Inverse design method for electroosmosis microfluid electrode layout

A design method and microfluidic technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve problems such as low design efficiency, lack of universality, flexibility, and electrode layout design limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in more detail below in conjunction with the drawings and embodiments.

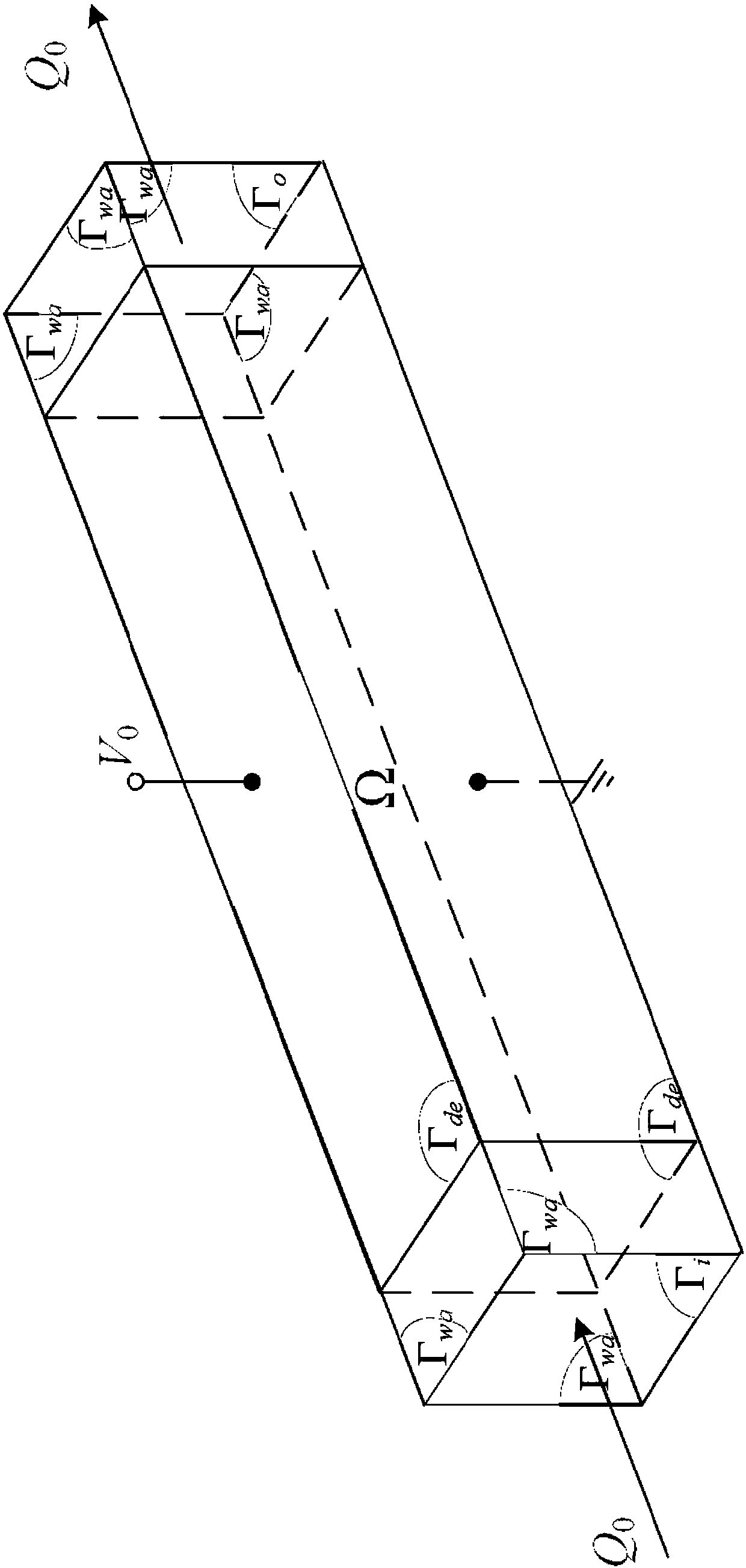

[0062] The invention discloses an inverse design method of electroosmotic microfluid electrode layout, please refer to figure 1 , Which includes the following steps:

[0063] Step S1, under the assumption of continuum, use Navier-Stokes equation to describe microfluid motion:

[0064]

[0065] In the formula, u is the fluid velocity, p is the fluid pressure, ρ is the density of the electrolyte solution, η is the dynamic viscosity of the electrolyte solution, Ω is the calculation area, and the inlet boundary is Γ i , The sidewall boundary is Γ w , The exit boundary is Γ o , And meet

[0066] Step S2, under the assumption that the thickness of the Debye layer is much smaller than the characteristic scale of the microfluid, according to the Helmholtz-Smoluchowski theory applied to the inner wall of the electroosmotic microchannel, it is concluded that the slip velocity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com