Heating body, heating assembly and heating device

A technology of heating body and heating part, which is applied in the direction of tobacco, etc., and can solve problems such as design temperature deviation, poor smoking experience, and mismatching baking temperature of tobacco or pods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

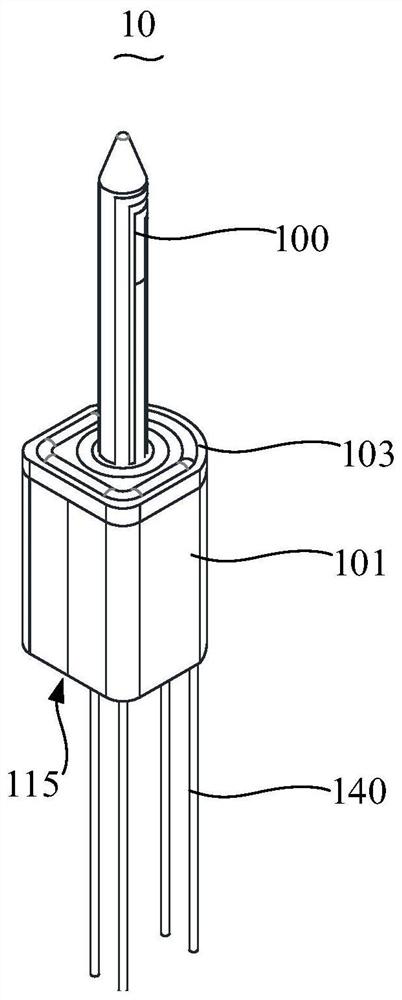

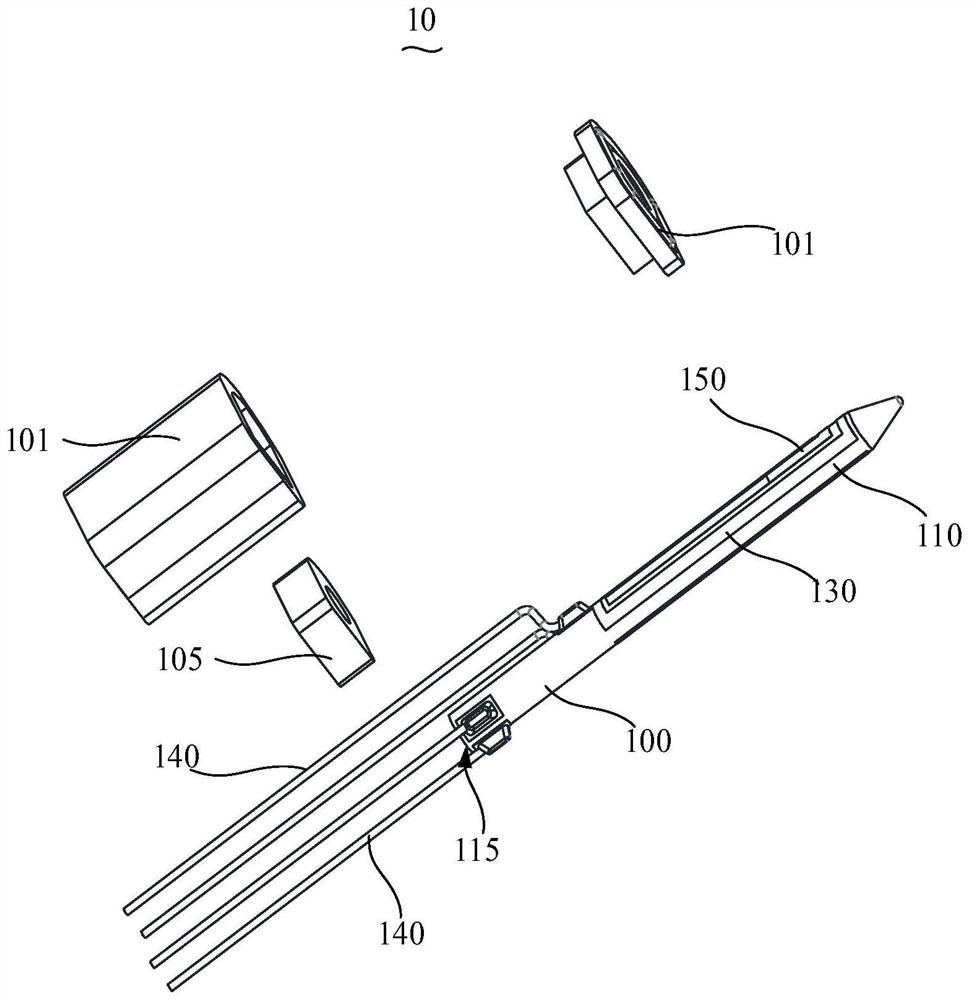

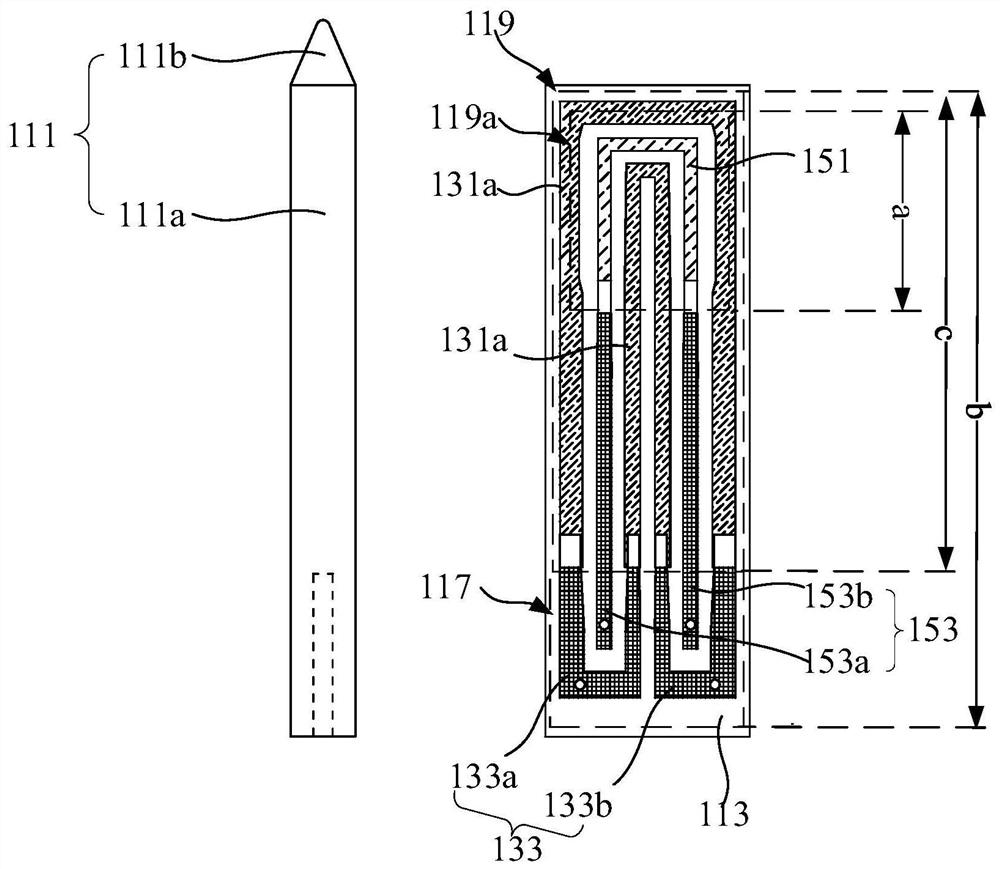

[0111] The structure of the heating assembly of embodiment 1 is as figure 1 As shown, wherein the base of the heating element is zirconia ceramics, the diameter is 3 mm, the length of the base is 16 mm, the thickness of the insulating layer wound on the base is 0.3 mm, and the length of the heating wire in the length direction of the base is 10 mm. The width of the heating line is 0.8mm, the maximum length of the heating line in the width direction of the base is 5.06mm, the length of the temperature measuring line in the length direction of the base is 4mm, the distance from the temperature measuring line to the two heating lines is equal, The resistance of the heating part at normal temperature is 1Ω, the square resistance of the heating part is 100mΩ / □, and the main material of the heating part is Ni; the resistance of the temperature measuring part at normal temperature is 10Ω, and the square resistance of the temperature measuring part is 150mΩ / □. The main material of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com