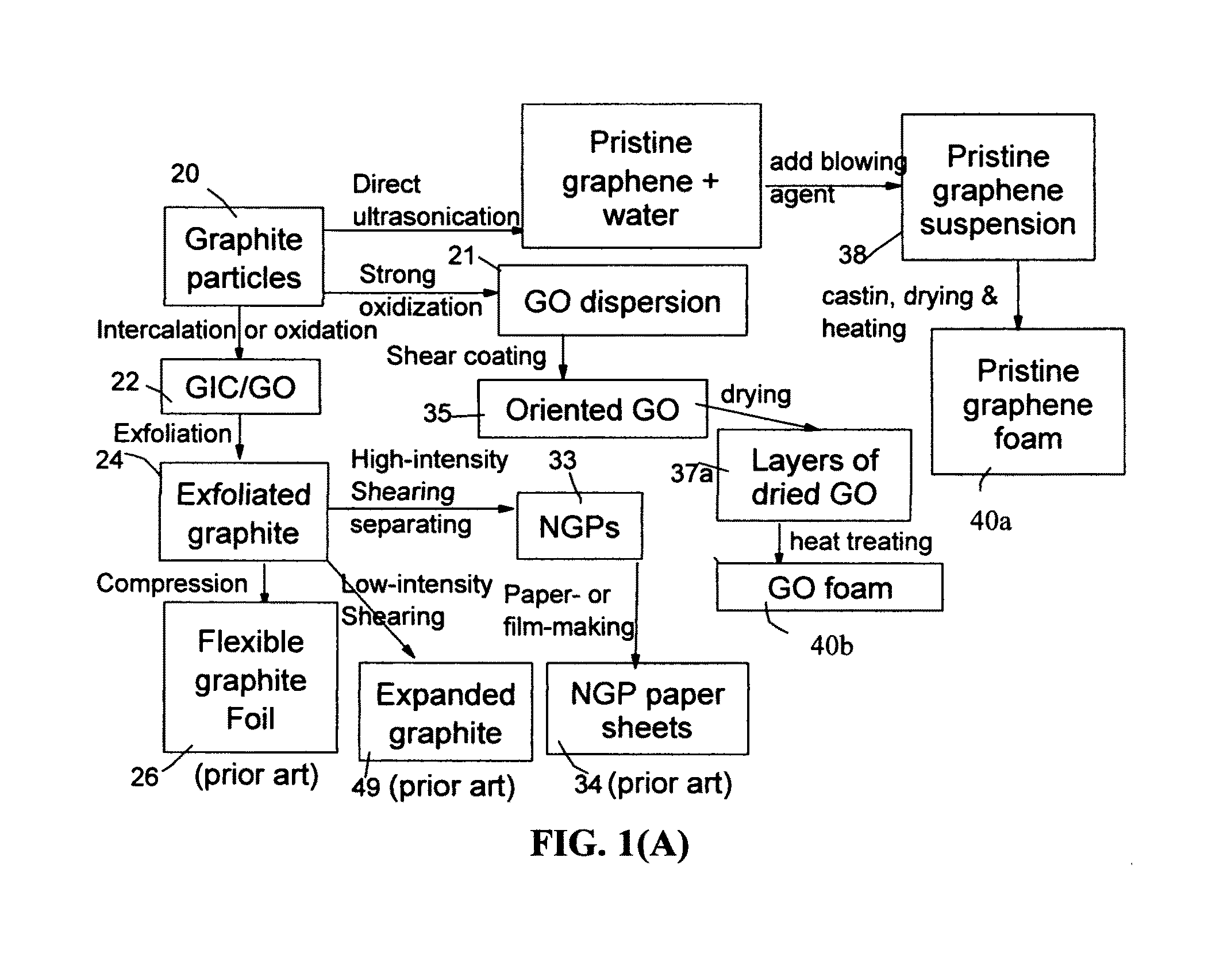

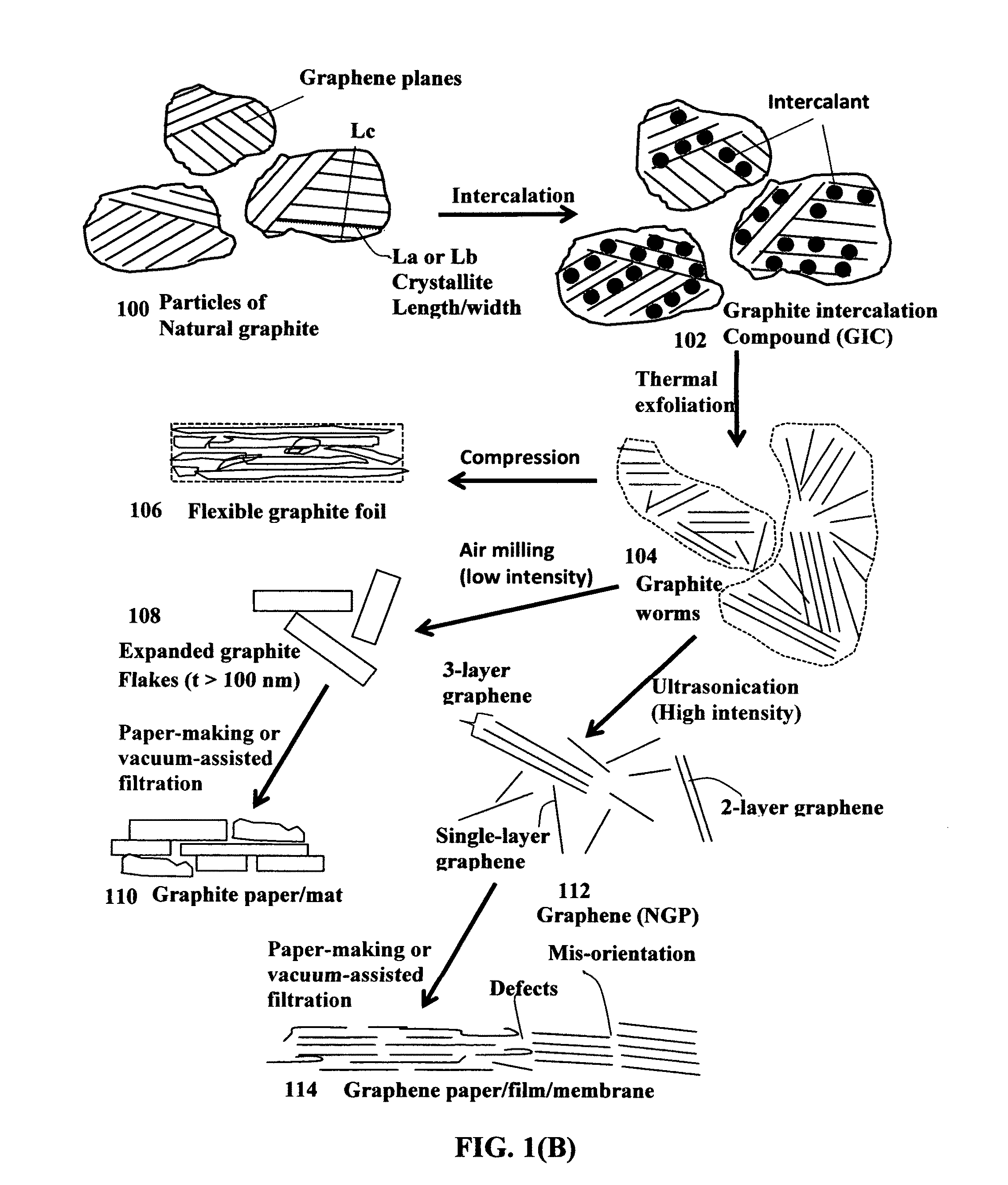

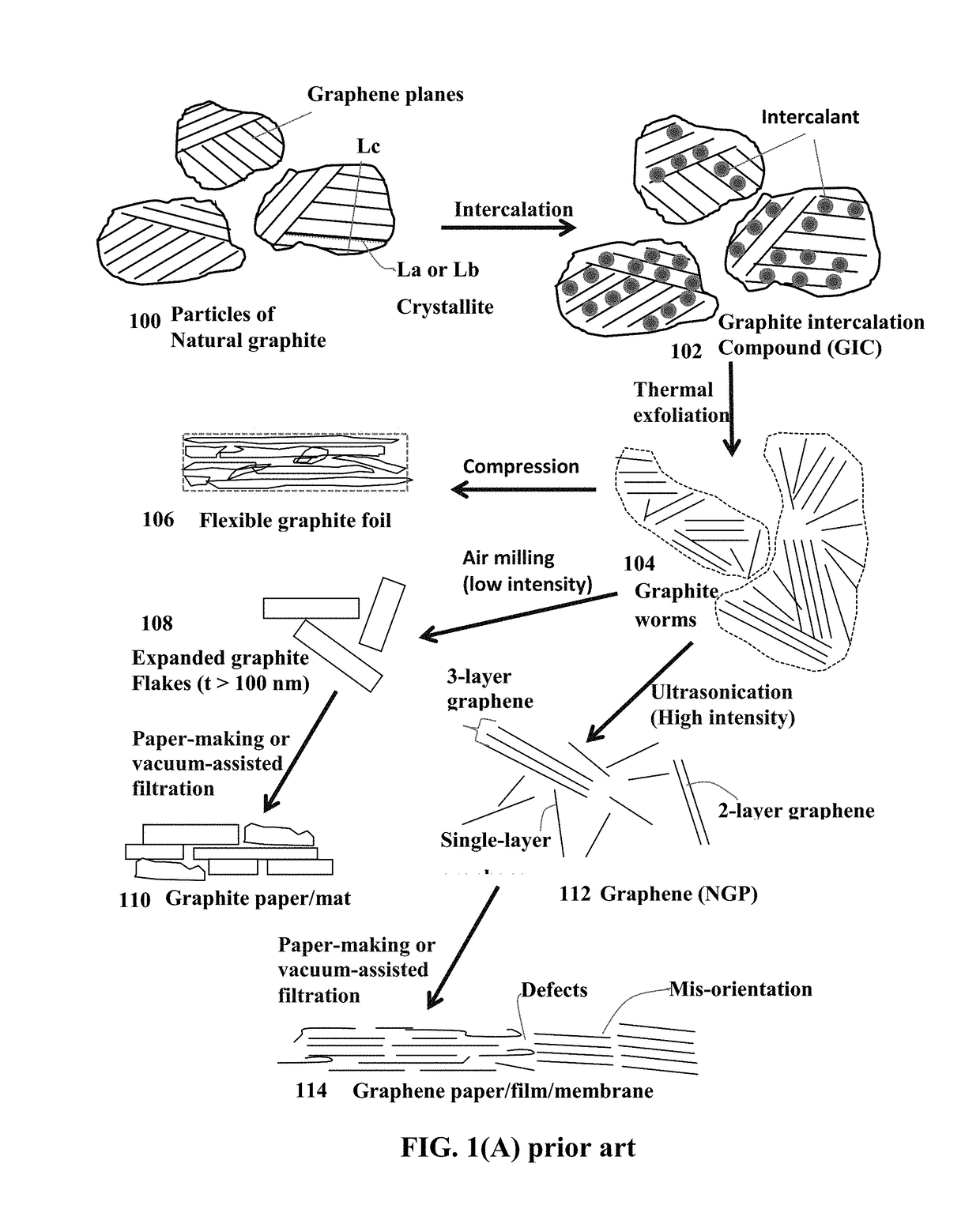

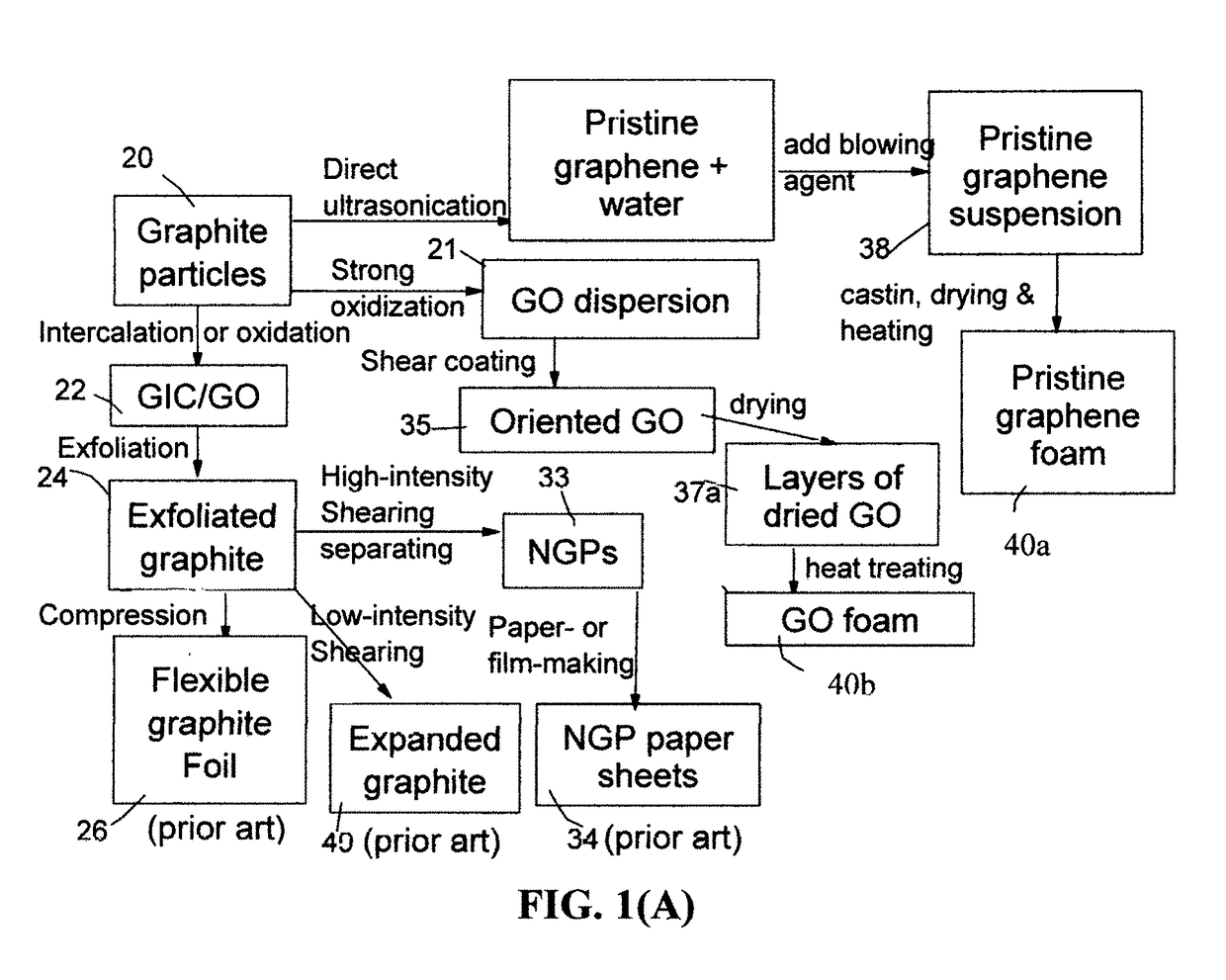

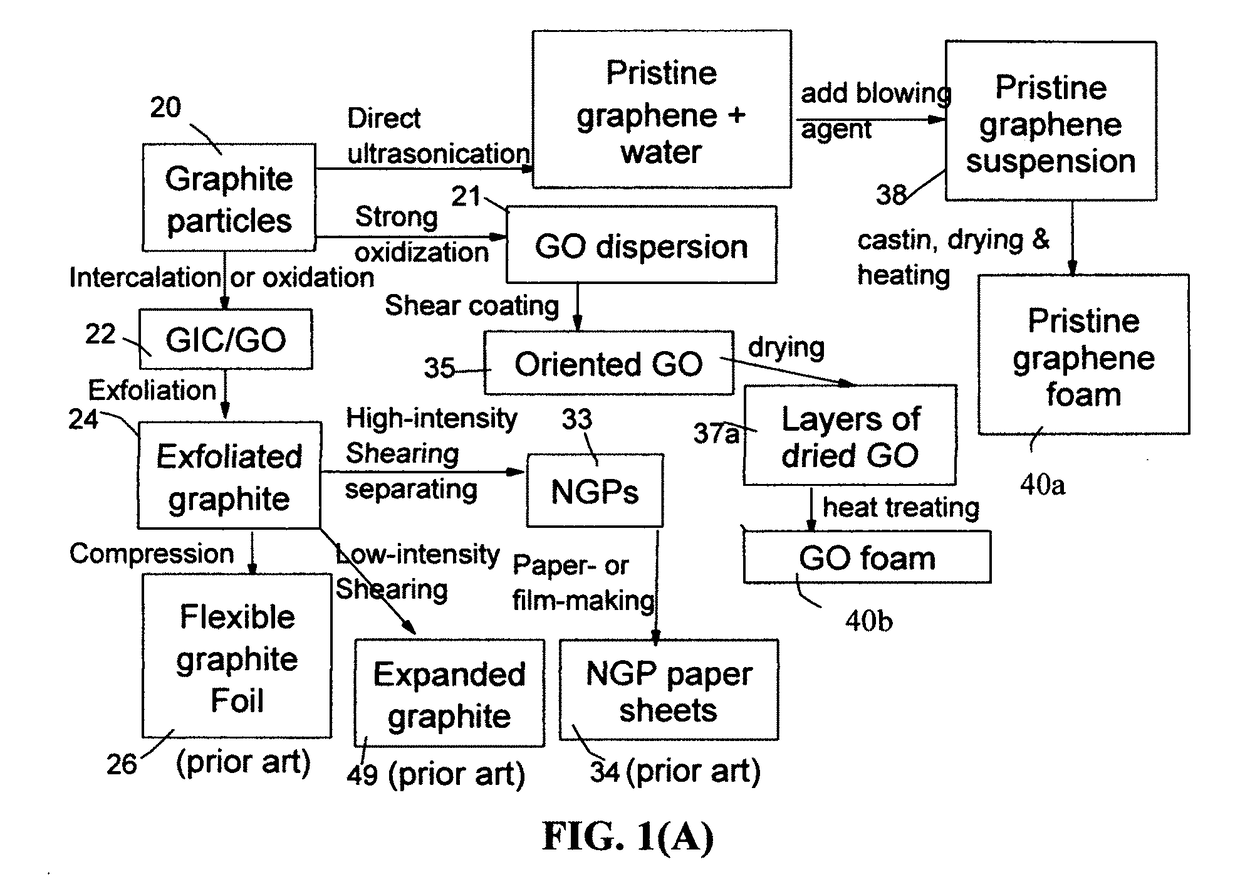

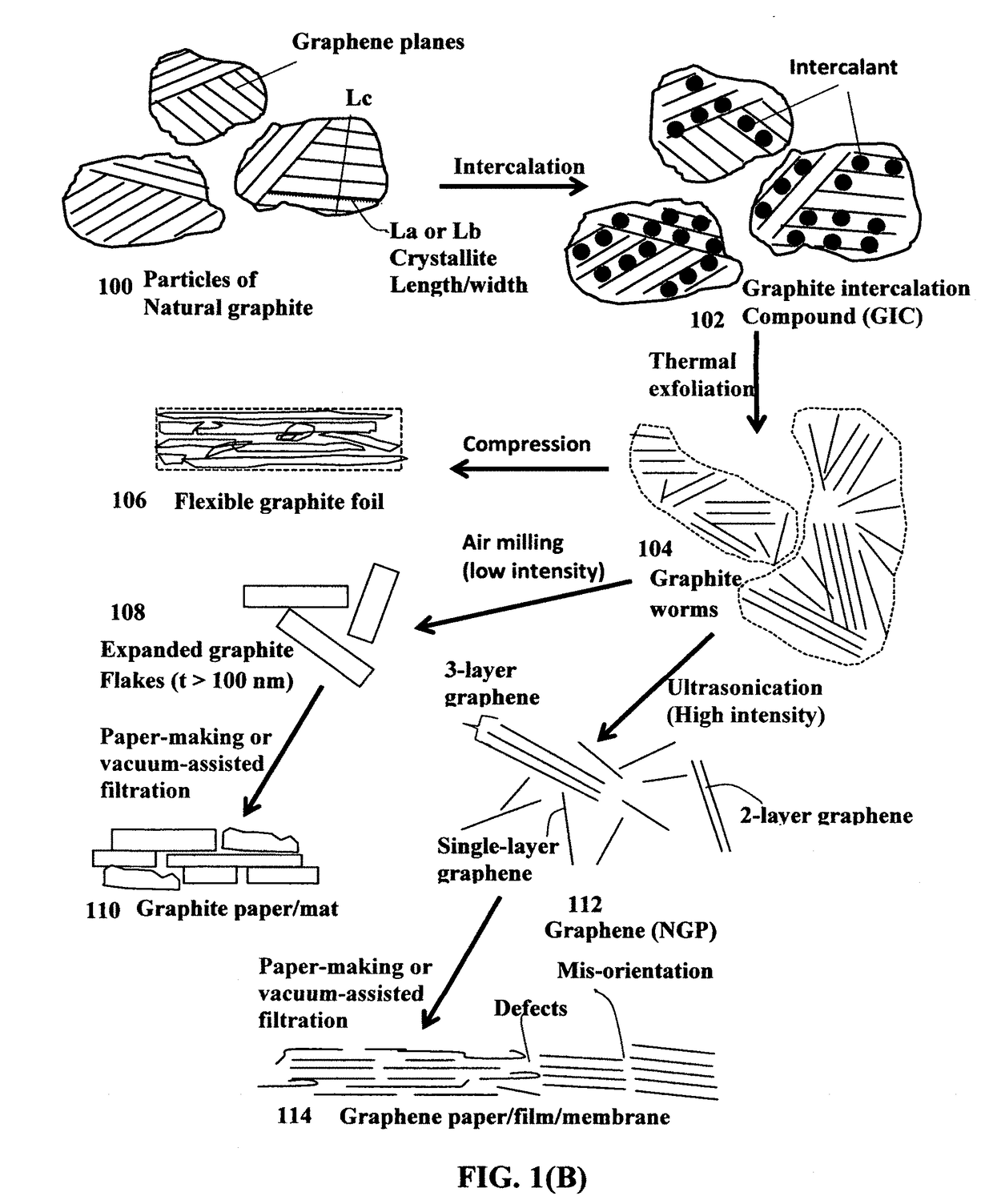

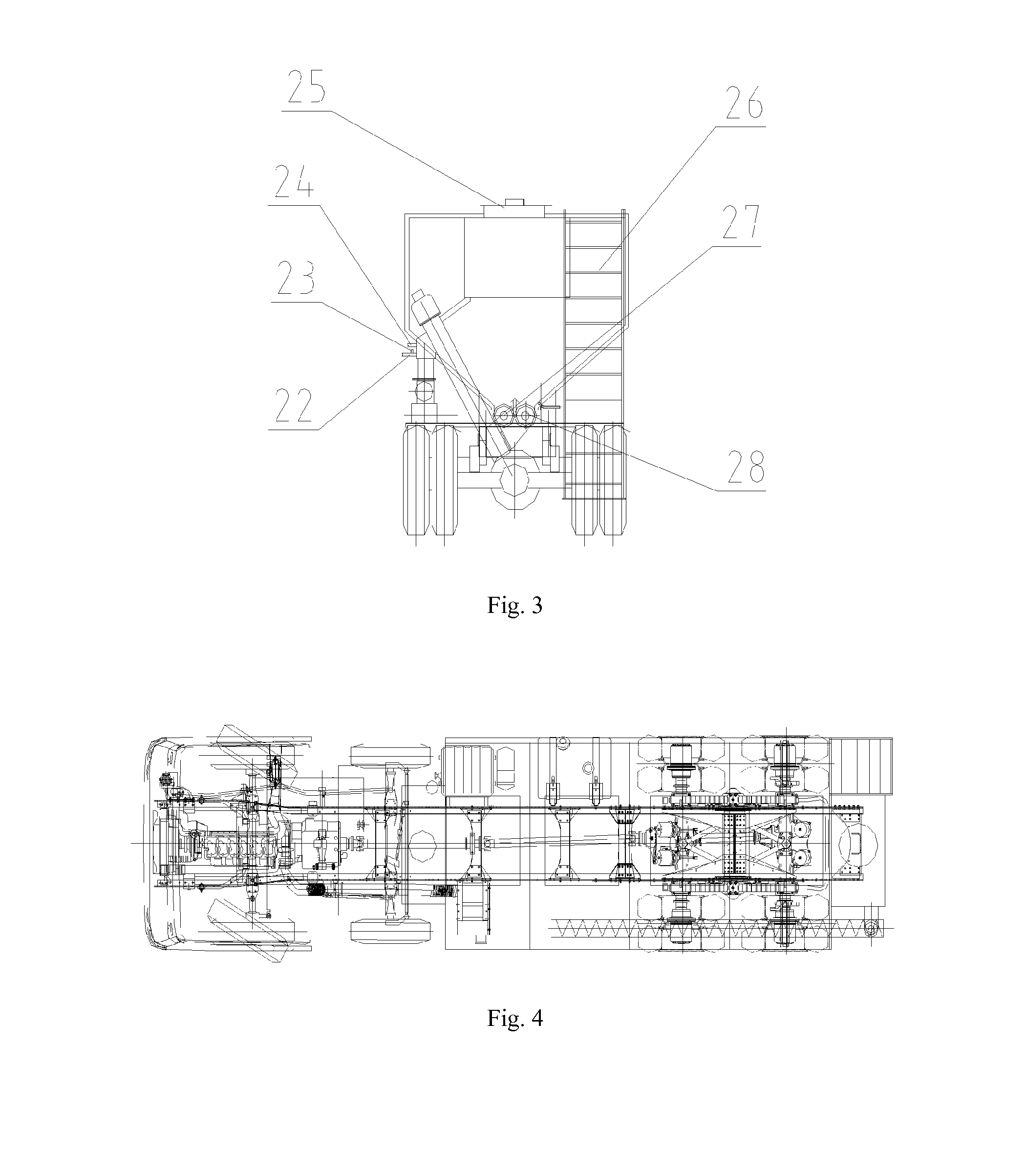

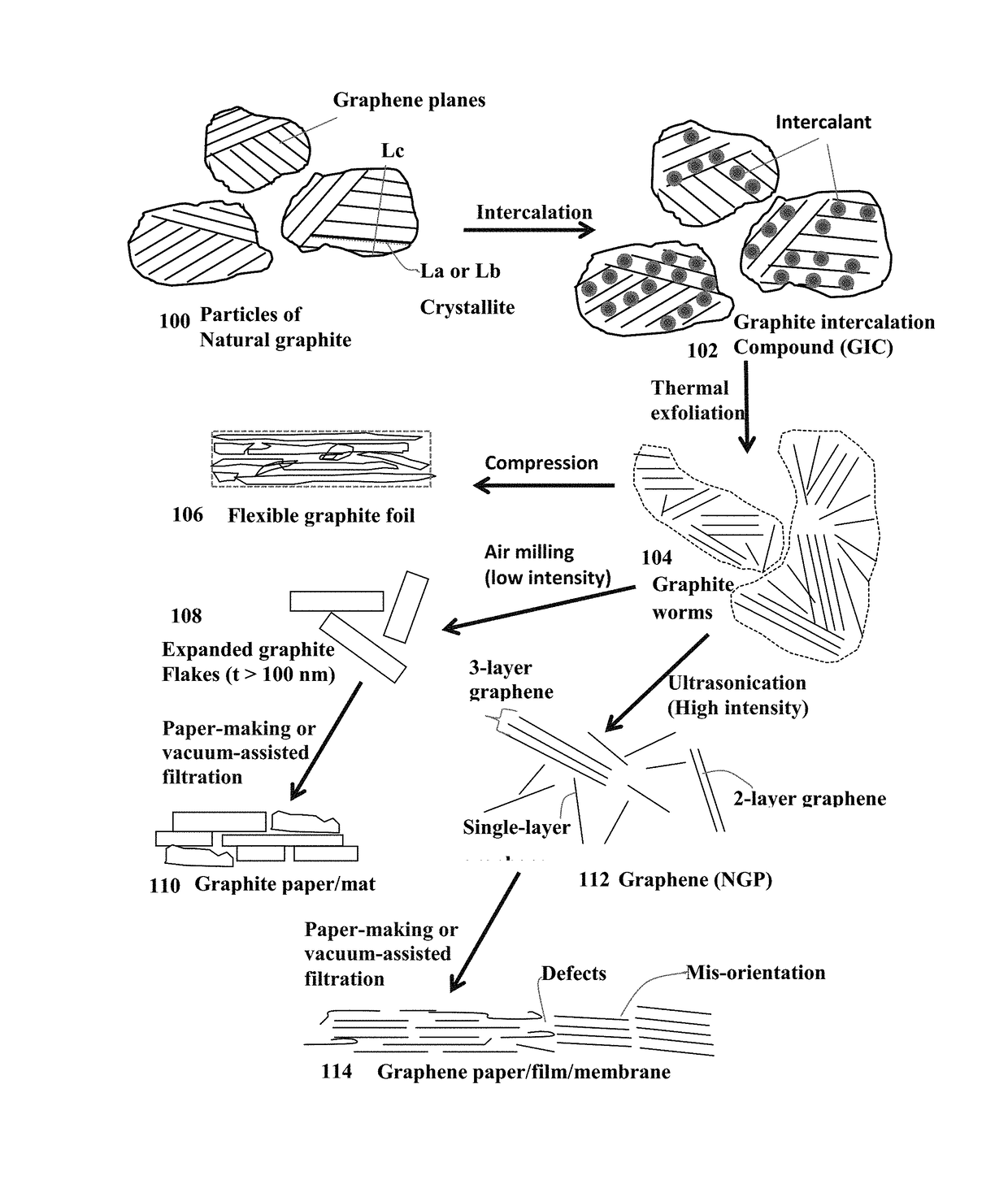

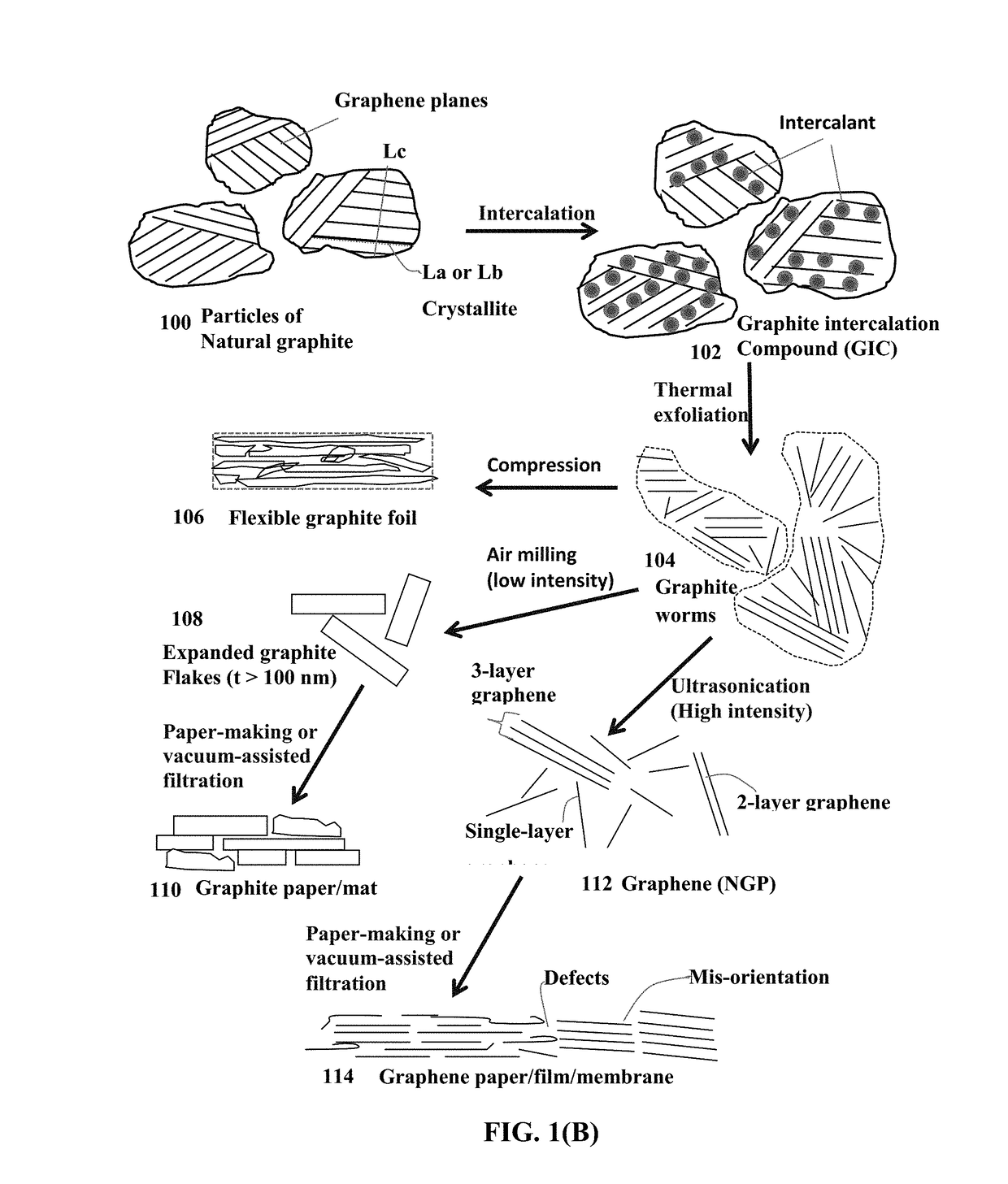

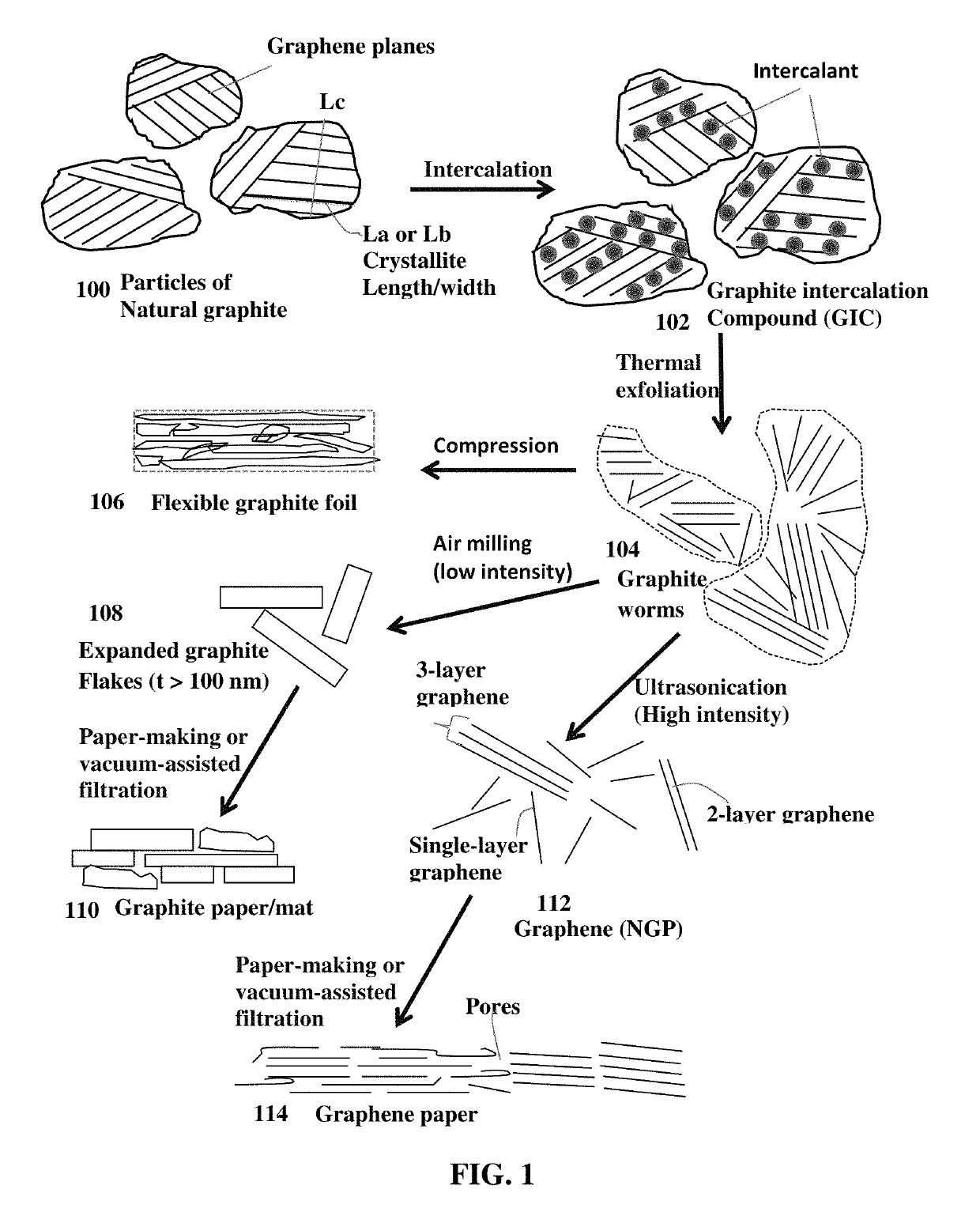

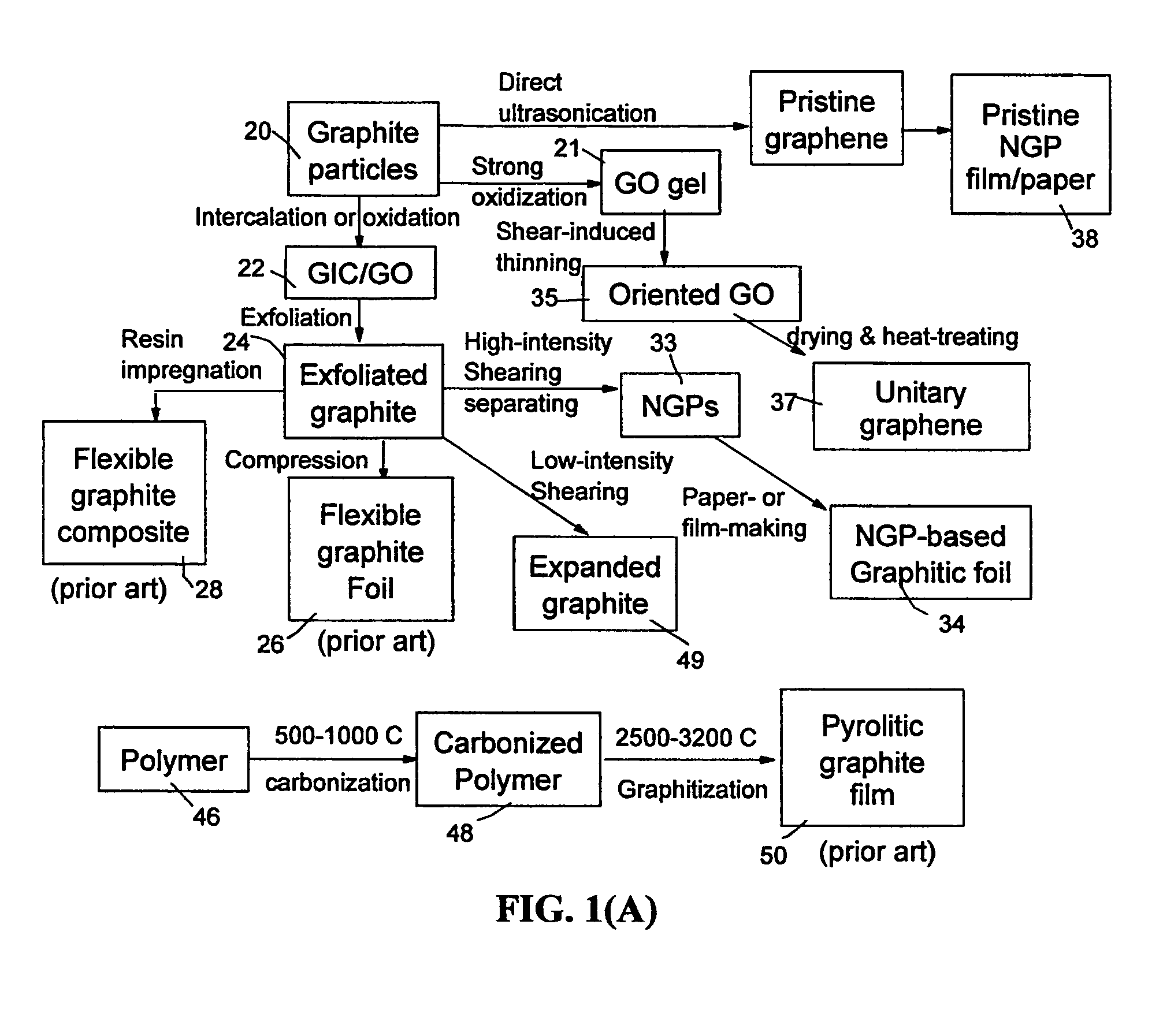

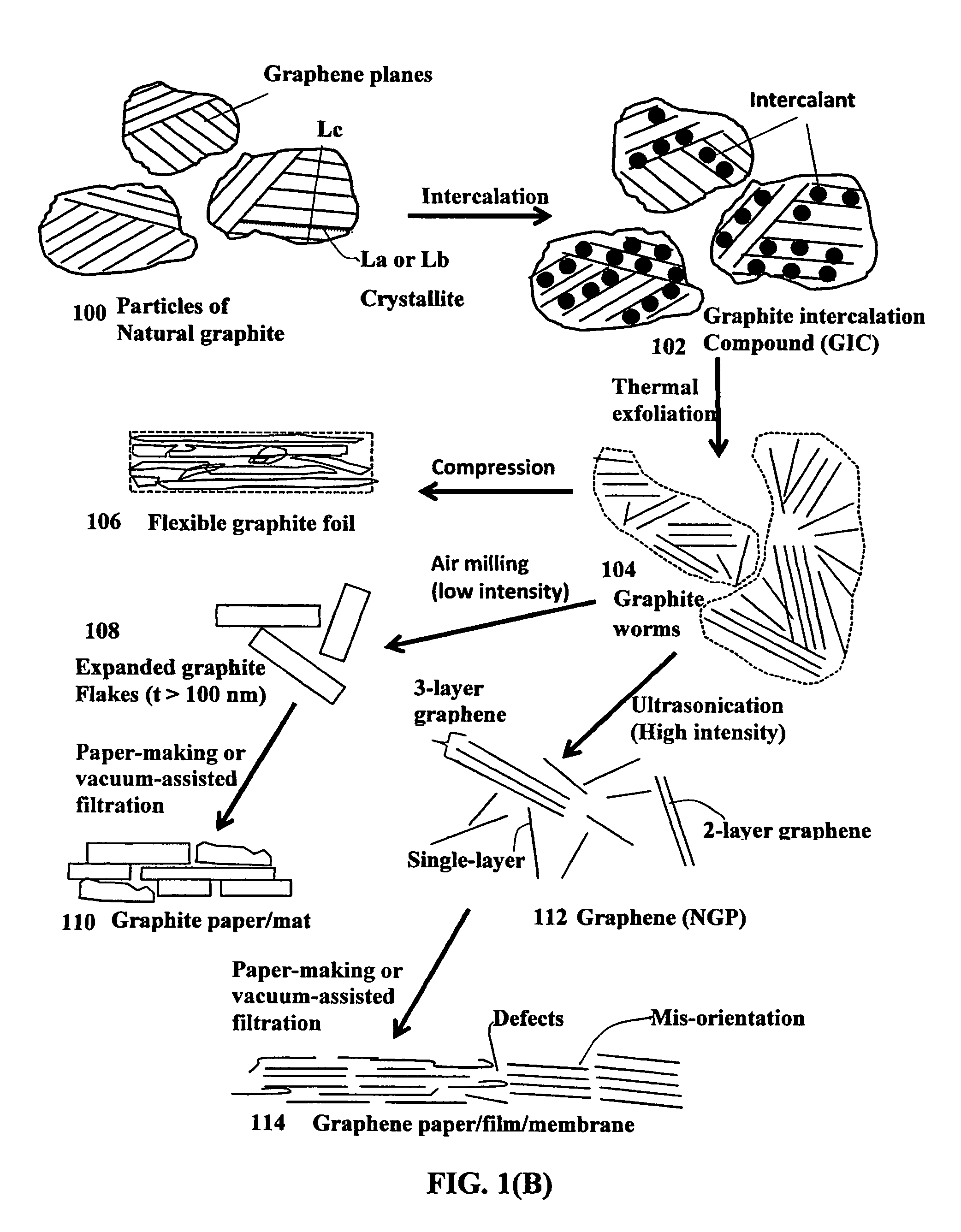

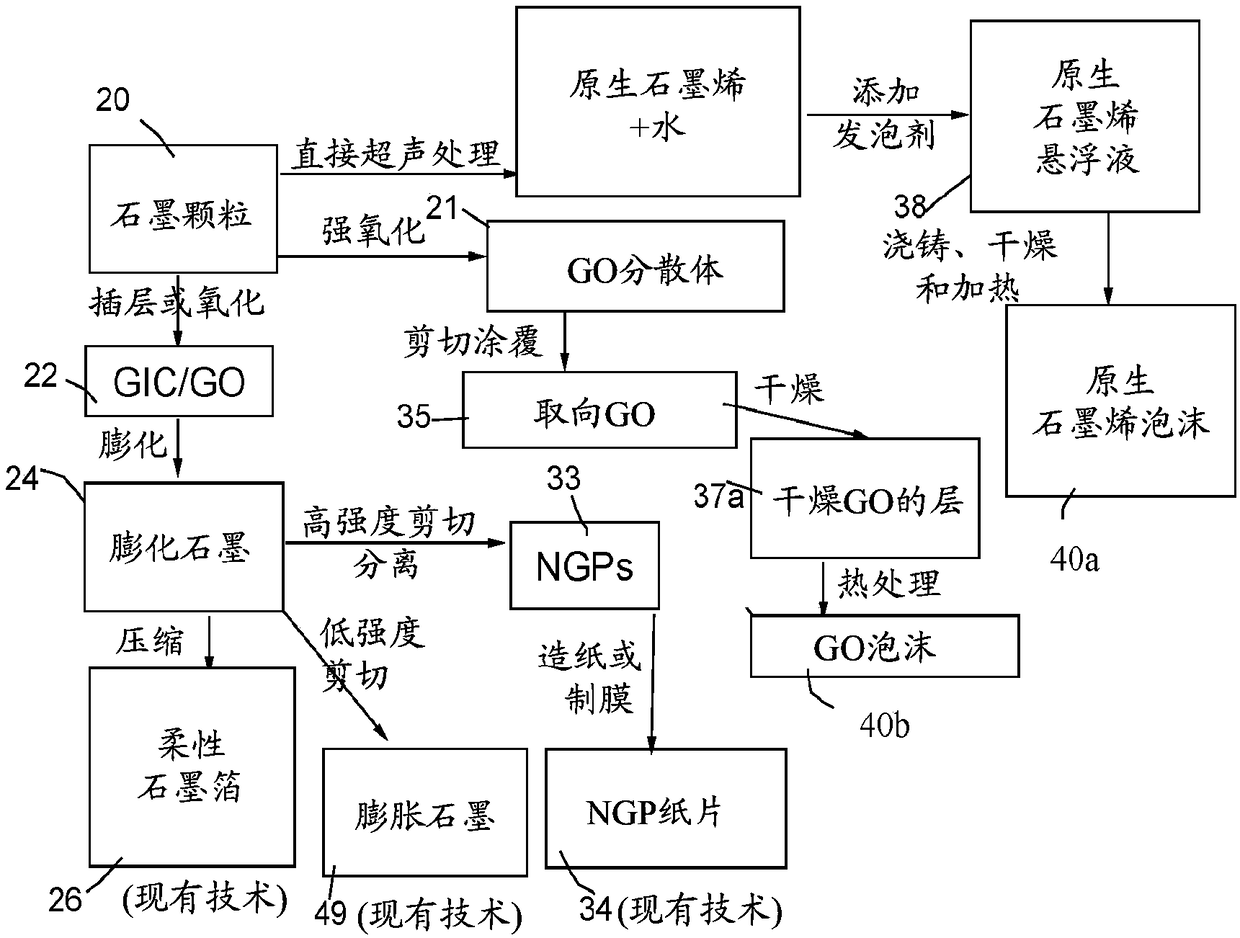

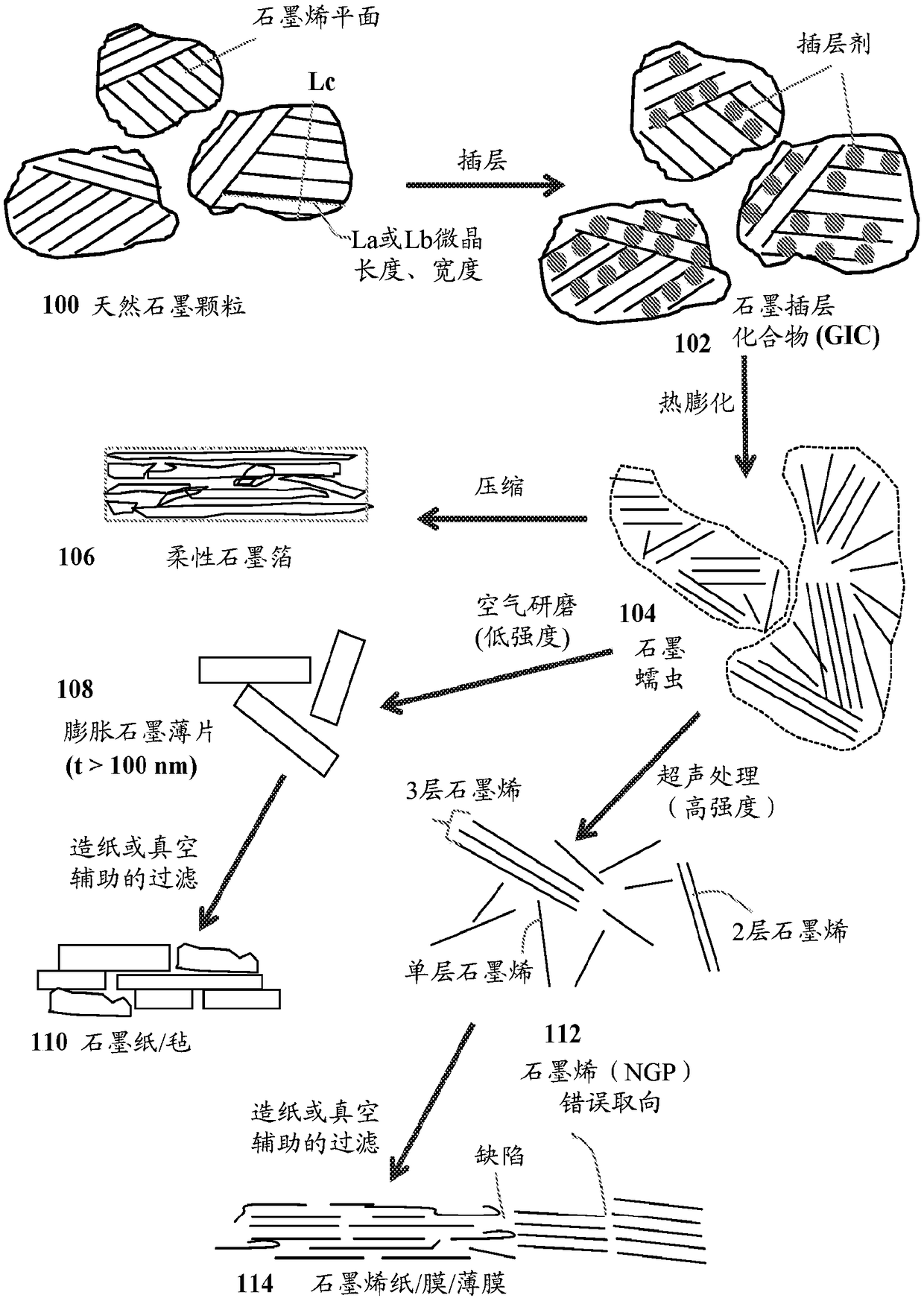

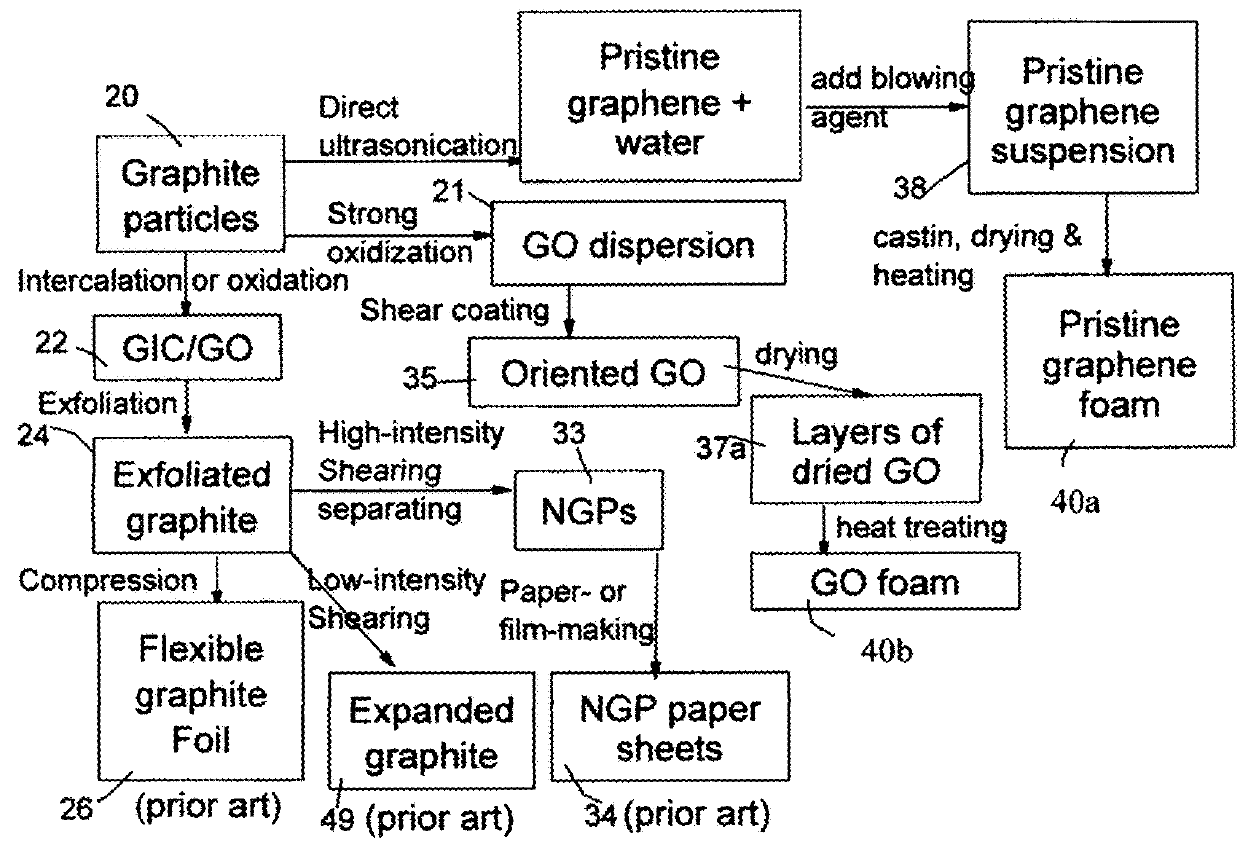

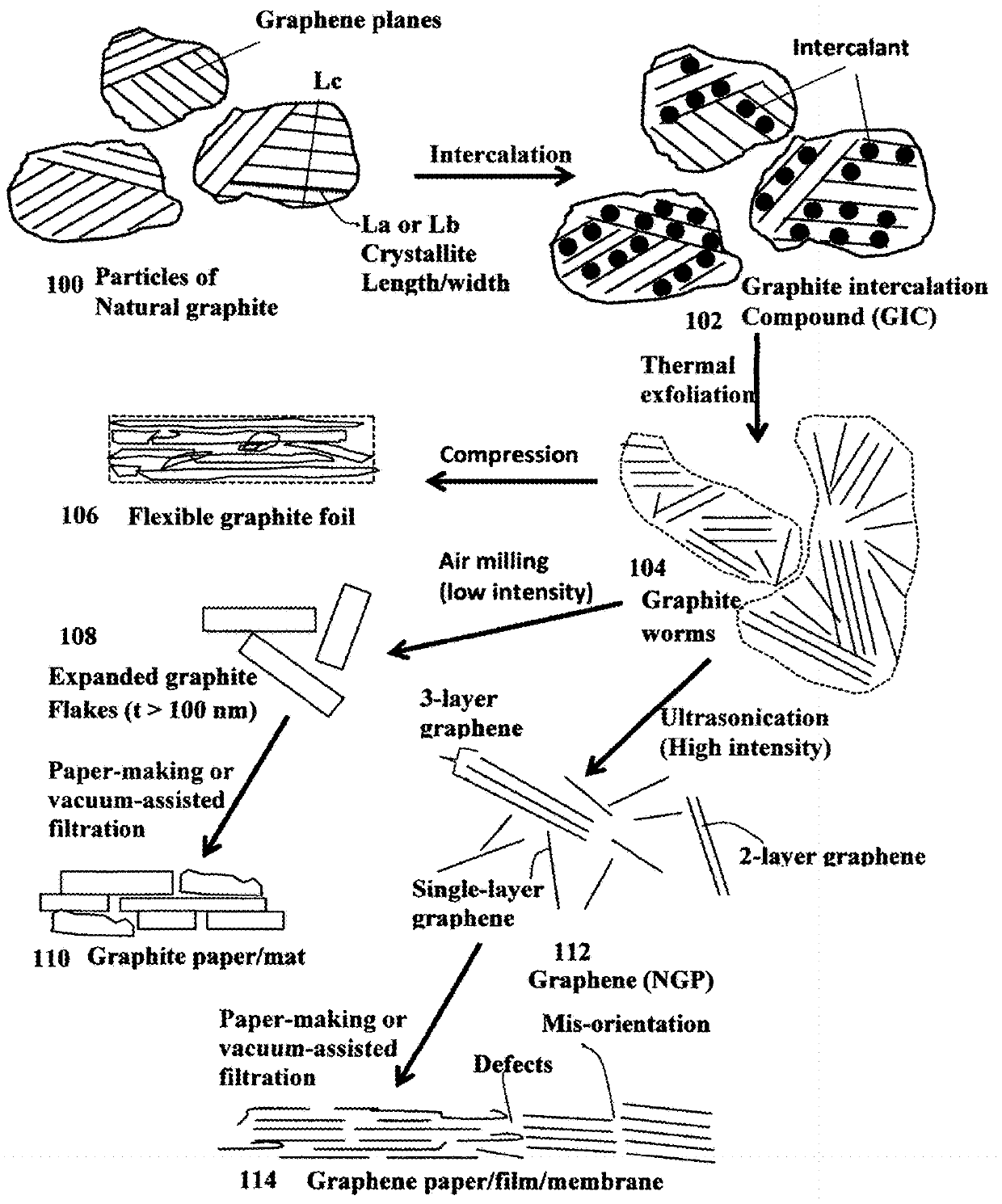

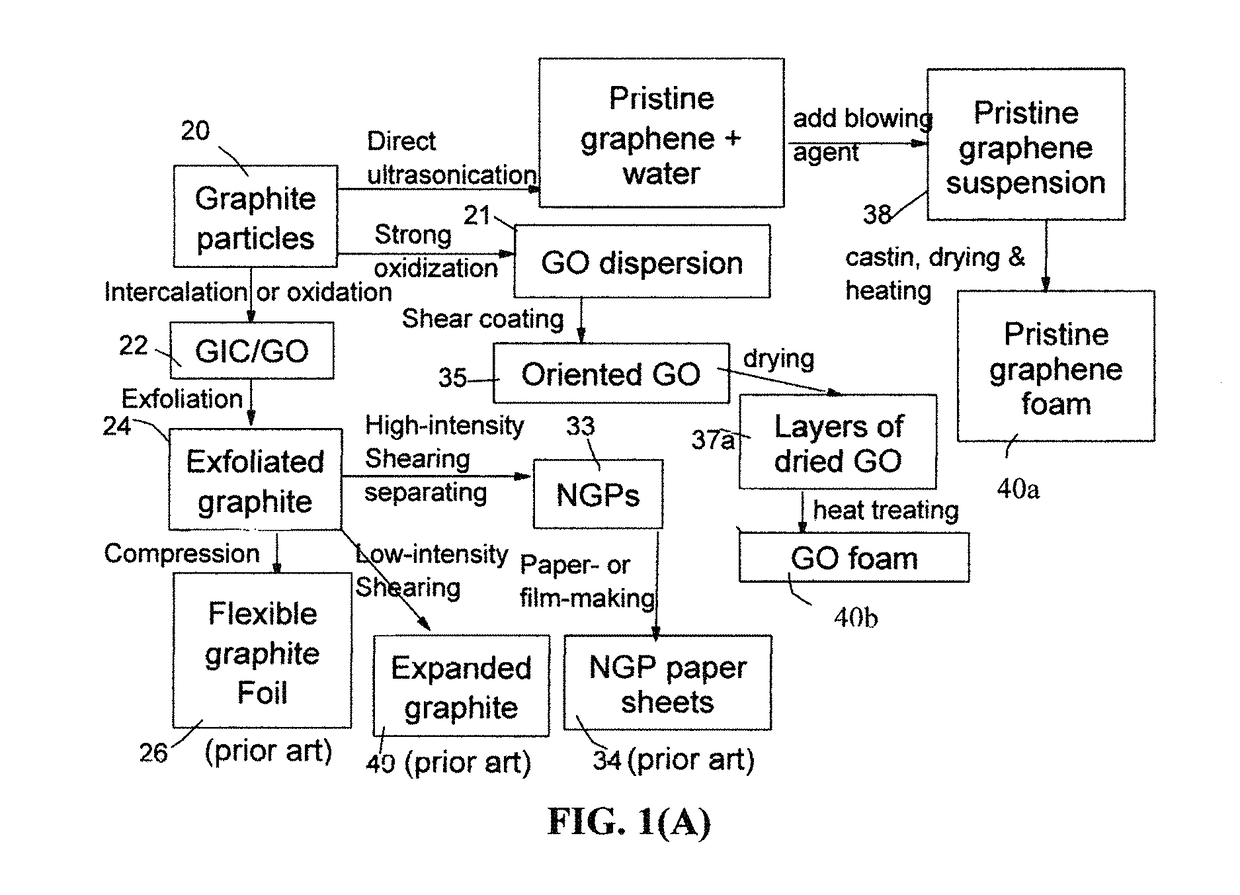

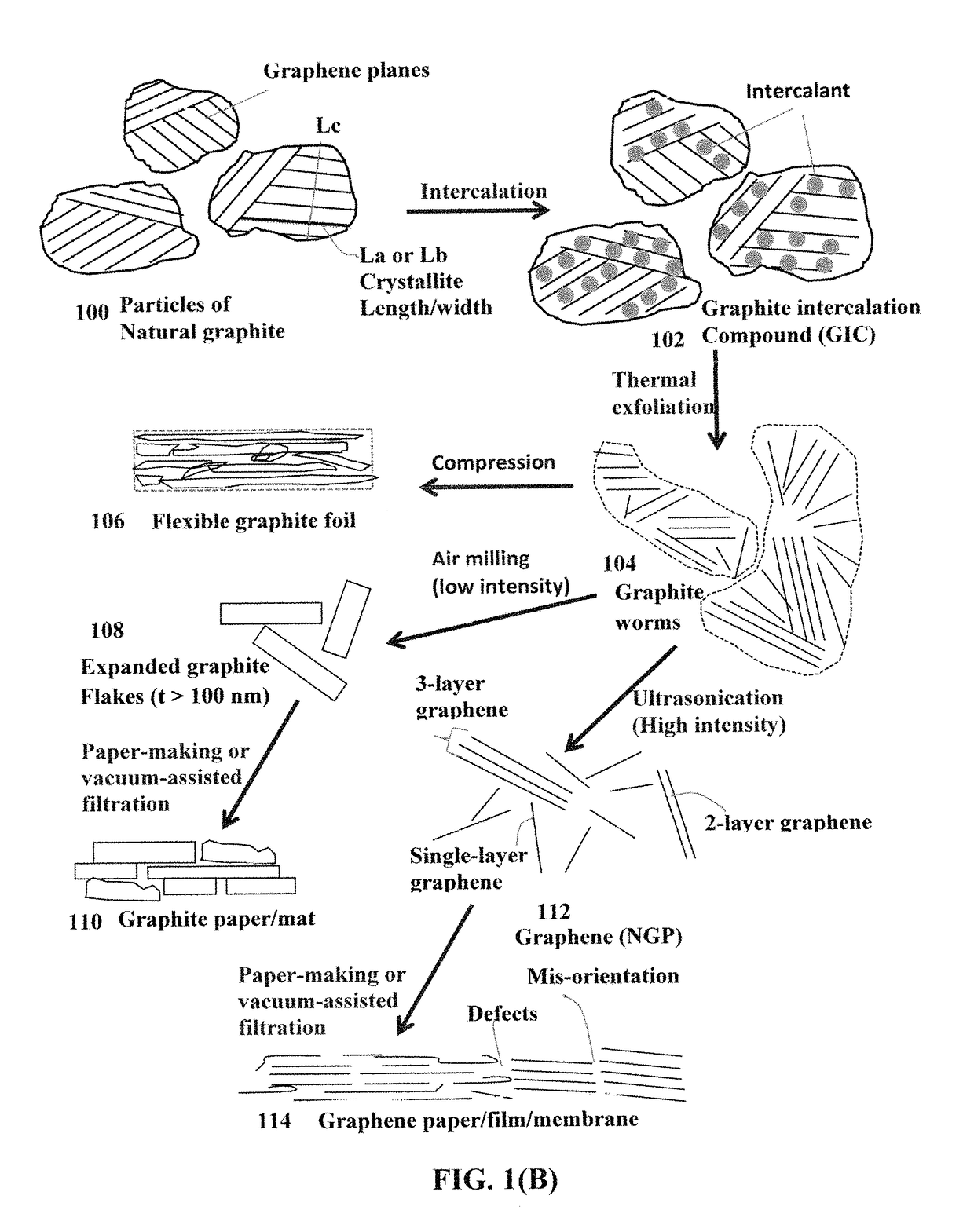

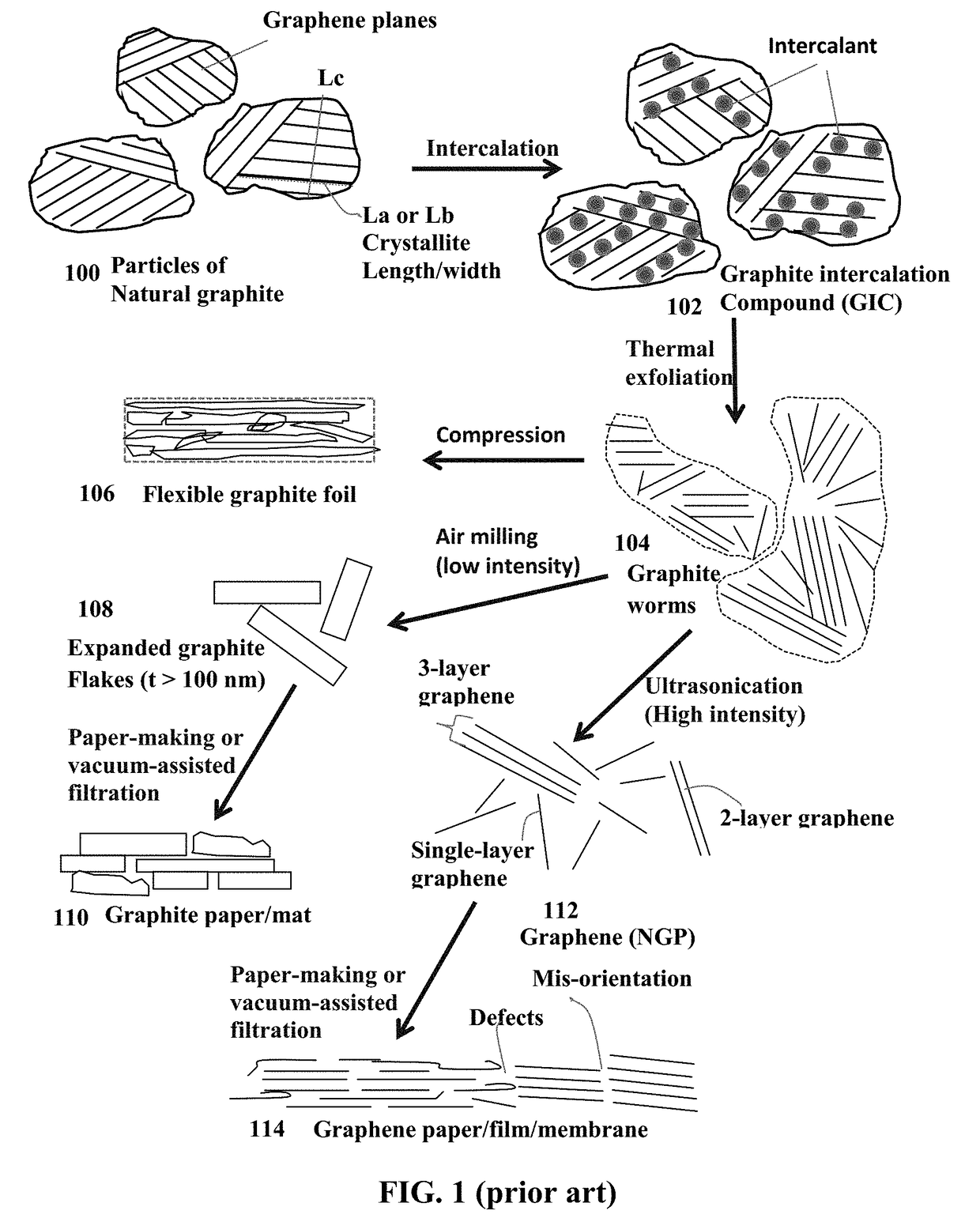

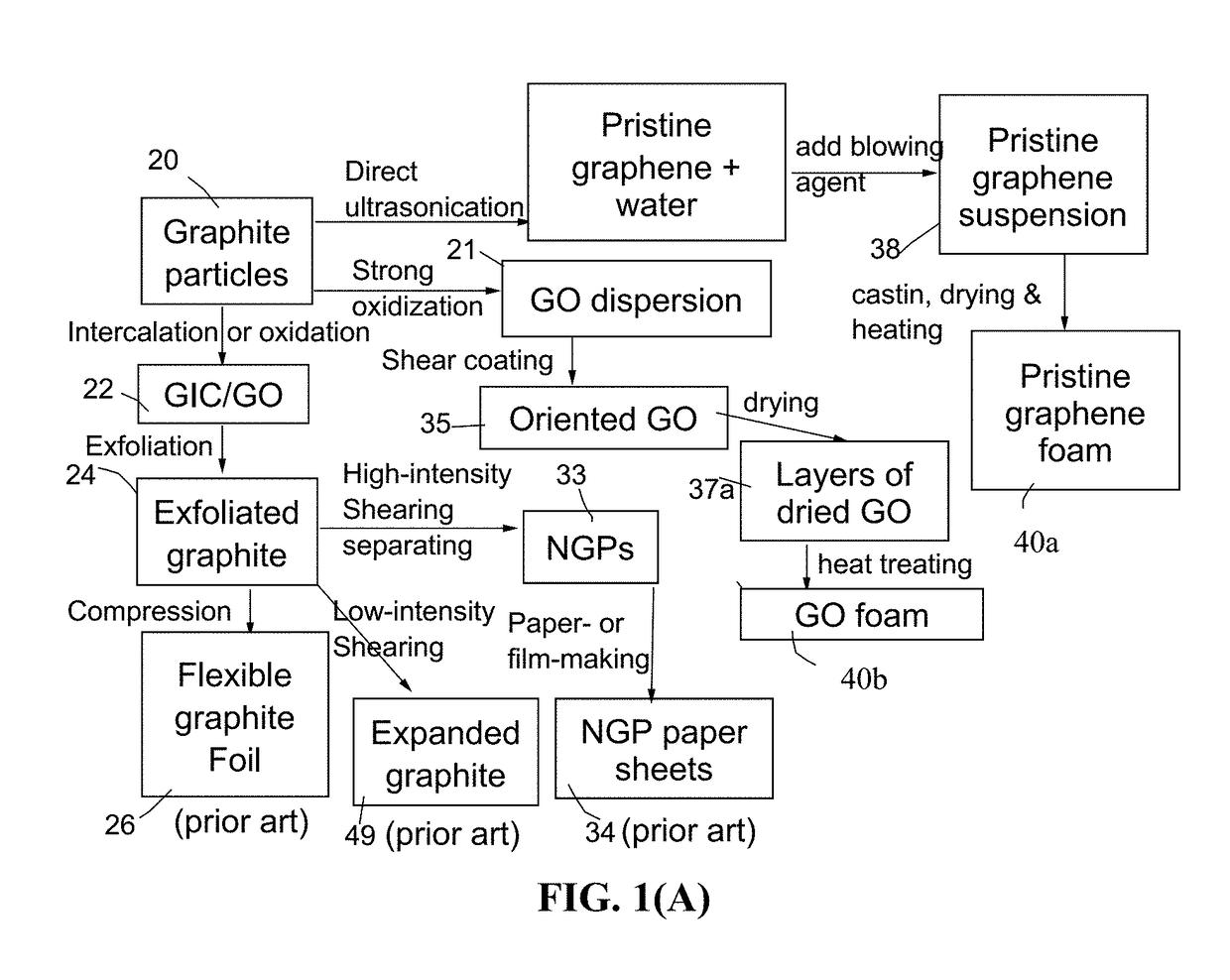

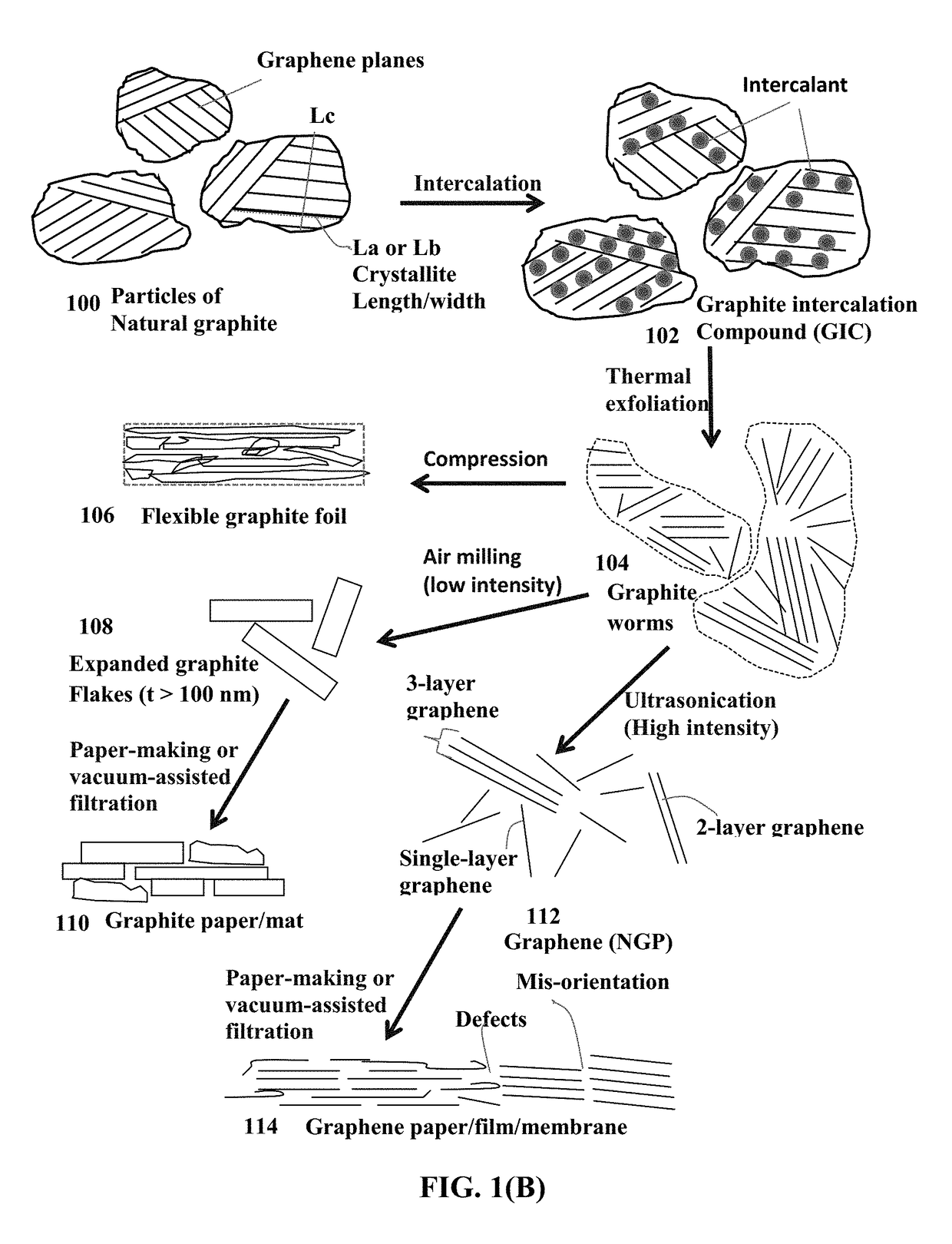

Process for producing graphene foam supercapacitor electrode

ActiveUS9437372B1Effective orientation-inducing stressEasy to mergeCarbon compoundsHybrid capacitor electrodesLiquid mediumMass loading

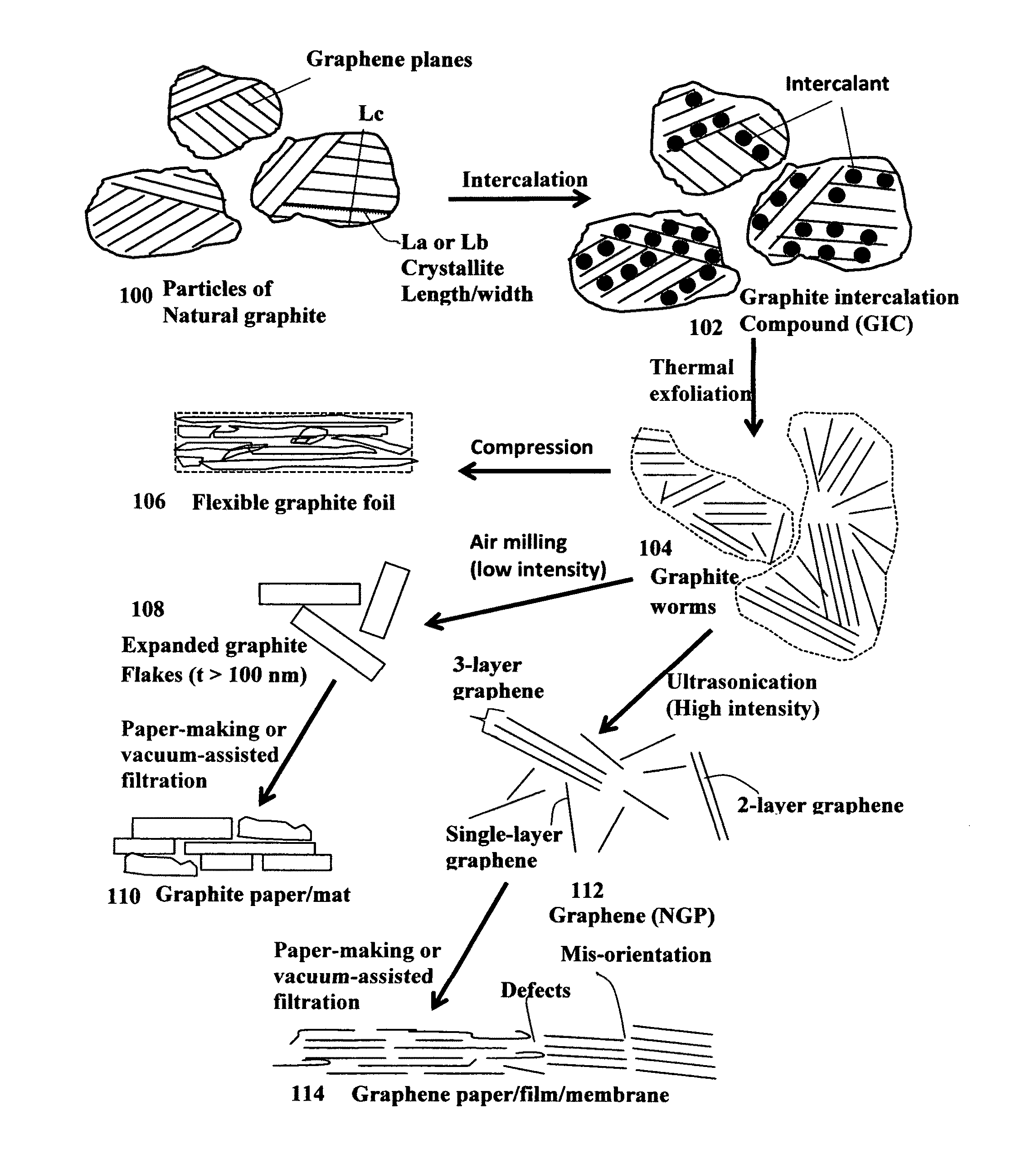

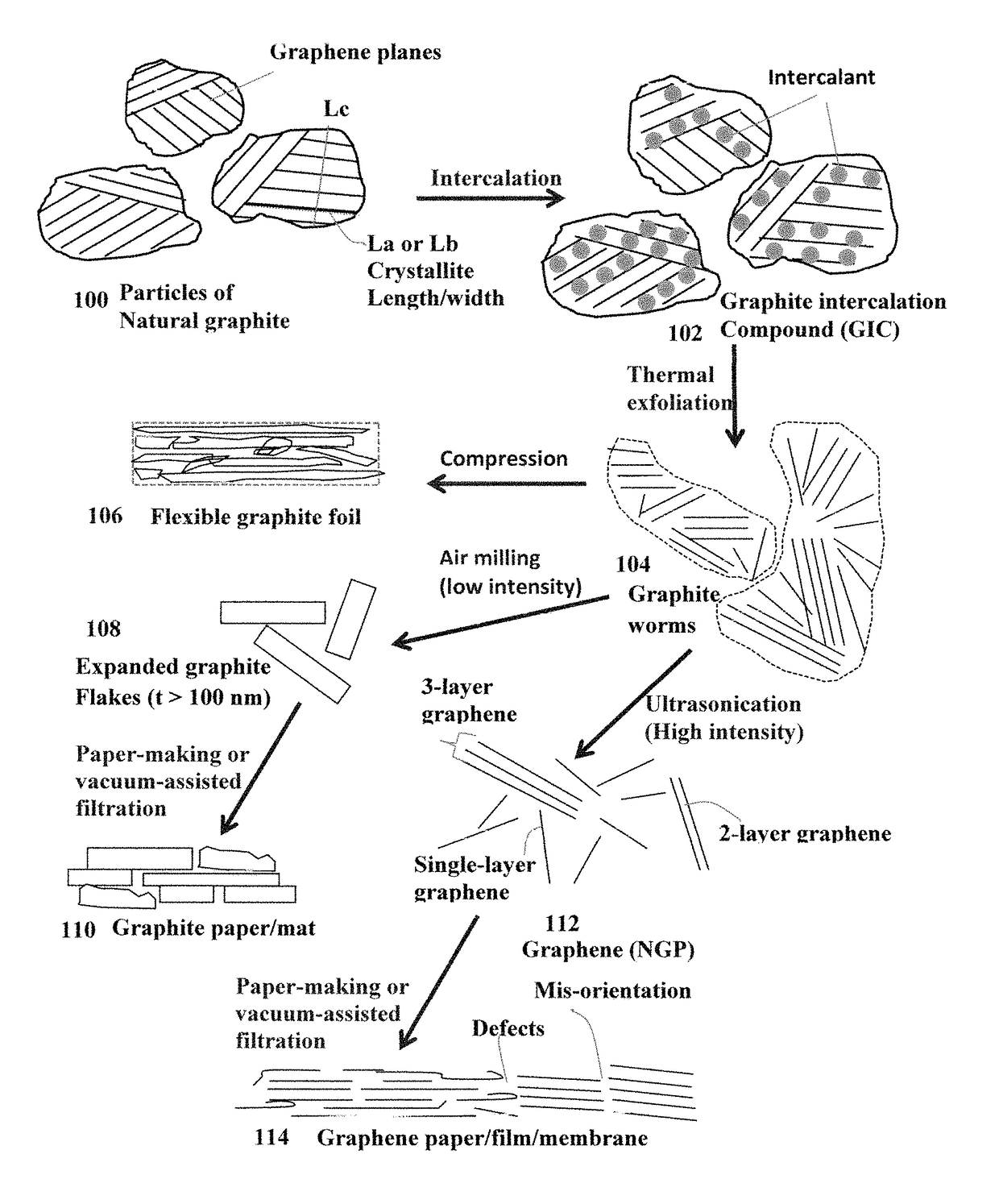

A process for producing a supercapacitor electrode, comprising: (a) preparing a graphene dispersion containing an optional blowing agent; (b) depositing the dispersion onto a supporting substrate to form a wet layer; (c) removing the liquid medium from the wet layer to form a dried layer of graphene material; (d) heat treating the dried layer at a temperature from 80° C. to 3,200° C. to induce volatile gas molecules from the non-carbon elements or to activate the blowing agent for producing a layer of solid graphene foam having a physical density from 0.01 to 1.7 g / cm3 and a specific surface area from 50 to 3,300 m2 / g; and (e) impregnating the foam with an electrolyte to form a layer of pre-impregnated graphene foam, which is compressed to form the electrode. This process leads to a supercapacitor having a large electrode thickness, high active mass loading, high tap density, and exceptional energy density.

Owner:NANOTEK INSTR GRP LLC

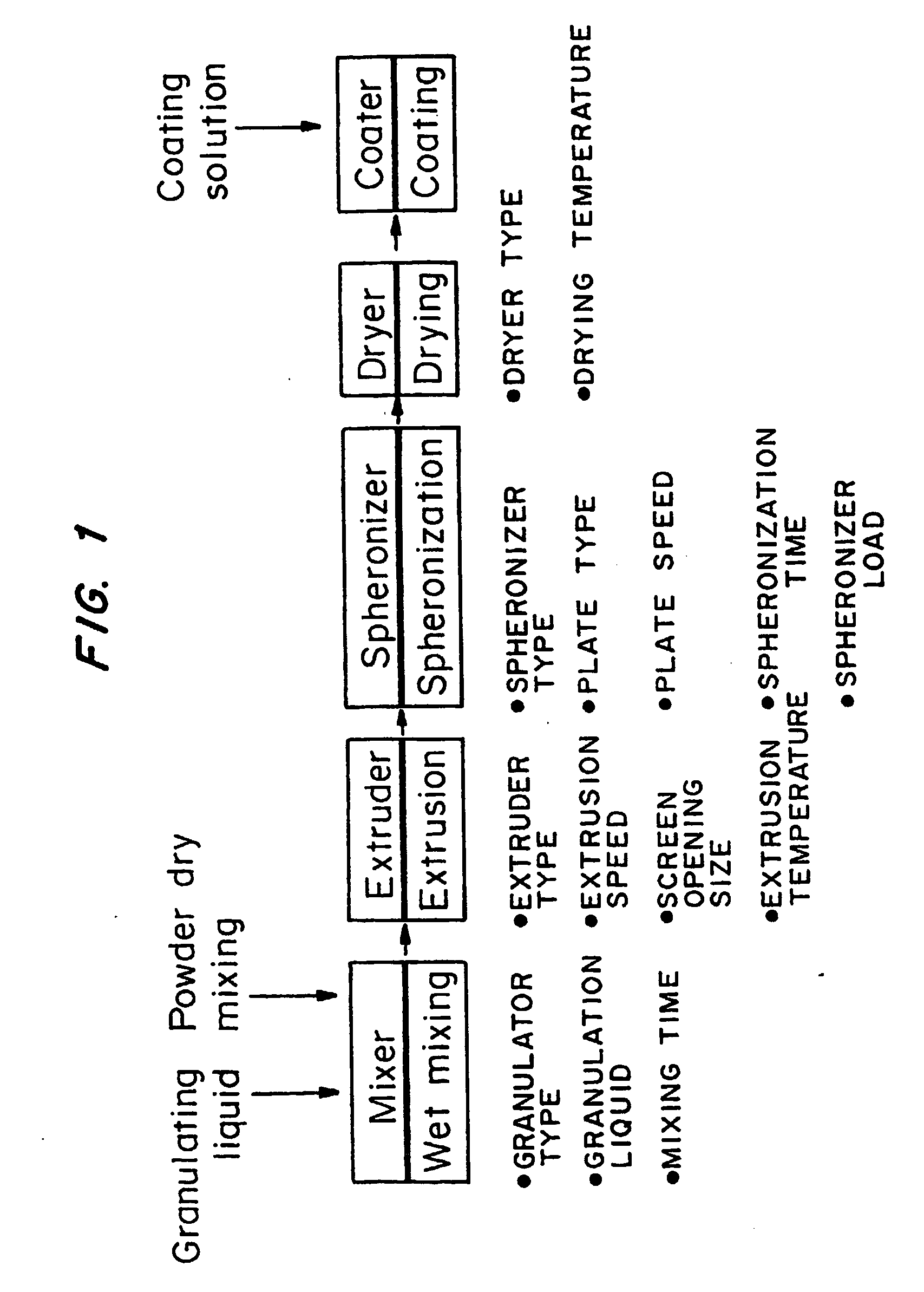

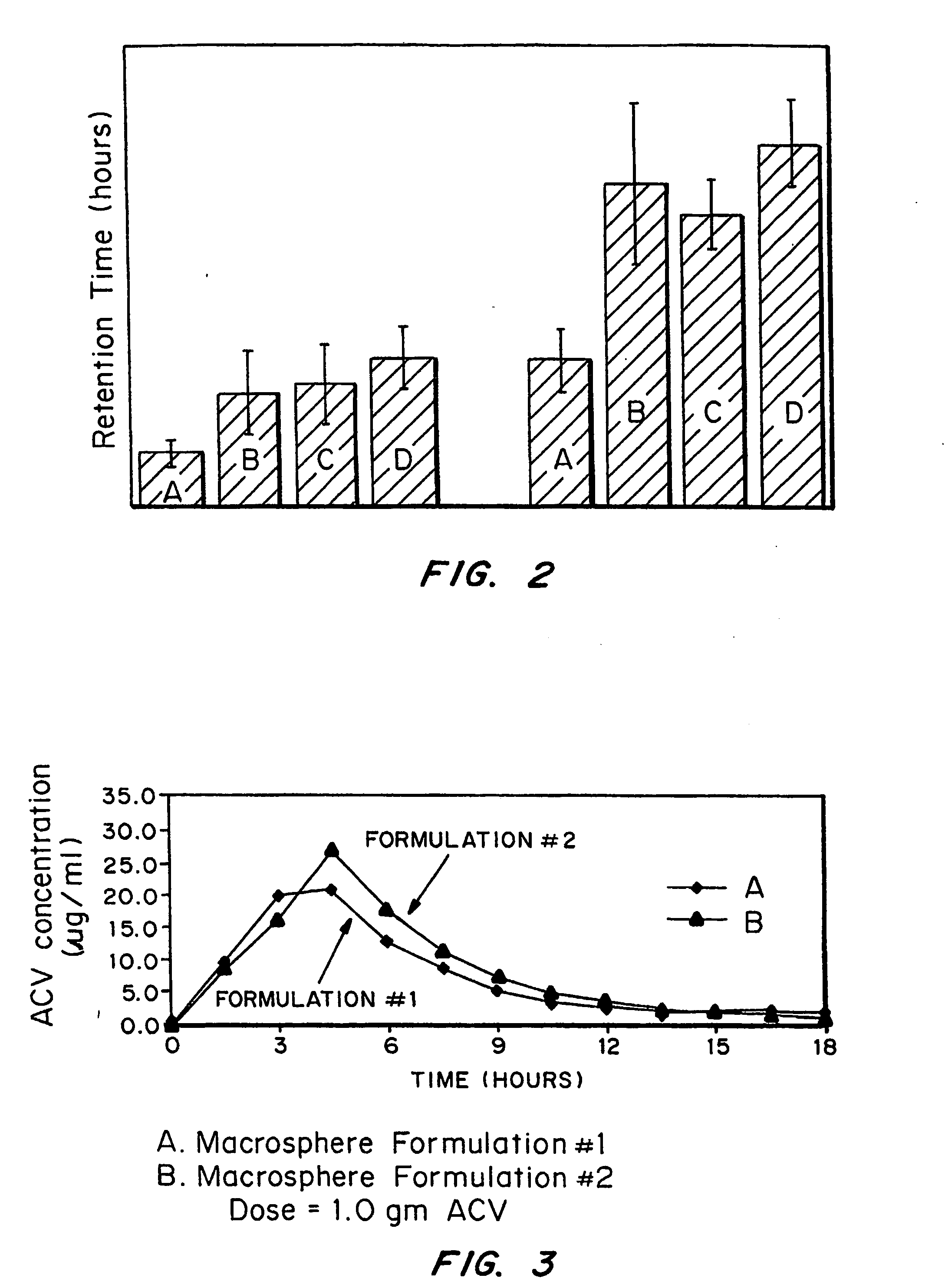

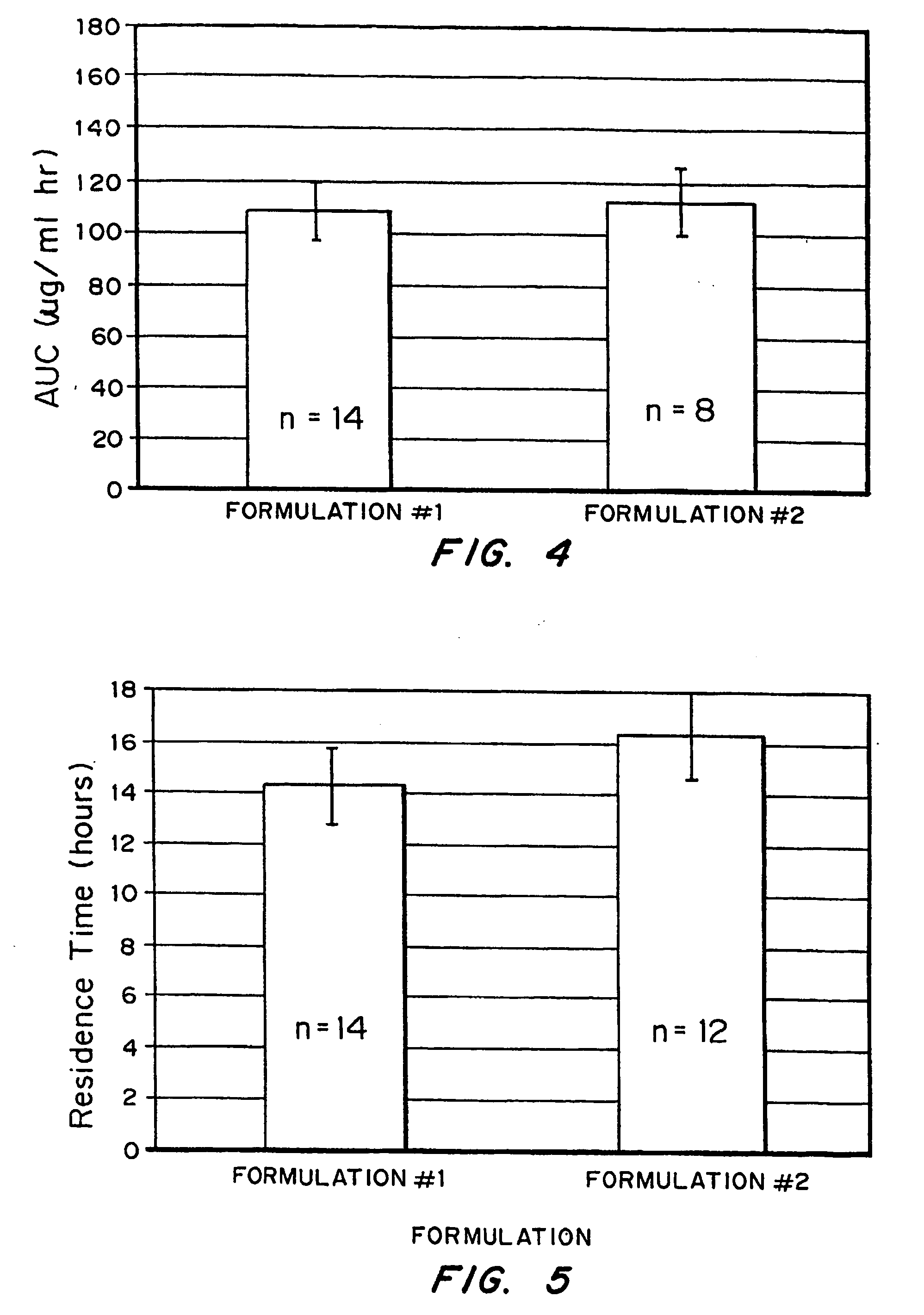

Bioadhesive drug delivery system with enhanced gastric retention

InactiveUS20050064027A1Prolonged gastric retention timeHigh retention rateBiocideCosmetic preparationsWhole bodyRetention time

Bioadhesive macrosphere delivery systems (“BDDS”) having prolonged gastric retention time due to bioadhesion rather than physical density or size are described. In general, the macrospheres have diameters that are greater than 200 microns, more preferably greater than 500 microns. The bioadhesive macrospheres are released in the stomach where they reside in close proximity to the gastric mucosa for a prolonged period of time. Increased residence of BDDS in the upper GI can lead to increased systemic absorption of drug in the preferred site of systemic absorption, namely the upper GI tract (upper to mid-jejunum). The BDDS may be engineered either as a capsule with drug delivery controlled by a diffusion-limited membrane or degradable shell, or as a solid matrix system with drug delivery controlled by a combination of diffusion and polymer degradation kinetics.

Owner:SPHERICS

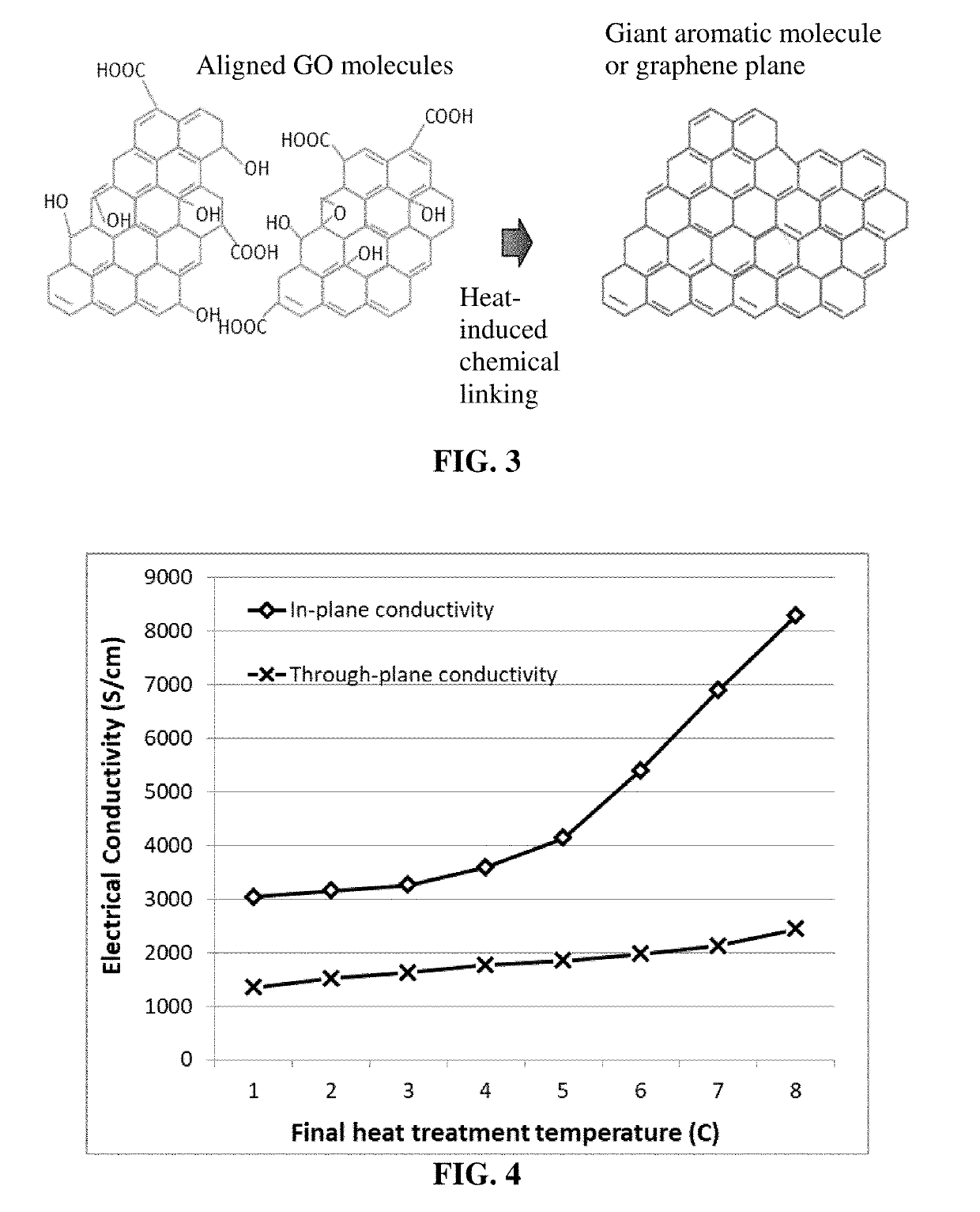

Humic acid-bonded metal foil film current collector and battery and supercapacitor containing same

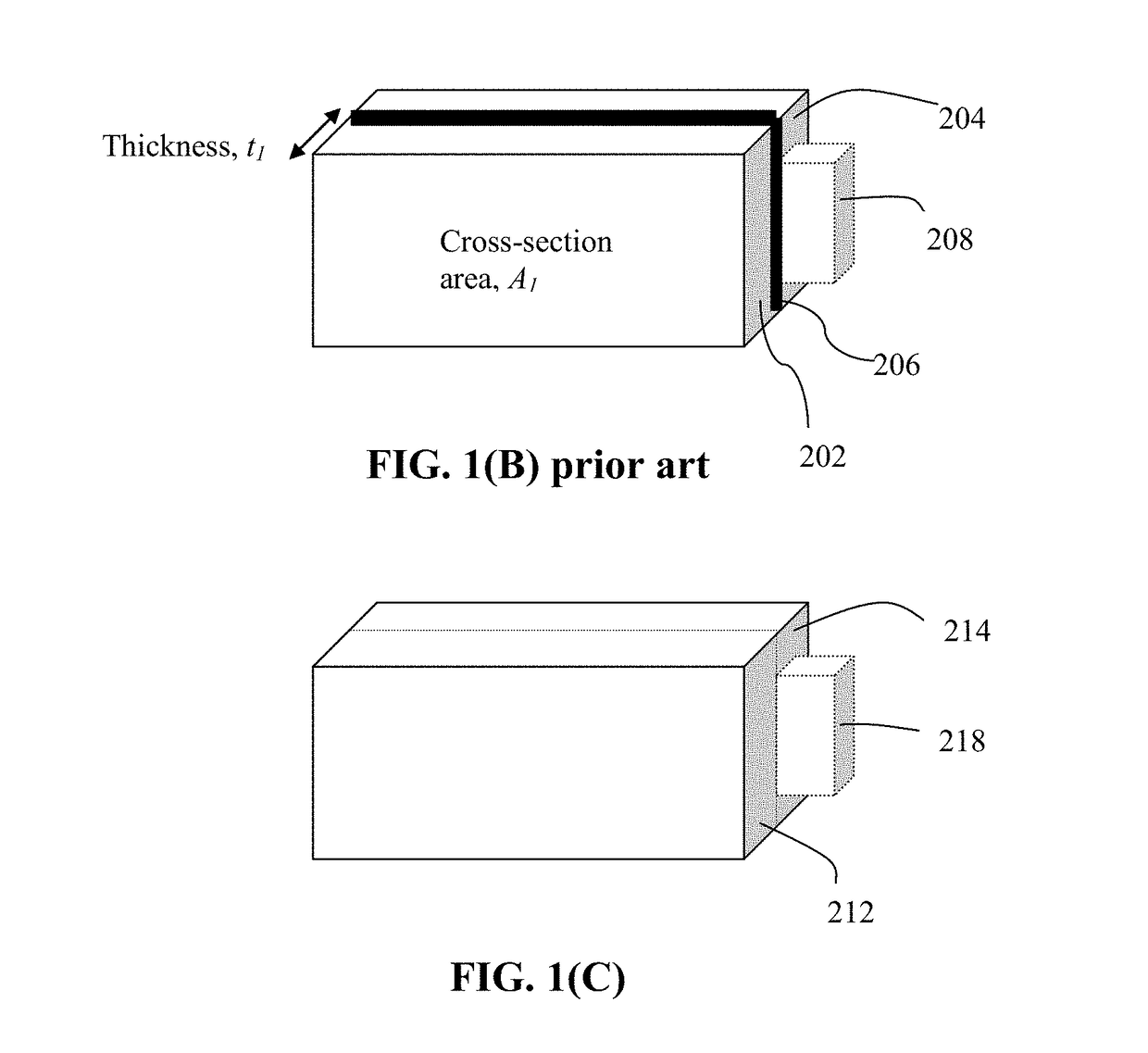

ActiveUS20180053931A1Increase the lengthIncrease widthOrganic chemistryFuel and secondary cellsChemical LinkageMetal foil

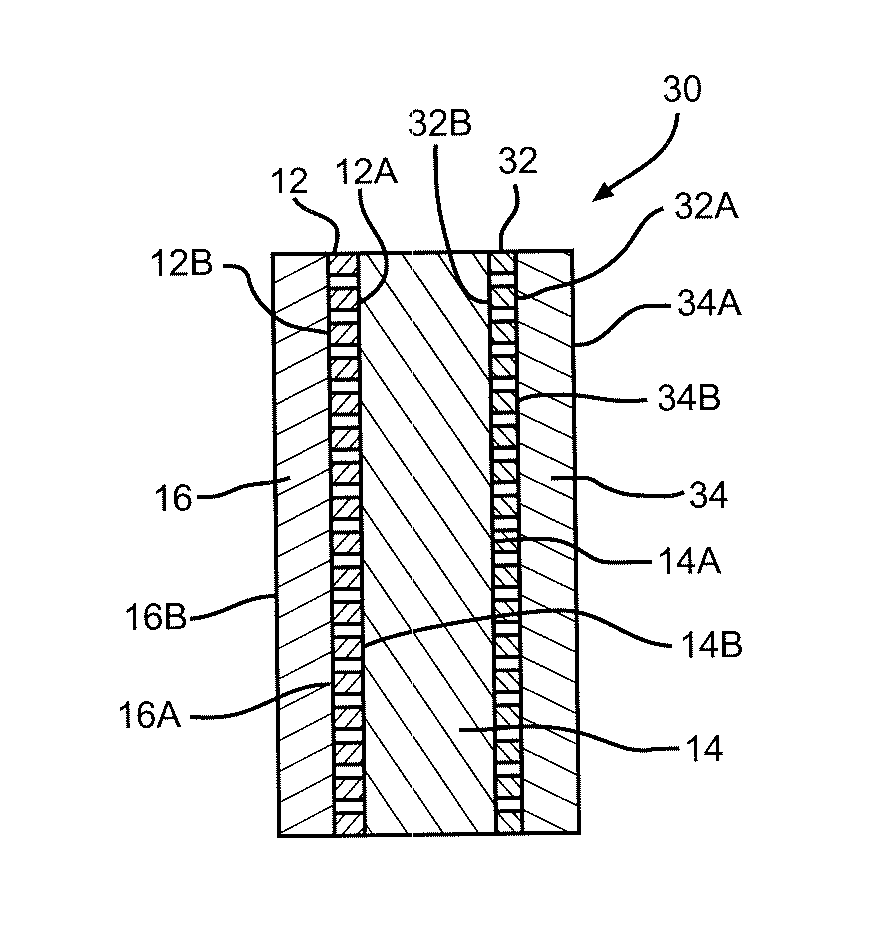

A humic acid-bonded metal foil current collector in a battery or supercapacitor, comprising: (a) a thin metal foil having two opposed but parallel primary surfaces; and (b) a thin film of humic acid (HA) or a mixture of HA and graphene, having hexagonal carbon planes, wherein HA or both HA and graphene are chemically bonded to at least one of the two primary surfaces; wherein the thin film has a thickness from 10 nm to 10 μm, an oxygen content from 0.01% to 10% by weight, an inter-planar spacing of 0.335 to 0.50 nm between hexagonal carbon planes, a physical density from 1.3 to 2.2 g / cm3, all hexagonal carbon planes being oriented substantially parallel to each other and parallel to the primary surfaces, exhibiting a thermal conductivity greater than 500 W / mK, and / or electrical conductivity greater than 1,500 S / cm when measured alone without the metal foil.

Owner:GLOBAL GRAPHENE GRP INC

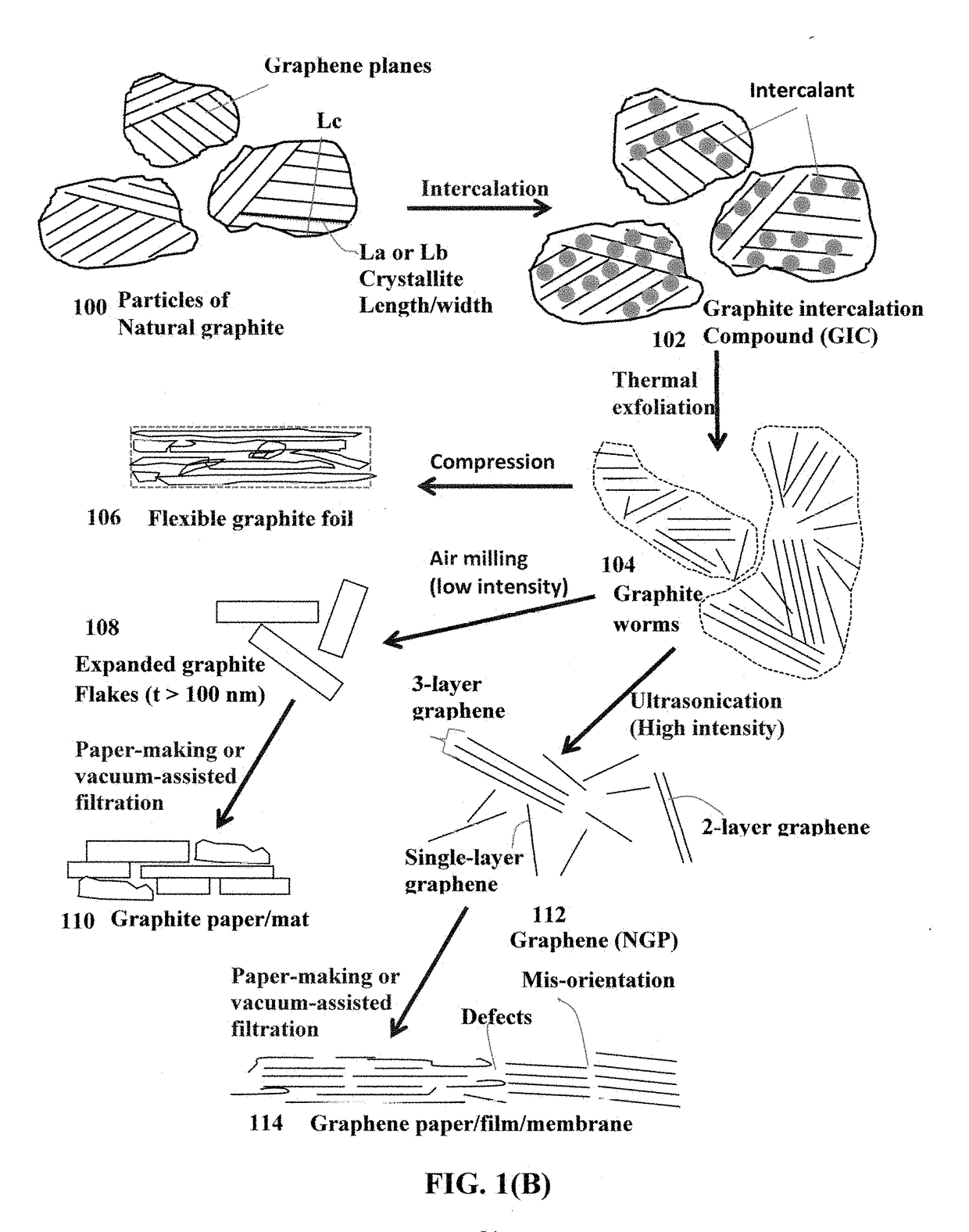

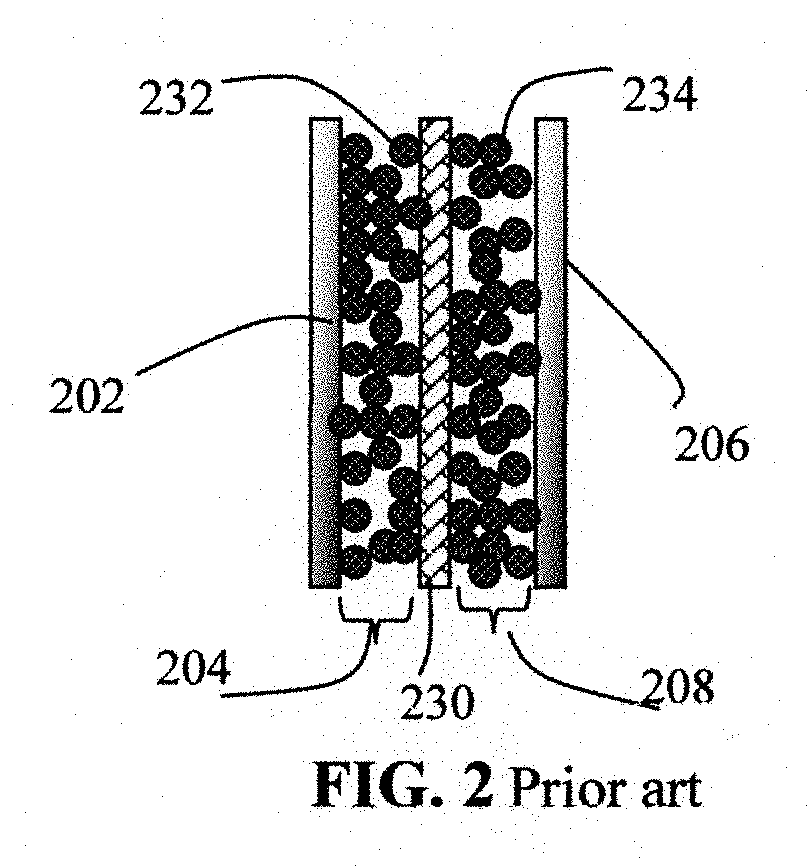

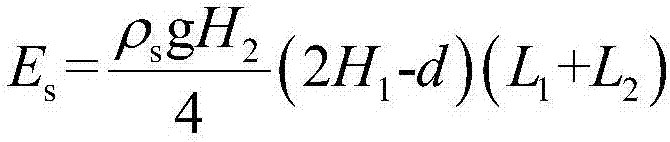

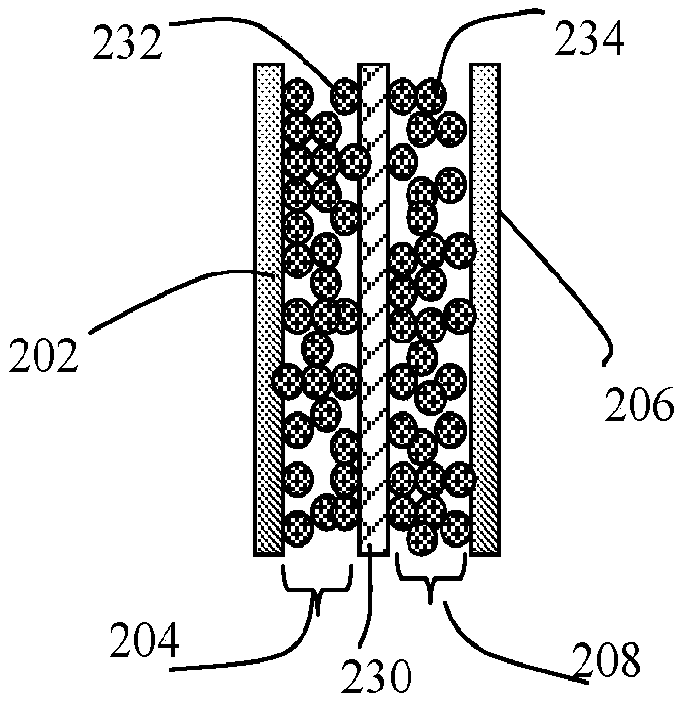

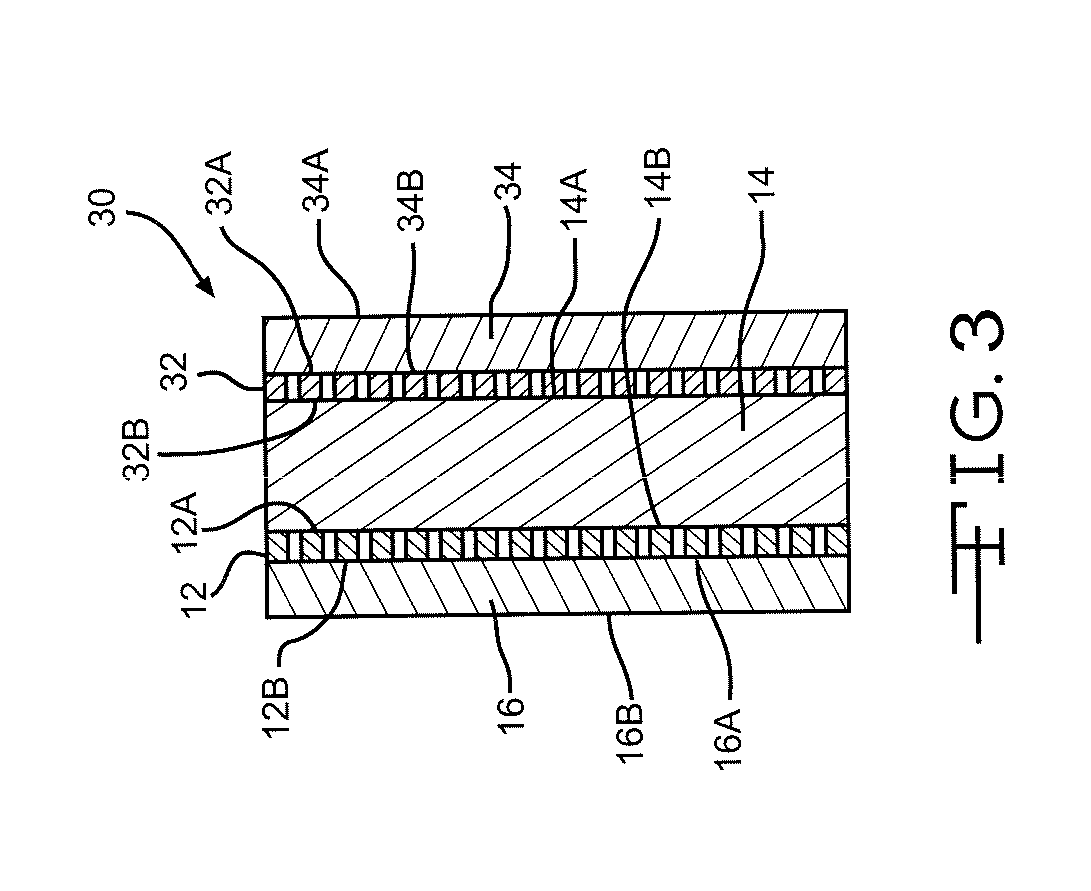

Supercapacitor electrode having highly oriented and closely packed graphene sheets and production process

ActiveUS20170221643A1Reduce thicknessImprove directionHybrid capacitor separatorsLamination ancillary operationsSupercapacitorMass loading

Provided is a process for producing an electrolyte-impregnated laminar graphene structure for use as a supercapacitor electrode. The process comprises (a) preparing a graphene dispersion having multiple isolated graphene sheets dispersed in an electrolyte; and (b) subjecting the graphene dispersion to a forced assembly procedure, forcing the multiple graphene sheets to assemble into an electrolyte-impregnated laminar graphene structure, wherein the multiple graphene sheets are alternately spaced by thin electrolyte layers, less than 5 nm in thickness, and the graphene sheets are substantially aligned along a desired direction, and wherein the laminar structure has a physical density from 0.5 to 1.7 g / cm3 and a specific surface area from 50 to 3,300 m2 / g, when measured in a dried state of the laminar structure with the electrolyte removed. This process leads to a supercapacitor having a large electrode thickness, high active mass loading, high tap density, and exceptional energy density.

Owner:NANOTEK INSTR GRP LLC

Supercapacitor having highly conductive graphene foam electrode

ActiveUS20170200565A1Effective orientation-inducing stressEasy to mergeHybrid capacitor electrolytesHybrid capacitor electrodesIodideMaterials science

A supercapacitor electrode comprising a solid graphene foam impregnated with a liquid or gel electrolyte, wherein the solid graphene foam is composed of multiple pores and pore walls, wherein pore walls contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.001% to 5% by weight of non-carbon elements wherein non-pristine graphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, chemically functionalized graphene, or a combination thereof, and the solid graphene foam, when measured in a dried state without electrolyte, has a physical density from 0.01 to 1.7 g / cm3, a specific surface area from 50 to 3,200 m2 / g, a thermal conductivity of at least 200 W / mK per unit of specific gravity, and / or an electrical conductivity no less than 2,000 S / cm per unit of specific gravity.

Owner:NANOTEK INSTR GRP LLC

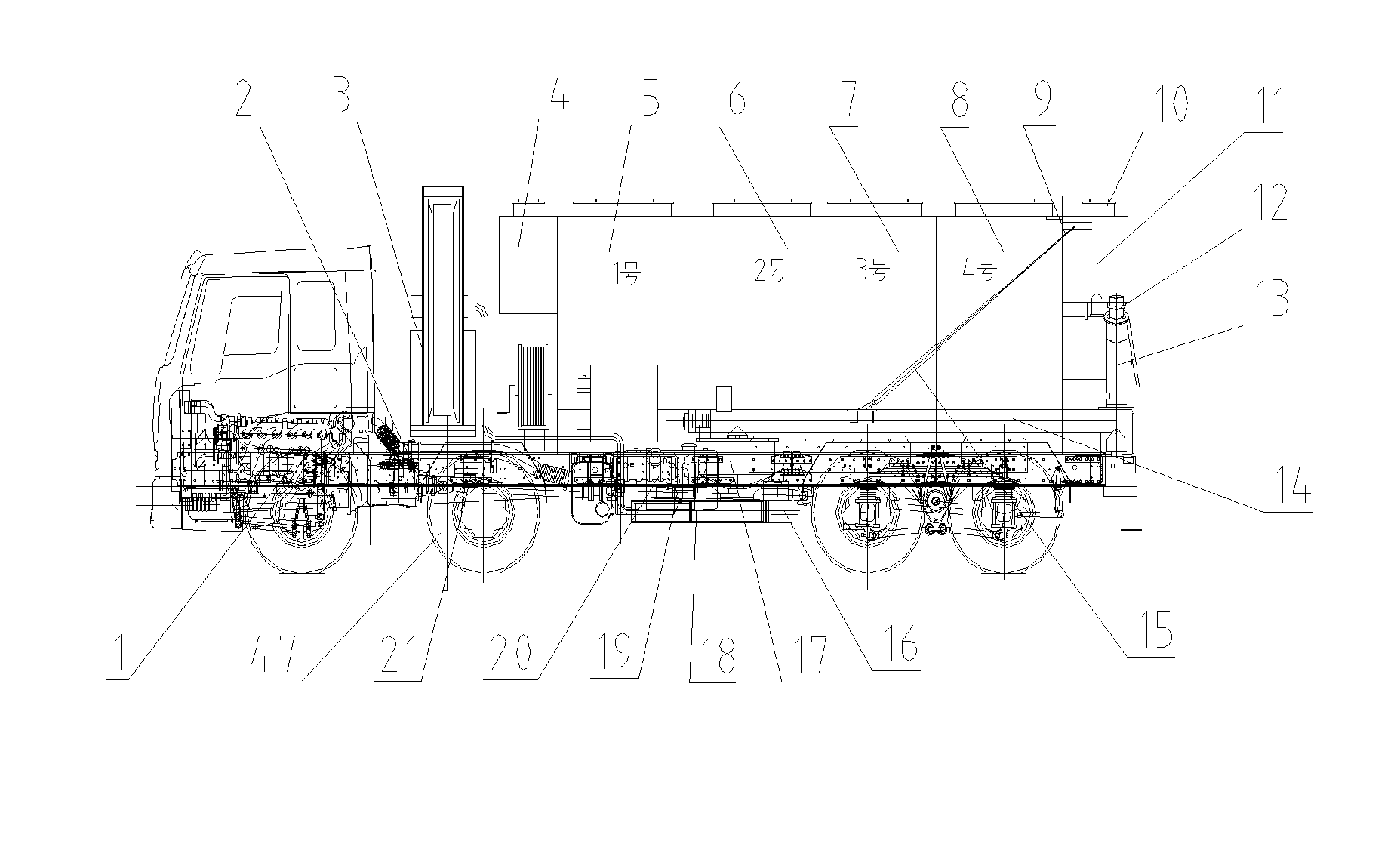

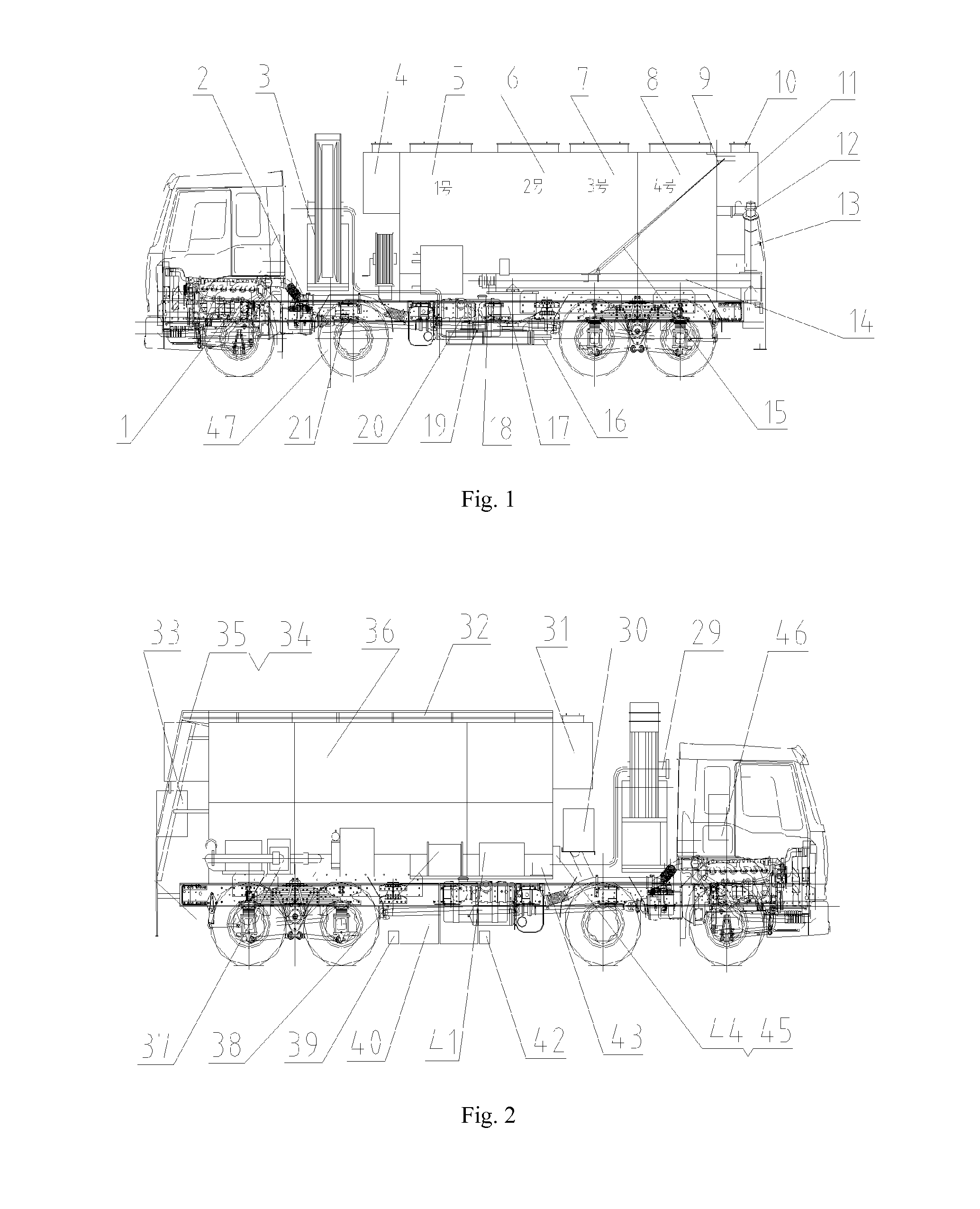

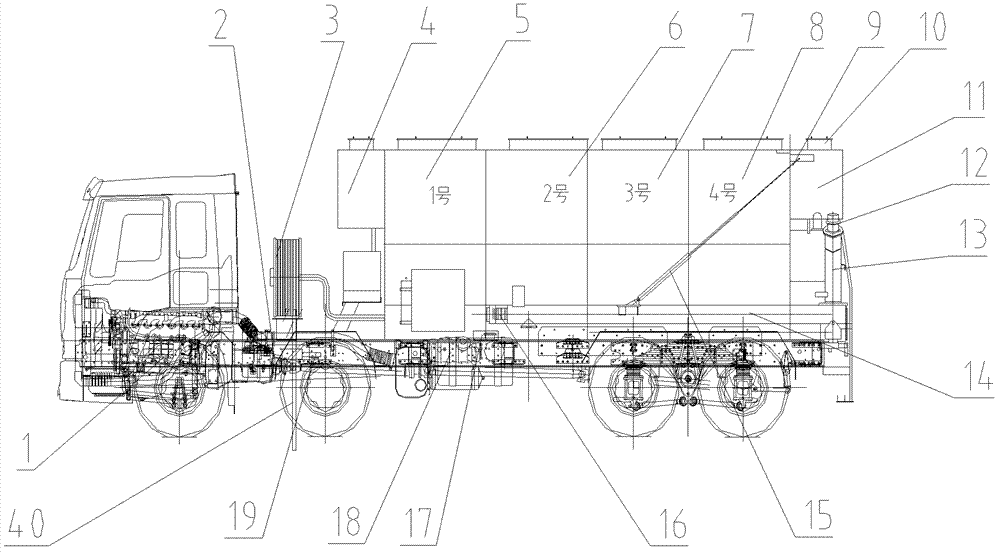

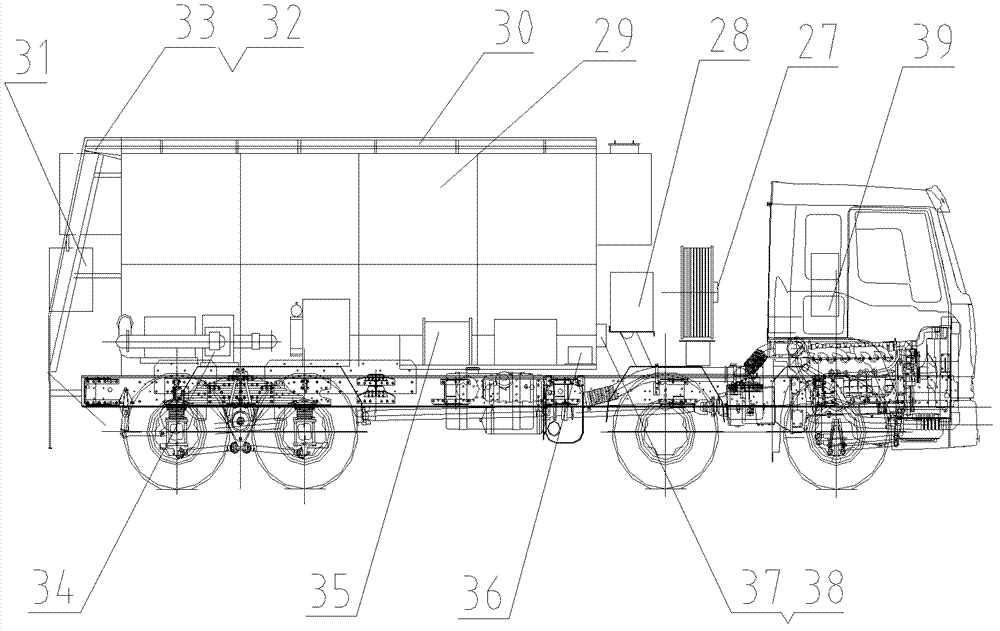

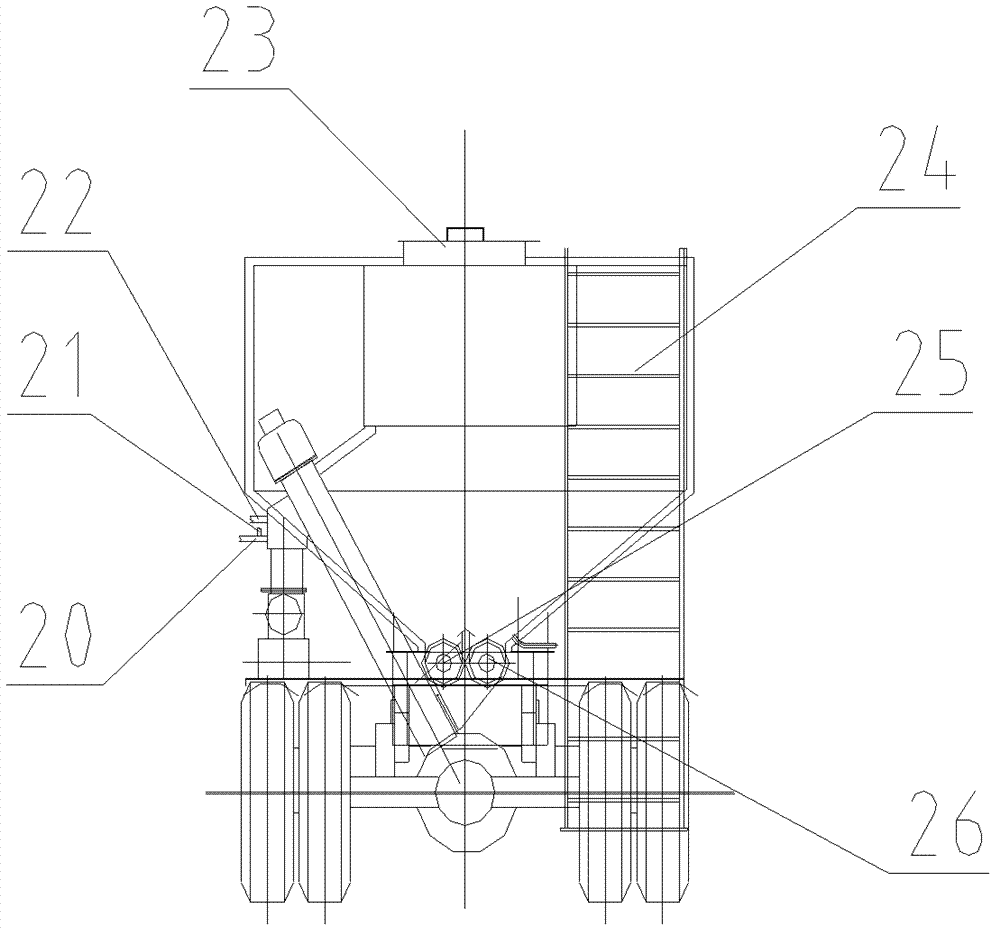

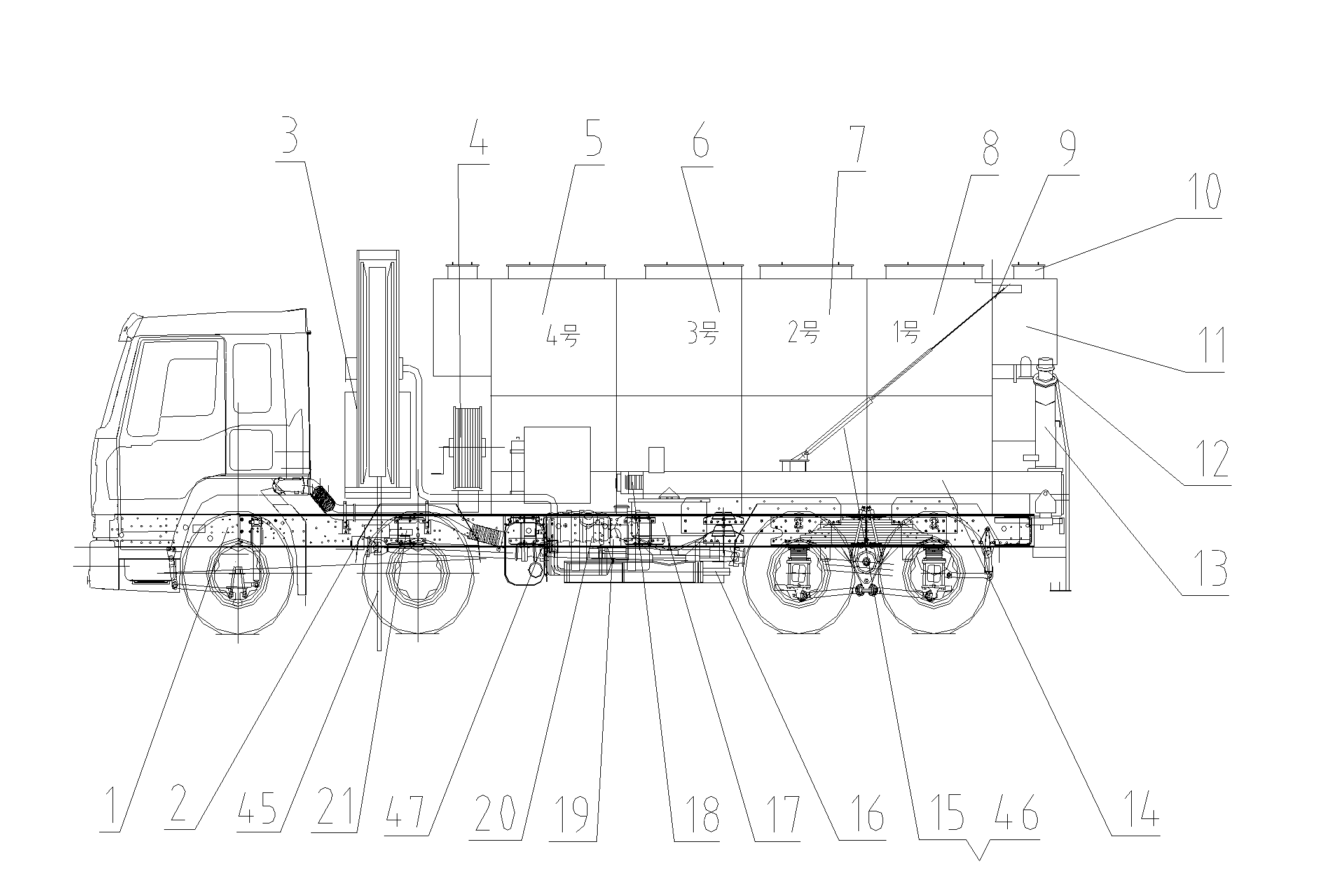

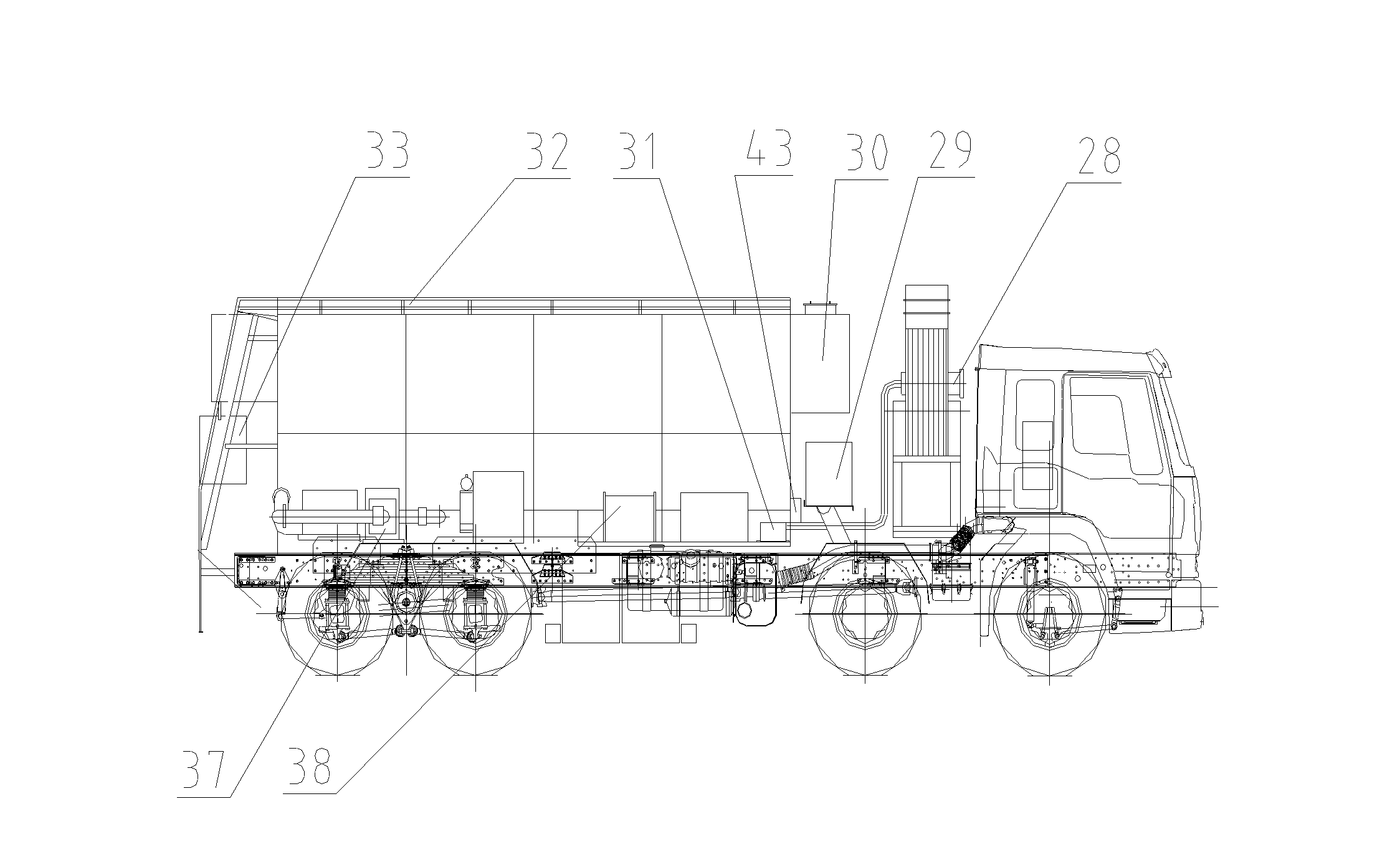

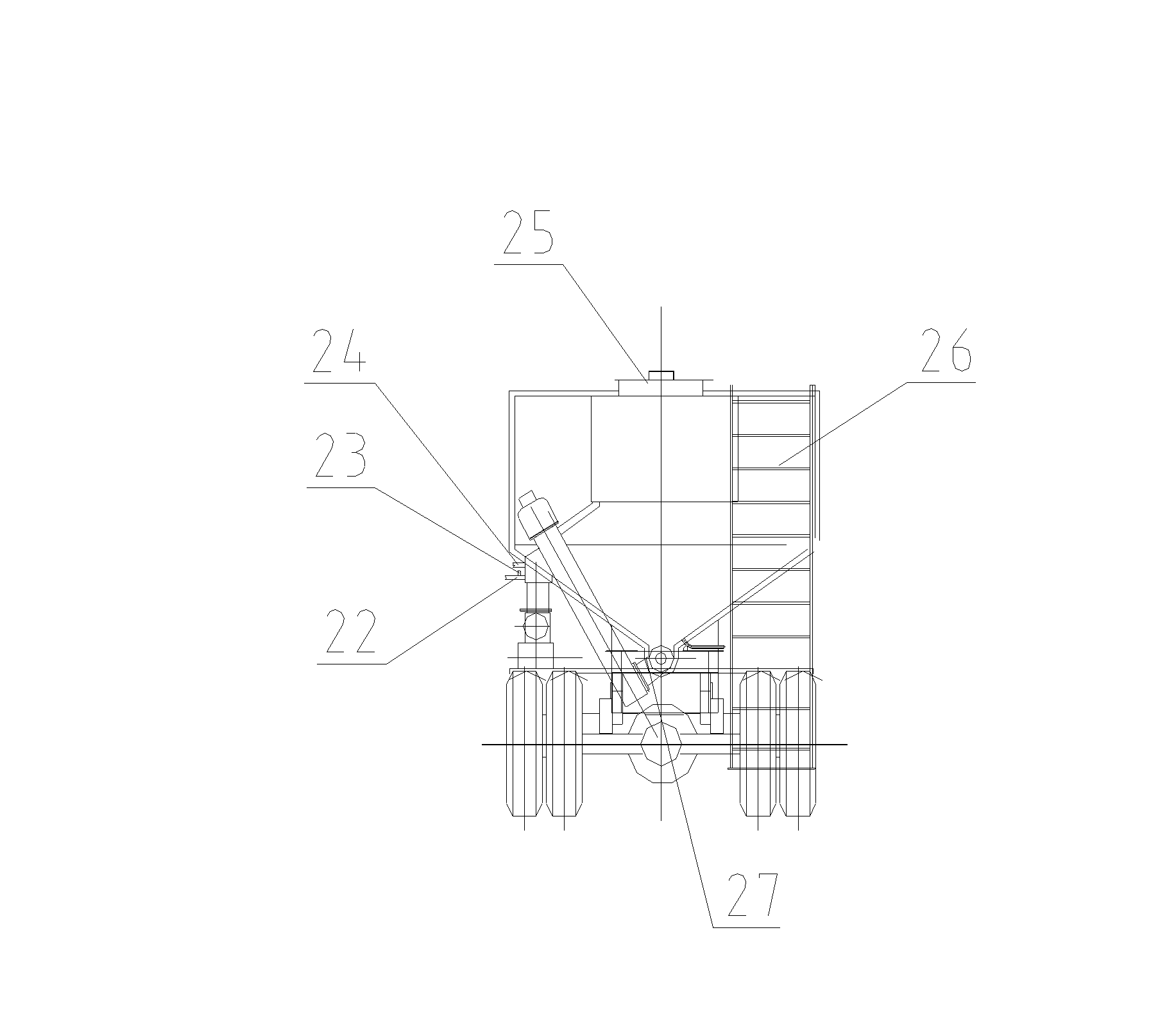

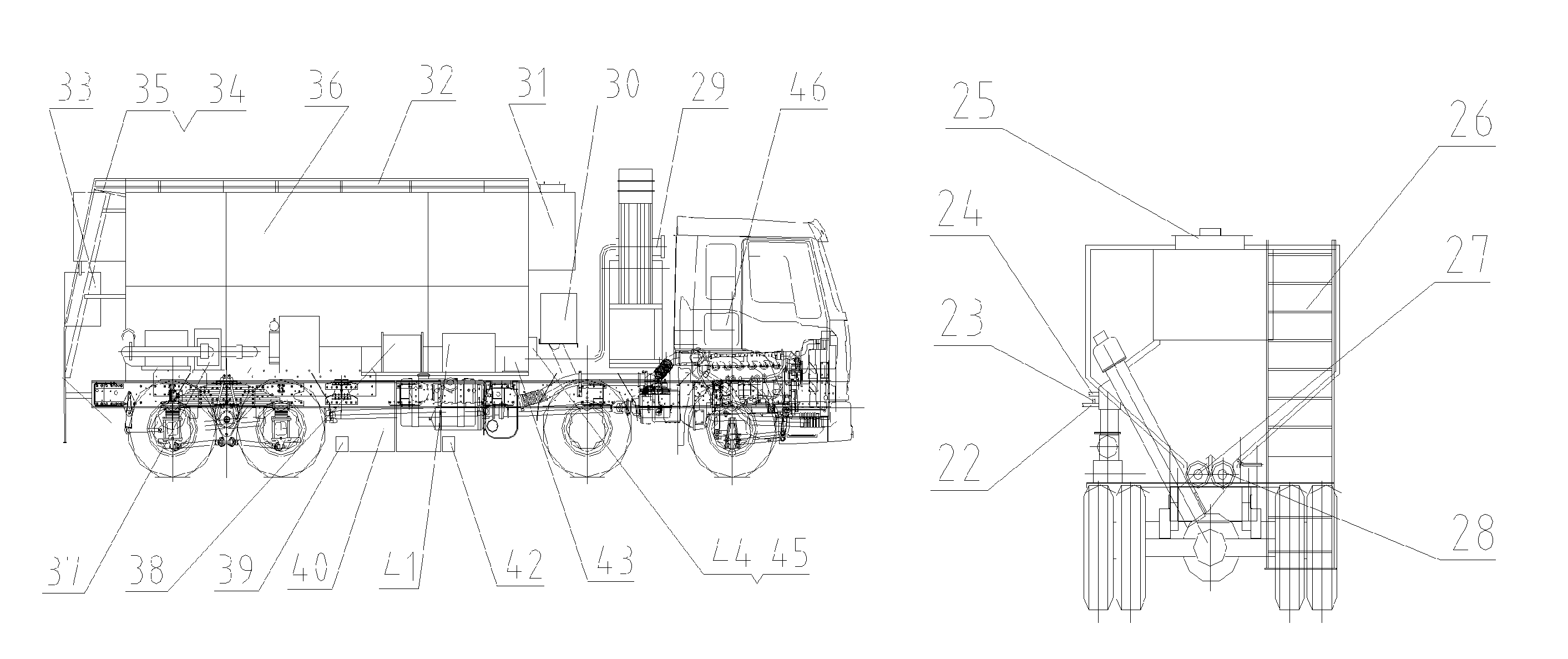

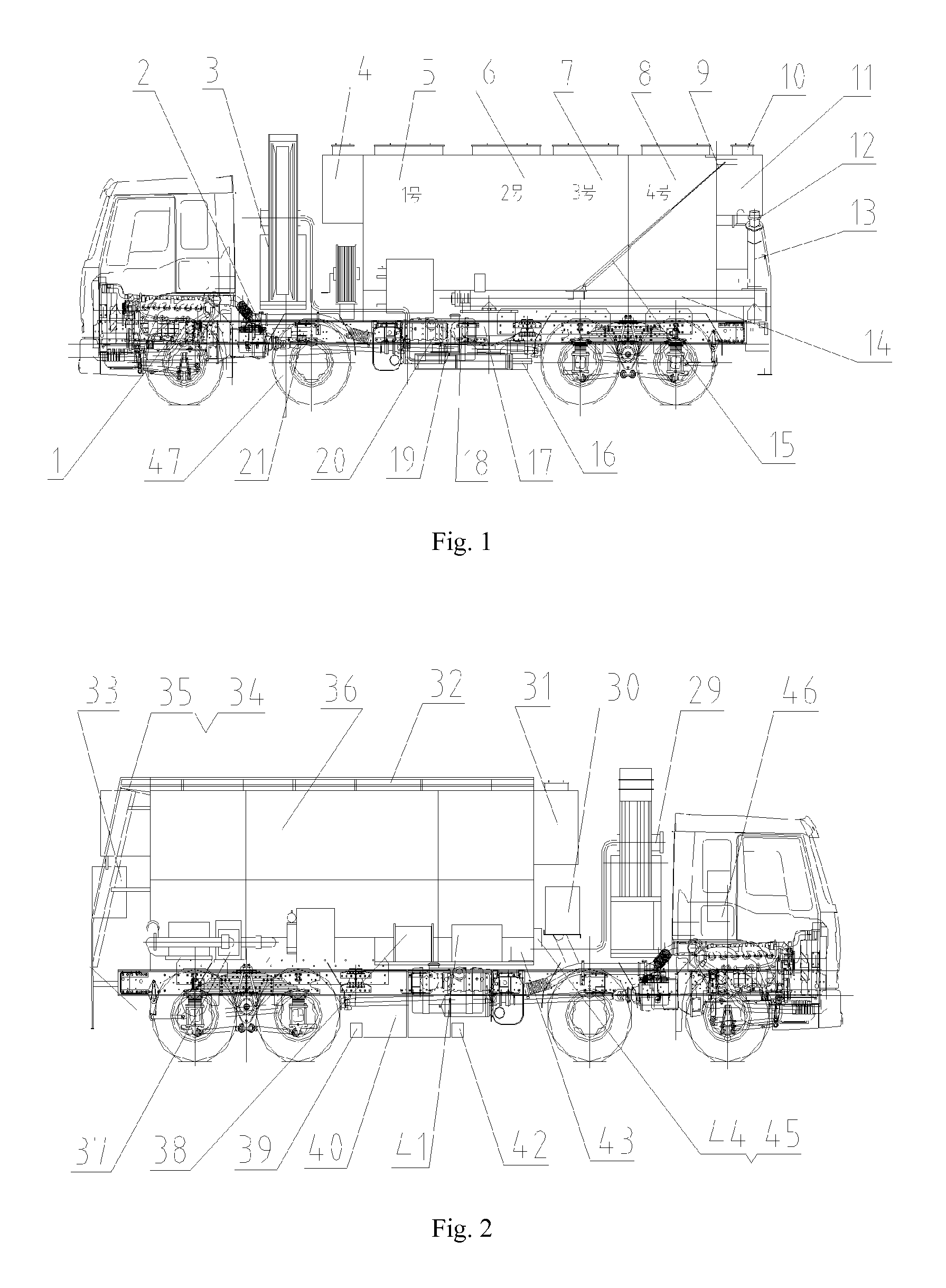

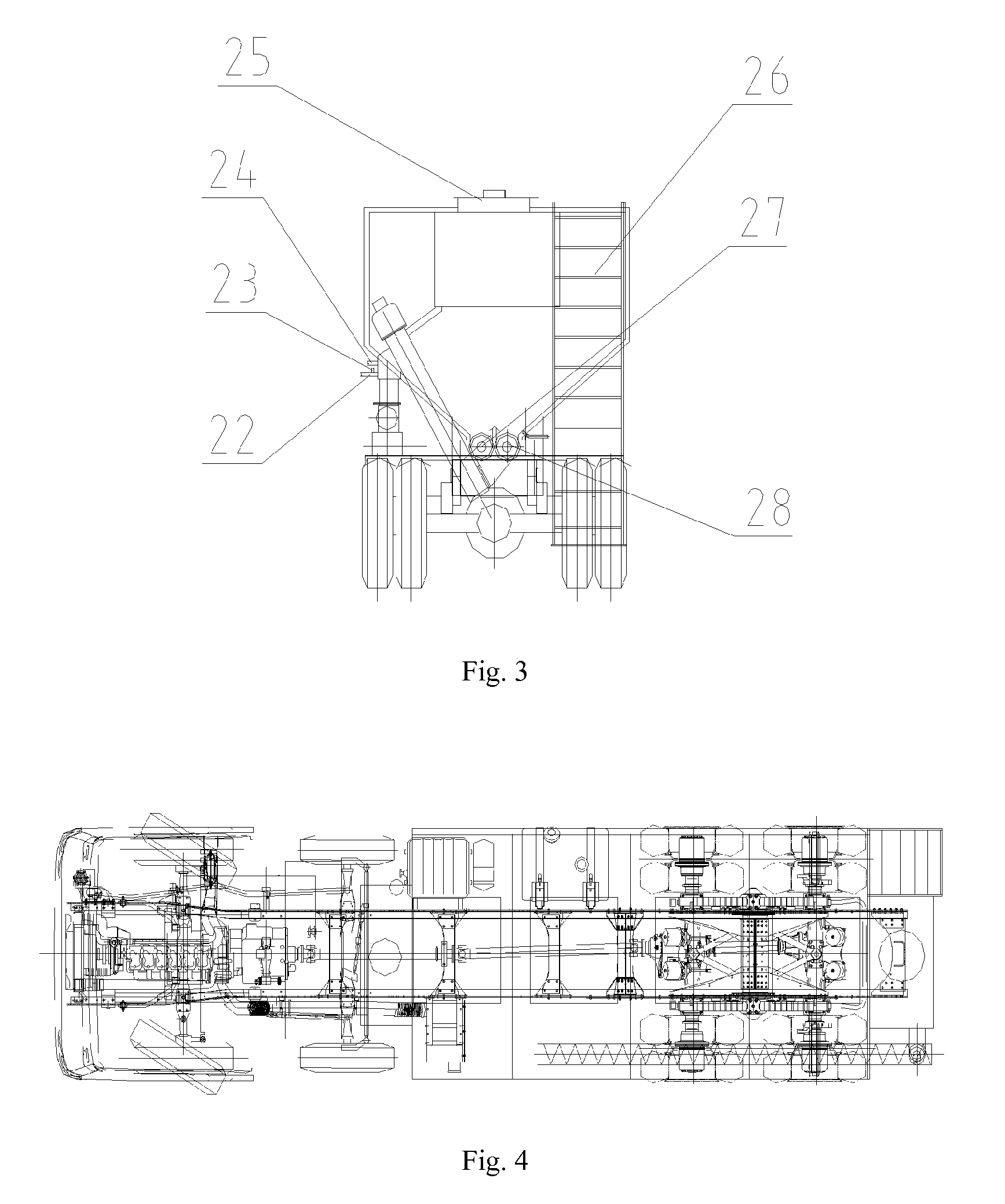

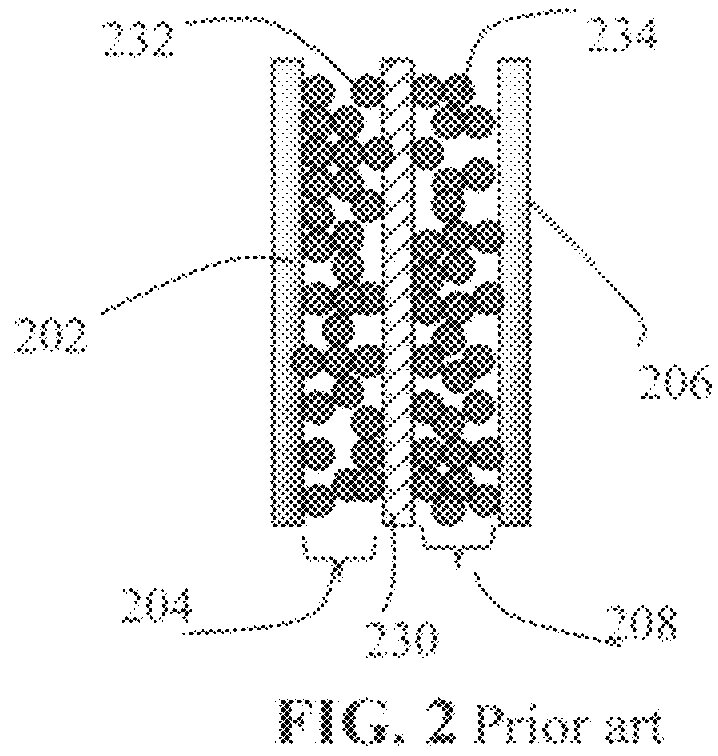

Site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities

ActiveUS20150003186A1Low densityOvercomes shortcomingControlling ratio of multiple fluid flowsTank vehiclesEmulsion explosiveFuel oil

Provided is a site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities. The vehicle contains a double-helix conveying system, a plurality of storage bins (5-8) and multiple sets of pipelines. Emulsified bases, porous granular ammonium nitrate and physical density modifier are stored in the main material storage bins, an adjuvant storage bin is provided with a diesel tank (4, 31), a sensitizing solution tank (40) and a washing water tank (11), and the technical effect that multiple kinds of explosives with different detonation velocities are mixed and loaded can be realized by using the different combinations of the different raw materials of the storage bins and various output pipelines and some baffle plates. The vehicle has the advantages of multiple purposes, capability of producing heavy emulsion explosive, density-modifiable heavy emulsion explosive, low density emulsion explosive, ultra-low density emulsion explosive, heavy ammonium nitrate fuel oil explosive, density-modifiable ammonium nitrate fuel oil explosive, porous granular ammonium nitrate fuel oil explosive, density-modifiable porous granular ammonium nitrate fuel oil explosive, and minor-diameter and long-distance conveying emulsion explosive, and applicability to the needs of various blasting operation environments and loading different kinds of explosives in the same blast hole.

Owner:QINGDAO TARGET MINING SERVICES

Graphene oxide-bonded metal foil thin film current collector and battery and supercapacitor containing same

ActiveUS20180040900A1Electrode manufacturing processesHybrid capacitor electrodesThin metalMetal foil

A graphene oxide-bonded metal foil current collector in a battery or supercapacitor, comprising: (a) a free-standing, non-supported thin metal foil having a thickness from 1 μm to 30 μm and two primary surfaces; and (b) a thin film of graphene oxide chemically bonded to at least one of the two primary surfaces without using a binder or adhesive wherein the primary surface does not contain a metal oxide layer and the thin film of graphene oxide has a thickness from 10 nm to 10 μm, an oxygen content from 0.1% to 10% by weight, an inter-graphene plane spacing of 0.335 to 0.50 nm, a physical density from 1.3 to 2.2 g / cm3, all graphene oxide sheets being oriented substantially parallel to each other and parallel to the primary surfaces, exhibiting a thermal conductivity greater than 500 W / mK, and / or electrical conductivity greater than 1,500 S / cm when measured alone without the thin metal foil.

Owner:GLOBAL GRAPHENE GRP INC

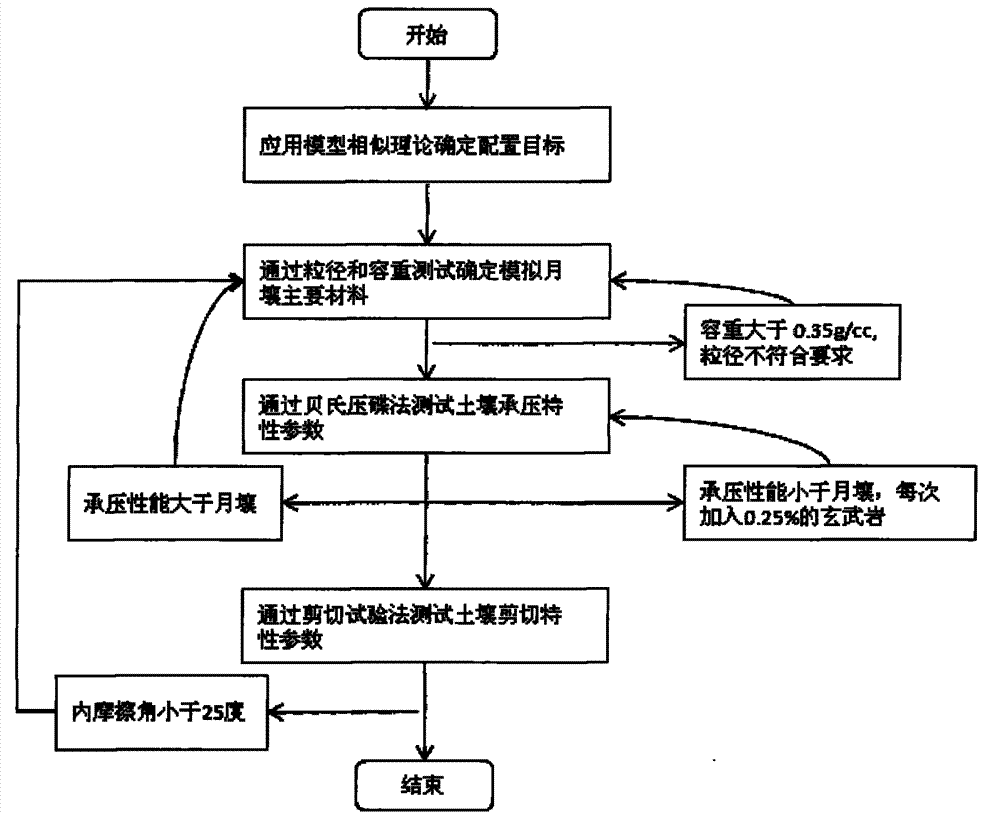

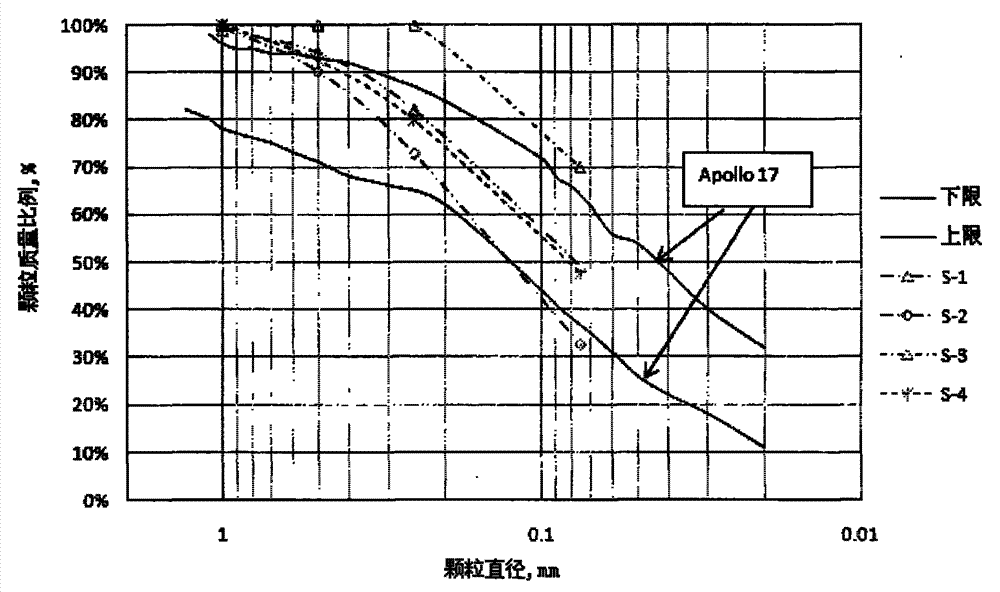

Low-gravity simulated lunar soil

InactiveCN102967498AImprove effectivenessTest status is stablePreparing sample for investigationJet aeroplaneSoil science

The invention belongs to the technical field of configuration of simulated lunar soil and particularly relates to low-gravity simulated lunar soil. The mechanical properties of the low-gravity simulated lunar soil can reach lunar soil in-situ mechanical properties as follows under the earth gravity of 1g: the pressure-bearing coefficient Kc is 0.14 N / cm<2> and kphi is 0.82 N / cm<3> and n is 1; the shearing coefficient C is 0.017 N / cm<2> and phi is 35 degrees and j is 1.8 cm; the physical density is 1 / 6 of the average density of the lunar soil, namely the density is 0.35 g / cc; and then, the simulated lunar soil is obtained by milling, sieving and grading grain diameters. The low-gravity simulated lunar soil can realize the full-simulation of the mechanical property of a lunar surface under the condition of ground gravity, and a manner of parabolic flight of an airplane does not need to be adopted to carry out a performance estimation test; and the test state is stable, the expenditure can be greatly saved and the low-gravity simulated lunar soil has the actual meaning of improving the effectiveness of a test check.

Owner:CHINA NORTH VEHICLE RES INST

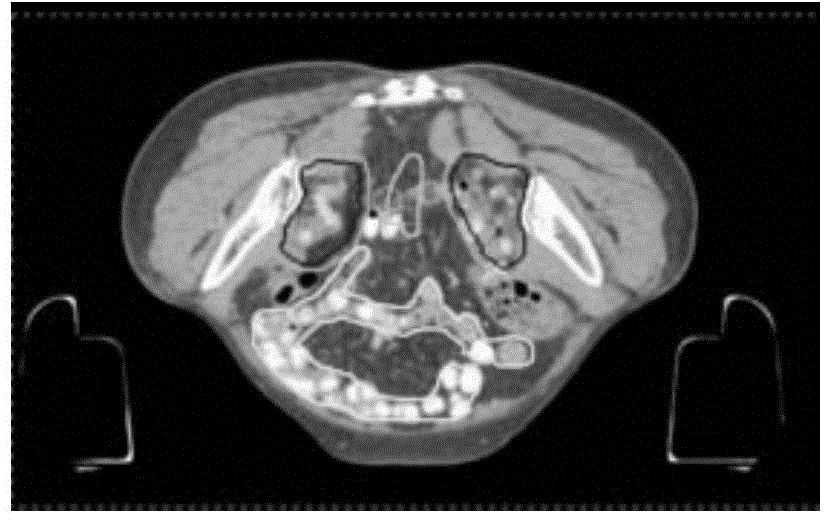

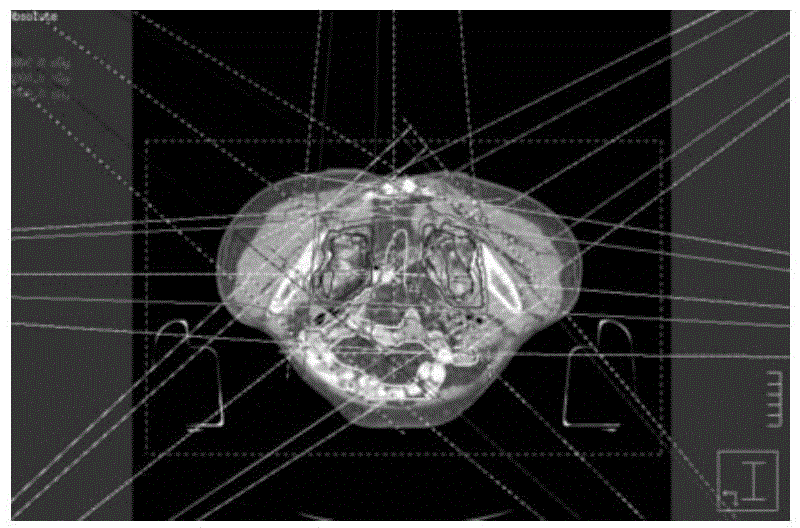

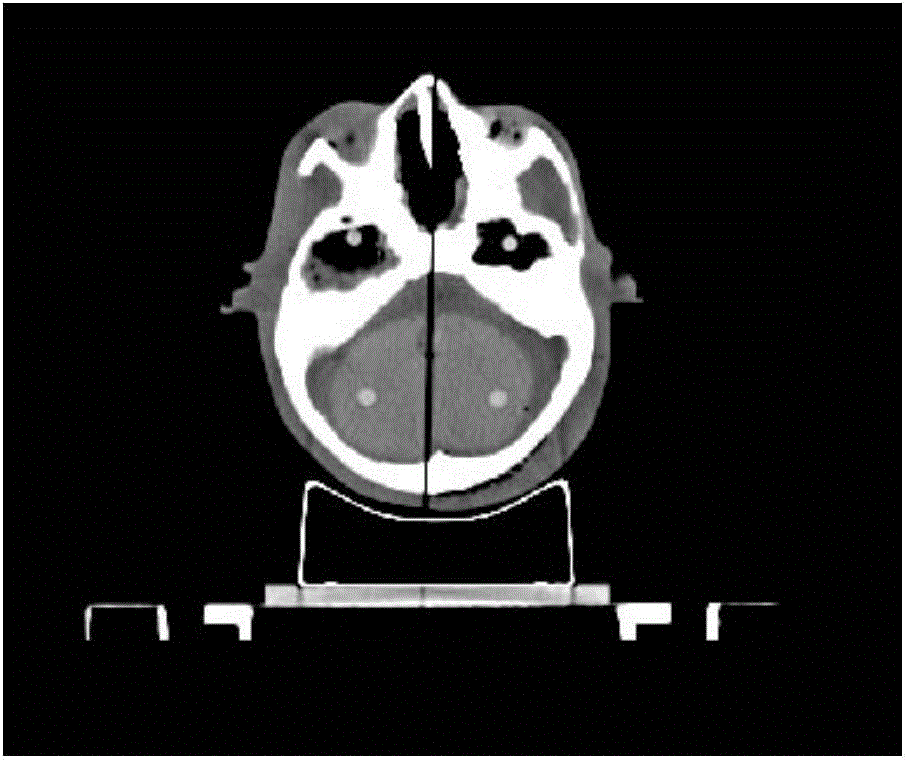

Verification method for ensuring accurate operation of intensity modulated radiation therapy

InactiveCN104888355AHigh precisionImprove accuracyRadiation therapyDose verificationElectronic density

The invention relates to a verification method for ensuring accurate operation of intensity modulated radiation therapy (IMRT). The method comprises the following steps: designing a plan, printing the model of a patient by using a 3D printing technology, scanning the model under the same positioning condition and scanning condition, transmitting the scanned model to a TPS (Therapy Planning System), calling an IMRT therapy plan to be verified, completely copying relevant therapy data of the plan to the model, placing the model on an accelerator therapy bed, adjusting the measurement points of the model to isocenter positions by means of laser rays, and performing absolute dose verification and relative dose verification. The method has the advantages: the verification model is prepared by adopting the 3D printing technology, and the model is completely consistent with the patient in size, physical density and electronic density, so that the precision and the accuracy of the absolute dose verification and the relative dose verification are improved.

Owner:倪昕晔

Preparation method of ammonium nitrate fuel oil explosives with different densities, and ammonium nitrate fuel oil explosives with different densities

InactiveCN103193562ASatisfy the demand of detonation speedMeet needsNon-explosive/non-thermic compositionsParticulatesFuel oil

The invention relates to explosives, and especially relates to a preparation method of ammonium nitrate fuel oil explosives with different densities, and ammonium nitrate fuel oil explosives with different densities. According to the invention, density is regulated by adding a particulate physical density regulating agent with particle size of 0.5-5.0mm and a bulk density of 0.03-0.30g / cm<3> during an ammonium nitrate fuel oil explosive preparation process. With the method, the density of porous particulate ammonium nitrate fuel oil explosive can be regulated to 0.3-0.95g / cm<3>, such that a porous particulate ammonium nitrate fuel oil explosive with detonation velocity of 1600-3600m / s can be obtained; or the density of heavy ammonium nitrate fuel oil explosive can be regulated to 0.3-1.25g / cm<3>, such that a heavy ammonium nitrate fuel oil explosive with detonation velocity of 1800-5000m / s can be obtained. Therefore, demands of different lithologies on different explosive detonation velocities can be satisfied, and demands of different blast-holes on different explosives can be satisfied.

Owner:QINGDAO TARGET MINING SERVICES

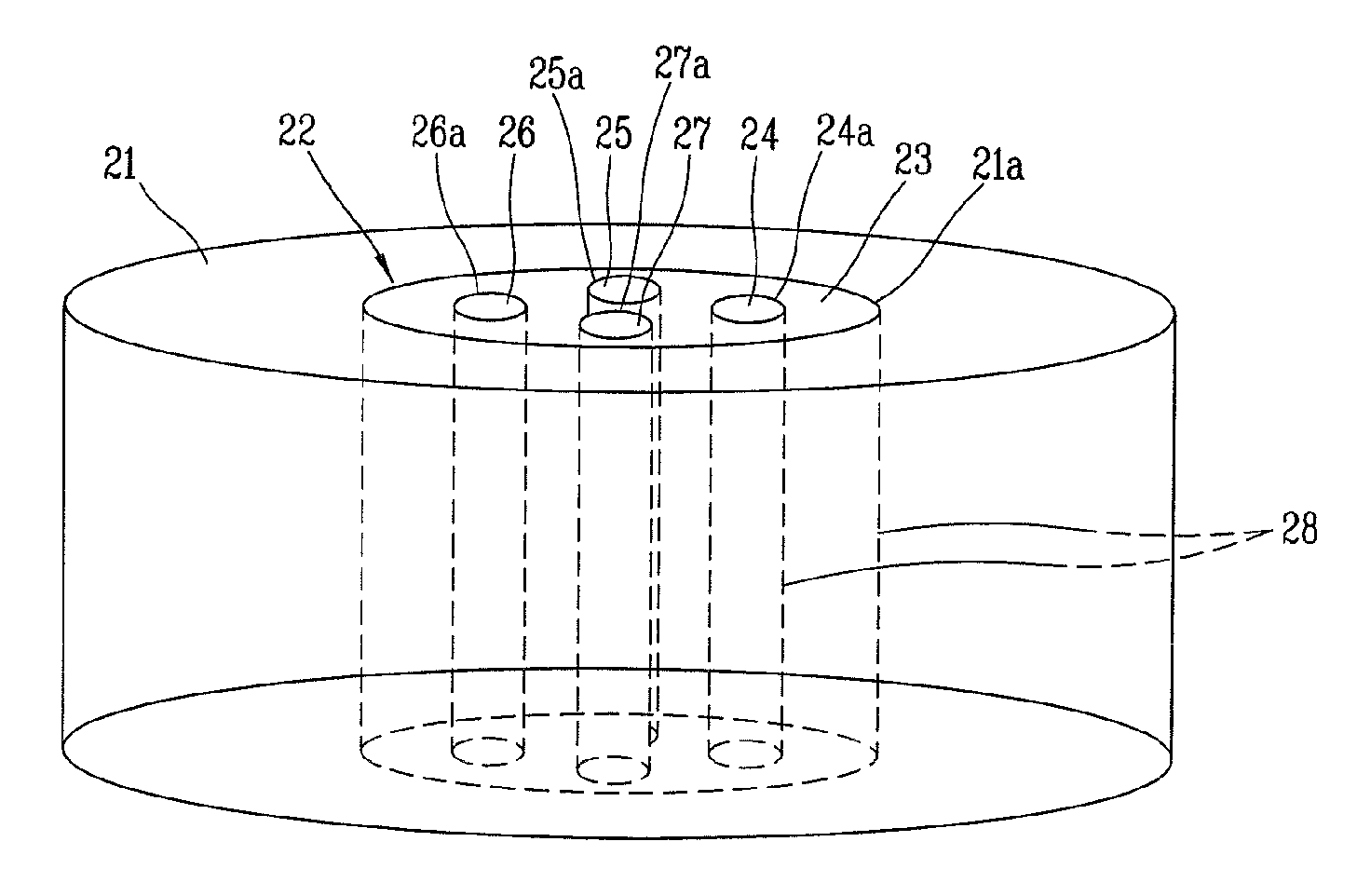

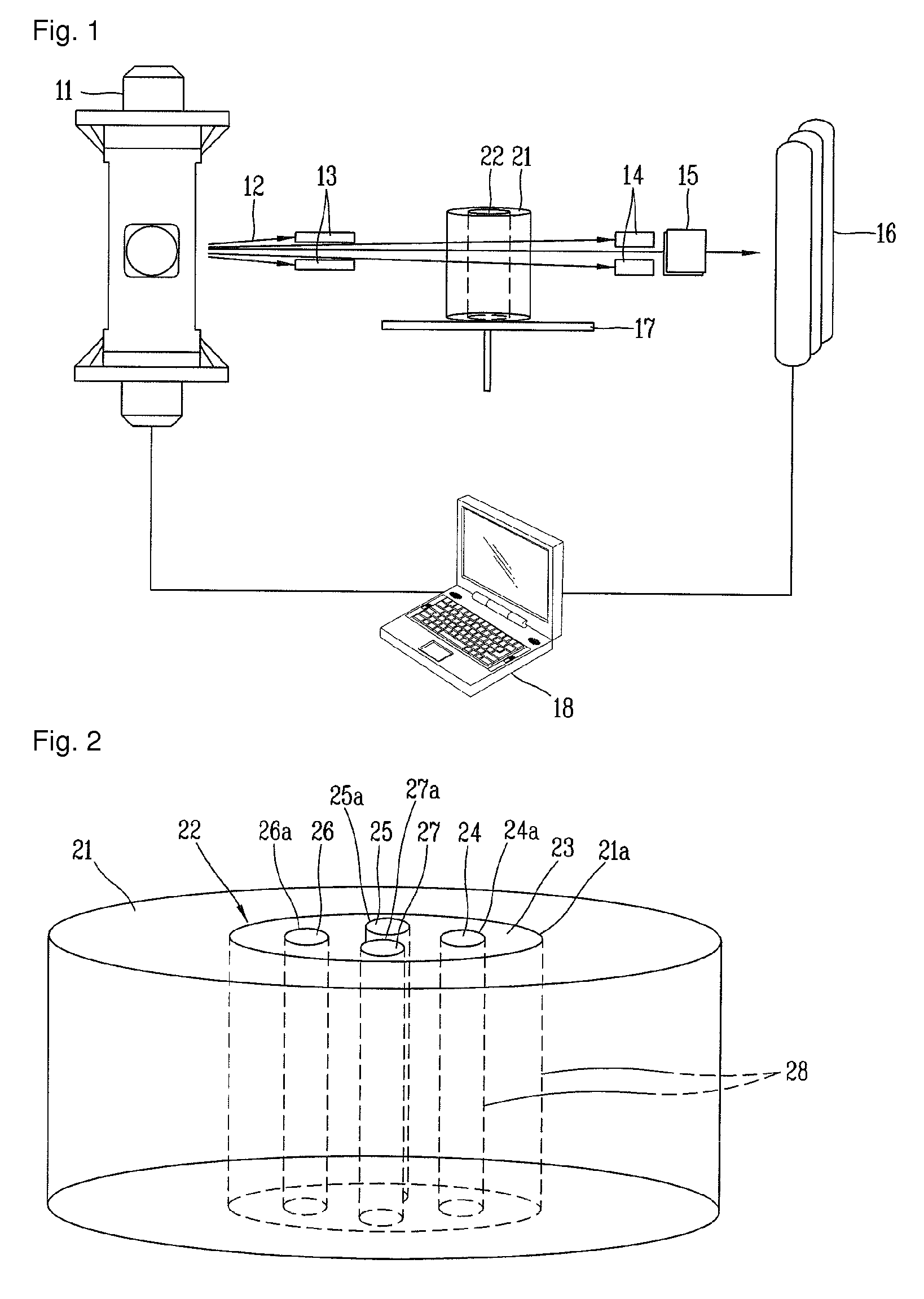

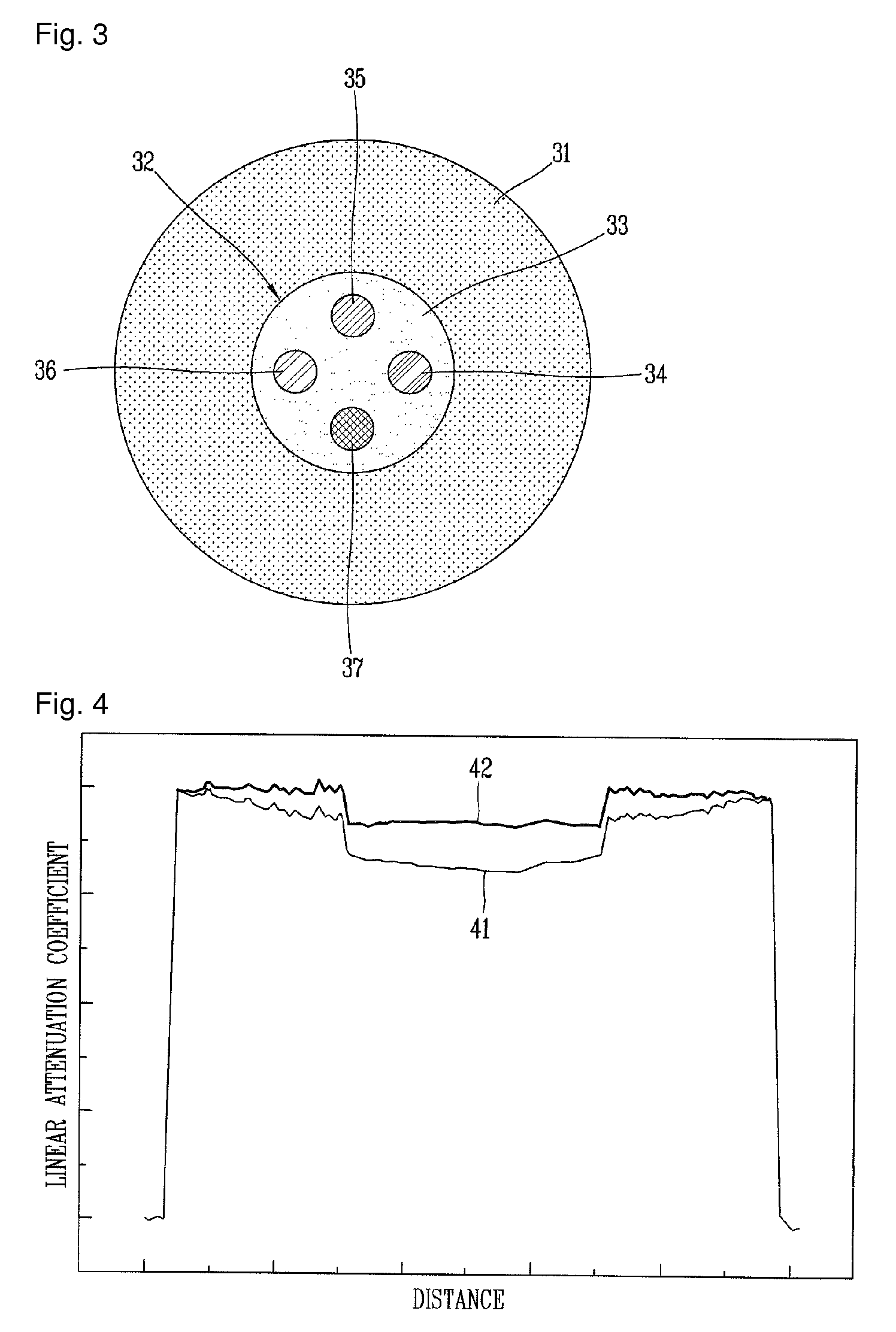

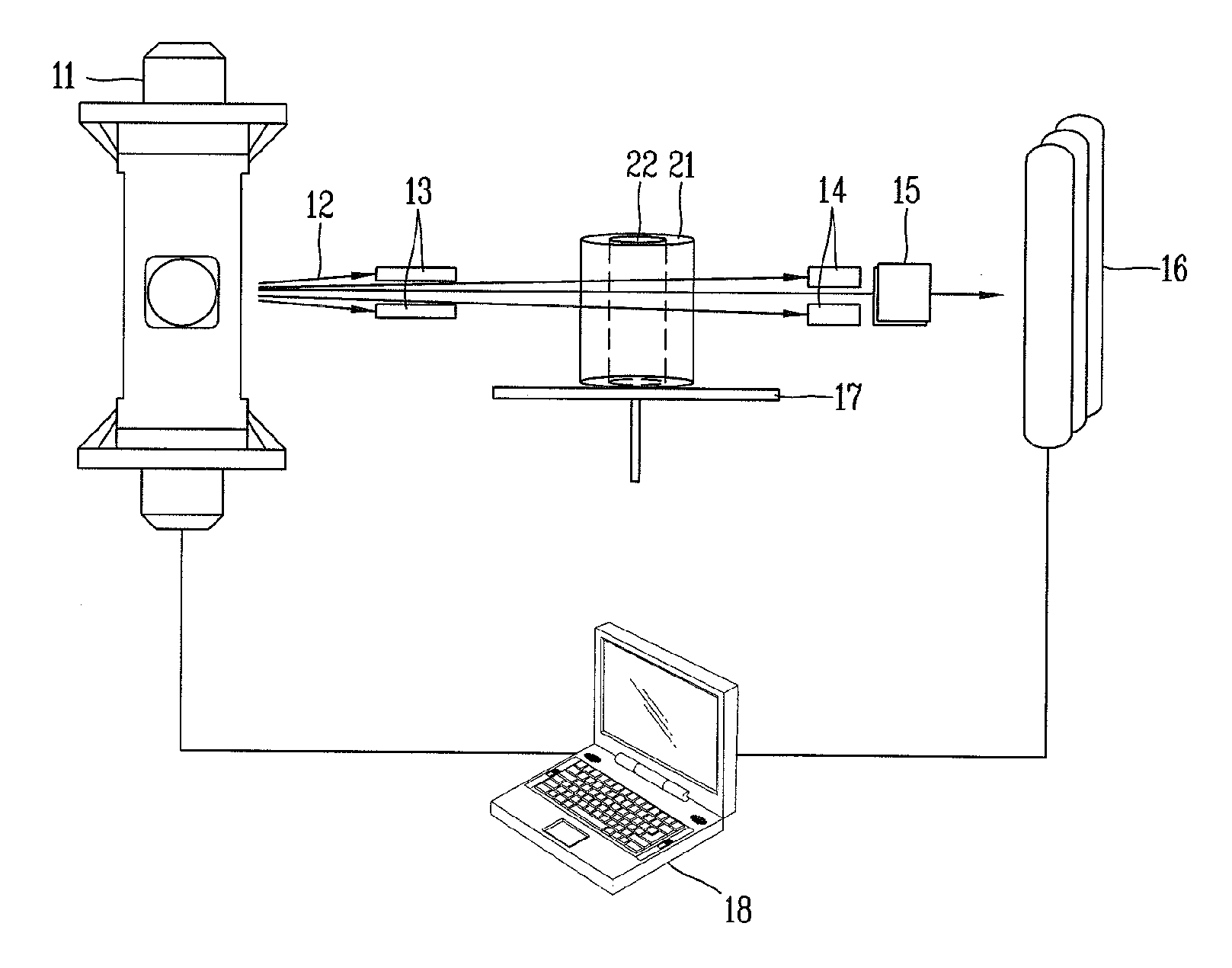

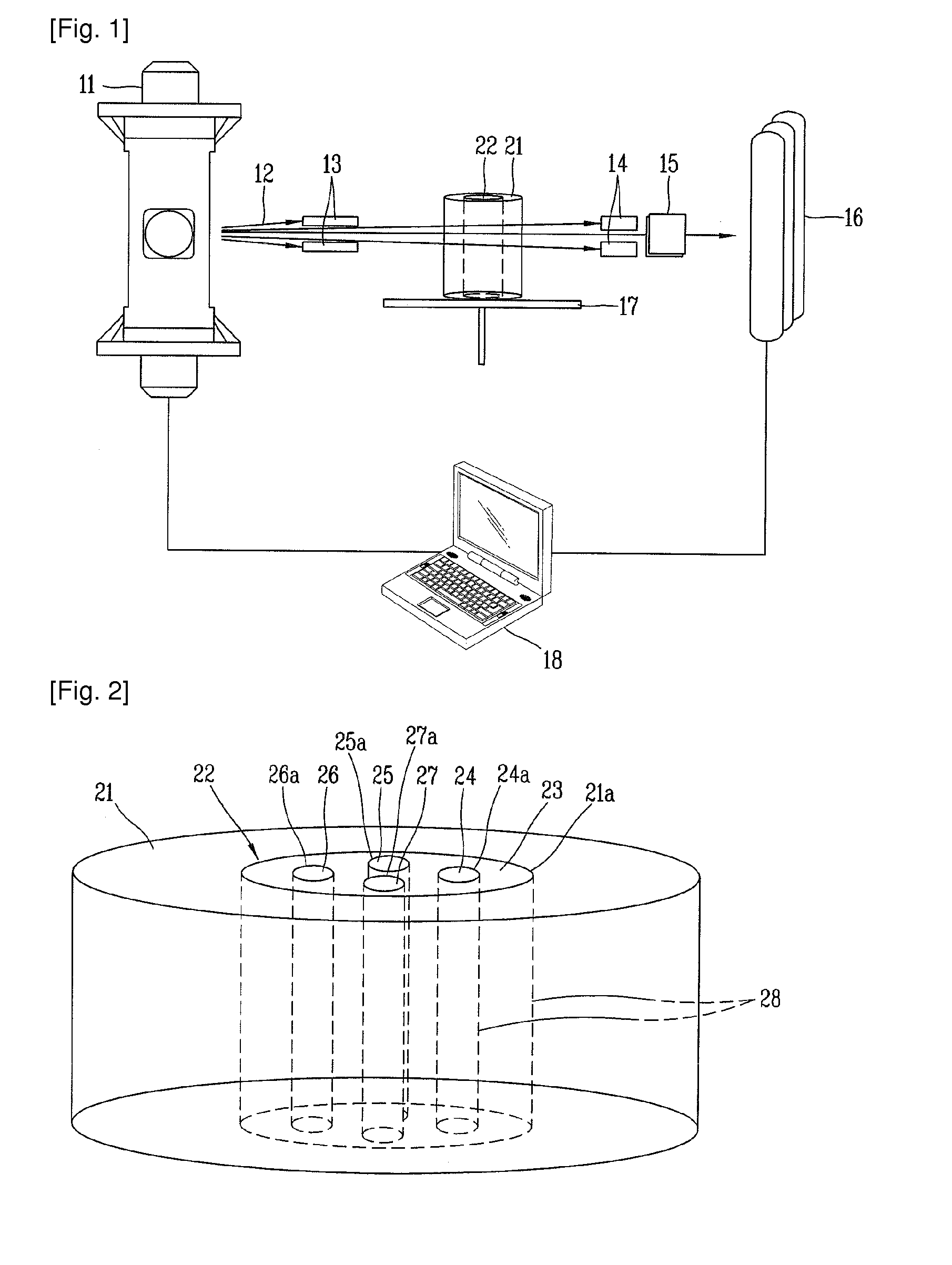

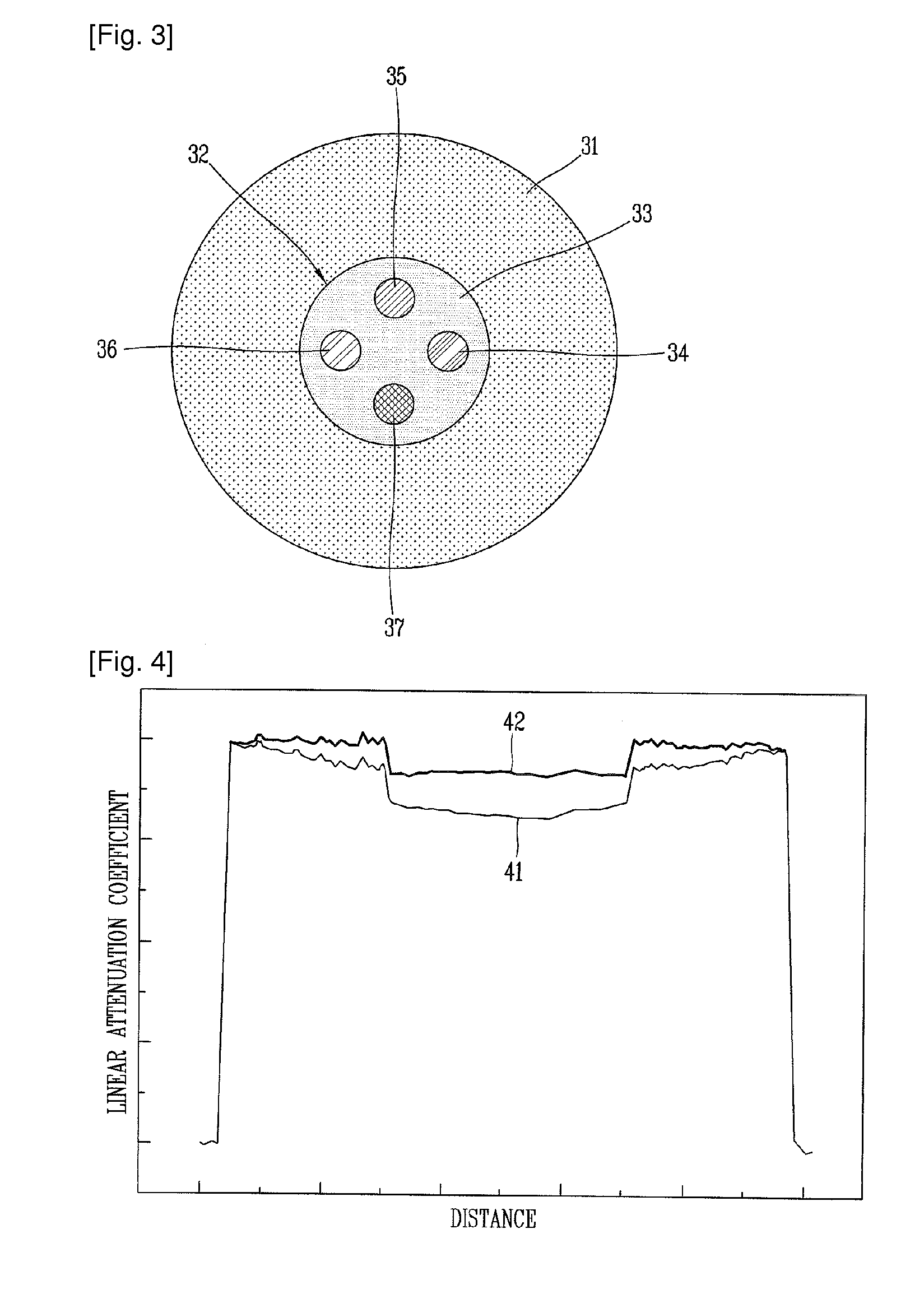

Method for evaluation of density profile in carbon/carbon material and method for production of standard density test block used therein

InactiveUS8989345B2Radiation/particle handlingMetal rolling stand detailsAttenuation coefficientX-ray

Disclosed are a method for evaluating a local density profile in a carbon / carbon material and a method for producing a standard density test block capable of quantitatively evaluating the density profile in the carbon / carbon material, wherein the method for evaluating the density profile includes a first step of preparing a standard density test block to be inserted in the carbon / carbon material, wherein the standard density test block is produced by using the same type of material as the carbon / carbon material and thereafter inserted in the carbon / carbon material, a second step of radiating X-rays onto the carbon / carbon material having the standard density test block inserted so as to obtain and correct computed tomographic image, and a third step of measuring a physical density by use of a linear attenuation coefficient of the computed tomographic image, whereby the local density profile can accurately be evaluated by use of a nondestructive testing and additionally such method can be utilized as an excellent means for improving processes and ensuring quality.

Owner:AGENCY FOR DEFENSE DEV

Multifunctional heavy ammonium nitrate fuel oil explosive mixed loading truck

InactiveCN103196337ARealize the technical purpose of on-site mixingRealize long-distance pumpingBlastingExplosivesNuclear engineeringEmulsion explosive

The invention provides a multifunctional heavy ammonium nitrate fuel oil explosive mixed loading truck which comprises a double-spiral feed system, a plurality of storage bins and a plurality of pipelines; an emulsion matrix, porous granulated ammonium nitrate and a physical density modifier are stored in a main storage bin; a diesel tank, a sensitizing solution tank and a cleaning water tank are designed in an auxiliary material bin; and the technical effect of mixed loading of various blasting explosives can be realized through different combinations of different raw materials in different storage bins, output pipelines and baffle plates. According to the invention, the multifunctional heavy ammonium nitrate fuel oil explosive mixed loading truck has multiple functions and wide applicability, can be used for producing the heavy ammonium nitrate fuel oil explosive, heavy ammonium nitrate fuel oil explosive with adjustable density, porous granulated ammonium nitrate fuel oil explosive, porous granulated ammonium nitrate fuel oil explosive with an adjustable density, heavy emulsion explosive with adjustable density, emulsion explosive with adjustable density, and long-distance delivery emulsion explosive, and meet the requirements of various blasting working environments and different varieties of explosives in one blast hole.

Owner:QINGDAO TARGET MINING SERVICES

Multifunctional explosive mixing and loading truck

InactiveCN103319288AImprove operational reliabilitySimple structureExplosivesEmulsion explosiveEngineering

The invention provides a multifunctional explosive mixing and loading truck which comprises a spiral material delivering system, a plurality of material bins and a plurality of pipelines. Emulsified base, porous granular-form ammonium nitrate or physical density controllers are stored in main material bins. A diesel oil tank, sensitizing solution tanks and a water tank for cleaning are provided in auxiliary material bins. By means of different combinations of different raw materials in the material bins, output pipelines, spirals, partitions and baffles, the truck can achieve the technical effect of mixing a plurality of explosives. The truck provided by the invention is a multi-purpose vehicle with wide applications. The truck can mix and load, on site, multi-density emulsion explosives, heavy emulsion or heavy anfo explosives, fixed-density heavy emulsion or heavy anfo explosives, porous granular anfo explosives, emulsion explosives for long-distance delivery, and negative oxygen balance-based heavy anfo or heavy emulsion explosives; and thus the truck meets the needs of a plurality of blasting operation environments.

Owner:QINGDAO TARGET MINING SERVICES

On-site mixed loading truck for explosives with different detonation velocities

ActiveUS9415360B2Lower performance requirementsHigh high consumptionTank vehiclesMixer accessoriesEmulsion explosiveFuel oil

Provided is a site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities. The vehicle contains a double-helix conveying system, a plurality of storage bins (5-8) and multiple sets of pipelines. Emulsified bases, porous granular ammonium nitrate and physical density modifier are stored in the main material storage bins, an adjuvant storage bin is provided with a diesel tank (4, 31), a sensitizing solution tank (40) and a washing water tank (11), and the technical effect that multiple kinds of explosives with different detonation velocities are mixed and loaded can be realized by using the different combinations of the different raw materials of the storage bins and various output pipelines and some baffle plates. The vehicle has the advantages of multiple purposes, capability of producing heavy emulsion explosive, density-modifiable heavy emulsion explosive, low density emulsion explosive, ultra-low density emulsion explosive, heavy ammonium nitrate fuel oil explosive, density-modifiable ammonium nitrate fuel oil explosive, porous granular ammonium nitrate fuel oil explosive, density-modifiable porous granular ammonium nitrate fuel oil explosive, and minor-diameter and long-distance conveying emulsion explosive, and applicability to the needs of various blasting operation environments and loading different kinds of explosives in the same blast hole.

Owner:QINGDAO TARGET MINING SERVICES

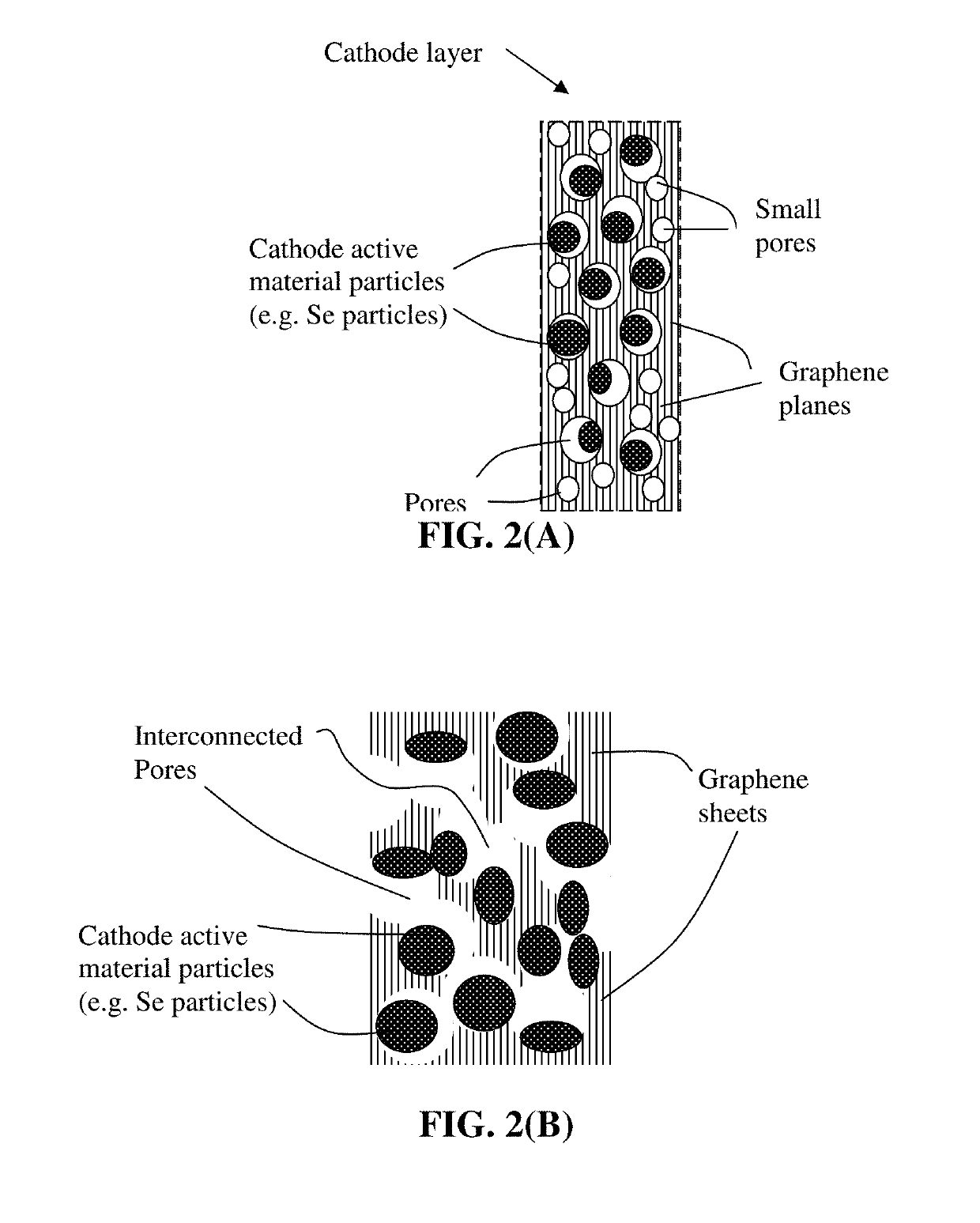

Production process for a graphene foam-protected selenium cathode and an alkali metal-selenium secondary battery containing same

PendingUS20190312261A1Shuttle effectEvenly dispersedElectrode thermal treatmentElectrode carriers/collectorsIodideCell wall

A process for producing a graphene foam-protected selenium cathode layer, the process comprising: (A) preparing a layer of solid graphene foam having pores (or cells) and pore / cell walls containing graphene sheets and having a physical density from 0.001 g / cm3 to 1.5 g / cm3; and (B) infiltrating or impregnating selenium into the pores to obtain the graphene foam-protected selenium cathode layer; wherein the graphene sheets are selected from a pristine graphene or a non-pristine graphene material, having a content of non-carbon elements greater than 2% by weight, selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, chemically functionalized graphene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

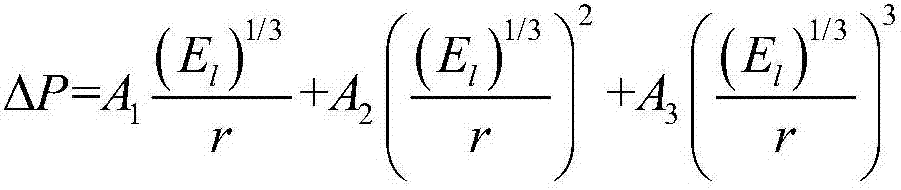

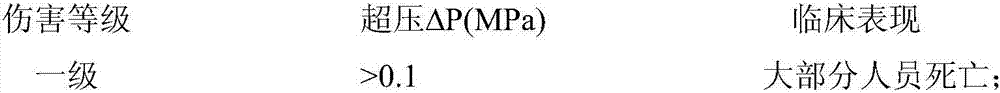

Method for estimating damage scope of physical explosion of natural gas pipeline for human body

ActiveCN107273696AAdaptableInformaticsSpecial data processing applicationsShock wave attenuationEstimation methods

The invention relates to a method for estimating a damage scope of physical explosion of a natural gas pipeline for a human body. The method provides a linear physical explosion energy concept of a high-pressure natural gas in the pipeline, an isentropic expansion principle based linear physical density energy estimation method, a natural gas pipeline physical explosion shock wave attenuation law, a peak value overpressure estimation method, and a grade division method for damage degrees of the physical explosion shock waves of the natural gas pipeline to surrounding personnel. Grade division of the damage degrees of the physical explosion shock waves of the natural gas pipeline to the personnel and the damage scope determined according to the grade division are determined according to parameters which are estimated by the method. The method for estimating the damage scope of the physical explosion of the natural gas pipeline for the human body is safe, reliable, strong in applicability and easy to use, and can realize estimation of the damage scope of the natural gas pipeline physical explosion shock waves to the personnel along the whole pipeline.

Owner:PETROCHINA WEST PIPELINE CO +1

Preparation method of emulsion explosives with different densities, and emulsion explosives with different densities

ActiveCN103193564AMeet needsReduce unit consumptionNon-explosive/non-thermic compositionsLithologyEmulsion explosive

The invention relates to explosives, and especially relates to a preparation method of emulsion explosives with different densities, and emulsion explosives with different densities. According to the emulsion explosive preparation method provided by the invention, a sensitizing solution is added into an emulsion substrate, and density is regulated by adding a physical density regulating agent. The physical density regulating agent is a lightweight insensitive particulate substance with a particle size of 0.5-5mm and preferably 2-4mm, and a bulk density of 0.03-0.30g / cm<3> and preferably 0.1-0.2g / cm<3>. With the emulsion explosive preparation method provided by the invention, emulsion explosive with density of 0.3-1.25g / cm<3> and detonation velocity of 1800-5500m / s can be obtained, such that demands of different lithologies on explosives with different detonation velocities can be satisfied. Also, the emulsion explosive is provided with certain waterproof and moisture-proof performances, such that remands of same water-containing blast-holes on different explosives can be satisfied.

Owner:QINGDAO TARGET MINING SERVICES

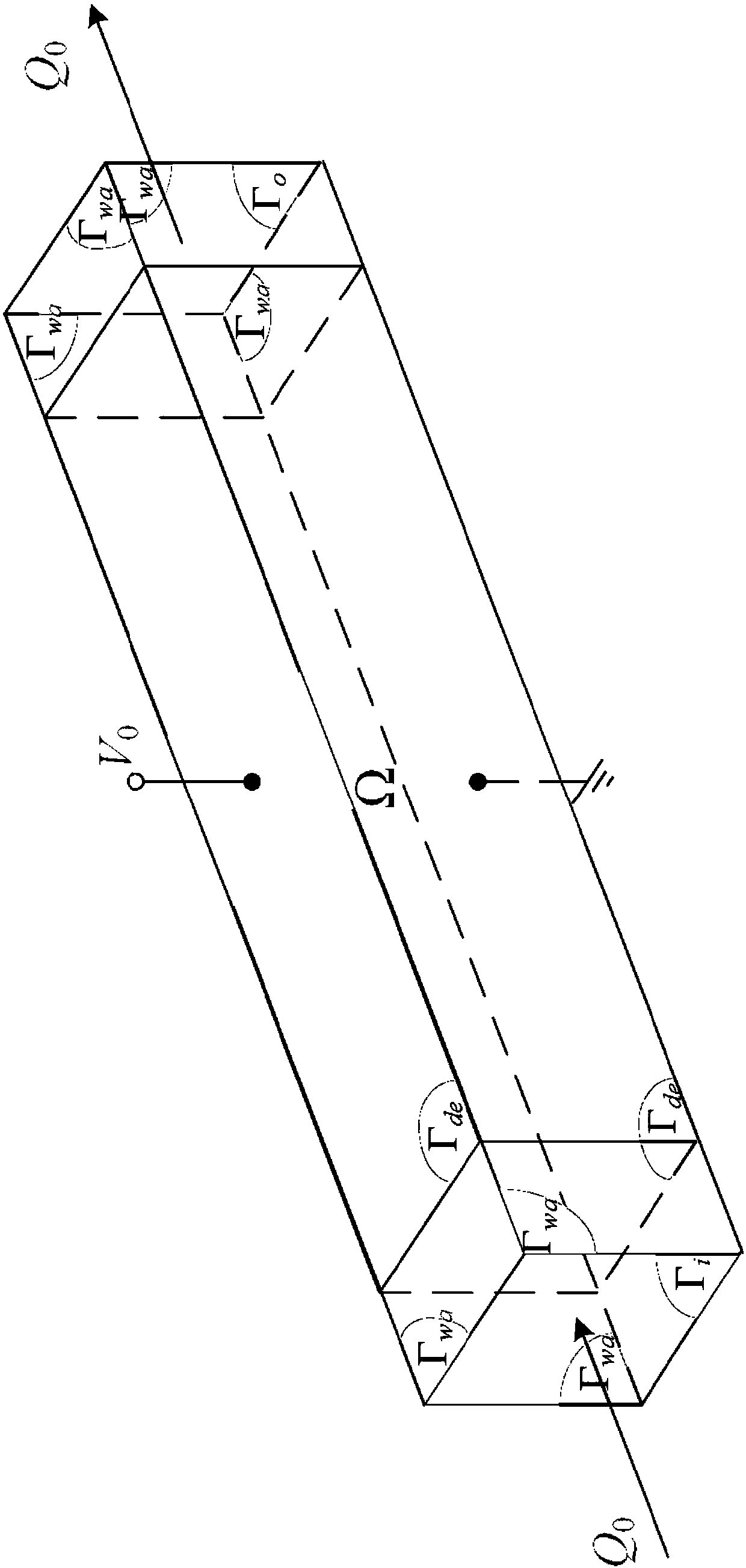

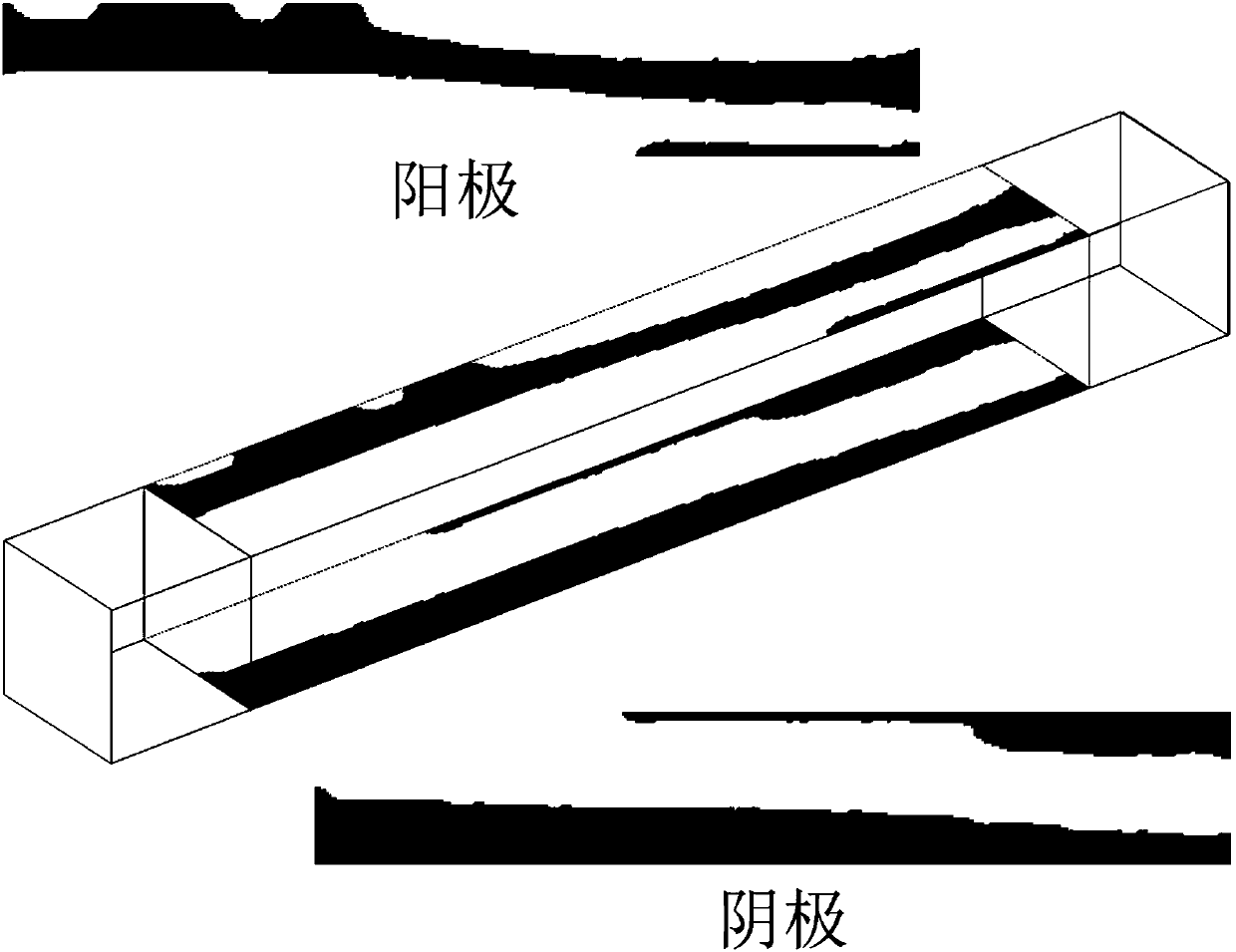

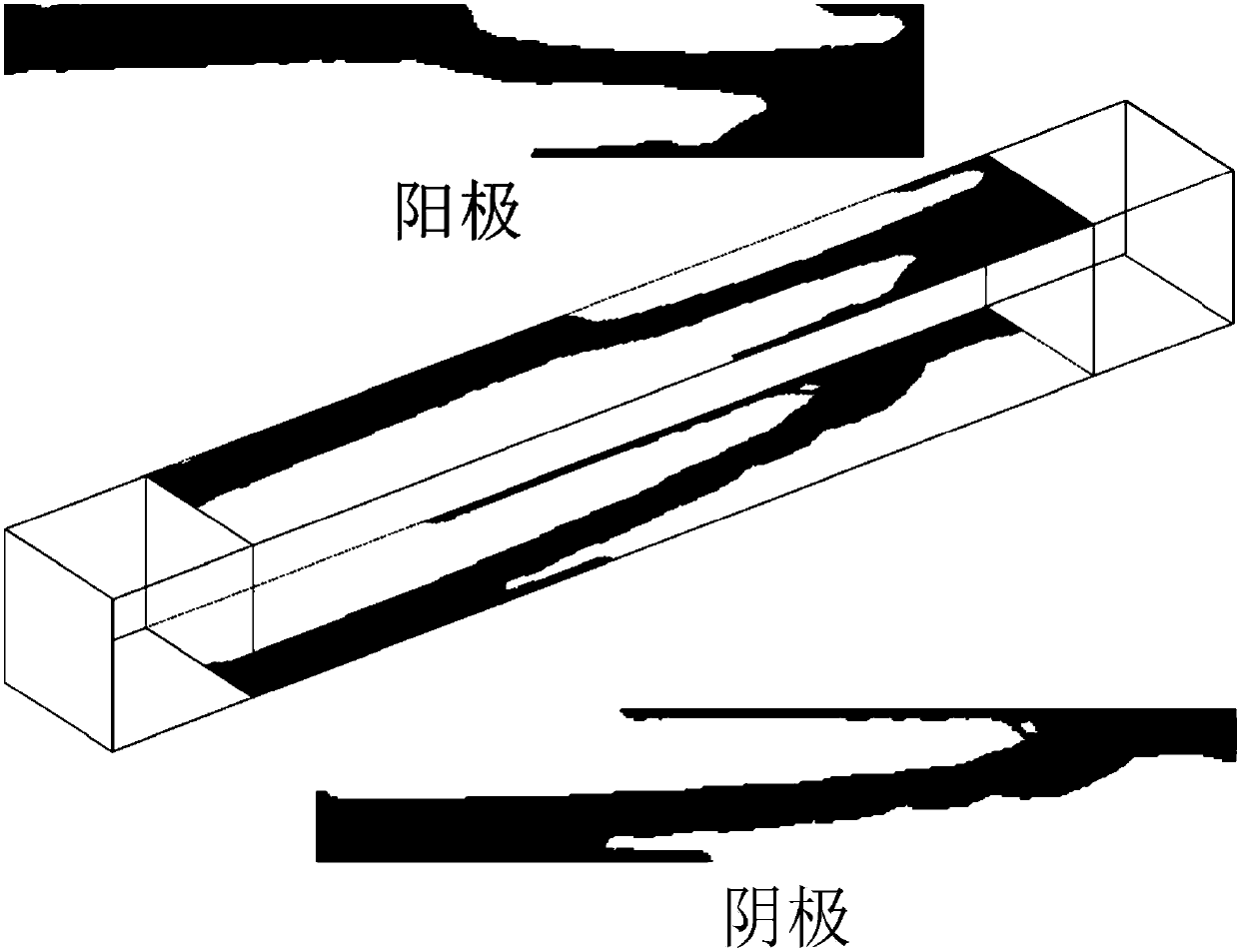

Inverse design method for electroosmosis microfluid electrode layout

InactiveCN107832531AReverse designOvercoming limitations in electrode designSpecial data processing applicationsElectricityElectrical field strength

The invention discloses an inverse design method for an electroosmosis microfluid electrode layout. The method comprises the following steps: step S1, in continuous medium hypothesis, using a Navier-Stokes equation to describe microfluid movement; step S2, based on that a Helmholtz-Smoluchowski theory is suitable for an electroosmosis microchannel inner wall, obtaining that slip velocity being indirect proportion to a tangential component of electric field intensity caused by an electrode; step S3, introducing a defected boundary condition on an entrance of the electroosmosis microfluid; stepS4, a side wall boundary [tau]w being divided into two parts, [tau]wa and [tau]de, a boundary condition of the[tau]de being interpolation of electric insulation and potential; step S5, using Helmholtz to filter a design variable, to control a feature size of a layout; step S6, using a threshold method to project the filtered design variable, eliminating values between 0 and 1, and deriving a physical density variable; step S7, through solving a variational problem, obtaining 0-1 distribution of physical density, to obtain an electrode layout on the boundary [tau]de. The method overcomes limitation on existing electrode design, and has universality and flexibility.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Large-grain graphene thin film current collector and secondary batteries containing same

A unitary graphene-based current collector in a battery or capacitor. The current collector is or contains a unitary graphene layer that is composed of closely packed and chemically bonded parallel graphene planes having an inter-graphene plane spacing of 0.335 to 0.40 nm and an oxygen content less than 5% by weight (more typically 0.001% to 1%), an average grain size larger than 5 μm (more typically >100 μm; some as large as >cm), a physical density higher than 1.8 g / cm3, and is obtained from heat-treating a graphene oxide gel at a temperature higher than 100° C. (typically and preferably from 1,000 to 3,000° C.). Such an integrated or unitary graphene entity is compatible with essentially all electrolytes commonly used in batteries and supercapacitors.

Owner:GLOBAL GRAPHENE GRP INC

Supercapacitor having a highly conductive graphene foam electrode

InactiveCN108604485AIncrease contactImprove conductivityNon-insulated conductorsHybrid capacitor electrodesIodideFunctionalized graphene

A supercapacitor electrode comprising a solid graphene foam impregnated with a liquid or gel electrolyte, wherein the solid graphene foam is composed of multiple pores and pore walls, wherein pore walls contain a pristine graphene material having essentially zero % of non-carbon elements, or a non-pristine graphene material having 0.001% to 5% by weight of non-carbon elements wherein non-pristinegraphene is selected from graphene oxide, reduced graphene oxide, graphene fluoride, graphene chloride, graphene bromide, graphene iodide, hydrogenated graphene, nitrogenated graphene, chemically functionalized graphene, or a combination thereof, and the solid graphene foam, when measured in a dried state without electrolyte, has a physical density from 0.01 to 1.7 g / cm3, a specific surface area from 50 to 3,200 m2 / g, a thermal conductivity of at least 200 W / mK per unit of specific gravity, and / or an electrical conductivity no less than 2,000 S / cm per unit of specific gravity.

Owner:NANOTEK INSTR

Supercapacitor having highly conductive graphene foam electrode

ActiveUS9966199B2Easy to mergeImprove directionLiquid electrolytic capacitorsHybrid capacitor electrodesIodideMaterials science

Owner:NANOTEK INSTR GRP LLC

Supercapacitor electrode having highly oriented and closely packed graphene sheets and production process

ActiveUS9847184B2Reduce thicknessImprove directionHybrid capacitor separatorsLamination ancillary operationsSupercapacitorMass loading

Owner:NANOTEK INSTR GRP LLC

Preparation method of explosives with differrnt densities and explosives with different density

InactiveUS20150013858A1Save consumptionImprove blasting effectNon-explosive/non-thermic compositionsLithologyExplosive material

Disclosed are explosives, especially a preparation method for explosives of different densities and explosives of different densities. The method adjusts physical density by adding granular form physical density adjusting agent with 0.5-5.0 mm grain diameter and 0.03-0.30 g / cm3 bulk density when preparing explosives. The method can adjust the explosive's density within a large range to produce the explosives with a wide range of detonation velocity to meet different needs for explosive velocity according to different lithology, and simultaneously meet needs for different explosives in the same blasthole.

Owner:QINGDAO TARGET MINING SERVICES

Fabric of continuous graphene fiber yarns from functionalized graphene sheets

ActiveUS20190352805A1High degreeSmooth connectionGrapheneCellulose/protein filament chemical after-treatmentCvd graphenePhysical density

Provided is a fabric comprising a layer of yarns combined (by weaving, braiding, knitting, or non-woven) to form the fabric wherein the yarns comprise one or a plurality of graphene-based long or continuous fibers. The long or continuous fiber comprises chemically functionalized graphene sheets that are chemically bonded with one another having an inter-planar spacing d002 from 0.36 nm to 1.5 nm as determined by X-ray diffraction and a non-carbon element content of 0.1% to 40% by weight, wherein the functionalized graphene sheets are substantially parallel to one another and parallel to the fiber axis direction and the fiber contains no core-shell structure, have no helically arranged graphene domains, and have a length no less than 0.5 cm and a physical density from 1.5 to 2.25 g / cm3. The graphene fiber typically has a thermal conductivity from 300 to 1,600 W / mK, an electrical conductivity from 600 to 15,000 S / cm, or a tensile strength higher than 1.0 GPa.

Owner:GLOBAL GRAPHENE GRP INC

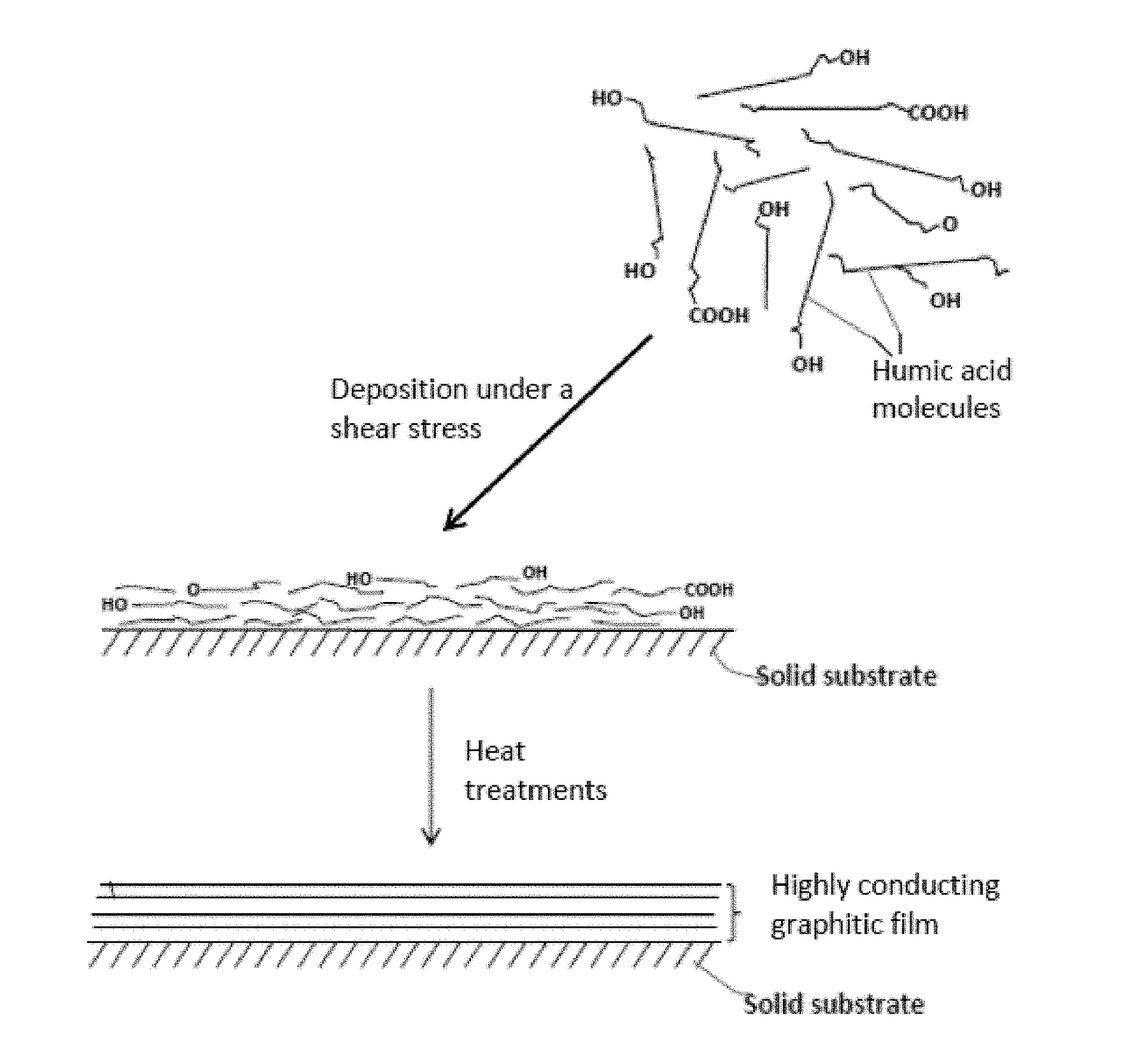

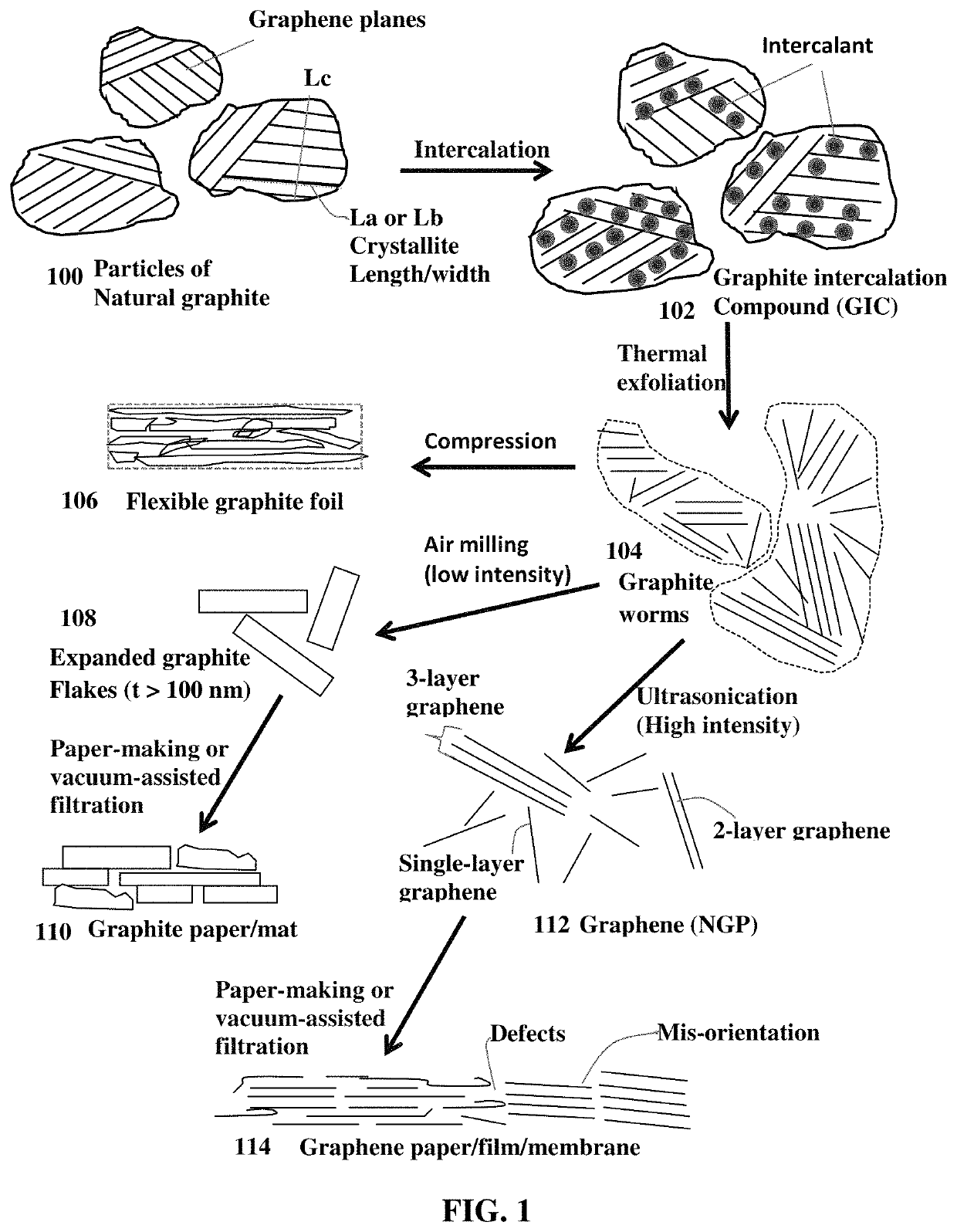

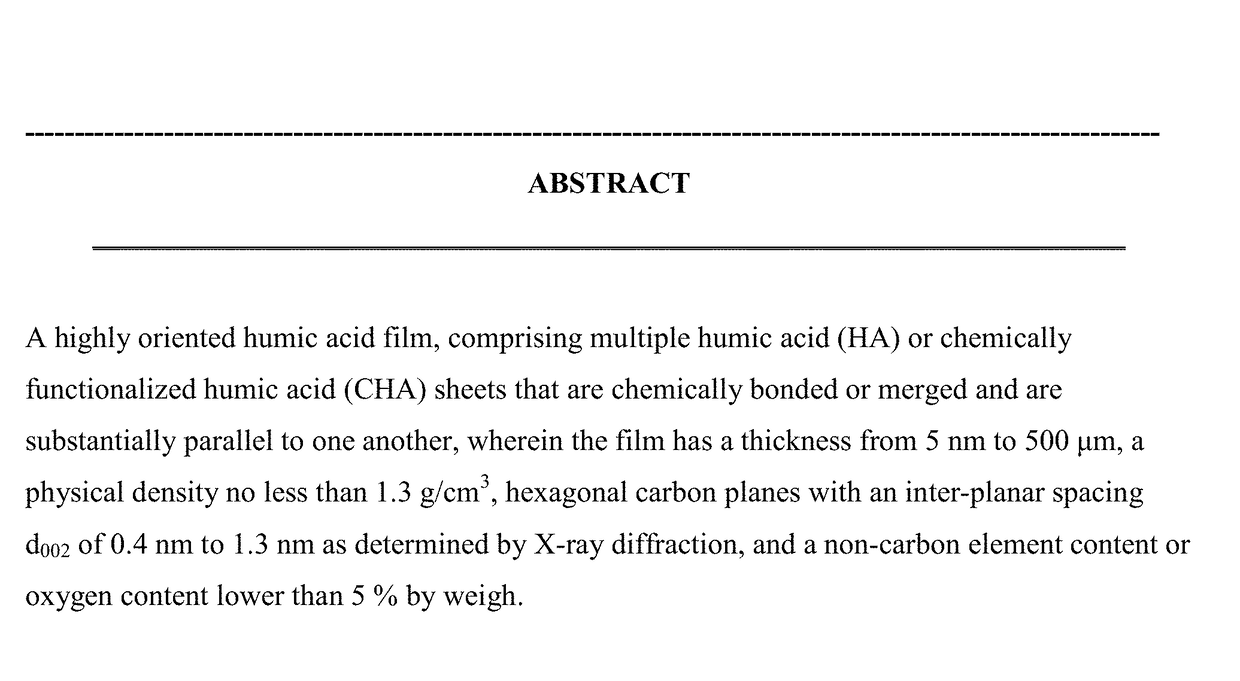

Highly Oriented Humic Acid Films and Highly Conducting Graphitic Films Derived Therefrom and Devices Containing Same

A highly oriented humic acid film, comprising multiple humic acid (HA) or chemically functionalized humic acid (CHA) sheets that are chemically bonded or merged and are substantially parallel to one another, wherein the film has a thickness from 5 nm to 500 μm, a physical density no less than 1.3 g / cm3, hexagonal carbon planes with an inter-planar spacing d002 of 0.4 nm to 1.3 nm as determined by X-ray diffraction, and a non-carbon element content or oxygen content lower than 5% by weigh.

Owner:GLOBAL GRAPHENE GRP INC

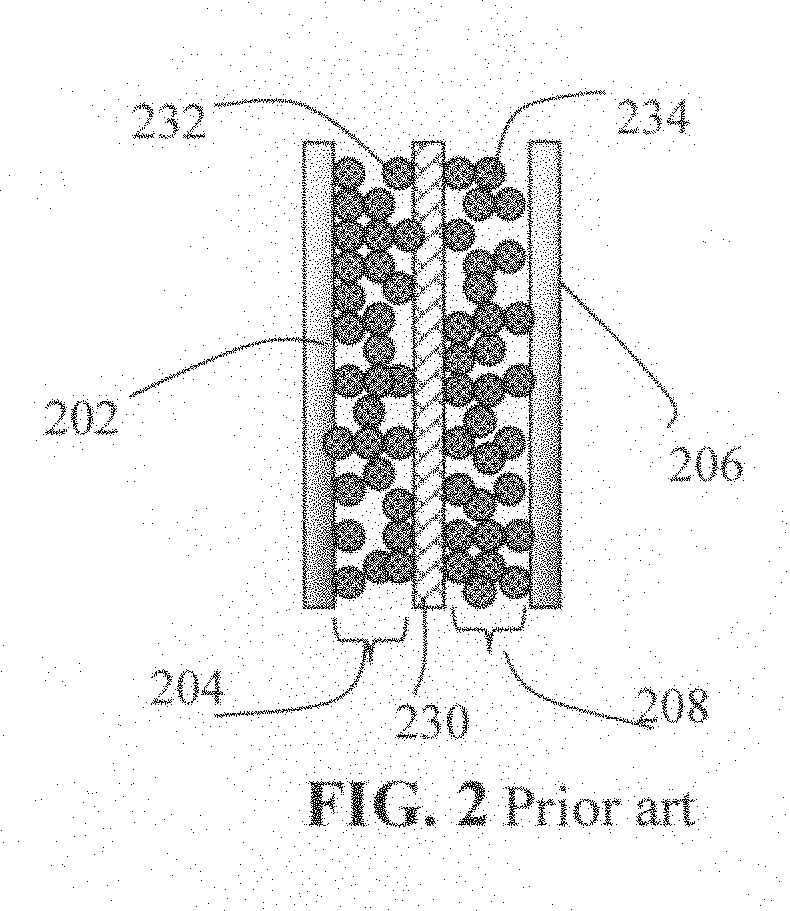

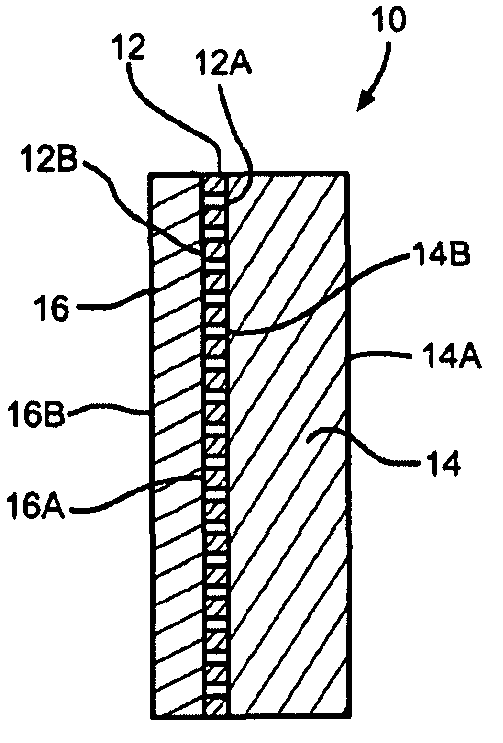

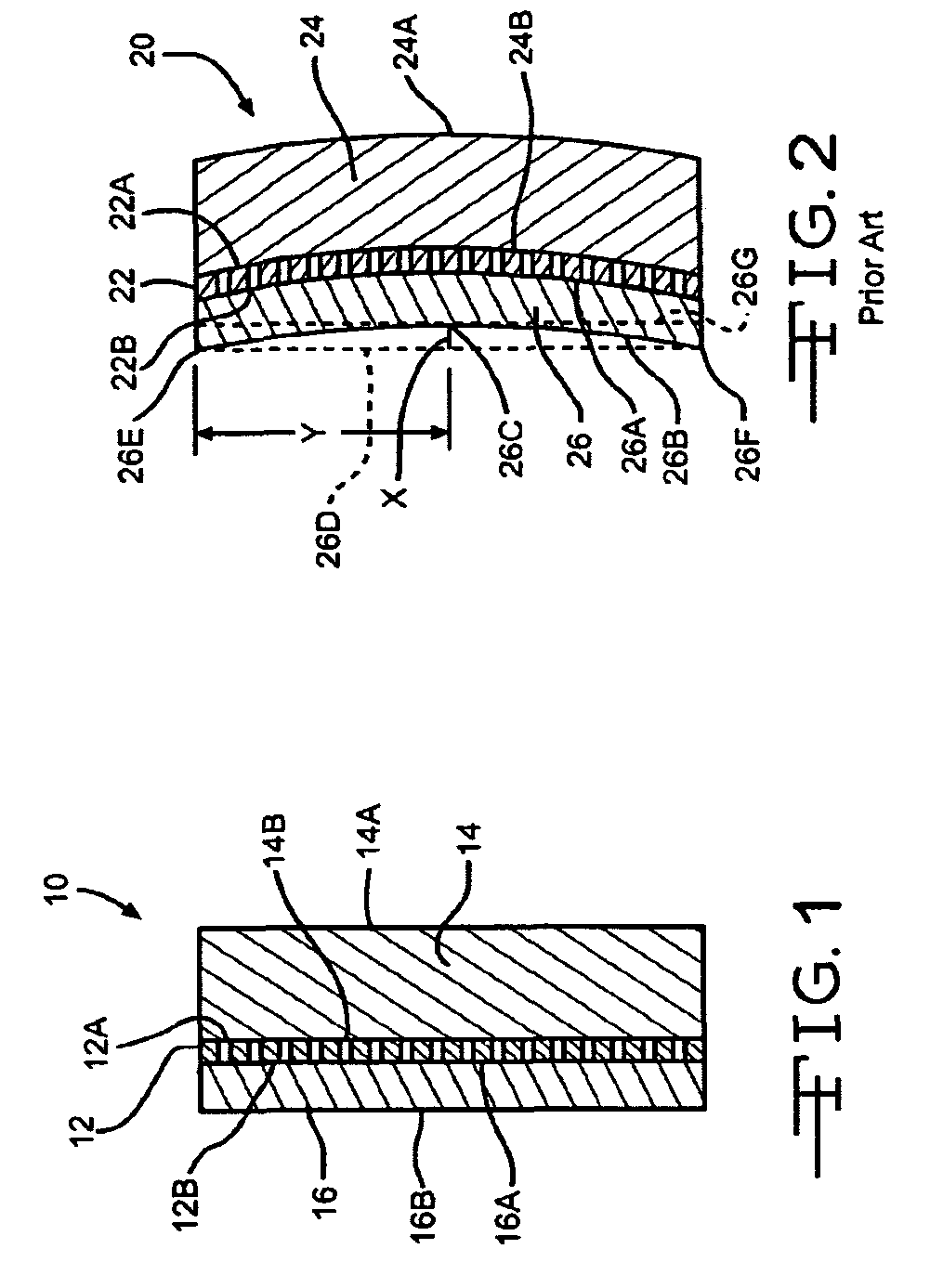

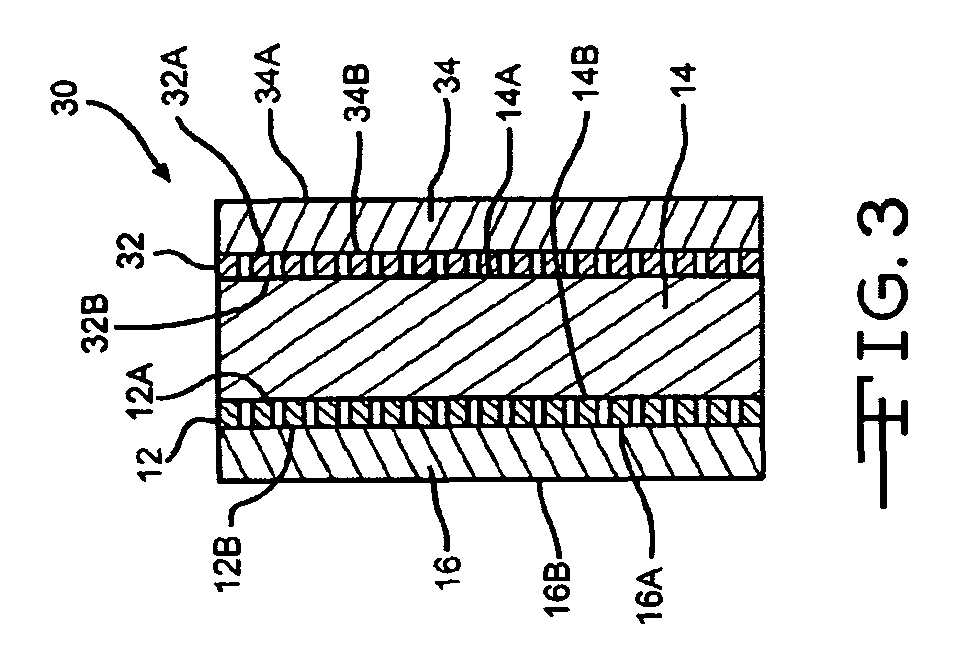

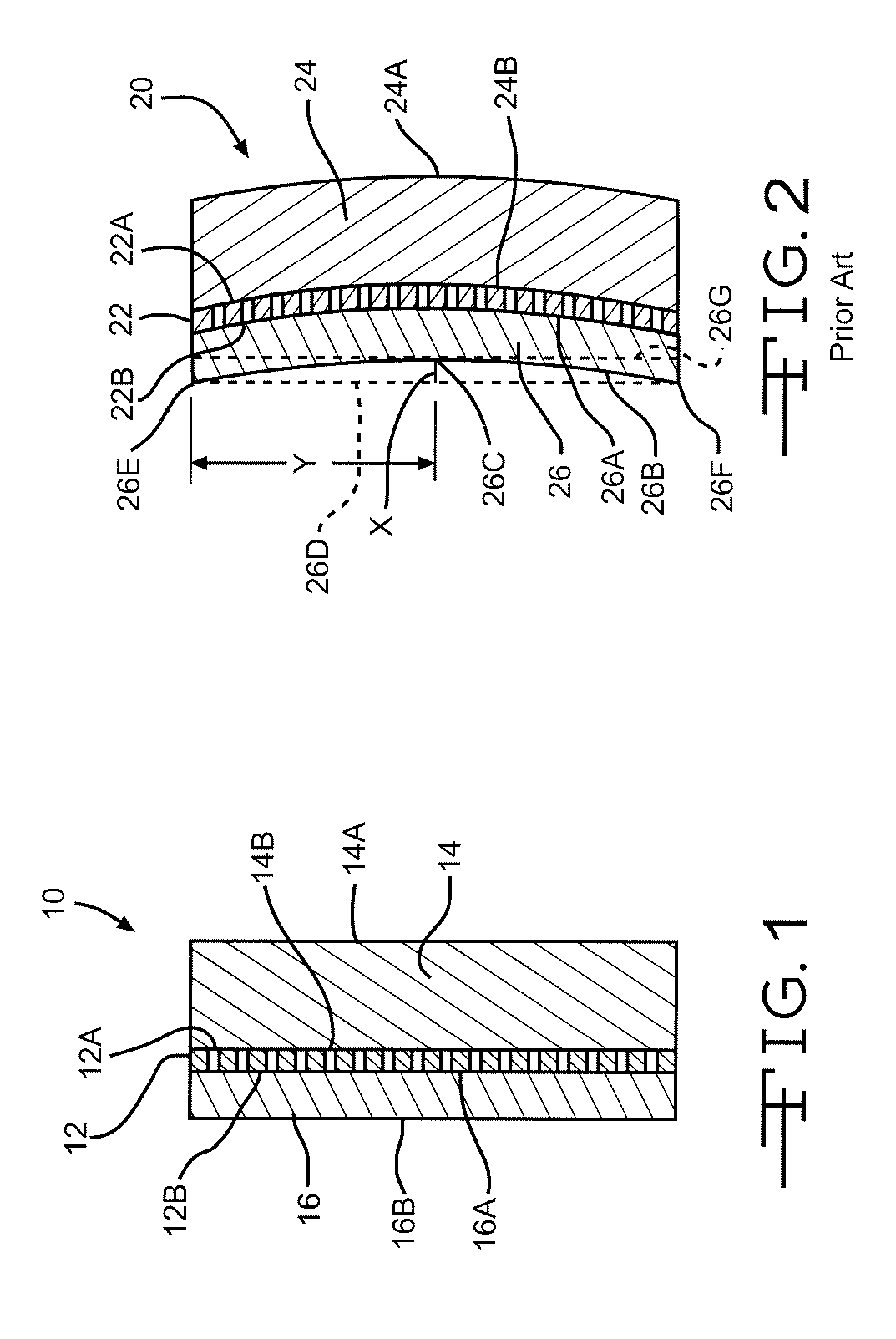

Method of using cyclic pressure to increase the planarity of SVO/current collector/CFX electrodes for use in lithium electrochemical cells

InactiveUS7771497B1Improve electrochemical performanceIncrease energy densityFinal product manufacturePrimary cellsLithiumEngineering

The traditional method of building a CFx / current collector / SVO assembly is by the application of a static pressing force. However, the density of the electrode and, particularly the CFx component, can be increase by using a cyclic pressing protocol. That is where the active materials are formed into a blank or contacted to a current collector by the use of at least two pressing events separated by a period when the pressure is removed. Not only does this cyclic pressing protocol increase the density of the CFx material, it also provides an electrode that is relatively flat, and not cupped. Conventional pressing techniques often result in badly cupped electrodes, especially when disparate active materials are contacting opposite sides of the current collector. Cupping consequently reduces the effective volumetric energy density of the electrode or necessitates the addition of a process step of flattening of the cathode, if at all possible. According to the new cyclic pressing protocol, the physical density of the cathode is increased and electrode cupping is effectively eliminated.

Owner:GREATBATCH INC

Method for making flat and high-density cathode for use in electrochemical cells

ActiveUS8241788B1Improve electrochemical performanceImprove flatnessFinal product manufactureElectrode carriers/collectorsHigh densityEngineering

The traditional method of pressing CFx, screen and SVO sheet assembly results in an electrode that is cupped and not flat. This results in the reduction of the effective volumetric energy density of the electrode or the addition of a process step of flattening of the cathode if at all possible. The new method of assembly effectively eliminates the cupping behavior and produces a flat electrode. In addition, the physical density of the cathode is also increased.

Owner:WILSON GREATBATCH LTD

Supercapacitor electrode having highly oriented and closely packed expanded graphite flakes and production process

ActiveUS10157714B1Reduce thicknessImprove directionHybrid capacitor separatorsHybrid capacitor electrolytesMass loadingSupercapacitor

Provided is a process for producing a supercapacitor electrode, comprising: (a) preparing a deformable mass of multiple flakes of exfoliated graphite worms or expanded graphite dispersed in or impregnated by a liquid or gel electrolyte; and (b) subjecting the deformable mass to a forced assembling and orientating procedure, forcing the deformable mass to form the electrode, wherein these fakes are spaced by thin electrolyte layers, having an electrolyte layer thickness from 0.4 nm to 10 nm, and the flakes are substantially aligned along a desired direction, and wherein the electrode has a physical density from 0.5 to 1.7 g / cm3 and a specific surface area from 50 to 3,300 m2 / g, when measured in a dried state of the flakes without the electrolyte. This process leads to a supercapacitor having a large electrode thickness, high active mass loading, high tap density, and exceptional energy density.

Owner:NANOTEK INSTR GRP LLC

Method for evaluation of density profile in carbon/carbon material and method for production of standard density test block used therein

InactiveUS20130003917A1Eliminating air spaceSamplingRadiation/particle handlingNon destructiveAttenuation coefficient

Disclosed are a method for evaluating a local density profile in a carbon / carbon material and a method for producing a standard density test block capable of quantitatively evaluating the density profile in the carbon / carbon material, wherein the method for evaluating the density profile includes a first step of preparing a standard density test block to be inserted in the carbon / carbon material, wherein the standard density test block is produced by using the same type of material as the carbon / carbon material and thereafter inserted in the carbon / carbon material, a second step of radiating X-rays onto the carbon / carbon material having the standard density test block inserted so as to obtain and correct computed tomographic image, and a third step of measuring a physical density by use of a linear attenuation coefficient of the computed tomographic image, whereby the local density profile can accurately be evaluated by use of a nondestructive testing and additionally such method can be utilized as an excellent means for improving processes and ensuring quality.

Owner:AGENCY FOR DEFENSE DEV

Flat and high-density cathodes for use in electrochemical cells

InactiveUS9231256B2Improve electrochemical performanceImprove flatnessElectrode manufacturing processesFinal product manufactureHigh densityEngineering

The traditional method of pressing CFx, screen and SVO sheet assembly results in an electrode that is cupped and not flat. This results in the reduction of the effective volumetric energy density of the electrode or the addition of a process step of flattening of the cathode if at all possible. The new method of assembly effectively eliminates the cupping behavior and produces a flat electrode. In addition, the physical density of the cathode is also increased.

Owner:WILSON GREATBATCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com