Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

264results about "Ohmic-resistance heating circuits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

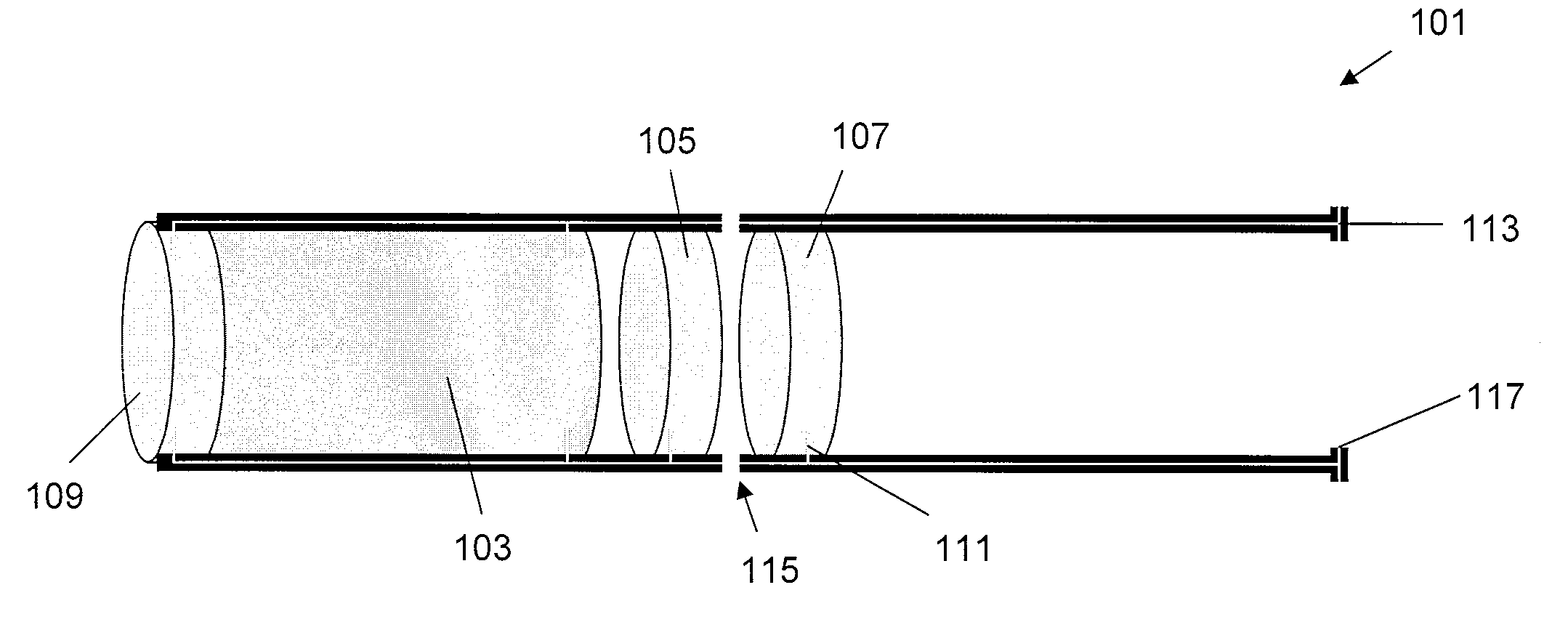

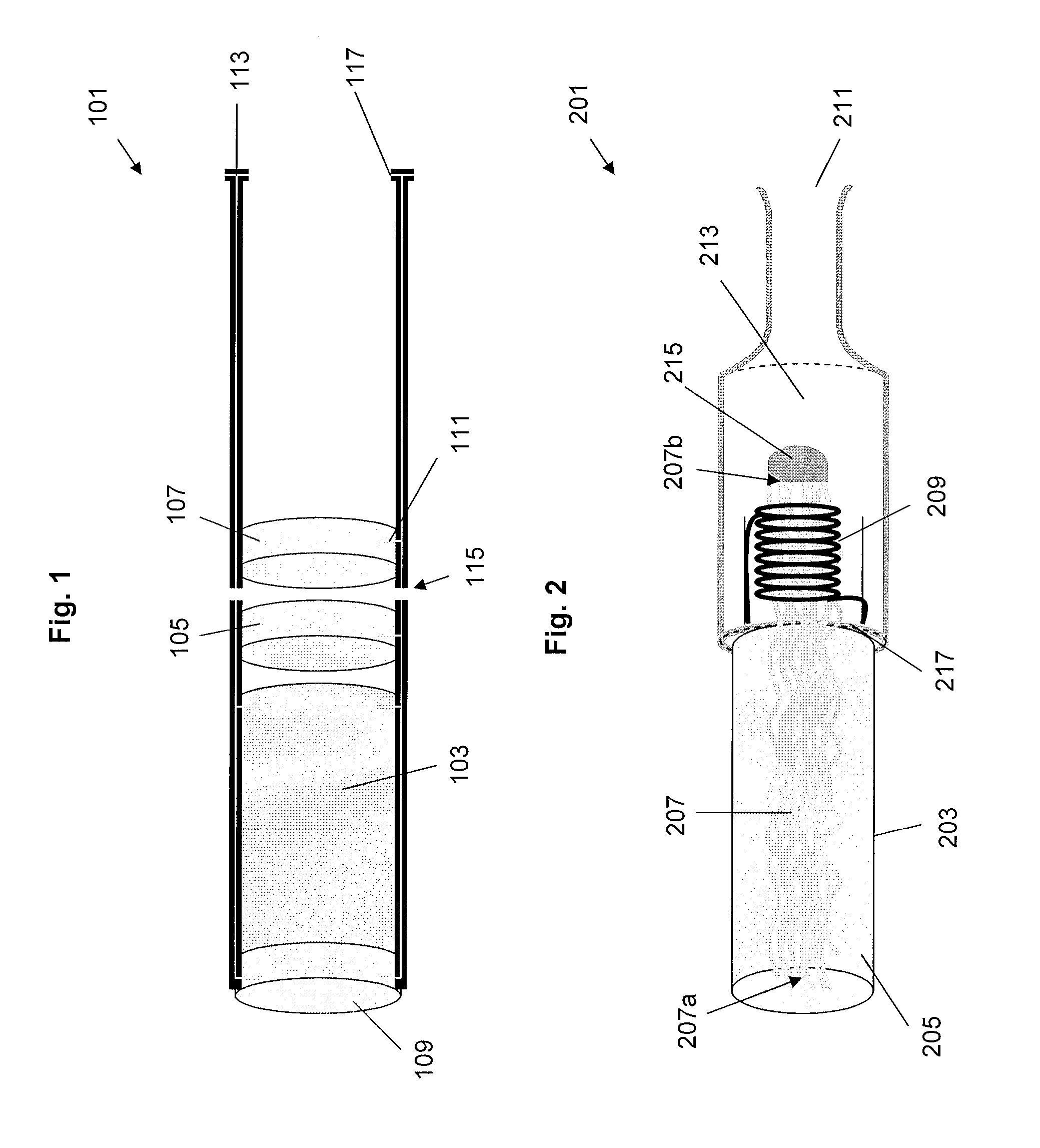

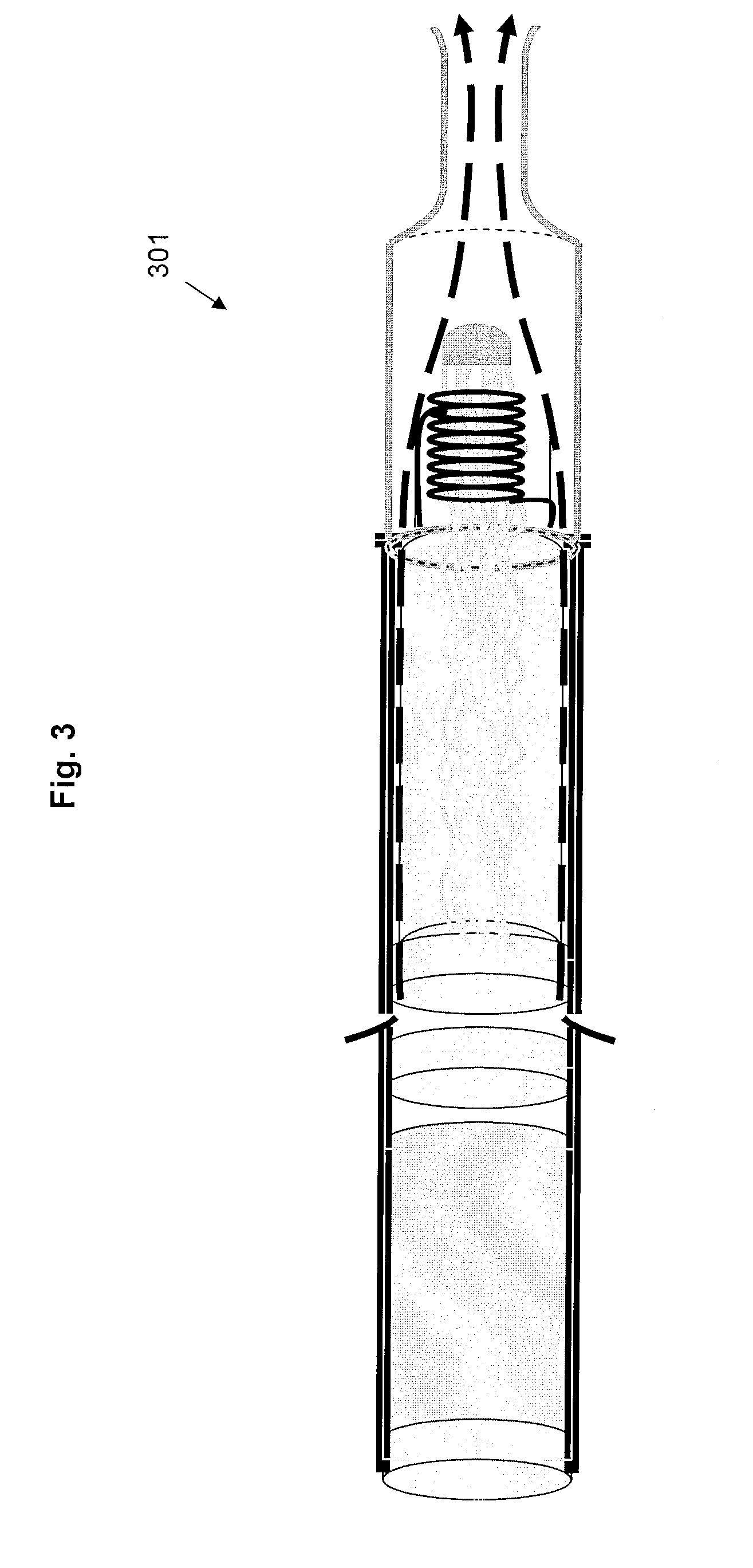

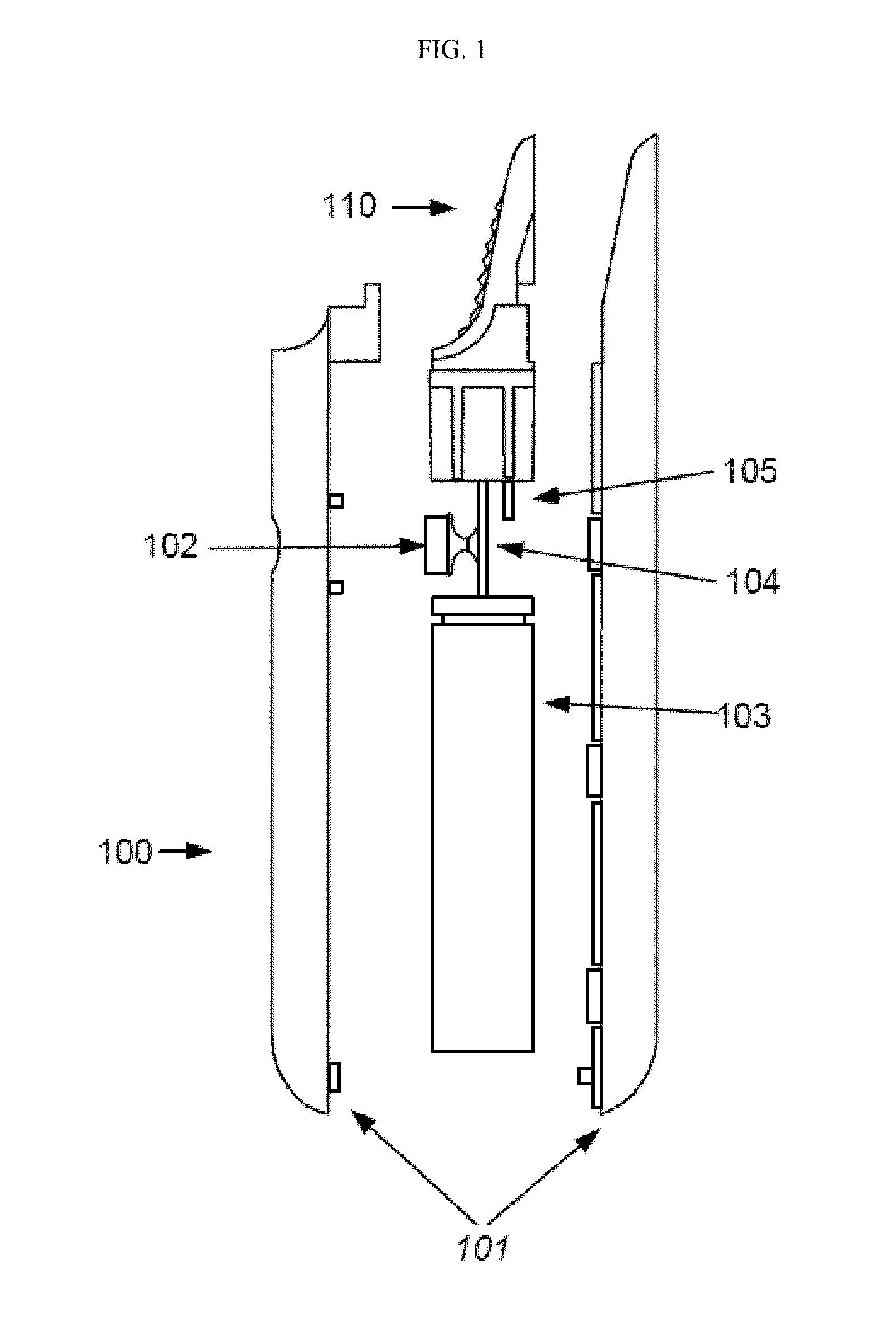

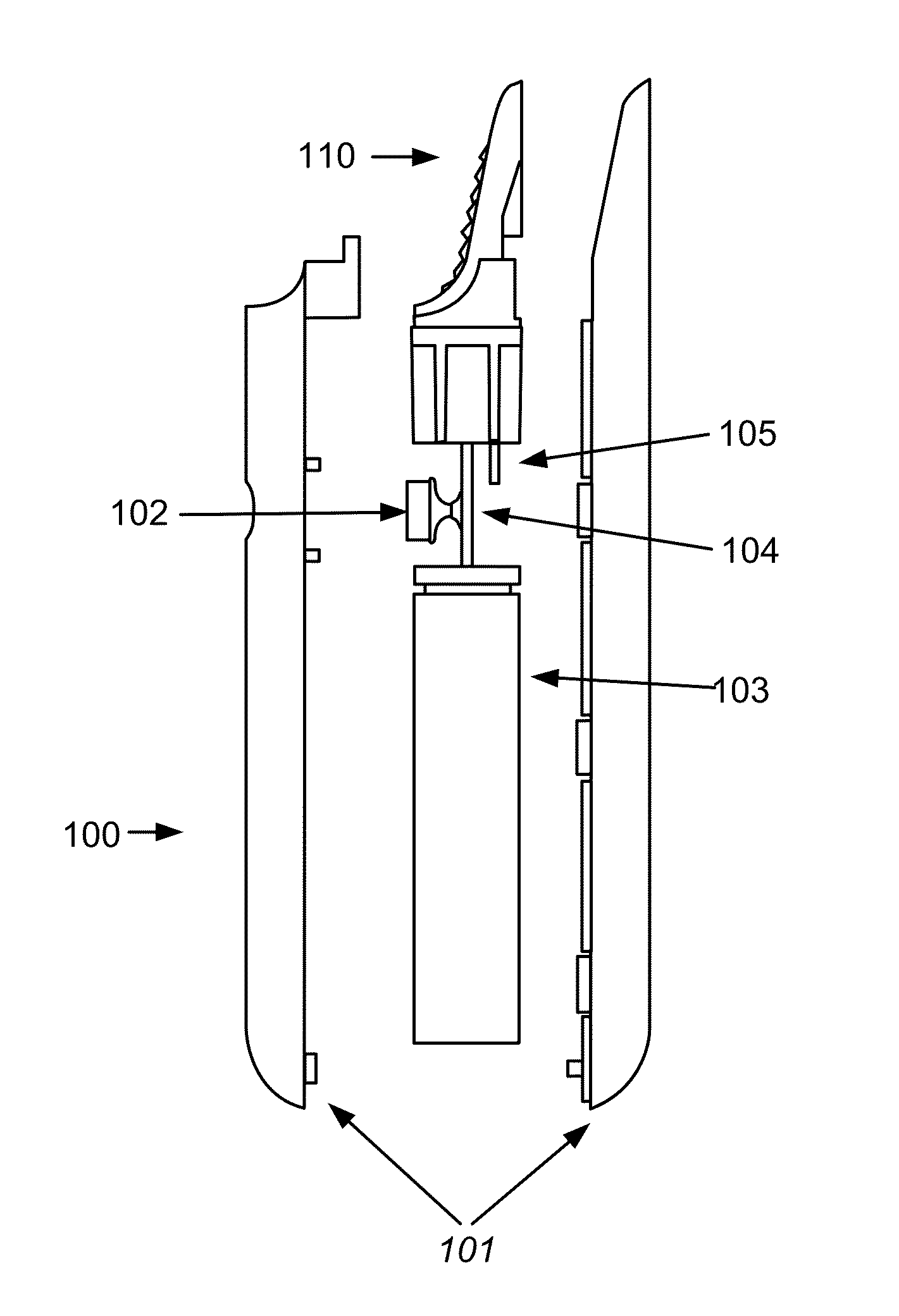

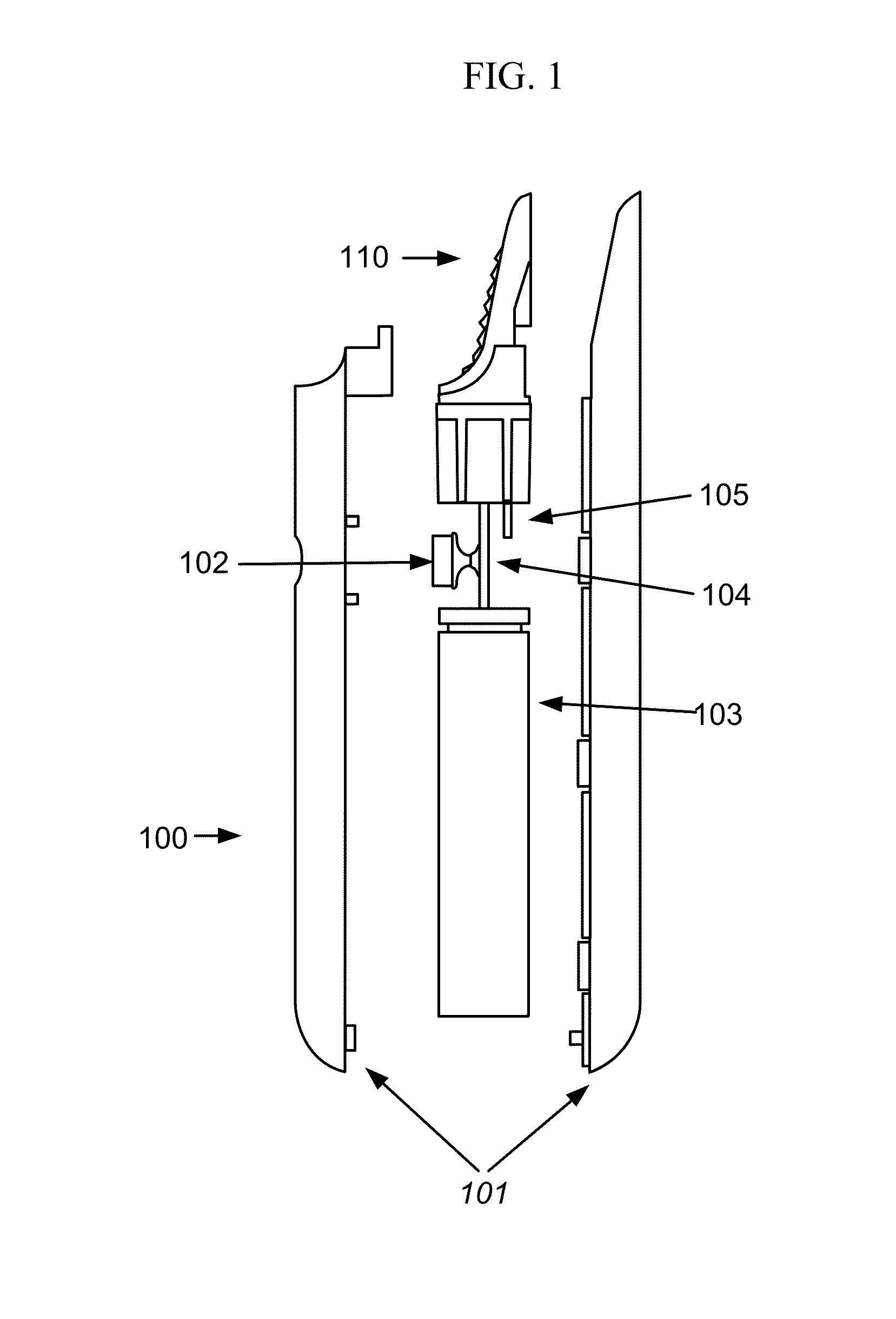

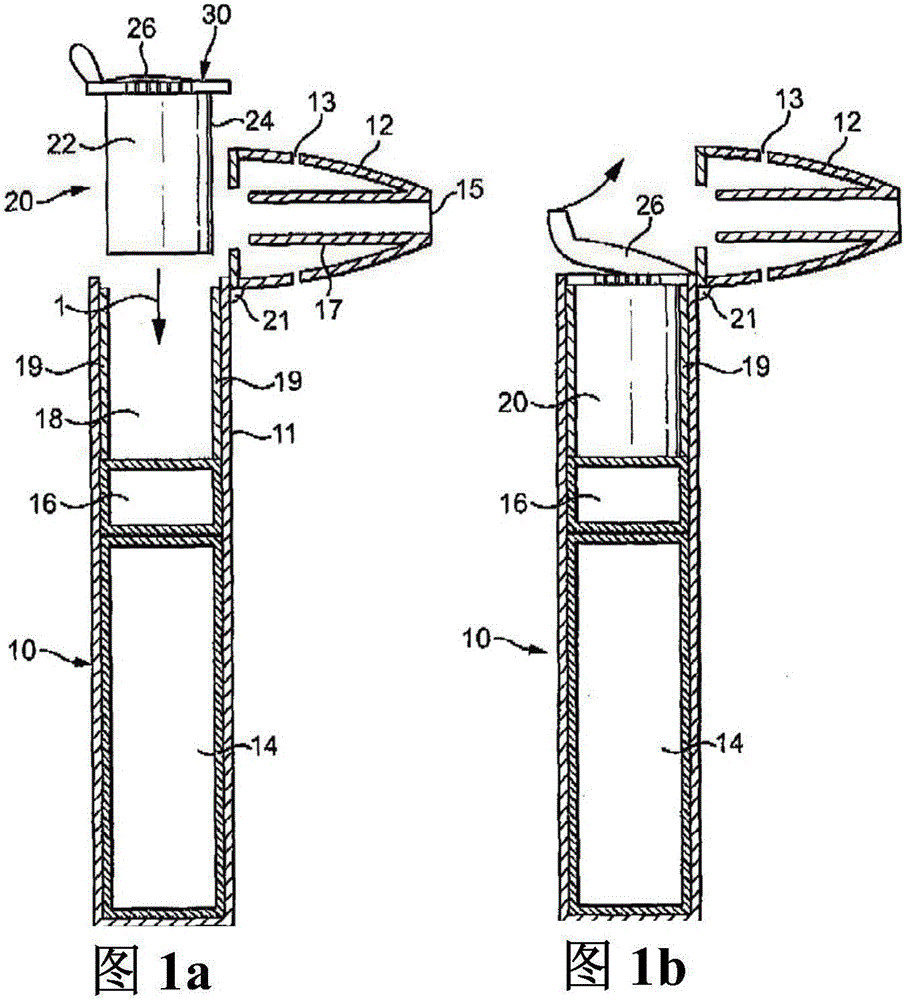

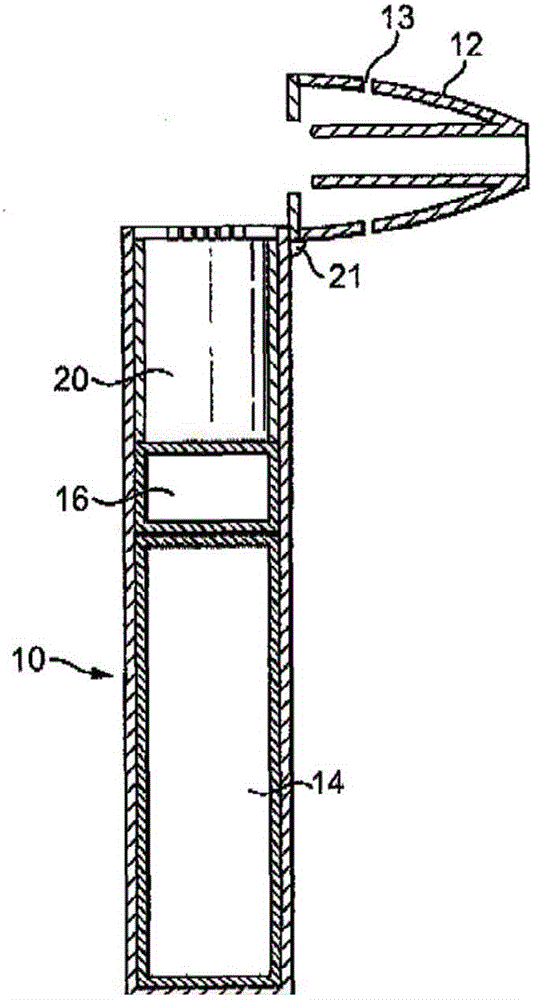

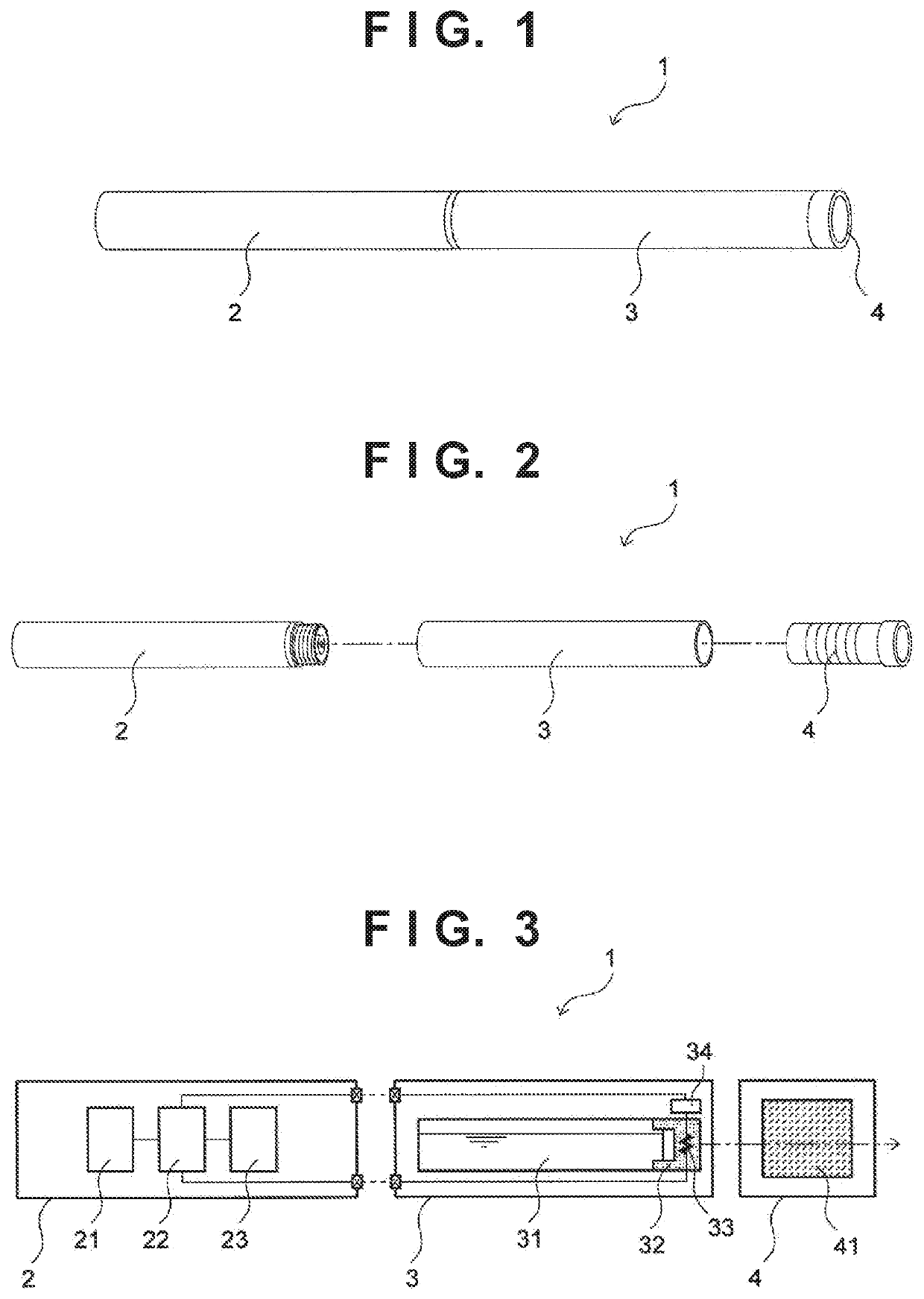

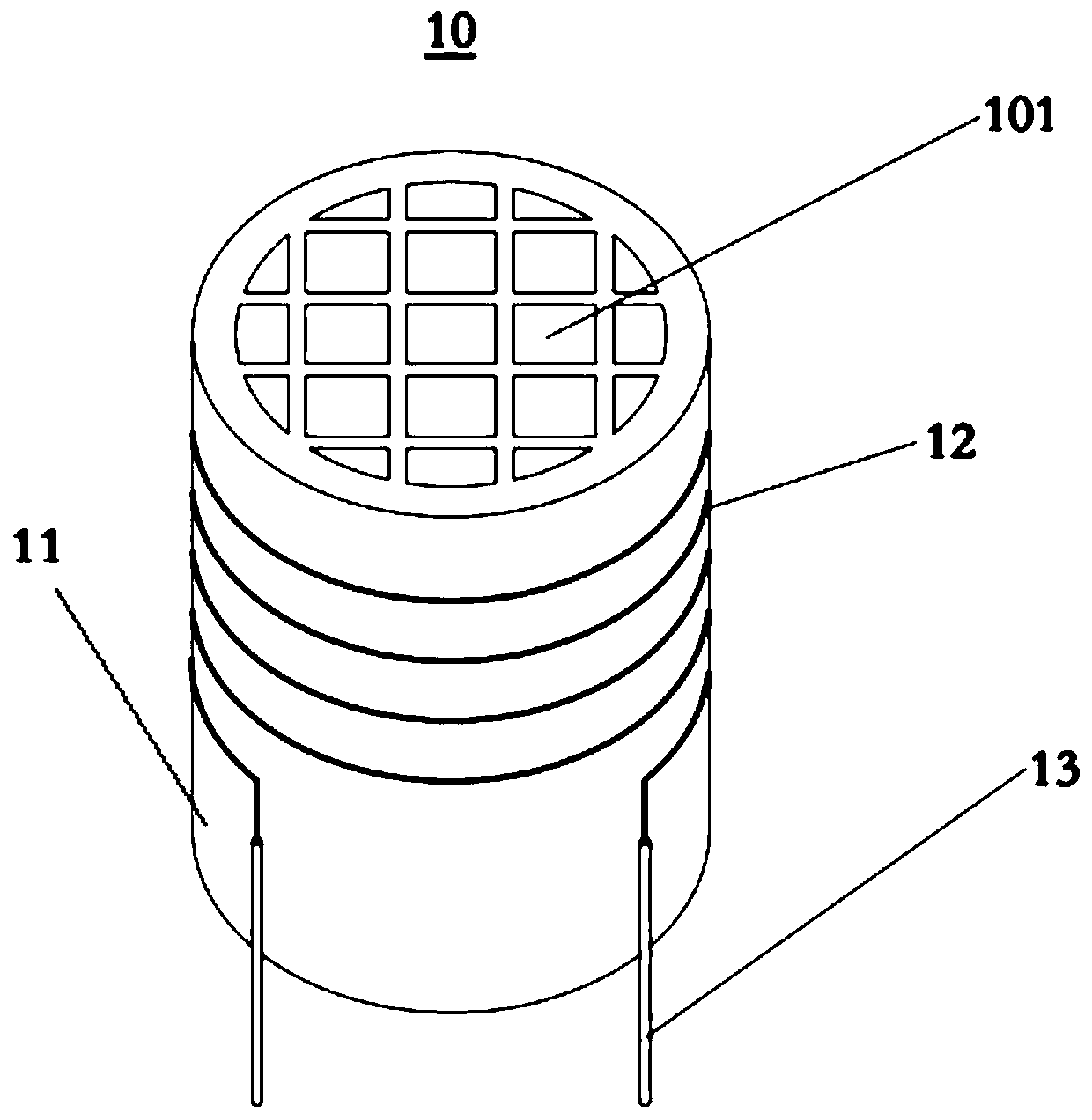

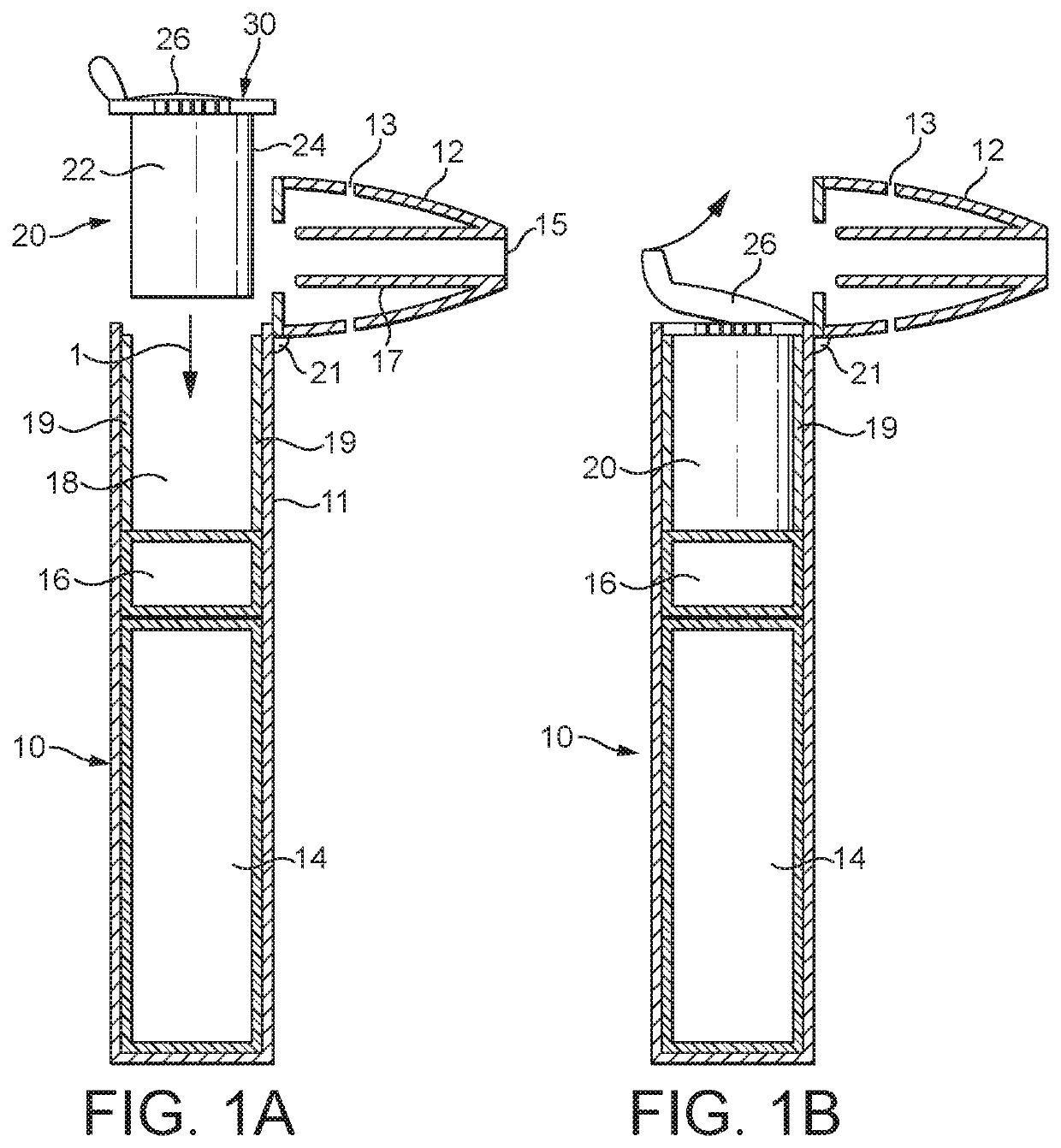

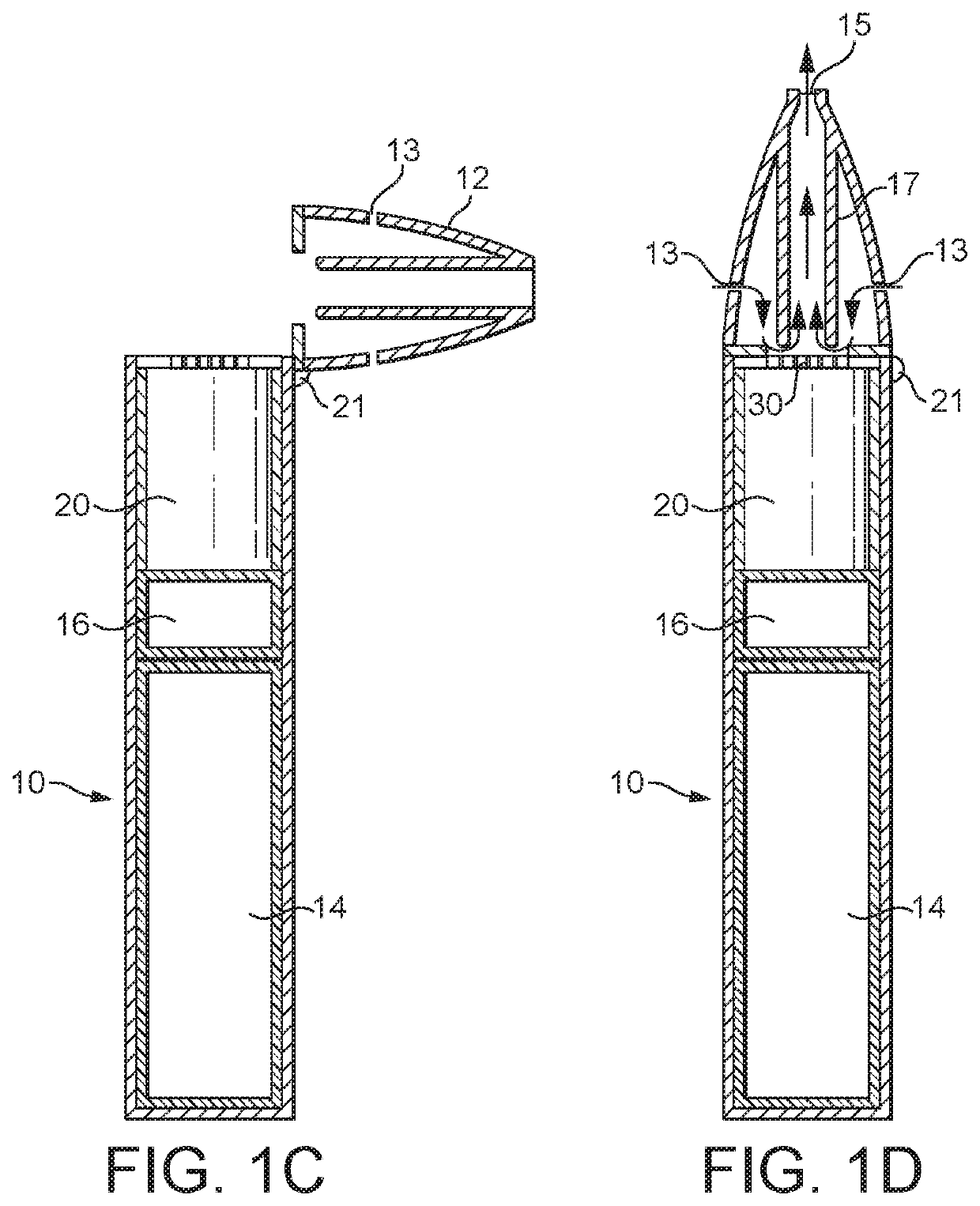

Electrically heated smoking system having a liquid storage portion

ActiveUS20090272379A1Prevent degradationSimple structureOhmic-resistance heating circuitsCoil arrangementsElectricityElectrical connection

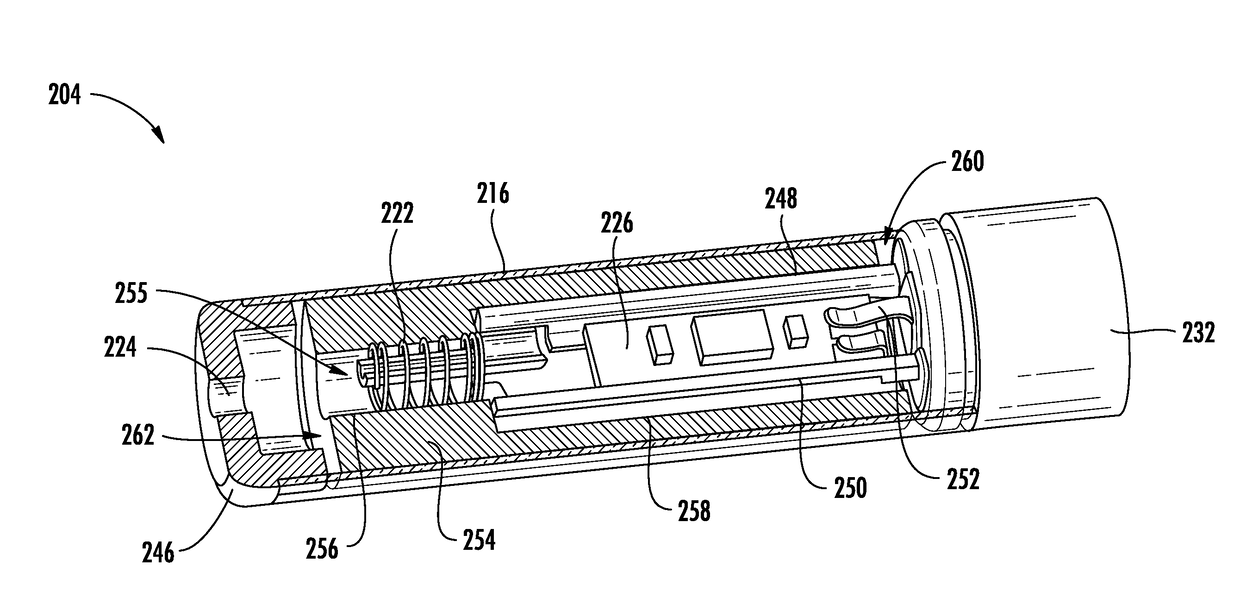

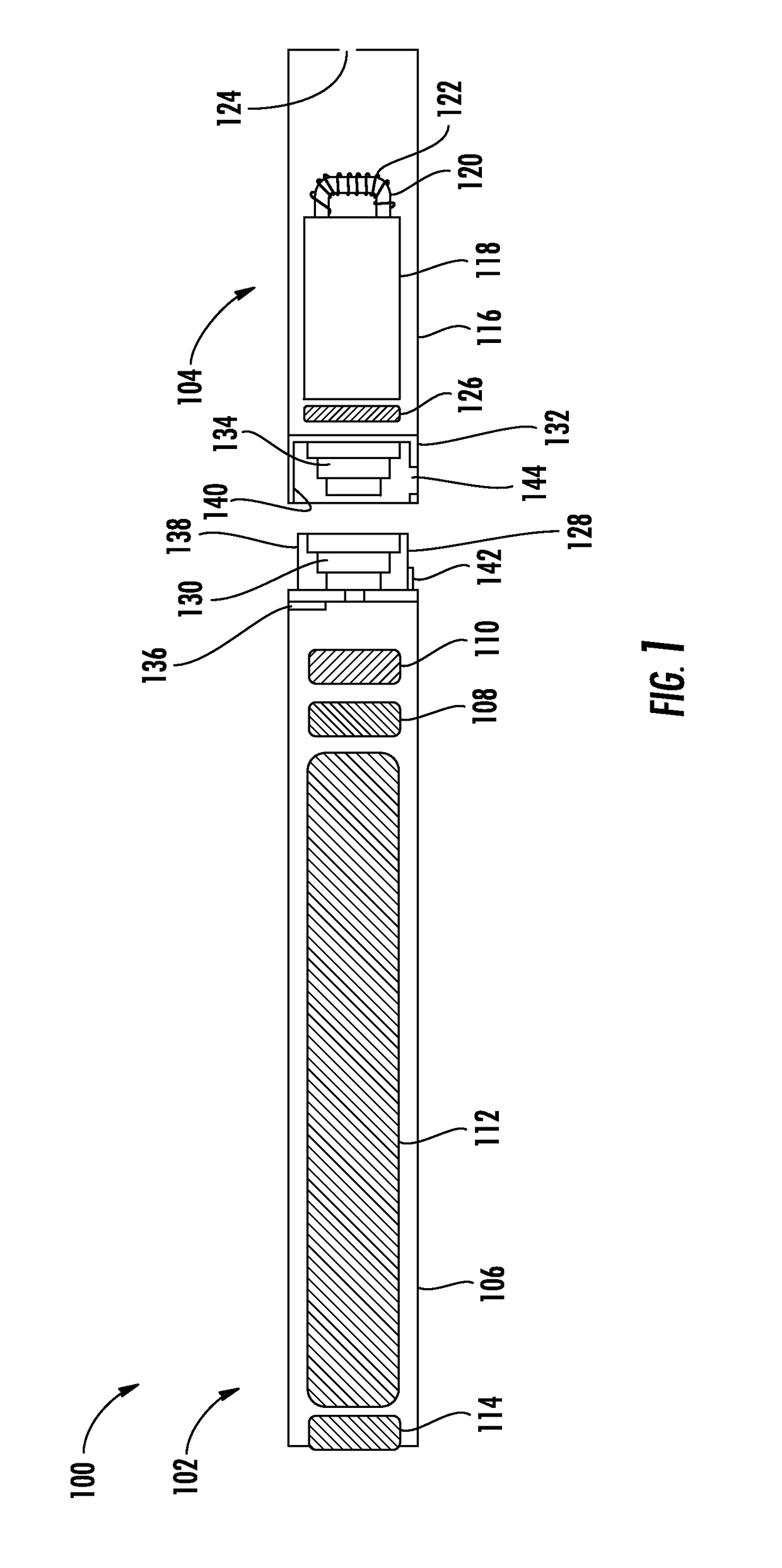

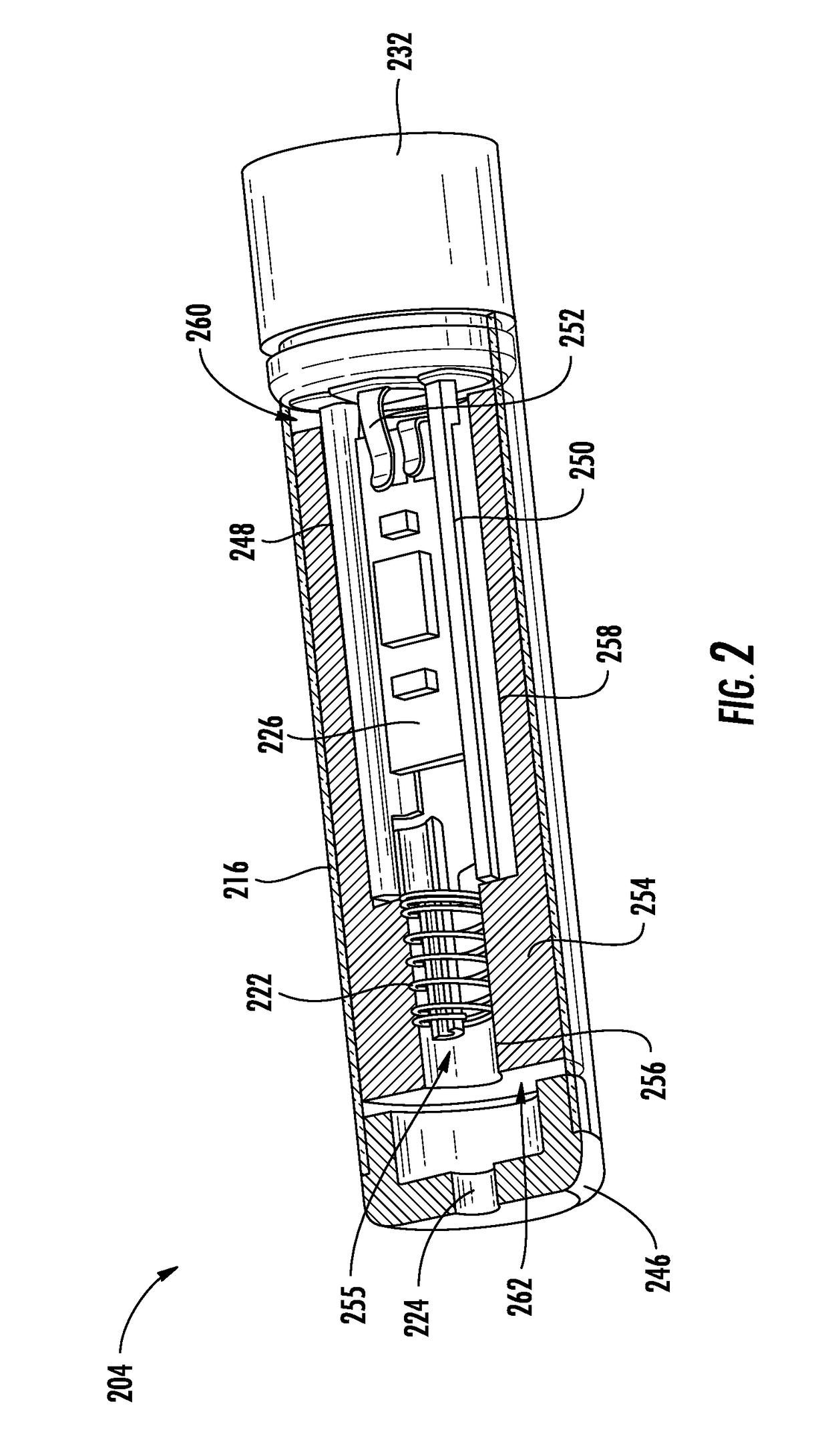

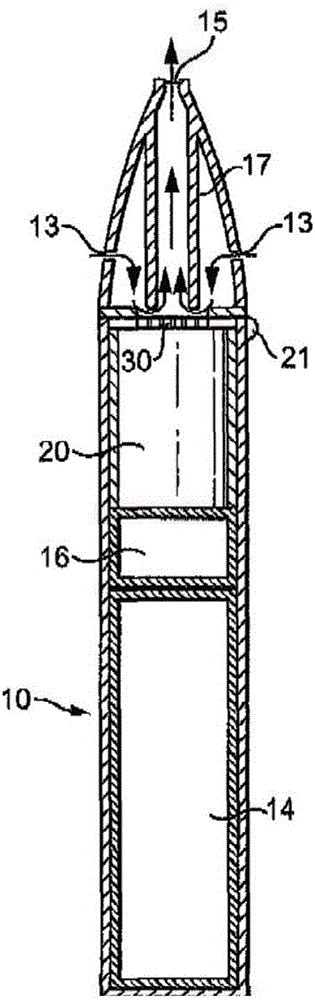

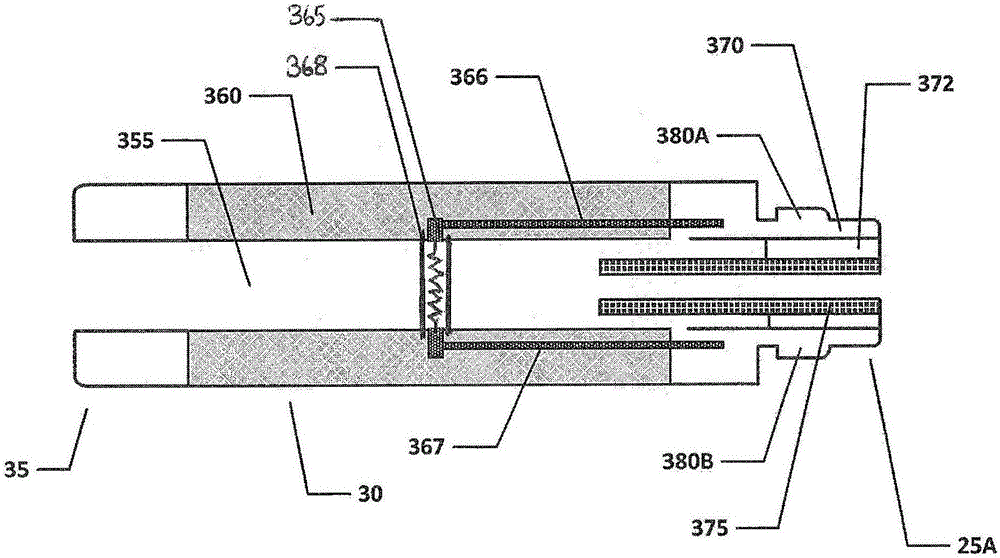

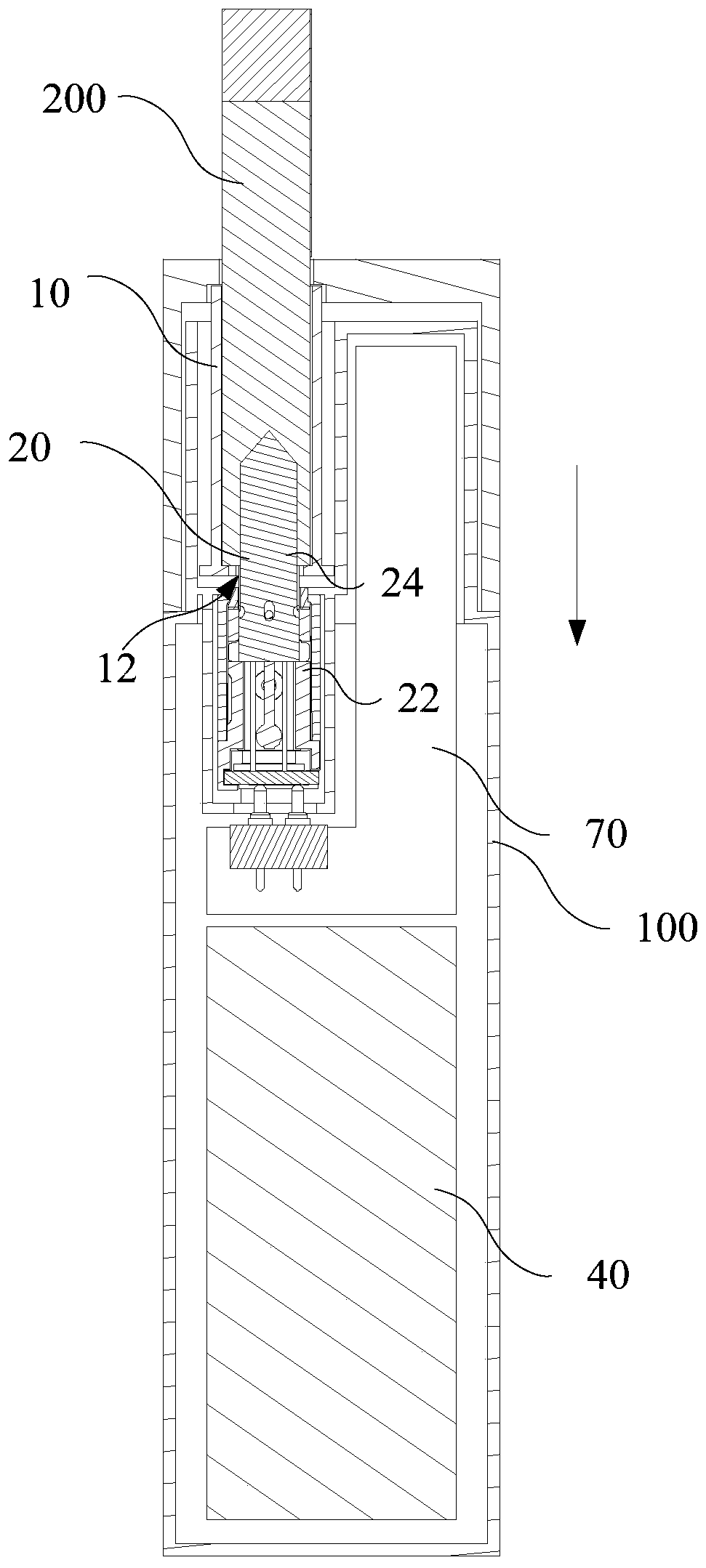

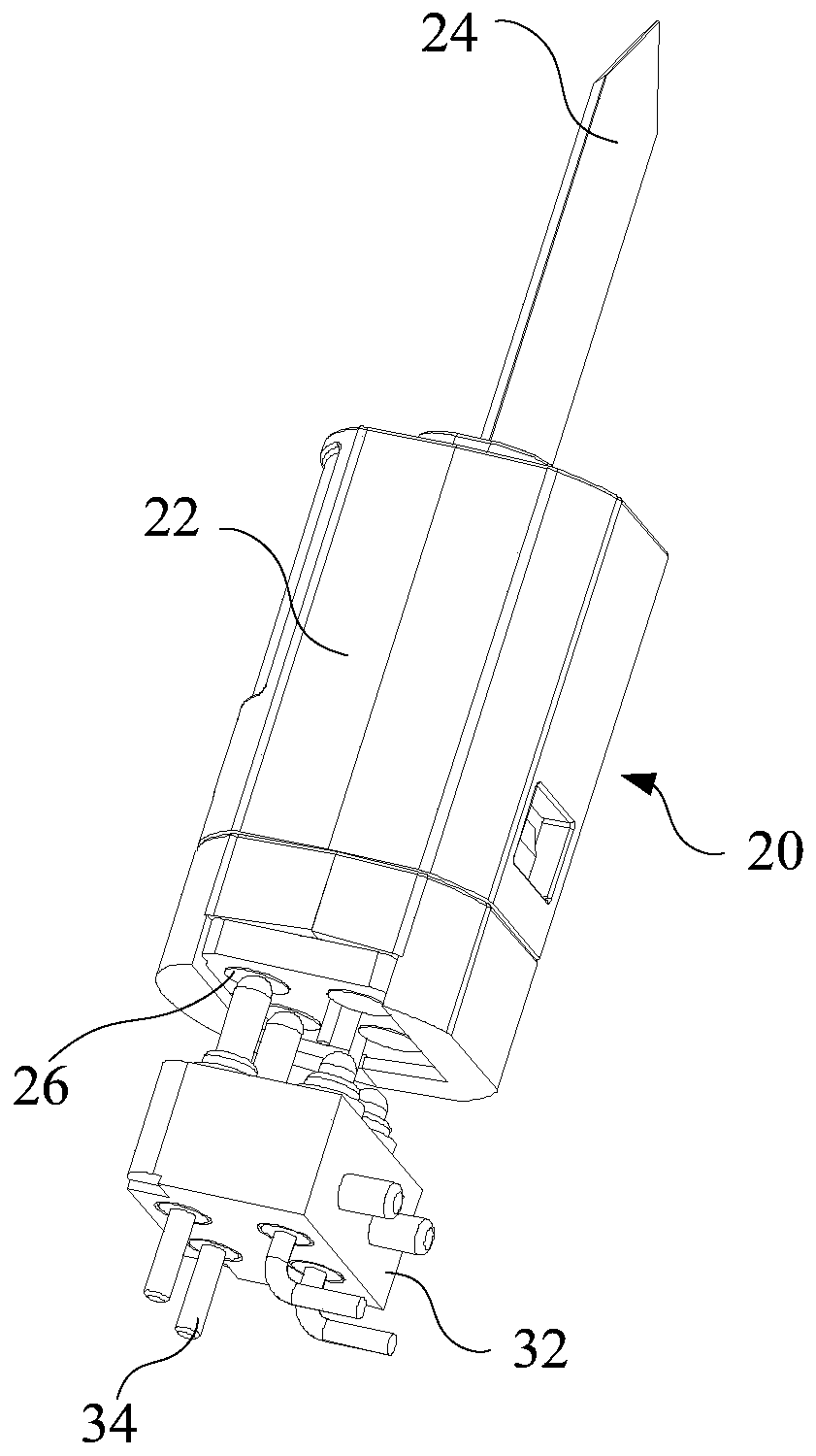

An electrically heated smoking system includes a shell and a replaceable mouthpiece. The shell includes an electric power supply and electric circuitry. The mouthpiece includes a liquid storage portion and a capillary wick having a first end and a second end. The first end of the wick extends into the liquid storage portion for contact with liquid therein. The mouthpiece also includes a heating element for heating the second end of the capillary wick, an air outlet, and an aerosol forming chamber between the second end of the capillary wick and the air outlet. When the shell and mouthpiece are engaged or connected, the heating element is in electrical connection with the power supply via the circuitry, and a flowpath for air is defined from at least one air inlet to the air outlet via the aerosol forming chamber. In use, liquid is transferred from the liquid storage portion towards the heating element by capillary action in the wick. Liquid at the second end of the capillary wick is vaporized by the heating element. The supersaturated vapor created, is mixed and carried in the air flow from the at least one air inlet to the aerosol forming chamber. In the aerosol forming chamber, the vapor condenses to form an aerosol, which is carried towards the air outlet.

Owner:PHILIP MORRIS USA INC

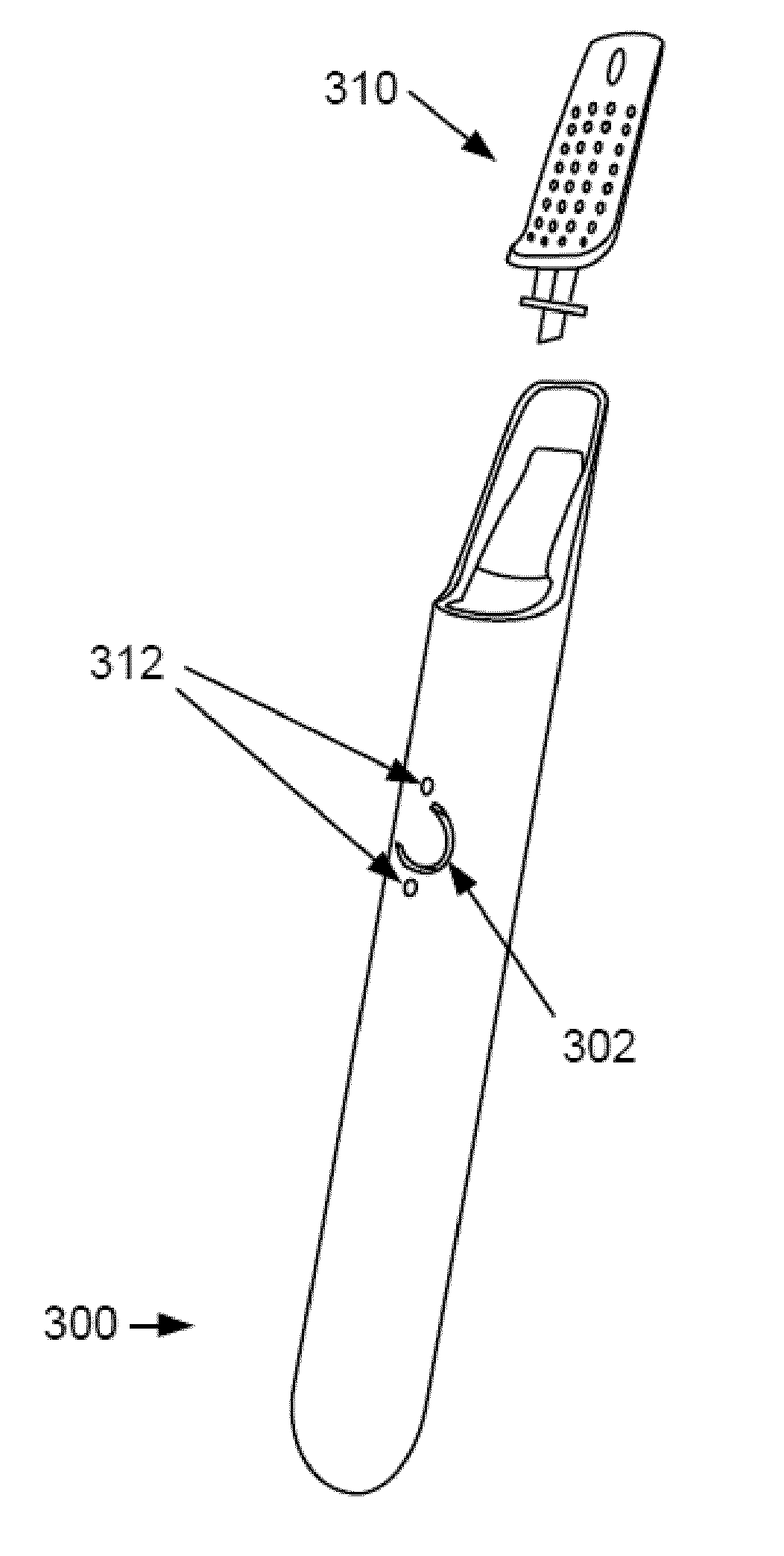

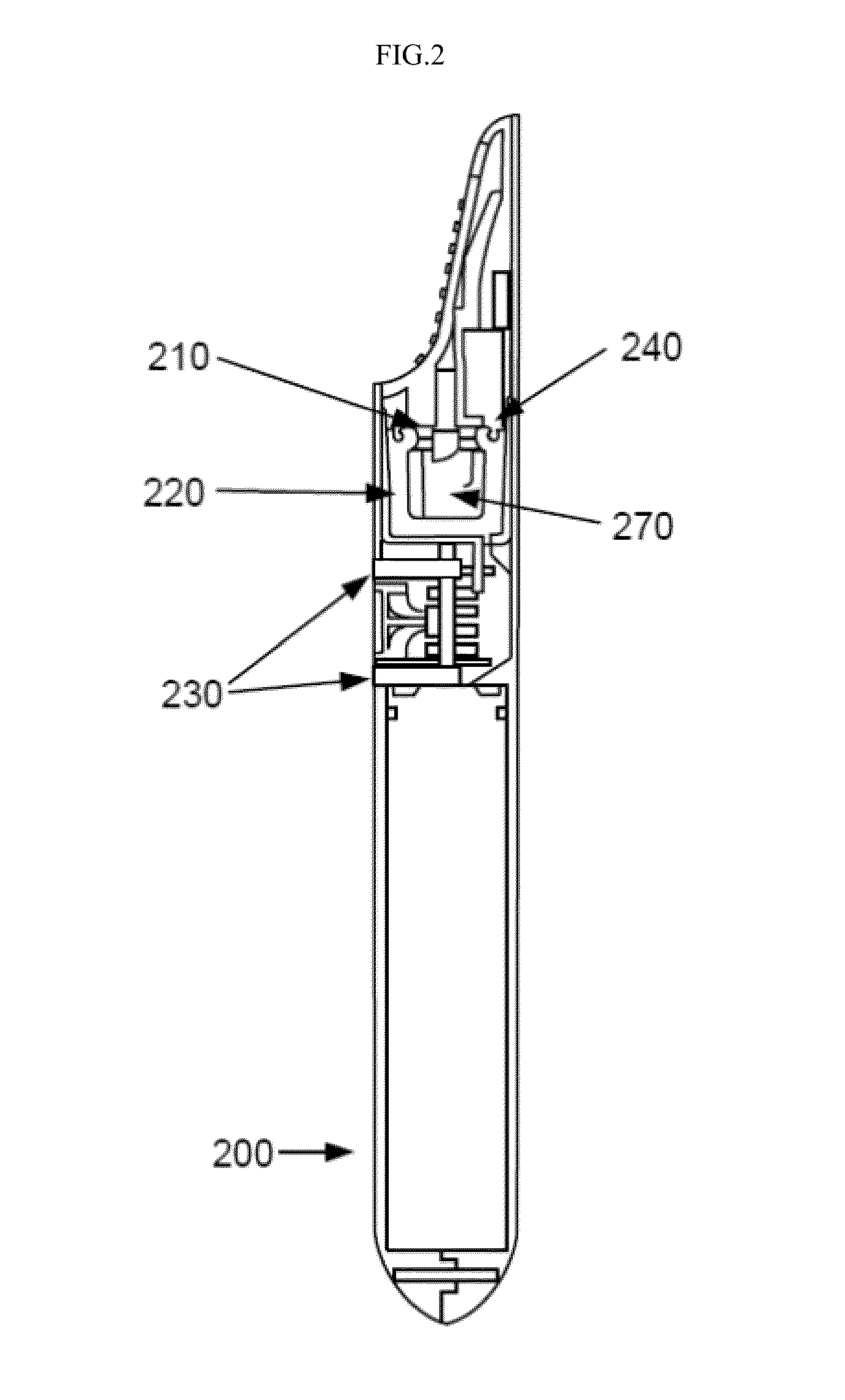

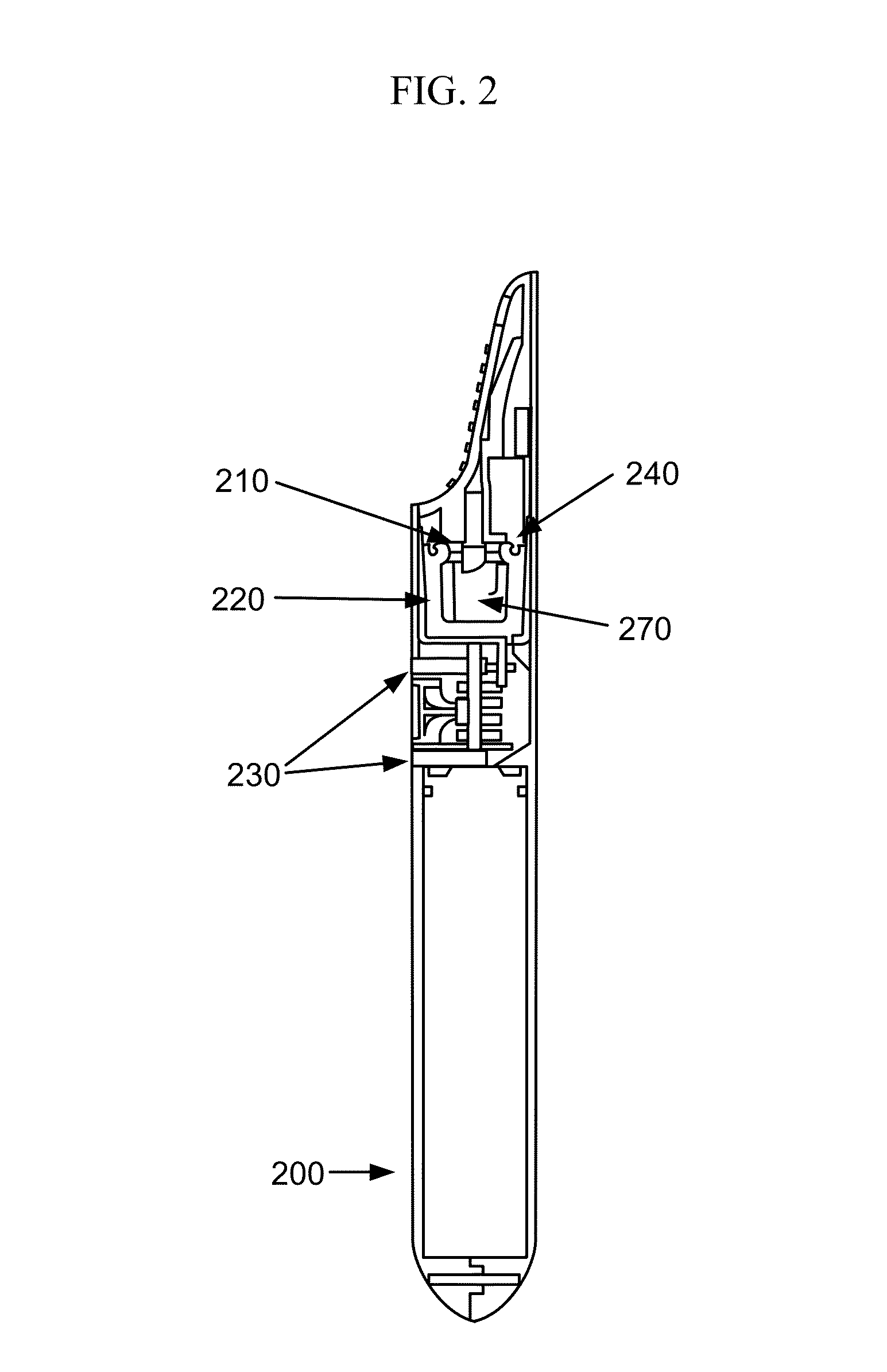

Low temperature electronic vaporization device and methods

ActiveUS20130042865A1Maintain efficiencyReduce the temperatureInput/output for user-computer interactionTobacco treatmentInhalationEnvironmental health

Low temperature electronic vaporization devices and method are described herein for emulating smoking wherein the devices generate an aerosol for inhalation by a subject by heating a viscous material that can have a tactile response in the mouth or respiratory tract.

Owner:JLI NAT SETTLEMENT TRUST

Electrically heated smoking system having a liquid storage portion

ActiveUS8794231B2Avoid wastingReduce riskOhmic-resistance heating circuitsCigar manufactureElectricityElectrical connection

An electrically heated smoking system includes a shell and a replaceable mouthpiece. The shell includes an electric power supply and electric circuitry. The mouthpiece includes a liquid storage portion and a capillary wick having a first end and a second end. The first end of the wick extends into the liquid storage portion for contact with liquid therein. The mouthpiece also includes a heating element for heating the second end of the capillary wick, an air outlet, and an aerosol forming chamber between the second end of the capillary wick and the air outlet. When the shell and mouthpiece are engaged or connected, the heating element is in electrical connection with the power supply via the circuitry, and a flowpath for air is defined from at least one air inlet to the air outlet via the aerosol forming chamber. In use, liquid is transferred from the liquid storage portion towards the heating element by capillary action in the wick. Liquid at the second end of the capillary wick is vaporized by the heating element. The supersaturated vapor created, is mixed and carried in the air flow from the at least one air inlet to the aerosol forming chamber. In the aerosol forming chamber, the vapor condenses to form an aerosol, which is carried towards the air outlet.

Owner:PHILIP MORRIS USA INC

Low temperature electronic vaporization device and methods

InactiveUS20130312742A1Maintain efficiencyReduce the temperatureInput/output for user-computer interactionTobacco treatmentInhalationEnvironmental health

Low temperature electronic vaporization devices and method are described herein for emulating smoking wherein the devices generate an aerosol for inhalation by a subject by heating a viscous material that can have a tactile response in the mouth or respiratory tract.

Owner:JUUL LABS INC

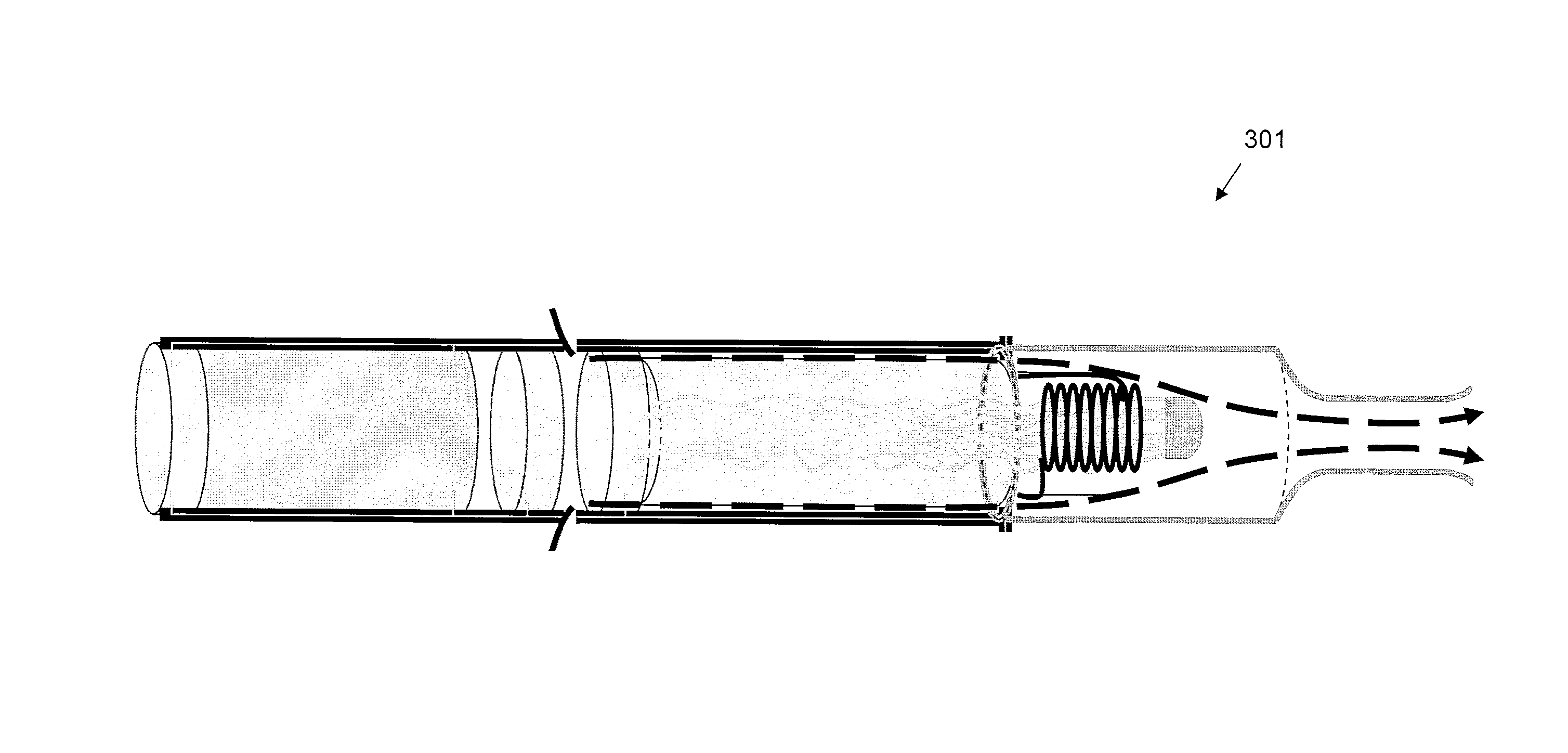

Aerosol delivery device with a liquid transport element comprising a porous monolith and related method

The present disclosure relates to aerosol delivery devices, methods of producing such devices, and elements of such devices. In some embodiments, the present disclosure provides devices configured for vaporization of an aerosol precursor composition that is contained in a reservoir and transported to a heating element by a liquid transport element. The liquid transport element may include a porous monolith.

Owner:RAI STRATEGIC HLDG INC

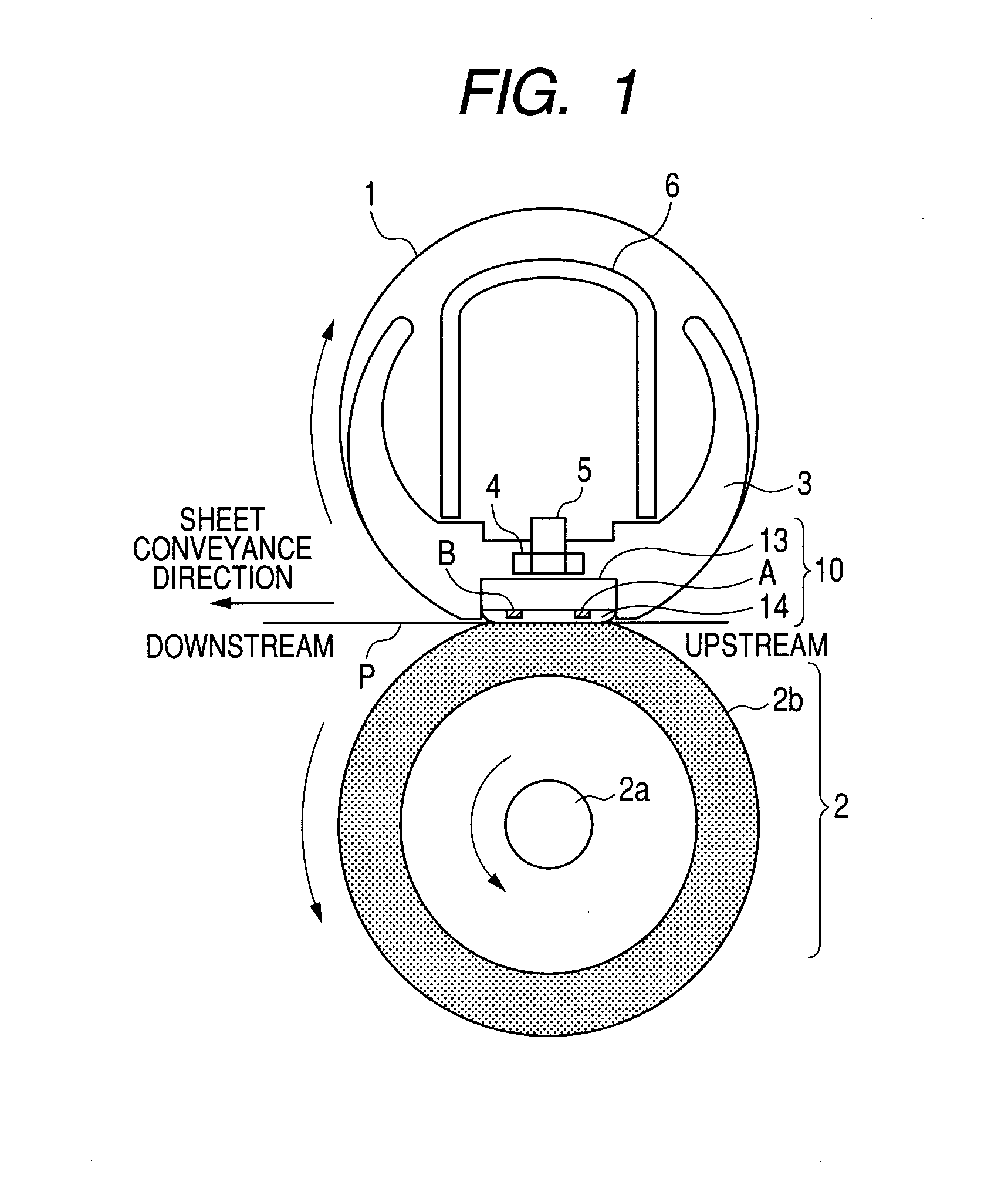

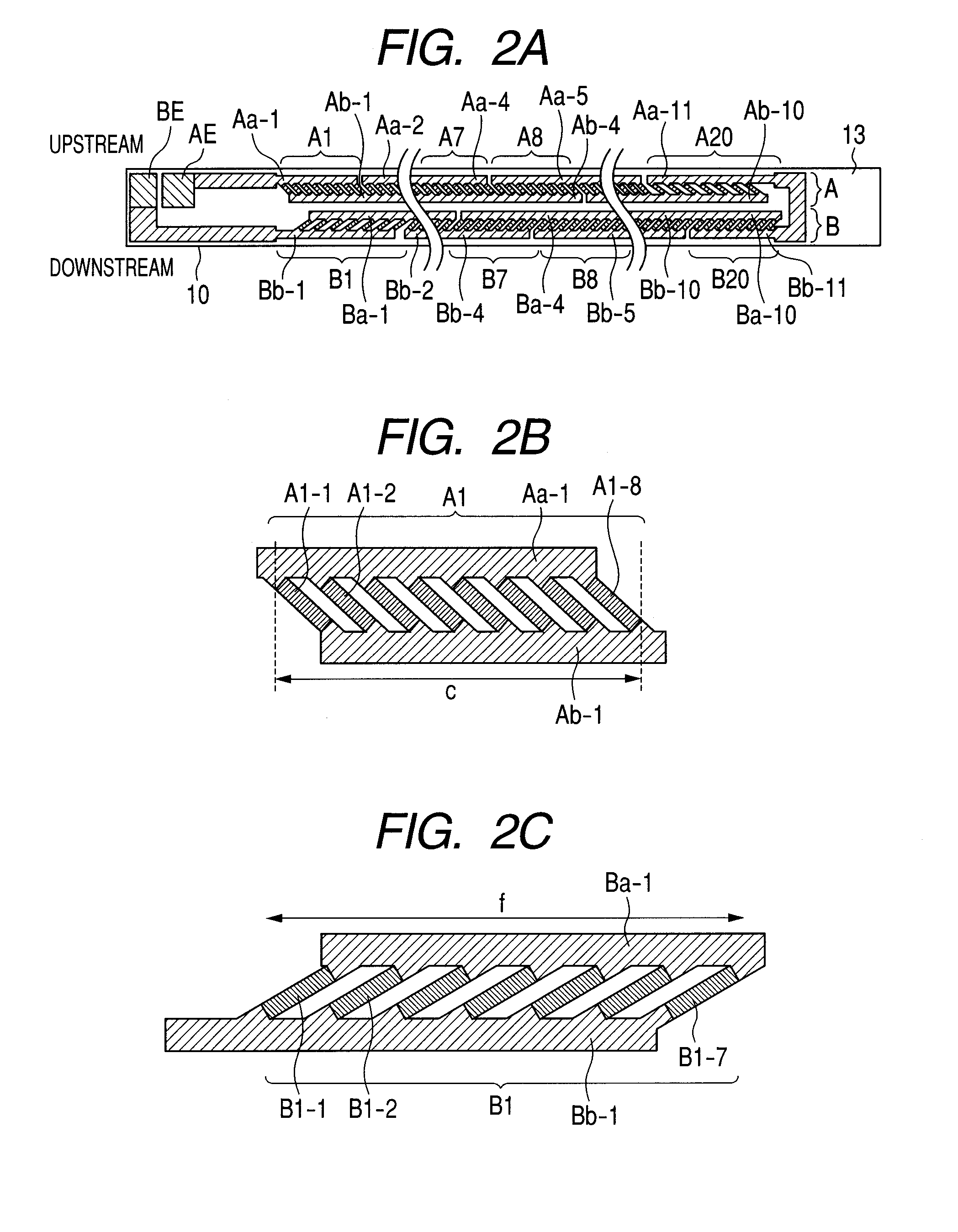

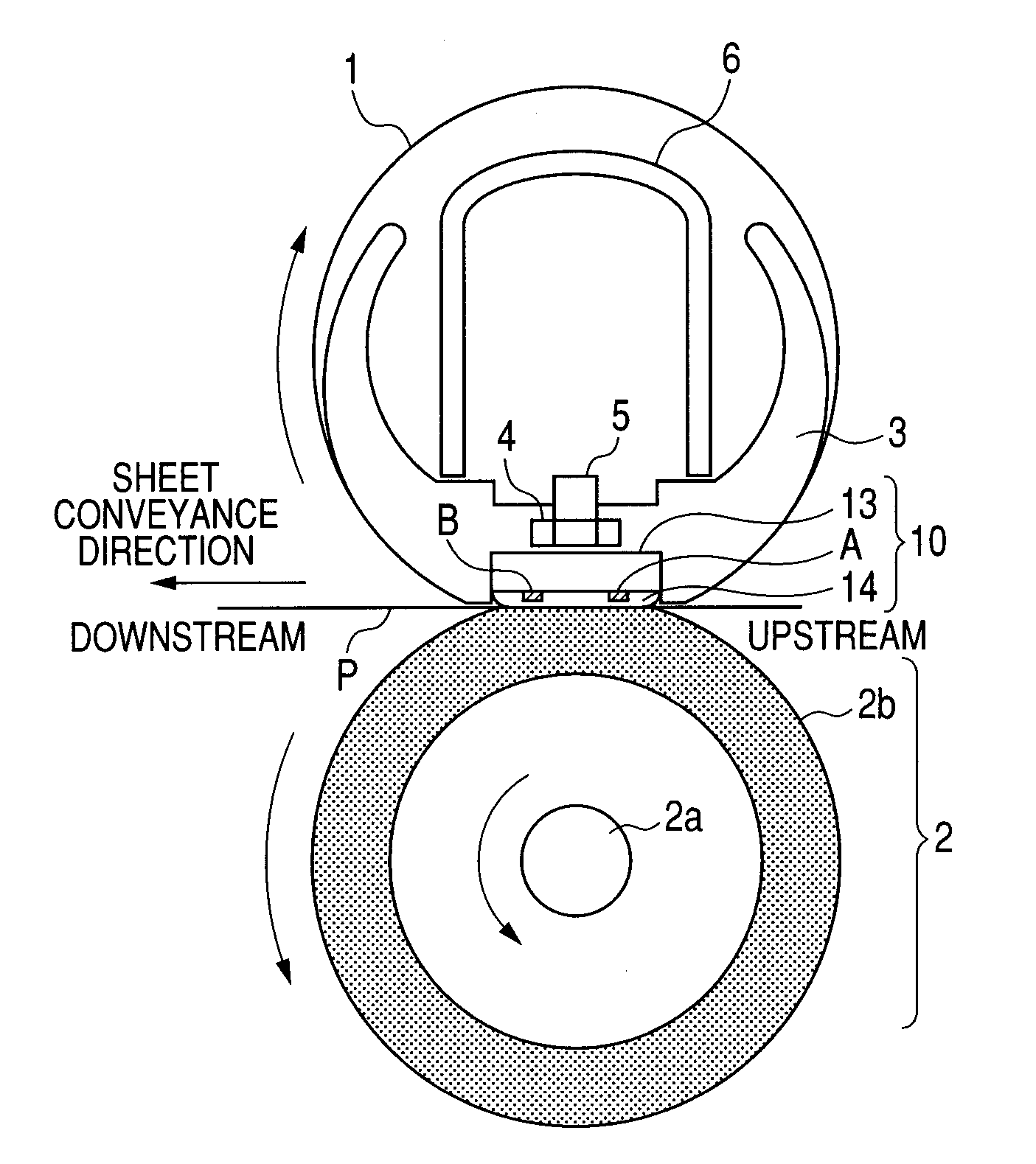

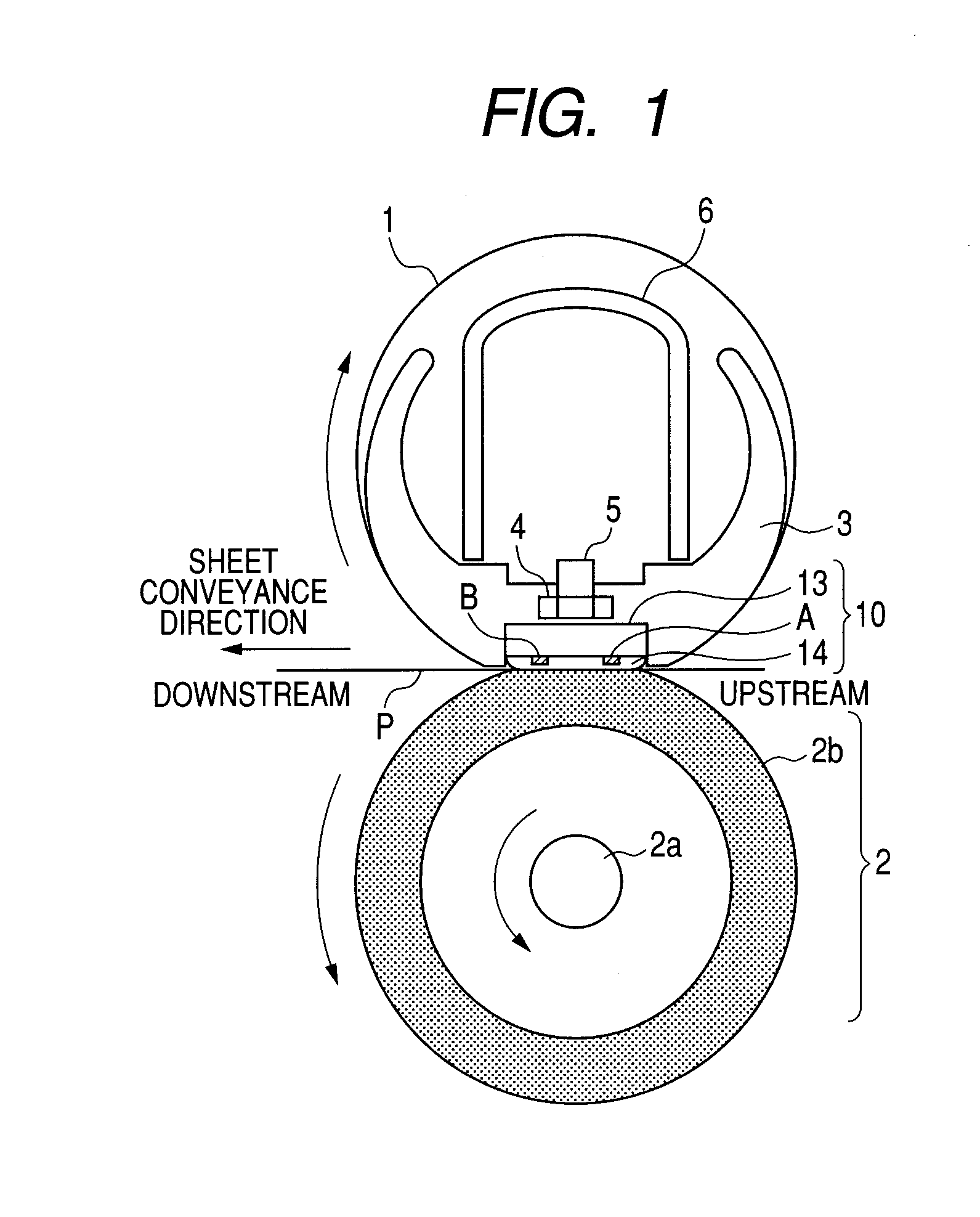

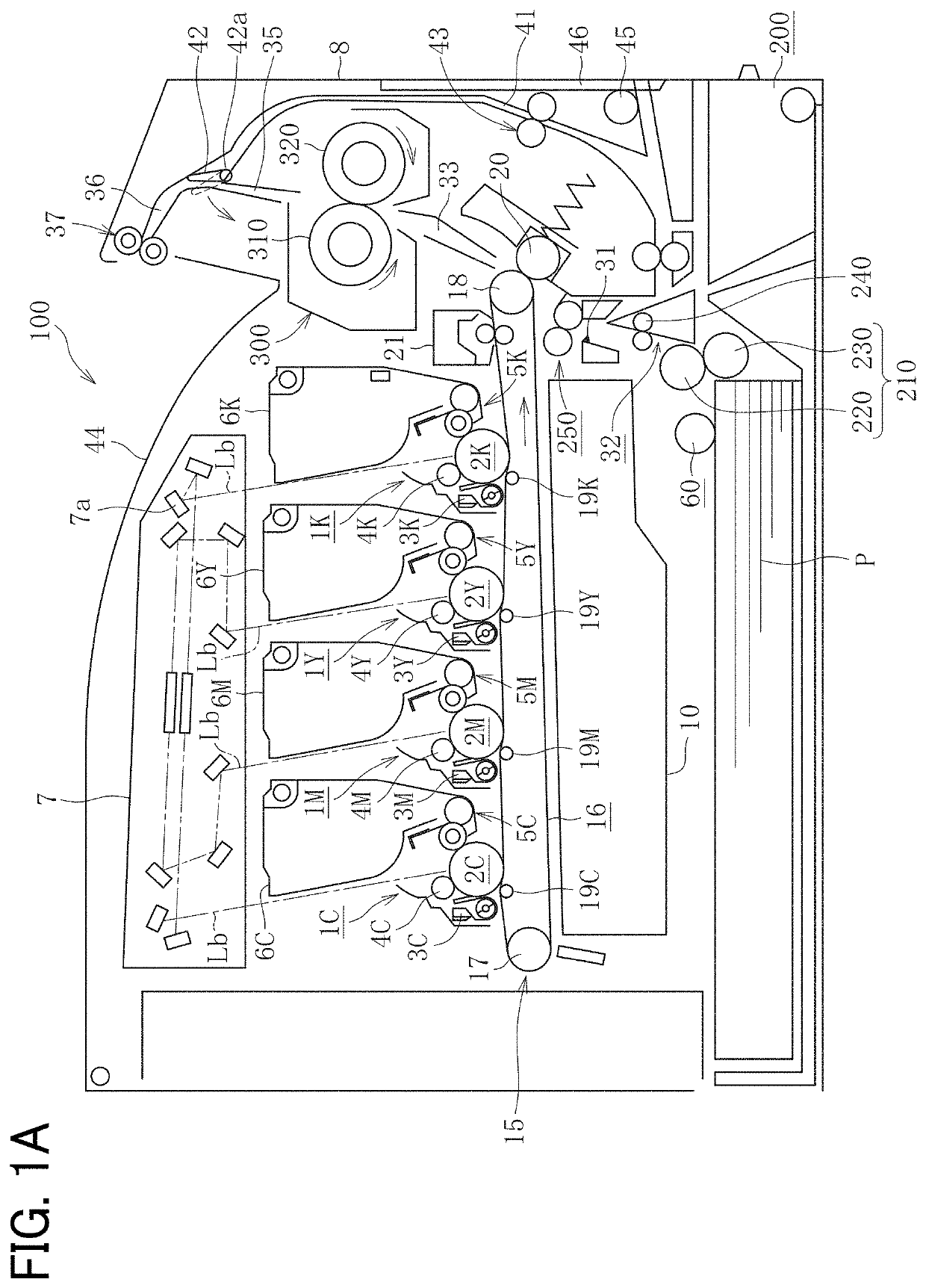

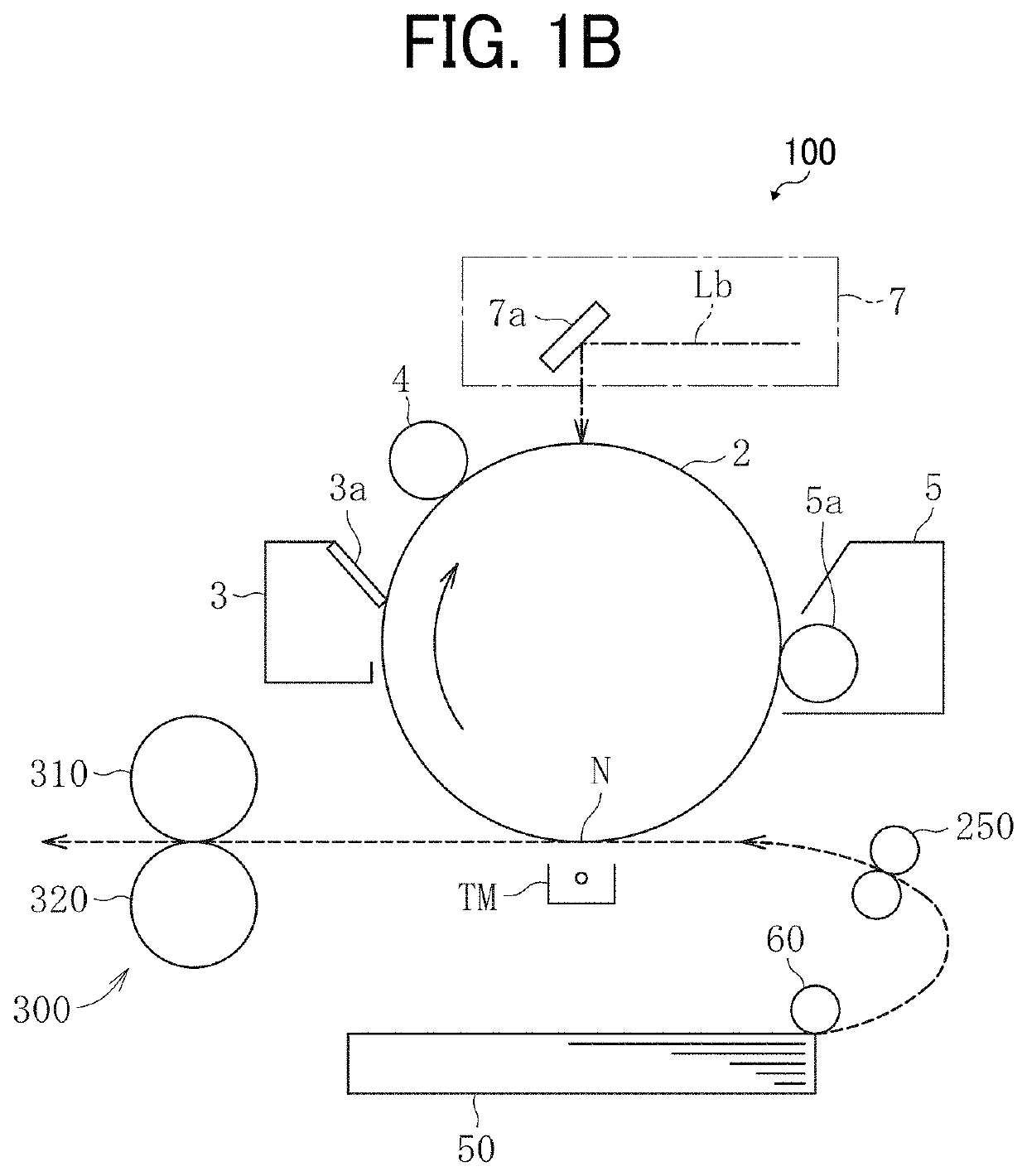

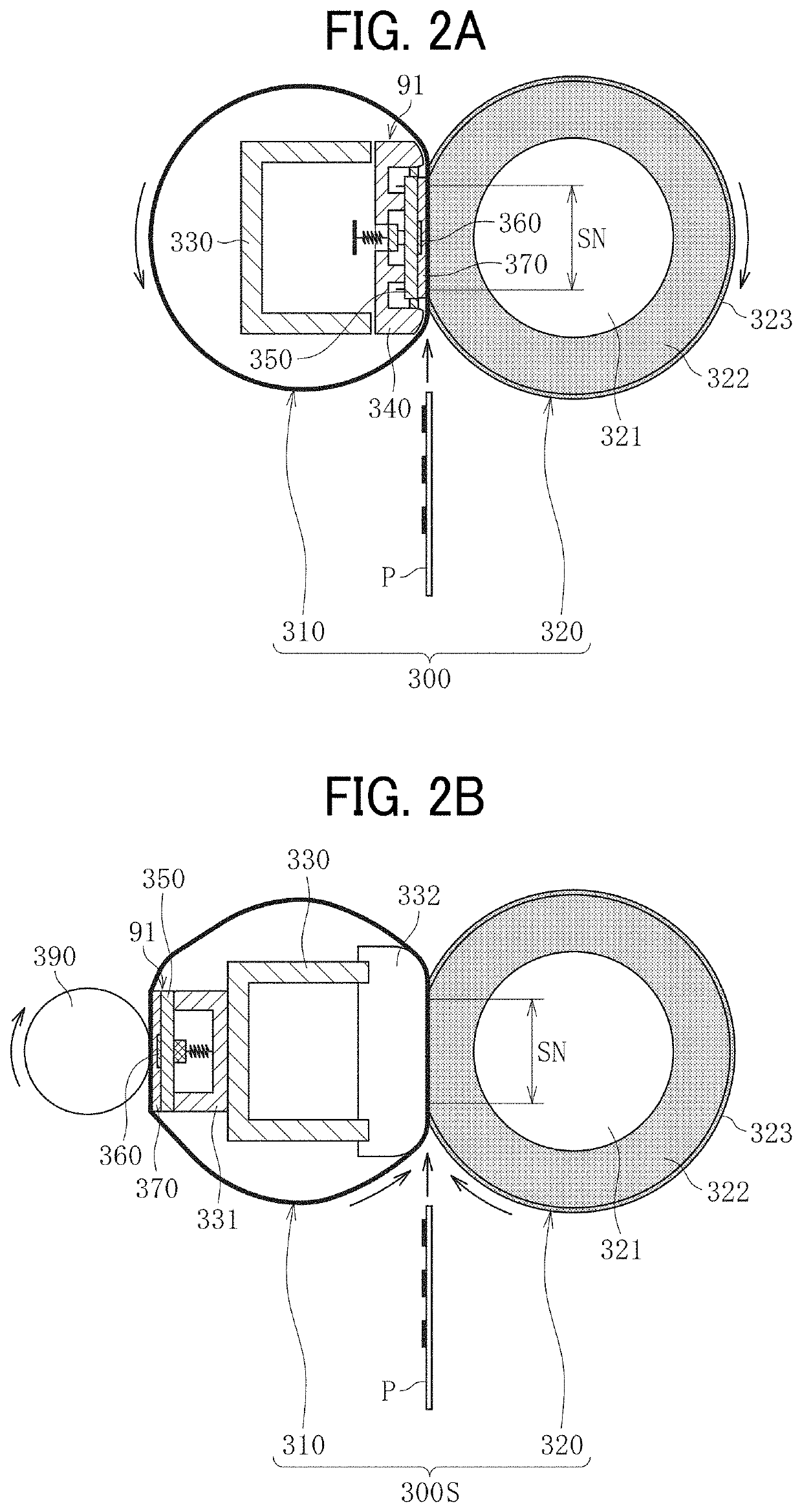

Heater, image heating device with the heater and image forming apparatus therein

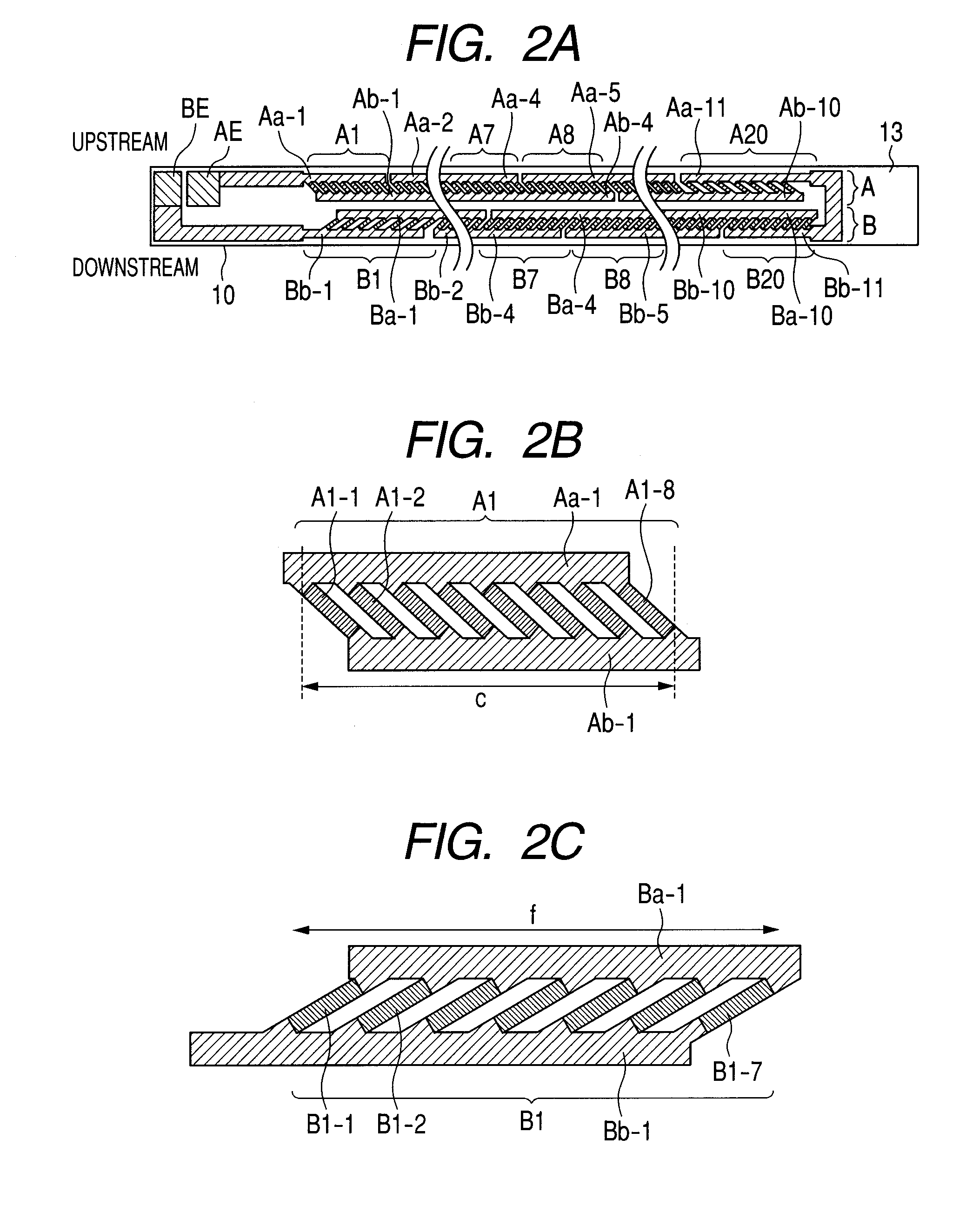

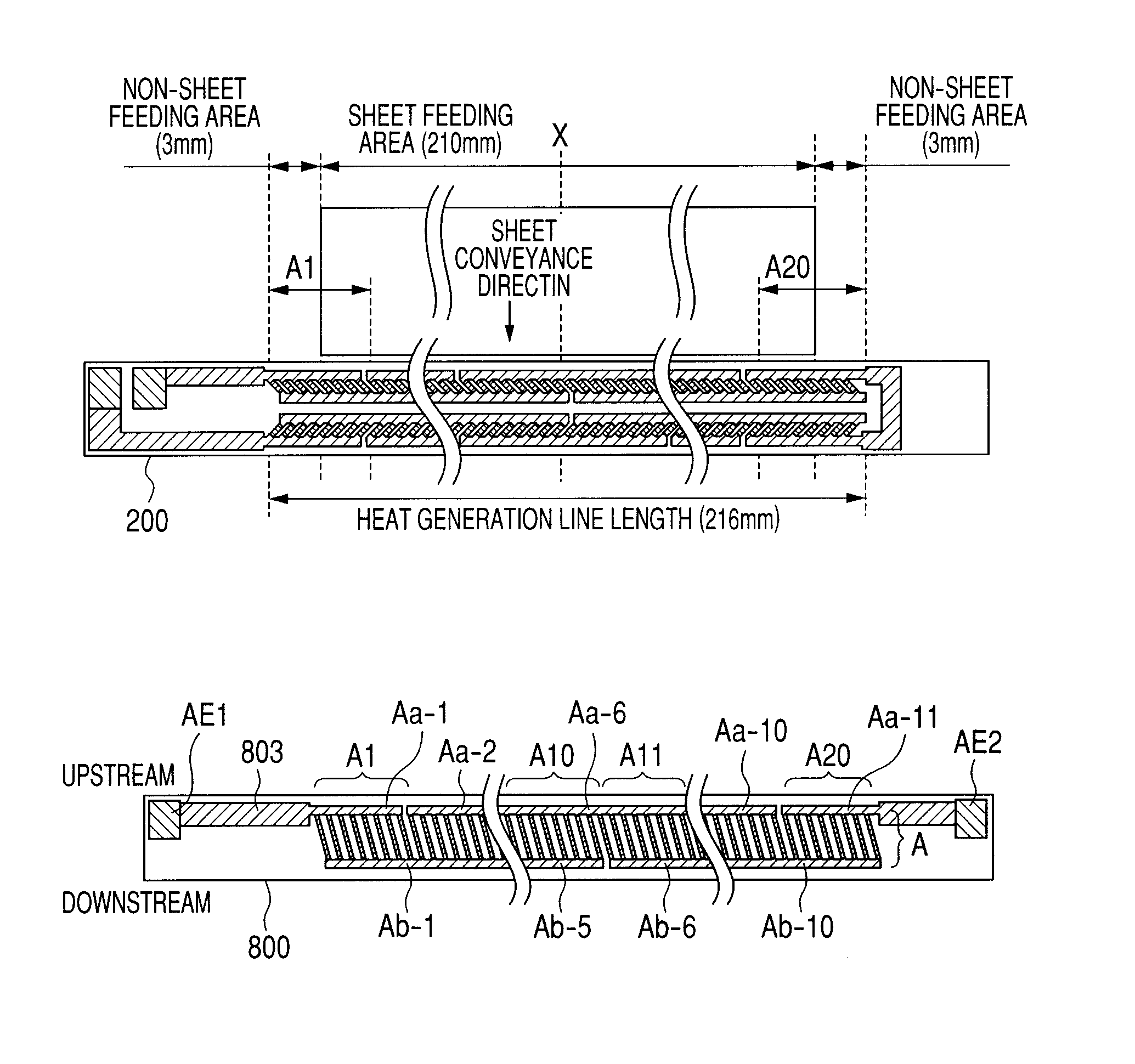

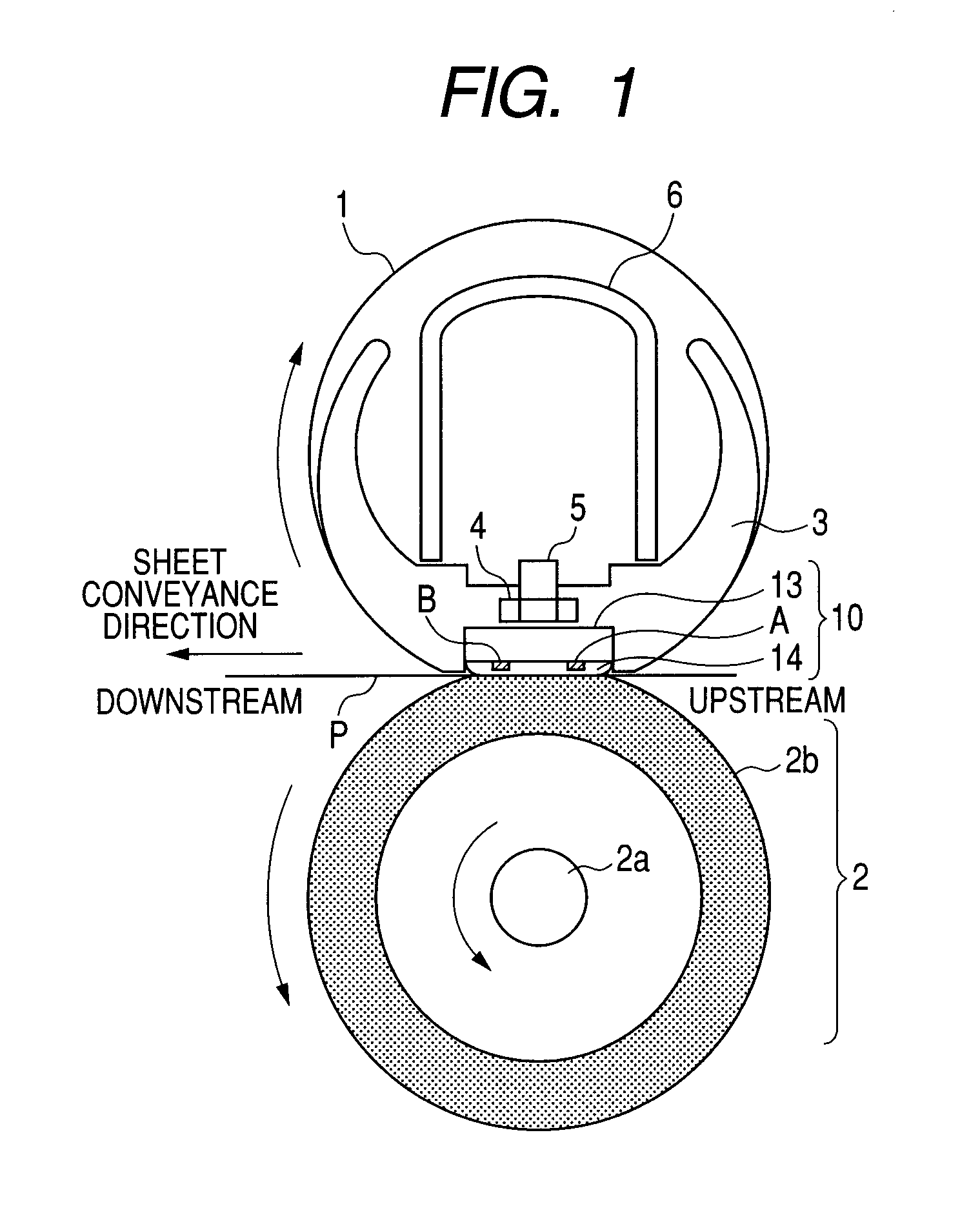

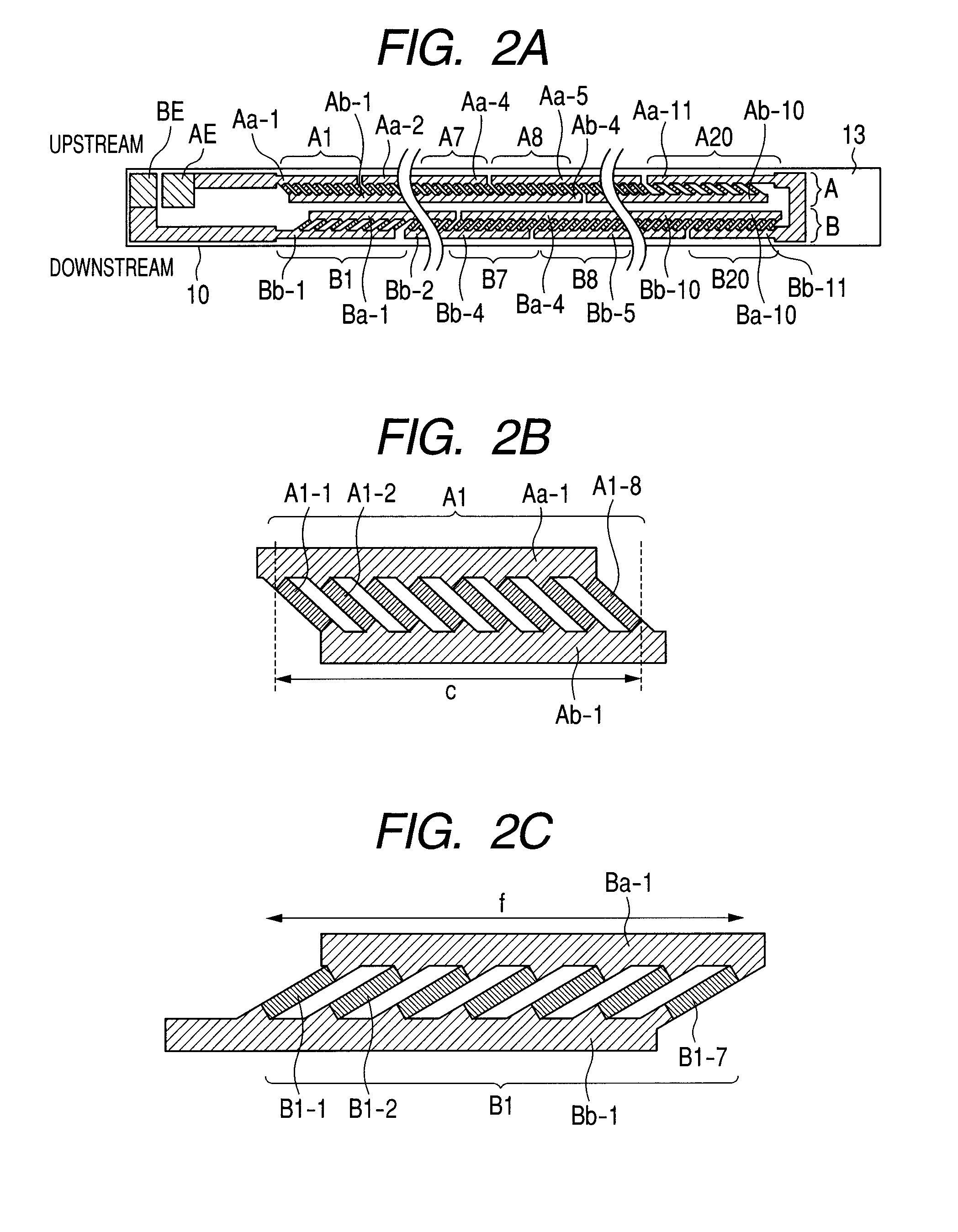

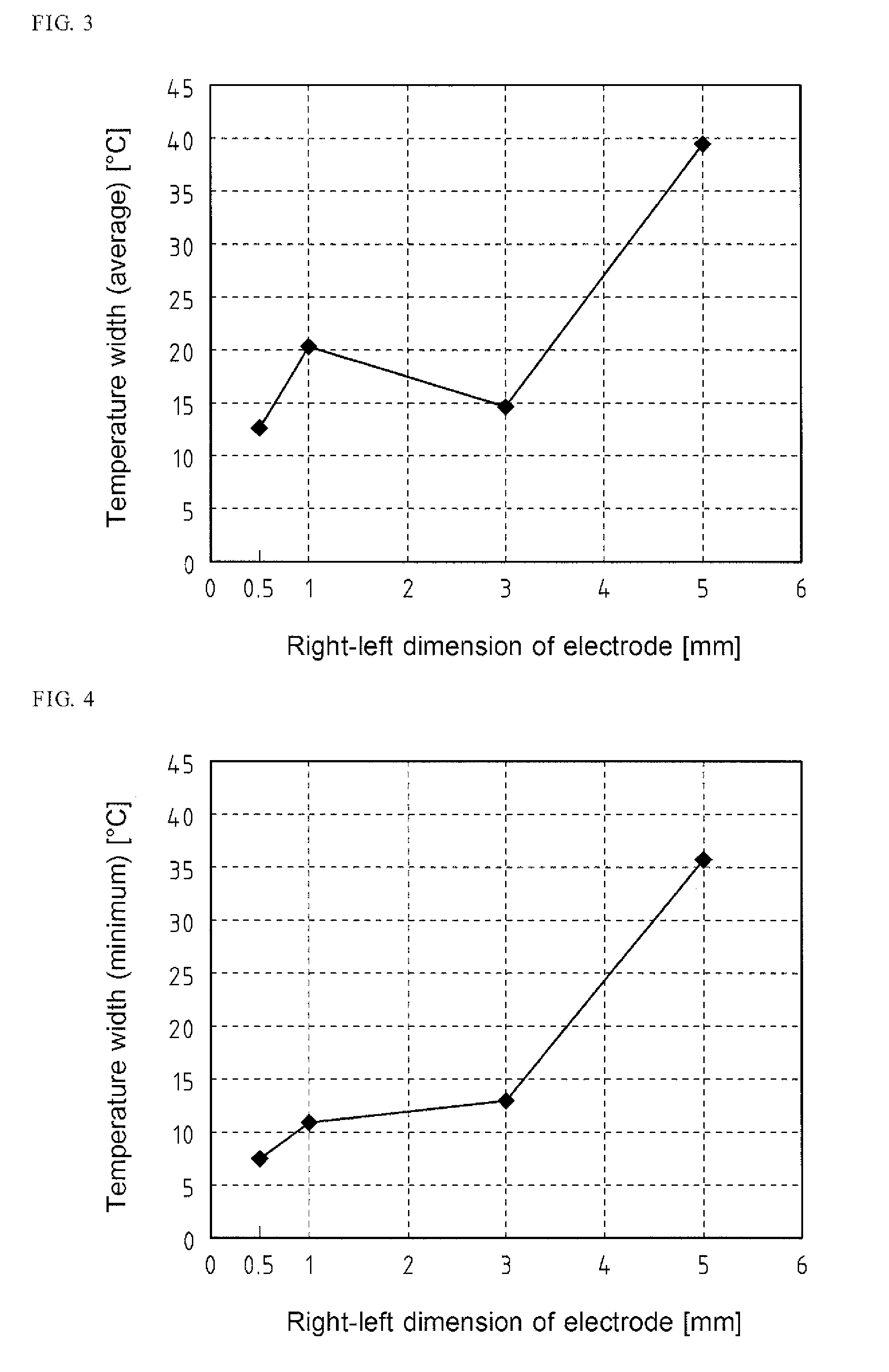

InactiveUS20120121306A1Uneven heat generationInhomogeneous suppressionOhmic-resistance heating circuitsHeater elementsElectricityHotline

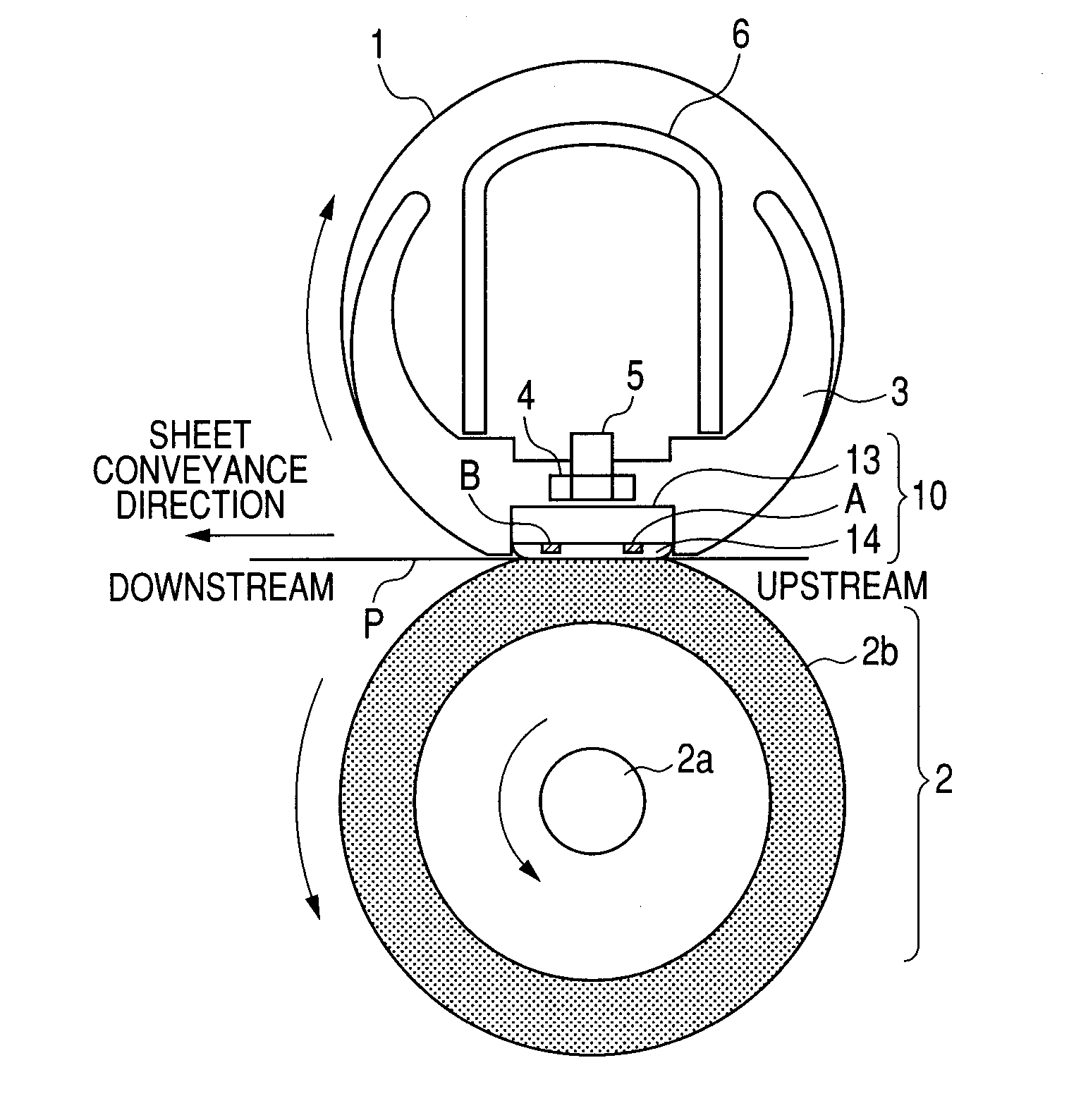

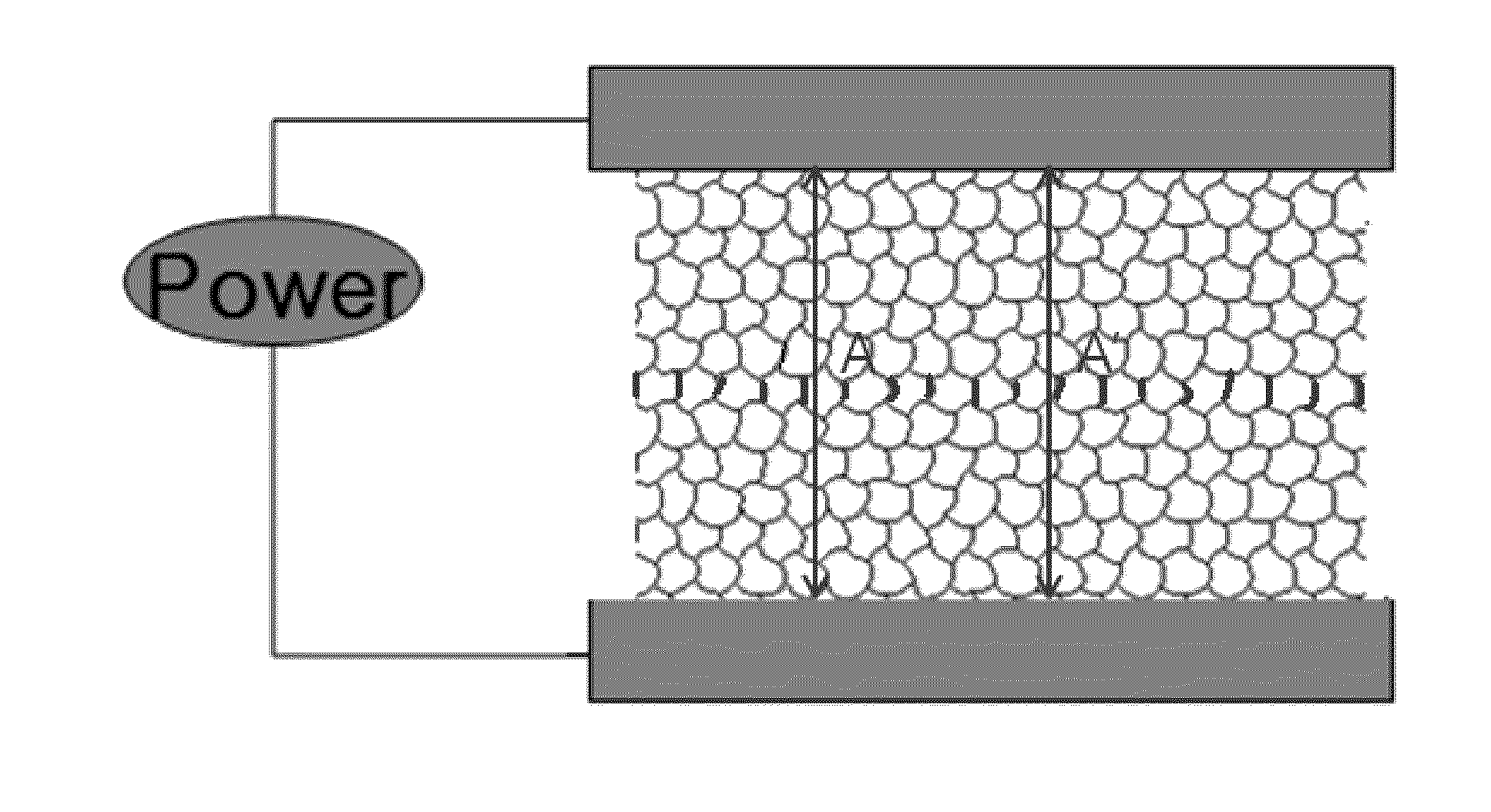

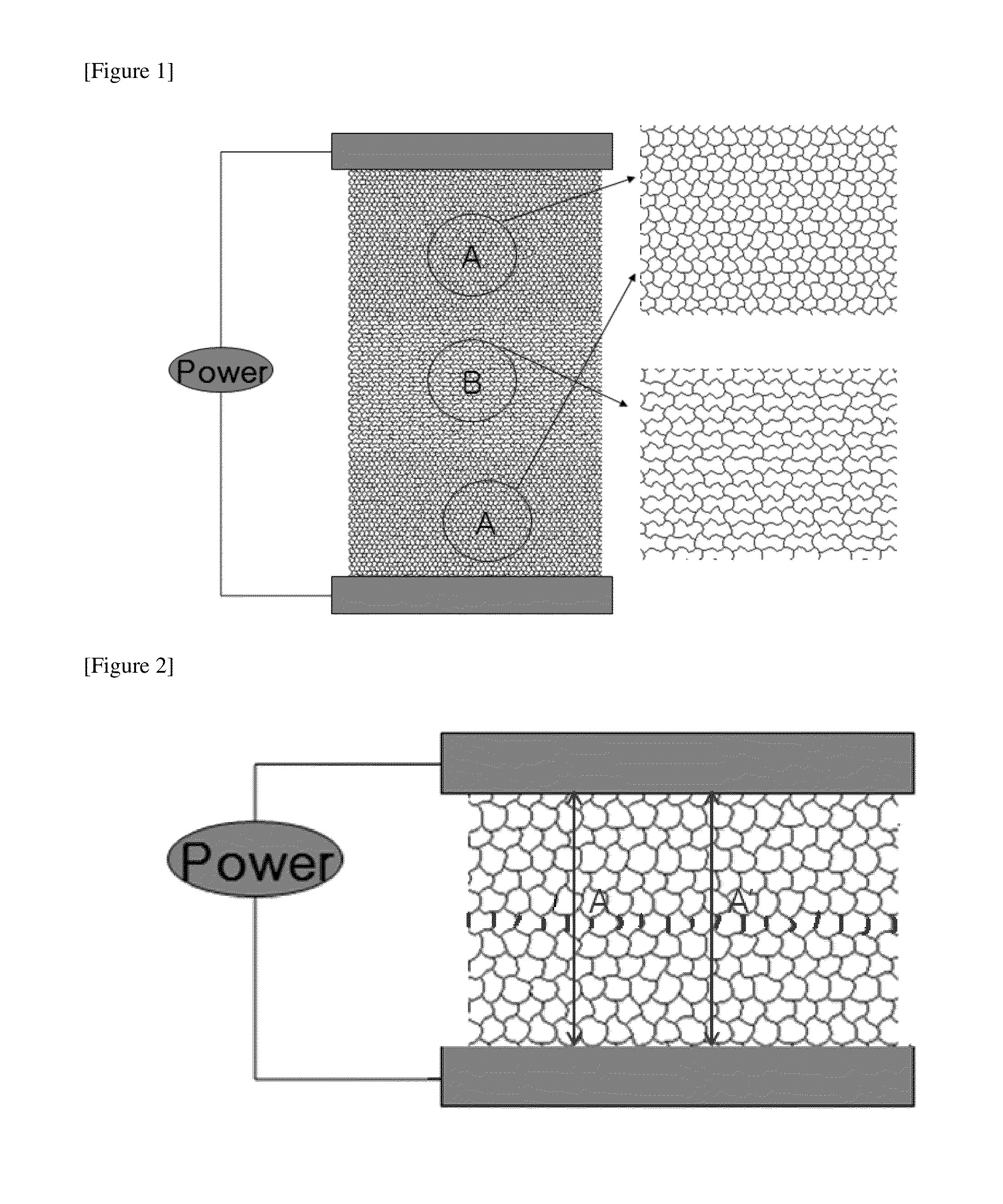

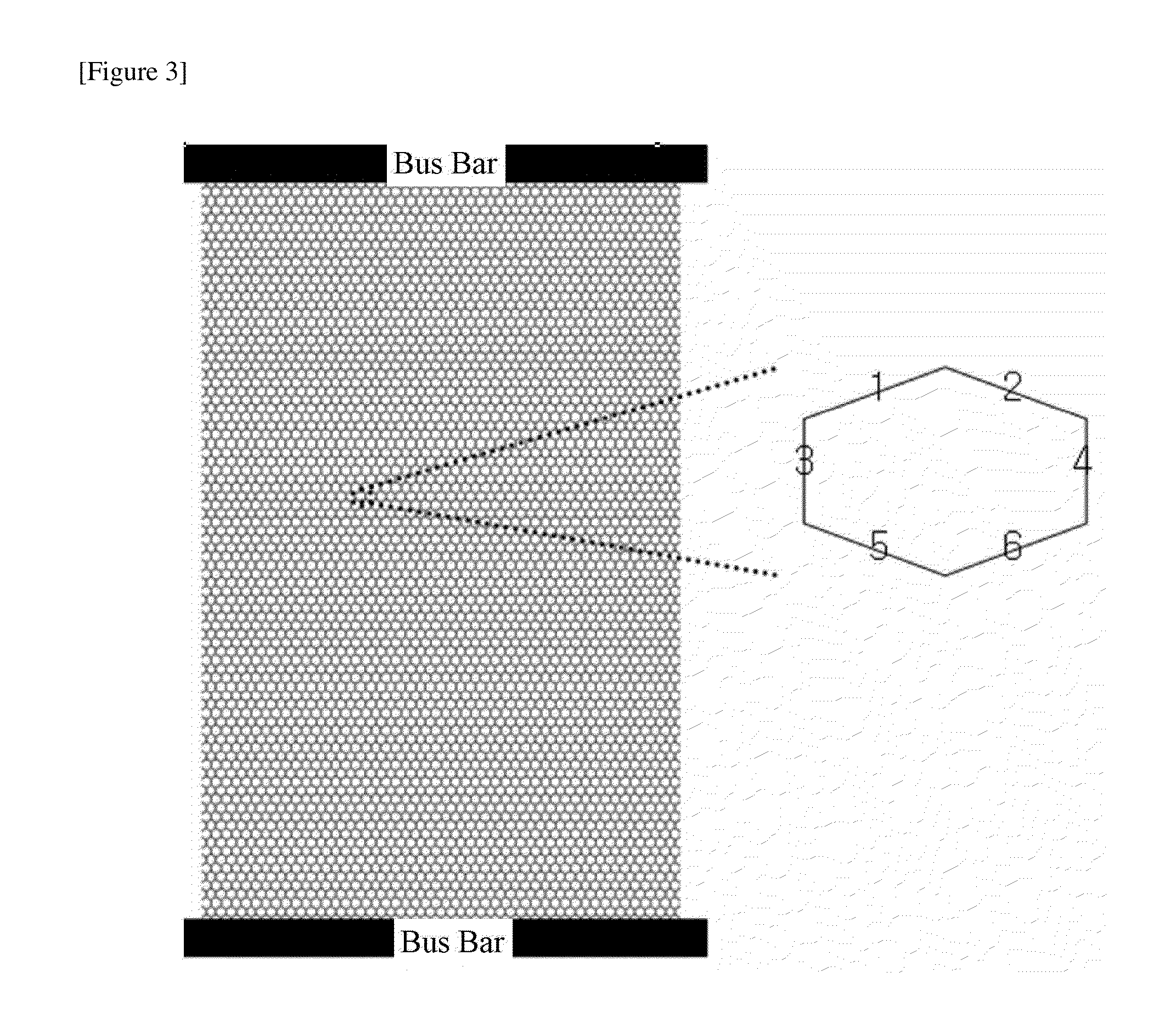

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

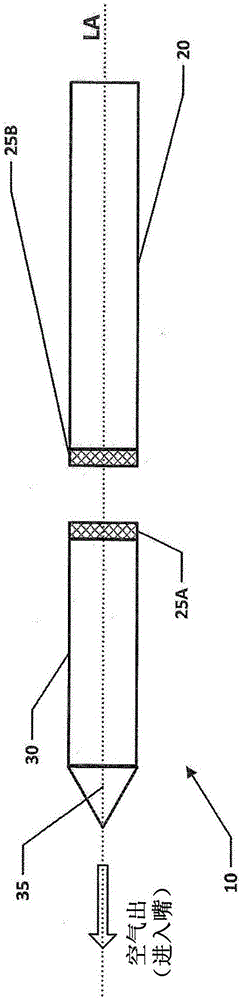

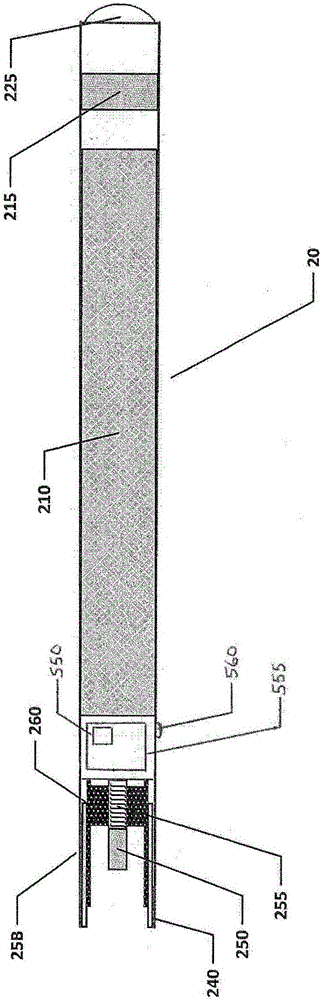

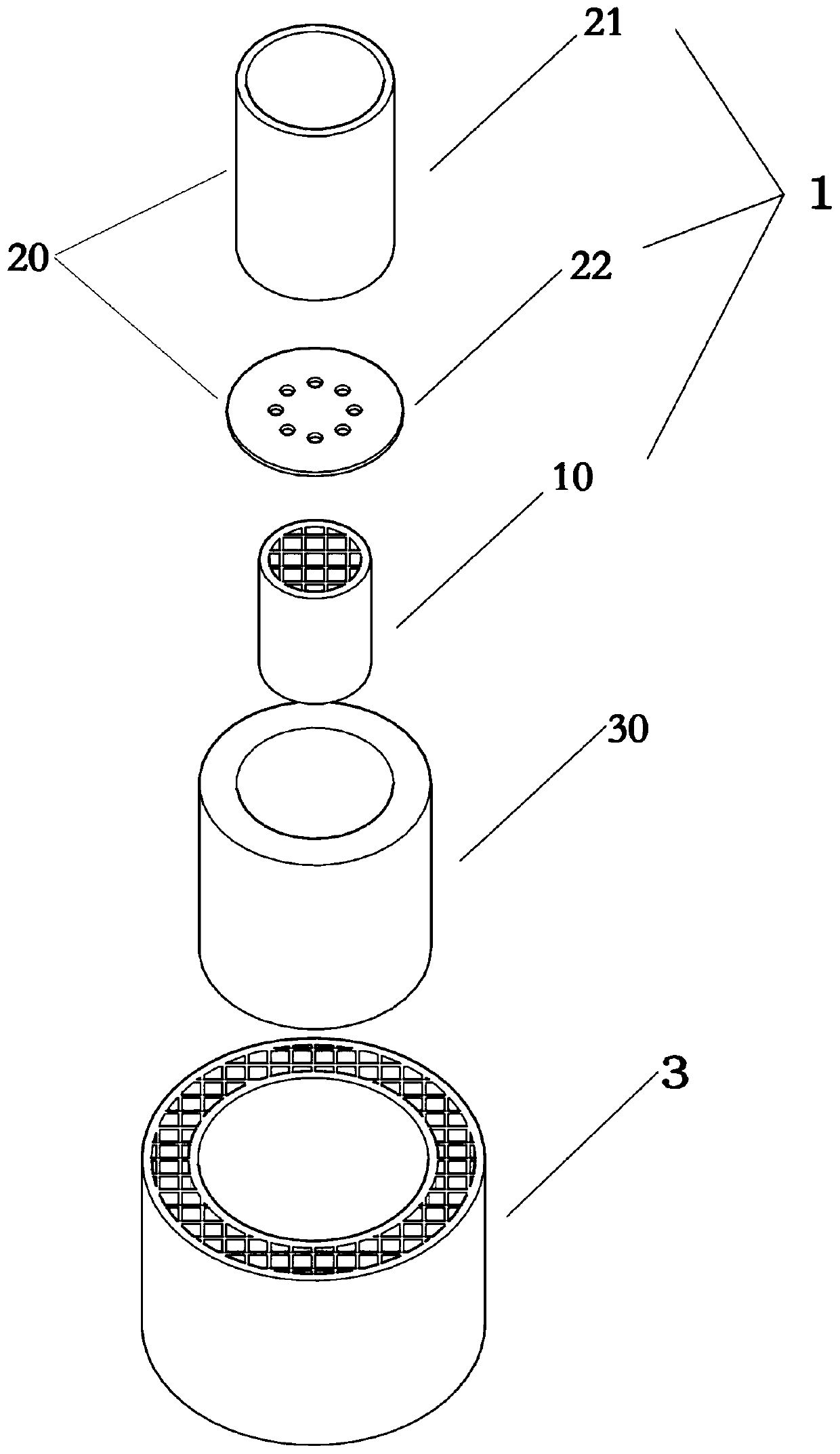

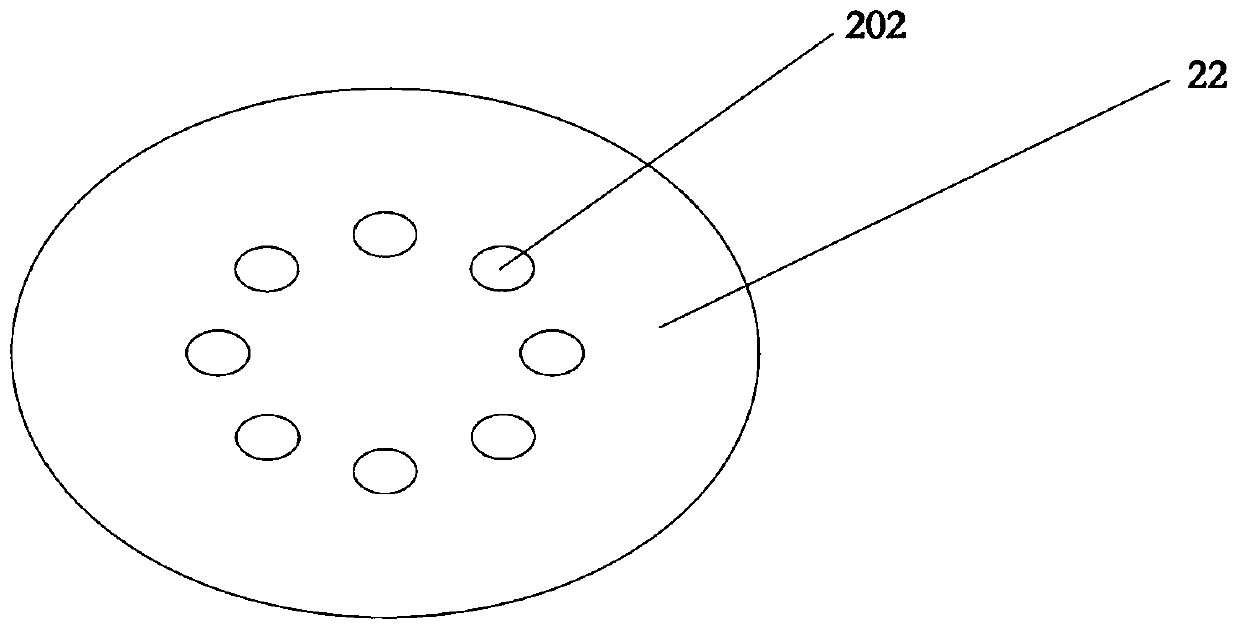

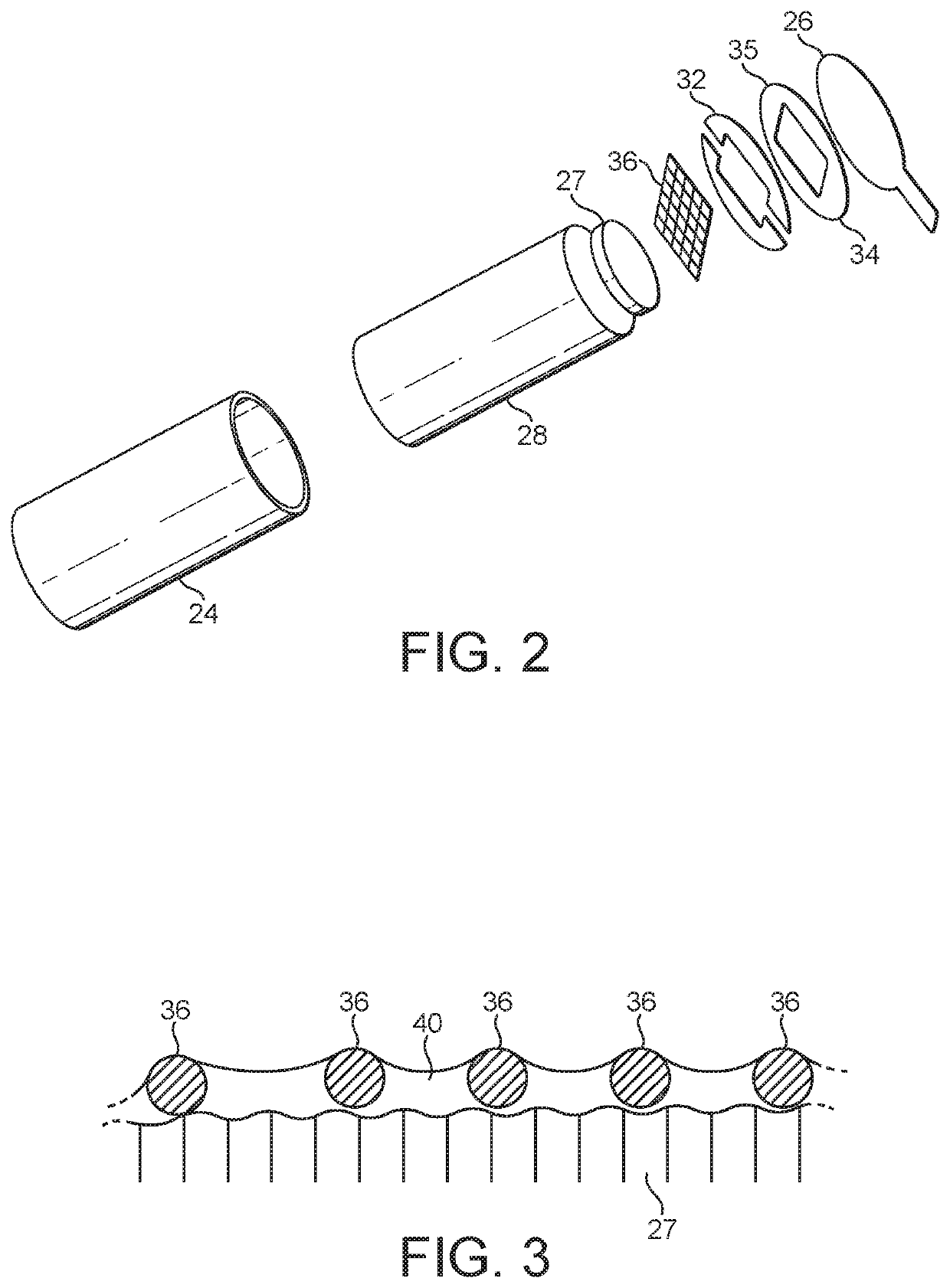

An aerosol-generating system having a heater assembly and a cartridge for an aerosol-generating system having a fluid permeable heater assembly

An aerosol-generating system comprising a liquid storage portion (20) comprising a rigid housing (24) holding a liquid aerosol-forming substrate, the housing having an opening and a fluid permeable heater assembly (30) comprising a plurality of electrically conductive filaments, wherein the fluid permeable heater assembly is fixed to the housing and extends across the opening of the housing. The provision of a heater assembly that extends across an opening of a liquid storage portion allows for a robust construction that is relatively simple to manufacture. This arrangement allows for a large contact area between the heater assembly and liquid aerosol-forming substrate. The heater assembly may be substantially flat allowing for simple manufacture.

Owner:PHILIP MORRIS PROD SA

Heating element and method for manufacturing same

ActiveUS20140117003A1Ohmic-resistance heating circuitsTransparent/reflecting heating arrangementsEngineeringHeating element

The present specification relates to a heating element in which a heating value for each region is controlled or a heating element in which the heating value for each region is controlled and which is inconspicuous, and a method for manufacturing the same.

Owner:LG CHEM LTD

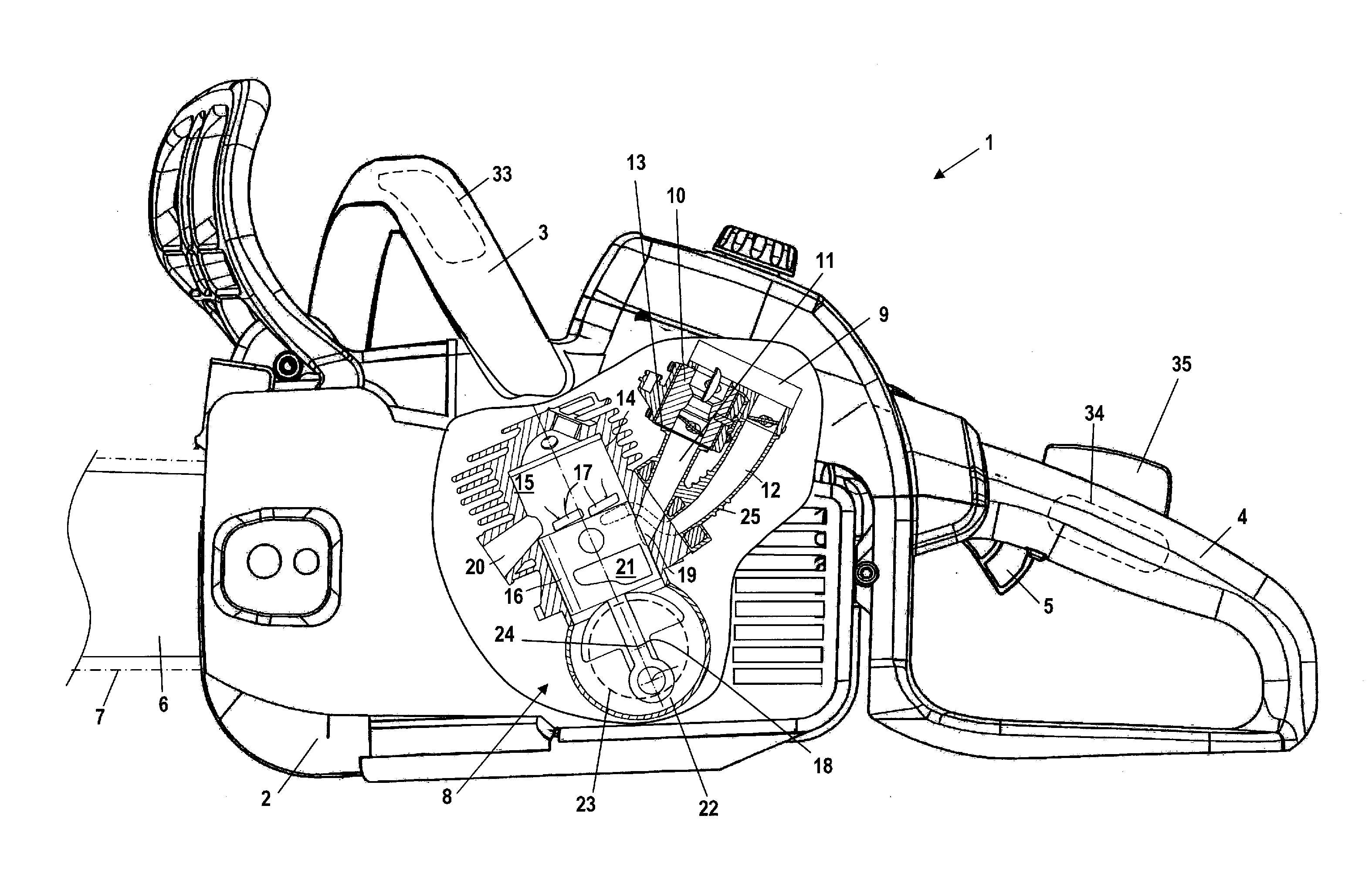

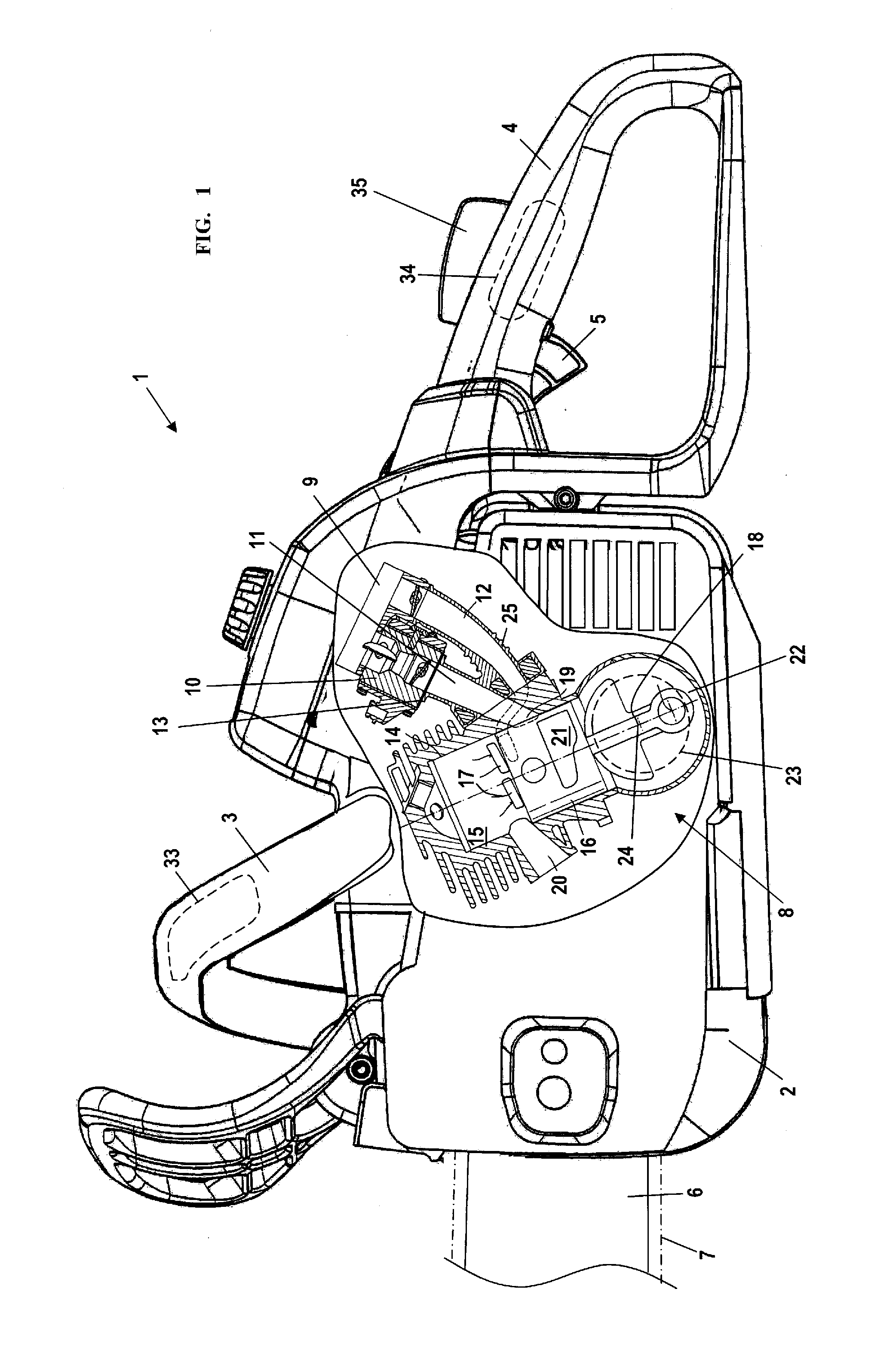

Handheld work apparatus having a control unit for an electric heating element

ActiveUS20120118254A1Precise temperature settingLittle technical effortMetal sawing devicesAir-treating devicesCarburetorInternal combustion engine

A portable work apparatus has a combustion engine for driving a work tool. An air / fuel mixture is supplied to the engine via a carburetor which is provided with an electrical heating element for heating to a given temperature. The heating element is connected to a switch via which electrical energy, which is provided by a generator driven by the engine, is supplied. When a given temperature is exceeded, the switch interrupts the energy supply. To achieve an exact temperature control, the ohmic resistance value of the heating element is stored in a memory in dependence on the temperature. The current flowing through the heating element and the voltage drop at the heating element are measured and the instantaneous resistance of the heating element is calculated therefrom. This calculated value is compared to the value stored in the memory to open or close the switch in dependence on the comparison.

Owner:ANDREAS STIHL AG & CO KG

Heater, image heating device with the heater and image forming apparatus therein

InactiveUS20140169846A1Inhomogeneous suppressionSolve even heatingOhmic-resistance heating circuitsHeater elementsElectricityImage formation

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

Heater, image heating device with the heater and image forming apparatus therein

InactiveUS8653422B2Inhomogeneous suppressionSolve even heatingOhmic-resistance heating circuitsOhmic-resistance electrodesElectricityHotline

The heater is capable of improving heat generation uniformity in a sheet feeding area while suppressing the temperature rise of a non-sheet feeding portion. Each of heat generation lines includes a plurality of heat blocks in which a plurality of heat generating resistors are electrically connected in parallel between two conductive members. The heat generation lines are arranged in a lateral direction of the substrate, and the heat blocks are arranged so that the end of the heat block in the heat generation line of a first row does not overlap with the end of the heat block in the heat generation line of a second row in a longitudinal direction of a heater.

Owner:CANON KK

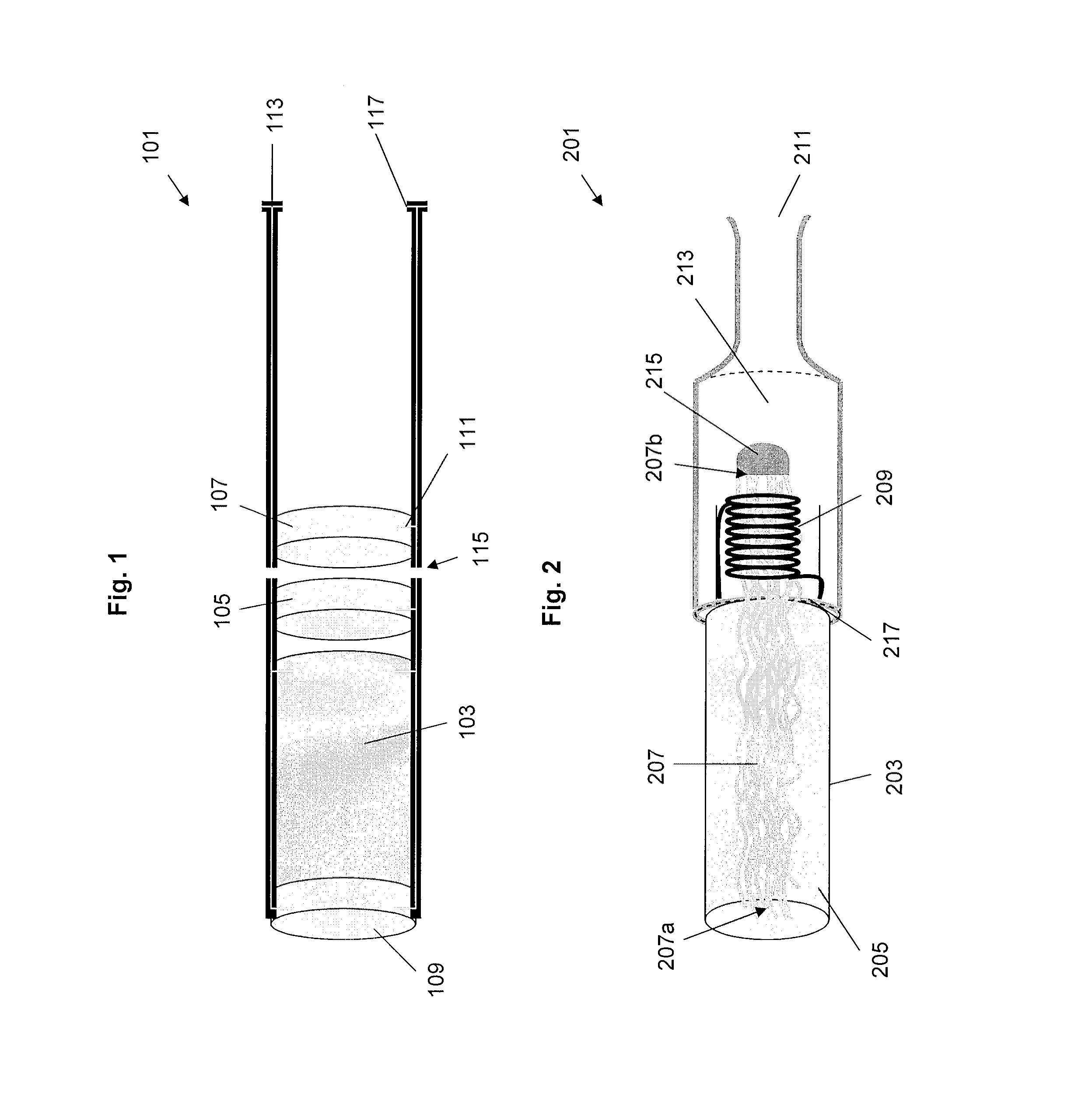

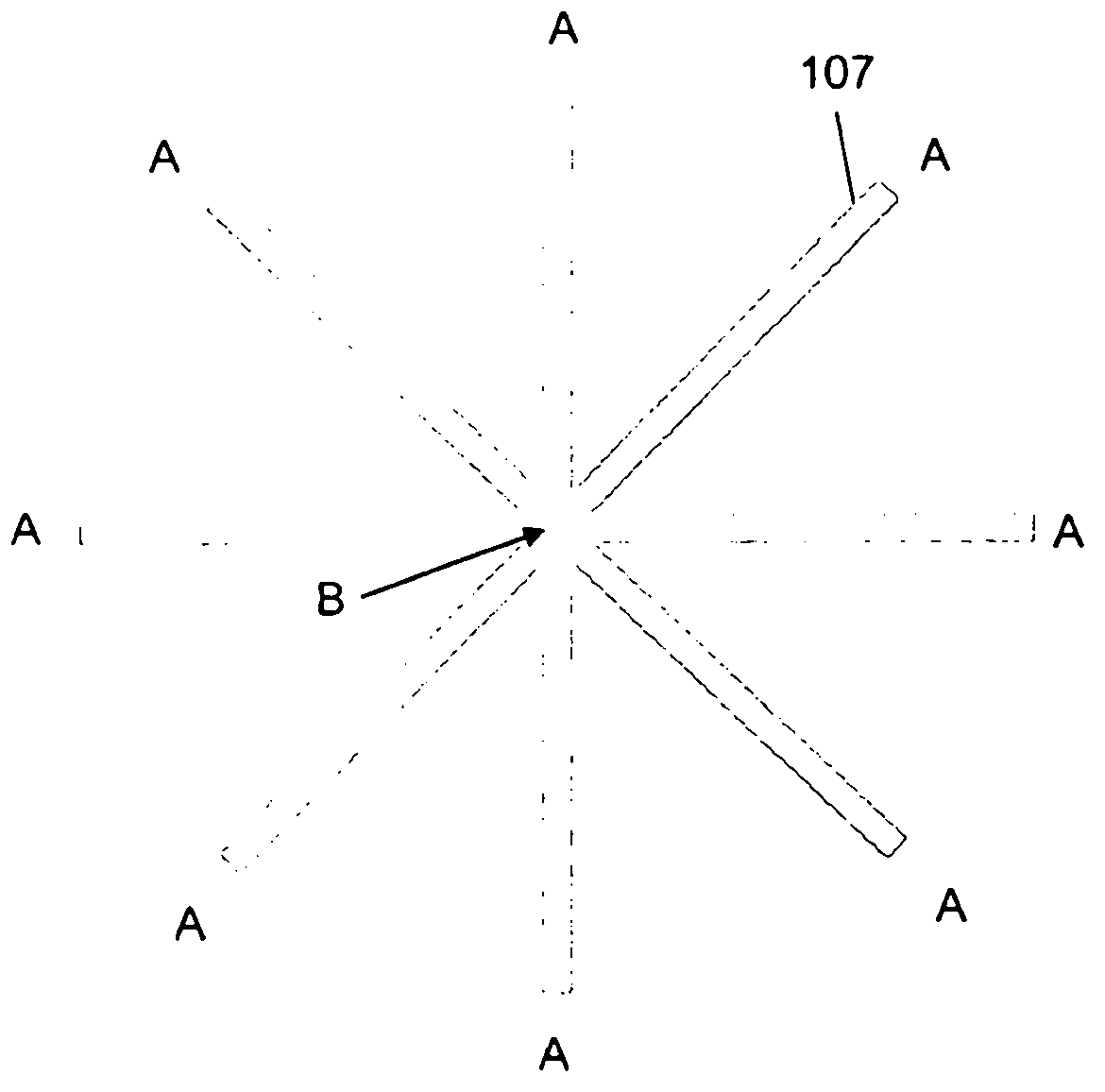

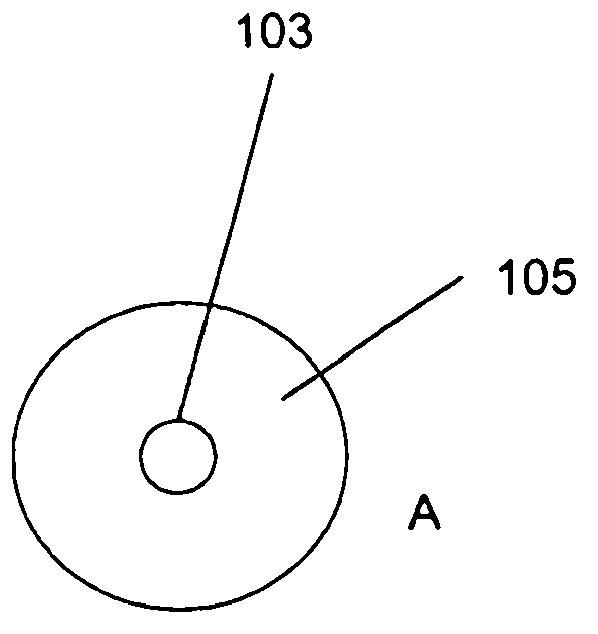

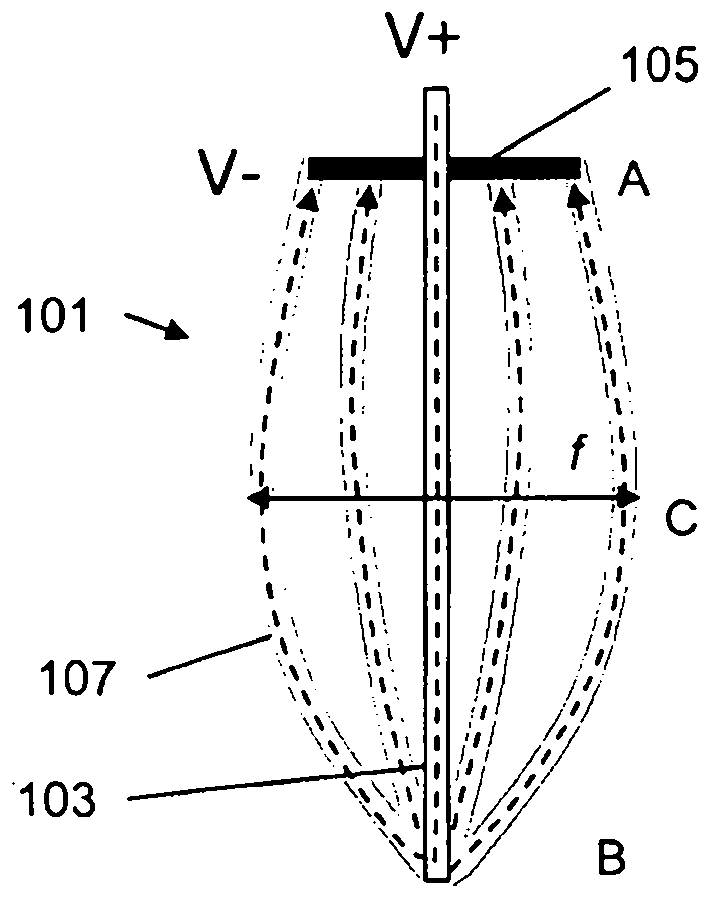

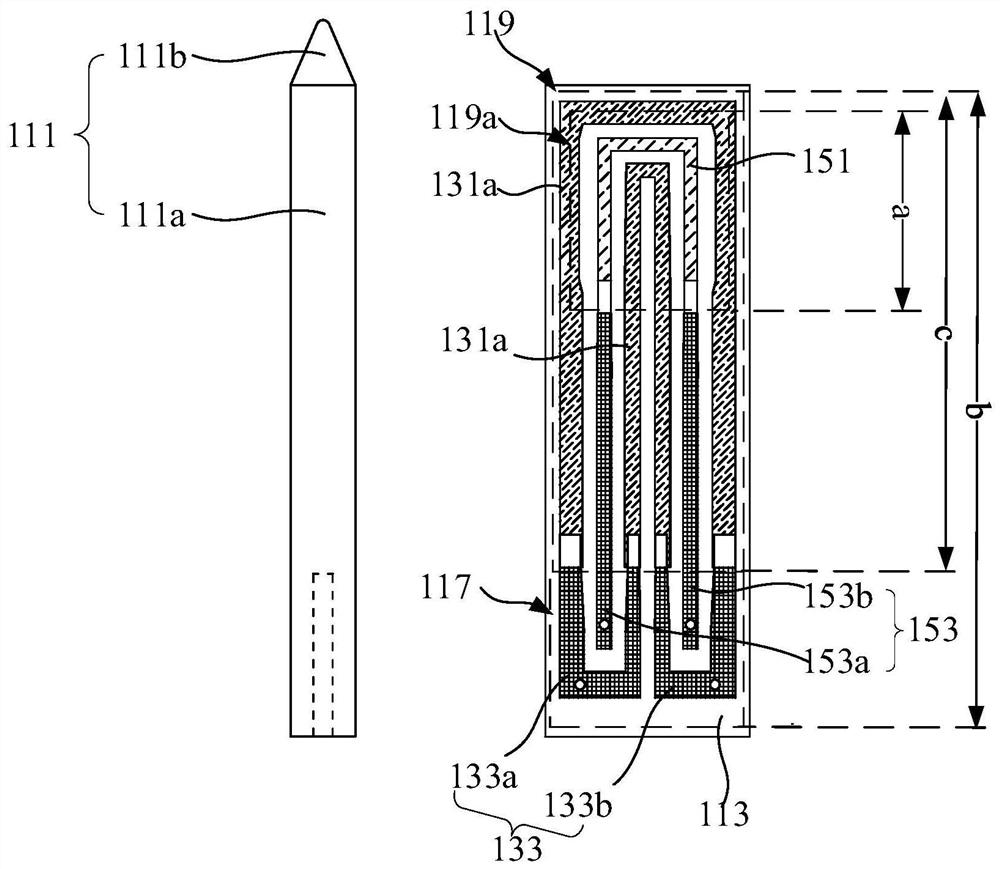

A shaped heater for an aerosol generating system

ActiveCN102781266AEfficient heatingEfficient heat treatmentOhmic-resistance heating circuitsTobacco treatmentElectricityEngineering

There is provided a heater (101) for heating an aerosol-forming substrate. The heater comprises a plurality of elongate heating elements (107) arranged in an elongate array. The elongate array has a support end with a first dimension, a heating end with a second dimension and a middle portion with a third dimension. The array is arranged to heat the substrate to form an aerosol. The third dimension is greater than the first dimension and greater than the second dimension. There is also provided an electrically heated aerosol generating system including such a heater.

Owner:PHILIP MORRIS PROD SA

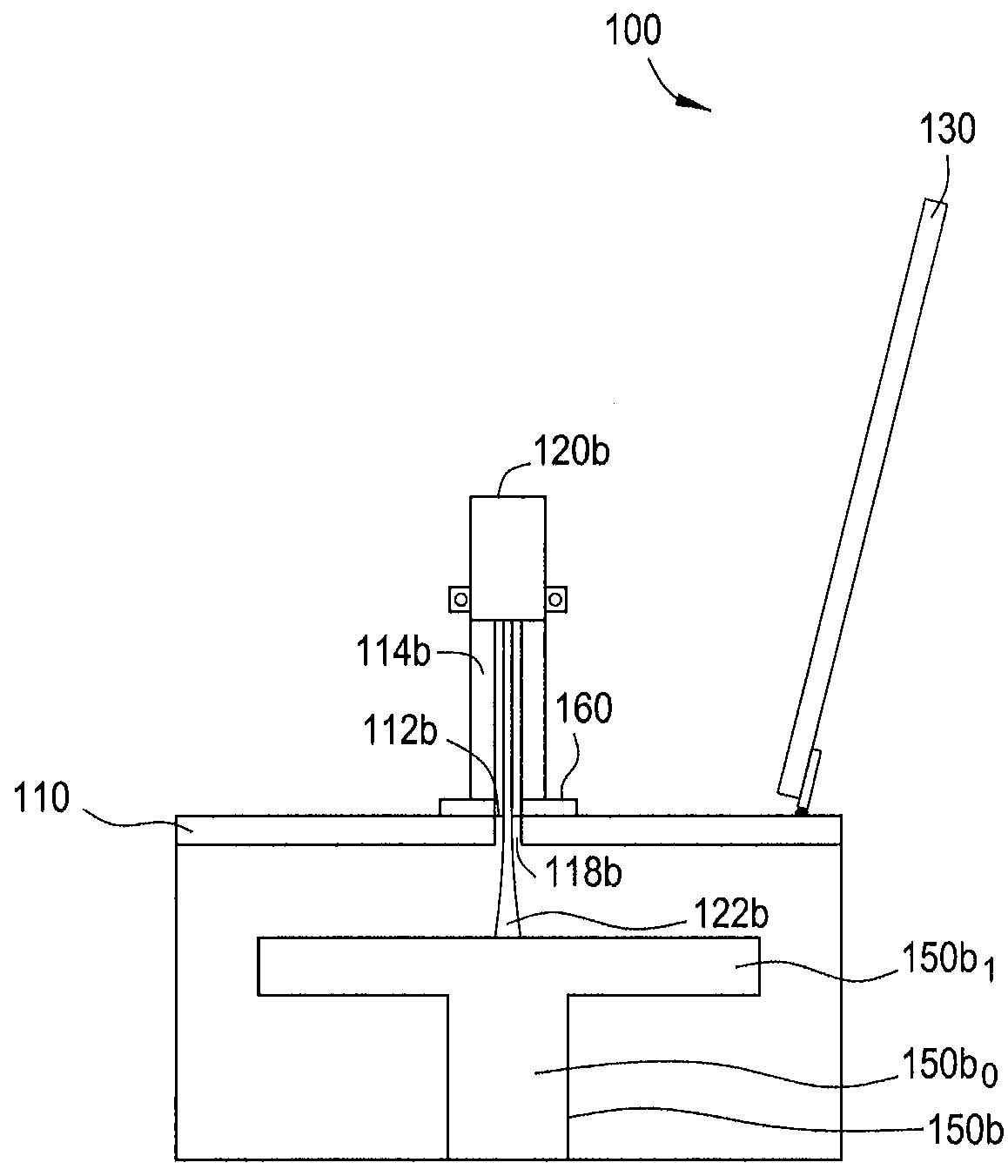

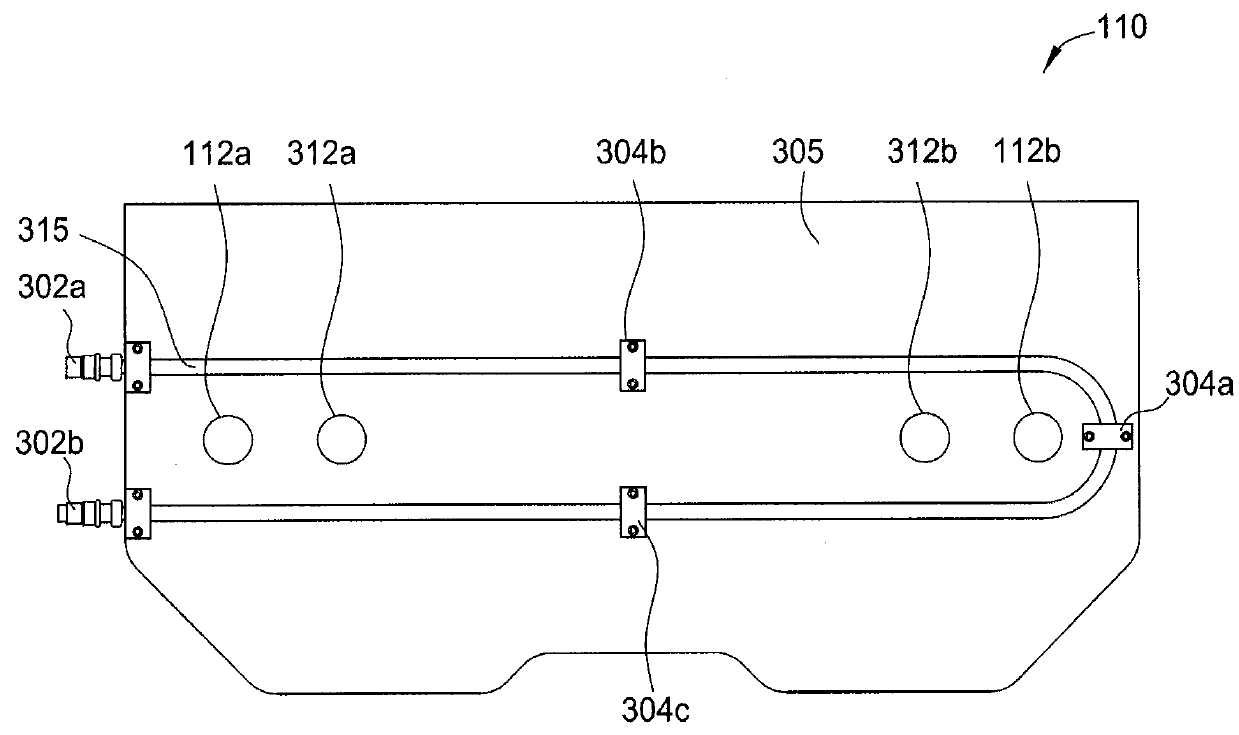

Non-contact temperature calibration tool for a substrate support and method of using the same

ActiveUS20180269089A1Ohmic-resistance heating circuitsSemiconductor/solid-state device testing/measurementTemperature controlElectrical resistance and conductance

Embodiments of the disclosure relate to methods for measuring temperature and a tool for calibrating temperature control of a substrate support in a processing chamber without contact with a surface of the substrate support. In one embodiment, a test fixture with a temperature sensor is removably mounted to an upper surface of a chamber body of the processing chamber such that the temperature sensor has a field of view including an area of the substrate support that is adjacent to a resistive coil disposed in the substrate support. One or more calibration temperature measurements of the area of the substrate support are taken by the temperature sensor and simultaneously one or more calibration resistance measurements of the resistive coil are taken corresponding to each calibration temperature measurement. Temperature control of a heating element disposed in the substrate support is calibrated based on the calibration temperature and calibration resistance measurements.

Owner:APPLIED MATERIALS INC

Electronic aerosol provision system

InactiveCN106604654ARespiratorsOhmic-resistance heating circuitsElectrical resistance and conductancePower flow

An aerosol provision system, such as an electronic cigarette, comprises a heating element for generating an aerosol from a source liquid and control circuitry for controlling a supply of electrical power from a power supply, such as battery / cell, to the heating element. The control circuitry is configured to measure an indication of a derivative of an electrical characteristic of the heating element with respect to time, for example a first time derivative or a second time derivative of a resistance of the heating element (or a related parameter, such as conductance, current draw, power draw or voltage drop). Based on the measured time derivative, the control circuitry is configured to determine whether or not a fault condition, e.g. localised heating of the heating element, has arisen for the electronic aerosol provision system. The overall change in the electrical characteristic for the heating element caused by the localised heating may be small and so difficult to reliably identify, but the rate at which the change occurs can be expected to be relatively high, which can mean the time derivative of the local characteristic is more reliable indicator of the occurrence of the fault condition.

Owner:NICOVENTURES TRADING LTD

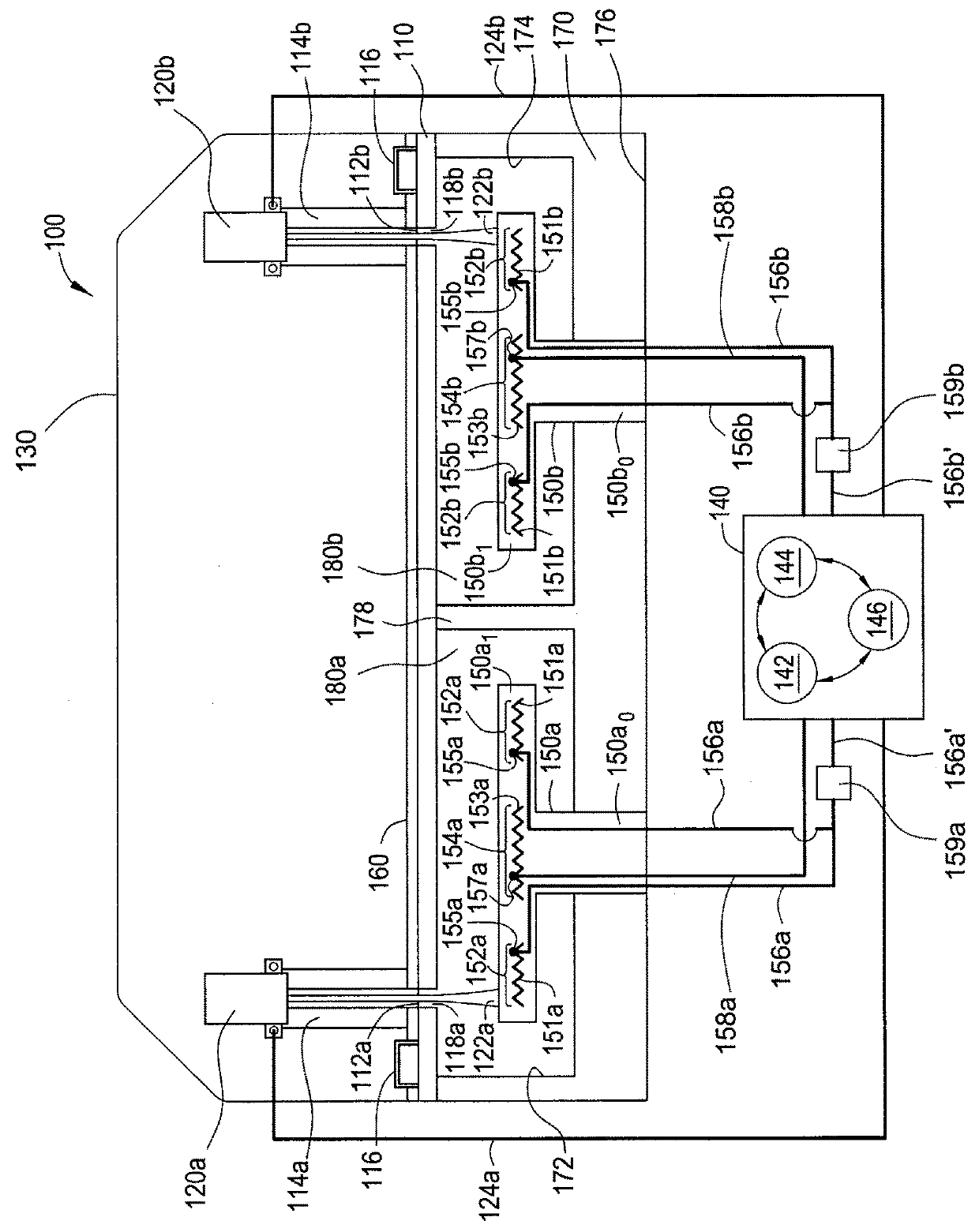

Voltage source converter based direct current deicer and controlling method thereof

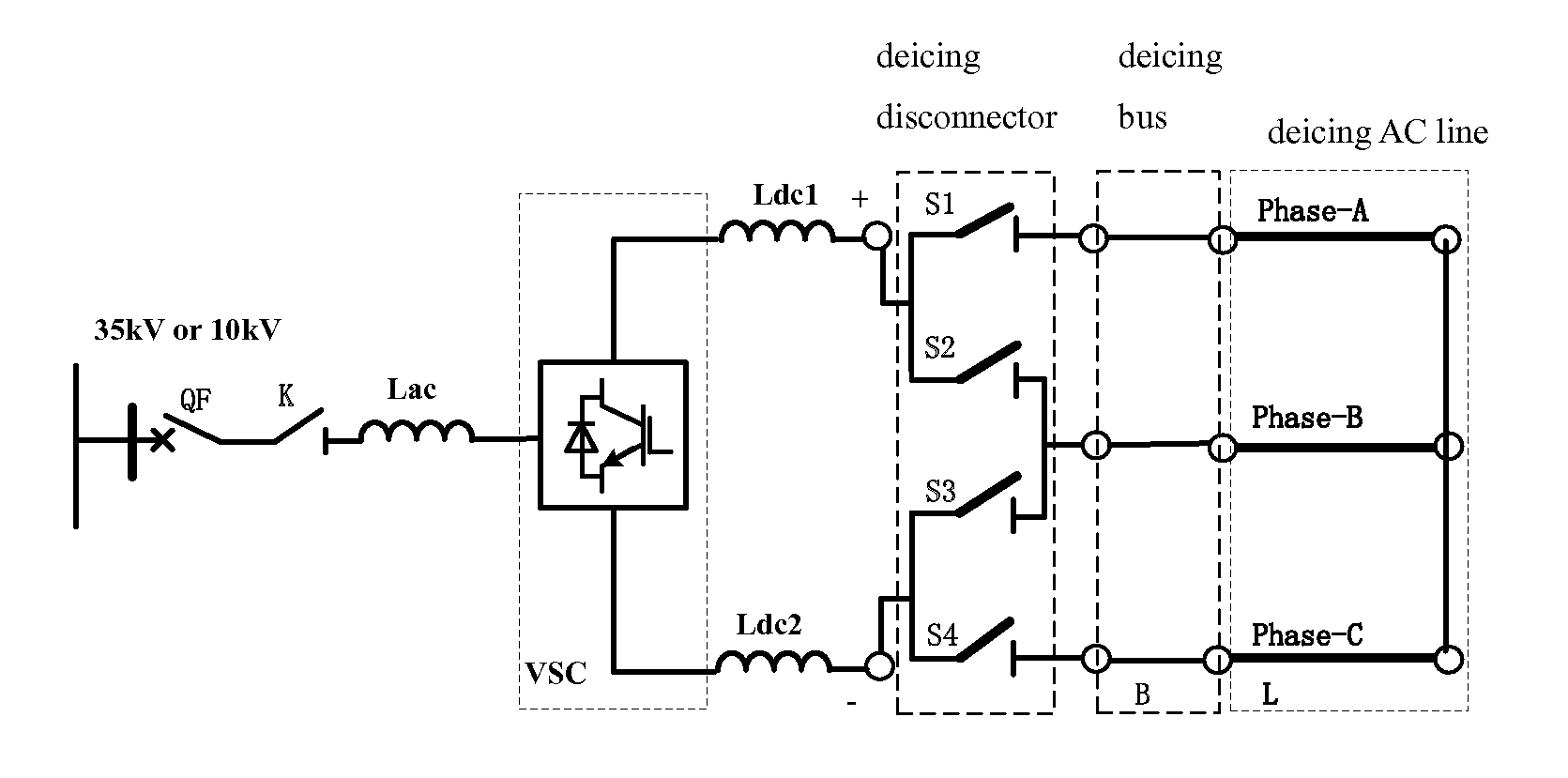

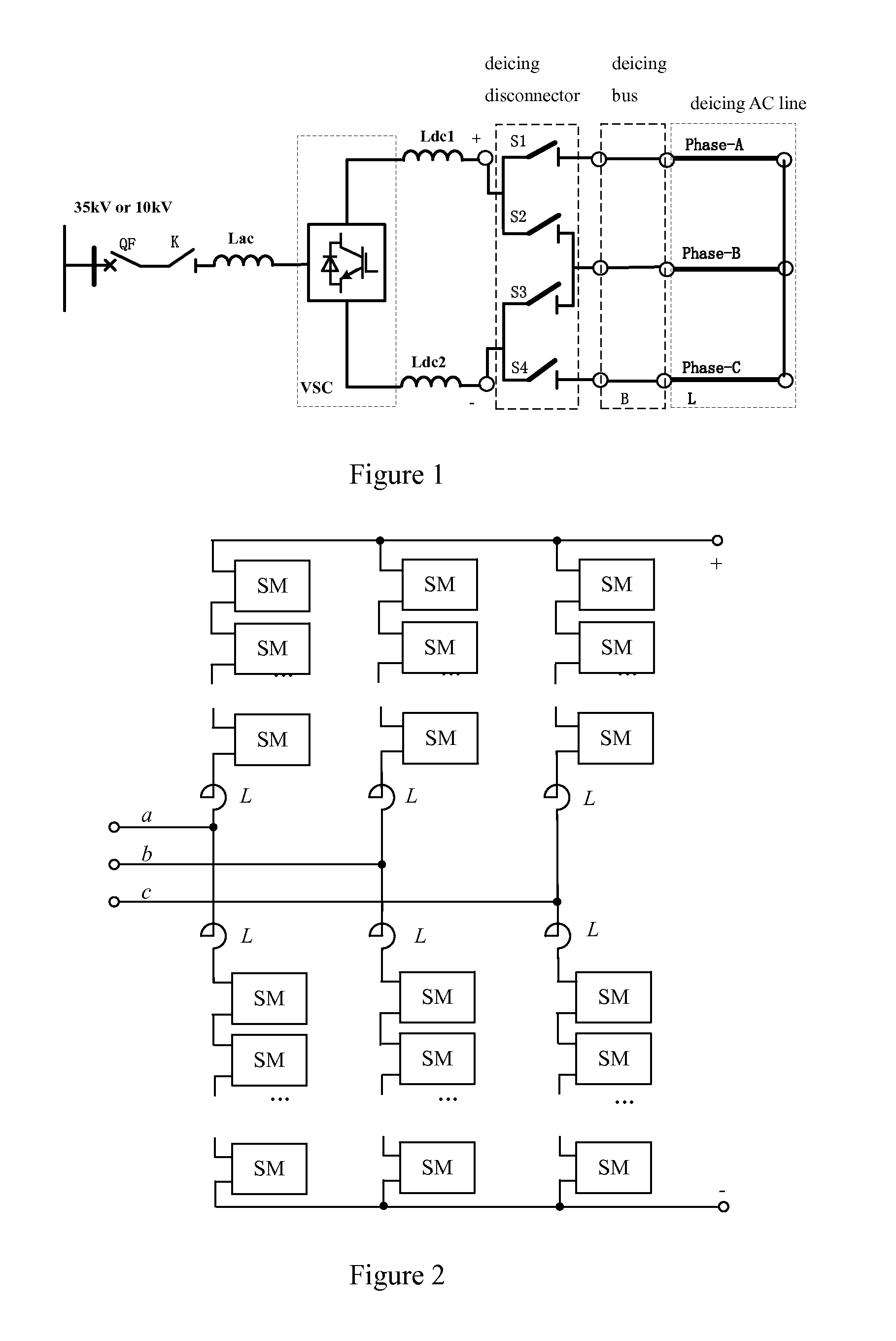

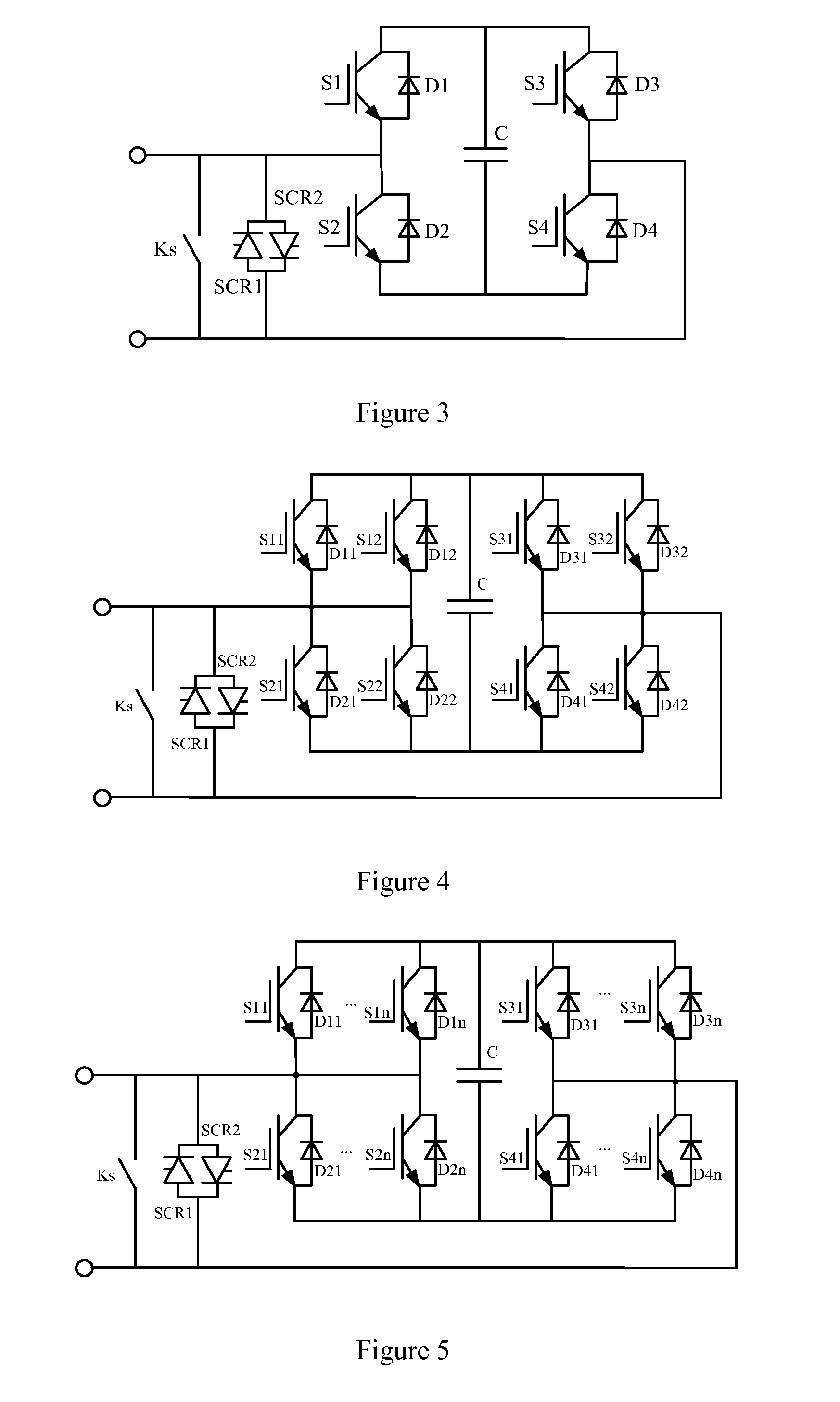

ActiveUS20160072267A1Ensure qualityWide applicationOverhead installationOhmic-resistance heating circuitsDisconnectorH bridge

A voltage source converter based DC deicer and its control method are provided. The voltage source converter based DC deicer includes a connecting reactor, a modular multilevel voltage source converter based on a full H-bridge submodule, smoothing reactors, deicing disconnectors, a deicing bus, and a deicing AC line. The AC side of the modular multilevel voltage source converter is connected to an AC side bus through the connecting reactor, an isolation disconnector and a breaker. The DC side of the modular multilevel voltage source converter is connected to the deicing AC line through the smoothing reactors, the deicing disconnectors, and the deicing bus.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

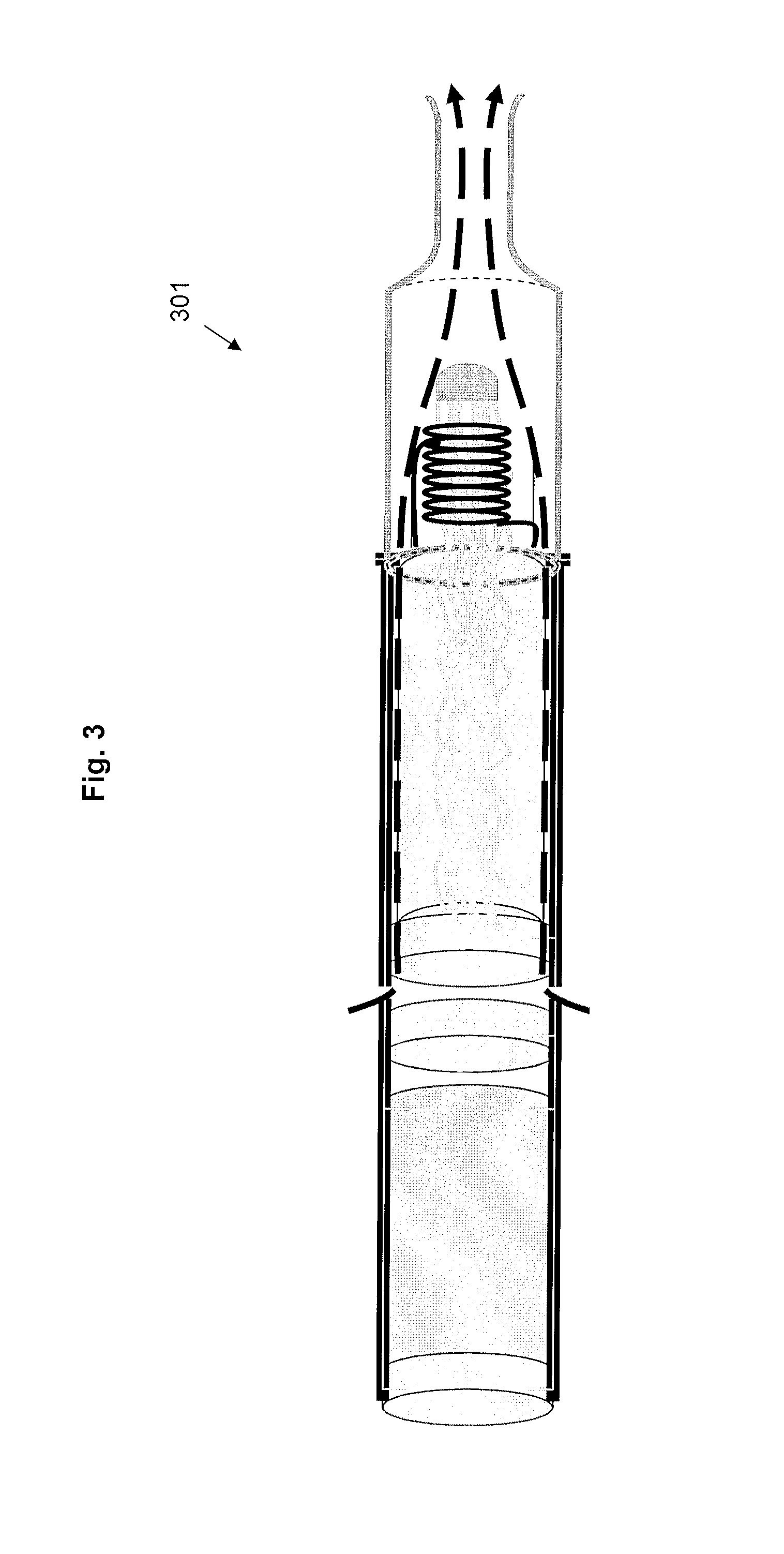

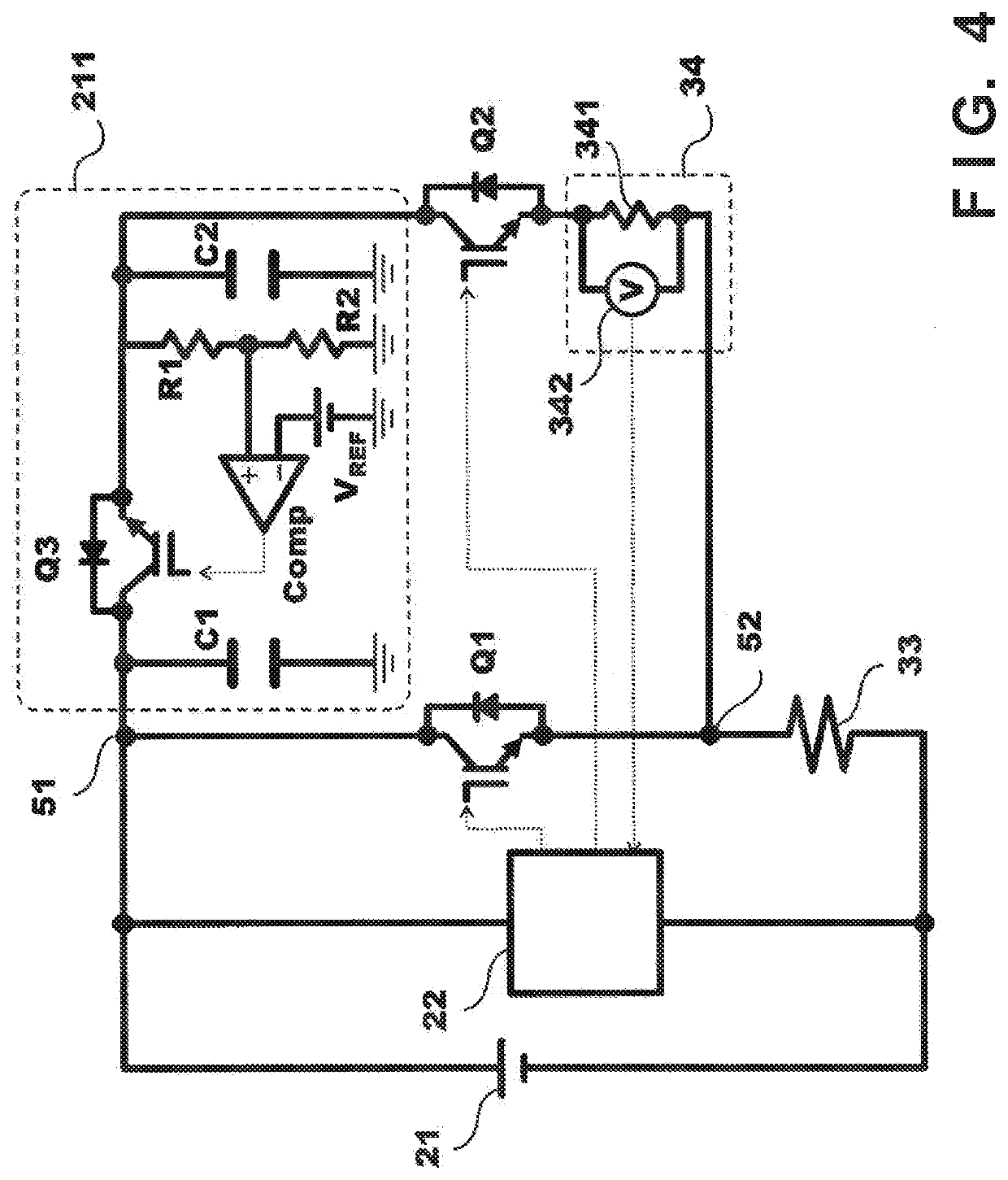

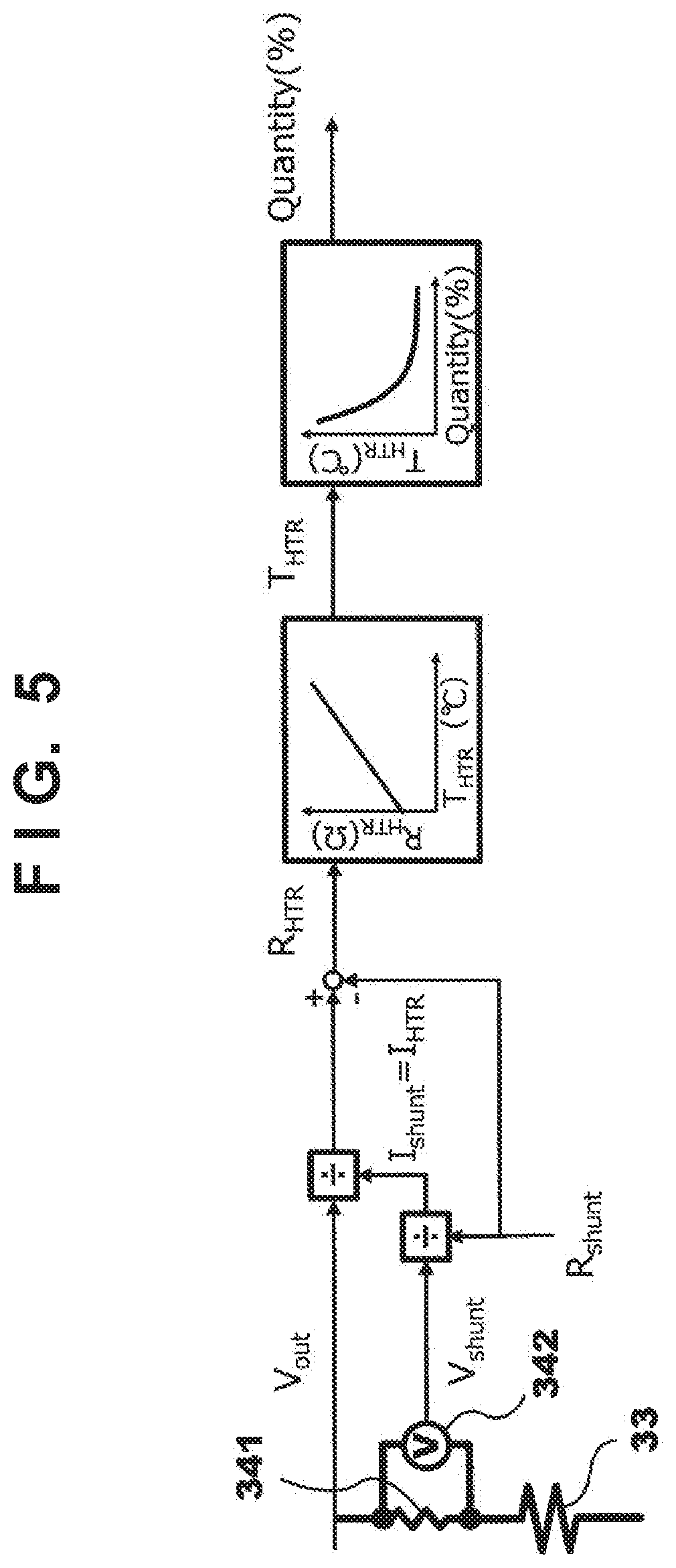

Aerosol generating apparatus

ActiveUS20200237013A1Suppress generationHigh precisionOhmic-resistance heating circuitsMedical devicesThermodynamicsControl power

An aerosol generating apparatus comprises: a power source; a load configured to have a resistance value that varies according to a temperature and generate an aerosol by atomizing an aerosol source or heating a flavor source when supplied with power from the power source; a sensor configured to include a resistor connected in series to the load and output a measurement value that is a current value of a current flowing through the resistor or a voltage value of a voltage applied to the resistor; and a control unit configured to control power supply from the power source to the load and receive output from the sensor, wherein the resistor has a resistance value that is set such that responsiveness of a change in the measurement value to a change in a temperature of the resistance value belongs to a prescribed range.

Owner:JAPAN TOBACCO INC

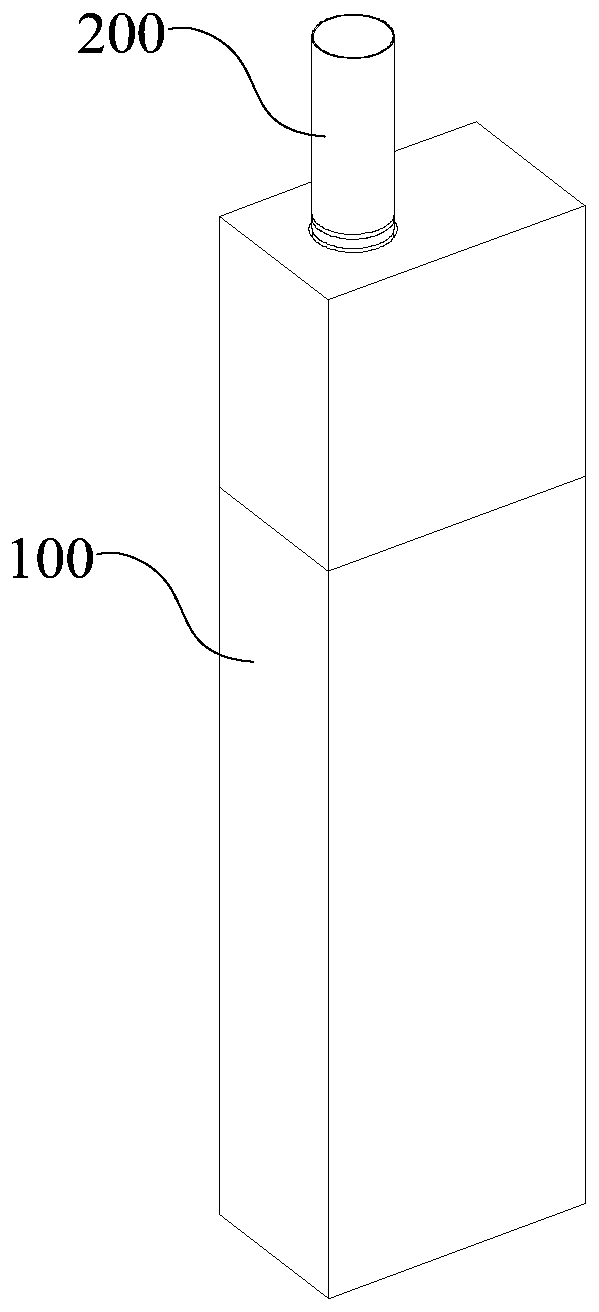

Electronic atomization device

PendingCN110652040AHigh degree of intelligenceAvoid dry burningOhmic-resistance heating circuitsCigar manufactureElectrical batteryMechanical engineering

The invention discloses an electronic atomization device comprising a smoke tube, a heating body assembly, an inductive switch and a reset piece. The smoke tube is used for inserting a cigarette; theheating body assembly can move in the smoke tube to turn on the inductive switch and enable a battery to supply power to the heating body assembly, and the reset piece is used for applying reset forceto the heating body assembly. According to the electronic atomization device, the inductive switch used for detecting cigarette insertion is arranged in the electronic atomization device so as to control the heating body assembly to heat, automatic detection of cigarette insertion can be achieved, the phenomenon that the heating body assembly is subjected to dry burning is avoided, and the intelligent degree of the electronic atomization device can be improved. Besides, the reset force applied to the heating body assembly by the reset piece can reset the heating body assembly after the heating body assembly emits heat, so that continuous heating of the heating body assembly can be realized only by one-time triggering, and the situation that the cigarette stops being heated due to accidental disconnection of the inductive switch in the heating process is avoided.

Owner:SHENZHEN MERIT TECH CO LTD

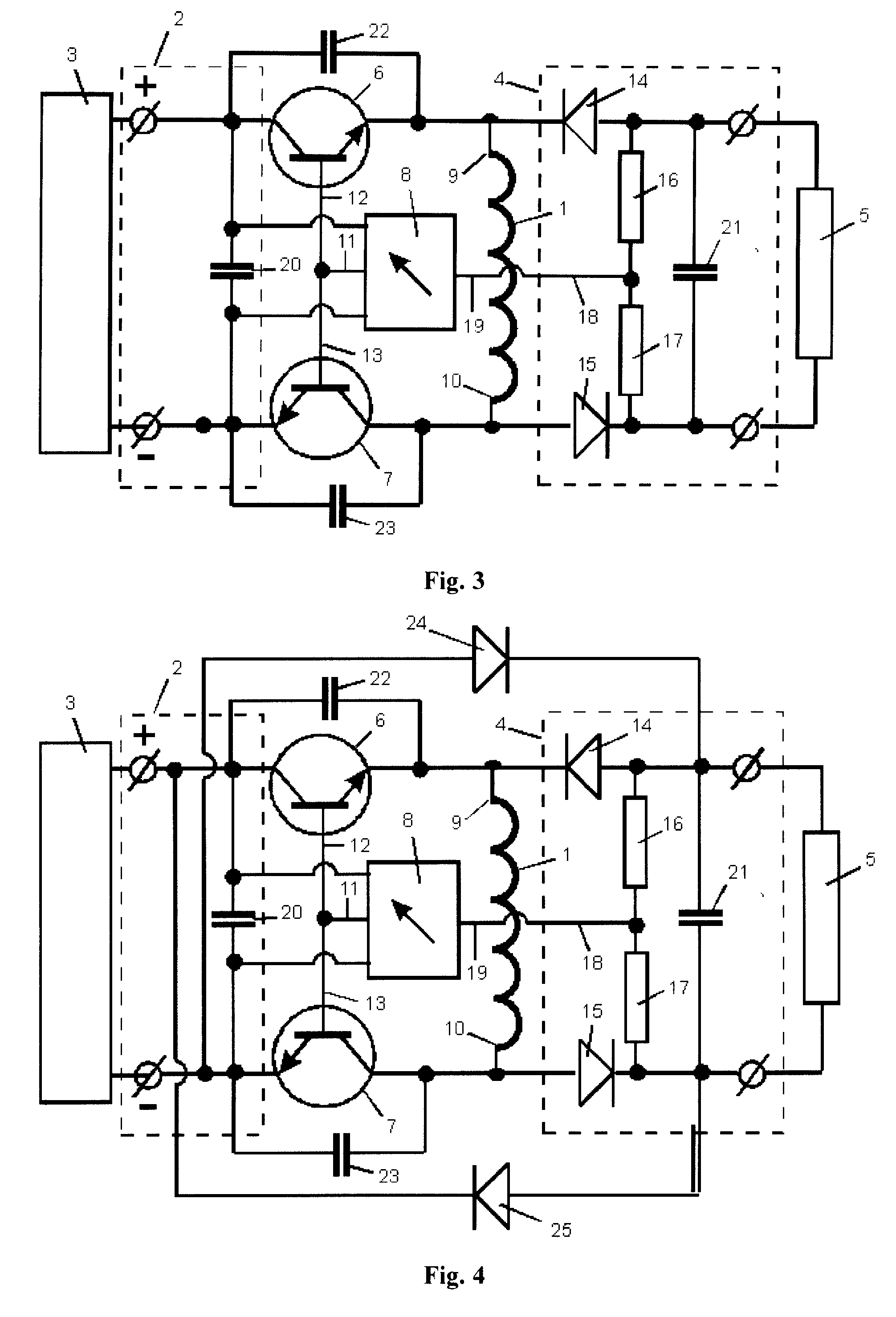

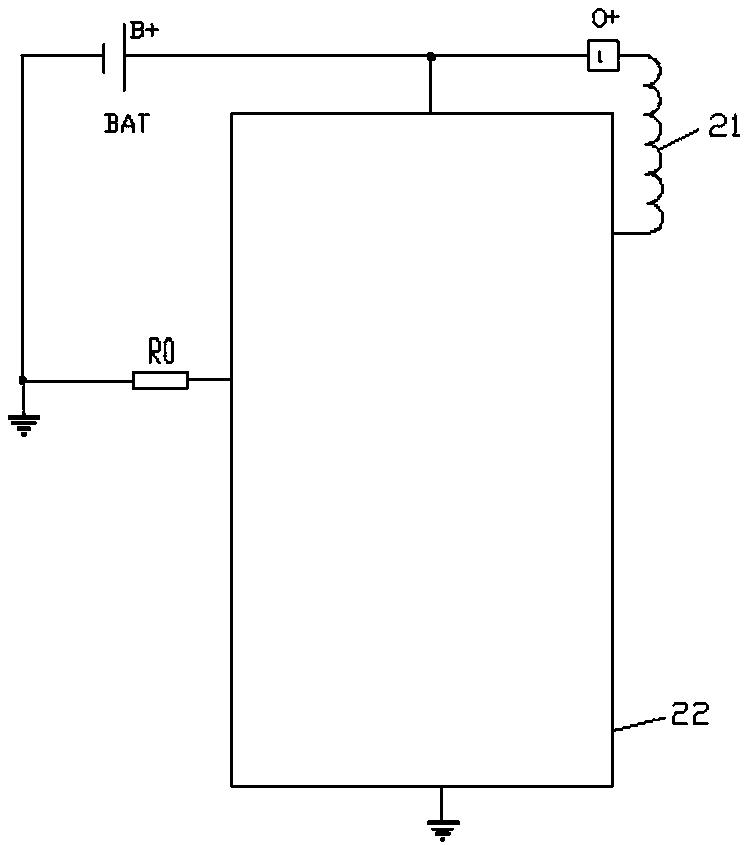

Power supply source for an electric heating system

InactiveUS20160043626A1Ohmic-resistance heating circuitsEfficient power electronics conversionLoad circuitElectronic switch

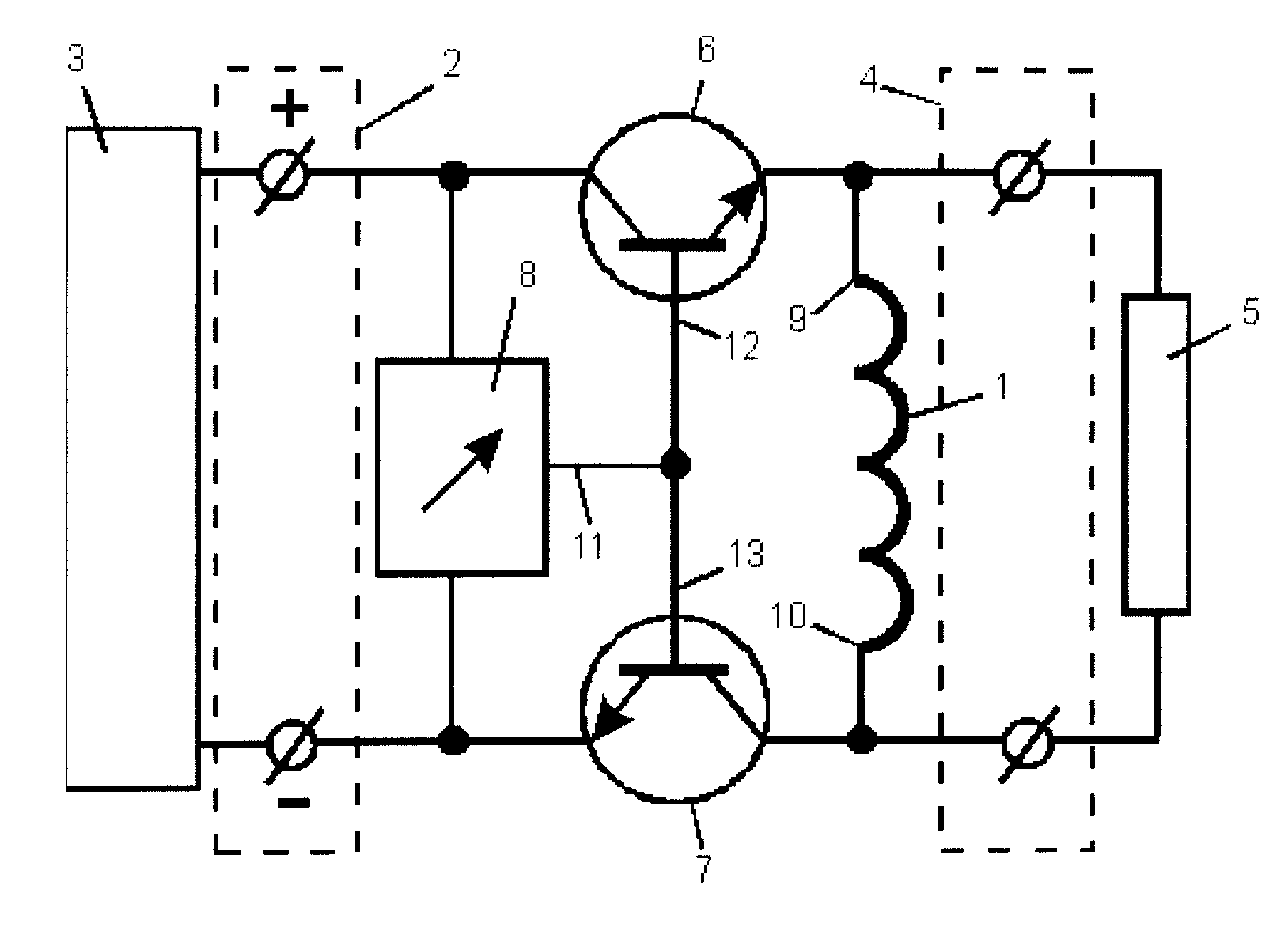

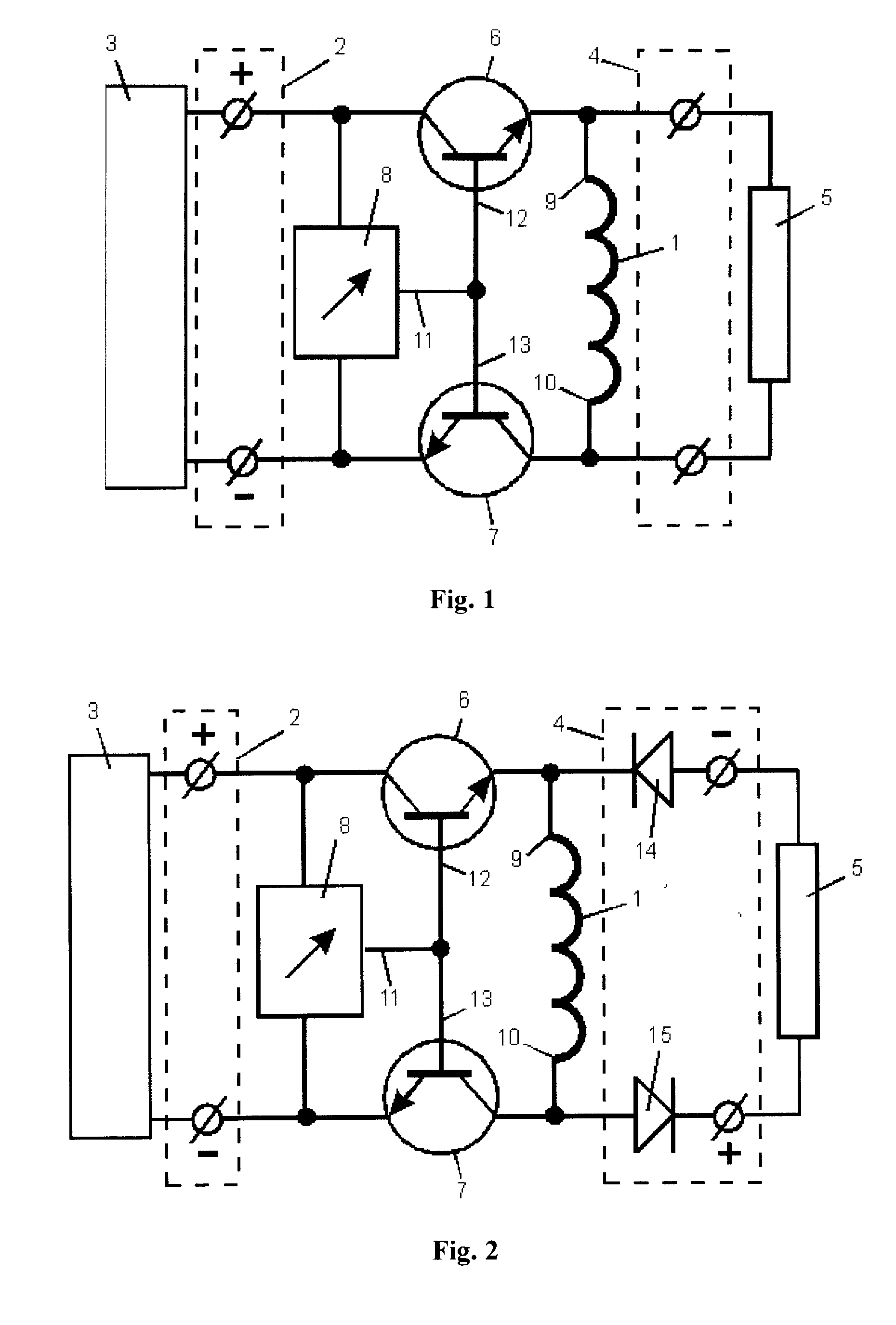

The invention relates to power engineering, in particular to electric heating systems for residential and other buildings. The power supply source for an electric heating system comprises an inductance coil (1), which is connected to a load circuit (4) and is connected to a primary source (3) of electrical energy with the possibility of periodic connection of one of the ends of said coil (9) to one of the terminals of the primary source (3) of electrical energy via an electronic switch (6), and a generator (8) of unipolarity pulses, the output of which is connected to the input of the electronic switch (6). According to the invention, the second end (10) of the inductance coil (1) is connected to the second terminal of the primary source (3) of electrical energy via a second electronic switch (7), the input of which is connected to the output of said generator (8) of pulses of single polarity so as Co ensure synchronized operation of said electronic switches (6, 7). The result which can be achieved consists in increasing the energy conversion ratio.

Owner:KLYOSOV VLADIMIR ALEKSEEVICH +1

Heater, fixing device, and image forming apparatus

ActiveUS20200249601A1Ohmic-resistance heating circuitsOhmic-resistance electrodesElectrical conductorImage formation

A heater includes a base and at least one resistive heat generator mounted on a face of the base. At least one electrode supplies power to the at least one resistive heat generator. A conductor couples the at least one electrode with the at least one resistive heat generator. A slide layer covers the at least one resistive heat generator and the conductor. The slide layer includes a projecting portion that defines a surface of the slide layer. The projecting portion is defined by a film thickness of at least one of the conductor and the at least one resistive heat generator. The projecting portion includes an upstream projection disposed opposite a lateral end of the base in a longitudinal direction of the base and a downstream projection disposed downstream from the upstream projection in a rotation direction of an endless belt that slides over the heater.

Owner:RICOH KK

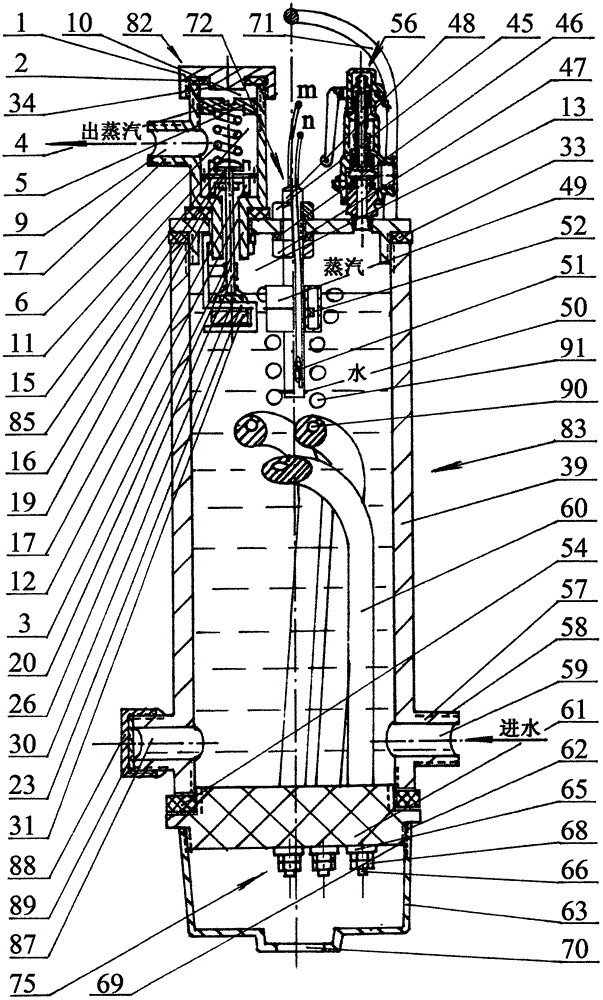

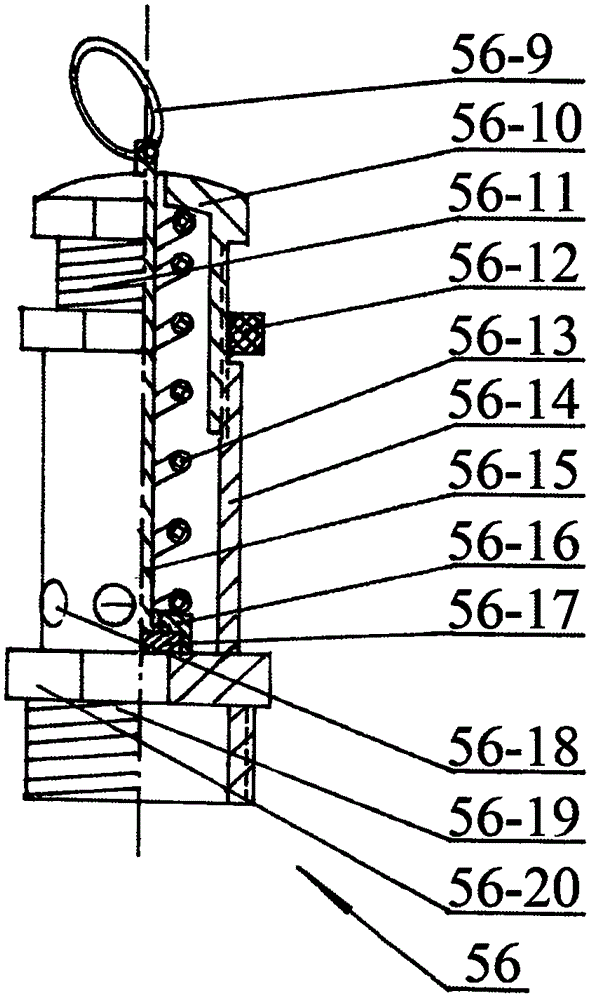

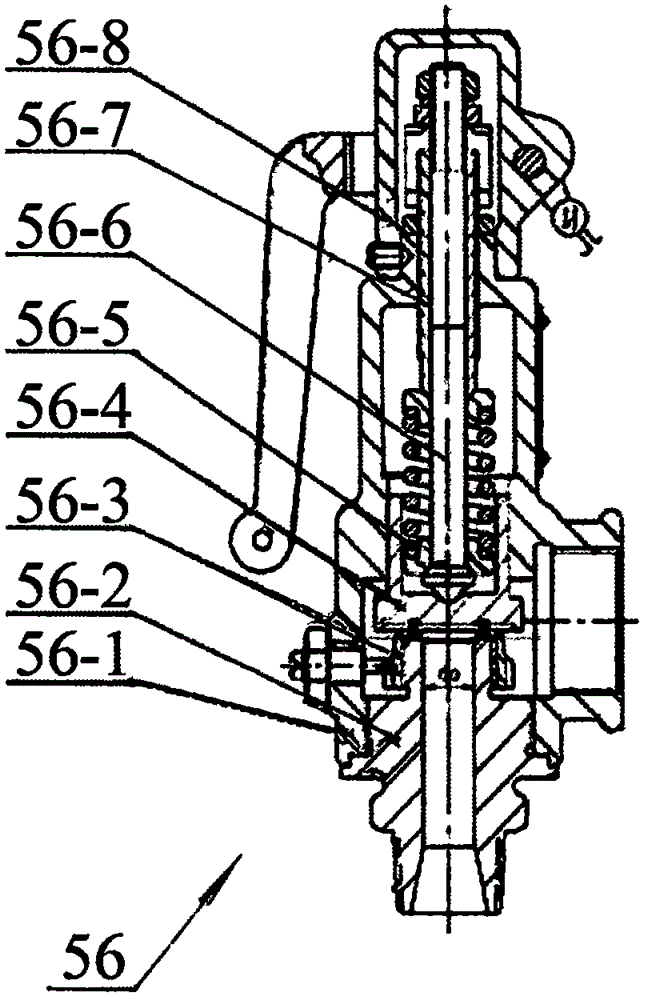

Electric steam boiler

ActiveCN105927959ATake advantage ofLow costOhmic-resistance heating circuitsSteam generation heating methodsElectricitySafety valve

The invention discloses a full-automatic electric steam boiler. In a steam-water separator (82), an S-shaped fixation support (23) is used for limiting the positions of a permanent magnet (30) and a temperature-sensing magnetic body (31); and attraction and non-attraction of the temperature-sensing magnetic body (31) and the permanent magnet (30) are used for controlling opening and closing of valve core seal rings to achieve the separation of steam and water and output. The electric steam boiler is characterized in that the third valve core seal ring (17) is round and concave and is in a circular cap shape with the middle provided with a round hole (74) or a circular ring shape; the permanent magnet (30) is inserted in a suction plate (28) and magnetizes in the thickness direction; a pull rod screw (20) is radially fixed by a guide tube (26); a screw plug (5) is used for adjusting the elastic force of a spring (6); a pressure vessel (83) is made from steel tubes; a floating ball liquid level apparatus (72), the steam-water separator (82) and at least one safety valve (56) are arranged on an upper seal head (73); electric heaters (75) are arranged on a lower seal head (61); a tap water inlet tube connector (57) is arranged on one side of the lower end of a shell of the electric steam boiler for water supplementing; and the floating ball liquid level apparatus (72) is used for controlling an intermediate relay ZJ and a contactor CJ to achieve dry burning resistant protection.

Owner:扬州纳新节能科技有限公司

Electronic cigarette heater and heating control method and device of ceramic heating element

PendingCN110710719AReduce the effect of temperatureClear thermal effectOhmic-resistance heating circuitsTobacco smoke filtersEngineeringElectronic cigarette

The invention discloses a non-contact electronic cigarette heater and a heating control method and device of a ceramic heating element. The ceramic heating element comprises a heating body and a heating circuit, and the heating circuit is arranged on the heating body to heat air passing through a porous channel; the heating control method comprises the following steps of controlling the heating circuit to perform heating work by adopting a first working voltage when the non-contact electronic cigarette heater is started, and timing the working time of the heating circuit; detecting the workingcurrent of the heating circuit; performing voltage reduction control on the working voltage of the heating circuit according to the working time of the heating circuit and the working current of theheating circuit; and adaptively adjusting the working voltage of the heating circuit according to the change rate of the working current of the heating circuit after the voltage reduction is finished,thereby realizing an effect of heating air for cigarette smoking by controlling the working voltage of the heating circuit. The control complexity is simplified, and the better control response effect is further realized.

Owner:XIAMEN FENGTAO CERAMICS CO LTD

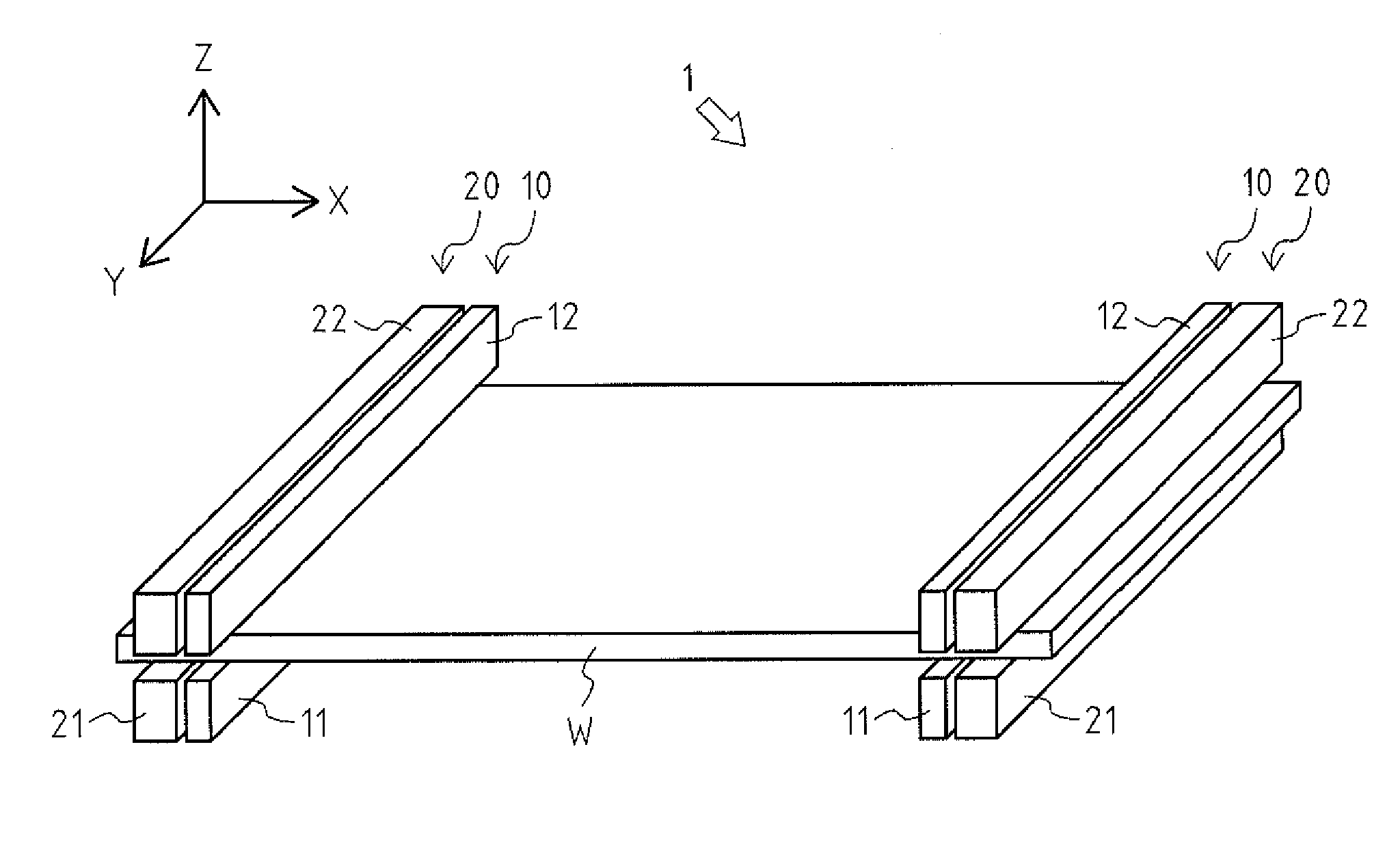

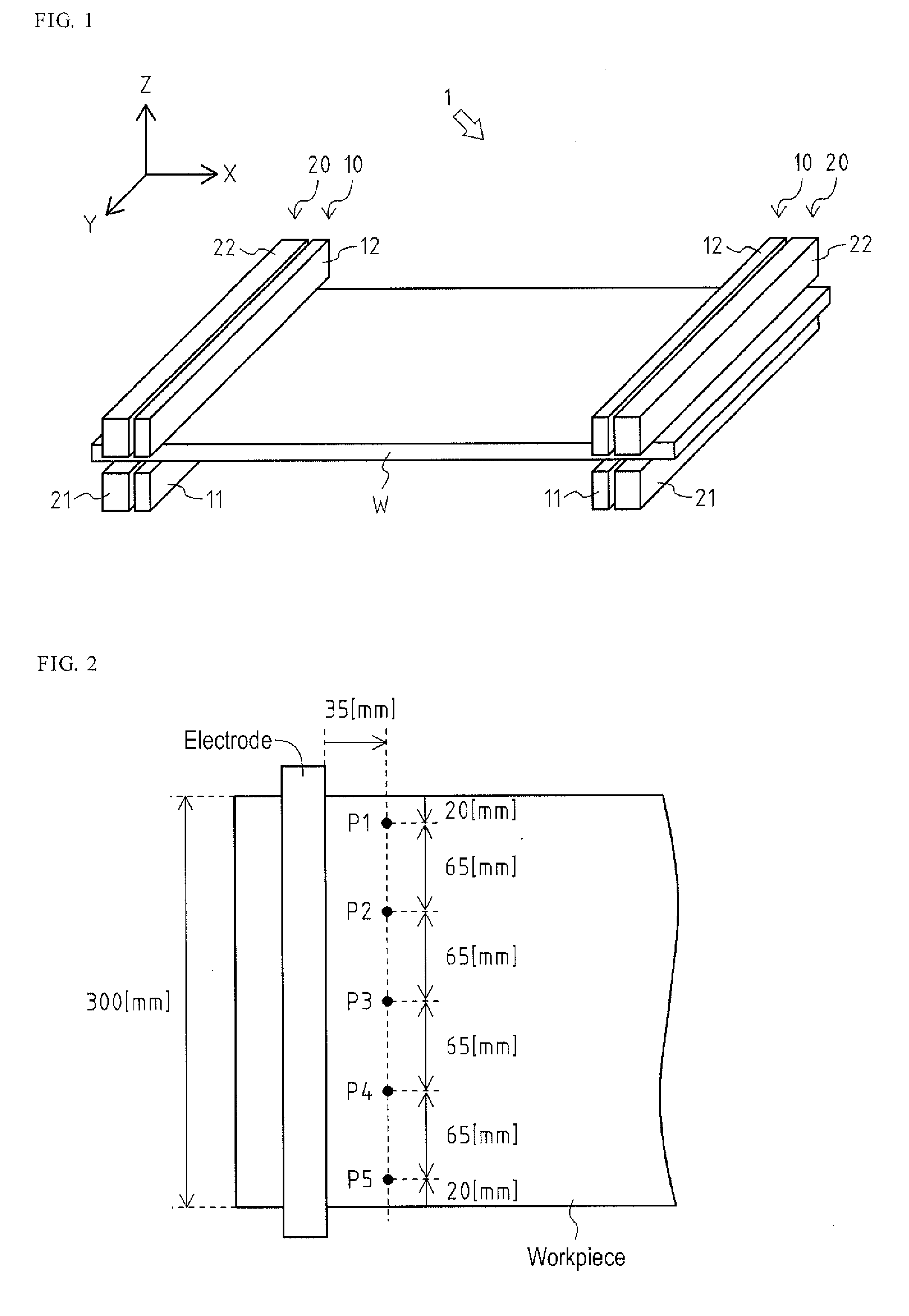

Electric heating device

ActiveUS20140209597A1Uniform applicationOhmic-resistance heating circuitsHeater elementsElectricityPower flow

Disclosed is an electric heating device capable of uniformly applying an electric current to a workpiece without causing abrasion of electrodes. An electric heating device includes a pair of electrodes for applying an electric current to a workpiece, and a pair of clamps for fixing the workpiece. The electrode extends along the surface of the workpiece in a direction perpendicular to an electric current direction while maintaining a constant length in the electric current direction, and sandwiches the workpiece therein. The clamp is arranged in the vicinity of the electrode, and sandwiches a part of the workpiece other than a part to be heated therein. A pressure at which the clamp sandwiches the workpiece therein is higher than a pressure at which the electrode sandwiches the workpiece therein.

Owner:TOYOTA JIDOSHA KK

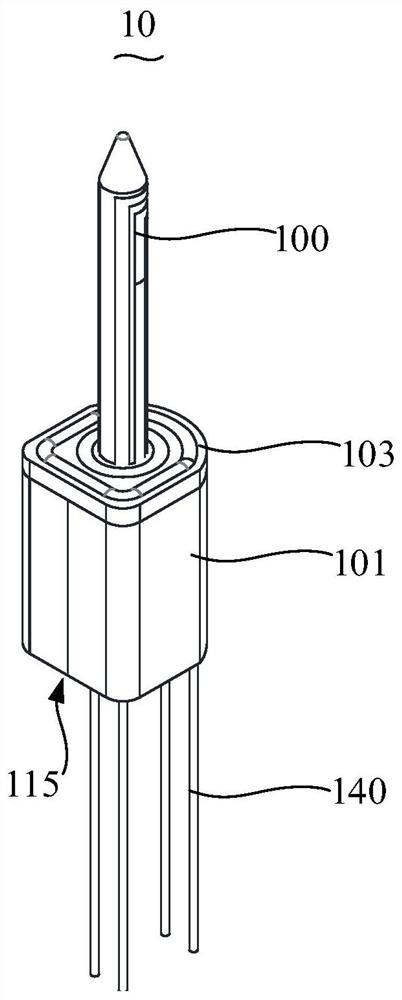

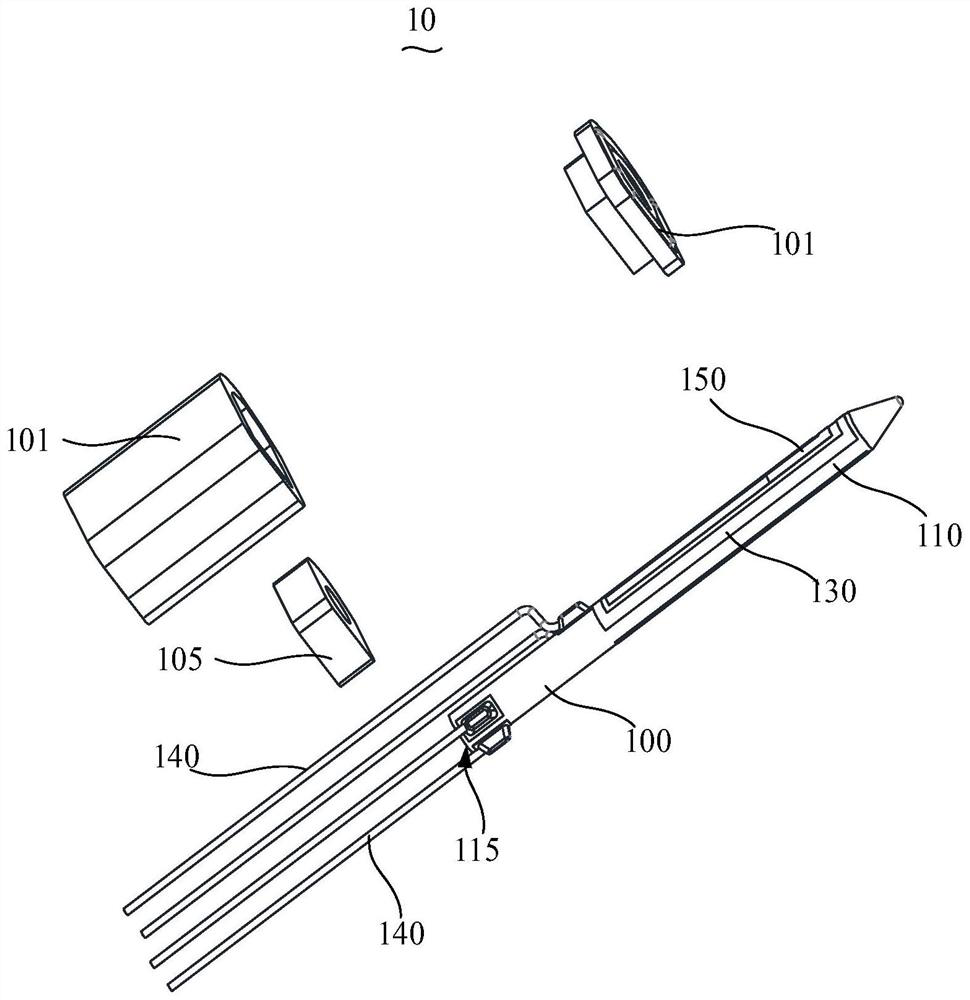

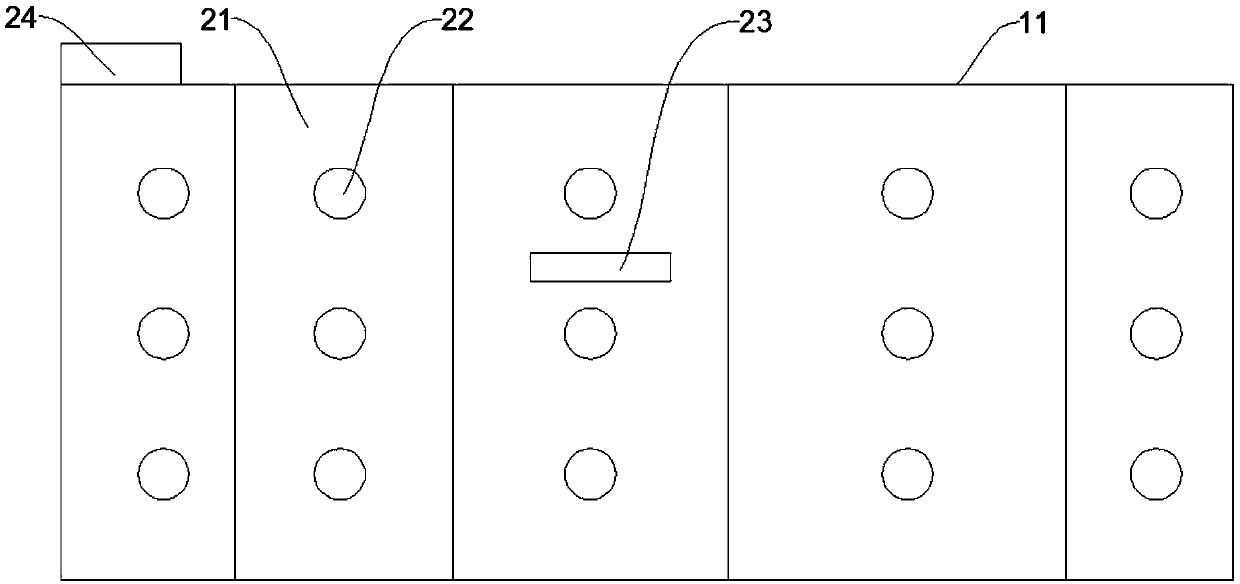

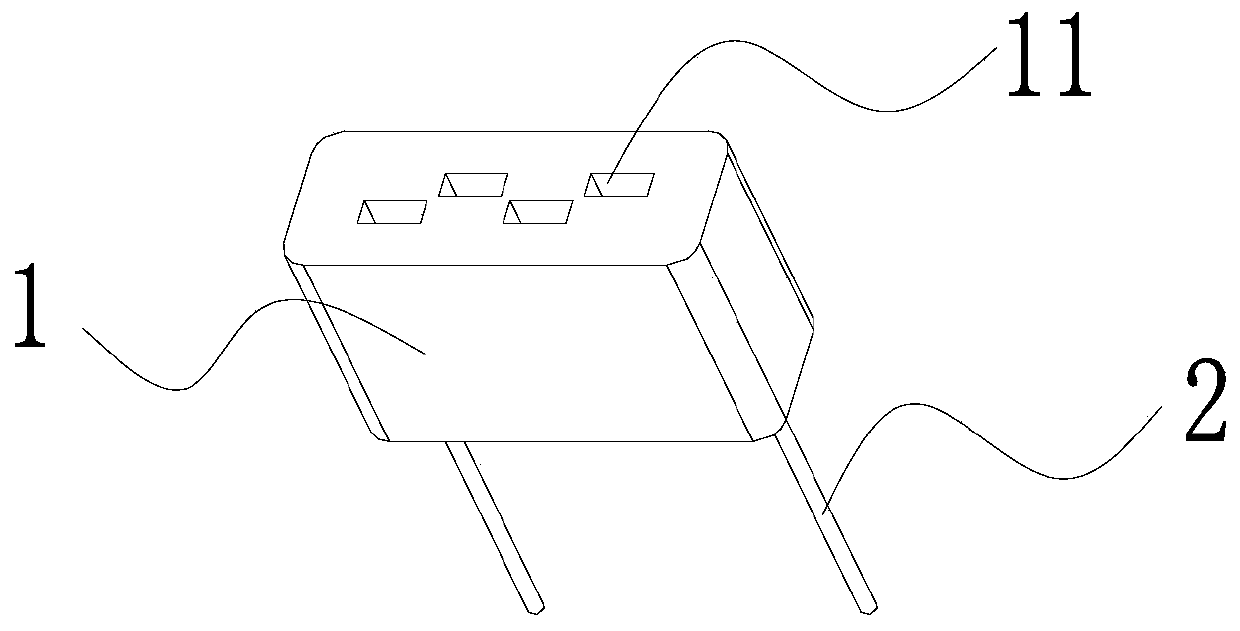

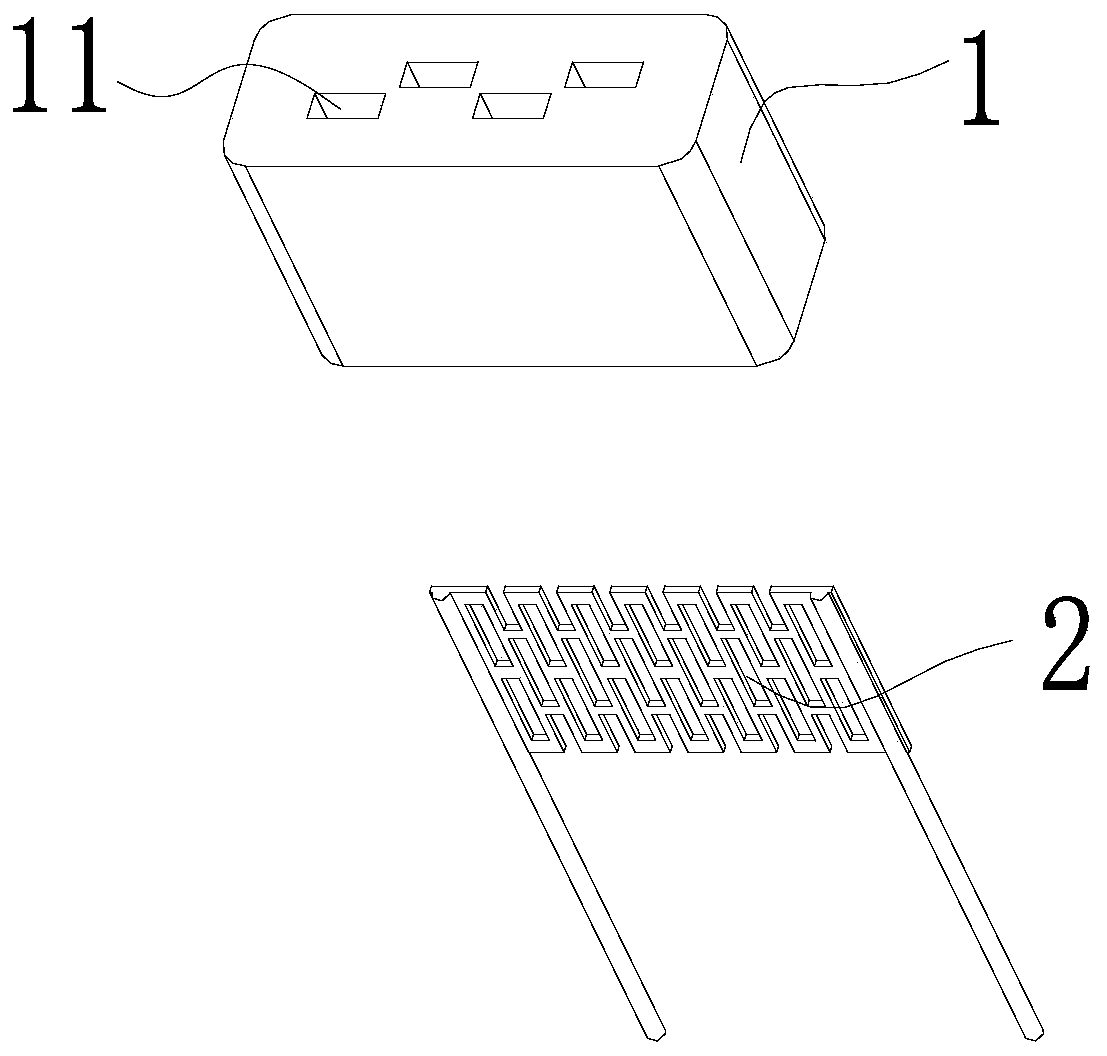

Heating assembly and heating device

PendingCN112244355ATobaccoOhmic-resistance heating circuitsEngineeringElectrical and Electronics engineering

The invention relates to a heating assembly and a heating device. The heating assembly comprises a mounting base and a heating body, the heating body comprises a base body and a heating circuit, the base body is provided with a bottom surface, the heating circuit is located on the base body, the heating circuit comprises a heating part and a heating electrode electrically connected with the heating part, the heating electrode is close to the bottom surface, and the mounting base is fixedly connected with the base body; the joint of the mounting base and the base body is located on the side, close to the bottom face, of the heating electrode. The heating assembly is long in service life.

Owner:SHENZHEN MERIT TECH CO LTD

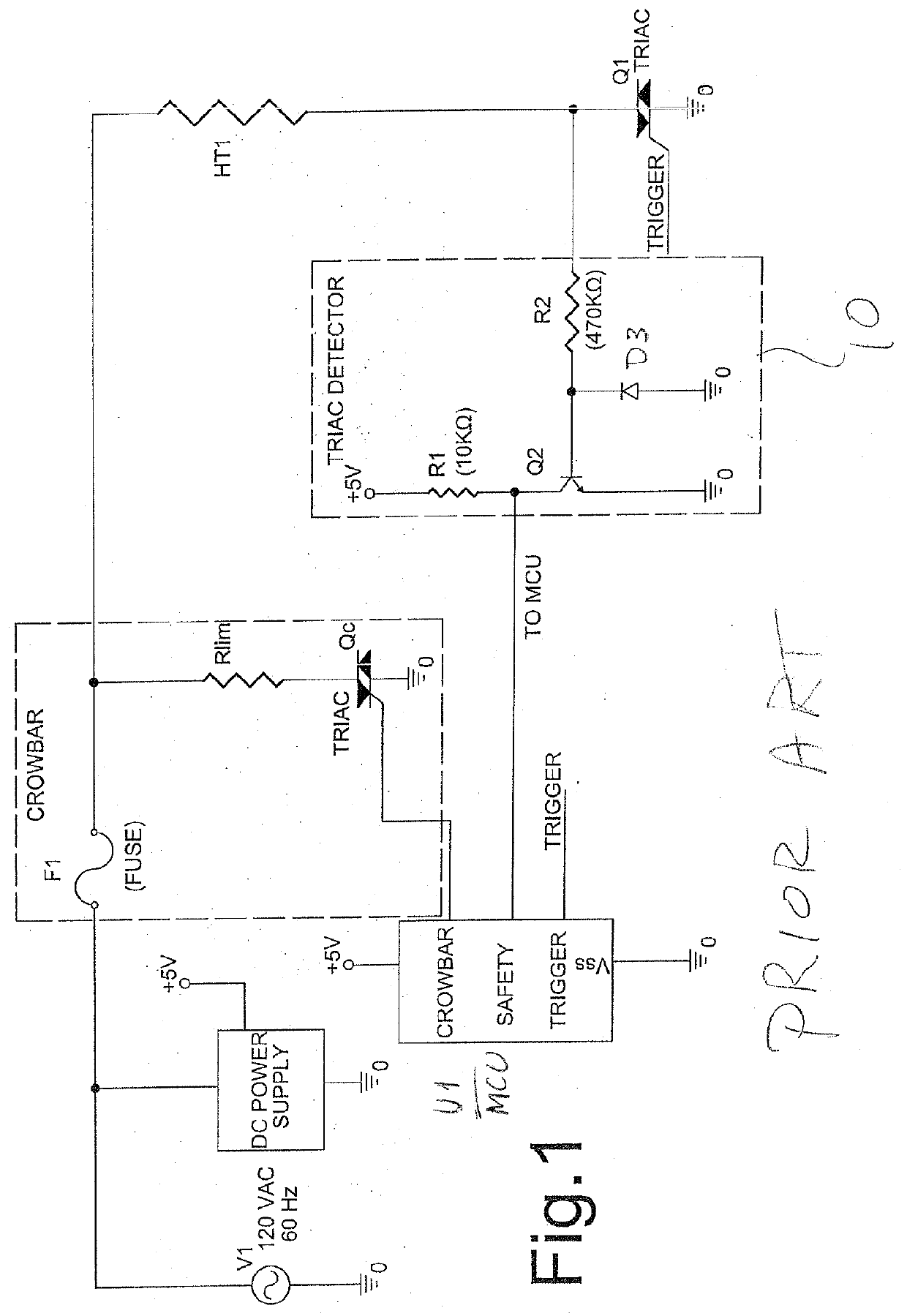

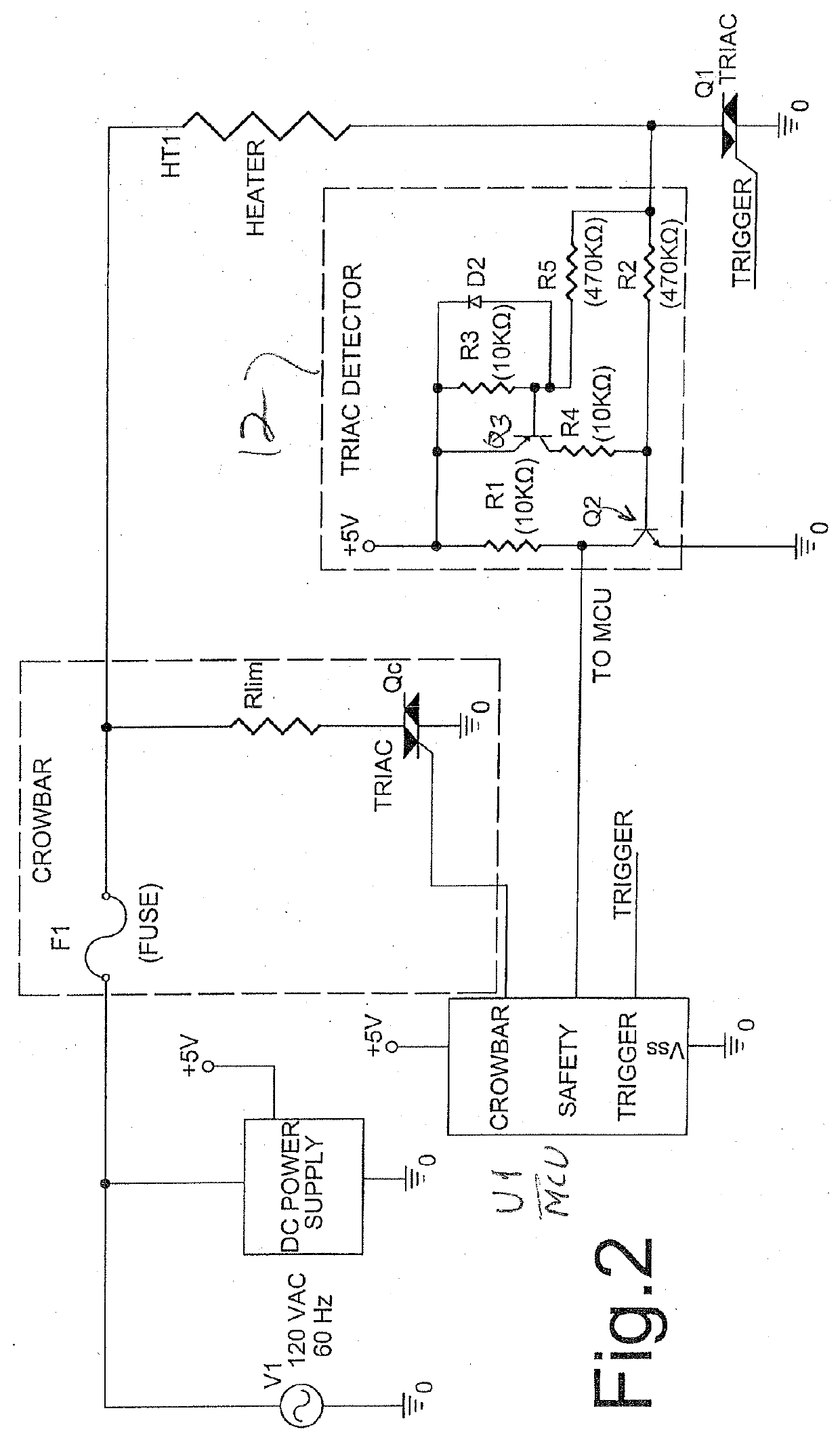

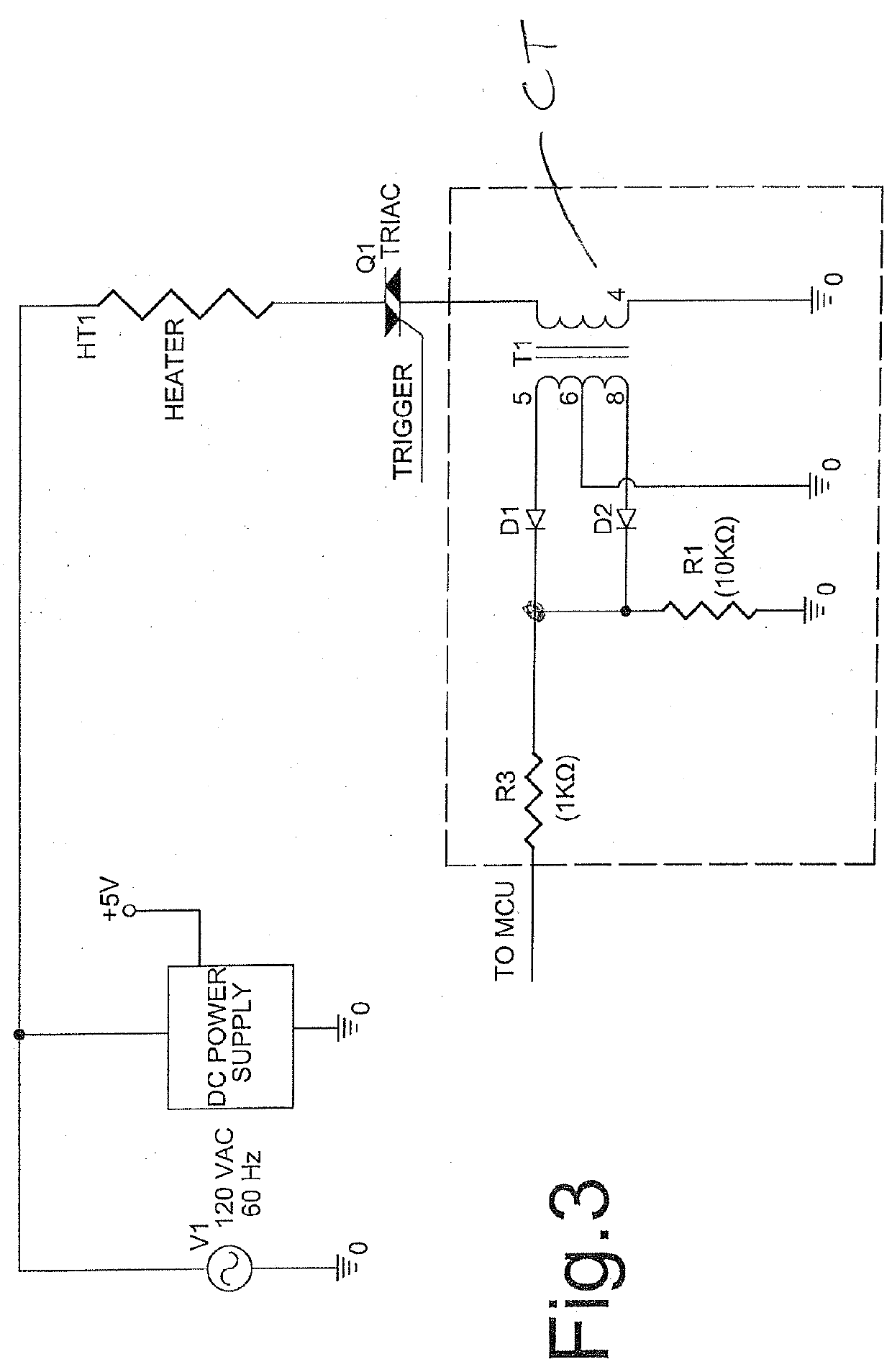

Bi-polar triac short detection and safety circuit

ActiveUS20160037582A1Ohmic-resistance heating circuitsOhmic-resistance heating detailsAC powerSolid-state

A safety circuit to disrupt power to a heating element of an appliance to be powered through a solid state switch (Tri-ac Q1), typically a triac, from an AC power source (V1) having a positive half cycle and a negative half cycle delivering power. A low resistance condition is sensed by detecting either the current through or voltage across the solid state switch during the positive half cycle and the negative half cycle of the AC power line, when the solid state AC switch is not actuated. A fault signal is generated to interrupt power to the heating element, preferably by a crowbar circuit opening a fuse, whenever the low resistance condition is detected.

Owner:MULTITECH MEDICAL DEVICES USA LLC

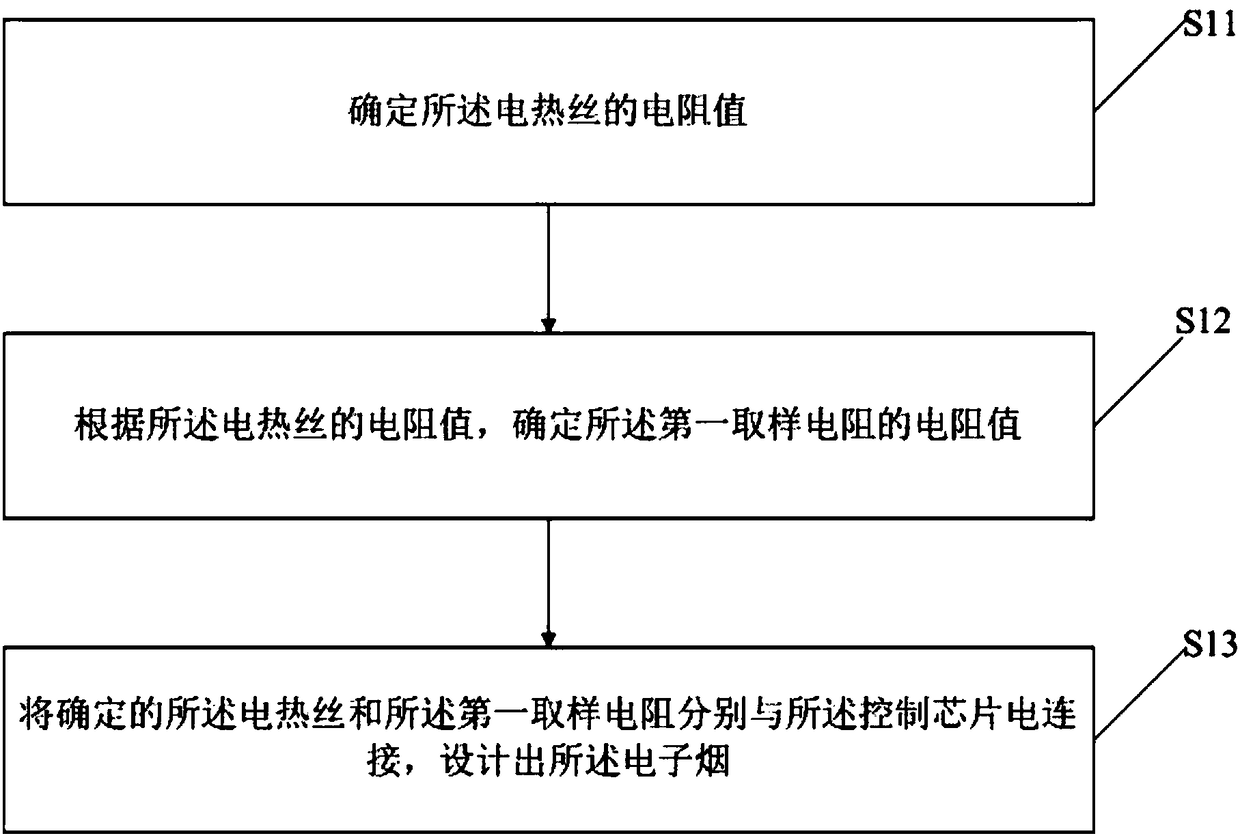

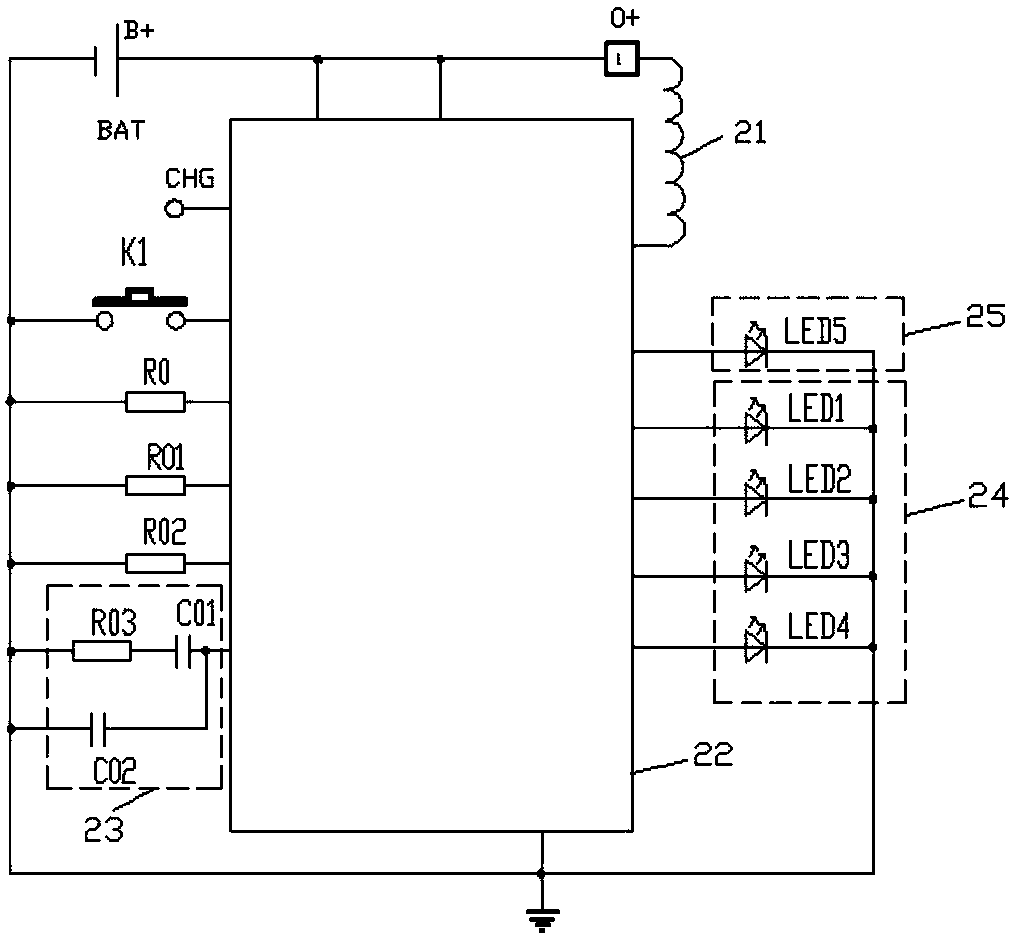

Design method and control method for electronic cigarettes and electronic cigarette

InactiveCN108201174ASimple designImprove experienceOhmic-resistance heating circuitsTobacco devicesElectrical resistance and conductanceElectricity

The invention discloses a design method for electronic cigarettes. The electronic cigarette comprises a heating wire, a first sampling resistor and a control ship; the heating wire is used for atomizing tobacco tar to form smog; the control chip is used for controlling the current in the heating wire when the electronic cigarette starts to work according to the resistance value of the first sampling resistor; the design method comprises following steps: S11. determining the resistance value of the heating wire; S12. determining the resistance value of the first sampling resistor according to the resistance value of the heating wire; S13. electrically connecting the determined heating wire and the first sampling resistor with the control chip to design the electric cigarettes. Correspondingly, the invention also discloses a control method for electronic cigarettes and an electronic cigarette. The invention integrates the main circuit of the electronic cigarette on a control chip, expands the use range of the control chip, and greatly simplifies the design process of the electronic cigarette, is convenient for manufacturing, has high production efficiency and low production cost.

Owner:HUIZHOU KIMREE TECH

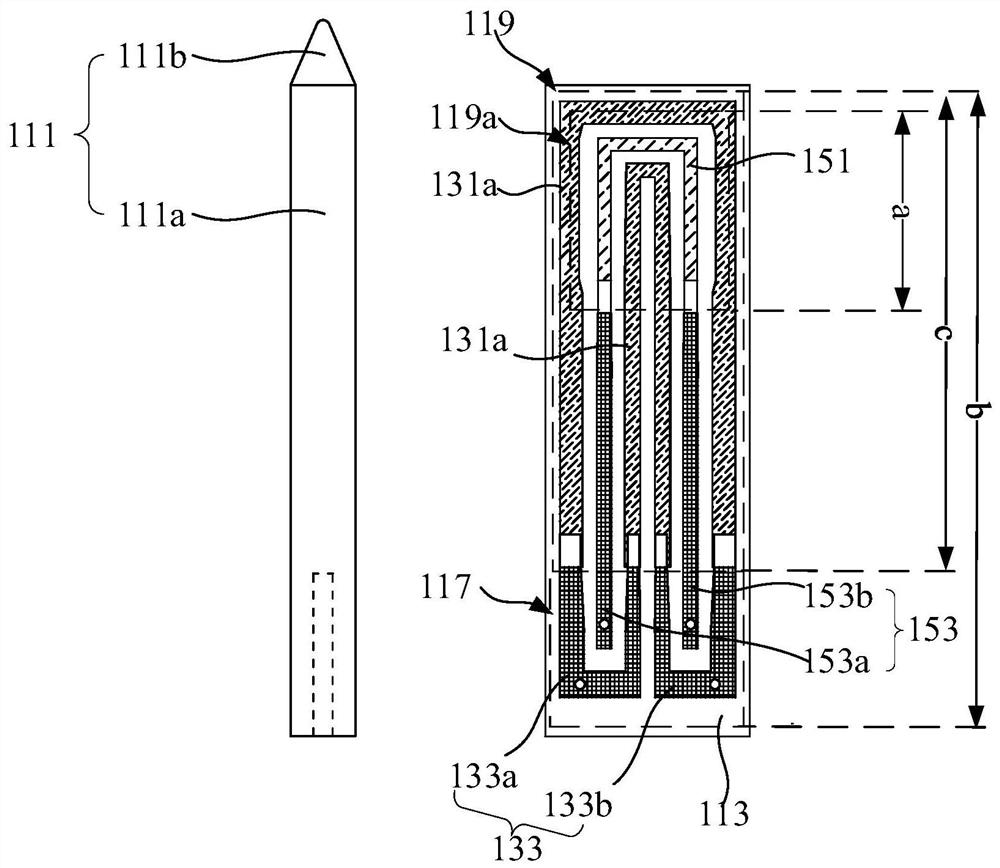

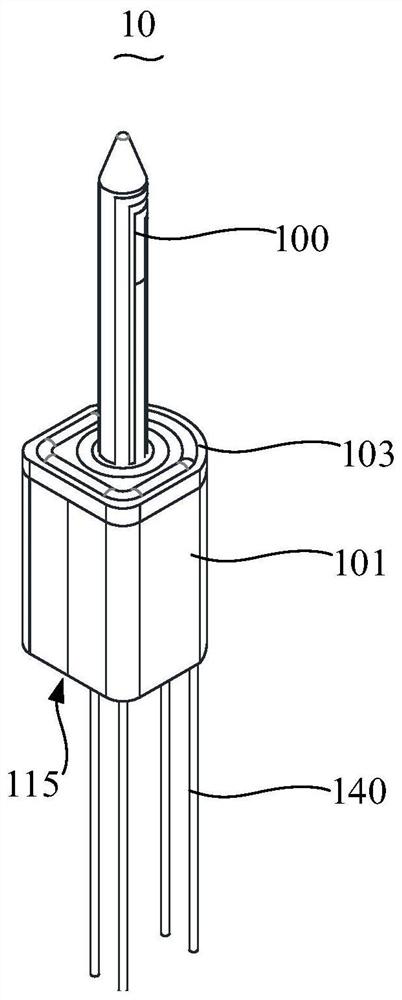

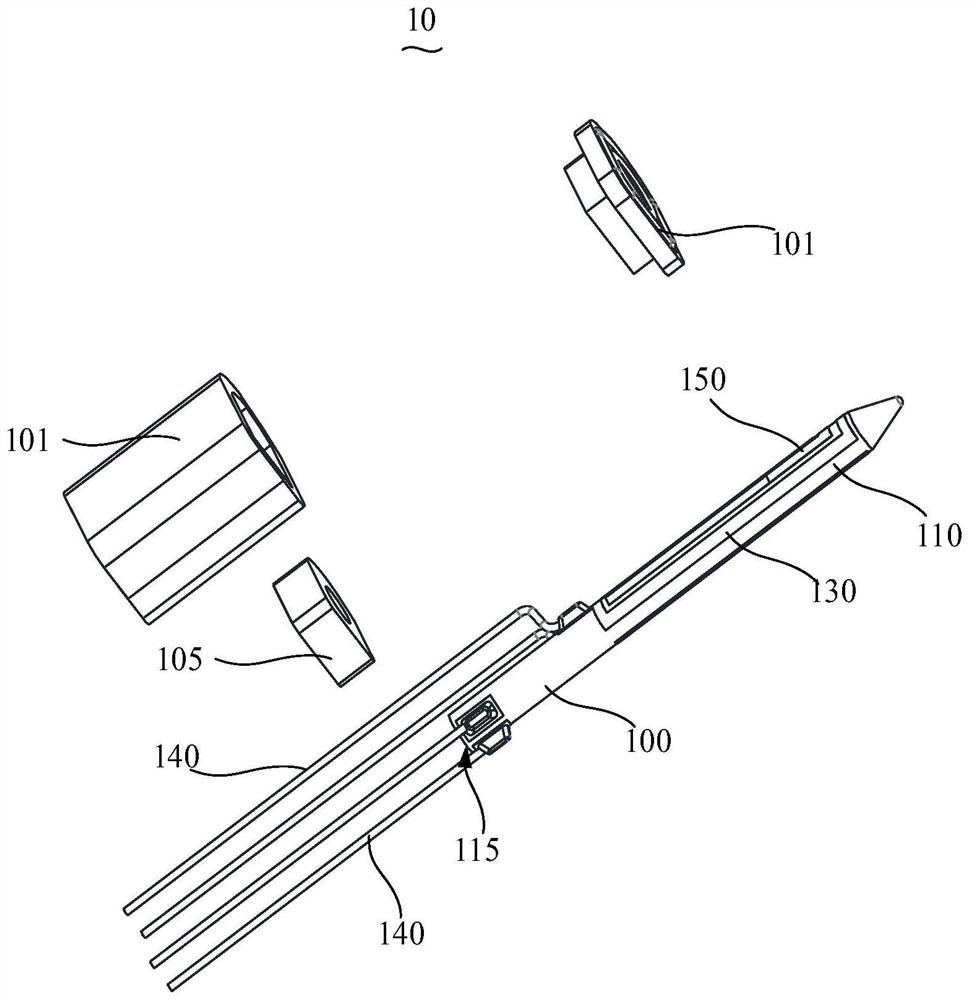

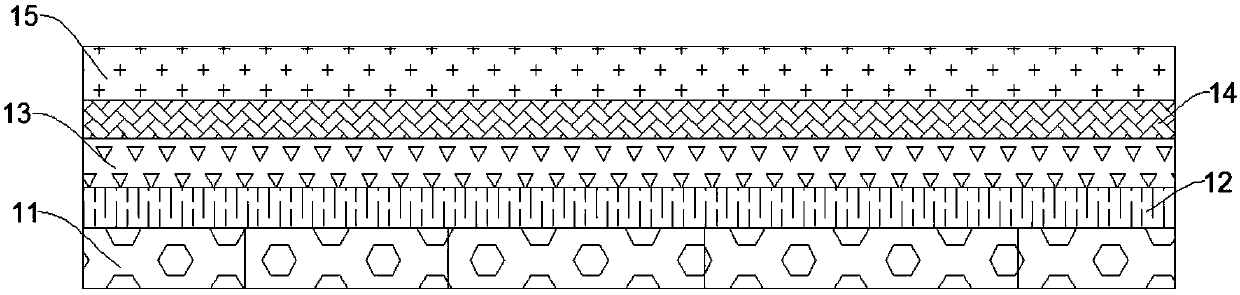

Heating body, heating assembly and heating device

PendingCN112244359AOhmic-resistance heating circuitsOhmic-resistance electrodesEngineeringMechanical engineering

The invention relates to a heating body, a heating assembly and a heating device. The heating body comprises a base body, a heating circuit and a temperature measuring circuit, the base body is provided with a bottom face, the base body is provided with a heating area and an electrode arrangement area adjacent to the heating area, and compared with the heating area, the electrode arrangement areais close to the bottom face. The heating circuit is located on the base body and comprises a heating part and a heating electrode electrically connected with the heating part, the heating part is located in the heating area, and the heating electrode is located in the electrode setting area; the temperature measuring circuit is located on the base body, the temperature measuring circuit and the heating circuit are arranged in a spaced mode, the temperature measuring circuit comprises a temperature measuring part and a temperature measuring electrode electrically connected with the temperaturemeasuring part, and the heating area comprises a high-temperature area and a temperature measuring part high-temperature area. The deviation between the actual temperature of the heating body in the heating initial stage and the design temperature is small.

Owner:SHENZHEN MERIT TECH CO LTD

Intelligent electric blanket

InactiveCN108684090AEasy to fold and carryAutomatic temperature adjustmentOhmic-resistance heating circuitsOhmic-resistance waterproof/air-tight sealsEngineeringFar infrared

The invention relates to the technical field of electric blankets, in particular to an intelligent electric blanket comprising an electric blanket body, a blanket surface, a heating device, a heat insulating layer, a waterproof layer and a touch screen. The electric blanket body is divided into at least two heating zones. The blanket surface is arranged over the electric blanket body. The heatingdevice comprises a heating controller, a far-infrared cloth and a heating film. Heating films are disposed in the heating zones. The far-infrared cloth is arranged between the electric blanket body and the blanket surface. A first temperature sensor and a pressure sensor are arranged in the electric blanket body. The touch screen is in communication connection with the heating controller. The touch screen is provided with a second temperature sensor. By means of simple structure, the intelligent electric blanket not only can separately generate heat in different zones, but also can generate heat by the combination of the heating films and far-infrared rays, can adjust temperature as required, has physiotherapy and steaming functions, has a sleep detection function, can automatically adjusttemperature, has an energy-saving function, is automatically powered off when nobody is present, and has good waterproof and heat preservation effects.

Owner:张健

Preparation method and application of low-voltage efficient nano carbon material electrothermal film

InactiveCN110191523AHeating temperature controlHigh mechanical strengthOhmic-resistance heating circuitsOhmic-resistance heating detailsLow voltageCarbon nanotube

The invention provides a nano carbon material electrothermal film. The nano carbon material electrothermal film comprises the following raw materials: carbon nano-tubes, graphene and nano-cellulose. Through the cooperative use of the carbon nano-tubes, the graphene and the nano cellulose, the prepared nano carbon material electrothermal film has the advantages of low pressure and high efficiency.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

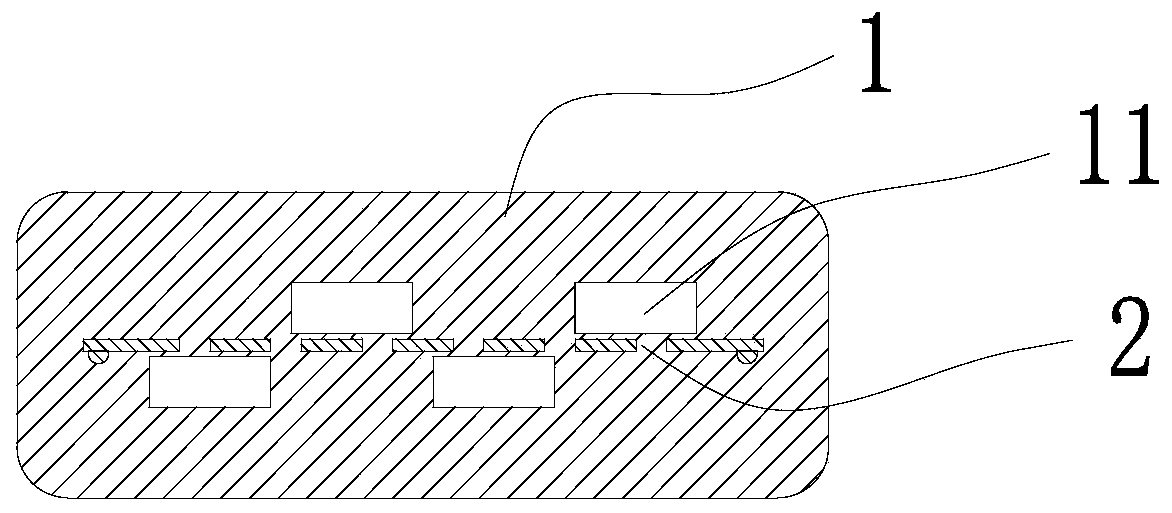

Netty sheet type porous heating and atomizing assembly and heating and atomizing device thereof

PendingCN111317174AImprove consistencyImprove structural strengthOhmic-resistance heating circuitsTobaccoHigh volume manufacturingEngineering

The invention discloses a net-shaped sheet type porous heating and atomizing assembly and a heating and atomizing device thereof. The assembly comprises a porous liquid guide body and one or more planar sheet-shaped electric heating tracks, the porous liquid guide body is used for sucking and conducting liquid, and the planar sheet-shaped electric heating tracks are arranged in the porous liquid guide body. The planar sheet-shaped electric heating tracks are used for heating liquid to atomize the liquid, one or more through type airflow through holes are formed in the porous liquid guide body,and each planar sheet-shaped electric heating track is a planar heating net formed by connecting one or more heating tracks in parallel. The invention further discloses a net-shaped sheet type porousheating and atomizing device which comprises the net-shaped sheet type porous heating and atomizing device assembly. The net-shaped sheet type porous heating and atomizing device assembly and the heating and atomizing device thereof have the advantages of being beneficial to mass production, uniform in heating, large in atomization area and large in smoke amount.

Owner:SHENZHEN HUACHENGDA PRECISION IND CO LTD

Heater management

An electrically operated aerosol-generating system is provided, including an electric heater including a heating element configured to heat an aerosol-forming substrate; a power supply; and electric circuitry for an electrically operated aerosol-generating device, in use the electric circuitry being connected to the heater and to the power supply, the electric circuitry including a memory, and being configured to measure an initial resistance, or an initial rate of change of resistance, of the heater within a predetermined time period after power is supplied to the heater, to compare the initial resistance or the initial rate of change of resistance of the heater with a range of acceptable values, and if the initial resistance or the initial rate of change of resistance is outside the range, to prevent the supply of power to the heater, or provide an indication, until the heater or the substrate is replaced.

Owner:PHILIP MORRIS PROD SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com